Patents

Literature

404results about How to "Lower junction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

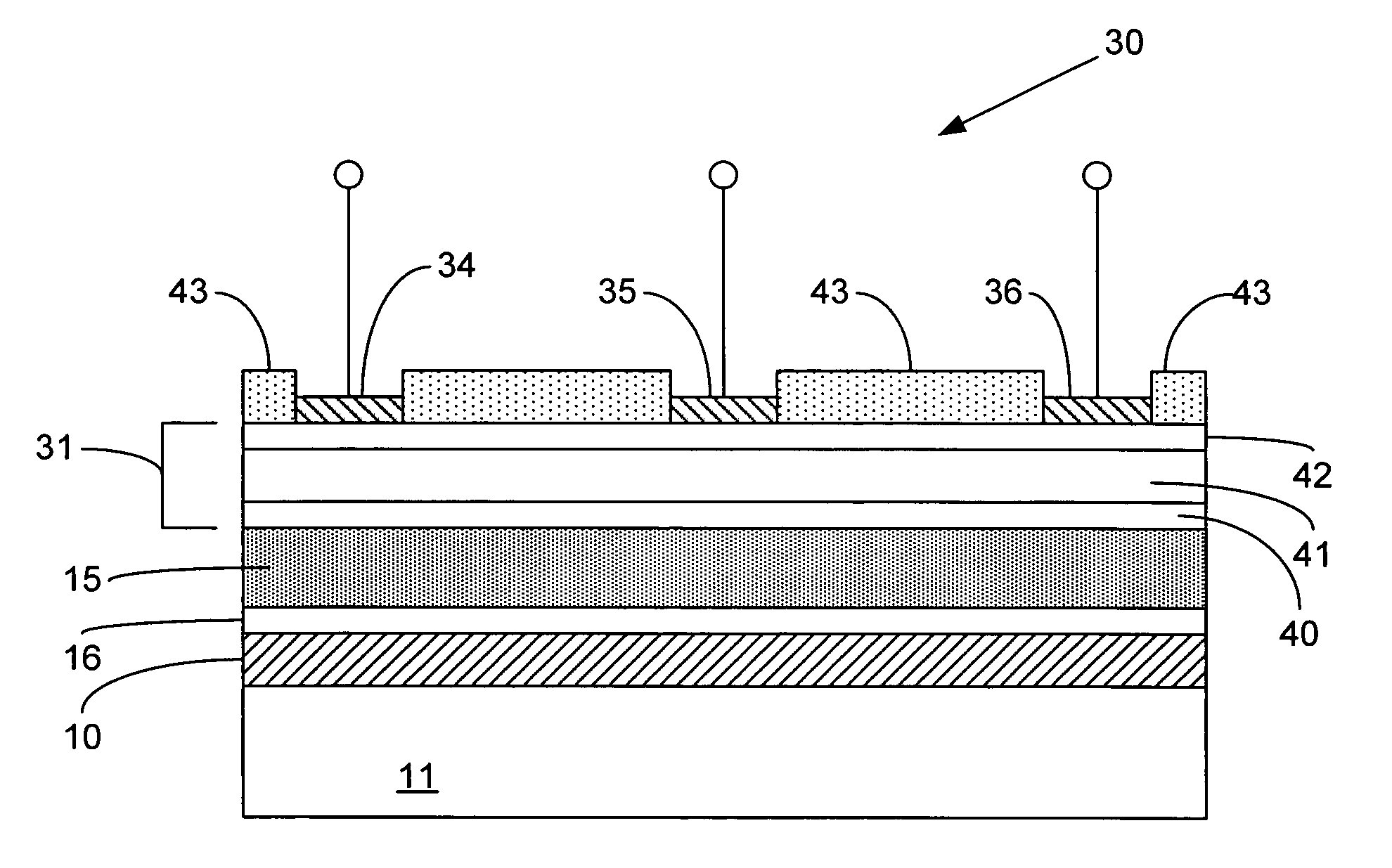

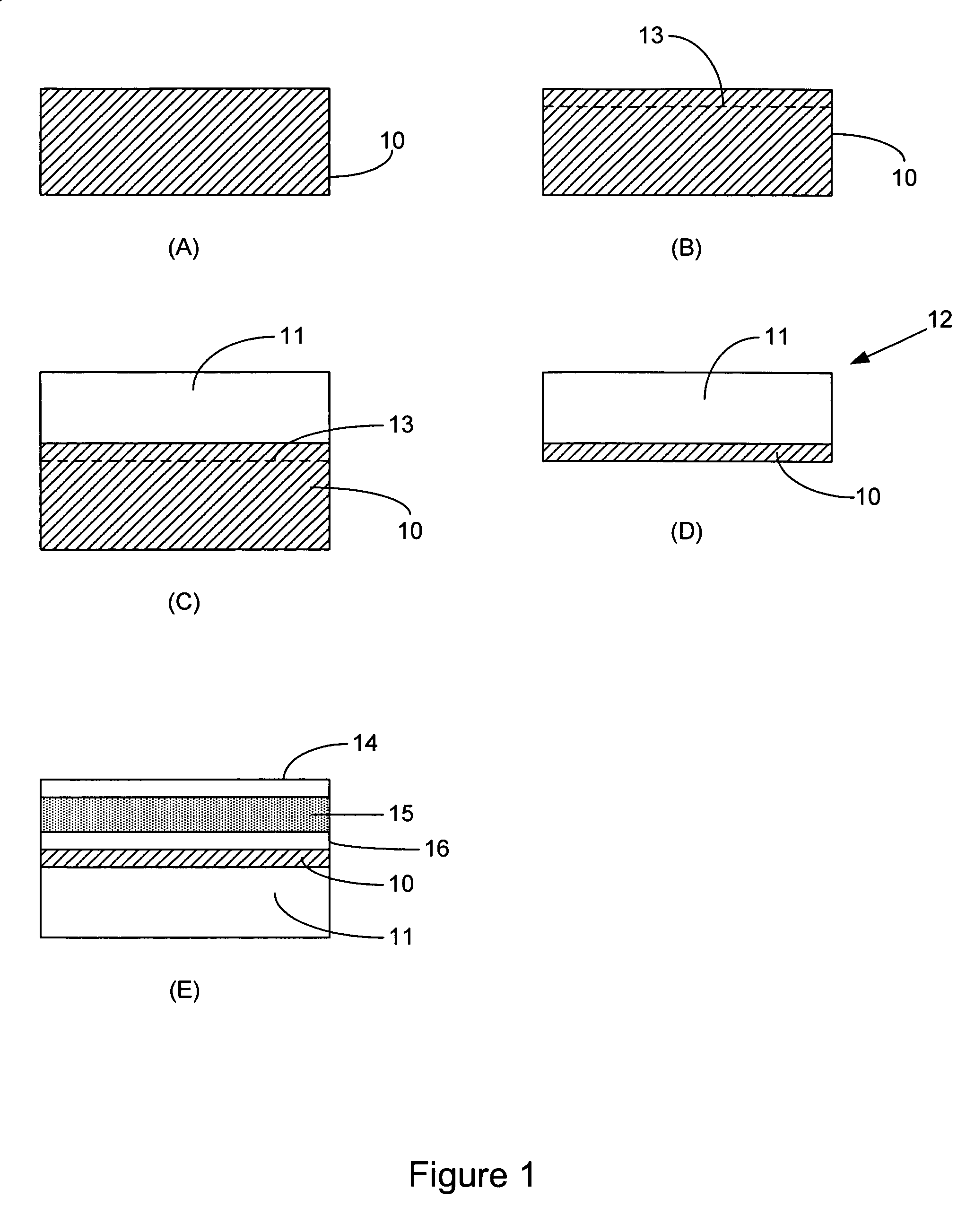

Silicon Carbide on Diamond Substrates and Related Devices and Methods

ActiveUS20050164482A1Improve thermal conductivityReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesWaferingSemiconductor structure

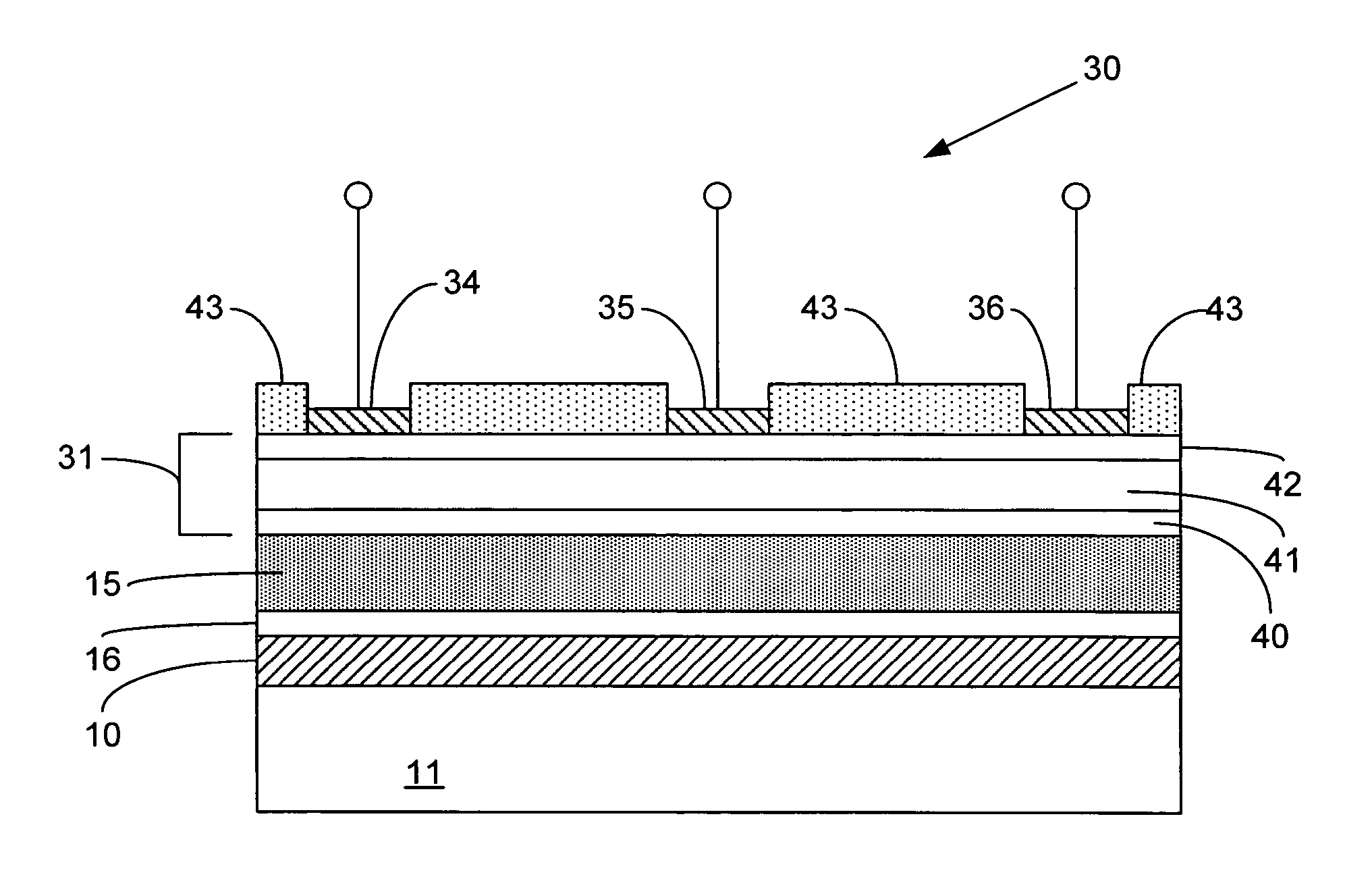

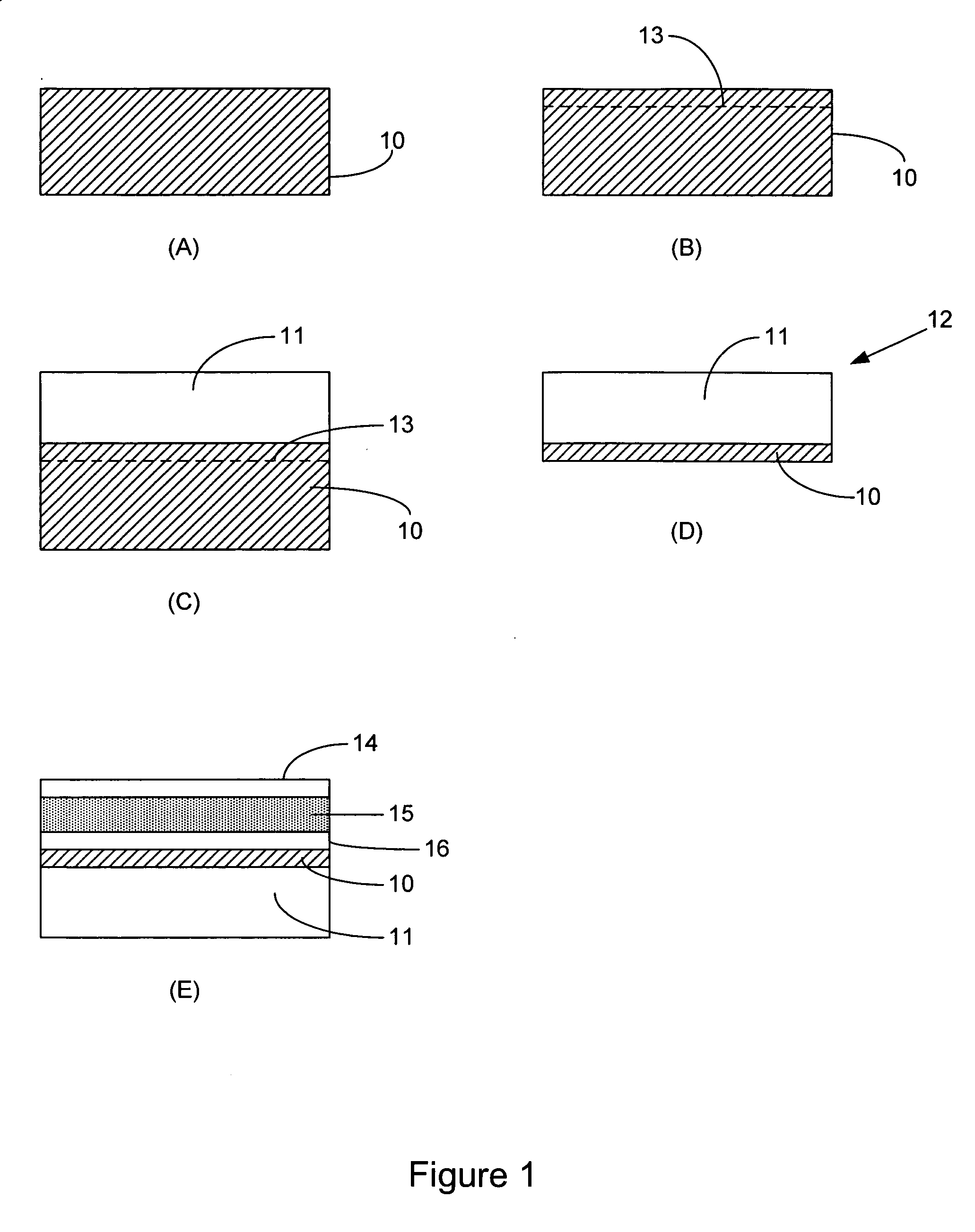

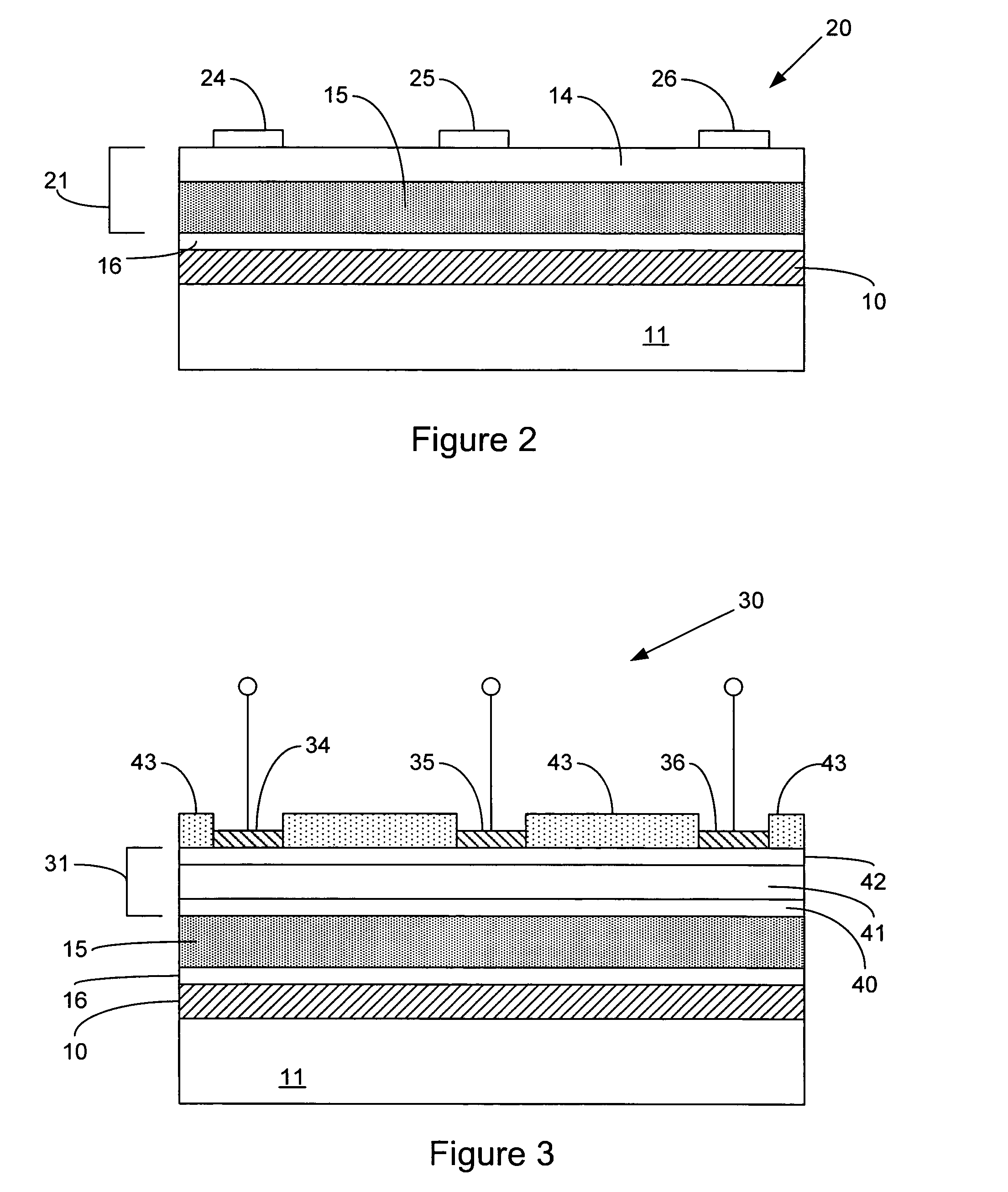

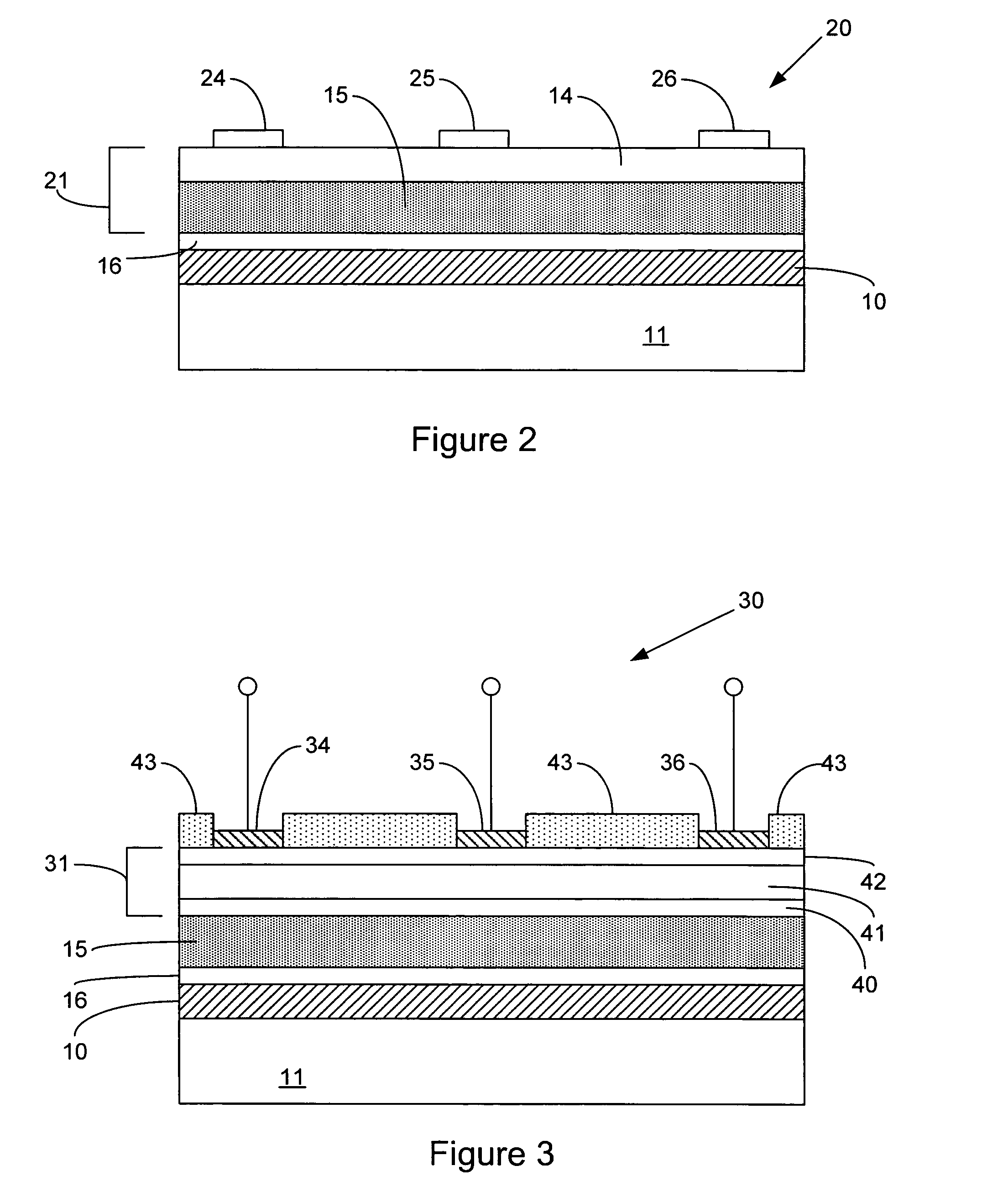

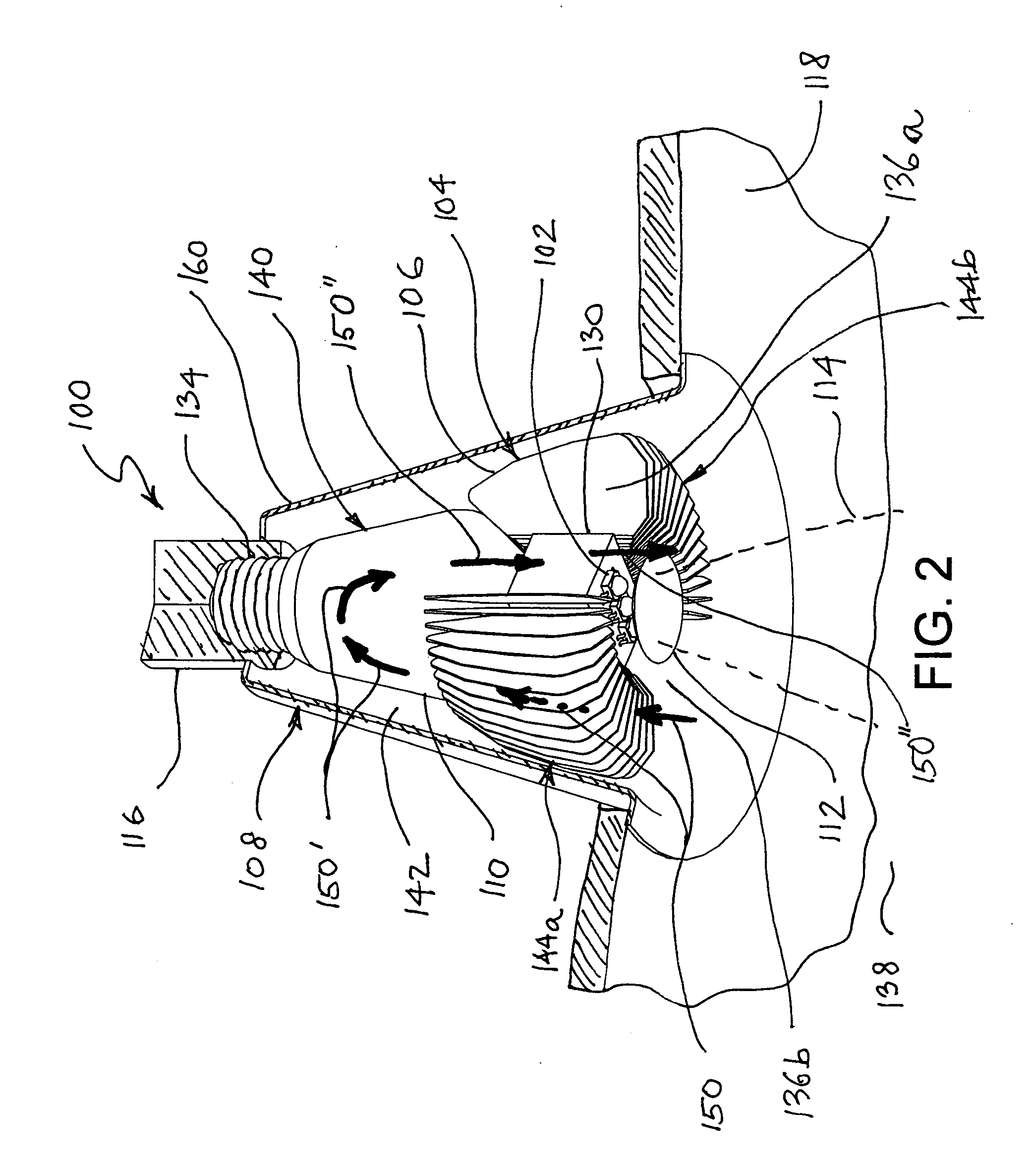

A method of forming a high-power, high-frequency device in wide bandgap semiconductor materials with reduced junction temperature, higher power density during operation and improved reliability at a rated power density is disclosed, along with resulting semiconductor structures and devices. The method includes adding a layer of diamond to a silicon carbide wafer to increase the thermal conductivity of the resulting composite wafer, thereafter reducing the thickness of the silicon carbide portion of the composite wafer while retaining sufficient thickness of silicon carbide to support epitaxial growth thereon, preparing the silicon carbide surface of the composite wafer for epitaxial growth thereon, and adding a Group III nitride heterostructure to the prepared silicon carbide face of the wafer.

Owner:WOLFSPEED INC

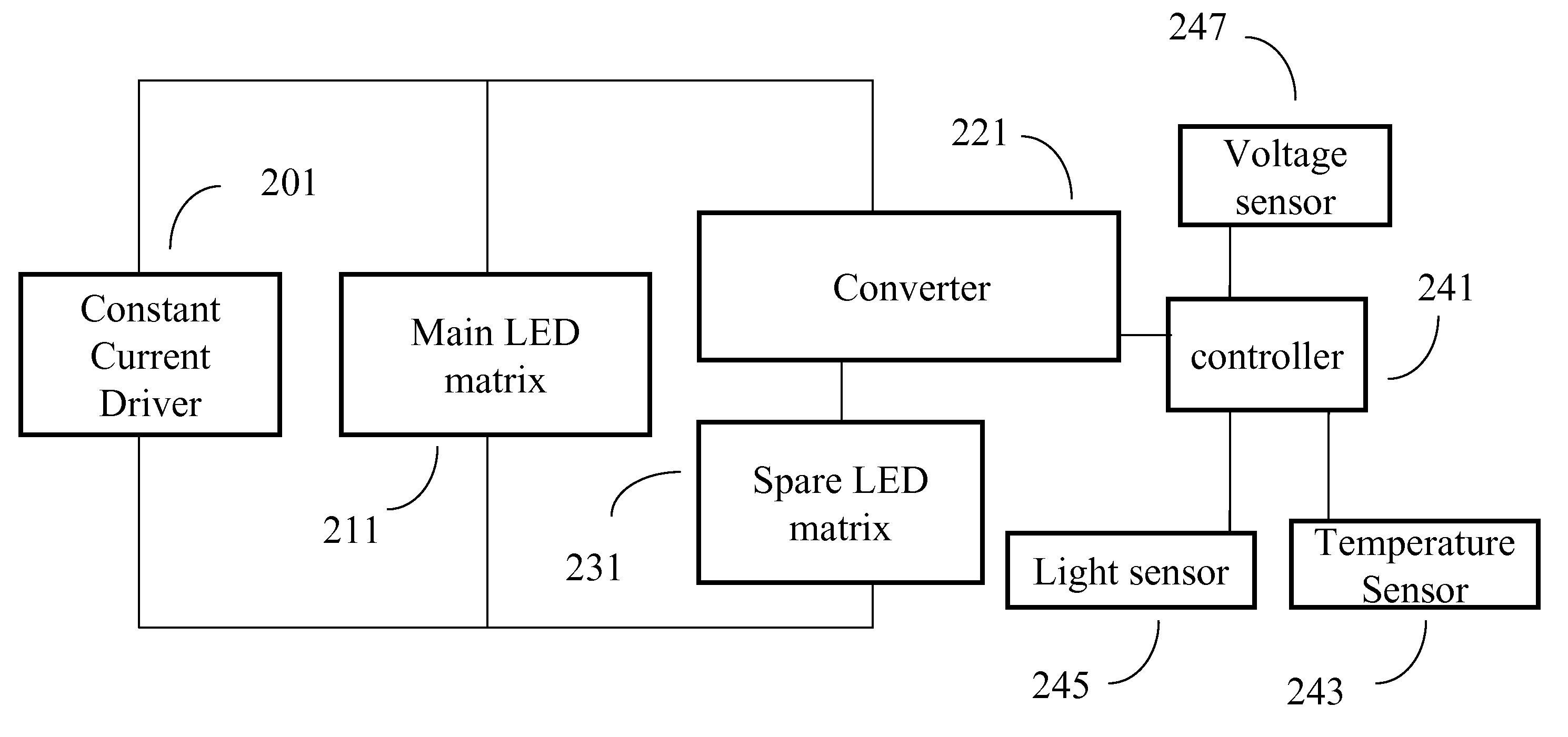

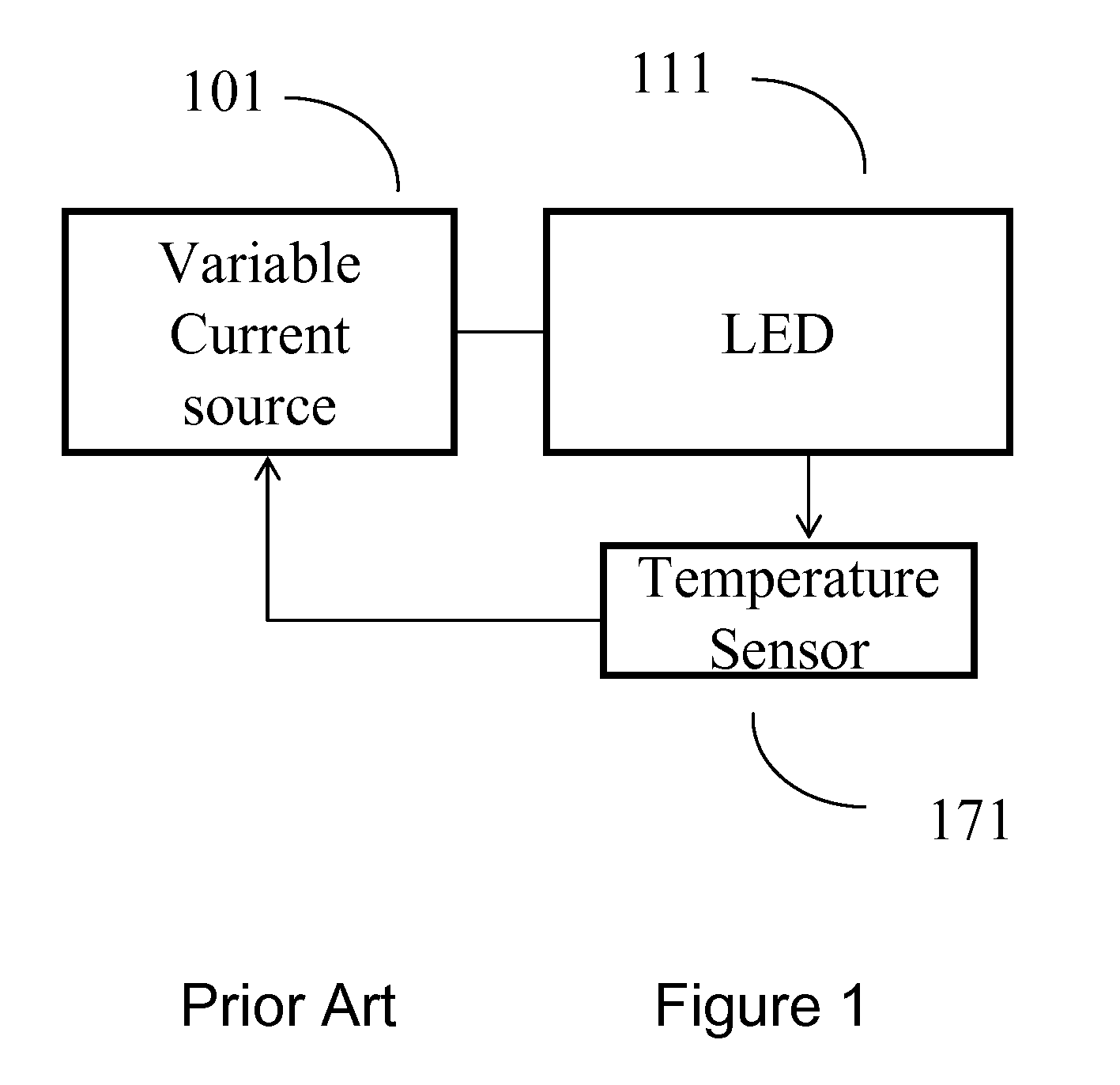

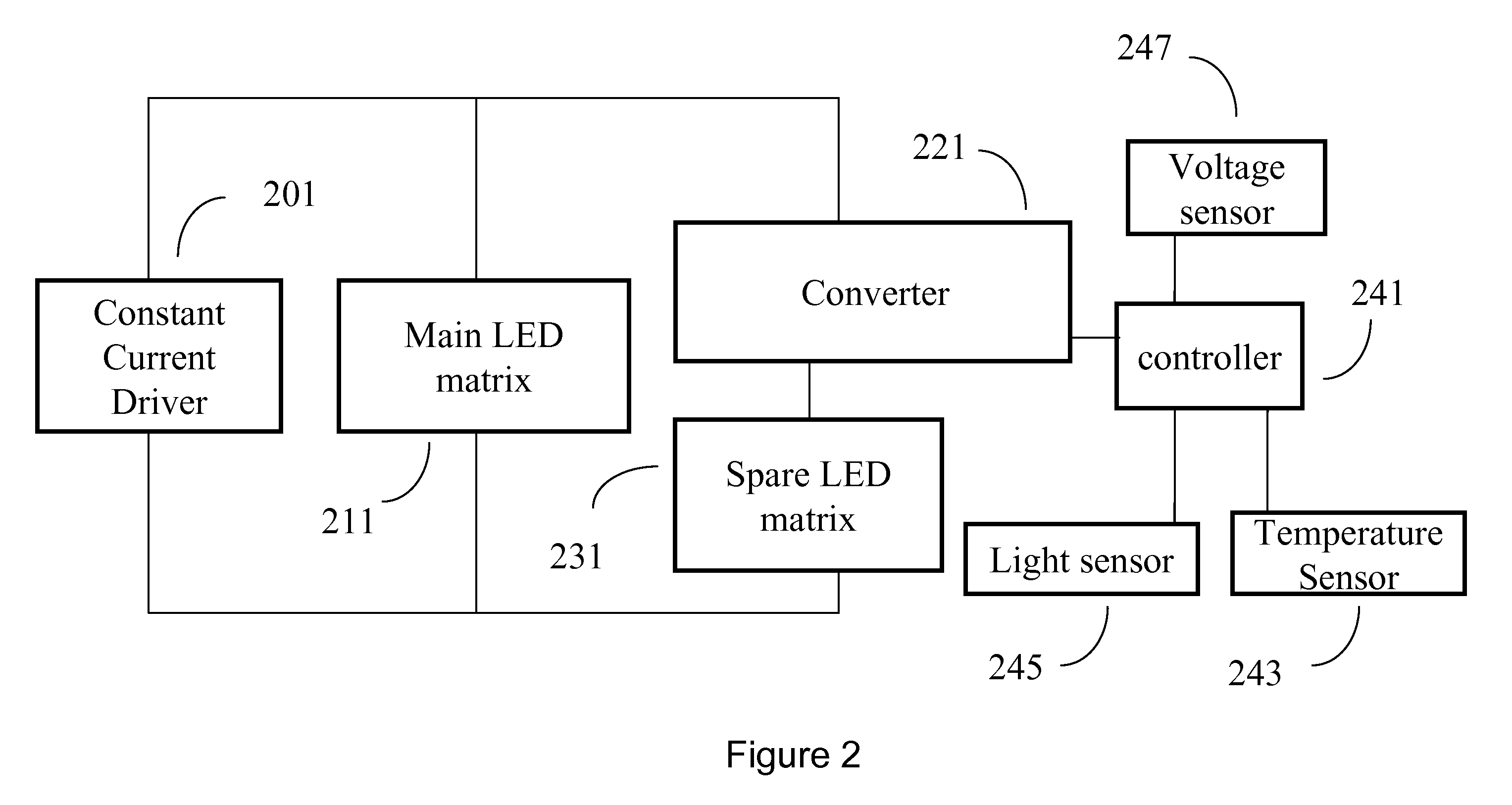

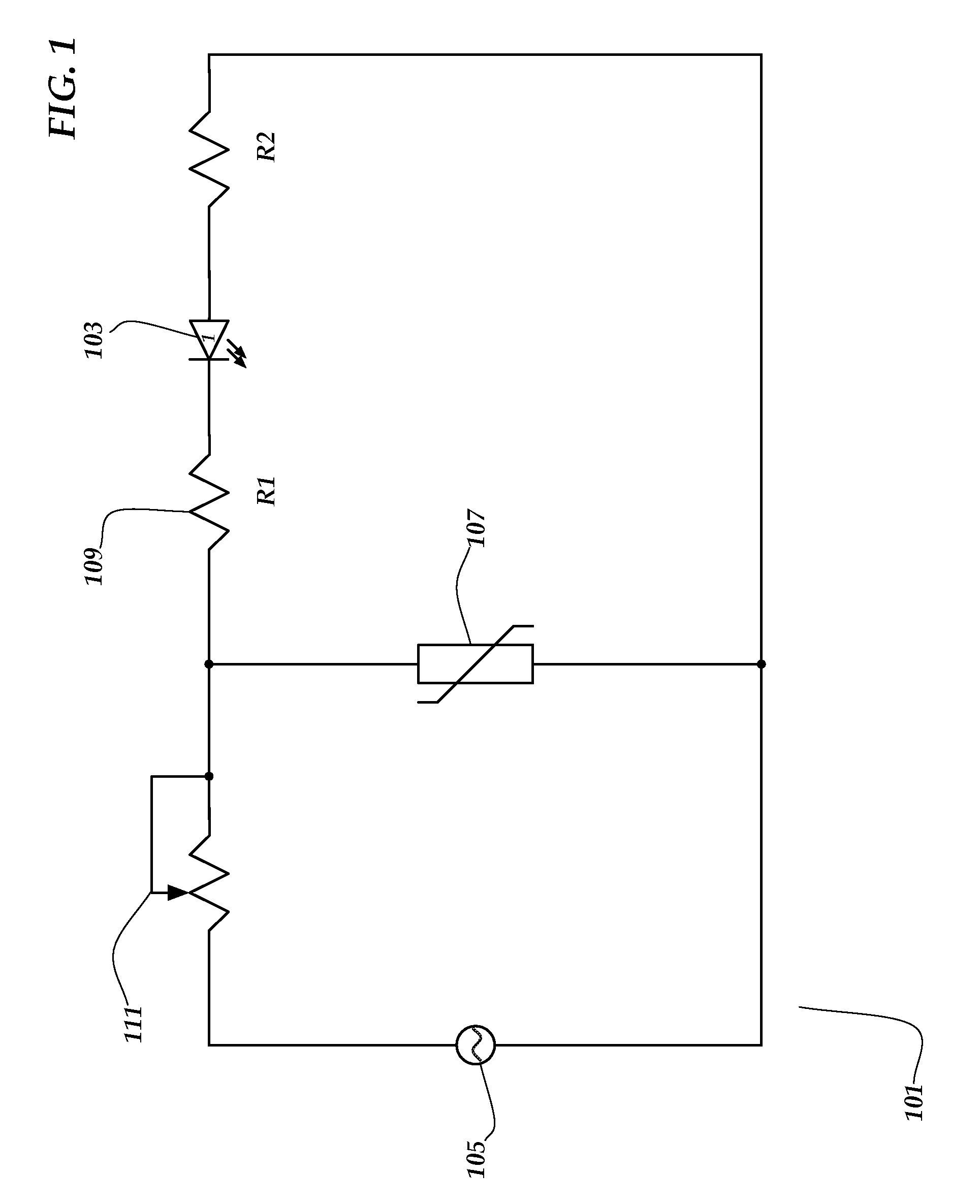

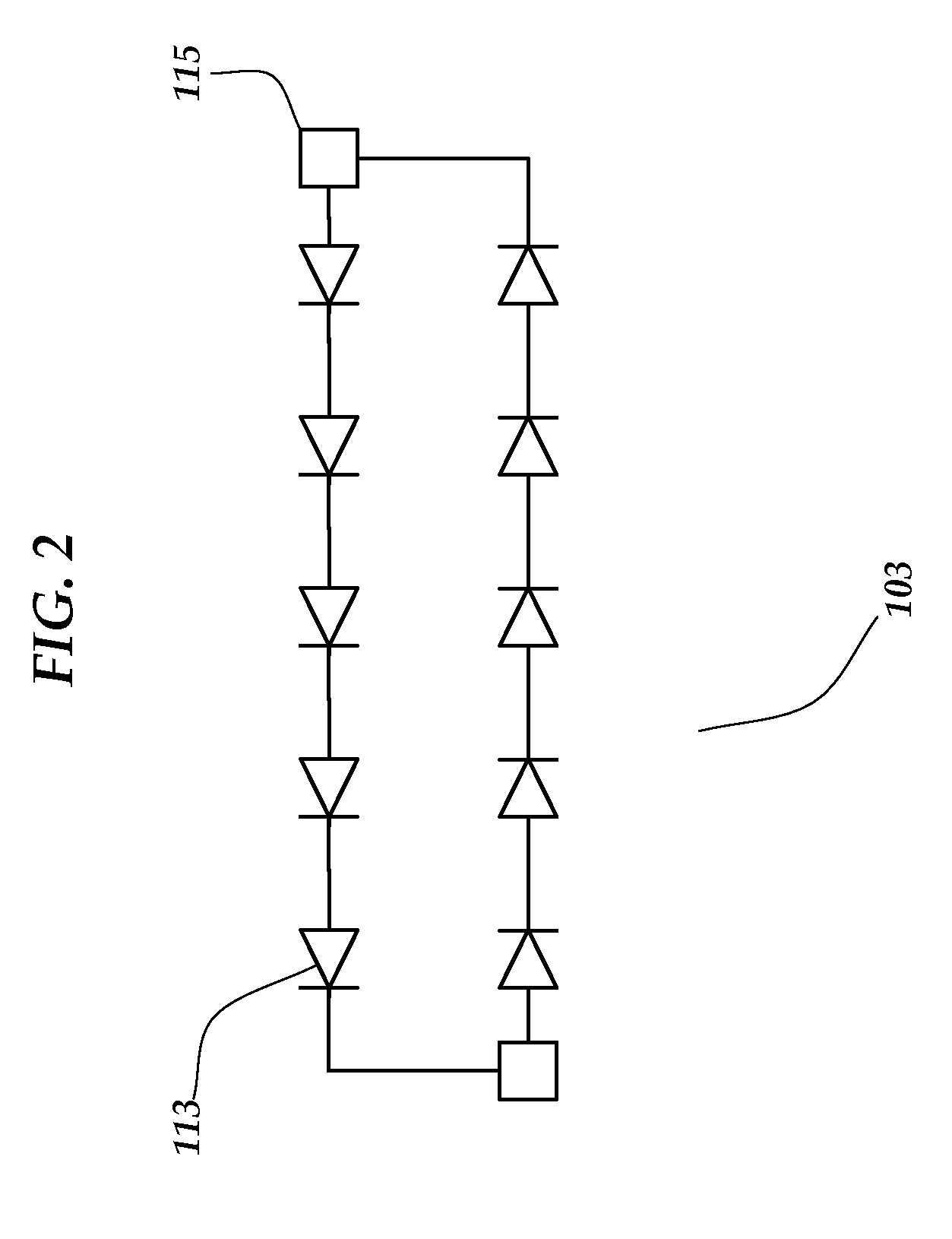

Apparatus and method to enhance the life of Light Emitting diode (LED) devices in an LED matrix

InactiveUS20100277077A1Prolong lifeLower junction temperatureElectrical apparatusElectroluminescent light sourcesDirect couplingEngineering

The present invention is an apparatus to enhance the Life of LED devices in an LED matrix for illumination. It comprises of a spare LED matrix in addition to a main LED matrix. It further comprises of a constant current source which is the power source. Such constant current source is coupled directly to said main LED matrix and powers it up accordingly. In adverse conditions, say when the ambient temperature is high, continuous operation of said main LED matrix at full power will deteriorate the LED life. A power converter coupled to said constant current source operates and draws current to power on said spare LED matrix. This relieves said main LED matrix from full power and the reduction in illumination is largely compensated by said spare LED matrix. This invention further comprises a controller which senses temperature and other parameters and operates said spare LED matrix intelligently. The present invention is also a method to operate said apparatus to maximize LED life or to maximize illumination.

Owner:PONG MAN HAY +1

Silicon carbide on diamond substrates and related devices and methods

ActiveUS7033912B2Improve thermal conductivityReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesWaferingSemiconductor structure

Owner:WOLFSPEED INC

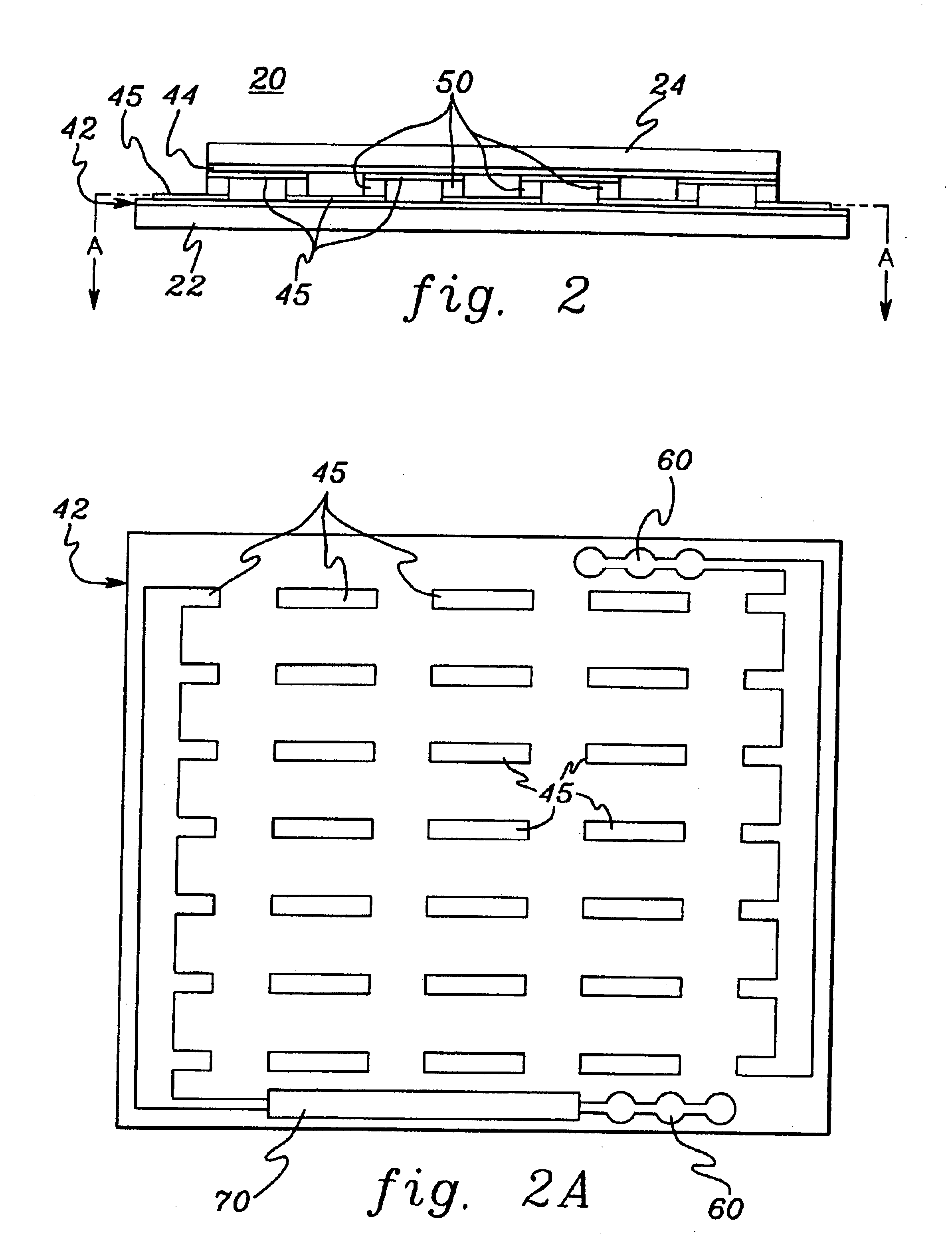

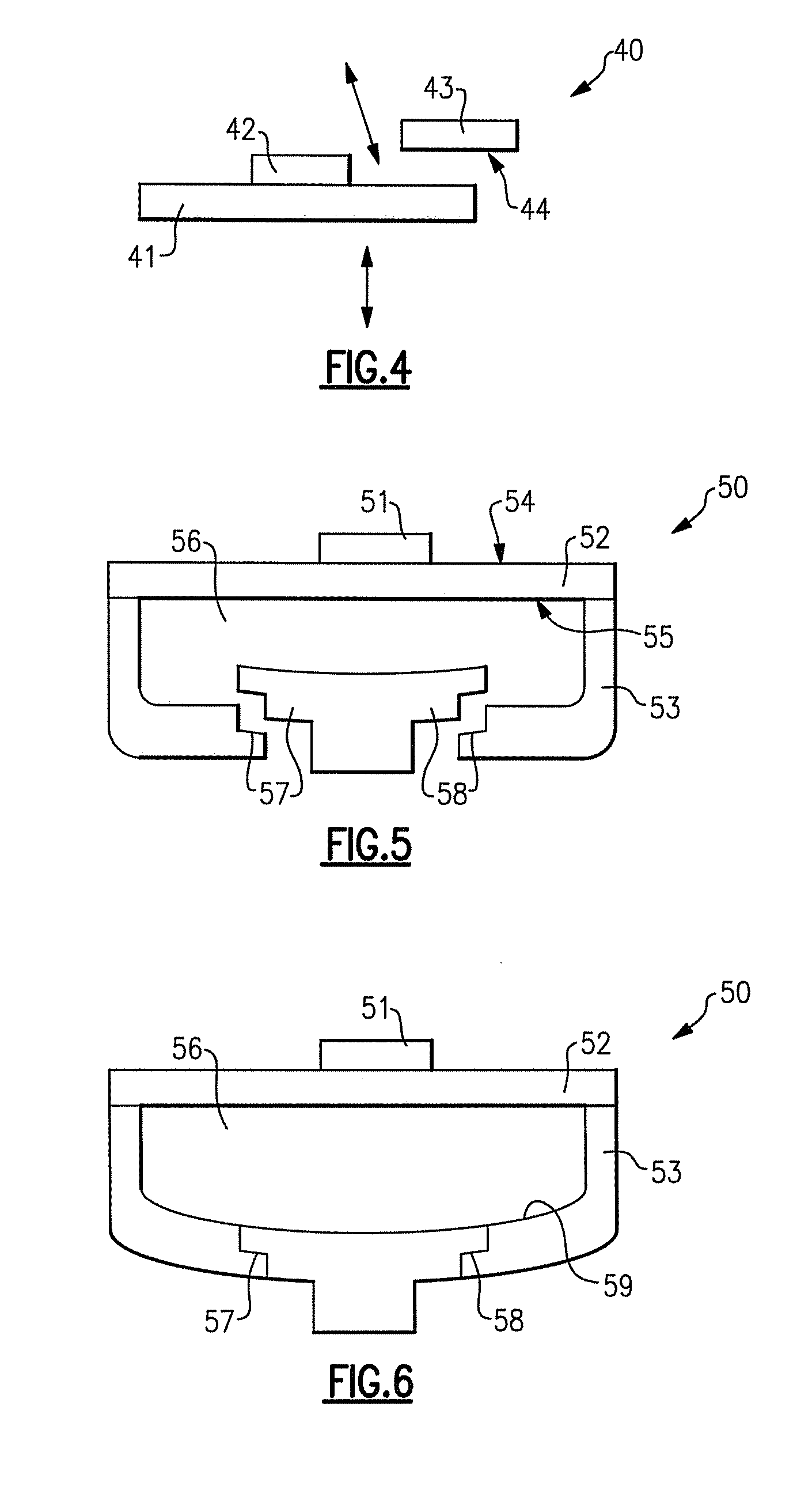

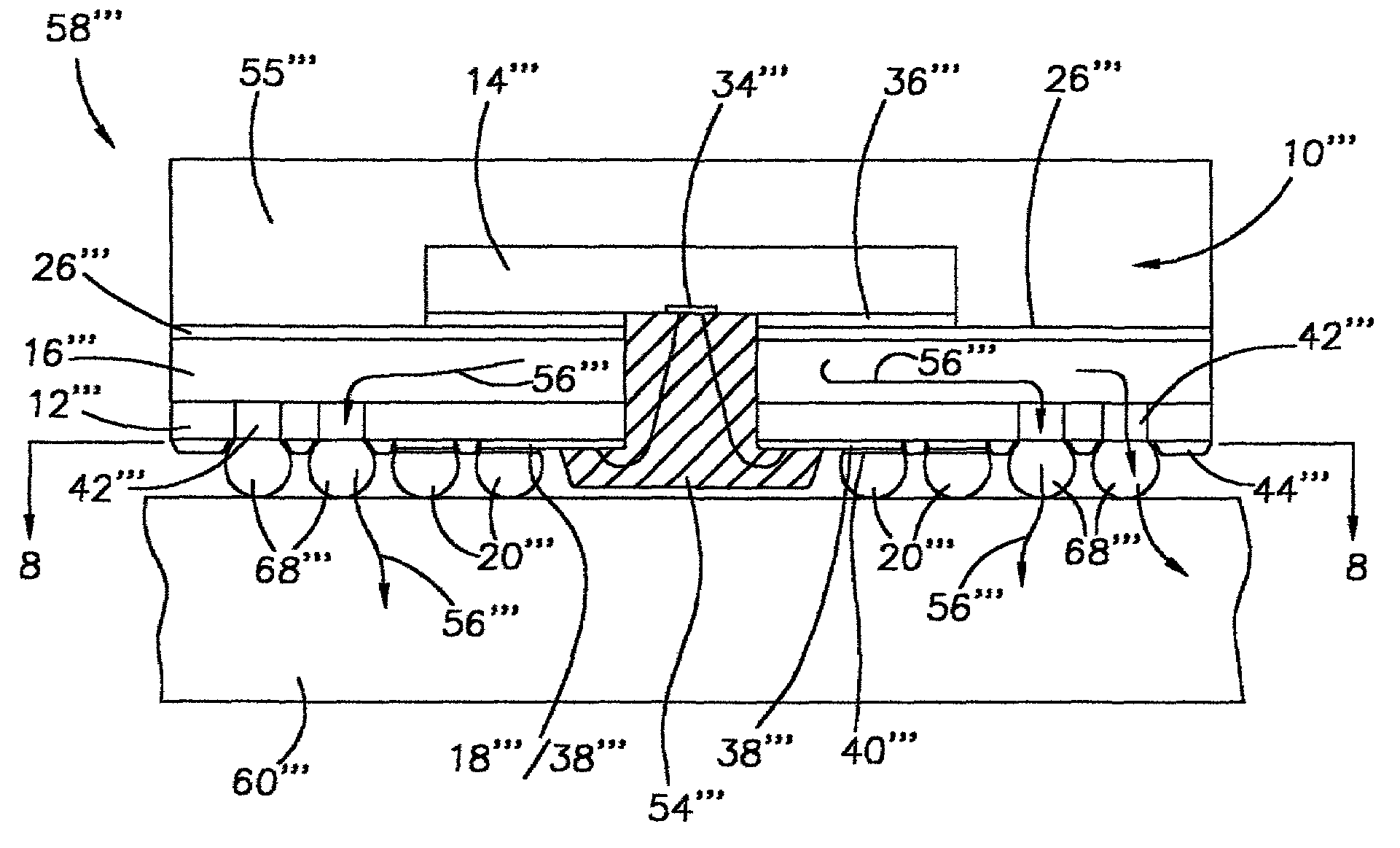

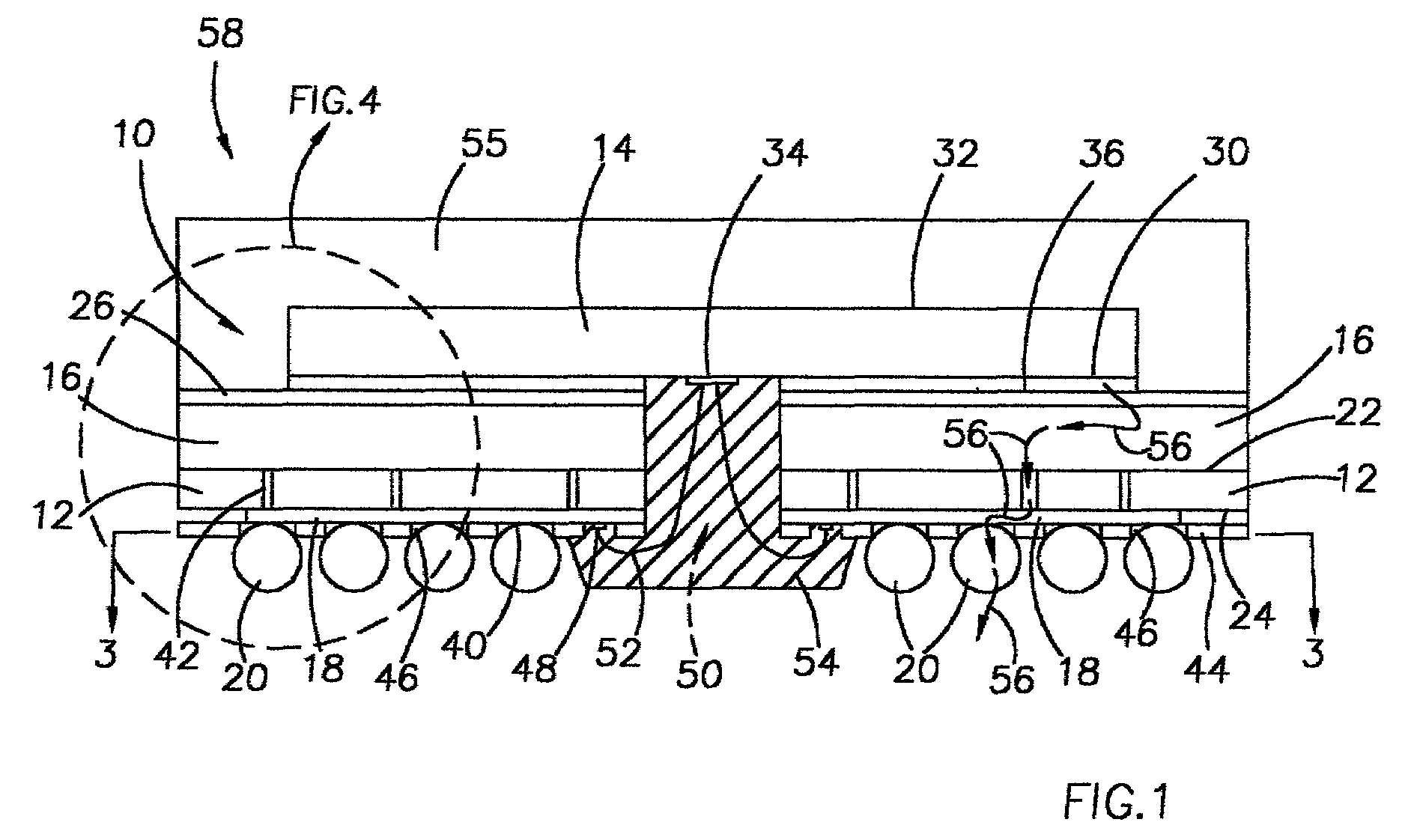

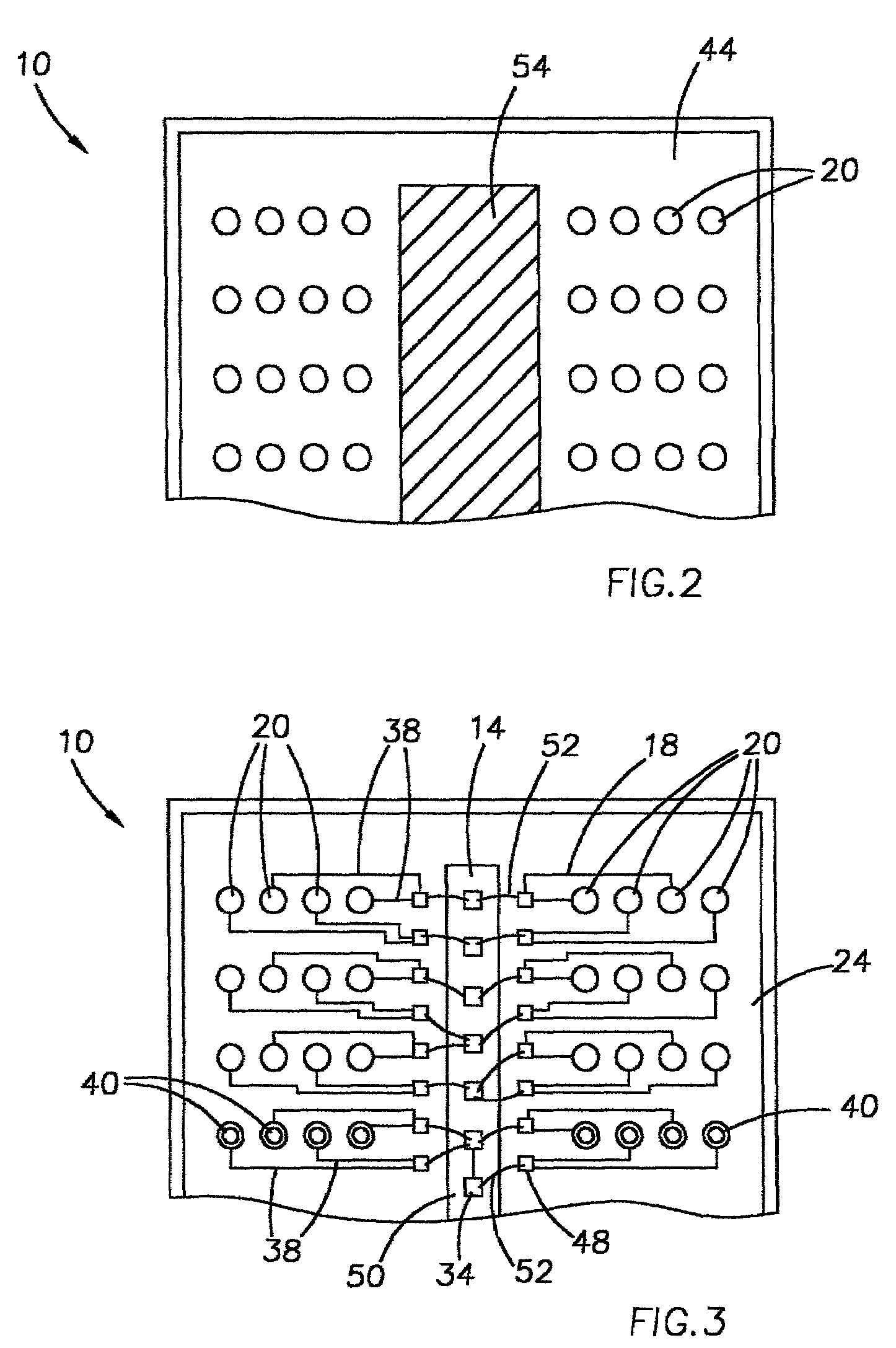

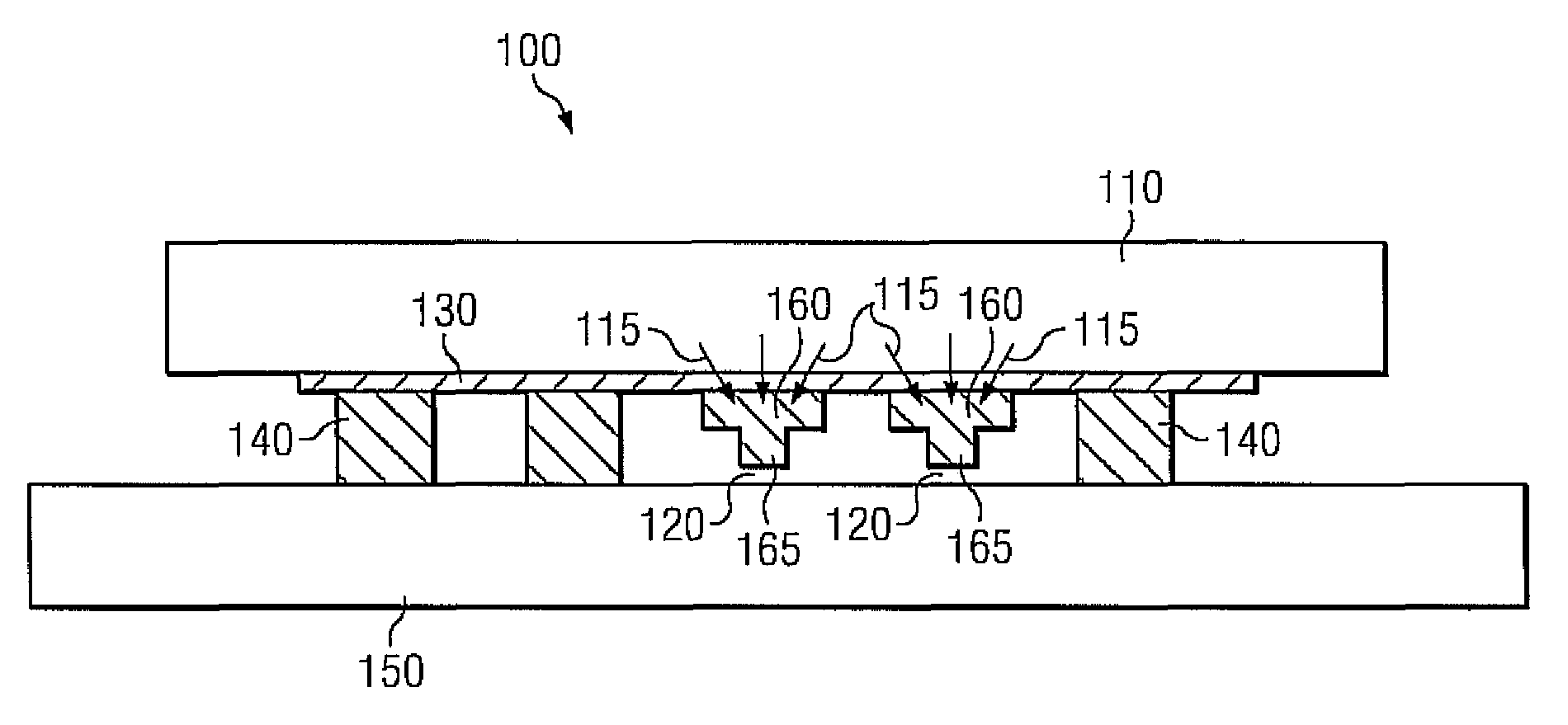

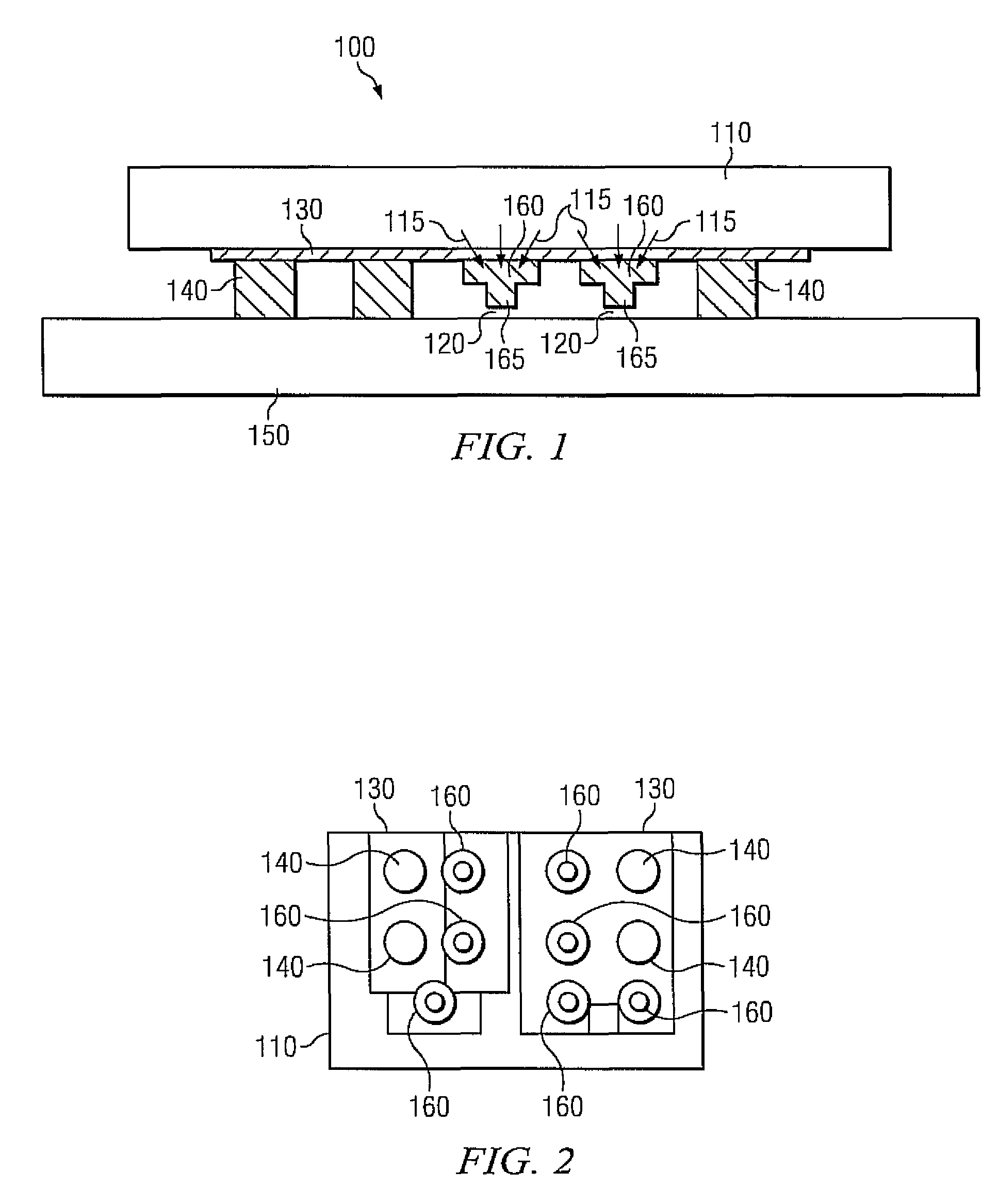

Intrinsic thermal enhancement for FBGA package

InactiveUS20050186704A1Signal integrationImprove performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialSolder ball

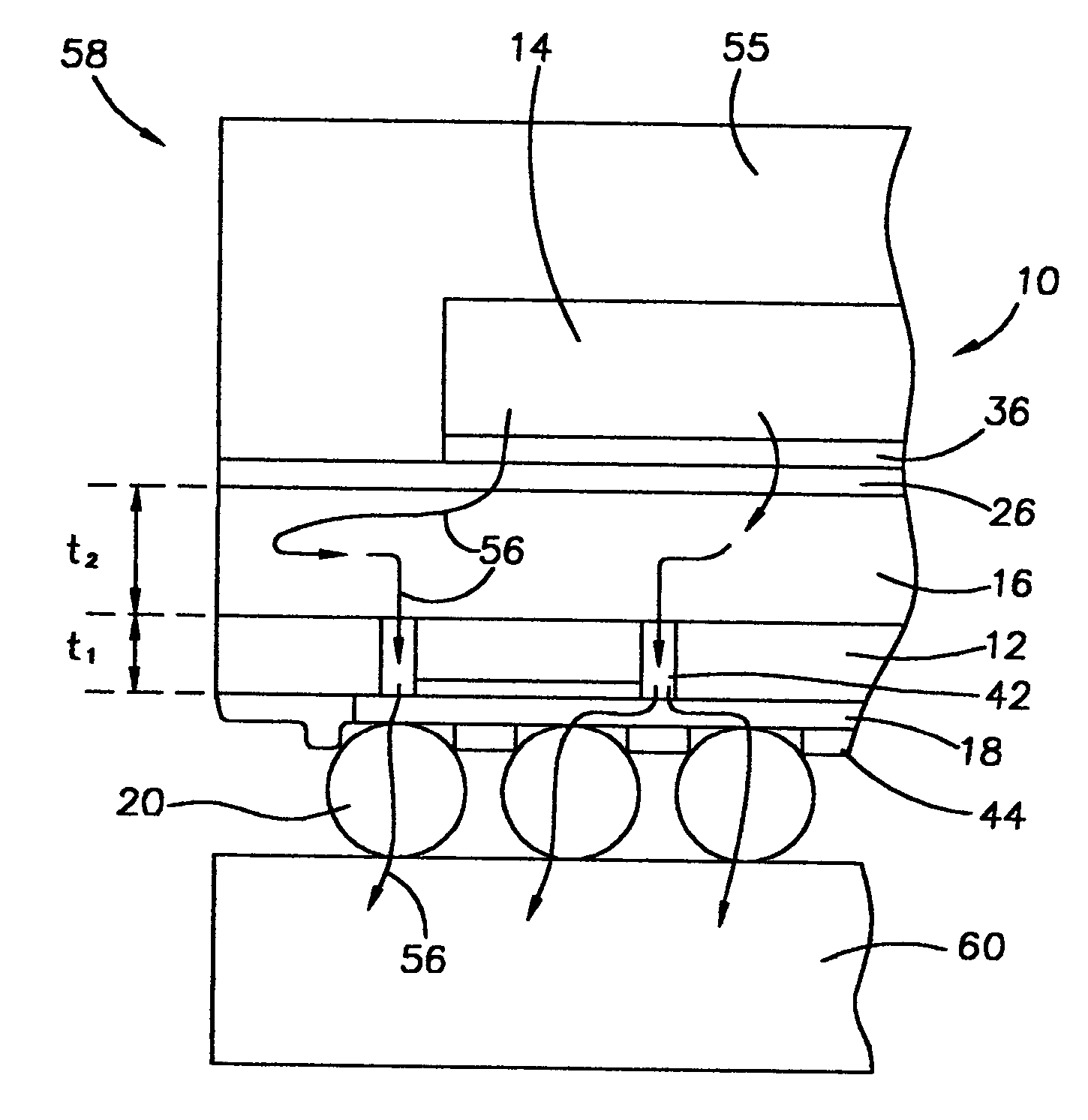

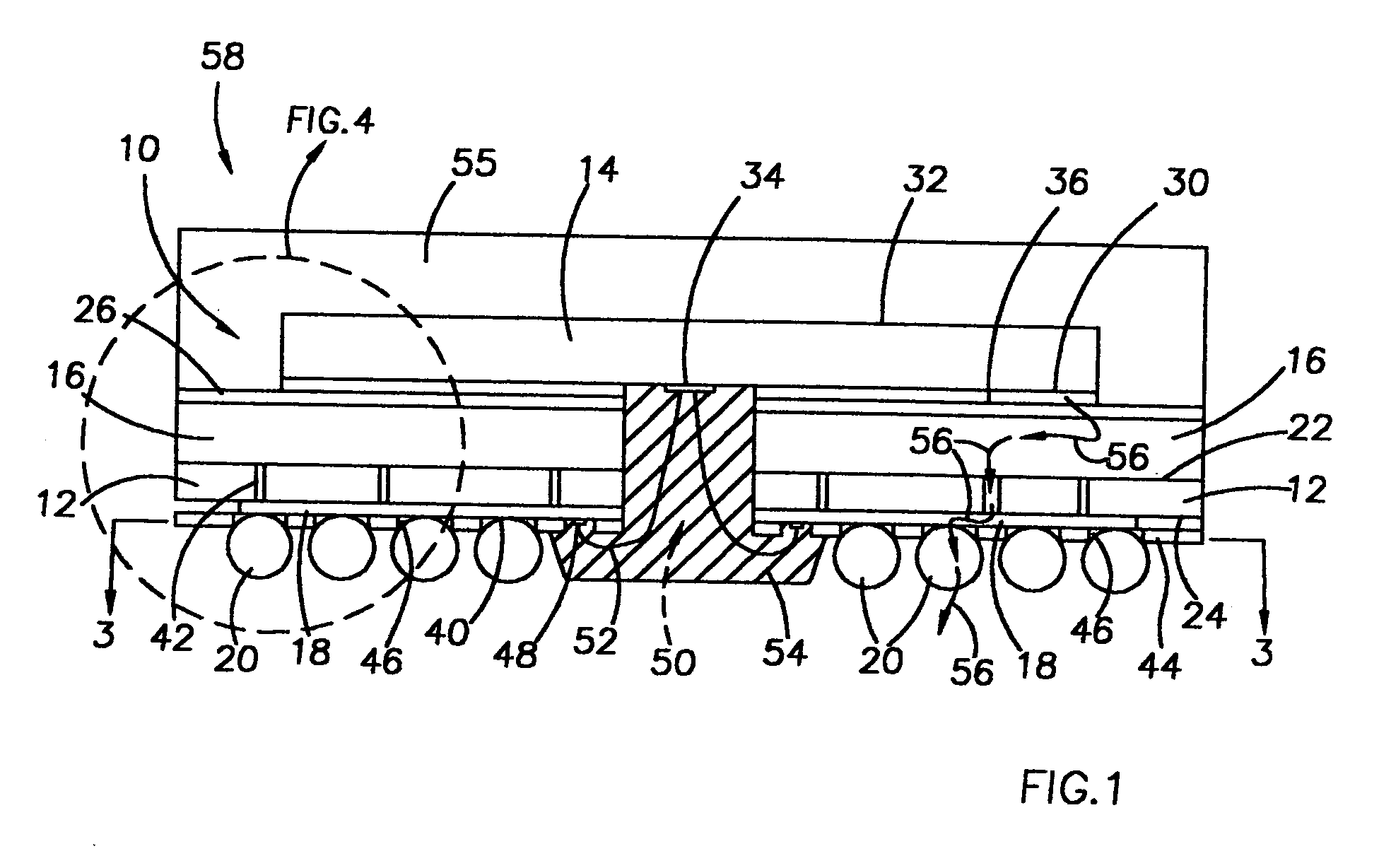

A semiconductor device for dissipating heat generated by a die during operation and having a low height profile, a semiconductor die package incorporating the device, and methods of fabricating the device and package are provided. In one embodiment, the semiconductor device comprises a thick thermally conductive plane (e.g., copper plane) mounted on a thin support substrate and interfaced with a die. Thermally conductive via interconnects extending through the substrate conduct heat generated by the die from the conductive plane to conductive balls mounted on traces on the opposing side of the substrate. In another embodiment, the semiconductor devices comprises a thick thermally conductive plane (e.g., copper foil) sandwiched between insulative layers, with signal planes (e.g., traces, bonding pads) disposed on the insulative layers, a die mounted on a first signal plane, and solder balls mounted on bonding pads of a second signal plane. A thermally conductive via interconnect extends through the substrate to provide a thermal path from the die and signal plane (traces) through the thick conductive plane and into the solder balls and external device (e.g., mother board). The present semiconductor device provides effective heat dissipation without the attachment of an external heat sink or spreader.

Owner:MICRON TECH INC

Electronic module with integrated programmable thermoelectric cooling assembly and method of fabrication

InactiveUS6767766B2Reduce fatigue lifeLow junction temperatureThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsPower controlVoltage

An electronic module and method of fabrication are provided employing an integrated thermal dissipation assembly. The thermal dissipation assembly includes a thermoelectric assembly configured to couple to an electronic device within the module for removing heat generated thereby, and a programmable power control circuit integrated with the thermoelectric assembly. The programmable power control circuit allows cooling capacity of the thermoelectric assembly to be tailored to anticipated heat dissipation of the electronic device by adjusting, for a given power source, voltage level to the thermoelectric elements of the thermoelectric assembly. Power to the thermoelectric assembly can be provided through conductive power planes disposed within a supporting substrate. The power control circuit includes one or more voltage boost circuits connected in series between the given power source and the thermoelectric elements of the associated thermoelectric assembly.

Owner:IBM CORP

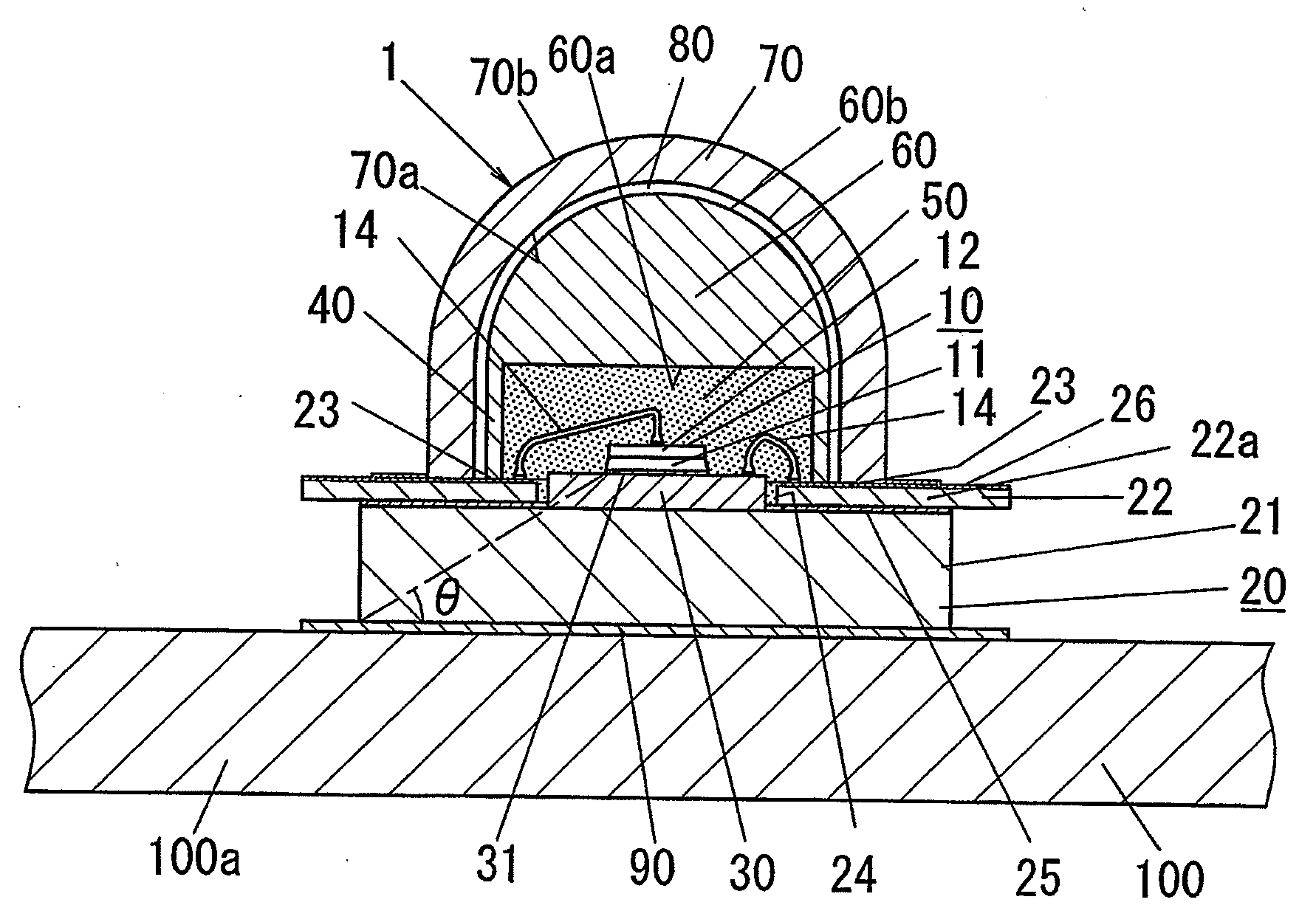

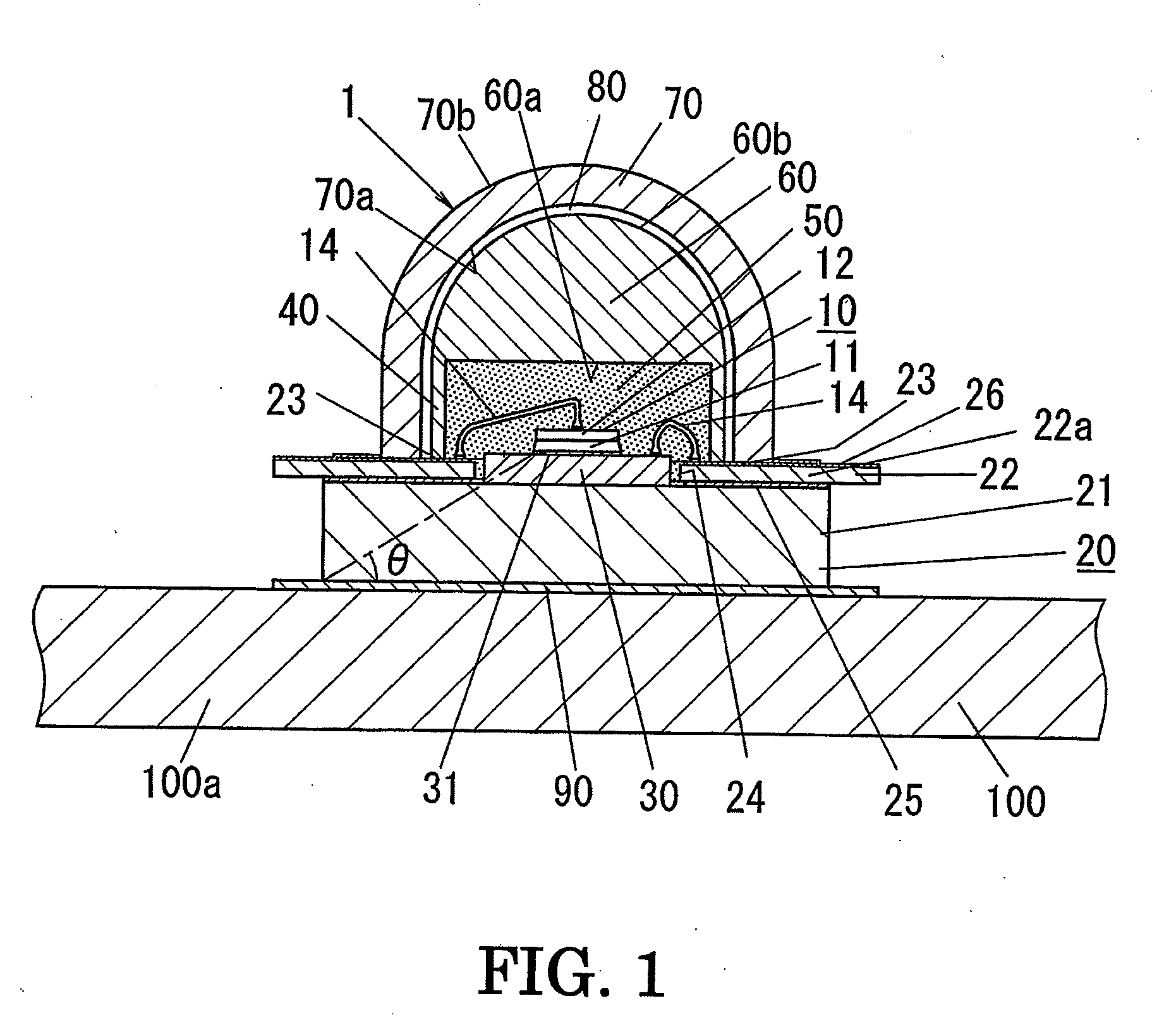

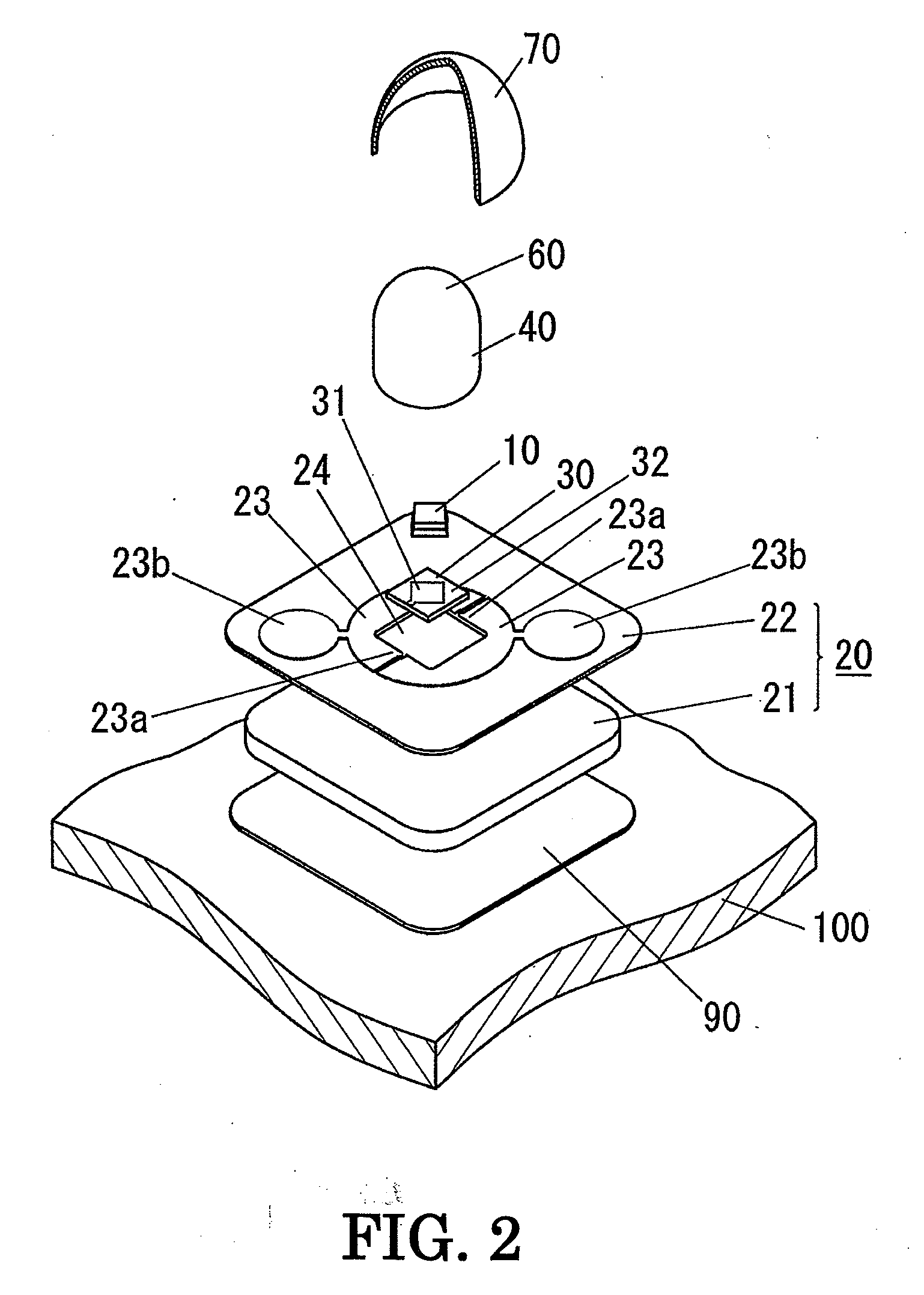

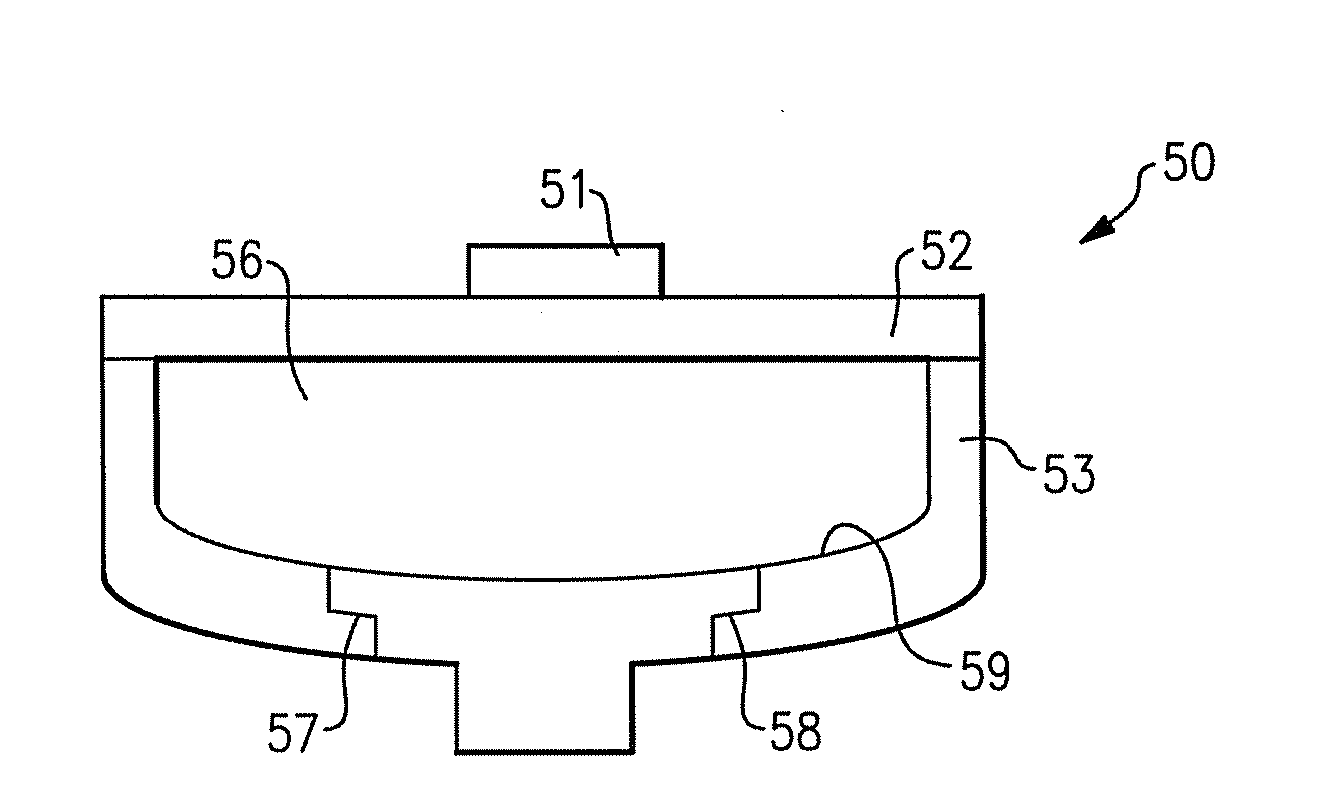

LED lighting fixture

InactiveUS20100148196A1Inhibit transferIncrease temperatureLighting support devicesSolid-state devicesConductive materialsColor changes

A light-emitting device held on a fixture body includes an LED chip, a heat transfer plate made of a thermally conductive material on which the LED chip is mounted, a wiring board having, on one side, patterned conductors, for supplying an electric power to the LED chip and formed with an aperture (exposure part) through which a LED chip mount surface of the heat transfer plate is exposed, an encapsulation part in which the LED chip is encapsulated on the one side of the wiring board, and a dome-shaped color-changing member made of a fluorescent material and an optically transparent material and placed on the one side of the wiring board. The light-emitting device is bonded to the fixture body with an insulating layer interposed therebetween, and the insulating layer has electrical insulating properties and is interposed between the heat transfer plate and the fixture body to thermally couple the same.

Owner:MATSUSHITA ELECTRIC WORKS LTD

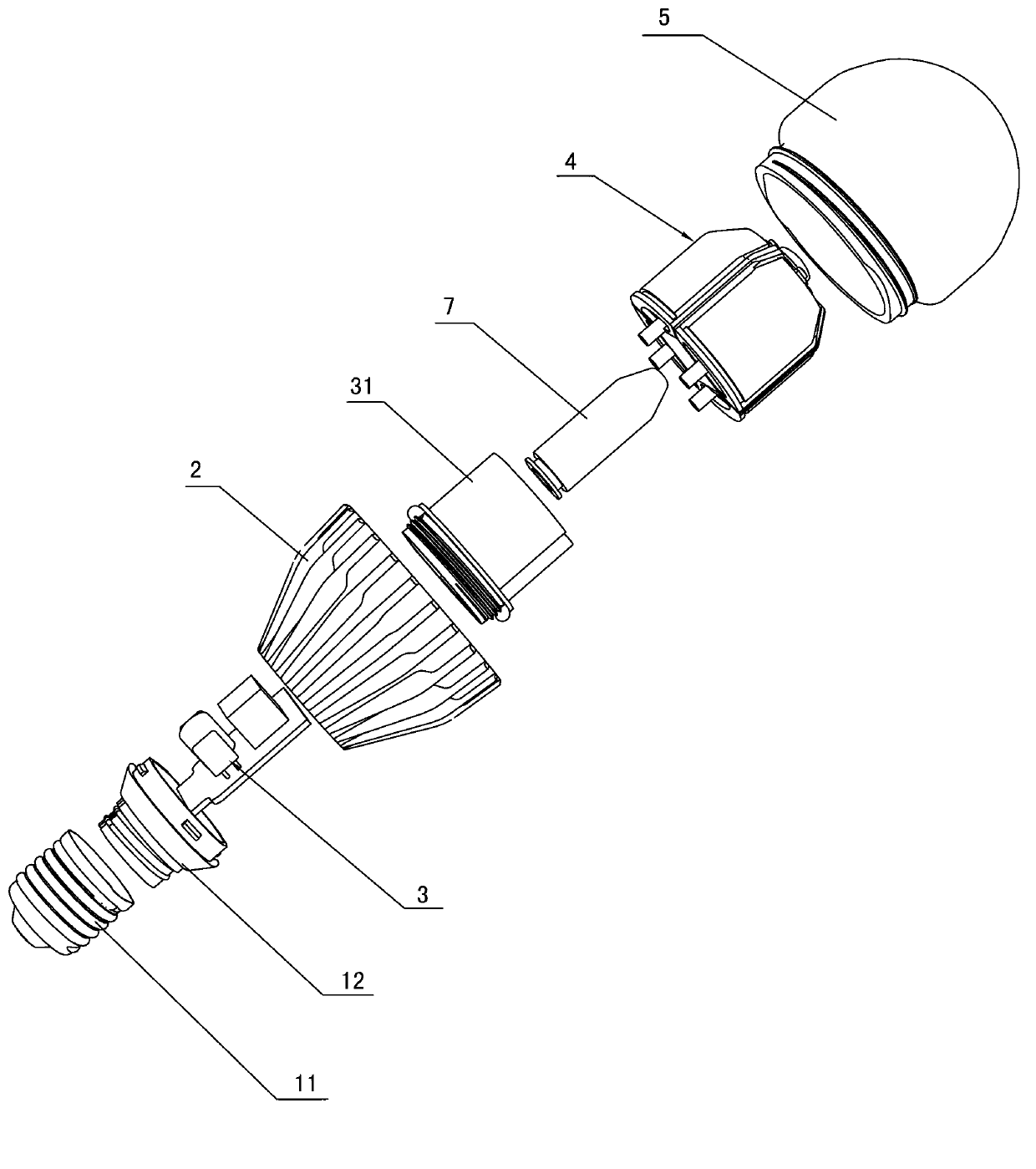

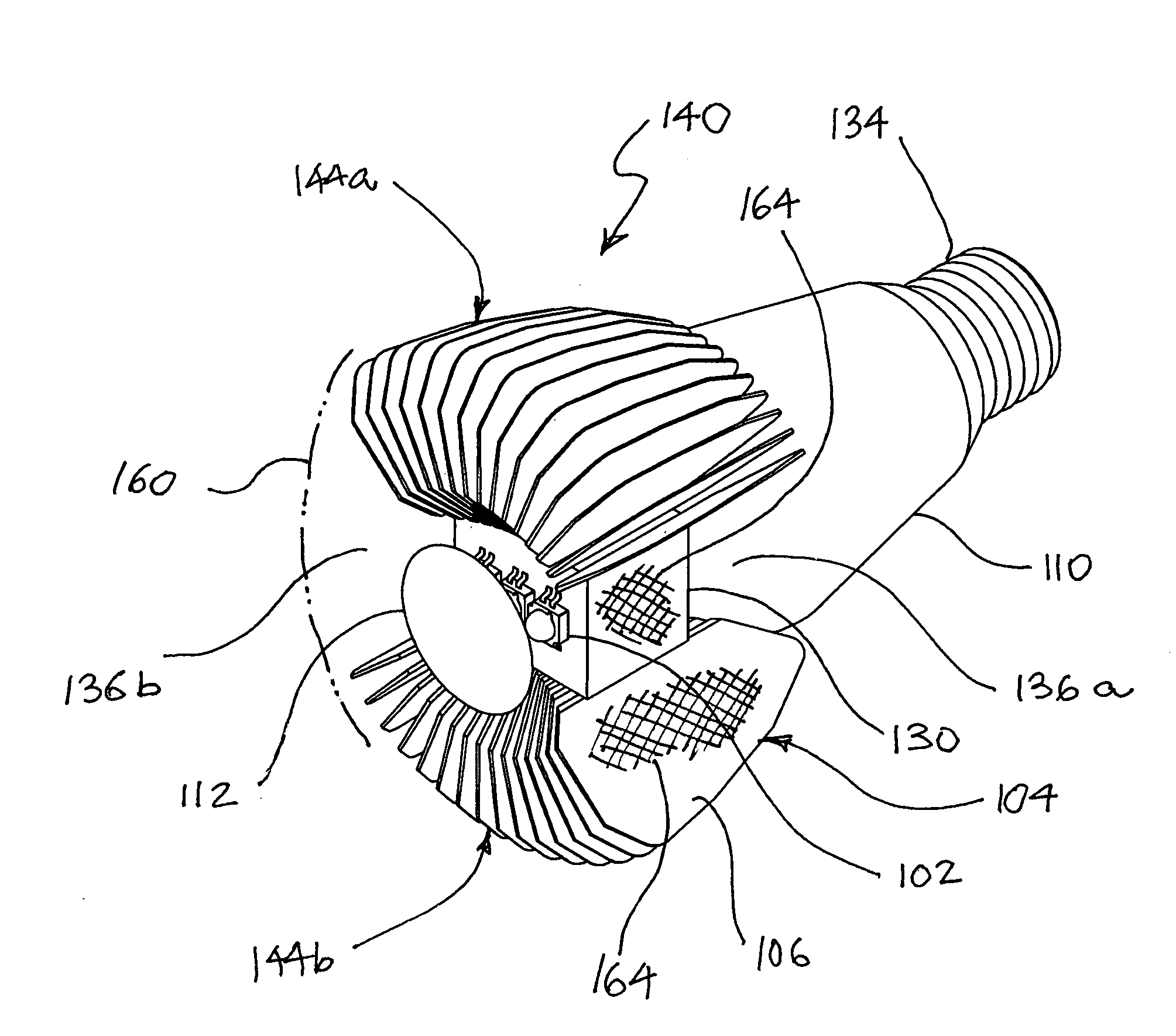

Lighting device and method of cooling lighting device

ActiveUS20100246177A1Solution to short lifeImprove efficiencyPoint-like light sourceLighting support devicesEffect lightEngineering

A lighting device comprising a solid state light emitter and a fan, the fan blowing fluid toward the emitter. A lighting device comprising a solid state light emitter and a baffle, the solid state light emitter being movable. A lighting device comprising a solid state light emitter, a substrate and a diaphragm, the diaphragm defining a chamber having a valve and being movable. A lighting device comprising a housing and a solid state light emitter within the housing, the solid state light emitter being movable. Also, methods of cooling a lighting device.

Owner:IDEAL IND LIGHTING LLC

Intrinsic thermal enhancement for FBGA package

InactiveUS7138711B2Signal integrationImprove performanceSemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor package

Owner:MICRON TECH INC

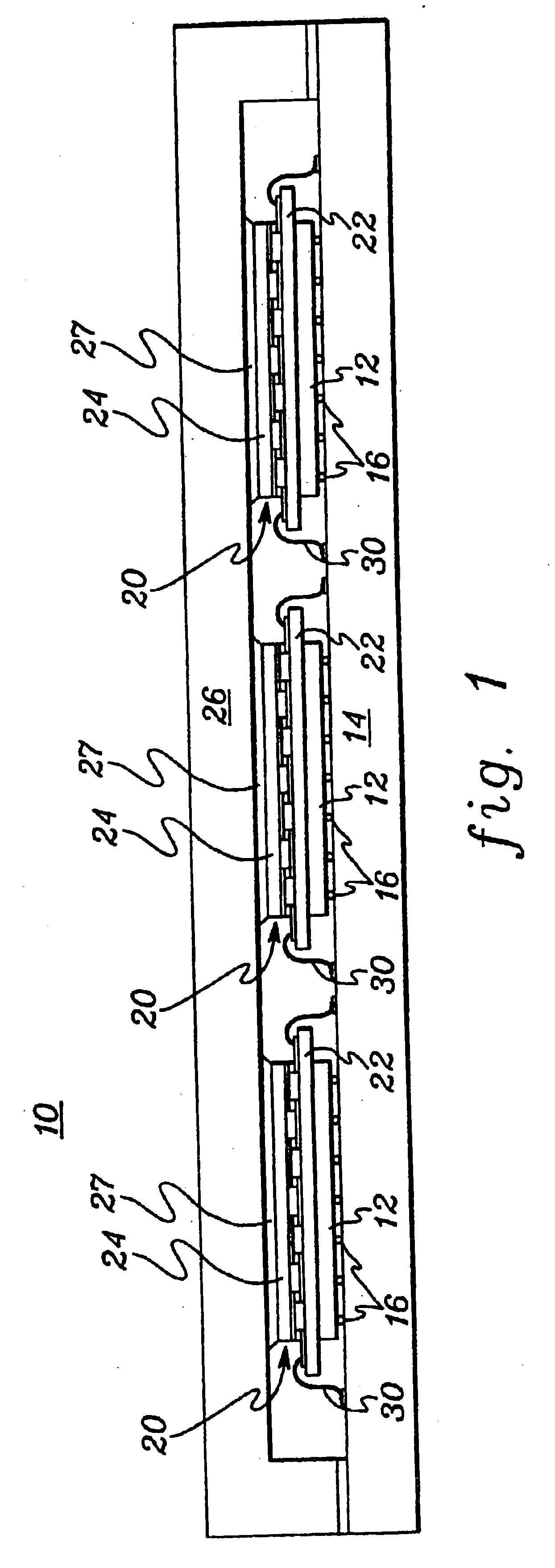

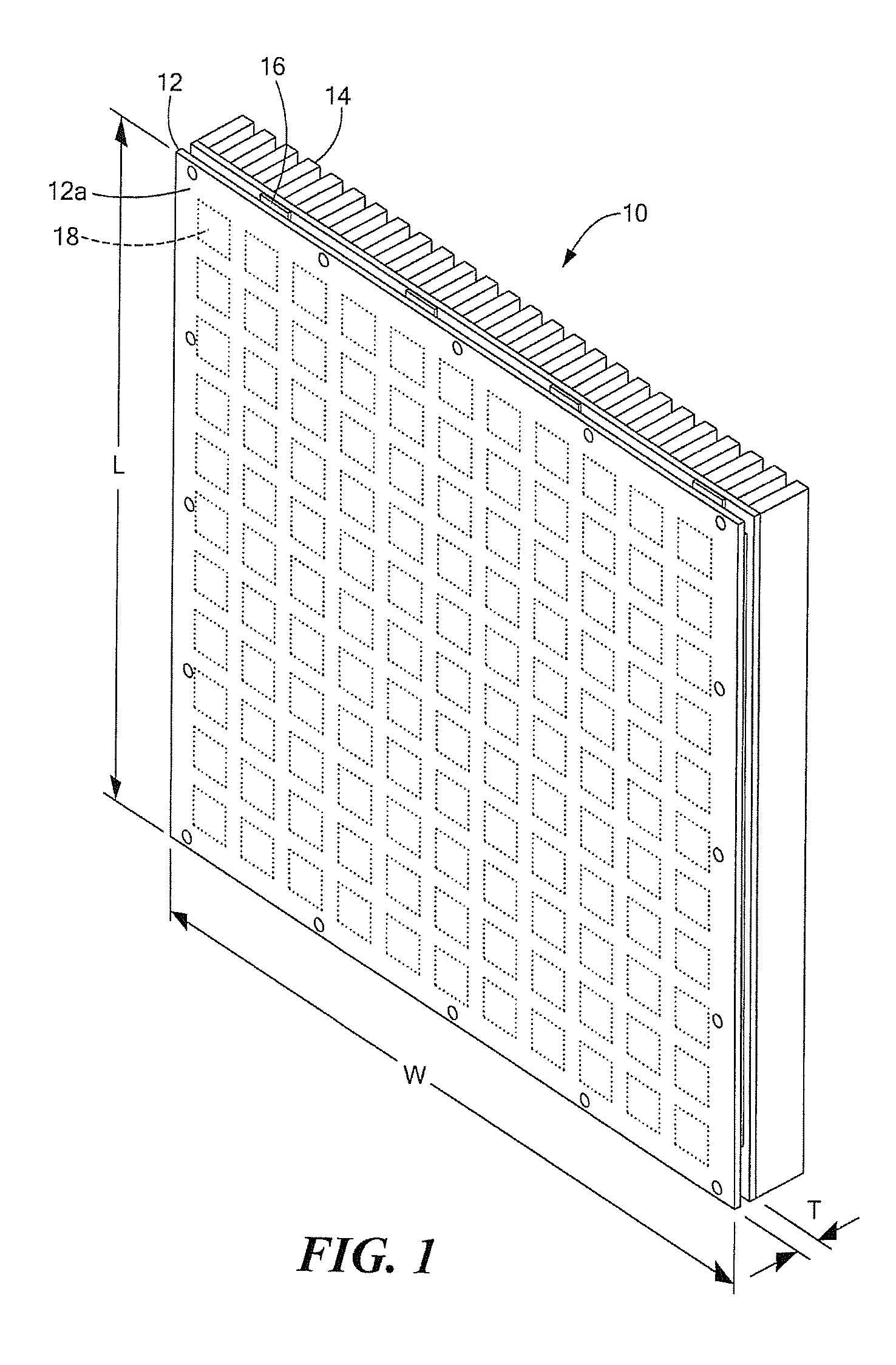

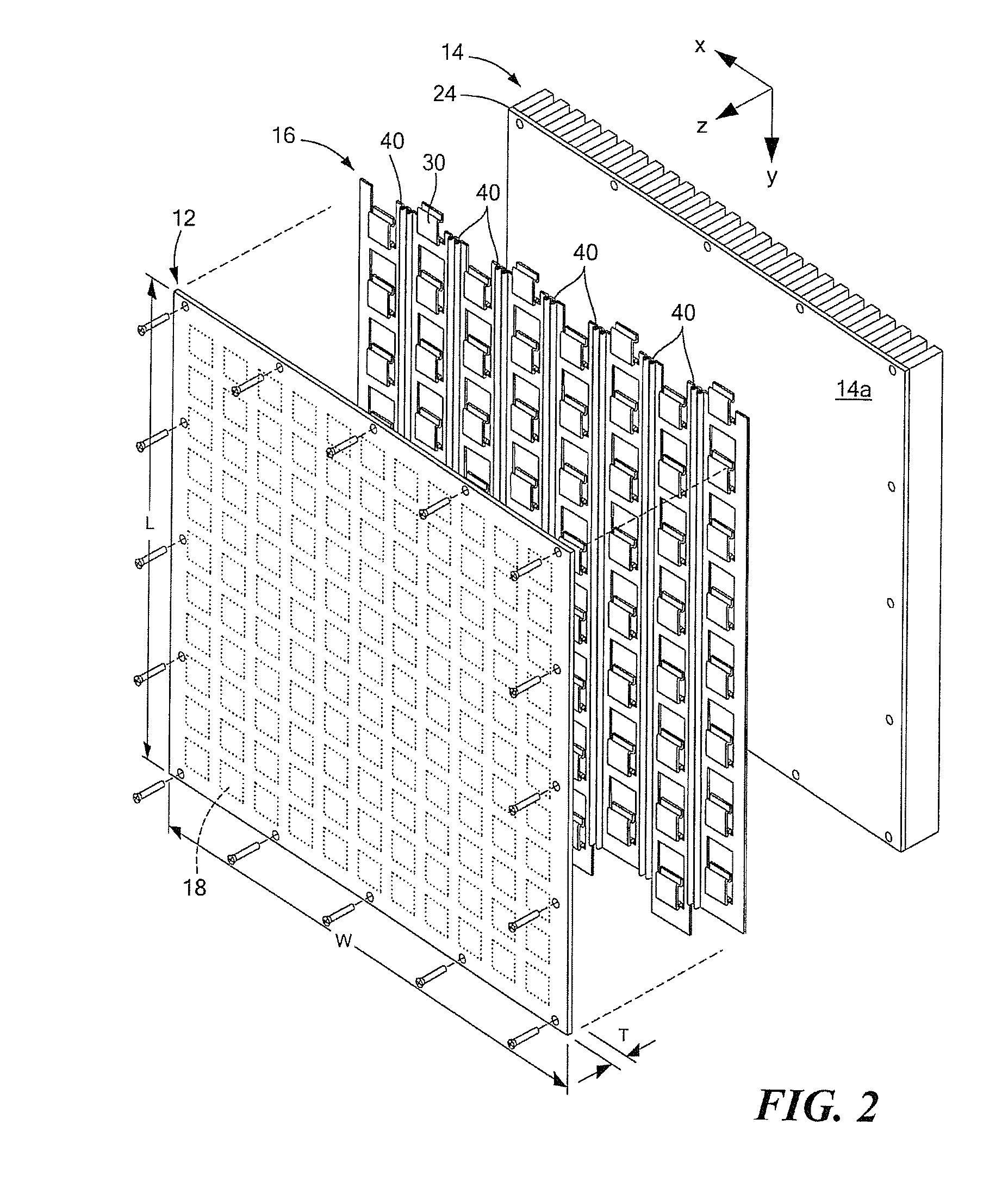

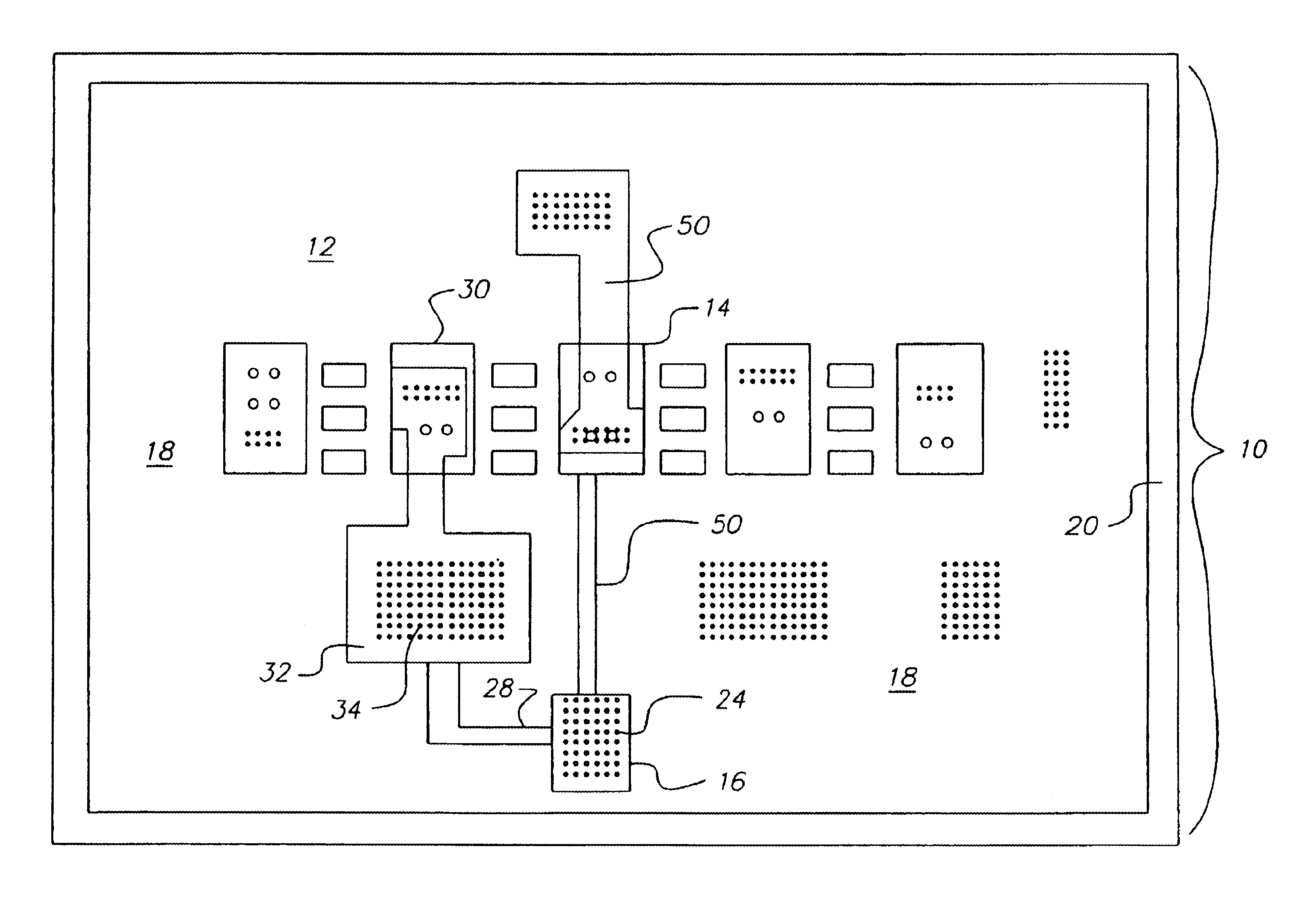

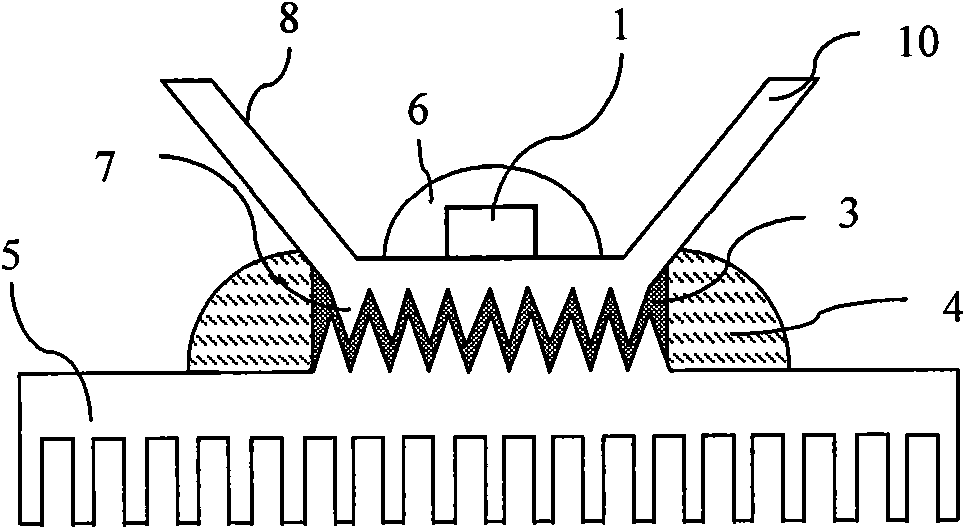

Heat Sink Interface Having Three-Dimensional Tolerance Compensation

ActiveUS20110075377A1Superior thermal pathLower junction temperatureModifications by conduction heat transferHeat exchange apparatusHeat spreaderFlip chip

A thermal interface includes a plurality of elevated regions and a plurality of mechanical tolerance circuits coupled to the plurality of elevated regions. The thermal interface is configured to be disposed between an array of heat generating elements and a heat sink with each of the plurality of elevated regions thermally coupled to a corresponding one or more of the array of heat generating elements. In one embodiment, the thermal interface provides a thermal path between a printed wiring board having a plurality of flip-chip circuit components disposed on an external surface thereof and a heat sink disposed over the flip-chip circuit components.

Owner:RAYTHEON CO

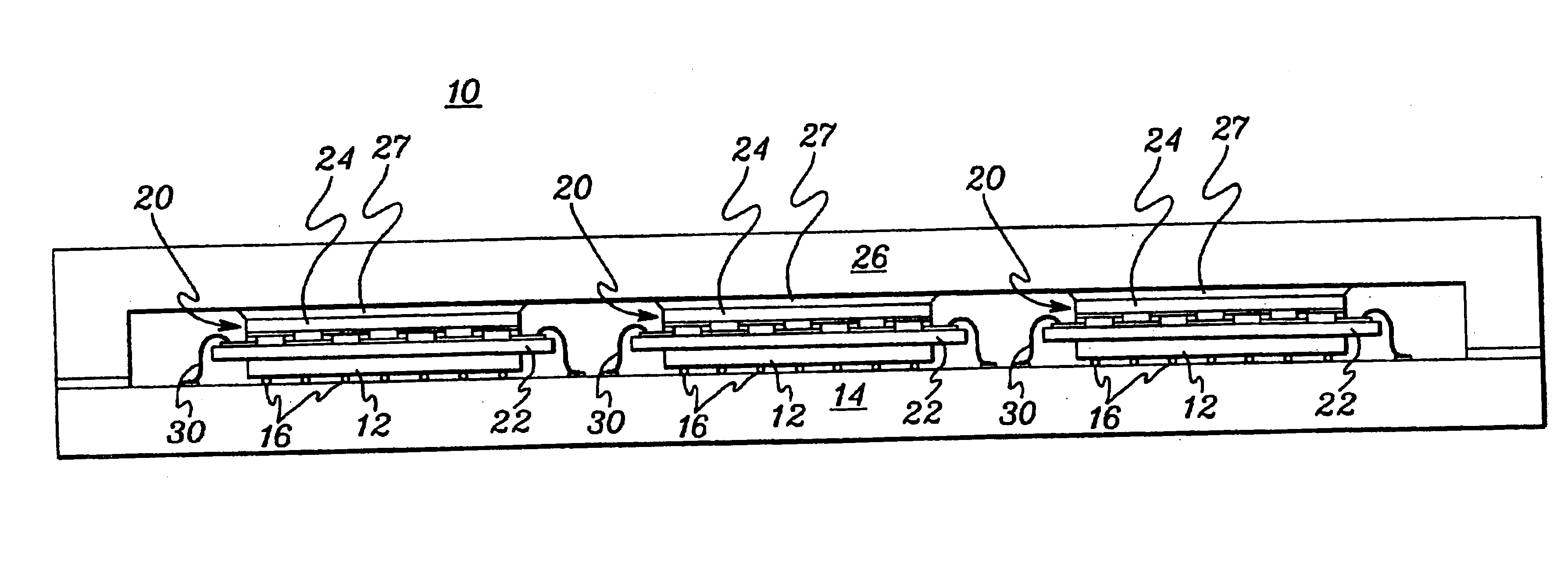

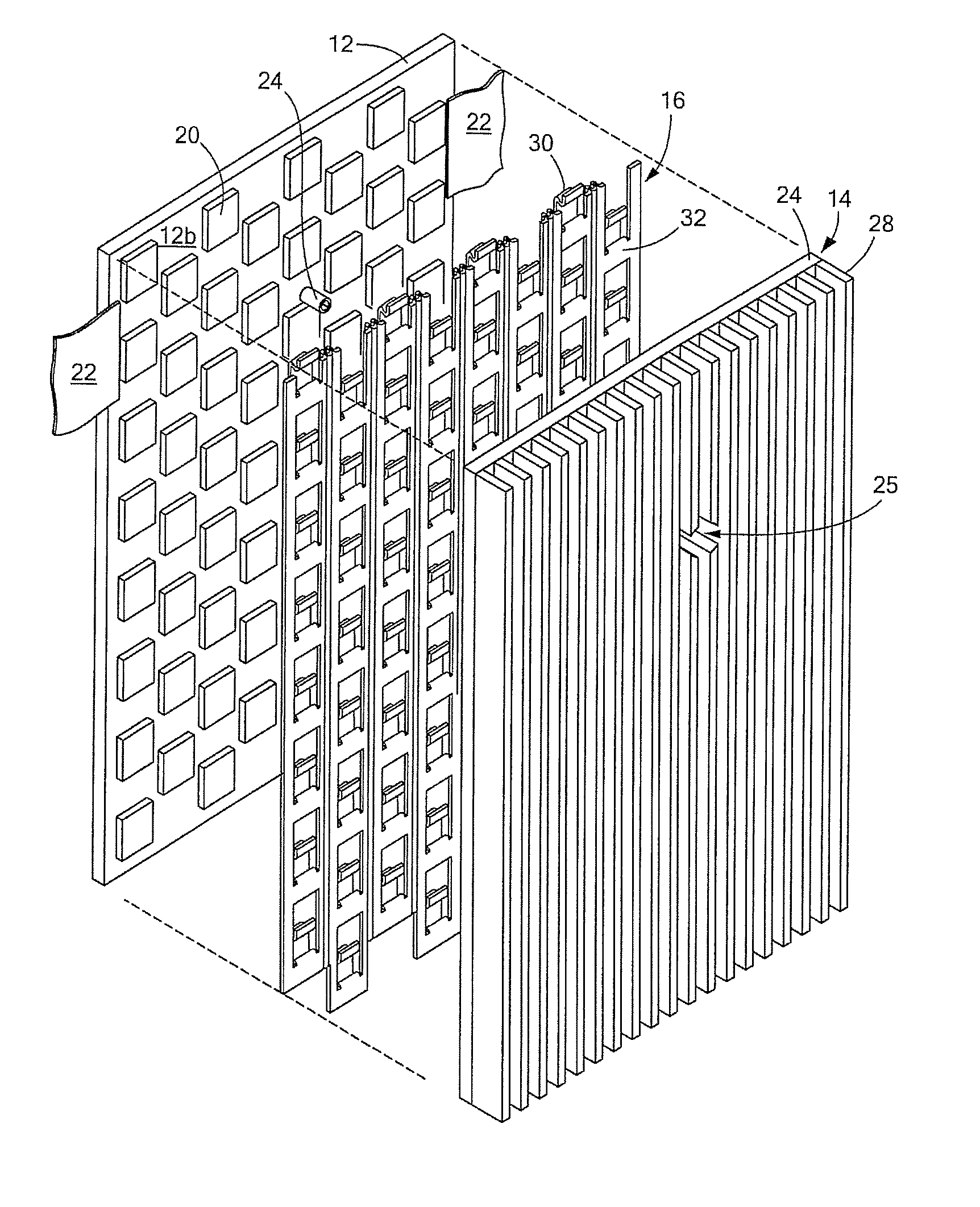

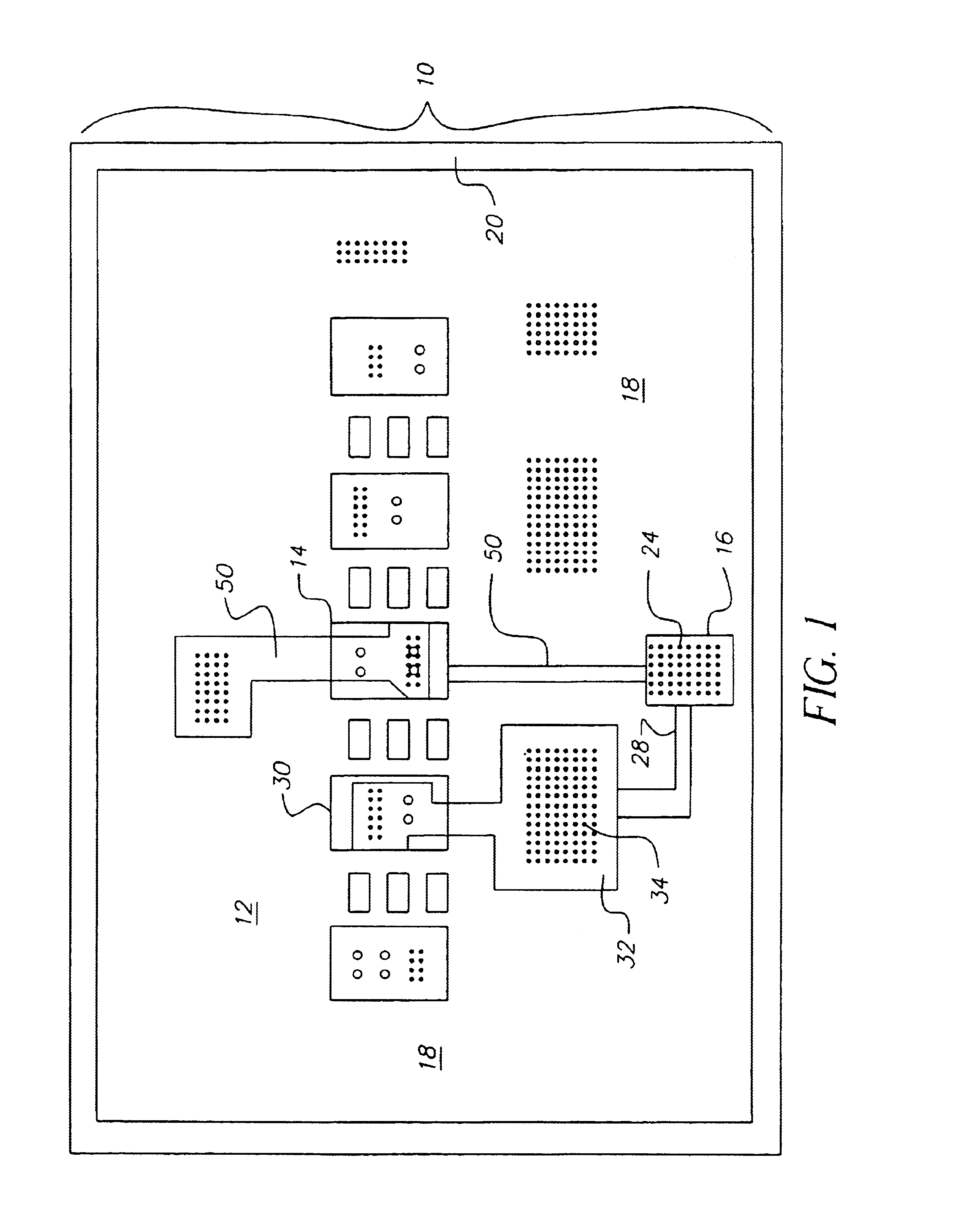

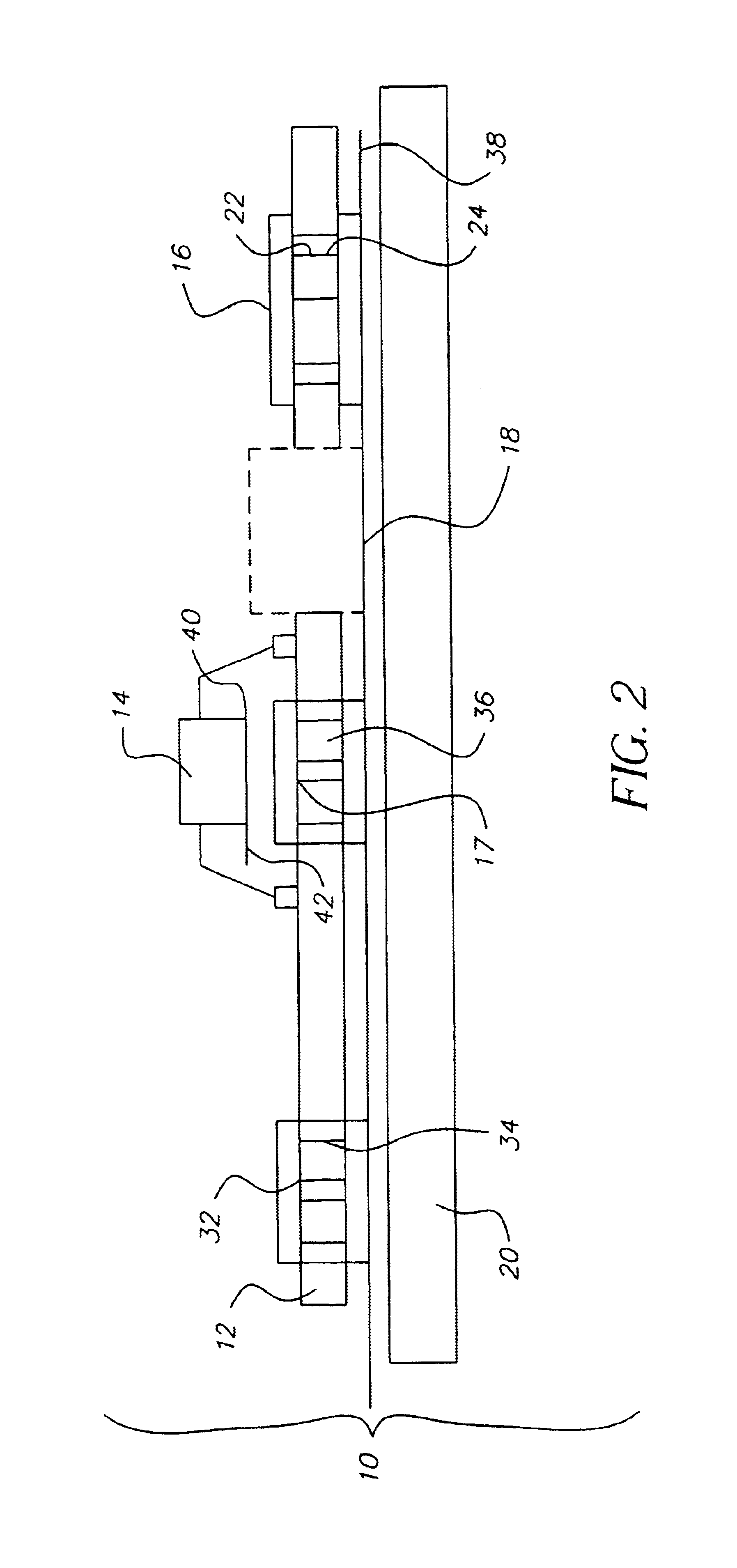

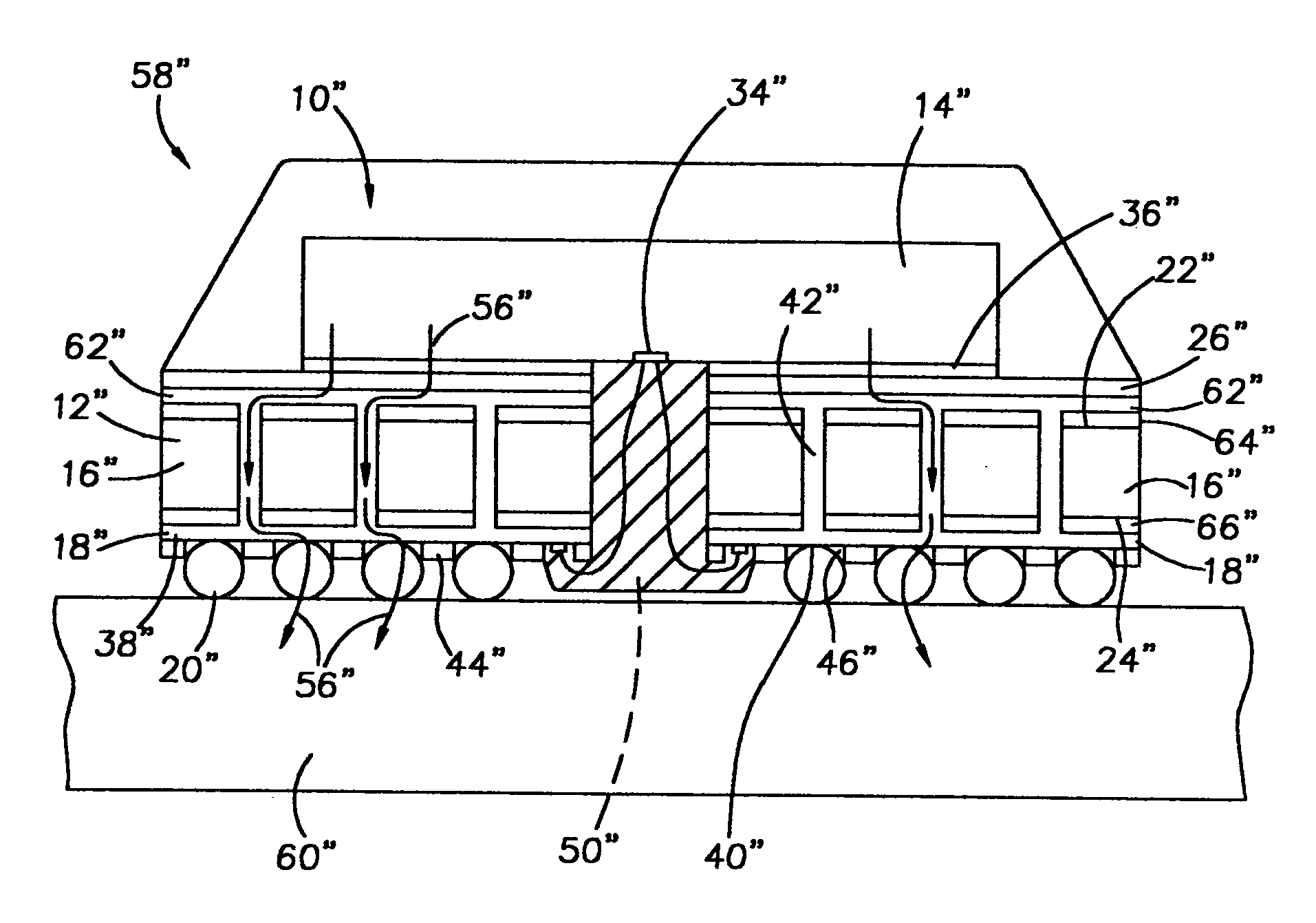

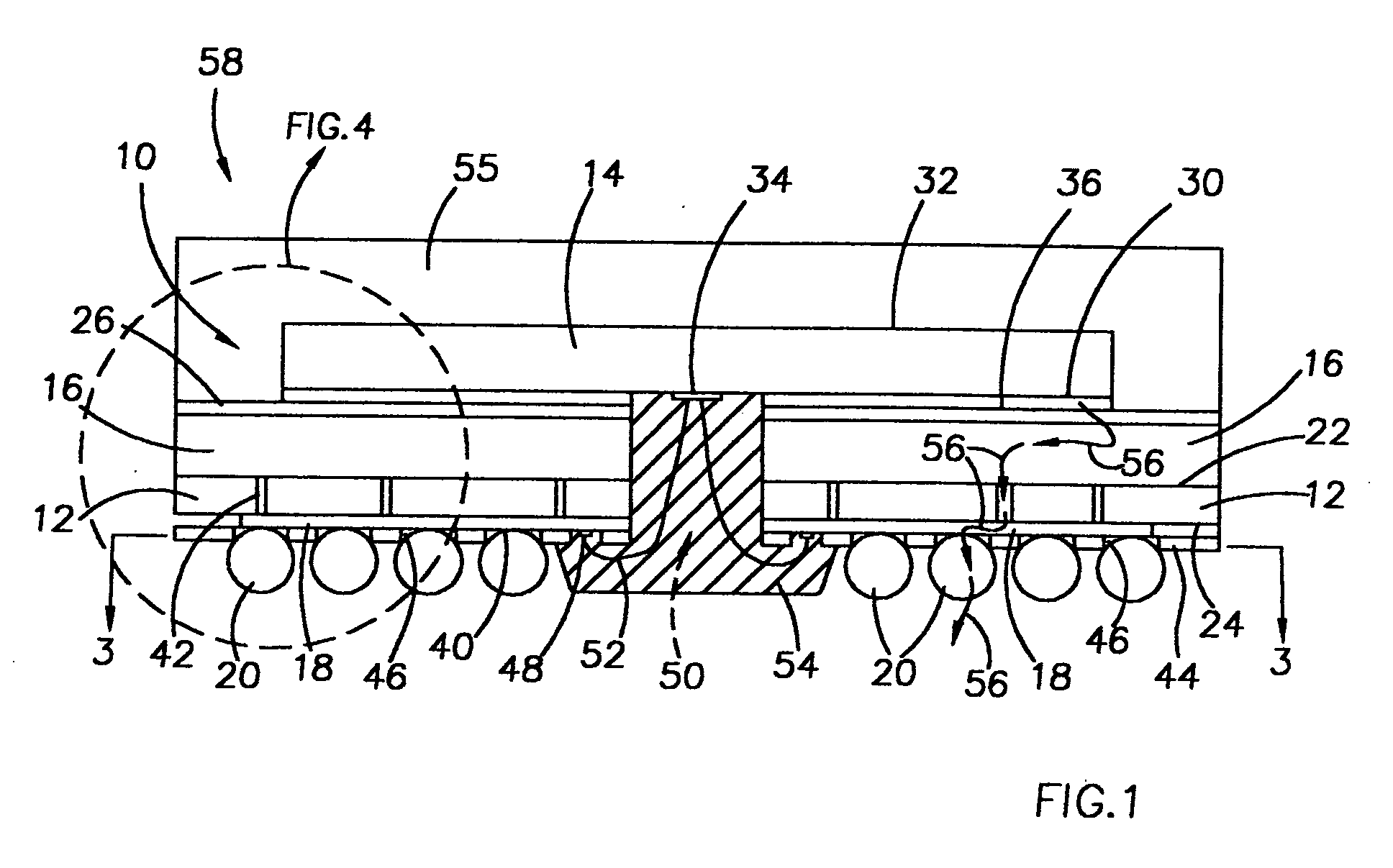

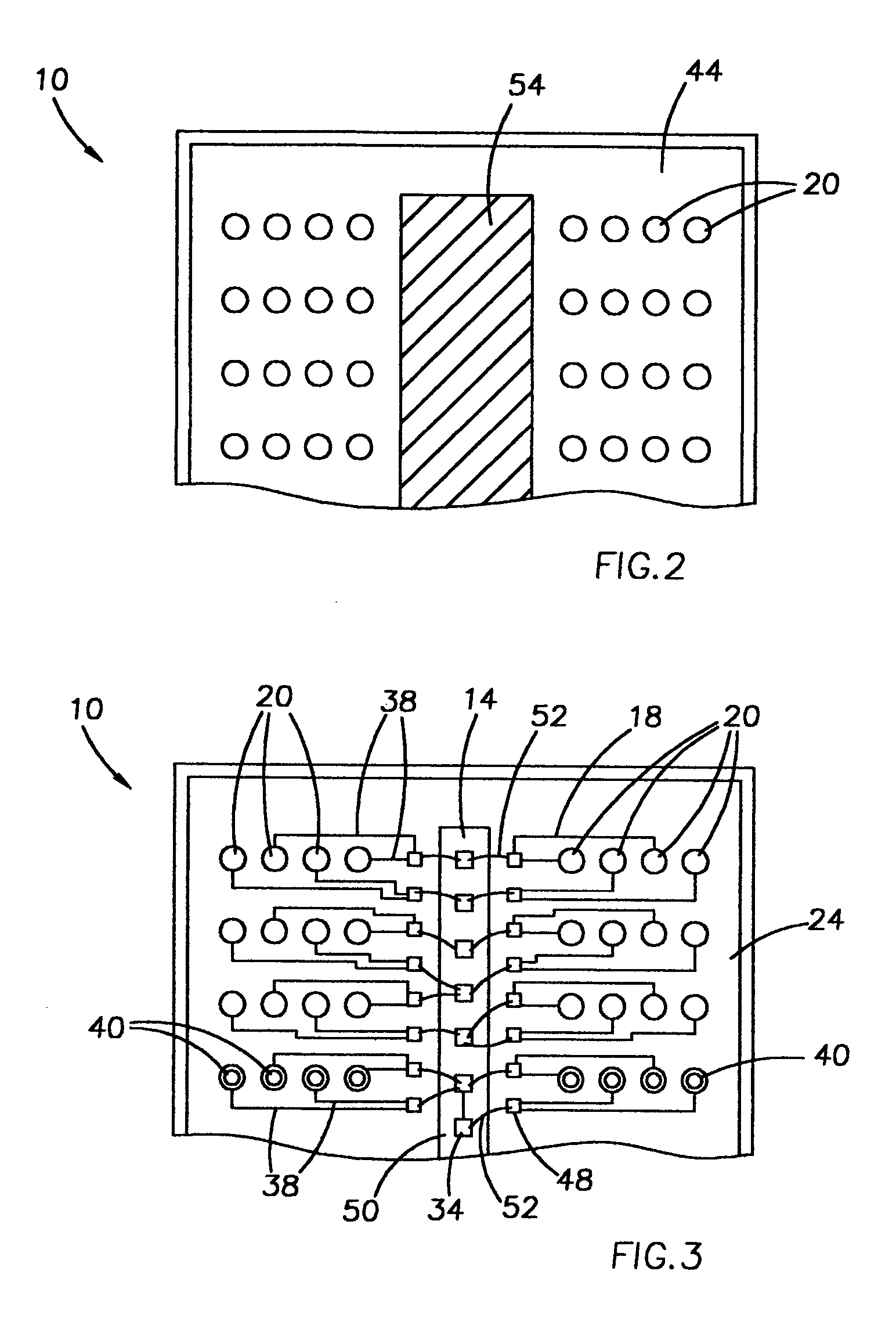

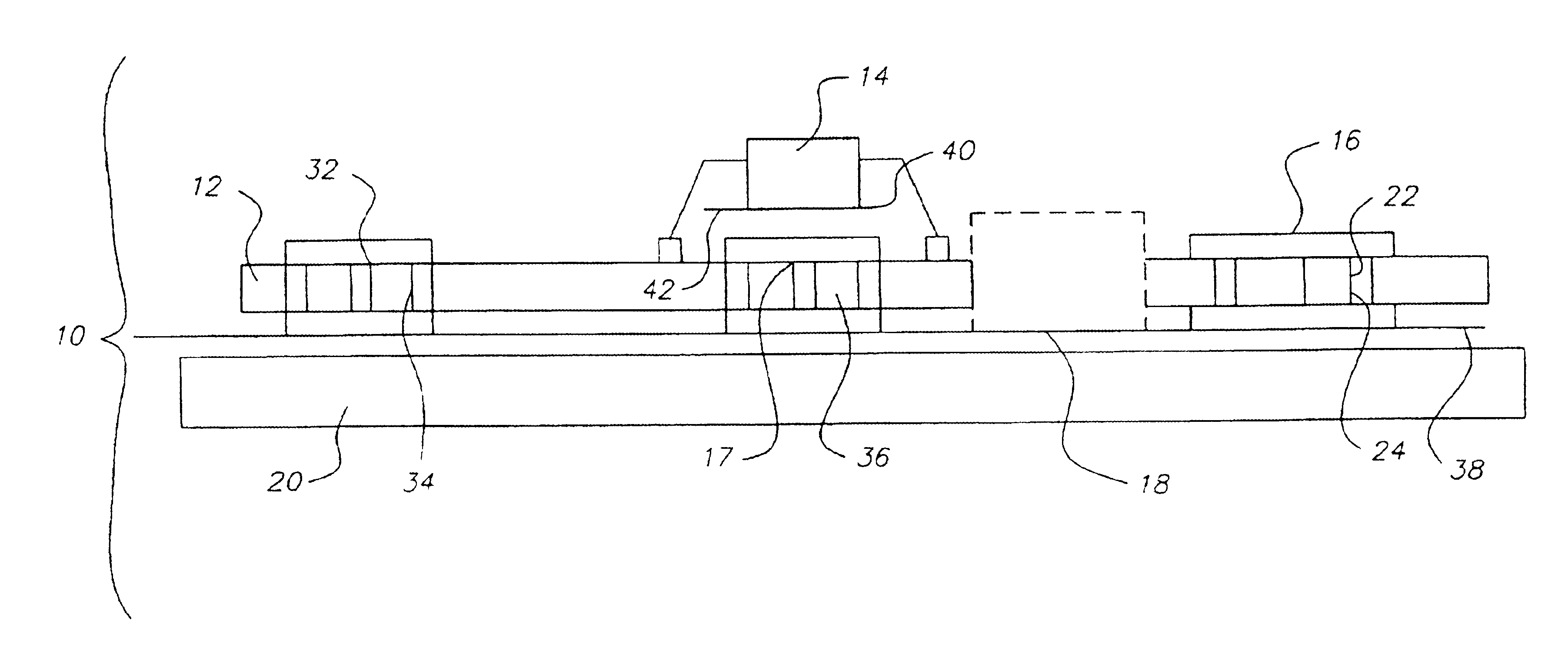

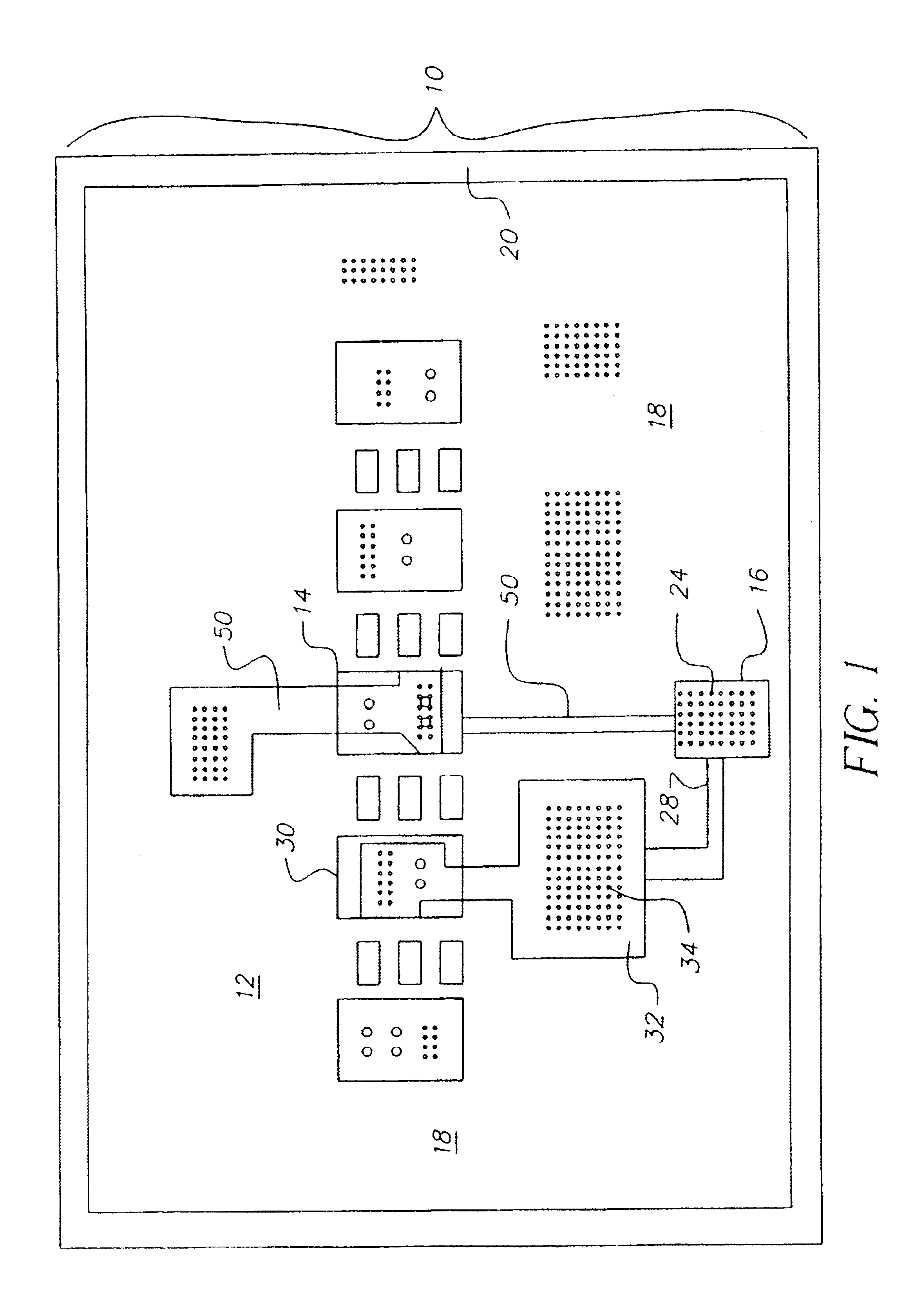

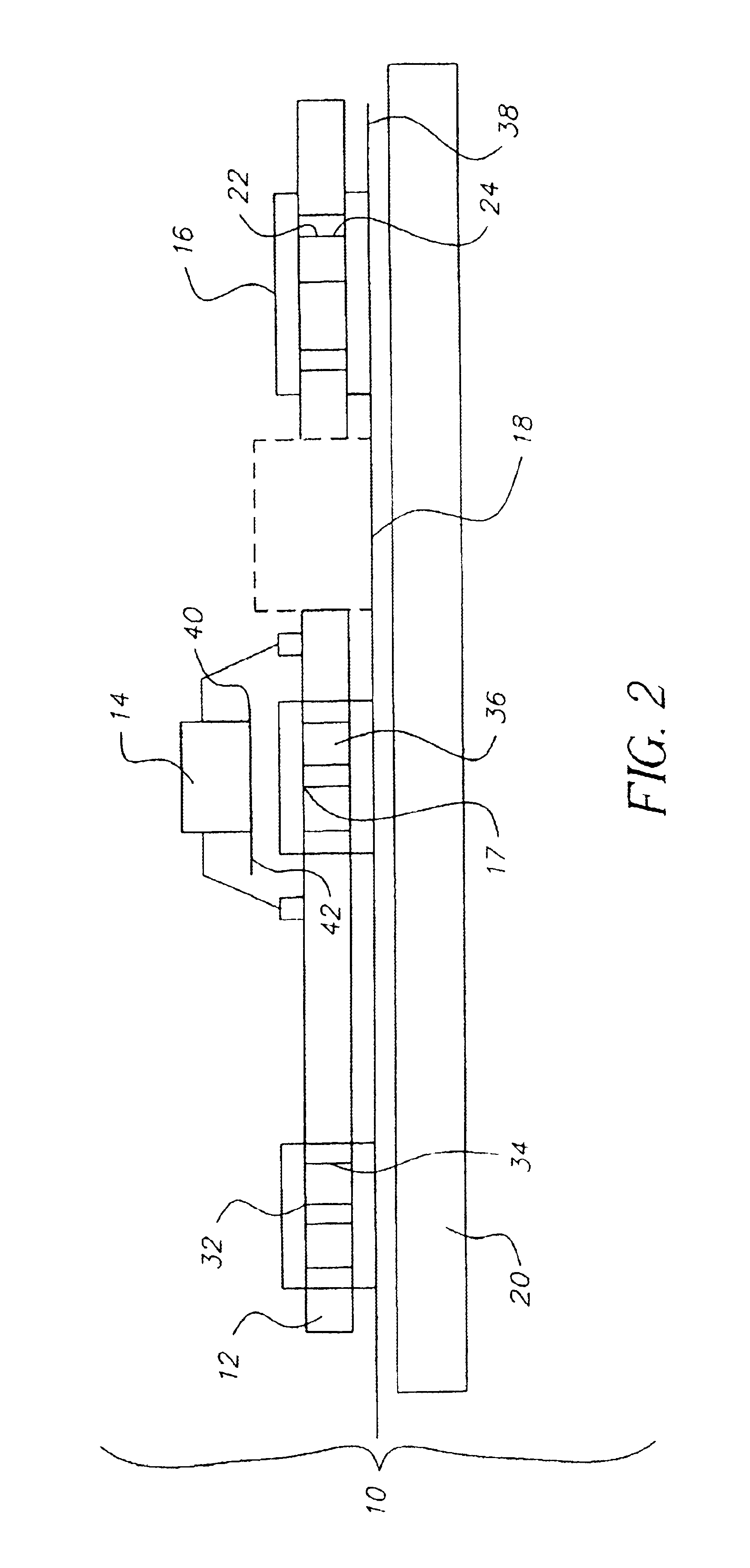

Densely packed electronic assemblage with heat removing element

InactiveUS6930885B2Lower operating temperatureLower junction temperatureSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringHeat sink

A densely packed electronic assemblage has a substrate medium for supporting at least one heat generating component and means for reducing the temperature of the at least one heat generating component. A heat sink cooperates with the at least one heat removing element for reducing heat of the heat generating component by absorbing heat from the at least one heat generating component.

Owner:APPLE INC

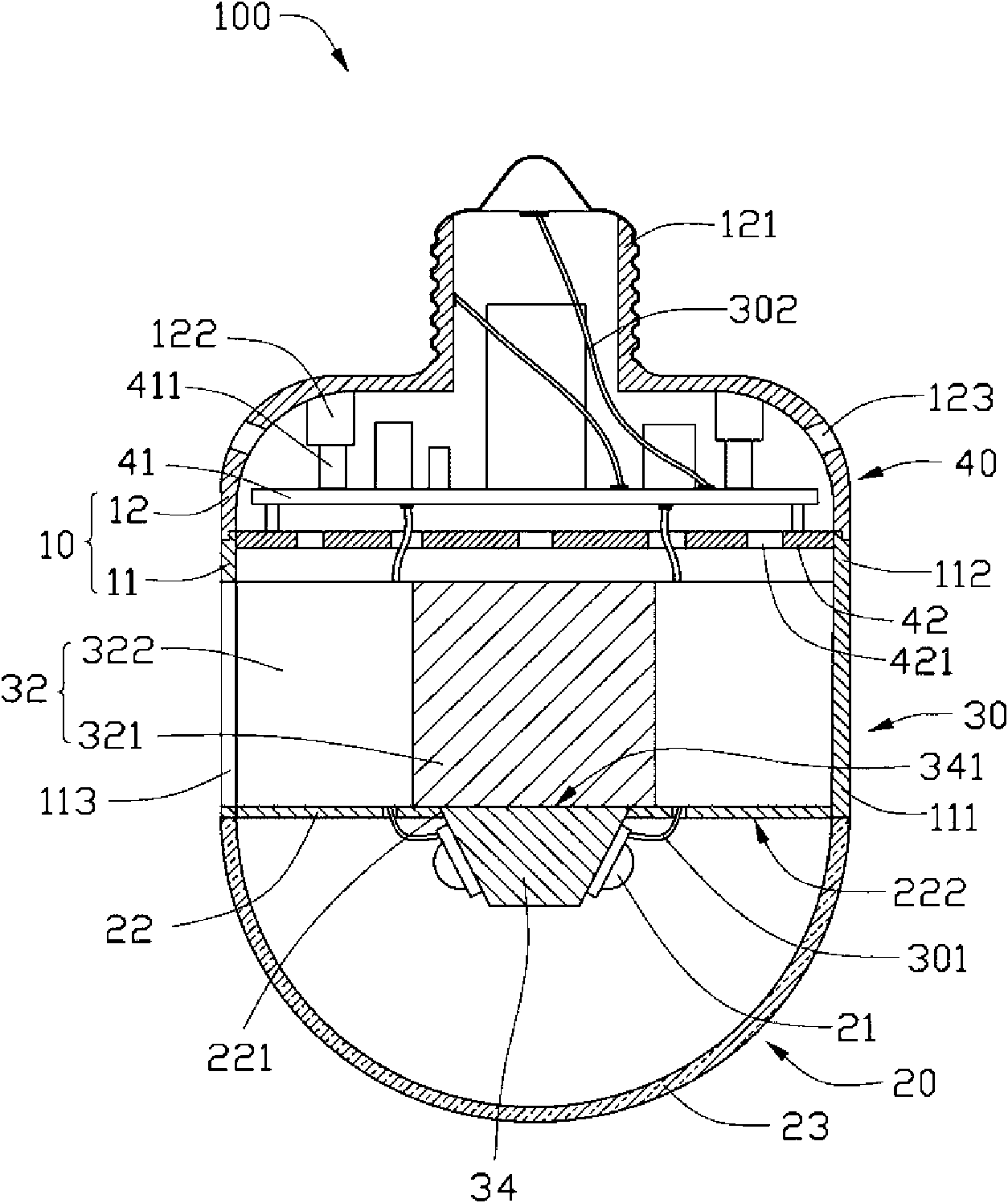

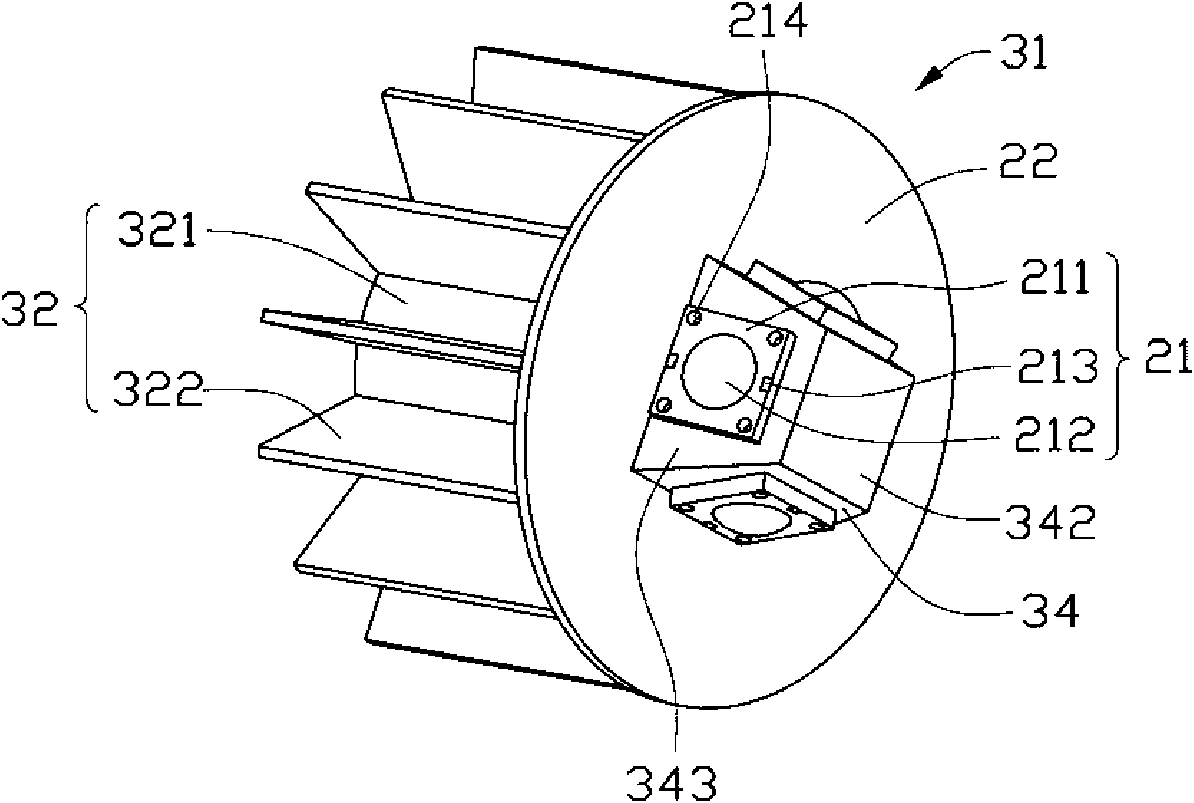

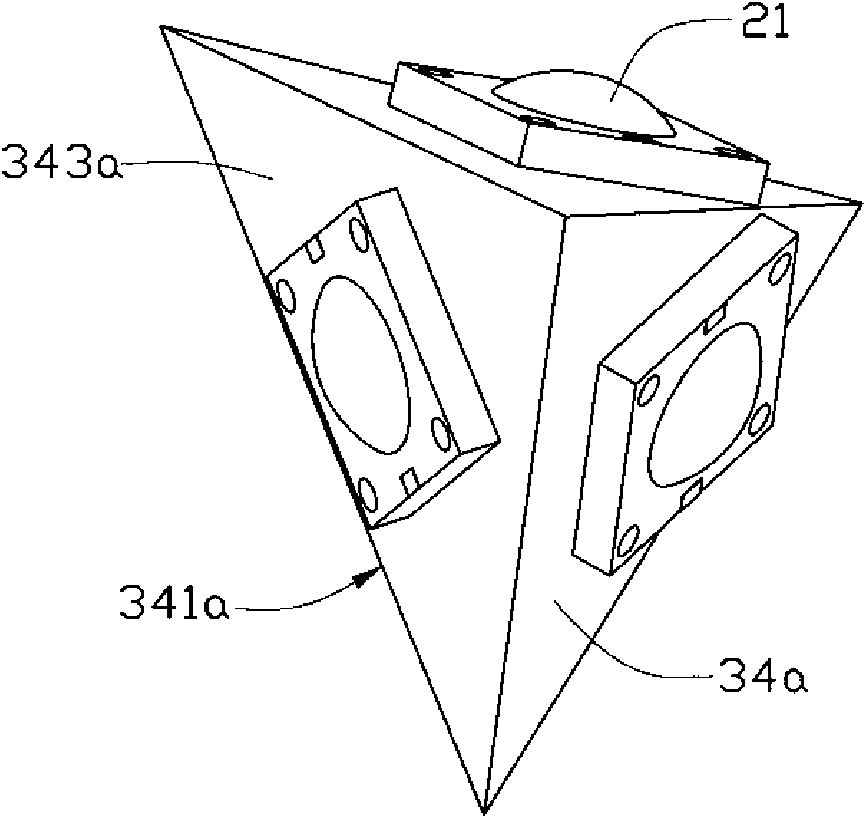

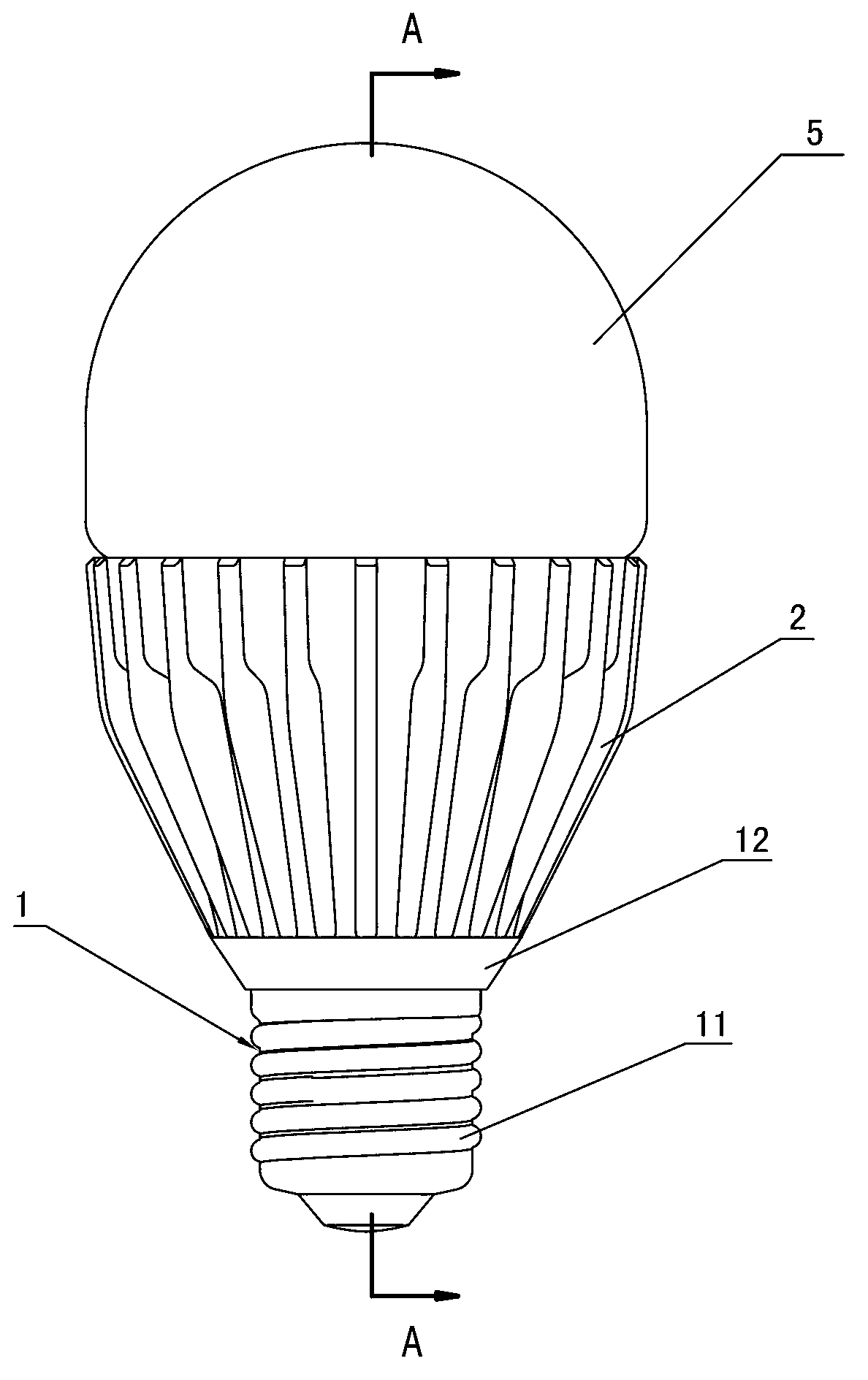

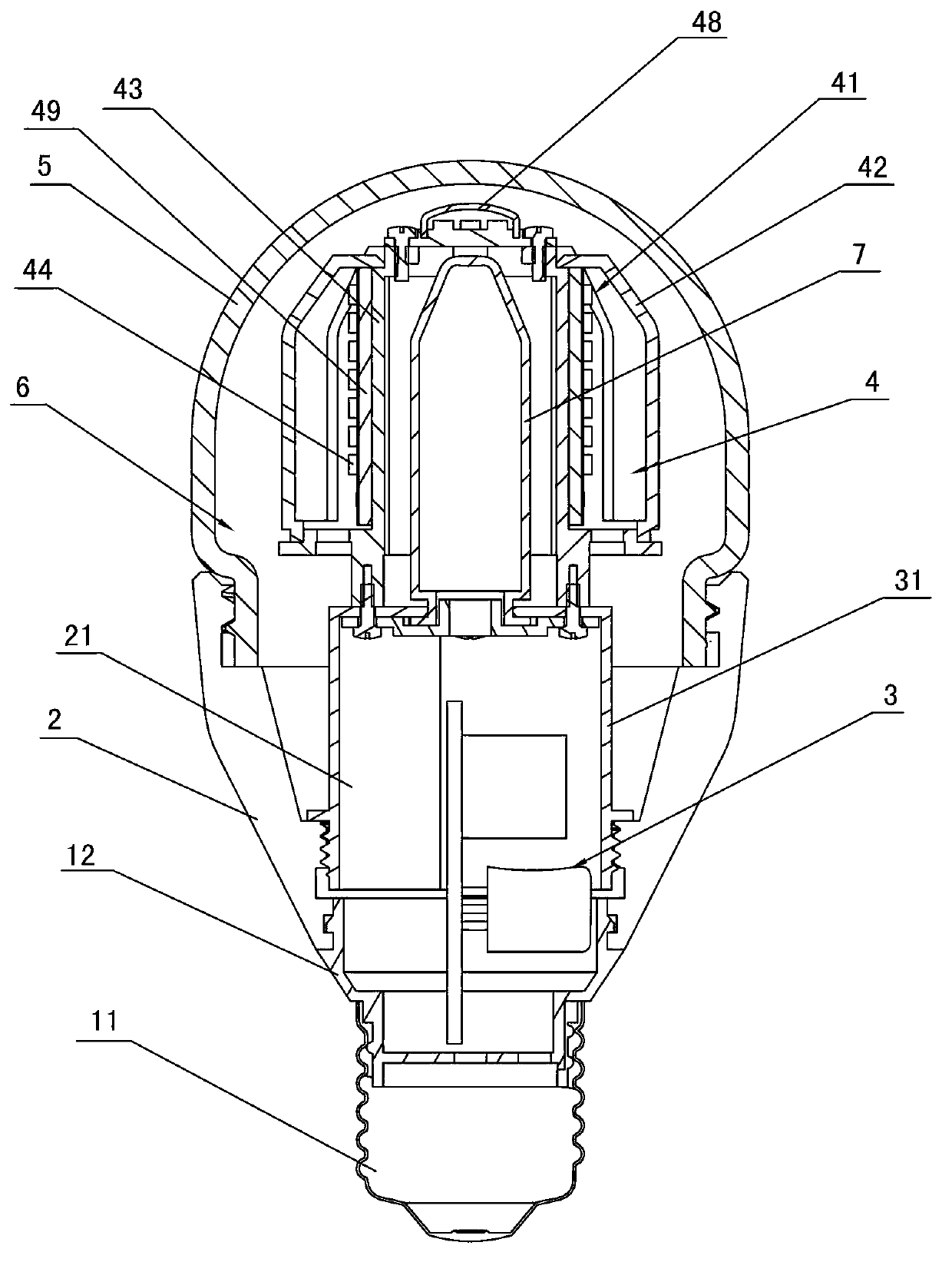

Light-emitting diode lamp

InactiveCN101865372AFlexible and diverse lighting distributionEfficient heat dissipationPoint-like light sourceElectric circuit arrangementsLight guideEngineering

The invention relates to a light-emitting diode lamp comprising a lamp body, an optics part, a heat radiation part and an electric part, wherein the lamp body is provided with a plurality of transom windows, the heat radiation part and the electric part are arranged in the lamp body, the heat radiation part comprises a mounting seat and a heat radiator provided with a plurality of fins. The mounting seat is arranged at one end of the heat radiator, near the optics part, and is in heat-conduction connection with the heat radiator; the mounting seat is a polyhedron and comprises a polygonal heat conduction surface facing the heat radiator and a plurality of heat absorption surfaces. The electric part is arranged at the rear end of the heat radiation part and comprises a circuit board. The optics part is arranged at the front end of the heat radiation part and comprises a plurality of light-emitting diode light sources, a reflecting cover and a light guide cover. The light sources are arranged on the heat adsorption surface of the mounting seat; the reflecting cover is arranged between the light sources and the heat radiator and is provided with a reflecting surface facing the light sources; the light guide cover is arranged at the outer side of the reflecting cover, and the light sources and the mounting seat are arranged in the light guide cover; and the heat adsorption surface extends towards the light guide cover from the margin of the heat conduction surface.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Intrinsic thermal enhancement for FBGA package

InactiveUS20060289989A1Signal integrationImprove performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialSolder ball

A semiconductor device for dissipating heat generated by a die during operation and having a low height profile, a semiconductor die package incorporating the device, and methods of fabricating the device and package are provided. In one embodiment, the semiconductor device comprises a thick thermally conductive plane (e.g., copper plane) mounted on a thin support substrate and interfaced with a die. Thermally conductive via interconnects extending through the substrate conduct heat generated by the die from the conductive plane to conductive balls mounted on traces on the opposing side of the substrate. In another embodiment, the semiconductor devices comprises a thick thermally conductive plane (e.g., copper foil) sandwiched between insulative layers, with signal planes (e.g., traces, bonding pads) disposed on the insulative layers, a die mounted on a first signal plane, and solder balls mounted on bonding pads of a second signal plane. A thermally conductive via interconnect extends through the substrate to provide a thermal path from the die and signal plane (traces) through the thick conductive plane and into the solder balls and external device (e.g., mother board). The present semiconductor device provides effective heat dissipation without the attachment of an external heat sink or spreader.

Owner:MICRON TECH INC

Electrical assemblage and method for removing heat locally generated therefrom

InactiveUS6882537B2Lower operating temperatureLower junction temperatureSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringHeat sink

Owner:APPLE INC

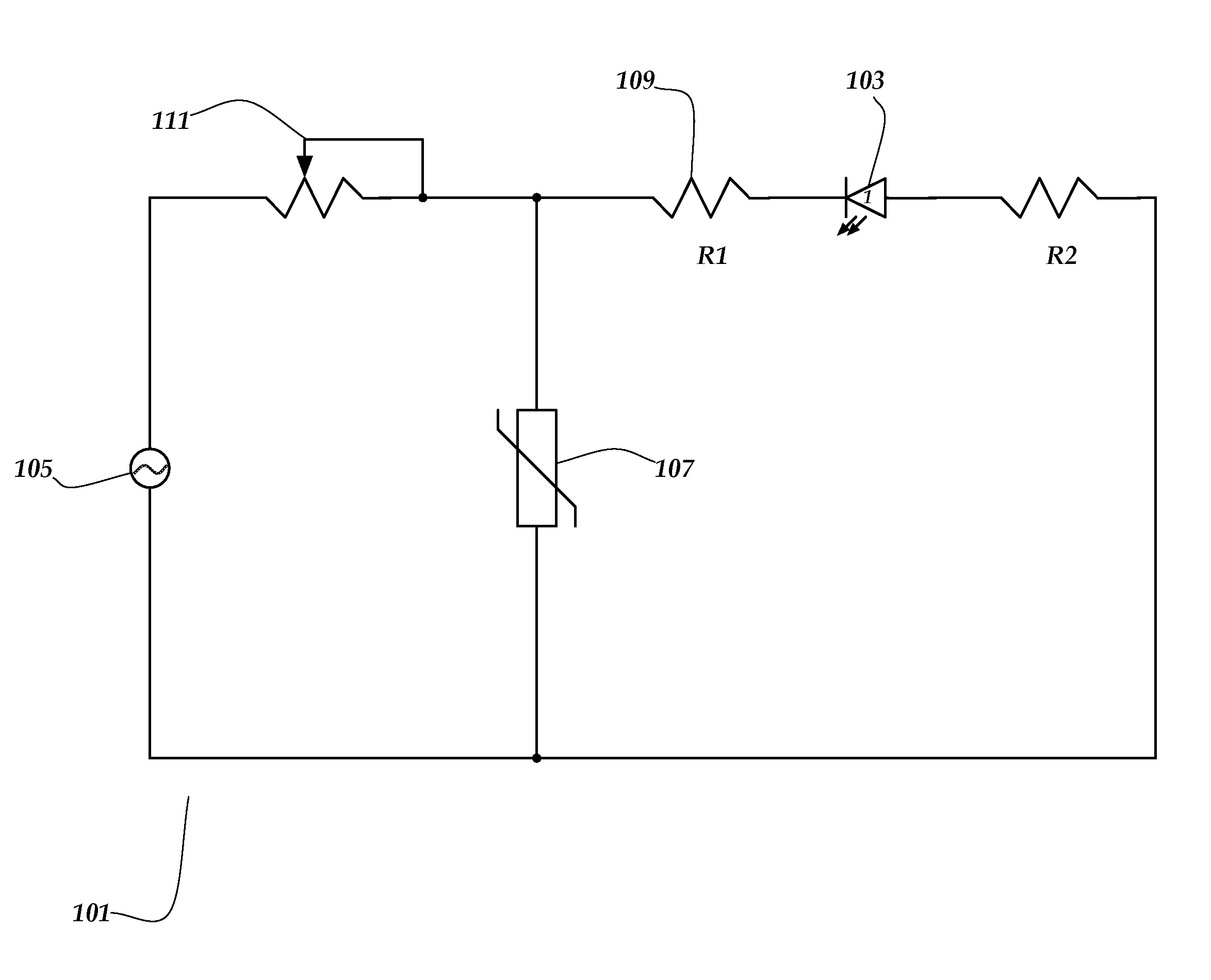

Dimmable LED lamp

InactiveUS7902761B2Reduce flickerImprove light outputElectroluminescent light sourcesElectric light circuit arrangementJunction temperatureEngineering

An LED lamp utilizes AC power and bi-directional LED chips to provide dimming capabilities. The dimming capabilities of the lamp reduce the junction temperature of the LEDs on the bi-directional LED chips and thus prolong the life expectancy of the LED lamp.

Owner:NEXT GEN ILLUMINATION

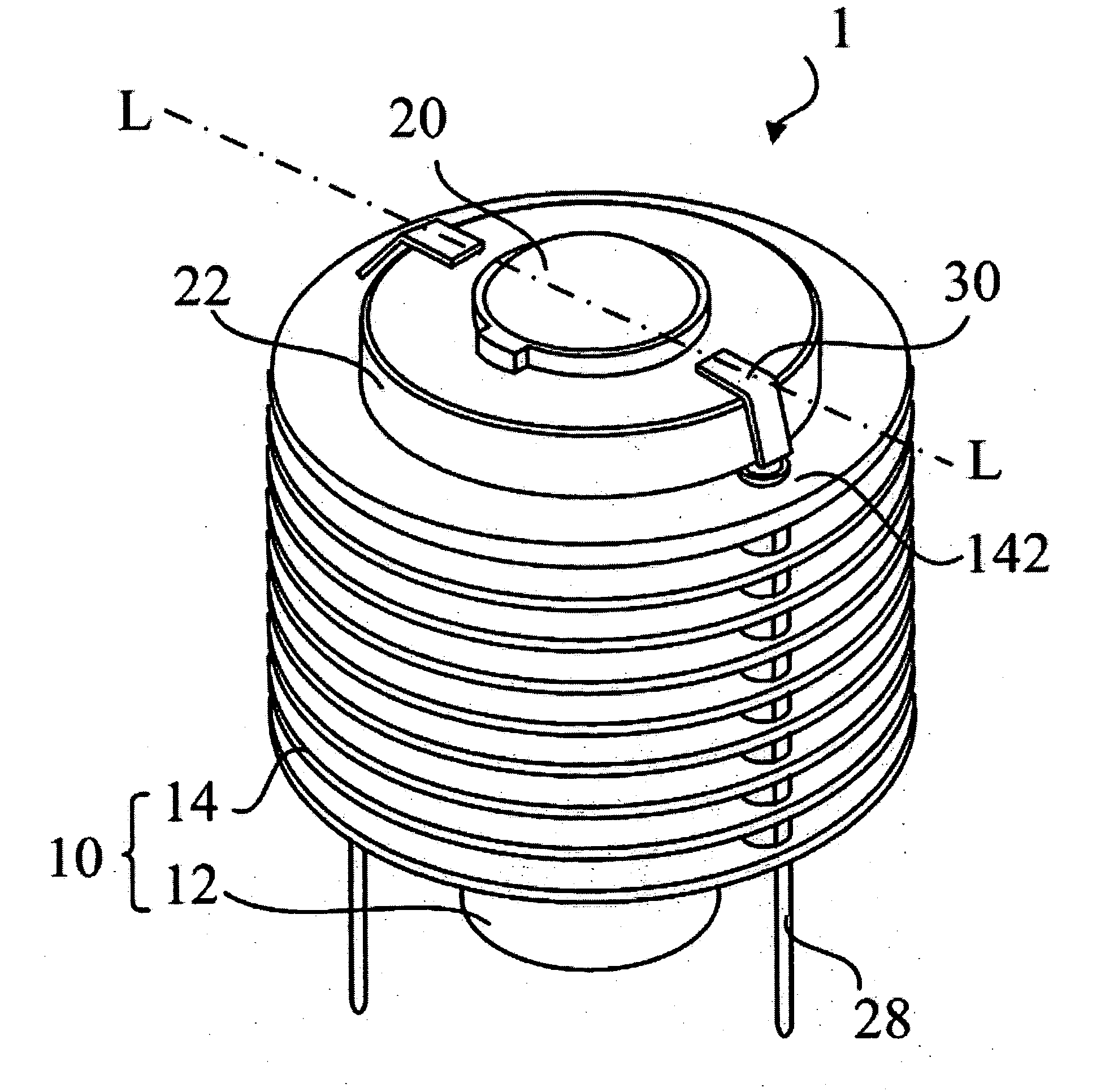

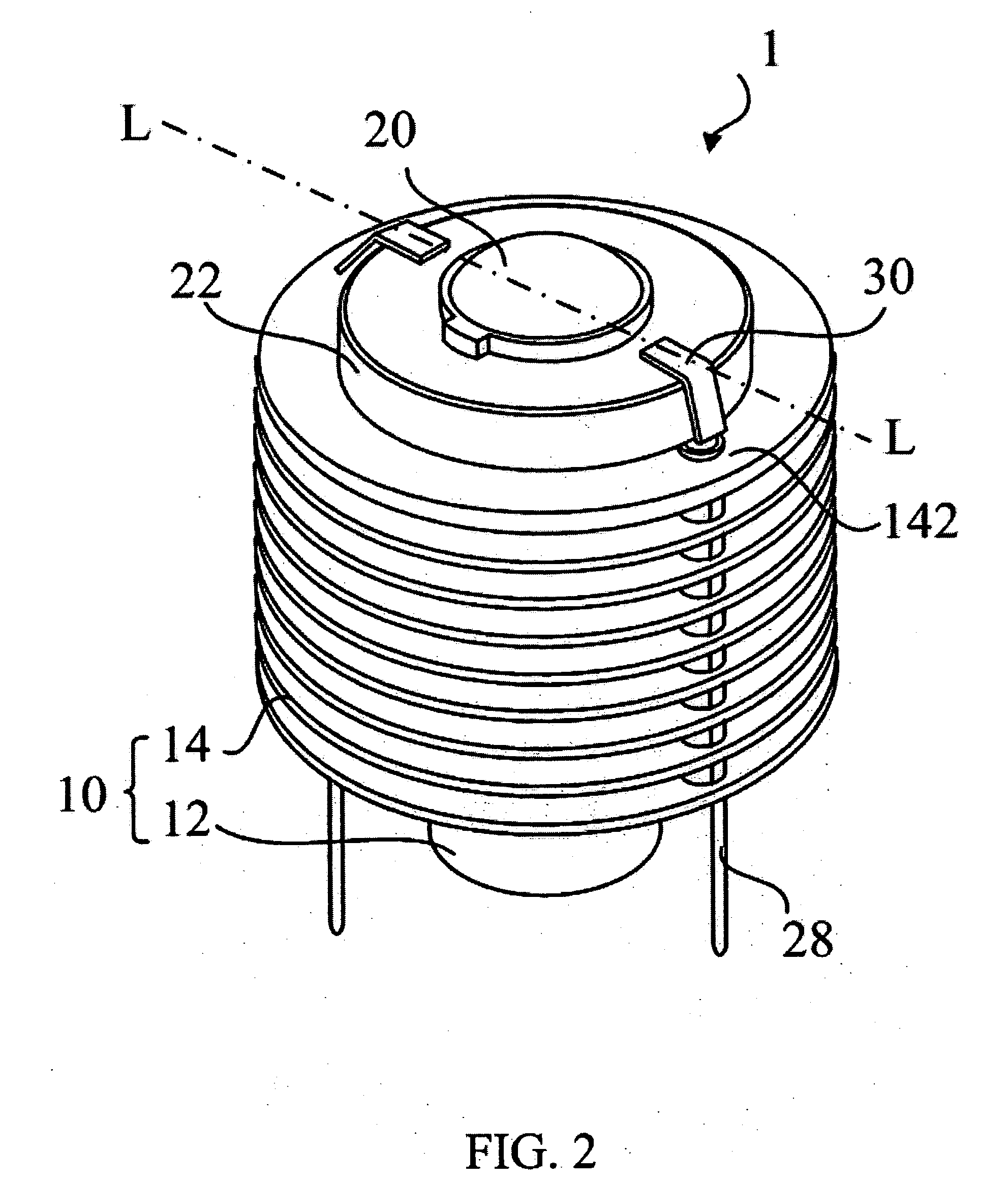

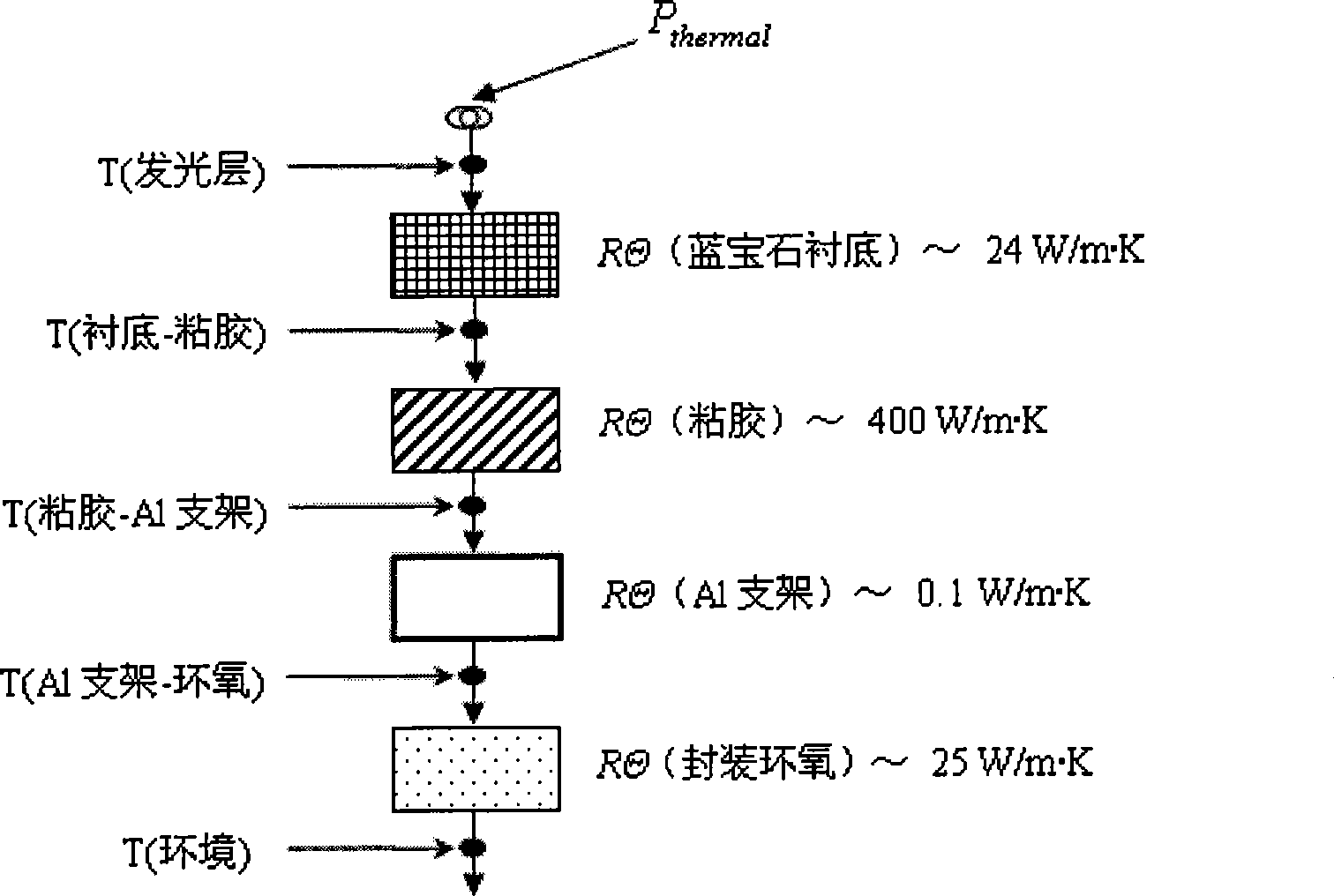

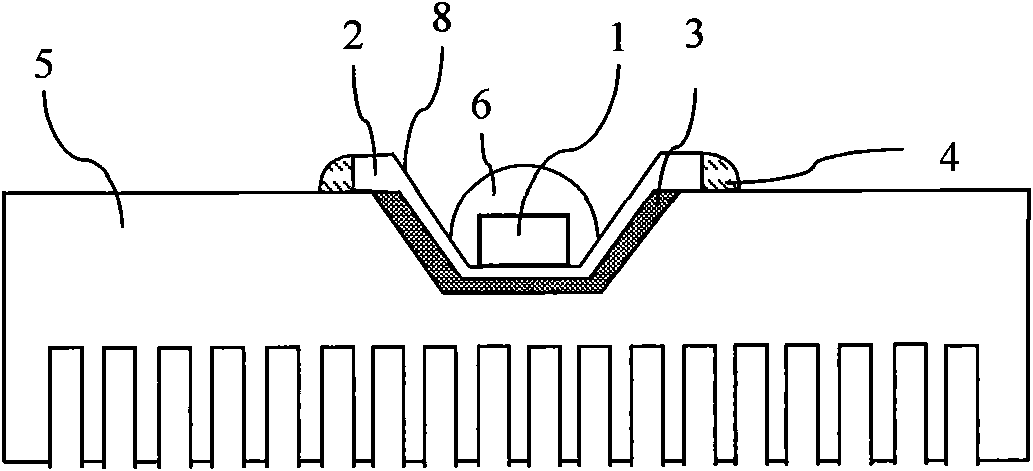

Semiconductor Light-Emitting Apparatus Integrated with Heat-Conducting/ Dissipating Module

InactiveUS20090225540A1Increase surface areaImprove cooling efficiencyNon-electric lightingLighting support devicesHeat conductingEngineering

The invention relates to a light-emitting apparatus. The light-emitting apparatus includes a heat-conducting / dissipating module and at least one semiconductor light-emitting module. The heat-conducting / dissipating module includes a substantially cylindrical heat-conducting device having at least one flat portion and at least one heat-dissipating fin mounted on the circumference of the heat-conducting device. The at least one semiconductor light-emitting module includes a carrier, a plurality of exterior electrodes, at least one semiconductor light-emitting die, and at least two conducting wires. The carrier is flatly mounted on the flat portion of the heat-conducting device. The plurality of exterior electrodes is disposed on the carrier. The at least one semiconductor light-emitting die is mounted on the carrier and respectively connected to the plurality of exterior electrodes. The at least two conducting wires are connected to a power source or a grounding by being electrically connected to the plurality of exterior electrodes.

Owner:NEOBULB TECHNOLOGIES INC

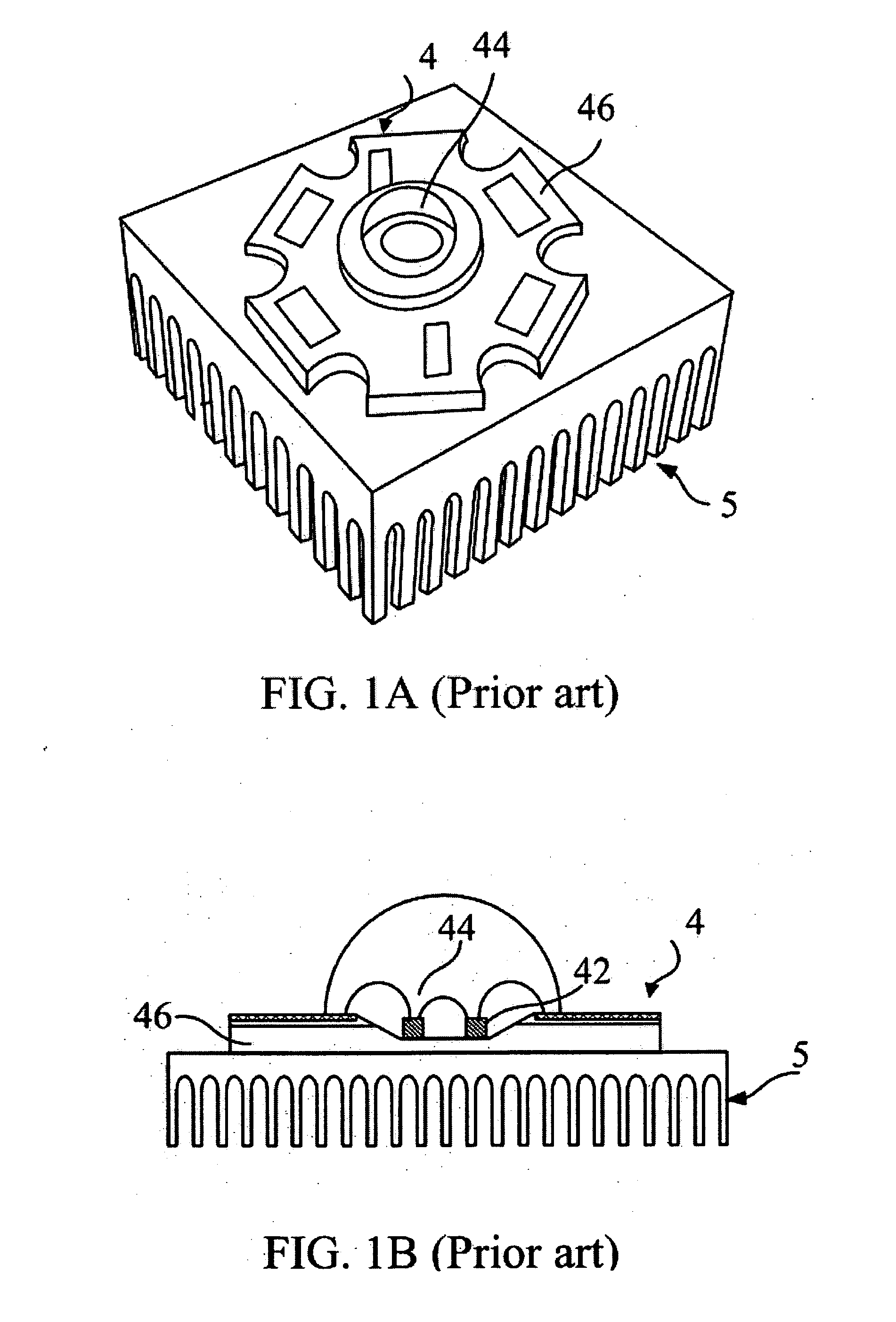

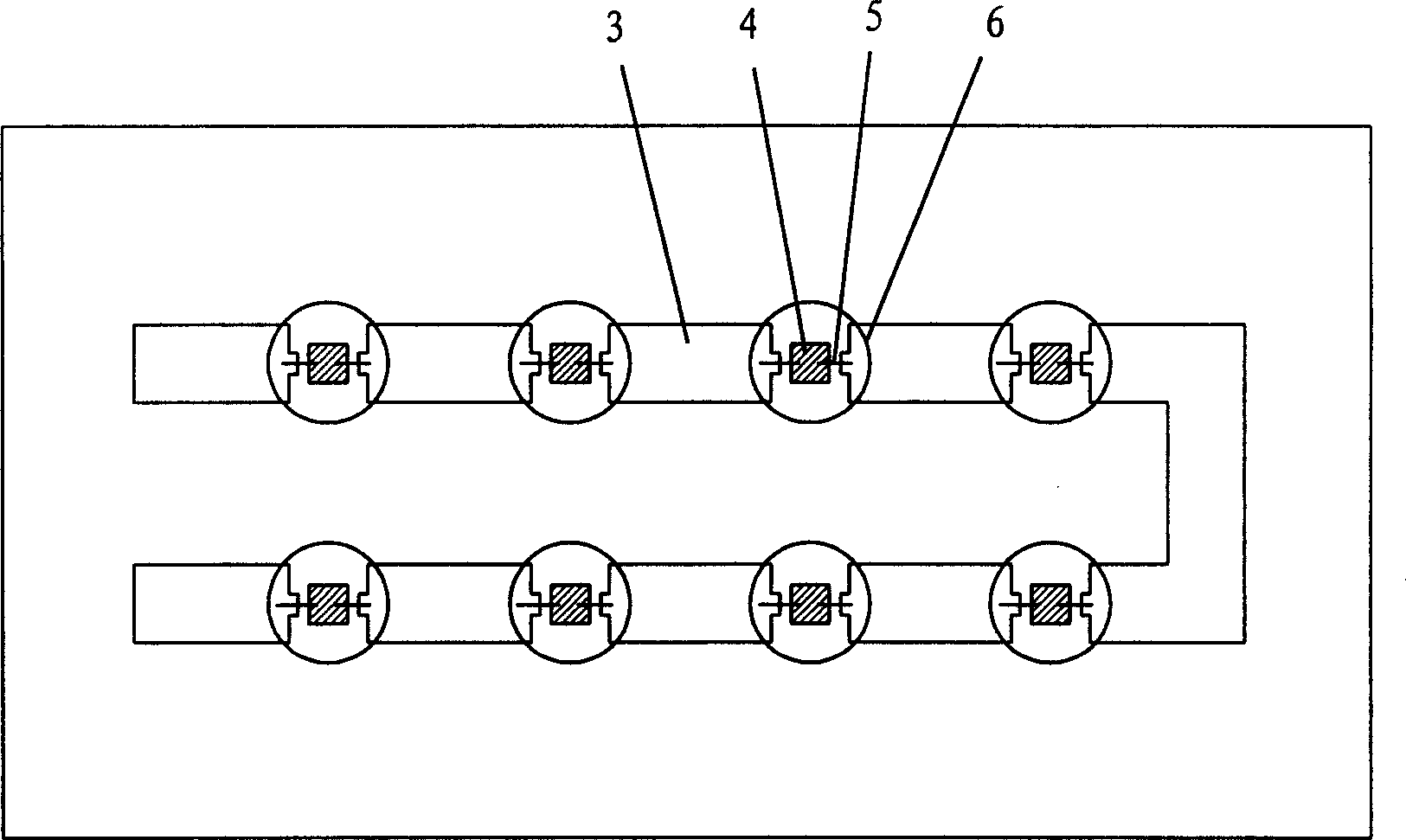

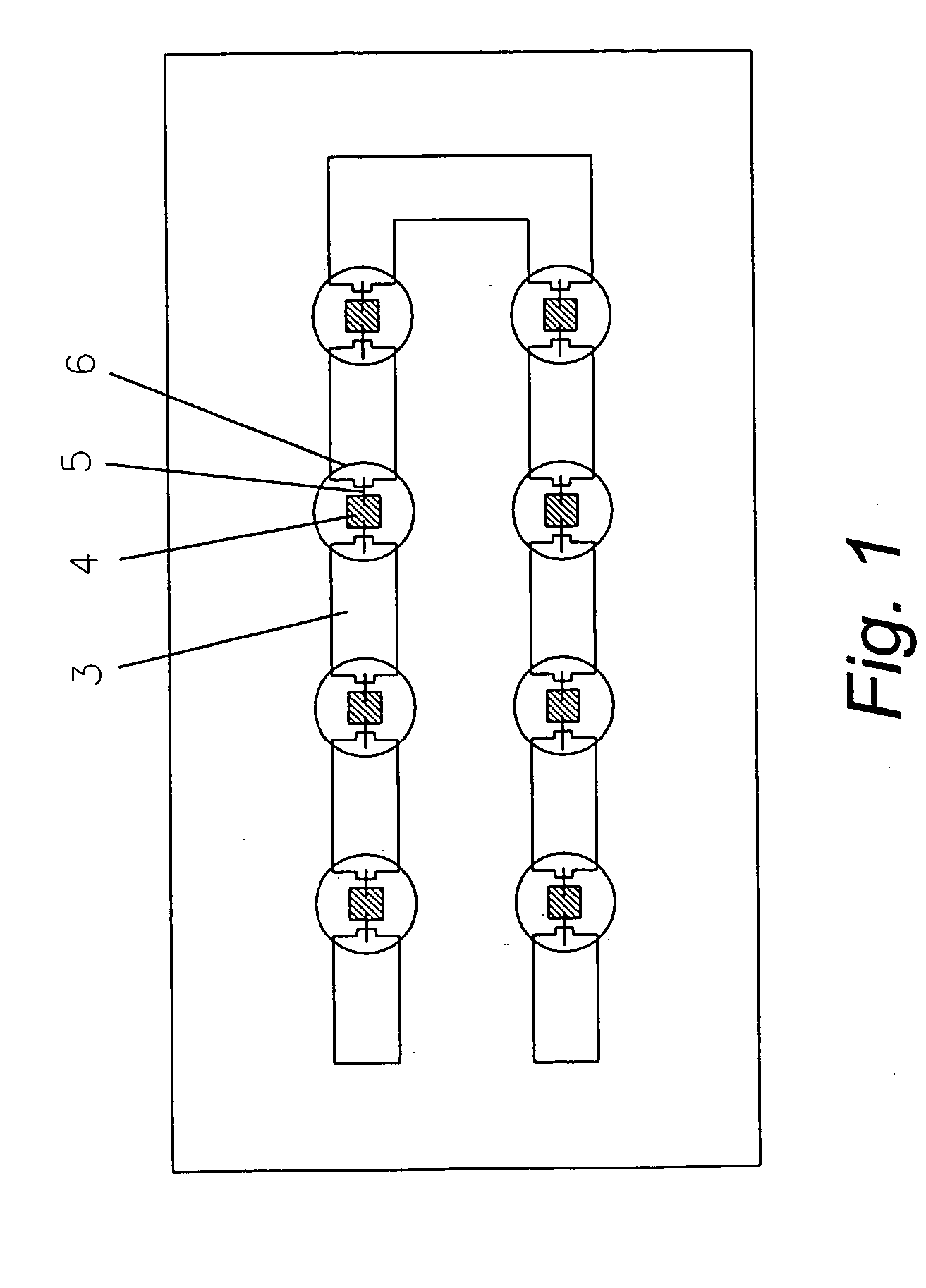

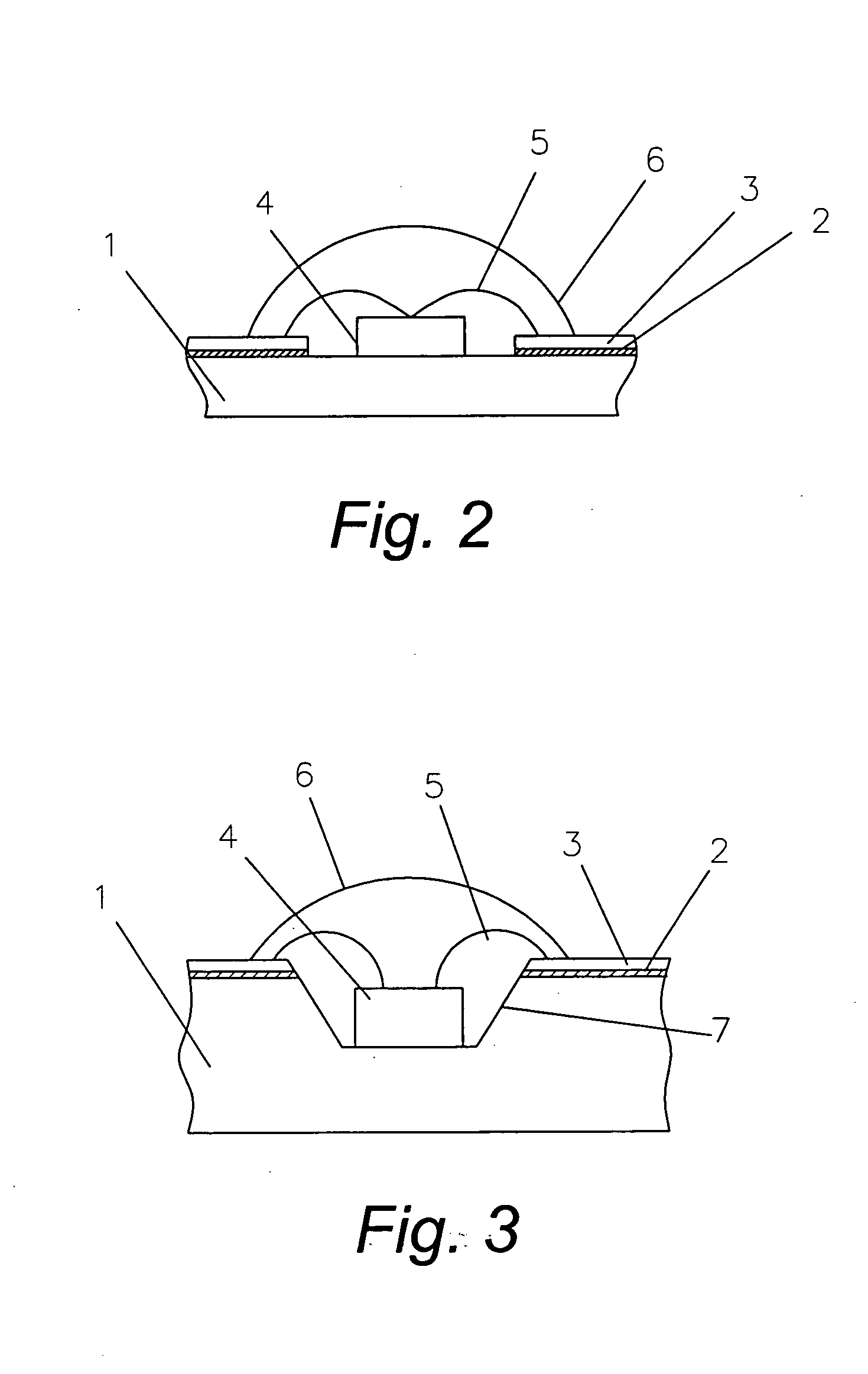

LED structure

InactiveCN1601768ALower junction temperatureImprove performanceSemiconductor/solid-state device detailsLighting heating/cooling arrangementsHeat conductingEngineering

Structure of the disclosed LED raises effect of heat elimination remarkably, reduces junction temp of luminescence chip, and raises luminous efficacy and lifetime of LED. Also the disclosed LED increases quantity of luminescence chip in unit area and luminous efficiency in unit area. Structure of LED is as following: circuits are setup at heat conducting base plate; there is a insulating layer between heat conducting base plate and circuit, and more than one luminescence chips are distributed among circuits; chips through metal wires are connected to circuit, and photic protection layer is covered on the luminescence chips. The heat conducting base plate reduces junction temp, raises efficiency and life time of chip as well as makes more chips possible be arranged on unit area.

Owner:FUJIAN JOINLUCK ELECTRONICS ENTERPRISE

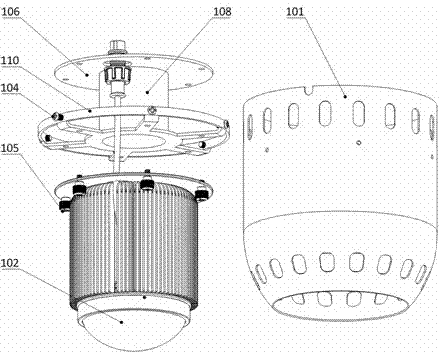

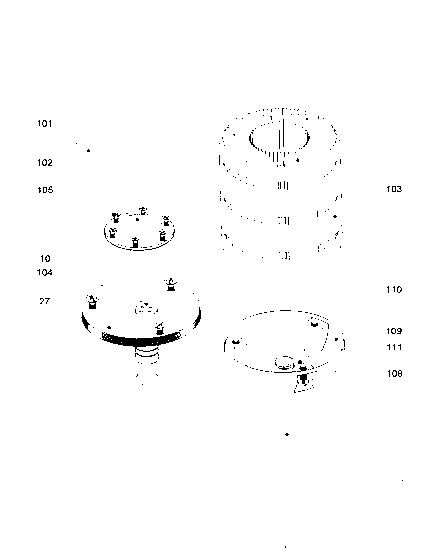

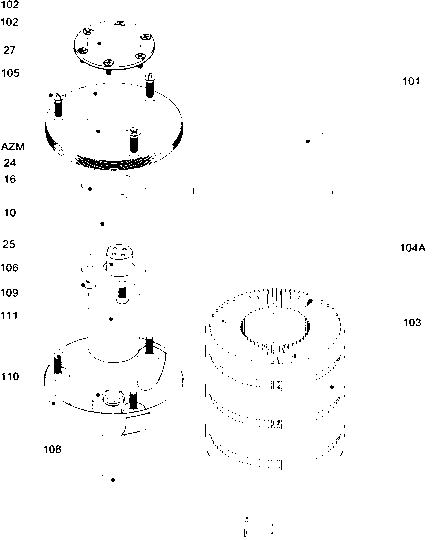

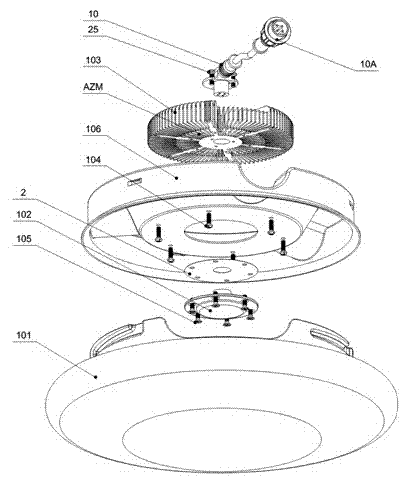

LED lighting lamp with mounting interface support combined component

ActiveCN102777824AEasy to passSimple structurePoint-like light sourceElectric circuit arrangementsEnergy efficient lightingLamp shell

The invention discloses an LED lighting lamp with a mounting interface support combined component. The LED lighting lamp is characterized by comprising the mounting interface support combined component, an LED bulb (102) with a radiator is arranged on the mounting interface support combined component, a metal punched or plastic die-cast lamp shell (101) is arranged outside the mounting interface support combined component, the mounting interface support combined component comprises a tube support (108), a lamp fixing flange (106) and a lamp shell and bulb fixing support (110) which are connected with one another, and the tube support (108) is formed by cutting standard tubes in a sectioned manner. The LED lighting lamp is simple in structure, low in manufacturing cost and convenient to mount, use and maintain. The bulb (an independent light source) of the LED lamp, a lighting fixture and a lighting control product can be respectively independent in production and use, production links of LED lighting products are greatly decreased, batch production is improved, and standard large-scale production and industrialization of the energy-saving LED lighting products are facilitated.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

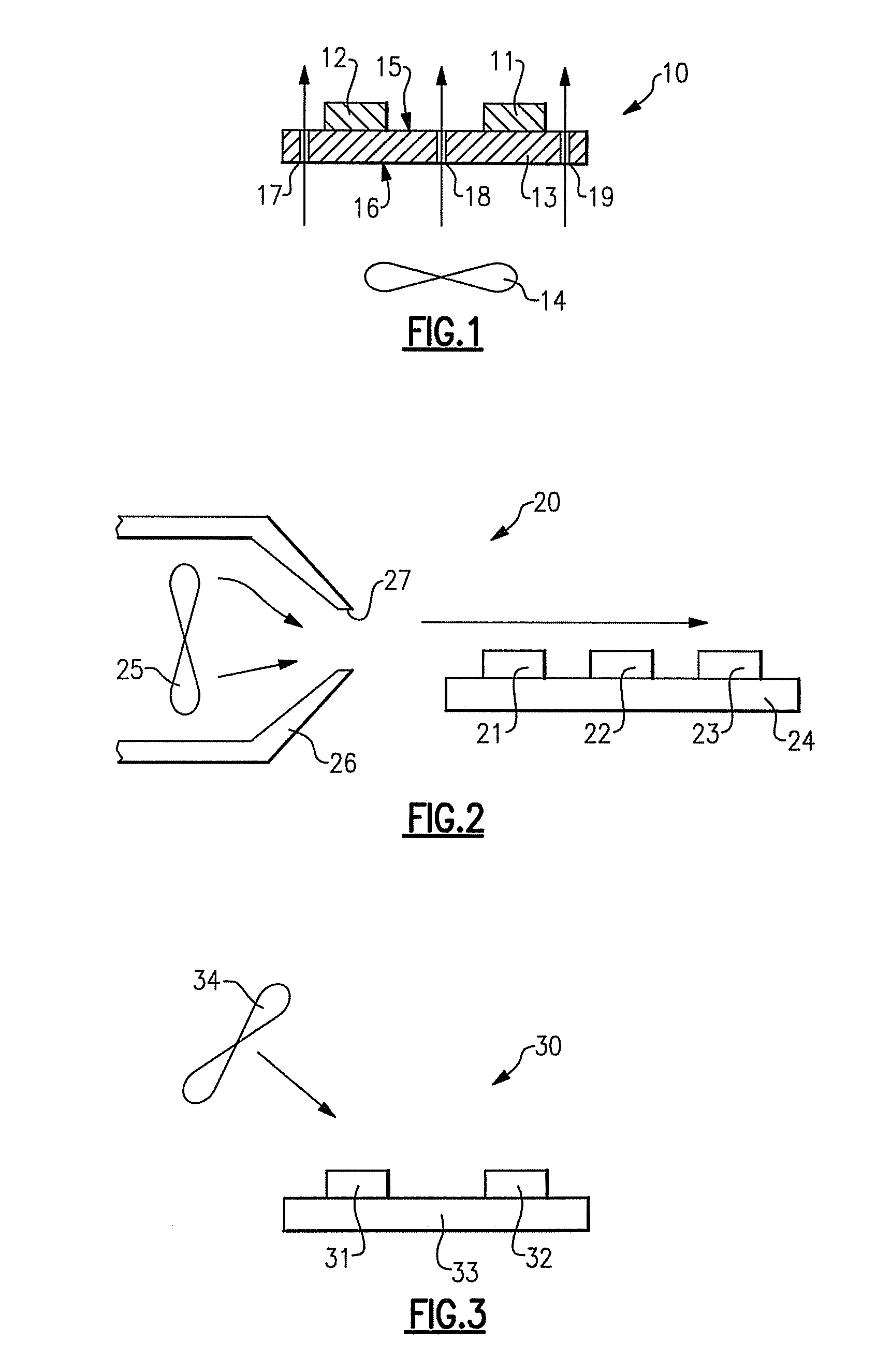

Light emission diode (LED)

InactiveUS20050062059A1Heat dissipation fastLower junction temperatureSemiconductor/solid-state device detailsLighting heating/cooling arrangementsElectrical conductorInsulation layer

A light emitting diode (LCD) comprised of a heat conduction substrate, a circuitry on the substrate, an insulation layer between the substrate and the circuit, multiple light emitting chips distributed in the space between the circuitry and the substrate, light emitting chips being connected to the circuitry through metallic conductor, and a light permeable protection layer being topped on those light emitting chips to significantly improve its power dissipation effect, lower light emission chip junction temperature, increase light emission efficacy and service life, increase the quantity of the light emission chip of unit area, and improve the light emission efficiency of unit area.

Owner:FUJIAN JOINLUCK ELECTRONICS ENTERPRISE

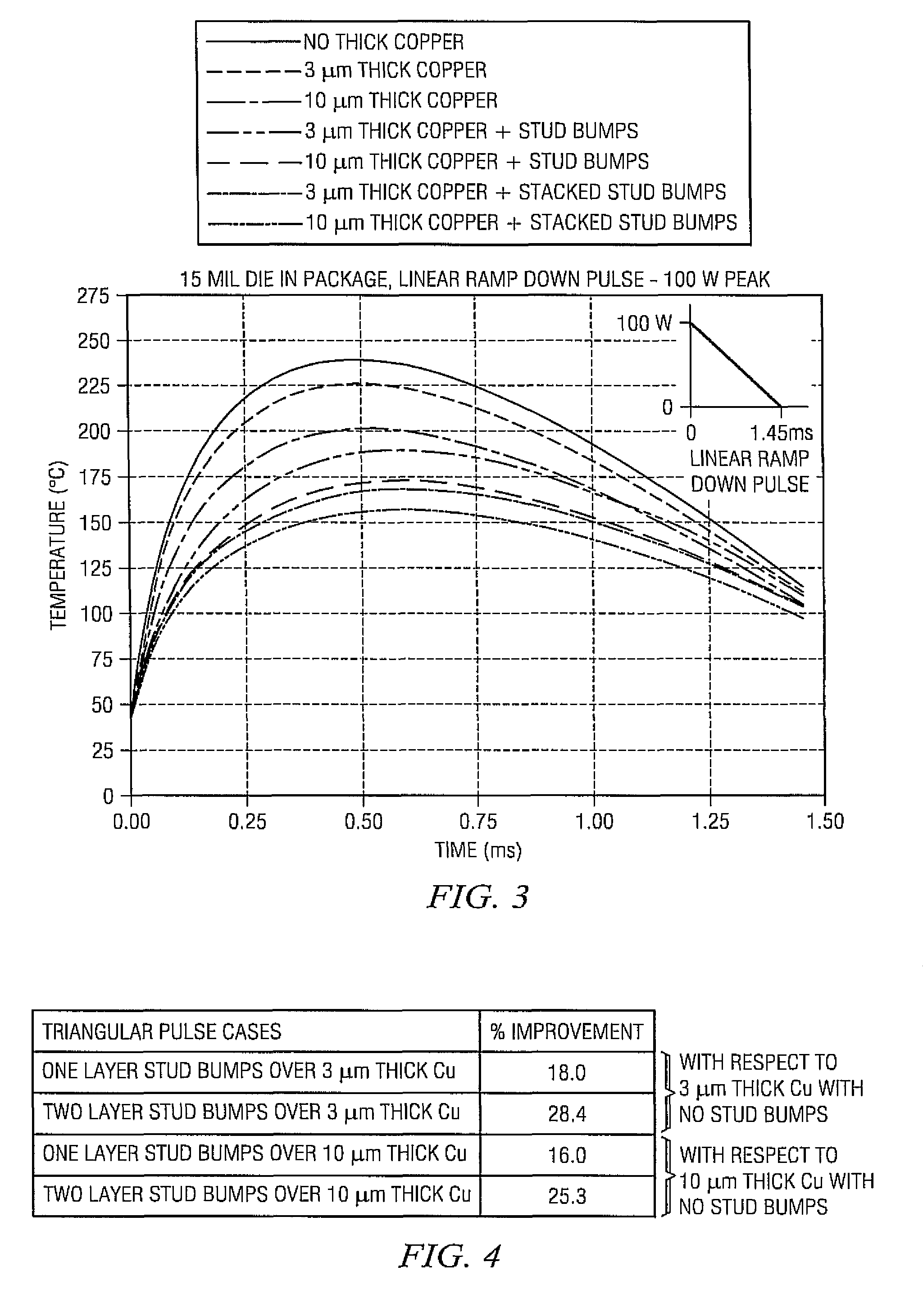

Stud bumps as local heat sinks during transient power operations

ActiveUS7838988B1Lower junction temperatureDissipate heat generatedSemiconductor/solid-state device detailsSolid-state devicesSemiconductorMetal

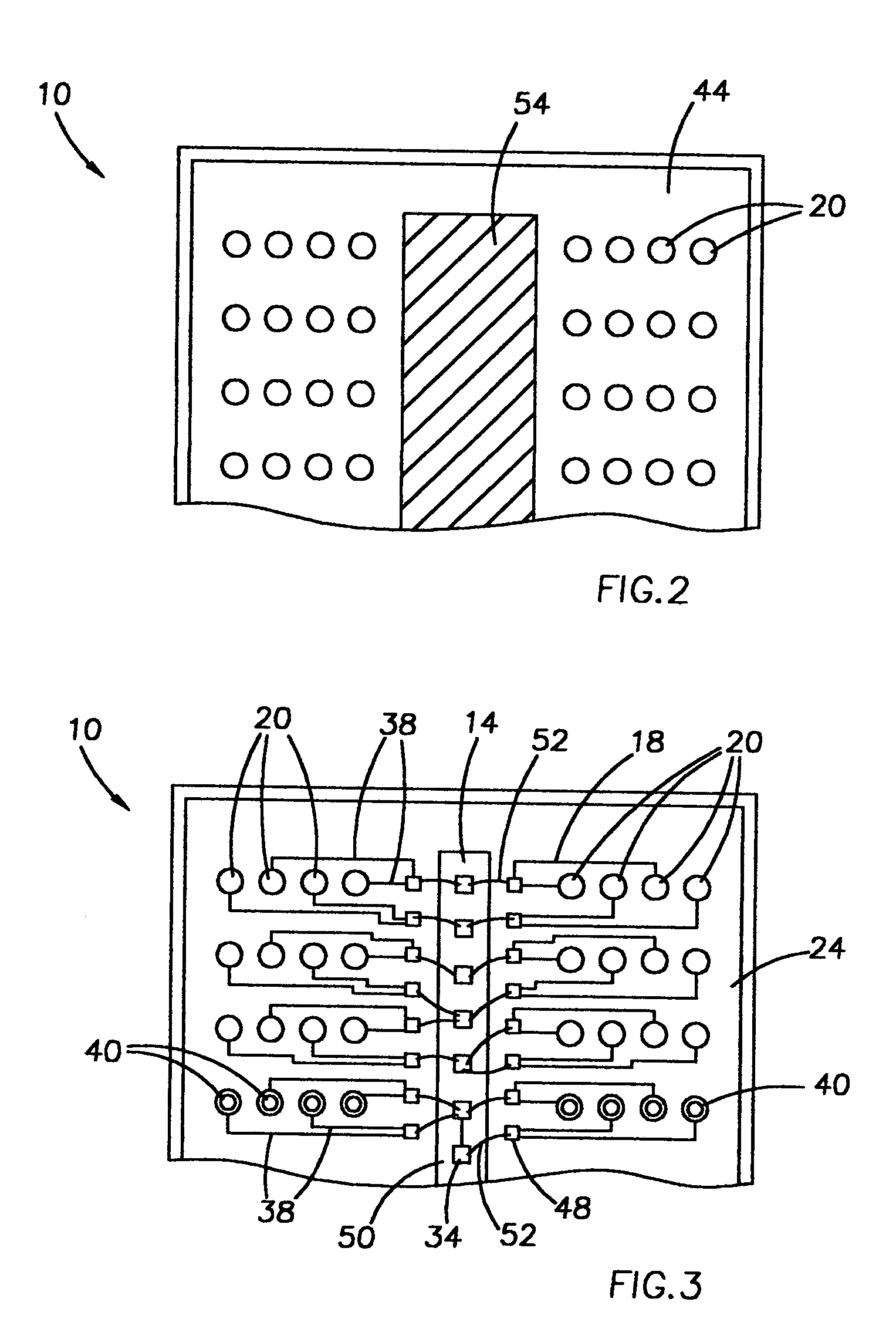

A thermal management configuration for a flip chip semiconductor device is disclosed. The device includes a high power silicon based die having a metal bonding surface. A plurality of interconnects are formed on the metal surface and connected to a substrate. A plurality of thermal management stud bumps are formed on the metal bonding surface, the thermal management stud bumps positioned distinct from the interconnects and local to die hot spots, exposed ends of the thermal management stud bumps spaced from the substrate.

Owner:TEXAS INSTR INC

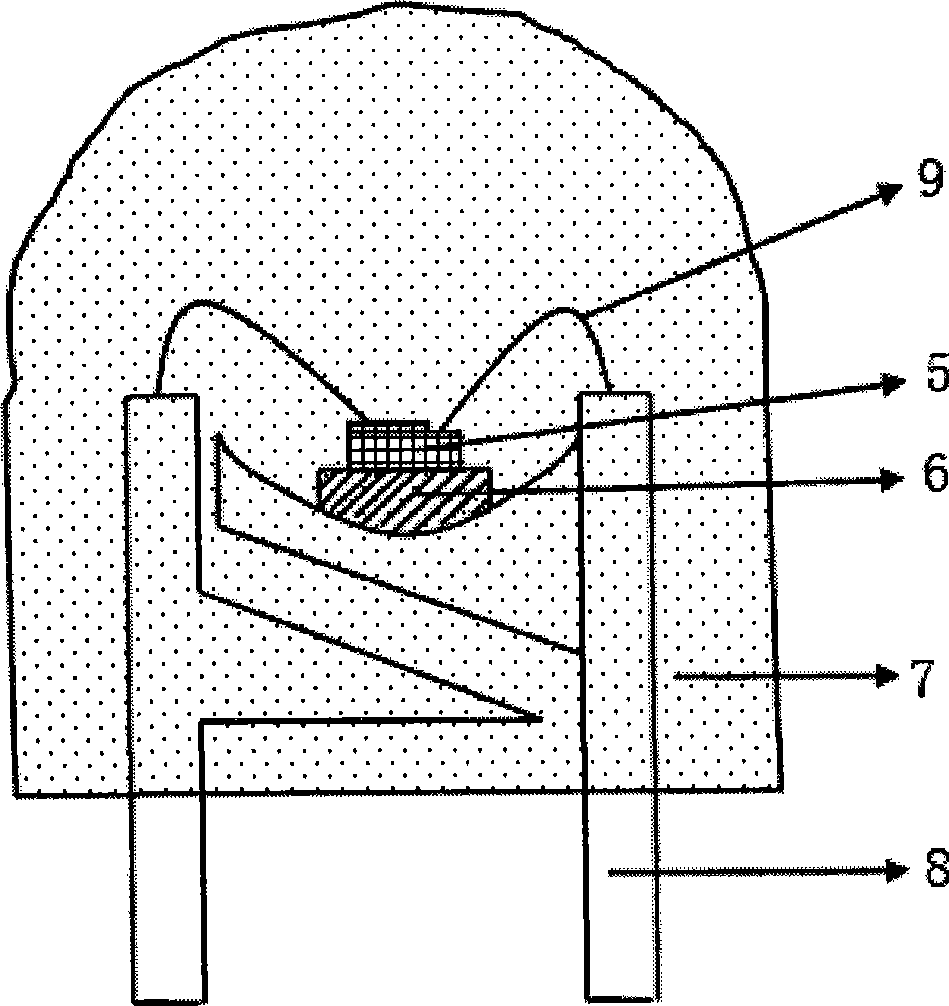

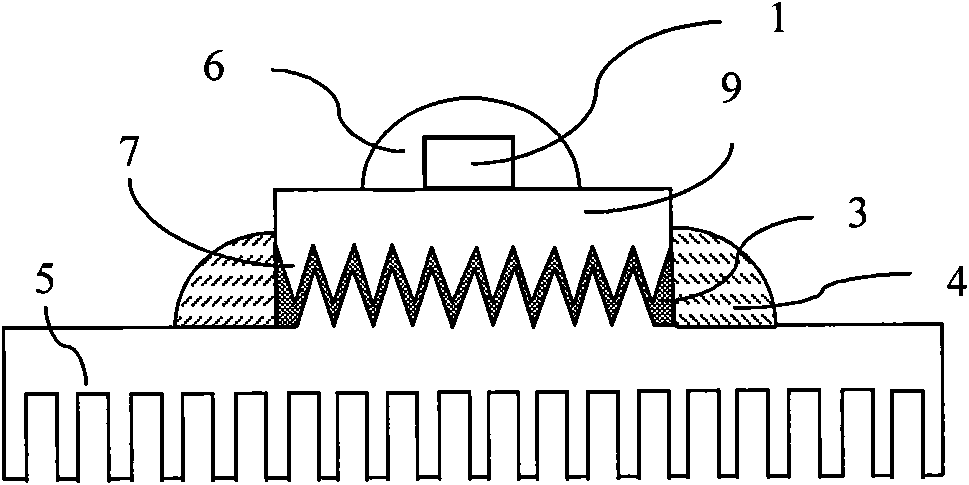

Structure of low thermal resistance LED and method for producing the same

InactiveCN101442099AExtended service lifeLower junction temperatureSolid-state devicesSemiconductor devicesDrain currentOptoelectronics

The invention provides a structure for a low thermal resistance LED chip and a method for manufacturing the same. The LED chip comprises P and N electrodes used for manufacturing electrodes, the LED luminous chip on a semiconductor epitaxial layer and a sapphire substrate, and a metallic reflector layer deposited on the bottom of the thinned sapphire substrate. The structure is characterized in that the LED chip comprises: (a) a heat radiating substrate with low thermal resistance, in which the size is larger than that of the LED luminous chip; and (b) solder deposited on the heat radiating substrate with low thermal resistance connected with the bottom of the metallic reflector layer. The area of the heat radiating substrate with low thermal resistance is 2 to 25 times larger than the area of the LED luminous chip. The invention can increase the area of heat dissipation channel when the LED luminous chip, significantly reduce thermal resistance of the LED luminous chip and packaged devices, reduce the light decay of LED devices and drain current, and prolong the life service of the devices.

Owner:HC SEMITEK CORP

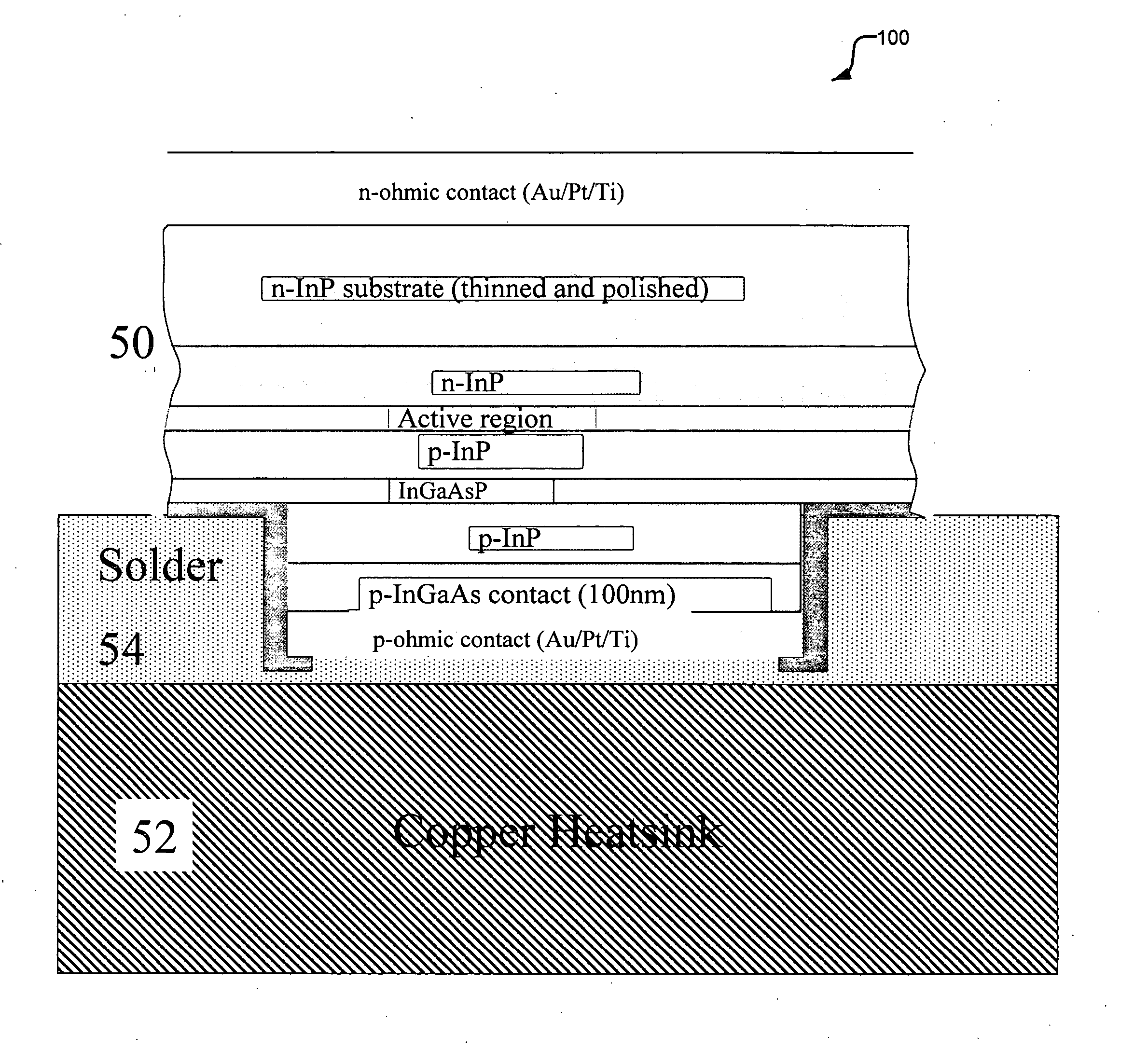

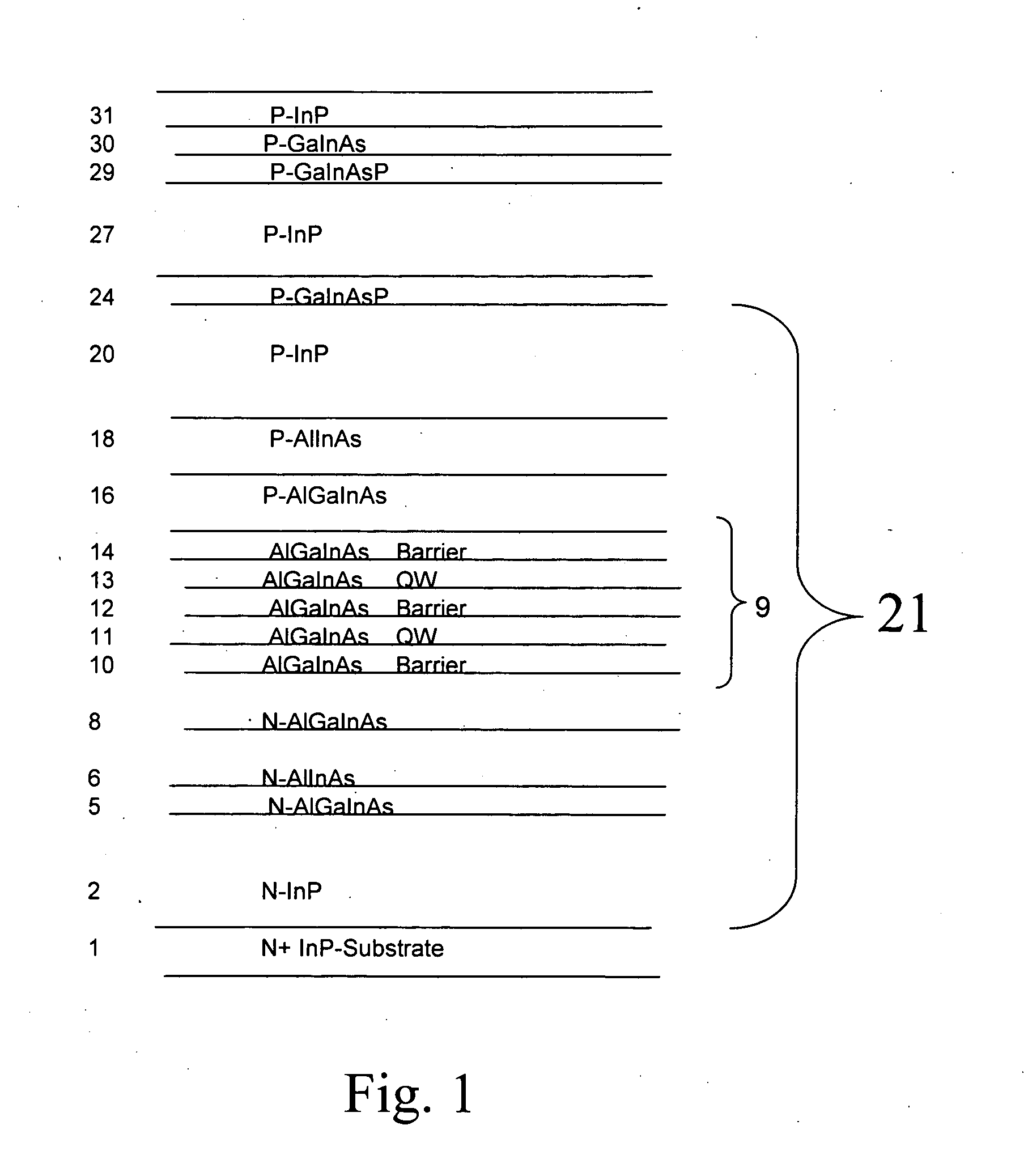

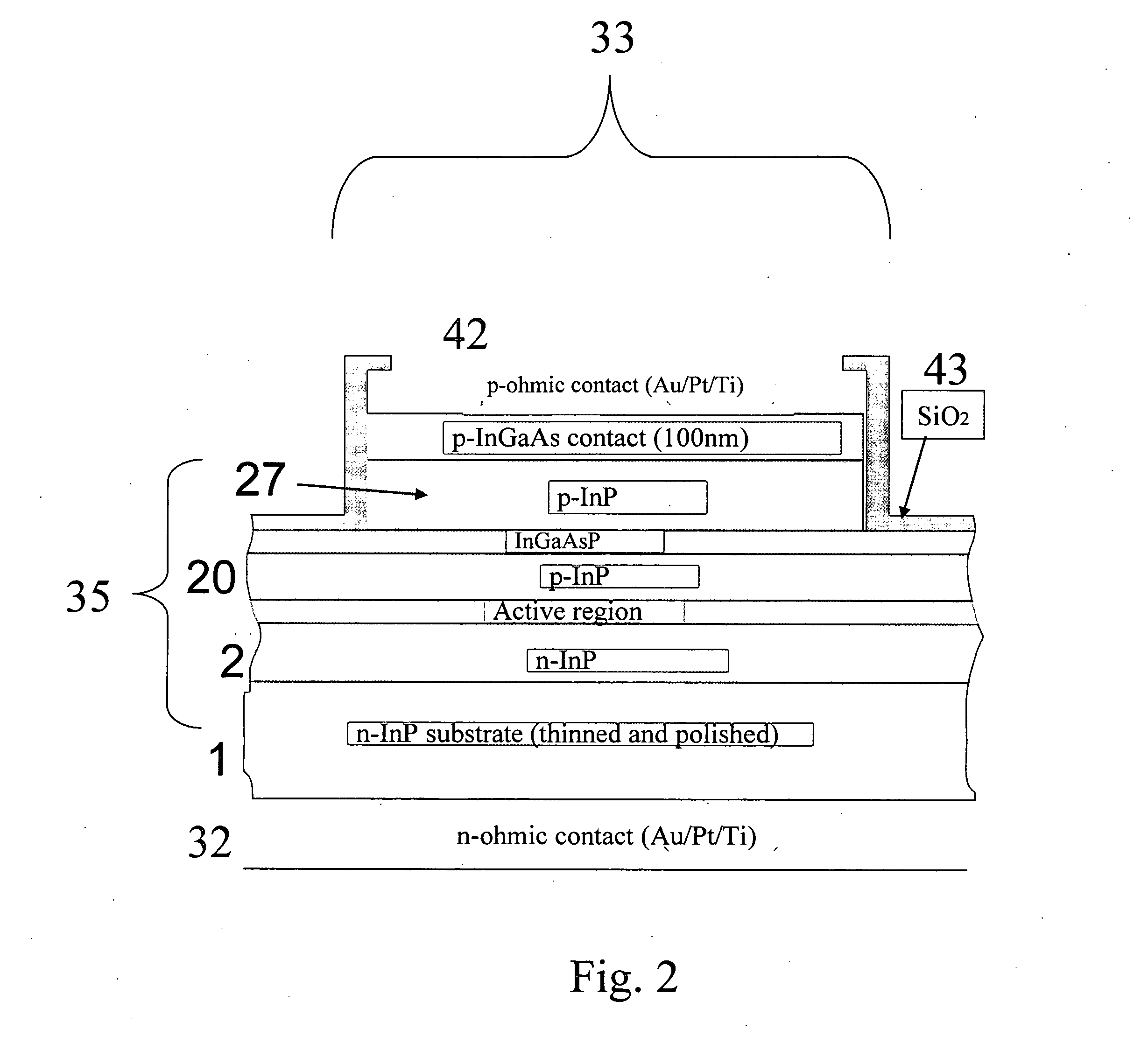

High-power infrared semiconductor diode light emitting device

ActiveUS20070002915A1High modulation speedMinimize temperature riseOptical wave guidanceNanoopticsIndium phosphideMicrometer

A semiconductor laser diode using the aluminum gallium, arsenide, gallium indium arsenide phosphide, indium phosphide, (AlGaInAs / GaInAsP / InP) material system and related combinations is disclosed. Both the design of the active layer and the design of the optical cavity are optimized to minimize the temperature rise of the active region and to minimize the effects of elevated active layer temperature on the laser efficiency. The result is a high output power semiconductor laser for the wavelengths between 1.30 and 1.61 micrometers for the pumping of erbium doped waveguide devices or for direct use in military, medical, or commercial applications.

Owner:SEMINEX CORP

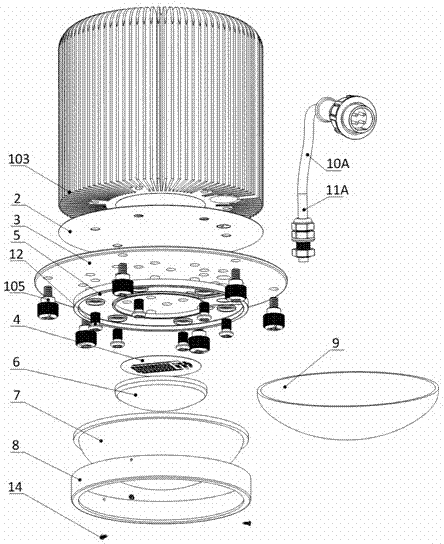

Light emitting diode (LED) spherical lamp transmitting heat through liquid

InactiveCN102927476AGood cooling effectLower junction temperaturePoint-like light sourceLighting heating/cooling arrangementsPhysicsThermal conductivity

The invention discloses a light emitting diode (LED) spherical lamp transmitting heat through liquid. The LED spherical lamp comprises a lamp cap assembly formed by a lamp cap and a lamp connecting seat, a hollow radiator, a driving power supply, a light emitting assembly formed by a light engine module and a high-transmittance temperature-resistant protective cover, and a glass cover, wherein a power supply containing cavity is arranged inside the hollow radiator, a seal cover is sleeved outside the driving power supply, the bottom of the seal cover is connected with the inner circumferential wall of the hollow radiator in sealed mode, a sealed liquid circulation radiating channel is formed by a gap between the high-transmittance temperature-resistant protective cover and the glass cover and a gap between the seal cover and the hollow radiator in communicated mode, and high-thermal conductivity liquid is installed in the liquid circulation radiating channel. Heat produced by light of lighting of LED lamp beads in the light engine module heats the high-thermal conductivity liquid, the high-thermal conductivity liquid produces convection in the liquid circulation radiating channel after being heated, the heat is diffused into air through the glass cover and the hollow radiator, and the radiating mode is good in effects, and the junction temperature of the LED lamp beads can be effectively reduced.

Owner:浙江阳光照明灯具有限公司

Solid state lighting

InactiveUS20100148652A1Widen meansProlong lifePoint-like light sourceElectric discharge tubesJunction temperatureEffect light

The present invention provides a solid-state lighting fixture and lamp for down light for use in applications especially in recessed lighting. In particular, the lamp of the subject invention may be configured as a direct screw-in replacement for common R-30 style incandescent flood lamp and it may be used existing luminaires. In one preferred embodiment of the present invention, a lamp mounted in a recessed light luminaire for down lighting has one or more light emitting diodes (LEDs) that are thermally coupled to a heat sink having fins for cooling by ambient air. The fins are configured so that air warmed by the fins can rise inside the luminaire and transfer its heat to it. Air cooled by the luminaire is allowed to sink and may flow out of the luminaire via a gap between the heat sink and the luminaire. Fresh cooler air may be drawn in between the fins to replace out-flowing air. This process of heating and cooling of air established a natural convection flow. Natural convective air flow allows for efficient thermal communication between the heat sink and the luminaire, thereby allowing for lower LED junction temperature and longer LED lifetime.

Owner:VETROVEC JAN

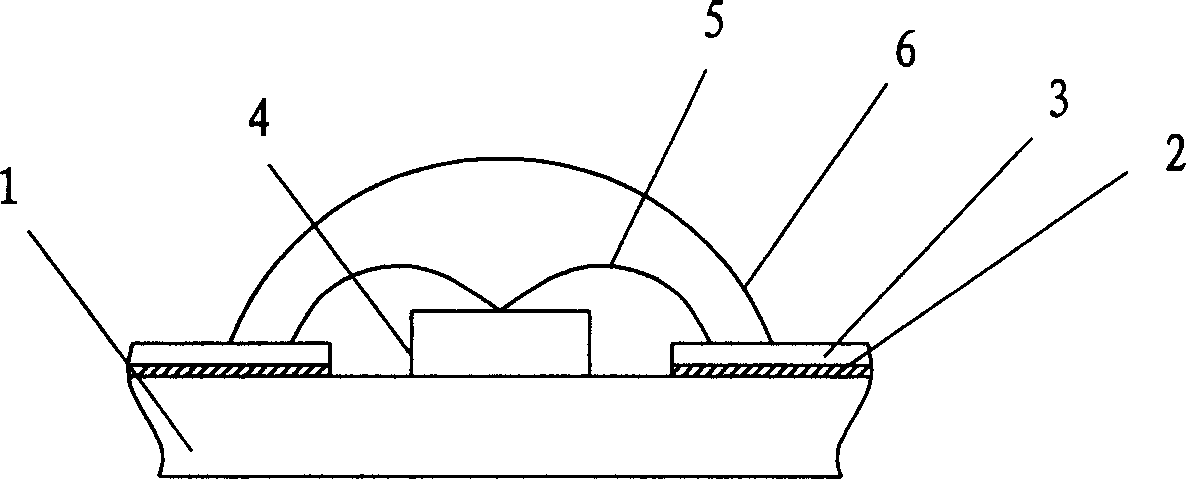

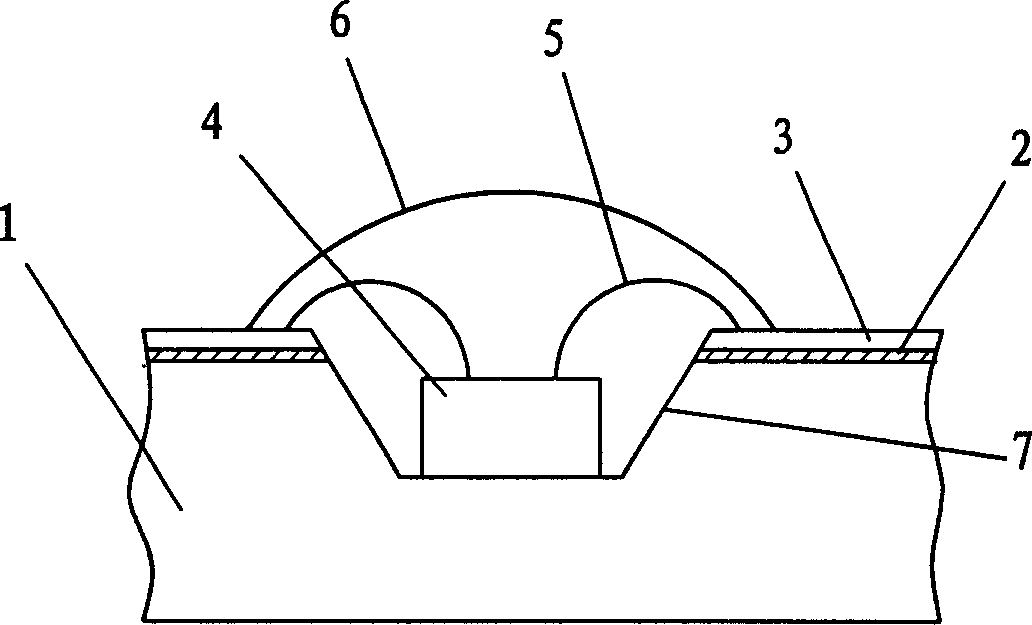

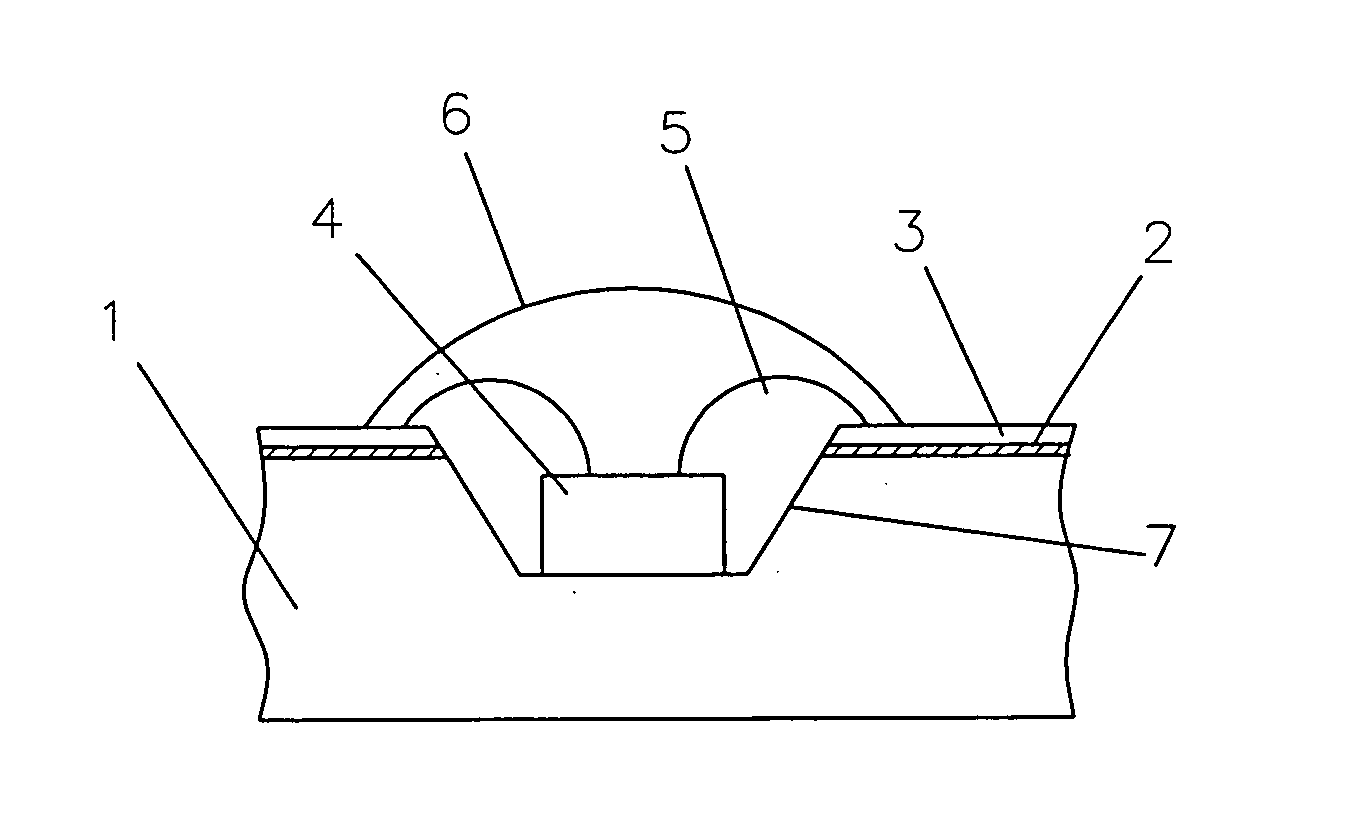

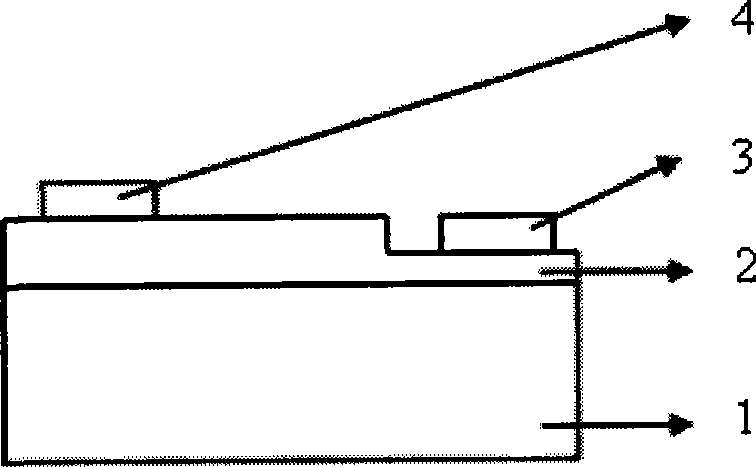

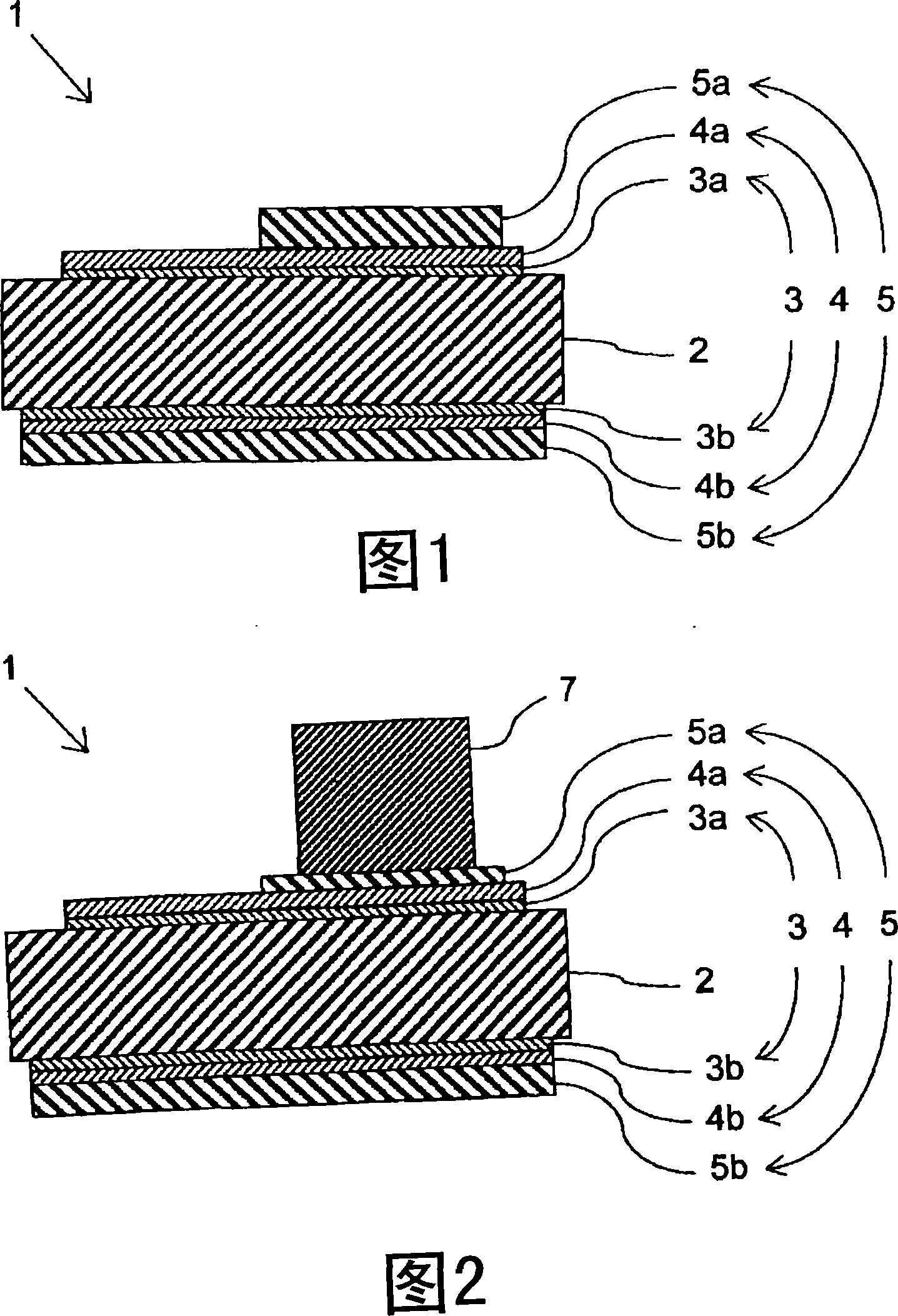

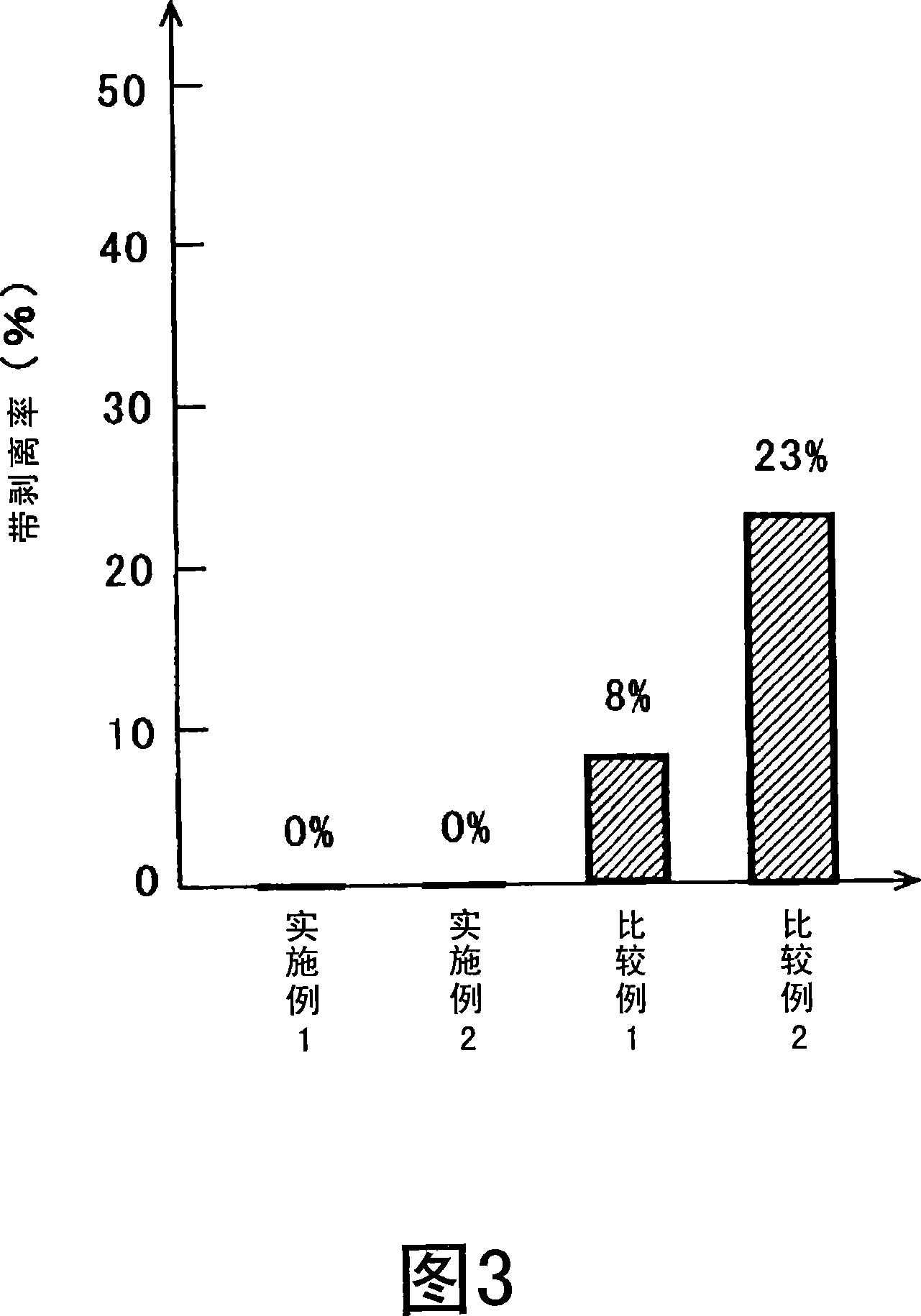

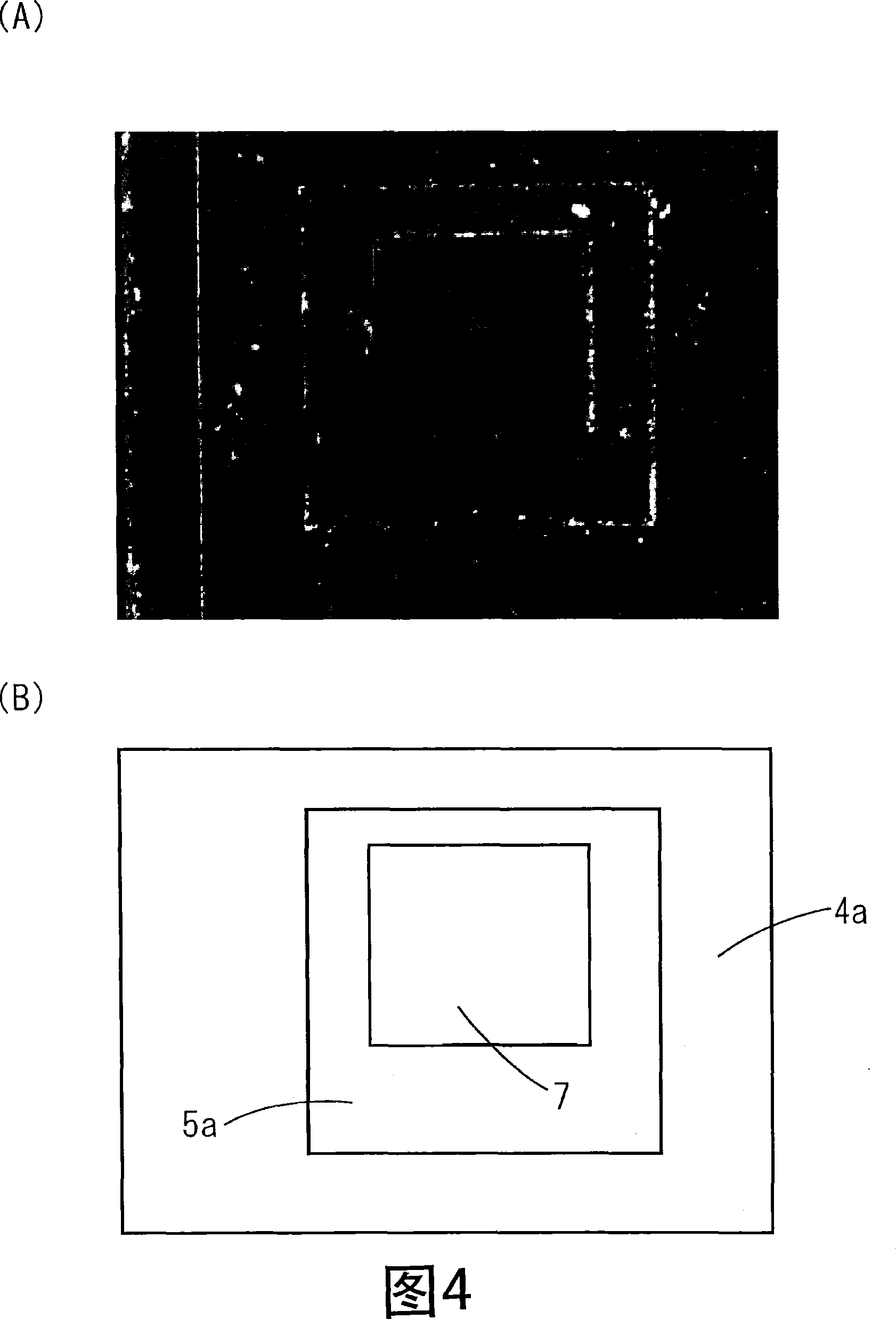

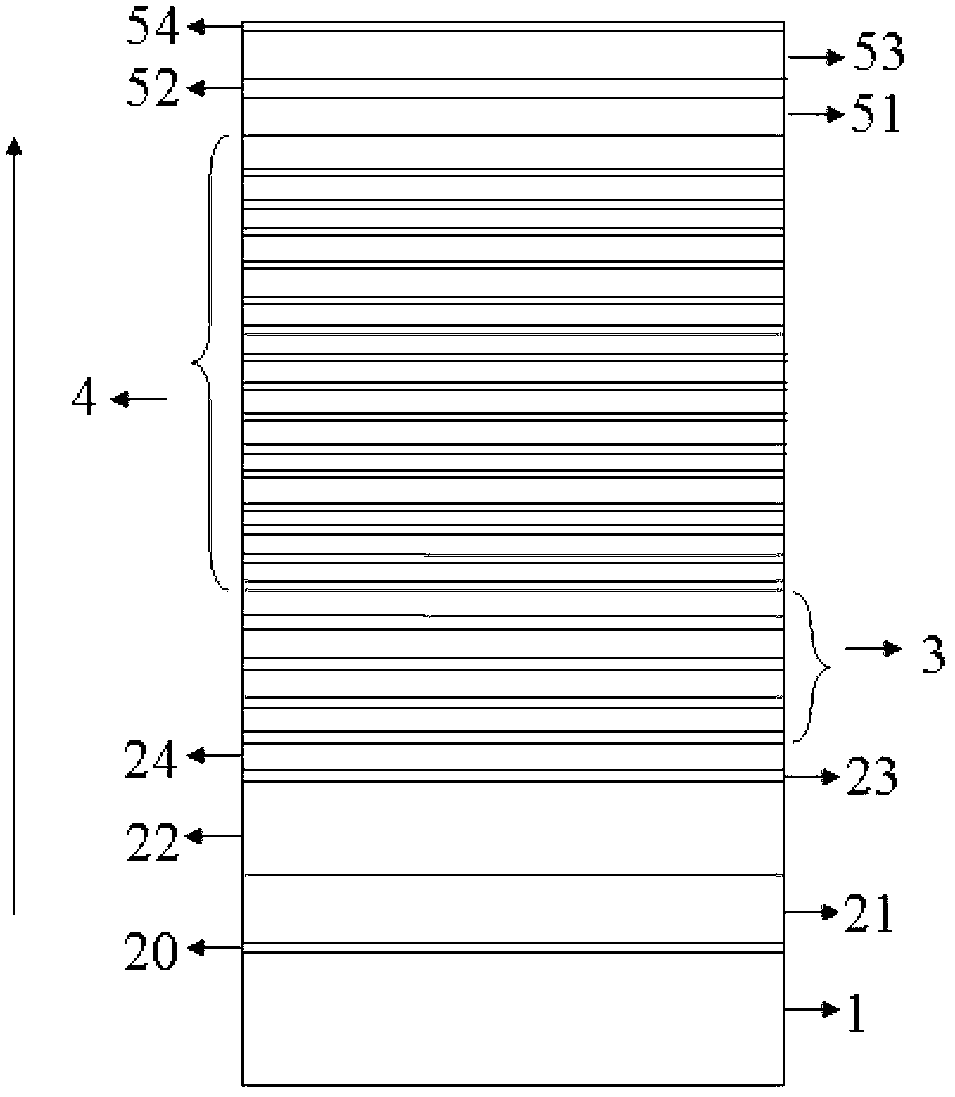

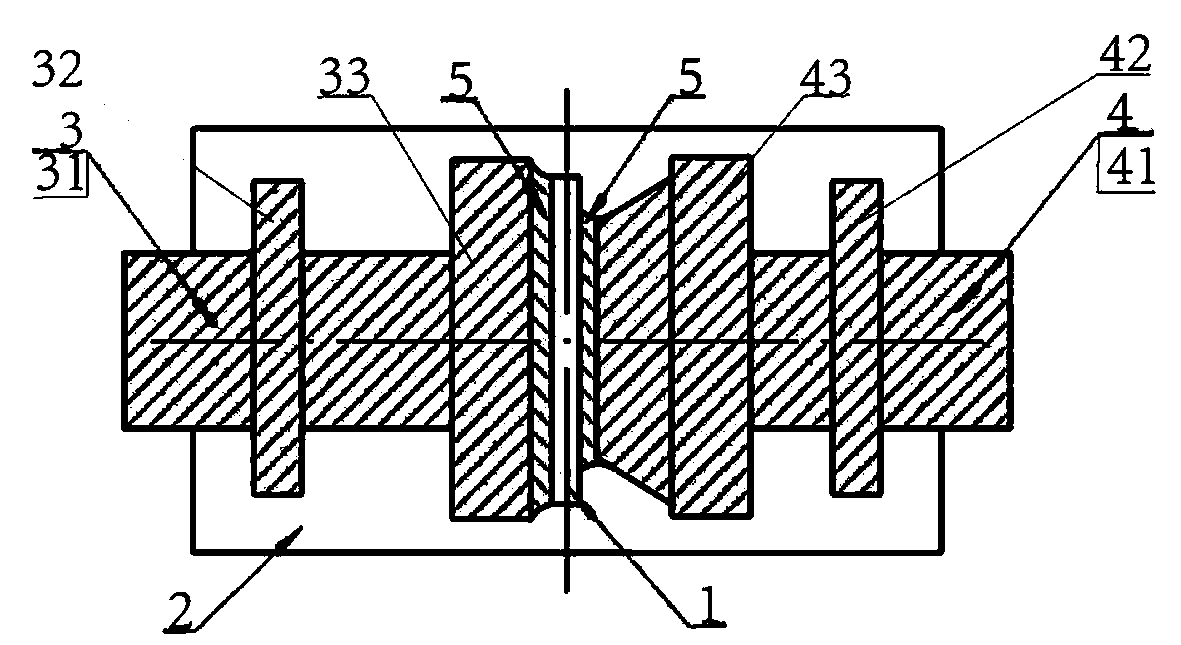

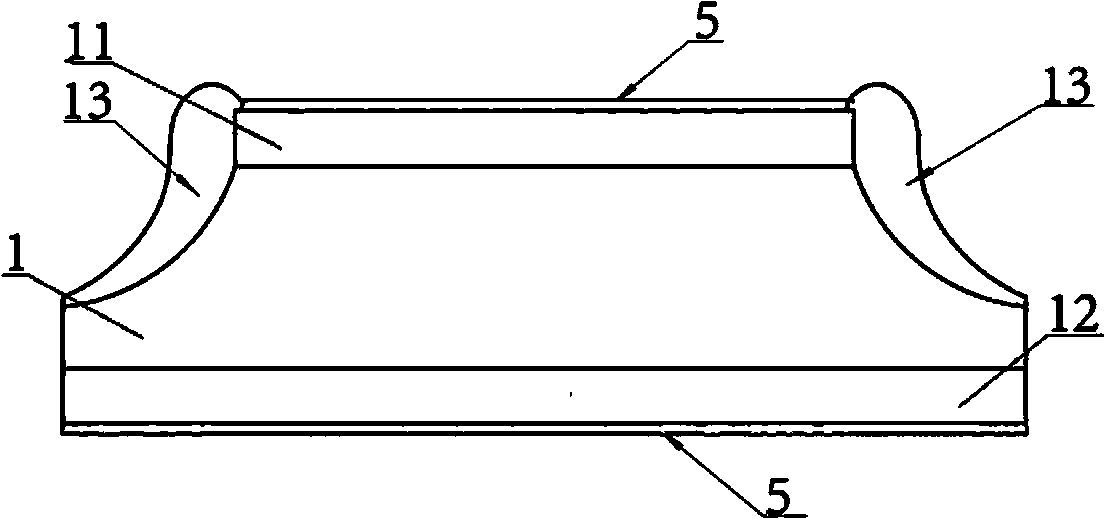

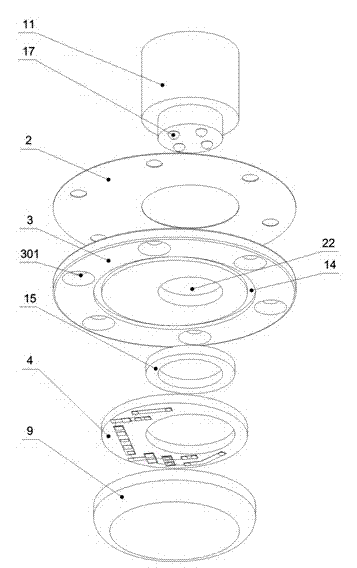

Sub-mount and its manufacturing method

InactiveCN101194359AImprove wettabilityImprove performanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceSurface roughness

A submount with an electrode layer having excellent wettability in soldering and method of manufacturing the same are disclosed. A submount (1) for having a semiconductor device mounted thereon comprises a submount substrate (2), a substrate protective layer (3) formed on a surface of the submount substrate (2), an electrode layer (4) formed on the substrate protective layer (3) and a solder layer (5) formed on the electrode layer (3) wherein the electrode layer (4) is made having an average surface roughness of less than 1 [mu]m. The reduced average surface roughness of the electrode layer (4) improves wettability of the solder layer (5), allowing the solder layer (5) and a semiconductor device to be firmly bonded together without any flux therebetween. A submount (1) is thus obtained which with the semiconductor device mounted thereon is reduced in heat resistance, reducing its temperature rise and improving its performance and service life.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

High power LED source for heat conduction by using room temperature liquid metal

ActiveCN101666433AIncrease contact areaImprove thermal conductivityPlanar light sourcesPoint-like light sourceAdhesiveLight source

The invention discloses a high power LED source for heat conduction by using a room temperature liquid metal, which comprises an LED chip, a concave package substrate, a room temperature liquid metallayer, a sealing layer, a radiator and a fluorescent adhesive layer. The LED chip is mounted on the concave package substrate, and an optical reflection surface is arranged on the concave package substrate. The fluorescent adhesive layer is covered on the LED chip and the concave package substrate is mounted on the radiator. A gap is arranged between the concave package substrate and the radiatorand is sealed by the sealing layer, and the gap is filled with the room temperature liquid metal layer. The method effectively solves the problem of the thermal contact resistance between the high power LED package substrate and the radiator by using the high heat conductivity of the room temperature liquid metal, thereby achieving a better heat conduction effect; and the heat generated by the LEDchip is transferred, and the junction temperature of the LED chip is kept at a low level, thereby improving the operation reliability of the high power LED and prolonging the service life thereof.

Owner:SHANGHAI CEYUAN IND

LED (light emitting diode) candle-type lamp

ActiveCN102798008ASimple structureLow costPoint-like light sourceLighting heating/cooling arrangementsEnergy efficient lightingPendant light

The invention discloses an LED (light emitting diode) candle-type lamp. The LED candle-type lamp comprises a candle-type lamp, wherein the candle-type lamp comprises a heat conduction converter board (27) and a radiator (103); the heat conduction converter board (27) is provided with an installation interface (AZM) which is used for fixedly installing an LED lamp bulb (102); and the heat conduction converter board (27) is connected with a candle-type lamp shell (101) through bonding, a threaded connection or a clamping manner, and the radiator (103) is arranged below the heat conduction converter board (27). The LED candle-type lamp provided by the invention has the advantages that the structure is simple, the manufacturing cost is low, the installation, use and the maintenance are rapid, cheap and convenient, the failure extensification is not easy, the independence of a lamp bulb, a lamp and a lighting control product of the LED candle-type lamp on manufacture and use is realized, the production link is greatly reduced, the batch production is realized, and the LED candle-type lamp is beneficial for the application and industry scale of LED energy-saving lighting products. The LED candle-type lamp provided by the invention can be applied to different candle-type ceiling lamps or other ceiling lamps with covers, and solves the problem that the traditional energy-saving lamp can not be applied to an incandescence candle lamp environment.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

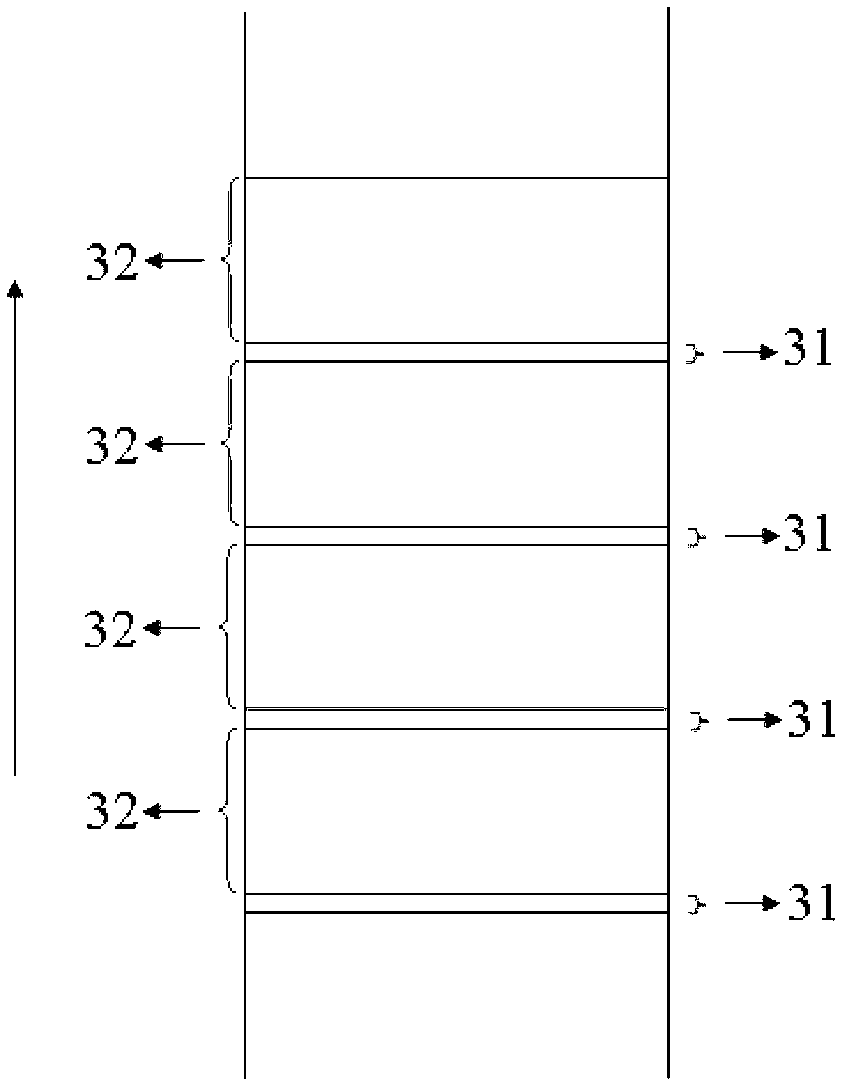

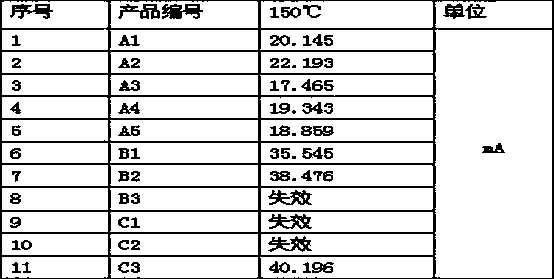

Quantum well semiconductor and manufacturing method thereof

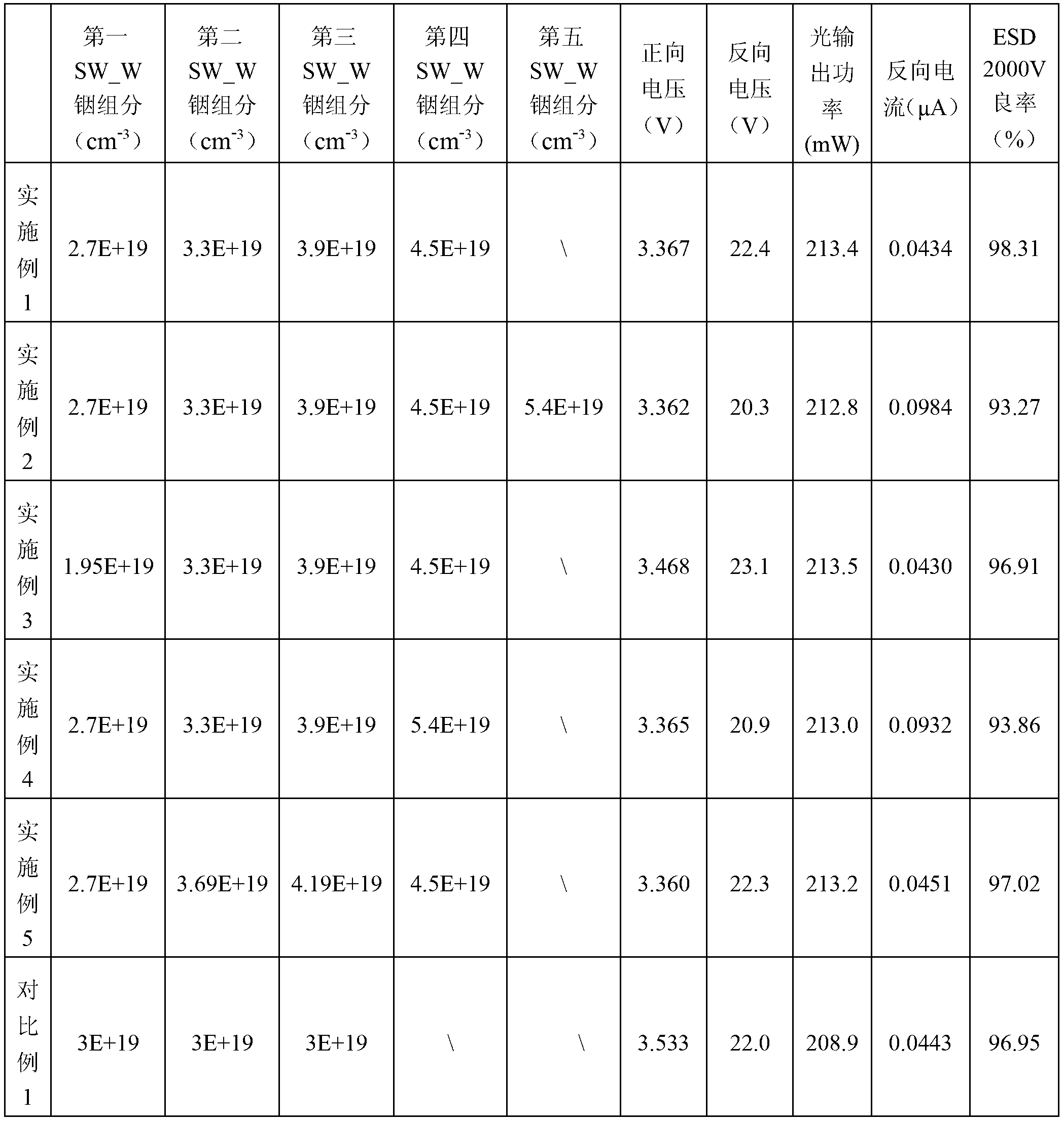

ActiveCN103227253AIncremental Compounding EfficiencyImprove compound efficiencySemiconductor devicesReverse currentElectron

The invention provides a quantum well semiconductor and a manufacturing method thereof. The quantum well semiconductor comprises a substrate, a shallow quantum well layer and a multiple quantum well light emitting layer that are arranged in sequence from inside to outside, wherein the shallow quantum well layer comprises at least four InGaN layers and GaN layers; the InGaN layer close to the substrate is a first InGaN layer; the number of the GaN layers is the same as that of the InGaN layers; the GaN layers and the InGaN layers are superposed in a crossed manner; the GaN layer close to the substrate is a first GaN layer; the first GaN layer is arranged between the substrate and the first InGaN layer; the content of In in the first InGaN layer is 1.95E+19-2.7E+19cm<-3>; and the content of In in each of all the InGaN layers except the first InGaN layer is greater than 3.0E+19cm<-3> and is increased gradually in the direction far away from the substrate. The shallow quantum well layer can prevent excessive reverse current, facilitates pass-through of electrons, reduces the forward voltage and heat productivity of a chip during operation, and improves the light emitting efficiency.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Novel photovoltaic diode and production process thereof

InactiveCN104112784AIngenious structureThe process is perfect and matureFinal product manufactureSemiconductor/solid-state device detailsEpoxyMode-locking

The invention relates to the field of a photovoltaic diode and specially relates to a novel photovoltaic diode and a production process thereof. The photovoltaic diode is ingenious in structure, perfect and mature in process, high in product processing and production efficiency, good in heat radiation of the product, low in temperature rise and long in service life. The advantages are that the photovoltaic diode is ingenious in structure, perfect and mature in process, high in product processing and production efficiency, good in heat radiation of the product, low in temperature rise and long in service life; epoxy resin is injected from the large nail head surface and recoiled to the surface of a chip, thereby reducing the impact on the chip to the largest degree and reducing injection molding stress effectively; in the product using process, the contact surface between the chip and leading wires is increased, and the heat produced by the chip can be dissipated quickly, thereby reducing chip junction temperature, prolonging the service life of the product, and improving the rectification efficiency; and the design of annular round plates on the leading wires of the photovoltaic diode plays a mode locking effect in the processing process, and the mechanical strength of the product is enhanced after injection moulding.

Owner:NANTONG HORNBY ELECTRONICS

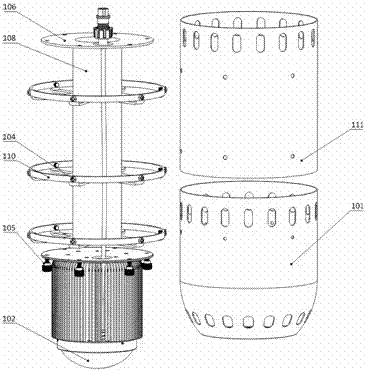

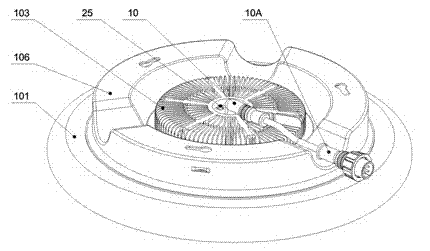

LED (Light-Emitting Diode) ceiling lamp

ActiveCN102818199AImprove cooling effectAvoid enteringPoint-like light sourceLighting heating/cooling arrangementsEnergy efficient lightingEngineering

The invention discloses an LED (Light-Emitting Diode) ceiling lamp comprising a lamp of the ceiling lamp. The lamp of the ceiling lamp comprises a ceiling lamp base (106) and a heat radiator (103); a bulb mounting interface is arranged on the ceiling lamp base (106); the heat radiator (103) is arranged on the bulb mounting interface; and a mounting interface (AZM) for fixedly mounting the LED lamp bulb (102) is arranged in the center of the lower part of the heat radiator (103). The LED ceiling lamp has the advantages of strong heat radiation capability, simple structure and low manufacturing cost, and is rapid, cheap and convenient to mount, use and maintain; the bulb, a lamp and an illumination control product of the LED ceiling lamp can be independently produced and used; the production link is greatly reduced; the mass production is implemented; and the LED ceiling lamp is beneficial to application and industrial mass production of an LED energy-saving illumination product.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

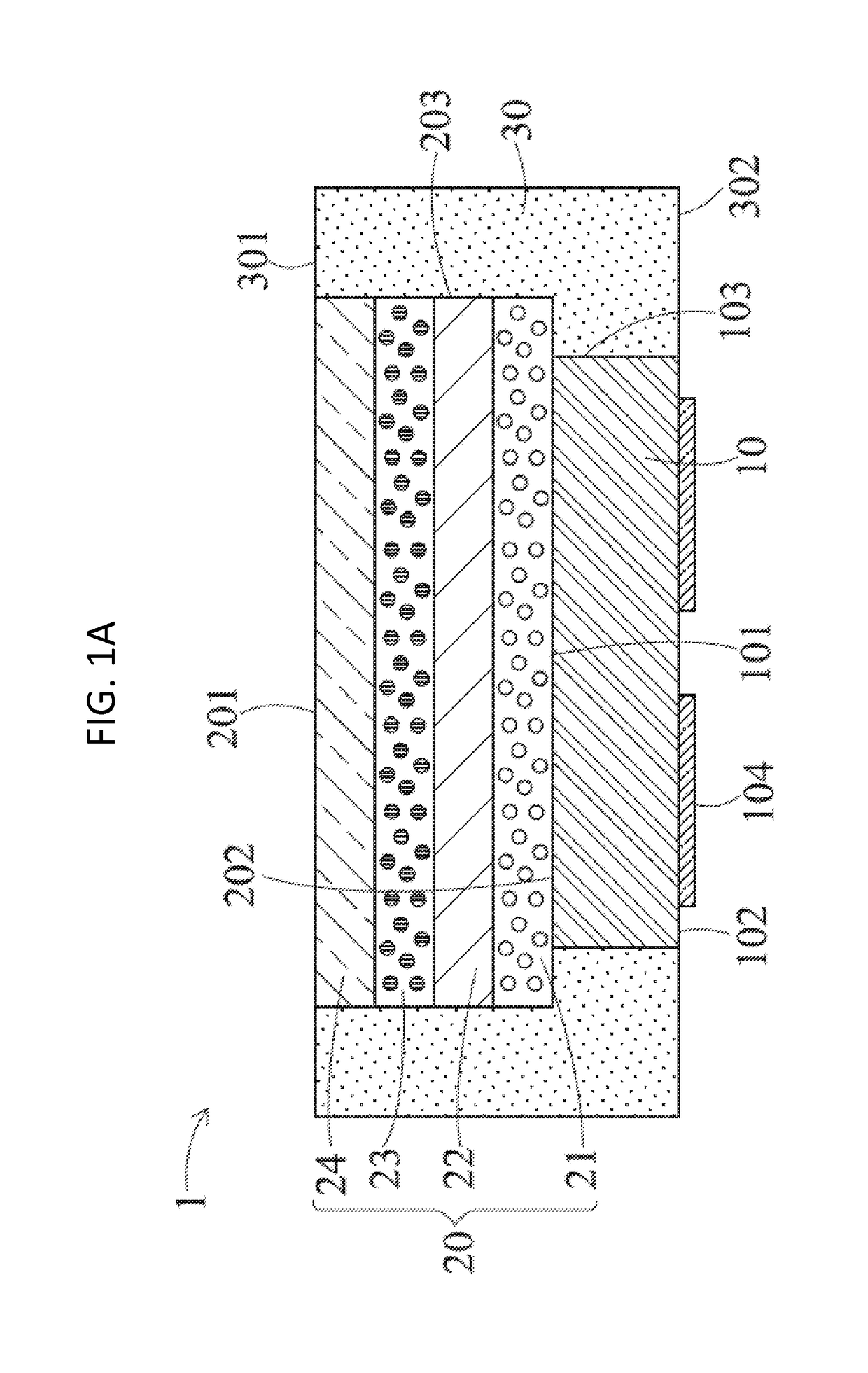

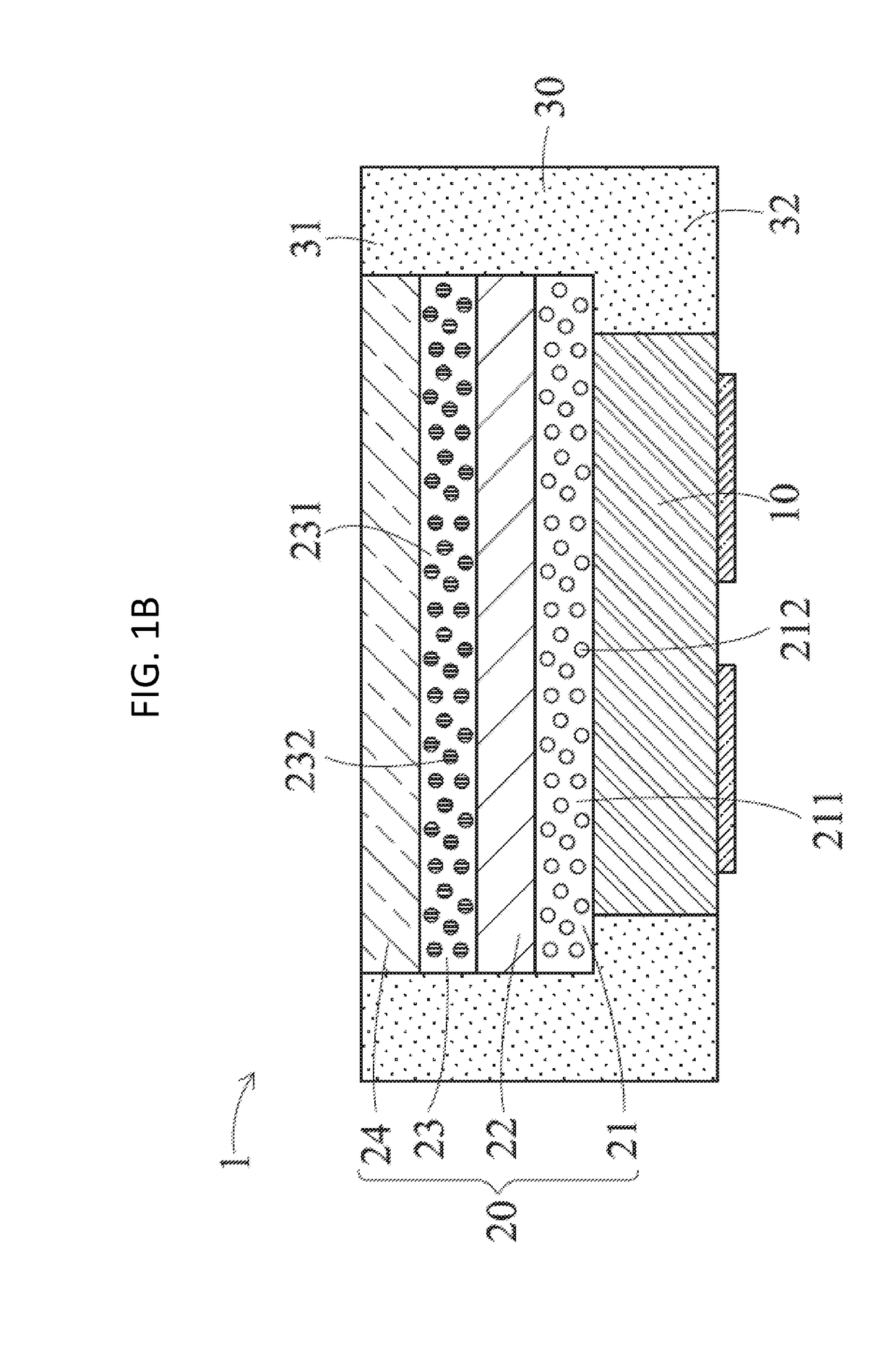

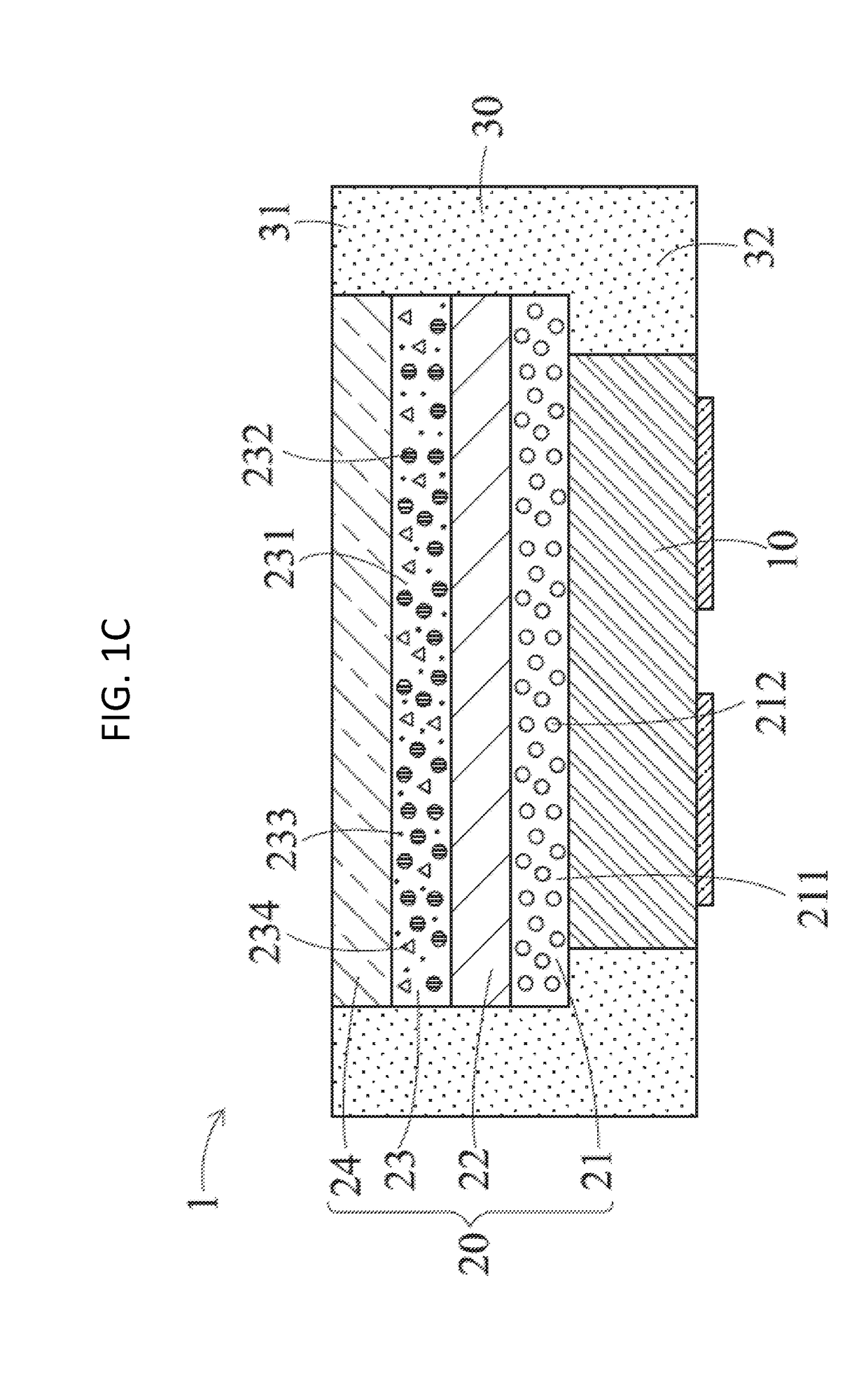

Quantum dot-based color-converted light-emitting device and method for manufacturing the same

ActiveUS20190081219A1Low thermal resistanceImprove thermal attenuationSemiconductor devicesEdge surfaceQuantum dot

A light-emitting device includes a flip-chip LED semiconductor chip to provide a primary light, a photoluminescent (PL) structure disposed on the LED semiconductor chip and a moisture-barrier reflective structure covering a chip-edge surface of the LED semiconductor chip and a photoluminescent-side surface of the PL structure. The sequentially stacked PL structure includes a first PL layer, a transparent isolation layer, a second PL layer and a transparent moisture barrier layer. For example, the LED semiconductor chip emits a blue light, the first PL layer includes a red phosphor material, and the second PL layer includes a green quantum dot (QD) material. Therefore, the red phosphor material of the first PL layer can convert a portion of the higher-energy-level blue light into a lower-energy-level converted red light, so as to reduce an intensity of an unconverted portion of the blue light reaching the green QD material within the second PL layer.

Owner:MAVEN OPTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com