LED (light emitting diode) candle-type lamp

An LED bulb and candle-shaped technology, applied in the field of candle-shaped lamps, can solve the problems of high manufacturing cost, mutual incompatibility, difficult maintenance, etc. Improve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

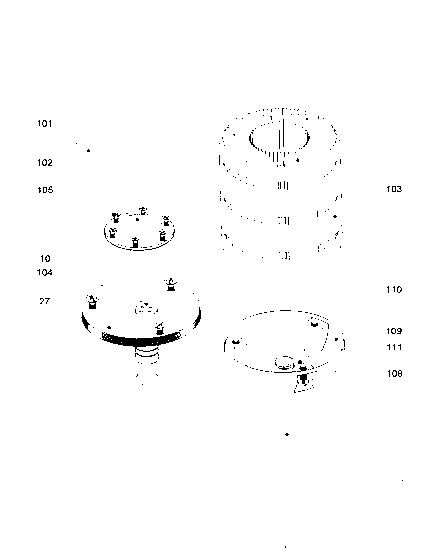

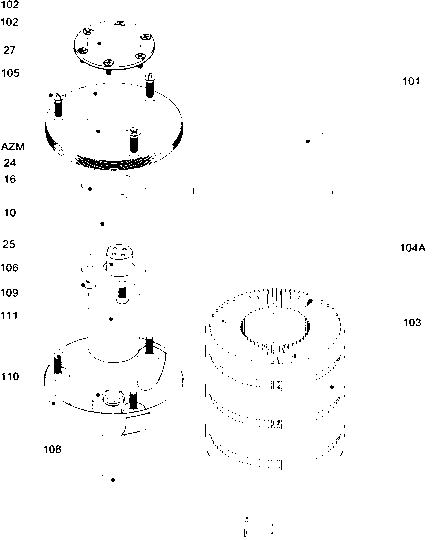

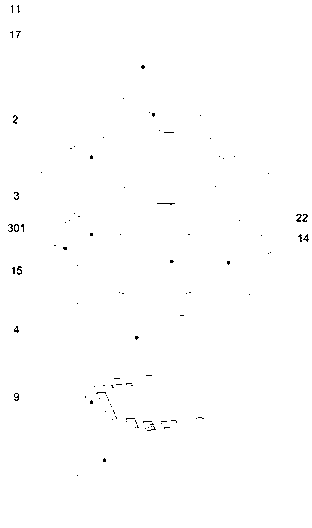

[0054] An LED candle lamp, such as figure 1 , Figure 12 , Figure 13 and Figure 21 As shown, it includes a candle-shaped light fixture, and the candle-shaped light fixture includes a heat conduction conversion plate 27 and a radiator 103; There is a heat conduction pad 2 ; the heat conduction conversion plate 27 is connected to the candle-shaped lamp housing 101 through bonding, screw connection or clamping, and the heat sink 103 is arranged under the heat conduction conversion plate 27 . The candle-shaped lamp also includes a wire tube 108 and an intermediate connector 110. The wire tube 108 is fixed to the intermediate connector 110 through the wire tube fixing screw 109, and the intermediate connector 110 is connected to the radiator 103 through the lamp cap fixing screw 111; the installation The interface includes a surface on the heat conduction conversion plate 27 that is in contact with the LED bulb 102 and a hole for connection. The radiator 103 is a column...

Embodiment 2

[0059] An LED candle lamp, such as figure 2 , Figure 12 , Figure 14 and Figure 21 As shown, it includes a candle-shaped light fixture, and the candle-shaped light fixture includes a heat conduction conversion plate 27 and a radiator 103; There is a heat conduction pad 2 ; the heat conduction conversion plate 27 is connected to the candle-shaped lamp housing 101 through bonding, screw connection or clamping, and the heat sink 103 is arranged under the heat conduction conversion plate 27 . The candle-shaped lamp also includes a wire tube 108 and an intermediate connector 110. The wire tube 108 is fixed to the intermediate connector 110 through the wire tube fixing screw 109, and the intermediate connector 110 is connected to the radiator 103 through the lamp cap fixing screw 111; the installation The interface includes a surface on the heat conduction conversion plate 27 that is in contact with the LED bulb 102 and a hole for connection. The radiator 103 is a column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com