Sub-mount and its manufacturing method

A manufacturing method and sub-mount technology, which can be used in manufacturing tools, semiconductor/solid-state device manufacturing, welding equipment, etc., and can solve the problems of increased substrate surface roughness, increased cost, and roughened electrode layer surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

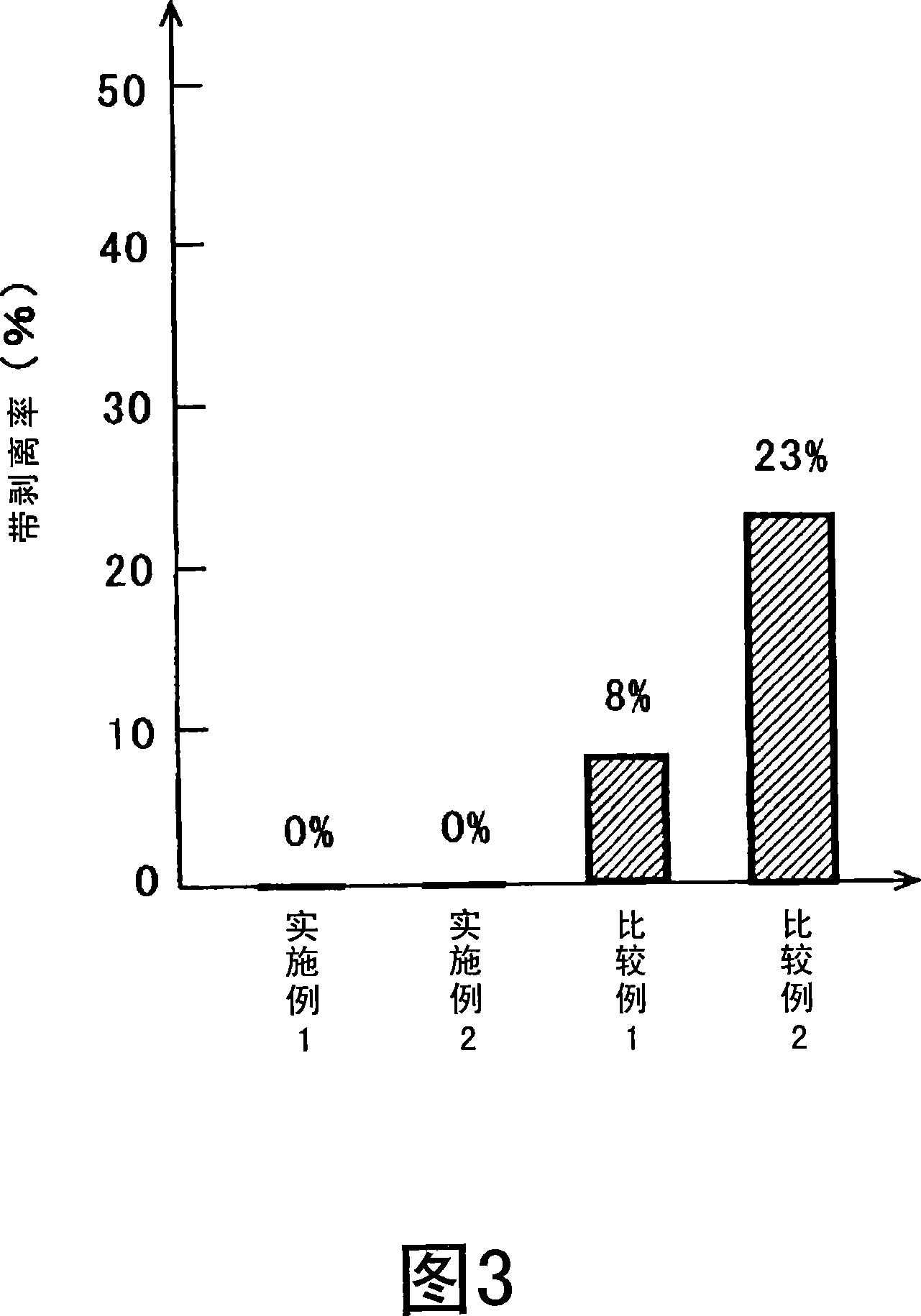

[0156] Hereinafter, the present invention will be explained in more detail based on examples.

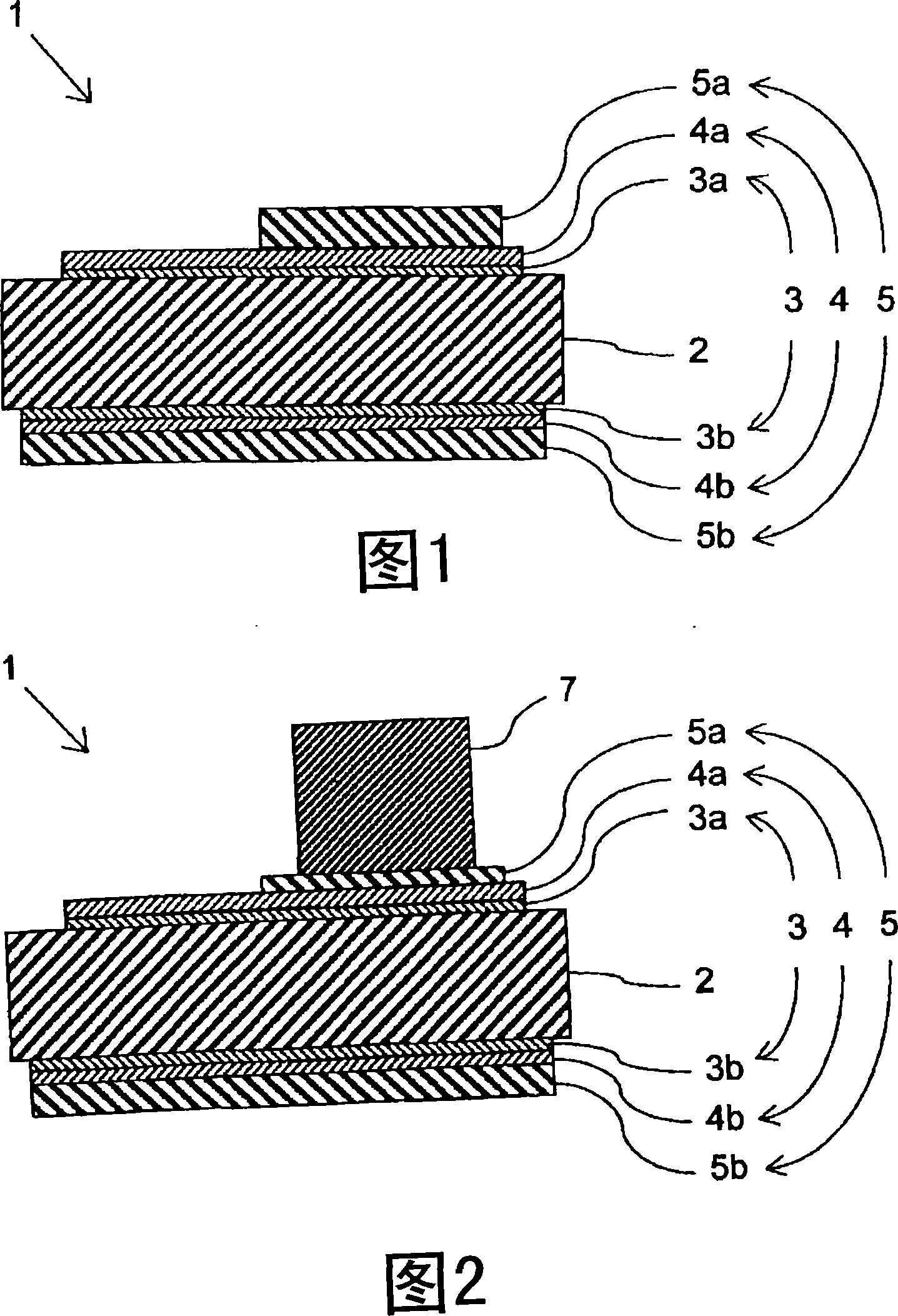

[0157] First, the manufacturing method of the submount will be described.

[0158] Both sides of a 55mm square and 0.3mm thick sintered aluminum nitride substrate 2 with high thermal conductivity (230W / mK) are ground by a polishing device, and the polishing device is used for finishing polishing to make the aluminum nitride substrate 2 rough The degree (Ra) is 0.07 μm.

[0159] The polished aluminum nitride substrate 2 is cleaned to clean the surface, and the substrate protective layer 3a made of titanium is deposited to a thickness of 0.05 μm on the entire surface of the substrate 2 by a vacuum vapor deposition device.

[0160] Next, in order to perform photolithographic layout, the entire surface of the substrate on which the substrate protective layer 3a has been deposited is uniformly coated with a resist using a spin coater, and then a predetermined baking is performed in a baking ...

Embodiment 2

[0165] The submount 1 of Example 2 was manufactured in the same manner as Example 1, except that the average roughness (Ra) of the aluminum nitride substrate 2 was 0.04 μm.

[0166] Next, a comparative example will be described.

Embodiment 3

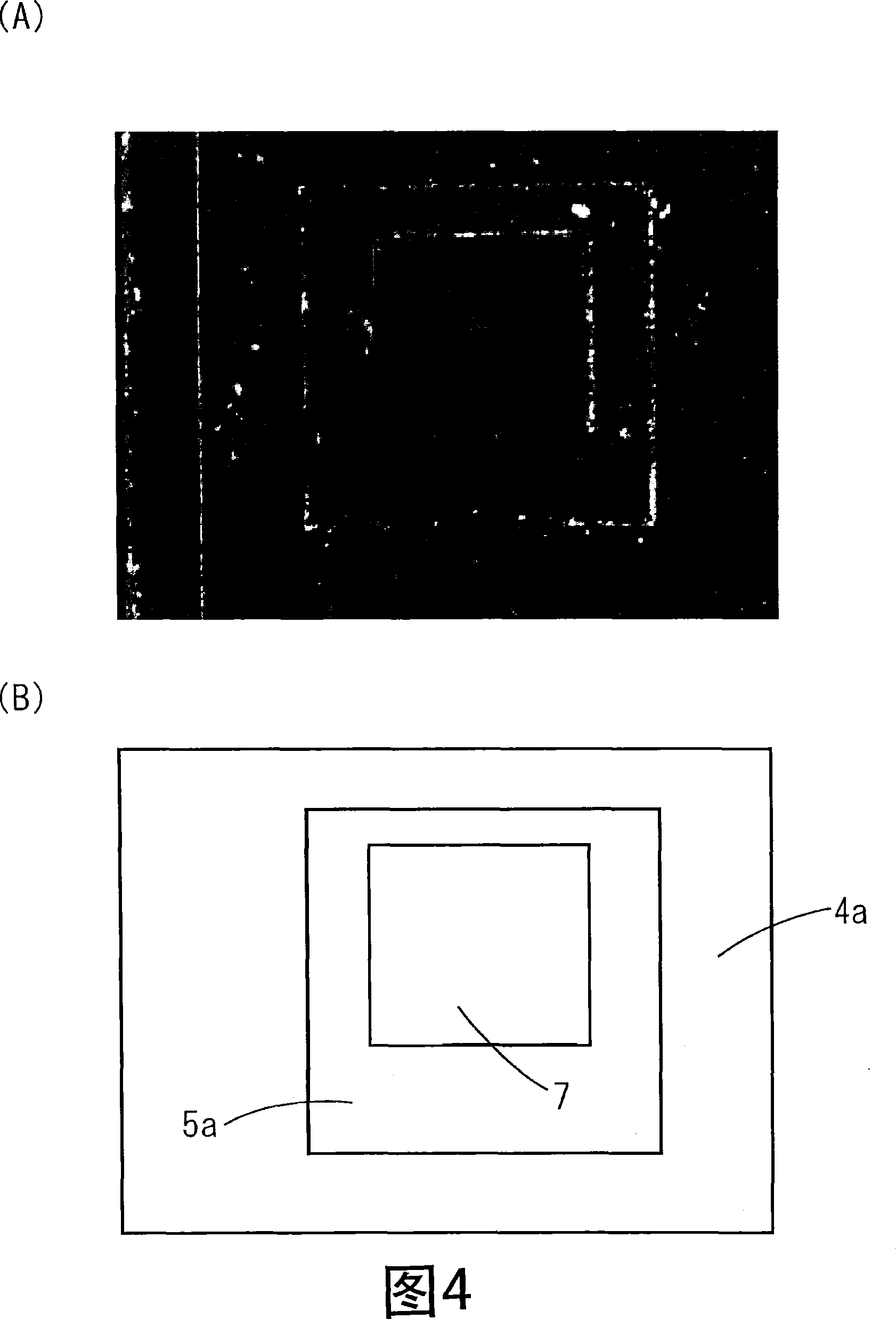

[0195] Hereinafter, the present invention will be explained in more detail based on Examples 3 and 4. First, the manufacturing method of the submount of the third embodiment will be described.

[0196] Grind both sides of a high thermal conductivity (230W / mK) aluminum nitride sintered substrate (55mm square, 0.3mm thick) with a polishing device. In addition, finishing grinding is performed using a polishing device. The polished aluminum nitride sintered substrate 12 is cleaned to clean the surface. In order to perform photolithographic patterning, a spin coater is used to uniformly coat the entire surface of the submount substrate 12 with a resist. A baking oven is used for predetermined baking, and a mask alignment device is used for gamma line contact exposure. The exposure mask is designed to be able to lay out 2500 at the same time with the submount size of 1mm square. After the exposure, the resist of the electrode layer is dissolved with a developer to expose the submount su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

| Surface average roughness | aaaaa | aaaaa |

| Surface average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com