Patents

Literature

393results about How to "Strong joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

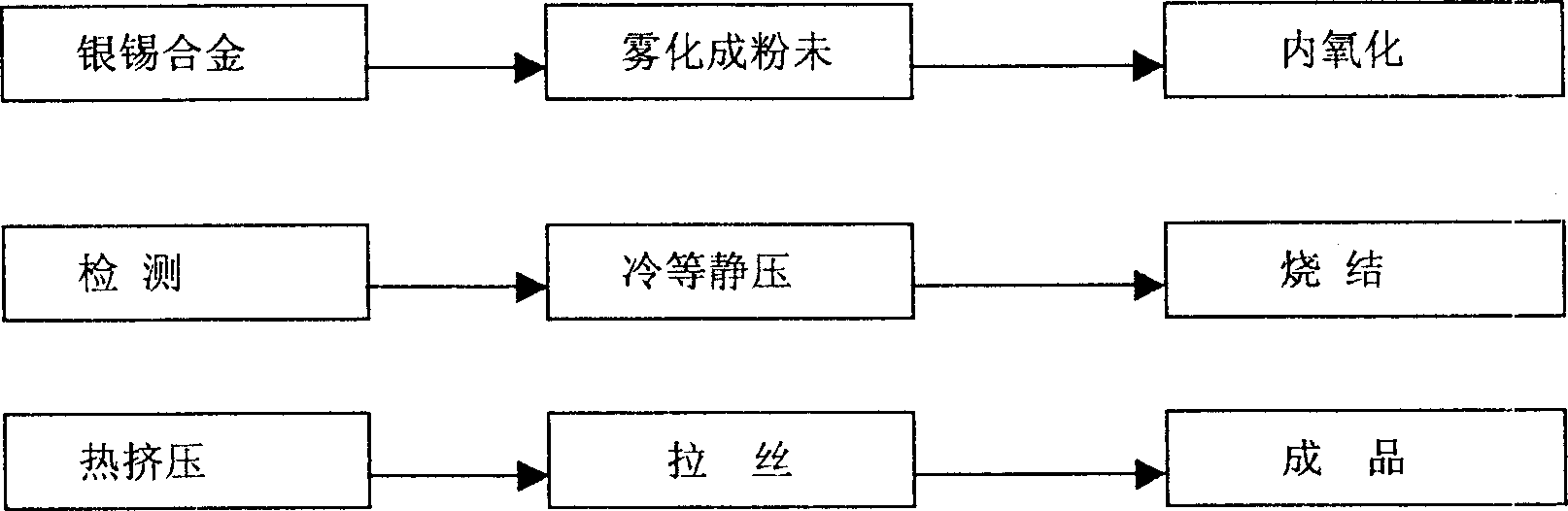

Process for preparing silver tin oxide material

InactiveCN1425790AGuaranteed uniformity of distributionNot limited by product sizeMedium frequencyIngot

The present invention relates to the preparation of contact material and is especially the preparation of silver-tin oxide material. The preparation process includes smelting silver and tin in certain ratio in a medium frequency furnace, alloy atomizing inside one high pressure water atomizing equipment, stoving to obtain powder, sieving, oxidation inside aninternal oxodizing furnace at certain temperature and oxygen pressure, cold hydrostatic processing to obtain ingot, sintering, extruding into wire and drawing into the product. The silver-tin oxide material has full oxidation of tin, firm combination between tin oxide and silver base and high comprehensive performance.

Owner:陈达峰

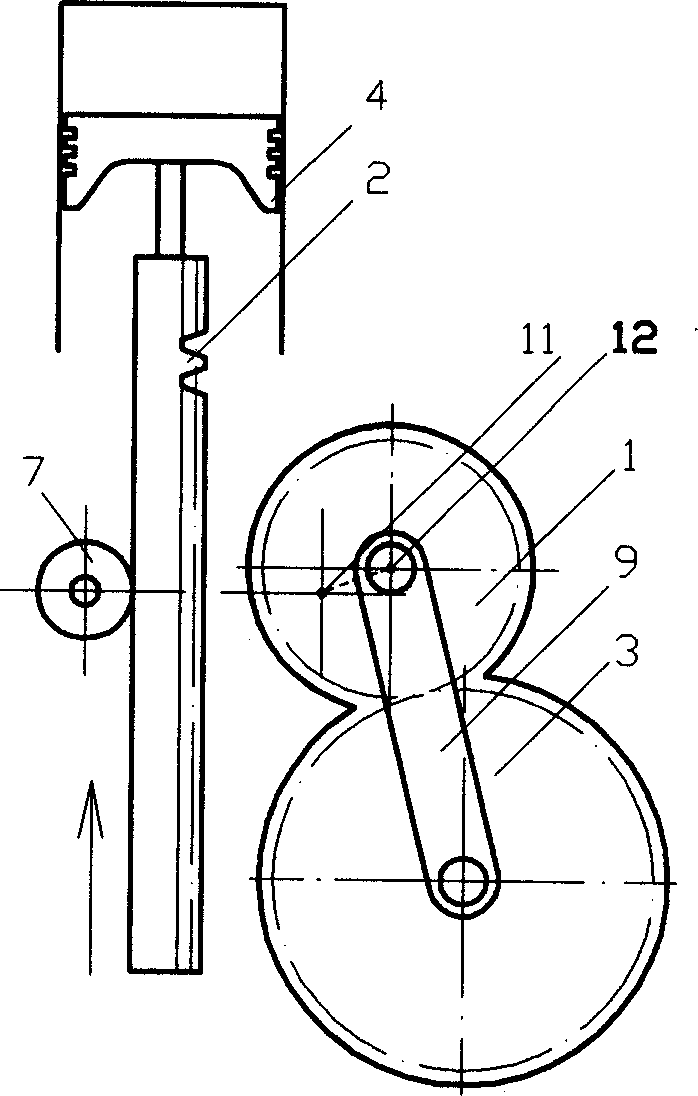

Piston crankshaftless engine

InactiveCN1529045ASimplify the constituent elementsSimple designMachines/enginesLine shaftGear wheel

The invention discloses a kind of piston engine without crank, a power converting mechanism made up of mobile gear, gear rack connected to the piston and the driving gear fixed on the straight output main shaft replaces traditional crank link mechanism, and it overcomes the deficiency of current crank-less engine; the mobile gear can move between the connection position and the non-connection position, thus the dynamic force device between the gear rack and the driving gear can be in on / off state; in the exposure distance of the piston, it can transmit force to the main shaft through the force transmitting chain; the back movement of piston doesn't affect the movement of the output main shaft; along with the joining movement of mobile gear, by mating with the other assistant system, the reciprocate straight movement can be changed into the power output with continuous single direction rotation of main shaft. The converter can be used in gasline, diesel, gas inner combustion machine.

Owner:程远

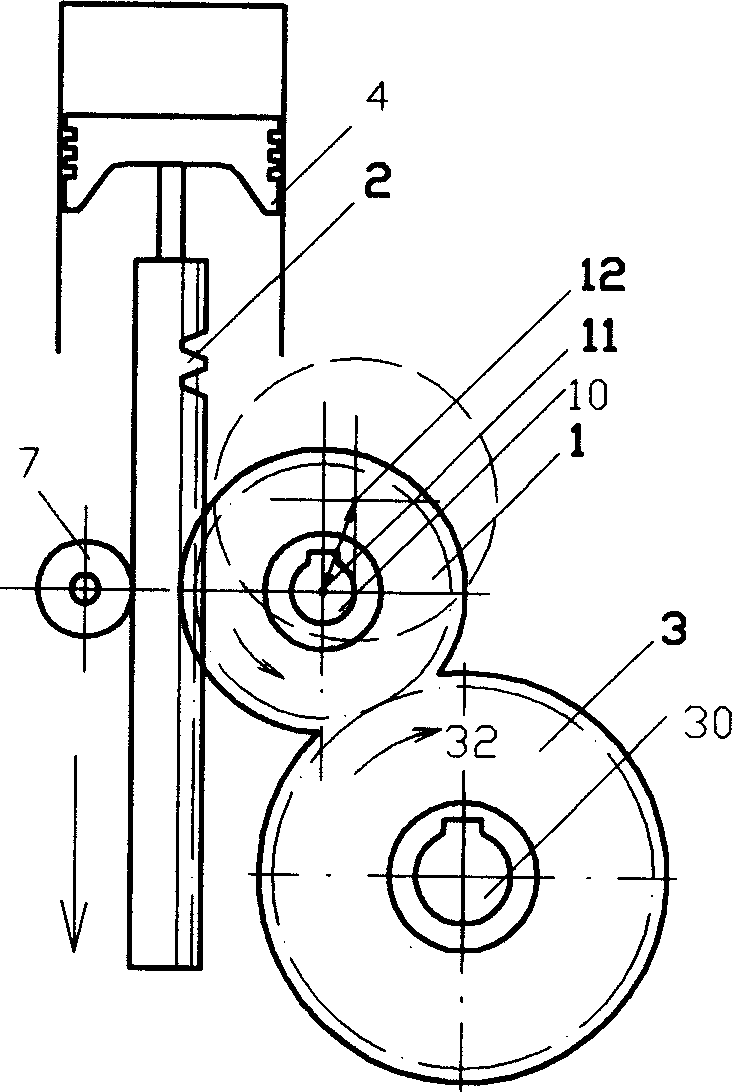

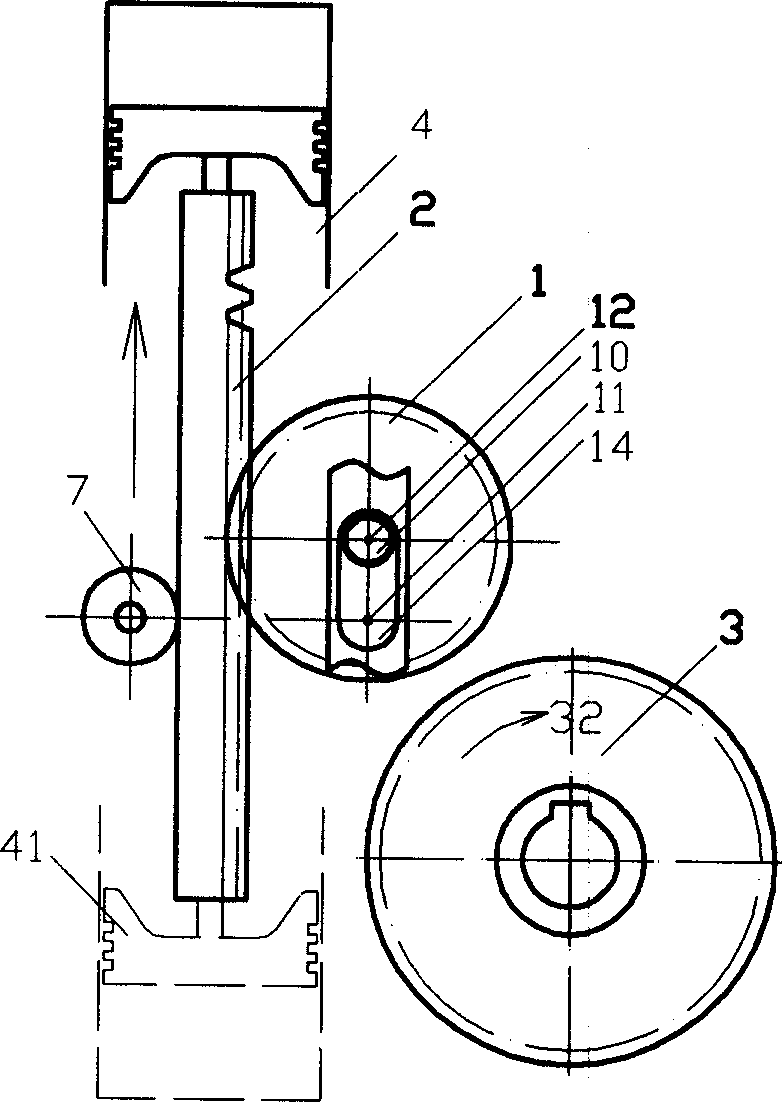

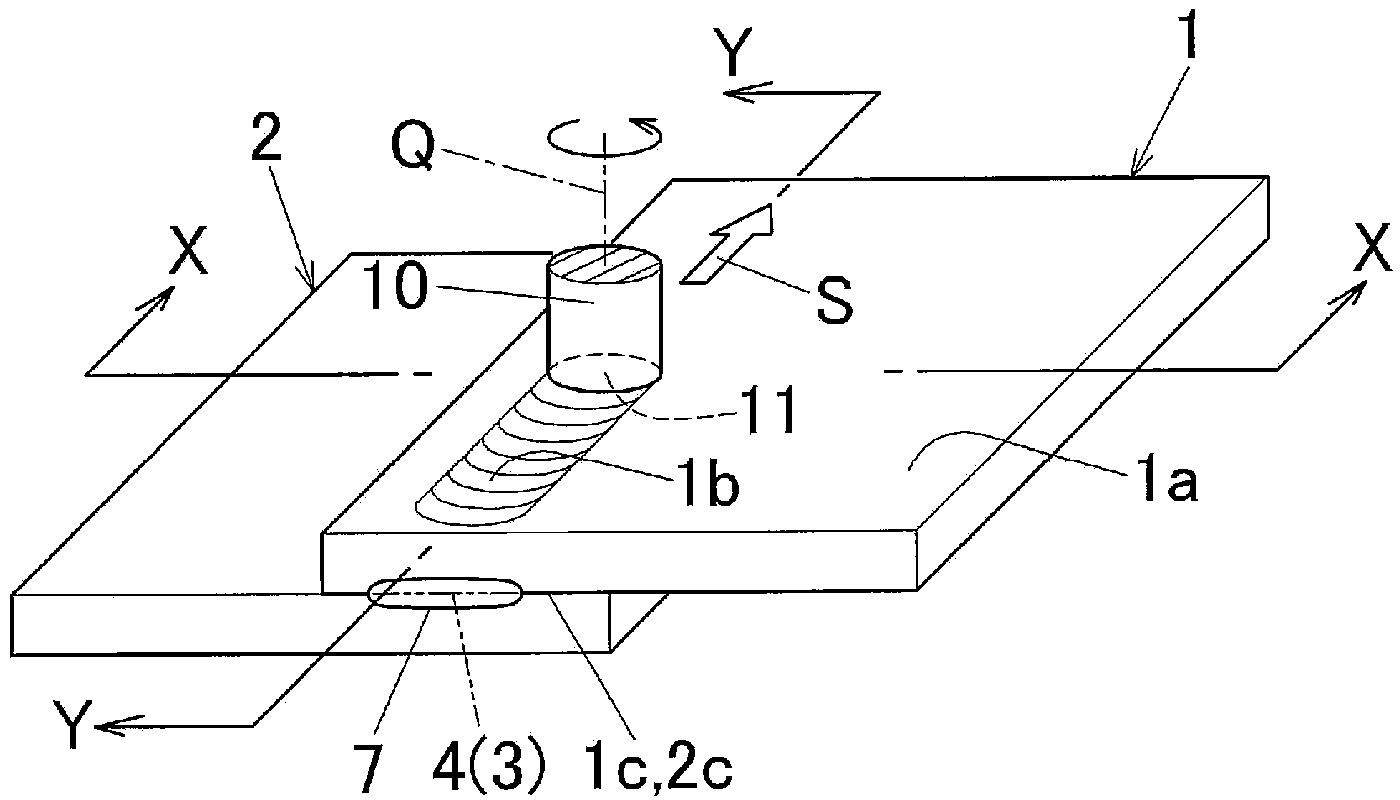

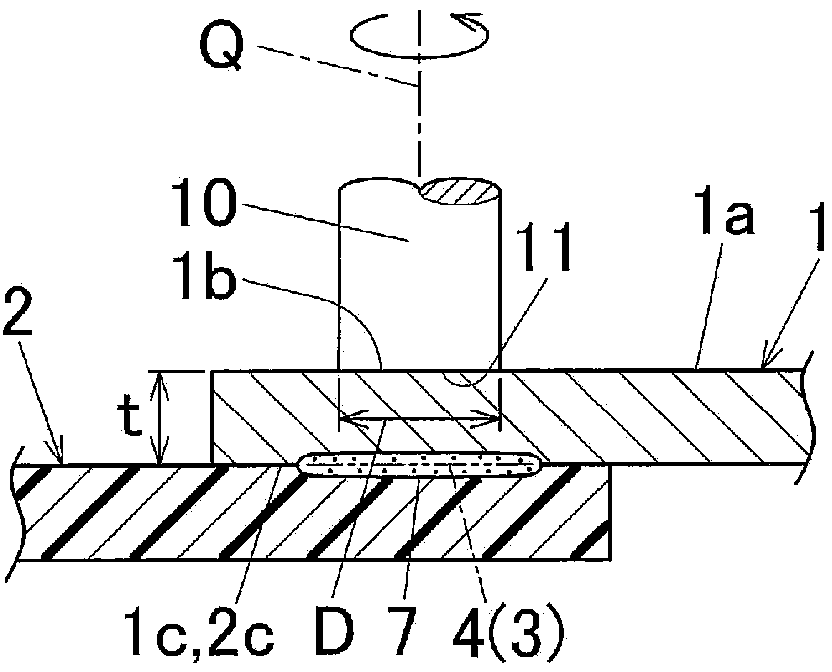

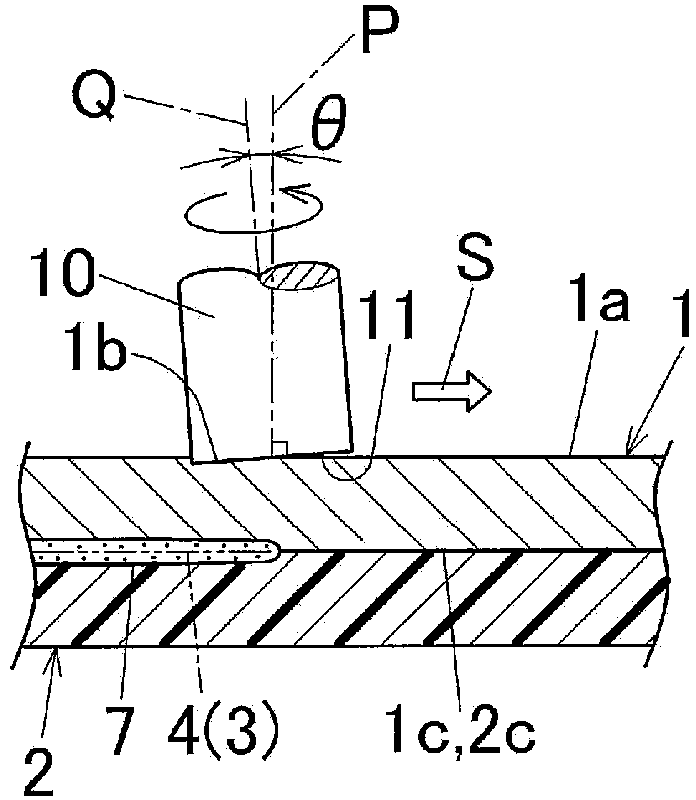

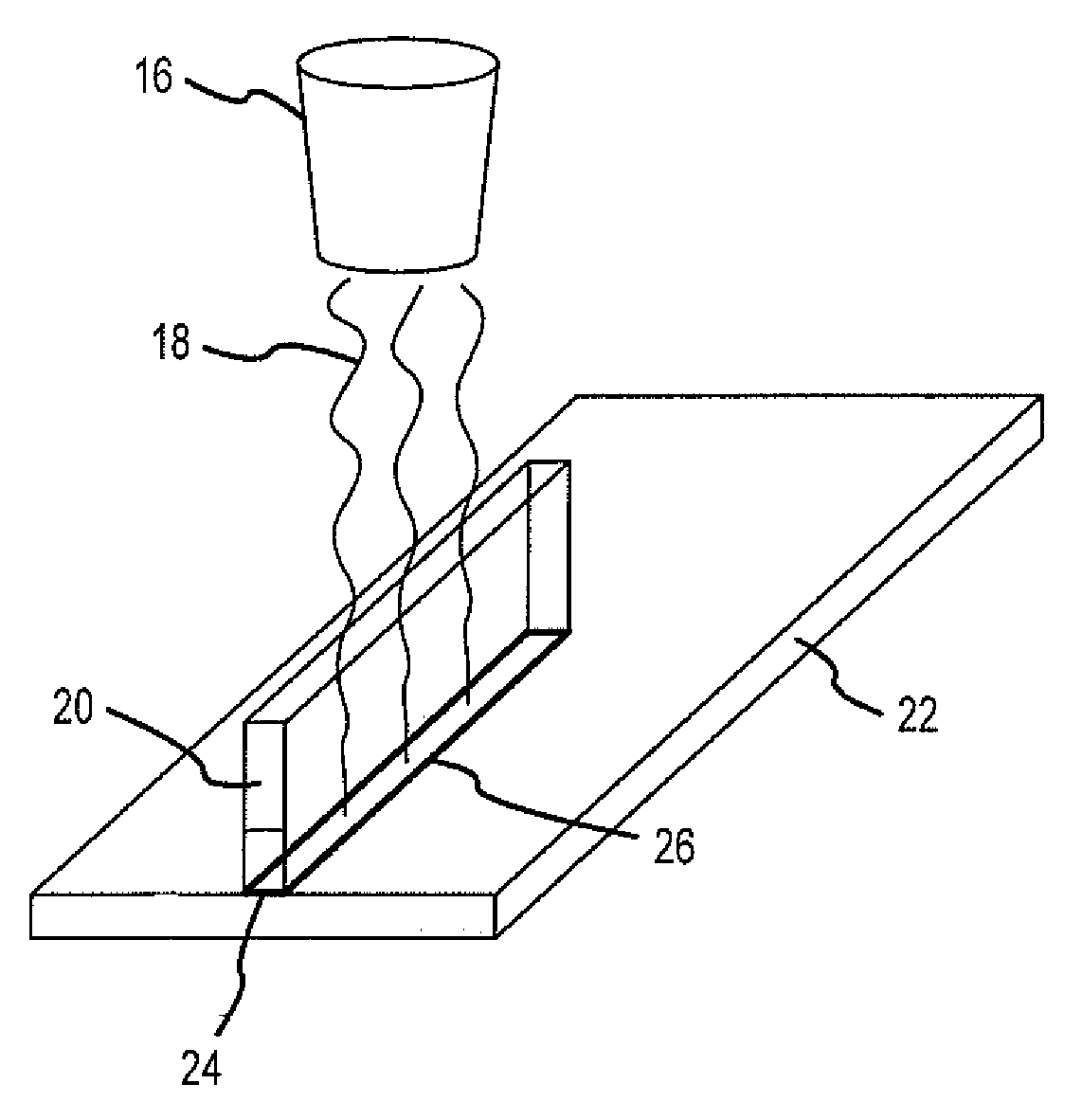

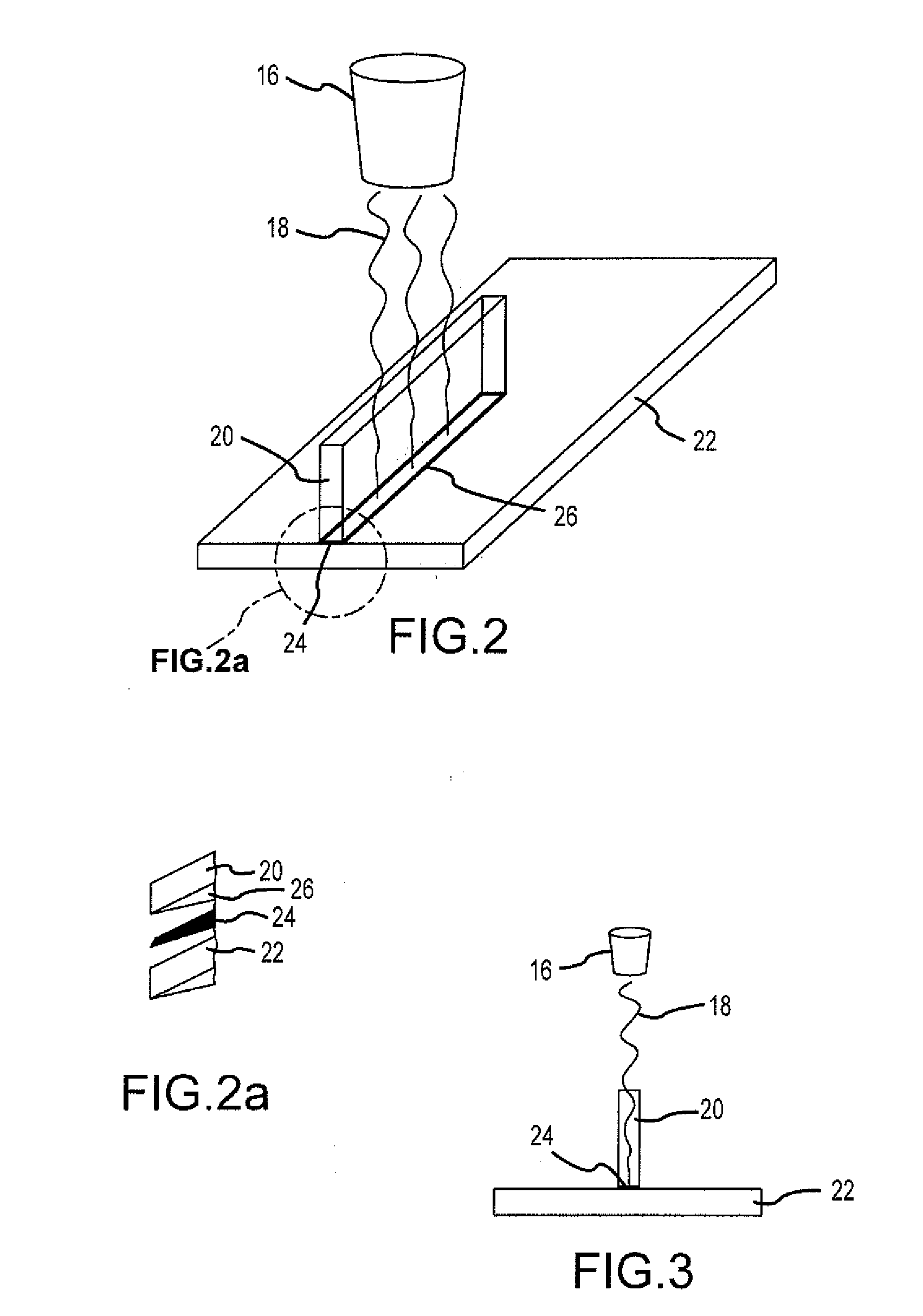

Method for bonding metal member and resin member

InactiveCN103391828AIncrease varietyJoint cheapDomestic articlesWelding/soldering/cutting articlesMetalComposite material

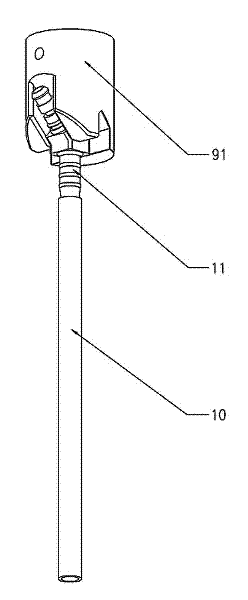

A metal member (1) and a resin member (2) are brought into contact without a resin layer being interposed therebetween. A rotation tool (10), while rotating, is inclined and pushed against a surface (1a) of the metal member (1) so that the inclination angle ? of the axis (Q) of the rotation tool (10) relative to a normal line (P) of the surface (1a) of the metal member (1) satisfies the condition 0 DEG <= 5 DEG . The metal member (1) is thereby conferred friction energy to bond the metal member (1) and the resin member (2).

Owner:RESONAC HOLDINGS CORPORATION +2

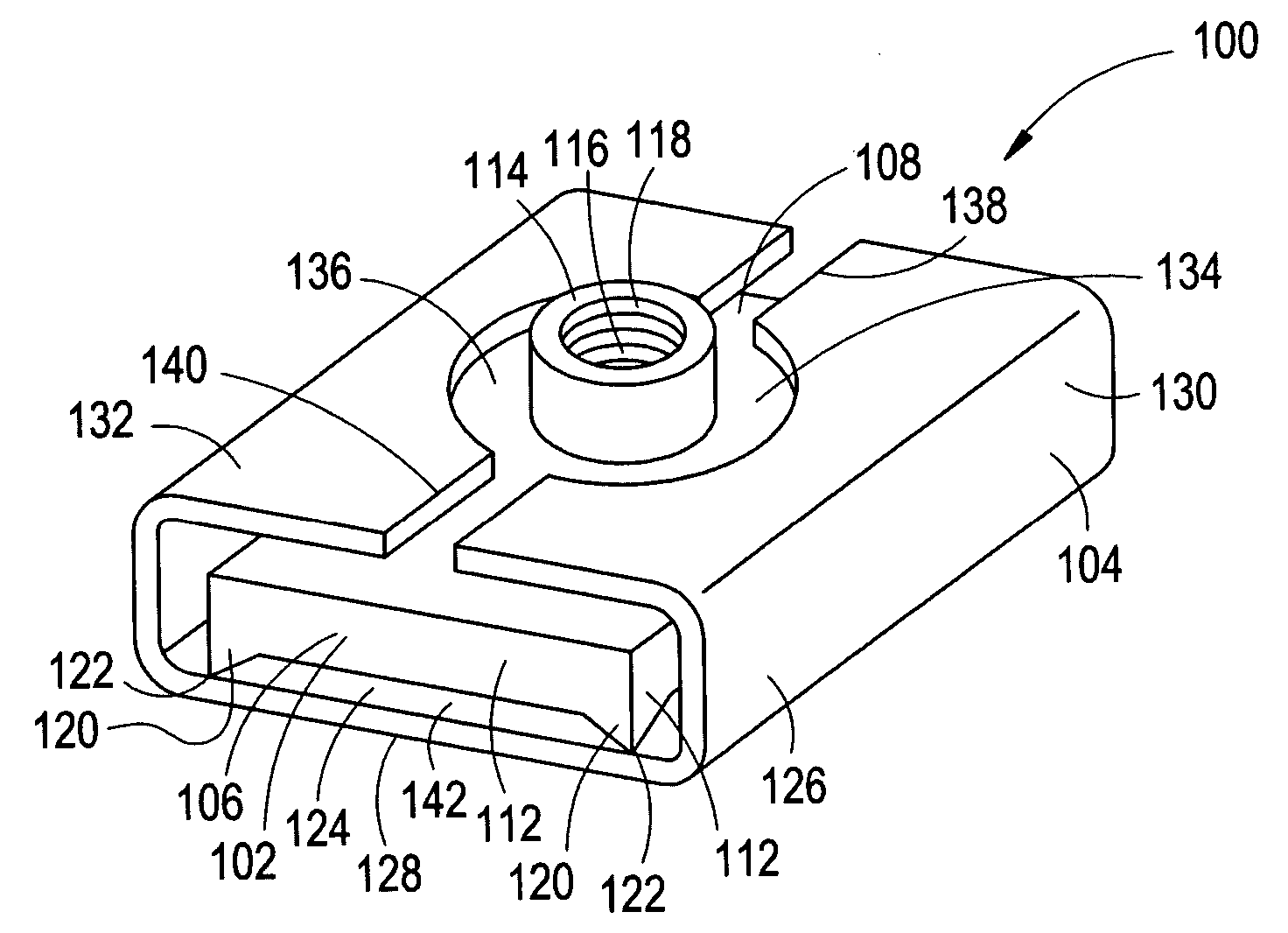

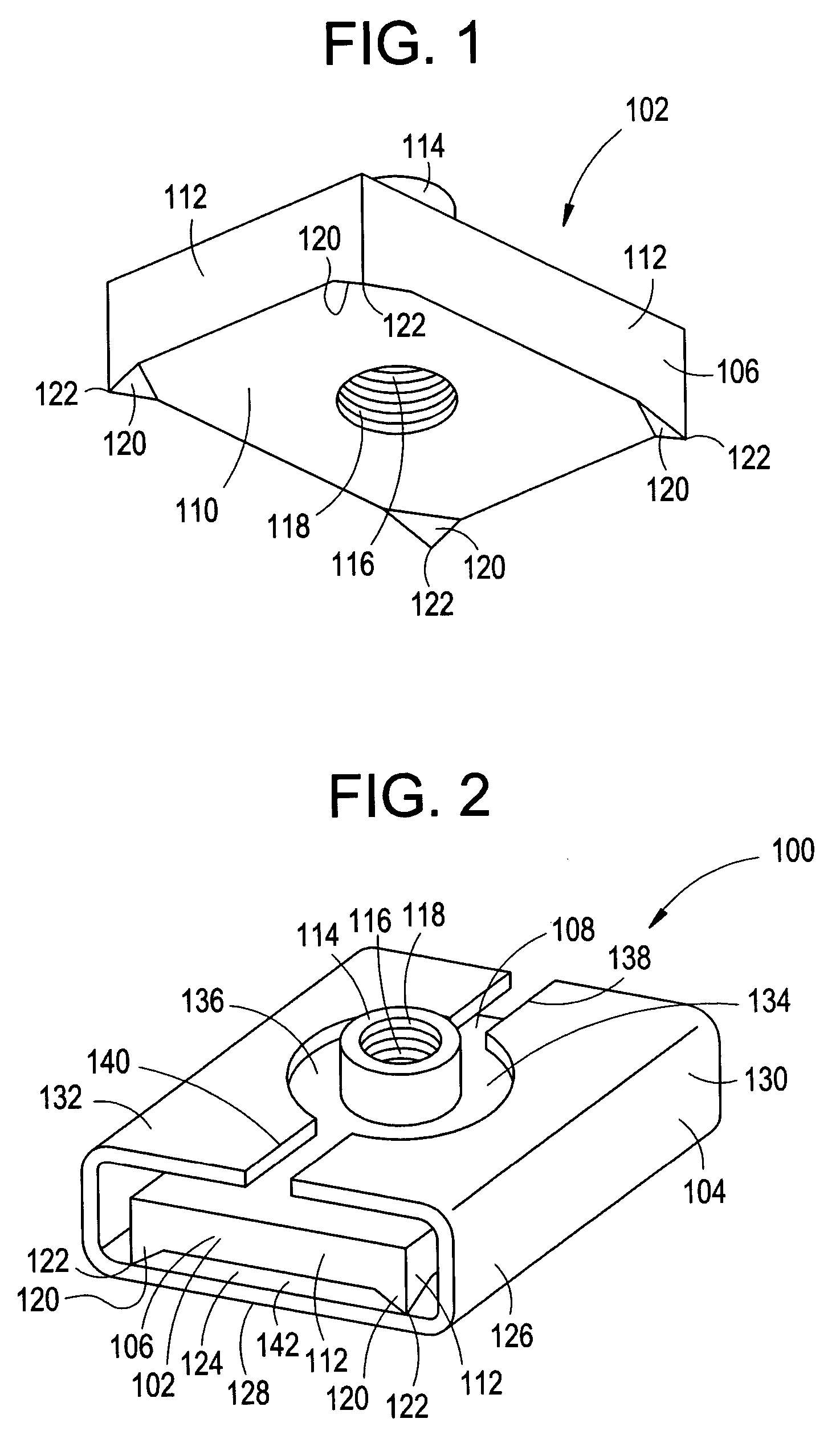

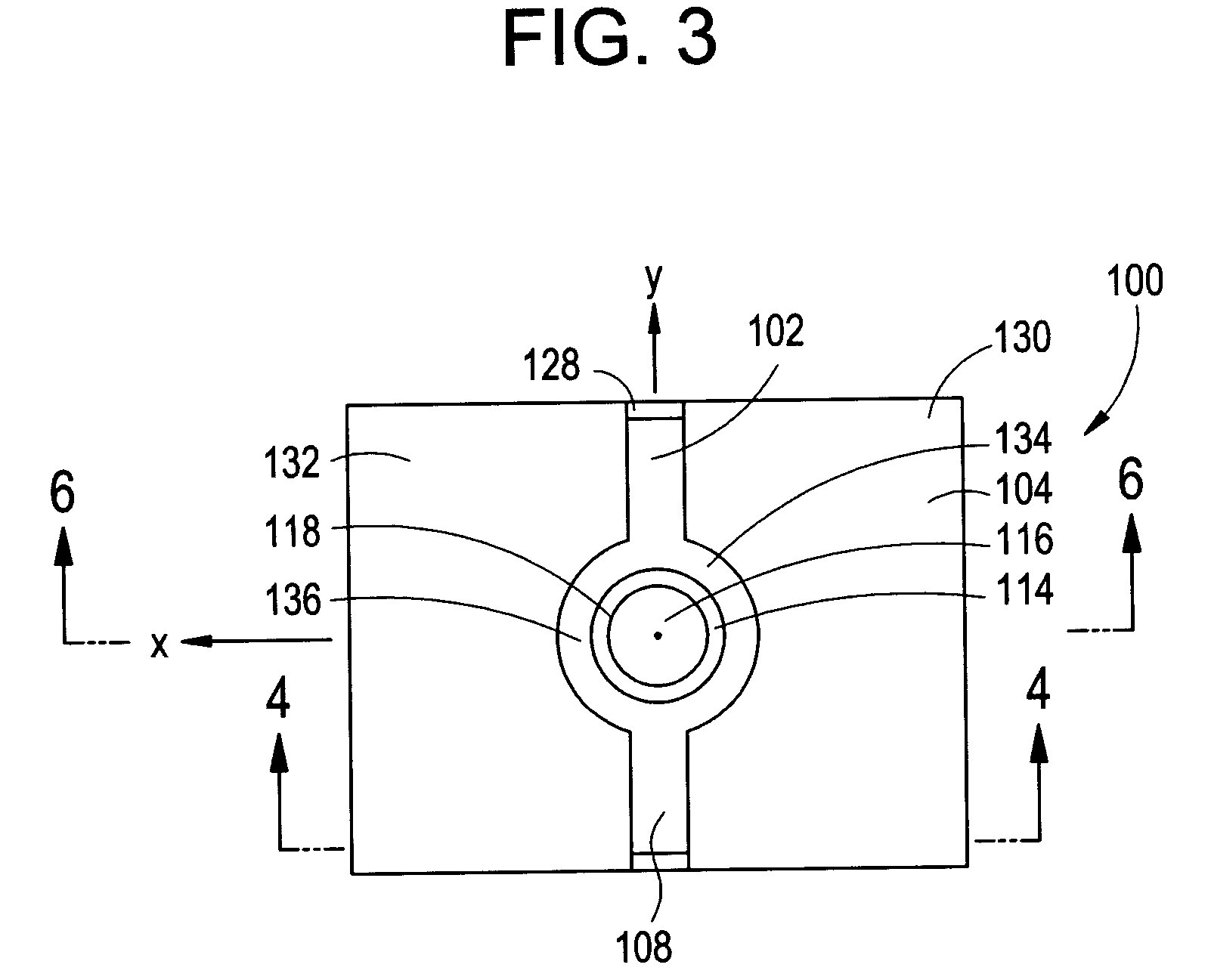

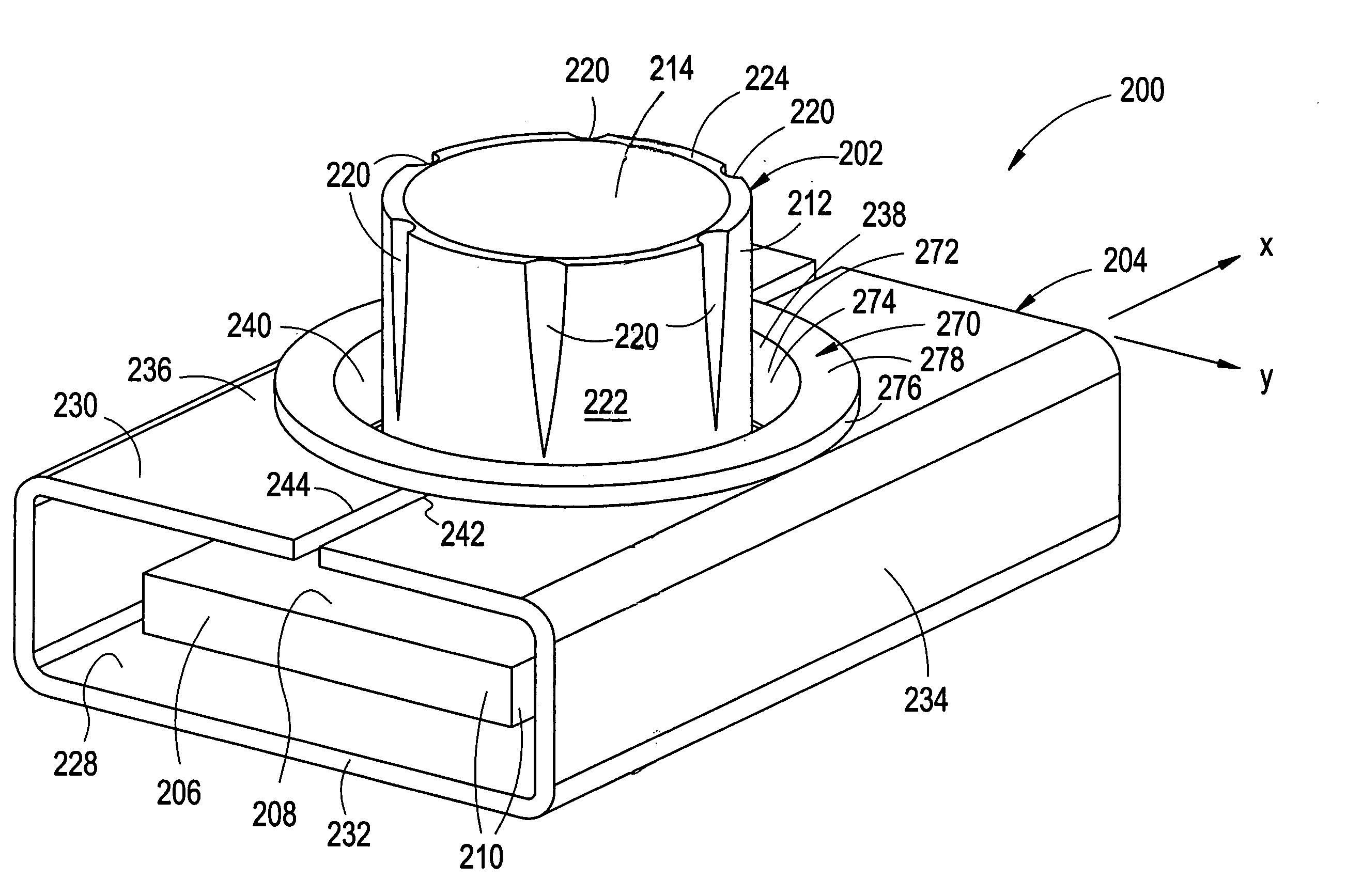

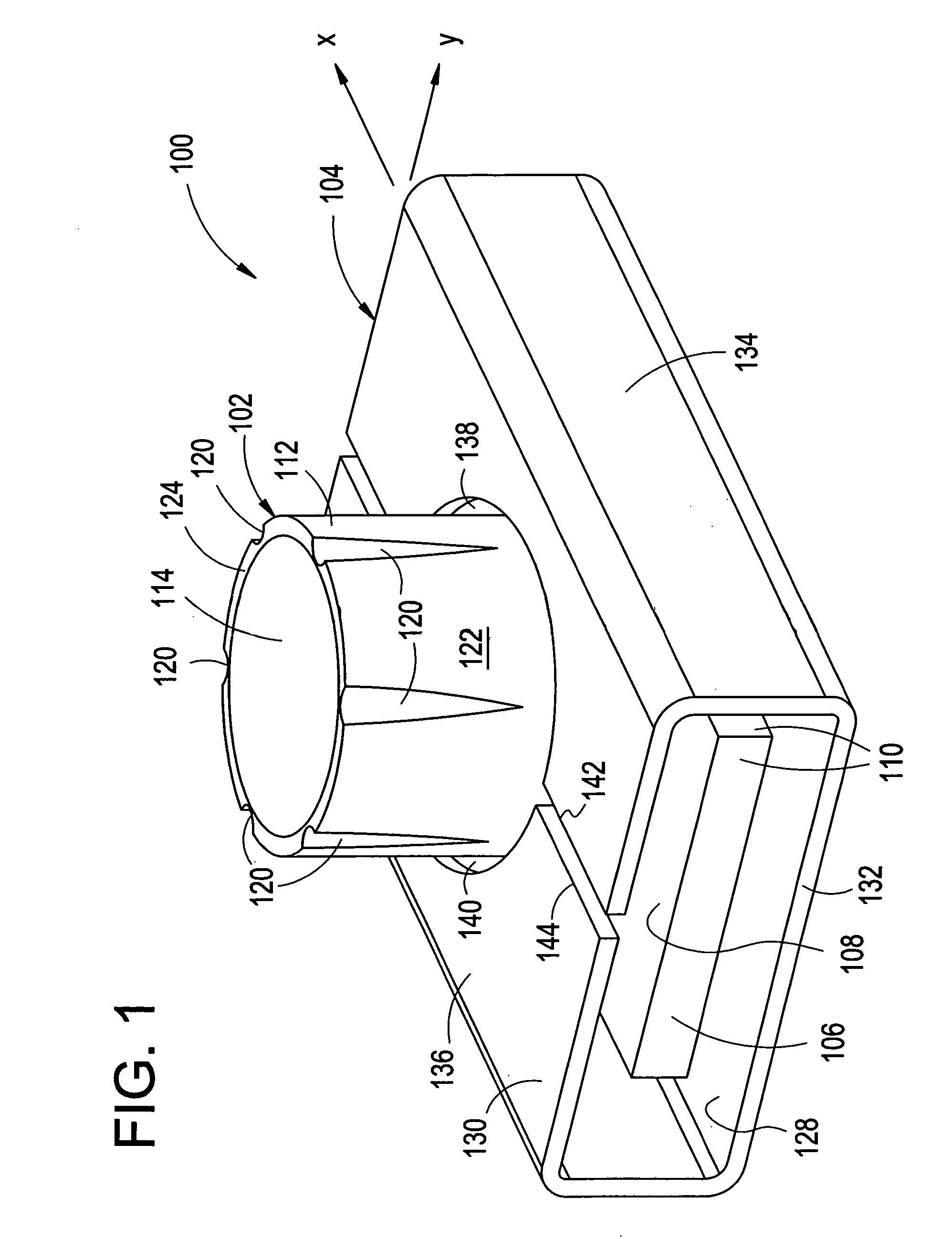

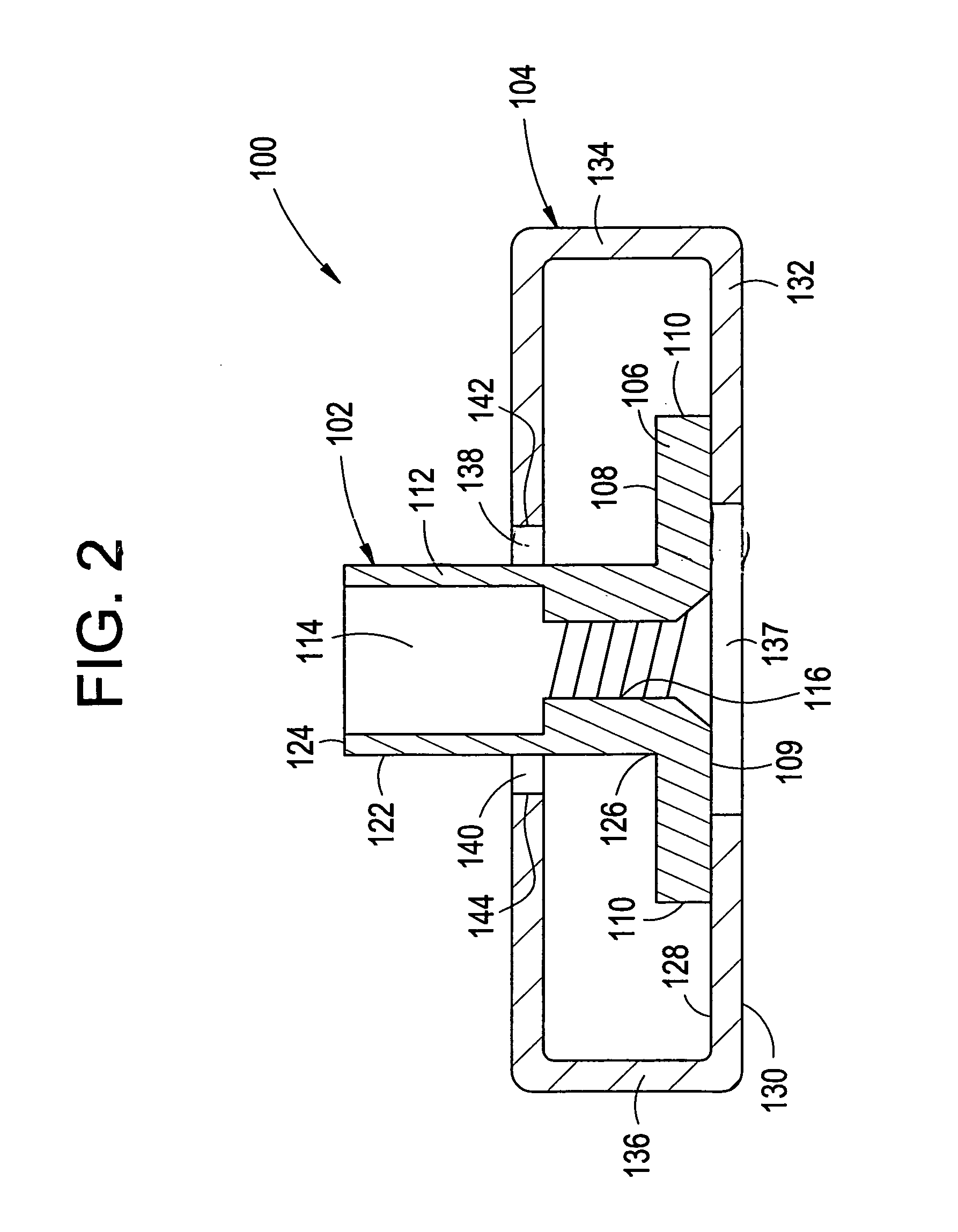

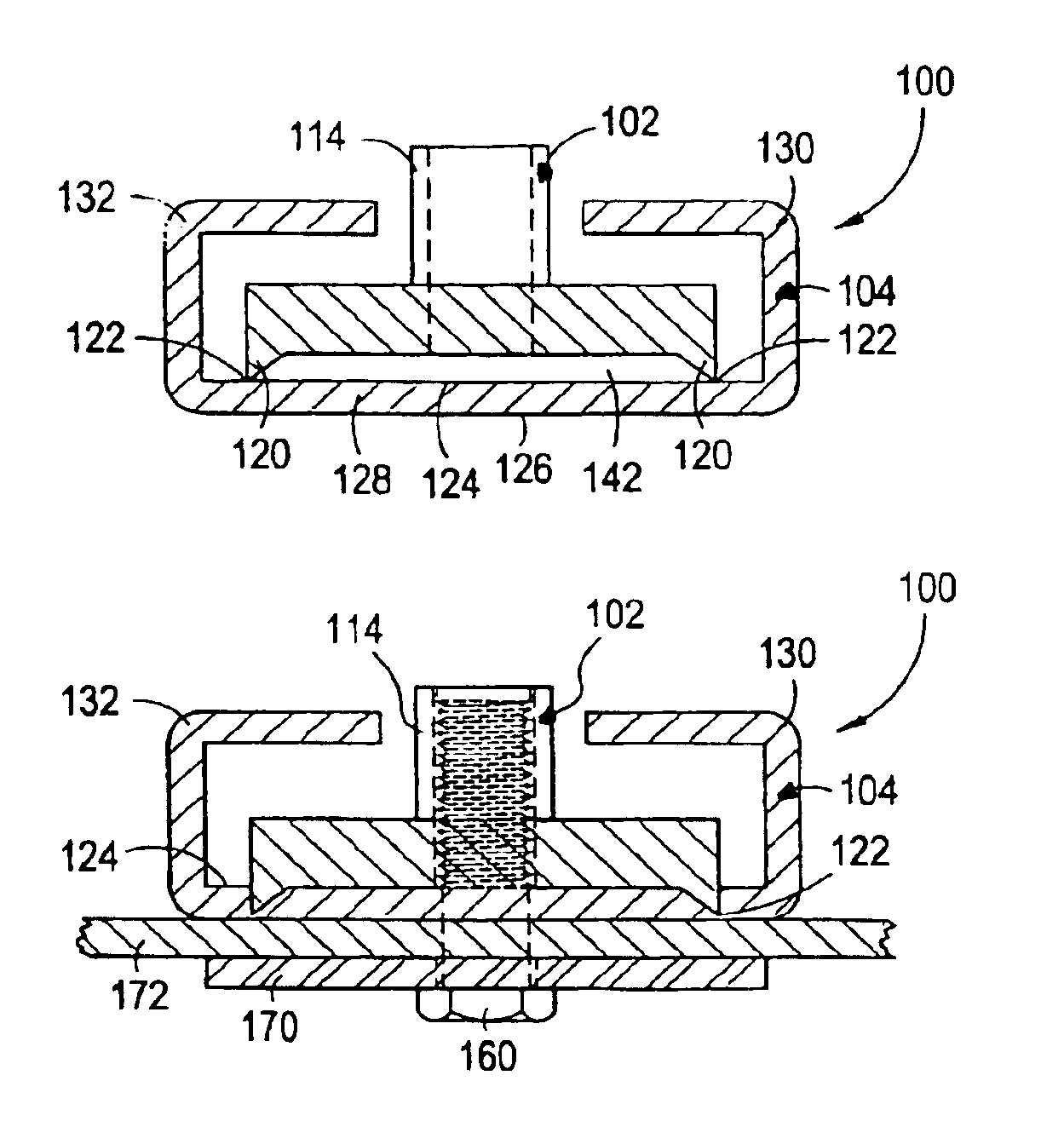

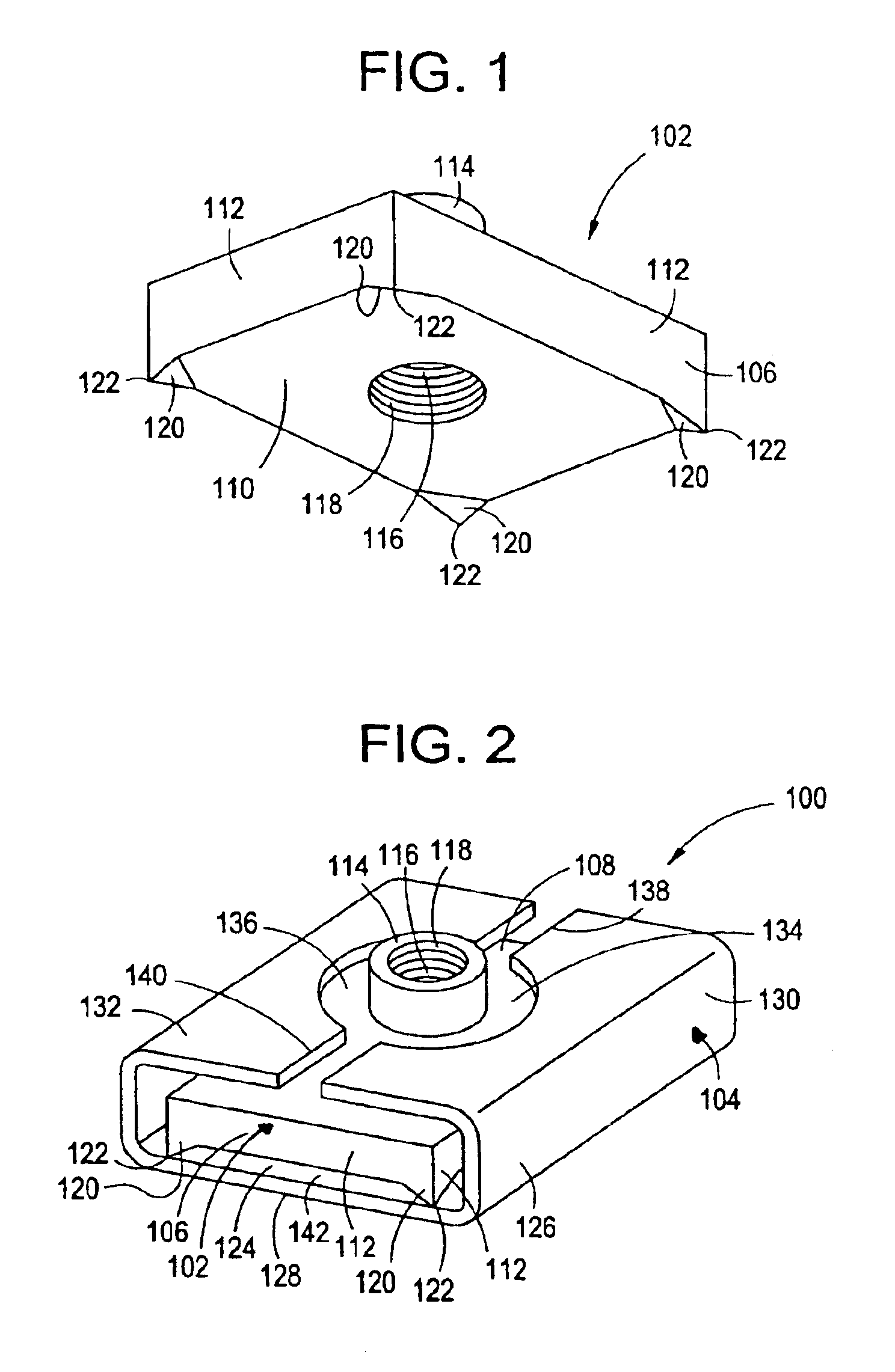

Cage nut assembly having a stand-off nut

A cage nut assembly is provided having a nut and a cage wrapped therearound. The nut has a number of stand-offs or protrusions provided on a lower surface thereof such that the stand-offs are the only part of the nut which are in contact with the cage. The stand-offs reduce the amount of bearing surface interface between the cage and the nut thus reducing the possibility that the two parts will stick to each other after a coating is applied to the mating surface which the cage is welded to. The nut is engaged by a male threaded fastener which is torqued into place and the stand-offs push into the material of the cage causing the cage material to flow out of the way such that the stand-offs embed into the material of the cage without deforming the stand-offs to a flattened condition.

Owner:ACUMENT INTPROP LLC

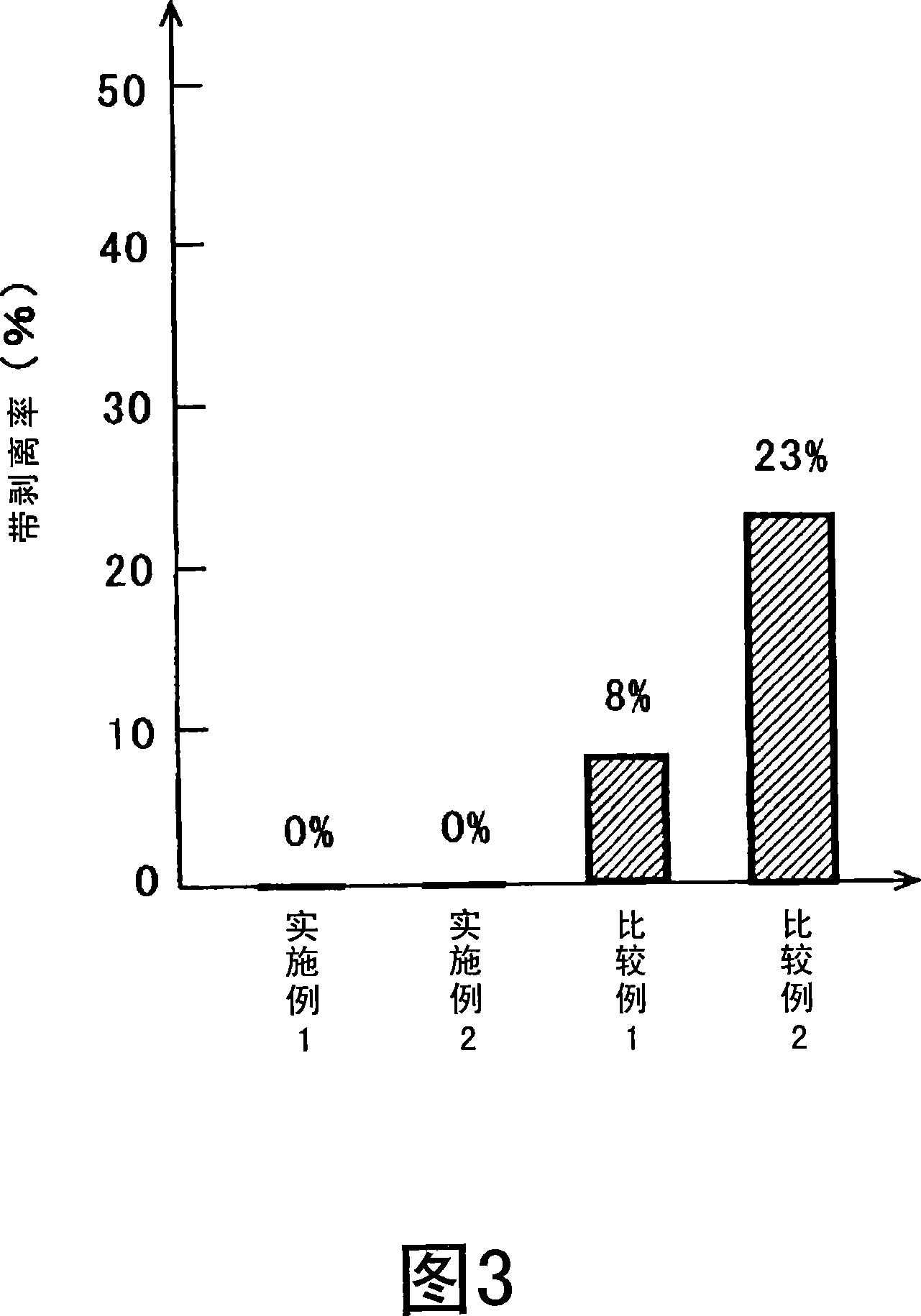

Method of bonding different metals and bonded structure

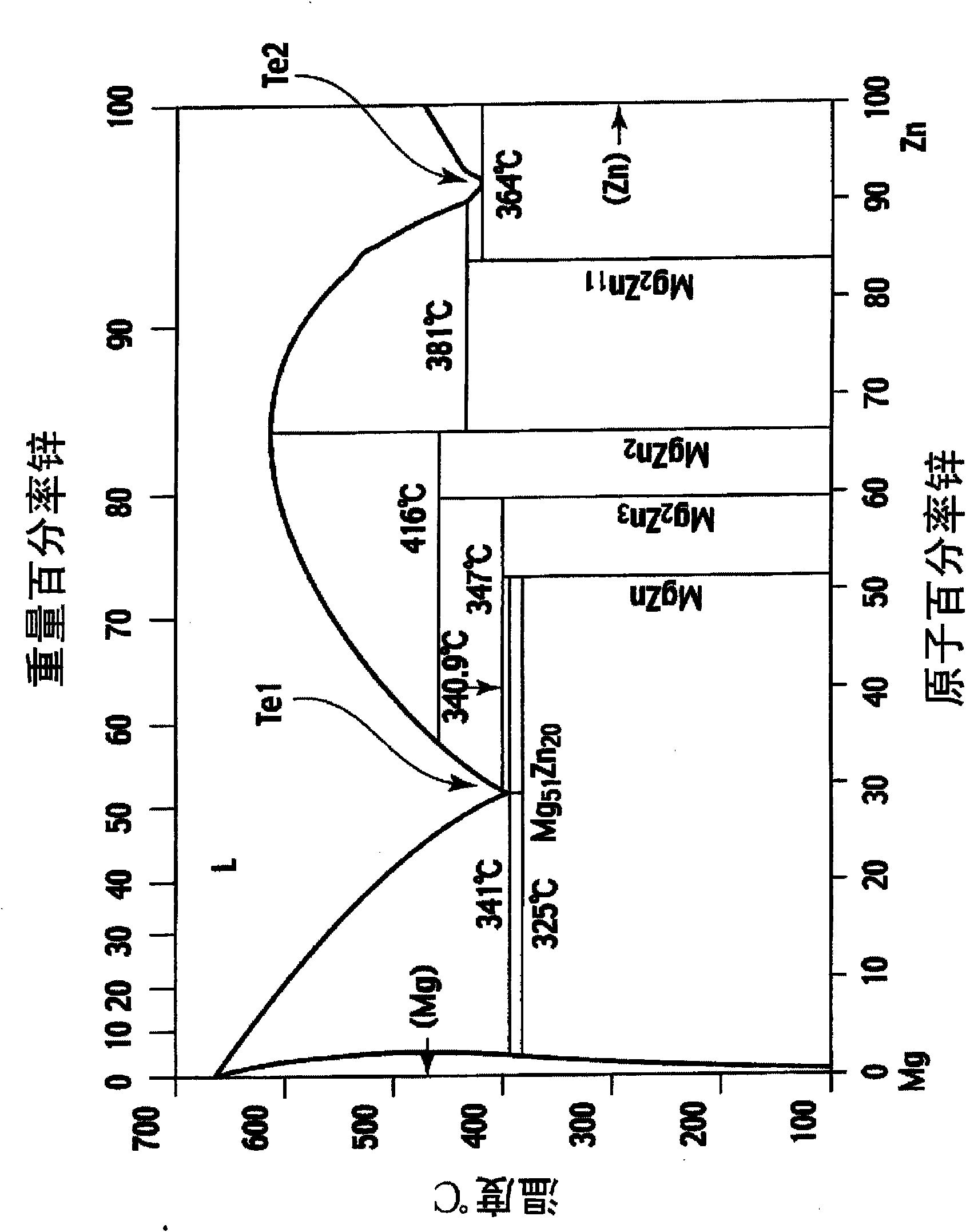

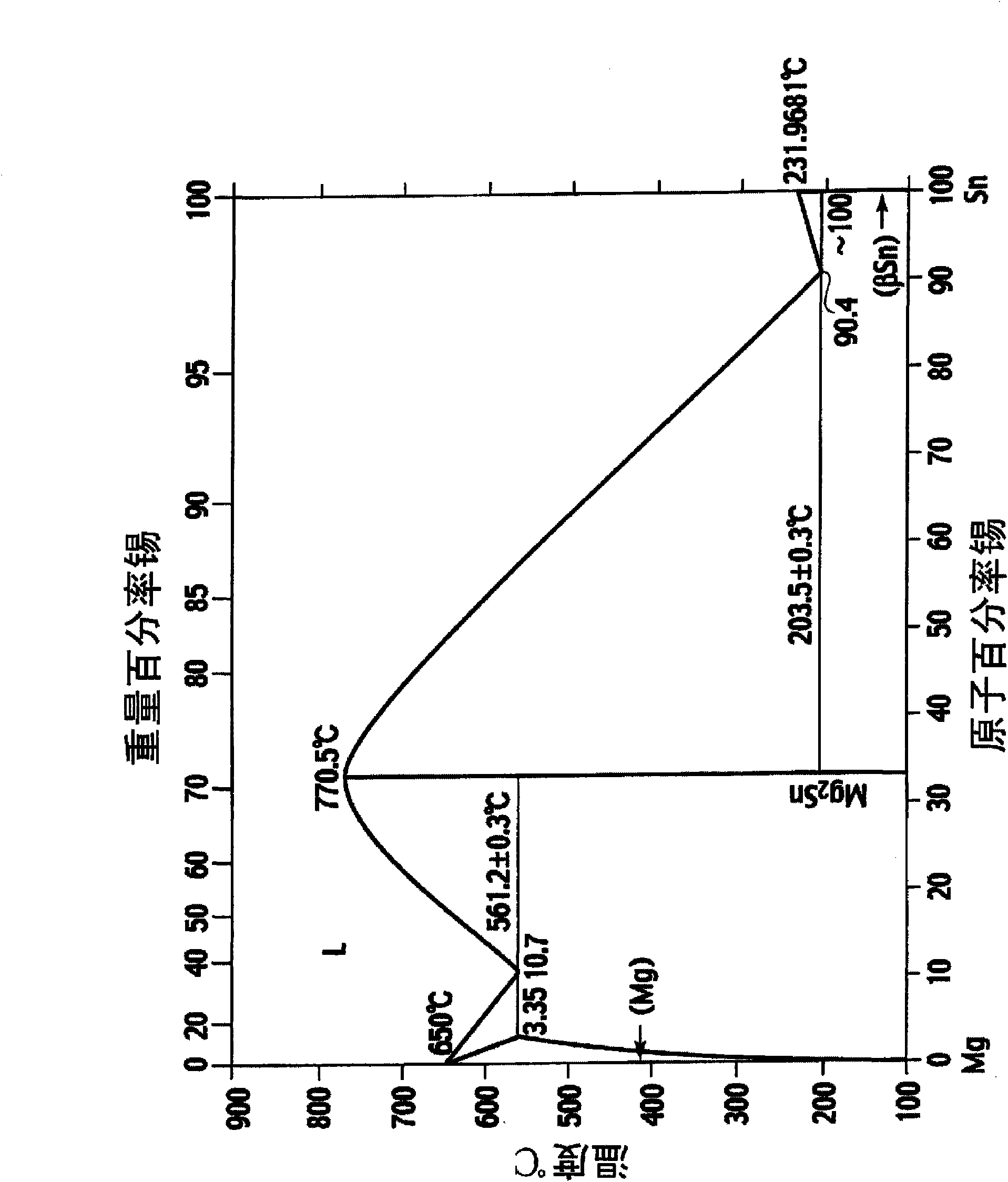

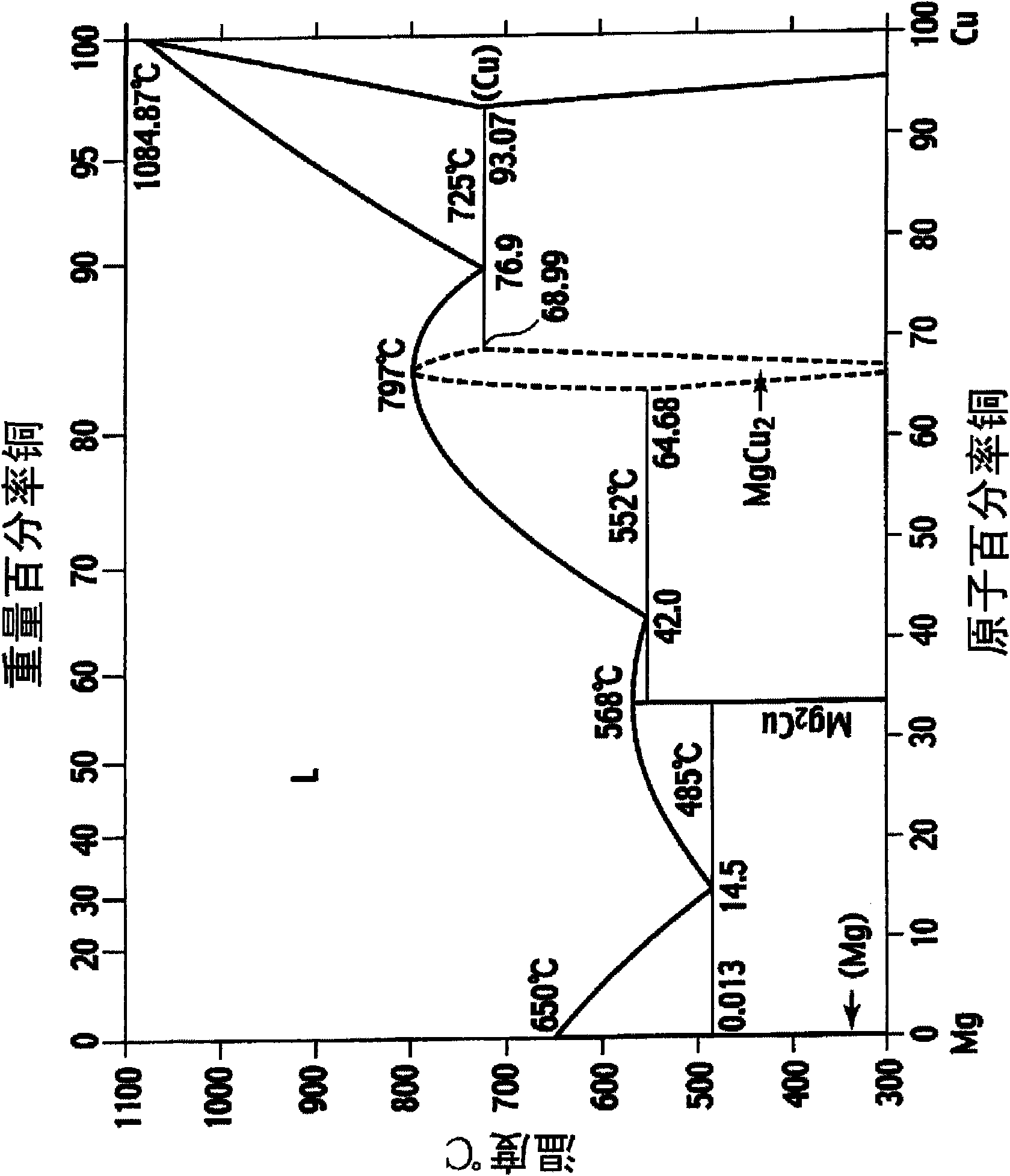

ActiveCN101918168AEasy to removeStrong jointSoldering apparatusHigh frequency current welding apparatusSheet steelChemical compound

A magnesium alloy material (1) (first material) is bonded to a steel material (second material). The steel material to be used is a galvanized steel plate (2), which has a deposit of zinc (metal (C)); and the magnesium alloy material (1) contains aluminum (metal (D)). In bonding the two materials, a magnesium-zinc eutectic melt is generated and the melt is discharged from the bonding interface together with an oxide coating film (1f), impurities, etc. Simultaneously therewith, an aluminum-magnesium intermetallic compound such as Al3Mg2 and an iron-aluminum intermetallic compound such as FeAl3 are generated. Thus, newly formed surfaces of the two materials (1) and (2) are bonded to each other through a compound layer (3) containing these intermetallic compounds.

Owner:NISSAN MOTOR CO LTD

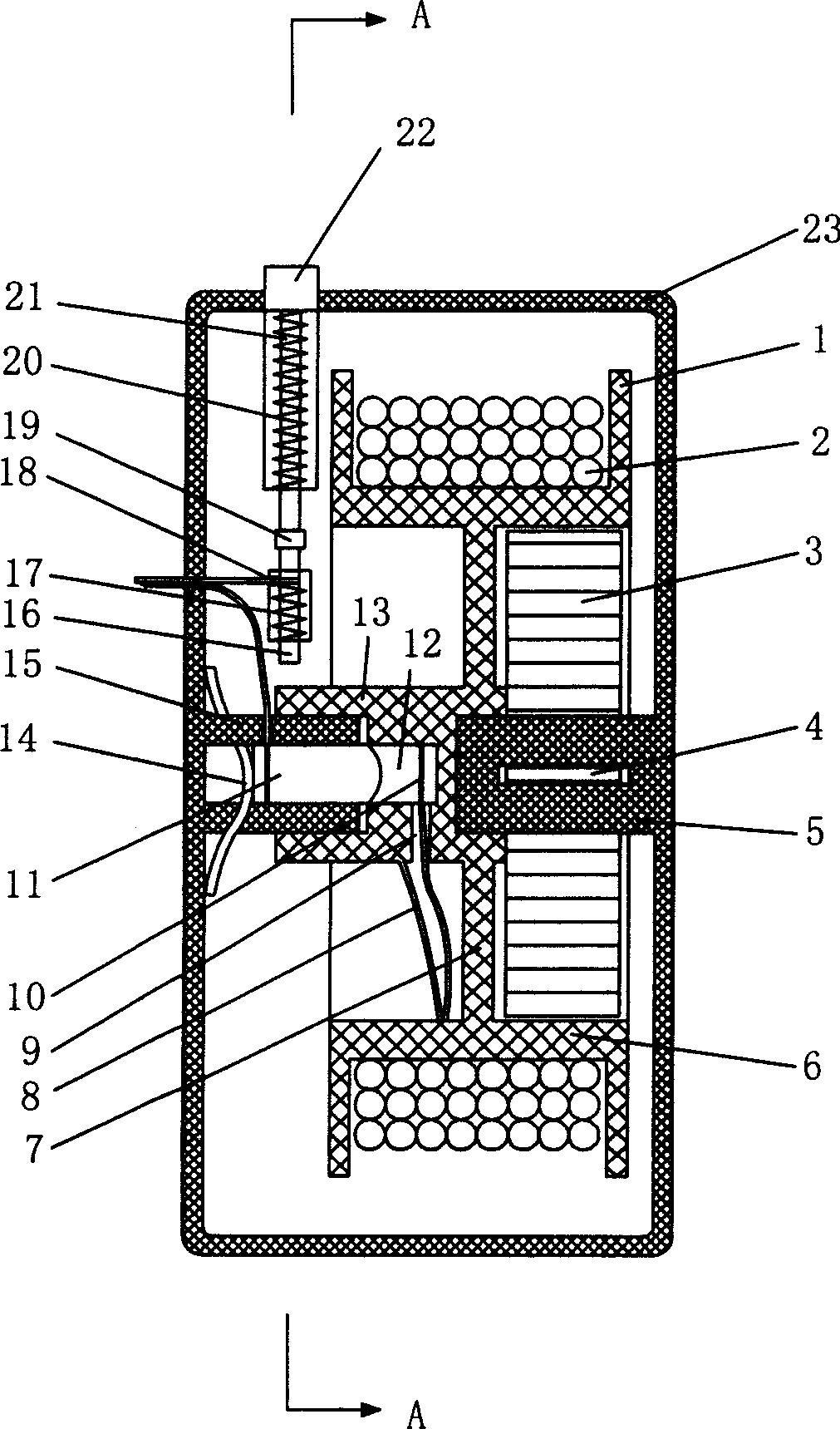

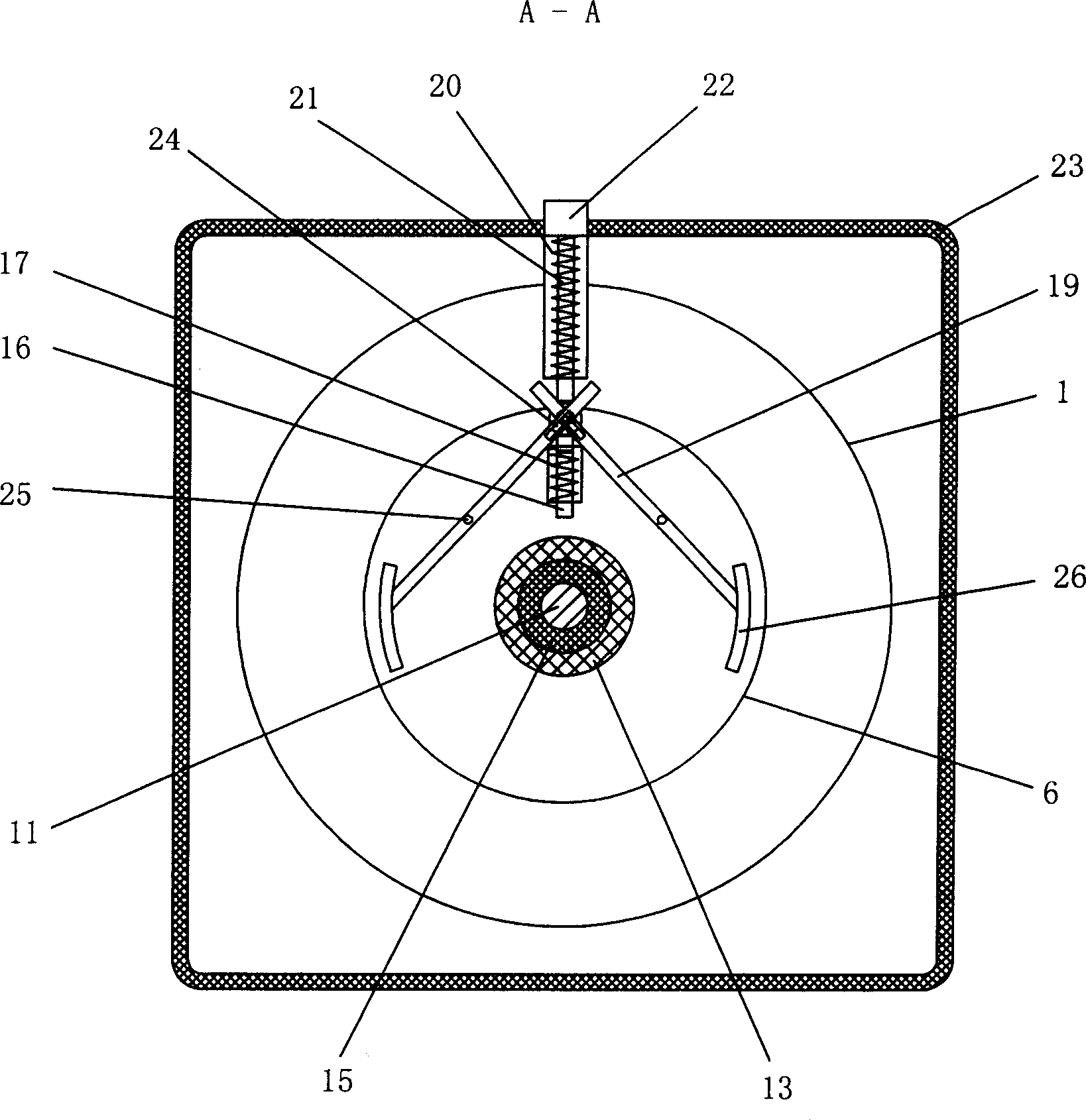

Power cord spooling machine

InactiveCN1738109AReduce vibrationReduce jitterFlexible lead accommodationElectrical connectionEngineering

Disclosed a coiling machine for power cord comprises a coiling box, a coiling wheel inside the coiling box, limited rings on the two ends of coiling wheel, and crinkle spring inside the coiling axle sleeve to connect the coiling axle corn. The invention is characterized in that the protruded part of coiling axle sleeve is equipped a electric connecting component formed by a conducting outer layer, a insulated inner layer and a conducting axle corn; a coiling-proof wheel formed by stop arm and vertical binding post is arranged on the outside of limited ring, as a stop connecting component which can rotate to make a group of electrical contacts connect. The stop function which is synchronous to the electrical connection can reduce the tensity between plug and the power cord, to make the plug connect the adapter firmly; in addition, it coils without electric to improve the safety of household appliance which also can prevent the knotting inside the box.

Owner:庞一鸣

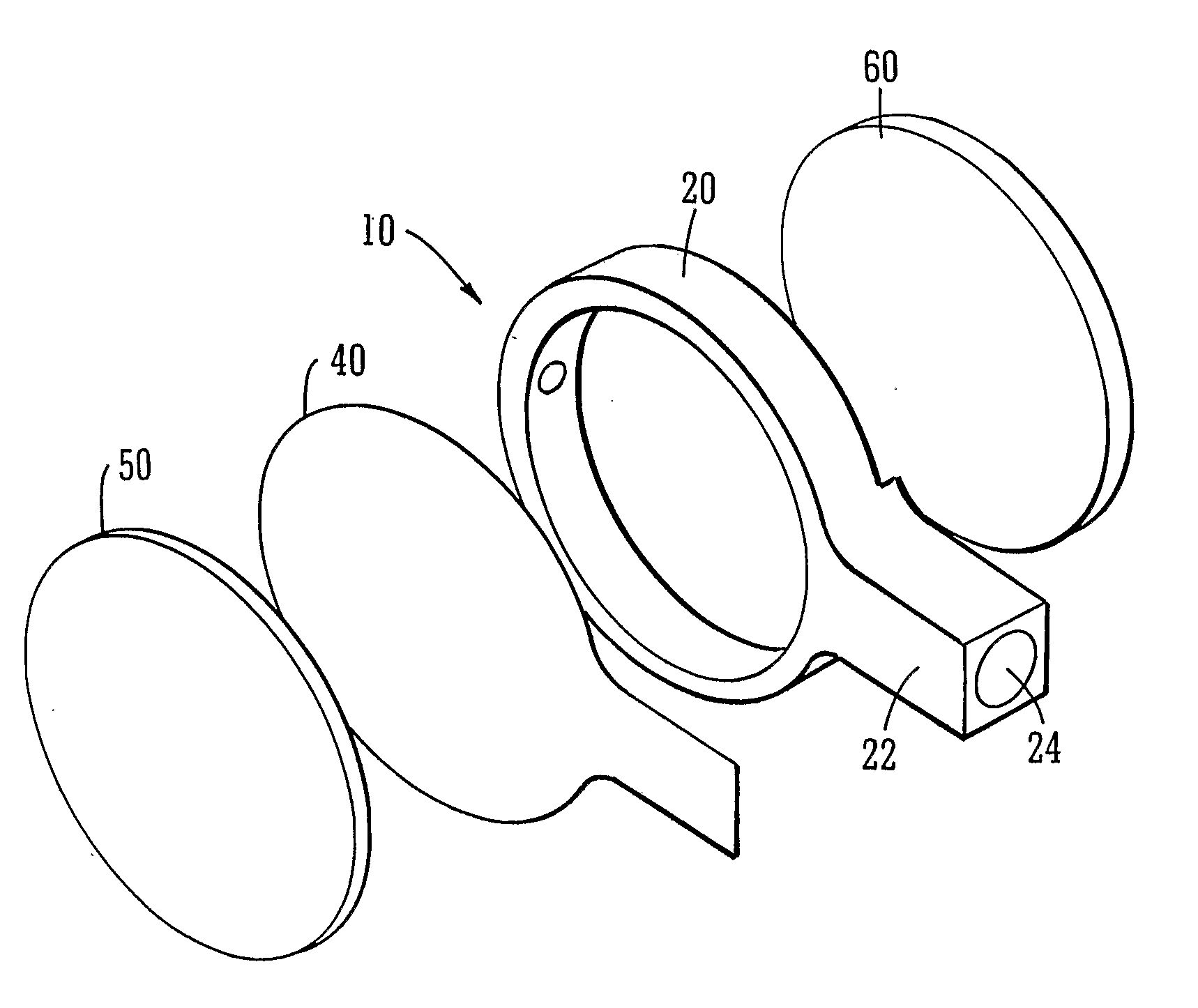

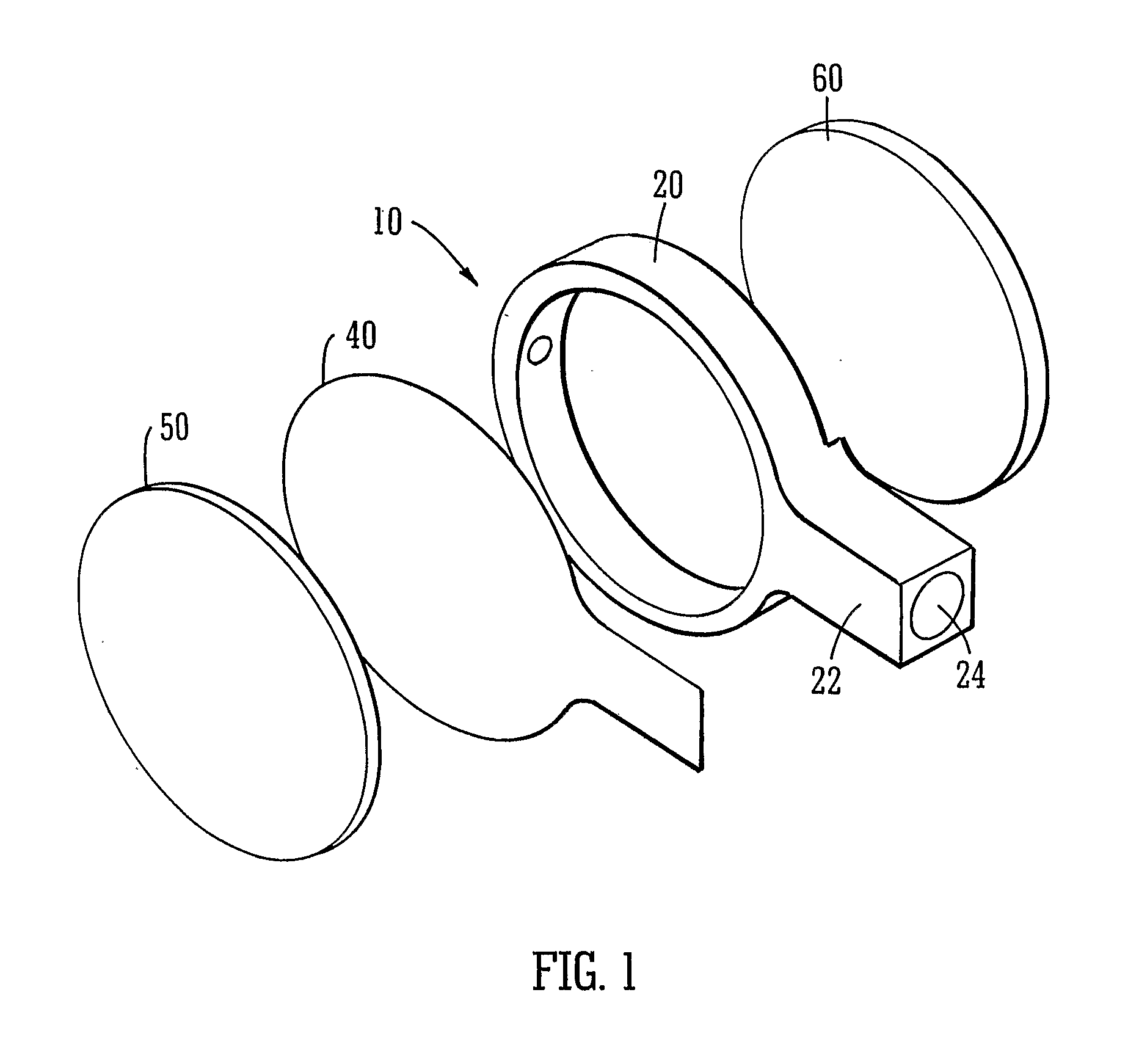

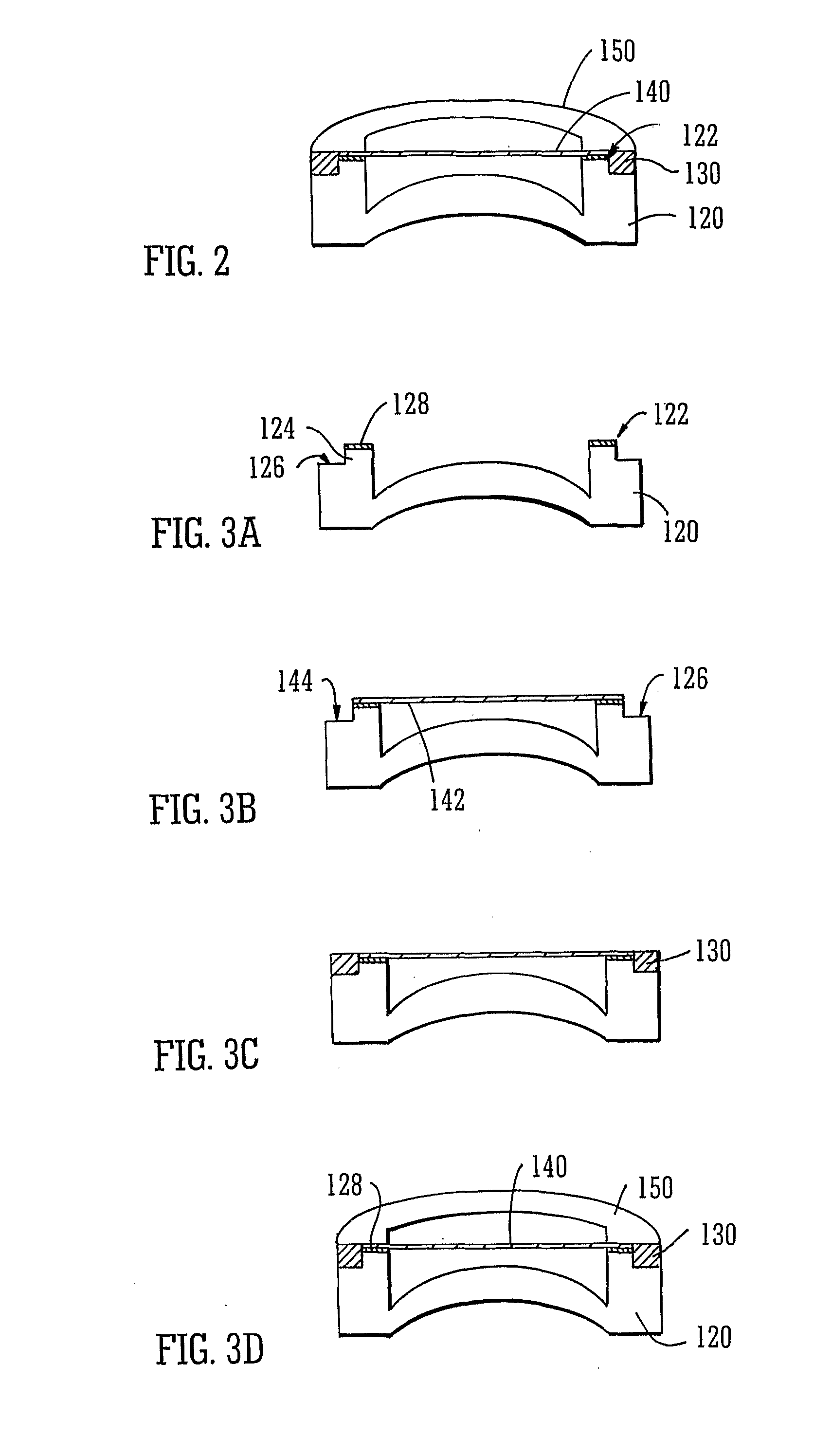

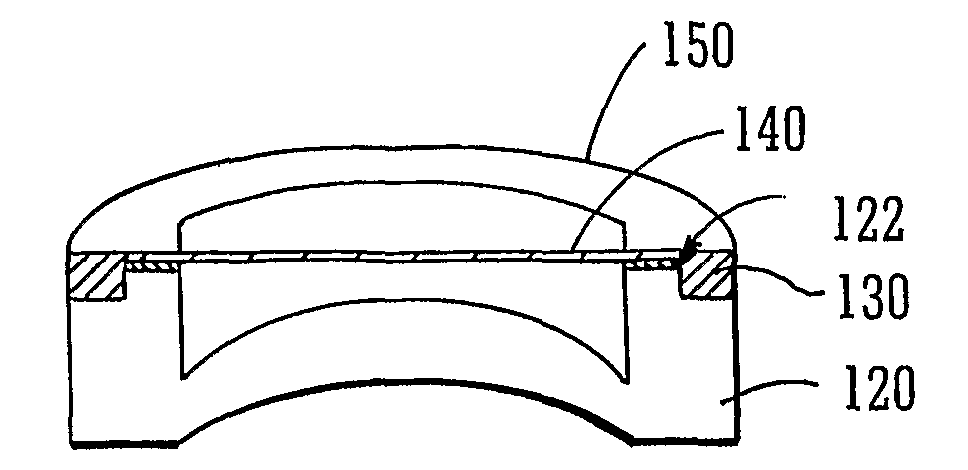

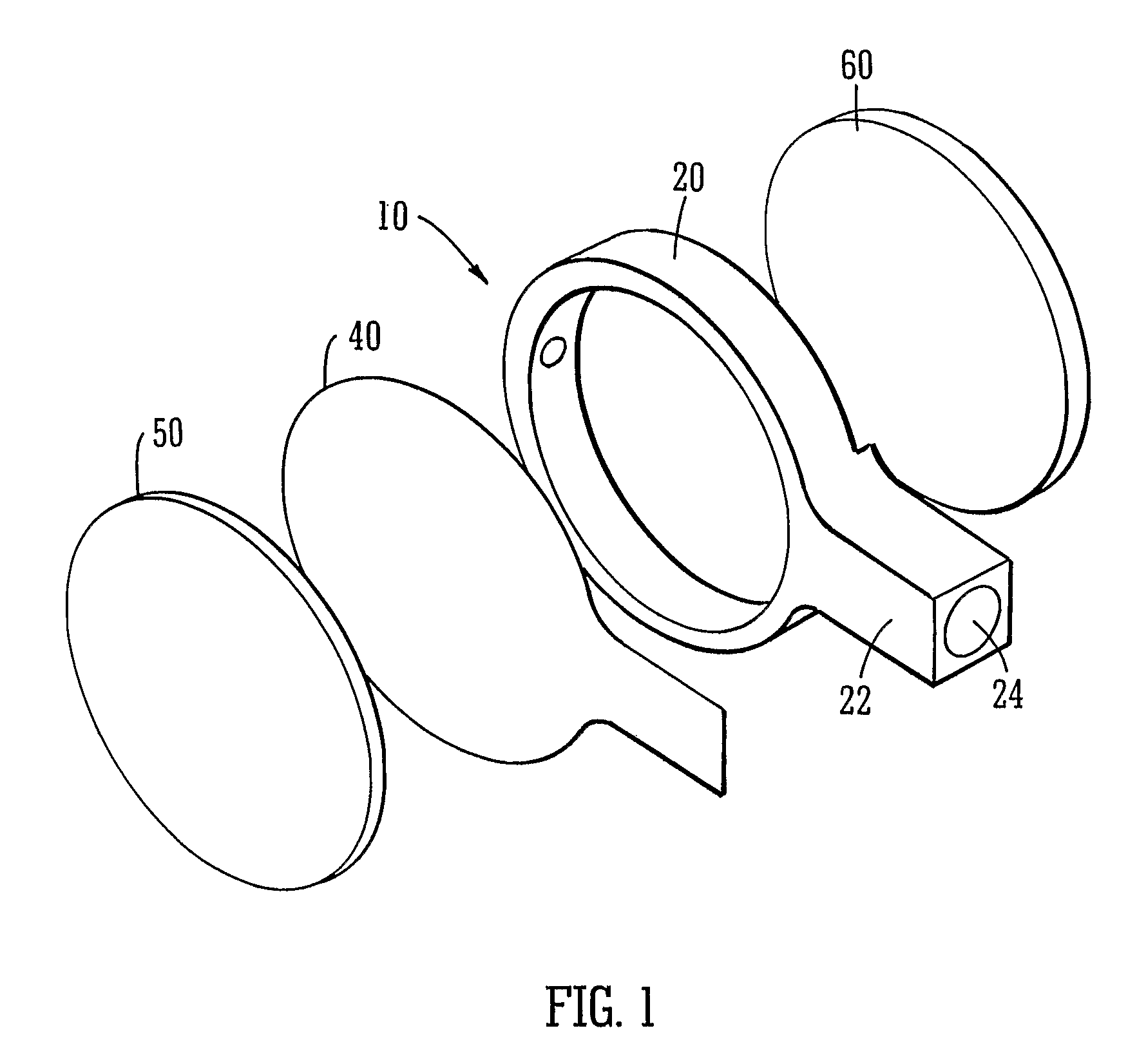

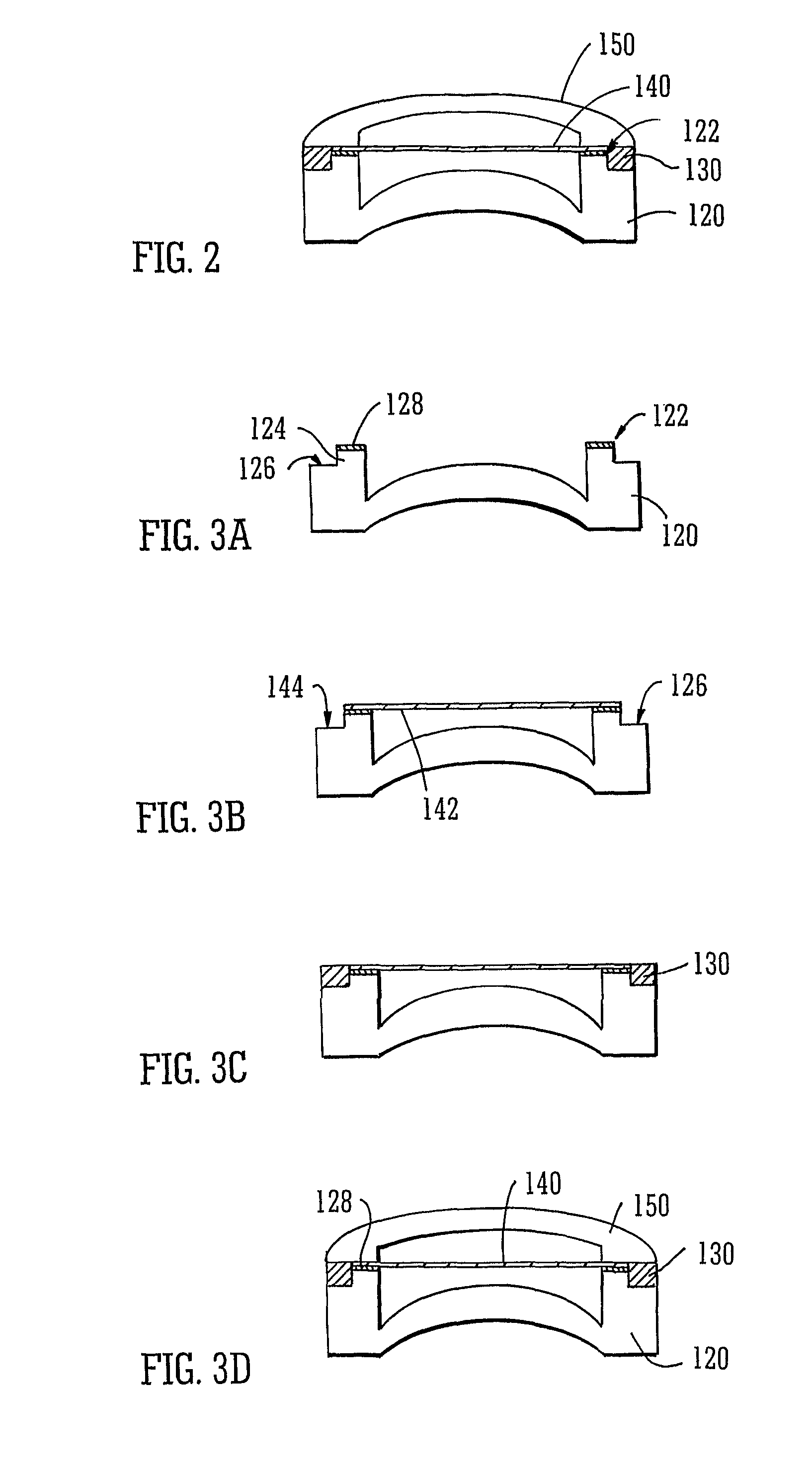

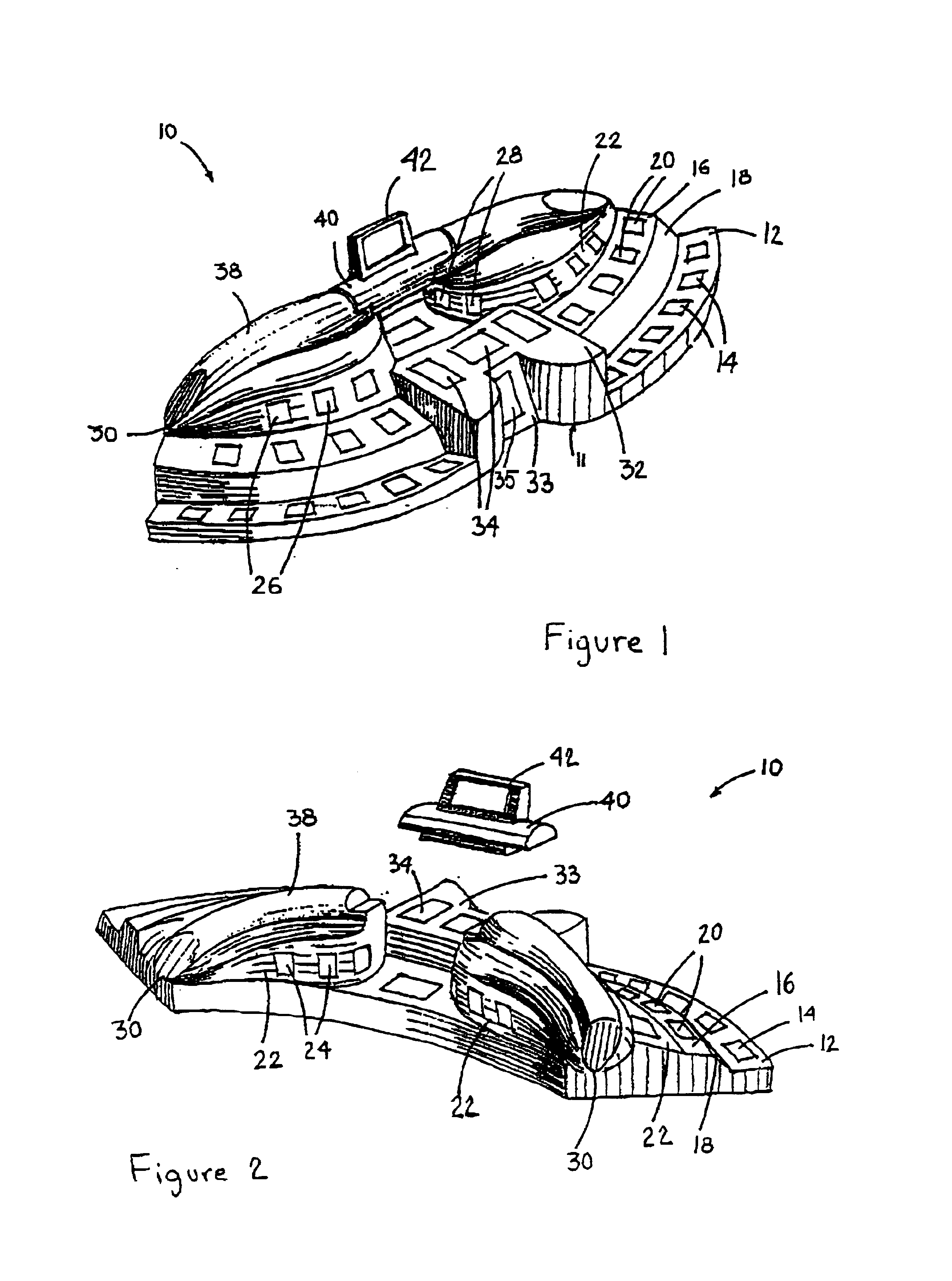

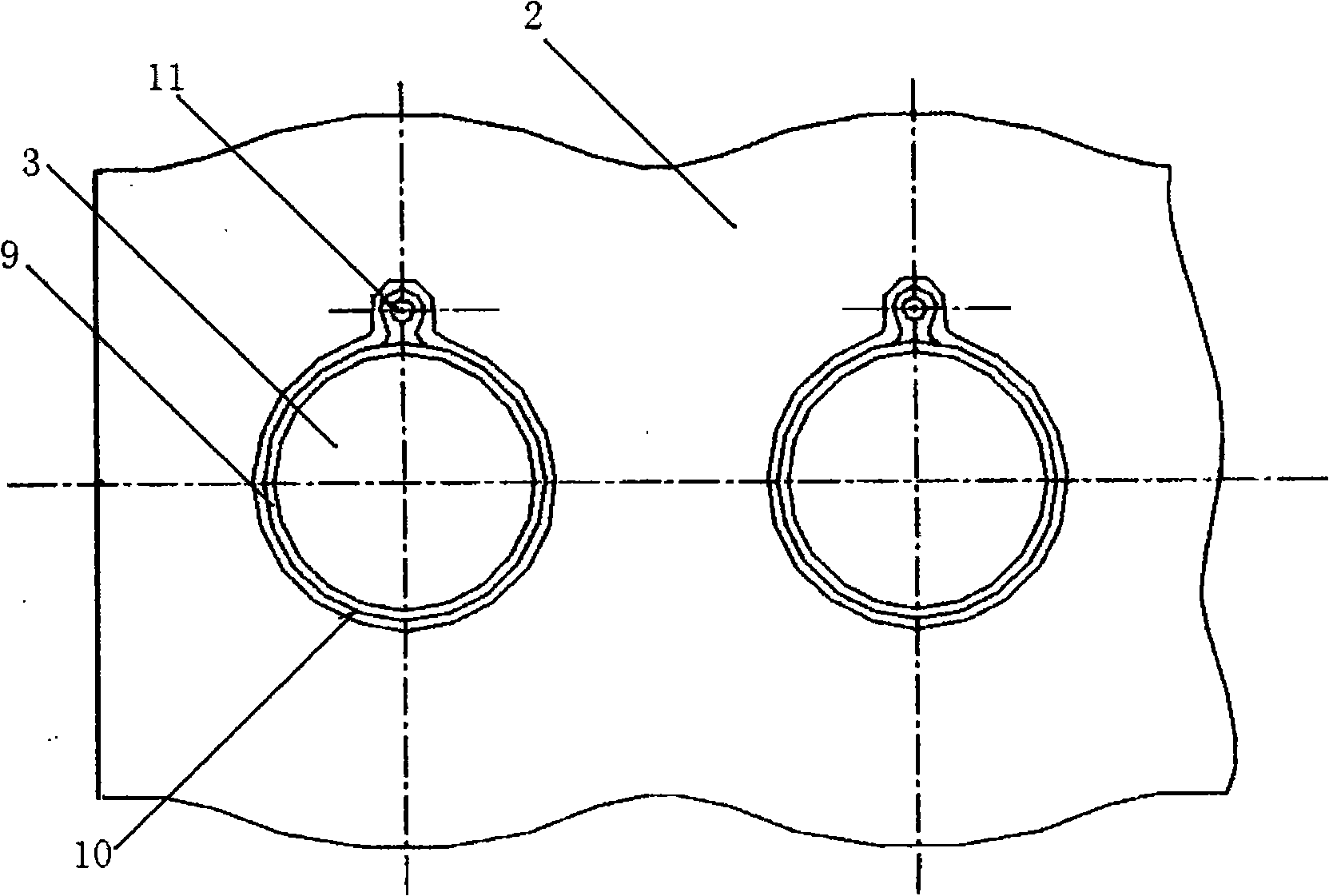

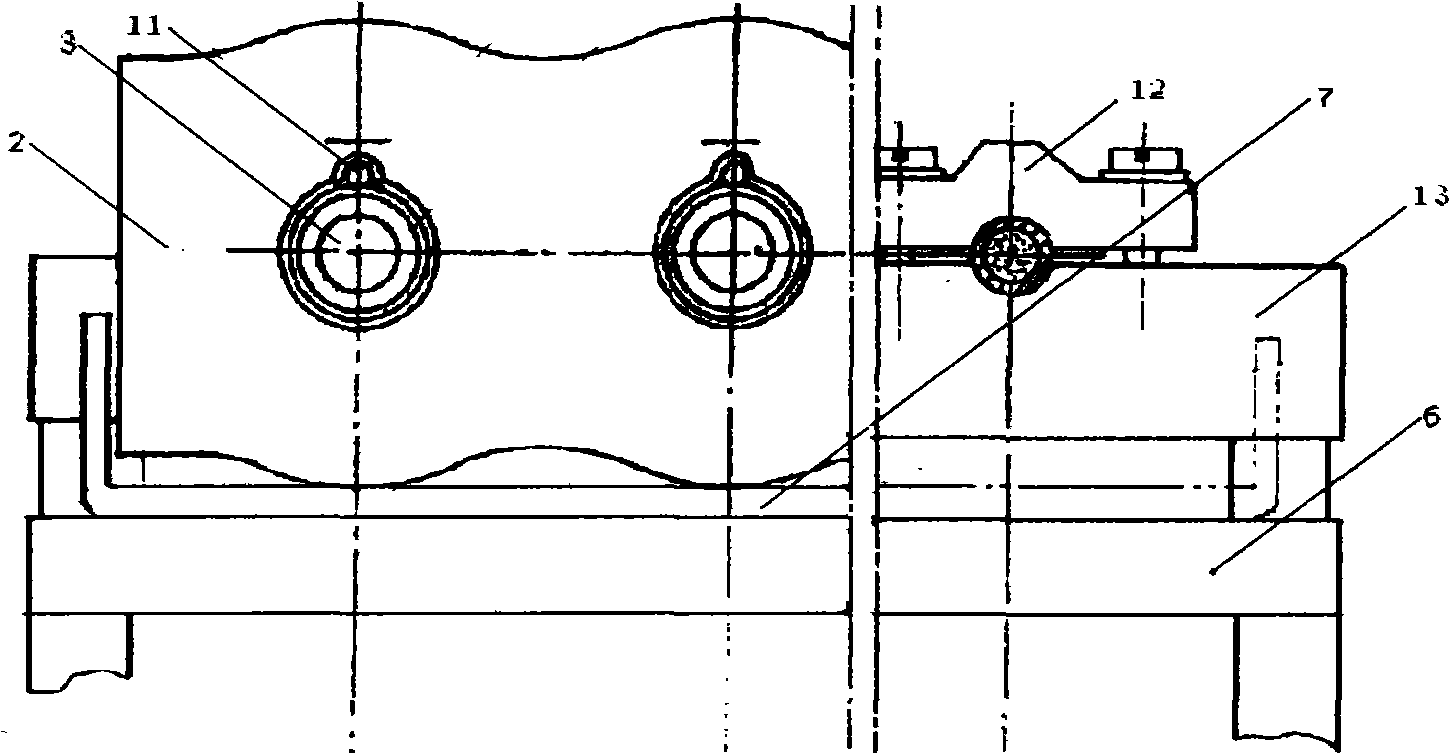

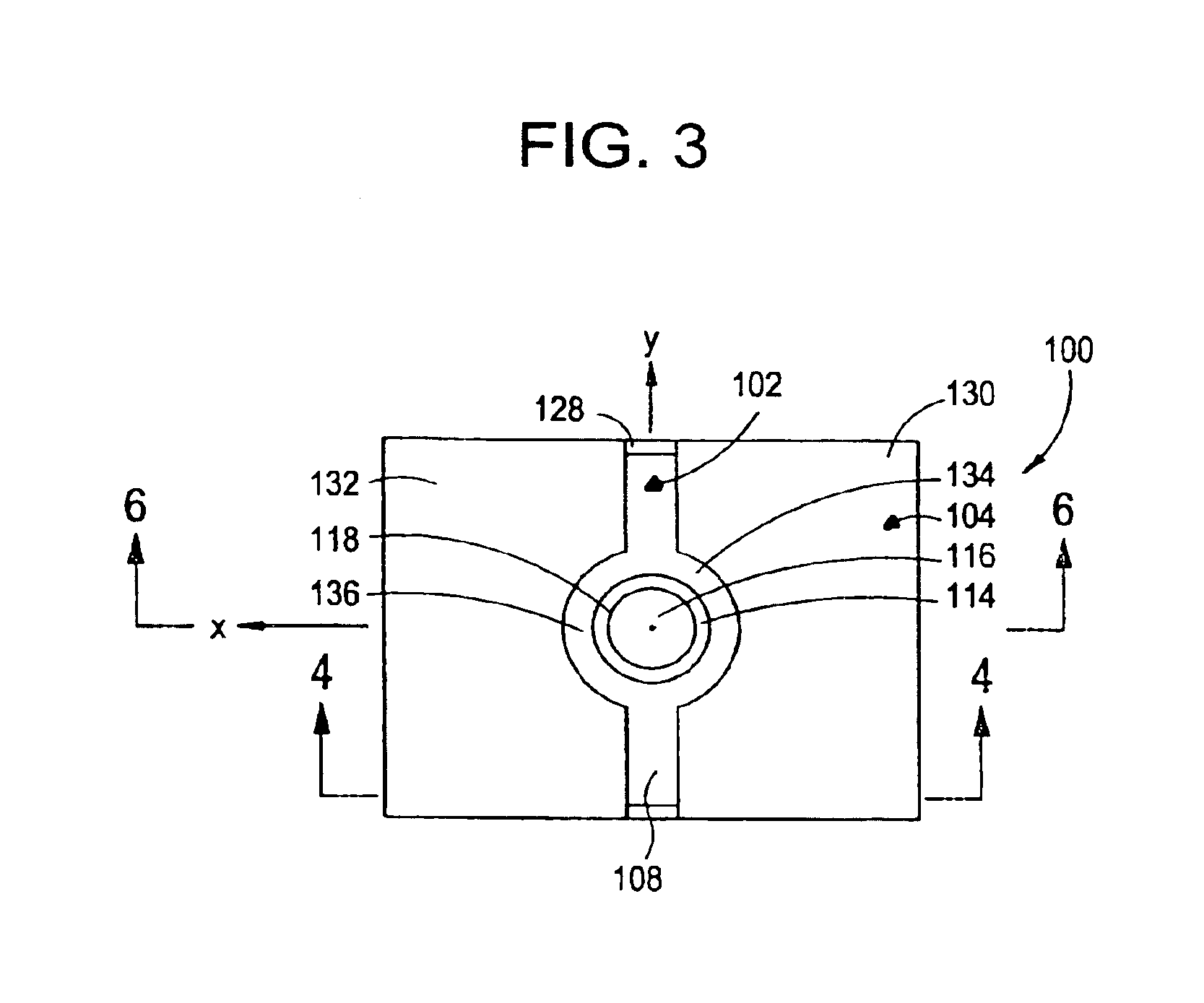

Variable focus lens and spectacles

The invention provides a variable focus lens formed from a ring with a front surface and a rear surface, a flexible membrane is attached to a radially inner part of the front surface, and a front cover is attached to a radially outer part of the front surface, a rear cover is provided on the rear surface of the ring, preferably integral with the ring, so that a variable volume cavity is defined between the flexible membrane, the ring and the rear cover, second flexible membrane can be provided between the ring and the rear cover, where the invention also provides a method of filling a variable focus lens, and an adjustment mechanism for varying the focus of the lens.

Owner:ADLENS

Variable focus lens and spectacles

The invention provides a variable focus lens formed from a ring with a front surface and a rear surface, a flexible membrane is attached to a radially inner part of the front surface, and a front cover is attached to a radially outer part of the front surface, a rear cover is provided on the rear surface of the ring, preferably integral with the ring, so that a variable volume cavity is defined between the flexible membrane, the ring and the rear cover, second flexible membrane can be provided between the ring and the rear cover, where the invention also provides a method of filling a variable focus lens, and an adjustment mechanism for varying the focus of the lens.

Owner:ADLENS

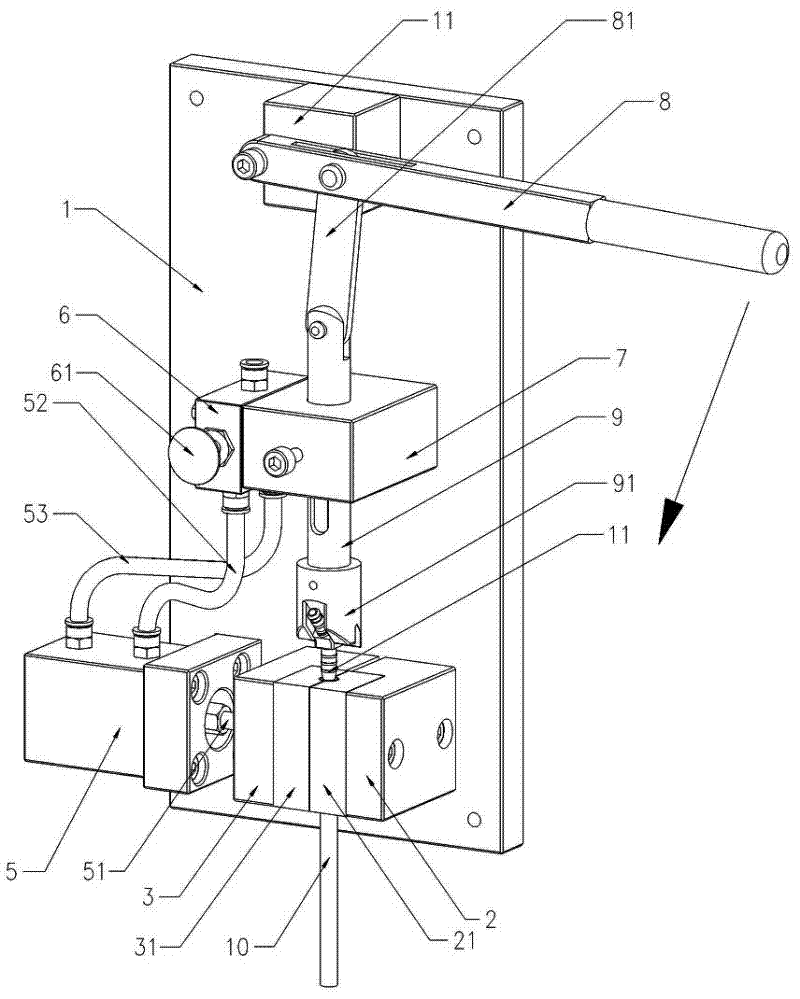

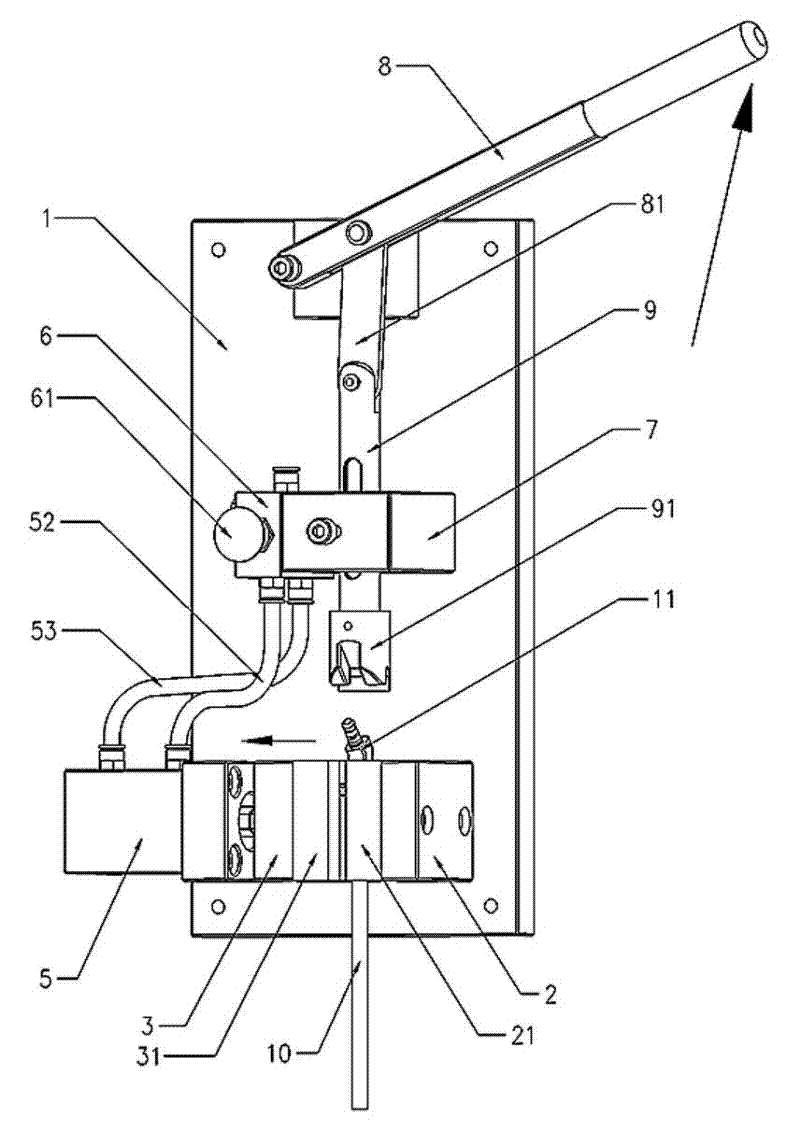

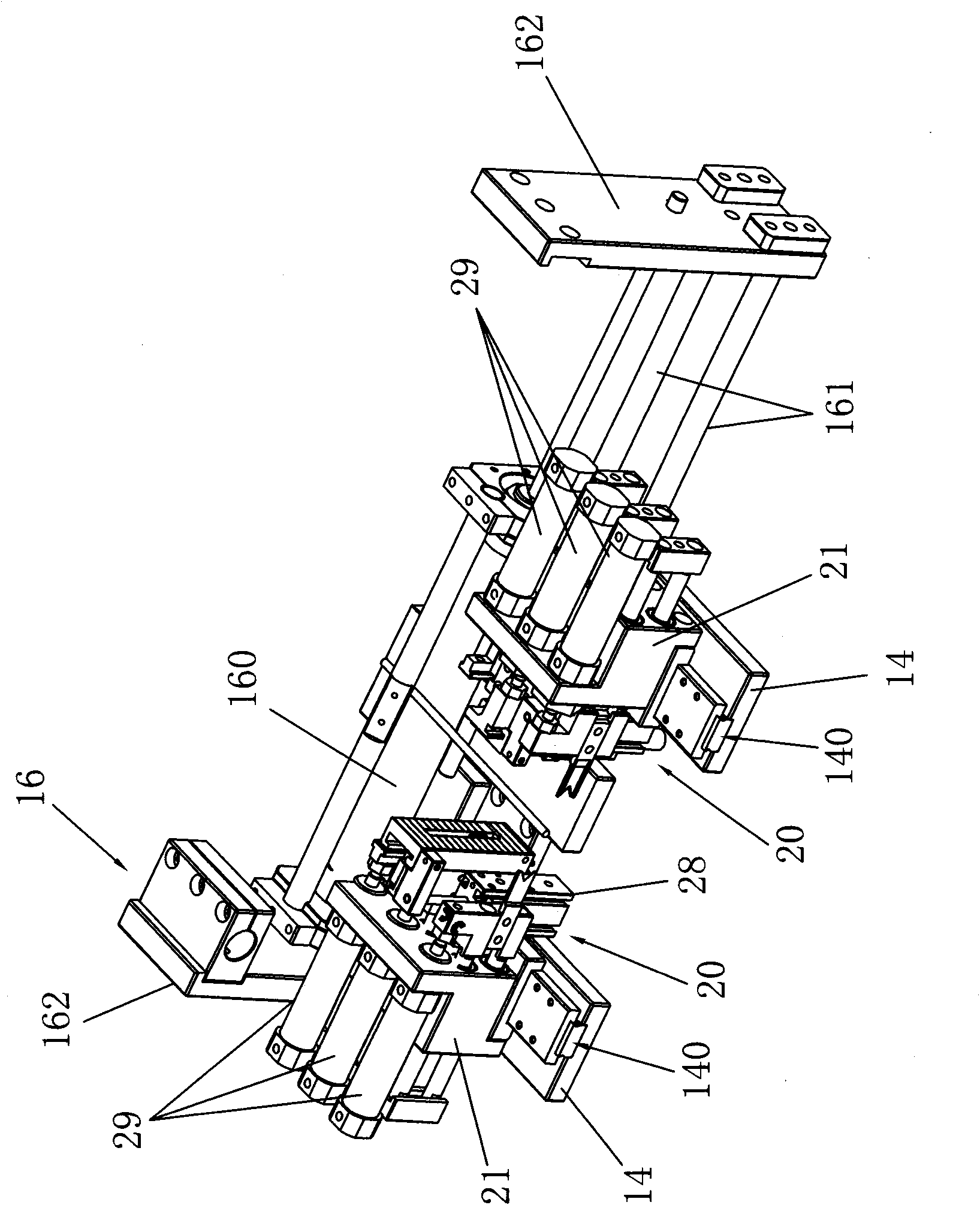

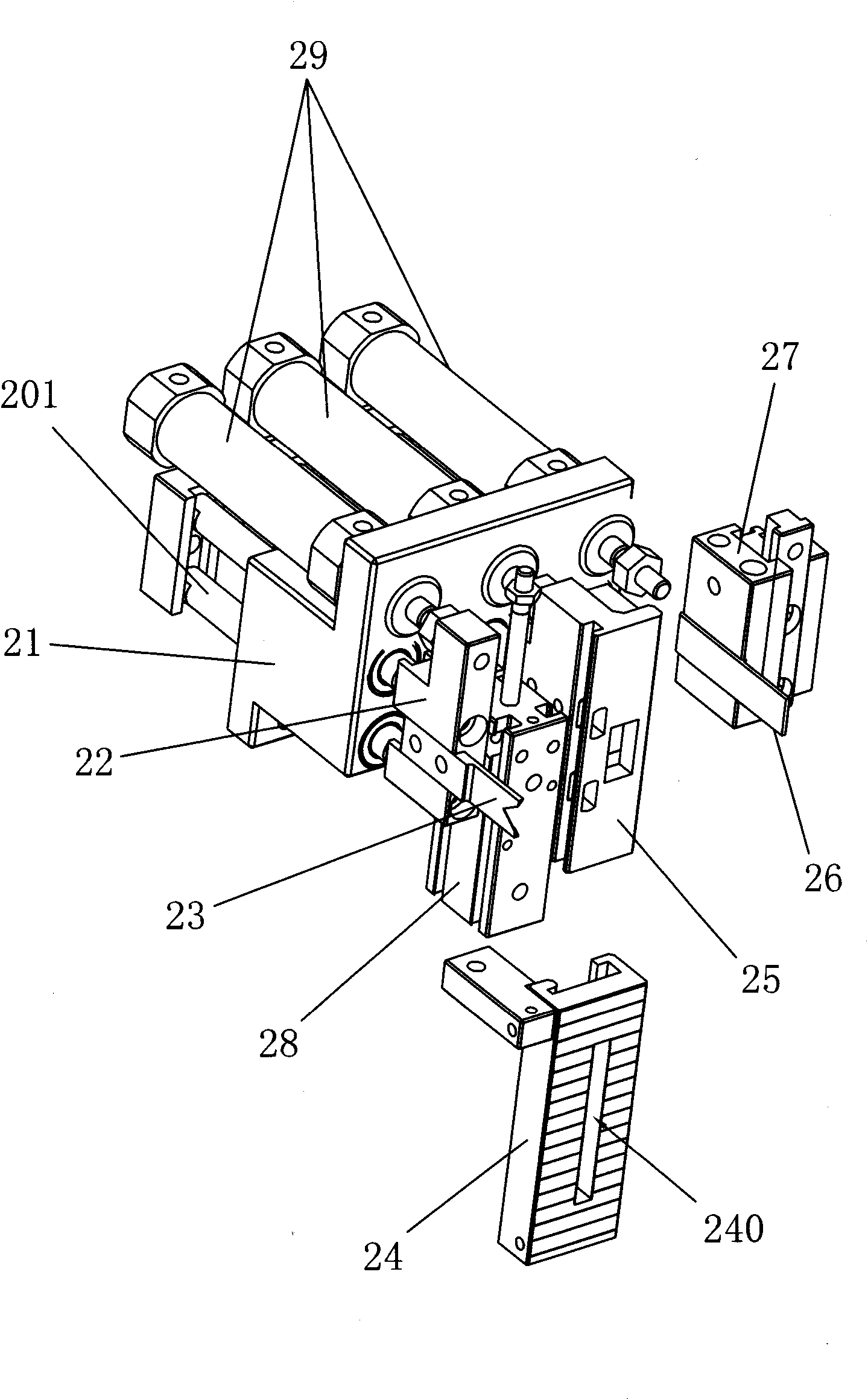

Hose fitting assembly station

InactiveCN102267122AAdvance and retreat smoothlyAccurate directionMetal-working hand toolsInterference fitPunch press

The hose joint assembly platform is fixed with a fixed block, cylinder, two-way valve, and support plate on the bottom plate; the two-way valve controls the advance and retreat of the piston push rod through the intake pipe; the sliding clamping block is pulled by the piston push rod. The fixed block is closed and separated; soft cushion blocks are respectively set on the mating surfaces of the fixed block and the sliding clamping block, and the corresponding parts have semicircular grooves, which are convenient for clamping the hose; the push-pull handle connects the push rod together with the punch Press against the pipe joint, rigidly insert the pipe joint into the inner wall of the rubber hose, and use the interference fit to fix the two tightly together. Equipping corresponding series of punches for pipe joints of different shapes and sizes can expand the scope of application, convenient and quick assembly, good sealing performance of joints, and high production efficiency.

Owner:ZHEJIANG BOSHITE MECHANICAL CO LTD

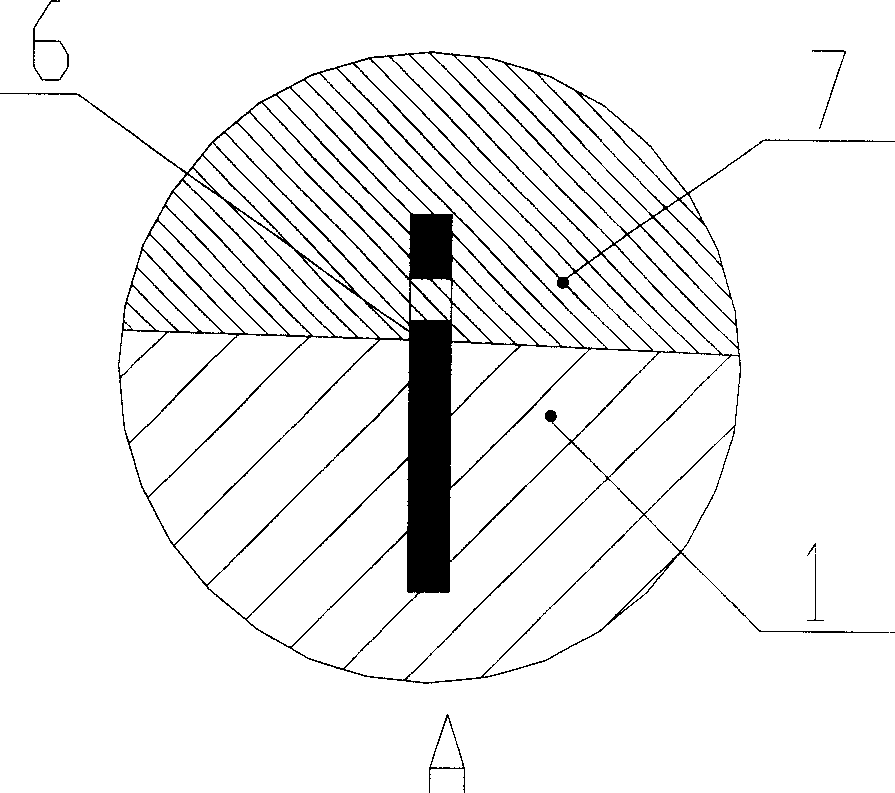

Sealing device for injection/extraction port of liquid drug

InactiveCN1420754APrevent looseningPrevent leakageClosuresPharmaceutical containersEngineeringBiomedical engineering

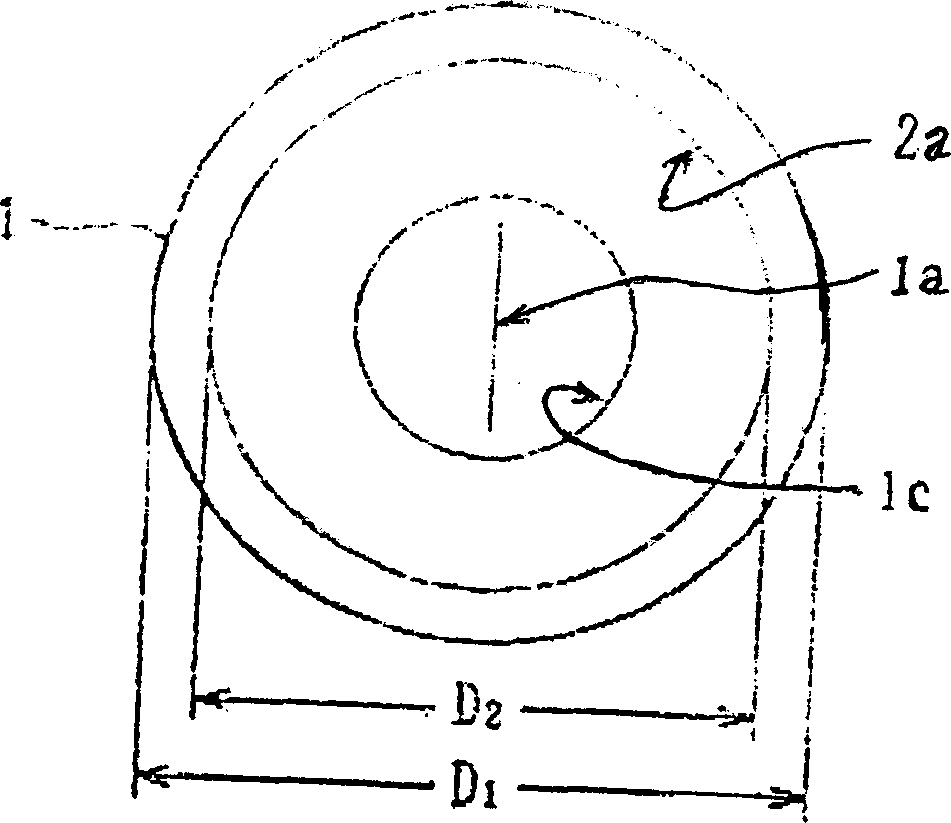

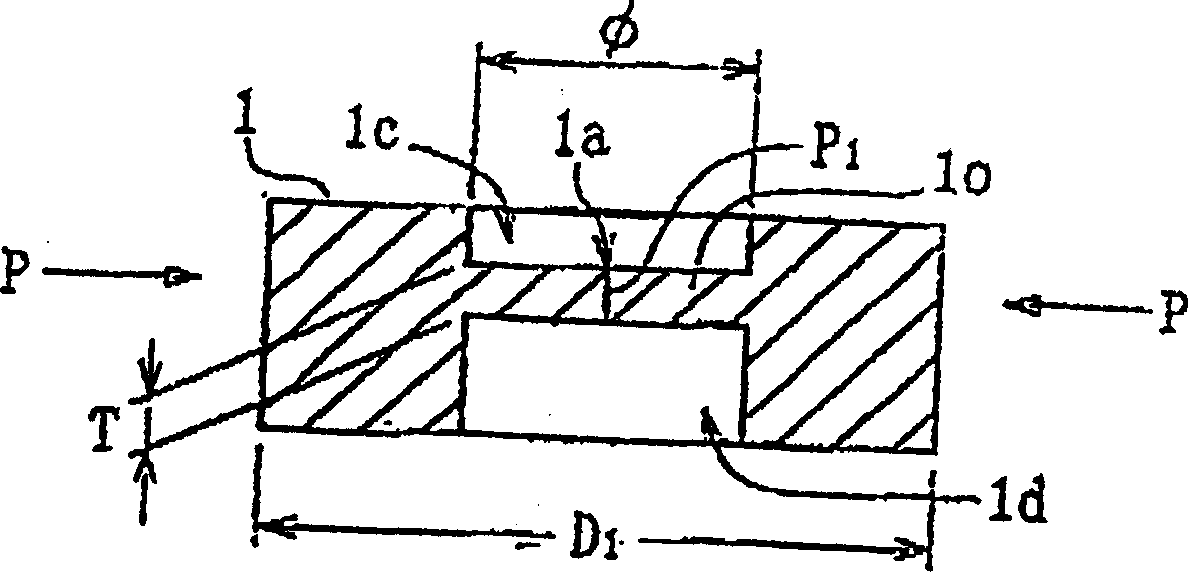

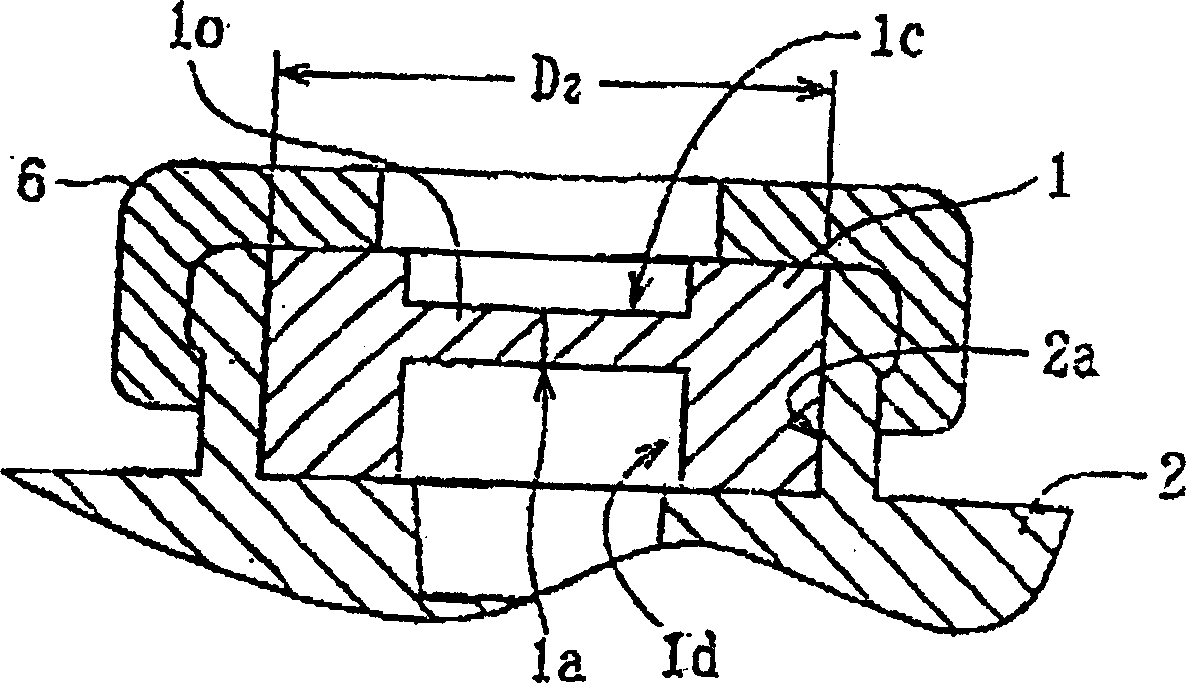

A liquid medicine or the like injection and extraction port seal valve comprises a plug main body (1) in the form of an elastic body formed with a linear cut portion (1a) or slit portion (1f) in the central region vertically extending therethrough, the outer diameter (D1) of the plug main body (1) being larger than the inner diameter (D2) of an injection and extraction port (2a) for liquid medicine, the arrangement being such that tightly fitting the plug main body (1) in the injection and extraction port (2a) for liquid medicine or the like produces a clamping pressure on the cut portion (1a) or slit portion (1f) to seal it. The cut portion (1a) or slit portion (1f) of the plug main body (1) is elastically deformed to open by tightly fitting the front end portion (3) of a syringe or connector, and is elastically restored to its original sealed state by pulling out the front end portion (3) of the syringe or connector.

Owner:FUKAI IND

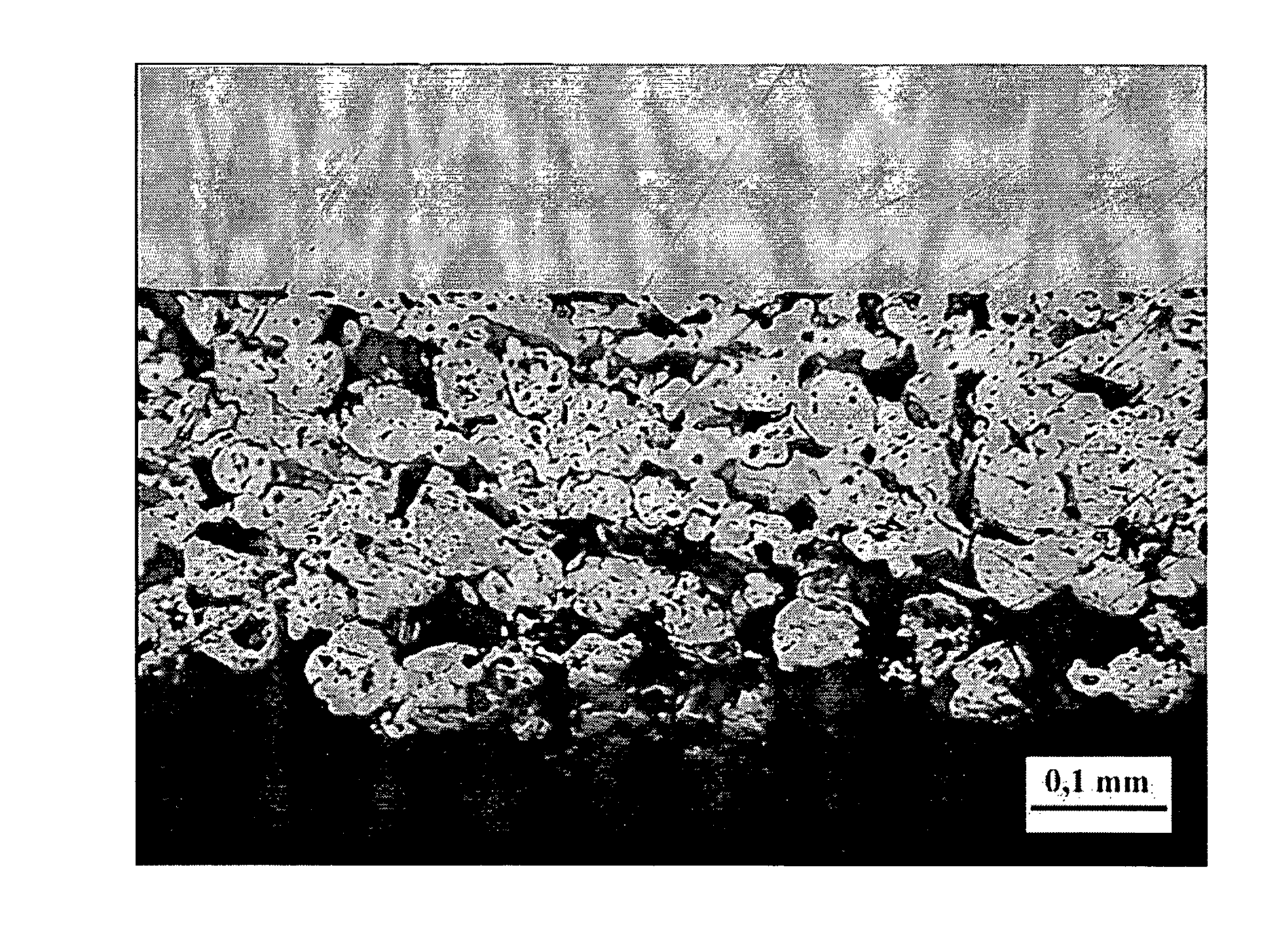

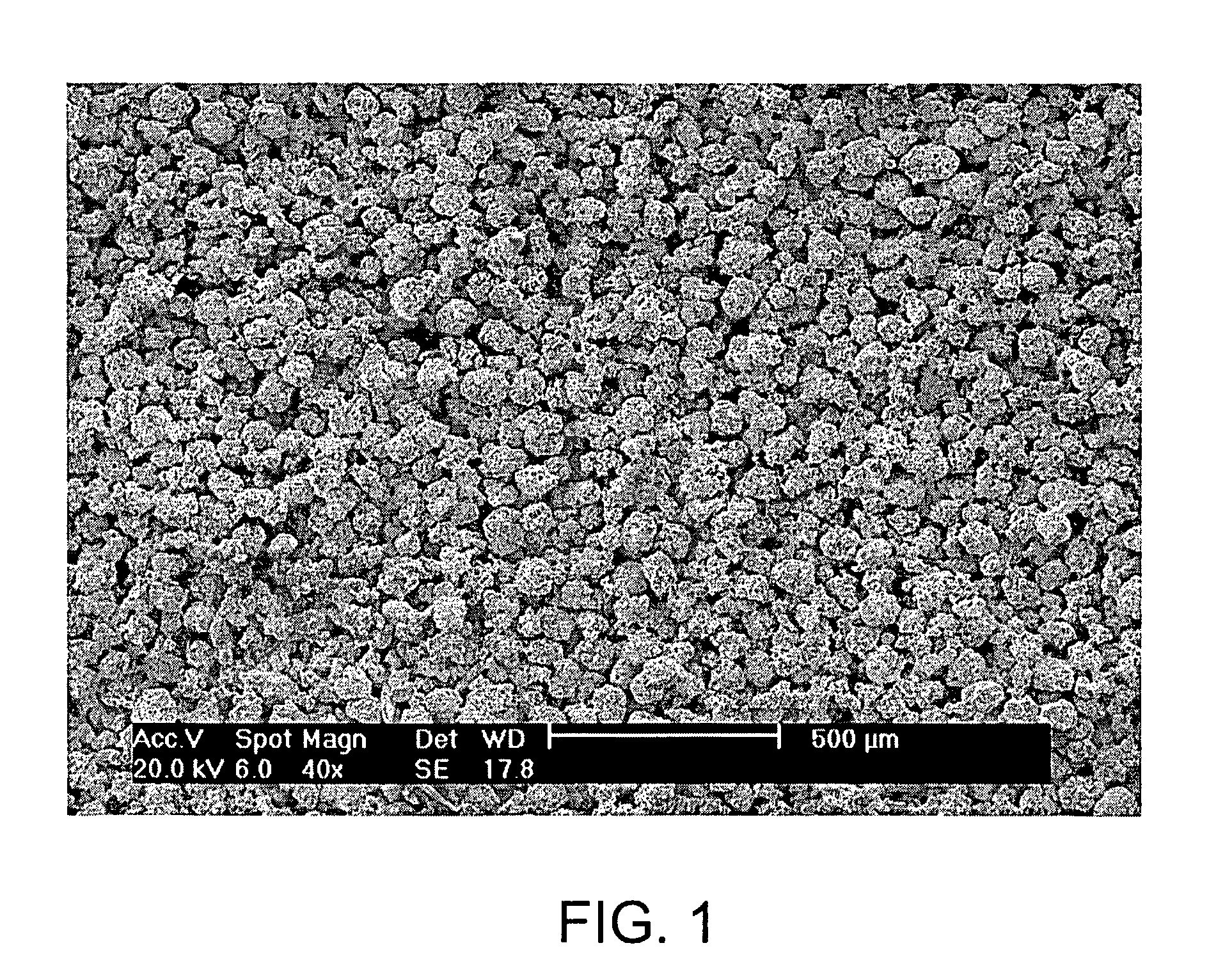

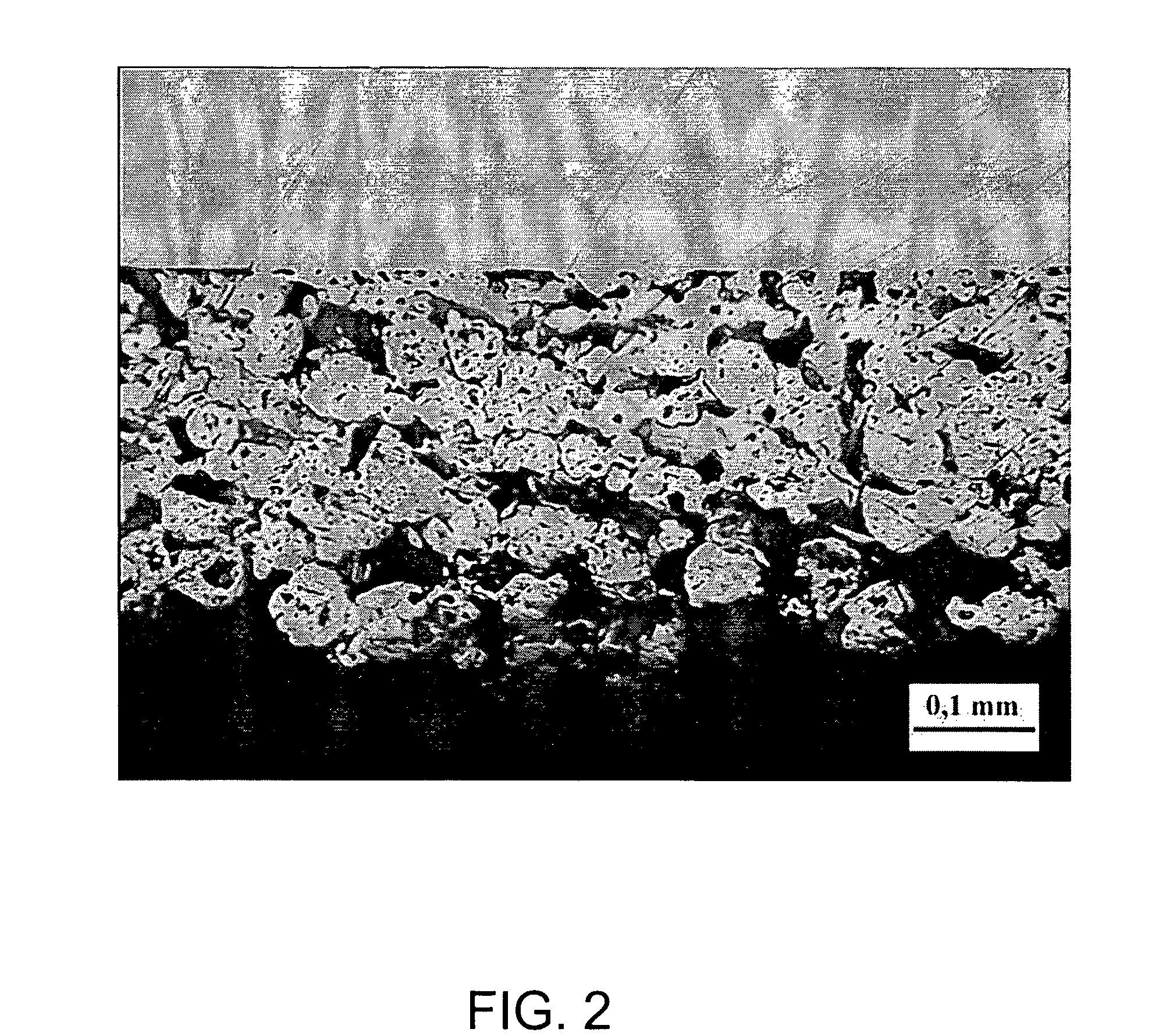

Method For Reducing Metal Oxide Powder And Attaching It To A Heat Transfer Surface And The Heat Transfer Surface

InactiveUS20070251410A1Clear energy savingLow investment costConductive materialPretreated surfacesSurface layerPorous layer

The purpose of the method developed is to form on top of a heat transfer surface a porous surface layer, which is to be fixed to the surface below it at a temperature and time applicable for industrial production. The heat transfer surface is copper or copper alloy. The powder forming a porous surface is fine-grained copper oxide powder, which is reduced to metallic copper on the heat transfer surface during heat treatment. The invention also relates to the heat transfer surface of copper or copper alloy, on which a porous layer has been formed from metallic copper, which is manufactured by reducing copper oxide powder and is attached using brazing solder.

Owner:RISSANEN PETRI +1

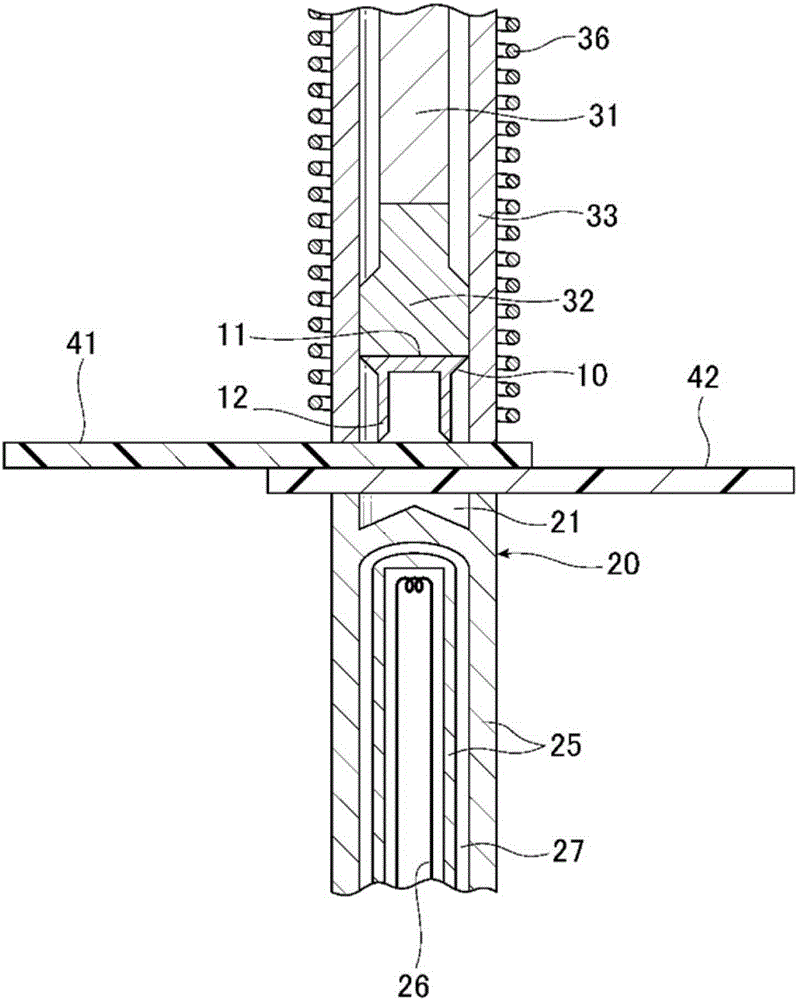

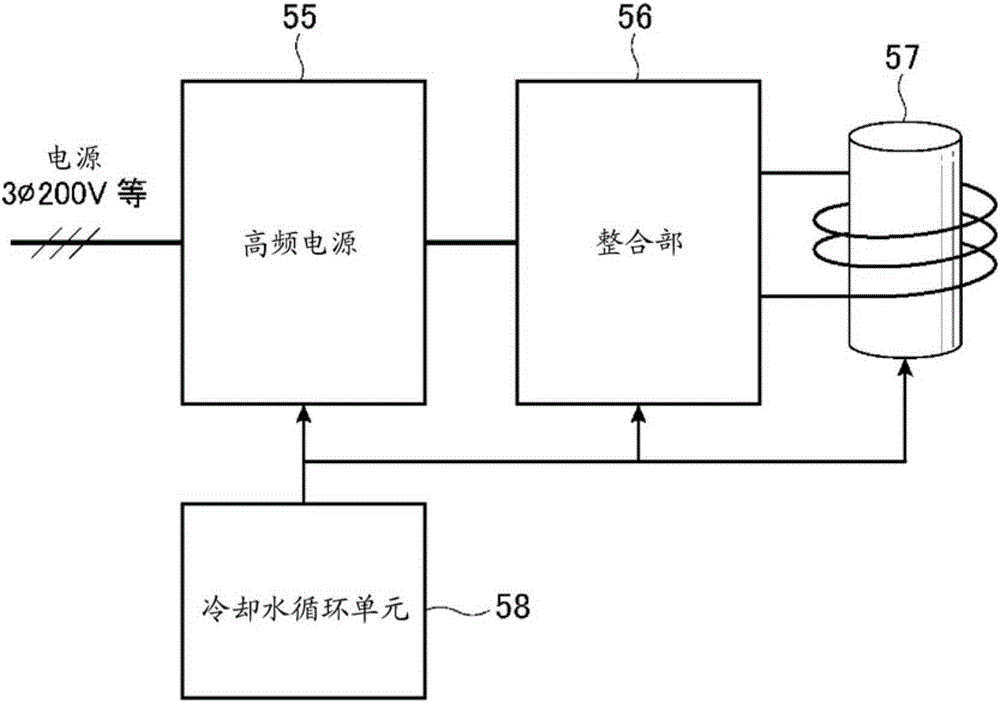

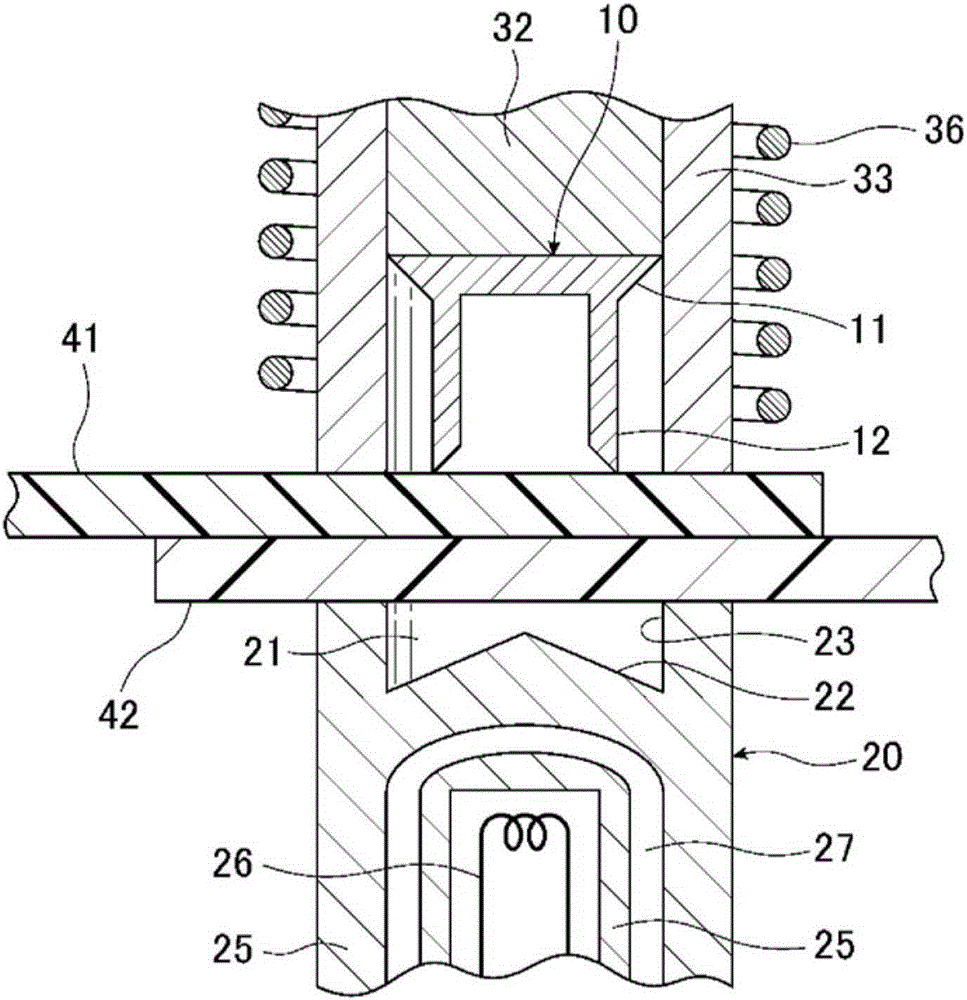

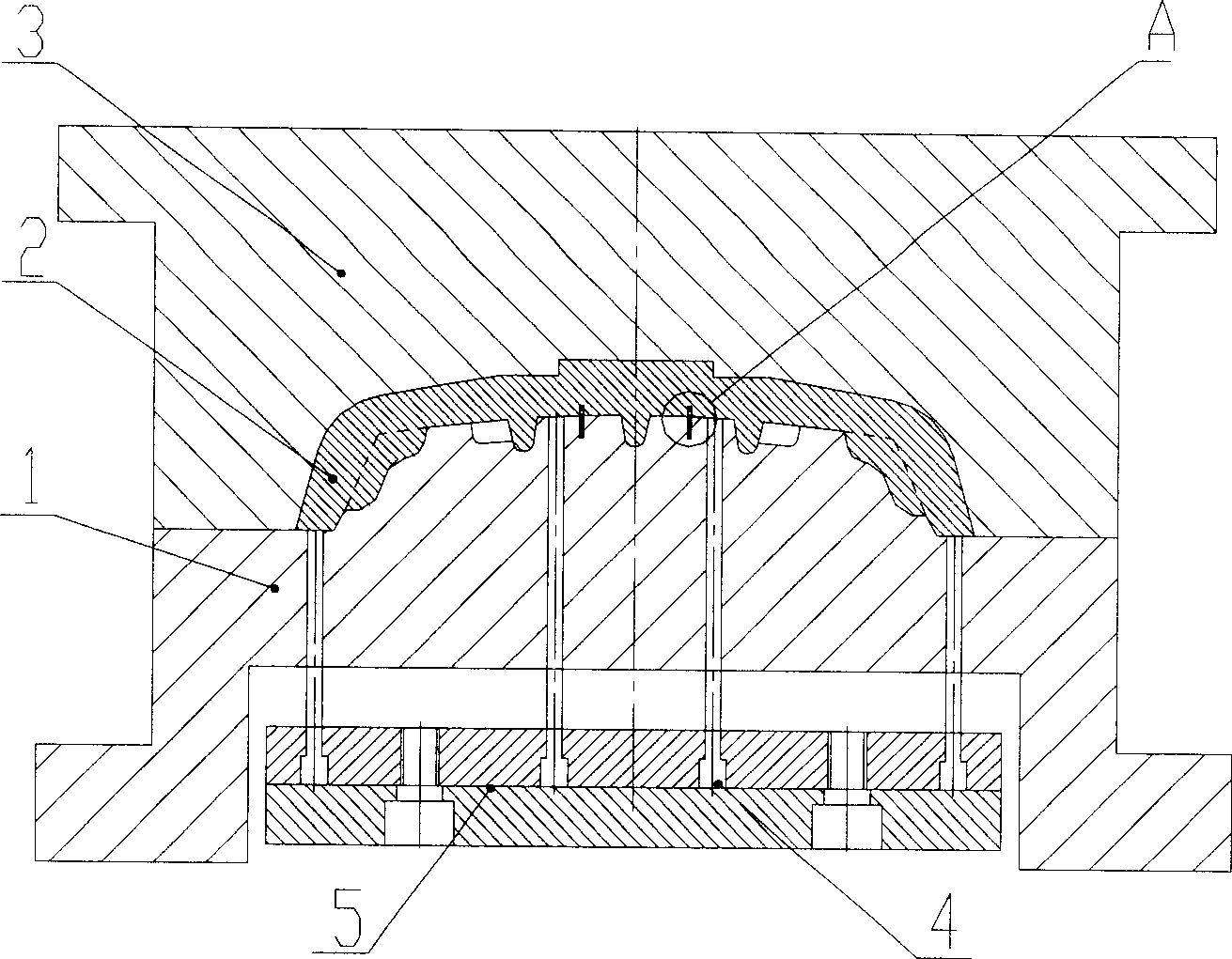

Joining device for resin member, joining structure, and joining method

A joining device whereby damage to a resin member is unlikely to occur when joining a plurality of resin members by using a self-piercing rivet. The joining device (1) a punch (31) to punch and join the self-piercing rivet (10) to the plurality of resin members (41, 42) arranged upon a die (20). The joining device (1) comprises: a die that receives a resin member and a leg section (12) of the self-piercing rivet; a die support member (25) comprising an insulating body, for supporting the die; a high-frequency electromagnetic induction coil (26) arranged inside the die support member; a pre-clamp (33) comprising an insulating body, for fixing the resin member on the die; a high-frequency electromagnetic induction coil (36) wound around the pre-clamp; and the punch (31) comprising an insulating body, for punching the self-piercing rivet. The plurality of resin members are joined by the punching of the self-piercing rivet and the fusing of the plurality of resin members.

Owner:NEWFREY

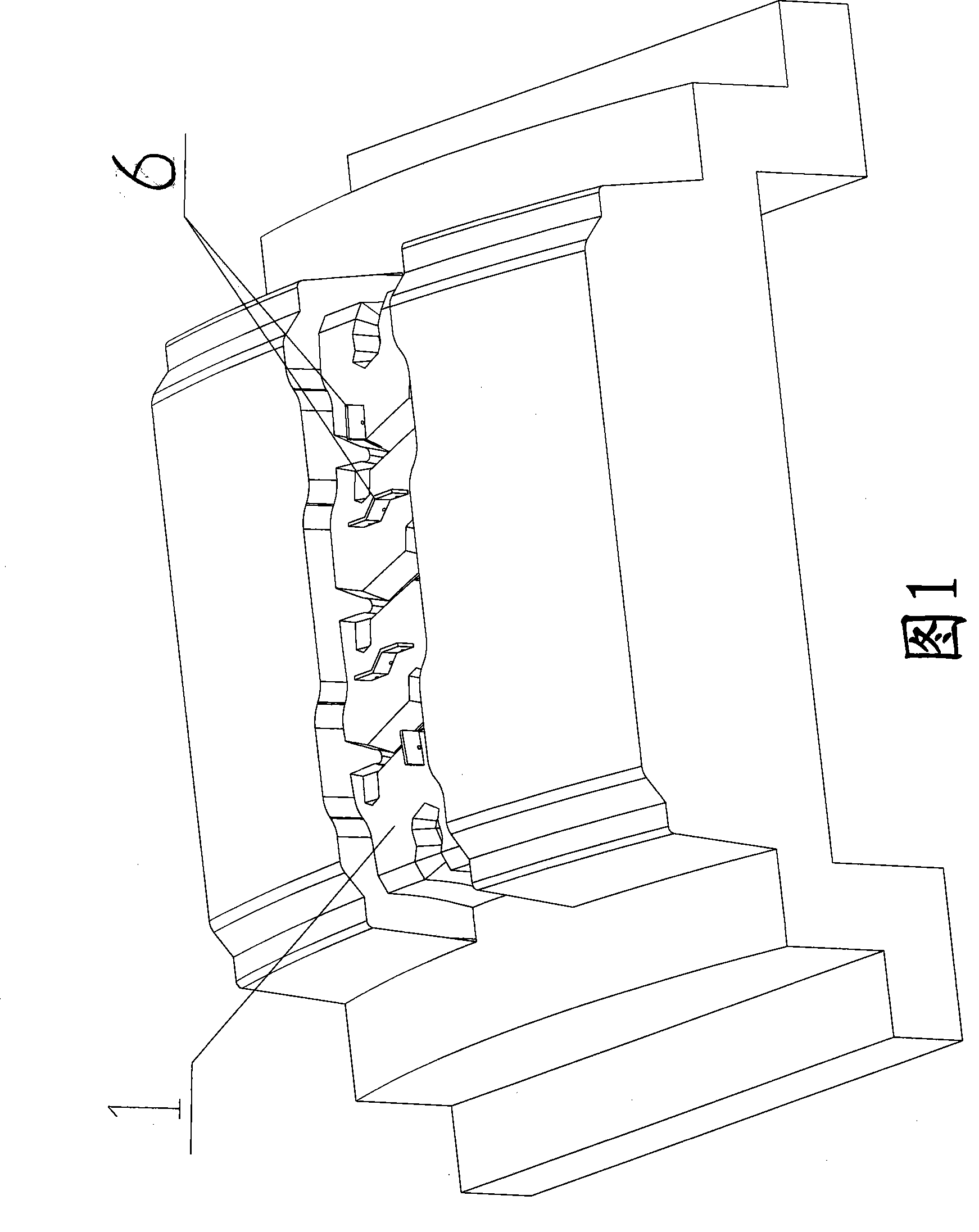

Implantation method of steel disc when casting pattern block of tyre mould at high pressure

The invention relates to a method for manufacturing tyre moulds, particularly a method for embedding steel sheets when casting pattern blocks of the tyre mould under a high pressure. The method mainly comprises the following steps: forming a depressed steel sheet groove between the patterns on the upper surface of a lower mould; inserting the pre-formed steel sheet into the steel sheet groove, forming a small hole at one end in the length direction of the steel sheet, and inserting the end of the steel sheet, at which no small hole is formed, into the steel sheet groove; and casting molten alloy materials, which pass through the small hole at the end of the steel sheet, and firmly fix the steel sheet in the pattern block after being solidified, under a high pressure in a mould cavity after the mould is matched, wherein the steel sheet which is fixed in the pattern block is pulled out of the lower mould along with the rise of the pattern block after the mould is unloaded. The method has the advantages that the process is simple, the implementation is convenient, the size and the position of the embedded steel sheet are accurate, the steel sheet is firmly spliced with the pattern blocks, and does not easily drop off, and the production cost is low.

Owner:QINGDAO YUANTONG MACHINERY CO LTD

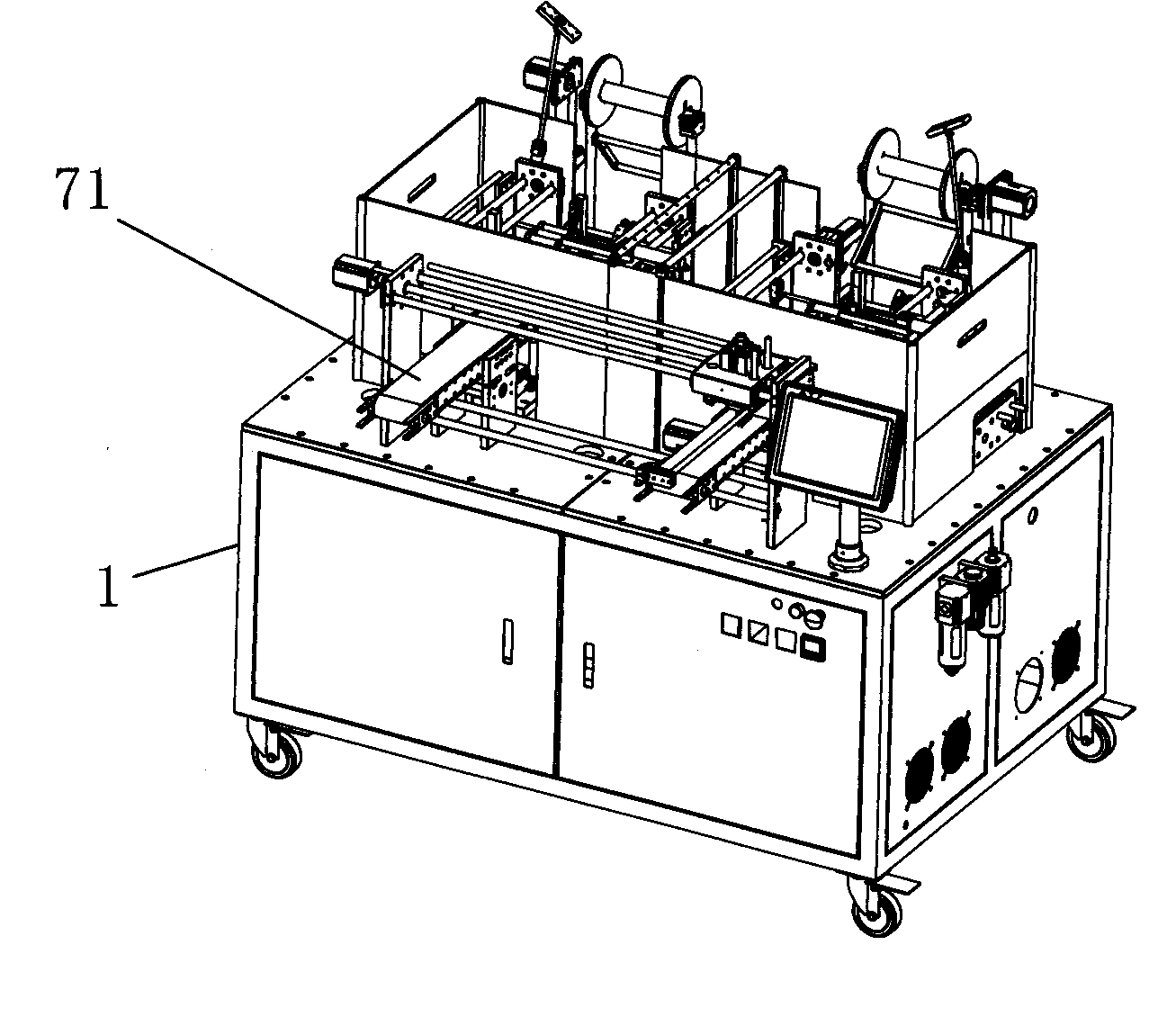

Automatically cutting and adhering machine

InactiveCN101863129AStrong jointImprove work efficiencyDomestic articlesElectric machineryManipulator

The invention relates to the technical field of cutting and adhering equipment, in particular to an automatically cutting and adhering machine. The automatically cutting and adhering machine comprises a machine frame, a control system, and a gear feeding device, a hot-press cutting device, a mechanical arm feeding and clamping device, a rotary glue-feeding device and a conveying device which are arranged on the machine frame sequentially, wherein the control system is connected with the gear feeding device, the hot-press cutting device, the mechanical arm feeding and clamping device, the rotary glue-feeding device and the conveying device; the hot-press cutting device comprises a pedestal and two groups of hot-press cutting mechanisms which are symmetrically arranged on the pedestal; the mechanical arm feeding and clamping device comprises two mechanical arms, an upper driving motor and a lower driving motor; each mechanical arm is provided with a clamping part; and the upper driving motor and the lower driving motor are used for driving the two mechanical arms respectively to move backwards and forwards. The automatically cutting and adhering machine has the advantages of capacity of automatically completing the whole production manufacturing process of a hair band, high degree of automation and great improvement on the production capacity and the quality of products.

Owner:LIVINGSTYLE ENTERPRISES

Collapsible nut

A cage nut assembly includes a nut having a cylindrical portion extending from a plate portion. The nut is encaged in a cage such that the cylindrical portion extends through an aperture in the cage. The cylindrical portion of the nut is collapsible such that the nut collapses and provides a plurality of flanges upon an application of force. The flanges are folded or curved / mushroomed such that the plate portion of the nut is suspended within the cage so that the nut will not, or will minimally, stick to the cage or workpiece when coated with e-coat or ELPO. Upon torqueing a fastener into place, the flanges are bent up to allow the plate portion to interface with the cage or a workpiece to provide a solid joint.

Owner:ACUMENT INTPROP LLC

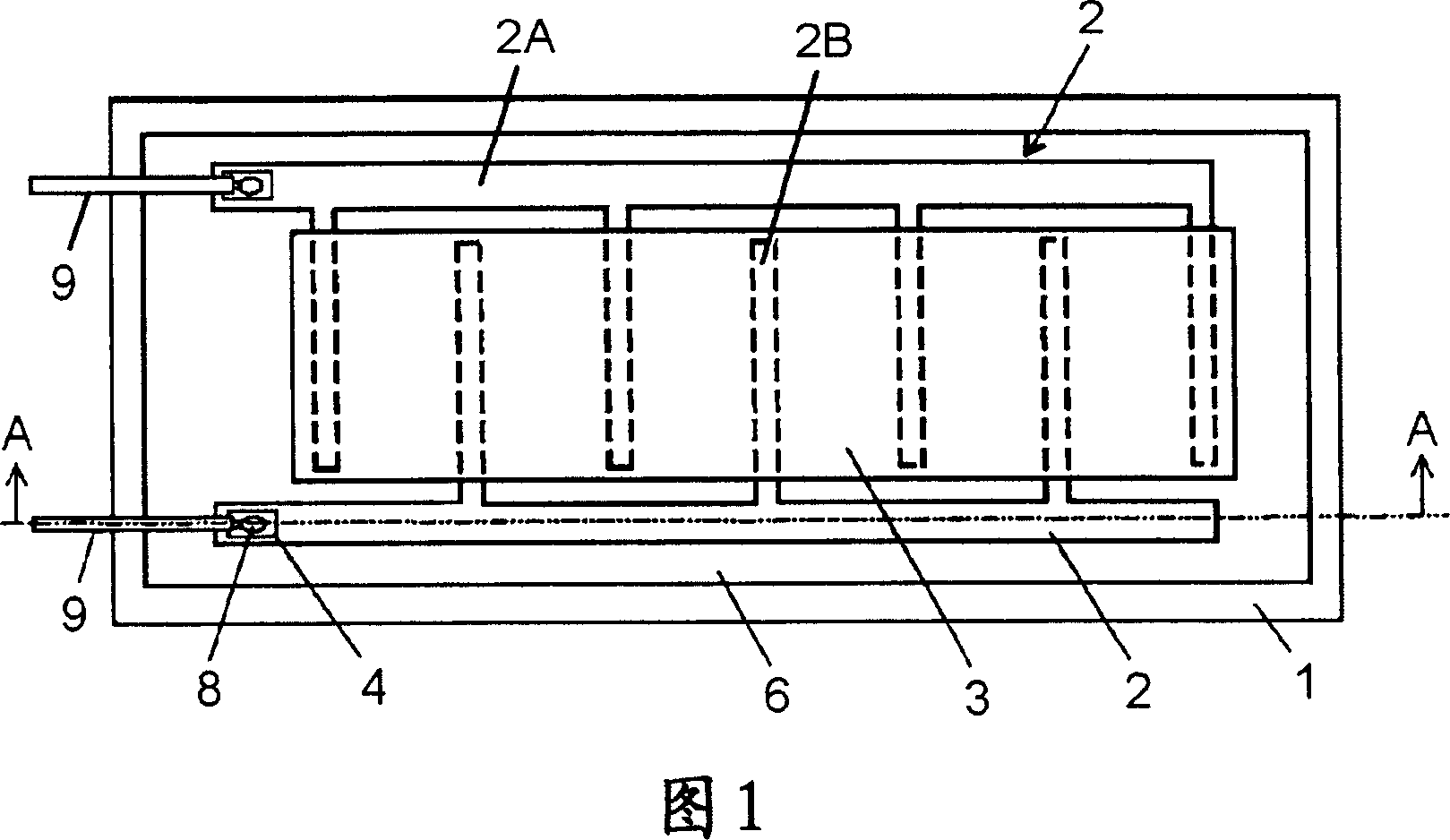

Heating element and production method thereof

InactiveCN1930918AHigh currentStrong jointSynthetic resin layered productsOhmic-resistance heating detailsElectrical resistance and conductanceHot melt

A heating element includes a base substrate, a pair of electrodes, a resistor capable of generating heat, a conductive resin, a terminal member, a hot melt adhesion metal, a hot melt cohesion metal, and a lead wire. The pair of electrodes is provided on the base substrate, and the resistor is formed between the pair of electrodes. The conductive resin is provided on each of the electrodes, and the terminal member is provided on the conductive resin. The adhesion metal is provided on the terminal member, and the cohesion metal forms a molten phase along with the adhesion metal. An end of the lead wire is welded to the cohesion metal. The conductive resin is provided in the vicinity of the adhesion metal so as to be affected by heat of the adhesion metal.

Owner:PANASONIC CORP

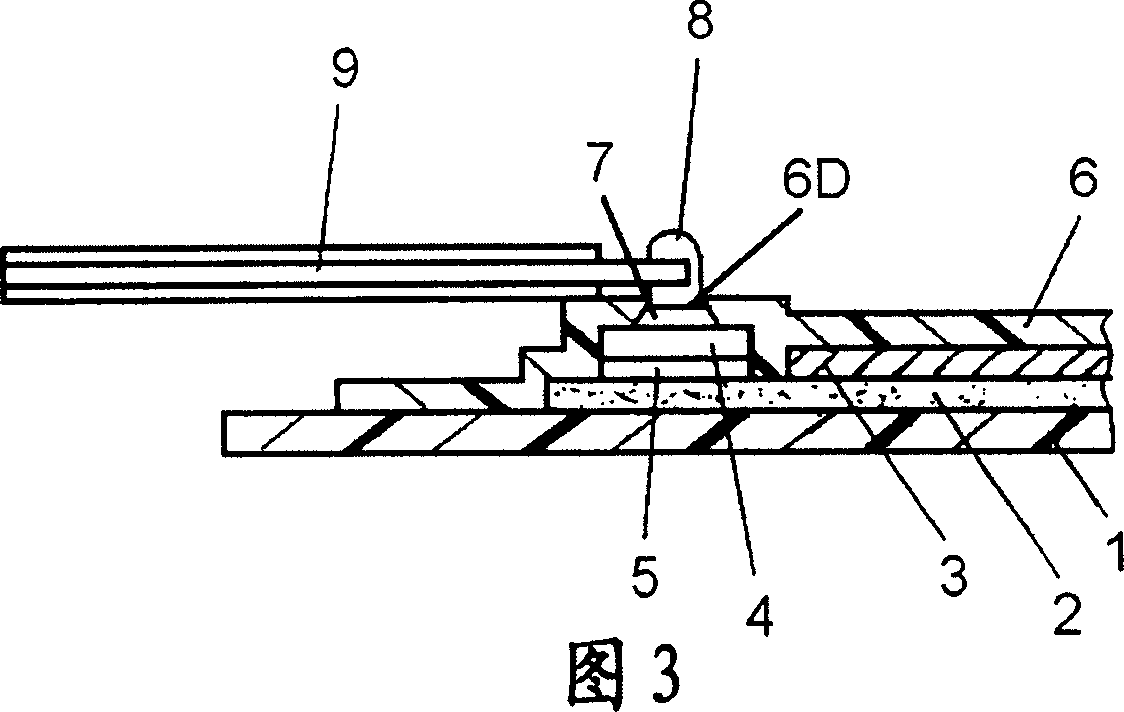

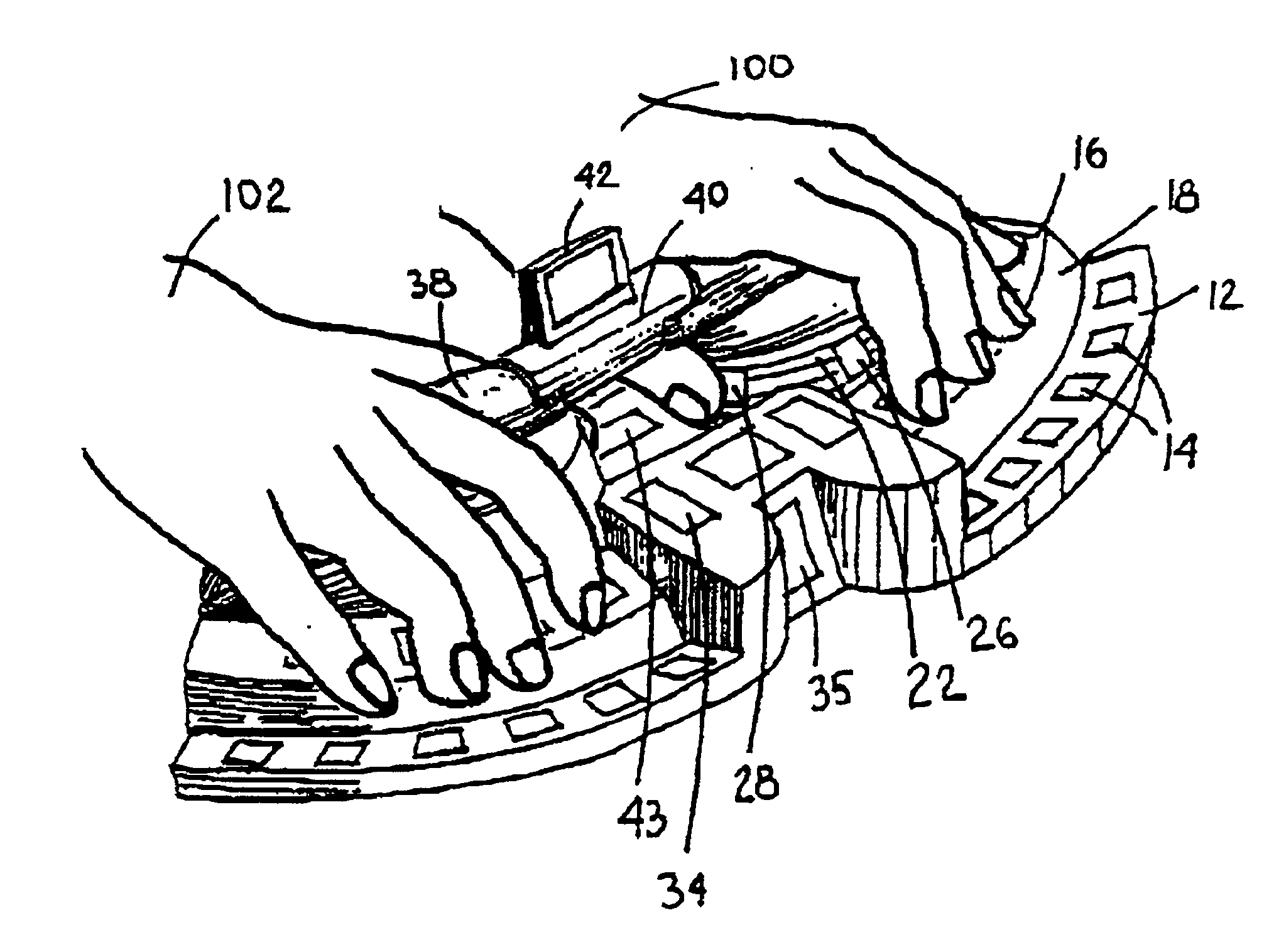

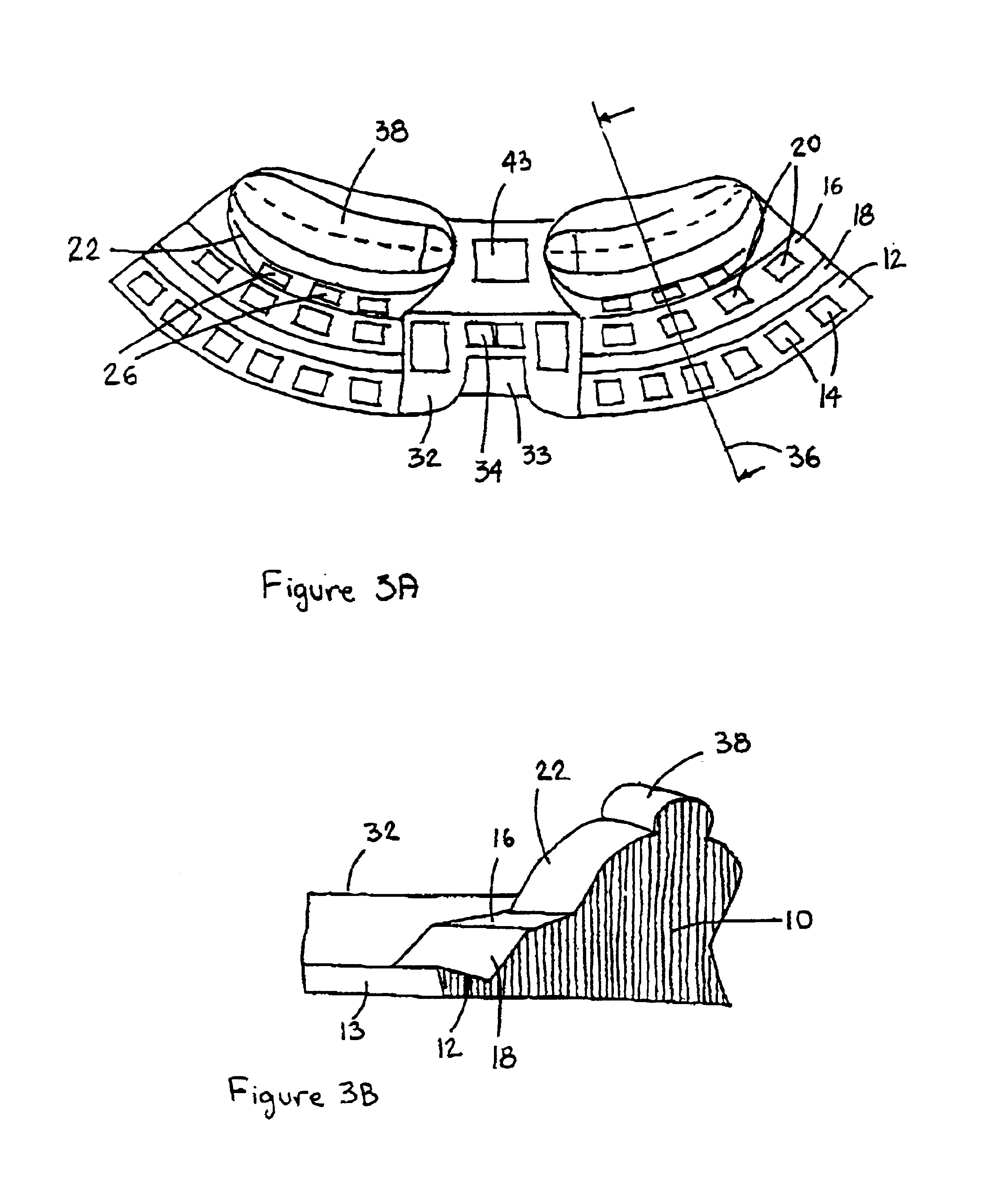

Ergonomic keyboard

InactiveUS6860661B1Reduce riskStrong jointInput/output for user-computer interactionOther printing apparatusHigh elevationEngineering

Owner:DAOUD DEEB

Tube fin brazing process and internal tube heating soldering machine for

InactiveCN101318245AUnchanged structureEasy to operateHeating appliancesMetal working apparatusCrystal structureEngineering

The invention discloses a tube fin brazing process and an in-tube heating brazing machine and is characterized in that a finned tubular pipe welding element well filled with solders is placed on a bracket and the surfaces of welding elements to be brazed are chemically cleaned; a rod type electric heating tube extends into the pipe to perform in-tube radiation heating to firstly moisten and apply the solders at the external wall of the pipe to fill the brazing gaps and then transfer the temperature to a finned folding edge by liquid solders; the metallurgical bonding is formed between the solders and the pipe as well as the folding edge by the atomic diffusion and solution. By adopting the in-tube heating brazing machine which consists of a machine stand, the bracket which is arranged at the front end of the machine stand and a heating tube holder arranged at the bracket, the tube fin brazing process and the in-tube heating brazing machine have the advantages of simple and convenient operation, minimal investment, no limitation to the geometric shapes of the brazed elements, no damage to the surfaces of the brazed elements and no change of the crystal structures in metals and solve the problems that the fins reach the brazing temperature before the pipes and the temperature is not easily controlled, and the brazing can not completely penetrate and fill the connection gaps and the brazing effect is bad, and the problems are caused by the traditional brazing heating ways.

Owner:AECC AERO SCI & TECH CO LTD

Hot rolled strip steel for automobile clutch diaphragm spring and manufacturing method thereof

The invention relates to hot rolled strip steel for an automobile clutch diaphragm spring and a manufacturing method thereof. The strip steel consists of the following components in percentage by mass: 0.45-0.57 percent of C, 0.12-0.43 percent of Si, 0.62-1.18 percent of Mn, 0.015-0.06 percent of Al, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.85-1.30 percent of Cr, 0.08-0.30 percent of V and less than or equal to 0.005ppm of N. The manufacturing method is characterized by comprising the following steps: I, external refining: LF deep desulfuration+RH vacuum degasification and Ca treatment of balling inclusion; II, slab continuous casting, wherein the casting speed is 0.6-2.0m / min; III, red charging of a slab, wherein the red charging temperature is higher than or equal to 150 DEG C; IV, slab heating, wherein the heating temperature is 1,210-1,280 DEG C; V, rough rolling unit rolling, wherein the rough rolling final temperature is 1,030-1,150 DEG C; VI, fine rolling unit rolling, wherein the fine rolling final temperature is 810-920 DEG C; and VII, strip steel coiling, wherein the coiling temperature is 600-800 DEG C. The tensile strength Rm of the hot rolled strip steel manufactured by using the method is less than or equal to 1,150MPa, the yield strength is less than or equal to 850MPa, the elongation percentage is more than or equal to 18 percent, and the thickness of a decarbonized layer is not larger than 1.1 percent of the thickness of strip belt.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

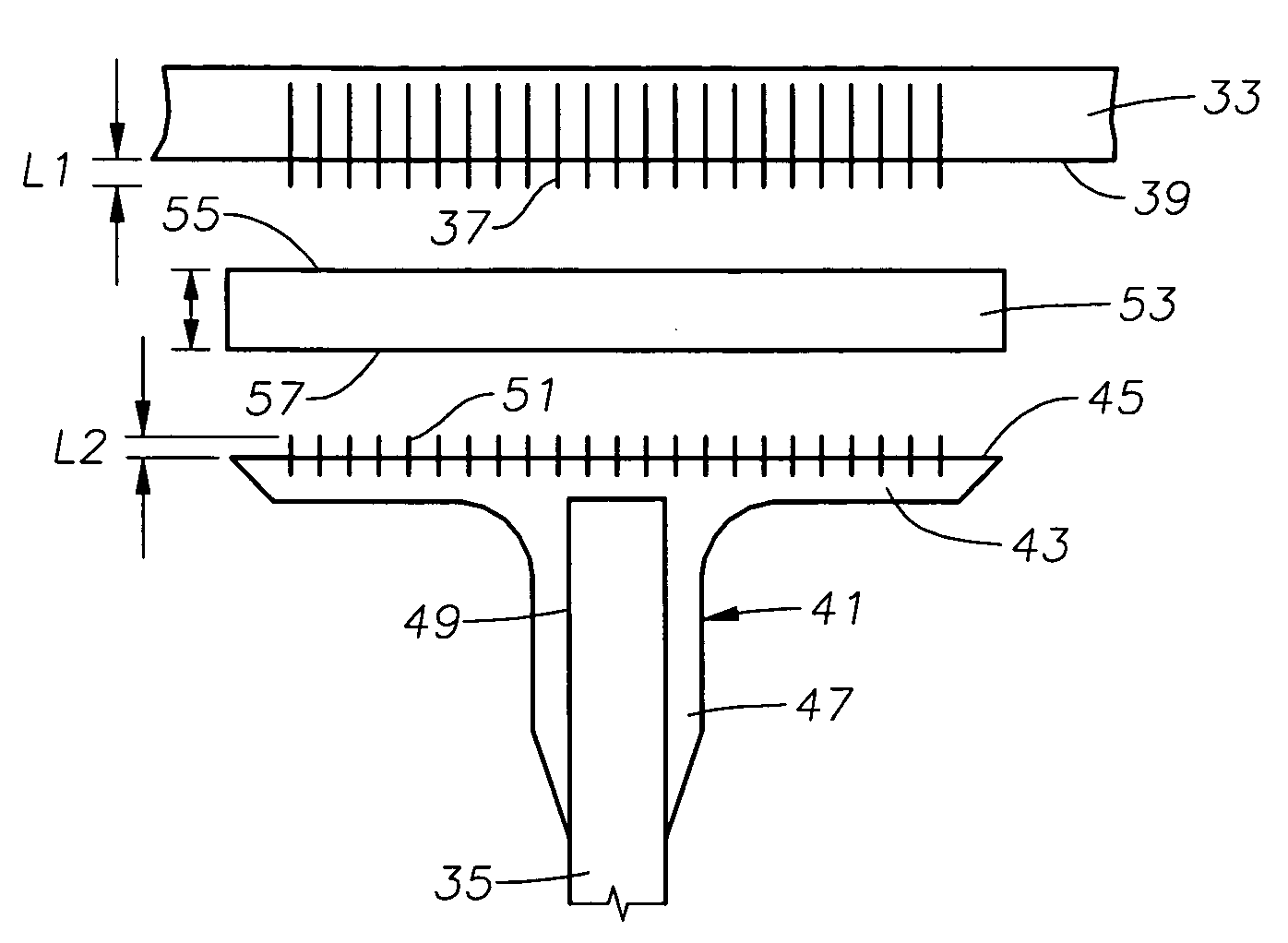

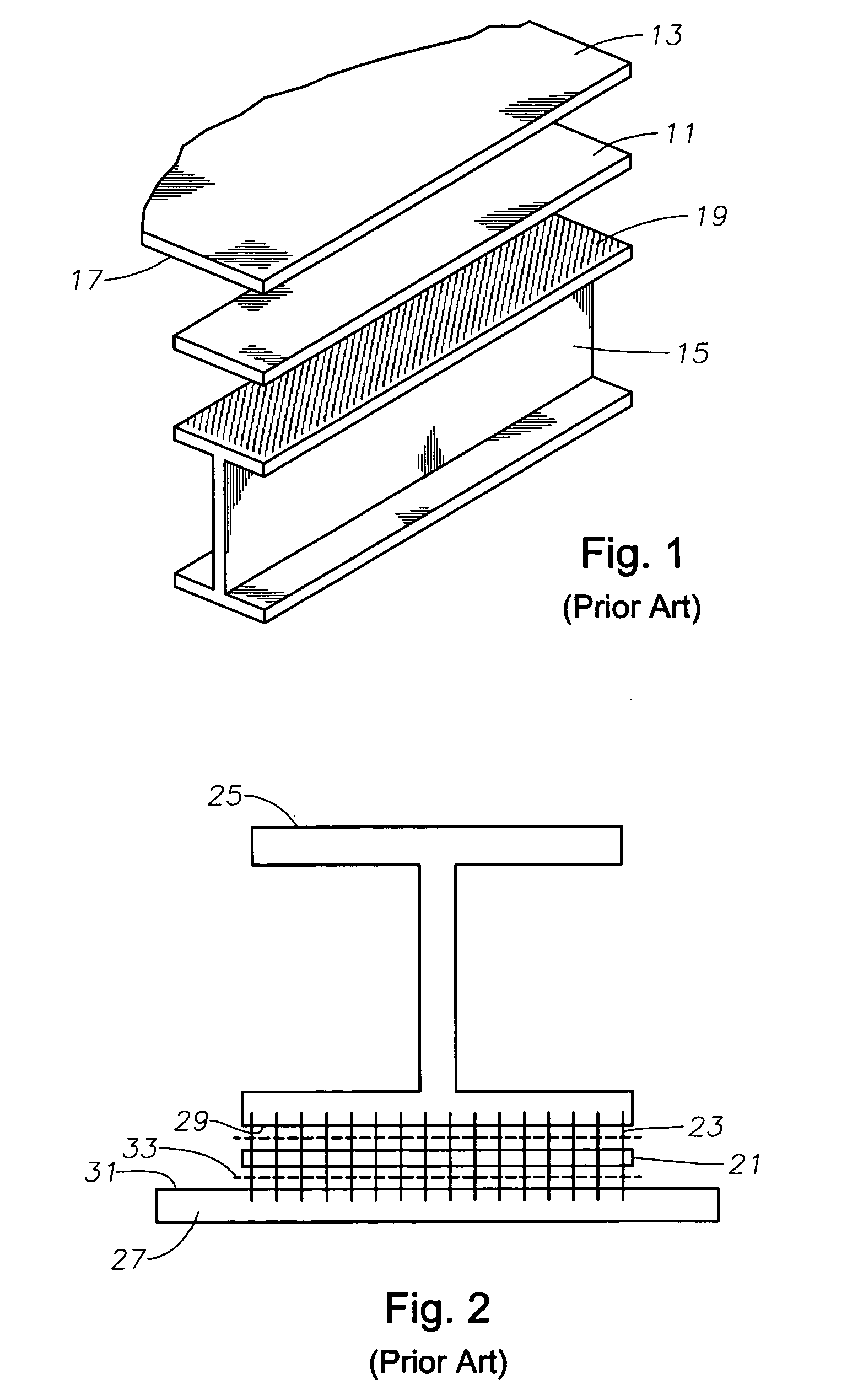

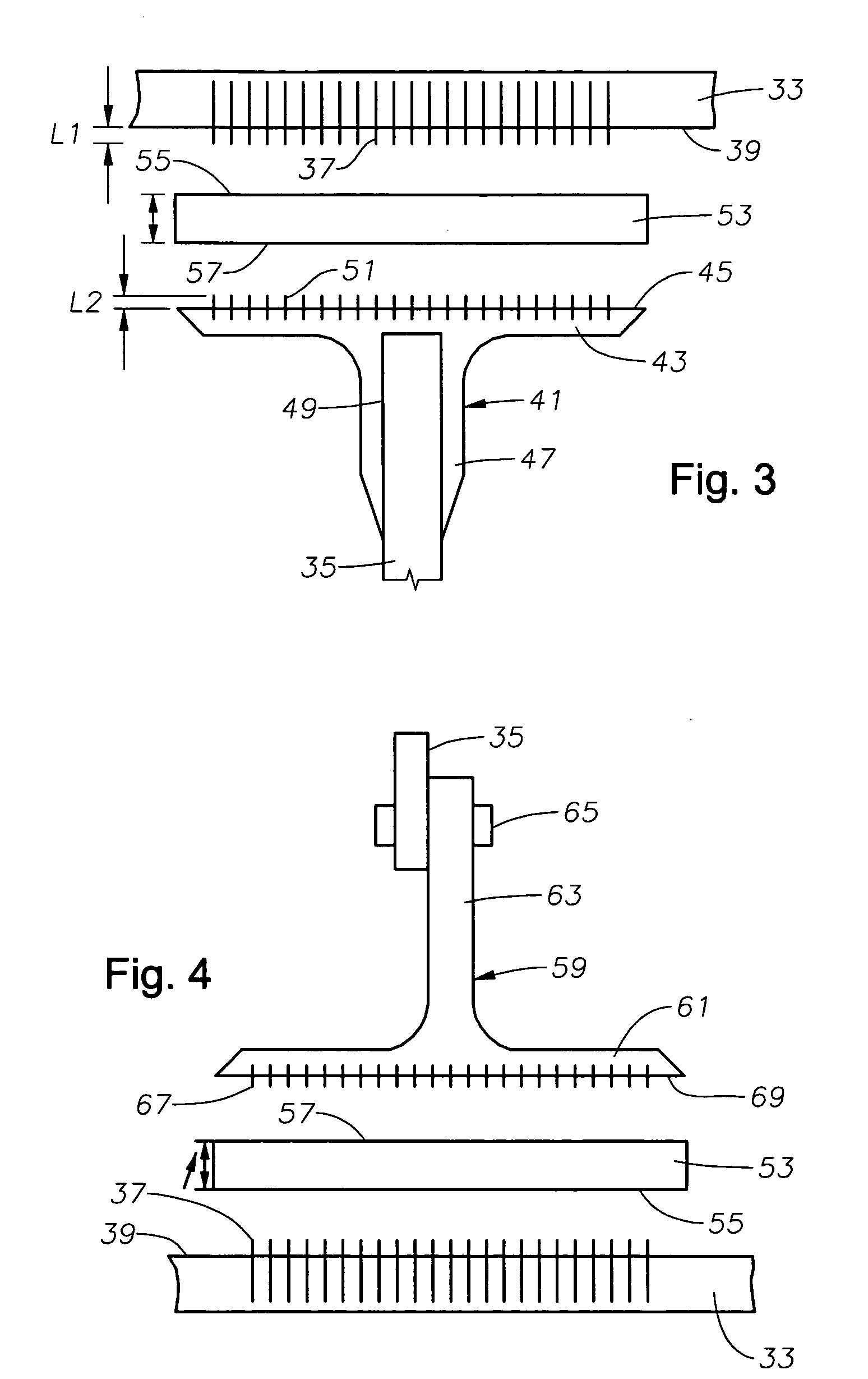

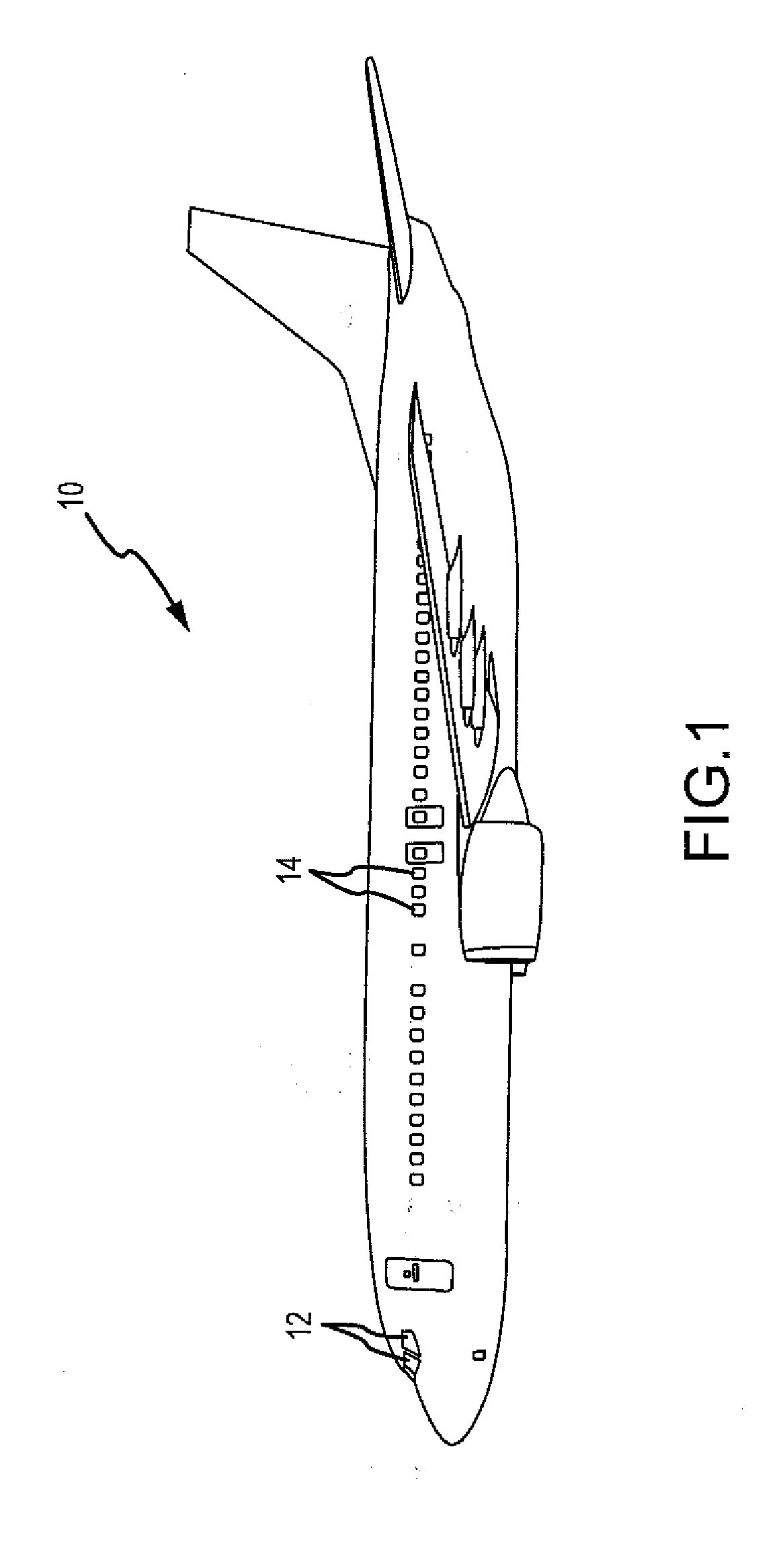

Z-pin closeout joint and method of assembly

InactiveUS20050186390A1Strong jointLarge dimensional toleranceLayered productsAdhesive processes with adhesive heatingAdhesiveMaterials science

A method uses a three-dimensional, adhesive-infused, woven preform to assemble two components, each component having z-pins extending from bonding surfaces. The components and preform are assembled with surfaces of the preform contacting surfaces of the components, the z-pins penetrating into the preform. The perform is equal or slightly greater in thickness than the protrusion lengths of the z-pins. The adhesive in the preform is then cured, adhering the preform to the components and retaining the z-pins within the preform.

Owner:LOCKHEED MARTIN CORP

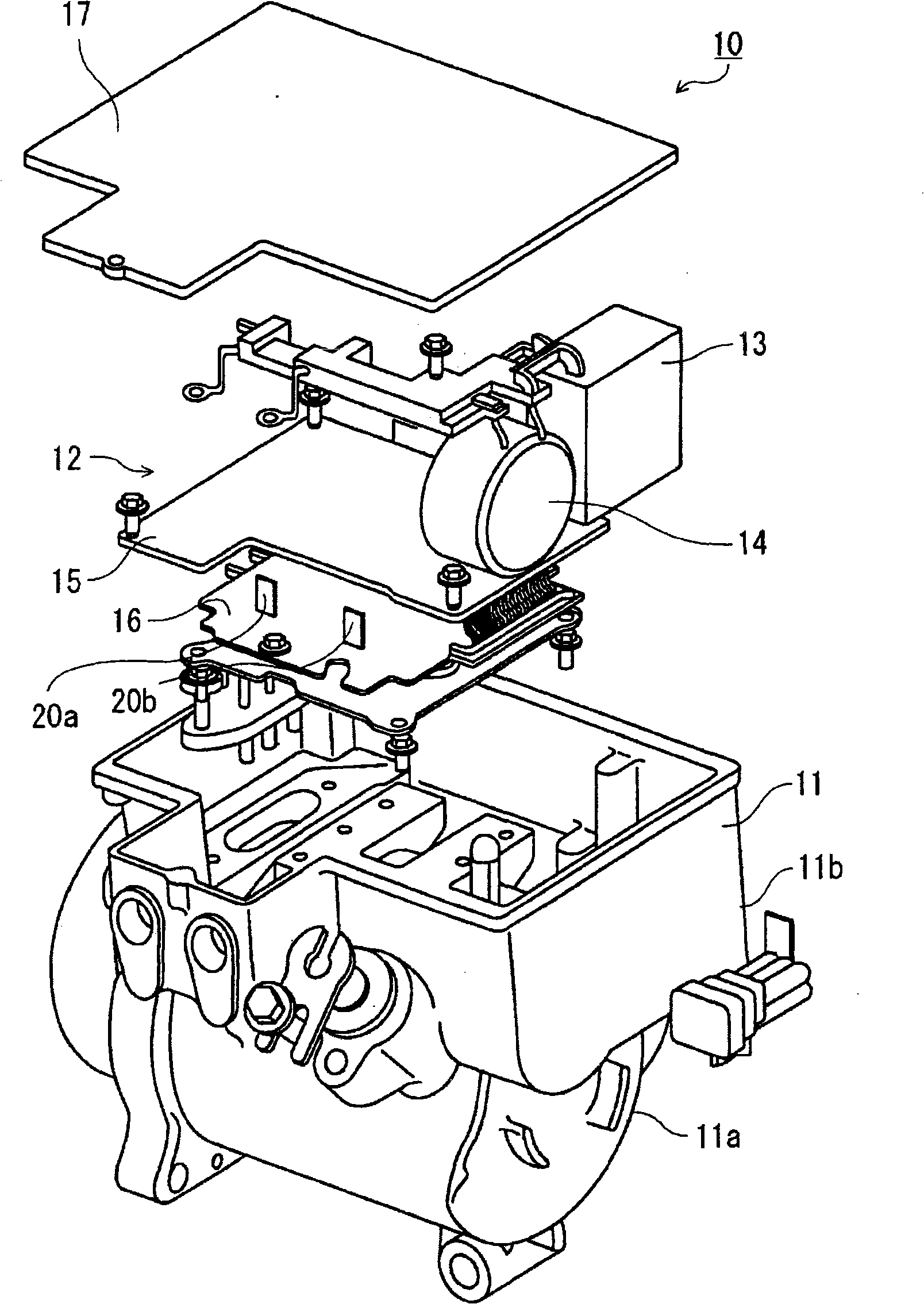

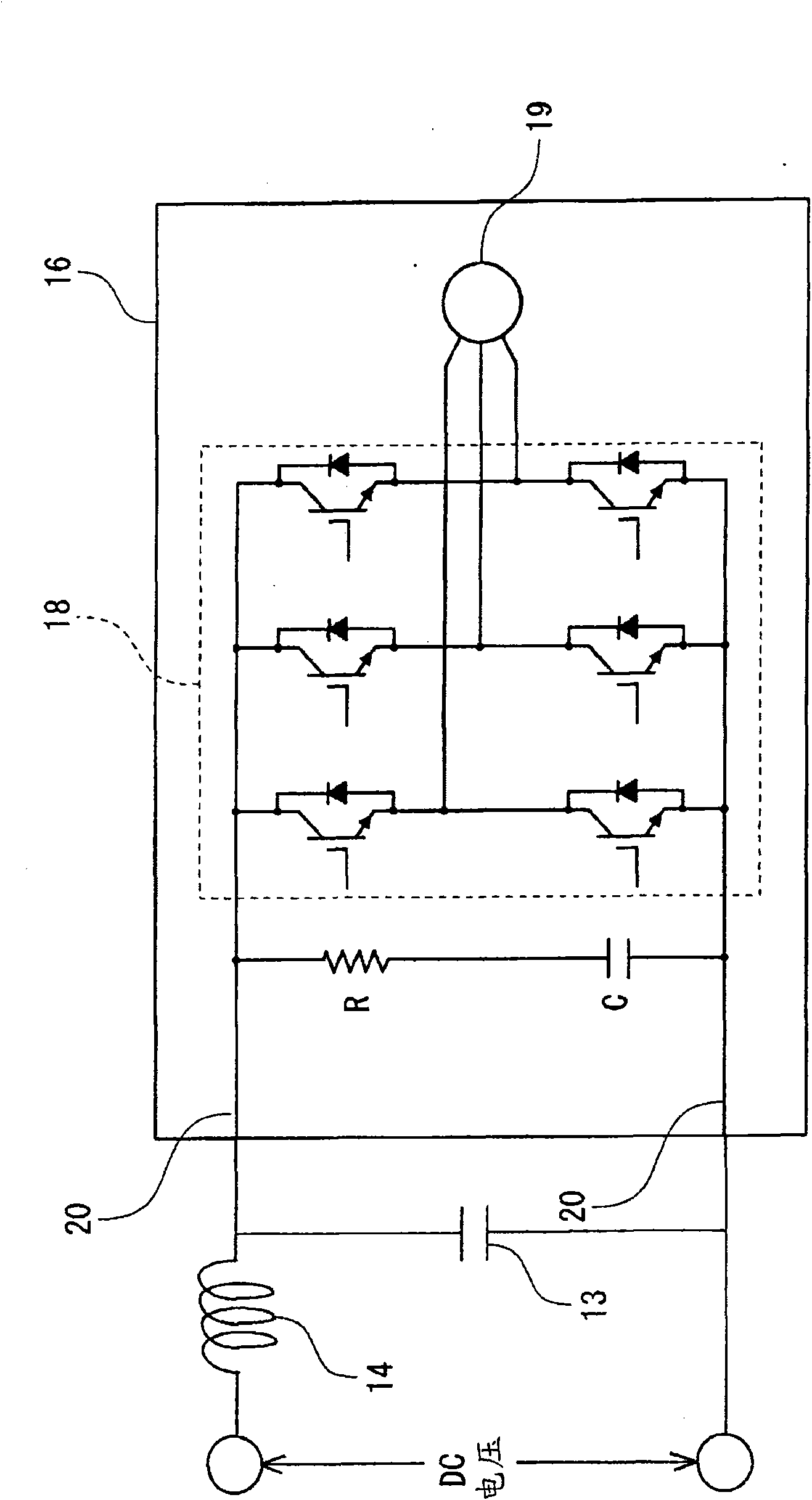

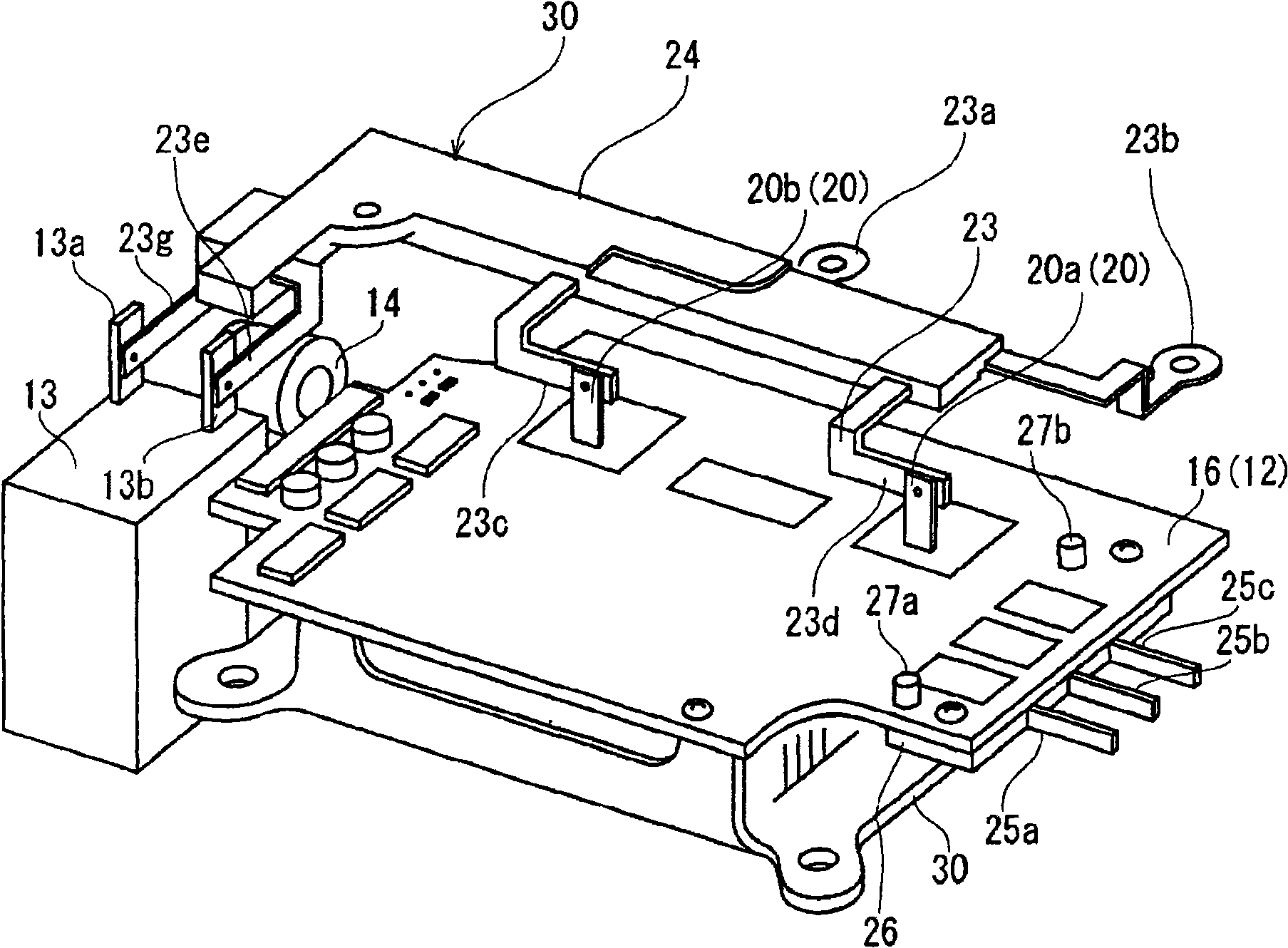

Integrated electric compressor

ActiveCN101573535AImprove reliabilityStrong jointAssociation with control/drive circuitsPositive displacement pump componentsElectricityElectrical connection

The present invention provides an integrated electric compressor which is improved in reliability. Bus bar connection is employed in each electrical connection between a power board (16) and the power supply side and between the power board (16) and the motor side, and welding is employed for bonding the bus bar to a capacitor (13) and a reactor (14), and for bonding the board side terminal of the bus bar to the PN terminals (20a, 20b), the UVW terminals (25a, 25b, 25c) and the housing side terminals (28a, 28b, 28c). The terminals can be mutually bonded with stabilized quality by using resistance welding. Furthermore, since a planar bonding plate is provided on one end side of the housing side terminals (28a, 28b, 28c) and the UVW terminals (25a, 25b, 25c) are welded thereto, reliable mutual bonding of terminals can be attained.

Owner:MITSUBISHI HEAVY IND LTD

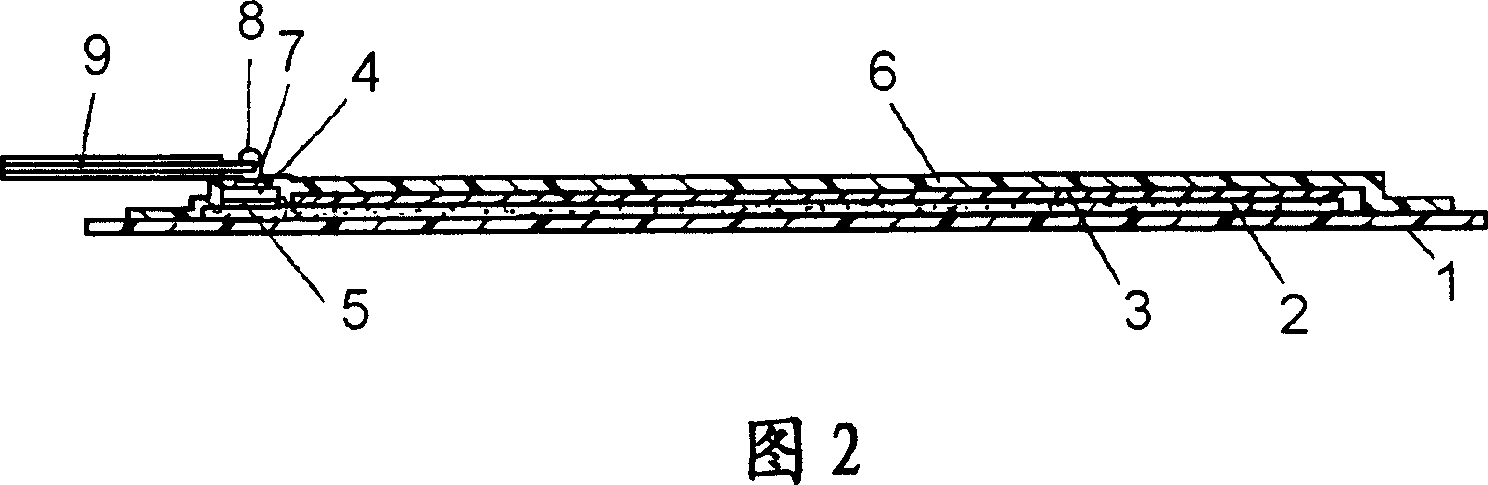

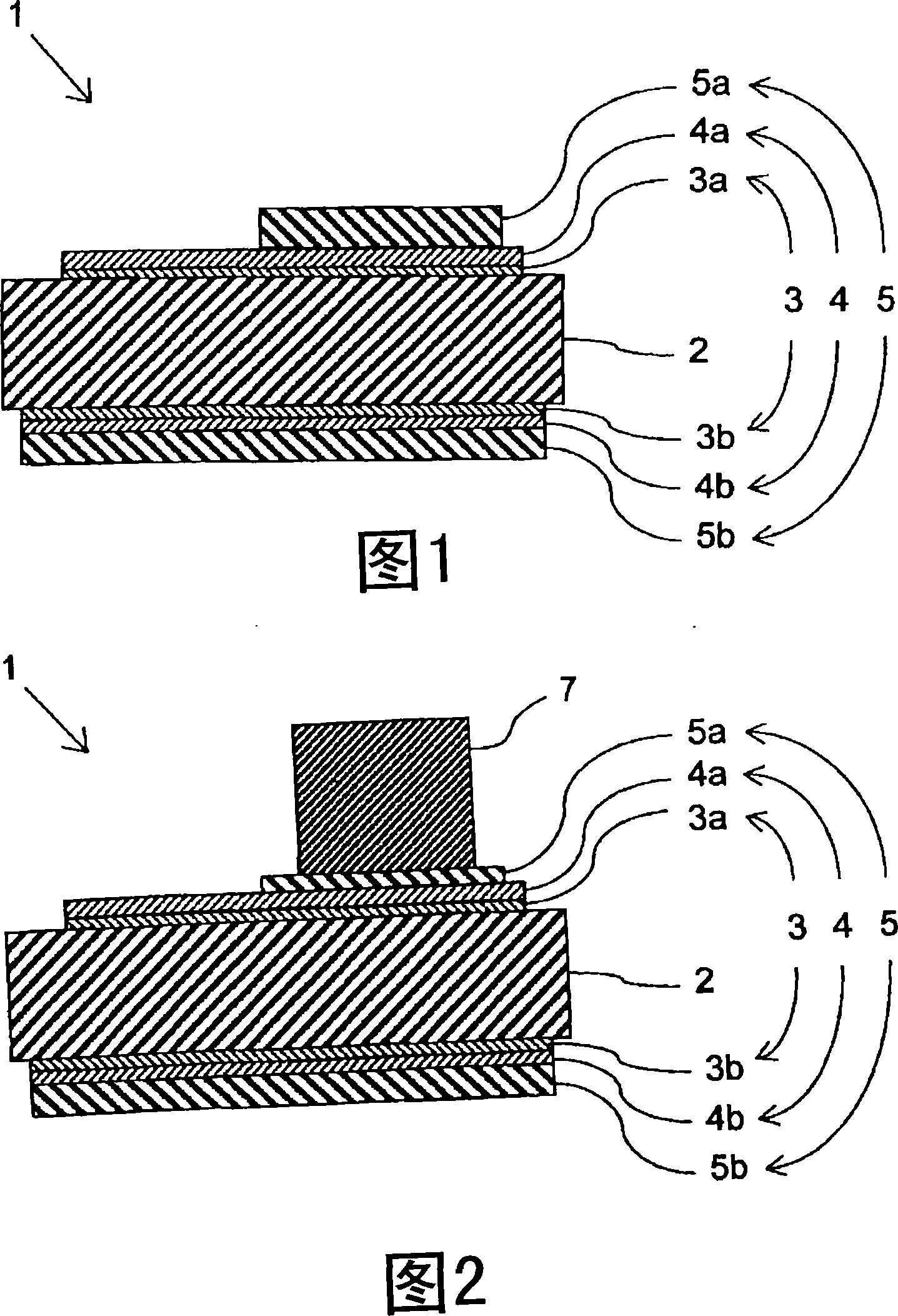

Sub-mount and its manufacturing method

InactiveCN101194359AImprove wettabilityImprove performanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceSurface roughness

A submount with an electrode layer having excellent wettability in soldering and method of manufacturing the same are disclosed. A submount (1) for having a semiconductor device mounted thereon comprises a submount substrate (2), a substrate protective layer (3) formed on a surface of the submount substrate (2), an electrode layer (4) formed on the substrate protective layer (3) and a solder layer (5) formed on the electrode layer (3) wherein the electrode layer (4) is made having an average surface roughness of less than 1 [mu]m. The reduced average surface roughness of the electrode layer (4) improves wettability of the solder layer (5), allowing the solder layer (5) and a semiconductor device to be firmly bonded together without any flux therebetween. A submount (1) is thus obtained which with the semiconductor device mounted thereon is reduced in heat resistance, reducing its temperature rise and improving its performance and service life.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

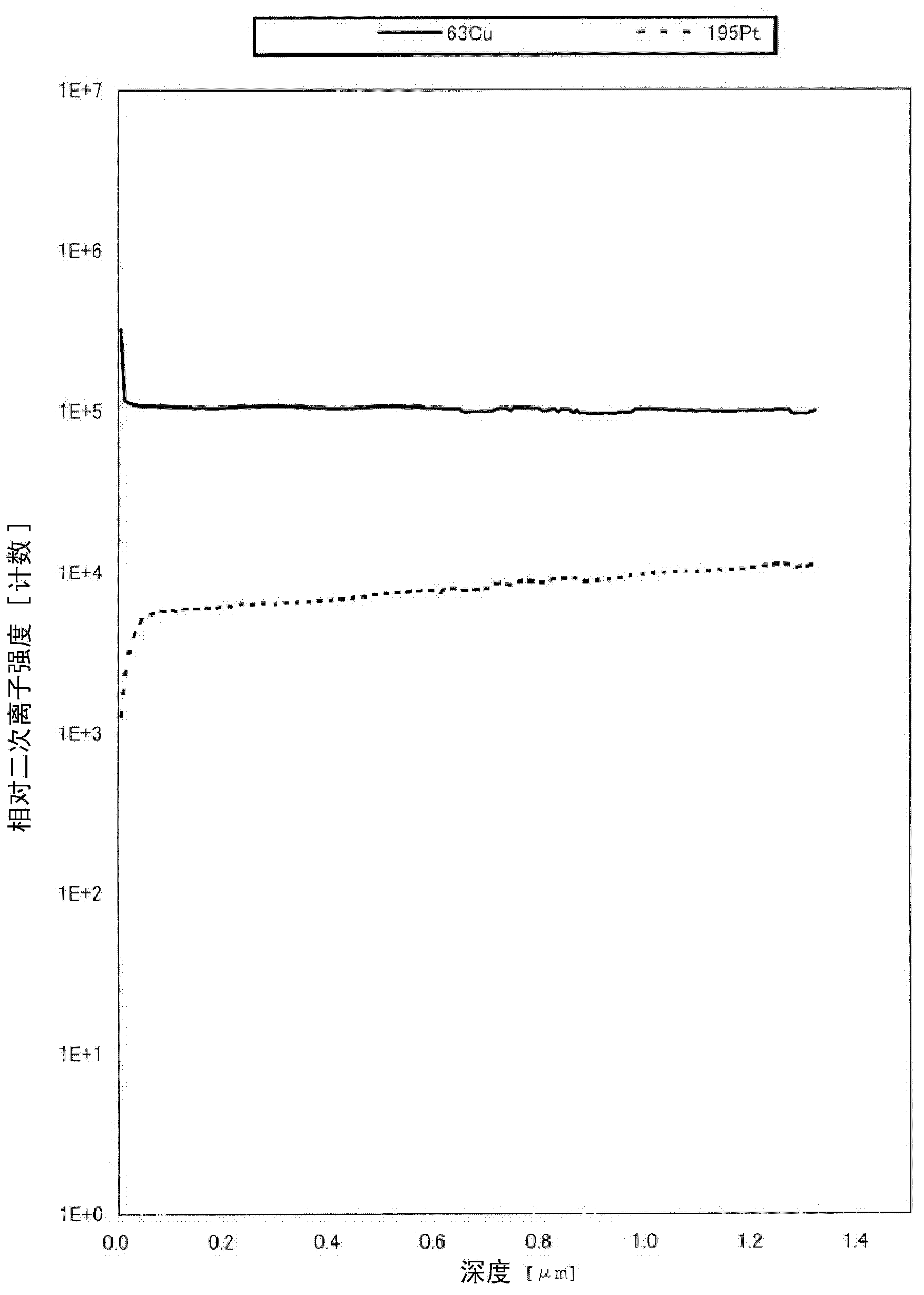

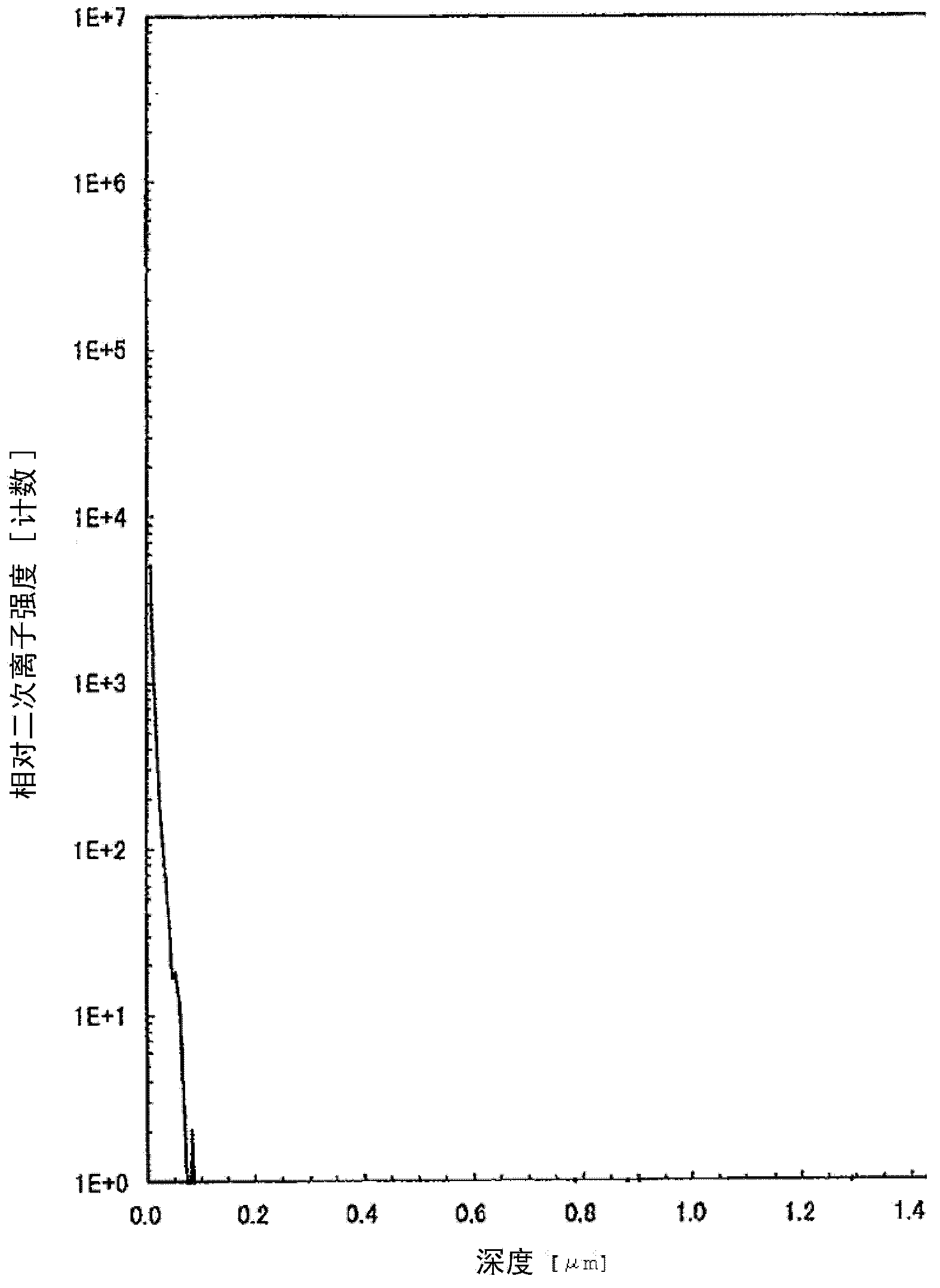

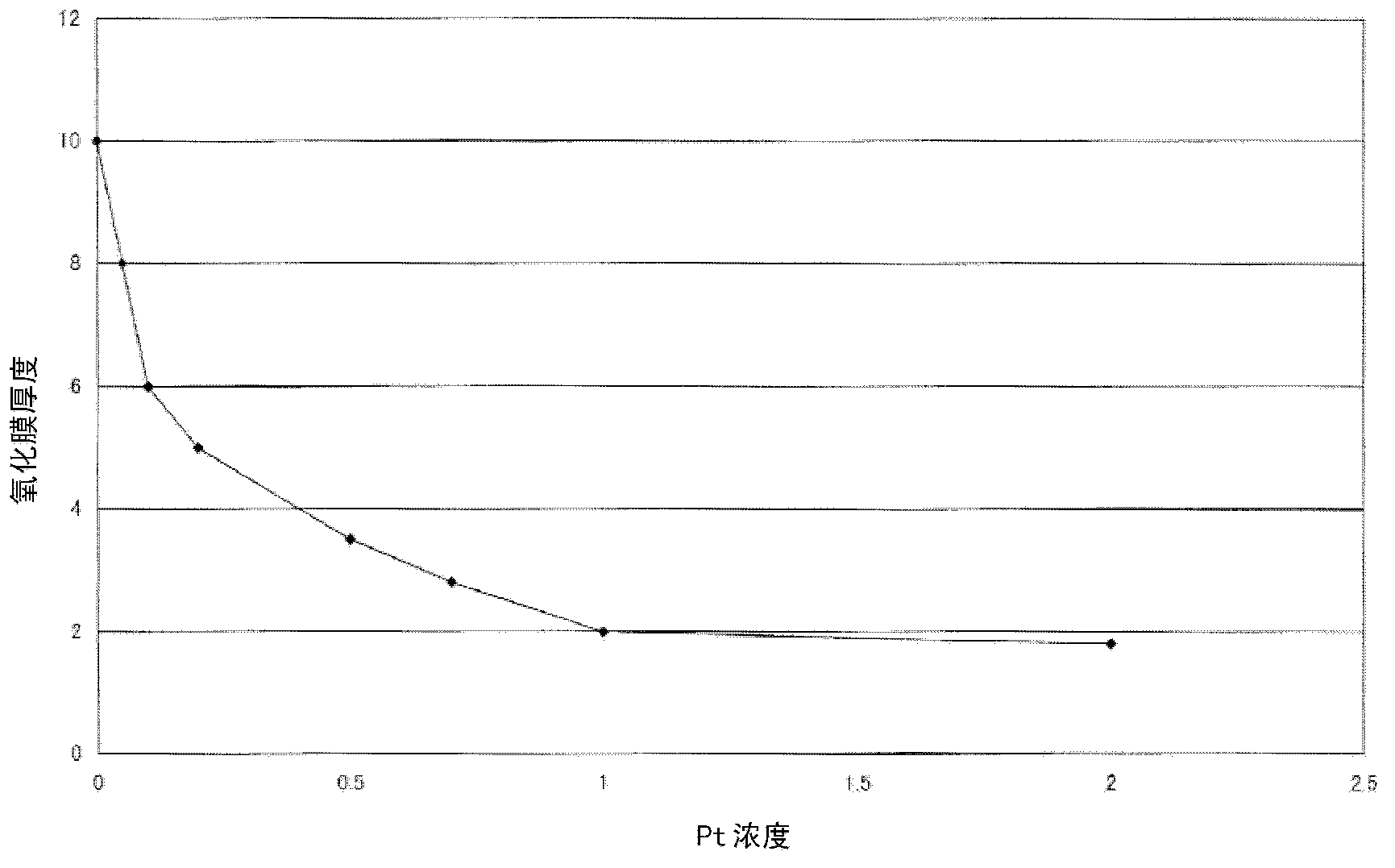

Copper-platinum alloy wire for connecting in semiconductor apparatus

ActiveCN103295993ADynamic strength does not increaseAvoid chip breakageSemiconductor/solid-state device detailsSolid-state devicesStatic strengthOxide

The invention relates to a copper-platinum alloy wire for connecting in a semiconductor apparatus. The copper-platinum alloy wire can improve a secondary joining property, prevent chip crack in ball bonding and improve ring formation performance in copper wires for the ball bonding. During preparing element wires of continuous casting of a fusing copper-platinum alloy containing high-purity copper (Cu), by mass, 0.1-2.0 % of platinum (Pt), 1-10 ppm sulphur (S) as a non-metal element, 10-150 ppm oxygen (O), optionally together with 1-5 ppm phosphorus (P), a very thin copper layer without the platinum is formed because of segregation, is subsequently oxidized in the atmosphere and a 6-2 nm oxide film is formed on a surface layer of the wires after continuous wire drawing is carried out. According to the joining wires of 77-105 Hv Vickers hardness, the uniform oxide film improves the secondary joining property, the elements added to a matrix restrain dynamic strength during ball bonding, so that aluminum splash is prevented and static strength incapable of leading to inclination is maintained.

Owner:TANAKA DENSHI KOGYO

Method of making a transparency

InactiveUS20090258233A1Strong jointHighly repeatable and consistentLamination ancillary operationsLayered product treatmentThermoplasticNear infrared absorption

A method of making a transparency is provided, the method comprising the steps of: layering at least two pieces of transparent thermoplastic, wherein a portion of at least one of the pieces of transparent thermoplastic is treated with a near infrared absorbing material; and, fusing the layered pieces of transparent thermoplastic together using a heat source to form an optically transparent and undistorted transparency. There is also provided a transparency comprising at least two layers of transparent thermoplastic, wherein the layers of transparent thermoplastic have been fused together using a heat source, such that the transparency is optically transparent and undistorted.

Owner:THE BOEING CO

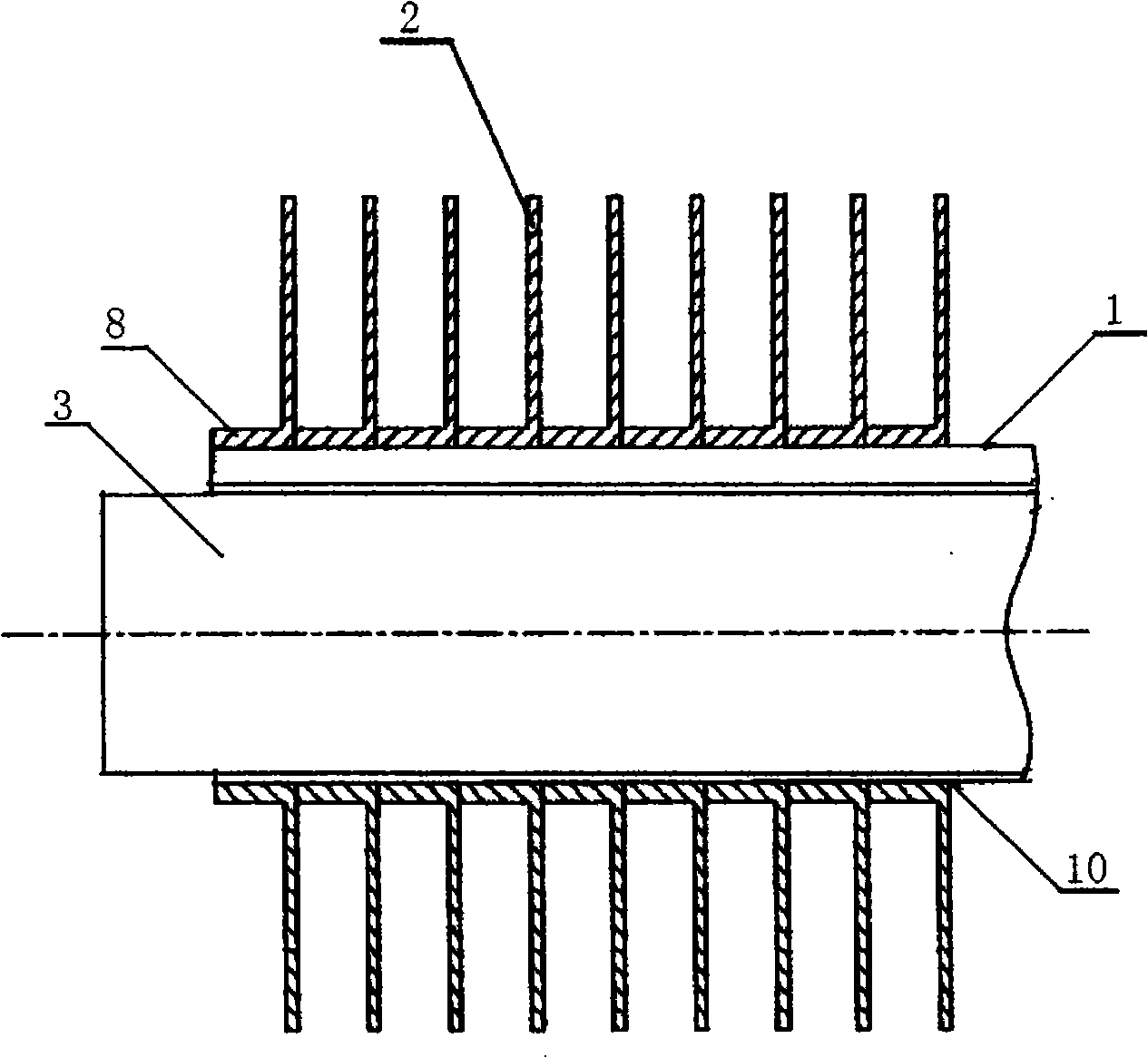

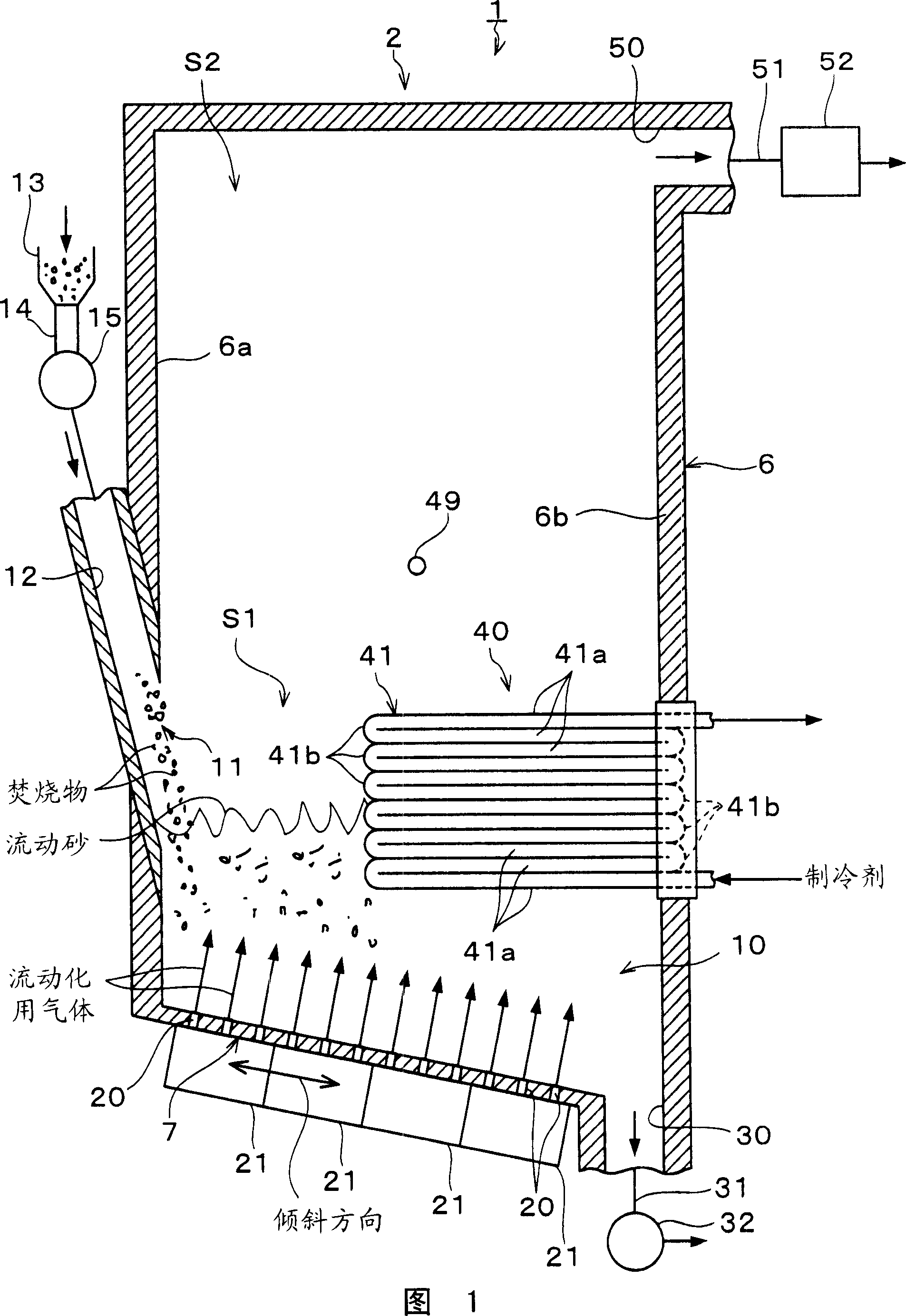

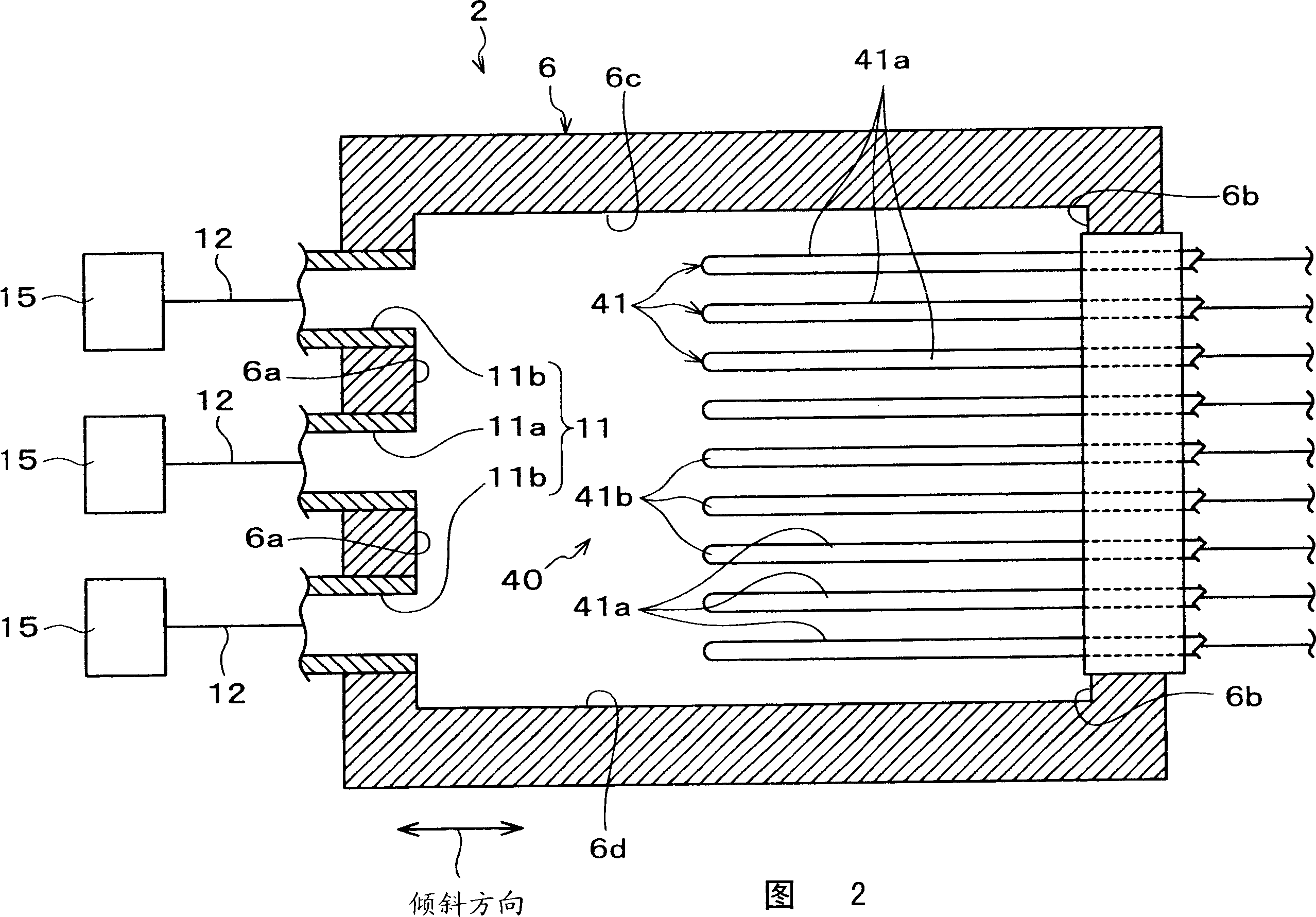

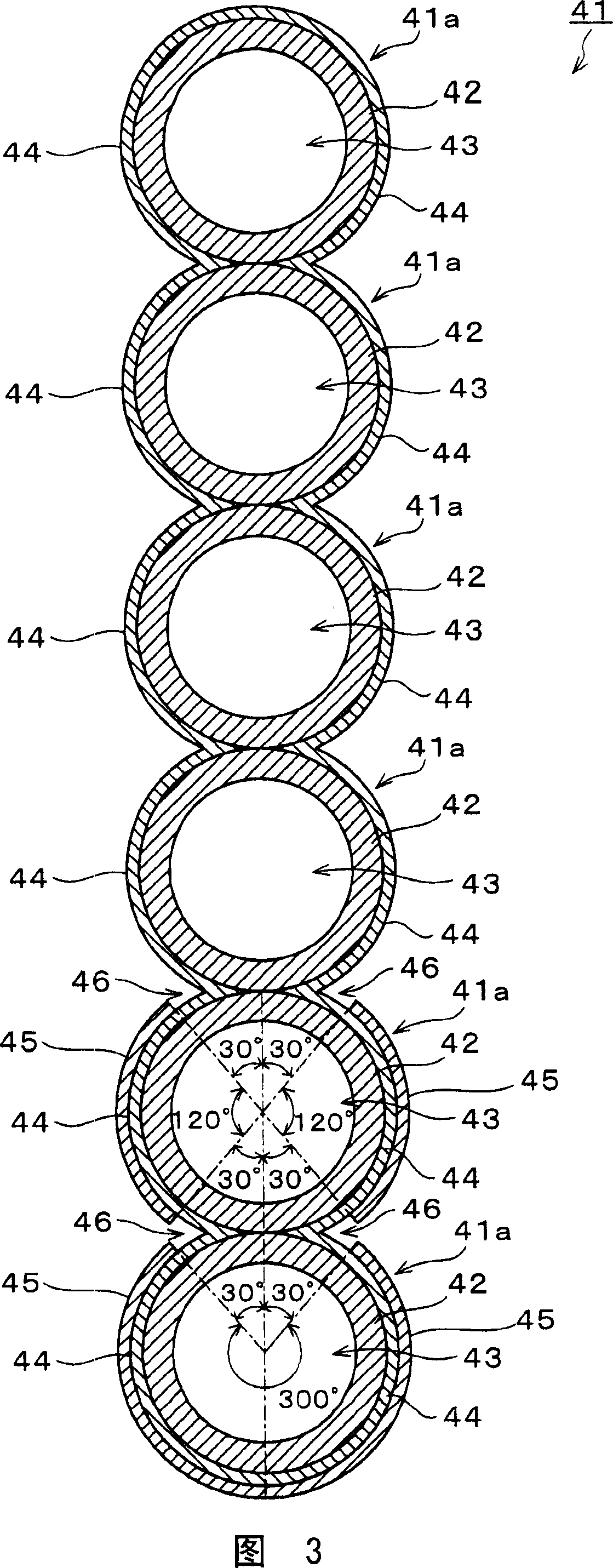

Heat exchanger tube, method of manufacturing heat exchanger tube, and fluidized-bed furnace

InactiveCN1991291AStrong jointEnough durabilityFluidized bed combustionReinforcing meansFluidized bedEngineering

A heat exchanger tube 41 includes: a first cover layer 44 provided on an outer side of a tube main body 42 to partly or completely cover a tube main body 42; and a second cover layer 45 provided on an outer side of the first cover layer 44 to partly or completely cover the first cover layer 44. The first cover layer 44 is formed by overlay-welding a material higher in ductility than the second cover layer 45 to the tube main body 42. The second cover layer 45 is formed by overlay-welding a material higher in hardness than the first cover layer 44 to the first cover layer 44.

Owner:DOWA HLDG CO LTD

Cage nut assembly having a stand-off nut

A cage nut assembly includes a nut and a cage wrapped therearound. The nut has a number of stand-offs or protrusions provided on a lower surface thereof such that the stand-offs are the only part of the nut which are in contact with the cage. The stand-offs reduce the amount of bearing surface interface between the cage and the nut thus reducing the possibility that the two parts will stick to each other after a coating is applied to the mating surface which the cage is welded to. The nut is engaged by a male threaded fastener which is torqued into place and the stand-offs push into the material of the cage causing the cage material to flow out of the way such that the stand-offs embed into the material of the cage without deforming the stand-offs to a flattened condition.

Owner:ACUMENT INTPROP LLC

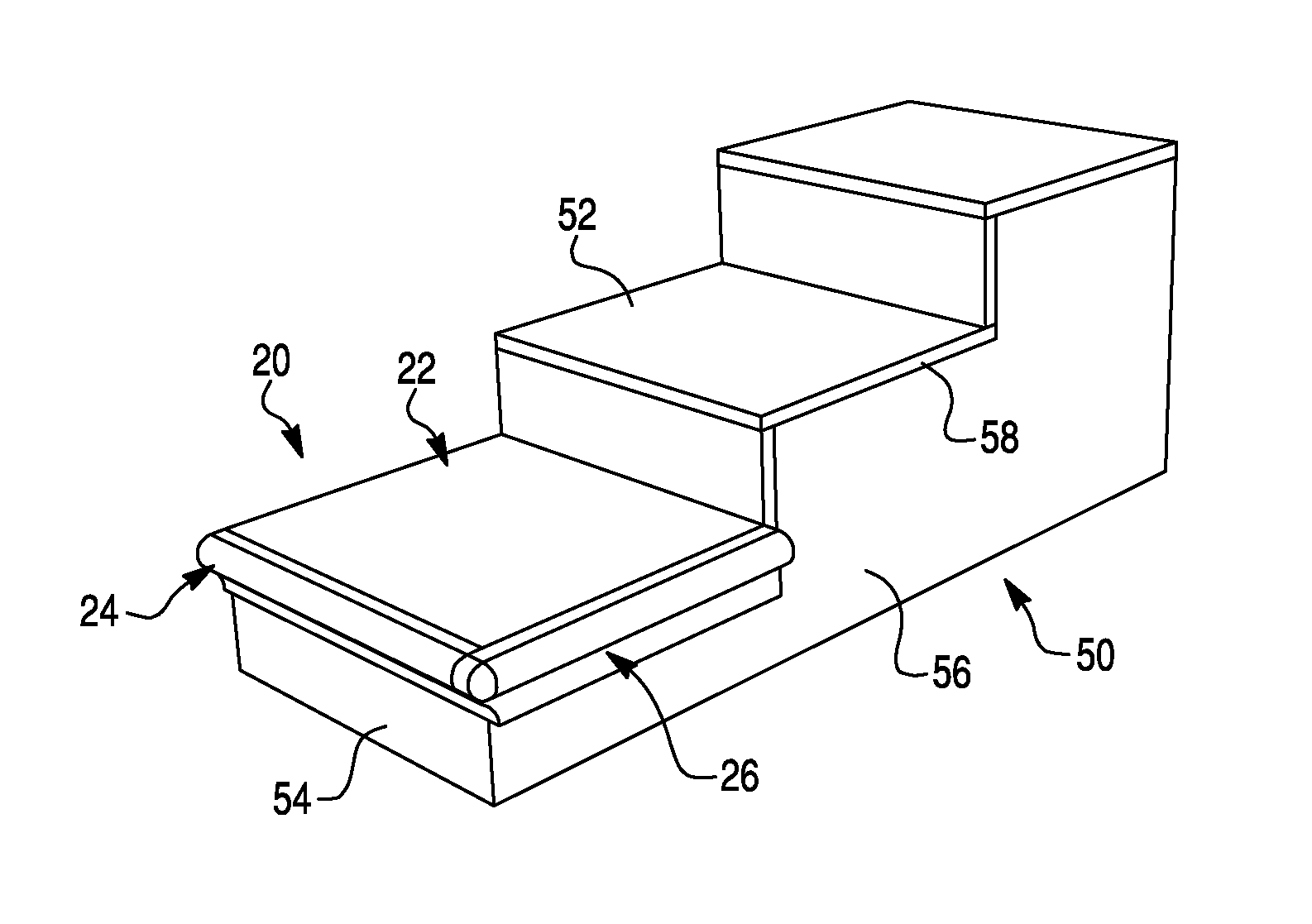

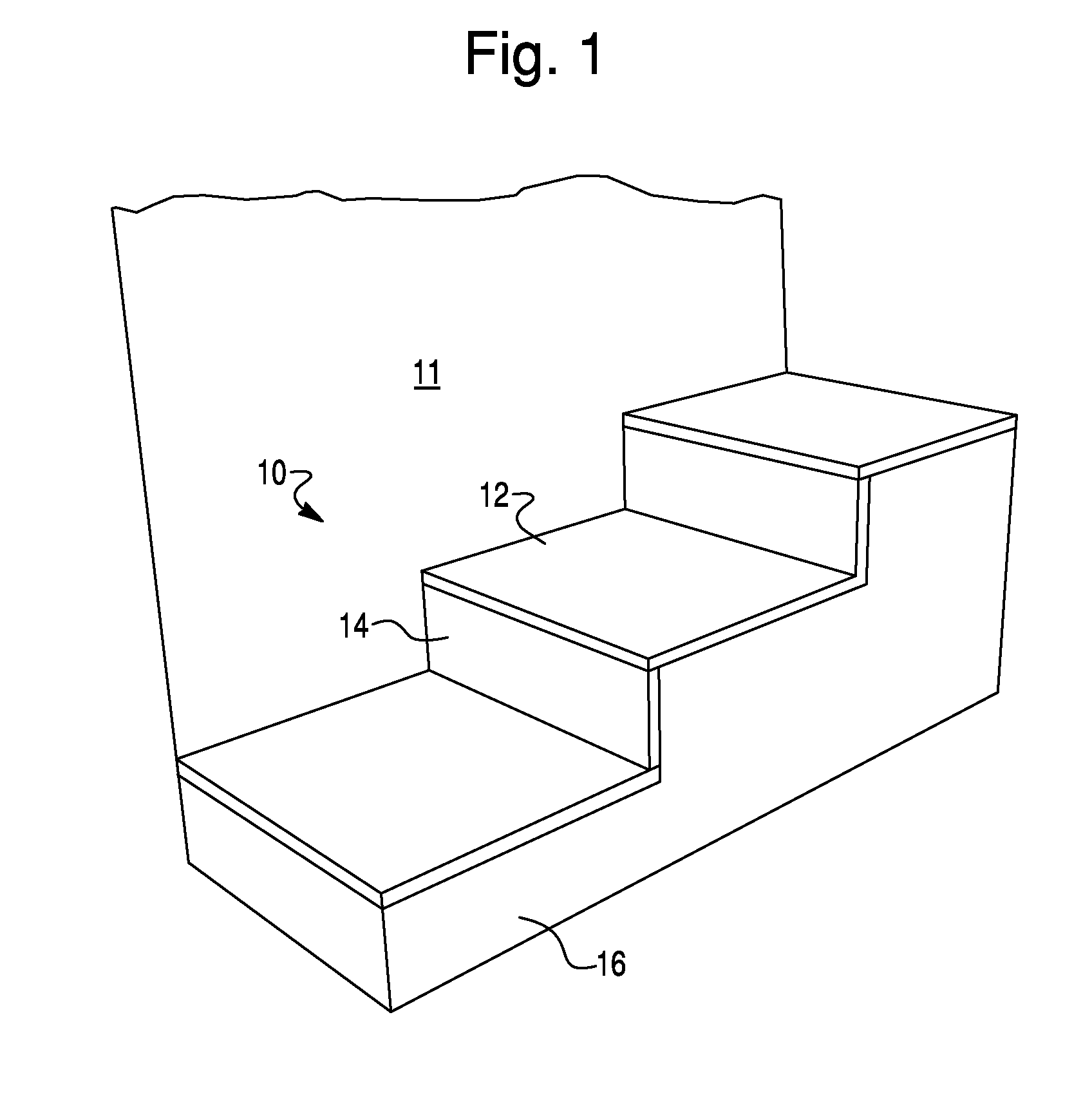

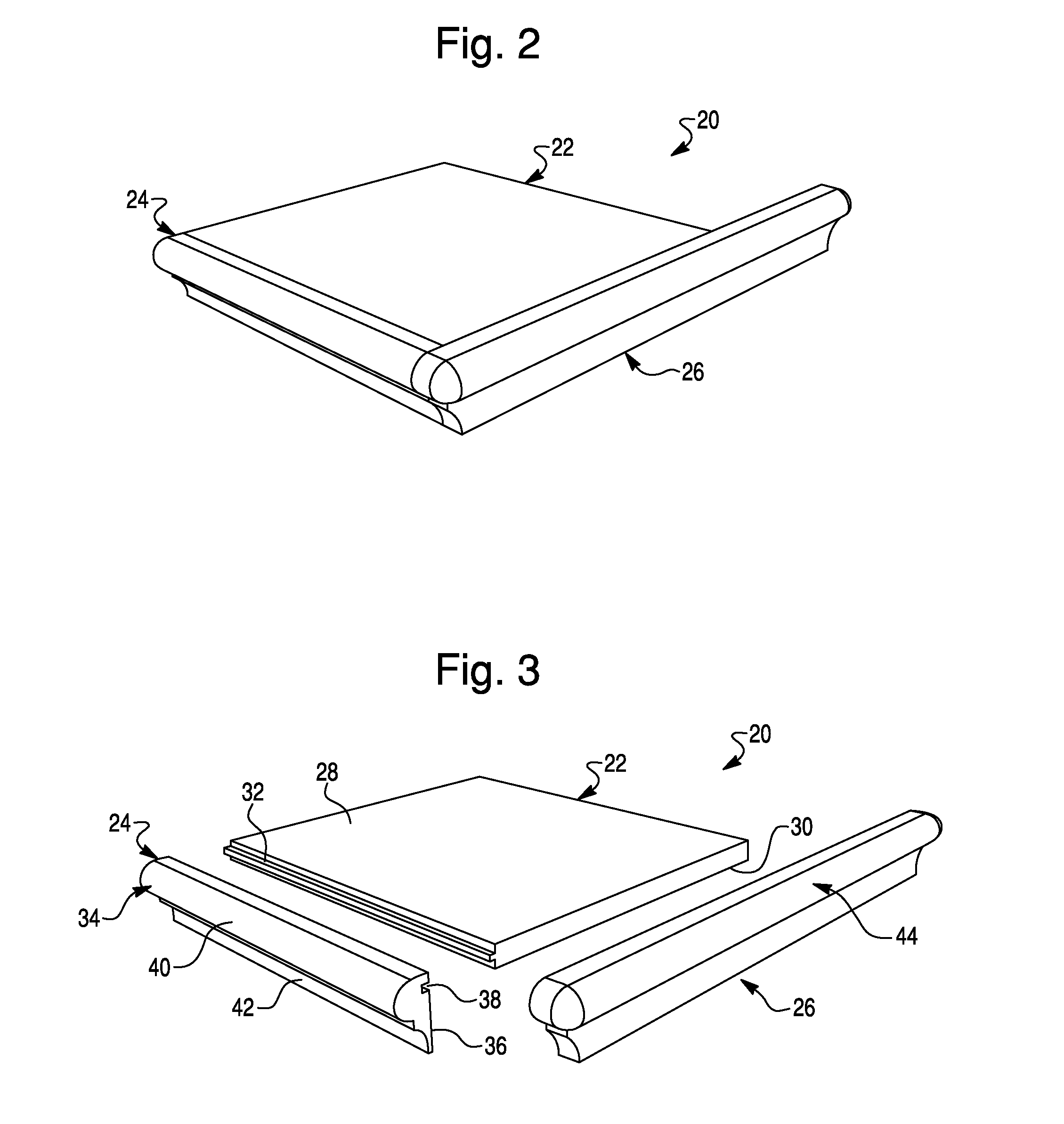

Stair tread overlay and method

ActiveUS8141321B2Resist damageMinimizes shear forceTreadsMetal-working apparatusAdhesiveTongue and groove

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

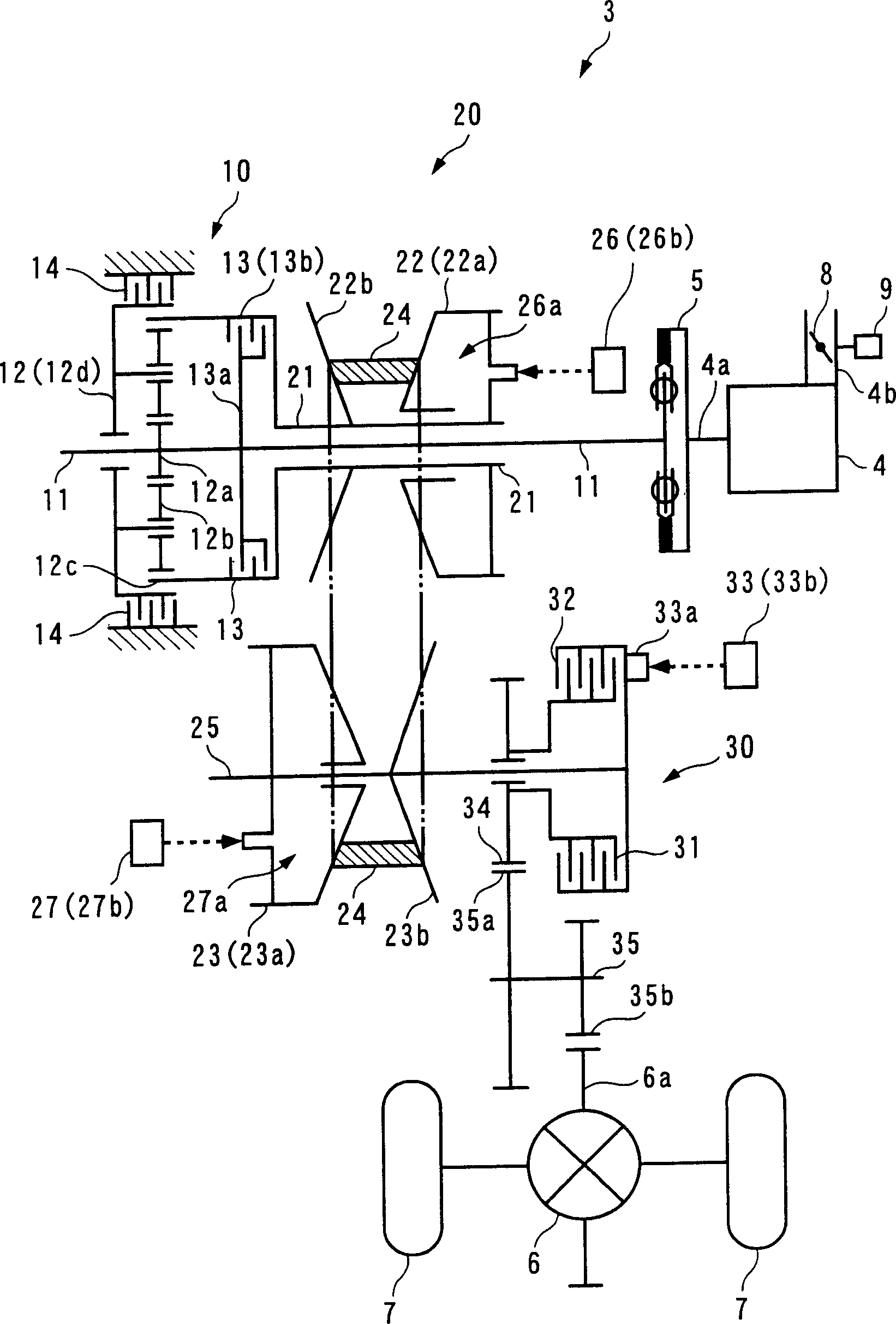

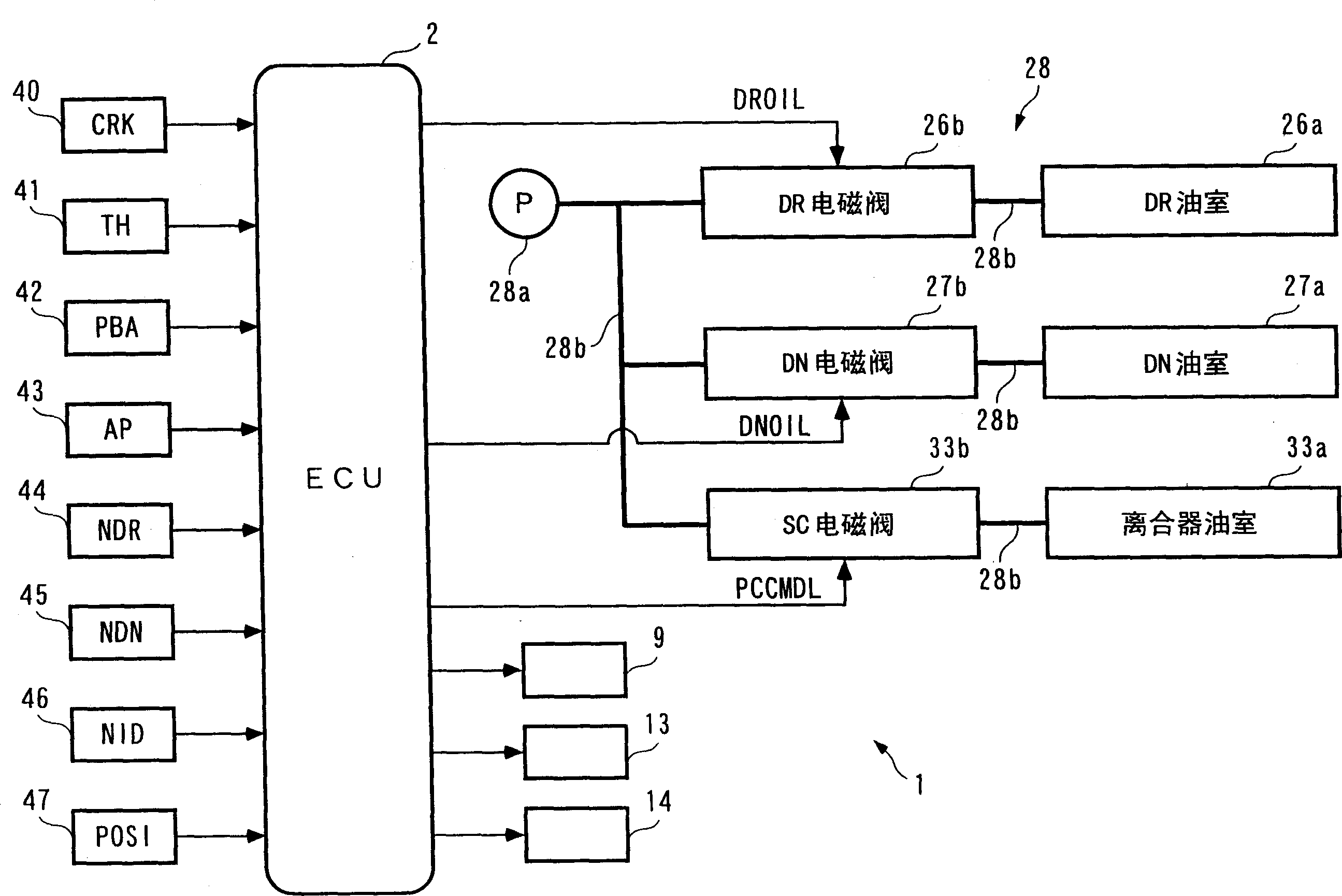

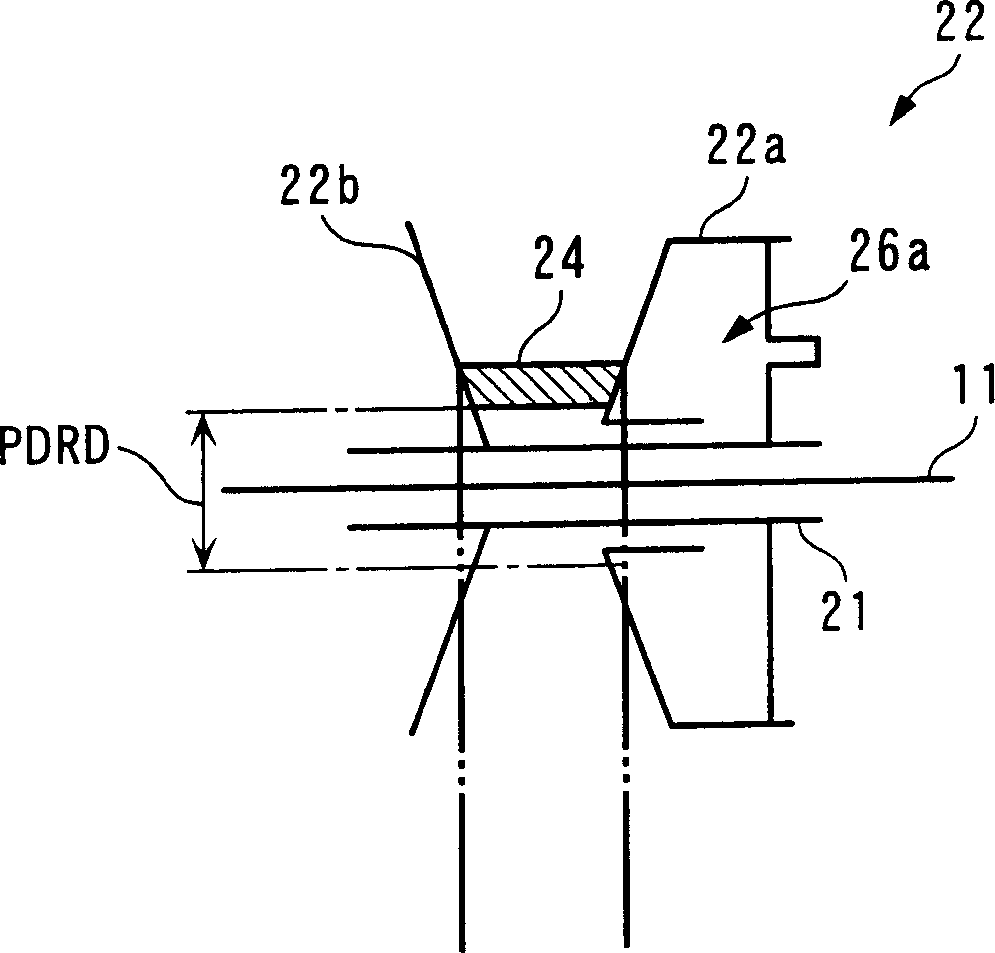

Vehicle control system

There is provided a control system for a vehicle, which is capable of increasing the service life of a transmission belt while preventing slippage thereof, and at the same time improving fuel economy and drivability. The control system for a vehicle sets a transmission transfer torque to be transmitted from a drive pulley of a continuously variable transmission to a driven pulley of the same, and a clutch transfer torque to be transferred by a clutch. When it is determined that the vehicle is traveling on a bad road, the clutch transfer torque is reduced, and the transmission transfer torque is set to a larger value as the clutch transfer torque is larger.

Owner:HONDA MOTOR CO LTD

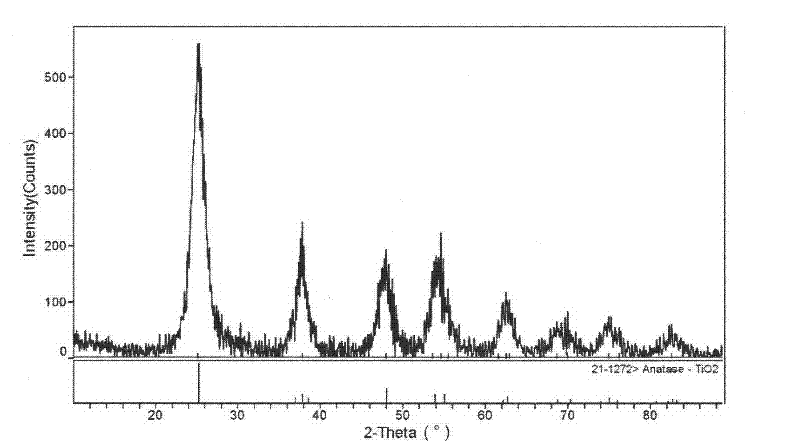

Nanometer photocatalysis surface protection material for stones and stone cultural relic and preparation method of same

InactiveCN102491781ALong-term protection engravingLong-term protective structureTitaniumSoil resistance

The invention relates to the field of protection of stones and stone cultural relic and provides a nanometer photocatalysis surface protection material for stones and stone cultural relic and a preparation method of the material. According to the invention, titanium alcoholate is taken as the main raw material; the titanium alcoholate, solvent, chelating agent, catalyst and the like are mixed, and are stirred fully under the condition of normal pressure and below the temperature of 100 DEG C to react, so as to obtain anatase titanium dioxide collosol surface protection liquid for stones and stone cultural relic; and a surface protection film made of anatase titanium dioxide photocatalysis material is formed on the surface of a stone, which is cleaned with solvent, through the method of brushing, soaking or the like. The nanometer photocatalysis surface protection material has the advantages that the reversibility is good; the compatibility with stones is good; the acid resistance is strong; the alkaline resistance is strong; the weatherability and the soil resistance are good; the self-cleaning capability is strong; the fungus resistance is good; and the appearance, the color and the hand feeling of the original stone are not affected.

Owner:YUNNAN UNIV

Filter medium for air filters, air filter, air purifier provided with air filter and air purifier with humidifying function

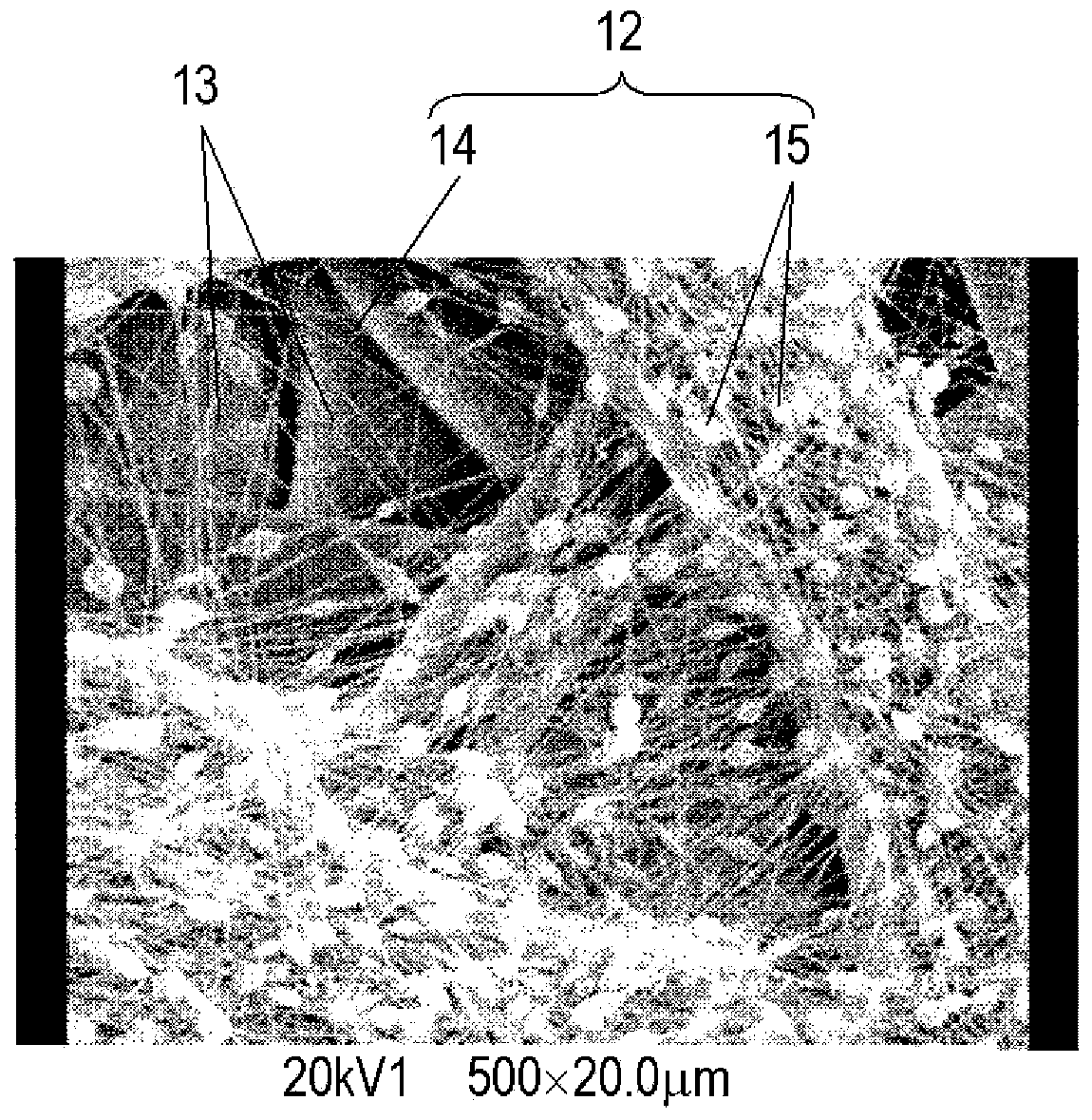

ActiveCN103732302ADoes not clog the openingIncrease joint areaLighting and heating apparatusMembrane filtersSurface layerAir purifiers

A filter medium for air filters of the present invention comprises a fine fiber layer configured from fine fibers having an average fiber diameter of 100 nm to 1000 nm and a base material for holding the fine fiber layer. The fine fibers are moniliform fibers consisting of fibers and beads and the fine fibers and the base material are welded by fusing the surface layer of the beads.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com