Power cord spooling machine

A technology of power cords and wire winders, which is applied in the direction of circuits, electrical components, and devices with bendable leads, and can solve problems that affect the fastness and reliability of the joint between the plug and the socket, affect the reliability of the electrical contacts, and are messy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

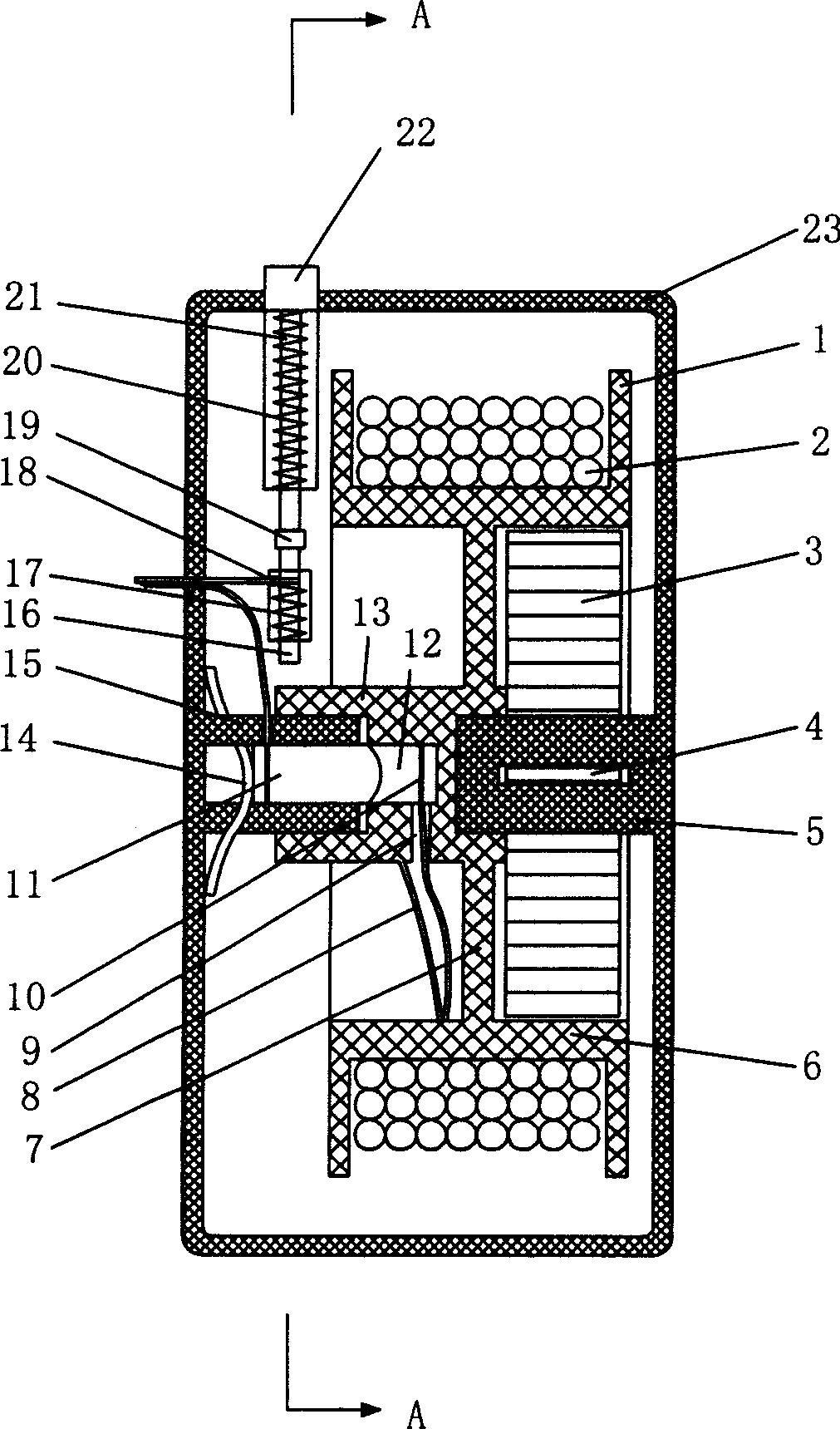

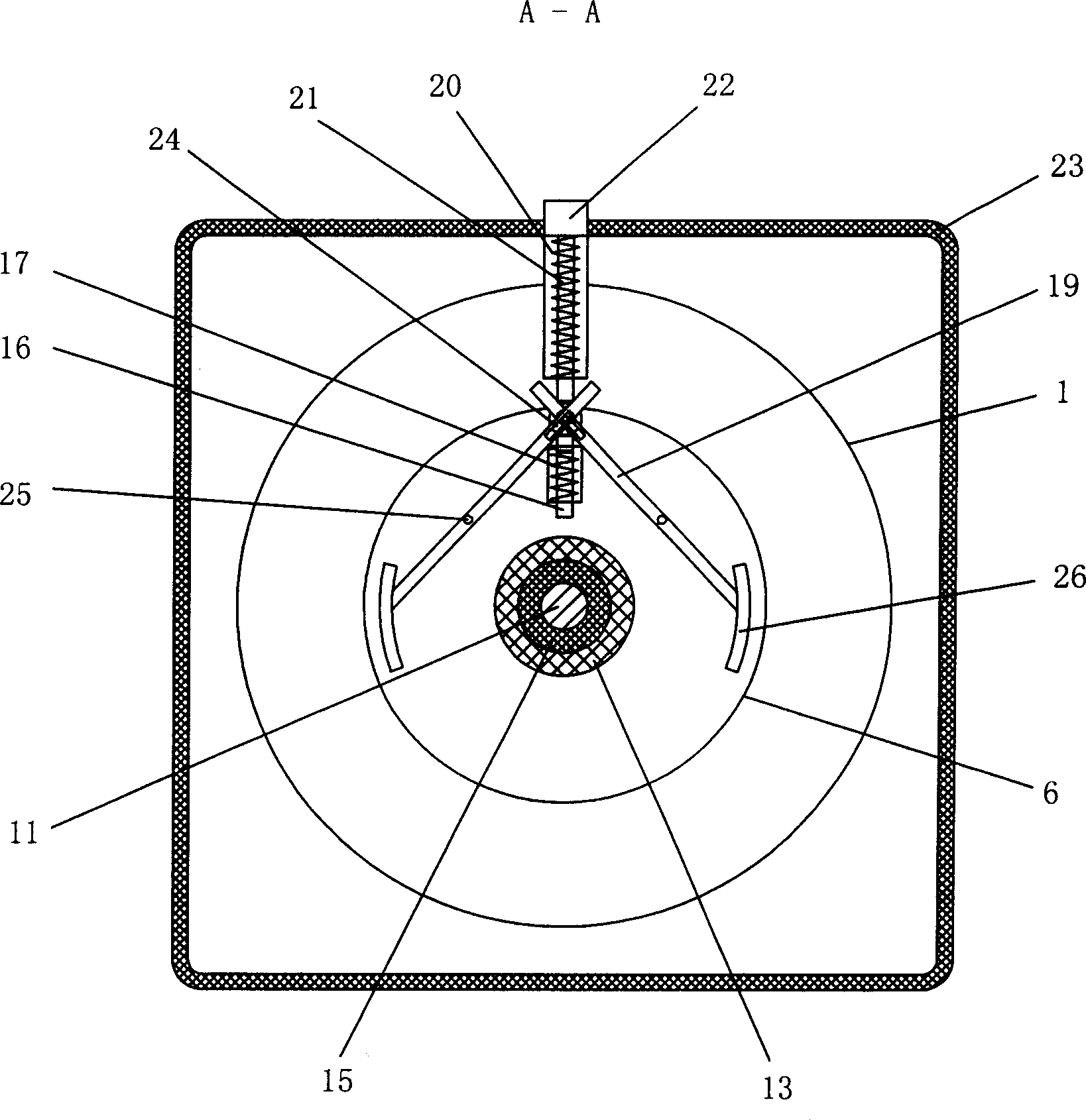

[0010] The utility model is further described below in conjunction with the drawings.

[0011] Reference figure 1 As shown, the winding box 23 includes a crimping spring assembly, a winding power cord assembly, an electrical connection assembly, and a stop joint assembly. The coil spring assembly includes a coil spring sheet 3, which is wound around the coil spring shaft core 5 in a concentric manner with the coil spring shaft core 5 as the center. One end of the coil spring shaft core 5 is fixed to the winding box 23, The crimping spring piece 3 is fixed by the crimping elastic piece socket 4 on one end of the crimping spring shaft core 5, and the other end is fixed at the base of the winding wheel 6. When the power cord 2 wound on the reel 6 is pulled, the reel 6 rotates to drive one end of the crimping spring fixed at the base of the reel 6 to rotate, so that the crimping spring sheet takes its fixed shaft core as The center rotates and gradually tightens to generate a crimpin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com