Patents

Literature

60results about How to "Improve robustness and reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

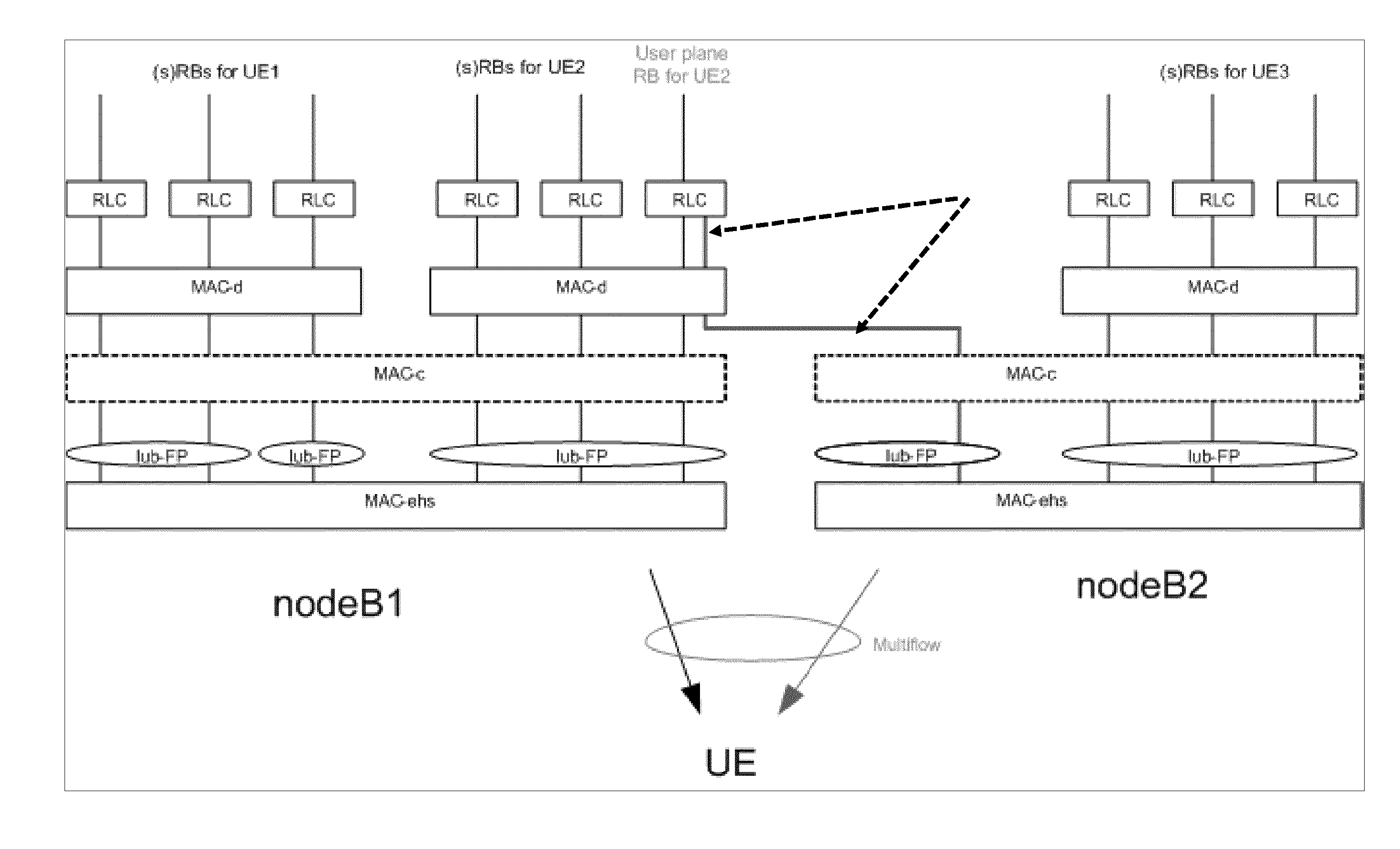

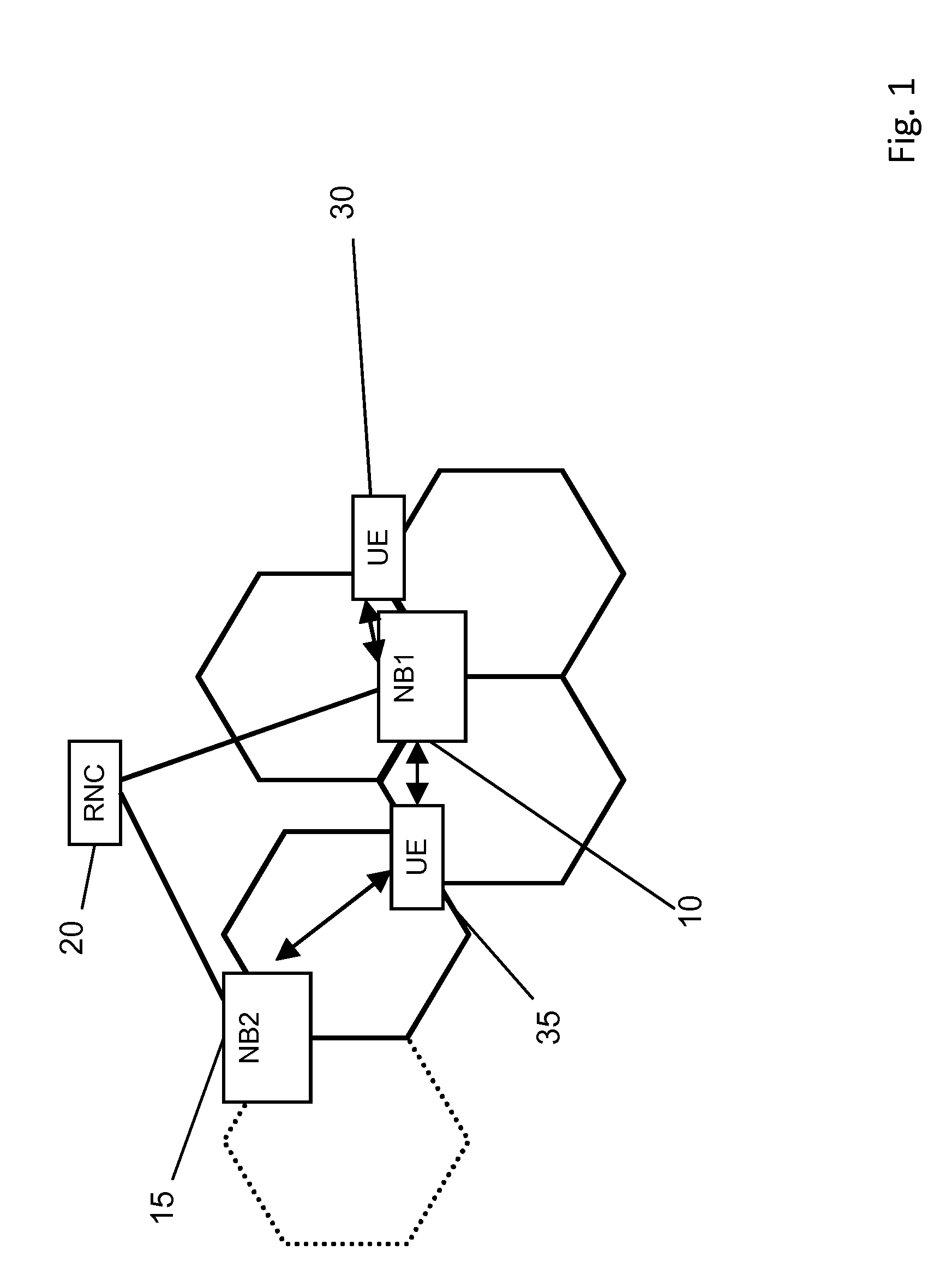

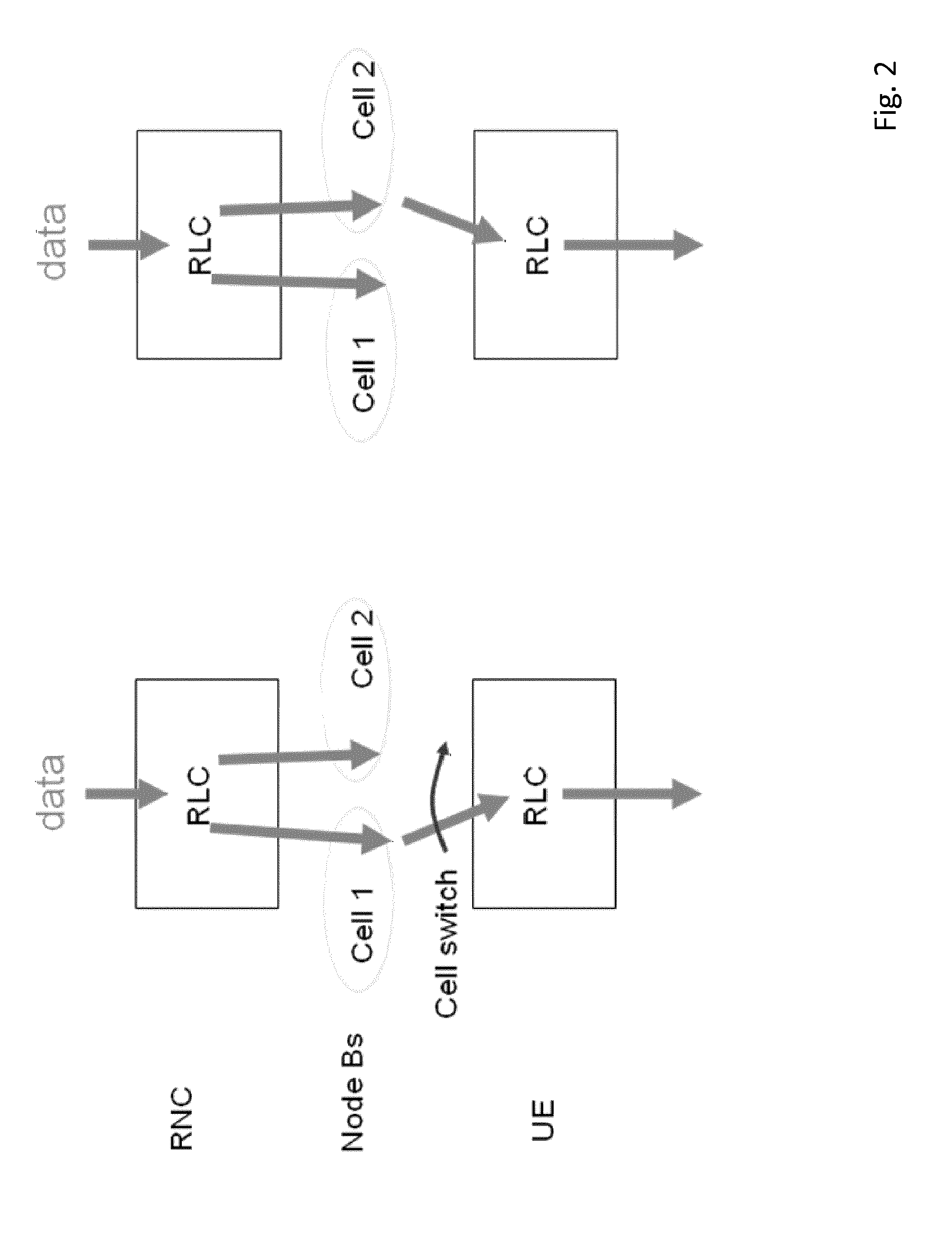

Data Transmission Mechanism with Improved Robustness Using Multiflow Connection

ActiveUS20150085657A1Improve robustnessImproved communication mechanismError preventionTransmission systemsTransceiverNetwork control

There is provided a mechanism for conducting data transmission from a network management entity of communication network control element to a terminal or UE with improved robustness. After a multiflow connection for data units via at least one network transceiver device and via at least two different paths is set up towards a terminal, selection criteria are applied so as to decide which data units are sent on which transmission path. Specifically, dependent on the applied selection criteria, data units of specific data are selected to be subjected either to bicasting each selected data unit using the at least two paths, or to dynamic flow switching so as to transmit each selected data unit using one of the at least two paths and wherein each selected data unit can be in dependently chosen to be transmitted over either of the at least two paths.

Owner:NOKIA SOLUTIONS & NETWORKS OY +1

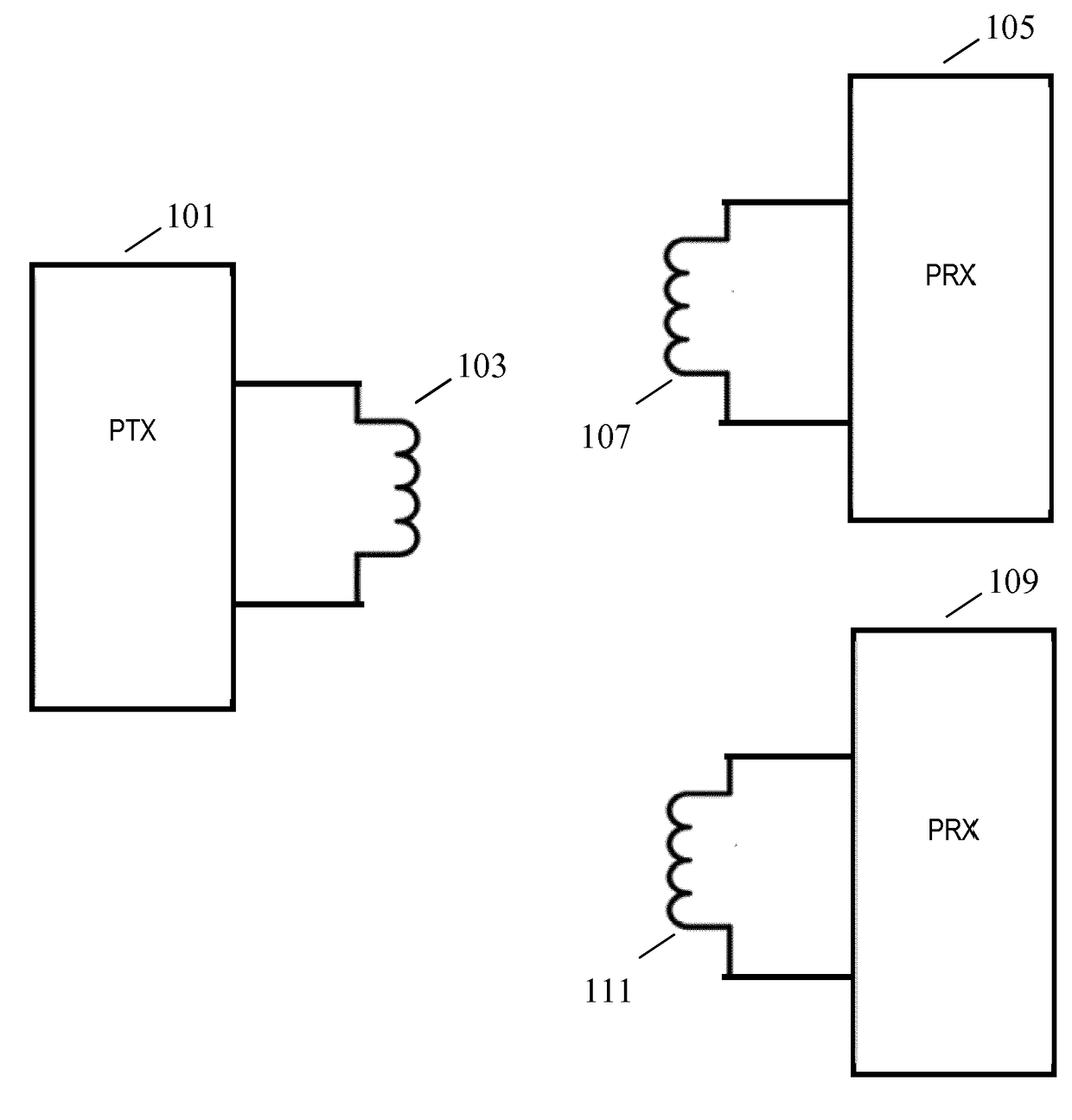

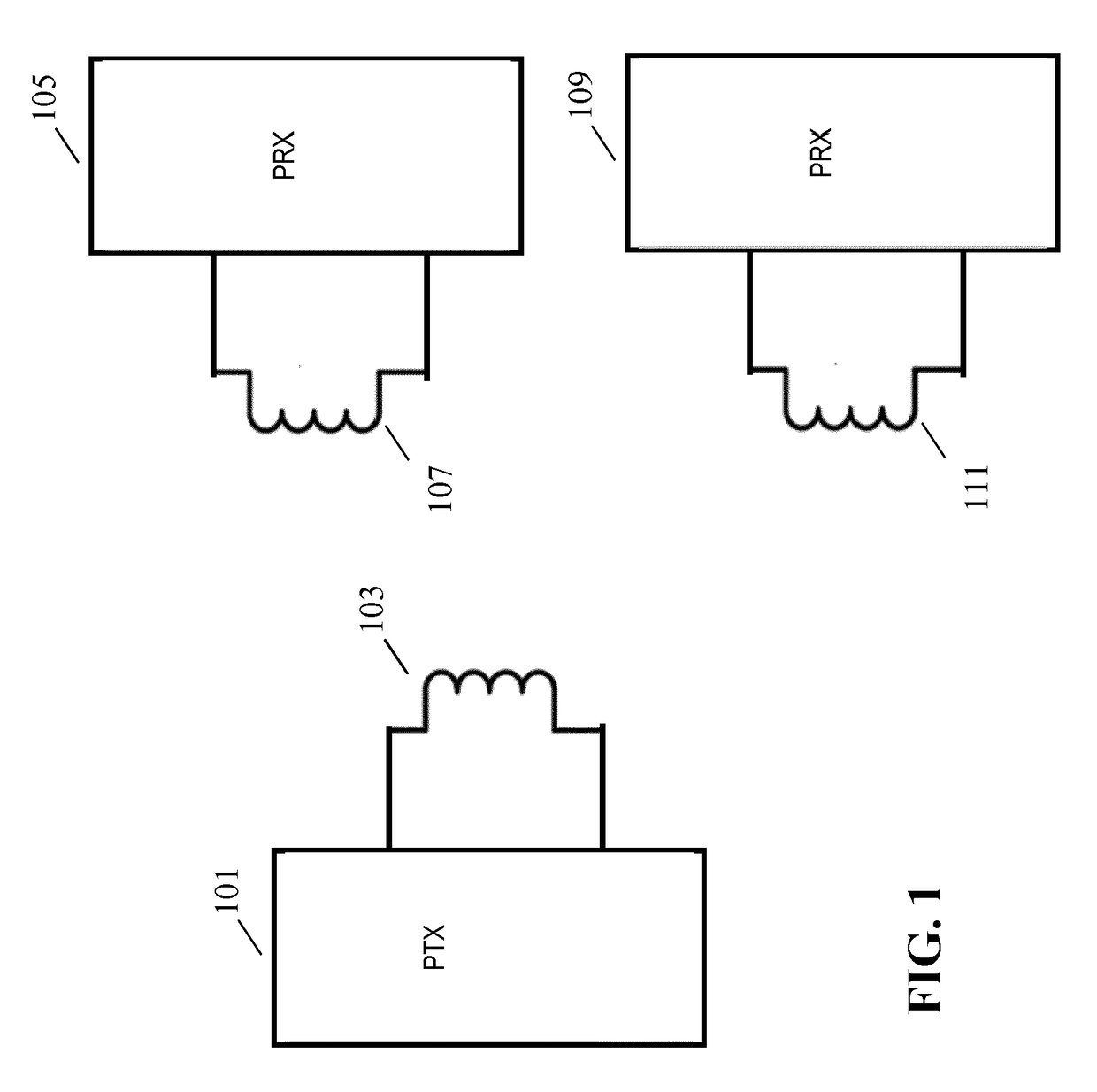

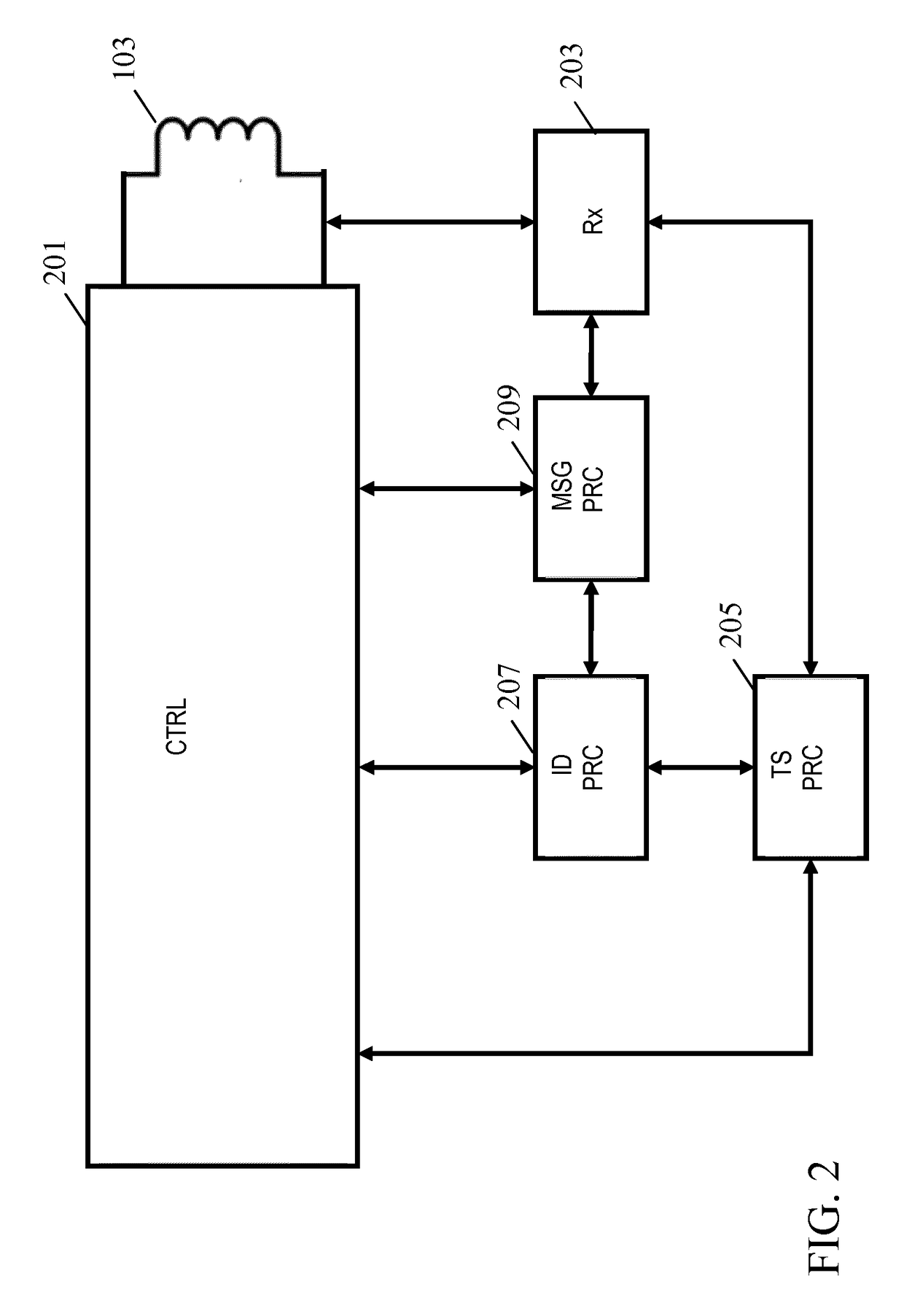

Wireless inductive power transfer

ActiveUS20170279305A1Improve performanceImprove operationNear-field transmissionCircuit arrangementsElectric powerTransmitter

A wireless power transfer system comprises a power transmitter generating a wireless power signal providing power to a plurality of power receivers (105, 109). The power transmitter (101) comprises a receiver (203) receiving data messages from the power receivers (105, 109) on a load modulation channel divided into time slots. A time slot processor (205) allocates time slots as dedicated time slots for individual power receivers or as common time slots for load modulation by any power receiver (105, 109). An identity controller (207) links a temporary identity to each of the power receivers (105) and a message processor (209) determines the source power receiver for messages in response to temporary identity information in the messages. Specifically, the message processor (209) determines the source for a first message received in a common time slot as the first power receiver (105) if the temporary identity information in the first message is indicative of a temporary identity assigned to the first power receiver (105).

Owner:KONINKLJIJKE PHILIPS NV

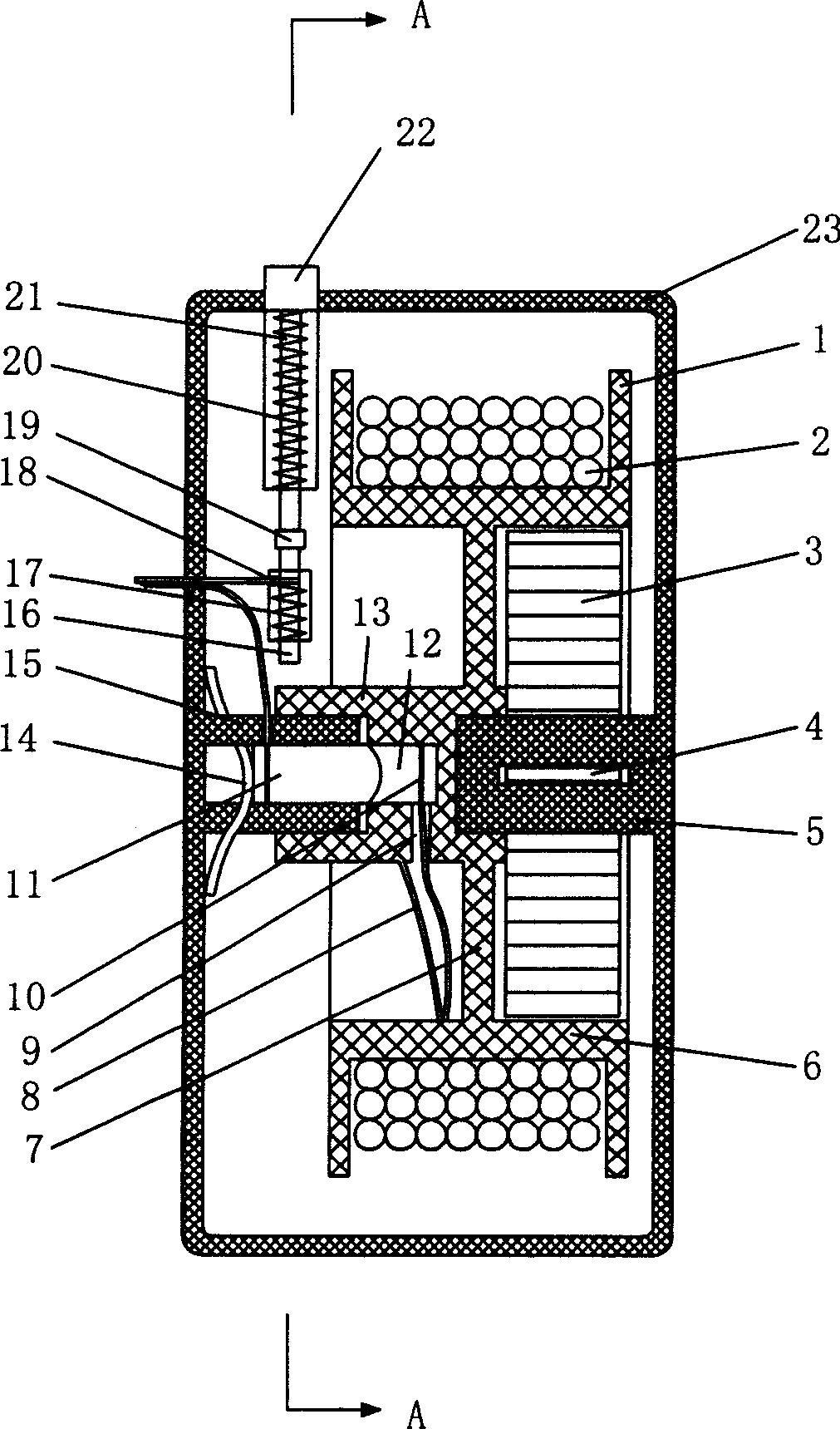

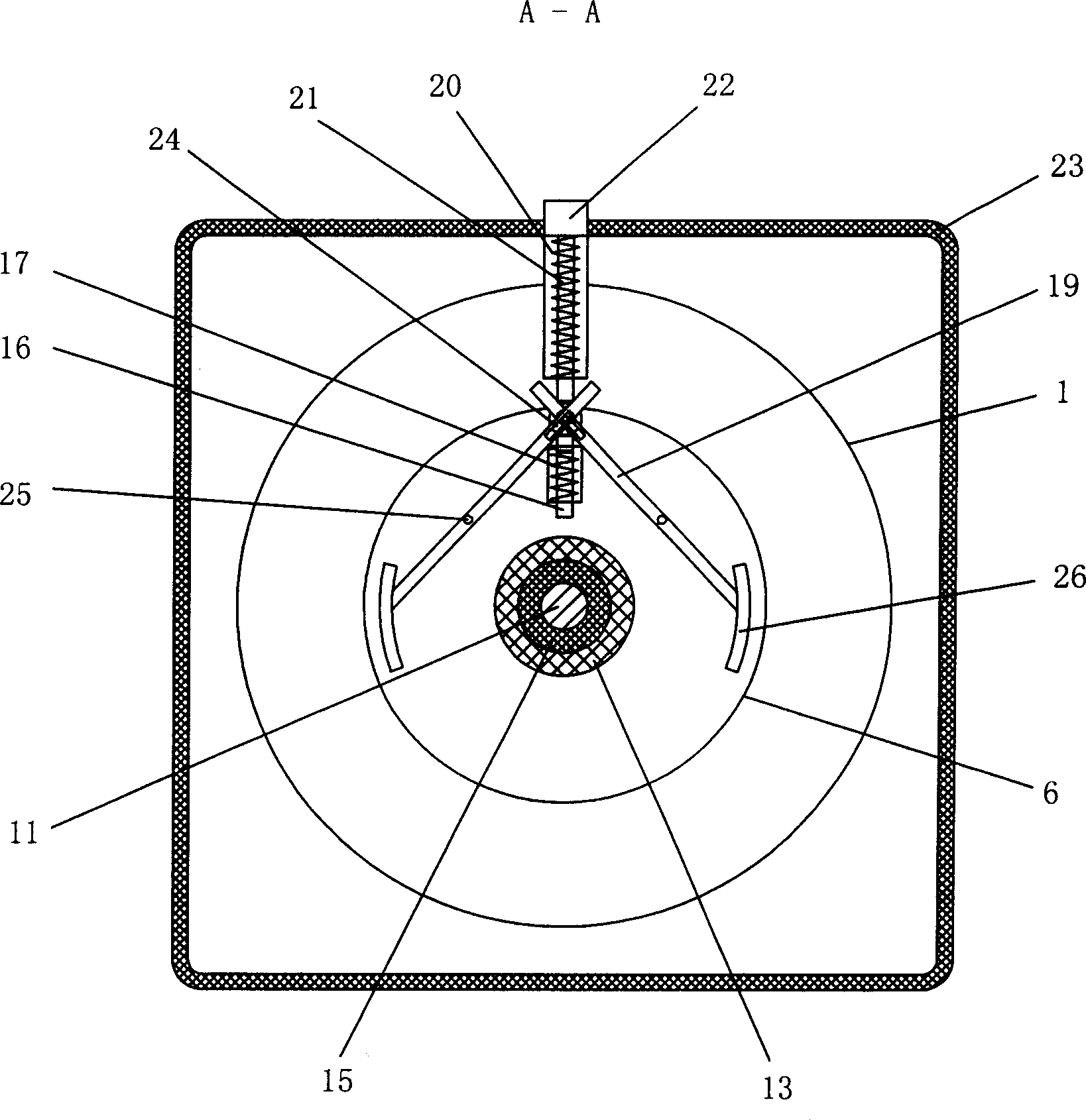

Power cord spooling machine

InactiveCN1738109AReduce vibrationReduce jitterFlexible lead accommodationElectrical connectionEngineering

Disclosed a coiling machine for power cord comprises a coiling box, a coiling wheel inside the coiling box, limited rings on the two ends of coiling wheel, and crinkle spring inside the coiling axle sleeve to connect the coiling axle corn. The invention is characterized in that the protruded part of coiling axle sleeve is equipped a electric connecting component formed by a conducting outer layer, a insulated inner layer and a conducting axle corn; a coiling-proof wheel formed by stop arm and vertical binding post is arranged on the outside of limited ring, as a stop connecting component which can rotate to make a group of electrical contacts connect. The stop function which is synchronous to the electrical connection can reduce the tensity between plug and the power cord, to make the plug connect the adapter firmly; in addition, it coils without electric to improve the safety of household appliance which also can prevent the knotting inside the box.

Owner:庞一鸣

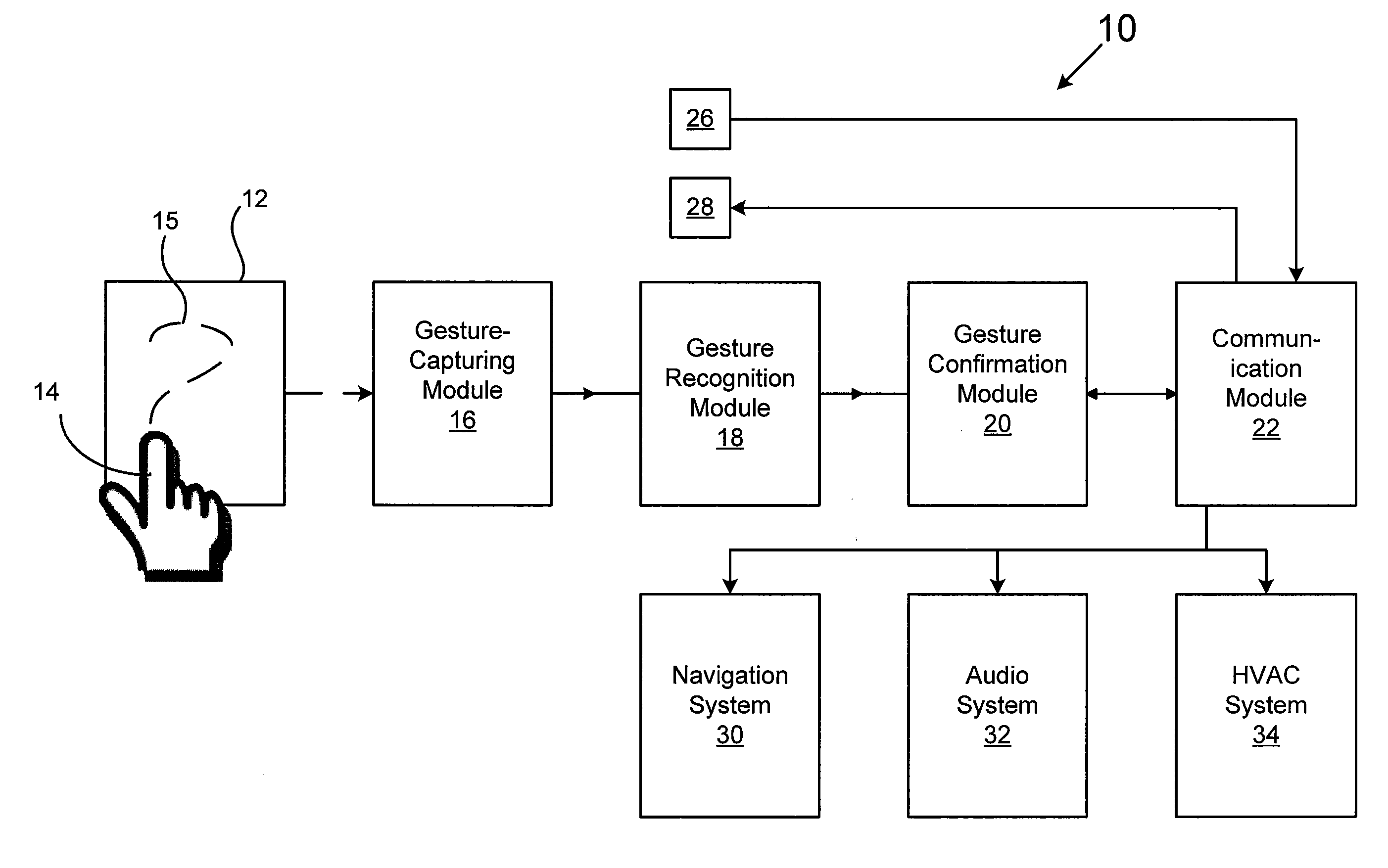

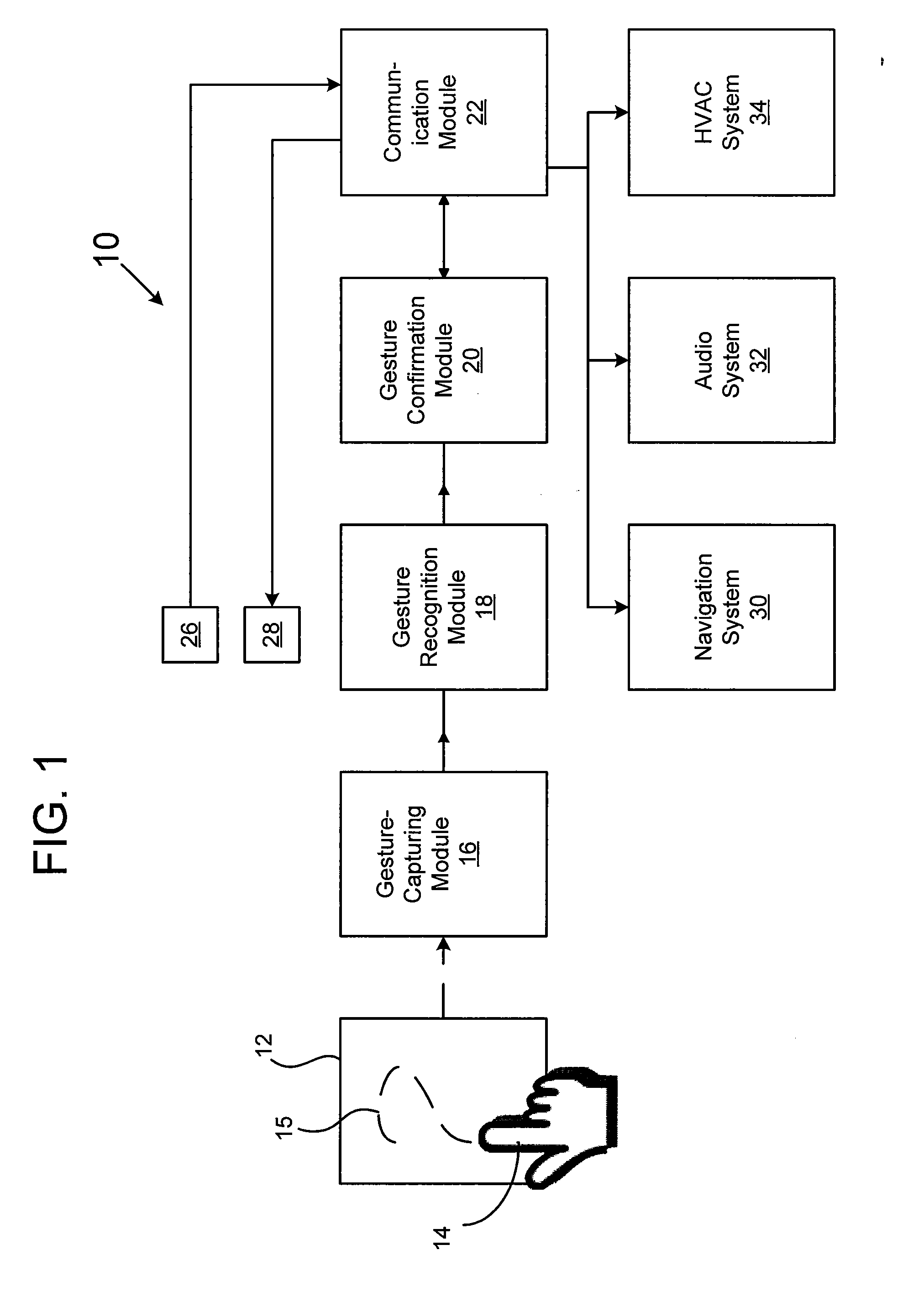

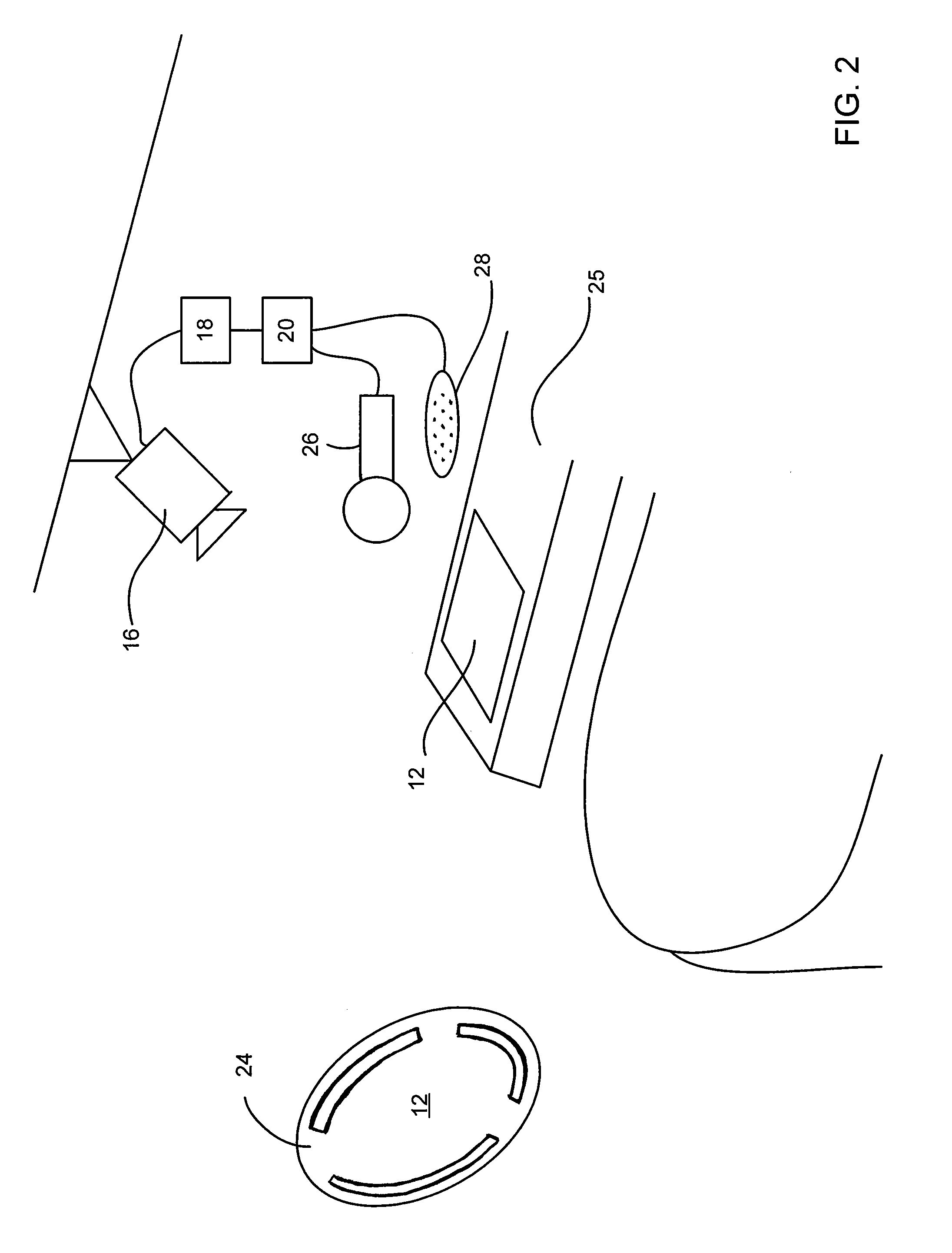

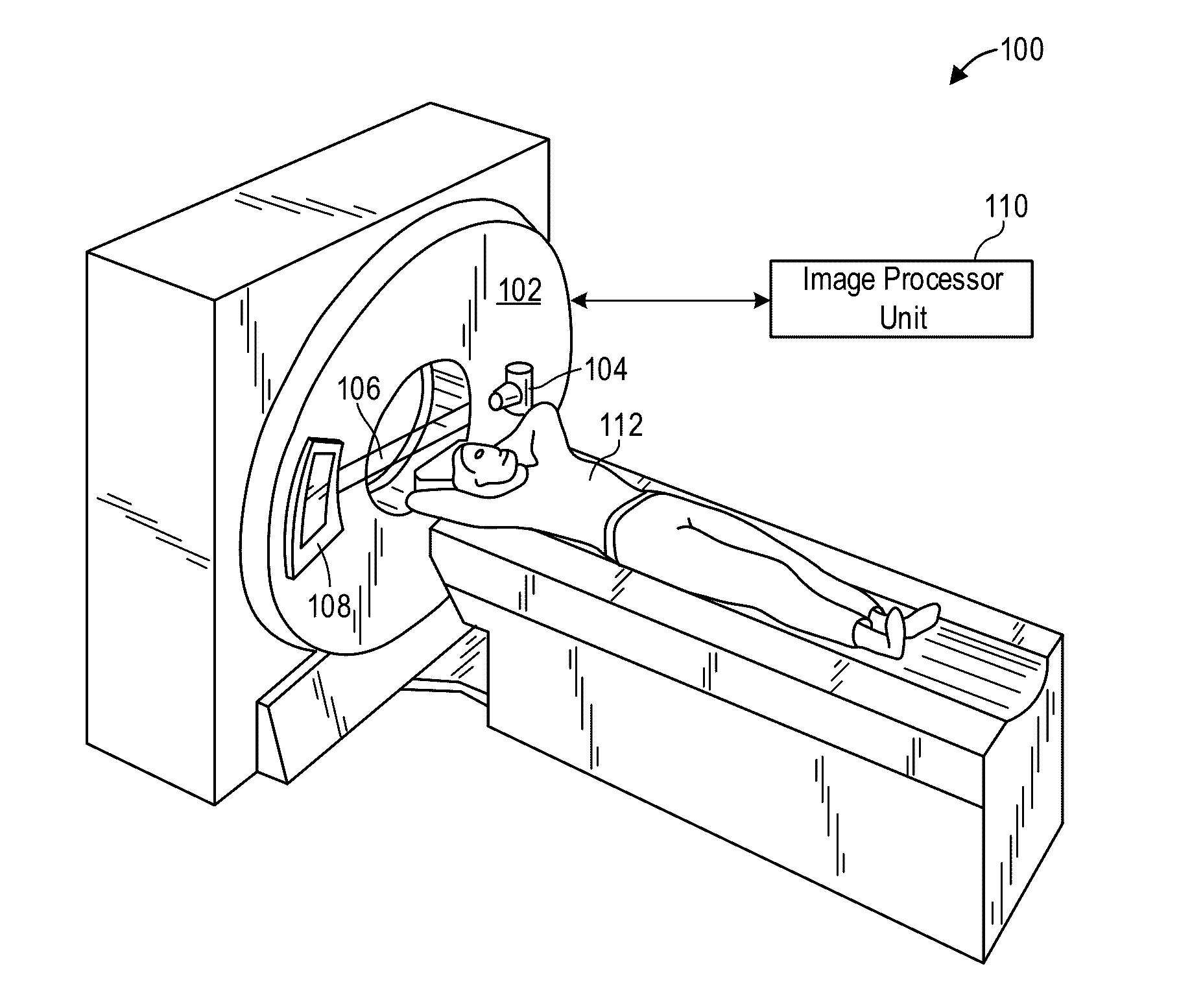

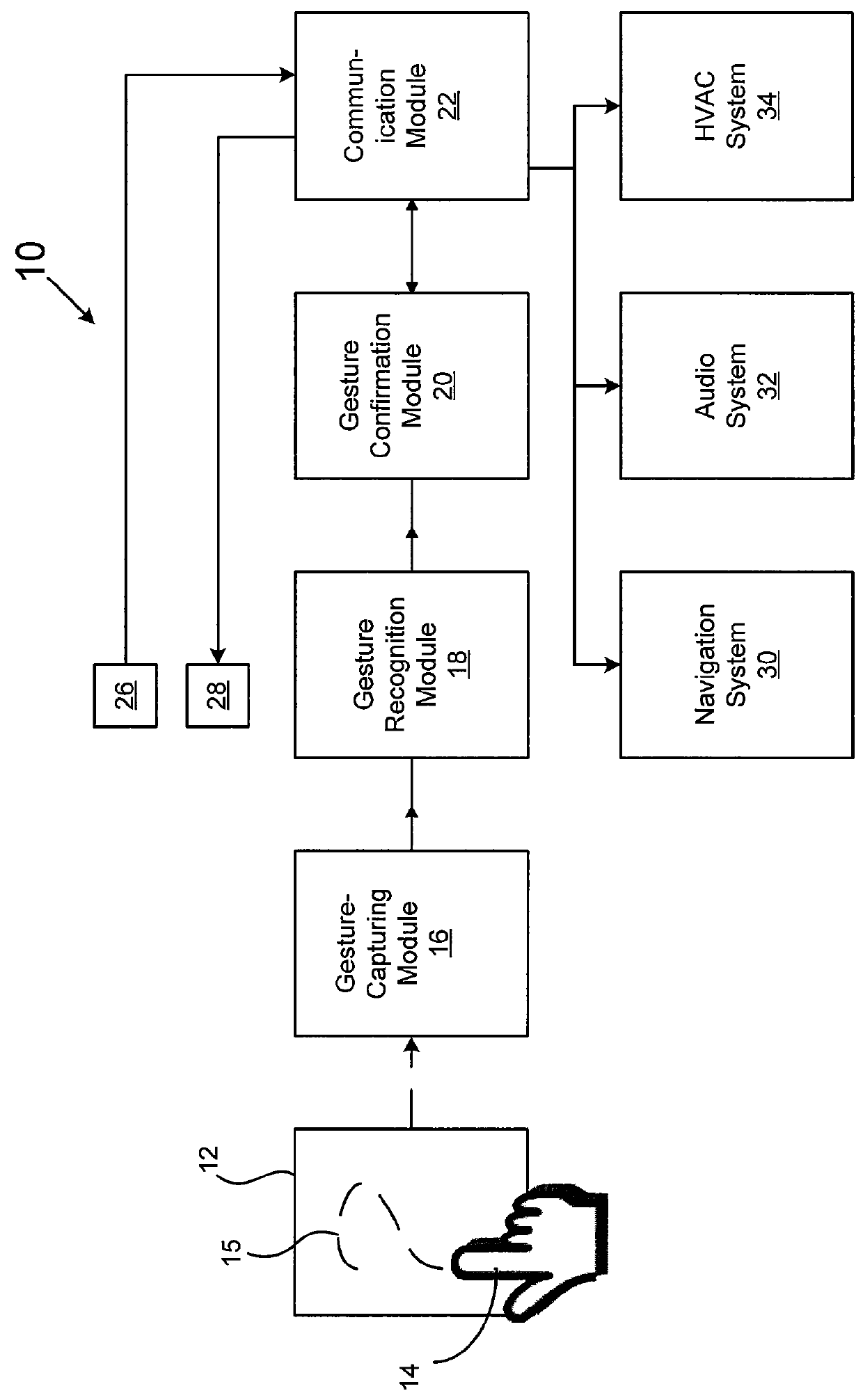

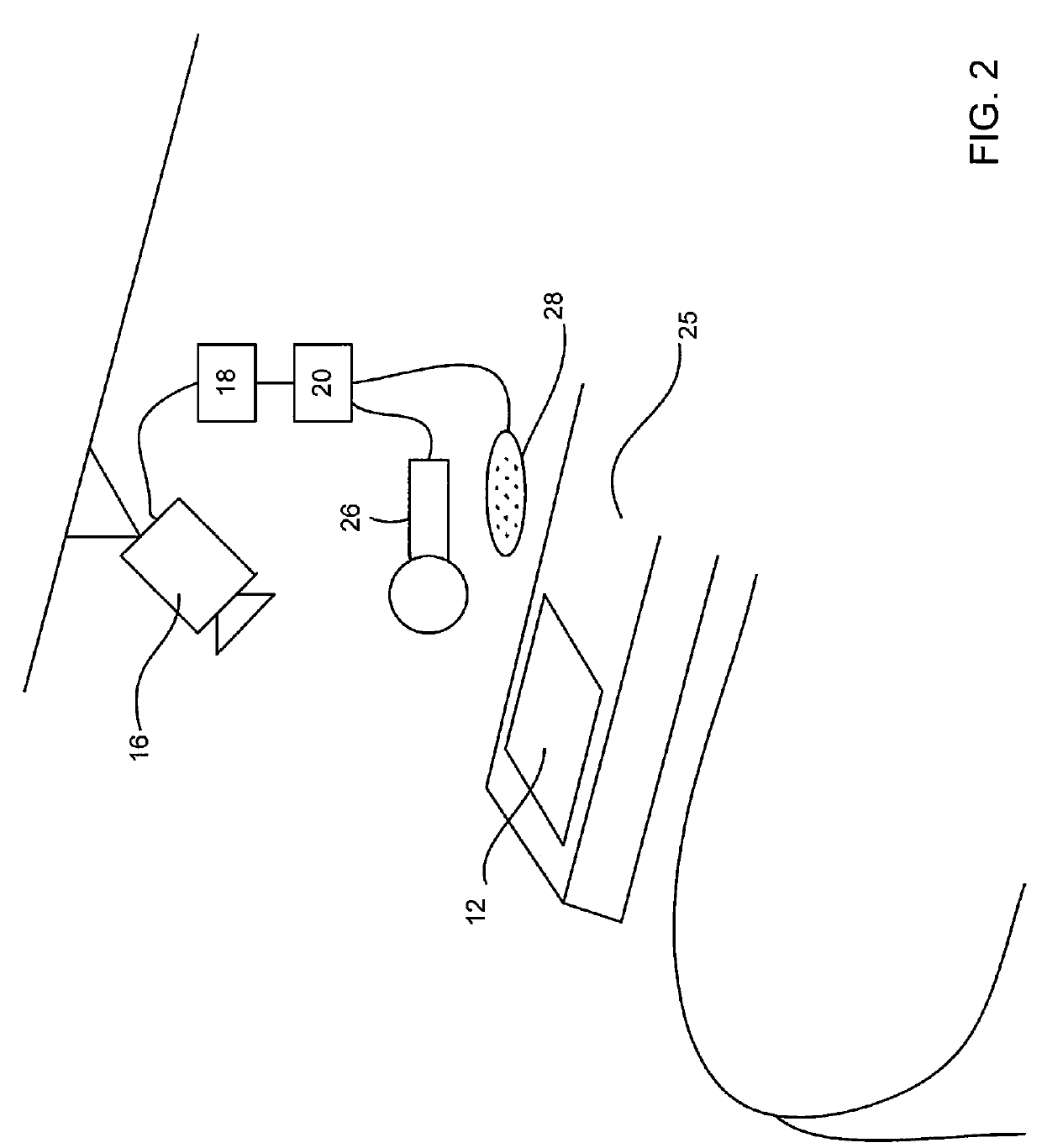

Method of Fusing Multiple Information Sources in Image-based Gesture Recognition System

ActiveUS20140089864A1Improve robustness and reliabilityEasy to useInput/output for user-computer interactionGraph readingStatistical modelImage based

A method of interpreting input from a user includes providing a surface within reach of a hand of the user. A plurality of locations on the surface that are touched by the user are sensed. An alphanumeric character having a shape most similar to the plurality of touched locations on the surface is determined. The determining includes collecting information associated with hand region localized modules, and modeling the information using statistical models. The user is informed of the alphanumeric character and / or a word in which the alphanumeric character is included. Feedback is received from the user regarding whether the alphanumeric character and / or word is an alphanumeric character and / or word that the user intended to be determined in the determining step.

Owner:ROBERT BOSCH GMBH

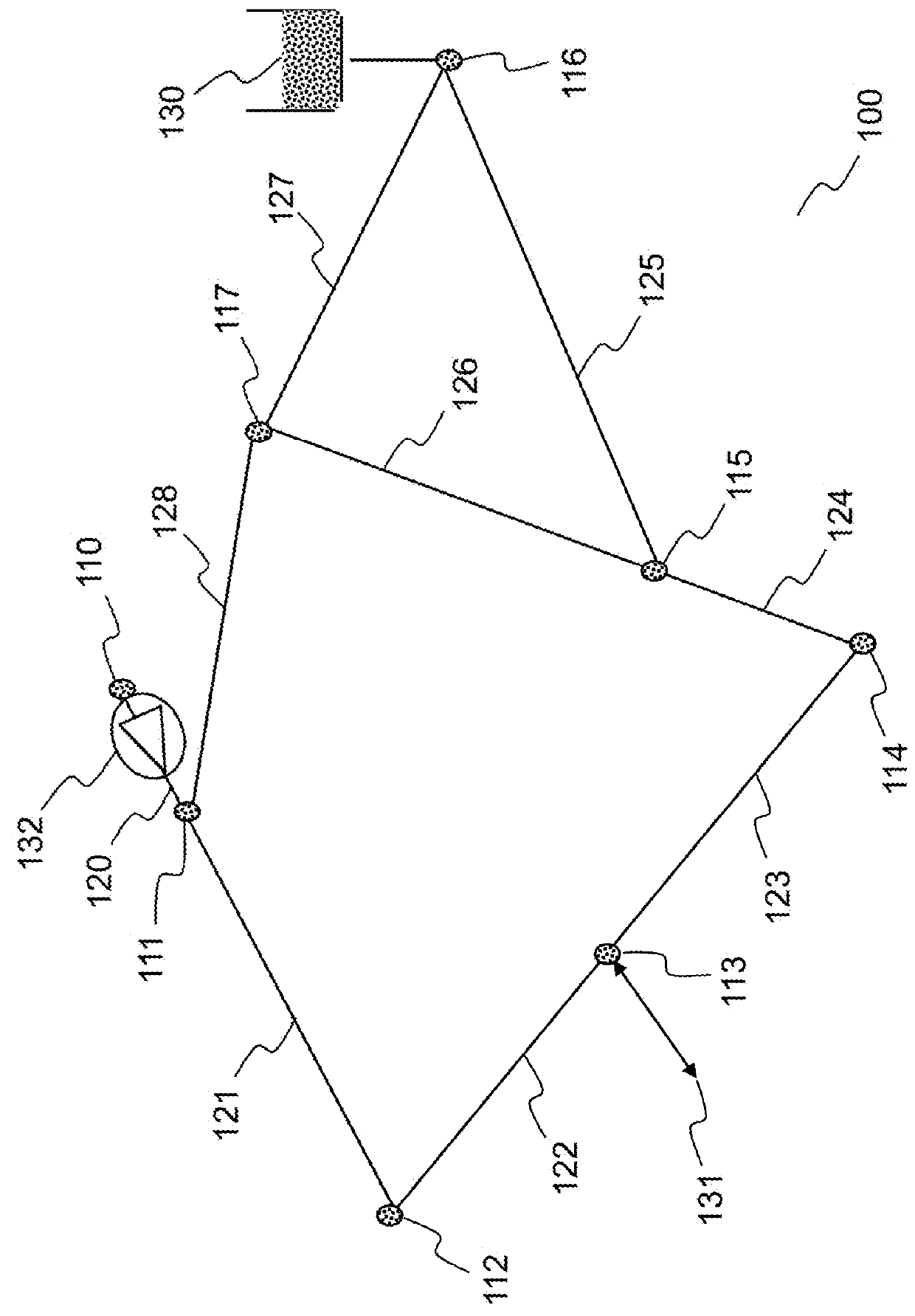

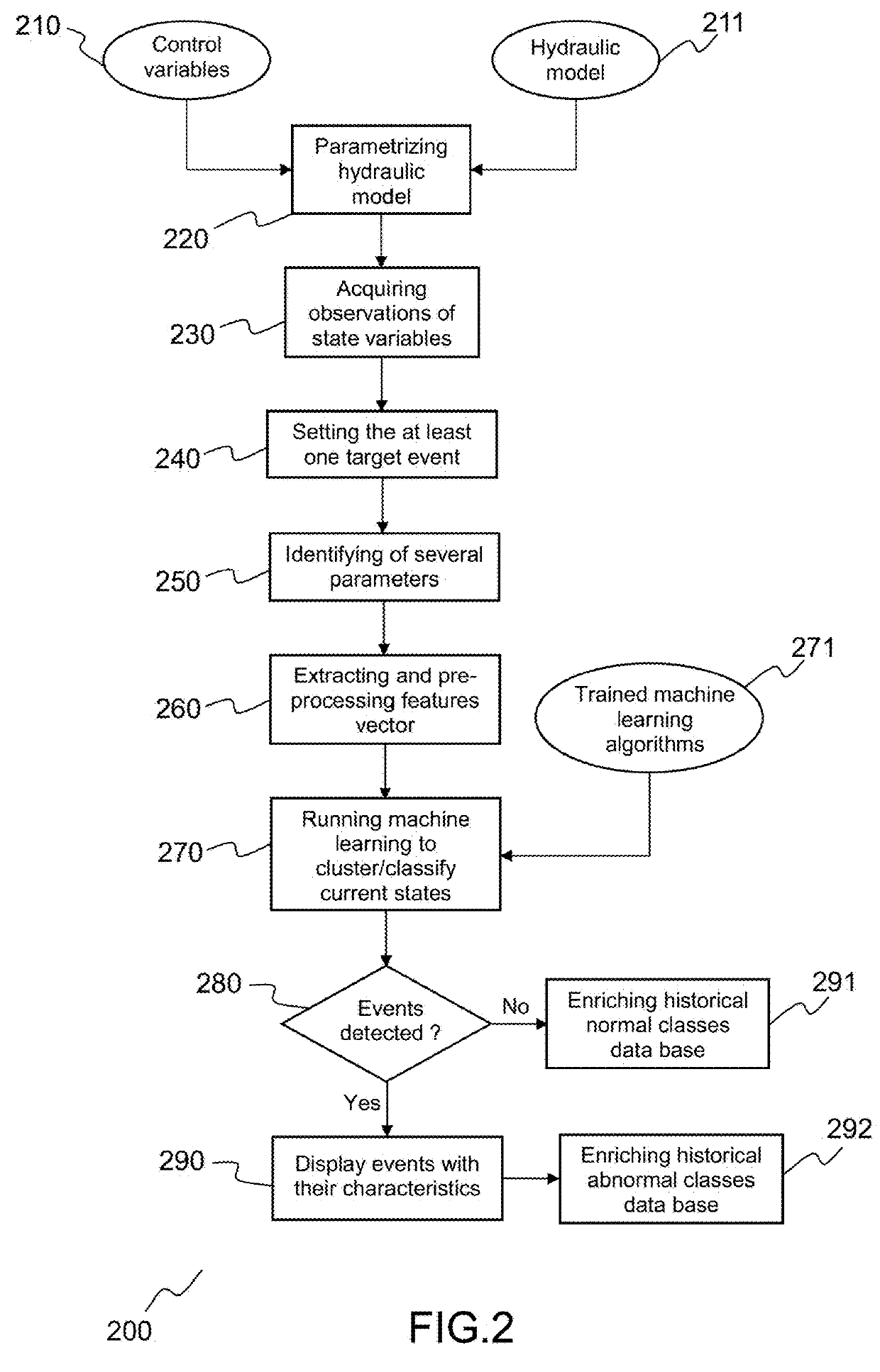

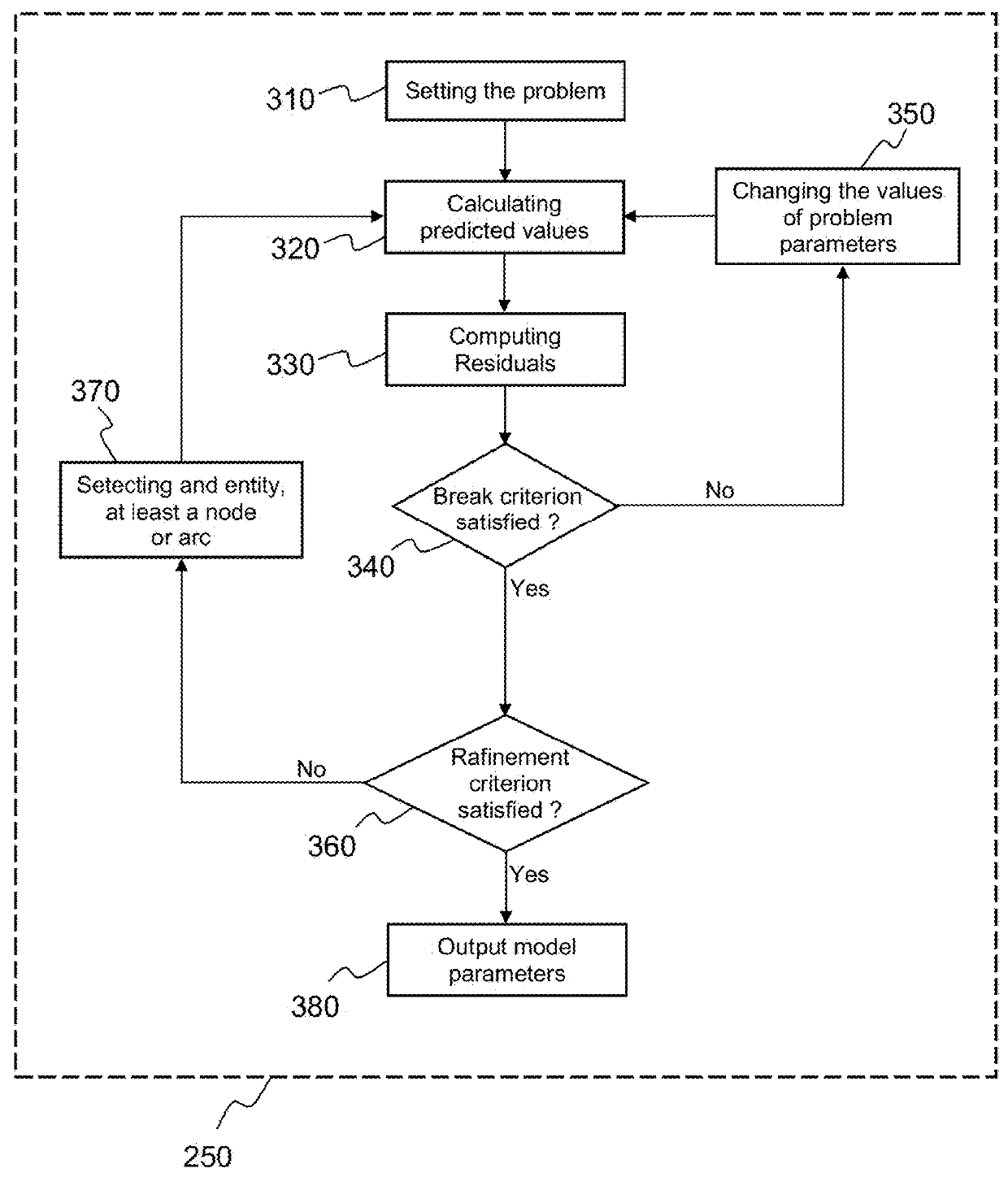

Method for detecting anomalies in a water distribution system

ActiveUS20180181111A1Improve accuracyImprove robustnessData processing applicationsSimulator controlControl variableDistribution system

A method and a system for detecting anomalies in a water distribution system comprises a network of nodes, and is equipped with sensors of at least water velocity at a subset of the nodes. The water distribution system is modeled by a hydraulic model. The method comprises parametrizing the hydraulic model with initial values of a set of control variables, using the sensors to obtain values of state variables of the network at the nodes, using the hydraulic model to calculate predicted values of state variables, recursively calculating the values of control variables which, applied to the hydraulic model, permit to obtain the predicted values of state variables the closest to the observed values, and classifying nodes of the network based on the values of control variables.

Owner:SUEZ GRP

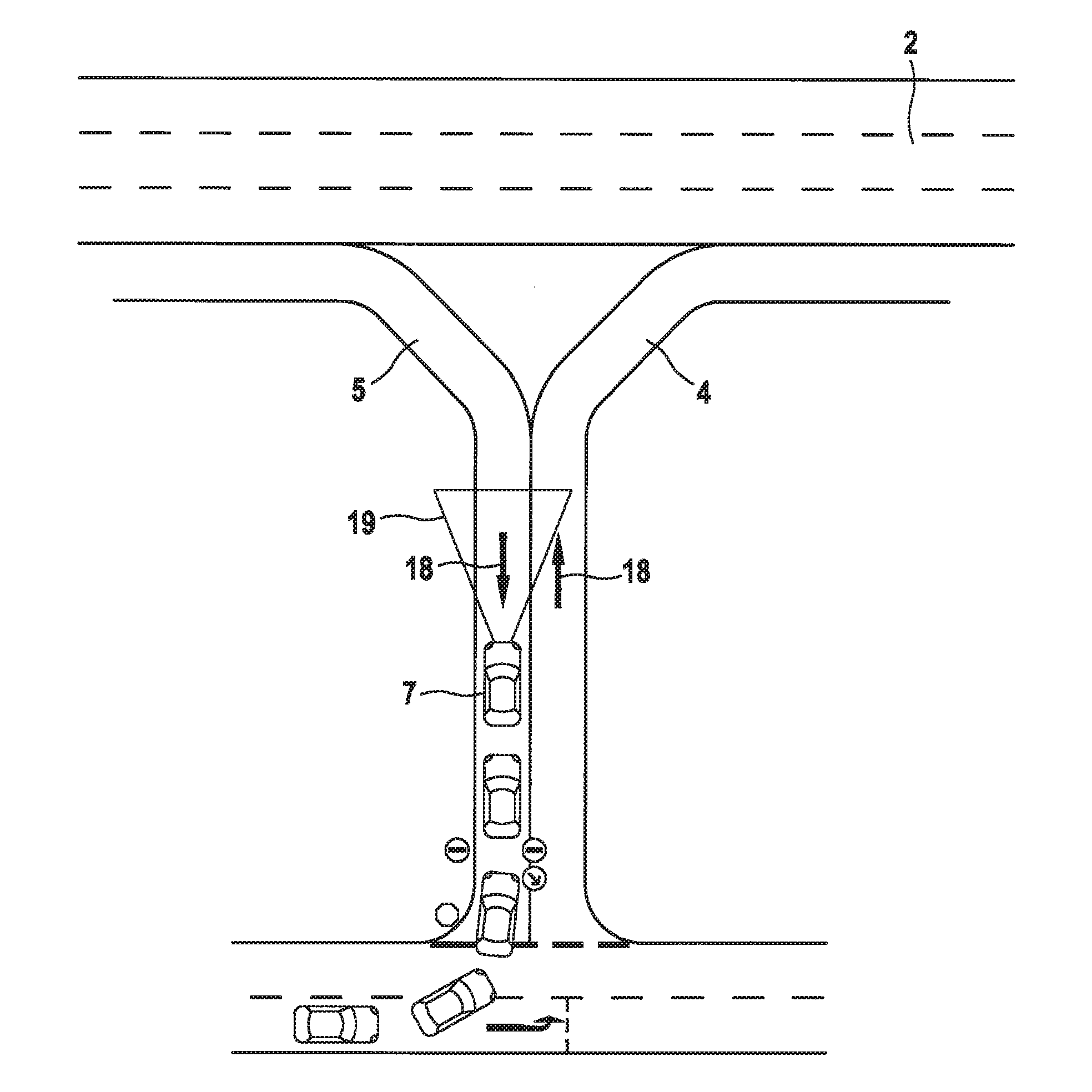

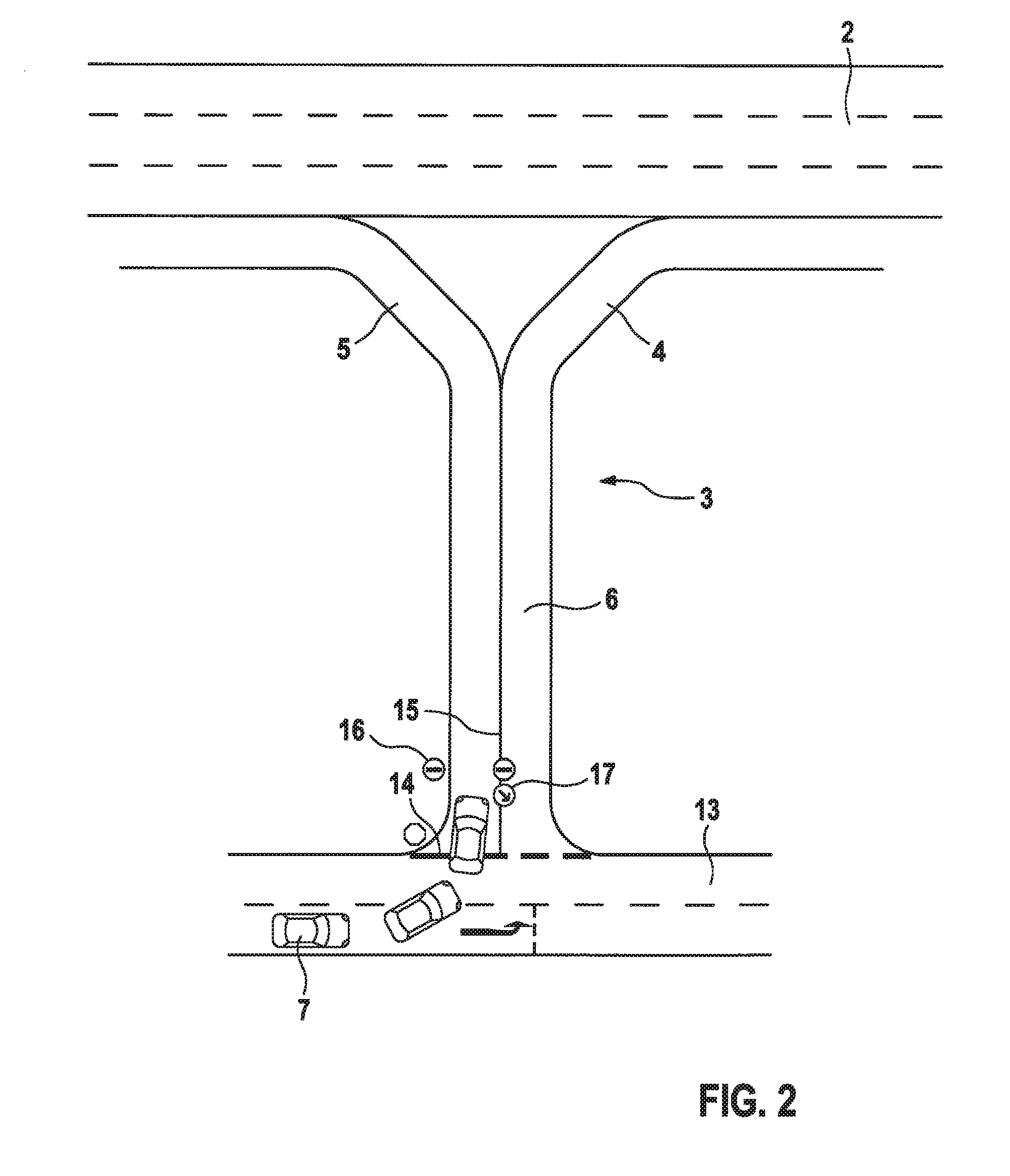

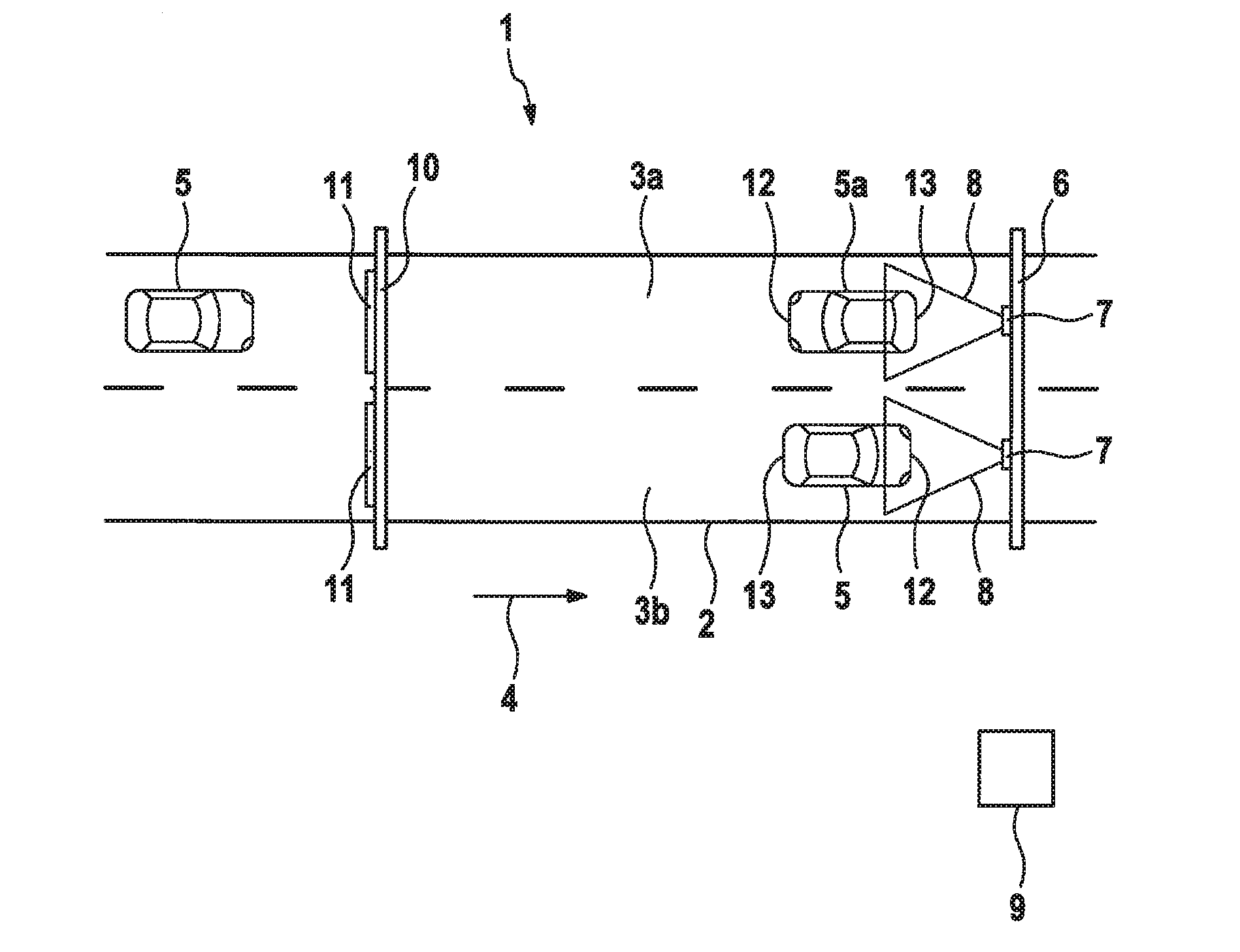

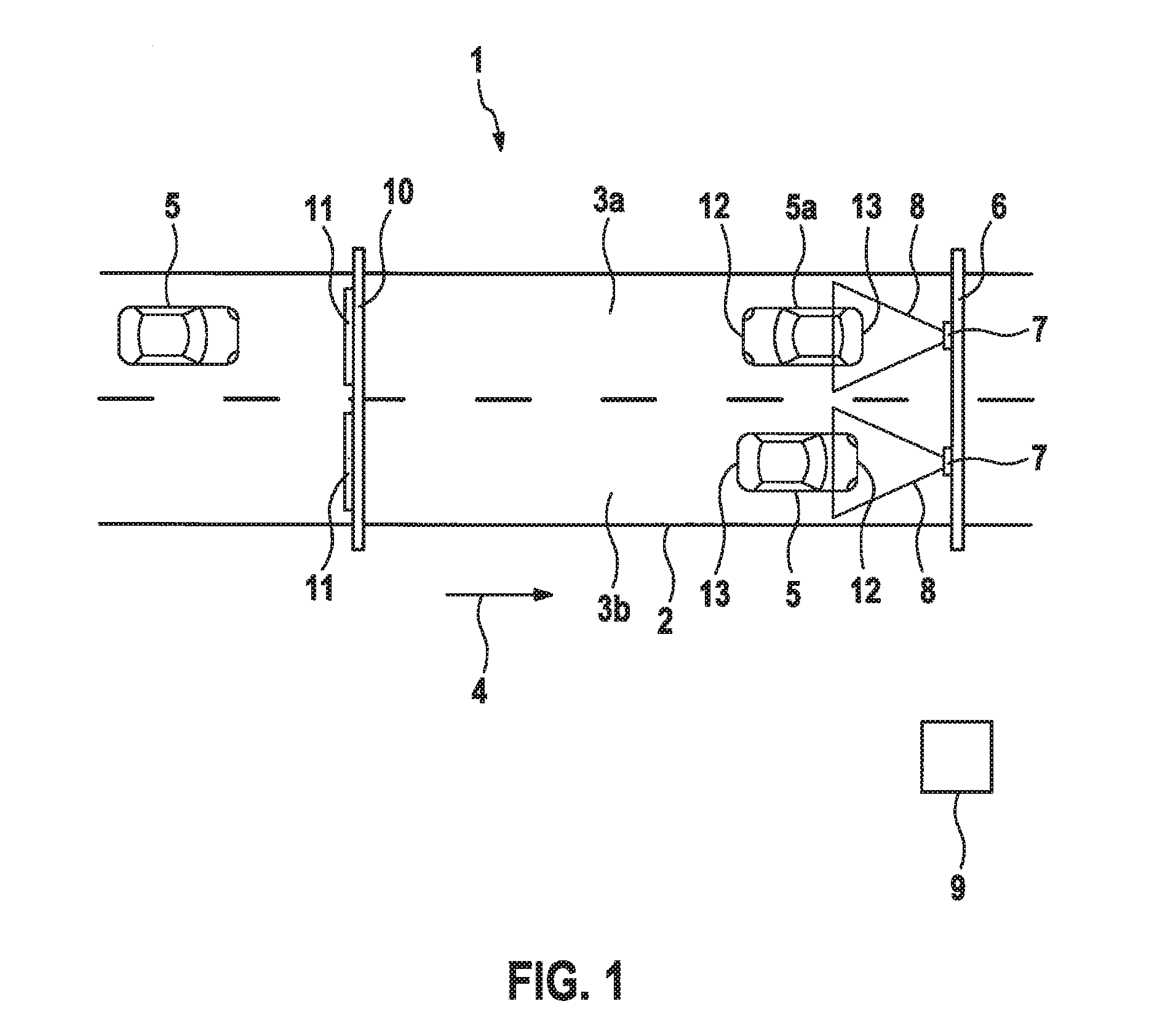

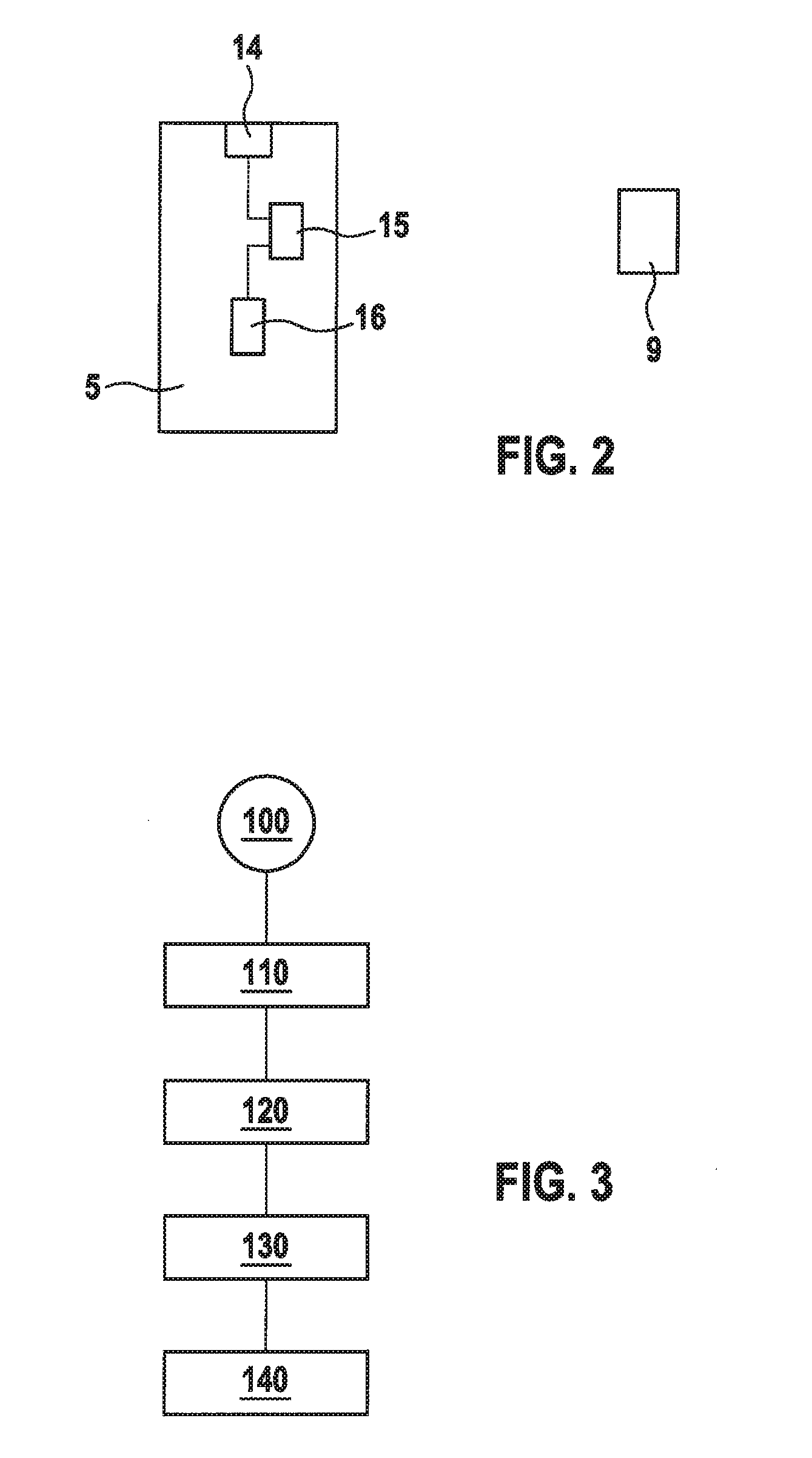

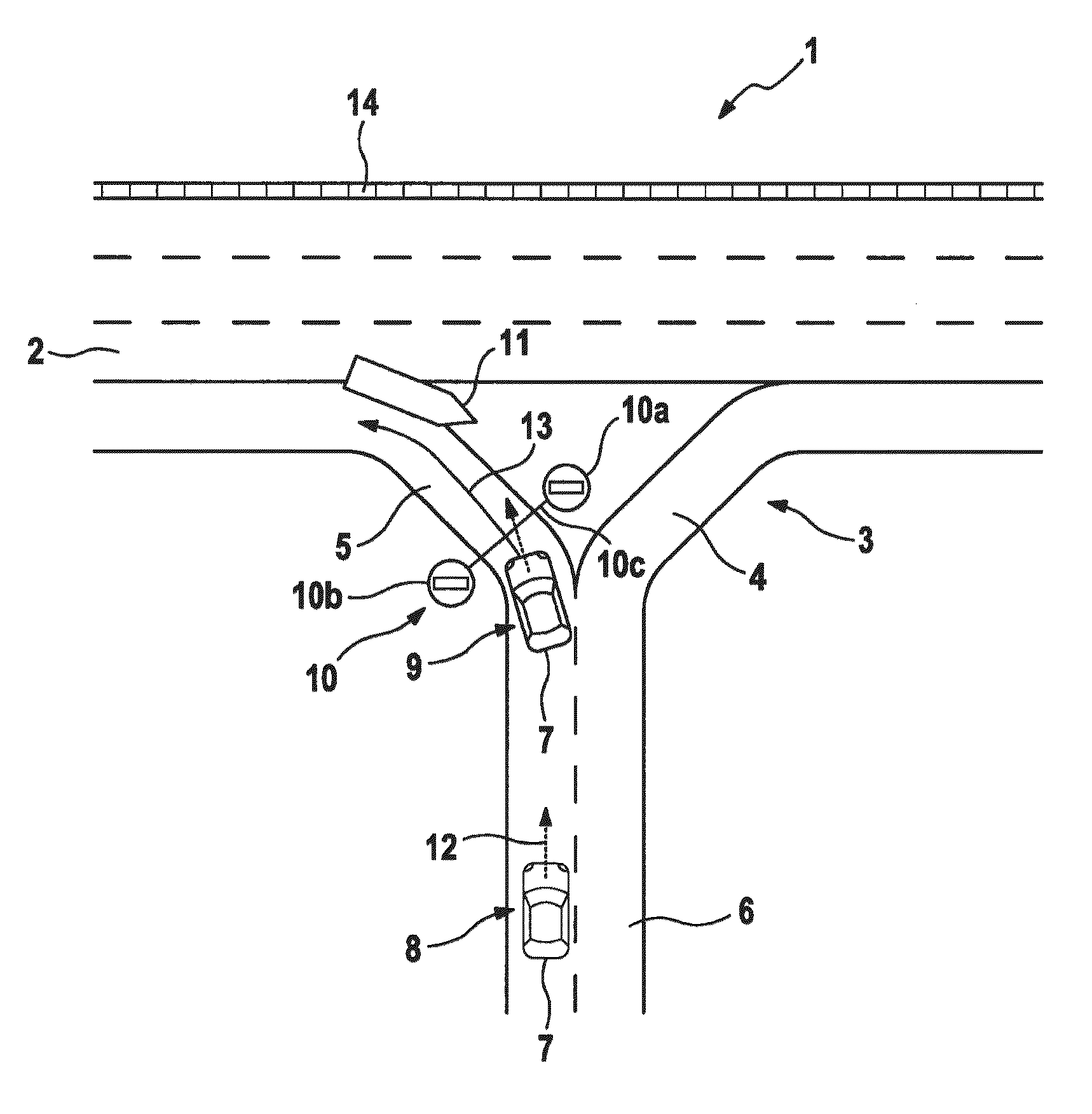

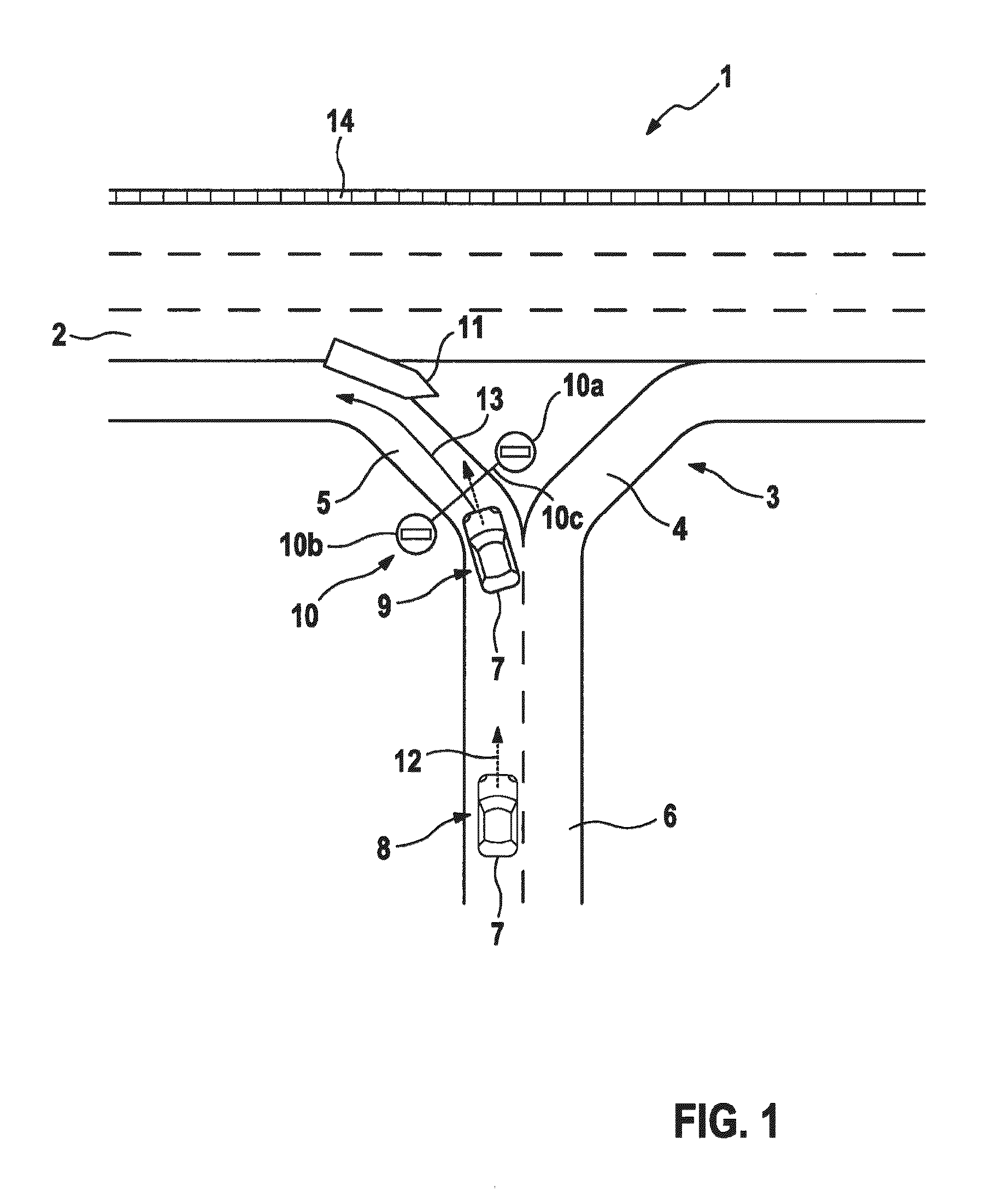

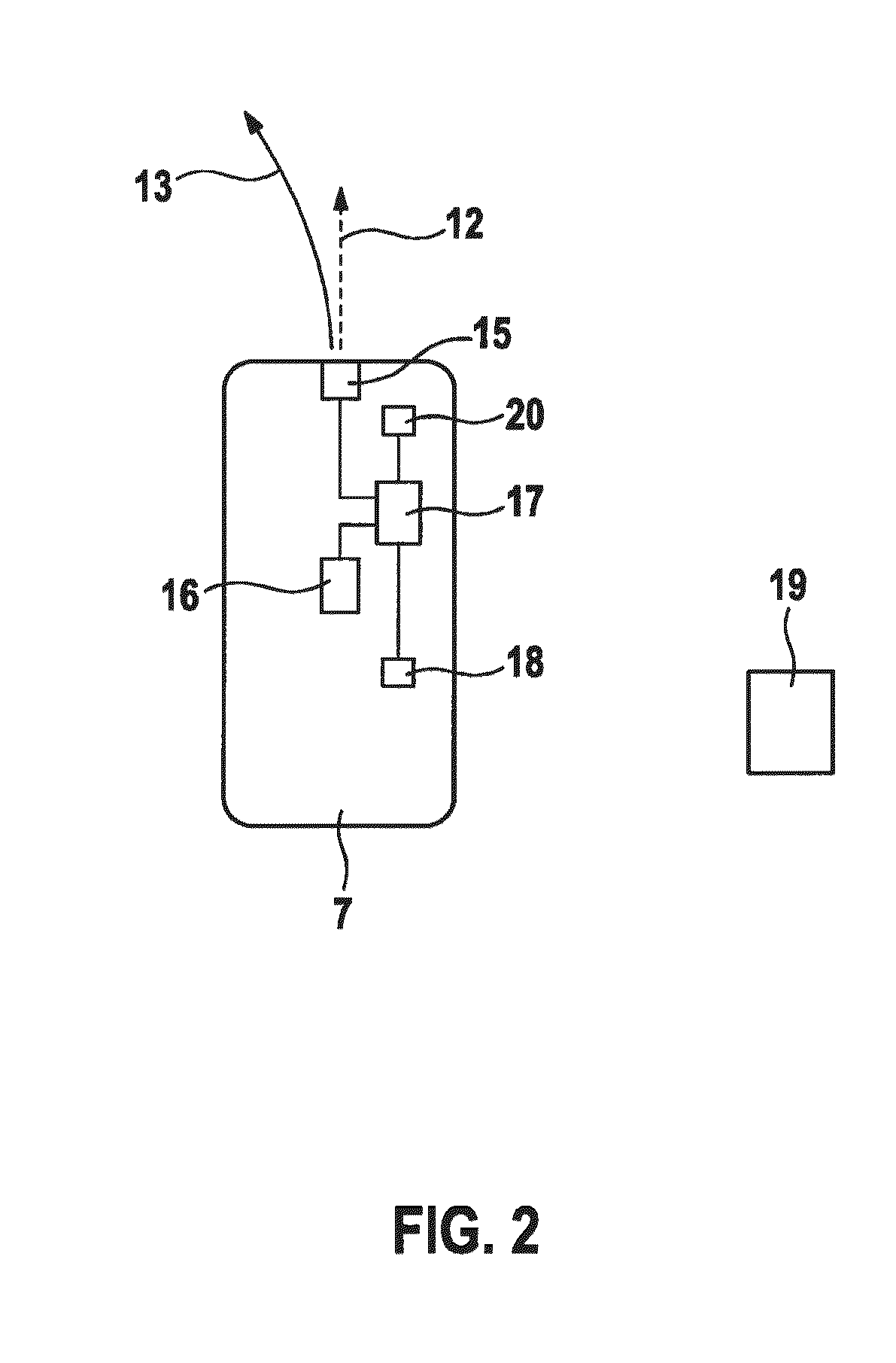

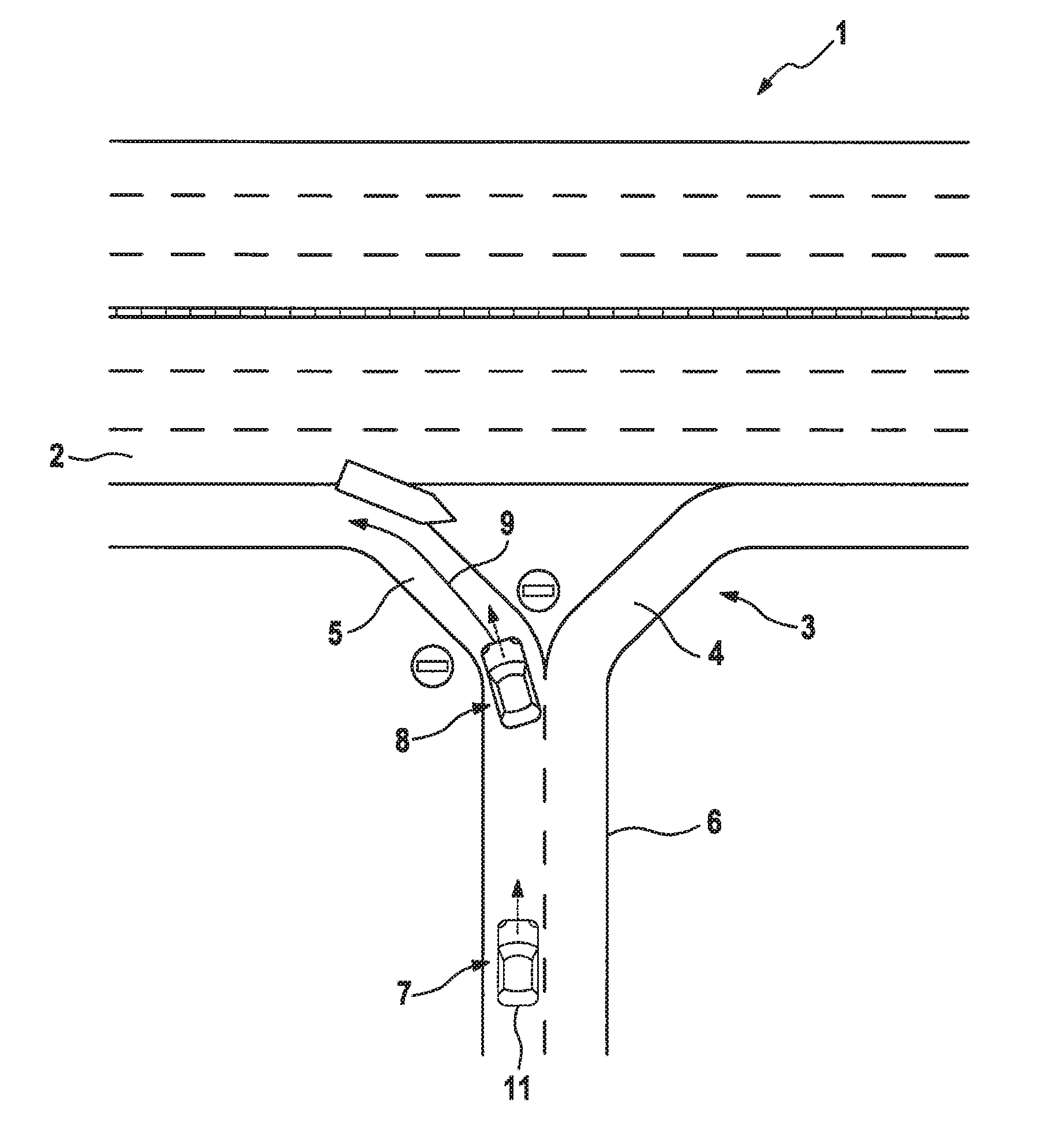

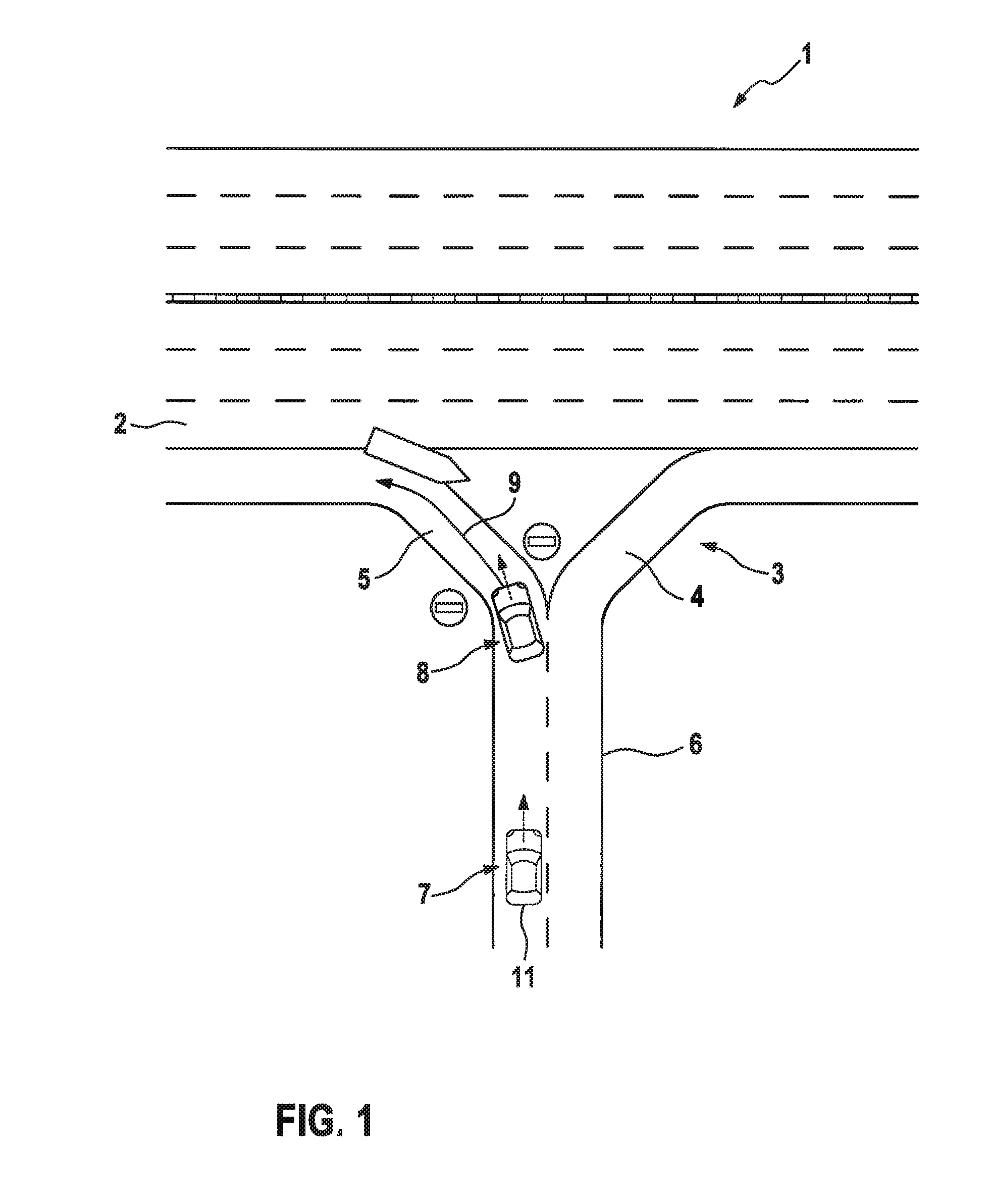

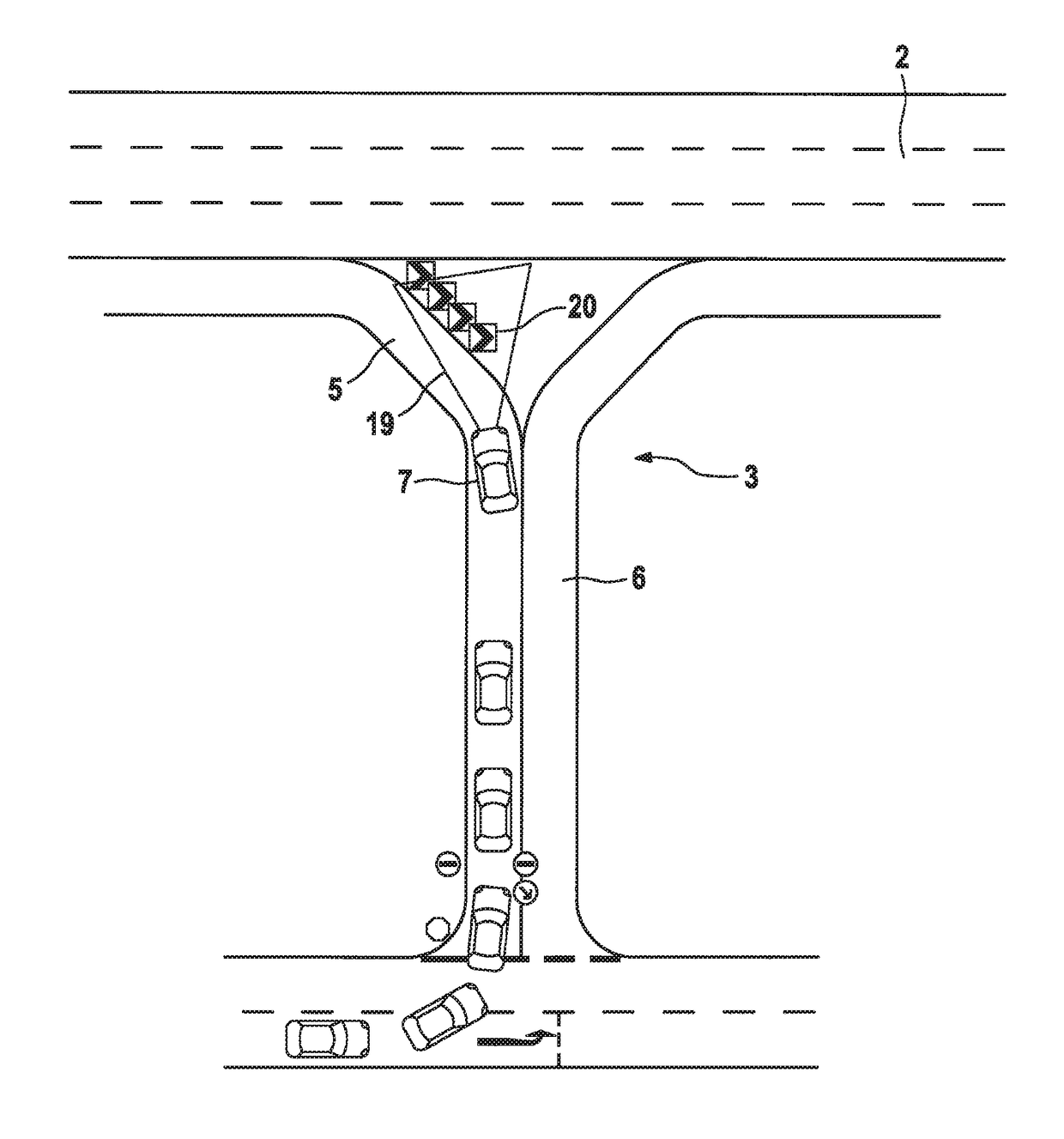

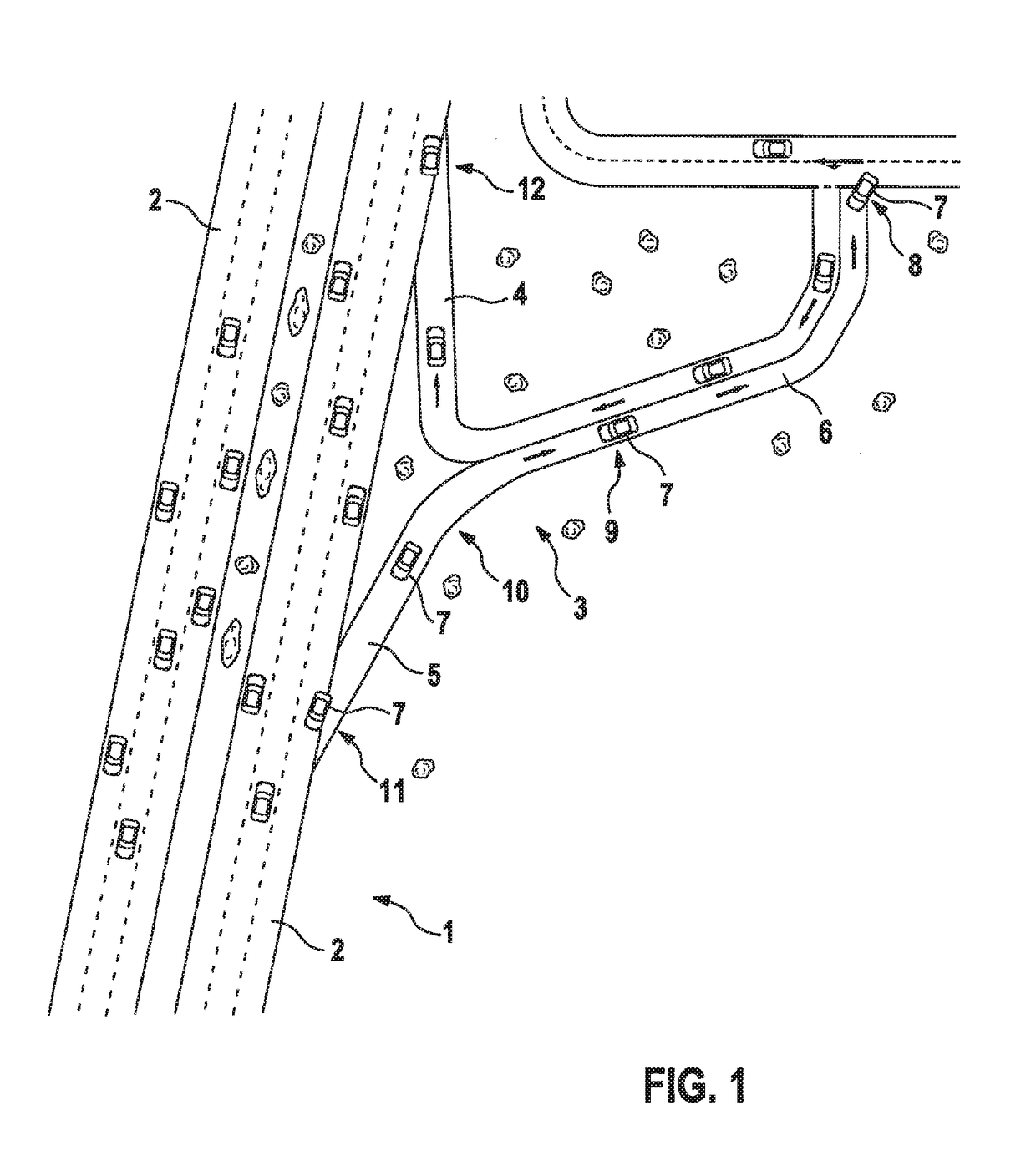

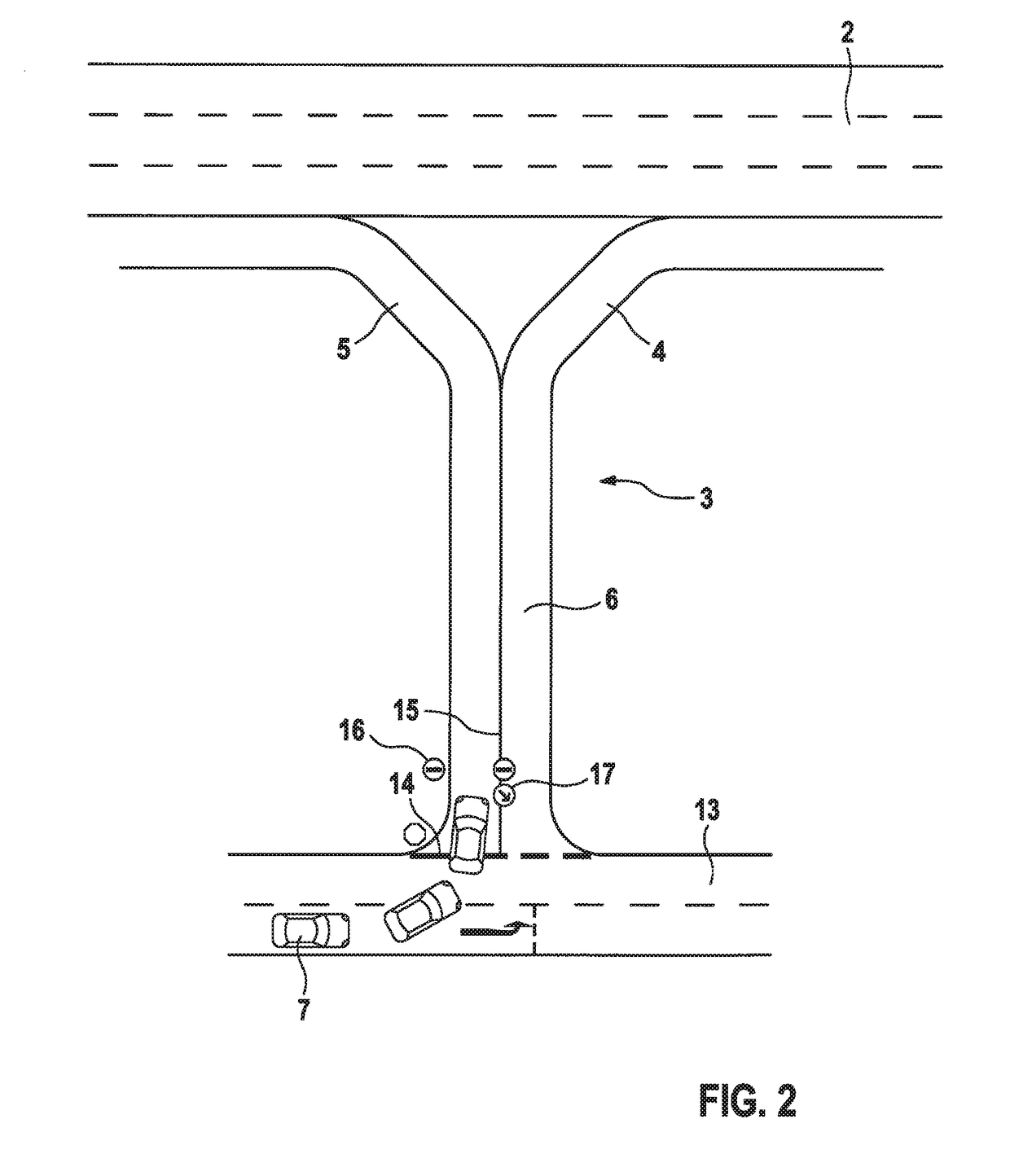

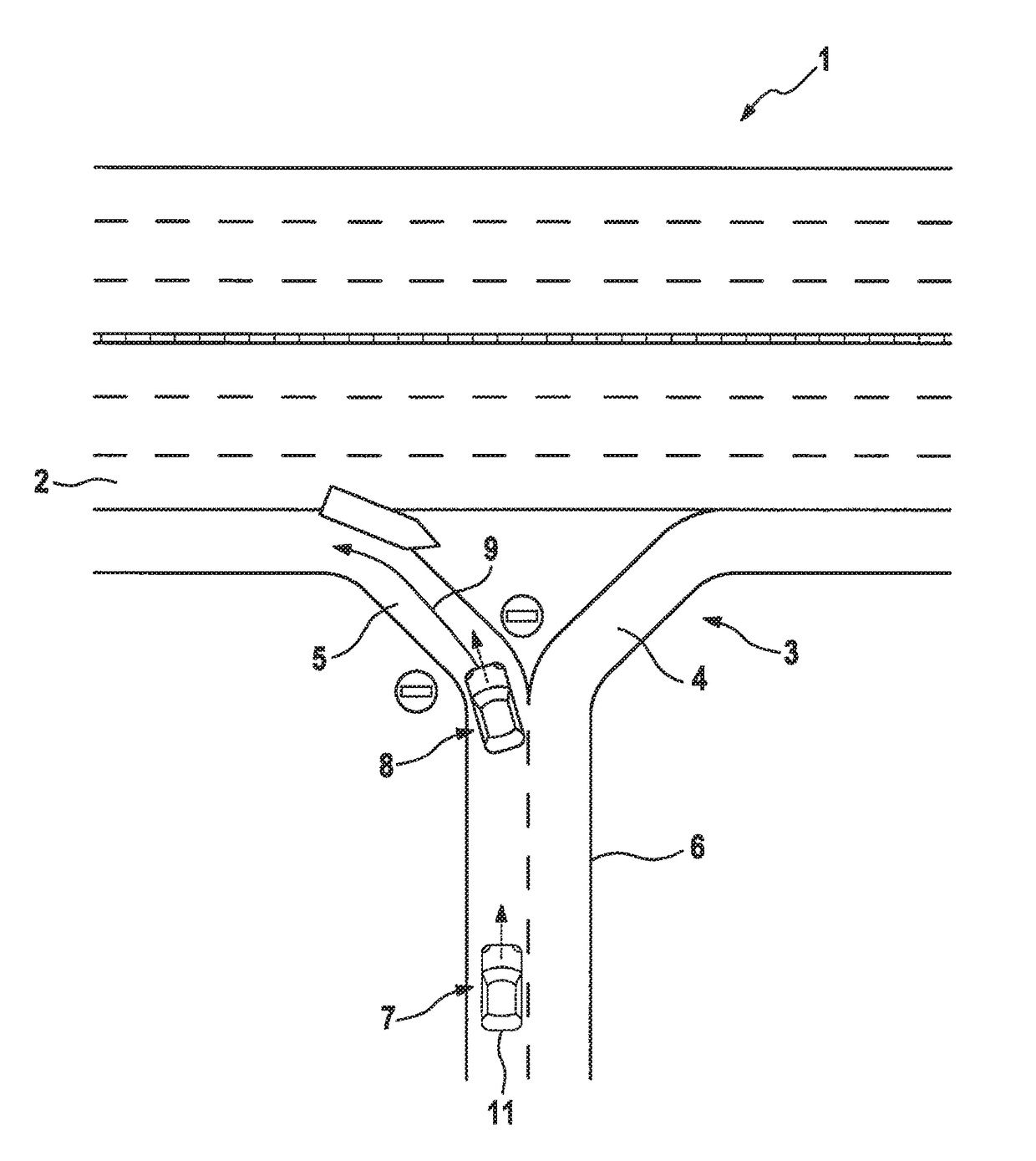

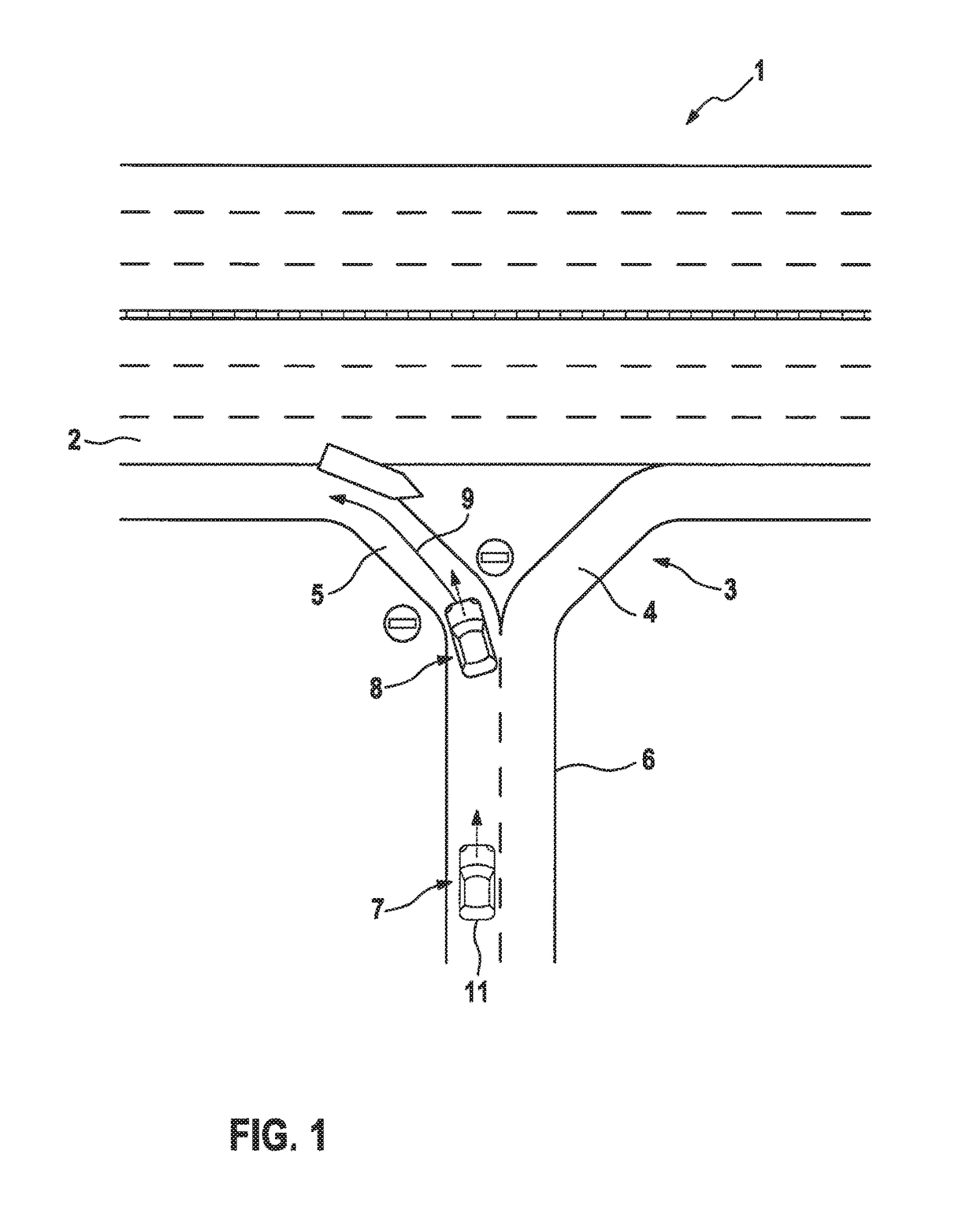

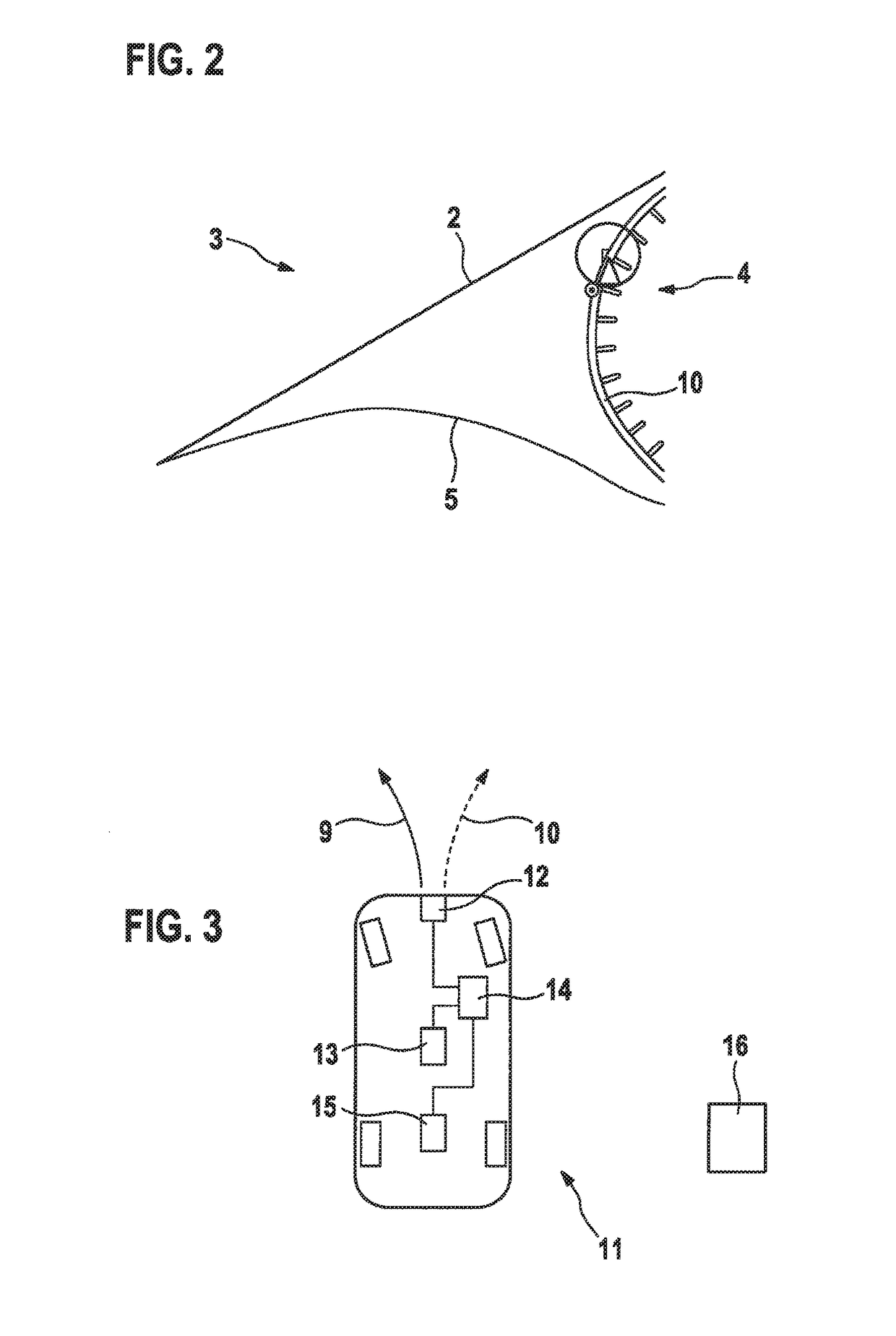

Method and control and detection unit for checking the plausibility of a wrong-way driving incident of a motor vehicle

ActiveUS20160217688A1Improve securityImprove robustness and reliabilityRoad vehicles traffic controlCharacter and pattern recognitionMobile vehicleWrong-way driving

In a method for checking the plausibility of a wrong-way driving of a motor vehicle when entering a unidirectional roadway, a traversing of a stop line or a solid line of a junction of the unidirectional roadway is detected and / or at least one item of directional information of a roadway of the junction, which is located ahead of the motor vehicle, is collected, and a probability of a wrong-way driving is ascertained based on the detection. The method is performed by a control and detection unit for checking the plausibility of a wrong-way driving.

Owner:ROBERT BOSCH GMBH

Method and traffic monitoring device for detecting a wrong-way driving incidnet of a motor vehicle

ActiveUS20160210855A1Improve reliabilityImprove securityDetection of traffic movementMobile vehicleWrong-way driving

Owner:ROBERT BOSCH GMBH

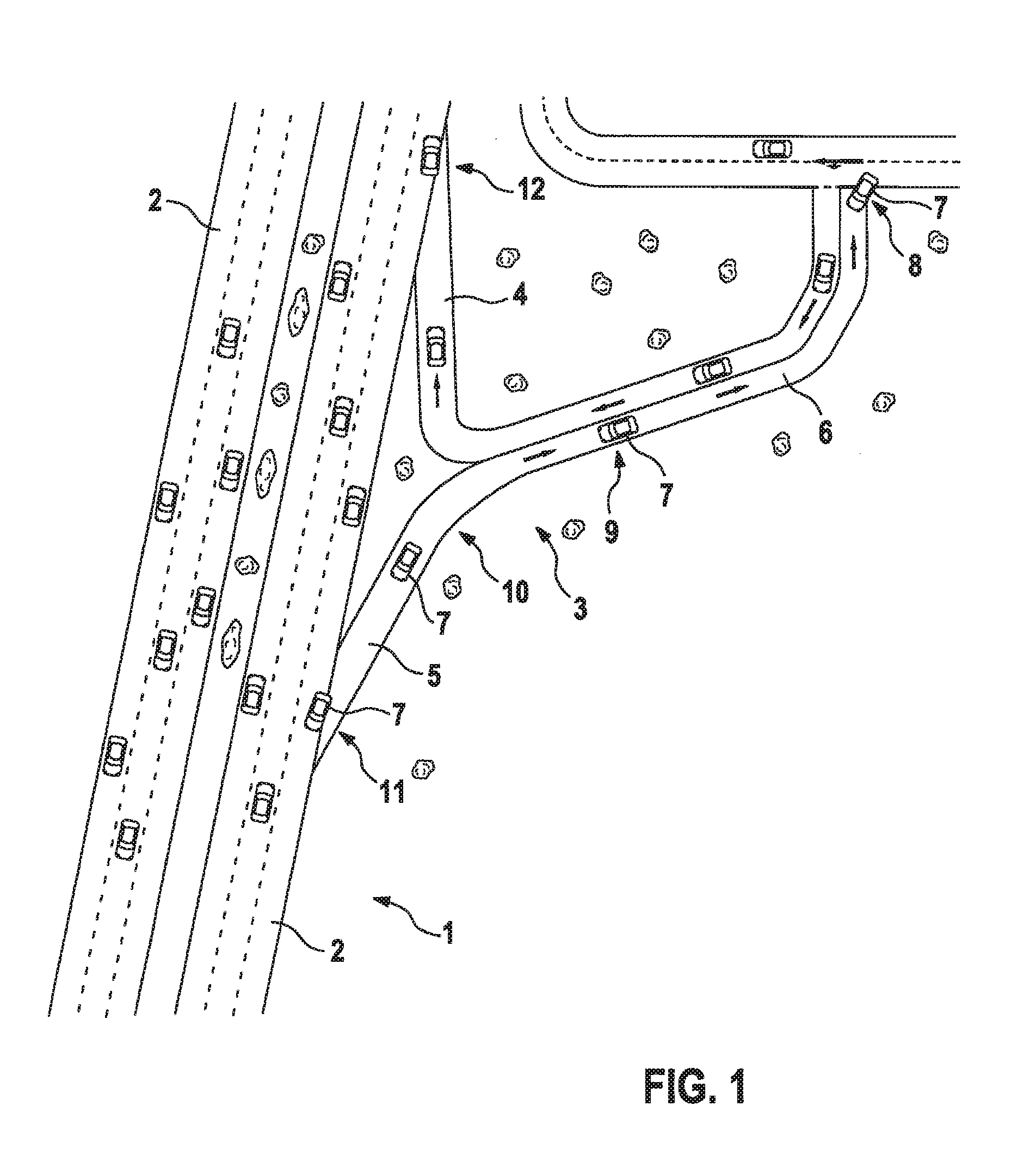

Method and control and detection device for a plausibility check of a wrong-way driving indcident of a motor vehicle

ActiveUS20160225256A1Easy to detectEasy to determineRoad vehicles traffic controlCharacter and pattern recognitionWrong-way drivingAutomotive engineering

A method and a control and detection device for a plausibility check of a wrong-way driving incident of a motor vehicle at a junction of a unidirectional roadway of a road, in which the plausibility check is activated by recognizing a direction feature of a roadway of the junction, and in which it is determined whether a current driving direction of the motor vehicle leads in the direction of a roadway having at least one prohibition sign, indicating that entry is prohibited, and / or in which it is determined whether a predicated driving route of the motor vehicle leads in the direction of a roadway having at least one prohibition sign.

Owner:ROBERT BOSCH GMBH

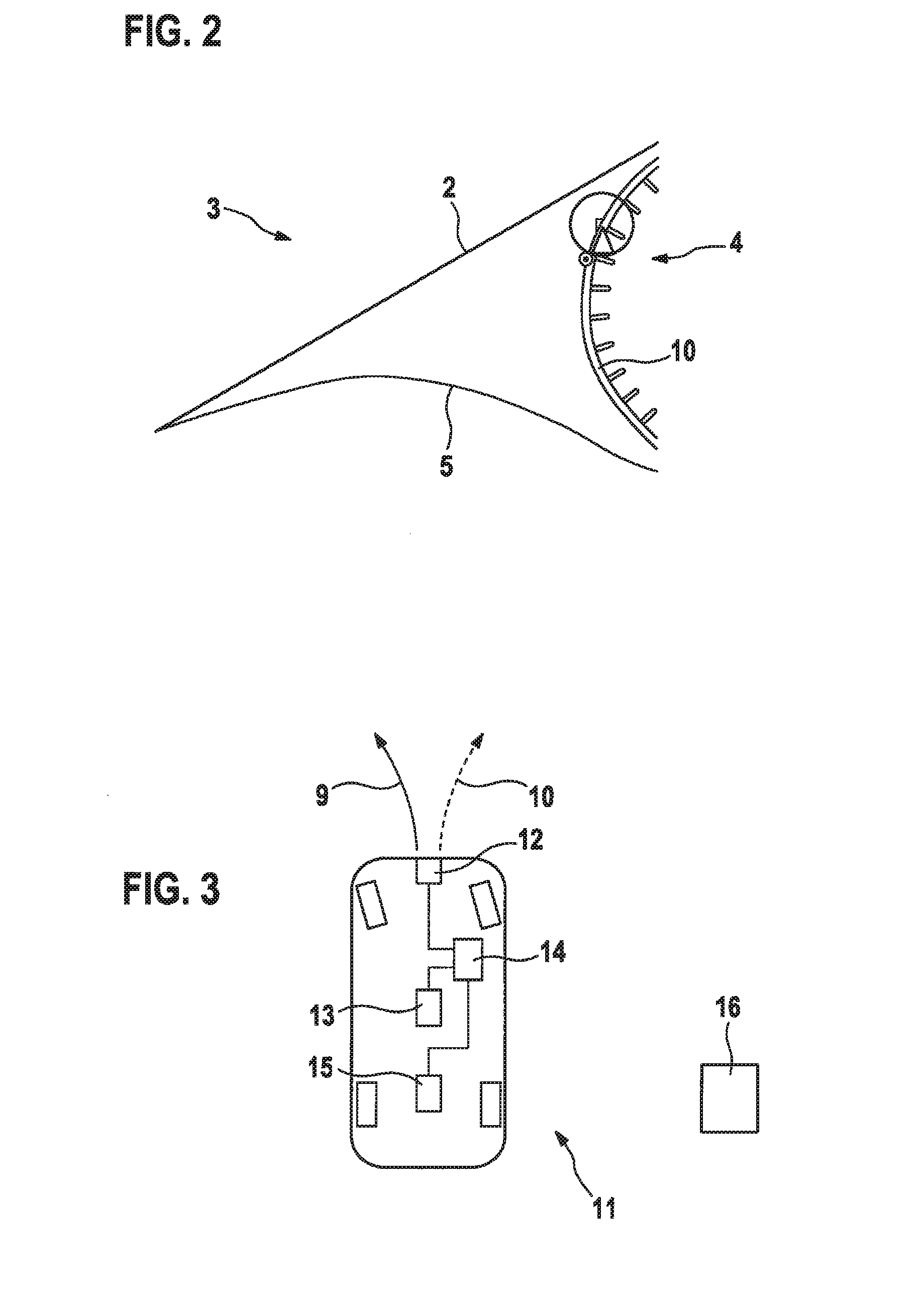

Method and control and detection device for determining the plausibility of a wrong-way travel of a motor vehicle

ActiveUS20160203716A1Solid foundationImprove reliabilityRoad vehicles traffic controlNavigation instrumentsSimulationLimit value

A method for determining the plausibility of a wrong-way travel of a motor vehicle when entering a directional roadway, in which at least one item of curve information of a current travel path of the motor vehicle is detected, at least one item of curve information of a permitted travel path is ascertained, a deviation between the detected item of curve information and the ascertained item of curve information is determined, and a wrong-way travel is plausibilized if a deviation exists or if a limit value for a deviation is breached. A control and detection device for determining the plausibility of a wrong-way travel of a motor vehicle when entering a directional roadway, includes an arrangement for detecting at least one item of curve information of a current travel path of the motor vehicle; an arrangement for ascertaining at least one item of curve information of a permitted travel path; an arrangement for determining a deviation between the detected item of curve information and the ascertained item of curve information; and an arrangement for determining the plausibility of a wrong-way travel if a deviation exists for when a limit value for a deviation is breached.

Owner:ROBERT BOSCH GMBH

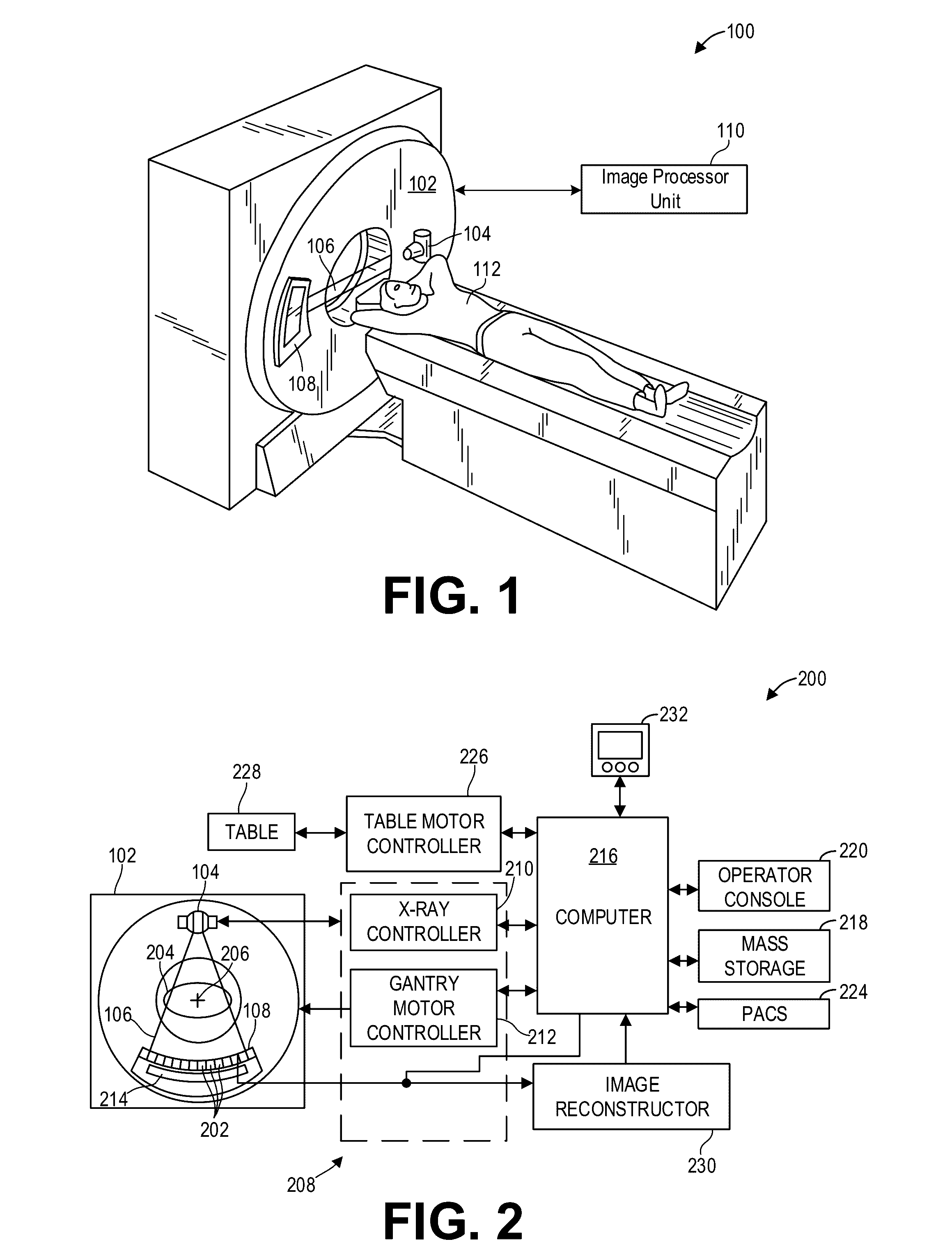

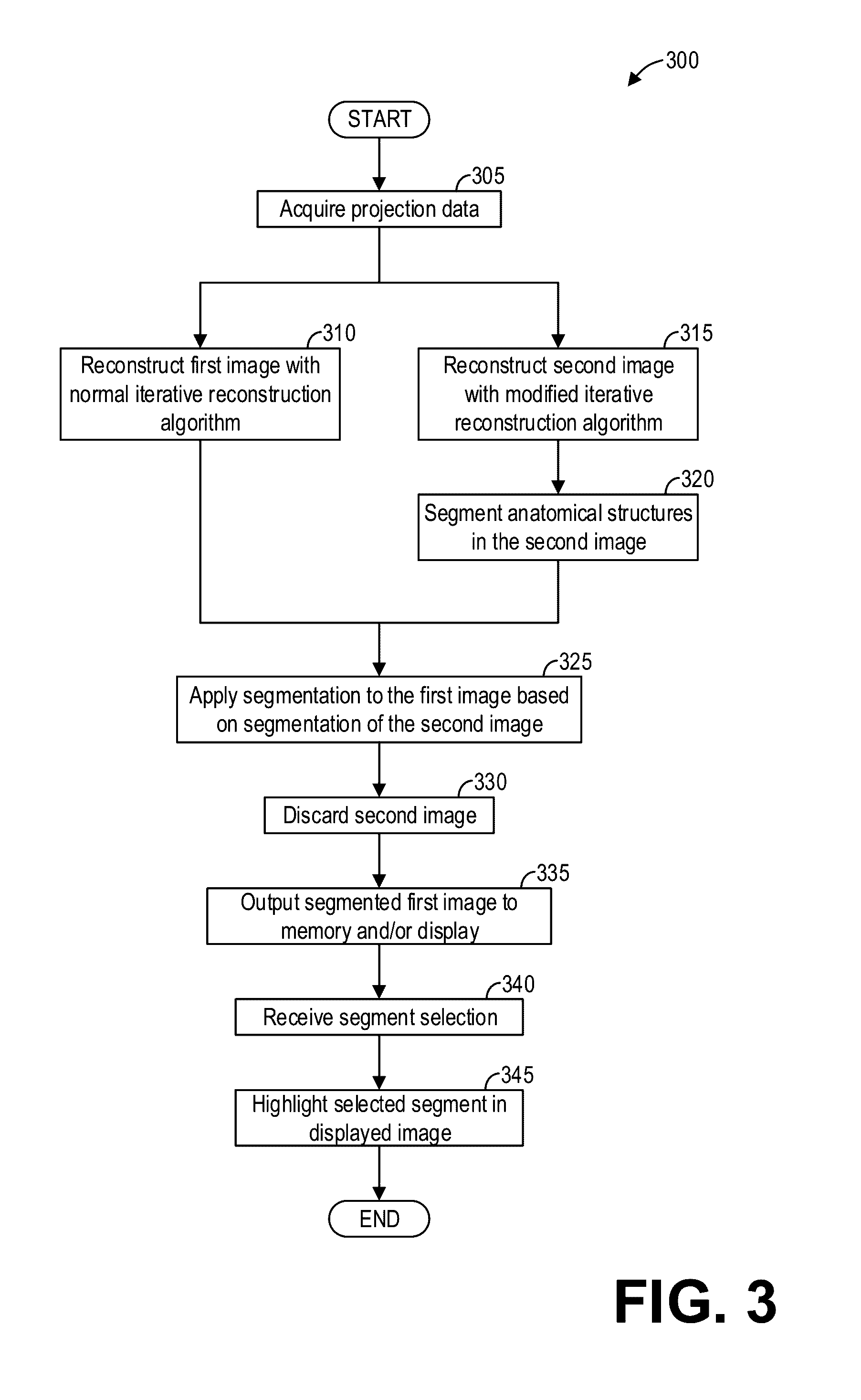

Methods and systems for automatic segmentation

InactiveUS20160292874A1Accurate segmentationSacrificing textural detail of imageImage enhancementReconstruction from projectionAutomatic segmentationImage based

Methods and systems are provided for reconstructing and automatically segmenting an image. In one embodiment, a method comprises generating a first image from acquired projection data based on an iterative reconstruction algorithm, generating a second image from the acquired projection data based on a modified iterative reconstruction algorithm, segmenting the second image to obtain segments, segmenting the first image based on the segments of the second image, and outputting the segmented first image to a display. In this way, an image which may otherwise prove challenging for an automatic segmentation process may be accurately segmented without sacrificing textural details of the image.

Owner:GENERAL ELECTRIC CO

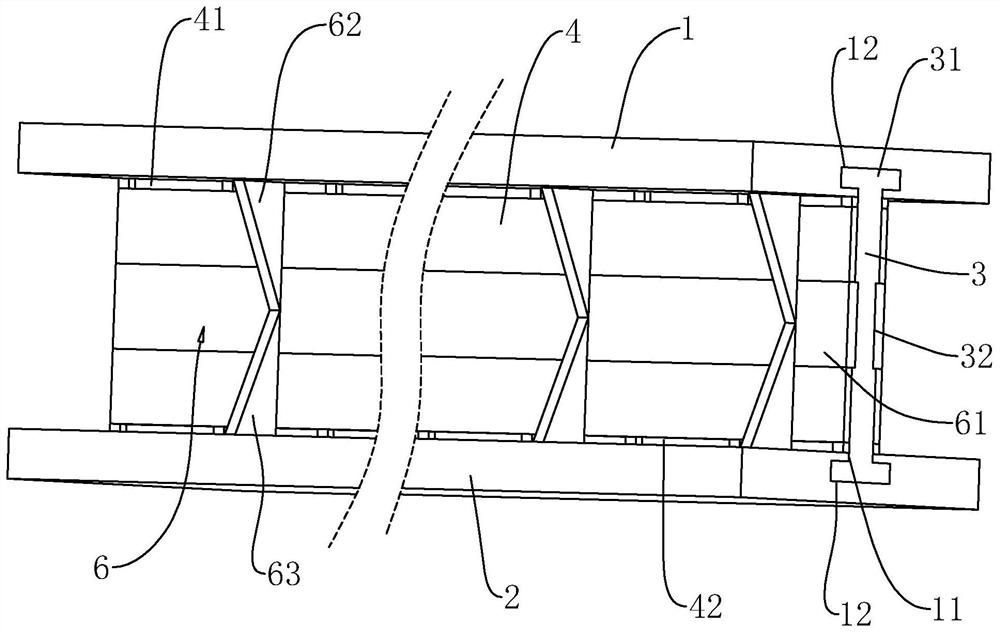

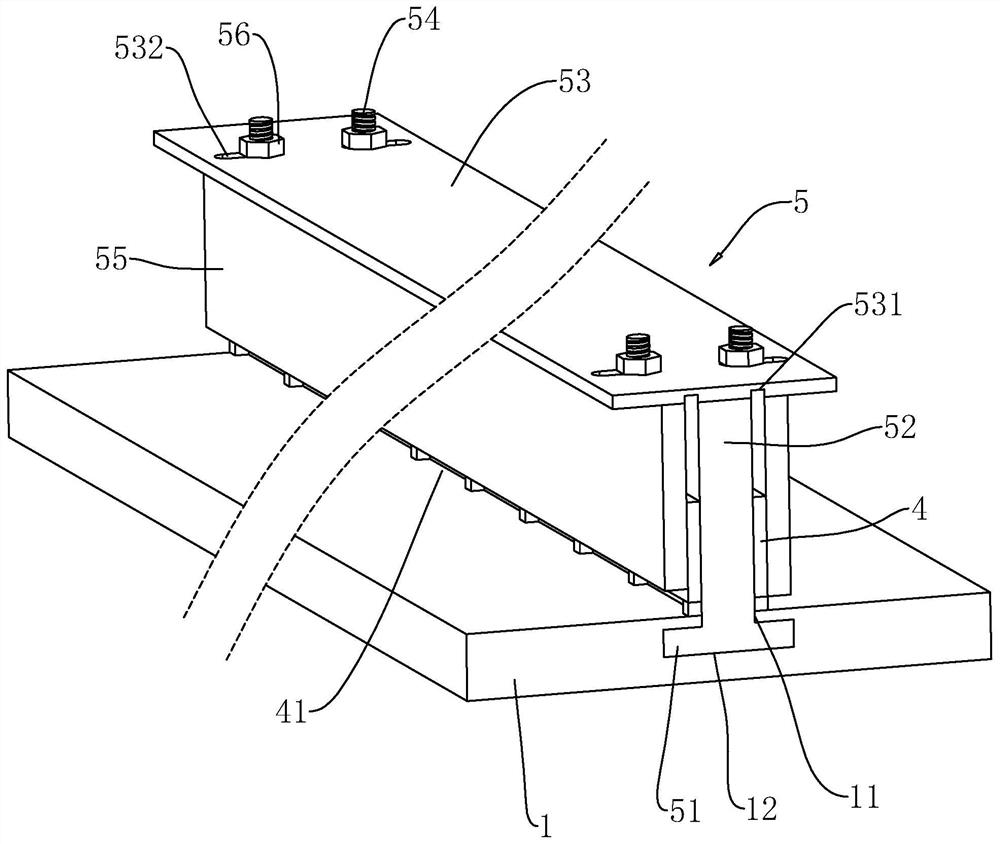

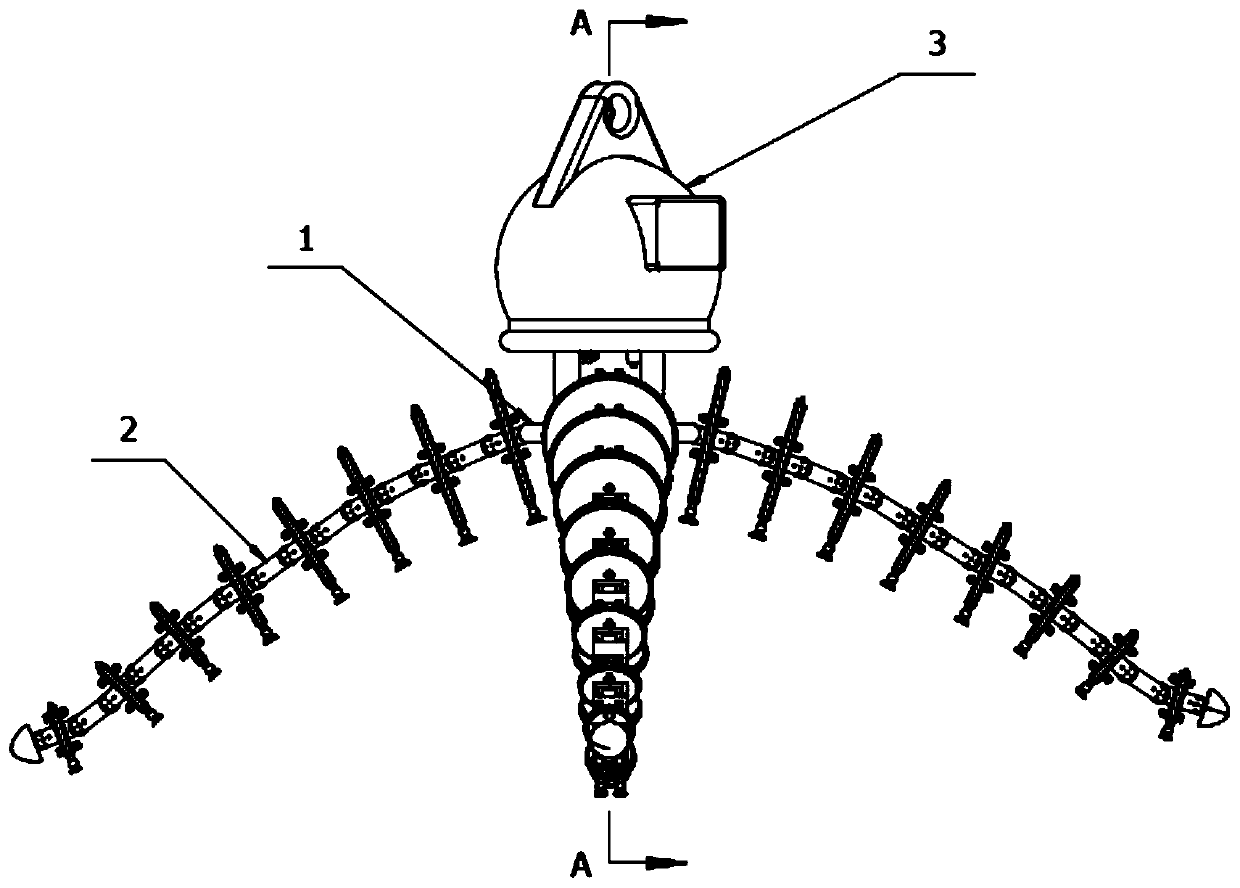

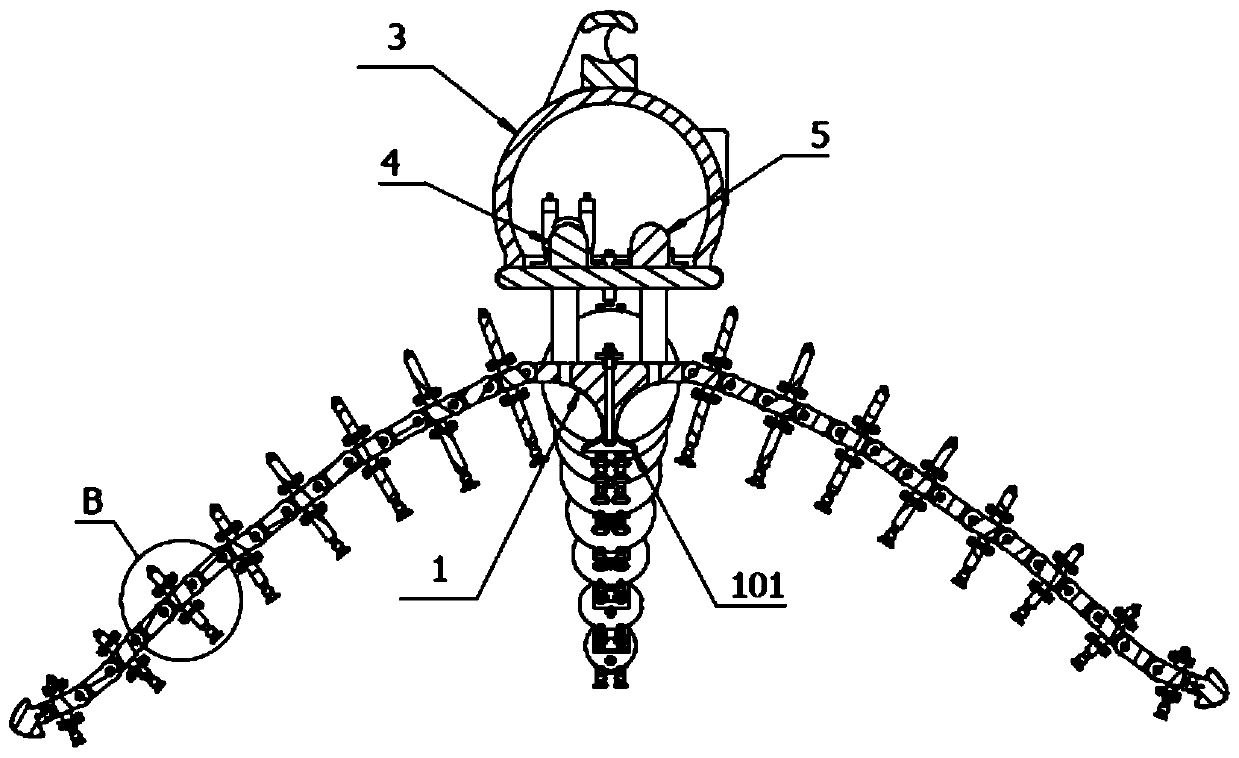

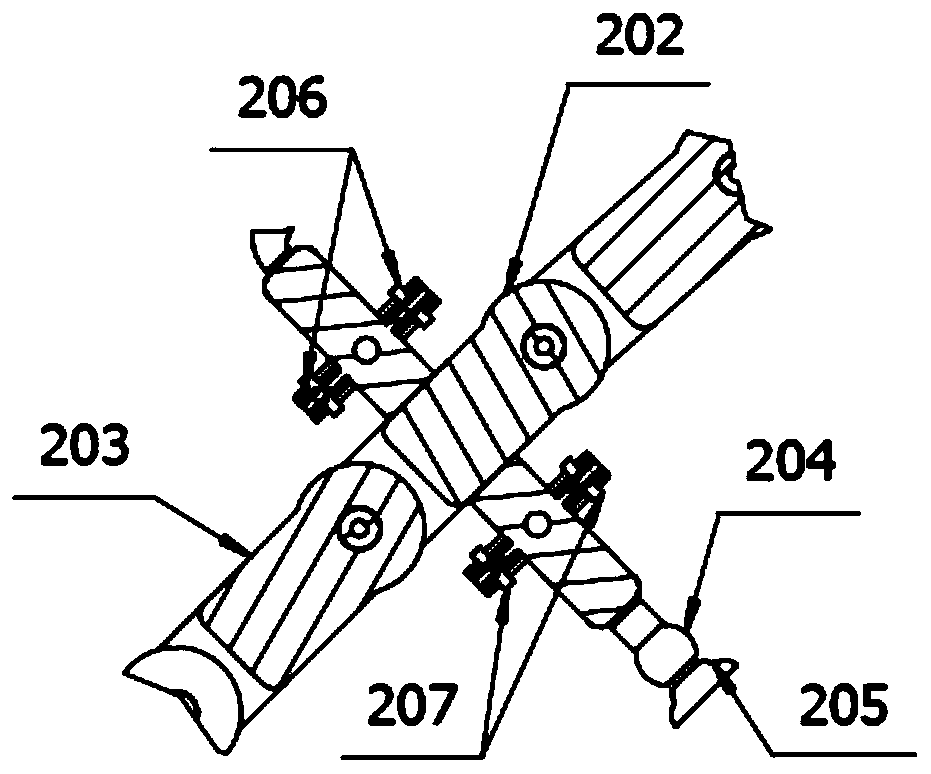

Sling vibration reduction mechanism of large-span suspension bridge

InactiveCN103835236ASolve Vibration ProblemsImprove robustness and reliabilityBridge structural detailsEngineeringSnubber

The invention discloses a sling vibration reduction mechanism of a large-span suspension bridge. The sling vibration reduction mechanism comprises a main cable, a sling clip, slings, a separator, a damper and a lifting lug plate. The slings are connected with the sling clip; the separator is used for separating the slings from each other, and the lifting lug plate is fixedly connected with the sling clip; one side of the damper is connected with the separator by a separator connecting rod, and the other side of the damper is connected with the lifting lug plate by a lifting lug plate connecting rod. The sling vibration reduction mechanism with the structure has the advantages that fundamental vibration frequencies of the slings and modal damping of the slings can be increased, so that vibration energy can be dissipated, the slings cannot meet vibration starting conditions, and the problem of vibration of existing slings can be fundamentally solved.

Owner:SOUTH CHINA UNIV OF TECH

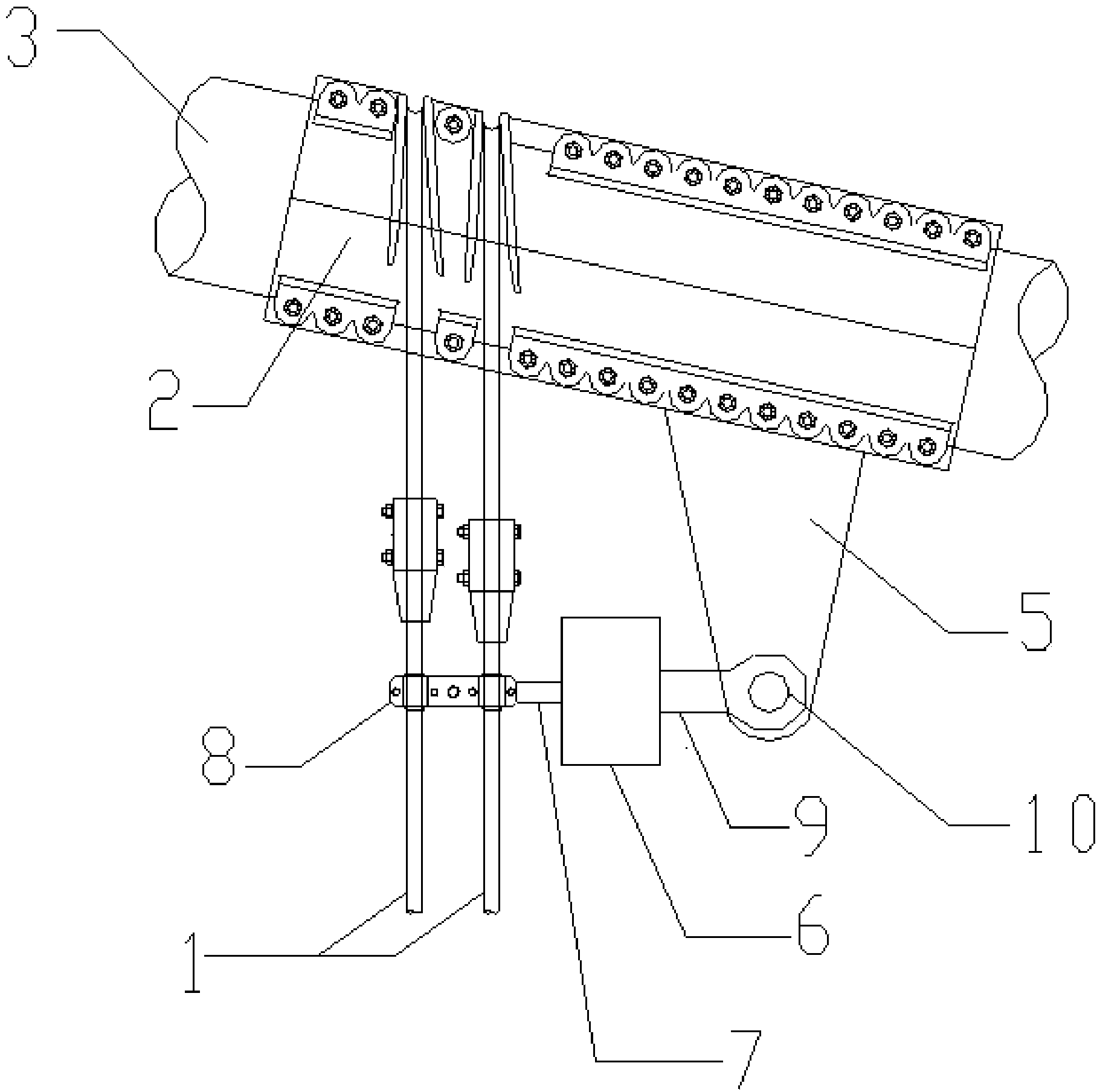

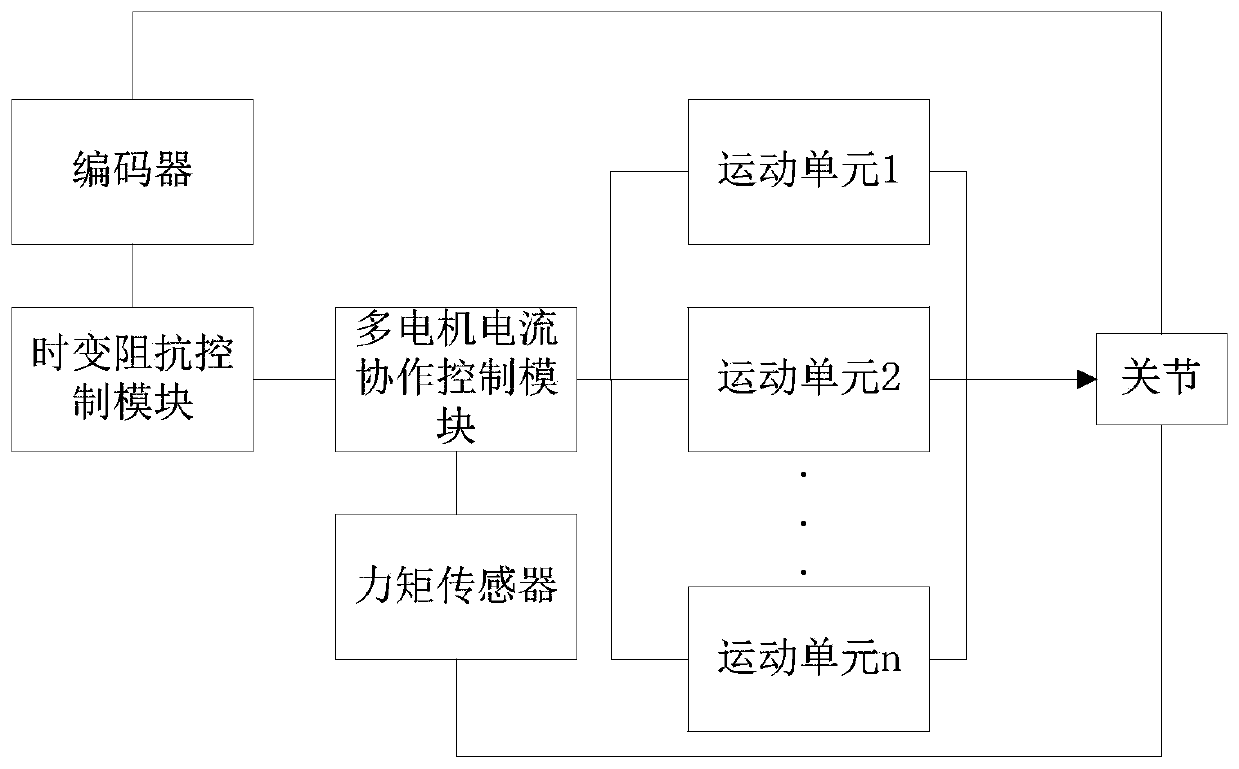

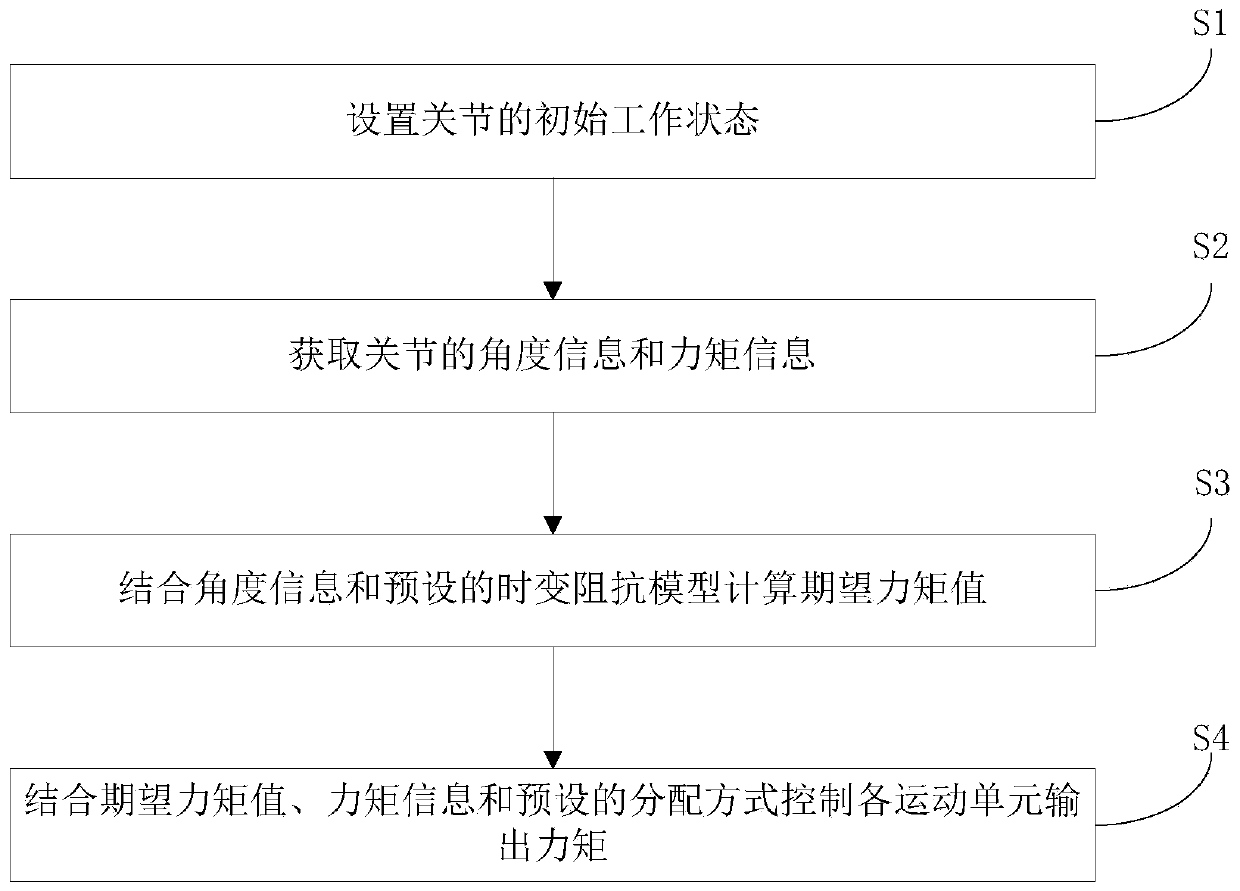

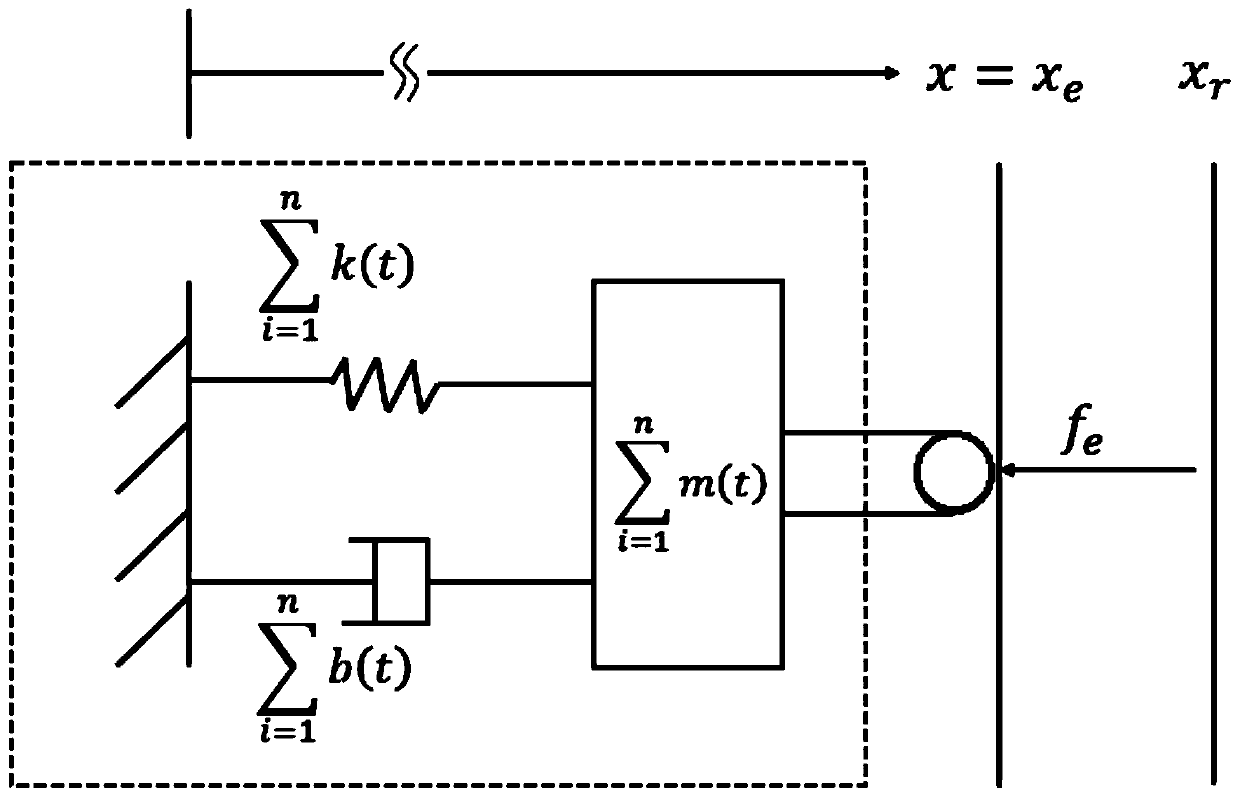

Bionic joint control system and method based on multi-motor drive

ActiveCN110027002AIncrease flexibilityIncrease stiffnessProgramme-controlled manipulatorMotor driveControl system

The invention discloses a bionic joint control system and method based on multi-motor drive. The method comprises the following steps of acquiring angle information and torque information of a joint,calculating a desired torque value by combining the angle information and a preset time-varying impedance model, and controlling each motion unit to output torque by combining an expected torque value, the torque information and a preset distribution mode. According to the control system and the control method, a plurality of motors are adopted to jointly drive the joint, the rigidity of the jointis controlled in real time, so that the plurality of motors can effectively cooperate like multiple pieces of muscles of a living being, the flexibility and the variable rigidity performance of the bionic joint are improved, the problems of poor variable rigidity performance, poor control flexibility and the like are solved, and the bionic joint can be widely applied to the technical field of robot joints.

Owner:深圳市智能机器人研究院

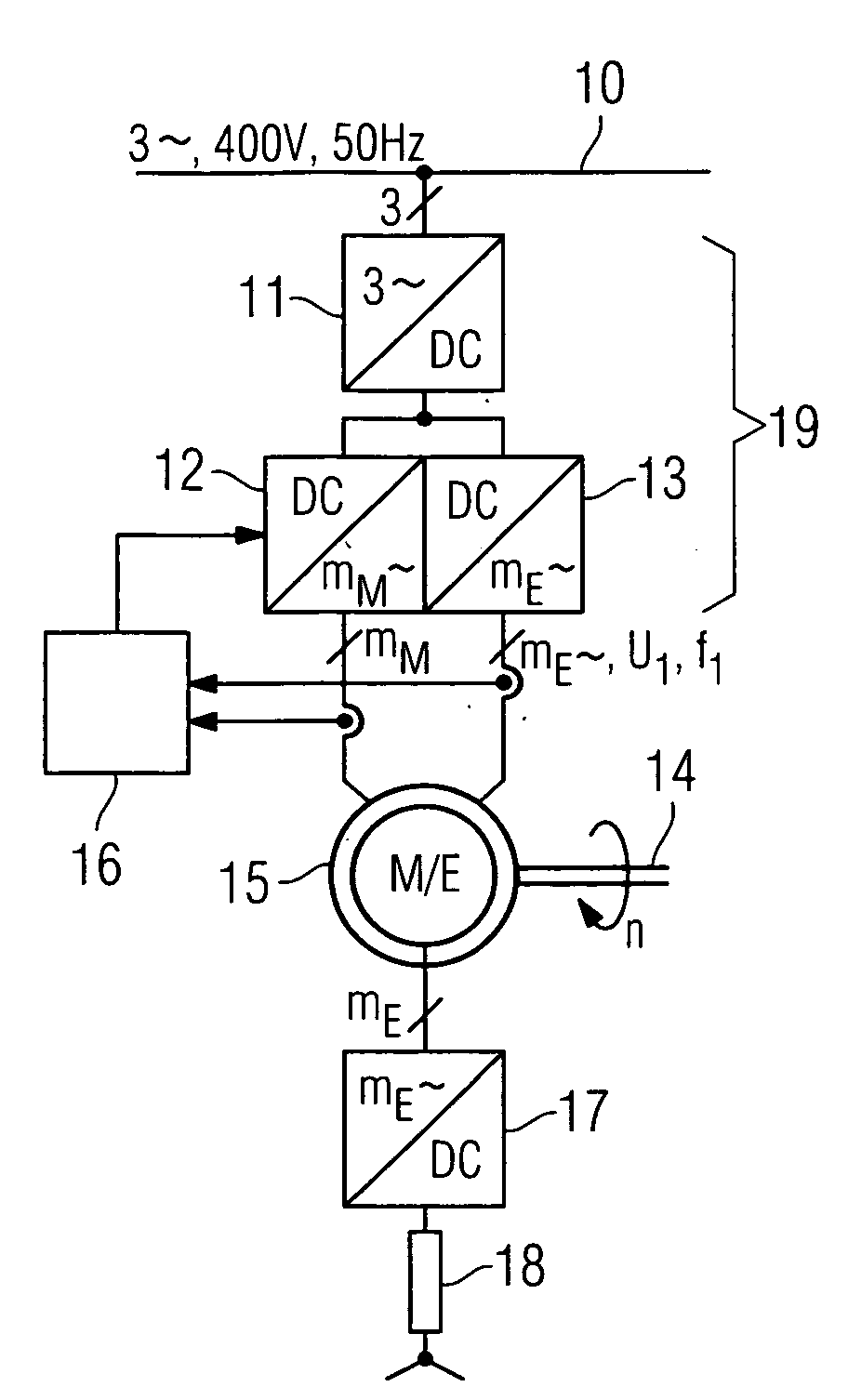

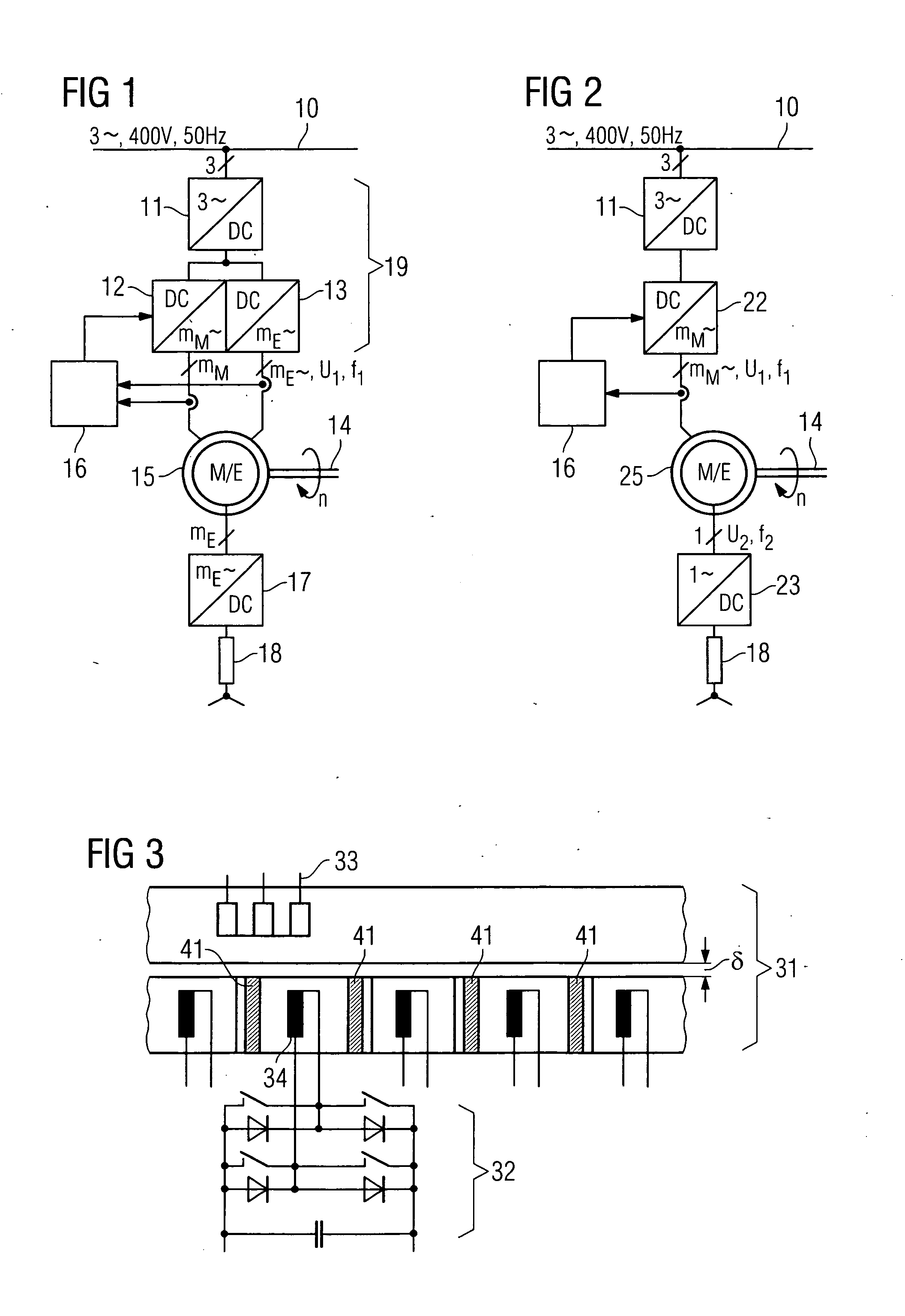

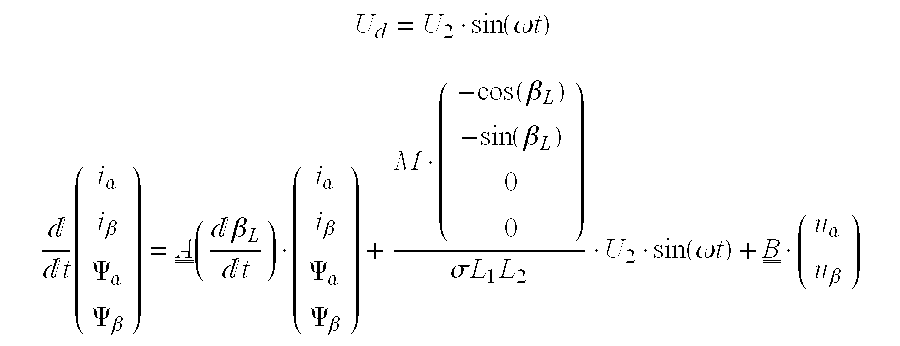

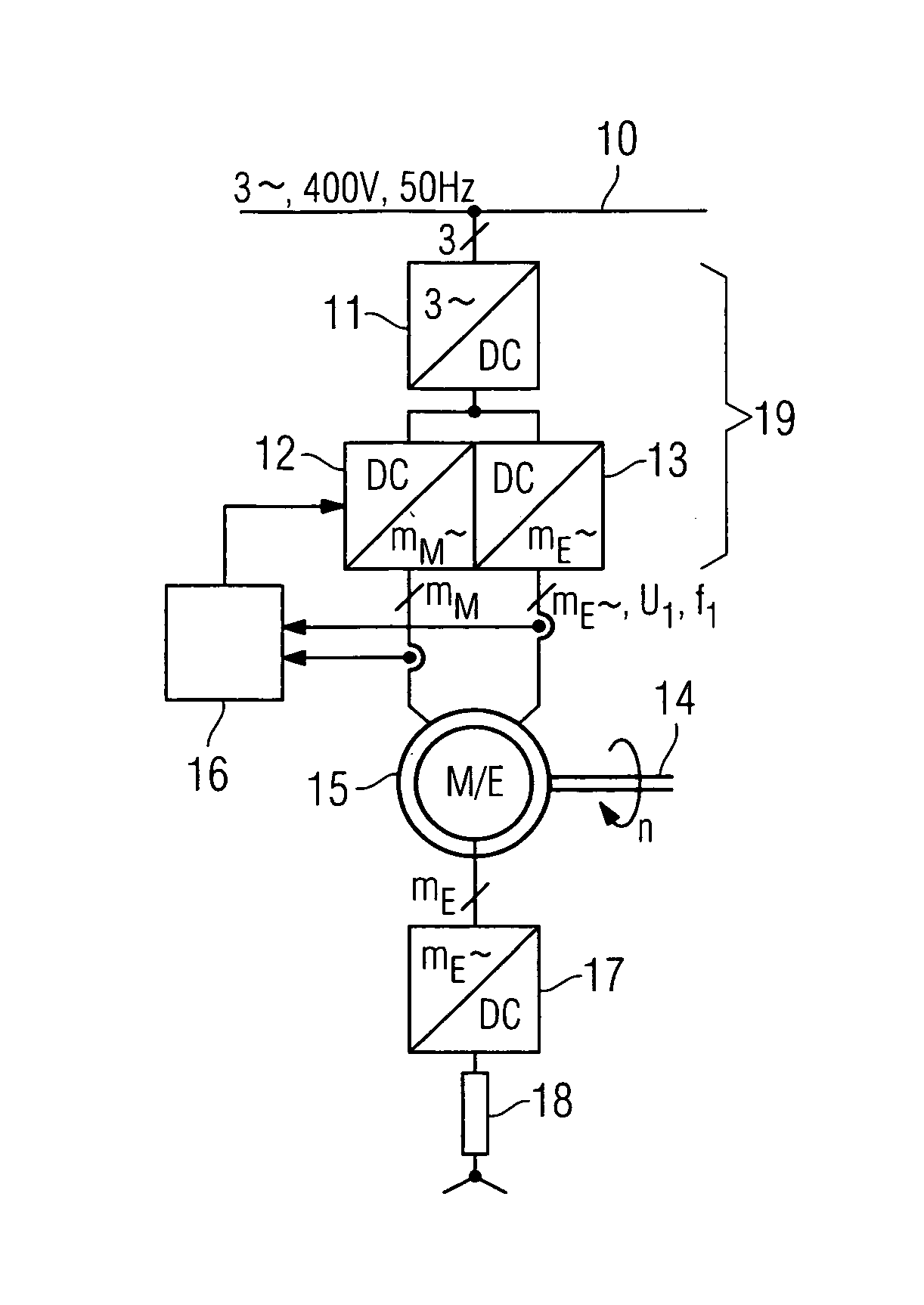

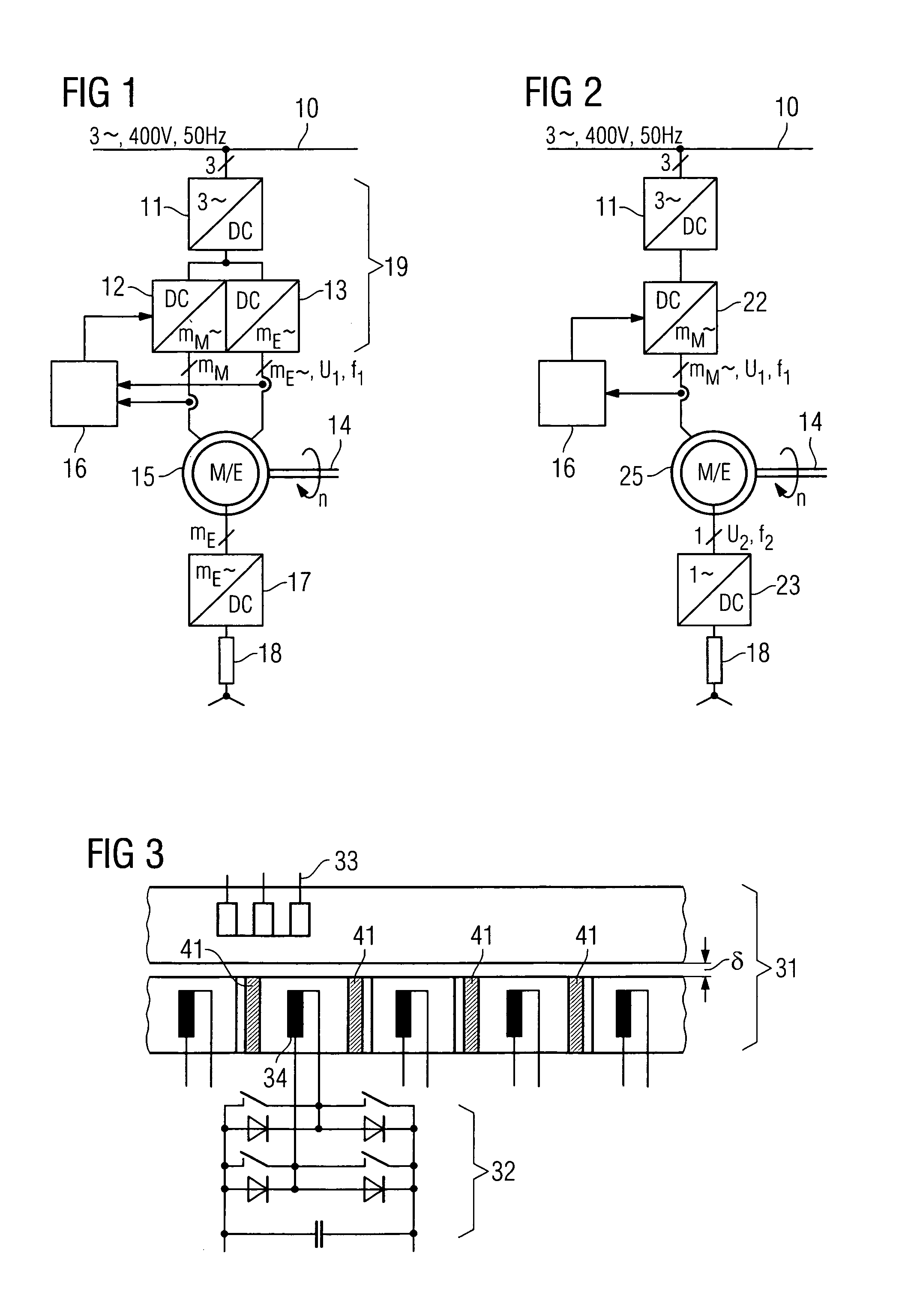

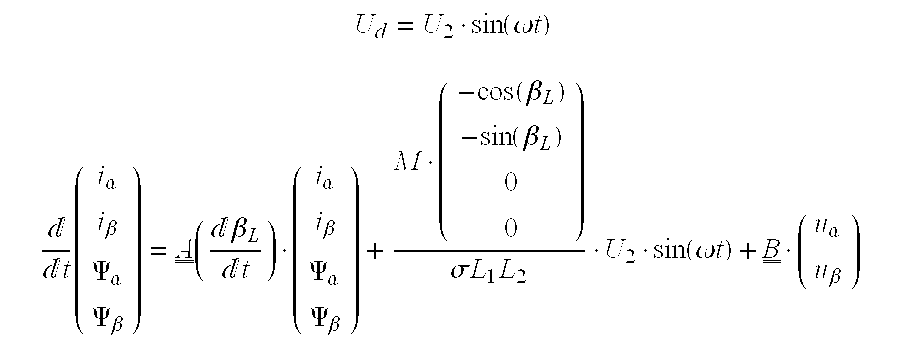

Electric drive unit

ActiveUS20090085505A1Improve robustness and reliabilitySaving complexityGenerator control circuitsMotor/generator/converter stoppersElectricityEngineering

Electric drive units comprising a common active part having a stator and a rotor, which has windings and / or permanent magnets for a drive function and an energy transmission function, enable the rotor winding that is provided for energy transmission to be used to allow position detection at a low additional cost. For this purpose, a power converter in the rotor, which provides the output of electrical energy for the energy transmission function, impresses an alternating voltage into the rotor winding, said voltage being detected in the stator and allowing the rotor position to be determined.

Owner:SIEMENS AG

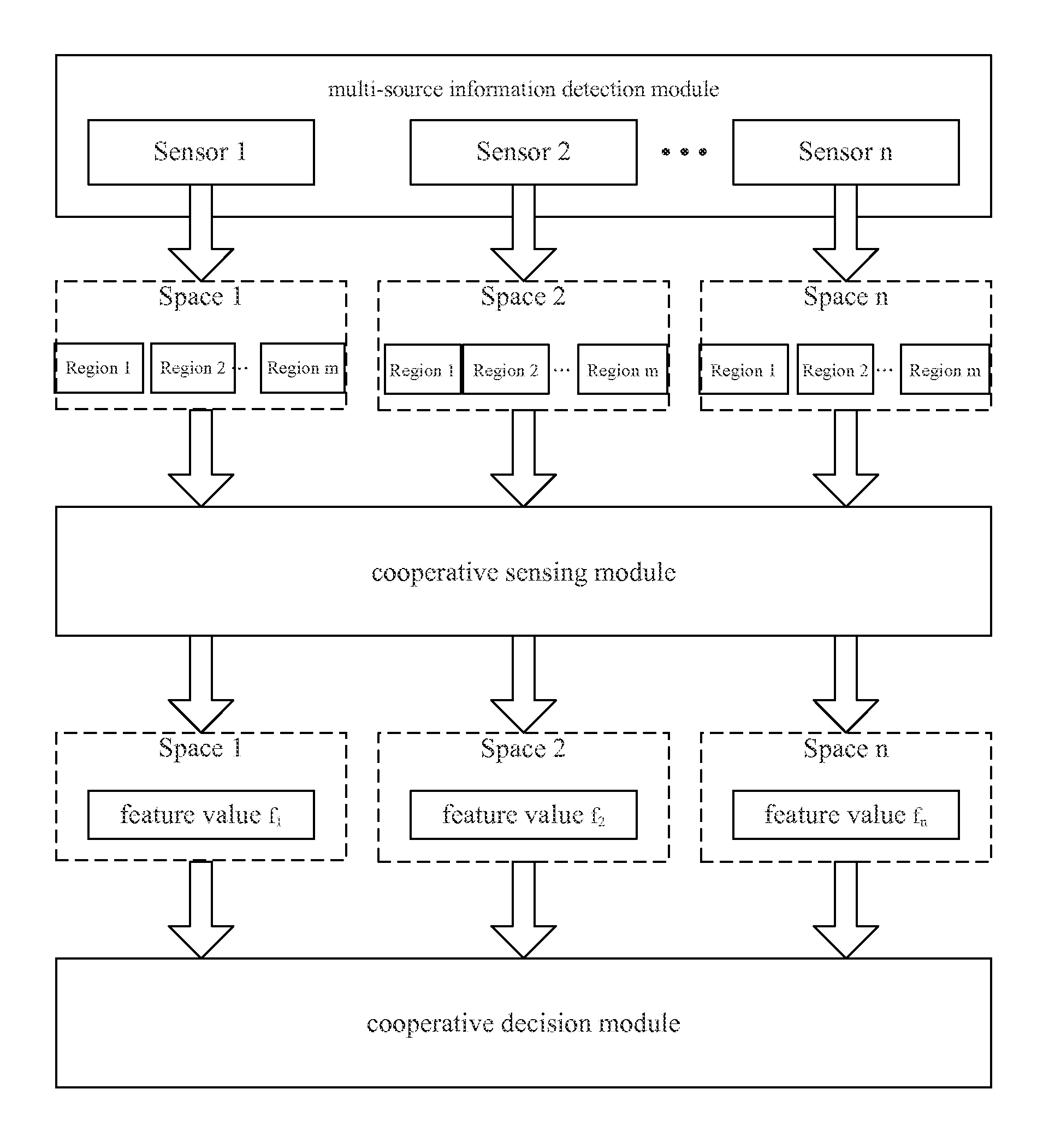

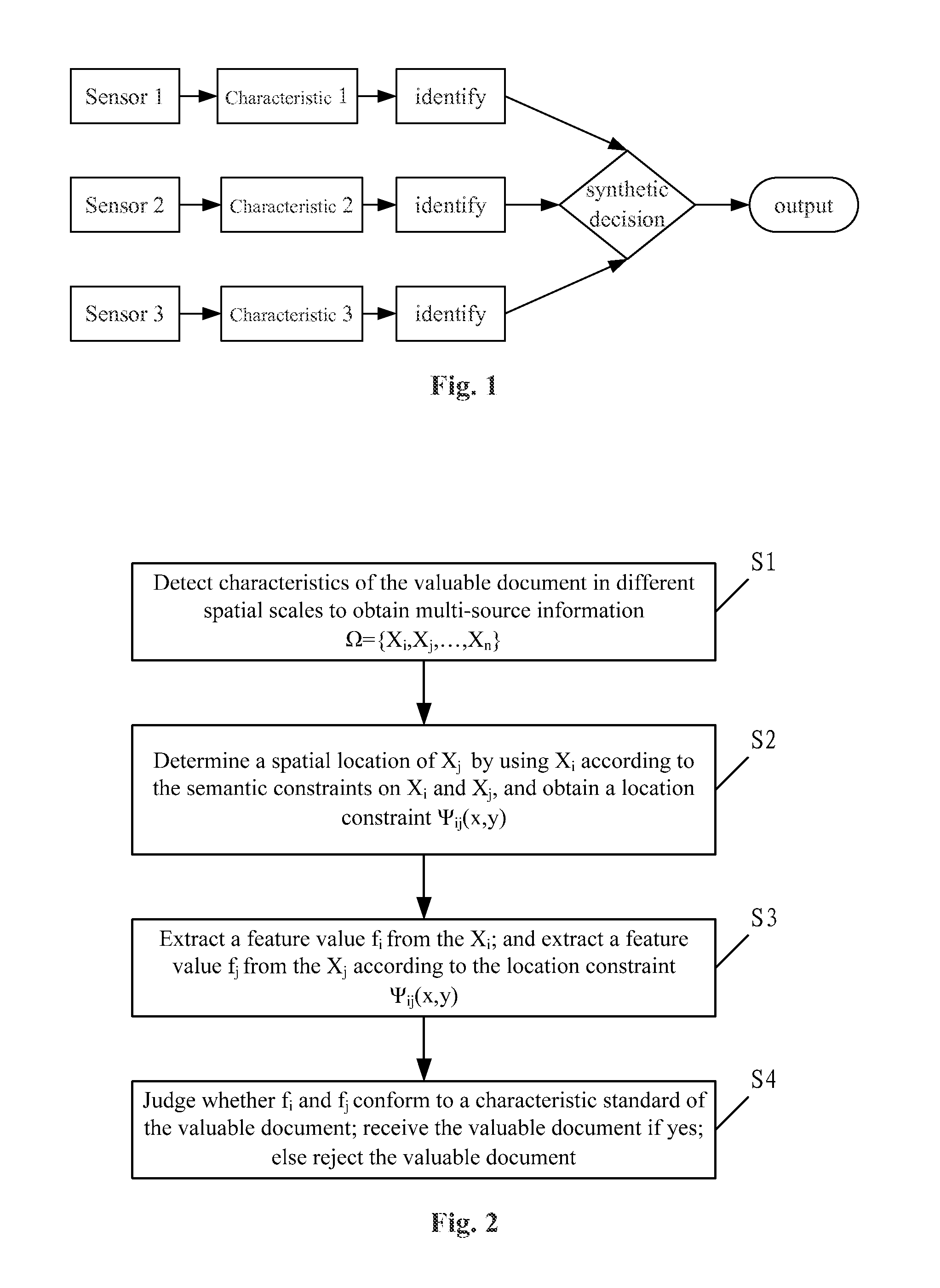

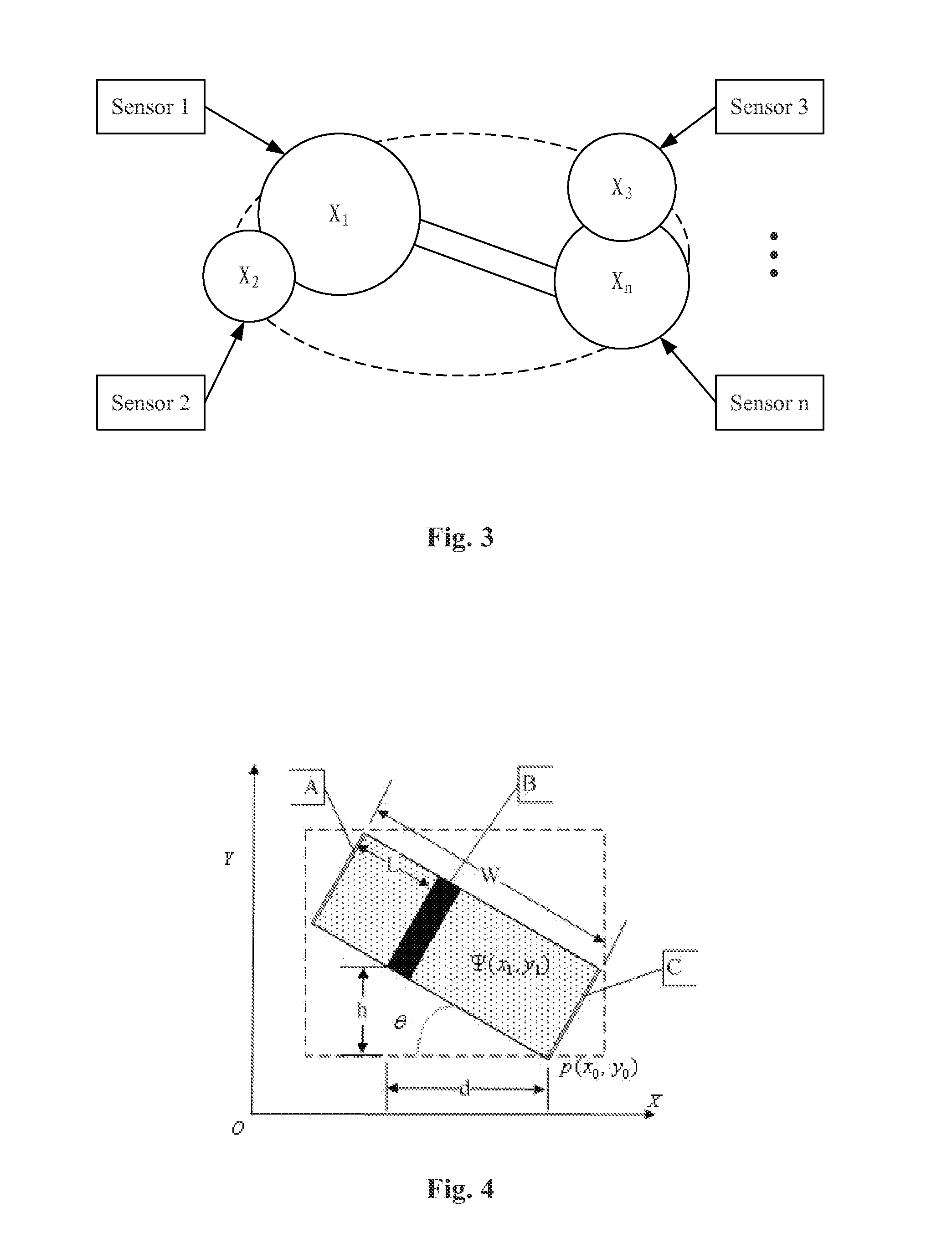

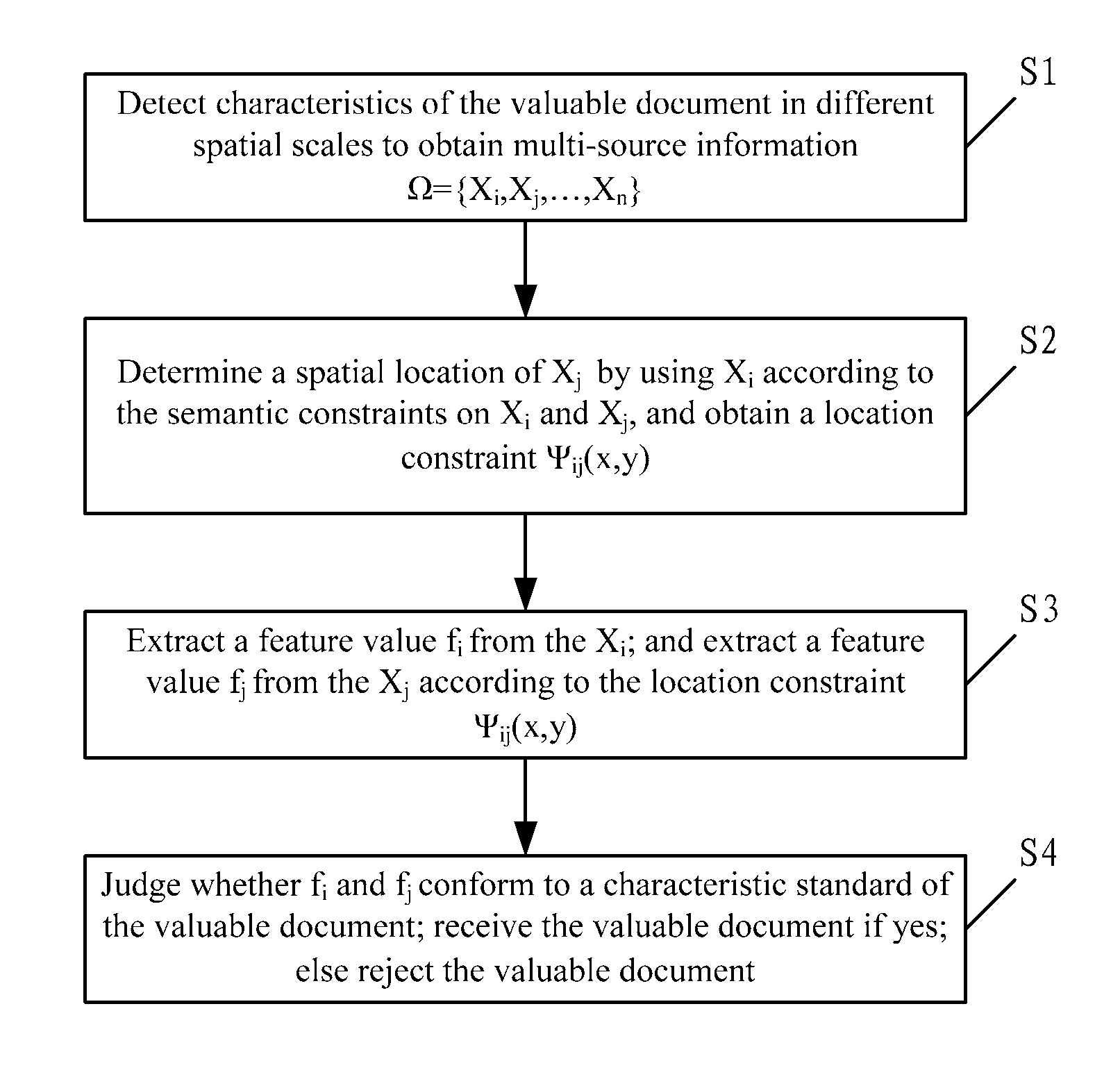

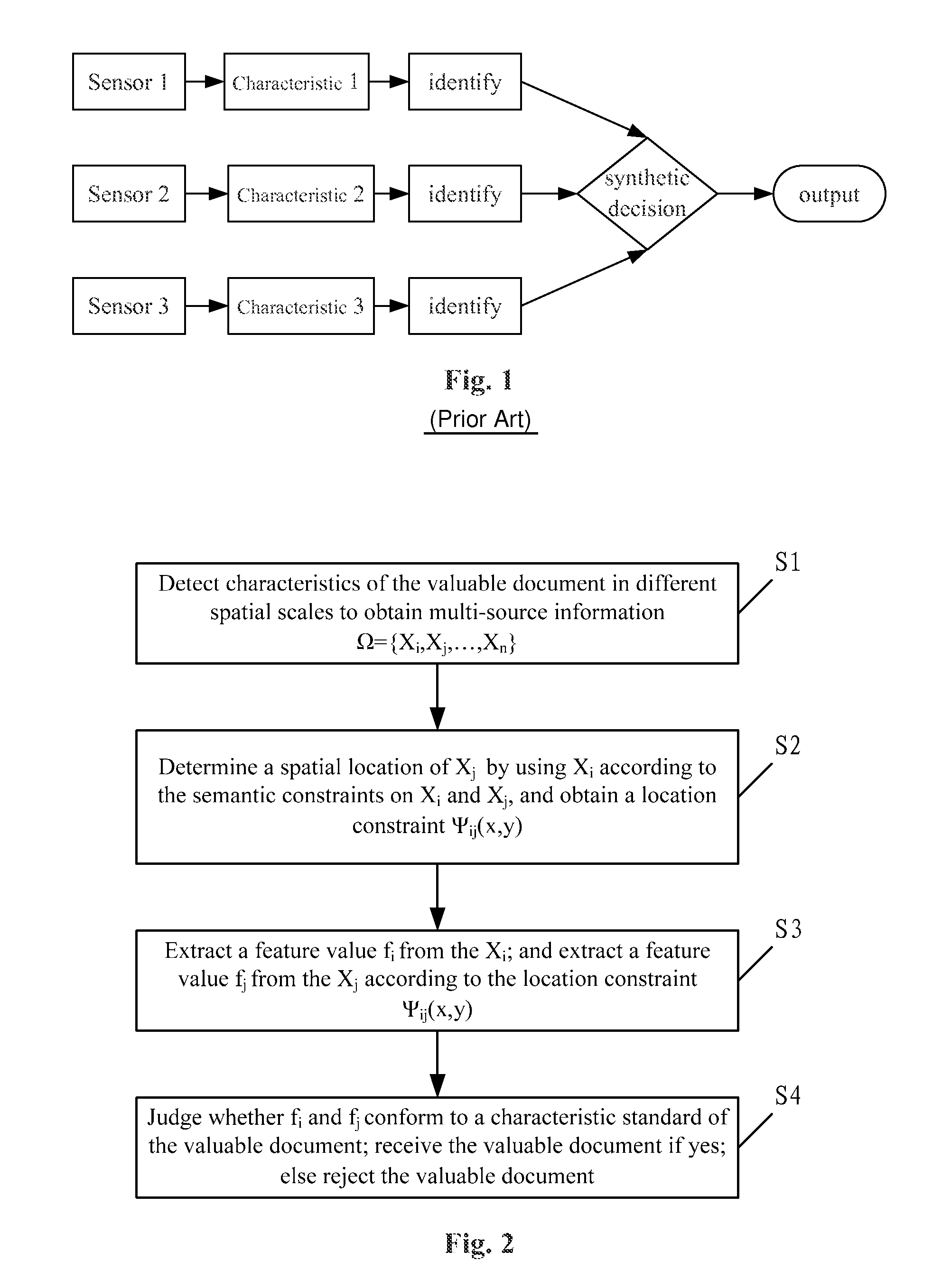

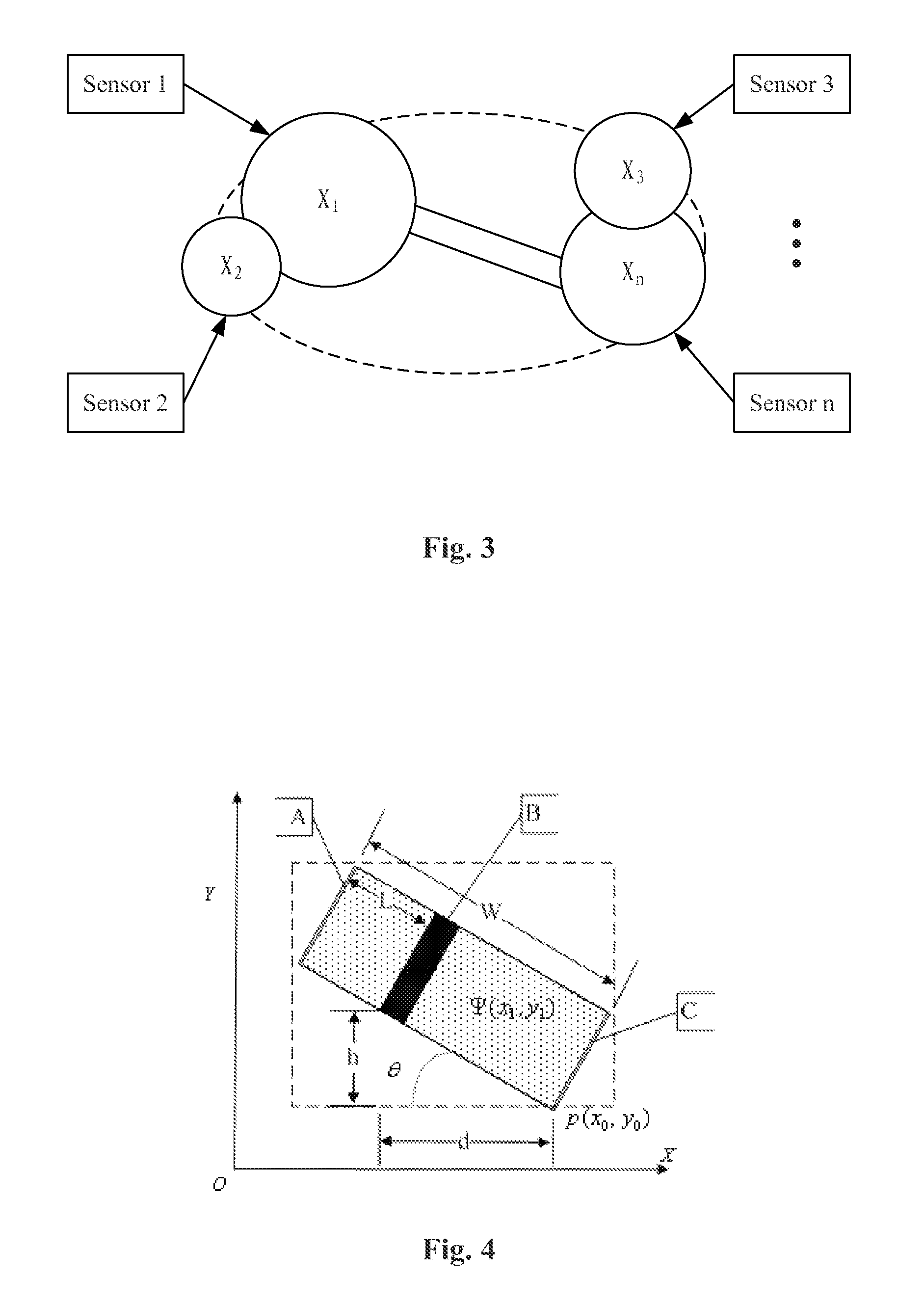

Valuable document identification method and system

InactiveUS20140205177A1Improve accuracyImprove reliabilityPaper-money testing devicesCharacter and pattern recognitionPaper documentDocument preparation

A valuable document identification method and system are provided. The method comprises, detecting features in different space ranges of a valuable document, and obtaining multi-source information Ω={Xi, Xj, . . . , Xn}, wherein Xi∩Xj≠φ, or Xi∩Xj≠φ and Xi<=>Xj; labeling the space position of Xj with Xi according to semantic constraints of Xi and Xj, and obtaining position constraints Ψij(x, y); extracting a characteristic value fi from Xi, and extracting a characteristic value fj from Xj according to the position constrains Ψij(x, y); determining whether fi, fj meet the characteristic criteria of the valuable document, if yes, then receiving the valuable document, or else, rejecting the valuable document. The method enables improved reliability and robustness of the valuable document identification system.

Owner:GRG BAKING EQUIP CO LTD

Method and control and detection unit for checking the plausibility of a wrong-way driving incident of a motor vehicle

ActiveUS9786166B2Improve robustness and reliabilityImprove securityArrangements for variable traffic instructionsAnti-collision systemsMobile vehicleWrong-way driving

In a method for checking the plausibility of a wrong-way driving of a motor vehicle when entering a unidirectional roadway, a traversing of a stop line or a solid line of a junction of the unidirectional roadway is detected and / or at least one item of directional information of a roadway of the junction, which is located ahead of the motor vehicle, is collected, and a probability of a wrong-way driving is ascertained based on the detection. The method is performed by a control and detection unit for checking the plausibility of a wrong-way driving.

Owner:ROBERT BOSCH GMBH

Method of fusing multiple information sources in image-based gesture recognition system

ActiveUS9335826B2Improve robustness and reliabilityEasy to useInput/output for user-computer interactionGraph readingInformation modellingStatistical model

Owner:ROBERT BOSCH GMBH

Method and control and detection device for determining the plausibility of a wrong-way travel of a motor vehicle

ActiveUS9767686B2Improve robustness and reliabilityReliable travelInstruments for road network navigationAnti-collision systemsMobile vehicleSimulation

A method for determining the plausibility of wrong-way travel of a motor vehicle when entering a directional roadway, including detecting at least one curve information item of a current travel path, ascertaining at least one curve information item of a permitted travel path, determining a deviation between the detected and ascertained curve information items, and plausibilizing a wrong-way travel if a deviation exists or a deviation limit value is breached. A control / detection device for determining the plausibility of wrong-way travel when entering a directional roadway, includes an arrangement for detecting at least one curve information item of a current travel path; an arrangement for ascertaining at least one curve information item of a permitted travel path; an arrangement for determining a deviation between detected and ascertained curve information items; and an arrangement for determining the plausibility of wrong-way travel if a deviation exists or a deviation limit value is breached.

Owner:ROBERT BOSCH GMBH

Electric drive unit

ActiveUS8102143B2Improve robustness and reliabilitySaving complexityElectronic commutation motor controlGenerator control circuitsElectricityEngineering

Electric drive units comprising a common active part having a stator and a rotor, which has windings and / or permanent magnets for a drive function and an energy transmission function, enable the rotor winding that is provided for energy transmission to be used to allow position detection at a low additional cost. For this purpose, a power converter in the rotor, which provides the output of electrical energy for the energy transmission function, impresses an alternating voltage into the rotor winding, said voltage being detected in the stator and allowing the rotor position to be determined.

Owner:SIEMENS AG

Valuable document identification method and system

InactiveUS9014458B2Improve robustness and reliabilityImprove applicabilityPaper-money testing devicesCharacter and pattern recognitionIdentification system

A valuable document identification method and system are provided. The method comprises, detecting features in different space ranges of a valuable document, and obtaining multi-source information Ω={Xi, Xj, . . . , Xn}, wherein Xi∩Xj≠φ, or Xi∩Xj≠φ and Xi<=>Xj; labeling the space position of Xj with Xi according to semantic constraints of Xi and Xj, and obtaining position constraints Ψij(x, y); extracting a characteristic value fi from Xi, and extracting a characteristic value fj from Xj according to the position constrains Ψij(x, y); determining whether fi, fj meet the characteristic criteria of the valuable document, if yes, then receiving the valuable document, or else, rejecting the valuable document. The method enables improved reliability and robustness of the valuable document identification system.

Owner:GRG BAKING EQUIP CO LTD

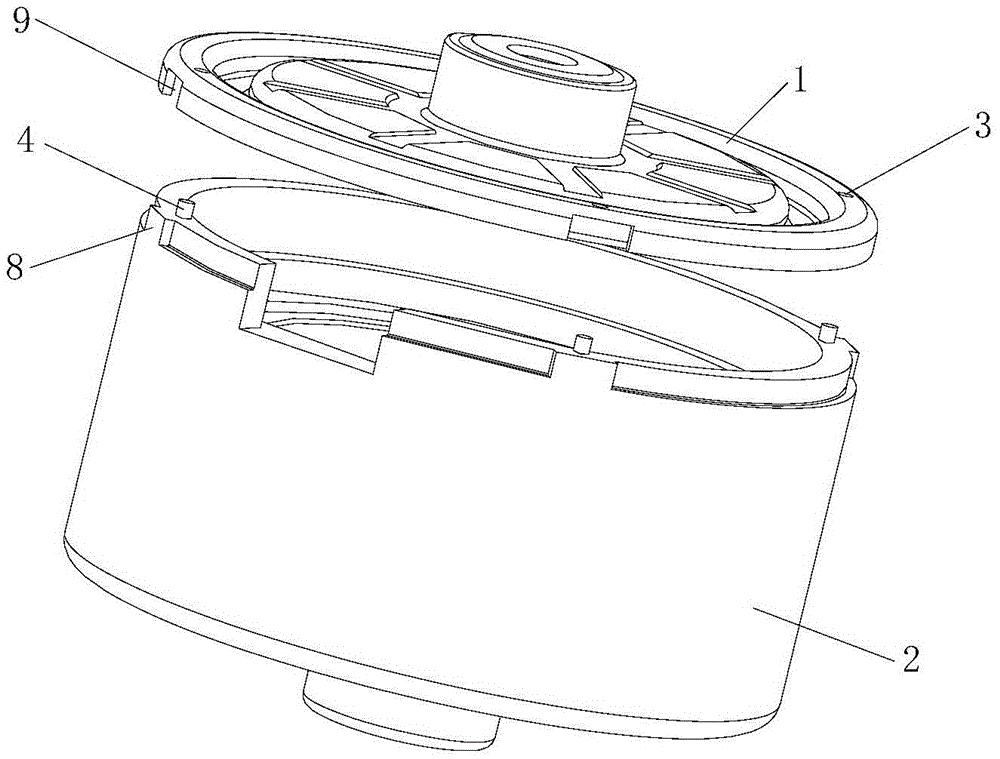

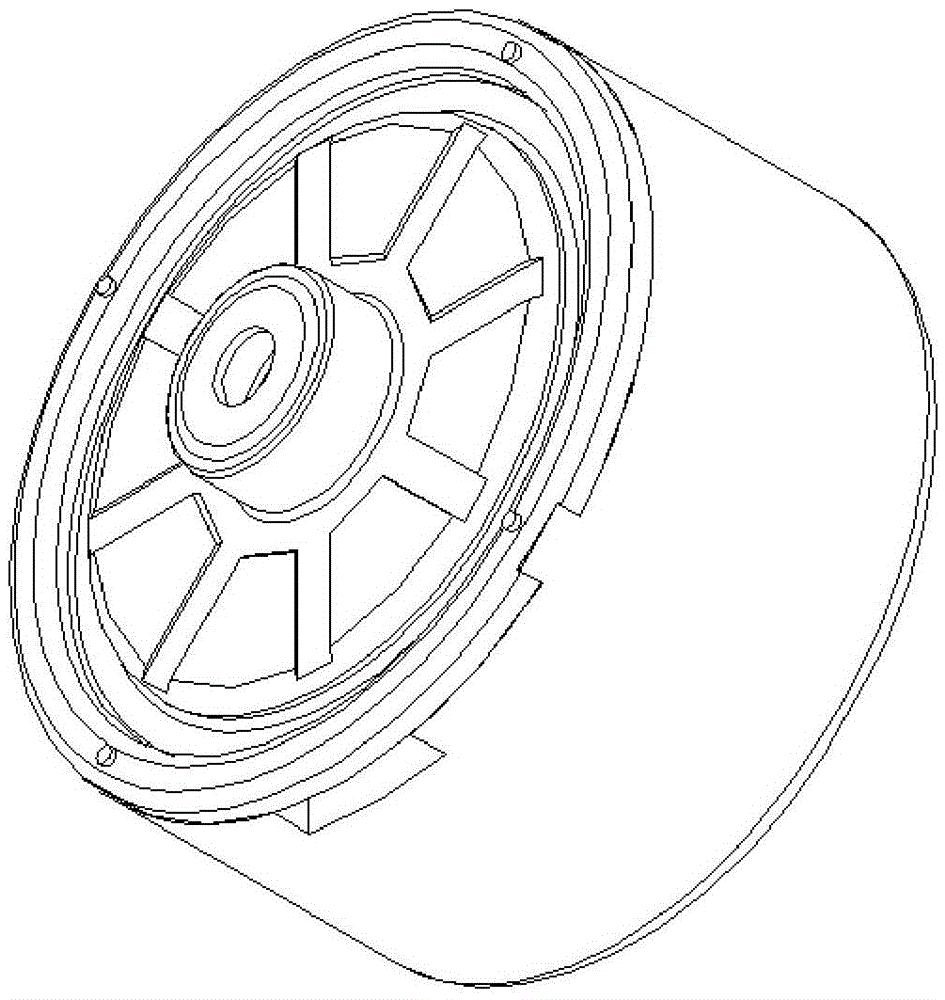

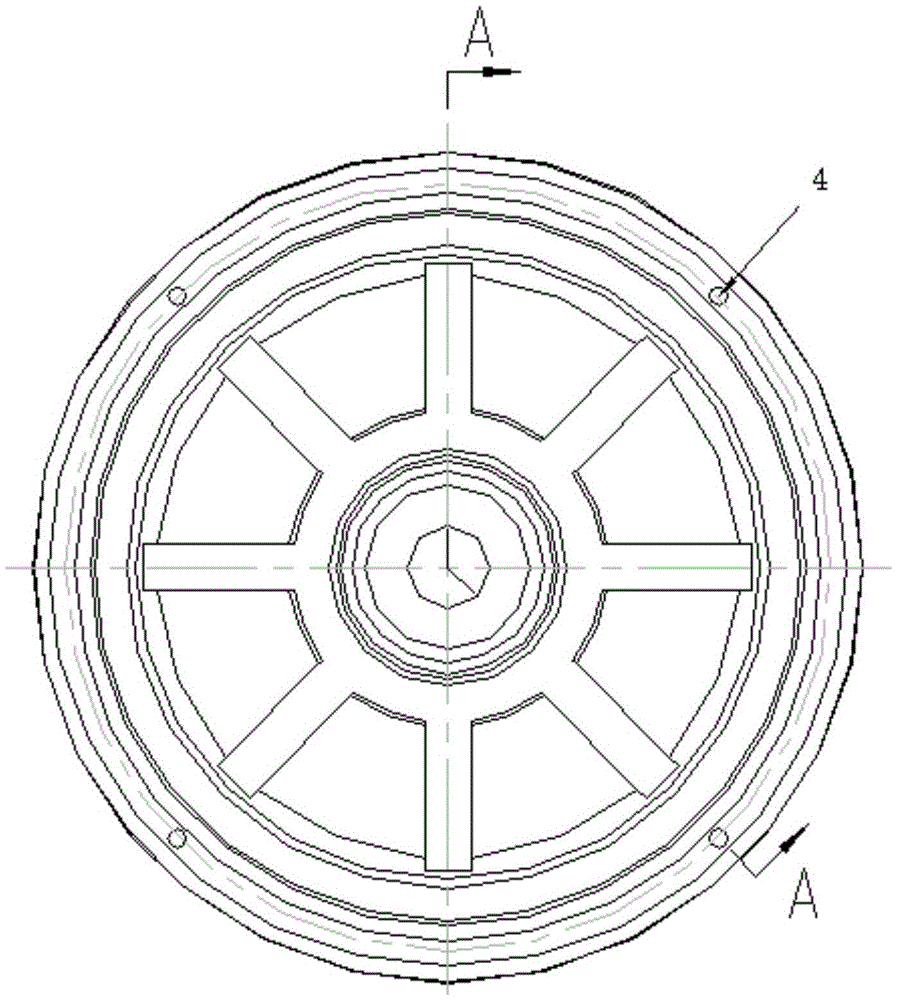

Plastic package motor with anti-loose end cover

InactiveCN105553161AImprove robustness and reliabilityEnsure stable operationStructural associationSupports/enclosures/casingsFastenerStator

The invention discloses a plastic package motor with an anti-loose end cover, comprising a plastic package stator, a plastic package motor end cover and a connection fastener; the plastic package stator comprises a plastic package shell body and a motor part installed in the plastic package shell body; a fixing hole is arranged on the plastic package motor end cover; the connection fastener penetrates the fixing hole to fix the plastic package motor end cover at the end part of the plastic package shell body. According to the invention, the plastic package stator and the plastic package motor end cover are connected together through the connection fastener; the assembly firmness and reliability between the plastic package stator and the plastic package motor end cover are improved; the mechanical property and the stable operation of the plastic package motor are ensured; and the risk that the end cover falls off after long term operation of the motor because the tolerance of the assembly size of the end cover is instable is avoided.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

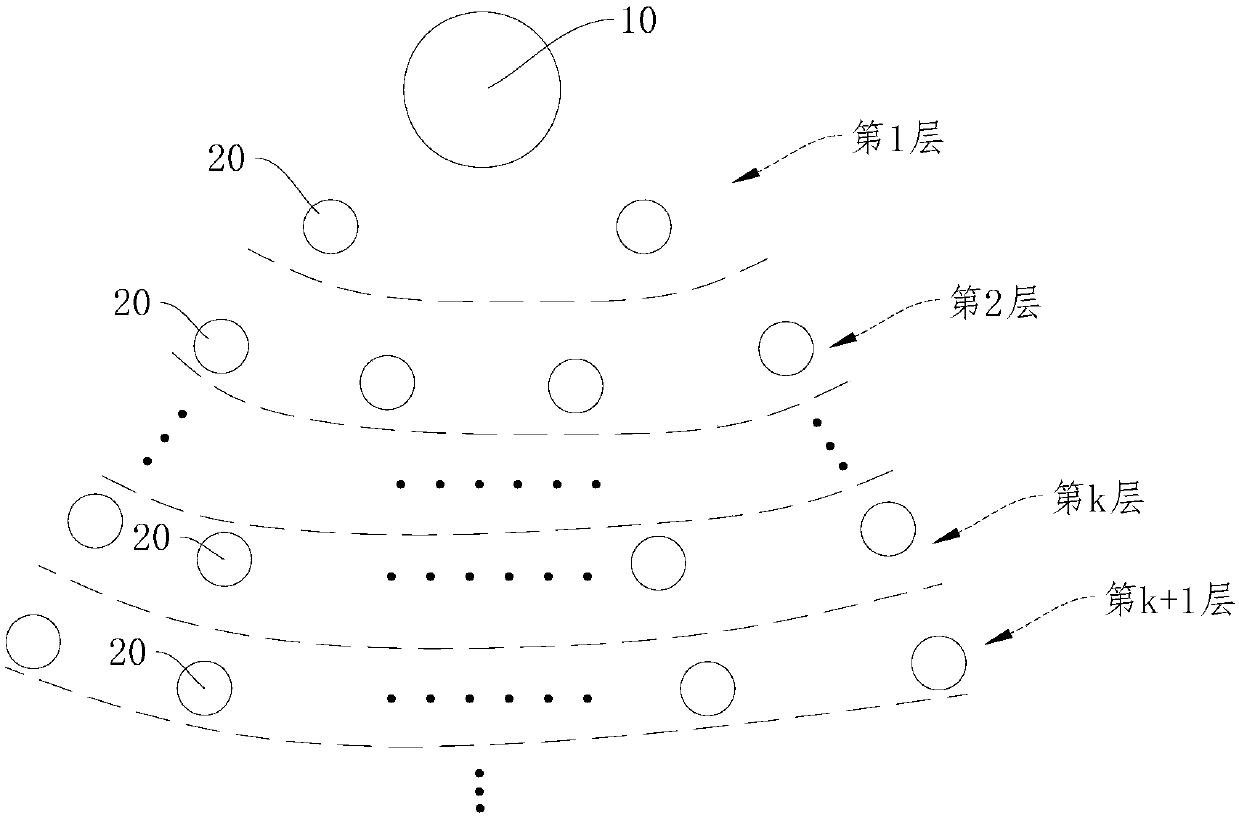

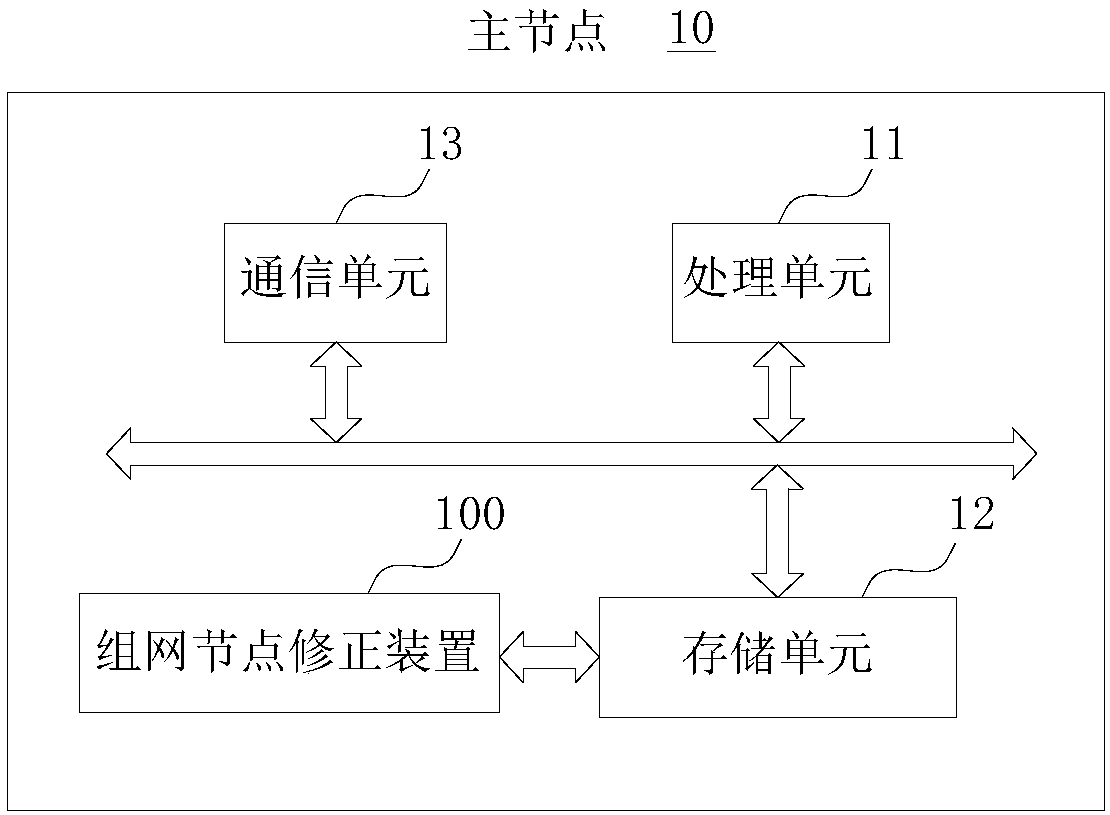

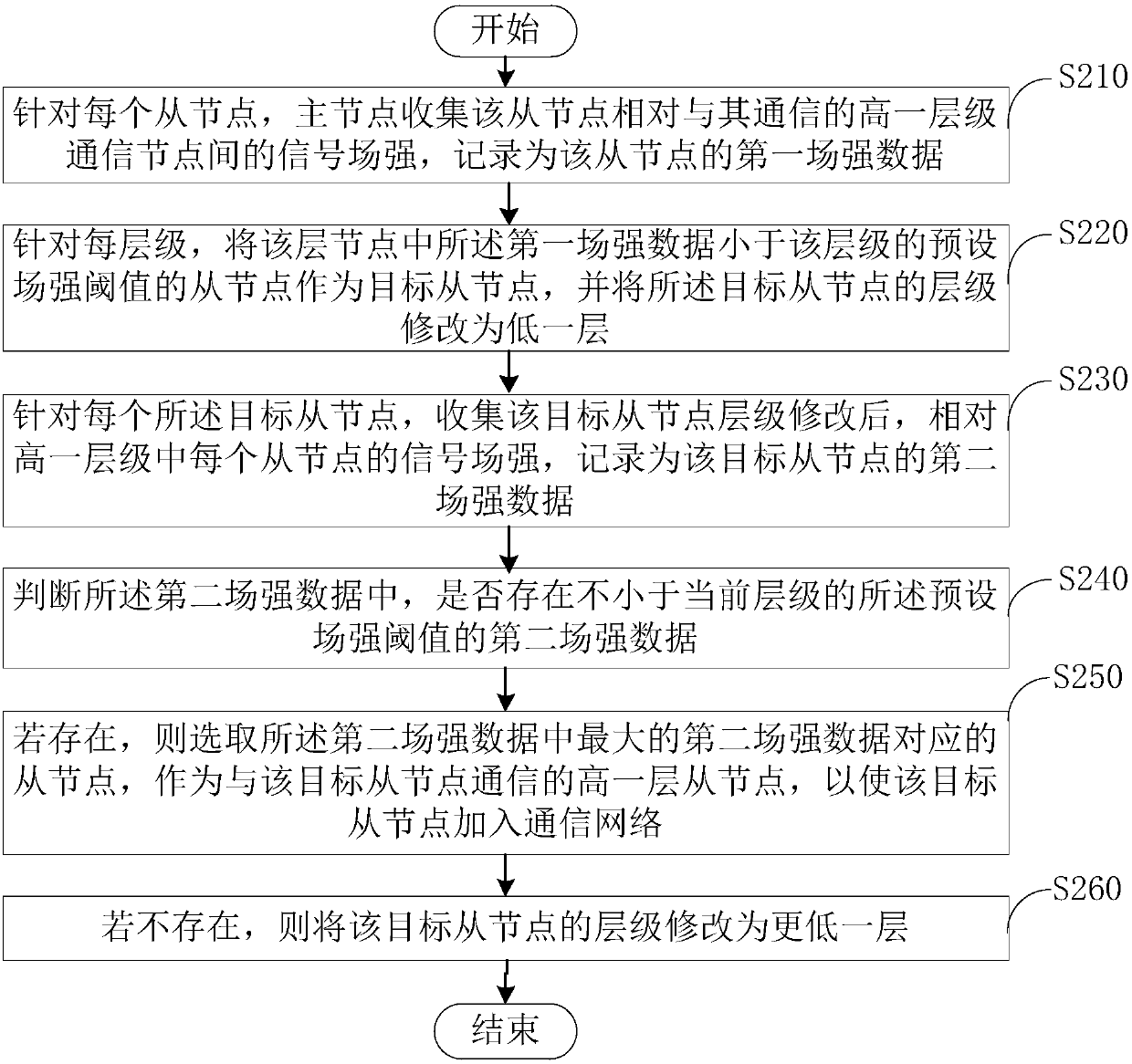

Networking node correcting method and device

ActiveCN107786390AImprove robustness and reliabilityEnsure smooth communicationData switching networksField intensityComputer science

The invention provides a networking node correcting method and device, and relates to the technical field of networking. In the method, communication nodes in a communication network can be correctedto improve robustness and reliability of the communication network, and smooth communication of all the communication nodes is ensured. Particularly, according to the scheme, field intensity data of communication node of a higher hierarchy relative to sub-nodes of each hierarchy is collected, the layer of the sub-nodes with the field intensity data smaller than the field intensity threshold valueof the corresponding hierarchy is revised to that of a lower hierarchy; if the field intensity data of the sub-nodes of the lower hierarchy relative to the sub-nodes of the higher hierarchy is still smaller than the corresponding threshold value, the revised sub-nodes of the lower hierarchy are revised to the further lower layer, so that the field intensity data of the sub-nodes of the revised hierarchy is larger than or equal to the field intensity threshold value of sub-nodes of the corresponding upper hierarchy, and then robustness of the communication network is improved.

Owner:武汉友讯达科技有限公司

H-shaped steel welding process

ActiveCN112388122AImprove connection strengthImprove welding precisionWelding/cutting auxillary devicesSheet joiningMetallurgyEngineering

The invention relates to an H-shaped steel welding process, and relates to the field of steel welding processes. The H-shaped steel welding process comprises the following steps that blanking is conducted; pre-assembling is conducted, specifically, guiding pieces are welded to the opposite sides of an upper wing plate and a lower wing plate; the H-shaped steel is assembled, specifically, the upperwing plate and a web plate and the lower wing plate and the web plate are guided and assembled through the guiding pieces; positioning welding is conducted, specifically, the ends of the assembled H-shaped steel are subjected to spot welding, then the joint between the upper wing plate and the web plate and the joint between the lower wing plate and the web plate are welded, finally, the guidingpiece located on the upper wing plate and one side of the web plate are welded and fixed, and the guiding piece located on the lower wing plate and the other side of the web plate are welded and fixed; straightening is conducted, specifically, the welded H-shaped steel is straightened; and inspection is conducted, specifically, the welding precision and the bending resistance of the finished product are inspected. The welding process has the effect of improving the welding precision among the upper wing plate, the lower wing plate and the web plate during welding.

Owner:安徽中纪建设集团股份有限公司

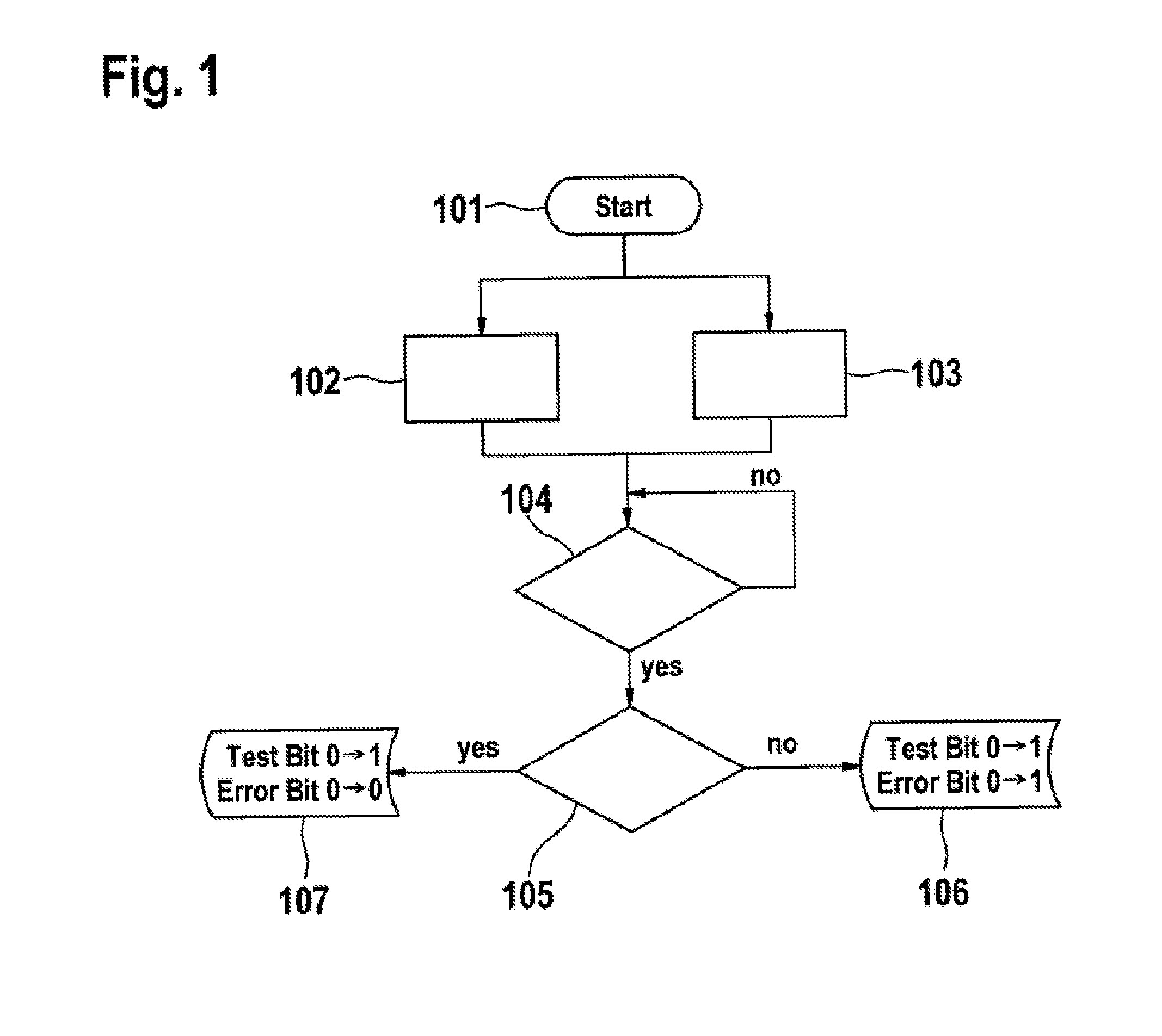

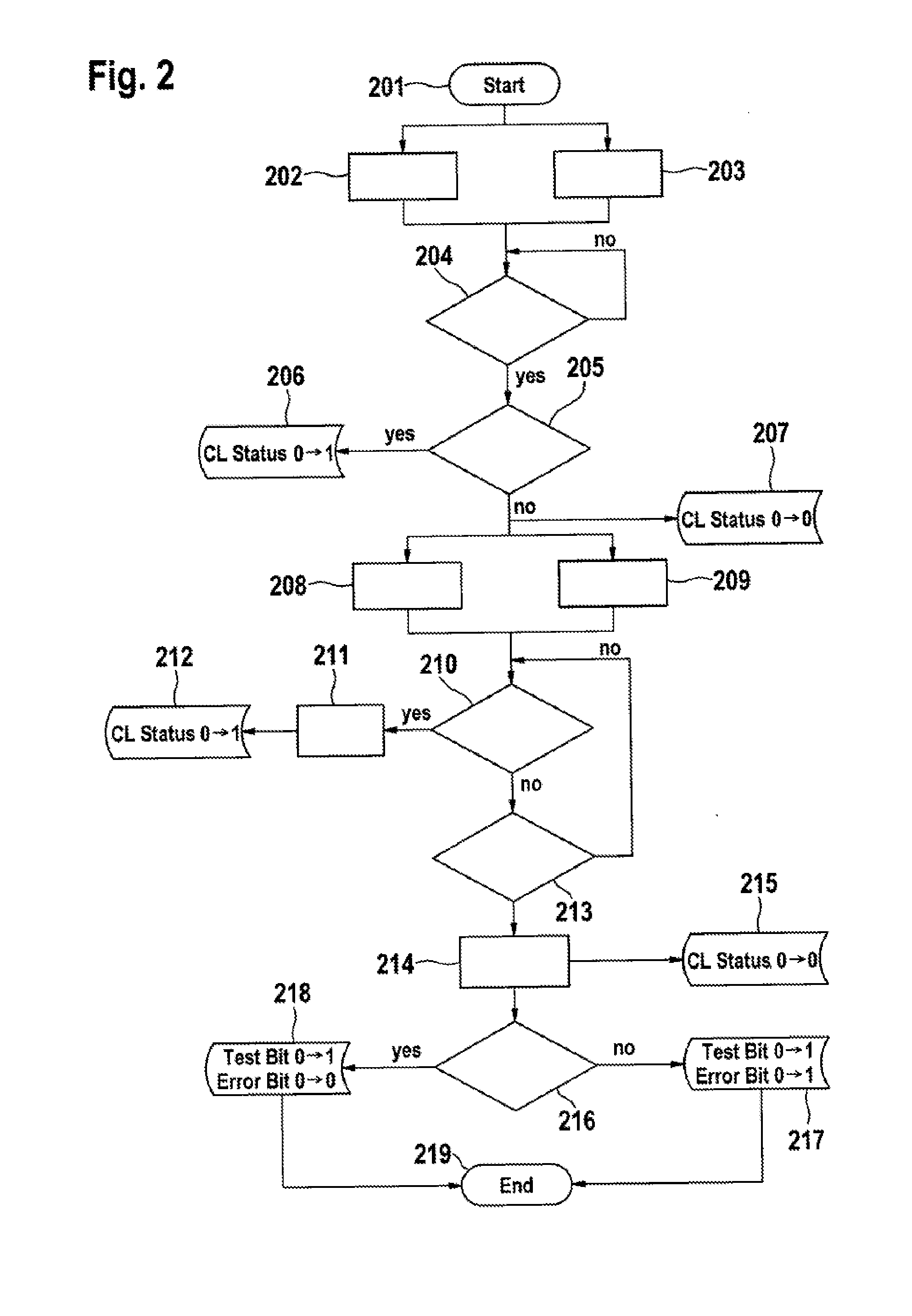

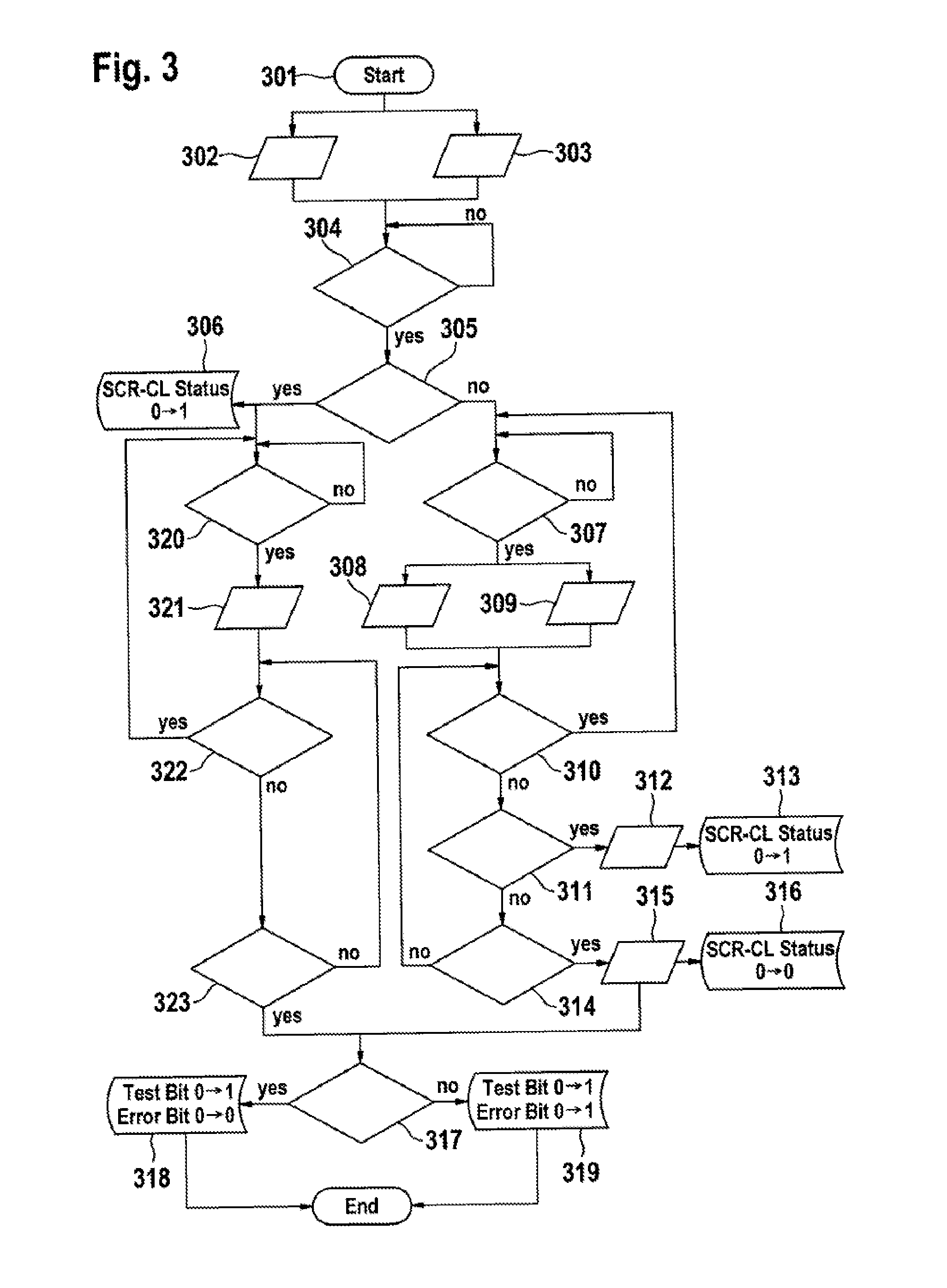

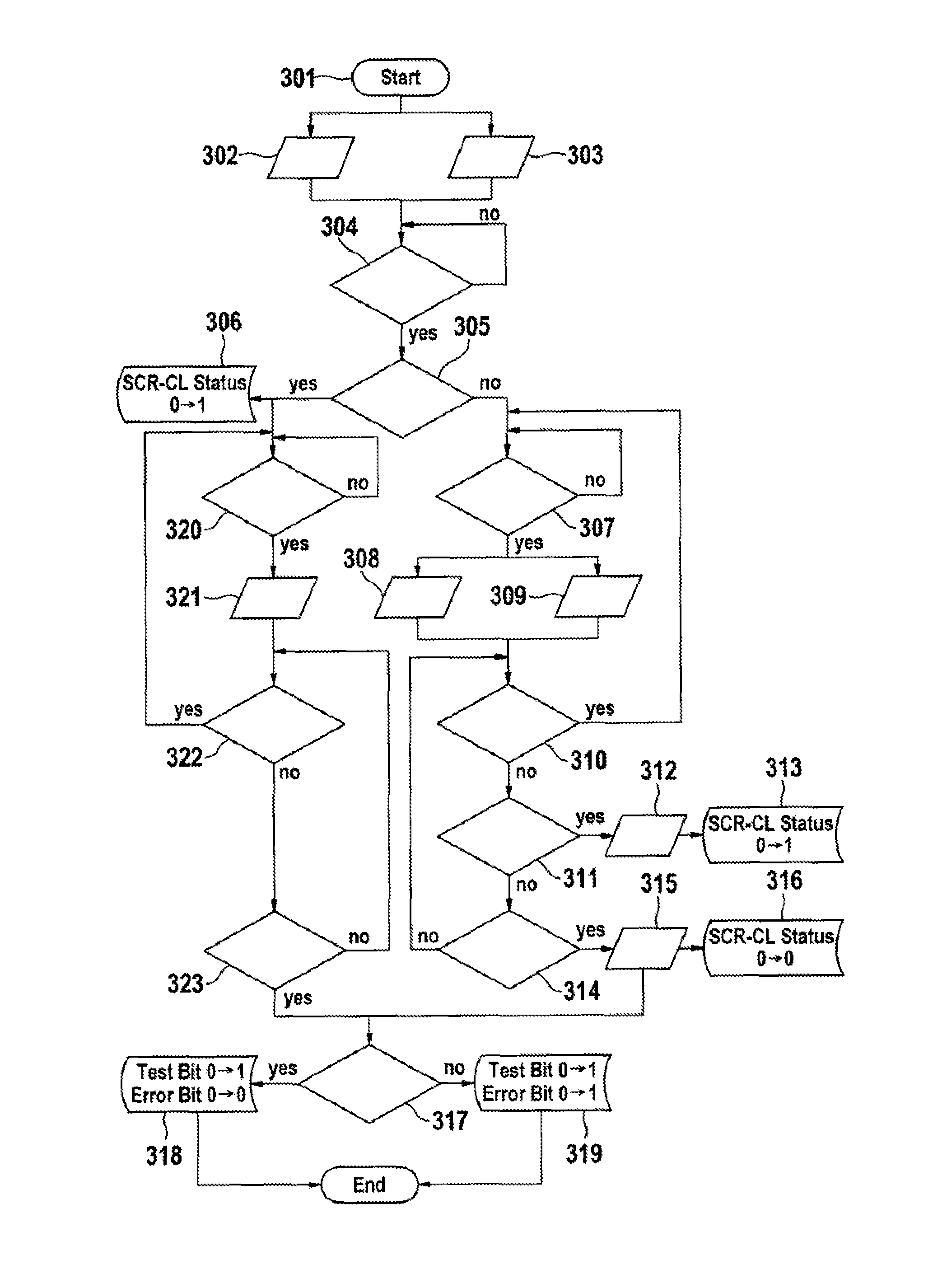

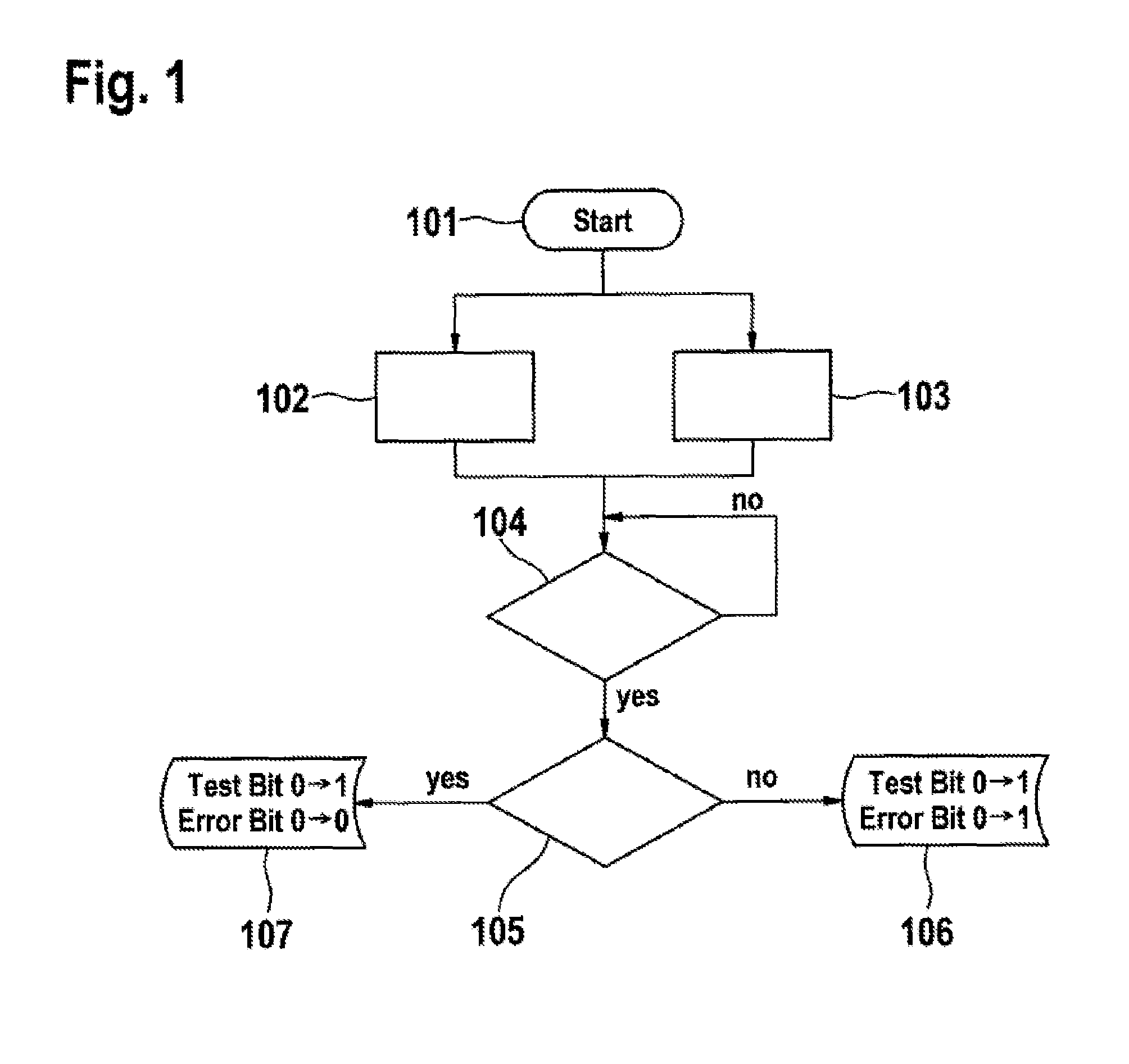

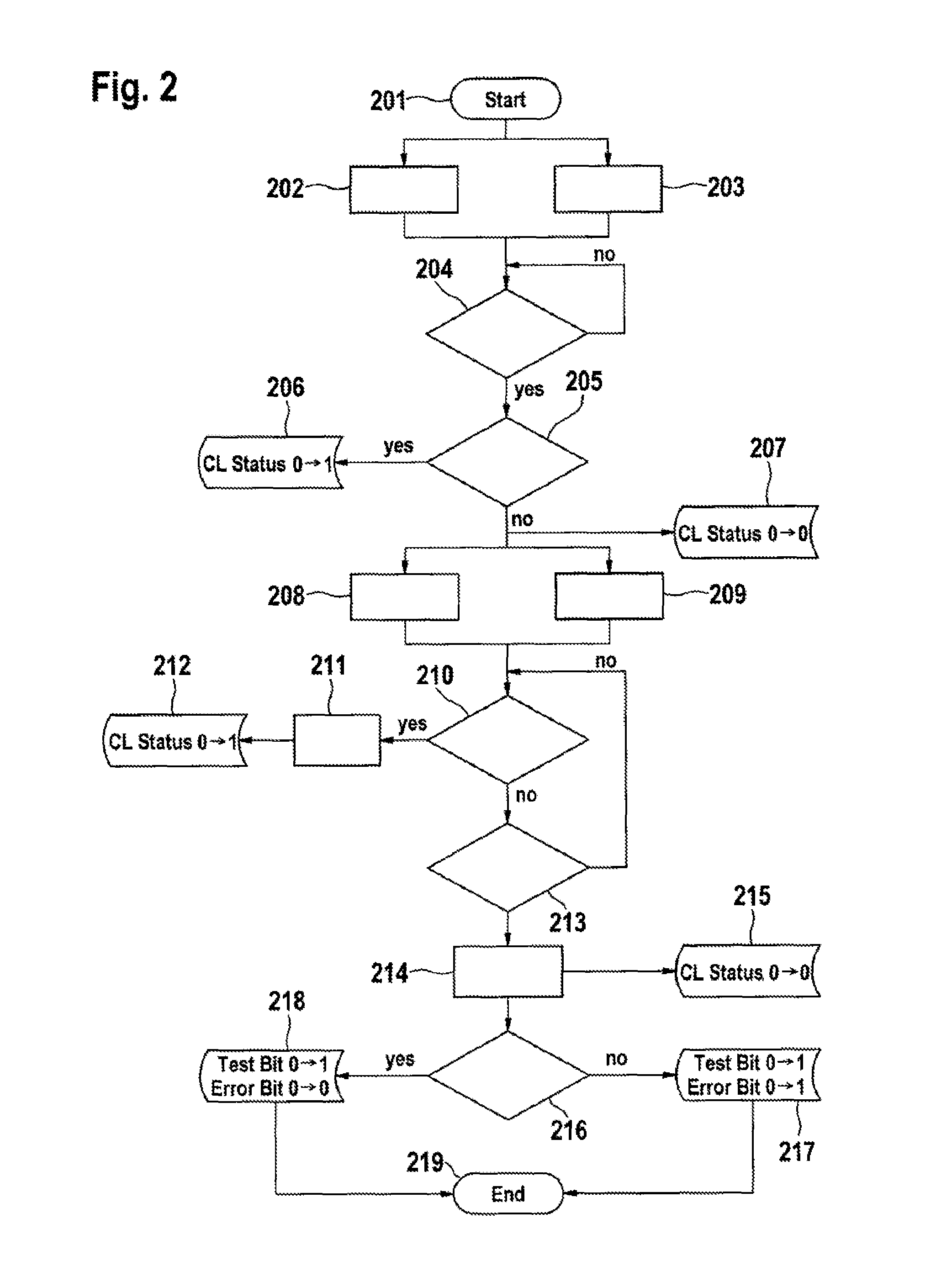

Method for monitoring the enabling of a system

ActiveUS20120191320A1Easily employedImprove robustness and reliabilityAnalogue computers for vehiclesElectrical controlMonitoring systemEngineering

A method for monitoring the enabling of a system which is assigned to an internal combustion engine, in which the readiness for operation of the system is dependent on an operating temperature, is characterized in that a fault in the enabling of the system is inferred (106) if operation of the system cannot be detected on expiry of a predeterminable time period after the starting of the internal combustion engine or on the recurrence of readiness for operation.

Owner:ROBERT BOSCH GMBH

Method for monitoring the enabling of a system

ActiveUS8924132B2Improve robustness and reliabilityIncrease working temperatureAnalogue computers for vehiclesElectrical controlMonitoring systemInternal combustion engine

A method for monitoring the enabling of a system which is assigned to an internal combustion engine, in which the readiness for operation of the system is dependent on an operating temperature, is characterized in that a fault in the enabling of the system is inferred (106) if operation of the system cannot be detected on expiry of a predeterminable time period after the starting of the internal combustion engine or on the recurrence of readiness for operation.

Owner:ROBERT BOSCH GMBH

Efficient grabbing method for complicated-shaped object

ActiveCN110712215AImprove solid reliabilitySimple control principleGripping headsMechanical engineeringRobot hand

Owner:CHINA JILIANG UNIV

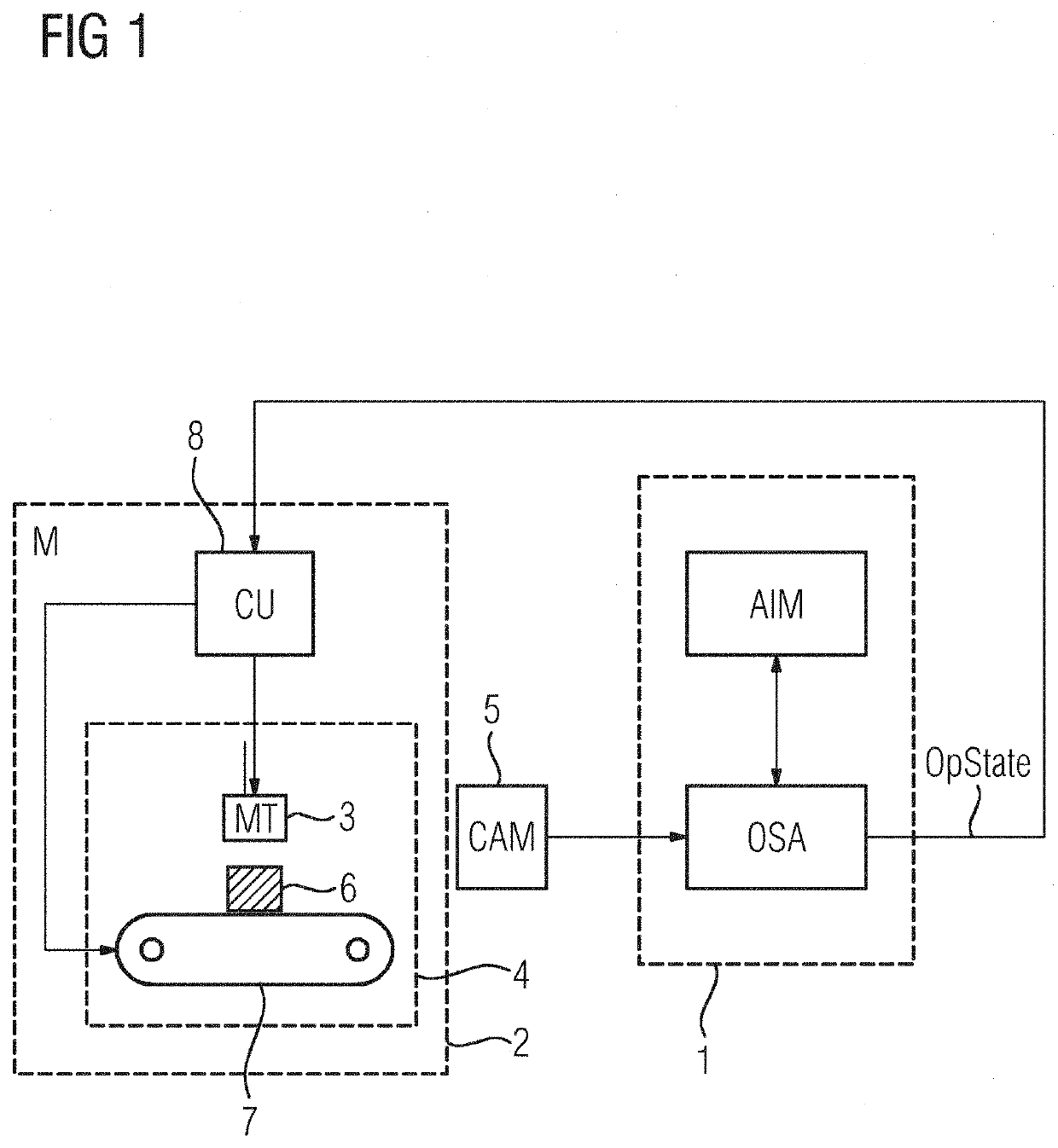

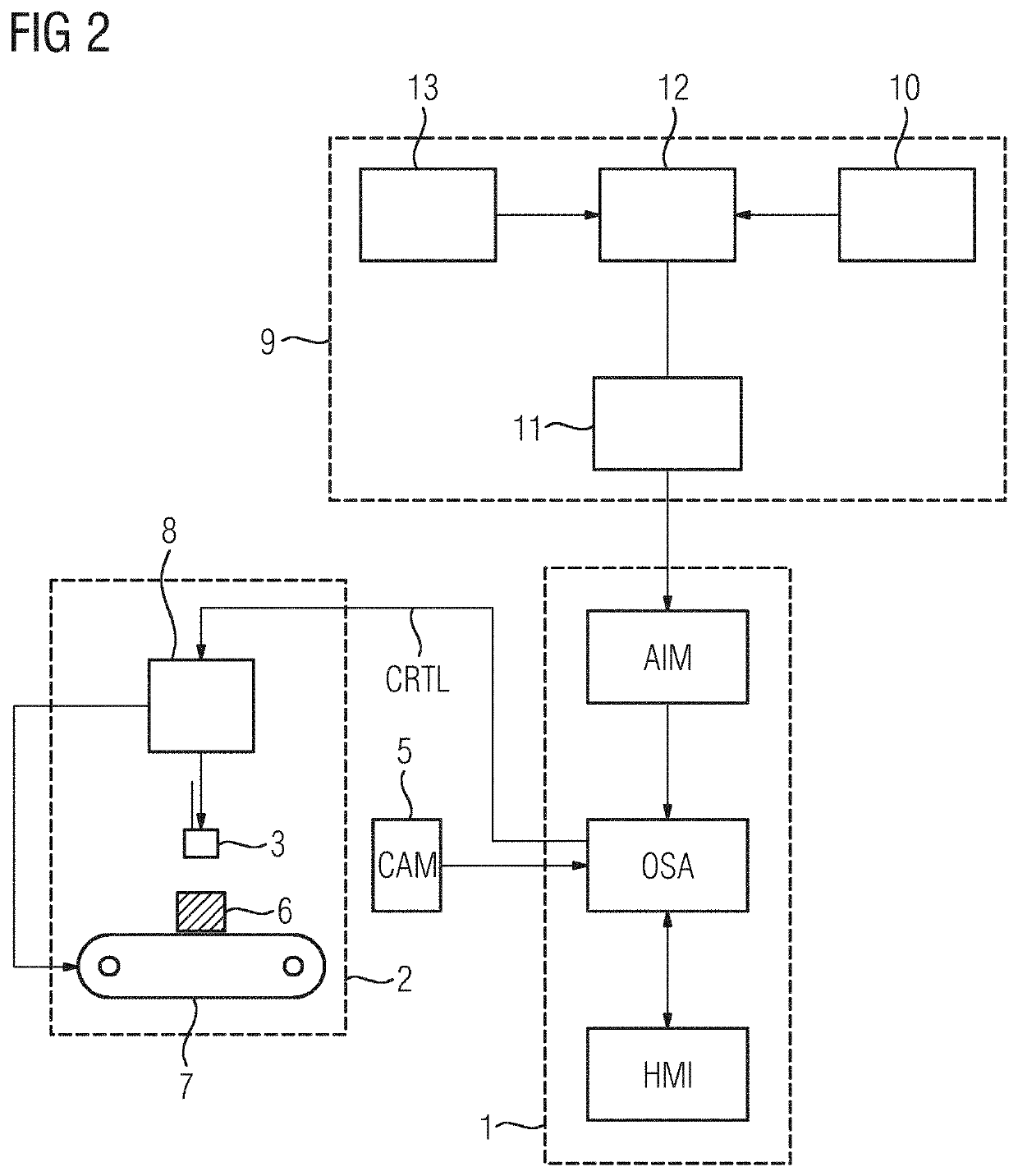

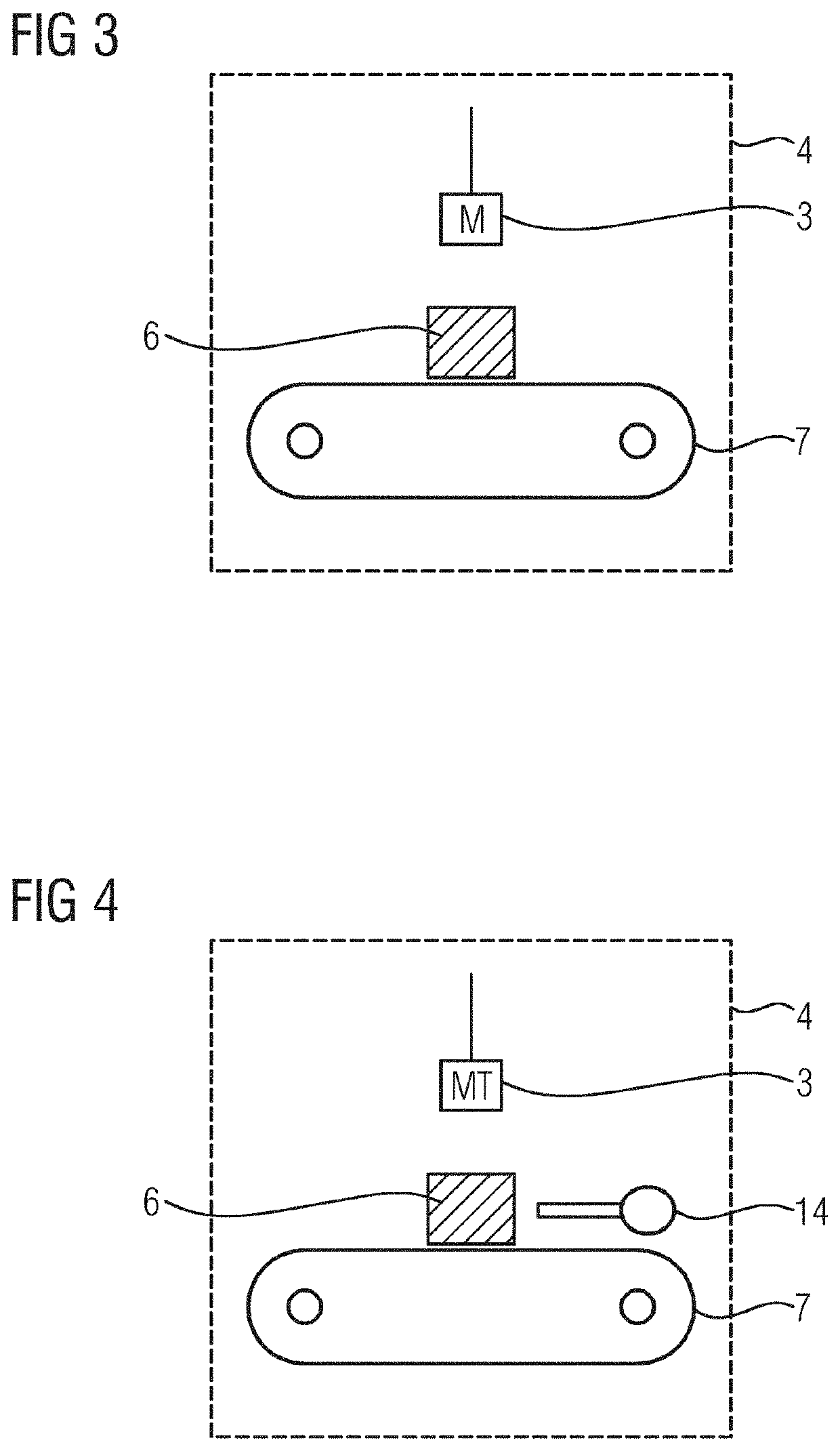

Method and system for detection of an abnormal state of a machine

ActiveUS20210089016A1Improve robustnessImprove reliabilityProgramme controlComputer controlEngineeringIdentification device

An object recognition apparatus for automatic detection of an abnormal operation state of a machine including a machine tool operated in an operation space monitored by at least one camera configured to generate camera images of a current operation scene is provided. The generated camera images are supplied to a processor configured to analyze the current operation scene using a trained artificial intelligence module to detect objects present within the current operation scene. The processor is also configured to compare the detected objects with objects expected in an operation scene in a normal operation state of the machine to detect an abnormal operation state of the machine.

Owner:SIEMENS AG

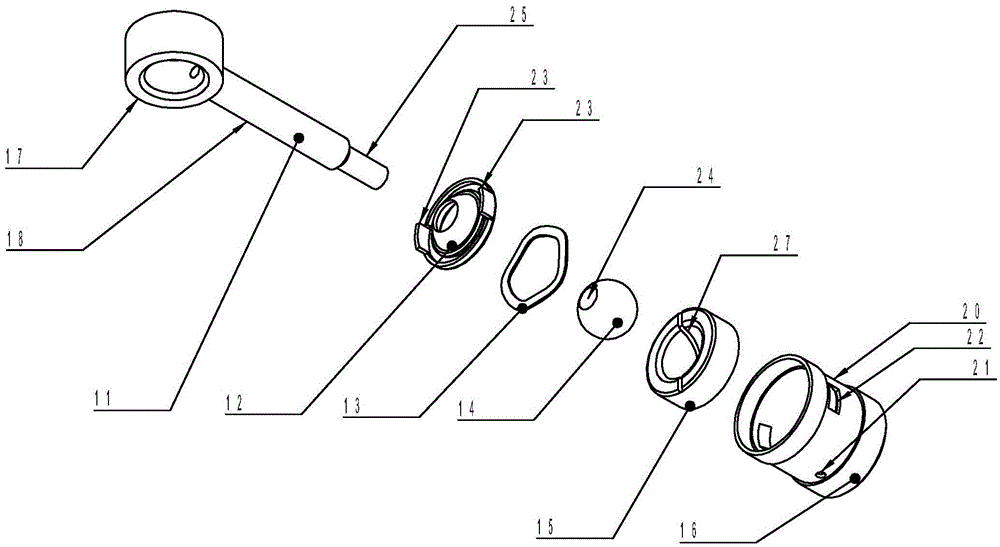

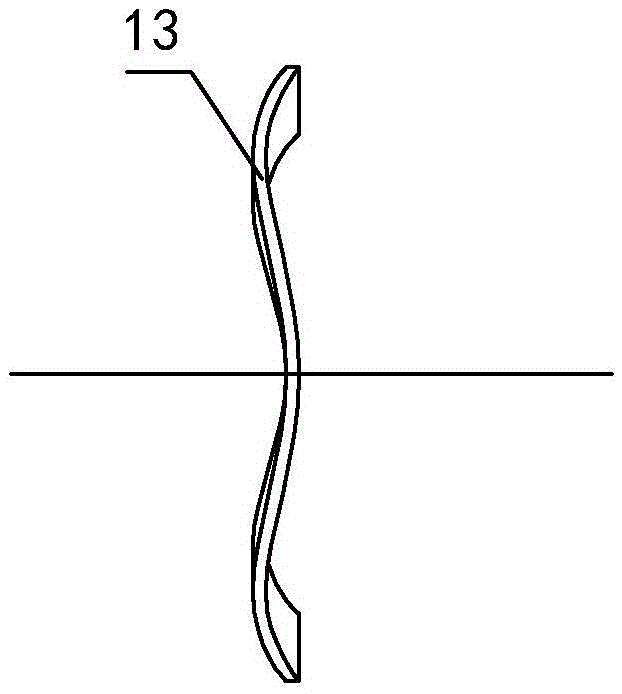

Piston-connecting rod structure used for refrigerating compressor

InactiveCN105570086AImprove robustness and reliabilityImprove work efficiency and service lifePositive displacement pump componentsPositive-displacement liquid enginesPistonEngineering

The invention discloses a piston-connecting rod structure used for a refrigerating compressor. The piston-connecting rod structure comprises a connecting rod, a ball cover, an elastic element, a ball body, a ball seat and a piston. The connecting rod, the ball seat or the ball body and the piston are provided oil ways which communicate with one another sequentially. The connecting rod, the ball cover and the ball body are connected to form a connecting rod assembly provided with a ball head. The ball seat and the piston are connected to form a piston assembly provided with the ball seat. The elastic element is arranged between the ball cover and the ball seat. The ball cover is fixedly connected with the piston so that the connecting rod assembly, the elastic element and the piston assembly can be connected closely. By the adoption of the piston-connecting rod structure, connection is more stable and reliable, defects caused by deformation of the piston can be avoided, the working efficiency of the compressor is effectively improved, and the service life of the compressor is effectively prolonged.

Owner:JIAXIPERA COMPRESSOR

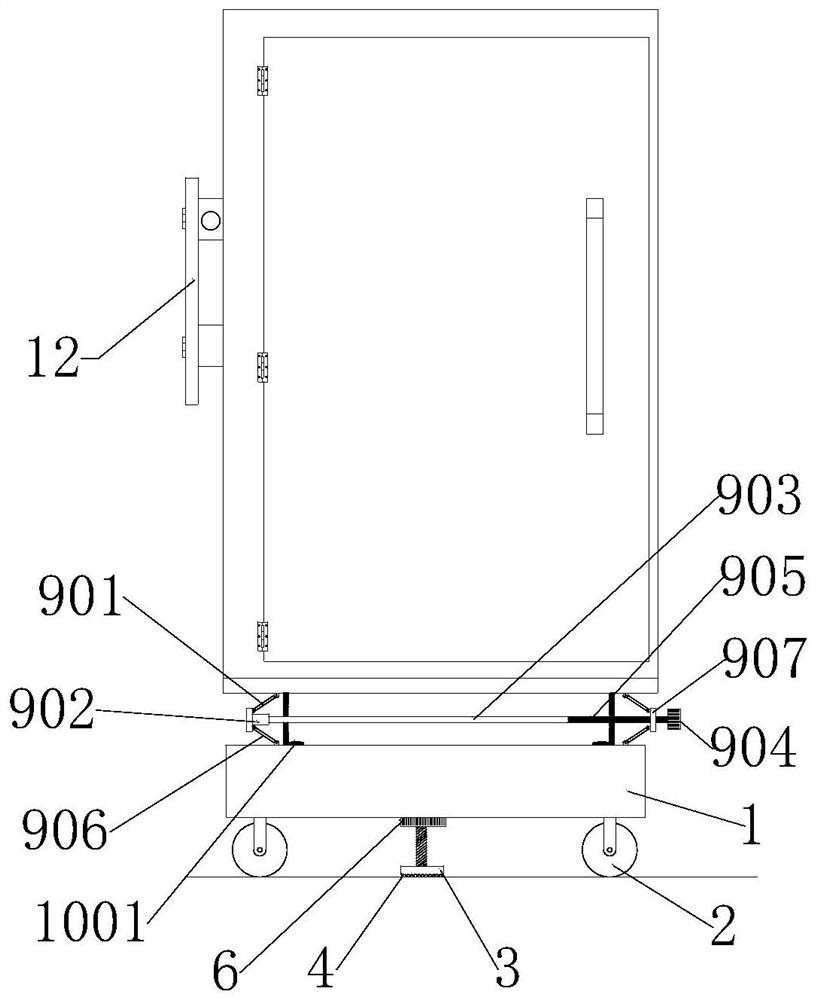

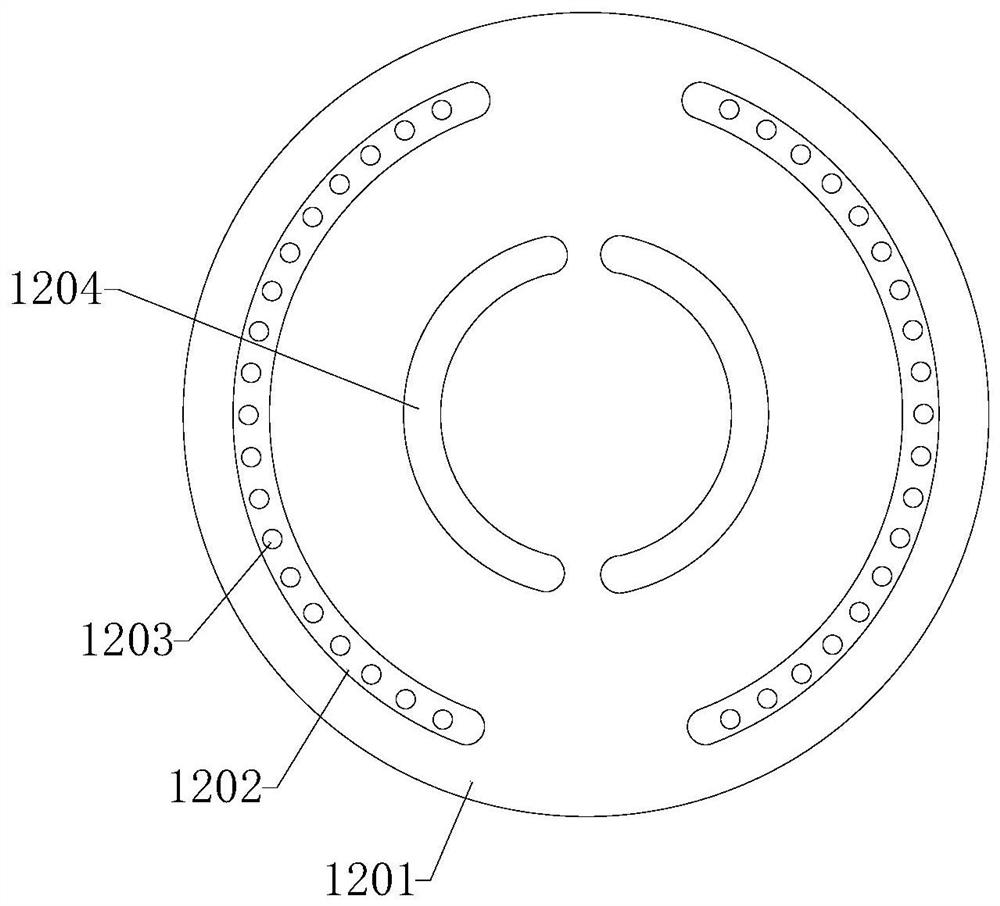

A kind of distribution cabinet assembly equipment and its assembly process

ActiveCN111478214BAvoid installationAvoid assemblySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringStructural engineering

Owner:SUZHOU HUAYUAN ELECTRIC

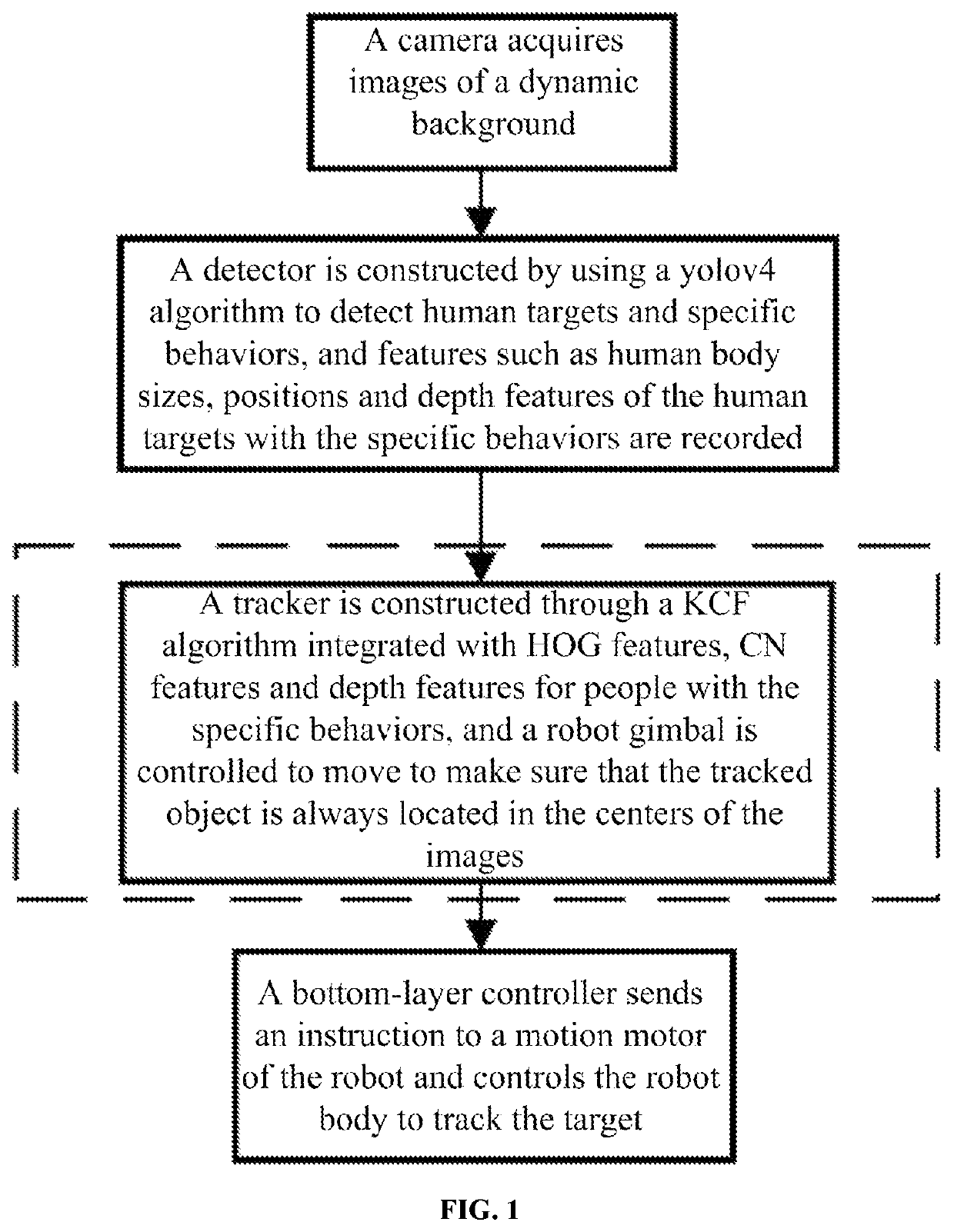

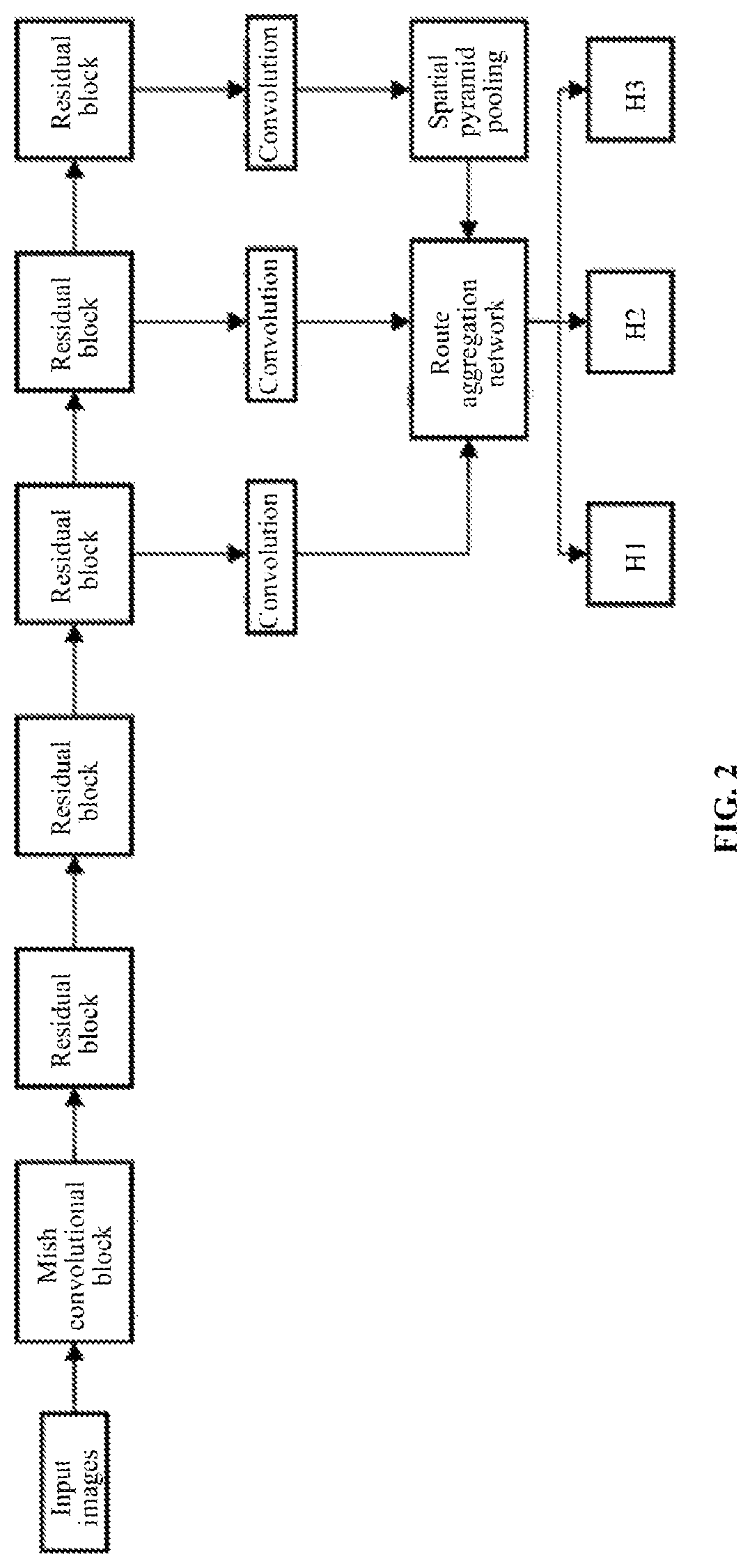

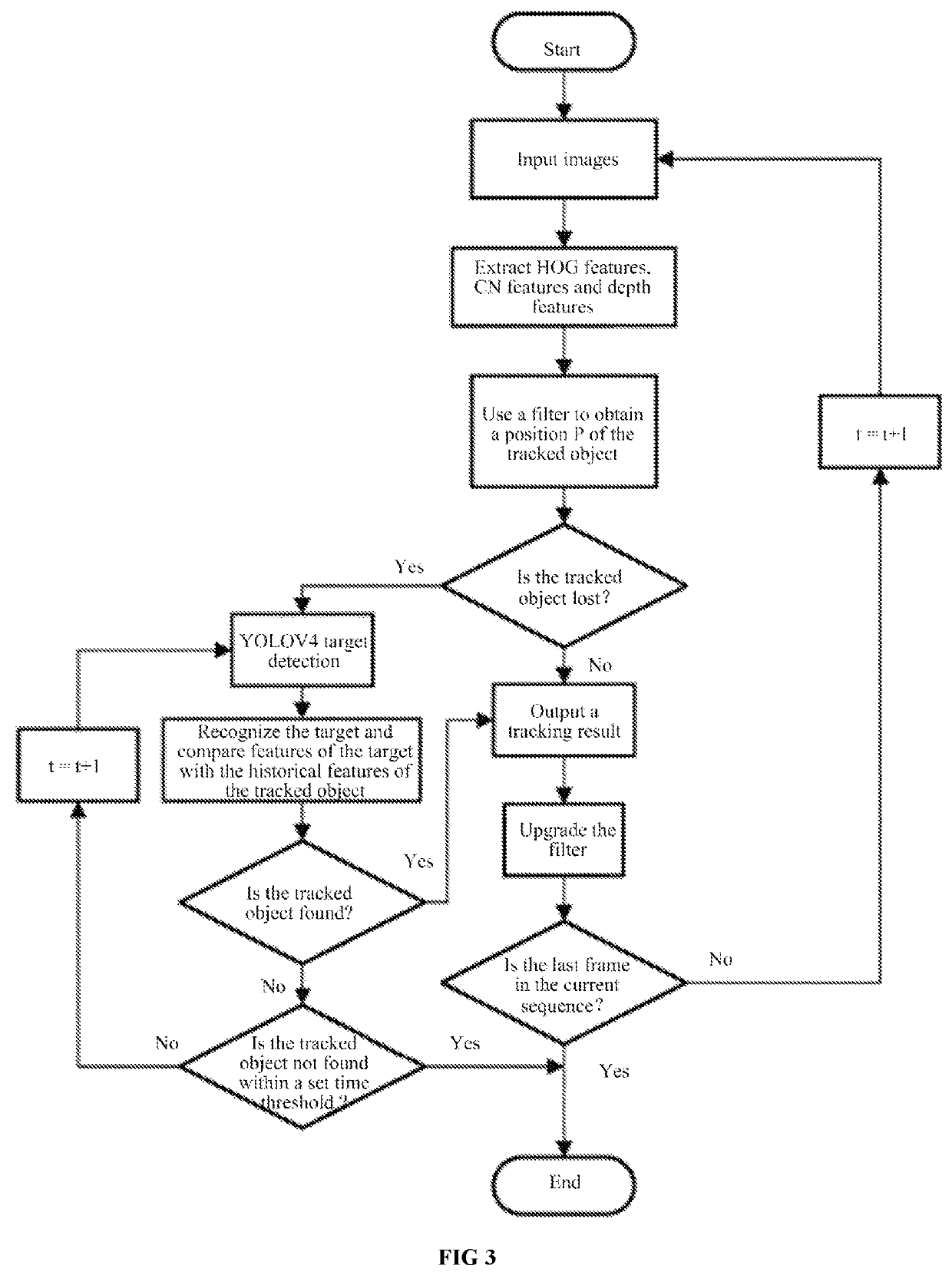

Neural network-based visual detection and tracking method of inspection robot

ActiveUS11462053B2Quickly and accurately detect specific behaviorImprove robustness and reliabilityTelevision system detailsProgramme-controlled manipulatorPattern recognitionEngineering

The present disclosure provides a neural network-based visual detection and tracking method of an inspection robot, which includes the following steps of: 1) acquiring environmental images of a dynamic background a movement process of the robot; 2) preprocessing the acquired images; 3) detecting human targets and specific behaviors in the images in the robot body, and saving the sizes, position information and features of the human targets with the specific behaviors; 4) controlling the orientation of a robot gimbal by using a target tracking algorithm to make sure that a specific target is always located at the central positions of the images; and 5) controlling the robot to move along with a tracked object. The neural network-based visual detection and tracking method of an inspection robot in the present disclosure has a quite high adaptive ability, achieves better detection and tracking effects on targets in a dynamic background scene.

Owner:CHONGQING UNIV

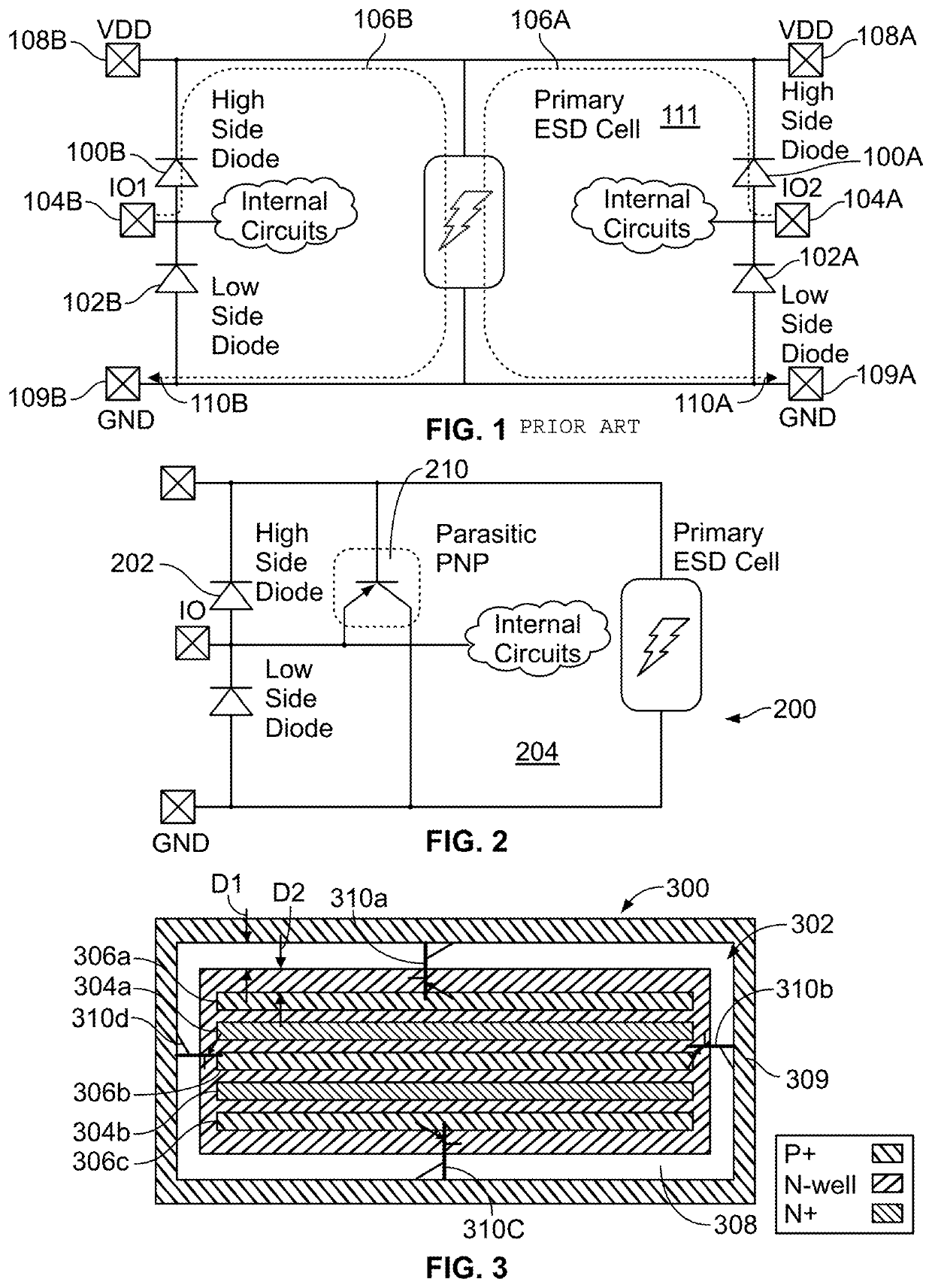

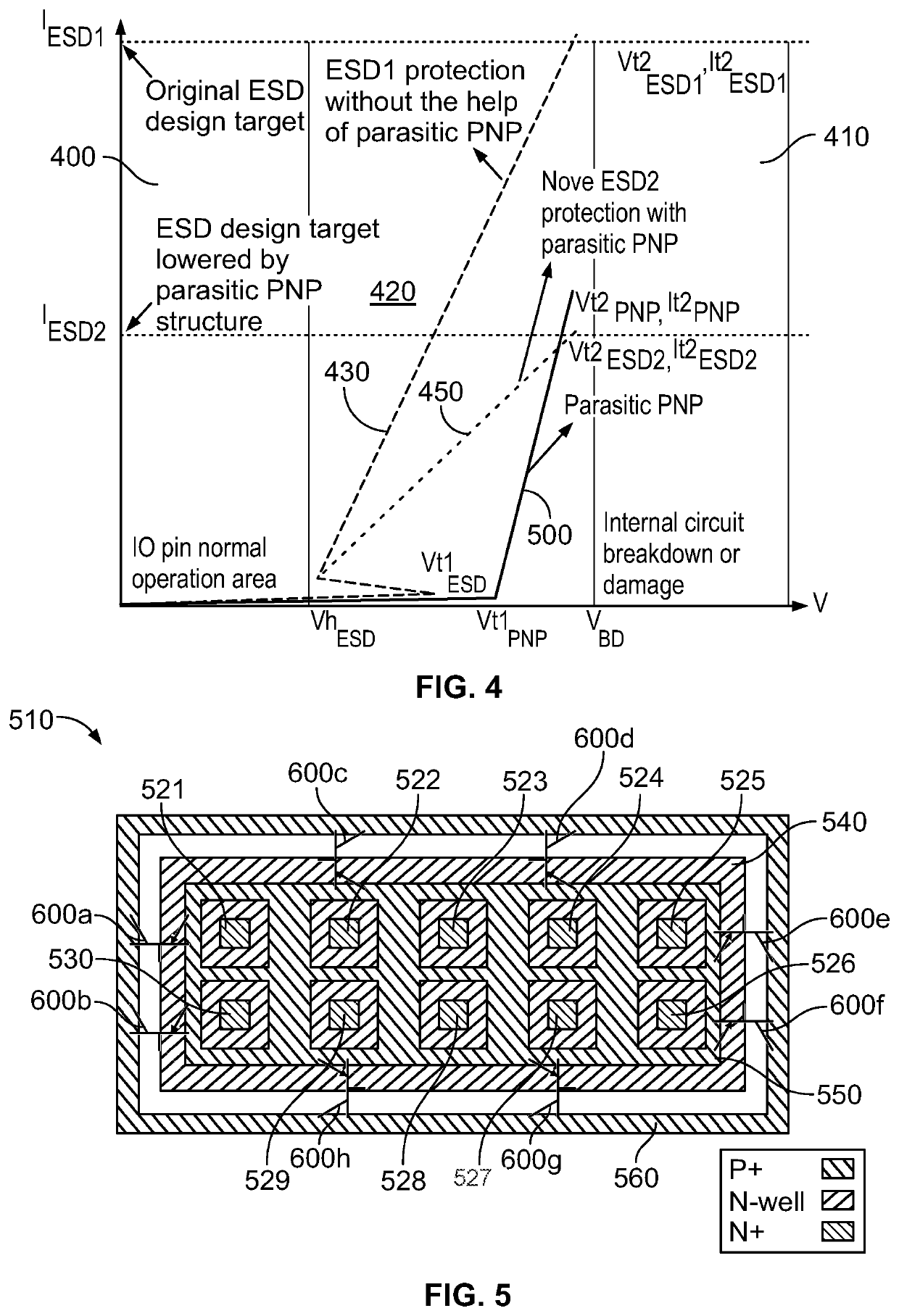

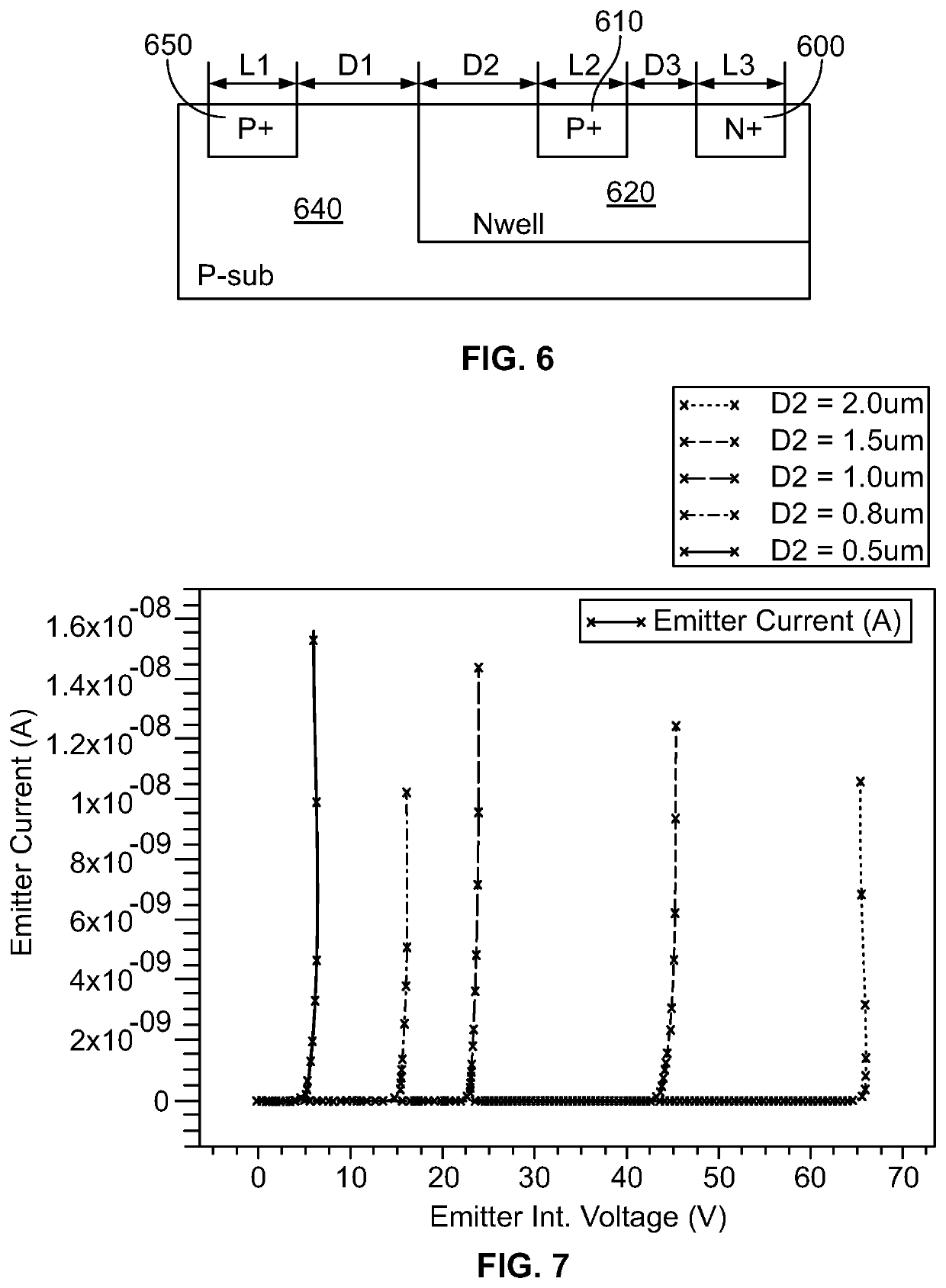

On-chip IEC ESD protection using parasitic PNP devices

ActiveUS11094690B2Improve robustness and reliabilityReduce capacitanceTransistorSolid-state devicesDevice materialEngineering

A semiconductor device having a P type substrate, an N type layer on the P type substrate that forms a PN junction therewith and the P type region, N type region and P type substrate form at least one parasitic PNP transistor.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com