Sling vibration reduction mechanism of large-span suspension bridge

A vibration damping mechanism and suspension bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as poor safety and durability, improve reliability and stability, solve vibration problems, and eliminate psychological anxiety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

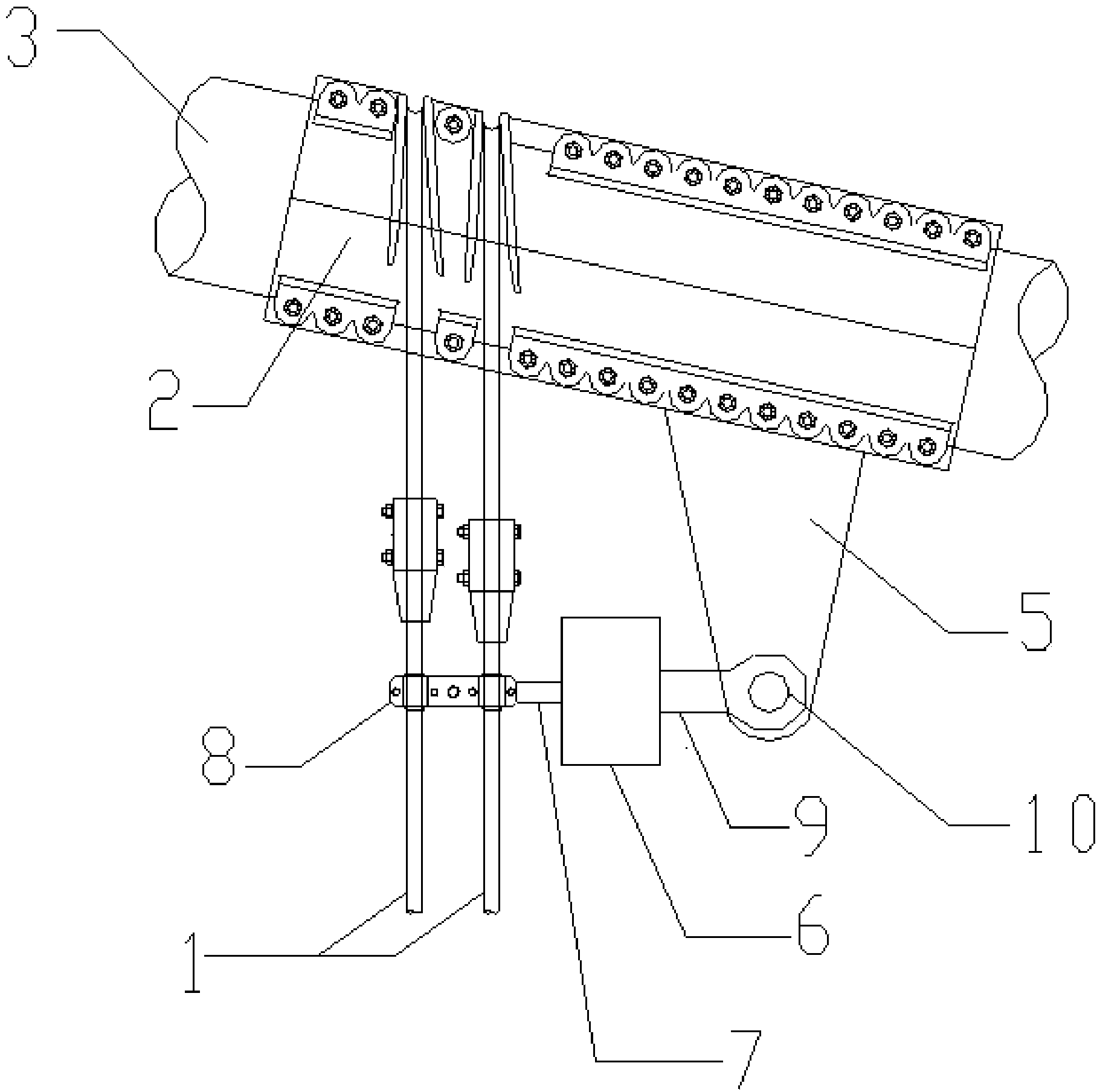

[0013] Such as figure 1 shown. The suspension cable vibration damping mechanism of the large-span suspension bridge of the present invention comprises a main cable 3, a cable clamp 2 and a sling 1 connected to the cable clamp 2; 6. The lug plate 5 fixedly connected with the cable clamp 2; one side of the damper 6 is connected to the divider 8 through the divider connecting rod 7, and the other side of the damper 6 is connected through the lug plate connecting rod 9 Lug plate 5.

[0014] The lug plate connecting rod 9 is connected with the lug plate 5 through a pin 10 .

[0015] The damper 6 can be a viscous shear damper, and of course, it can also be a damper of various other forms capable of damping vibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com