Rubber gasket for track traffic and manufacturing method thereof

A technology for rail transit and rubber pads, applied in the field of vibration damping materials, can solve the problems of poor bonding between the rubber layer and the fiber reinforced layer, affecting product life, cumbersome production process, etc. Simple effect of molding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in conjunction with accompanying drawing and specific embodiment:

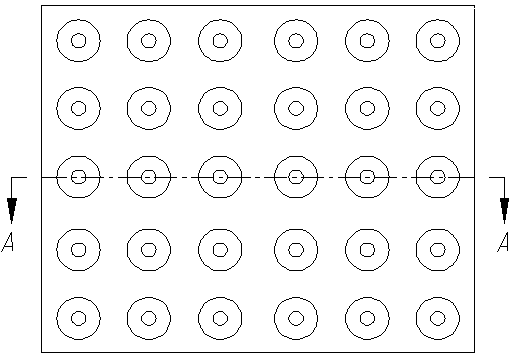

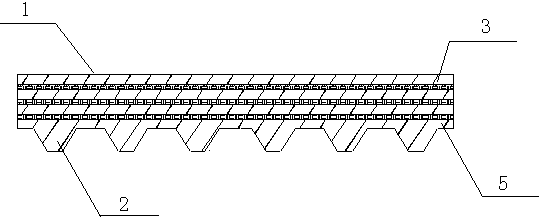

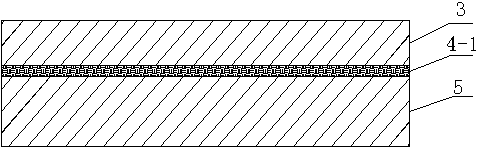

[0036] Such as figure 1 , figure 2Shown, a kind of rubber pad for rail transit, described rubber pad comprises the plate 1 as base and a plurality of studs 2 that are positioned on the plate; Described plate 1 is made of rubber layer of rubber material and reinforcing Fiber-reinforced layer composite; such as image 3 As shown, in this embodiment, the fiber-reinforced layer is one layer: fiber-reinforced layer I4-1; the upper and lower surfaces of the fiber-reinforced layer I4-1 have rubber layers; the fiber-reinforced layer I4-1 -1 is a fiber cloth with densely distributed mesh; the diameter of the mesh on the fiber reinforced layer I4-1 is not less than 0.5 mm; the fiber reinforced layer is an organic fiber mesh cloth or an inorganic fiber mesh cloth or a metal mesh; The rubber layer on the upper surface of the fiber-reinforced layer I4-1 is the covering layer 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com