Patents

Literature

273results about How to "Simple forming method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic composite material, and preparation method and application thereof

The invention belongs to the field of polymer composite materials, and discloses a thermoplastic composite material, and a preparation method and an application thereof. The composite material is composed of the components of, by weight: 1-99 parts of a prepreg and 1-99 parts of a thermoplastic composition or thermoplastic resin. The preparation method comprises the steps that: the 1-99 parts of thermoplastic composition or thermoplastic resin is added into a feeding hopper of an injection molding machine, and is mixed with the 1-99 parts of prepreg already in an injection mold; and injection molding is carried out. The invention also discloses an application of the thermoplastic composite material in car bumpers, car door inner panels, car bumper beams, cars toe-boards, car hood, car rear lift door, building templates, biogas digesters, train sidings, train wall panels, or train roof panels. The composite material provided by the invention has the advantages of smooth outer surface, high gloss, good appearance, excellent mechanical performance, high strength, and good impact resistance.

Owner:HEFEI GENIUS NEW MATERIALS

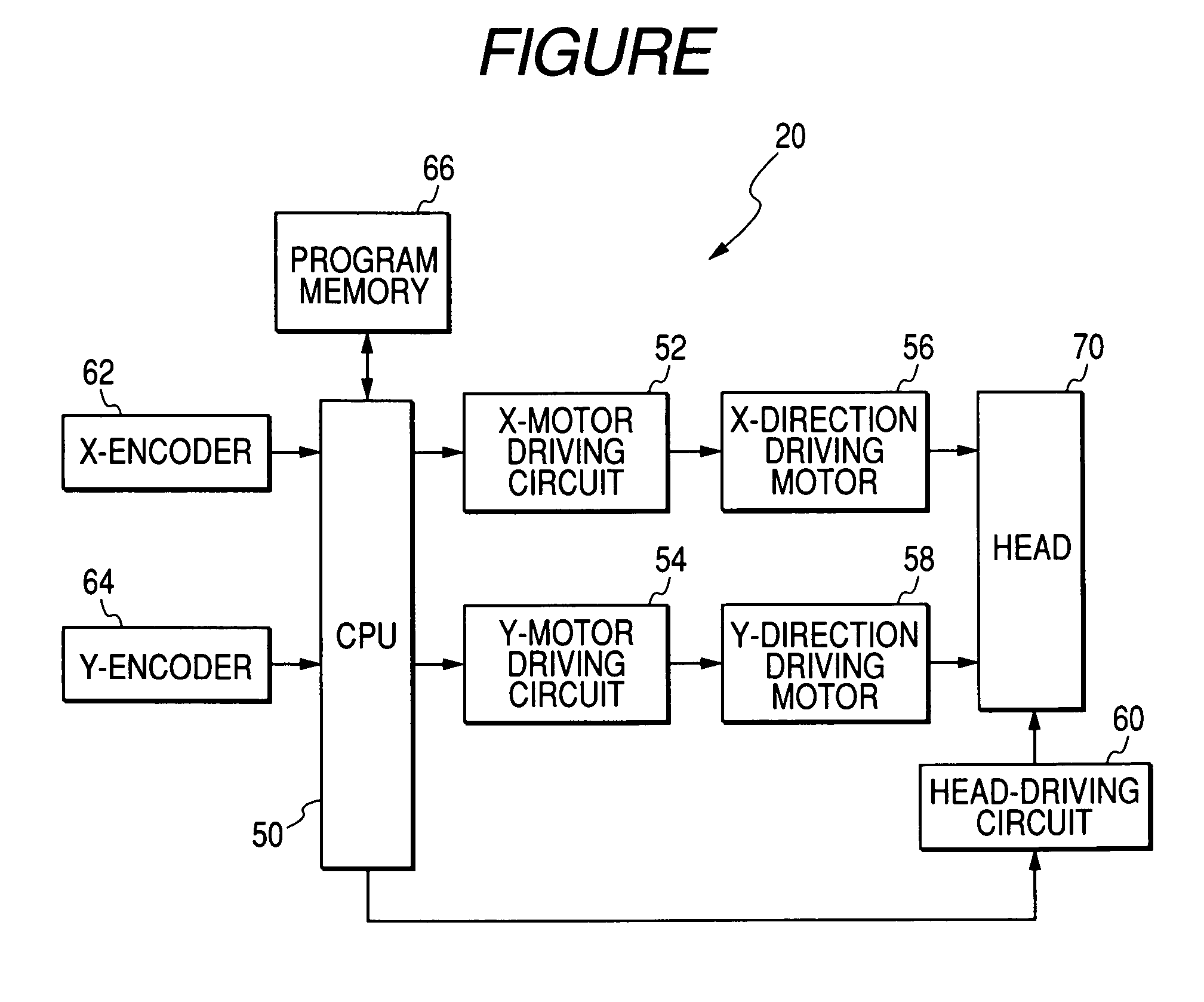

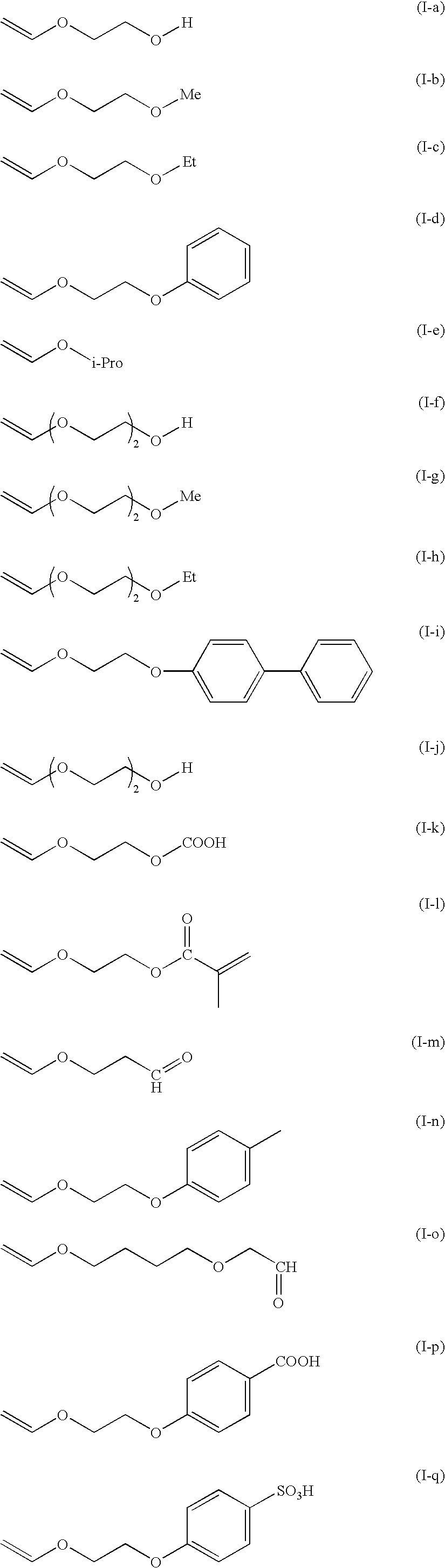

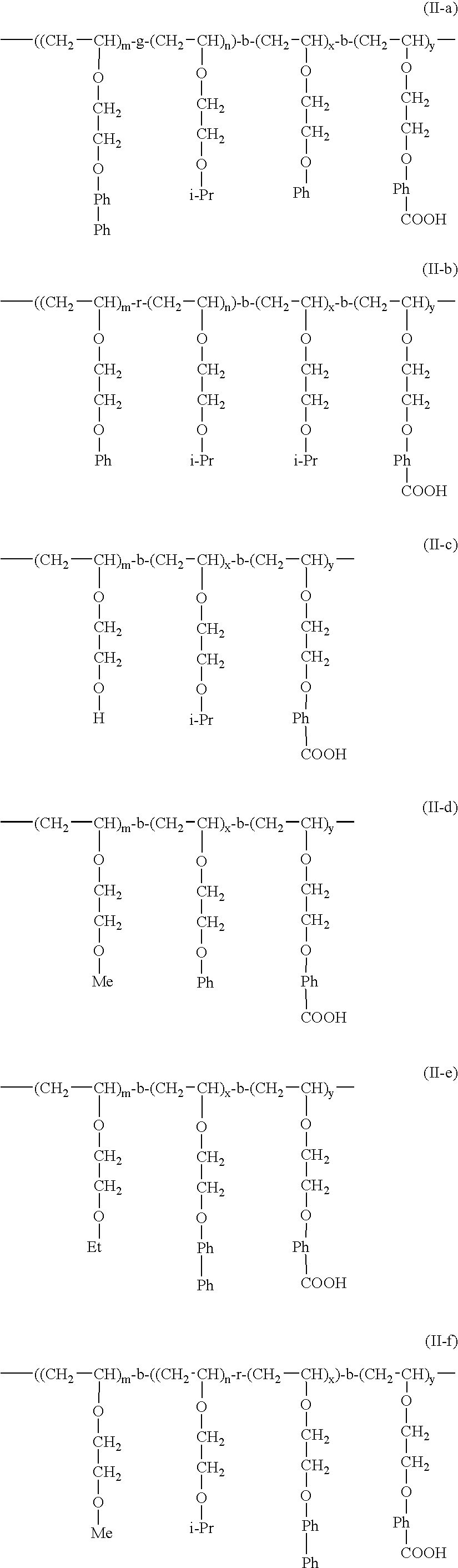

Novel polymer compound, composition containing the compound, ink composition, ink-applying method, and ink-applying apparatus

InactiveUS20050239918A1Ink composition is improved in dispersion of colorantGood dispersionInksCoatingsHydrogenEther

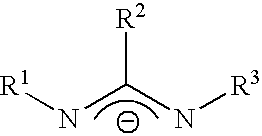

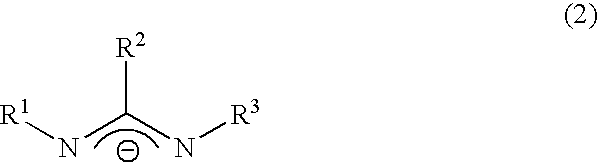

A block copolymer comprises three block segments of a first segment, a second segment, and a third segment, and containing a polyalkenyl ether main chain, wherein the first segment is hydrophilic or hydrophobic, the second segment is hydrophobic, and the third segment is ionic; and at least one of the block segments has a structure represented by General Formula (1) below: —(CRaRb-CRc(OR1))— (1) wherein Ra, Rb, and Rc are respectively H or CH3; R1 is selected from the group consisting of linear, branched, or cyclic alkyl groups of 1 to 18 carbon atoms, —(CH(R2)—CH(R3)—O)l—R4, and —(CH2)m—(O)n—R4; l and m are an integer from 1 to 12; n is 0 or 1; R2 and R3 are H or CH3; R4 is selected from the group consisting of H, linear, branched or cyclic alkyl groups of 1 to 6 carbon atoms, -Ph, -Pyr, -Ph-Ph, -Ph-Pyr, —CHO, —CH2CHO, —CO—CH═CH2, —CO—C(CH3)═CH2, —CH2COOR5, -PhCOOR5, —CH2SO3R5, and -PhSO3R5; the hydrogen on the carbon atoms constituting R4 except R5 moiety may be replaced by a linear or branched alkyl group of 1 to 4 carbon atoms, and the carbon in the aromatic ring may be replaced by nitrogen; and R5 is H, an alkyl group of 1 to 5 carbon atoms, or mono- or higher-valent cation.

Owner:CANON KK

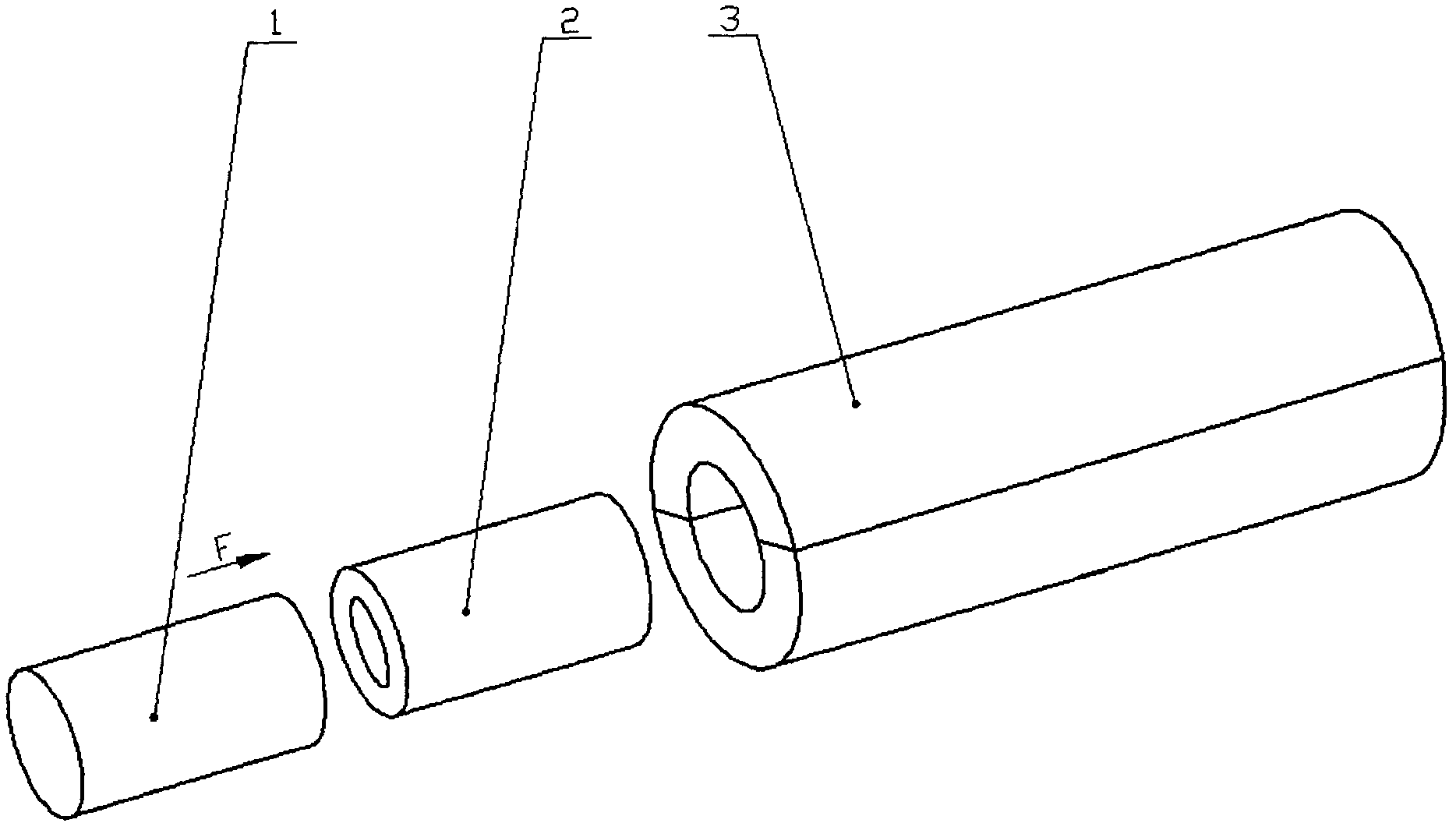

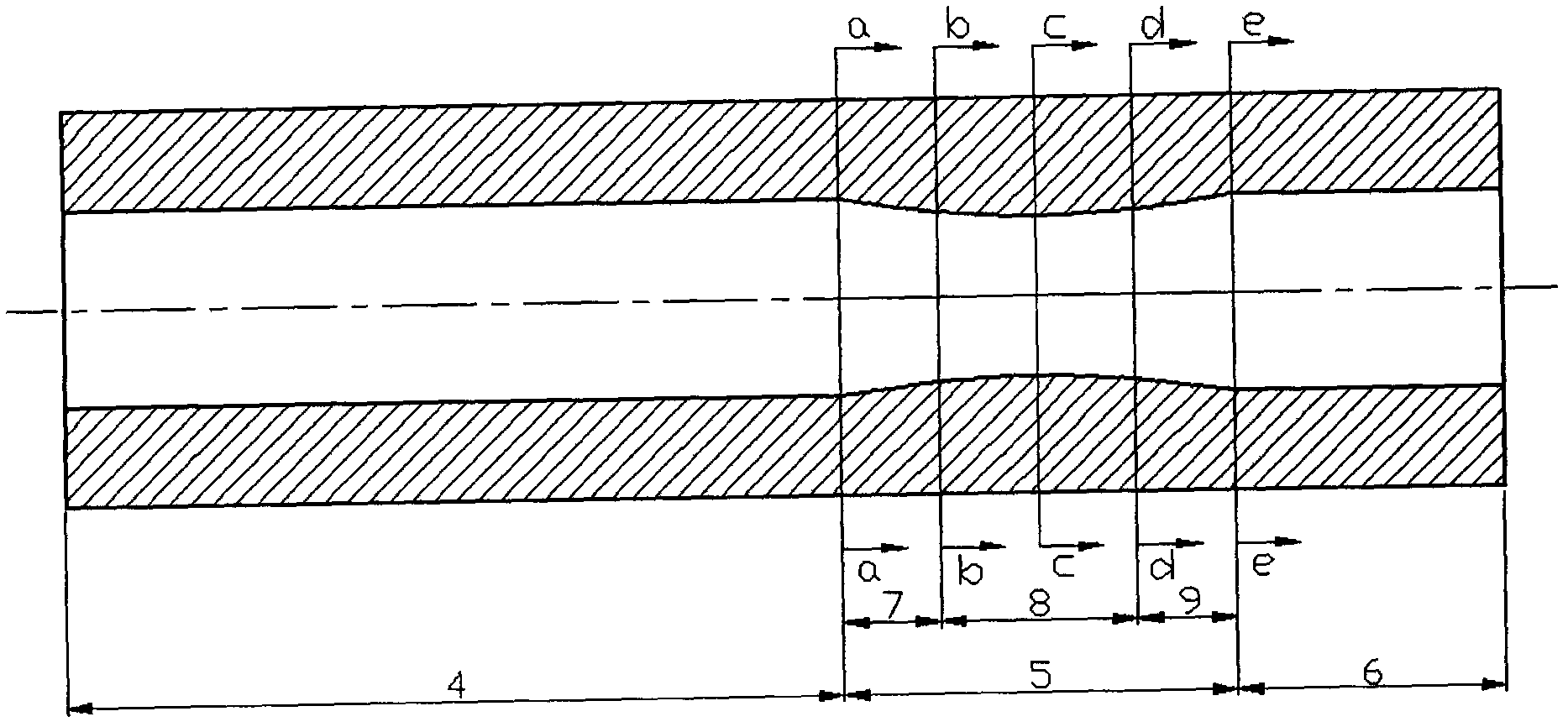

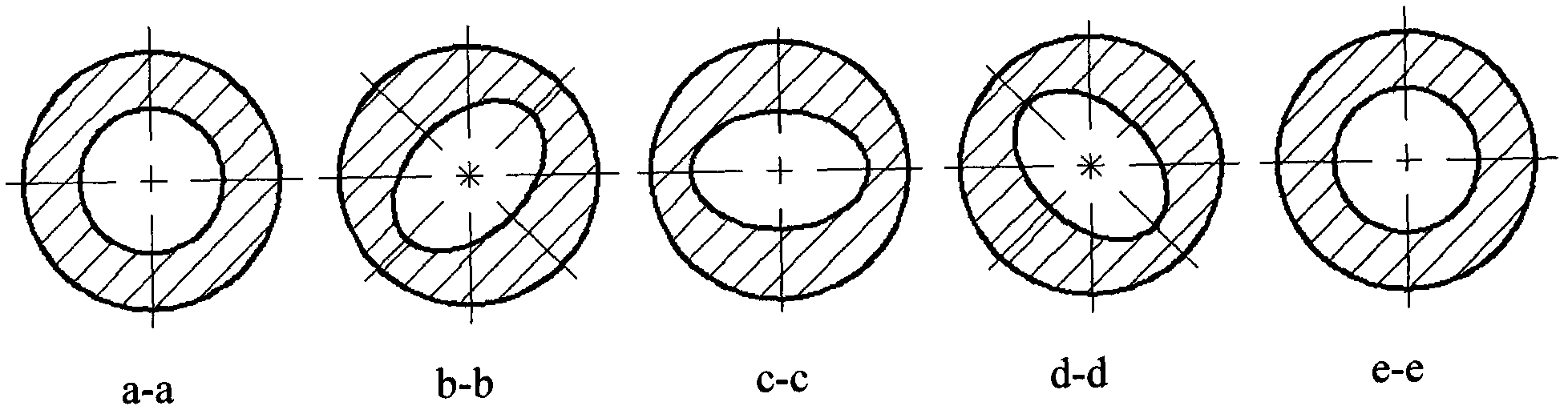

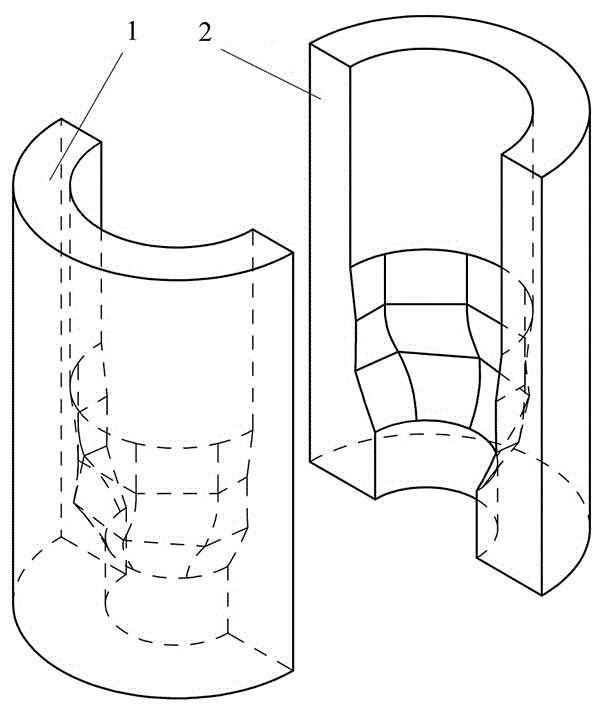

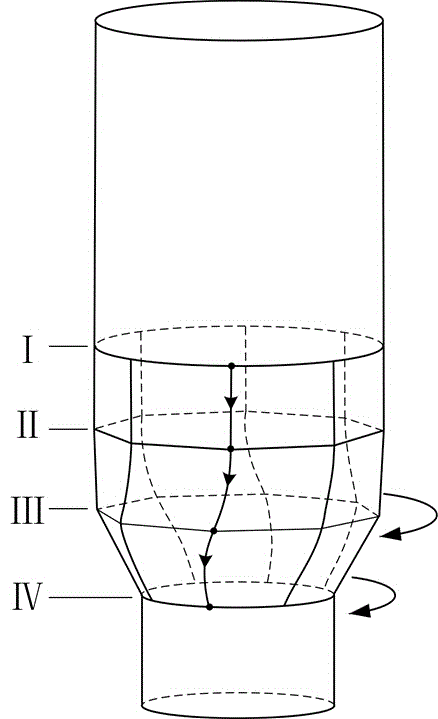

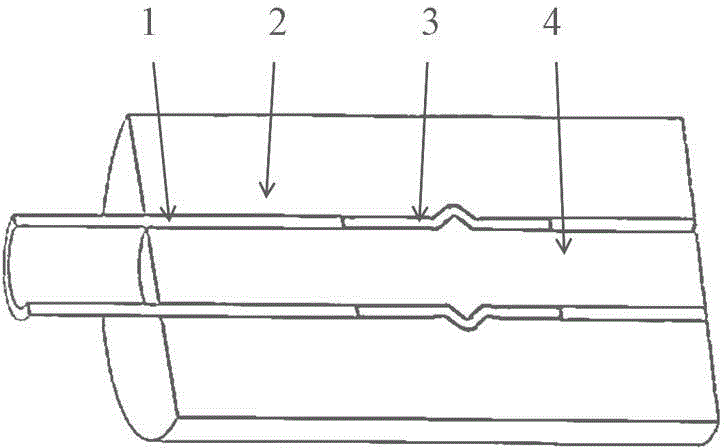

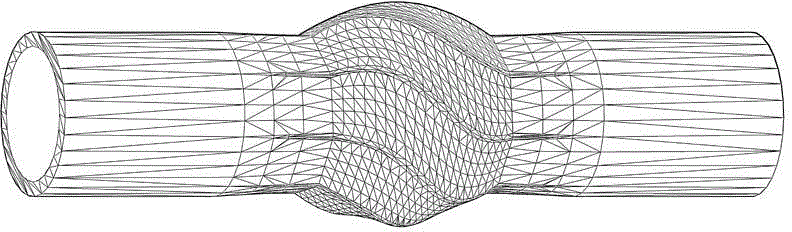

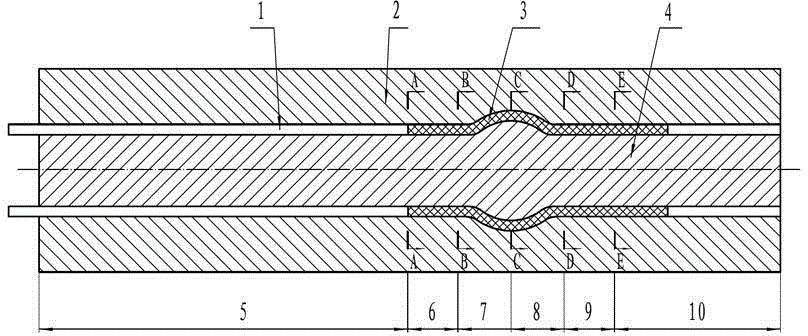

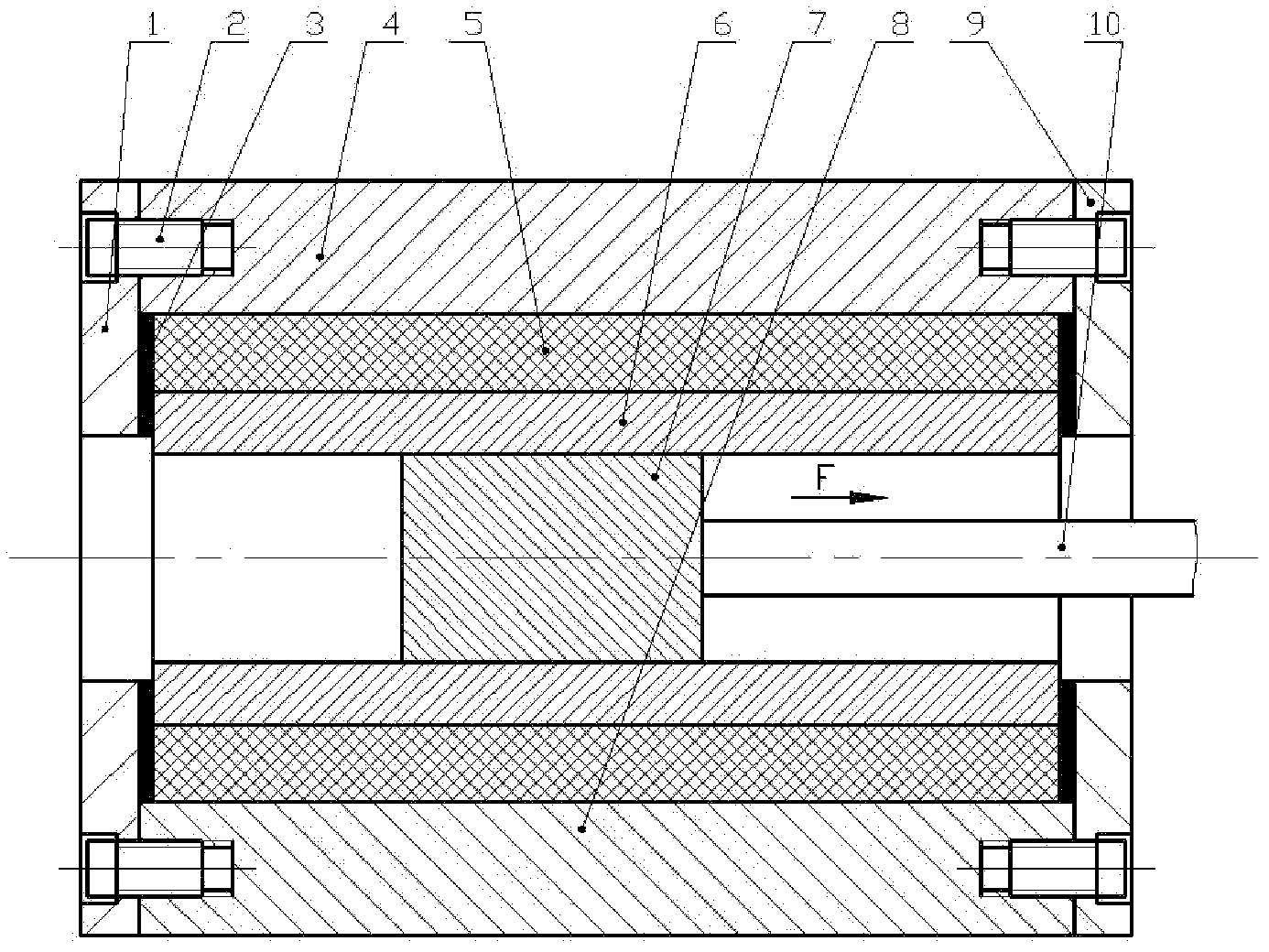

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Twist extrusion forming die and twist extrusion forming method

The invention discloses a twist extrusion forming die and a twist extrusion forming method. The forming die comprises a first half die and a second half die, wherein the first half die and the second half die are tightly buckled through a bolt to form a cylinder, an extrusion die cavity is formed inside the cylinder, and a die joint of the first half die is fit and level with a die joint of the second half die; the extrusion die cavity is sequentially formed by a guide section, a large circular-regular octagonal transitional section, a regular octagonal twist section, an octagonal-small circular twist transitional section and an outlet section from an extrusion inlet to the lower side. The twist extrusion forming die has the advantages of good transformation effect, high speed and high efficiency, the weaknesses of the prior art such as non-uniformity in transformation and existence of transformation dead corner can be overcome, the stress distribution inside a material can be greatly improved, and the comprehensive performance of the material also can be improved.

Owner:TAIYUAN UNIV OF TECH

Equal channel forming die for thick-wall pipe and method of forming die for forming pipe

InactiveCN104307908AImproved strain distributionIncrease stressExtrusion diesDeformation effectShearing deformation

The invention relates to the technical field of forming pipes with thick walls (a ratio of pipe diameter to wall thickness is less than 20) of such metals as aluminum, copper and steel and round cross sections, and in particular discloses an equal channel forming die for a thick-wall pipe and a method of the equal channel forming die for forming the pipe. An equal channel corner variable-cross section twist extrusion forming technical scheme adopted by the invention is similar to combination of twist shear deformation and upsetting and drawing extrusion-bulging deformation on a cross section, thus realizing combination of multiple deformation modes in an extrusion process. The equal channel forming die disclosed by the invention has the advantages of good deformation effect, quick speed and high efficiency; and the equal channel forming die can overcome a shortcoming of a current process which is uneven in deformation, greatly improve stress-strain distribution and a deformation texture in the material, and simultaneously improve material performance.

Owner:TAIYUAN UNIV OF TECH

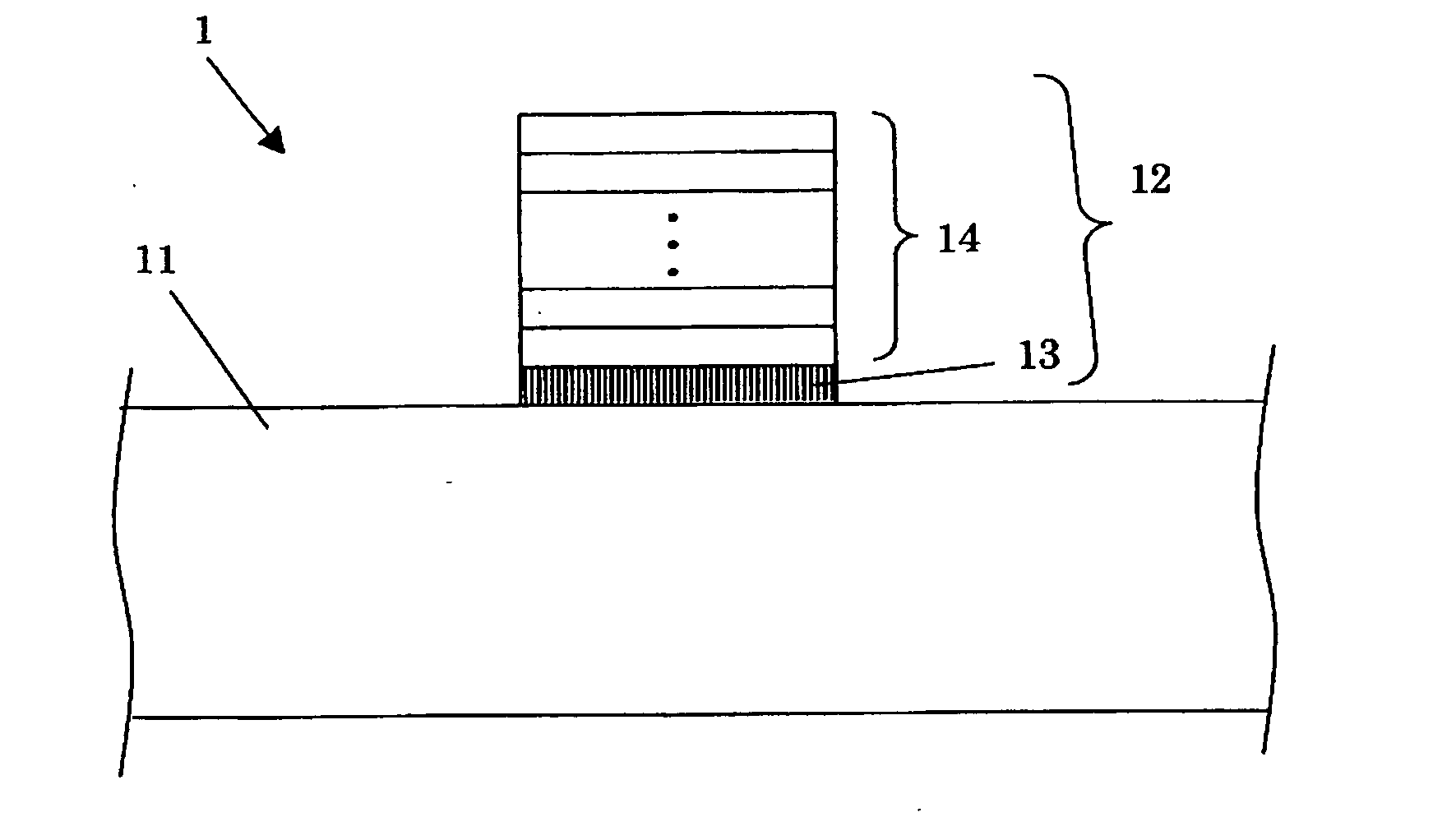

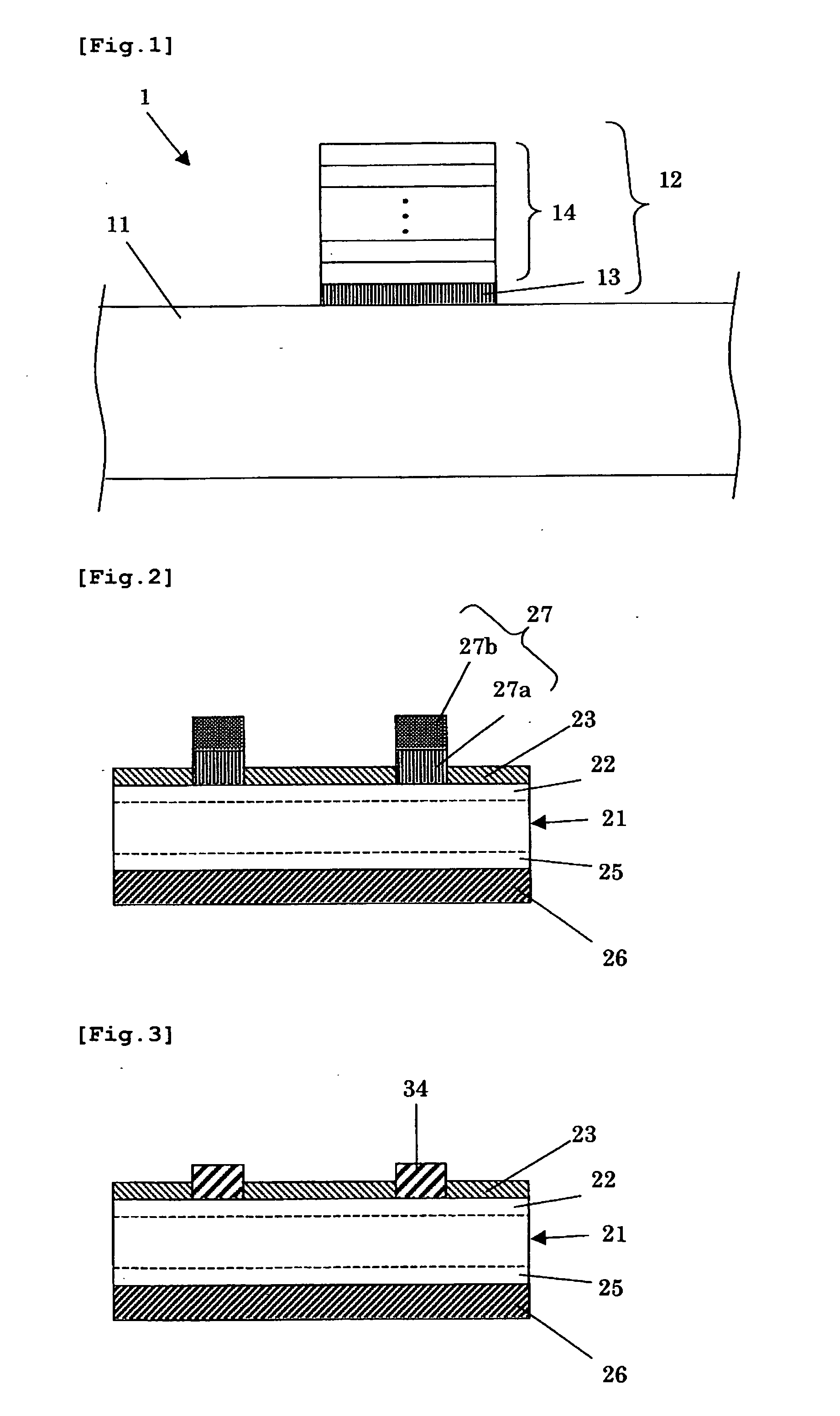

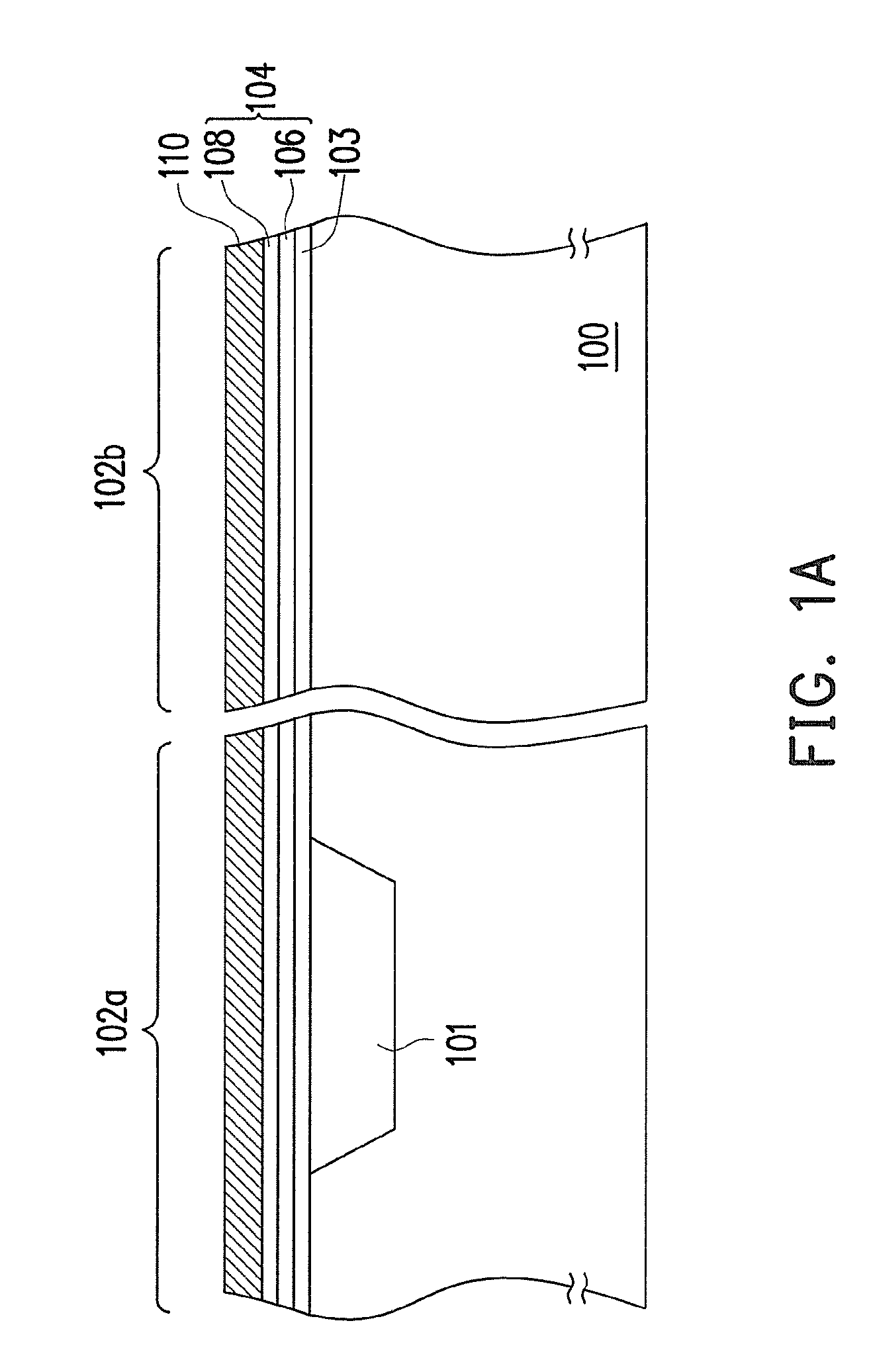

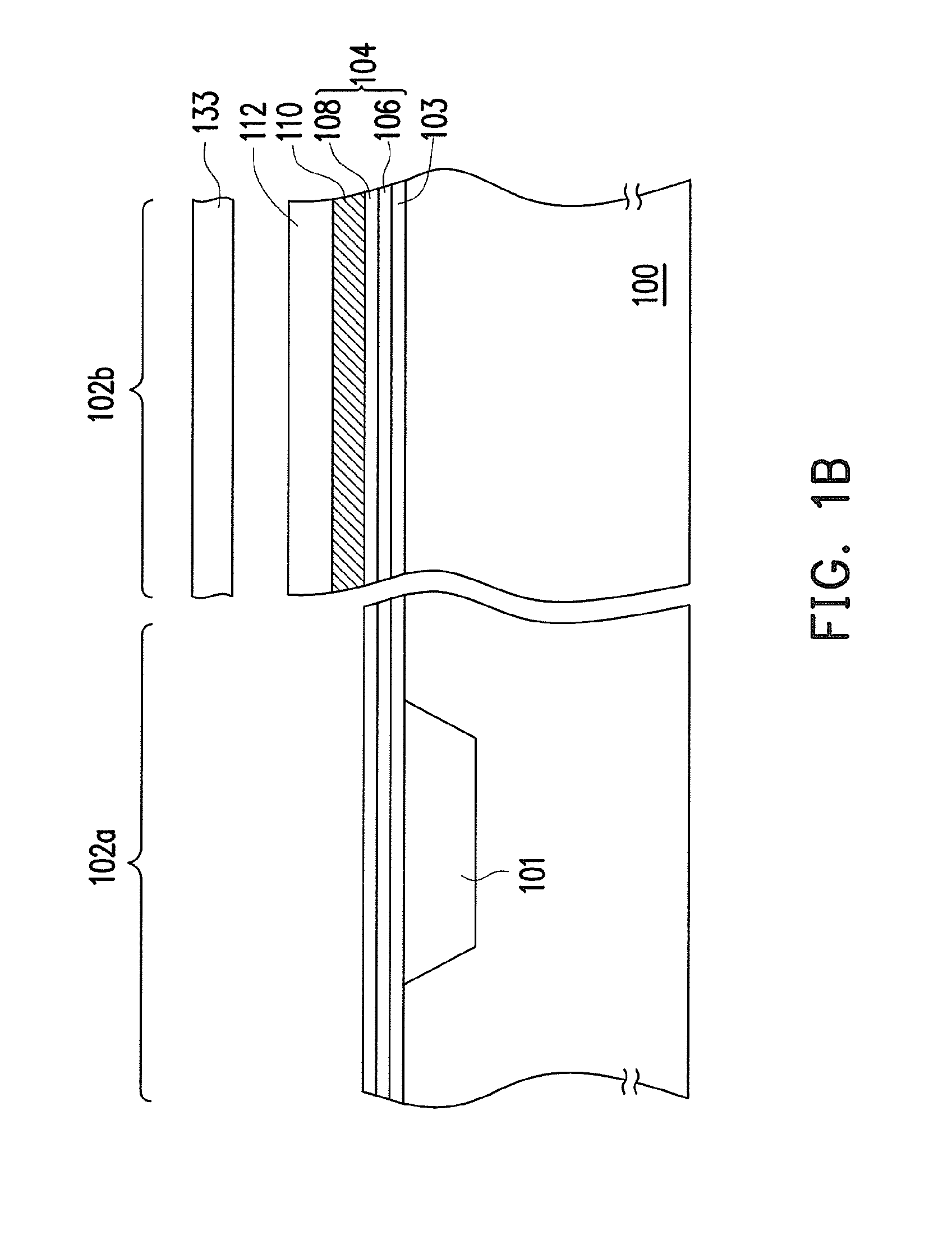

Semiconductor substrate, electrode forming method, and solar cell fabricating method

ActiveUS20090243111A1High aspect ratioImprove conversion efficiencySemiconductor/solid-state device detailsConductive materialConductive pasteFrit

The present invention is directed to a semiconductor substrate having an electrode formed thereon, the electrode including at least silver and glass frit, the electrode including: a multi-layered structure constituted of a first electrode layer joined directly to the semiconductor substrate, and an upper electrode layer formed of at least one layer and disposed on the first electrode layer; wherein the upper electrode layer is formed by firing a conductive paste having a total silver content of 75 wt % or more and 95 wt % or less, the content of silver particles having an average particle diameter of 4 μm or greater and 8 μm or smaller with respect to the total silver content in the upper electrode layer being higher than that in the first electrode layer. As a consequence, it is possible to form the electrode, which has the high aspect ratio and hardly suffers an inconvenience such as a break, on the semiconductor substrate by a simple method.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

Method for forming circuit board without location holes

ActiveCN105338746ASimple forming methodFlat edgePrinted circuit manufactureMolding machineEngineering

The invention discloses a method for forming a circuit board without location holes. A circuit board to be processed with two technological edge is included, and each technological edge is provided with two location holes. The method comprises the following concrete steps: S1, carrying out a primary milling formation to prepare semi-finished product circuit boards A; S2, carrying out an electric test; S3, successively aligning the semi-finished product circuit boards A and overlapping the semi-finished product circuit boards A on the bench surface of a formation machine, one technological edge of the multiple semi-finished product circuit boards A is fixed by use of a positioning pin, and boring is performed at board edge positions of the multiple semi-finished product circuit boards A, and the semi-finished product circuit boards A are fixed by use of positioning pins; S4, carrying out secondary milling to prepare semi-finished product circuit boards B; S5, boring is performed at positions, close to board edges, of the semi-finished product circuit boards B after the technological edges are milled, and the semi-finished product circuit boards B are fixed by use of the positioning pins; S6, carrying out third-time milling to prepare a finished product circuit board; and S7, cleaning, and performing drying processing. According to the invention, milling formation is used for three times, a circuit board formation method is optimized, the board edge of the circuit board is enabled to be flat and smooth, splicing application is facilitated, the quality of the circuit board is improved, the production time is reduced, and the production efficiency is improved.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

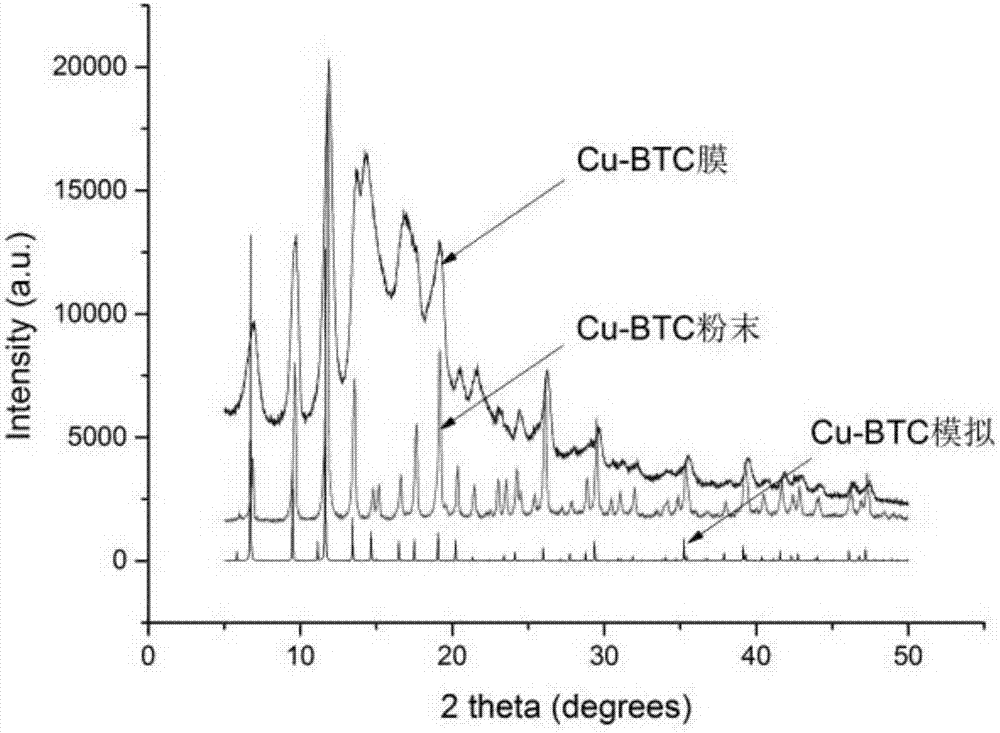

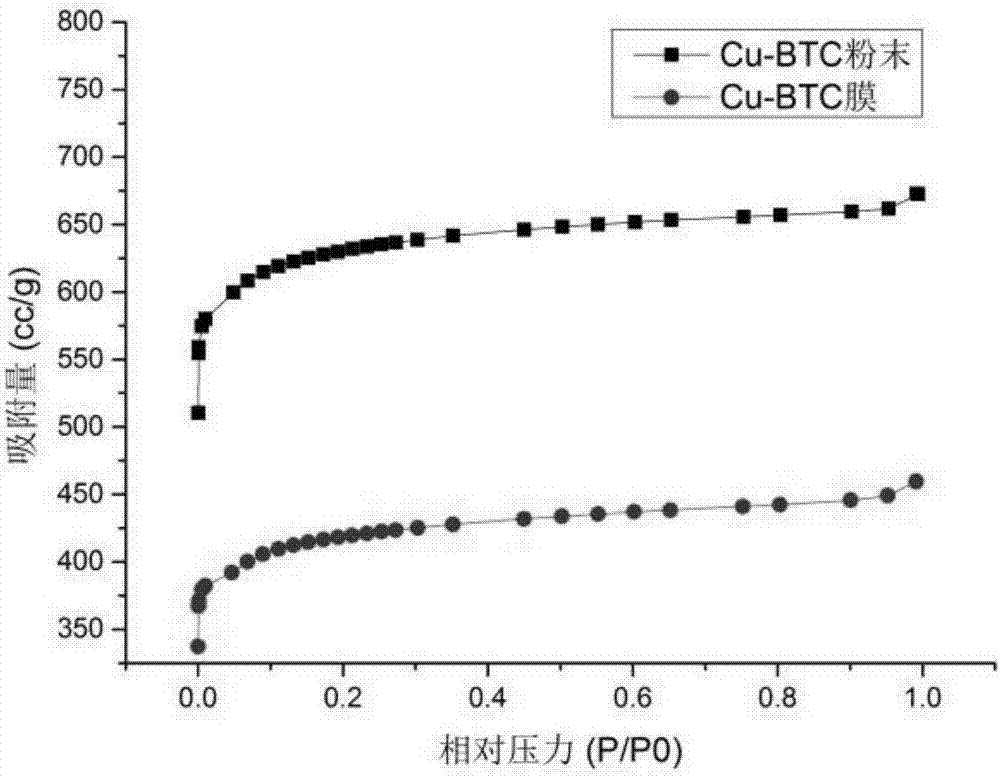

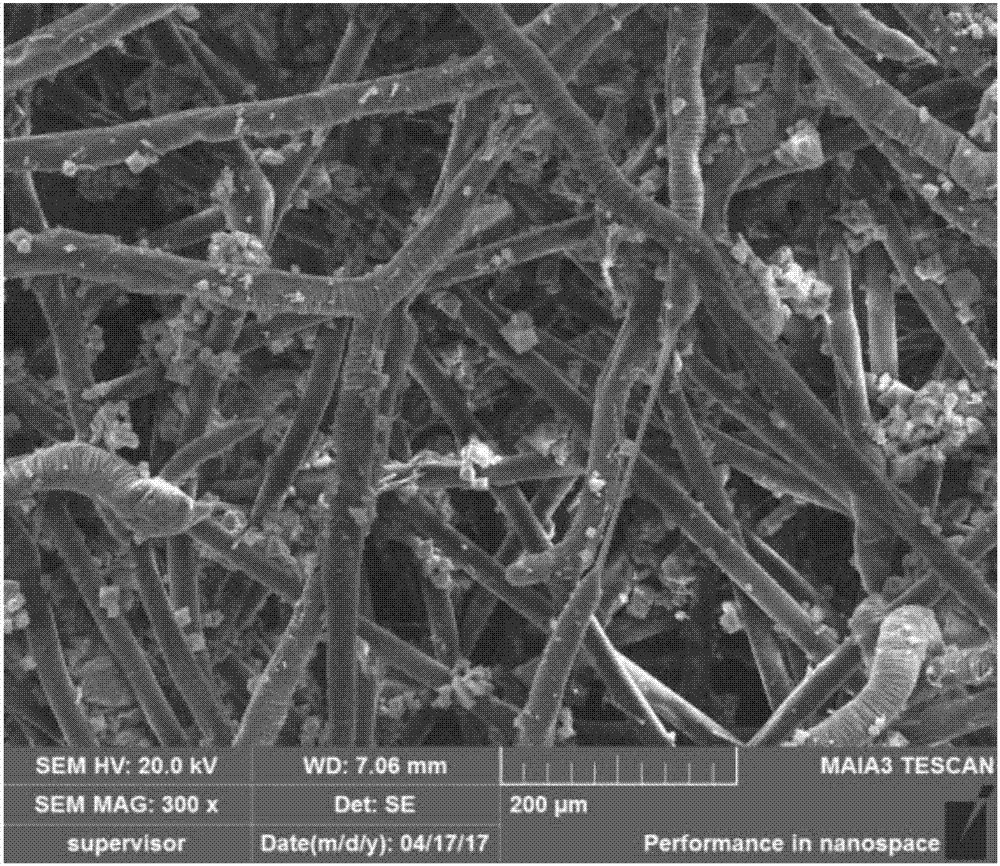

Molded metal-organic framework material and molding method thereof

InactiveCN107029670AGood bonding performanceHigh strengthOther chemical processesDispersed particle separationMetal-organic frameworkOrganic solvent

The invention discloses a molded metal-organic framework material and a molding method thereof. The molding method comprises the following steps: preparing a binder solution with a proper concentration to allow the binder solution to minimally block holes in a metal-organic framework material while maintaining good bonding performance; then uniformly mixing the binder solution with a suspension of the metal-organic framework material; placing a substrate membrane in the mixed solution obtained in the previous step to allow the surface of the substrate membrane to be uniformly adhered by a layer of the metal-organic framework material; and then soaking the substrate membrane uniformly adhered by the metal-organic framework material in an organic solvent to allow water molecules in the pore channels of the metal-organic framework material to be displaced out so as to reinforce the strength of the metal-organic framework material adhered on a substrate, wherein the molded metal-organic framework material with a large specific surface area and high mechanical strength is eventually obtained. Thus, the molding method provided by the invention overcomes the technical problems of complex molding process, a long molding period, severe conditions, high cost, severe loss of specific surface areas and the like in the prior art.

Owner:HUAZHONG UNIV OF SCI & TECH

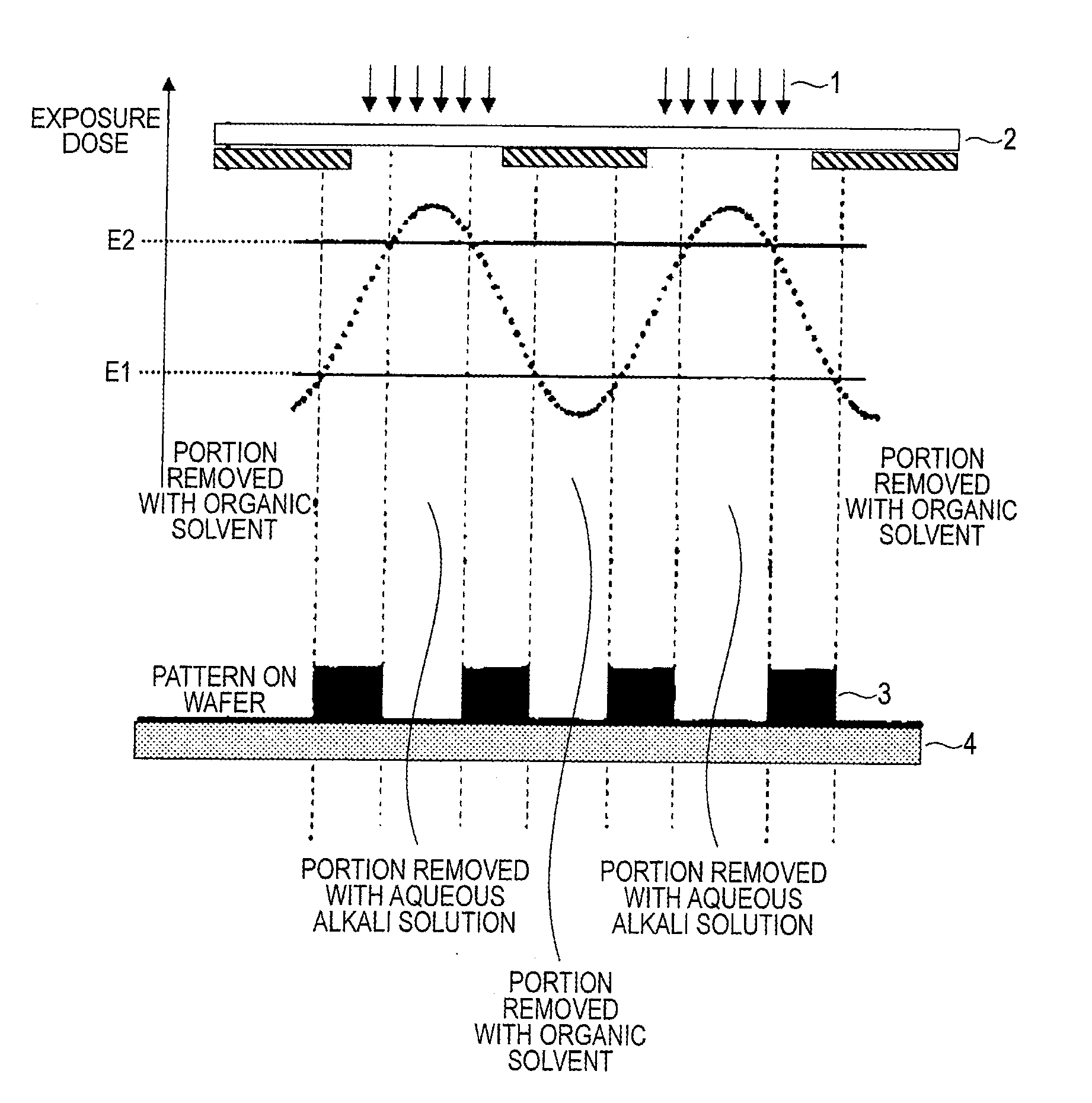

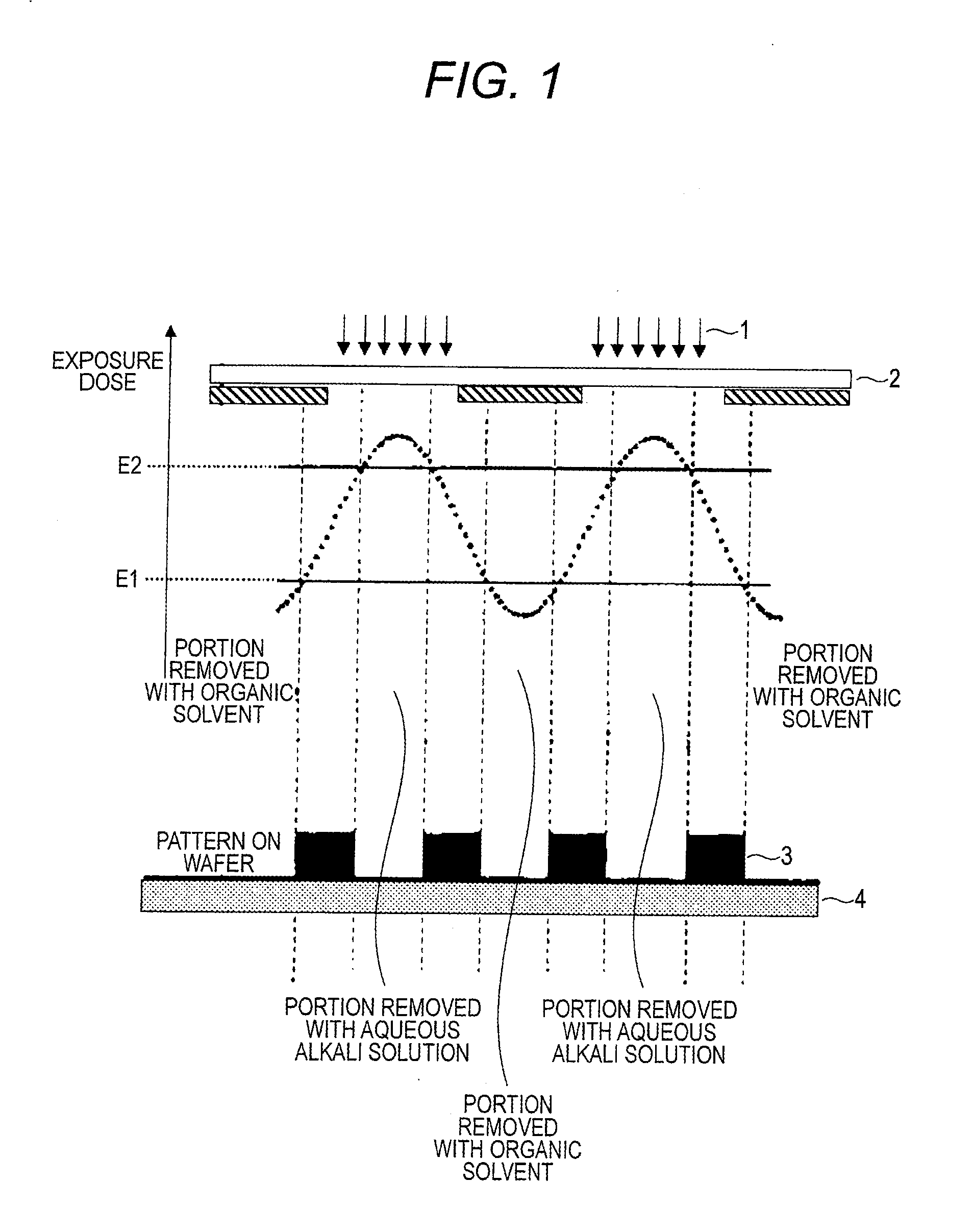

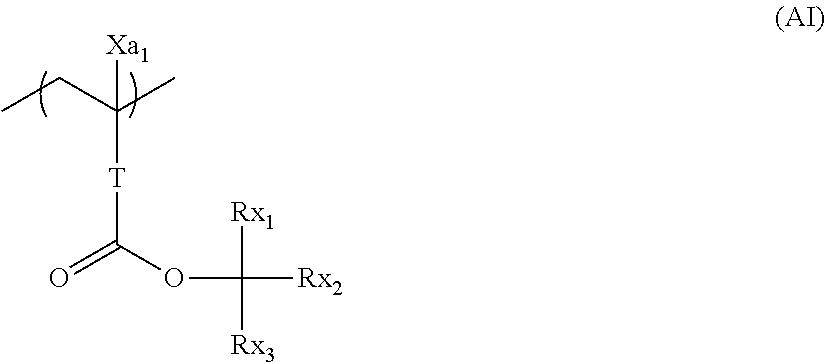

Pattern forming method, chemical amplification resist composition and resist film

ActiveUS20120058427A1Simple forming methodOrganic chemistryPhotosensitive materialsChemical compoundActinic Rays

A pattern forming method, including: (i) forming a film from a chemical amplification resist composition; (ii) exposing the film, so as to form an exposed film; and (iii) developing the exposed film by using a developer containing an organic solvent, wherein the chemical amplification resist composition contains: (A) a resin capable of decreasing a solubility of the resin (A) in the developer containing an organic solvent by an action of an acid; (B) a compound capable of generating an acid upon irradiation with an actinic ray or radiation; and (C) a basic, compound or ammonium salt compound whose basicity decreases upon irradiation with an actinic ray or radiation, and a resist composition used for the pattern forming method and a resist film formed from the resist composition are provided.

Owner:FUJIFILM CORP

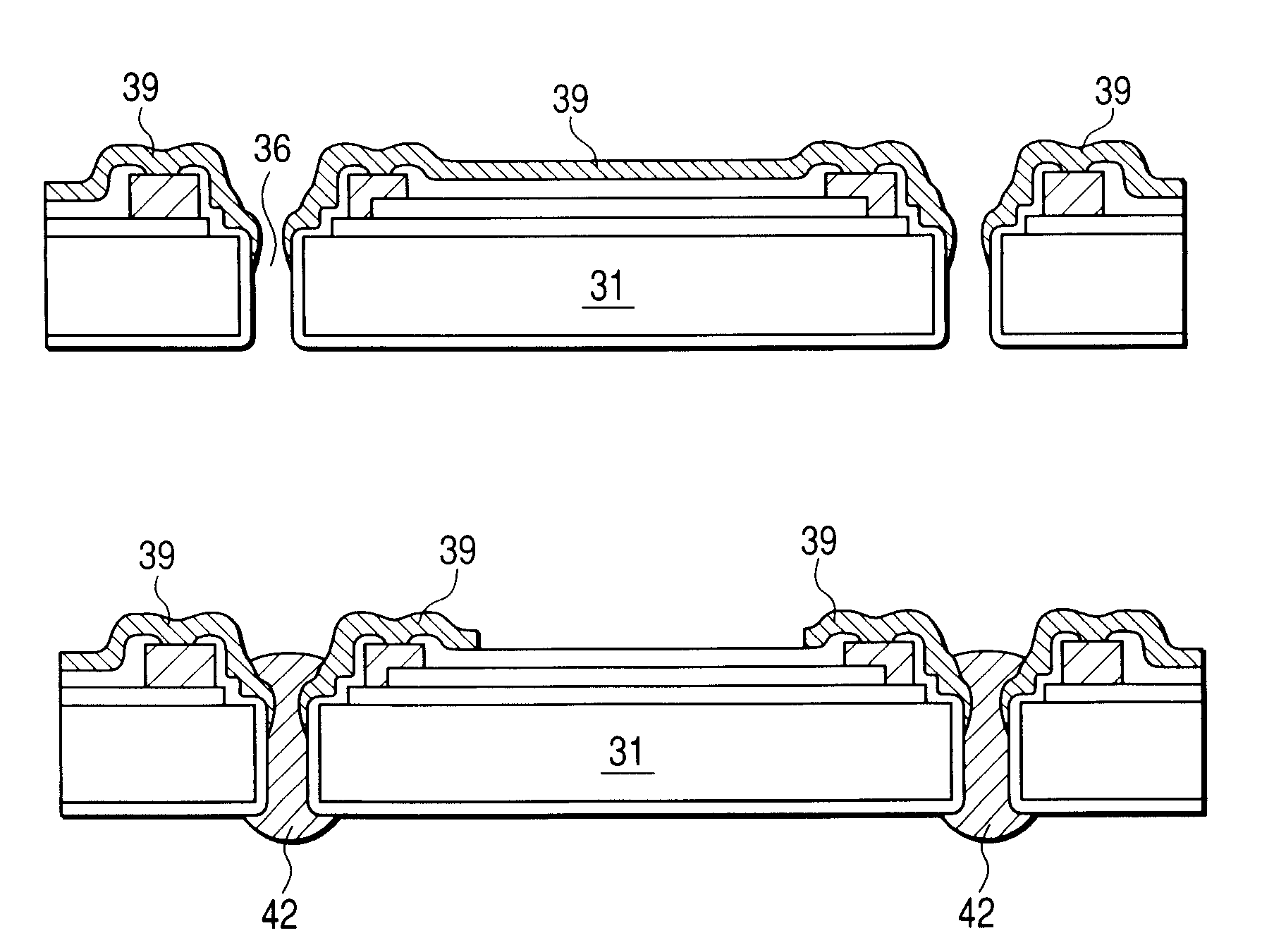

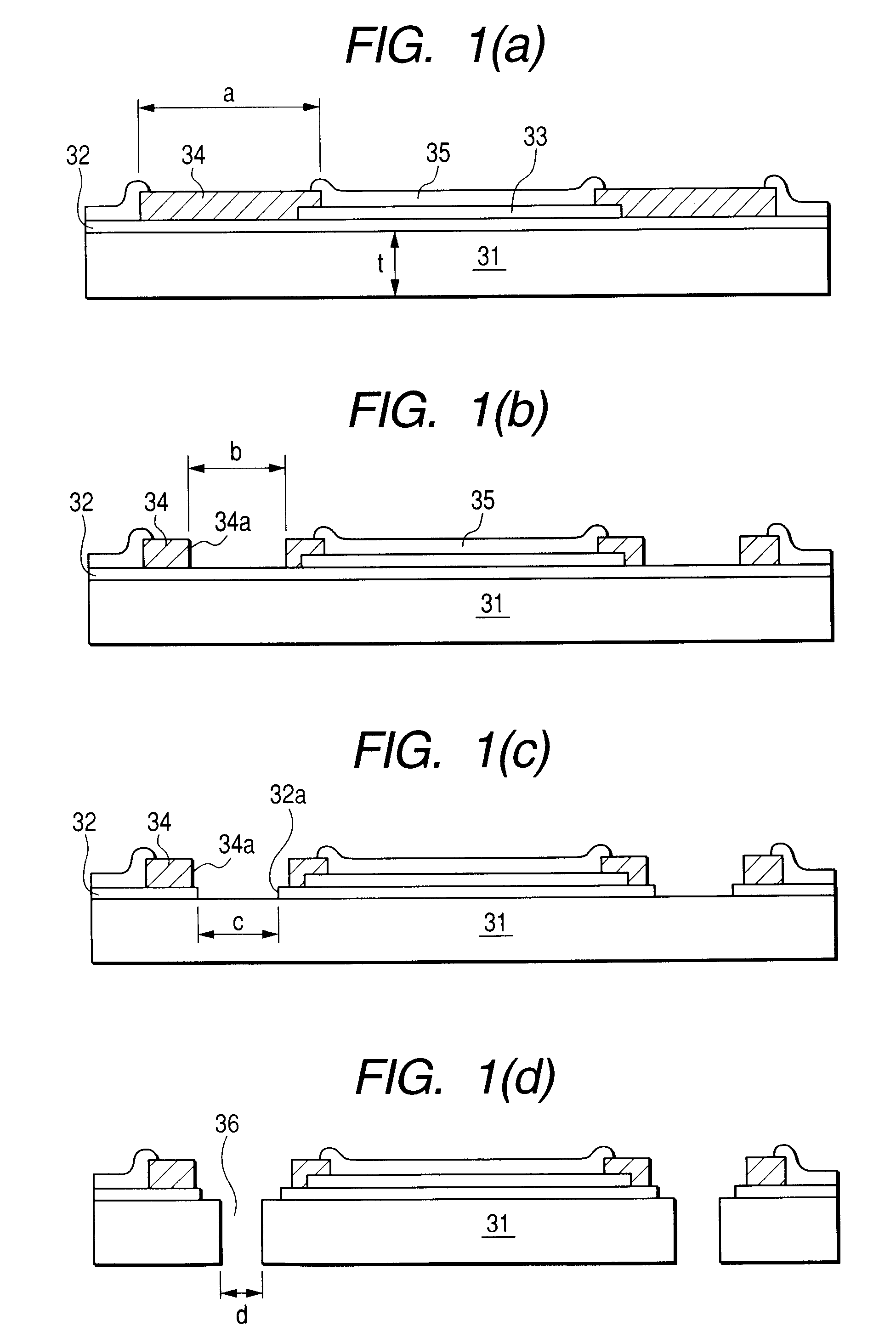

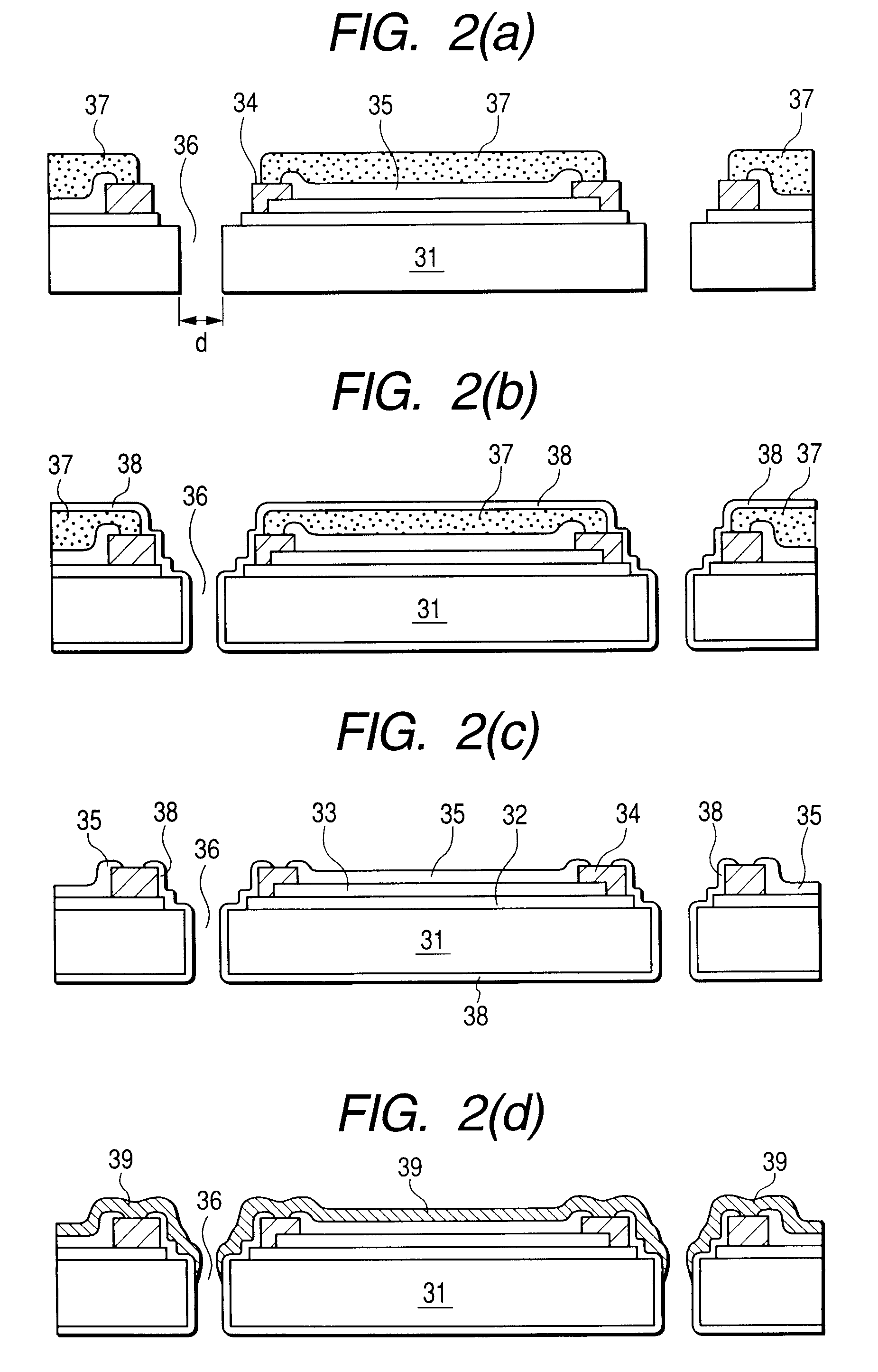

Semiconductor device having through electrode and method of manufacturing the same

ActiveUS7524753B2Low costSmall sizeSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneElectroplating

Owner:SHINKO ELECTRIC IND CO LTD

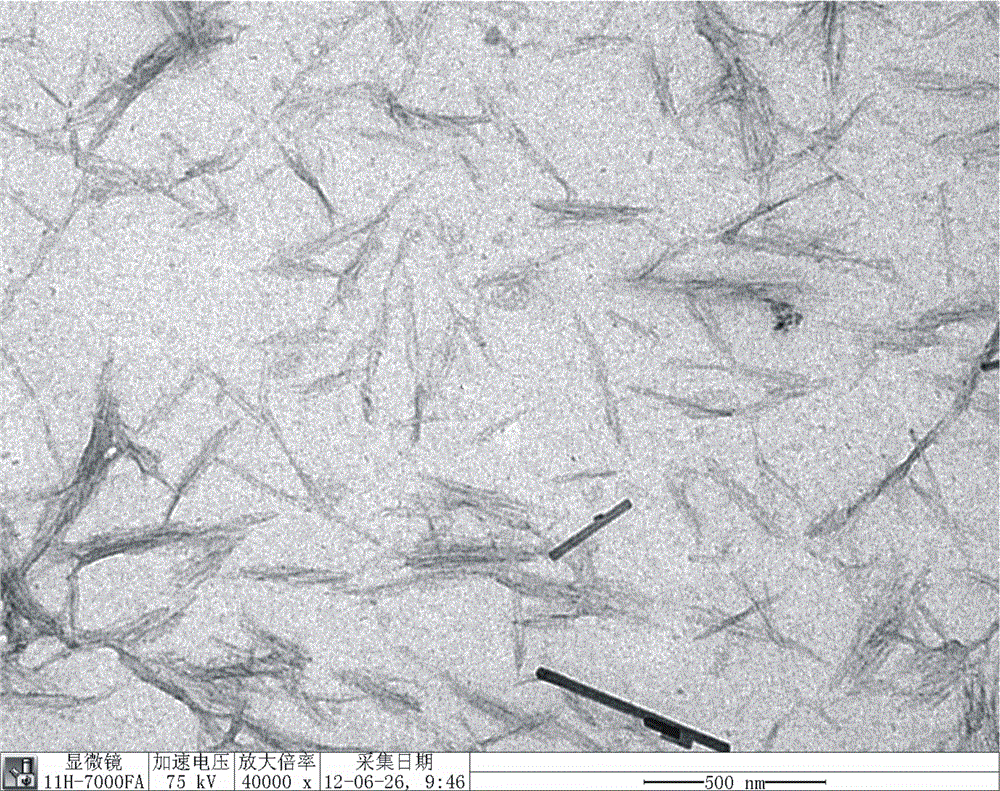

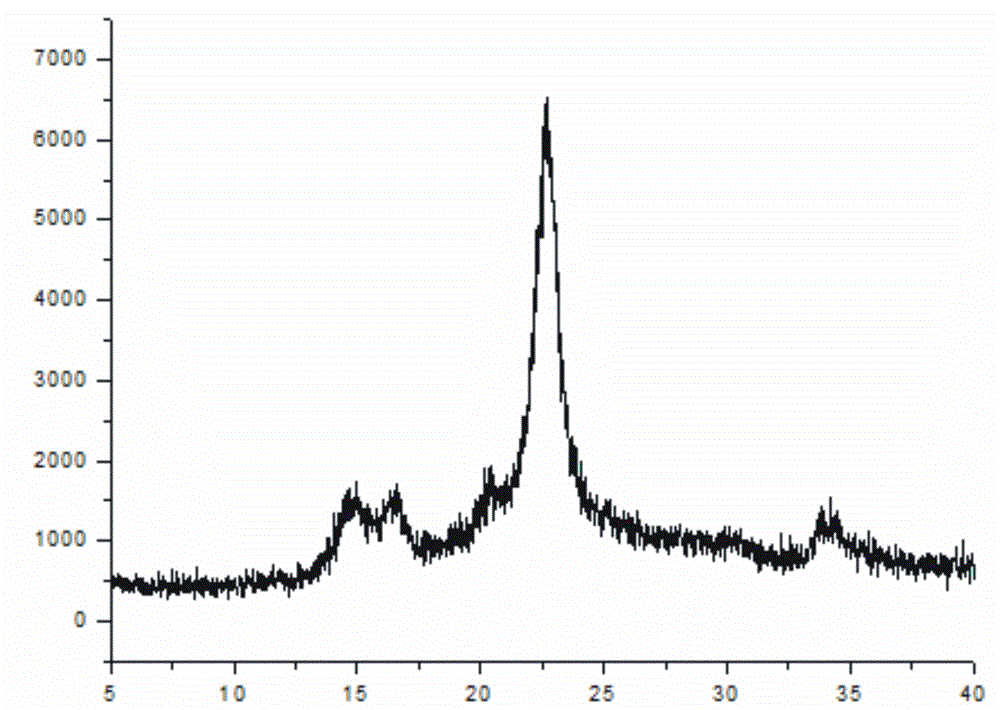

Cellulose/polylactic acid blend material and preparation method thereof

The invention discloses a blend material of cellulose and a polylactic acid. The blend contains 0.1-99.9% of cellulose and 99.9-0.1% of polylactic acid. The method comprises the following steps: with a 30-100% N-methylmorpholine-N-oxide (NMNO) water solution as a solvent, adding cellulose and a polylactic acid to the NMMO solution; dissolving at constant temperature of 35-150 DEG C for 0.1-100 hours; completely dissolving the cellulose and the polylactic acid, so as to prepare the mixed solution of the cellulose and the polylactic acid; precipitating a molding product of the mixed solution by a precipitant; and pelletizing and drying the obtained blend in vacuum, so as to prepare the blend material of the cellulose and the polylactic acid. The raw material of the cellulose is any one or a mixture of more than two of straws, bagasse, wood fiber, jute fiber, beet pulp, bamboo fiber, cotton pulp, hemp pulp, bamboo pulp and recycled cellulose, and the polylactic acid is a homopolymer, a copolymer or a blend thereof.

Owner:NANJING FORESTRY UNIV

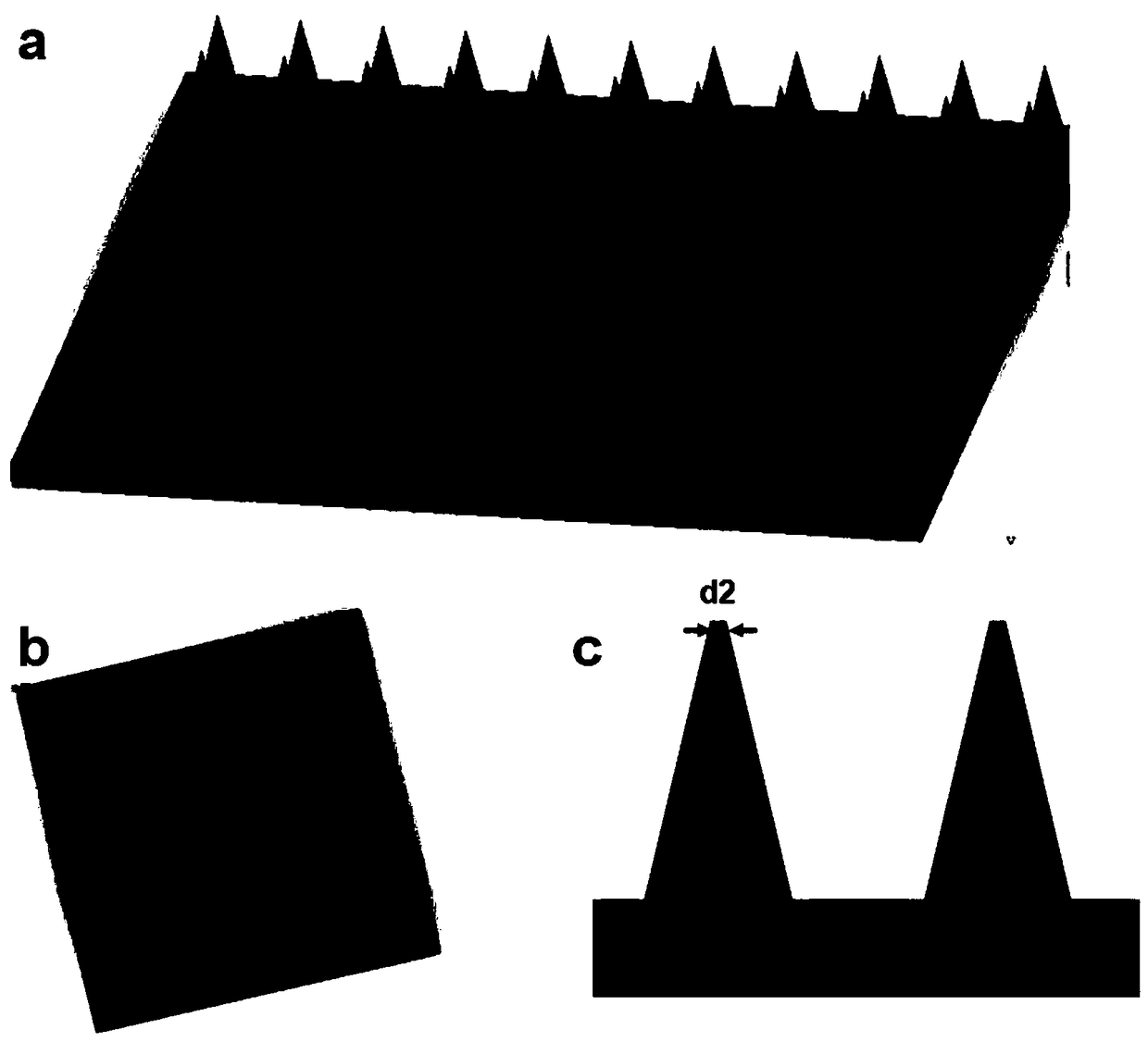

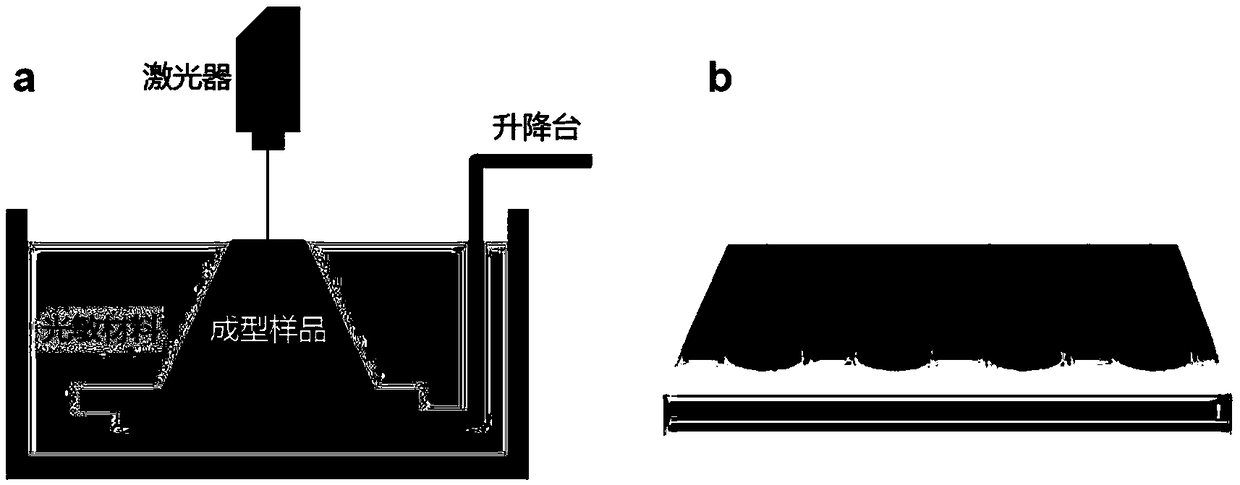

3D printing microneedle patch for intelligent blood sugar regulation and a preparation method thereof

ActiveCN109125912ASimple forming methodHigh mechanical strengthAdditive manufacturing apparatusMicroneedlesBiocompatibility TestingBlood sugar

The invention discloses a 3D printing microneedle patch for intelligent blood glucose regulation and a preparation method thereof, belonging to the biomedical field. The 3D printing microneedle patchof the invention is mainly made of photosensitive material with good biocompatibility, and comprises two parts of a substrate and a microneedle array, wherein the microneedle array comprises a plurality of conical microneedles, and the microneedles contain medicaments for intelligently regulating blood sugar, and the medicaments include carrier materials, glucose-responsive sensitive switching factors and medicaments molecules. The 3D printing microneedle patch of the invention is mainly made of photosensitive material with good biocompatibility. Firstly, the three-dimensional model of micro-needle patch is built by using modeling software, and the model is imported into the printing software of 3D printer. Then the 3D printing technology of photocuring is used to solidify the photosensitive material solution containing photoinitiator and drug according to the structure of the three-dimensional model of the micro-needle patch to obtain the 3D printing micro-needle patch. The microneedle patch of the invention can puncture the skin and intelligently release the loaded insulin according to the blood glucose concentration in the body so as to intelligently regulate the blood glucose level. The invention realizes painless, intelligent and responsive blood glucose regulation.

Owner:WUHAN UNIV

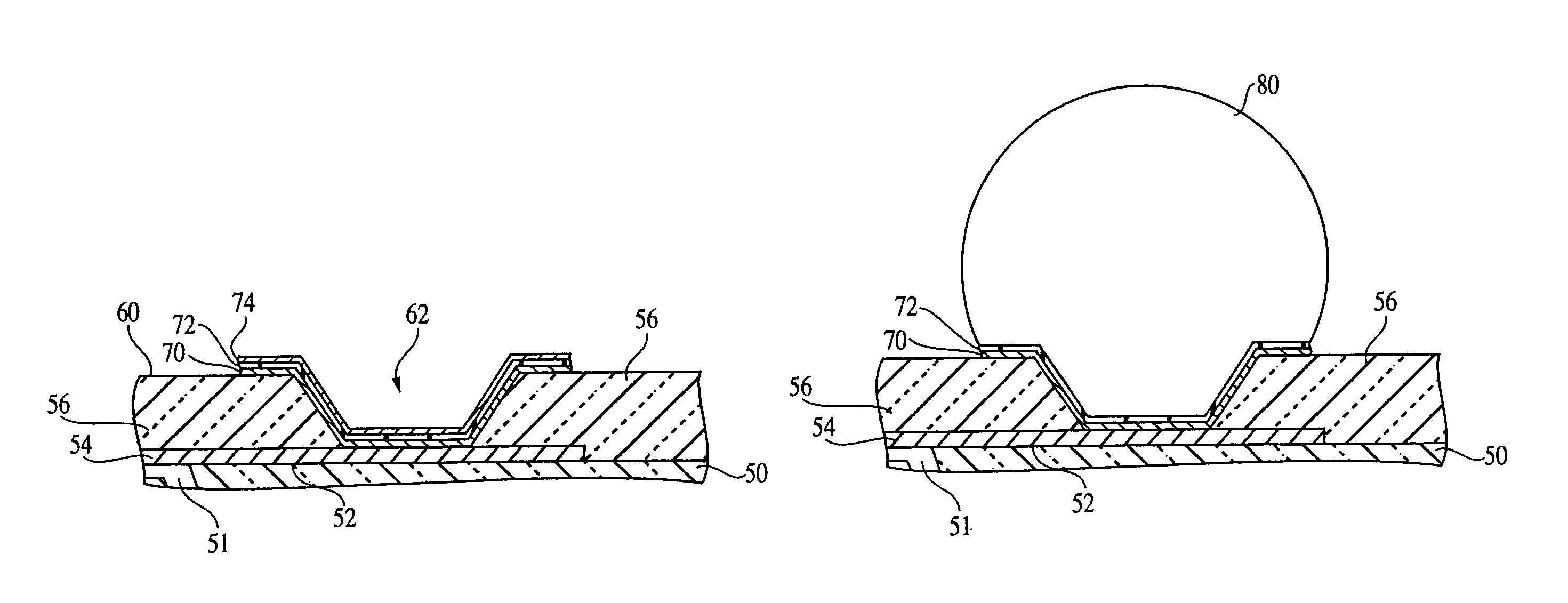

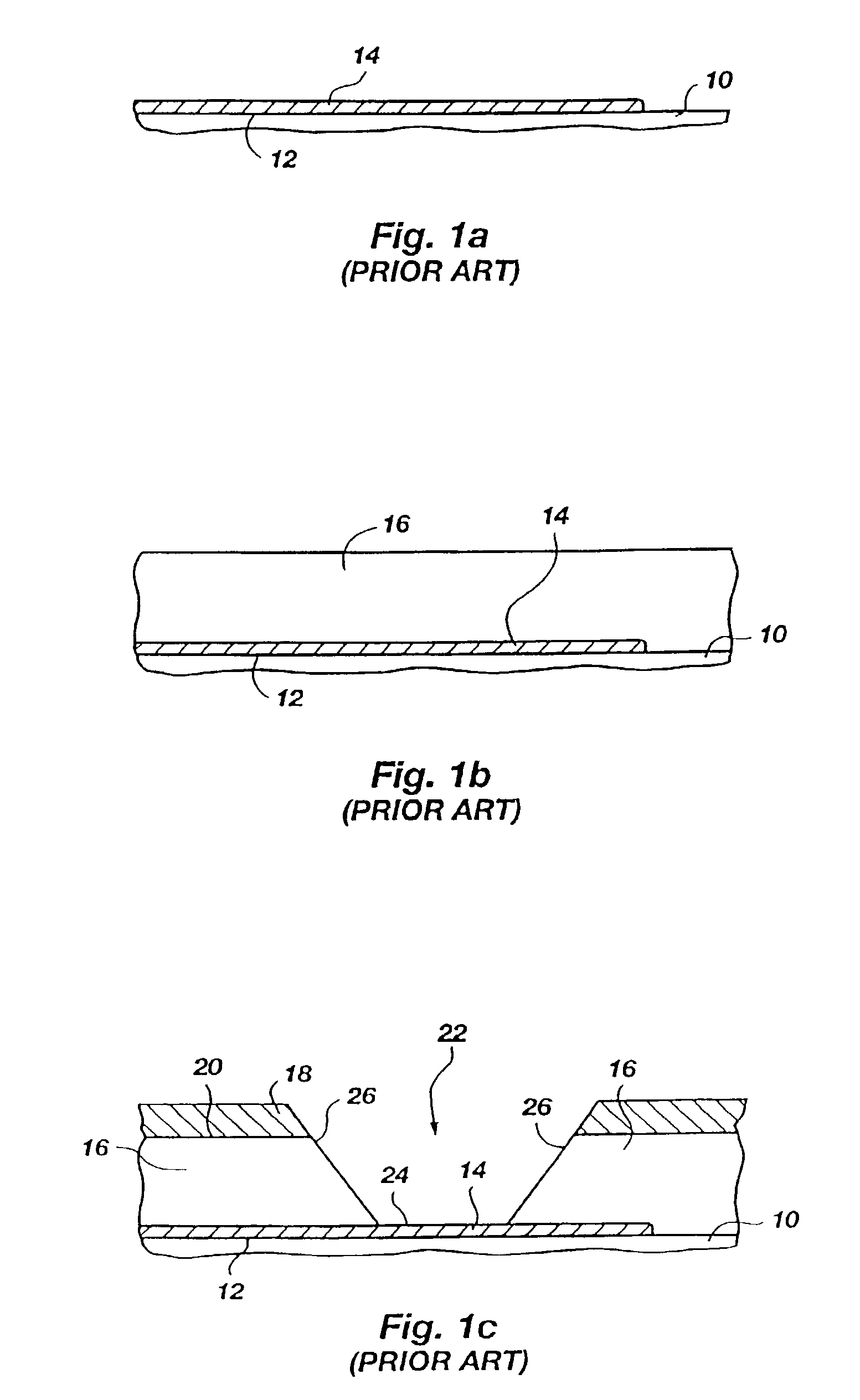

Under bump metallization pad and solder bump connections

InactiveUS7205221B2Eliminate needReduce in quantitySemiconductor/solid-state device detailsSolid-state devicesImproved methodUnder bump metallurgy

The present invention relates to an improved method of forming and structure for under bump metallurgy (“UBM”) pads for a flip chip which reduces the number of metal layers and requires the use of only a single passivation layer to form, thus eliminating a masking step required in typical prior art processes. The method also includes repatterning bond pad locations.

Owner:ROUND ROCK RES LLC

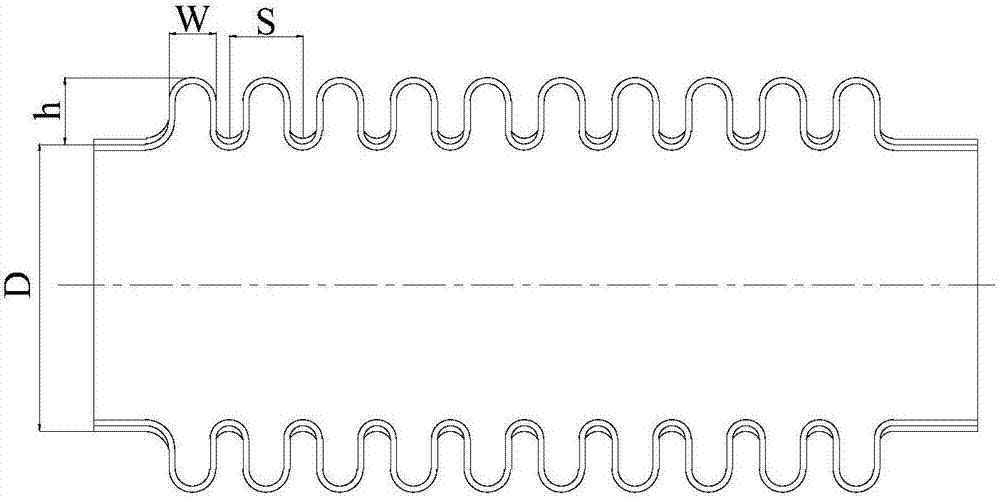

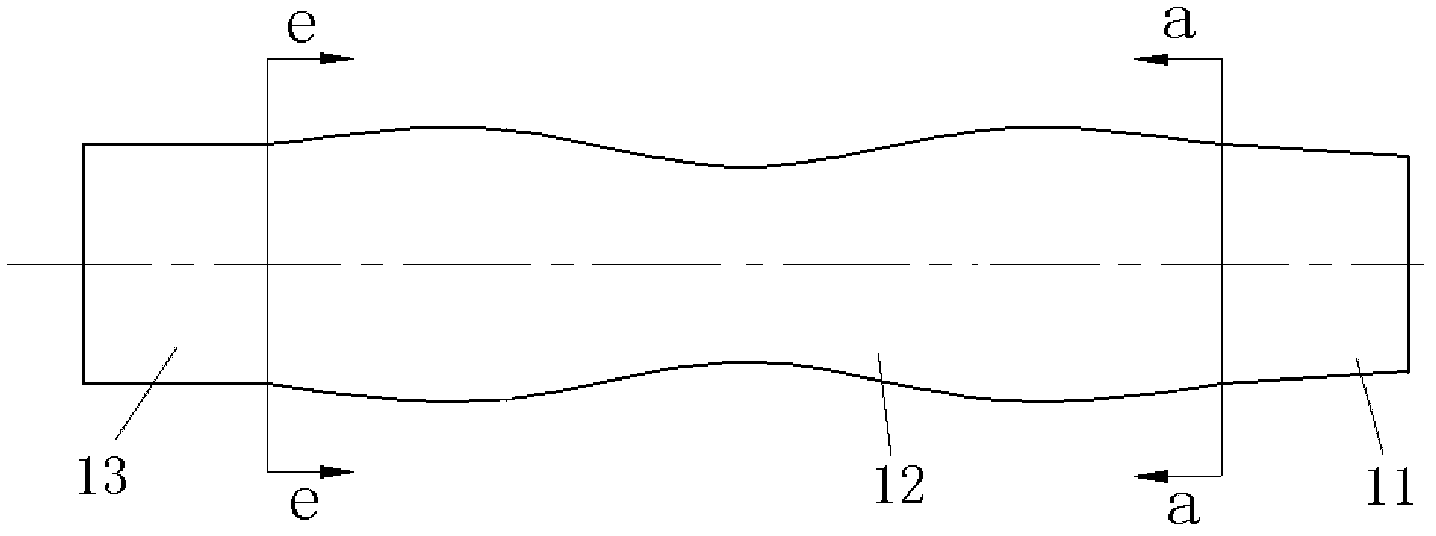

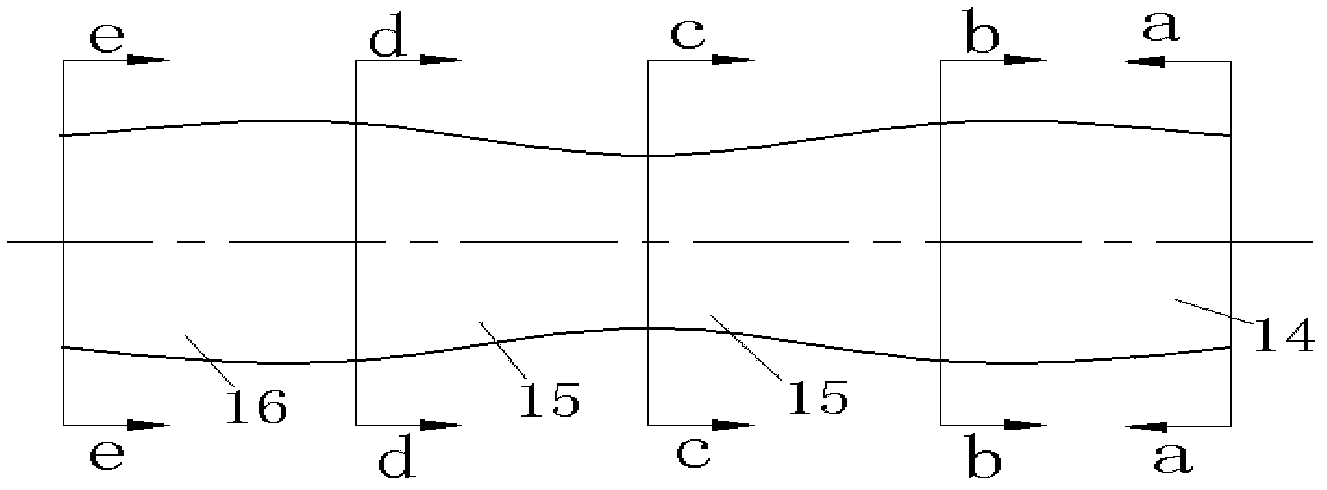

Metal bellows with axial stiffeners, and forming method

ActiveCN107413882AHigh bending deformation stiffnessExtended service lifeFlexible pipesEngineeringMetal

The invention provides a metal bellows with axial stiffeners. The metal bellows is a corrugated metal hose with the axial stiffeners at the wave trough position. The forming method of the corrugated metal hose comprises the steps of rolling plates to form corrugation, then curling and welding, and finally bulging on a bulging machine; flat expanding axial waves at the wave peak position so that the wave peak position has no the axial stiffeners, while the axial stiffeners at the wave trough position are reserved, so that the corrugated metal hose with the axial stiffeners at the wave trough position is obtained. The bending deformation rigidity of the corrugated metal hose is high; in case of axial elongation deformation, the deformation mainly focuses on the wave peak position, while the wave trough position is hardly deformed; and the service life of the corrugated metal hose is prolonged effectively.

Owner:JIANGSU HONGYUAN PIPES

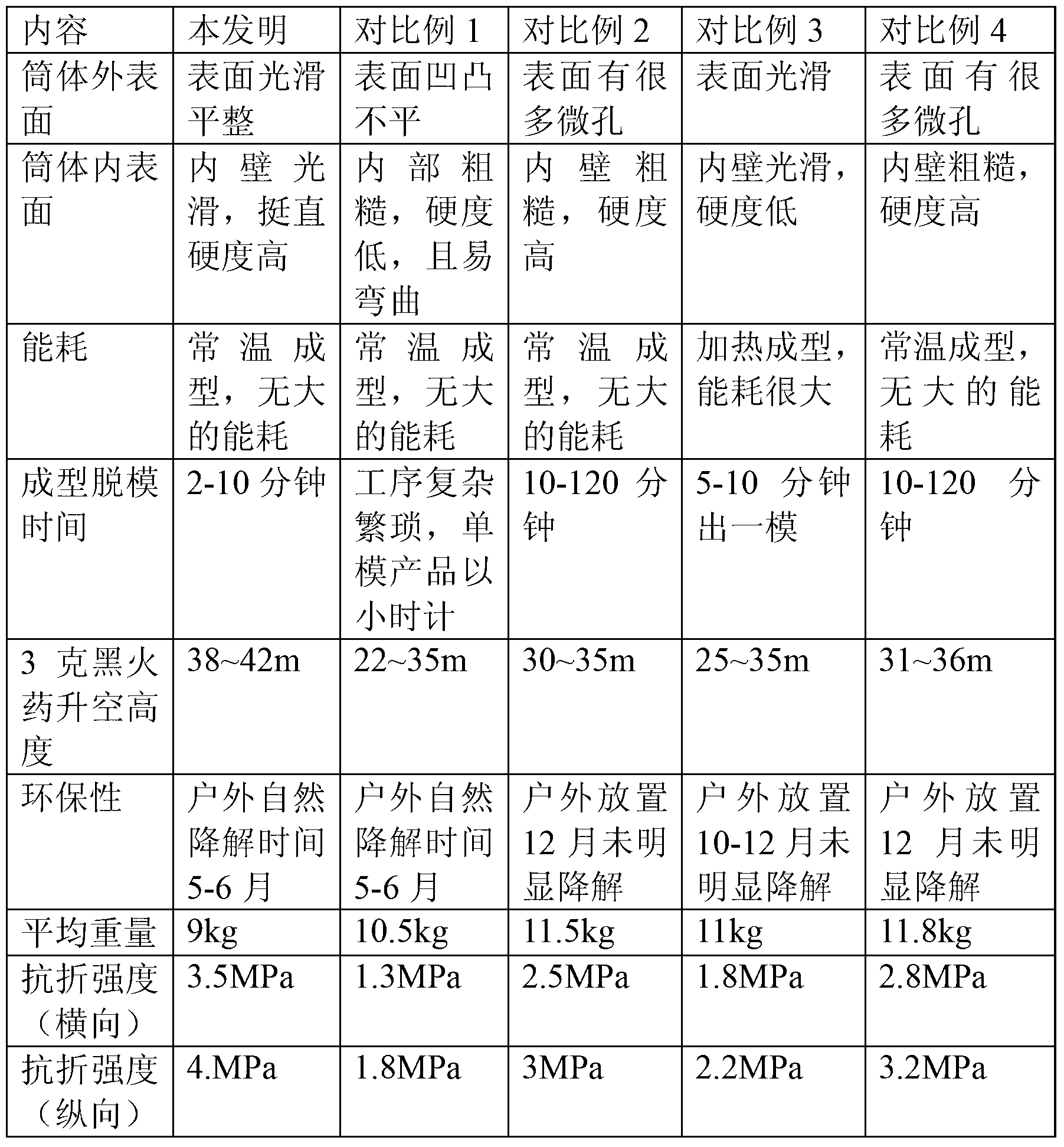

Firework cylinder material and preparation method thereof

The invention discloses a firework cylinder material which is prepared from the following components in percentage by mass: 20-55% of plant fiber, 0-15% of reinforcing fiber, 1-5% of fiber finishing agent, 25-39% of air hardening material, 0.1-2% of catalyst, 5-25% of filler, 0-2% of lubricant, 0-2% of water-condensing agent, 5-15% of toughener and 0-5% of foaming agent, wherein stabilizer accounts for 2-15% of the total mass of the formula. The invention also discloses a preparation method of the firework cylinder material. The technical scheme can completely replace the traditional firework cylinder production mode, and is high in processing operability, high in molding speed and easy to realize large-scale stable production; and meanwhile, the raw materials are abundant, easy to acquire and low in cost. Besides, the produced firework cylinder can achieve qualified mechanical strength and favorable physical / chemical stability, causes no environmental pollution and can be degraded naturally.

Owner:汤华荣 +1

Bar shaped catalyst for preparing bio-based acrylic acid and molding method thereof

InactiveCN101462069AReduce consumptionHigh catalytic activityOrganic chemistryMolecular sieve catalystsMolecular sievePolymer science

The invention discloses an extruded catalyst for producing acrylic acid by dehydrating biomass lactic acid and a molding method thereof. The catalyst mainly comprises Y molecular sieve raw powder, an adhesive, an extrusion aid and water, wherein the weight ratio of the Y molecular sieve raw powder to the adhesive is 2-50: 1, the weight ratio of the Y molecular sieve raw powder to the extrusion aid is 10-100: 1, the weight ratio of the water to the Y molecular sieve raw powder is 0.3-1: 1, and various raw materials are mixed evenly and then are orderly subjected to kneading, aging, extruded molding and drying to obtain the extruded catalyst. The catalyst has the advantages of simple components, low cost, high activity, good selectivity and high strength. In addition, the molding method for the catalyst is simple and easy to operate, and has low production cost and good industrialized prospect.

Owner:CHINA PETROLEUM & CHEM CORP

Vacuum rush gum forming method of fiber-reinforced resin matrix compound material

The invention relates to a resin flowing compound material forming method which is aided by vacuum. A fiber-reinforced material is tailored and then paved in a mould cavity according to the design of layer quantity and structure of a product. Resin and firming agent are prepared into dipping glue solution which is evenly coated in the mould cavity and ensured to permeate the fiber-reinforced material. A mould is sent into a vacuum bag which is sealed and then vacuumized till a vacuum bag film closely clings to the surface of the reinforced material supported by the mould. A panel with elastic planes is used for expel foams and surplus glue solution in the vacuum bag to the edges outside the mould cavity. Then, in the conditions of normal temperature or heating and vacuum, the product gradually undergoes solidification and demoulding. The method can improve the mechanical properties and the surface quality of the compound material product, reduce the cost on production apparatuses and auxiliary materials and simplify the method operation.

Owner:SHENZHEN OYA CARBON TECH +1

Tube drawing forming method and forming mould

InactiveCN102423770AImproved strain distributionIncrease stressDrawing diesStress distributionShear stress

The invention discloses a tube drawing forming method and forming mould. In the forming method, extrusion-bulging deformation is performed on a tube by using a drawing torsion variable-section core to realize combination of various deformation modes in a primary forming process. The tube wall of the formed tube is subjected to the extrusion-bulging of the core and is in a strong three-way compressive stress state due to the limitation of a polyurethane filling layer; at a deformation stage of circular-elliptical-circular and elliptical torsion change, the tube enters a torsion shearing deformation zone of a metal transition region; under the action of shearing stress, the internal organization of the material is subjected to rotation and shear strain to cause the orientation of a materialorganization structure, namely a new texture is formed, thereby improving deformation texture under the equivalent deformation degree. The drawing variable-section core extrusion-bulging tube deformsto achieve larger deformation degree compared with that of the conventional forming process, so that strain distribution and stress distribution in the tube are improved, the casting organization remained in the broken tube is facilitated, the form and the distribution of inclusion are changed, and the defects of the internal organization of the tube are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

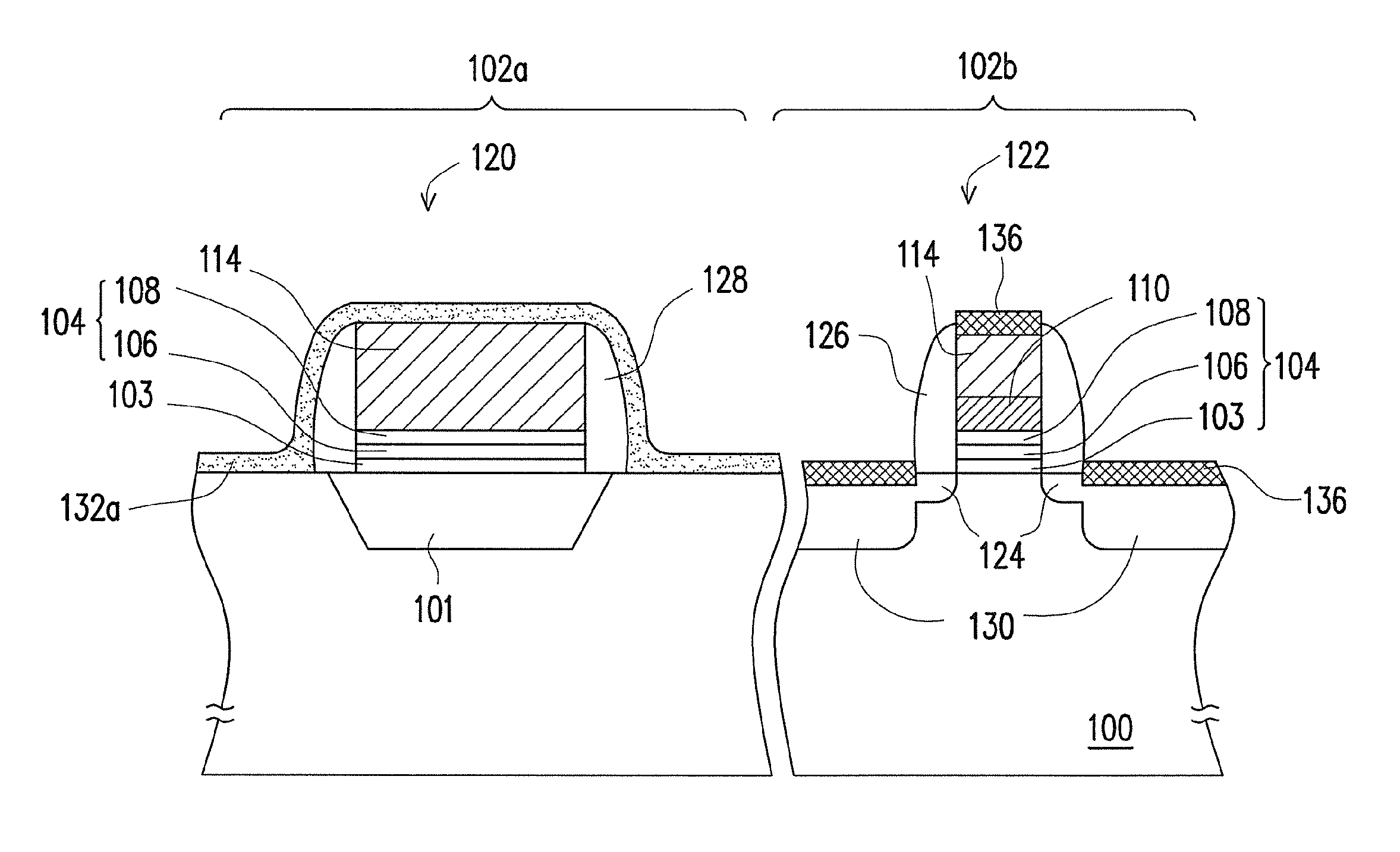

Semiconductor structure and method of forming the same

ActiveUS8093118B2Simple forming methodIncrease resistanceTransistorSolid-state devicesSemiconductor structureEngineering

A semiconductor structure and a method of forming the same are provided. The semiconductor structure includes a substrate, a resistor and a metal gate structure. The substrate has a first area and a second area. The resistor is disposed in the first area, wherein the resistor does not include any metal layer. The metal gate structure is disposed in the second area.

Owner:UNITED MICROELECTRONICS CORP

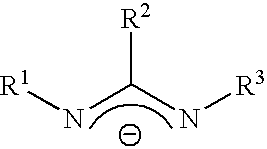

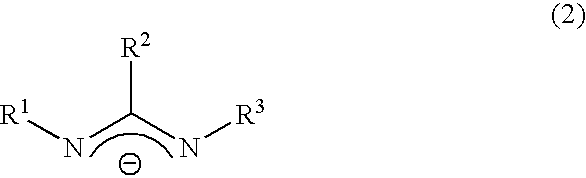

Chemical vapor deposition material and chemical vapor deposition

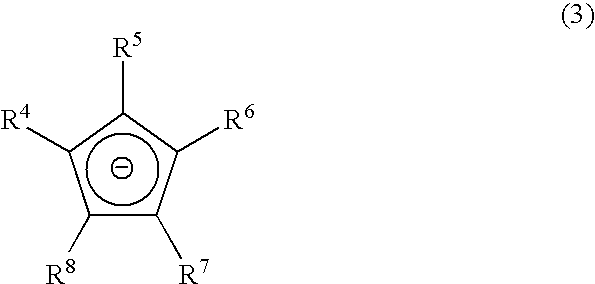

ActiveUS20060024443A1Quality improvementWell formedRuthenium organic compoundsVacuum evaporation coatingHydrogen atomGas phase

A chemical vapor deposition material comprising a ruthenium compound having a ligand represented by the following formula: wherein R1, R2 and R3 are each independently a hydrogen atom, fluorine atom, trifluoromethyl group or hydrocarbon group having 1 to 10 carbon atoms, and a method of forming a ruthenium film from the chemical vapor deposition material by chemical vapor deposition. A high-quality ruthenium film even when it is very thin can be obtained.

Owner:JSR CORPORATIOON

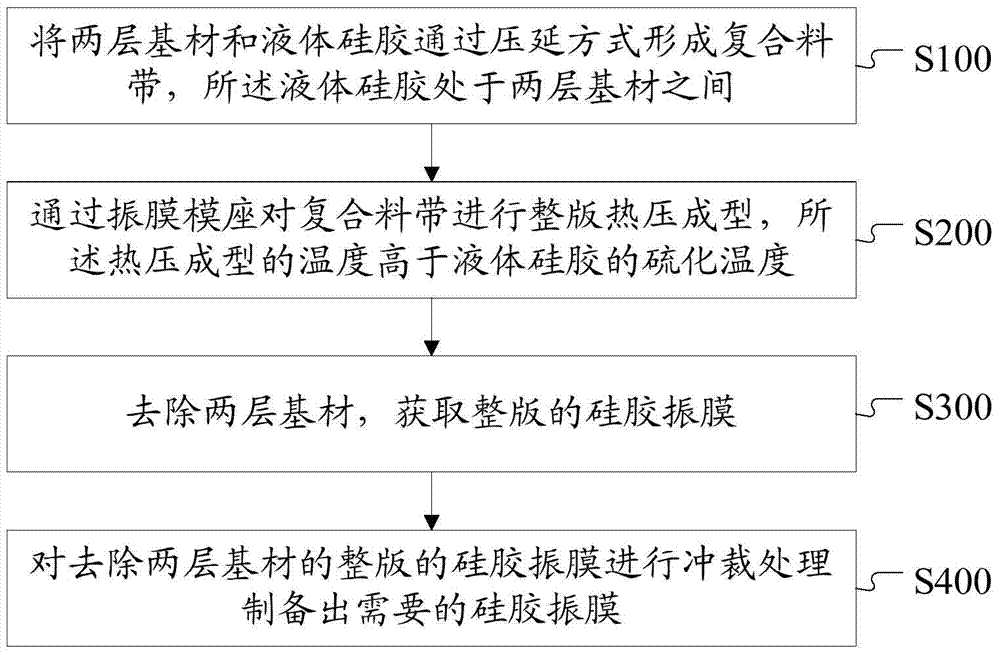

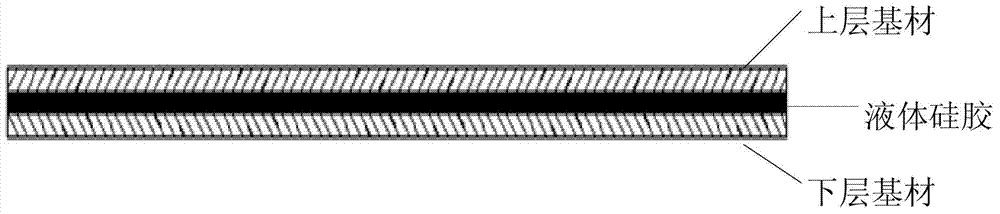

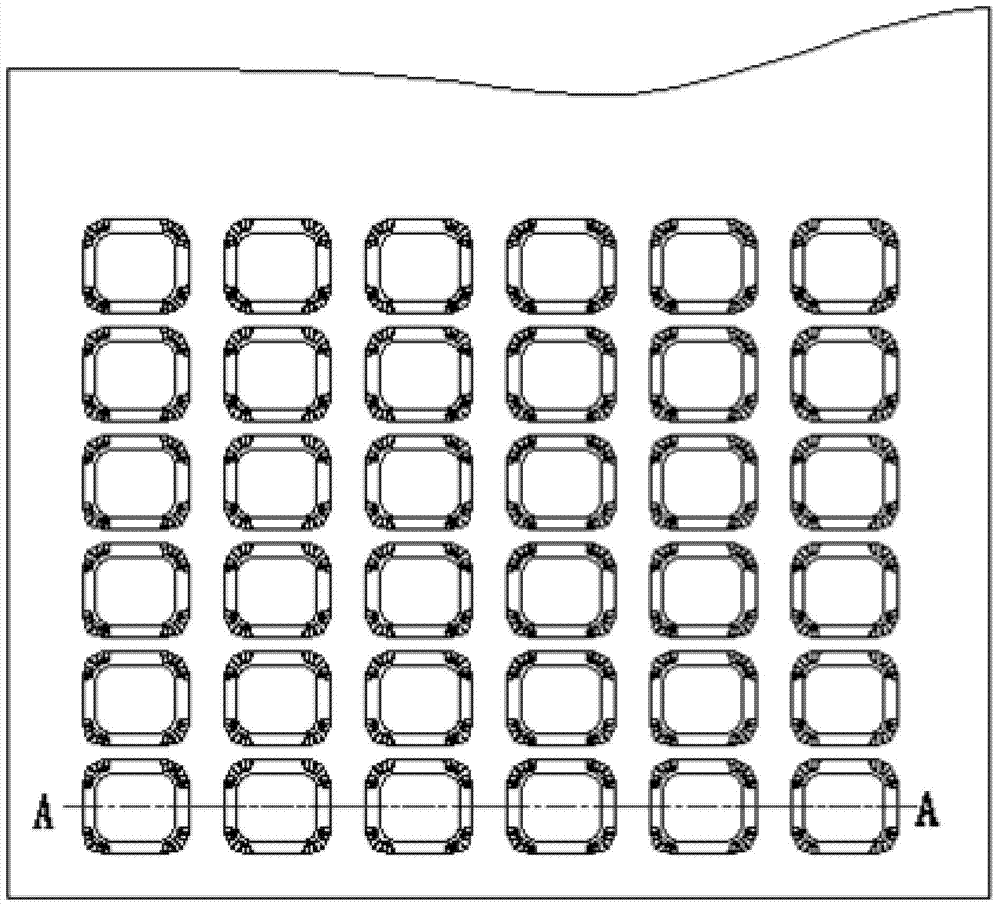

Method for preparing silica gel diaphragm and silica gel diaphragm

ActiveCN104853303ARich styleSimple forming methodPolymeric diaphragmsDomestic articlesPolymer scienceSilica gel

The invention discloses a method for preparing a silica gel diaphragm and the silica gel diaphragm. The method comprises: forming a composite material tape by two layers of substrates and liquid silica gel through a calendering method, the liquid silica gel being between the two layers of substrates; performing full-plate hot press molding on the composite material tape through a diaphragm die holder, temperature of the hot press molding being higher than vulcanizing temperature of the liquid silica gel; removing the two layers of substrates, to obtain a full-plate silica gel diaphragm; and performing blanking on the full-plate silica gel diaphragm from which the two layers of substrates are removed, so as to prepare a required silica gel diaphragm. Compared with a conventional scheme, the technical scheme is advantaged by simple forming method, low cost, diverse diaphragm forms, and thin diaphragm thickness.

Owner:GOERTEK INC

Chemical vapor deposition material and chemical vapor deposition

Owner:JSR CORPORATIOON

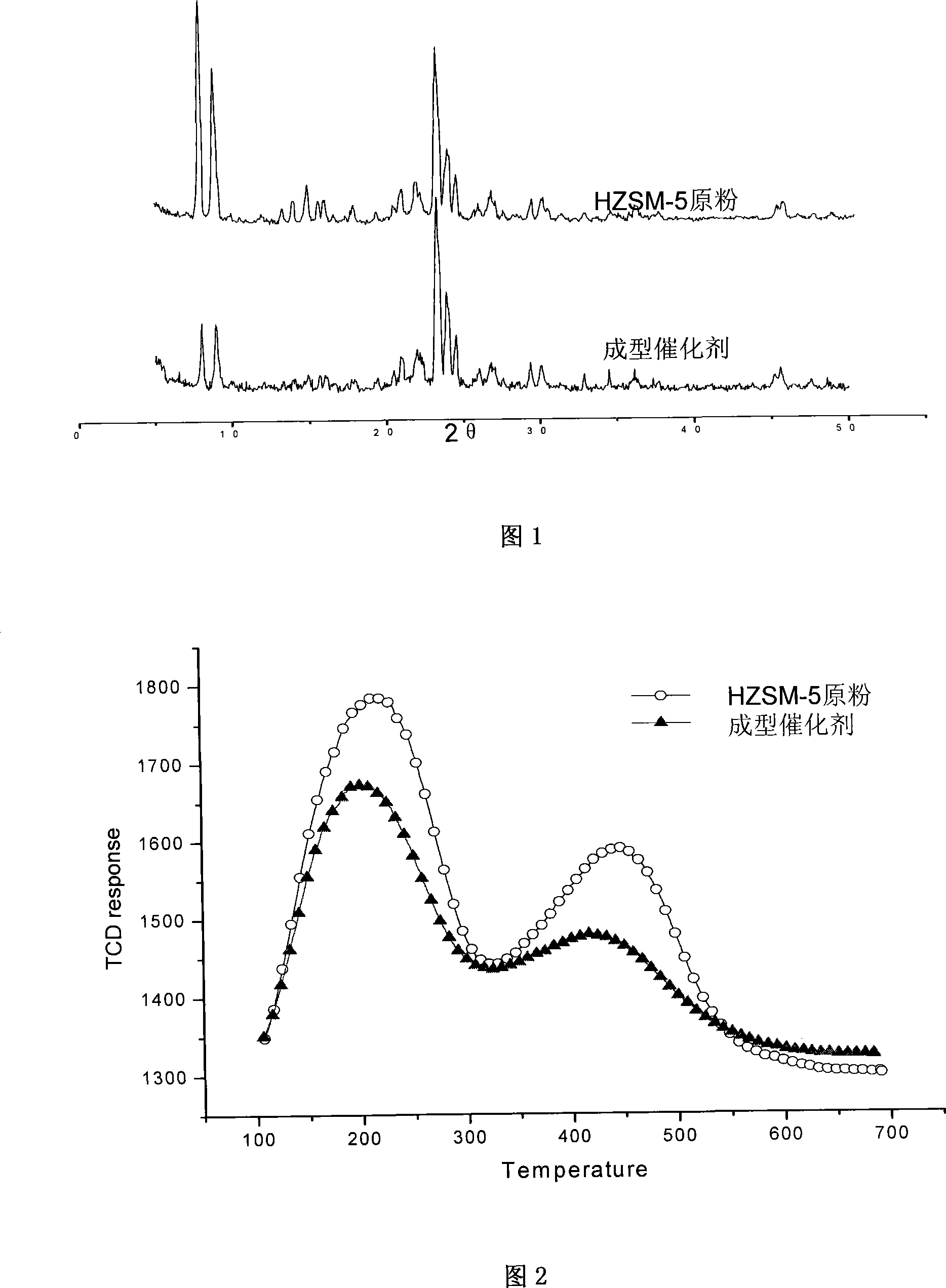

Catalyzer for producing biological ethane and shaping method thereof

InactiveCN101138735AHigh strengthImprove stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePhosphor

The present invention relates to the chemical technical field and in detail relates to a preformed catalyst used for dehydration of ethanol to ethane and a molding and preparation method of the catalyst. For preparation of the catalyst, HZSM-5 molecular sieve initial powder is used as a main material and a bonding agent and a phosphor-containing compound is used as the promoter. The weight rate of the HZSM-5 molecular sieve initial powder and the bonding agent is 0.3-10: 1, and the weight rate of the HZSM-5 molecular sieve initial powder and the phosphor-containing compound is 2.5-60:1. The catalyst is made from the materials through the procedures of mixing, kneading, melting, molding by band-extruding, drying, calcining and so on. The catalyst is provided with the simple components, the low cost, the strong activity, the large intensity, and the long usable life. The preparation procedures of the catalyst are simple, easy for control and low in the cost. Thus, the catalyst is provided with a good prospect of industrial application.

Owner:NANJING UNIV OF TECH

All-biomass composite modified foamed material and preparation method thereof

Owner:WUHAN UNIV OF TECH

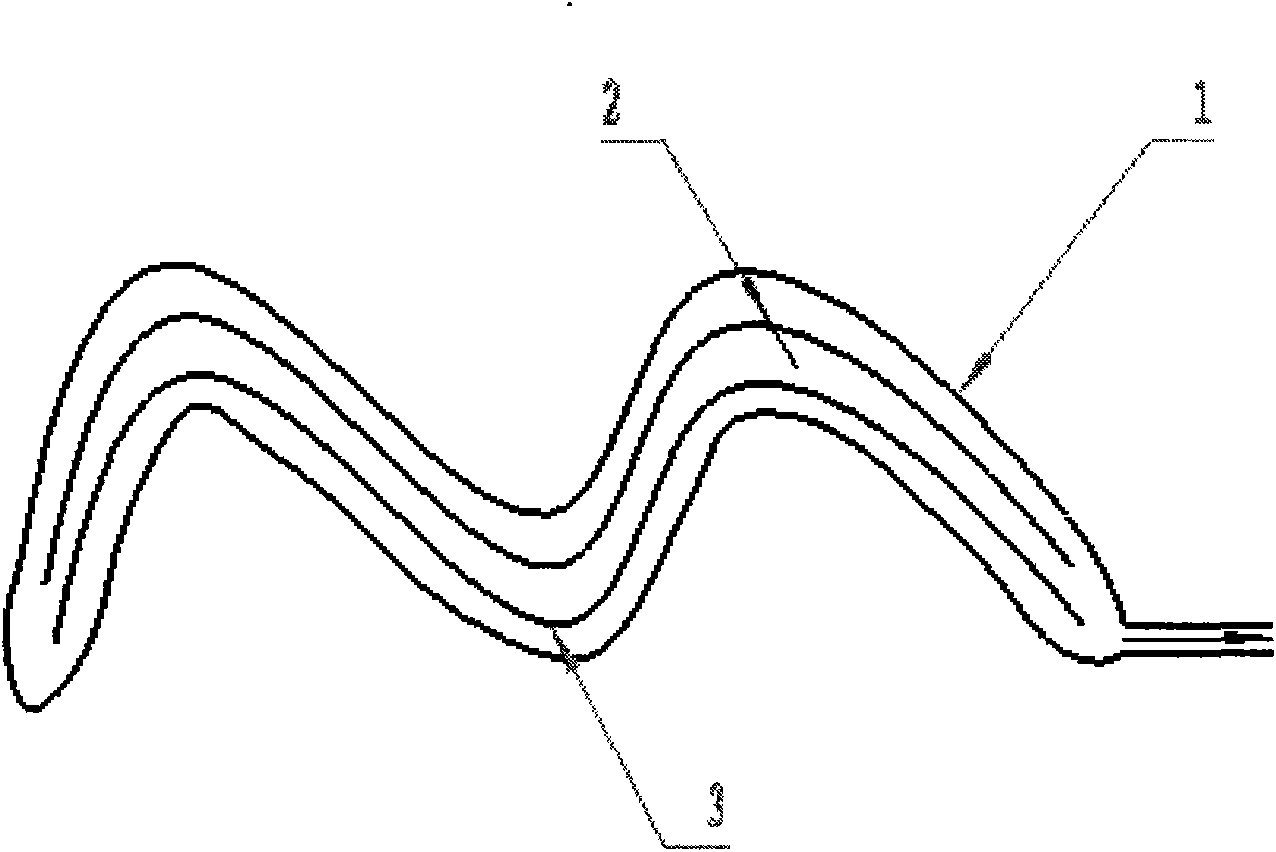

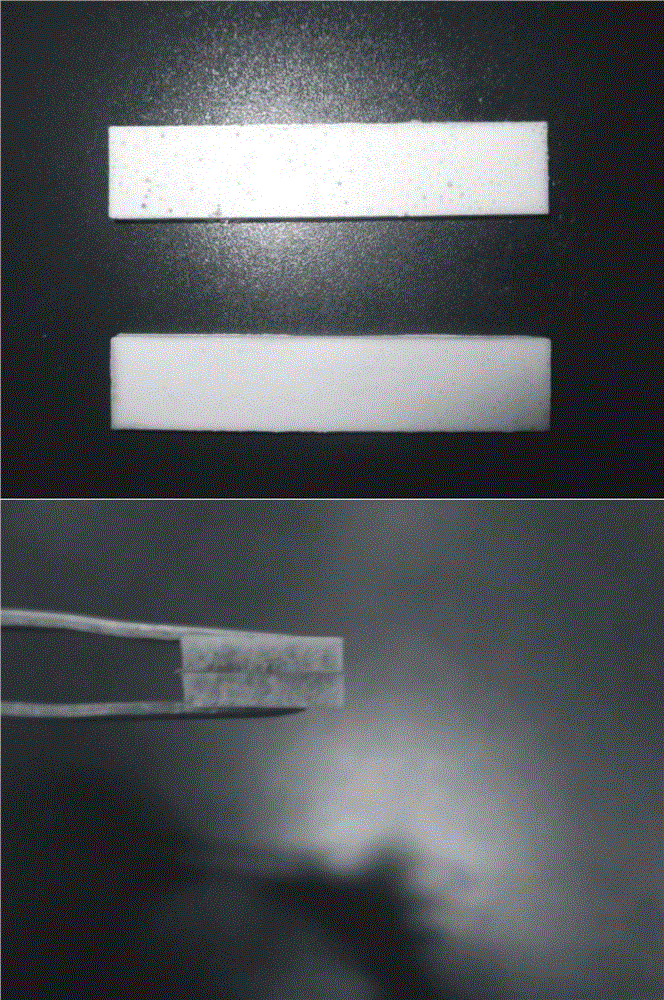

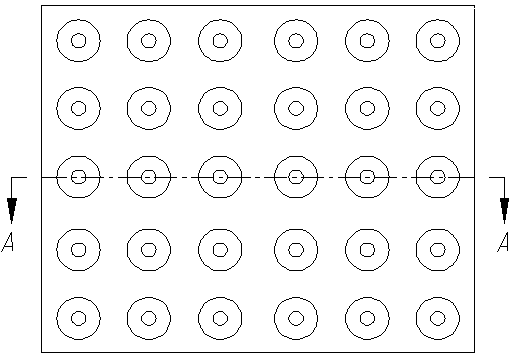

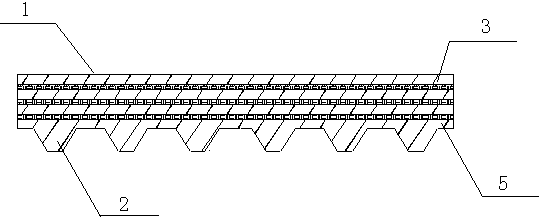

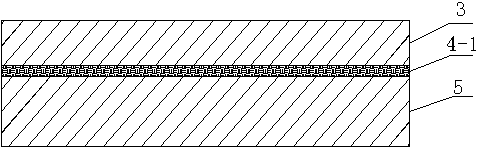

Rubber gasket for track traffic and manufacturing method thereof

InactiveCN103225240AExtended service lifeGuaranteed vibration isolation performanceRail fastenersEngineeringUltimate tensile strength

The invention belongs to the technical field of damping material, and relates to a rubber gasket for track traffic and the manufacturing method thereof. The invention provides the rubber gasket for track traffic, which comprises a flat plate (1) used as a base, and a plurality of studs (2) positioned on the flat plate (1); the flat plate (1) is formed by the composition of rubber layers and at least one fiber enhancement layer; both the upper surface and the lower surface of the fiber enhancement layer are provided with the rubber layers; the fiber enhancement layer is made of fiber cloth with densely distributed meshes; the rubber layer on the upper surface of the fiber enhancement layer penetrates the meshes on the fiber enhancement layer and is combined with the rubber layer on the lower surface of the fiber enhancement layer; and the rubber layer on the lower surface of the fiber enhancement layer penetrates through the meshes on the fiber enhancement layer and is combined with the rubber layer on the upper surface of the fiber enhancement layer. According to the invention, the adhesive strength of the rubber layers and the fiber enhancement layer is enhanced, the vibration isolating effect of the rubber gasket is ensured, the safety is enhanced, and the problems of vibration and noses in a subway can be solved.

Owner:洛阳双瑞橡塑科技有限公司

Impact dummy skin and preparation technology

The invention relates to an impact dummy skin and a preparation technology, and belongs to the field of safety detection of automobiles. The material of the dummy skin shall be designed with the softness and hardness degree that the elasticity of the dummy skin can be simulated, and certain strength (for resisting multiple types of impacts and shocks) can be reached. The preparation technology shall have the advantages that the technology is simple, the implementing is easy, and the cost is low. Two types of macromolecular materials, such as universal PVC (polyvinyl chloride) with low cost, and TPU (thermoplastic polyurethane) with good toughness, are used as the raw materials, and are physically mixed according to a ratio. The preparation technology comprises the following steps of enabling a double-rotor mixer to heat, and mixing at certain ration speed and determined mixing time; after mixing, enabling a tableting machine to tablet the skin material with certain thickness. The toughness of the prepared finished product of skin is different along with the different content of TPU, so that the different requirements of impact test can be met. The skin product has the advantages that the skin product can be used for multiple times of impact test of automobiles, and the other side of the skin can accurately receive the information of injury to a human body by impact waves.

Owner:天津瑷睿赛福科技有限公司

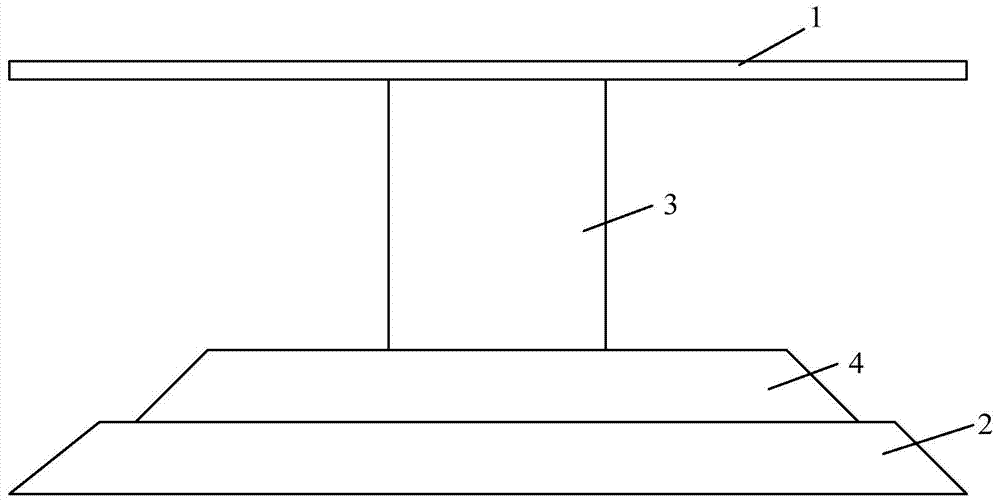

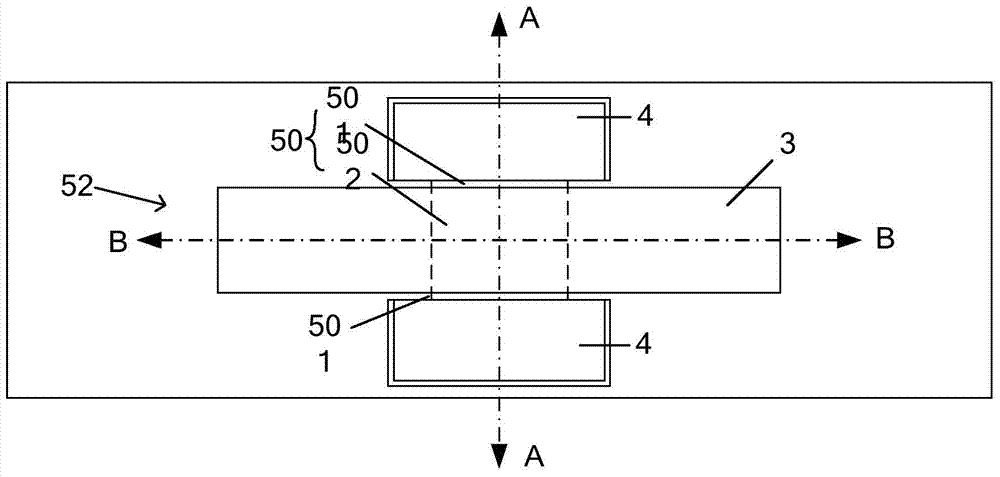

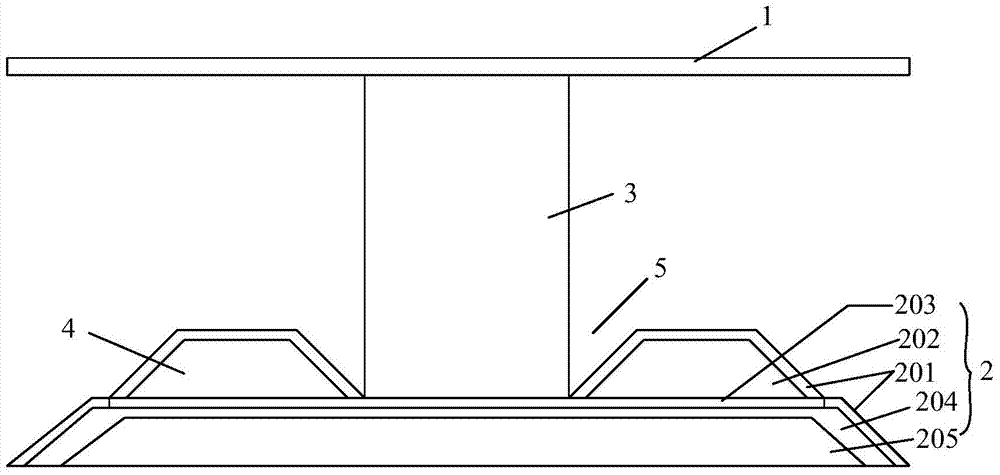

Liquid crystal panel and manufacturing method thereof

InactiveCN103676340AImprove imaging effectStrengthen the middle limitNon-linear opticsLiquid-crystal displayRelative motion

The invention provides a liquid crystal panel which comprises a first substrate and a second substrate. A supporting column is arranged between the two substrates, and an underlay is arranged on the substrate on the opposite side. Limit parts are arranged between the supporting column and the underlay and used for limiting in different directions so that relative motion between the substrates can be prevented from happening. The limit parts in at least two directions are arranged on the underlay and mutually matched with the supporting column so that limit can be performed on the supporting column in the different directions, then the two substrates are prevented from shifting front and back and left and right, and the effect of preventing light leakage is achieved. The limit parts are combined in various modes, pairs of grooves or protrusions are arranged on the two side edges of the supporting column so that the side positions of the supporting columns can be limited, meanwhile, a groove or a protrusion can be arranged in the middle of the underlay and mutually fastened with the supporting column, middle limiting of the supporting column is strengthened, and therefore the purpose of limiting a supporting base in a multi-point and multi-position mode is achieved. The invention further provides a manufacturing method of the liquid crystal panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

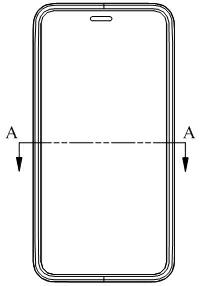

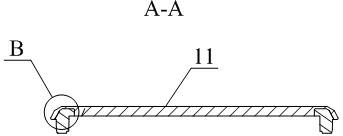

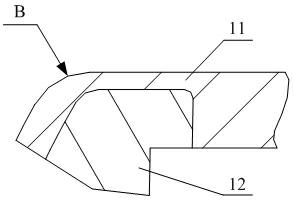

Hand-held mobile equipment shell and forming method thereof

InactiveCN102256454ASimple forming methodEasy to operateCasings/cabinets/drawers detailsDomestic articlesHand heldEngineering

The invention relates to a hand-held mobile equipment shell and a forming method thereof. The forming method comprises the following steps of: processing a glass component and a supporting component respectively, wherein the glass component is used as a viewing window of the hand-held mobile equipment shell and the supporting component is used for supporting the glass component; placing the glass component on the supporting component in a staggered way, namely exposing one end of the supporting component out of the glass component; and performing injection molding on the supporting component on which the glass component is placed to form the hand-held mobile equipment shell which is wrapped by the glass component and the supporting component. The forming method of the hand-held mobile equipment shell is simple, easy to operate and low in operating cost; the glass component, the supporting component and the shell are subjected to injection molding, so that a sequent assembling process is reduced, and the border of the viewing window made of glass can be perfectly combined with the shell so as to achieve an offset-free and seamless visual effect; and the viewing window is made of glass, so the viewing window is high in hardness and is difficult to abrade.

Owner:BALDA SOLUTION BEIJING

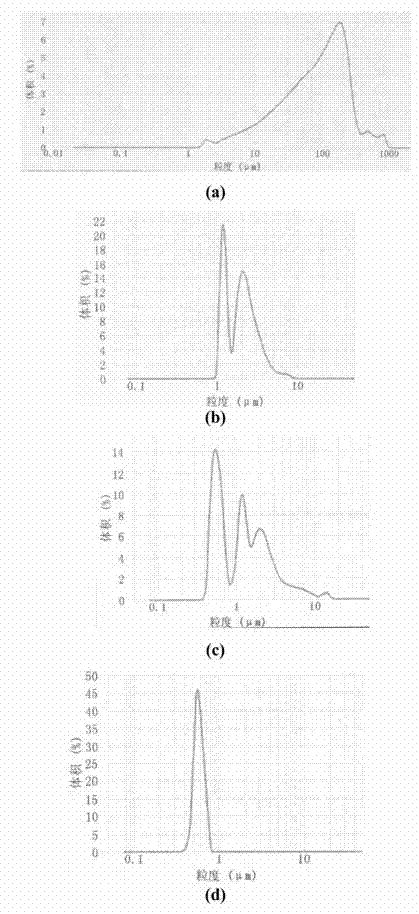

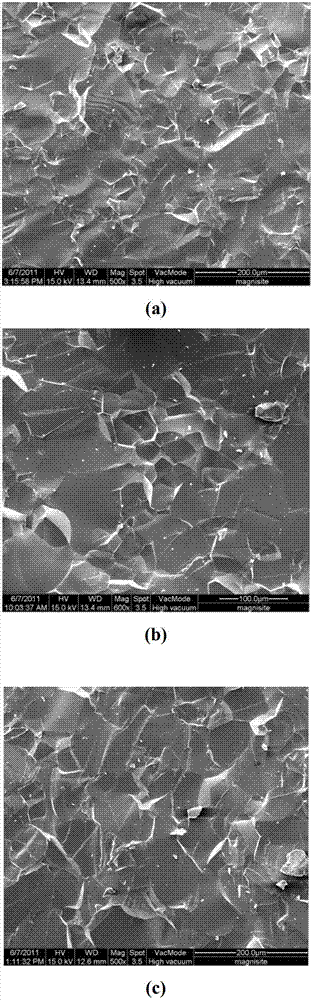

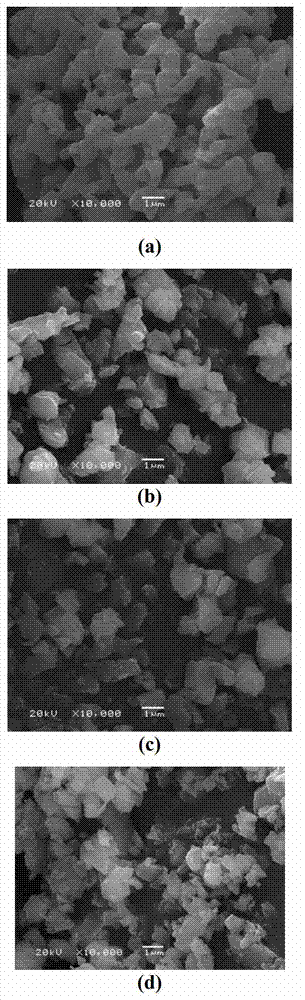

Low temperature fast preparation method of AlON crystalline ceramics

The invention relates to a low temperature fast preparation method of AlON crystalline ceramics, and belongs to the technical field of crystalline ceramic preparation. The preparation method provided by the invention applies ball-milling modification to AlON powder by adopting a planetary ball mill, the modified powder has tiny particles, and has the grain size distribution characteristics of single-modal, double-modal, multi-modal and the like, while possessing the characteristic of narrow molecular distribution, so as to be beneficial to improve the compactness of blank bodies and promote the sintered densification. The AlON powder which is manufactured through ball-milling modification and has the grain size distribution characteristics can be formed through preforming without adding binder, and further isostatic cool pressing is not required. The compactness of the blank bodies is high, and AlON crystalline ceramics with transmittance greater than 80% can be obtained through keeping the heat of the blank bodies at a temperature below 1900 DEG C with the effect of sintering agents. The preparation method has the advantages of low sintering temperature, short heat preservation time and good energy-saving effect; and the requirement for equipment is not high. The preparation method can be used for preparing construction members in abnormal shapes, so that the applied range is wide, the cost is low, the operation is simple and easy, and the industrialization is easy to realize.

Owner:DALIAN MARITIME UNIVERSITY

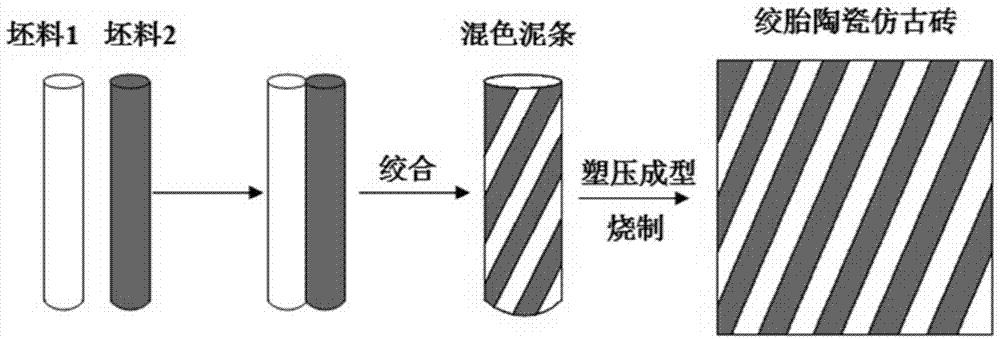

Preparation method of twisted pottery archaized bricks

The invention relates to a preparation method of twisted pottery archaized bricks. The preparation method comprises the steps: (1) respectively breaking raw materials, sieving the broken raw materials by using a 250-mesh sieve, and uniformly mixing to obtain a mixture; (2) putting the mixture in a vacuum pugging machine, adding water and pugging to obtain uniform clay strips, and ageing to obtain preform bodies; (3) dividing the preform bodies into n parts, wherein n is greater than or equal to 2, one of the n parts is recorded as the preform body 1, respectively adding different pigments to the rest of preform bodies for pugging so as to obtain clay strips with colors, ageing to obtain the preform body 2, ..., n (n is greater than or equal to 2); (4) twisting the preform body 1 and the preform body 2, ..., n by using a mixing pugging machine so as to obtain the clay strips with assorted colors; (5) putting the assorted colors in a plaster mold, and molding by adopting a plastic pressing method so as to obtain green bodies; and (6) applying transparent glaze after drying the green bodies, then putting in a roller kiln and firing to obtain the twisted pottery archaized bricks. The preparation method is simple in technology and low in sintering temperature. The prepared twisted pottery archaized bricks are good in ornamental effect and low in water absorption.

Owner:XINLAILI CERAMIC DEV CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com