Equal channel forming die for thick-wall pipe and method of forming die for forming pipe

A technology of forming molds and equal channels, applied in metal extrusion molds and other directions, can solve the problems of complex production process and uneven deformation, and achieve good deformation effect, change shape and distribution, and improve stress and strain distribution and deformation texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

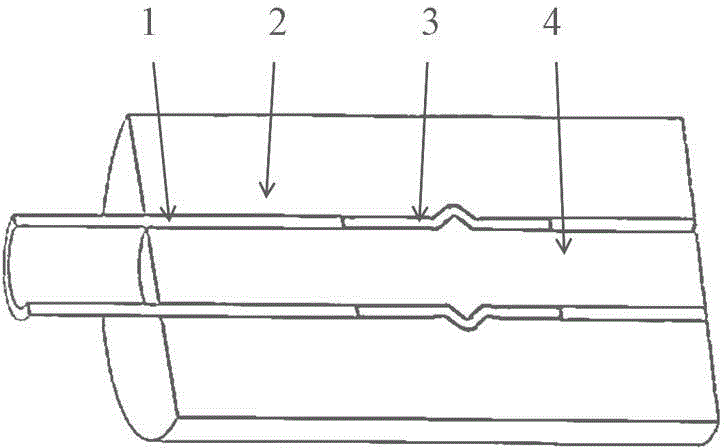

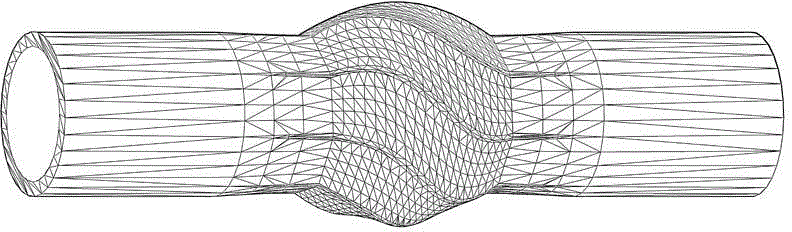

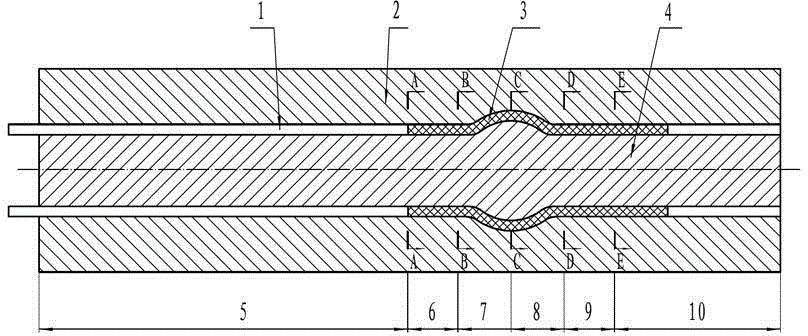

[0026] Such as Figure 1-Figure 8As shown, the present invention is mainly formed by fastening an outer mold and an inner mold, and the outer mold and the inner mold are combined to form an extrusion die cavity of a pipe, and the cross section of the extrusion die cavity smoothly transitions from a circular ring to a regular octagonal ring and then changes In a circular shape, the cross section of the regular octagonal ring is twisted at the center axis of the outer mold or the inner mold in the first and second angle torsion sections as the center axis of the torsion, and the value is 30°~90°, where α is the reference point angle, which is an arbitrary value; the clearance of the entire extrusion die cavity remains unchanged, which is equal to the wall thickness b of the preformed pipe.

[0027] The extrusion die includes a first male die, an outer die and an inner die.

[0028] The first punch is a pipe fitting, the left end of the first punch is connected to the clamping a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com