Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

A technology of extrusion forming and variable cross-section, which is applied in the direction of metal extrusion dies, metal extrusion mandrels, etc., can solve problems such as cracking, affecting the safety and reliability of aircraft pipelines, and insufficient strength, to achieve large deformation and eliminate Effects of Internal Tissue Defects, Material Organization and Performance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The equal-channel variable-section extrusion die for pipes proposed by the present invention is suitable for Aluminum, copper and steel pipes with a wall thickness of 1-5mm and a length of 10-50mm are extruded. In the present embodiment, formed pipe material is aluminum pipe, and the diameter of this aluminum pipe is The wall thickness is 2mm and the length is 20mm.

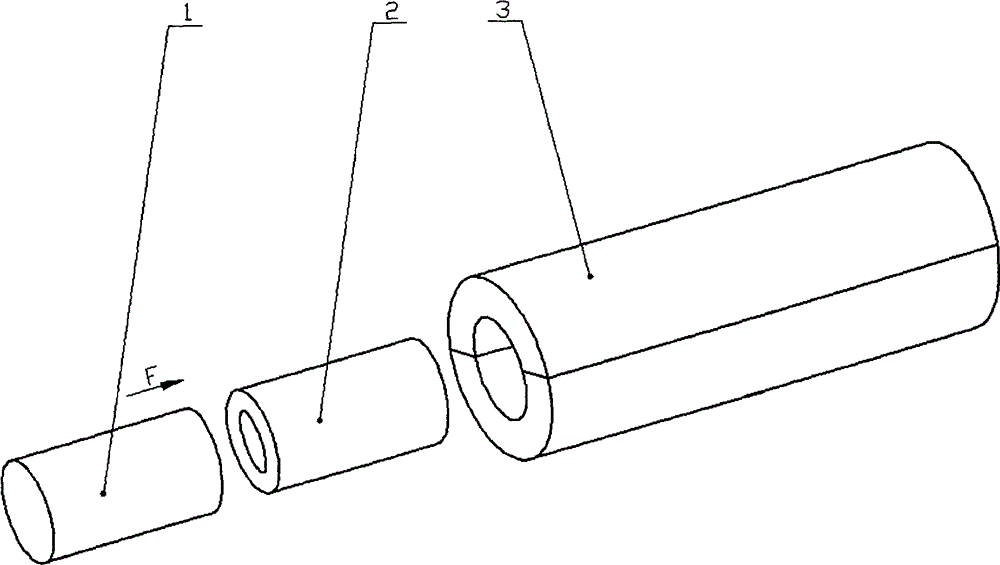

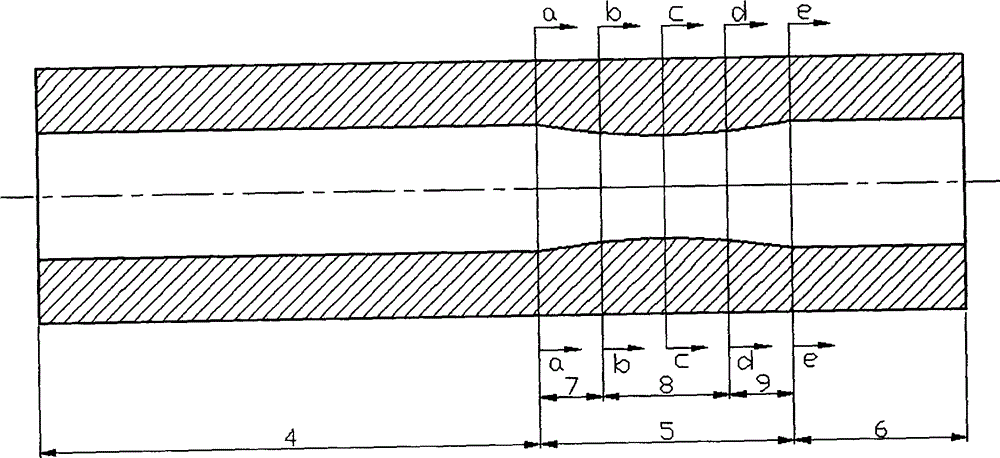

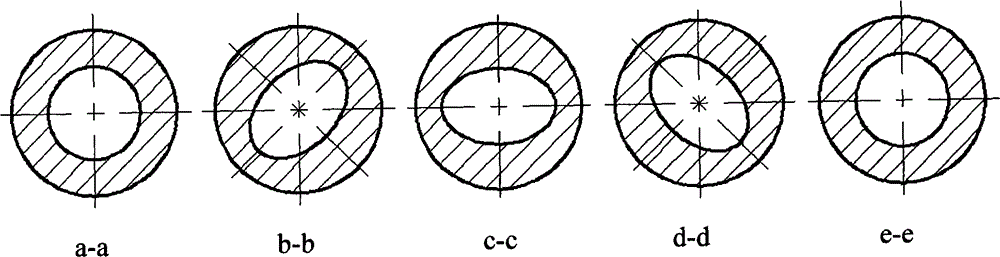

[0032] This embodiment is an equal-channel variable-section extrusion die for pipes, including a male die 1 and a female die 3 . The punch 1 is cylindrical, one end is connected to the clamping and fixed end of the extrusion device, and the other end is the extrusion working end, which is in contact with one end surface of the formed pipe 2; the diameter of the punch 1 is the same as that of the formed pipe 2 , the length of the punch 1 is 1.3 to 1.5 times the length of the pipe 2 to be formed, and in this embodiment, the length of the punch 1 is 1.4 times the length of the pipe 2 to be formed. During...

Embodiment 2

[0039] This embodiment is a method for extruding a pipe using the equal-channel variable-section extrusion die for pipes described in Embodiment 1.

[0040] The diameter of the aluminum tube formed in this embodiment is The wall thickness is 1mm and the length is 20mm.

[0041] When utilizing the prefabricated parts of the present invention, the polyurethane foaming filler is first sprayed into the inside of the pipe to play the role of elastic cushioning and deformation restraint for the deformed pipe, and then the punch is driven by the extrusion equipment, so that the punch is extruded Pipe, so that the pipe passes through the feeding section, deformation section and shaping section of the cavity of the equal-channel variable cross-section extrusion die in sequence. Circular cross-section, and can carry out multi-pass extrusion, and finally form a prefabricated workpiece.

[0042] The method for extruding aluminum tubes and other channels with variable cross-sections pro...

Embodiment 3

[0049] This embodiment is a method for extruding a pipe using the equal-channel variable-section extrusion die for pipes described in Embodiment 1.

[0050] The diameter of the copper pipe formed in this embodiment is The wall thickness is 3mm and the length is 30mm.

[0051] When utilizing the prefabricated parts of the present invention, the polyurethane foaming filler is first sprayed into the inside of the pipe to play the role of elastic cushioning and deformation restraint for the deformed pipe, and then the punch is driven by the extrusion equipment, so that the punch is extruded Pipe, so that the pipe passes through the feeding section, deformation section and shaping section of the cavity of the equal-channel variable cross-section extrusion die in sequence. Circular cross-section, and can carry out multi-pass extrusion, and finally form a prefabricated workpiece.

[0052] The variable cross-section extrusion method for channels such as copper pipes proposed in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com