Patents

Literature

220results about How to "Increase the degree of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wearable hand rehabilitation training device

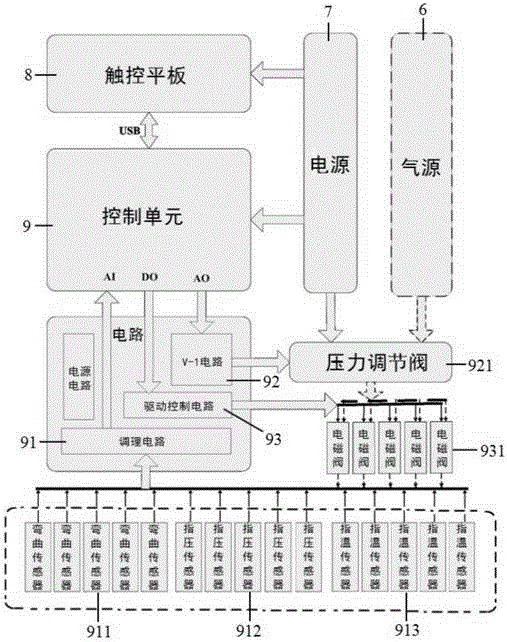

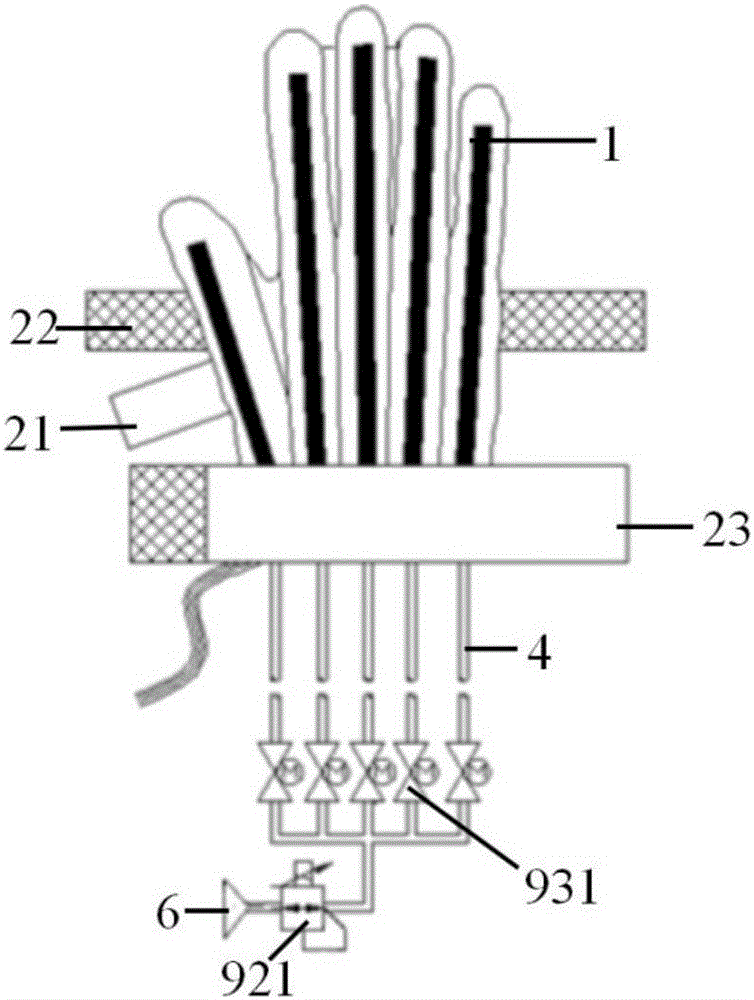

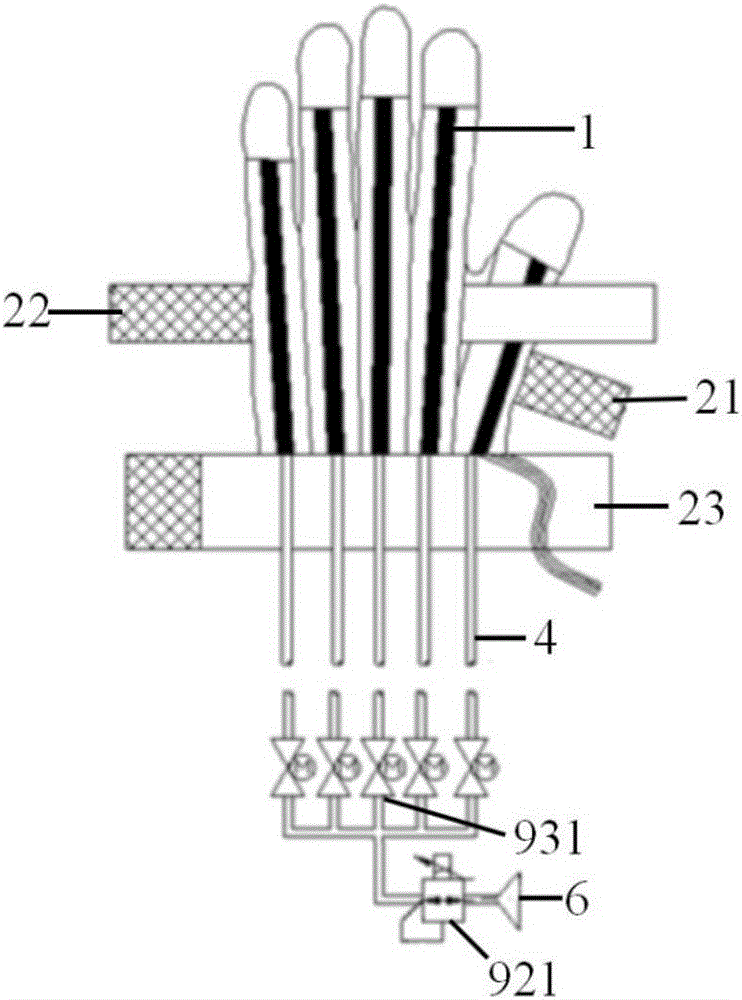

The invention discloses a wearable hand rehabilitation training device which can achieve rehabilitation training of human body hands. The wearable hand rehabilitation training device includes: a glove body; the glove body includes a set of bionic muscle strips; each of the bionic muscle strips is internally provided with a plurality of inflatable airbags which are mutually independent; the bionic muscle strips can drive a human body hand to achieved multi-freedom motion such as bending, stretching, retracting inward, expanding outward, and rotating. The wearable hand rehabilitation training device is convenient and comfortable in wearing, can achieve all-round training of fingers, meet disease demands of different patients, and can allow hand functional rehabilitation training of stroked patients.

Owner:海门奥勃纳机电科技有限公司

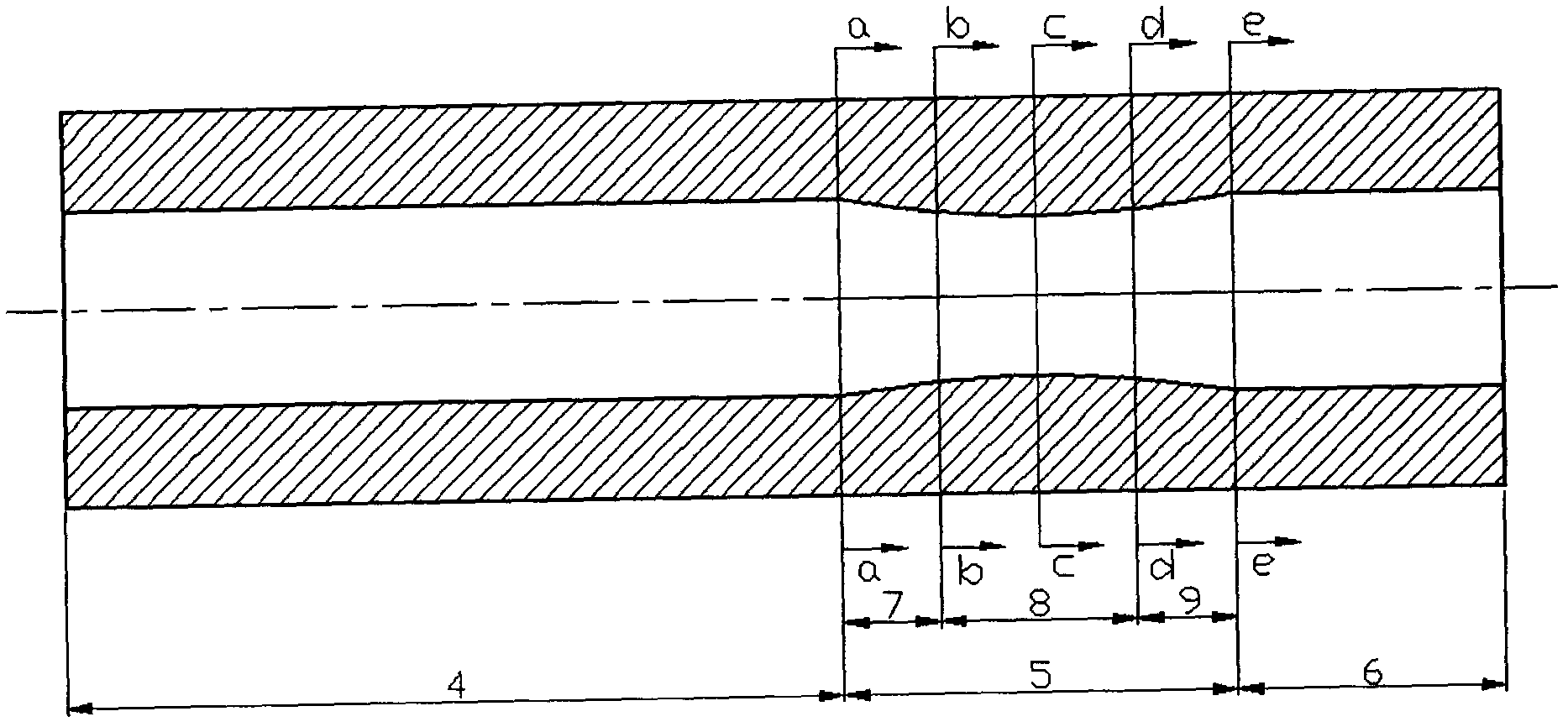

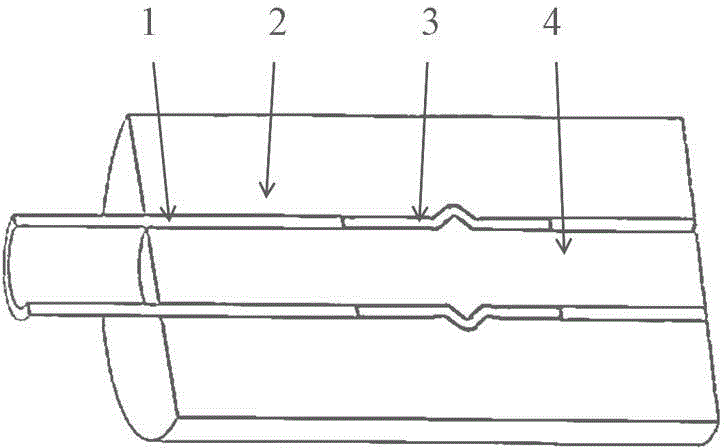

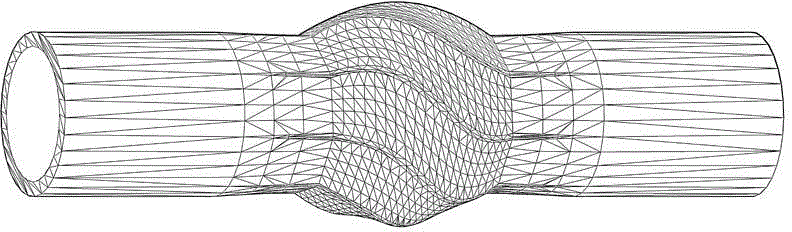

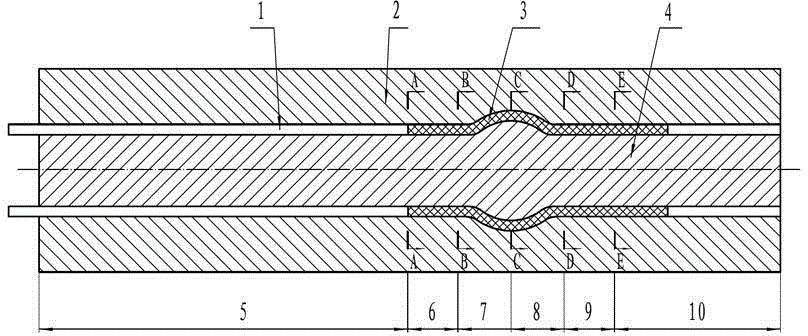

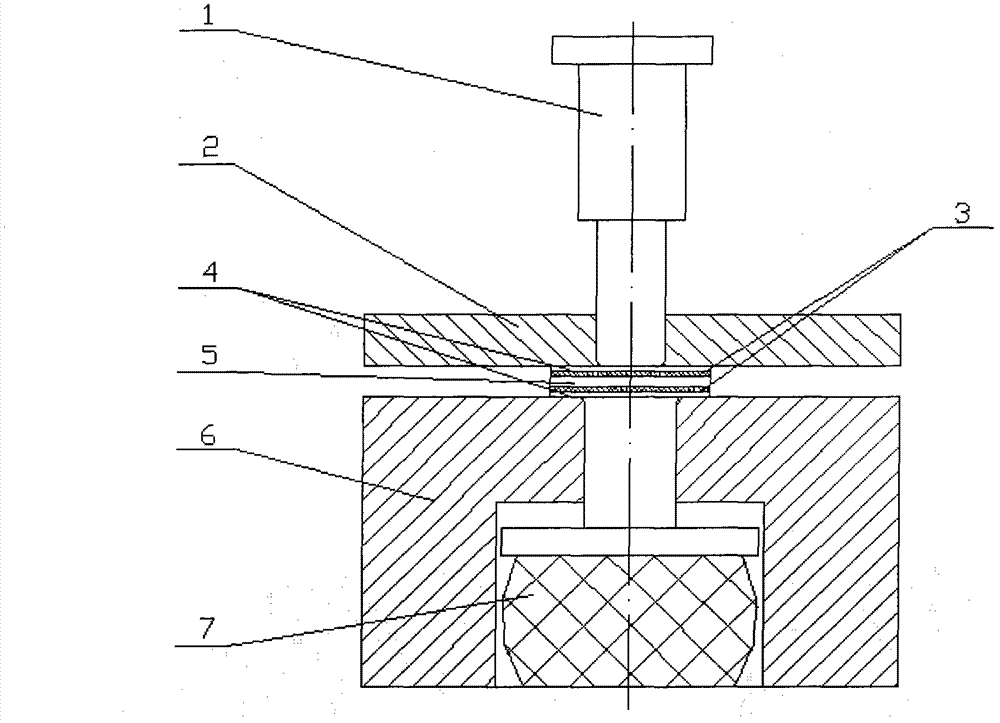

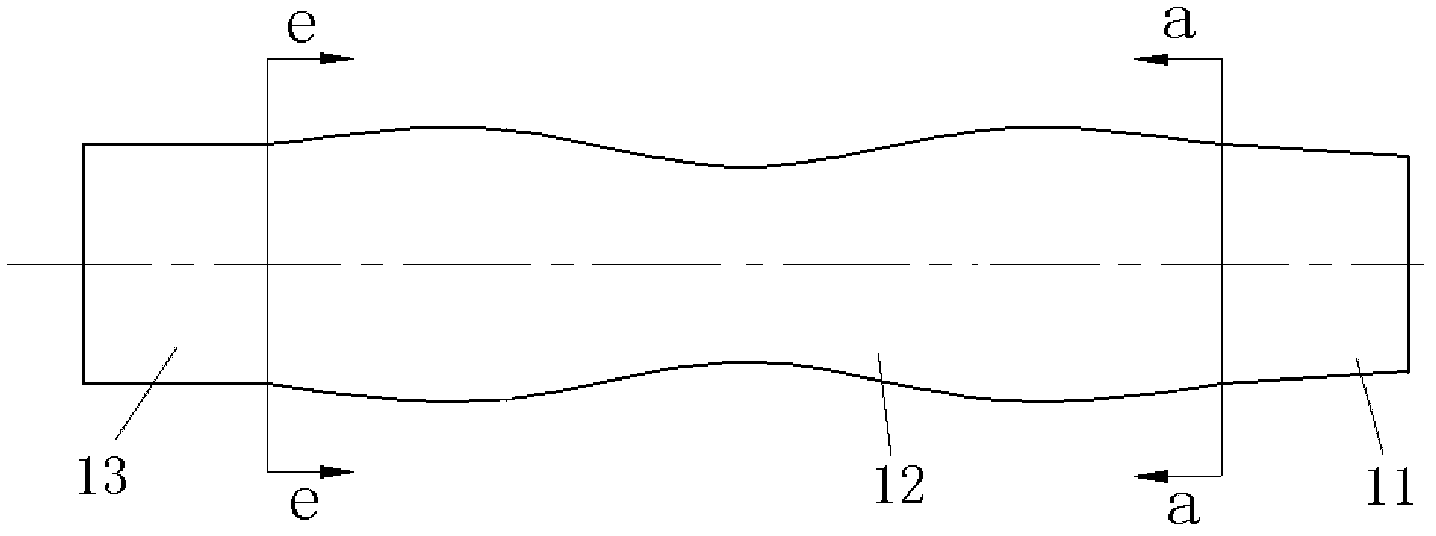

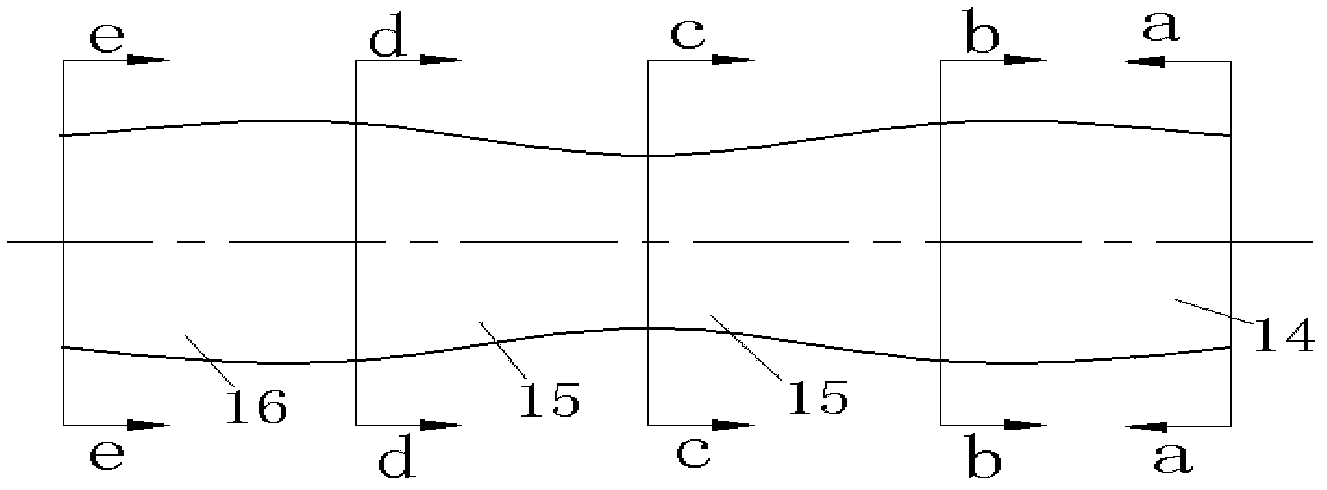

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

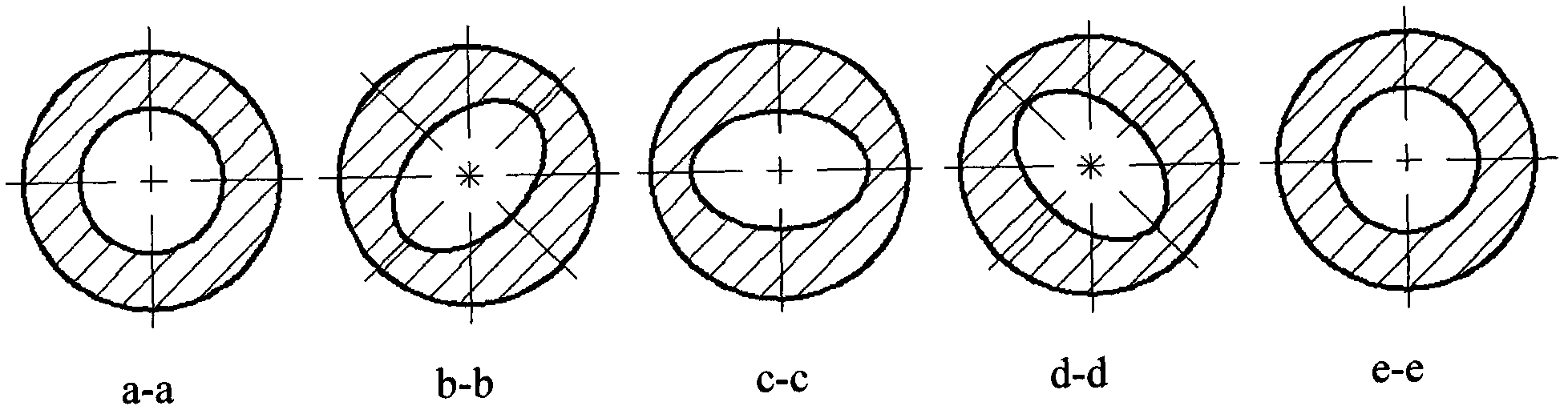

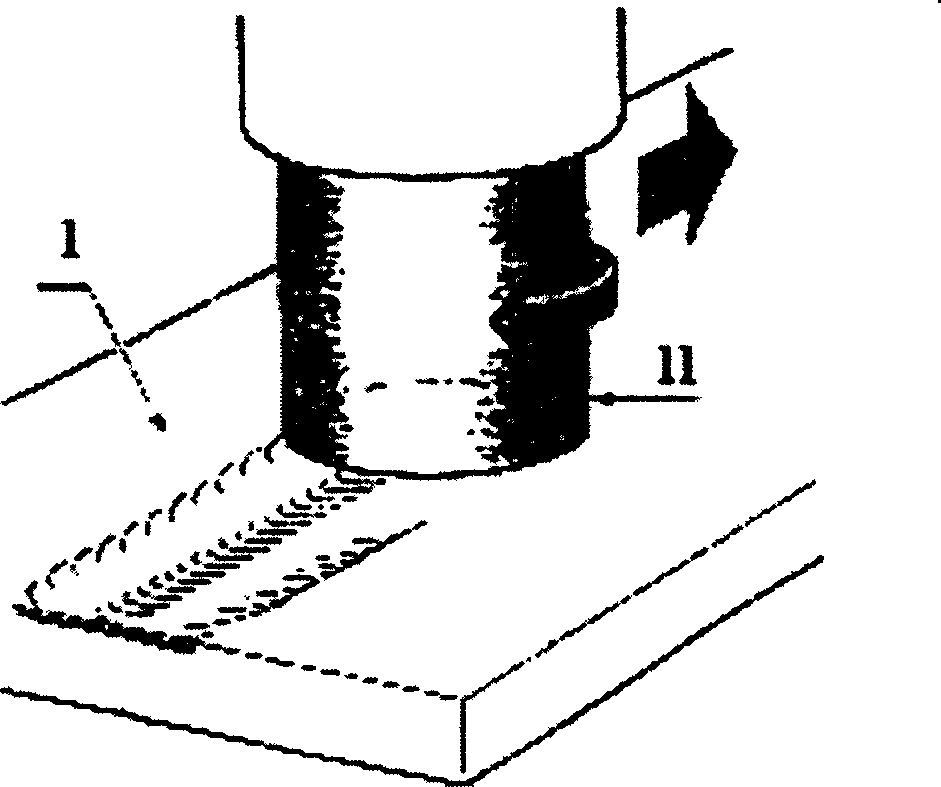

Method for preparing super fine crystal material

A process for preparing large-area or rod-shaped ultrafine-grain crystal material by the transfer method in strong deformation region features that A pression-torsion head pressing on a planar metal material is rotating at a certain speed while transversely moving to treating the surface of the material line by line, breaking the metallic crystal grains and generating large-area ultrafine-grain crystal material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

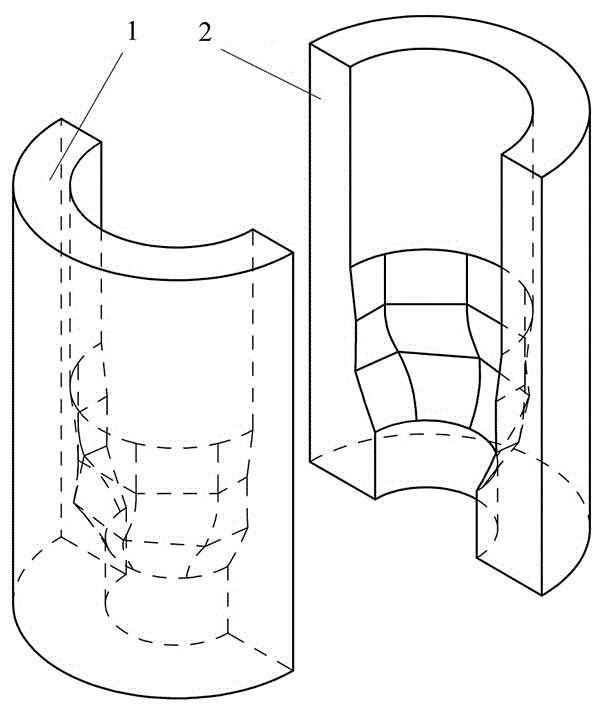

Twist extrusion forming die and twist extrusion forming method

The invention discloses a twist extrusion forming die and a twist extrusion forming method. The forming die comprises a first half die and a second half die, wherein the first half die and the second half die are tightly buckled through a bolt to form a cylinder, an extrusion die cavity is formed inside the cylinder, and a die joint of the first half die is fit and level with a die joint of the second half die; the extrusion die cavity is sequentially formed by a guide section, a large circular-regular octagonal transitional section, a regular octagonal twist section, an octagonal-small circular twist transitional section and an outlet section from an extrusion inlet to the lower side. The twist extrusion forming die has the advantages of good transformation effect, high speed and high efficiency, the weaknesses of the prior art such as non-uniformity in transformation and existence of transformation dead corner can be overcome, the stress distribution inside a material can be greatly improved, and the comprehensive performance of the material also can be improved.

Owner:TAIYUAN UNIV OF TECH

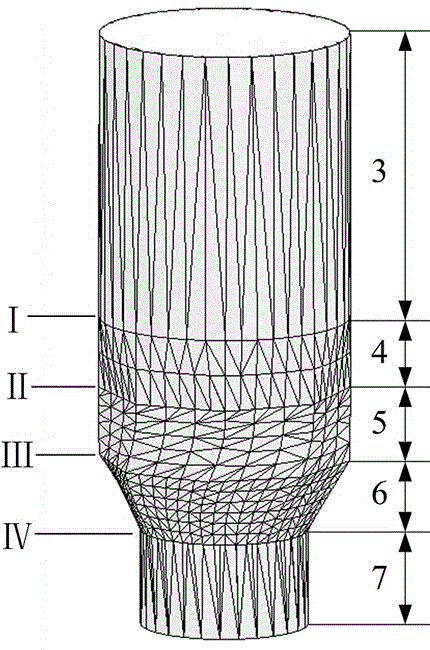

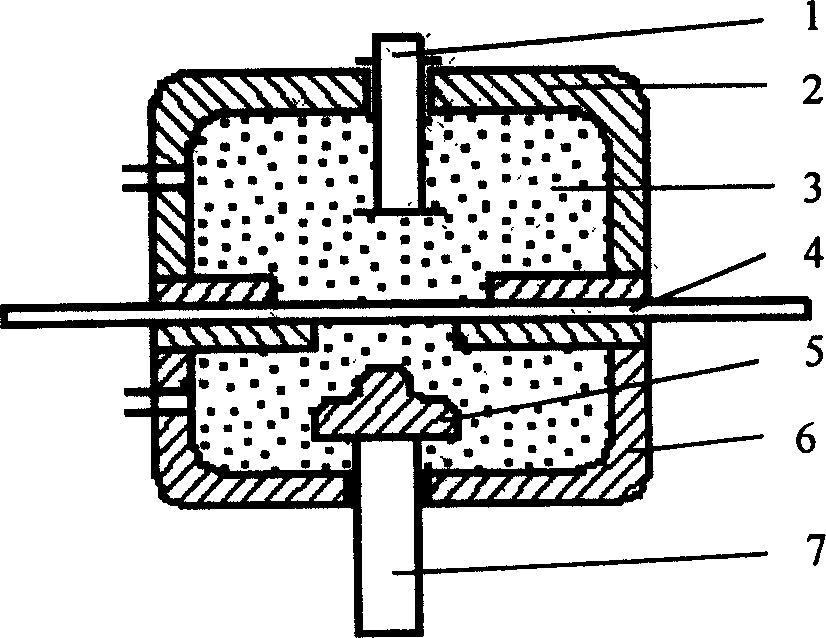

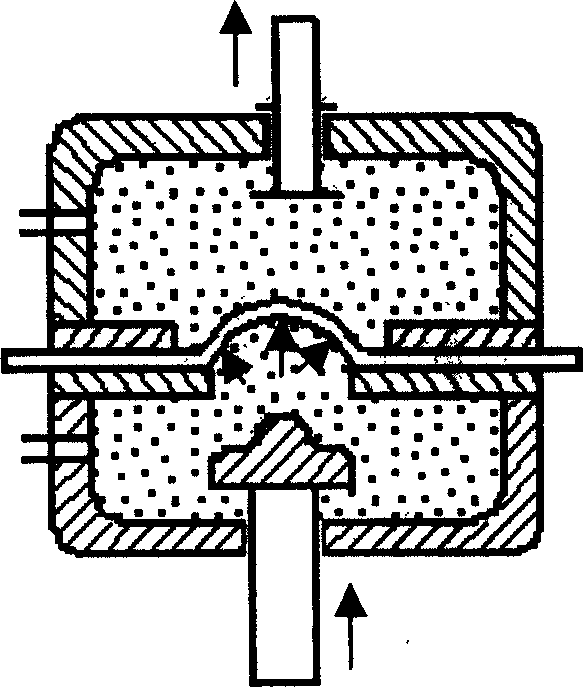

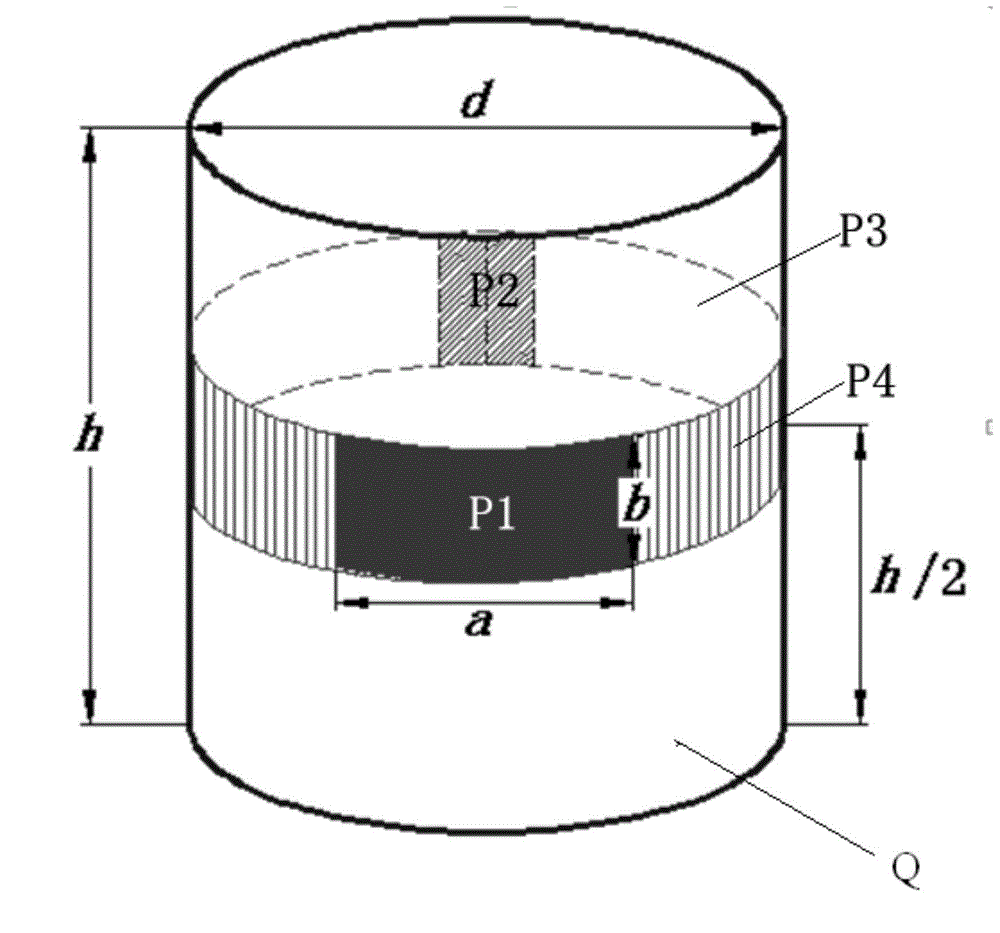

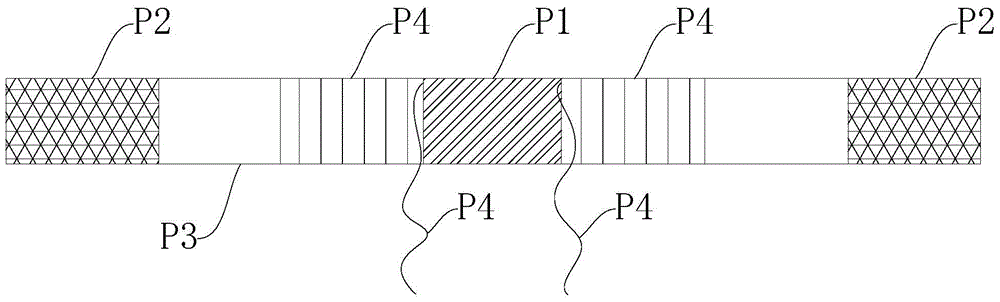

Equal channel forming die for thick-wall pipe and method of forming die for forming pipe

InactiveCN104307908AImproved strain distributionIncrease stressExtrusion diesDeformation effectShearing deformation

The invention relates to the technical field of forming pipes with thick walls (a ratio of pipe diameter to wall thickness is less than 20) of such metals as aluminum, copper and steel and round cross sections, and in particular discloses an equal channel forming die for a thick-wall pipe and a method of the equal channel forming die for forming the pipe. An equal channel corner variable-cross section twist extrusion forming technical scheme adopted by the invention is similar to combination of twist shear deformation and upsetting and drawing extrusion-bulging deformation on a cross section, thus realizing combination of multiple deformation modes in an extrusion process. The equal channel forming die disclosed by the invention has the advantages of good deformation effect, quick speed and high efficiency; and the equal channel forming die can overcome a shortcoming of a current process which is uneven in deformation, greatly improve stress-strain distribution and a deformation texture in the material, and simultaneously improve material performance.

Owner:TAIYUAN UNIV OF TECH

Prepn of columnar superfine crystal material

The preparation process of columnar superfine crystal material features that the rod metal material to be fined is set inside cooled sleeve, made to contact with the bottom tightly, driven to rotate at high speed and applied with certain pressure, while cooling water is introduced into the cooling sleeve, so that the rod metal material at the contact surface produces intense shearing plastic deformation and torsion deformation layer with fragmentated crystal grains. Owing the torsion deformation layer has the upper side temperature higher than lower side temperature, the torsion deformation layer is transferred from the initial friction surface to upper side high temperature area to form superfine crystal material piling layer in the lower part, and the torsion and cooling is continued until forming complete superfine crystal material. The columnar superfine crystal material is then annealed. The present invention has high deformation and low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Control method for plate shape of high-strength steel plate

InactiveCN101367091AReduce deformation resistanceImprove plasticityRoll force/gap control deviceTemperature control deviceCooling temperatureSteel plates

The invention provides a method for controlling the shape of a high-strength steel plate. The method comprises the main steps of heating, rolling, cooling after rolling and straightening; and the heating temperature, the rolling pressure, the rolling temperature, the single-pass reduction amount, the rolling speed, the cooling temperature and the like are controlled. The method has simple operation, simplifies production procedure, shortens production cycle, reduces the transportation and transferring of the steel plate in the middle procedure, saves energy consumption, reduces the increase of unscheduled quantity and can achieve good plate shape; and practices prove that the performance of the steel plate is unchanged, meets various standards and has obvious economical benefit.

Owner:WUYANG IRON & STEEL

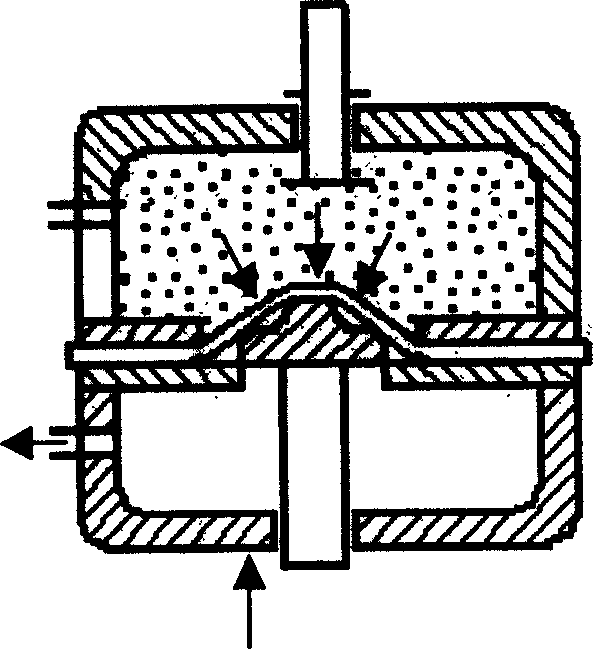

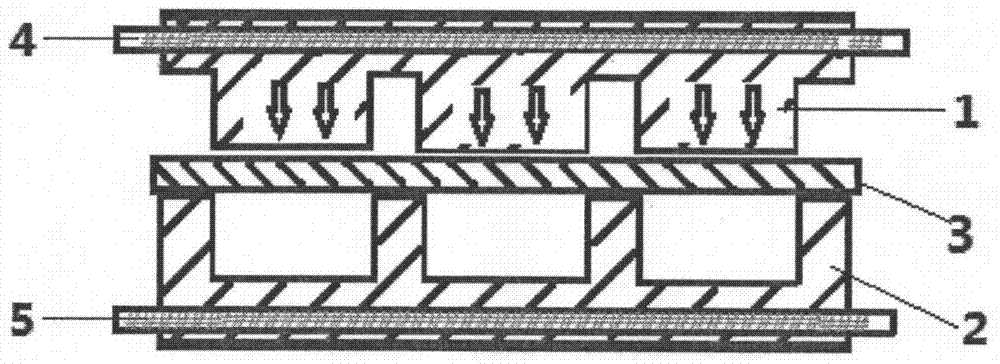

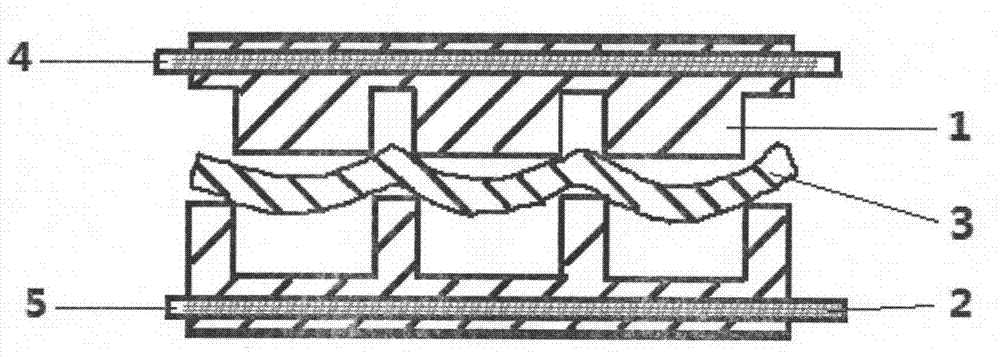

Sheet bar reciprocating type forming method based on force transferring by viscoelastic medium

The invention is a type way based on the flexibility plate. It uses the flexibility material as the medium, utilizing the shape equipment of up and down cavities and pistons put the material between the two cavities, bulge film is fixed on the piston top, by the moving of piston, the material type first. Then type last by opposite direction, and we get the product. The type way can increase the material transform degree and the product transform limit, and decrease the steps to produce and get the high quality product, so it has very good foreground to apply.

Owner:CHONGQING UNIV OF TECH

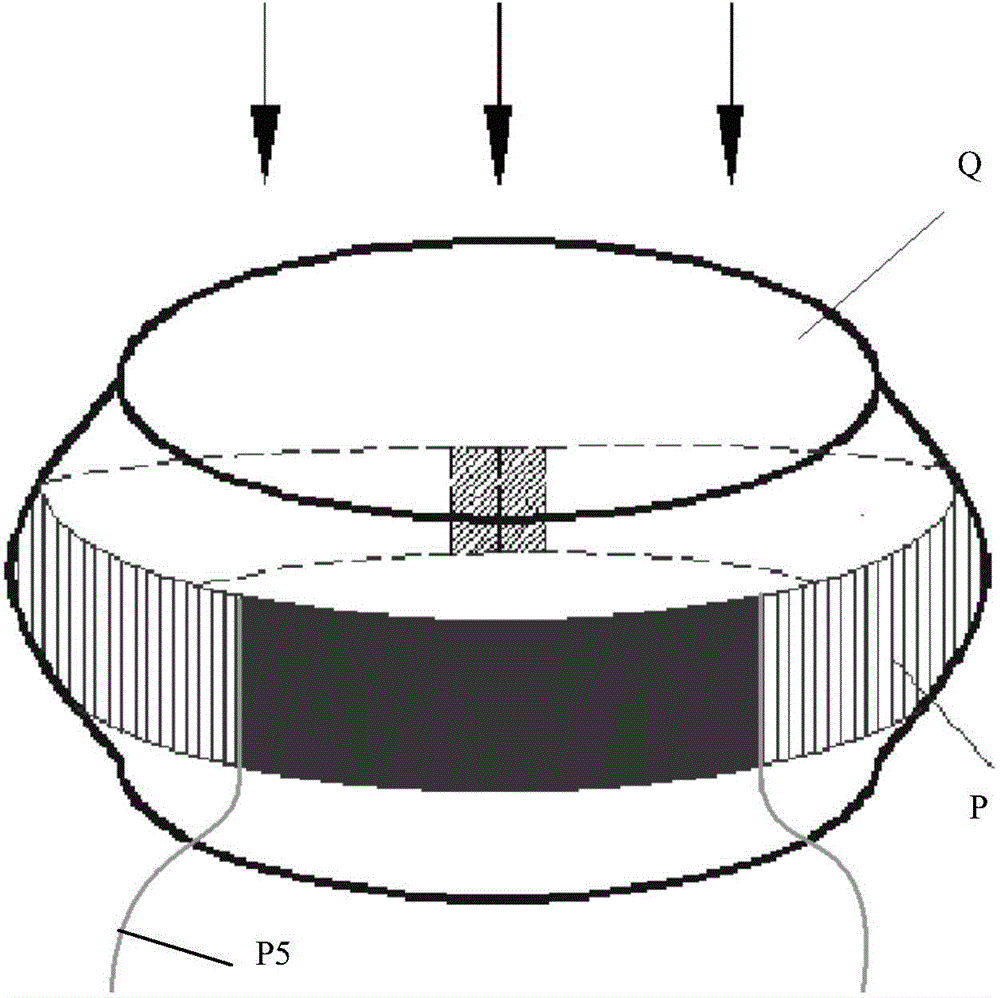

Bridge pier protective device

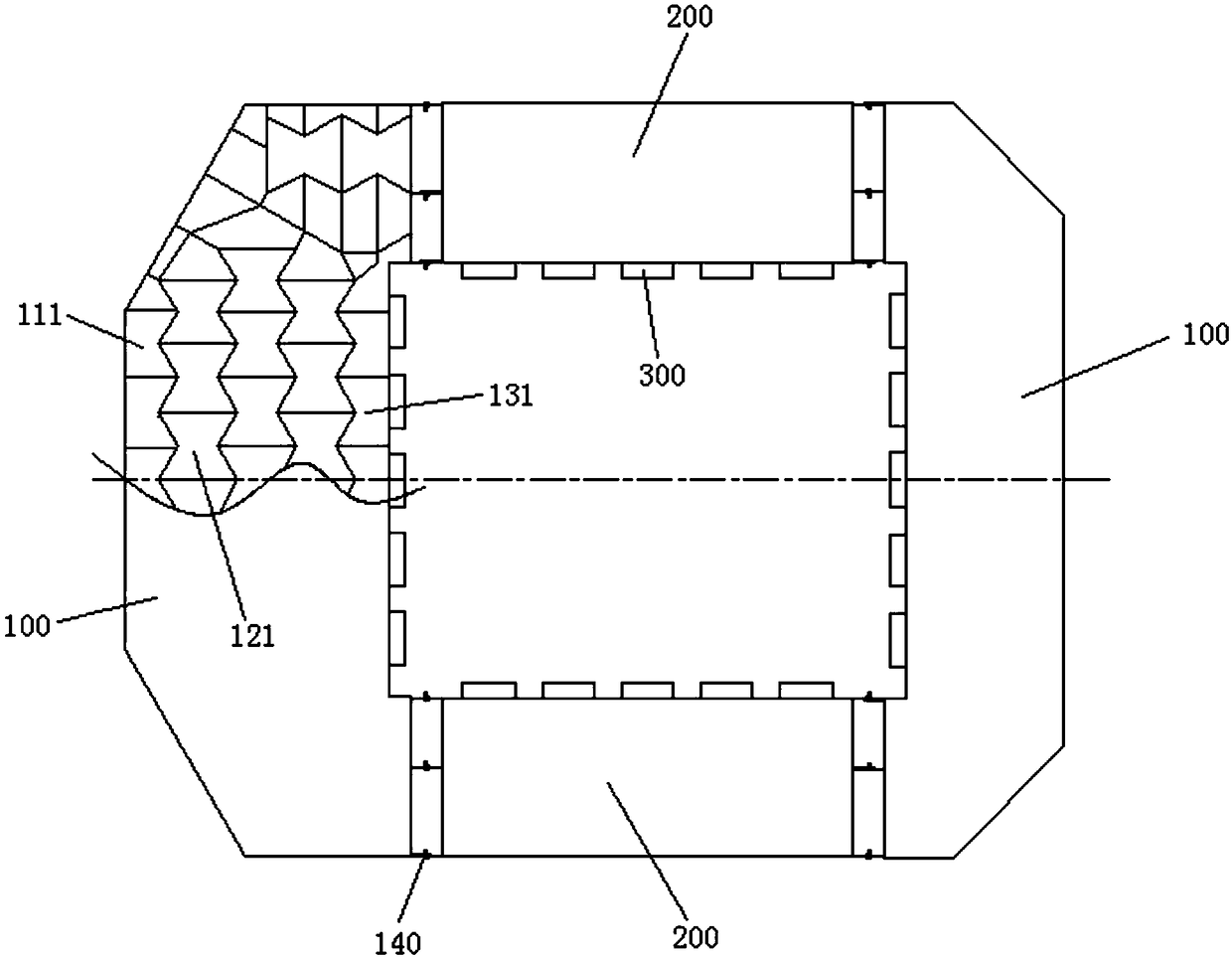

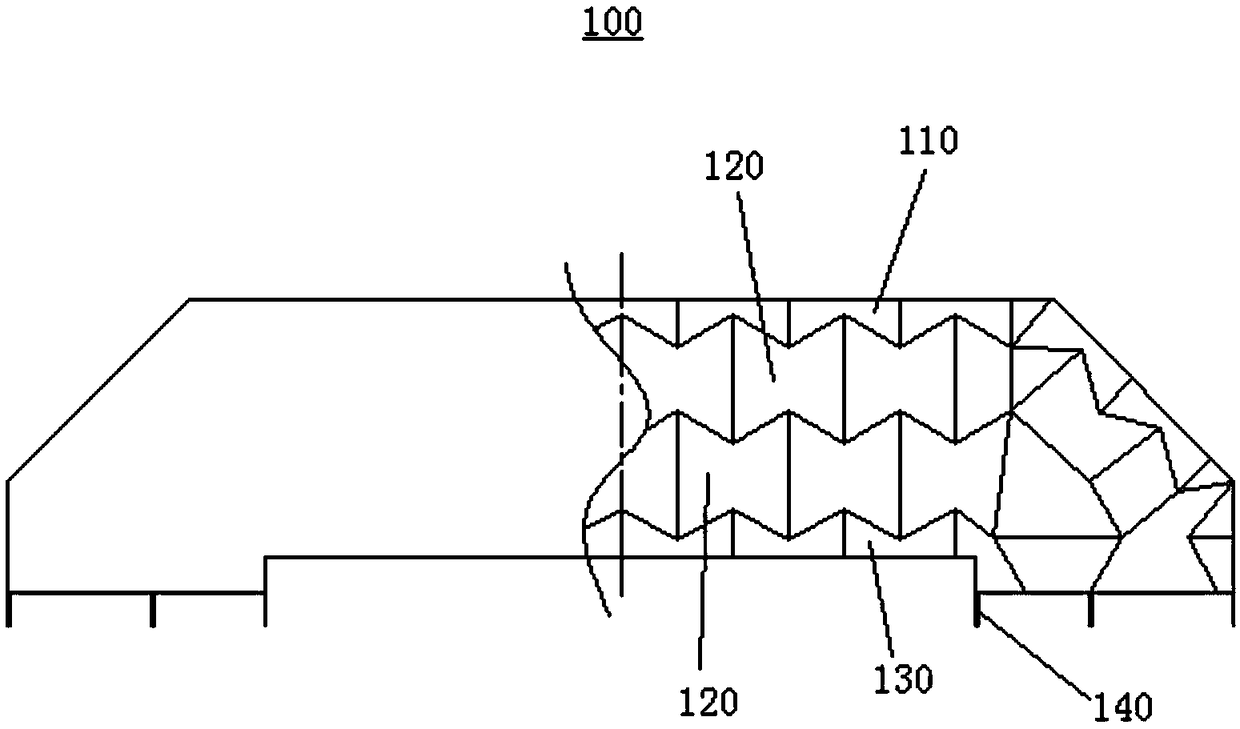

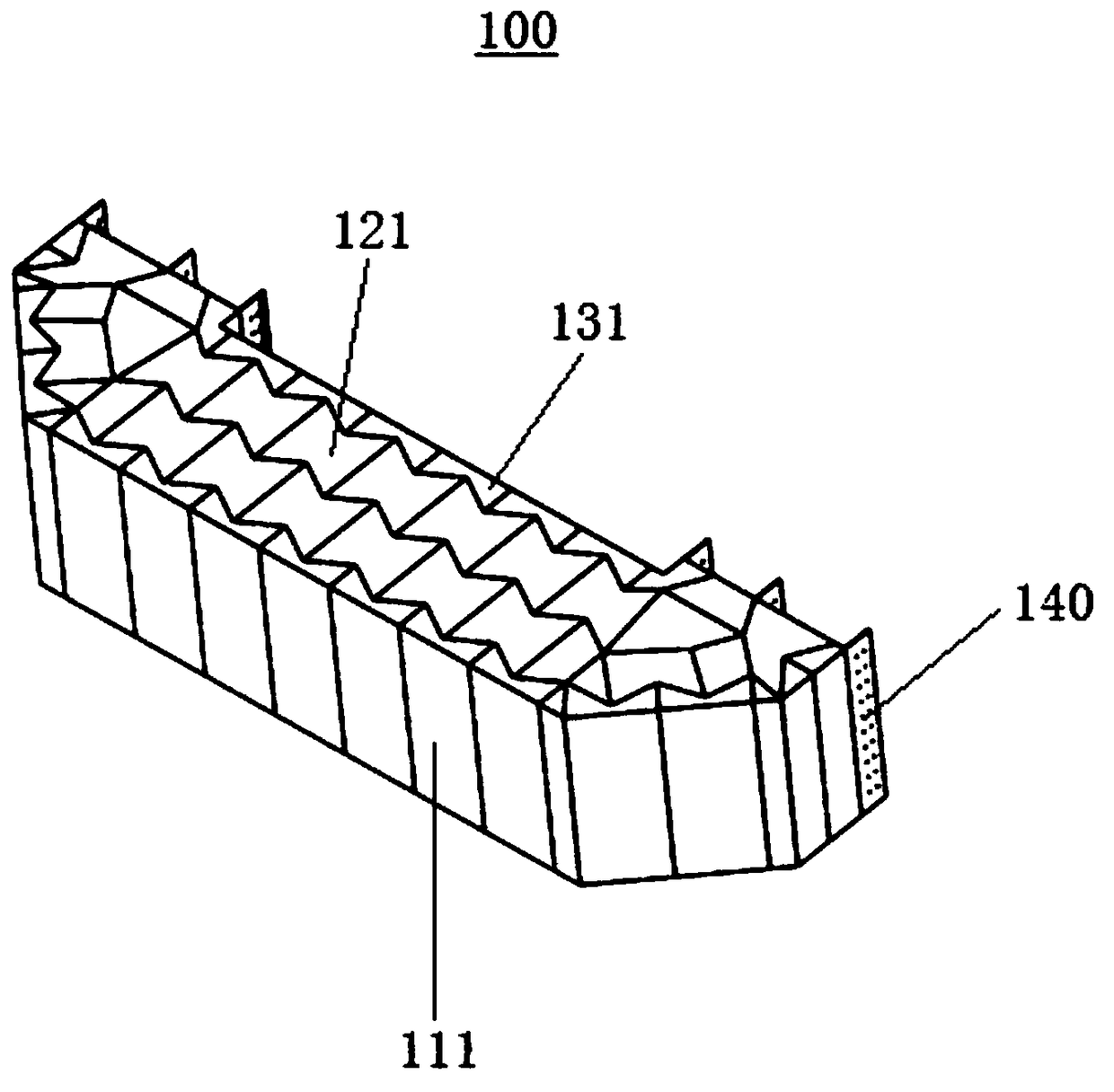

PendingCN109137832AHas negative Poisson's ratio propertiesIncrease the degree of deformationClimate change adaptationBridge structural detailsEnergy absorptionEngineering

The invention relates to a bridge pier protective device comprising at least one anti-collision structure and connection structures used for connecting the adjacent anti-collision structures or the anti-collision structure and a bridge pier. Each anti-collision structure comprises an outer layer collision bearing structure, a middle energy-absorbing supporting structure and an inner layer protective structure, wherein the middle energy-absorbing supporting structure is a negative poisson ratio structure formed in the manner that multiple layers of energy absorbing units are arranged in an intersecting manner according to a certain law, each energy-absorbing unit is in an inwards concave hexagon and comprises a group of opposite side plates and a group of inwards concave folded plates opposite to each other, and the included angle between each side plate and the corresponding inwards concave folded plate is smaller than 90 degrees. The anti-collision structure has the negative poisson ratio feature, the energy dissipation time is effectively prolonged, the deformation degree of the energy absorption material is effectively improved, the protective function of the anti-collision device on the bridge pier and other aquatic buildings is greatly improved, and the structure stability is also improved. The structure of the energy-absorbing units is periodically arranged, so that the structure is simple, the production technology is simple, and the product quality is easy to control; and in this way, the anti-collision effect can be improved, and the manufacturing cost is reduced.

Owner:武汉海威船舶与海洋工程科技有限公司

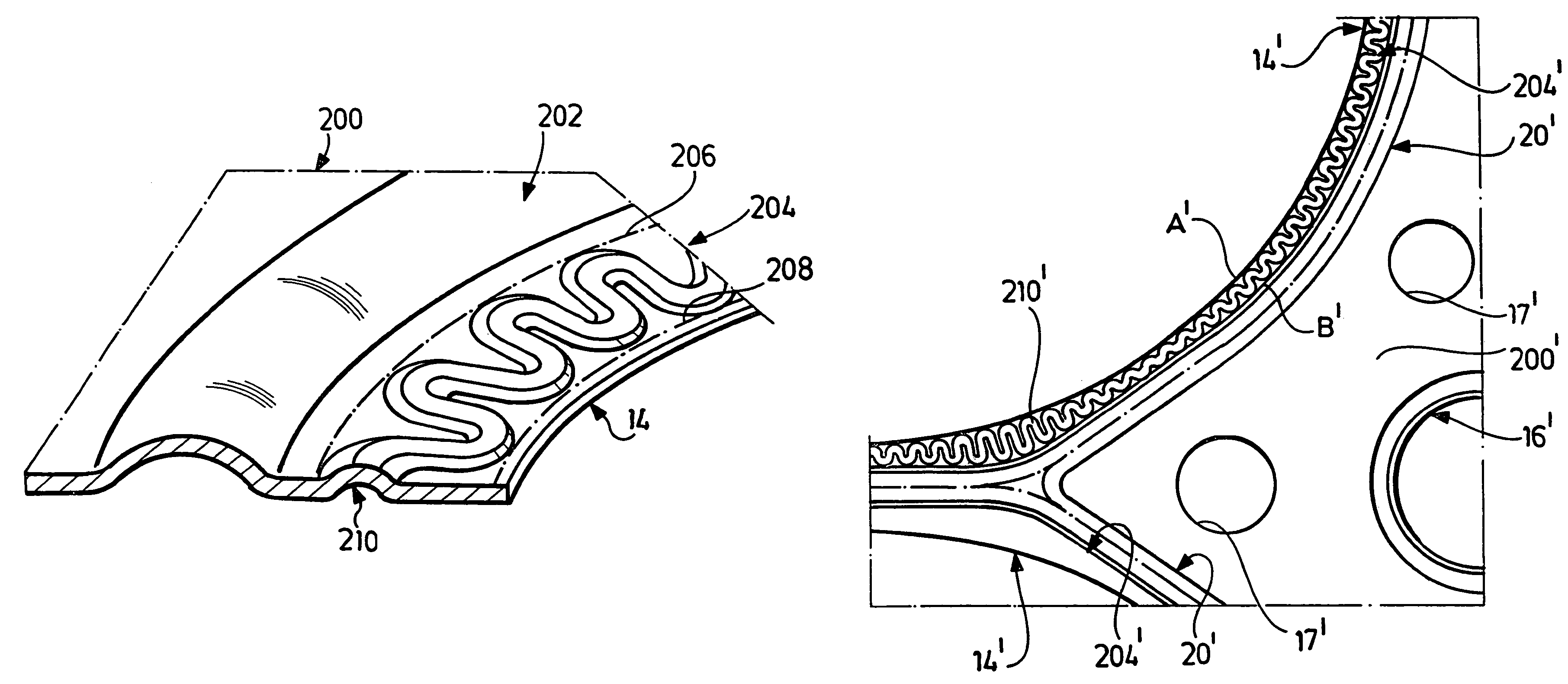

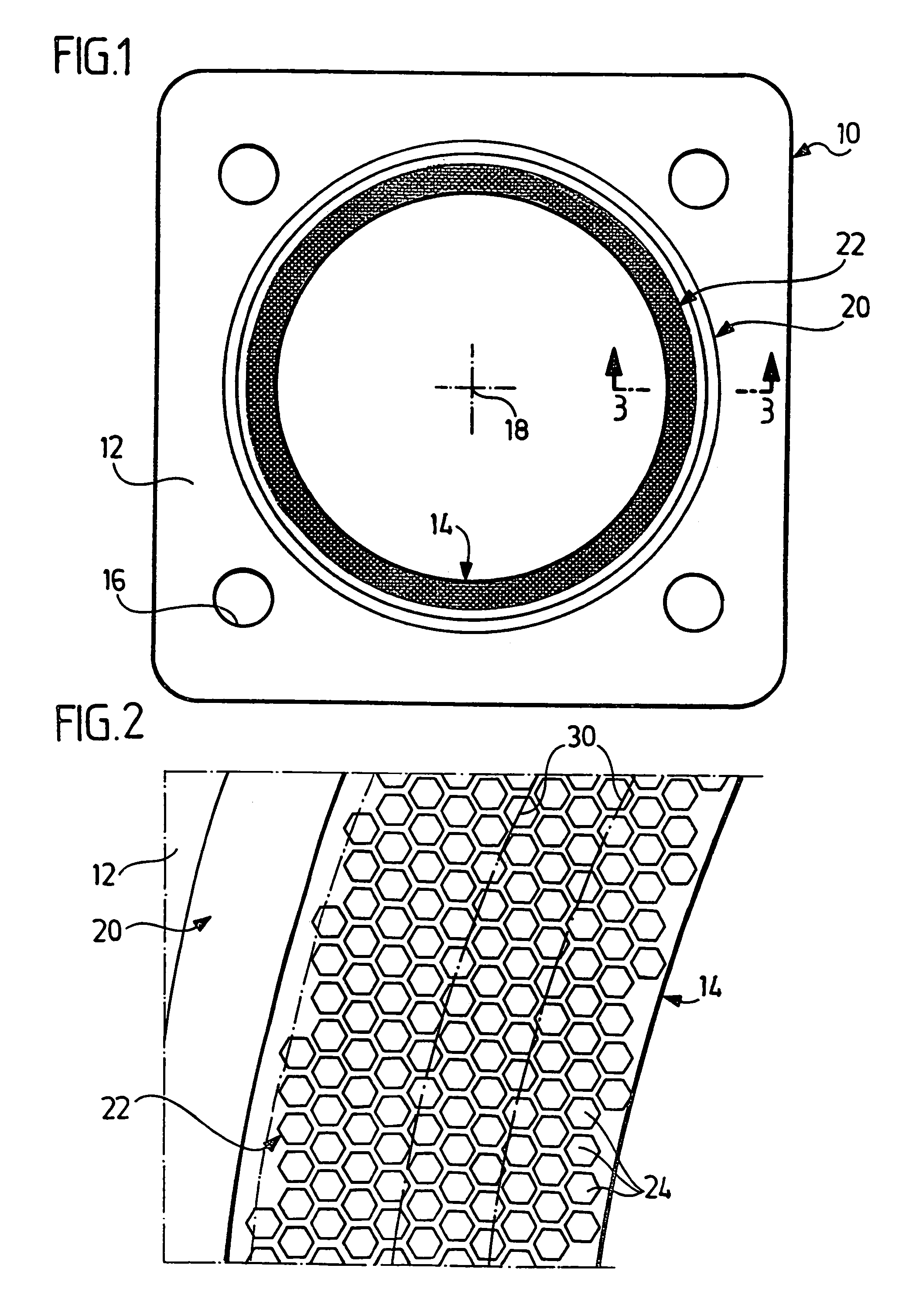

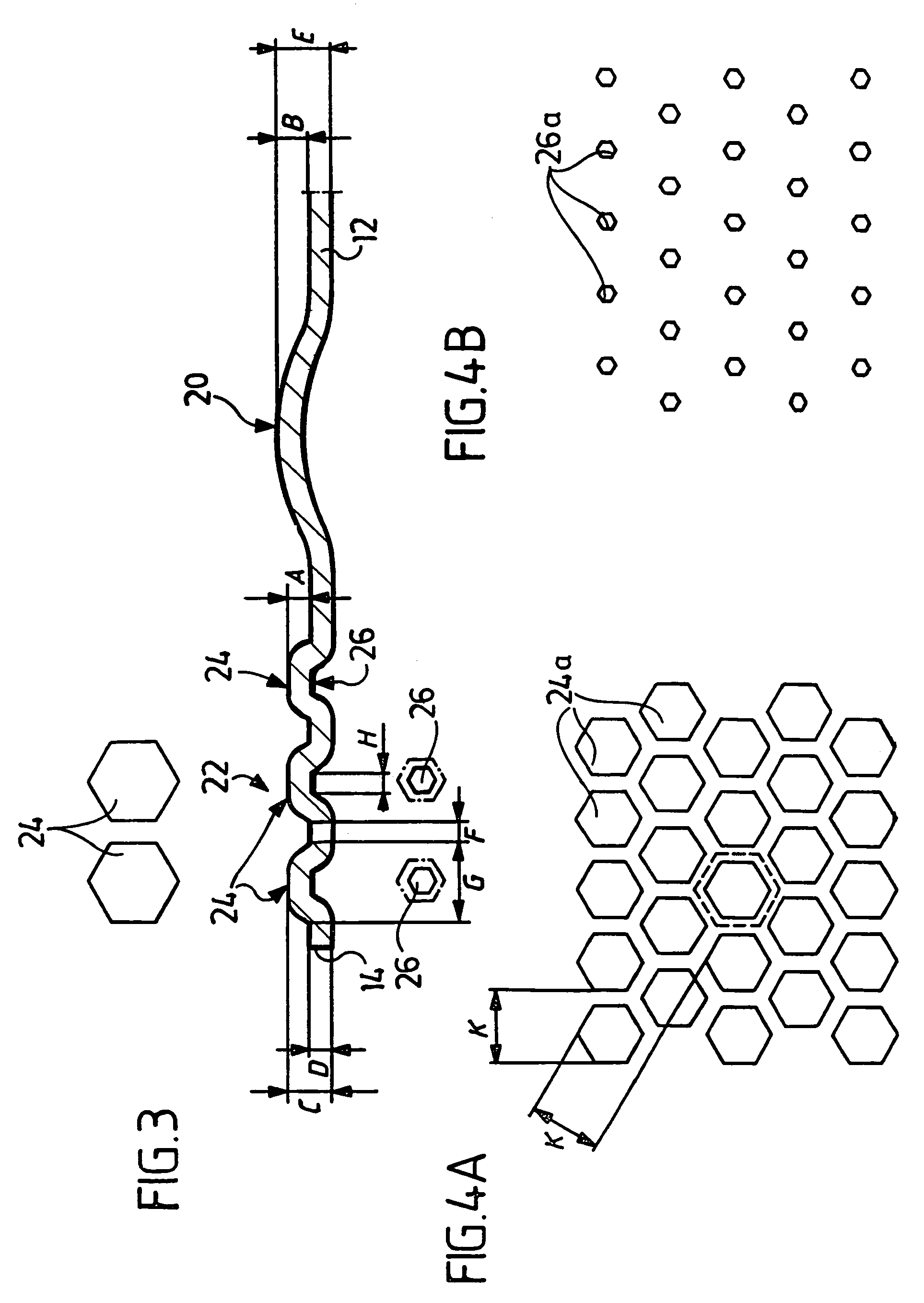

At least substantially metallic cylinder head gasket

InactiveUS7490835B2Easy to provideImprove the immunityEngine sealsFlanged jointsEngineeringMetal cylinder

Cylinder head gasket with a metallic gasket plate comprising a combustion chamber opening enclosed by a bead, and a stopper surrounding the opening and delimiting deformation of the bead, the stopper formed by elevations of a gasket sheet metal layer which are obtained by deformation thereof, the stopper is designed such that in sections through the sheet metal layer along circular cylindrical surfaces coaxial with the opening the stopper comprises a row of discrete elevations following one another in a circumferential direction of the opening and corresponding depressions located directly opposite these elevations, and in a plan view of the sheet metal layer in the area of the stopper, the total area occupied by the elevations is at least half of the total area of the stopper, and the shape of the elevations differs from the shape of circular arcs at least partially enclosing the opening.

Owner:ELRINGKLINGER AG

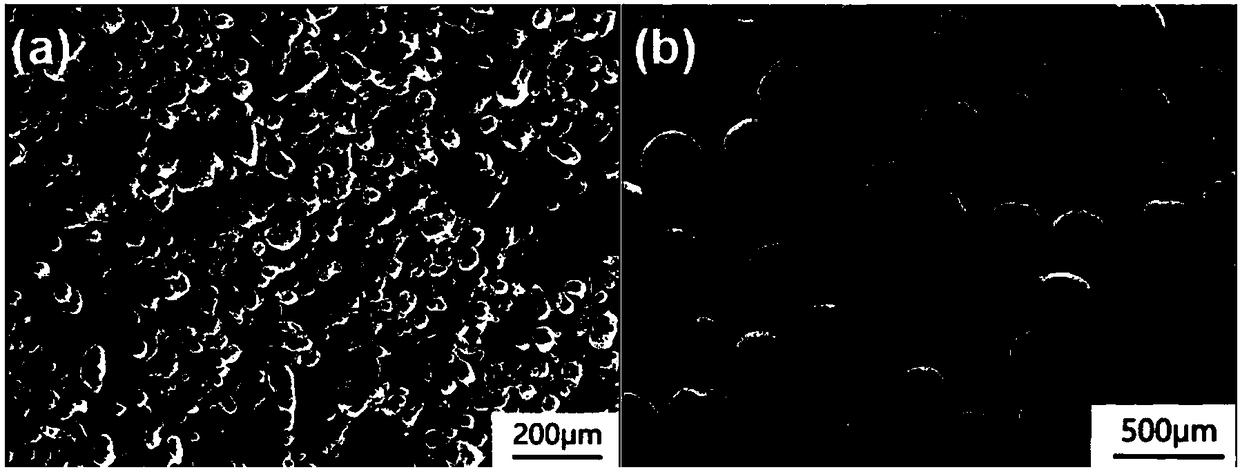

Flexible pressure sensor, manufacturing method therefor, and flexible pressure sensor array

InactiveCN105841851ASimple structureLight in massForce measurement using piezo-resistive materialsTension measurementElectrical resistance and conductanceConductive coating

The invention relates to a flexible pressure sensor, a manufacturing method therefor, and a flexible pressure sensor array. The flexible pressure sensor comprises an elastic main body which is used for generating deformation according to external pressure; and a fabric strain sensor which is attached to the outer side of the elastic main body. The fabric strain sensor comprises a conductive coating layer which is disposed on a substrate layer in a coating manner and attached to the elastic main body in a close manner, and is used for sensing the deformation and correspondingly generating a resistance change according to the deformation; a knitted fabric substrate layer which is used for supporting the conductive coating layer; a flexible conductor which is connected with the conductive coating layer and is used for outputting the resistance change; and a protection layer which is disposed on the surface of the conductive coating layer in a coating manner, and is used for guaranteeing the uniform deformation of the conductive coating layer and reducing the sensing difference of all parts of the conductive coating layer.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

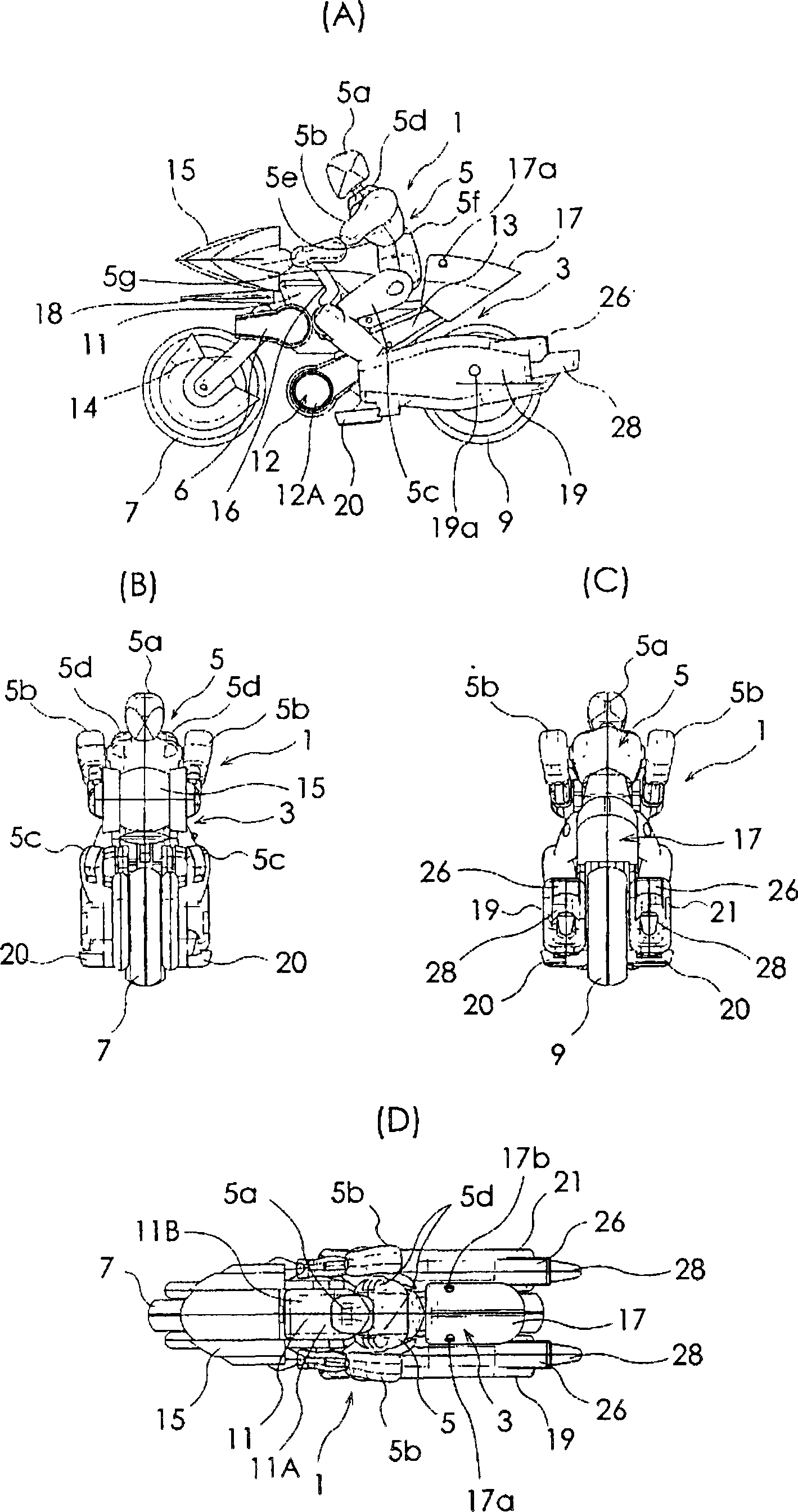

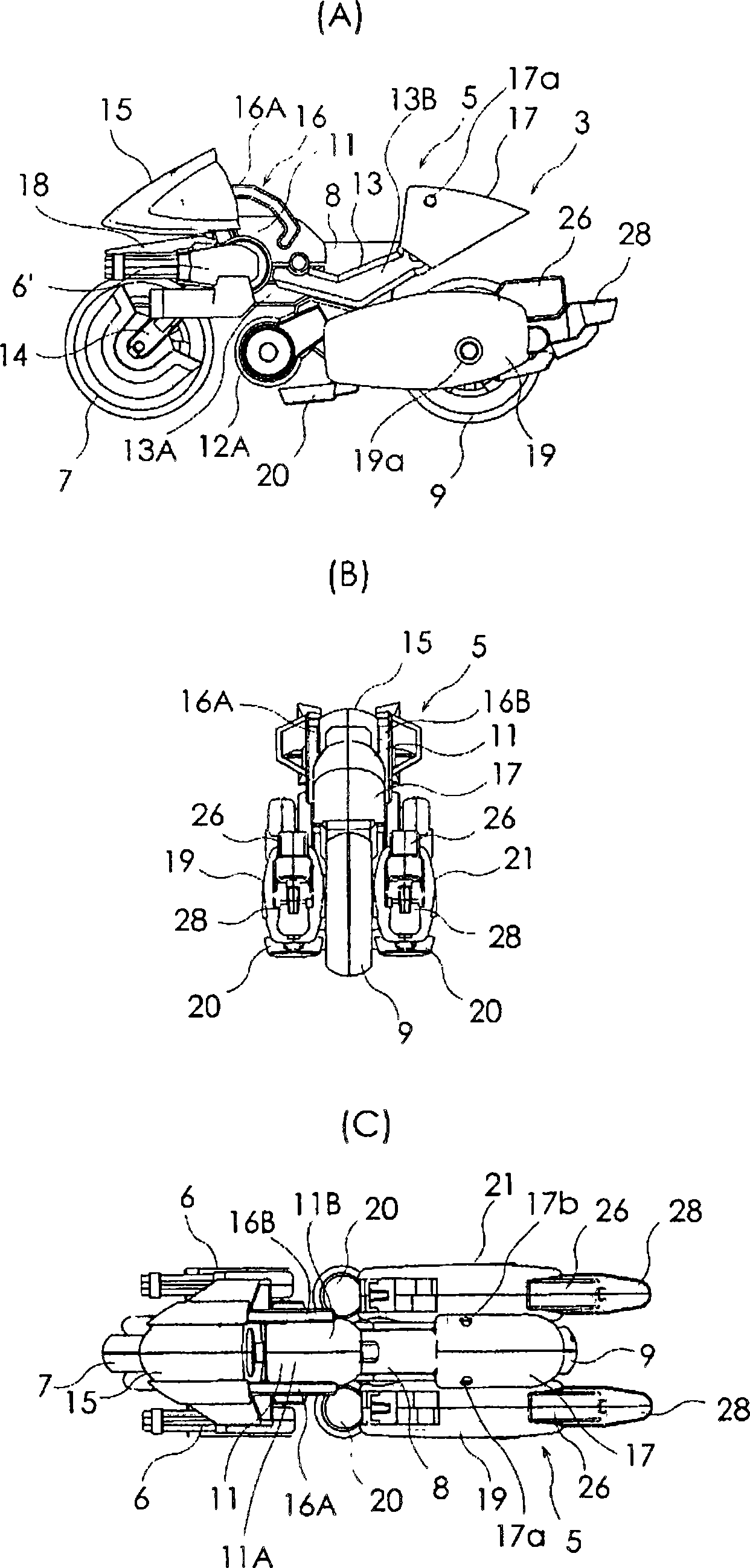

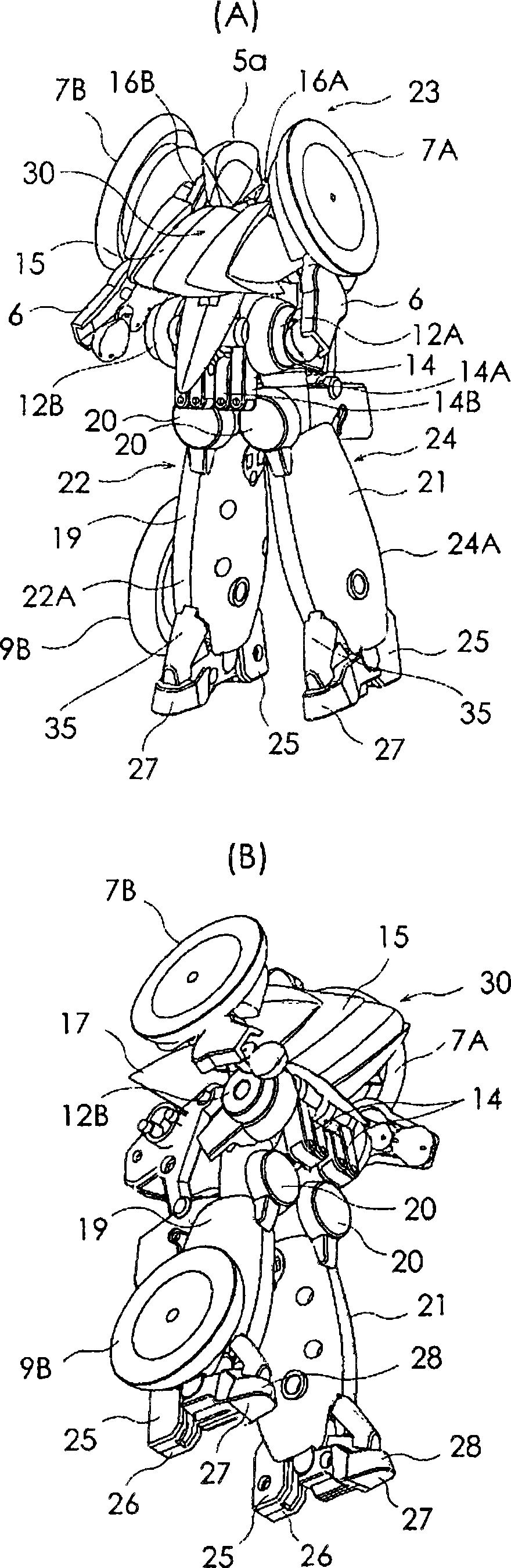

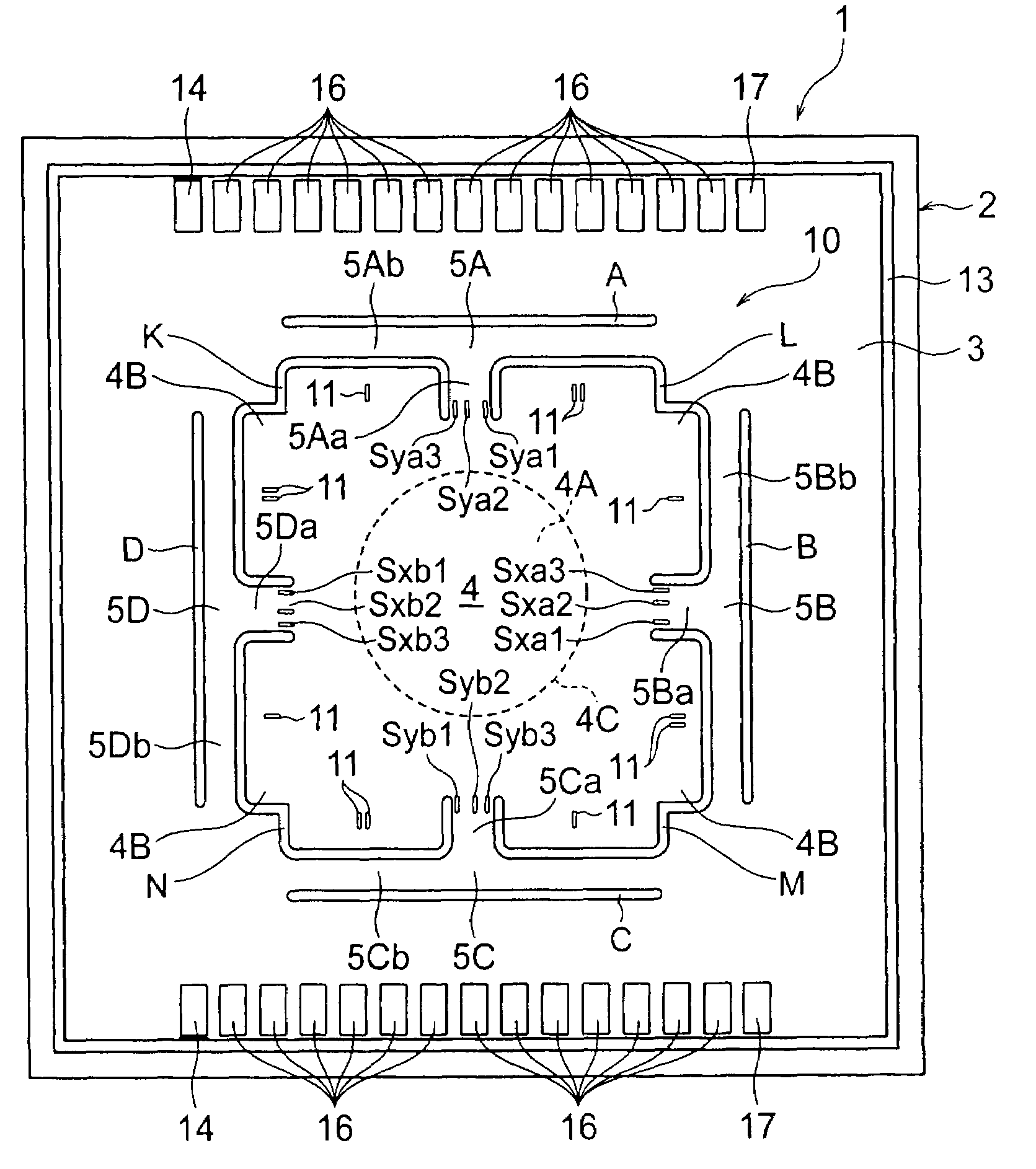

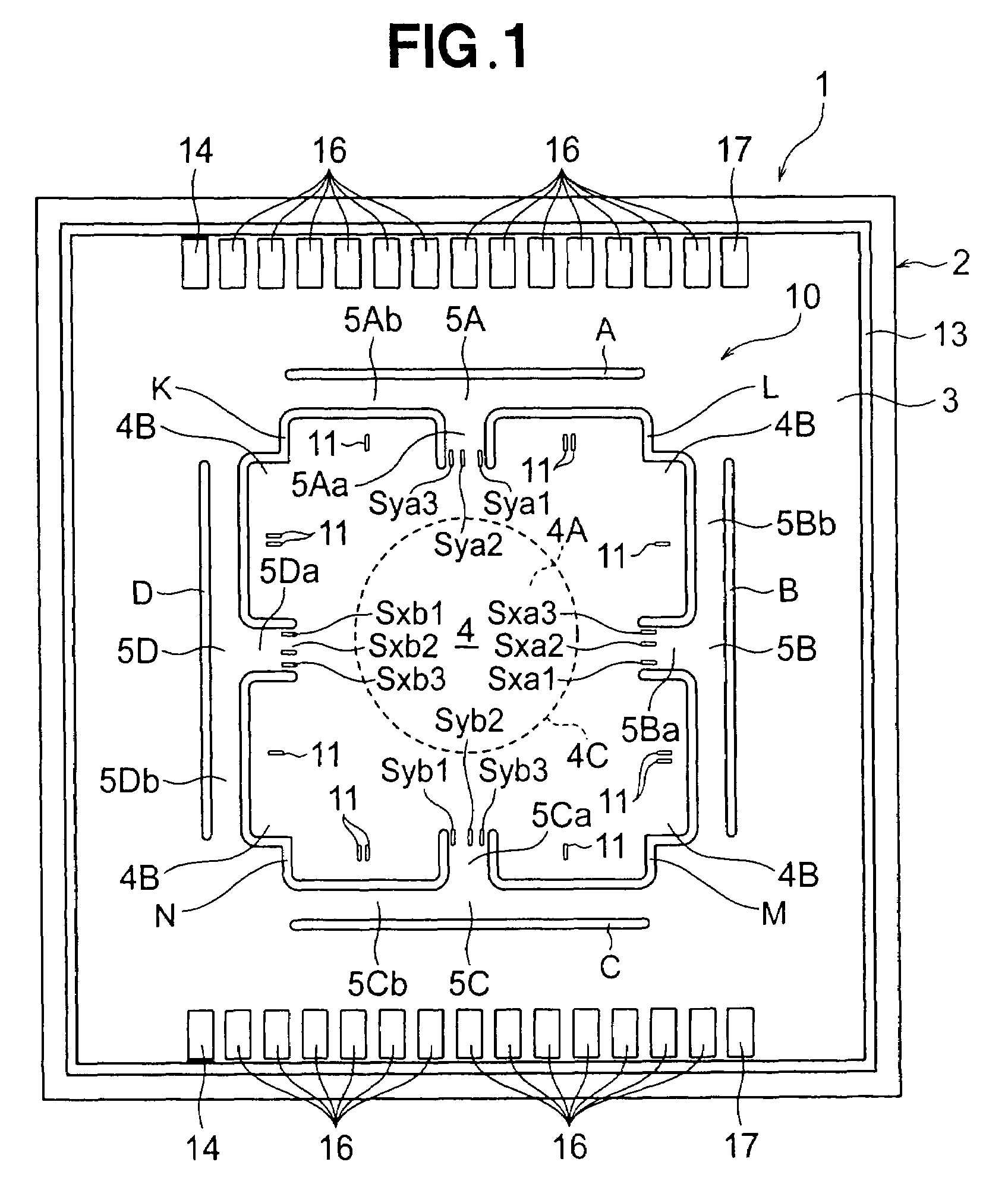

Transformable toy and leg structure for toys

ActiveCN1909948AReduce tracesIncrease the degree of deformationDollsToy vehiclesEngineeringMechanical engineering

A transformable toy in which its unprecedented process of transformation can be enjoyed. A movable toy includes assembled parts composed of a plurality of parts which are mounted on the upper half of a toy doll to constitute the exterior (30) of the upper half of a toy robot. The assembled parts are constituted by first through third assembled parts constituting sections. The first assembled parts constituting section (13A, 14, 15) is disposed in the front of the toy doll. The second assembled parts constituting section (11, 13B, 17) is connected to first assembled parts constituting section and disposed in the back of the toy doll. Handles (16A, 16B) constituting the third assembled parts constituting section connect the first and second assembled parts constituting sections. The first through third assembled parts constituting sections are annularly fitted together to constitute the exterior (30) of the toy doll.

Owner:KONAMI DIGITAL ENTERTAINMENT CO LTD

High-temperature alloy plate drawing method

A high-temperature alloy plate drawing method includes: evenly applying lubricant to the upper and lower surfaces of a high-temperature alloy plate, covering the high-temperature alloy plate with plastic films, as large as the high-temperature alloy plate, to serve as protective films which are 0.04-0.06mm in thickness generally, drawing the high-temperature alloy plate by a die, and removing the protective films and the lubricant after draw-forming of the part. The high-temperature alloy plate drawing method mainly includes the steps of applying the lubricant to double surfaces of a plate part before drawing, covering the double surfaces of the plate part with the protective films (0.04-0.06mm plastic films) as large as the plate part before drawing, drawing the part, removing the protective films, and cleaning the lubricant. By the aid of the method, friction coefficient between material and the die can be reduced, drawing force is reduced by 30%, deforming degree of the material is increased, and limit drawing coefficient is reduced. Practice shows that the original limit drawing coefficient can be reduced from 0.45-0.47 to 0.37-0.40 by using the method.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

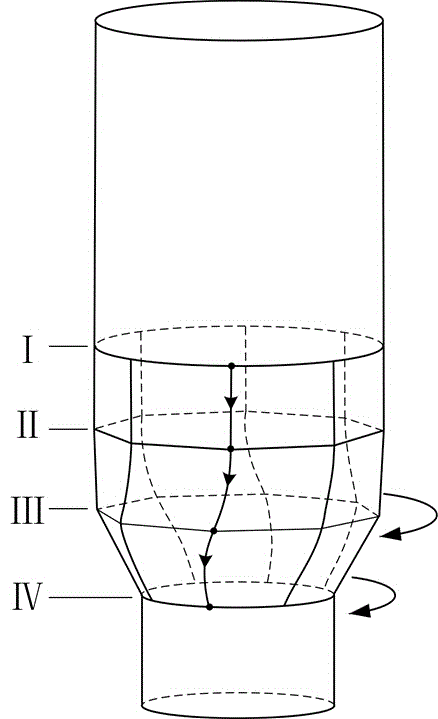

Tube drawing forming method and forming mould

InactiveCN102423770AImproved strain distributionIncrease stressDrawing diesStress distributionShear stress

The invention discloses a tube drawing forming method and forming mould. In the forming method, extrusion-bulging deformation is performed on a tube by using a drawing torsion variable-section core to realize combination of various deformation modes in a primary forming process. The tube wall of the formed tube is subjected to the extrusion-bulging of the core and is in a strong three-way compressive stress state due to the limitation of a polyurethane filling layer; at a deformation stage of circular-elliptical-circular and elliptical torsion change, the tube enters a torsion shearing deformation zone of a metal transition region; under the action of shearing stress, the internal organization of the material is subjected to rotation and shear strain to cause the orientation of a materialorganization structure, namely a new texture is formed, thereby improving deformation texture under the equivalent deformation degree. The drawing variable-section core extrusion-bulging tube deformsto achieve larger deformation degree compared with that of the conventional forming process, so that strain distribution and stress distribution in the tube are improved, the casting organization remained in the broken tube is facilitated, the form and the distribution of inclusion are changed, and the defects of the internal organization of the tube are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

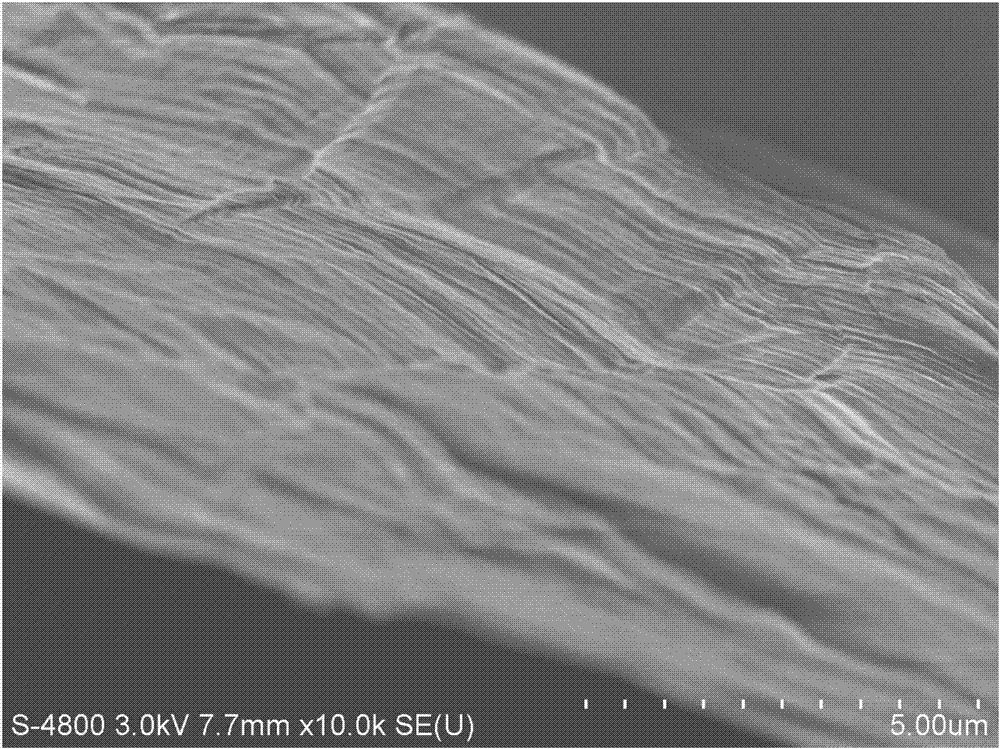

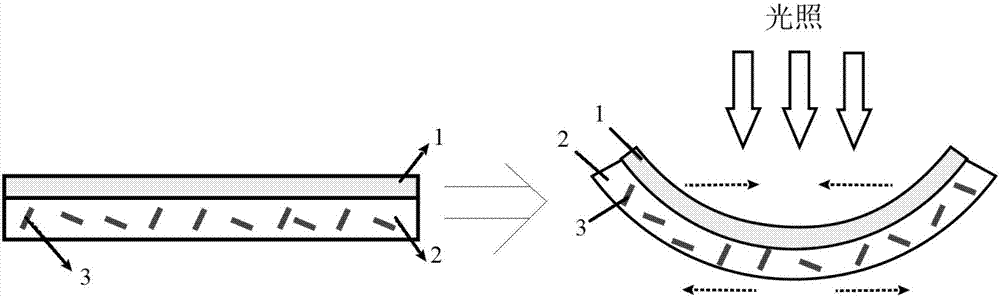

Oxidized graphene based light-driven two-layer composite membrane and preparation method and application thereof

ActiveCN107029565AQuick responseIncrease the degree of deformationSemi-permeable membranesLaboratory glasswaresMicrofluidic chipLight driven

The invention discloses an oxidized graphene based light-driven two-layer composite membrane and a preparation method and application thereof. The oxidized graphene based light-driven two-layer composite membrane produces bending deformation under light irradiation and comprises a PDMS and precious metal nano material mixture layer and an oxidized graphene film flatly laid and fixed to the mixture layer and having optical transparency. The preparation method of the oxidized graphene based light-driven two-layer composite membrane comprises the steps that the oxidized graphene film having optical transparency is prepared; the PDMS and precious metal nano material mixture layer is prepared; the two-layer composite membrane is prepared. The oxidized graphene based light-driven two-layer composite membrane produces controllable bending deformation under simulated sunlight irradiation and the coupling effect of optical-thermal-mechanical asymmetric composite structure, has the advantages of being transparent, flexible, large in deformation degree, good in controllability, remotely controllable and operatable and the like and can be applied to a light-driven flexible mechanical device, micro-vale for controlling microfluidics in a micro-fluidic chip and the like.

Owner:HEFEI UNIV OF TECH

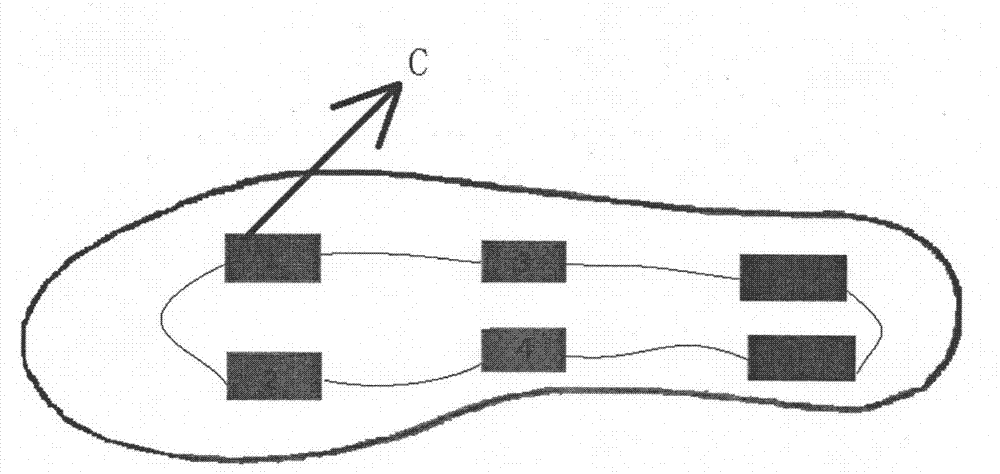

Plantar pressure testing device and total-fabric insole with plantar pressure testing device

ActiveCN104280177AImprove comfortIncrease elasticityInsolesApparatus for force/torque/work measurementFiberEngineering

The invention discloses a plantar pressure testing device and a total-fabric insole with the plantar pressure testing device. The plantar pressure testing device is characterized by comprising a plurality of sensor generating devices corresponding to points to be tested, each sensor generating device comprises an electrostatic spinning PVDF pressure fiber mesh, the upper side and the lower side of each electrostatic spinning PVDF pressure fiber mesh are provided with a pair of conductive corduroy, and protruding strips on the electrostatic spinning PVDF pressure fiber meshes and the conductive corduroy are arranged in a relatively staggered mode; the first conductive corduroy and the second conductive corduroy are connected with a signal transmission device, and the function of detecting the plantar pressure is achieved by monitoring the first conductive corduroy and the second conductive corduroy. According to the plantar pressure testing device, the pressure of the different plantar positions can be measured at any time and any place through electric signals produced through plantar pressurizing. The plantar pressure testing device can be used for dynamically testing any frequency produced during walking, running, jumping and the like, the plantar pressure testing device can be combined with shoes worn in daily life, and using is convenient and comfortable.

Owner:DONGHUA UNIV

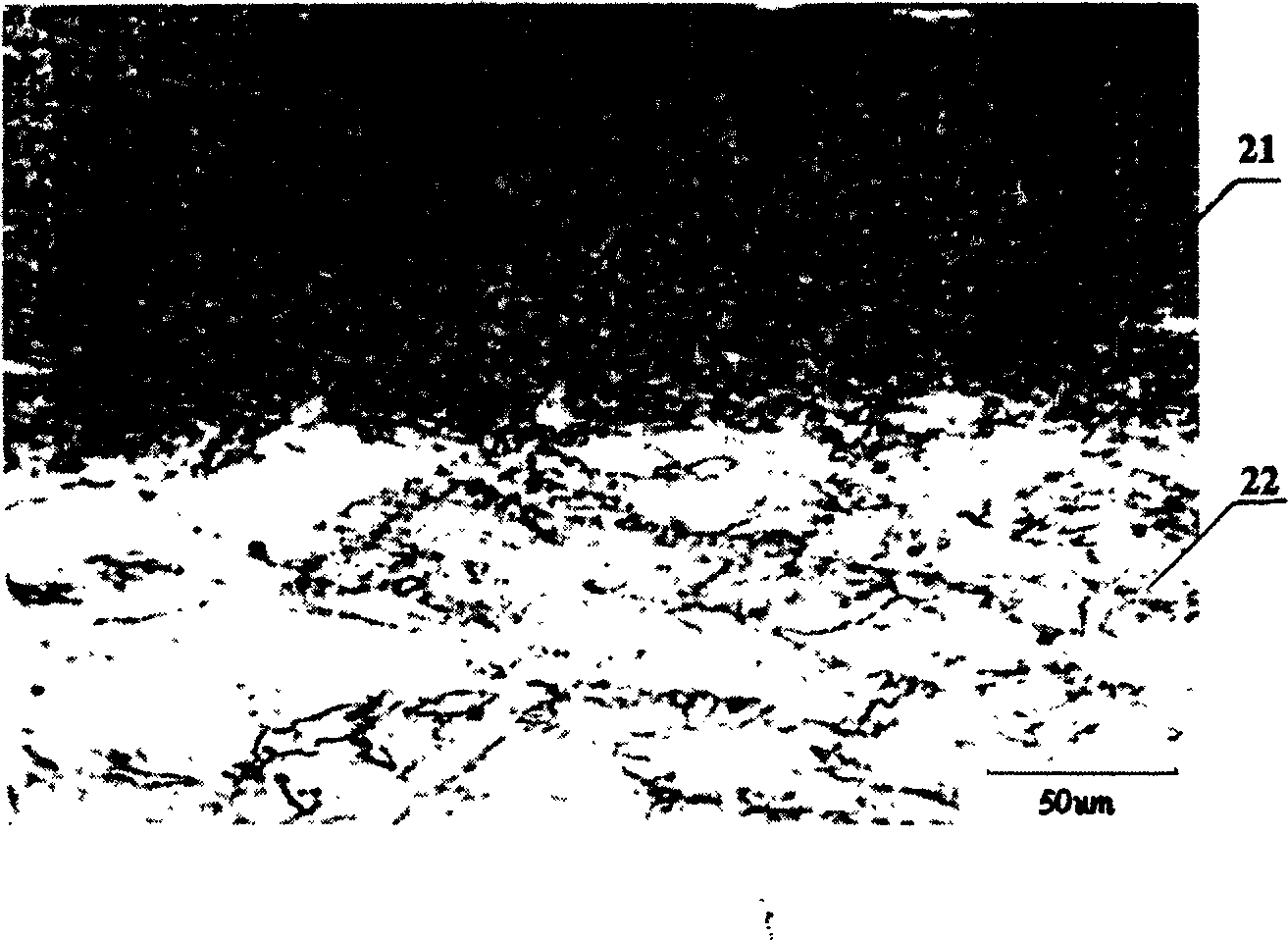

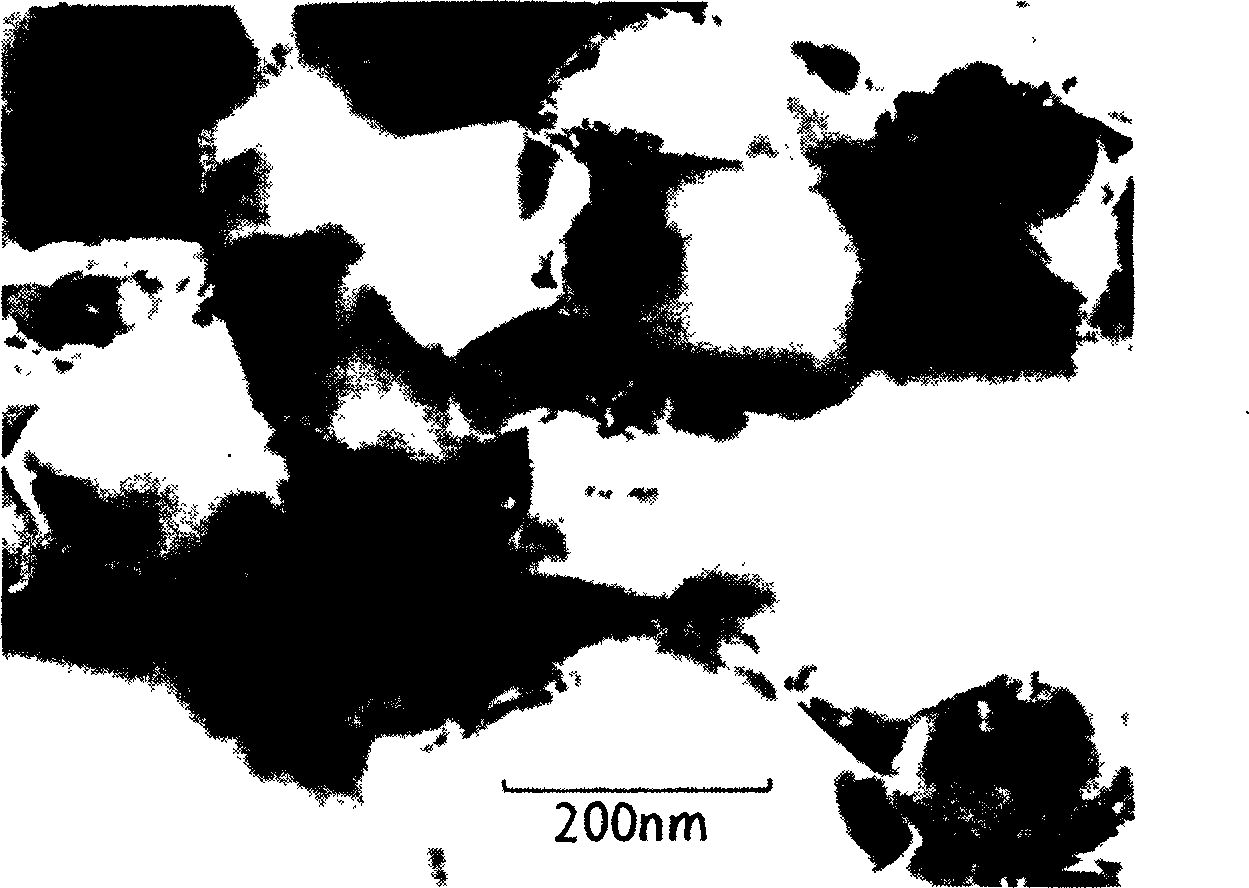

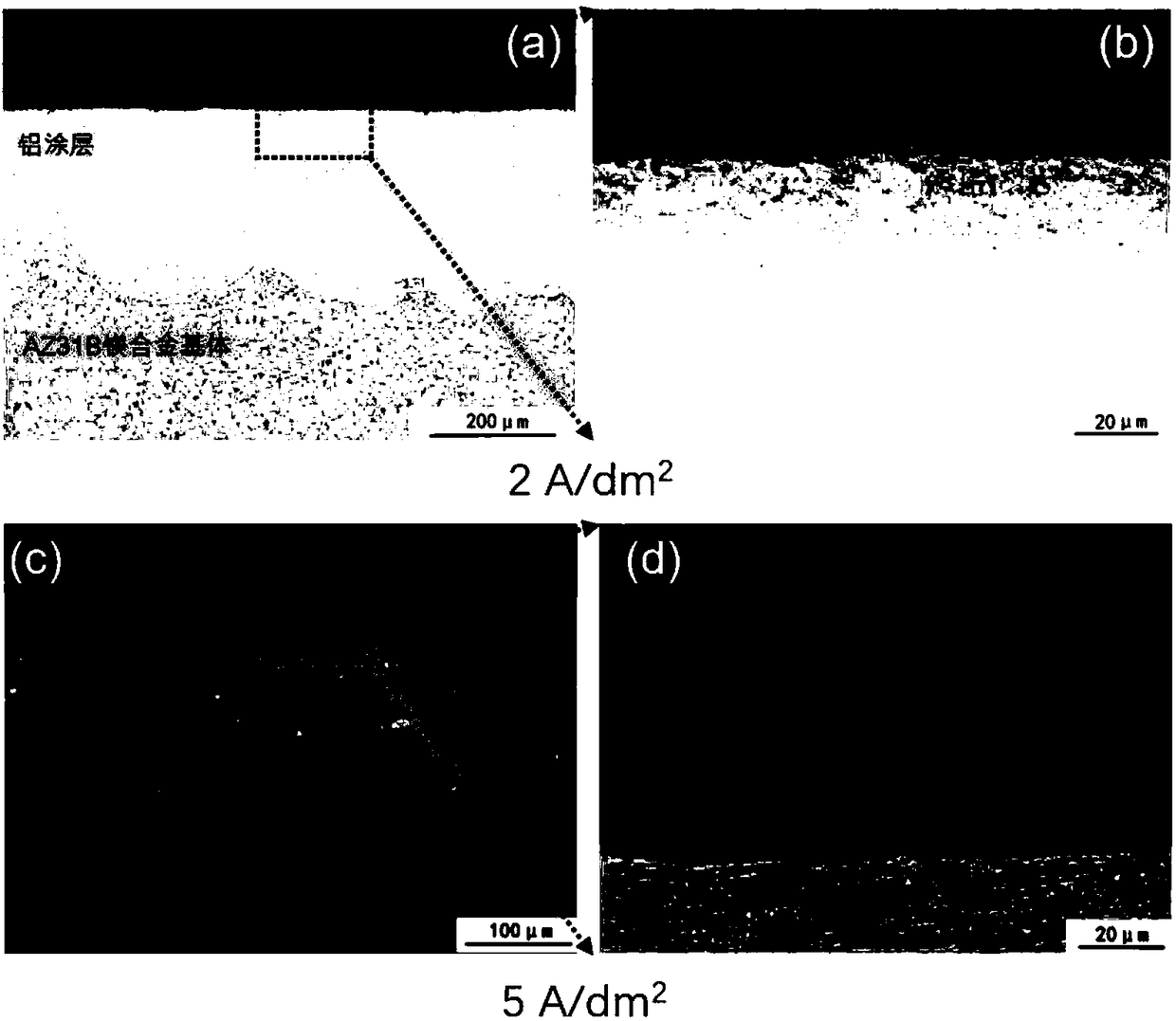

Anticorrosive and wear-resistant low density composite structure coating on surface of magnesium alloy, and production method thereof

PendingCN108559987AAchieve corrosiveAchieve protectionAnodisationSuperimposed coating processIsolation effectWear resistant

The invention discloses an anticorrosive and wear-resistant low density composite structure coating on the surface of a magnesium alloy, and a production method thereof. The composite structure coating comprises an anticorrosive bottom layer and a wear-resistant top layer which are sequentially arranged on the surface of the magnesium alloy from bottom to top, the anticorrosive bottom layer is a high-density aluminum layer or aluminum alloy layer, and the wear-resistant top layer is a high-hardness alumina ceramic layer. The high wear resistance of the surface of the magnesium alloy is realized by means of the high-hardness alumina top layer, and the great improvement of the corrosion resistance of the magnesium alloy substrate is realized by the physical isolation effect of the high-density aluminum or aluminum alloy coating and the top alumina layer to a corrosion medium in order to finally achieve the corrosion and wearing dual protection effects of the magnesium alloy substrate. The production method makes the low-cost production of a magnesium alloy protection layer with anticorrosion and wear resistance dual characteristics become possible, and the residual compressive stressin the aluminum and aluminum alloy coating can delay the generation and cracking of cracks under a periodical load condition and improve the fatigue life of the magnesium alloy, so the application field of the magnesium alloy is significantly expanded.

Owner:XI AN JIAOTONG UNIV

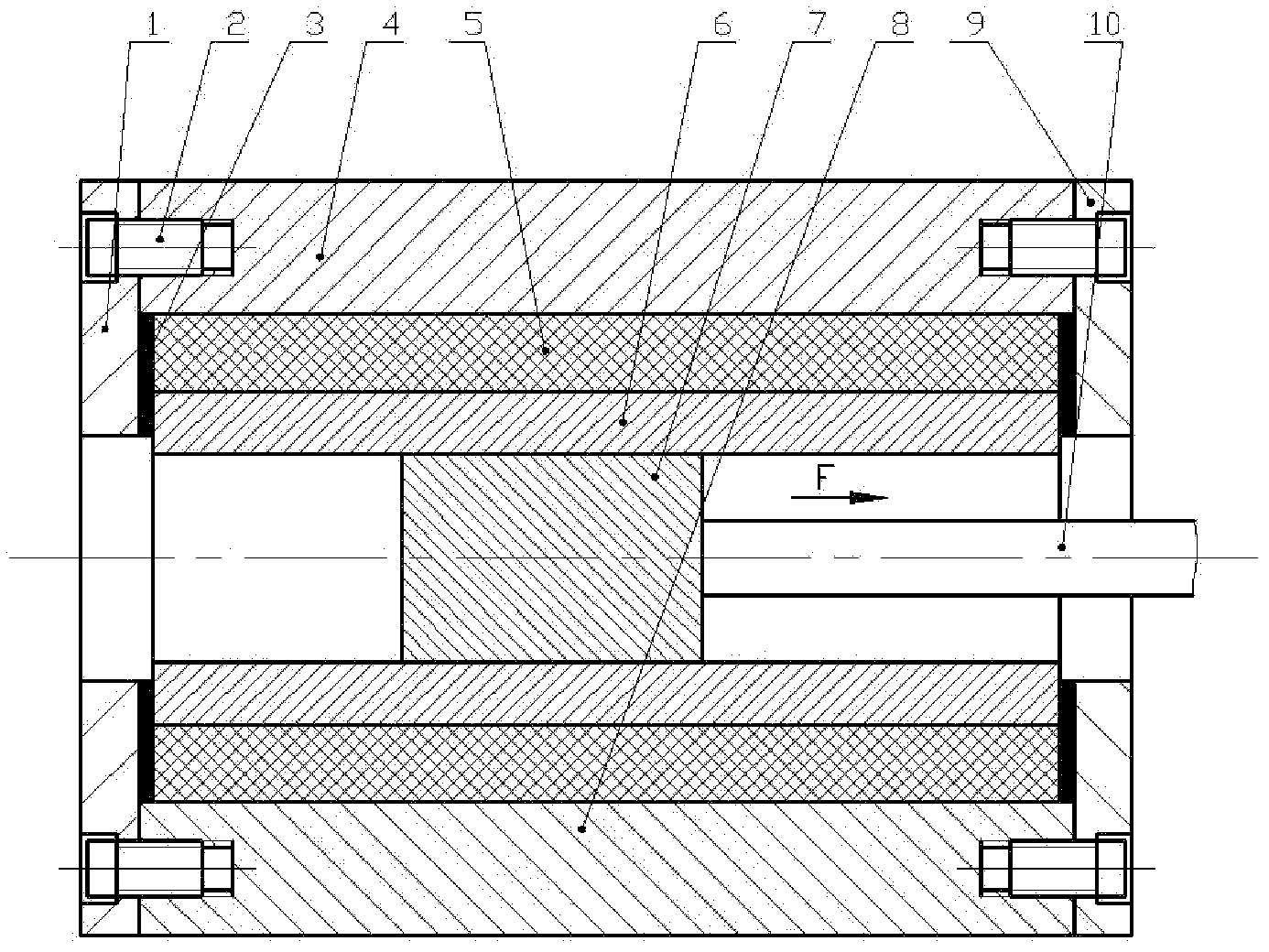

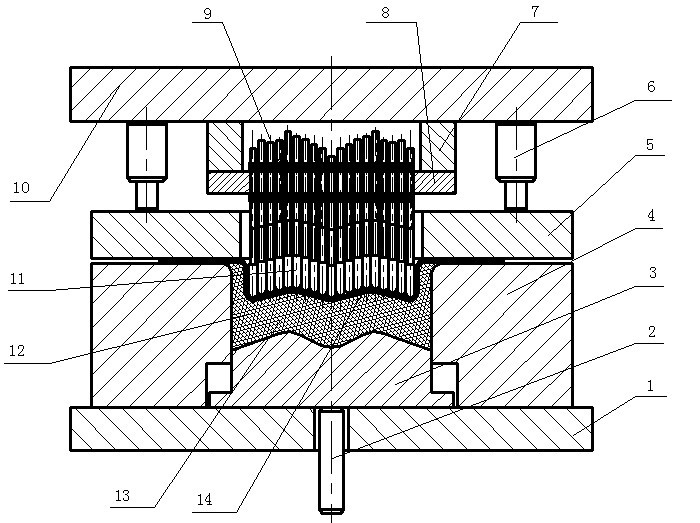

Multipoint forming die based on solid particle medium back pressure

The invention relates to a multipoint forming die based on solid particle medium back pressure, which comprises a lower die holder, a top bar, a cushion block, a female die, a pressure plate, an air cylinder, a sizing block, a supporting plate, bolts, an upper die holder, a male die, a solid particle bottom die and the like. During die assembly and manufacturing, solid particles are used as the flexible forming bottom die and are filled in a bottom die cavity among the female die, a top block and a blank. Compared with liquid medium back pressure, by using the solid particle medium back pressure, the formation can be realized very easily, no special equipment is required, the leakage can be effectively avoided by using the solid particles, the environment is not polluted and the safe and reliable production can be realized. The solid particle medium back pressure can realize non-even back pressure, can effectively improve panel veneer deformation extent and can enable the thickness of the product to be evenly distributed. Since the solid particle bottom die is used as the flexible bottom die and the shape of the solid particle bottom die can be adjusted through the shape of the cushion block according to needs, the product quality is higher. Since the male die can be adjusted and varied according to the shape of the product, the die is particularly suitable for new product trial production and small and medium mass production.

Owner:CHONGQING UNIV OF TECH

Force sensor chip

ActiveUS7536923B2Improve balanceHigh detection sensitivityForce measurementApparatus for force/torque/work measurementOperating pointEngineering

A force sensor chip having a multiaxial force sensing function is disclosed. The force sensor chip comprises a base member having an operating part provided with an external force application area, a supporting part for supporting the operating part, connecting parts for connecting the operating part and the supporting part, and strain resistance elements disposed in the connecting parts or within boundaries between the connecting parts and the operating part. The base member has a thin area formed with a small thickness, and the boundaries of the thin area are disposed in the supporting part and operating part.

Owner:HONDA MOTOR CO LTD

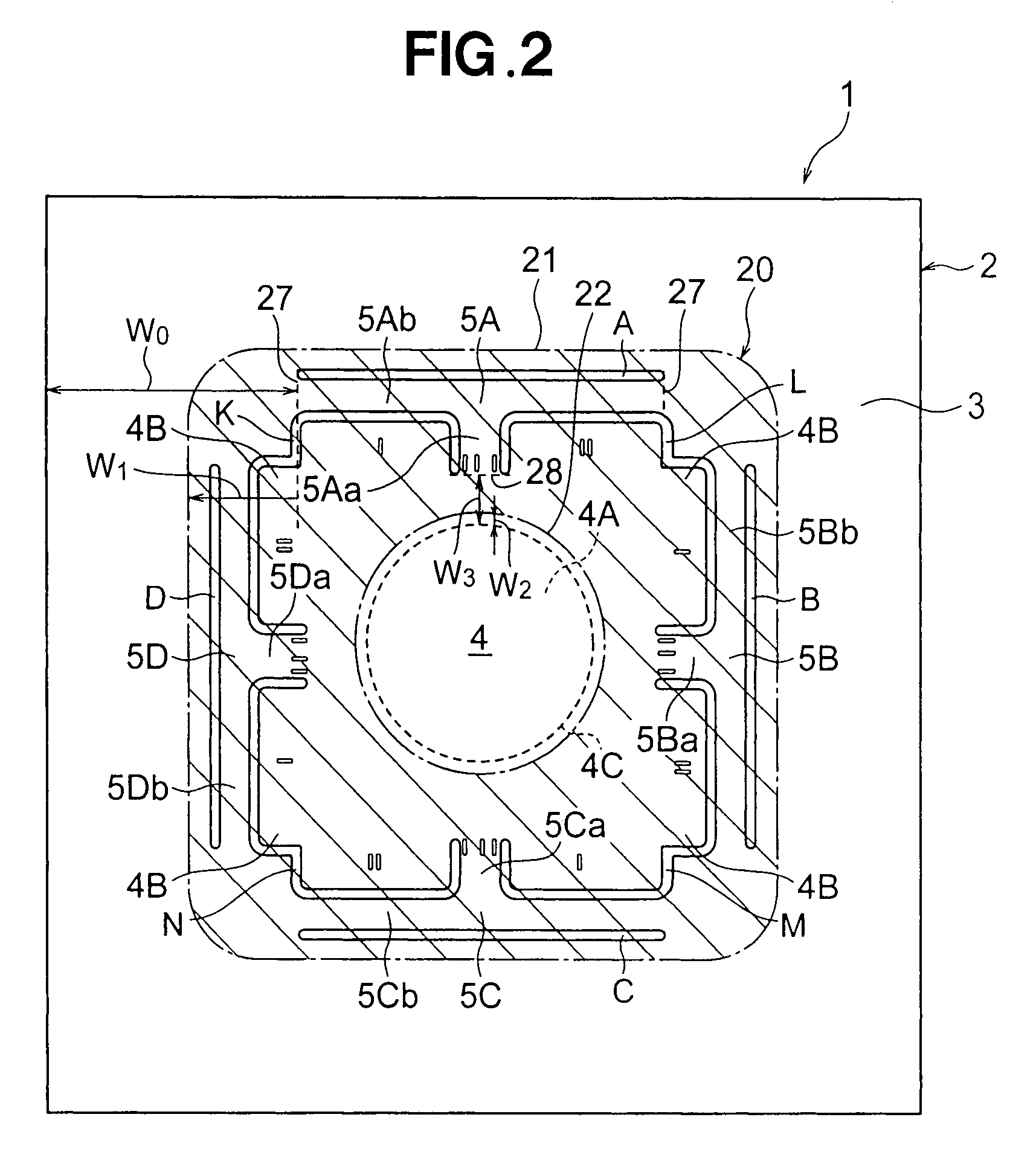

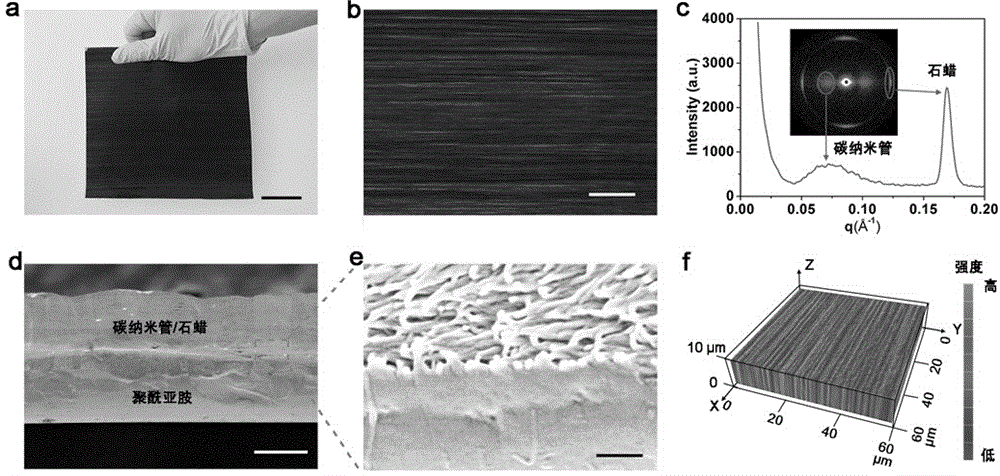

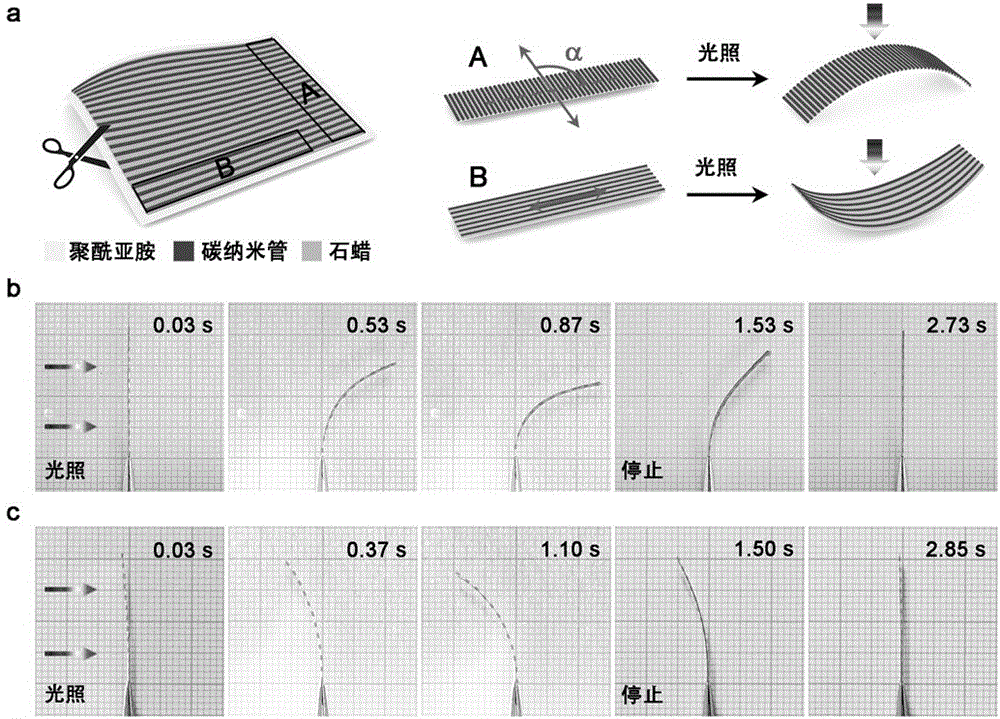

Light-drive deformation-controllable composite and preparation method thereof

InactiveCN105479836AClose contactGood reversibilitySynthetic resin layered productsLaminationCarbon nanotubeLight driven

The invention belongs to the technical field of sensitive materials, and particularly discloses a light-drive deformation-controllable composite and a preparation method thereof. According to the composition and structure of the composite, a polyimide film serves as the substrate, an anisotropy composite layer composed of orientation carbon nanotubes and paraffine serves as the upper layer, and the substrate and the composite layer make close contact. By means of the composite, the response of light drive and thermal drive can be achieved. By controlling the orientation direction of the orientation carbon nanotubes, various deformation forms of facing towards light, backing from light, three-dimensional deformation and the like can be achieved, the content of carbon nanotubes and paraffine is further optimized, and rapid and large-magnitude deformation can be achieved. By means of the light-drive deformation material, a new concept is provided for other intelligent response materials.

Owner:FUDAN UNIV

Tube nozzle forging method and nuclear main pump shell profiled forging process

The invention relates to the field of forging, and discloses a tube nozzle forging method and a nuclear main pump shell profiled forging process. The tube nozzle forging method comprises the followingsteps: forging of a first tube nozzle: processing a positioning hole in a barrel blank; locally heating the positioning hole; placing the barrel blank on a lower die, arranging a guide column which is matched with the positioning hole in a flute of the lower die, and enabling the guide column to penetrate through the positioning hole to position the barrel blank; carrying out pre-punching in thebarrel blank by using a first punch, forming a first guide hole which corresponds to the guide column in the first punch, inserting the guide column into the first guide hole to form a cavity in the barrel blank, and carrying out impact extrusion in the barrel blank by using the first punch, wherein the diameter of the second punch is smaller than that of the first punch; and forming a second guide hole which corresponds to the guide column in the second punch, and inserting the guide column into the second guide hole during impact extrusion to form a first tube nozzle. The utilization rate ofmaterials can be increased, the machining amount is reduced, the deformation degree of forge pieces is large, the quality of the forge pieces is good, and the performance is excellent.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

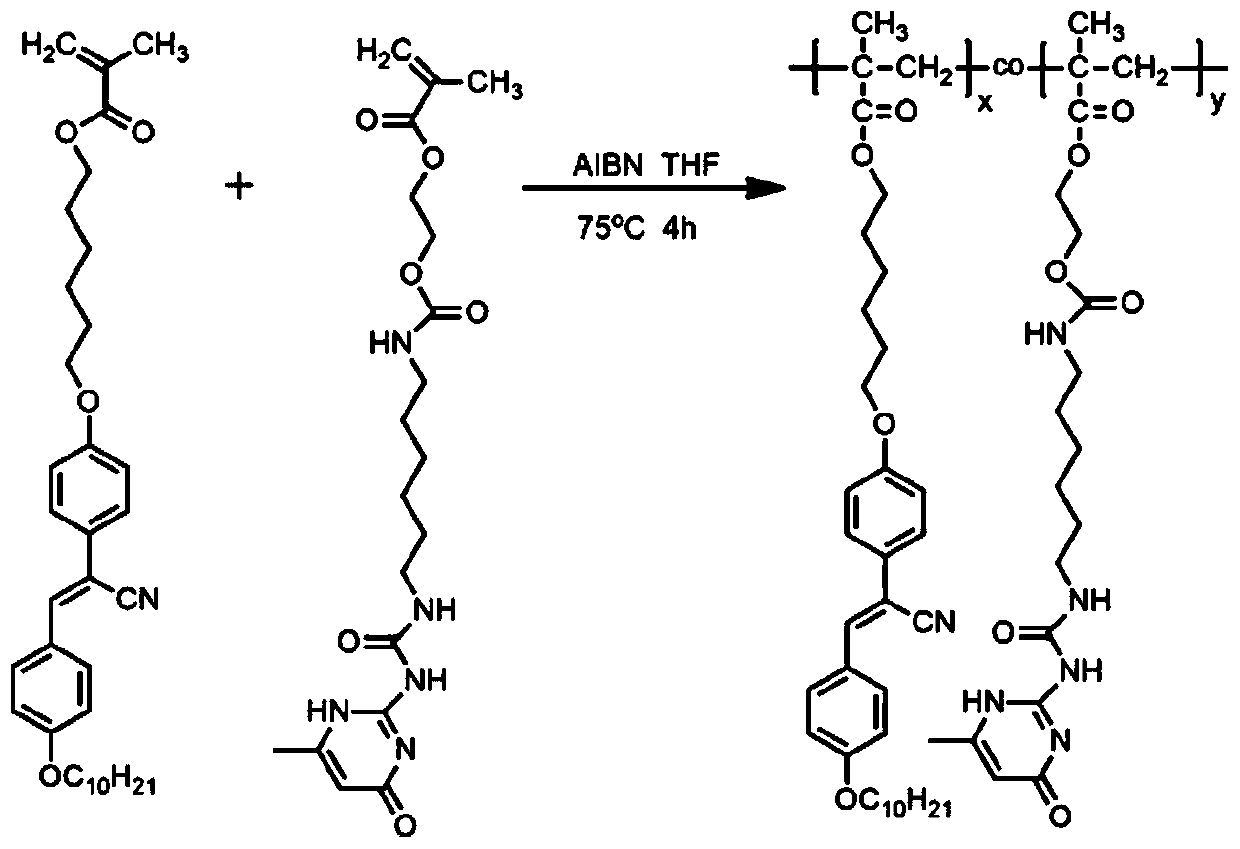

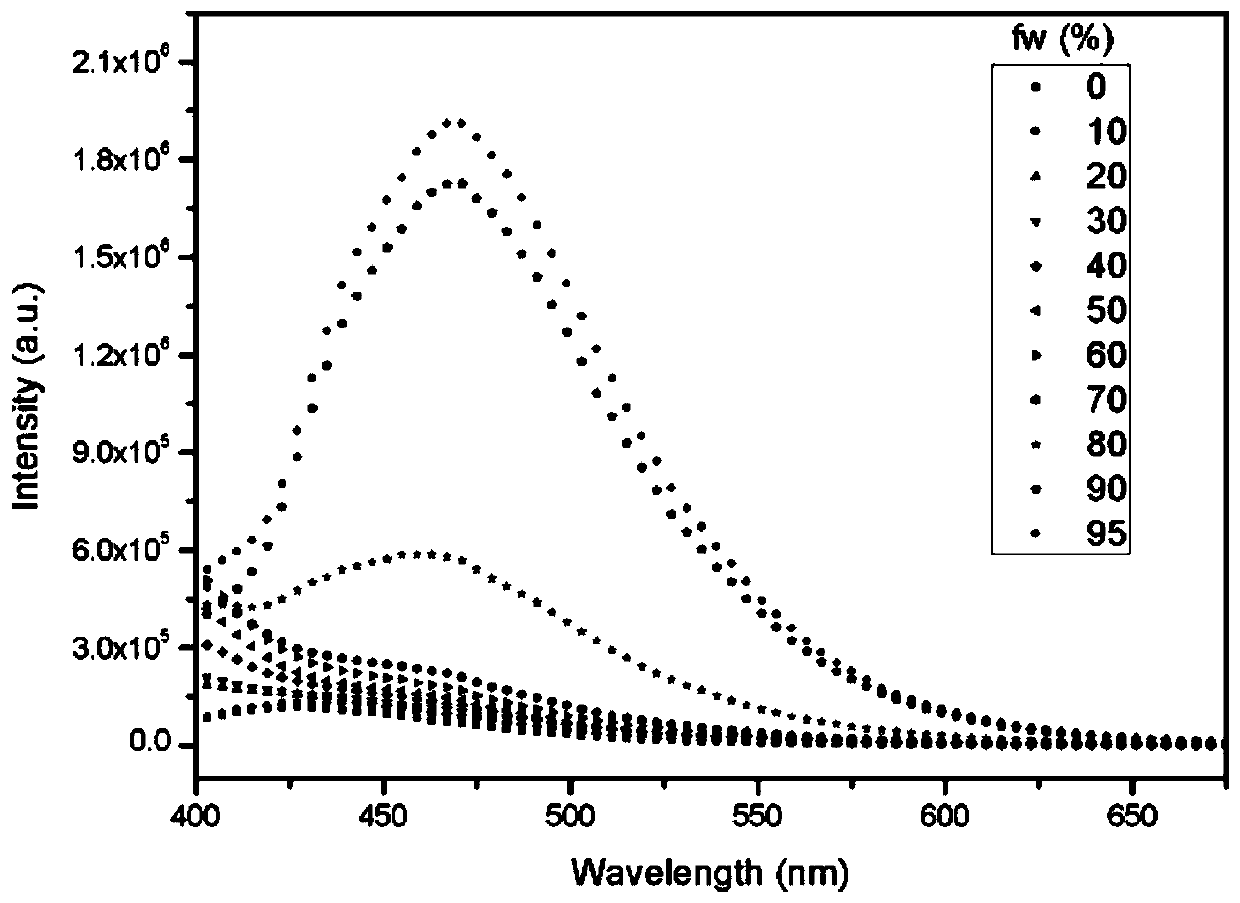

Cyano-distyrene-containing photo-responsive luminescent liquid crystal elastomer material and preparation method thereof

PendingCN110330589AEasy to synthesizeStrong controllability of chemical structureMonocomponent synthetic polymer artificial filamentLuminescent compositionsFiberFluorescence

The invention discloses a cyano-distyrene-containing photo-responsive luminescent liquid crystal elastomer material and a preparation method thereof. The liquid crystal elastomer material disclosed bythe invention is prepared by performing copolymerization on a cyano-distyrene group-containing monomer and a hydrogen bond crosslinking agent monomer, or performing copolymerization on the cyano-distyrene group-containing monomer, the hydrogen bond crosslinking agent monomer and a monomer containing a non-liquid crystal structural unit. The liquid crystal elastomer material disclosed by the invention shows a typical aggregation-induced fluorescence enhancement effect, can emit very strong fluorescent light in an aggregation state; in addition, the orientated single domain liquid crystal elastomer fibre also has photo-response; under the irradiation of ultraviolet light, the single domain liquid crystal elastomer fibre can deform, has the advantages that the deformation degree is high, thedeformation speed is high, the deformation can be stored for a long time and the like, and shows a broad application prospect in the fields of intelligent actuators, biomaterials, optical materials and the like.

Owner:XIANGTAN UNIV

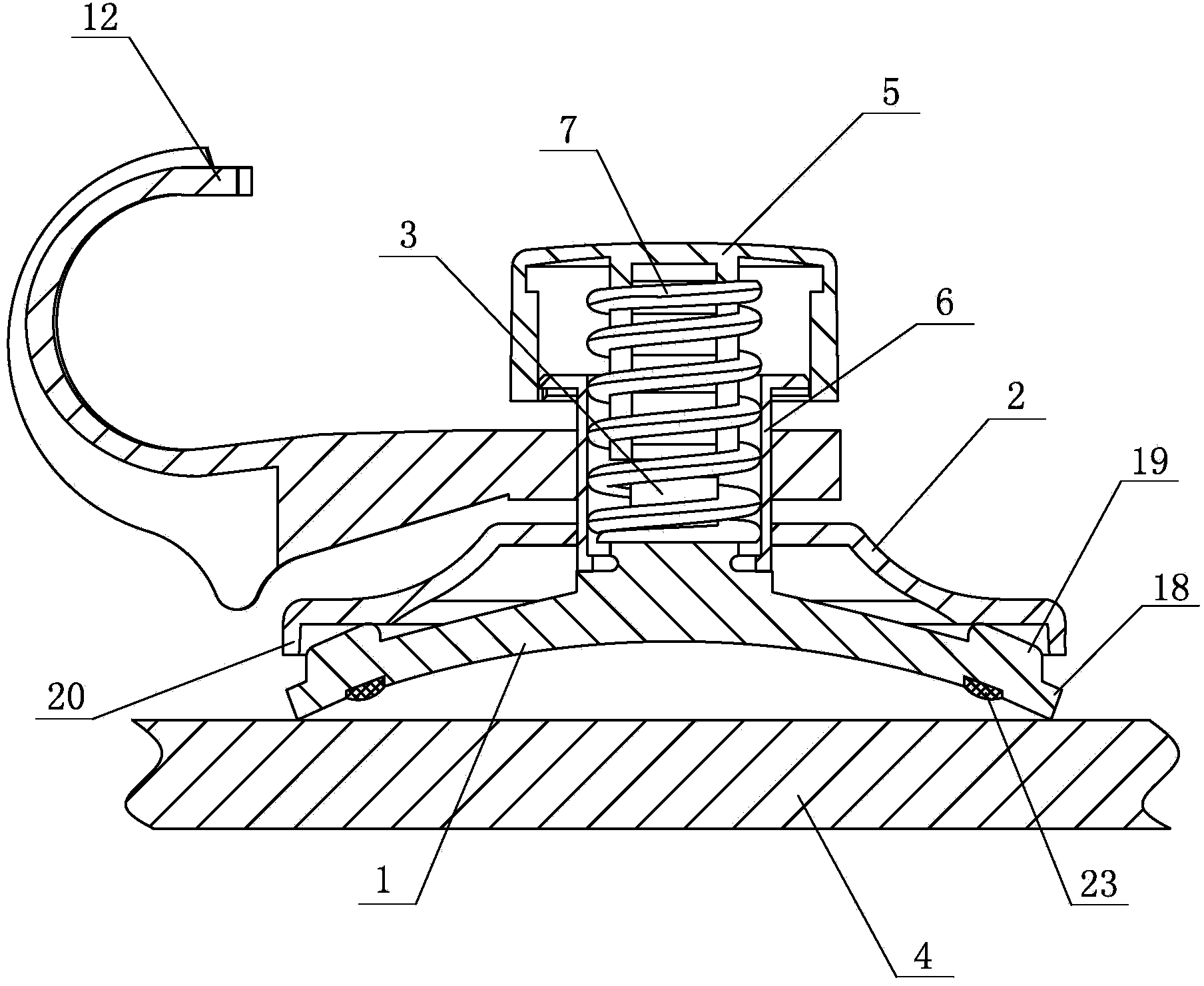

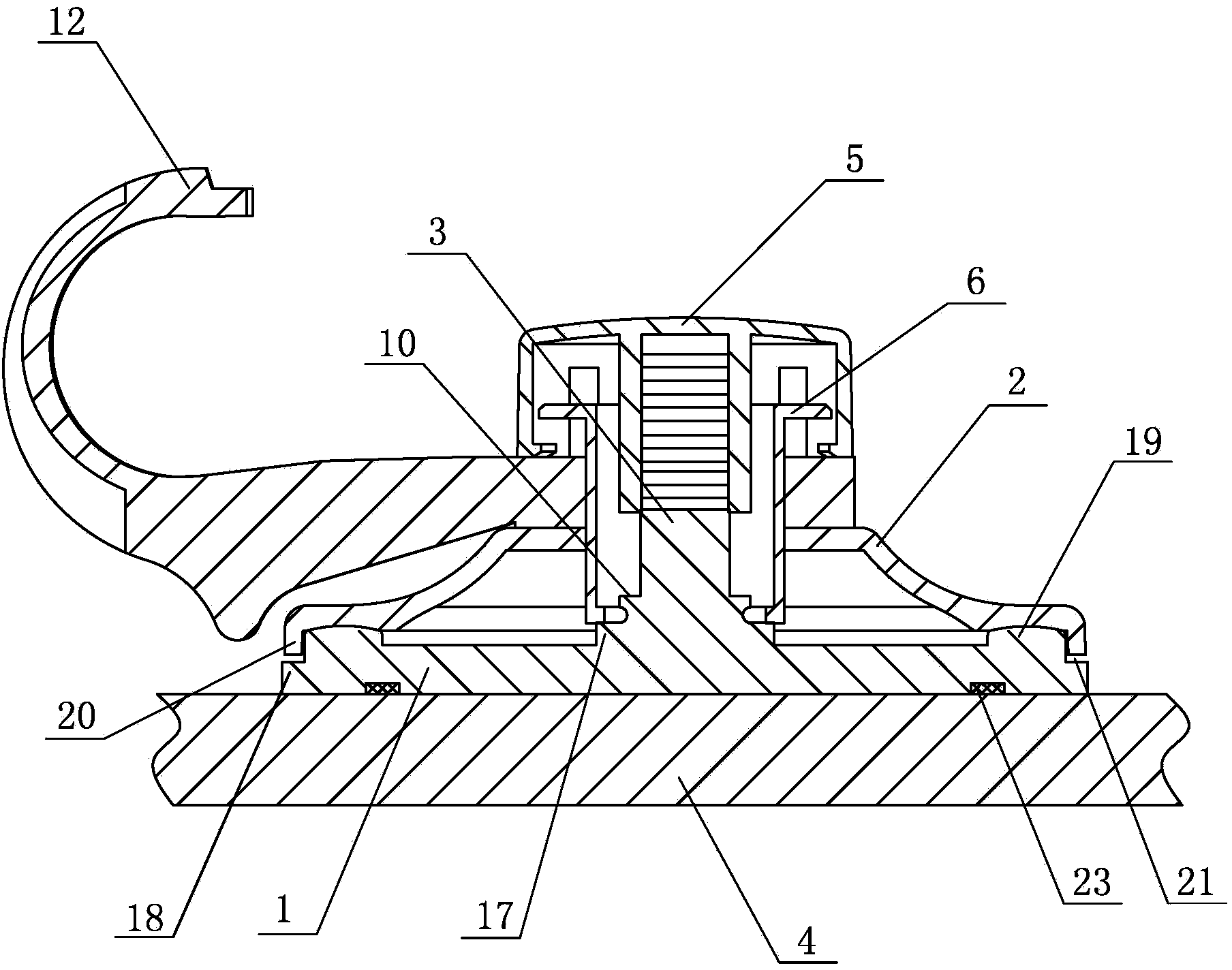

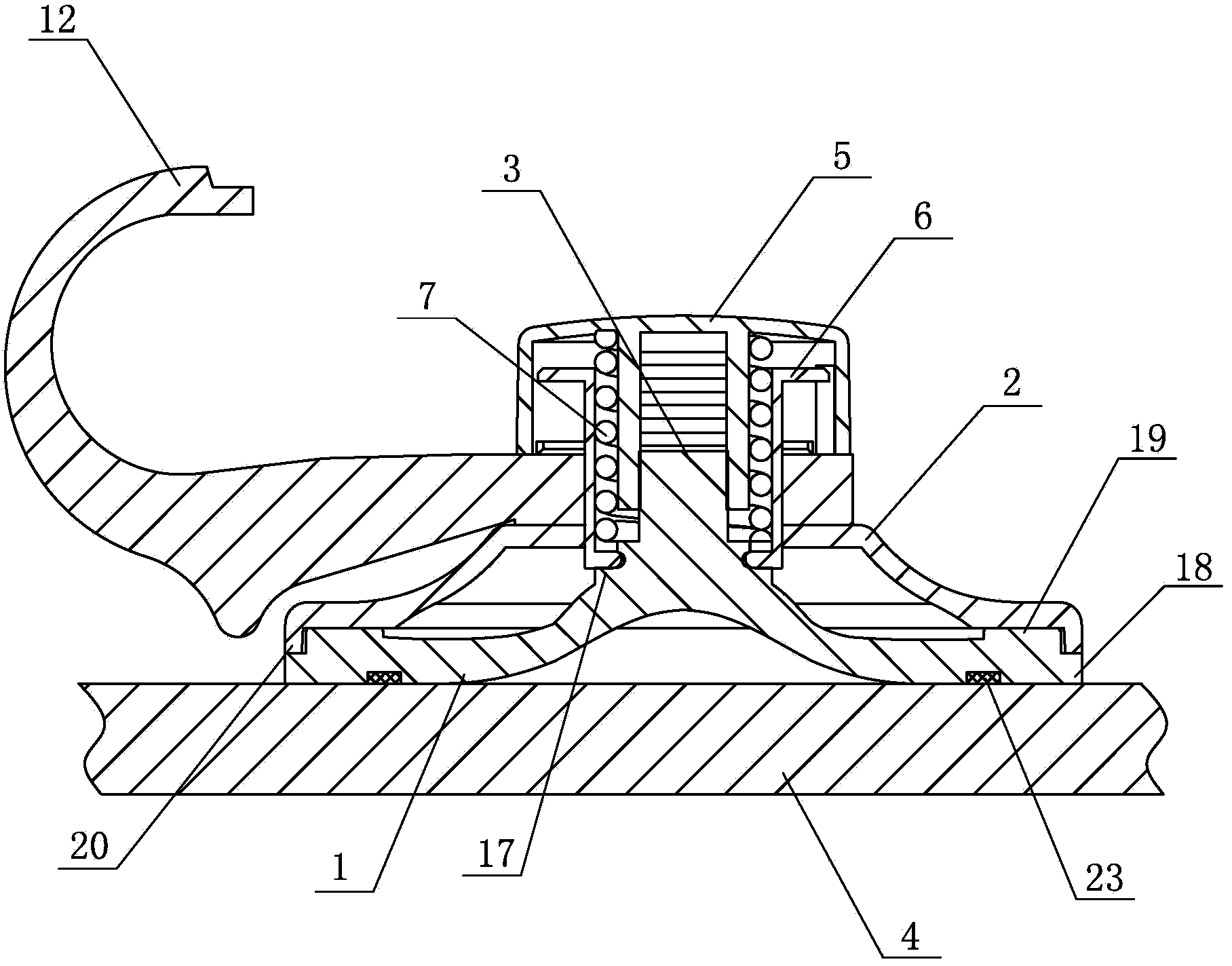

Sucker and sucking method thereof

InactiveCN103758848AAvoid installation errorsEasy to installSuction cupsEngineeringInstallation Error

The invention discloses a sucker. The sucker comprises a sucker base made of an elastic material, a sucker cover plate and an elastic pressing part. The sucker cover plate and the elastic pressing part are arranged on the back of the sucker base. The sucker is characterized in that the elastic pressing part comprises an outer cover, an inner cover and a spring, the spring is arranged between the outer cover and the inner cover, a sleeve is arranged inside the outer cover, the sleeve can penetrate the spring and the inner cover to be in threaded connection with a center connecting piece, the outer cover and the inner cover are movably connected, and the bottom of the center connecting piece is connected with the bottom of the inner cover. Mounting error of a consumer can be effectively avoided, firmness and durability of the sucker are improved, and the sucker is human friendly and reusable.

Owner:TECMAGIC TECHMOLOGIES JIANGYIN CO LTD

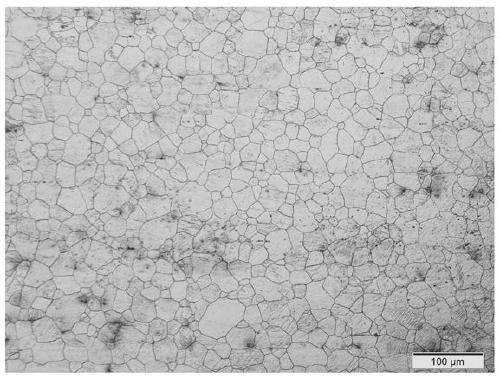

Method for quickly preparing magnesium alloy fine crystalline wire and superfine magnesium alloy wire based on drawing process

ActiveCN110193525AIncrease the degree of deformationReduce the temperatureNonferrous metalRoom temperature

The invention discloses a method for quickly preparing a magnesium alloy fine crystalline wire and a superfine magnesium alloy wire based on a drawing process, belongs to the field of nonferrous metalplastic forming, and aims to solve the technical problem that an existing magnesium alloy drawing process is liable to have wire breakage, and is not ideal in crystalline grain size. The method for preparing the magnesium alloy fine crystalline wire comprises the following steps: thermally extruding magnesium alloy cast ingots into bars with diameters Phi being 6mm-10mm, and annealing the bars; II, performing thermal drawing on the bars, and immediately water-cooling the bars to the room temperature after each-pass thermal drawing; III, performing continuous cold-drawing on the bars, and air-cooling the bars to the room temperature; and IV, repeating operations of steps II to III until the diameters Phi of the bars are 1.0mm-1.5mm. The method for preparing the superfine magnesium alloy wire comprises the following steps: step 1, performing continuous cold-drawing on the magnesium alloy fine crystalline wire until the diameter Phi of the wire is lower than 1.0 mm, and air-cooling the wire to the room temperature after annealing; and step 2, repeating the operation of step 1 until the diameter Phi of the wire is 0.10mm. The Phi 0.10mm wire prepared by the method has an average crystalline grain size of 1[mu]m.

Owner:HARBIN UNIV OF SCI & TECH

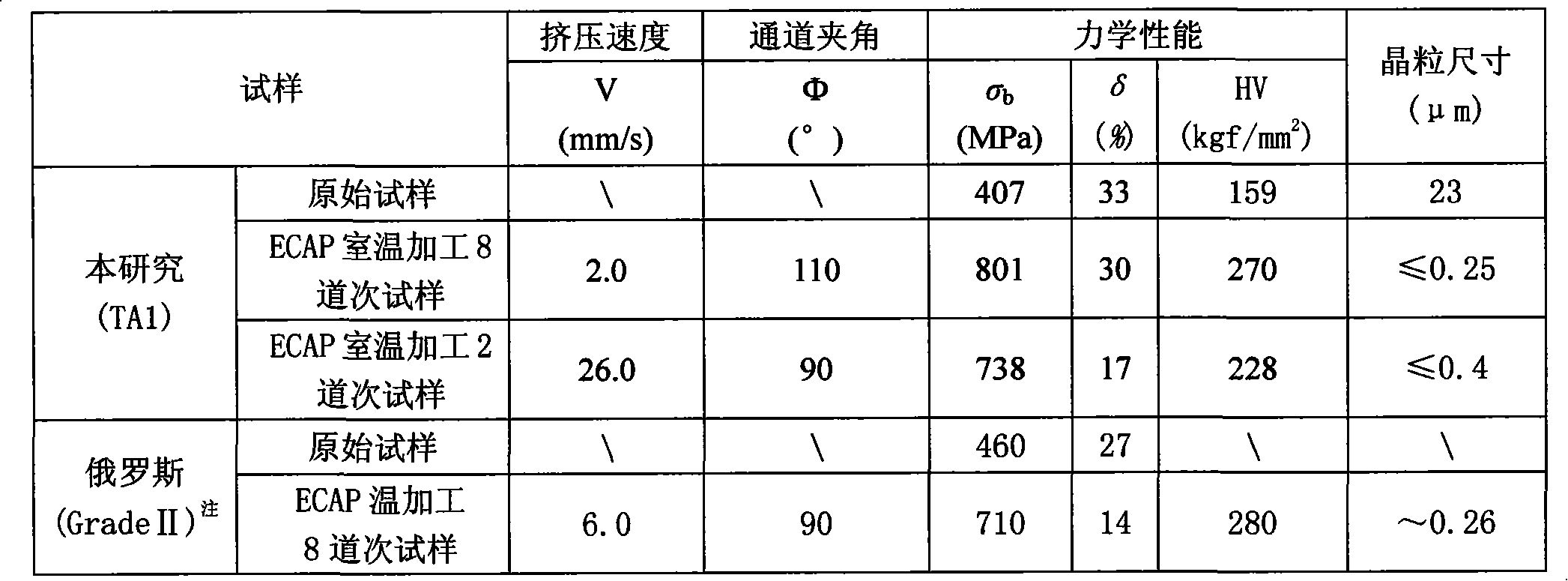

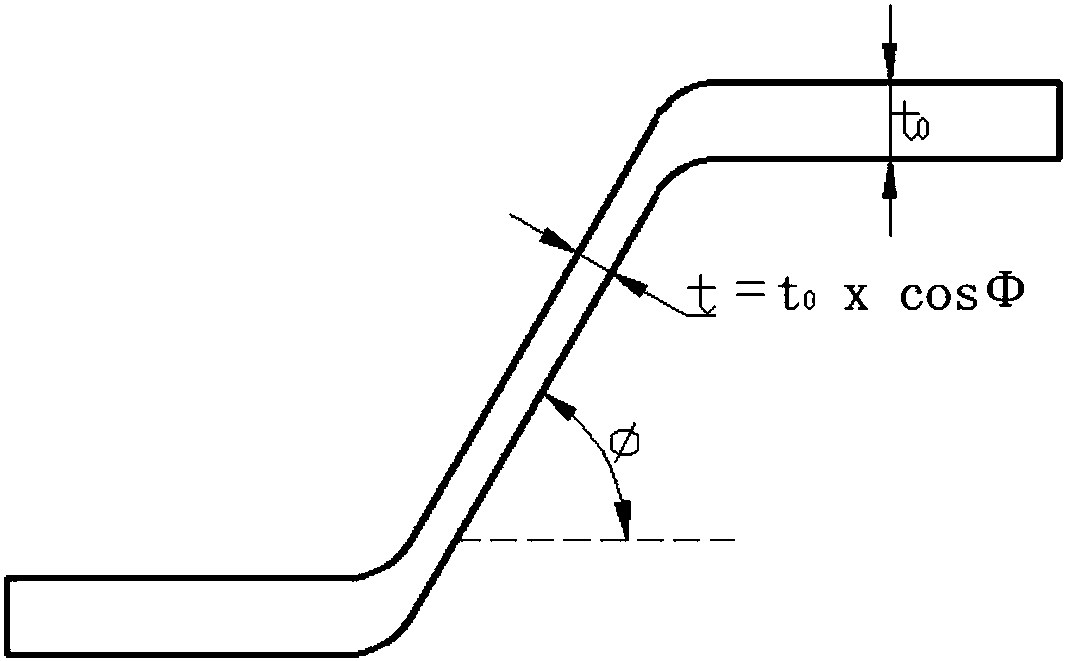

Preparation method for difficult-to-deformation metal block material room temperature equal-diameter bending passage deformation

The invention discloses a preparation method for difficult-to-deformation metal block material room temperature equal-diameter bending passage deformation; the method selects industrially pure titanium hot-rolling sheet material as raw material; after annealing, the industrially pure titanium hot-rolling sheet material is cut into blank; and then surface finish treatment is carried out on the blank, the included angle of the blank is phi=90 degrees to 110 degrees with the passage, and the inner surface of the cavity of a mould, exterior round corner of which is psi=10 degrees to 45 degrees, is coated with compound lubricant comprising molybdenum disulfide and graphite; and finally ECAP deformation is carried out in the room temperature. The invention can increase the room temperature intensity of the pure titanium and the comprehensive mechanical property thereof; in the preparation process, the lesser deformation passage number can be utilized for generating obvious detailing effect, thus obtaining high-strength industrial pure titanium by utilizing lesser passage number, reducing the treatment cost of the pure titanium and increasing rate of finished products.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

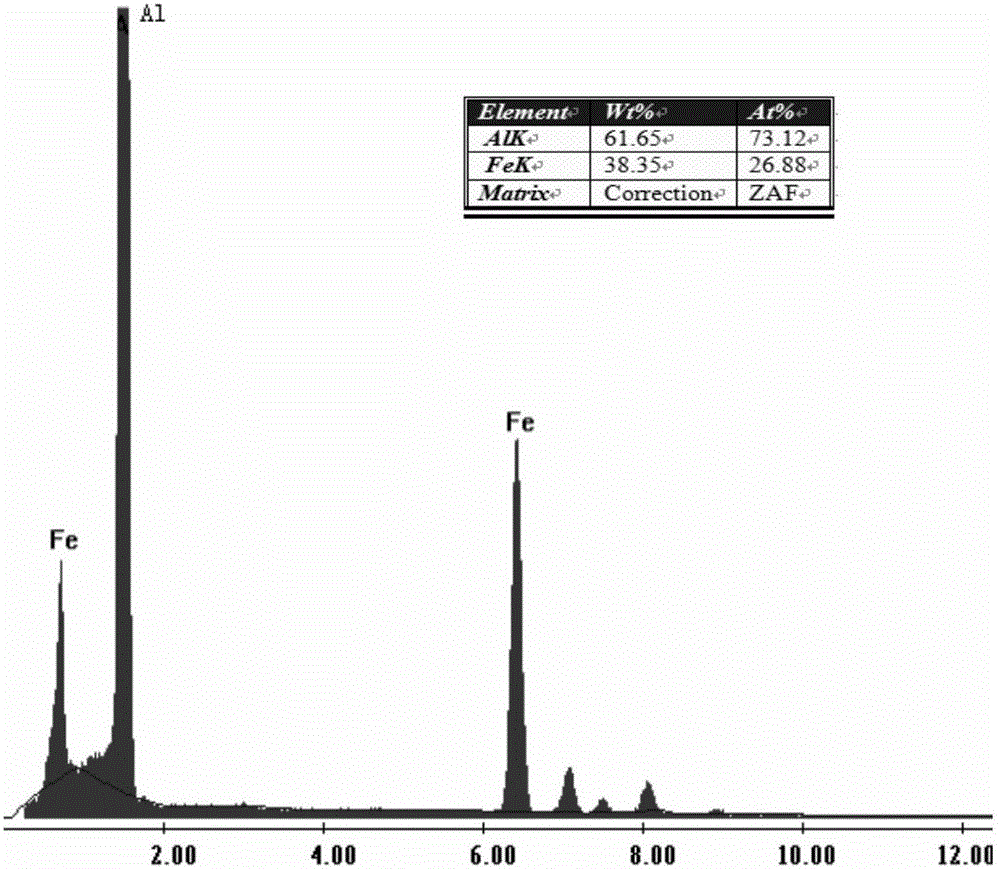

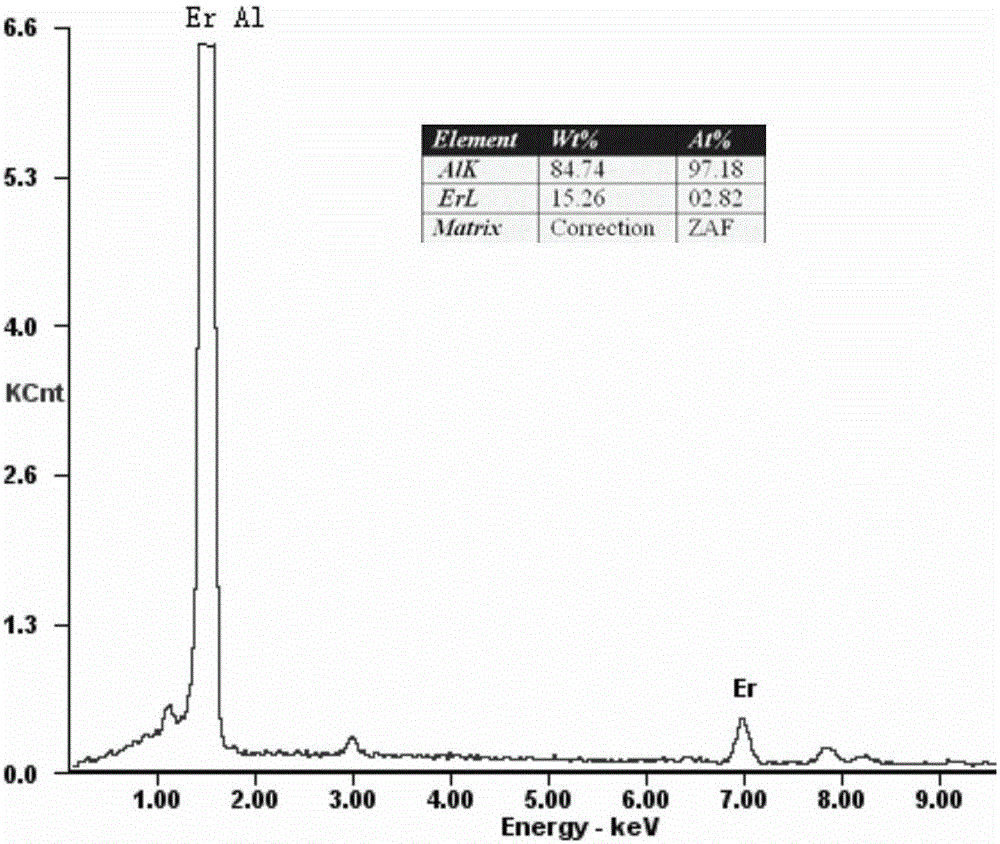

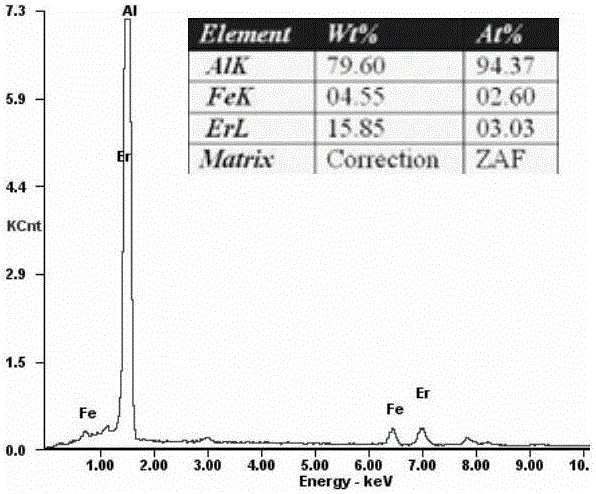

Light high-conductivity and heat-resistant aluminum conductor and preparation method thereof

ActiveCN105734353AImprove conductivityOo fullConductive materialMetal/alloy conductorsElectricityHeat resistance

The invention discloses a light high-conductivity and heat-resistant aluminum conductor and a preparation method thereof. The aluminum conductor is composed of, by weight, 0.035-0.06% of B, 0.1-0.2% of Zr, 0.1-0.3% of Er, inevitable impurities and the balance Al. The technological process comprises the steps of smelting, on-the-spot fast component analyzing, refining, rapid cooling casting, blank annealing, extruding and drawing. The added B element has the refining and modifying effects and mainly has the effect of promoting supersaturated solid solutions containing Zr and Er to separate out Al3(Er and Zr) ternary composite phases; the Al3(Er and Zr) composite phases are nano particles which are coherent with a matrix and have shell-core structures, are dispersed in the aluminum matrix and can greatly improve the electricity conductivity and the heat resistance of the aluminum conductor; the density of obtained monofilaments is smaller than or equal to 2.71 g / cm<3>, the electricity conductivity of the monofilaments is greater than or equal to 62%IACS, the short-time heat-resistance temperature of the monofilaments reaches 230 DEG C, the long-term heat-resistance temperature of the monofilaments reaches 210 DEG C, and the tensile strength of the monofilaments is greater than or equal to 165 MPa; the economic benefits are remarkable, the energy is greatly saved, and the environmental friendliness is high.

Owner:CENT SOUTH UNIV

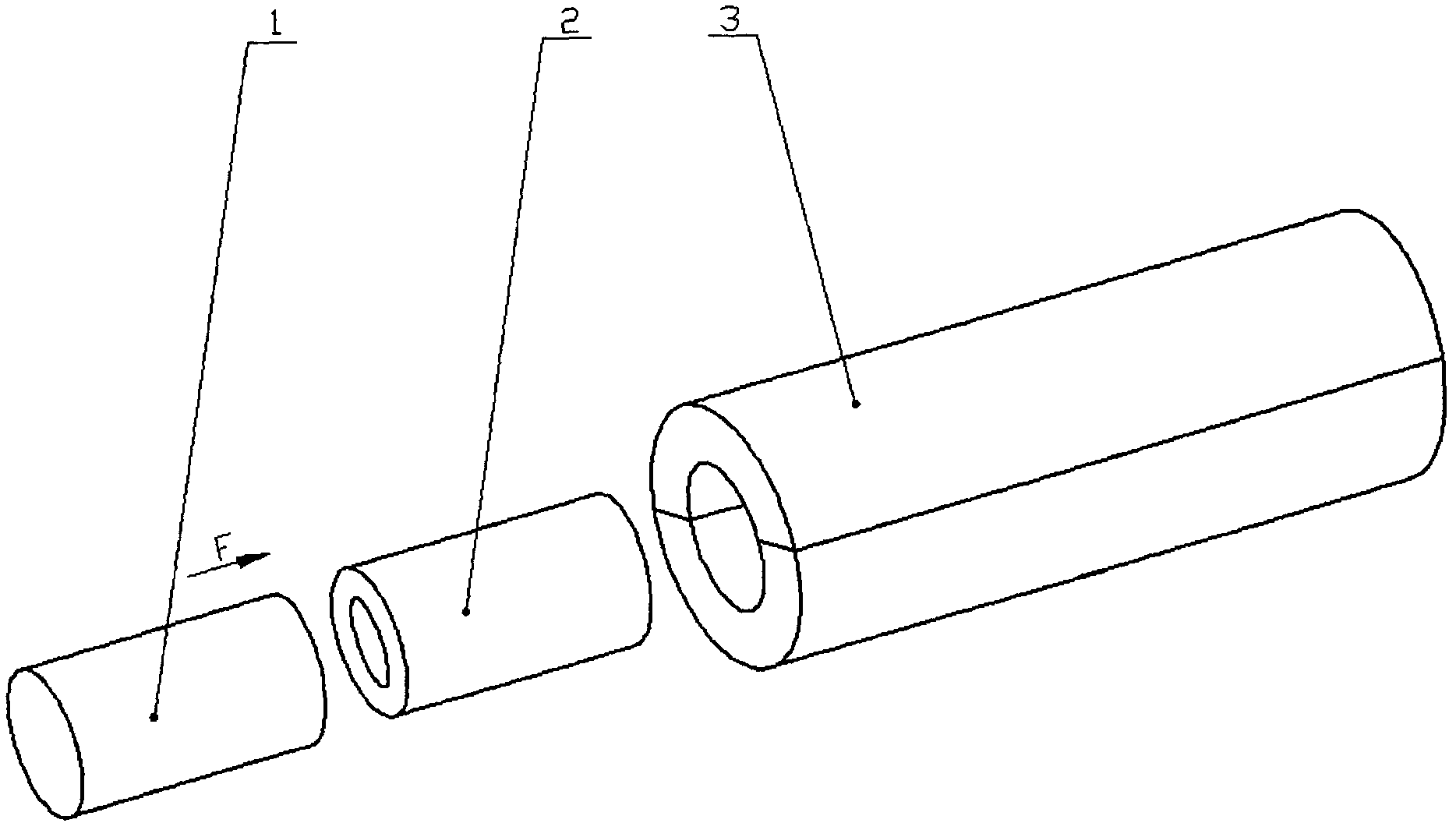

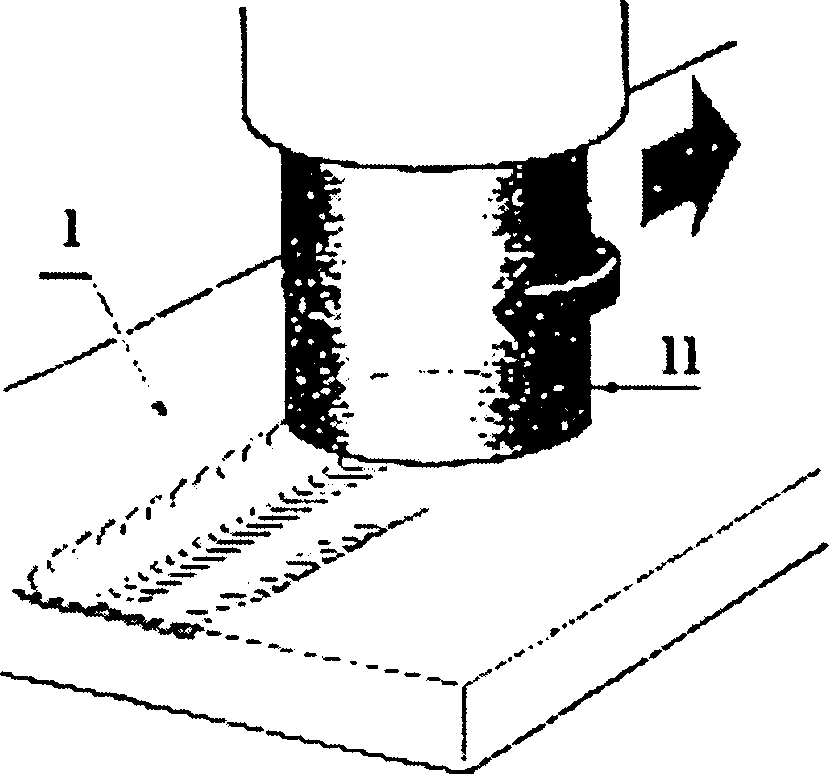

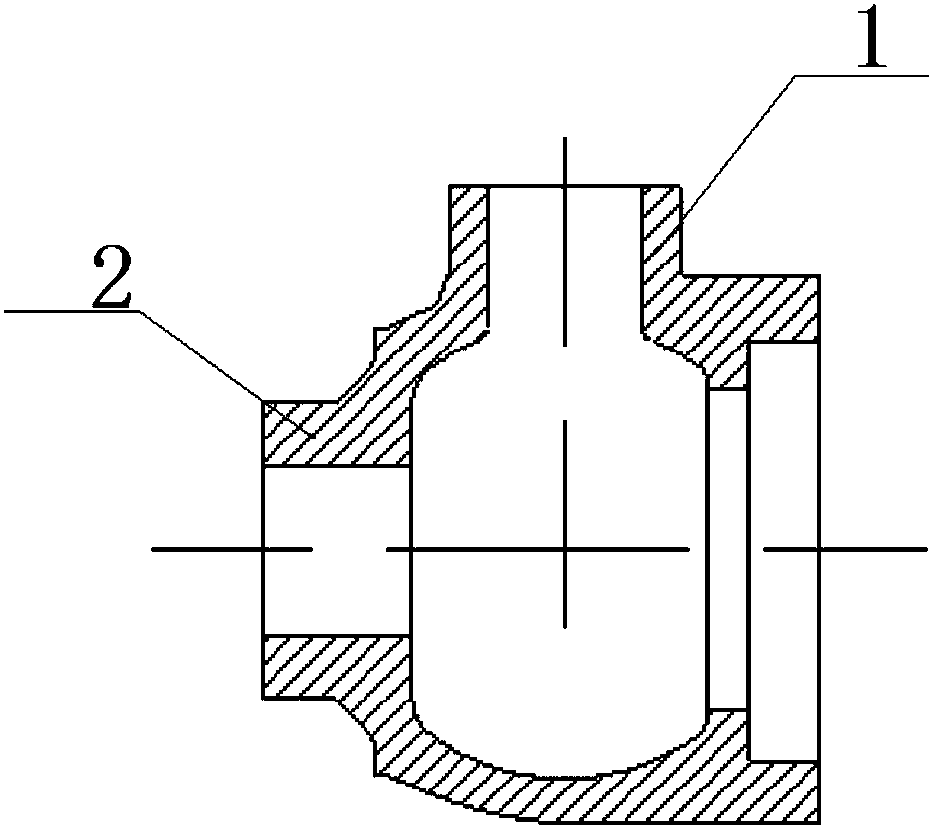

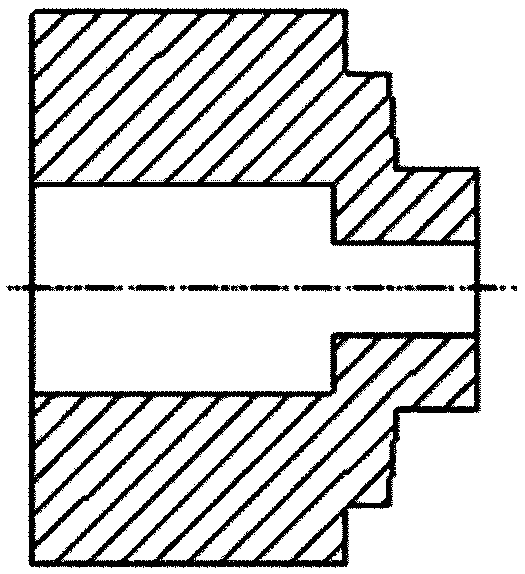

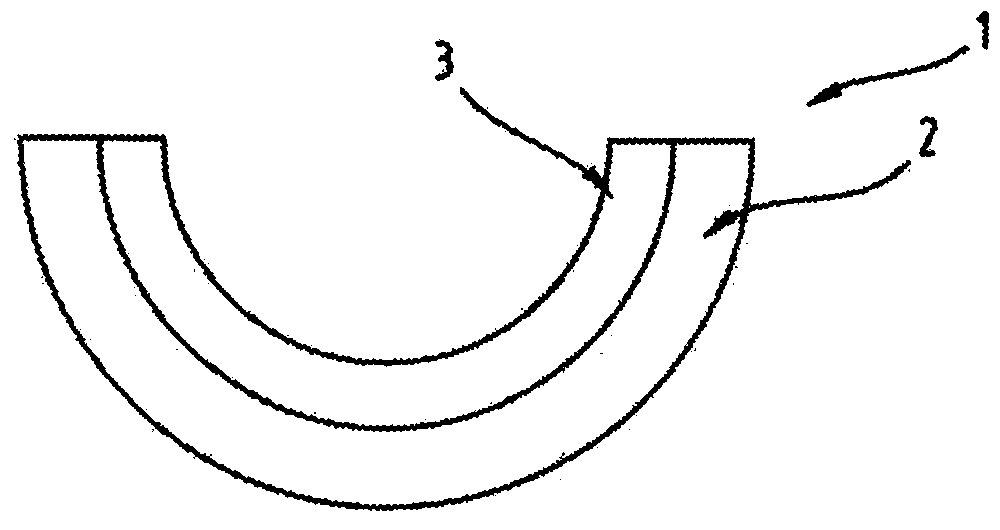

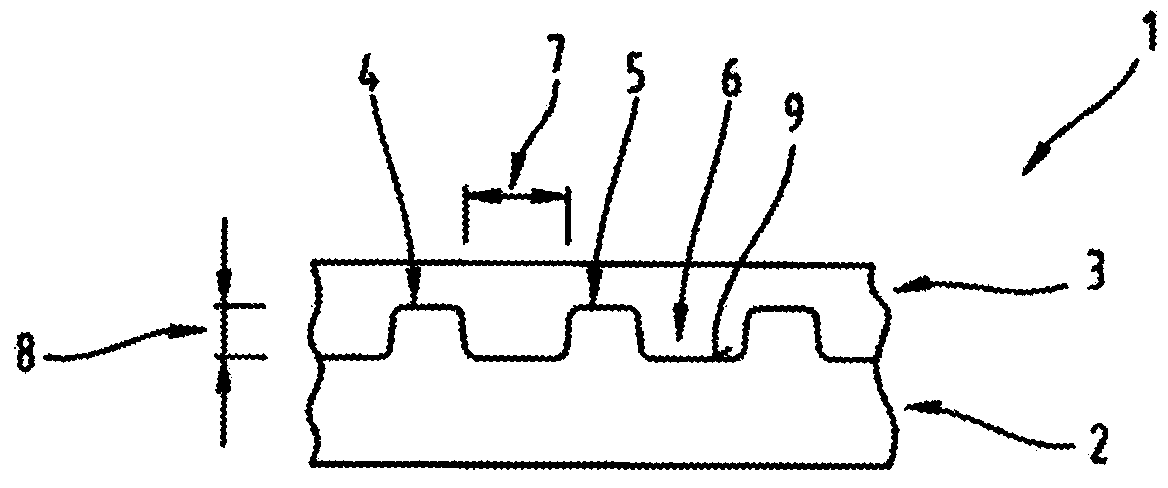

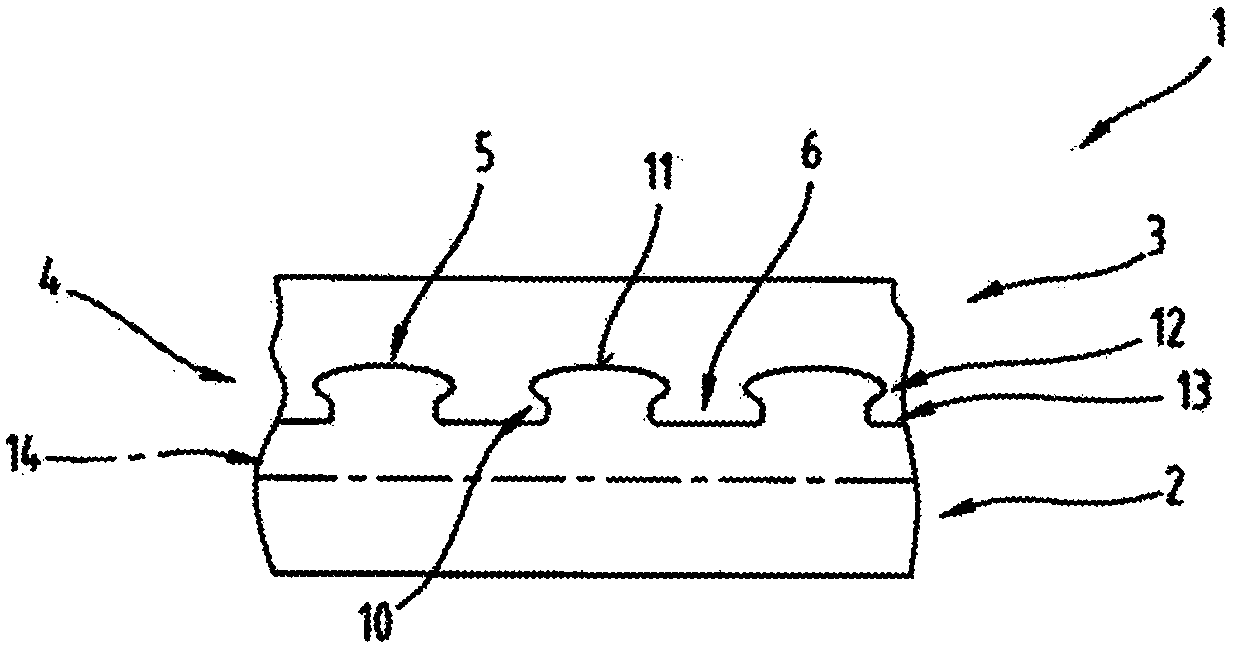

Method for producing sliding bearing, and sliding bearing

The invention relates to a method for producing a sliding bearing (1) comprising a supporting layer (2) and a sliding bearing layer (3), wherein the supporting layer (2) is connected to the sliding bearing layer (3) by way of roll bonding, and wherein prior to the roll bonding a surface structuring (4) is produced on the surface of the supporting layer (2) and the sliding bearing layer (3) is then rolled onto the surface structuring (4).

Owner:MIBA SINTER AUSTRIA

Processing method of refining grains of biphasic titanium alloy bar

The invention discloses a processing method of refining grains of a biphasic titanium alloy bar. A preform body of the biphasic titanium alloy bar is rolled, the temperature X of the phase transformation point of the rolled preform body of the biphasic titanium alloy bar is measured, the rolled preform body of the biphasic titanium alloy bar is drawn by three passes, and the biphasic titanium alloy bar with the refined grains is obtained; the drawing temperatures of the three passes are all (X-100) to (X-200) DEG C, and the drawing speeds are all 3-5m / min; and the drawing deformation quantities of the three passes are 4%-8%. Under the total deformation amount of the titanium alloy bar is constant, the drawing process is increased, and the deformation process is increased. On a certain basis, the deformation degree of bar processing can be increased to achieve grain refinement through reasonable processing and distribution. The processing method of the titanium alloy bar with ultra-finegrain suitable for mass production is provided under the premise of small cost increasing.

Owner:西安赛特思迈钛业有限公司

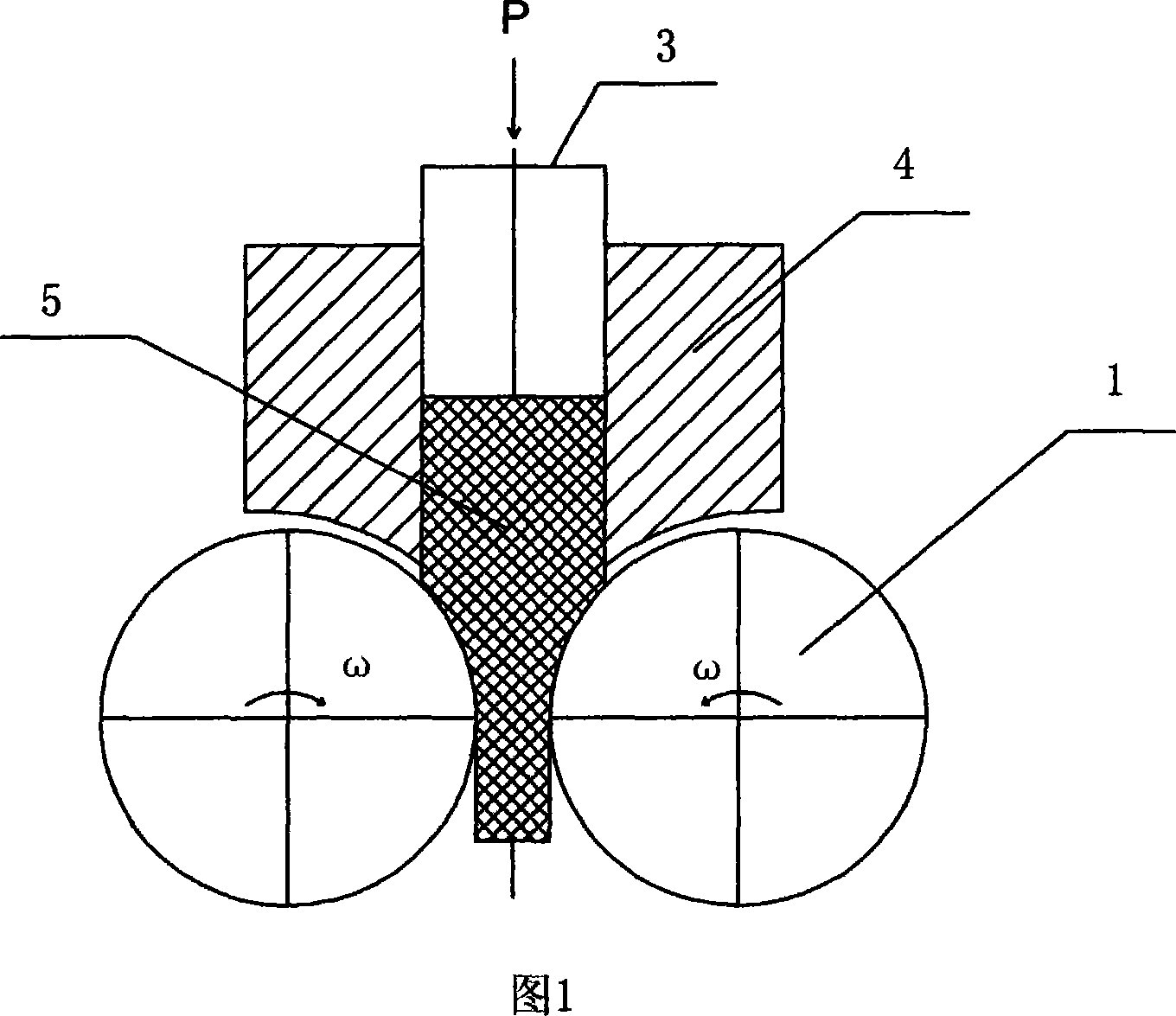

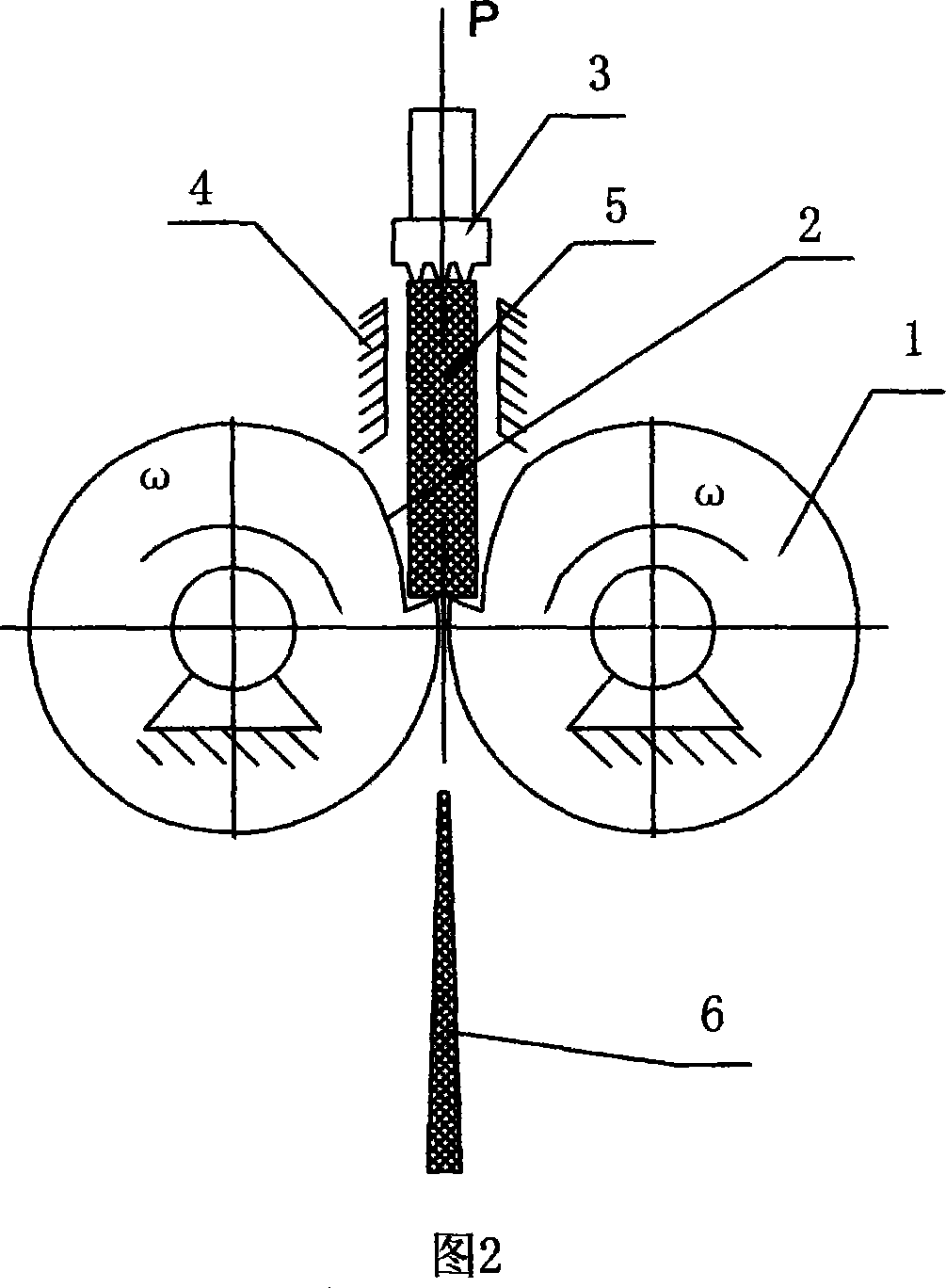

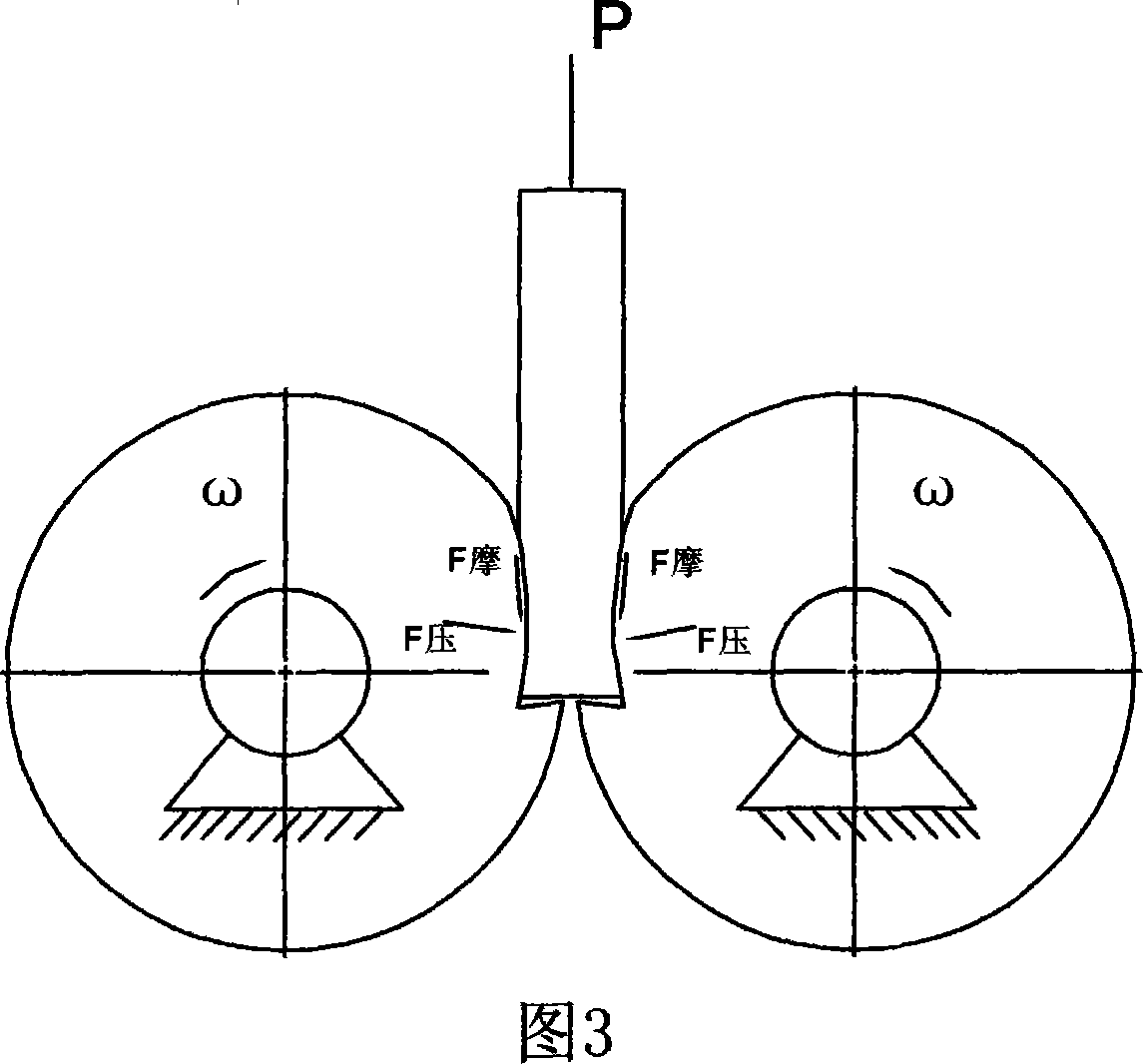

Roller type cavity die extrusion molding method

InactiveCN101062511ASmall tonnageReduce energy consumptionExtrusion diesRams/plungersBending forceFriction force

The invention relates to a roller wheel concave mold compression, using a pair of rolling wheel at the circumference surface of the concave mold cavities, featuring in a set of push rod and compression cylinder. The blank is formed by stuffing the blank into the compression cylinder, pushing the rod to the blank to the rolling wheel concave, with two rolling wheels rotating in the same speed in opposite directions, under the friction on both sides of the blank squeezing the blank to deformation, fostering the flow of the metal, with blank extended in the forwarding, and released out from the space between two rolling wheels. It improves the fluidness of the deformed blank, improved in stress status, forming force, easy to achieve the forming goal, reduced in bended force, improved in mold durability, being able to form in precision.

Owner:ZHONGBEI UNIV

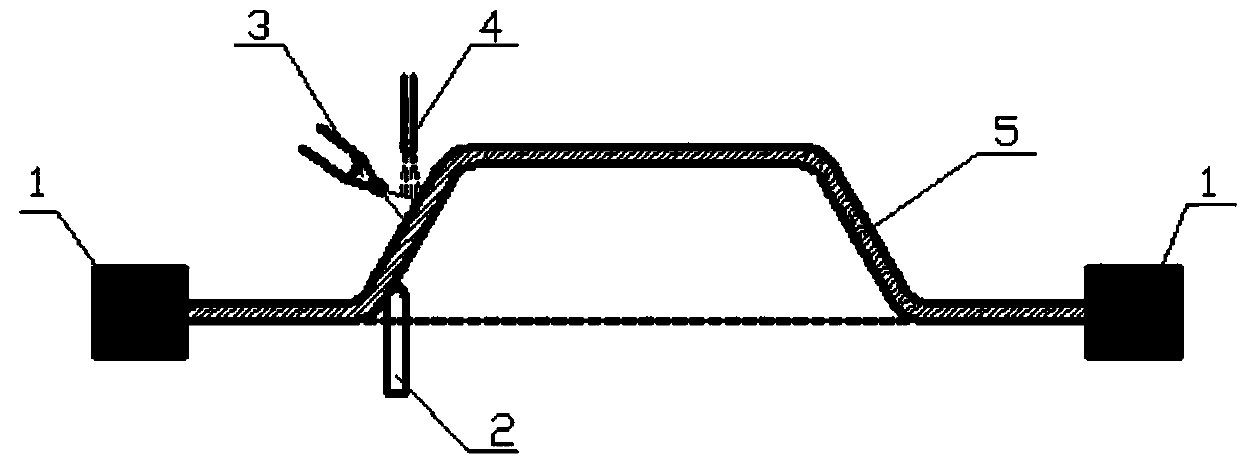

Machining method and device for sheet metal part with variable wall thickness based on 3D printing and incremental forming technology

InactiveCN107737929AMeet wall thickness requirementsHigh forming precisionAdditive manufacturing apparatusIncreasing energy efficiencyLaser beamsPowder Spray

The invention discloses a machining method and device for a sheet metal part with a variable wall thickness based on a 3D printing and incremental forming technology. The machining device comprises anincremental forming chuck (1), an incremental forming tool head (2), a laser beam (3) and a powder spraying head (4); the powder spraying head (4) sprays powder on the place where needs to increase the wall thickness or is prone to becoming thinner in the forming process on a sheet; the laser beam (3) is used for making the powder to clad on the surface of the sheet, the material thickness is increased, and for the area where thinning is not required for the part or the wall thickness does not need to be increased, powder feeding operation is not conducted; meanwhile, the laser beam (3) is also used for heating the surface of a material, so that plastic forming is facilitated; and the material is formed by the incremental forming tool head through the heating area. According to the methodcombining a laser synchronous powder feeding 3D printing technology with the incremental forming technology, the problems that the side wall becomes thin during incremental forming of the sheet, andthe thickness cannot be controlled are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com