Anticorrosive and wear-resistant low density composite structure coating on surface of magnesium alloy, and production method thereof

An anti-corrosion and wear-resistant composite structure technology, applied in the field of material engineering, can solve problems such as poor wear resistance, harmful emissions, and low hardness of dense coatings, and achieve the effect of improving corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A method for preparing a corrosion-resistant and wear-resistant low-density composite structural coating on the surface of a magnesium alloy disclosed by the invention comprises the following steps:

[0039] First, under the synergistic effect of powder preheating and higher cold spraying parameters or by introducing in-situ micro-forging effect during the spraying process, high-density pure aluminum is prepared on the surface of magnesium alloy substrates using low-cost nitrogen or compressed air. or aluminum alloy coating;

[0040] Secondly, the high-density pure aluminum or aluminum alloy coating on the surface of the magnesium alloy substrate is subjected to anodic oxidation treatment or micro-arc oxidation treatment, and part of the pure aluminum or aluminum alloy coating is converted into a high-hardness aluminum oxide coating. In this way, a double-layer composite structure coating with a high-density pure aluminum or aluminum alloy coating as the bottom layer an...

Embodiment 1

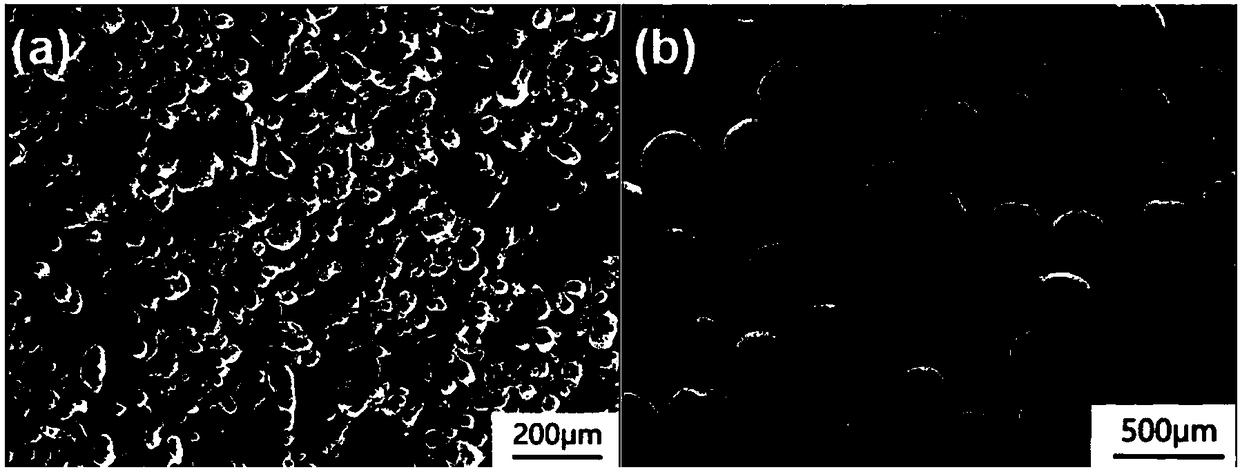

[0043] Pure aluminum with a particle size of 5-35 μm is used as spray powder, and 410 martensitic stainless steel particles with a particle size of 150-250 μm are used as micro-forged particles, and their shapes are as follows: figure 1 Shown in (a) and (b). During the spraying process, the pure aluminum powder and the micro-forged particles are sent to the cold spray gun and the micro-forged spray gun at a volumetric powder feed rate of 1:1, and the outlet of the spray gun is adjusted so that the two powder streams cover the same area.

[0044] Before spraying, use 40# brown corundum sand for the AZ31B magnesium alloy substrate, and perform sandblasting roughening on the surface of the substrate under the condition of compressed air pressure of 0.6MPa, so that the roughness can reach Ra 1.0-4.0.

[0045] With nitrogen as the accelerating gas, the gas temperature is 240°C, the main gas pressure is 2.0MPa, the powder feeding rate is 2.6g / min, the spray gun moving speed is 40mm / ...

Embodiment 2

[0051] Use 6061 aluminum alloy powder with a particle size of 20-65 μm as the spray powder, such as Figure 6 shown. Before spraying, use 40# brown corundum sand for the AZ91D magnesium alloy substrate, and perform sandblasting roughening on the surface of the substrate under the condition of compressed air pressure of 0.6MPa, so that the roughness can reach Ra 5.7 microns.

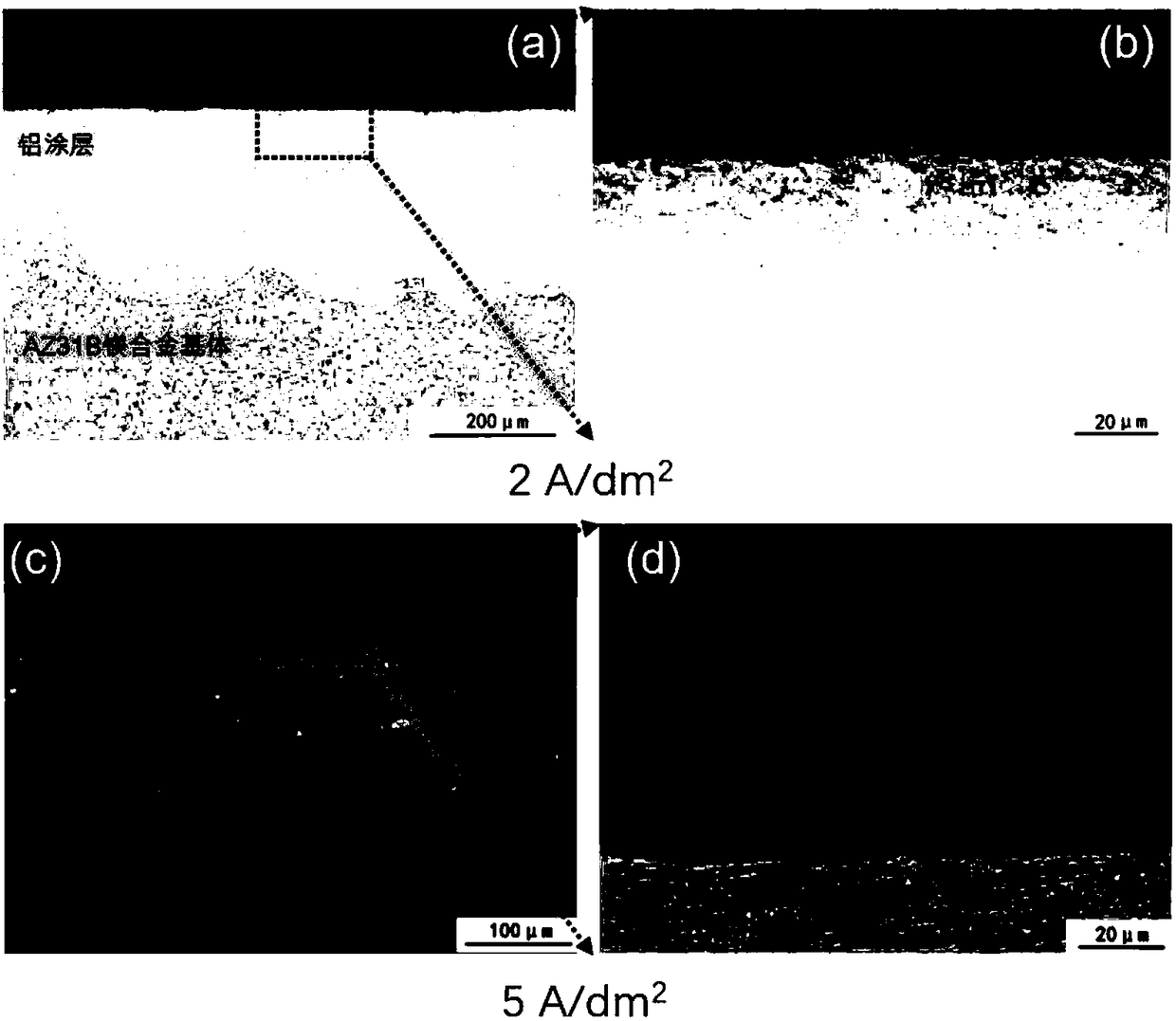

[0052] Nitrogen is used as the accelerating gas, the gas temperature is 460°C, and the main gas pressure is 5MPa. A cold spray gun with a 250mm powder preheating section at the rear end of the spray gun is used to preheat the powder to above 350°C at a relatively low gas velocity. The powder feeding rate is 30g / min, the spray gun moving speed is 200mm / s, and the spraying distance is 20mm, under the parameter conditions, a high-density 6061 aluminum alloy coating with a thickness of about 400μm is deposited. Use a sulfuric acid concentration of 180g / L and a current density of 2 and 5A / dm 2 , the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com