High-strength corrosion-resistant steel bar prepared from vanadium-nitrogen alloy and preparation method of high-strength corrosion-resistant steel bar

A vanadium-nitrogen alloy and high-strength technology, which is applied in the field of vanadium-nitrogen alloy preparation of high-strength corrosion-resistant steel bars and its preparation, can solve the problems of limiting the practical application of corrosion-resistant steel bars, economic losses, and undetermined anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

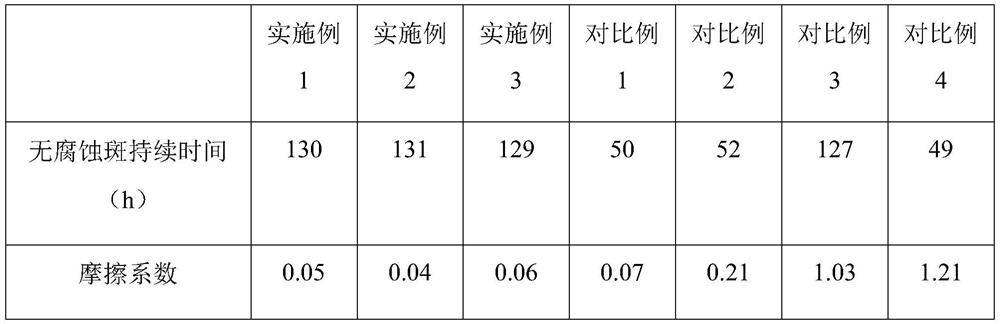

Examples

Embodiment 1

[0029] A high-strength corrosion-resistant steel bar prepared by a vanadium-nitrogen alloy, mainly including: 100 parts of pig iron, 50 parts of lime, 25 parts of dolomite, 2 parts of magnesite ball slagging, 40 parts of composite alloy, and 2 parts of deoxidized agent, 1 part molten steel covering agent.

[0030] A preparation method for preparing high-strength corrosion-resistant steel bars by vanadium-nitrogen alloys, the preparation method for preparing high-strength corrosion-resistant steel bars by vanadium-nitrogen alloys mainly includes the following preparation steps:

[0031] (1) Add pig iron and molten iron into the converter according to the mass ratio of 1:18, raise the temperature to 1480°C, keep warm for 40 minutes, blowing, and then add lime, dolomite and magnesite ball slag, lime according to the mass ratio of 1:0.5:0.04 The mass ratio to pig iron is 1:0.5, the tapping temperature is 1670°C, the whole process of tapping argon is adopted, the flow rate of argon...

Embodiment 2

[0036] A high-strength corrosion-resistant steel bar prepared by a vanadium-nitrogen alloy, mainly including: 150 parts of pig iron, 75 parts of lime, 43 parts of dolomite, 5 parts of magnesite slag, 70 parts of composite alloy, and 5 parts of deoxidized Agent, 3 parts of molten steel covering agent.

[0037] A preparation method for preparing high-strength corrosion-resistant steel bars by vanadium-nitrogen alloys, the preparation method for preparing high-strength corrosion-resistant steel bars by vanadium-nitrogen alloys mainly includes the following preparation steps:

[0038] (1) Add pig iron and molten iron into the converter at a mass ratio of 1:18.5, raise the temperature to 1500°C, keep warm for 35 minutes, and then blow it, then add lime, dolomite and magnesite balls to make slag and lime at a mass ratio of 1:0.573:0.0667 The mass ratio to pig iron is 1:0.5, the tapping temperature is 1675°C, the whole process of bottom blowing argon is adopted in the tapping process...

Embodiment 3

[0043] A high-strength corrosion-resistant steel bar prepared by a vanadium-nitrogen alloy, mainly including: 200 parts of pig iron, 100 parts of lime, 60 parts of dolomite, 8 parts of magnesite slag, 100 parts of composite alloy, and 8 parts of deoxidized agent, 4 parts of molten steel covering agent.

[0044] A preparation method for preparing high-strength corrosion-resistant steel bars by vanadium-nitrogen alloys, the preparation method for preparing high-strength corrosion-resistant steel bars by vanadium-nitrogen alloys mainly includes the following preparation steps:

[0045] (1) Add pig iron and molten iron into the converter at a mass ratio of 1:19, raise the temperature to 1520°C, keep it warm for 30 minutes, blow it, and then add lime, dolomite and magnesite ball slag, lime at a mass ratio of 1:0.6:0.08 The mass ratio to pig iron is 1:0.5, the tapping temperature is 1680°C, the whole process of bottom blowing argon is adopted in the tapping process, the argon flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com