Anti-corrosion and anti-rust treatment process and anti-corrosion and anti-rust coating on iron-based material

An iron-based material, anti-corrosion and anti-rust technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of non-compliance with national economic development requirements, toxic and harmful gas emissions, inconvenient promotion and application, etc. , to achieve the effect of easy promotion and application, low input cost, easy implementation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

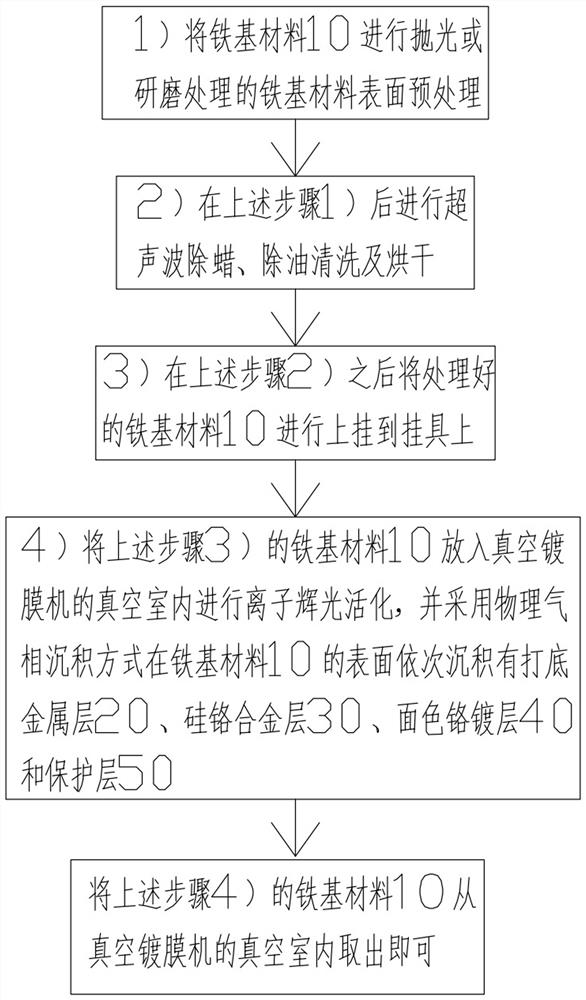

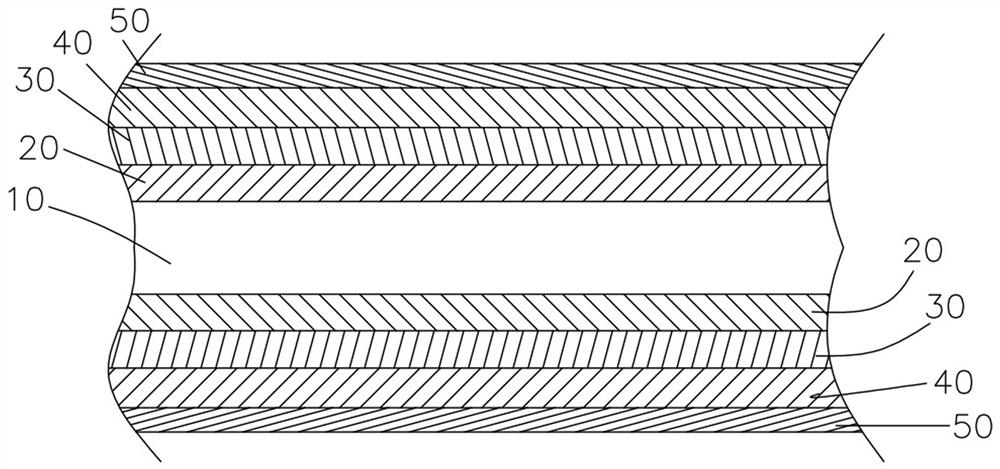

[0050] An anti-corrosion and anti-rust treatment process on an iron-based material, wherein the iron-based material 10 is aimed at a soldering iron tip, and is characterized in that its preparation method is as follows:

[0051] 1) Grinding the tip of the soldering iron;

[0052] 2) The ground soldering iron tip is ultrasonically dewaxed, degreased, cleaned and dried;

[0053] 3) Hang the pre-treated soldering iron tip on the hanger, which uses a hanging plate (workpiece hanging plate, a hanging plate that can hang the soldering iron tip), by hanging the soldering iron tip in step 2) On the hanging plate, it is beneficial to the uniform vacuum plating of the subsequent process;

[0054] 4) First heat the vacuum chamber of the vacuum coating machine to 120 ° C, and the background vacuum degree reaches 6.0E ~ 3Pa, then put the soldering iron tip into the vacuum chamber of the vacuum coating machine, then close the throttle valve, and start to The vacuum chamber of the vacuum c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com