Patents

Literature

391 results about "Chromium coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

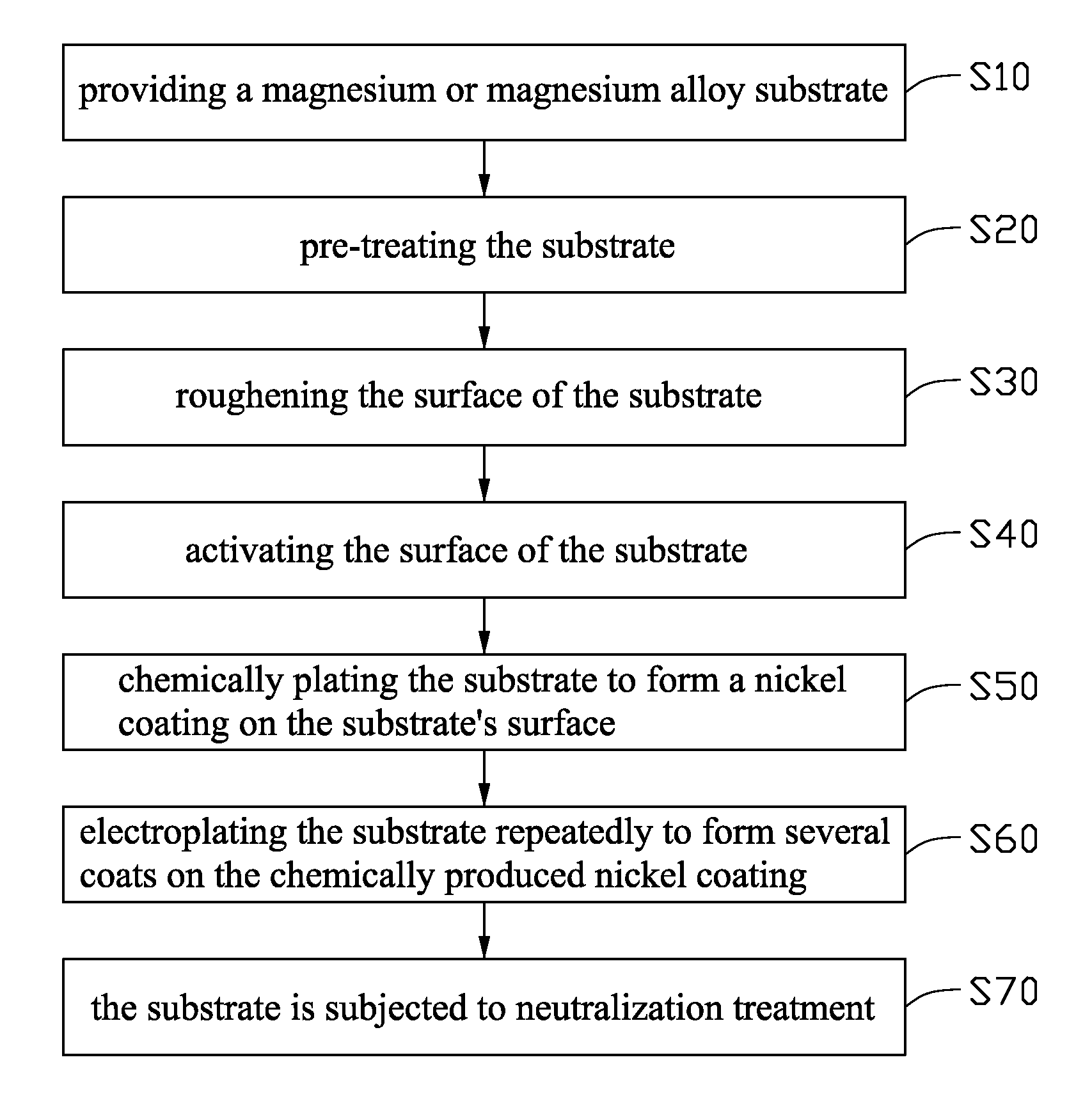

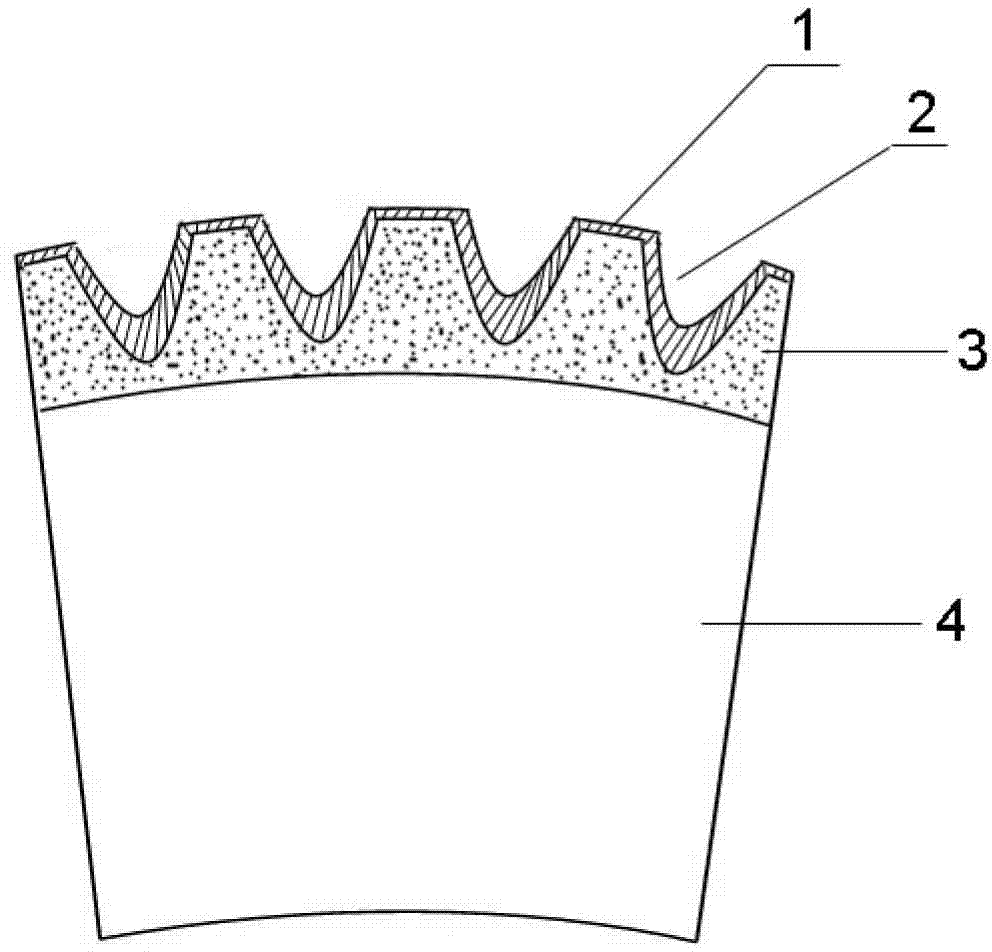

Electroplating method for magnesium and magnesium alloy

An electroplating method for magnesium and magnesium alloys, comprising: providing a magnesium or magnesium alloy substrate and pre-treating it to be cleaned; roughening the surface of the substrate; activating the surface of the substrate; chemically plating the substrate to form a nickel coating on its surface; and electroplating the substrate to form, in order, a first nickel coating, a copper coating, a second nickel coating, and a chromium coating on the chemically produced nickel coating.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

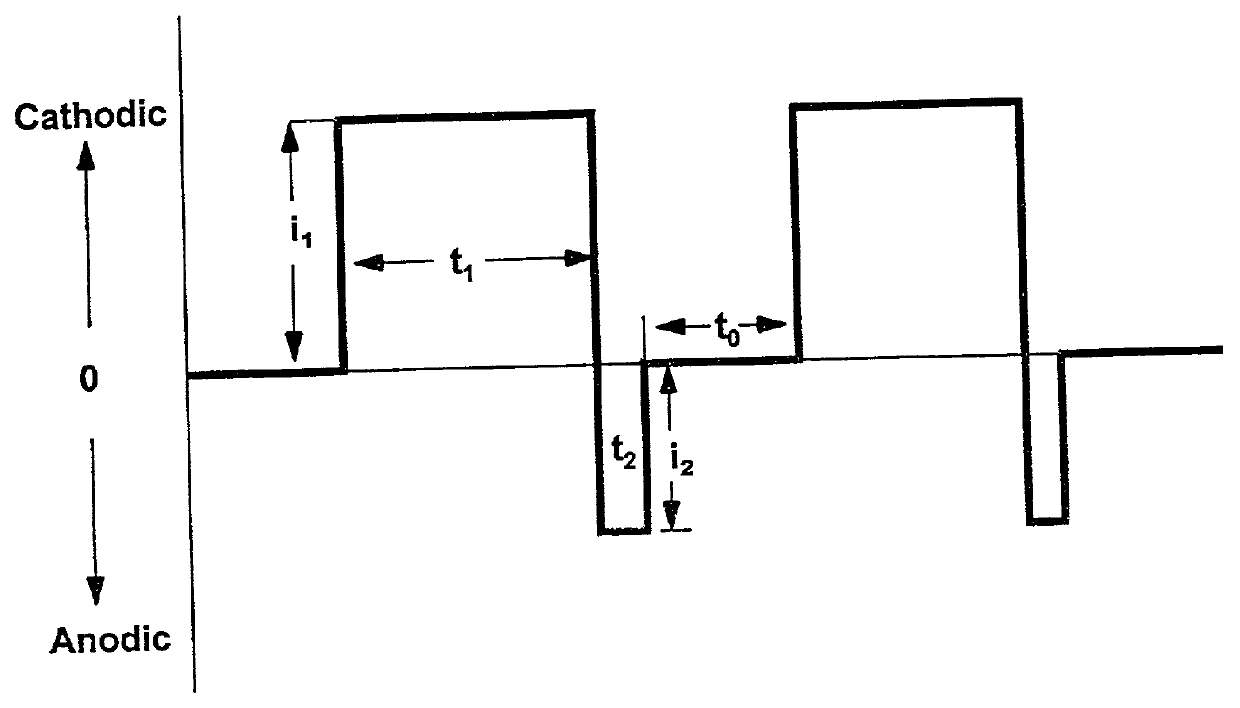

Electroplating of metals using pulsed reverse current for control of hydrogen evolution

Excessive evolution of hydrogen in electrolytic deposition of metals on a cathode substrate can be controlled by using a pulsed reverse current. Reverse current pulses interposed between the forward current pulses consume at least some of the nascent hydrogen and prevent the local pH at the cathode surface from becoming excessively alkaline. Control of hydroxide ion concentration by pulsed reverse current alleviates problems caused by reaction of metal-bearing-ions with hydroxide ions generated near the cathode by evolution of hydrogen. The method is useful in depositing functional chromium coatings on electrically conductive substrates from plating baths comprising aqueous solutions of trivalent chromium salts. In such a method the current comprises forward pulses having a duty cycle of from about 50% to about 90% and reverse pulses having a duty cycle of from about 5% to about 30%, and a frequency of from about 5 Hz to about 700 Hz.

Owner:FARADAY TECH INC

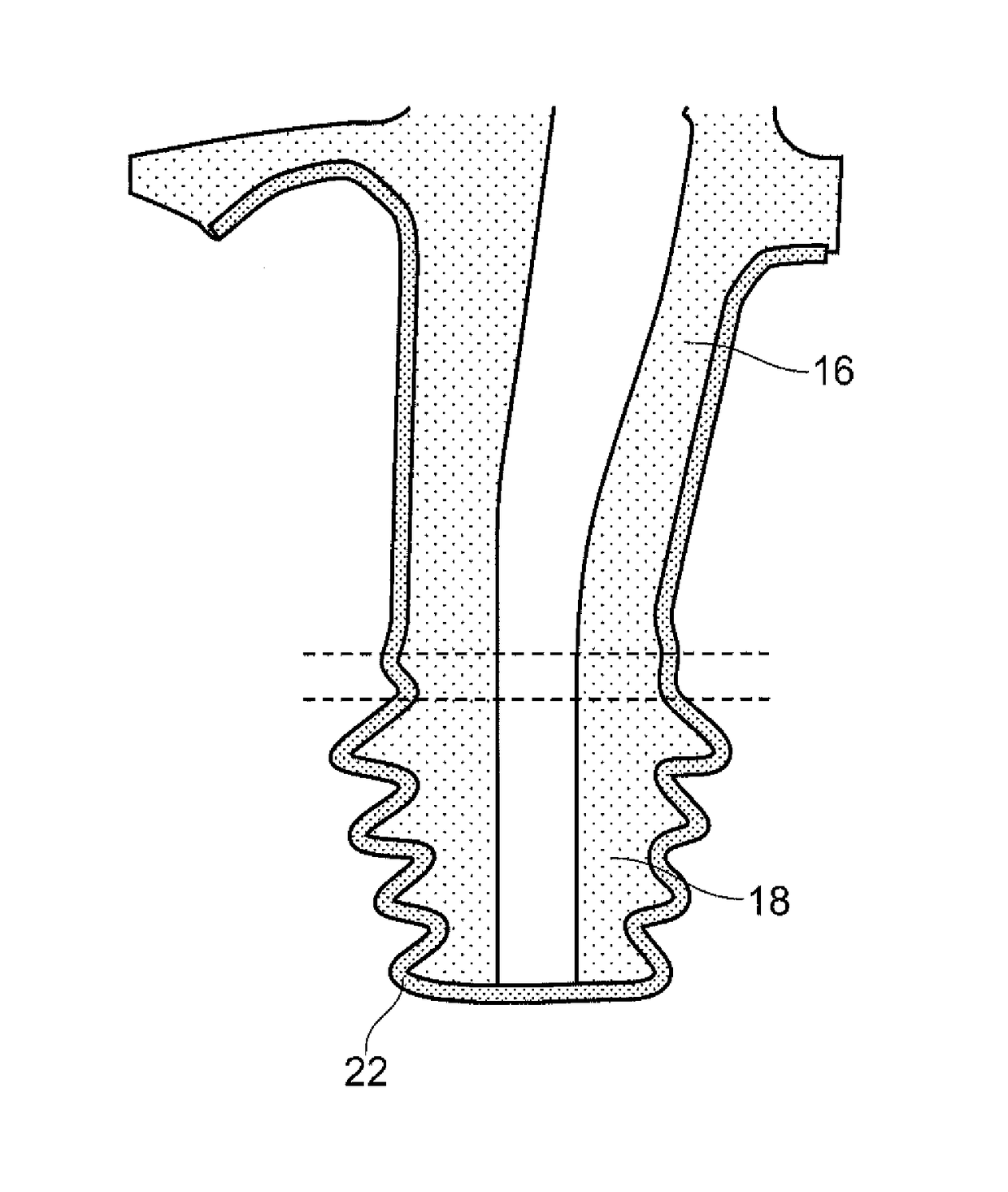

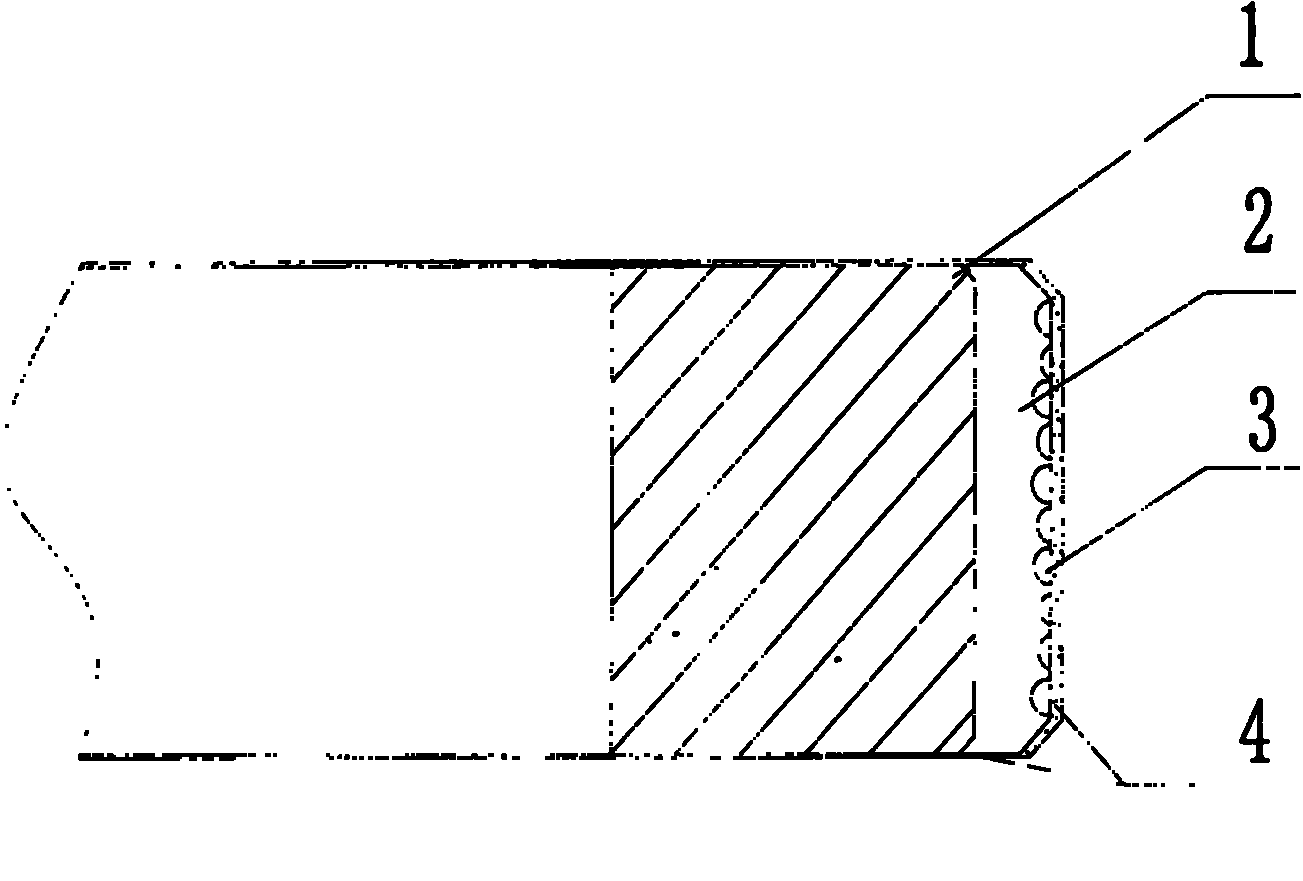

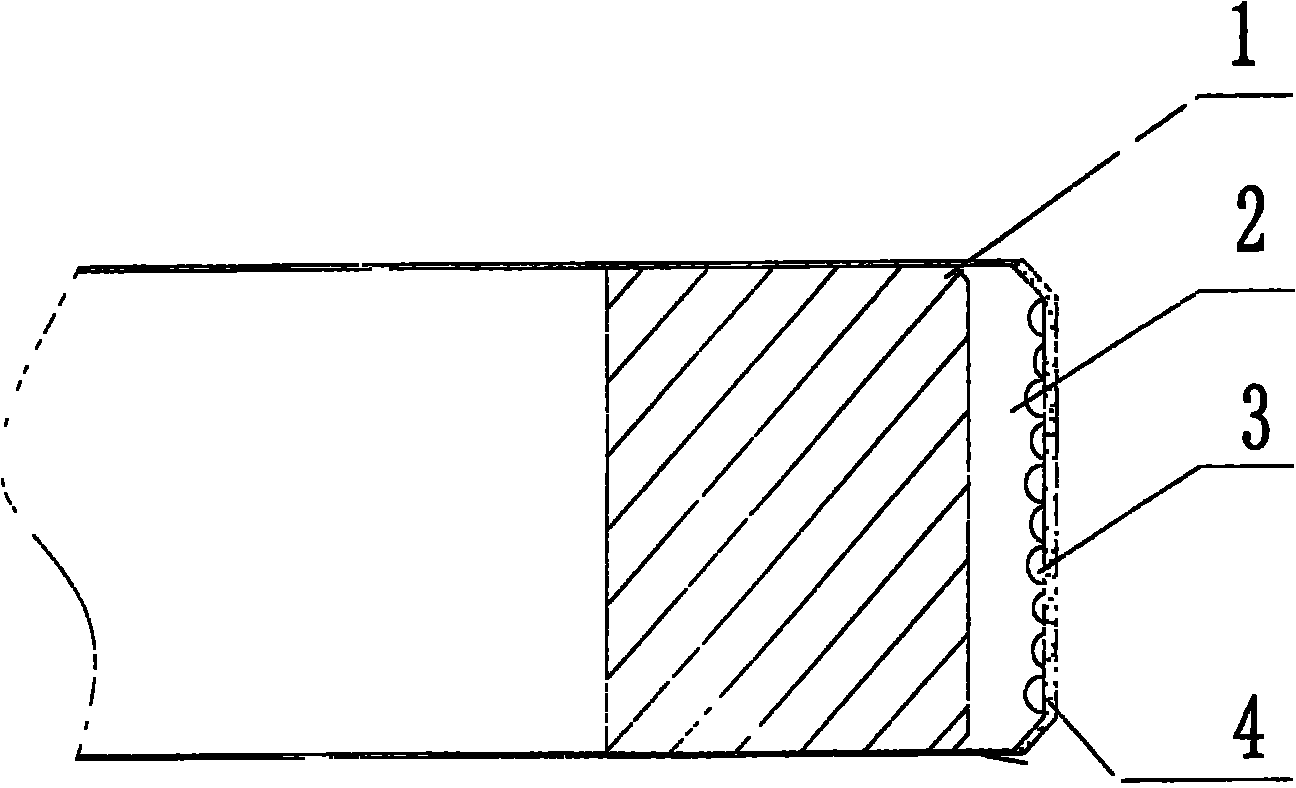

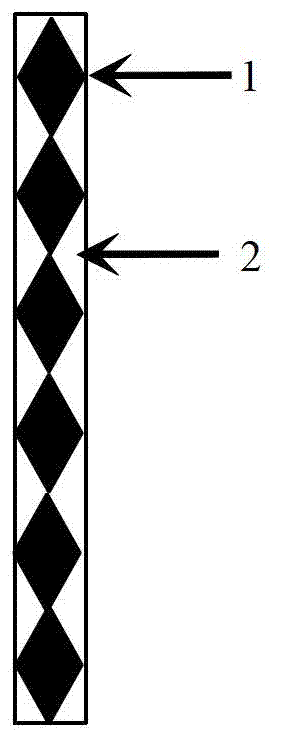

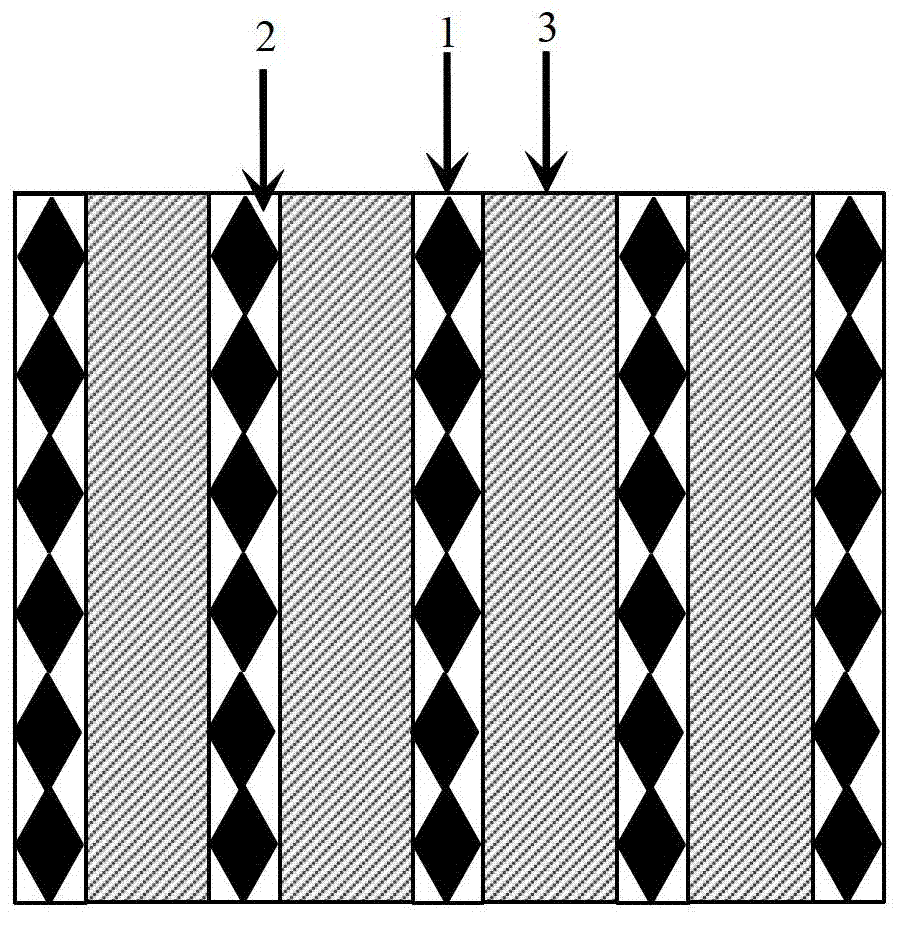

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

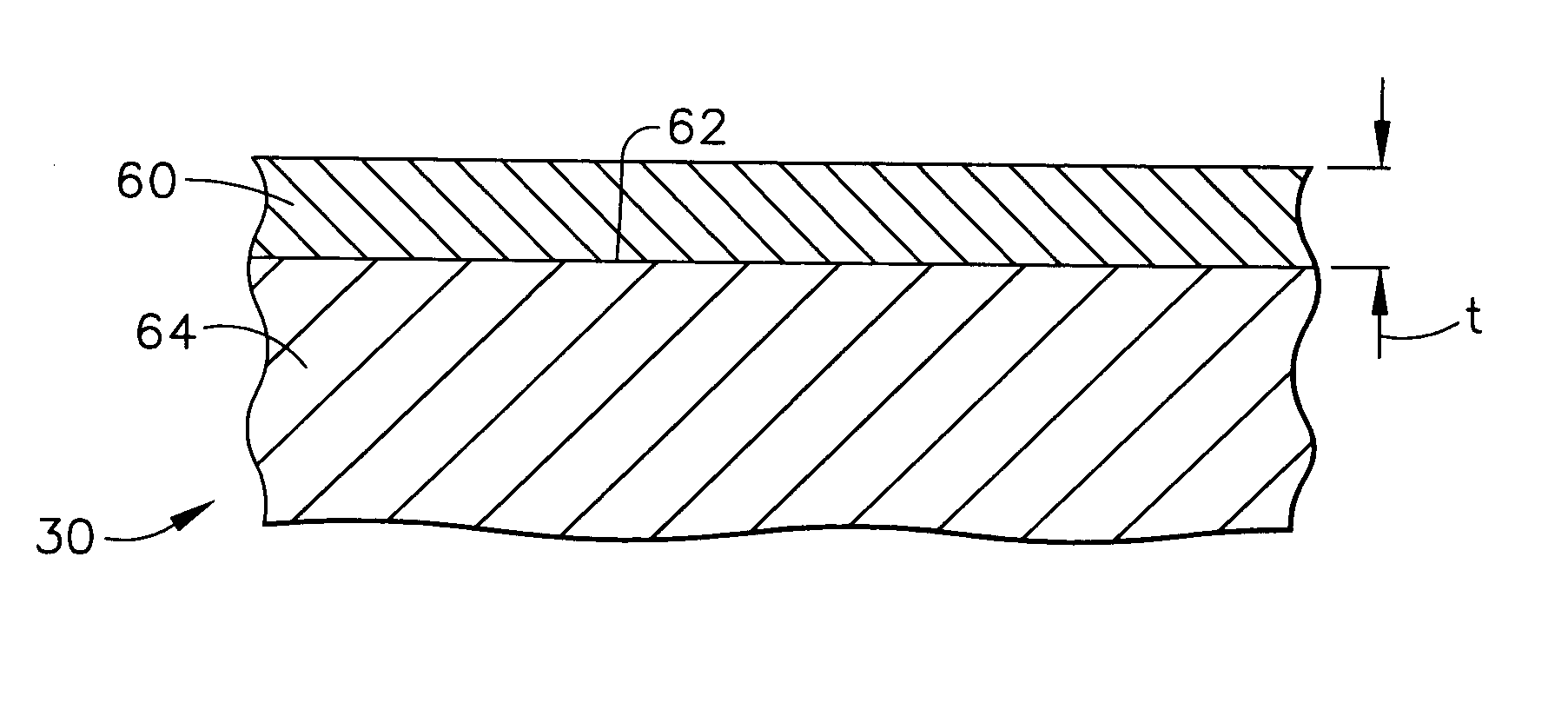

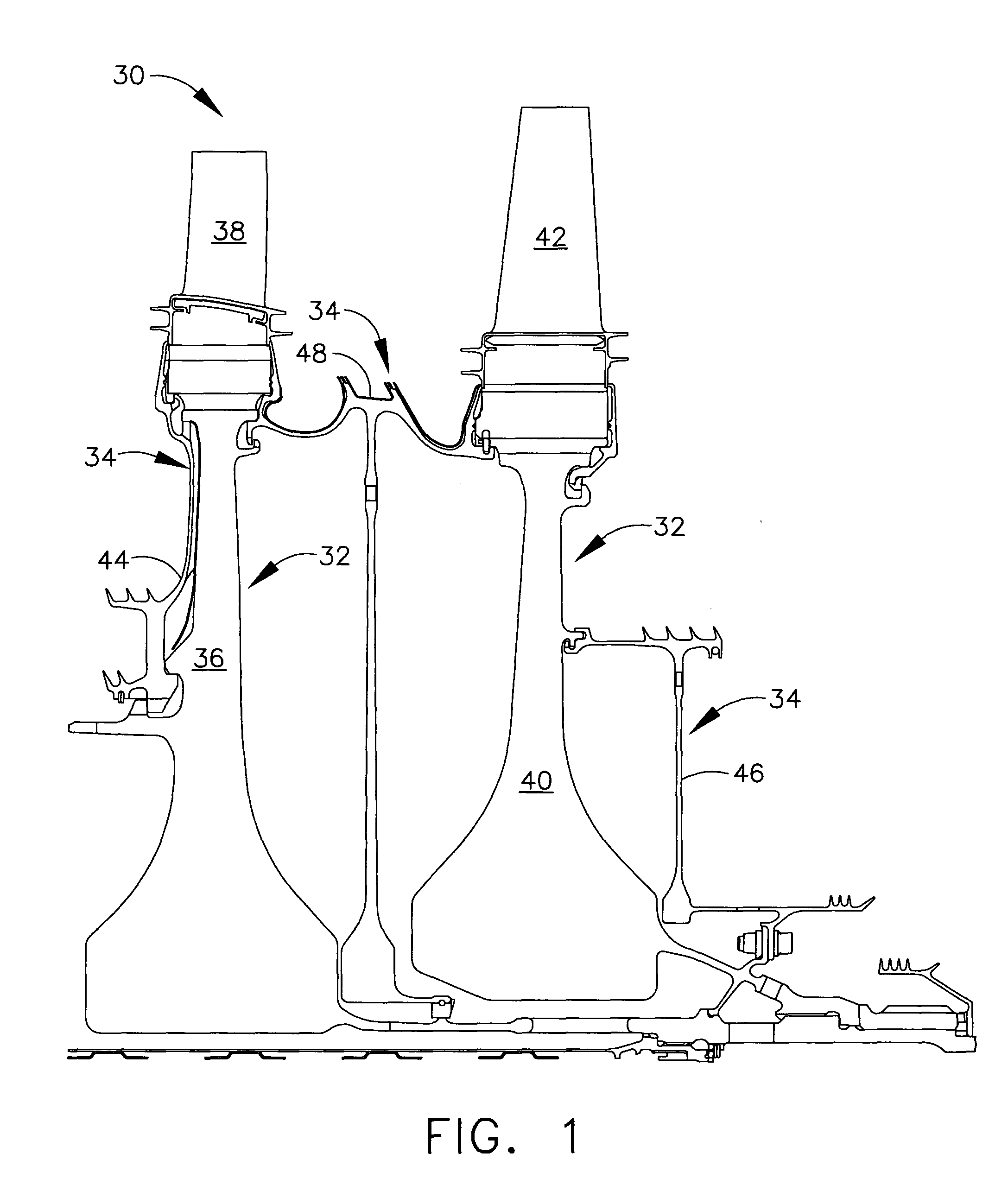

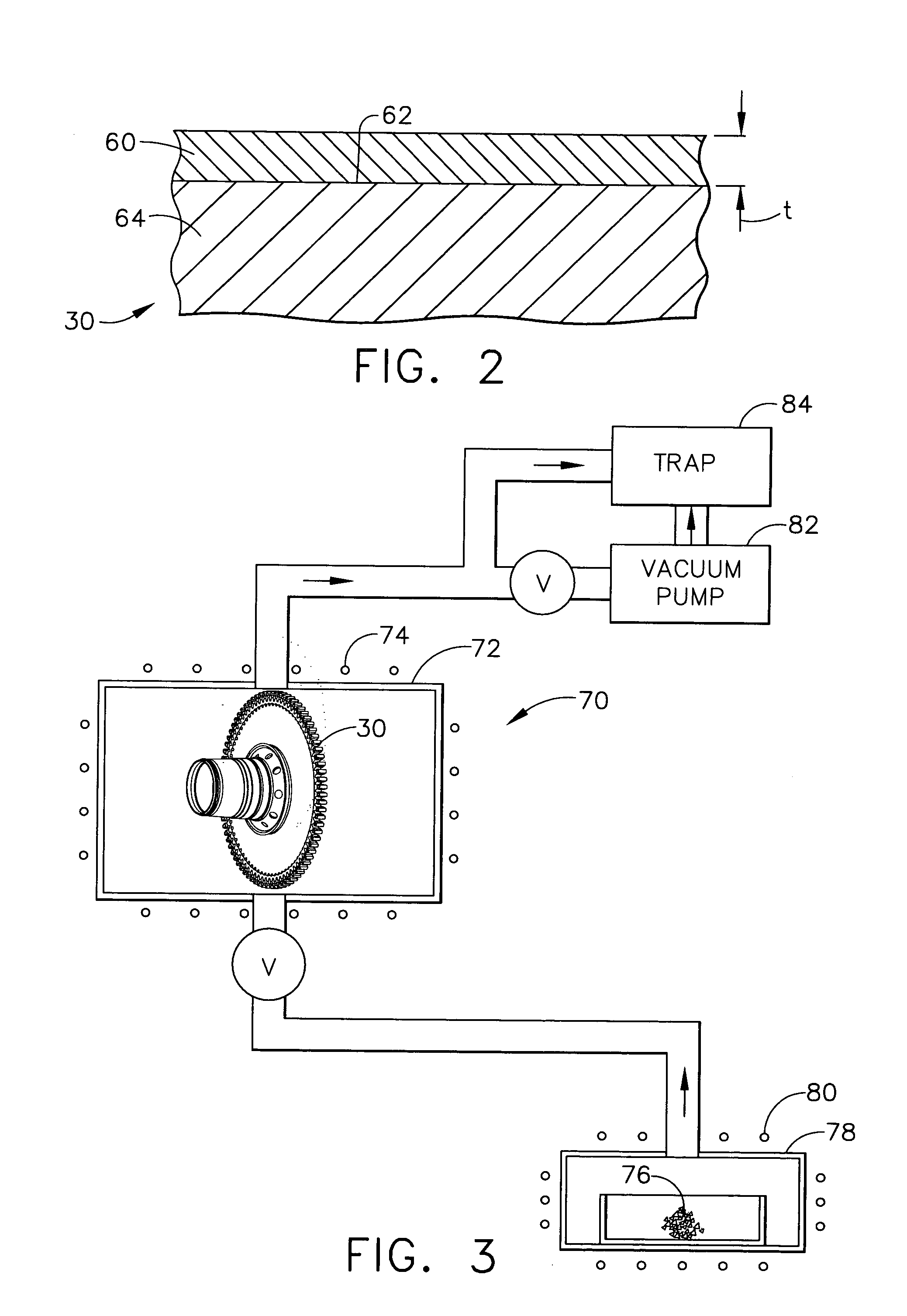

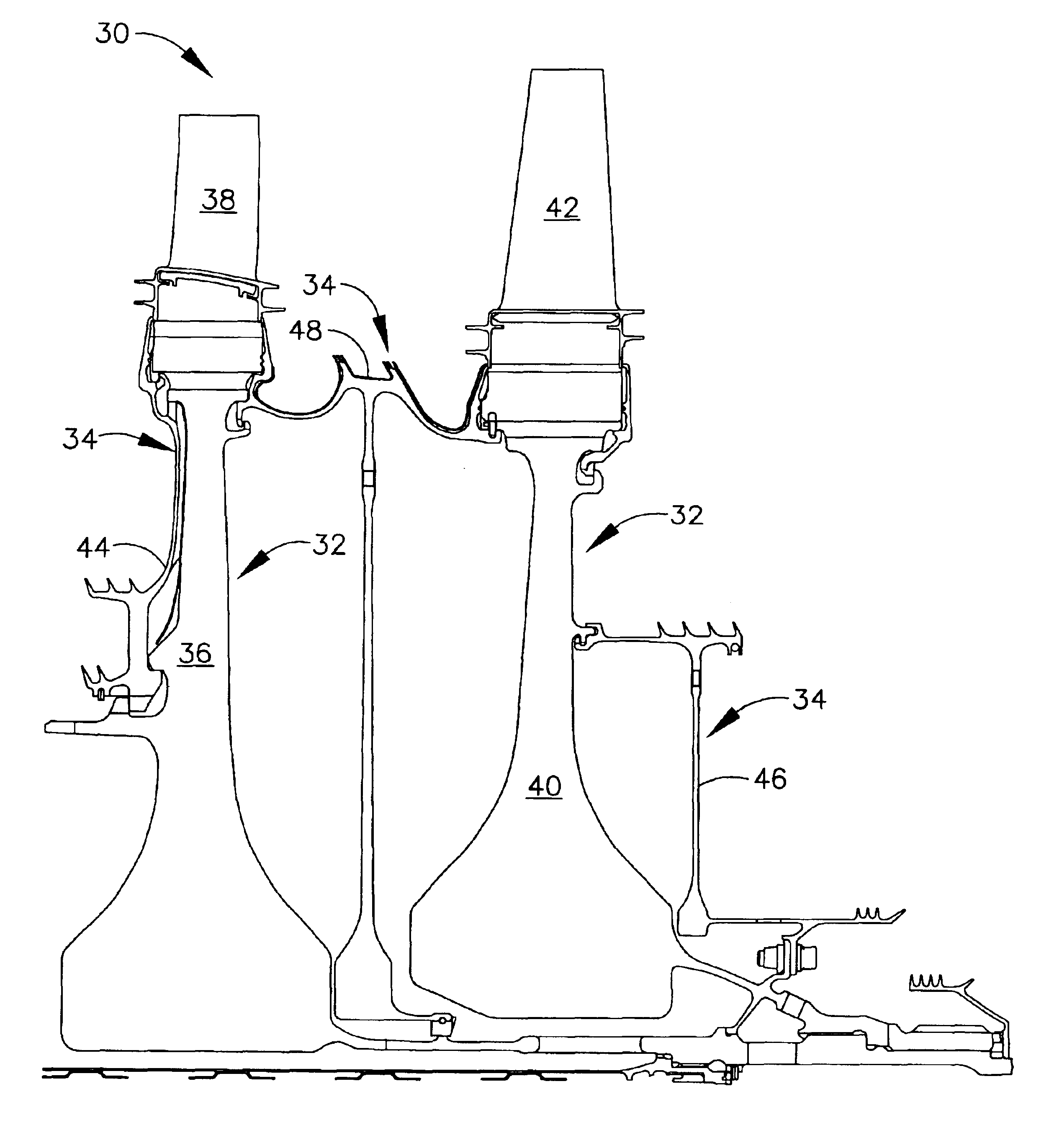

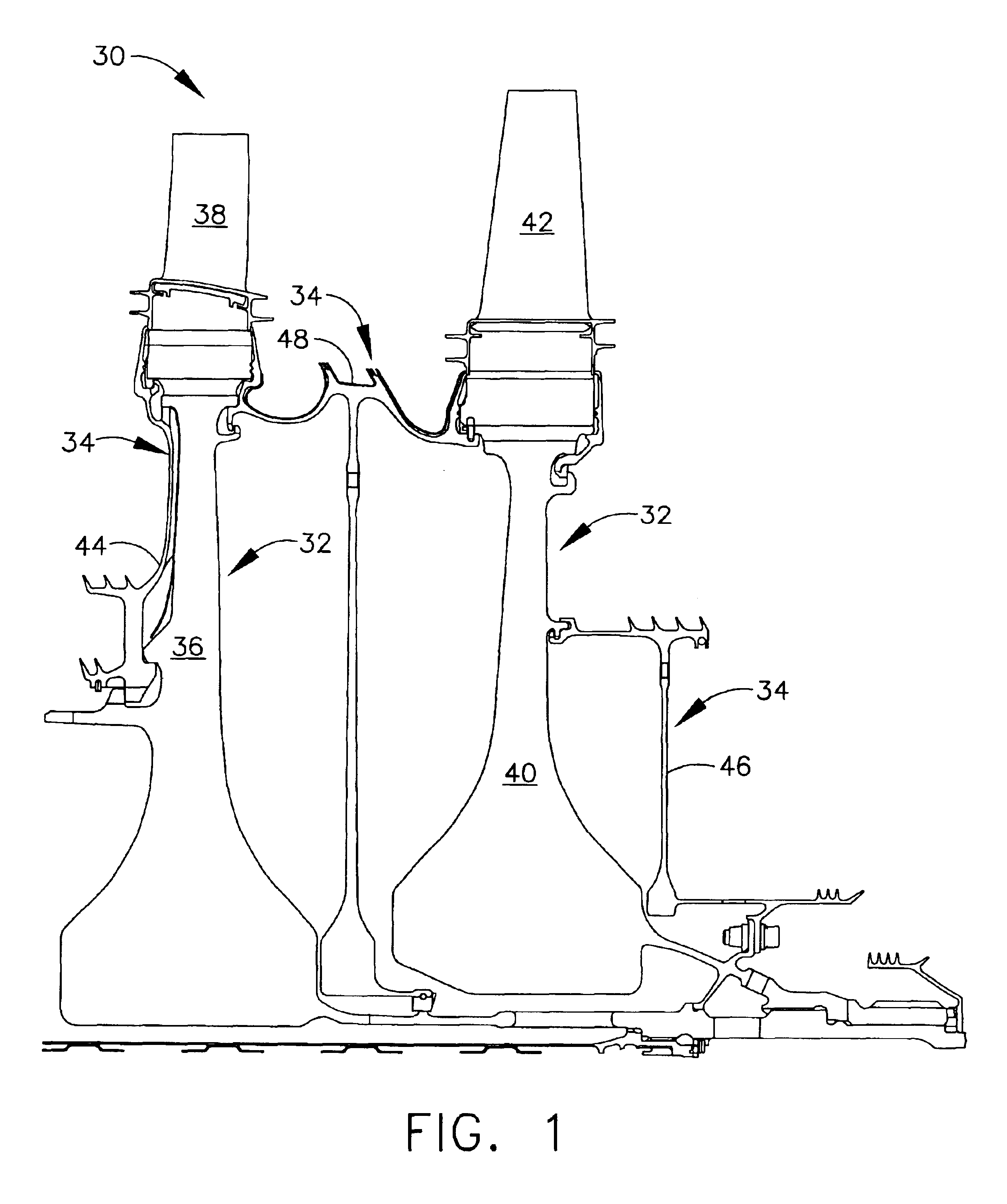

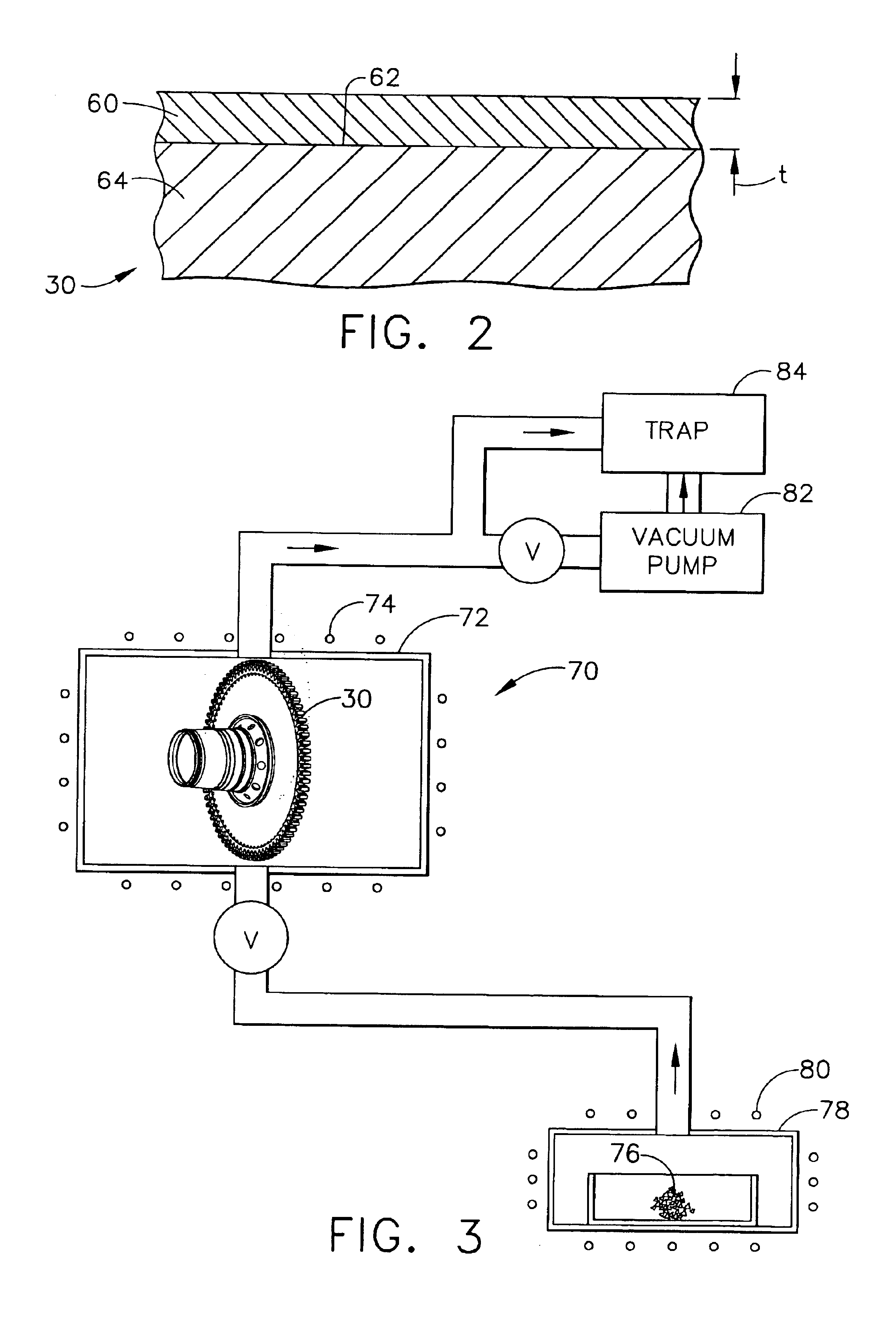

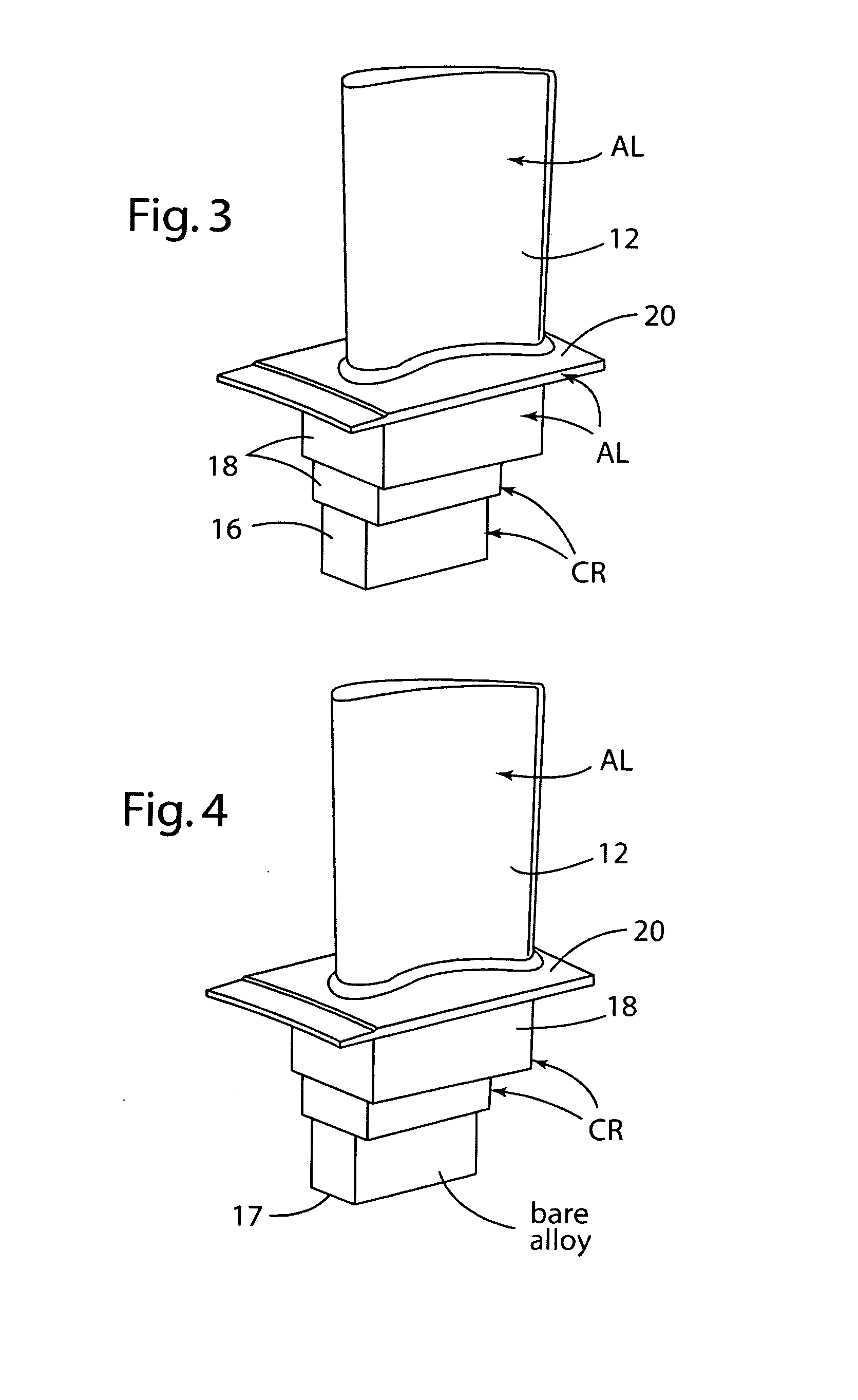

Aluminide or chromide coating of turbine engine rotor component

A turbine engine rotor component, such as a compressor or turbine disk or seal element, is protected from corrosion by depositing an aluminum or chromium coating on the component. The deposition can be performed by a vapor deposition process, such as metal organic chemical vapor deposition (MOCVD), to a coating thickness of from about 0.2 to about 50 microns, typically from about 0.5 to about 3 microns. In one embodiment, the method is conducted in a vapor coating container having a hollow interior coating chamber, and includes the steps of loading the coating chamber with the component to be coated; and flowing a tri-alkyl aluminum or chromium carbonyl coating gas into the loaded coating chamber at a specified temperature, pressure, and time to deposit an aluminum or chromium coating on the surface of the component. The coated component is then heated in a nonoxidizing atmosphere to a specified temperature to form an aluminide or chromide coating on the surface. The coated component is typically then heated or maintained at an elevated temperature in the presence of oxygen to form an oxide coating on the surface of the component.

Owner:GENERAL ELECTRIC CO

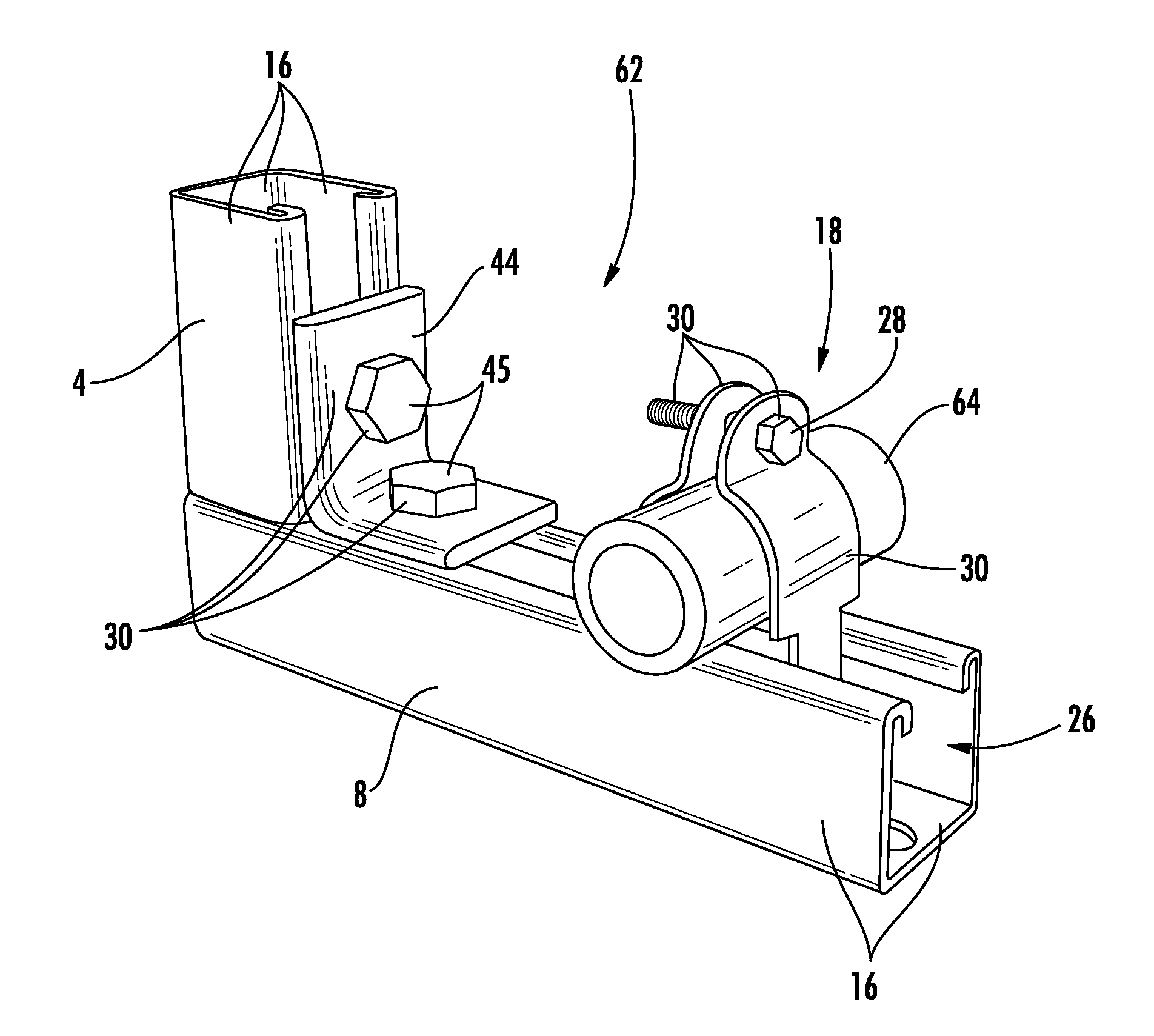

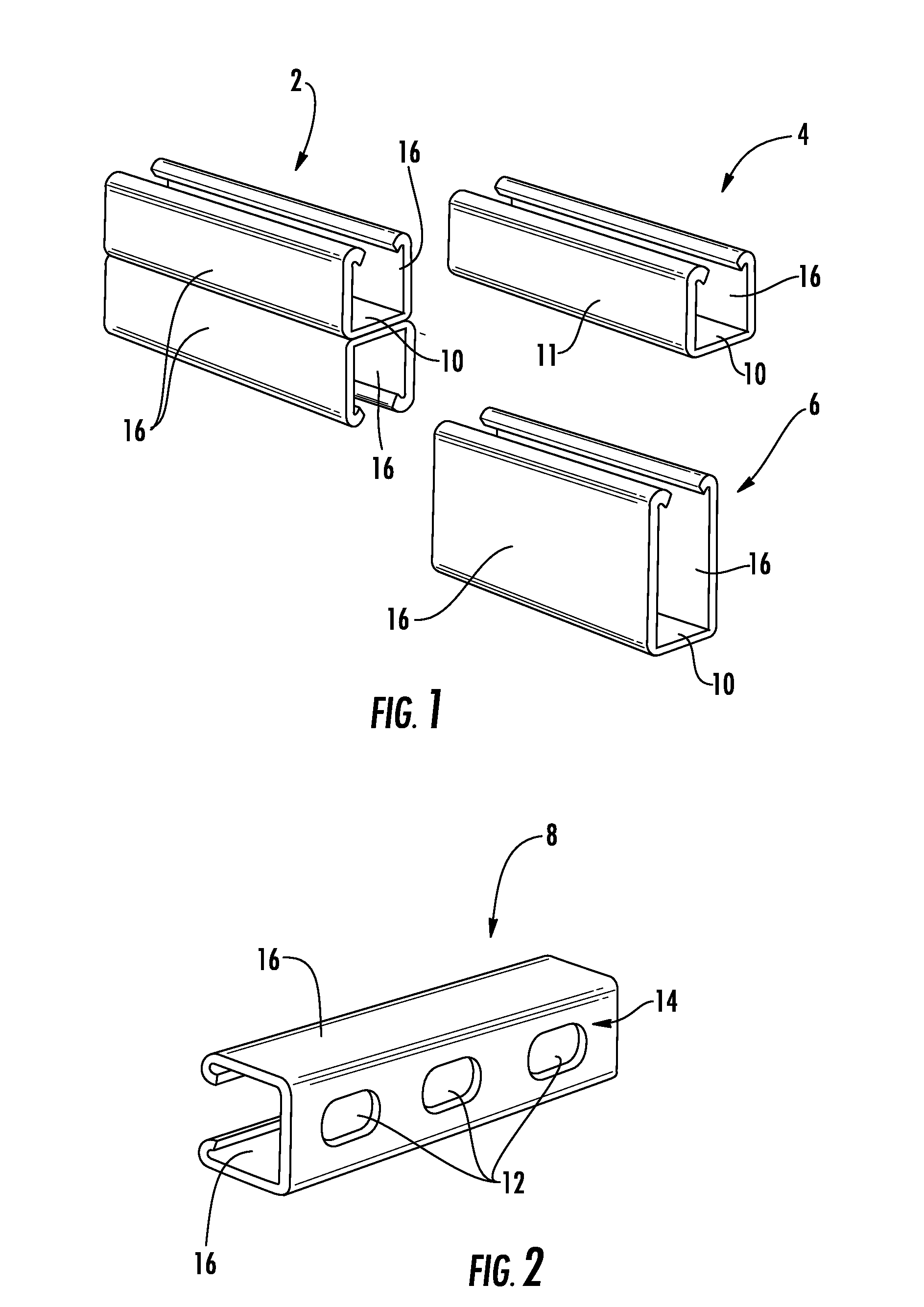

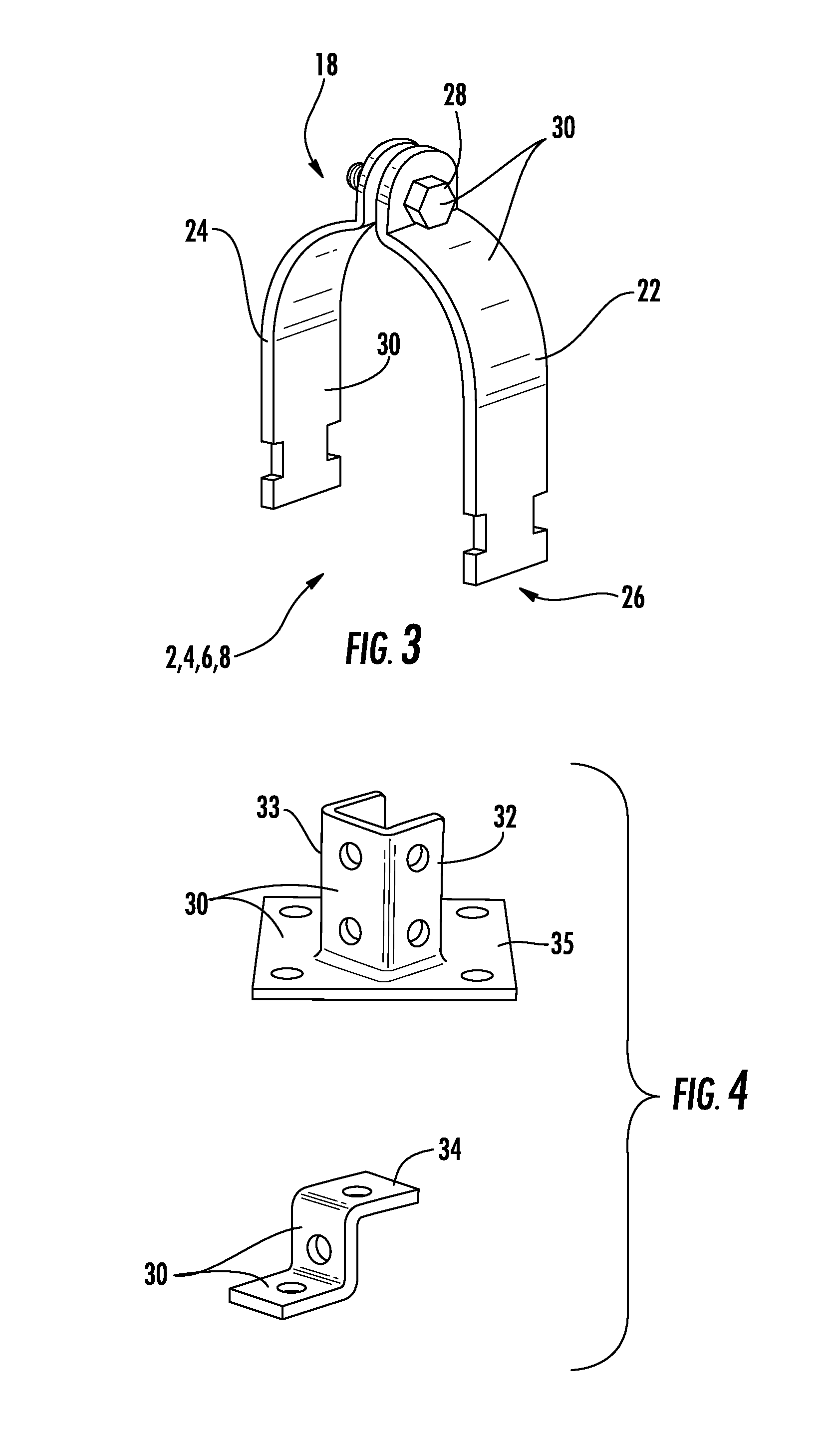

Enhanced corrosion resistant channels, fittings and fasteners

A corrosion resistant support system includes a first channel member having a first corrosion resistant coating. The first corrosion resistant coating is a zinc-aluminum-magnesium coating. A fitting is engageable with said channel member and a first mechanical fastener to couple the fitting to the channel member, the fitting and the first mechanical fastener having a second corrosion resistant coating. The second corrosion resistant coating is a thermal diffusion galvanized coating or a zinc-aluminum-magnesium coating. The first channel member and the first mechanical fastener may also have a third corrosion resistant coating disposed over the first and second corrosion resistant coatings, respectively. The third corrosion resistant coating can be a Perma-Green™ coating, a powder coating, an electrocoating (E-coat or Electrophoretic deposition coating), a paint coating, an epoxy coating, a polyvinyl chloride (PVC) coating, a trivalent chromium coating, a hexavalent chromium coating, a zinc coating, and / or a copper coating.

Owner:UNISTRUT INT CORP

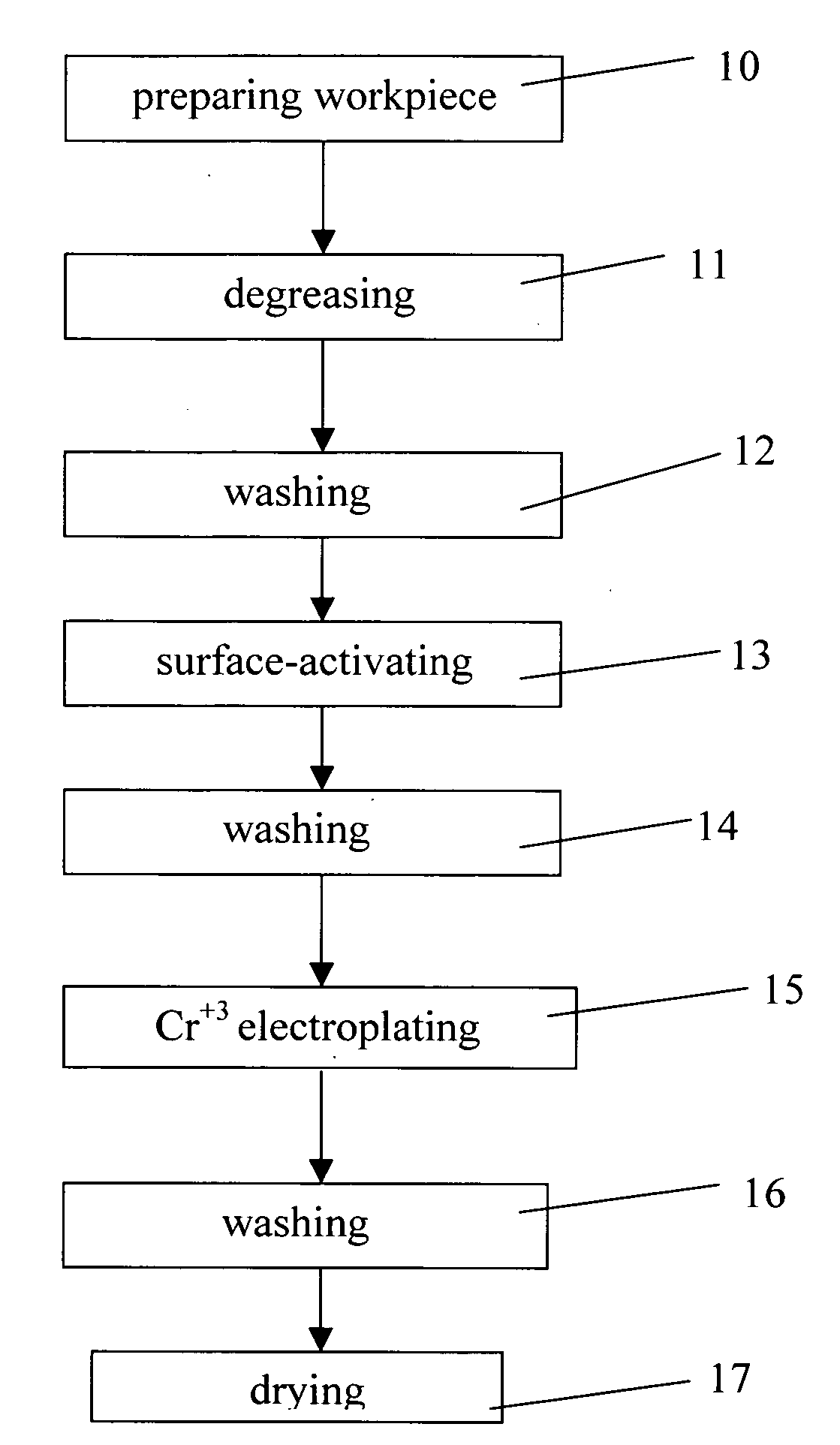

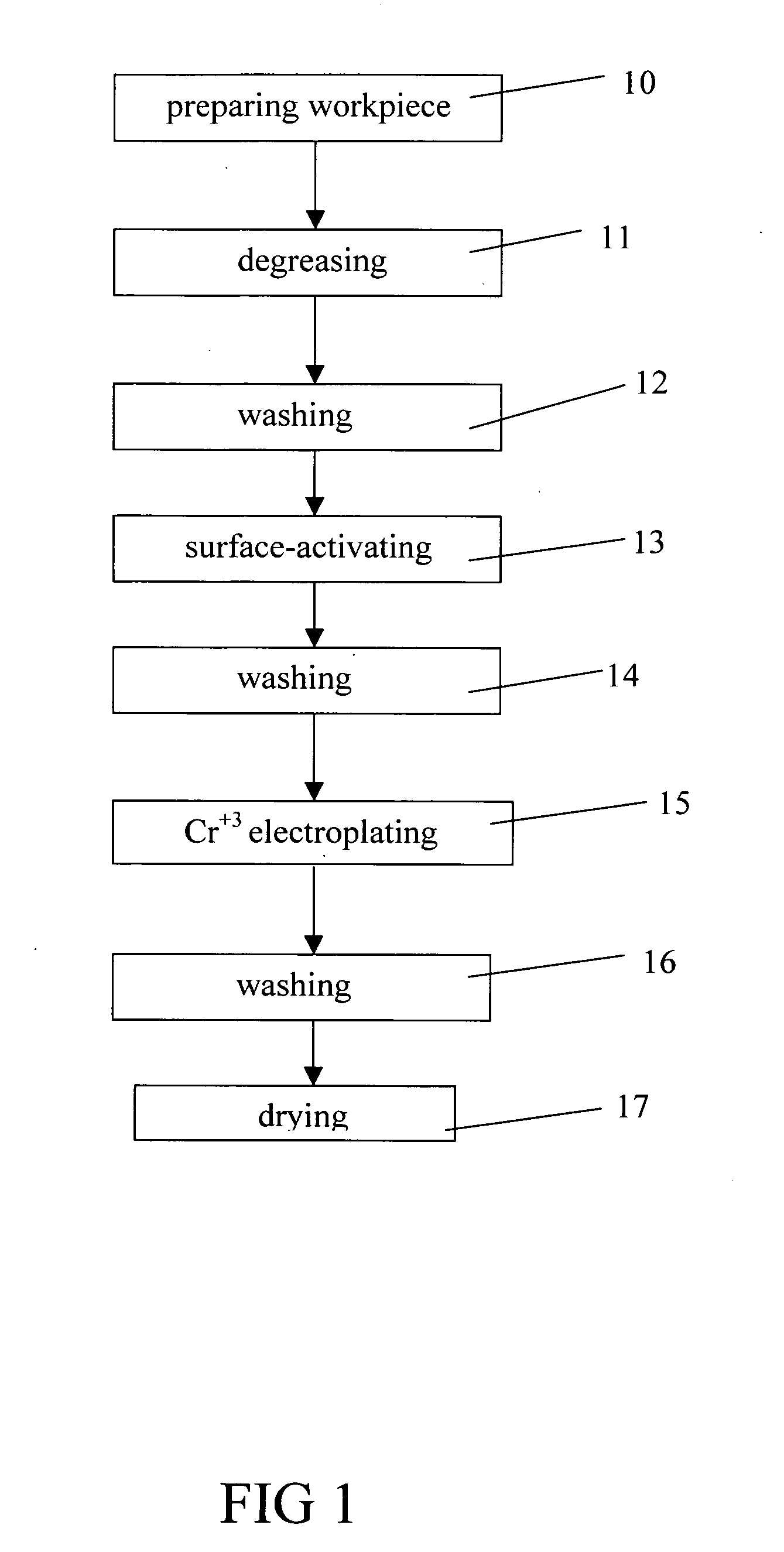

Trivalent chromium electroplating solution and an electroplating process with the solution

A trivalent chromium electroplating solution in accordance with the present invention contains at least one trivalent chromium salt for electroplating a chromium coating layer on a workpiece. By using the low toxic trivalent chromium to substitute highly toxic hexavalent chromium, an electroplating process of the present trivalent chromium electroplating solution has less pollution.

Owner:CHANG GUNG UNIVERSITY

Aluminide or chromide coating of turbine engine rotor component

Owner:GENERAL ELECTRIC CO

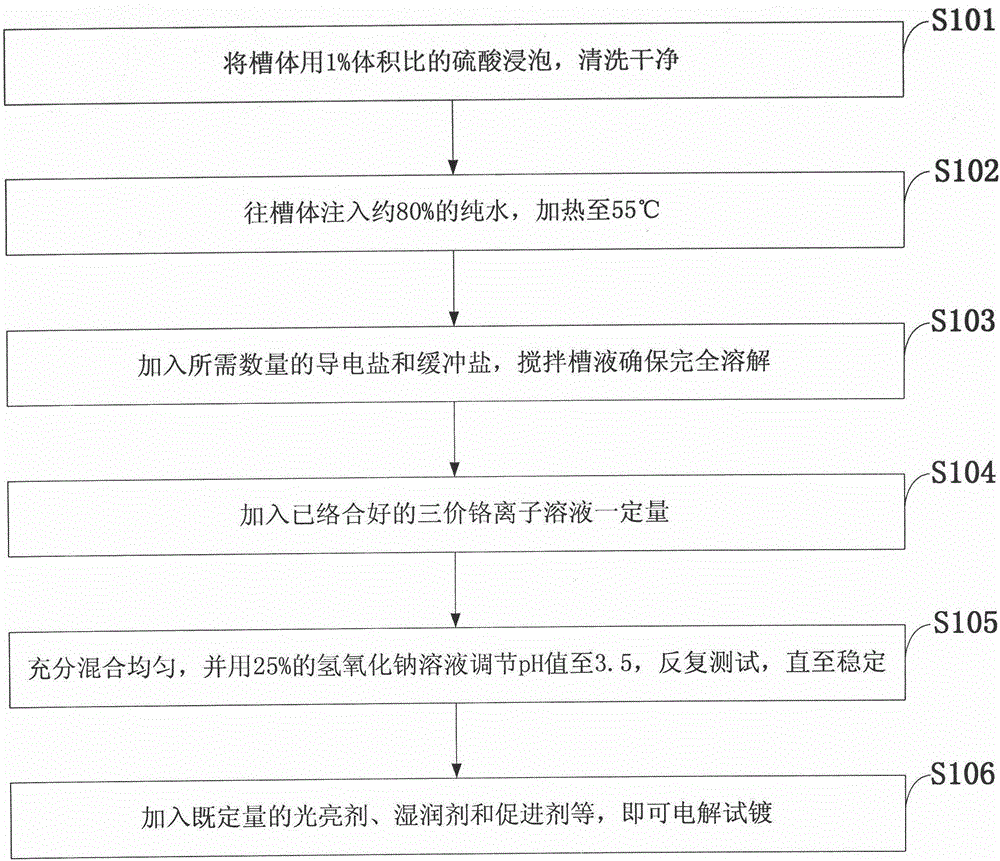

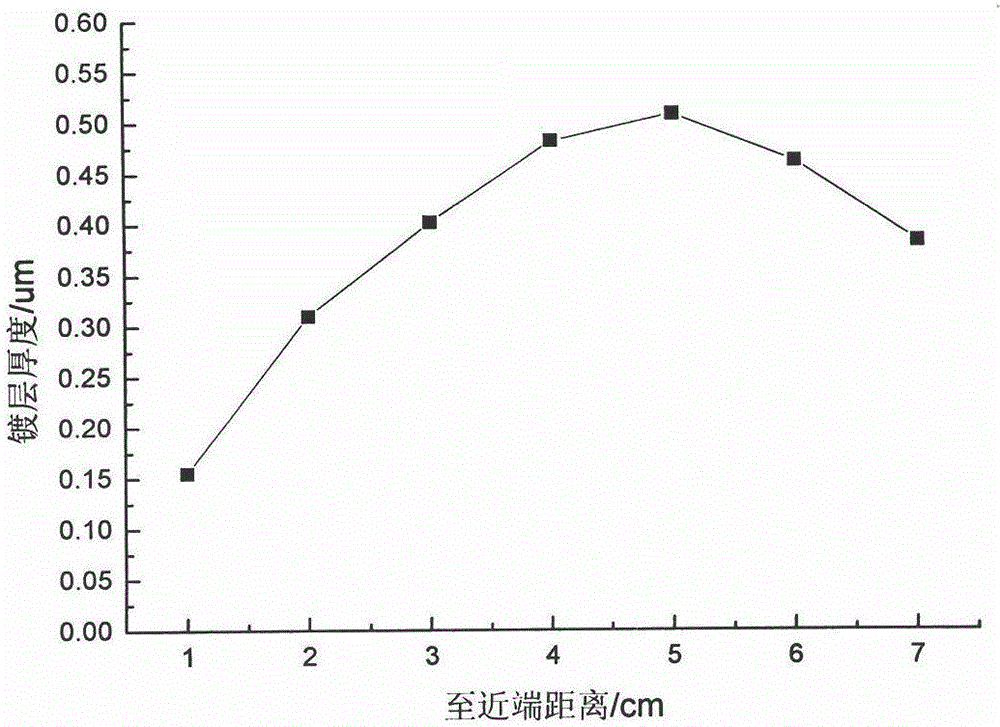

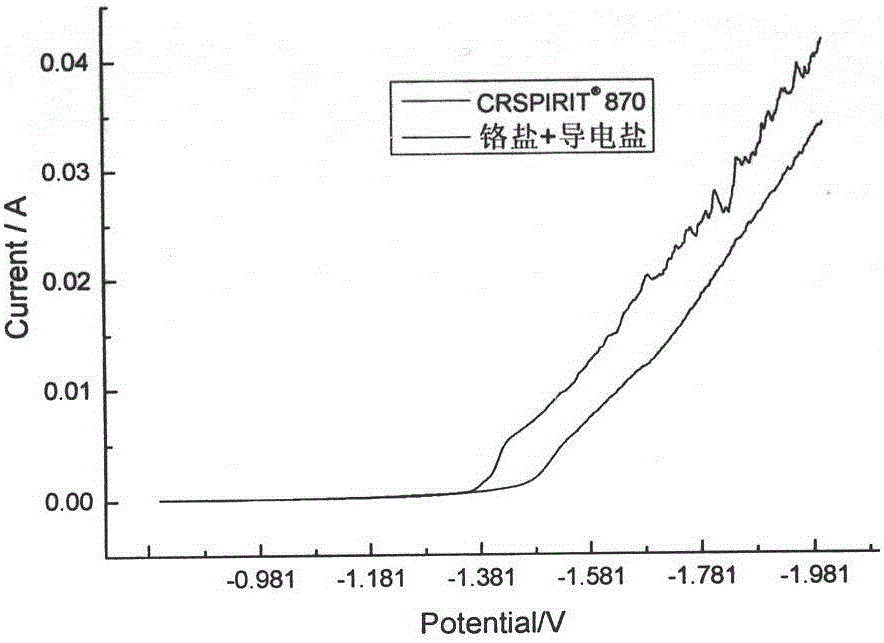

Sulfate trivalent chromium electroplating solution and preparation method thereof

The invention discloses a sulfate trivalent chromium electroplating solution and a preparation method thereof. Ionic solution; add a predetermined amount of brightener, wetting agent and accelerator, then electrolytic test plating. The sulfate trivalent chromium electroplating solution includes: conductive salt 150g / L~250g / L, buffer salt 60g / L~120g / L, trivalent chromium ion 5g / L~20g / L, complexing agent 10g / L~ 20g / L, brightener 0.1g / L~1g / L, C~S compound 1g / L~5g / L, saccharin sodium reactant 1g / L~4g / L, wetting agent 0.1g / L~1g / L. The invention improves the performance of the sulfate trivalent chromium electroplating process; the obtained trivalent chromium plating layer is white and fine, has fast deposition rate of the plating layer, and has excellent covering ability and throwing ability.

Owner:济南德锡科技有限公司

Erosion resistant coating

A platinum plus chromium coating applied to the roots and firtrees of turbine blades where the inclusion of chromium creates a single phase outer zone which minimizes diffusion paths for sulphur which can preferentially diffuse down phase boundaries and enables a chromium rich outer oxide scale to form on top of the coating.

Owner:ROLLS ROYCE PLC

Coating and coating method for gas turbine engine component

InactiveUS20160010472A1Improve fatigue lifeVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsChromium coatingAlloy

The present invention provides a protective coating for a gas turbine blade or other component wherein the duplex coating includes an aluminum-bearing coating, such as a diffusion aluminide, formed on a first, relatively higher temperature region of the blade / component and a later-applied chromium-bearing diffusion coating formed on an adjacent relatively lower temperature region of the blade / component subject to hot corrosion in service. The chromium-bearing coating is applied after the aluminum-bearing coating by masking that coating and depositing a metallic chromium coating on the adjacent region followed by diffusing the chromium into the blade / component alloy to form a chromium-enriched diffusion coating thereon.

Owner:HOWMET CORPORATION

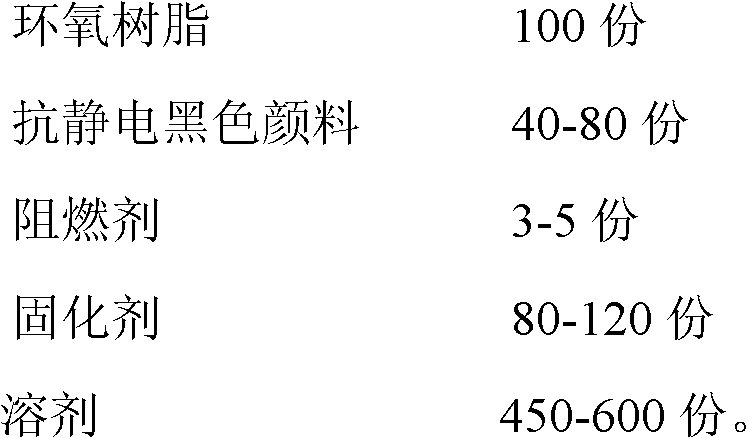

Alloy antiseptic composite coating for coal mine underground gas pipe

ActiveCN102181191AImprove corrosion resistanceImprove flame retardant performanceCorrosion preventionAnti-corrosive paintsElectrical resistance and conductanceCombustion

The invention discloses an alloy antiseptic composite coating for a coal mine underground gas pipe. The coating is formed by compounding an aluminum, zinc and chromium coating which is formed by sintering a coating sprayed onto a pipe wall at the temperature of between 300 and 350 DEG C, and a flame retardant antistatic antiseptic coating II which is formed by sintering a coating which is sprayedonto the coating II at the temperature of between 160 and 180 DEG C. The hardness of the alloy antiseptic composite coating is more than or equal to 2H; the impact intensity is more than or equal to 50kg.cm; the coating adhesion is more than or equal to a level 3; neutral salt spray resistance is more than 500h; the indexes of the flam resistance are that: the arithmetic mean value of the flame combustion time of six test pieces is less than or equal to 3s, the arithmetic mean value of the flame combustion time of one test piece is less than or equal to 8s; and the arithmetic mean value of the spark combustion time of six test pieces is 0s and the unit value of the spark combustion time of one test piece is 0s; and the index of conductivity performance is that: surface resistance is less than or equal to 1*10<6>Omega.

Owner:ANHUI HAICHENG RAILWAY EQUIP TECH

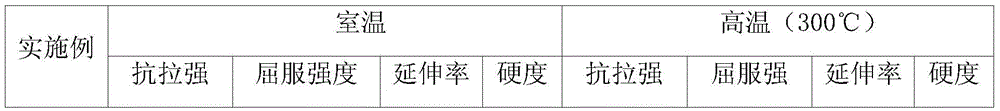

Aluminum alloy cylinder sleeve for automobile engine and preparation method of aluminum alloy cylinder sleeve

The invention discloses an aluminum alloy cylinder sleeve for an automobile engine. The aluminum alloy cylinder sleeve comprises a tubular aluminum alloy substrate and a chromium coated layer, wherein the chromium coated layer is arranged on the inner surface of the aluminum alloy substrate; the aluminum alloy substrate is prepared from the following aluminum alloys in percentage by weight: 13-15% of Si, 1-2% of Cu, 0.2-0.5% of Mg, 0.1-0.3% of Mn, 0.1-0.3% of Cr, 0.1-0.3% of C, 0-0.5% of Zn, 0-0.15% of Ti, 0.1-0.3% of RE and the balance of Al. The invention further provides a preparation method of the aluminum alloy cylinder sleeve for the automobile engine. By adopting the aluminum alloy cylinder sleeve, the strength, the hardness, the high temperature stability and the wearing resistance of a cylinder sleeve are improved, the use property of the aluminum alloy cylinder sleeve is improved, the service life of the aluminum alloy cylinder sleeve is prolonged, and requirements of a conventional engine can be met.

Owner:SHANDONG HUICHUAN AUTO PARTS

Strip process for superalloys

InactiveUS20070116875A1Reduce the amount requiredBlade accessoriesSolid state diffusion coatingAlloy substrateChromium coating

A process for forming a coated substrate comprises providing a nickel base alloy substrate, depositing a chromium coating onto the nickel base alloy substrate and diffusing chromium from said coating into the substrate, applying a MCrAlY coating onto the nickel base alloy substrate and heat treating the substrate with the deposited chromium and the MCrAlY coating so that chromium diffuses into an outer region of the substrate. Further, in accordance with the present invention, a strip process for removing a coating from a substrate broadly comprises the steps of providing a nickel base alloy substrate having chromium diffused into an outer region and a MCrAlY coating deposited over the substrate with the diffused chromium and removing the MCrAlY coating by immersing the nickel base alloy substrate in an acid solution containing a sulfuric acid-hydrochloric acid mixture in water.

Owner:UNITED TECH CORP

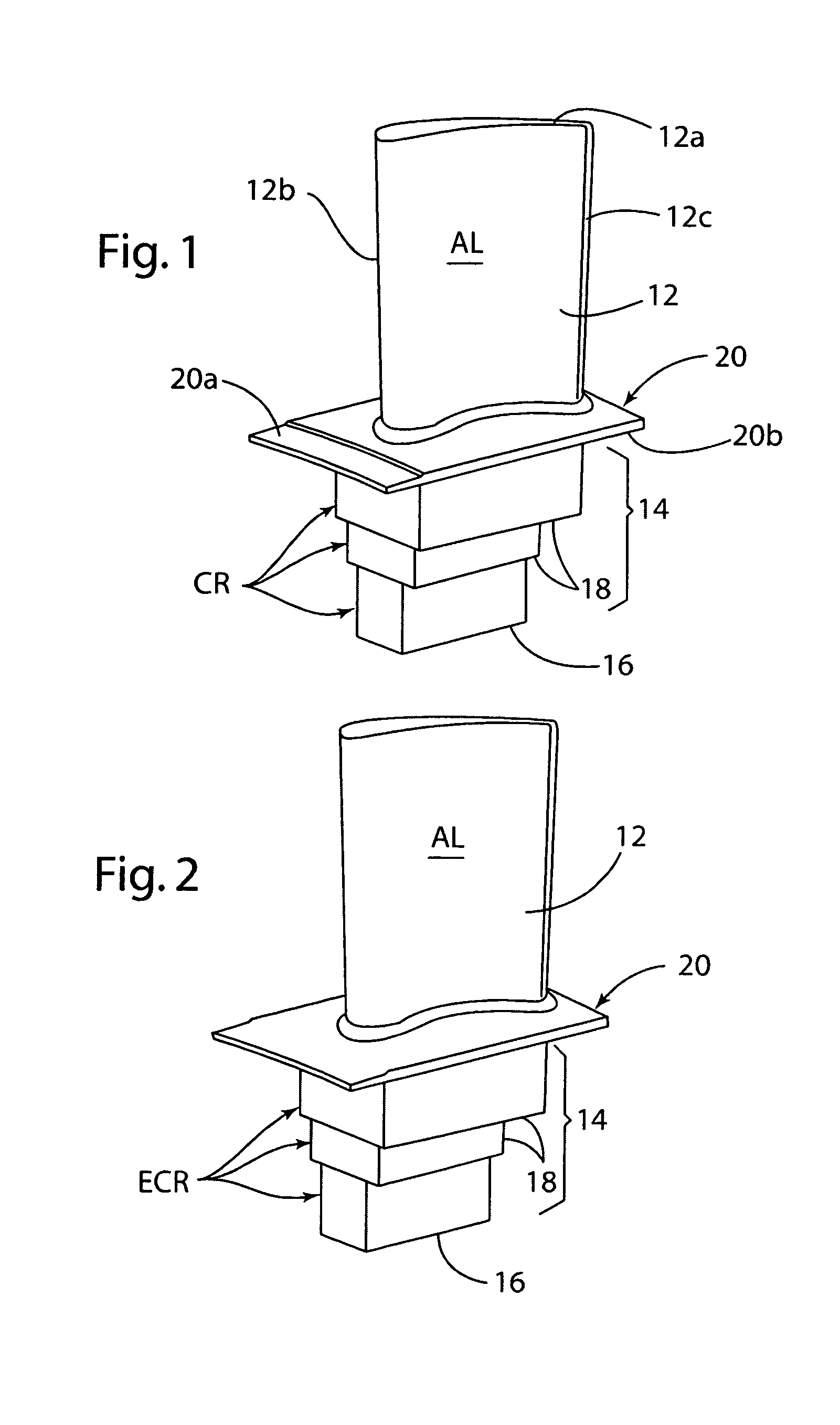

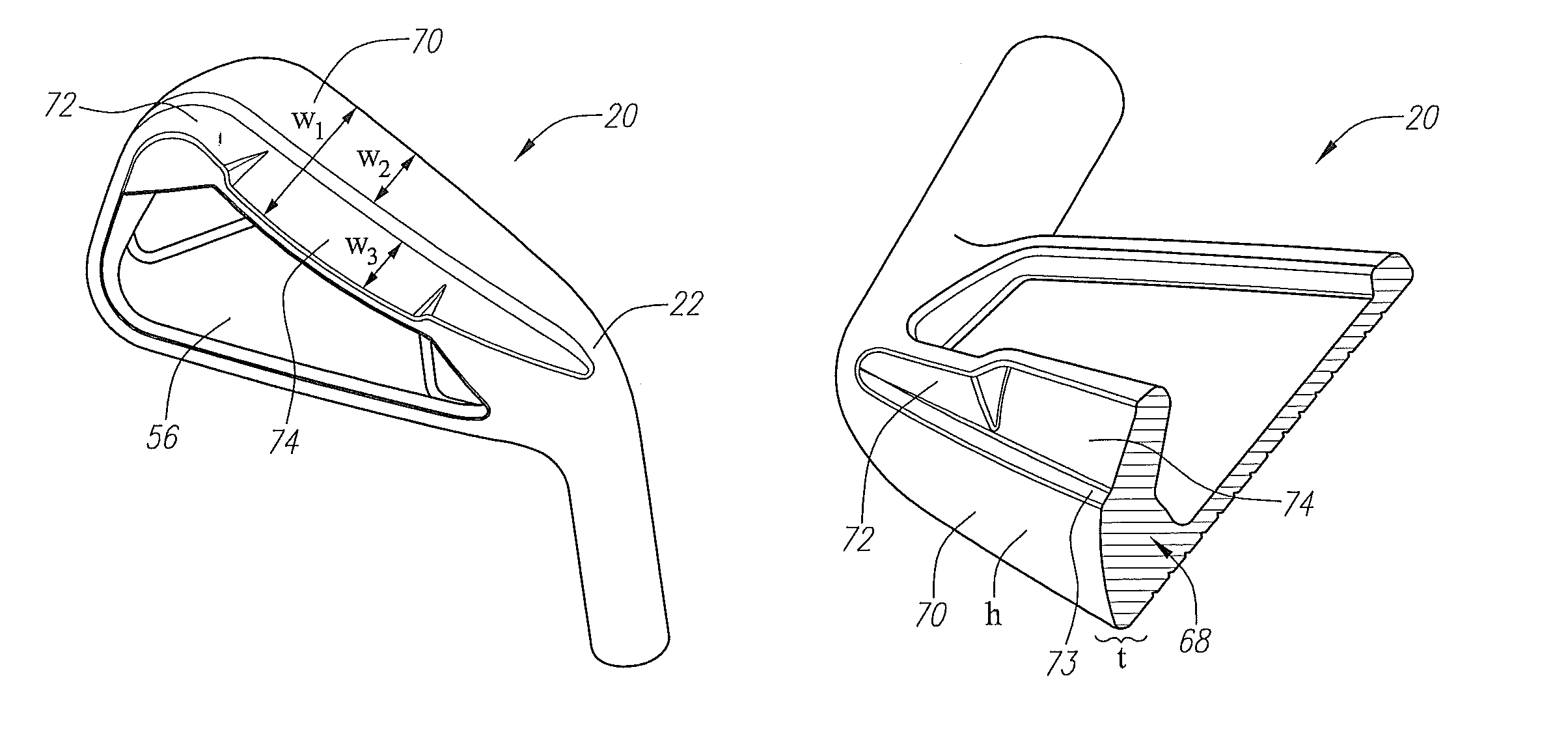

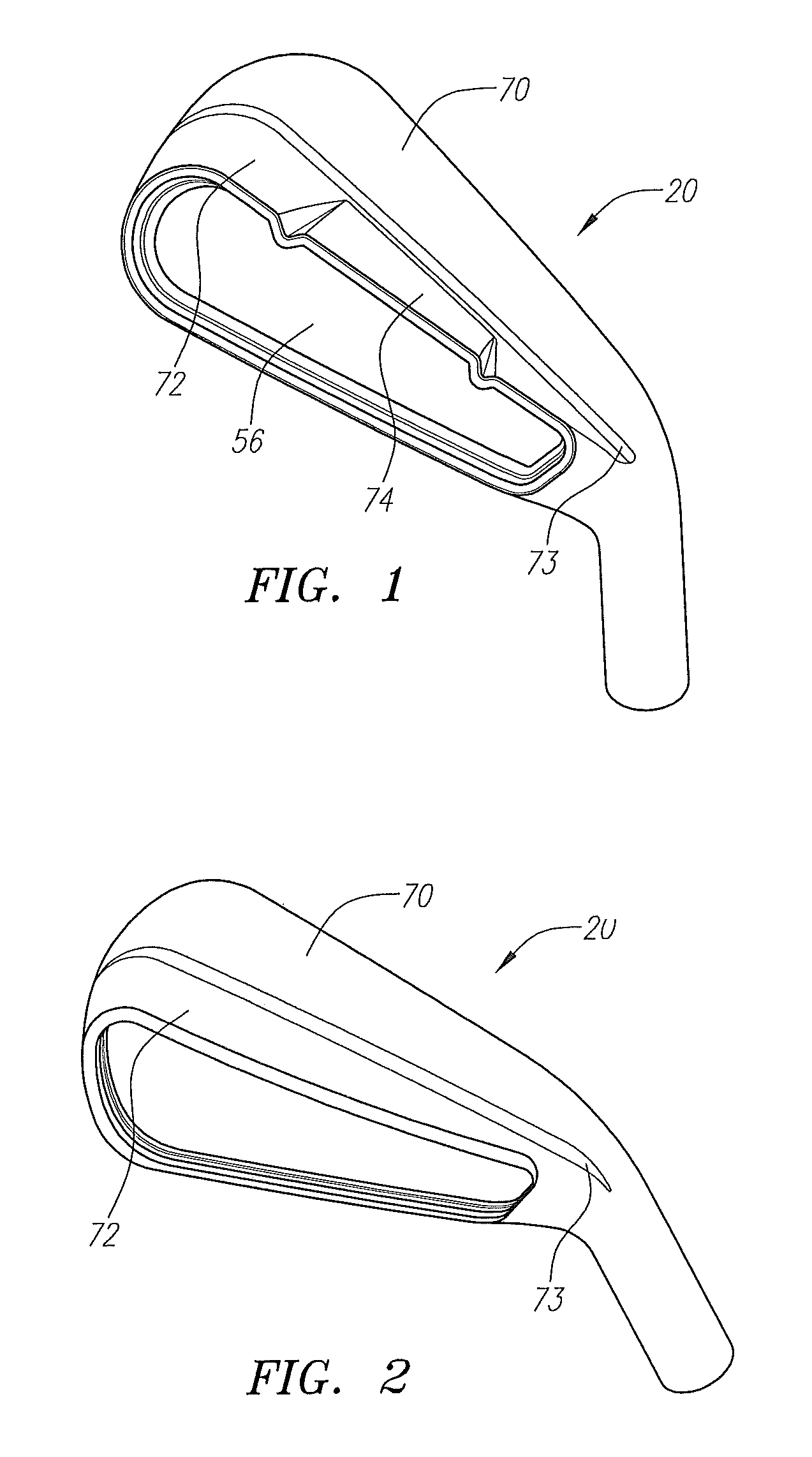

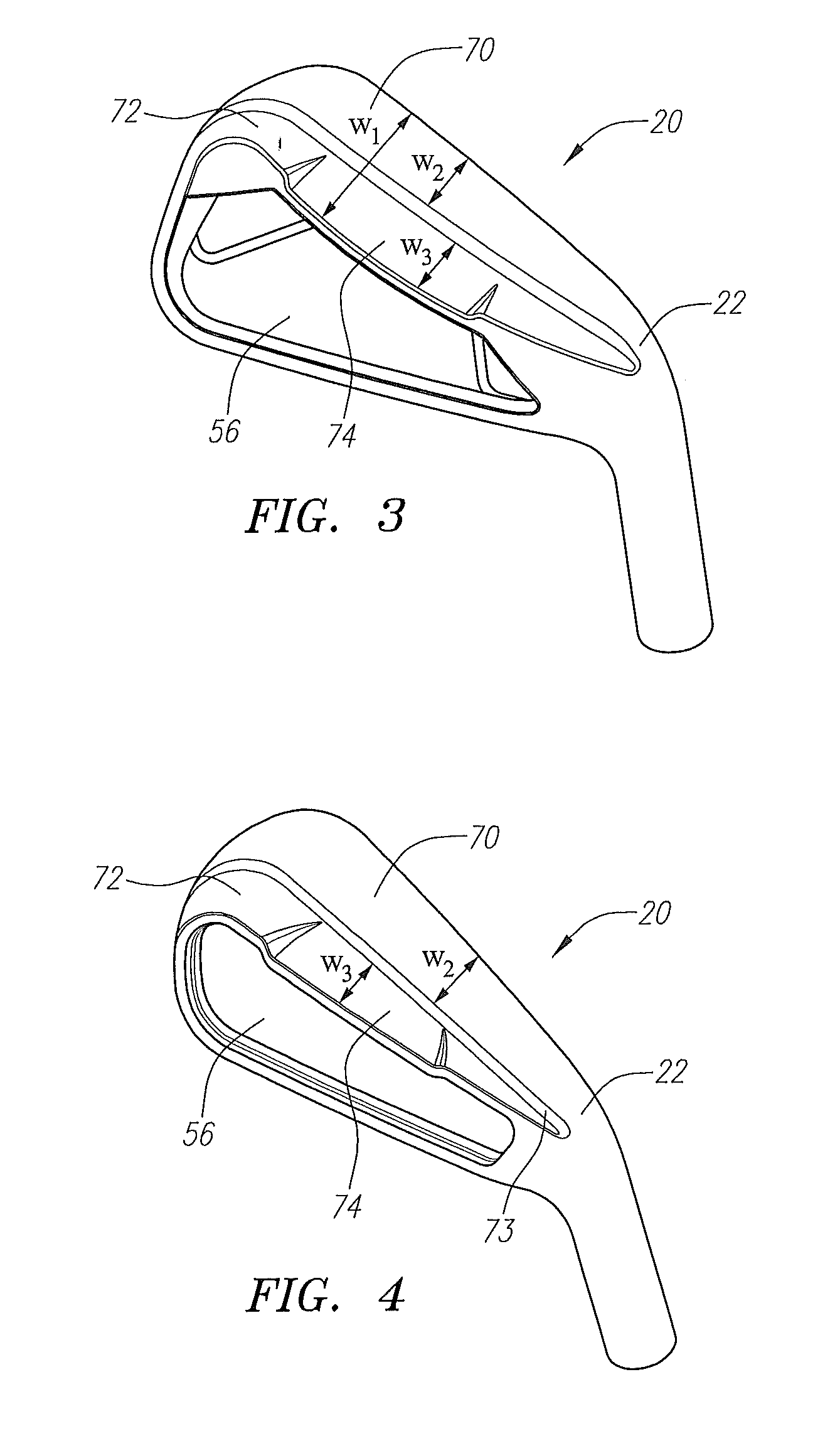

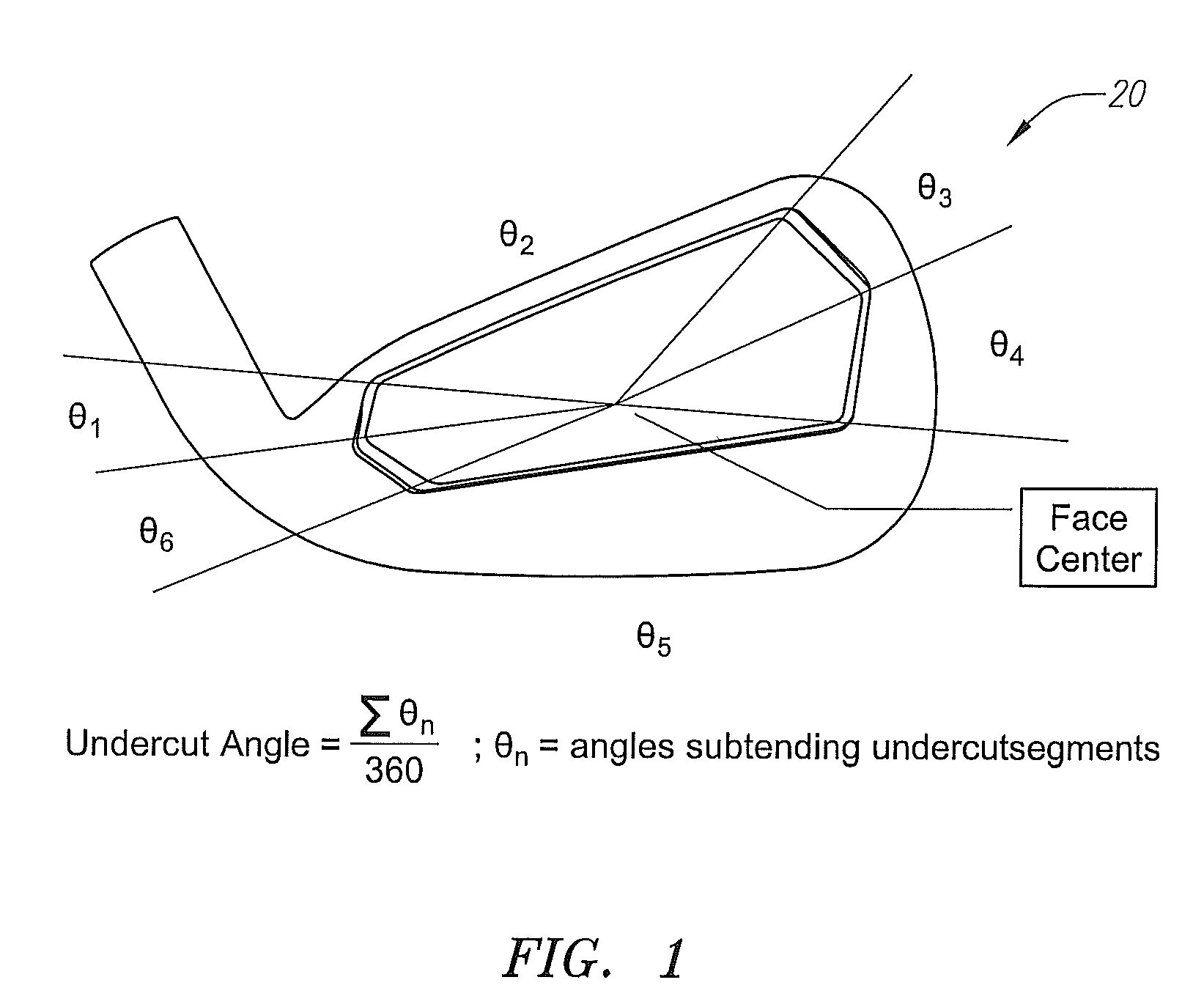

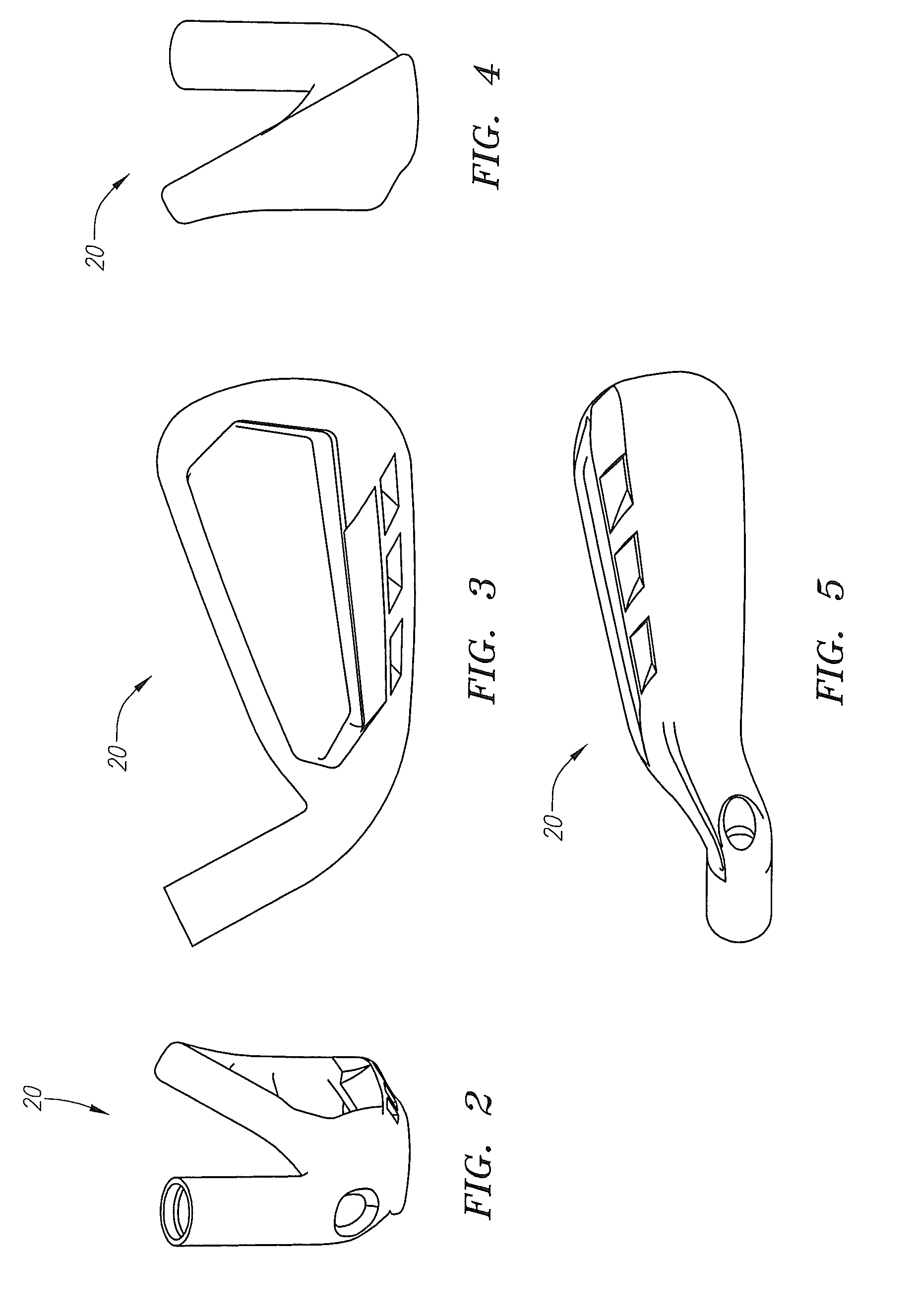

Sole for iron golf club head

The present invention discloses an iron-type golf club head in which the sole portion has a main surface and a stepped surface. Further, the sole portion comprises a chromium coating. The invention creates a unique combination of head shape and surface friction coefficients that minimize the bad effects of turf impact.

Owner:TOPGOLF CALLAWAY BRANDS CORP

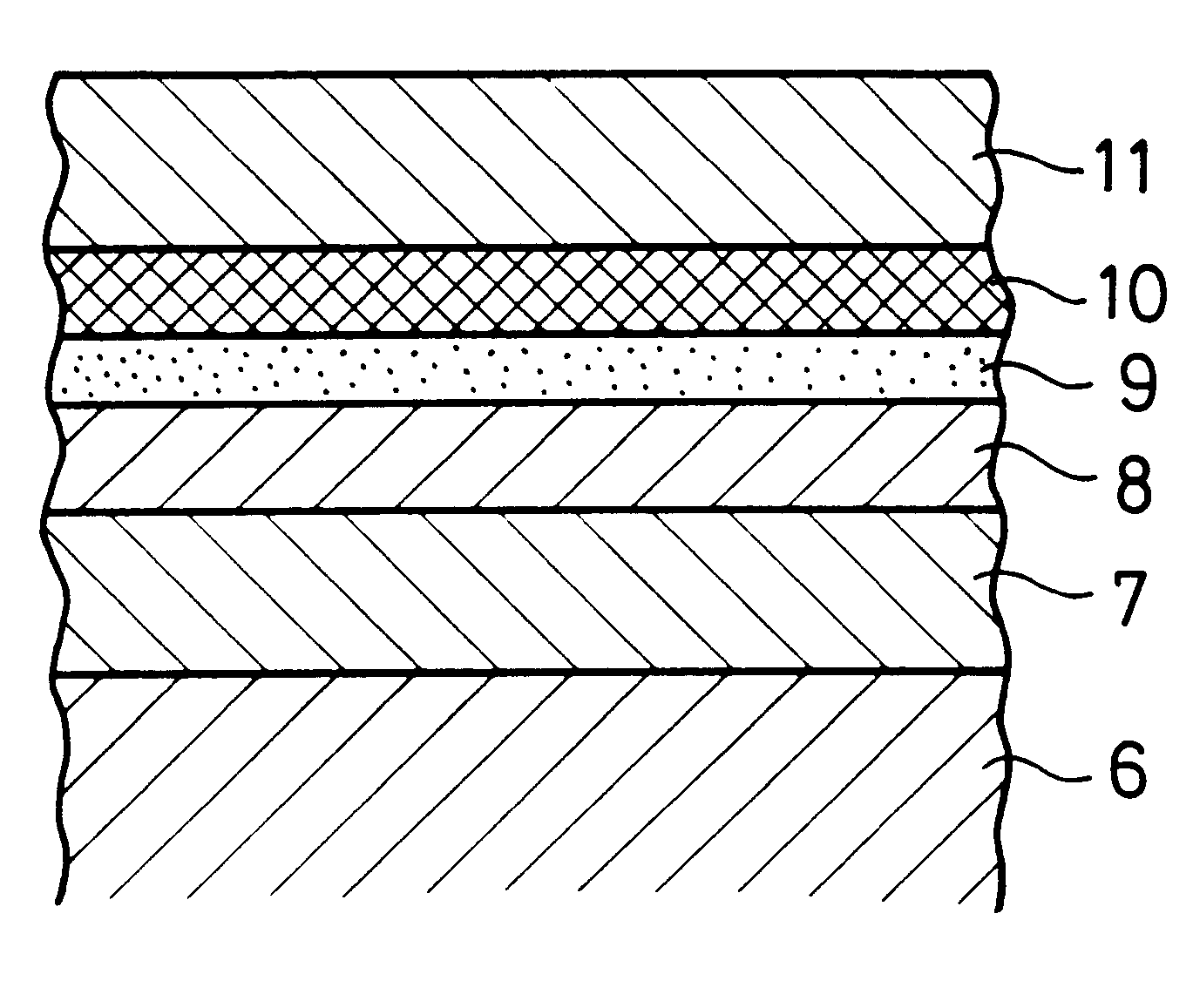

Hard carbon coating-clad base material

InactiveUS6180263B1Excellent in abrasionImprove adhesionSuperimposed coating processThin material handlingCarbon coatingMetal coating

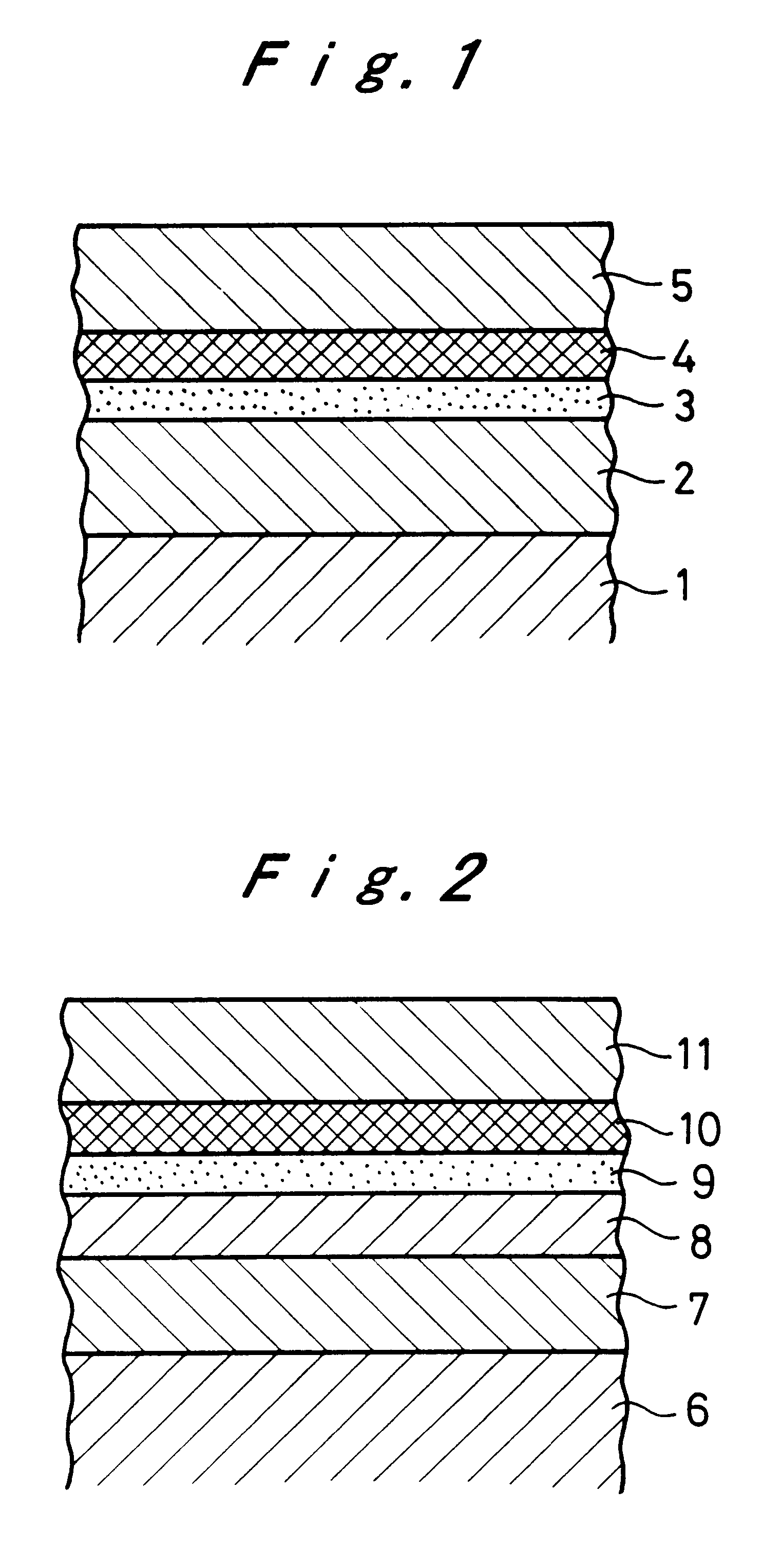

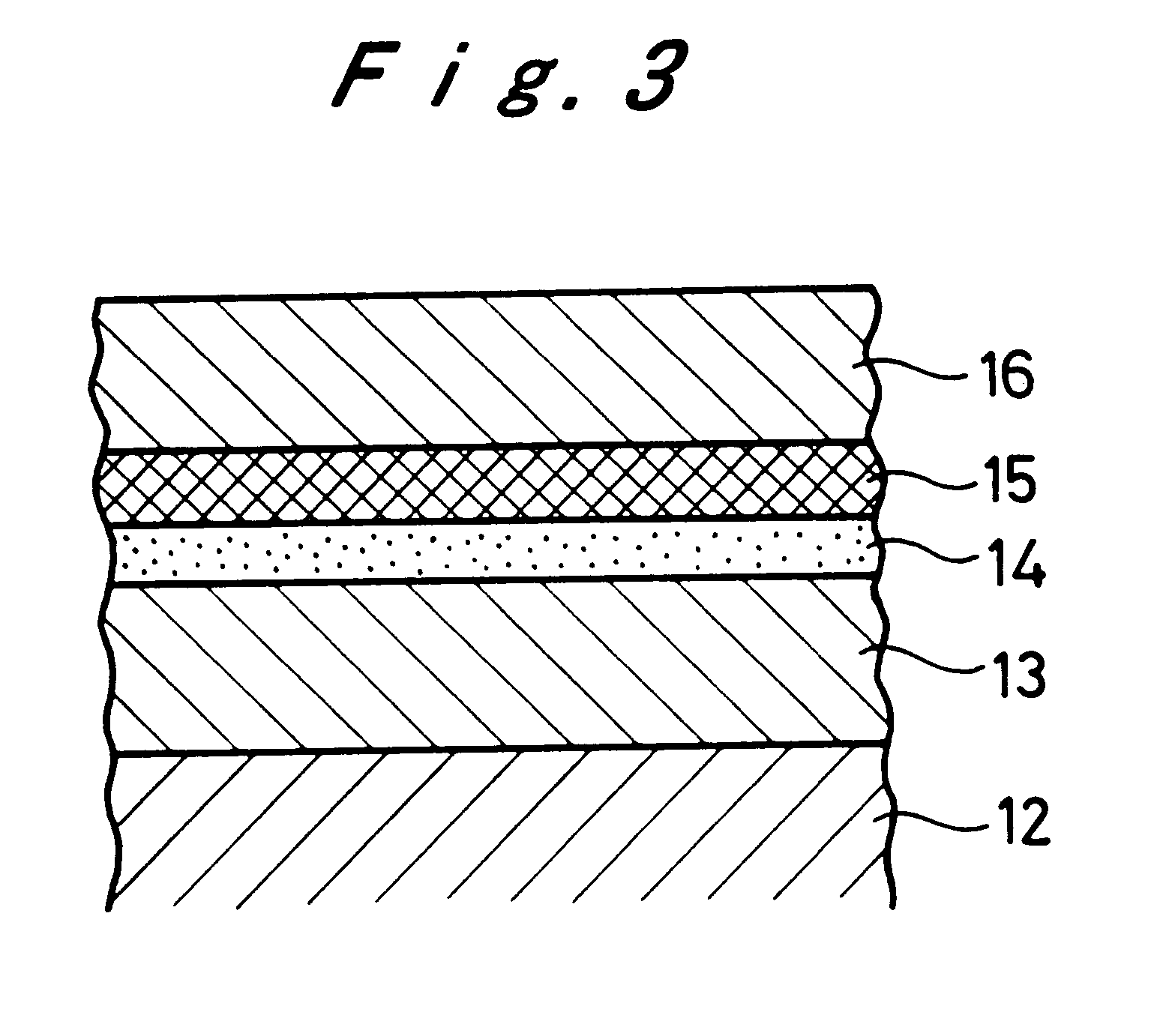

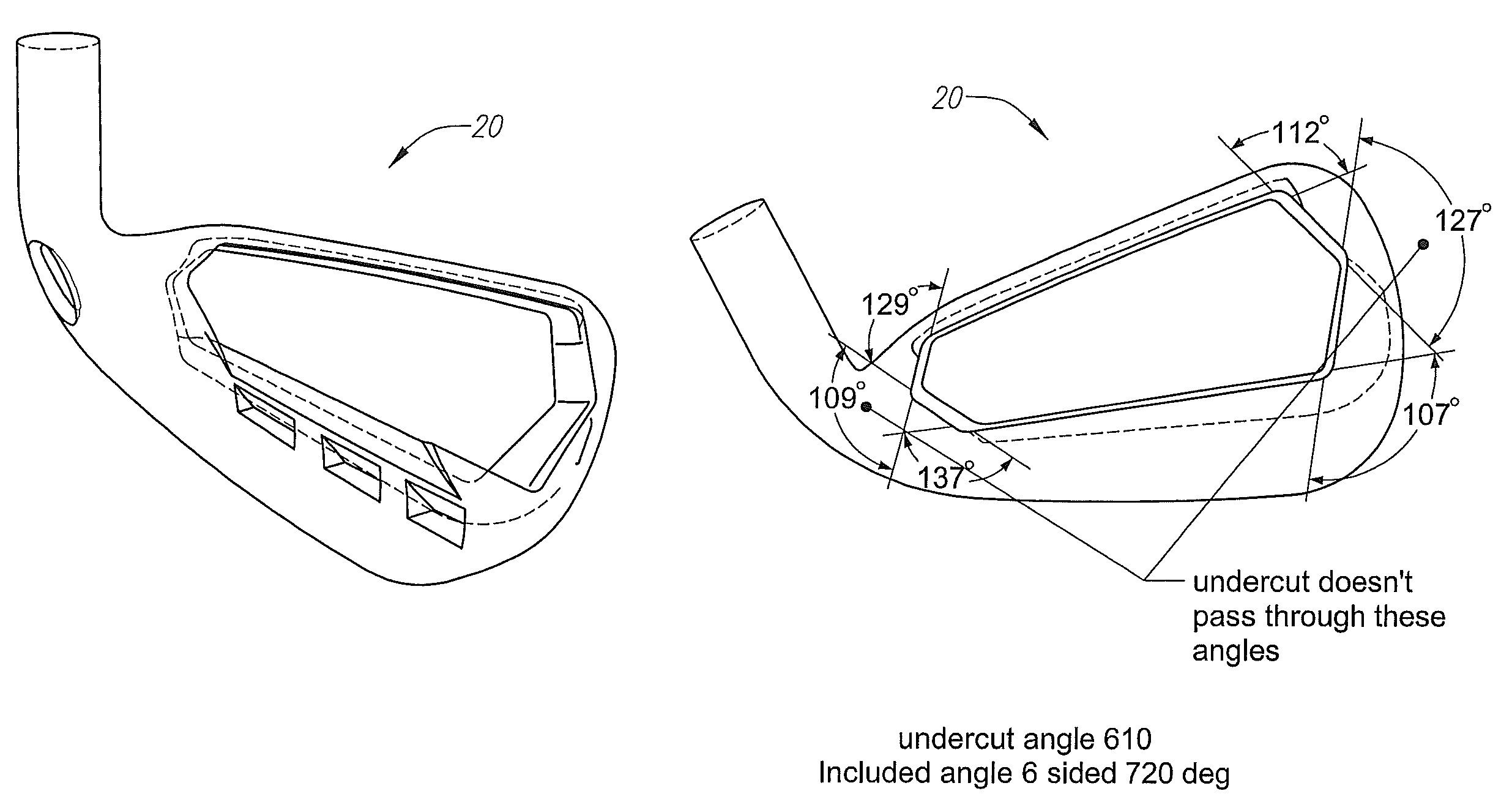

The hard carbon coating-clad base material of the present invention comprises a base material, a substratal metal coating formed on the base material by a wet plating process, an intermediate metal coating comprising a titanium or chromium coating formed on the substratal metal coating by a dry plating process and a silicon coating formed on the titanium or chromium coating by a dry plating process, and a hard carbon coating formed on the silicon coating by a dry plating process. According to the present invention, a highly reliable hard carbon coating which is excellent in corrosion resistance, adhesion and abrasion resistance can be formed even on brass or an iron base material having poor corrosion resistance, such as SK steel and martensitic and ferritic stainless steels.

Owner:CITIZEN WATCH CO LTD

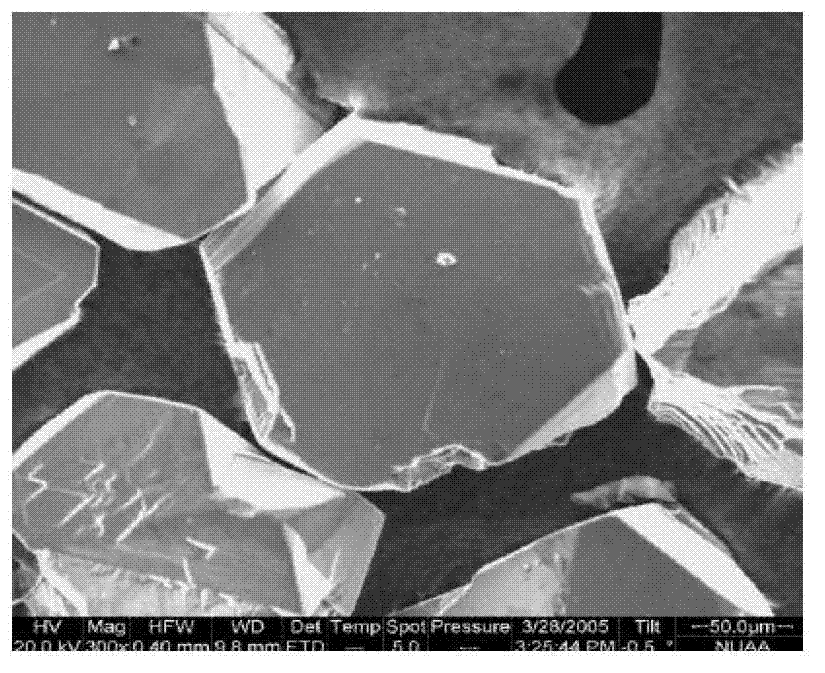

Crystallizer copper tube with transitional chromium coating and hard chromium coating and production process thereof

The manufacture technique for a crystallized copper tube with transient Cr-plating layer and hard Cr-plating layer comprises: cleaning the base copper tube to remove dust and oil; reverse nicking treatment before plating; preparing electroplate liquid; plating; cleaning; then, arranging transient plating layer with medium thermal-expansion coefficient and hardness between the base tube inner wall and surface hard plating layer. This invention ensures the tube resistance to high temperature, wear and corrosion, and endows the plating layer resistance peel, and has high yield efficiency with stable quality and low cost.

Owner:张喜成 +1

Method for manufacturing nickel-chromium plating steel band for battery steel shell

The invention discloses a method for manufacturing a nickel-chromium plating steel band for a battery steel shell. According to the method, ingredients of low-carbon steel are adjusted, proper amount of alloy elements of Ti, Ni, Nb and the like is added, and the content of N and O is controlled to improve surface states; parameters of a cold milling process and an annealing process are adjusted aiming at the adjusted ingredients of the steel; a chromium coating is used as a diffusion impervious layer, so that the diffusion of iron can be blocked effectively; and an anticorrosive coating which contains 20 to 30 percent of chromium and has a quasi-stainless steel structure is formed in the diffusion layer, so that the anticorrosive performance is enhanced doubly. Aiming at double-layer plating design concept of nickel-chromium plating, the ingredients of a nickel plating solution and a chromium plating solution and a plating process are adjusted, so that the coating has the characteristics of bright surfaces, low porosity and high mechanical performance.

Owner:WUXI FANGZHENG METAL LIGATURE

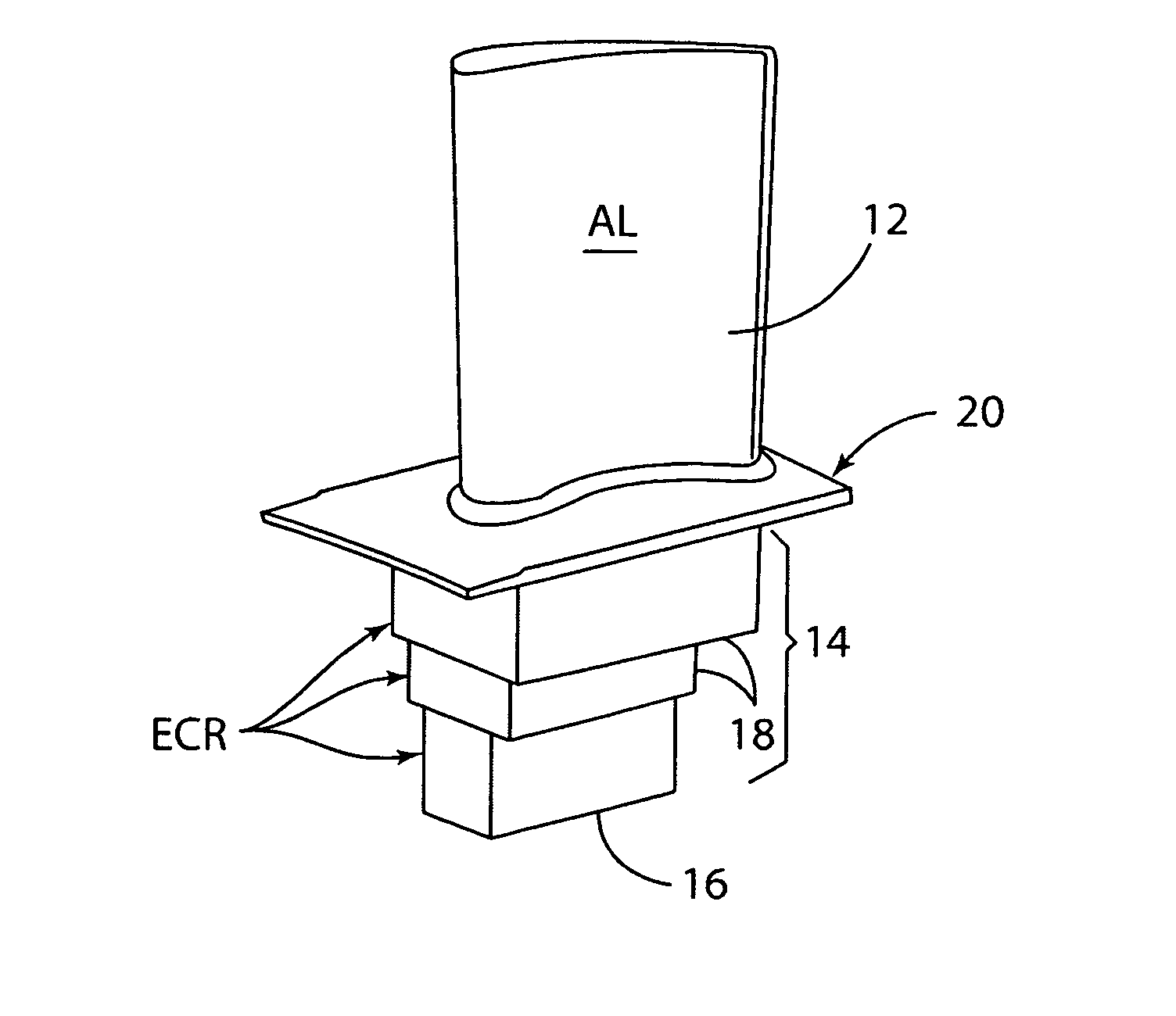

Iron-type golf club head with chamfered leading edge

An iron-type golf club head having a coated stepped sole is disclosed herein. The coated stepped sole is stepped such that the sole surface furthest from the face is raised away from the turf to minimize the turf contact through a golfer's swing particularly for the longer, less lofted irons. The surface friction is reduced by applying a thin dense chromium coating thorough electroplating to the stepped sole.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Piston ring and surface spongy tin plating technique thereof

The invention relates to a piston ring and a surface spongy tin plating technique thereof. The technical scheme thereof is as follows: the surface of a piston ring body is provided with a chromium plating layer, the outer surface of the chromium plating layer is provided with a spongy reticulate pattern, and the outer surface of the spongy reticulate pattern is provided with a tin plating layer. The invention comprises the following procedures: preplating, etching, chromium plating, washing, removal of hydrogen, hole loosing, washing and drying and tin plating treatment. The invention utilizes a reticulate pattern groove on the surface of the piston ring to store lubricating oil, thus greatly reducing the friction coefficient between the piston ring and a cylinder sleeve, improving oil absorbing property, and prolonging the service life of the piston ring and the cylinder sleeve; and compared with the prior art, the invention prolongs the service life of the piston ring and the cylinder sleeve by more than three thousand hours, improves the power of an internal combustion engine by more than 30 percent, saves oil by 25 percent, is capable of reducing the exhaust amount of gas / smoke of the internal combustion engine, reduces the environment requirements of atmosphere pollution, solves the mechanical wear of the piston ring during running-in period and obtains more perfect use performances.

Owner:XIANGFAN XINLI HENGXING PISTON RINGS

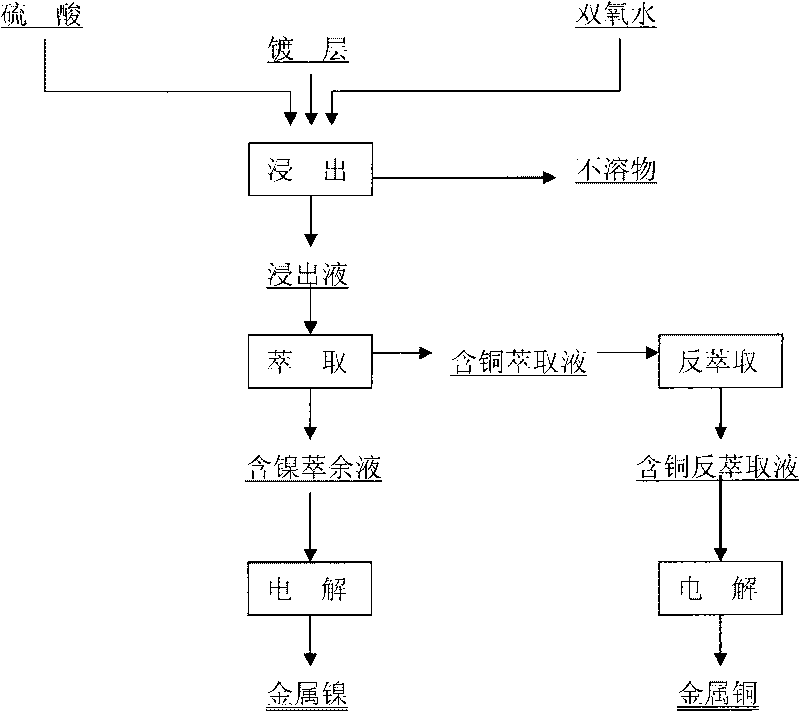

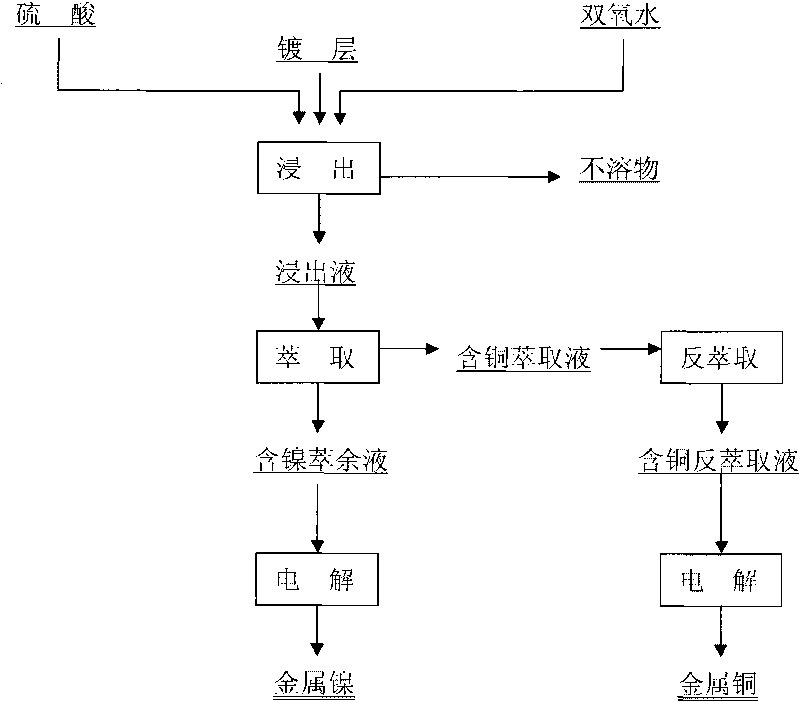

Method for recovering copper and nickel from plastic chromium coatings

InactiveCN101717955AImprove leaching rateReduce pollutionPhotography auxillary processesProcess efficiency improvementSal ammoniacPregnant leach solution

The invention provides a method for recovering copper and nickel from plastic chromium coatings. The method is characterized by consisting of the following steps of: 1, weighing the plastic chromium coatings, adding mixed solution of H2SO4 and H2O2 to the plastic chromium coatings for leaching, and filtering the mixed solution to obtain leachate and insoluble substances; 2, adjusting a pH value of the leachate, extracting the leachate by a mixture, serving as an extractant, of 2-hydroxyl-5-dodecyl salicylaldoxime and 2-hydroxyl-5-nonyl acetophenone oxime to obtain copper containing extraction solution and nickel containing raffinate, and back-extracting the copper containing extraction solution by sulfuric acid to obtain the copper containing back extraction solution; and 3, electrolyzing the copper containing back extraction solution and the nickel containing raffinate to obtain metal copper and metal nickel respectively. The method for recovering copper and nickel is lower in cost, causes little environmental pollution, and is suitable for the recycling of the plastic chromium coatings.

Owner:GUANGDONG INST OF RARE METALS

Door rod strengthening technology for air pump recycling regulation door

InactiveCN102330049AEliminate heavy pollutionRich varietyMolten spray coatingAbrasive blastingSpray coating

The invention discloses a door rod strengthening technology for an air pump recycling regulation door, which comprises the following steps of: 1. preliminary working: abrading the rod part of the door rod to remove the thickness of 0.18-0.20mm; 2. workpiece surface purification: purifying the surface until the surface is free from macroscopic oil stains; 3. surface pretreatment: carrying out abrasive blasting on the surface of the rod part of the door rod by 12# brown fused alumina sand, wherein the pressure of compressed air is 0.5-0.7kg / cm<2>, and the surface roughness after abrasive blasting reaches Sa 3 level; 4. metal ceramic coating spraying: spraying a metal ceramic coating on the surface of the rod part of the door rod by a supersonic speed flame spray gun, wherein the material is NiCr-C2C3 spraying powder, the flame center line of the spray gun and the axis of the workpiece are intersectant with the error within + / -5 degrees, the spraying distance is 220-250mm, parameters are controlled as follows: 15-18SCFM (standard cubic foot per minute) of O2, and 200-240SCFH (standard cubic foot per hour) of C3H6, and the temperature of the workpiece is controlled to below 200DEG C; and 5. mechanical processing of the coating. In the door rod strengthening technology, the supersonic speed spraying coating replaces a chromium coating so as to improve the abrasive resistance of the door rod, and the door rod strengthening technology is convenient to operate, is flexible and efficient, is environmentally-friendly and protects environment.

Owner:广州市天河区金棠表面工程技术有限公司

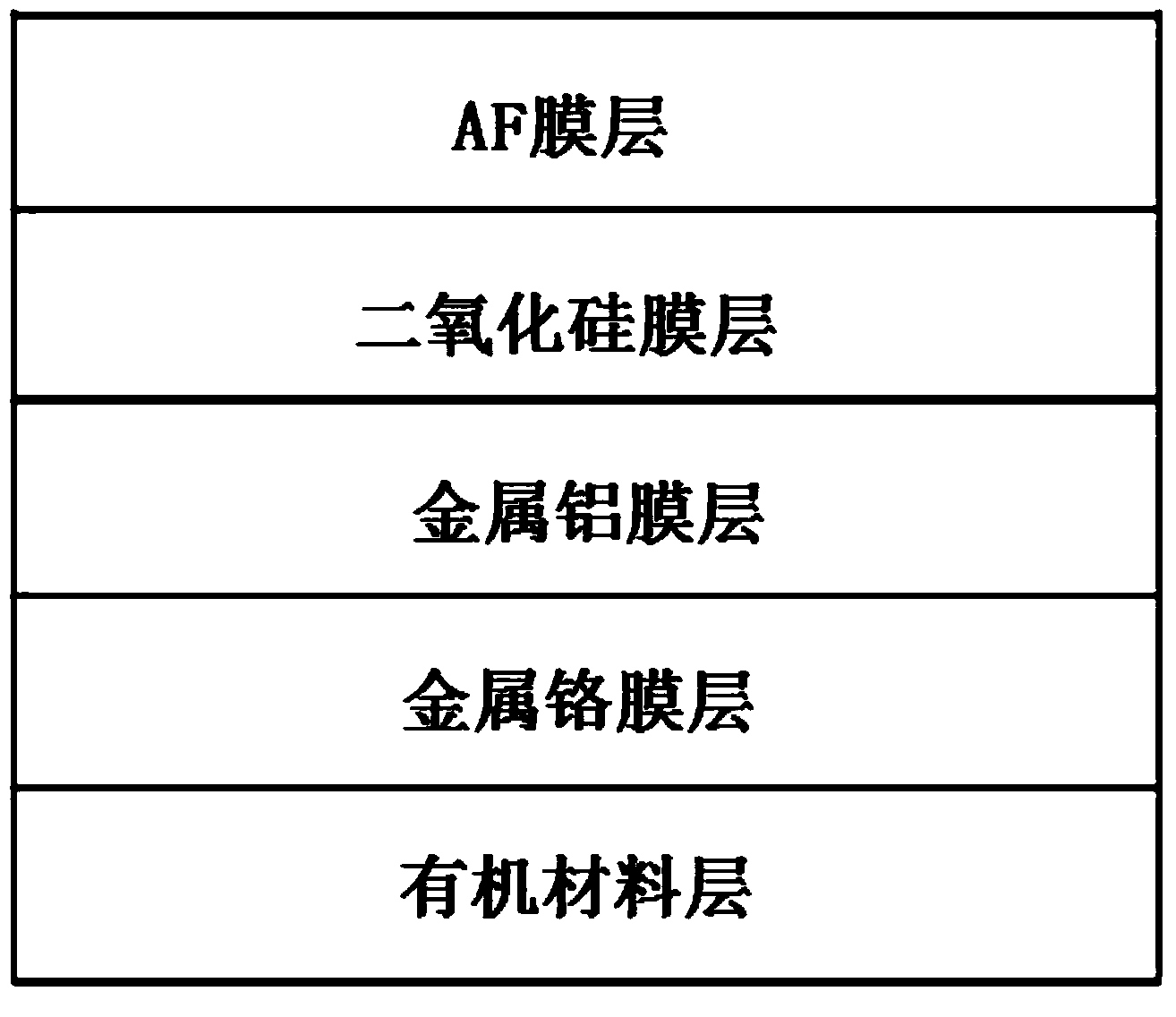

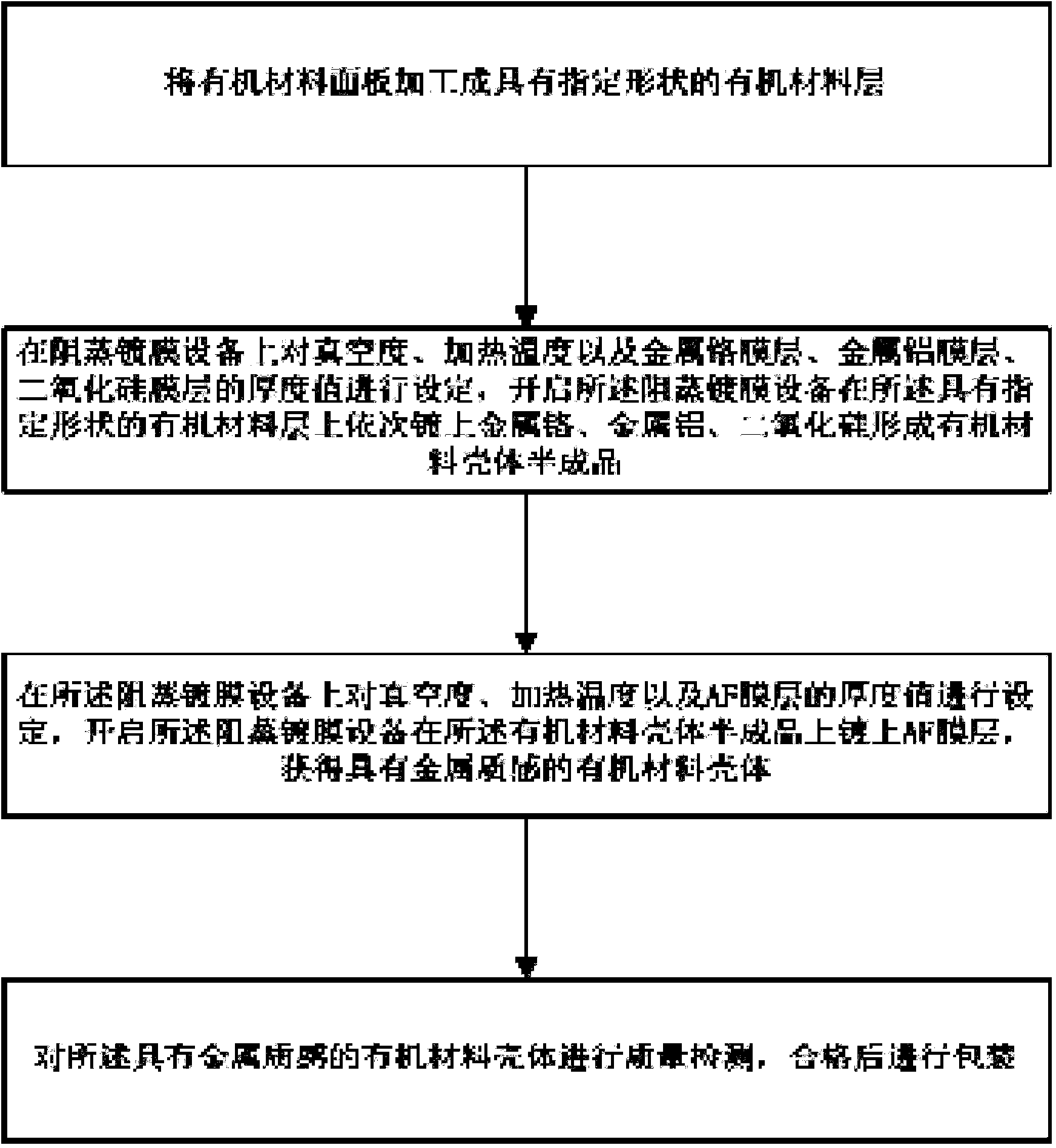

Organic material shell with metal texture and coating method thereof

ActiveCN103924199AStrong film stabilityHigh surface glossVacuum evaporation coatingCasings/cabinets/drawers detailsChromium coatingSilicon dioxide

The invention discloses an organic material shell with metal texture and a coating method thereof. The metal texture is obtained by depositing a chromium coating, an aluminum coating, a silicon dioxide coating and an AF (anti-fingerprint) coating on an organic material layer in a layer-by-layer manner; the obtained organic material shell has good characteristics that the coatings are good in stability and thin, the wear resistance is relatively good, the surface glossiness is high and the anti-fingerprint and dirt-resistant effects are achieved, and the requirements on electronic products caused by modern people are met.

Owner:SUZHOU ANJIE TECH

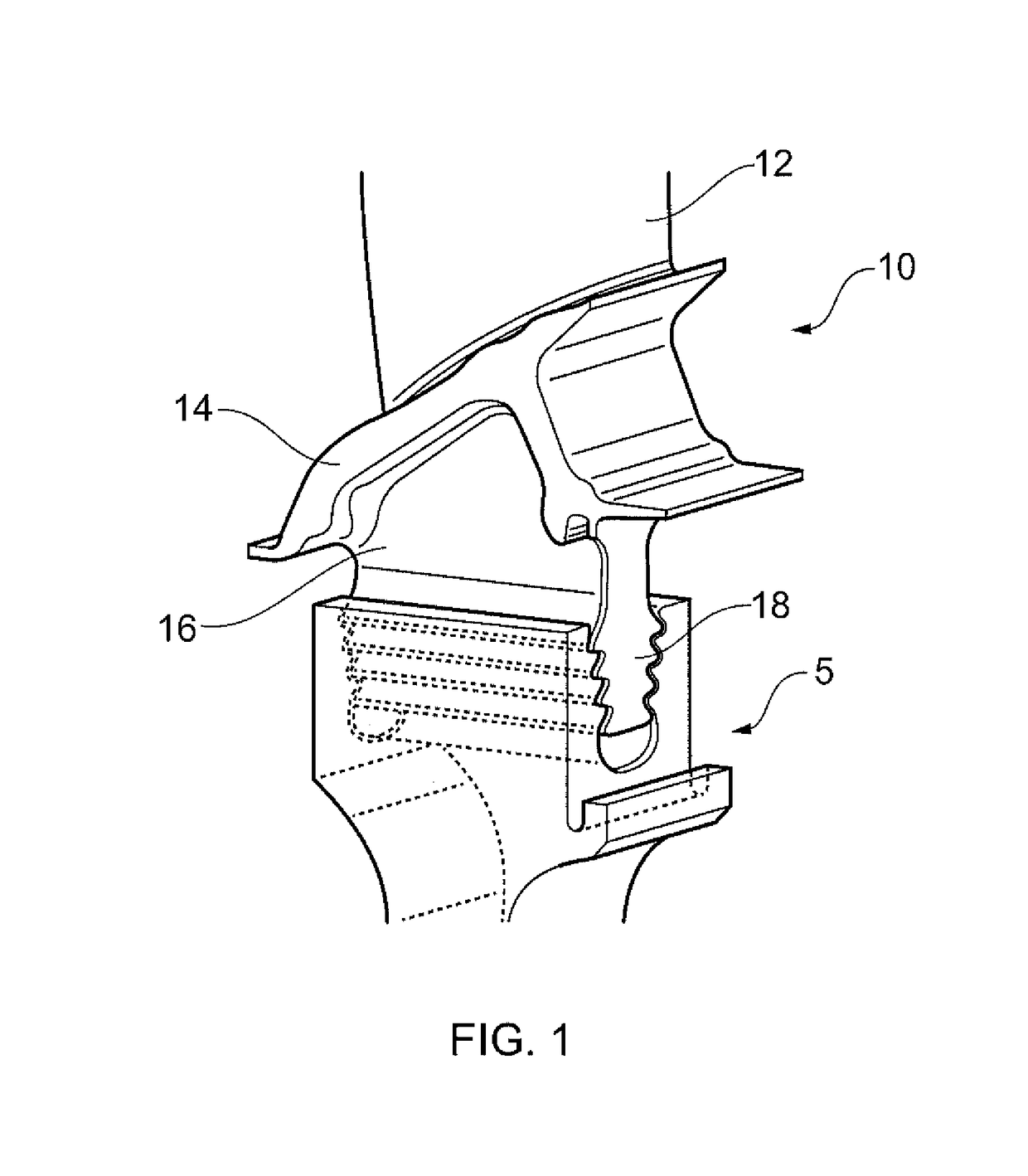

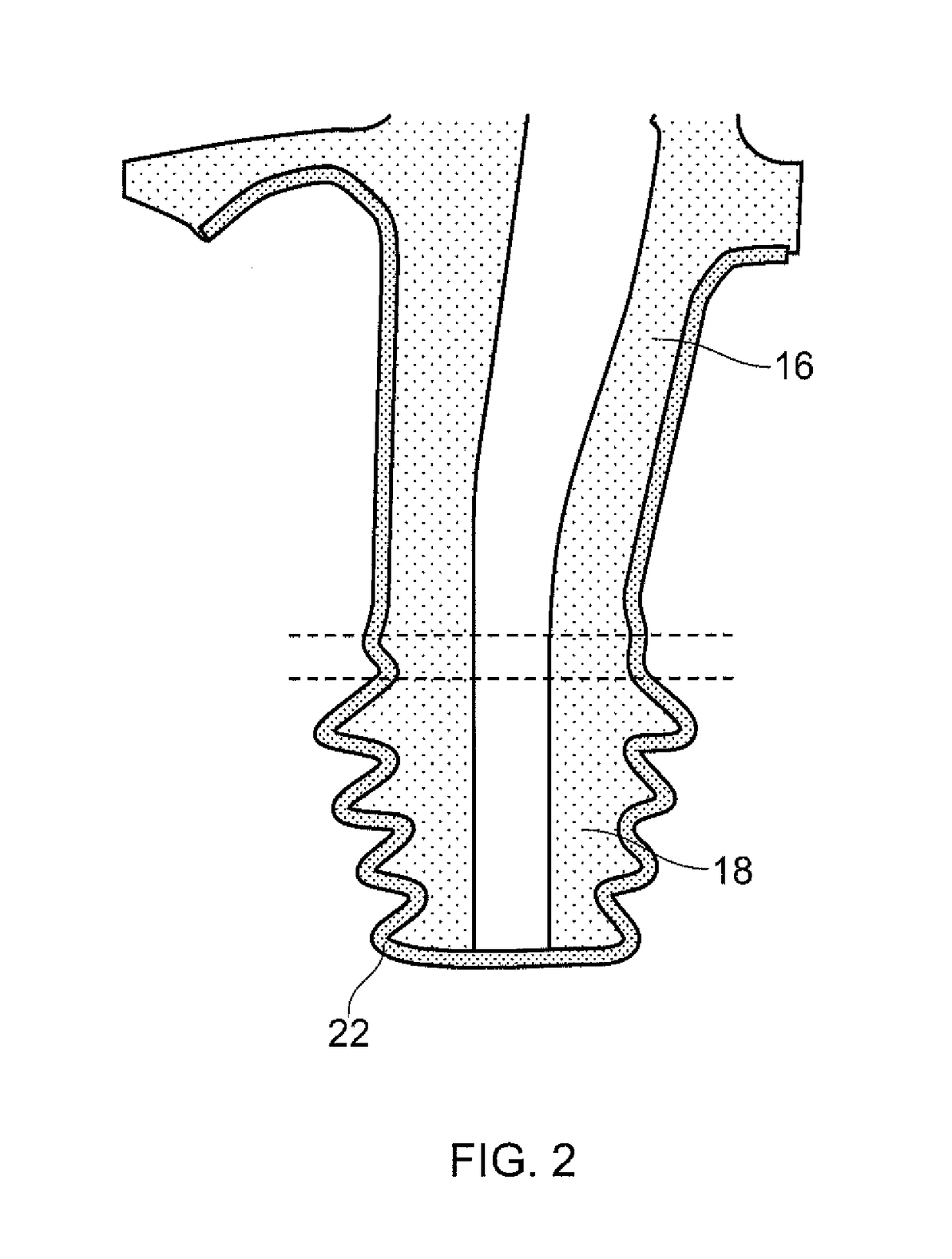

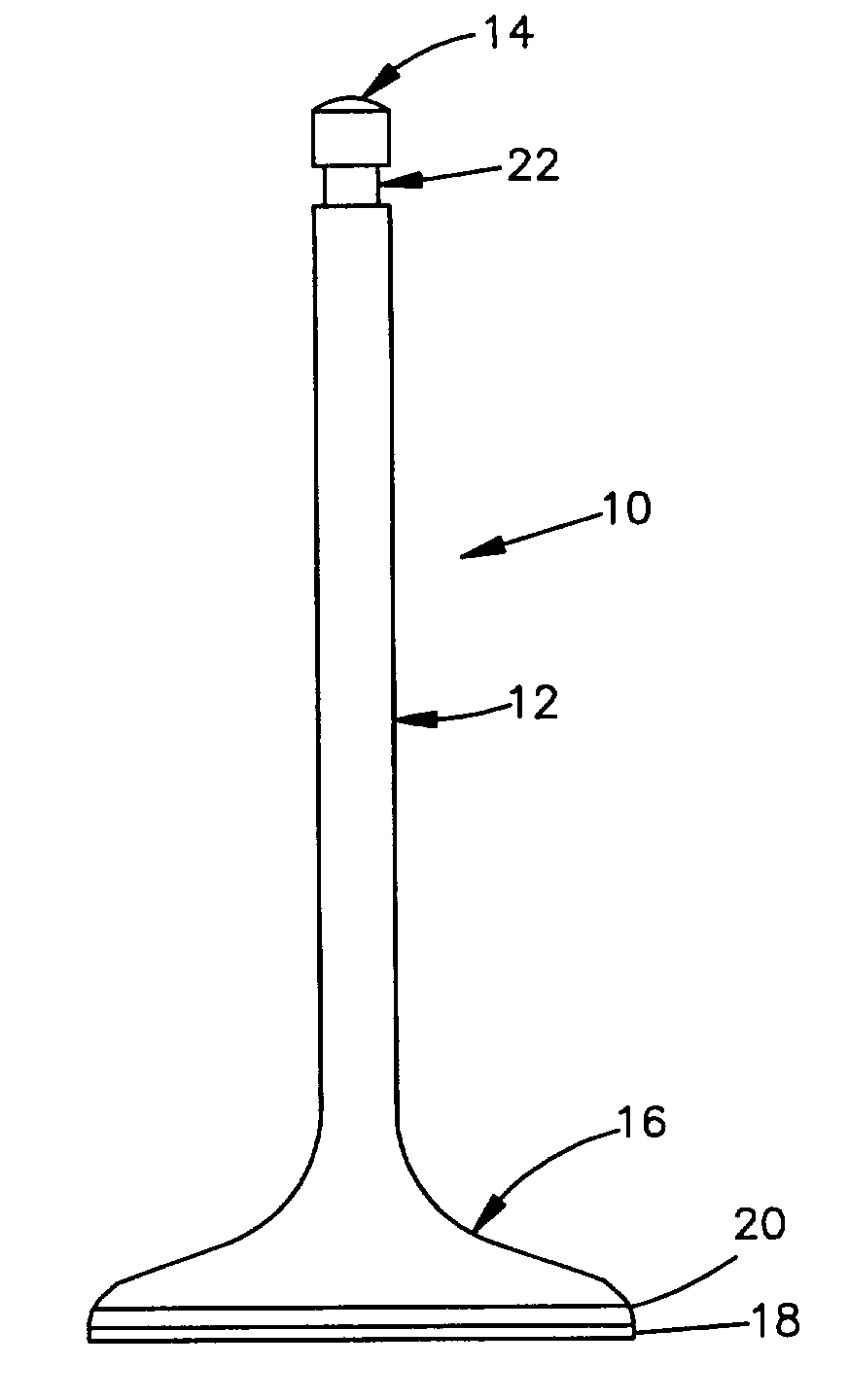

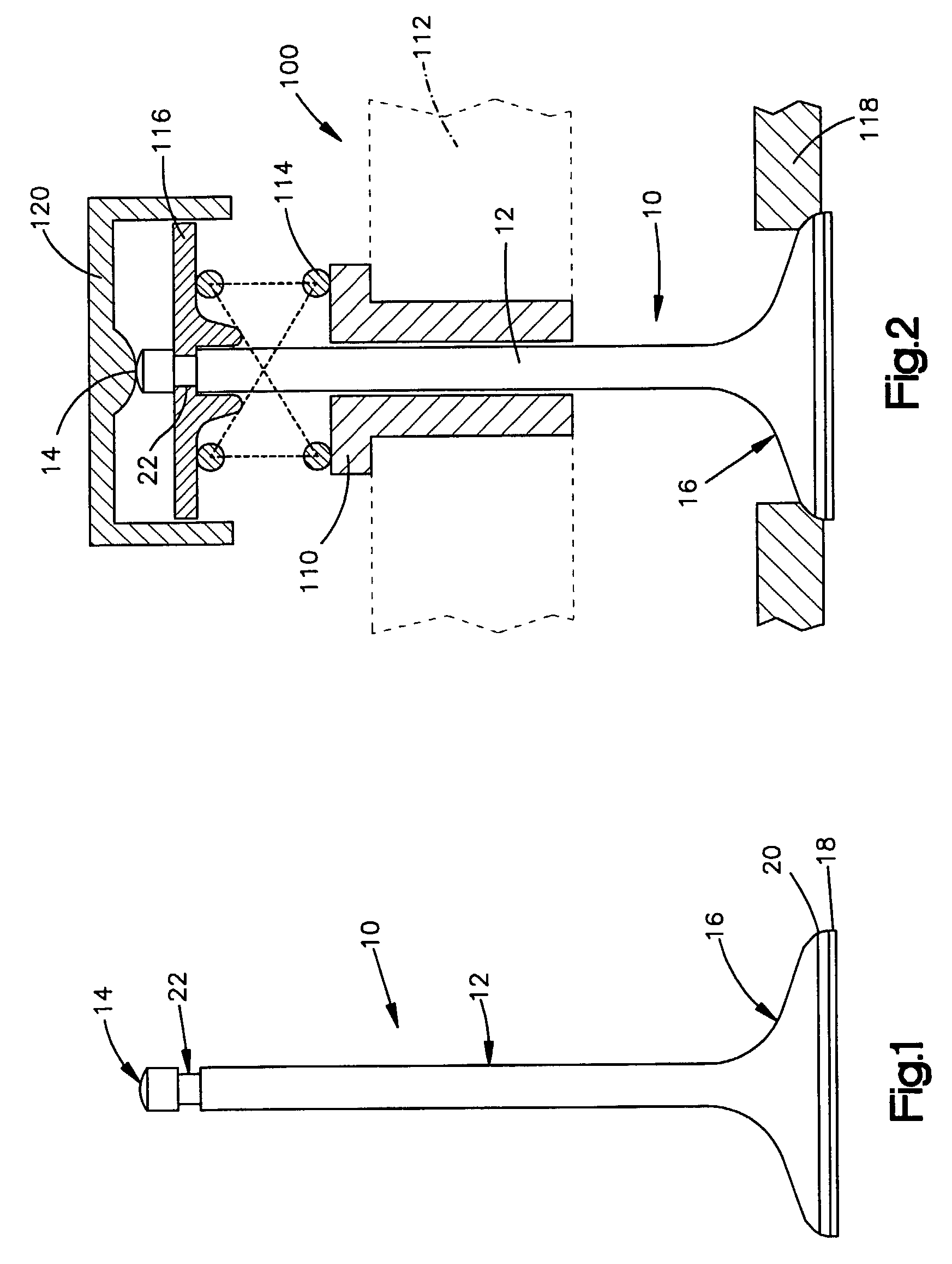

Chrome plated engine valve

A valve (10) for use in an internal combustion engine comprises a base metal. The base metal is covered with a thin, dense chromium coating.

Owner:TRW INC +1

Titanium nitride chromium coating and double glow plasma seepage preparing method thereof

InactiveCN105349944AHigh hardnessImprove wear resistanceSolid state diffusion coatingTitanium nitrideChromium coating

The invention relates to a metal surface cladding material, in particular to a titanium nitride chromium coating and a double glow plasma seepage preparing method of the titanium nitride chromium coating. The titanium nitride chromium coating is composed of titanium nitride and chromium nitride, and the mass ratio of the titanium element to the chromium element in the titanium nitride chromium coating is 100:10-50. The titanium nitride chromium coating is used for metal surface metallurgy. According to the prepared titanium nitride chromium coating, the surface modification layer formed by processing of a double glow plasma seepage metal technology is compact and even; and the titanium nitride chromium coating is an alloy layer with alloying elements distributed in a graded manner, the problem in common membrane base combination does not exist, and the problem that cracking and peeling of a modified layer prepared through an existing surface modified technique (physical vapor deposition method, chemical vapor deposition method, ion implantation and the like) under the bearing condition occur, and consequently, the stainless steel surface is easily corroded is solved. According to the metal surface cladding material, an adopted device is simple, the controllability is high, operation is easy, and the application scope is wide.

Owner:浙江百纳橡塑设备有限公司 +1

Cubic boron nitride fiber abrasive particles and preparation method thereof

ActiveCN102732213AMeet the requirements of self-sharpening and other aspectsOther chemical processesFiberBoron nitride

The invention relates to cubic boron nitride (CBN) fiber abrasive particles and a preparation method thereof. The CBN fiber abrasive particles comprise CBN abrasive particles and a bonding material, wherein the CBN abrasive particle surface is provided with a titanium coating or a chromium coating, and the thickness of the coating is 5-10 mum; the bonding material comprises 16-20wt% of Al2O3 powder, 28-32 wt% of B2O3 powder, 3-10 wt% of Na2O powder, and the balance of SiO2 powder; the sintering method is characterized by heating up to achieve a highest heating temperature of 795-805 DEG C by stage heating and preserving the heat for 18-22 min. The CBN fiber abrasive particles of the invention can realize the regular arrangement of the CBN abrasive particles in resin, ceramic, metal binder grinding wheel abrasive layers, and have the characteristics of high strength, good wear resistance and good self-sharpening performance, thus the grinding efficiency and quality are raised. The application of the CBN fiber abrasive particles in preparing grinding wheels can satisfy the grinding requirements of key components in aerospace, automobile and other industries.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

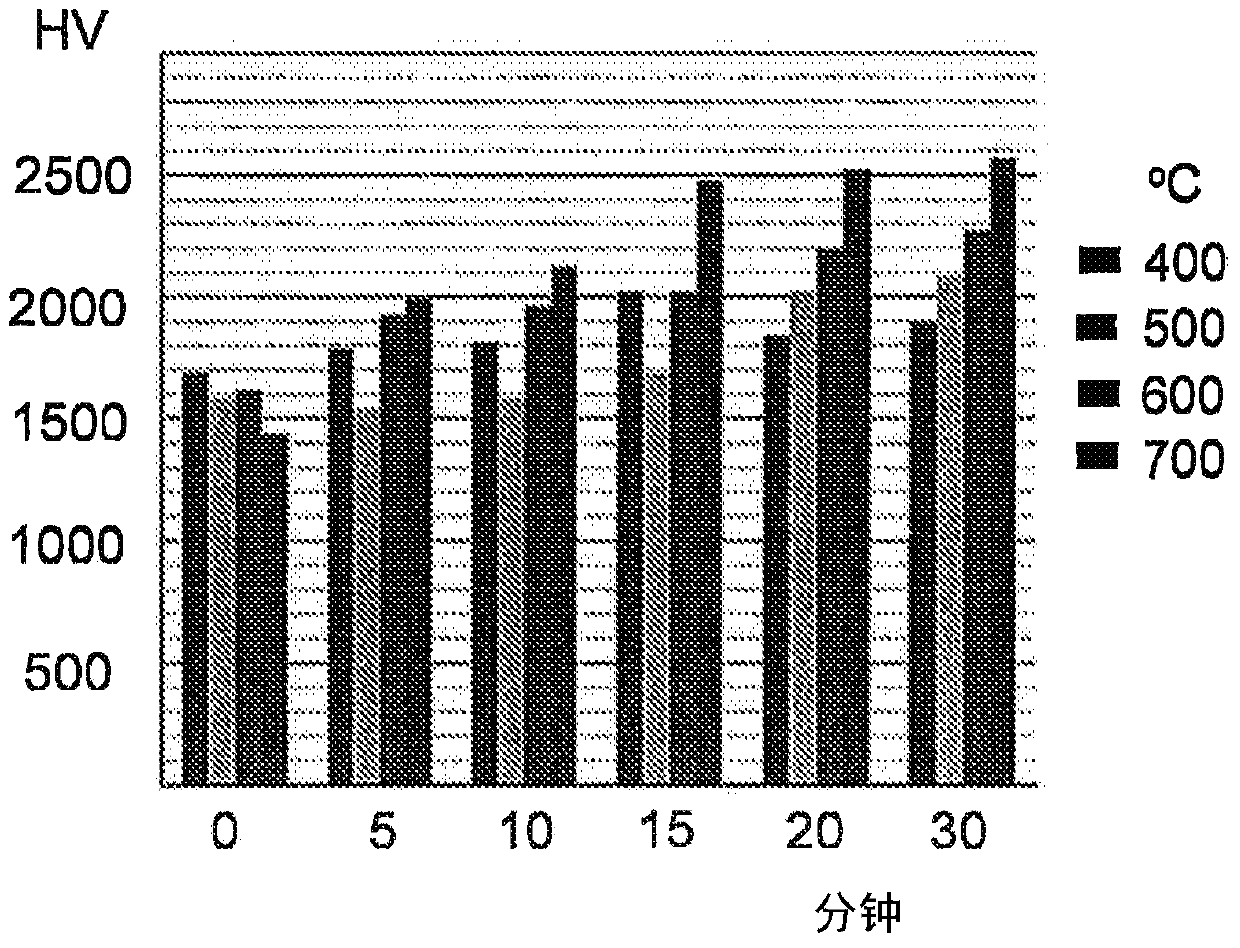

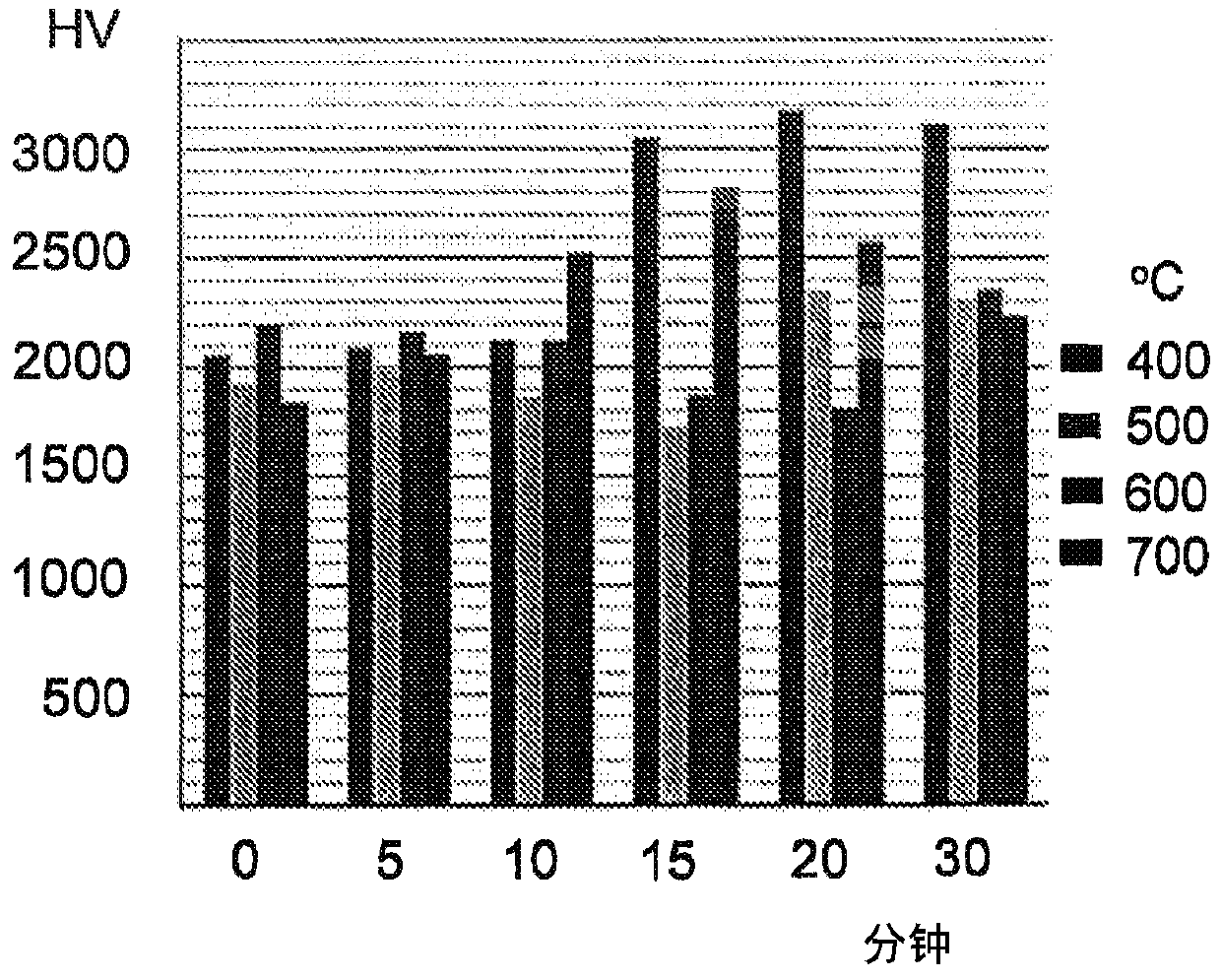

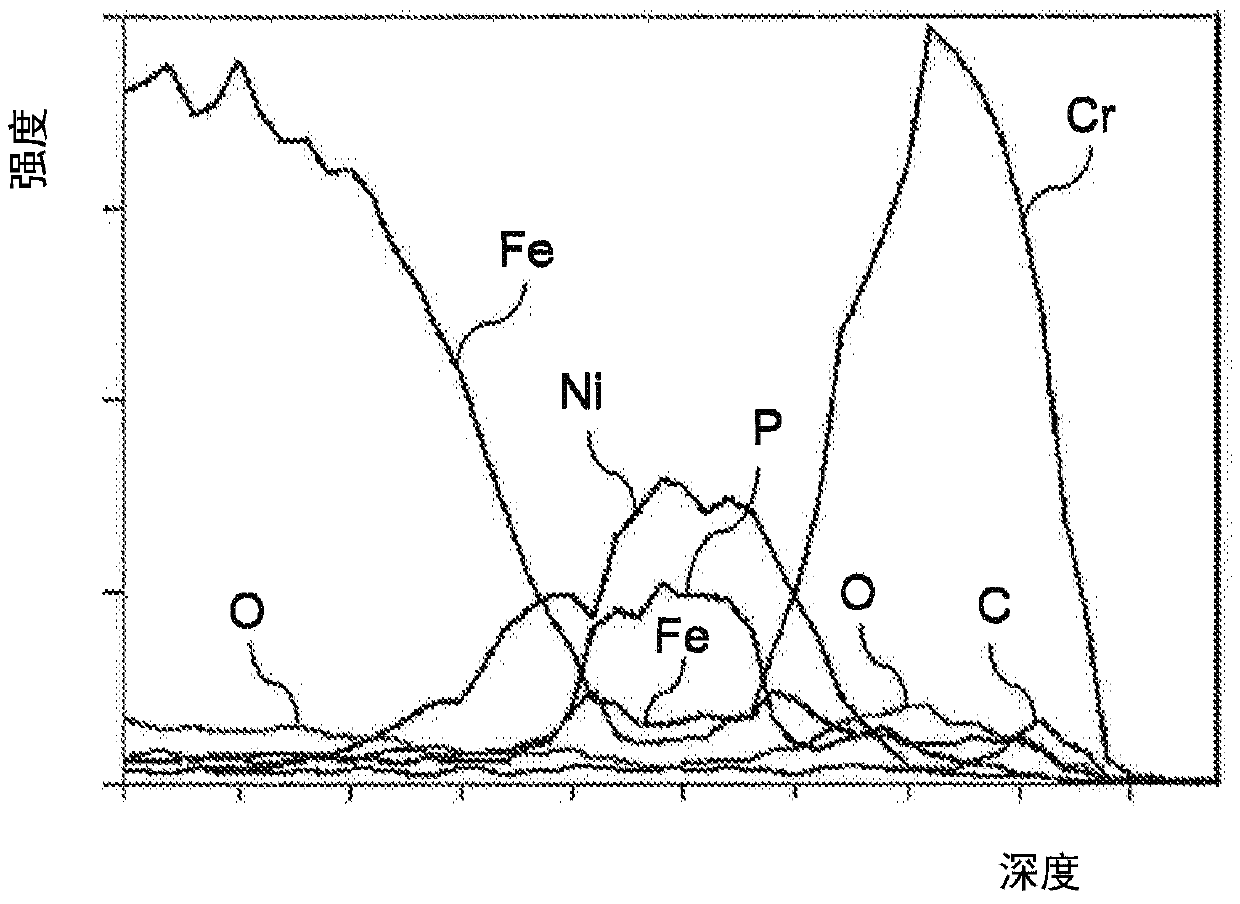

Method for producing a chromium coating on a metal substrate

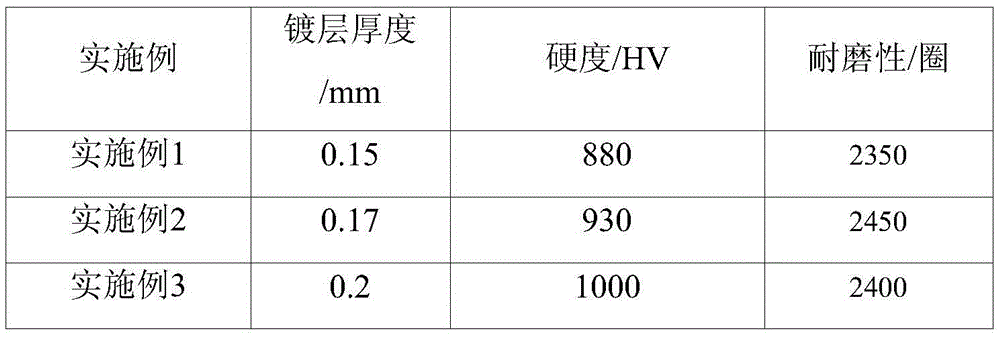

In the method for producing a trivalent chromium based coating on a metal substrate,a layer of nickel phosphorus alloy is deposited on a metal substrateanda trivalent chromium layer is electroplated on the Ni-P layer. The coated metal substrate is subjected to one or more heat treatments to harden the coating and to produce multiphase layers including at least one layer containing crystalline Ni and crystalline Ni 3 P, and at least one layer containing crystalline Cr and crystal- line CrNi.By using this method it is possible to pro- duce coatings having a Vickers microhardness value higher than 2000 HV.

Owner:SAVROC

Manufacturing method of submarine oil well valve base

ActiveCN103614632AImprove compactnessImprove continuityWell/borehole valve arrangementsSealing/packingManganeseChromium coating

The invention discloses a manufacturing method of a submarine oil well valve base. Chrome-molybdenum low-alloy steel is selected as a blank. The chrome-molybdenum low-alloy steel comprises the following components in percentage by mass: 0.3-0.32% of carbon, 0.18-0.36% of silicon, 0.50-0.70% of manganese, 0.90-1.10% of chrome, 0.20-0.30% of molybdenum, 0-0.02% of phosphorus, 0-0.025% of sulfur, 0-1.8ppm of hydrogen, 0-0.40% of nickel, 0-0.03% of vanadium, 0-0.30% of copper, 0-0.9% residual element and the balance of Fe. The manufacturing method disclosed by the invention can enhance the pressure resistance and toughness of the valve base and prevent the chrome coating from shedding.

Owner:镇江市华阳机电制造有限公司

Method for obtaining vacuum chromium-coated layer on high-temperature-resisting plastic workpiece

InactiveCN101029391AChange glossVariety of colorsLiquid surface applicatorsVacuum evaporation coatingCooking & bakingHeat deflection temperature

A method for producing vacuum chromium-cladding layer on high-temperature-resisting plastic piece has chromium-plating and decorative functions. The process is carried out by selecting plastic piece with thermal-deformation temperature above 100degree, spraying baking paint onto plastic piece surface with curing temperature below 100degree as primer paint, obtaining vacuum chromium-cladding layer on primer surface of multi-arc vacuum ion coating apparatus, and re-spraying baking paint with curing temperature below 100degree onto chromium-cladding layer surface as finish. It has excellent abrasive and anti-corrosion performances.

Owner:张金勇

Method of pulse chromium plating with trivalent chromium

The invention discloses a method of pulse chromium plating with trivalent chromium, which comprises the following steps: dissolving an rare-earth oxide in an acid to prepare a rare-earth salt solution; dissolving chromium sulfate salt, aluminum sulfate, sodium fluoride, urea and a complexing agent in water, and then adding the rare-earth salt solution to prepare an electroplating solution containing the chromium sulfate salt, the aluminum sulfate, the sodium fluoride, the urea, the complexing agent and the rare-earth salt; putting a part to be plated in the electroplating solution for electroplating, and controlling the electroplating process conditions as follows: the current density is 28-90A / dm<2>, the pH value of the electroplating solution is 1-4, the temperature is 25-60 DEG C, the agitating speed is 100-600 rpm, the plating time is 30-90 min, the duty ratio is 5-100%, and the pulse frequency is 100-5000 Hz; and after electroplating, washing the plated part with water and drying with air, thereby finishing pulse chromium plating with trivalent chromium of the part to be plated. The hardness and wear resistance of the obtained chromium coating are obviously improved, wherein the hardness is larger than or equal to 960HV, and the mass loss during wear is less than or equal to 0.03mg.

Owner:SHANGHAI INST OF TECH

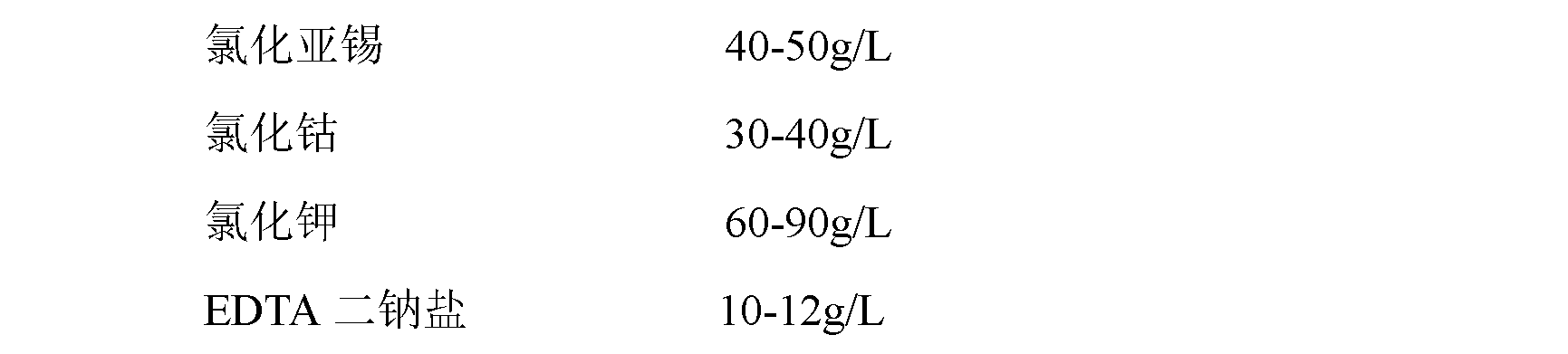

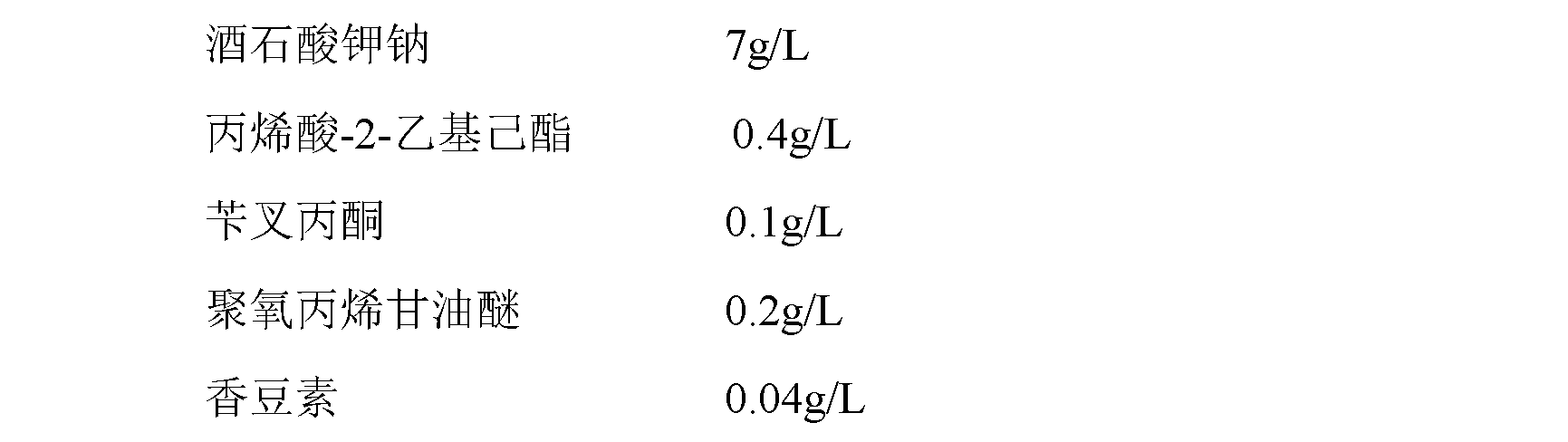

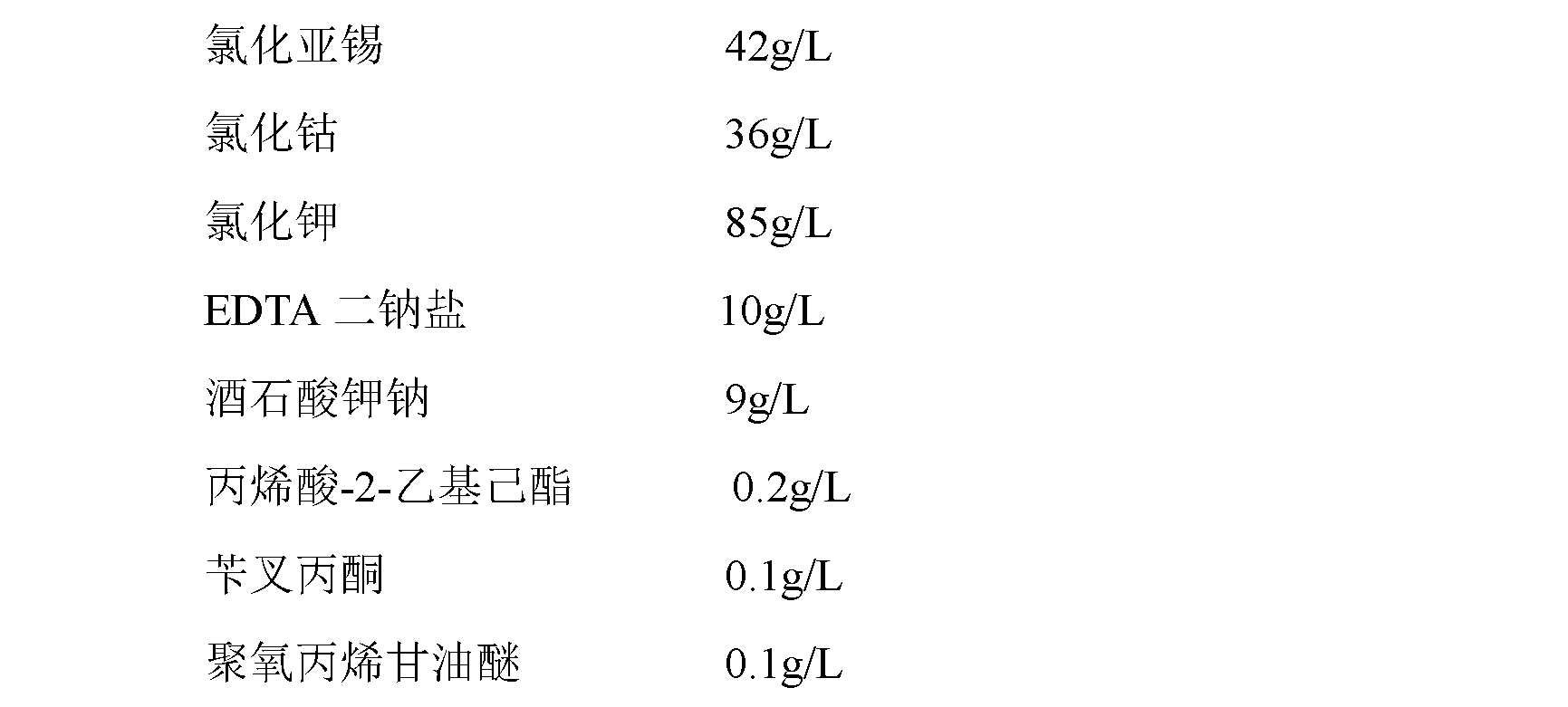

Tin-cobalt alloy decorative chromium-substituted electroplate liquid and electroplate method thereof

ActiveCN103014792ABright appearanceExtended service lifeSodium potassium tartrate tetrahydrateChromium coating

The invention discloses a tin-cobalt alloy decorative chromium-substituted electroplate liquid and an electroplate method thereof. The electroplate liquid consists of the following components: 40-50 g / L of stannous chloride, 30-40 g / L of cobalt chloride, 60-90 g / L of potassium chloride, 10-12 g / L of EDTA disodium salt, 5-10 g / L of sodium potassium tartrate tetrahydrate, 0.2-0.5 g / L of crylic-2-ethyl hexyl ester, 0.1-0.2 g / L of benzalacetone, 0.1-0.2 g / L of polyoxypropylene glycerol ether and 0.02-0.05 g / L of coumarin. Compared with the electroplated coating obtained by the present tin-cobalt alloy electroplate liquid, the coating obtained according to the invention is closer to a chromium coating in apperance, can be widely applied to decorative chromium-substituted technique, and has the advantages of smoothness of the electroplated coating, uniformity and compactness, good adhesive force, long service life of the electroplate liquid and the like.

Owner:合肥华清高科表面技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com