Tin-cobalt alloy decorative chromium-substituted electroplate liquid and electroplate method thereof

A tin-cobalt alloy and decorative technology, which is applied in the tin-cobalt alloy decorative chromium-substituting electroplating solution and its electroplating field, can solve problems such as narrow range, and achieve the effects of long service life, bright appearance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

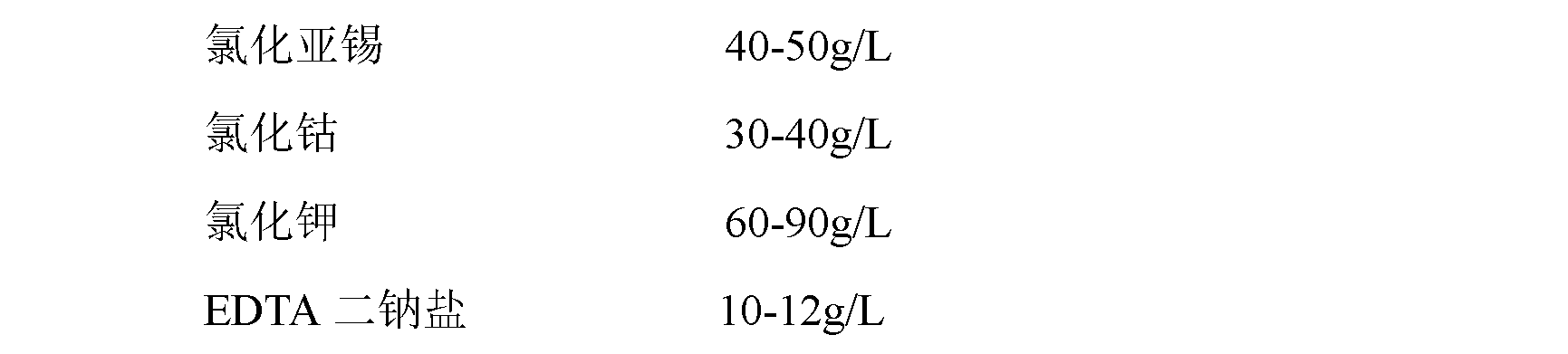

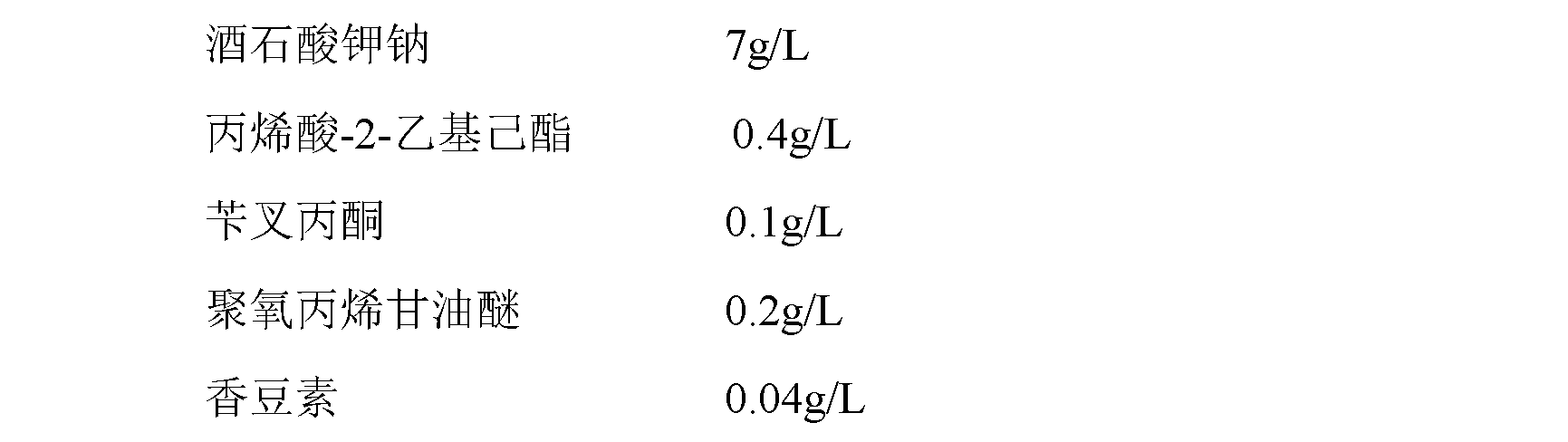

[0019] A tin-cobalt alloy decorative chromium-substituting electroplating solution, its plating solution formula consists of:

[0020]

[0021]

[0022] The electroplating method of the tin-cobalt alloy decorative chromium-substituting electroplating solution: stainless steel is put into the electroplating solution as an anode, the workpiece is cleaned and activated according to the conventional pre-plating treatment, and then electroplated with bright nickel, and the above-mentioned workpiece electroplated with bright nickel is placed Into the electroplating solution of the present invention as the cathode, at a temperature of 50-60°C, a pH value of 8.0-9.0, and a cathode current density of 0.3-1.0A / dm 2 electroplating under conditions.

Embodiment 2

[0024] A tin-cobalt alloy decorative chromium-substituting electroplating solution, its plating solution formula consists of:

[0025]

[0026] The electroplating method of the tin-cobalt alloy decorative chromium-substituting electroplating solution: stainless steel is put into the electroplating solution as an anode, the workpiece is cleaned and activated according to the conventional pre-plating treatment, and then electroplated with bright nickel, and the above-mentioned workpiece electroplated with bright nickel is placed Into the electroplating solution of the present invention as the cathode, at a temperature of 50-60°C, a pH value of 8.0-9.0, and a cathode current density of 0.3-1.0A / dm 2 electroplating under conditions.

Embodiment 3

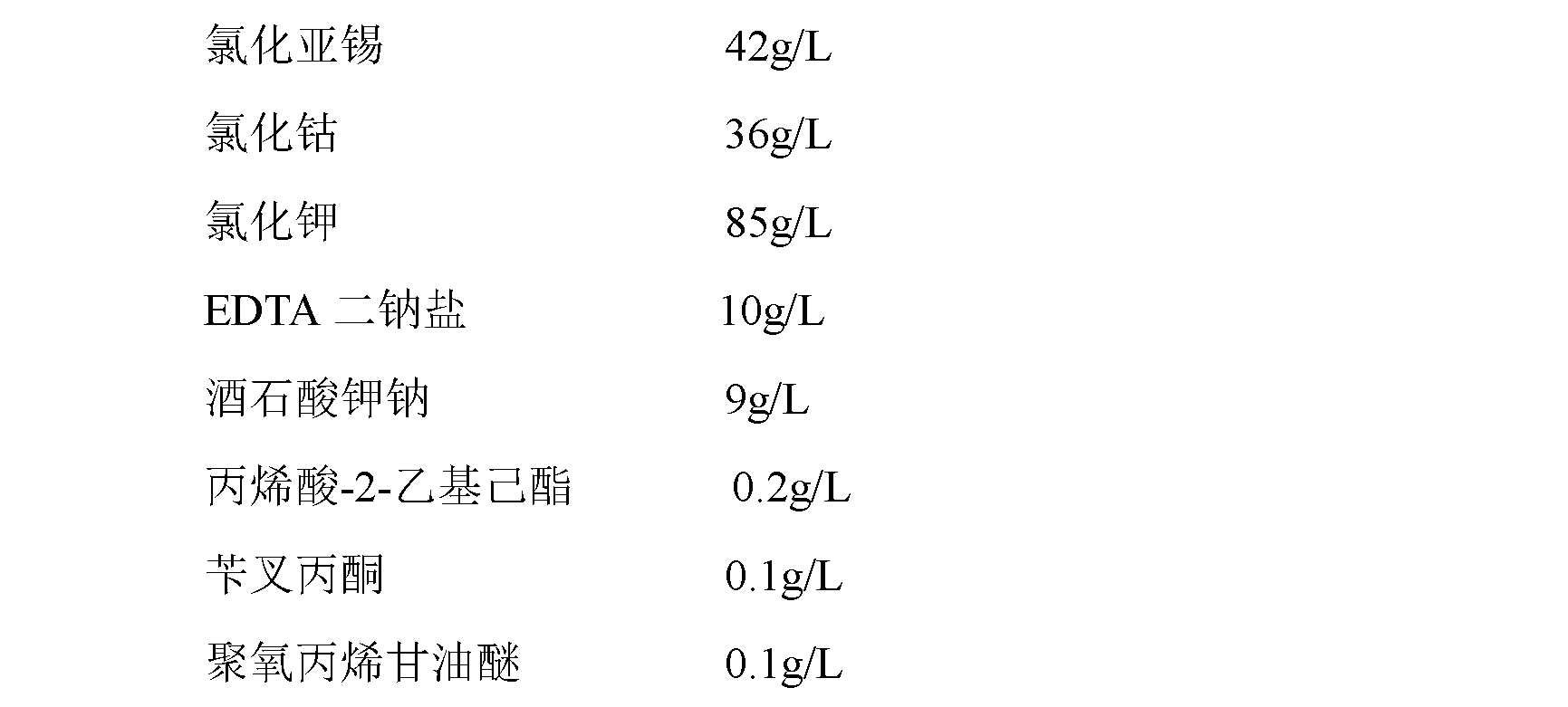

[0028] A tin-cobalt alloy decorative chromium-substituting electroplating solution, its plating solution formula consists of:

[0029]

[0030]

[0031] The electroplating method of the tin-cobalt alloy decorative chromium-substituting electroplating solution: stainless steel is put into the electroplating solution as an anode, the workpiece is cleaned and activated according to the conventional pre-plating treatment, and then electroplated with bright nickel, and the above-mentioned workpiece electroplated with bright nickel is placed Into the electroplating solution of the present invention as the cathode, at a temperature of 50-60°C, a pH value of 8.0-9.0, and a cathode current density of 0.3-1.0A / dm 2 electroplating under conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com