Alkaline non-cyanide zinc plating nickel alloy plating solution and electroplating process thereof

An electroplating process and zinc-nickel technology, applied in the field of alkaline cyanide-free zinc-nickel alloy plating solution and its electroplating process, can solve problems such as low current efficiency, achieve high current efficiency, low waste liquid pollution, and stable plating solution Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

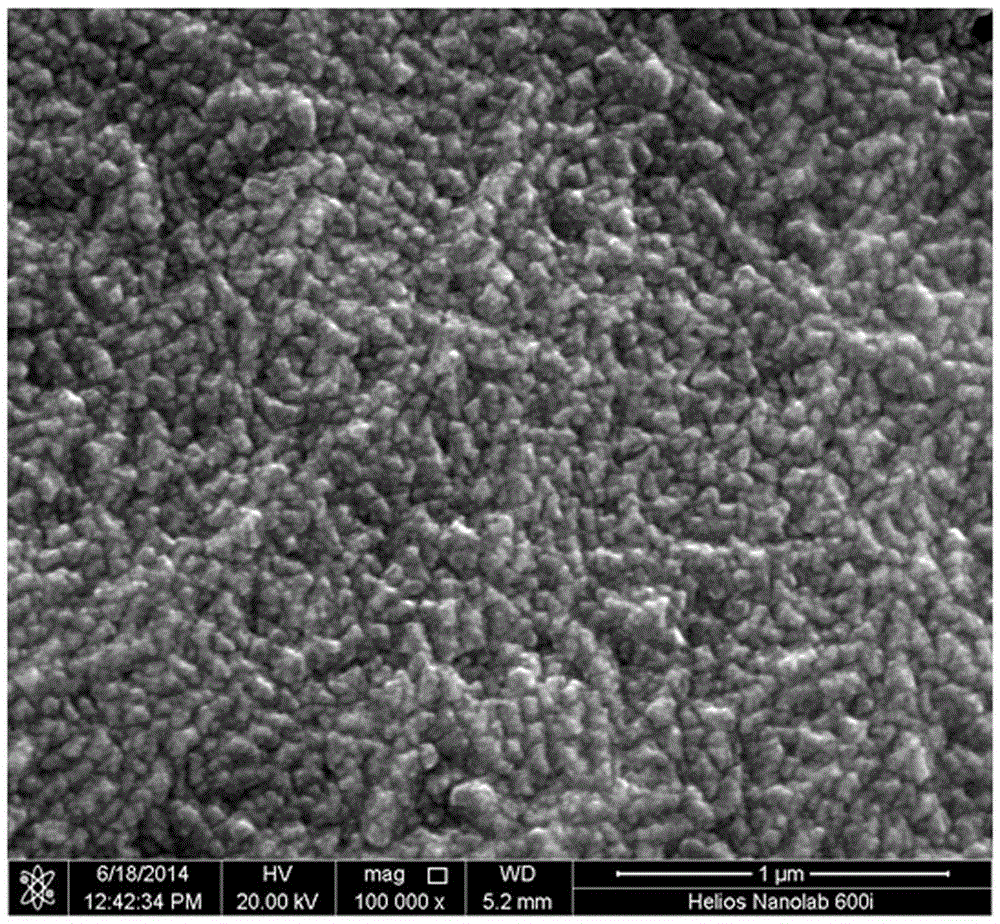

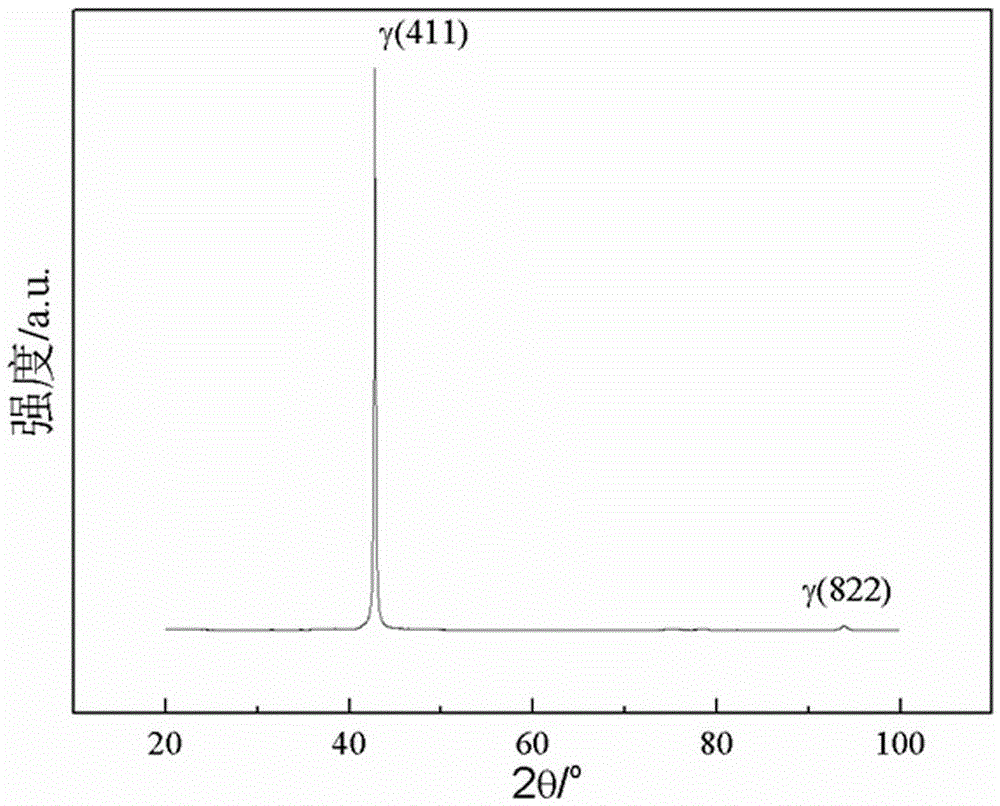

[0029] Embodiment 1: The alkaline cyanide-free zinc-nickel alloy plating solution is composed of: 1,3-dibromo-5,5-dimethylhydantoin 125g / L, triethanolamine 20g / L, potassium carbonate 130g / L, Zinc Sulfate 55g / L, Nickel Sulfate 20g / L, the copper sheet is used as the cathode after alkaline degreasing, 1:1 HCI aqueous solution pickling and water washing, and the inert metal is used as the anode, and the distance between the cathode and the anode is 5cm, bath temperature is 60℃, pH is 10, current density is 1.5A / dm 2 , the stirring speed is 600rpm, the electroplating time is 40min, the current efficiency of the obtained plating solution is more than 85%, the appearance of the coating is bright, uniform and smooth, the nickel content of the coating is 13.58wt.%. figure 1 Shown), the XRD detection coating is composed of a single γ phase.

Embodiment approach 2

[0030] Embodiment 2: The alkaline cyanide-free zinc-nickel alloy plating solution is composed of: 1,3-dimethylol-5,5-dimethylhydantoin 135g / L, triethylenetetramine 10g / L , Potassium carbonate 100g / L, zinc sulfate 65g / L, nickel sulfate 30g / L, the copper sheet is used as the cathode after alkaline degreasing, 1:1 HCI aqueous solution pickling and water washing, and the inert metal is used as the anode. The distance between them is 4cm, the temperature of the bath is 50°C, the pH is 10, and the current density is 4A / dm 2 , the stirring speed is 800rpm, the electroplating time is 10min, the current efficiency of the obtained plating solution is more than 85%, the appearance of the coating is bright, uniform and smooth, and the nickel content is 13.71wt.%. Composed of a single γ phase.

Embodiment approach 3

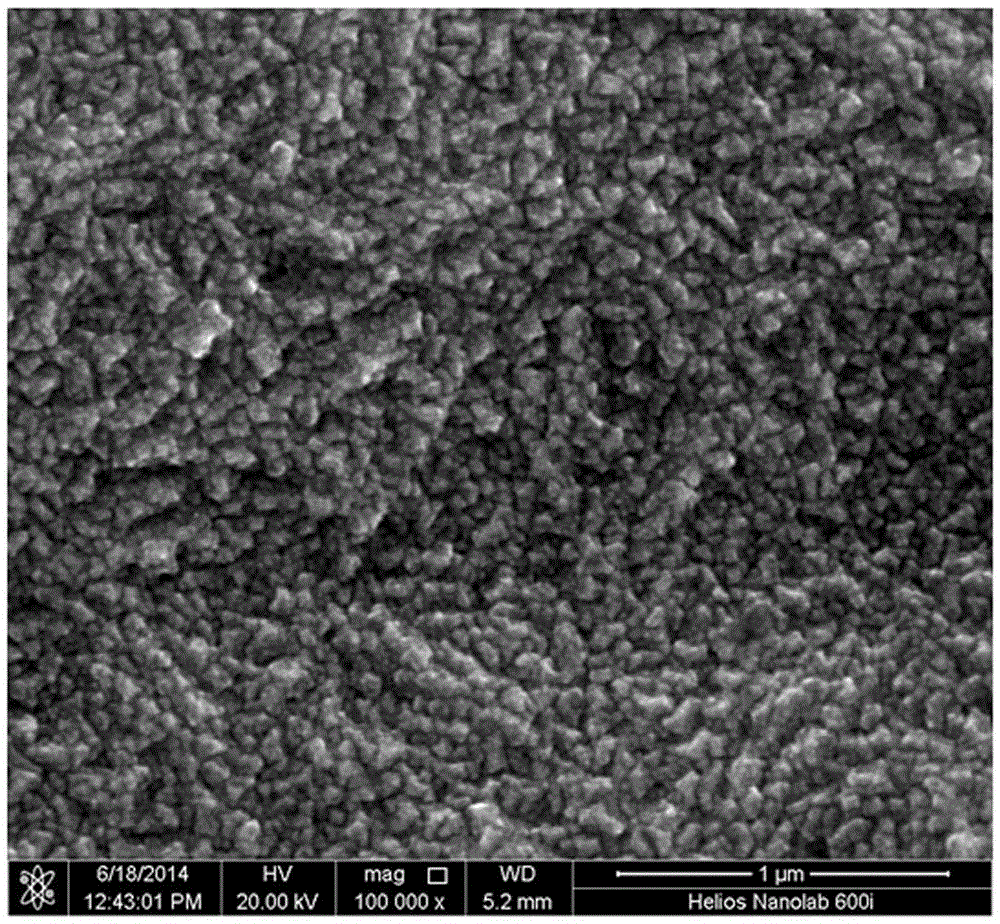

[0031] Embodiment 3: The alkaline cyanide-free zinc-nickel alloy plating solution is composed of: 1,3-dimethylol-5,5-dimethylhydantoin 45g / L, sodium citrate 5g / L, Potassium carbonate 50g / L, zinc sulfate 25g / L, nickel sulfate 10g / L, copper sheet after alkaline degreasing, 1:1 HCI aqueous solution pickling and water washing as cathode, inert metal as anode, between cathode and anode The distance is 10cm, the temperature of the bath is 45°C, the pH is 8, and the current density is 0.5A / dm 2 , the stirring speed is 200rpm, the electroplating time is 60min, the current efficiency of the obtained plating solution is more than 85%, the appearance of the coating is bright, uniform and smooth, and the content of the coating is 12.63wt.%. SEM observes that the coating crystal is fine, dense, and has no pores. XRD detects the coating Composed of a single γ phase.

[0032] Embodiment 4: The alkaline cyanide-free zinc-nickel alloy plating solution is composed of: 1,3-dibromo-5,5-dimethylhyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com