Patents

Literature

91 results about "Sodium potassium tartrate tetrahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for inhibiting amine degradation during c02 capture from a gas stream

ActiveUS20090205496A1Induce degradationGas treatmentOther chemical processesHydroxylamineSulfite salt

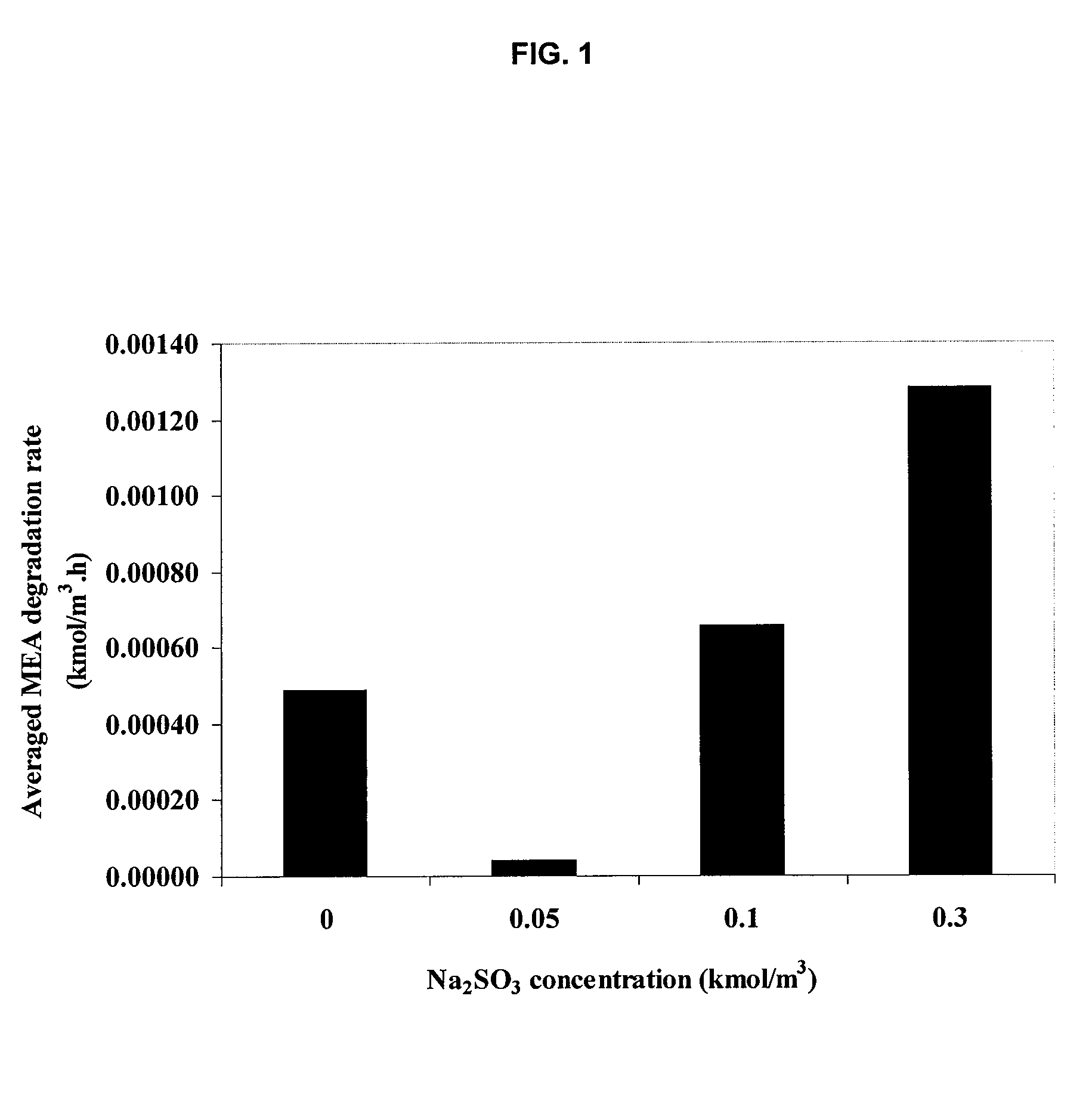

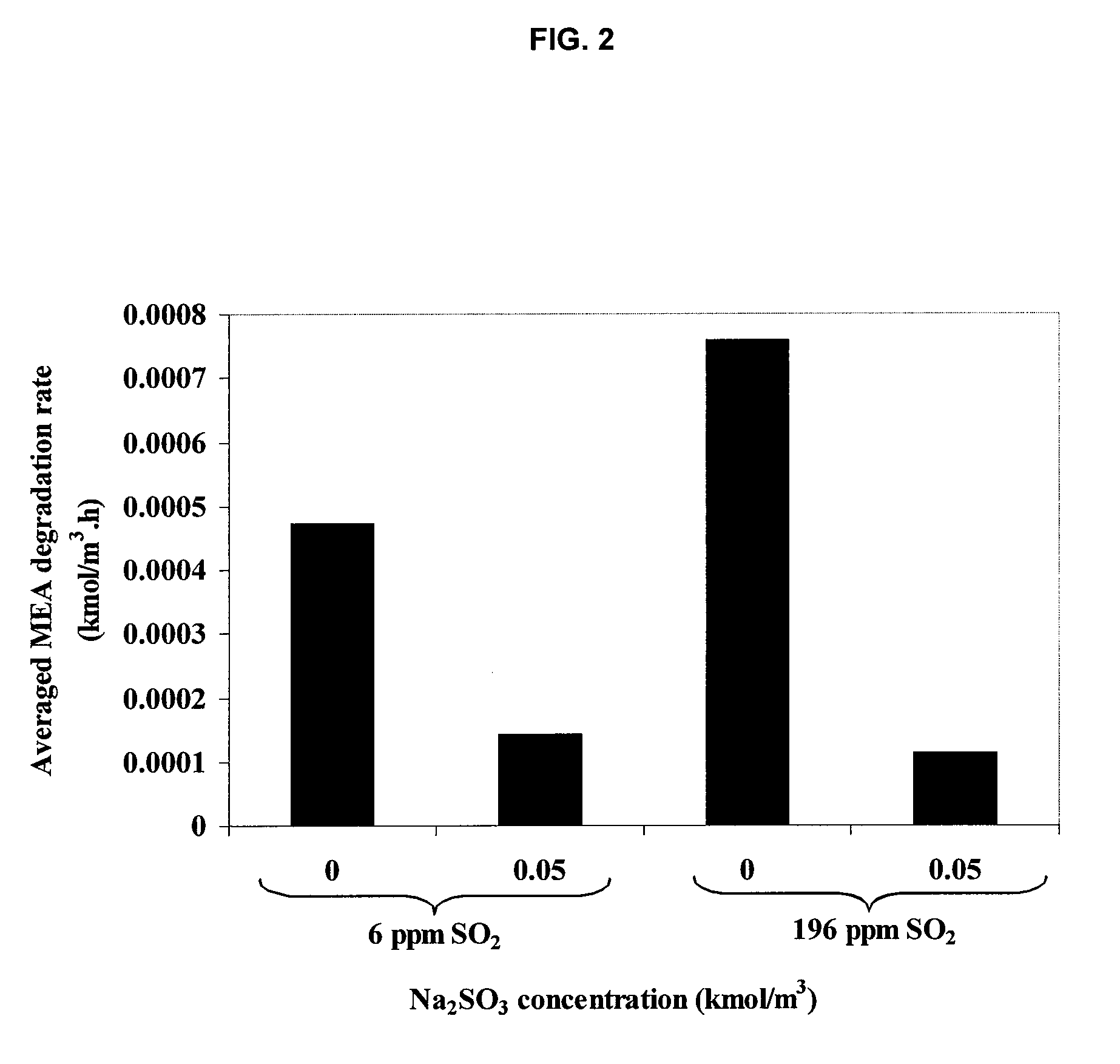

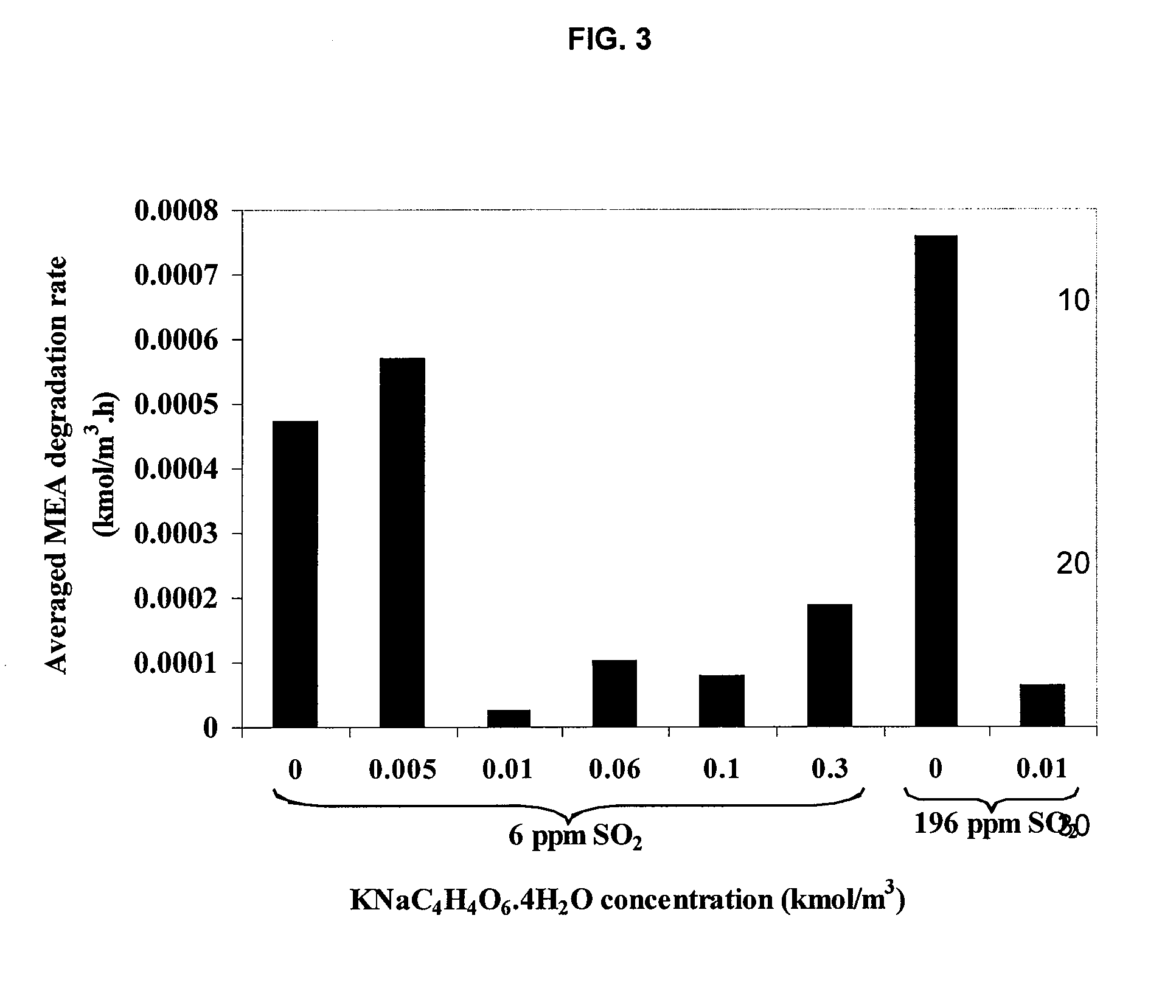

The present application includes a method for inhibiting amine degradation during CO2 capture from flue gas streams. Particularly, the present disclosure relates to a method of inhibiting O2- and / or SO2-induced degradation of amines using sodium sulfite (Na2SO3), potassium sodium tartrate tetrahydrate (KNaC4H4O6.4H2O), ethylenediaminetetraacetic acid (EDTA) or hydroxylamine (NH2OH), or analogs or mixtures thereof during CO2 capture by amines.

Owner:UNIVERSITY OF REGINA

Masking-agent-containing test strip for detecting content of cadmium in Chinese herbal medicine

ActiveCN103776826AExtended storage timeEasy to carryMaterial analysis by observing effect on chemical indicatorSodium potassium tartrate tetrahydrateThiourea

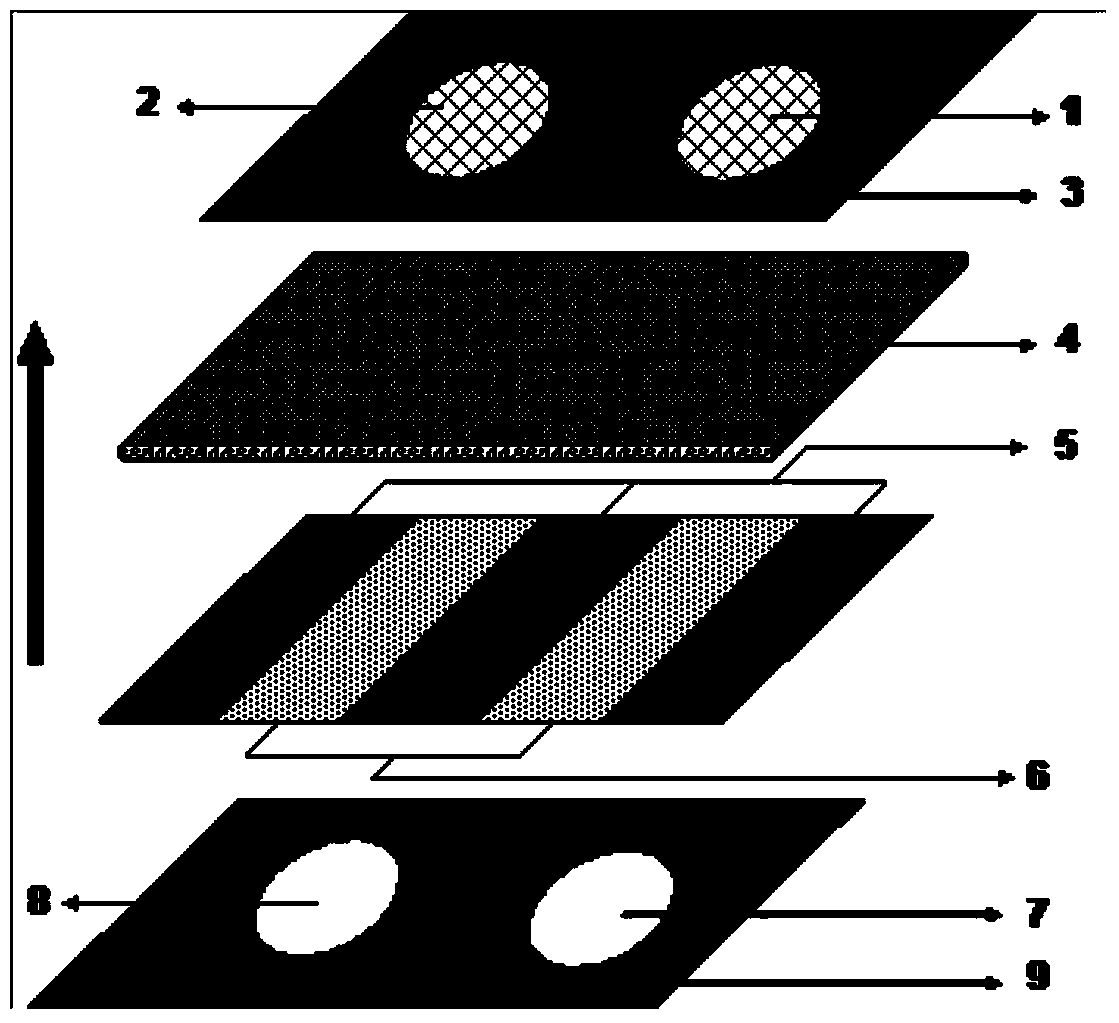

The invention discloses a masking-agent-containing test strip for detecting the content of cadmium in a Chinese herbal medicine. The test strip comprises a loading substrate, a glass fiber layer, a reaction substrate and a supporting substrate which are sequentially overlapped on one another, wherein the loading substrate is provided with a test hole and a contrast hole, the glass fiber layer contains a masking agent, the reaction substrate contains a cadmium color developing agent, and the supporting substrate is provided with two observation holes, and the two observation holes respectively correspond to the test hole and the contrast hole; the masking agent is the combination of two or more than two formulae in the following five formulae: a formula I including hydroxylamine hydrochloride and glycine; a formula II including sodium thiosulfate and sodium citrate; a formula III including thiourea and sodium pyrophosphate; a formula IV including sodium potassium tartrate tetrahydrate and thiourea; and a formula V including diethyl dithiocarbamate and phenanthroline. The test strip disclosed by the invention is convenient to carry, is simple to operate, low in cost, high in detection sensitivity and specificity and wide in application range and can realize the rapid spot detection on the heavy metal cadmium in the Chinese herbal medicine.

Owner:INFINITUS (CHINA) CO LTD

Self-lubricating modified light calcium carbonate filler and preparation method thereof

InactiveCN104194191AGood self-lubricating performanceImprove water delivery capacityPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsZno nanoparticlesNuclear chemistry

The invention discloses self-lubricating modified light calcium carbonate filler which is prepared from the following raw materials in parts by weight: 2-3 parts of zinc stearate, 3-5 parts of polyoxyethylene, 0.5-0.7 part of inulin, 2-3 parts of graphite fluoride, 0.2-0.3 part of sodium potassium tartrate tetrahydrate, 0.1-0.2 part of sodium lignin sulfonate, 1-1.5 parts of nano crystalline cellulose, 0.5-0.8 part of benzotriazole, 1-1.5 parts of sulfo-diethylene glycol, 2-3 parts of butyl acrylate, 1-2 parts of a crylic acid, 0.4-0.5 part of poly(oxy-1,2-ethanediyl), 2-3 parts of nano zinc oxide, 0.1-0.2 part of ammonium persulfate, 80-85 parts of light calcium carbonate, 13-16 parts of aids and 120-140 parts of water. The filler disclosed by the invention is good in dispersibility; a modifier can form a uniform and integral coating layer on the surface of the nano calcium carbonate, so that the water delivery property of the surface of the calcium carbonate is good, and the strength and wear resistance of the surface of the calcium carbonate are increased; and due to addition of nano zinc oxide, the age resistance of PVC is increased.

Owner:CHIZHOU RUIXIANG CALCIUM IND

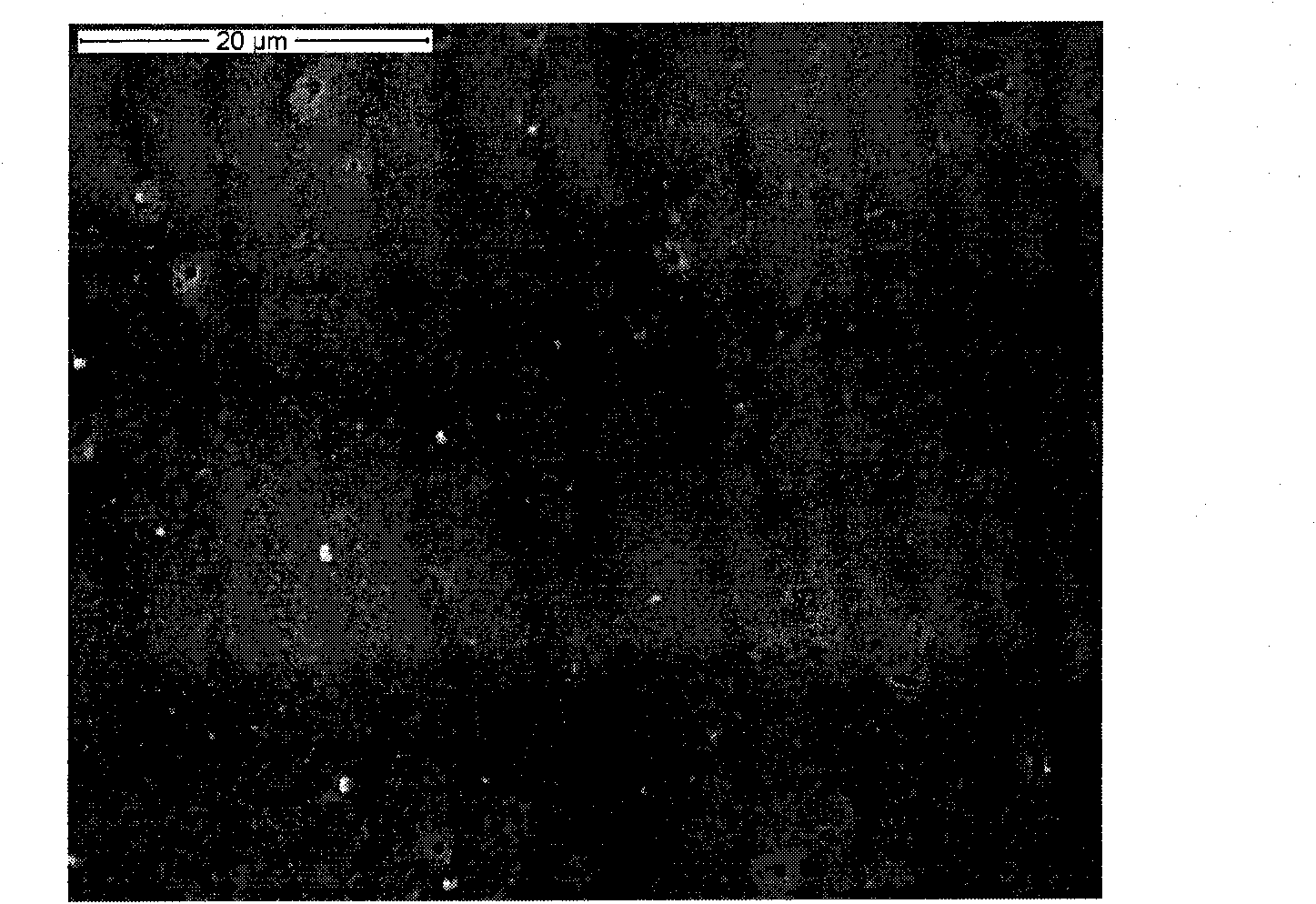

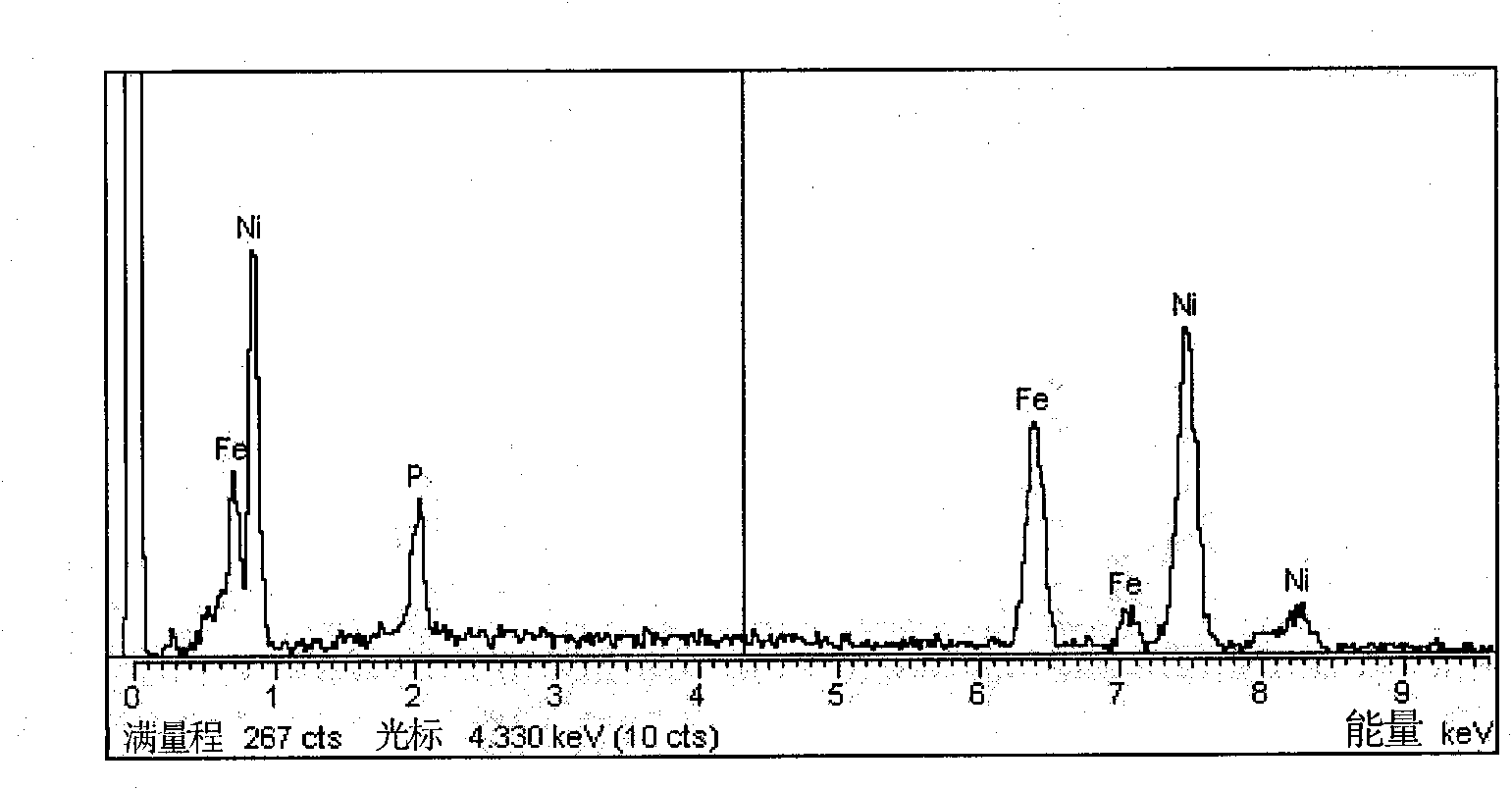

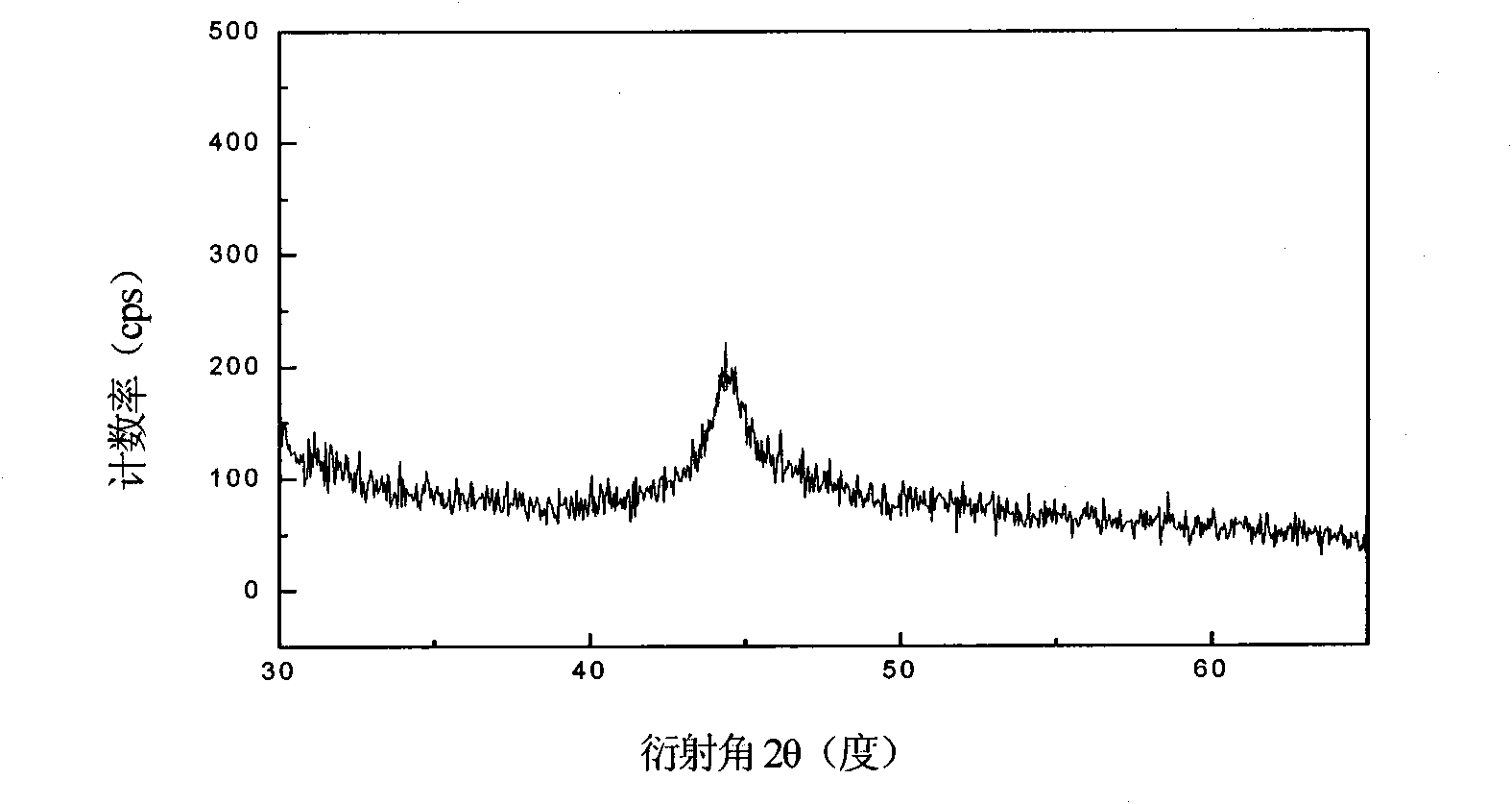

Method for preparing iron-nickel-phosphorus chemical plating

InactiveCN101906624AHigh in ironAdjust reaction speedLiquid/solution decomposition chemical coatingChemical platingSodium potassium tartrate tetrahydrate

The invention belongs to the technical field of chemical deposition, in particular to a new method for preparing an iron-nickel-phosphorus chemical plating. The plating can be widely used in (micro) electronic industry and space navigation and general projects. In the method, a compound complex system consisting of sodium potassium tartrate tetrahydrate, trisodium citrate, two organic mixed additives having N(CH2COOH)2 groups and ammonia water is used for controlling Fe<2+> and Ni<2+> concentrations, reducing the reduction speed of nickel and improving the reduction speed of iron so as to improve the iron content of the plating; the compound complex system can be complexed with impurity ions to improve the containable metal impurity ion concentration of the solution. The method is particularly suitable for preparing high-iron content iron-nickel-phosphorus chemical plating on silicon chips or copper surfaces. The plating on a silicon chip surface comprises 0 to 50 percent (controllable) of iron atoms, 2 to 18 percent of phosphorus atoms and the balance of nickel; and the plating on a copper surface contains 0 to 90 percent (controllable) of iron atoms, 2 to 16 percent of phosphorus atoms and the balance of nickel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

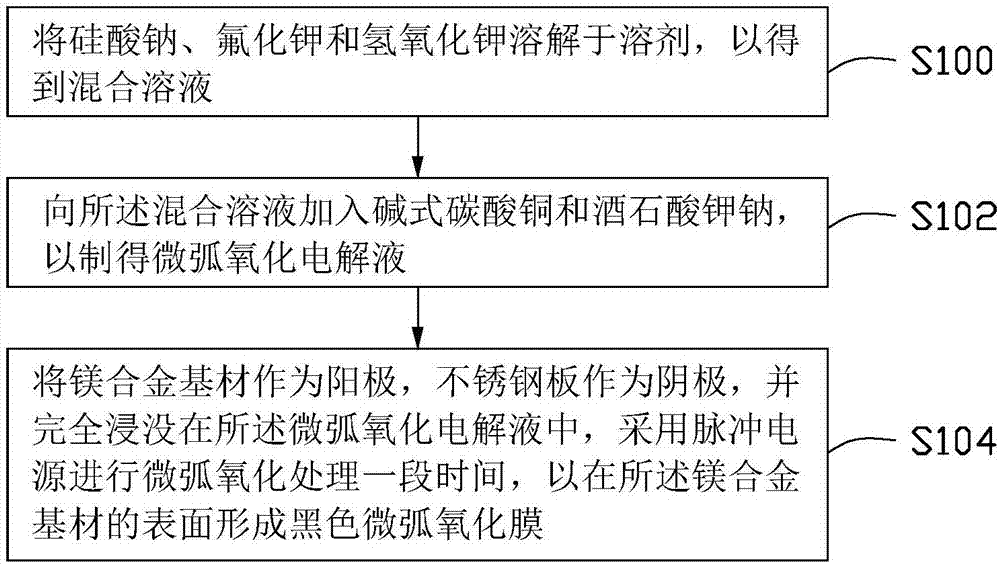

Preparing method for magnesium alloy black microarc oxidation film

InactiveCN107419315AImprove uniformityImprove compactnessAnodisationPlasma electrolytic oxidationMicro arc oxidation

Disclosed is a preparing method for a magnesium alloy black microarc oxidation film. The preparing method for the magnesium alloy black microarc oxidation film comprises the following steps that sodium silicate, potassium fluoride and potassium hydroxide are dissolved in a solvent, and a mixed solution is obtained; basic cupric carbonate and sodium potassium tartrate tetrahydrate are added into the mixed solution so as to prepare a microarc oxidation electrolyte solution, and the dosage of the basic cupric carbonate is 2-5 g / L; and a magnesium alloy base material is used as an anode, a stainless steel plate is used as a cathode, the magnesium alloy base material and the stainless steel plate are completely submerged in the microarc oxidation electrolyte solution, and microarc oxidation treatment is conducted for a period of time by using pulsed power supply, so that the black microarc oxidation film is formed on the surface of the magnesium alloy base material. According to the preparing method for the magnesium alloy black microarc oxidation film, the preparing technology is simple, the cost is low, and the black microarc oxidation film formed on the surface of the magnesium alloy base material is good in uniformity and compactness.

Owner:深圳市粤辉煌环保技术有限公司

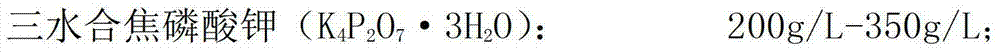

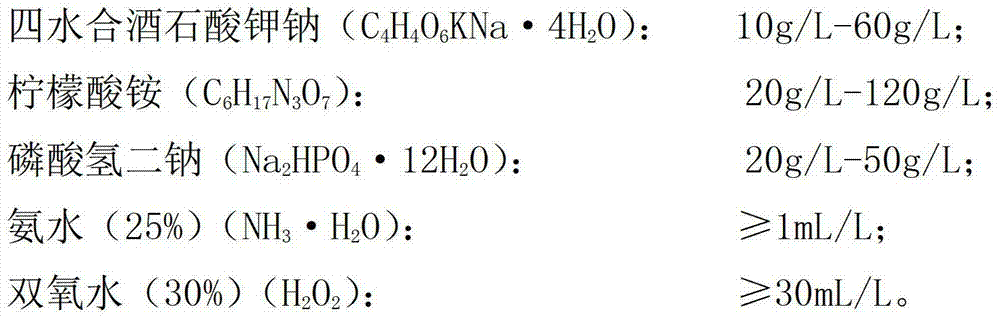

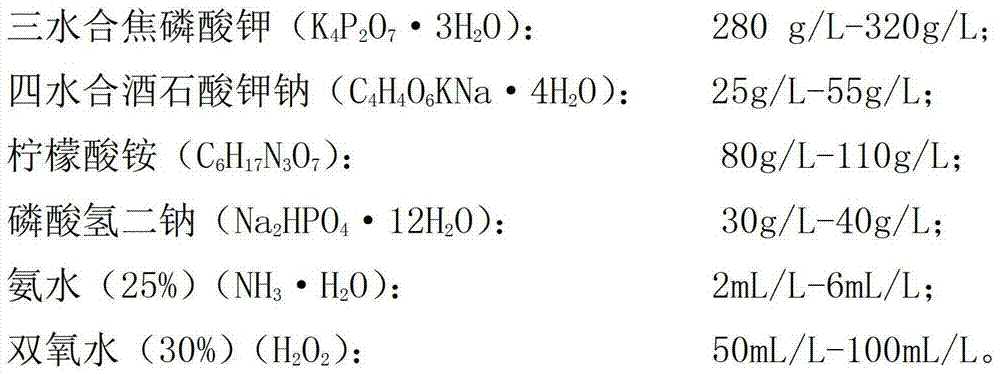

Environment-friendly de-plating liquid of copper plating layer and de-plating process of reproducible de-plating liquid

The invention relates to the technical field of electroplating, and particularly relates to a de-plating liquid and a de-plating process. The environment-friendly de-plating liquid of the copper plating layer is prepared from the raw materials of the de-plating liquid: potassium pyrophosphate, sodium potassium tartrate tetrahydrate, ammonium citrate, disodium hydrogen phosphate, 25% ammonia water and 30% hydrogen peroxide. According to the de-plating process of the reproducible de-plating liquid, copper in the de-plating liquid is recovered by electro-deposition, so that copper ions in the de-plating liquid are reduced, and the de-plating liquid is reproduced and can be recycled by appropriately supplementing hydrogen peroxide. By adopting the technical scheme, compared with the prior art, the de-plating liquid provided by the invention is stable, free from corrosion to the surface of a plate matrix, free from harmful gases, reproducible and recyclable, long in service period and cost-saving, and satisfies the purpose of environment-friendliness and conservation with more social demands.

Owner:SHANGHAI INST OF TECH

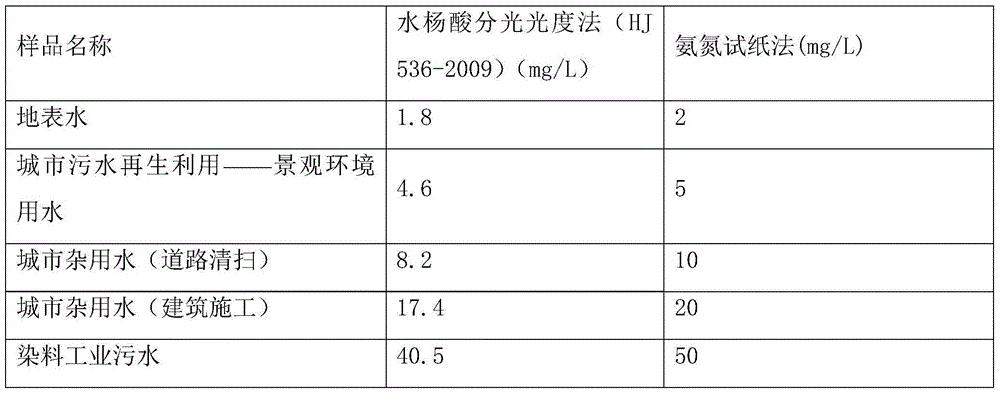

Ammonia nitrogen test paper and application method thereof

InactiveCN104568936AEasy to makeEasy to operateMaterial analysis by observing effect on chemical indicatorSodium potassium tartrate tetrahydrateRoom temperature

The invention discloses ammonia nitrogen test paper and an application method thereof. The test paper is prepared according to the following steps: (1) preparing a reagent solution, namely dissolving analytically pure sodium salicylate, sodium potassium tartrate tetrahydrate and sodium nitroprusside in ammonia-free water to prepare a solution in which the concentration of the sodium salicylate is 280g / L to 380g / L, the concentration of the sodium potassium tartrate tetrahydrate is 50g / L to 68g / L and the concentration of the sodium nitroprusside is 0.40g / L to 0.54g / L; (2) soaking, namely completely soaking quantitative immediate-speed filter paper in the solution (1), oscillating for 60 to 120 minutes on a constant-temperature oscillator; (3) molding, namely taking out the filter paper, arranging in parallel at room temperature, suspending, drying in air, cutting and sealing by plastic for later use. The test paper is simple to prepare, convenient to operate, short in color development time, high in removability and capable of being used for rapidly and accurately testing the content range of ammonia nitrogen in water.

Owner:HEBEI UNIV OF TECH

Liquid fertilizer capable of preventing soil-borne diseases and preparation method therefor

InactiveCN105110879AReduce dosageMake up for the lossFertilizer mixturesEcological environmentSodium potassium tartrate tetrahydrate

The invention discloses a liquid fertilizer capable of preventing soil-borne diseases. The liquid fertilizer is prepared from the following raw materials, by weight, 36-40 parts of biogas residue mud, 5-7 parts of sodium potassium tartrate tetrahydrate, 6-8 parts of citric acid, 40-50 parts of corn germ meal, 15-19 parts of urea, 55-65 parts of dry chicken manure, 120-140 parts of waste livestock and poultry feathers, 6-7 parts of copper sulphate, 4-6 parts of ferrous sulphate, 4-5 parts of GM microbial preparations and a proper amount of water. Biogas residue mud, chicken manure and the like are employed in the raw materials of the liquid fertilizer and contain a lot of microbes with various kinds, the GM microbial preparations are added to raise the beneficial bacterium content, thus the liquid fertilizer becomes a microbe resource base, the soil microbial community structure can be adjusted after drip irrigation and spraying of the liquid fertilizer, the soil microbial diversity is raised, the soil micro-ecological environment is improved, the survival scope of plant pathogens is narrowed, and therefore the purpose of preventing soil-borne diseases is achieved.

Owner:HEFEI ZHONGYUE HEALTH TECH

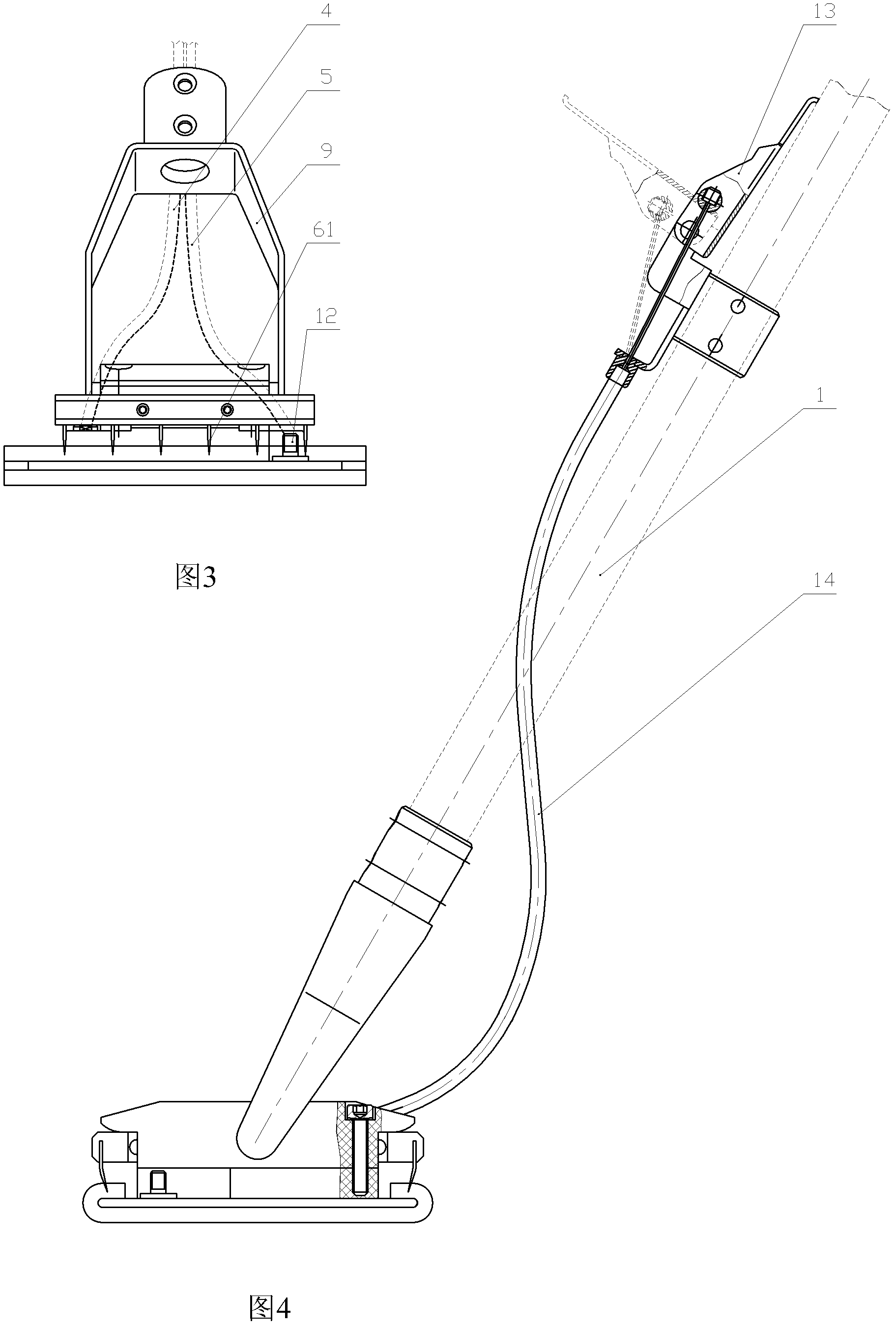

Electrolyte capable of removing nuclear pollution and movable cathode electrochemical cleaning device

InactiveCN102628176AHigh decontamination rateShort processing timeCleaning using liquidsRadioactive decontaminationSodium potassium tartrate tetrahydrateElectrochemistry

The invention discloses electrolyte capable of removing nuclear pollution, which is composed of deionized water and additives, wherein the additives comprise 25-65g / L of sodium sulfate, 25-65 g / L of sodium potassium tartrate tetrahydrate and 5-50 g / L of ethylene diamine tetraacetic acid corresponding to the deionized water. The invention further discloses a movable cathode electrochemical cleaning device, which comprises a handle, a support member, a cathode electrode, a porous material, an electrolyte conveying pipeline and an electrolyte conveying guide line. The handle is arranged on the support member, the cathode electrode is arranged at the bottom of the support member, the porous material is connected at the bottom of the cathode electrode, the electrolyte conveying pipeline and the guide line are both connected with the cathode electrode, and the cathode electrode is provided with a through hole communicated with the porous material. The electrolyte is high in dirt removing rate, short in processing time, small in corrosion on metal devices and materials, can be used for performing electrochemical cleaning processing on metal devices with large volumes or different to move, fast and efficient in dirt removing, few in secondary pollutants and favorable for promotion and application of the electrochemical cleaning technology.

Owner:广东白云国际科学研究院有限公司

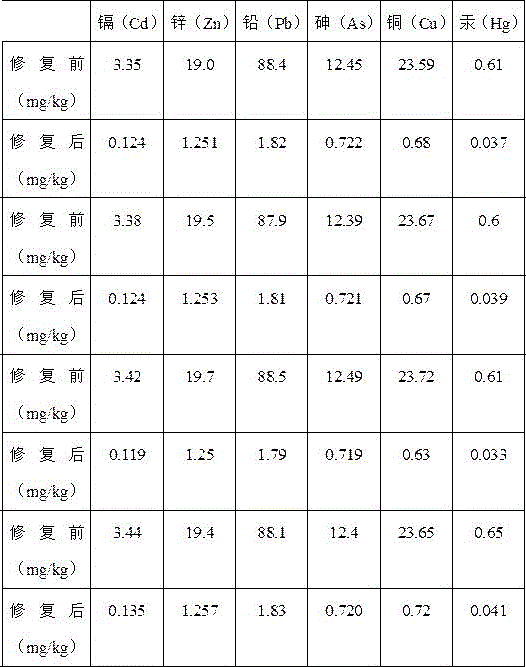

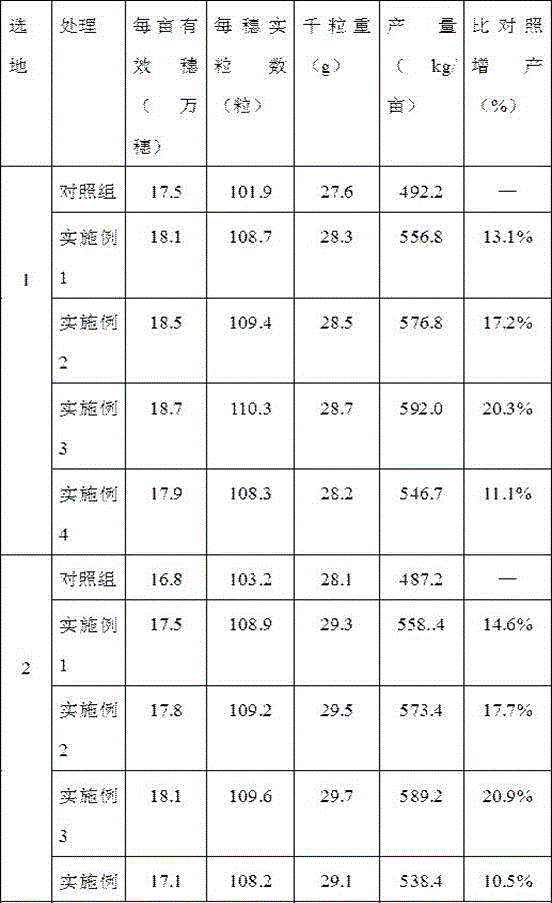

Soil remediation agent and preparation method thereof

InactiveCN106316686AReduce heavy metal contentIncrease productionCalcareous fertilisersAgriculture tools and machinesSodium BentonitePhosphate

The invention discloses a soil remediation agent. The soil remediation agent comprises, by weight, 8-12 parts of hydrated lime, 30-50 parts of limestone, 40-60 parts of bentonite, 5-7 parts of sepiolite, 5-10 parts of biological charcoal, 2-3 parts of diethylenetriamine pentaacetic acid, 2-3 parts of sodium dimercaptosulphonate, 3-5 parts of sodium lignosulfonate, 1-3 parts of cysteine, 1-1.8 parts of sodium potassium tartrate tetrahydrate, 1-1.5 parts of phosphate ore and 0-0.5 part of sodium sulfide. A preparation method of the soil remediation agent includes the steps of firstly, weighing the phosphate ore, the sepiolite and the biological charcoal, and grinding into powder; secondly, adding the cysteine, the sodium potassium tartrate tetrahydrate and the sodium sulfide into the ground powder, and stirring; thirdly, continuously adding the rest of substances, and mixing. The preparation method is simple and low in cost, and the prepared soil remediation agent can lower the heavy metal activity in soil, improve the soil, increase soil fertility and increase crop yield.

Owner:SICHUAN HUAZHI BIOLOGICAL ENG

Electronickelling method for neodymium iron boron sheet magnetic steel product

The invention discloses an electronickelling method for a neodymium iron boron sheet magnetic steel product. Nickel preplating, semi-bright nickel plating and bright nickel plating are sequentially conducted, a double-pulse power supply is adopted in the nickel preplating process, high current density is used by the double-pulse power supply, and therefore a nickel preplated coating large in density, high in hardness, low in porosity and high in uniformity is formed on the surface of the neodymium iron boron sheet magnetic steel product where nickel preplating is conducted. In the subsequent semi-bright nickel plating process, a semi-bright nickel solution is composed of nickel sulfate, nickel chloride, boric acid, sodium potassium tartrate tetrahydrate, triethanolamine, ammonium sulfate, ammonium hydroxide and water according to a specific ratio, sodium potassium tartrate tetrahydrate serves as a coordination agent in the semi-bright nickel solution, ammonium sulfate serves as conducting salt, uniformity of a semi-bright nickel coating is improved, and finally a bright nickel layer high in uniformity is generated on the semi-bright nickel coating. The electronickelling method has the beneficial effects that a nickel-plated layer is composed of the nickel preplated layer, the semi-bright nickel layer and the bright nickel layer which are high in uniformity, and the coating distribution uniformity of the neodymium iron boron sheet magnetic steel product is greatly improved.

Owner:NINGBO YUNSHENG MAGNET DEVICES TECH +2

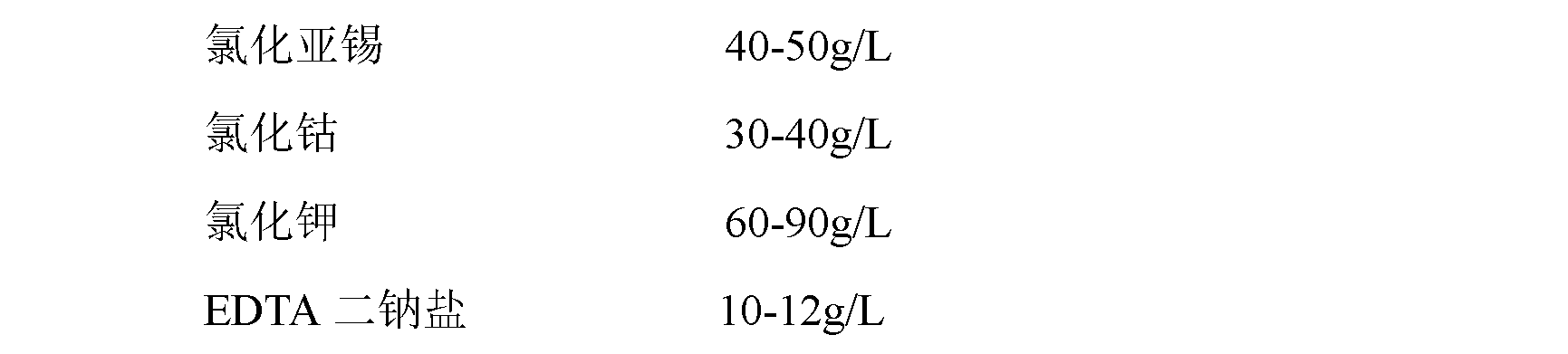

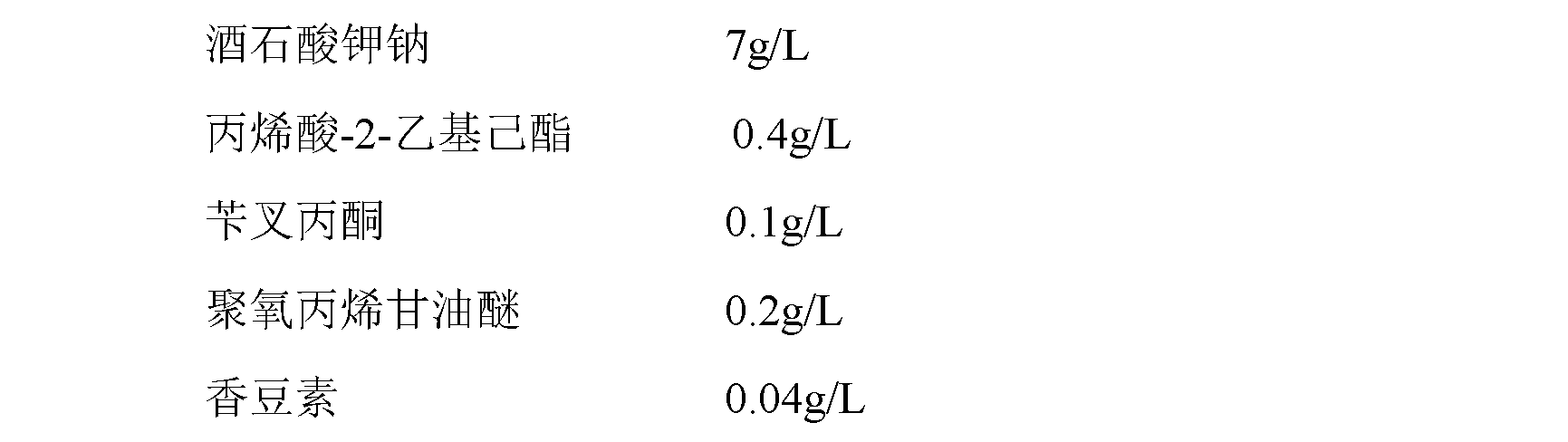

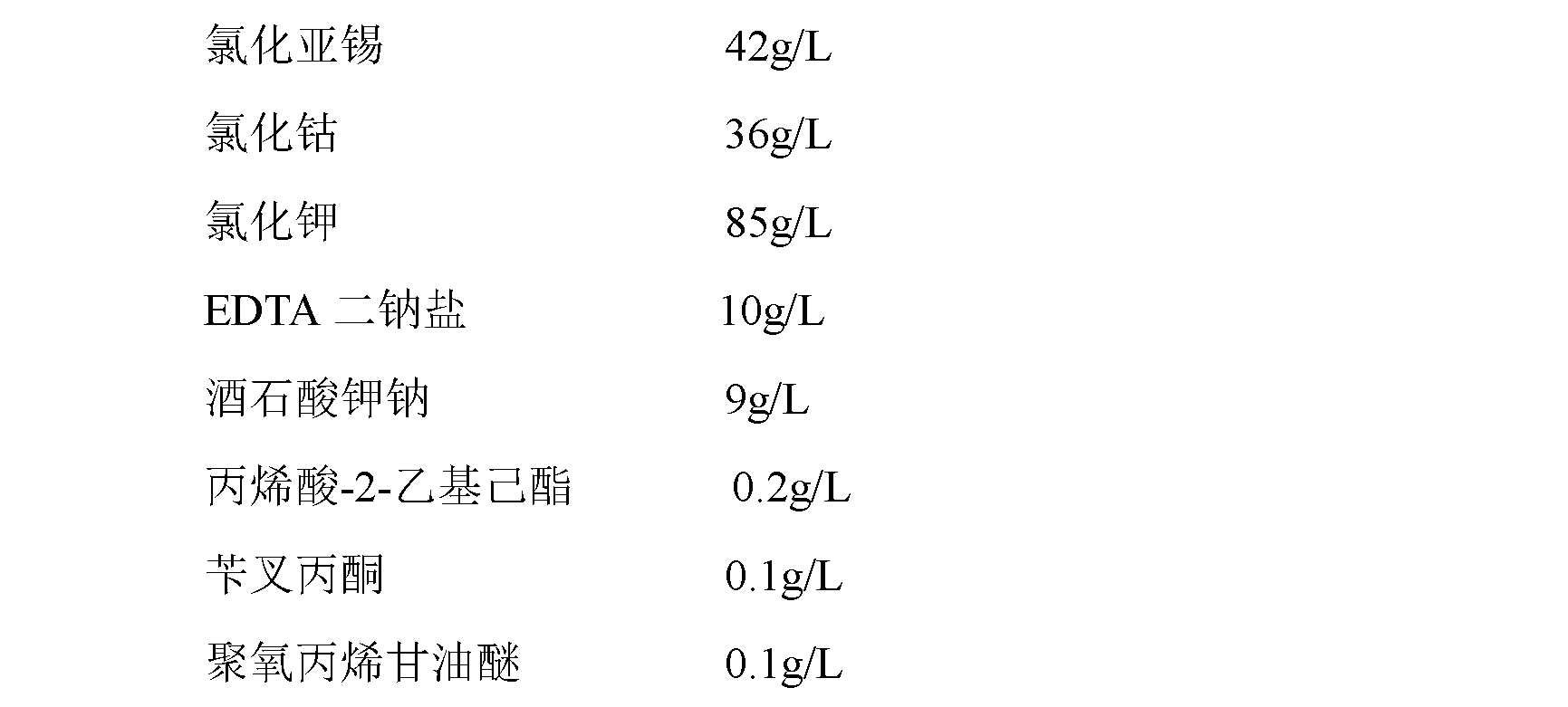

Tin-cobalt alloy decorative chromium-substituted electroplate liquid and electroplate method thereof

ActiveCN103014792ABright appearanceExtended service lifeSodium potassium tartrate tetrahydrateChromium coating

The invention discloses a tin-cobalt alloy decorative chromium-substituted electroplate liquid and an electroplate method thereof. The electroplate liquid consists of the following components: 40-50 g / L of stannous chloride, 30-40 g / L of cobalt chloride, 60-90 g / L of potassium chloride, 10-12 g / L of EDTA disodium salt, 5-10 g / L of sodium potassium tartrate tetrahydrate, 0.2-0.5 g / L of crylic-2-ethyl hexyl ester, 0.1-0.2 g / L of benzalacetone, 0.1-0.2 g / L of polyoxypropylene glycerol ether and 0.02-0.05 g / L of coumarin. Compared with the electroplated coating obtained by the present tin-cobalt alloy electroplate liquid, the coating obtained according to the invention is closer to a chromium coating in apperance, can be widely applied to decorative chromium-substituted technique, and has the advantages of smoothness of the electroplated coating, uniformity and compactness, good adhesive force, long service life of the electroplate liquid and the like.

Owner:合肥华清高科表面技术股份有限公司

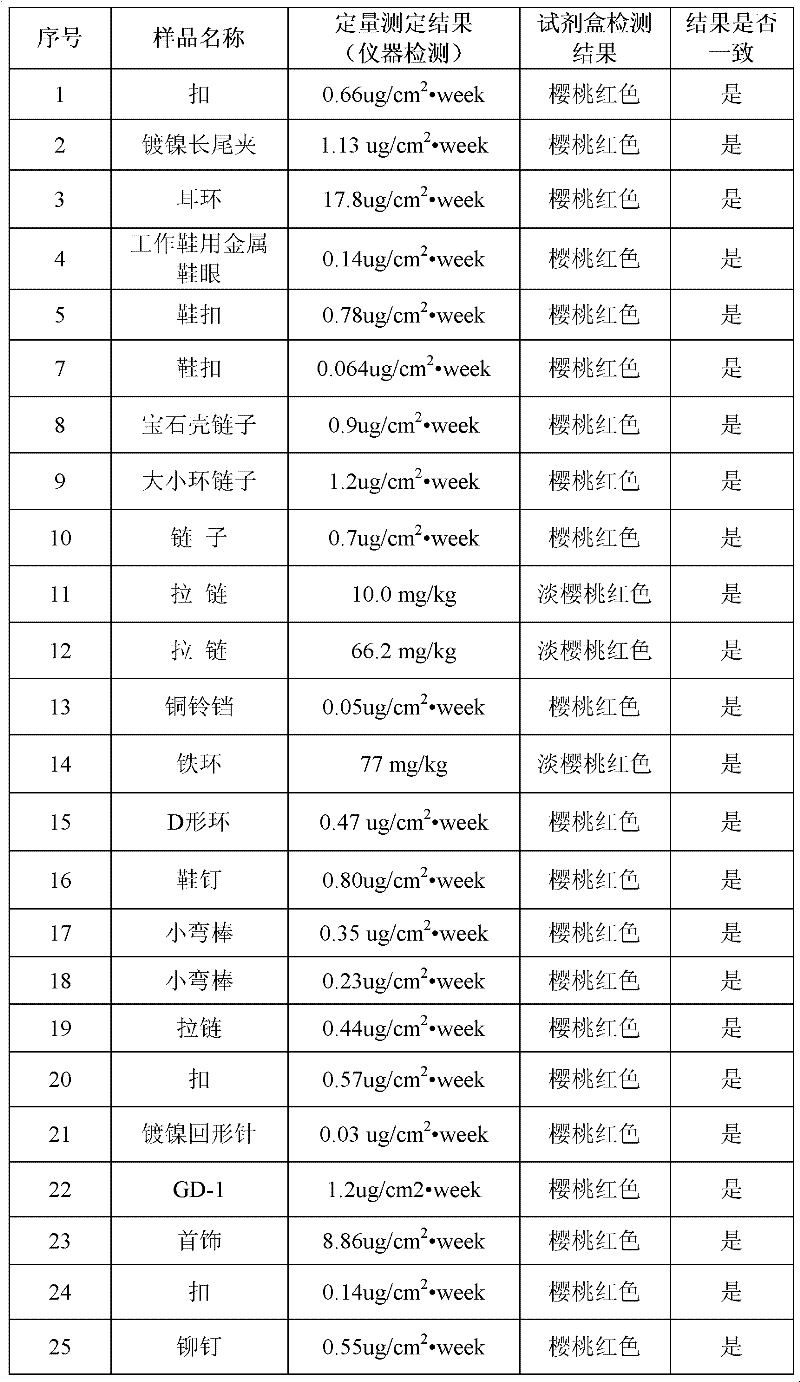

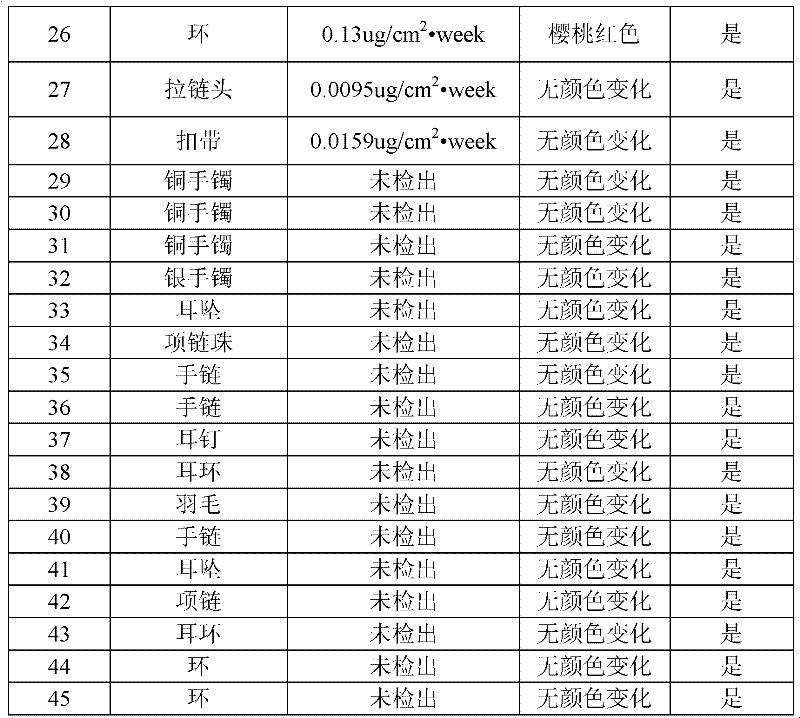

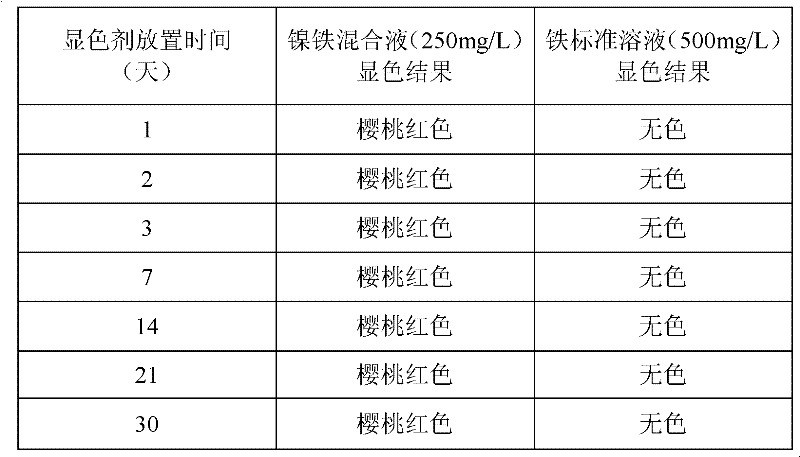

Rapid detection kit and detection method of nickel in garment metal accessories and imitation ornaments

InactiveCN102495050ASimple and fast operationEasy to operateMaterial analysis by observing effect on chemical indicatorSodium potassium tartrate tetrahydrateAmmonium hydroxide

The invention discloses a rapid detection kit of nickel in garment metal accessories and imitation ornaments, comprising 1) 0.5 mL of an immersing solution A consisting of an HCl solution having a concentration of 6 mol / L; and 2) 0.1 mL of a developer solution B consisting of a dimethyl glyoxime ammonia solution having a concentration of 10 g / L, an ammonium persulfate solution having a concentration of 40 g / L, and a sodium potassium tartrate tetrahydrate solution having a concentration of 300 g / L, wherein the volume ratio of the three solutions is 3:1:1. According to the invention, the advantages of simple operation, rapidness, low cost and the like are achieved; a chromogenic qualitative determination can be directly realized, and coexistent ions interfering the chromogenic determination, such as Fe, Cu, Co and the like, can be completely sheltered; any device is not needed, and the detection cost is greatly reduced.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

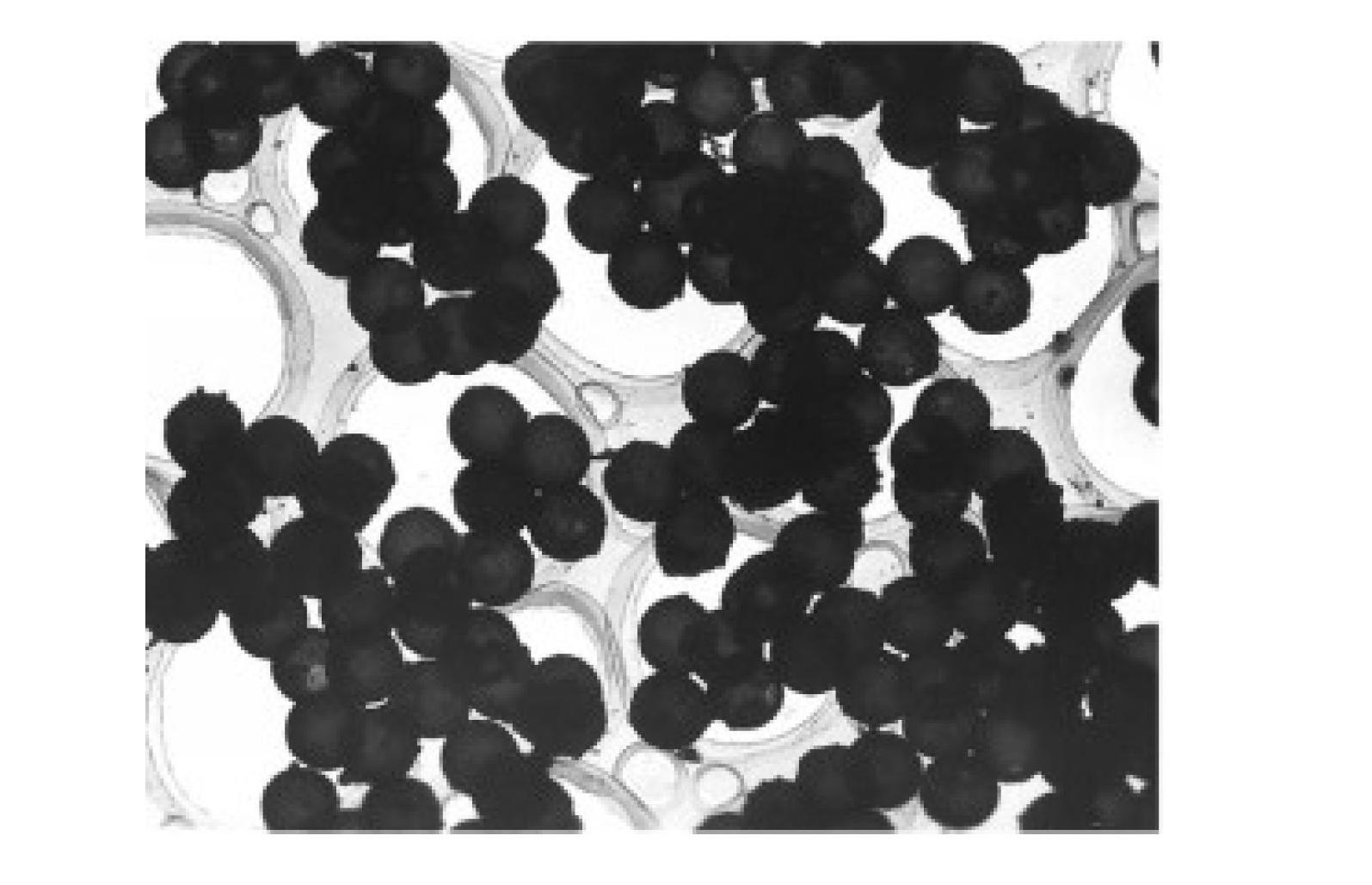

Method for preparing sustained-release silver-based antibacterial agent

ActiveCN102669178APlay a bactericidal and antibacterial roleInhibitory activityBiocideDisinfectantsMicrosphereSodium potassium tartrate tetrahydrate

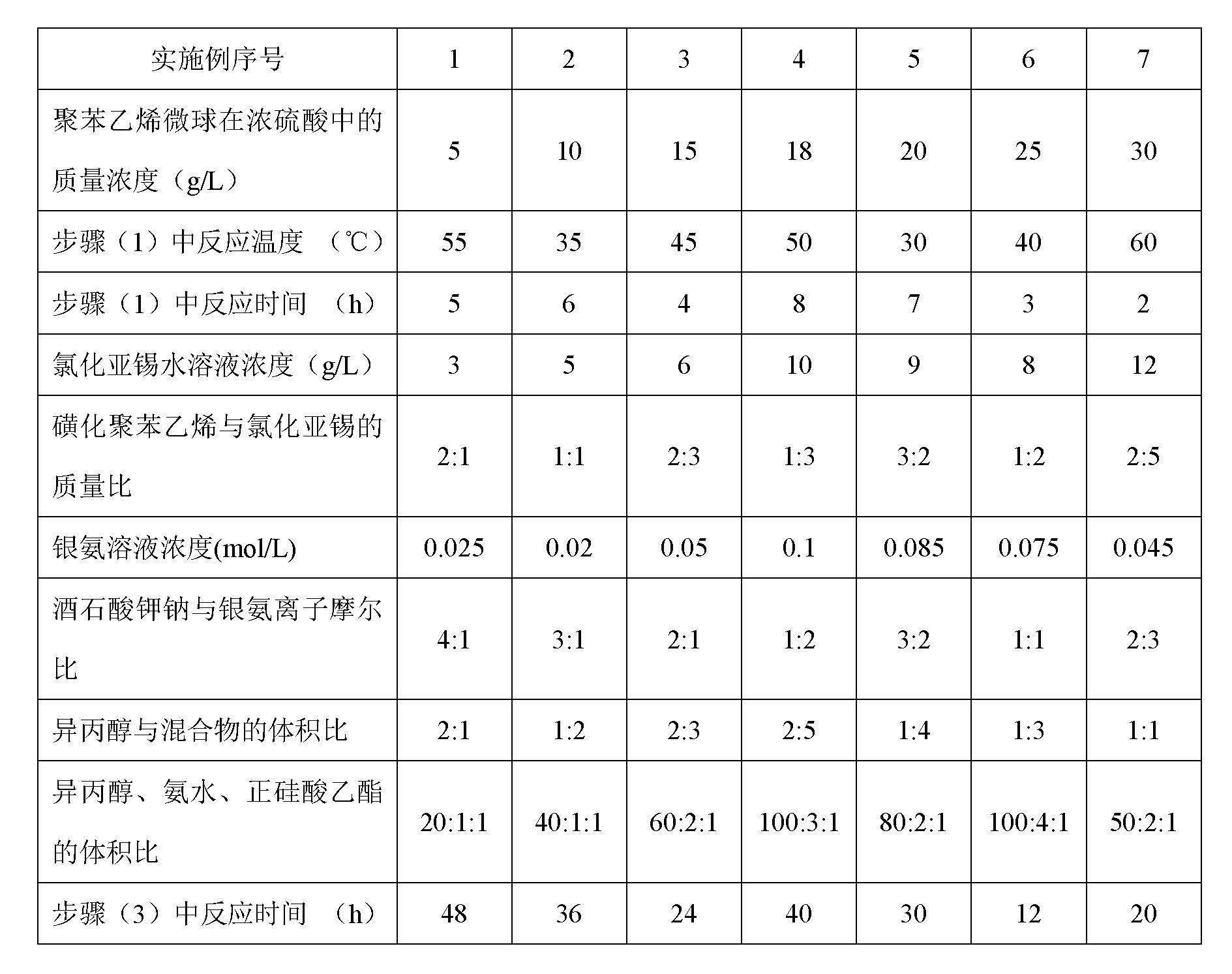

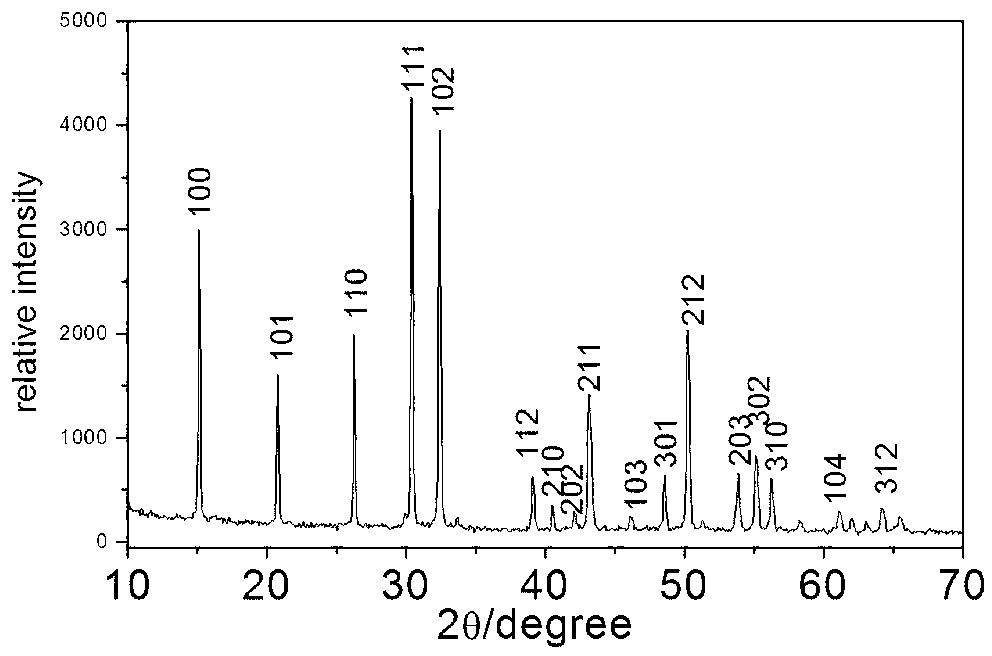

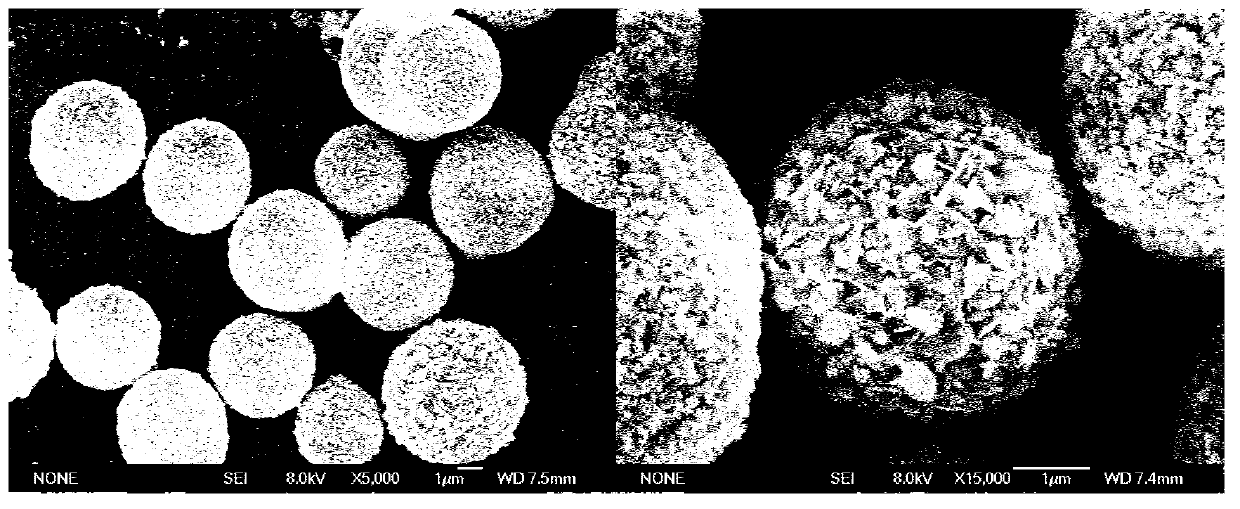

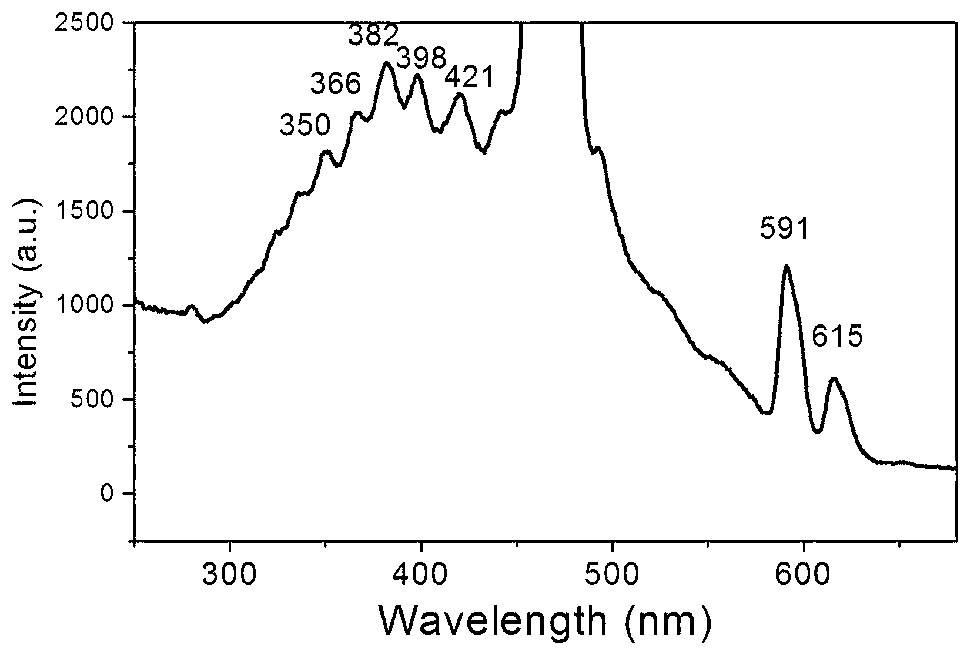

The invention relates to the preparation of an antibacterial agent and aims to provide a method for preparing a sustained-release silver-based antibacterial agent, which comprises the following steps of: adding polystyrene sphere into concentrated sulfuric acid, stirring for 2 to 8 hours, centrifuging repeatedly, washing, dispersing into absolute ethanol, and obtaining dispersion of sulfonated polystyrene; adding aqueous solution of stannous chloride, stirring at room temperature, centrifuging, washing and adding a solid product into a tollens' reagent of sodium potassium tartrate tetrahydrate, stirring at room temperature, adding isopropanol, and obtaining silver and polystyrene composite sphere dispersion; adding tetraethyl orthosilicate and ammonia water and stirring at room temperature; and centrifuging the product, washing and calcining at 550 DEG C and obtaining the sustained-release silver-based antibacterial agent. When the method is used, silver loaded onto the inner walls of silicon dioxide sphere shells can disperse to the outside of the sphere shells from meso pores on the sphere shells, thereby producing an antibacterial effect; and problems of active ingredient loss and low antibacterial capacity of the conventional antibacterial agents due to the silver loaded on the outside surface of the material can be solved.

Owner:ZHEJIANG UNIV

Eu doped YPO4 microballoon and preparation method thereof

InactiveCN103131417AThe size is easy to controlShape is easy to controlLuminescent compositionsSodium potassium tartrate tetrahydrateMicrosphere

The invention provides an Eu doped YPO4 microballoon and a preparation method thereof. The method adopts a hydrothermal method. The Eu doped YPO4 microballoon is synthetized with one step through the reaction of YC13 and EuC13 as well as trisodium phosphate under the coordination of tartaric acid base. The preparation method comprises the following steps of mixing a certain amount of YC13 solution and EuC13 solution firstly, then sequentially adding solid sodium potassium tartrate tetrahydrate and the trisodium phosphate, stirring to dissolve completely, then regulating the pH value of the mixed solution to 2 with diluted hydrochloric acid, then transferring the mixed solution to a stainless steel reaction kettle with a polytetrafluoroethylene lining, sealing, reacting for 6-24 hours at 160-200 DEG C, then cooling naturally to room temperature, washing and drying so as to obtain the product. The composition of the product is regulated by regulating the mass ratio of the EuC13 and the YC13 as well as the mole ratio of the sodium potassium tartrate tetrahydrate and the trisodium phosphate. The Eu doped YPO4 microballoon is simple in technology, low in cost and high in yield, and is applicable to industrialized production, and the size, the composite and the appearance of the product are easy to control.

Owner:QINGDAO UNIV OF SCI & TECH

Yield-increasing water retention fertilizer special for hickory nuts

InactiveCN106365817AImprove soil fertilityImproves soil fertility and increases pecan yieldsCalcareous fertilisersMagnesium fertilisersSodium BentoniteSlag

The invention discloses a yield-increasing water retention fertilizer special for hickory nuts. The fertilizer is prepared from, by weight, 50-150 parts of organic fertilizer, 5-15 parts of steel slag, 5-15 parts of urea, 15-25 parts of diammonium phosphate, 5-10 parts of ammonium bicarbonate, 3-15 parts of potassium sulfate, 2-10 parts of magnesium sulfate, 10-20 parts of calcium cyanamide, 3-10 parts of calcium sulfate, 1-10 parts of calcium oxide, 4-8 parts of microelements, 0.1-1 part of gamma-polyglutamic acid, 0.3-1.5 parts of vermiculite powder, 0.5-1.5 parts of bentonite, 5-15 parts of ardealite, 0.05-0.3 part of malic acid, 0.1-0.5 part of phosphate solubilizing bacteria, 0.5-3 parts of glucose, 2-5 parts of sodium potassium tartrate tetrahydrate, 2-5 parts of rare-earth salt and 1-5 parts of water-retaining agent. The yield-increasing water retention fertilizer special for the hickory nuts is reasonable in formula, comprehensive and balanced in nutrition, high in water retaining ability and capable of increasing the yield of the hickory nuts, improving quality and improving physical and chemical properties of soil.

Owner:ANHUI SIERTE FERTILIZER IND

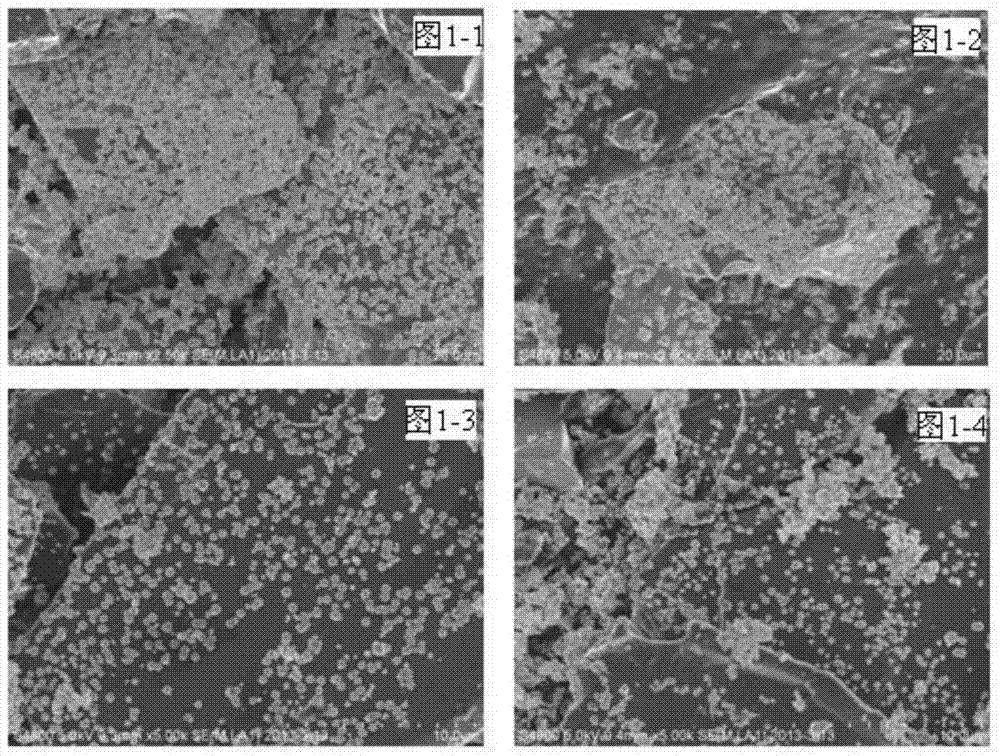

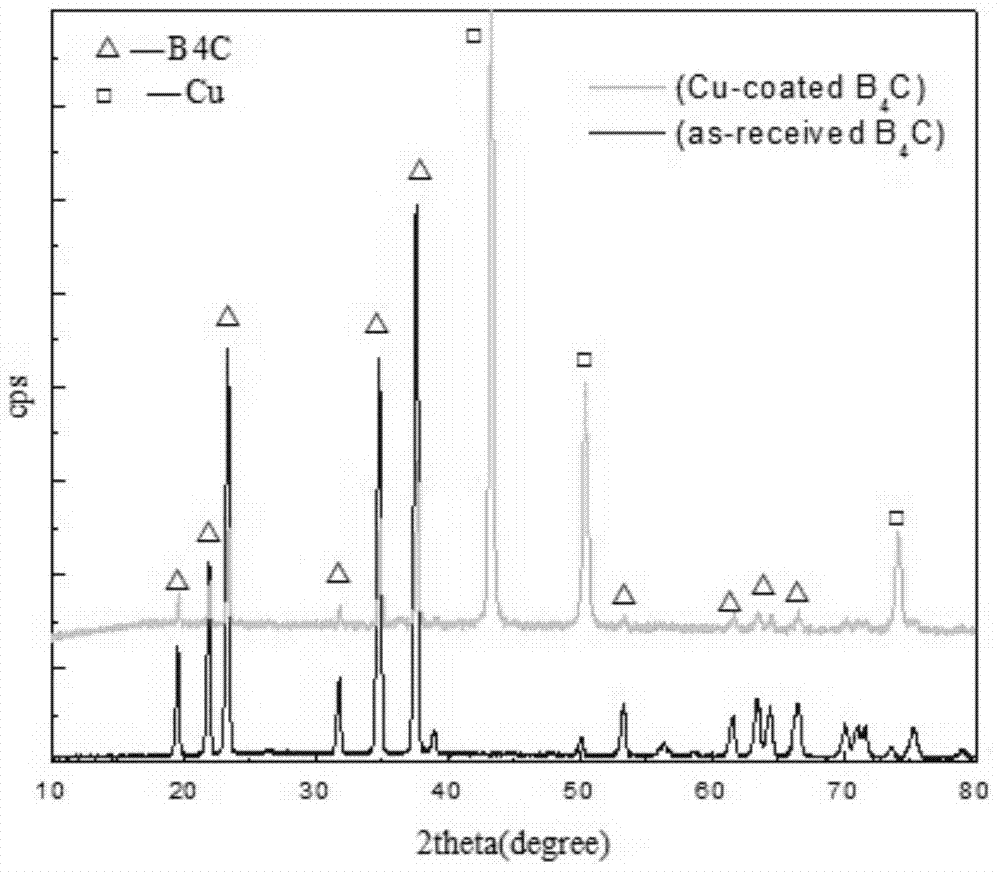

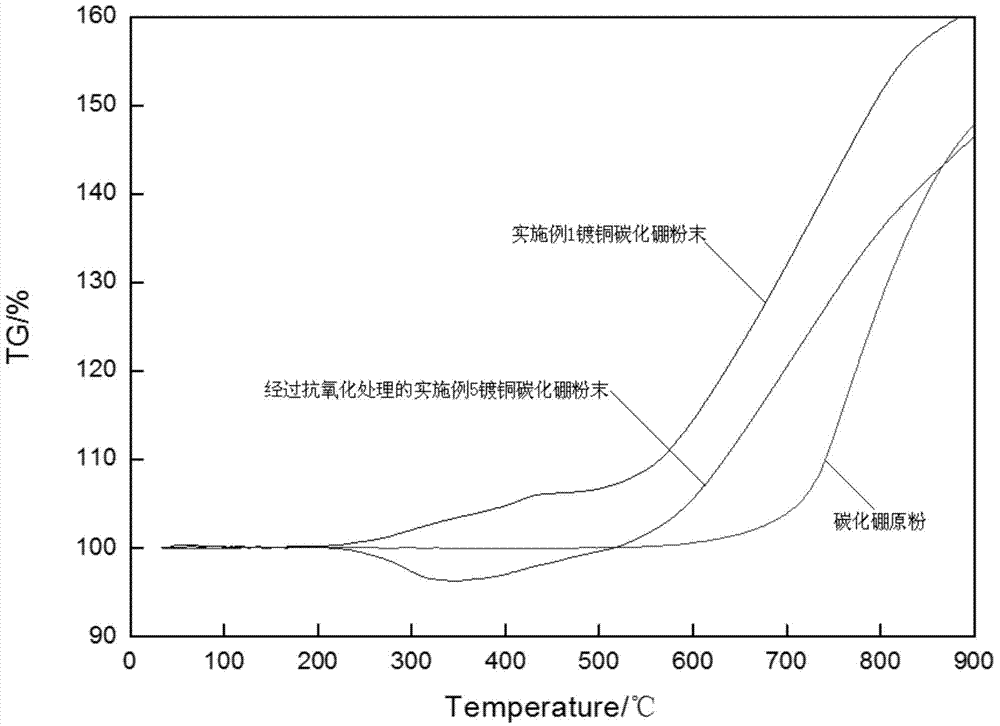

Method of electroless copper plating on surface of boron carbide powder and electroless plating solution for electroless copper plating

InactiveCN103805976AWill not polluteReduce pollutionLiquid/solution decomposition chemical coatingEthylenediamineInterfacial reaction

The invention discloses an electroless plating solution for electroless copper plating on the surface of boron carbide powder. The electroless plating solution comprises 15-20g / L of copper sulfate, 20-30g / Lof ethylenediamine tetraacetic acid disodium salt, 10-15 g / L of sodium potassium tartrate tetrahydrate and 15-20 ml / L of hydrazine hydrate by concentration; and the pH value of the electroless plating solution is 12-13. In the electroless plating solution for the electroless copper plating on the surface of the boron carbide powder, a reducing agent is the hydrazine hydrate and low in cost, does not pollute environments and has very strong reducing capacity under an alkaline condition, an oxidative product is clean N2, no impurities and metal ions are introduced, and complexing agents are the sodium potassium tartrate tetrahydrate and the ethylenediamine tetraacetic acid disodium salt, have little environmental pollution and strong complexing power and can keep the plating solution stable for a long term at a high temperature under a strong base condition. In addition, the invention also discloses a method of electroless copper plating on the surface of the boron carbide powder. According to the method, a layer of nanoscale uniform and compact copper coating can be formed on the surface of the boron carbide powder, and wetting angles and the interfacial reaction between the boron carbide powder and a metal base material can be effectively reduced.

Owner:中广核工程有限公司 +2

Novel cyanide-free alkaline copper plating solution and preparation method thereof

The invention discloses a novel cyanide-free alkaline copper plating solution which comprises the following components: 120-180 g / L of sodium citrate, 20-30 g / L of copper sulfate, 25-35 g / L of sodium potassium tartrate tetrahydrate, 6-10 g / L of sodium bicarbonate, 30-40 g / L of cyani salt, 1-3 ml / L of a brightener and 0.5-0.9 / L of tea saponin. The novel cyanide-free alkaline copper plating solution, disclosed by the invention, has the following advantages: the stability is excellent, the clad layer crystal is delicate, the covering power is excellent, the current range is wide, a semi-bright clad layer is excellent in binding force, the clad layer with the thickness of more than 10 microns can be plated, and traditional toxic cyaniding copper plating can be replaced.

Owner:HUZHOU FANGMING ENVIRONMENT PROTECTION TECHCO LTD

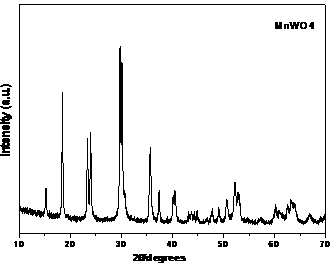

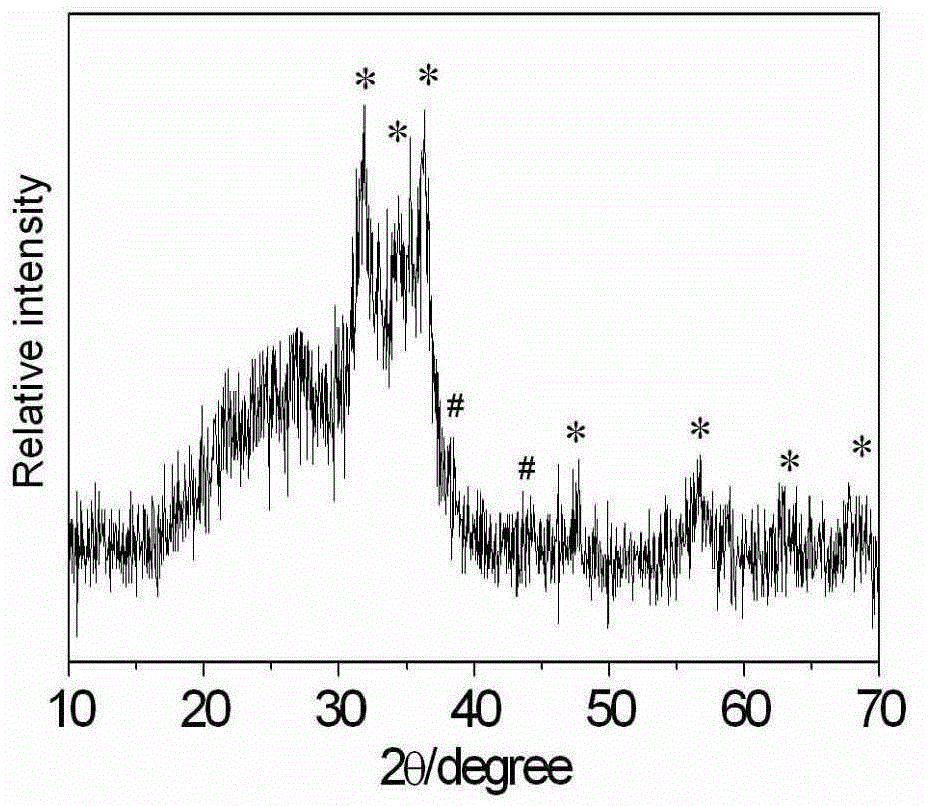

Preparation method of manganese tungsten single-crystalline nanowire

InactiveCN104192914AQuality improvementAvoid wastingMaterial nanotechnologyManganese compoundsNanowirePhotoluminescence

The invention discloses a preparation method of a manganese tungsten single-crystalline nanowire. The method comprises the following steps: firstly, preparing a manganese tungsten precursor by using manganese chloride, potassium carbonate and sodium potassium tartrate tetrahydrate; and then mixing sodium tungstate with the prepared manganese tungsten precursor; and carrying out hydrothermal reaction at 120-200 DEG C, so as to obtain the manganese tungsten single-crystalline nanowire. The manganese tungsten single-crystalline nanowire has the advantages of controllable morphology, simple process and low cost, can be put into industrial production, and has a single-crystalline structure and a very high draw ratio; therefore, the preparation method has a very wide application prospect on the aspects of multiferroic materials, photocatalysts, photoluminescence, optical fibers, scintillators, humidity sensors and magnetic materials.

Owner:LUOYANG INST OF SCI & TECH

Special fertilizer for honey locust

InactiveCN103553774AImprove qualityReduce the frequency of fertilizationFertilizer mixturesAnimal scienceSodium potassium tartrate tetrahydrate

The invention discloses a special fertilizer for a honey locust. The special fertilizer for the honey locust comprises the following raw materials in parts by weight: 16-20 parts of urea, 35-40 parts of waste vinasse, 8-10 parts of mushroom dreg, 15-20 parts of animal urine, 12-15 parts of silkworm excrement, 12-15 parts of cabbage residue, 1-3 parts of corn flour, 2-3 parts of ammonium polyphosphate, 4-6 parts of sodium potassium tartrate tetrahydrate, 2-4 parts of edetic acid, 1-3 parts of heptahydrate, 2-4 parts of manganese sulfate monohydrate, 3.5-4.5 parts of bowlder powder, 3-5 parts of castor leaf powder, 2-4 parts of Artemisia santonica powder, 1-2 parts of colored leaf grass meal, 2-3 parts of pepper leaf powder and 5-8 parts of modified loess. The waste vinasse, mushroom dreg, animal urine, silkworm excrement, cabbage residue and corn flour are used for fermentation and a large number of fertilizers such as urea and Chinese herbal medicine powder are used, so that the needs of the honey locust in different growing periods can be met, pests and diseases can be controlled, the fertilizing frequencies are reduced, the soil quality is improved and the quality of honey locusts can be improved.

Owner:安徽环绿建设工程有限公司

Dampness-heat-resistant water-based antirust agent and preparation method thereof

InactiveCN104387940AExcellent heat and humidity resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedSucrose

The invention discloses a dampness-heat-resistant water-based antirust agent. The dampness-heat-resistant water-based antirust agent is characterized by being prepared from the following raw materials in parts by weight: 4-6 parts of waterborne polyurethane resin, 0.5-1 part of polydimethylsiloxane, 1-2 parts of sodium N-acyl glutamate, 0.2-0.4 part of octadecyl dihydroxyethyl amine oxide, 1-2 parts of sodium potassium tartrate tetrahydrate, 0.2-0.4 part of terpinyl acetate, 2-4 parts of triethanolamine borate, 0.5-1 parts of poloxamer, 1-2 parts of mannitol, 1-2 part of flaxseed gum, 0.5-1 part of sucrose fatty acid ester, 6-8 parts of a modifying auxiliary and 30-40 parts of water. A film formed by the dampness-heat-resistant water-based antirust agent on a metal surface has good dampness-heat resistance, good corrosion resistance, a good antifouling and antistatic effect and good resistance, and corrosion can be effectively prevented.

Owner:HEFEI DAAN PRINTING

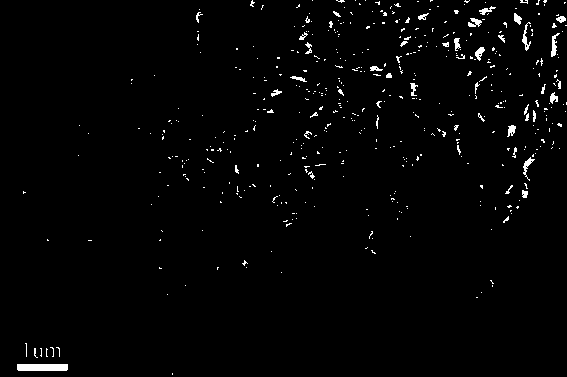

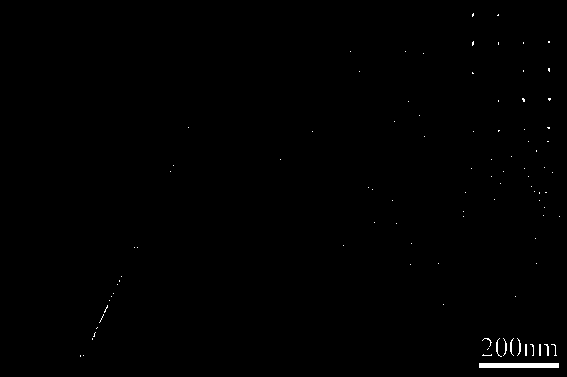

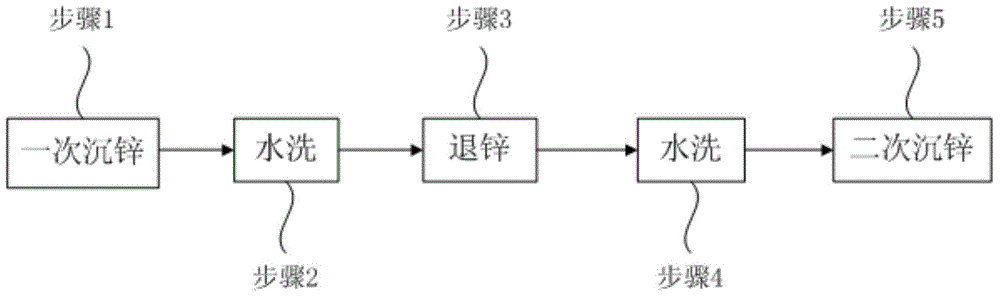

Surface treatment method of die casting aluminum alloy piece and die casting aluminum alloy product

ActiveCN105063703AImprove surface adhesionQuality improvementLiquid/solution decomposition chemical coatingSodium potassium tartrate tetrahydrateDie casting

The invention belongs to the field of surface treatment technologies, and discloses a surface treatment method of a die casting aluminum alloy piece and a die casting aluminum alloy product in order to solve the problem that a adhesive force of the conventional die casting aluminum alloy product is not good after surface treatment. The surface treatment method of the die casting aluminum alloy piece is characterized in that a to-be-treated die casting aluminum alloy piece is subjected to at least one time of zinc deposition after activated and before plated; a zinc deposition solution at least comprises the following ingredients: ZnO, NaOH, sodium potassium tartrate tetrahydrate and FeCl3. The die casting aluminum alloy product adopts the surface treatment method. The surface treatment method of the die casting aluminum alloy piece can improve the surface adhesive force of the to-be-treated die casting aluminum alloy piece, and the quality and the corrosion resistance of a plating layer, and can lay a good foundation for a subsequent chemical nickel plating process. The die casting aluminum alloy product has very high corrosion resistance.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

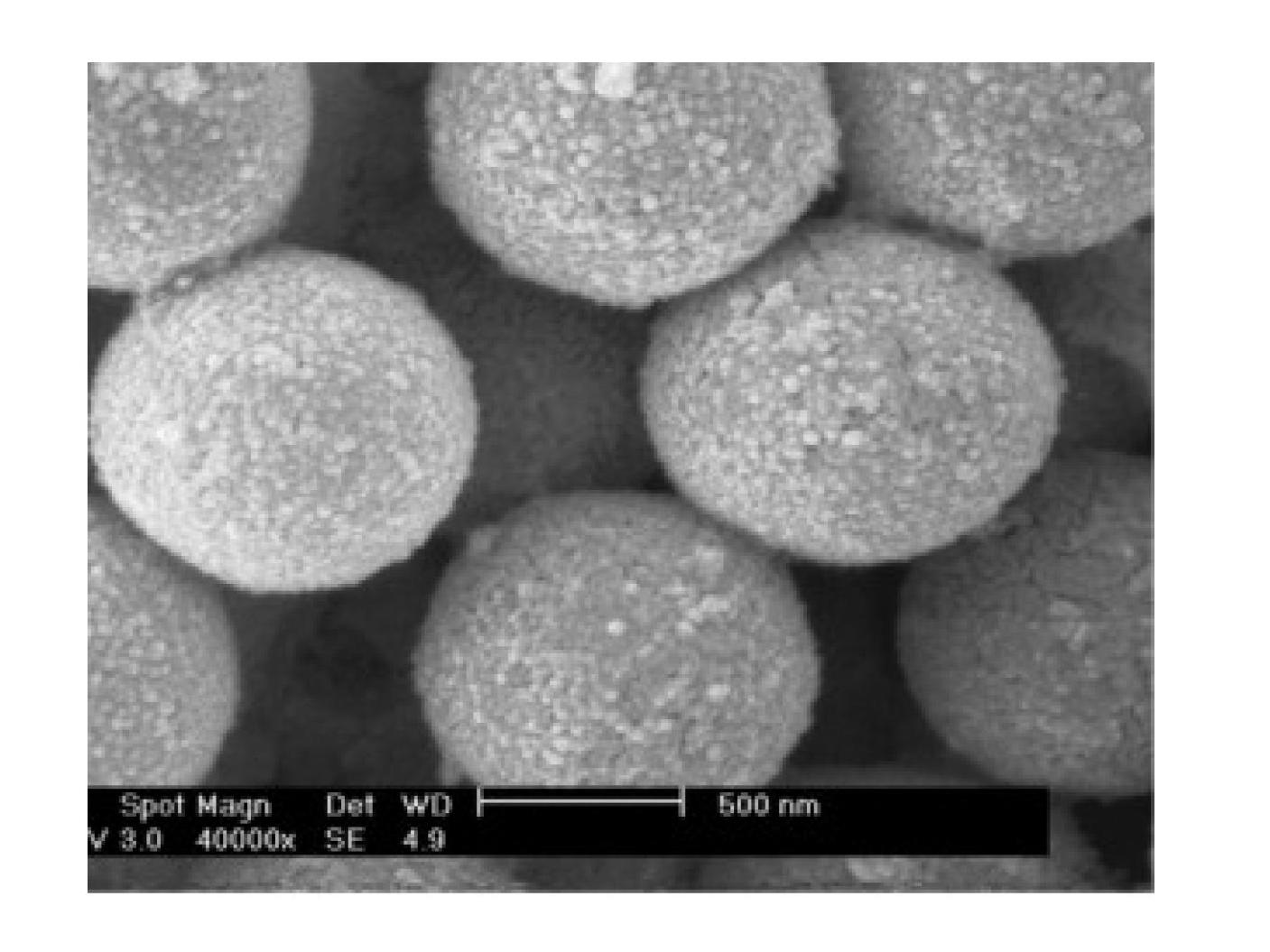

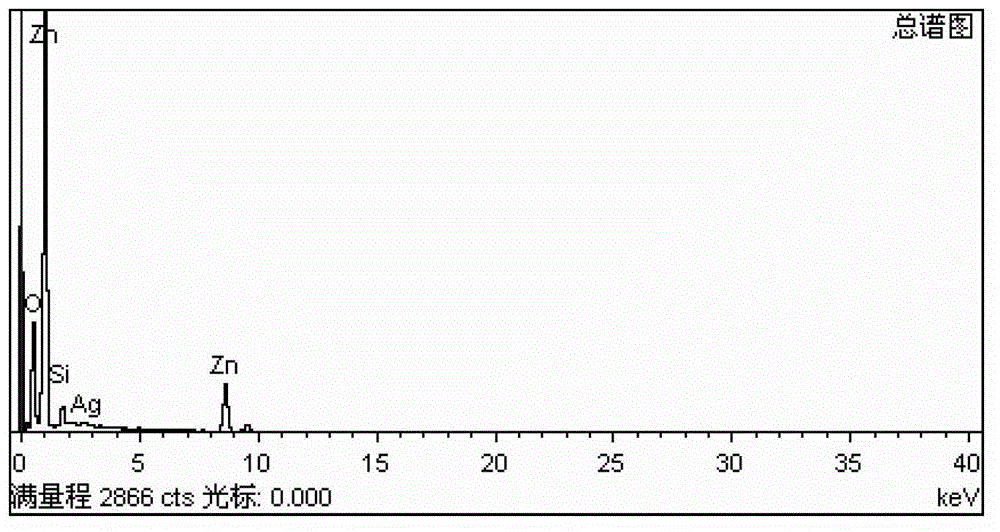

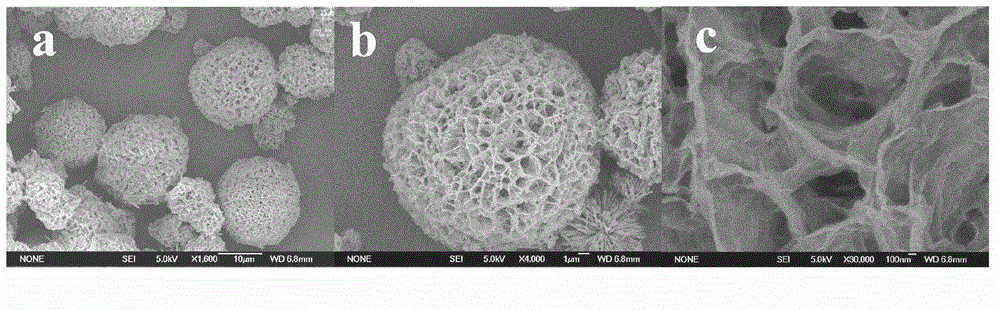

Preparation method of Ag/ZnO hierarchical structure microsphere

ActiveCN103143355AReduce usageLow costMetal/metal-oxides/metal-hydroxide catalystsPhoto catalyticOrganic dye

The invention provides a preparation method of an Ag / ZnO hierarchical structure microsphere. The preparation method comprises the following steps: taking water as a reaction medium, zinc sulfate as a zinc source, silver nitrate as a silver source, sodium potassium tartrate tetrahydrate as a ligand and hexamethylenetetramine as a precipitating agent to react under a certain condition; and centrifugally washing and drying the acquired product Ag / ZnO after the reaction is ended, then roasting and thermally decomposing the Ag / ZnO in a tube furnace to acquire a regularly-shaped and controllable Ag / ZnO hierarchical structure microsphere. The structure form of the microsphere remains complete. The preparation method of the Ag / ZnO hierarchical structure microsphere disclosed by the invention is simple; the size, structure and shape of the product Ag / ZnO microsphere are easily controlled; the yield is high; the problems of poor regularity and easy agglomeration in the using process of the Ag / ZnO structure in the prior art are solved; and the Ag / ZnO hierarchical structure microsphere prepared by the preparation method has excellent photo-catalytic property for organic dyes such as methyl orange and the like.

Owner:徐州市正峰锌业有限公司

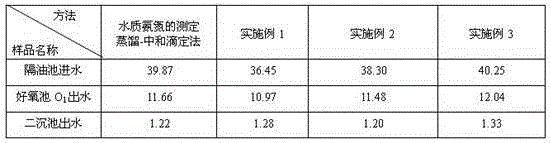

Reagent and method for rapidly measuring ammonia nitrogen content of oil refining sewage through electrode method

InactiveCN106568816AReduce typesSimple configurationMaterial electrochemical variablesSodium potassium tartrate tetrahydratePotassium sodium tartrate

The invention aims to provide a reagent and method for rapidly measuring the ammonia nitrogen content of oil refining sewage through an electrode method. The method is rapid and efficient, and the operation is quick and efficient. The reagent is composed of a standard solution and a buffer solution. The standard solution is an ammonium chloride solution. The buffer solution is a mixed solution of sodium hydroxide, sodium potassium tartrate tetrahydrate, and EDTA (Ethylene Diamine Tetraacetic Acid), wherein the mass percentage of sodium hydroxide: sodium potassium tartrate tetrahydrate: EDTA is 40-200: 28.2-141: 7.44-74.4. During the measuring process, sodium hydroxide in the buffer solution is used to adjust the pH value of a water sample until the pH value of the water sample reaches more than 11; sodium potassium tartrate tetrahydrate and EDTA can eliminate the interference of multiple metal ions such as aluminum, zinc, cadmium, copper, iron, and the like; and thus the reagent is very suitable for measuring the ammonia nitrogen content of oil refining sewage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cordierite-polylactic acid fiber composite blue-green alga treating agent and preparing method thereof

InactiveCN105776402AGood flocculationHigh activityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSodium BentoniteSodium potassium tartrate tetrahydrate

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

Lead-free conductive silver paste used for crystalline silicon solar cell and manufacturing method of lead-free conductive silver paste

InactiveCN104091627AReduce oxidationIncrease the open circuit voltageNon-conductive material with dispersed conductive materialCable/conductor manufactureSodium potassium tartrate tetrahydrateSuccinic acid

The invention discloses a lead-free conductive silver paste for a crystalline silicon solar cell. The lead-free conductive silver paste is characterized by being prepared from, by weight, 40-50 parts of silver powder, 2-3 parts of methyl formate, 1-2 parts of ethylenediamine tetraacetic acid disodium, 0.4-0.9 part of sodium potassium tartrate tetrahydrate, 1.4-2.6 parts of stearic acid, 2.3-3.6 parts of redispersible latex powder, 0.3-0.7 part of dinonyl naphthalene barium sulfonate, 1.2-2.8 parts of dodecenyl succinic acid, 30-40 parts of additives and appropriate amount of water. Through optimization of the production technology and the formula, oxidization of sliver particles can be effectively reduced, open-circuit voltage and electric performance of the cell can be improved, and therefore the solar cell is high in conversion efficiency.

Owner:CHINALAND SOLAR ENERGY

Method for preparing compounded brassinolide plant growth regulator easy to degrade

InactiveCN105831161ANo pollution in the processNo need to useBiocidePlant growth regulatorsSodium potassium tartrate tetrahydrateNutrient solution

The invention discloses a method for preparing a compounded brassinolide plant growth regulator easy to degrade, and belongs to the technical field of preparation of plant growth regulators .Rape pollen and agar weeds are mixed in a hydrochloric acid solution to be soaked, pretreatment mixed powder is prepared for use, a hypha suspension liquid is prepared from the pretreatment mixed powder, a nutrient solution and a waste edible mushroom culture medium for mixed fermentation, an extrusion solution is obtained through extruding and mixed with ethyl acetate, and a base solution of the compounded brassinolide plant growth regulator easy to degrade is obtained through centrifugation and concentration; the base solution, filterable matter obtained through enzymolysis and filtering and sodium potassium tartrate tetrahydrate are mixed and react, discharging and filtering are carried out to obtain filterable matter, and the compounded brassinolide plant growth regulator easy to degrade is prepared .The method has the advantages that the preparation steps are simple, no organic solvent is needed, the preparation process is free of pollution to the environment, and the cost is lower than that of other methods by 18% or above; the product yield is higher than that of other methods by 13.2% or above, and the purity is higher than that of other products by 20.3% or above.

Owner:袁春华

Agent for cleaning greasy dirt from surface of metal and preparation method thereof

InactiveCN104357855AEasy to cleanLittle effect of surface propertiesSodium potassium tartrate tetrahydrateMonocalcium phosphate

The invention discloses an agent for cleaning greasy dirt from the surface of a metal. The agent is prepared from the following raw materials in parts by weight: 8-10 parts of medical stone powder, 3-5 parts of disodium dodecyl sulphonatosuccinate, 2-4 parts of sodium laureth sulfate, 0.1-0.2 part of methylisothiazolinone, 1-2 parts of seaweed gel, 0.3-0.5 part of pectin, 1-2 parts of konjac glucomannan, 0.3-0.5 part of corn gluten meal, 0.5-1 part of calcium dihydrogen phosphate, 0.3-0.5 part of sodium hydrogen carbonate, 1-2 parts of sodium potassium tartrate tetrahydrate, 3-5 parts of auxiliaries and 40-50 parts of water. The agent for cleaning greasy dirt from the surface of the metal disclosed by the invention has an effect of powerfully cleaning greasy dirt from the surface of the metal, is suitable for cleaning metal materials and workpieces with relatively serious greasy dirt on the surfaces, is strong in greasy dirt removal effect and is free of secondary pollution, and the surface property of the material is hardly affected.

Owner:HEFEI DAAN PRINTING

Machining product cleaning agent

InactiveCN104928061AStrong decontamination and cleaning abilityDry fastOrganic detergent compounding agentsAnionic-cationic-non-ionic surface-active compoundsButanedioic acidSodium potassium tartrate tetrahydrate

The invention relates to a machining product cleaning agent. The cleaning agent comprises, by mass, 1.5-4 parts of oil acyl methyl taurine sodium, 6-20 parts of bis-naphthalenesulfonic aci sodiumsalt, 4-10 parts of sodium potassium tartrate tetrahydrate, 10-20 parts of acryloyloxyethyl trimethyl ammonium chloride, 4-12 parts of dioctyl sodium sulfosuccinate, 6-20 parts of ricinoleic acid, 10-20 parts of cocoanut fatty acid diethanolamide, 10-20 parts of 2-phosphonic acid butane-1, 2, 4-tricarboxylic acid, 10-20 parts of dodecyl trimethyl ammonium chloride and 30-80 parts of deionized water. The machining product cleaning agent has the advantages of being great in stain removing and cleaning capacity, fast in drying, free of residue, wide in compatibility, free of combustion and explosion, safe, environment friendly, safe to use and the like. According to the cleaning treating fluid, the biodegradability is high, the stains and grease on a machining product can be effectively removed, the skin is not injured, and the cleaning efficiency is larger than 99%.

Owner:龚灿锋

Bismuth-plating electroplating liquid and pulse plating method for bismuth thin film

The invention discloses a bismuth-plating electroplating liquid and a pulse plating method for a bismuth thin film. The bismuth-plating electroplating liquid comprises components in concentration as follows: 40-80 g / L of bismuth sulfate, 100-150 g / L of sodium potassium tartrate tetrahydrate, 30-40 g / L of sodium citrate, 0.15-0.20 g / L of antimony potassium tartrate or ethylenediamine tetraacetic acid disodium salt, 40-50 g / L of sodium gluconate, 5-7 ml / L of a stabilizer and the balance of a solvent A, wherein the solvent A is water; the stabilizer comprises 2-5 g / L of polyethylene glycol, 2-4 g / L of vitamin C, 15-20 g / L of sodium hypophosphite and the balance of a solvent B which is water. Compared with the prior art, the bismuth-plating electroplating liquid is better in stability and long in service life and has higher dispersion and covering capacity as well as high conduction performance, concentration polarization is reduced due to use of a pulsed power supply, and the current efficiency is improved.

Owner:WUXI QIAOYANG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com