Preparing method for magnesium alloy black microarc oxidation film

A technology of micro-arc oxidation and magnesium alloy, applied in the direction of anodizing and other directions, can solve the problems of easy fading and discoloration of the surface, environmental pollution, cyanide in the plating solution, etc., and achieve the effects of simple preparation process, low cost and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

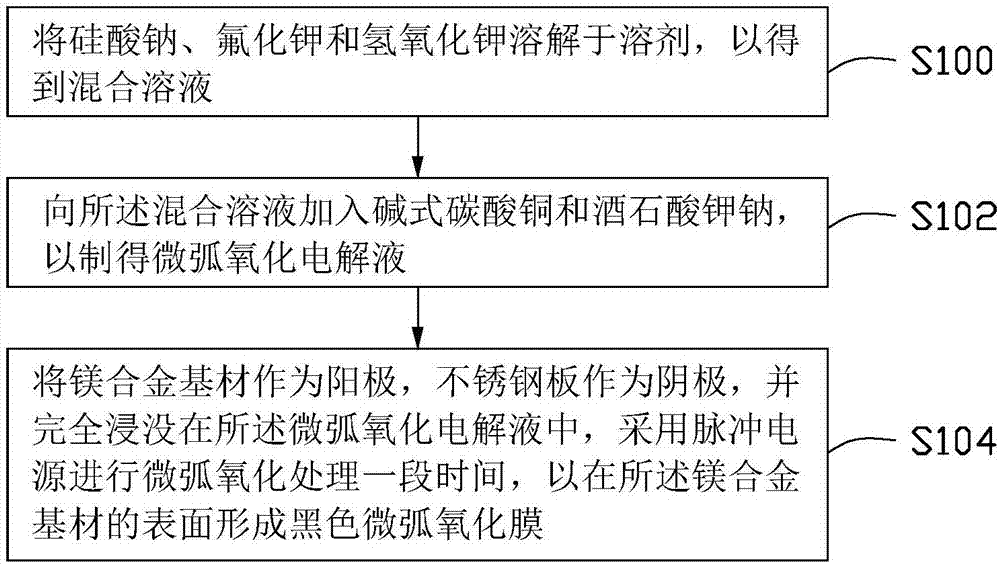

[0028] see figure 1 , a synthesis flow chart of a black micro-arc oxidation film on magnesium alloy according to a preferred embodiment of the present invention. The preparation method of the black micro-arc oxidation film of the magnesium alloy comprises the following steps:

[0029] Step S100, dissolving sodium silicate, potassium fluoride and potassium hydroxide in a solvent to obtain a mixed solution.

[0030] Wherein, the solvent is, for example, but not limited to pure water, high-purity water or ultra-pure water, and other solutions without impurity ions can also be used in the present invention.

[0031] It can be understood that pure water (deionized water) refers to pure water after removing impurities in the form of ions. High-purity water mainly refers to water with a conductivity of less than 0.1us / cm, a pH value of 6.8-7.0, and water that removes other impurities and bacteria when the temperature of the water is 25°C. Ultrapure water refers to water with a res...

Embodiment 1

[0045] Mix the sodium silicate, potassium fluoride and potassium hydroxide with deionized water in proportion to obtain a mixed solution. Wherein, the consumption of the sodium silicate is 8g / L, the consumption of the potassium fluoride is 5g / L, and the consumption of the potassium hydroxide is 7g / L. Subsequently, basic copper carbonate and potassium sodium tartrate were added to the mixed solution and stirred evenly to obtain a micro-arc oxidation electrolyte. Wherein, the consumption of described basic copper carbonate is 5g / L. The consumption of described sodium potassium tartrate is 3g / L.

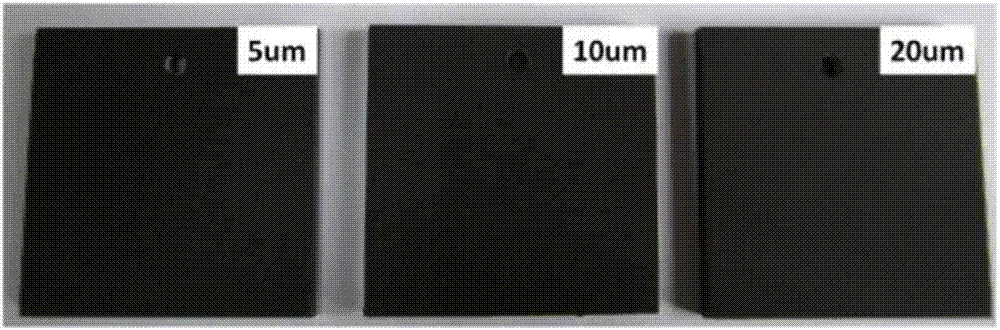

[0046] The magnesium alloy substrate and the stainless steel plate are placed in the micro-arc oxidation electrolyte for micro-arc oxidation treatment. Wherein, the magnesium alloy substrate is used as the anode, and the stainless steel plate is used as the cathode, and the process parameters for controlling the micro-arc oxidation are shown in Table 1. After 3 minutes of electrificat...

Embodiment 2

[0050] Mix the sodium silicate, potassium fluoride and potassium hydroxide with deionized water in proportion to obtain a mixed solution. Wherein, the consumption of the sodium silicate is 8g / L, the consumption of the potassium fluoride is 5g / L, and the consumption of the potassium hydroxide is 7g / L. Subsequently, basic copper carbonate and potassium sodium tartrate were added to the mixed solution and stirred evenly to obtain a micro-arc oxidation electrolyte. Wherein, the consumption of described basic copper carbonate is 4g / L. The consumption of described sodium potassium tartrate is 2g / L.

[0051]The magnesium alloy substrate and the stainless steel plate are placed in the micro-arc oxidation electrolyte for micro-arc oxidation treatment. Wherein, the magnesium alloy substrate is used as the anode, and the stainless steel plate is used as the cathode, and the process parameters for controlling the micro-arc oxidation are shown in Table 2. After 6 minutes of electrificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com