Patents

Literature

353 results about "Basic copper carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Basic copper carbonate is a chemical compound, more properly called copper(II) carbonate hydroxide. It is an ionic compound (a salt) consisting of the ions copper(II) Cu²⁺, carbonate CO²⁻₃, and hydroxide OH⁻.

Use of sub-micron copper salt particles in wood preservation

InactiveUS20060062926A1Little dangerSmall particle sizeBiocideLiquid surface applicatorsPhosphateCopper nitrate

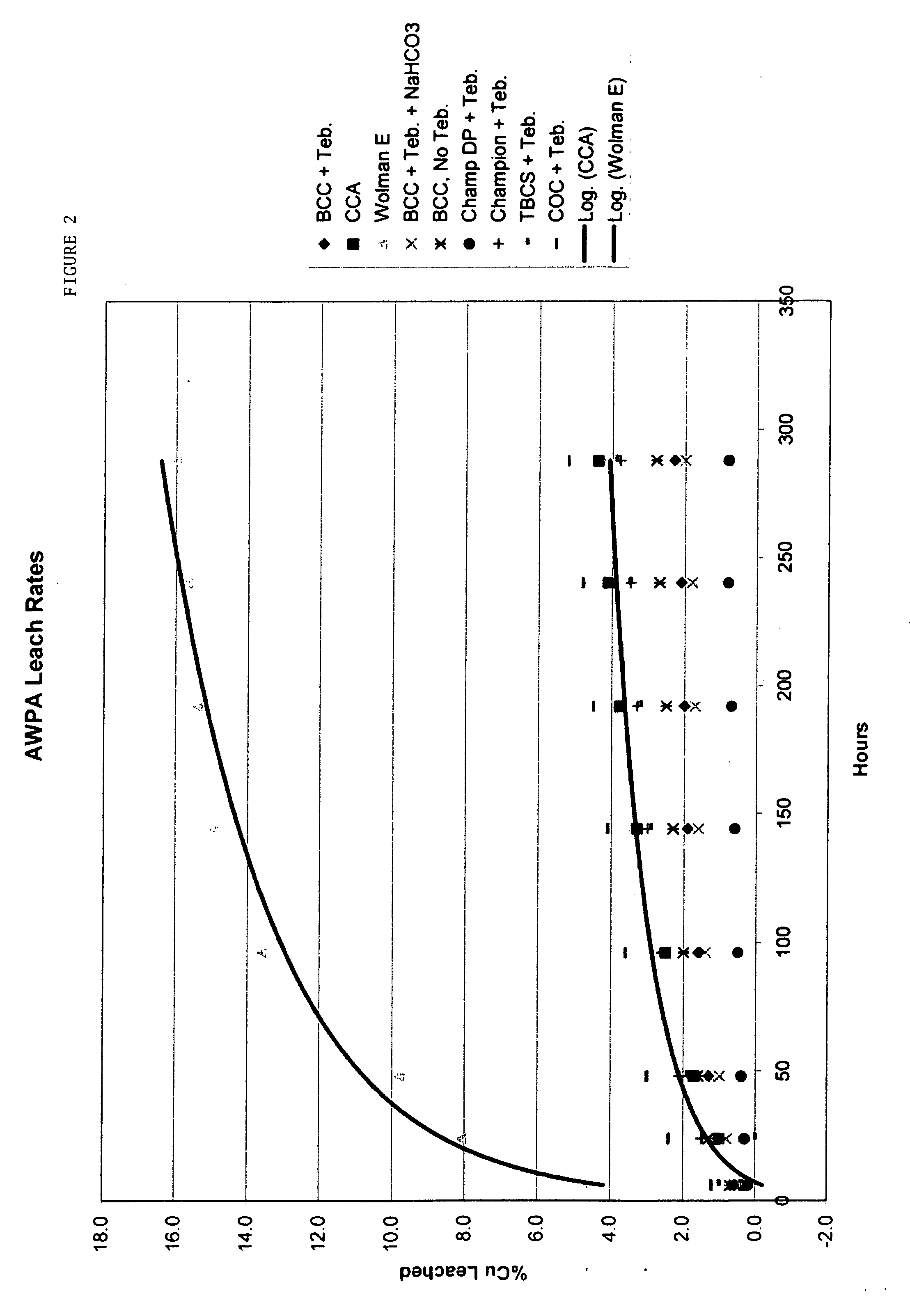

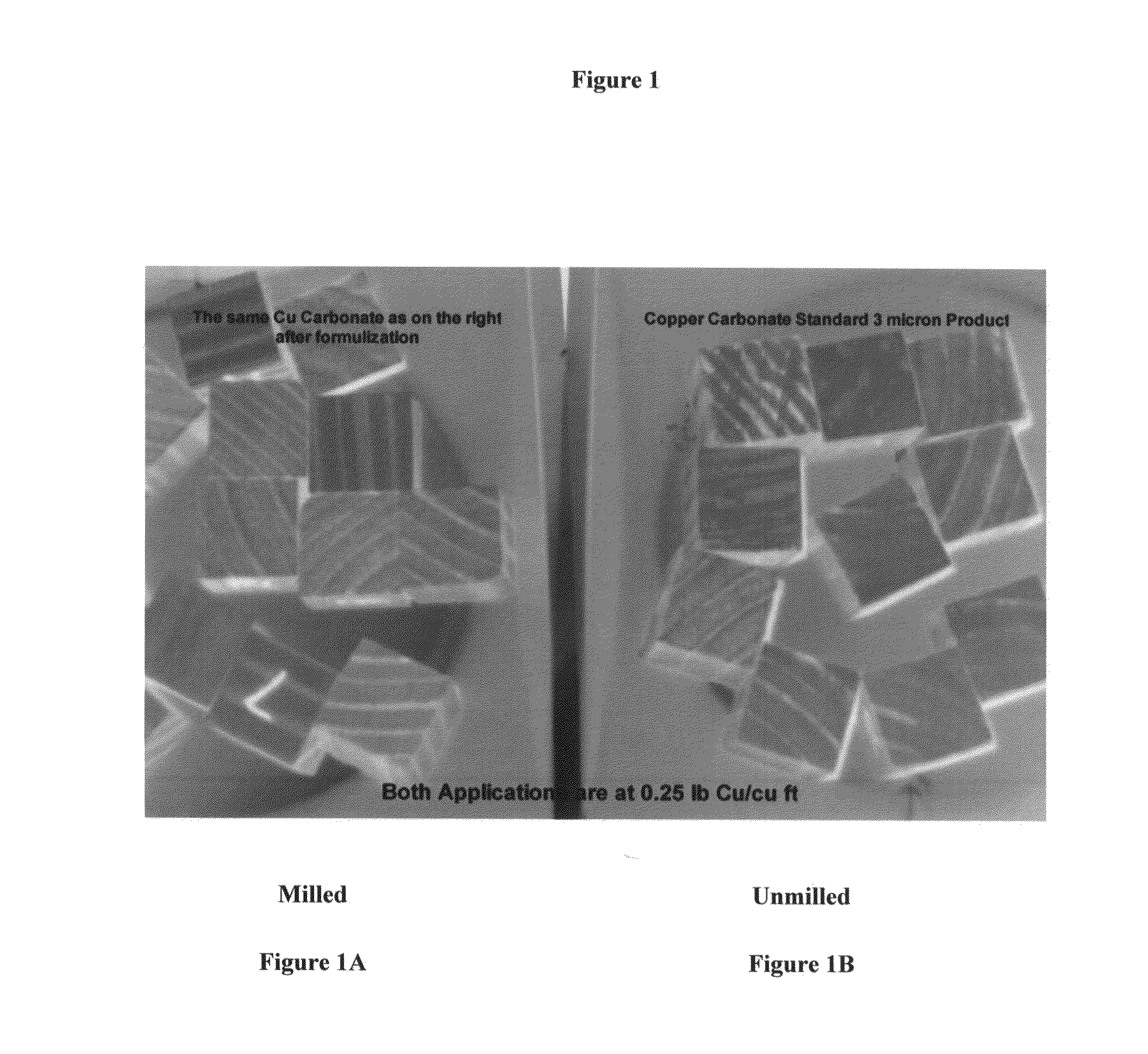

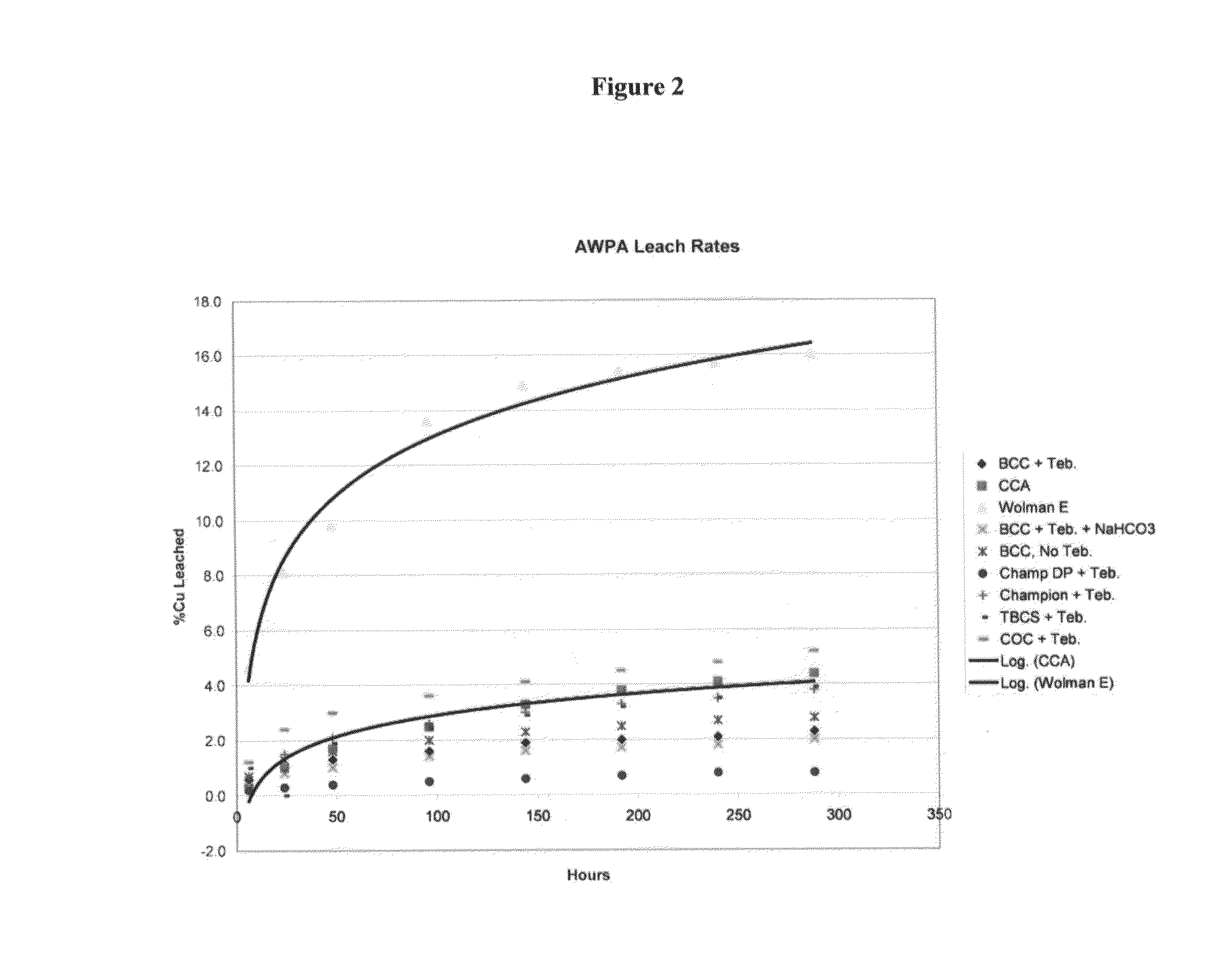

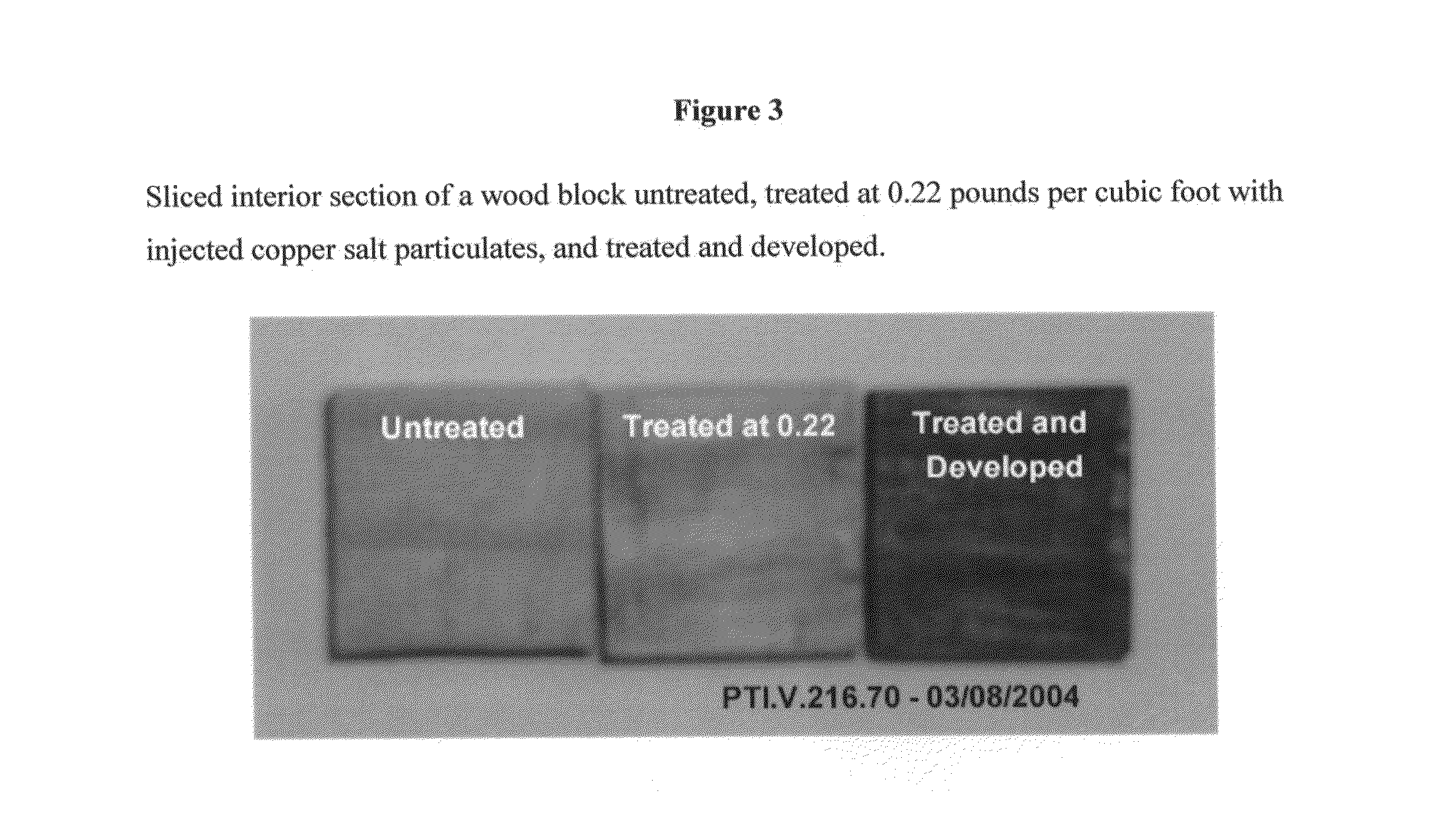

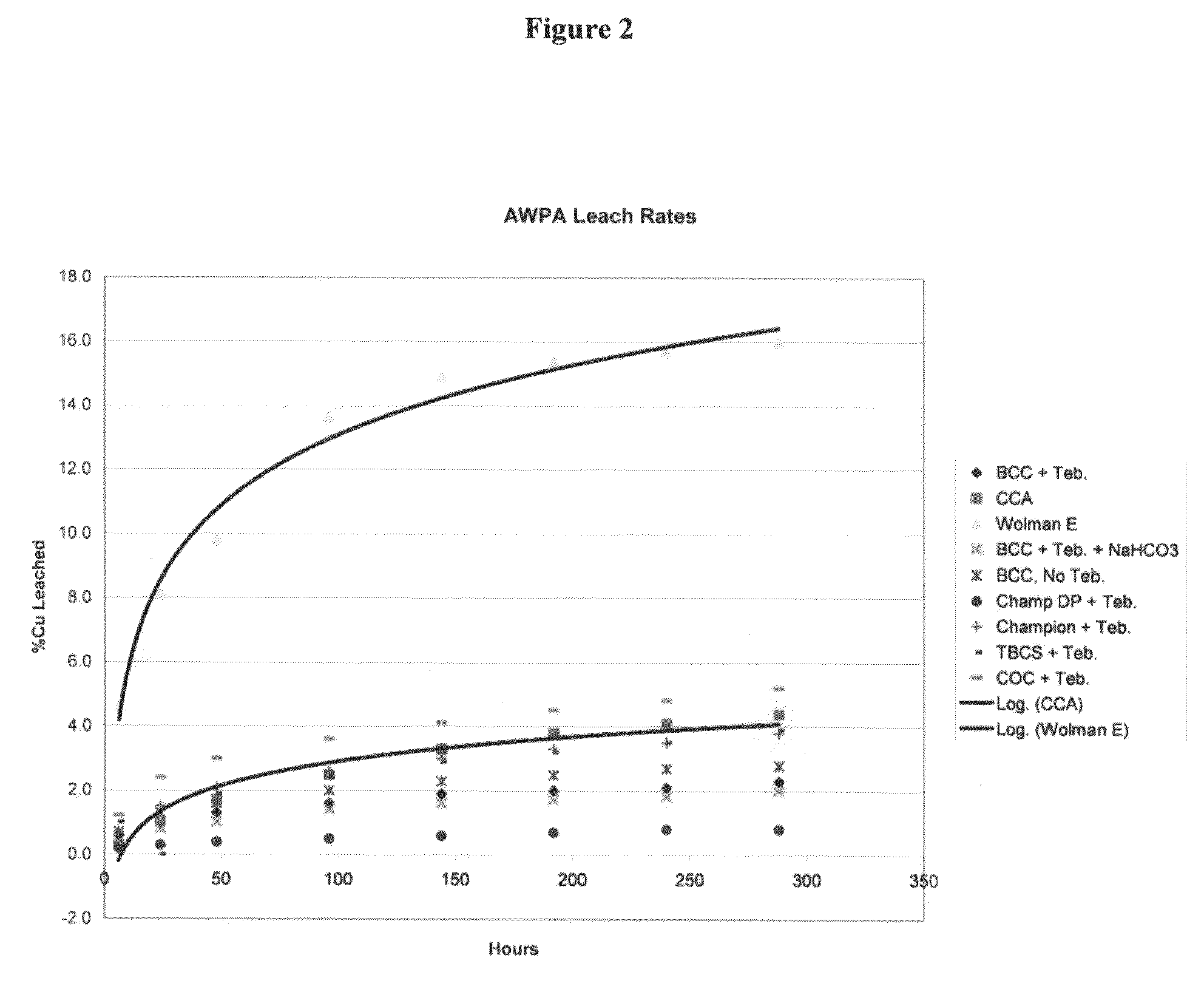

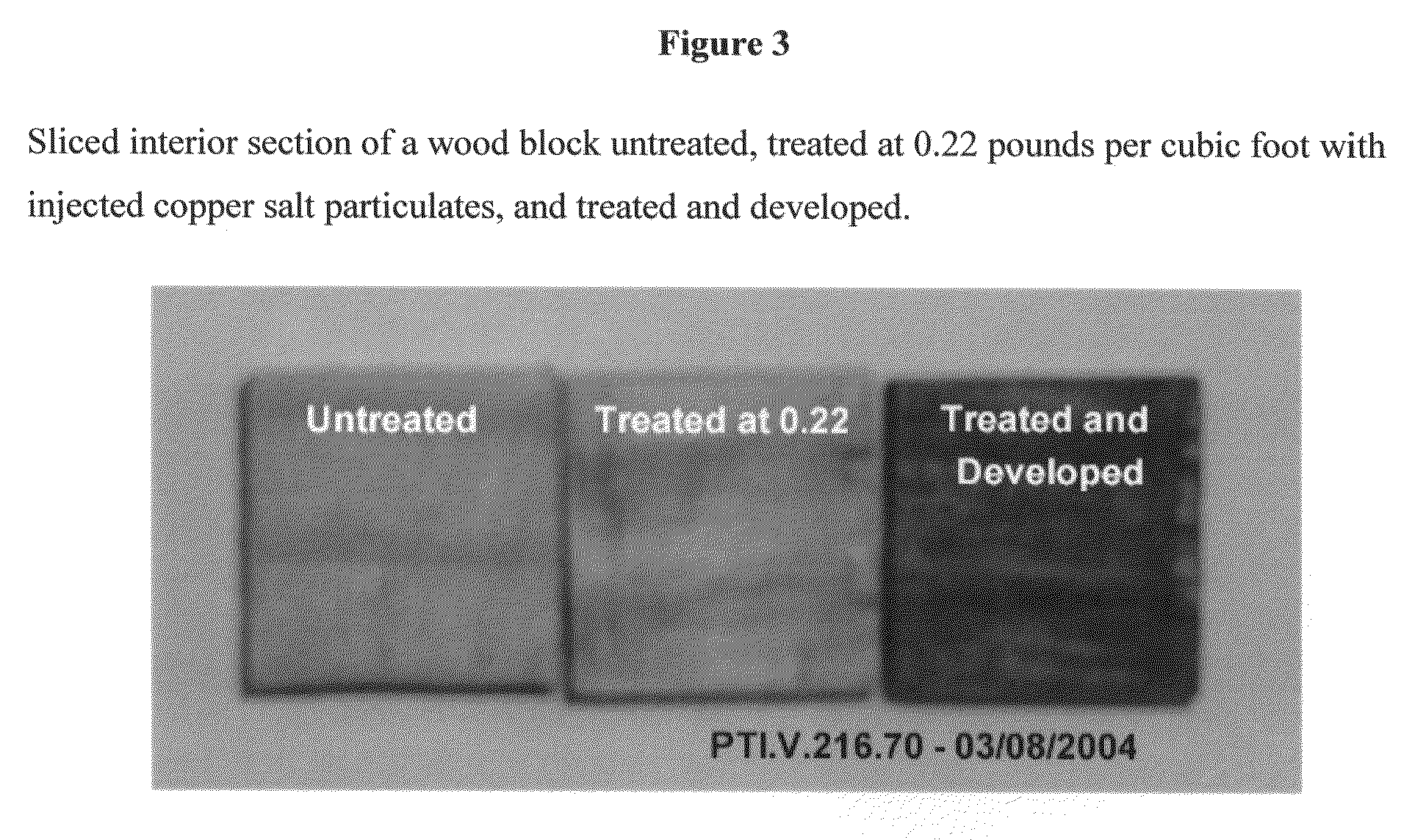

A method for preserving wood by injecting into the wood a slurry having: particles of a sparingly soluble copper salt, copper hydroxide, or both, wherein the weight average diameter d50 of the particles in the slurry is between 0.1 microns and 0.7 microns and the d98 of the particles in the slurry is less than about 1 micron; a dispersant; and water. The dispersant is anionic or a mix of anionic and non-ionic. Advantageously, less than 20% by weight of the particles have a diameter less than 20 nanometers. Useful copper salts include basic copper carbonate, tri-basic copper sulfate, copper oxychloride, basic copper nitrate, basic copper borate, copper borate, basic copper phosphate, or copper silicate. The slurry most preferably includes copper hydroxide particles. The slurry further advantageously includes at least one organic biocide, wherein at least a portion of the organic biocide is coated on the particles.

Owner:OSMOSE

Catalyst for production of 1,4-butynediol and preparation method of catalyst

ActiveCN102950014AHigh activityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationBASIC CUPRIC CARBONATESlurry reactor

The invention discloses a catalyst for production of 1,4-butynediol and a preparation method of the catalyst, belongs to the field of catalyst research, more particularly relates to a load type catalyst for production of 1,4-butynediol in a slurry reactor and a preparation method of the catalyst. According to the method, nanosilicon dioxide which has a larger external specific surface is used as a carrier, copper and bismuth are attached to the carrier by adopting a settling and depositing method, the active components of the catalyst exist in a form of basic cupric carbonate, and the catalyst comprises the following components in percentage by mass: 20-50 percent of carrier, 35-70 percent of basic cupric carbonate and 2-15 percent of bismuth subcarbonate. The prepared catalyst has the characteristics of good activity and high selectivity and is easy to activate.

Owner:大连瑞克科技股份有限公司

Particulate wood preservative and method for producing same

InactiveUS20050252408A1Reduce the amount requiredWide particle size distributionBiocideAntifouling/underwater paintsCopper(II) hydroxideBasic copper carbonate

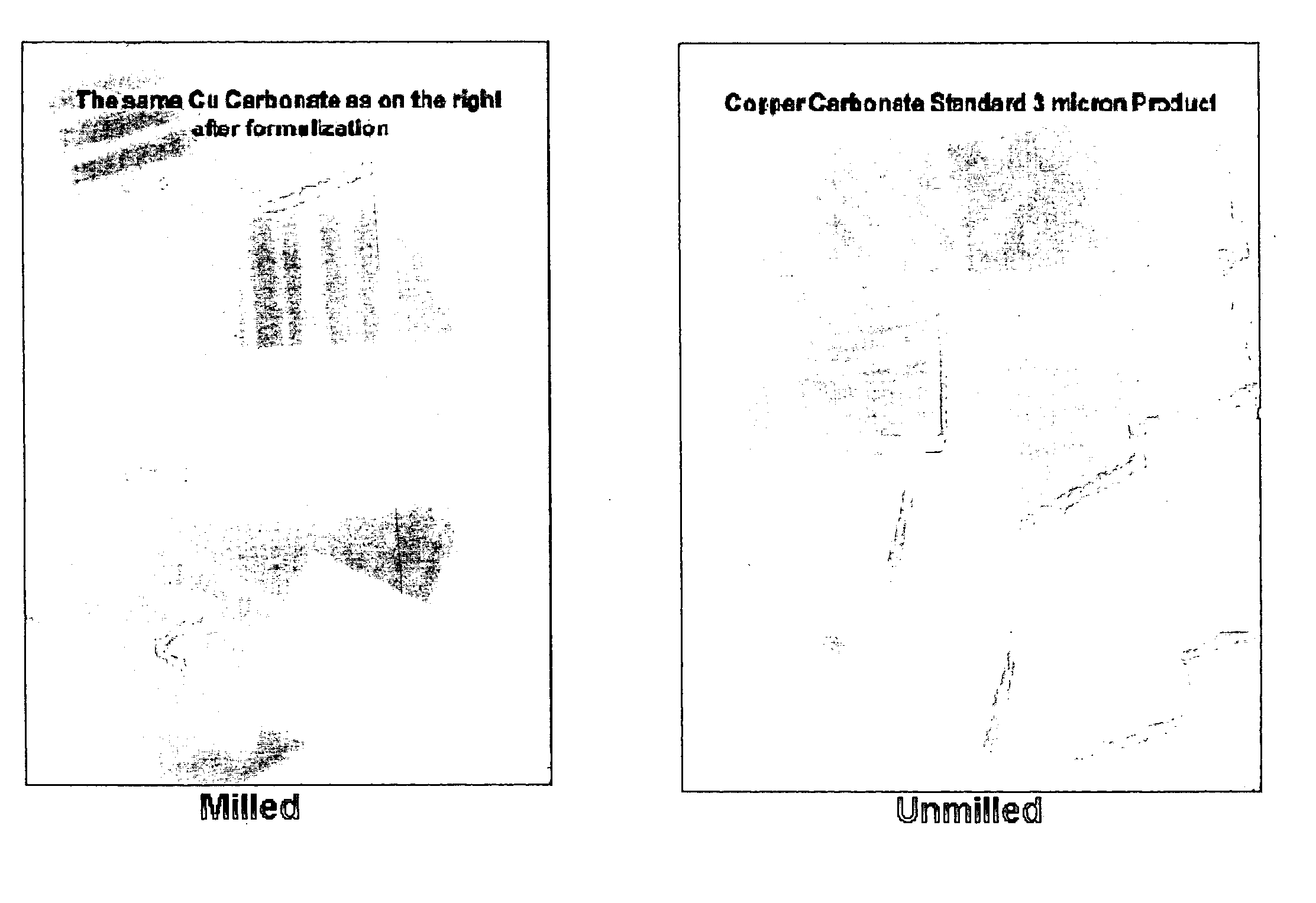

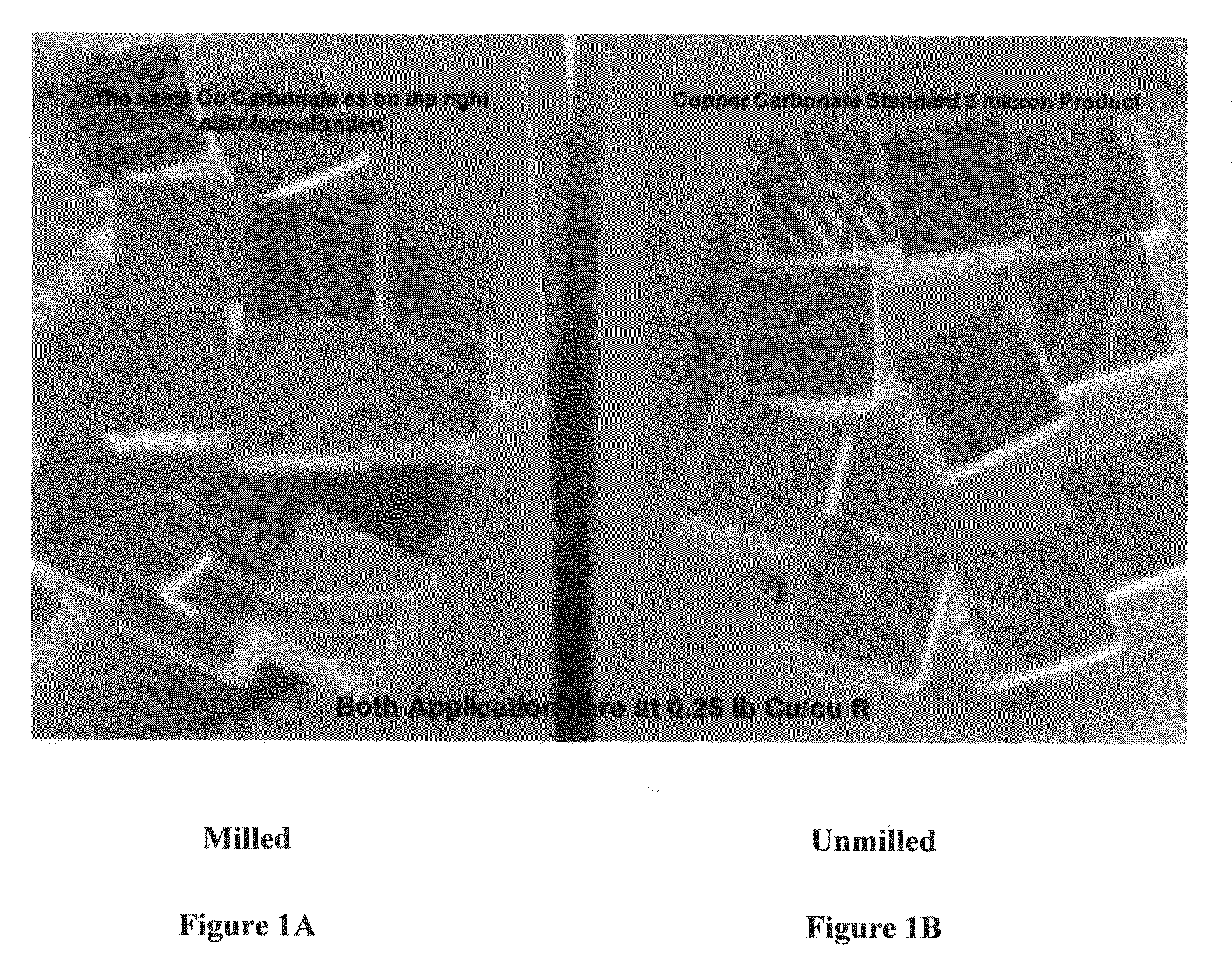

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:OSMOSE

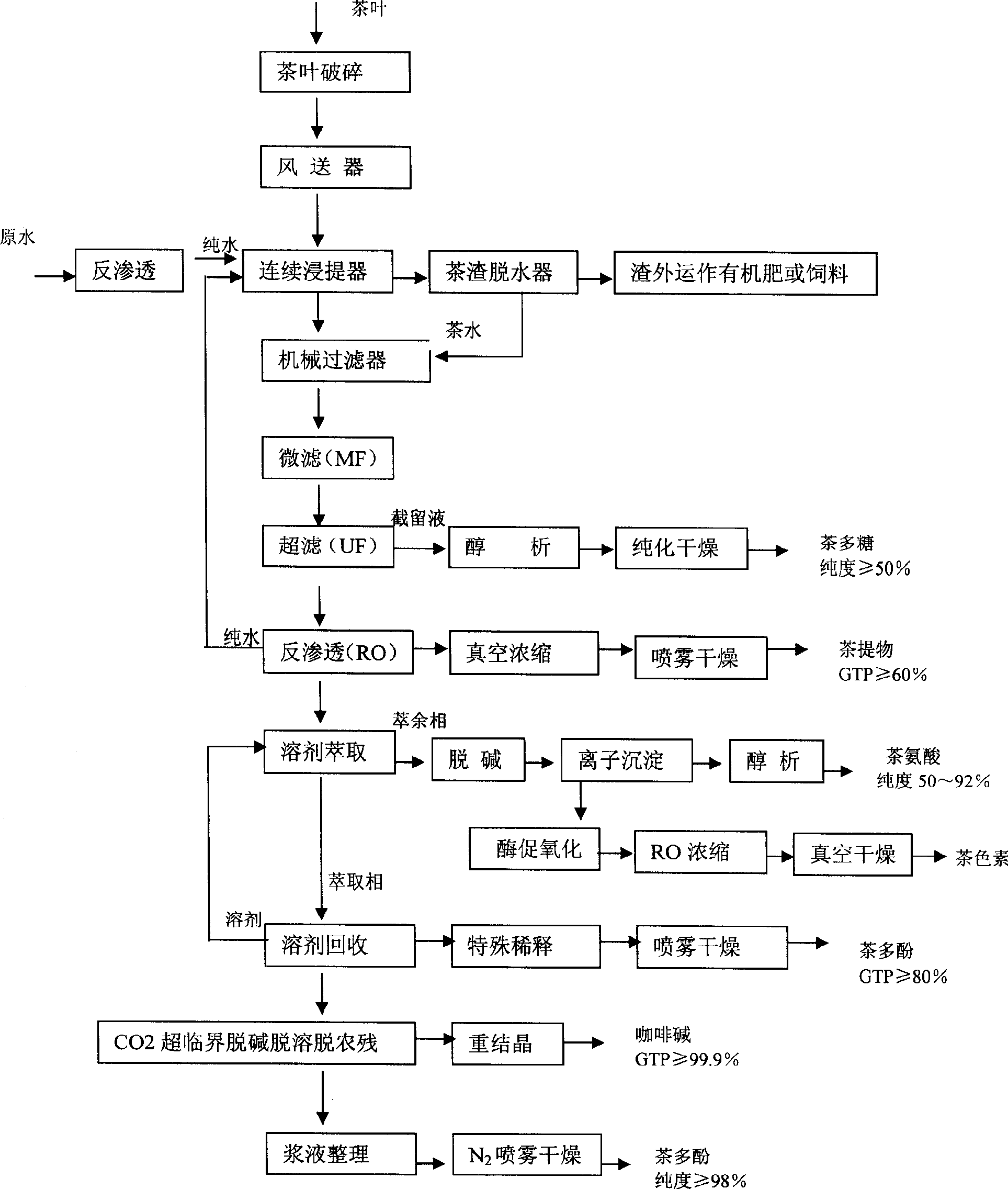

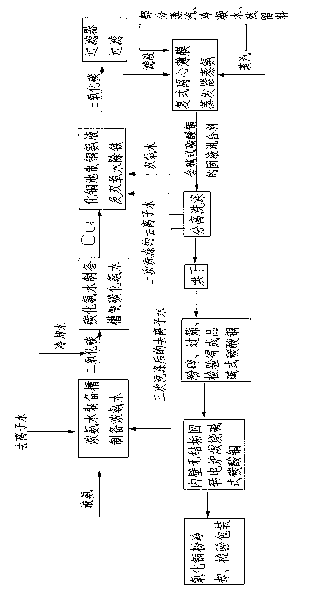

Process for extracting tea polyphenol, theanine, tea polysaccharide and tea pigment from tea

InactiveCN1837201AHigh purityReduce labor intensityCarboxylic acid amide separation/purificationBulk chemical productionForeign matterPhenolic content in tea

The invention discloses an extracting polyphenol, theanine, tea polysaccharide and tea pigment method from tea, which is characterized by the following: using deionized water for lixiviating tea at constant temperature with continuous flow upstream at multi-speed; adopting microstrainer to dislodge the foreign matter of raffinate; using hyperfiltration for putting-off pectin and protein; concentrating by hyperfiltration and dehydration; extracting tea polyphenol by acetic acid ethyl ester and recovering dissolvant; stripping caffeine of extracting extract phase, pesticide residue and dissolvant by CO2 supercritical fluid; getting tea polyphenol by low-temperature nitrogen spray-drying; using alcohol separation and low temperation vacuum drying by hyperfiltration trapped fluid to prepare tea polysaccharide; separating alcohol recrystallization by basic copper carbonate and hydrogen sulfide to get theanine; using enzymatic oxidation and alkaline air to oxygenate remain polyphenols substance of liquid phantom; getting tea pigment by hyperfiltration dehydration compression and vacuum drying; merging caffeine form carbon dioxide above-critical fluid and caffeine from carrene; recovering dissolvent; using deionized water for washing; obtaining caffeine by recrystallization vacuum drying.

Owner:张守政

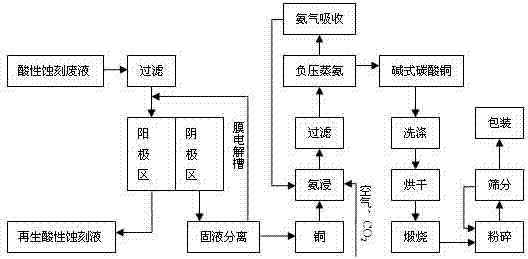

Technique for producing soluble copper oxide from acidic etching waste liquor

ActiveCN102730742AEnable online recyclingEliminate Risk During TransfersPhotography auxillary processesCopper oxides/halidesElectrolysisBasic copper carbonate

The invention discloses a technique for producing soluble copper oxide from acidic etching waste liquor, which comprises the following steps: electrolyzing acidic etching waste liquor to generate copper; dissolving electrolyzed cathode copper in an ammonia water-CO2 system to form a copper-ammonia solution; carrying out negative pressure ammonia evaporation on the copper-ammonia solution to form basic copper carbonate; and calcining the generated basic copper carbonate to generate copper oxide. The technique disclosed by the invention has the advantages of low production cost, simple technique and low environmental pollution in the production process; and the produced copper oxide has the advantages of low impurity content and high activity and is soluble in a plating solution.

Owner:昆山市千灯三废净化有限公司

Non-cyanide alkaline copper plating bath, preparation and use method thereof

The present invention is a new non-cyanide alkaline copper plating bath, preparation and use method thereof. In the copper plating bath, using copper sulfate or basic copper carbonate as main salt, using hydroxy-ethylidene diphosphonic acid as main complexant, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator; the operation conditions are: cathode current density is 0.5-3.0 A / dm [2], pH of plating bath controlled between 12 and 13, plating bath temperature is 50-70 DEG. Comparing with the prior known technology, the invention has following advantages or positive effects: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

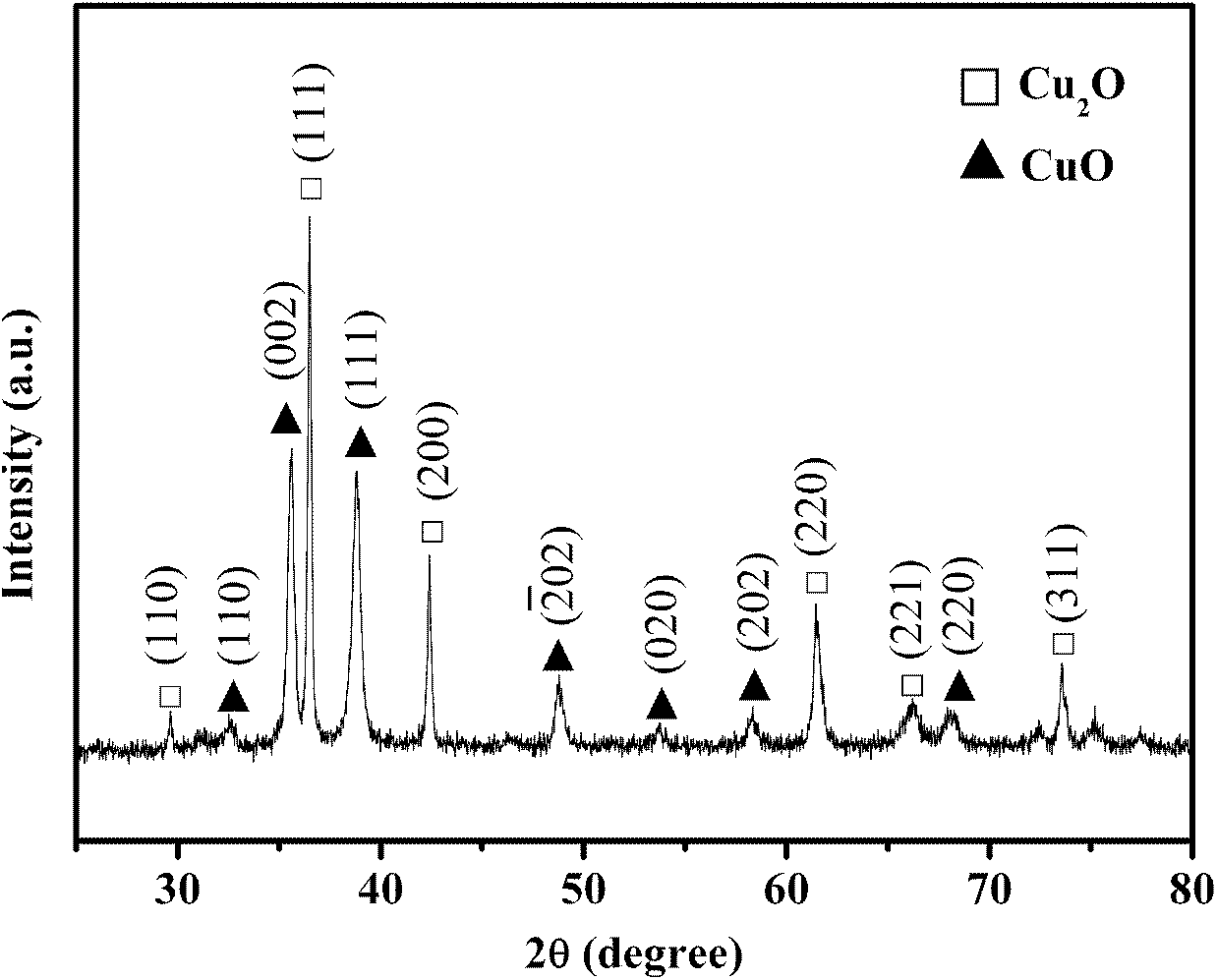

Preparation method of Cu2O-CuO composite oxide

ActiveCN103466682ANo pollution in the processZero emissionNanotechnologyCopper oxides/halidesReaction temperatureControllability

The invention discloses a preparation method of a Cu2O-CuO composite oxide. The preparation method comprises the following steps: adding a glucose solution with certain concentration and a certain amount of basic copper carbonate powder into a hydrothermal kettle, fully stirring, placing the hydrothermal kettle in an oven with a preset temperature, taking out a product after reacting for a period of time, and carrying out vacuum drying on the product to obtain the Cu2O-CuO composite oxide. According to the preparation method, the glucose content, the reaction temperature and the reaction time are adjusted to control the preparation, and no surfactant or acid-base reagent is added, so that the whole process is environment-friendly, the reaction condition are mild, the operation is convenient and efficient, the controllability and repeatability are good, and a high-yield spherical Cu2O-CuO composite oxide assembled by nanometer pieces can be prepared.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

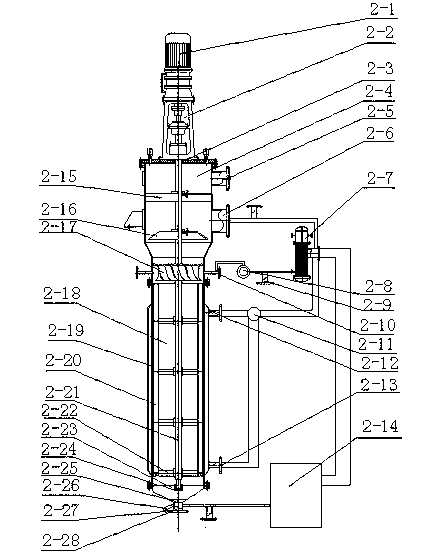

Preparation method for active copper oxide

InactiveCN103991894AEmission reductionAvoid bringing inCopper oxides/halidesElectrolysisBasic copper carbonate

The invention discloses a preparation method for active copper oxide by using a spray flashing calciner. The method comprises the following steps: with copper, liquefied ammonia and ammonium bicarbonate as raw materials, preparing concentrated ammonia liquor with a concentration of 10 to 12% at first; then adding excess concentrated ammonia liquor into electrolytic copper, adding ammonium bicarbonate, introducing air at the same time and carrying out leaching and synthesis at a temperature of 60 to 70 DEG C so as to prepare cuprammonia; after filtering, pumping the cuprammonia into a reaction vessel for thermal decomposition so as to prepare a basic copper carbonate feed liquid; and filling the spray flashing calciner with the basic copper carbonate feed liquid, carrying out calcining at a temperature of 450 to 600 DEG C so as to prepare active copper oxide and recovering and reusing gas produced in the reaction by using an absorption tower. The method provided by the invention has the advantages of an increased reaction speed, substantially improved production efficiency, higher product purity, lower production cost and a wider product application scope; moreover, since the spray flashing calciner is used, heat dissipation is small, the resource of coal is saved, and requirements for energy conservation and environmental protection are better met.

Owner:JIANGSU TEHO METAL IND

Fire coal efficient catalysis combustion-supporting agent and preparation method and use method thereof

InactiveCN102061212AImprove combustion performanceImprove burnout rateSolid fuelsBasic copper carbonateUrea

The invention provides a fire coal efficient catalysis combustion-supporting agent and a preparation method and use method thereof. The combustion-supporting agent provided by the invention comprises the following components in parts by weight: 20-40 parts of basic copper carbonate, 10-25 parts of calcium oxide, 5-20 parts of citric acid, 5-10 parts of ammonium metavanadate, 5-10 parts of urea, 5-10 parts of potassium carbonate and 5-10 parts of borax. The combustion-supporting agent can also contain 5-10 parts of lanthanide oxide, 5-15 parts of magnesium powder and 0-10 parts of iron nitrate. The invention has the following beneficial effects: the components of the combined combustion-supporting agent release or transfer active oxygen at the high temperature; the macromolecular structures of coal are damaged to break the bridge bonds between the connecting structure units, improve the combustibility of fire coal and increase the burn-off rate of coal, thus fire coal can be fully utilized and the aim of energy saving can be achieved; and the combustion-supporting agent performs combination reactions with the combustion products of coal such as SO2 and the generated solids which are difficult to volatilize enter ash, thus the emissions of gaseous pollutants can be reduced.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

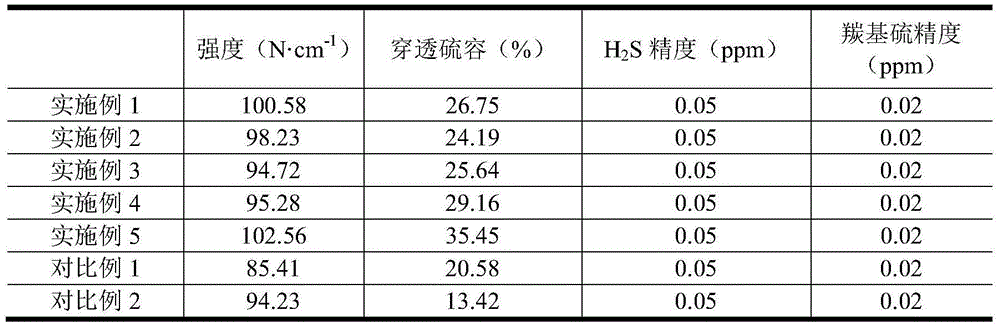

Desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time

ActiveCN104437074AHigh mechanical strengthEvenly distributedDispersed particle separationCarbonyl sulfideAccelerant

The invention discloses a desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time. The desulfurizing agent is prepared through the following steps that S1, a compound containing zinc, a binder and an accelerant are mixed, kneaded and formed; S2, a mixture formed after mixing, kneading and forming in the S1 is dried, and then a dried desulfurizing carrier precursor is obtained; S3, the desulfurizing carrier precursor obtained in the S2 is calcinated, and then a desulfurizing agent carrier is obtained; S4, the desulfurizing agent carrier is impregnated in a first copper salt solution, and copper active components are loaded on the desulfurizing agent carrier, wherein the first copper salt solution is an ammonium hydroxide solution of basic cupric carbonate; S5, an impregnated sample obtained in the S4 is dried and calcinated, and then the desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time is obtained. The obtained desulfurizing agent is high in strength and not prone to pulverization, the impregnation effect of the active components is better, and hydrogen sulfide and carbonyl sulfide impurities in a high-temperature industrial gas source can be efficiently removed at the same time.

Owner:SHENYANG SANJUKAITE CATALYST

Active copper oxide powder preparation method

The invention relates to an active copper oxide powder preparation method which is characterized in that: a copper ammonia complex solution is prepared from a copper plate as a raw material by use of ammonia leaching method, by precision filtration and micro negative pressure evaporation basic copper carbonate is obtained, and an active copper oxide powder product is obtained by low temperature calcination. When in reaction, first a certain proportion of ammonia water, water and ammonium hydrogen carbonate are added into a reaction kettle to be used as a base solution, a certain mass of cyclone copper plate is added into the base solution, air is blown into the reaction kettle, stirring is started for reaction at room temperature, the reaction time is controlled in 6-12 hours to ensure the concentration of copper ions to achieve preparation requirements, and the active copper oxide powder product is obtained by precision filtration, evaporation, solid-liquid separation and calcinations of the prepared copper ammonia solution. The copper oxide prepared by the method has high product activity, high purity, controllable granularity, low energy consumption, easy continuous production and other advantages.

Owner:JINCHUAN GROUP LIMITED

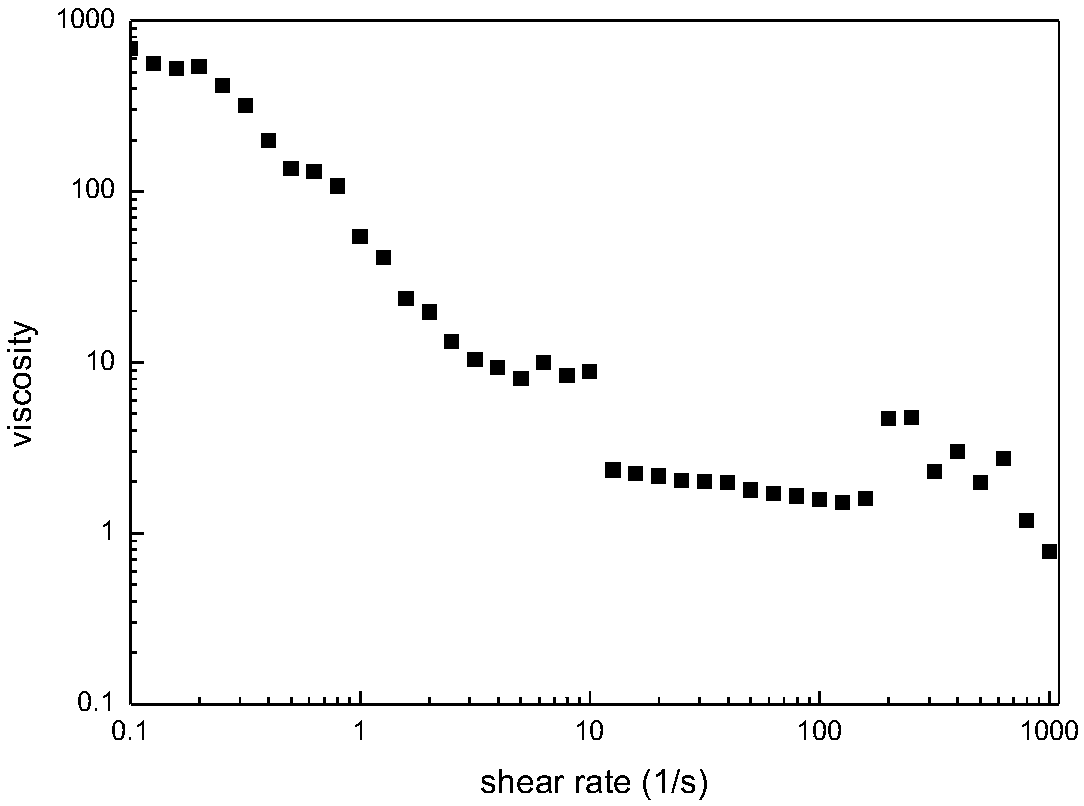

3D direct writing zirconium oxide ceramic ink

The invention relates to 3D direct writing zirconium oxide ceramic ink, which comprises zirconium oxide particles, a solvent, a binder, a dispersant and a salt, wherein the particle size of the zirconium oxide particles is 0.1-2 [mu]m, the solid content of the zirconium oxide particles in the ink is 40-58 vol%, the dispersant is one or a variety of materials selected from polyacrylic acid, polyvinyl acid, ammonium polyacrylate, polyvinyl acid salt, polyacrylate, polycarboxylate and polyacetyl imine, the dispersant accounts for 0.1-2% of the mass of the zirconium oxide particle dry powder, andthe salt is one or a variety of materials selected from ammonium chloride, zinc acetate, sodium chloride, magnesium chloride, potassium chloride, barium chloride, ammonium bicarbonate, anhydrous calcium chloride, potassium carbonate, sodium bicarbonate, sodium carbonate, anhydrous sodium carbonate, anhydrous sodium acetate, anhydrous calcium chloride, copper sulfate, basic copper carbonate, ammonium sulfate, ammonium bicarbonate, potassium aluminum sulfate and sodium citrate, and accounts for 0.001-0.1% of the mass of the ink. According to the present invention, the 3D direct writing zirconiumoxide ceramic ink can be printed at the room temperature, has high solid content while can flow out of the fine spraying nozzle and cannot cause the clogging, can be quickly cured into the fine wirewith a certain strength, and has good rheological property.

Owner:CENT SOUTH UNIV

Non-cyanide copper plating solution

Cyanogen-free preplated copper solution belongs to the technical field of surface treatment electroplating. The solution adopts a nontoxic organic phosphine compound to replace cyanide as a complexing agent for the preplated copper, and is particularly suitable for preplated copper used to electroplate steel, aluminum, magnesium, zinc, titanium and titanium alloy. The cyanogen-free preplated copper solution has the following main technical characteristic that the solution consists of (a) one sort of copper sulphate, basic cupric carbonate or copper nitrate with the volume concentration of between 30 and 60 g / L; (b) one sort or two sorts of compounds selected from methylene diphosphonic acid, 1-hydroxyethylidene 1.1 diphosphonic acid and 1-hydroxybutyleneidene 1.1 diphosphonic acid with the volume concentration of between 120 and 160 g / L; (c) one sort or two sorts of compounds selected from methylamino dimethylene diphosphonic acid, hexamethylene diamine tetramethylene phosphonic acid and ethylenediamine tetramethylene phosphonic acid with the volume concentration of between 2 and 5 g / L; (d) one sort of potassium citrate, amine citrate or seignette salt with the volume concentration of between 6 and 12 g / L, and (e) polyethyleneimine alkyl slat or aliphatic amine ethoxy sulfonated substance (AESS) with the volume concentration of between 0.02 and 0.05 g / L. The cyanogen-free preplated copper solution has the characteristics of stable service performance, simple solution compositions, convenient maintenance, high safety, environmental protection, reliable plating coat binding and the like.

Owner:江南工业集团有限公司

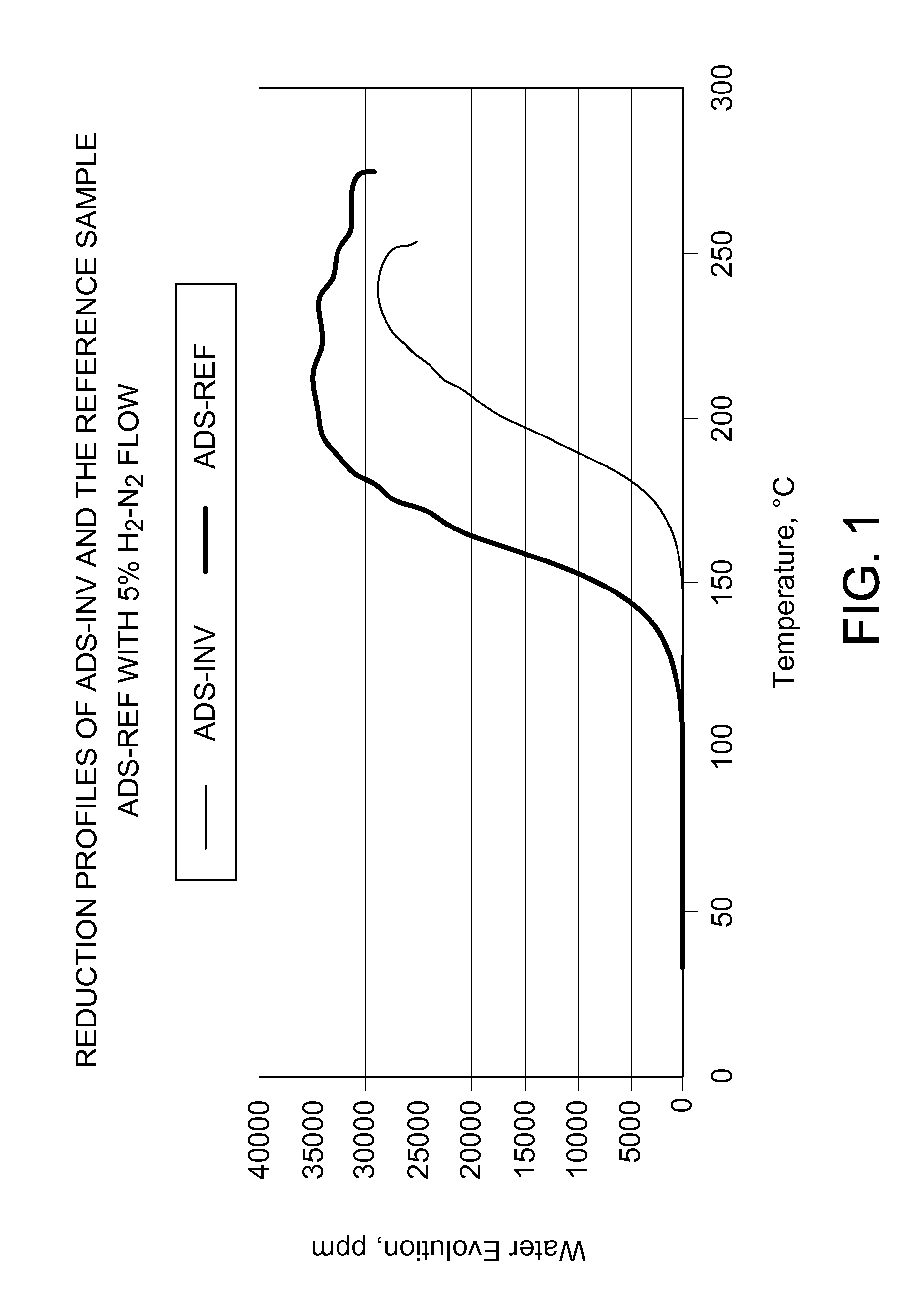

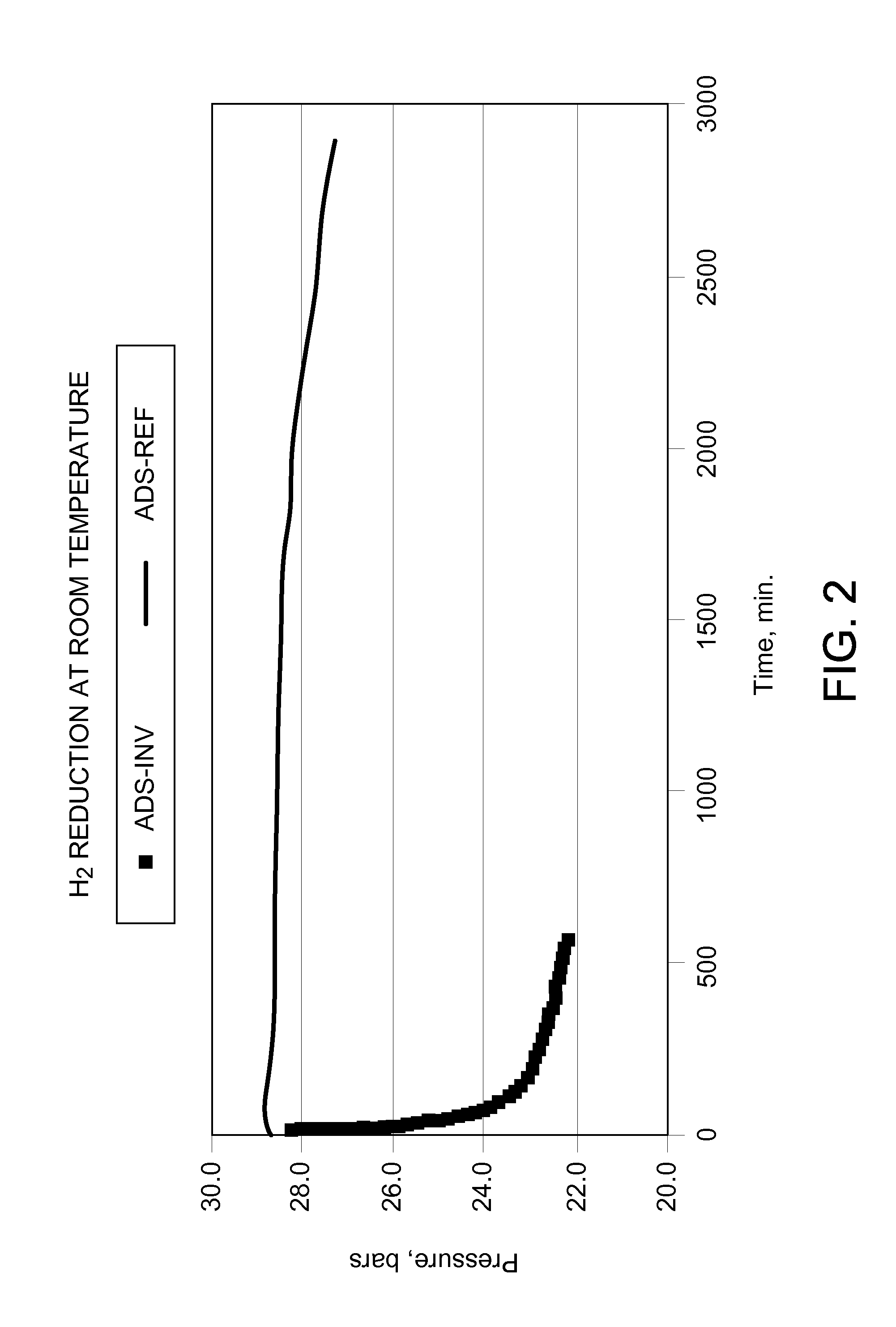

Synthesis gas purification by selective copper adsorbents

InactiveUS20130047850A1Reduce componentsImprove the immunityGas treatmentHydrogen separation using solid contactSorbentCopper oxide

Effective synthesis gas purification is achieved by applying copper adsorbents which are resistant to the reduction by the components of the synthesis gas H2 and CO at normal operation conditions. The novel adsorbents are produced by admixing small amounts of an inorganic halide, such as NaCl, to the basic copper carbonate precursor followed by calcination at a temperature sufficient to decompose the carbonate. The introduction of the halide can be also achieved during the forming stage of adsorbent preparation. These reduction resistant copper oxides can be in the form of composites with alumina and are especially useful for purification of synthesis gas or gas streams containing hydrogen carbon monoxide or other reducing agents.

Owner:UOP LLC

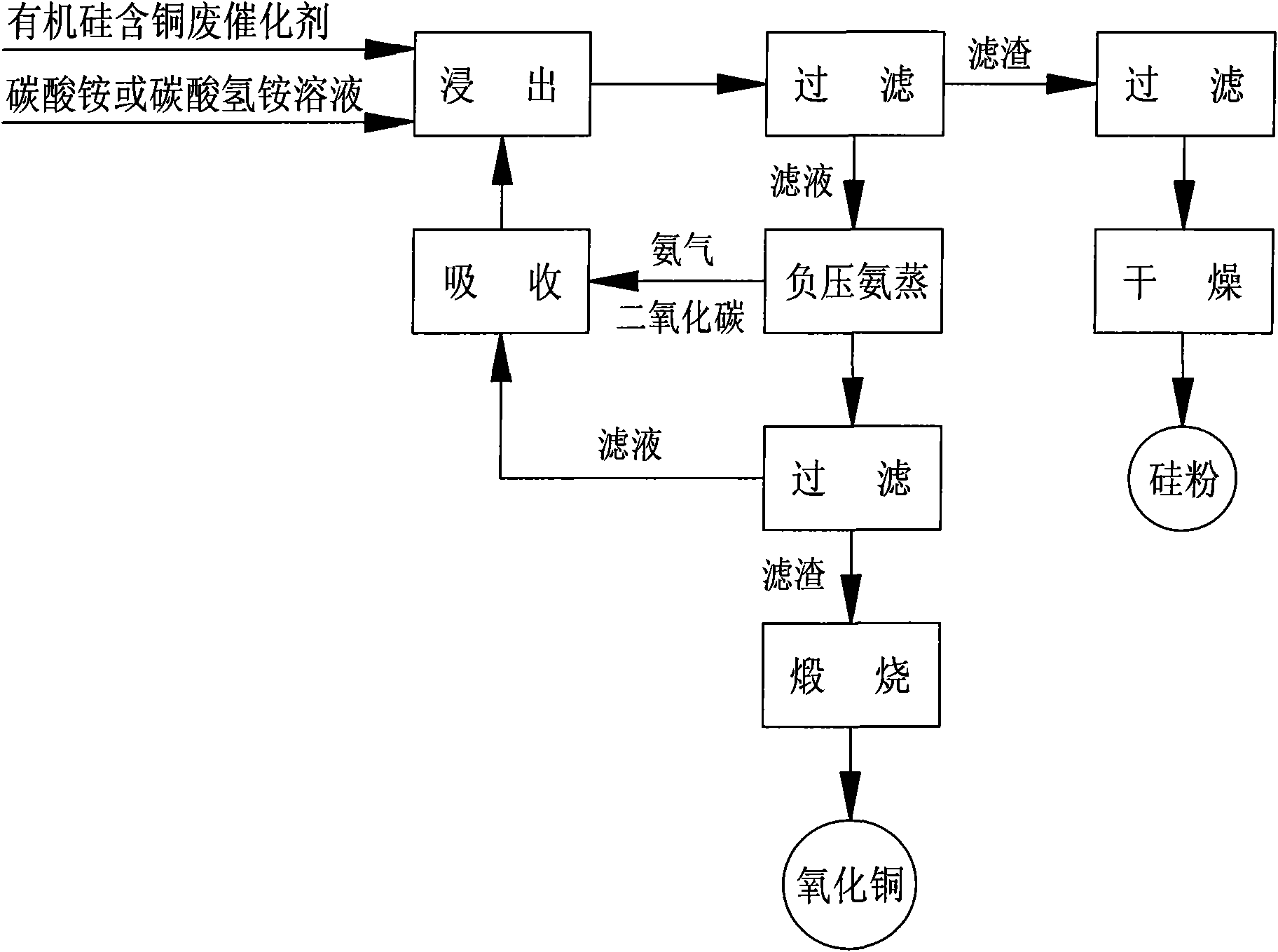

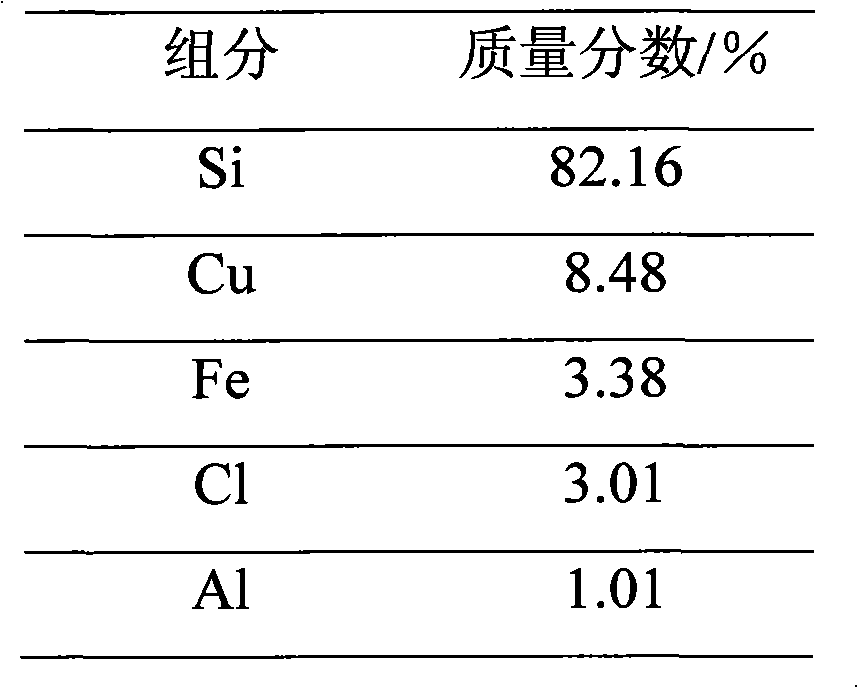

Disposal method of organic silicon copper-containing waste catalyst

InactiveCN102020307AHigh puritySolve pollutionSolid waste disposalCopper oxides/halidesCopper oxideCopper carbonate

The invention discloses a disposal method of an organic silicon copper-containing waste catalyst, which has the advantages of less investment, low cost and environment protection and is simple for operation. The disposal method comprises the following steps of: immersing the organic copper-containing waste catalyst into an ammonium carbonate or ammonium hydrogen carbonate solution with the concentration of 1.2-2.0 molar / liter according to the solid to liquid ratio of 1 to 4-6; stirring continuously; immersing for 4-8 hours at 40-60 DEG C; carrying out solid-liquid separation to the immersed liquid; cleaning and drying the separated solid phase to form a silicon-containing raw material; carrying out negative pressure ammonia still to the separated ammonium copper solution; recycling ammonia and carbon dioxide generated in the process of the negative pressure ammonia still; filtering the solution obtained by carrying out the negative pressure ammonia still; filtering to obtain filter residues containing alkali copper carbonate and copper oxide; and calcining the filter residues for 2-4 hours at 200-400 DEG C to obtain a raw material of copper oxide used as a main component. The disposal method is suitable for comprehensive utilization of devitalization waste catalyst in the process of producing organic silicon monomer by using a direct method and particles discharged from a fluidized bed during gas-solid separation.

Owner:ZHANGJIAGANG KAINA INFORMATION TECH

Active carbon desulfurizer and preparation method thereof

ActiveCN101664689AStrong water resistanceReduce manufacturing costOther chemical processesGas purification by catalytic conversionBASIC CUPRIC CARBONATEBasic copper carbonate

The invention relates to an active carbon desulfurizer prepared by a kneading method and a preparation method thereof. The preparation method comprises the following steps: evenly mixing copper oxideor basic cupric carbonate and pulverized coal or charcoal powder with a certain quantity of water, then adding tar and rolling evenly, and then extruding bands to mold, drying and activating to prepare the active carbon desulfurizer for loading the copper oxide. Holes of the active carbon desulfurizer prepared by the kneading method are more than that of the active carbon desulfurizer prepared bya dipping method; the specific surface area of the active carbon desulfurizer is larger than 1,000<2> / g; the active carbon desulfurizer loading CuO and prepared by a kneading method is not only suitable for desulfuration in petrochemical industry, but also suitable for desulfuration of water gas; and when used for desulfuration of water gas, the active carbon desulfurizer not only has high activity, but also achieves over 30 percent of working sulfur capacity and has the advantages of regeneration, strong water resisting property, no argillization, low production cost and simple process.

Owner:一重集团大连工程建设有限公司

Particulate wood preservative and method for producing the same

ActiveUS8409627B2Effective, long-lasting, environmentally responsible, non-staining/coloringLow dissolution ratePowder deliveryBiocideCopper(II) hydroxideCopper nitrate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper based particles of the invention.

Owner:KOPPERS PERFORMANCE CHEM

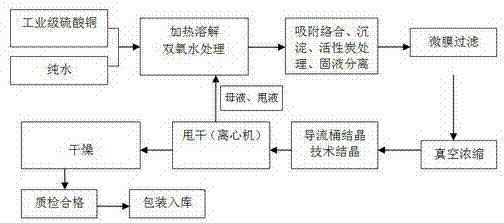

Production method of high-purity copper sulphate

InactiveCN102826584ASimple and fast operationImprove product qualityCopper sulfatesFiltrationTechnical grade

The invention discloses a production method of high-purity copper sulphate. The production method of high-purity copper sulphate comprises the following steps of: dissolving industrial grade copper sulphate into ultrapure water, heating to the temperature of 40-70 DEG C, dropwise adding sulphuric acid to regulate pH to be 1.0-2.0, stirring and dissolving, and then adding hydrogen peroxide; mixing polymeric ferric sulphate with basic copper carbonate in a mass ratio of 1: (2.5-4.5) to prepare a precipitation complexing agent, adding the precipitation complexing agent the weight of which is 0.5-2.5wt% of weight of the solution into the insulated solution, then adding activated carbon the weight of which is 0.5-2.5wt% of the weight of the solution, stirring for 3-7 hours, cooling to room temperature, and standing overnight; and carrying out rough filtration on the solution, then filtering with a microporous membrane with the size of 0.2mu m, and concentrating and crystallizing filtrate to obtain high-purity copper sulphate.

Owner:XILONG SCI CO LTD

Gas generating composition

InactiveUS20120055593A1LoomsPedestrian/occupant safety arrangementBASIC CUPRIC CARBONATEBasic copper carbonate

The present invention is a gas generating composition including fuel and an oxidizing agent, which can be used for an inflator of a vehicle airbag apparatus, wherein the oxidizing agent includes basic copper carbonate, the gas generating composition having the content of the basic copper carbonate of more than 40% by mass and 60% by mass or lower, and satisfying the following requirements (a) to (c):(a) the burning rate is 7.0 mm / sec or above;(b) the gas output is 2.30 mol / 100 g or above; and(c) the calorific value per mol of generated gas is 100 kJ / mol or lower.

Owner:DAICEL CHEM IND LTD

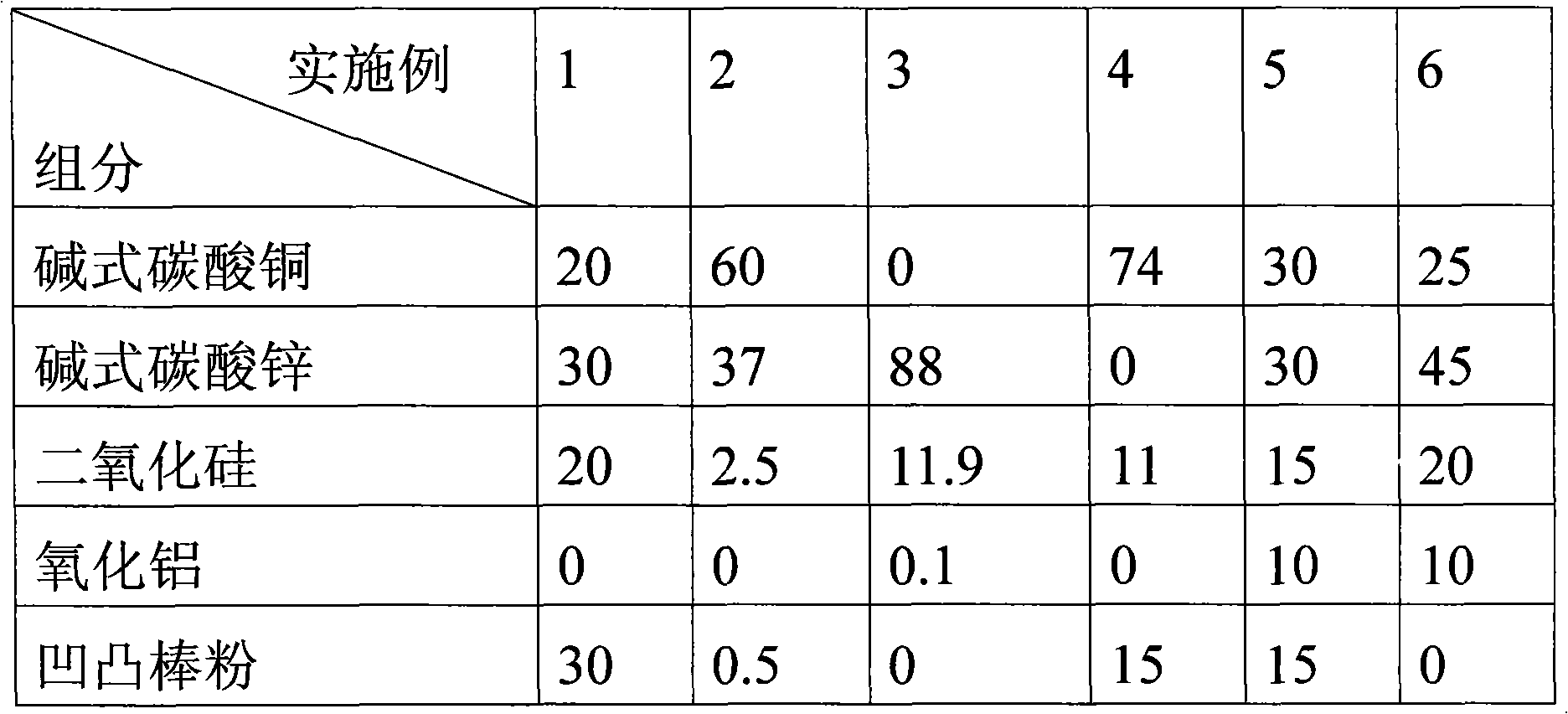

Desulfurizer

InactiveCN101961594AHigh precisionHigh sulfur capacityDispersed particle separationBASIC CUPRIC CARBONATEDecomposition

The invention discloses a desulfurizer which is composed of subcarbonate, silica and accessory ingredient. Based on the total weight of the desulfurizer, the desulfurizer comprises, in percentage by weight, 50-97 wt% of subcarbonate, 2.5-20 wt% of silica and 0.1-30 wt% of accessory ingredient, wherein the subcarbonate is at least one of basic cupric carbonate and basic zinc carbonate, and the accessory ingredient is at least one of alumina and attapulgite powder. The desulfurization (H2S) precision of the desulfurizer can be less than 0.05mg / M3, and sulphur content is about 20% (Wt / Wt). Because the raw material does not need high-temperature decomposition, energy consumption can be greatly lowered by more than 50%, thus obtaining the purpose of energy saving and emission reduction.

Owner:昆山市精细化工研究所有限公司

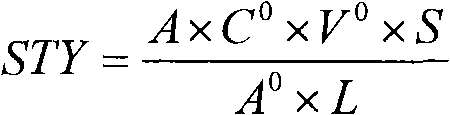

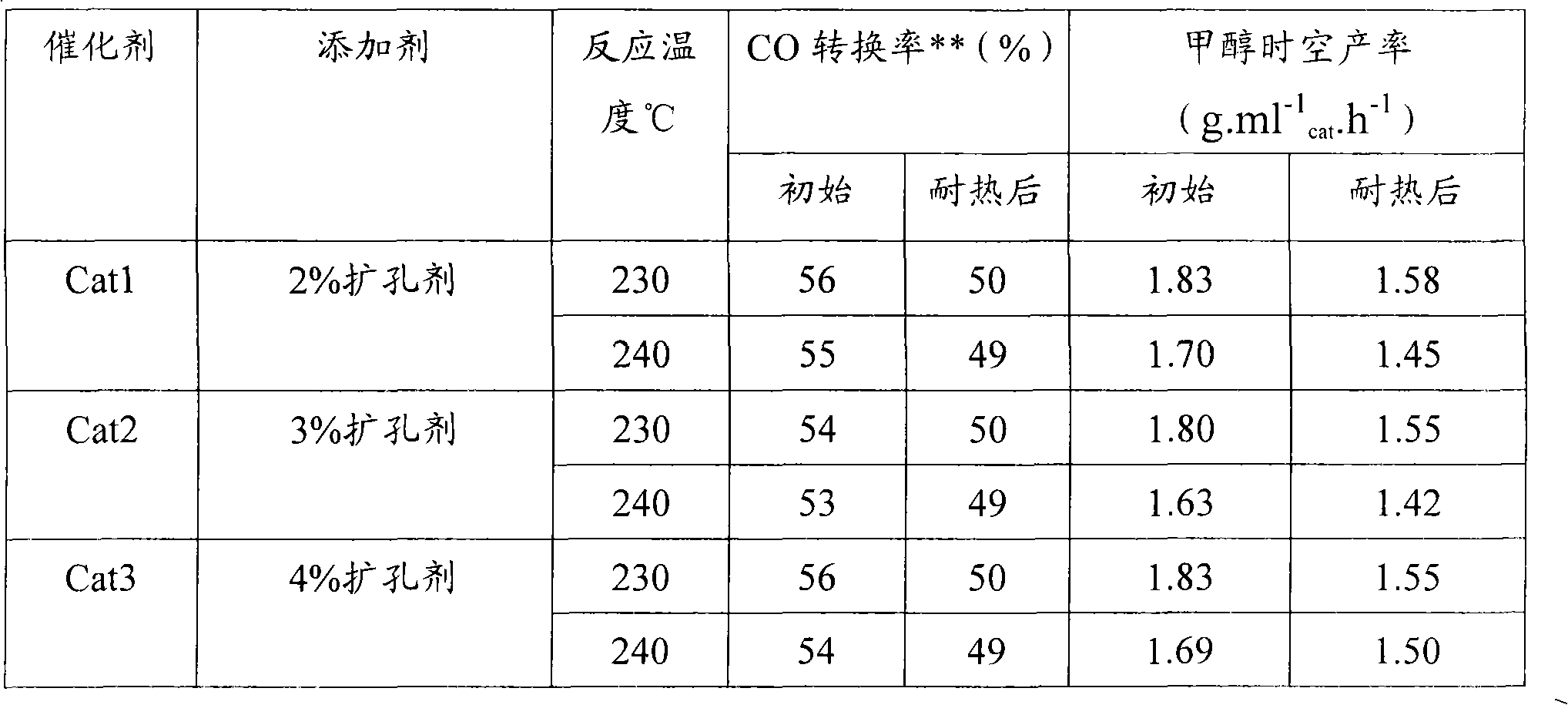

Copper-based catalyst containing inorganic expanding agent and preparation method thereof

ActiveCN101850253AIncrease the apertureHigh activityOrganic compound preparationHydroxy compound preparationBasic copper carbonateThermal stability

The invention provides a forming expanding agent of a copper-based catalyst for synthesizing methanol through a synthesis gas reaction, a preparation method and an application thereof, a copper-based catalyst and a preparation method thereof. The forming expanding agent is a mixture of basic cupric zinc carbonate and aluminum hydroxide, and the copper-based catalyst comprises oxides of cupric, zinc and aluminous. The aperture of the copper-based catalyst can be increased, the activity and the thermal stability of the copper-based catalyst can be improved by the forming expanding agent.

Owner:DATANG INT CHEM TECH RESINST +1

Method of removing impurities from gas or liquid streams using copper oxide and halide salt

ActiveUS20100012578A1Improve the immunitySimple materialCation exchanger materialsDispersed particle filtrationHydrogenBasic copper carbonate

Mixing small amounts of an inorganic halide, such as NaCl, to basic copper carbonate followed by calcination at a temperature sufficient to decompose the carbonate results in a significant improvement in resistance to reduction of the resulting copper oxide. The introduction of the halide can be also achieved during the precipitation of the carbonate precursor. These reduction resistant copper oxides can be in the form of composites with alumina and are especially useful for purification of gas or liquid streams containing hydrogen or other reducing agents. These reduction resistant copper oxides can function at near ambient temperatures.

Owner:UOP LLC

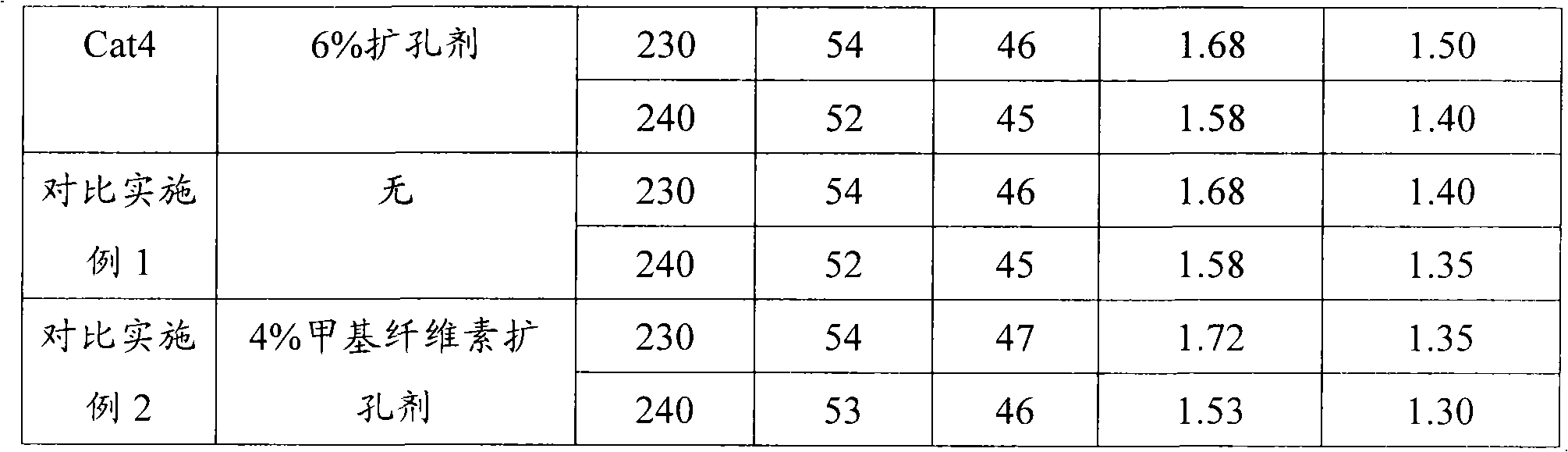

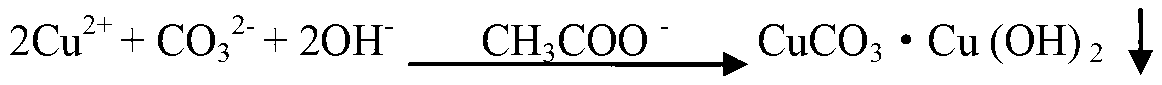

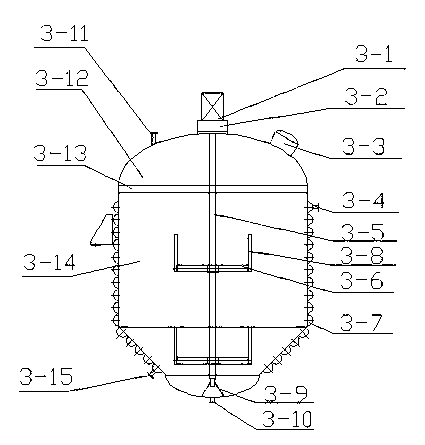

Method of preparing basic copper carbonate

ActiveCN103232055ALow priceReduce manufacturing costCopper compoundsBasic copper carbonateCopper chloride

The present invention provides a method of preparing basic copper carbonate, comprising the steps of: injecting a Cu<2+> containing acidic solution, a CO3<2-> and OH<-> containing solution and a CH3COO<-> containing solution into a container for a primary reaction, and performing washing and preliminary dehydration treatments to a solid product in the mixed solution to obtain a water containing solid product; and after performing a powerful dehydration treatment, drying at a temperature of 50 DEG C -150 DEG C to obtain the target product basic copper carbonate. According to the invention, copper chloride and copper sulfate are used as starting materials, wherein the copper chloride can be obtained through treatment of waste copper circuits or direct use of circuit board copper chloride waste fluid, and the copper sulfate can be obtained through reextraction by using sulfuric acid after extraction of copper ores or waste copper materials; so the starting materials of the method have relatively low prices, and the use of cheap, readily available and non-toxic starting materials improves production efficiency and product quality, and reduces production costs of the basic copper carbonate.

Owner:苏州长湖纳米科技有限公司

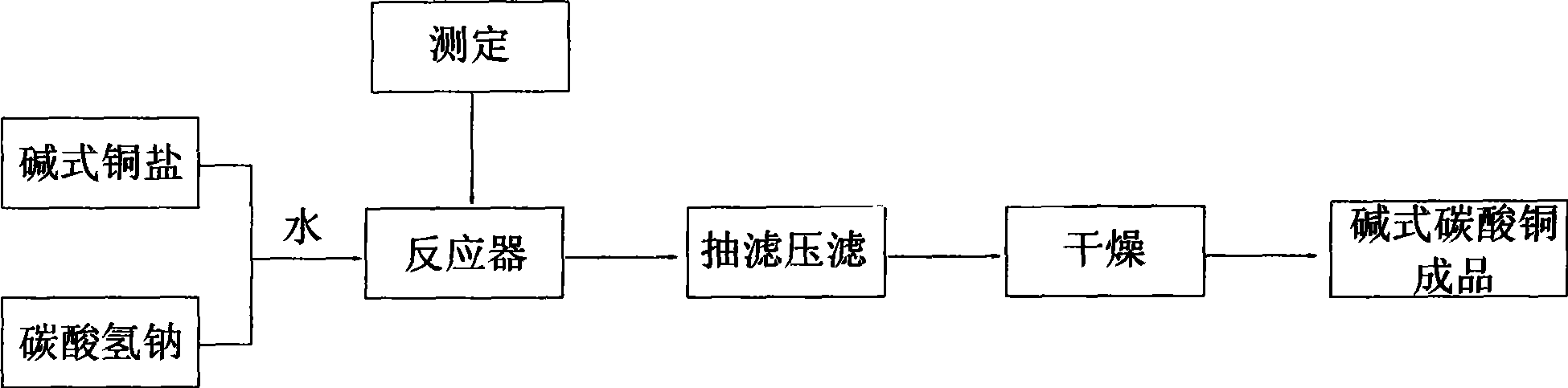

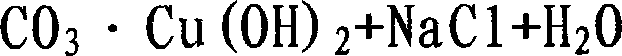

Process for producing basic copper carbonate

The invention discloses a preparation method of basic cupric carbonate, which comprises the following steps: step 1, stirring the solid basic cupric carbonate or cupric hydroxide and water into a paste shape in a reactor; step 2, adding solid sodium bicarbonate in the reactor to carry out solid state reaction and controlling the temperature to be between 20 DEG C and 140 DEG C; and step 3, after the completion of measurement and conversion, firstly preparing the wet basic cupric carbonate and then preparing the finished wet basic cupric carbonate after the wet basic cupric carbonate are subjected to solid-liquid separation, and washed and dried. The invention has the advantages of high purity, low cost and less amount of waste water produced.

Owner:沈祖达

Particulate wood preservative and method for producing the same

ActiveUS20090280185A1Low dissolution rateEasy to characterizePowder deliveryBiocideCopper nitrateTribasic copper sulfate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper based particles of the invention.

Owner:KOPPERS PERFORMANCE CHEM

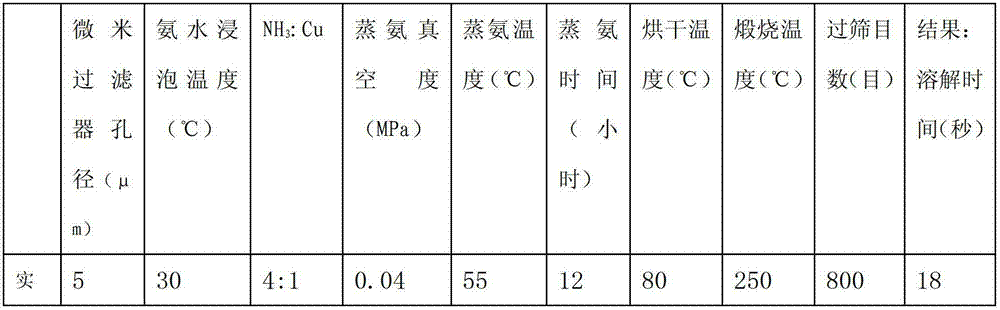

Method for preparing high-purity low-chlorine electroplating-grade cupric oxide

InactiveCN103101957AAvoid bringing inGuaranteed purityEnergy inputCopper oxides/halidesDecompositionCarbonization

The invention discloses a method for preparing high-purity low-chlorine electroplating-grade cupric oxide. According to the method, copper, liquid ammonia and high-purity carbon dioxide are taken as raw materials, stronger ammonia water is prepared firstly, carbonated ammonia water is obtained through introducing the high-purity carbon dioxide into the stronger ammonia water and controlling carbonization degree, the carbonated ammonia water reacts with the copper under certain air pressure so as to prepare copper-ammonia complexation liquid, the copper-ammonia complexation liquid is then subjected to heating, ammonia distilling, separating, washing, drying and sieving so as to prepare high-purity heavy basic copper carbonate, and the heavy basic copper carbonate is then subjected to heating calcination and decomposition, thereby preparing the high-purity low-chlorine electroplating-grade cupric oxide. According to the method, the carbon dioxide is directly used as a raw material, so that the problems of the traditional method that impurities, such as heavy metal ions and chloride ions, are introduced by raw materials used in the production of basic copper carbonate are solved, the rate of reaction is increased, the production cycle is shortened, the production efficiency is greatly increased, and products are low in impurity content, high in purity, high in activity and wider in application; and meanwhile, the method is high in yield, low in energy consumption, and low in cost and hardly causes pollution.

Owner:TAIXING SMELTING PLANT

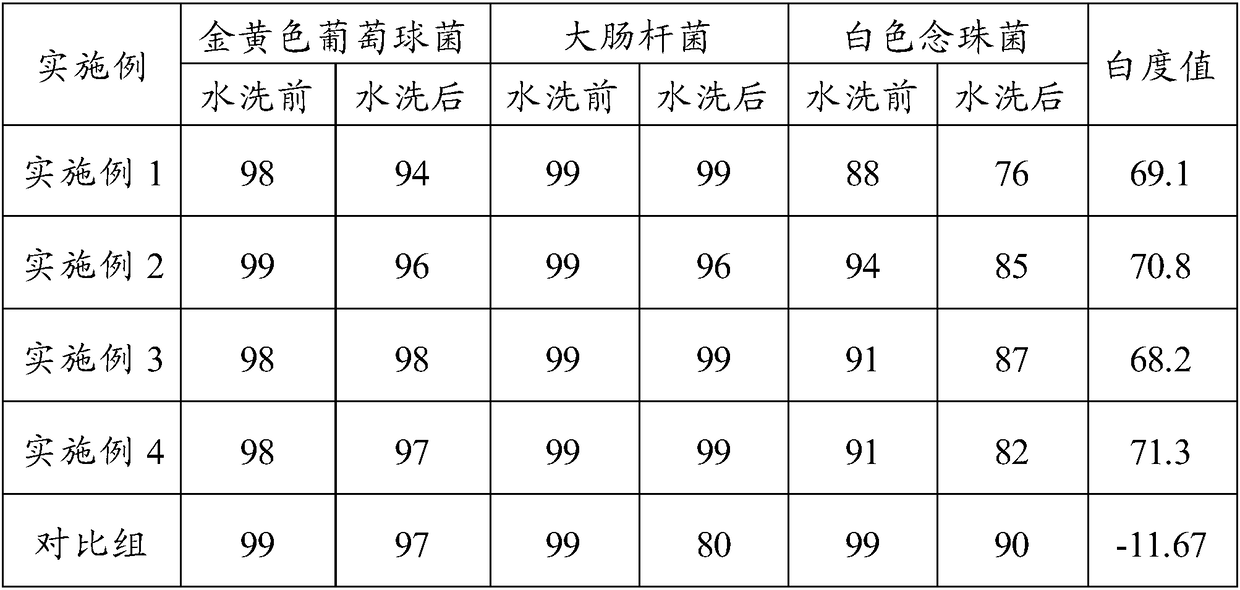

Preparation method for durable antibacterial cellulose fibres

ActiveCN109440450AImprove antibacterial propertiesHigh whiteness valueBiochemical fibre treatmentVegetal fibresSodium bicarbonateZinc hydroxide

The invention provides a preparation method for durable antibacterial cellulose fibres. The preparation method comprises the following steps: S1, removing impurities from cellulose fibres in a physical mechanical mode to obtain impurity-removed fibres; S2, performing pre-treatment on the impurity-removed fibres, and dewatering to obtain dewatered fibres, wherein the pre-treatment comprises a cleaning process and / or a refining and bleaching process; S3, performing antibacterial finishing on the dewatered fibres with an antibacterial working liquid to obtain durable antibacterial cellulose fibres, wherein the antibacterial working liquid comprises an antibacterial agent, an alkaline auxiliary agent and a penetrating agent; the antibacterial agent is one or more of magnesium carbonate, coppernitrate, copper chloride, copper hydroxide, copper carbonate, basic cupric carbonate, zinc chloride, zinc sulphate, zinc hydroxide and zinc carbonate; and the alkaline auxiliary agent is one or moreof sodium hydroxide, potassium hydroxide, sodium bicarbonate, ammonium carbonate, ammonia water, sodium phosphate and sodium carbonate. The prepared cellulose fibres have a durable antibacterial effect; and the whiteness value of the fibres is high.

Owner:山东欣悦健康科技有限公司 +1

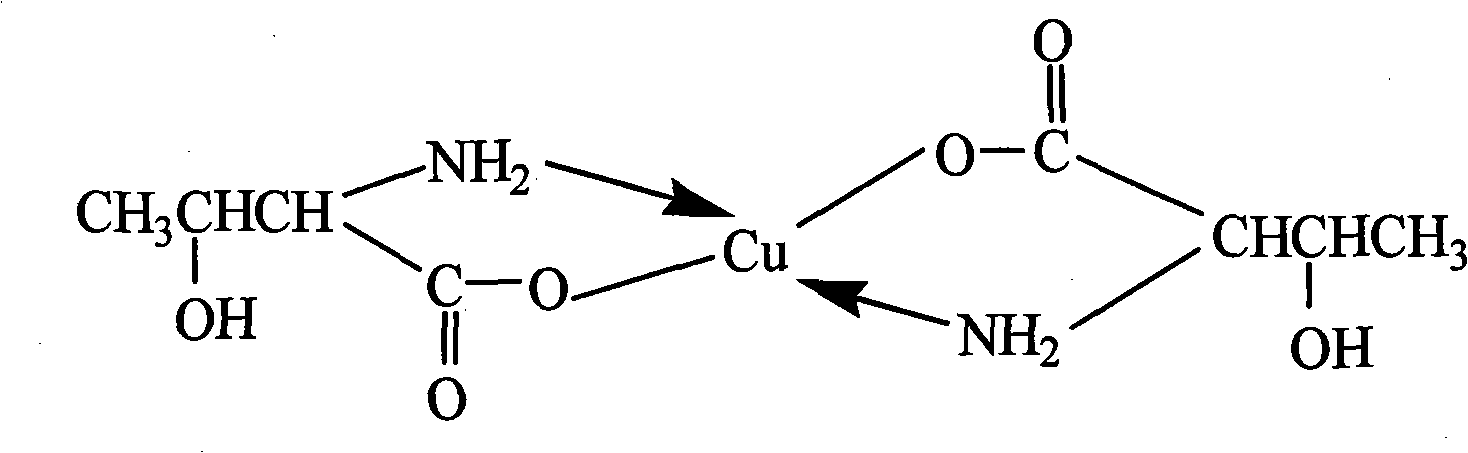

Extraction method of theanine

ActiveCN105061249ASimple stepsIncrease the burdenCarboxylic acid amide separation/purificationUltrafiltrationTheanine

The invention provides an extraction method of theanine. The extraction method comprises the steps of ultrafiltration, precipitation, dissolution, electroosmosis, vacuum concentration, ethanol addition, sulfuric acid removal and the like. Specifically, the extraction method comprises the steps that after the ultrafiltration is performed on waste liquid to remove macromolecular substances, basic cupric carbonate reacts with theanine to generate theanine-basic cupric carbonate precipitation, then dilute sulphuric acid reacts with theanine-basic cupric carbonate to generate theanine-bluestone, then copper ions and sulfate ions in the theanine-bluestone are simultaneously removed through the electroosmosis, then moisture in a fresh water chamber is removed through vacuum concentration, and then sulfuric acid is separated from sulfuric acid-theanine by using absolute ethyl alcohol. The invention provides a simple method for extracting the theanine from the waste liquid after tea polyphenol is extracted from tea on the premise that substances such as sulfuretted hydrogen, barium hydroxide are not used, and the concentration of the theanine in theanine crude products reaches 70 to 90%.

Owner:CHANGSHA BOTANIX

Method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate

InactiveCN103101958AGuaranteed purityOvercoming the disadvantages of static calcinationCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

The invention discloses a method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate. According to the method, pure copper, liquid nitrogen and high-purity carbon dioxide are taken as materials to prepare the high-purity basic cupric carbonate through a centrifugal film evaporator or a scraper reaction kettle; the problem of impurities such as chlorine which may be caused by production of the basic cupric carbonate material by the traditional method is avoided; the purity of the basic cupric carbonate is improved; the high-purity low-chorine electroplating grade copper oxide is burnt from the high-purity basic cupric carbonate through a rotary kiln; the defects of inactivation, a plurality of impurities, large labor intensity, un-continuous production, long period, high energy consumption, large cost and the like due to the fact that the basic cupric carbonate at the low-temperature part is not burnt thoroughly and the content is not enough when a pushed slab kiln statically burns while copper oxide at the high-temperature part is burnt to death are overcome; the product activity is ensured; and the method is high in product quality, less in energy consumption, small in cost and more environment-friendly.

Owner:TAIXING SMELTING PLANT

Method for preparing DL-threonine chelated copper serving as feed additive

InactiveCN101838214AHigh yieldRaw materials are easy to getOrganic compound preparationAnimal feeding stuffGlycineFood additive

The invention discloses a method for preparing DL-threonine chelated copper serving as a feed additive. The invention adopts a technical scheme of taking aminoacetic acid as raw material, allowing aminoacetic acid to react with basic copper carbonate to form glycine chelated copper and allowing glycine chelated copper to react with acetaldehyde to form DL-threonine chelated copper. Compared with the conventional method for preparing threonine chelated copper, the method of the invention has the following outstanding advantages that: 1) as threonine and threonine chelated copper are prepared from aminoacetic acid, the method is readily available in raw material, needs no threonine and is low in cost; 2) as the feed additive amino-acid chelated copper does not need separation, and DL-threonine copper is directly utilized, so over 50 percent of cost is reduced; and 3) the preparation of the DL-threonine chelated copper is performed at normal temperature under normal pressure and is short in reaction route, little in equipment investment and convenient for industrial production.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com