Copper-based catalyst containing inorganic expanding agent and preparation method thereof

A technology of copper-based catalyst and pore-enlarging agent, which is applied in the preparation of organic compounds, catalysts for physical/chemical processes, chemical instruments and methods, etc. and other problems, to achieve the effect of increasing the pore size, simple processing materials, and improving heat resistance and activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of CuZnAl Mixed Oxide Catalyst Precursor

[0043] 1. Take 1mol L -1 Cu(NO 3 ) 2 Solution 140mL and 1mol L -1 Zn(NO 3 ) 2 Solution 60mL, put in a 400mL beaker, stir to mix;

[0044] 2. Take 0.5mol L -1 Na 2 CO 3 Put 440mL of the solution in a 1000mL beaker, heat to 78°C, and add the mixture obtained in Step 1 to Na at a rate of 25mL / min under stirring. 2 CO 3 In the solution, control the pH=8.2 after the feeding is completed, and stop the heating and stirring after the Cu and Zn masterbatches are aged at 82°C for 1 hour;

[0045] 3. Add 1.6g of pseudo-boehmite to the aged Cu and Zn masterbatch, stir for 20 minutes, and wash the obtained material with deionized water until Na-free + ;

[0046] 4. Filter and drain, dry the filter cake at 110°C for 2 hours, crush it, bake it in a muffle furnace at 380°C for 3 hours, take it out for later use.

[0047] Preparation of Pore Expander Mixture of Basic Copper Zinc Carbonate and Aluminum Hydroxide

[0048...

Embodiment 2-4

[0054] Get 0.15 grams, 0.2 grams and 0.3 grams of the basic copper-zinc carbonate and aluminum hydroxide mixture pore-enlarging agent prepared in Example 1, mix them with 5 grams of copper-zinc-aluminum mixed oxide catalyst precursor respectively, and grind together for 20 minutes until they are evenly mixed , after tableting, crush and sieve to 20-40 mesh. In the prepared catalyst, the added amount of the pore-enlarging agent is respectively 3% by weight, 4% by weight, and 6% by weight, which are recorded as cat 2, cat 3, and cat 4.

Embodiment 5

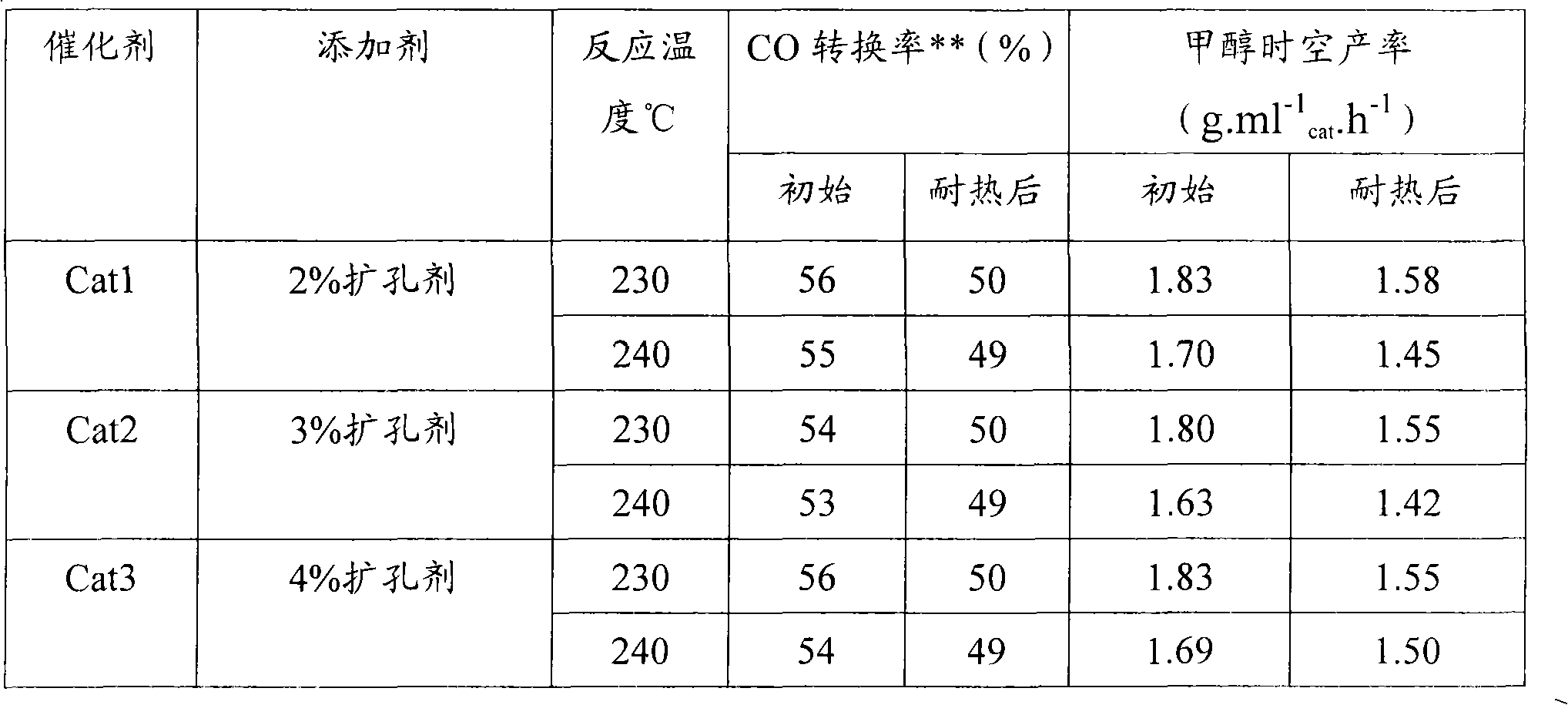

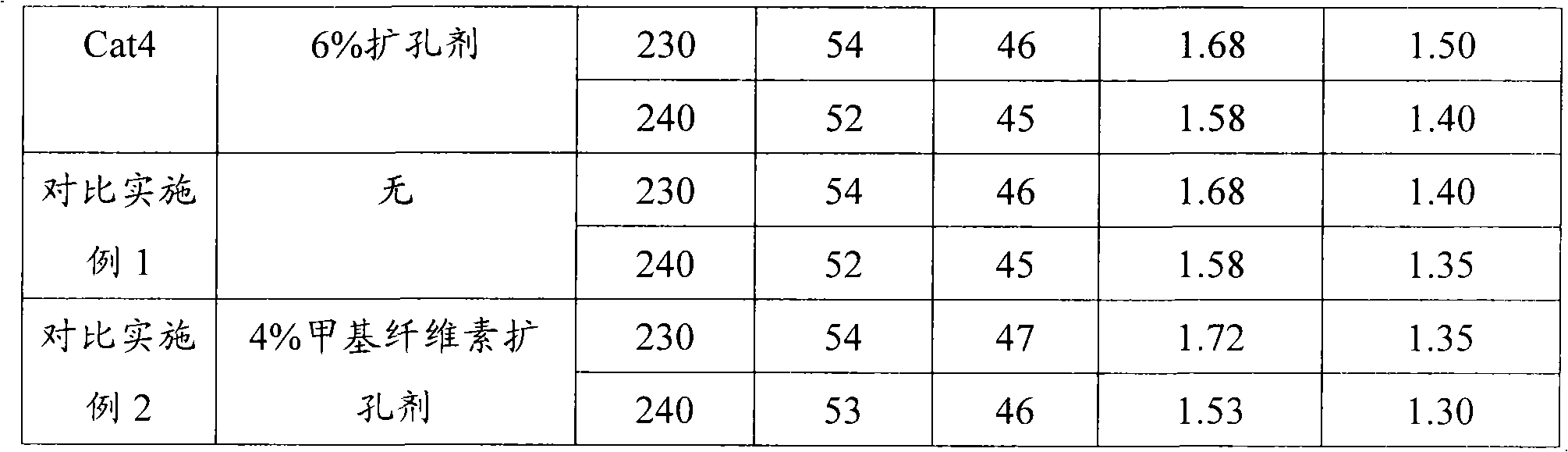

[0059] Embodiment 5 Forming pore-enlarging agent of the present invention influences on catalyst

[0060] The initial activity and activity after heat treatment of the catalysts prepared in Examples 1-4 and Comparative Examples 1 and 2 were tested by using a miniature fixed-bed reaction device, and the results are shown in Table 1. Adopt full-automatic physicochemical adsorption tester Micromeritics Tristar3000 (produced by U.S. Mike Instrument Company) to test the BET characterization effect of the catalysts prepared in Examples 1-4 and Comparative Examples 1 and 2, the results are shown in Table 2, and the test uses high-purity Nitrogen is the adsorbate, and the test was carried out at the temperature of liquid nitrogen (77k). Before the test, the sample was treated in vacuum at 120°C for 1 hour, and then at 300°C for 3 hours. The amount of sample used was about 0.1g.

[0061] Table 1: The copper-based catalyst of the present invention, the copper-based catalyst without po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com