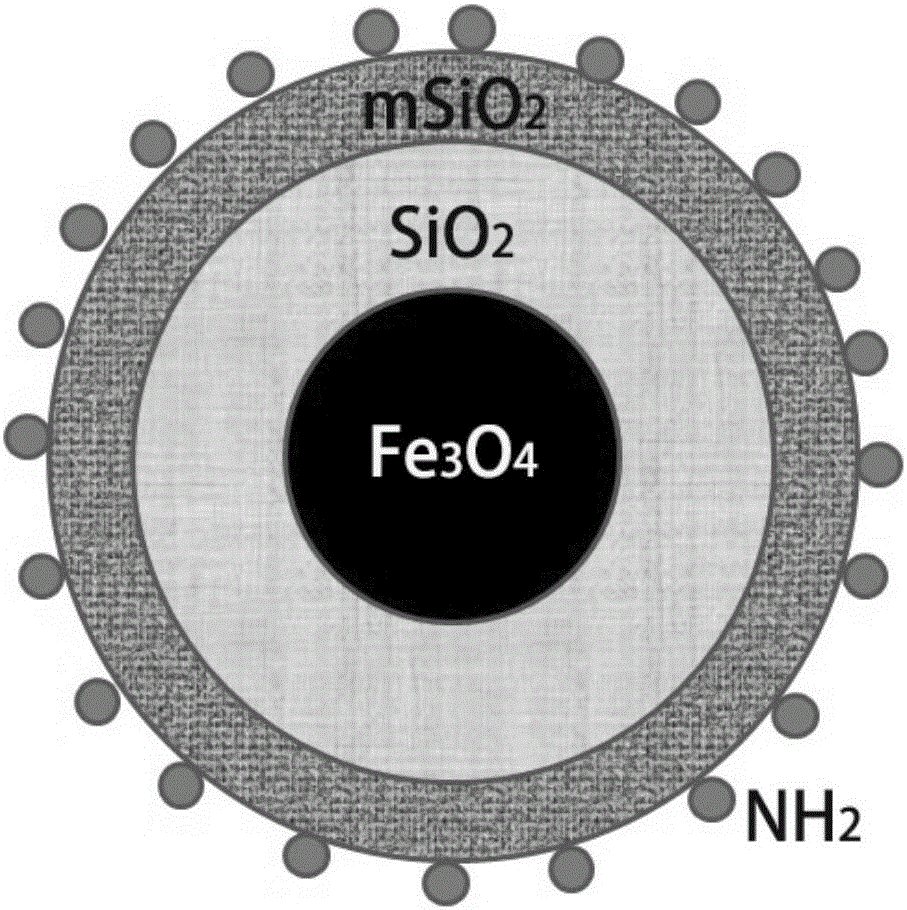

Preparation and application of amino modified Fe3O4@SiO2@mSiO2 composite particles with mesoporous structure

A technology of amino modification and composite particles, which is applied in water/sludge/sewage treatment, silicon compounds, alkali metal compounds, etc. It can solve the problems of decreased adsorption capacity, weak magnetism, and insufficient specific surface area of materials to improve adsorption capacity. , Good superparamagnetism, increase the effect of small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

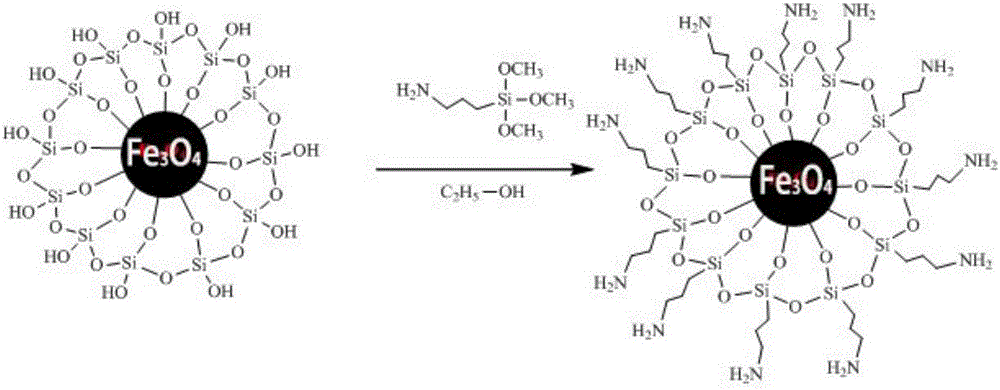

Method used

Image

Examples

Embodiment 1

[0055] An amino-modified Fe with mesoporous structure 3 o 4 @SiO 2 @mSiO 2 A method for preparing composite particles, comprising the steps of:

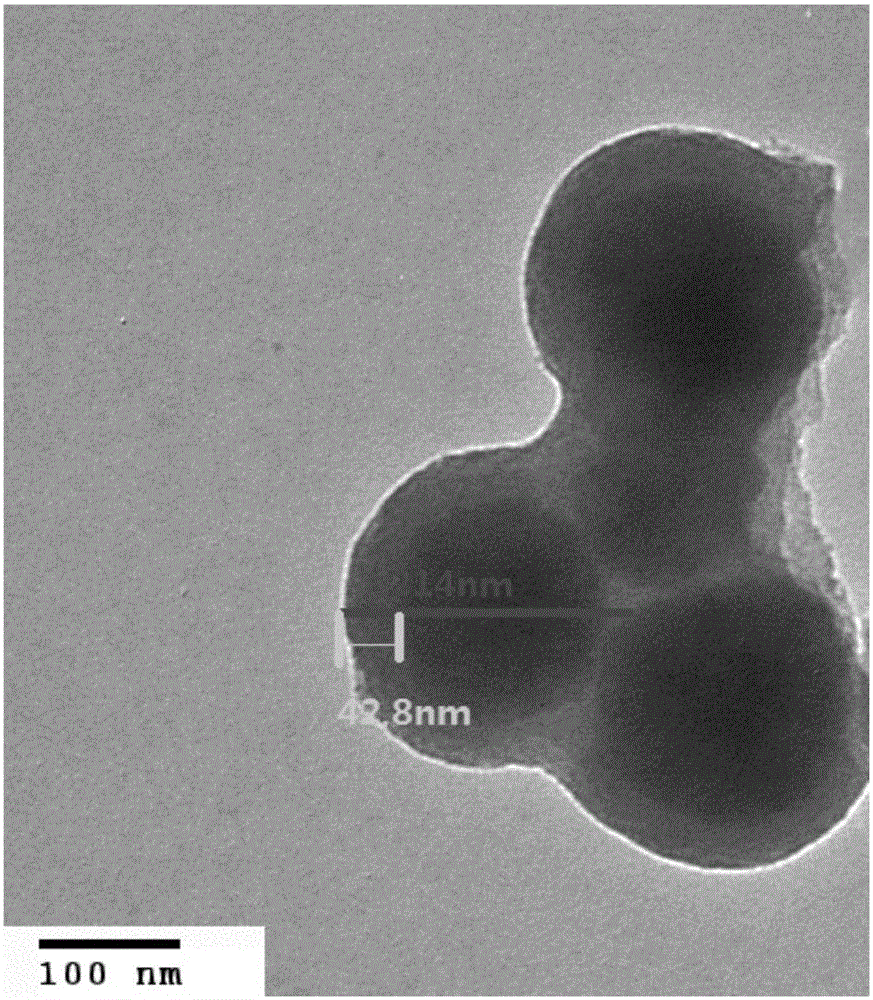

[0056] Step 1: Use a certain amount of ethylene glycol as a solvent, dissolve the ferric ion compound and sodium acetate in ethylene glycol, add an appropriate amount of polyethylene glycol under the condition of magnetic high-speed stirring to continue stirring to obtain a mixed solution, and then transfer to In a high-pressure reactor, heat to a certain temperature to crystallize for several hours, then wash and dry to obtain Fe 3 o 4 The nanoparticle has a diameter of 120nm and a coercive force of 68.95emu / g.

[0057] Crystallization temperature: 200°C, crystallization time: 8h; stirring rate: 600r / min; the molecular weight of polyethylene glycol is required to be 20000; ferric chloride is added to the ethylene glycol solution with a concentration of 0.03mol / L; Anhydrous sodium acetate is 0.08g. The ferric ion compound is: ...

Embodiment 2

[0065] An amino-modified Fe with mesoporous structure 3 o 4 @SiO 2 @mSiO 2 A method for preparing composite particles, comprising:

[0066] Step 1: Preparation of Fe 3 o 4 @SiO 2 powder;

[0067] Step 1.1: Preparation of Fe 3 o 4 Nanoparticles: use ethylene glycol as a solvent, dissolve ferric nitrate and sodium acetate in ethylene glycol, add the concentration of ferric nitrate to 0.03mol / L, and the concentration of sodium acetate to 0.01mol / L after adding to the ethylene glycol solution, stir Then add polyethylene glycol and continue to stir to obtain a mixed solution. The molecular weight of polyethylene glycol is 20,000 to 40,000, and the addition amount is 0.002mol / L, and then transferred to a high-pressure reactor, heated and crystallized, and then washed and dried. Get Fe 3 o 4 Nanoparticles; among them: crystallization temperature: 180°C, crystallization time: 8-24h; stirring rate: 600-900r / min; obtained Fe 3 o 4 The diameter of the nanoparticles is 100-15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com