Method for preparing magnetic resonance contrast medium in microminiature and superparamagnetism

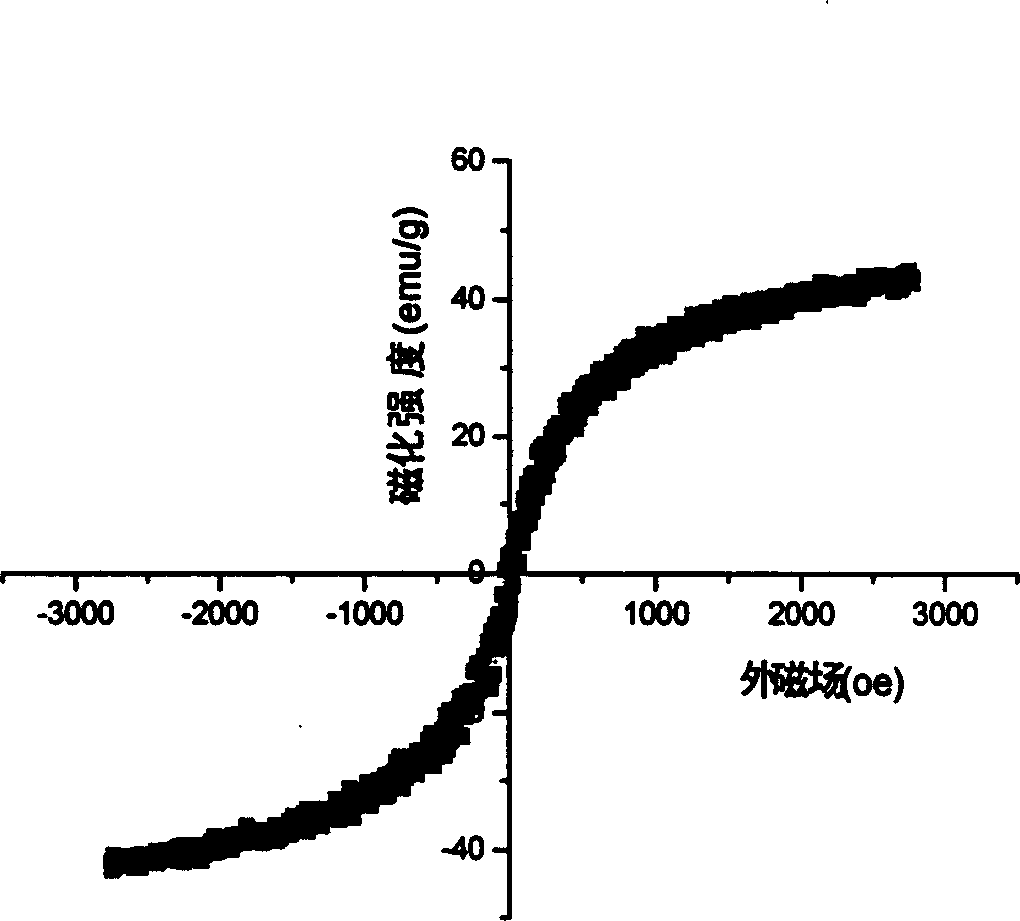

A magnetic resonance contrast agent and superparamagnetic technology, applied in the nano field, can solve the problems of poor dispersion effect, high cost, particle agglomeration, etc., and achieve the effects of good safety, cost reduction and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 10 grams of dextran with a molecular weight of 20,000 was mixed with 2.34 grams of ferric chloride and 0.86 grams of ferrous chloride to form an aqueous solution. At a temperature of 5 ° C and a mechanical stirring speed of 1500 rpm, 30 ml of dextran was gradually added dropwise at 5 ° C. The concentration is 28% ammonia water, after the ammonia water is added dropwise, the temperature is heated to 80° C. within 30 minutes, and the stirring is continued, and the temperature is controlled at 80° C. for about 1 hour. After cooling, dilute hydrochloric acid was added to adjust the pH to 7.4-7.6, and then phosphate buffer (ie PBS) was added to maintain the pH of the buffer system. Sterilize by filtration, add 50% glucose solution, and store at 4°C.

Embodiment 2

[0026] 15 grams of dextran with a molecular weight of 20,000 are mixed with 2.34 grams of ferric chloride and 0.86 gram of ferrous chloride to form an aqueous solution. At a temperature of 5 ° C and a mechanical stirring speed of 1500 rpm, 30 ml of dextran is gradually added dropwise at 5 ° C The concentration is 28% ammonia water, after the ammonia water is added dropwise, the temperature is heated to 80° C. within 30 minutes, and the stirring is continued, and the temperature is controlled at 80° C. for about 1 hour. After cooling, dilute hydrochloric acid was added to adjust the pH to 7.4-7.6, and then phosphate buffer (ie PBS) was added to maintain the pH of the buffer system. Sterilize by filtration, add 50% glucose solution, and store at 10°C.

Embodiment 3

[0028] 25 grams of dextran with a molecular weight of 20,000 are mixed with 2.34 grams of ferric chloride and 0.86 grams of ferrous chloride to form an aqueous solution. At a temperature of 5 ° C and a mechanical stirring speed of 1500 rpm, 30 ml of dextran is gradually added dropwise at 5 ° C. The concentration is 30% ammonia water, after the ammonia water is added dropwise, the temperature is heated to 80°C within 30 minutes, and the stirring is continued, and the temperature is controlled at 80°C for about 1 hour. After cooling, dilute hydrochloric acid was added to adjust the pH to 7.4-7.6, and then phosphate buffer (ie PBS) was added to maintain the pH of the buffer system. Sterilize by filtration, add 50% glucose solution, and store at 10°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com