Organism/expansion graphite composite phase transformation heat storaging material and preparation process and heat storing apparatus thereof

A technology of expanded graphite and composite phase change, applied in heat exchange materials, chemical instruments and methods, cooling/ventilation/heating transformation, etc., to achieve the effects of insignificant volume change, high thermal conductivity, and fast heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Using straight chain alkanes C 40 h 82 It is a phase change material with a phase change temperature of 62°C, a phase change latent heat of 192kJ / kg, and a thermal conductivity of 0.23W / m.K.

[0028] The acidified graphite was expanded in a muffle furnace at a temperature of 800°C for 40 seconds to prepare expanded graphite. Put 4g of the above-mentioned organic phase-change heat storage material and 6g of expanded graphite in an oven at 75°C for blending and adsorption for 1 hour to prepare an organic / expanded graphite composite phase-change heat storage material. The mass percentage of organic matter in the composite phase-change heat storage material is The content is 40%. The phase change temperature of the composite phase change heat storage material is 62°C, the latent heat of phase change is 76.8kJ / kg, and the thermal conductivity is 4.52W / m.K.

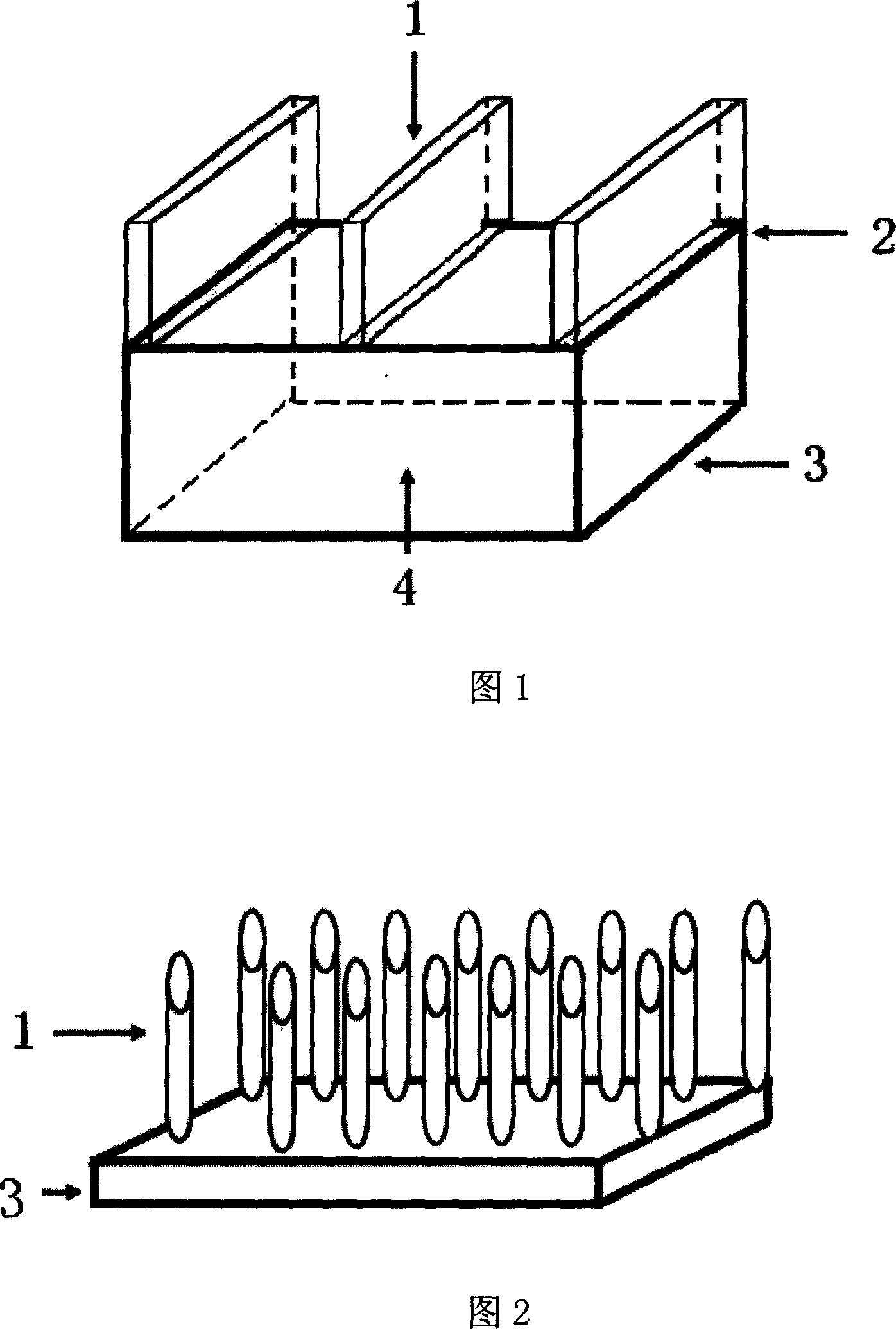

[0029] As shown in Figure 1, a red copper plate (2 mm thick) of 200 × 150 × 100 mm (length × width × height) is use...

Embodiment 2

[0031] Using straight chain alkanes C 30 h 62 It is a phase change material with a phase change temperature of 60°C, a phase change latent heat of 190kJ / kg, and a thermal conductivity of 0.24W / m.K.

[0032] The acidified graphite was expanded in a muffle furnace at a temperature of 900° C. for 30 seconds to prepare expanded graphite. Put 6g of the above-mentioned organic phase-change heat storage material and 4g of expanded graphite in an oven at 85°C for 2 hours of blending and adsorption to prepare an organic / expanded graphite composite phase-change heat storage material. The mass percentage of organic matter in the composite phase-change heat storage material is The content is 60%. The phase change temperature of the composite phase change heat storage material is 60°C, the latent heat of phase change is 114kJ / kg, and the thermal conductivity is 2.26W / m.K.

[0033] As shown in Figure 1, a red copper plate (2 mm thick) of 200 × 150 × 100 mm (length × width × height) is us...

Embodiment 3

[0035] Use straight chain alkanes as C 60 h 122 It is a phase change material with a phase change temperature of 71°C, a phase change latent heat of 200kJ / kg, and a thermal conductivity of 0.24W / m.K.

[0036] The acidified graphite was expanded in a muffle furnace at a temperature of 1000°C for 20 seconds to prepare expanded graphite. 9g of the above-mentioned organic phase change heat storage material and 1g of expanded graphite were placed in an oven at 85°C for 4 hours of blending and adsorption to prepare an organic / expanded graphite composite phase change heat storage material. The mass percentage of organic matter in the composite phase change heat storage material The content is 90%. The phase change temperature of the composite phase change heat storage material is 71°C, the latent heat of phase change is 180kJ / kg, and the thermal conductivity is 1.24W / m.K.

[0037] As shown in Figure 1, a red copper plate (2 mm thick) of 200 × 150 × 100 mm (length × width × height)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com