Patents

Literature

88results about How to "Fast heat transfer rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

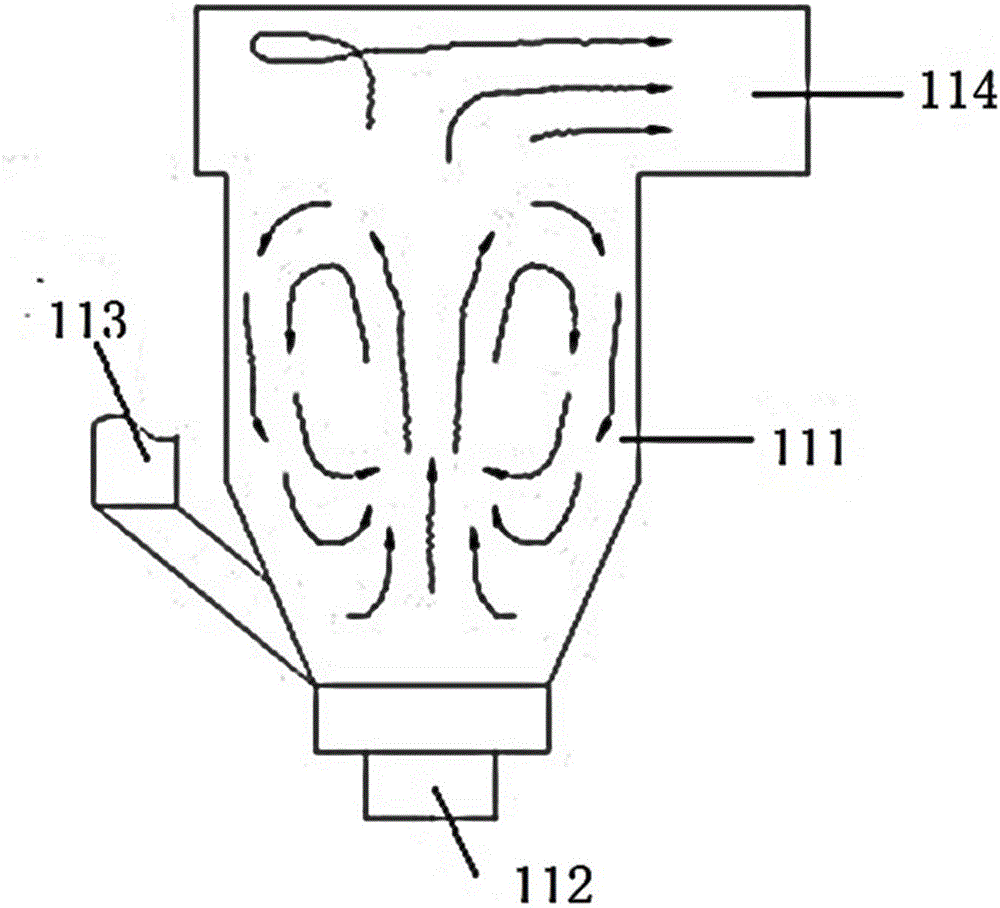

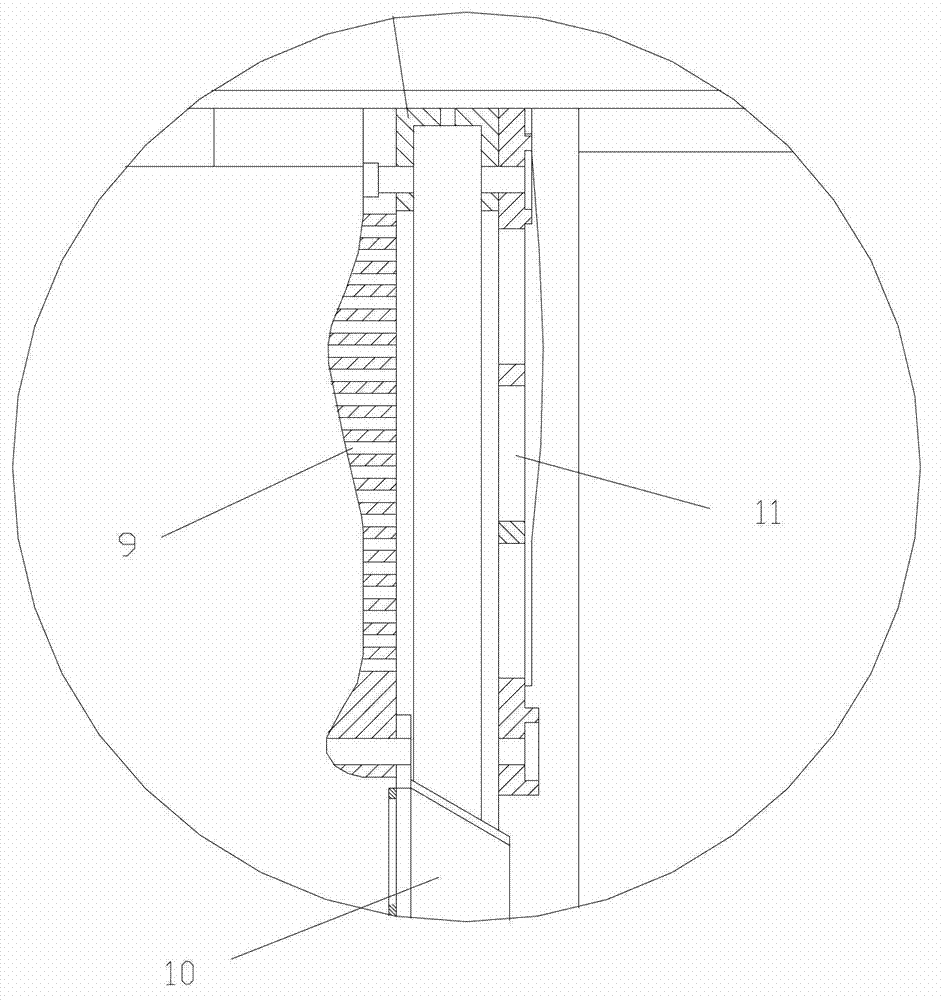

Rapid cycled fluidized calcining procedure for superfine kaolin and equipment

InactiveCN1600687AIncrease productivityImprove thermal efficiencyPigmenting treatmentAluminium silicatesCycloneEngineering

The invention relates to superfine Kaolin calcining process and device, the prodn, method includes; preheating kaolin raw powder material, then putting it in fluidization calcining furnace from the bottom, at same time, sending fuel into the furnace, preheated primary air is sent from plenum under the furnace burns with the fuel and to form a reducibility atmosphere calcining area in the lower section, the volume content of CO+H2 in reduction area is 0-10 percent, secondary air is sent from top of the reduction area to burn residual CO+H2 completely, airflow speed is 1-6m / s in the furnace, raw powder material is in fluidization, kaolin is circularly burned for 0.3-3 hours in temp. 700-1100 deg.C, then is sent into cyclone cooling system to be cooled to obtain superfine kaolin by mixer-grinding and depolymerizing.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Organism/expansion graphite composite phase transformation heat storaging material and preparation process and heat storing apparatus thereof

InactiveCN100999657AHigh thermal conductivityFast heat transfer rateHeat-exchange elementsCooling/ventilation/heating modificationsGraphite compositeLatent heat

The present invention discloses composite phase change heat storage organic matter / expandable graphite material and its preparation process and corresponding heat storage device. Of the composite material, the organic matter absorbed into the micropores of the expandable graphite accounts for 40-90 wt%, and is saturated fatty acid or linear paraffin as the phase change heat storage material with phase change temperature of 60-75 deg.c, phase change latent heat of 70-180 J / g and heat conductivity coefficient of 1.12-4.52 W / m.K. The heat storage device is one container, which is made of high heat conductivity metal material, has filled and sealed composite phase change heat storage organic matter / expandable graphite material, and is provided with metal fins. The device is used to cool electronic element fast.

Owner:SOUTH CHINA UNIV OF TECH

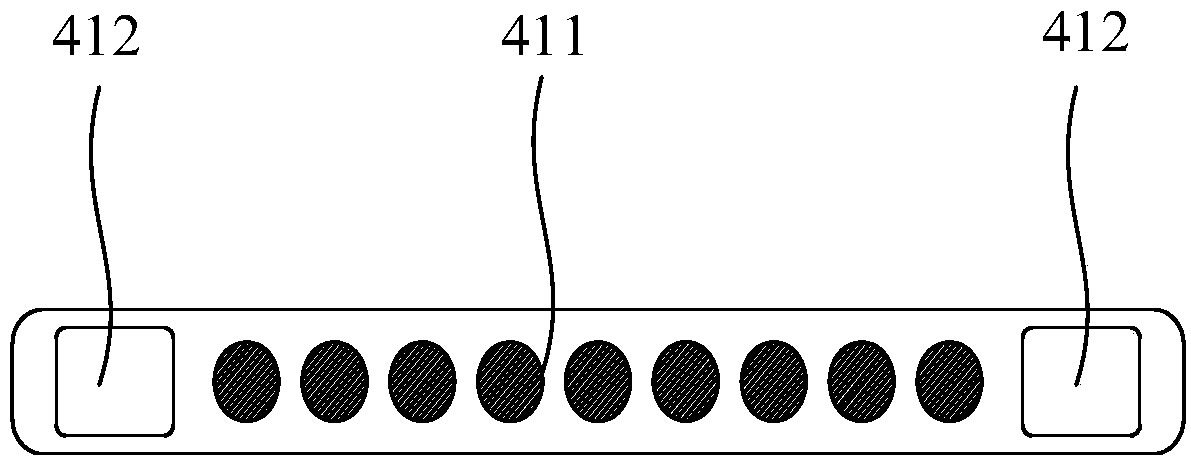

Preparation method of 48K polyacrylonitrile-based carbon fiber

InactiveCN106637521AFast heat transfer rateLess fiber damageWet spinning methodsMonocomponent synthetic polymer artificial filamentYarnMechanical properties of carbon nanotubes

The invention discloses a preparation method of 48K polyacrylonitrile-based carbon fiber and belongs to the preparation technology of fiber in the textile science art. The method comprises steps as follows: fiber bundles are spread by a yarn spreading device, and precursor fibers are preoxidized at four temperature zones by means of a preoxidation furnace; preoxidized fibers are carbonized at six temperature zones and four temperature zones respectively by the aid of a low-temperature carbonization furnace and a high-temperature carbonization furnace respectively; finally, the 48K polyacrylonitrile-based carbon fiber is obtained through an oiling and drying technology. The precursor fibers for T300-level 48 K carbon fiber are prepared with a ternary water phase suspension polymerization and wet-process two-step technology. The technology is convenient to operate, equipment is simple, the production cost is low, the problems of non-uniform oiling and inconsistent drafting in the production process of large-tow carbon fiber, concentrated heat release at the peroxidation and carbonization stage and the like are solved, and the method is applicable to engineering production of large-tow polyacrylonitrile-based carbon fiber to obtain mechanical property parameters of the material and reduce microscopical deformation, damage and breakage of the material.

Owner:CHANGCHUN UNIV OF TECH

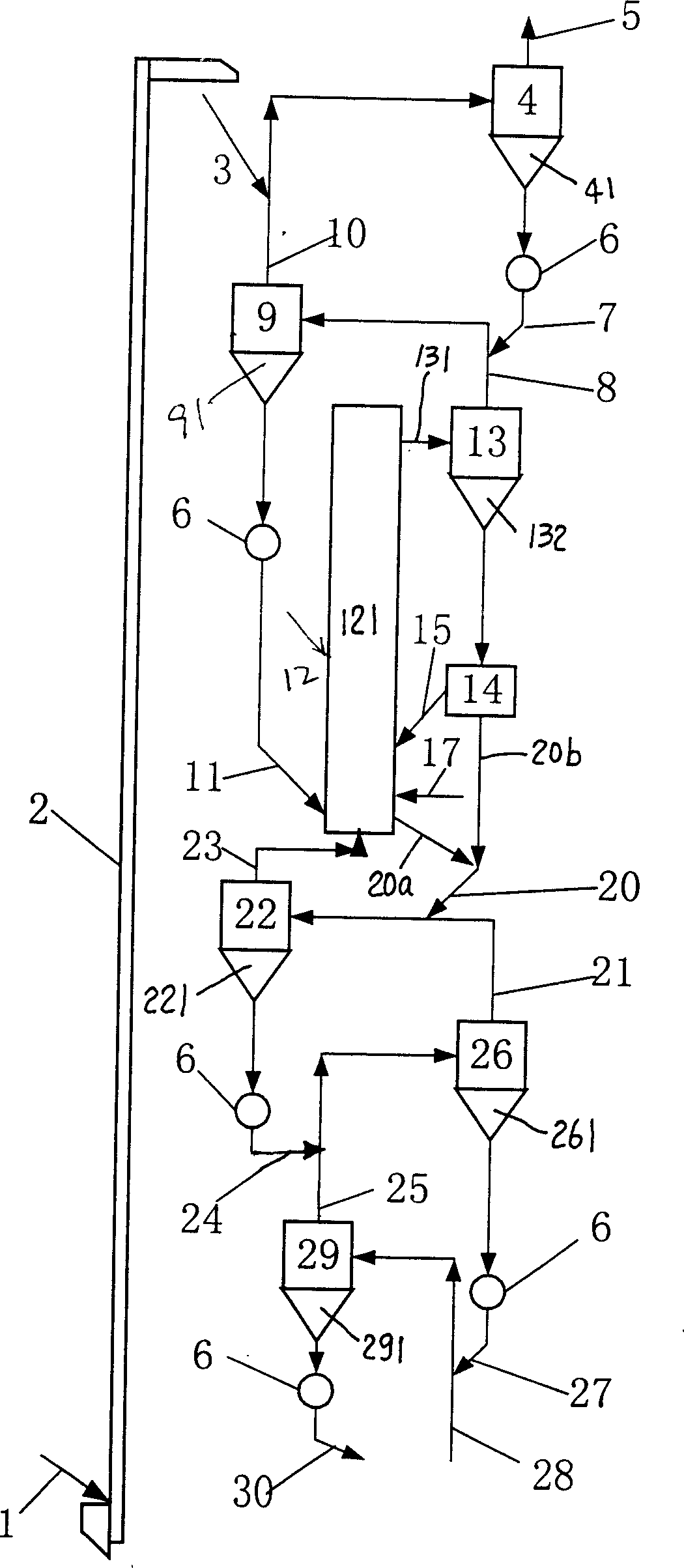

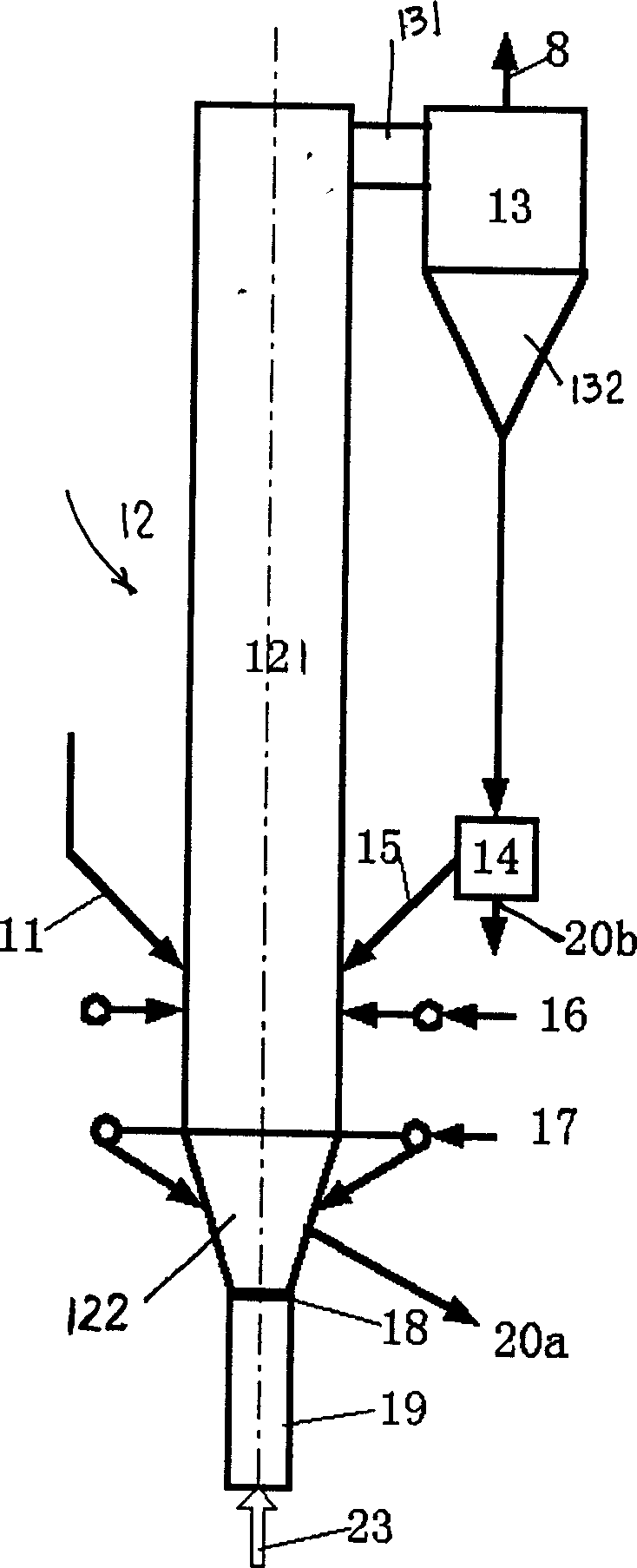

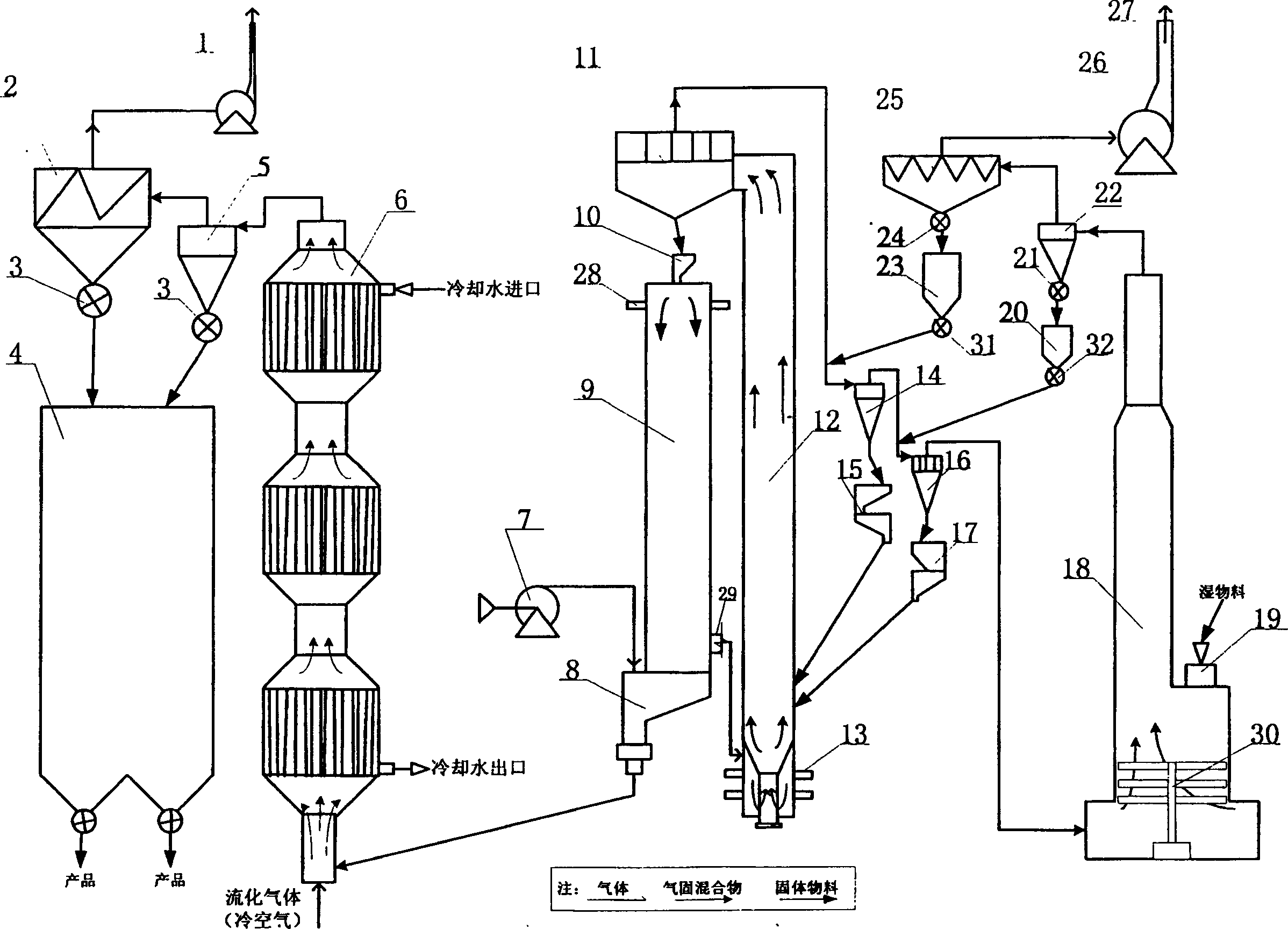

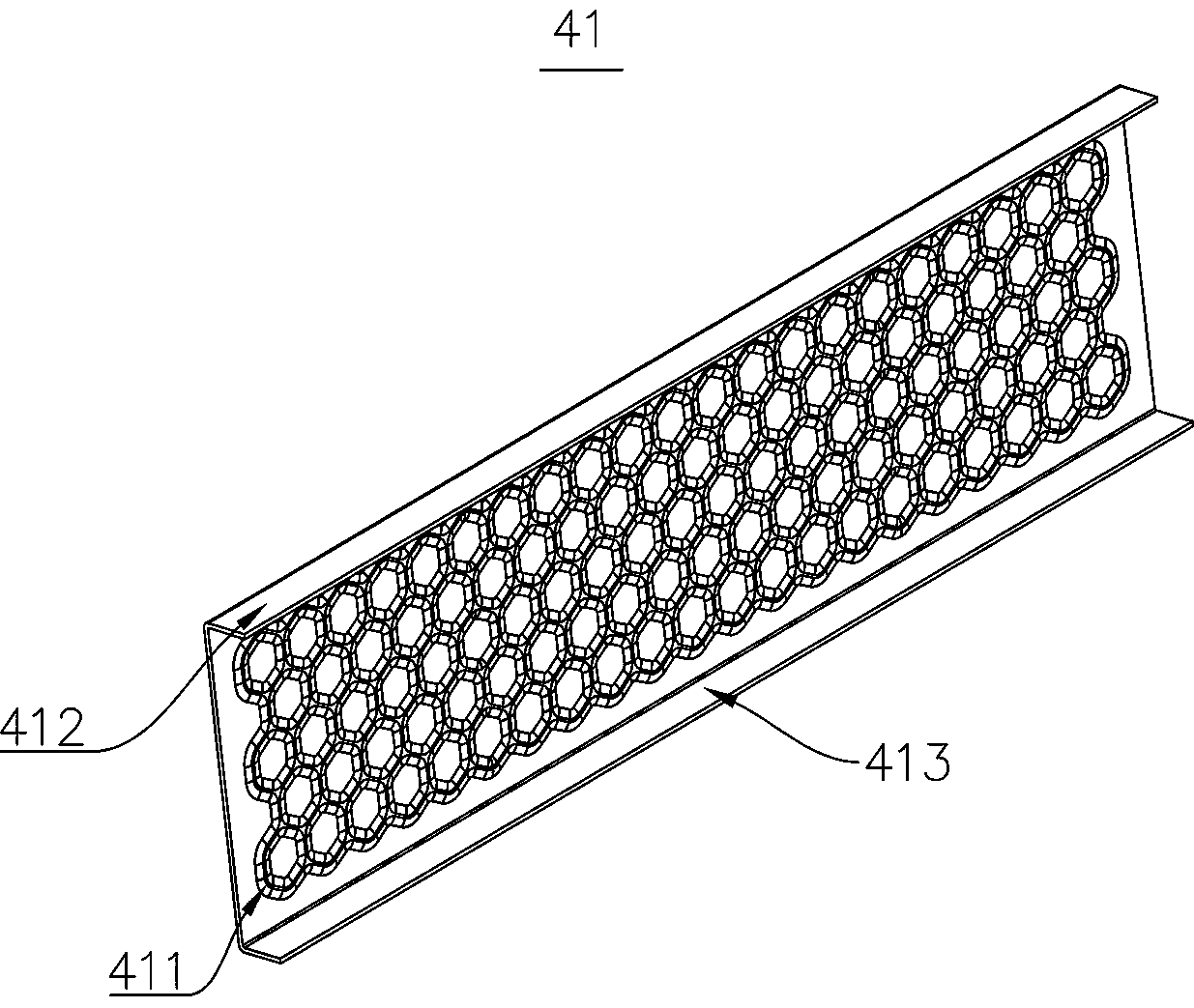

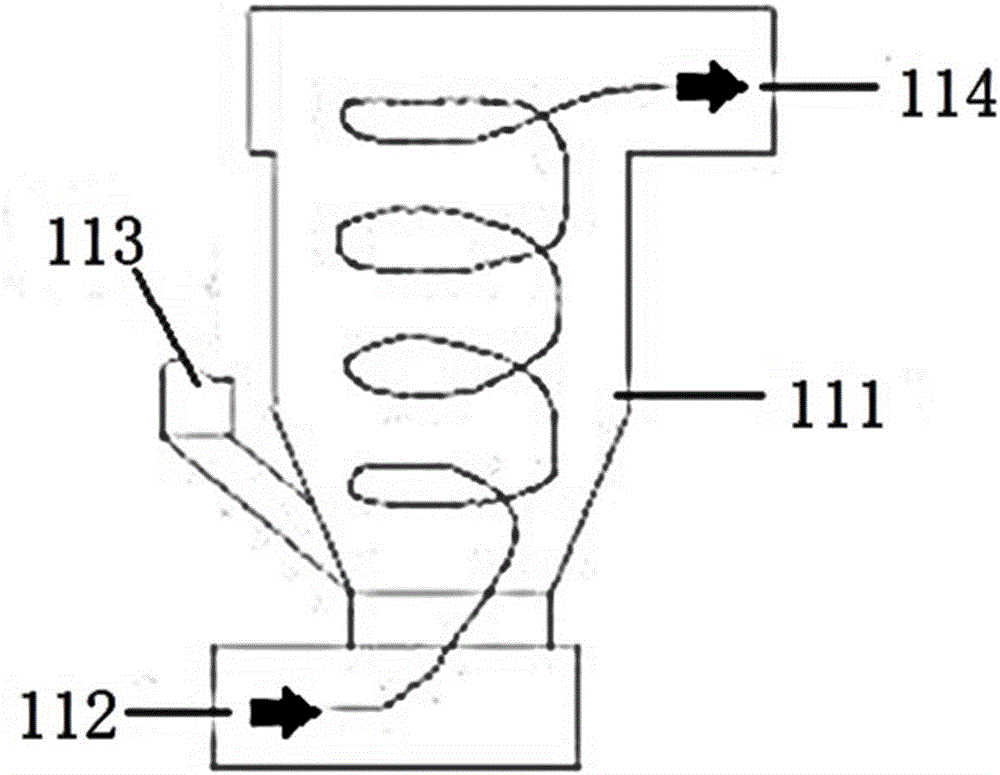

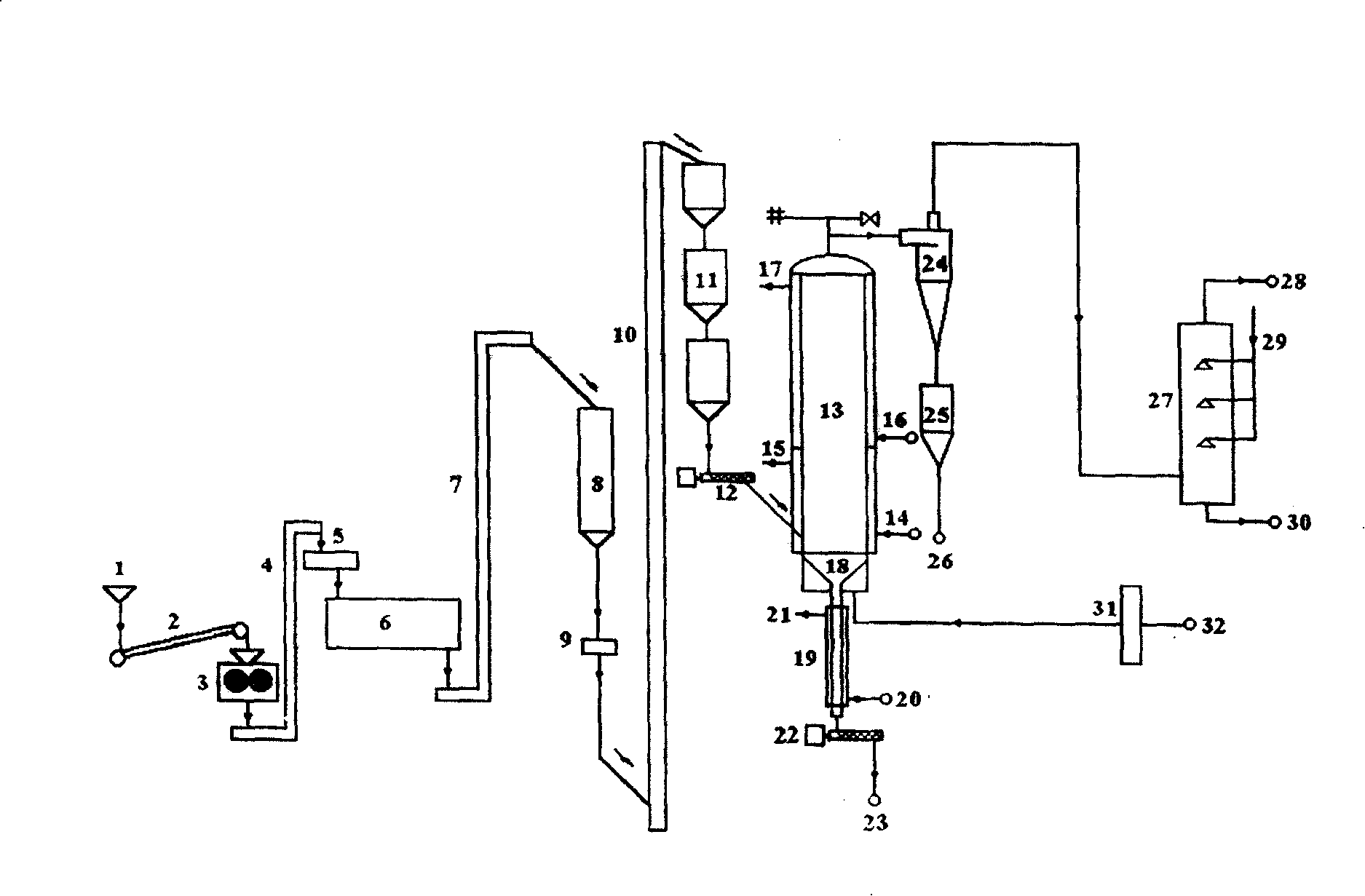

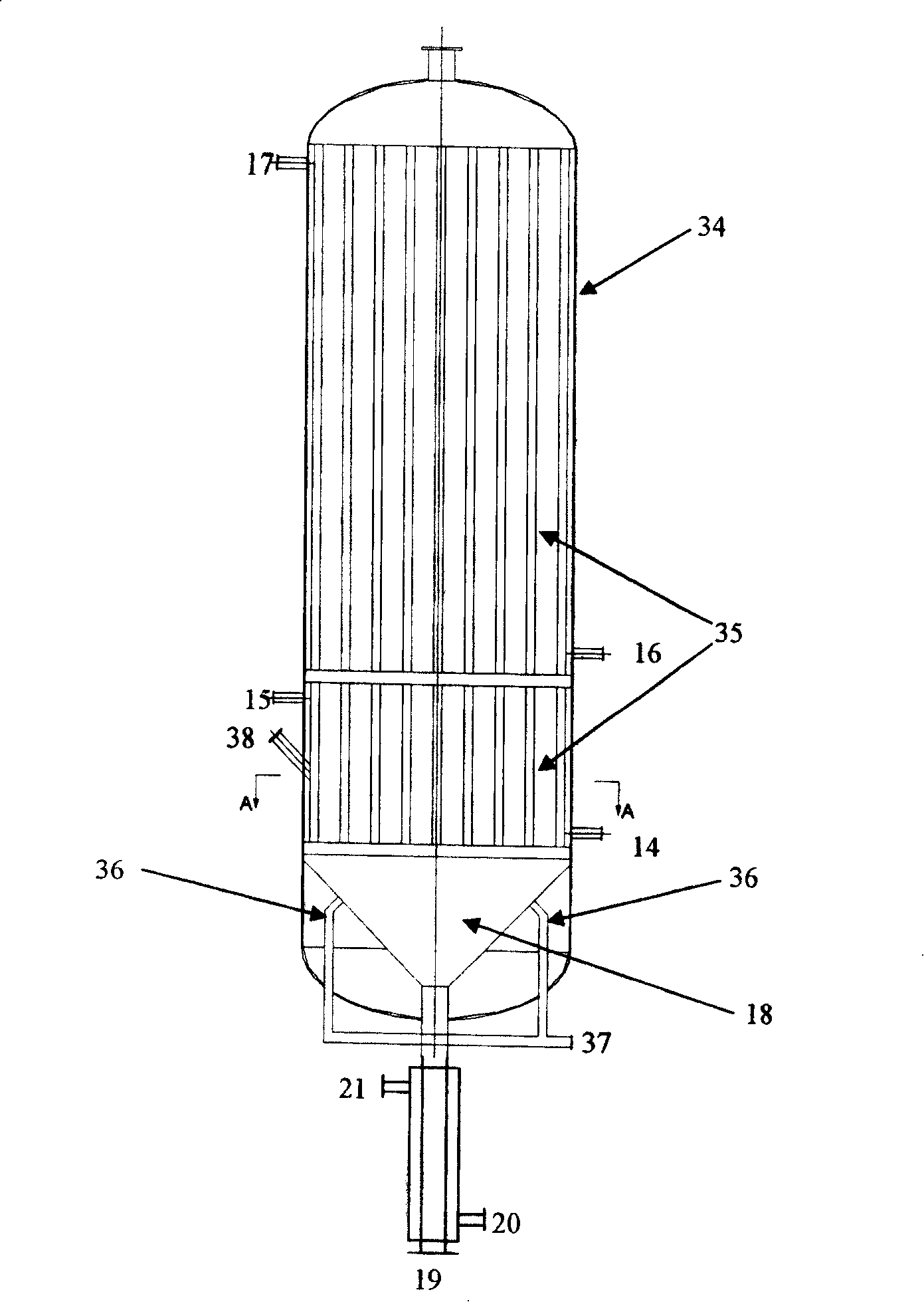

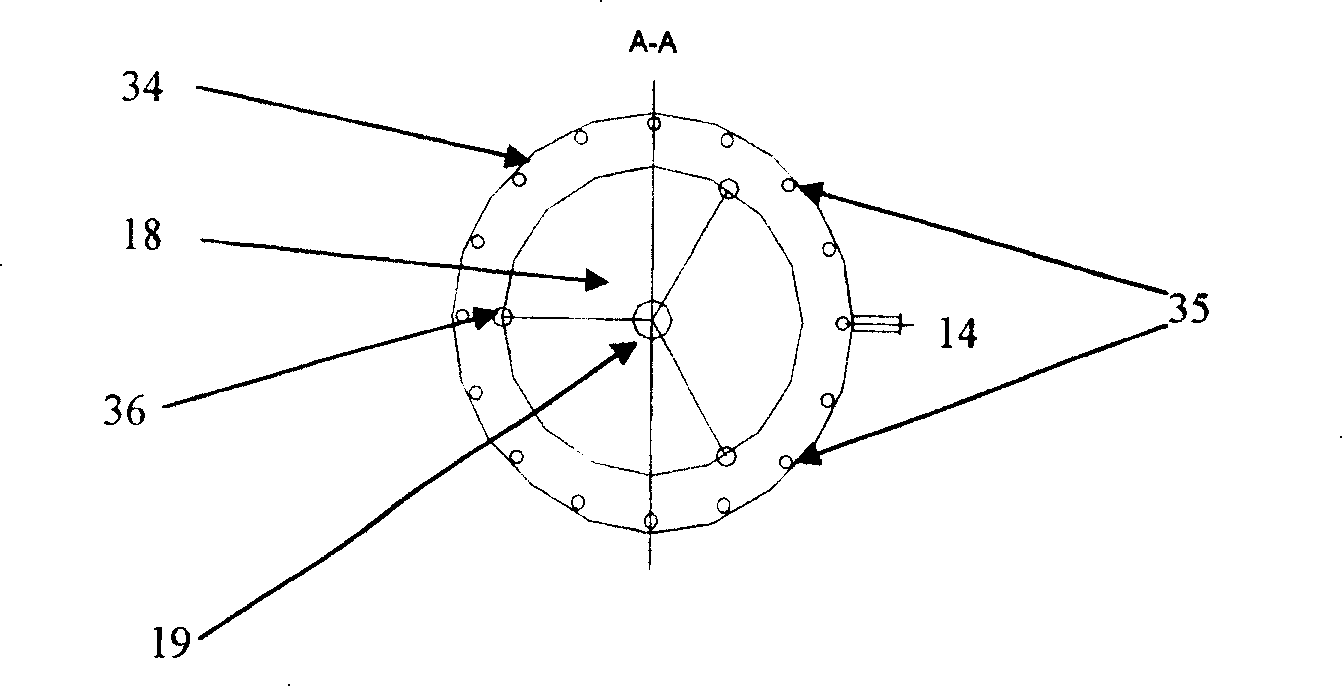

Fast fluidized calcining process

InactiveCN1632436AThe calcination reaction time is uniform and adjustableFast heat transfer rateFluidized bed combustionFluidised-bed furnacesMoving bedHigh-temperature corrosion

The invention is a new type of rapid fluidized calcination process, which effectively improves the conversion rate of the rapid fluidized calcination reaction of materials. It uses high-temperature flue gas to form gas-solid rapid fluidized mixing and heating of the material. Utilizing the characteristics of rapid fluidization, the material is quickly heated and mass transferred, and then the high-temperature material enters the moving bed calcination reactor through the high-temperature gas-solid separator; using the mobile The push flow of the material in the bed makes the calcination reaction time of the material uniform, the calcination reaction is sufficient, and the conversion rate is high; at the same time, the hot gas separated by the high-temperature gas-solid separator passes through the preheater to preheat the material and then enters rapid fluidization drying The wet material is dried in a dryer; the sensible heat of the calcined high-temperature material is recovered using a rapid fluidized cooler, and the material is cooled at the same time. The calcination process of the present invention has the characteristics of low energy consumption, large production capacity and easy amplification. The calcination temperature of the material can be adjusted from 500°C to 1300°C, and the calcination reaction time can be adjusted from a few minutes to a few hours.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

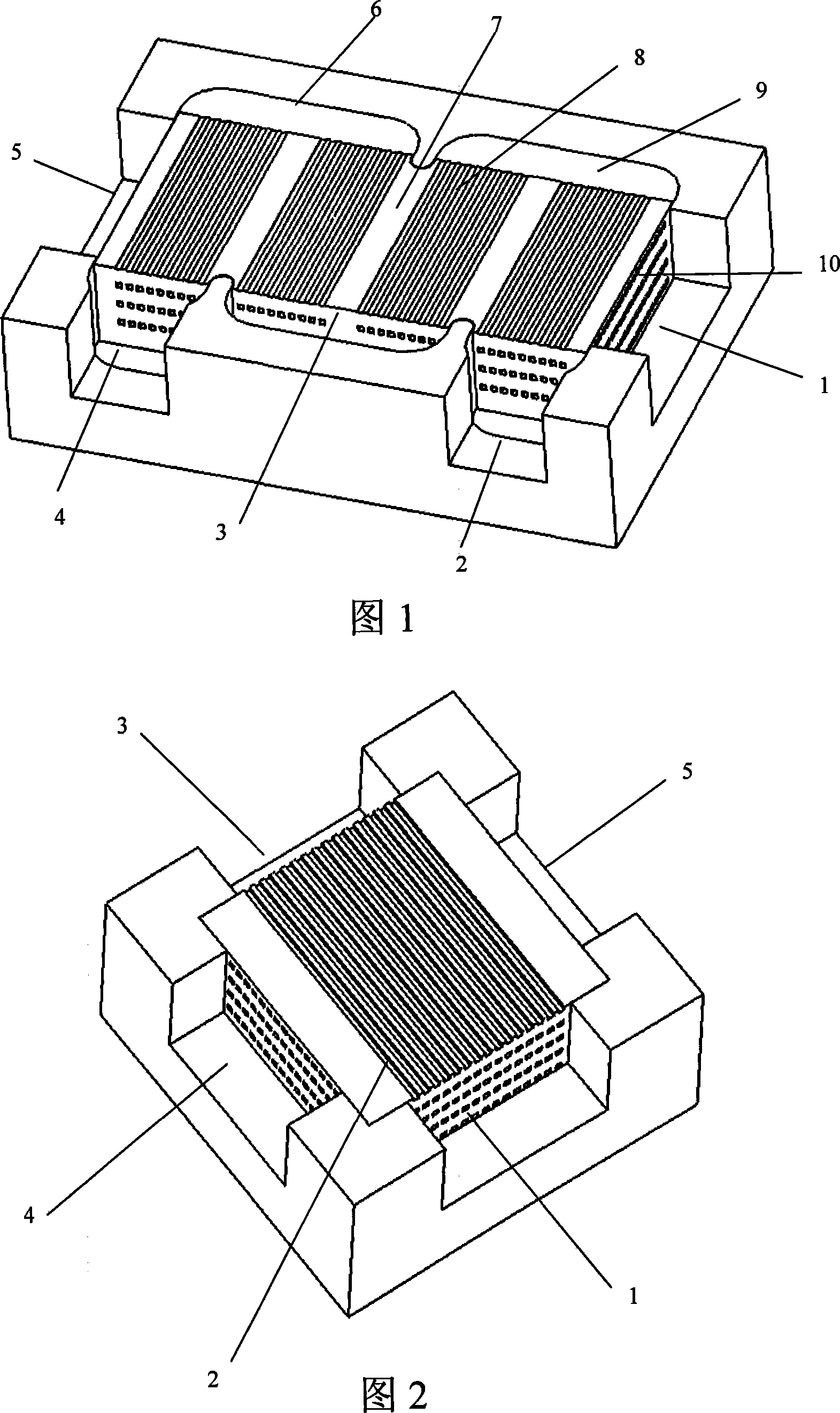

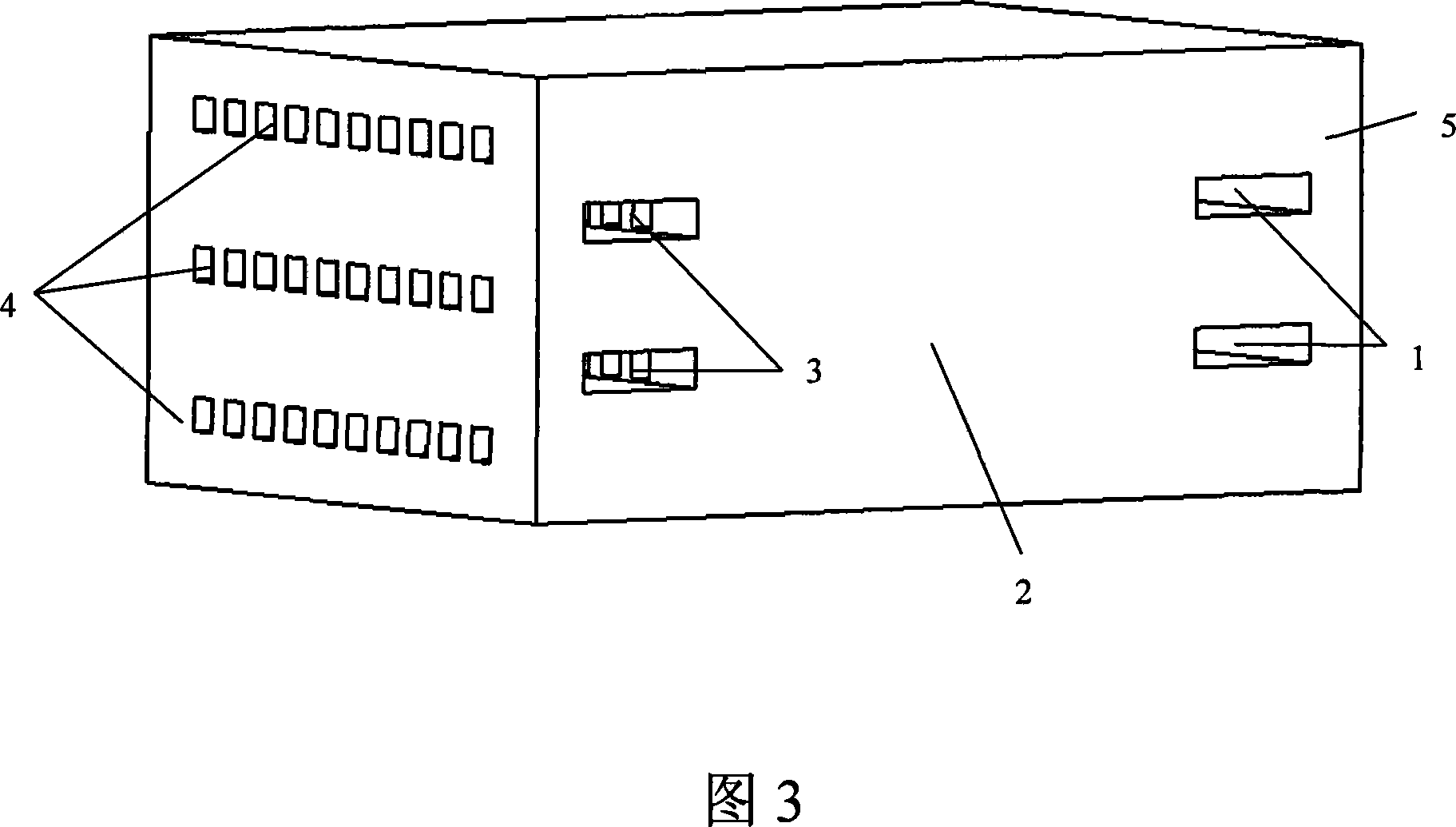

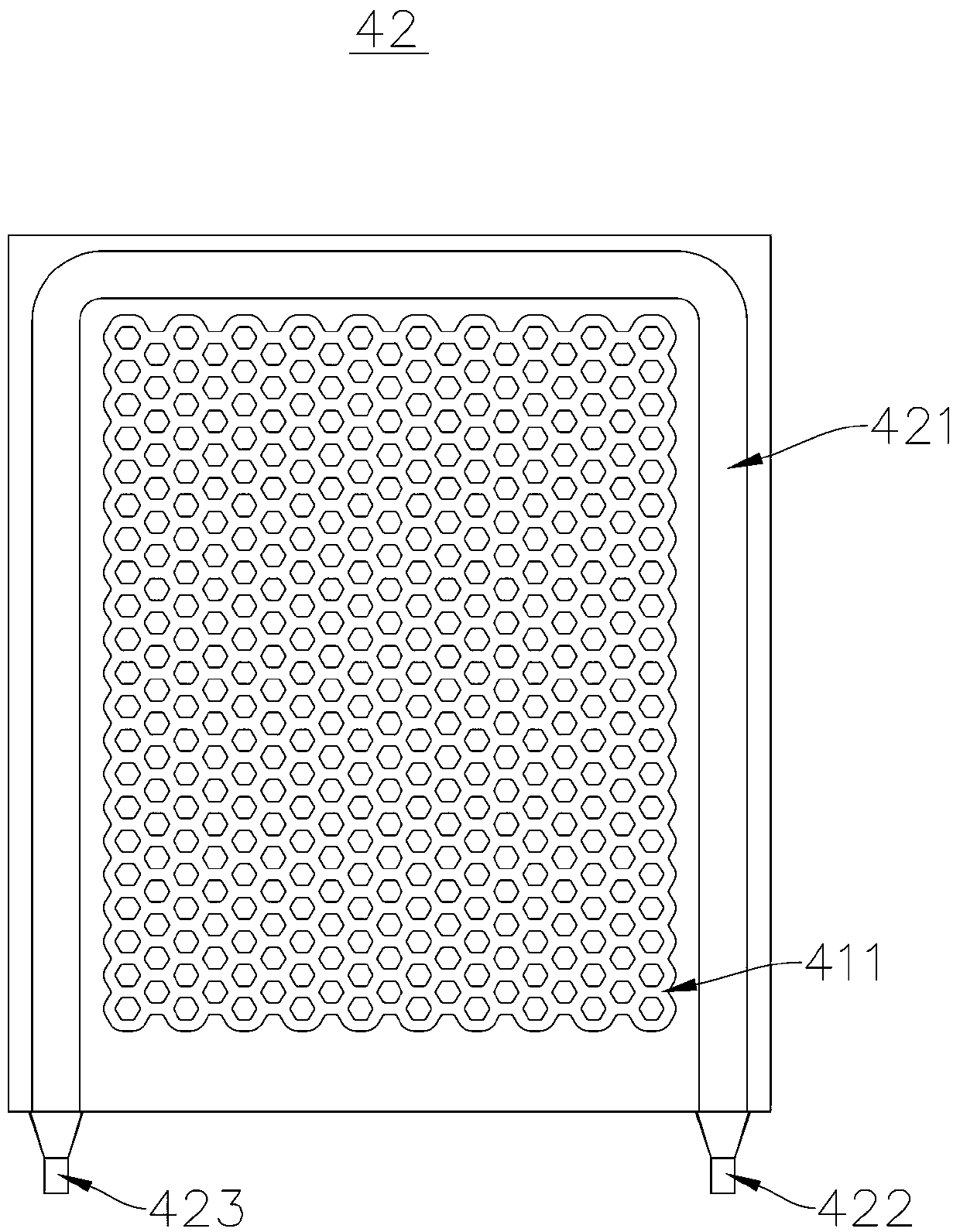

Continuous heat-storage type fume residual heat recovering device

InactiveCN101122446AImprove thermal conductivityIncrease the heat transfer specific surface areaStationary plate conduit assembliesFailure riskThermal transmittance

A continuous regenerative flue gas residual heat recycle device belongs to the industrial furnace energy saving field. The device is made from high heat resistance and conduction materials. A gas passage in the device is separated into mutually independent multistory spaces. Flue gas passages and air (gas) passages are arranged in a stratified and staggered way (that is a layer of flue gas passage is connected with a layer of air (gas) passage in the height direction, a staggered arranged sandwich structure). Every layer of gas flow passage is a honeycomb channel, which is made from high thermal conductivity materials. The hest recycle device has the advantages mentioned below. First, the heat exchange rate is fast. The thermal conductivity rate of a regenerator is high. And heat exchange between flue gas and air can be done rapidly. Second, the device can work continuously. Communication is not required in the wind supply and the smoke exhaust. And the system is simple. Third, utmost waste recovery is really realized. No heat and fuel loss caused by volume effect is made during the communication. Fourth, with a long service life, the device can be flexibly arranged. And the device has relative small relevance with the furnace, which makes the failure risk lowered and is convenient for the engineering management.

Owner:UNIV OF SCI & TECH BEIJING

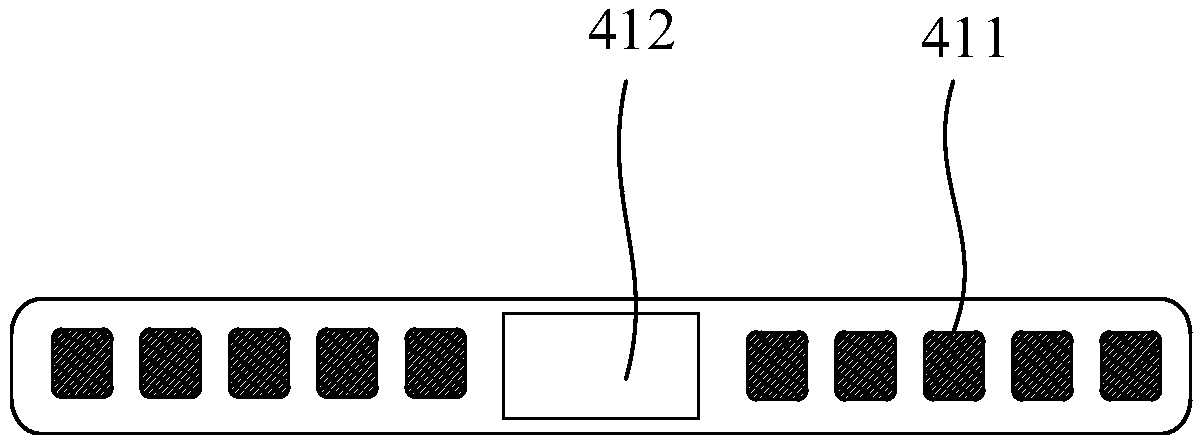

Manufacturing method for 48K polyacrylonitrile-based carbon fiber precursor

InactiveCN105463607AReduce manufacturing costAvoid damageMonocomponent synthetic polymer artificial filamentCarbon fibersRedox

The invention provides a manufacturing method for a 48K polyacrylonitrile-based carbon fiber precursor and belongs to the technical field of carbon fiber precursor manufacturing. The method comprises the steps that a polyacrylonitrile-based carbon fiber precursor is mixed with a reaction solvent through polymer powder at the temperature between -18 DEG C and 0 DEG C to prepare slurry, the slurry is vacuumized to be under the pressure between 45 KPa and 90 KPa and dissolved at the temperature between 40 DEG C and 55 DEG C for 1-2 hours, and then a spinning solution is obtained; the obtained spinning solution is squeezed out through a spinning nozzle and enters a spinning pipe in a coagulating bath, the temperature of the coagulating bath is between 30 DEG C and 60 DEG C, the spinning solution is shaped in the spinning pipe and then negatively drafted in the coagulating bath by 0.4-0.9%, and then a polyacrylonitrile nascent fiber is obtained; lastly, the polyacrylonitrile nascent fiber is washed, drawn, oiled, dried and drafted, and then the 48K polyacrylonitrile-based carbon fiber precursor is obtained. Through the method, the heat exchange rate in the later period of a reaction is high, a redox initiation system containing no metal ions is adopted, and production cost is low.

Owner:CHANGCHUN UNIV OF TECH

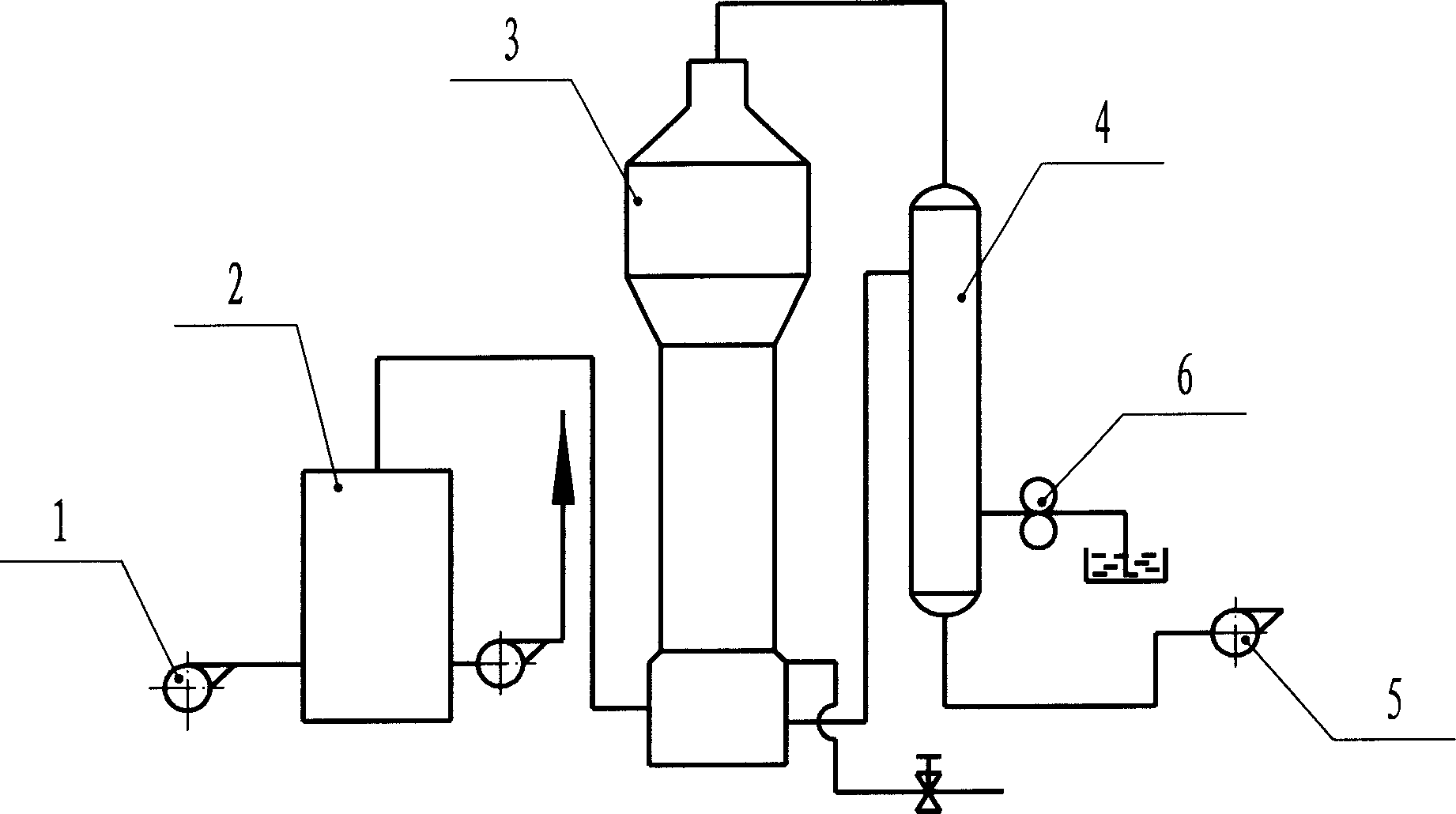

Hot-air mediated evaporation and concentration method

InactiveCN1522779AExtend continuous running timeVisible energy-saving effectEvaporationAgricultural engineeringEvaporation

The present invention relates to the field of concentration by evaporation technology. Said equipment is mainly composed of hot-air indirectly-heating hot-blast furnace, evaporator, condenser and hot-air transferring equipment. The hot-air outlet of indirectly heat-exchanged hot-blast furnace is connected with evaporator by pipeline, the outlet of evaporator is connected with condensation heat-exchanger, and the air outlet of condenser is connected with blower fan by pipeline, so that they are formed into the connected evaporation and condensation system.

Owner:辽宁东大粉体工程技术有限公司

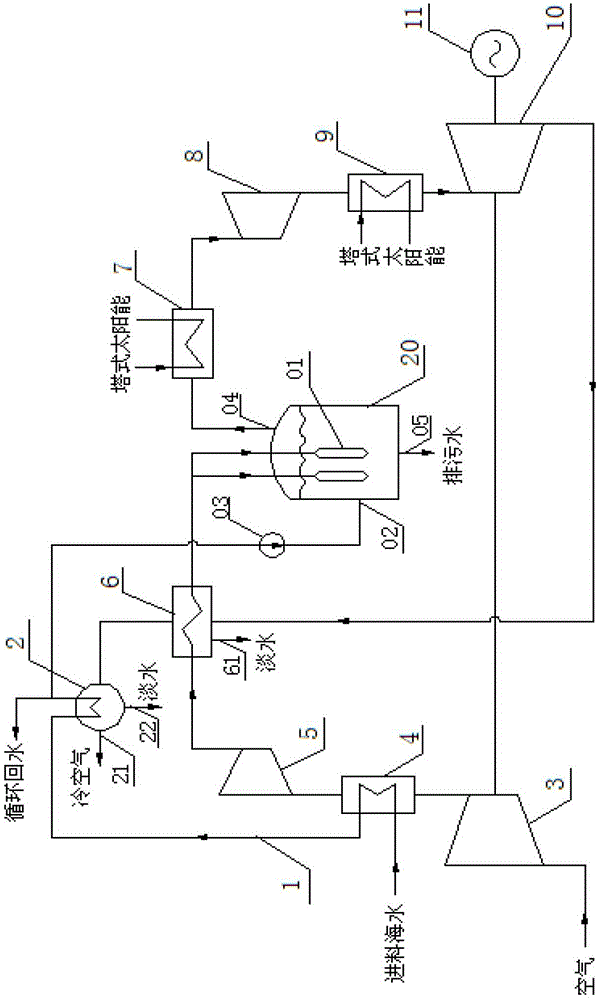

Solar moist air circulating electricity-water cogeneration system

InactiveCN104929709AGood distillationImprove heat transfer efficiencyGeneral water supply conservationSeawater treatmentAir cycleCogeneration

Owner:JIMEI UNIV

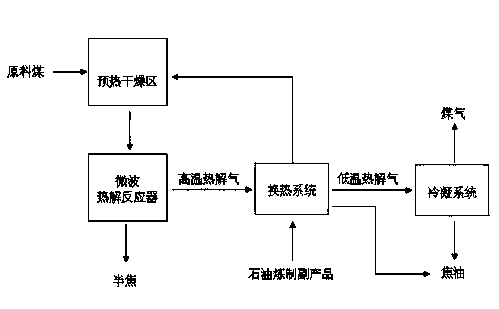

Combined process for co-pyrolysis of coal and petroleum refining by-product

ActiveCN103788968AIncrease polarityImprove microwave absorption performanceDirect heating destructive distillationSpecial form destructive distillationMicrowave pyrolysisTar

The invention discloses a combined process for co-pyrolysis of coal and petroleum refining by-products. Feed coal is crushed, sent into a preheating drying zone, and mixed with petroleum refining by-products from a heat transfer system; and the mixture of coal and petroleum refining by-products is sent into a microwave pyrolysis reactor to generate semi coke and high temperature pyrolysis gas, the pyrolysis gas carries out heat exchange with the petroleum refining by-products in the heat transfer system and is separated into tar and low temperature pyrolysis gas, and the low temperature pyrolysis gas enters into a condenser system for further separation into tar and coal gas. The combined process can realize simultaneous pyrolysis of coal and petroleum refining by-products in the same temperature range to generate synergistic effect, so as to increase the yield of coal tar and improve the quality of coal tar.

Owner:CHINA PETROLEUM & CHEM CORP +1

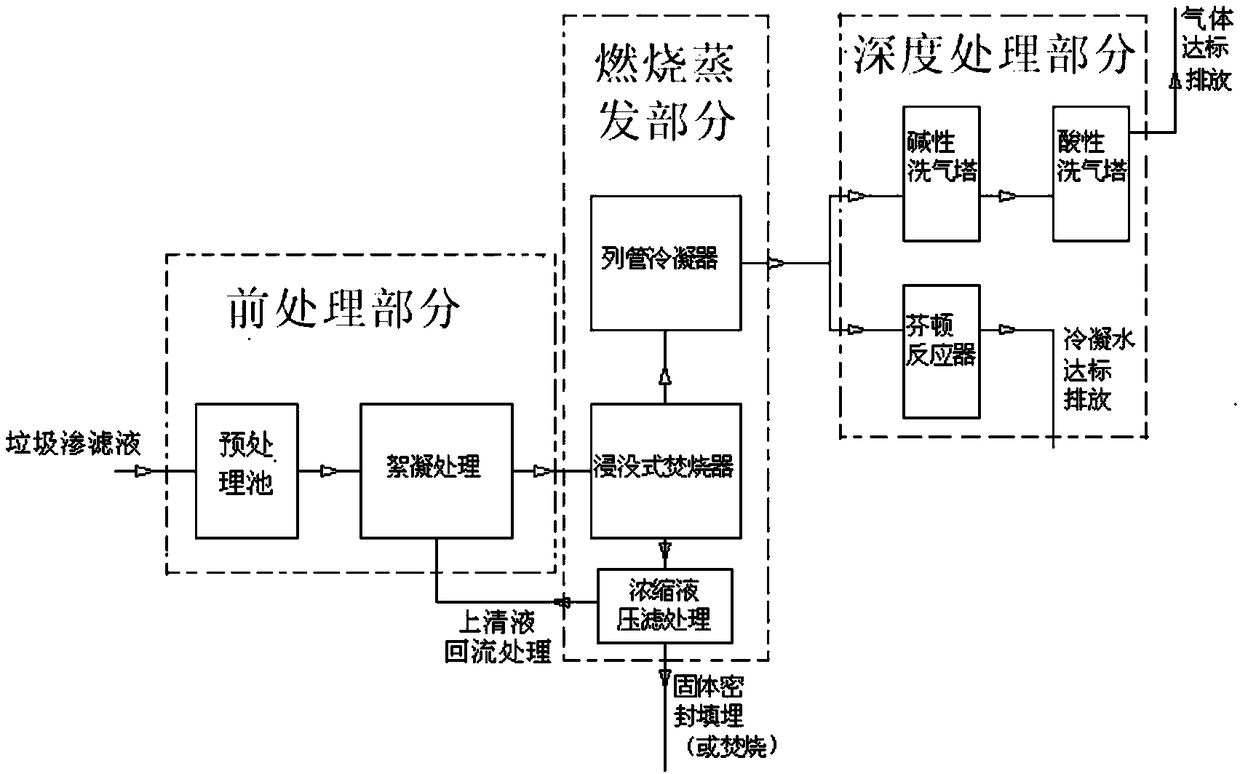

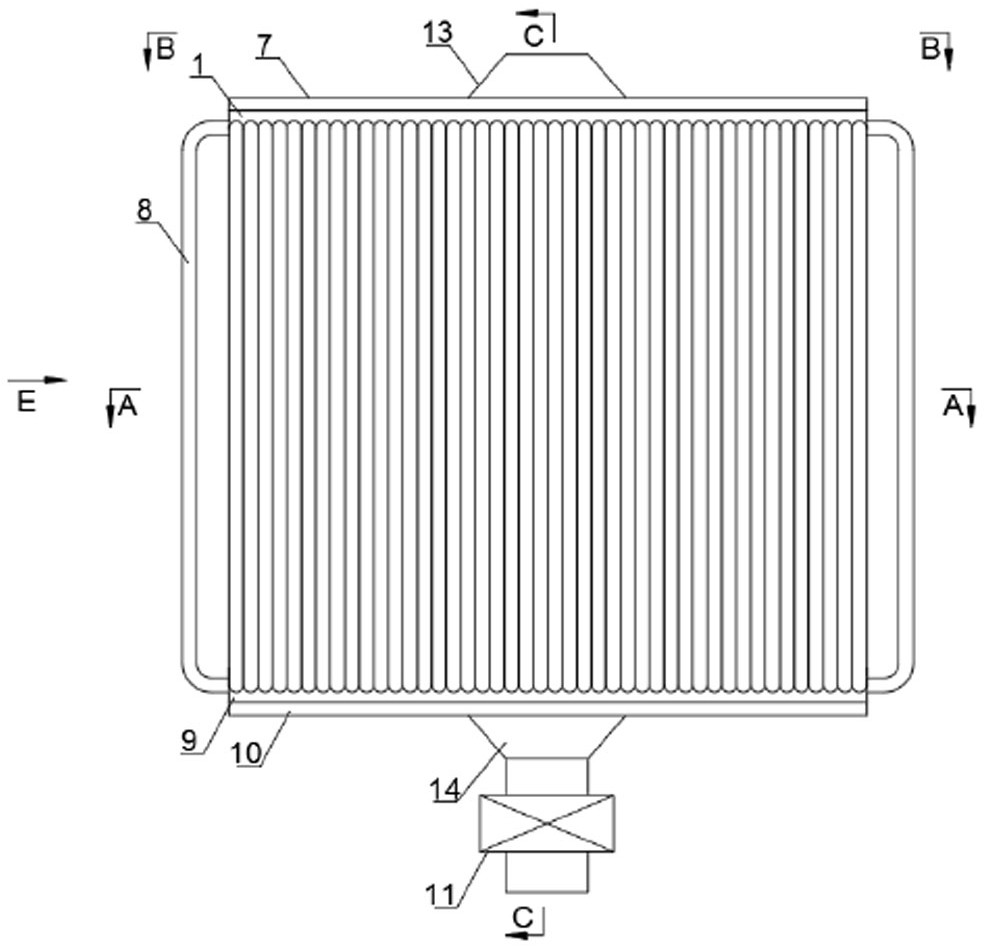

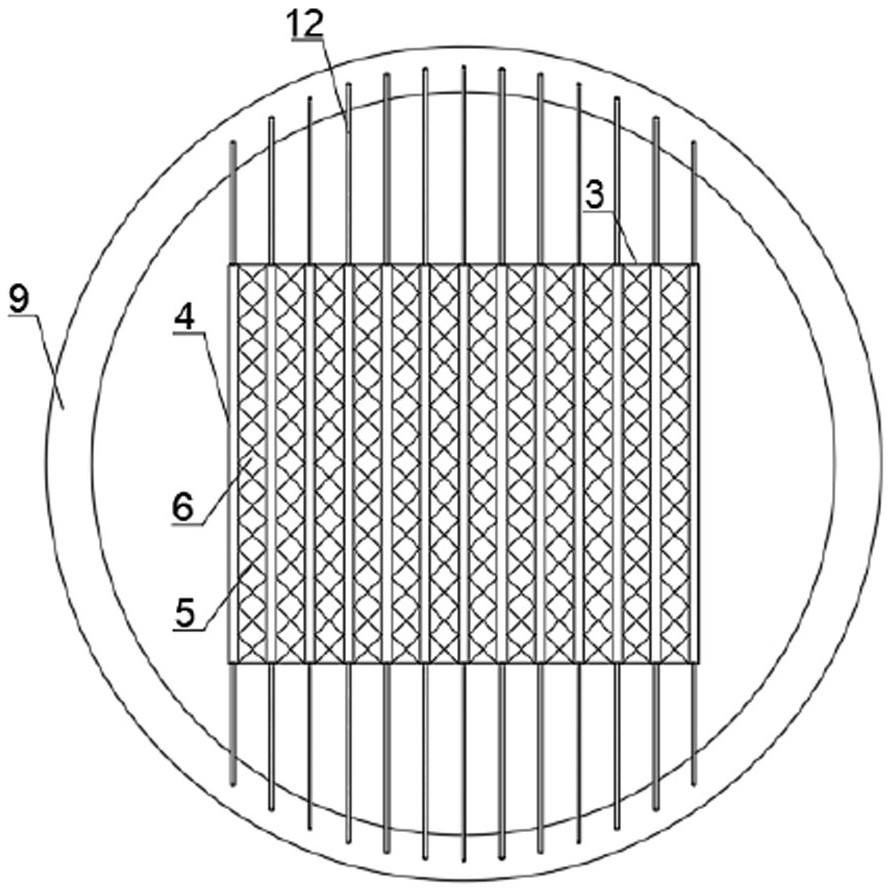

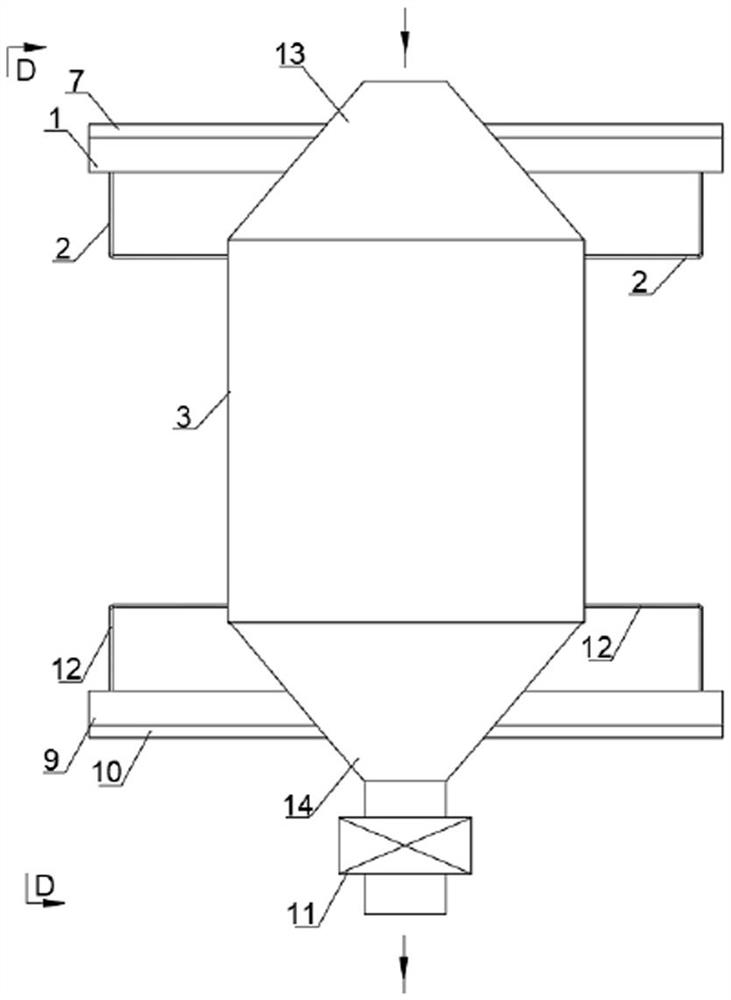

Immersed combustion treatment system for refuse leachate

InactiveCN108609787ALow costIncrease heat transfer areaWater treatment compoundsDispersed particle separationFlocculationCombustion chamber

The invention discloses an immersed combustion treatment system for refuse leachate, which includes: a pretreatment part, which includes a pretreatment tank and a flocculation reaction apparatus communicated therewith; a combustion and evaporation part, which includes an immersed incinerator, a tubular condenser, and a concentrate press filter device, wherein the immersed incinerator is provided with a combustion chamber comprising a fuel gas inlet, a combustion-supporting gas inlet, and an igniter, a steam outlet is disposed on the upper end of the immersed incinerator and the bottom of the immersed incinerator is conical in shape and is provided with a concentrate discharge outlet, after treatment in the flocculation reaction apparatus, a fluid flows into the immersed incinerator, then the tubular condenser is connected to the immersed incinerator through the steam outlet and the concentrate press filter device is connected to the immersed incinerator through the concentrate discharge outlet; a deep processing part, which includes an alkaline gas washing tower, an acidic gas washing tower, and a Fenton reactor, wherein the alkaline gas washing tower is connected to the gas outletof the tubular condenser, the acidic gas washing tower is connected to the alkaline gas washing tower, and the Fenton reactor is connected to a condensate discharge outlet on the tubular condenser.

Owner:BEIJING GREEN USE ENVIRONMENTAL PROTECTION SCI & TECH

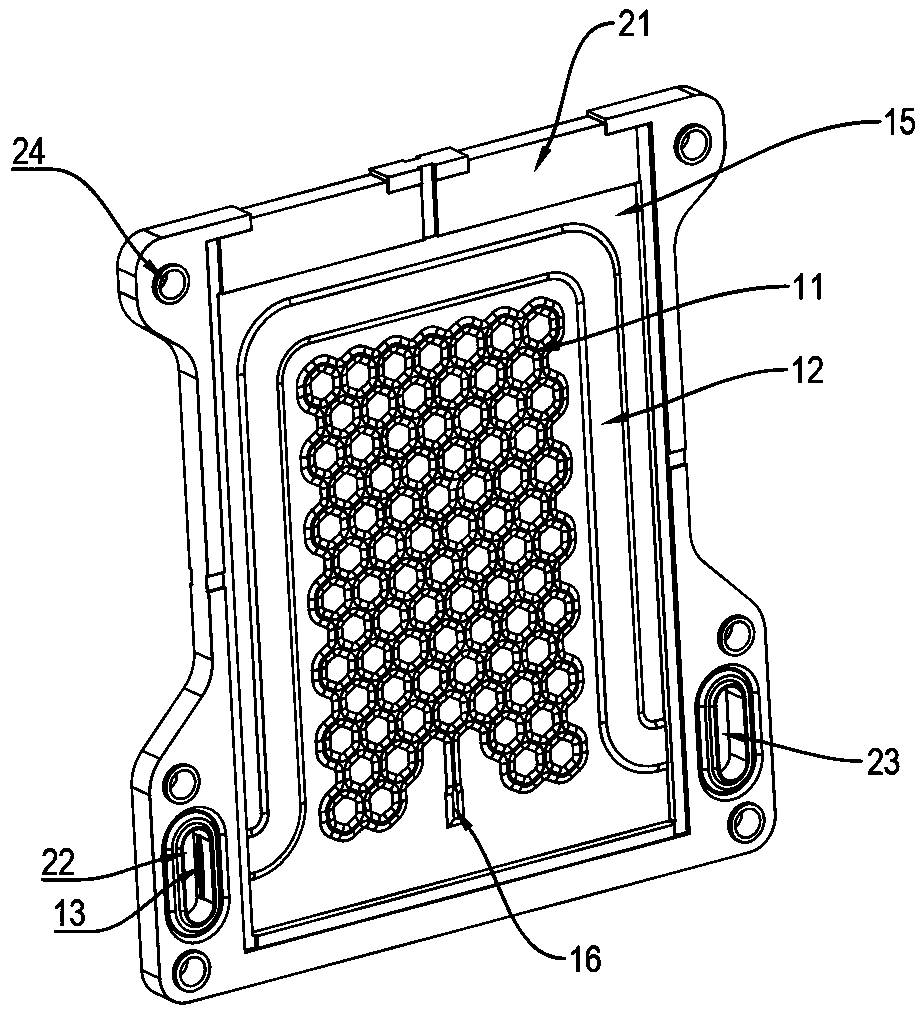

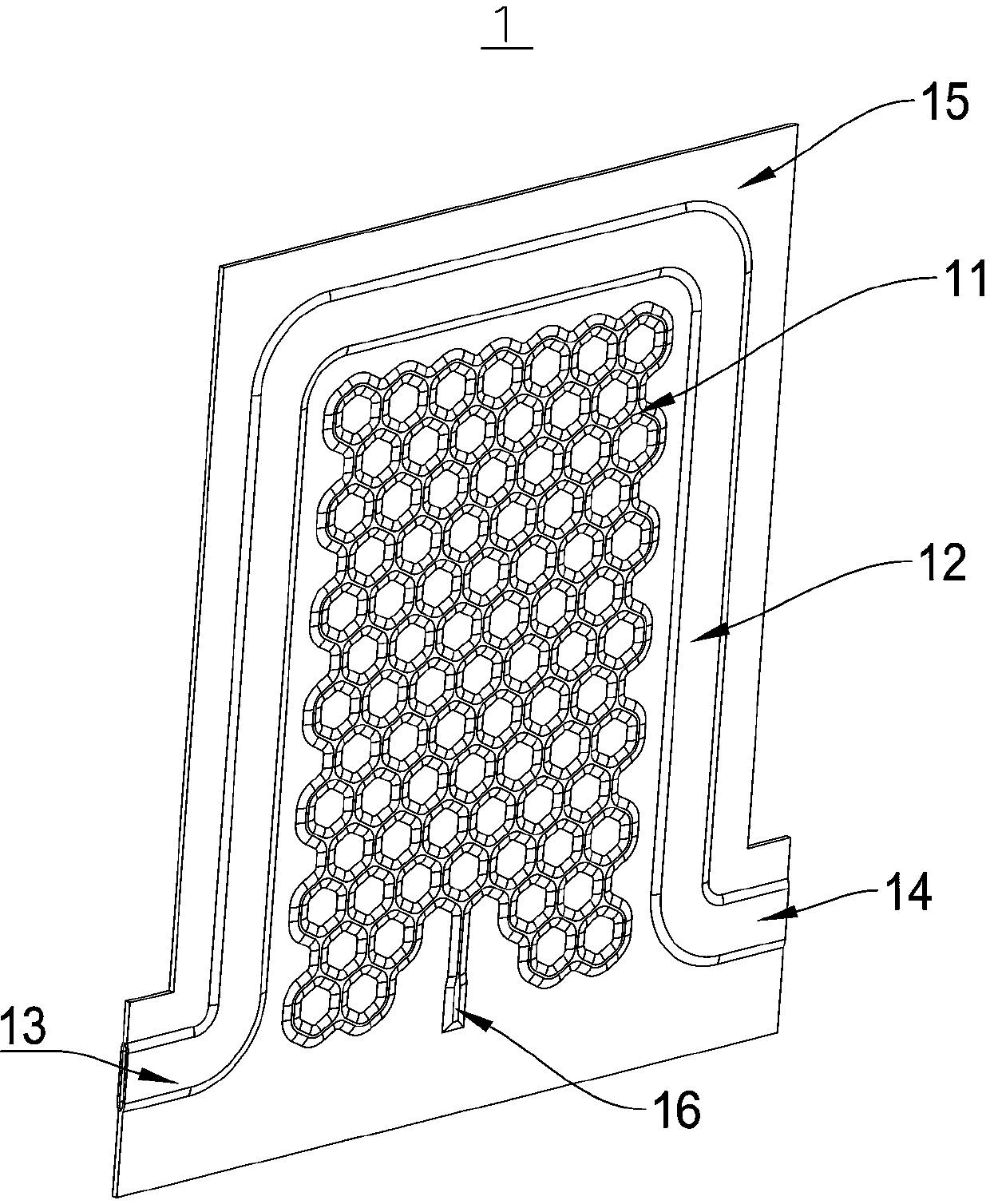

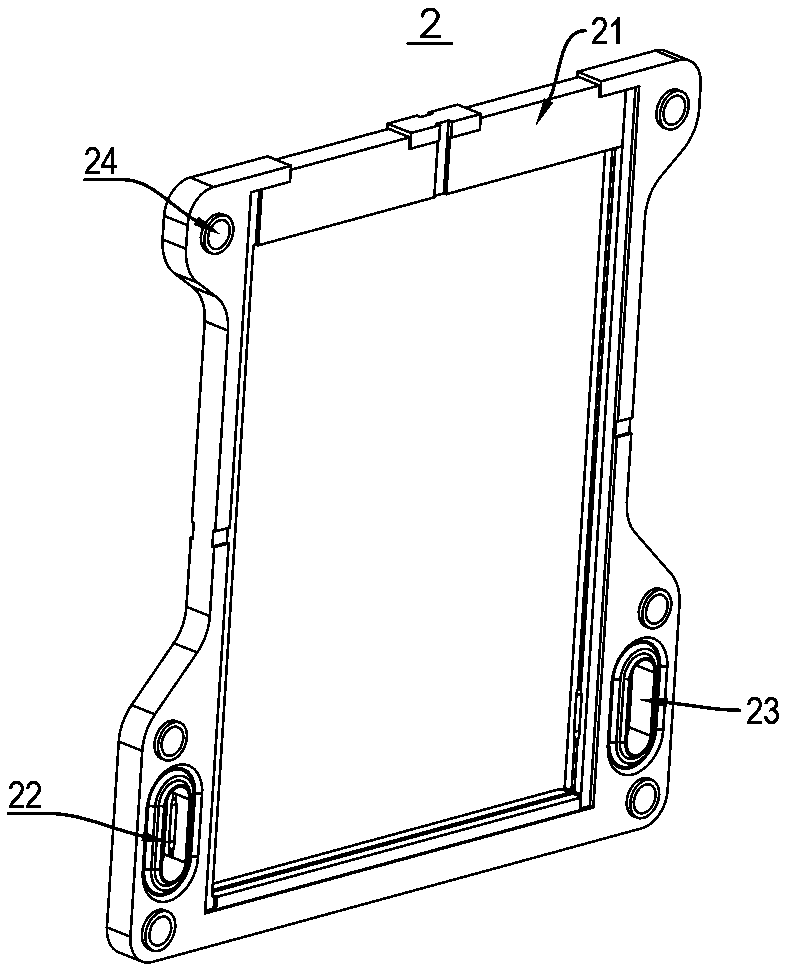

Cooling plate and manufacturing method thereof

PendingCN110567301ATake away quicklyFirmly connectedIndirect heat exchangersLaminated elementsCooling effectEngineering

The invention provides a cooling plate and a manufacturing method of the cooling plate. The cooling plate comprises a metal plate and a frame. Closed thermal superconduction pipelines are arranged inthe metal plate and communicate with one another. Each thermal superconduction pipeline is filled with a heat transfer working medium. The metal plate further comprises a refrigerant channel, so thatthe cooling effect of the cooling plate can be improved. The metal plate and the frame are tightly connected through an insert injection molding technology. The frame is divided by the metal plate into at least one containing cavity.

Owner:ZHEJIANG JIAXI TECH CO LTD

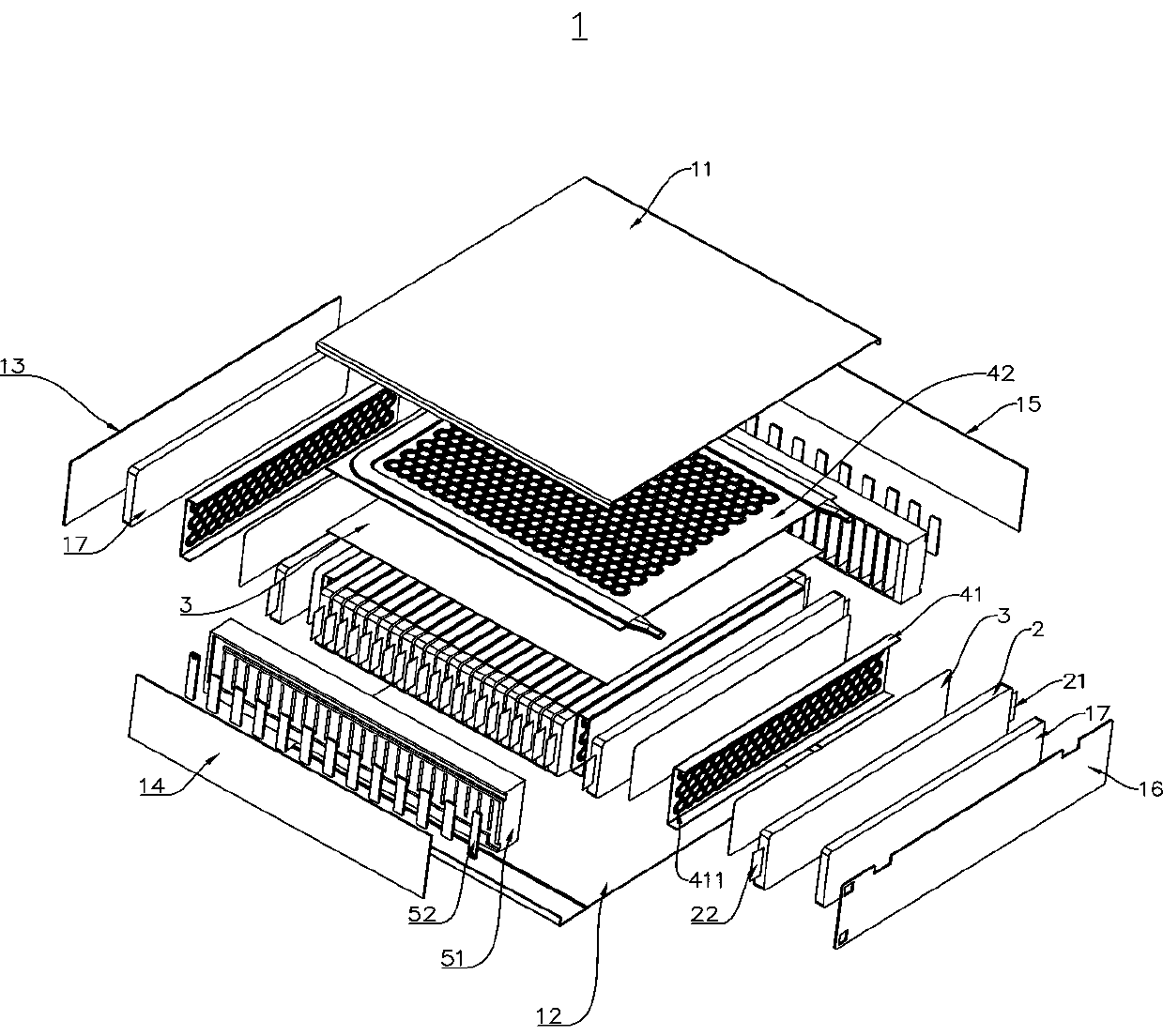

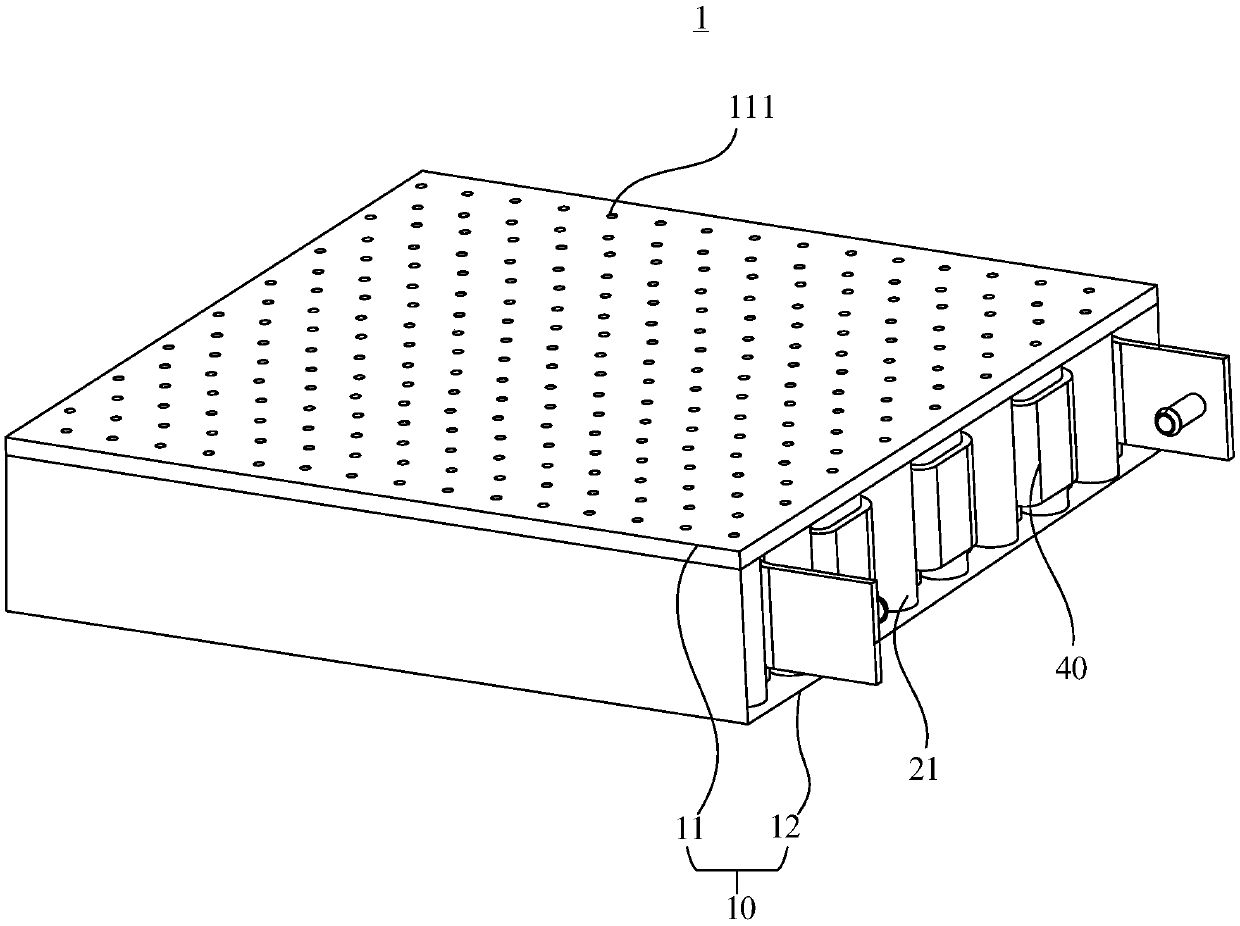

Battery module, battery pack, electric vehicle, and power grid system

PendingCN110311189ATake away quicklyFast heat transfer rateSecondary cellsCell component detailsPower gridElectric vehicle

The invention provides a battery module comprising a casing, battery cells, a heat equalizing plate and a heat dissipating device. The casing includes six panels in the up, down, front, rear, left andright directions respectively. The battery cells are disposed in the casing. The heat equalizing plate is installed in the casing, is sandwiched between the battery cells, and is filled with a heat transfer working medium. The heat dissipating device has heat equalization, heat exchange and heat dissipation functions. The present invention also provides a battery pack having the battery module, an electric vehicle, and a power grid system. The heat equalizing plate filled with the heat transfer working medium can quickly absorb the heat generated during the charging and discharging processesof the battery cells, and distributes the heat to transfer the heat to the heat dissipating device to quickly dissipate the heat inside the battery module. Therefore, it is possible to prevent the insufficient heat dissipation of the battery modules in the battery pack, the electric vehicle, and the power grid system from influencing the normal use or causing a safety accident.

Owner:ZHEJIANG JIAXI TECH CO LTD +1

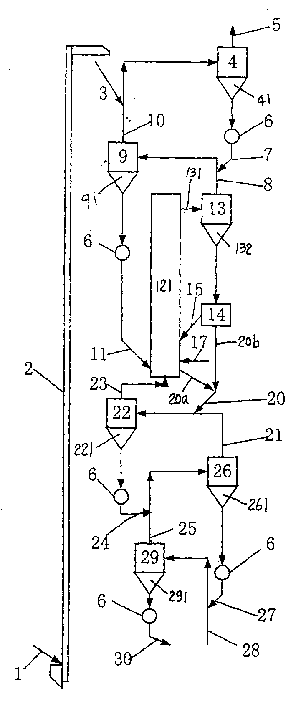

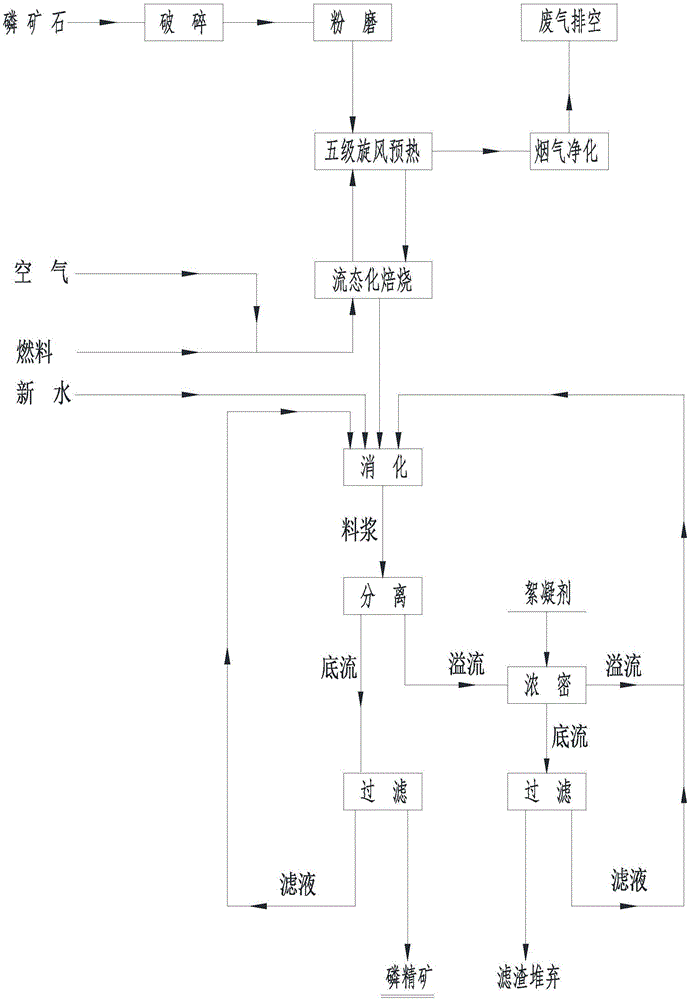

Beneficiation method and system for calcium or calcareous and siliceous phosphorite and application method of beneficiation system

InactiveCN106669962AImprove efficiencyImprove energy savingProcess efficiency improvementWet separationCarbonizationSizing

The invention discloses a beneficiation method for extracting phosphorus, reducing calcium and recovering magnesium for calcareous or calcareous and siliceous phosphorite containing high magnesium or low magnesium. The beneficiation method includes the steps that the phosphorite is subjected to multi-stage heat treatment and is then subjected to fluidized roasting, water is added to obtained phosphorite roasting powder for stirring, and sizing is obtained after digestive treatment; the sizing is separated to obtain underflow and overflow, and phosphorus concentrates and filter liquid are obtained after the underflow is filtered; and when the phosphorite contains high magnesium, the filter liquid is merged with the overflow, then carbonization pyrolysis treatment is conducted, and magnesium is recovered. The invention further discloses a beneficiation system which comprises a fluidized roasting system, a tail gas purifying system and a digestion separation system. The fluidized roasting system comprises a fluidized roasting decomposing furnace, a feeding assembly, a suspension preheating assembly, a gas supplying assembly and a combustion assembly; and the beneficiation system further comprises a carbonization pyrolysis system when being used for the high-magnesium phosphorite. The beneficiation system can be adopted for conducting treatment such as suspension preheating, fluidized roasting decomposing, digestion separation and carbonization pyrolysis. The beneficiation method and the beneficiation system have the beneficial effects of being high in efficiency, environment-friendly, capable of saving energy, high in valuable metal recovery rate and the like.

Owner:SICHUAN JIUCHANG SCI & TECH

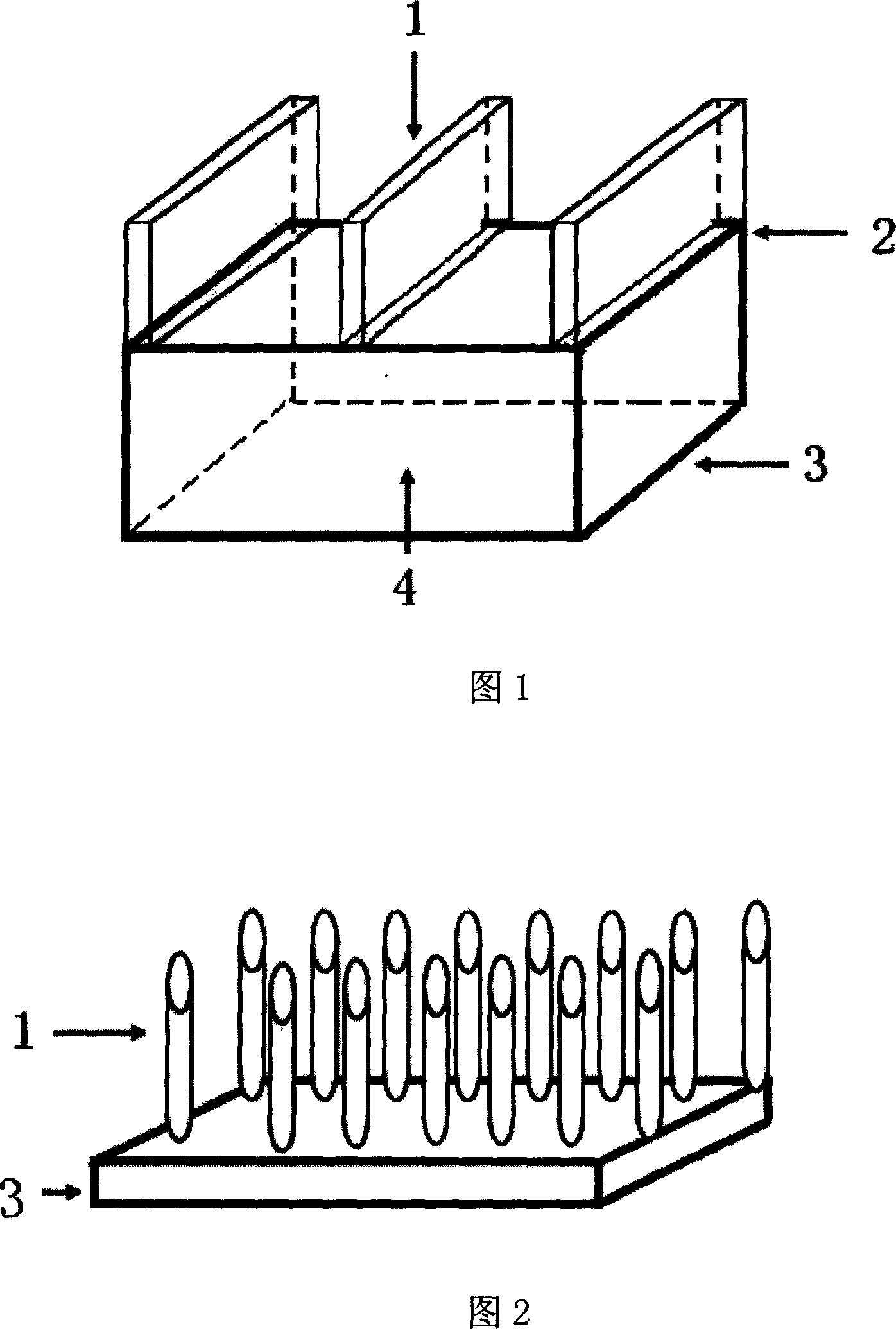

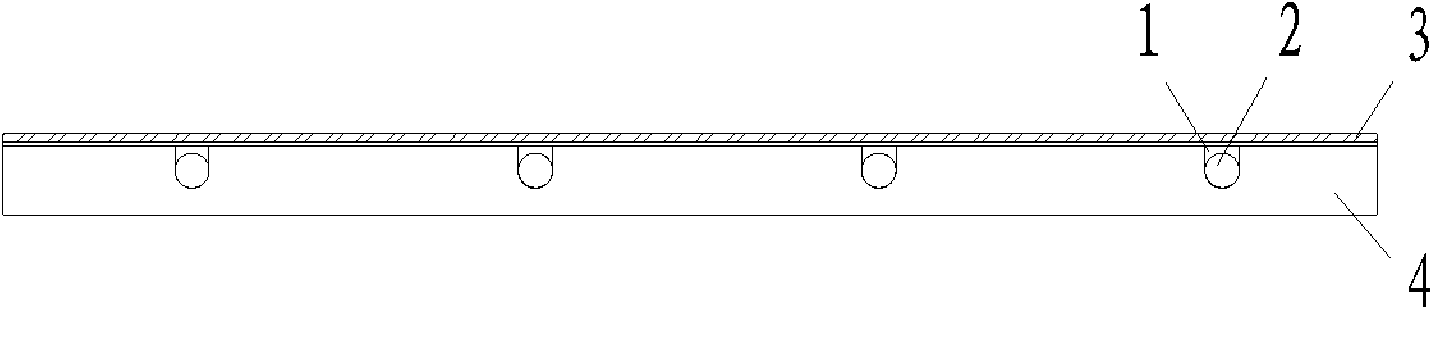

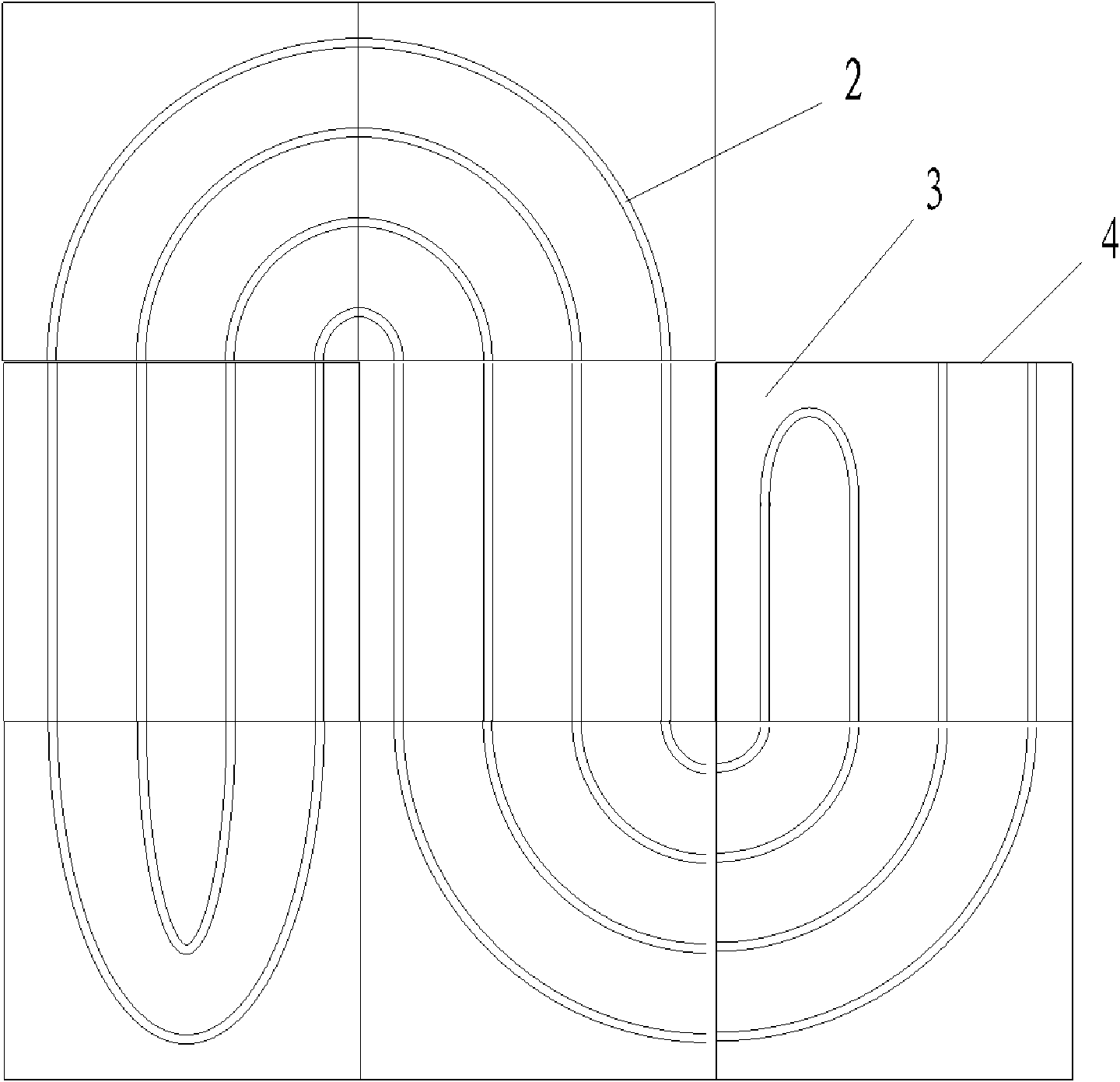

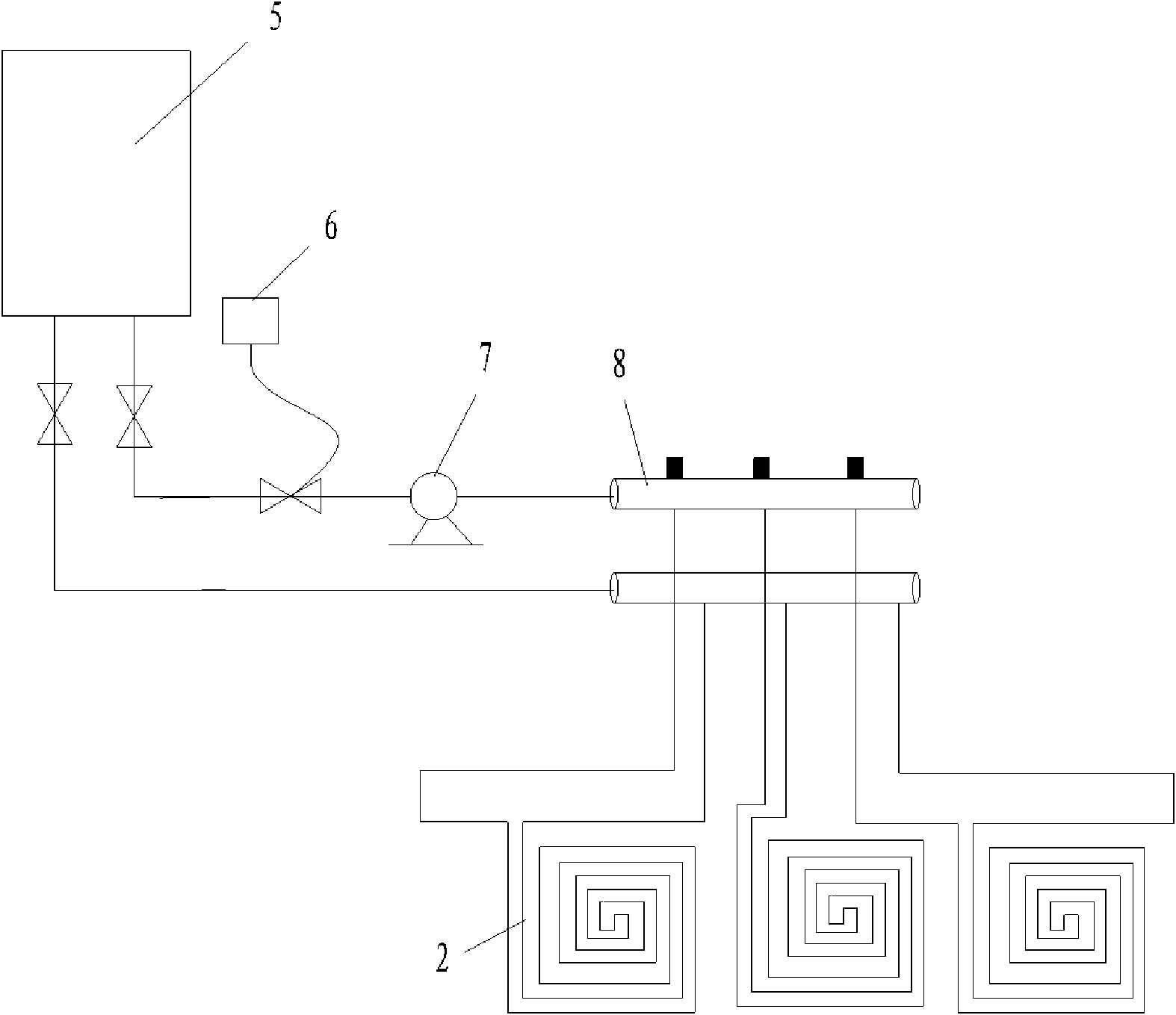

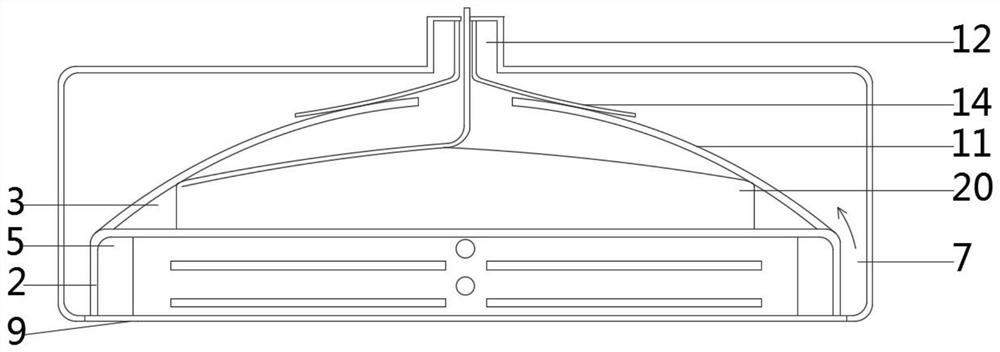

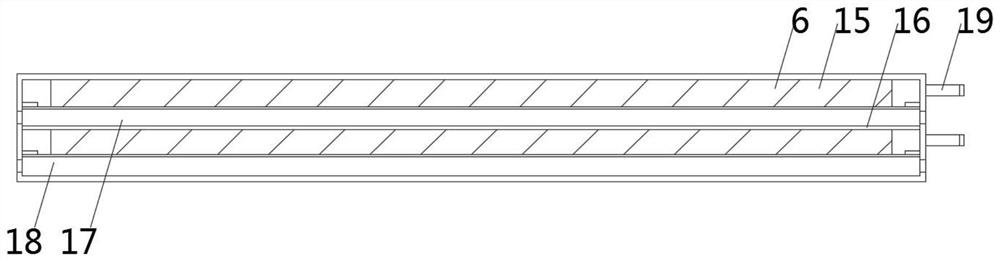

Integrated ground heating floor

InactiveCN101639239AHigh thermal conductivityReduce intervalLighting and heating apparatusFlooringThermal insulationEngineering

The invention discloses an integrated ground heating floor, the upper surface of a ground heating thermal-insulation basal plate (4) is provided with a ground heating trough (1) in which a ground heating tube is paved, and a metal floor (3) is arranged on the upper surface of the ground heating thermal-insulation basal plate (4). The invention is the integrated ground heating floor which has fastheating, convenient maintenance, long service life, environmental protection without harms, simple structure and reliable performance and is used for heating in winter for household and various publicoccasions (closed).

Owner:蔡春

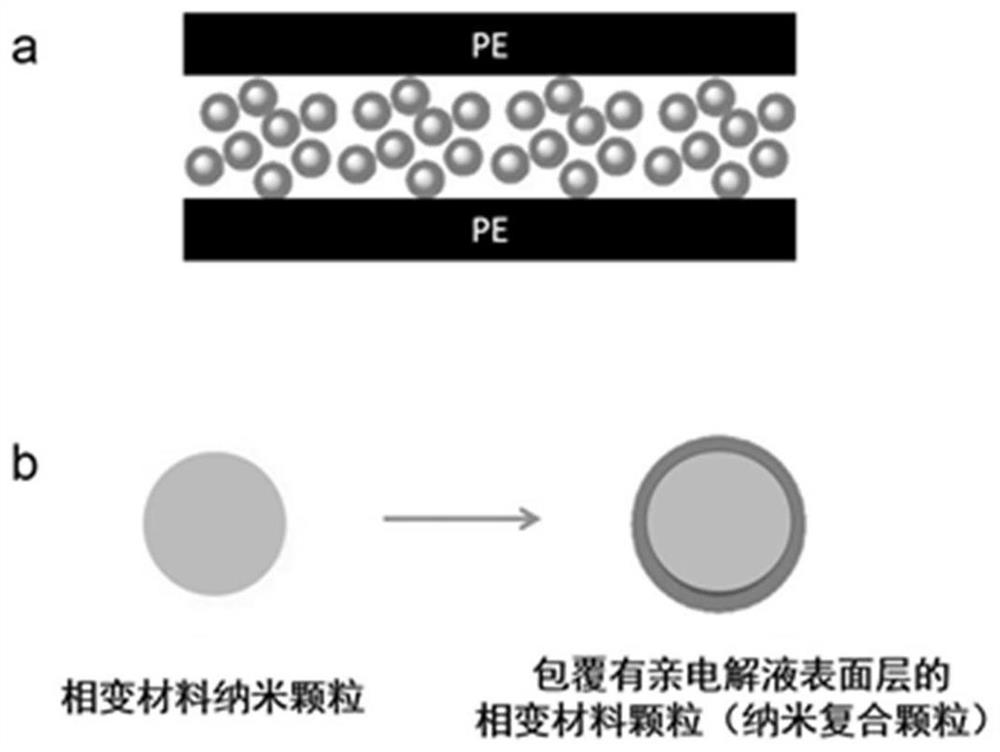

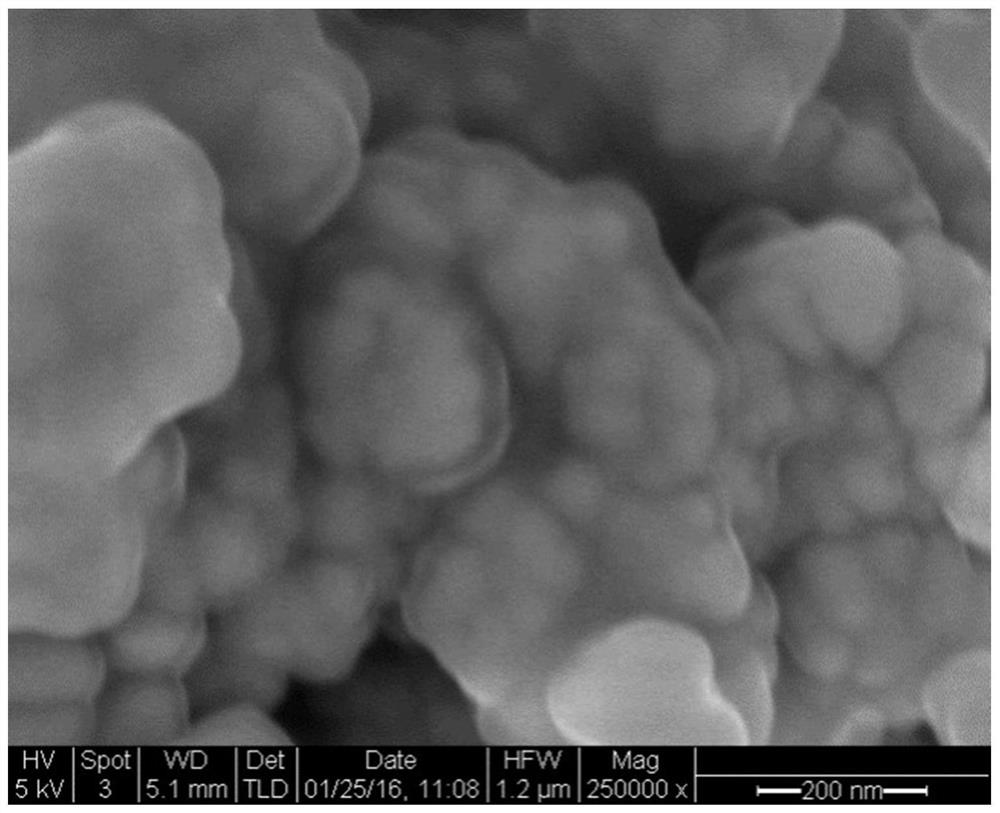

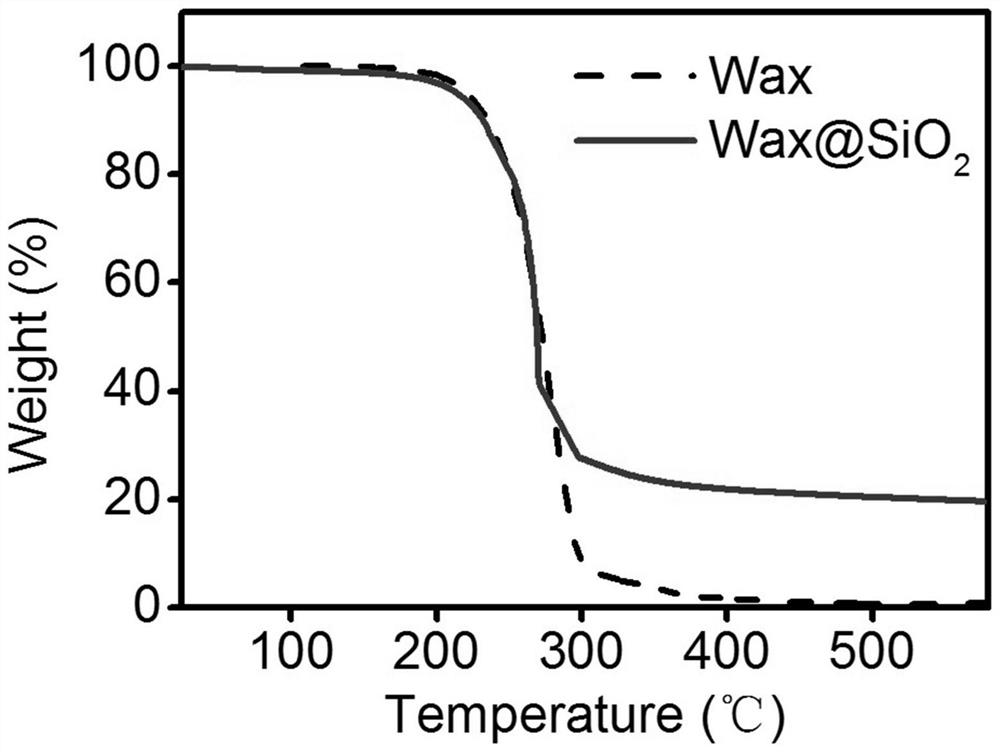

Composite particle for battery, battery separator, and lithium ion battery

InactiveCN111916632AEnsure safetyTemperature controlSecondary cellsCell component detailsElectrical batteryLithium-ion battery

The invention belongs to the field of batteries, and particularly relates to a composite particle for a battery, a battery diaphragm and a lithium ion battery. The composite particle for the battery comprises a phase change particle and an inorganic compound coating layer coating the surface of the phase change particle, wherein the phase change particles are paraffin, crystalline hydrated salt ormolten salt; and the inorganic compound coating layer is silicon dioxide, attapulgite, kaolinite, montmorillonite, hydrotalcite, vermiculite, sepiolite, mica, illite, diatomite, titanium dioxide, zinc oxide, aluminum oxide or nanocellulose. The composite particle for the battery provided by the invention can effectively control the internal temperature of the lithium ion battery, reduce the internal temperature fluctuation of the lithium ion battery during charging and discharging, absorb part of heat during thermal runaway, reduce the heat release amount of the battery to a certain extent, ensure the safety of the lithium ion battery, and does not affect the electrochemical performance of the battery.

Owner:TSINGHUA UNIV +1

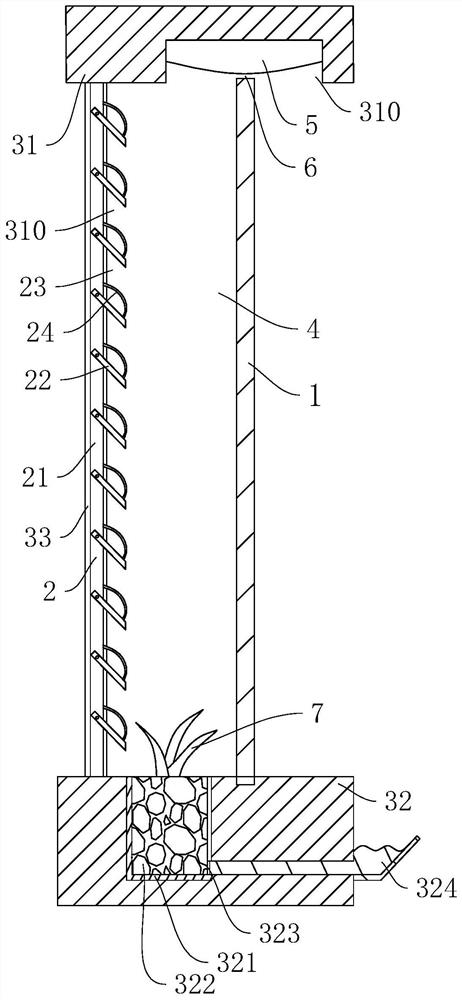

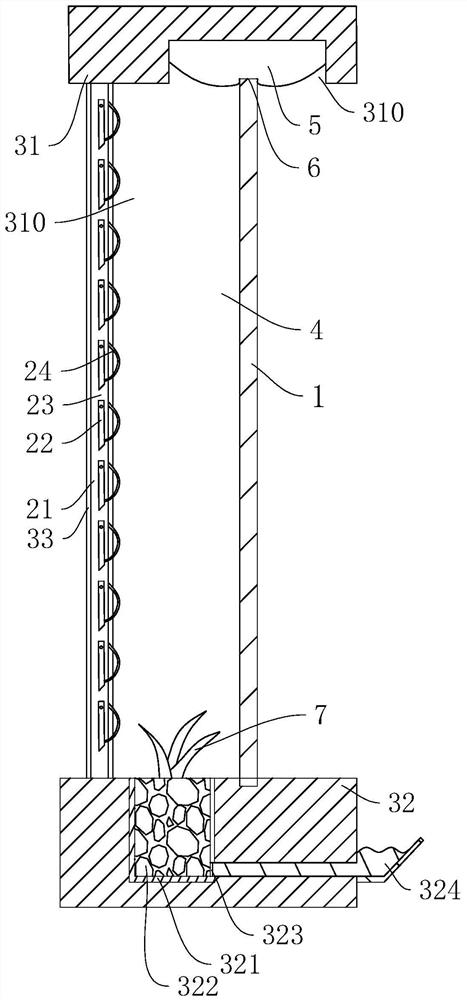

Ventilation type double-layer curtain wall system

InactiveCN112696747AIncrease temperatureReduce widthWallsLighting and heating apparatusIndoor air qualityEngineering

The invention relates to a ventilation type double-layer curtain wall system. The ventilation type double-layer curtain wall system comprises a light-transmitting outer wall, a ventilation inner wall and a heat transfer frame, the ventilation inner wall and the light-transmitting outer wall are oppositely installed in the heat transfer frame, the ventilation inner wall, the light-transmitting outer wall and the heat transfer frame are matched to form a containing cavity, and a communicating groove is formed in the position, connected with the light-transmitting outer wall, of the top of the heat transfer frame. The communicating groove communicates with the containing cavity and the outside, an elastic air bag is arranged at the groove bottom of the communicating groove, a communicating air gap is formed between the elastic air bag and the light-transmitting outer wall, the elastic air bag absorbs heat to expand and blocks the communicating air gap, the elastic air bag releases heat to contract and opens the communicating air gap, and green plants are planted in the containing cavity. A controllable air gap communicating the containing cavity with the indoor space is formed in the ventilation inner wall, and the width of the controllable air gap is in negative correlation with the temperature of the ventilation inner wall. The indoor and outdoor air exchange rate is regulated and controlled according to the environmental influence, and the indoor air quality is guaranteed.

Owner:SHENZHEN YIJINGSHENG DECORATION ENG

External particle heat absorber and solar power generation system

ActiveCN112728776ASolve the problem of low heat absorption efficiencyRaise the average endothermic temperatureSolar heating energyFrom solar energySolar powerMechanical engineering

The invention discloses an external particle heat absorber and a solar power generation system. A particle heat exchanger internally provided with a particle channel and a working medium channel is arranged, meanwhile, a heat absorption pipe group is arranged to be communicated with two ends of the working medium channel to form a circulating pipeline, the working medium channel is in heat transfer contact with the particle channel, and after a phase change working medium in the heat absorption pipe group absorbs heat and is evaporated into a gaseous phase change working medium, the gaseous phase change working medium enters the working medium channel to exchange heat with the cold particles in the particle channel and is condensed into a liquid phase change working medium which flows back to the heat absorption pipe group. The heated hot particles can be output to next external equipment from the output end of the particle channel. The liquid phase change working medium is arranged as the middle heat exchange medium, heat is transmitted to the particles after evaporation, and the particles are heated to the needed temperature, so that high efficiency is achieved, and the problem that an existing particle heat absorber is low in heat absorption efficiency is solved. Meanwhile, the particle technology is low in price and higher in heat absorption temperature, and the kilowatt-hour cost of a photo-thermal power station can be greatly reduced under the condition of the same heat absorption efficiency.

Owner:浙江高晟光热发电技术研究院有限公司

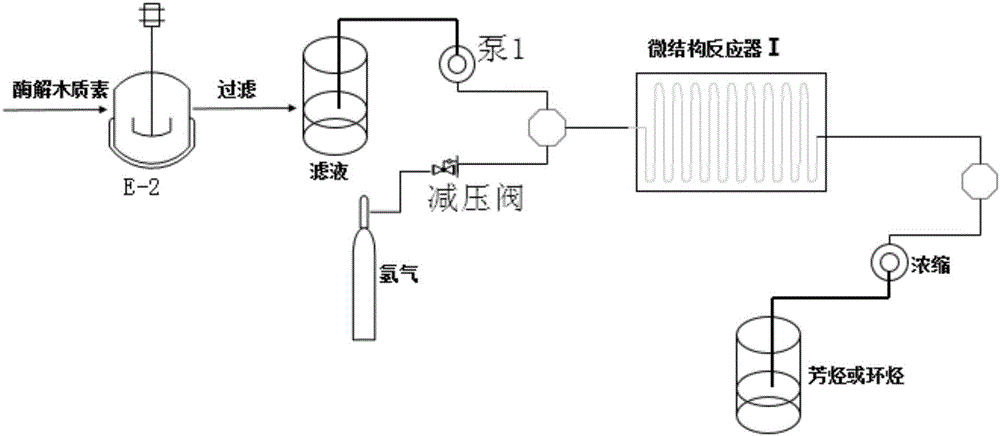

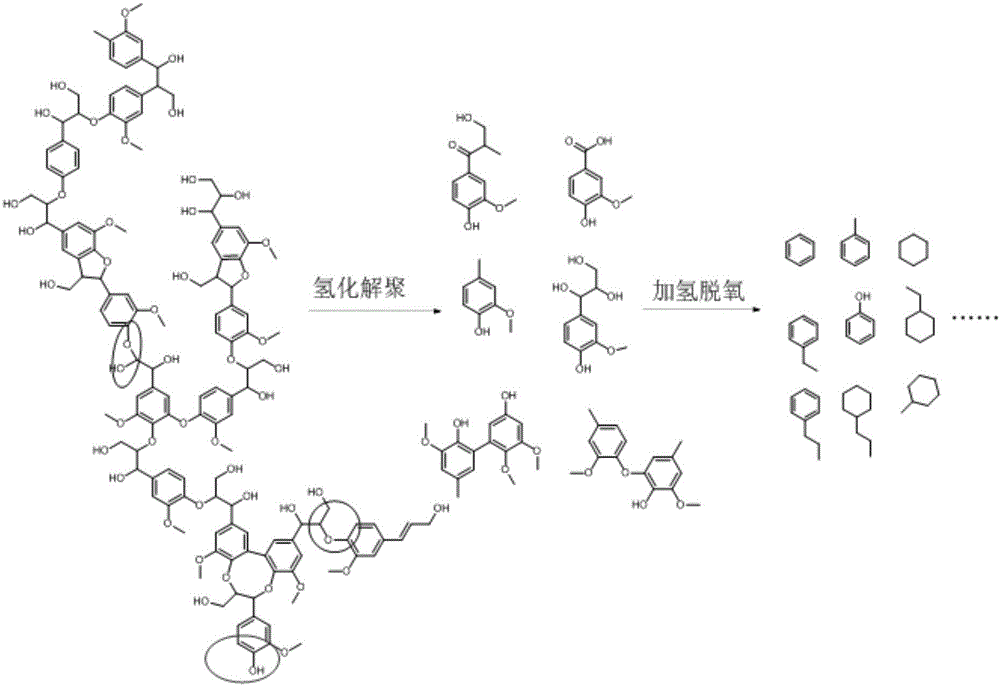

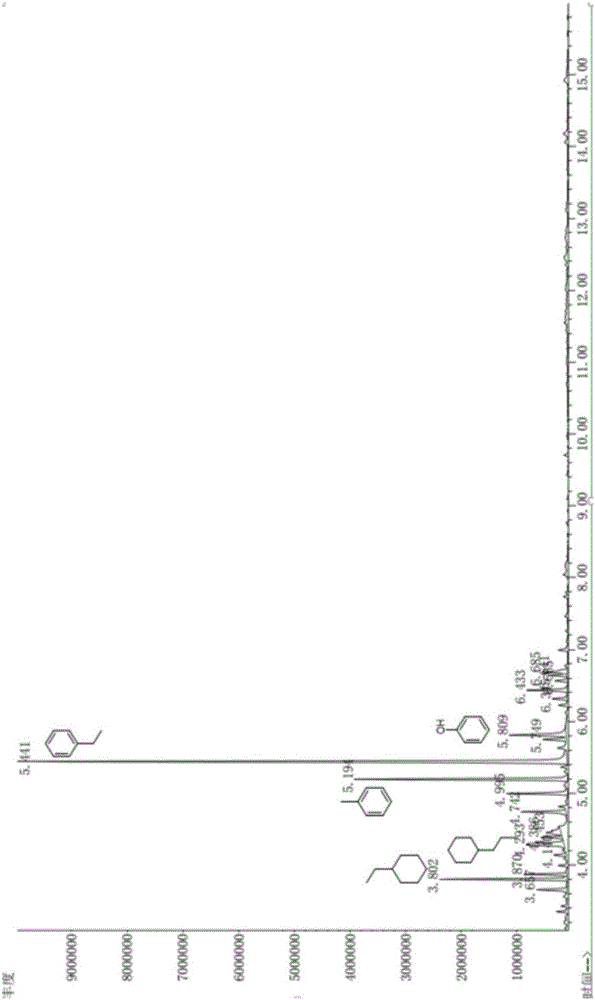

Method for continuously catalyzing and degrading lignin bio-oil into aromatic hydrocarbons and naphthenic hydrocarbons with micro-channel reaction device

InactiveCN106146234AIntermolecular diffusion distance is shortLarge specific surface areaHydrocarbon from oxygen organic compoundsCyclic alkaneMicro structure

The invention provides a method for continuously catalyzing and degrading lignin bio-oil into aromatic hydrocarbons and naphthenic hydrocarbons with a micro-channel reaction device. The method comprises the following steps that firstly, in an alcohols solvent, a base catalyst is used for catalyzing lignin to be hydrogenated and depolymerized into phenolic bio-oil; secondly, the base catalyst in the phenolic bio-oil is filtered out, the phenolic bio-oil and hydrogen are pumped into the micro-structure reaction device respectively at the same time and mixed evenly and then react in the micro-channel reaction device, and the phenolic bio-oil is hydrocracked into aromatic hydrocarbons or naphthenic hydrocarbons, wherein the micro-channel reaction device is filled with a dual-functional catalyst; thirdly, aromatic hydrocarbons or naphthenic hydrocarbons are extracted from reaction liquor.

Owner:NANJING UNIV OF TECH

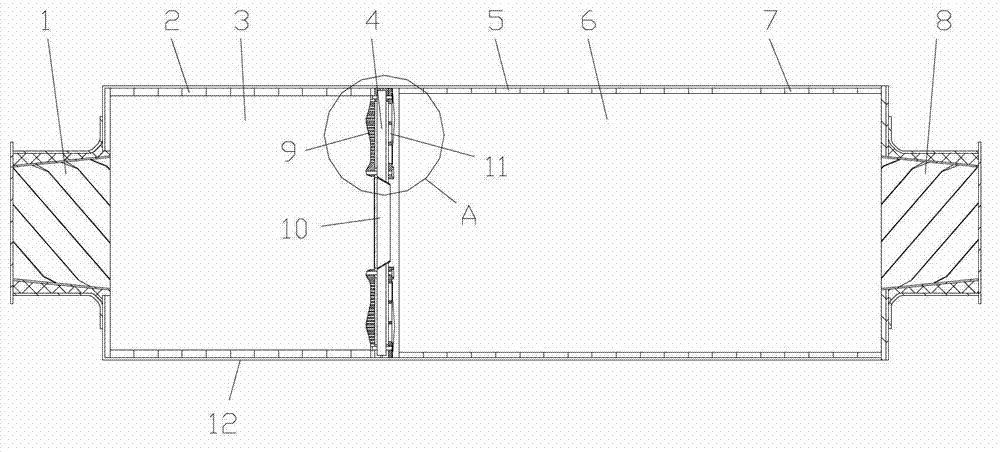

Battery module, battery pack, electric vehicle and power grid system

PendingCN109686892AHeat dissipation fastFast heat transfer rateSecondary cellsCell component detailsPower gridElectric vehicle

The invention provides a battery module. The battery module comprises a shell, a plurality of cylindrical battery cells and a heat exchanging device. The shell comprises a first panel and a second panel which are oppositely arranged; the multiple cylindrical battery cells are arranged in the shell and mounted on the second panel and extends toward the first panel; and the heat exchanging device ismounted in the shell and comprises a plurality of heat exchanging plates, and the heat exchanging plates are filled with heat transfer working media. The invention further provides a battery pack with the battery module, an electric vehicle and a power grid system. Heat generated in the cylindrical battery cell charging and discharging processes can be quickly absorbed by the heat exchanging plates filled with the heat transfer working media, and the heat is spread equally, and thus the heat in the battery module is quickly dissipated; and in addition, the battery module can be quickly subjected to heat dissipating, and thus the situation that normal using of the battery pack, the electric vehicle and the power grid system is affected or safety accidents occur due to insufficient heat dissipating of the battery module can be avoided.

Owner:ZHEJIANG JIAXI TECH CO LTD +1

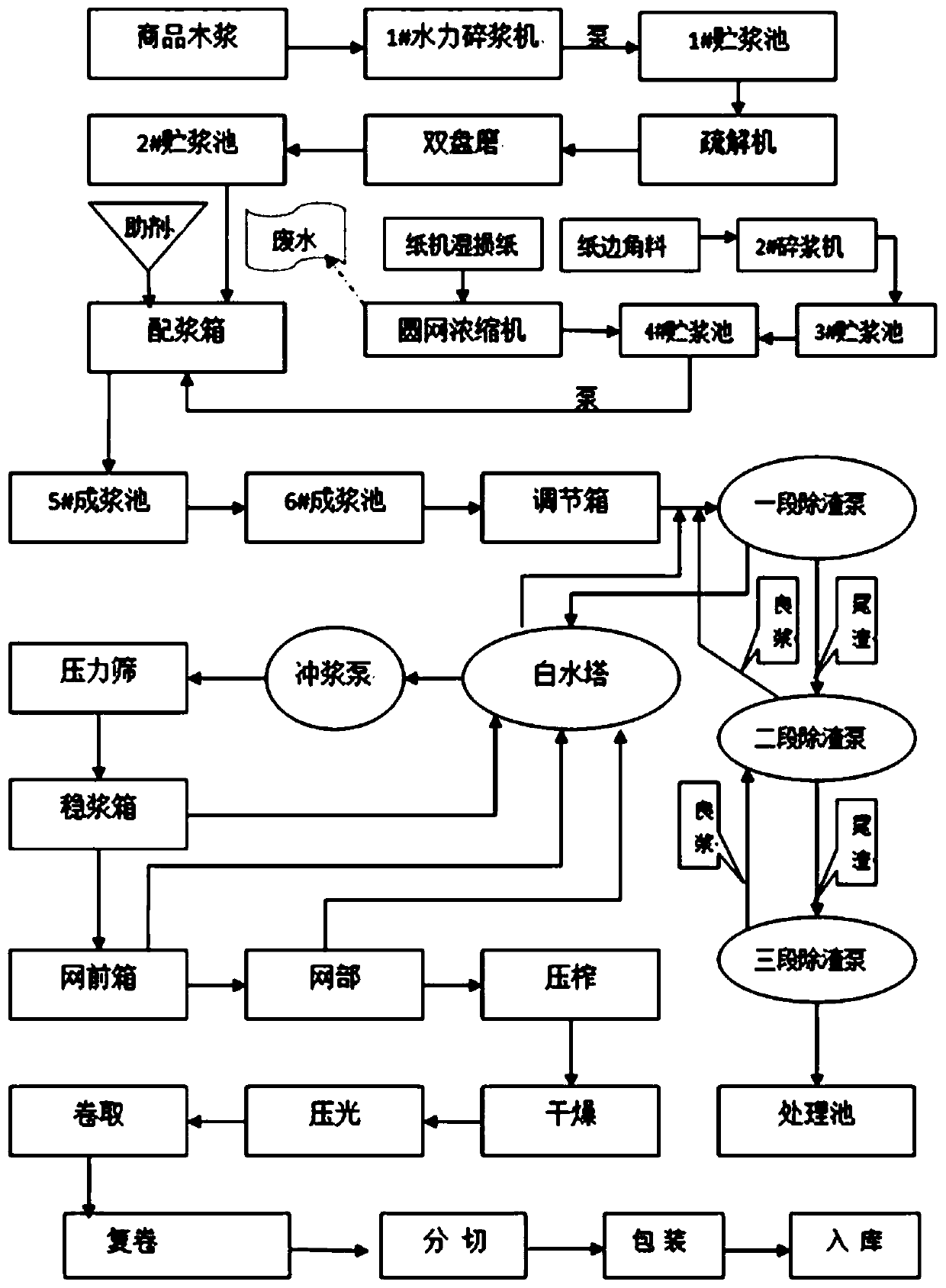

Production process of hot-pressing tympan paper taking pressing copper-clad plate as cushion layer as well as application of hot-pressing tympan paper

Hot-pressing tympan paper taking a pressing copper-clad plate as a cushion layer takes natural-color needlebush pulp, natural-color broadleaf wood pulp and kraft paper leftover materials as fiber rawmaterials; short fiber free pulping is adopted; the current of a pulping machine, the beating degree and the wet weight are controlled; finally, the quantity is 192+ / -4 g / m<2>, the thickness is 0.320+ / -0.02 mm, the tensile strength is more than or equal to 10 KN / m, the air permeability is more than or equal to 10 [mu]m / pa*s, the folding resistance is more than or equal to 10 times, the water-absorbing property is more than or equal to 100 mm / min, and the tightness is controlled to 550 to 600 kg / m<3>. Through cell cavity filling, on one hand, the fiber raw materials are reduced and the cost isgreatly saved; and on the other hand, fillers are added into the cell cavities, so the paper strength is not influenced. Therefore, the hot-pressing tympan paper has double advantages of improving theproperties of the tympan paper and reducing the cost.

Owner:建滔(佛冈)绝缘材料有限公司

Quick-freezing liquid for preserving food, preparation method and use method of quick-freezing liquid

InactiveCN107455443AMaintain colorKeep the smellMeat/fish preservation by freezing/coolingQuick FreezeSide effect

The invention provides quick-freezing liquid for preserving food. The quick-freezing liquid comprises the following components in parts by weight: 30-35 parts of purified water, 8-10 parts of sodium chloride, 25-30 parts of ethyl alcohol, 15-20 parts of chitosan, 0.5-2 parts of acetic acid or 1.5-6 parts of alginic acid and 10-15 parts of active components. The quick-freezing liquid for preserving food provided by the invention has an excellent antibacterial property, is free from toxic and side effects or secondary pollution to food and is high in heat conduction rate in the freezing process of food, so that the ice crystal formed in the food histocyte is small, the cells are prevented from mechanical damage and no drying loss is generated; no nutrient substance is lost in the unfreezing process; the original color, flavor and tissue state of food are kept; after the quick-freezing liquid is regulated with a harmless additive, the freezing speed and the antibacterial property are both kept, so that the quick-freezing liquid is reusable, high in use ratio, low in cost and expected to be widely used in the field of food quick-freezing processing.

Owner:明洋

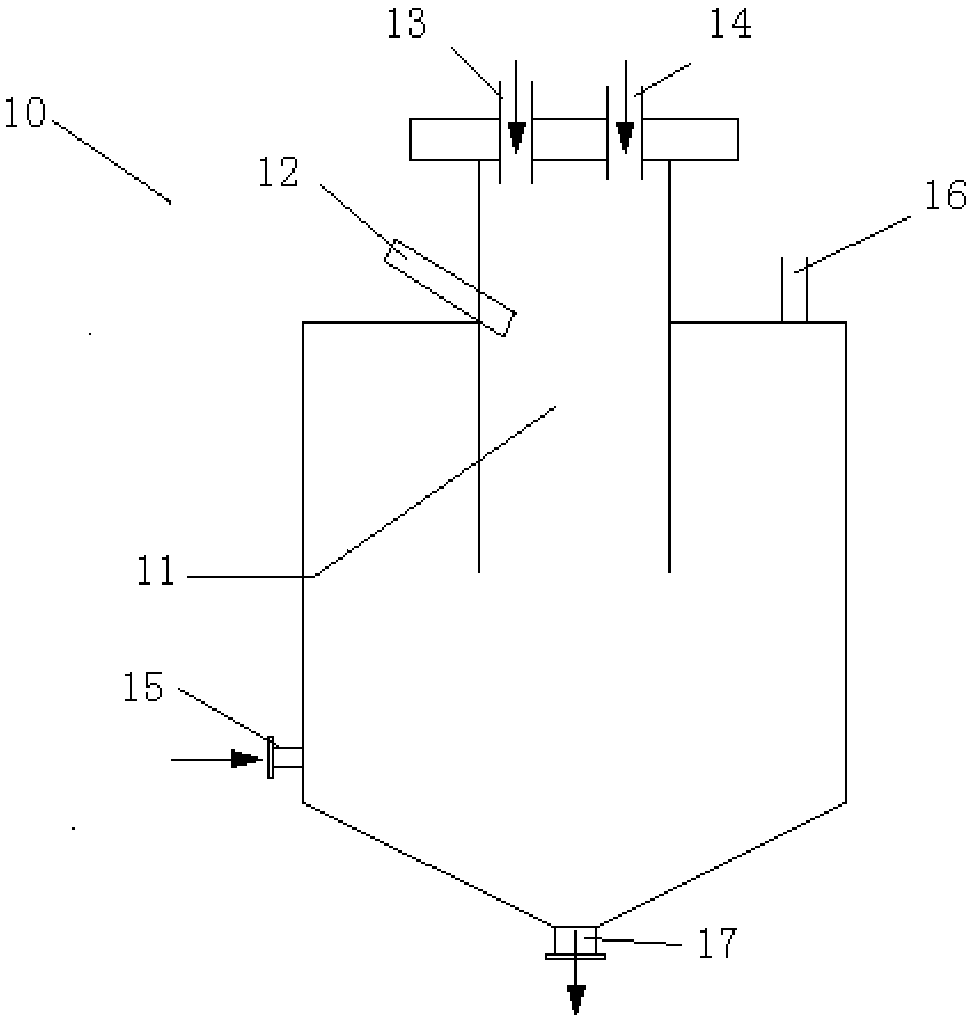

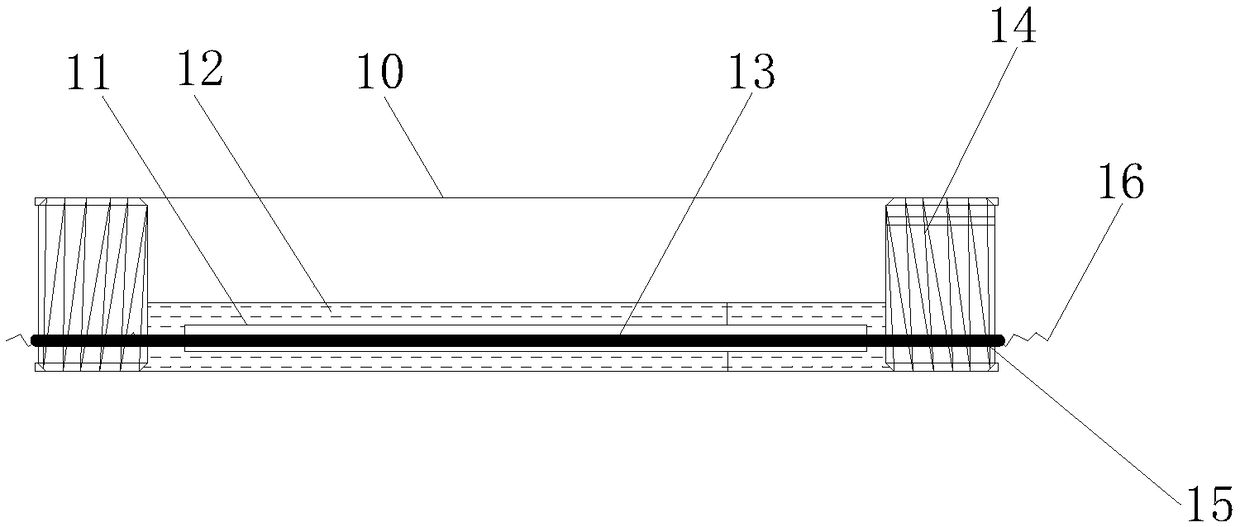

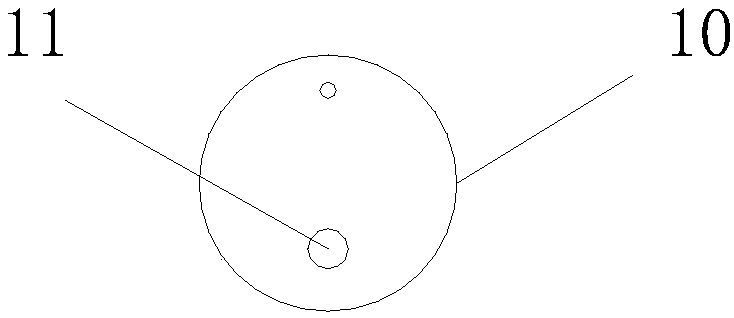

Lime powder calcination device

The invention relates to a lime powder calcinations device, and in particular relates to a rotary kiln for calcining dust ores such as lime stone, dolomite. The lime powder calcination device comprises a powder pre-heater, a powder rotary kiln and a powder cooler. The upper part of the powder pre-heater is sealed and fixed with a powder adding tube and a waste gas pipeline, and the lower part of the powder pre-heater is sealed and fixed with the left end of the powder rotary kiln; the right end of the powder rotary kiln is sealed and fixed with the left end of the powder cooler; and a finished product discharge device is arranged on the lower end of a finished product discharge hole on the right end of the powder cooler. The lime powder calcination device can calcine the lime stone which is less than 3mm.

Owner:XINXING HEBEI ENG & RES INC

Fluidized bed pump-out gas deoxidation and equipment thereof

InactiveCN100393852CSimple structureLess investmentCombined combustion mitigationGranular/pulverulent flues gasificationPartial oxidationFluidized bed

The pumping and venting deoxygenation method with fluid bed comprises: with coked particle as the deoxidizer and fluid bed reactor, pumping gas into the fluid bed to fluidize the particle and mix the gas and solid completely; producing part oxidation reaction by the O2 in gas and C in coked particle at low temperature as 400-500Deg to consume O2 and release some heat; removing the residual heat conveniently for the fast heat transfer rate of fluid bed, and realizing the deoxygenation purpose. This fluid bed reactor needs small investment for simple structure, has high gas treatment capacity with low energy consumption and no explosion hazard.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

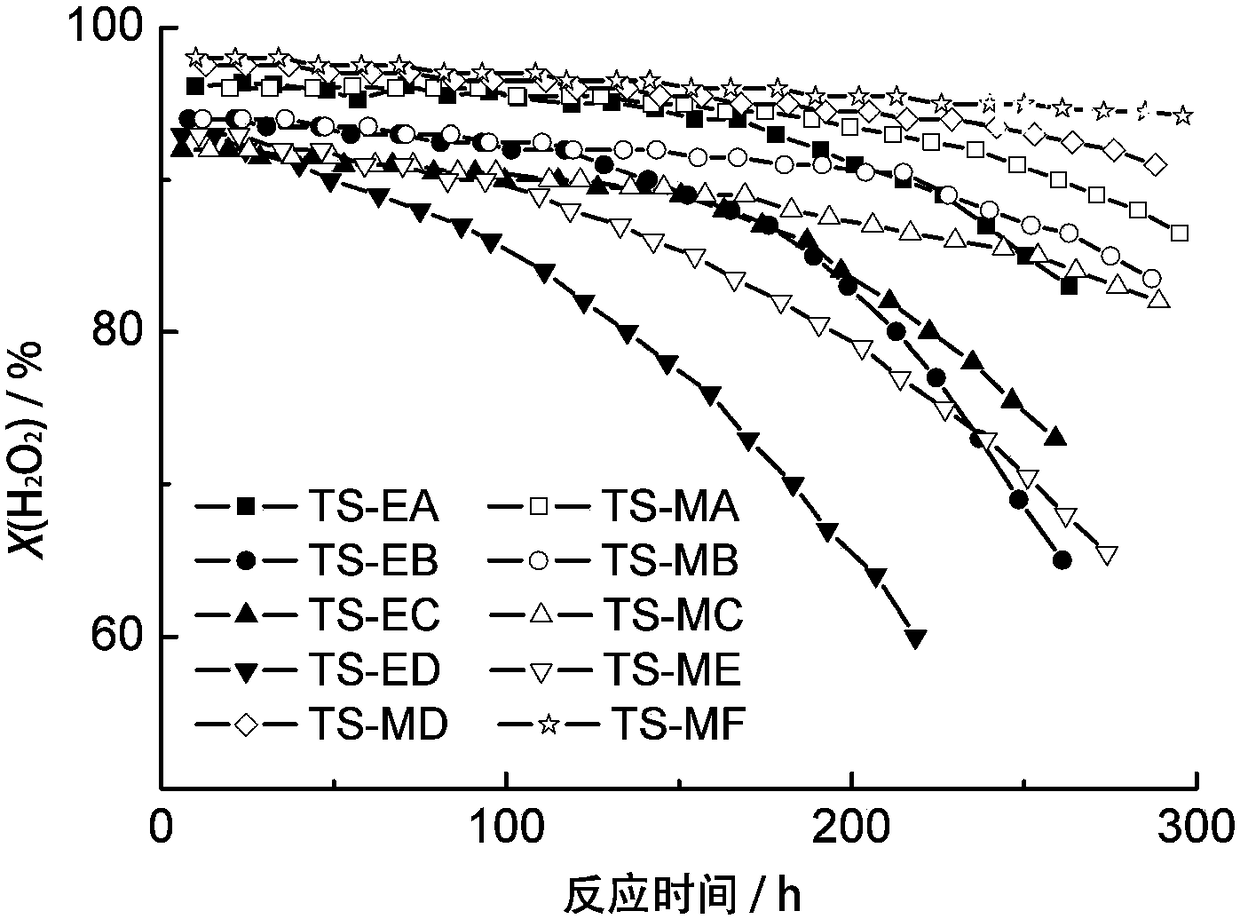

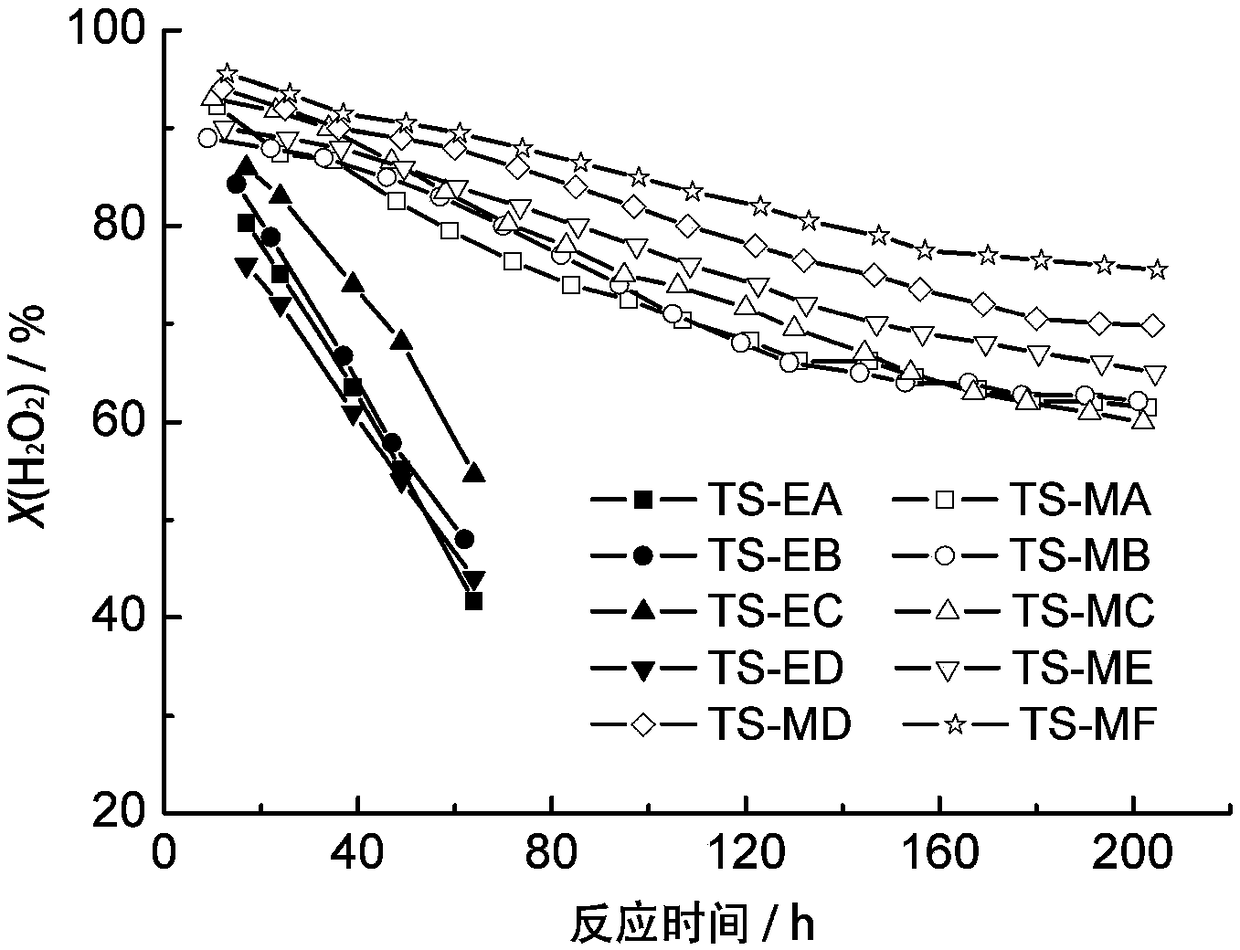

High-stability integral titanium-silicalite-molecular-sieve catalyst and preparation method thereof

ActiveCN108479848AHigh selectivityImprove stabilityOrganic chemistryMolecular sieve catalystsMolecular sieveAlcohol

The invention provides a high-stability integral titanium-silicalite-molecular-sieve catalyst. The high-stability integral titanium-silicalite-molecular-sieve catalyst comprises active component titanium silicalite molecular sieves and a stainless steel carrier with certain ducts. The invention further provides a preparation method of the high-stability integral titanium-silicalite-molecular-sievecatalyst. According to the preparation method, after the active component titanium silicalite molecular sieves are mixed with adhesives, alcohols and water proportionally, the mixture is applied to the surface-treated stainless steel carrier with the certain ducts to enhance heat transfer. The high-stability integral titanium-silicalite-molecular-sieve catalyst has the advantages that the heat transfer speed is high, main reactions in strong exothermic reactions are promoted, auxiliary reactions are inhibited, and stability is improved; simplicity and convenience in filing and demounting areachieved, the load adjustment range of the active component is wide, the load intensity is high, and the like.

Owner:DALIAN UNIV OF TECH

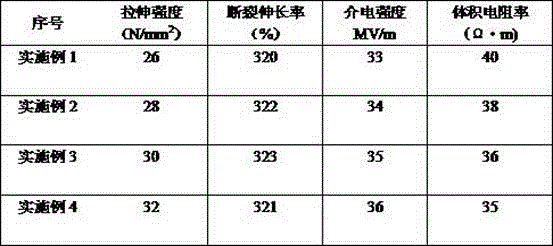

Preparation method of heat-shrinkable anticorrosive material containing graphene

InactiveCN106674698AImprove anti-corrosion performanceHigh mechanical strengthPolymer scienceHigh energy

The invention discloses a preparation method of a heat-shrinkable anticorrosive material containing graphene. Graphene or modified graphene and an additive are added to a polyethylene raw material, and extruded and pelletized through physical mixing to obtain a base material granulation material; the polyethylene base material granulation material is put into a radiation field, and multiple active particles are formed in solid polyethylene under the action of a high-energy ray to form a crosslinked three-dimensional net structure in polyethylene, and crosslinking or grafting reaction is carried out to obtain the crosslinked polyethylene material containing graphene. The crosslinked polyethylene material containing graphene can be effectively used for corrosion prevention of buried and overhead steel pipe welding seams and corrosion prevention of heat preservation coating joints of heat preservation pipes.

Owner:CARBORN TIME TECH CO LTD

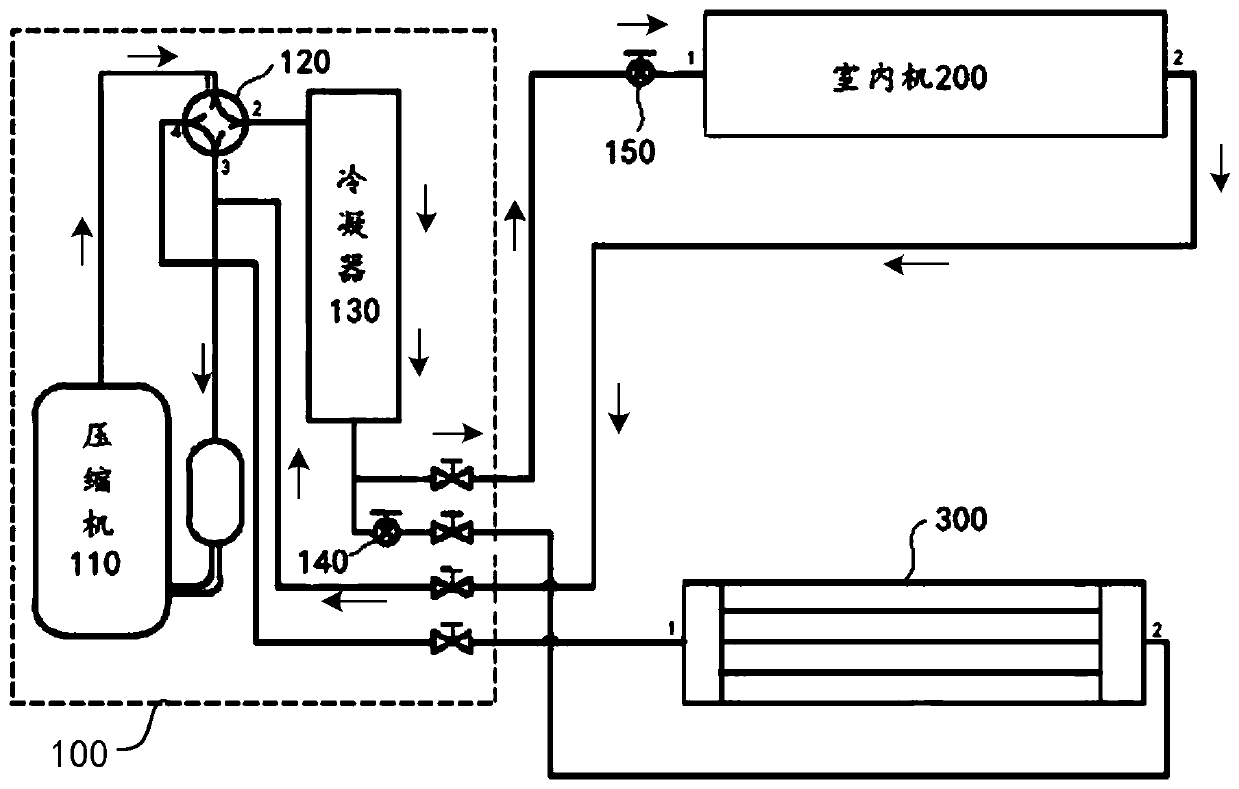

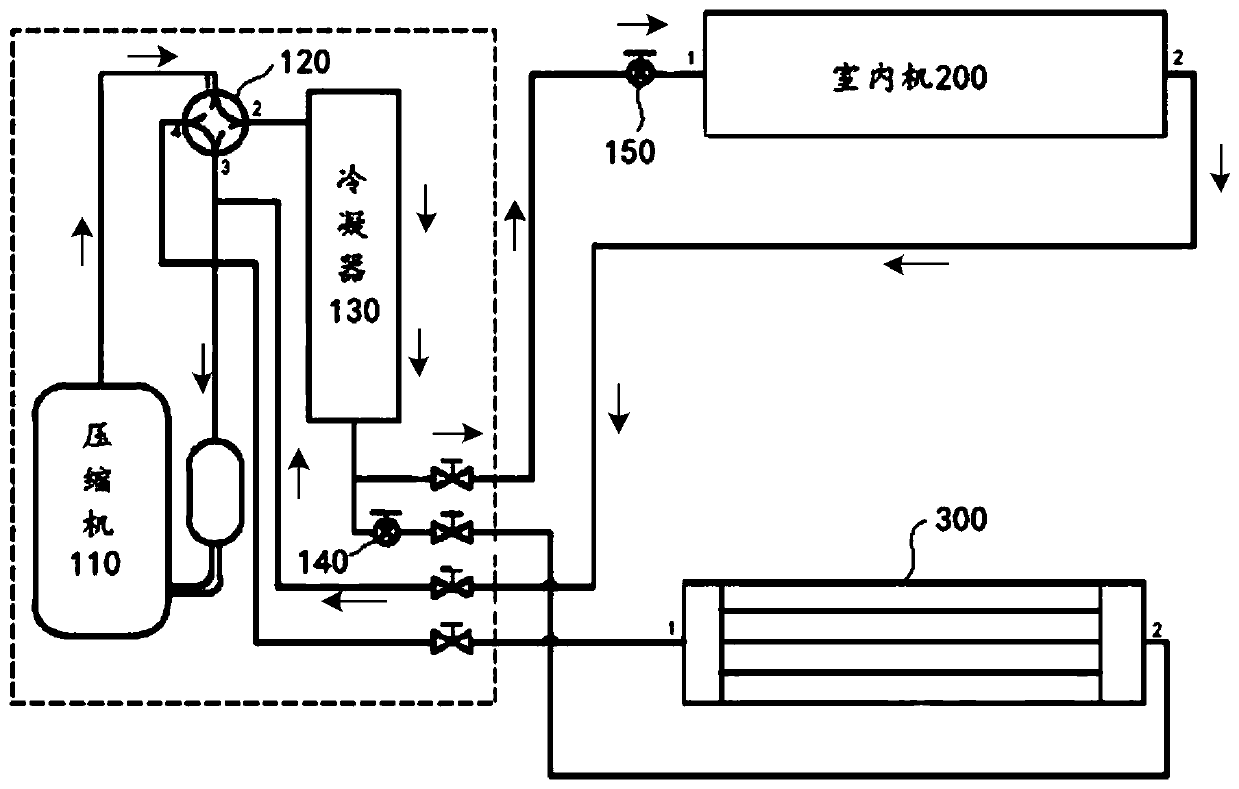

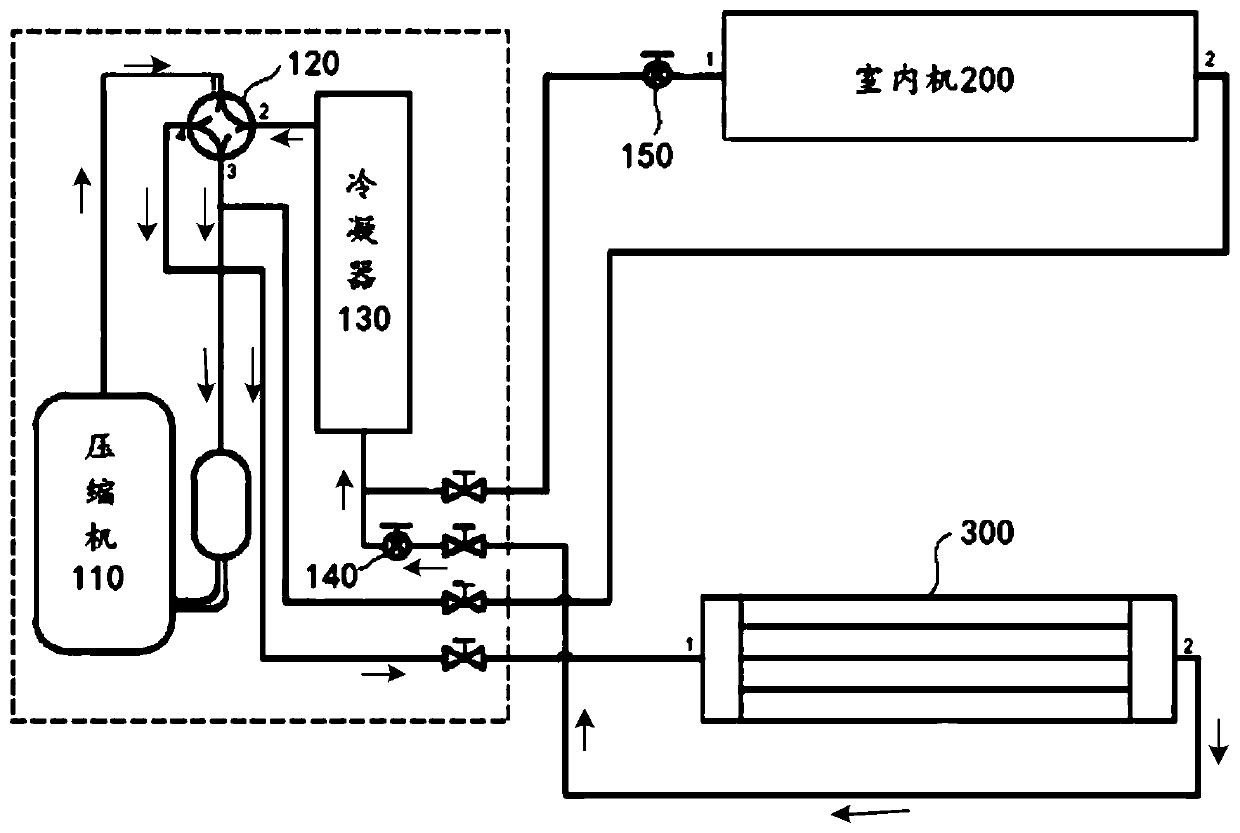

Defrosting control method and defrosting control device of air conditioner system and air conditioner

ActiveCN111442475AReduce ambient temperatureNo coolingMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsControl theory

The invention discloses a defrosting control method and defrosting control device of an air conditioner system and an air conditioner, and relates to the technical field of air conditioners. The defrosting control method and the defrosting control device are used for reducing the influence of the air conditioner system on the indoor environment temperature in the defrosting process, and meanwhile,the defrosting time of the air conditioner system can be shortened. The defrosting control method of the air conditioner system comprises the steps that when the air conditioner system meets the defrosting condition, the air conditioner system is controlled to carry out indoor unit defrosting operation; the exhaust temperature of a compressor is obtained; and according to the exhaust temperature,a first adjusting step is operated. The defrosting control device of the air conditioner system comprises a processor and a communication connector. The air conditioner comprises the air conditionersystem, the defrosting control device of the air conditioner system and a temperature sensor.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

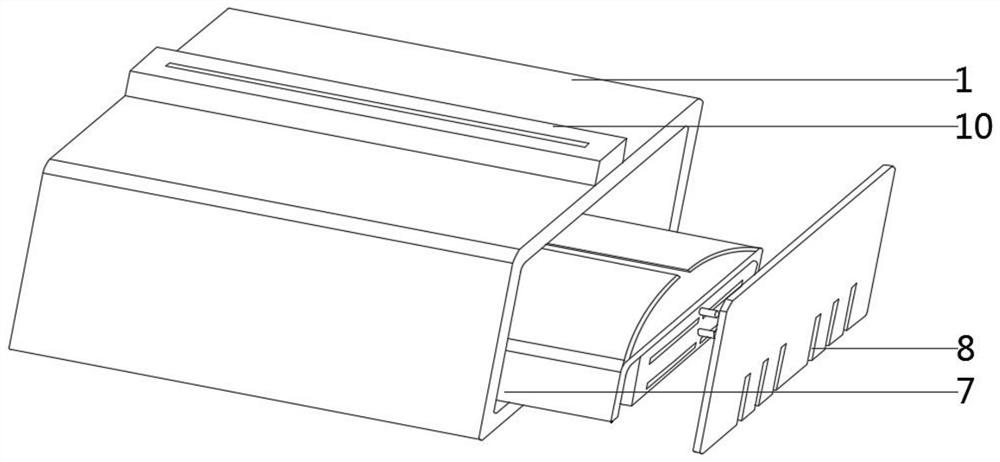

Separation heating device capable of heating wet tissues

ActiveCN112648735AIn accordance with the rising principleFast heat transfer rateStorage heatersExothermal chemical reactions for heatingHeat transferElectric heating

The invention discloses a separating heating device capable of heating wet tissues. The separating heating device comprises a main shell, the main shell is of a hollow structure, an empty groove is formed in the main shell, a partition plate is arranged in the empty groove, and the interior of the empty groove is transversely divided into an upper storage part and a lower storage part through a partition plate. The upper storage part is used for containing a first object, the lower storage part is used for containing a heating body, and the heating body heats the first object by emitting heat. The partition plate is in a C shape, the two side edges of the partition plate vertically extend downwards and are fixedly connected with the bottom face of the main shell, and flow channels are reserved between the two side edges, in the left-right direction, of the partition plate and the inner wall of the main shell. The interior of the main shell is divided into the upper storage part and the lower storage part, direct heat transfer between the upper storage part and the lower storage part is avoided, electric heating is replaced with the characteristics of stable reaction and uniform temperature rise of the heating body, the communication direction is designed in the main shell, heat migration is conformed, the hot air flow rising principle is met, good conditions are created for heat migration, and the heat transfer rate is high.

Owner:安徽紫竹健康科技股份有限公司

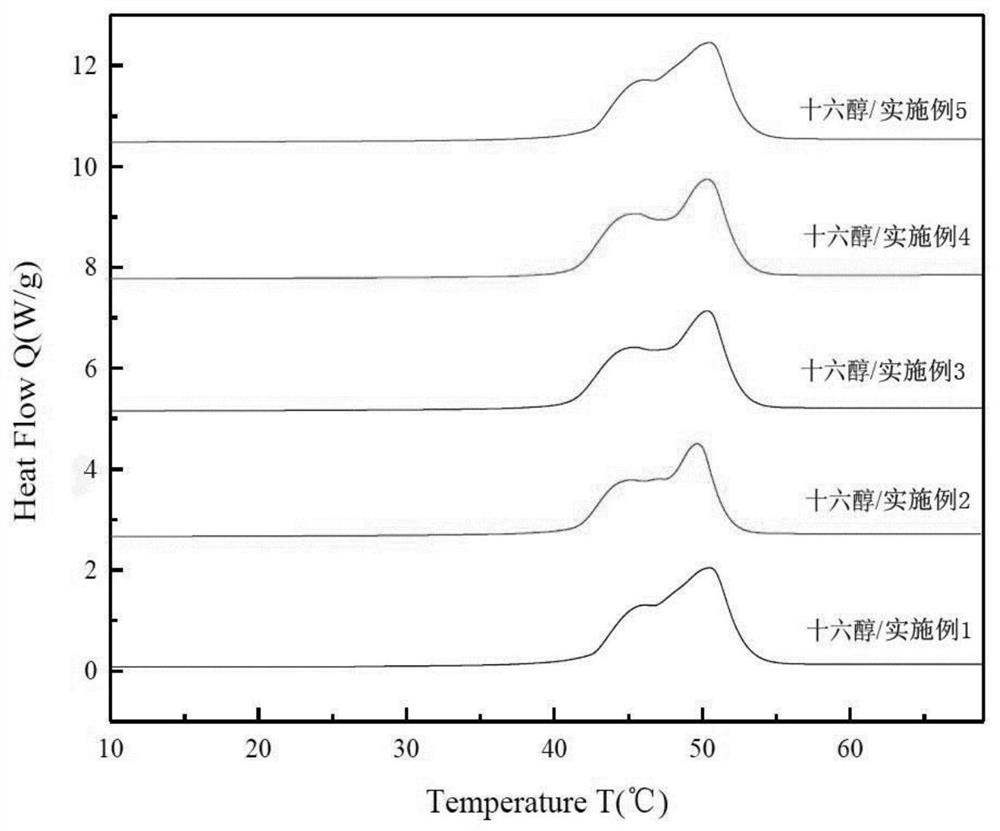

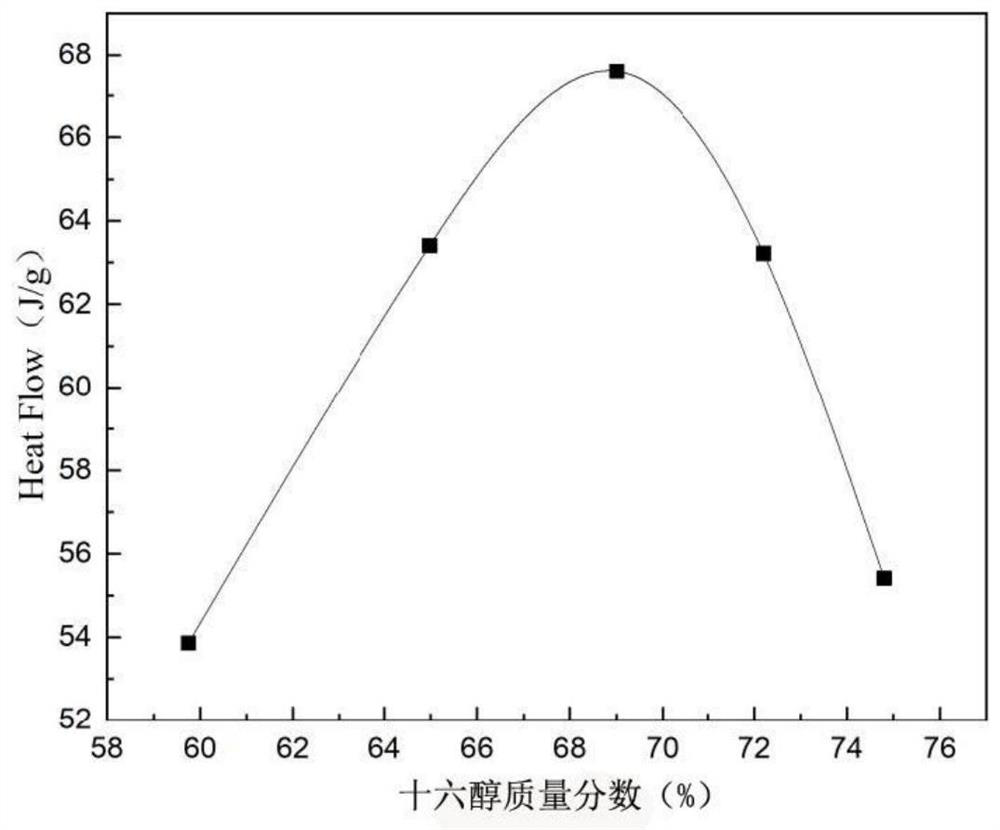

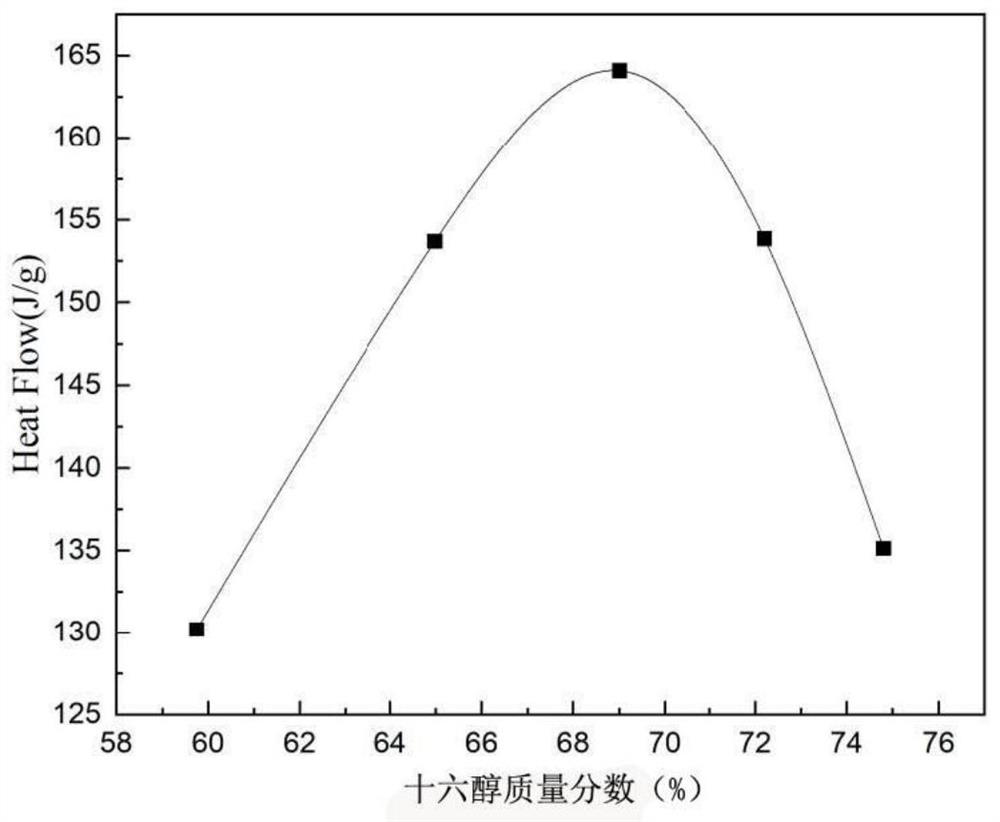

Organic-inorganic coupling phase change material without leakage at normal temperature

ActiveCN113528094AHigh latent heat of phase changeImprove thermal conductivityHeat-exchange elementsMeth-Pyrrolidinones

The invention relates to an organic-inorganic coupling phase change material without leakage at normal temperature. The material is prepared by the following steps: adsorbing sodium sulfate decahydrate into diatomite through vacuum adsorption and physical adsorption to prepare a sodium sulfate decahydrate / diatomite composite material; adding acrylamide, N, N-methylene bisacrylamide, polyvinylpyrrolidone and distilled water into a beaker, dissolving acrylamide into a water phase under ultrasonic waves, adding an emulsifier and hexadecanol, and stirring; and adding the sodium sulfate decahydrate / diatomite composite material, uniformly stirring, and quickly adding ammonium persulfate and N, N, N, N-tetramethylethylenediamine to polymerize the composite material into a solid, thereby obtaining the organic-inorganic coupling phase change material. The sodium sulfate decahydrate / diatomite composite material and hexadecanol are coated in polyacrylamide by an emulsion polymerization method, so that the phase separation phenomenon of sodium sulfate decahydrate is relieved; and the phase change latent heat of the obtained phase change material is 164.13 J / g, the heat conductivity coefficient is 0.2061 W / (m.k), and good heat storage performance is shown.

Owner:TARIM UNIV

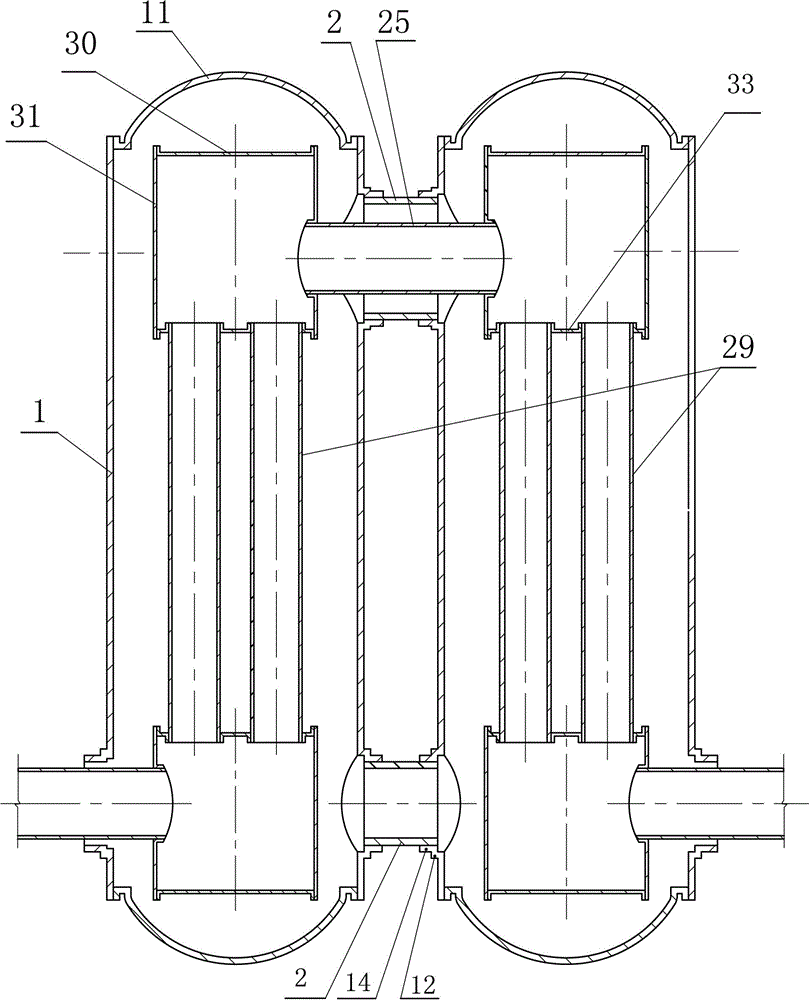

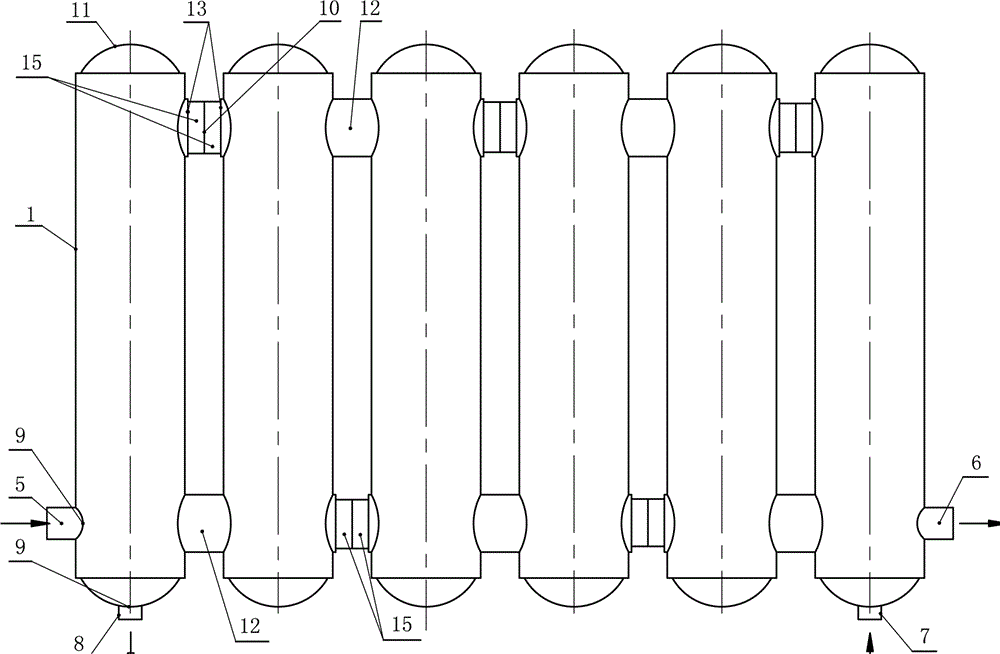

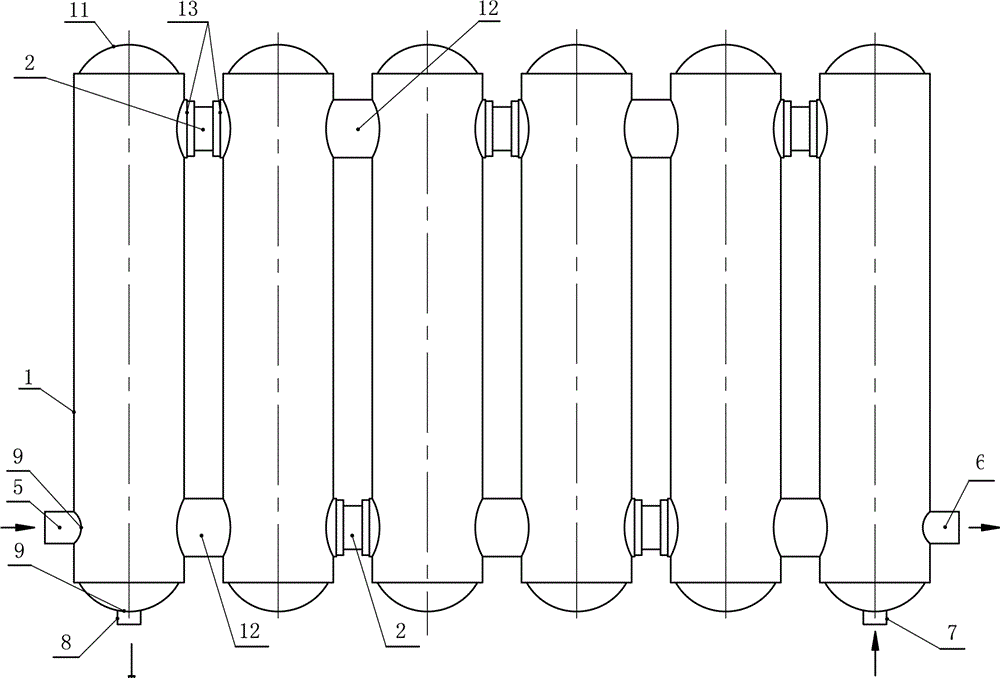

Pipe connection instant heating type heat exchanger with part of shell tubes storing water

ActiveCN105758231AReduce trafficReduce flow rateHeat exchanger casingsStationary tubular conduit assembliesHeat transmissionEngineering

The invention discloses a pipe connection instant heating type heat exchanger with part of shell tubes storing water.A pipe connection partition board is arranged at the position of a shell tube connection welding hole, and a partition board connection pipe welding hole and a partition board cold water pipe welding pipe are formed in the pipe connection partition board so as to facilitate welding connection; at least one cold water heat absorption pipe is arranged in cavities of part of shell tubes, and heating pipes are arranged in cavities of part of shell tubes; the port, welded and communicated with the heating pipes, of a central heating connection pipe is inserted into a pipe connection partition board hole and communicated with the inner cavity of the adjacent shell tube, so that the fluid channel, pipe diameter and circulating heat transmission flow path are changed; an orifice of each cold water heat absorption pipe is inserted into the pipe connection partition board hole to be communicated with the inner cavity of the adjacent shell tube, so that the fluid channel, pipe diameter and circulating heat absorption flow path are changed.The circulating path of heat storage water in the cavities of part of shell tubes changes to increase return heating of built-in cold water thin pipes, flow and flow rate are reduced, exchange route is lengthened, sufficient exchange space is gained, heat exchange rate is increased fast, and the expectation of maximizing heat exchange effect is realized.

Owner:山东利能换热器有限公司

Double-vacuum superconducting tube based on metal tubes

InactiveCN108061472AFast heat transfer rateShort warm-up timeIndirect heat exchangersDouble tubeFluid layer

The invention discloses a double-vacuum superconducting tube based on metal tubes. The double-vacuum superconducting tube comprises a first outer tube body, a second outer tube body, a nano metal barand sealing plugs. A superconducting chamber is arranged inside the first outer tube body. The sealing plugs are arranged at the two ends of the first outer tube body separately to make the superconducting chamber of the first outer tube body form an enclosed space. The superconducting chamber is sequentially divided into a vacuum layer and a superconducting fluid layer from top to bottom. The second outer tube body is embedded into the center of the superconducting fluid layer. A silica gel heating line is tightly wound onto the nano metal bar and penetrates through wire holes in the sealingplugs. The silica gel heating line is further connected with flexible conductors arranged outside the corresponding sealing plugs. A vacuum chamber is arranged at the center of the second outer tube body. The first outer tube body and the second outer tube body are both the metal tubes. According to the double-vacuum superconducting tube based on the metal tubes, the double-tube mode is adopted, and the second outer tube body is embedded into superconducting fluid in the first outer tube body, the temperature can be quickly transferred onto the pipe walls through the superconducting fluid andheat is transferred onto the ground; and meanwhile the metal tubes are adopted, the heat transfer speed is high, preheating time is short and thermal efficiency can reach the limit rapidly.

Owner:SICHUAN YANSEN FURNACE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com