Integrated ground heating floor

An integrated, floor heating technology, applied in the field of flooring, can solve the problems of room environment and human health hazards, the impact of room floor height, and troublesome tile floors, etc., and achieve the effect of long service life, environmentally friendly and harmless structure, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

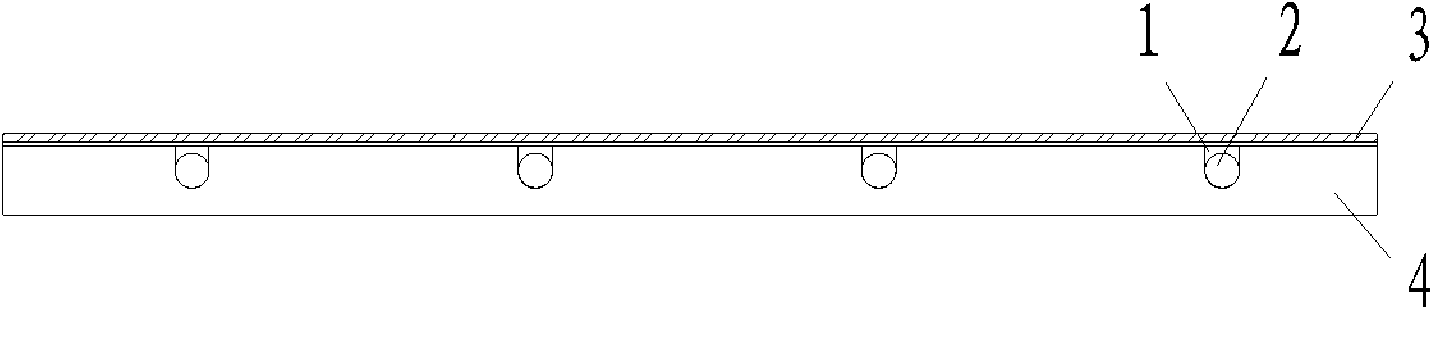

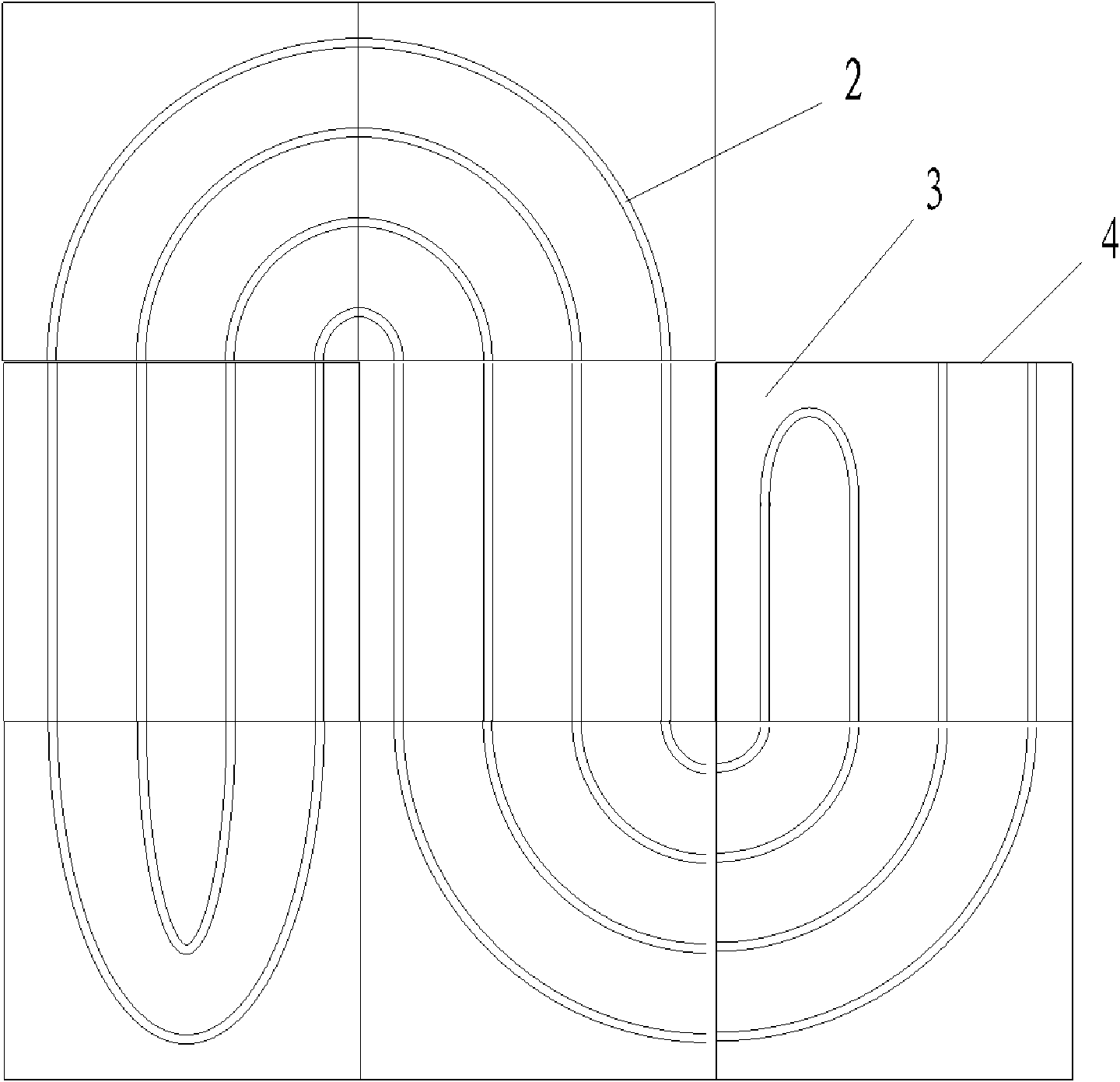

[0023] see figure 1 A floor heating tank 1 is provided on the upper surface of the floor heating and heat preservation substrate 4 , a PE-RT floor heating pipe 2 is laid in the floor heating groove 1 , and a metal floor 3 is arranged on the upper surface of the floor heating and heat preservation substrate 4 .

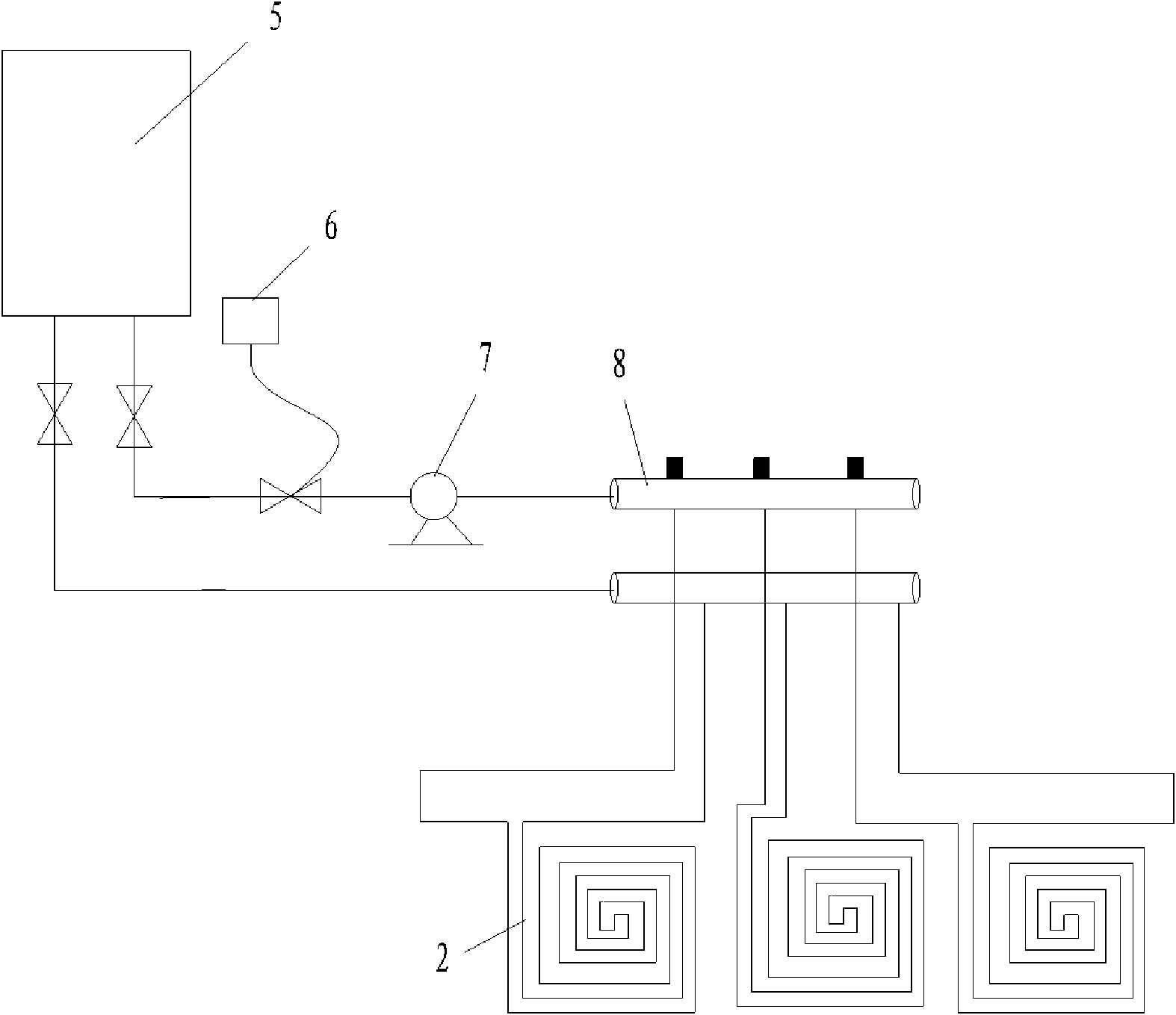

[0024] see figure 2 and image 3 , multiple integrated floor heating floors are laid into floors through metal staples and caulking materials, PE-RT floor heating pipes 2 of each integrated floor heating floor are connected, and boiler 5 is connected to PE-RT floor heating pipe 2 butt joint.

[0025] Instructions:

[0026] In the case of local laying, the floor heating can be turned on at any time by using a special switch:

[0027] Note: When the laying area is more than 50% of the heating space, it should be used together with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com