Hot-air mediated evaporation and concentration method

A technology of evaporation concentration and hot air, which is applied in the direction of evaporation, separation methods, chemical instruments and methods, etc., can solve the problems of easy scaling on the heat exchange surface, non-continuous operation, low thermal efficiency, etc., and achieve the effect of increasing the continuous operation time of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

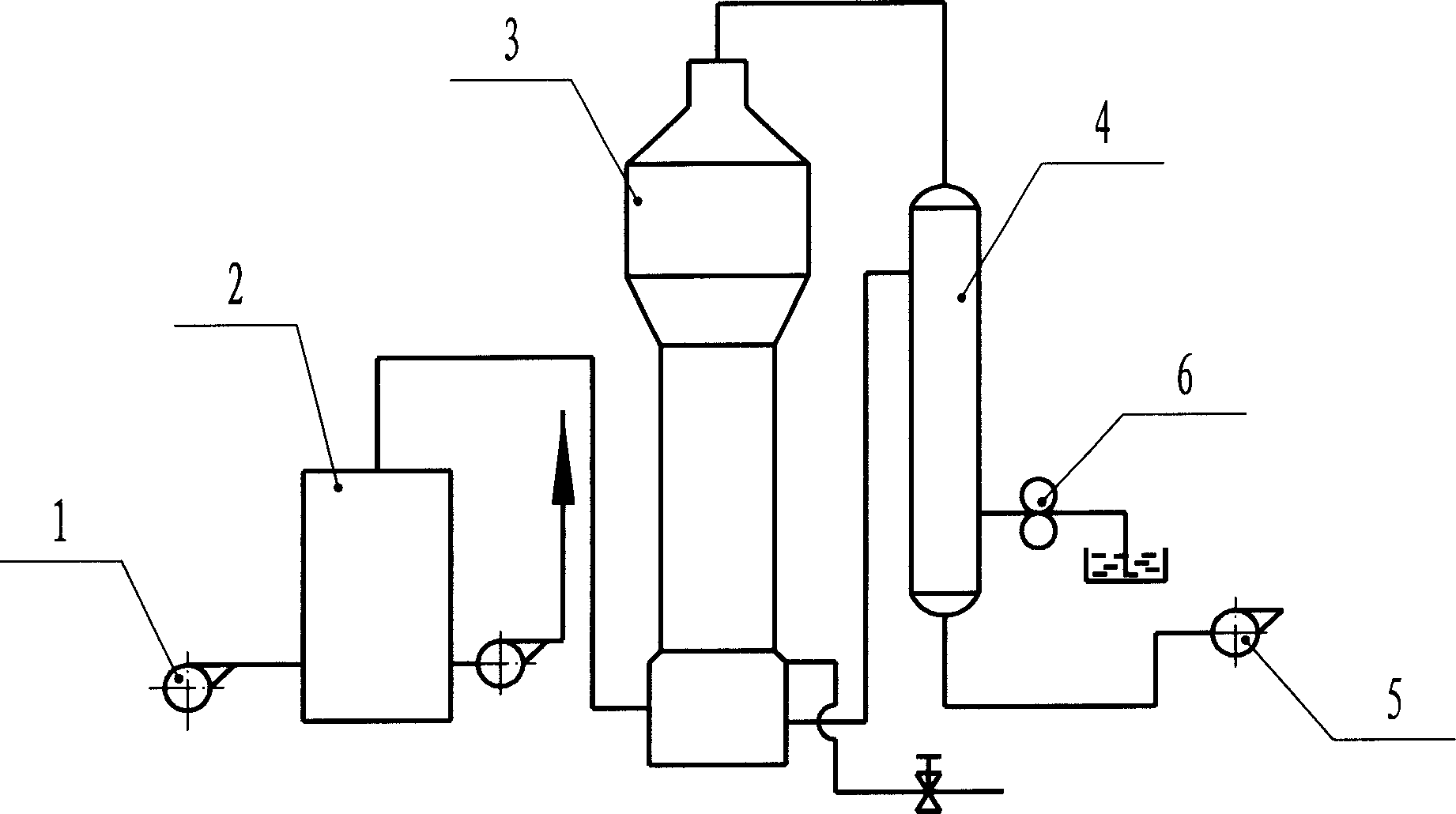

[0011] figure 1 It is a process flow diagram of the present invention, and its structure is described as follows: the air is sent into the gas heating furnace (2) by the delivery fan (1), and enters the evaporator (3) after indirect heating, and the liquid to be evaporated and concentrated is pumped by the pump (6) ), mixed with hot gas at a certain temperature and boiled, part of the liquid forms steam and is discharged from the outlet of the condensing evaporator and enters the condensation preheater, and the condensed gas is discharged from the outlet of the condenser by the induced draft fan. By adjusting the gas heating furnace (2), liquid delivery pump (6), air delivery fan (1), induced draft fan (5) and other components, the air temperature and the concentration of the evaporated liquid can be controlled, so as to ensure the evaporation of the liquid The process requires that the evaporation and concentration process be completed in a very short time.

[0012] The stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com