Patents

Literature

34results about How to "Increase separation area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flax thick yarn supercritical CO2 biological enzyme scouring device and scouring method thereof

ActiveCN106676788AReduce usageReflect the concept of modern lifeTextile treatment containersTextile treatment machine arrangementsYarnBreaking strength

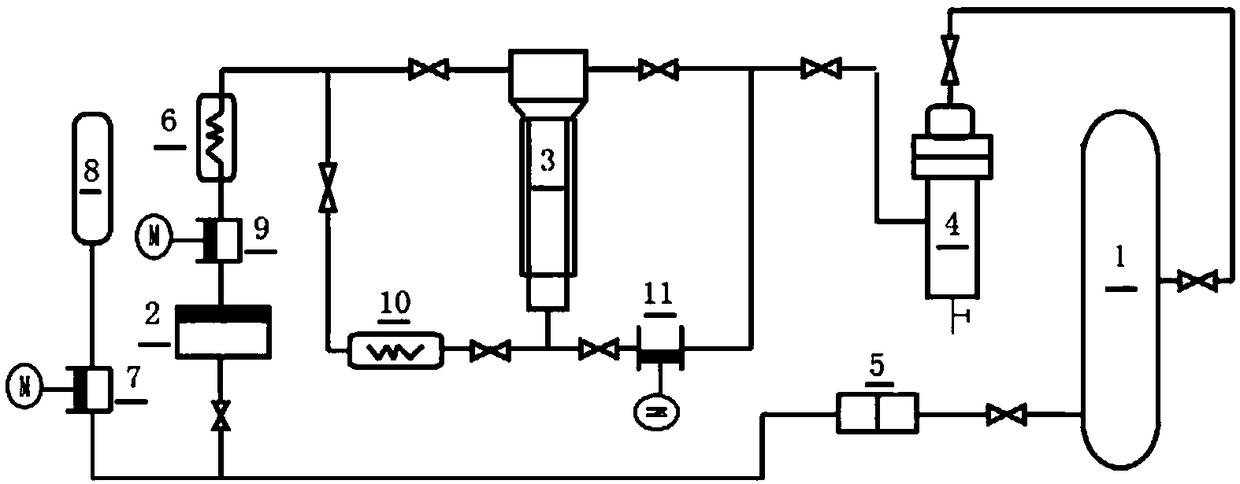

The invention discloses a flax thick yarn supercritical CO2 biological enzyme scouring device and a scouring method thereof. Flax thick yarn is placed in supercritical CO2 fluid where a biological enzyme scouring agent is dissolved, flax fibers are swollen for 10-30 min at 30-40 DEG C and 8-15 MPa; the flax thick yarn is scoured for 30-60 min under dynamic conditions of a flow velocity of supercritical CO2 at 10-50 g / min at 40-60 DEG C and 15-25 MPa; the flax thick yarn is processed through a scouring-separation combined process for 10-30 min at 40-60 DEG C and 15-25 MPa; after the scouring, the weight loss rate of the flax thick yarn is 6-12%, the residual gum rate is 7-15%, the single fiber breaking strength is 6-13 cN / dtex, and the elongation at break is 4.5-8.5%. The whole scouring process is free of pollution and has zero release, requirements of commercialized production are met, and the modern life idea of fashionable bast fiber spinning and green bast fiber spinning is embodied.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

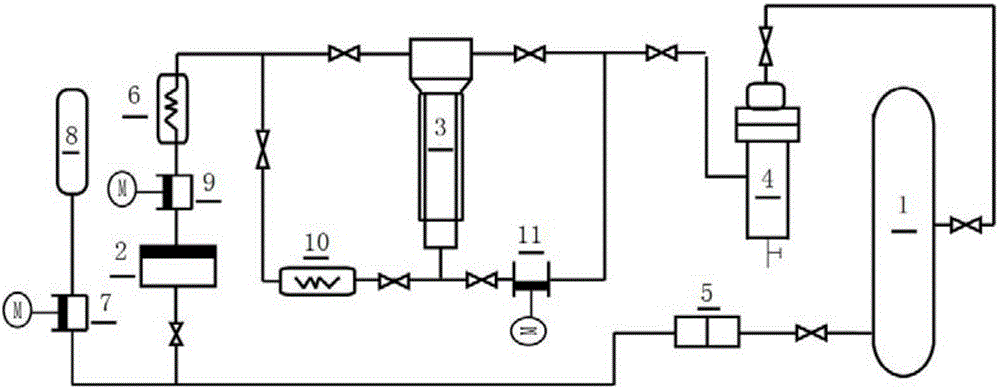

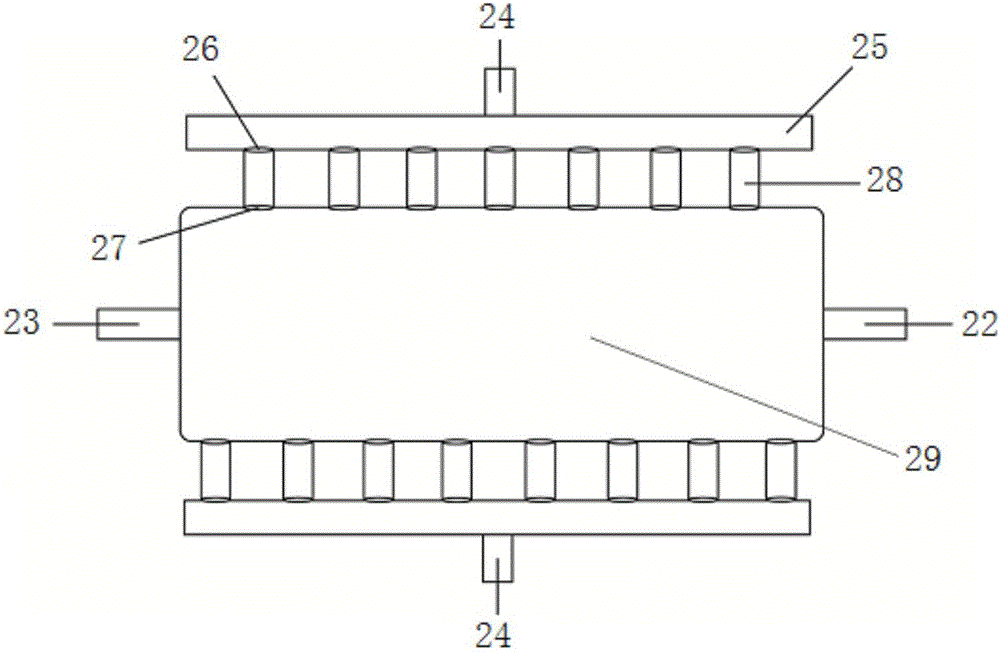

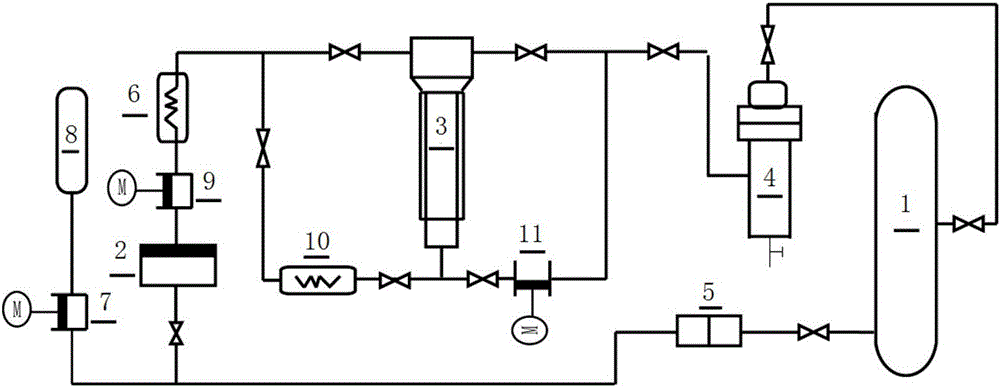

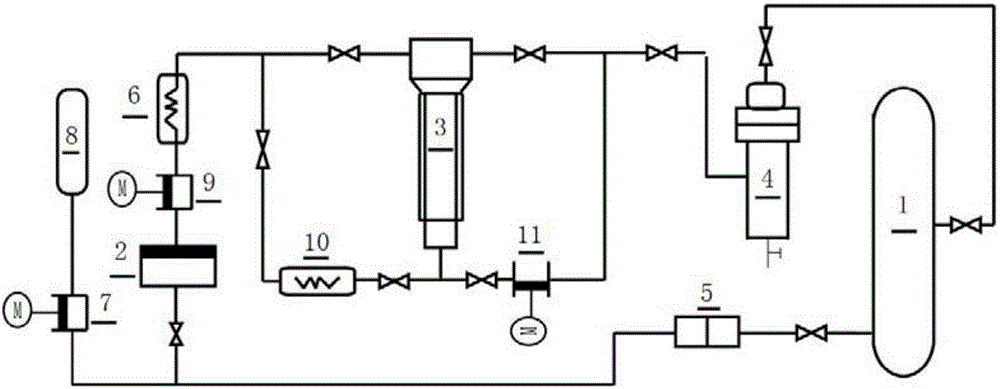

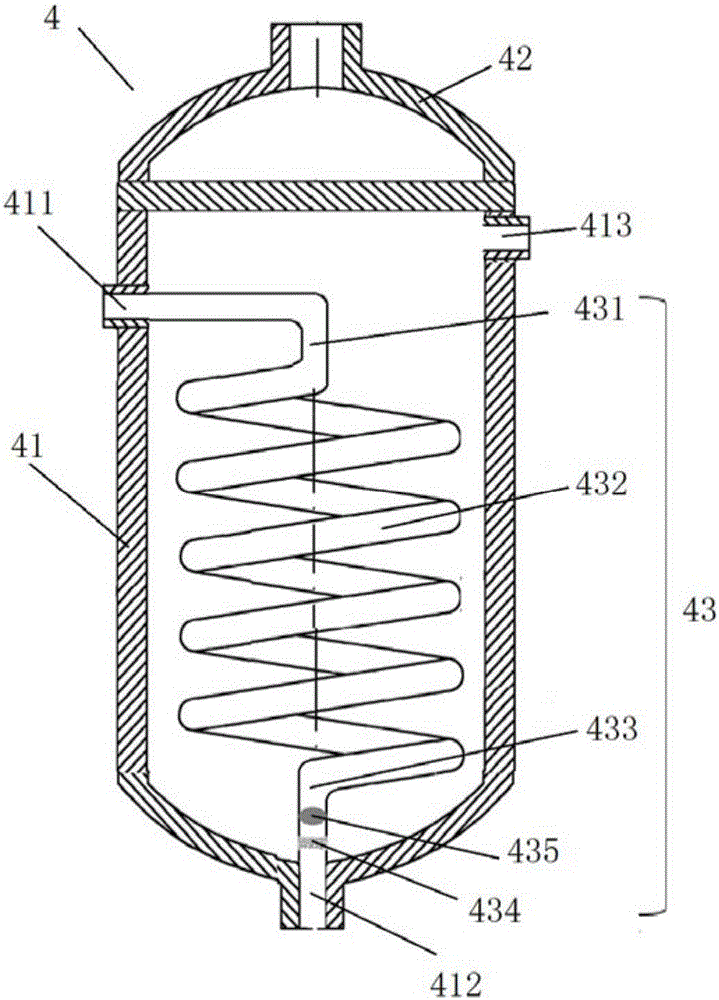

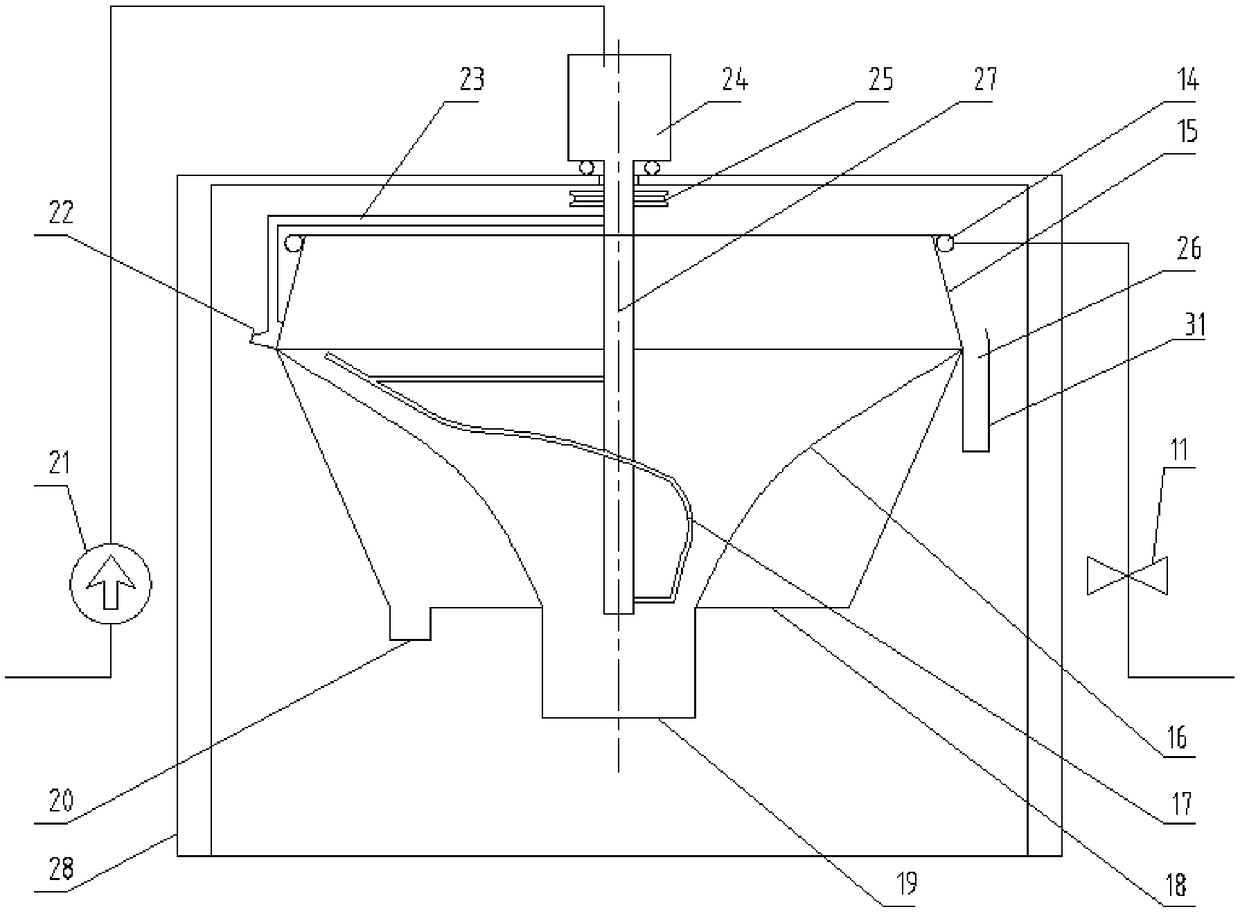

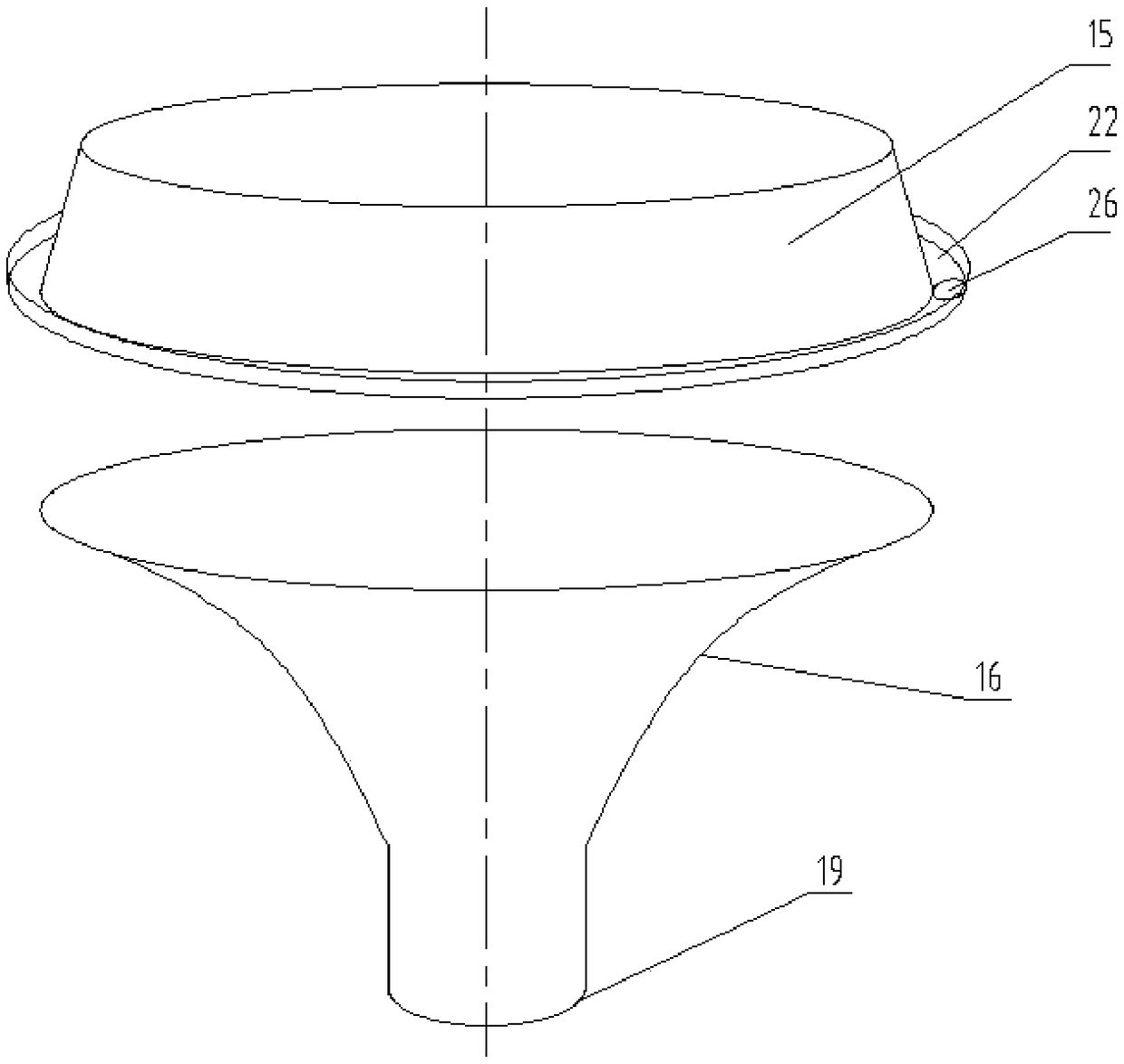

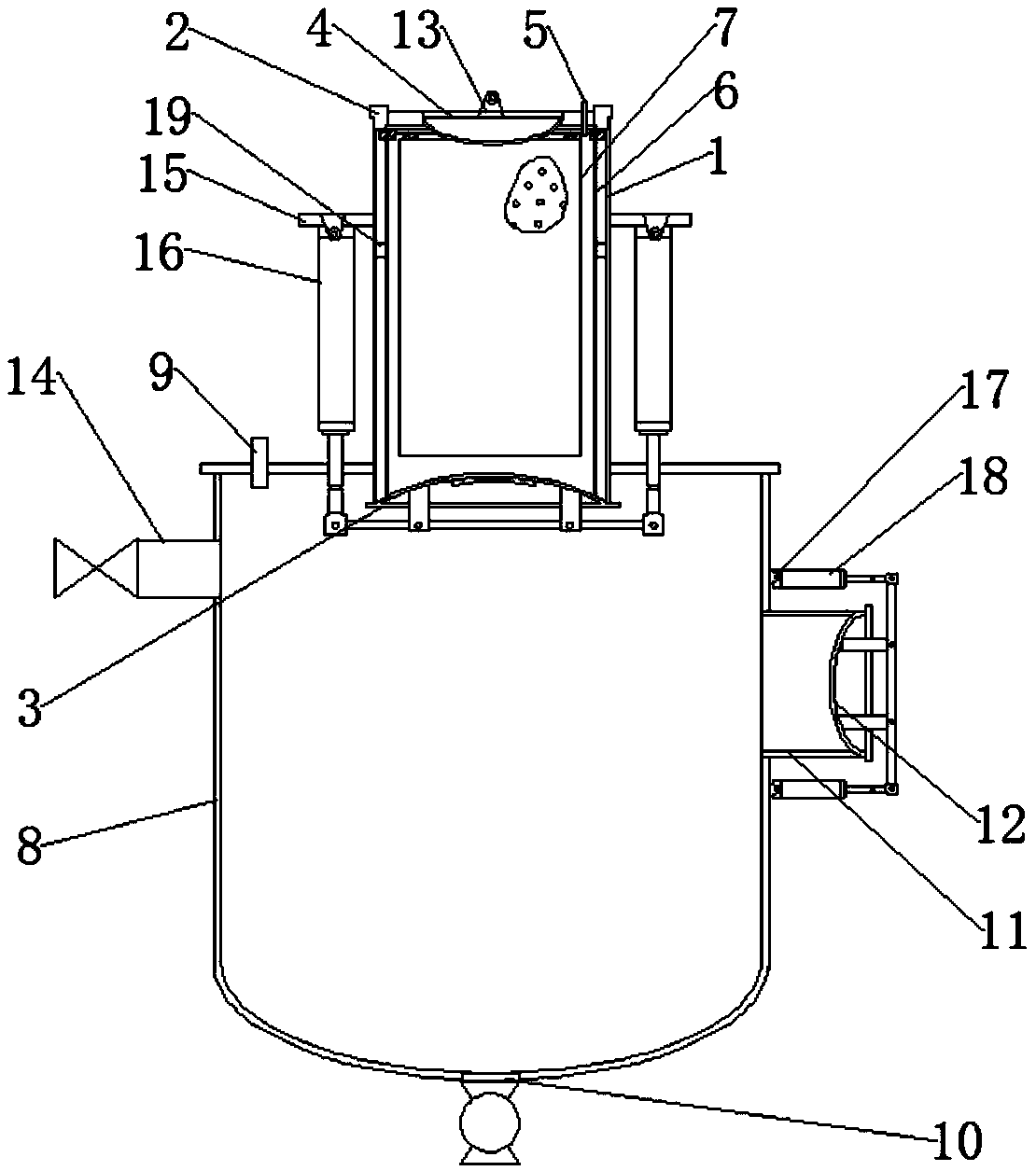

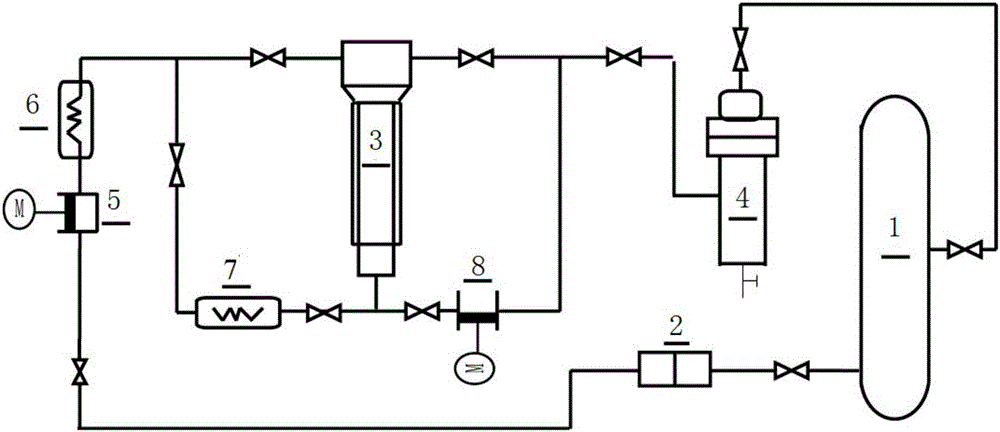

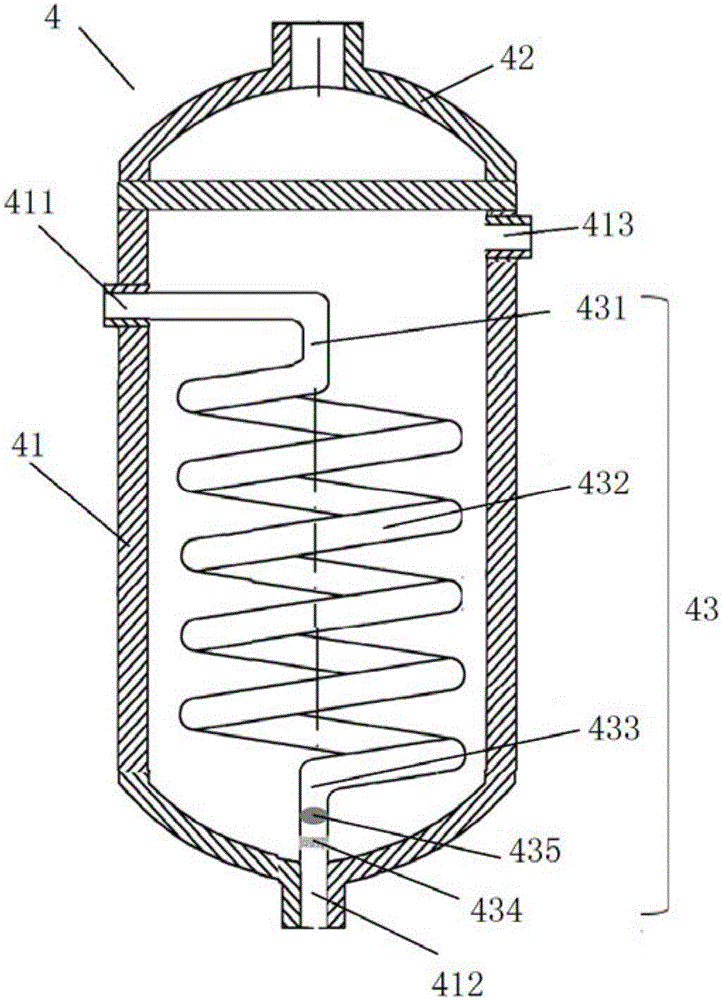

Supercritical CO2 waterless bleaching device and method for linen coarse yarns

ActiveCN106676796AAchieve hybridInject evenlyTextile treatment containersTextile treatment machine arrangementsYarnSingle fiber

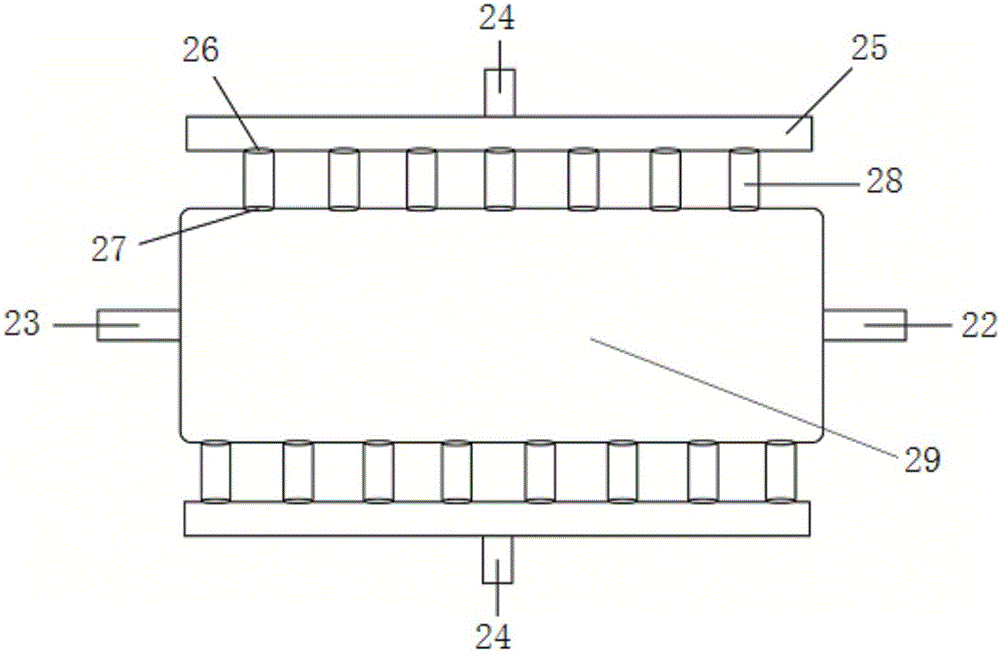

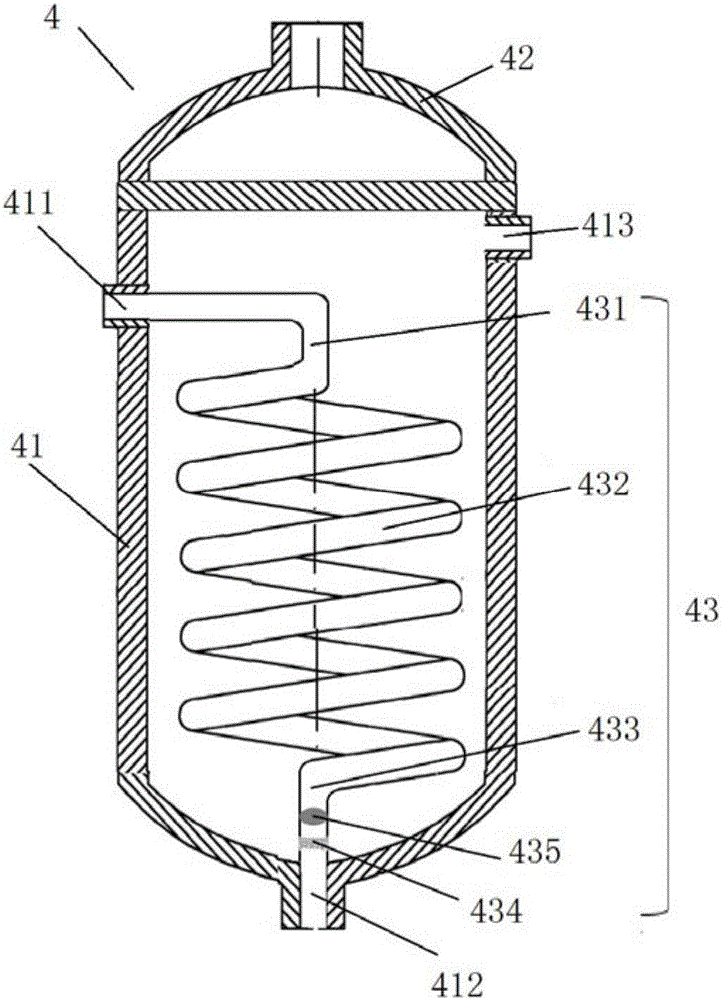

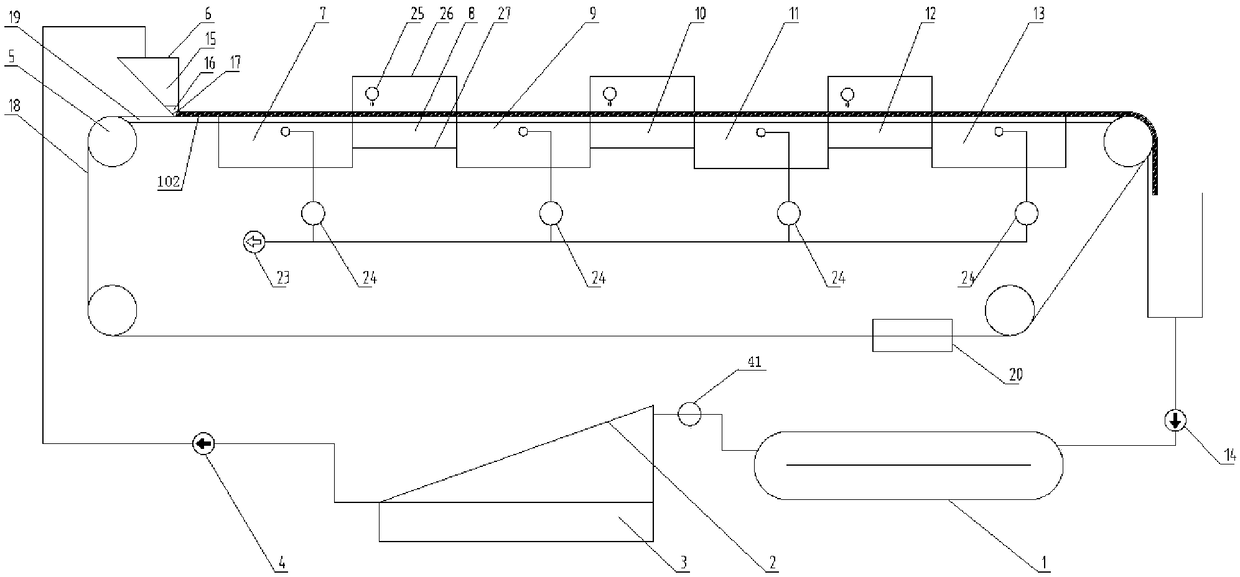

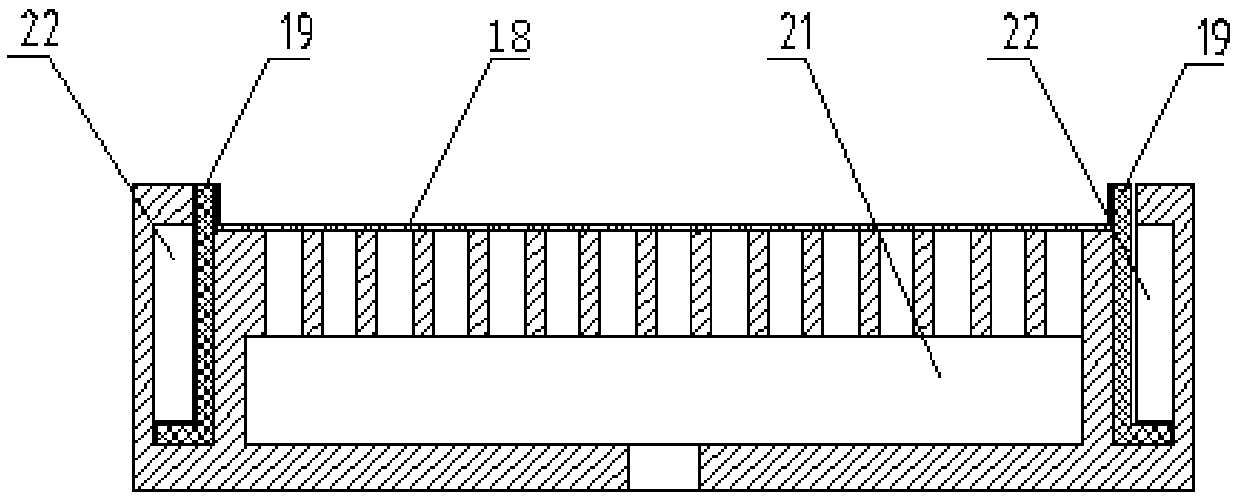

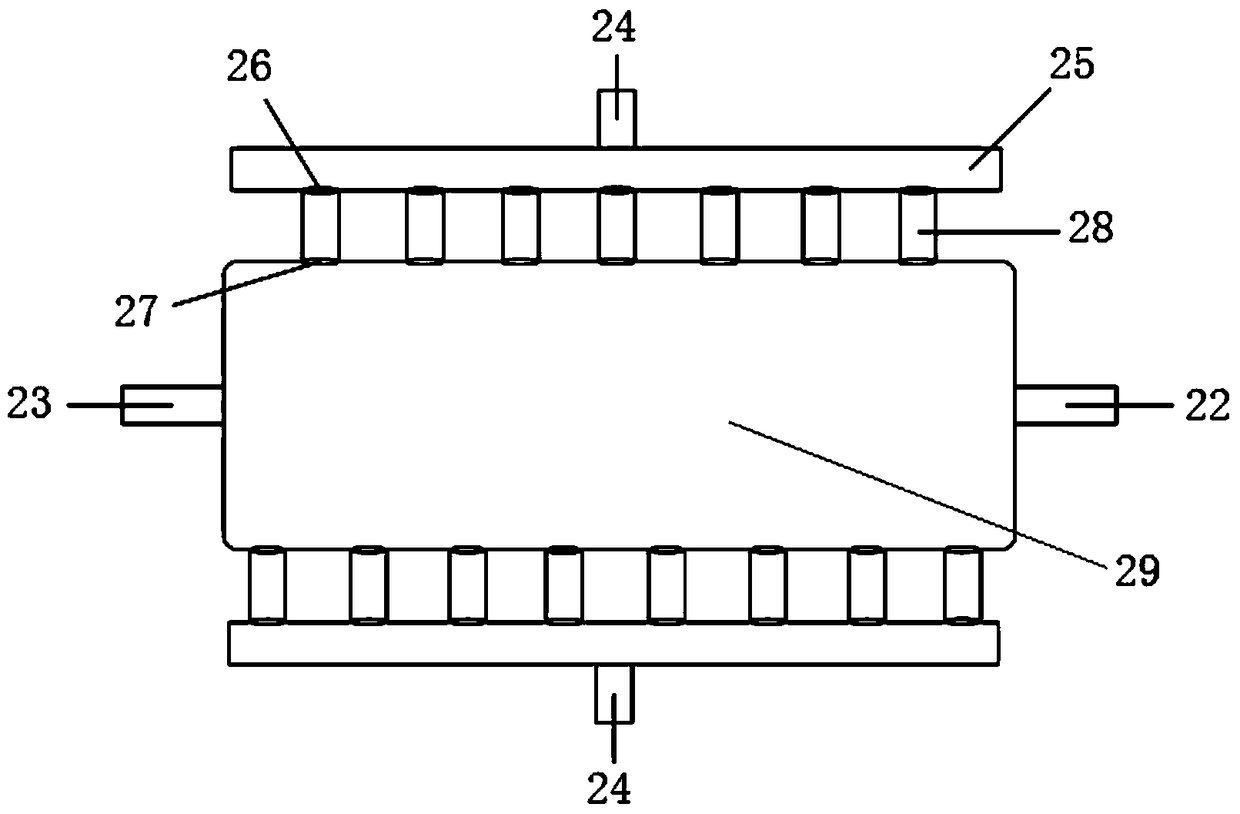

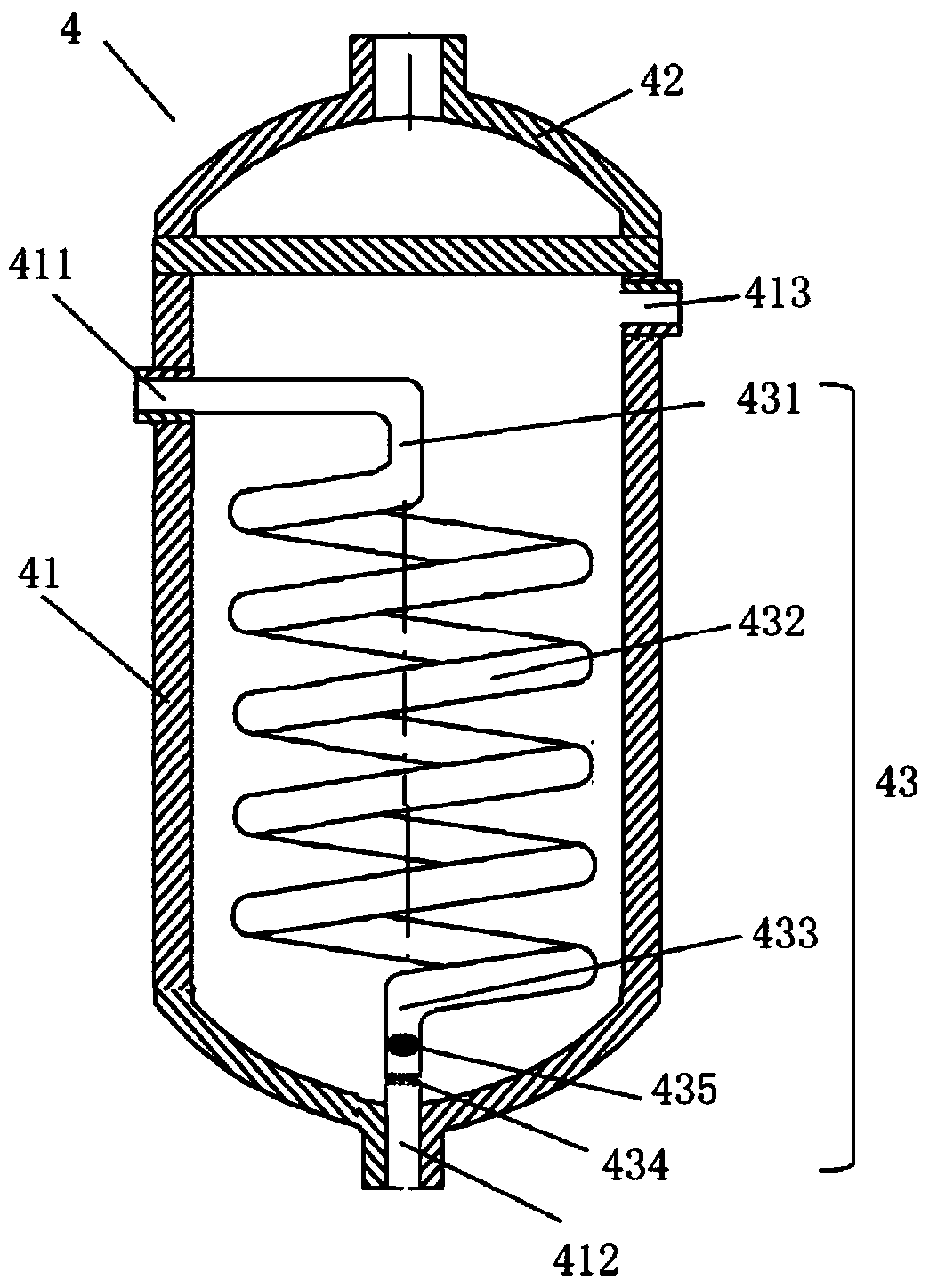

The invention discloses a supercritical CO2 waterless bleaching device and method for linen coarse yarns. On the basis of the prior art, structures of a blending device and a separator are improved, when bleaching is conducted, the linen coarse yarns are placed into a bleaching kettle in sequence, a H2O2 solution serves as a cosolvent, and when a supercritical CO2 state is achieved, bleaching is conducted for 30-150 min on the conditions that the temperature ranges from 50 DEG C to 150 DEG C, the pressure ranges from 8 MPa to 30 MPa, and the CO2 fluid flow rate ranges from 10 g / min to 50 g / min. The whiteness of the linen coarse yarns obtained after bleaching is 40%-75%, the weight loss ratio is 7%-10%, the residual gum content is 7%-12.5%, the single fiber tensile strength is 5-12 cN / dtex, and the elongation at break is 5%-8%. Accordingly, CO2 is utilized for replacing a water medium to achieve clean bleaching production of the linen coarse yarns, the whole process of bleaching is free of pollution and achieves zero emission, and the modern life concepts of fashion bast fiber spinning and green bast fiber spinning are embodied.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

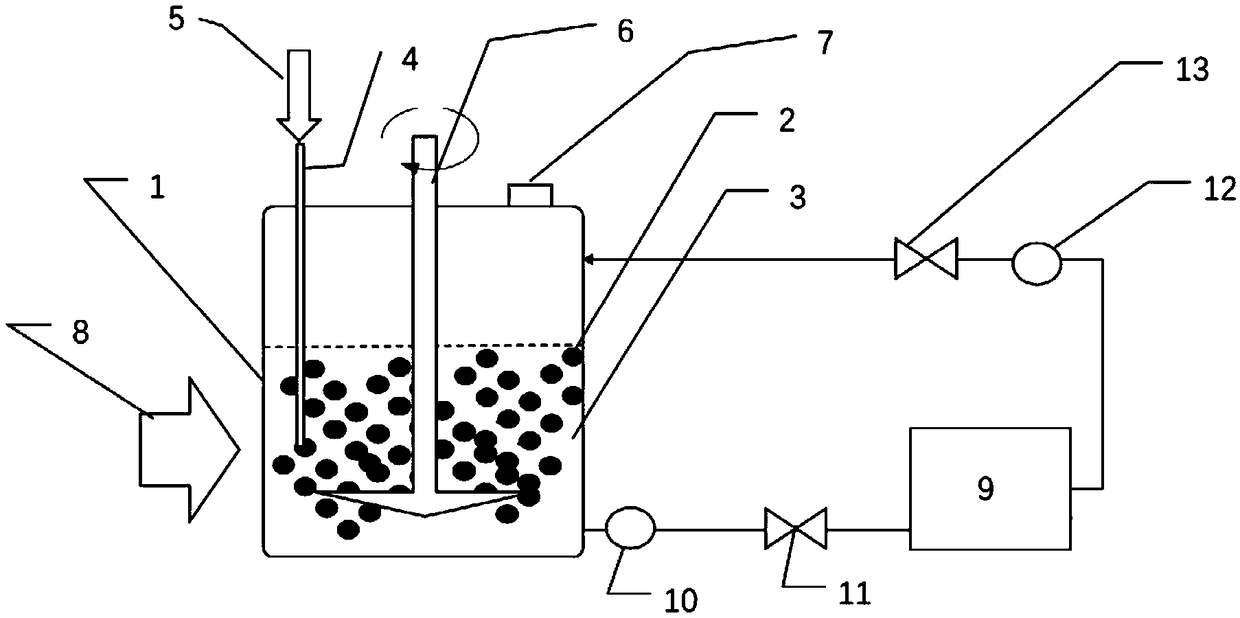

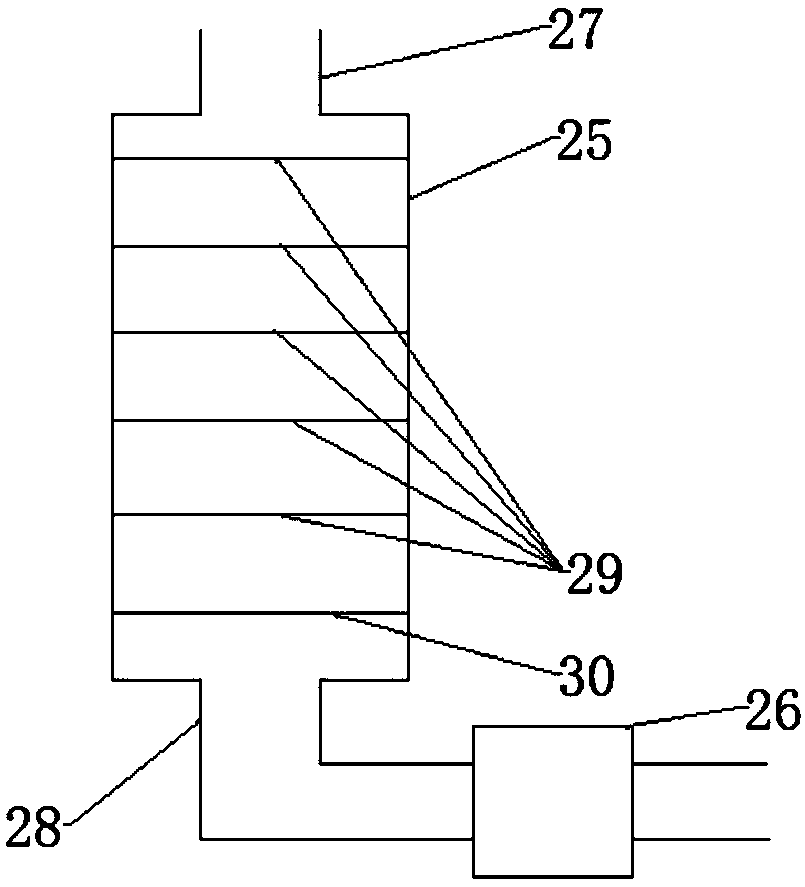

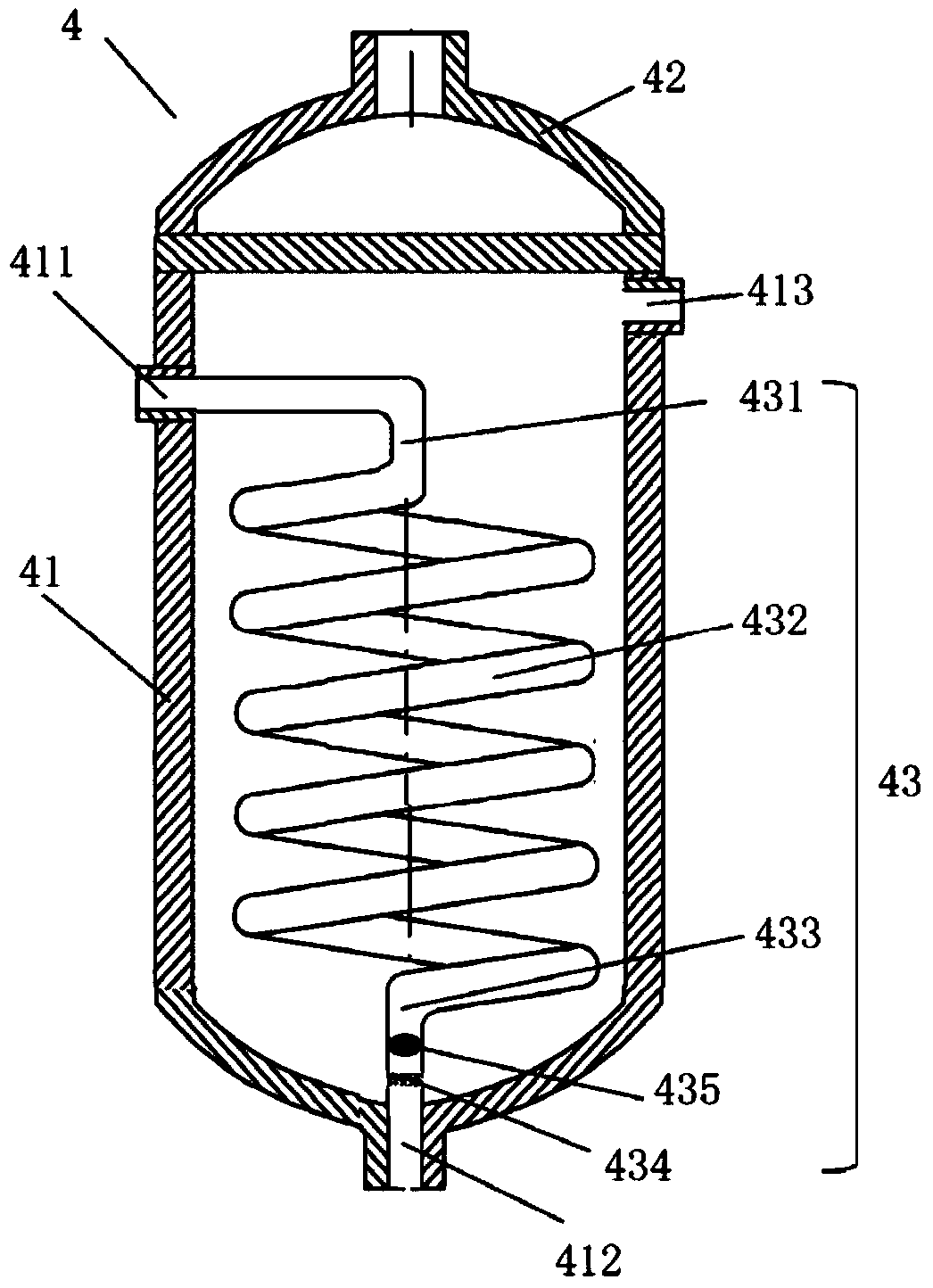

Process and system for industrially producing glycosylglycerol

ActiveCN108949523AIncrease separation areaEasy to moveBioreactor/fermenter combinationsBiological substance pretreatmentsCell activityCollection system

The invention relates to a process and system for industrially producing glycosylglycerol, and belongs to the field of glucoside preparation. The system comprises a culture system, a collection system, an extraction system and a purification system which are connected in sequence. When a microalgae cell with high content of GG is cultured, a mixed solution of a metabolic product extracted from themicroalgae cell by utilizing the ecological characteristic of microalgae cell metabolic response mechanism while the microalgae cell activity and biology are relatively stable, and a mated device isdesigned, so that the efficiency for collecting and extracting the microalgae cell can be greatly improved, and the production cost for the metabolic product in the microalgae cell can be remarkably reduced. Finally, the invention further develops a process for separating and purifying GG from an extracting solution, and a whole set of process and system for industrially producing glycosylglycerol, which have an important practical significance for GG large-scale application.

Owner:青岛中科蓝智生物科技发展有限公司

Flax roving supercritical CO2 biological enzyme bleaching device and bleaching method thereof

ActiveCN106835559AReduce usageReflect the concept of modern lifeSolvent treatment with solvent recoveryTextile/flexible product manufactureBleachSingle fiber

The invention discloses a flax roving supercritical CO2 biological enzyme bleaching device and a bleaching method thereof. The bleaching method comprises the steps that flax roving is bleached for 30-120 minutes in supercritical CO2 fluid with dissolved bio-enzyme bleach, at a temperature of 25-65 DEG C, a pressure of 15-25 MPa, and CO2 fluid flow of 10-50 g / min. The enzyme bleaching agent contains 0.2-3% (o. w. f) xylanase and 0.2-5% (o. w. f) glucose oxidase. By the adoption of the bleaching method, the whiteness of the flax roving can reach 45-70%, the weight loss rate is 7-12%, the adhesive residue is 9-15%, a single fiber breaking tenacity is 6.5-13.5 cN / dtex, and the elongation at the breaking is 5-8.5%. By the flax roving supercritical CO2 biological enzyme bleaching device and the bleaching method, a clean bleaching production of flax roving is achieved using CO2 instead of aqueous medium, the use of a large amount of chemical reagents such as hydrogen peroxide and sodium hypochlorite is avoided; the whole bleaching process is free of filth and zero in emission, and the modern living concept of fashion and green for flax is expressed.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

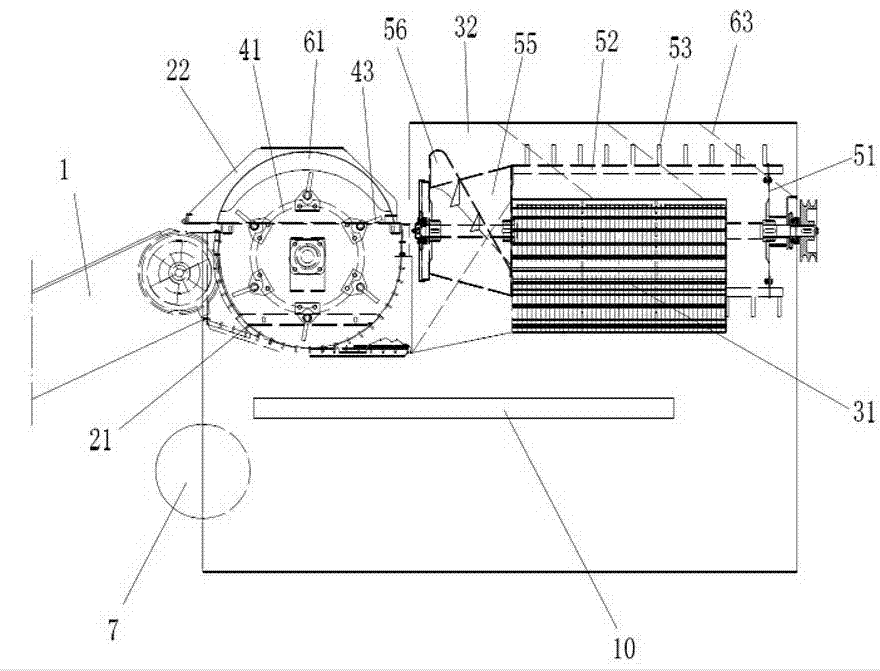

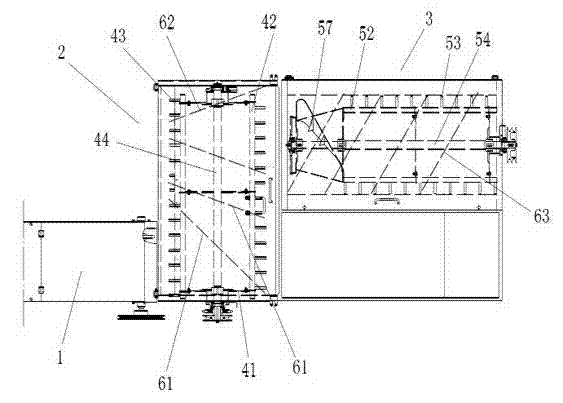

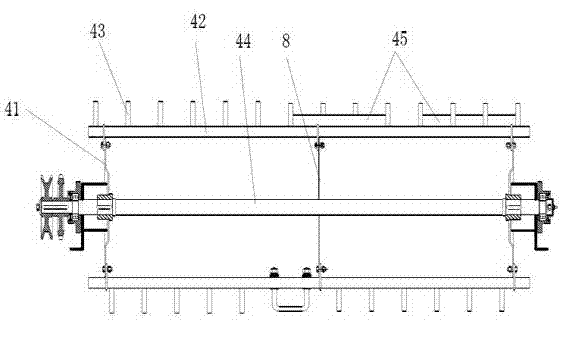

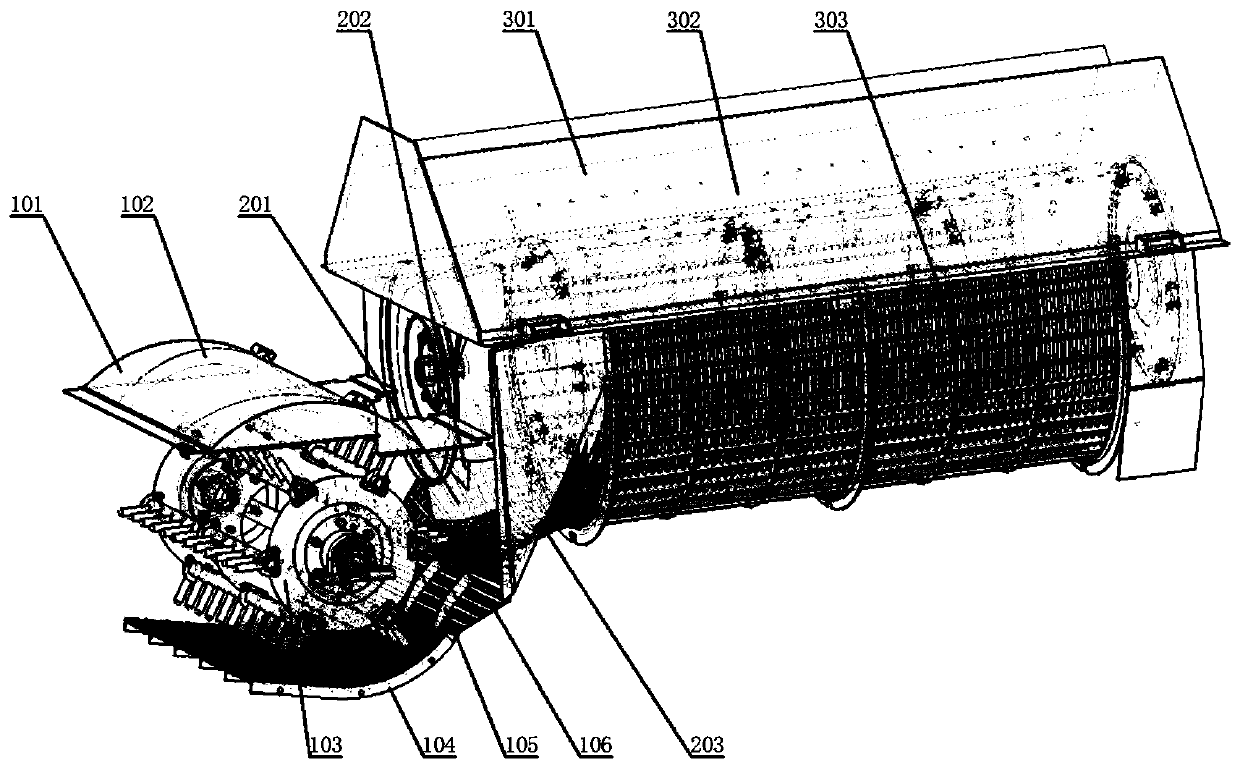

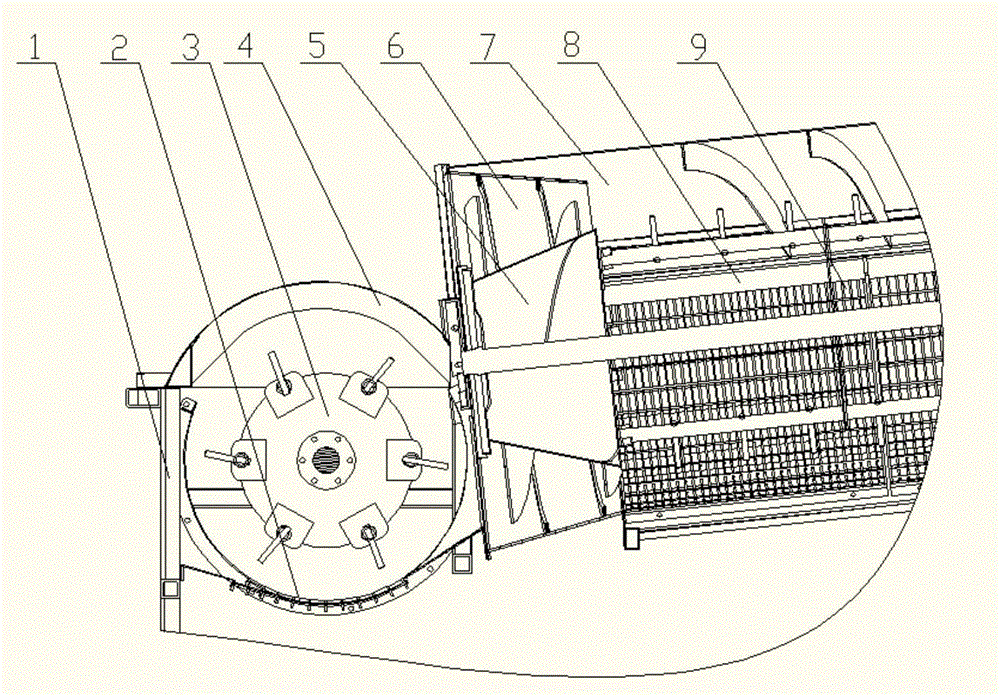

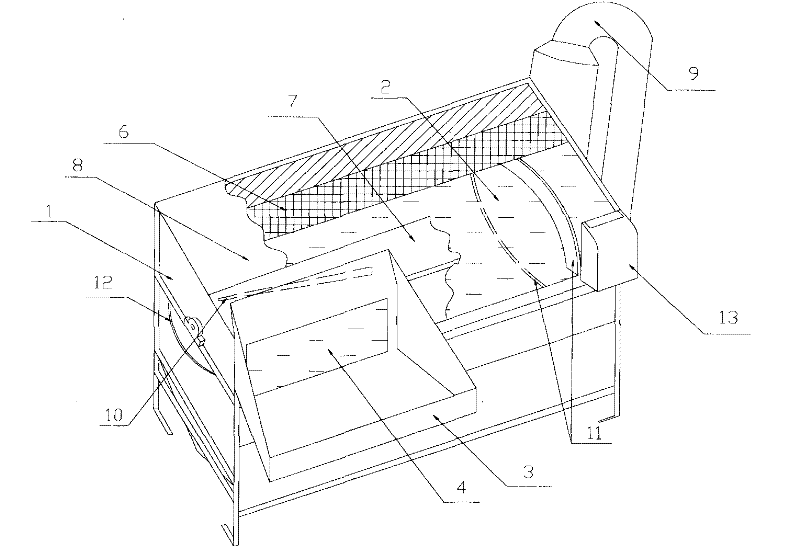

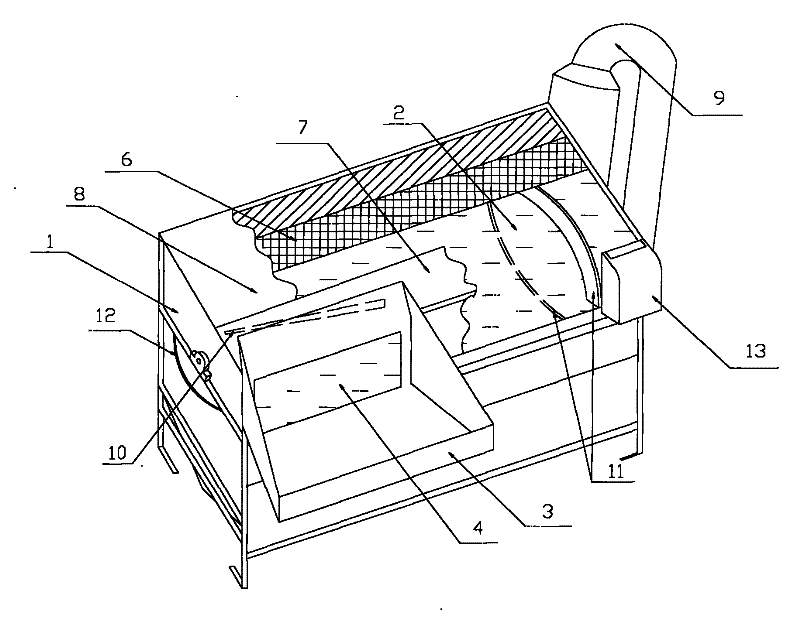

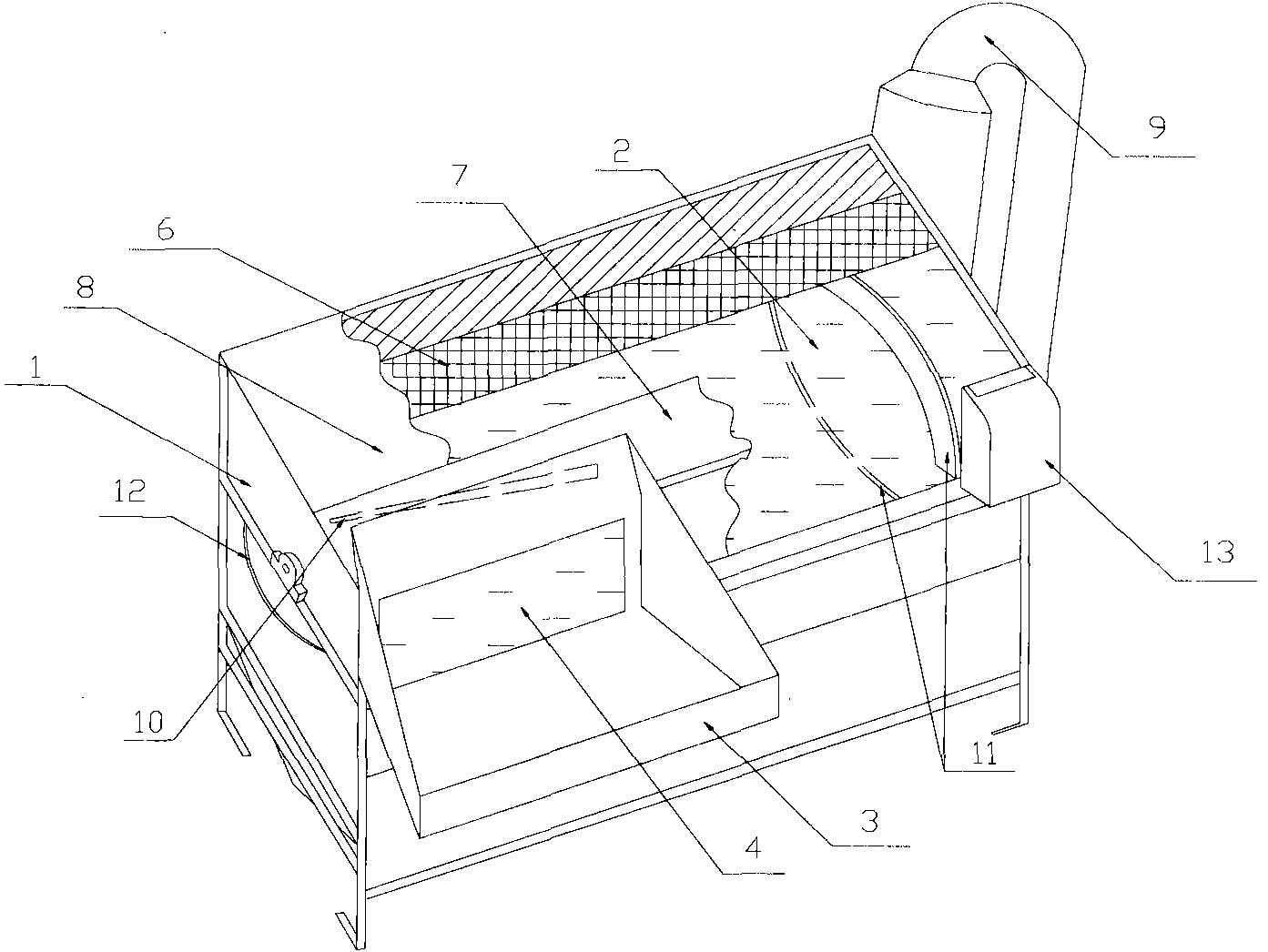

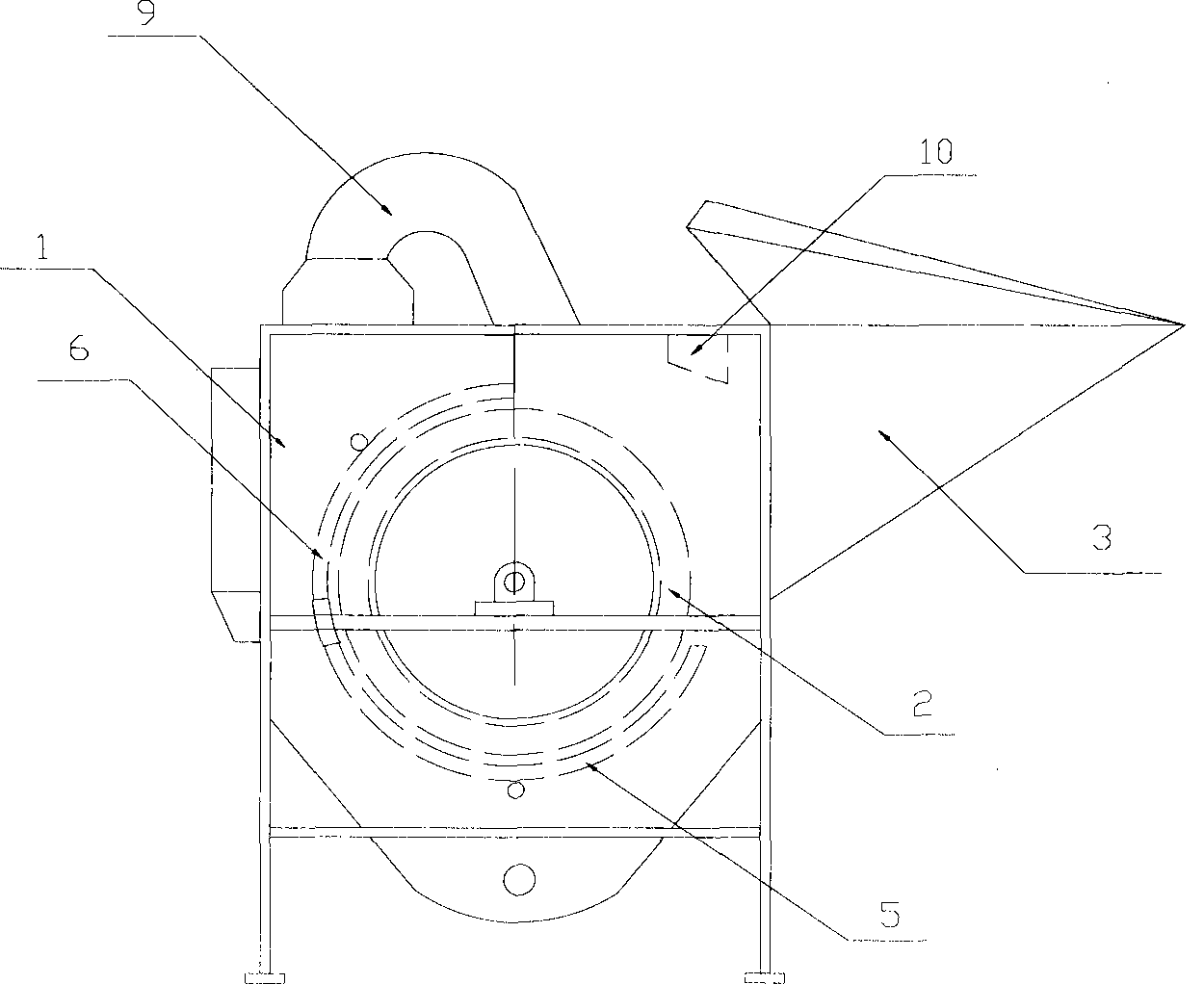

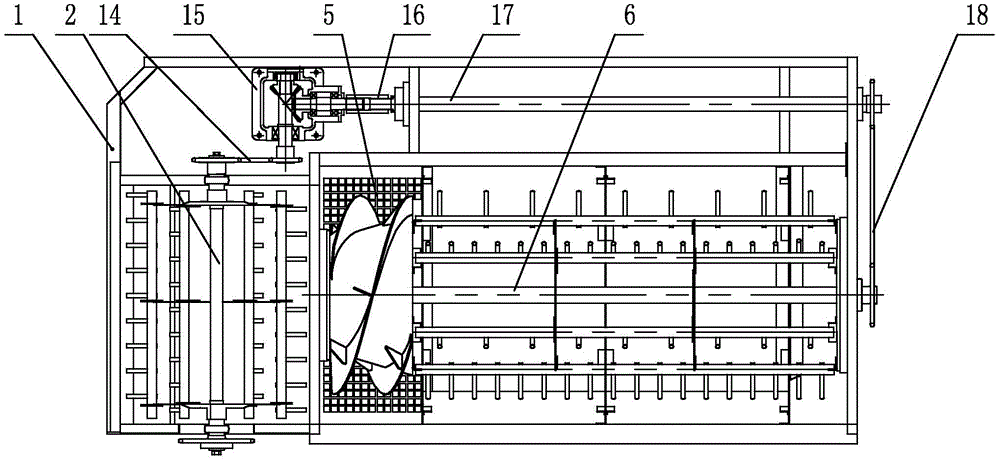

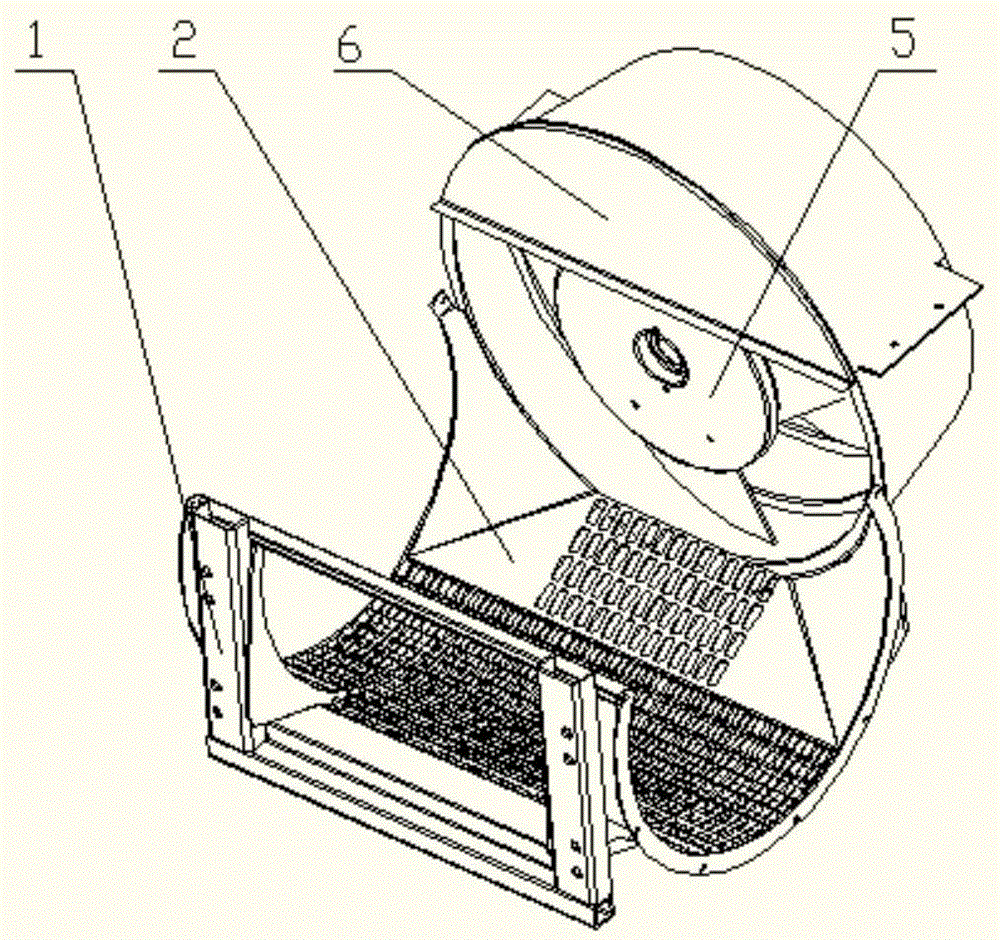

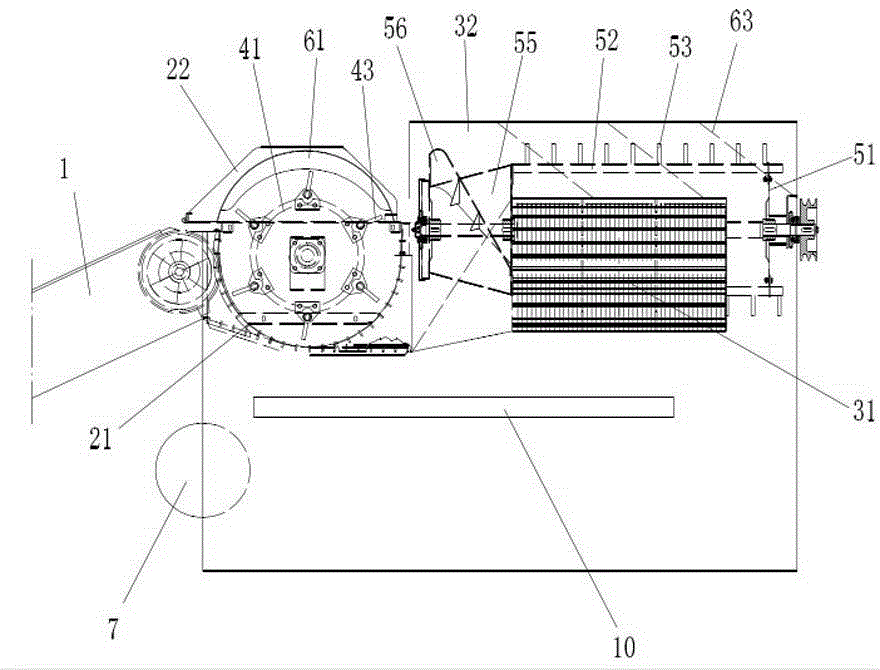

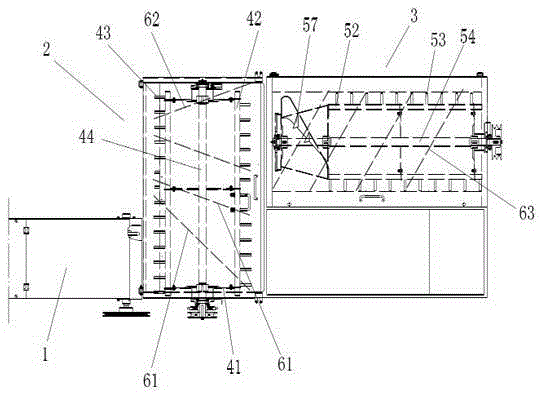

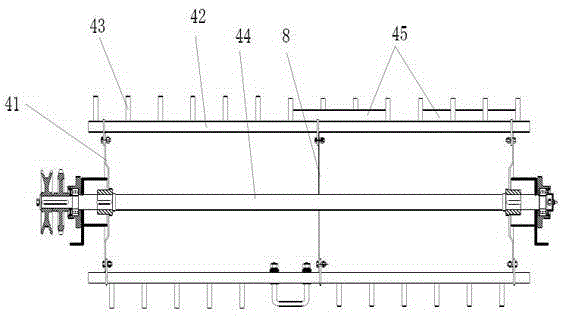

Threshing structure of L-shaped horizontal and longitudinal axial flow full-feeding combine harvester

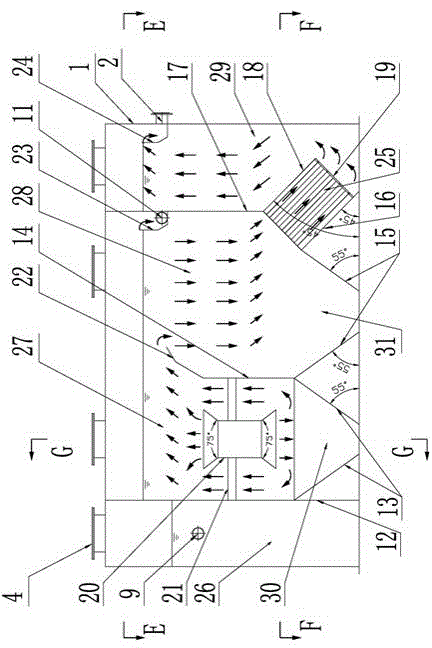

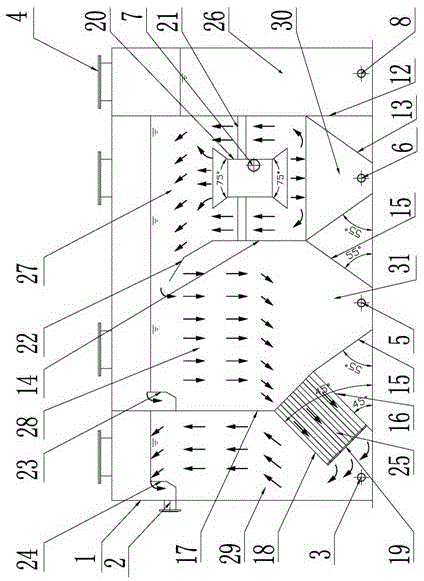

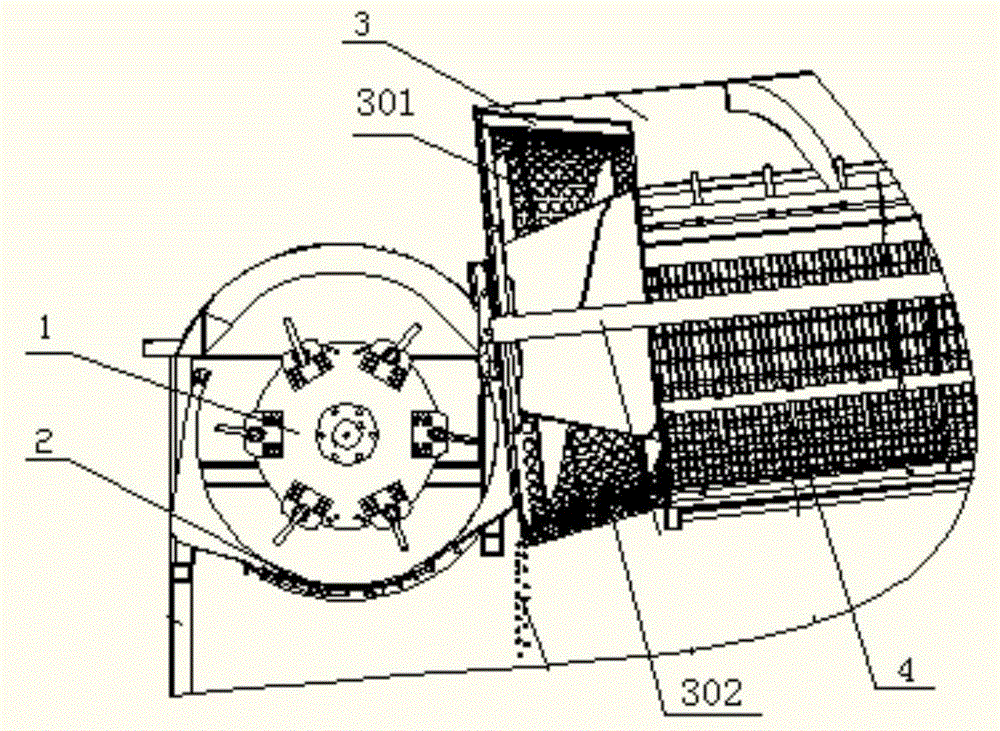

InactiveCN103609250ALarge amount of feedImprove work efficiencyMowersThreshersTransverse axisEngineering

The invention relates to the technical field of agricultural machinery, in particular to a threshing structure of an L-shaped horizontal and longitudinal axial flow full-feeding combine harvester. The threshing structure comprises a threshing rack, a vibrating screen arranged on the threshing rack, an air blower and a middle conveyor connected on the upper portion of the front end of the threshing rack, a threshing drum communicated with the rear end of the middle conveyor is arranged on the threshing rack and comprises a horizontal axial flow drum and a longitudinal axial flow drum which are in communicated connection and perpendicular to each other to be L-shaped, two ends of the horizontal axial flow drum are connected with the middle conveyor and the longitudinal axial flow drum respectively, and the middle conveyor and the longitudinal axial flow drum are arranged on two sides of the horizontal axial flow drum respectively. The threshing structure is large in feeding quantity and high in operating efficiency during harvesting, connection of a threshing, cleaning and selecting drum and a discharging port of the middle conveyor is smooth and small in loss, crops in the horizontal axial flow drum are good in threshing, cleaning and selecting effect, and a notch board screen is large in separating area.

Owner:曾联

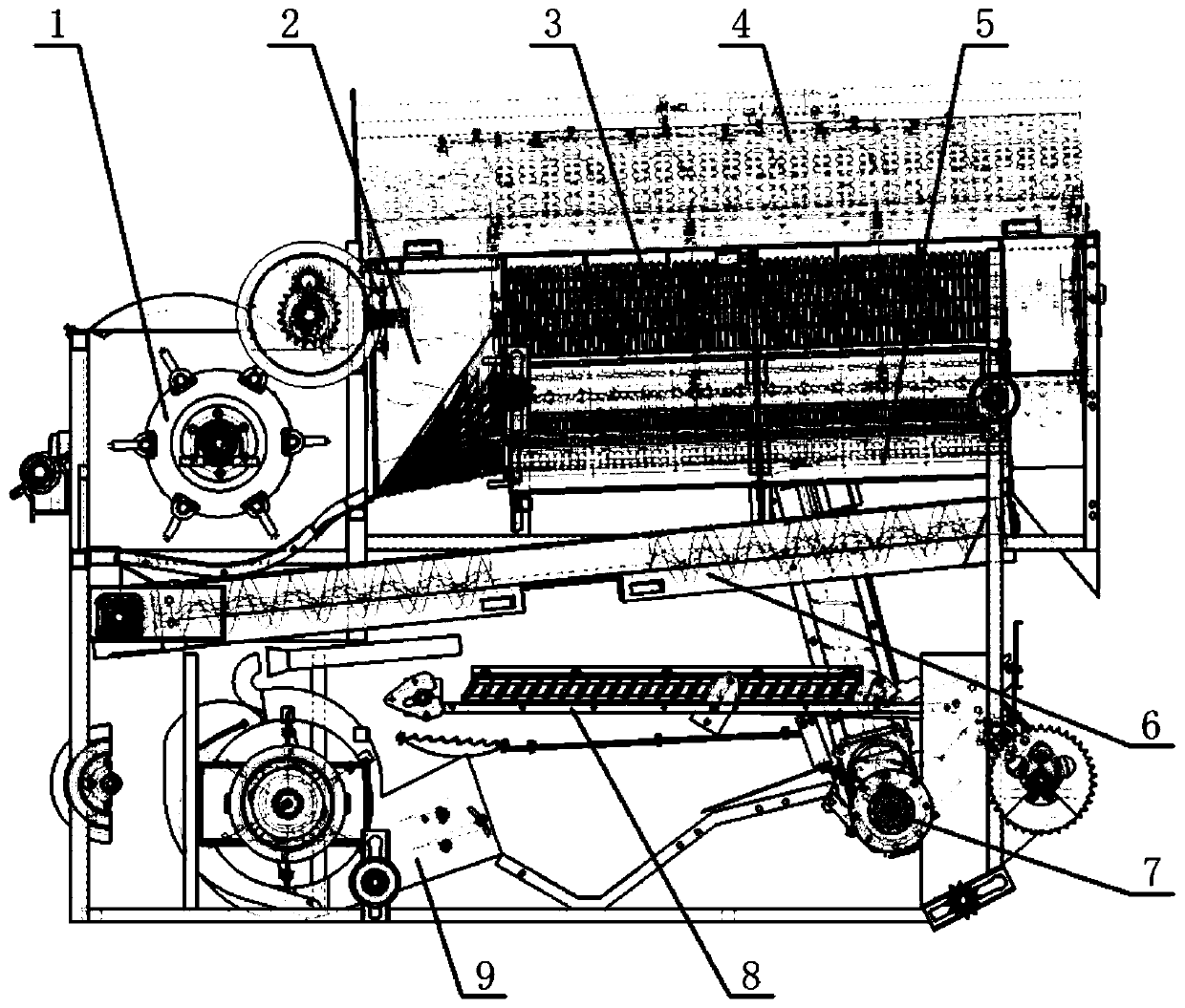

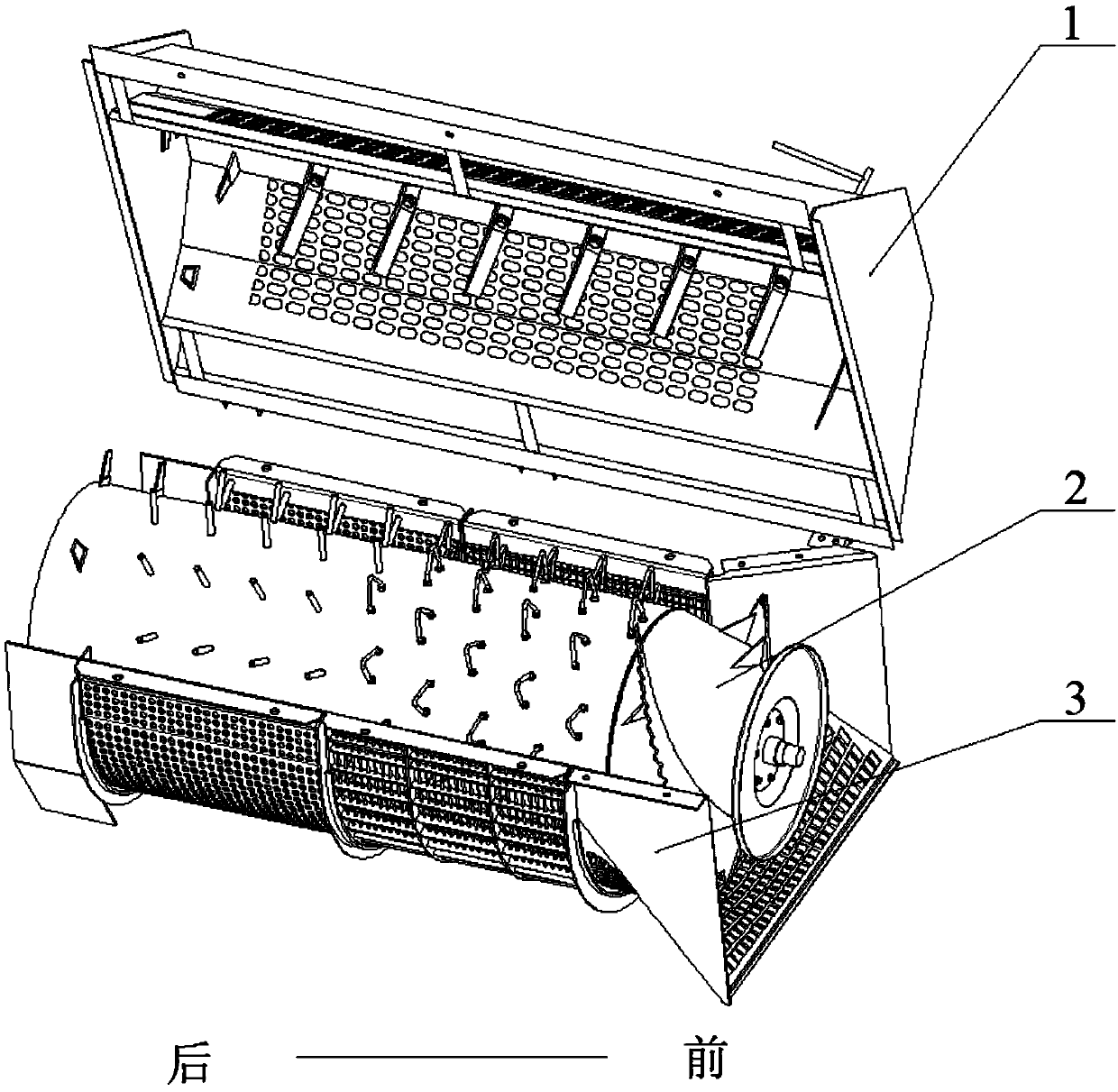

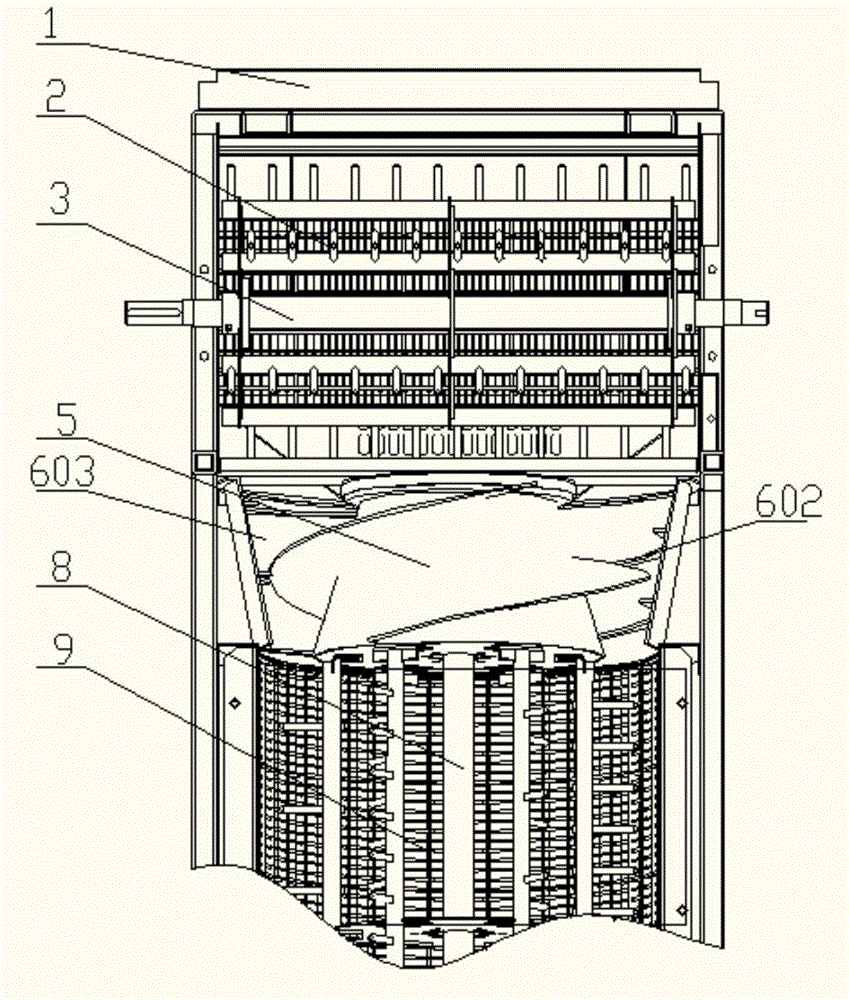

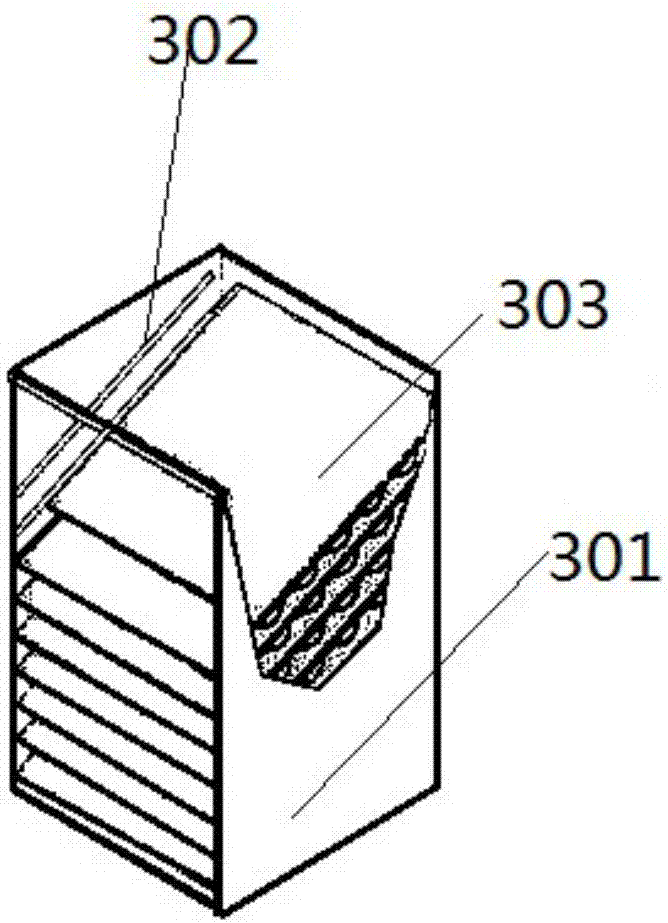

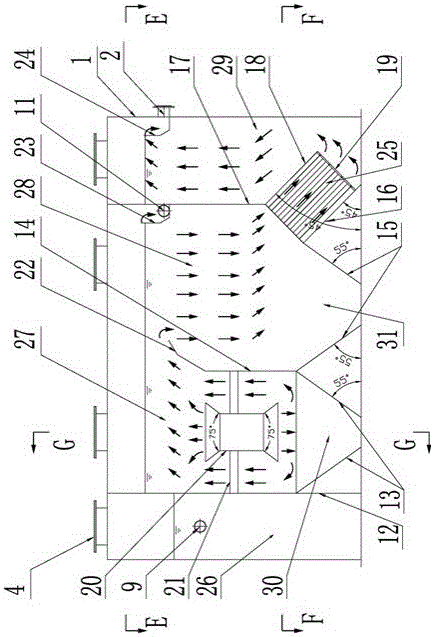

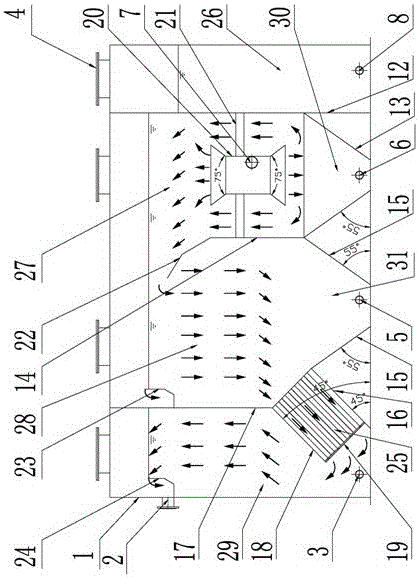

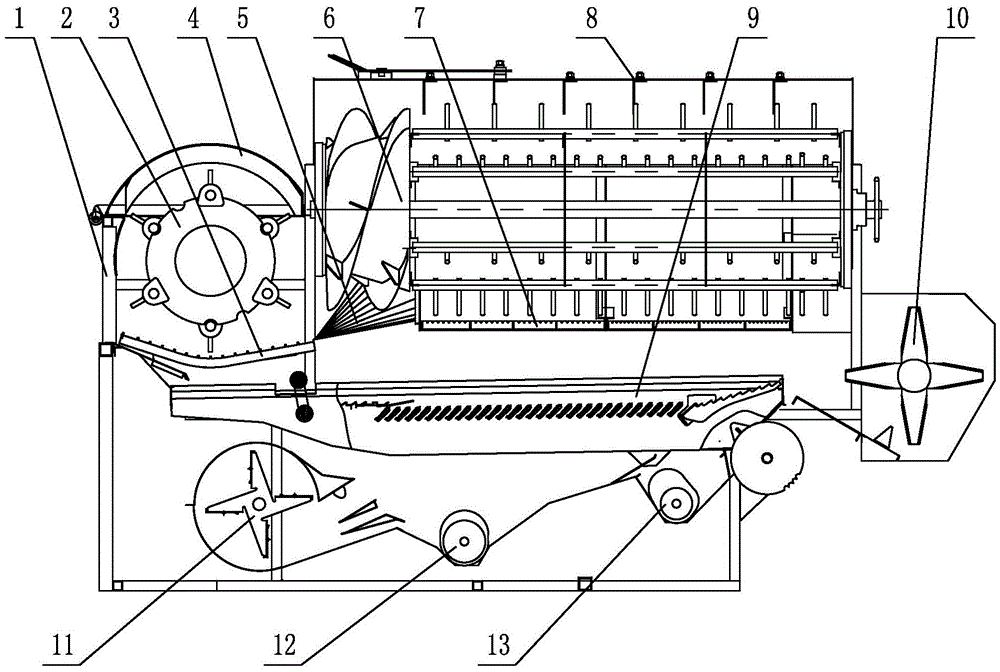

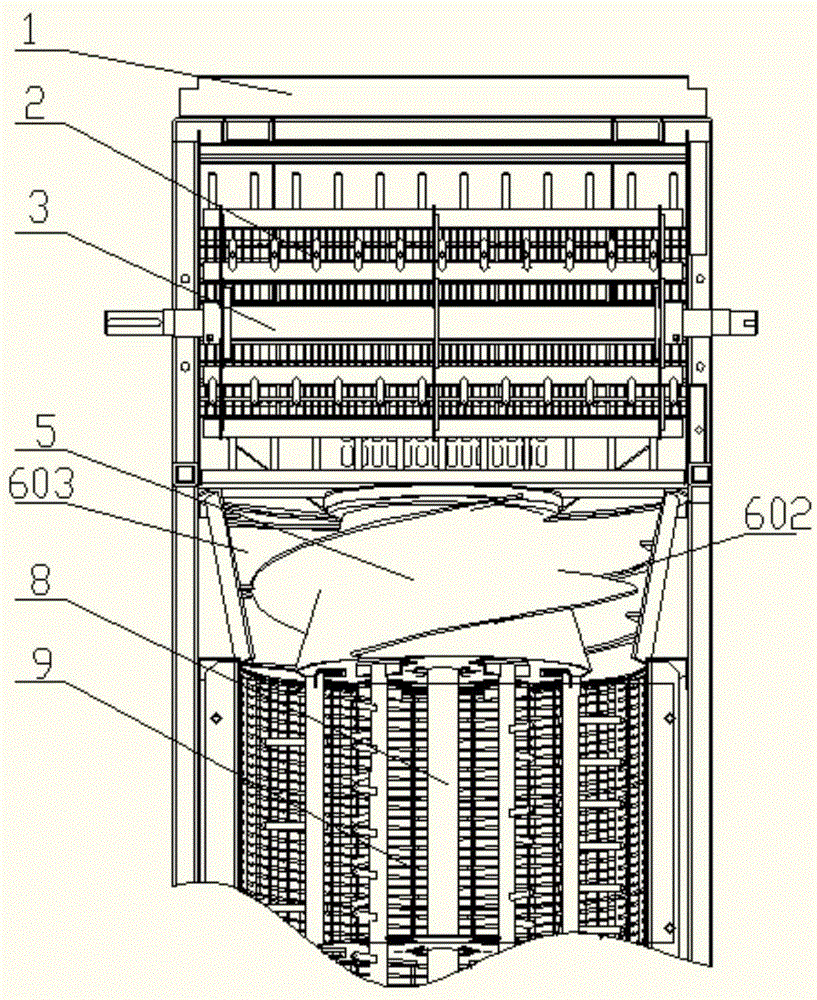

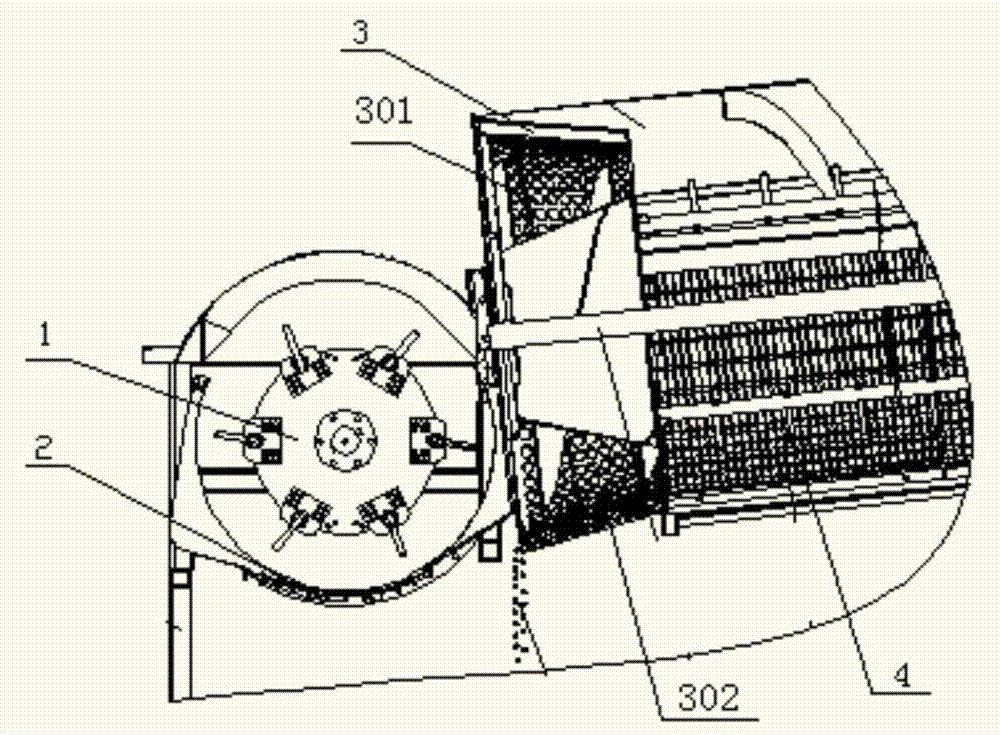

Efficiency threshing and cleaning device and harvester

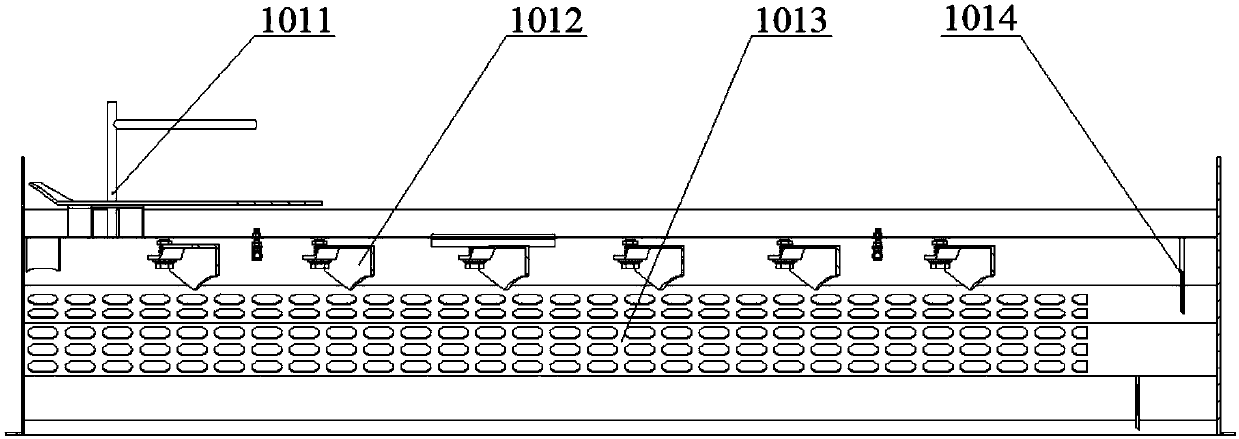

PendingCN109906779AFully threshed and separatedEvenly distributedMowersThreshersEngineeringThreshing

The invention provides an efficient threshing and cleaning device and a harvester. The device comprises a shear threshing and separating device, a feeding device, a longitudinal axial flow threshing and separating device, a variable diversion top cover, a threshed material distribution regulating device, a threshed material conveying device, a vibrating screen and a cleaning fan; the screw feedingdevice is installed between the shear threshing and separating device and the longitudinal axial flow threshing and separating device, the variable diversion separating top cover is installed on theupper portion in the longitudinal axial flow threshing and separating device; the threshed material distribution regulating device is installed on the lower portion of the longitudinal axial flow threshing and separating device; the threshed material conveying device is located below the shear threshing and separating device and the threshed material distribution regulating device; the vibrating screen is installed on the lower portion of the threshed material conveying device; the cleaning fan is located below the vibrating screen. Accordingly, threshing and separation of crops can be sufficient, threshed materials in the cleaning process are distributed more evenly and conveyed more smoothly, the threshing, separation and cleaning efficiency and performance can be significantly improved,and the device is compact in structure and high in stability.

Owner:JIANGSU UNIV

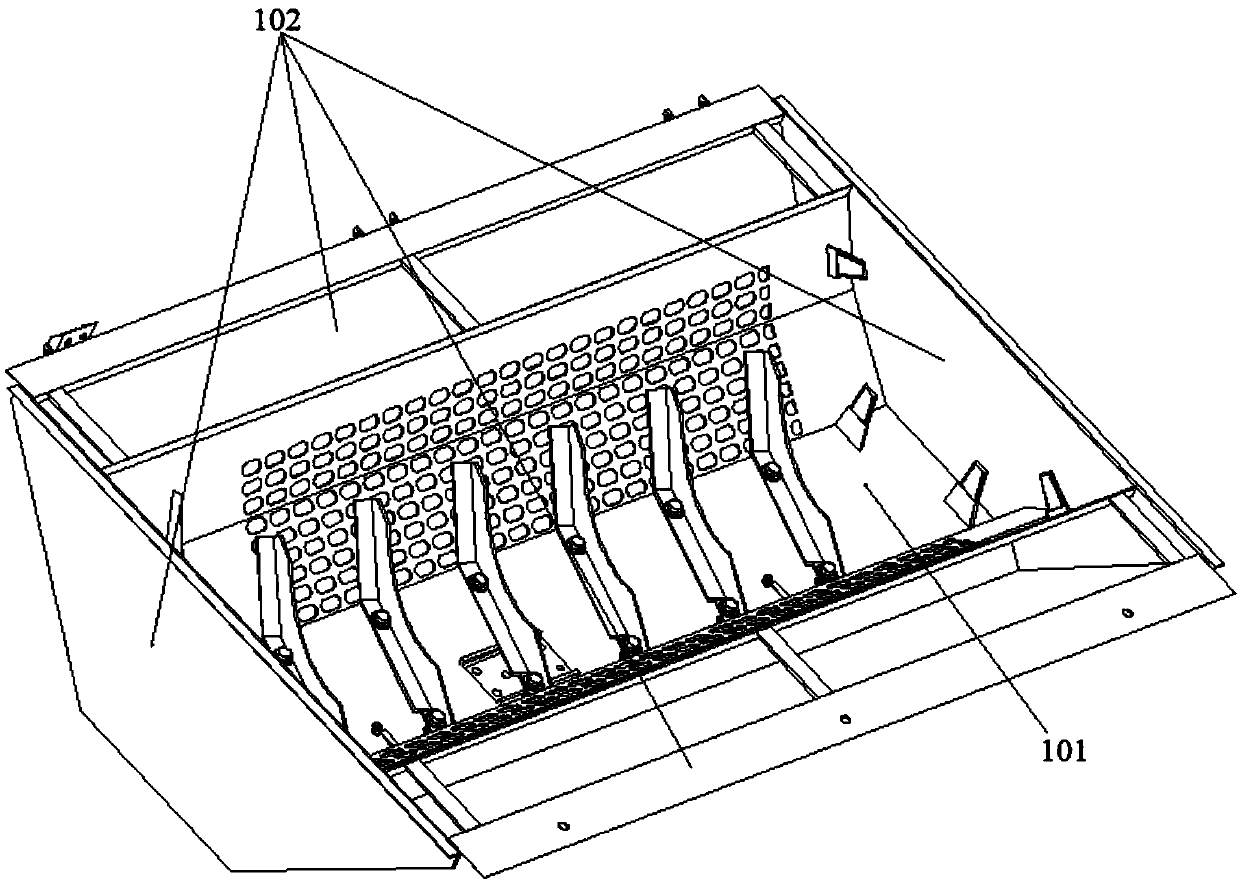

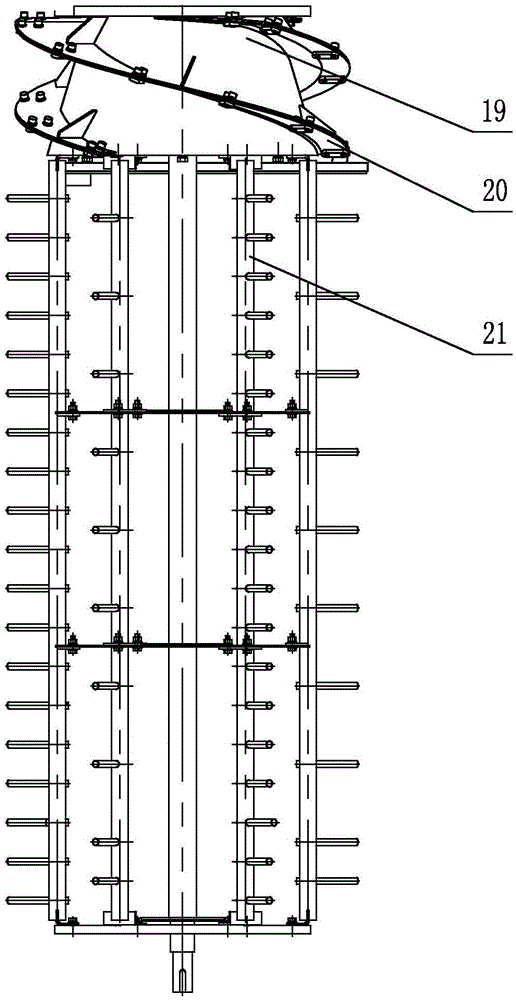

Forced feeding, threshing, separating and smashing integrated device for first-harvest rice

PendingCN109588120AClear division of laborReduce breakage rateMowersThreshersSpiral bladeEngineering

The invention provides a forced feeding, threshing, separating and smashing integrated device for first-harvest rice. The forced feeding, threshing, separating and smashing integrated device for first-harvest rice comprises a closed multifunctional threshing cylinder, a flow guide separable grass breaking top cover and a combined concave plate, wherein the threshing cylinder comprises a cylinder shaft feeding head and a cylinder body, a spiral blade is mounted on the feeding head, and an arc tooth group, a spike tooth group and a roller rotating blade group are distributed on the circumferenceof the cylinder body sequentially; the combined concave plate is located below the closed multifunctional threshing cylinder and comprises a transition concave plate, a threshing concave plate, a separating concave plate and a grass guiding concave plate sequentially; the flow guide separable grass breaking top cover is mounted above the closed multifunctional threshing cylinder and comprises a top cover inner shell and reinforcing plates, and the top cover inner shell comprises an adjusting mechanism, flow guide bars, punching plates and top cover fixed blades. The forced feeding, threshing,separating and smashing integrated device is applicable to feeding, threshing, separating and smashing of the first-harvest rice with different characteristics, has the advantages of compact structure, large separation area, light weight and the like, can effectively improve threshing performance and efficiency of the first-harvest rice and has lower power consumption.

Owner:JIANGSU UNIV

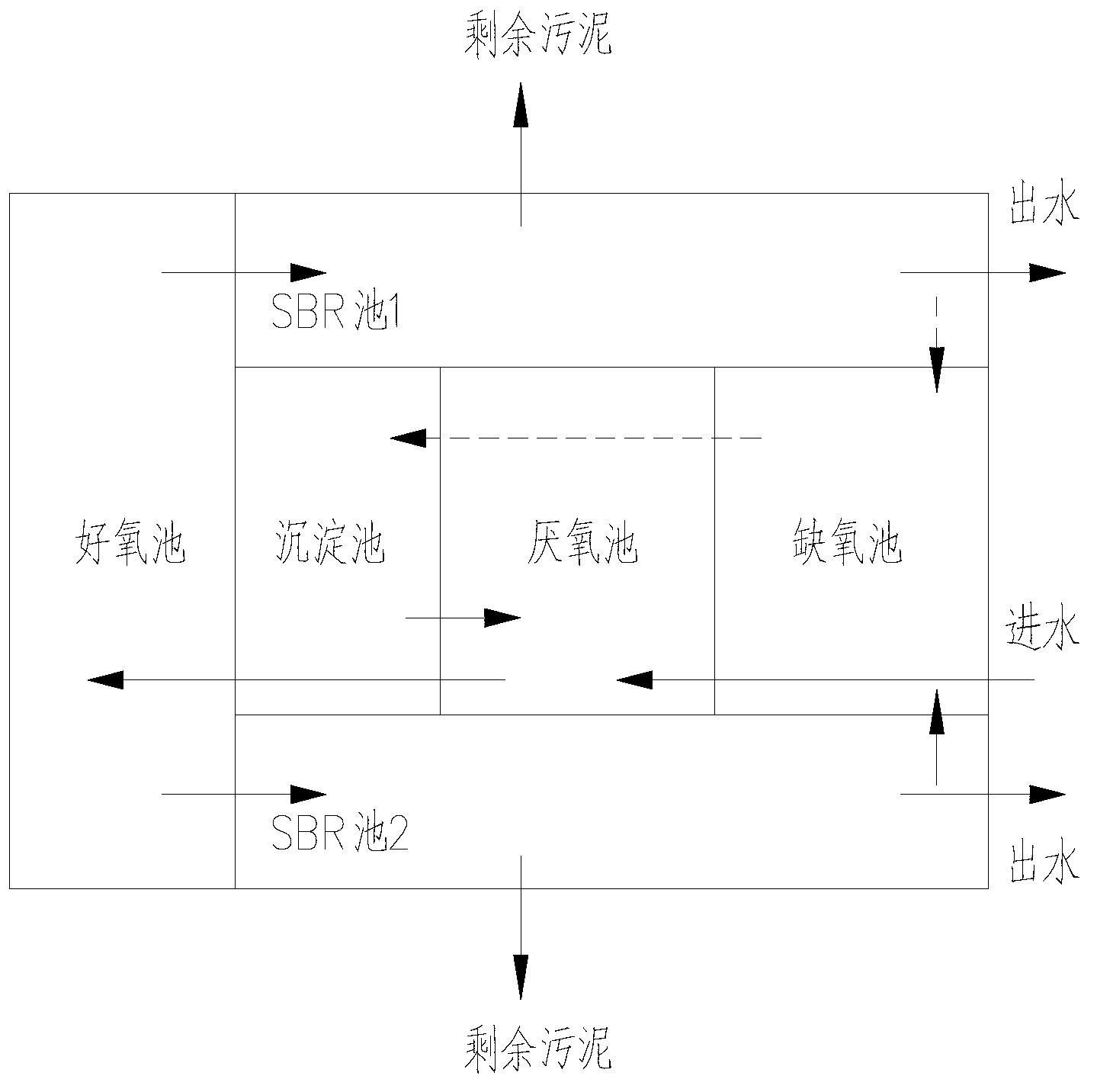

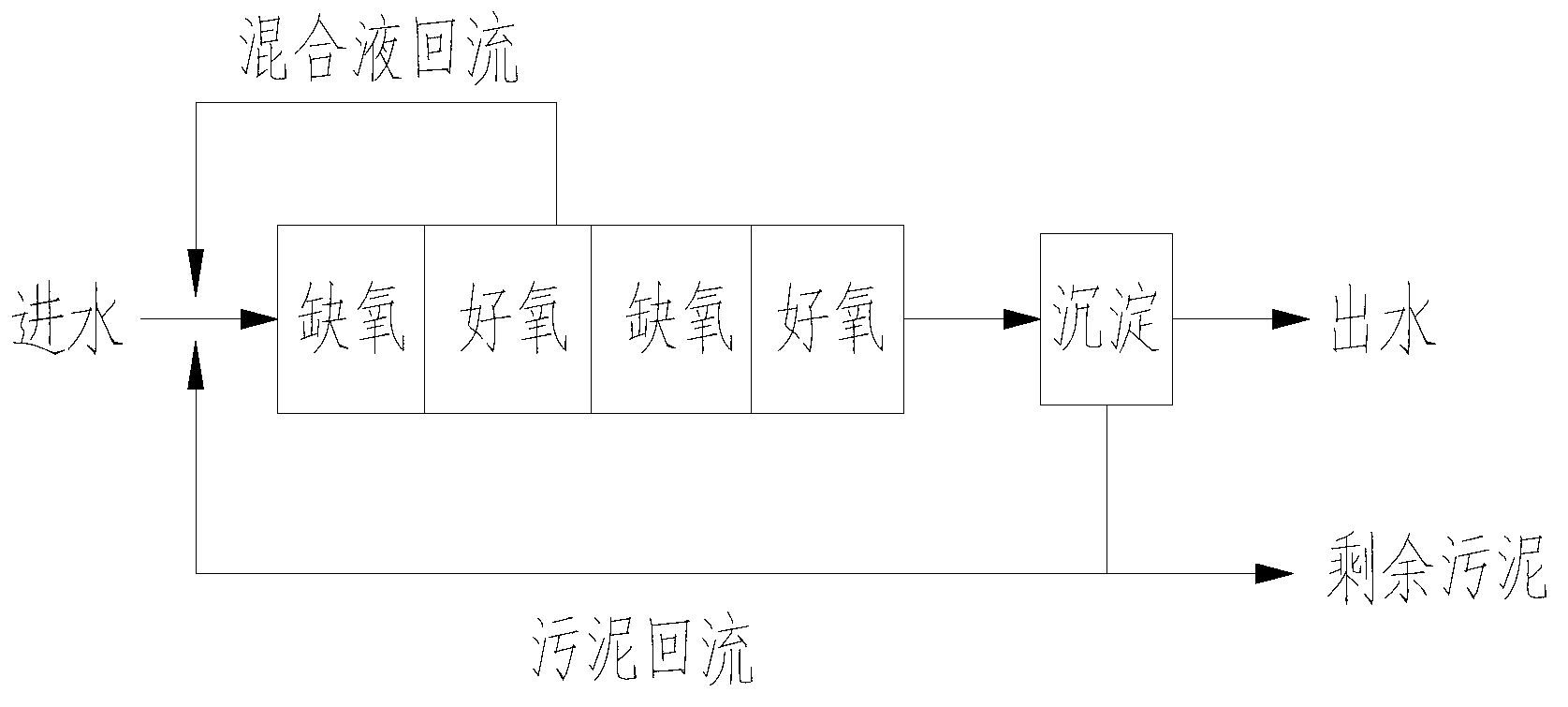

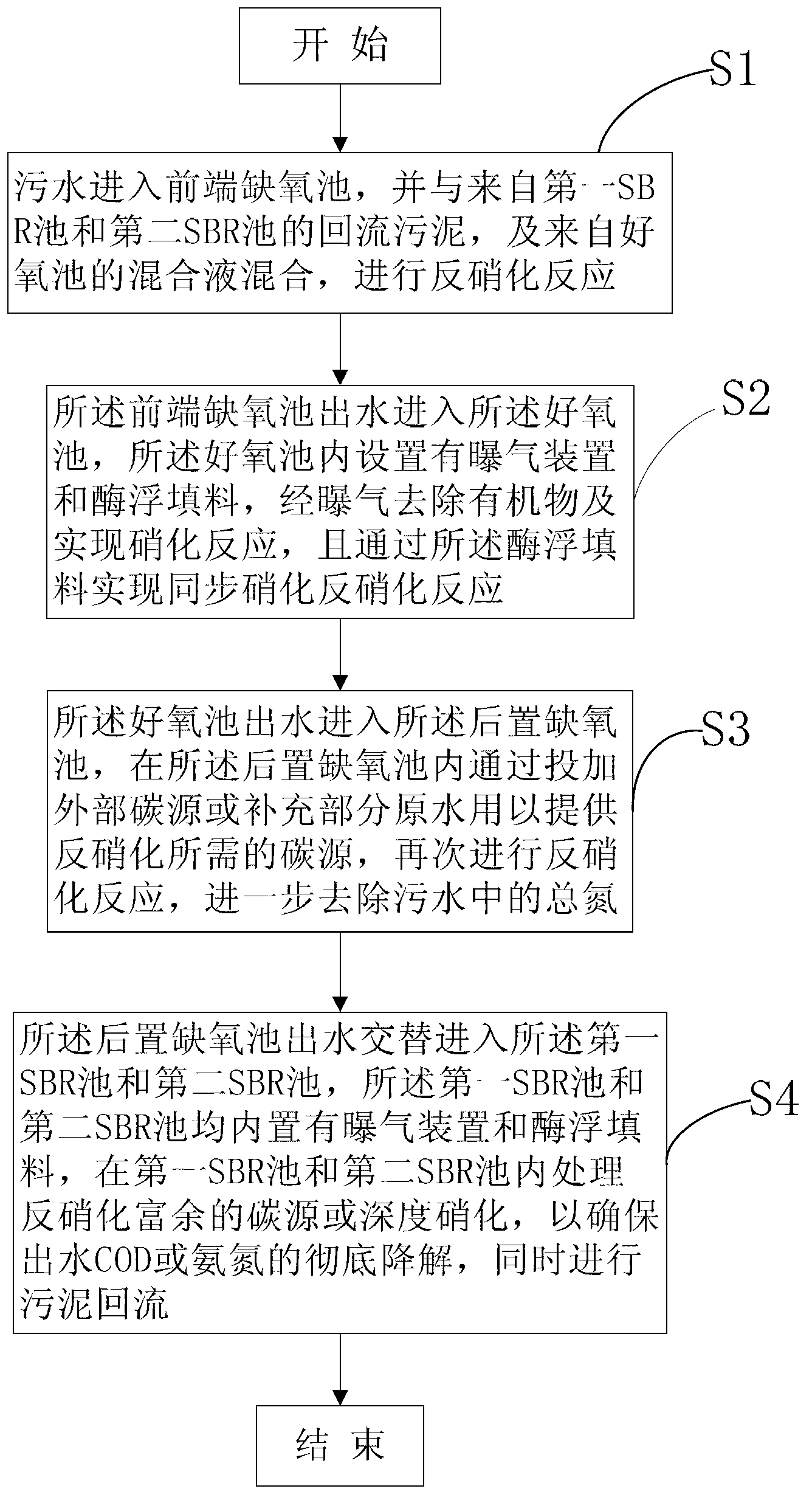

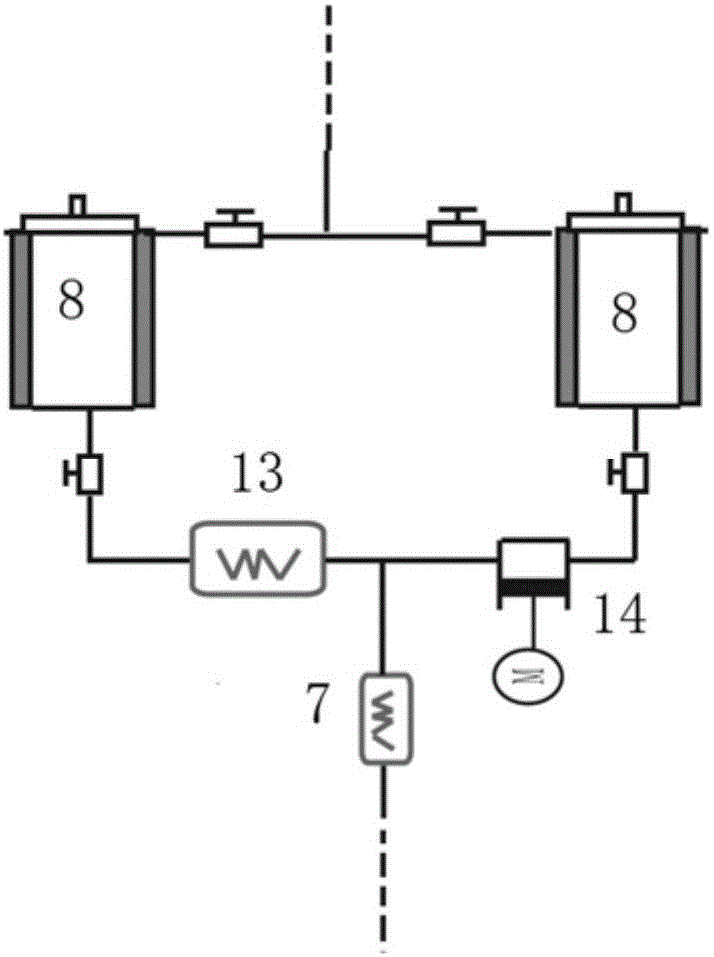

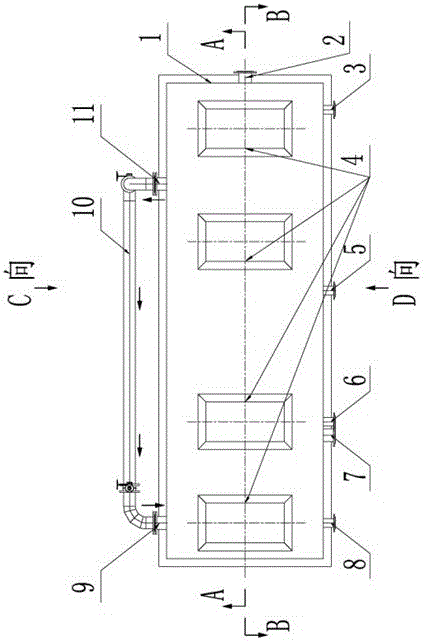

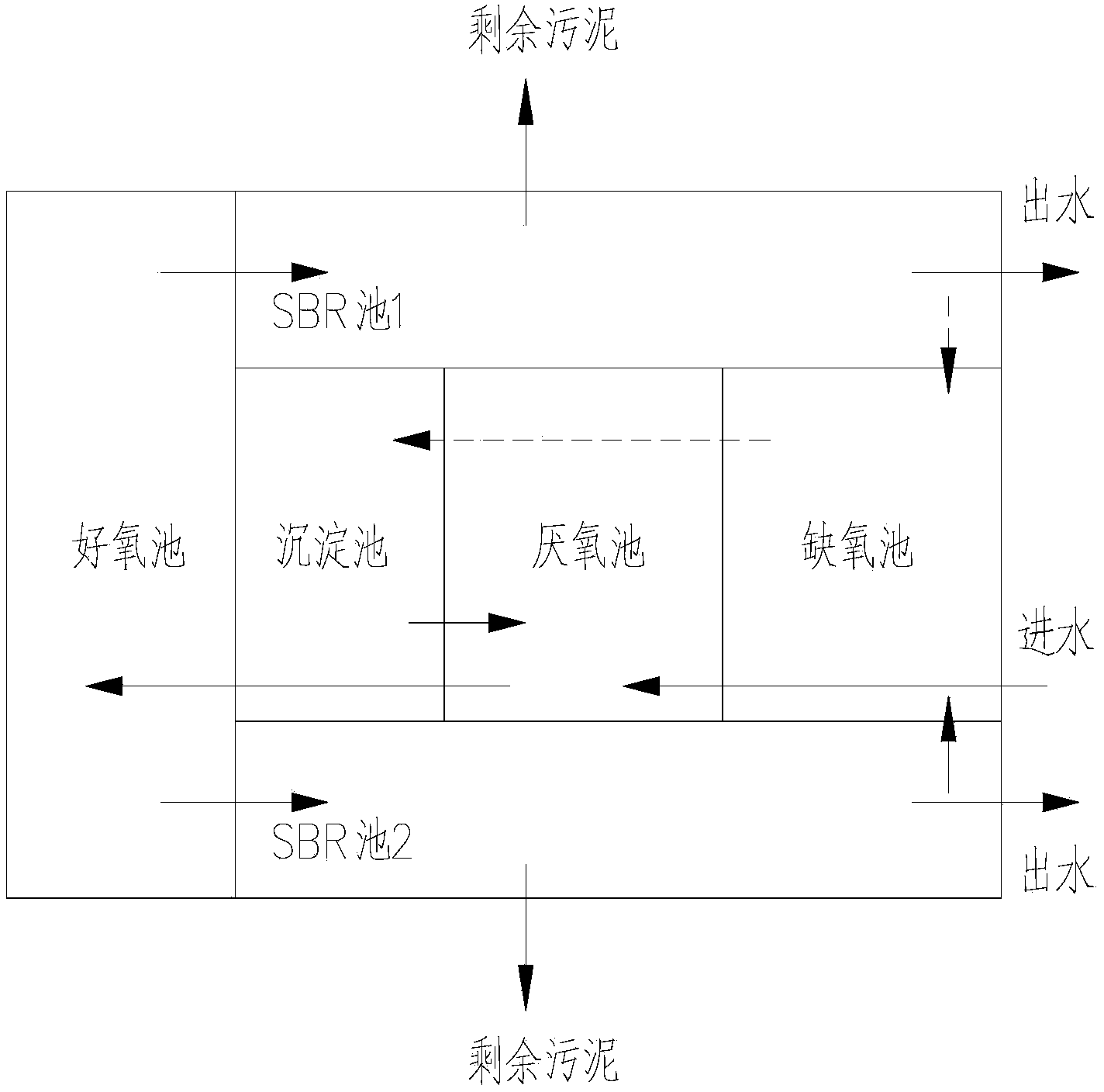

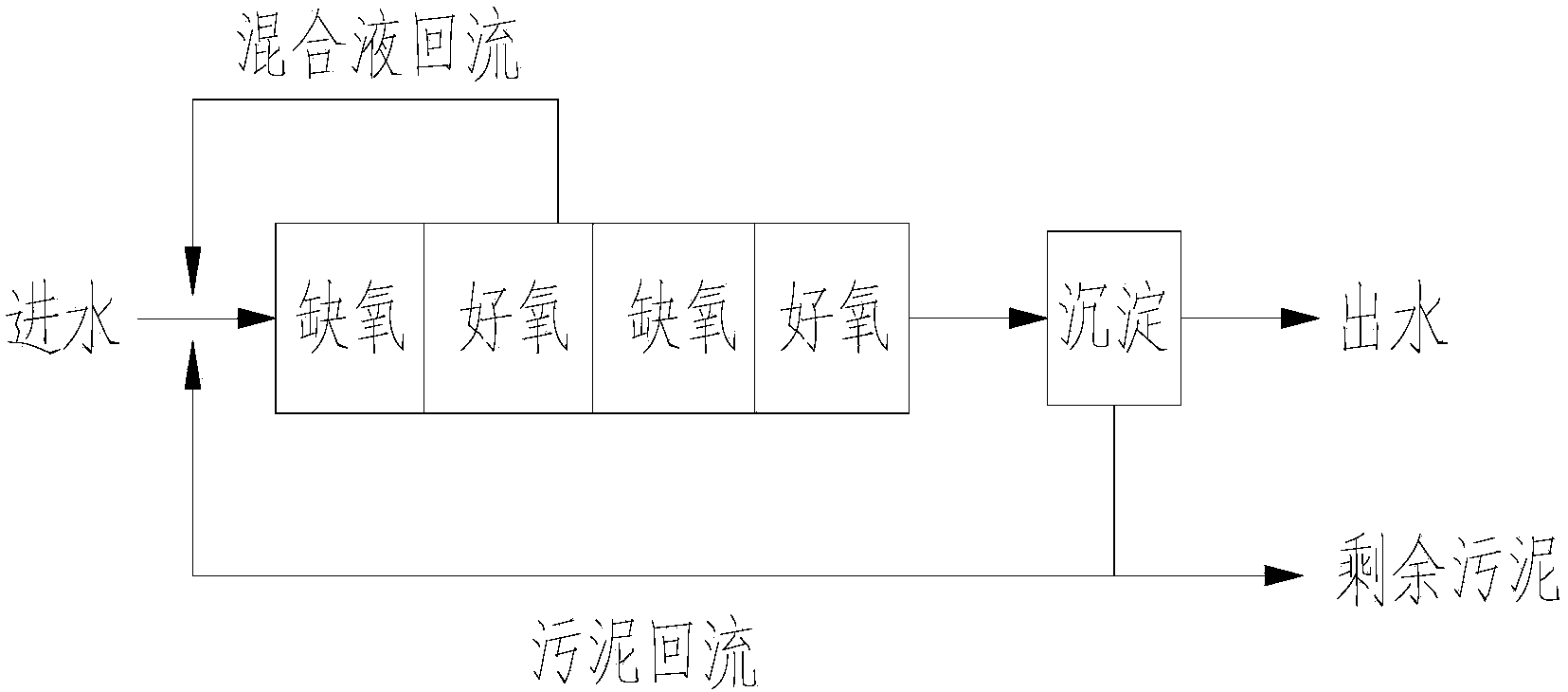

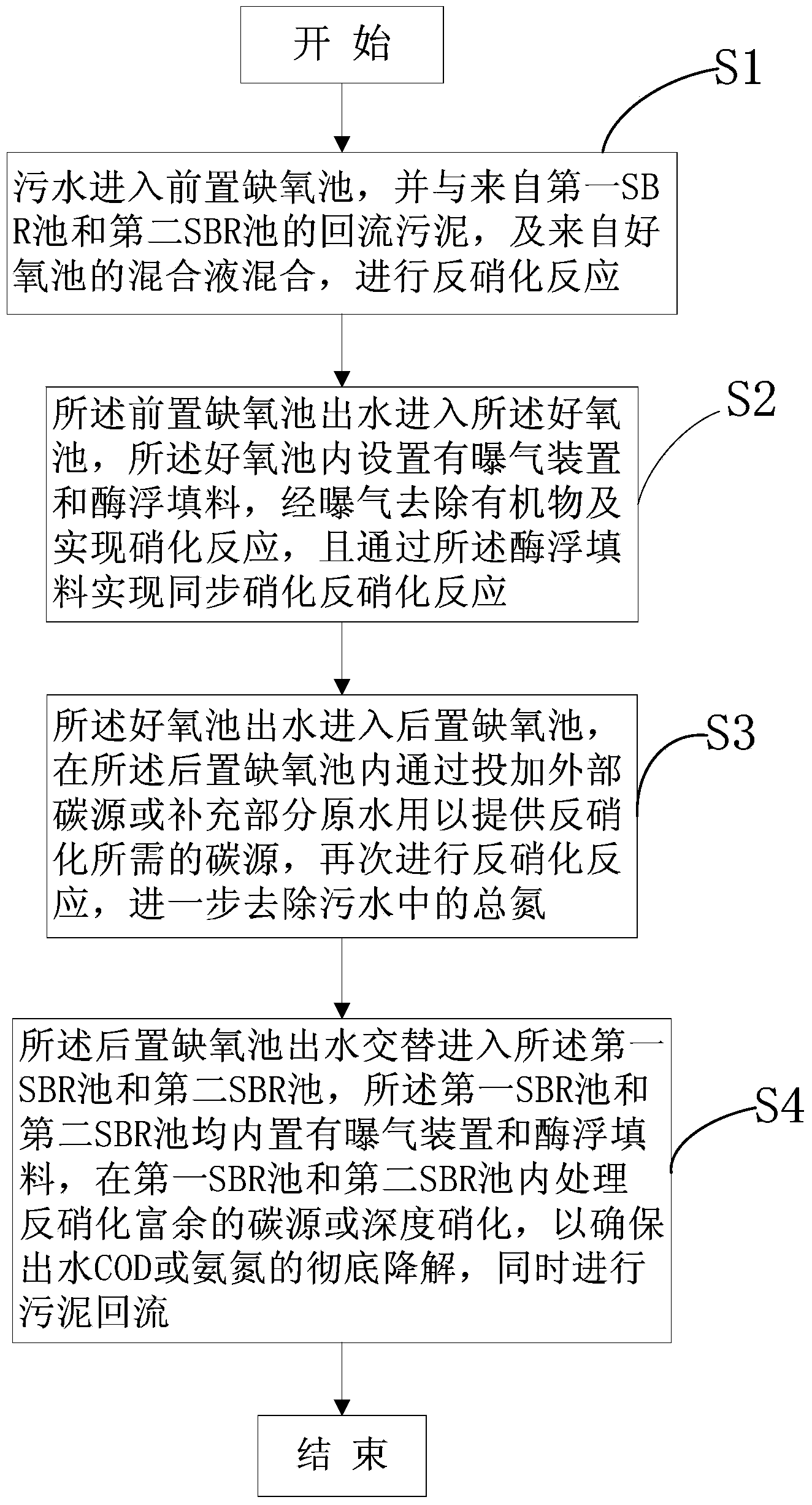

Coupling type biological denitrification method and system thereof

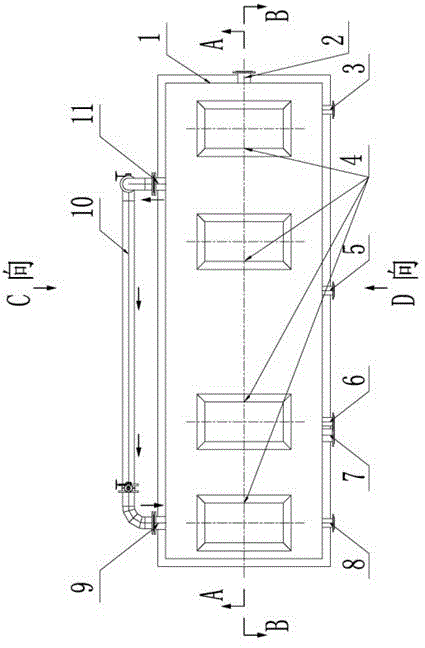

ActiveCN103183454AImprove denitrification effectGood effectMultistage water/sewage treatmentSequencing batch reactorChemical oxygen demand

The invention discloses a coupling type biological denitrification method which comprises the following steps: enabling sewage to enter a front-end anoxic pool, mixing with returned sludge and mixed liquid and carrying out denitrification reaction; entering an aerobic pool, removing an organic matter through aeration, realizing the nitration reaction and synchronizing the nitration reaction and the denitrification reaction; entering a rear anoxic pool and carrying out denitrification reaction again; and alternately entering a first SBR (Sequencing Batch Reactor) pool and a second SBR pool, treating a surplus carbon source generated in the denitrification or deeply nitrating and simultaneously carrying out sludge return. The invention also provides a coupling type biological denitrification system. The coupling type biological denitrification method and the coupling type biological denitrification system have the beneficial effects that pre-denitrification plus aerobic denitrification and CODcr degrading plus post-denitrification plus sequencing batch aerobic reaction are adopted to overcome the influence of an excessive denitrification carbon source on outlet water, the nitrogen removal efficiency is greatly improved, the nitrogen removal effect is remarkable, and the coupling type biological denitrification system is suitable for degrading high ammonia nitrogen and high COD (Chemical Oxygen Demand) wastewater and particularly has an remarkable effect on coal chemical industry wastewater treatment.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

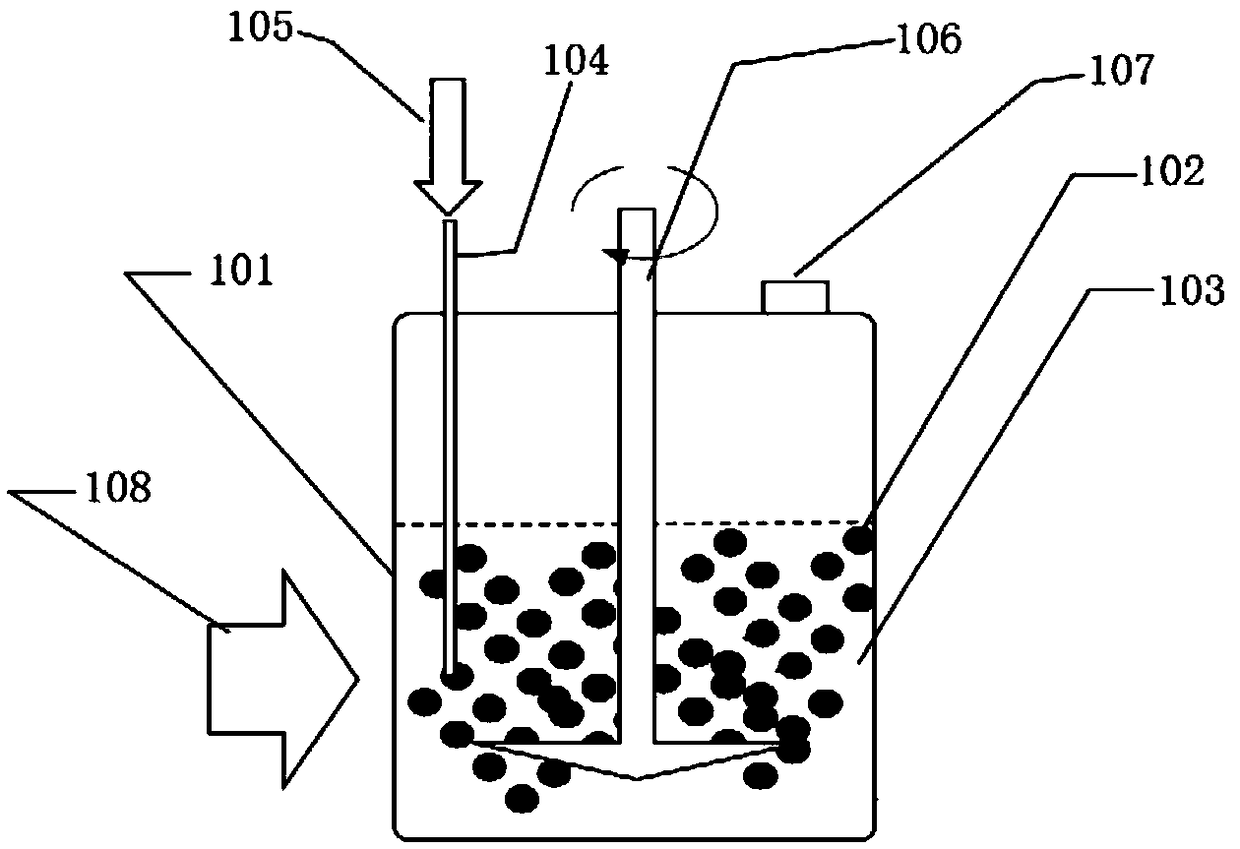

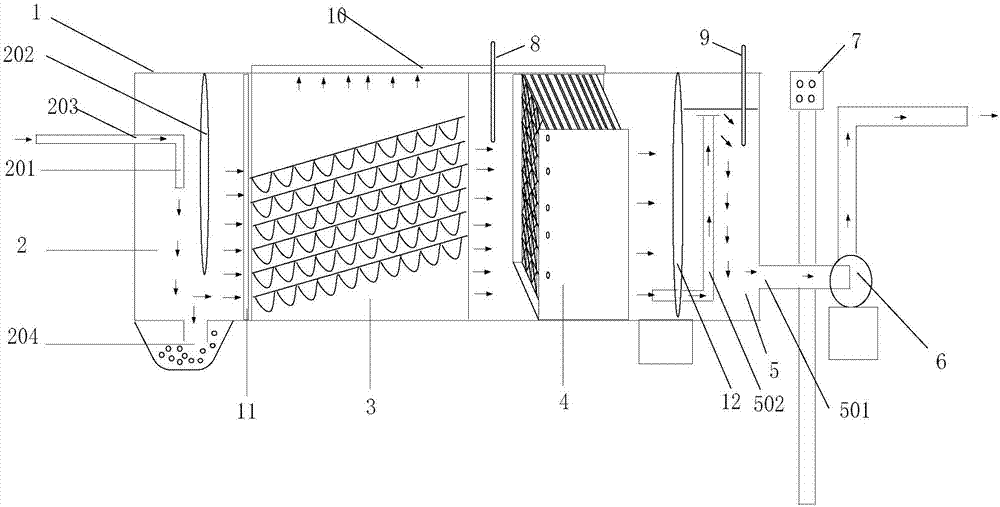

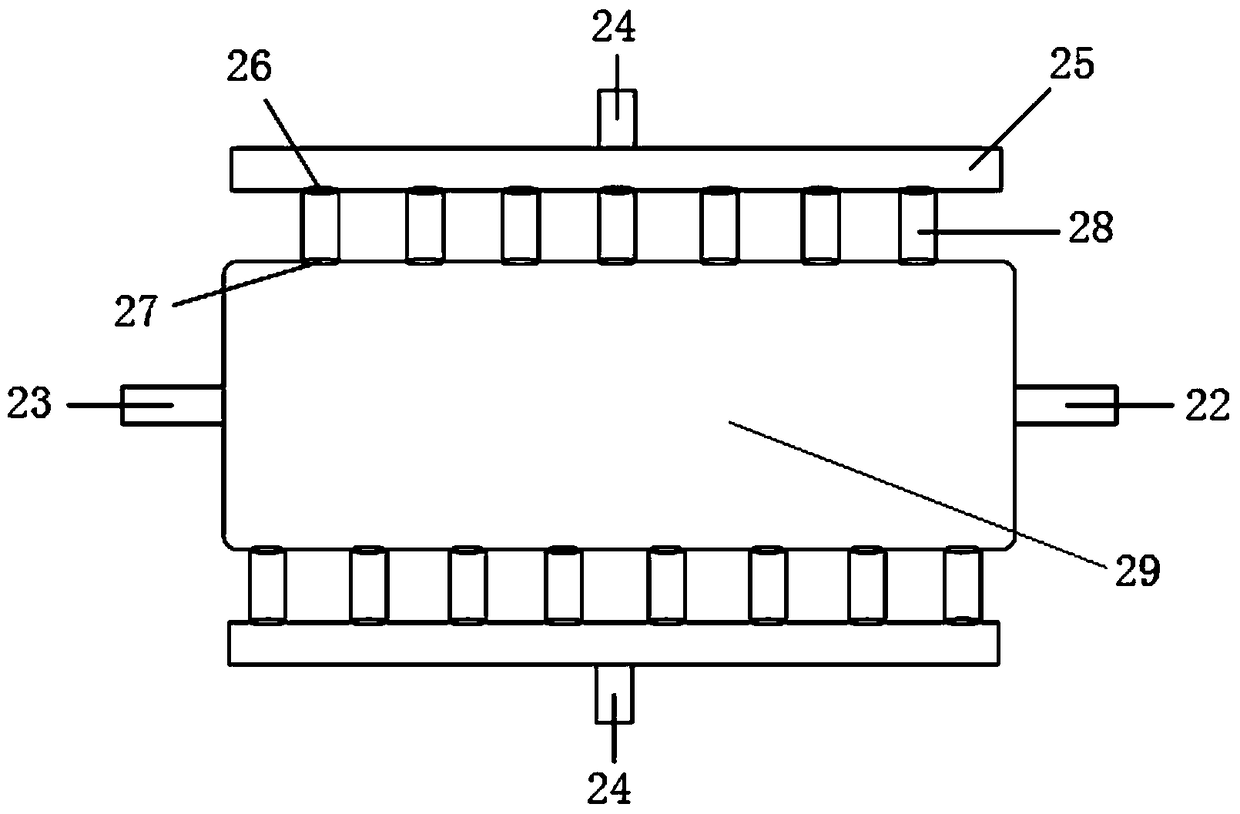

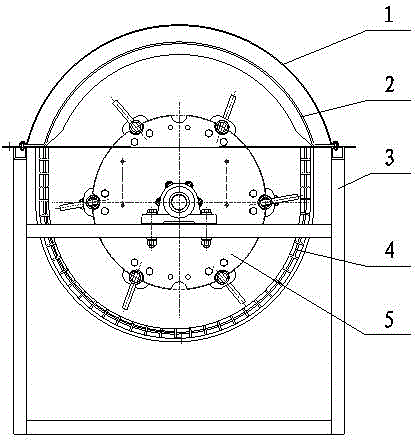

Microalgae cell culture and collection integrated system and method

PendingCN108823072AWell mixedAbsorb evenlyBioreactor/fermenter combinationsBiological substance pretreatmentsIntegrated systemsPhotosynthesis

The invention relates to a microalgae cell culture and collection integrated system and belongs to the technical field of microalgae culture and collection. The culture system comprises a photoreactor, an air inlet pipe, a stirrer, an exhausting port and a light source. One end of the air inlet pipe is inserted into a culture solution of the photoreactor, the stirrer is arranged in the photoreactor, the exhausting port is formed above the liquid level of the culture solution, and the light source is arranged inside and / or outside the photoreactor. The collection system is composed of a filterresidue bed and a collection bed, wherein the filter residue bed is arranged above the collection bed, and the photoreactor and the filter residue bed in the culture system are connected through a pipe. The microalgae cell culture and collection integrated system performs microalgae cell culture by adopting a photosynthesis culture process and then quickly collects microalgae cells through a collecting bed with an inclination angle changing from 0 degree to 90 degrees in a continuous or gradient way, thorough separation of the microalgae cells and a culture solution is ensured, the problem ofunsmooth microalgae cell discharging is also effectively avoided, and the microalgae cell collection efficiency is remarkably improved.

Owner:青岛中科蓝智生物科技发展有限公司

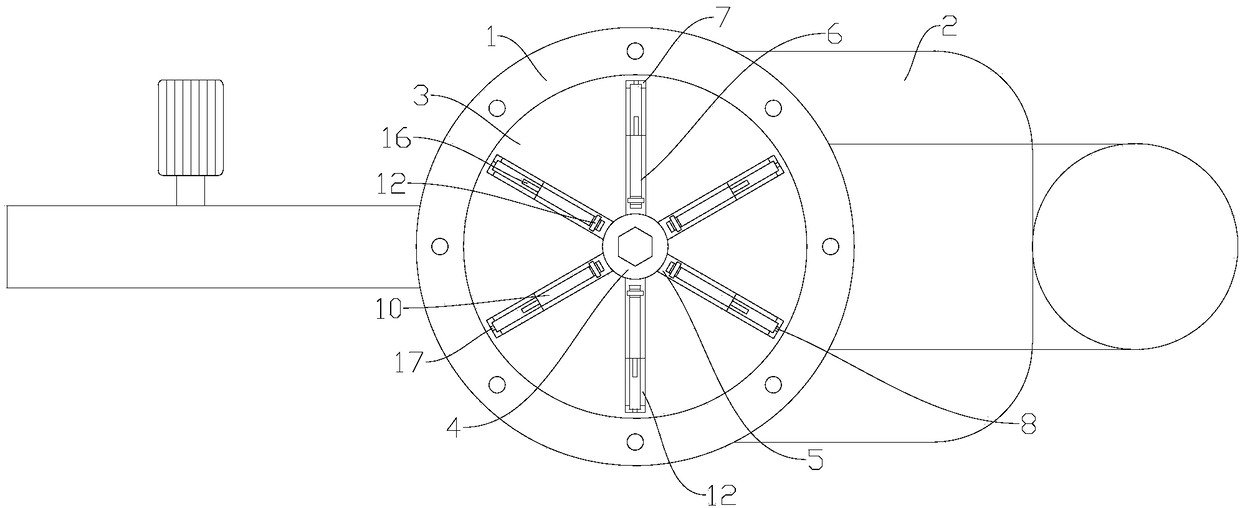

Powder discharging device with adjustable inner structure

PendingCN108854655AIncrease separation areaAdjustable structureTransportation and packagingRotary stirring mixersMotor driveLow speed

The invention relates to the technical field of powder processing and production equipment and in particular relates to a powder discharging device with an adjustable inner structure. According to thepowder discharging device with the adjustable inner structure, provided by the invention, a separation blade with an integrated structure and a lateral stirring frame body located on outer side faceof the separation blade are arranged on an arc-shaped surface of the outer side of an assembling shaft barrel; the separation blade is internally provided with an assembling sliding groove which is internally provided with an external retractable plate; a centrifugal force is generated when a transmission motor drives the separation blade to rotate, so that the separation blade is driven to outward stretch into a lateral sliding groove to be in sliding connection with the lateral stirring frame body; the separation area at the outer side of the separation blade is improved according to a rotary speed and the structure is adjustable, so that the separation efficiency is improved; a longitudinal hoisting opening which is internally provided with a metal counterweight rod is formed in the separation blade and the separation blade is controlled to be automatically reset through an inclined adjusting groove inserted into the assembling sliding groove and a stirring effect is not influencedunder low-speed operation, and the functionality and the practicability are greatly improved.

Owner:张家港市沃尔特精密机械有限公司

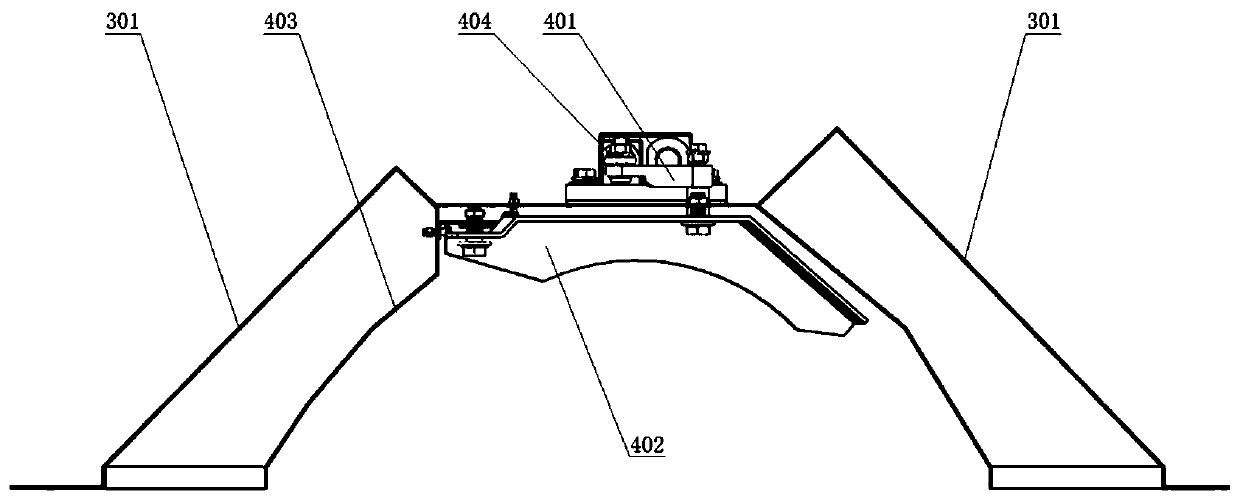

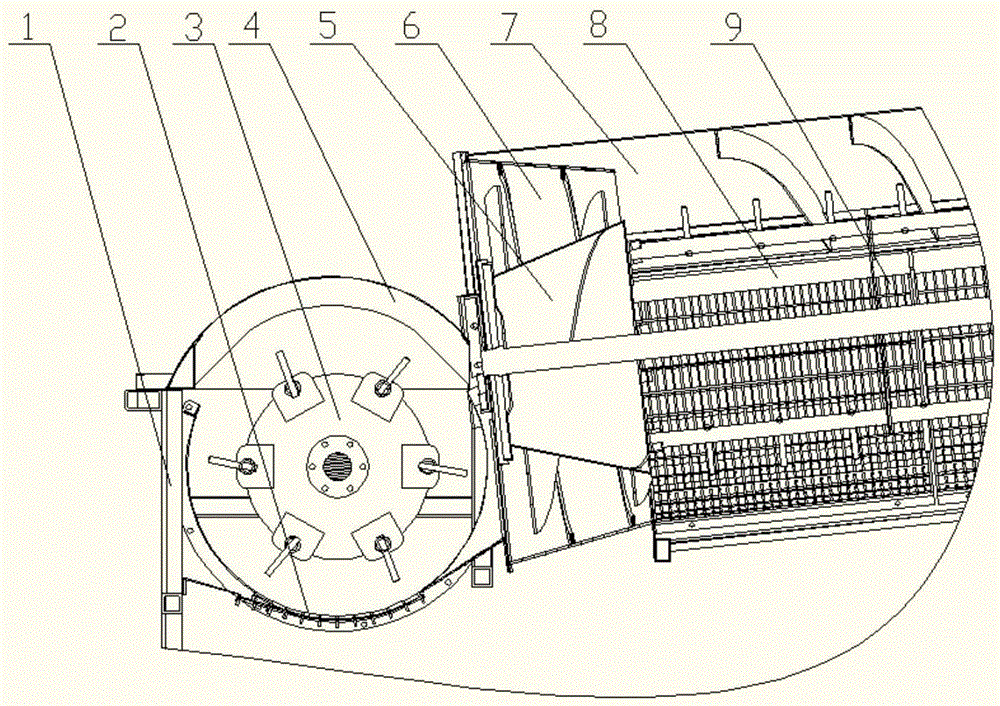

Tangential and longitudinal axial flow roller butt-joint negative pressure airflow feeding device

The invention provides a tangential and longitudinal axial flow roller butt-joint negative pressure airflow feeding device which comprises a tangential flow threshing separation device, a conical spiral feeding device, a conical flow guide cover assembly and a longitudinal axial flow threshing separation device. An area for containing a tangential roller is defined by a tangential flow concave grid assembly and a tangential flow top cover in the tangential flow threshing separation device. The two ends of a concave grid plate in the tangential flow concave grid assembly are each coaxially connected with a fixing arc plate. A feeding flat plate and two supporting arc plates connected with the two ends of the feeding flat plate are welded to the inlet of the concave grid plate along the tangent line. An arc punching cross connecting plate connected with the rear end of the concave grid plate is welded between the two fixing arc plates, is of a concave structure and is provided with a plurality of through holes. A concave grid baffle is welded to the joint between the arc punching cross connecting plate and a lower flow guide cover. The problem that tangential and longitudinal axial flow threshing separation device is prone to blockage at the large- feeding-amount position is avoided, and tangential flow and longitudinal axial flow mechanical conveying and airflow conveying performance is better exploited.

Owner:JIANGSU UNIV

Hard bone liquefaction equipment and method for synchronously producing bone collagen polypeptides and ultrafine bone powder

ActiveCN109007235AEasy to handleImprove processing efficiencyConnective tissue peptidesTransportation and packagingEngineeringBiomedical engineering

The invention discloses hard bone liquefaction equipment. The hard bone liquefaction equipment comprises an outer chamber, a first liquefaction chamber, a stainless steel cage and a second liquefaction chamber; an upper cap is arranged at the upper end of the outer chamber in a detachable way, and a lower sealing cap which can be opened / closed so as to have the outer chamber sealed is arranged atthe lower end of the outer chamber; the first liquefaction chamber which is capable of vertically sliding is coaxially arranged in the outer chamber; the stainless steel cage is coaxially arranged infirst liquefaction chamber; and a top surface of the second liquefaction chamber is fixedly connected to an outer side wall of the outer chamber so as to have the lower end of the outer chamber positioned inside the second liquefaction chamber. The invention further provides a method for synchronously producing bone collagen polypeptides and ultrafine bone powder on basis of the hard bone liquefaction equipment. The method for synchronously producing the bone collagen polypeptides and the ultrafine bone powder comprises the following steps: selecting hard bones, and carrying out crushing; carrying out first-stage liquefaction and second-stage liquefaction so as to obtain a liquid phase and a solid phase; performing centrifuging, concentrating and drying on the liquid phase so as to obtainthe bone collagen polypeptides; and performing drying, crude crushing and ultrafine crushing on the solid phase so as to obtain the ultrafine bone powder. The method for synchronously producing the bone collagen polypeptides and the ultrafine bone powder has the beneficial effects of being simplified in processing flow, improved in production efficiency, decreased in production cost and reduced inequipment investment.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI +1

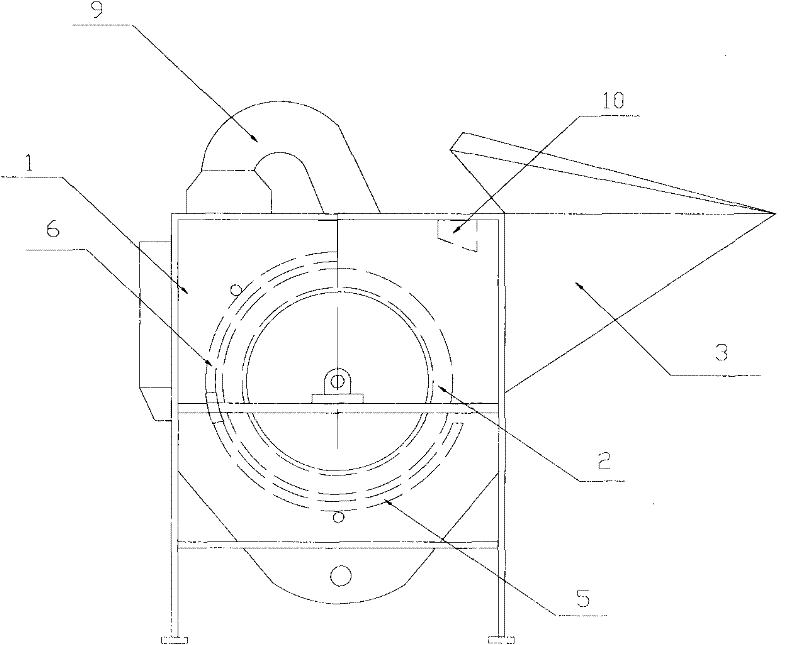

Multifunctional threshing machine

InactiveCN102342212AImprove threshing efficiencyEasy threshingThreshersAgricultural engineeringThreshing machine

The invention discloses a multifunctional threshing machine, which comprises a frame with an open upper part, a feeding hopper, a separator, a residue discharge hole, a threshing cylinder and a lower screen below the threshing cylinder, wherein the feeding hopper is fixedly connected to the front side of the frame close to the left end; the front side of the frame is provided with a through hole communicated with the feeding hopper; an upper screen is arranged above the threshing cylinder; the upper screen can cover the upper half part of the threshing cylinder; a movable cover plate is arranged above the upper screen; a fixed cover plate is arranged at one side of the movable cover plate close to the feeding hopper; the fixed cover plate is provided with a guide plate at a feeding hole; and an arc-shaped partition plate is respectively arranged at the upper part and the lower part of the right side of the cylinder, the two partition plates are staggered, the partition plates are positioned between two adjacent columns of arc teeth of the threshing cylinder, and two ends of the partition plates are fixedly connected with the frame respectively. The multifunctional threshing machine can be applied to various crops, is convenient to use, and has high efficiency and little waste.

Owner:CHENGDU JINCHUANTIAN AGRI MACHINE MFG

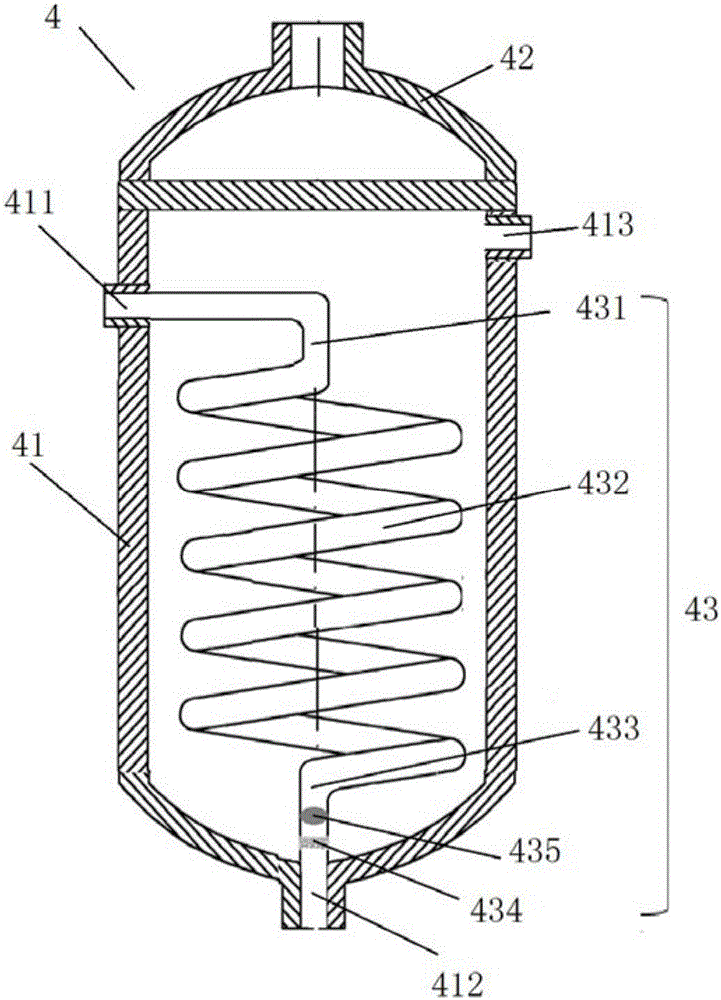

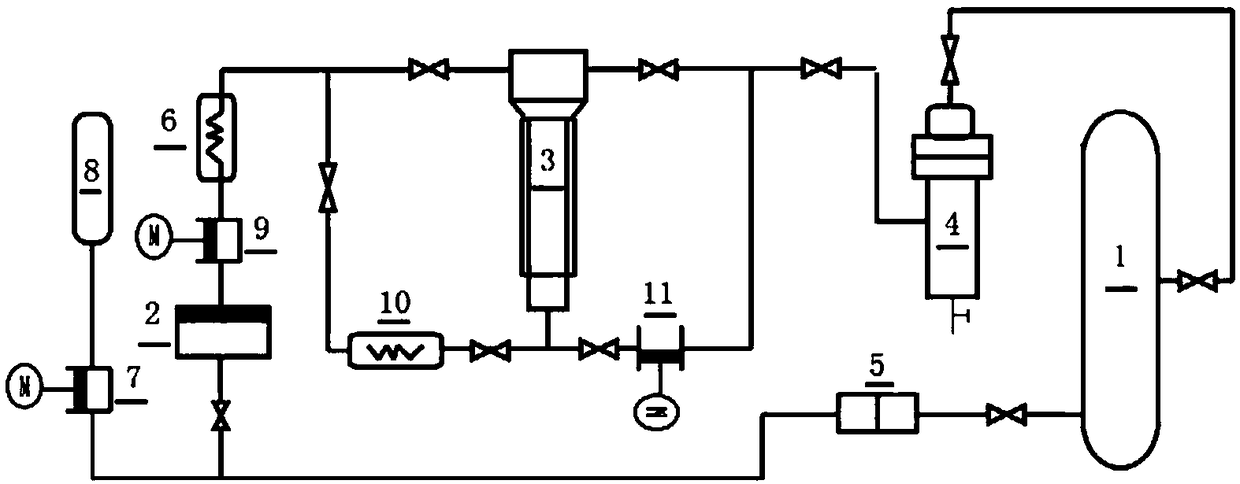

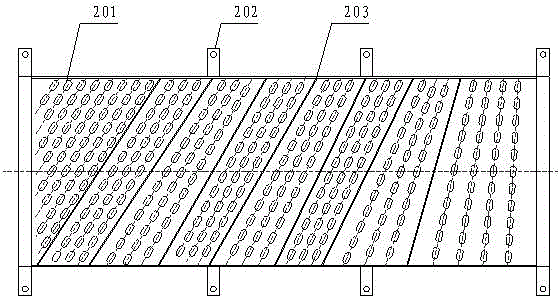

Supercritical CO2 waterless boiling-off device and boiling-off method for flax roving

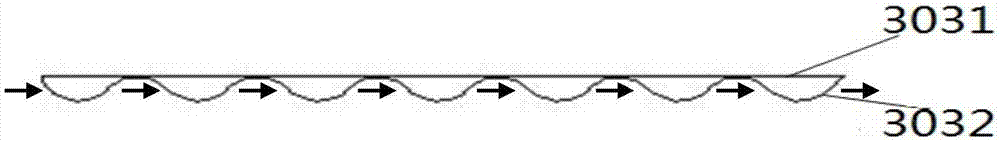

ActiveCN106801307AIncrease separation areaRealize clean scouring productionTextile treatment containersSolvent treatment with solvent recoveryBreaking strengthSingle fiber

The invention discloses a supercritical CO2 waterless boiling-off device and boiling-off method for flax roving. The structure of a separator and a boiling-off process are improved on the basis of the prior art, and when boiling-off is conducted, the flax roving is sequentially placed in a boiling-off kettle and subjected to boiling-off for 30-60 min under the conditions that the temperature ranges from 30 DEG C to 120 DEG C, the pressure ranges from 8 MPa to 20 MPa, and the CO2 fluid flow is 10-50 g / min when the supercritical CO2 state is achieved. For the flax roving obtained after boiling-off, the weight loss ratio is 7%-10%, the residual gum ratio is 8%-12%, the single fiber breaking strength is 6-12 cN / dtex, and the elongation at break is 4%-7%. According to the device and method, a water medium is replaced with CO2 to achieve clean boiling-off production of the flax roving, the overall boiling-off process is free of pollution or discharge, and the modern life ideas of fashional flax spinning and green flax spinning are embodied.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

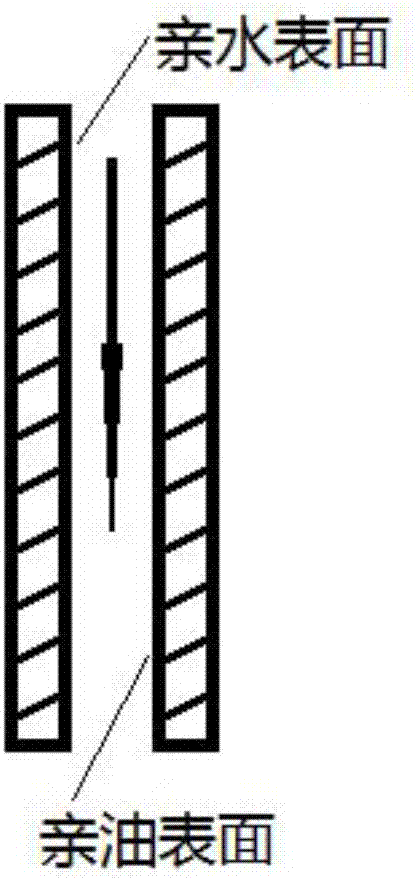

Liquid-liquid separation method constructed by difference of plate type solid surface force field

ActiveCN107349638ATo achieve the separation effectGood effectNon-miscible liquid separationEngineeringOil water

The invention discloses a liquid-liquid separation method constructed by difference of a plate type solid surface force field. The method comprises the following steps: a to-be-separated oil-water mixed liquid flows through a gap between a panel A and a panel B, wherein the surfaces of the panel A and the panel B separately have hydrophilic and hydrophobic properties and hydrophilic and oleophobic properties; and different adhesive forces are generated by means of the difference of surface force field of the surfaces of the panel A and the panel B on the oil-water mixed liquid and the through liquid is collected and left to stand to separate oil and water. The separation method disclosed by the invention not only comprises coalescent and separation processes of a diffused phase, but also comprises coalescent and separation processes of a continuous phase, so that the separating time is shortened, and the separating effect is improved. The method has a good effect in oil-water separation process, demulsifying process and extraction process.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

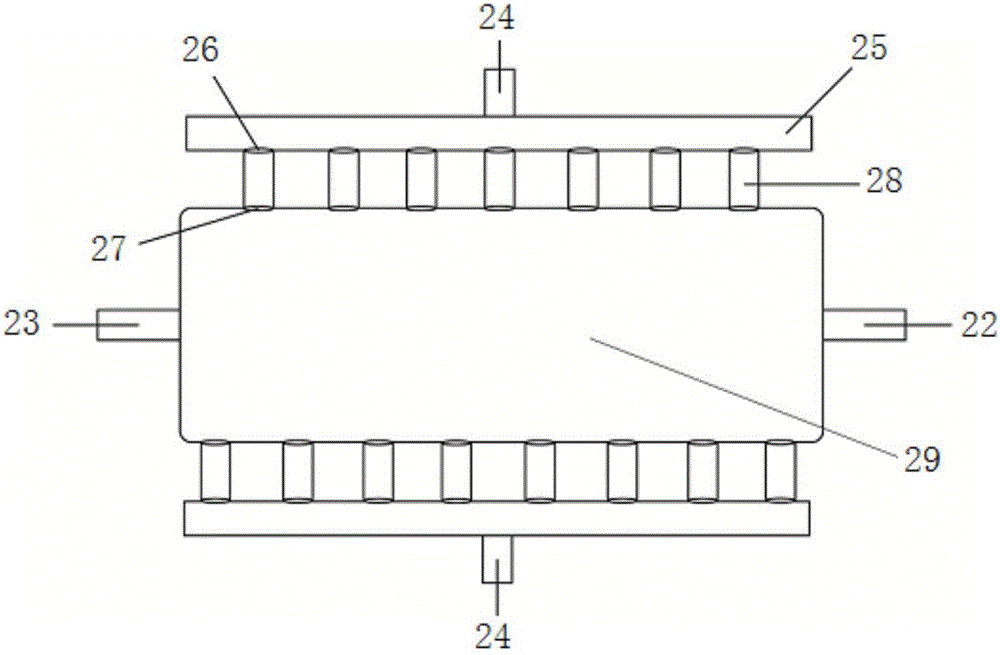

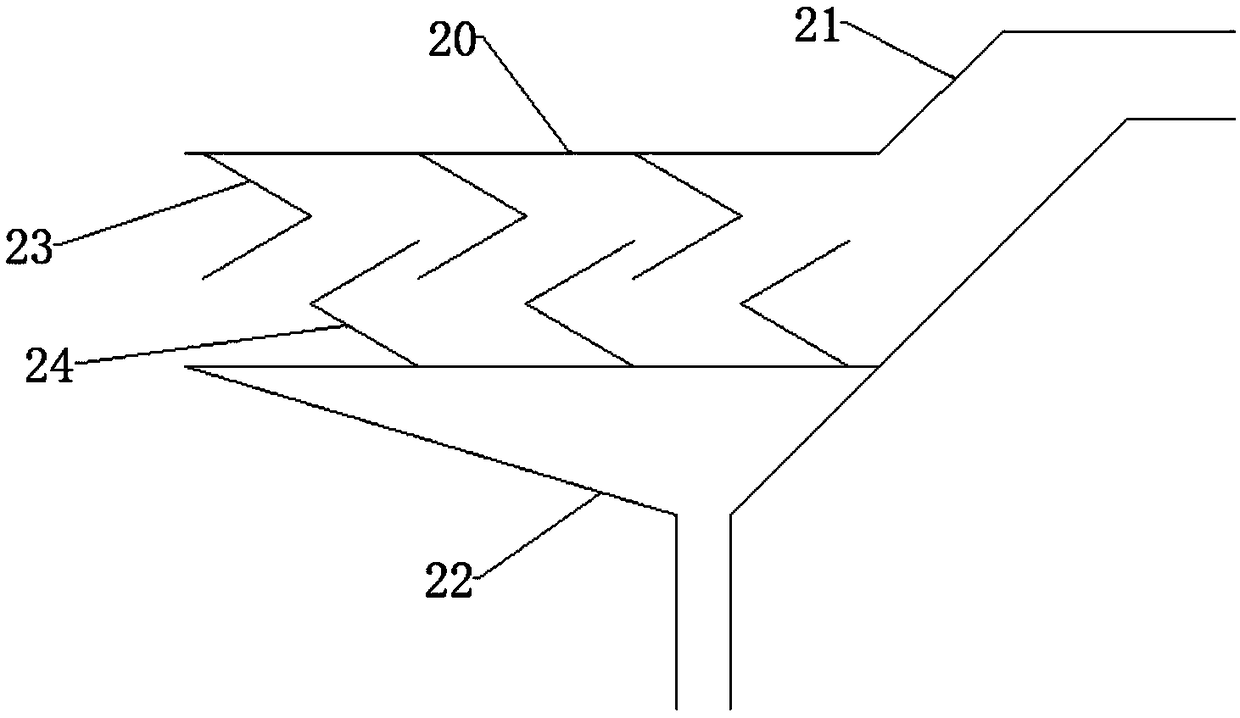

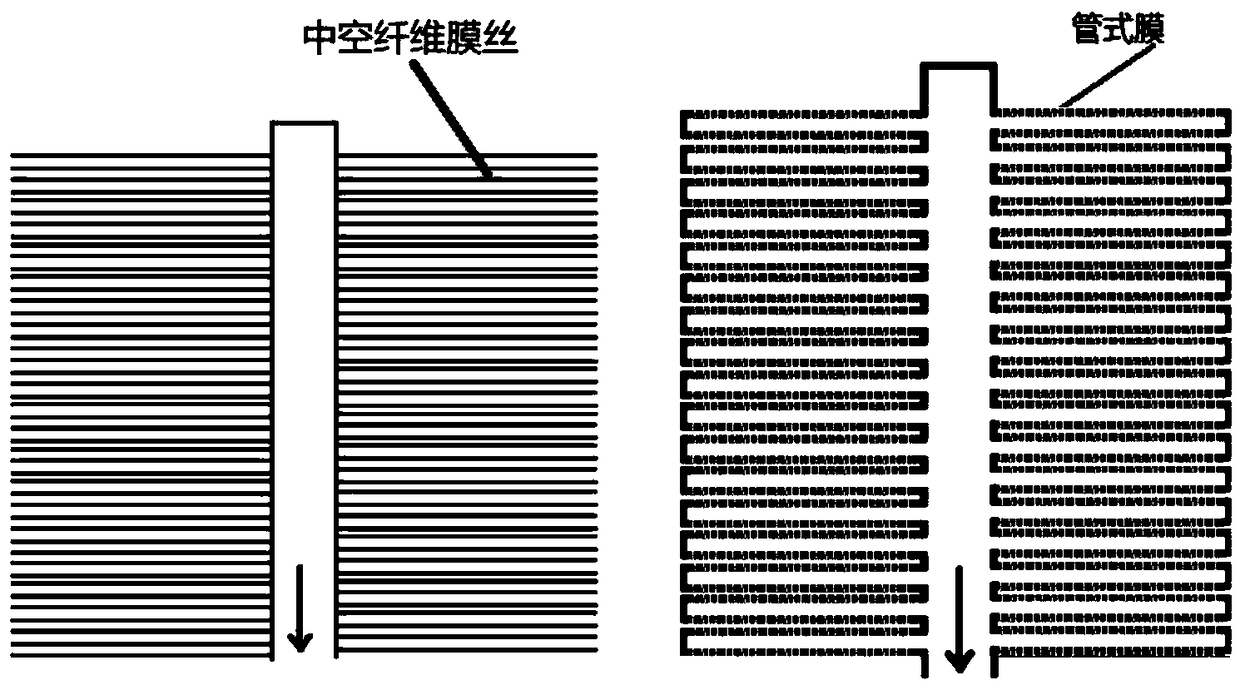

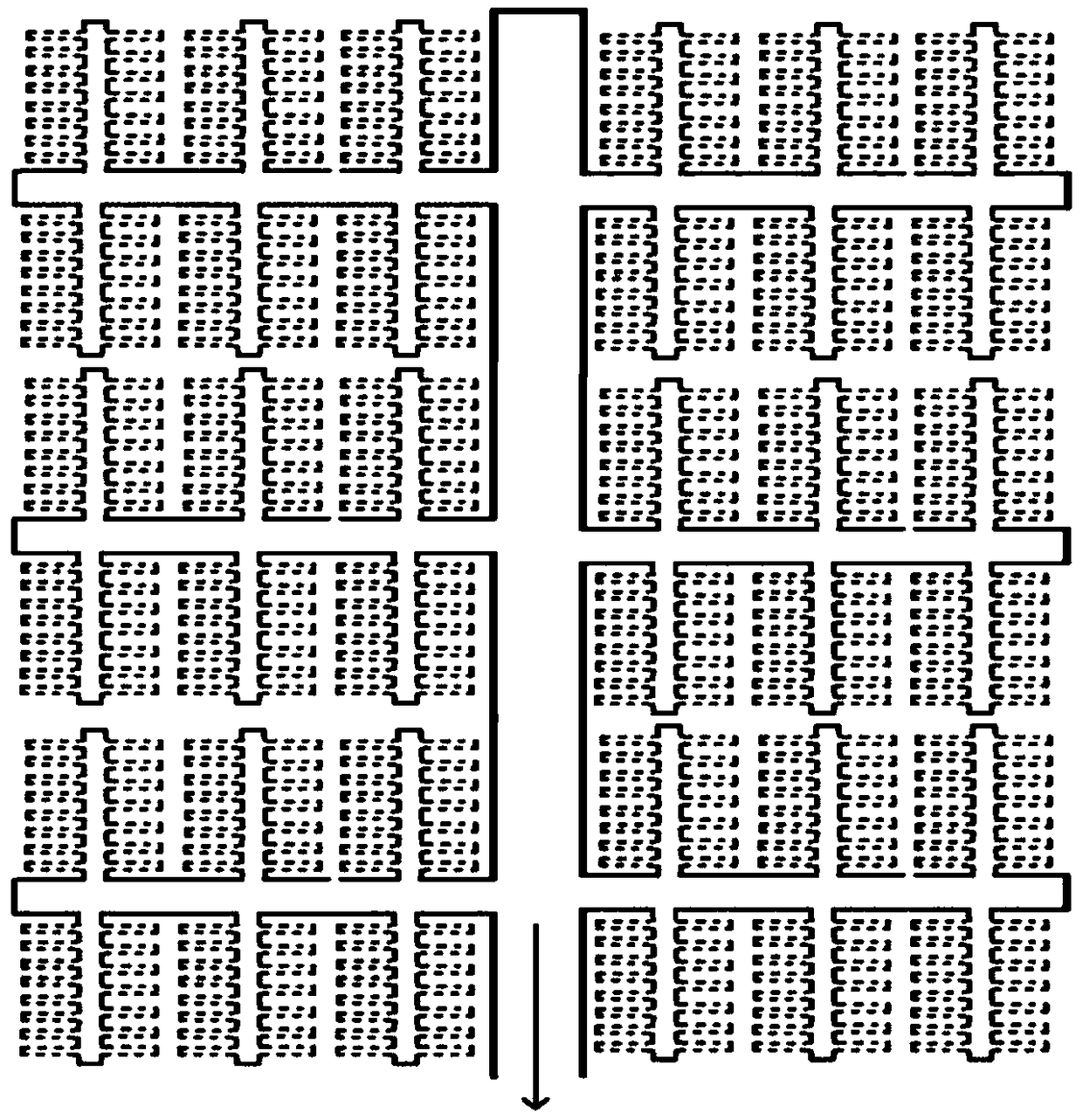

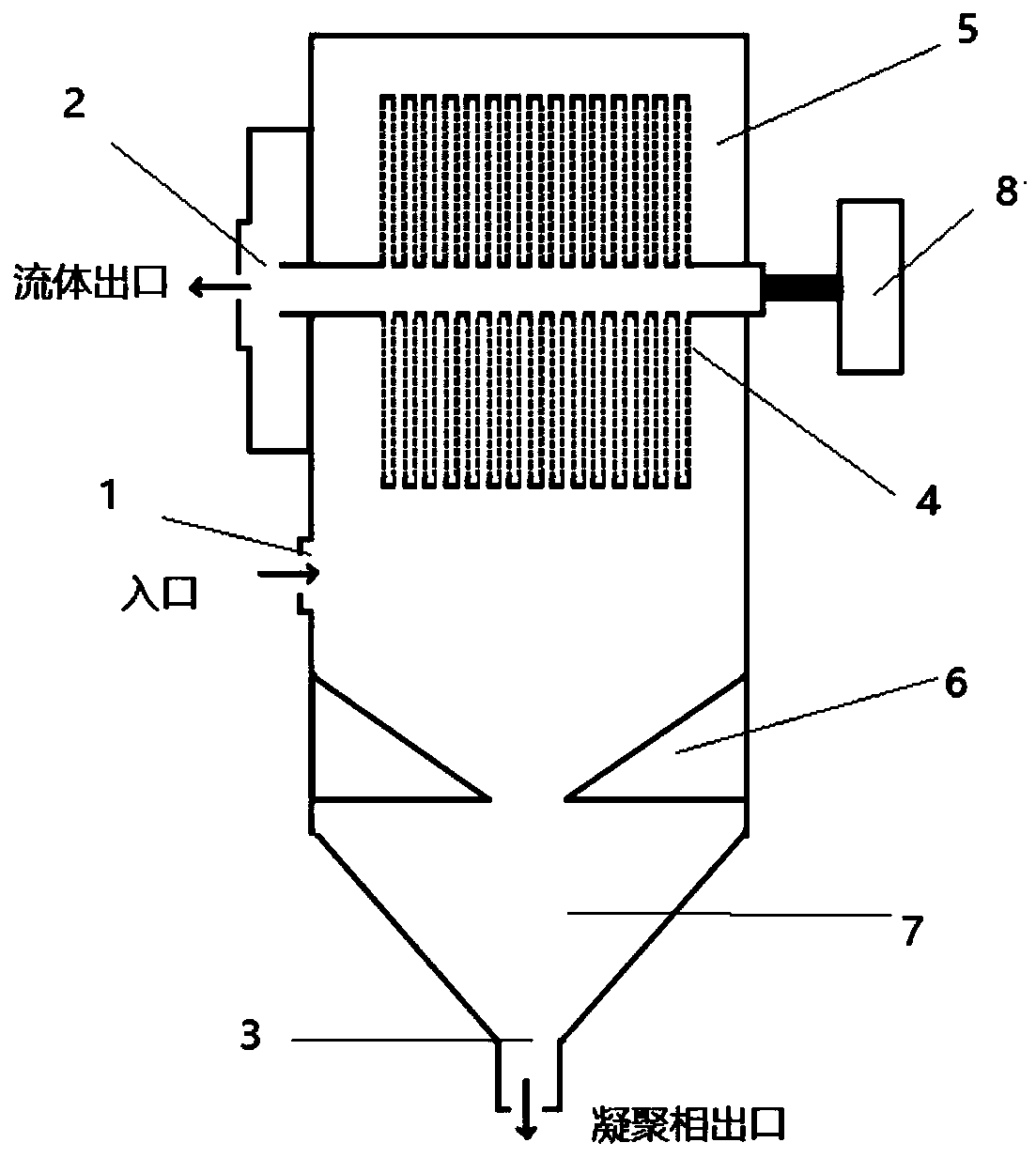

Heterogeneous phase separation device with tubular type fractal structure

PendingCN108722095AIncrease separation areaImprove separation efficiencyCombination devicesFiltration circuitsCENBOLContinuous operation

The invention discloses a heterogeneous phase separation device with a tubular type fractal structure. The heterogeneous phase separation device comprises a separation chamber, a motor, and fractal assemblies; the separation chamber is a column body; the upper end of the column body is sealed, the side surface is provided with a heterogeneous phase fluid inlet, the lower end is provided with a settling chamber; the bottom end of the settling chamber is provided with a condensed phase outlet; the fractal assemblies are arranged at the upper part of the separation chamber, are inserted into thetubular wall of a fluid channel in a centrosymmetrical manner; one end of the fluid channel is connected with the motor, and is taken as a rotating shaft, and is driven by the motor arranged on the external side surface of the separation chamber to rotate, and the other end of the fluid channel is designed to stretch out from the separation chamber to form a continuous phase fluid outlet. The heterogeneous phase separation device is capable of avoiding separation device blocking, prolonging separation device continuous operation time obviously; the motor is adopted to drive the tubular type fractal structure to rotate, or the tubular type fractal structure is pushed by fluid to rotate, so that gas flow turbulence is enhanced, the amount of accumulated solid on branch pipe walls is reducedby more than 90%, and the separation device continuous operation time is prolonged by 2 to 5 times.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

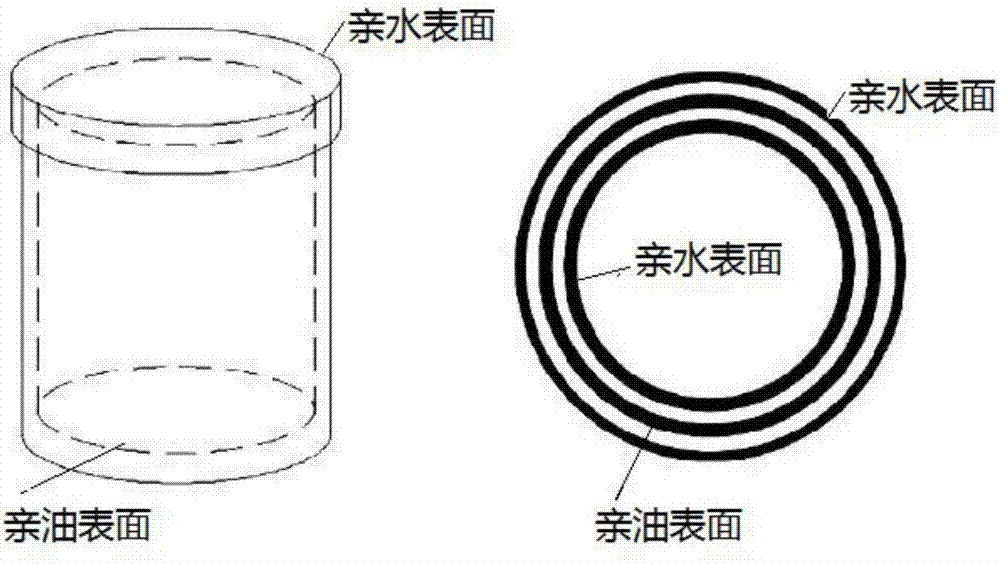

Liquid-liquid separation method constructed by cylindrical soil surface force field differences

ActiveCN107569872AIncrease separation areaImprove the separation effectLiquid separationEngineeringSeparation method

The invention discloses a liquid-liquid separation method constructed by cylindrical soil surface force field differences. The liquid-liquid separation method comprises the following steps: enabling ato-be-separated oil-water mixed solution to flow through a gap between a cylindrical material A and a cylindrical material B, wherein the surfaces of the cylindrical material A and the cylindrical material B respectively have lipophilic-hydrophobic property and hydrophilic-oleophobic property; producing different adhesive force by virtue of the surface force field differences of the surfaces of the cylindrical material A and the cylindrical material B to the oil-water mixed solution, collecting the passing liquid, and standing, thereby realizing oil-water separation. The separation method disclosed by the invention comprises a coalescence and separation process of a dispersion phase and further comprises a coalescence and separation process of a continuous phase, so that the separation time is shortened, the separation effect is improved, and the method has excellent effects in the oil-water separation process, a demulsification process and an extraction process.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Oily sewage separator

PendingCN107540049AImprove separation efficiencyAchieve separationWaste water treatment from quariesFatty/oily/floating substances removal devicesOily water separatorSludge

The invention discloses an oily sewage separator. There is at least an inlet on the shell at one end of the separator, and at least an outlet on the other end of the shell; a pretreatment device is arranged in sequence from the inlet to the outlet, which is used to settle and store the sludge in the oily sewage; the inclined plate separation device, its top and bottom The ends are closely connected with the top and bottom of the separator for primary oil-water separation; the top and bottom of the coagulation separation device are tightly connected with the top and bottom of the separator for secondary oil-water separation; the sewage conveying device, It is used to accommodate and transport the sewage to be discharged; the top of the sloping plate separation device and the coagulation separation device is provided with an oil tank for receiving and containing the separated oil; the outlet is connected with a delivery pump for pumping the sewage out of the separator. The separator can separate oil droplets with a particle size of more than 20 microns, and the oil removal rate is 99%. The separated sewage meets the national A1 oilfield water injection standard, and the cost is reduced by half, low energy consumption, small size, and a service life of 5-8 years.

Owner:刘超 +1

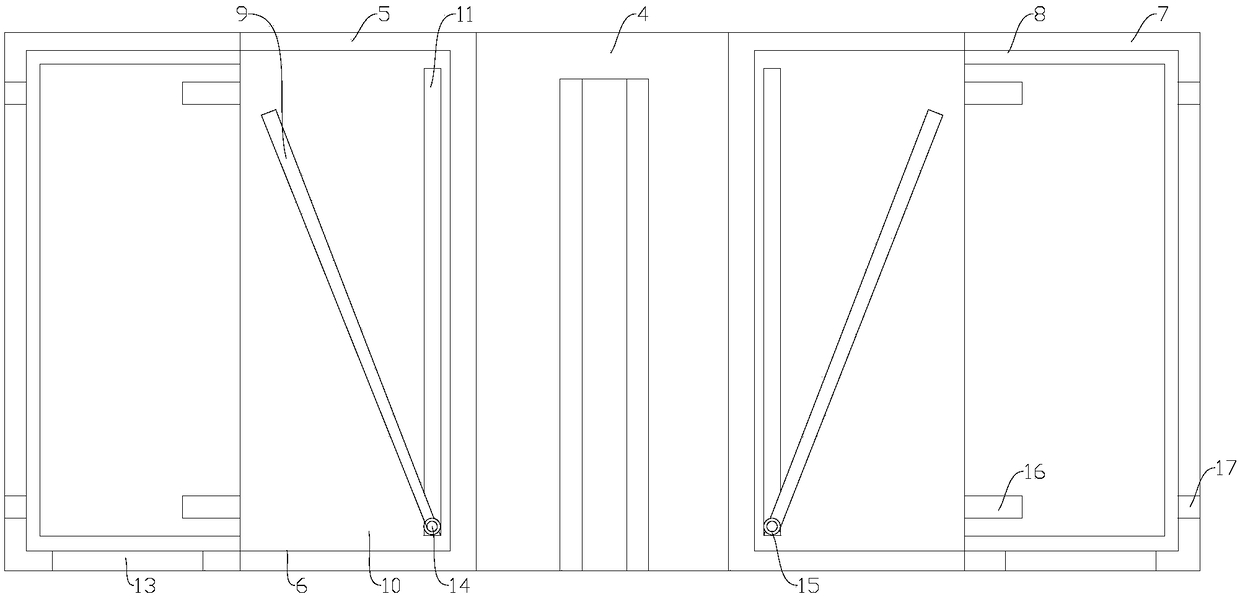

A combined oil separation and recovery equipment

ActiveCN104649453BImprove recycling efficiencyEasy to separateFatty/oily/floating substances removal devicesMultistage water/sewage treatmentModular compositionOil separation

The invention relates to a sewage treatment apparatus, particularly an oil-separation recovery combination apparatus capable of simultaneously recovering heavy oil and light oil. A primary oil-separation recovery heavy oil apparatus, a secondary oil-separation recovery light oil apparatus, an oil collection apparatus and the like are combined into a serial modular combination apparatus, and all the apparatuses are separated by partitions. The oil-separation recovery combination apparatus can simultaneously recover heavy oil, floating oil and partial dispersed light oil substances in sewage, and is beneficial to green circular economy.

Owner:江苏江大环境工程有限责任公司

A flax roving supercritical CO2 biological enzyme scouring device and scouring method thereof

ActiveCN106676788BAchieve hybridInject evenlyTextile treatment containersBiochemical fibre treatmentYarnBreaking strength

The invention discloses a flax thick yarn supercritical CO2 biological enzyme scouring device and a scouring method thereof. Flax thick yarn is placed in supercritical CO2 fluid where a biological enzyme scouring agent is dissolved, flax fibers are swollen for 10-30 min at 30-40 DEG C and 8-15 MPa; the flax thick yarn is scoured for 30-60 min under dynamic conditions of a flow velocity of supercritical CO2 at 10-50 g / min at 40-60 DEG C and 15-25 MPa; the flax thick yarn is processed through a scouring-separation combined process for 10-30 min at 40-60 DEG C and 15-25 MPa; after the scouring, the weight loss rate of the flax thick yarn is 6-12%, the residual gum rate is 7-15%, the single fiber breaking strength is 6-13 cN / dtex, and the elongation at break is 4.5-8.5%. The whole scouring process is free of pollution and has zero release, requirements of commercialized production are met, and the modern life idea of fashionable bast fiber spinning and green bast fiber spinning is embodied.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

Oil-separation recovery combination apparatus

ActiveCN104649453AImprove recycling efficiencyEasy to separateFatty/oily/floating substances removal devicesMultistage water/sewage treatmentModular compositionOil separation

The invention relates to a sewage treatment apparatus, particularly an oil-separation recovery combination apparatus capable of simultaneously recovering heavy oil and light oil. A primary oil-separation recovery heavy oil apparatus, a secondary oil-separation recovery light oil apparatus, an oil collection apparatus and the like are combined into a serial modular combination apparatus, and all the apparatuses are separated by partitions. The oil-separation recovery combination apparatus can simultaneously recover heavy oil, floating oil and partial dispersed light oil substances in sewage, and is beneficial to green circular economy.

Owner:江苏江大环境工程有限责任公司

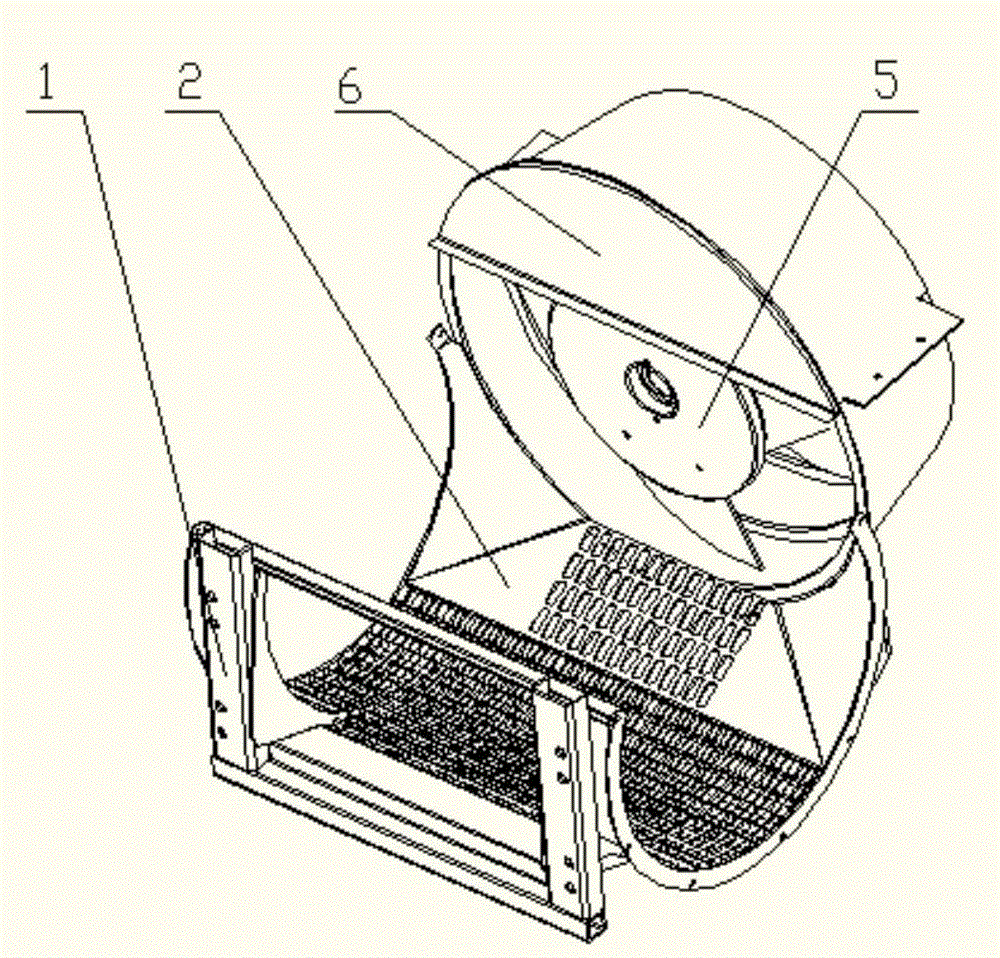

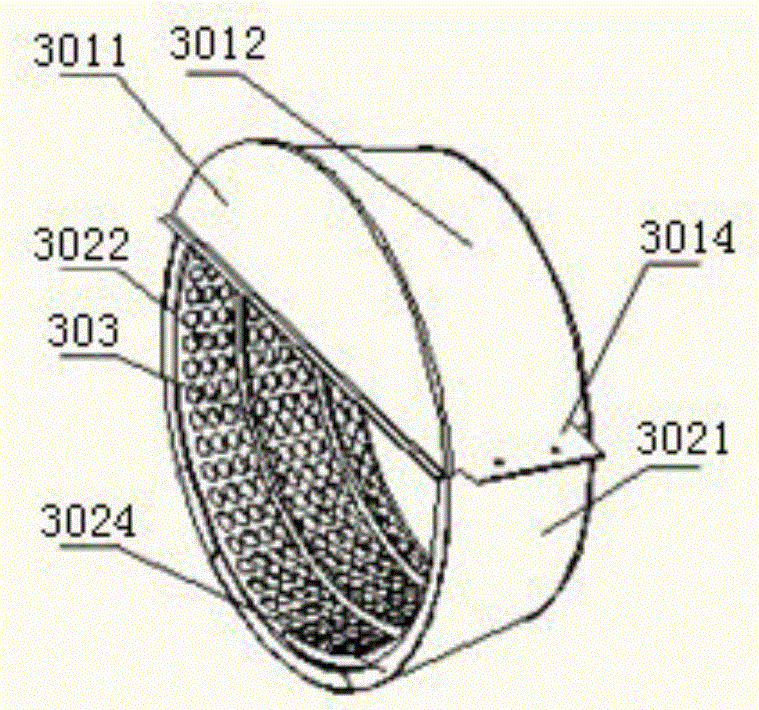

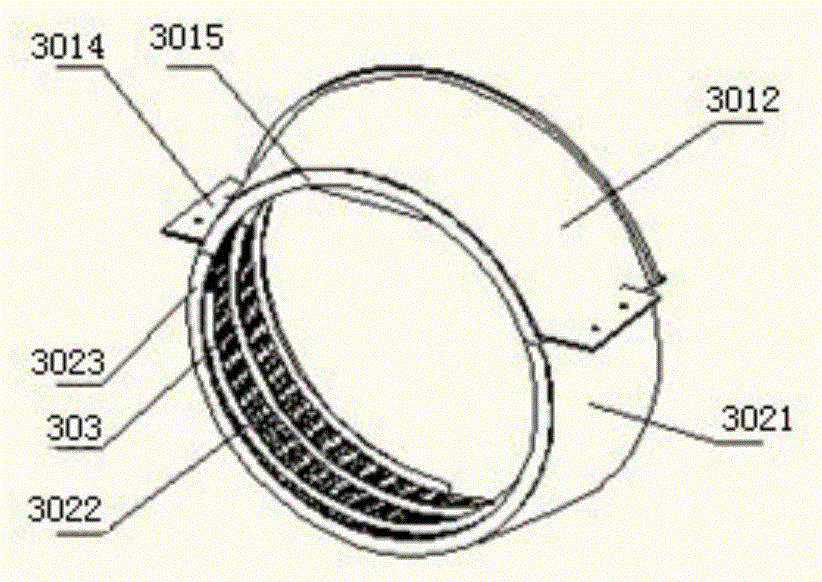

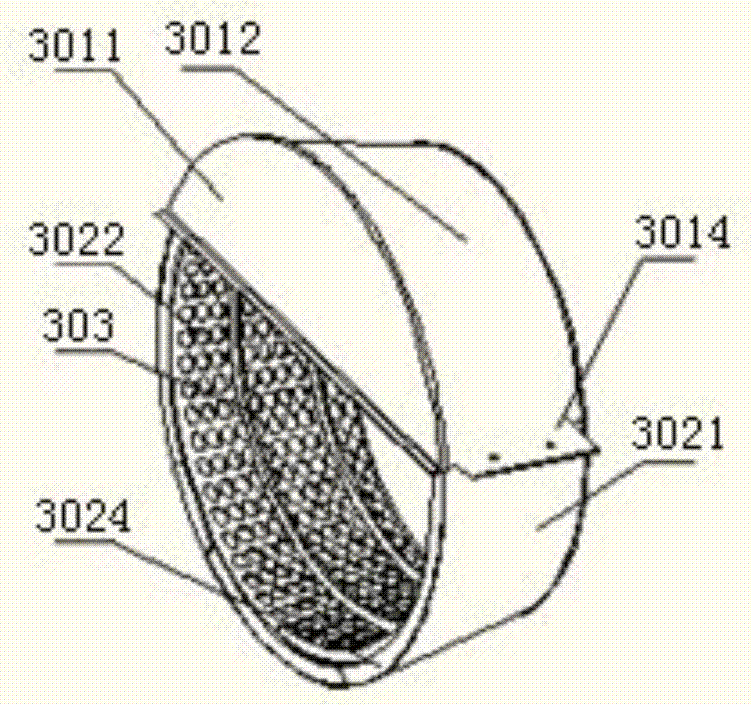

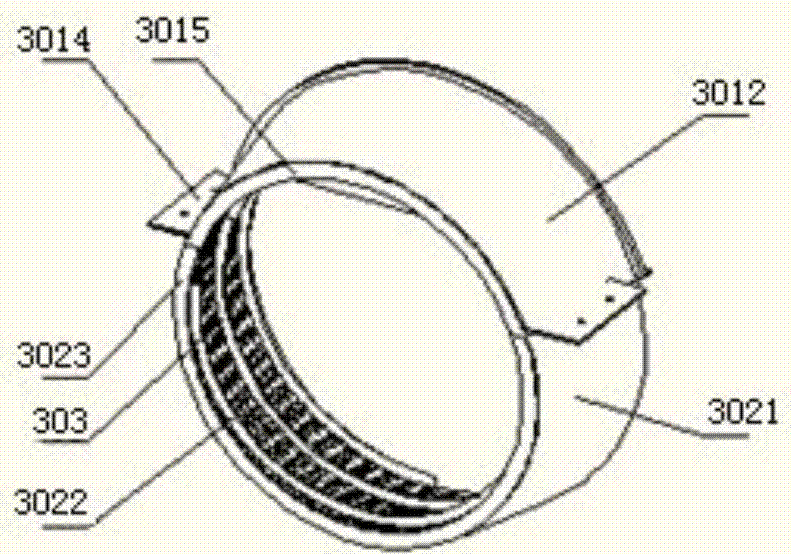

360-degree grain separating double-layer flow guide cover

The invention provides a 360-degree grain separating double-layer flow guide cover. The flow guide cover comprise an upper flow guide cover assembly and a lower flow guide cover assembly which are of a double-layer arc structure, wherein the radius of the double-layer arc structure is gradually reduced from the inlet end to the outlet end. The inner layers of the upper flow guide cover assembly and the lower flow guide cover assembly are punched separating flow guide cover bodies, the outer layers of the upper flow guide cover assembly and the lower flow guide cover assembly are closed flow guide cover bodies, and the arc face of each punched separating flow guide cover body is provided with multiple separating holes; the upper flow guide cover assembly and the lower flow guide cover assembly are detachably connected and form an annular cavity together; the upper flow guide cover assembly comprises a baffle, the upper closed cover body, the upper punched separating flow guide cover body, upper installing lugs and an upper circular ring plate, and the lower flow guide cover assembly comprises the lower closed cover body, the lower punched separating flow guide cover body, a lower circular ring plate, an outlet circular ring plate and lower installing lugs. The grain separating double-layer flow guide cover can increase the grain separating area, improve the separating capacity, and reduce entrainment loss and has high airflow conveying capacity in cooperation with a spiral feeding head.

Owner:JIANGSU UNIV

Multifunctional threshing machine

The invention discloses a multifunctional threshing machine, which comprises a frame with an open upper part, a feeding hopper, a separator, a residue discharge hole, a threshing cylinder and a lower screen below the threshing cylinder, wherein the feeding hopper is fixedly connected to the front side of the frame close to the left end; the front side of the frame is provided with a through hole communicated with the feeding hopper; an upper screen is arranged above the threshing cylinder; the upper screen can cover the upper half part of the threshing cylinder; a movable cover plate is arranged above the upper screen; a fixed cover plate is arranged at one side of the movable cover plate close to the feeding hopper; the fixed cover plate is provided with a guide plate at a feeding hole; and an arc-shaped partition plate is respectively arranged at the upper part and the lower part of the right side of the cylinder, the two partition plates are staggered, the partition plates are positioned between two adjacent columns of arc teeth of the threshing cylinder, and two ends of the partition plates are fixedly connected with the frame respectively. The multifunctional threshing machine can be applied to various crops, is convenient to use, and has high efficiency and little waste.

Owner:CHENGDU JINCHUANTIAN AGRI MACHINE MFG

A threshing device for full-feed combine harvesting

The invention relates to a threshing device for full-feed combined harvesting, which includes a machine body on which a front transverse cutting flow drum, a transition guide plate and a rear longitudinal axial flow roller are installed in sequence, and a front grid is arranged under the front transverse cutting flow roller Grid concave screen, the rear grid concave screen is installed under the rear longitudinal axial flow drum, and the swing vibrating screen is installed under the front grid concave screen and the rear grid concave screen. A fan, a primary auger and a secondary auger are installed at the bottom, and a stalk chopping device is installed behind the swinging vibrating screen; The axial centerlines of the two are on the same straight line; several punching holes are evenly arranged on the transition guide plate. The rear longitudinal axial flow drum includes a threshing gear bar and a feeding head installed at the end of the threshing gear bar. Three helical blades are arranged on the circumferential surface of the feeding head. The invention can improve conveying and threshing ability, increase feeding amount and reduce loss rate.

Owner:WUXI COMBINE HARVESTER

A cutting and longitudinal flow drum butt joint negative pressure airflow feeding device

Owner:JIANGSU UNIV

A kind of flax roving supercritical CO2 biological enzyme bleaching device and bleaching method thereof

ActiveCN106835559BAchieve hybridInject evenlySolvent treatment with solvent recoveryTextile/flexible product manufactureSingle fiberBleach

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

A threshing structure of an L-shaped horizontal and vertical axial flow full-feed combine harvester

InactiveCN103609250BLarge amount of feedImprove work efficiencyMowersThreshersTransverse axisEngineering

The invention relates to the technical field of agricultural machinery, in particular to a threshing structure of an L-shaped horizontal and longitudinal axial flow full-feeding combine harvester. The threshing structure comprises a threshing rack, a vibrating screen arranged on the threshing rack, an air blower and a middle conveyor connected on the upper portion of the front end of the threshing rack, a threshing drum communicated with the rear end of the middle conveyor is arranged on the threshing rack and comprises a horizontal axial flow drum and a longitudinal axial flow drum which are in communicated connection and perpendicular to each other to be L-shaped, two ends of the horizontal axial flow drum are connected with the middle conveyor and the longitudinal axial flow drum respectively, and the middle conveyor and the longitudinal axial flow drum are arranged on two sides of the horizontal axial flow drum respectively. The threshing structure is large in feeding quantity and high in operating efficiency during harvesting, connection of a threshing, cleaning and selecting drum and a discharging port of the middle conveyor is smooth and small in loss, crops in the horizontal axial flow drum are good in threshing, cleaning and selecting effect, and a notch board screen is large in separating area.

Owner:曾联

A 360° grain separation double-layer shroud

The present invention provides a 360° grain separation double-layer shroud, which includes an upper shroud assembly and a lower shroud assembly, both of which are double-layer arc-shaped structures , and the radius gradually decreases from the inlet end to the outlet end; the inner layer of the upper shroud assembly and the lower shroud assembly is a punched separation shroud, and the outer layer is a closed shroud, and the punched separation shroud A plurality of separation holes are opened on the arc surface of the cover; the upper shroud assembly and the lower shroud assembly are detachably connected and jointly form an annular cavity; the upper shroud assembly includes a baffle plate, a closed upper shroud, The punching separates the upper cover, the upper mounting ear, and the upper ring plate; the lower shroud assembly includes, closes the lower cover, punches and separates the lower cover, the lower ring plate, the outlet ring plate, and the lower mounting ear. The grain separation double-layer guide cover of the present invention can increase the grain separation area, improve the separation ability, reduce the entrainment loss, and can also cooperate with the screw feeding head to form a strong air flow conveying ability.

Owner:JIANGSU UNIV

Coupling type biological denitrification method and system thereof

ActiveCN103183454BImprove denitrification effectGood effectMultistage water/sewage treatmentSequencing batch reactorChemical oxygen demand

The invention discloses a coupling type biological denitrification method which comprises the following steps: enabling sewage to enter a front-end anoxic pool, mixing with returned sludge and mixed liquid and carrying out denitrification reaction; entering an aerobic pool, removing an organic matter through aeration, realizing the nitration reaction and synchronizing the nitration reaction and the denitrification reaction; entering a rear anoxic pool and carrying out denitrification reaction again; and alternately entering a first SBR (Sequencing Batch Reactor) pool and a second SBR pool, treating a surplus carbon source generated in the denitrification or deeply nitrating and simultaneously carrying out sludge return. The invention also provides a coupling type biological denitrification system. The coupling type biological denitrification method and the coupling type biological denitrification system have the beneficial effects that pre-denitrification plus aerobic denitrification and CODcr degrading plus post-denitrification plus sequencing batch aerobic reaction are adopted to overcome the influence of an excessive denitrification carbon source on outlet water, the nitrogen removal efficiency is greatly improved, the nitrogen removal effect is remarkable, and the coupling type biological denitrification system is suitable for degrading high ammonia nitrogen and high COD (Chemical Oxygen Demand) wastewater and particularly has an remarkable effect on coal chemical industry wastewater treatment.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

360-degree axial flow threshing separation system

The invention relates to a 360-degree axial flow threshing separation system which is used for 360-degree axial flow threshing separation of a combined harvester. The 360-degree axial flow threshing separation system comprises an axial flow threshing cylinder, a concave plate sieve, a top cover and a frame, and the top cover is of a double-layer structure and comprises a closed upper cover located on the outside and a porous flow guide sleeve located on the inside. A 360-degree separation system is formed by the porous flow guide sleeve above the axial flow threshing cylinder and the concave plate sieve below the axial flow threshing cylinder, and a plurality of separation holes are arranged on an arc cylindrical surface of the porous flow guide sleeve. A plurality of guide stripes are installed on one side of the arc cylindrical surface of the porous flow guide sleeve facing to the cylinder to control residence time and axial movement speed of grains in the threshing separation system. A separation area of the 360-degree axial flow threshing separation system increases by almost one time under the condition that a total size of a threshing separation device is unchanged, clamping loss of grains is reduced, threshing performance is improved, length of the threshing cylinder is shortened, size of a threshing device is reduced, and the 360-degree axial flow threshing separation system is simple in structure, low in cost and convenient to install.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com