Process and system for industrially producing glycosylglycerol

A technology of glucoside and glycerol, which is applied in the direction of supporting/immobilizing microorganisms, biochemical instruments, and sterilization methods, and can solve problems such as death, large harvesting membrane devices, and increased energy consumption for harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

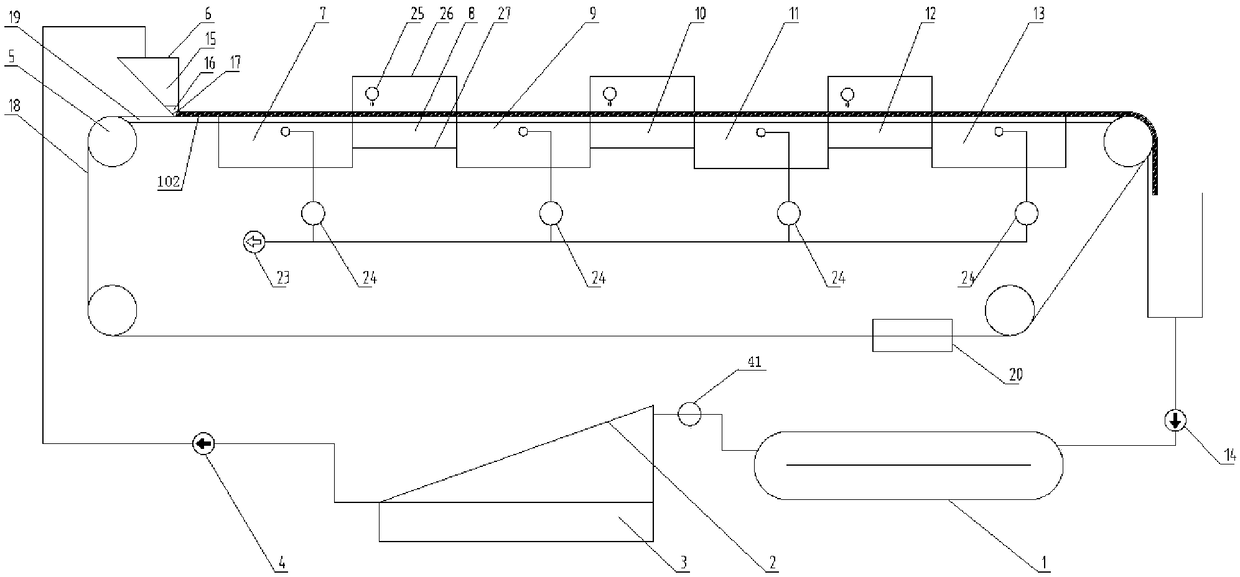

[0115] Such as Figure 1-5 , 7-8, a system for industrialized production of glycerol glucoside, including a cultivation system 1, a harvesting system 2 and an extraction system, the cultivation system 1, the harvesting system 2, and the extraction system are connected in sequence, and the cultivation system 1 is used for the growth of microalgae cells; the harvesting system 2 is used for separating the microalgae cells and culture fluid from the culture system, and sending the microalgae cells into the extraction system after separation.

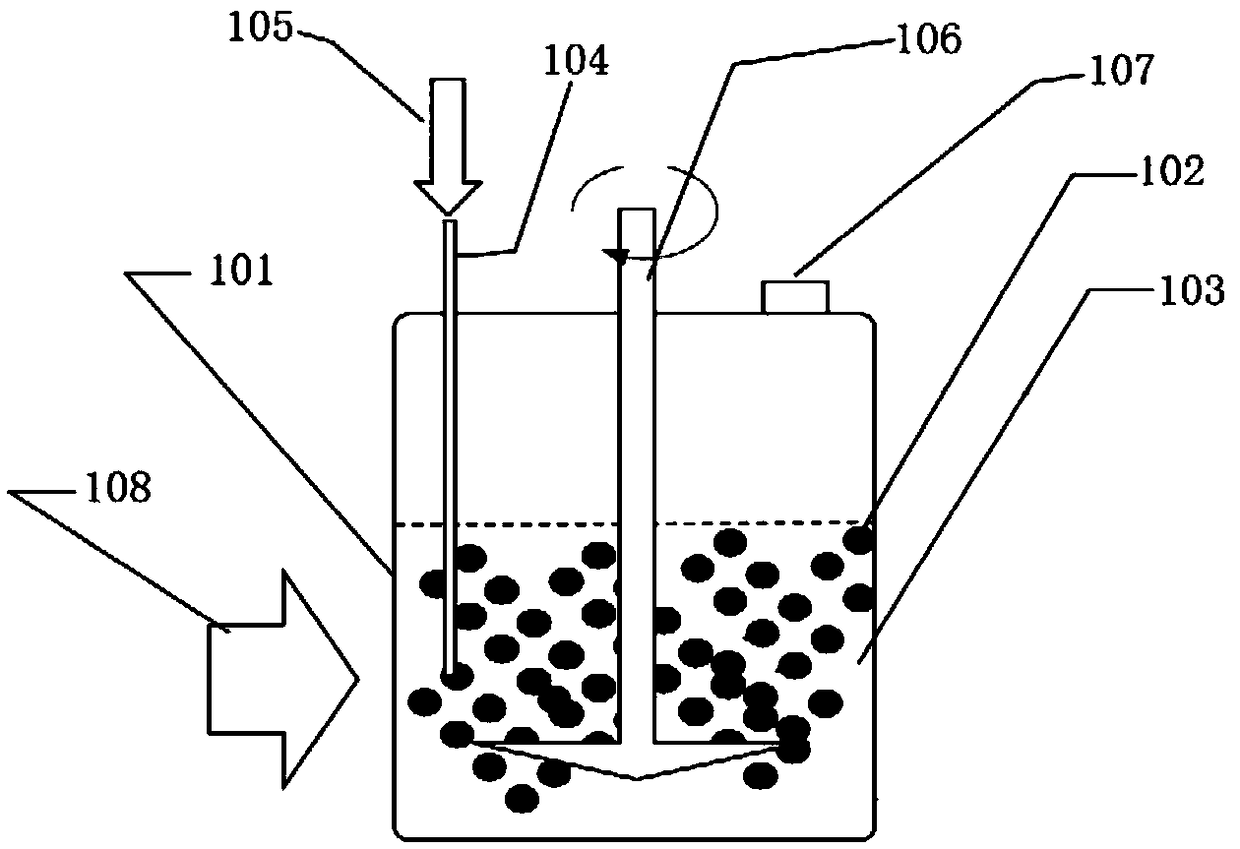

[0116] The culture system includes: a photoreactor 101 , an inlet pipe 104 , a carbon-containing source gas 105 , an agitator 106 , an exhaust port 106 , and a light source 107 .

[0117] The cylindrical photoreactor 101 is filled with a mixture of microalgae cells 102 and culture solution 103, one end of the inlet pipe 104 is inserted into the culture solution 103, and the other end is connected to the gas source of the carbon source gas 10...

Embodiment 2

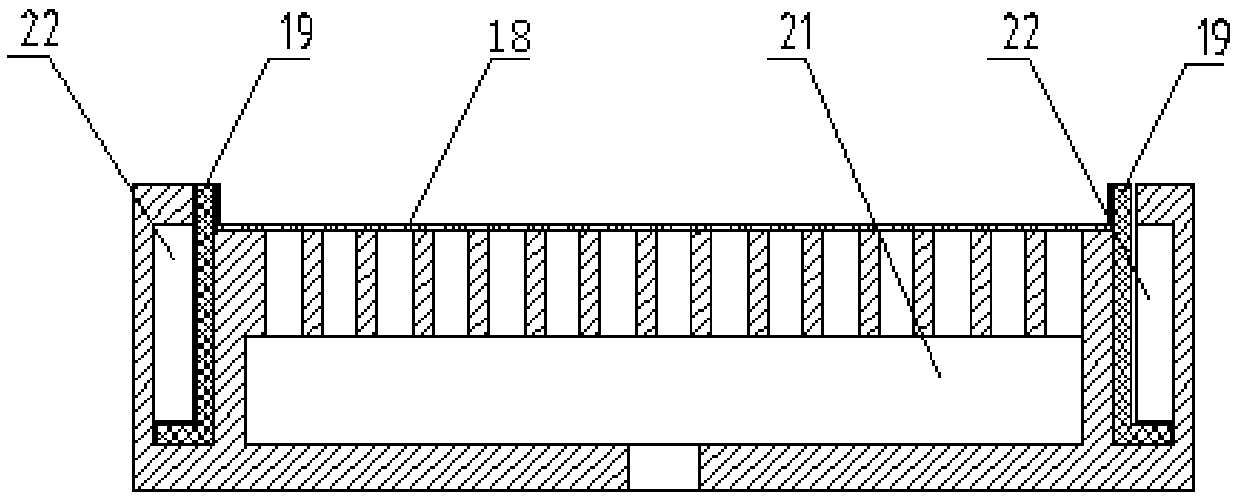

[0155] A system for industrialized production of glycerol glucoside is the same as that in Example 1, except that: (1) the bed surface of the filter residue bed 29 is made of a hard membrane material with membrane pores of 80 mesh.

[0156] (2) The bed surface of the recovery bed 30 is made of soft filter cloth with membrane holes of 100 mesh.

[0157] (3) The bed surface of the recovery bed 30 is divided into 4 gradients with respect to the inclination angle α gradient of the horizontal plane, followed by α 1 =5°, α 2 =15°, α 3 = 45°, α 4 =85°, such as Figure 6 shown.

[0158] (4) The uniform material port 16 is a combined device of a silo discharge port and a distribution plate. The silo discharge port injects the algae mud into the filter belt, and the accumulated algae mud is spread on the filter belt by the distribution plate.

[0159] (5) The filter belt 18 is made of a membrane material with a filter aperture of 1000 mesh.

Embodiment 3

[0161] A system for industrialized production of glycerol glucoside is the same as that in Example 1, except that: (1) the bed surface of the filter residue bed 29 is made of a hard membrane material with membrane pores of 30 mesh.

[0162] (2) The bed surface of the recovery bed 30 is made of soft filter cloth with membrane holes of 400 mesh.

[0163] (3) The material equalizing port 16 is a combined device of a silo discharge port and a distribution rod, the silo discharge port injects the algae mud into the filter belt, and the piled algae mud is spread on the filter belt by the distribution rod.

[0164] (4) The filter belt 18 is made of a membrane material with a filter aperture of 600 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com