A 360° grain separation double-layer shroud

A diversion cover, double-layer technology, applied in the field of separation diversion cover, can solve the problem of increasing the separation area of grains, such as the airflow conveying effect, and achieve the effect of low cost, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

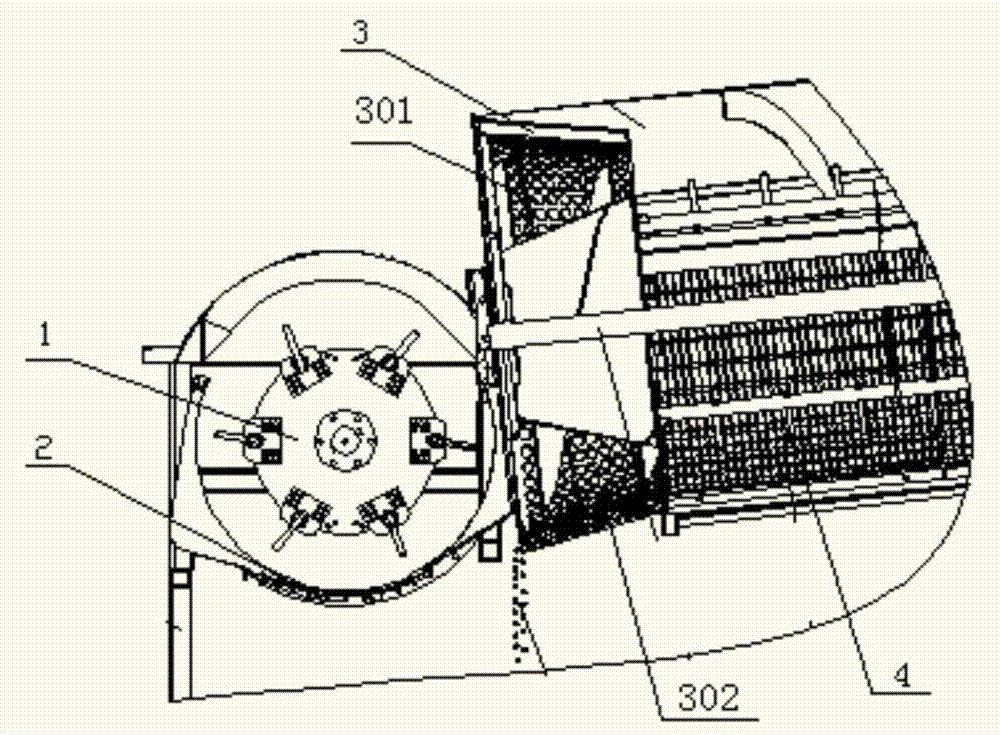

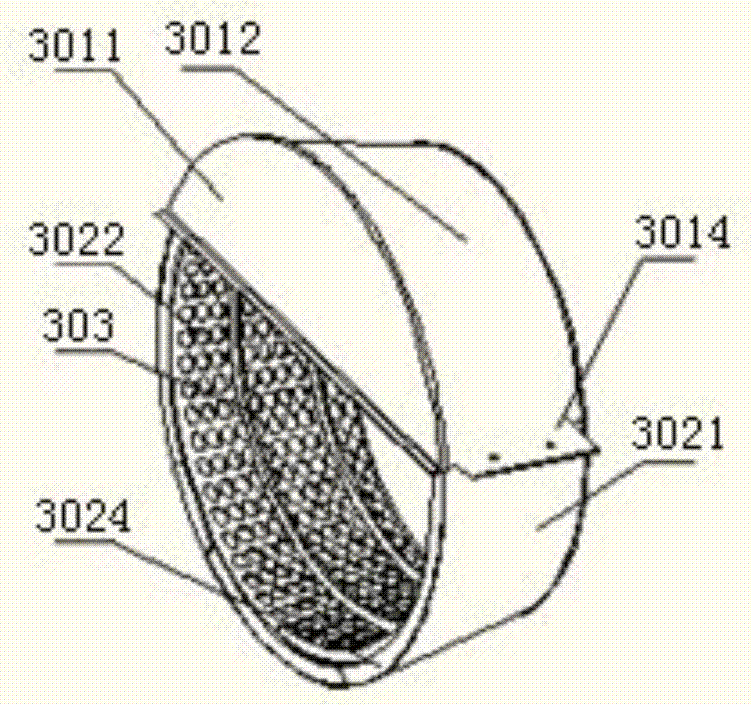

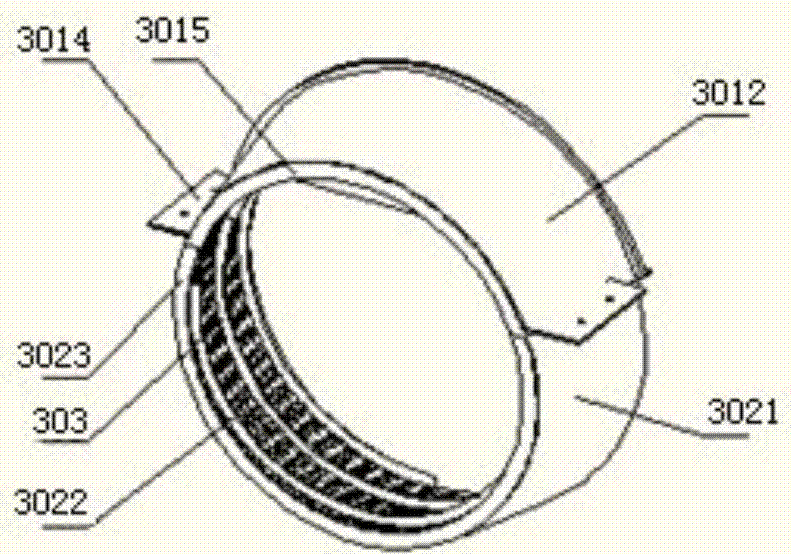

[0022] Such as figure 2 with image 3 As shown, a kind of 360° grain separation double-deck shroud comprises upper shroud assembly 301 and lower shroud assembly 302, and described upper shroud assembly 301 and lower shroud assembly 302 are double-layer round Arc-shaped structure, the ratio of the height of the two arcs is 1:2; the radius of the grain inlet end of the double-layer shroud is greater than the radius of the outlet end, which is an inverted cone shape, and the inner layer is a punched and separated shroud. There are multiple separation holes on the curved surface of the hole separation shroud to separate the mixture; the outer layer is a closed shroud. With the cooperation, a strong air flow is formed. The upper deflector assembly 301 and the lower deflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com