Patents

Literature

63results about How to "Reduce entrainment loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

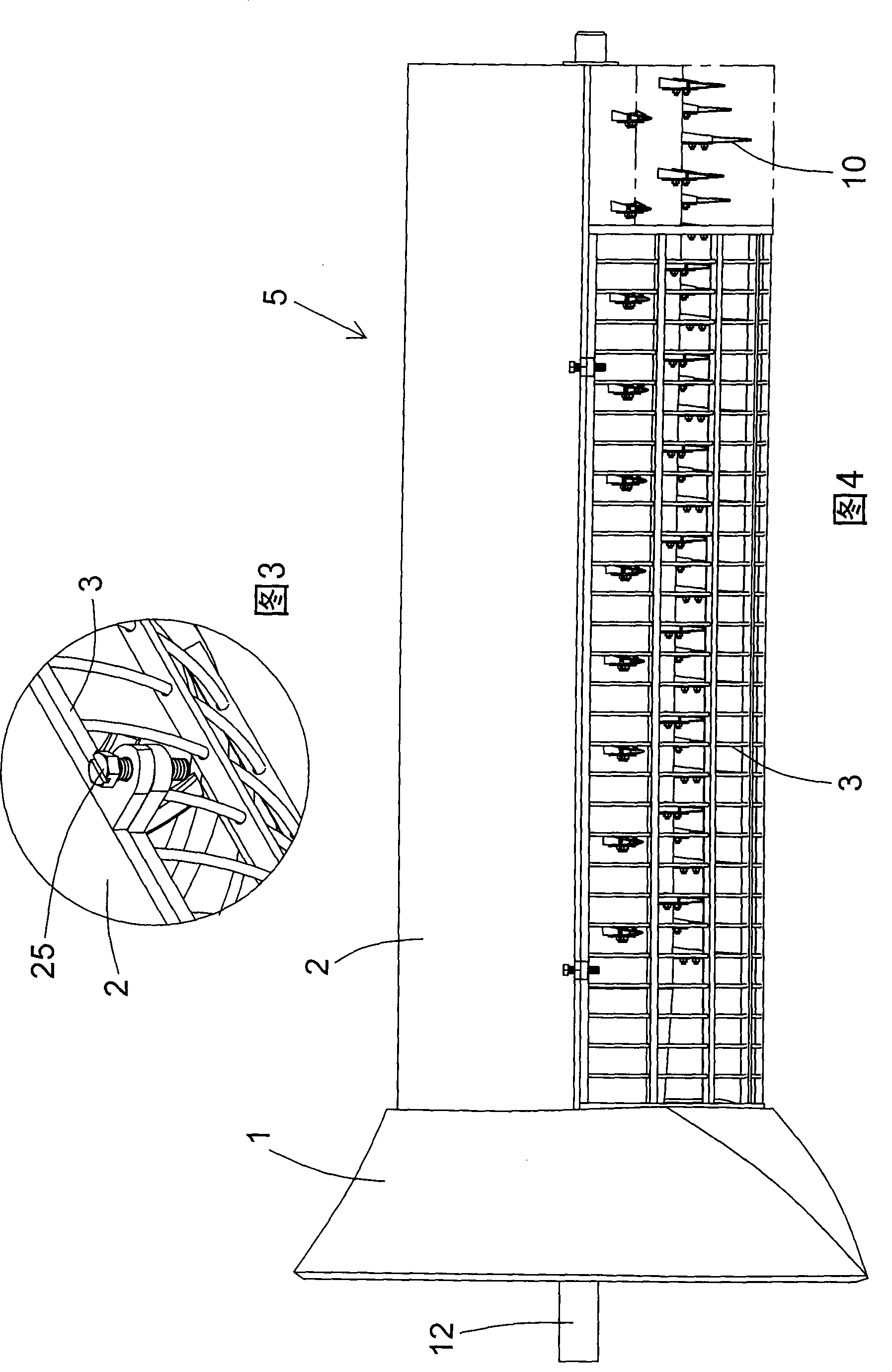

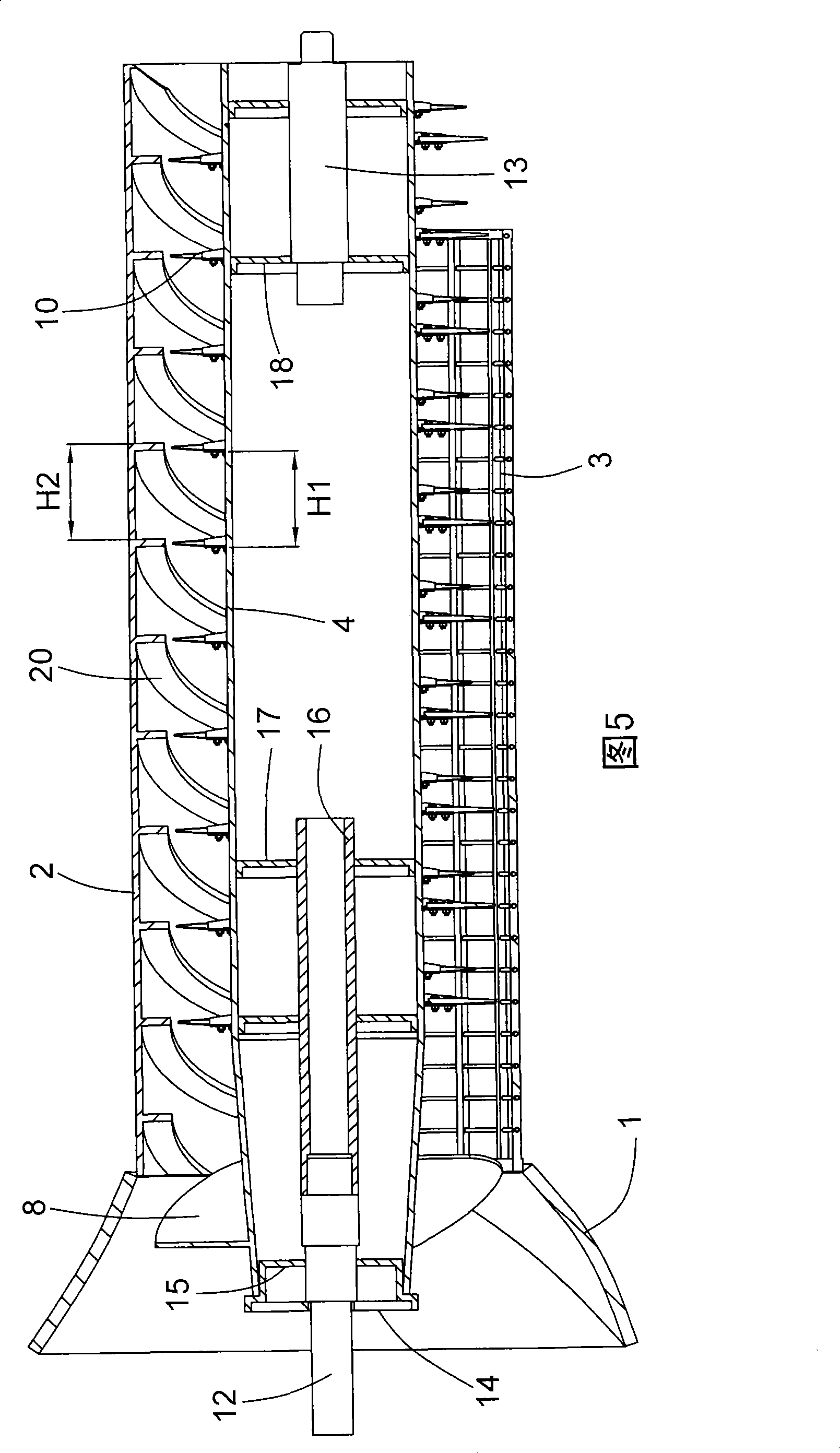

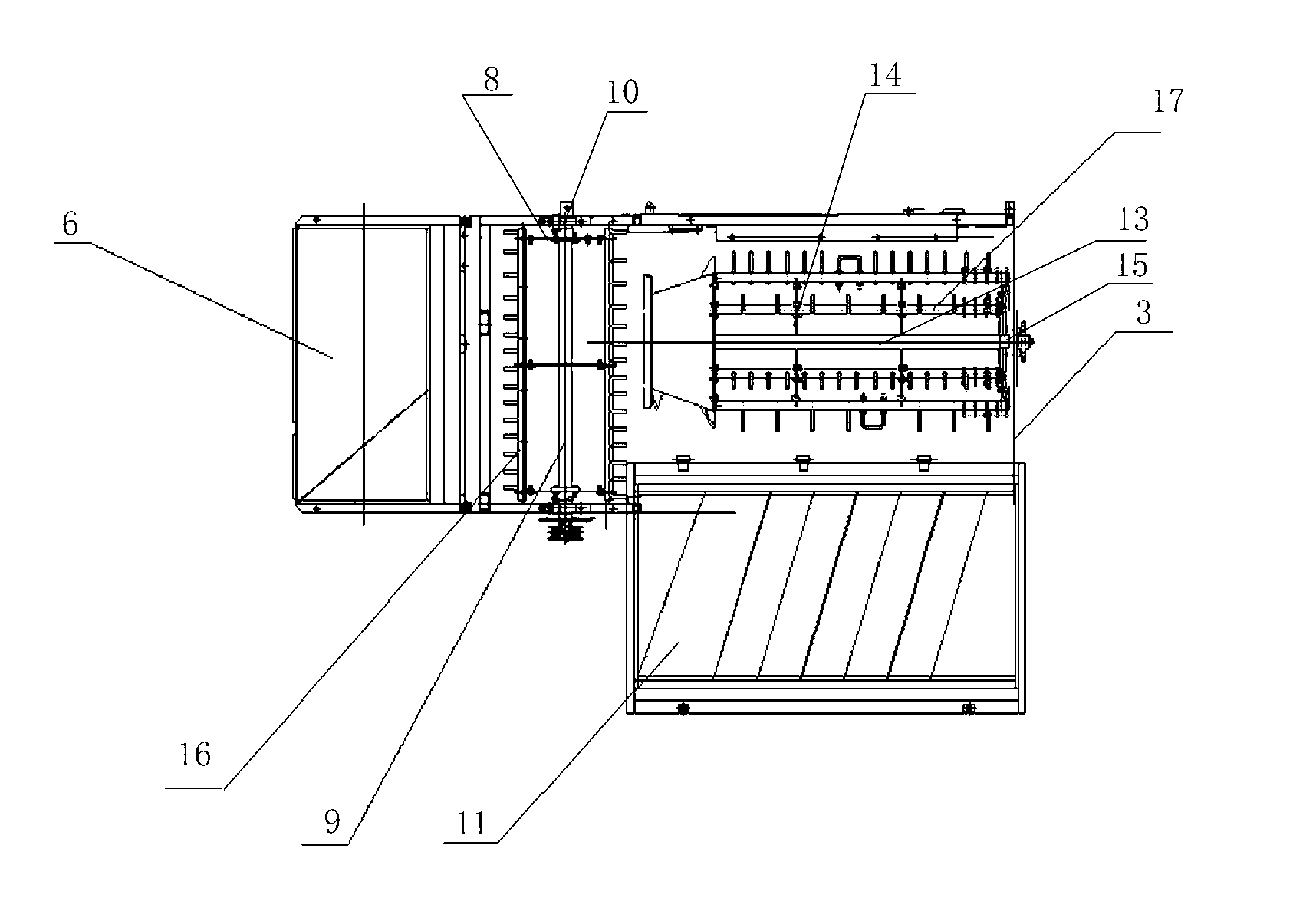

Grain threshing separation device

A grain threshing and separating device consists of a feed inlet, an upper cover, a concave grid and a roller; a plurality of arc stock guide plates are arranged on the inner wall of the shell of the feed inlet, each arc stock guide plate is arranged at a deflection angle in relation to the radial direction of the feed inlet; the roller consists of a front section and a rear section, the front section roller takes a conical shape, the rear section roller takes a cylindrical shape, a blade for feeding is welded on the external surface of the front section roller, a plurality of groups of threshing toothholders are welded on the external surface of the rear section roller, each group of the toothholders is arranged along spiral line direction, each toothholder is fixedly connected with a threshing tooth, the toothholder is connected with the threshing tooth in a dismountable way by a bolt fastener; the two ends of the roller are respectively provided with a front spindle nose and a rear spindle nose, and a plurality of arc flow deflectors are obliquely arranged on the top of the inner wall of the upper cover. The grain threshing and separating device has the advantages of fast feeding, thorough threshing, low entrapment loss, is not likely to be blocked by twisting grass, and can thresh a plurality of grains and harvest various grains in fields.

Owner:黄宝玉

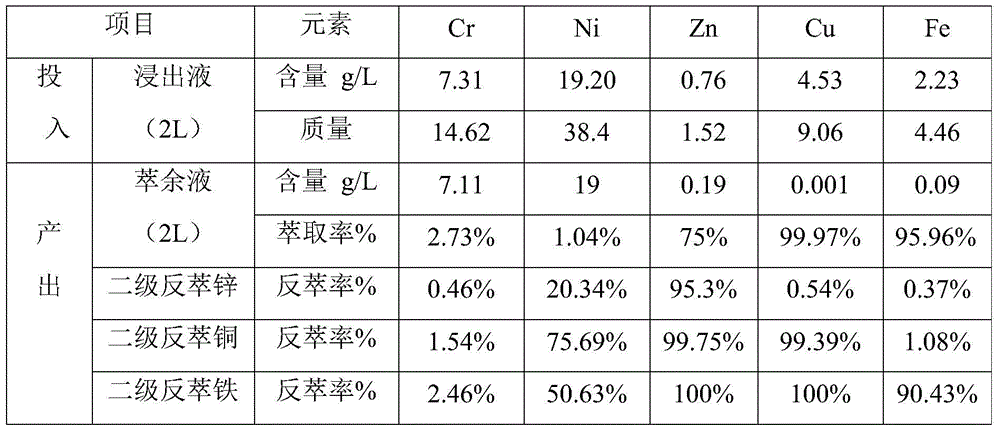

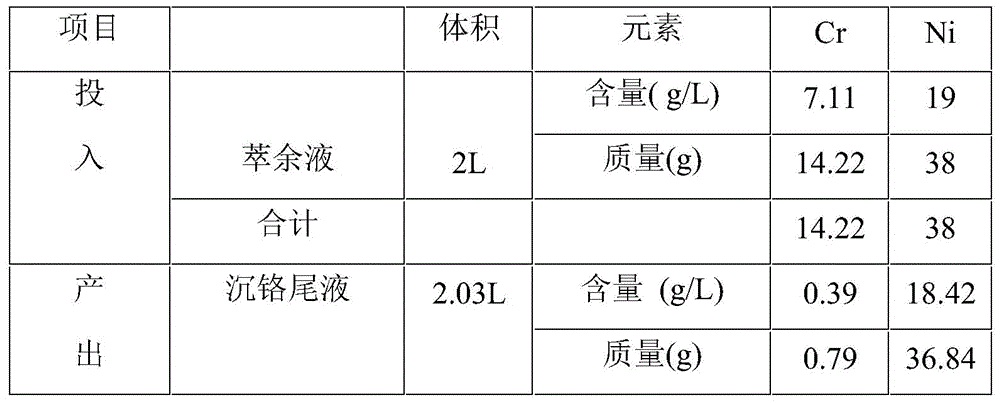

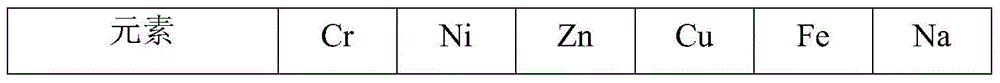

Harmless disposal and resource utilization method for electroplating sludge

InactiveCN105734294ADetoxify thoroughlyAdaptableProcess efficiency improvementResource utilizationSludge

The invention provides a harmless disposal and resource utilization new technology for electroplating sludge and particularly for complex electroplating sludge rich in copper, iron, nickel, zinc and chromium. Selected microorganisms are high in adaptation to the electroplating sludge and good in leaching performance; one-step extraction is adopted to extract copper, iron and zinc, follow-up nickel and chromium separation and purification are facilitated, in the whole technology, the iron cannot form any solid phase, and the problem that according to an existing reported technology, during iron separation, entrainment is serious or iron precipitation is not thorough is solved; a metallurgical method is adopted to carry out separating and recycling on extraction raffinate, the separation effect is good, and an obtained product is high in purity; and according to the technological process, cleaning and efficient high-value recycling of valuable metal in the electroplating sludge are achieved, the method is high in adaptation to various kinds of electroplating sludge, the electroplating sludge meets the harmless requirement, and the method extremely has the industrialized utilization value.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

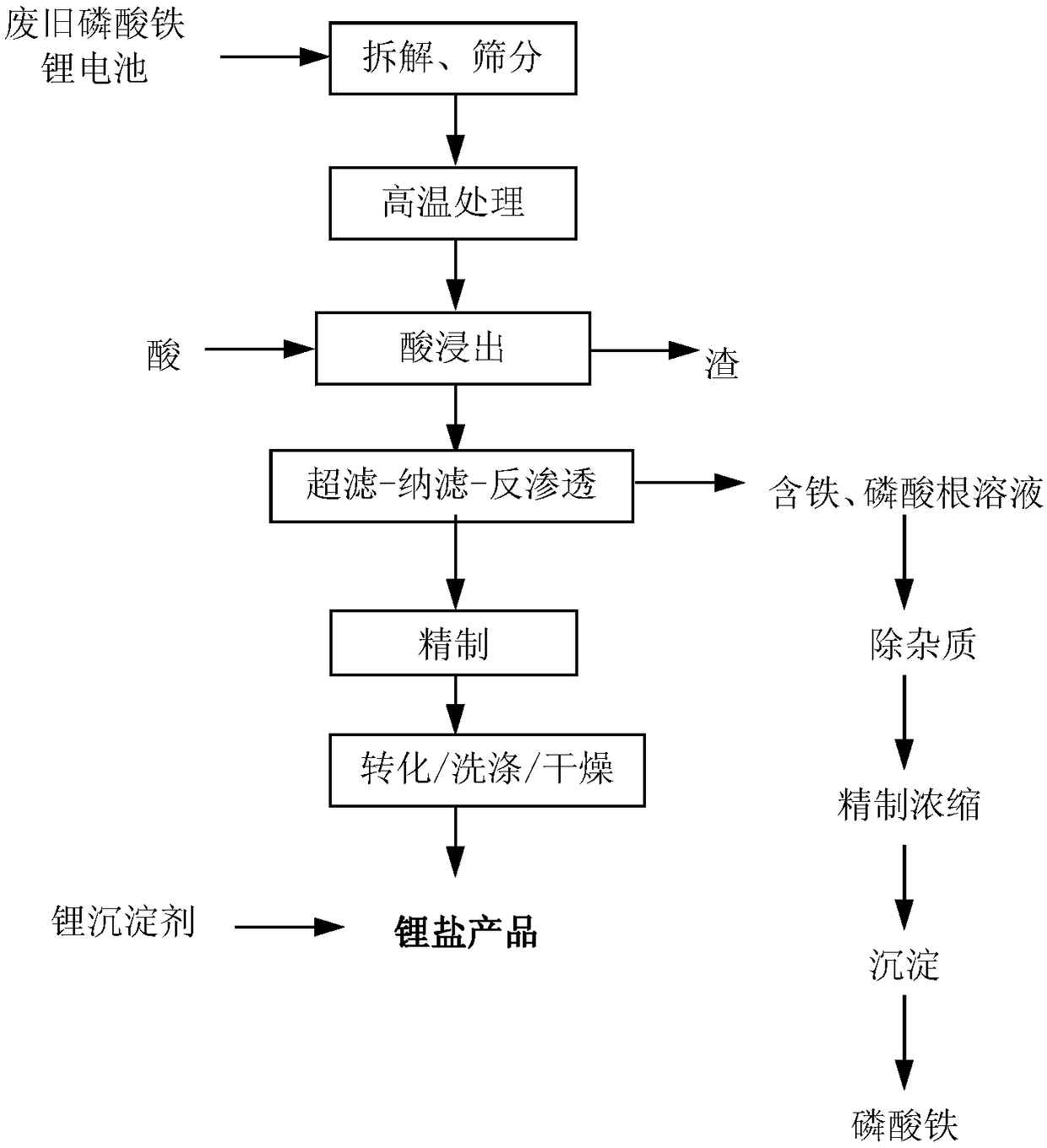

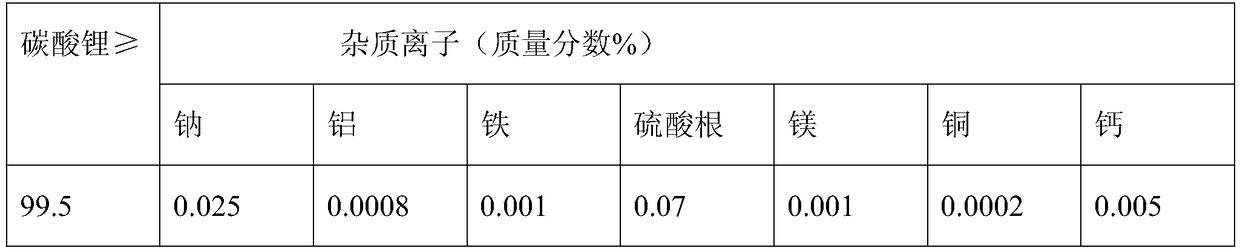

Method and system for recovering lithium from waste lithium iron phosphate battery

ActiveCN109207730AAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionLithium iron phosphate

The invention discloses a method and system for recovering lithium from a waste lithium iron phosphate battery. The method comprises the following steps that a positive plate is disassembled from thewaste lithium iron phosphate battery; a binder in the positive plate is removed, valuable metal elements in the positive plate are leached by an acid solution, and an acidified leaching solution is obtained; ultrafiltration treatment is carried out on the acidified leachate by using an ultrafiltration membrane; by using a nanofiltration membrane technology, lithium ions in the acidified leachate are separated from other cations different from lithium ions, a solution containing lithium and a solution containing other cations are obtained, and then a reverse osmosis technology is adopted for concentration and enrichment correspondingly, wherein the other cations comprise iron ions; and a lithium precipitant is adopted to precipitate and separate lithium ions in the lithium-containing solution, alkaline substances are adopted to precipitate and separate iron ions in the solution containing other cations, and lithium recovery is realized. According to the method and system, the ultrafiltration-nanofiltration-reverse-osmosis combined technology is adopted, and the method and system have the beneficial effects of simple process, environmental protection, less acid and alkali consumption, good and stable membrane separation effect and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

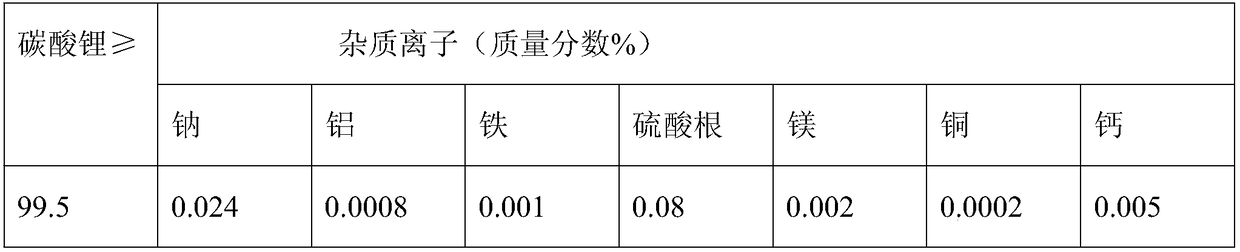

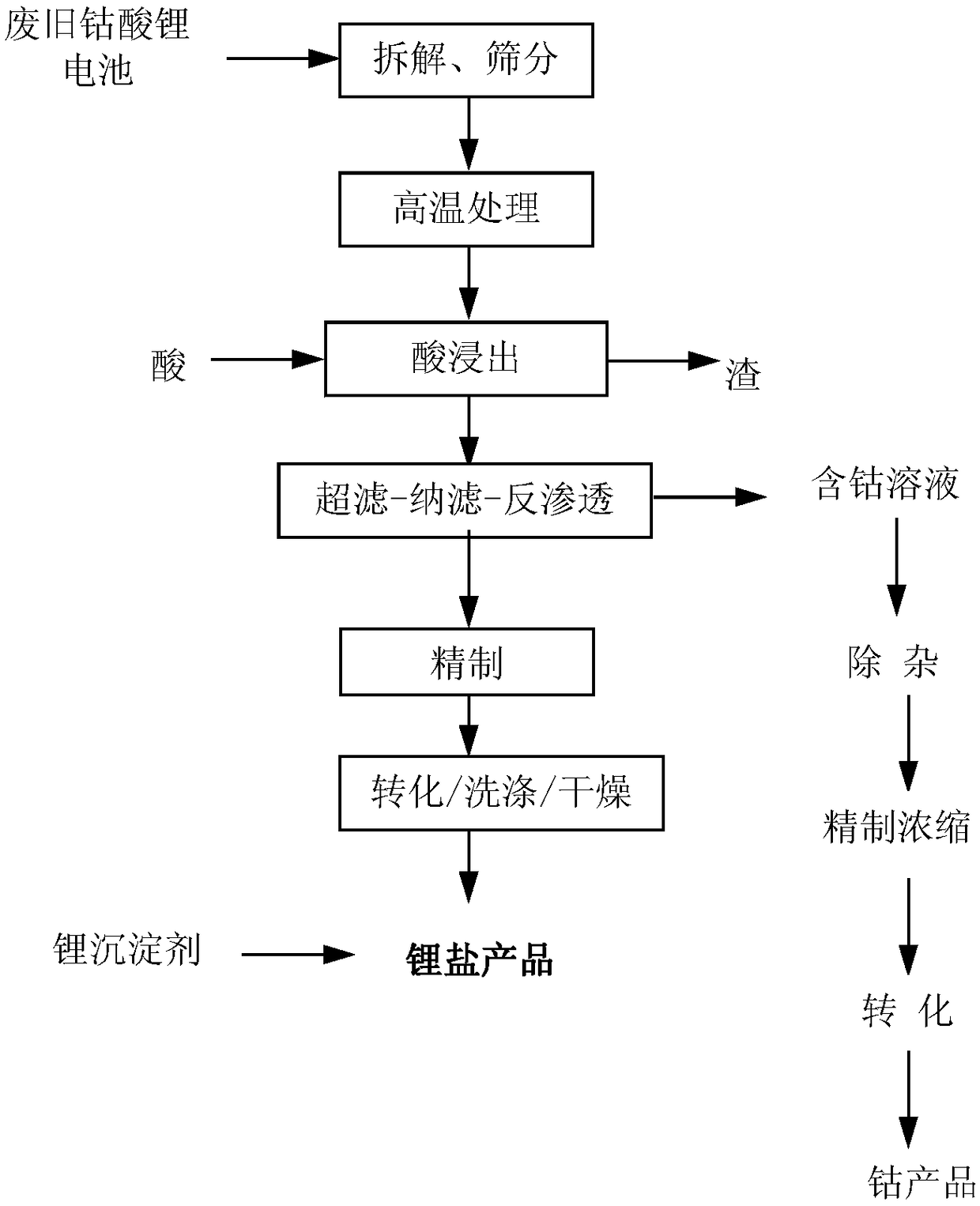

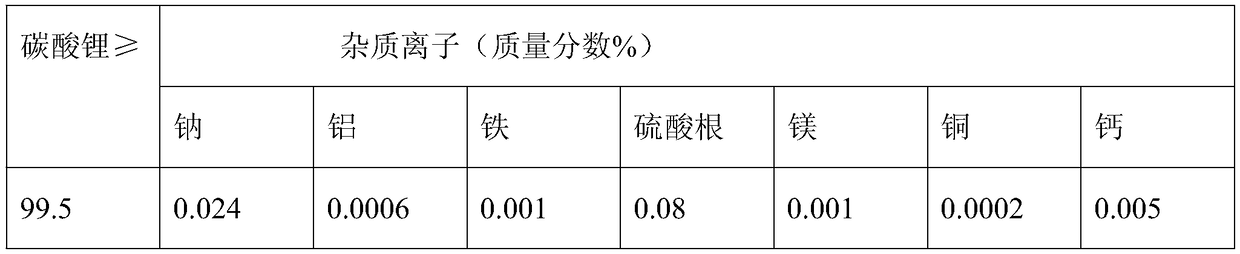

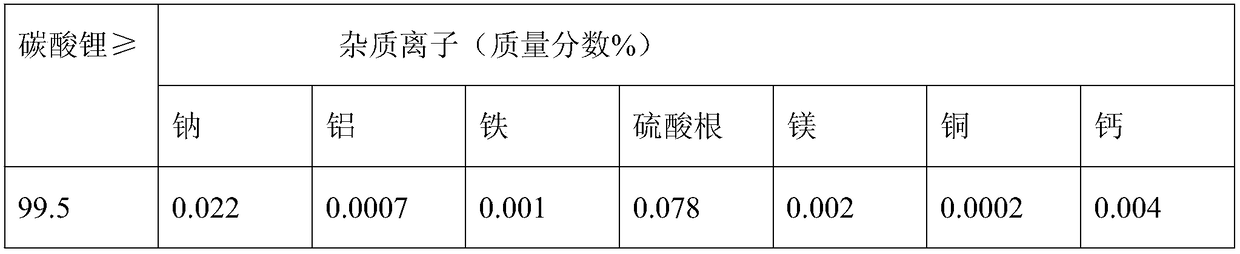

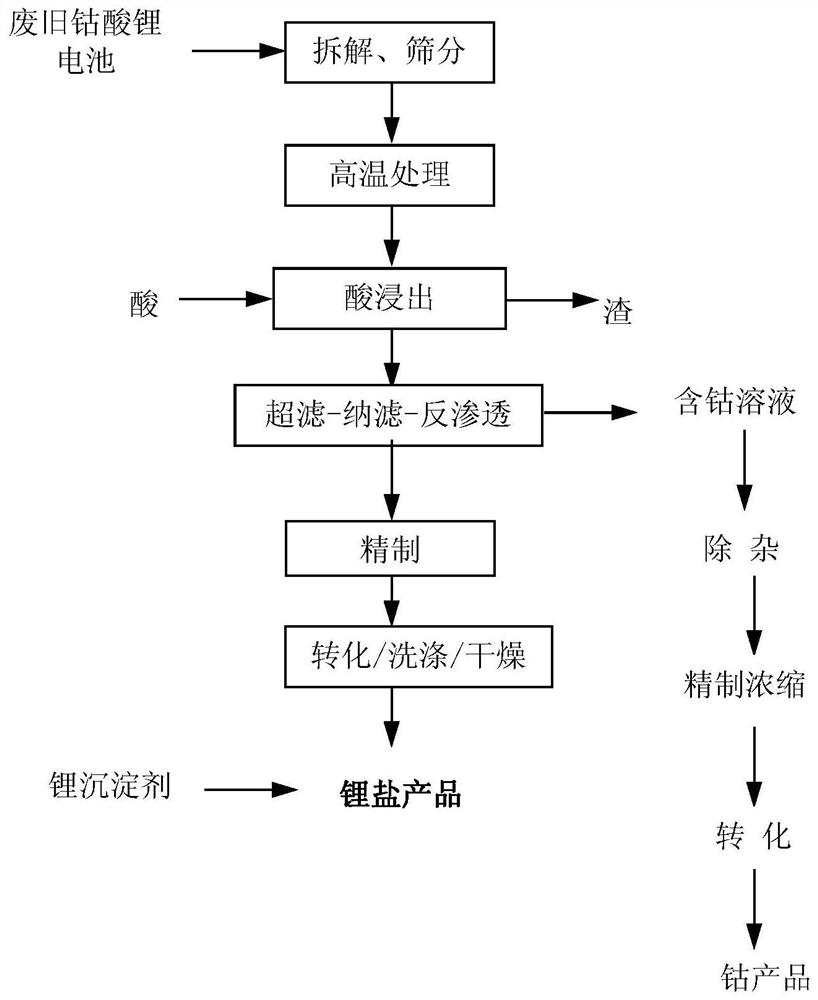

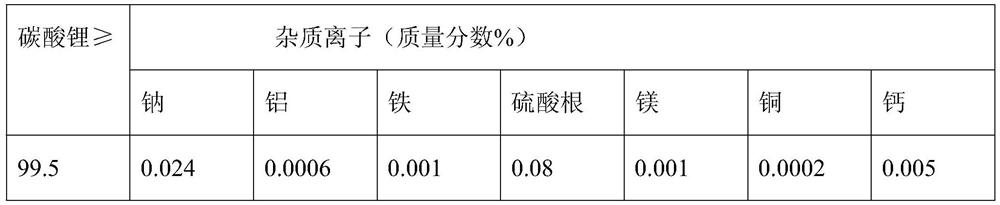

A method and system for recovering lithium and cobalt from spent lithium cobalt oxide batteries

ActiveCN109256597AAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionLithium

The invention discloses a method and a system for recovering lithium and cobalt from waste lithium cobalt oxide batteries. The method comprises the following steps of: disassembling a positive electrode sheet from a waste lithium cobalt oxide battery; Removing the binder in the positive electrode sheet, and then acid leaching the valuable metal elements in the positive electrode sheet to obtain anacidizing leaching solution; The acidified leachate was treated by ultrafiltration membrane. Separating lithium ions in acidified leaching solution from other cations different from lithium ions by using nanofiltration membrane technology to obtain lithium-containing solution and solution containing other cations, and concentrating and enriching the lithium-containing solution and the solution containing other cations respectively by reverse osmosis technology, wherein the other cations include cobalt ions; And a lithium precipitant is used to precipitate lithium ions from a lithium-containing solution, and an alkaline substance is used to precipitate cobalt ions from a solution containing other cations, thereby realizing the recovery of lithium and cobalt. The adoption of ultrafiltration-Nanofiltration-Reverse osmosis combined technology has the characteristics of simple process, less acid and alkali consumption, good and stable membrane separation effect and so on.

Owner:青海中科德方能源科技研究有限公司

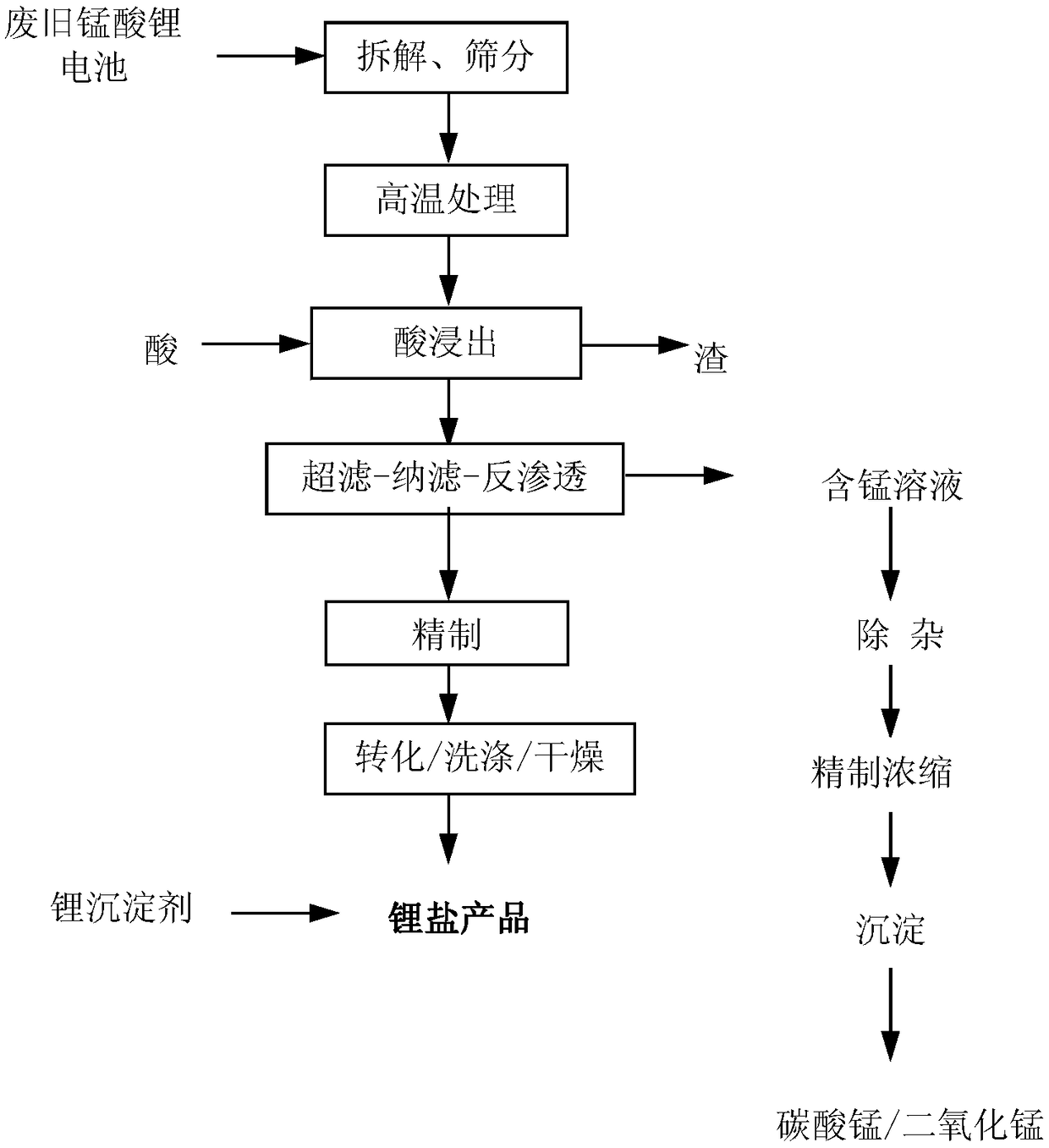

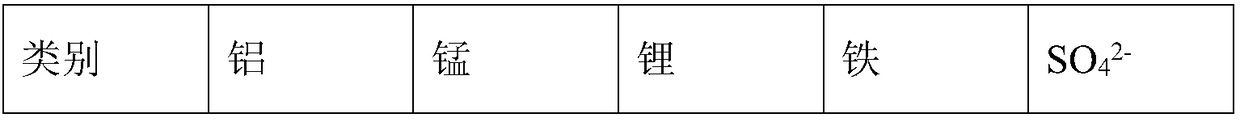

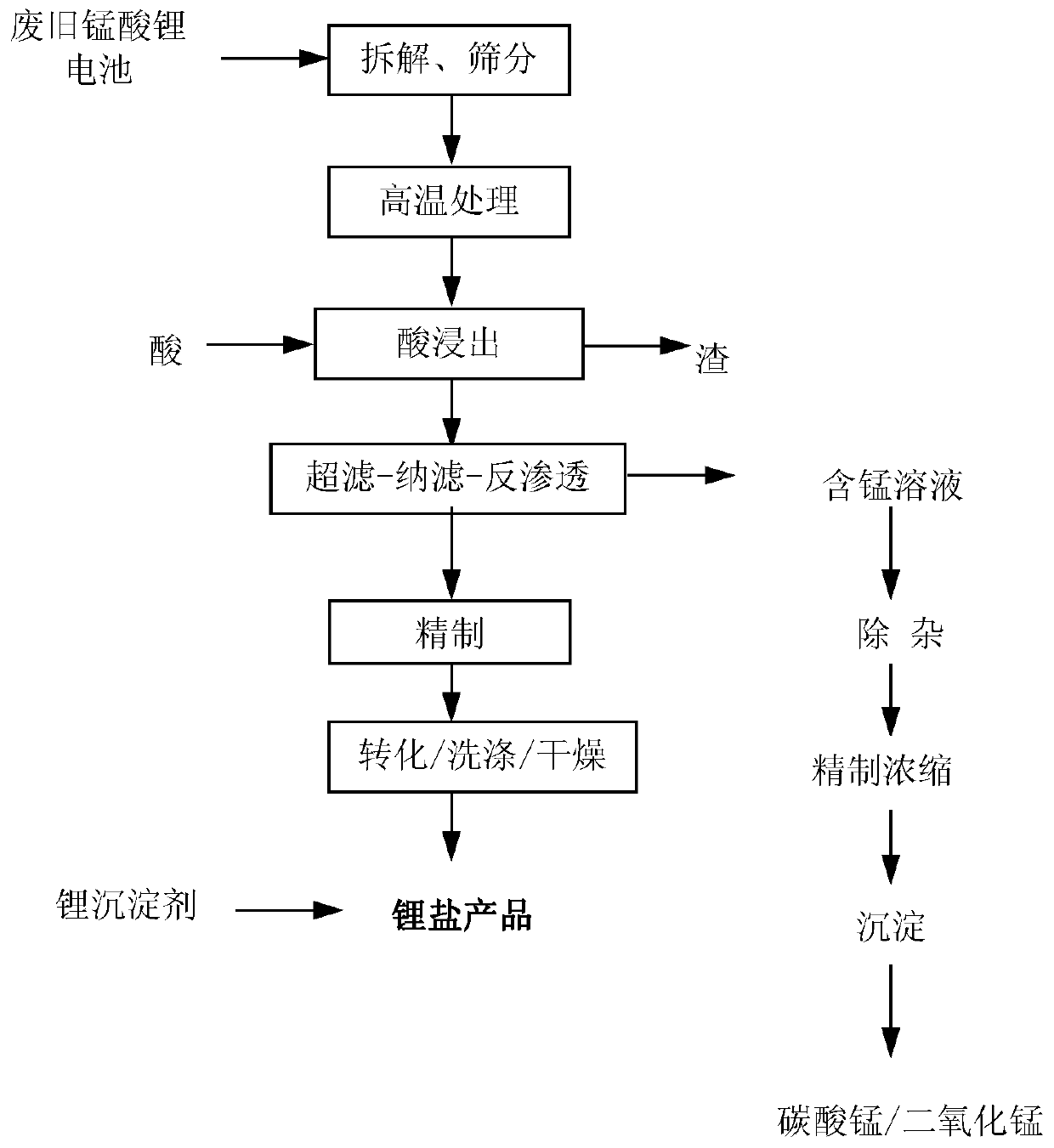

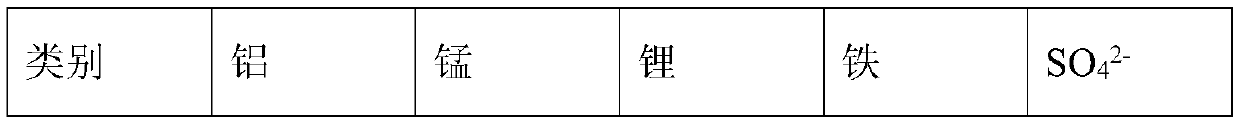

Method and system for recovering lithium and manganese from waste lithium manganate battery

ActiveCN109207725AAdvanced separation technologyEasy to separateWaste accumulators reclaimingBattery recyclingMembrane technologyManganese

The invention discloses a method and system for recovering lithium and manganese from a waste lithium manganate battery. The method comprises the following steps that a positive plate is disassembledfrom the waste lithium manganate battery; a binder in the positive plate is removed, valuable metal elements in the positive plate are leached by acid dissolution, and acidified leachate is obtained;ultrafiltration treatment is carried out on the acidified leachate by using an ultrafiltration membrane; by using a nanofiltration membrane technology, lithium ions in the acidified leachate are separated from other cations different from lithium ions, a solution containing lithium and a solution containing other cations are obtained, and then a reverse osmosis technology is adopted for concentration and enrichment correspondingly, wherein the other cations comprise manganese ions; and a lithium precipitant is adopted to precipitate and separate lithium ions in the lithium-containing solution,and alkaline substances are adopted to precipitate and separate manganese ions in the solution containing other cations, so that the recovery of lithium and manganese is realized. According to the method and system, the ultrafiltration-nanofiltration-reverse osmosis combined technology is adopted, and the method and system have the beneficial effects of simple process, environmental protection, less acid and alkali consumption, good and stable membrane separation effect and the like.

Owner:青海中科德方能源科技研究有限公司

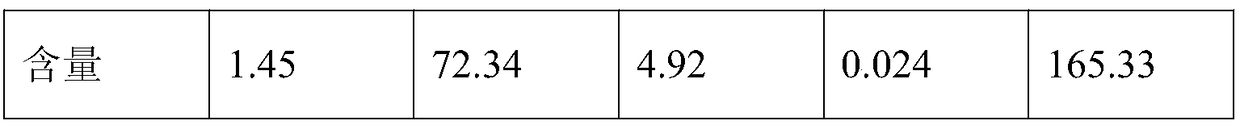

Smelting separation method of rare earth ores

ActiveCN106282553AHigh recovery rateTo achieve the purpose of removing impuritiesProcess efficiency improvementHigh concentrationCarbonization

The invention provides a smelting separation method of rare earth ores. The method comprises the following steps: carrying out leaching, neutralization and impurity removal on sulfuric acid roast ores by using an aqueous solution of magnesium bicarbonate, and carrying out solid-liquid separation to obtain a magnesium-containing rare earth sulfate solution; and carrying out aqueous magnesium bicarbonate solution saponification P507 or P204 extraction transformation or magnesium bicarbonate precipitation transformation enrichment to obtain a high-concentration mixed rare earth chloride solution, carrying out extraction separation, and recovering rare earth from the above obtained aqueous magnesium bicarbonate solution precipitate to obtain various rare earth compound products. Magnesium sulfate-containing wastewater generated in the above process undergoes alkali transformation by cheap alkaline compounds of calcium and magnesium, and CO2 recovered in the smelting separation process is introduced to carry out carbonization purification in order to obtain an aqueous magnesium bicarbonate solution which can be reused in rare earth leaching, transformation, extraction separation and precipitation processes. The method has the advantages of realization of recycling of magnesium and CO2 and zero discharge of ammonia nitrogen and wastewater, great reduction of the production cost, improvement of the recovery rate of rare earths, and realization of green, environmentally-friendly and high-efficient clean production of the rare earths.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Clean production method for dioctyl phthalate

InactiveCN1884249AReasonable useEmission reductionOrganic compound preparationCarboxylic acid esters preparationWater vaporOctanol

The invention discloses a cleaning manufacturing method of phthalic acid dioctyl, which is characterized by the following: setting esterification and dealcoholization within one equipment; adopting benzoic anhydride and octanol as raw material at 1:2-3 weight percentage; utilizing titanic hydroxide four propyl ester as catalyst; setting addictive quantity at 0.0015%-0.005% in the total material; generating coarse ester in the autoclave under normal pressure; controlling reacting final temperature at 220-240 deg.c; flashing octanol through residual heat in the autoclave; dehydrating excess 60-80% octanol in the esterifying reaction; collecting sedimenting water after condensing; cooling temperature in the autoclave at 170-190 deg.c; inputting water at this temperature; distilling steam in the autoclave; removing residual octanol.

Owner:TIANJIN TIANRONG CHEM

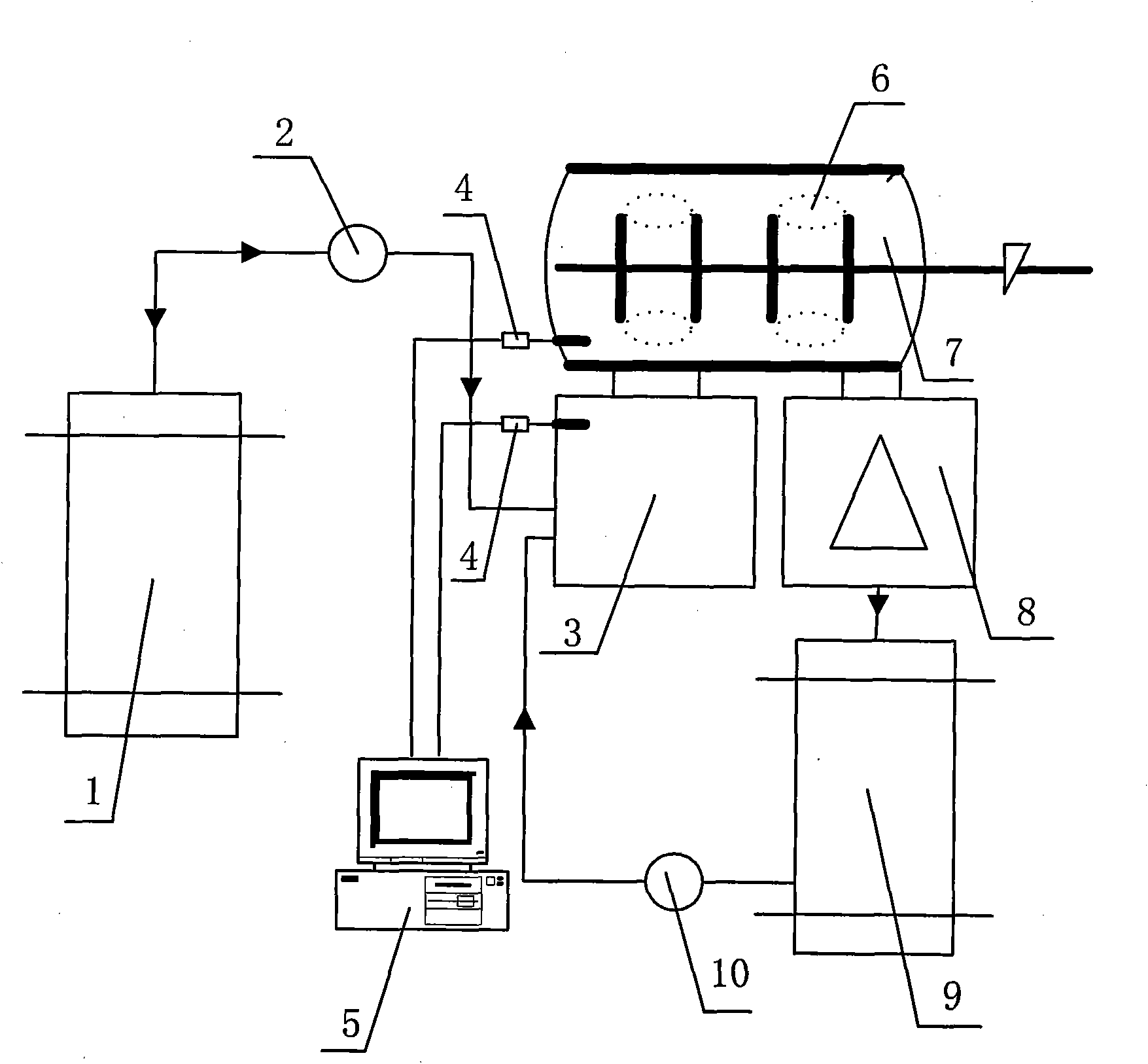

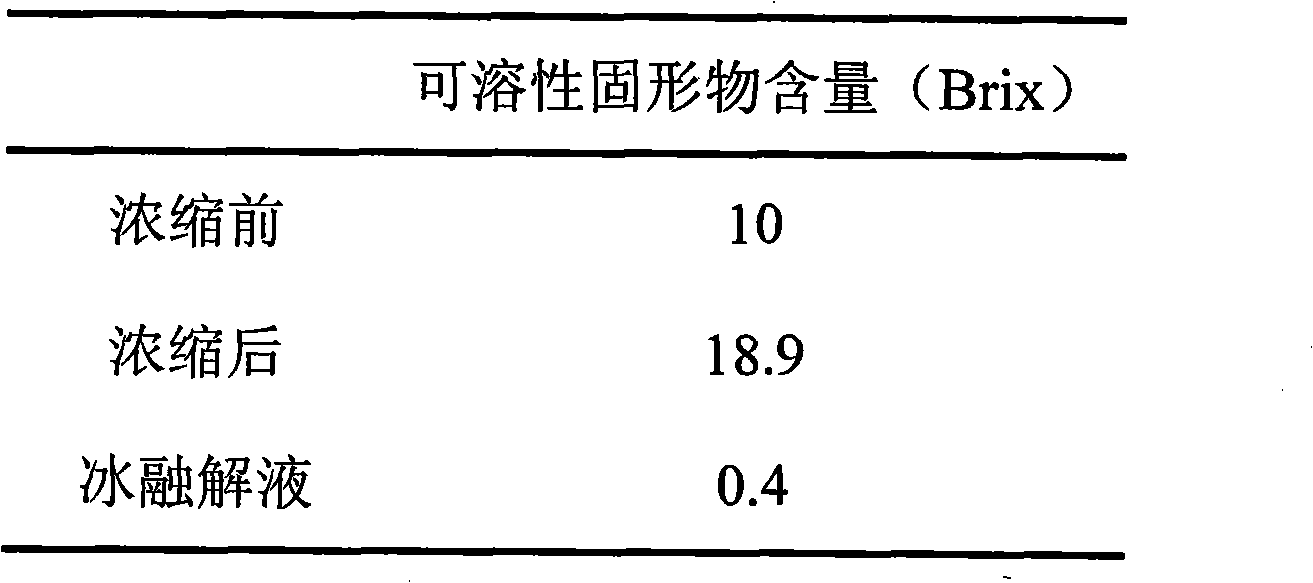

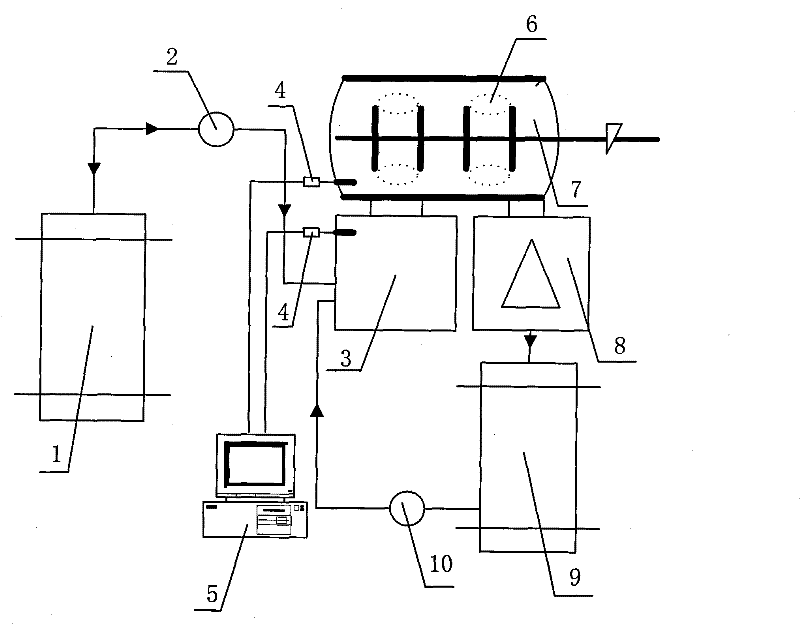

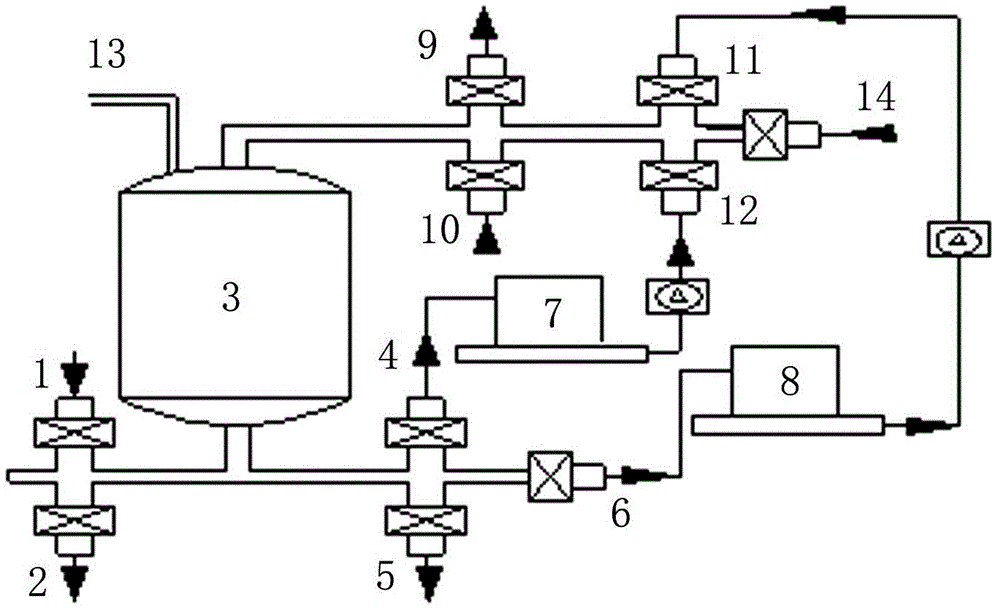

Ultrasonic synergetic crystal growing fruit juice freezing and concentrating method and equipment thereof

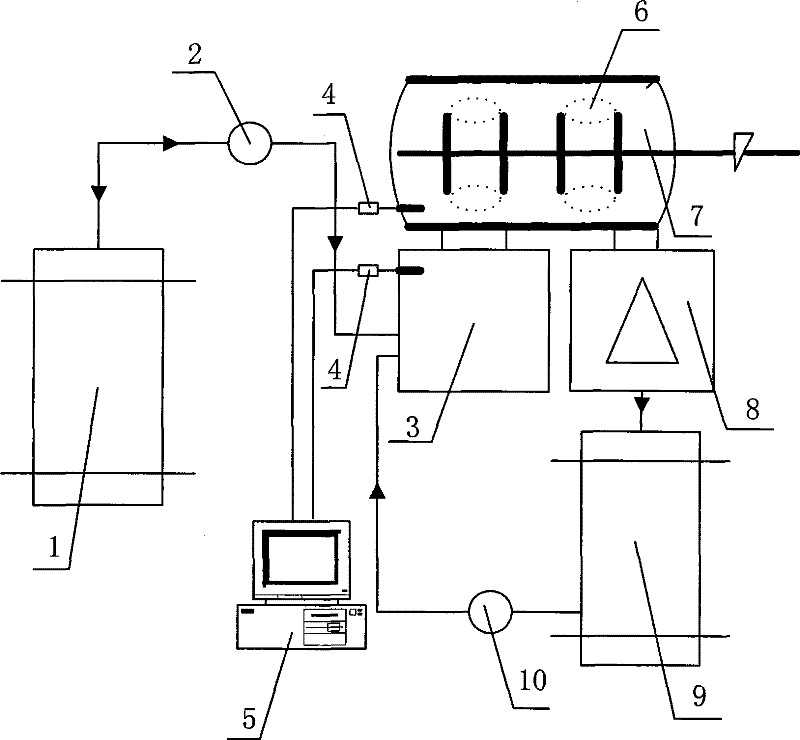

ActiveCN101664214AReduce entrainment lossGood separation effectFood scienceCentrifugal pumpFruit juice

The invention discloses an ultrasonic synergetic crystal growing fruit juice freezing and concentrating method and an equipment thereof. A fruit juice storage tank of the equipment is connected with ascraper-type heat exchanger by a centrifugal pump, and the scraper-type heat exchanger and a centrifugal machine are positioned under a crystal growing tank with a heat preservation jacket and are connected with the crystal growing tank with the heat preservation jacket respectively; an energy converter is arranged in the crystal growing tank with the heat preservation jacket and connected with an ultrasonicator; and the centrifugal machine is connected with a collecting tank which is connected with the scraper-type heat exchanger by a pump. In respect of the method, clear fruit juice is obtained firstly and is pumped into the scraper-type heat exchanger for precooling. After the temperature of feed liquid in the scraper-type heat exchanger is reduced to freezing point and small ice crystals are generated, an agitating valve and an ultrasonic field generator in the crystal growing tank are started and concentrated solution is discharged and the ice crystals are separated after the icecrystals mature. In the invention, the ultrasonic synergetic effect greatly shortens time from core formation to maturing of ice crystals and the entrainment loss of active ingredients of fruit juiceis reduced, thus not only improving production efficiency but also meeting purpose of saving energy.

Owner:SOUTH CHINA UNIV OF TECH

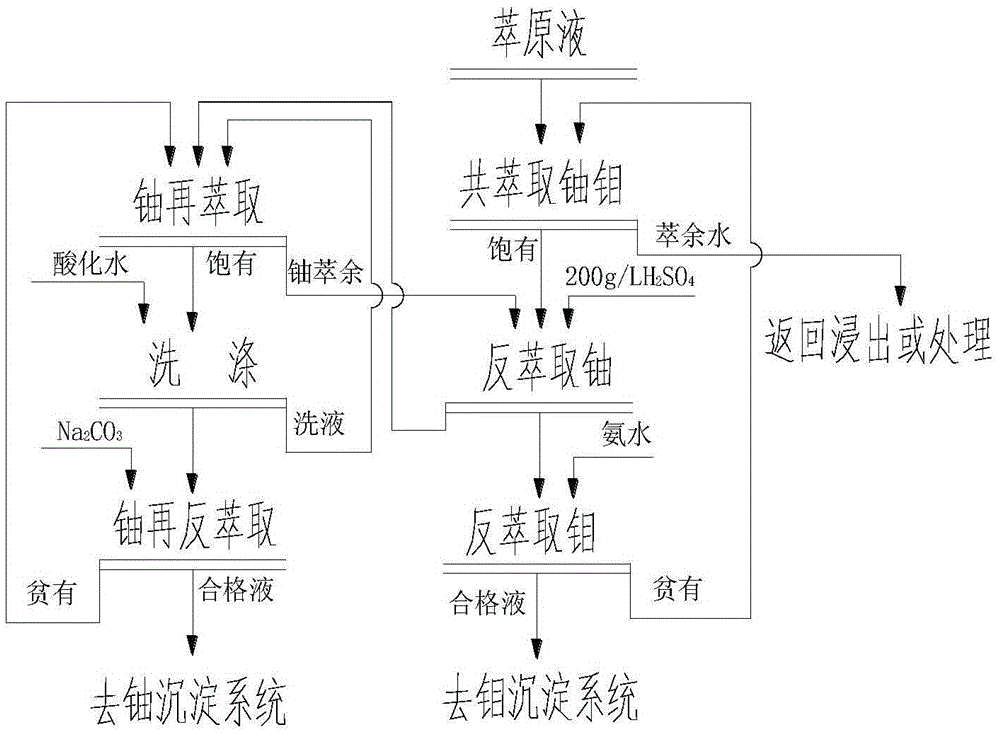

Method for synchronously extracting and separating uranium and molybdenum

The invention belongs to the technical field of hydrometallurgy, and particularly relates to a method for synchronously extracting and separating uranium and molybdenum. Overcoming the defects in the prior art is the purpose, a method for acid leaching of uranium and molybdenum in a solution is provided, wherein the method is simple in technology, high in uranium and molybdenum recycling rate, capable of not introducing complex ions and environmental-friendly, and the method is suitable for industrial application. Efficient uranium and molybdenum separation can be achieved through N235 uranium and molybdenum co-extraction-200 g / L sulfuric acid solution uranium back extraction-ammonium hydroxide molybdenum back extraction-P204 uranium re-extraction-Na2CO3 uranium repeated back extraction, and the uranium and molybdenum extraction rate is high and can reach more than 99.5%. The contact frequency between an extraction stock solution and an organic phase can be reduced through co-extraction of uranium and molybdenum, the generating amount of suspended matter in the extraction residual water phase is reduced, and the entrainment loss of the organic phase is reduced. Circular utilization of a P204 extraction residual solution (200 g / L sulfuric acid solution) is achieved, and the consumption amount of reagent sulfuric acid is reduced. The accumulation of sodium sulfate in the uranium sediment motor liquor can be reduced. The complex ions hard to treat are not introduced in the whole technology process, and later waste water treatment is facilitated.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

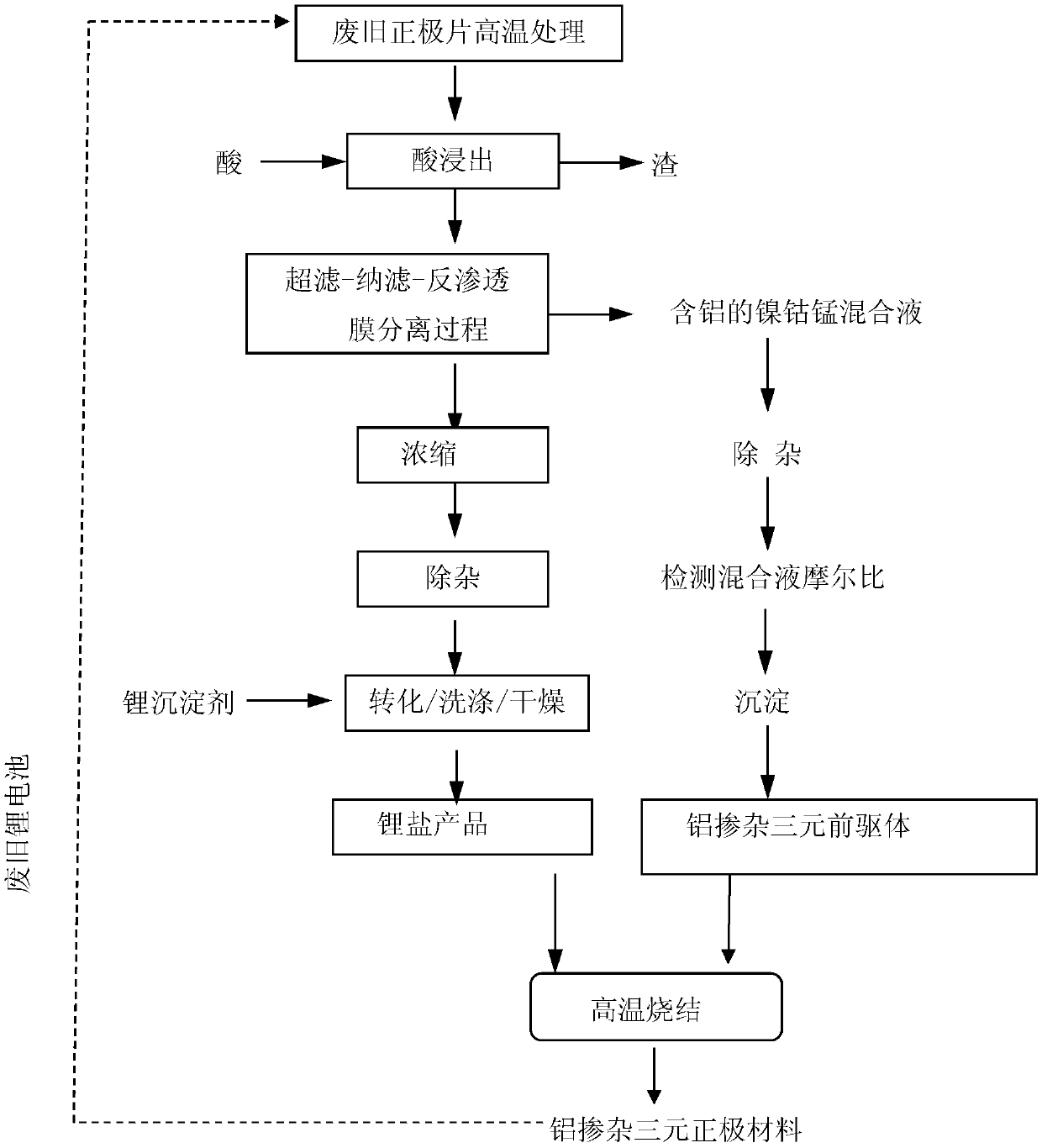

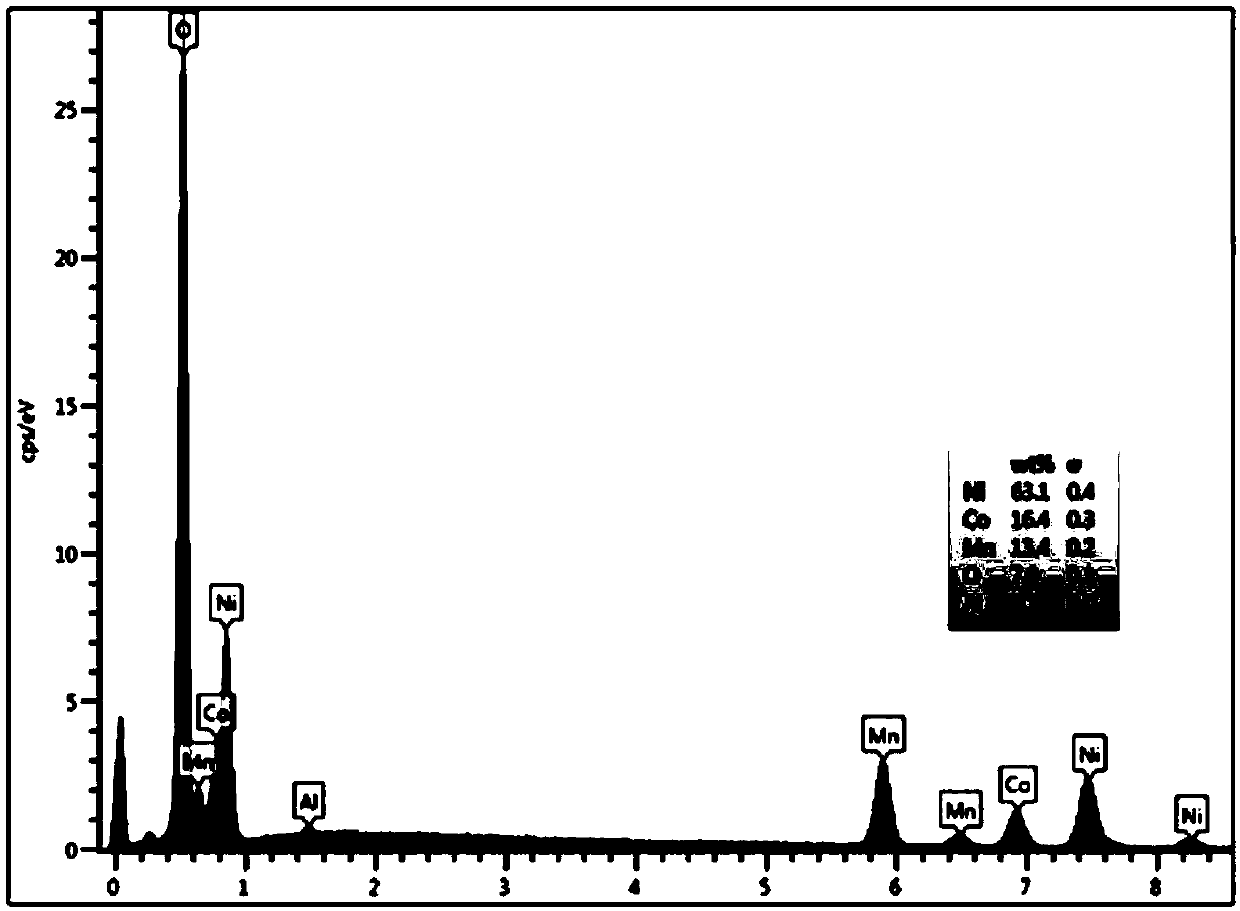

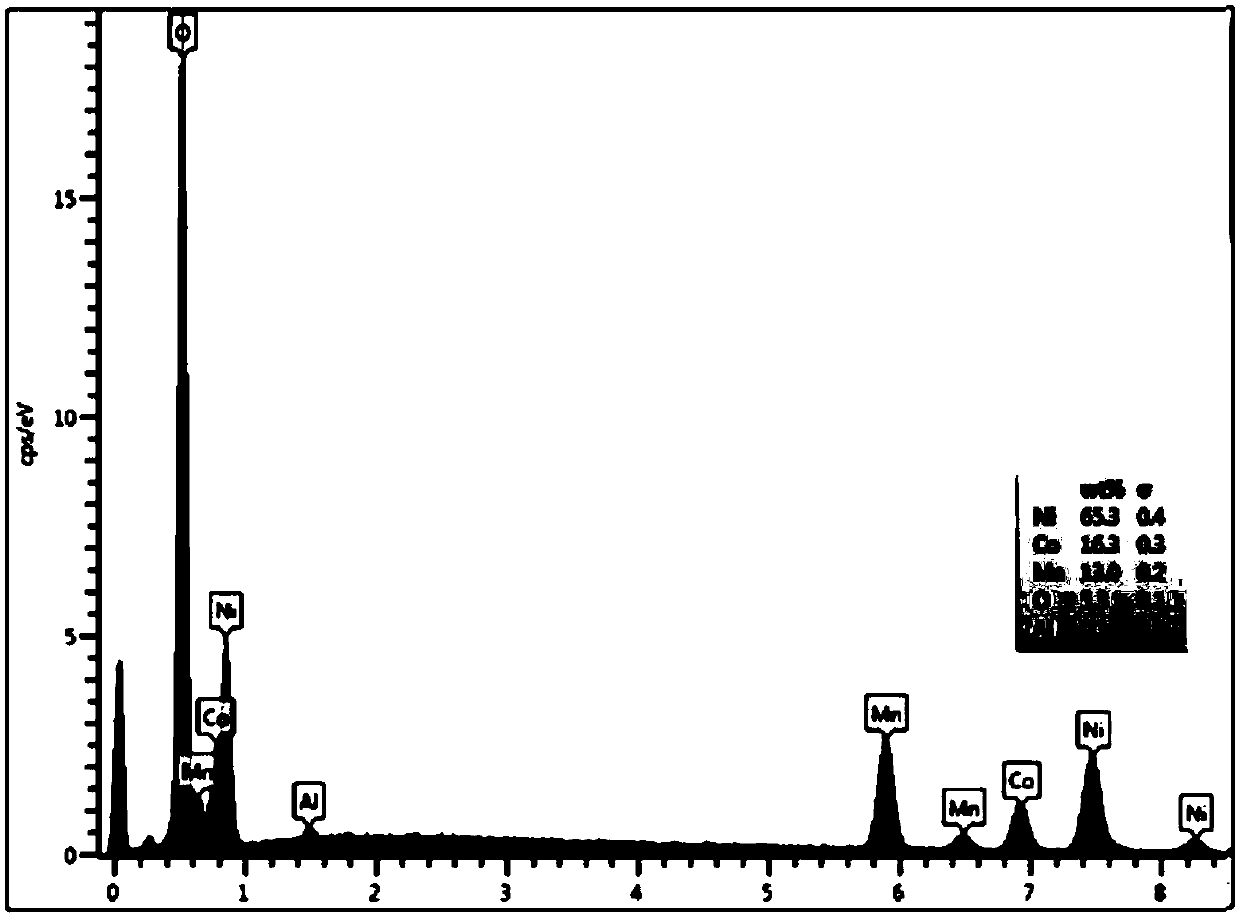

A method and system for reverse preparation of aluminum-doped ternary precursor

ActiveCN109256596AAdvanced separation technologyEasy to separateCell electrodesWaste accumulators reclaimingAluminum IonUltrafiltration

The invention discloses a method and a system for reversely preparing an aluminum doped ternary precursor. The method comprises the following steps of: disassembling a positive electrode sheet from awaste ternary lithium battery; Removing the binder in the positive electrode sheet, and then acid leaching the valuable metal elements in the positive electrode sheet to obtain an acidizing leaching solution; The acidified leachate was treated by ultrafiltration membrane. Using nanofiltration membrane technology, lithium ion in acidified leaching solution was separated from other cations differentfrom lithium ion, and then concentrated by reverse osmosis technology. A lithium ion is precipitate and precipitated by a lithium precipitant, and a nickel ion, a cobalt ion, a manganese ion and an aluminum ion are coprecipitate and precipitated by an alkaline substance to obtain an aluminum doped nickel cobalt manganese ternary precursor. The adoption of ultrafiltration-Nanofiltration The aluminum doped ternary precursor was directly synthesized by reverse osmosis combined with trace aluminum in acidification leaching solution. The process is simple and environmentally friendly, and the valuable elements are recycled comprehensively.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

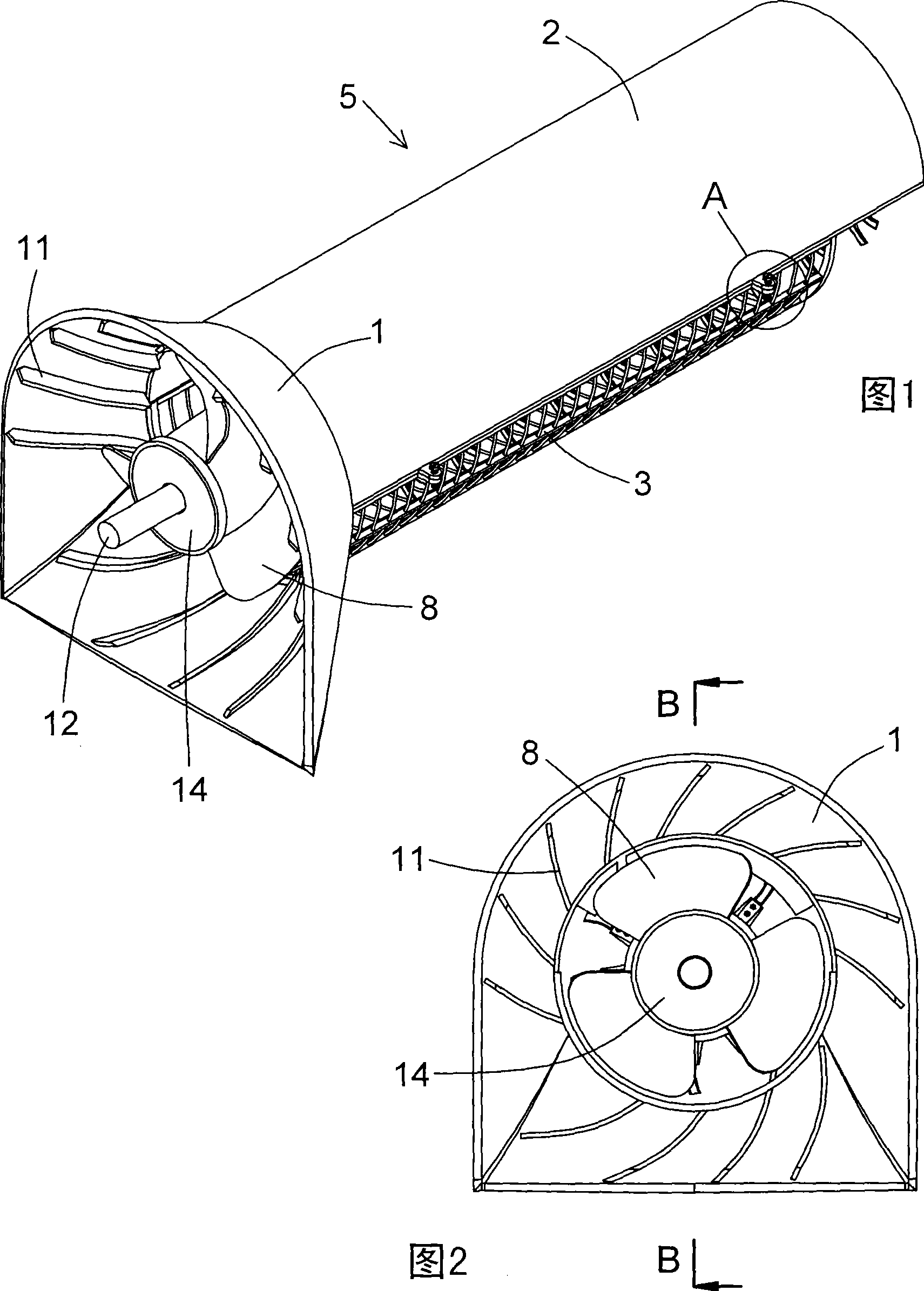

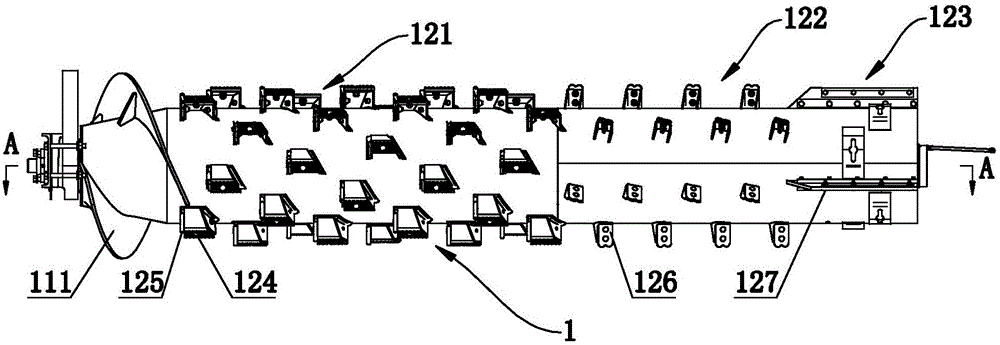

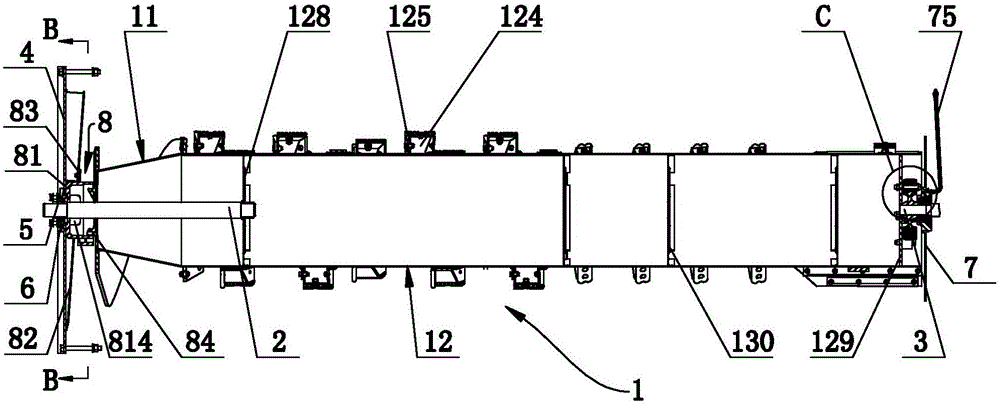

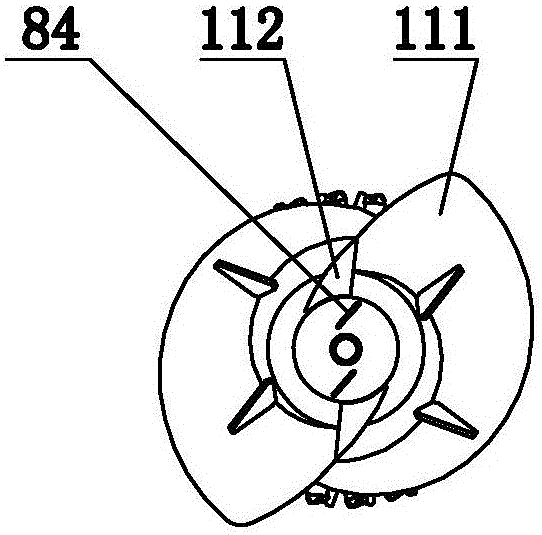

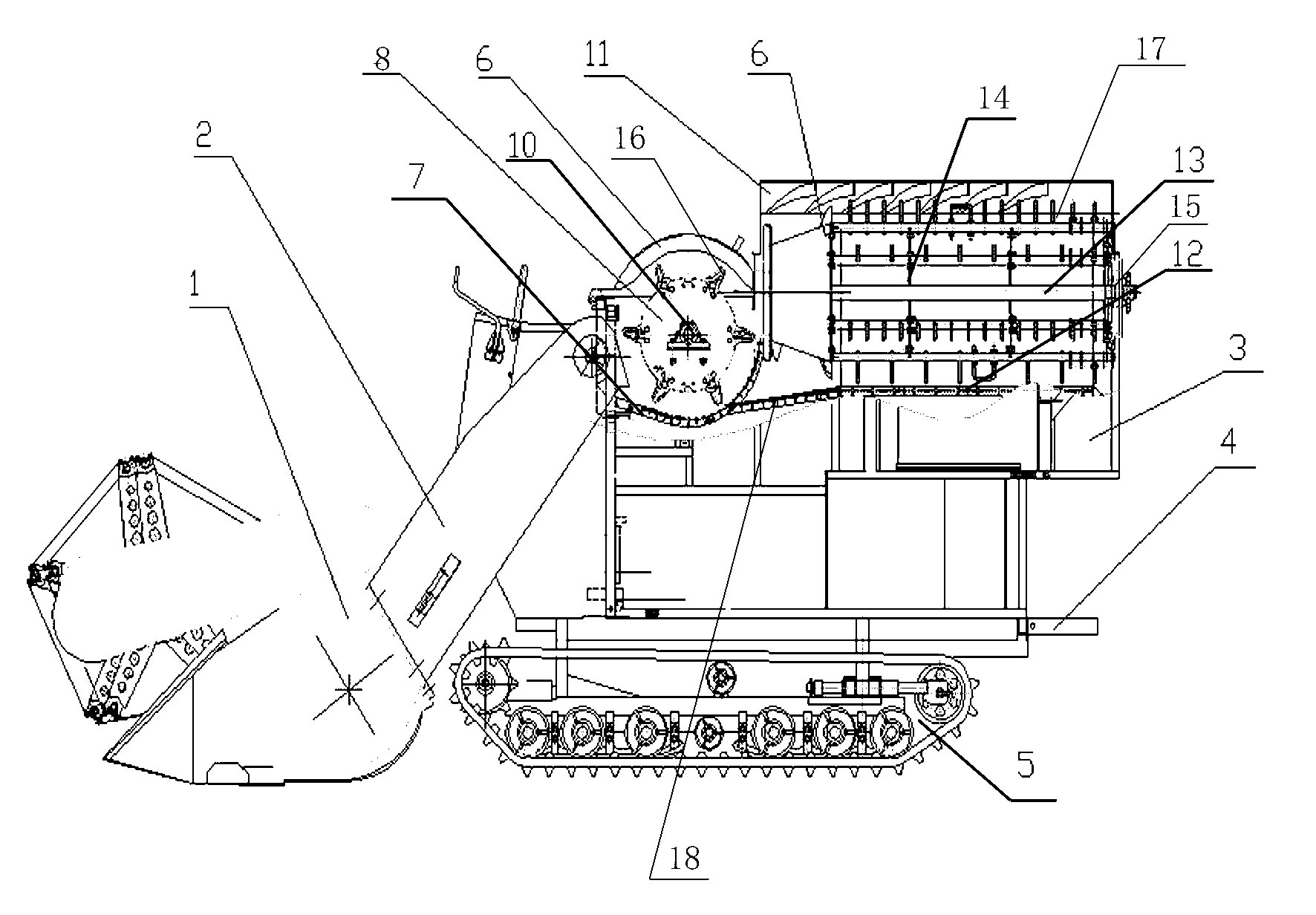

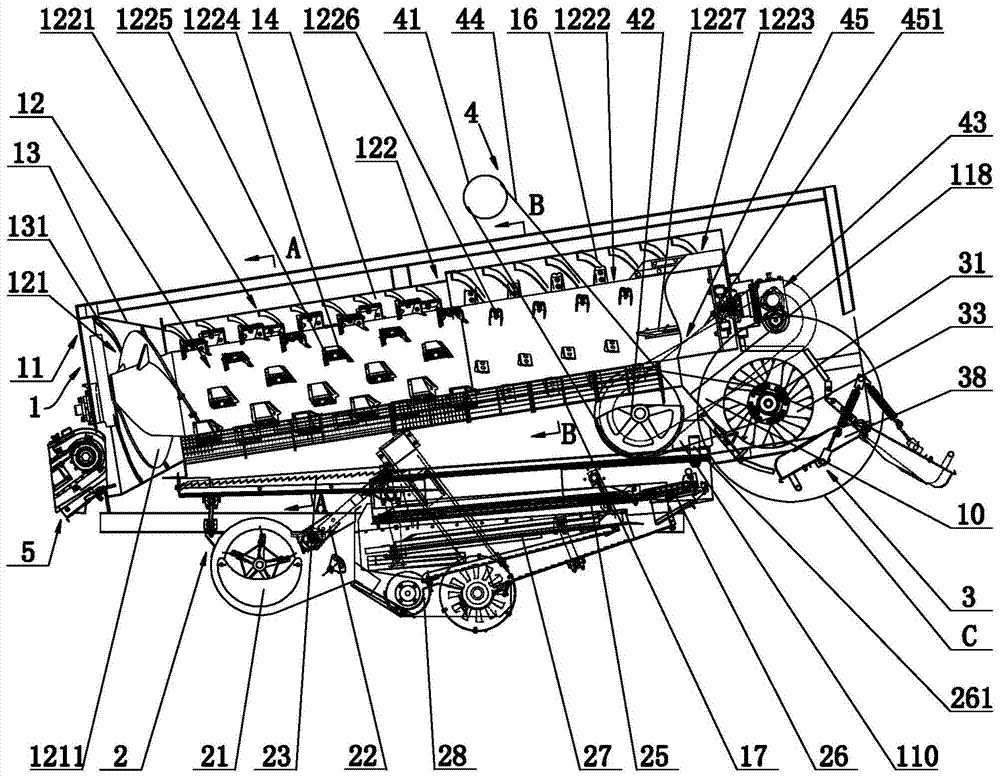

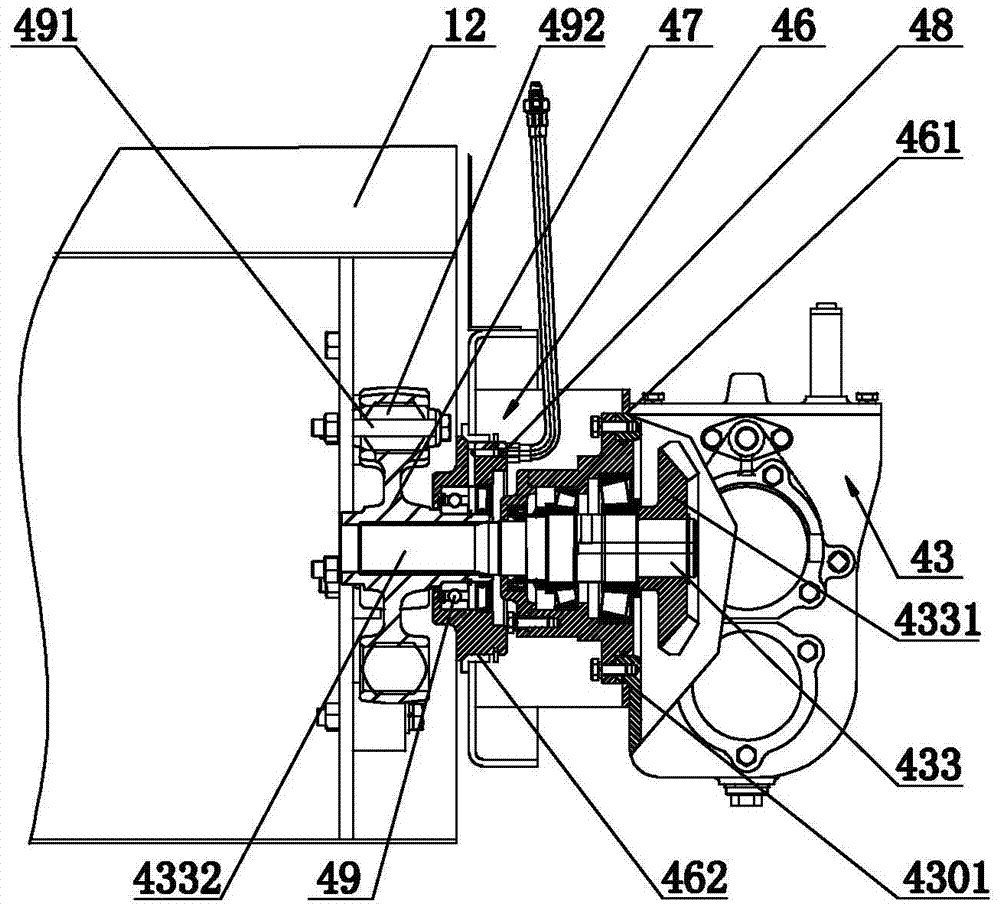

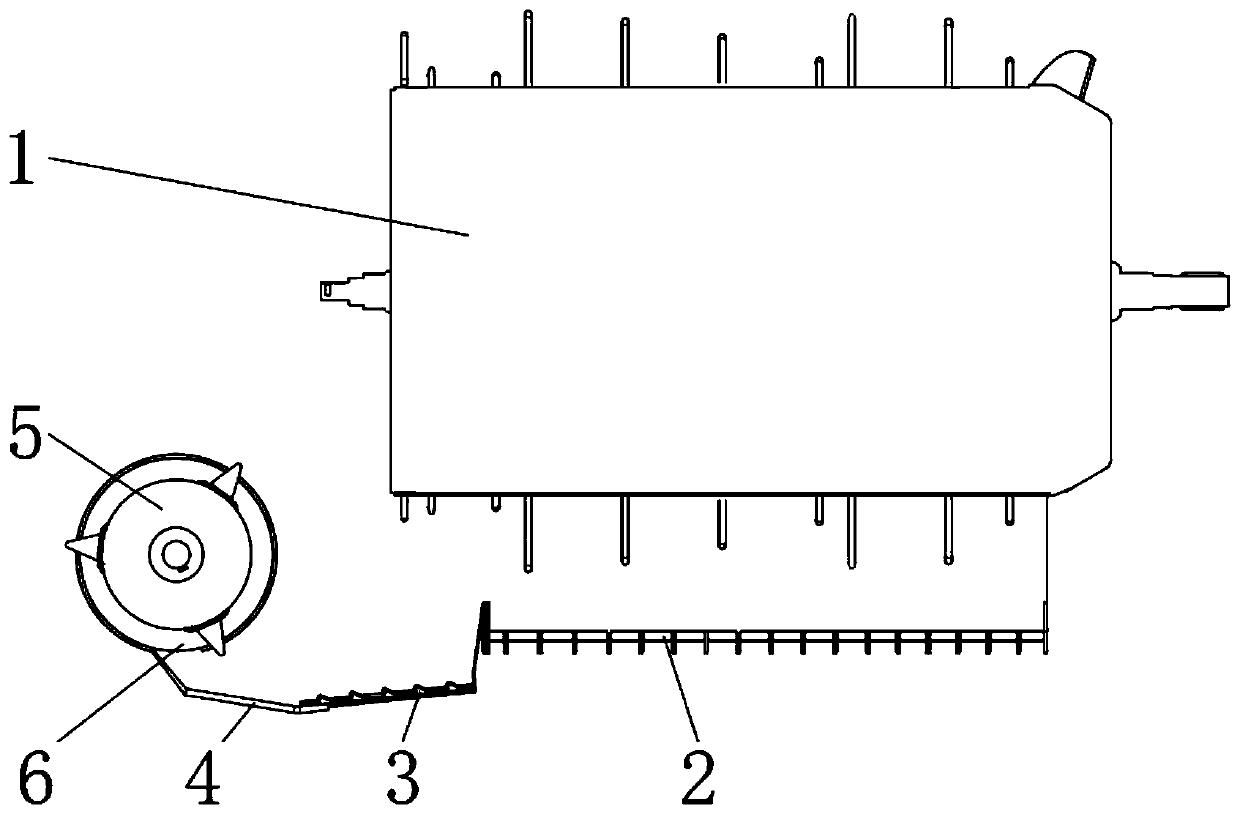

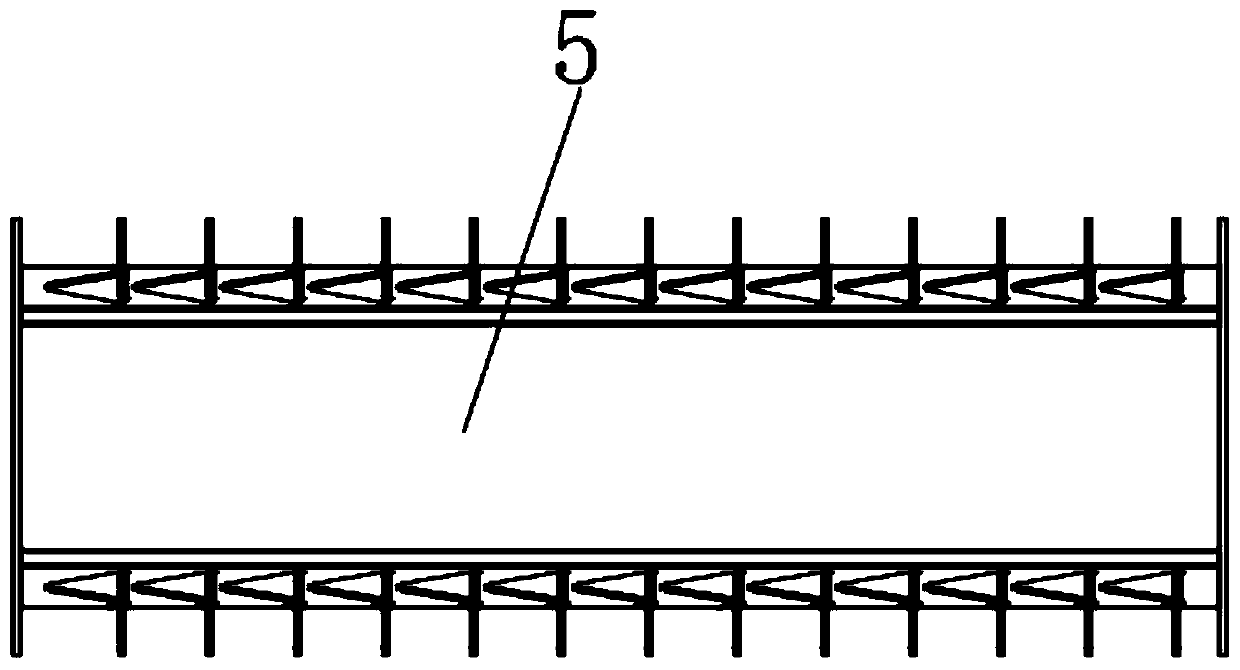

Longitudinal-axial-flow roller

The invention discloses a longitudinal-axial-flow roller, and belongs to the technical field of combine harvester threshing separating devices. The longitudinal-axial-flow roller comprises a roller body, a roller front shaft, a power input shaft, a roller front support and a roller rear support. The roller body comprises a feeding-in part and a roller body part, and an anti-tangling element is arranged between the roller front support and the feeding-in part and comprises a guiding crescent moon, a wedge-shaped roller front cover, a roller front cover seal cover and roller front protrusions wherein the guiding crescent moon and the wedge-shaped roller front cover are fixed to the roller front support, the guiding crescent moon comprises a disc and a guiding plate, one end of the disc is fixedly installed on the roller front support, and an opening is formed in the other end of the disc. The disc penetrates through an installing hole in the roller front cover, the roller front cover seal cover is fixed to the roller front cover, and the roller front protrusions are fixed to the front end face of the feeding-in part and located inside the opening. In harvesting, the roller front shaft is not likely to be tangled with weeds, working efficiency is high, kinds of crops are harvested without replacing the roller, and the requirements for earnings of a user are met.

Owner:LOVOL HEAVY IND CO LTD

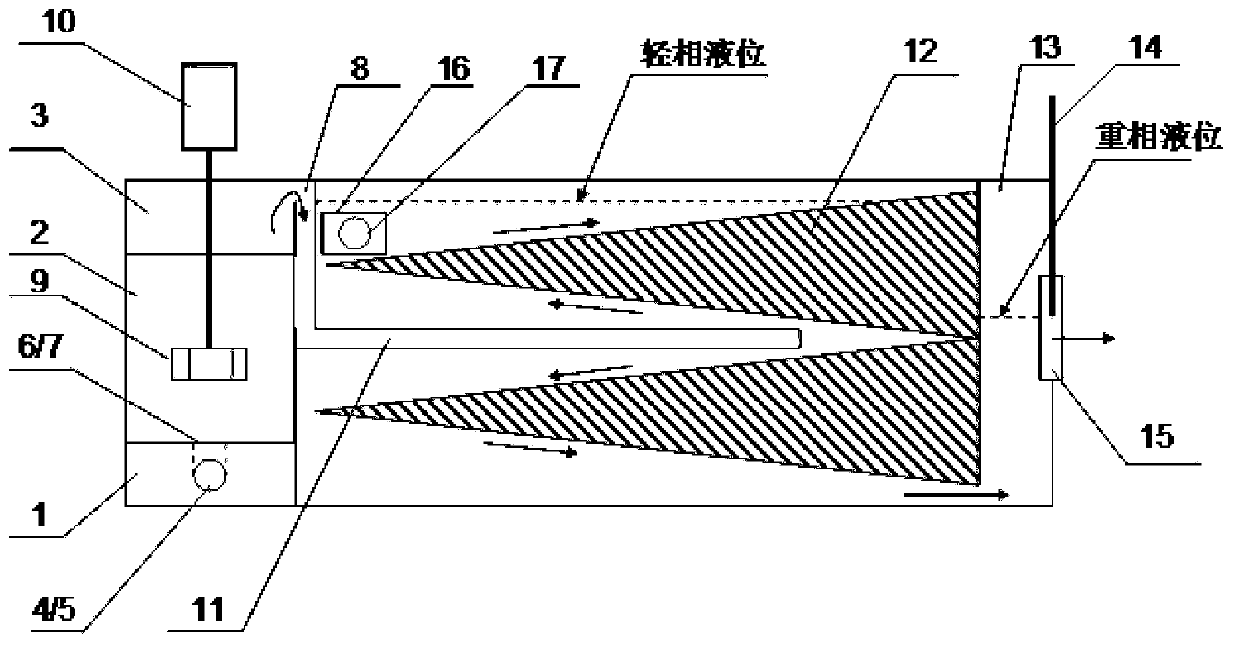

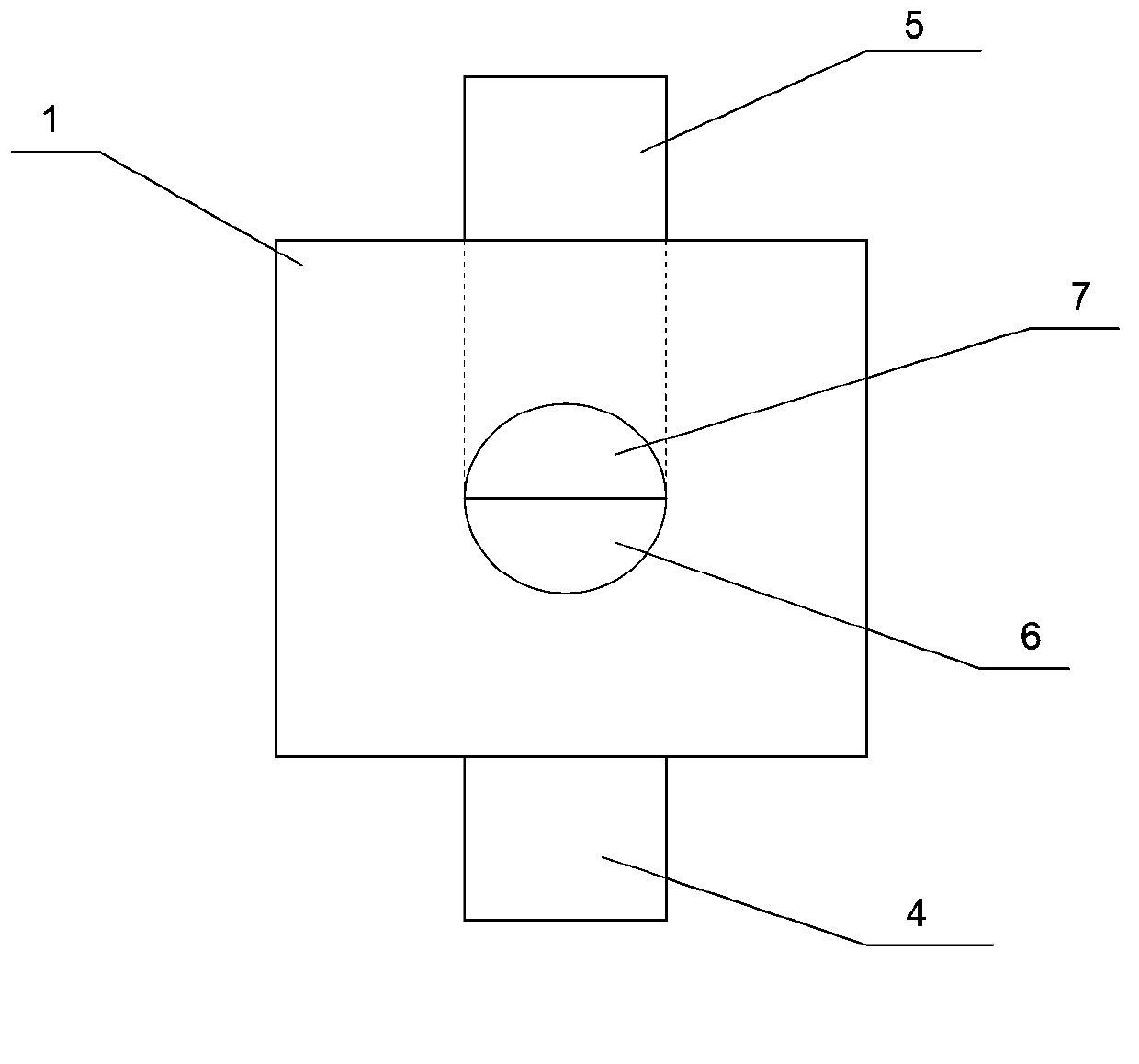

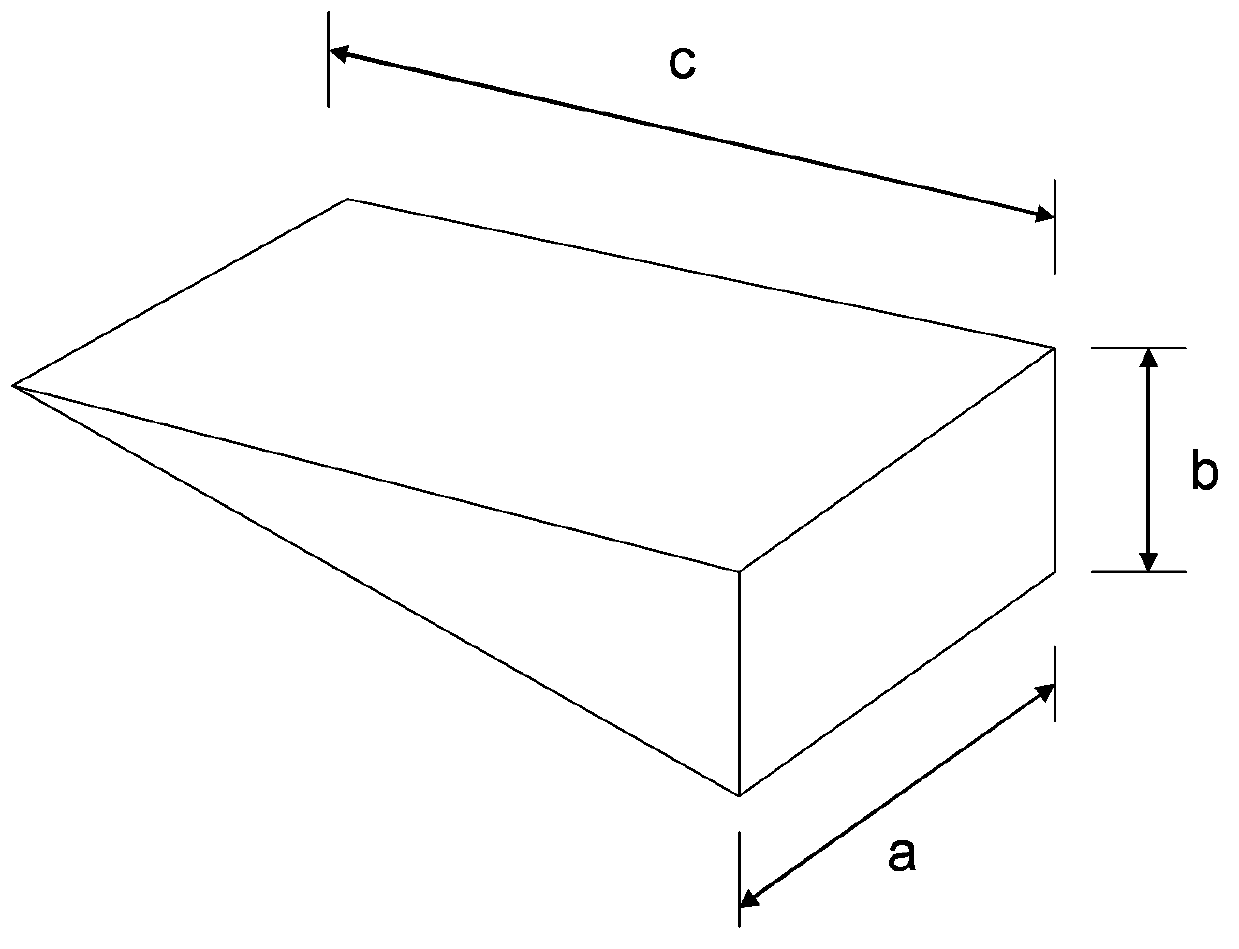

Liquid-liquid extraction mixer-settler and extraction method and application thereof

InactiveCN103120863AIncrease the settlement areaReduce holdupLiquid solutions solvent extractionSingle stagePhase splitting

The invention relates to a liquid-liquid extraction mixer-settler and an extraction method and an application thereof. The mixer-settler comprises a mixing chamber and a clarifying chamber, wherein the side in the clarifying chamber near the mixing chamber is provided with a guide pipe which extends to the tail end of the clarifying chamber from an outlet of the mixing chamber; and at least the upper part or the lower part of the guide pipe in the clarifying chamber is transversely and fixedly provided with a wedge-shaped body. As the upper part and / or the lower part of the guide pipe in the clarifying chamber is fixedly provided with the wedge-shaped body, not only is the storage amount of organic phases in the settling chamber reduced, but also a large light-heavy two-phase settling area is provided so that the clarifying phase-splitting time is prolonged, and the clarifying separation effect is remarkable for an easily-emulsifying system or a system with larger viscosity; and the mixer-settler provided by the invention can be used for single-stage continuous extraction operation or multi-stage series-connected countercurrent continuous extraction operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

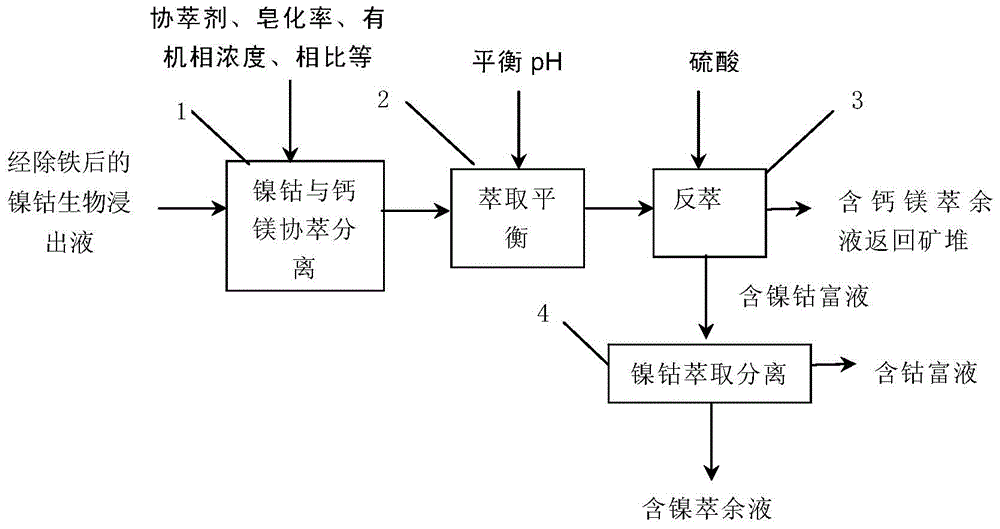

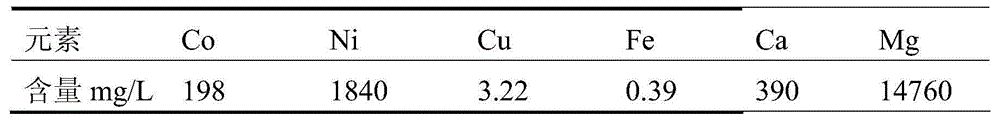

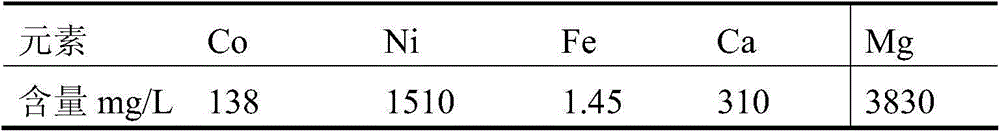

Method for removing calcium and magnesium from bioleaching solution of nickel cobalt by synergetic extraction method

ActiveCN105803197ARealize separation and purificationReduce entrainment lossProcess efficiency improvementPregnant leach solutionCobalt

The invention provides a method for removing calcium and magnesium from a bioleaching solution of nickel cobalt by a synergetic extraction method. The method comprises the following steps: homogeneous saponification is separately carried out for a nickel cobalt extractant Versatic10 and a synergic extractant Cynaex301 by using a NaOH solution, and saponification rate is 40-60%; an organic phase is composed of a combined extractant and a diluent Mextral DT100; the combined extractant comprises 20-40V% of the synergic extractant Cynaex301 and 80-60V% of the extractant Versatic; the volume of the combined extractant is 10-30% of the total volume of the organic phase; when an initial pH value is 1.5-3.0, the organic phase and the bioleaching solution of nickel cobalt are mixed with shaking, the pH value is controlled at 3.0-4.0 for balancing extraction, and after standing, the organic phase and the aqueous phase are separated; sulfuric acid is added into the organic phase for back extraction of nickel cobalt, so that effective separation between nickel cobalt as well as calcium and magnesium is realized.

Owner:有研资源环境技术研究院(北京)有限公司

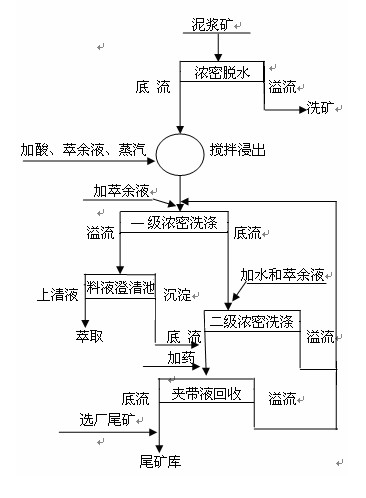

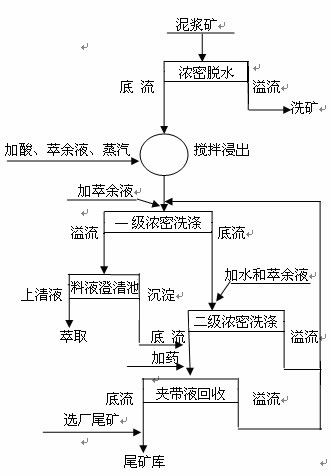

Leaching method of low-grade copper oxide mud ore

ActiveCN102251104AReduce entrainment lossFacilitate solid-liquid separationProcess efficiency improvementMining engineeringCopper oxide

The invention provides a leaching method of low-grade copper oxide mud ore, which comprises the following process steps: concentration, leaching, washing, settling separation, dilution, clarification separating, and the like. Therefore, the leaching of low-grade refractory copper oxide ore with high mud content is realized; reliable raw material guarantee is provided for subsequent extraction of valuable elements; not only resources are integrated and valuable elements in resources are fully recovered, but also the invention has a high leaching rate, a short leaching period, and less tailing entrainment; the overflow is returned for recycle during the leaching process; the leached solid residues are neutralized with tailing slurry discharged by concentrators, and then are stored in tailing reservoirs, so no pollutant is discharged outwards, which facilitates environmental protection; additionally, the invention also has the advantages of investment saving, low operation cost, low labor intensity, and high productivity.

Owner:YUNNAN DIQING MINING DEV

Ultrasonic synergetic crystal growing fruit juice freezing and concentrating method and equipment thereof

ActiveCN101664214BUniform growthAvoid it happening againSolution crystallizationFood scienceFruit juiceEnrichment methods

The invention discloses an ultrasonic synergetic crystal growing fruit juice freezing and concentrating method and an equipment thereof. A fruit juice storage tank of the equipment is connected with a scraper-type heat exchanger by a centrifugal pump, and the scraper-type heat exchanger and a centrifugal machine are positioned under a crystal growing tank with a heat preservation jacket and are connected with the crystal growing tank with the heat preservation jacket respectively; an energy converter is arranged in the crystal growing tank with the heat preservation jacket and connected with an ultrasonicator; and the centrifugal machine is connected with a collecting tank which is connected with the scraper-type heat exchanger by a pump. In respect of the method, clear fruit juice is obtained firstly and is pumped into the scraper-type heat exchanger for precooling. After the temperature of feed liquid in the scraper-type heat exchanger is reduced to freezing point and small ice crystals are generated, an agitating valve and an ultrasonic field generator in the crystal growing tank are started and concentrated solution is discharged and the ice crystals are separated after the ice crystals mature. In the invention, the ultrasonic synergetic effect greatly shortens time from core formation to maturing of ice crystals and the entrainment loss of active ingredients of fruit juice is reduced, thus not only improving production efficiency but also meeting purpose of saving energy.

Owner:SOUTH CHINA UNIV OF TECH

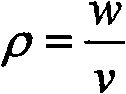

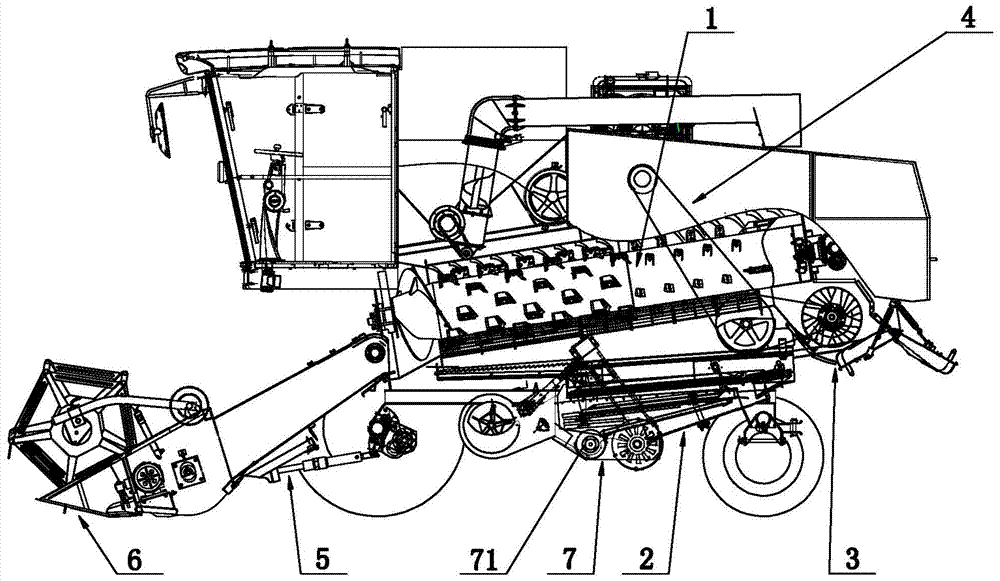

Track self-running type cutting longitudinal flow full-feeding combine harvester

The invention discloses a track self-running type cutting longitudinal flow full-feeding combine harvester. A threshing rotary drum assembly comprises an arch tooth cutting flow threshing barrel and a nail tooth longitudinal axial flow threshing rotary drum; the arch tooth cutting flow threshing barrel is radially arranged at the front part of a stander (3); and the nail tooth longitudinal axial flow threshing rotary drum is axially arranged at the rear part of the stander (3). The track self-running type cutting longitudinal flow full-feeding combine harvester is high in threshing performance, small in entrainment amount and low in seed breakage rate; and furthermore, the track self-running type cutting longitudinal flow full-feeding combine harvester can smoothly and efficiently run in long-straw and high-yield difficultly threshed grain fields without being blocked.

Owner:泰州德锋农业机械有限公司

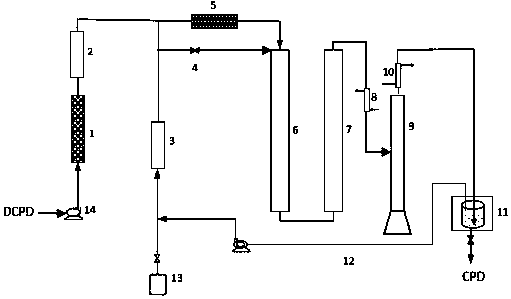

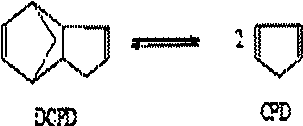

Method for preparing cyclopentadiene through gas-phase depolymerization of dicyclopentadiene

ActiveCN106699497AReduce entrainment lossReduce pollutionHydrocarbon by depolymerisationTemperature controlDepolymerization

The invention provides a method for preparing cyclopentadiene through gas-phase depolymerization of dicyclopentadiene. According to the method, a depolymerizing device is in subsection series connection design and subjected to subsection temperature control; on one hand, the depolymerization time is shortened, and the coking possibility is reduced, so that the service life of the depolymerizing device is prolonged to the maximum, and the depolymerization energy consumption is also reduced by adopting the method provided by the invention; and on the other hand, the DCPD depolymerization rate and CPD yield are further improved by adopting the method provided by the invention and respectively reach 99.9% and 99.5%, especially the CPD yield is also improved by 5% under the condition that the life is prolonged compared with the prior art, and the service life of the depolymerizing device is prolonged to be more than 1200h.

Owner:抚顺华兴石油化工有限公司

A silicon slag electroseparation method that effectively improves the recovery rate of silicon metal

ActiveCN108726522BHigh recovery rateMaximize recyclingElectrostatic separationSilicon compoundsMetal recyclingMolten slag

The invention discloses a silicon slag electric separation method for effectively improving the recycling rate of silicon metal. The method comprises the following steps: 1) crushing silicon slag: firstly, sufficiently crushing the silicon slag; controlling the granularity of the crushed silicon slag to be 60 to 200 meshes; 2) pre-treating the surface of the silicon slag: adding a surfactant intothe silicon slag crushed through step (1), and sufficiently and uniformly stirring; 3) heating the silicon slag: heating and drying the silicon slag treated by step (2), wherein the temperature is 60to 120 DEG C; drying for 10 to 30min; 4) carrying out electric separation: adding the silicon slag obtained by step (3) into electric separation equipment; separating according to the difference of electrical properties of elemental silicon and molten slag in the silicon slag to obtain ore concentrate and silicon slag tailings. According to the silicon slag electric separation method disclosed bythe invention, the elemental silicon is extracted from industrial silicon waste slag by adopting an electric separation manner; an extraction method is simple and the cost is low; the recycling rate of the silicon metal in the silicon slag is improved to 90 percent or more from current about 65 percent, and maximum recycling of a silicon slag resource is effectively realized.

Owner:云南永昌硅业股份有限公司

Method for removing heat-stable salt in flue gas desulfurization solution by normal-pressure ion exchanger

ActiveCN102908806AAchieve purificationReduce entrainment lossDispersed particle separationSolid sorbent liquid separationLiquid wasteIon exchange

The invention provides a method for removing heat-stable salt in a flue gas desulfurization solution by a normal-pressure ion exchanger. The method can purify the flue gas desulfurization solution under normal pressure, the clamping loss of the desulfurization solution is low and the desalting efficiency is high; and purification treatment of the flue gas desulfurization solution is organically combined with a flue gas desulfurization system, so that the utilization rate of the desulfurization solution and the utilization rate of a regenerated waste solution are improved and the method is environment-friendly.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vertical Axial Flow Combine Harvester

ActiveCN105123094BAchieve bothMeet income requirementsCrop conditionersMowersAgricultural engineeringCombine harvester

Owner:LOVOL HEAVY IND CO LTD

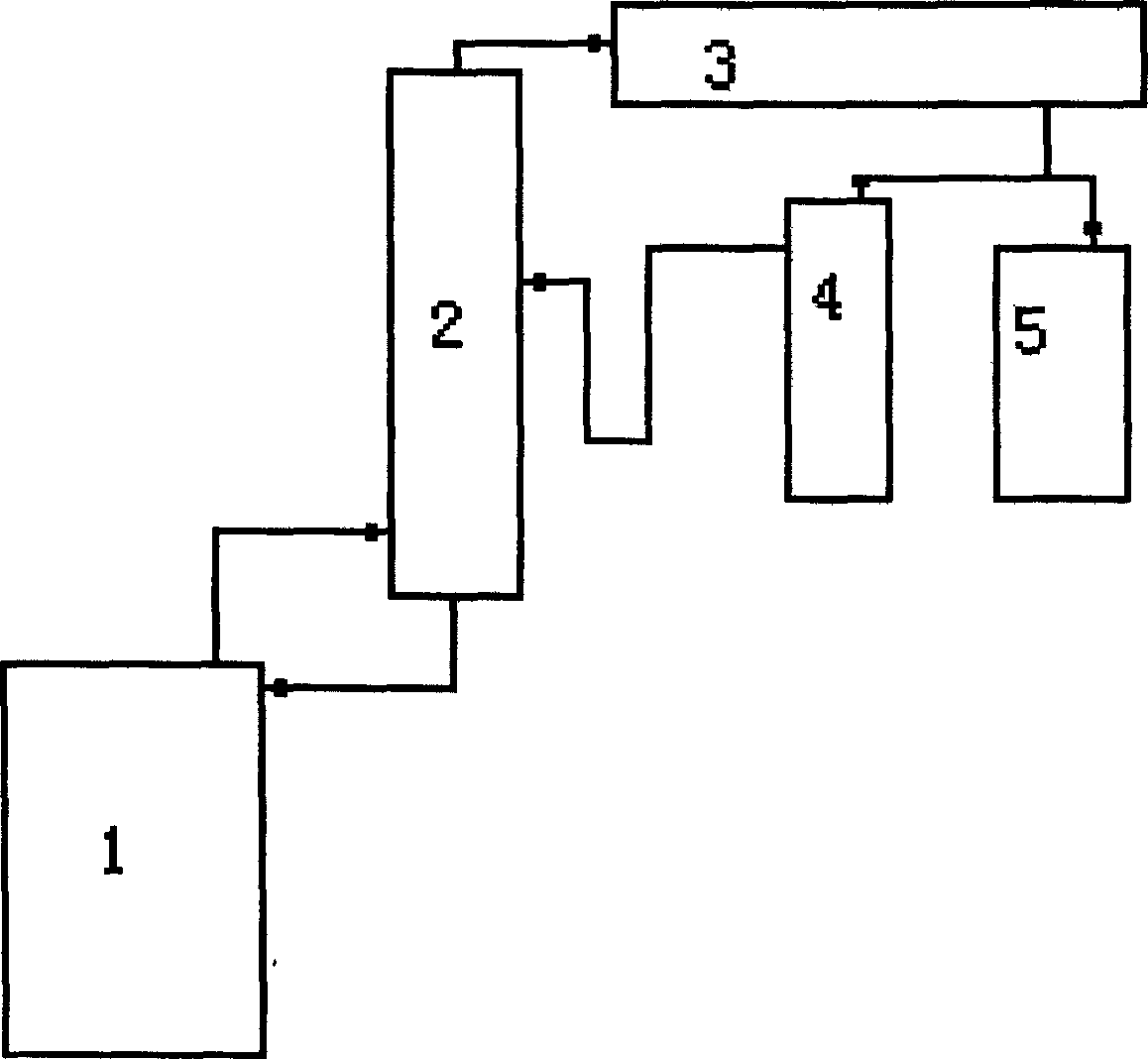

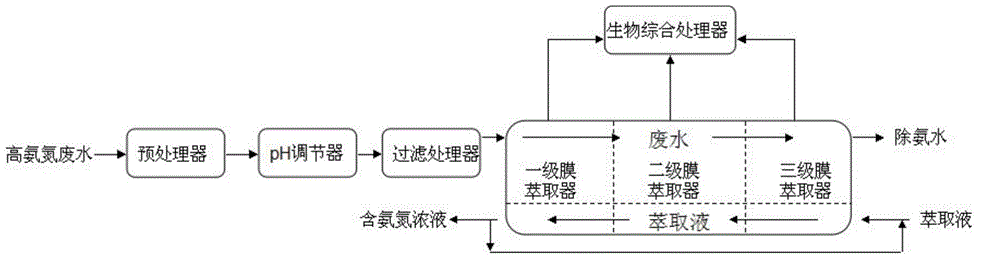

Multistage-membrane-extraction biological integrated treatment system for processing high ammonia nitrogen in wastewater, and method thereof

InactiveCN103553264AReduce concentrationReduce entrainment lossMultistage water/sewage treatmentPre treatmentPre processor

The invention discloses a multistage-membrane-extraction biological integrated treatment system for processing high ammonia nitrogen in wastewater, and a method thereof. The multistage-membrane-extraction biological integrated treatment system comprises: a pre-processor provided with a first water inlet for the entrance of high ammonia nitrogen wastewater; a pH adjuster connected with a first water outlet of the pre-processor; a filter connected with a second water outlet of the pH adjuster through a pipeline; a multistage membrane extractor sequentially comprising a first-stage membrane extractor, a second-stage membrane extractor and a third-stage membrane extractor, wherein the first-stage membrane extractor is connected with a third water outlet of the filter, the first-stage membrane extractor, the above three membrane extractors are connected through a pipeline, an extraction membrane is arranged in each of the membrane extractors, and the extraction membrane parallels to the flow direction of the wastewater and an extracting liquid; and a biological integrated process connected with the first-stage membrane extractor, the second-stage membrane extractor and the third-stage membrane extractor respectively, and a water outlet of the third-stage membrane extractor is provided with an deammoniated water collector.

Owner:SUZHOU SUJING ENVIRONMENTAL ENG

Method for preparing high-purity graphite at high temperature and under vacuum

The invention discloses a method for preparing high-purity graphite at a high temperature and under vacuum, and belongs to the technical field of preparation of ultra-pure graphite, solving the problems of high energy consumption, high pollution, low productivity and high production cost in a purification process of graphite powder in the prior art. The method includes the following steps: S1, making raw graphite powder into balls or blocks; S2, drying formed graphite; S3, performing graphite purification in a high-temperature vacuum furnace; S4, discharging the high-purity graphite. The method is suitable for the preparation of the high-purity graphite.

Owner:钢研晟华科技股份有限公司

A method and system for recovering lithium and cobalt from waste lithium cobalt oxide batteries

ActiveCN109256597BAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementMembrane technologyReverse osmosis

Owner:青海中科德方能源科技研究有限公司

Secondary separation mechanism of harvester

PendingCN110999642AReduce entrainment lossReduce wasteThreshersAgricultural engineeringMechanical engineering

The invention discloses a secondary separation mechanism of a harvester. The secondary separation mechanism of a harvester comprises a roller, a vibrating screen, a straw feeding plate, a supporting plate, a separation tube and a feeding opening, wherein the vibrating screen is arranged on the outer wall of the bottom end of the roller; the straw feeding plate is arranged in a position, positionedon the outer wall of the vibrating screen, of the roller;; the supporting plate is connected onto the outer wall of the bottom end of the straw feeding plate through screw bolts; the separation tubeis rotationally arranged on the outer wall of one side of the roller; the feeding opening is formed in the outer wall of the bottom end of the separation cylinder; one end of the straw feeding plate is inserted into and connected with the inside of the feeding opening; and the roller and the separation tube are in a cylindrical shape. The secondary separation mechanism of the harvester is used forperforming secondary separation on grain particles and rice and wheat straws when the harvester is used for harvesting rice or wheats, so that the grains and the straws can be more cleanly separated;the retention rate is improved; the entrainment loss of grains is reduced; in addition, the structure is simple; the operation efficiency is high; the grain and straw separation effect is good, so that the grain waste is reduced; and the economic benefits of farmers are increased.

Owner:HUNAN NONGFU ELECTROMECHANICAL

A method and system for recovering lithium and manganese from waste lithium manganese oxide batteries

ActiveCN109207725BAdvanced separation technologyEasy to separateWaste accumulators reclaimingBattery recyclingMembrane technologyPhysical chemistry

The invention discloses a method and a system for recovering lithium and manganese from waste lithium manganate batteries. The method includes: dismantling the positive electrode sheet from the waste lithium manganese oxide battery; removing the binder in the positive electrode sheet, and then leaching the valuable metal elements in the positive electrode sheet through acid solution to obtain an acidified leachate; using an ultrafiltration membrane to The acidified leachate is subjected to ultrafiltration treatment; the lithium ions in the acidified leachate are separated from other cations different from lithium ions by using nanofiltration membrane technology to obtain a lithium-containing solution and a solution containing other cations, which are then concentrated and enriched by reverse osmosis technology. set, the other cations include manganese ions; and, the lithium ions in the lithium-containing solution are precipitated by using a lithium precipitant, and the manganese ions in the solution containing other cations are precipitated by using an alkaline substance, so as to realize the separation of lithium and manganese Recycle. The invention adopts ultrafiltration-nanofiltration-reverse osmosis combined technology, and has the characteristics of simple and environmentally friendly process, less acid and alkali consumption, good and stable membrane separation effect, and the like.

Owner:青海中科德方能源科技研究有限公司

A separation method for associated rich fluorite and low-grade cassiterite in tungsten beneficiation tailings

A method for separating associated fluorite-rich and low-grade cassiterite from tungsten tailings. The tungsten tailings containing fluorite CaF216-25% and tin-SnO20.1-0.3% are directly put into the flotation column for roughing Fluorspar: Separating fluorspar from calcite and iron-containing pyroxene to obtain fluorspar rough concentrate and anti-enrichment tin-containing tailings; the fluorite coarse concentrate is separated by flotation machine for five times to obtain fluorspar Concentrate products and flotation fluorite tailings; the anti-enrichment tin-containing tailings are separated by two-stage separation, and the sub-concentrate is concentrated and rewashed by shaking table re-election technology to obtain tin rough concentrate products and tin tailings. The invention has simple technological process, can reduce the loss of fluorite and cassiterite in the overflow water at the same time, and is beneficial to the improvement of the comprehensive recycling rate of the fluorite and cassiterite.

Owner:YUNNAN TIN

A method for preparing high-purity graphite in high-temperature vacuum

The invention discloses a method for preparing high-purity graphite in high-temperature vacuum, which belongs to the technical field of ultra-pure graphite preparation and solves the problems of high energy consumption, high pollution process, low production capacity and high production cost in the purification process of graphite powder in the prior art. The method of the invention comprises the following steps: S1. forming raw graphite powder into balls or blocks; S2. drying the formed graphite; S3. purifying graphite in a high-temperature vacuum furnace; S4. discharging. This method is suitable for the preparation of high-purity graphite.

Owner:钢研晟华科技股份有限公司

Method for extracting lithium from salt lake brine with high magnesium-lithium ratio

PendingCN111484046ARealize comprehensive utilizationEasy to separateHydrotalciteLithium oxides/hydroxidesHigh magnesiumChemical composition

The invention belongs to the technical field of salt lake brine resource utilization. The invention provides a method for extracting lithium from salt lake brine with a high magnesium-lithium ratio. The method mainly comprises the steps: by taking magnesium in brine as a raw material, adding an aluminum source and a precipitant, precipitating magnesium and aluminum into layered double hydroxides (MgAl-LDHs), filtering and separating, reserving lithium ions in filtrate, concentrating or performing ion selective adsorption to enrich lithium, precipitating lithium with carbonate ions, and thus obtaining lithium carbonate. The chemical general formula of the obtained layered double hydroxides (MgAl-LDHs) is Mg[1-x]Al[x](OH)[2](A<n->[x / n]).yH[2]O, and the ratio of Mg<2+> to Al<3+>of LDHs can beadjusted within a certain range according to application requirements, so that the chemical composition of LDHs is changed, and the chemical properties and the charge density of laminates are furthermodulated to adapt to new applications. The method has the advantages that the obtained LDHs are magnesium-based functional materials while lithium extraction of the salt lake brine with the high magnesium-lithium ratio is achieved, the method is widely applied to the aspects of flame retardance, wastewater treatment, soil remediation and the like, and comprehensive utilization of brine resourcescan be achieved. The method is short in technological process, easy to operate and good in magnesium-lithium separation effect, magnesium resources can be fully utilized while lithium is extracted, and the magnesium damage problem of the salt lake can be well solved.

Owner:QUZHOU UNIV +1

Method for uranium element enrichment in bittern

The invention relates to the technical field of microelement extraction and particularly discloses a method for uranium element enrichment in bittern. The method comprises the following steps: S1, alternatively carrying out low-temperature separation out and high-temperature evaporation on bittern to obtain treated old bittern; S2, carrying out multistage solid-liquid separation treatment on the old bittern under normal temperature, wherein mass ratio of content of uranium element in the liquid phase obtained from the back-stage solid-liquid separation to content of element in the liquid phase obtained from the front-stage solid-liquid separation is 1.7:1 to 1.8 :1; and S3, concentrating to obtain uranium element. With adoption of the method, the problem that microelements in old bittern of the existing salt lake is difficult for enrichment is solved, and the yield of uranium element is increased to equal to or greater than 60.0% by directly utilizing natural energy and through a multistage separation method of a multistage salt pan, so that the cost is reduced, the time is shortened, and the salt lake resource is reasonably utilized.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A method for enriching uranium in brine

The invention relates to the technical field of microelement extraction and particularly discloses a method for uranium element enrichment in bittern. The method comprises the following steps: S1, alternatively carrying out low-temperature separation out and high-temperature evaporation on bittern to obtain treated old bittern; S2, carrying out multistage solid-liquid separation treatment on the old bittern under normal temperature, wherein mass ratio of content of uranium element in the liquid phase obtained from the back-stage solid-liquid separation to content of element in the liquid phase obtained from the front-stage solid-liquid separation is 1.7:1 to 1.8 :1; and S3, concentrating to obtain uranium element. With adoption of the method, the problem that microelements in old bittern of the existing salt lake is difficult for enrichment is solved, and the yield of uranium element is increased to equal to or greater than 60.0% by directly utilizing natural energy and through a multistage separation method of a multistage salt pan, so that the cost is reduced, the time is shortened, and the salt lake resource is reasonably utilized.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com