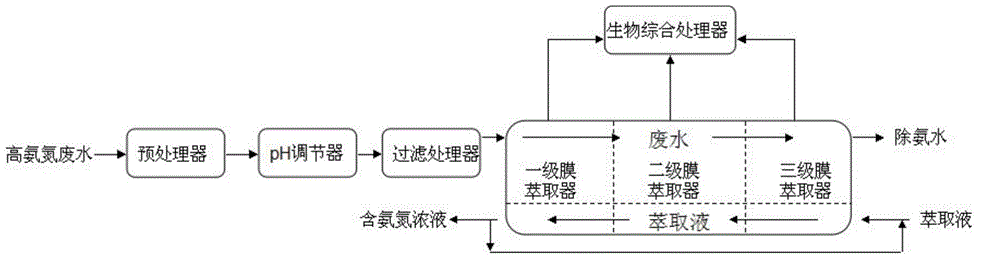

Multistage-membrane-extraction biological integrated treatment system for processing high ammonia nitrogen in wastewater, and method thereof

A wastewater treatment and comprehensive treatment technology, which is applied in the field of environmental water purification, can solve the problems of ineffective utilization of disposal, low removal rate of air stripping process, and low concentration of ammonium sulfate, so as to improve efficiency, avoid solvent loss, and improve transmission efficiency. The effect of mass efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The ammonia nitrogen concentration of the landfill leachate in a landfill site is 1000mg / L. The particulate matter in the leachate is removed by grid filtration, and then filtered through a high-efficiency fiber filter and a security filter in turn. The pH of the leachate is adjusted to about 10 with lime. Entering the first-stage extraction membrane treatment, under the action of the ammonia partial pressure difference on both sides of the membrane, the ammonia nitrogen in the wastewater is converted into ammonia molecules NH 3 The form permeates the membrane and is absorbed by the acid to form an ammonium salt. After testing, the concentration of ammonia nitrogen in the effluent of the first-stage extraction membrane dropped to 360mg / L, and then treated by the second-stage extraction membrane, the concentration of ammonia nitrogen dropped to below 100mg / L, and after comprehensive biological treatment, the concentration of ammonia nitrogen dropped to below 5mg / L The el...

Embodiment 2

[0021] The average concentration of ammonia nitrogen in a chemical and pharmaceutical wastewater is 5600 mg / L. The particulate matter in the leachate is removed by grid filtration, and the pH of the leachate is adjusted to about 11 with sodium hydroxide, and then filtered through a disc filter to enter the primary extraction. Membrane treatment, under the action of the ammonia partial pressure difference on both sides of the membrane, the ammonia nitrogen in the wastewater is converted into ammonia molecules NH 3The form permeates the membrane and is absorbed by sulfuric acid to form ammonium sulfate. After testing, the concentration of ammonia nitrogen in the effluent of the first-stage extraction membrane dropped to 2200mg / L, and then treated by the second-stage extraction membrane, the concentration of ammonia nitrogen dropped to below 560mg / L, and after the treatment of the third-stage extraction membrane, the concentration of ammonia nitrogen dropped to below 6mg / L. The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com