Patents

Literature

196results about How to "Simple process flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

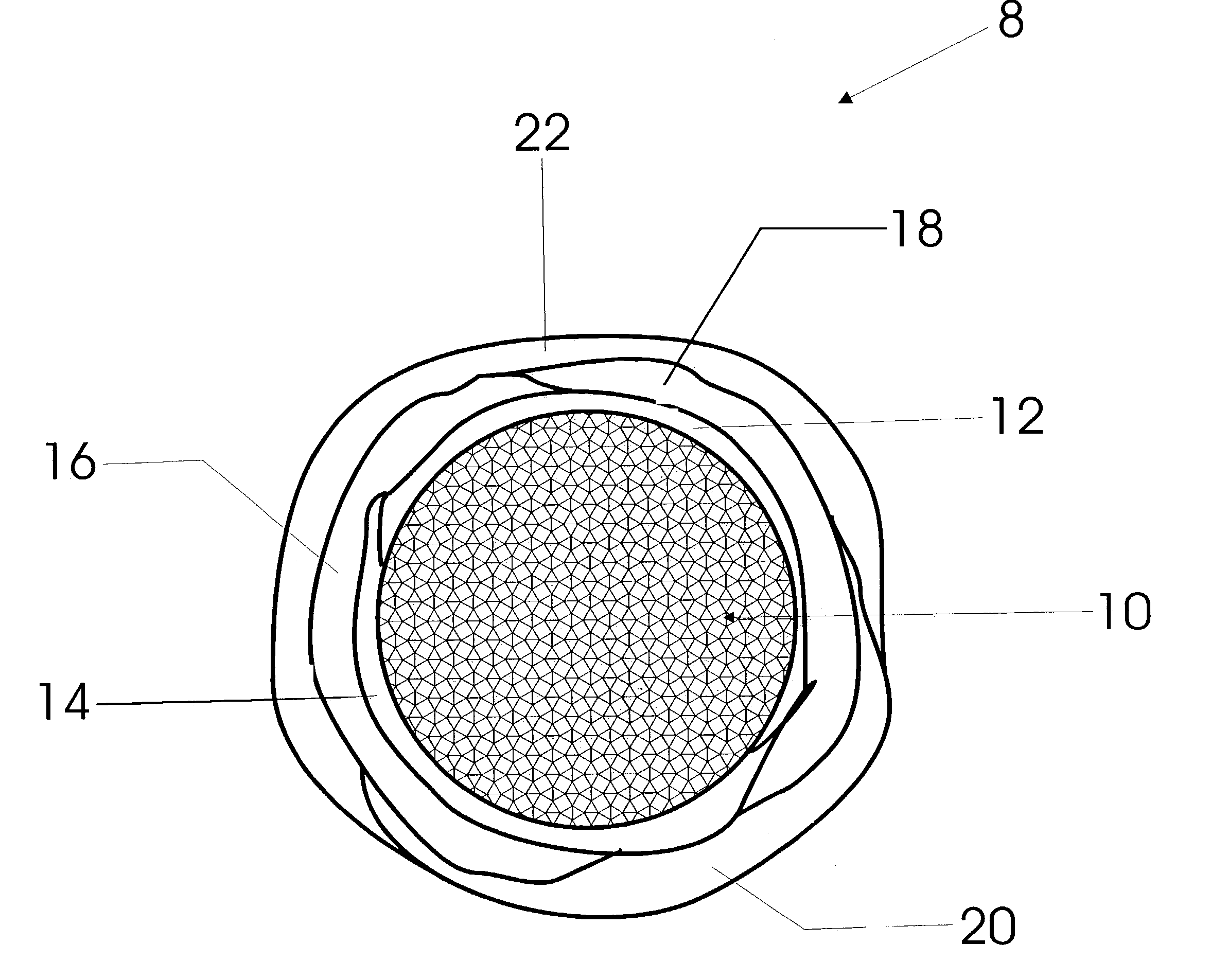

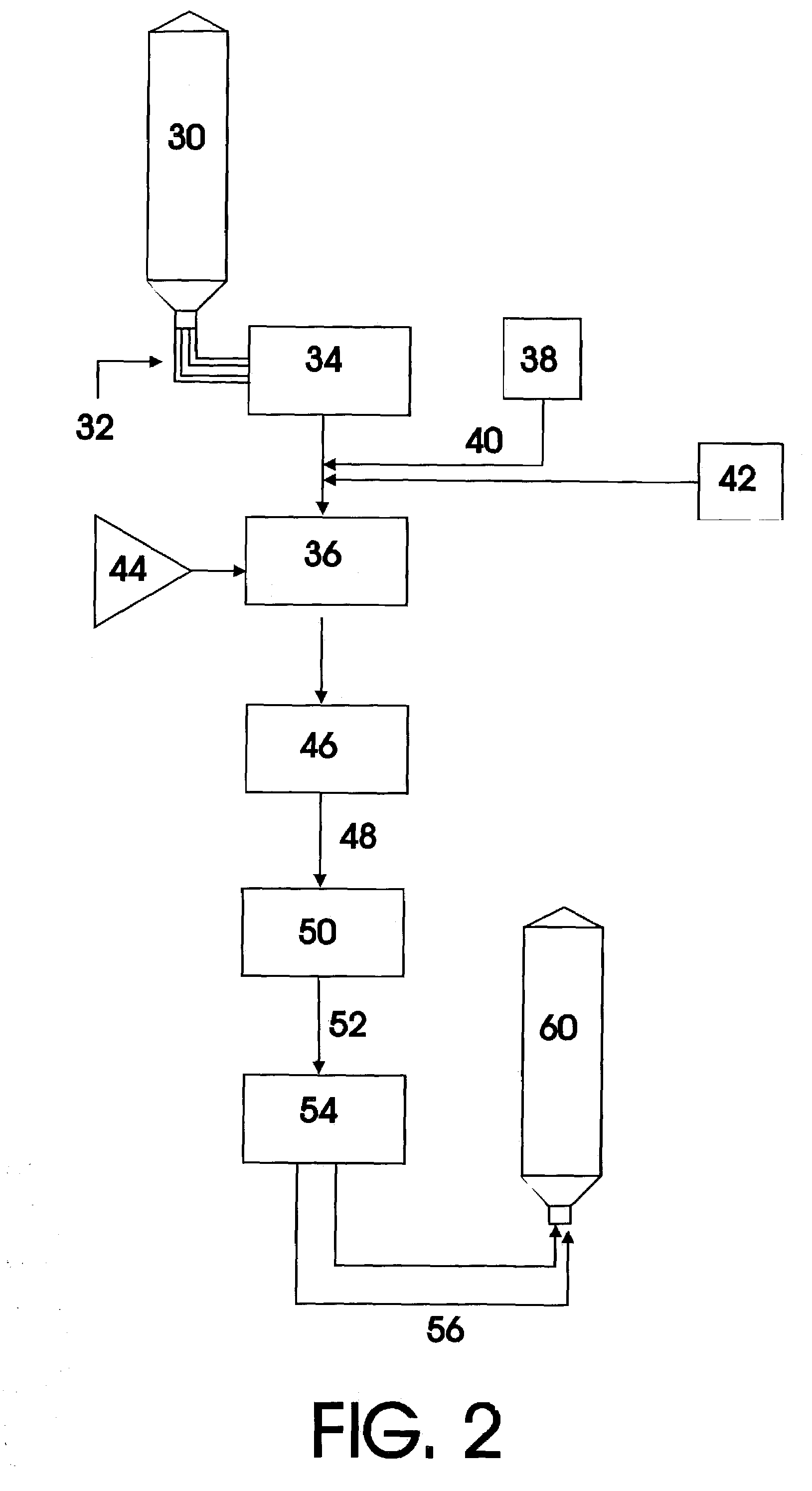

Process for incremental coating of proppants for hydraulic fracturing and proppants produced therefrom

ActiveUS7135231B1Simple process flowEffect degree of curabilityNanotechLiquid surface applicatorsHigh intensityMaterials science

A high strength composite particle comprised of a series of incrementally applied resin microlayer coatings such that each of the microlayer partial coatings are interleaved with each other is described. Methods of making the composite particles, as well as methods of using such particles as a proppant in oil and gas well hydraulic fracturing are also described.

Owner:FAIRMOUNT SANTROL

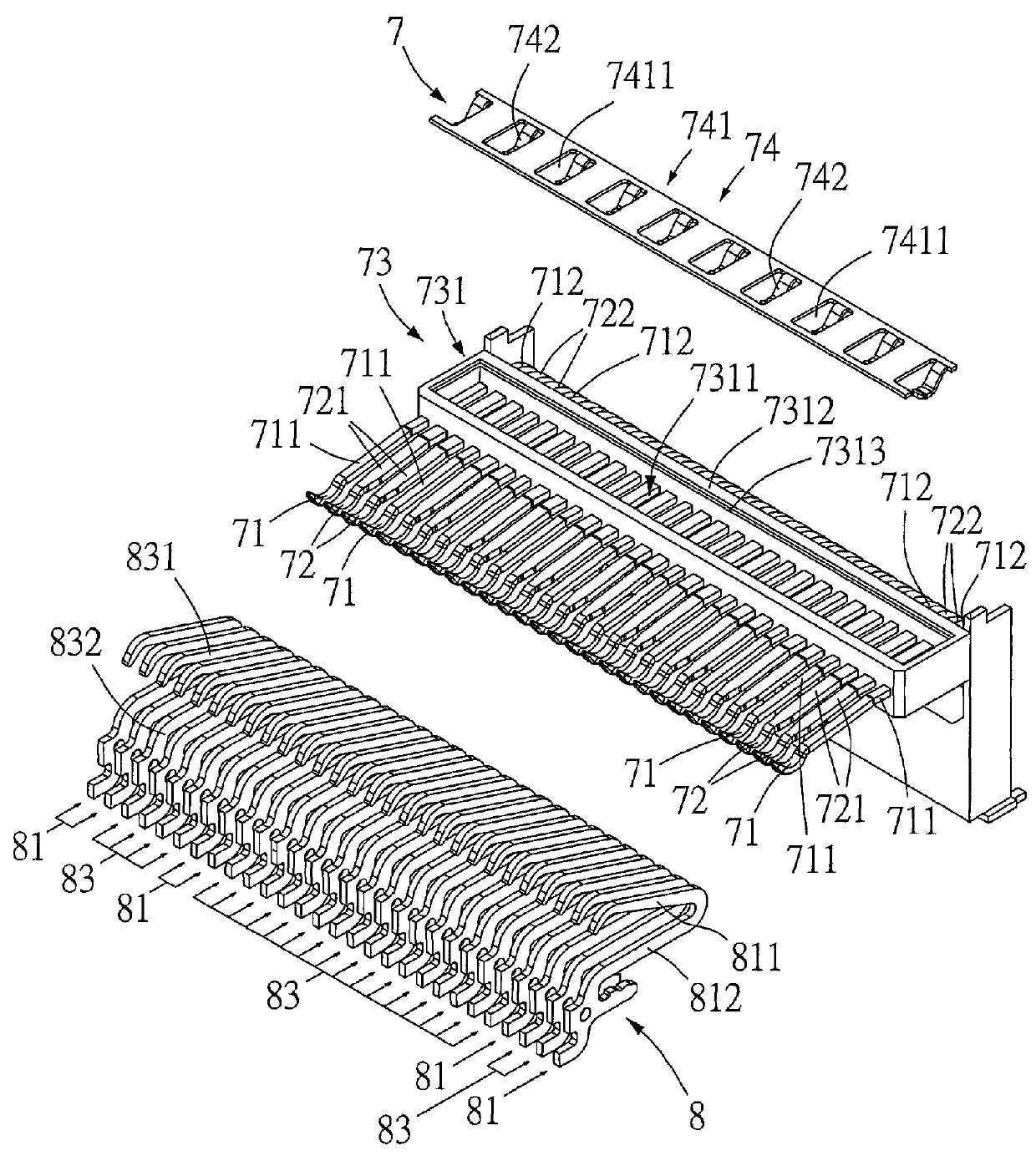

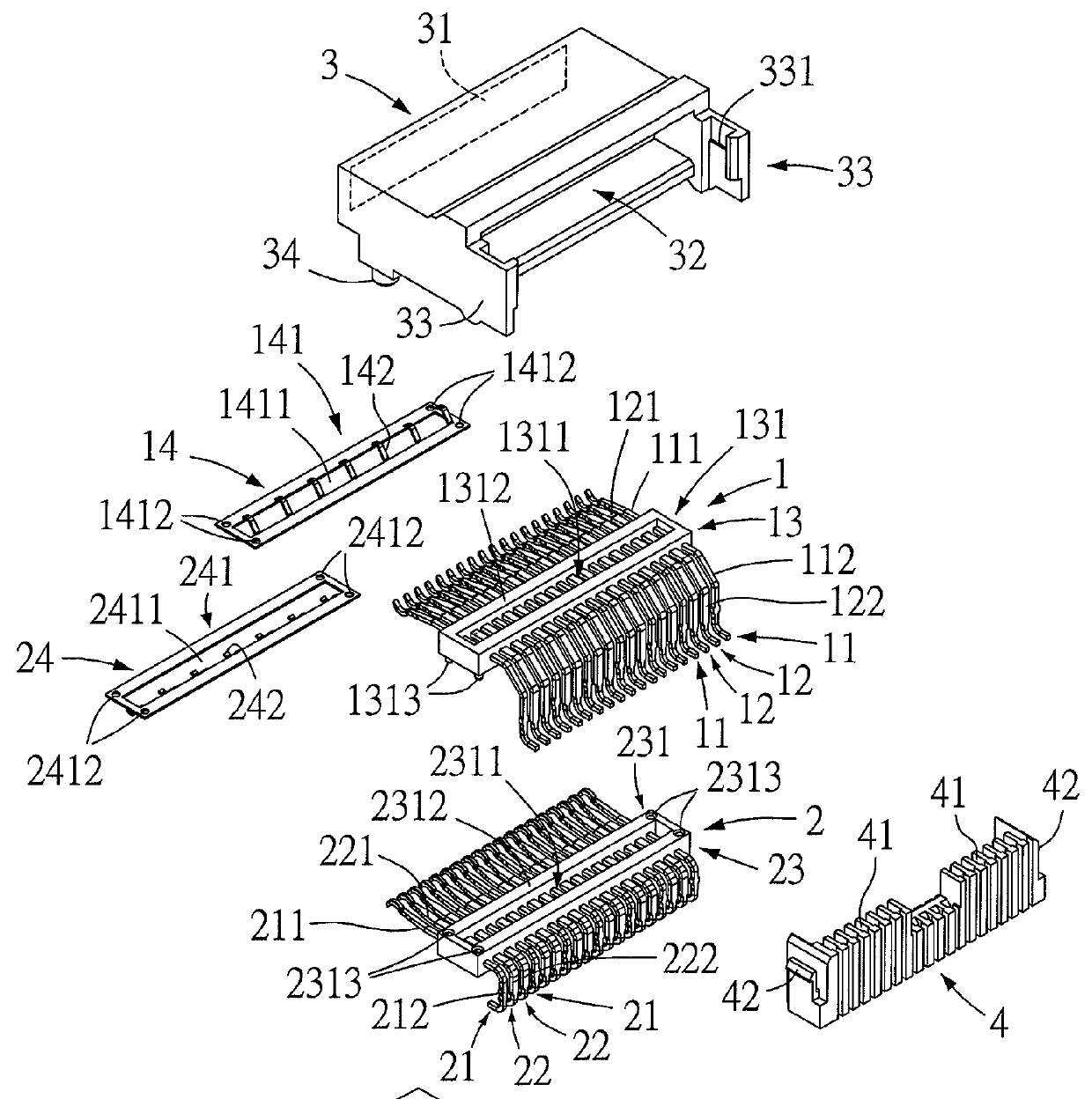

Terminal structure and electrical connector having the same

InactiveUS9337585B1Good vibesReduce signal lossCoupling device detailsTwo-part coupling devicesElectricityResonance

A terminal structure includes ground terminals, signal terminals, connection elements, and ground electrical connection elements. The connection elements connect the ground terminals to the signal terminals, respectively. The ground electrical connection elements are in connection with connection elements and in electrical contact with at least a ground terminal. An electrical connector includes two terminal structures and a casing. The connection elements are connected to each other. An insertion slot is disposed on the front side of the casing. The terminal structure is disposed at the casing. The resilient ground electrical contact segments and the resilient signal electrical contact segments face the insertion slot. The ends of the ground electrical connection segments and the ends of the signal electrical connection segments are exposed from the casing. The terminal structure and the electrical connector improve resonance, adjust impedance, reduce signal loss, simplify die structures, and extend service life of a die.

Owner:ALL BEST PRECISION TECH

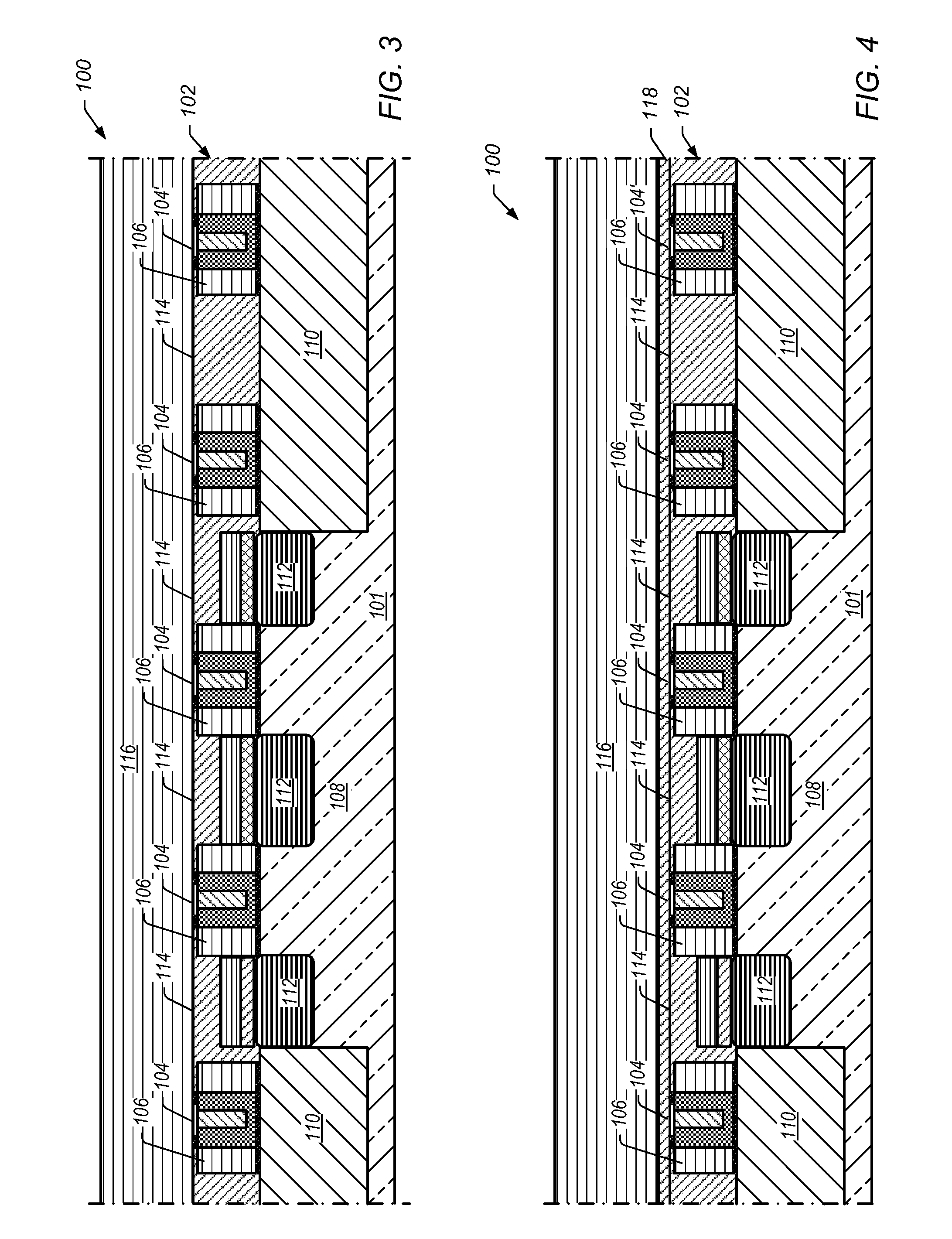

Trench silicide and gate open with local interconnect with replacement gate process

ActiveUS20130119474A1Reduce in quantityImprove production yieldTransistorSemiconductor/solid-state device manufacturingSalicideConductive materials

A semiconductor device fabrication process includes forming insulating mandrels over replacement metal gates on a semiconductor substrate with first gates having sources and drains and at least one second gate being isolated from the first gates. Mandrel spacers are formed around each insulating mandrel. The mandrels and mandrel spacers include the first insulating material. A second insulating layer of the second insulating material is formed over the transistor. One or more first trenches are formed to the sources and drains of the first gates by removing the second insulating material between the insulating mandrels. A second trench is formed to the second gate by removing portions of the first and second insulating materials above the second gate. The first trenches and the second trench are filled with conductive material to form first contacts to the sources and drains of the first gates and a second contact to the second gate.

Owner:ADVANCED MICRO DEVICES INC

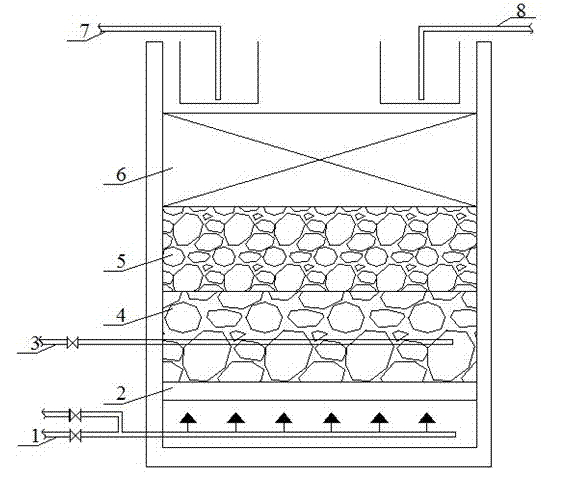

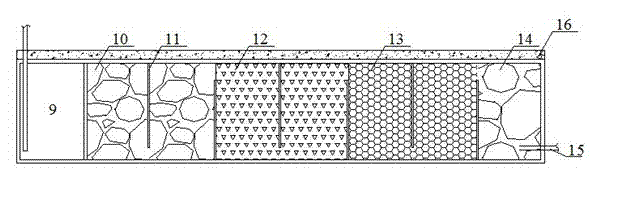

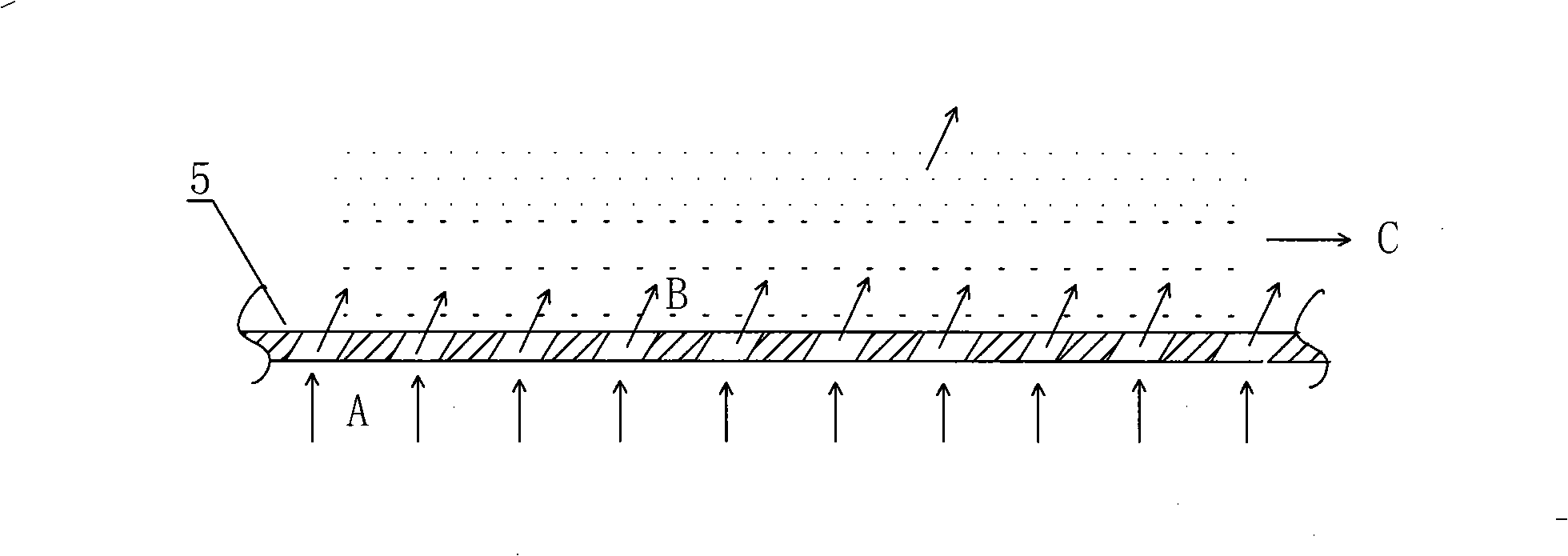

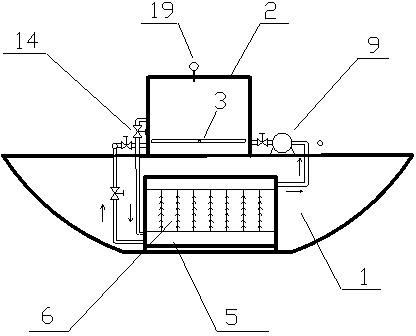

Reclaimed water treatment system combining upflow aerating biological filter with horizontal underflow artificial wetland

InactiveCN103043865AShort hydraulic retention timeHigh volume loadMultistage water/sewage treatmentSites treatmentConstructed wetland

The invention discloses a reclaimed water treatment system combining an upflow aerating biological filter with horizontal underflow artificial wetland. The system consists of the upflow aerating biological filter and the horizontal underflow artificial wetland; the upflow aerating biological filter comprises a water inlet guide tube positioned at the bottom of the filter; a filter plate, a supporting layer, an A section filler area, a B section filler area and a water outlet area are sequentially arranged above the water inlet guide pipe; a communicating water pipe is mounted on the water outlet area, and communicated with a regulating tank of the horizontal underflow artificial wetland; an aerator pipe is led out of the supporting layer; the regulating tank and a matrix area parallel to the regulating tank are arranged at the lower layer of the horizontal underflow artificial wetland; the matrix area sequentially comprises a macadam area, a steel slag area, a zeolite area and a water outlet gravel area from left to right; the water outlet gravel area is equipped with a water outlet pipe; and a soil covering layer and aquatic plants are arranged at the upper layer of the horizontal underflow artificial wetland. With the adoption of the system, on-site treatment and utilization of sewage are achieved; the sewage treatment process flow is simplified; and operation and management costs are lowered.

Owner:CHONGQING UNIV

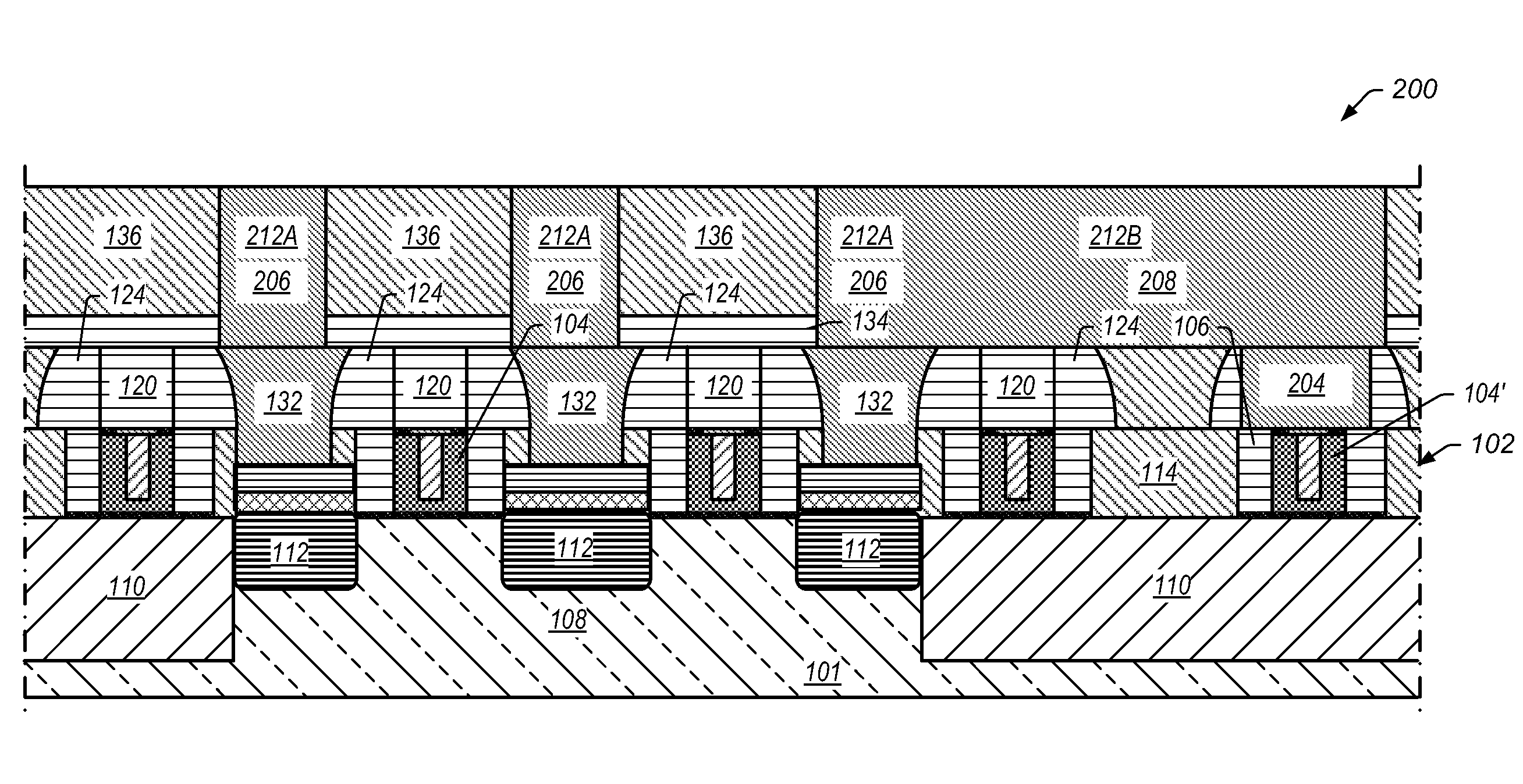

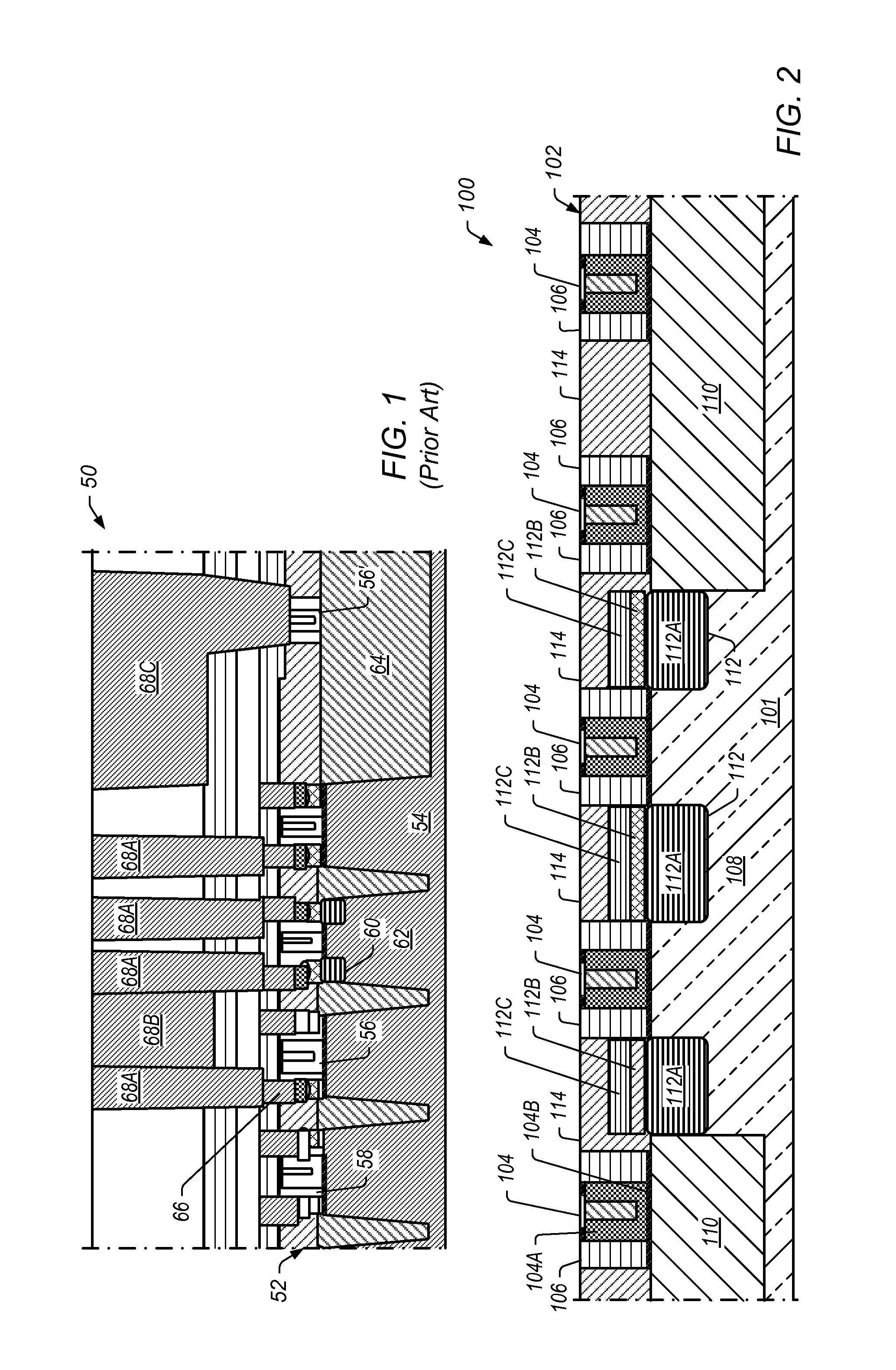

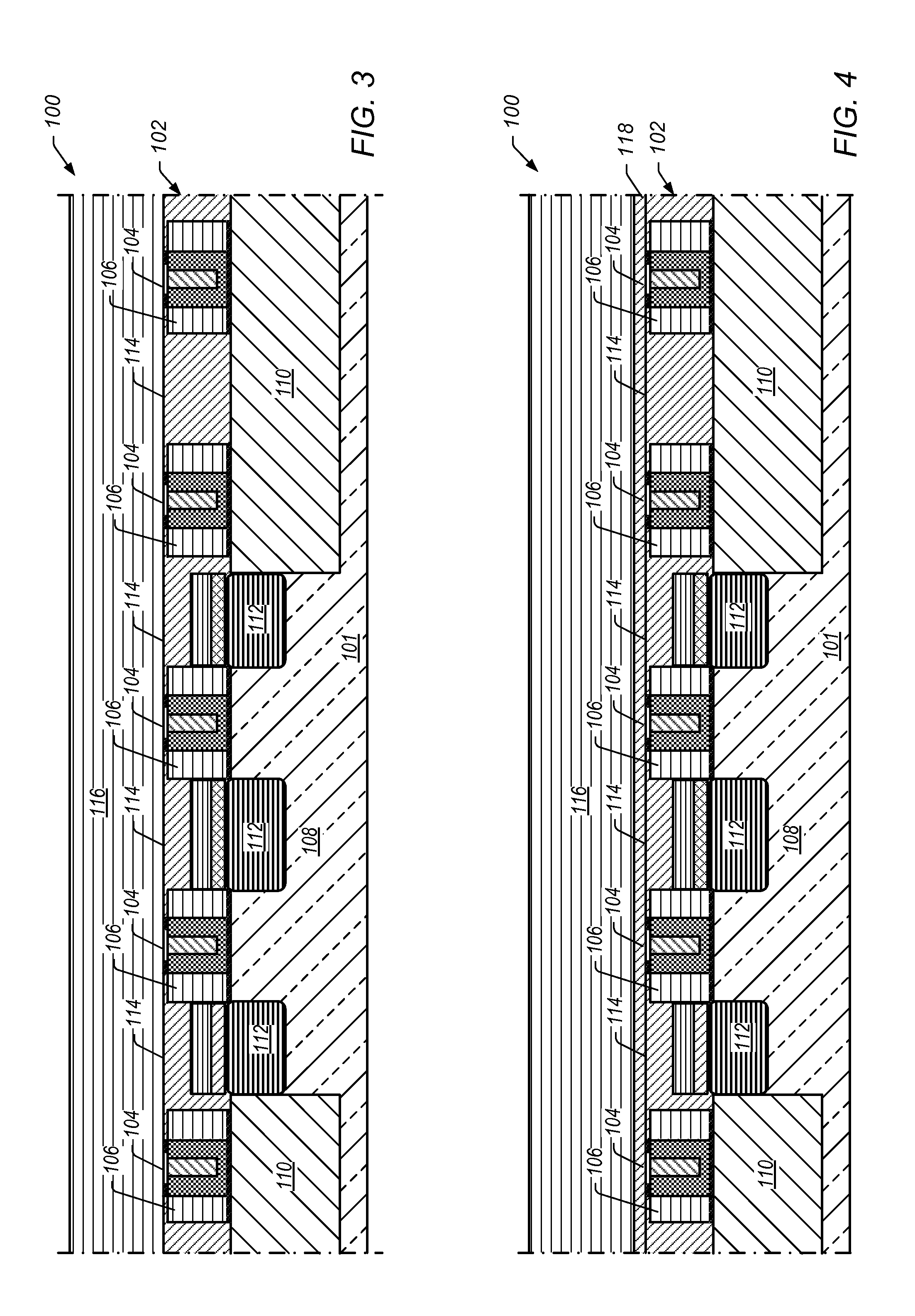

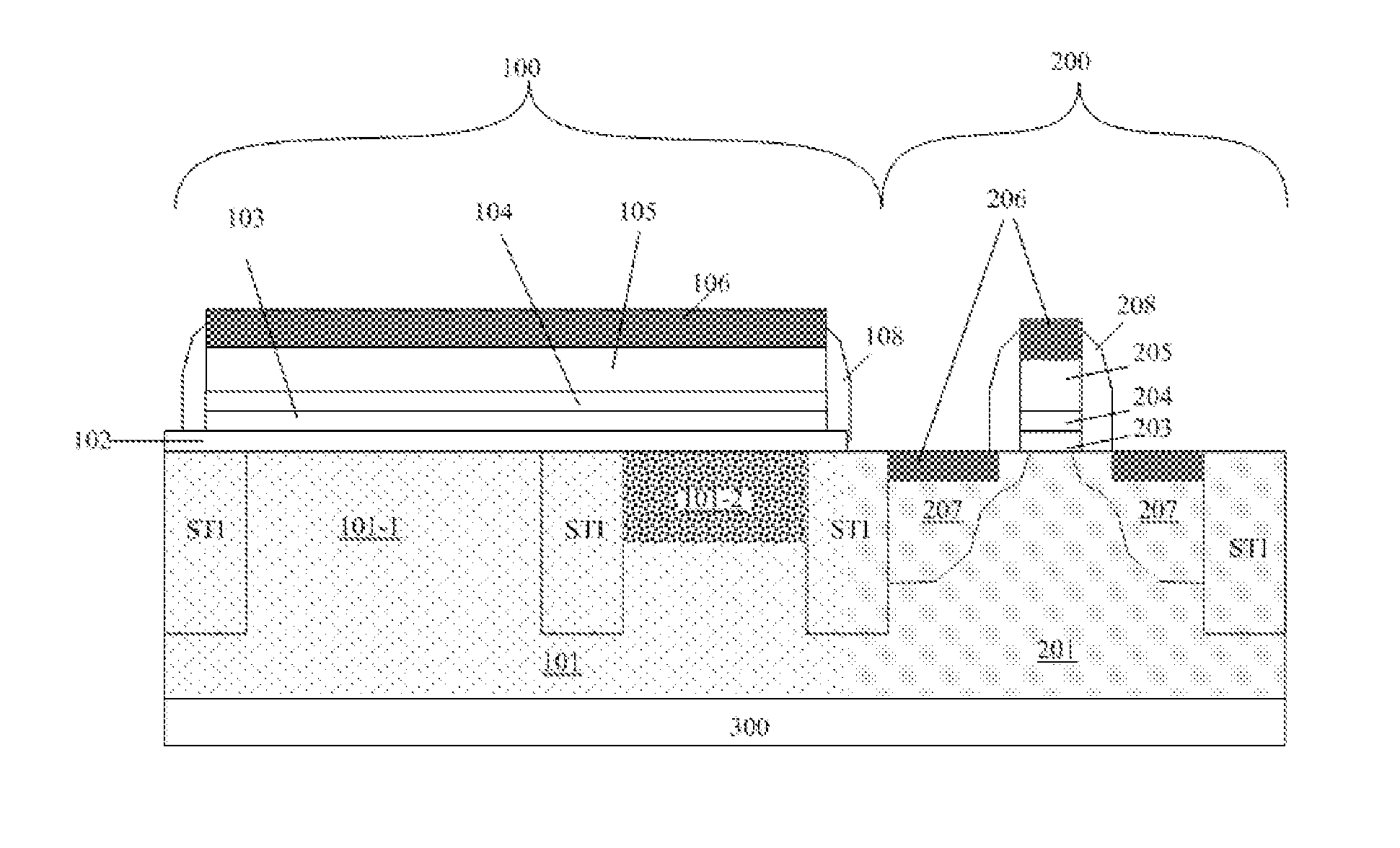

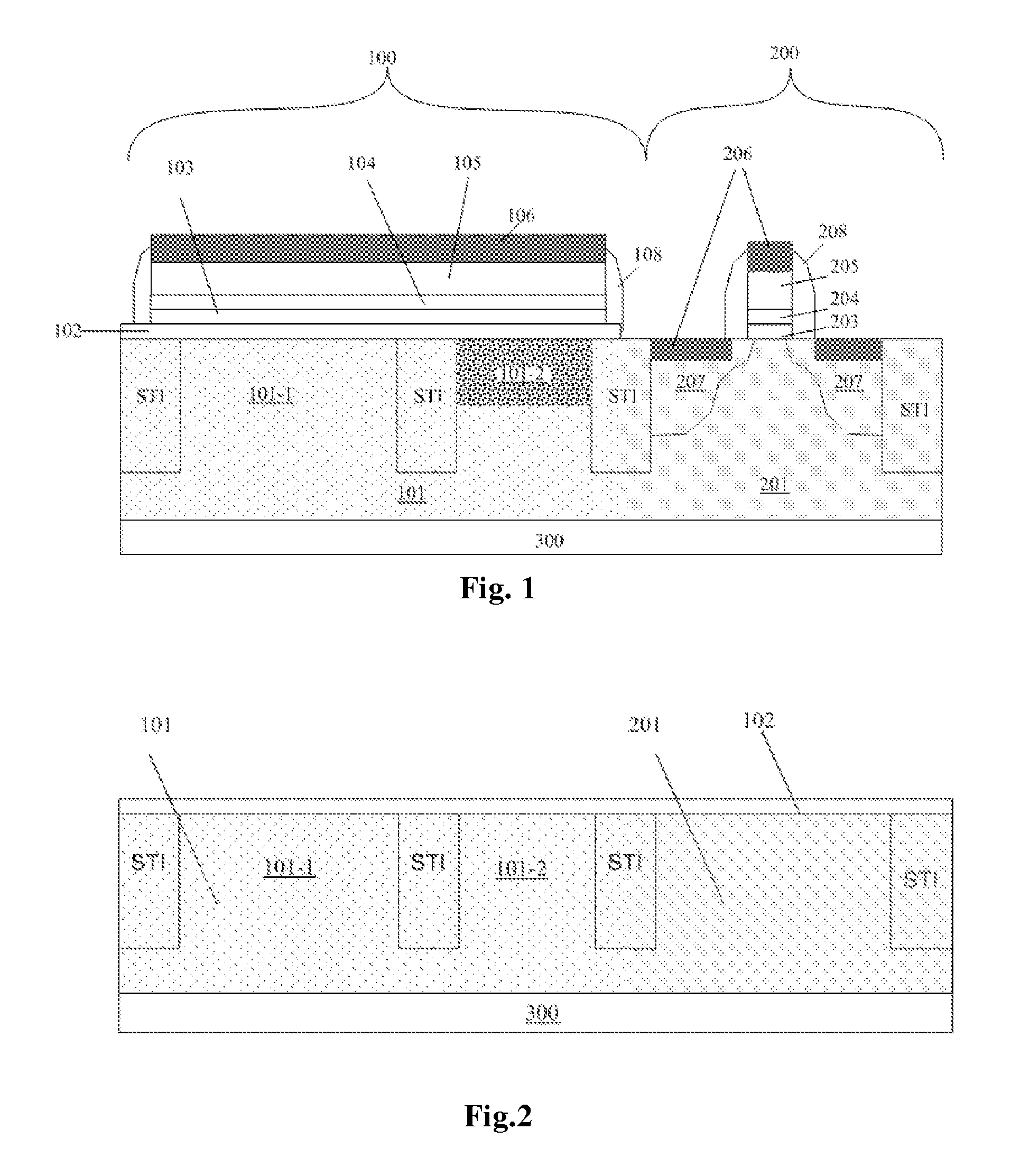

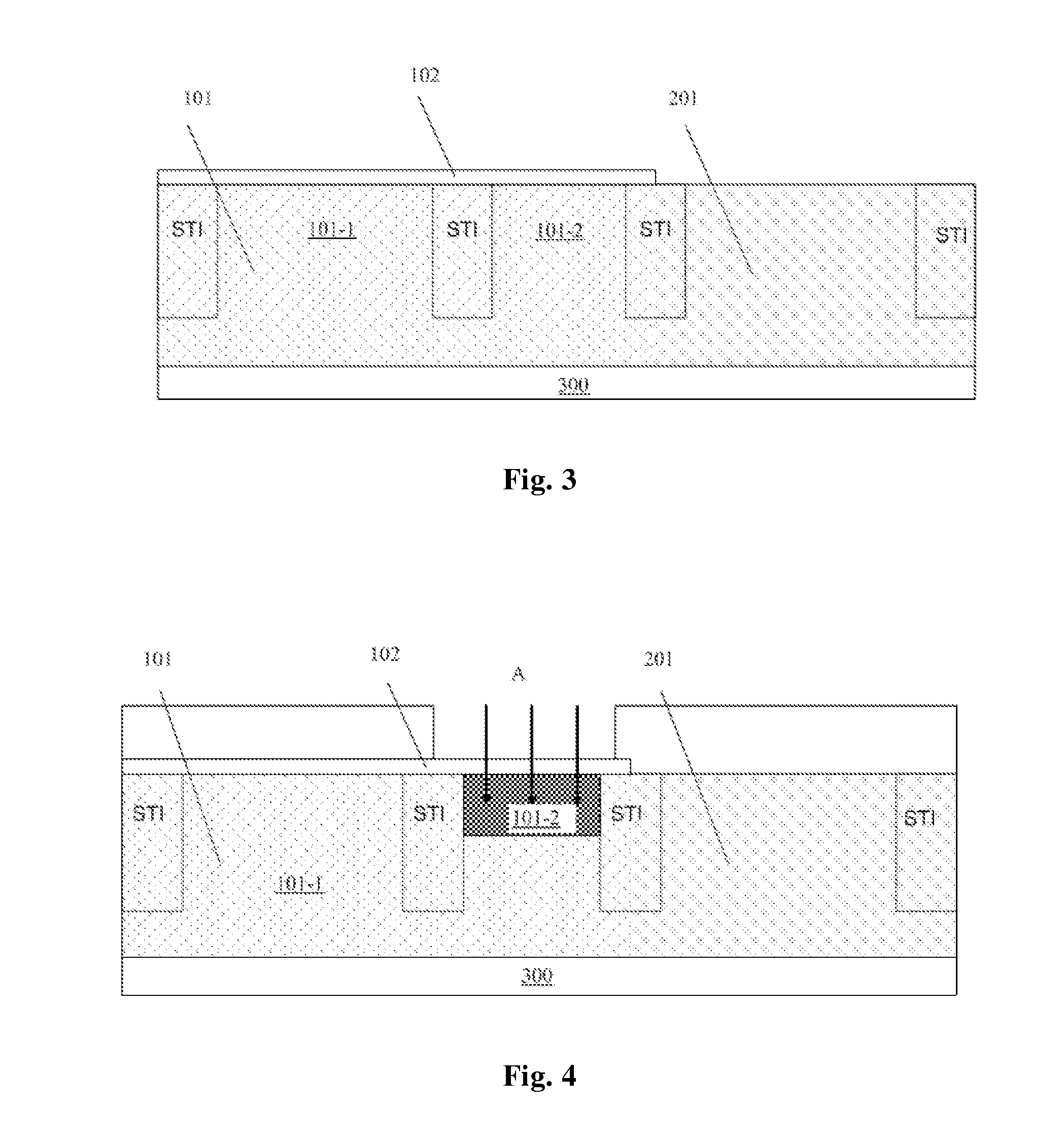

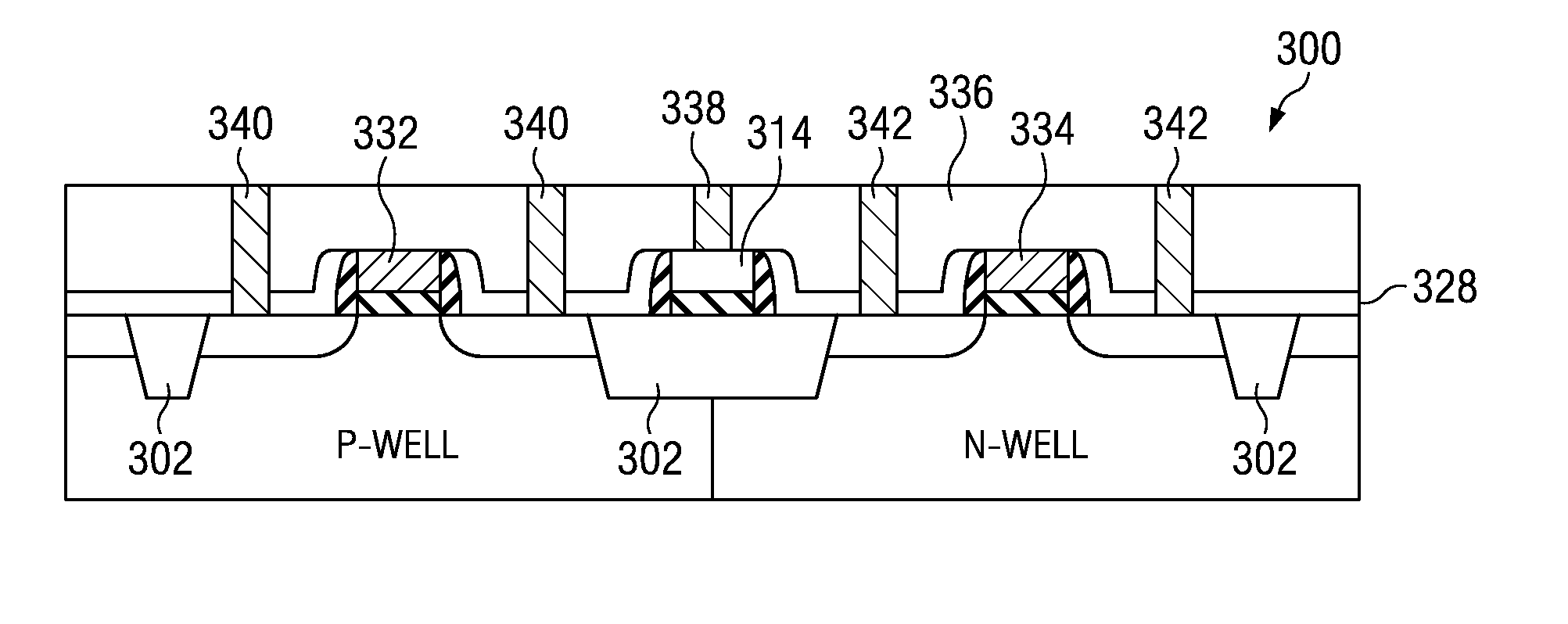

Self-aligned trench contact and local interconnect with replacement gate process

ActiveUS20120313148A1Good manufacturing yieldSimple process flowSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringConductive materials

A semiconductor device fabrication process includes forming insulating mandrels over one or more replacement metal gates on a semiconductor substrate. The mandrels include a first insulating material. Each mandrel has approximately the same width as its underlying gate with each mandrel being at least as wide as its underlying gate. Mandrel spacers are formed around each insulating mandrel. The mandrel spacers include the first insulating material. Each mandrel spacer has a profile that slopes from being wider at the bottom to narrower at the top. A second insulating layer of the second insulating material is formed over the transistor. Trenches to the sources and drains of the gates are formed by removing the second insulating material from portions of the transistor between the mandrels. Trench contacts to the sources and drains of the gates are formed by depositing conductive material in the first trenches.

Owner:ADVANCED MICRO DEVICES INC

Processing method of zinc smelting byproducts

InactiveCN101519727AEliminate mutual interferenceSimple process flowPhotography auxillary processesProcess efficiency improvementAmmonium sulfateDiammonium carbonate

The invention relates to a processing method of zinc smelting byproducts. The method comprises the following steps: firstly, using a mixed aqueous solution of ammonia and ammonia sulfate (or salvolatile) to leach copper-cadmium slag or cadmium-rich soot after heat treatment at a room temperature; then, decoppering a leaching solution by an organic solvent extraction method; directly producing metal cadmium from a solution containing zinc and cadmium by a low current density electrolytic method instead of a technological method of adopting zinc powder replacement to obtain sponge cadmium; using a sulphuric acid solution as strip liquor to strip copper from a decoppered organic extraction agent and then electrolyzing the copper-contained strip liquor to prepare the metal copper; in addition, electrolyzing the decoppered leaching solution which only contains zinc and cadmium to extract the cadmium; eliminating the mutual interference of copper ions and cadmium ions in the electrolytic process of the cadmium; and returning the electrolyzed leaching solution to the zinc production process. The method simplifies the processing technological process, shortens the product period, can respectively obtain a purer copper product and a purer cadmium product and decreases the zinc smelting byproducts and the processing cost.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

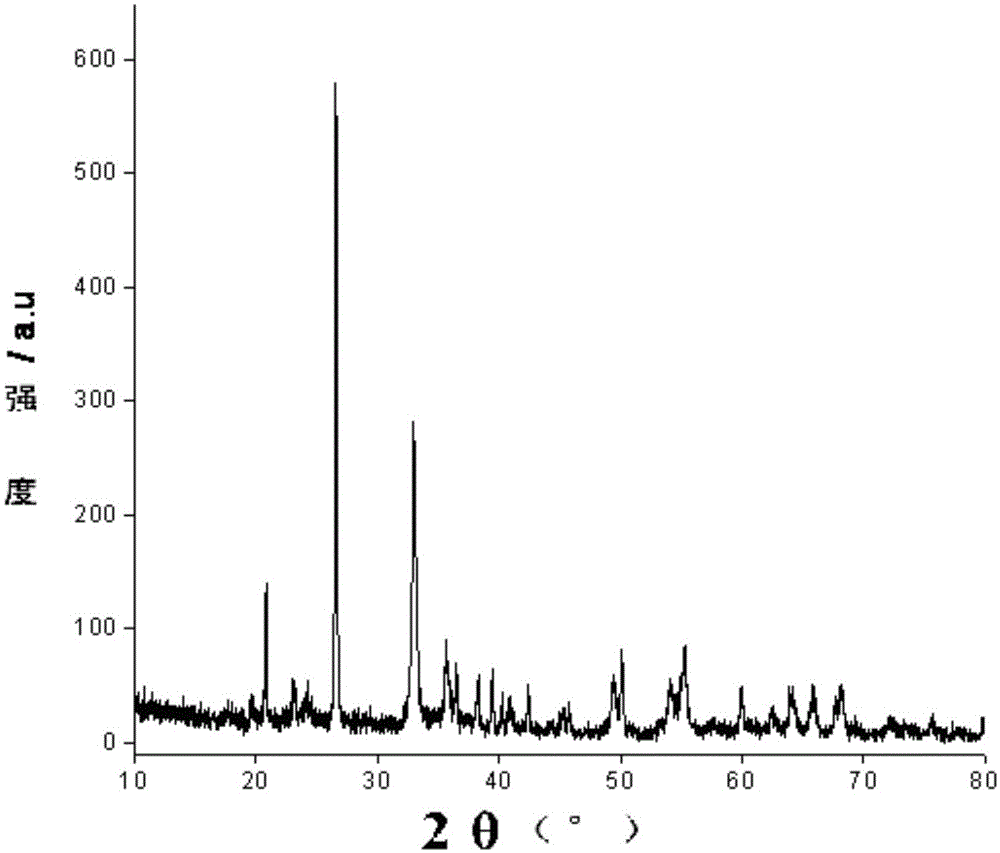

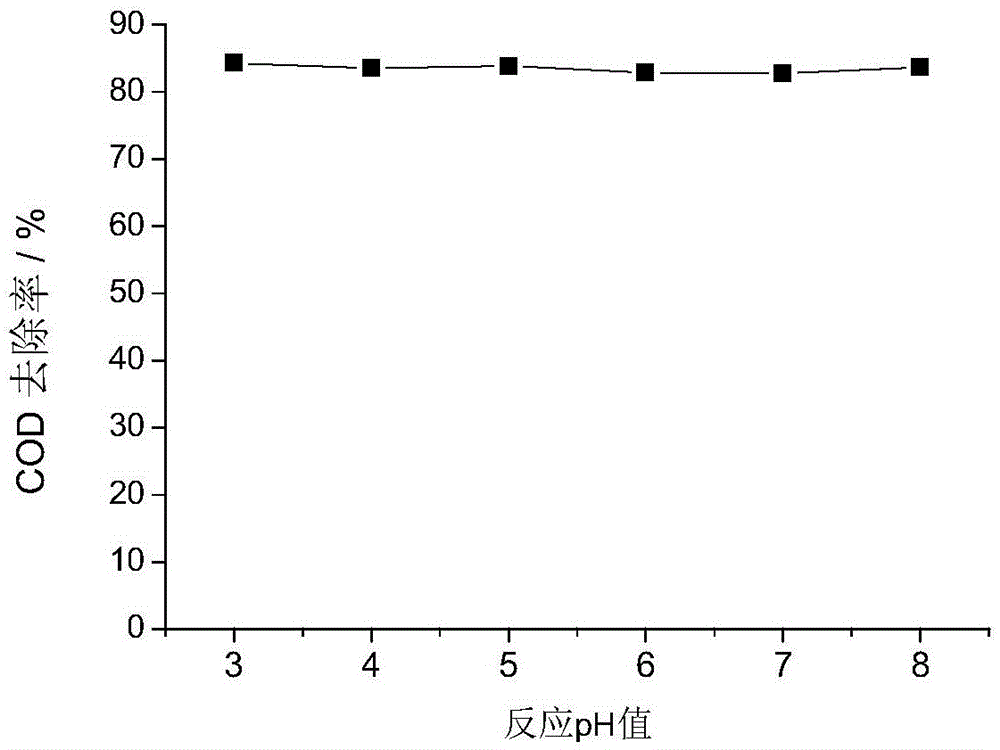

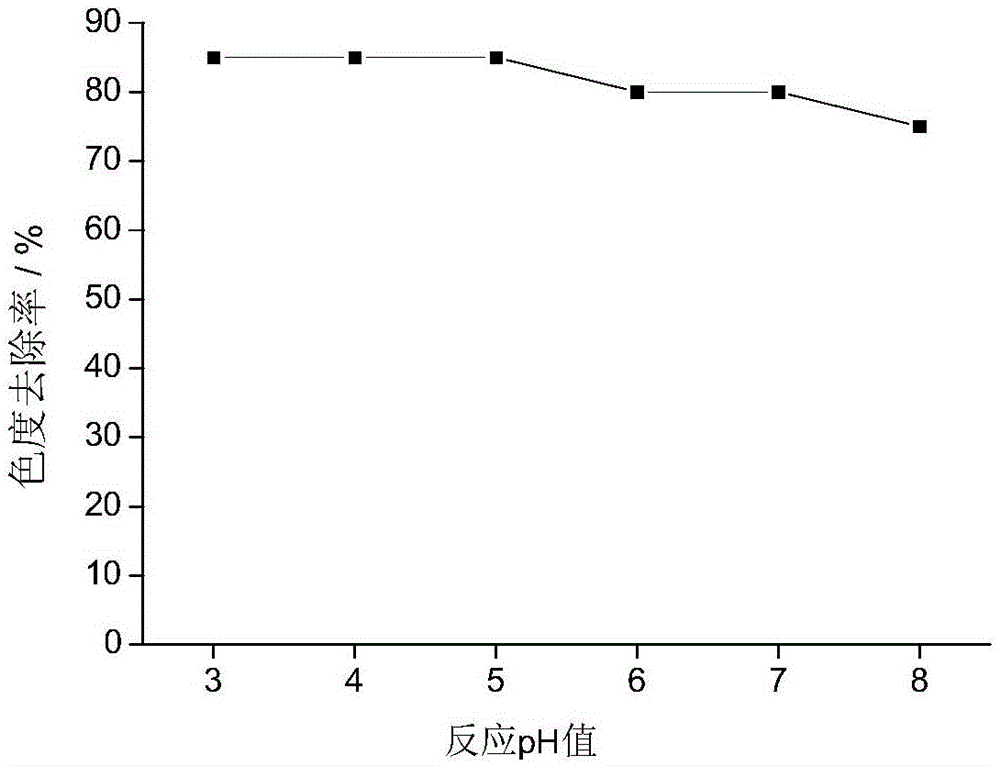

Ferro-manganese composite oxide catalyst and preparation method thereof

ActiveCN105107522APromote degradationLow costWaste water treatment from plant processingMetal/metal-oxides/metal-hydroxide catalystsPolyvinyl alcoholSludge

The invention relates to a ferro-manganese composite oxide catalyst and a preparation method thereof. The ferro-manganese composite oxide catalyst is granular and is prepared by calcining polyvinyl alcohol, sodium dodecyl benzene sulfonate (SDBS), ferrous sulfate, sodium carbonate and natural ferro-manganese ore after reaction. The catalyst can be used for advanced degradation of papermaking wastewater after biochemical treatment. The catalyst disclosed by the invention is changed to ferro-manganese composite oxide particles from conventional ferrous sulfate, can be reused after calcination, is low in chemical sludge output, can save sludge treatment cost, can reduce production of secondary pollution, and can easily realize solid-liquid separation.

Owner:W STARTECH BEIJING ENVIRONMENTAL TECH

Oily sludge recycling and treatment method

InactiveCN107253813AImprove extraction efficiencyAvoid separation and recycling inefficientWaste water treatment from quariesSludge treatmentChemistryUltrasonic oscillation

The invention discloses an oily sludge recycling and treatment method. The oily sludge recycling and treatment method comprises the following steps: mixing oily sludge, water and an extracting agent in a mass ratio of 1:2:(0.3-0.7), wherein the extracting agent is a mixture containing a low-boiling-point organic solvent, a dispersing agent and an anionic surfactant; carrying out ultrasonic oscillation on the mixture in the step S1, and forming an oily sludge extracting agent mixed solution; carrying out solid-liquid centrifugal separation on the oily sludge extracting agent mixed solution, so that deoiled sludge and oil-water extracting agent mixed solution are obtained; and carrying out water separation and oil purification and recycling on the oil-water extracting agent mixed solution. The oily sludge recycling and treatment method provided by the invention is low in separation cost and high in efficiency and can realize extraction and recycling of petroleum in oily sludge, so that resources are utilized again.

Owner:湖南云平环保科技有限公司

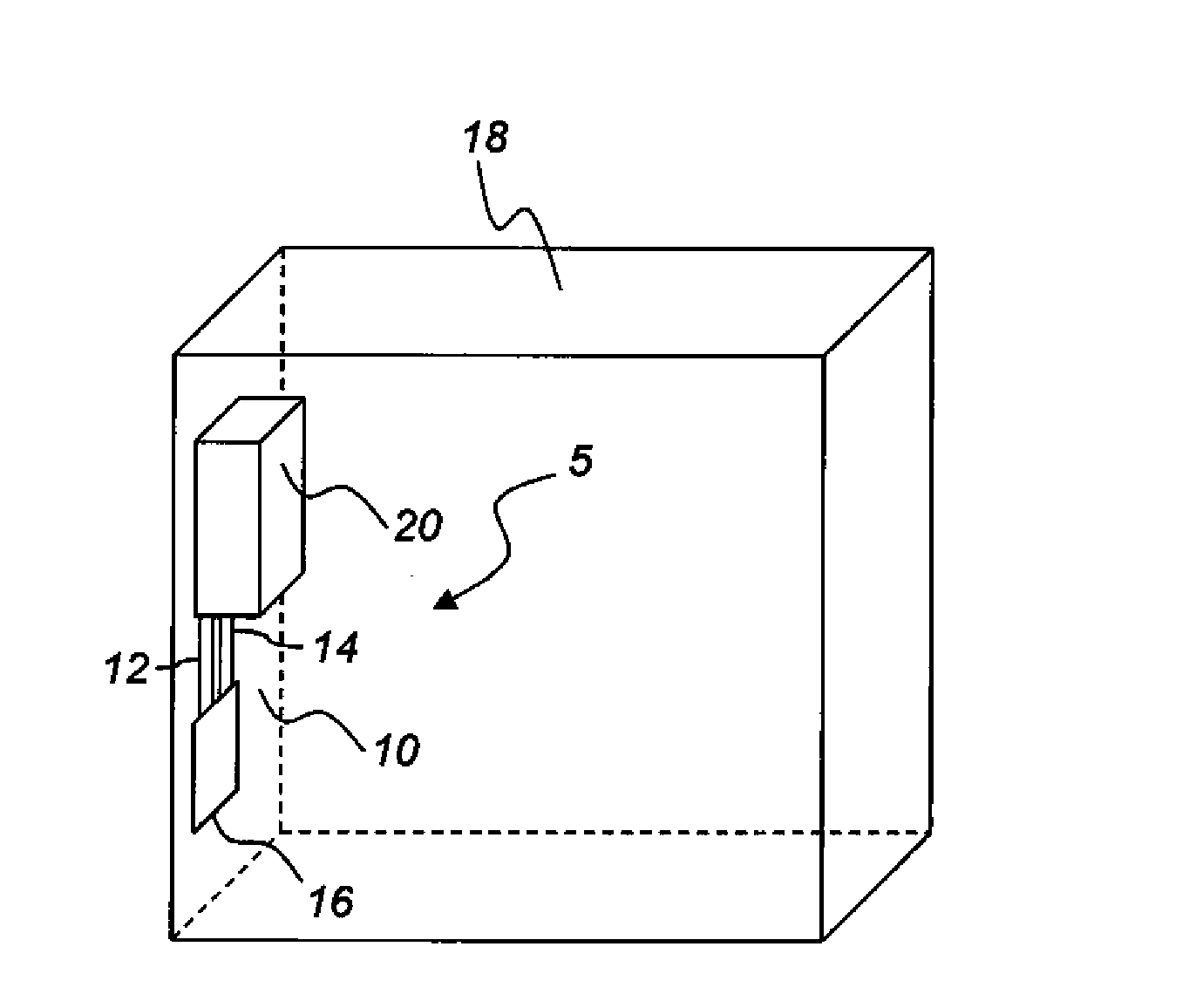

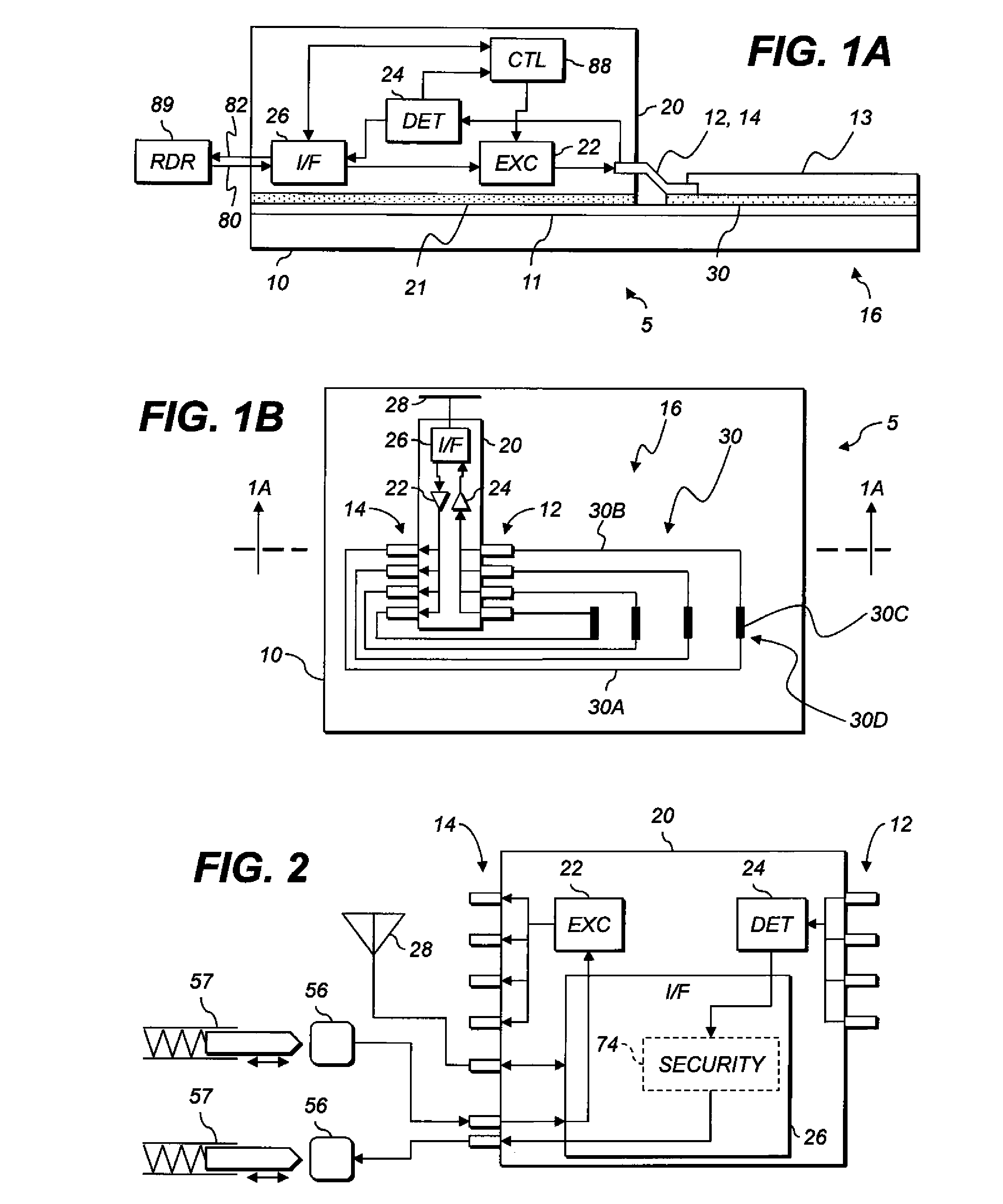

Electronic storage system with environmentally-alterable conductor

InactiveUS20130284812A1Lower-cost equipmentLow costRecord carriers used with machinesElectricityElectrical conductor

An electronic storage system includes a substrate with a detection region, a transceiver having an interface, and a code circuit separate from the transceiver and disposed over the substrate. The transceiver has an output electrical-connection pad, an excitation circuit that provides an excitation signal to the output pad, an input electrical-connection pad, and a detection circuit connected to the input pad. The code circuit connects the output pad to the input pad and includes a conductor having an electrical state and located in the detection region. The detection circuit thus detects an electrical state of the input pad in response to the excitation signal and the electrical state of the conductor. The interface is responsive to a downlink signal to transmit an uplink signal representing the electrical state of the input pad. The conductor in the detection region is adapted to change electrical state in response to an environmental factor.

Owner:EASTMAN KODAK CO

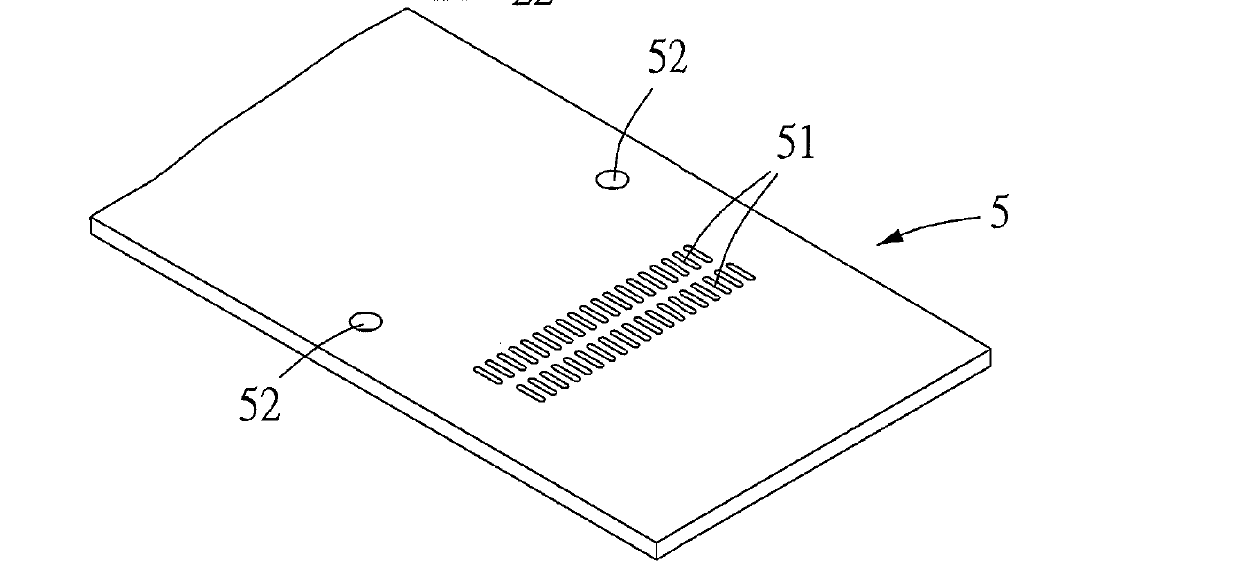

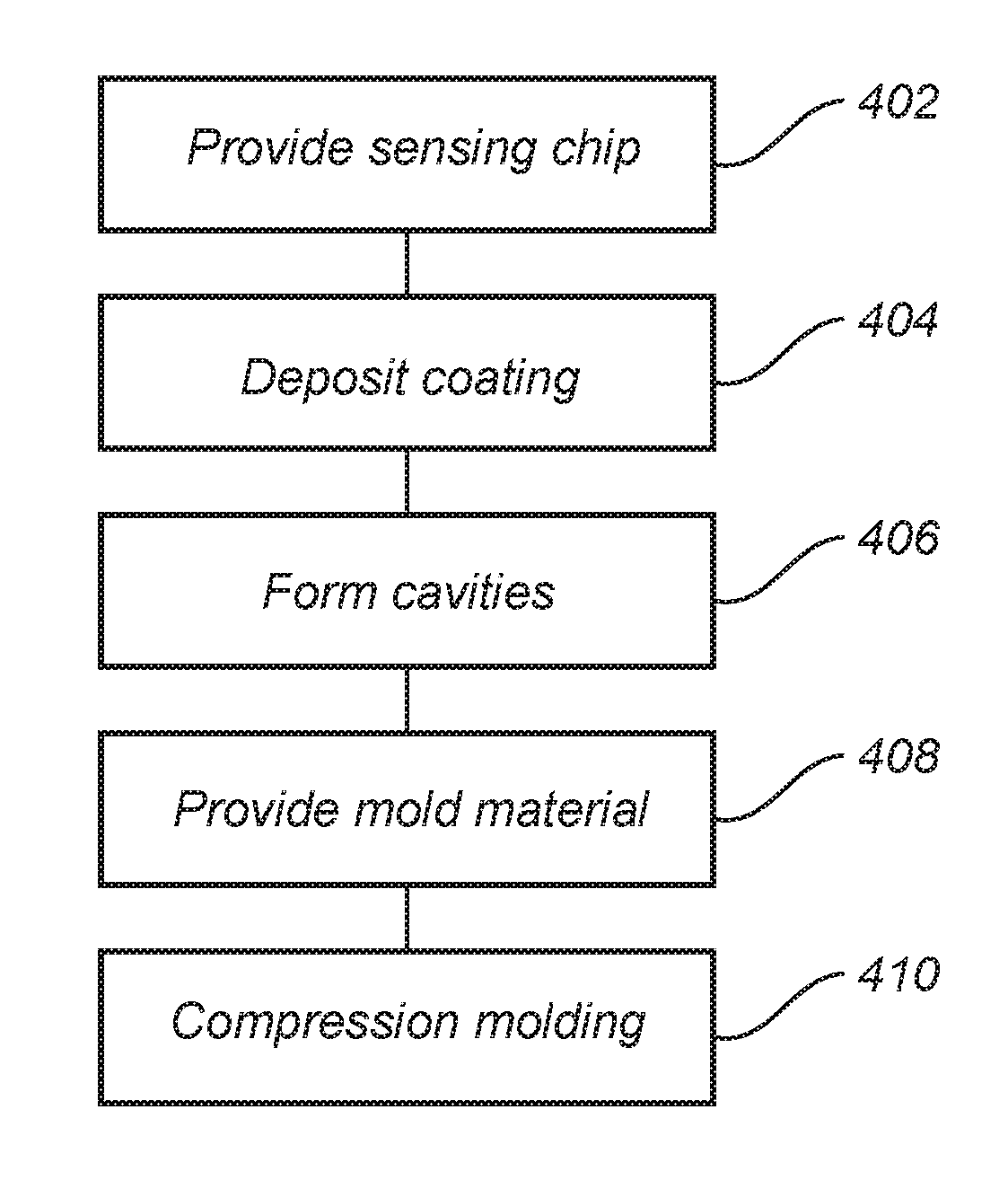

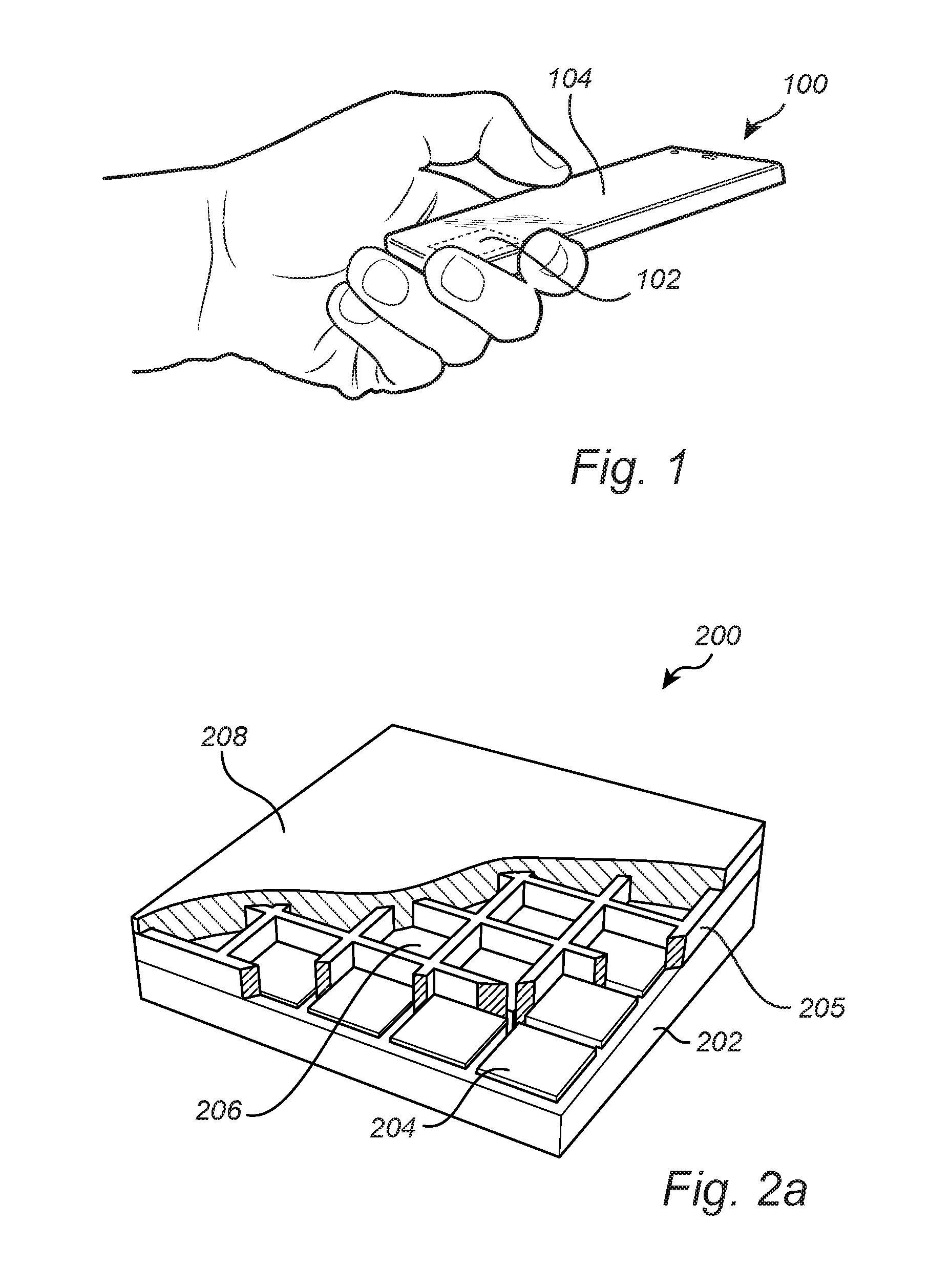

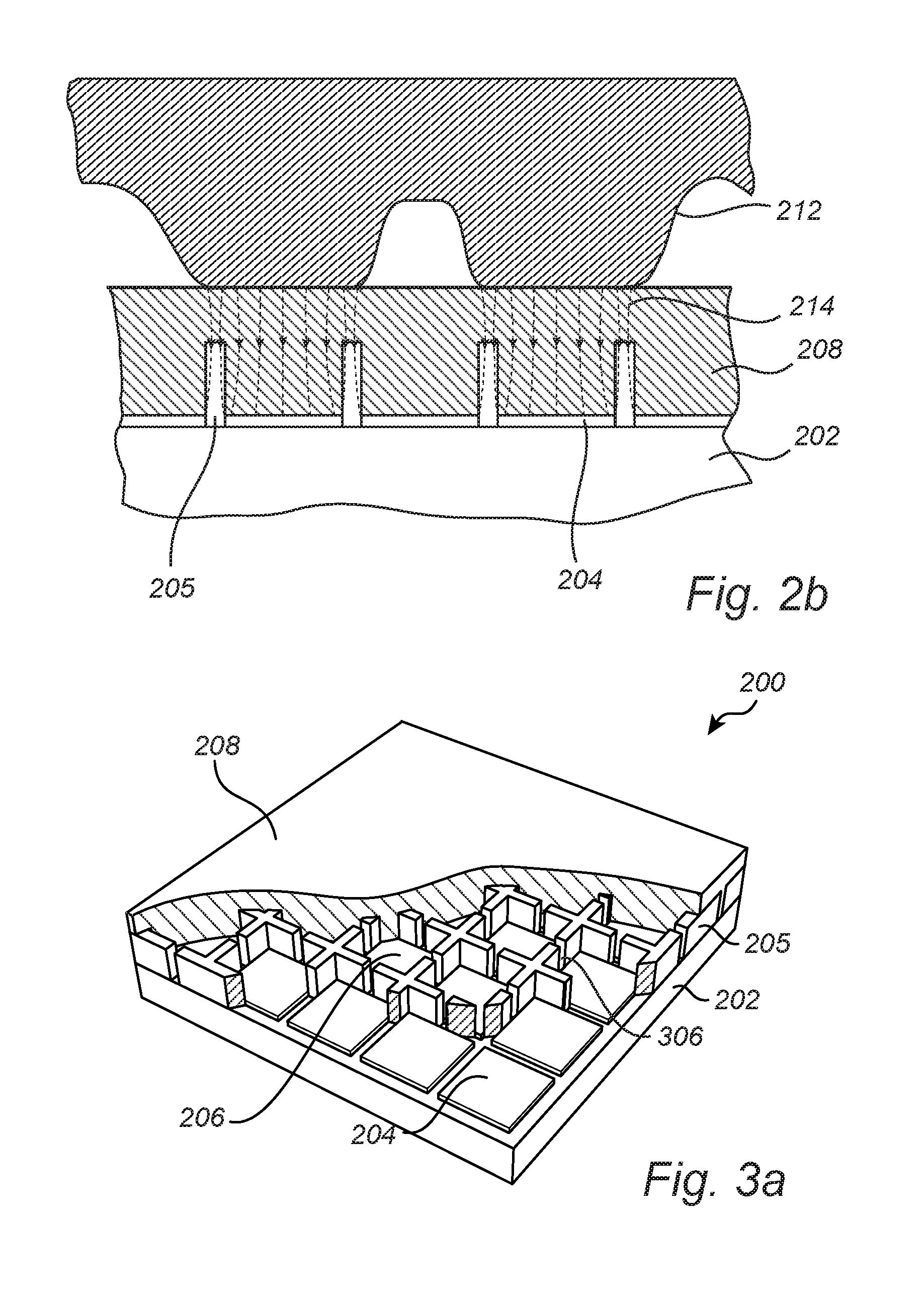

Fingerprint sensing device with heterogeneous coating structure comprising a mold

ActiveUS20160354801A1Simple process flowHigh degree of accuracyLiquid surface applicatorsPrint image acquisitionFingerprintEngineering

The invention relates to a fingerprint sensing device comprising a sensing chip comprising an array of capacitive sensing elements. The sensing device comprises a coating material arranged in a layer on top of the array of sensing elements, the coating material comprising a plurality of cavities filled with a mold material; wherein locations of the cavities correspond to locations of the sensing elements, such that a cross-section area of a cavity covers at least a portion of an area of a corresponding sensing element; and wherein a dielectric constant of the mold material is higher than a dielectric constant of the coating material. The invention also relates to a method for manufacturing such a device.

Owner:FINGERPRINT CARDS ANACATUM IP AB

Method for recovering copper from brownification waste liquid

ActiveCN103510107AHigh recovery rateReduce subsequent processing costsPhotography auxillary processesProcess efficiency improvementElectrolysisCopper

The invention discloses a method for recovering copper from brownification waste liquid. The method comprises the following steps: within the temperature of 30 to 100 DEG C, adding an alkaline substance in the brownification waste liquid, controlling the adding amount of the alkaline substance to control the pH value of the waste liquid to be 2-3, then filtering the liquid, adding an electrolytic additive into the filtrate, and carrying out electrolysis at 30-60 DEG C. Through the adoption of the method, copper can be effectively recovered from the brownification waste liquid to reduce waste metal pollution. According to the invention, the copper recovery rate is up to 99%, and after liquid is processed, the content of copper in the waste liquid is less than 100 mg / L. After recovery of copper, the follow-up processing cost for the organic waste in the brownification waste liquid is greatly reduced.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD +1

Method for removing endotesta of Chinese tumion seed

The invention discloses a method for removing endopleura from Chinese torreya seeds. The method comprises the following steps: the Chinese torreya seeds are put into microwave equipment and processed by electromagnetic wave at 2450 plus or minus 50MHz or 915 plus or minus 25MHz for 1-7min; the endopleura clinging to kernel cracks after processing of the Chinese torreya seed and the endopleura is removed; and the Chinese torreya seeds have hull or have no hull. The method can help easily and effectively separate the endopleura from the kernel, and can help respectively obtain the endopleura and the kernel which basically keep the original nutrients and active ingredients.

Owner:ZHEJIANG UNIV

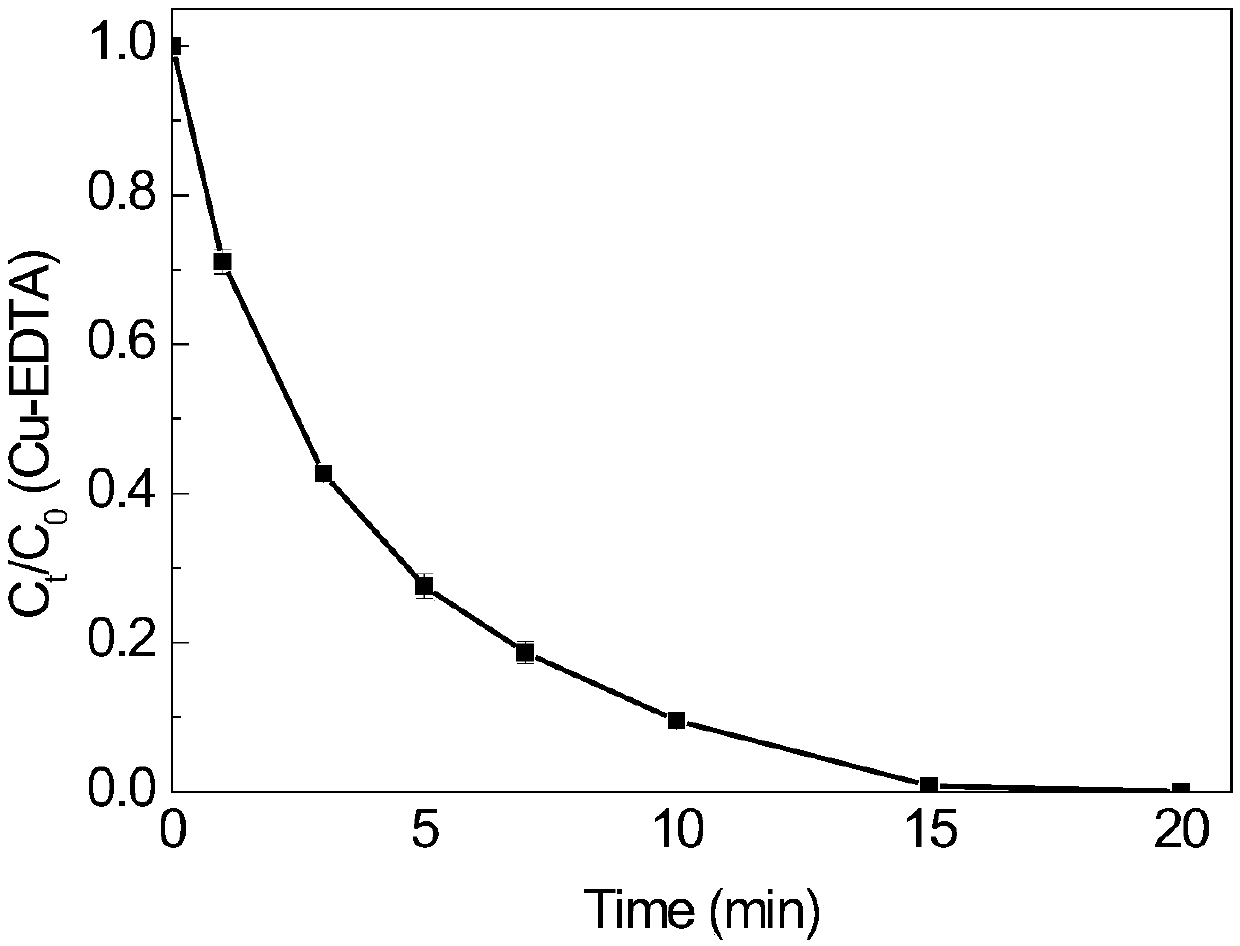

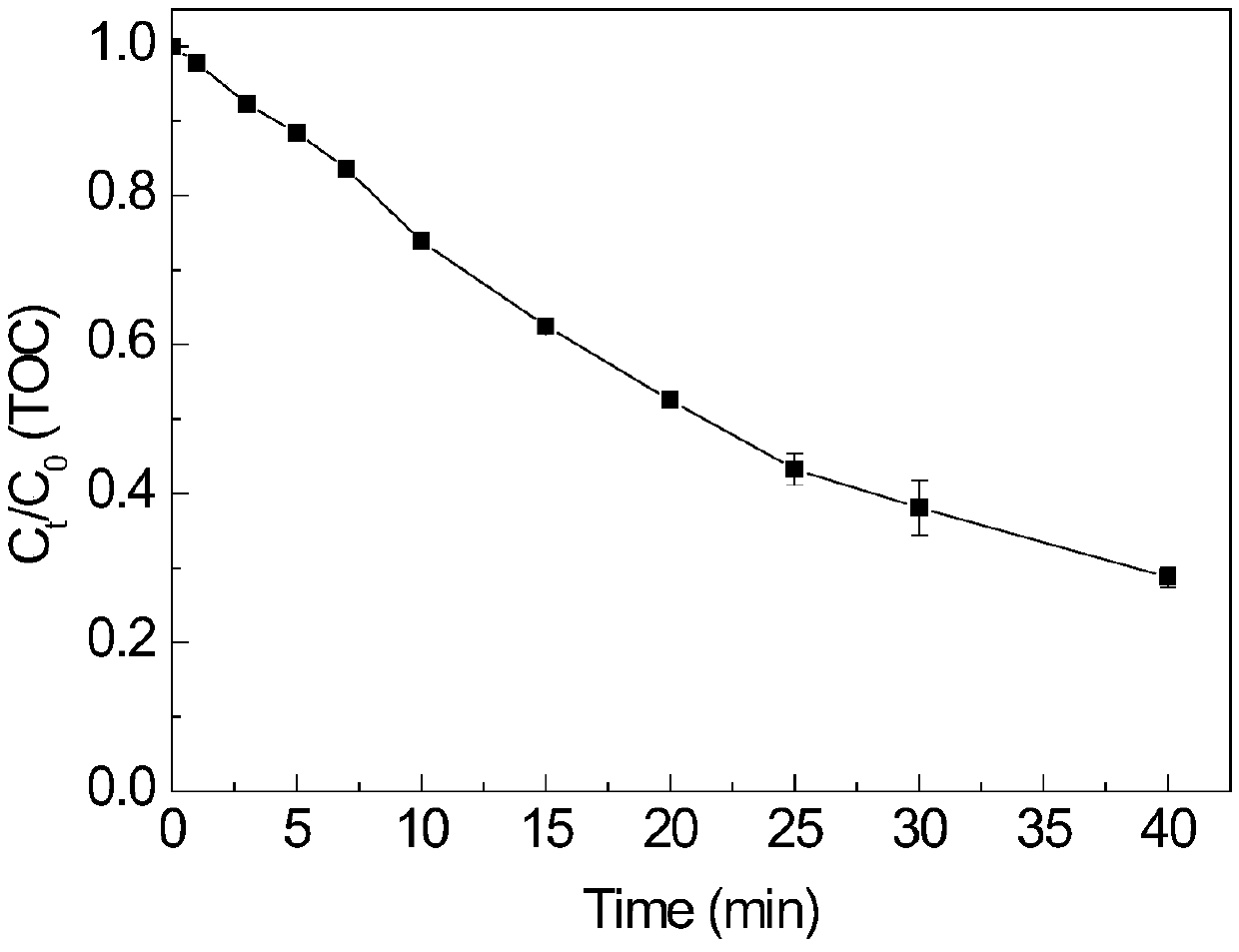

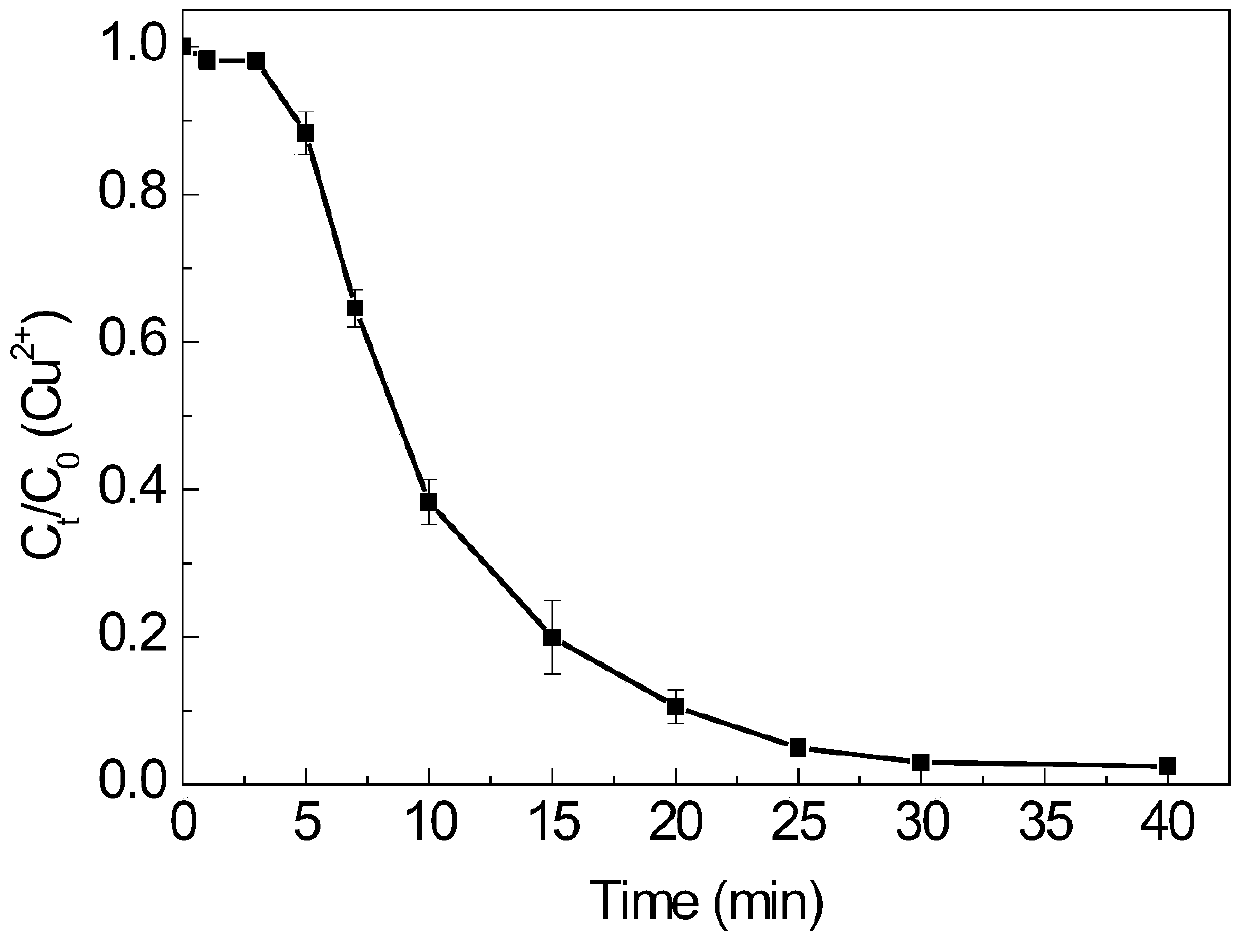

Method for synchronous complex breaking and heavy metal removal based on self-strengthening ozone

ActiveCN105502739AAchieve removalSimple process flowMultistage water/sewage treatmentWater/sewage treatment by oxidationWastewaterMetal

The invention discloses a method for synchronous complex breaking and heavy metal removal based on self-strengthening ozone and belongs to the technical field of wastewater treatment. The method for synchronous complex breaking and heavy metal removal based on self-strengthening ozone includes the steps that firstly, pH-adjusted heavy metal complex wastewater containing heavy metal A and a complexing agent B is added to an ozone contact pool, ozone is continuously introduced through micro-pores in the bottom of the ozone contact pool, hydraulic cycle stirring is adopted for assistance, and it is guaranteed that the reaction is uniform; secondly, after the ozone oxidation reaction is completed, a micro-pore filter membrane device is used for filtering for solid-liquid separation, and synchronous complex breaking and heavy metal removal are achieved. The method can be economical, efficient and easy and convenient to operate, engineering application is easy to achieve, complex breaking and metal ion removal are synchronously carried out, and heavy metal complex in the wastewater is removed based on self-strengthening ozone oxidation.

Owner:NANJING UNIV

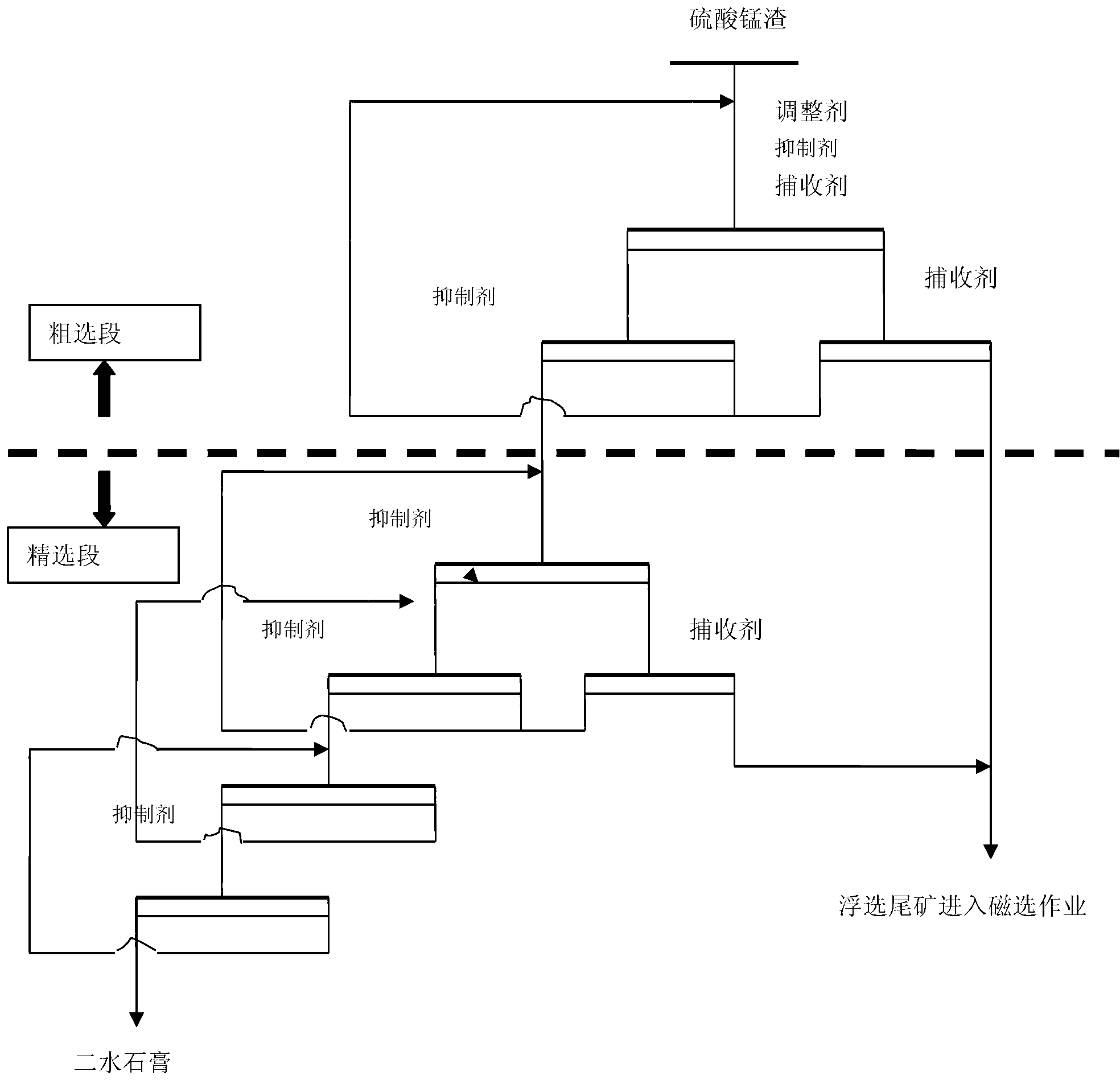

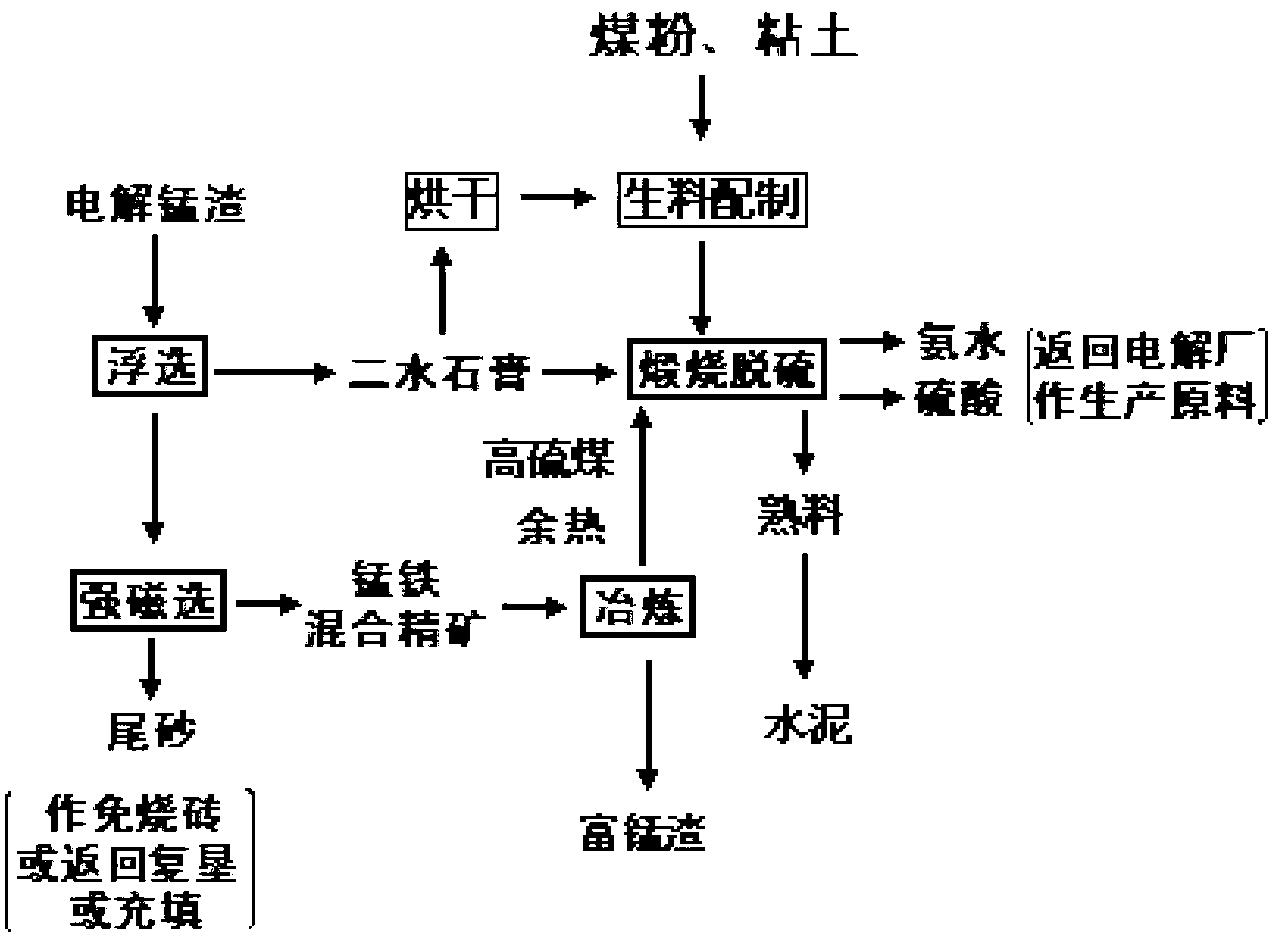

Method for comprehensively utilizing electrolytic manganese residues

ActiveCN103214201ASolve environmental problemsFix security issuesSulfur compoundsEnergy inputBrickElectrolysis

The invention discloses a method for comprehensively utilizing electrolytic manganese residues. The method comprises the following steps of: firstly carrying out flotation on electrolytic manganese residues in a flotation machine, and screening out dihydrate gypsum; carrying out strong magnetic separation on tailings subjected to flotation, and singling out ferromanganese bulk concentrate and tailings; smelting the ferromanganese bulk concentrate to obtain rich-manganese slag; and burning the dihydrate gypsum obtained through floatation with smelting waste heat so as to remove ammonia and sulfur for production of ammonia water and sulfuric acid and co-production of cement. The tailings discharged in the end are non-toxic and harmless and can be used for producing baking-free bricks, land rehabilitation or underground filling. According to the method, lots of manganese residues can be consumed, multiple related products are obtained while the environmental problem and the safety problem are solved, and thus the purposes of turning waste into wealth and cyclical utilization are achieved.

Owner:广西天工冶金科技有限公司

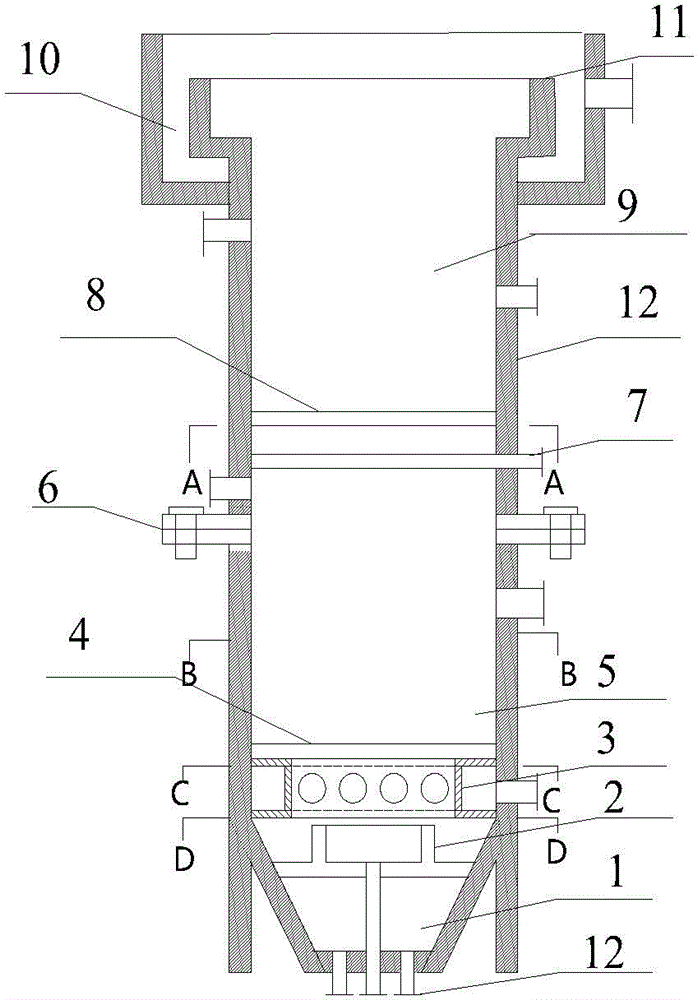

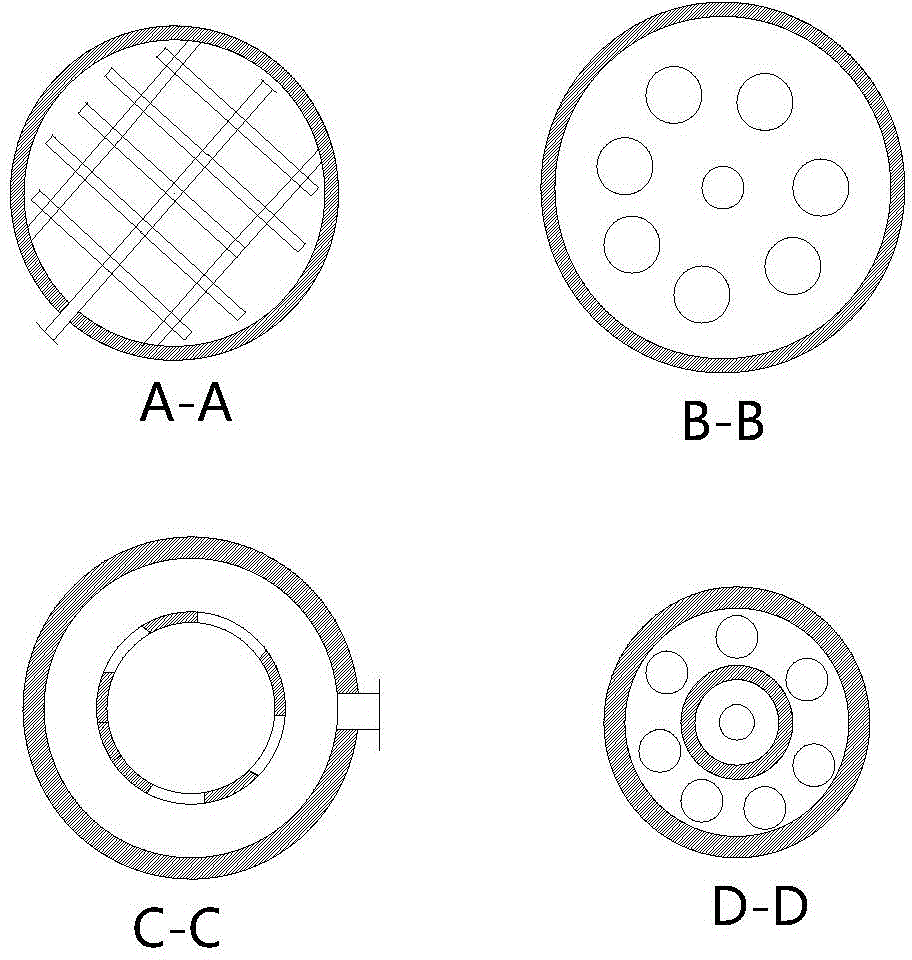

Zero-valent iron reduction-Fenton oxidation integrated reaction device and method for treating nitroaromatic compound wastewater by using zero-valent iron reduction-Fenton oxidation integrated reaction device

ActiveCN104591426ASimple process flowLow running costWater contaminantsMultistage water/sewage treatmentEngineeringIron reduction

The invention discloses a zero-valent iron reduction-Fenton oxidation integrated reaction device. The reaction device comprises a reactor body with a hollow cylindrical structure, wherein the inner part of the reactor body is divided into four reaction areas, namely an iron mud collecting area, a zero-valent iron reduction area, a zero-valent iron Fenton oxidation area and a sedimentation area from bottom to top; the four reaction areas are communicated with one another, and iron scraps fills up the zero-valent iron reduction area and the zero-valent iron Fenton oxidation area. According to the zero-valent iron reduction-Fenton oxidation integrated reaction device disclosed by the invention, a zero-valent iron reduction technology and a zero-valent iron Fenton oxidation technology are combined to ensure that the effective space of a reactor can be used to a greatest extent, the technological process of wastewater treatment can be simplified, and the running cost can be reduced; and according to the zero-valent iron reduction-Fenton oxidation integrated reaction device, the zero-valent iron reduction technology and the Fenton oxidation technology are coupled, iron ions produced by a zero-valent iron reduction working section can be fully used in a Fenton oxidation working section as catalysts, and thus the treatment efficiency of the Fenton oxidation working section can be improved.

Owner:NANJING UNIV OF SCI & TECH

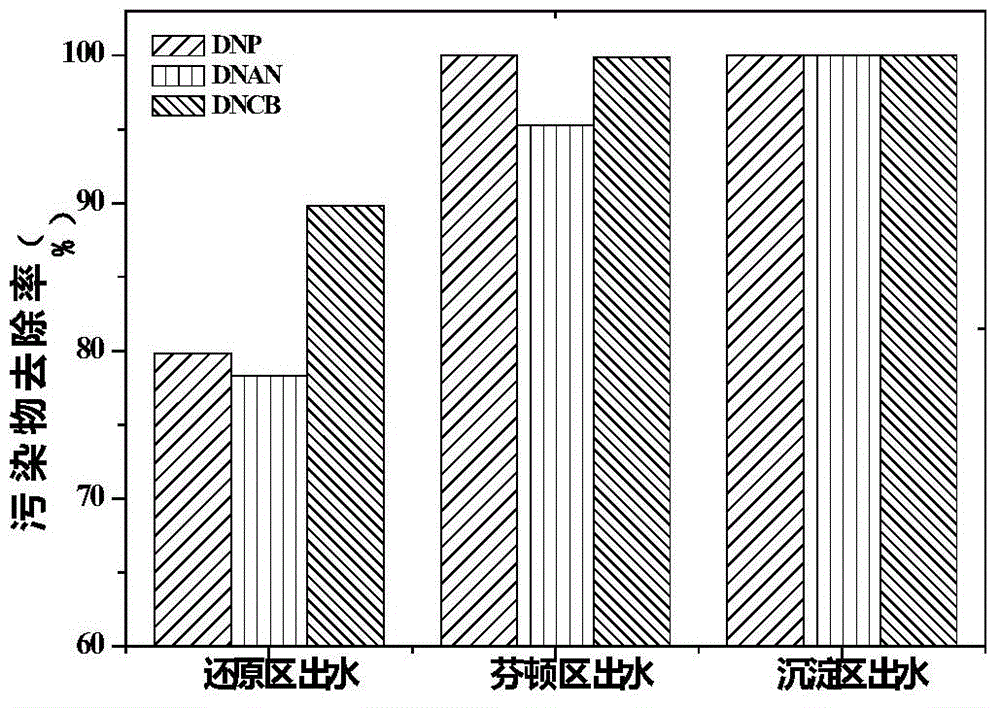

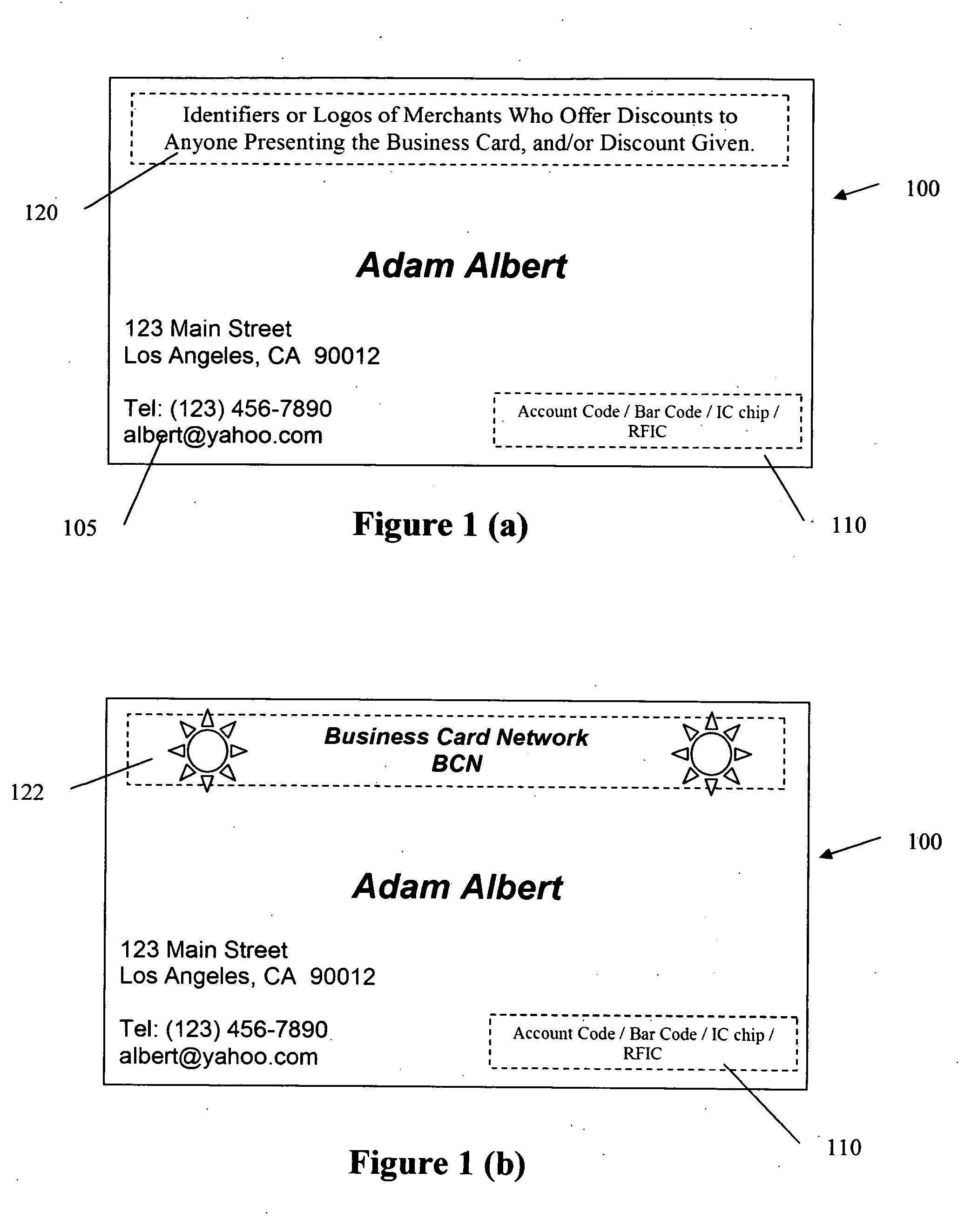

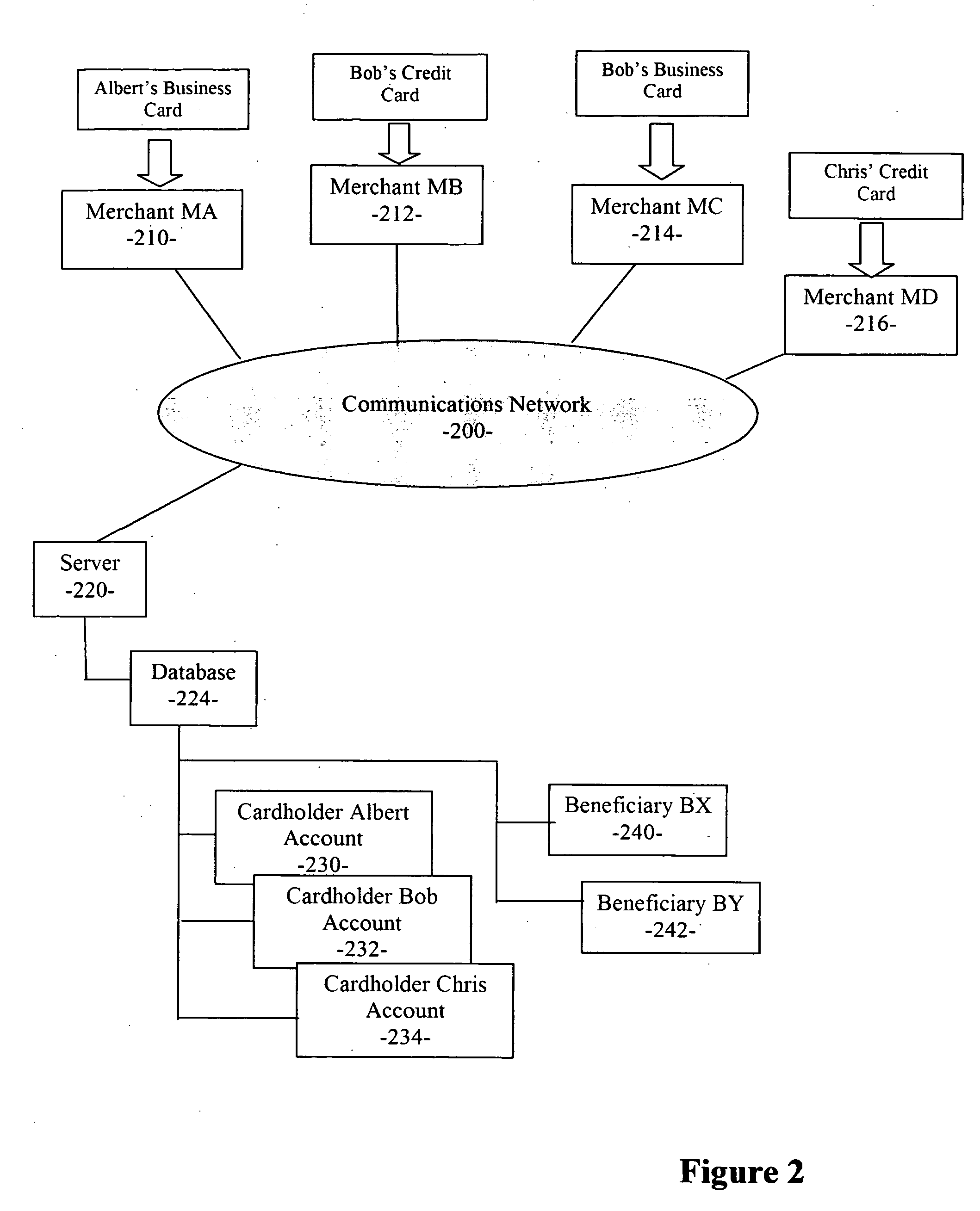

Method and system for multiple income-generating business card and referral network

InactiveUS20050279830A1Simple process flowMore motivationComplete banking machinesFinanceCredit cardPersonalization

A system and method for using a communications network with a server and a database to provide income-generating business card and referral card network. In one embodiment, a credit card issuer provides a set of personalized business cards to a first customer for his use, upon qualifying the first customer for a credit card from the card issuer. The business cards can be used to receive a discount from a merchant within certain network affiliated with the card issuer. At the same time, the business cards provide a linkage to the first customer's account, so that the first customer will receive a credit to his account, based on the second customer's use of the business card at an affiliated merchant. The second customer is then invited to apply for a credit card from the card issuer. If the second customer qualifies and accepts the credit card, the second customer receives his own set of personalized business cards for distribution. Whenever the second customer uses his credit card anywhere, another credit is applied to the first customer. Also, whenever a third customer uses the second customer's business card during a commercial transaction, the second customer will receive a credit in his account. If the third customer also becomes a credit card holder from the card issuer, the second customer will then receive a credit whenever the third customer uses his credit card anywhere. The system may be set up so that the customers who refer continue to receive credits whenever customers from one or more levels below use the business cards for discounts, or use their own credit cards.

Owner:CHAO LI HSIANG

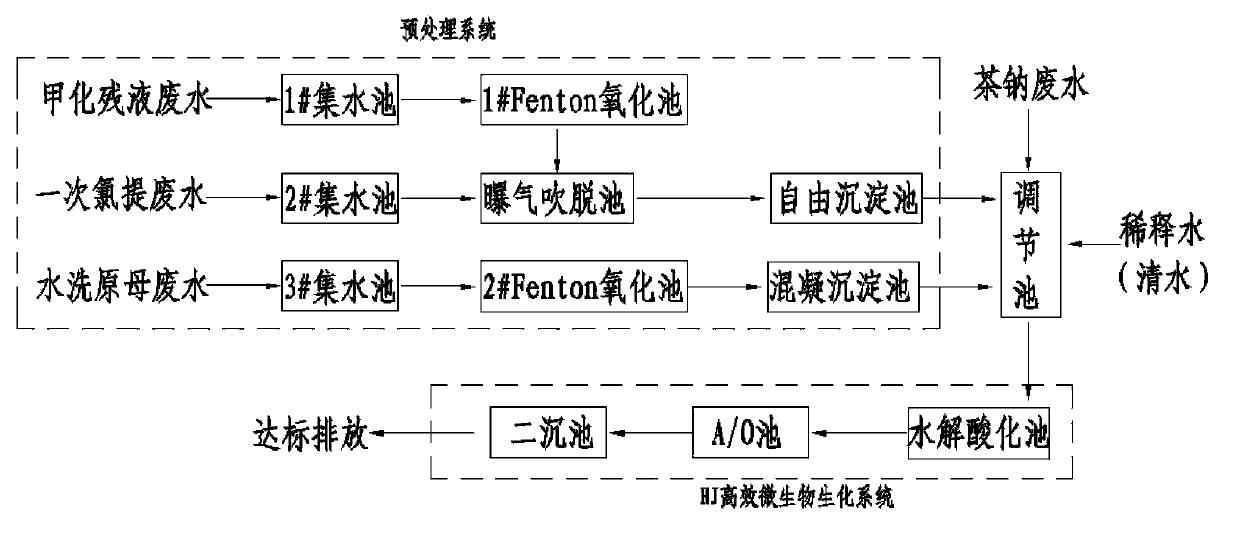

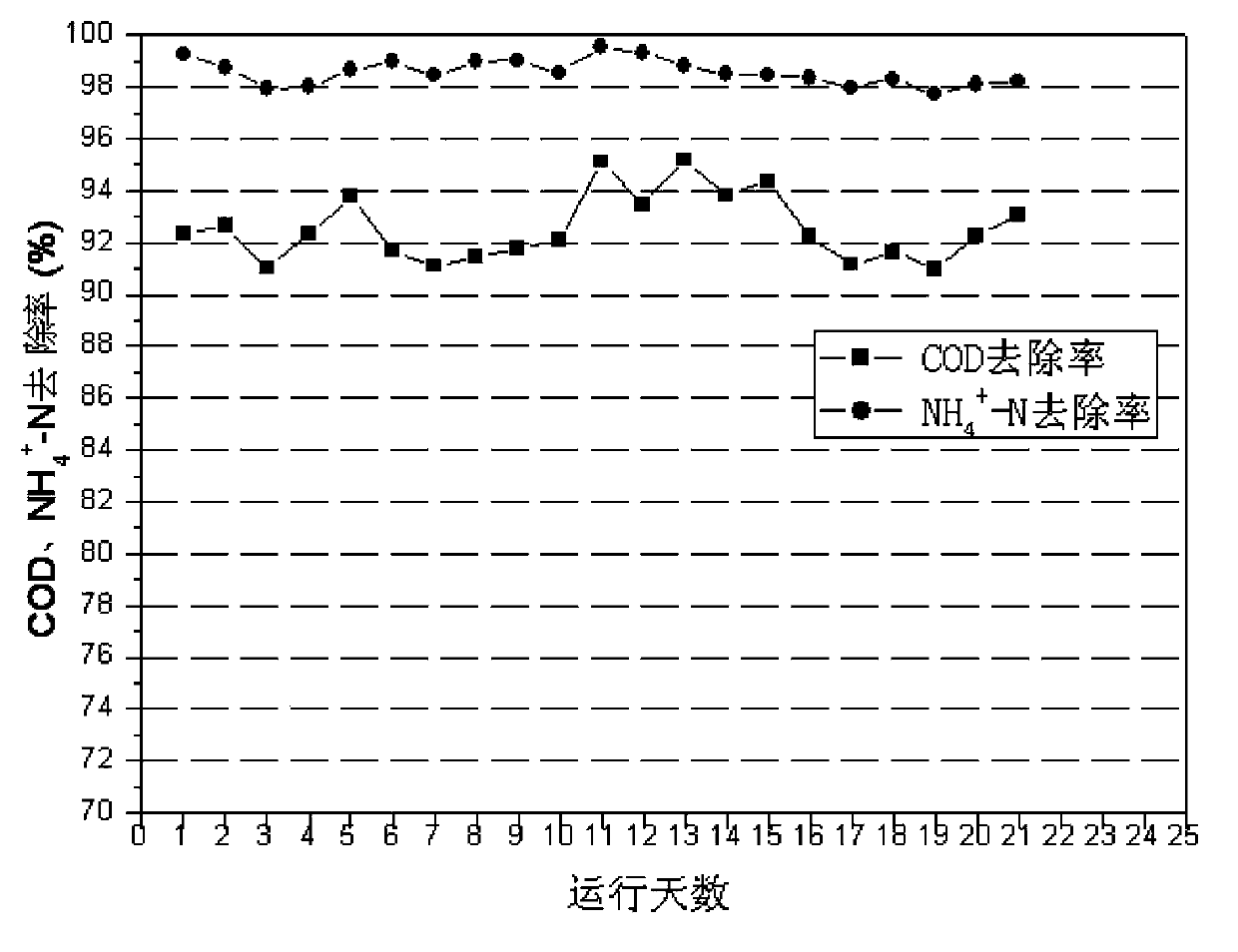

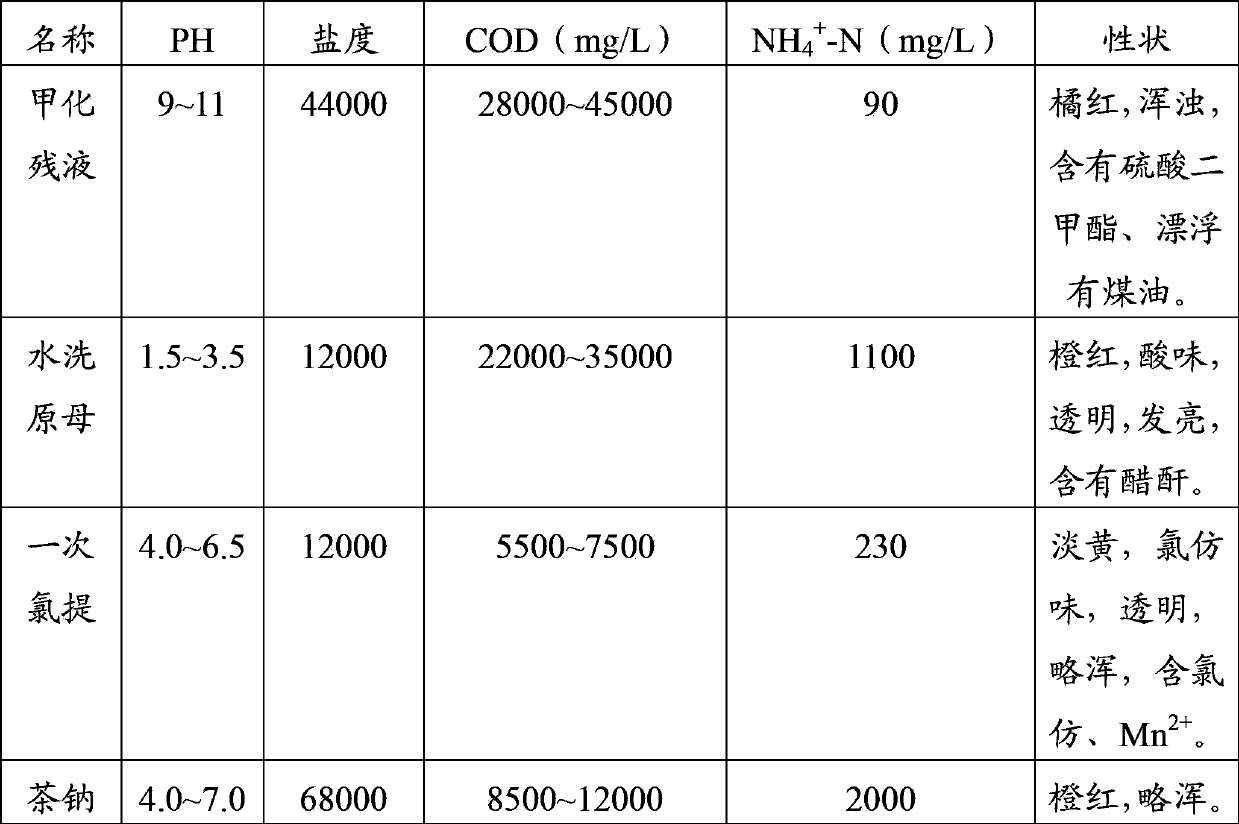

Caffeine production wastewater treatment method

InactiveCN103864261AImprove water qualityGuarantee continuous and stable operationMultistage water/sewage treatmentTherapeutic effectTreated water

The present invention discloses a caffeine production wastewater treatment method, which comprises: respectively carrying out pre-treatment on water washing raw mother wastewater, primary chlorine extraction wastewater and methylating residue liquid wastewater, mixing untreated tea sodium wastewater, the pre-treated water washing raw mother wastewater, the pre-treated primary chlorine extraction wastewater and the pre-treated methylating residue liquid wastewater, adding the obtained mixture to an adjustment tank, adopting clear water to dilute, adding nutrients required by microorganism growth, sequentially carrying out hydrolysis acidification and aerobic biochemical reaction, and discharging the wastewater meeting the standard. The caffeine production wastewater treatment method has the following beneficial effects that: the wastewater treatment effect is substantially improved, the treatment process is simple, the management operation is convenient, and the operation management cost is low.

Owner:NINGBO HENGJIE WATER DEV

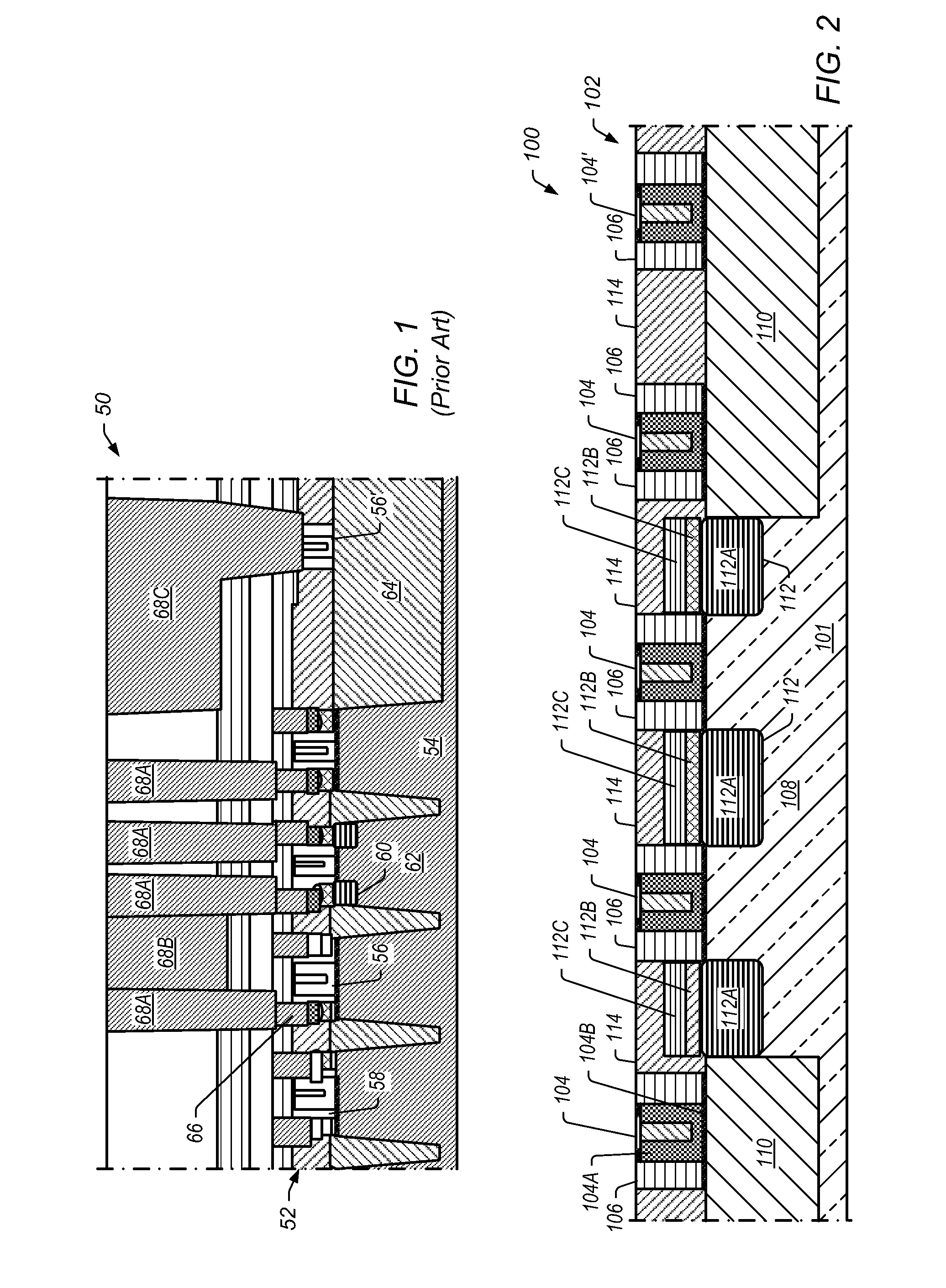

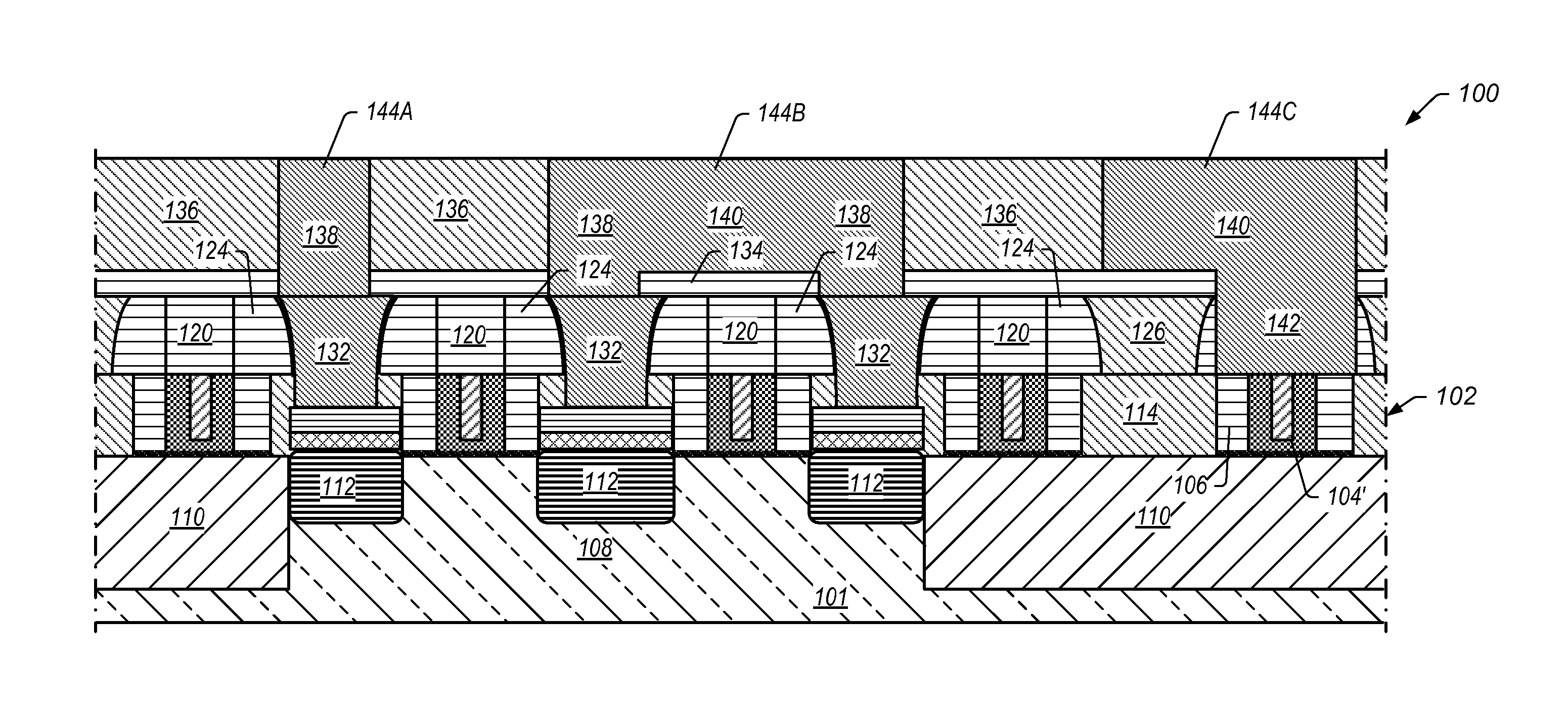

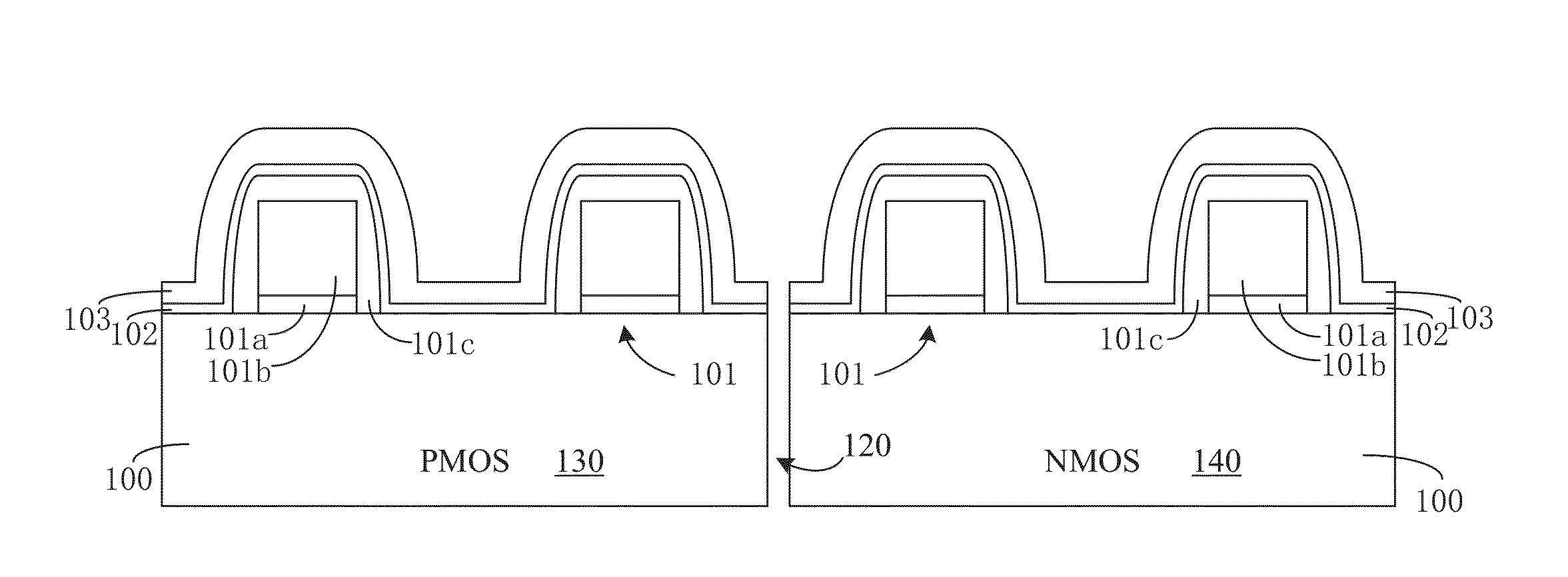

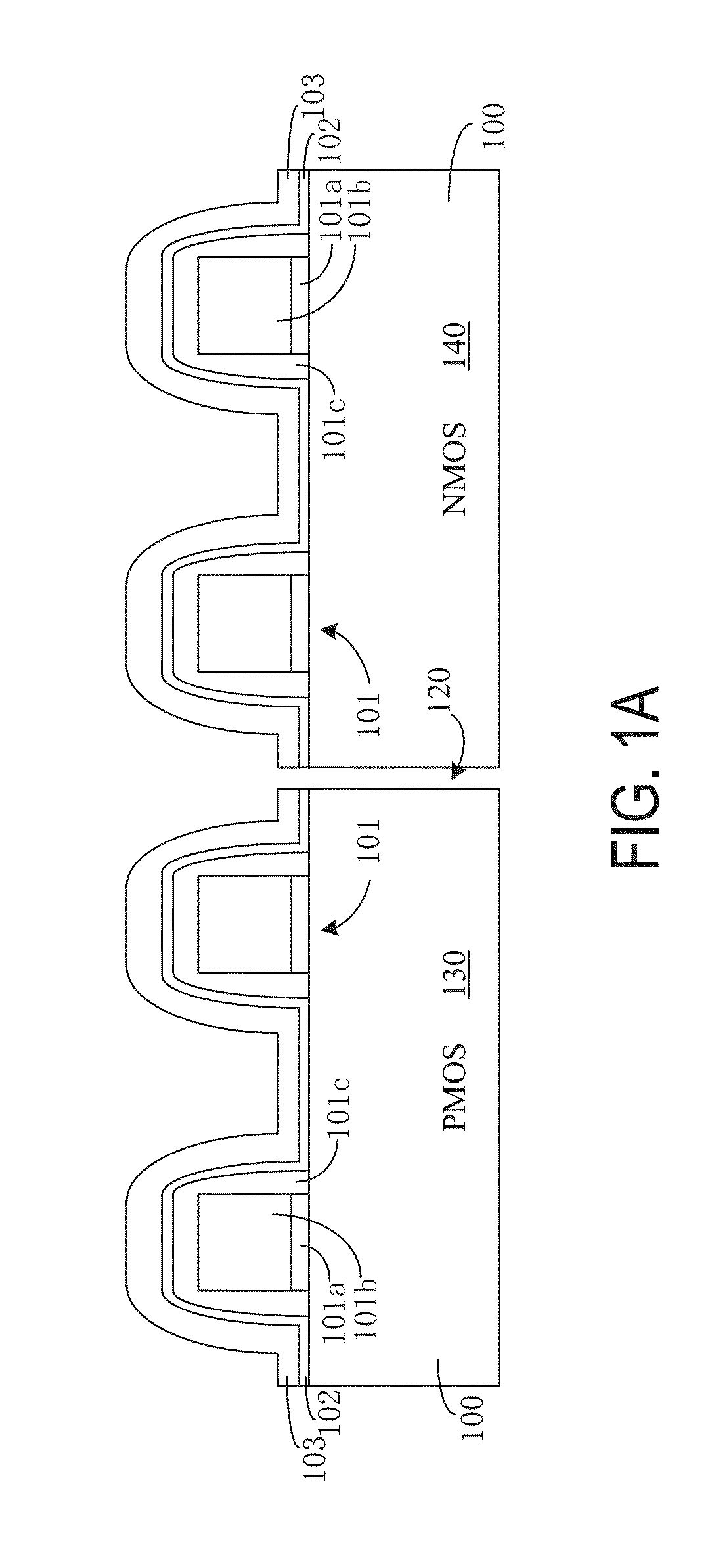

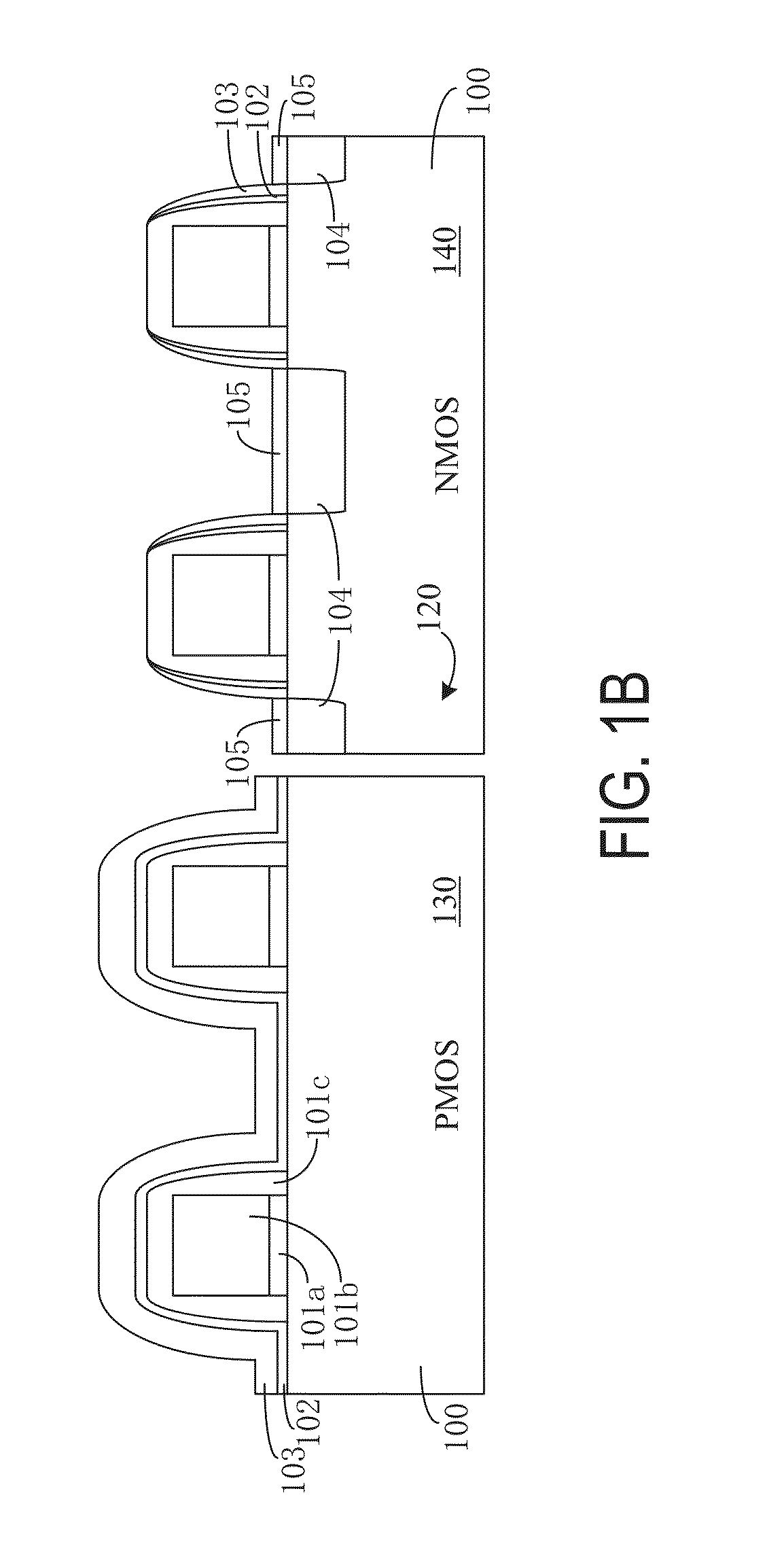

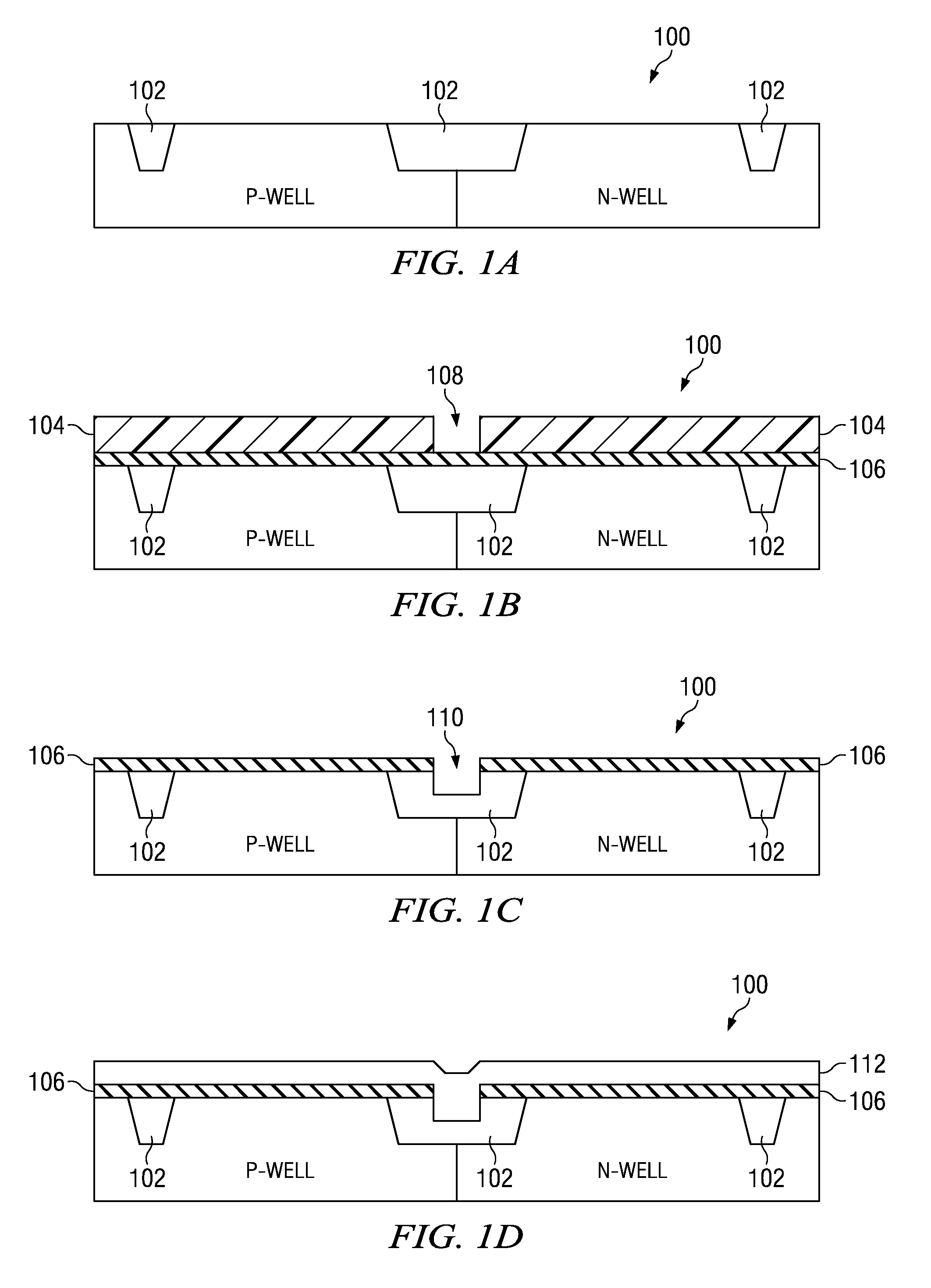

METHODS FOR HIGH-K METAL GATE CMOS WITH SiC AND SiGe SOURCE/DRAIN REGIONS

ActiveUS20160087040A1Reduce processing costsSimple process flowSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSEngineering

A method of manufacturing a semiconductor device includes forming a PMOS region and an NMOS region in a semiconductor substrate, forming dummy gate structures in the PMOS and NMOS regions, and forming a gate hard mask layer overlying top portions and sidewalls of the dummy gate structures. The method includes forming silicon carbon regions embedded in the semiconductor substrate on both sides of the dummy gate structure in the NMOS region, removing the hard mask layer on top of the dummy gate in the NMOS region, and forming silicon germanium regions embedded in the semiconductor substrate on both sides of the dummy gate structure in the PMOS region. After forming the silicon carbon regions and the silicon germanium regions, while retaining the hard mask layer on top of the dummy gates in the PMOS region, performing ion implant to form source / drain regions in the NMOS region and the PMOS region.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Two-stage anaerobic treatment system for cassava alcohol wastewater

ActiveCN103172215AReduce outputImprove processing efficiencyMultistage water/sewage treatmentAlcoholProcess engineering

The invention discloses a two-stage anaerobic treatment system for cassava alcohol wastewater. The system comprises a primary heat exchanger, a high temperature anaerobic fermentation tank, a primary drum screen, a secondary drum screen, a secondary heat exchanger, a sedimentation pool, an air floatation pool, an adjustment pool and a medium temperature UASB reactor. Wastewater goes by the primary heat exchanger for cooling, enters the high temperature anaerobic fermentation tank for high temperature anaerobic fermentation, goes by the two-stage drum screen, the secondary heat exchanger, the sedimentation pool and the air floatation pool for removing suspending matters and partial COD, and enters the UASB reactor for medium temperature anaerobic fermentation. The system has the following advantages: biogas generated in the two-stage fermentation is collected and used, and wastewater enters a subsequent aerobic segment for continuous treatment; and the whole treatment process flow is concise, the management is convenient, the energy consumption of the production and the operation is low, the treatment efficiency is high, and sludge has a less output and is easy to dispose.

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

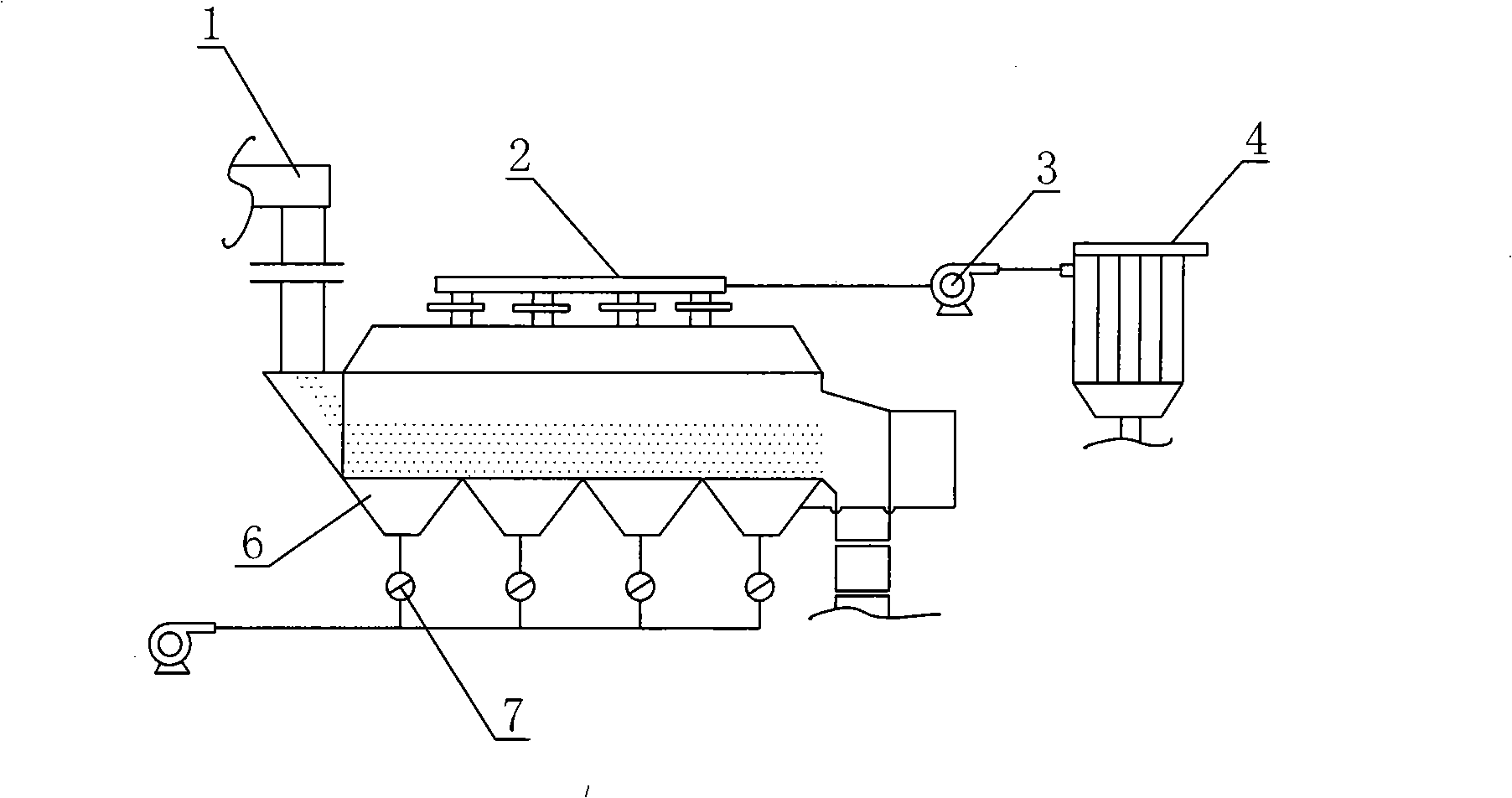

Hydrocarbon black powder removing method and device

ActiveCN101318180AEasy to handleAchieve high volumeGas current separationManufacturing technologyFluidized bed

The invention relates to a carbon black powder removing method and a device, belonging to the technical field of carbon black manufacturing. The carbon black powder removing method is used for removing the carbon black powder in carbon black pellets; the dried carbon black pellets containing powders are added to the feed end of a fluidized bed of a powder remover; the carbon black pellets run through the fluidized bed under the blowing of the air entering aslant below the fluidized bed and are discharged through the discharge end of the fluidized bed; at the same time, the powders are discharged through the top of the fluidized bed. The invention adopts the method of winnowing products under suspension state, has the advantages of high powder removing efficiency, low product damage rate, cooling product, meeting black storage requirements, improving packaging conditions, simple and efficient technology, and saving resources; besides, the adopted devices has simple and reasonable structure and easy production and maintenance, can effectively improve winnowing and cooling efficiency and realize reasonable energy utilization. The invention can be widely applied to the technical field of carbon black pellet processing and can effectively improve production efficiency and product quality.

Owner:SUZHOU BAOHUA CARBON BLACK

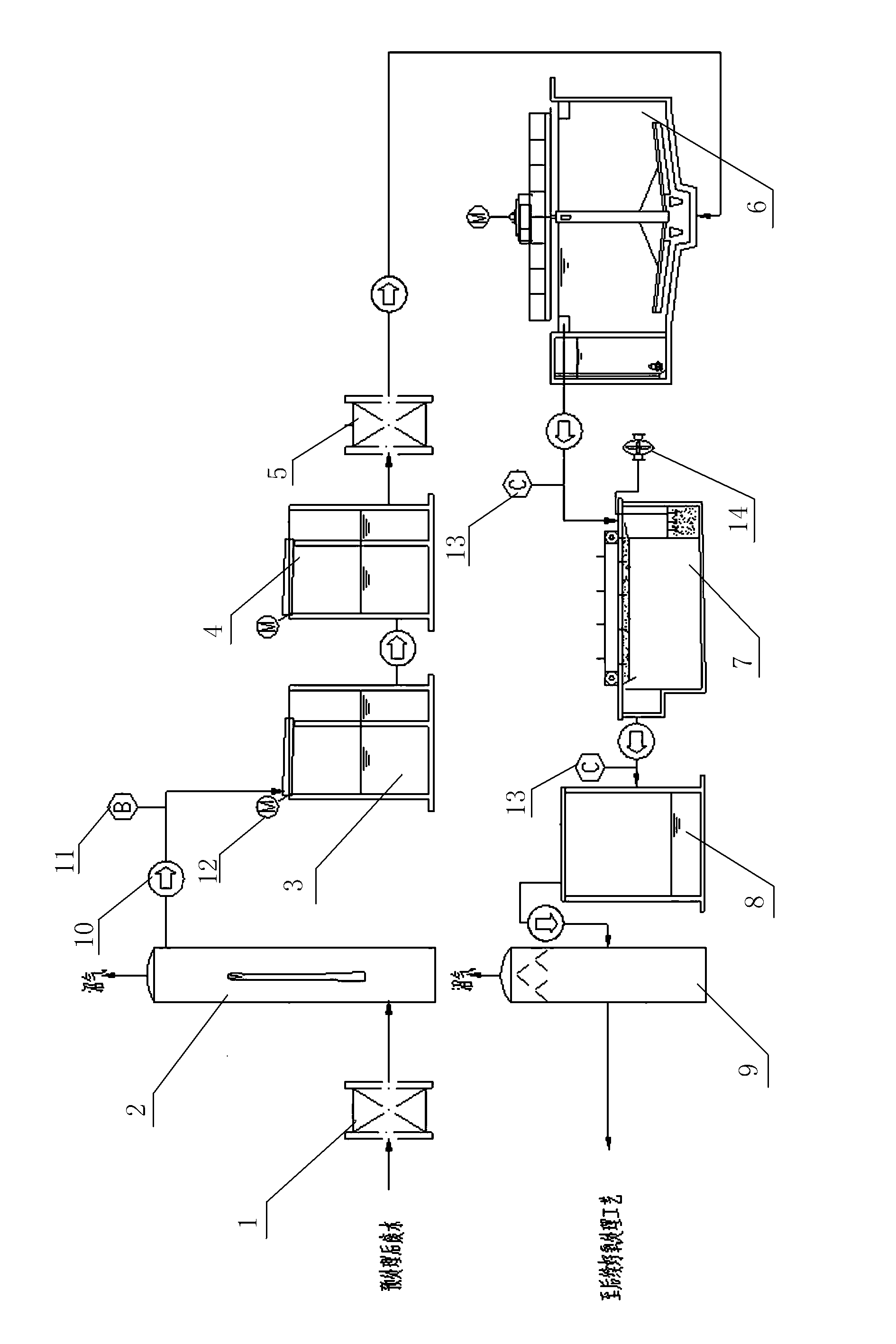

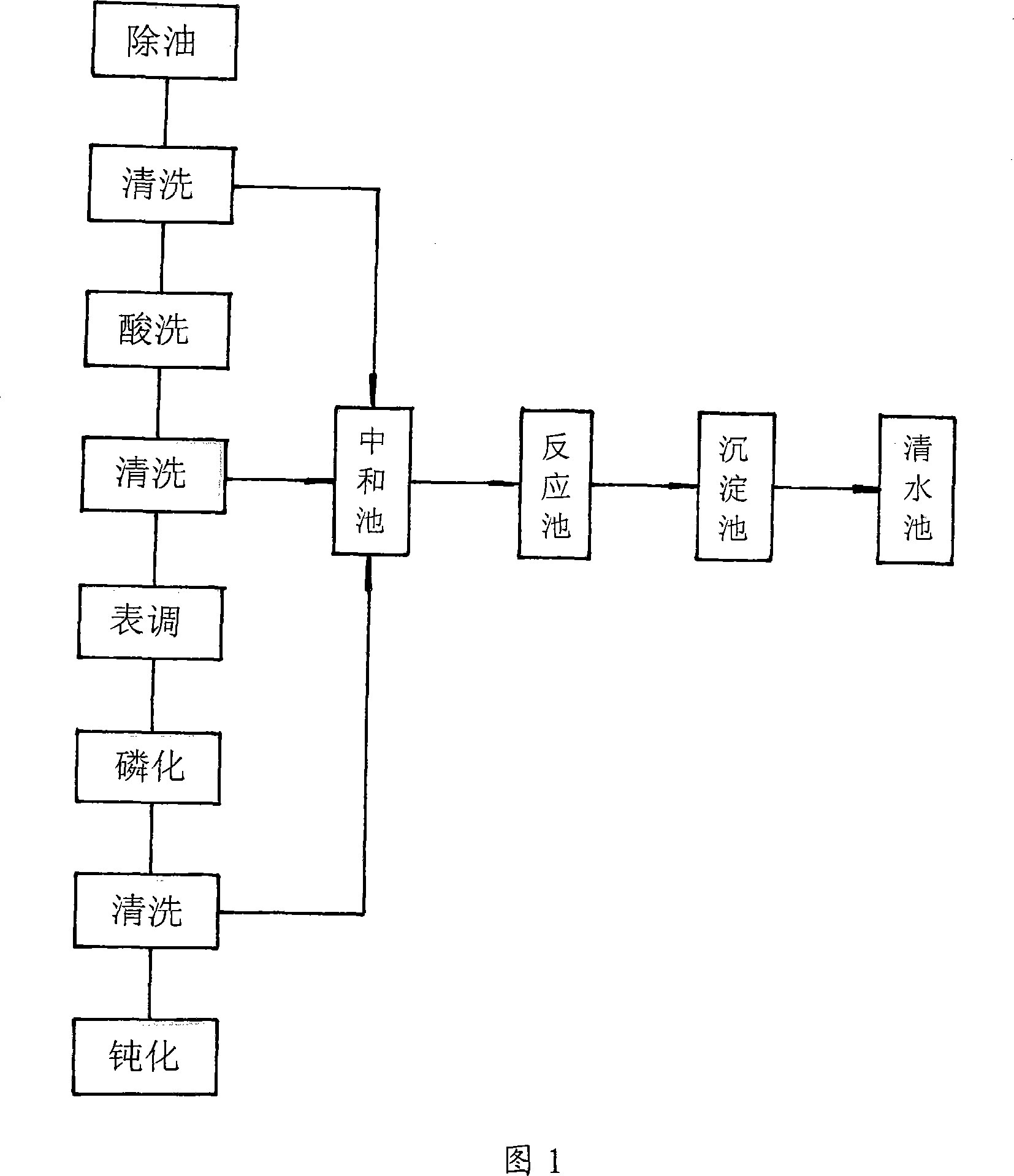

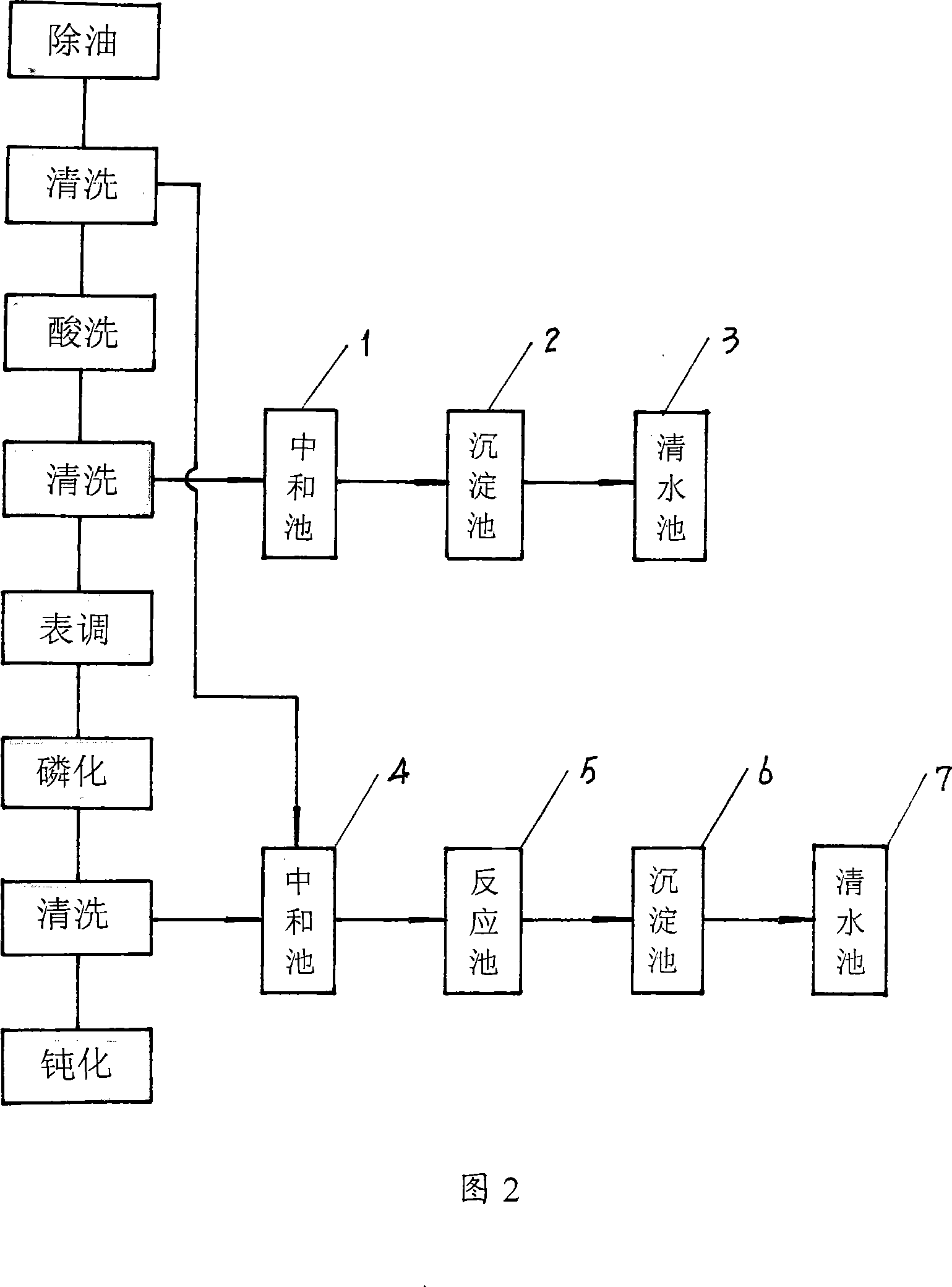

Process for reclaiming and treating phosphorization sewage

InactiveCN101100339AReduce processing difficultyReduce processing costsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentTotal phosphorusZinc

This invention discloses a method for treatment and recovering of waste-water from bonderizing process. The method comprises procedures of: (1), waste-water from oil-removing washing of bonderizing process of from bonderizing process washing step is fed into neutralization tank (IV), adding alkali or acid to regulate its pH value of 7-9; then (2), it is fed into reaction tank (V), adding flocculating agent, and agitating, controlling the oil<=1.0mg; total phosphorous<=1.0mg, Zinc<=3.2mg; (3), it is then fed into settling tank (VI), controlling its suspension solid<=0.7mg; (4), after settling, the water is fed into clarification tank (VII), and stored for cyclic utilization. The advantages of this invention are: low cost, reducing water consumption and reducing water pollution.

Owner:胡建平

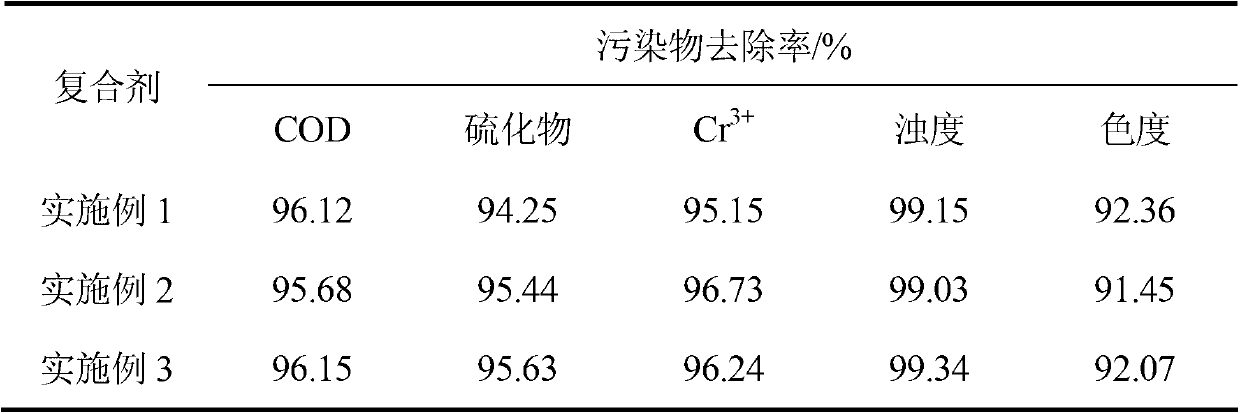

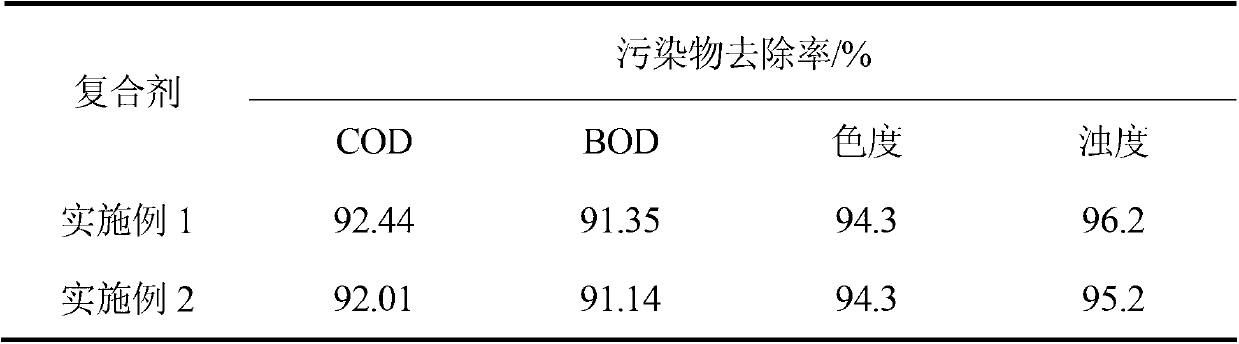

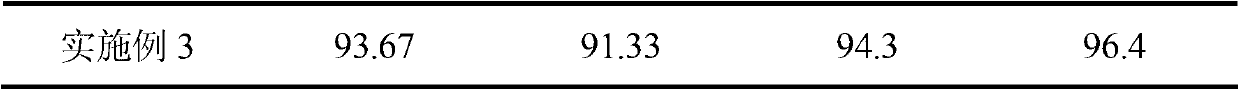

Water treatment compound agent based on potassium ferrate and preparation method of water treatment compound agent

InactiveCN103121745AEasy to handleReduce cost inputWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionBiocompatibility TestingTherapeutic effect

The invention discloses a water treatment compound agent based on potassium ferrate. The water treatment compound agent comprises the following components by mass percent: 8-35 percent of potassium ferrate, 25-50 percent of polymeric ferric sulfate, 20-40 percent of diatomite, 5-20 percent of calcium hydroxide and 3-8 percent of sodium hydroxide. A preparation method of the water treatment compound agent comprises the following steps of: adding the components into a dry vessel one by one, introducing dry inert gas to carry out protection, uniformly mixing under the condition of room temperature, and storing a mixture in the inert gas environment and a sealed and dark position without water. With the adoption of the water treatment compound agent, the cost investment in the water treatment process is effectively lowered, and the water treatment effect of potassium ferrate can also be further improved; and the water treatment compound agent is wide in component source and good in biocompatibility, has low cost, does not have environmental toxicity and accords with the requirement of greening of water treatment.

Owner:XIJING UNIV

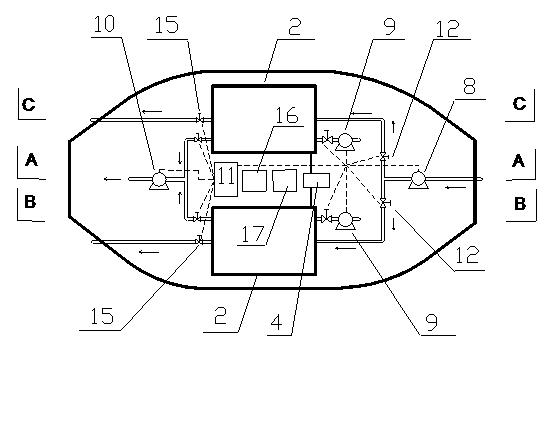

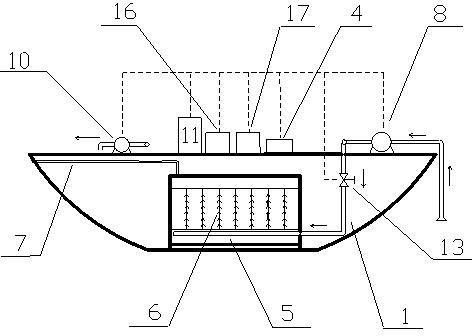

Boat type sewage treatment system based on sequencing batch reactor (SBR) process

InactiveCN102659245AEasy to moveDo not damage water bodiesTreatment with aerobic and anaerobic processesSequencing batch reactorWater discharge

The invention discloses a boat type sewage treatment system based on a sequencing batch reactor (SBR) process. The boat type sewage treatment system consists of four subsystems including a movement subsystem (a boat body and a contraction wheel), a sewage treatment subsystem (an SBR water treatment device, an anaerobic pool, a water inlet pump, a reflux pump, a sludge discharge pump and an aeration pump), a motive power subsystem (an electric cabinet and a generator) and a control subsystem (a programmable logic controller (PLC) control box, a water inlet valve, a reflux valve and a water discharge valve). When water bodies are locally polluted, the sewage treatment system can be conveniently moved to the pollution region, and sewage can be fast and effectively treated. The method has the advantages that the local and paroxysmal pollution of the water bodies can be eliminated, the water quality of the water bodies is improved, and important practical significances and wide application prospects are realized for maintaining the long-period stability of the water quality of the water bodies.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

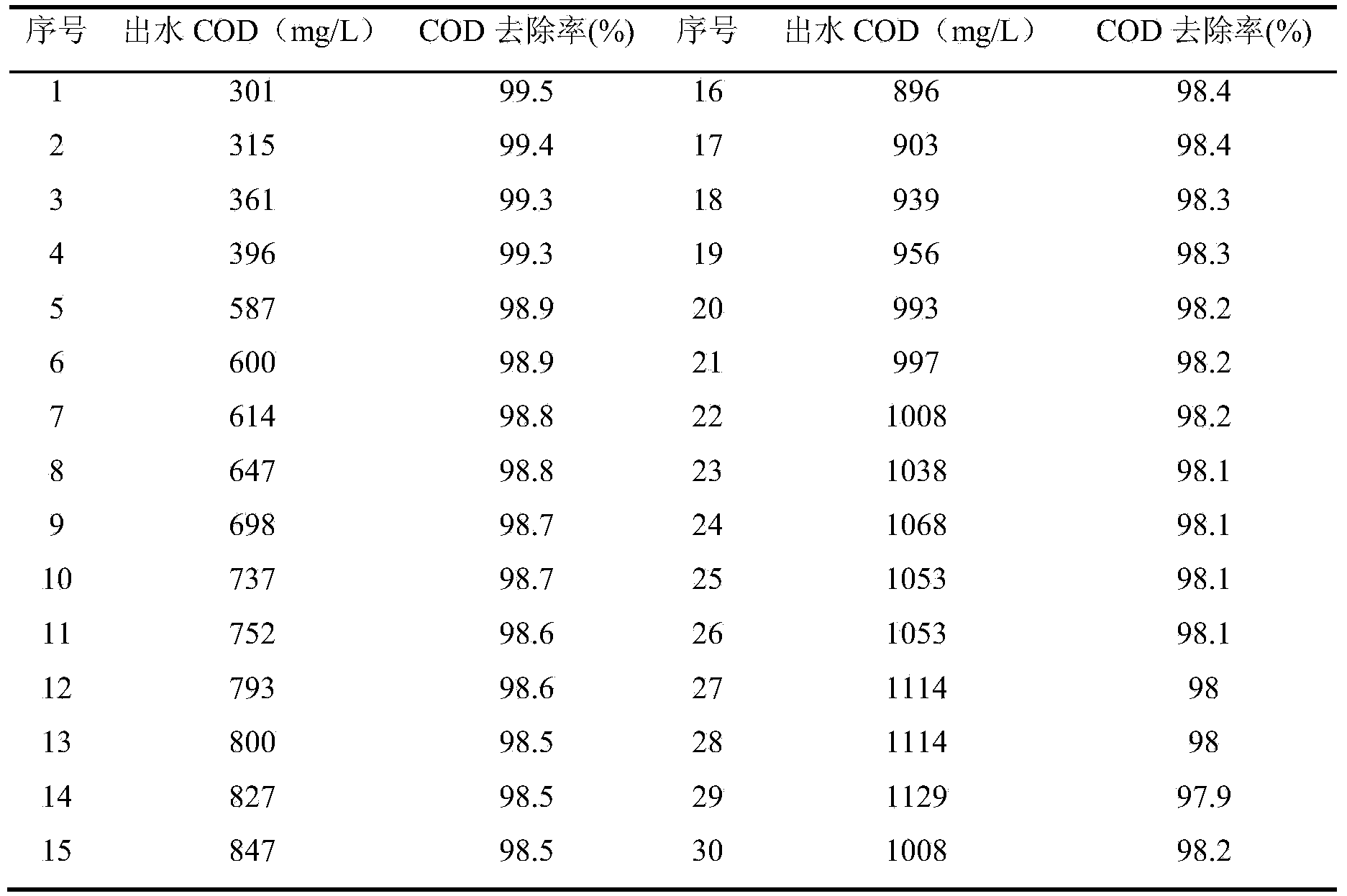

Pretreatment method for fluorenone production wastewater

ActiveCN103819024AImprove biodegradabilityImprove removal efficiencyMultistage water/sewage treatmentChemical industryPretreatment method

The invention belongs to the technical field of treatment of wastewater from the chemical industry and particularly relates to a pretreatment method for fluorenone production wastewater. The pretreatment method is characterized by comprising the two steps of acidification and oxidation by activated carbon and Fenton's reagent. Specially, the pretreatment method comprises the following steps: (1) acidification: adding industrial sulfuric acid to the fluorenone production wastewater to adjust the pH to 1-3, stirring, and standing for layering; (2) oxidation by activated carbon and Fenton's reagent: simultaneously adding H2O2, FeSO4.7H2O and activated carbon to the wastewater subject to acidification, and conducting reactions under the condition of 35-55 DEG C for 30-120 min. Adsorption, oxidation and regeneration of activated carbon all occur in the step (2). Compared with the prior art, the pretreatment method has the benefits as follows: the pollutant removal efficiency for the fluorenone production wastewater is high; the COD removal rate can reach more than 97%; the biodegradability of the wastewater is significantly improved; the B / C is increased to more than 0.4 from less than 0.2. Therefore, the pretreatment method is of great significance for the sustainable development of fluorenone production enterprises and other chemical production enterprises.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Flash memory device and manufacturing method thereof

InactiveUS20120280305A1OptimizationSimple process flowTransistorSolid-state devicesPhysicsDielectric

The present invention discloses a flash memory device. The flash memory device comprises a semiconductor substrate and a flash memory area located on the semiconductor substrate. The flash memory area comprises a first doped well, which is divided into a first region and a second region by an isolation region, the second region being doped with an impurity having an electrical conductivity opposite to that of the first doped well; a high-k gate dielectric layer located on the first doped well; and a metal layer located on the high-k gate dielectric layer. The present invention enables compatibility between the high-k dielectric metal gate and the erasable flash memory and increases the operation performance of the flash memory. The present invention also provides a manufacturing method of the flash memory device, which greatly increases the production efficiency and yield of flash memory devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

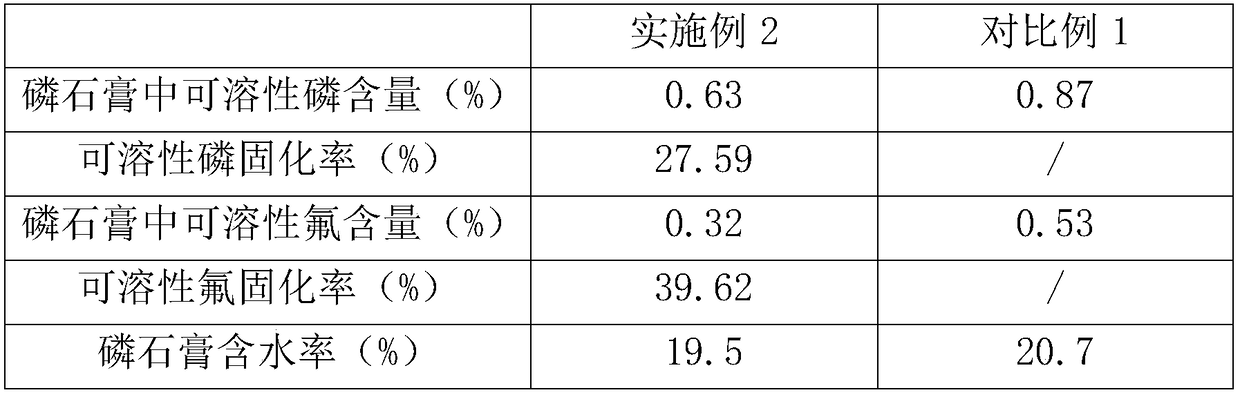

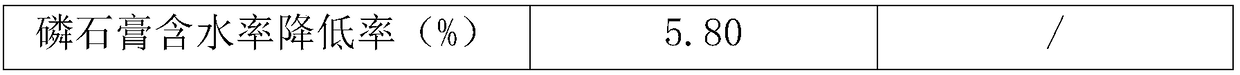

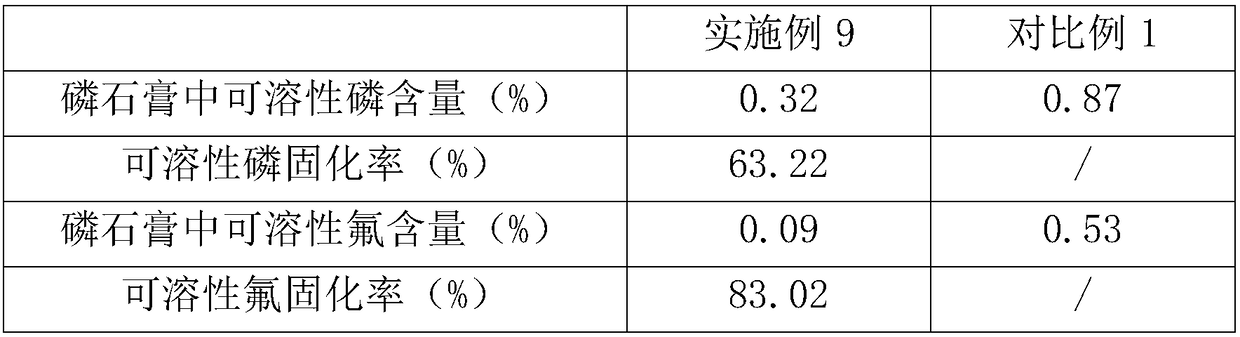

Method for stabilizing/curing soluble phosphorus and fluorine in phosphogypsum

InactiveCN109320111AReduce moisture contentSimple process flowCalcium/strontium/barium sulfatesGypsumChemistry

The invention discloses a method for stabilizing / curing soluble phosphorus and fluorine in phosphogypsum. The method is characterized by comprising the following steps: (1) placing the phosphogypsum in a container A, adding water into the container A at a stirring state, adding a mixture A and stirring to obtain a mixture B, wherein the mixture A comprises calcium carbonate, magnesium carbonate and calcium hydroxide; the weight ratio of the phosphogypsum to water is 1: (2.5 to 3); the weight ratio of the calcium carbonate to the magnesium carbonate to the calcium hydroxide is 1: 1: 1, and theweight ratio of the mixture A to the phosphogypsum is (0.5 to 1): 100; (2) at the stirring state, adding a hydrophobic surfactant into the container A and continuously stirring until homogeneity to obtain a mixture, wherein a weight volume ratio (mg:L) of the mixture B to polydimethylsiloxane is (5 to 10): 1; and (3) enabling the mixture obtained in step (2) to react for 2 to 3 hours at the stirring state, and unloading the material to obtain the stabilized / cured mixture.

Owner:CHONGQING UNIV

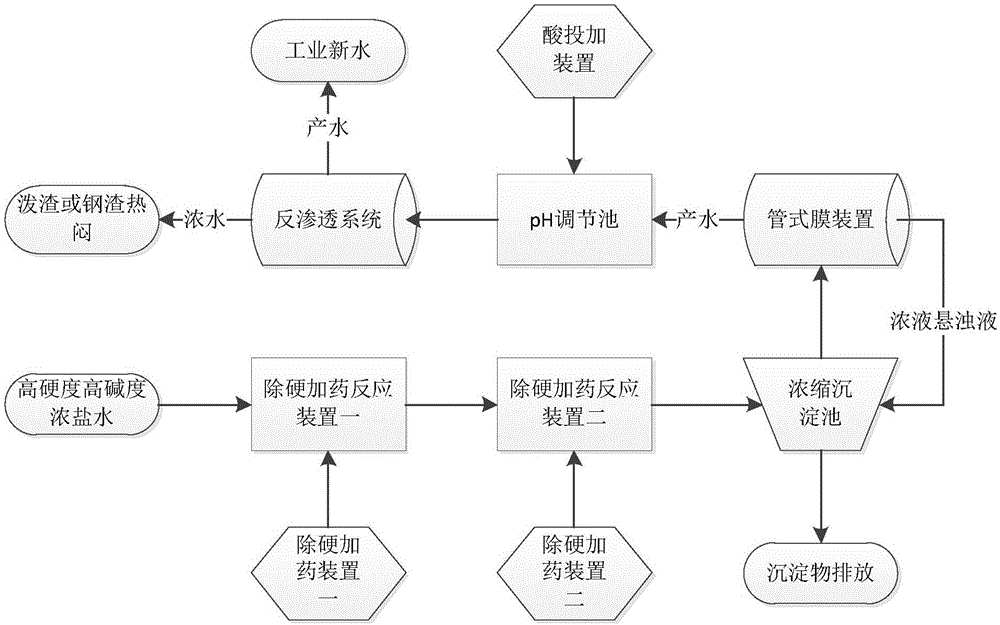

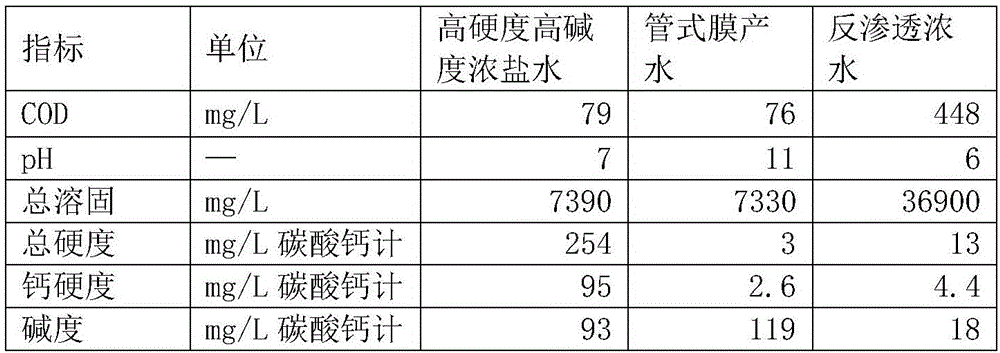

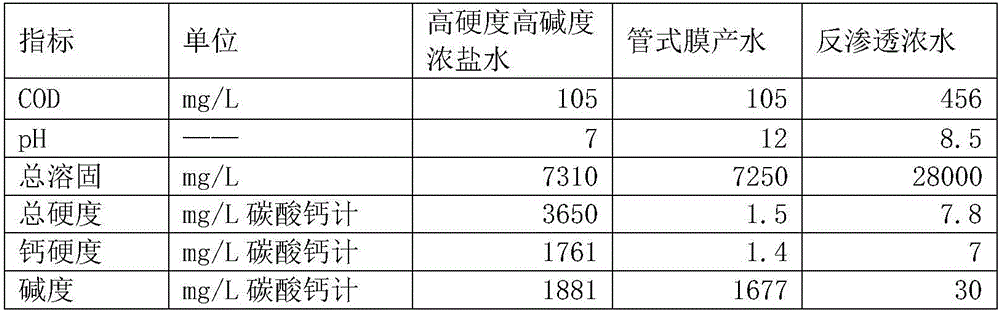

Process and device for treating high-hardness and high-alkalinity strong brine from iron and steel plants

PendingCN106396169APrevent salinizationBreak the salt balanceWater treatment parameter controlWater softeningEcological environmentFiltration membrane

The invention relates to a process and a device for treating high-hardness and high-alkalinity strong brine from iron and steel plants. The process includes steps of (1), feeding the high-hardness and high-alkalinity strong brine into chemical feeding, hardness removing and reaction devices, separately adding sodium hydroxide into the chemical feeding, hardness removing and reaction devices at two steps, mixing and stirring the high-hardness and high-alkalinity strong brine and the sodium hydroxide and carrying out sufficient reaction; (2), feeding the high-hardness and high-alkalinity strong brine mixed with chemicals into a concentration and sedimentation tank; (3), feeding mixed liquid formed by the high-hardness and high-alkalinity strong brine and sediments in the concentration and sedimentation tank into tube micro-filtration membranes, carrying circulation filtration on the high-hardness and high-alkalinity strong brine and the sediments, feeding hardness-removed produced water into a pH (potential of hydrogen) regulating tank and feeding strong liquor back to the concentration and sedimentation tank; (4), adding hydrochloric acid into strong brine in the pH regulating tank to regulate the pH of the strong brine until the strong brine is neutral, then feeding the strong brine into a reverse osmosis device and concentrating the strong brine; (5), recycling produced water of the reverse osmosis device as new industrial water and delivering concentrated water to the iron and steel plants for carrying out heating stuffing treatment on splashing slag or steel slag. The process and the device have the advantage that the problem of influence on local aquatic ecological environments of enterprises due to the fact that high-hardness and high-alkalinity strong brine only can be treated and discharged at present can be solved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

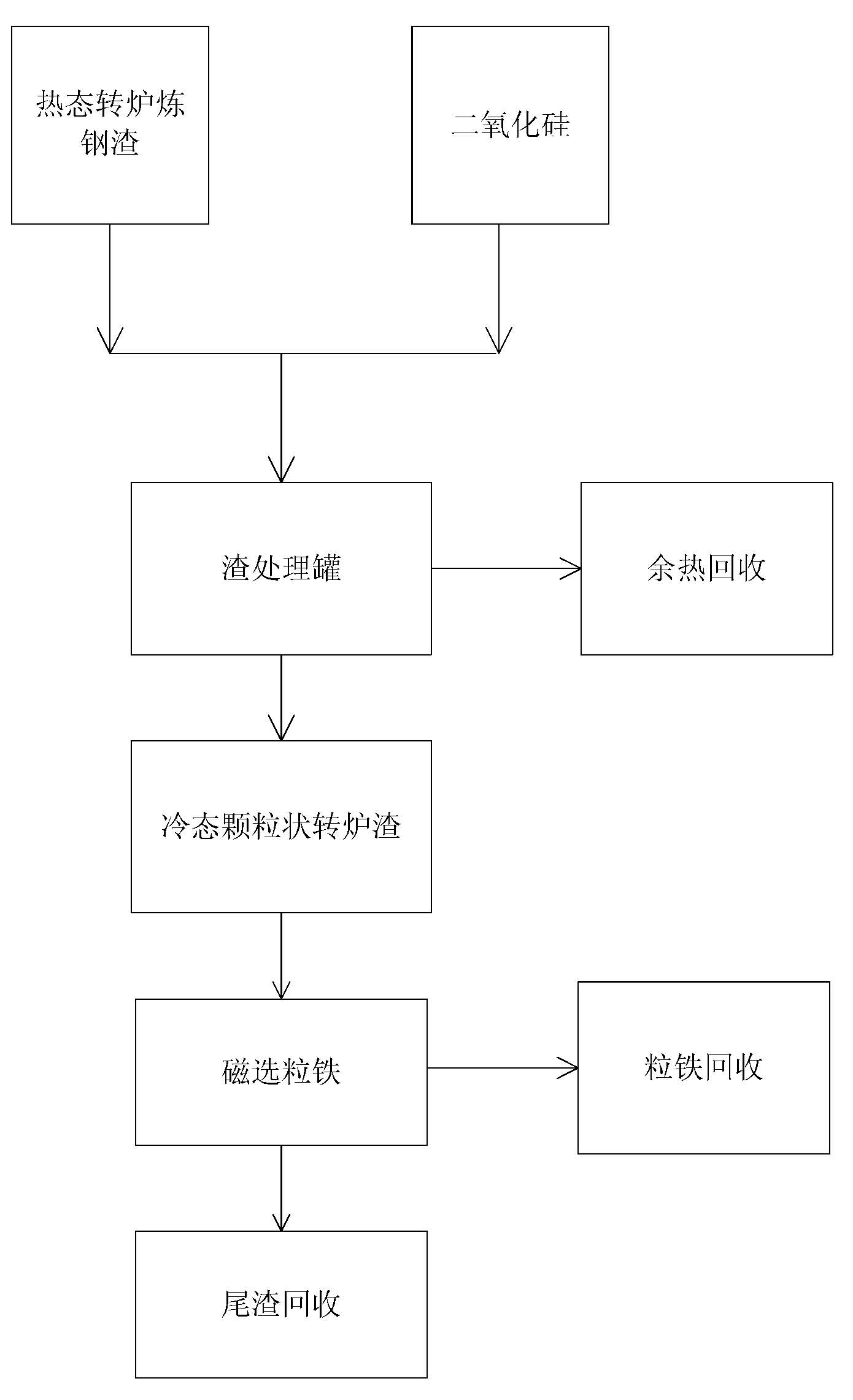

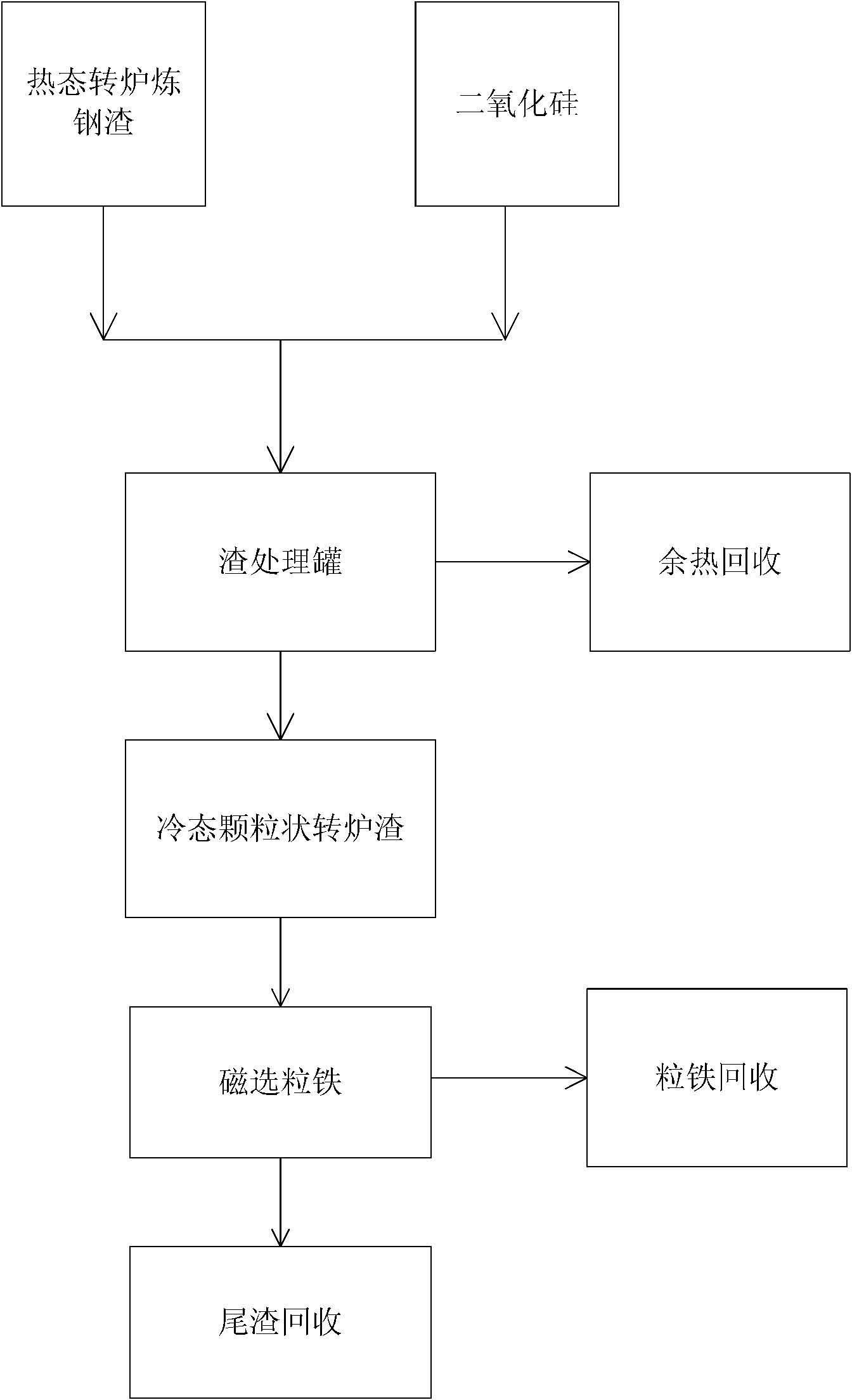

Method for processing convertor steelmaking slag

InactiveCN102534070AAchieve natural pulverizationUniform particle sizeRecycling and recovery technologiesSteelmakingVolume expansion

The invention relates to a method for processing convertor steelmaking slag. A raw material containing SiO2 is added into thermal convertor steelmaking slag, so that CaO in the convertor steelmaking slag generates 2CaO.SiO2 through a solid-phase reaction in a high temperature. The 2CaO.SiO2 generating crystal transformation and volume expansion in a cooling process of the convertor steelmaking slag is utilized to realize the natural pulverization of the convertor steelmaking slag, convertor slag with even grain sizes is obtained, and grained iron is magnetically separated. According to the technical scheme, the raw material containing the SiO2 is added into the convertor steelmaking slag in the high temperature, the crystal transformation and the volume expansion of the 2CaO.SiO2 in the cooling process of the convertor steelmaking slag are utilized to realize the natural pulverization of the convertor steelmaking slag, the convertor slag with even grain sizes is obtained, the grained iron is magnetically separated, tailings are recovered, and large amounts of heat energy of high-temperature convertor steelmaking slag in the cooling process are recovered.

Owner:WISDRI ENG & RES INC LTD

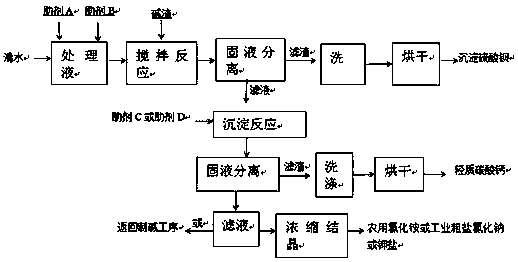

Comprehensive waste soda ash residue recycling method

ActiveCN107555462ASimple processLess investmentCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesCalcium carbonateAmmonium chloride mixture

The invention discloses a comprehensive waste soda ash residue recycling method. The comprehensive waste soda ash residue recycling method comprises the following steps: preparing a treatment solution; mixing a waste soda ash residue and the treatment solution for a stirring reaction; performing solid-liquid separation for recycling precipitated barium sulfate; recycling light calcium carbonate; recycling agricultural-grade ammonium chloride, industrial crude salt sodium chloride or potassium salt. By the comprehensive waste soda ash residue recycling method, the waste soda ash residue is comprehensively recycled, so that zero discharge of the waste residue and waste water during soda ash production is achieved; an alkali residue treatment technology is simple in flow path, low in investment, quick in effect, low in treatment cost and considerable in benefits.

Owner:赵阳臣

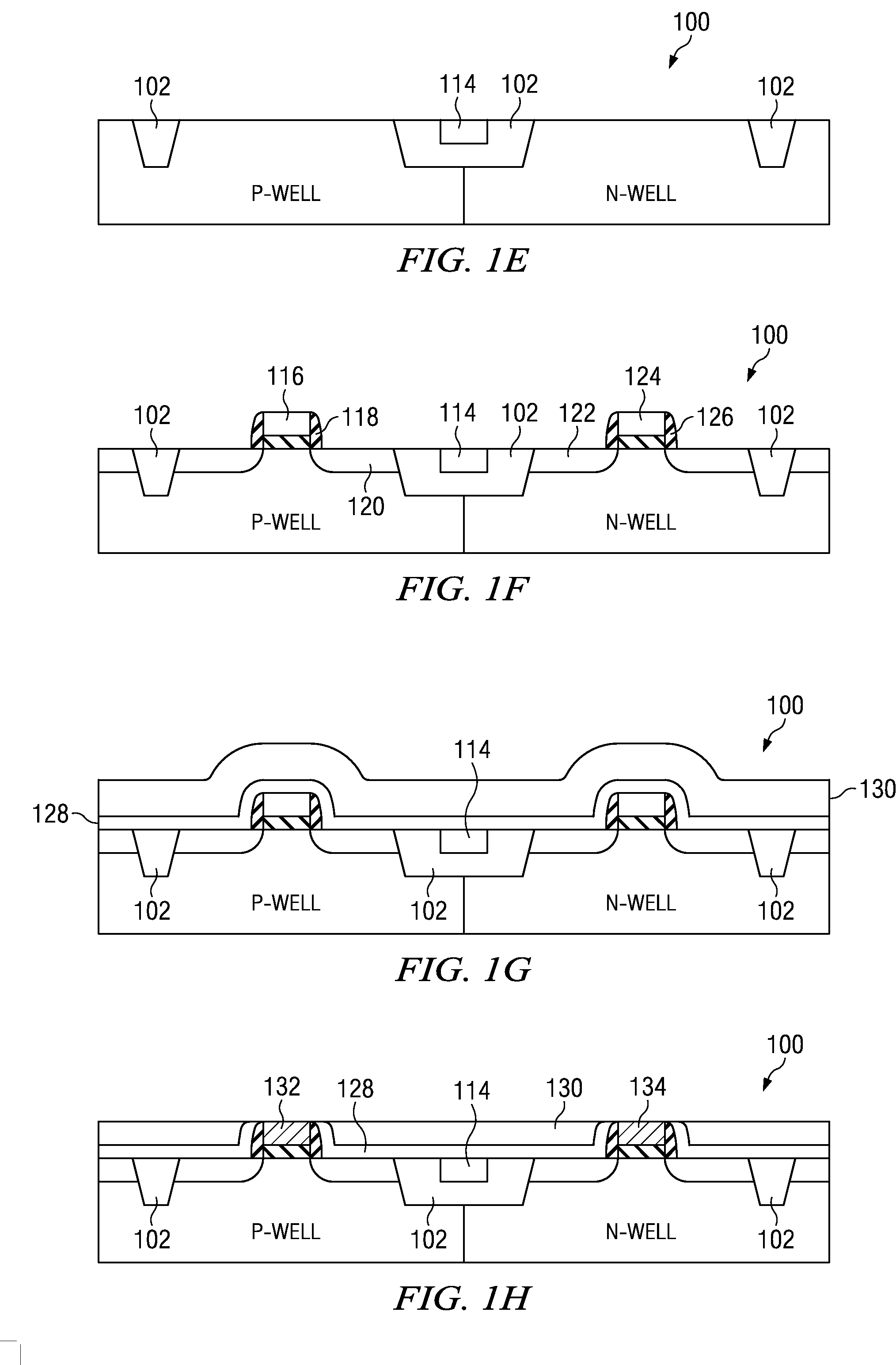

Polycrystalline silicon efuse and resistor fabrication in a metal replacement gate process

InactiveUS20140011333A1Simple process flowTransistorSemiconductor/solid-state device detailsP channelMetal

A method of fabricating an integrated circuit is disclosed (FIGS. 1-2). The method comprises providing a substrate (200) having an isolation region (202) and etching a trench in the isolation region. A first conductive layer (214) is formed within the trench. A first transistor having a first conductivity type (n-channel) is formed at a face of the substrate. The first transistor has a gate (216) formed of the first conductive layer. A second transistor having a second conductivity type (p-channel) is formed at the face of the substrate. The second transistor has a gate (224) formed of the first conductive layer. The method further comprises replacing the first conductive layer of the first transistor with a first metal gate (132) and replacing the first conductive layer of the second transistor with a second metal gate (134).

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com