Hydrocarbon black powder removing method and device

A technology of powder and carbon black, which is applied in chemical instruments and methods, solid separation, and separation of solids from solids with airflow, etc. It can solve the problems of reducing the economic benefits of manufacturers, high damage rate of carbon black particles, and high cost. , to achieve the effect of improving packaging conditions, low product damage rate and excellent efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

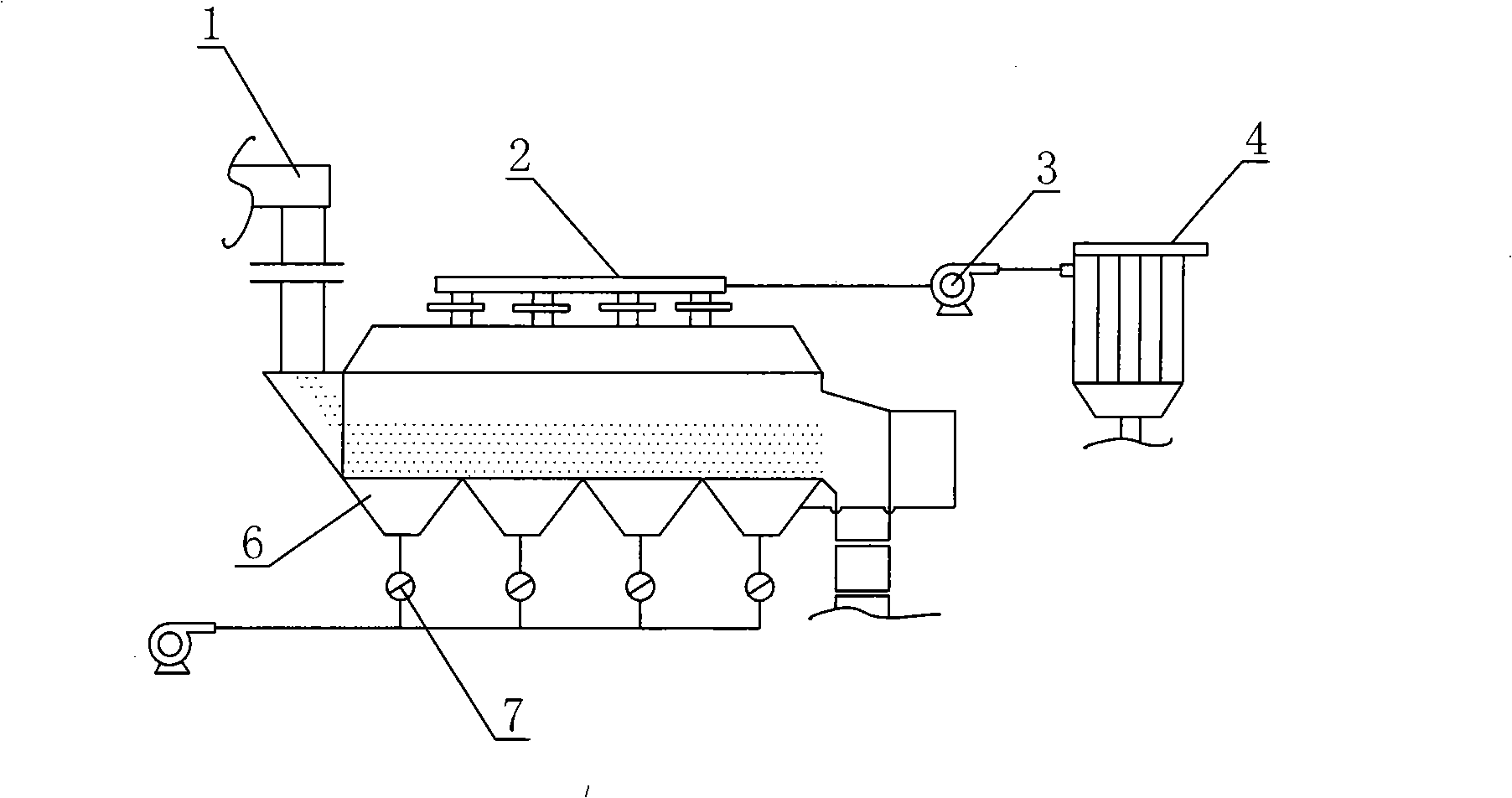

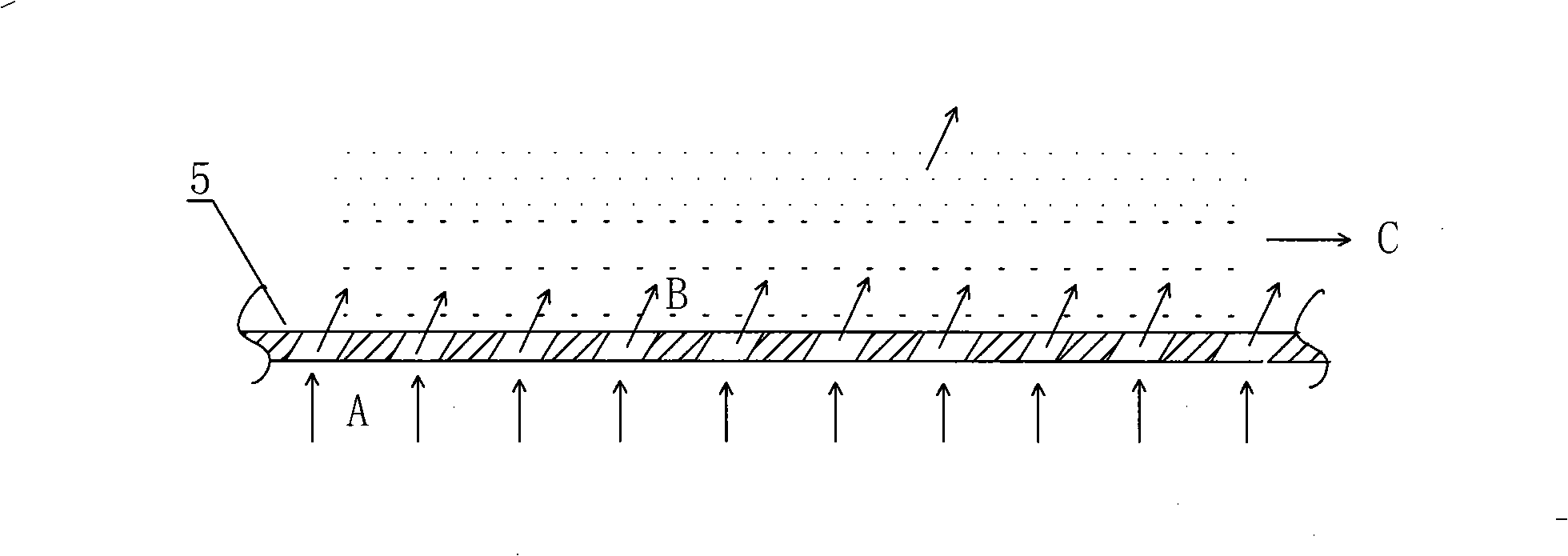

[0024] Such as figure 1 and figure 2 As shown, the carbon black powder removal device is mainly composed of an air-flow conveying device such as a blower 3 and a powder remover fluidized bed 2, wherein a horizontal sieve plate 5 is arranged on the powder remover fluidized bed, and the sieve plate is covered with presses. The same direction as the movement direction of carbon black particles obliquely penetrates the horizontal sieve plate, that is, the upper end is biased towards the discharge end of the fluidized bed of the powder remover, and the lower end is biased towards the air hole at the feed end of the fluidized bed of the powder remover, and the bottom of the fluidized bed is set Four air inlets 6 are connected to a blower 3 through an air delivery pipe 7 with an air pressure regulating valve and an air pressure gauge. Each of the above air inlets and the horizontal sieve plate form a winnowing cooling section. Also, the top of the above-mentioned fluidized bed comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com