Patents

Literature

139results about How to "Achieve high volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial feed of sesamia inferens walker as well as preparation method and feeding method thereof

InactiveCN101971931ANormal growth and developmentGreat tasteAnimal feeding stuffAccessory food factorsShootCorn meal

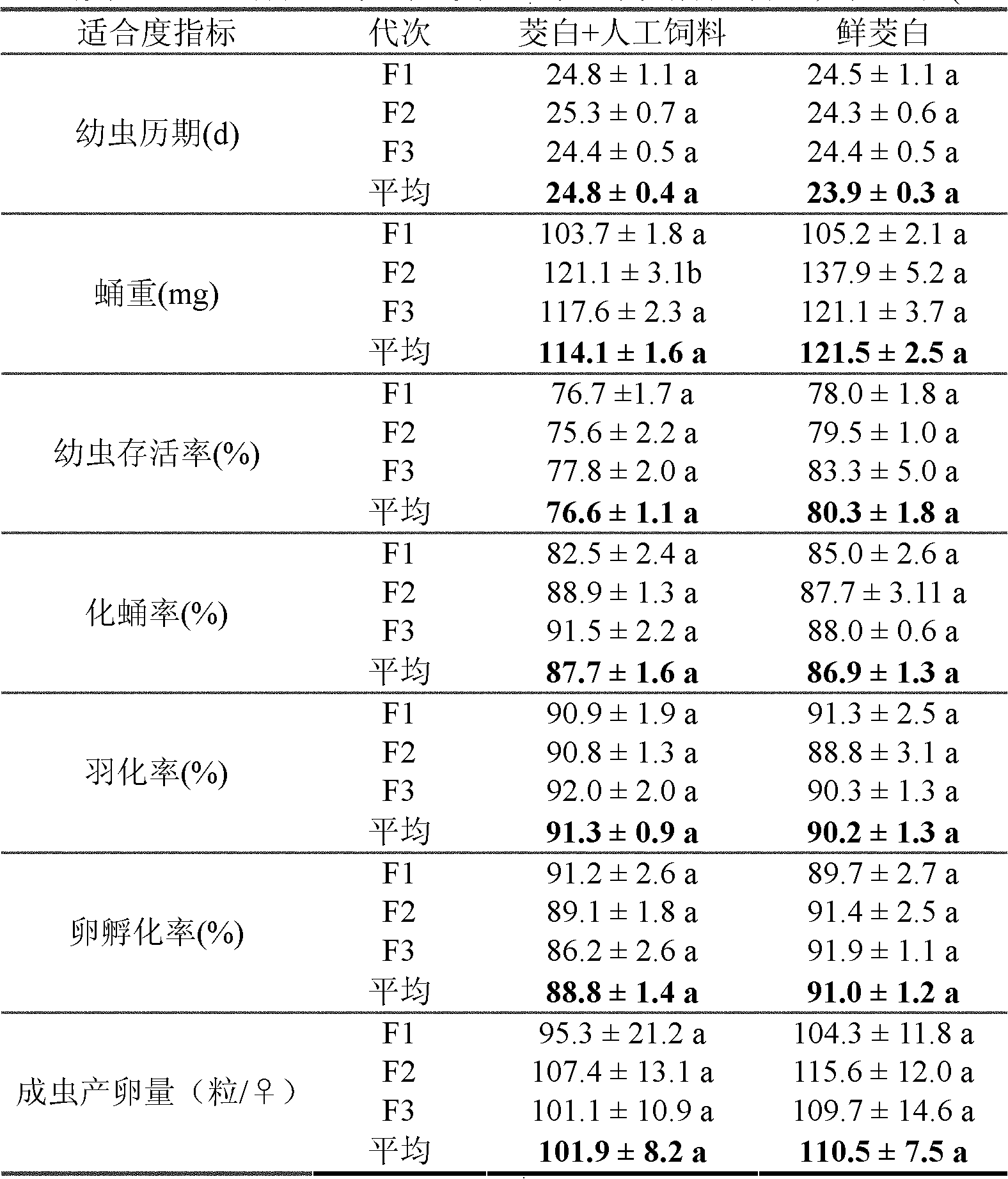

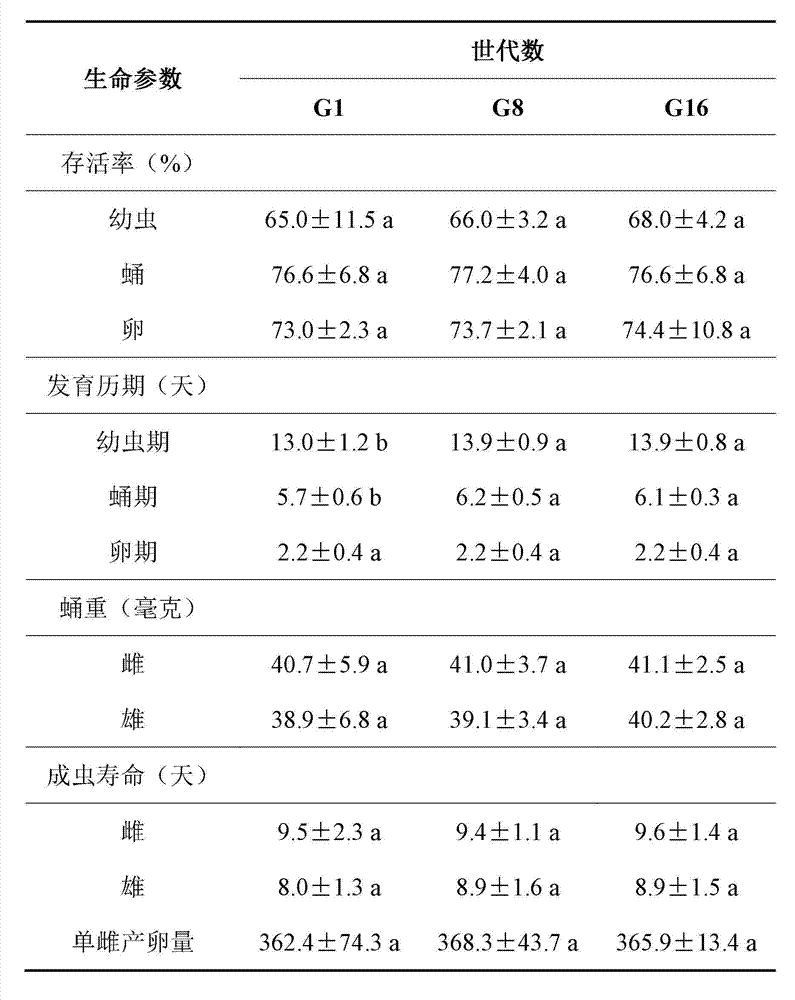

The invention relates to an artificial feed of sesamia inferens walker as well as a preparation method and a feeding method thereof, belonging to the technical field of insect feeding. The artificial feed comprises soybean meal, corn meal, wheat germ, yeast powder, casein, cane sugar, honey, fresh wild rice shoots or fresh rice stems, ascorbic acid, cholesterol, choline chloride, Fiske salt, vitamin B complex, vitamin E, sorbic acid, methyl parahydroxybenzoats, 40 percent formaldehyde, 98.18 percent rice ketone, agal-agal and water. A long-term and successive feeding method of the sesamia inferens walker is carried out by adopting a wild rice shoots (young larva) and artificial feed (old larva until pupation). The fed larva of the sesamia inferens walker have development period of 24.8 days, larva survival rate of 76.6 percent, percentage of pupation of 87.7 percent, eclosion rate of 91.3 percent, egg laying amount of 101.9 for single adult and egg hatching rate of 88.8 percent. The invention has the advantages of low cost, practicability, simple preparation, and the like, and is suitable for massive, long-term and successive feeding of standard test sesamia inferens walkers.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

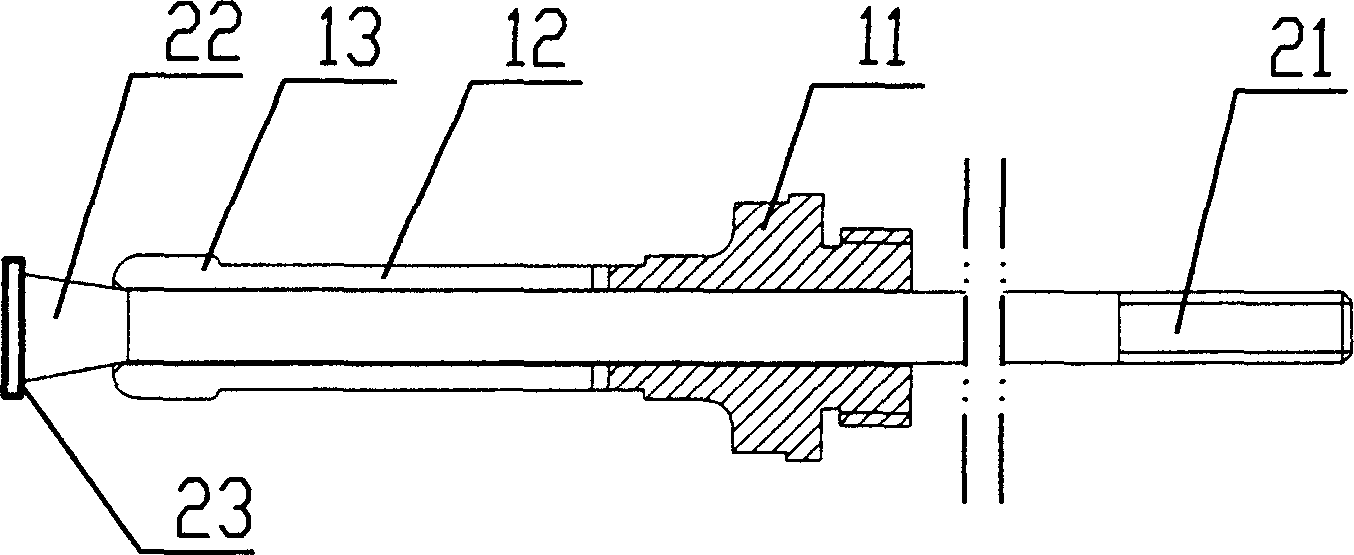

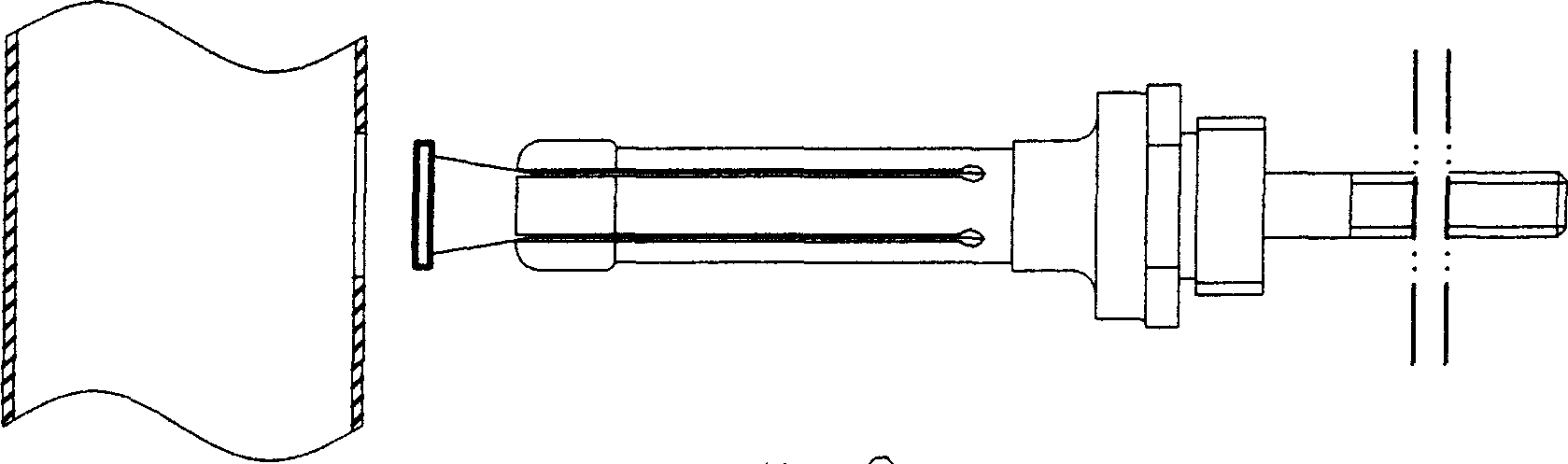

Micro optical probe of endoscope

ActiveCN102401995AImmune to environmental factorsAchieve high volumeSurgeryDiagnostic recording/measuringOptomechatronicsEndoscope

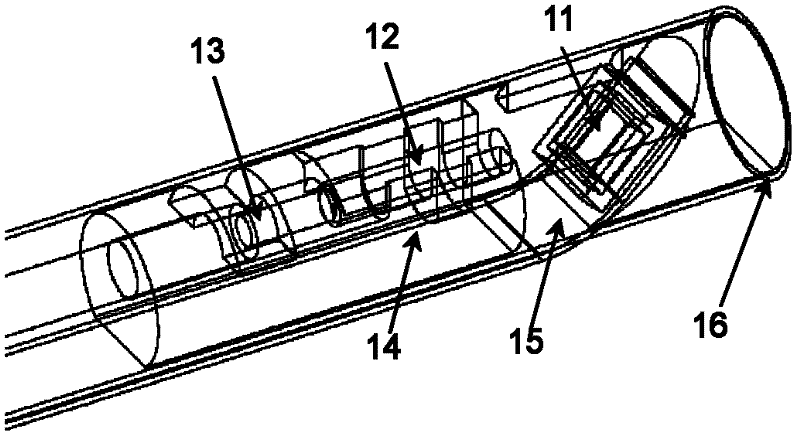

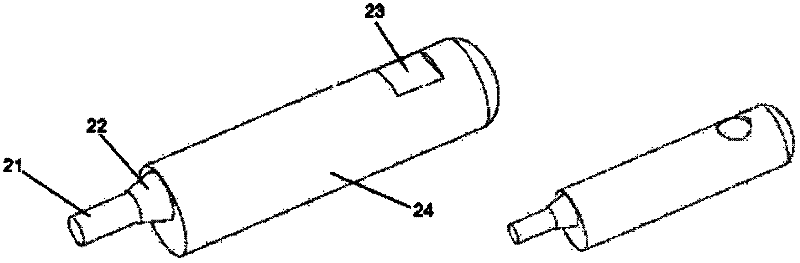

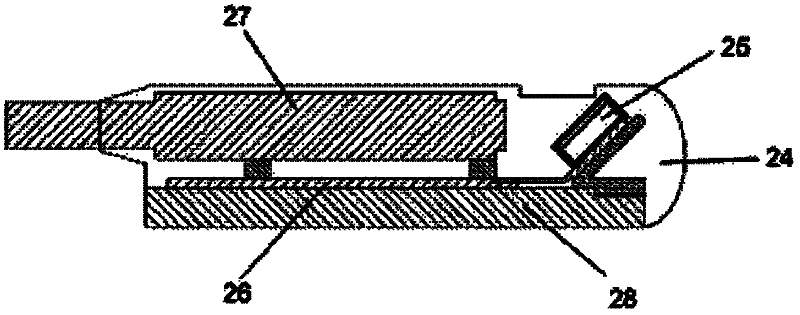

The invention discloses a micro optical probe of endoscope, which comprises an MEMS microscope, a circuit board, a self focusing optical assembly, a locating bottom plate and a housing; the micro optical probe of endoscope is characterized in that: the endoscope probe is designed by using integrated symmetrical structure, the MEMS microscope; the circuit board and the self focusing optical assembly are assembled on the locating bottom plate according to design requirements of optomechatronics to form a probe body, and a probe housing is formed by injection molding or casting and is tightly connected with the probe body. The housing opposite to the microscope surface of the MEMS microscope can be formed with an optical window, or the housing material is transparent to the used light. The probe housing is formed at a time by injection molding / casting technology, and this structure can protect the MEMS microscope from being influenced with environment factor and can bear a certain vibration impact and random shock; the sealed probe can work in various liquid environments; and large-batch and low-cost processing production of probes can be realized, and the aim of disposable probes will be fulfilled.

Owner:无锡微文半导体科技有限公司

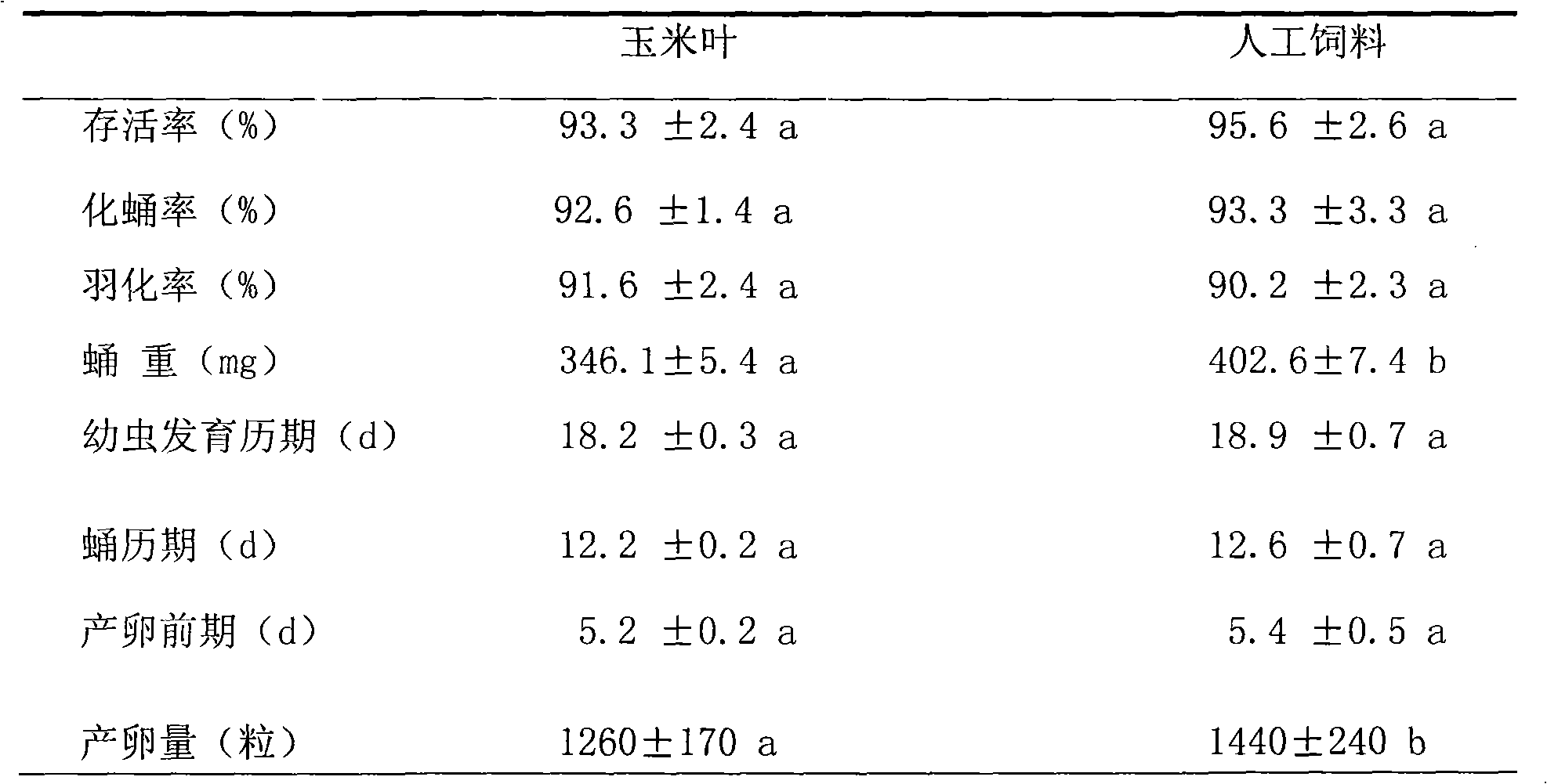

Artificial feed for armyworm, preparation method thereof, and feeding method

InactiveCN101856085AEasy accessImprove anti-corrosion performanceAnimal feeding stuffBiotechnologySucrose

The invention relates to an artificial feed for armyworm, a preparation method thereof, and a feeding method, and belongs to the technical field of insect feeding. The artificial feed for the armyworm is mainly prepared from the following components: soybean meal, yeast powder, casein, dry corn leaf meal, cholesterol, sucrose, ascorbic acid, sorbic acid, agal-agal, hydroxybenzoate methyl paraben, vitamin solution and distilled water. The feed has strong adaptivity and is a favorite food for the armyworm, so the armyworm has normal growth and development and the nutrition requirement of the armyworm of the whole generation and the followed generation can be met. The feed and the feeding method are used for feeding the armyworm, the problem that the successive generation feeding of the armyworm throughout the year cannot be carried out caused by season change, particularly insufficient natural feed in winter and early spring seasons is solved, and the massive, annual and successive generation feeding of standard worm sources is realized.

Owner:罗礼智 +1

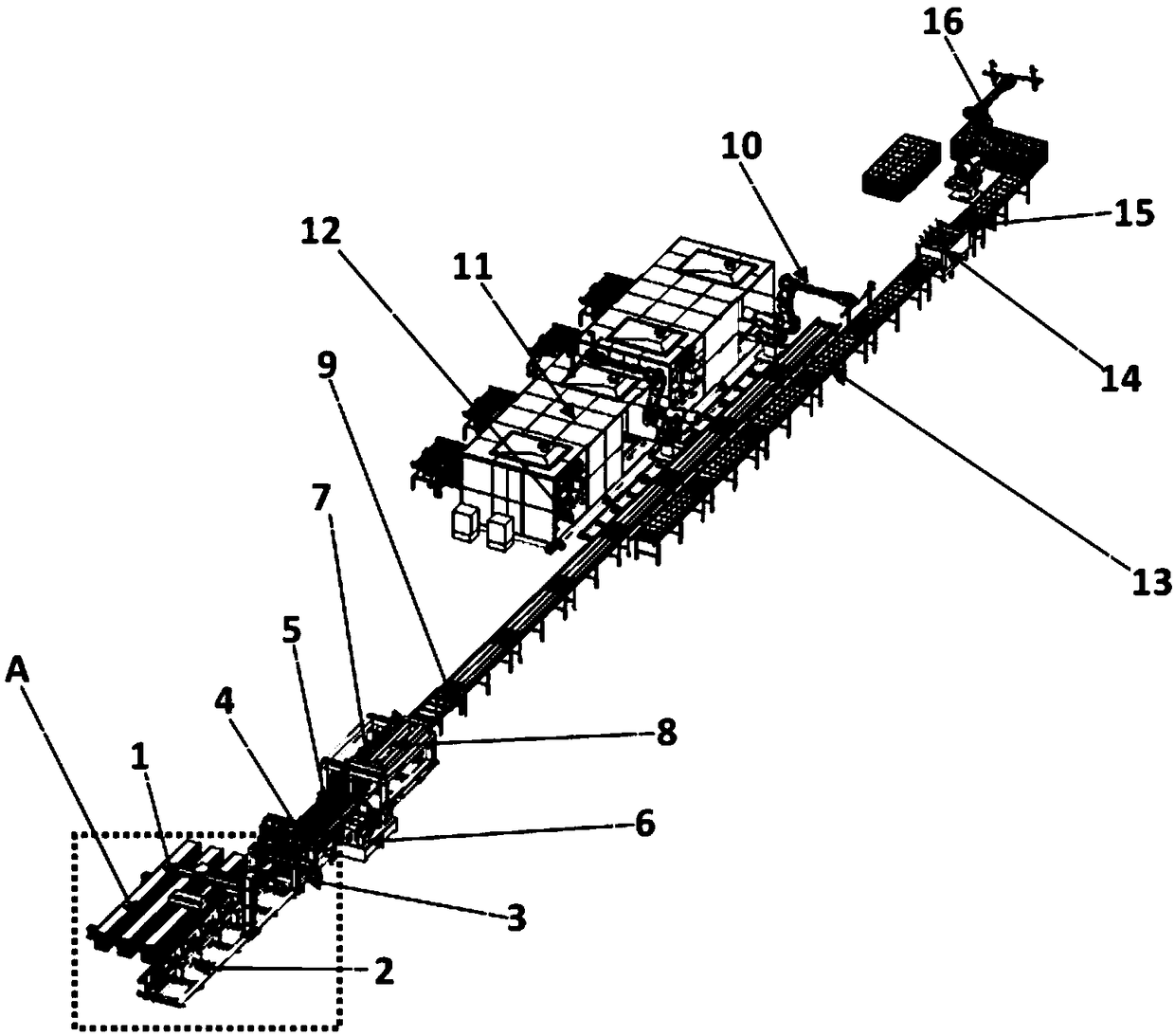

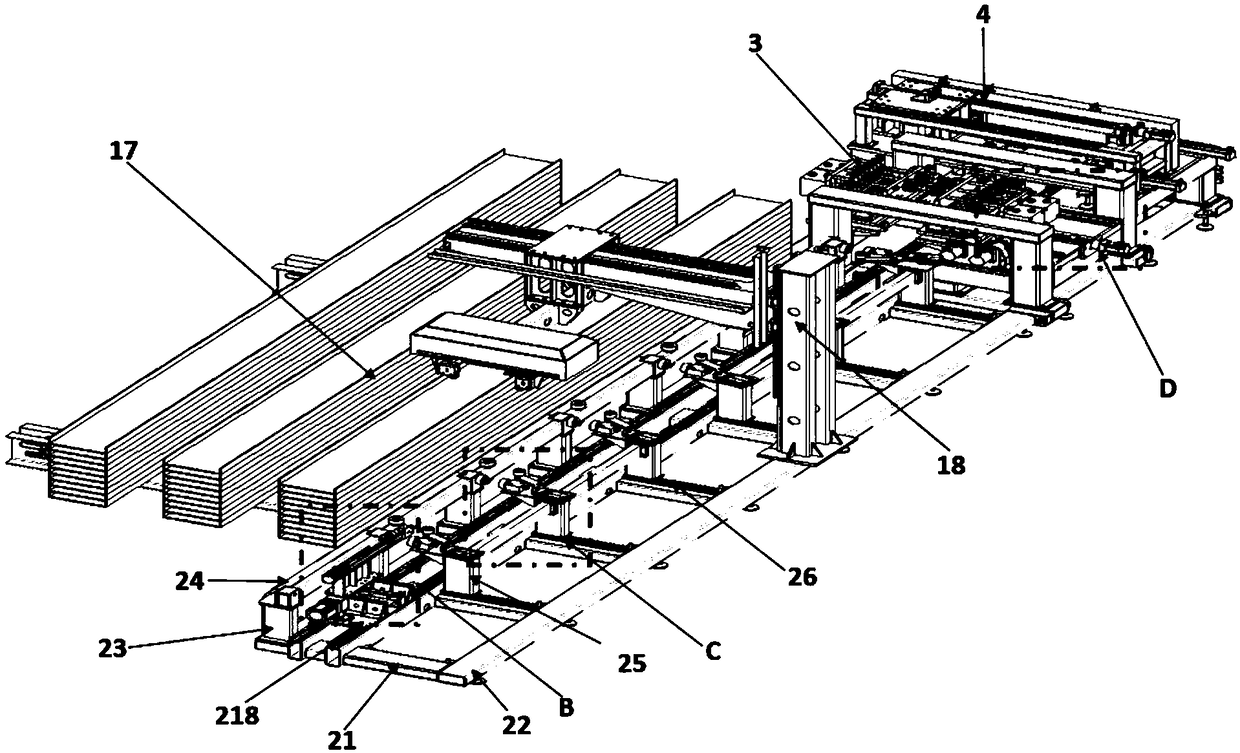

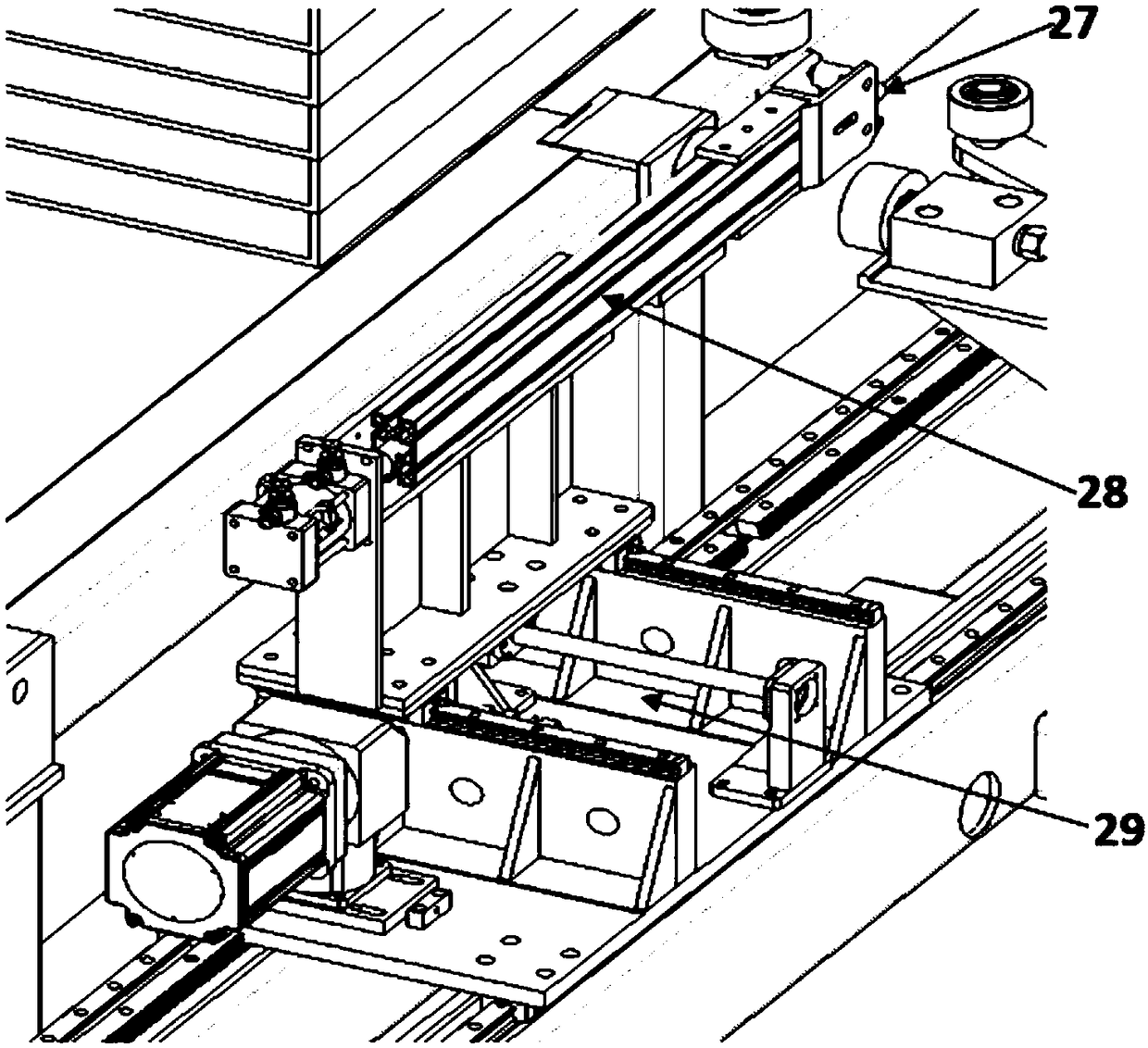

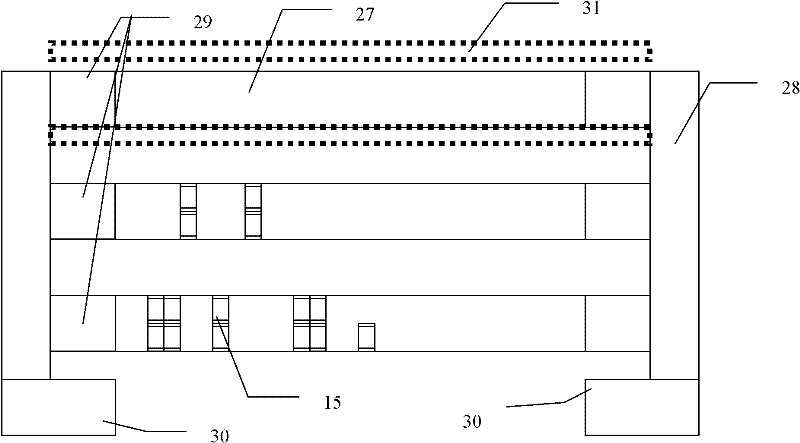

Automatic aluminum template production line

ActiveCN108637698AHigh degree of automationIncrease productivityOther manufacturing equipments/toolsProduction linePunching

The invention relates to the field of aluminum template machining equipment, in particular to an automatic aluminum template production line. The automatic aluminum template production line comprisesan automatic feeding unit, a first feeding unit, a punching unit, a saw cutting unit, a second feeding unit, a groove milling unit, a drilling unit, a third feeding unit, a carrying robot, a dust removal room unit, a welding station unit, a shape correcting unit and a stacking robot unit. The automatic aluminum template production line is high in automation degree, the production efficiency can beimproved, the production cost is reduced, the machining precision is improved, and large-batch and high-quality production organization can be achieved.

Owner:广东斯丹诺智能装备有限公司

Prefabricated assembled box culvert and construction method thereof

InactiveCN102418319AImprove construction progressQuality assuranceGround-workRc framesArchitectural engineering

The invention discloses a prefabricated assembled box culvert and a construction method thereof. The box culvert is in an assembled structure and consists of a reinforced concrete culvert body, wing walls, a foundation and deformation joints, wherein the culvert body of the box culvert is in an integral closed-type reinforced concrete framework structure formed by combining transition culvert joints, non-standard culvert joints and standard culvert joints. The culvert body and the wing walls adopt assembly and construction. By utilizing the prefabricated assembled box culvert, batch production can be performed in a factory, field assembly is realized, the construction progress of the culvert is accelerated, the construction period is shortened and the quality of the culvert is ensured. Therefore, the problems of long culvert construction period and difficult control on the quality during the current road construction can be solved.

Owner:新疆交通科学研究院有限责任公司

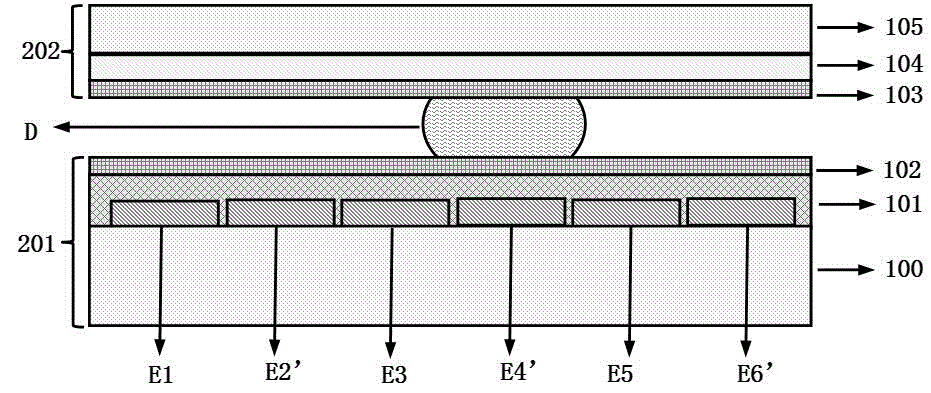

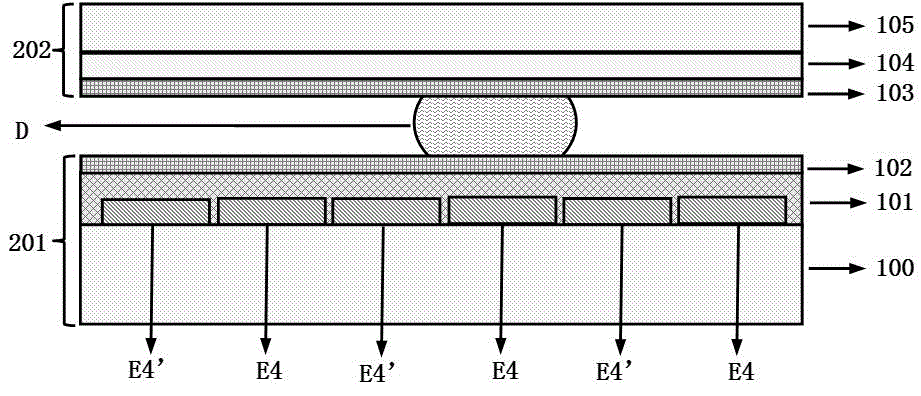

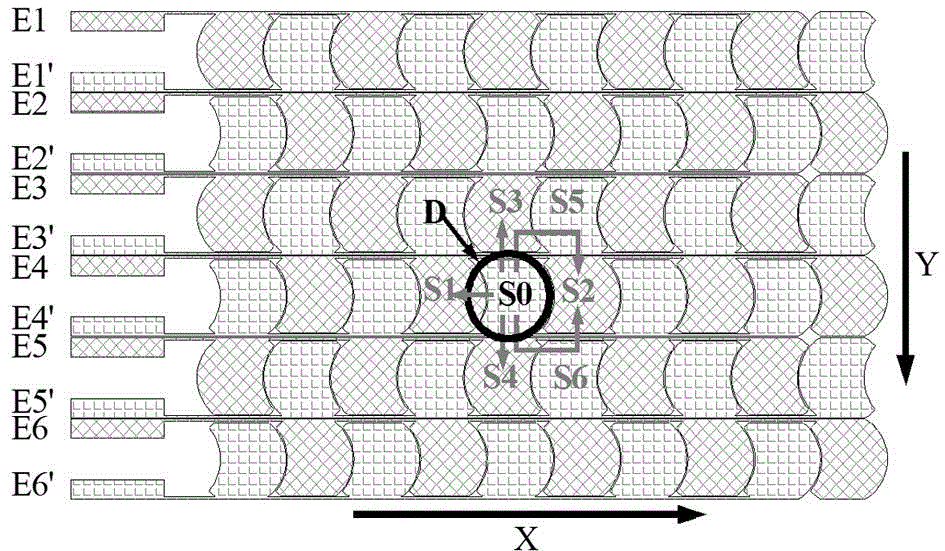

Two-dimensional digital micro-fluidic chip based on one-way liquid drop transport

InactiveCN103143406ASimple controlSimple control signalLaboratory glasswaresBatch processingControl manner

The invention belongs to the technical field of digital microfluidics and in particular relates to a two-dimensional digital micro-fluidic chip based on one-way liquid drop transport. According to the chip, a single-plane chessboard-shaped liquid drop control unit is formed due to the moon-shaped one-way liquid drop transport electrode, reasonable electrode arrangement and simple control signal configuration, and M*N control units (N can be infinitely great) can be controlled by using 2*M control signals, so that two-dimensional liquid drop drive is realized. The provided digital micro-fluidic chip has the advantages of novel and simple control mode, simple manufacturing process, high driving capacity, high batch processing degree, high throughput operation and the like, the defects of the traditional digital micro-fluidic chip are overcome, and the application functions and application range of the digital micro-fluidic chip are greatly widened.

Owner:FUDAN UNIV

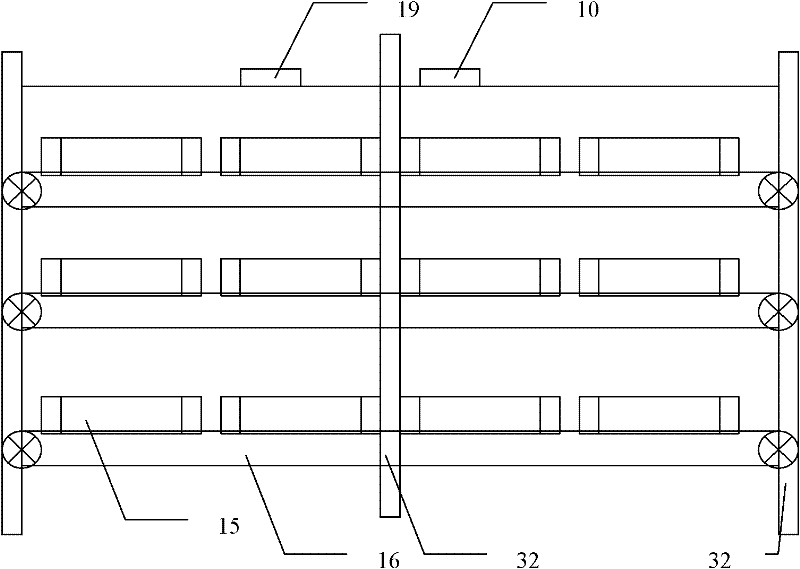

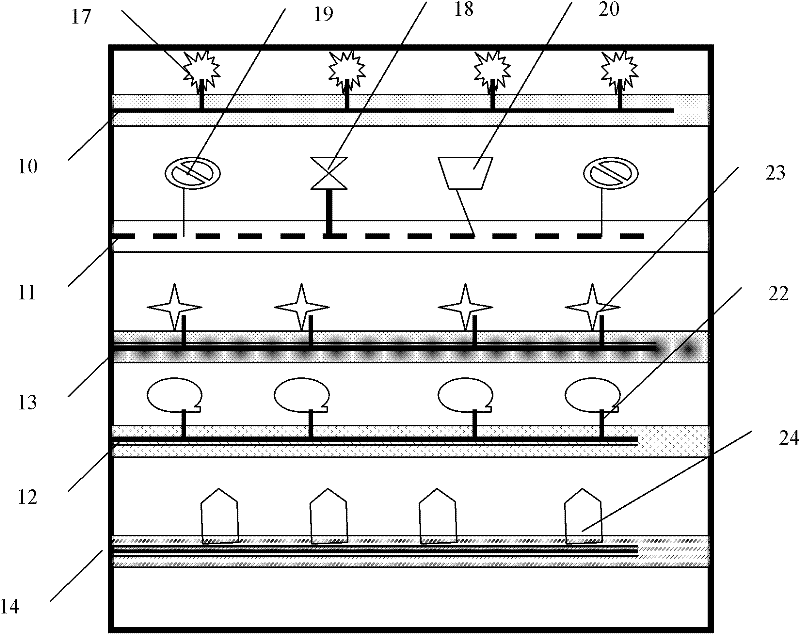

Factory agricultural automatic production line

InactiveCN102293133AAchieve high volumeRealize intelligenceClimate change adaptationGreenhouse cultivationTemperature controlProduction line

The purpose of the present invention is to provide a factory agricultural automatic production line, which can realize large-scale, intelligent, modularized, new energy, and factory-like facilities for agricultural production. The agricultural production box is placed on the transmission equipment, and through Temperature control, light supplement, liquid supply, information collection and other devices are installed around the planting box to realize accurate, dynamic, partitioned, intelligent, and energy-saving control of temperature, humidity, carbon dioxide concentration, and nutrient solution concentration in the production process, which realizes agricultural The transmission of the production box also realizes the control of its artificial environment, thereby realizing industrialization and low-cost agricultural production, suitable for mass production of breeding, aquatic products, livestock, fungi, etc.

Owner:CHENGDU AONENGPU TECH

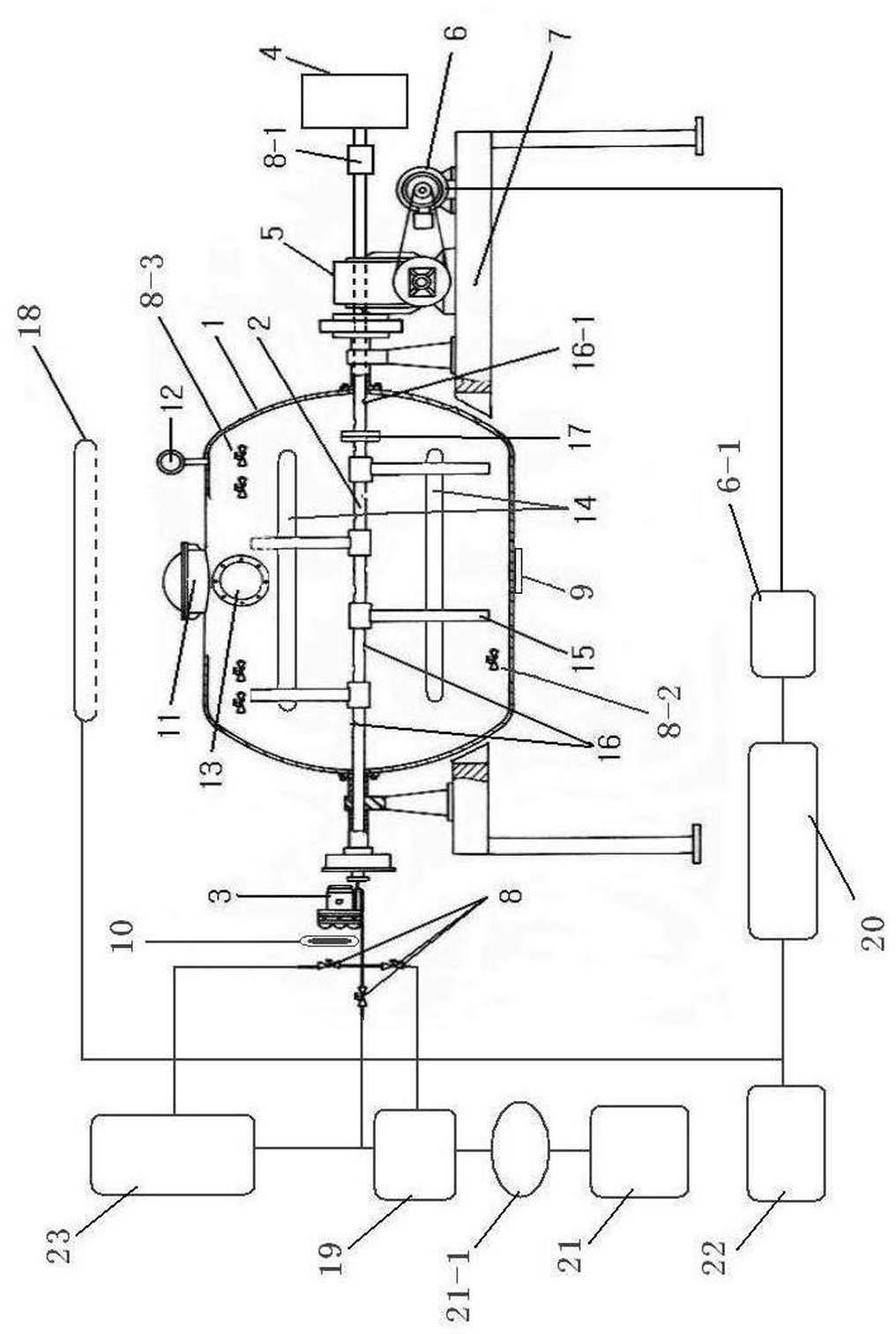

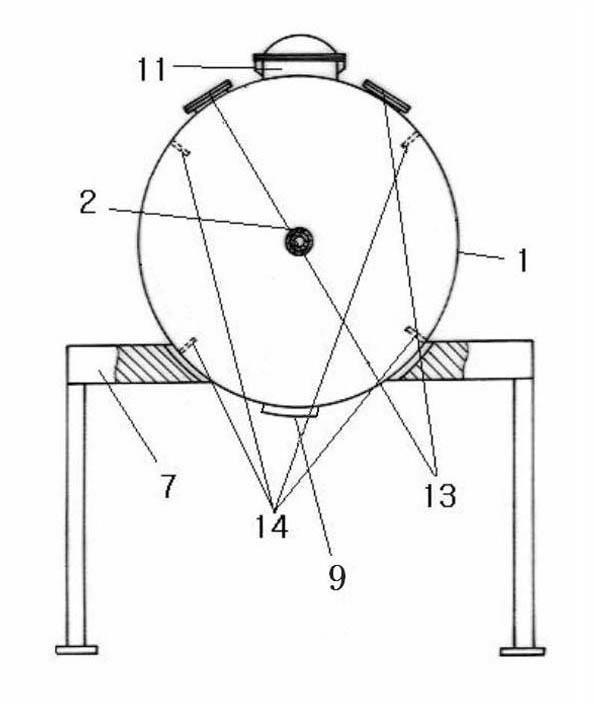

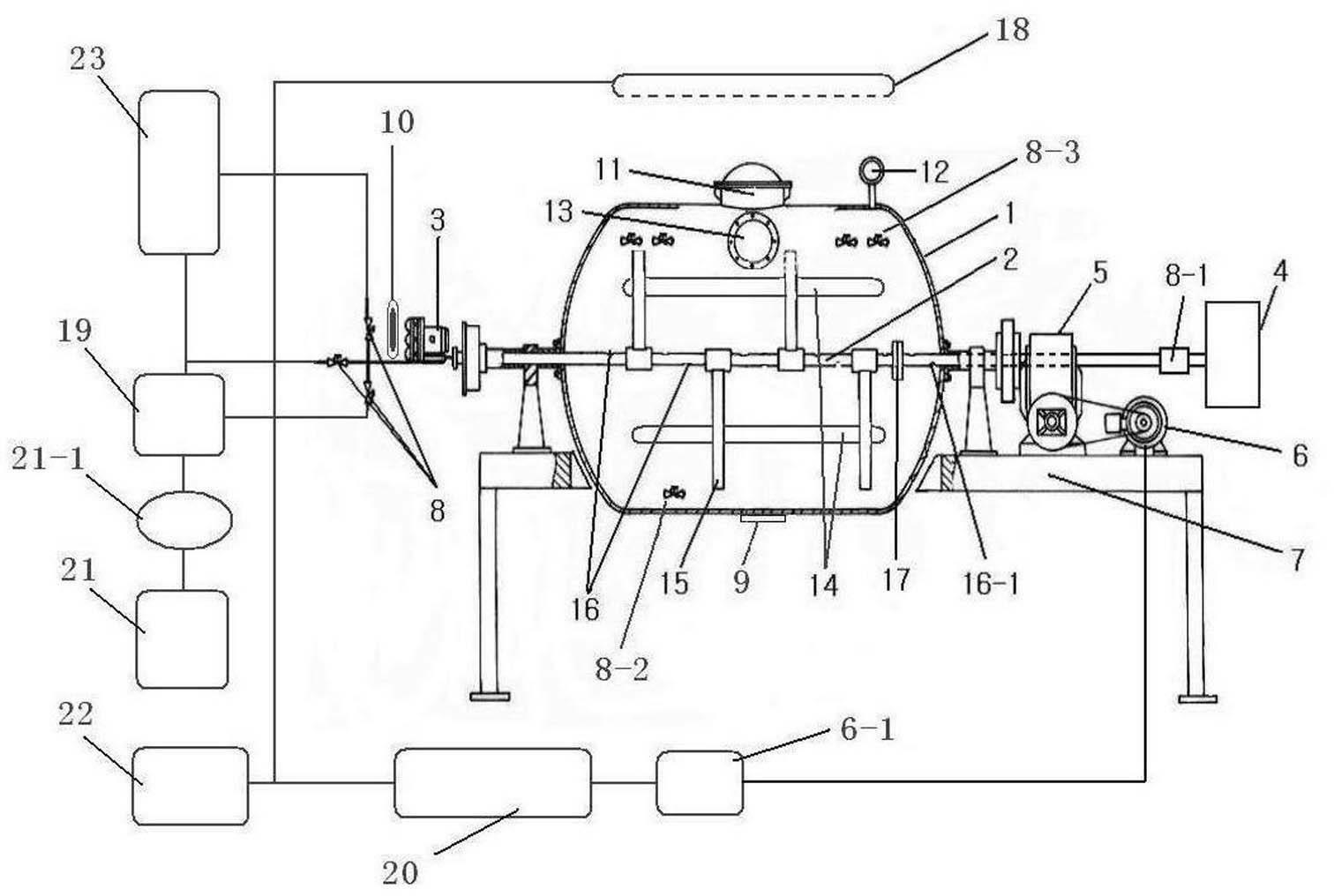

Solid-state fermentation equipment and method for preparing red yeast rice using same

InactiveCN102318789ARealize automated production operationsAvoid pollutionFood shapingFood preparationRed yeast riceMycotoxin

The invention discloses solid-state fermentation equipment and a method for preparing red yeast rice using the same. The solid-state fermentation equipment comprises a fermentation tank, a supply tube, a supply pump, a mixing blade, a driving device, a heat exchanger, a gathering barrel and a support, wherein the mixing blade is arranged on the supply tube, and the driving device is connected with the fermentation tank to rotate the fermentation tank. The production flows after batch feeding to before gaining ferment substances are integrally be carried out in the fermentation tank, and miscellaneous bacterium pollution and mycotoxins production are prevented. Moreover, according to the optimized fermentation condition, the rotating speed and direction of the fermentation tank and the temperature, humidity, pressure, air flow and the like in the fermentation tank are controlled at any time, and a central electronic control board is provided and is respectively connected with the fermentation tank and peripheral devices thereof, so that the automatic production operation of the solid-state fermentation equipment is realized. Thus, the solid-state fermentation equipment can efficiently and safely conduct the mass solid-state fermentation production in a short time, the same-batch homogeneity is ensured, and meanwhile the economical efficiency of the solid-state fermentation equipment is enhanced.

Owner:东莞市天益生物发酵技术有限公司

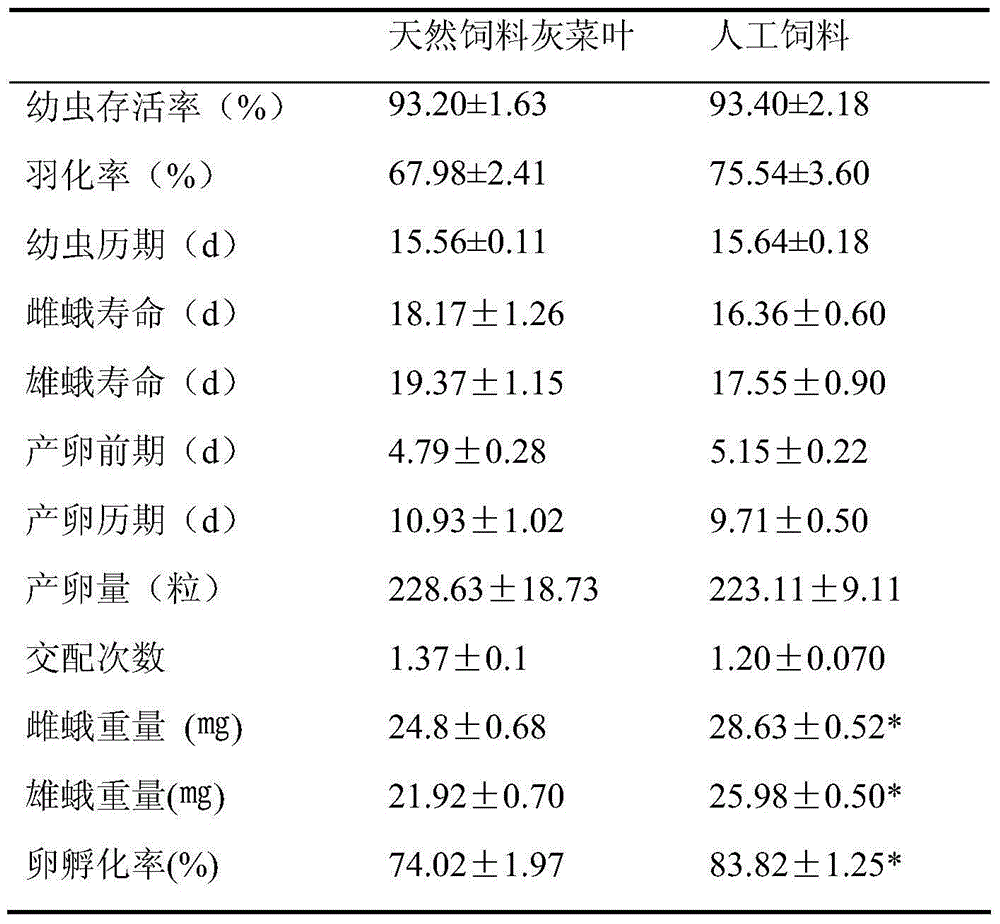

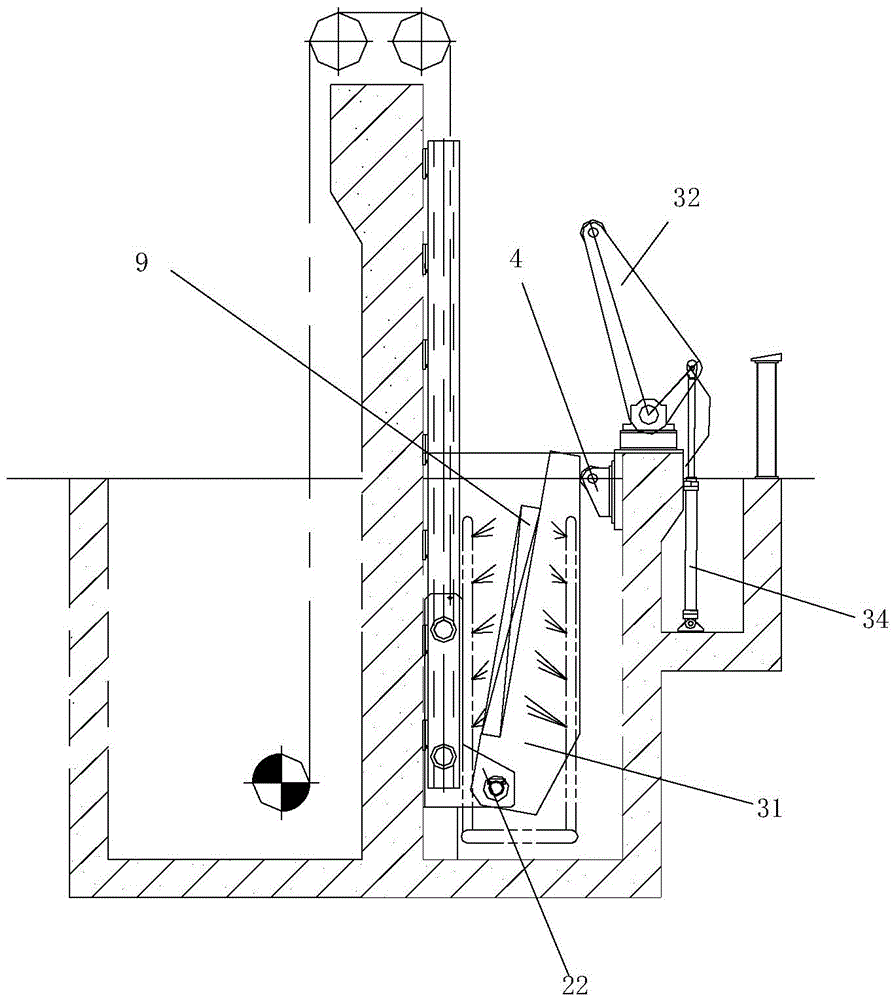

Artificial feed for loxotage stictalis, preparation method of artificial feed and feeding method for loxotage stictalis

InactiveCN104686837AEasy accessImprove anti-corrosion performanceFood processingAnimal feeding stuffAnimal scienceCholesterol

The invention relates to artificial feed for loxotage stictalis, a preparation method of the artificial feed and a feeding method for the loxotage stictalis, and belongs to the technical field of insect feeds. Based on natural feed chenopodium album leaf powder of the loxotage stictalis, the artificial feed is added with auxiliary materials of wheat bran, soya bean meal and the like, and added with cholesterol, inositol, linoleic acid and the like, so that required nutrient substances for the whole-generation or across-generation development of the loxotage stictalis can be met, and the feed is only required to be added once for one generation of larva. The feed disclosed by the invention is suitable for the loxotage stictalis larva to get food, so that the larva development velocity, the survival rate, the moth weight and the eclosion rate can be remarkably increased, the feeding effects and the natural host chenopodium album leaves are free of remarkable difference.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Flanging arrangement for wall hole of thin metal pipe

The hole outer flanging set for thin wall metal pipe wall includes one cutter and one driving device. The cutter has several cutter bits, which are distributed homogeneously and axially around cutter handle and include an elastic part fixed to the cutter handle and a flanging edge set in the end of the elastic part each; and a cutter body with pull rod capable of expanding the flanging edges along elastic parts inside an axial hole. The flanging edges under the action of the elastic parts are in free state for the cutter head to be inserted into the hole easily. After the cutter head is inserted into the hole, the pull rod is pulled to expand the flanging edges and to form the outer flange before the cutter is rotated and withdrawn. The present invention needs no inner mold, has simple technological process and high work efficiency, and suitable for automatic production.

Owner:杜明干

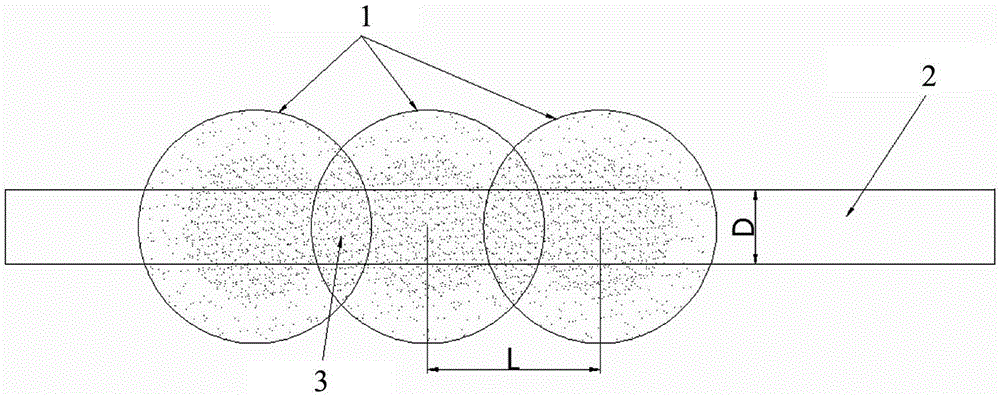

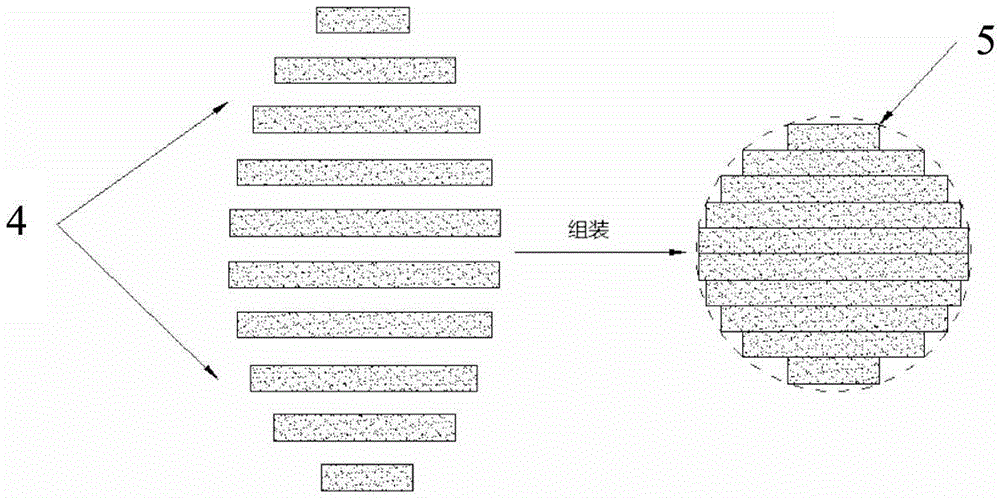

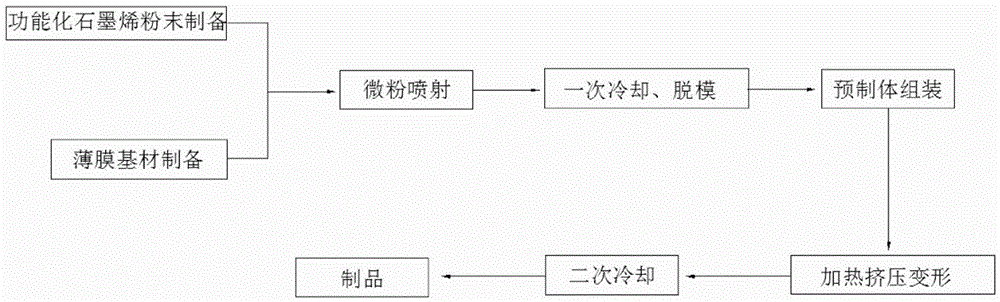

Graphene 3D printing wire rod and preparation method thereof

ActiveCN105295323ADispersion range controllableUniform dispersionSynthetic resin layered productsCvd grapheneMetal mold

The invention relates to a graphene 3D printing wire rod and a preparation method thereof. The graphene 3D printing wire rod comprises functional graphene powder and thermoplastic resin. The preparation method comprises pouring thermoplastic resin powder into a width-adjustable metal mold cavity, carrying out stricking and heating to obtain a melt film base, spraying the functional graphene powder into the film base by a micropowder injection method, carrying out primary cooling and demolding to obtain graphene wire rod preforms with different widths, assembling the preforms in an order, putting the assembled body into a metal mold with a hole, carrying out extrusion under heating conditions so that the preforms deform and are fused, and carrying out secondary cooling to obtain the graphene 3D printing wire rod. The graphene 3D printing wire rod has good mechanical properties, conductive performances and flexibility and can easily realize large scale production and cost control.

Owner:CHINA THREE GORGES UNIV

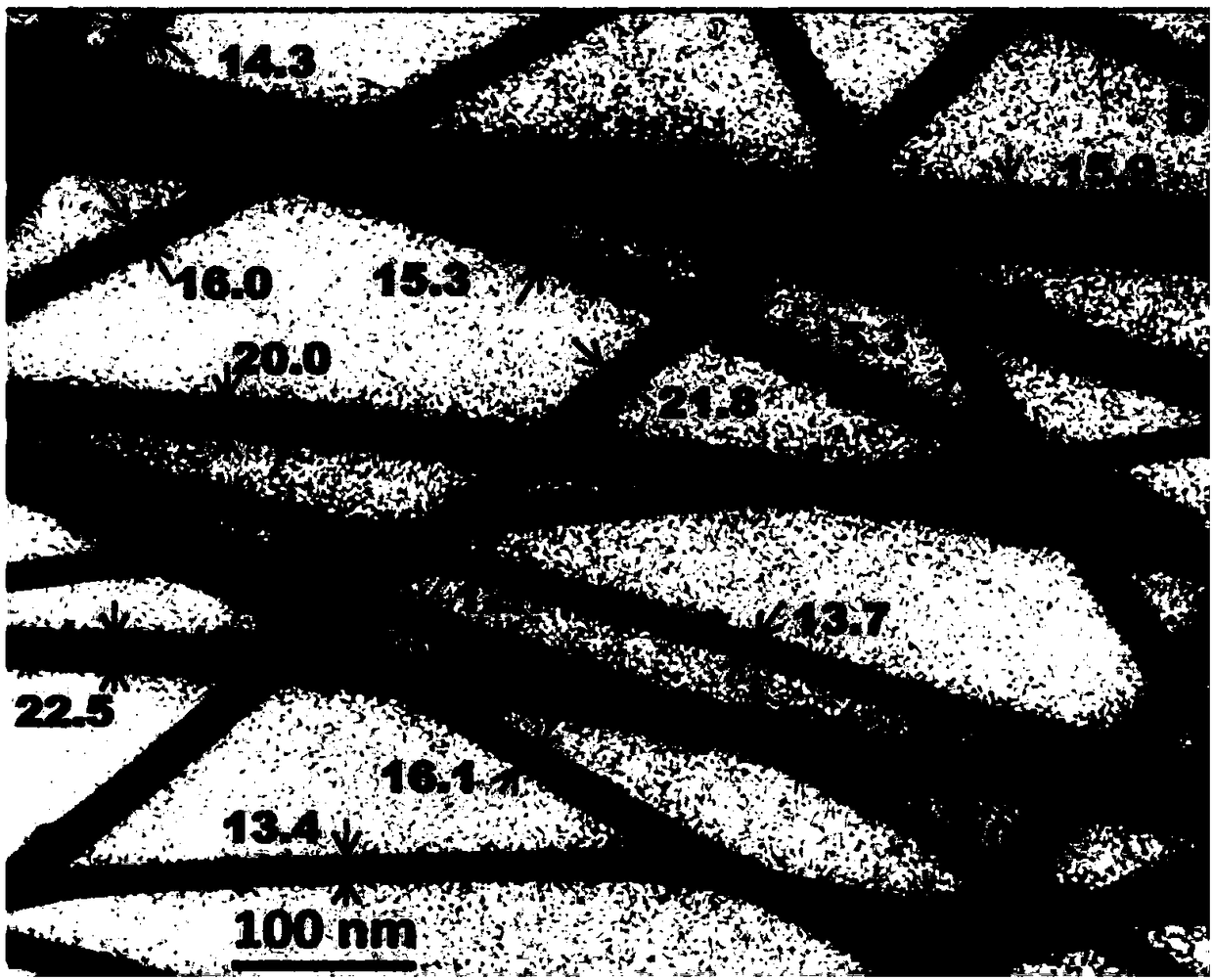

Method for large-batch synthesizing and high-efficiency purifying of superfine silver nano wires

The invention relates to the field of nano material synthesizing and application and aims at providing a method for large-batch synthesizing and high-efficiency purifying of superfine silver nano wires. The method includes the steps that polyvinylpyrrolidone and AgNO3 are added into glycol under the stirring condition and are evenly mixed and dissolved; a chloridion halogeno salt-ethylene glycol solution and a bromide ion halogeno salt-ethylene glycol solution are added continuously, and a reaction is carried out in the N2 atmosphere; supernatant liquor is taken centrifugally, acetone is addedunder the stirring condition, and standing is conducted so that flocculent solids can be deposited; ionized water is used for dispersing, and a uniform dispersion solution is formed; and acetone is added under the stirring condition, and the adding action is stopped when flocculent solids occur again, the operation is repeated for 6 times to 10 times, and the high-purity superfine silver nano wires are obtained. By means of the method, the processes of Ag crystal nucleus forming, crystal growth and the like can be controlled, and large-batch and stable preparing of the superfine AgNWs is achieved. Large-particle-size nano particle impurities are removed completely, and small-particle-size nano particles are separated from the AgNWs; the prepared silver nano wires do not have silver nano particle impurities, and the purity is nearly 100%; and the diameter of the silver nano wires is smaller than or equal to 40.0 nm.

Owner:TAIZHOU BRANCH ZHEJIANG-CALIFORNIA INT NANOSYSTEMS INST +1

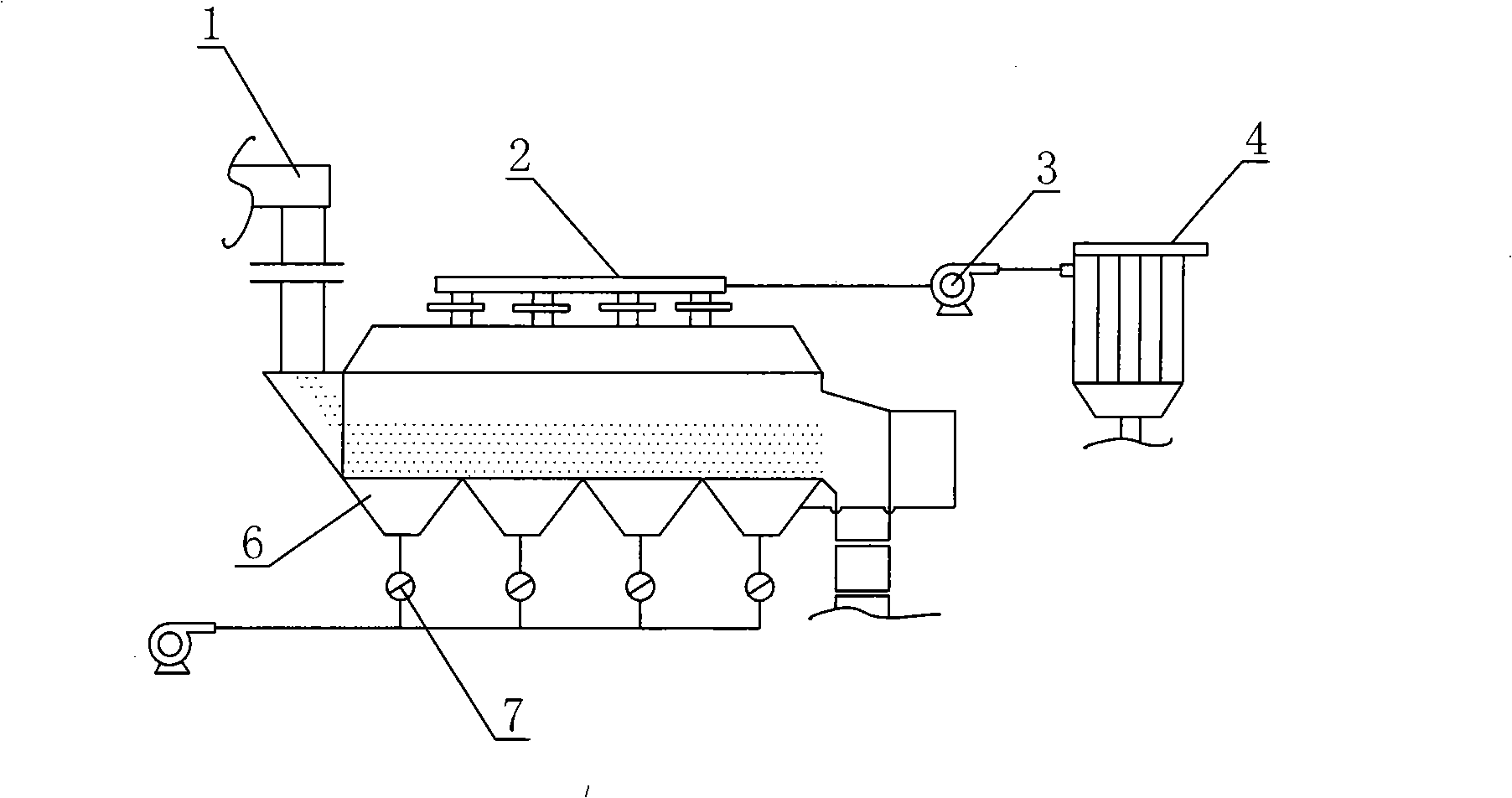

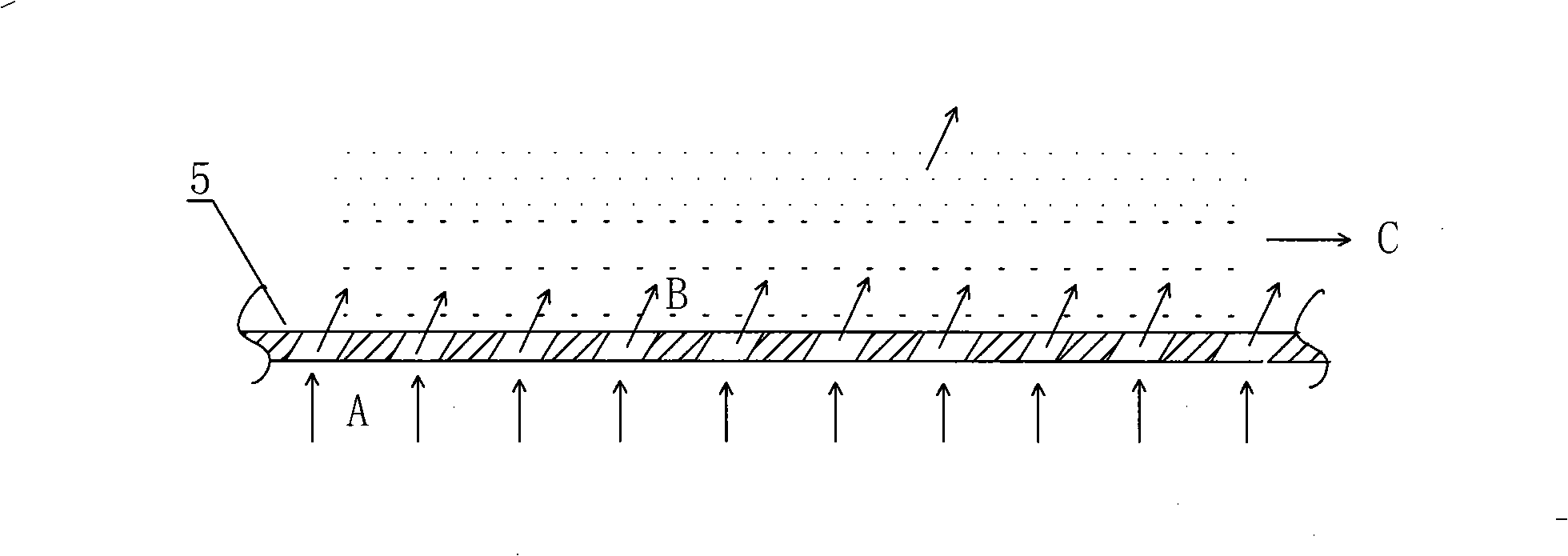

Hydrocarbon black powder removing method and device

ActiveCN101318180AEasy to handleAchieve high volumeGas current separationManufacturing technologyFluidized bed

The invention relates to a carbon black powder removing method and a device, belonging to the technical field of carbon black manufacturing. The carbon black powder removing method is used for removing the carbon black powder in carbon black pellets; the dried carbon black pellets containing powders are added to the feed end of a fluidized bed of a powder remover; the carbon black pellets run through the fluidized bed under the blowing of the air entering aslant below the fluidized bed and are discharged through the discharge end of the fluidized bed; at the same time, the powders are discharged through the top of the fluidized bed. The invention adopts the method of winnowing products under suspension state, has the advantages of high powder removing efficiency, low product damage rate, cooling product, meeting black storage requirements, improving packaging conditions, simple and efficient technology, and saving resources; besides, the adopted devices has simple and reasonable structure and easy production and maintenance, can effectively improve winnowing and cooling efficiency and realize reasonable energy utilization. The invention can be widely applied to the technical field of carbon black pellet processing and can effectively improve production efficiency and product quality.

Owner:SUZHOU BAOHUA CARBON BLACK

Bean pod borer artificial feed and preparation method thereof

The invention discloses bean pod borer artificial feed and a preparation method thereof. The bean pod borer artificial feed comprises, by weight, 62.5-70% of water, 2.5-3.0% of agar, 15.0-20.0% of cooked soybean meal, 4.0-6.0% of cooked wheat embryo powder, 1.0-2.0% of cane sugar, 1.0-1.5% of yeast powder and 3.0-5.0% of auxiliary materials. The auxiliary materials comprise ascorbic acid, choline chloride, methyl parahydroxybenzoate, potassium sorbate, formaldehyde, salt and vitamin complex. The bean pod borer artificial feed is simple in formula, low in price and affordable, raw materials are all common substances and are easy to obtain, a problem of shortage of natural hosts such as cowpea and hyacinth bean limited by seasons is solved, and massive and subculture feeding of indoor bean pod borer standard worm source is achieved.

Owner:HUAZHONG AGRI UNIV

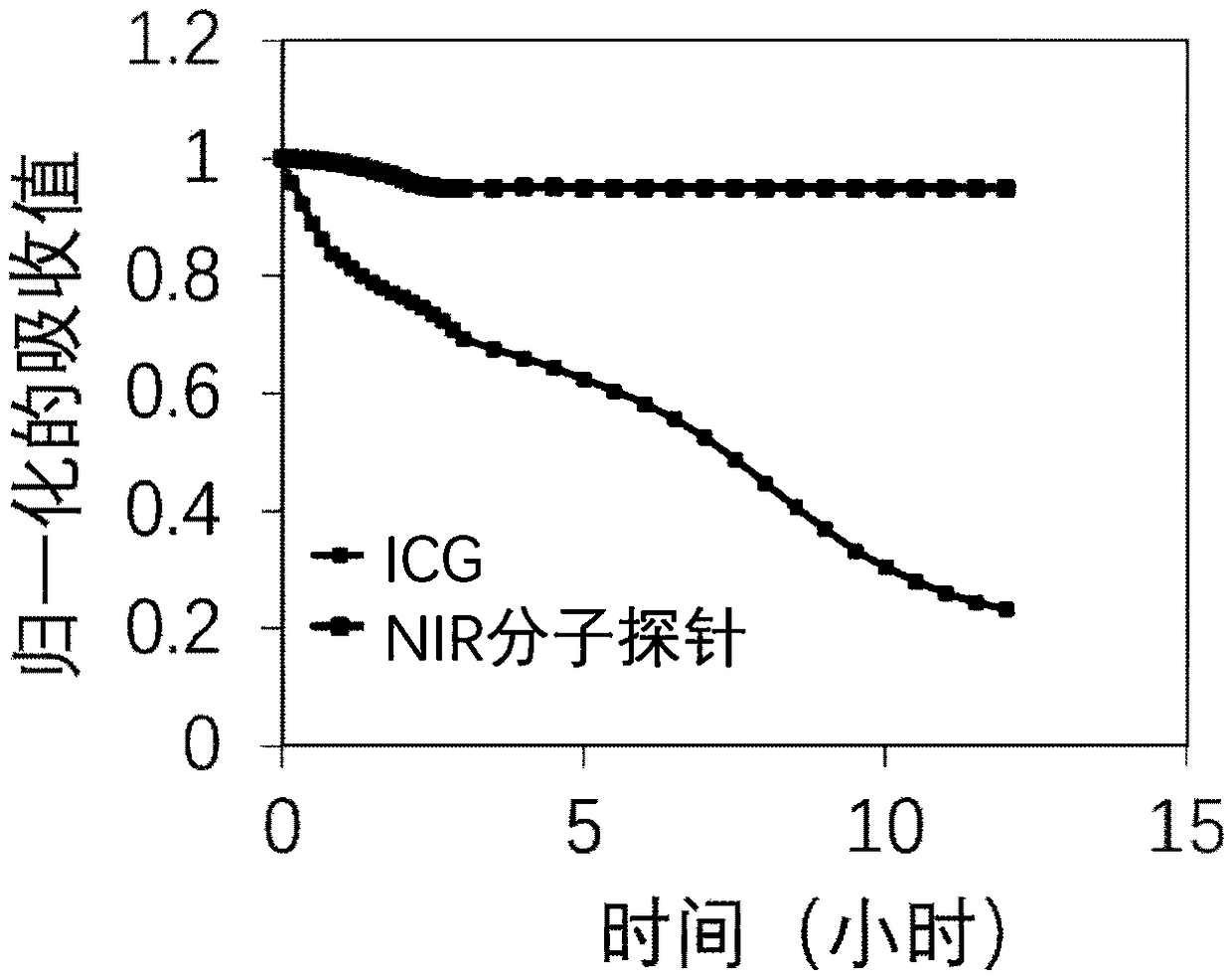

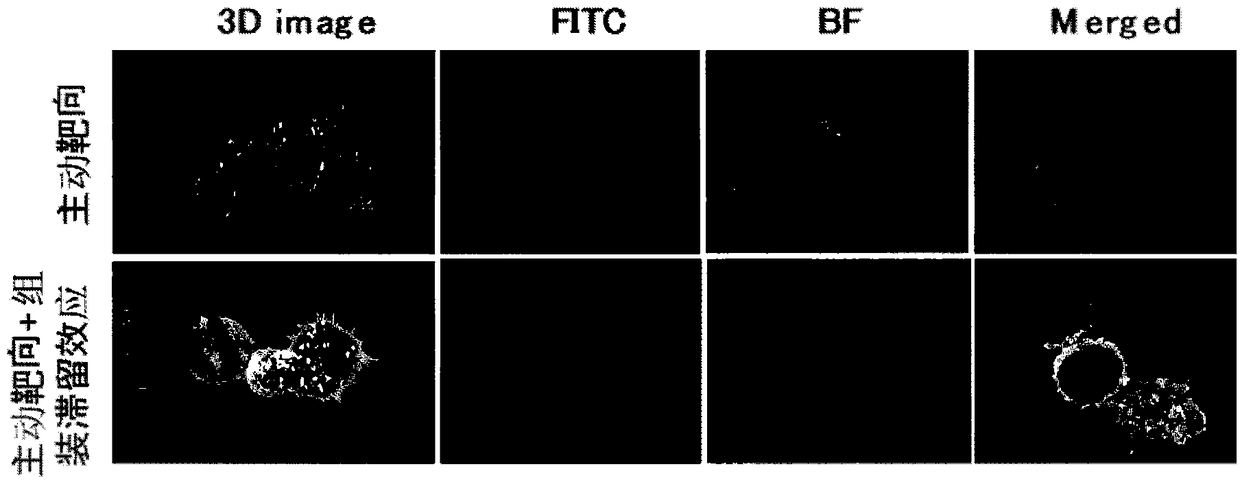

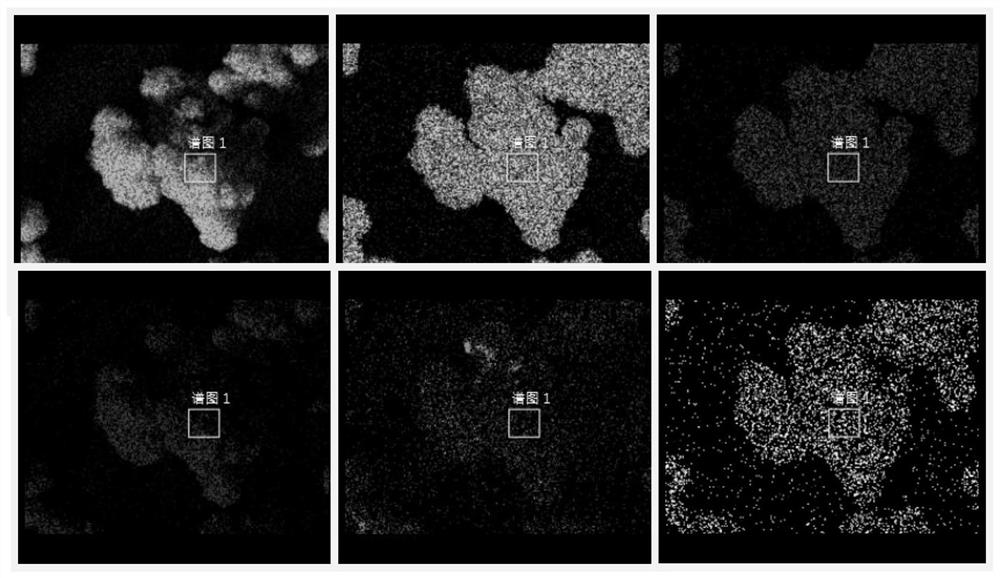

Molecular imaging probe and application thereof

ActiveCN108949147AAchieve high volumeAchieve long-term enrichmentFusions for specific cell targetingIn-vivo testing preparationsLife qualityMolecular imaging

The invention provides a molecular imaging probe which is a polypeptide molecule, including a specific targeted section on one end, a responding assembly-retention section in the middle, and a color developing section on a side chain; wherein the responding assembly-retention section includes a responding sequence as the SEQ ID No.1 and an assembling sequence as the SEQ ID No.2. The molecular imaging probe can recognize a tumor cell through the specific targeted section and achieves assembly retention in a tumor microenvironment through a "responding assembly-retention effect", thereby achieving high-amount and long-acting imaging in a tumor tissue; through near-infrared light excitation, the molecular imaging probe can achieve imaging navigation during a stable and long-acting operation on a tumor focus part, thus achieving visible localization of the tumor. The accuracy of resection of tumors by a doctor is improved, operation success rate is greatly increased and post-operation recurrence rate is reduced; the molecular imaging probe can improve the post-operation life quality of patients.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

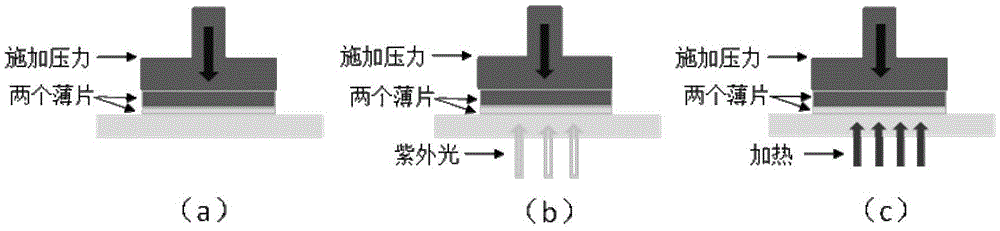

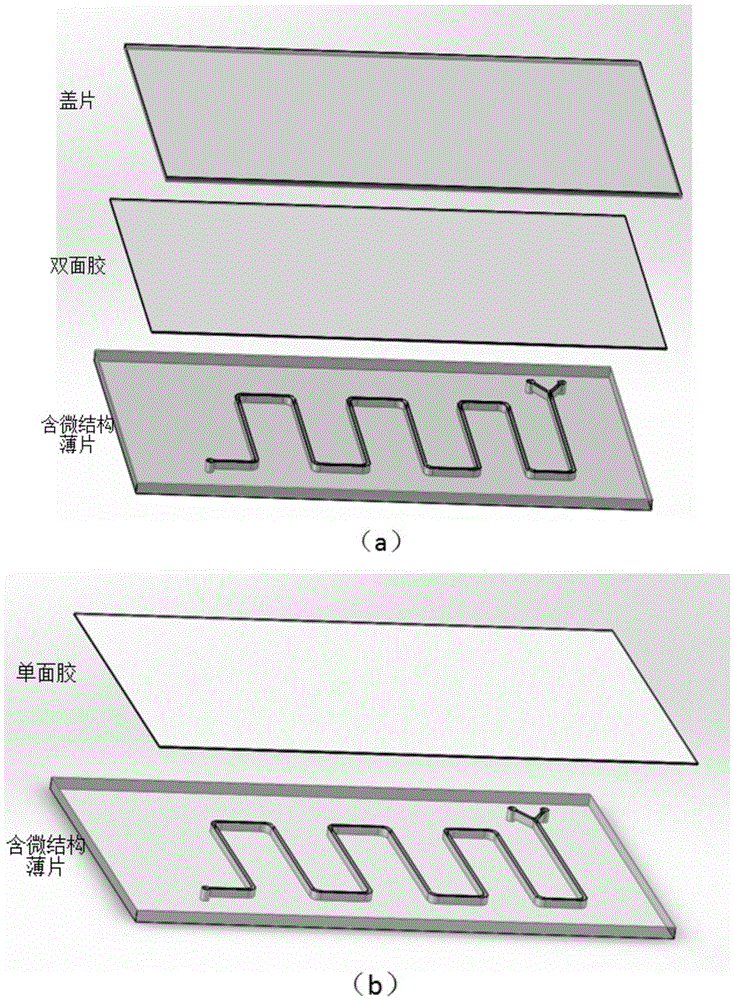

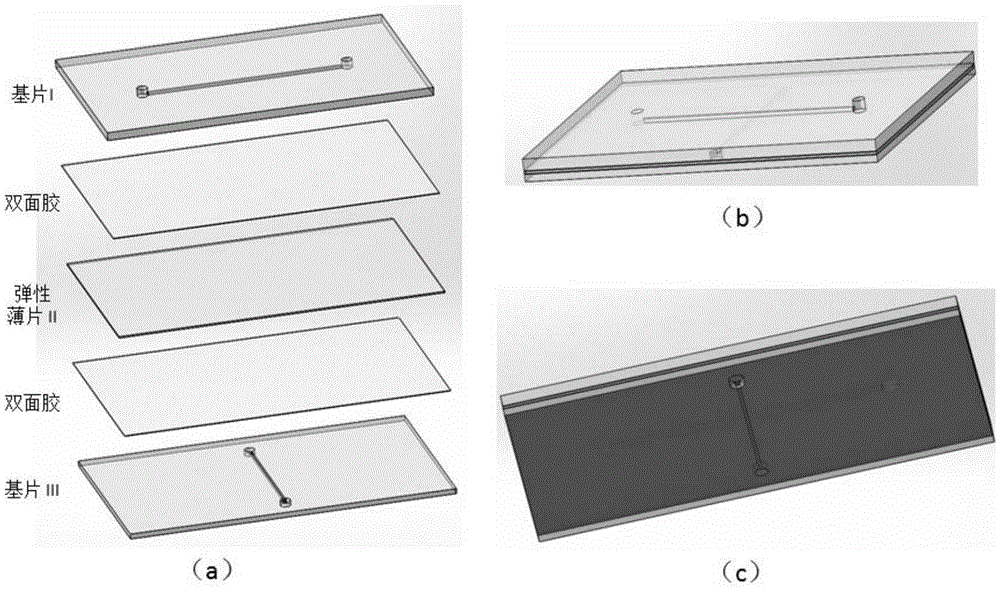

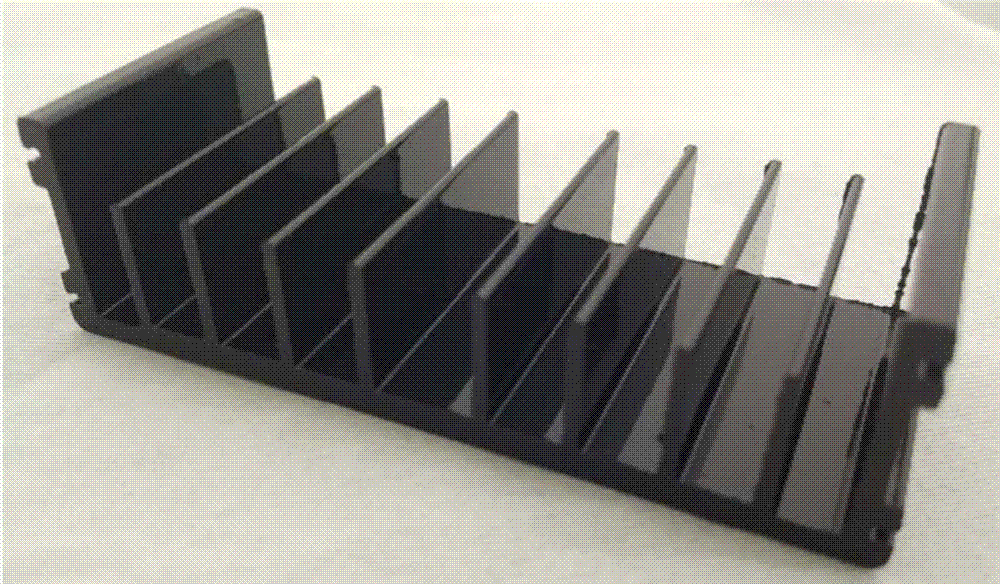

Chip packaging method

InactiveCN105460888AAchieve scaleAchieve high volumePrecision positioning equipmentSoldering apparatusVacuum pumpingBonding process

The invention discloses a chip packaging method. In the method, one-step vacuum-pumping pressurization packaging is performed after a substrate and a cover plate of a micro-fluidic chip are laminated with a double-sided adhesive or a single-sided adhesive. Through adoption of the method, the problems of poor firmness of a bonding surface and remaining of a large quantity of blisters on the surface of the chip after bonding in a conventional solid-state double-sided adhesive bonding method are solved; the problems of micro-channel distortion and micro-channel blockage in a current micro-fluidic chip bonding process are solved; and an outer packaging procedure of a finished chip is implemented synchronously. The chip packaging method is simple and effective in auxiliary equipment and manufacturing process, and high fidelity of a chip micro-channel and high packaging strength of a packaged chip are ensured. A packaging procedure provided by the invention is particularly suitable for the field of manufacturing of micro-fluidic chips on a large scale at low cost.

Owner:CAPITALBIO CORP

Anti-corrosion and heat-conducting composite coating on light-alloy radiator surface, preparation method of anti-corrosion and heat-conducting composite coating and light alloy radiator

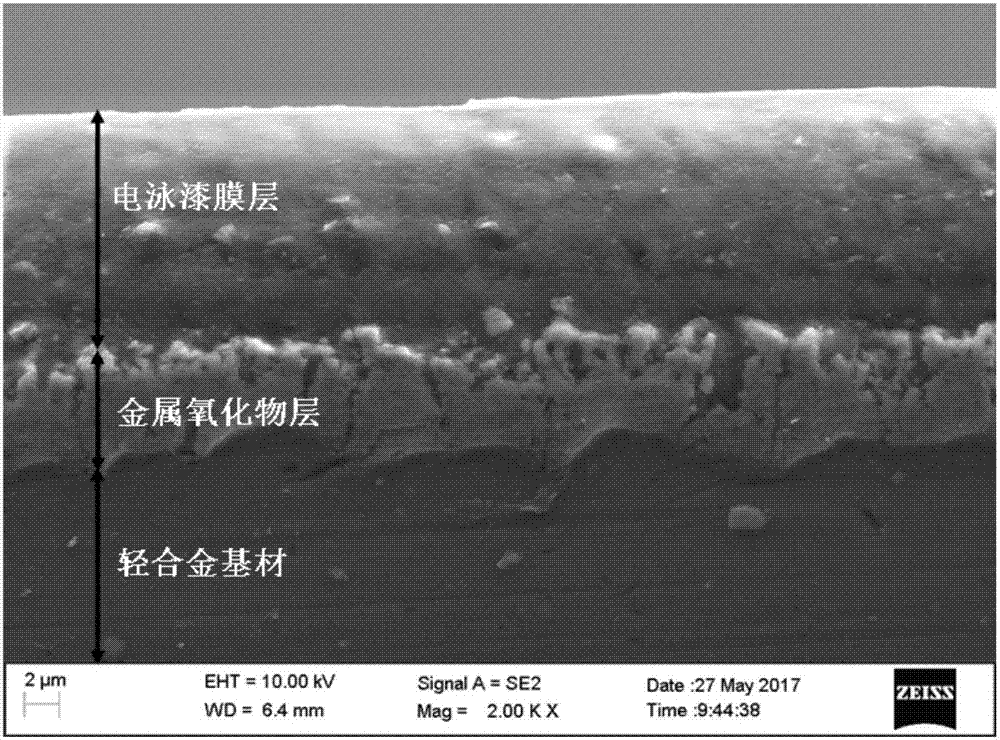

InactiveCN107513746AImprove heat transfer performanceImprove cooling effectAnodisationElectrophoretic coatingsMicro arc oxidationPlasma electrolytic oxidation

The invention discloses an anti-corrosion and heat-conducting composite coating on the light-alloy radiator surface, a preparation method of the anti-corrosion and heat-conducting composite coating and a light alloy radiator with the anti-corrosion and heat-conducting composite coating. The composite coating comprises a metal oxide layer formed by oxidizing light alloy radiator base metal in situ and an electrophoretic paint film layer provided with carbon nano-particles dispersedly distributed and located on the metal oxide layer in a covering manner. The preparation method comprises the steps that (1), micro-arc oxidation is conducted, and the metal oxide layer formed by oxidizing the light alloy radiator base metal in situ is formed on the surface of the light alloy radiator base material; and (2), electrophoretic deposition is conducted, and the layer of electrophoretic paint film is deposed on the surface of the metal oxide layer. The composite coating has the beneficial effects of being uniform, dense, excellent in anticorrosion performance, good in thermal conductivity, ultralong in service life and the like. The preparation method is environmentally-friendly, safe, reliable, good in repeatability, capable of achieving automatic large-batch industrial production with low cost and short processes.

Owner:NANJING UNIV OF TECH

Weak solvent or offset printing thermal transfer paper and production process thereof

ActiveCN102848767AAchieve high volumeRapid productionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyamideEngineering

The invention relates to a weak solvent or offset printing thermal transfer paper. The thermal transfer paper from bottom to top is provided with a paper base, a first thermal transfer adhesive layer and a weak solvent or offset printing absorption dielectric layer. The first thermal transfer adhesive layer comprises the following components, by weight: 40-50% of polycaprolactone polyurethane, 30-40% of butadiene styrene or styrene copolymer, 10-15% of copolymerization polyamide resin, 5-10% of copolyester resin and 2-5% of pentaerythritol ester of rosin. At the same time, the invention also relates to a corresponding production process. According to the invention, the drew image can be freely printed by a weak solvent inkjet printer, a solvent-type ink-jet printer, a digital printing machine and a digital label printing machine, and then transferred to any textile through a hot pressing tool; a textile pattern can be finished in a few minutes, so as to fully meet the needs on small batch and rapid production by thermal transfer printing; and the production process has advantages of low labor intensity, high production efficiency, energy saving and environmental protection.

Owner:FUZHOU AIRUI DIGITAL IMAGING

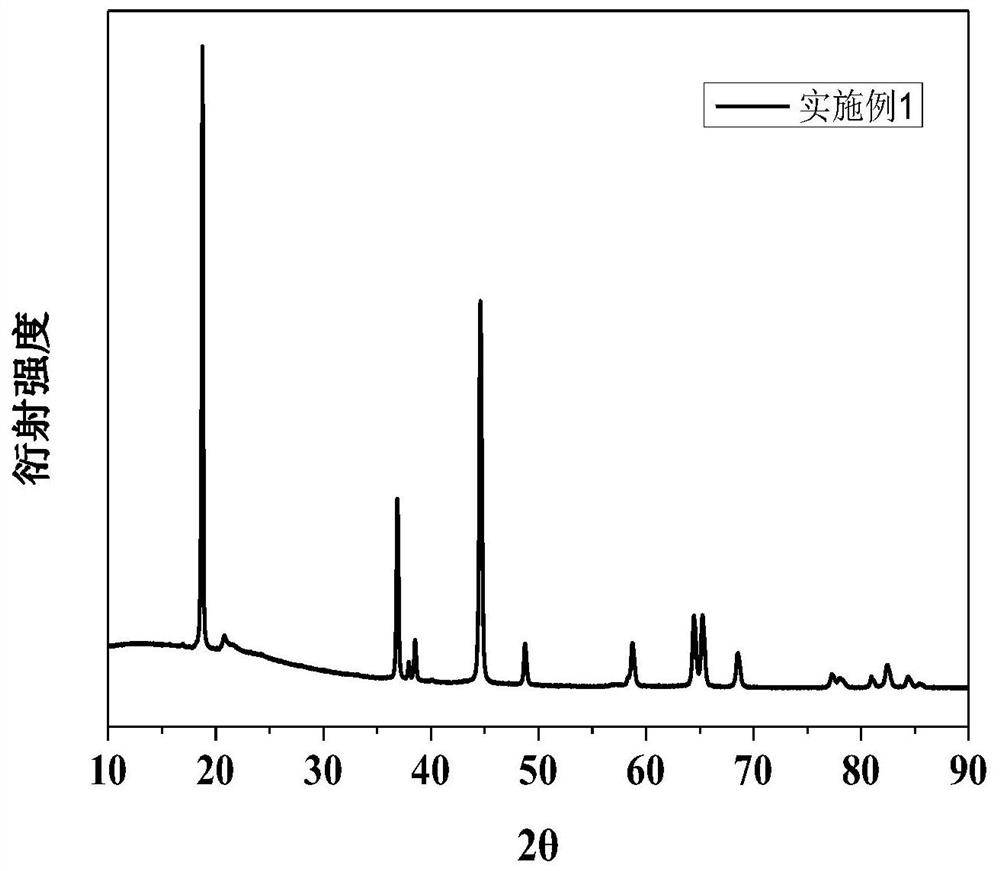

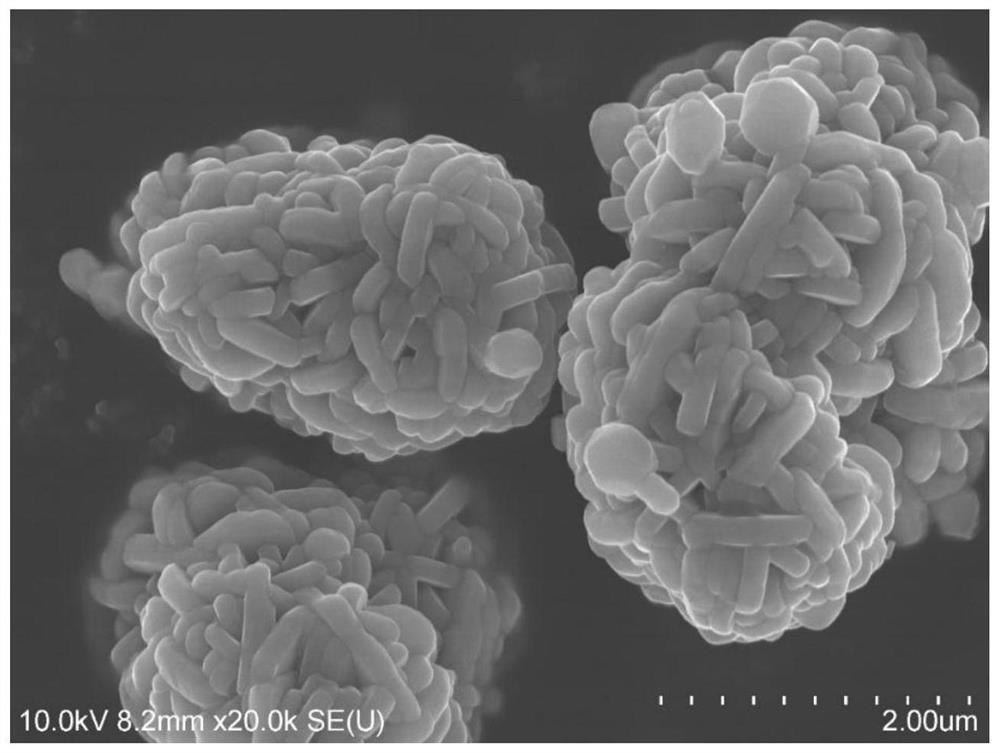

Preparation method of fluorine-doped lithium-rich manganese-based positive electrode material

ActiveCN112701273AImprove cycle performanceImprove doping uniformityCell electrodesSecondary cellsLithiumPhysical chemistry

The invention discloses a preparation method of a fluorine-doped lithium-rich manganese-based positive electrode material. The lithium-rich manganese-based positive electrode material has a chemical general formula of xLi2MnO3.(1-x) LiMO<2-y>F<2y>, wherein x is larger than or equal to 0.1 and smaller than or equal to 0.9, y is larger than 0 and smaller than or equal to 0.05, and M is one or more of Ni, Co, Mn, Cr, Fe, Ti, Mo, Ru, V, Nb, Zr and Sn. The preparation method comprises the following steps of: preparing a fluorine-doped lithium-rich manganese-based precursor through a precipitation reaction by adopting soluble metal salt, a precipitator, a soluble fluorine-containing compound and water; and uniformly mixing the fluorine-doped lithium-rich manganese-based precursor with a lithium salt, and carrying out presintering and high-temperature sintering to obtain the fluorine-doped lithium-rich manganese-based positive electrode material. According to the method, the soluble fluorine-containing compound is used as a fluorine source, fluorine doping is synchronously realized during coprecipitation of the lithium-rich manganese-based precursor, the doping uniformity is relatively good, and the cycle performance of the doped lithium-rich material is greatly improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

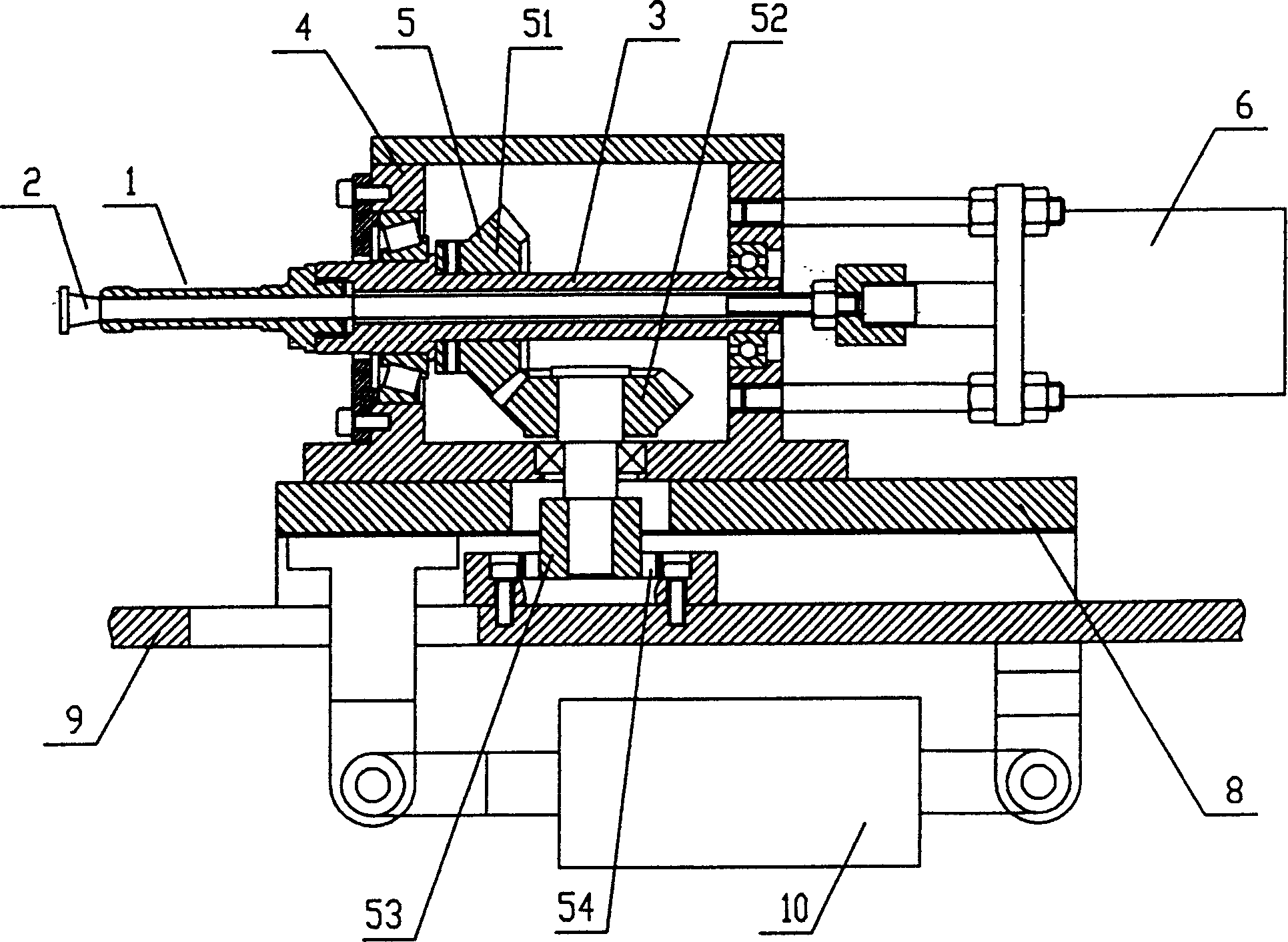

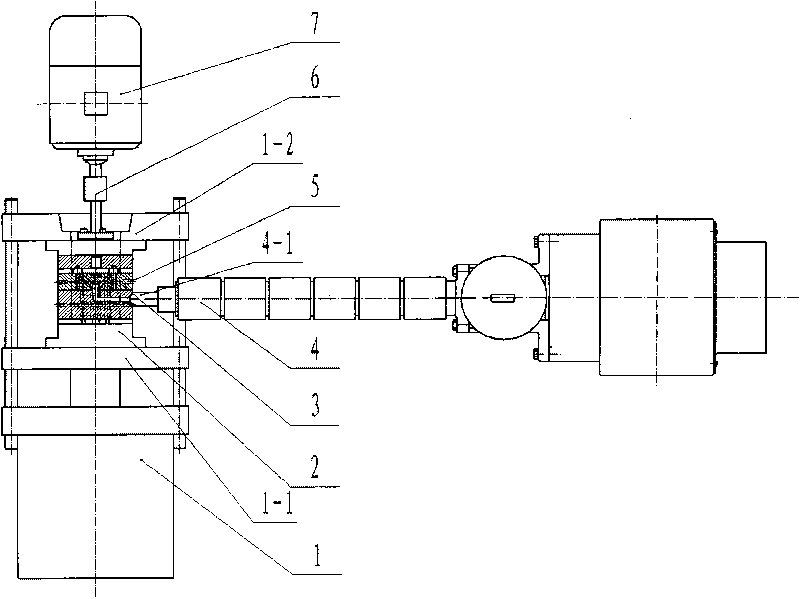

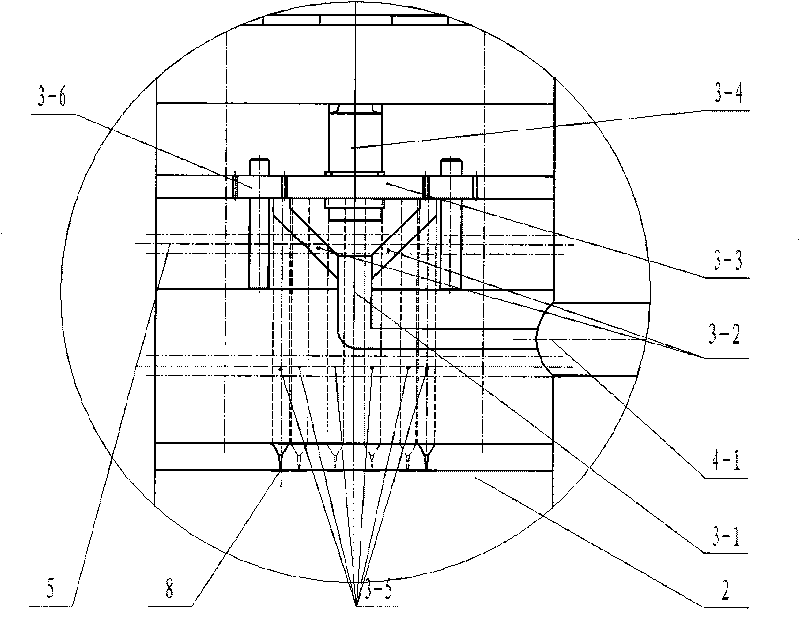

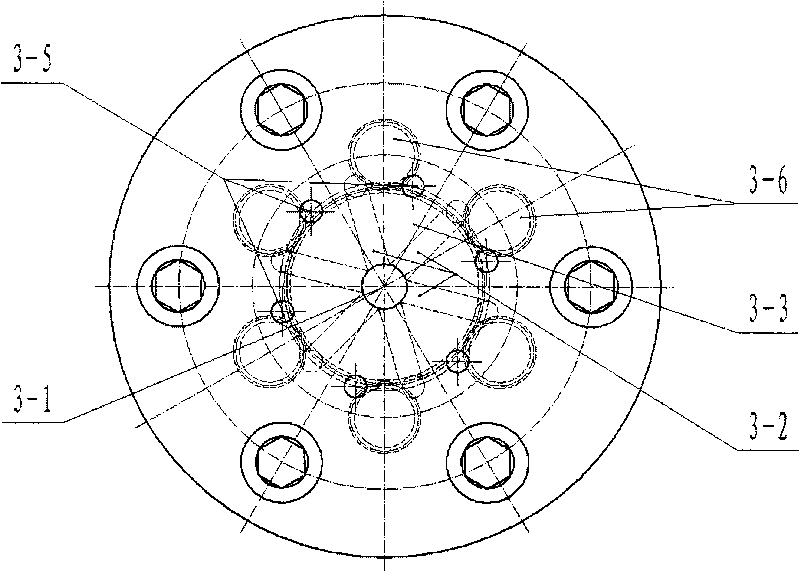

Fusant differential precise injection molding machine

The invention relates to a fusant differential precise injection molding machine which mainly comprises an injection molding system, a die combining system and a metering and shunting system, wherein the injection molding system and the die combining system are the same with the conventional injection molding machine; the metering and shunting system comprises a planetary gear pump, a coupling, a drive motor, a controller and a heating device; and the planetary gear pump is provided with a main inlet and a plurality of outlets and used for transmitting, shunting, pressurizing and metering a high-temperature fusant. The invention is the injection molding machine which can produce a miniature product, combines the beneficial conditions of the conventional injection molding machine, overcomes the defects of the traditional micro-injection molding machine by introducing the metering and shunting system, has the advantages of good plasticizing effect and high injection pressure and injection speed and can realize precise metering and the large-scale and low-cost production of parts with high precision and high fineness. The injection molding system and the die combining system of the conventional injection molding machine are adopted, thereby improving the common injection molding machine directly and realizing the functional of differential injection molding by adding the metering and shunting system.

Owner:BEIJING UNIV OF CHEM TECH

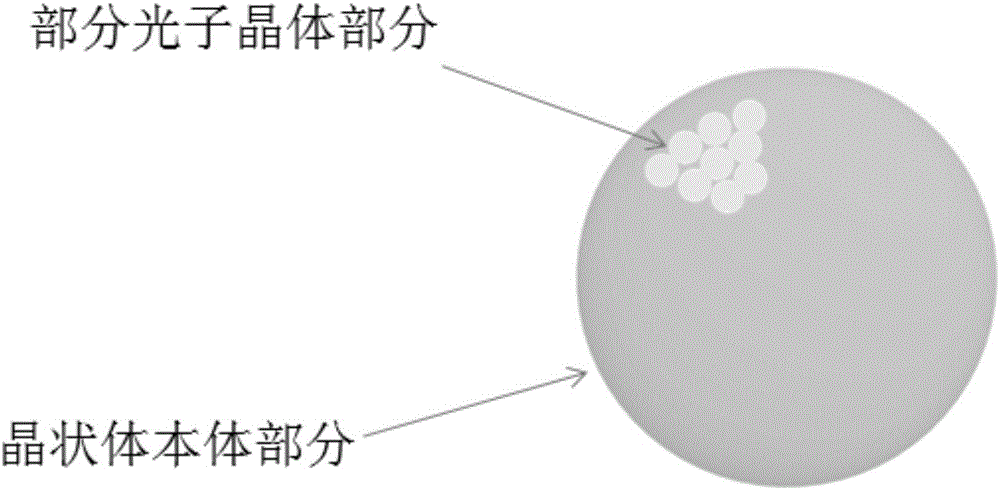

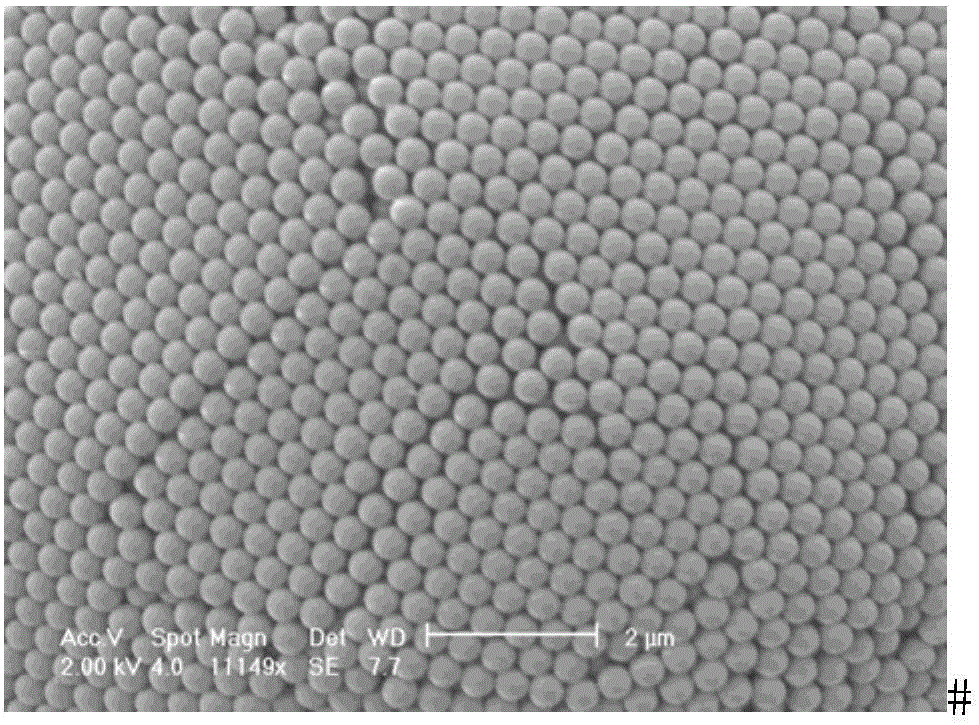

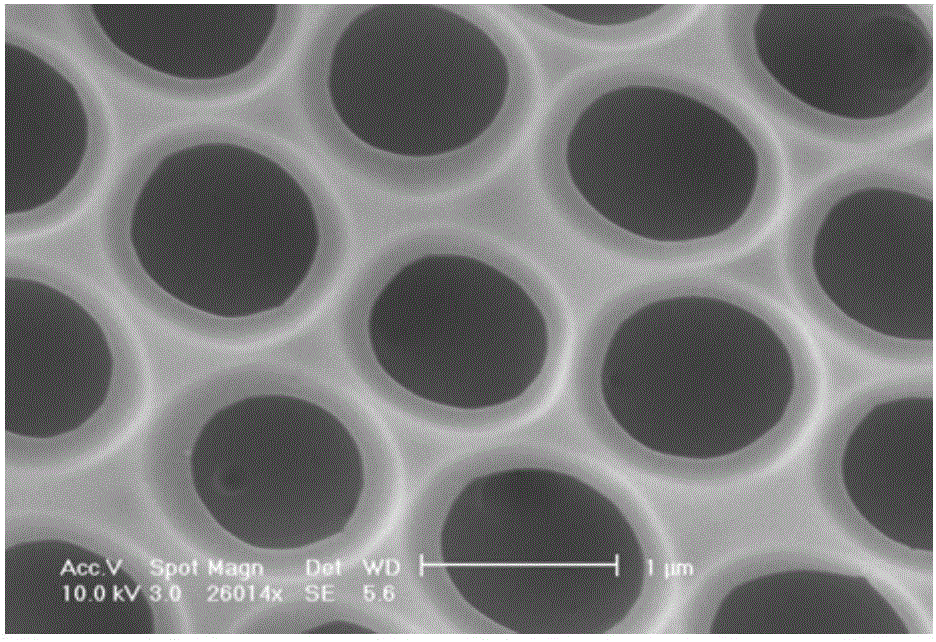

Implanted device and preparation method thereof

InactiveCN106580247ABright colorNo more fear of dryness and other symptomsTonometersMicroscale sensorsPhotonic crystalIntraocular pressure

The invention provides an implanted device. The implanted device comprises an optical crystal; the optical crystal is acted as a color element and distributed in an artificial crystal body and forms a structural color pattern. The implanted device can be popularized to the implanted vision adjusting material, eye pressure monitoring, and cataract crystal body design; more importantly, the color variable implanted device can be used for accurately monitoring intraocular tension in real time, the real-time monitoring or physical sign monitoring of the intraocular tension can be realized only through the color change, and the major difficulties that the existed intraocular tension and glucose monitoring are not in real time and inaccurate, and data reading is difficult can be solved. The mould method can realize the high-efficiency and high-quality preparation on a large batch of the implanted device.

Owner:SHENZHEN INST OF ADVANCED TECH

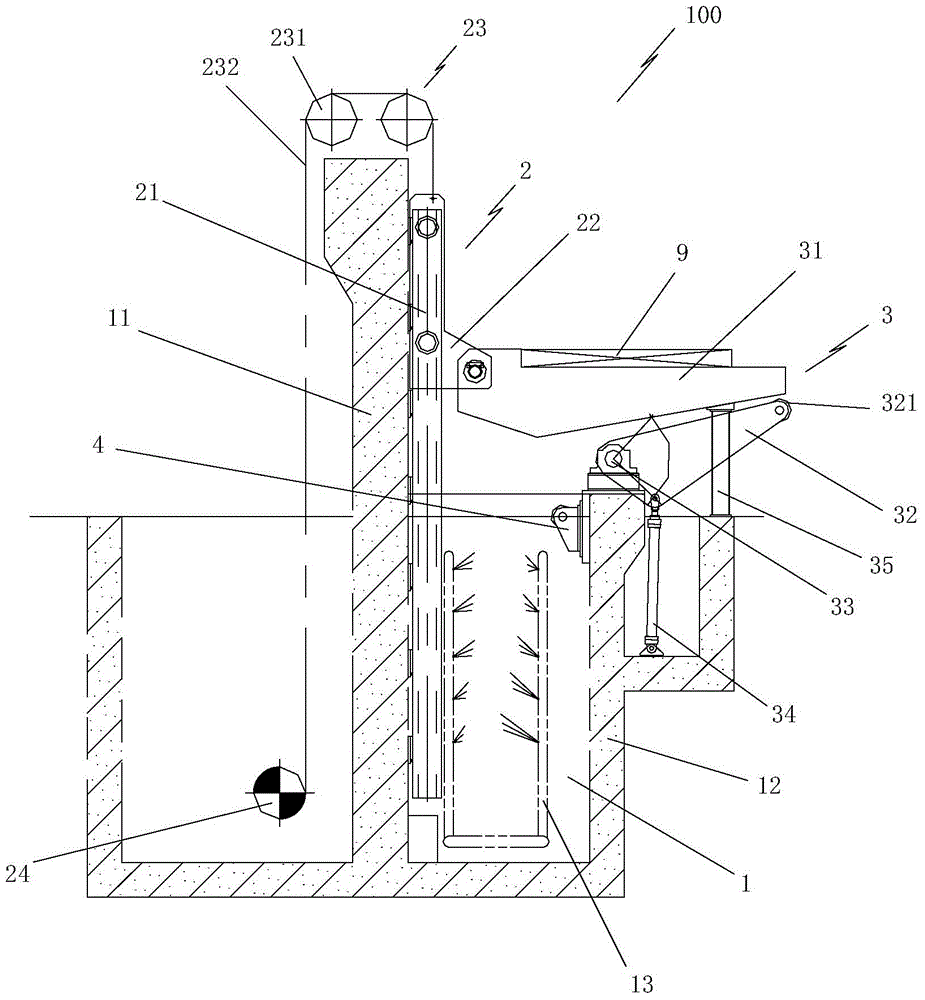

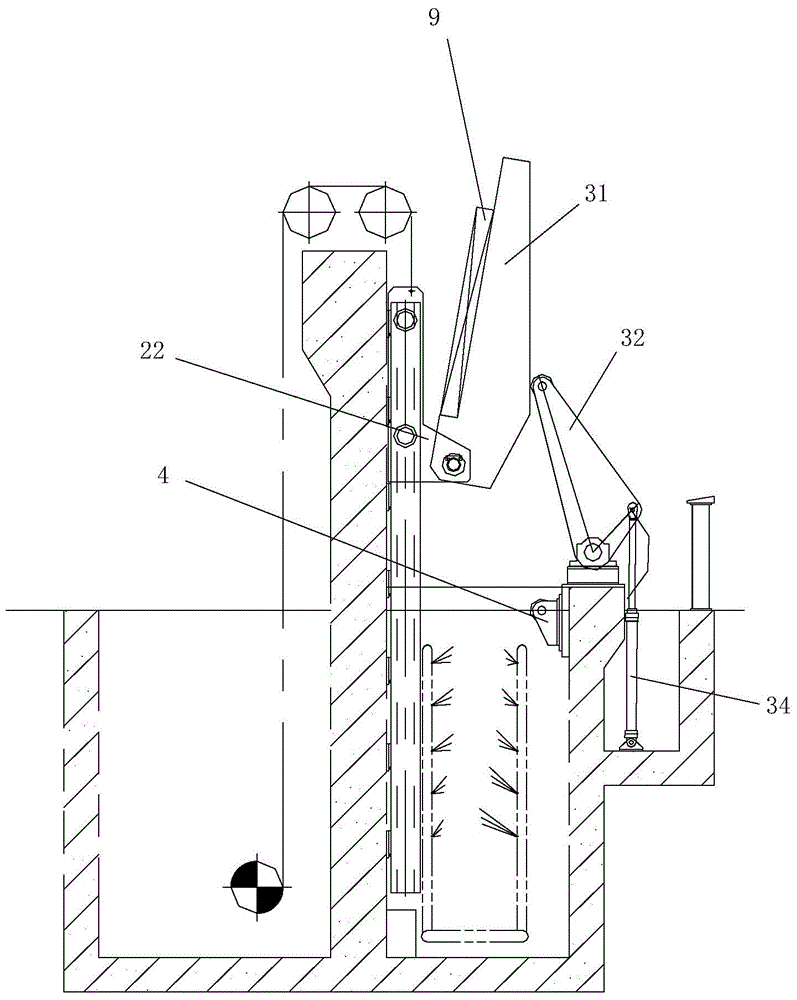

Vertical water-entry thick plate quenching machine

InactiveCN104357645ASmall footprintUniform cooling rateFurnace typesHeat treatment furnacesThick platePerformance index

The invention discloses a vertical water-entry thick plate quenching machine. The quenching machine comprises a quenching tank, wherein one side of the quenching tank is provided with a lifting device, and the other side, corresponding to the lifting device, of the quenching tank is provided with a swinging device, the lifting device comprises a plurality of lifting tracks arranged on one side wall of the quenching tank at intervals, and the lifting track is provided with a lifting trolley, the swinging device comprises beams hinged with the lifting trolleys, and the tank body edge at other side of the quenching tank is provided with a plurality of swinging cranks at intervals; one end of the swinging crank is fixedly connected with a rotating shaft, and the other end of the swinging crank is propped against the bottom of the beam, the swinging crank is driven by a driving device to swing around the rotating shaft; and spraying pipes are respectively arranged at interval parts corresponding to the beams and in the quenching tank. The quenching machine can enter the steel plate into the water in the vertical state, and is capable of effectively improving the quenching effect of the steel plate and improving the mechanical performance index of the product; the floor area of the quenching machine is reduced, and the equipment cost is lowered.

Owner:CERI PHOENIX INDAL FURNACE CO TD +1

Feed for raising chilo venosatus walkers and preparation method of feed

ActiveCN104920824AReasonable formulaFormulation ScienceFood processingAnimal feeding stuffSucroseAnimal science

The invention discloses a feed for raising chilo venosatus walkers and a preparation method of the feed. The feed is prepared from the following raw materials in parts by weight: 750-770 parts of water, 36-40 parts of yeast extract powder, 28-32 parts of casein, 13-17 parts of agar, 0.4-0.5 part of potassium hydroxide, 3.5-4.0 parts of ascorbic acid, 0.25-0.35 part of multivitamin and minerals tablets, 13-17 parts of cane sugar, 6-8 parts of wheat bran, 8.5-11.5 parts of maize flour, 113-118 parts of sugarcane stem powder and 0-4.4 parts of a preservative. The preparation method comprises the step of uniformly mixing all the raw materials. The feed prepared by the preparation method disclosed by the invention is suitable for feeding the chilo venosatus walkers, the developmental rate, the survival rate, the pupal weight and the pupation rate of a larva can be greatly increased, the developmental physiological status of an insect source are basically consistent, and requirements for nutrient substances of the development of a whole generation or development of generations of the chilo venosatus walkers can also be met.

Owner:广东省科学院南繁种业研究所

Strength enhancement method of alumina porous material based on powder bed melting

ActiveCN110204318AAchieve high volumeFast preparationCeramic shaping apparatusCeramicwareCerium3d printer

Provided is a strength enhancement method of an alumina porous material based on powder bed melting. The strength enhancement method of the alumina porous material based on powder bed melting includesthe steps that firstly, strength enhancement material powder is poured into an initial raw material for mixing; then the mixed raw material is placed in a powder bed melting 3D printer, and a primaryblank is printed according to a designed three-dimensional model of a porous structure; then, the primary blank is immersed in a silica sol, a magnesium sol, a cerium sol or a zirconium sol, and placed in a vacuuming machine for vacuum treatment, so that the primary blank is fully immersed; then the immersed primary blank is taken out and dried in an oven; finally the immersed and dried blank ofthe alumina porous material is subjected to degreasing and then high-temperature calcination to obtain the porous structure with a strength satisfying requirements. The strength enhancement method ofthe alumina porous material based on powder bed melting can be used for producing the alumina porous material with the strength satisfying the requirements.

Owner:陕西斐帛思凯科技发展有限公司

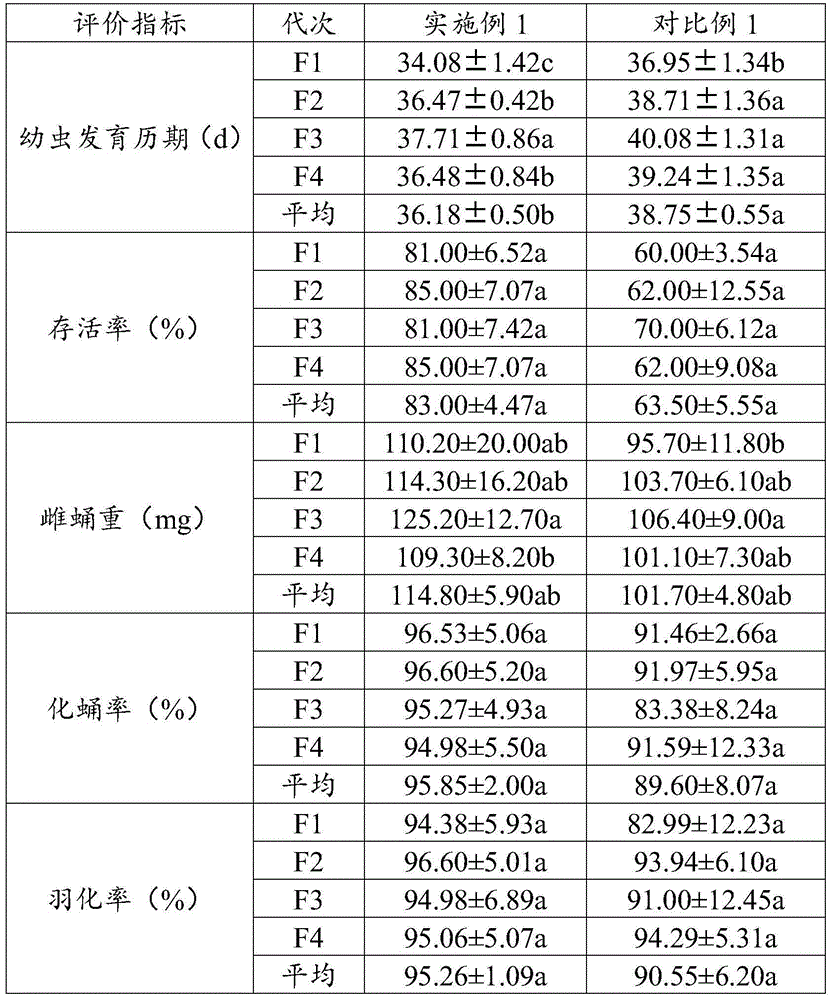

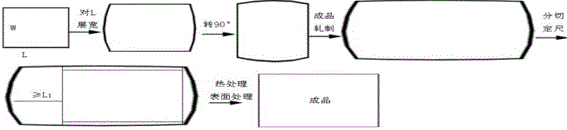

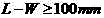

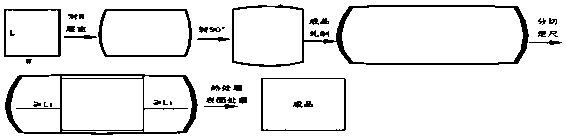

Short-flow preparation method of TA5 titanium alloy medium-thickness plate for ship

ActiveCN105951016AAvoid causing production abnormalitiesNovel process routeThick plateTitanium alloy

The invention discloses a short-flow preparation method of a TA5 titanium alloy medium-thickness plate for a ship. According to the short-flow preparation method, the design concept of a whole-flow technology is adopted, and the edge crack, the plate shape, the structure and the property of the TA5 titanium alloy medium-thickness plate are comprehensively controlled from the aspects of slab selection, broadening reversing rolling, heat treatment technology design and the like; According to the method, the slab used for a thick plate in the production is smaller, the production is convenient and flexible, and the requirement for the capability of equipment is lower.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

A short-process preparation method of ta5 titanium alloy medium-thick plate for ships

ActiveCN105951016BAvoid causing production abnormalitiesNovel process routeThick plateTitanium alloy

A short-process preparation method of TA5 titanium alloy medium-thick plate for ships, which adopts the whole-process process design concept, and comprehensively controls the edge of TA5 medium-thick plate from the aspects of slab selection, widening and reversing rolling, heat treatment process design, etc. Cracks, plate shape, structure and performance, the slab used in the production of medium and thick plates by this method is small, the production is convenient and flexible, and the requirements for equipment capacity are low.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

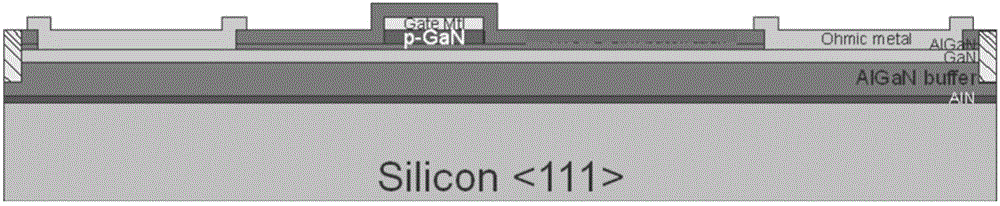

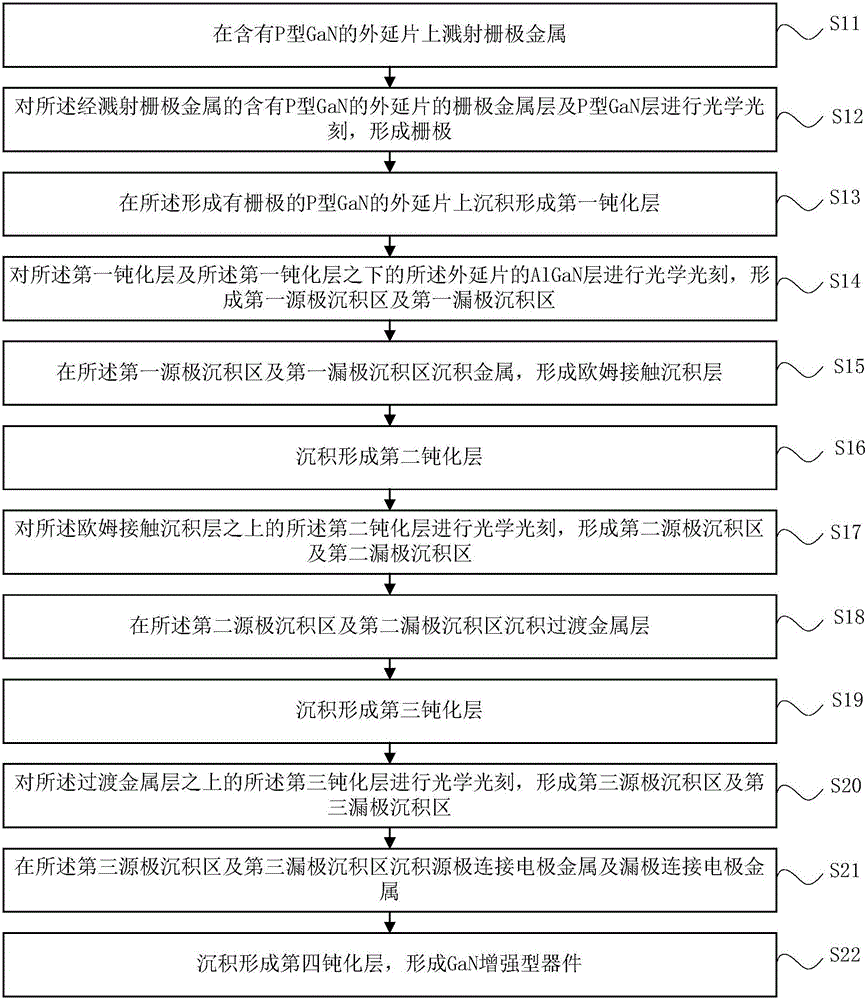

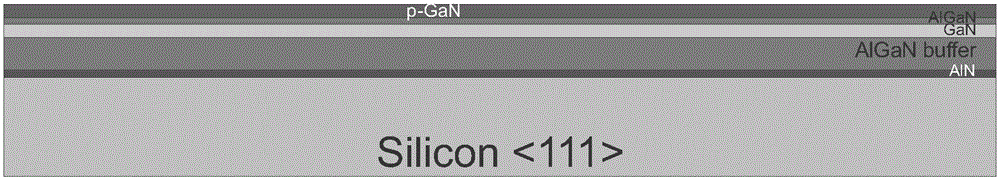

Fabrication method of GaN enhancement device and formed GaN enhancement device

ActiveCN106206295ALow costAchieve high volumeSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringElectron

The invention provides a fabrication method of a GaN enhancement device and the formed GaN enhancement device. According to the fabrication method of the GaN enhancement device, a gate, a source and a drain are formed on an epitaxial wafer containing P-type GaN by a process compatible with a complementary metal oxide semiconductor (CMOS) process. The fabrication process of the GaN enhancement device is compatible with the CMOS process, and thus, the production and the fabrication of an enhancement electronic power switch device in mass production and with low cost can be achieved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

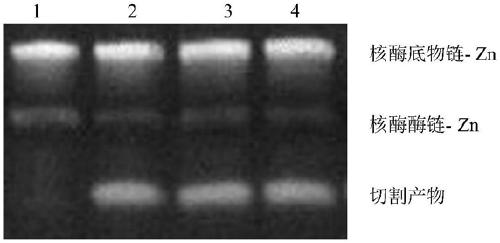

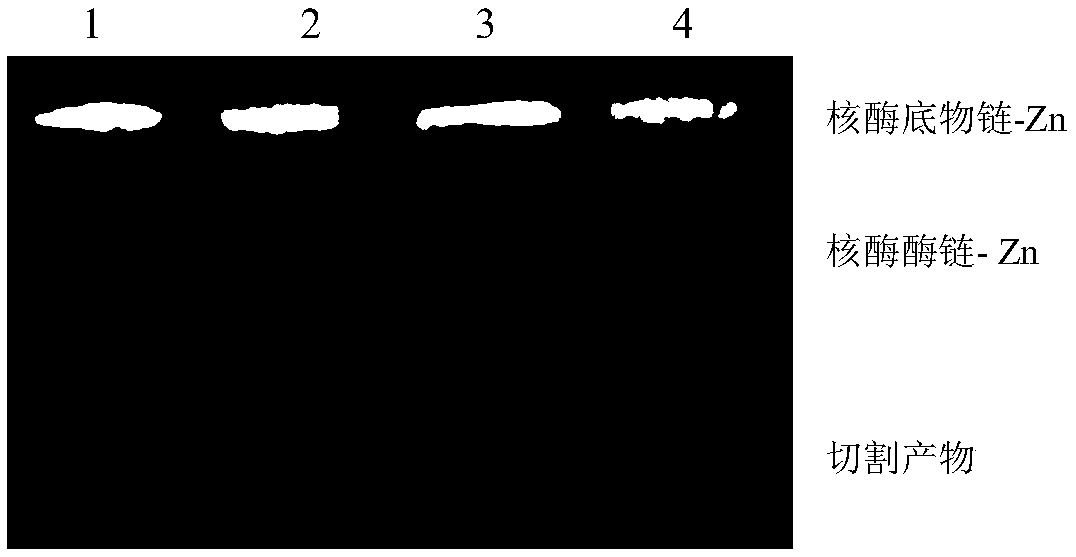

Cleavage type universal-partition ultrafast-amplification visual sensor for zinc ions

ActiveCN108949931AShorten detection timeTroubleshoot visualization issuesMicrobiological testing/measurementPeroxiredoxin activityABTS

The invention provides a cleavage type universal-partition ultrafast-amplification visual sensor for zinc ions. The visual sensor comprises (1) a cleavage system, (2) a sPCR amplification system, (3)a HCR system, and (4) a detection system containing an ABTS developing solution. According to the invention, primers, a template and probes are ingeniously designed, so ultrafast amplification of thetemplate can be realized in the presence of zinc ions, and an amplification product is allowed to form a G-quadruplex in a proper environment by triggering a HCR reaction; and color development is performed by utilizing the peroxidase-like activity of the G-quadruplex. Thus, the problem of difficulty in realizing visual detection of traditional PCR products is overcome, and rapid and visual detection of zinc ions is realized. Moreover, the sensor provided in the invention has the characteristics of high specificity and high sensitivity to zinc ions, and is more objective and accurate in detection results.

Owner:CHINA AGRI UNIV

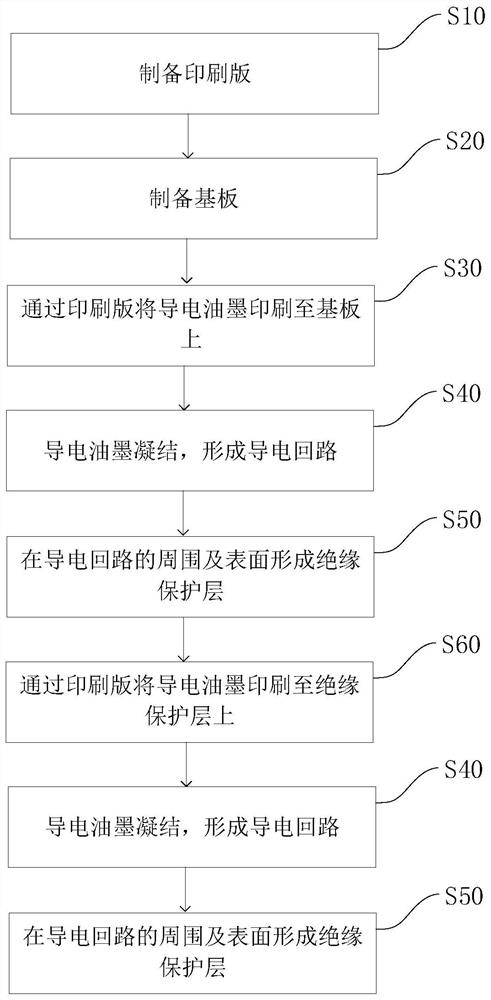

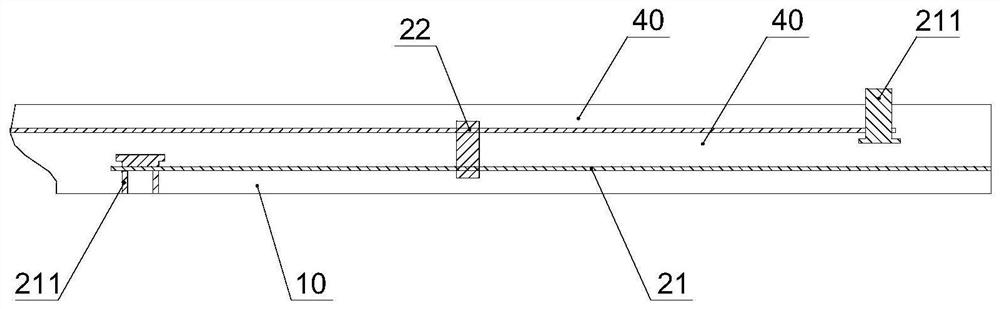

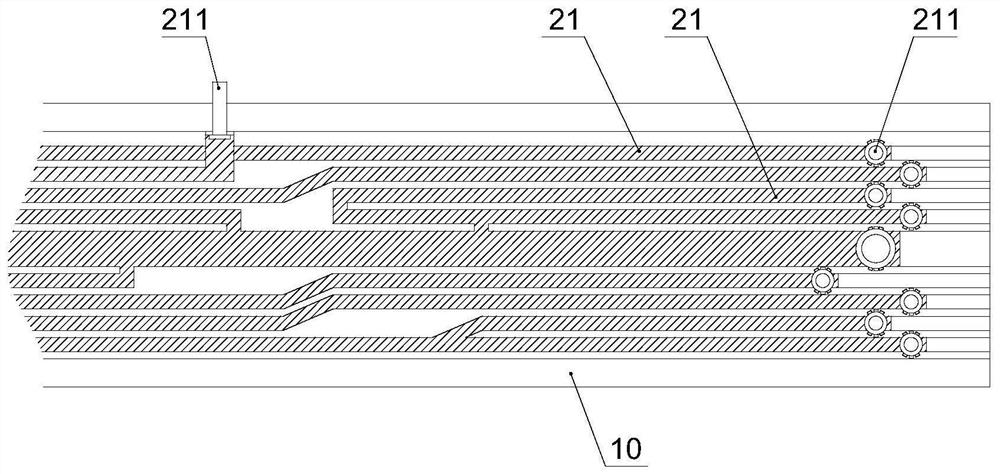

Production method of wire harness and wire harness

ActiveCN113593776ARealize the electrical connection functionImprove molding efficiencyInsulated cablesInsulated conductorsProtection layerConductive ink

The invention provides a production method of a wire harness and the wire harness. The production method of the wire harness comprises the steps of S10 preparing a printing plate; S20 preparing a substrate; S30 printing conductive ink on the substrate through the printing plate; S40 condensing the conductive ink to form a conductive loop; and S50 forming an insulating protection layer around and on the surface of the conductive loop. According to the invention, the technical problems of relatively complex production process and relatively high processing cost of the wire harness for electrically connecting an electric device are solved.

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

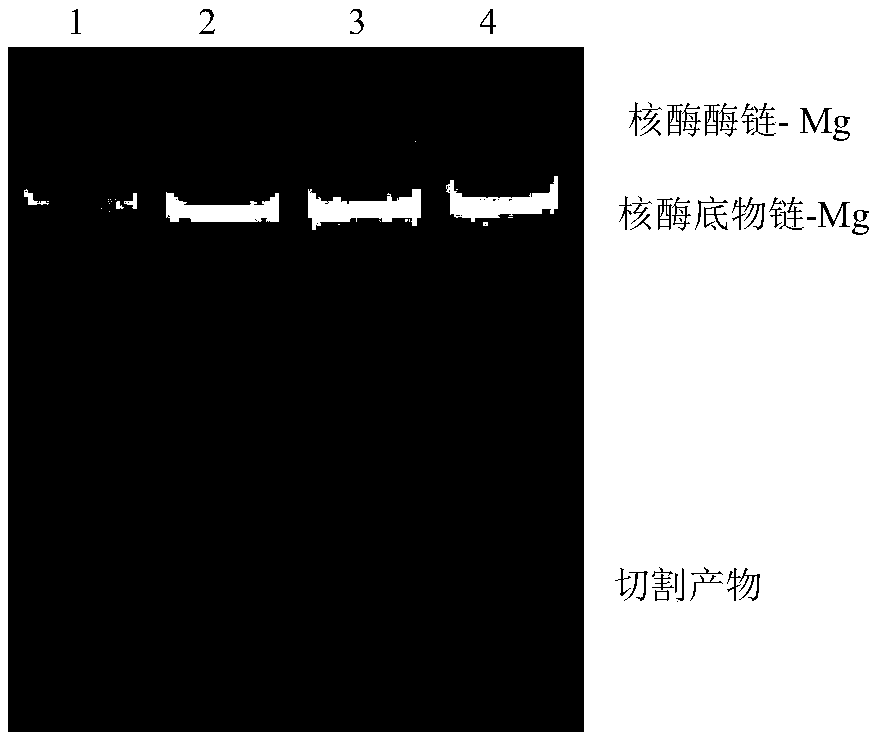

Visual detection method of magnesium and zinc cutting type functional nucleic acids for universal partition and ultra-fast amplification

ActiveCN108841937AShorten detection timeTroubleshoot visualization issuesMicrobiological testing/measurementUltra fastPeroxiredoxin activity

The invention provides a visual detection method of magnesium and zinc cutting type functional nucleic acids for universal partition and ultra-fast amplification. The visual detection method providedby the invention can perform ultra-fast amplification on templates the presence of magnesium and zinc ions by ingeniously designing primers, the templates and probes, enables amplification products toform a G-quadruplex in a suitable environment, further uses peroxidase-like activity of the G-quadruplex for color development, solves a problem that traditional PCR products are hard to be detectedvisually, and realizes fast and visual detection of magnesium and zinc ions. Moreover, the visual detection method provided by the invention has the characteristics of high specificity and high sensitivity to magnesium and zinc ions, and more objective and accurate detection results.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com