Chip packaging method

A packaging method and chip technology, which are applied in the field of micro-total analysis systems, can solve the problems of air bubbles on the bonding surface, chip products need vacuum packaging, and the bonding surface is not strong, and achieve high packaging strength, high fidelity, and simple packaging process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

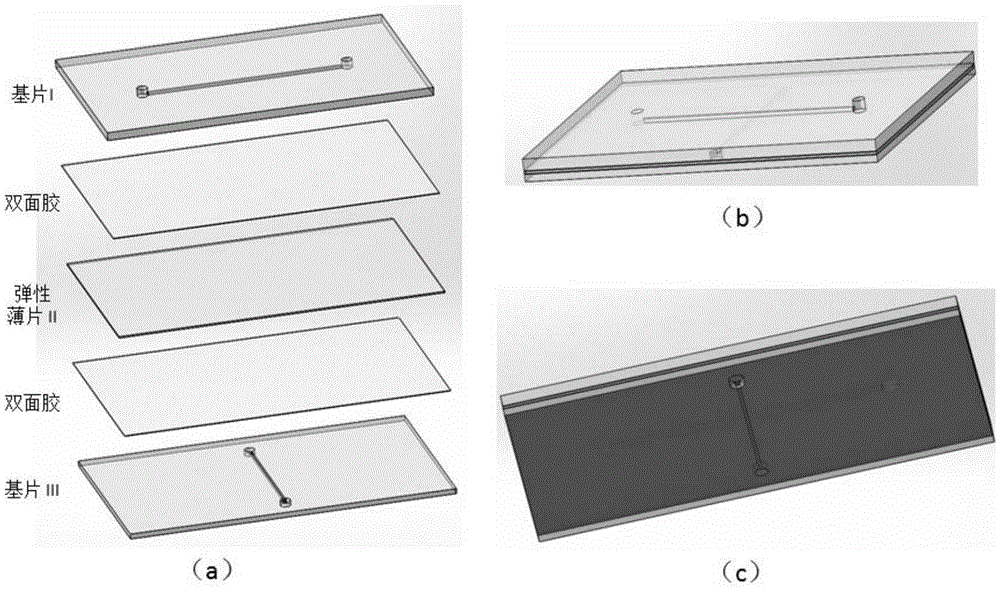

[0039] image 3 It is a schematic diagram of encapsulation of multi-layer sheets in the encapsulation method of the present invention.

[0040] According to the procedure of the present invention, the lower surface of the microfluidic chip substrate I and the upper surface of the substrate III are cut as follows with a milling cutter image 3 The microstructure shown; use a perforator to punch through the holes corresponding to the inlet and outlet holes of the microstructure in the substrate I and the substrate III; seal the microstructures of the substrate I and the substrate III with the elastic sheet II covered with double-sided adhesive on both sides. Pipes and micropores; put the bonded chip into a packaging bag for vacuum packaging, and then place the bag on a pneumatic punching machine to punch the chip in the bag for 1 minute, so that the three layers of sheets are tightly bonded.

[0041] image 3 (a) is an exploded schematic diagram of a multilayer chip applying t...

Embodiment 2

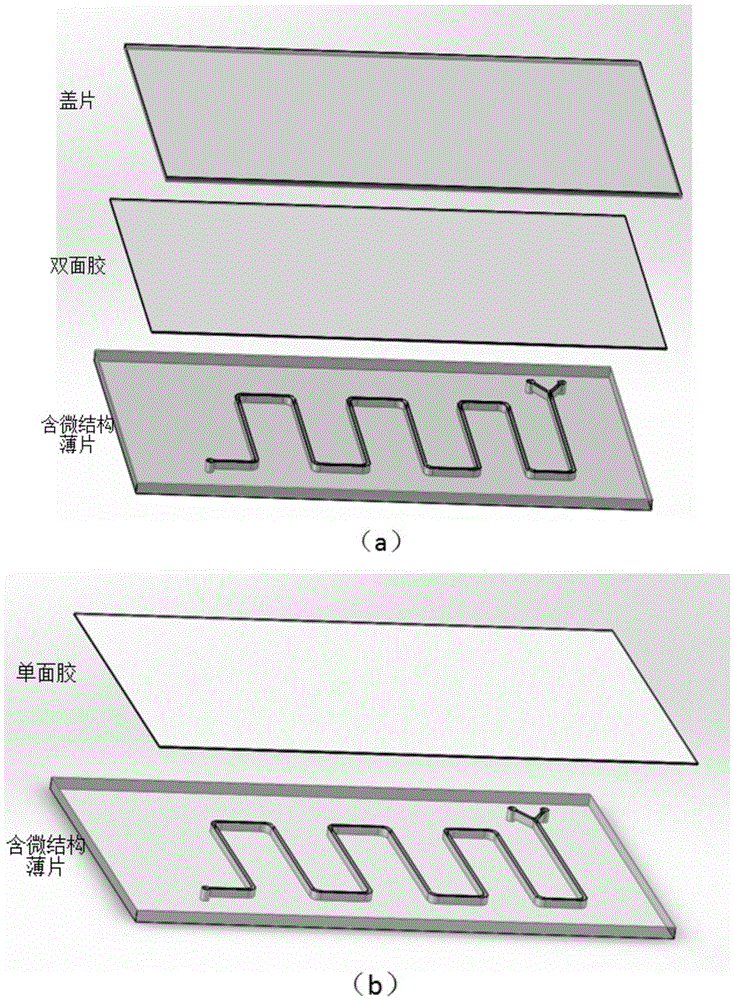

[0043] Such as Figure 4 As shown, the base and cover sheets can be of various shapes. First, attach the double-sided adhesive to the lower surface of the cover sheet, then attach the cover sheet covered with double-sided adhesive to the microstructure surface of the substrate, and then put the attached chip into the packaging bag for vacuum treatment. Finally, the packaging bag containing the chip was placed on the punching device for punching with a pressure of 0.7 MPa and kept for 1 minute so that the substrate and cover sheet of the microfluidic chip were tightly bonded. Figure 4 (a) is to add the solution centrifugation that contains dye to the chip after sealing, 70 ℃ heat 60 minutes chip physical picture, can observe that according to the chip that packaging process of the present invention makes even if long-term high-temperature heating, its adhesive surface There are no bubbles, and the microchannel is tightly sealed without leakage, which not only realizes the aes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com