Polylactic-acid block copolymer and its preparing method

A technology of block copolymer and polylactic acid, which is applied in the field of polylactic acid block copolymer and its preparation, and achieves the effects of low cost, improved mechanical properties and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

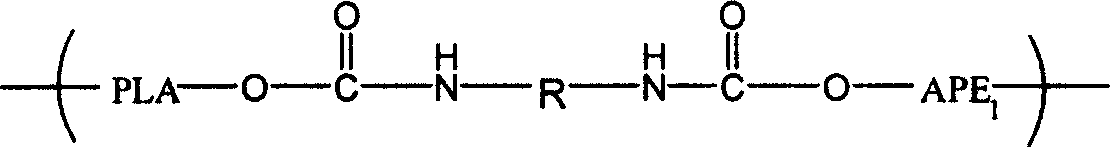

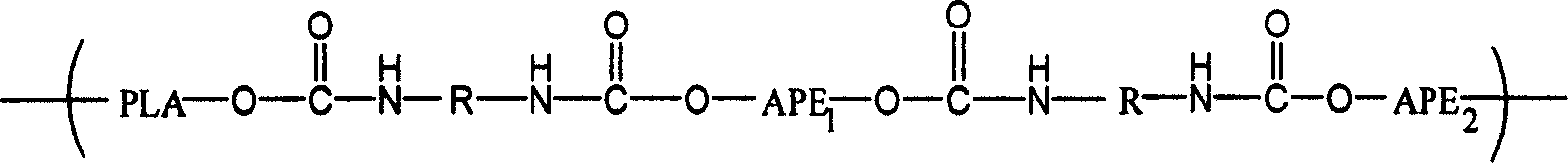

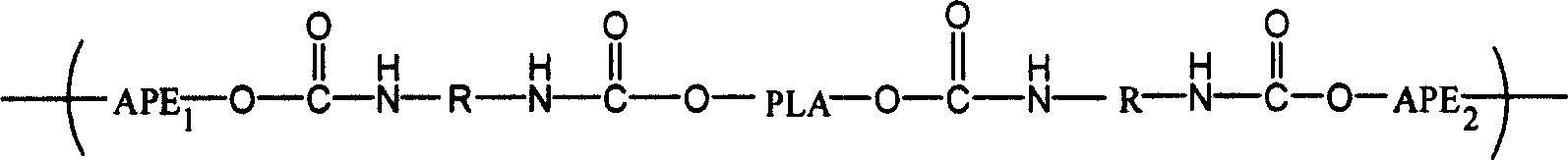

Method used

Image

Examples

Embodiment 1

[0024] The hydroxyl-terminated polylactic acid prepolymer and polyethylene glycol ester diol with intrinsic viscosities of 0.09dL / g and 0.12dL / g were weighed in a weight ratio of 1:1 and placed in a reaction flask, Under the protection of nitrogen, heat up to 140°C, stir, melt and mix evenly, then add chain extender toluene diisocyanate in an amount of 8.9% of the total weight of the prepolymer, and react at 140°C for 20 minutes.

[0025]Using chloroform as a solvent for the obtained product, the intrinsic viscosity was measured at 25°C with an Ubbelohde viscometer to be 0.81dL / g; For the film, the mechanical properties of the film were measured according to GB / T1040-92. The tensile strength of the film was 20.35 MPa, and the elongation at break was 275%.

Embodiment 2

[0027] The hydroxyl-terminated polylactic acid prepolymer and polybutylene oxalate diol with intrinsic viscosities of 0.13dL / g and 0.17dL / g were weighed in a weight ratio of 1:1 and placed in a reaction flask, Under the protection of nitrogen, heat up to 160°C, stir, melt and mix evenly, then add chain extender hexamethylene diisocyanate in an amount of 5.3% of the total weight of the prepolymer, and react at 160°C for 30 minutes.

[0028] The obtained product was measured according to the method listed in Example 1. Its intrinsic viscosity was 1.39 dL / g; the tensile strength of the film was 27.35 MPa, and the elongation at break was 473%.

Embodiment 3

[0030] The hydroxyl-terminated polylactic acid prepolymer and polyhexamethylene adipate diol with intrinsic viscosities of 0.16dL / g and 0.21dL / g were weighed in a weight ratio of 1:1 and placed in a reaction flask, Under the protection of nitrogen, heat up to 160°C, stir, melt and mix evenly, then add chain extender toluene diisocyanate in an amount of 4.1% of the total weight of the prepolymer, and react at 160°C for 45 minutes.

[0031] The obtained product was measured according to the method listed in Example 1 to have an intrinsic viscosity of 1.35 dL / g; the tensile strength of the film was 28.49 MPa, and the elongation at break was 642%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com