Patents

Literature

34results about How to "Save production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

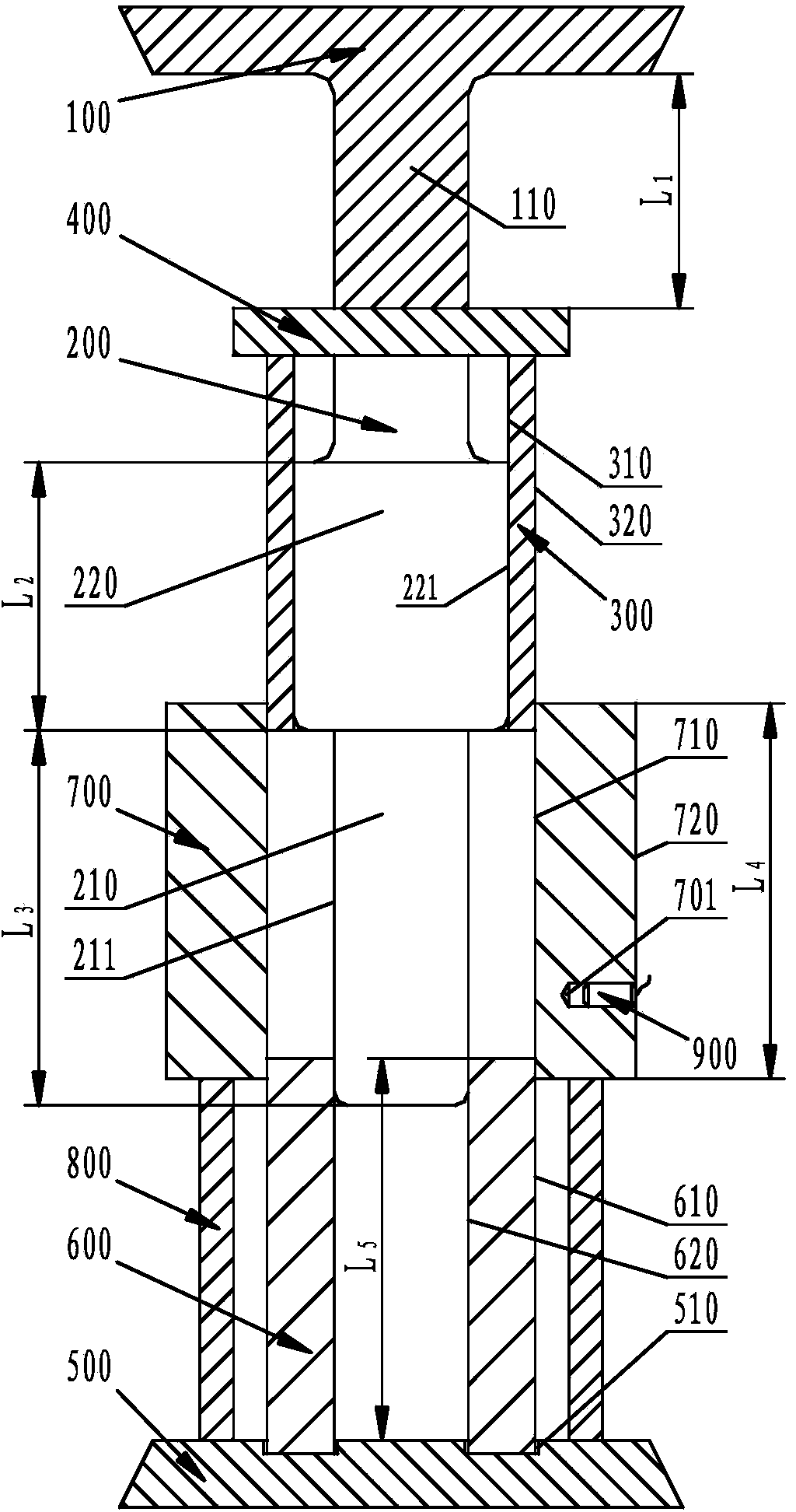

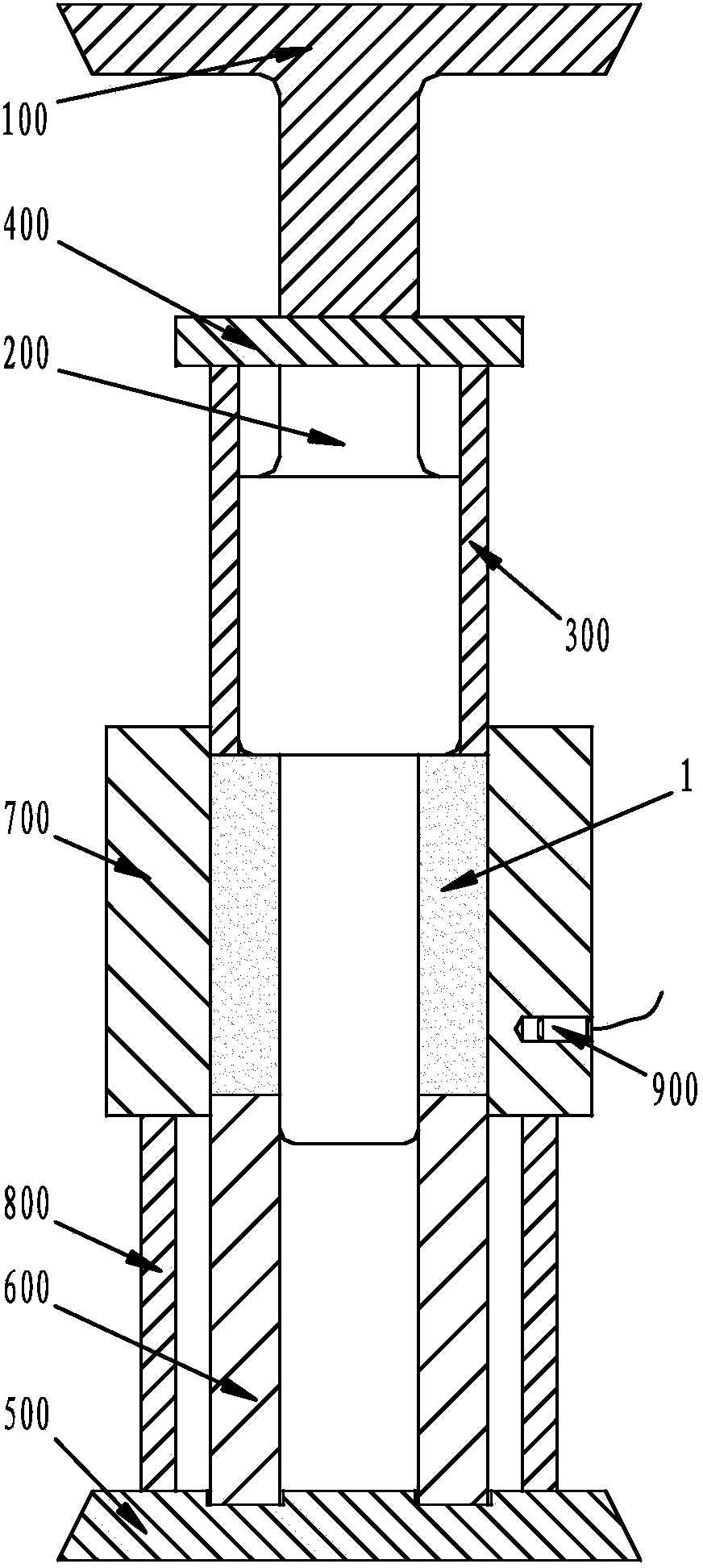

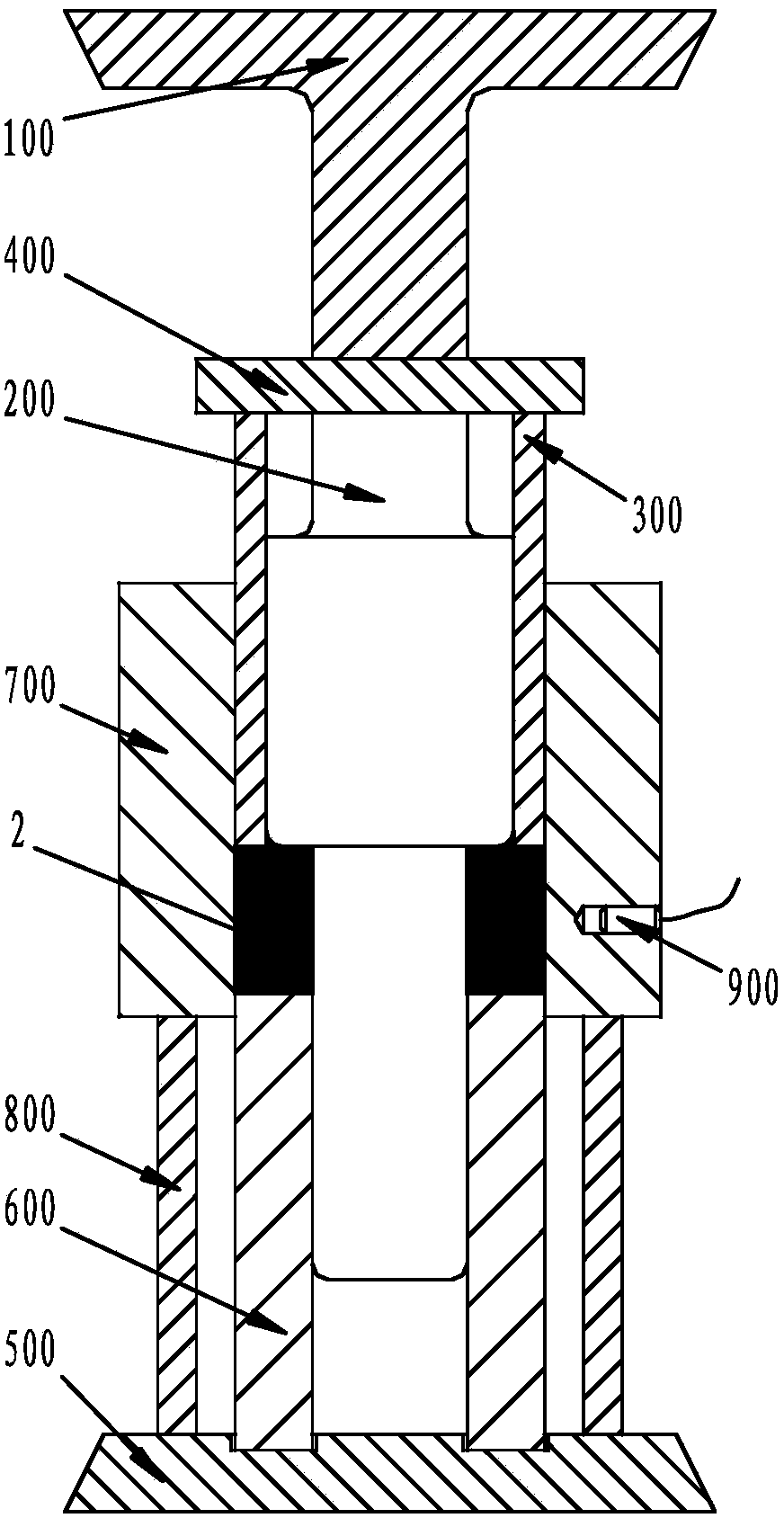

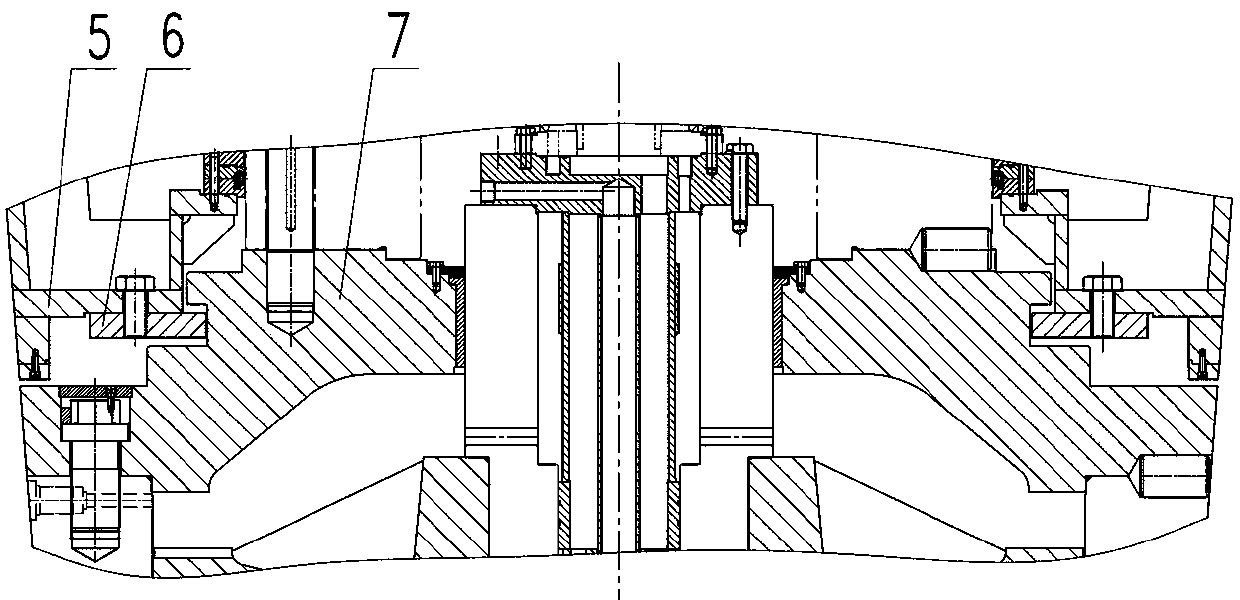

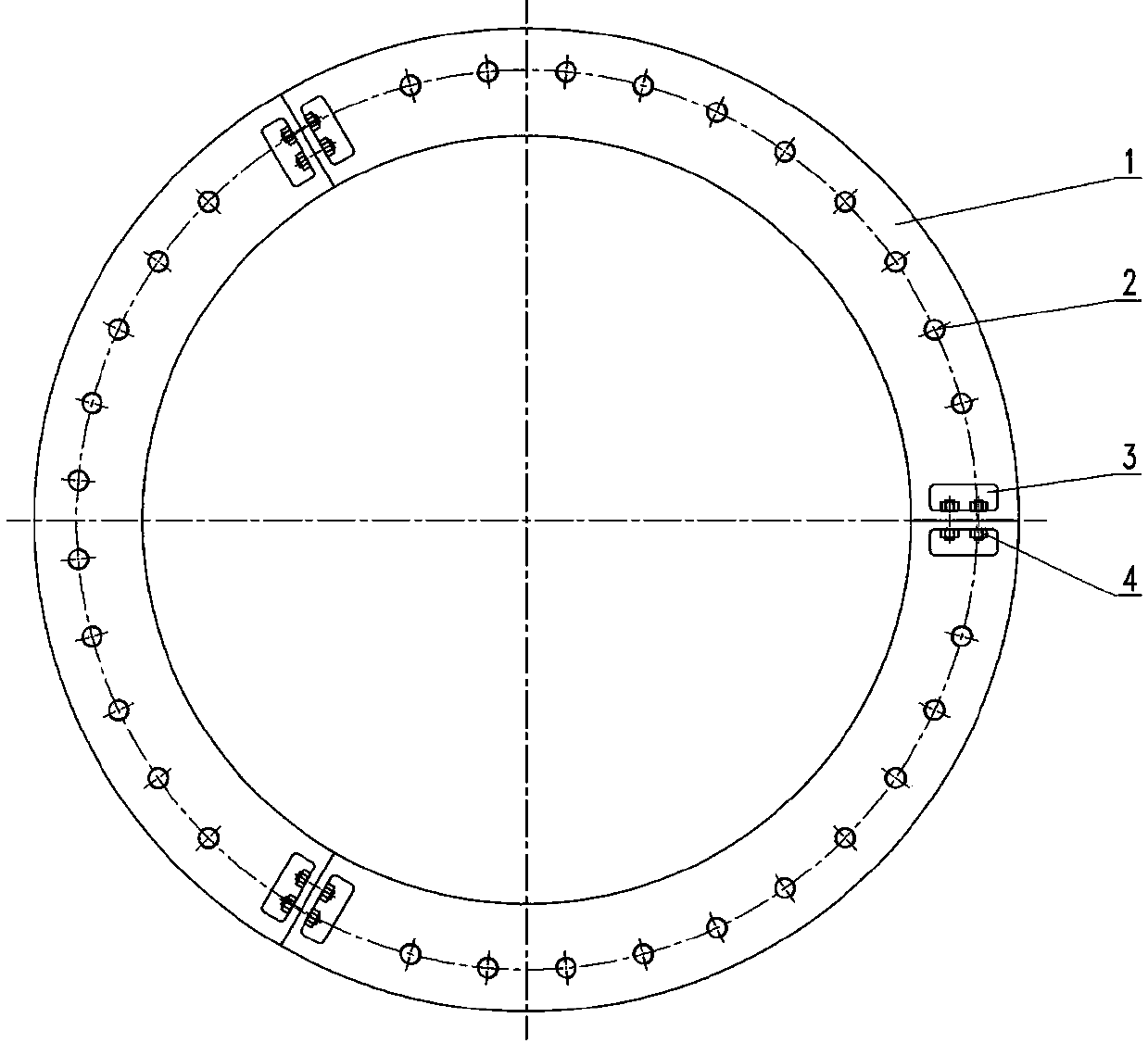

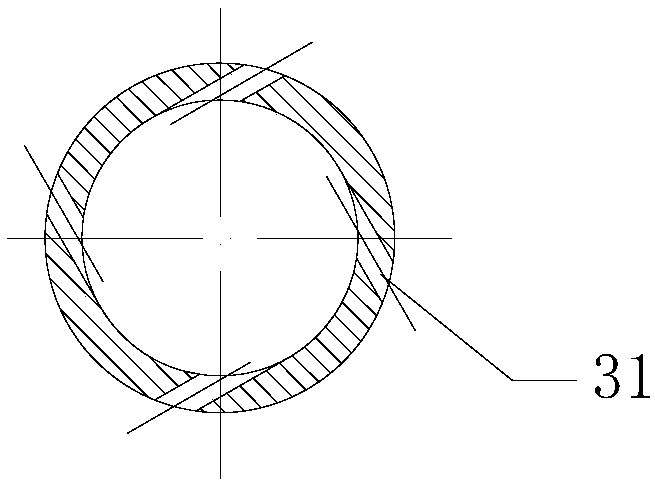

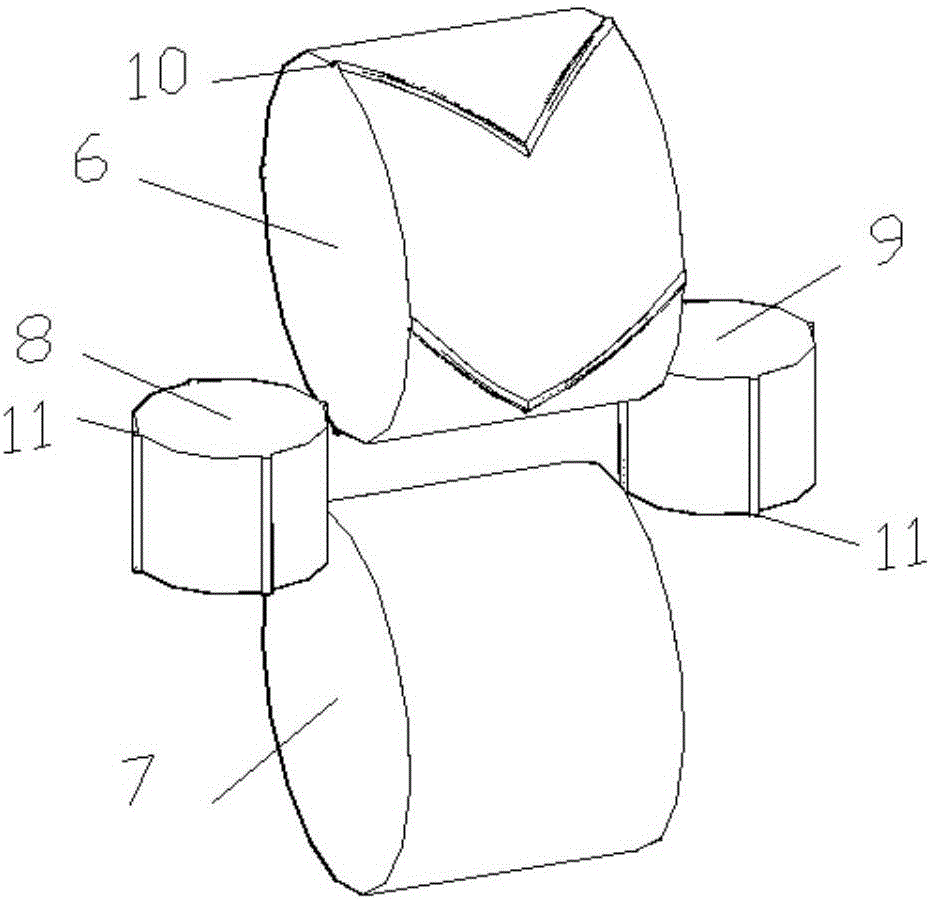

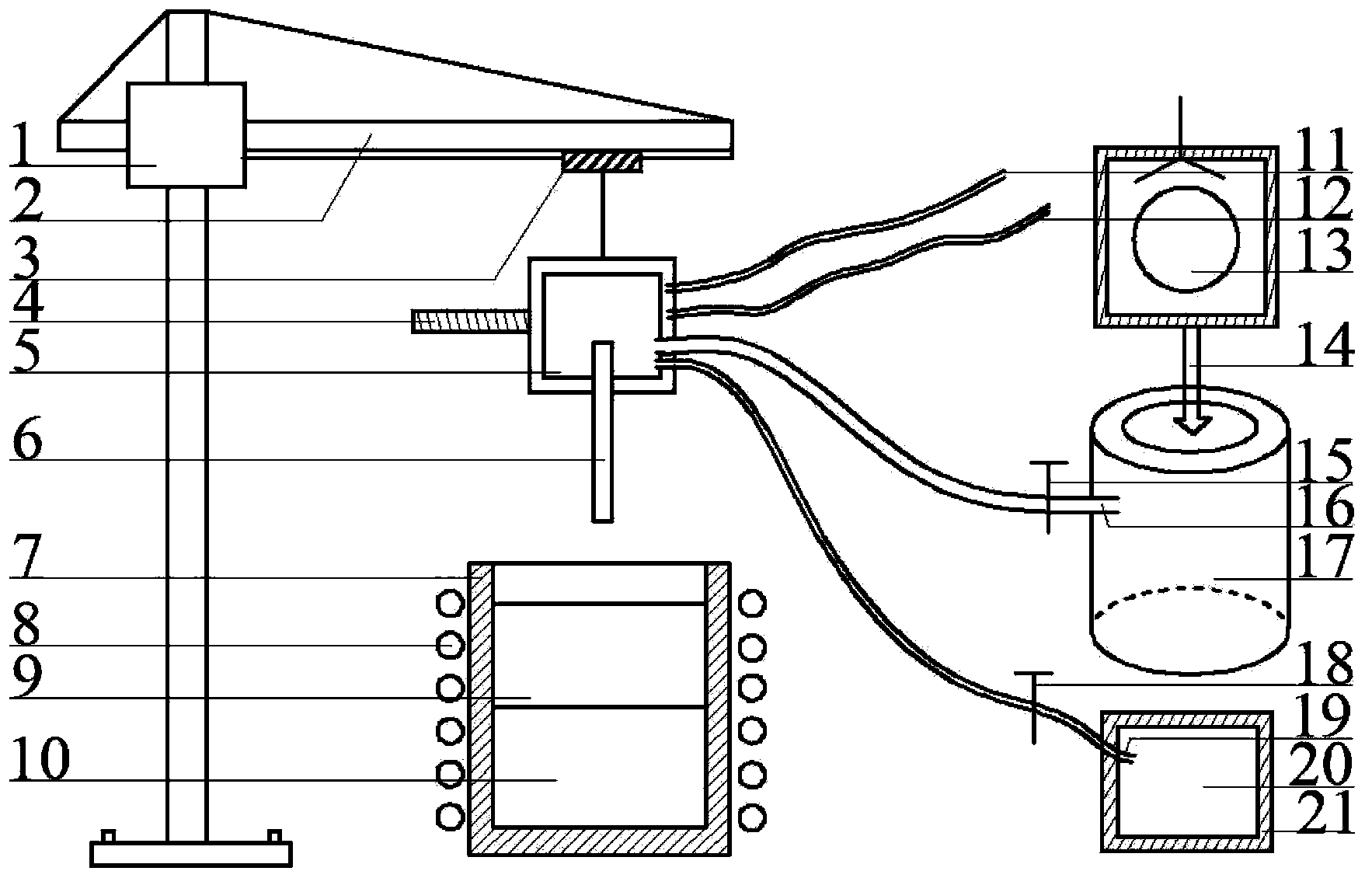

Forming method and die of anisotropic annular magnet

InactiveCN103894607AIncrease productivitySave production costInductances/transformers/magnets manufactureEngineeringInert gas

The invention provides a die of an anisotropic annular magnet. The die comprises an upper die body and a lower die body; the upper die body comprises an upper annular punch and an upper die core punch arranged inside the upper annular punch, the top of the upper annular punch and the top of the upper die core punch are provided with a base plate, and an upper base is arranged above the base plate; the lower die body comprises a female die supporting ring and a lower annular punch arranged in the female die supporting ring, the female die supporting ring and the lower annular punch are arranged on a lower base, and an annular female die is arranged above the female die supporting ring; the outer wall of the upper annular punch is matched with the inner wall of the annular female die, and the outer wall of a die core of the upper die core punch is matched with the inner wall of the lower annular punch. The invention further provides a forming method of the anisotropic annular magnet. The method comprises the steps that a cavity formed by the upper die core punch, the upper annular punch and the annular female die of the die is filled with magnetic powder, then a hot-pressing technology and a hot deformation technology are conducted in a vacuum or inert gas environment, and the anisotropic annular magnet is processed and formed. By means of the method and the die, the hot-pressing technology and the hot deformation technology are conducted continuously, and production efficiency is high.

Owner:SHANGHAI JIAO TONG UNIV

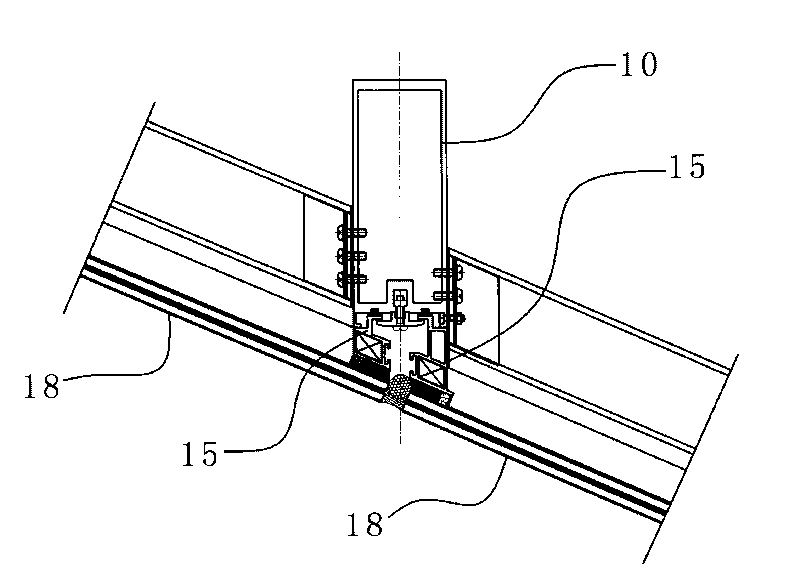

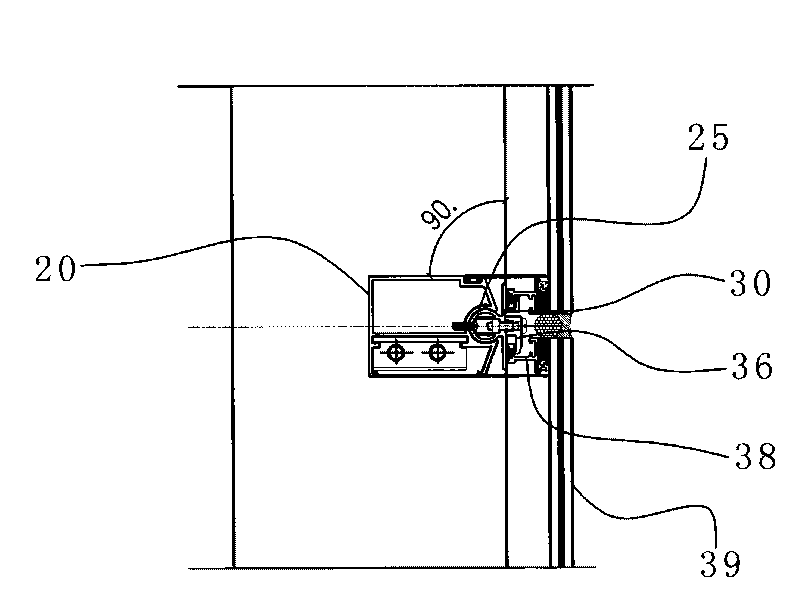

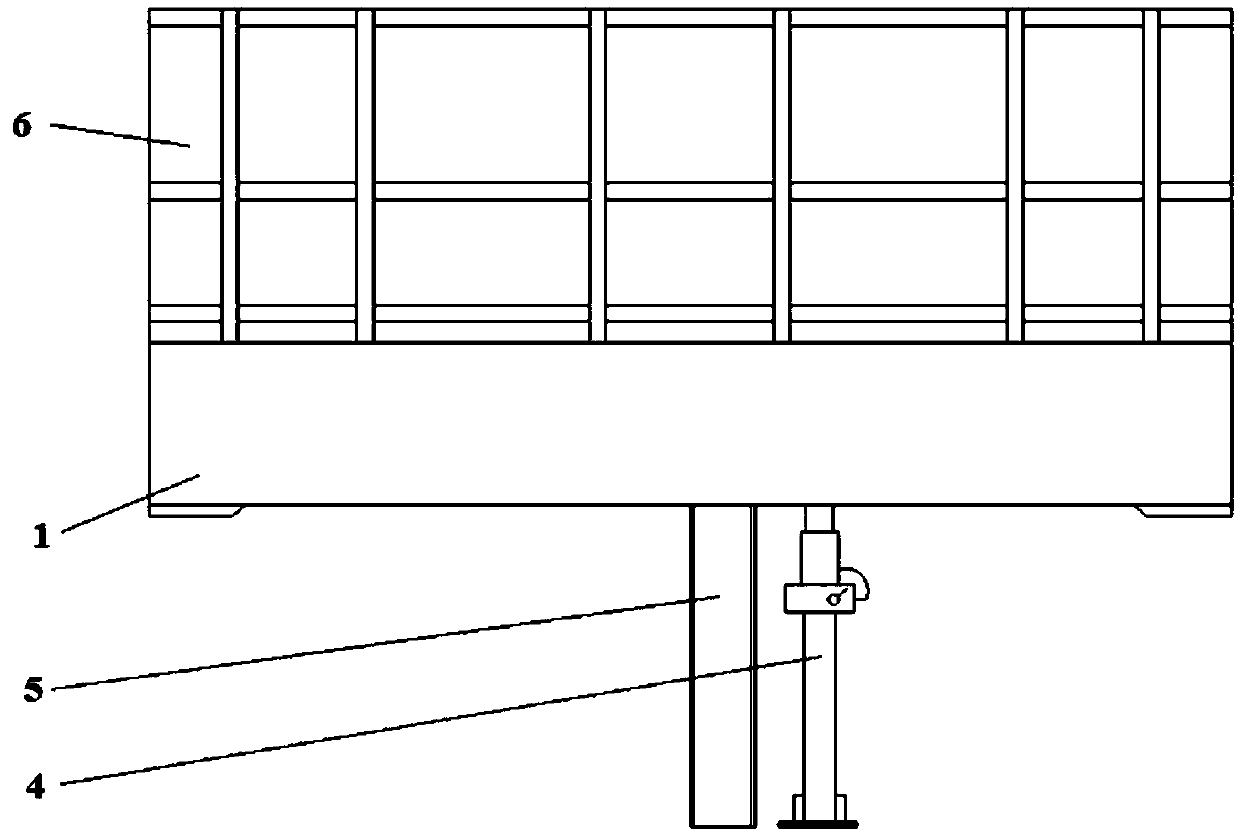

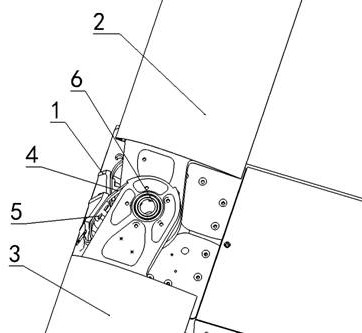

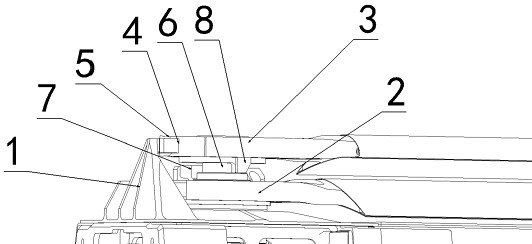

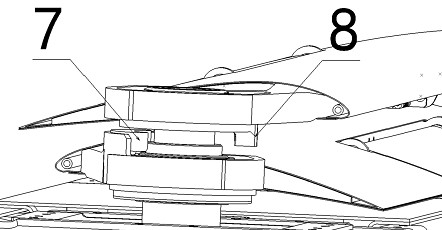

Glass curtain wall hidden frame

ActiveCN101736837AReduce specification requirementsSave manufacturing costWallsKeelBuilding construction

The invention discloses a glass curtain wall hidden frame which comprises a keel assembly, an auxiliary frame and a pressure plate, wherein the keel assembly comprises a main keel and a keel accessory, the main keel and the keel accessory are hinged, the pressure plate is installed on the keel accessory, and the auxiliary frame is compressed on the keel accessory. When the glass curtain wall hidden frame is used, the installation angle can be adjusted as required, thereby easily realizing the installation of a frame type glass curtain wall between a glass plate block and a building upright post (building crossbeam) in different angles, easily realizing the effect of a slope glass curtain wall in different angles, reducing the specification requirements for installing the main keel or the auxiliary frame on the curtain wall, saving the manufacturing cost and the production period of a mould, simultaneously improving the installation accuracy of the slope glass curtain wall, improving the universality of the frame installed on the curtain wall, greatly reducing the opening mould quantity of an aluminum shaped material, having no need of predefining and manufacturing frame fittings with different specifications, shortening the construction period of curtain wall installation and providing a technical guarantee for the standardization of a curtain wall frame.

Owner:GUANGZHOU JANGHO CURTAIN WALL SYST ENG +2

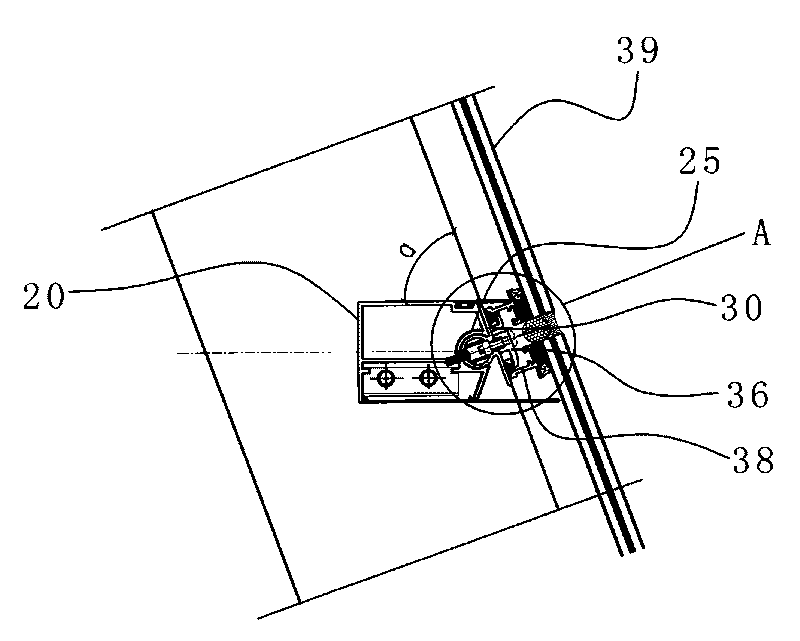

Method and equipment for rapid collection and purification of polycrystalline silicon through directional solidification of tailing

The invention belongs to the technical field of metallurgy purification, and particularly relates to a method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing. According to the method, under the inert gas shielding environment, abluent silicon is heated to be fully melted so as to carry out directional solidification; ingot pulling is stopped when solidification is completed by 85-90%, a graphite bent pipe is stretched into surplus unset silicon at the upper layer, then the other end of the graphite bent pipe is vacuumed through a vacuum unit, so that the surplus unset silicon at the upper layer enters the graphite bent pipe under the action of pressure difference and enters a water cooling collection box through the guide of the graphite bent pipe; heating is stopped after all the surplus unset silicon at the upper layer enters the water cooling collection box, and cast ingot solidified in a crucible is silicon cast ingot of high purity. Due to the method, back-diffusion of impurity is prevented, technology processes are reduced, and the yield of cast ingot is improved. The equipment is convenient to improve and install, and a tailing collection device can be used repeatedly, can collect more tailings, and is safe and reliable.

Owner:QINGDAO NEW ENERGY SOLUTIONS

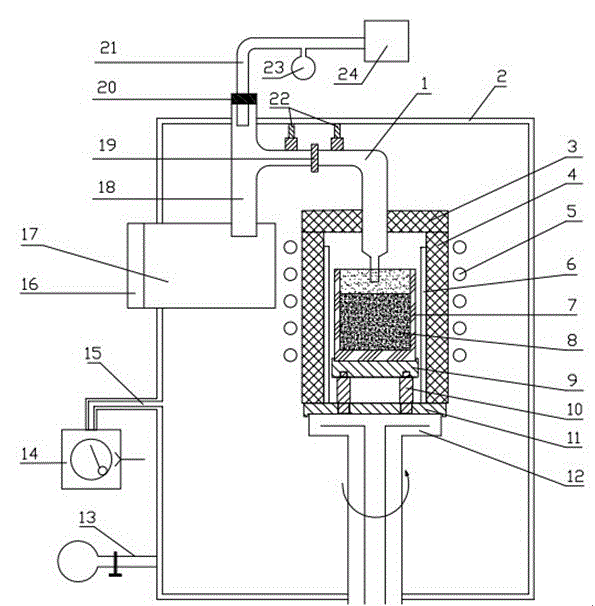

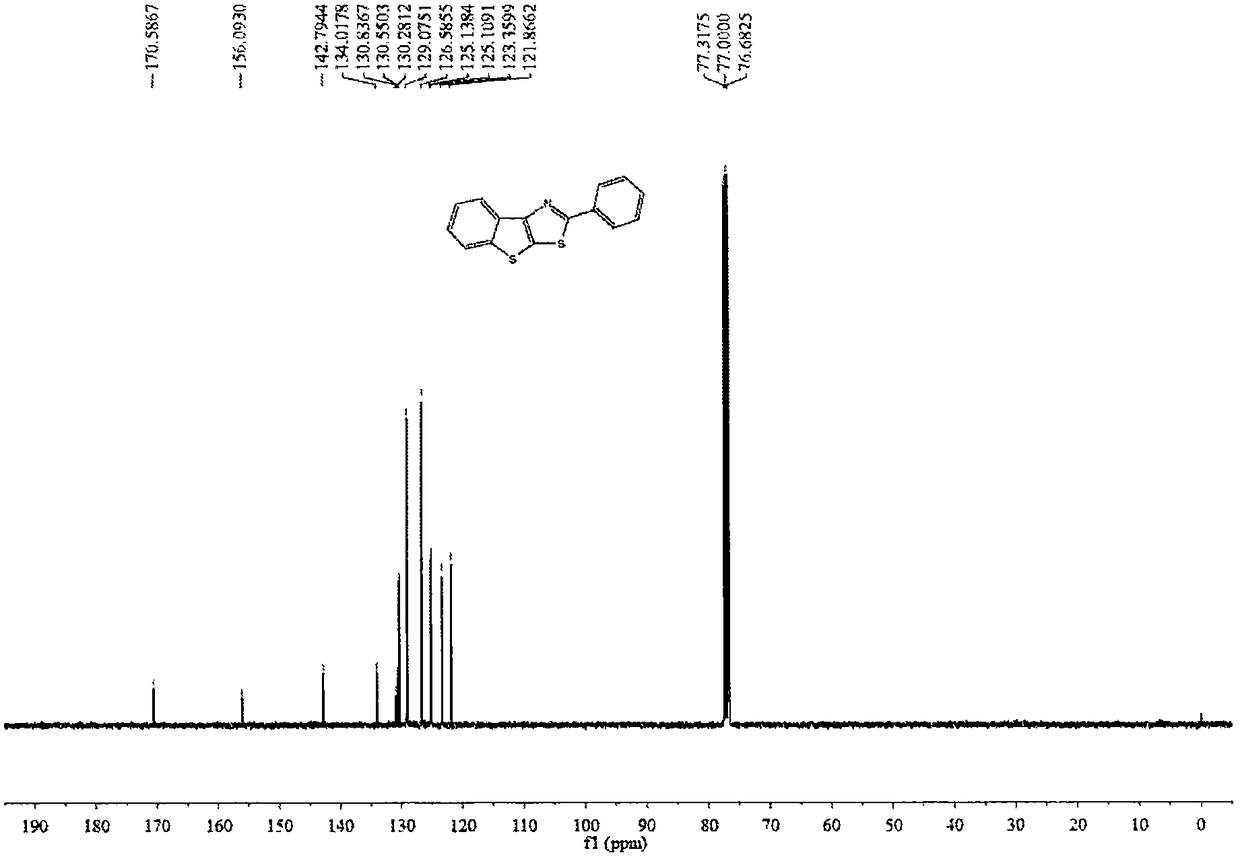

Polysubstituted benzothiophene thiazole and derivative and synthetic method thereof

ActiveCN108558911AReduce pollutionReaction raw materials are cheap and easy to obtainOrganic chemistryChemical recyclingAir atmosphereThiazole

The invention relates to a polysubstituted benzothiophene thiazole and a derivative and a synthetic method thereof. The method comprises the steps that ketoxime ester compounds, formaldehyde compoundsand powdered sulfur are converted into 2-polysubstituted benzothiophene-[3,2-d] thiazole and the derivative in the air atmosphere under Cu catalysis for the first time, and the obtained product is stable in molecular structure and good in chemical property. According to the synthesis method, reaction raw materials are cheap and easy to obtain, no preprocessing is needed, and the atom economy of the reaction is high; only cheap copper catalyst needs to be adopted in the reaction, environment contaminations are reduced, raw materials are saved, and the reaction cost is lowered; the whole reaction system is simple, reaction conditions are mild, a small amount of reaction equipment is needed, the experiment operation is easy and convenient, and the adopted materials are wide in source.

Owner:XIANGTAN UNIV

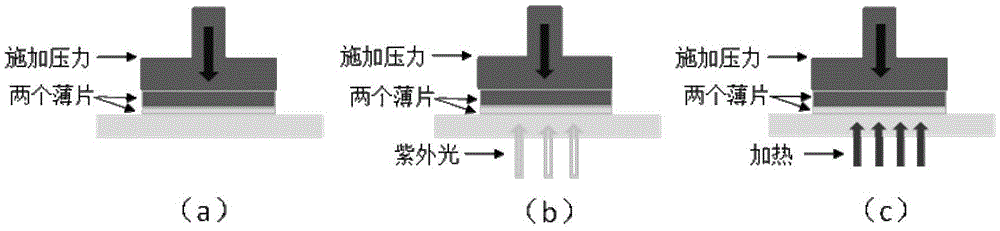

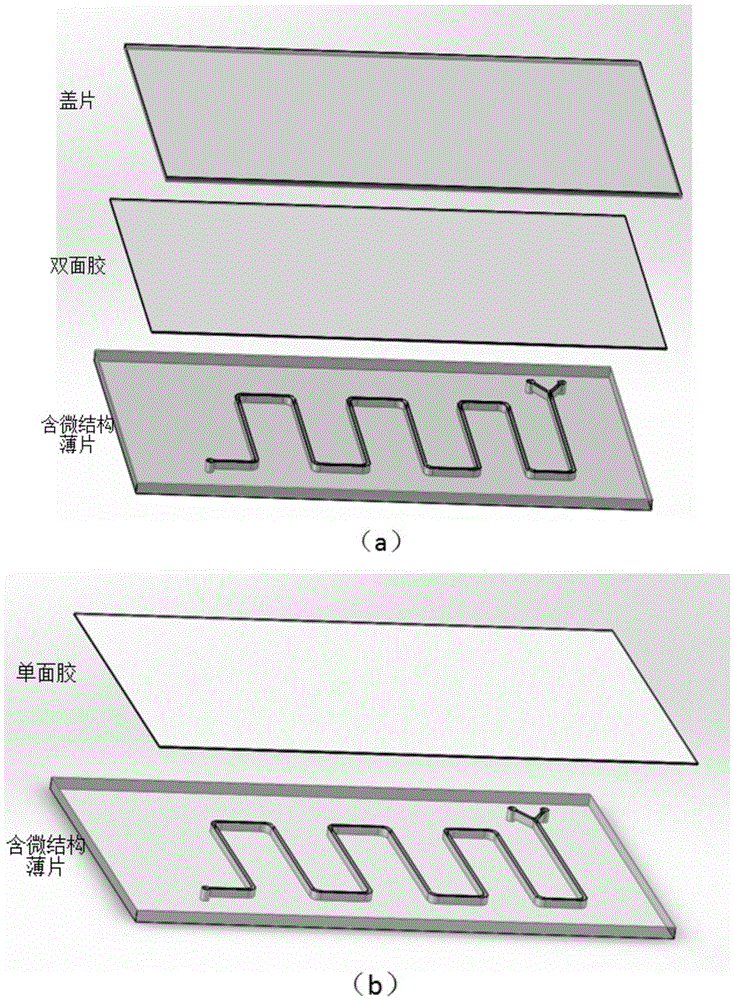

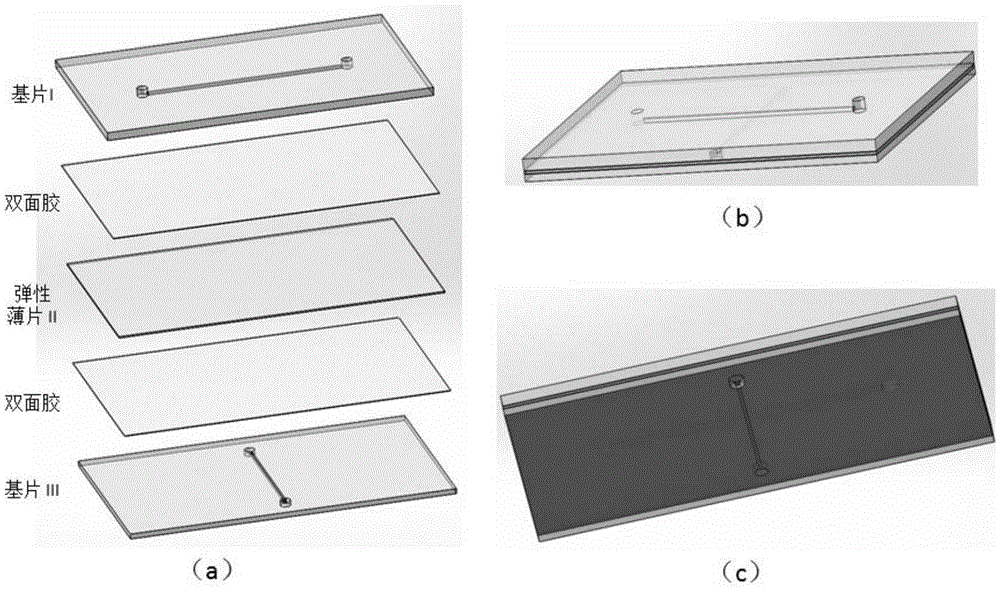

Chip packaging method

InactiveCN105460888AAchieve scaleAchieve high volumePrecision positioning equipmentSoldering apparatusVacuum pumpingBonding process

The invention discloses a chip packaging method. In the method, one-step vacuum-pumping pressurization packaging is performed after a substrate and a cover plate of a micro-fluidic chip are laminated with a double-sided adhesive or a single-sided adhesive. Through adoption of the method, the problems of poor firmness of a bonding surface and remaining of a large quantity of blisters on the surface of the chip after bonding in a conventional solid-state double-sided adhesive bonding method are solved; the problems of micro-channel distortion and micro-channel blockage in a current micro-fluidic chip bonding process are solved; and an outer packaging procedure of a finished chip is implemented synchronously. The chip packaging method is simple and effective in auxiliary equipment and manufacturing process, and high fidelity of a chip micro-channel and high packaging strength of a packaged chip are ensured. A packaging procedure provided by the invention is particularly suitable for the field of manufacturing of micro-fluidic chips on a large scale at low cost.

Owner:CAPITALBIO CORP

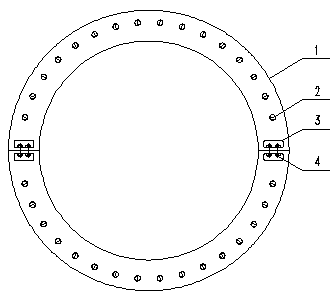

Axial-flow kaplan turbine rotating-wheel hoisting and suspension method

ActiveCN104176619AConvenience guaranteedGuaranteed accuracyLoad-engaging elementsHydraulic turbinesKaplan turbine

The invention discloses an axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring. The axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring solves the problem that the existing axial-flow kaplan turbine rotating-wheel hoisting and suspension method has complex processes and is inconvenient for operation. The axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring comprises at least two arc-shaped snap ring bodies and the snap ring bodies are uniformly provided with screw holes for combining the snap ring bodies and a kaplan turbine diversion cone. The axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring has a simple structure, is free of tooling holes of a base ring and blade main bodies, is free of a concave ring groove or a raised ring belt of a main shaft, can be simply and conveniently operated, saves many processes, and greatly improves set installation and unkeep work efficiency.

Owner:DONGFANG ELECTRIC MACHINERY

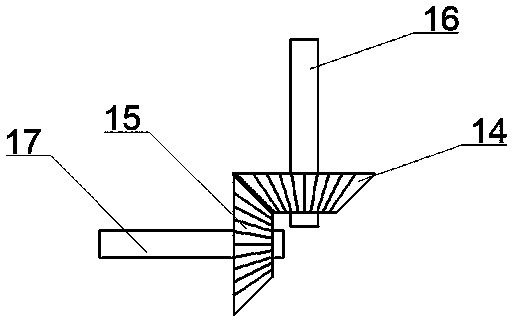

Wide working condition liquid hydrogen liquid oxygen torch type electric ignition device

ActiveCN109404166AAdapt to a wide range of working conditionsEasy to detectRocket engine plantsThrust chamberTorch

The invention discloses a wide working condition liquid hydrogen liquid oxygen torch type electric ignition device. The device comprises an ignition chamber, an oxygen nozzle, a hydrogen cavity outershell and a spark plug, wherein the hydrogen cavity outer shell is a shell body, and a liquid hydrogen inlet is formed in the wall of the shell body; the oxygen nozzle is provided with n through holeswhich axes are intersected with one point, the liquid oxygen is enabled to collide, and atomizing is carried out; a liquid oxygen inlet is formed in the upper end of the ignition chamber, the lower end of the ignition chamber is sleeved with the hydrogen cavity outer shell, and a cavity between the outer wall of the lower end of the ignition chamber and the hydrogen cavity outer shell serves as aliquid hydrogen cavity; the oxygen nozzle is installed inside the ignition chamber, the interior of the ignition chamber is divided into a liquid oxygen cavity and a second inner cavity, and the lower end face of the oxygen nozzle faces the second inner cavity; and a plurality of rows of through holes are formed in the inner wall of the second inner cavity, the lower end face of the ignition chamber is connected with a head part of a lower-level pre-combustion chamber or the head part of a thrust chamber, and the spark plug is inserted into the second inner cavity of the ignition chamber. Thedevice is detachable, high in adaptability, fault detection and maintenance of the electric ignition chamber and the spark plug are facilitated, and the production period and the development cost aresaved.

Owner:BEIJING AEROSPACE PROPULSION INST

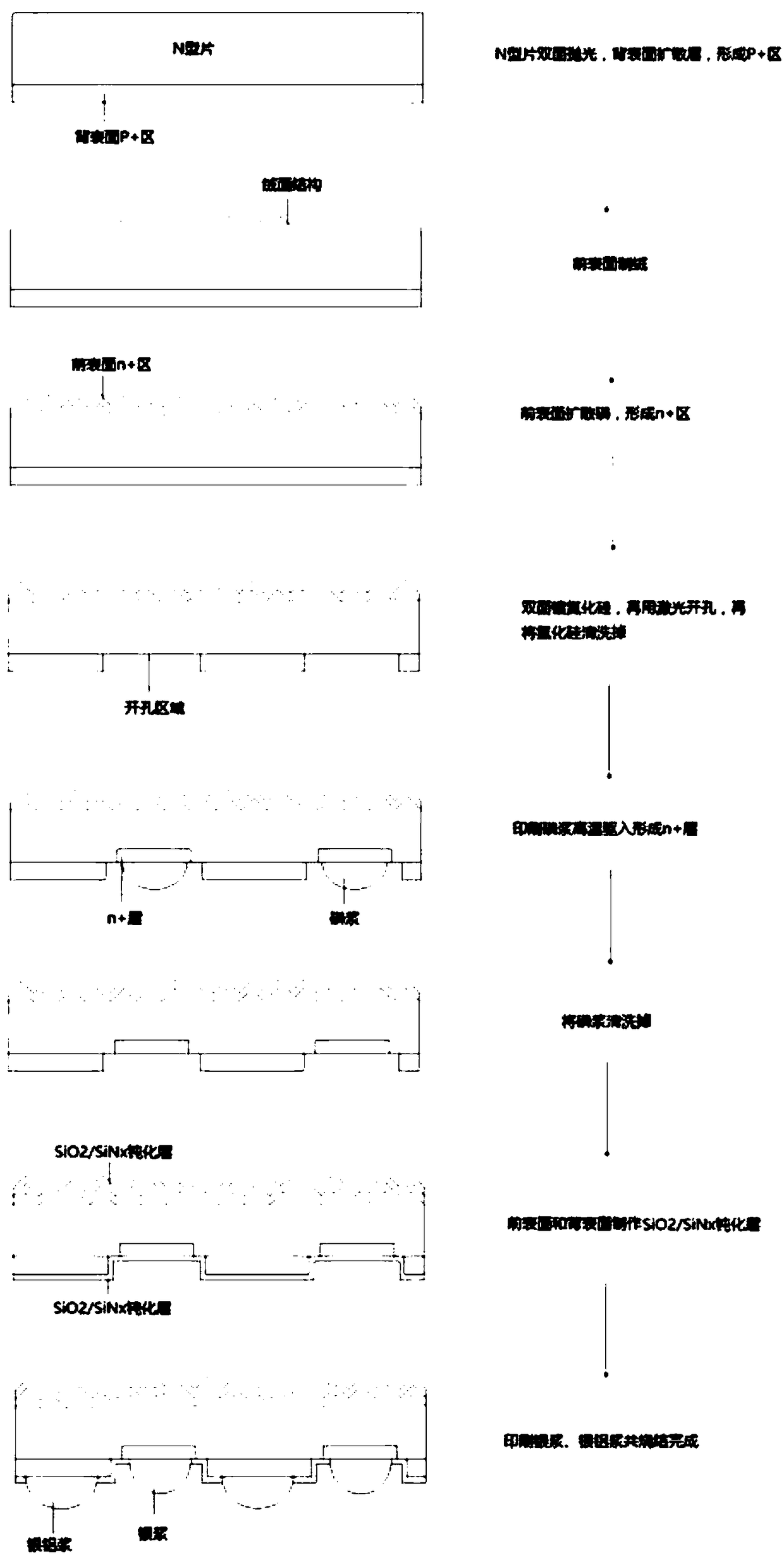

N type IBC battery and preparation method therefor

ActiveCN108538958AImprove life expectancyLight attenuation is smallFinal product manufactureSemiconductor devicesSlurrySilicon dioxide

The invention provides an N type IBC battery and a preparation method therefor. The preparation method for the N type IBC battery comprises the following steps: double faces of a silicon chip are polished, polished faces of the silicon chip are subjected to single face boron diffusion operation, HF acid is used for removing borosilicate glass, a front surface is flocked, a front surface of the silicon chip is subjected to phosphorus diffusion via use of a diffusion furnace, a PECVD device is used for plating silicon nitride on two faces of the silicon ship, a back surface of the silicon chip is perforated via laser, a perforated area of the back surface is corroded via alkali liquid, the silicon nitride is washed away via hydrofluoric acid, a phosphoric paste is printed on the back surface, cleaning operation is performed after the phosphoric slurry is driven in at a high temperature, silica and silicon nitride are grown on the front surface and the back surface of the silicon chip soas to perform passivation operation, a silver electrode and a silver-aluminium paste are printed on the back surface of the silicon chip, and one-time sintering operation is performed. According to the battery and the preparation method disclosed in the invention, an IBC battery structure can be prepared via simple equipment and technology, laser equipment and screen printing are used for preparing a main structure of the IBC battery; the battery and the method are simple in processing steps and low in cost and is suitable for large scale industrial production.

Owner:锦州阳光能源有限公司 +1

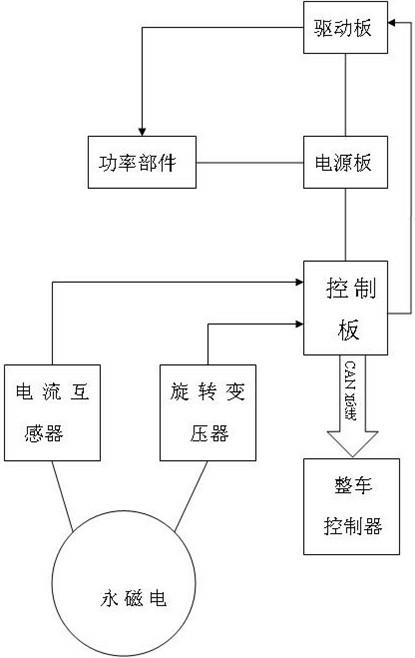

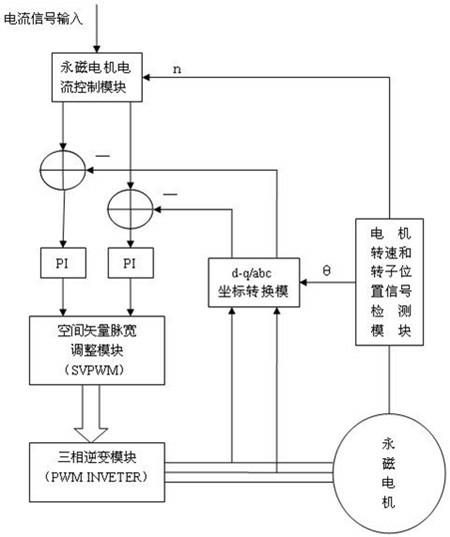

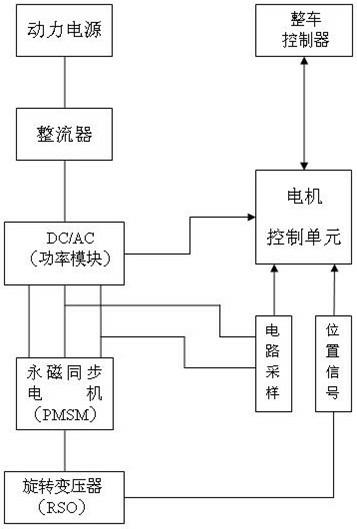

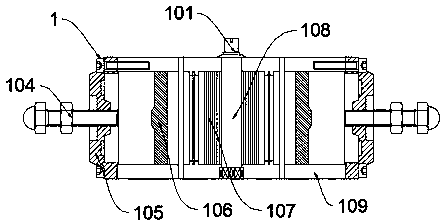

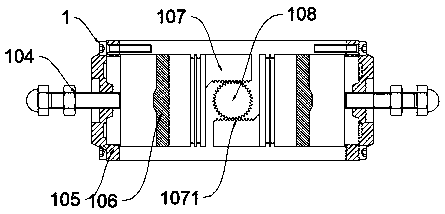

Permanent magnet motor controller applied to pure electric car and control method

InactiveCN102684576AGuaranteed uptimeImprove acceleration characteristicsElectronic commutation motor controlAC motor controlMotor speedElectric machine

The invention discloses a permanent magnet motor controller applied to a pure electric car and a control method. The controller is mainly composed of a power panel, a control board, a drive board and a power component; the power panel is connected with the control board, the drive board and the power component; the control board is connected with a vehicle controller through a CAN bus; the control output of the control board is connected with the drive board; the output of the drive board is connected with the power component; a group of analogue quantity inputs of the control board are respectively connected with a current transformer and a rotary transformer; the current transformer is connected with a power terminal of the permanent magnet motor, and the rotary transformer is connected with the rotating shaft of the permanent magnet motor. The permanent magnet motor controller applied to the pure electric car disclosed by the invention can precisely control the rotating speed of the motor, effectively reduces the switching loss and greatly improves the dynamic response speed of the system and the acceleration characteristics of the motor. The controller can meet the requirement of the pure electric car, of which the power requirement is less than 60KW, just by exchanging a cooler and the drive board as to the electric cars with different requirements, and saves the production cost and the production cycle for a manufacturing plant of the controller.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

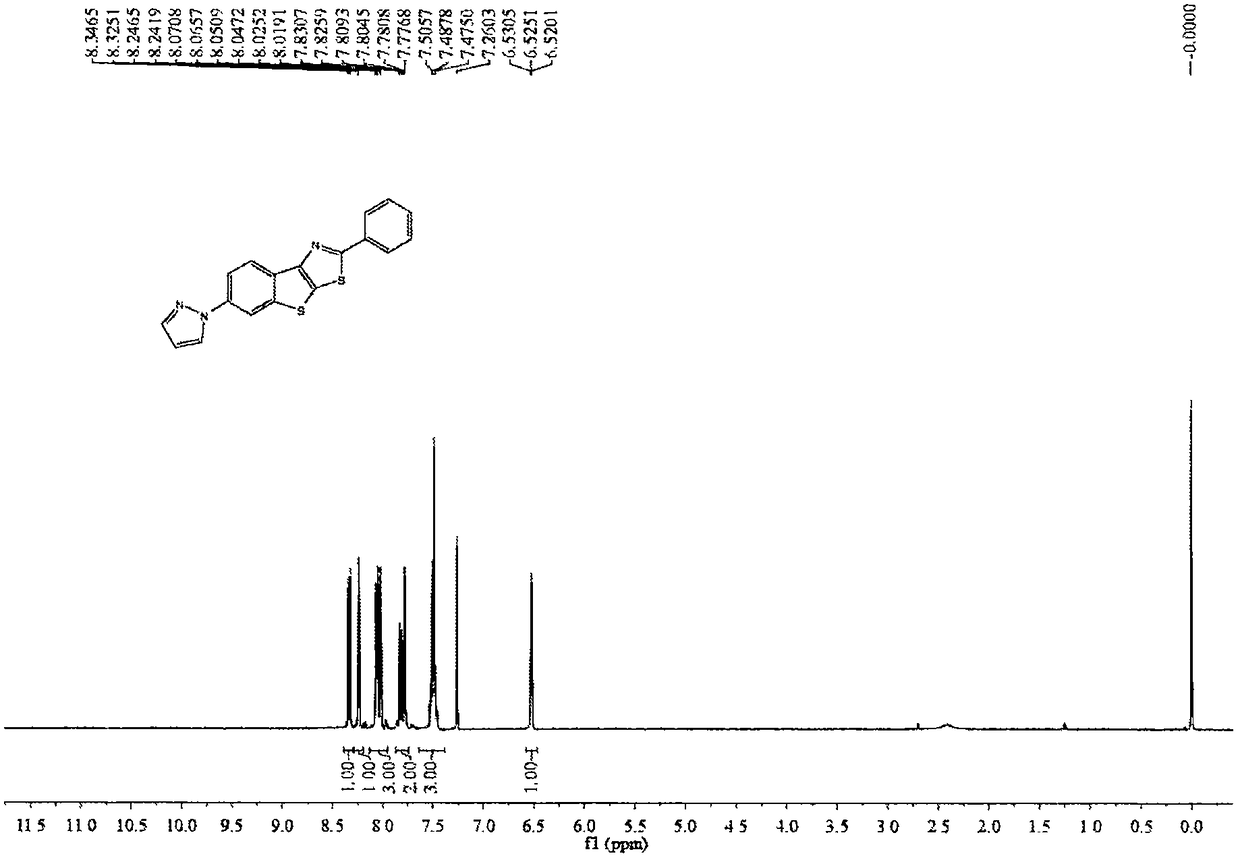

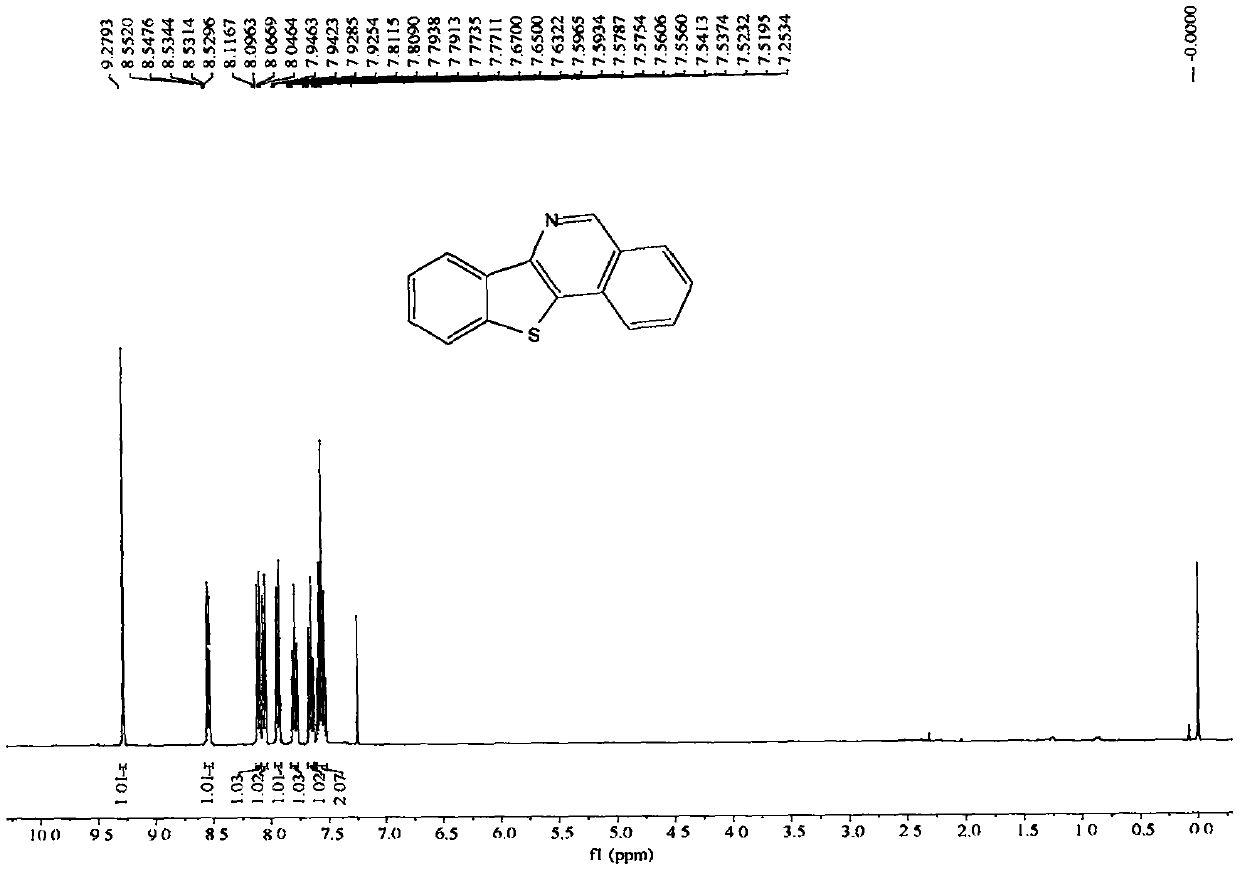

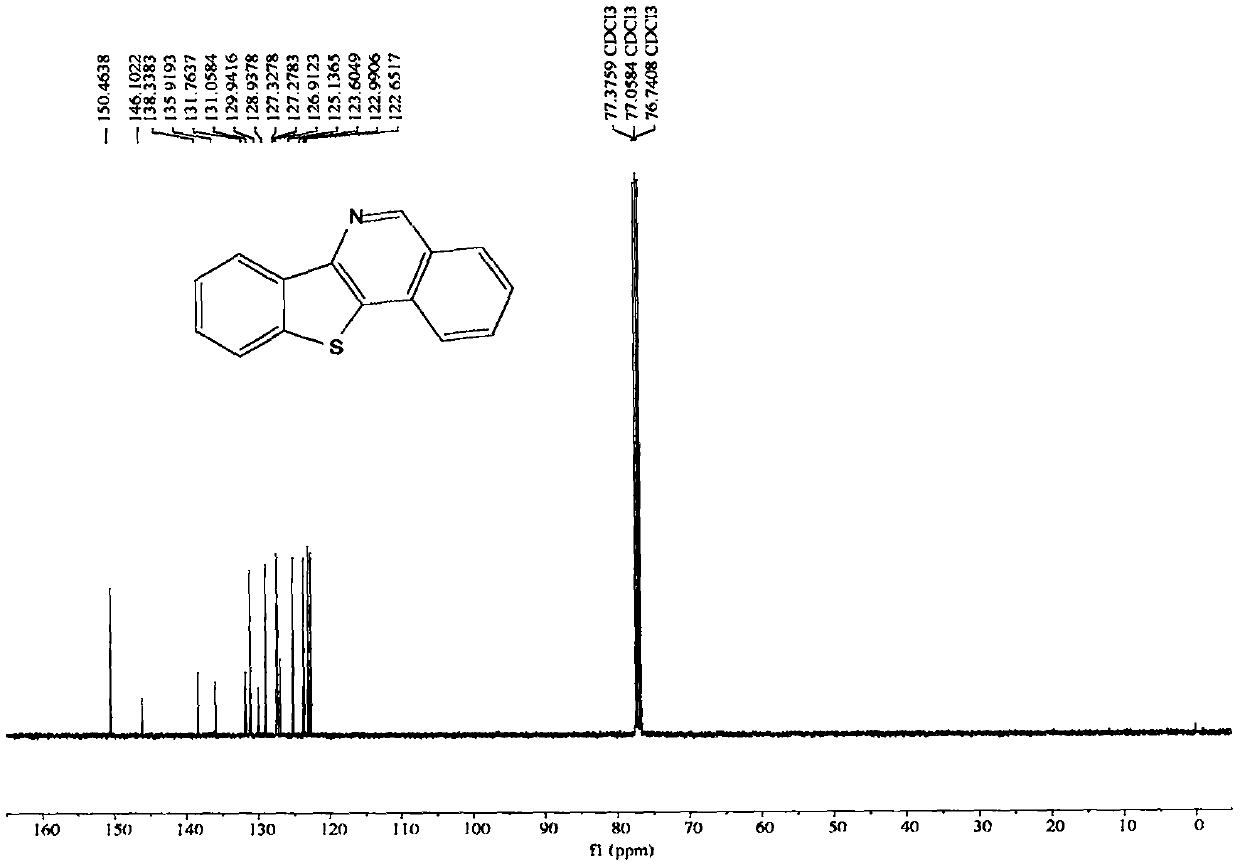

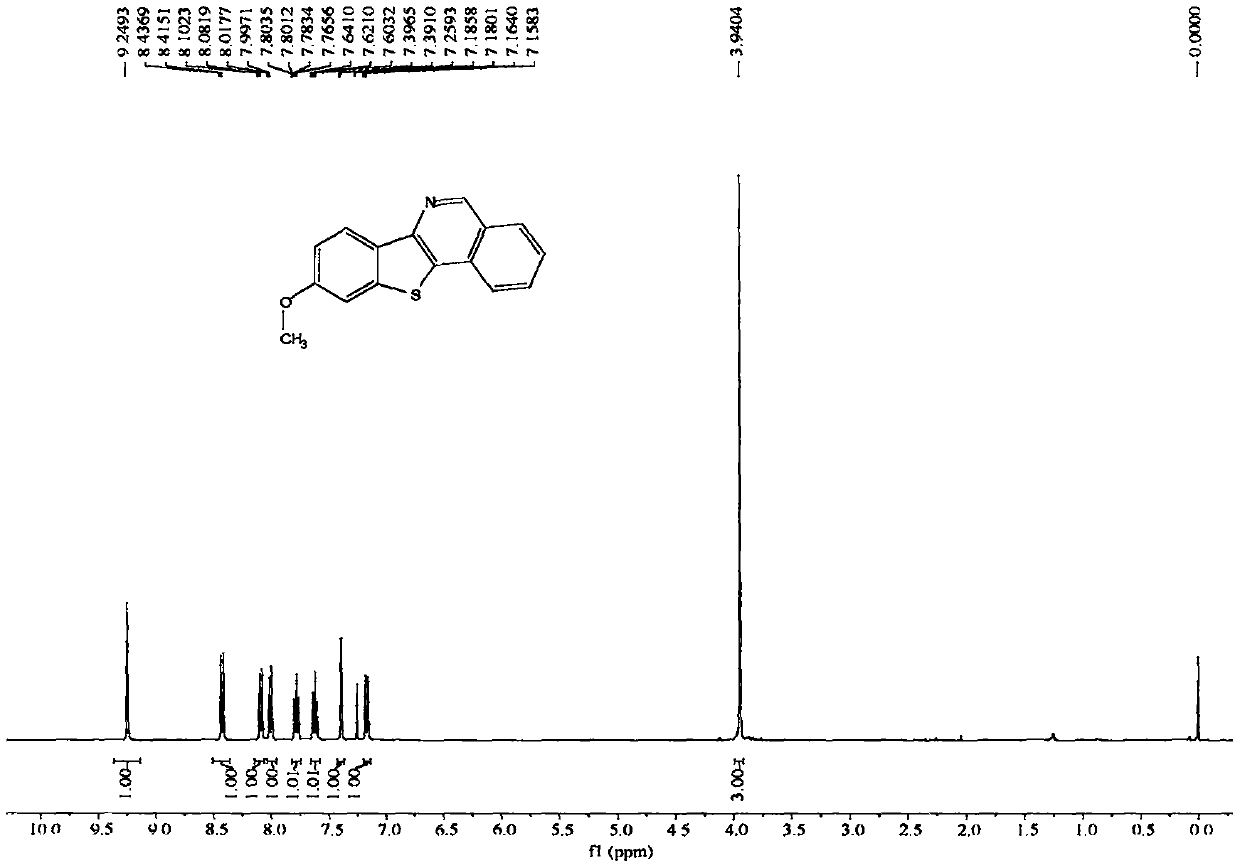

Polysubstituted benzothienoisoquinoline, derivative and synthesis method thereof

ActiveCN110606855AReduce pollutionReaction raw materials are cheap and easy to obtainOrganic chemistryAir atmosphereSynthesis methods

The invention relates to a polysubstituted benzothienoisoquinoline, a derivative and a synthesis method thereof. According to the method, a ketoxime ester compound, an o-chlorobenzaldehyde compound and sulfur powder are converted into benzo[4,5]thieno[3, 2-C]isoquinoline and derivatives thereof for the first time under the catalysis of Cu in the air atmosphere, wherein the prepared benzo[4,5]thieno[3, 2-C]isoquinoline is stable in molecular structure and excellent in chemical property. Reaction raw materials of the synthesis method are cheap and easy to obtain, pretreatment is not needed, andthe atom economy of the reaction is high; only a cheap copper catalyst is used in the reaction, environmental pollution is reduced, raw materials are saved, and reaction cost is reduced; the whole reaction system is simple, reaction conditions are mild, reaction equipment is less, experimental operation is simple and convenient, and material sources are wide.

Owner:XIANGTAN UNIV

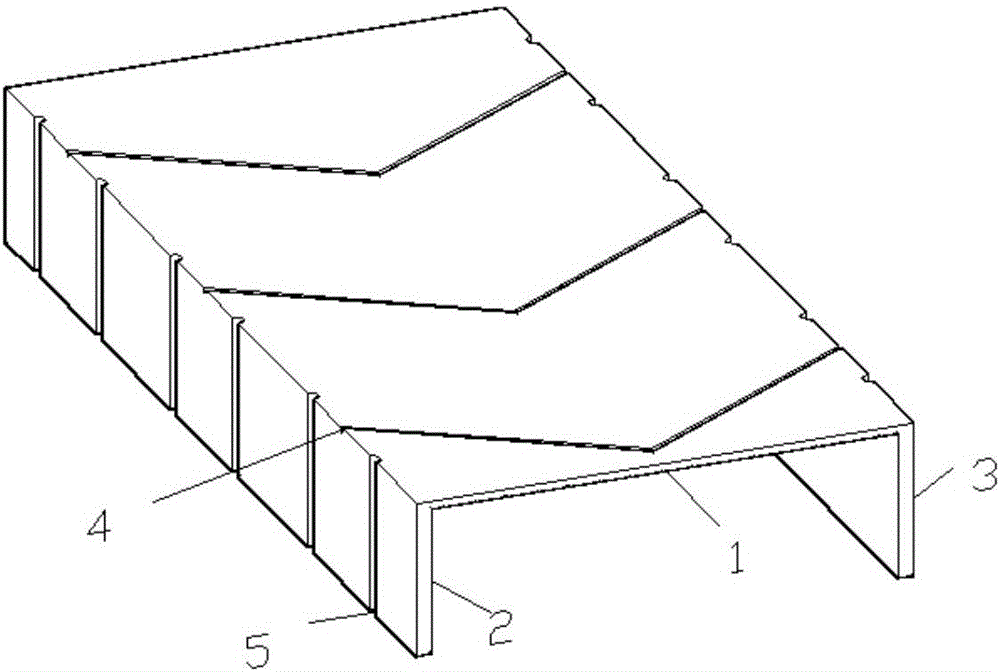

Steel channel for pipe ditch cover plate, rolling device of steel channel for pipe ditch cover plate and rolling method

ActiveCN106345804ATimely exclusionTo meet manufacturing needsMetal rolling stand detailsMetal rolling arrangementsEngineeringDitch

The invention discloses a rolling device of hot-rolled steel channel for a pipe ditch cover plate and a production method. The steel channel comprises a web plate, a first wing plate and a second wing plate, wherein the web plate is rectangular, and two ends of the web plate are respectively connected with the first wing plate and the second wing plate. The rolling device comprises a rolling device body for rolling a hot-rolled steel channel body for the pipe ditch cover plate and a finishing mill for rolling web plate outer side stripes and flange outer side stripes on the hot-rolled steel channel body for the pipe ditch cover plate. The finishing mill is provided with an upper horizontal roller and a lower horizontal roller, and the central axis of the upper horizontal roller and the central axis of the lower horizontal roller are mutually parallel. The finishing mill is provided with a left vertical roller and a right vertical roller, and the central axis of the left vertical roller and the central axis of the right vertical roller are mutually parallel. By the adoption of the technical scheme, the production period of a streel structure production enterprise is shortened, the manufacturing cost of the enterprise is saved, and the stability and rigidity of the hot-rolled steel channel for the pipe ditch cover plate are improved.

Owner:SHANDONG IRON & STEEL CO LTD

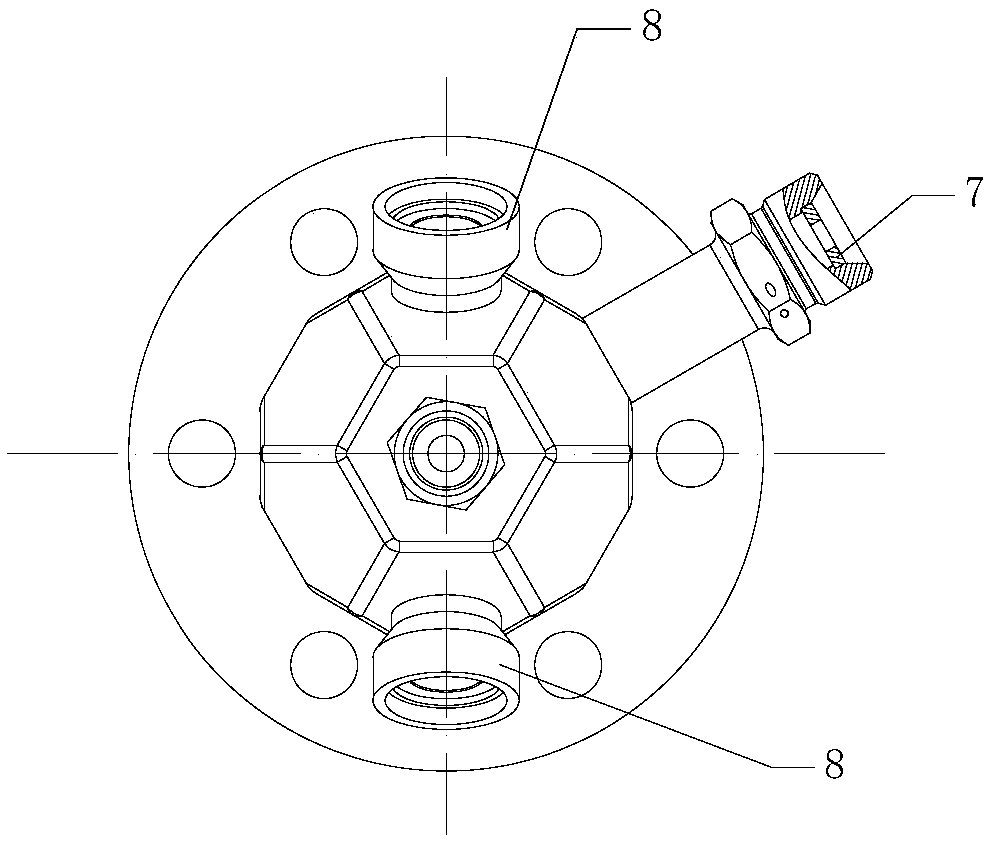

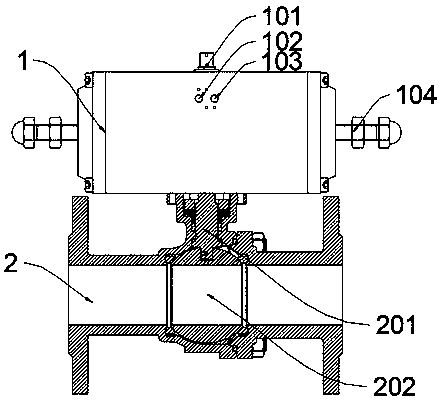

Total-travel regulating pneumatic valve

PendingCN110440048AGuaranteed accuracyCut costsPlug valvesOperating means/releasing devices for valvesPneumatic valveCylinder block

The invention discloses a total-travel regulating pneumatic valve, relates to the field of pneumatic valves, and solves the problem that in the prior art, the travel of a pneumatic executing mechanismis adjusted only at two positions of 0 degree and 90 degrees. A lengthening and limiting regulating screw is mounted between the two sides of a pneumatic executing mechanism; the pneumatic executingmechanism comprises a cylinder block; a gear is mounted in the middle of the inner part of the cylinder block; saw-toothed thrust sliding blocks are correspondingly arranged on two sides of the gear;a piston is mounted on one side of each saw-toothed thrust sliding block; the saw-toothed thrust sliding blocks comprise sliding racks; an air inlet and an air outlet are formed in the middle of the upper end of the front end surface of the pneumatic executing mechanism; an output shaft is mounted in the middle of the upper end of the pneumatic executing mechanism; end covers are correspondingly mounted on two sides of the cylinder block; and a valve body is mounted at the lower end of the pneumatic executing mechanism, and comprises a valve rod and a valve ball.

Owner:SHANGHAI JULIANG VALVE GRP CO LTD

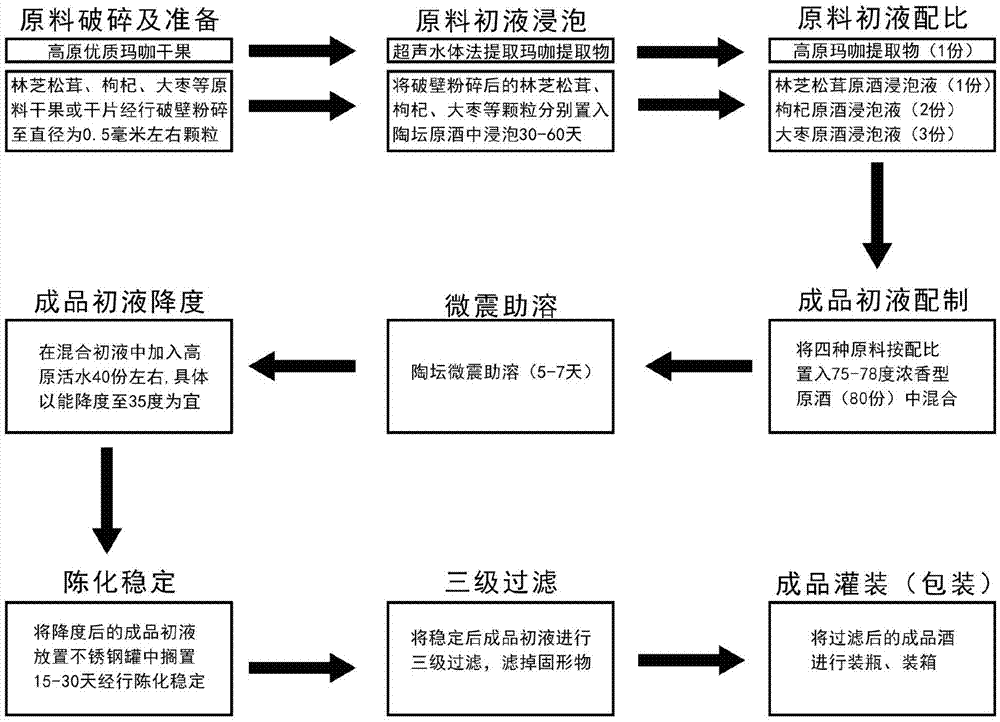

Health wine containing lepidium meyenii walp and preparation technique of health wine

InactiveCN104726303AExemption time periodGuaranteed accuracyDigestive systemAlcoholic beverage preparationLepidium meyeniiMatsutake

The invention discloses health wine containing lepidium meyenii walp and a preparation technique of the health wine. The health wine containing the lepidium meyenii walp, with the alcoholicity of 18-45 degrees, is prepared from 1 part of lepidium meyenii walp extract, 1 part of matsutake base wine soak liquid, 2 parts of Chinese wolfberry base wine soak liquid, 3 parts of Chinese date base wine soak liquid, 80 parts of base wine and the balance glacial water. The preparation technique includes lepidium meyenii walp extract preparation, preparation of the matsutake base wine soak liquid, the Chinese wolfberry base wine soak liquid and the Chinese date base wine soak liquid, mixing, solubilization helping, alcoholicity decreasing and aging. The preparation technique has the advantages that the lepidium meyenii walp extract is dissolved in the base wine directly, so that accuracy and controllability of macaenes and macamides content are guaranteed, a lepidium meyenii walp soaking time period is omitted, and production cycle and cost are saved greatly; dry slices or dry fruits of matsutake, Chinese wolfberries and Chinese dates are subjected to wall breaking and crushing to form fine particles with the diameter about 0.5mm for soaking, so that respective nutrient substances can be separated out quickly and sufficiently; by means of mixing and vibrating slightly to help solubilization, quick dissolution, sufficient stability and nonuniform dissolution elimination can be achieved, so that nutrition and efficacy quality of a wine body are guaranteed.

Owner:TIBET NYINGCHI FANWANG LIQUOR CO LTD

High-quality tool steel heat treatment steel strip and production method and application thereof

InactiveCN109338086AIncrease cooling ratePromote formationFurnace typesHeat treatment furnacesHeating furnaceMechanical property

The invention belongs to the technical field of steel manufacturing, and particularly relates to a high-quality tool steel heat treatment steel strip and a production method and application thereof. The production method of the high-quality tool steel heat treatment steel strip comprises the following steps that a cold-rolled tool steel strip serves as a raw material, heating is conducted in an austenitizing heating furnace, and then after salt bath quenching, hot leveling, tempering, cooling, straightening and coiling, the high-quality tool steel heat treatment steel strip is obtained. The produced high-quality tool steel heat treatment steel strip is uniform in mechanical property, has no obvious oxides, no decarbonization layer and no grain boundary oxidation layer on the surface, and is short in production cycle and low in production cost.

Owner:湖南华菱涟源钢铁有限公司 +1

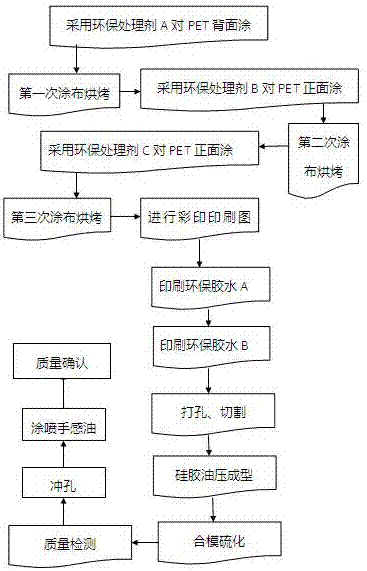

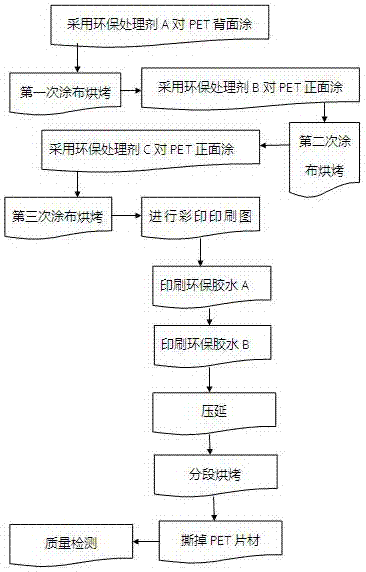

In-mold integral pattern forming technology for silica gel watch band with large radian surface

PendingCN107351303ASave production cycleSave production costBraceletsWrist-watch strapsColloidal silicaColor printing

The invention belongs to the technical field of in-mold transfer printing molding of silica gel finished products, in particular to an in-mold integral pattern forming technology for a silica gel watch band with a large radian surface. The in-mold integral pattern forming technology for the silica gel watch band with the large radian surface includes the following steps that step 1, an environment-friendly treatment agent A is adopted to conduct coating on the back face of a PET; step 2, a first coating drying is conducted; step 3, an environment-friendly treatment agent B is adopted to conduct coating on the front face of the PET; step 4, a second coating drying is conducted; step 5, an environment-friendly treatment agent C is adopted to conduct coating on the front face of the PET; step 6, a third coating drying is conducted; step 7, a 4 + 1 type Heidelberg printing press is adopted to conduct color printing to print a pattern; step 8, environment-friendly glue A is printed, and a fourth coating drying is conducted; step 9, environment-friendly glue B is printed, and a fifth coating drying is conducted; step 10, punching and cutting are conducted according to a mold structure and a product structure after the step 9; step 11, oil pressing forming is conducted on silica gel; step 12, desulfurization treatment is conducted by adopting a vulcanization technology; step 13, quality detection is conducted after the step 12; step 14, punching is conducted after the quality detection; step 15, hand feeling oil is coated on the surface; and step 16, quality determination is conducted. According to the in-mold integral pattern forming technology for the silica gel watch band with the large radian surface, integral production is achieved, the pattern can be printed on the large radian surface of the product, and perfect combination with the silica gel can be achieved.

Owner:东莞市松烁硅胶科技有限公司

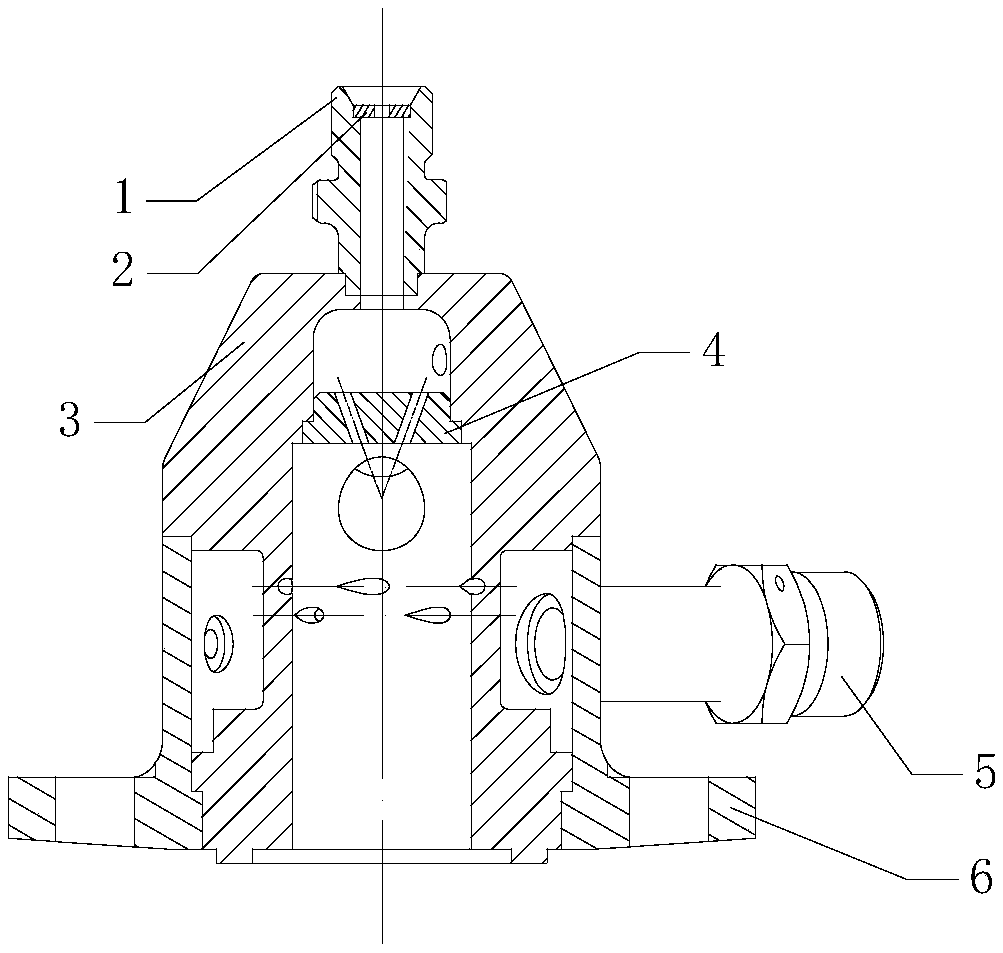

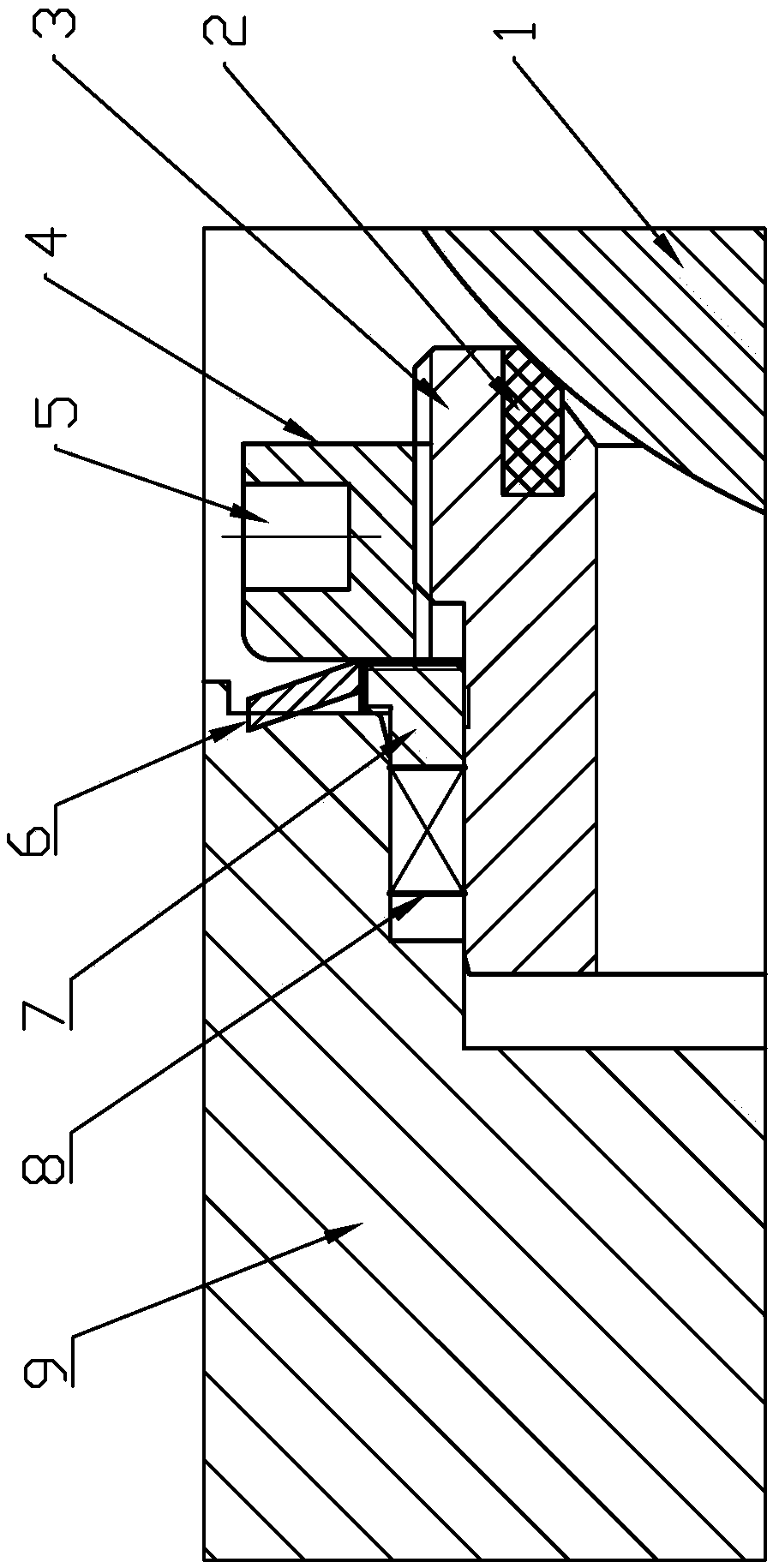

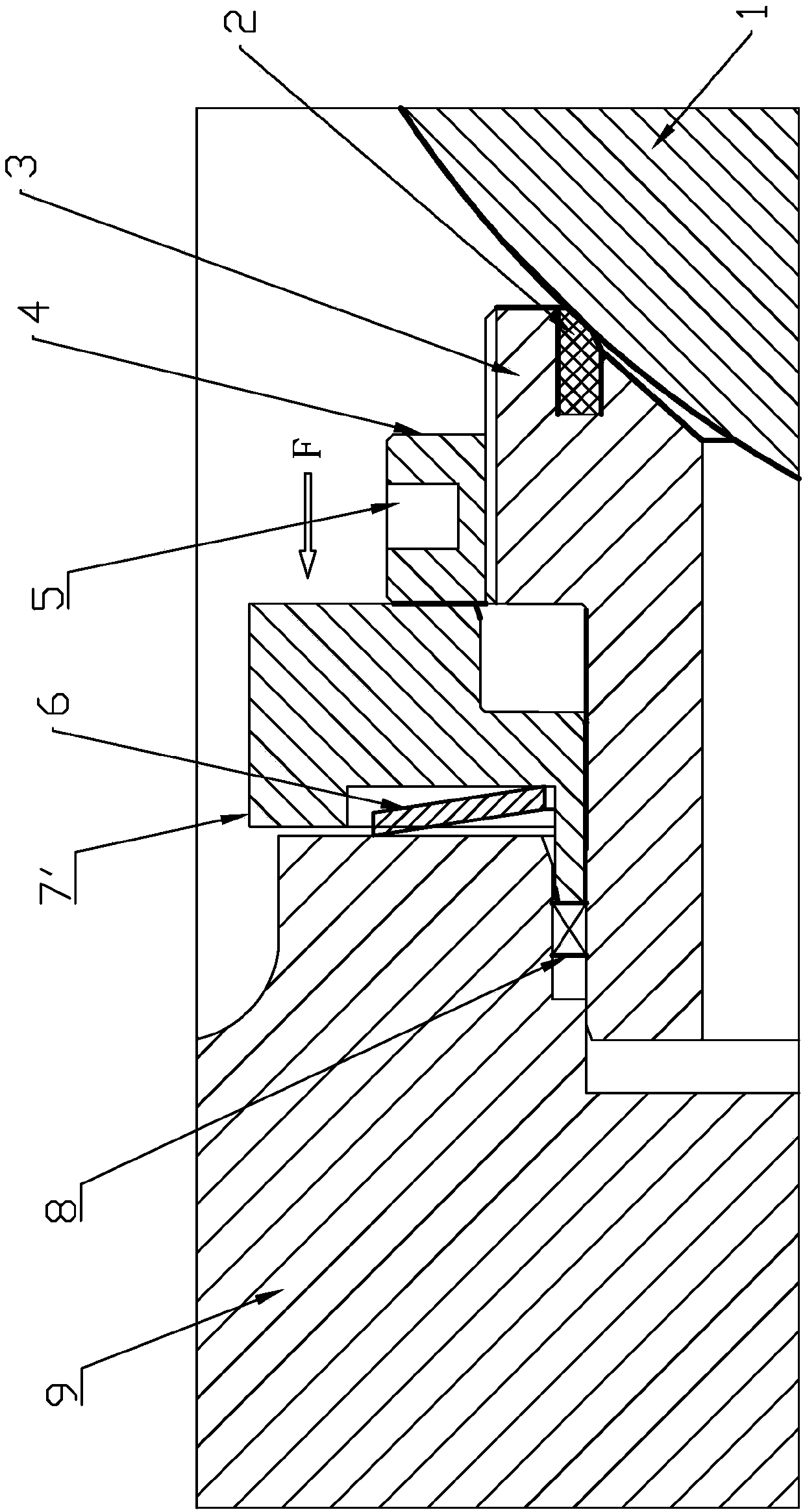

Low-temperature top-mounted ball valve seat structure and on-line maintenance disassembly method thereof

The invention provides a low-temperature top-mounted ball valve seat structure and an on-line maintenance disassembly method thereof. The low-temperature top-mounted ball valve seat structure comprises a valve body, a ball body, a valve seat metal ring, a tightening nut, a spring base, a spring base, a spring and a sealing ring, wherein one end of the valve seat metal ring extends into the valve body, and the other end is connected with the ball body hermetically; the sealing ring is arranged in a clearance formed by the valve seat metal ring and the valve body, and is connected with the valvebody hermetically; the tightening nut is connected to the outer side of the valve seat metal ring through threads; the spring base sleeves the outer part of the valve seat metal ring, and is locatedbetween the valve body and the tightening nut; the inner side end surface of the spring base presses the sealing ring tightly; the outer diameter of the spring base exceeds the diameter of the tightening nut; and the spring is connected between the valve body and the spring base in a resisted manner. During assembly or disassembly, a disassembly force is provided for pushing the spring base to move for a certain distance, so that the spring base is out of contact with the tightening nut; and the tightening nut can be screwed or unscrewed easily, so that time and labor are saved.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Blank blade correction method

ActiveCN104826895AThe orthopedic process is simpleSave production costShaping toolsHeat-affected zoneEngineering

The invention relates to a blank blade correction method. A cast blank blade is photographed, pictures are transmitted to a computer, the size of the blank blade is fit through a measuring scale and a three-dimensional number model, the blank blade is compared with a standard blade numerical model, and the deformation region and the deformation amount of the blank blade are determined; the blade is fixed to a steel plate platform and heated through a stacking heating wall and a heating burner, the blade is corrected multiple times through a jack via external force, and therefore the blank blade correction purpose is achieved; finally, the blade is delivered into a heat treatment furnace for relieving stress and shaping. By the adoption of the method, the correction process is simple, production cost is saved, a production period is shortened, a welding heat influence region is reduced, and product quality is improved.

Owner:LIAONING FU-AN HEAVY INDUSTRY CO LTD

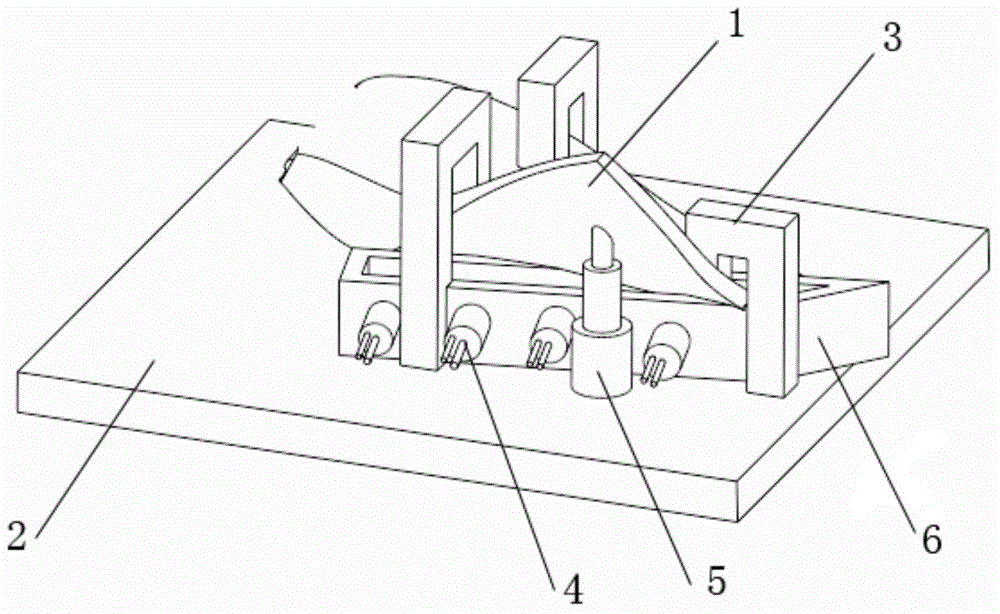

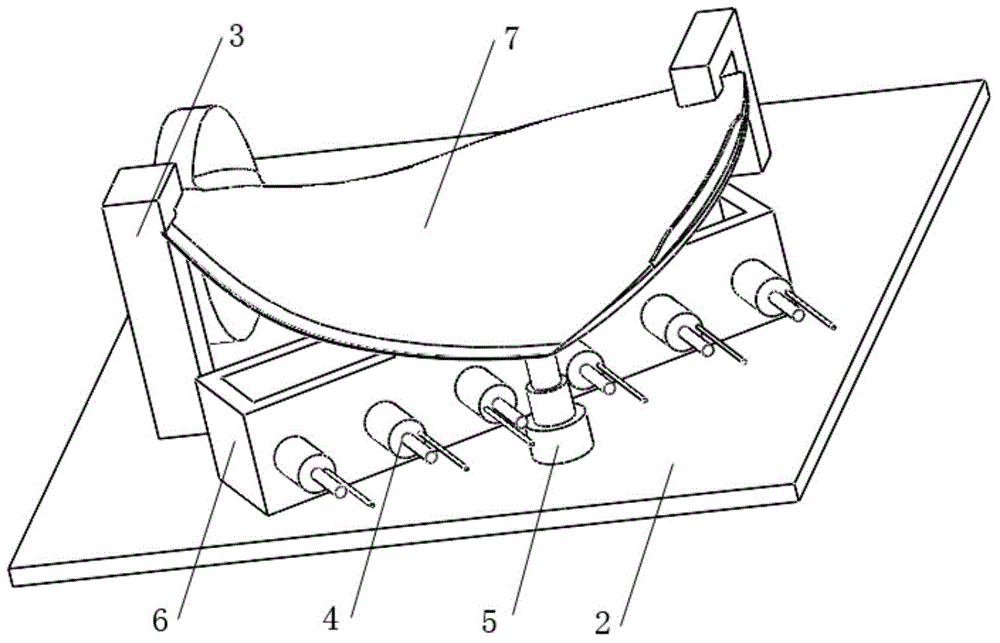

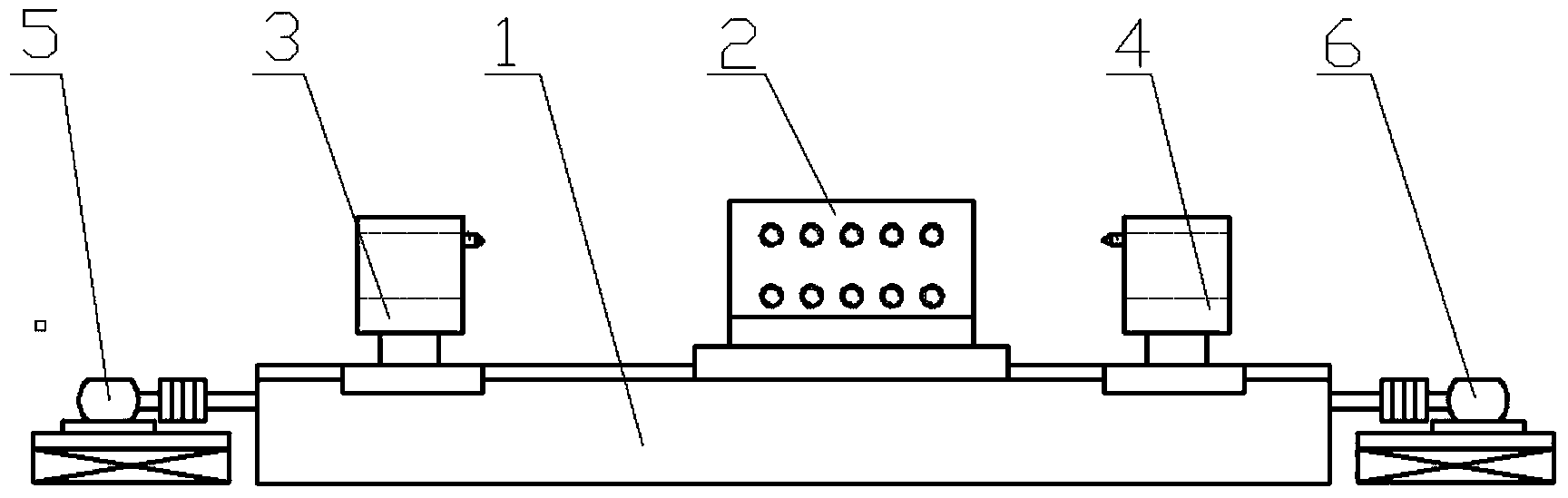

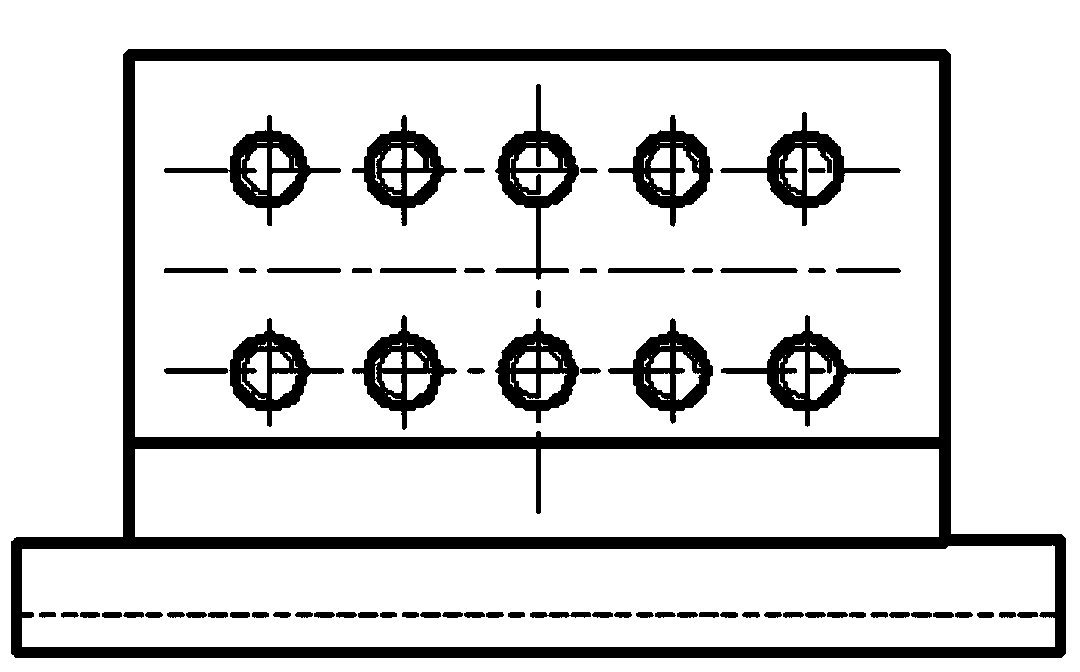

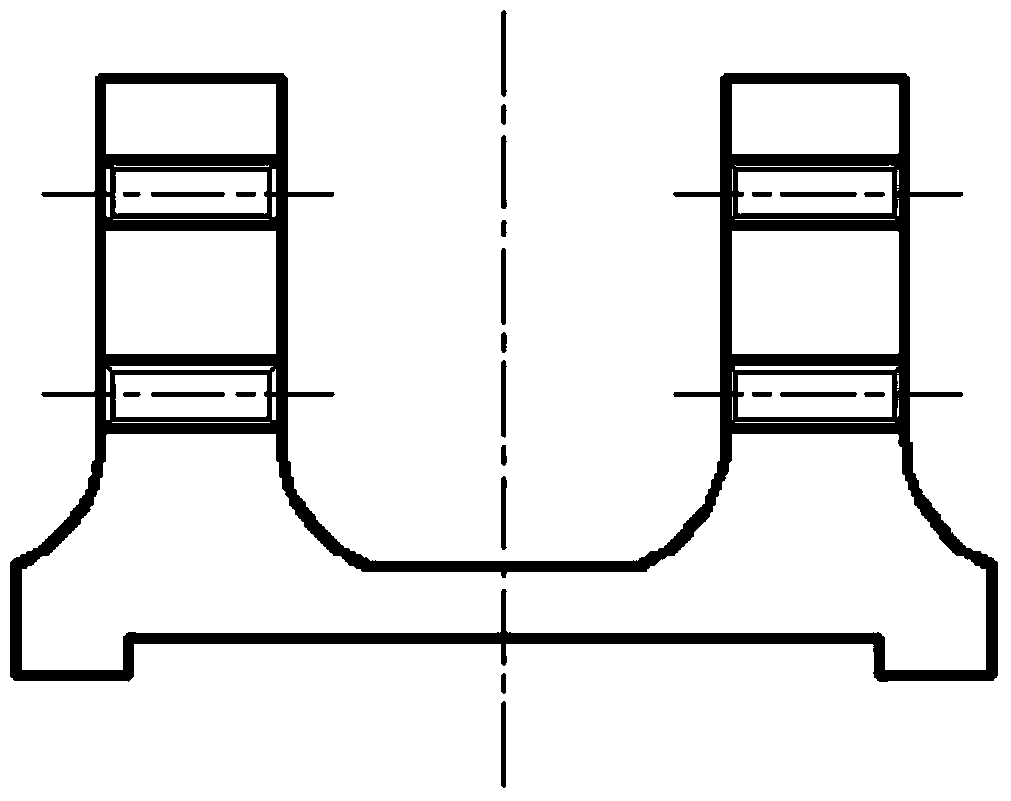

Large-scale water turbine guide vane two-end journal synchronous-processing device and method

InactiveCN104384583AReduce processing stepsAvoid repeated hangingWorkpiecesMilling equipment detailsWater turbineEngineering

The invention discloses a large-scale water turbine guide vane two-end journal synchronous-processing device and method. The device comprises a bed body, a guide vane positioning tool, a left milling head, a right milling head, a left driving tool and a right driving tool. Through one-step alignment, the device realizes synchronous-milling of two-end journals of a guide vane. The device and the method have the characteristics of strong versatility, operation simpleness, good repeatability and low production cost and satisfy processing requirements on various types of guide vane two-end journals.

Owner:HARBIN ELECTRIC MASCH CO LTD

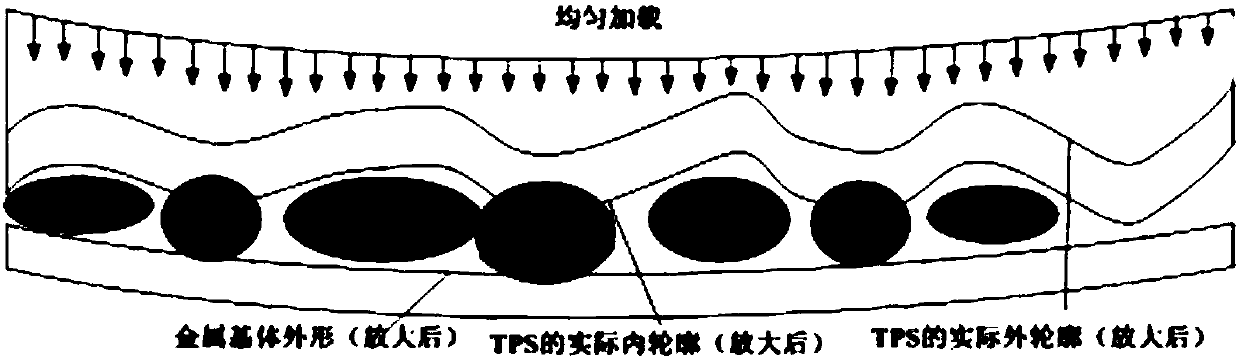

Repair method of multi-layer composite thermal protection component

The invention belongs to the technical field of thermal protection, and particularly relates to a repair method of a locally-damaged multi-layer composite thermal protection component. When the damaged area is not larger than 20mm*20mm and fiber suture lines are not damaged, the locally-damaged part is cleaned, and then the cleaned partially-damaged part is sealed with a thermal insulating tile; the bottom surface with adhesives, and the side surfaces with adhesives, of the thermal insulating tile, are glued; in order to protect the connection strength of the thermal insulating tile, grooves are designed in the side surfaces of the tile as adhesive storage grooves, so that the glue joint area can be increased; and the final aerodynamic configuration is obtained by polishing the upper surface of the thermal insulating tile. When the damaged area is larger than 20mm*20mm or the fiber suture lines are damaged, the locally-damaged part is cleaned, and then the multi-layer composite thermalprotection component is glued; the bottom surface, with adhesives, of the multi-layer composite thermal protection component is glued with a load-bearing structure; the gap between the multi-layer composite thermal protection component and the surrounding thermal protection component is sealed through a flexible thermal insulation material; and the adhesive layer thickness is adjusted according to the step difference between butt joint gaps of a repair part and the original gluing part, the adhesive layer thickness is controlled within 0.2mm - 0.8mm, and the final aerodynamic configuration isguaranteed.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

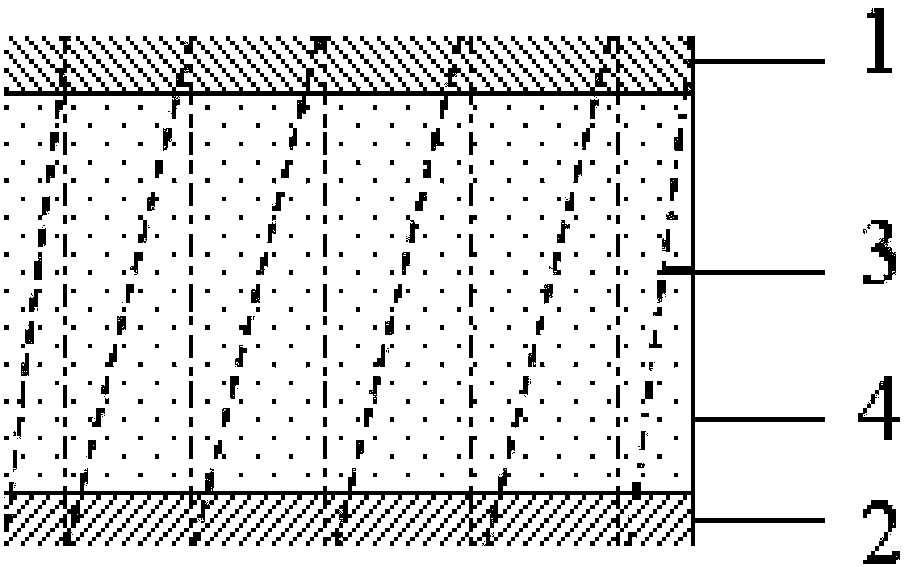

Process for integrally forming cloth and patterns through silica gel

The invention belongs to the technical field of silica gel manufactured products, and particularly relates to a process for integrally forming cloth and patterns through silica gel. The process comprises the following steps that an environment-friendly treating agent A is adopted for coating the back face of PET; coating baking is carried out for the first time; an environment-friendly treating agent B is adopted for coating the front face of the PET; coating baking is carried out for the second time; an environment-friendly treating agent C is adopted for coating the front face of the PET; coating baking is carried out for the third time; a 4+1 type Heidelberg printer is adopted for printing patterns through color printing; environment-friendly glue A is printed, and coating baking is carried out for the fourth time; environment-friendly glue B is printed, and coating baking is carried out for the fifth time; calendering is carried out after the step (9); sectional baking is carried out; and then quality checking is carried out. According to the process, production is completed integrally, the patterns can be printed on large-radian surfaces of products, and perfect combination with the silica gel is achieved.

Owner:东莞市松烁硅胶科技有限公司

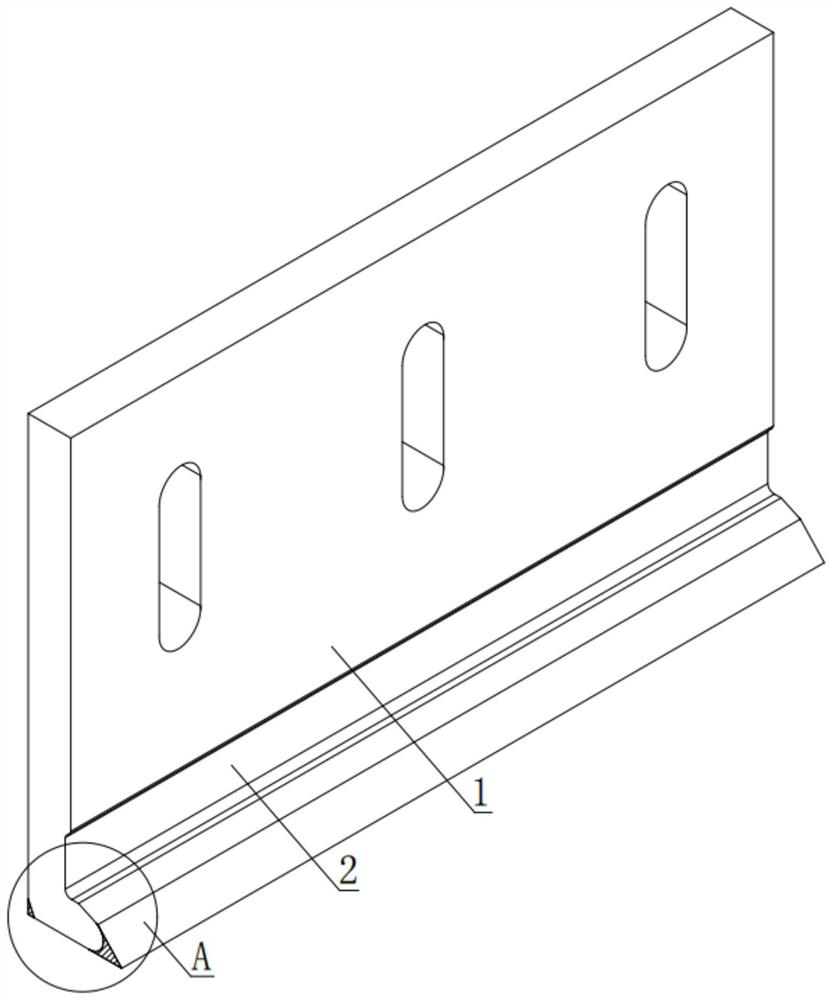

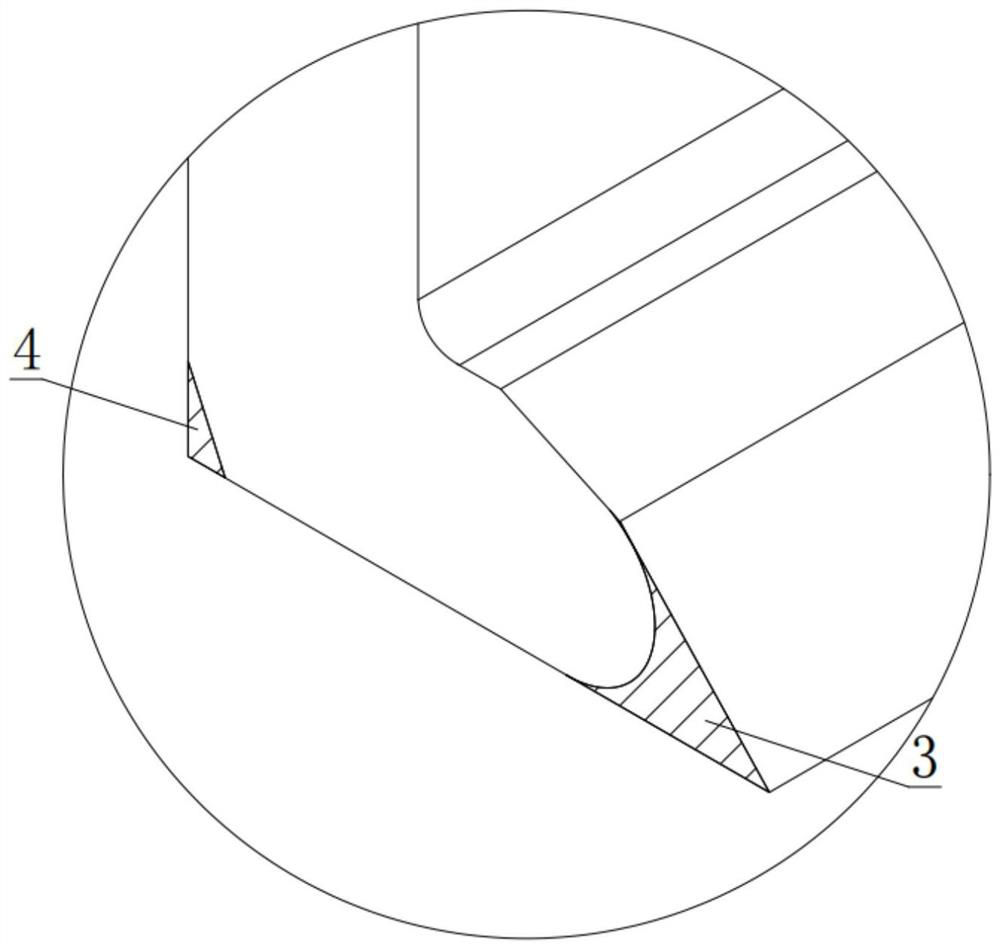

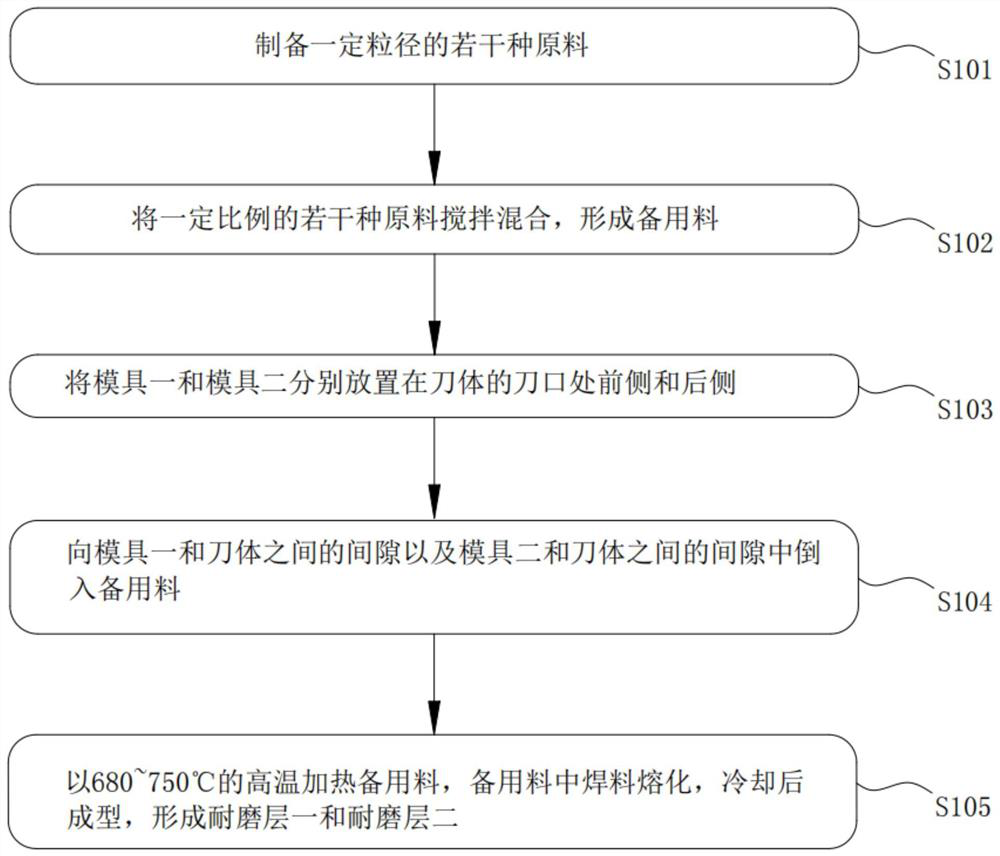

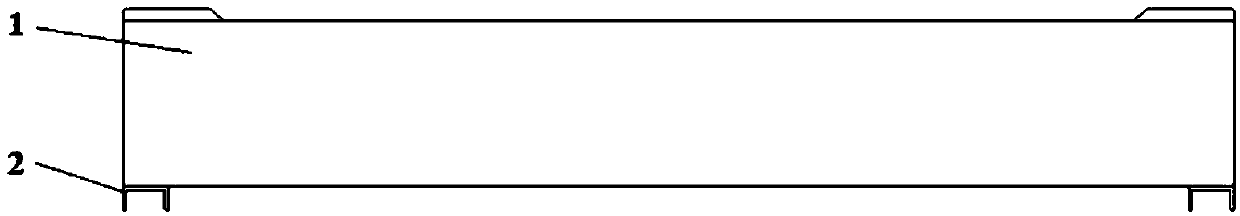

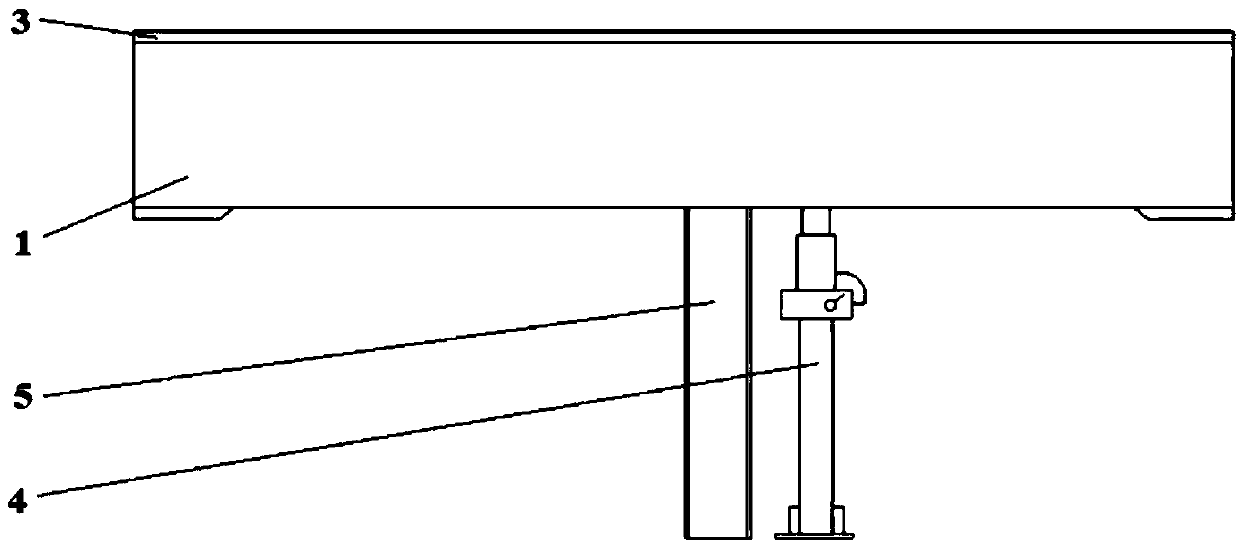

Scraper with wear-resistant layer at knife edge and production process of scraper

The invention discloses a scraper with a wear-resistant layer on a scraper edge and a production process of the scraper, belongs to the technical field of scrapers, and solves the problem that a wear-resistant layer of an existing scraper is severely abraded. The scraper comprises a scraper body, a flow guide groove, a first wear-resistant layer and a second wear-resistant layer, the scraper edge at the lower end of the scraper body extends forwards, and the end of the extending part is coated with the first wear-resistant layer; a first abrasion-resistant layer is arranged at the end corner of the lower end of the rear side of the cutter body, a diversion trench is formed above the cutter edge, a second abrasion-resistant layer is arranged at the end corner of the lower end of the rear side of the cutter body, and the first abrasion-resistant layer and the second abrasion-resistant layer are each composed of, by mass, 45%-73% of carborundum, 15%-30% of silica powder and 12%-25% of high-manganese steel welding flux. Various components with different particle sizes are mixed, the compactness of the scraper is improved, silica powder is added, the smoothness of the wear-resistant layer of the scraper can be improved, the hardness of the wear-resistant layer of the scraper can be further improved, and the wear resistance of the wear-resistant layer of the scraper is improved.

Owner:马鞍山宝祥机械刀模有限公司

Preparation and drying methods of pachymaran powder

ActiveCN108261418AExpensive to solveSolve the problem of energy consumptionPowder deliveryOrganic active ingredientsSodium bicarbonateSolubility

The invention belongs to the technical field of Chinese pharmaceutical manufacturing, and particularly discloses preparation and drying methods of pachymaran powder, for preparing and drying to obtainpachymaran powder by taking poria cocos as a raw material. The preparation method includes steps of extracting, desalination and drying. In the method, sodium hydroxide solution or sodium bicarbonatesolution is used for stirring extraction, and thus cost and energy consumption of organic reagents are reduced greatly, production cycle and cost are saved and environmental protection is facilitatedas compared with conventional water-reflux extraction ethanol precipitation method or ethanol reflux extraction method. The drying method refers to the method of preparing pachymaran powder by decompression drying after ambient drying, which solves the problems of low spray drying efficiency, poor product quality and the like due to the fact that pachymaran with poor water solubility is not easyto form a homogeneous system in water. The preparation and drying methods are simple, convenient to operate, and good for industrial production.

Owner:武汉回盛生物科技股份有限公司

Non-core-plate bearing vehicle body deflection forming method

ActiveCN109552348ASatisfy the requirement of upward deflection 2mm~12mm”Eliminates the effect of welding downdeflectionRailway transportAxle-box lubricationVehicle frameEngineering

The invention discloses a non-core-plate bearing vehicle body deflection forming method. By the adoption of the method, through multiple times of pre-deflection, a middle beam and side beams between two sleeper beams of a non-core-plate bearing vehicle body deflect upwards by 2 mm to 12 mm. The method includes the following steps that firstly, after the front face of a vehicle frame is assembled and welded, the vehicle frame is overturned, the two ends of the vehicle frame are cushioned by steel channels, and the back face is welded; secondly, after the vehicle frame is welded and before an iron floor is welded, the two ends of the vehicle frame are fixed, the middle portion of each side beam deflects 10 mm to 15 mm in advance, and then the iron floor is welded; thirdly, before the vehicleframe and an upper body are combined, the two ends of the vehicle frame are fixed, the middle portion of each side beam deflects 10 mm to 15 mm in advance, and then the vehicle frame and the upper body are combined; and fourthly, before a skin is assembled, the two ends of the vehicle frame are fixed, the middle portion of each side beam deflects 10 mm to 15 mm in advance, and then the vehicle body is covered with the skin. By the adoption of the non-core-plate bearing vehicle body deflection forming method, through multiple times of pre-deflection, the middle beam and the side beams betweenthe two sleeper beams of the non-core-plate bearing vehicle body deflect upwards by 2 mm to 12 mm.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Airfoil unfolding mechanism and folding wing flight device

ActiveCN114802709ASimple processing technologyIncrease profitWing adjustmentsWire cuttingEngineering

The airfoil surface unfolding mechanism comprises an airfoil rotating shaft, the airfoil rotating shaft is sequentially sleeved with a first airfoil and a second airfoil, an unfolding mechanism mounting base is arranged on one side of the airfoil rotating shaft, and the first airfoil and the second airfoil are connected with the unfolding mechanism mounting base through elastic pieces; a boss is further arranged on the unfolding mechanism mounting seat, the elastic sheet can effectively prevent the second wing and the first wing from reversing after being unfolded, and the boss prevents the second wing and the first wing from being excessively unfolded, namely the second wing and the first wing are prevented from continuing to rotate after being unfolded in place; according to the folding wing flying device, the structure is simple, the number of parts is small, the weight is light, buffering parts are made of finished foamed aluminum, locking reeds are machined through spring steel wire cutting, the machining technology is simple, the material utilization rate is high, the production period can be greatly shortened, and the production cost can be greatly reduced. And the wing surface unfolding mechanism is mounted on the fuselage by utilizing the unfolding mechanism mounting seat.

Owner:XIAN LINGKONG ELECTRONICS TECH CO LTD

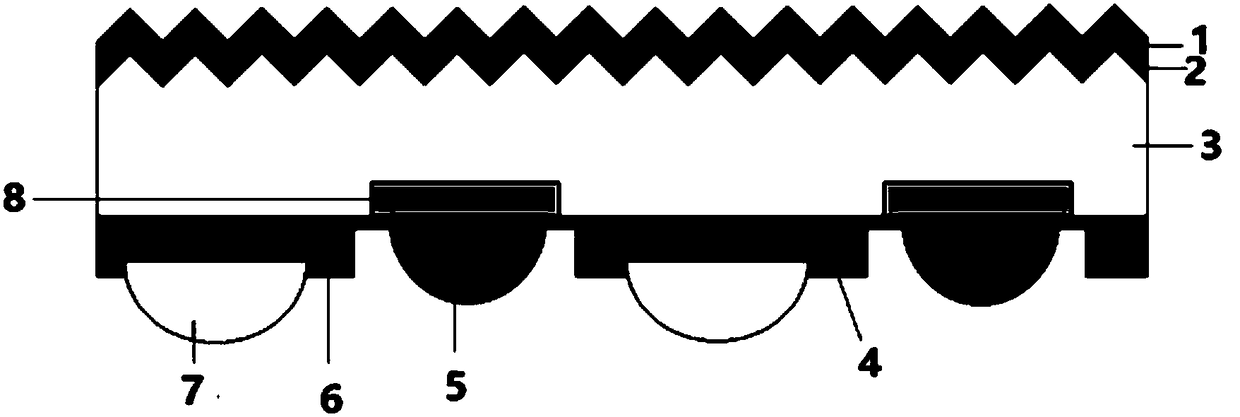

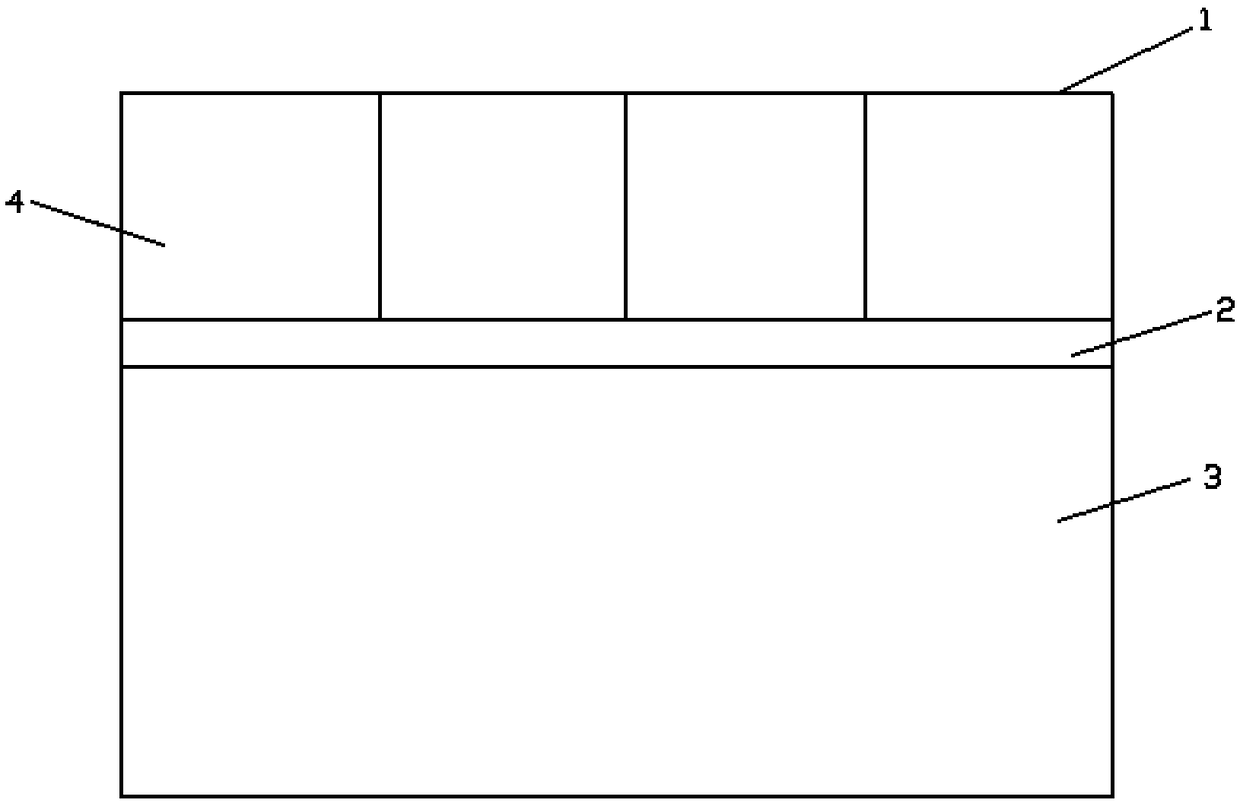

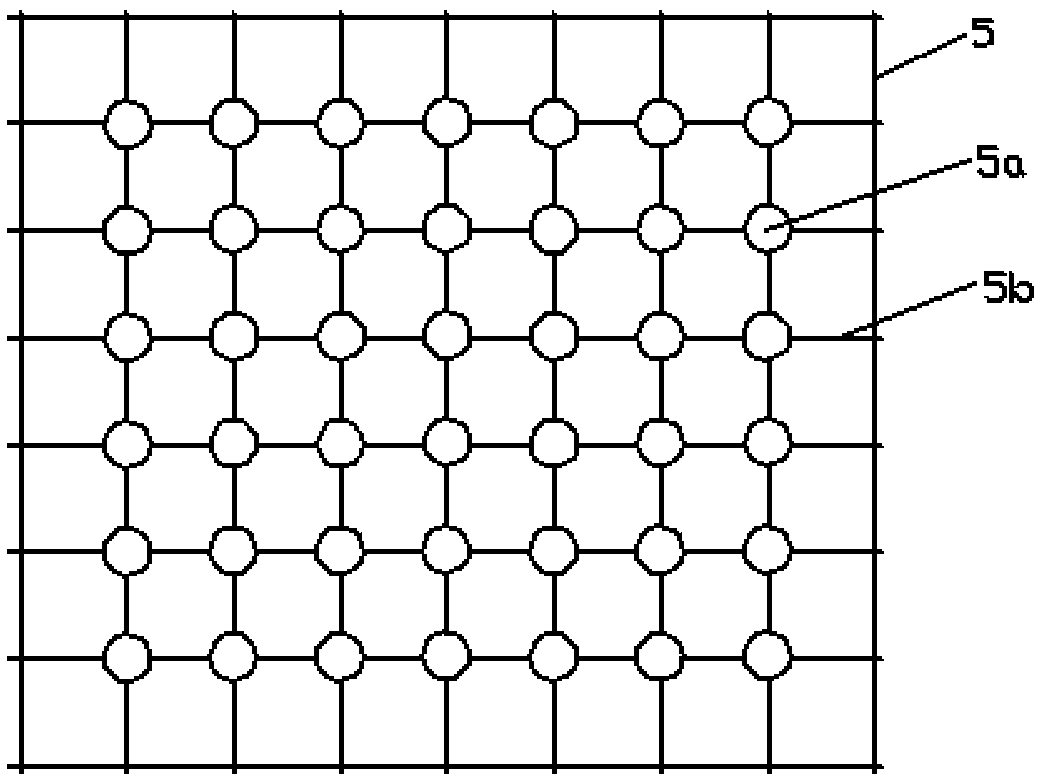

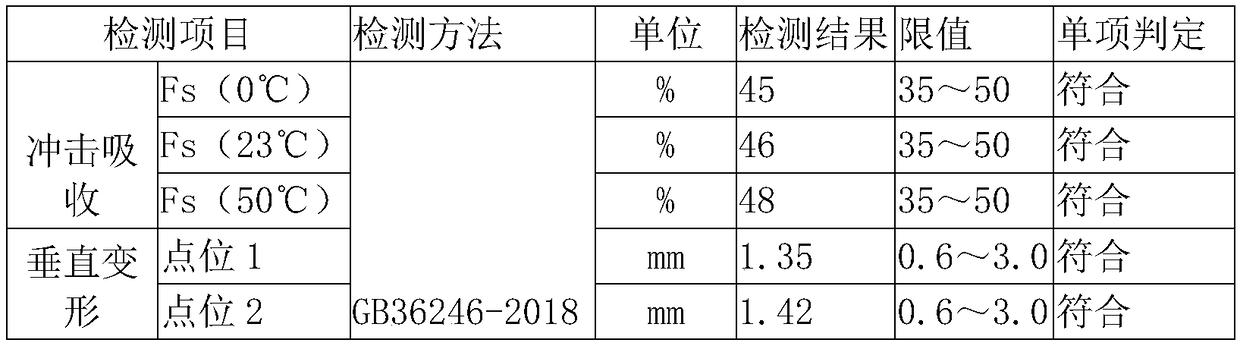

ETPU (expanded thermoplastic polyurethane) prefabricated type sport floor and method for preparing same

InactiveCN109487658ALow costMeet the sports experienceGround pavingsSurface layerPolyurethane adhesive

The invention discloses an ETPU (expanded thermoplastic polyurethane) prefabricated type sport floor which comprises a surface layer, a glue layer and a foundation layer. The surface layer, the glue layer and the foundation layer are sequentially arranged from top to bottom, the surface layer is an ETPU prefabricated block layer, the thickness of the surface layer is 8-25 mm, and the foundation layer is a concrete or asphalt poured ground. The invention further discloses a method for preparing the ETPU prefabricated type sport floor. The method includes steps of 1), preparing TPU (thermoplastic polyurethane) molding plates from TPU particles by the aid of injection molding processes; 2), preparing ETPU prefabricated blocks from the TPU molding plates, which are prepared at the step 1), bythe aid of physical foaming processes; 3), thoroughly cleaning the surfaces of the foundation layer and paving polyurethane adhesive on the foundation layer to obtain the glue layer; 4), paving the ETPU prefabricated blocks, which are prepared at the step 2), on the glue layer. The TPU molding plates are grid plates, and a plurality of support columns are arranged on the lower surfaces of the TPUmolding plates.

Owner:湖北科蓝科技有限公司

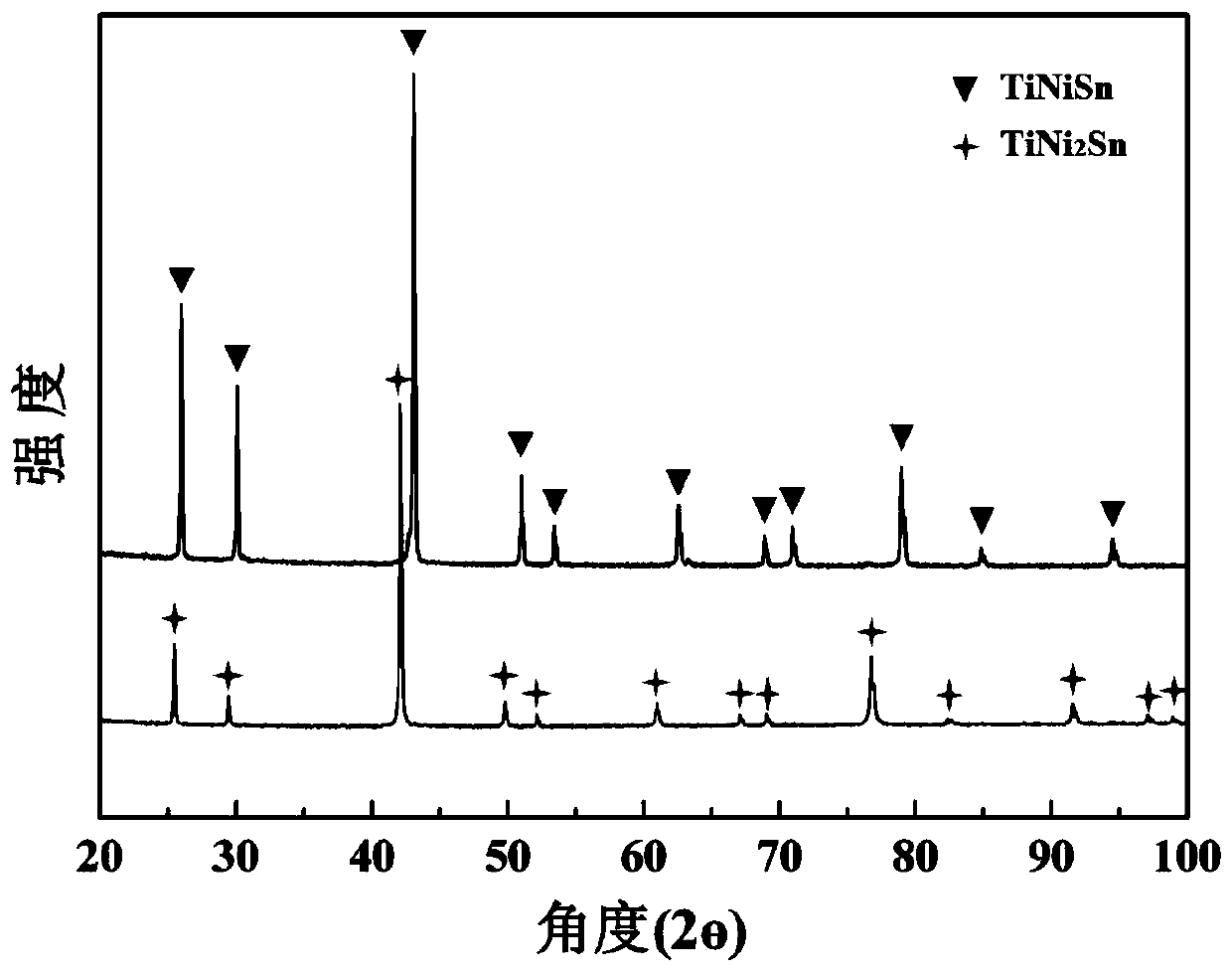

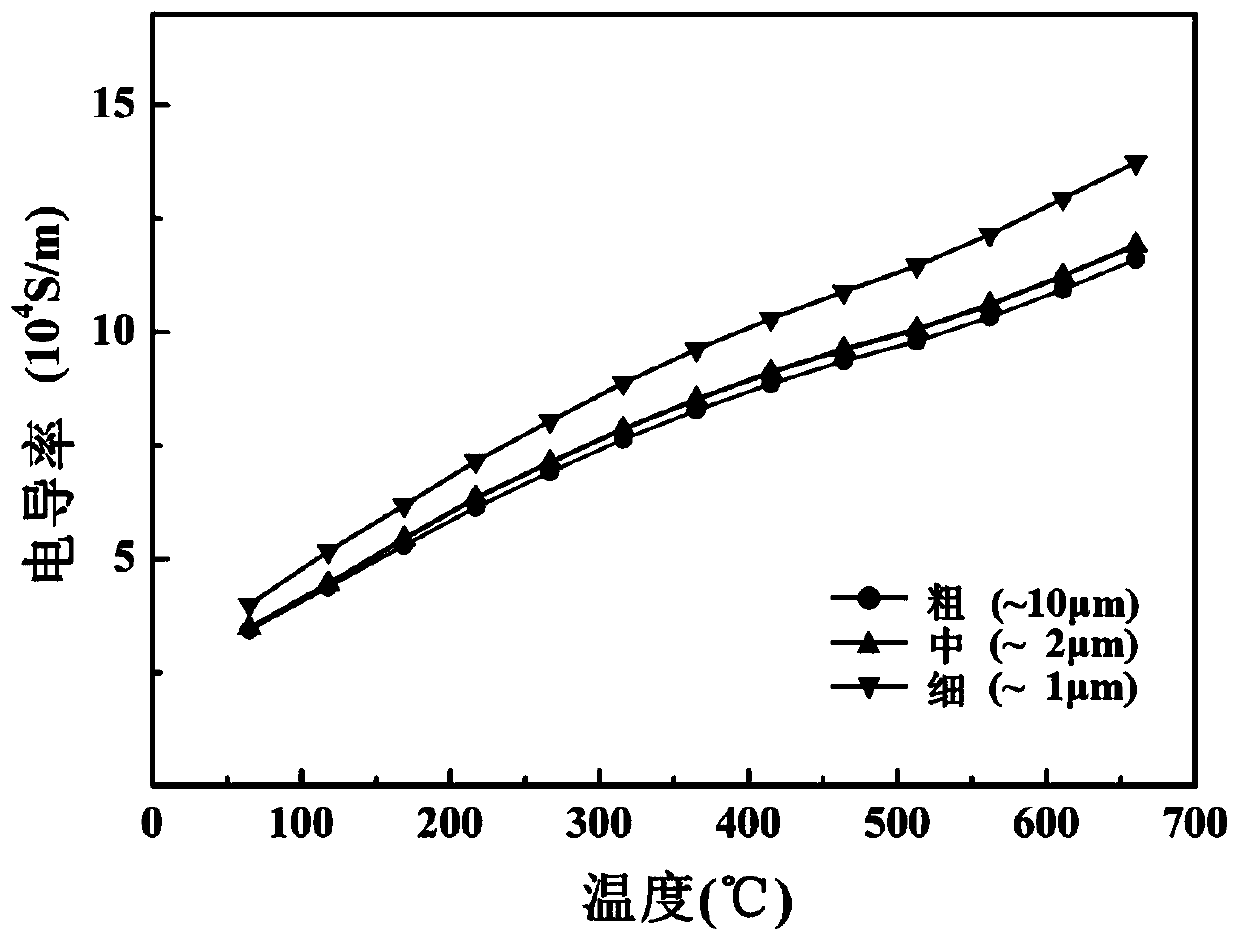

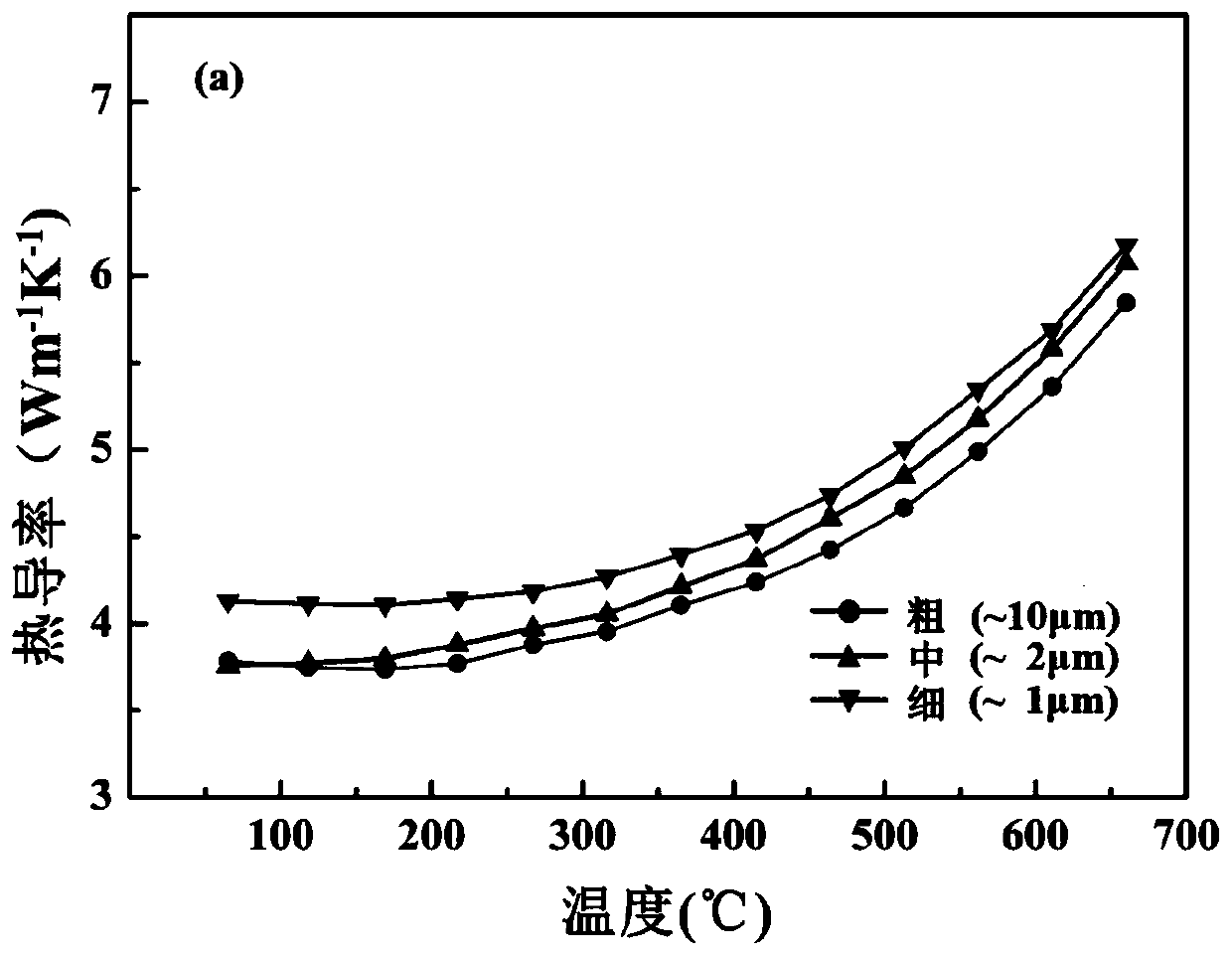

TiNiSn-based Half-Heusler thermoelectric material doped with second phase and preparation method thereof

InactiveCN110649147AImprove thermoelectric performanceImprove thermoelectric figure of merit ZTThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsMetallurgy

The invention provides a TiNiSn-based Half-Heusler thermoelectric material doped with a second phase and a preparation method thereof. The processing method of the thermoelectric material comprises the following steps: preparing TiNiSn and TiNi2Sn raw materials; smelting the TiNiSn and TiNi2Sn raw materials; grinding and drying a TiNiSn cast ingot and a TiNi2Sn cast ingot; preparing a dried TiNi2Sn second phase and a dried TiNiSn matrix with different average grain sizes according to a target component TiNi<1.01-1.20>Sn; performing drying treatment; and sintering prepared powder by adopting adischarge plasma sintering technology to obtain a TiNiSn-based Half-Heusler thermoelectric material doped with a second phase. The method has the advantages of short process, few steps and easiness incontrol. The problem that the morphology, size and distribution of in-situ growth of a second phase prepared by a traditional method cannot be controlled is solved.

Owner:DALIAN UNIV OF TECH

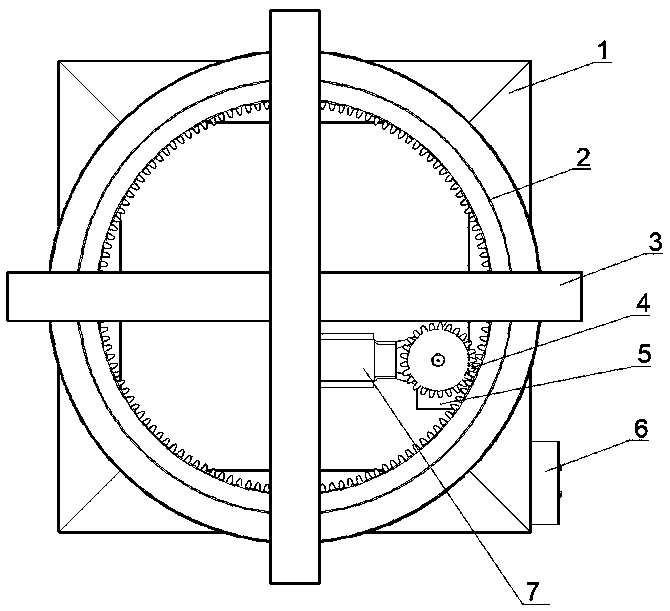

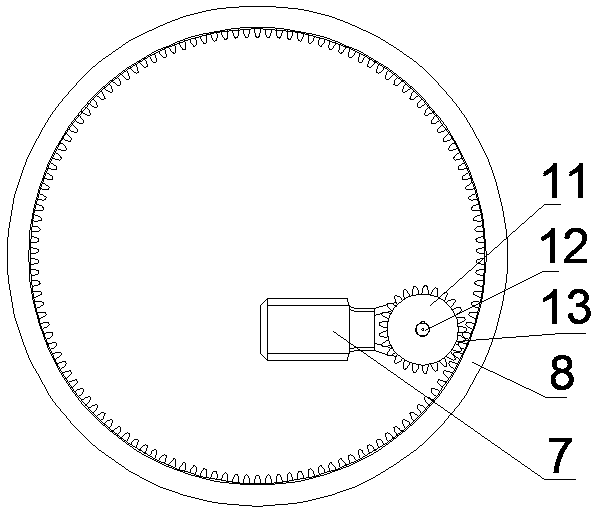

Convenient horizontal rotating device

PendingCN111496359ASolve the difficulty in realizing the shear ring plateSolve the problem of horizontal submerged arc welding of the cylinderWelding accessoriesGear driveSwitch box

The invention discloses a convenient horizontal rotating device. The convenient horizontal rotating device comprises a bottom platform; a rolling ball rotating system is arranged above the bottom platform; the rolling ball rotating system is driven through a gear transmission system; a switch box is arranged on the side surface of the bottom platform; the switch box is connected with a motor; themotor is fixed to the bottom platform through a safety fixing device; and the motor is connected with the gear transmission system. According to the convenient horizontal rotating device, horizontal submerged arc welding of an anti-shear annular plate and a cylinder is realized; the horizontal rotating device is easy to operate, small in occupied place; the safety of a welder is greatly improved;the workshop production efficiency is improved; and the production cost and the production period are reduced.

Owner:NANJING CHINA CONSTR CHEM EQUIP MFG +1

In-mold integral-forming image and text transfer printing method for silicone button

InactiveCN109263322ASave production cycleSave production costDuplicating/marking methodsOther printing apparatusKey pressingVulcanization

The invention provides an in-mold integral-forming image and text transfer printing method for a silicone button. The method comprises the following steps of 1) back coating of a PET sheet; 2) front coating of the PET; 3) coating on paraffin; 4) color printing of the image and text; 5) printing of environment-friendly glue; 6) adoption of a special punching machine for punching positioning holes;7) silicone oil pressure forming; 8) tearing of the PET sheet after vulcanization is completed so that a pattern can be transfer-printed on a silicone button product, and out-taking of the silicone button product. According to the method, positioning is needed during surface printing on the silicone button, and when silicone is made at first and afterwards printing is conducted, the shrinkage of the silicone is inconsistent, so that the deviation of printing positioning is caused; the mode of printing the pattern on the PET and then conducting mold pressing is adopted, the printing position isvery accurate, and the error can be 0.05 mm.

Owner:东莞市松烁硅胶科技有限公司

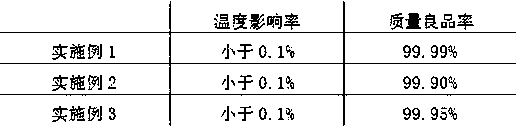

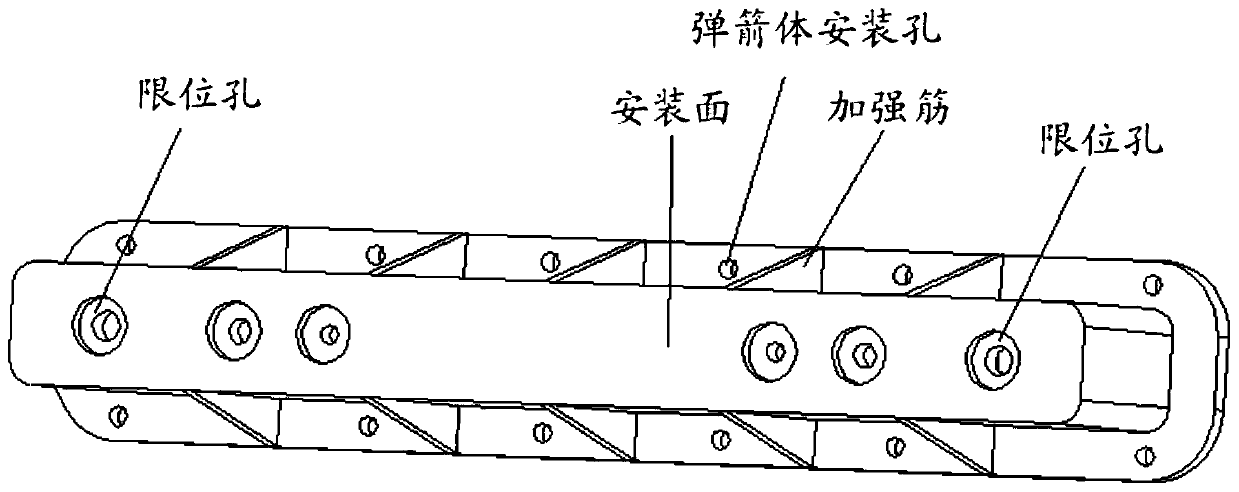

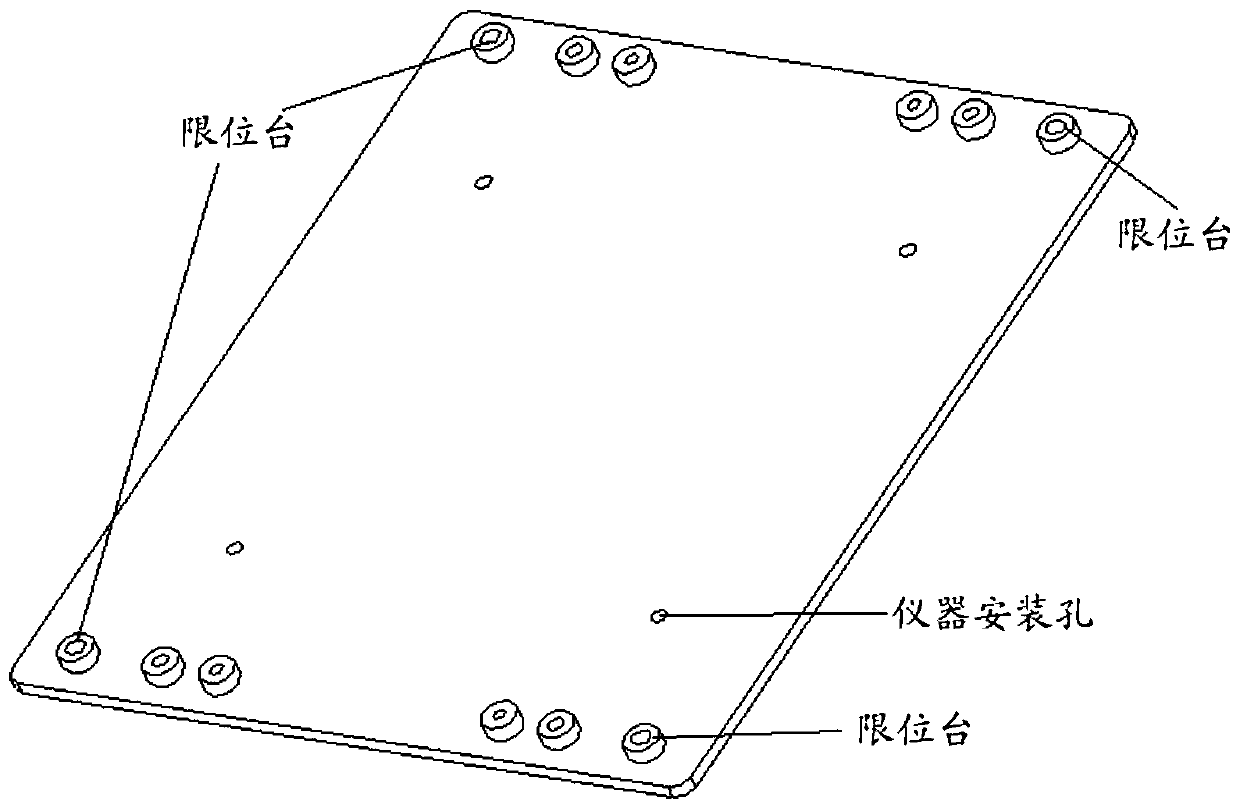

Expandable vibration damping type self-adaptive instrument mounting platform

ActiveCN111022559AReduce in quantityReduce investmentNon-rotating vibration suppressionStands/trestlesThree stageStrong coupling

The invention discloses an expandable vibration damping type self-adaptive instrument mounting platform. A two-stage split structure or a three-stage split structure is adopted to release the strong coupling between a rocket body structure and instrument equipment. As for the portion connected with a projectile rocket body, characteristics of a main body structure are mainly considered, and the connection strength and the connection rigidity are simultaneously optimized; and as for the portion connected with the instrument equipment, interface mounting of the instrument equipment is mainly considered. The structure of the portion connected with a projectile rocket body main body structure is relatively complex, so that universal design is realized as much as possible, and the investment oftooling and dies is reduced. The structure of an instrument mounting part is as simple as possible, the machining is convenient, and the cost is low so as to adapt to the diversity of interfaces of the instrument equipment.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

Slag fetching device used after slagging smelting and use method thereof

Belonging to the technical field of metallurgical slagging, the invention in particular relates to a slag fetching device used after slagging smelting and a use method thereof. On the basis of original slagging equipment, a slag storer, a graphite pipe and a vacuum instrument are added. The use method includes: firstly heating a silicon material and slag to a molten state to form a silicon liquid and a slag agent, stopping heating, extending the graphite pipe into the bottom of the silicon liquid, and then filling the silicon liquid with gas; at the end of gas filling, moving the graphite pipe to the surface layer of the slag agent, then performing vacuum pumping to the other end of the graphite pipe by a vacuum tank, letting the slag agent of the upper layer enter the slag storer under the action of pressure difference, simultaneously extending the graphite pipe downward, ensuring the bottom end of the graphite pipe to dip into the slag agent till all the slag agent enters the slag storer, then opening the slag storer and taking the slag agent out. The device provided by the invention has the advantages of convenient reconstruction and installation, and simple operation. The graphite pipe can extract the slag agent cleanly and dump the slag agent, so that the finally purified polysilicon has improved quality and high yield of primary product, and no dust or other garbage can be generated during production. Thus, the device is applicable to industrial mass production.

Owner:QINGDAO NEW ENERGY SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com