Large-scale water turbine guide vane two-end journal synchronous-processing device and method

A processing device and water turbine technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve problems such as repairing vehicles out of tolerance, increasing guide vane production cycle and other workloads, etc., to achieve easy operation and shorten production. Periodic and versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

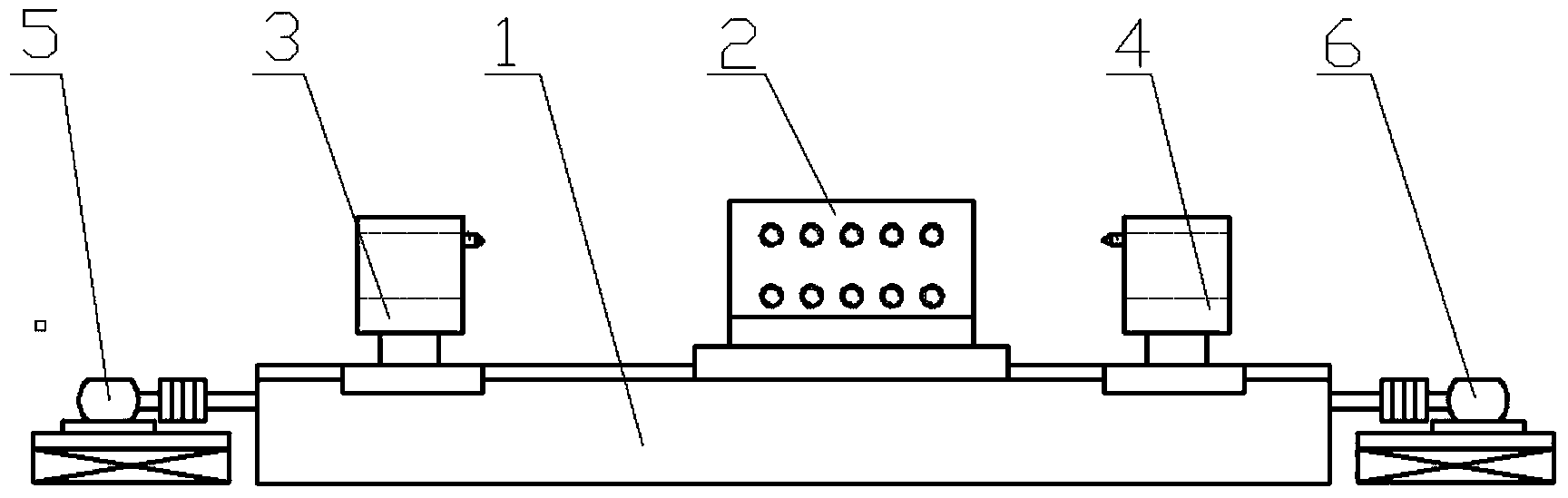

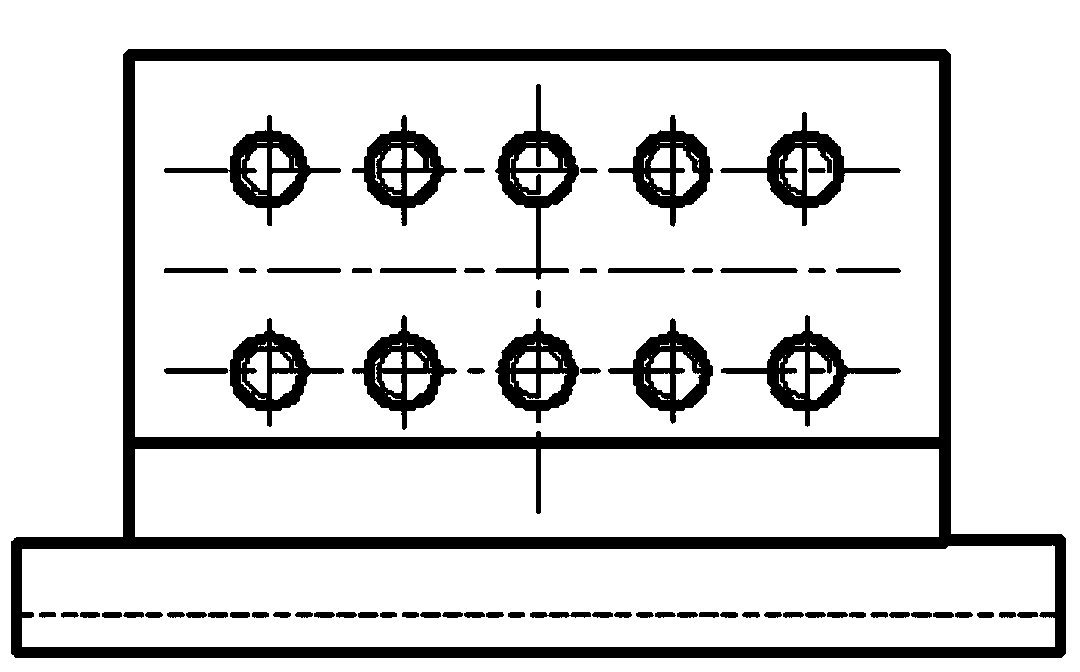

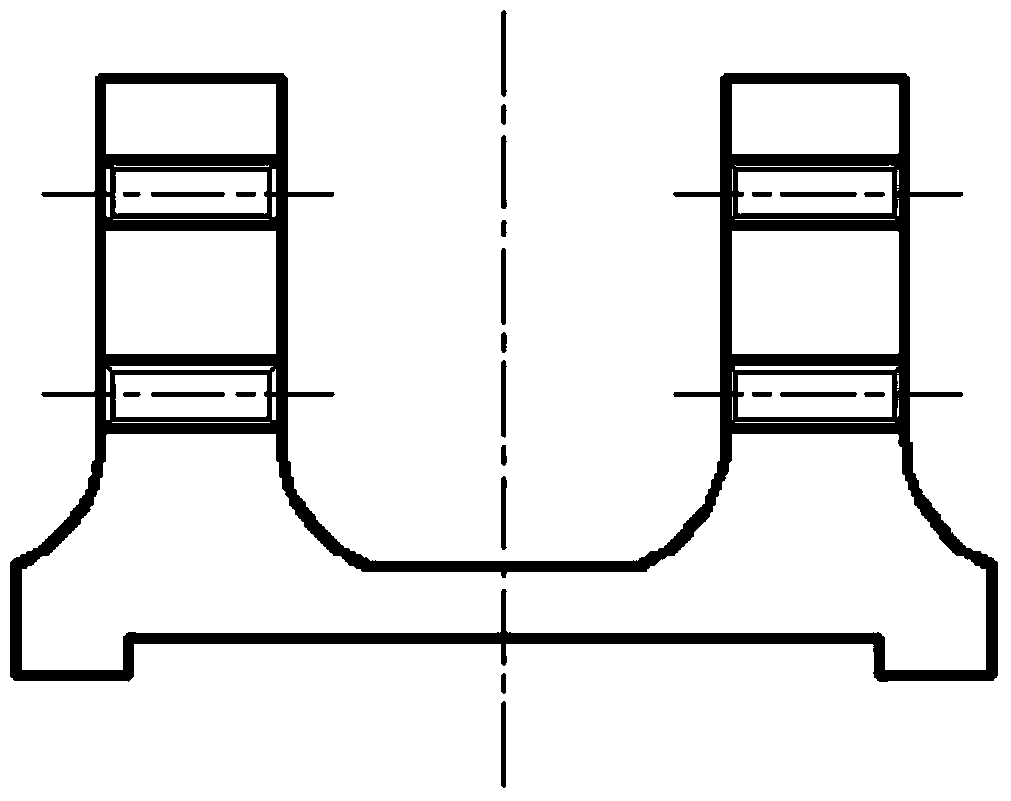

[0014] The specific implementation of the present invention will be described below by taking the processing of guide vanes of a water turbine as an example. The guide vane of a water turbine weighs 6510Kg, the length is 4.5 meters, and the guide vane body is 2.3 meters. like figure 1 , figure 2 , image 3 As shown, the device of the present invention is composed of a bed 1, a guide vane positioning tool 2, a left milling head 3, a left driving tool 4, a right milling head 5, and a right driving tool 6, and the guide vane positioning tool 2 is arranged on the bed 1 to move Connection, the left milling head 3 and the right milling head 5 are meshed with the power output shafts of the left driving tool 4 and the right driving tool 6 respectively, the left milling head 3 and the right milling head 5 are arranged on the bed 1 and connected flexibly, and the left driving tool 4 and the right driving tool 6 are arranged on both sides of the bed 1 . Align the guide vane to be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com