Patents

Literature

37results about How to "Meet the clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

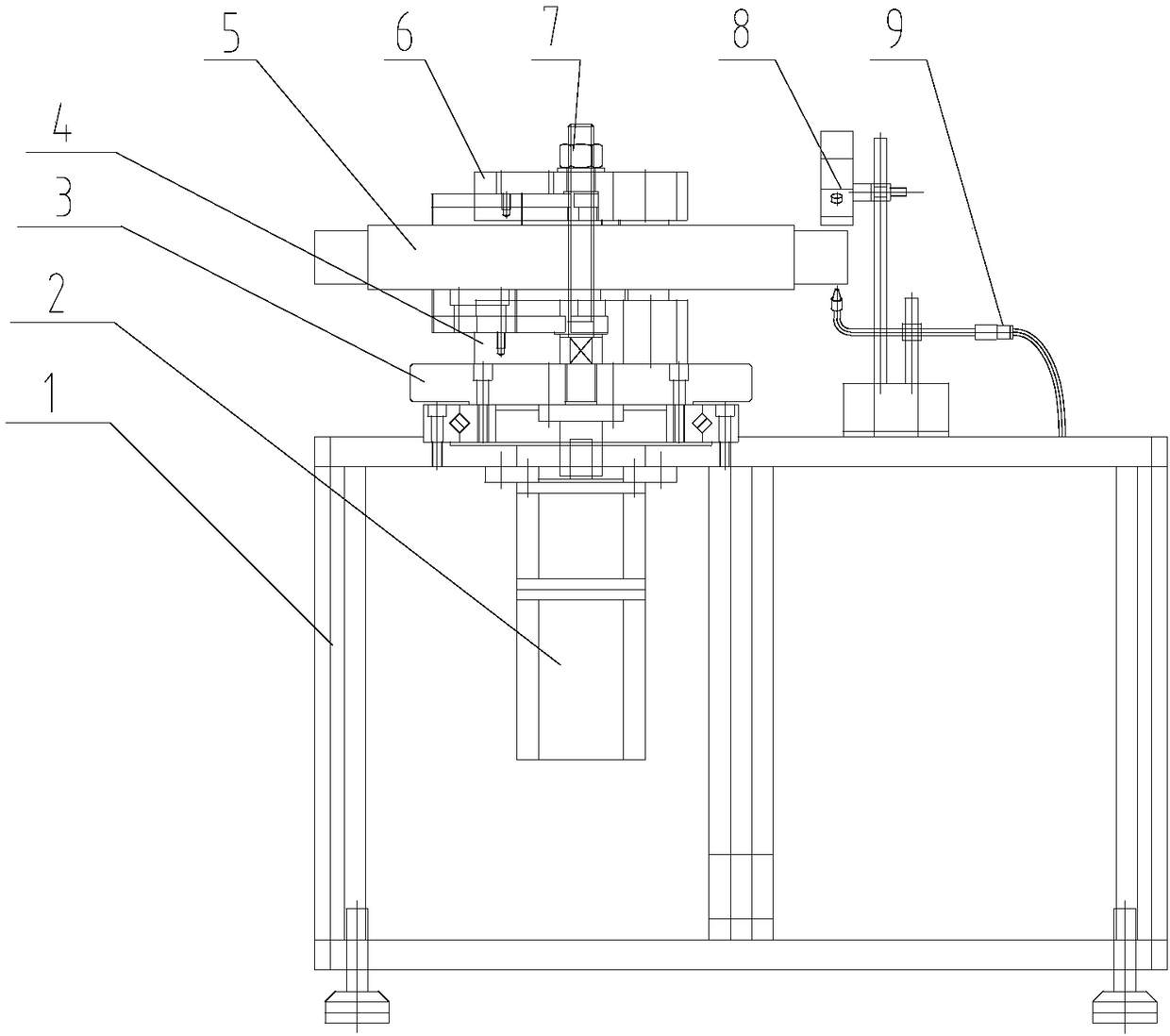

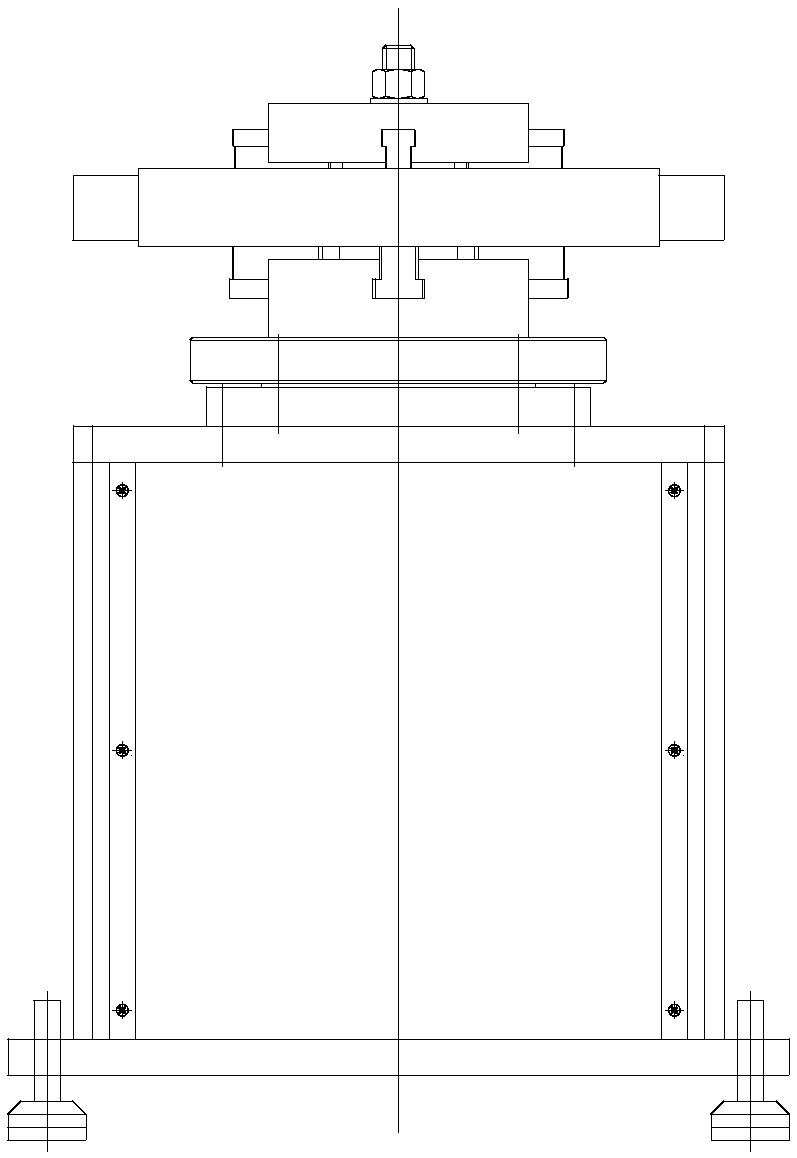

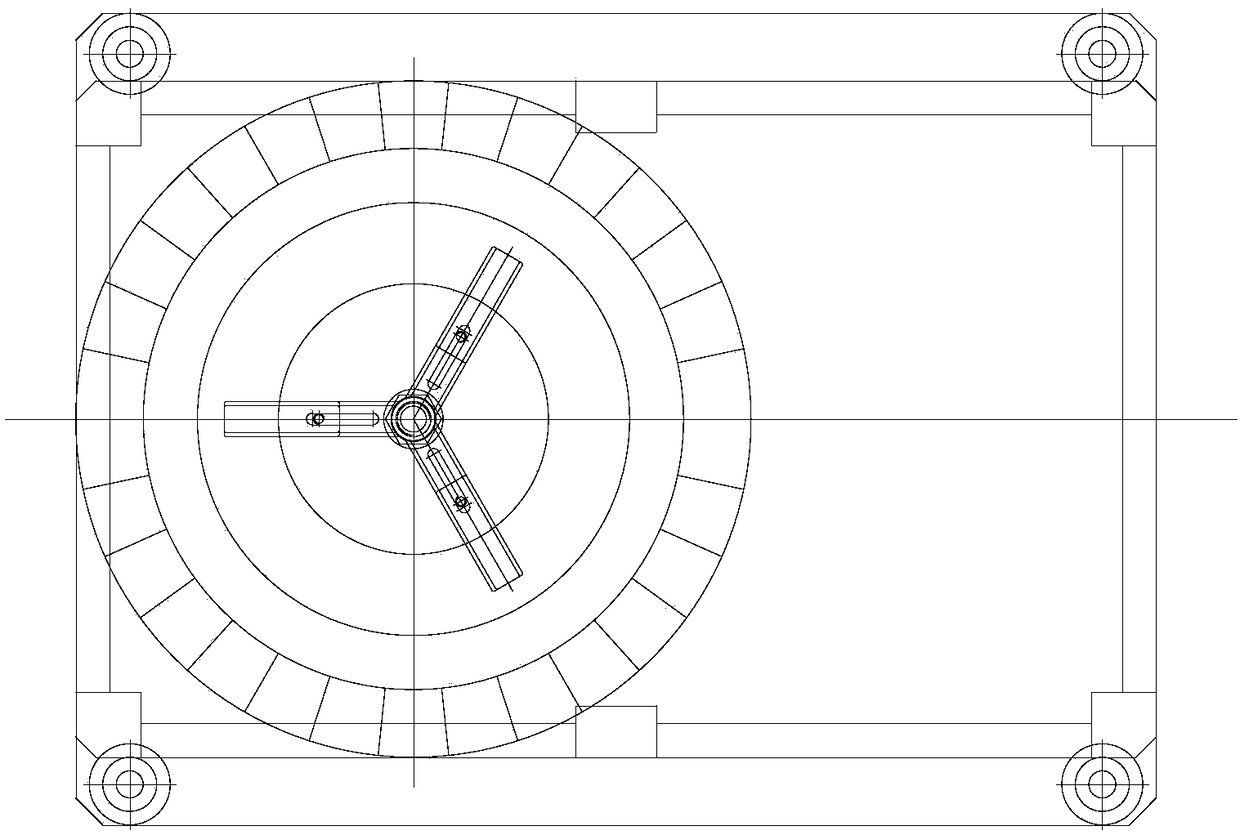

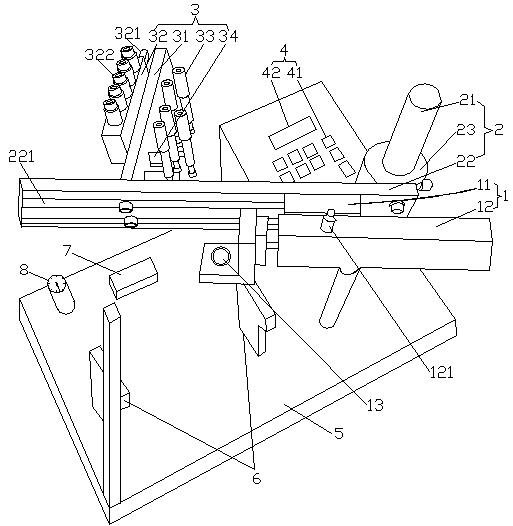

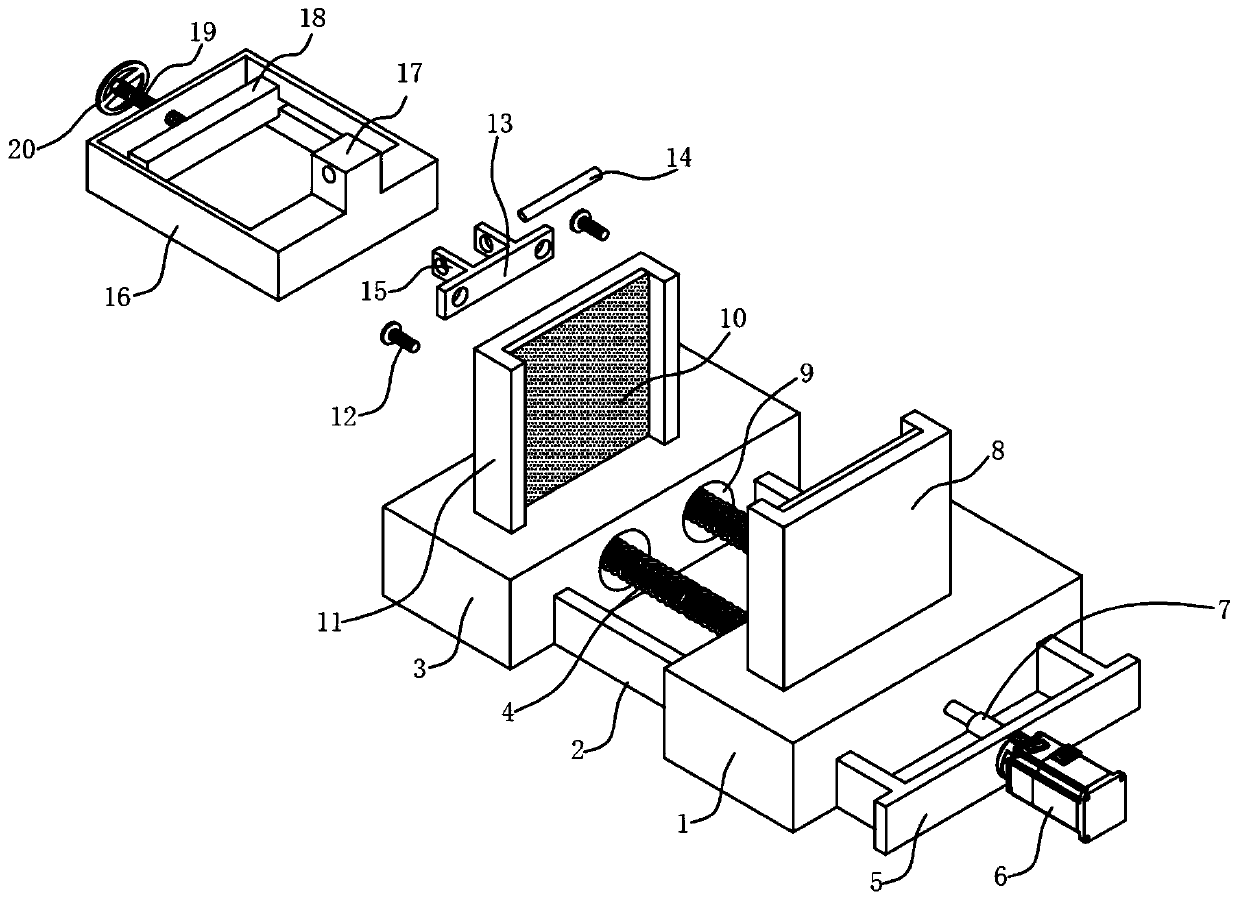

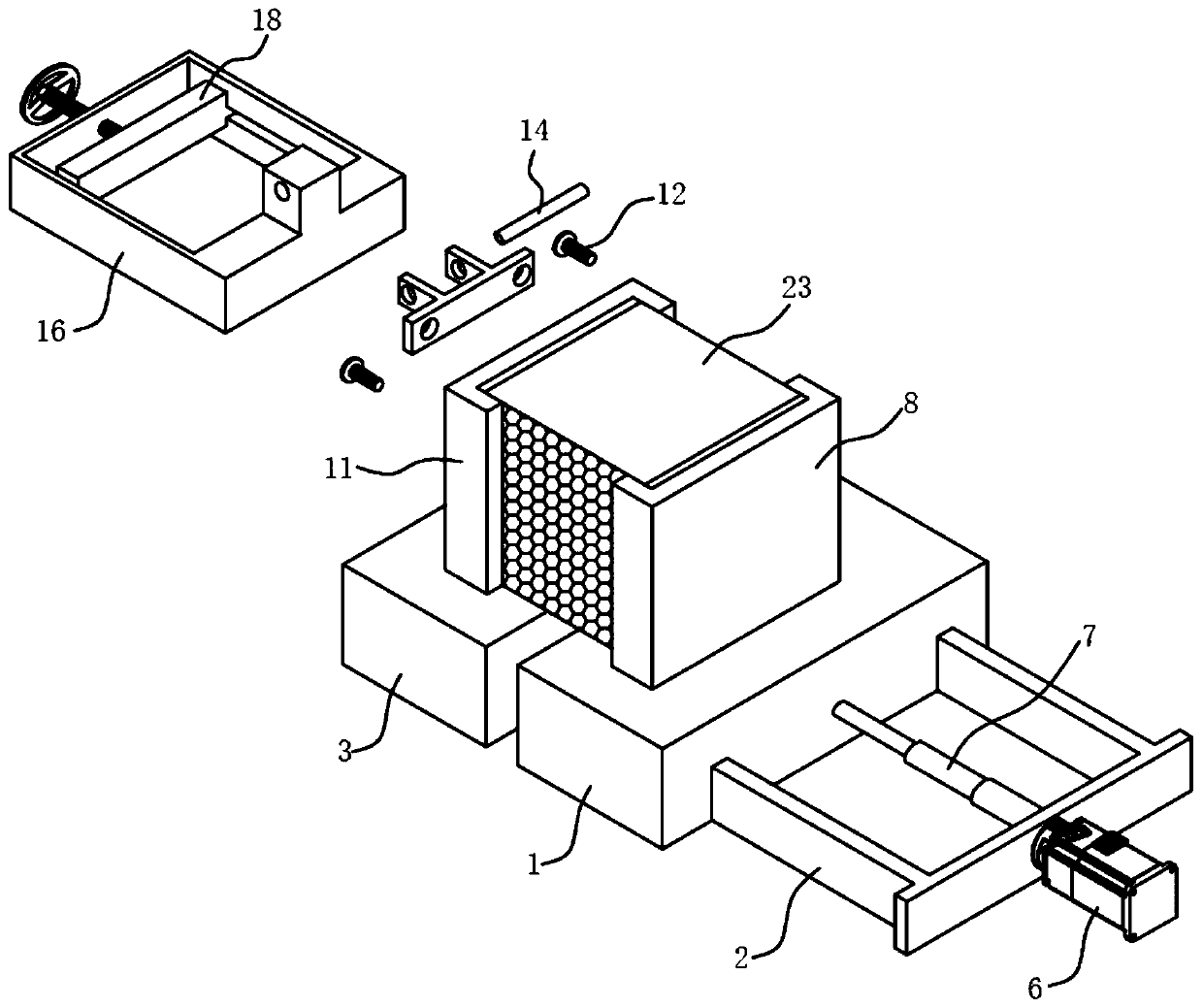

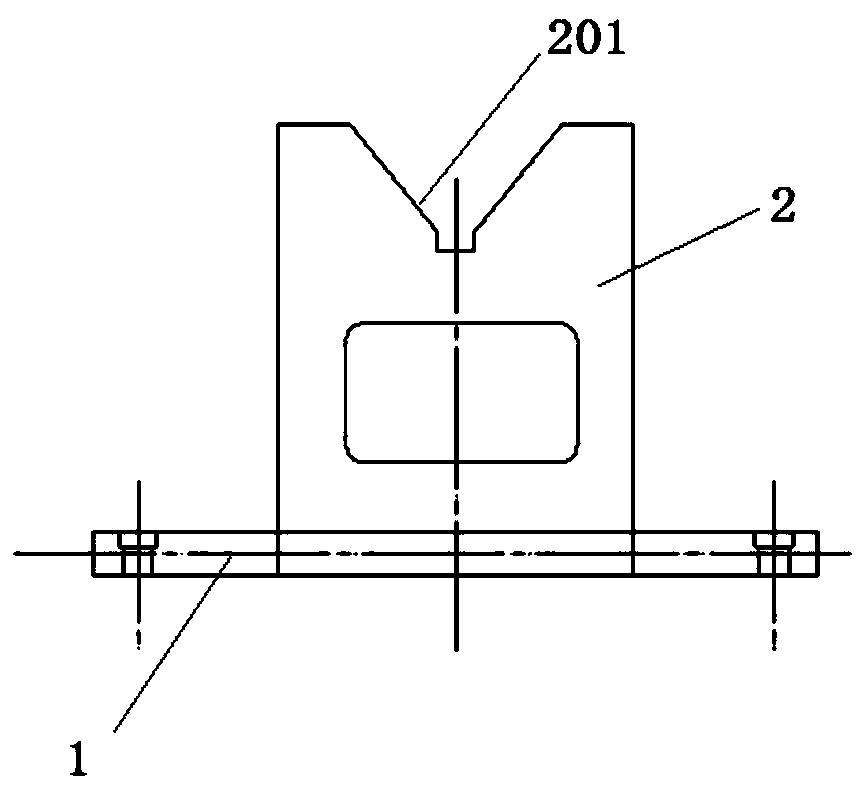

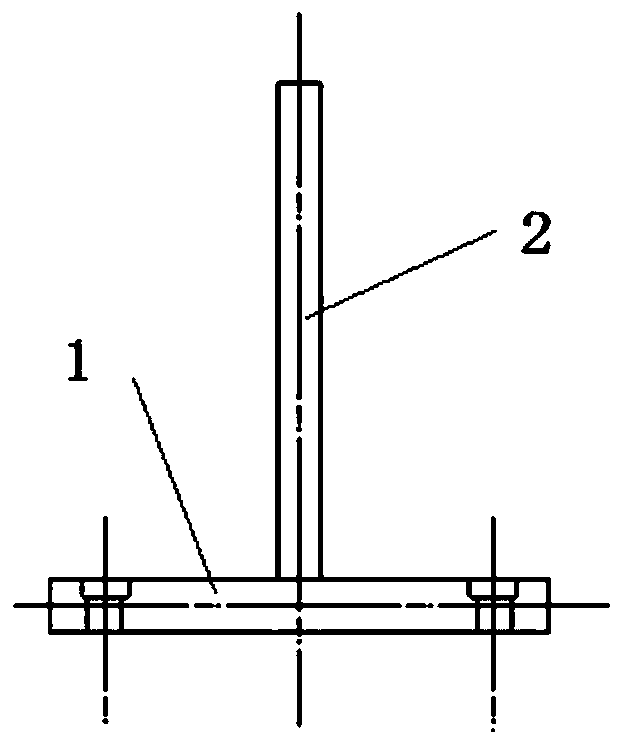

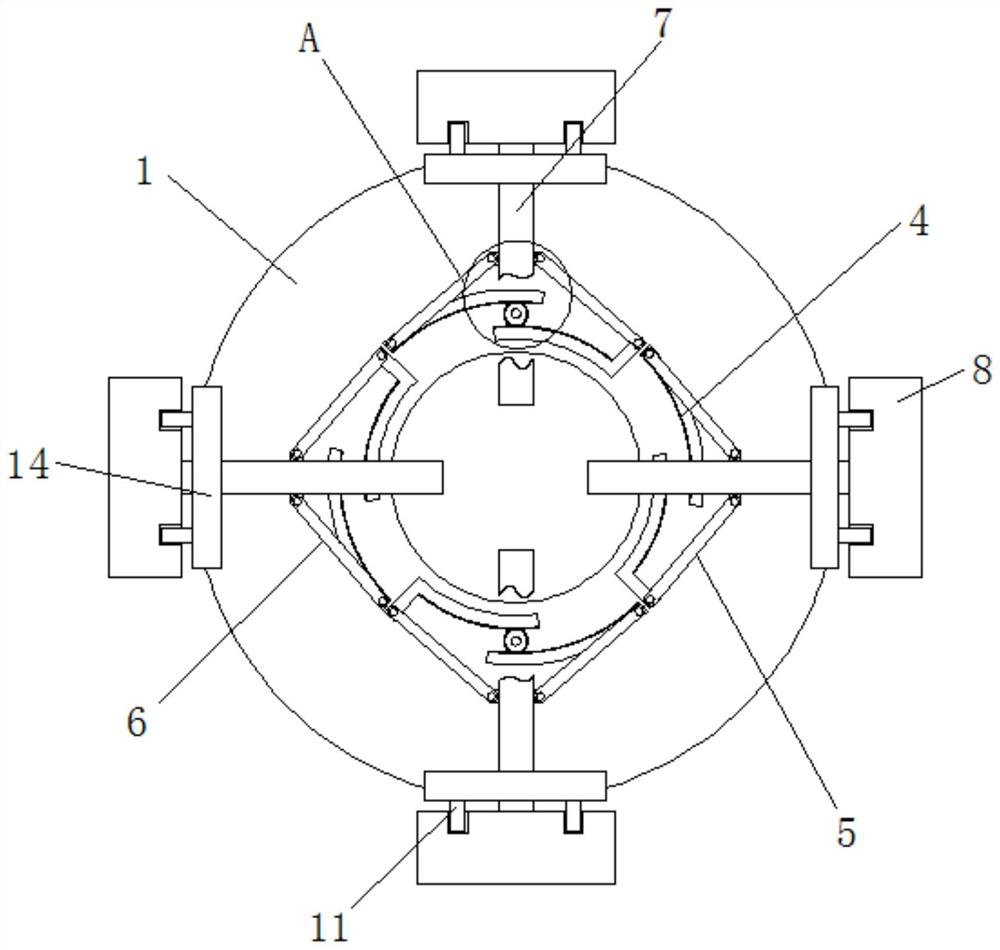

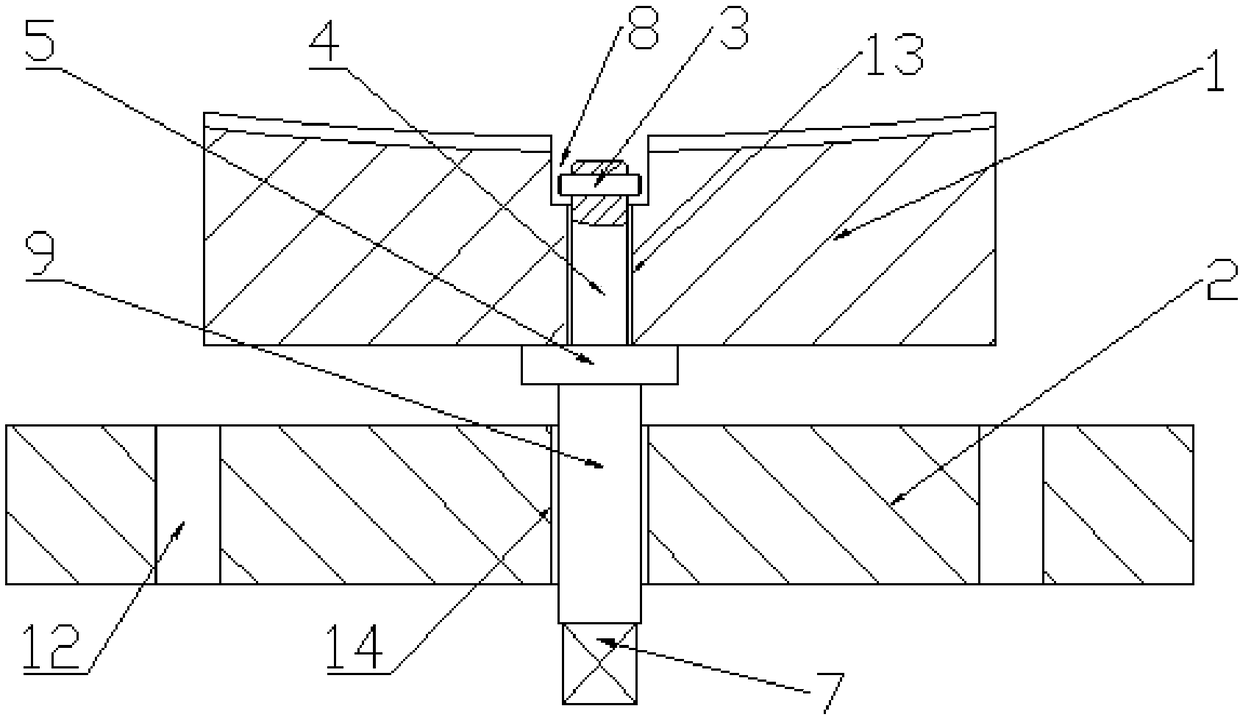

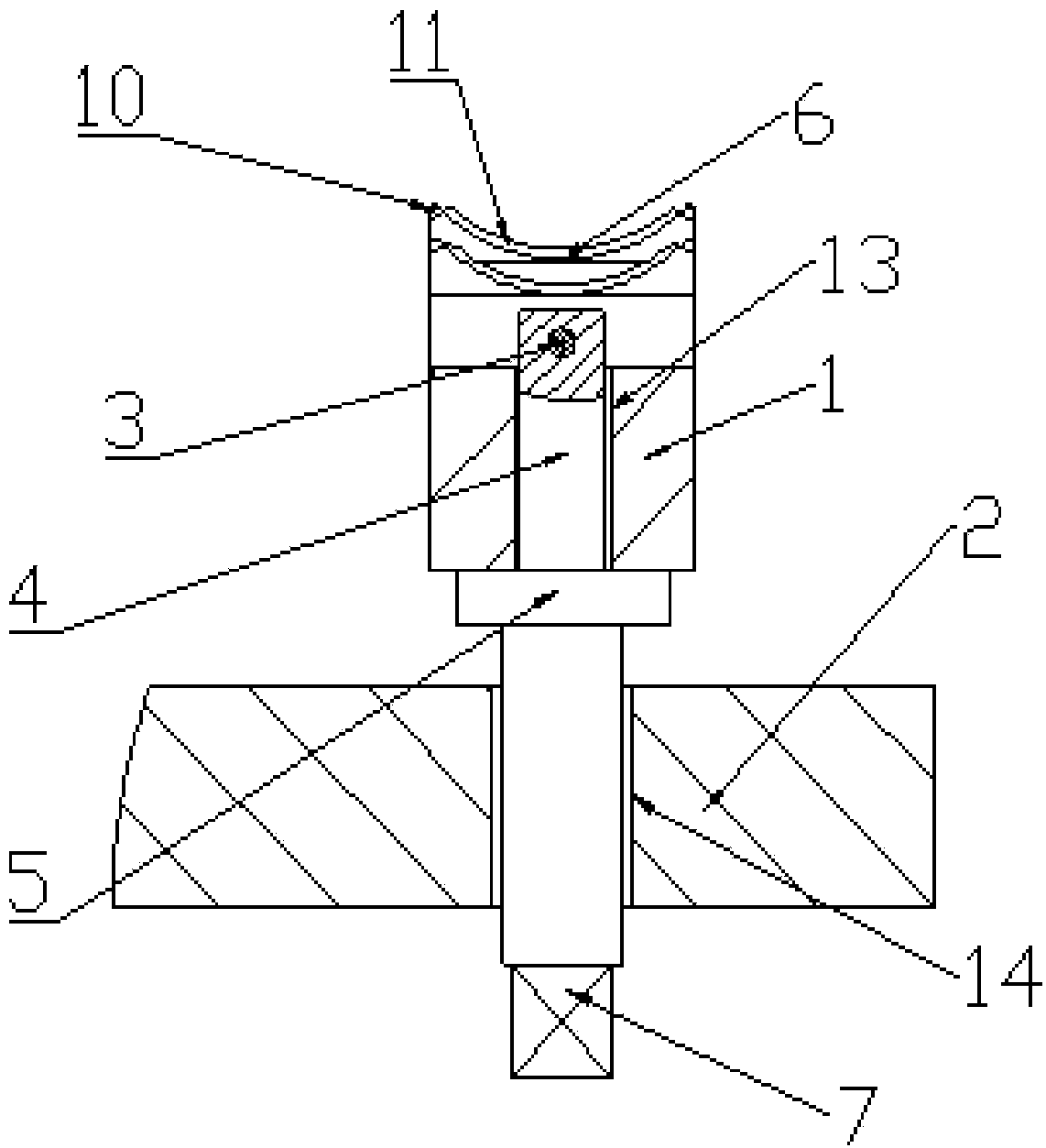

Blade inherent frequency automatic testing system

InactiveCN108593230ALow skill level requiredHigh degree of automationVibration testingTest efficiencyMotor drive

The invention relates to a blade inherent frequency automatic testing system which comprises an external control analysis system, a base, a stepping motor, a rotating disc, a clamping assembly, a laser displacement sensor and a jetting assembly. The stepping motor drives the rotating disc to axially rotate so as to drive the to-be-tested blade to rotate; the jetting end interruptedly injects the gas at equal time to enable the to-be-tested blade to vibrate, and meanwhile, the vibration displacement of the to-be-tested blade is measured through the laser displacement sensor, and the obtained vibration displacement information and the vibration frequency information are transmitted to the external control analysis system, so that the inherent frequency of each order of the to-be-tested bladeis obtained. The middle test process does not need manual intervention, the automation degree is high, the requirement for the technical level of an operator is low, and the testing efficiency is high. The technical level and the testing efficiency of related industries can be greatly improved, and the application prospect is good.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

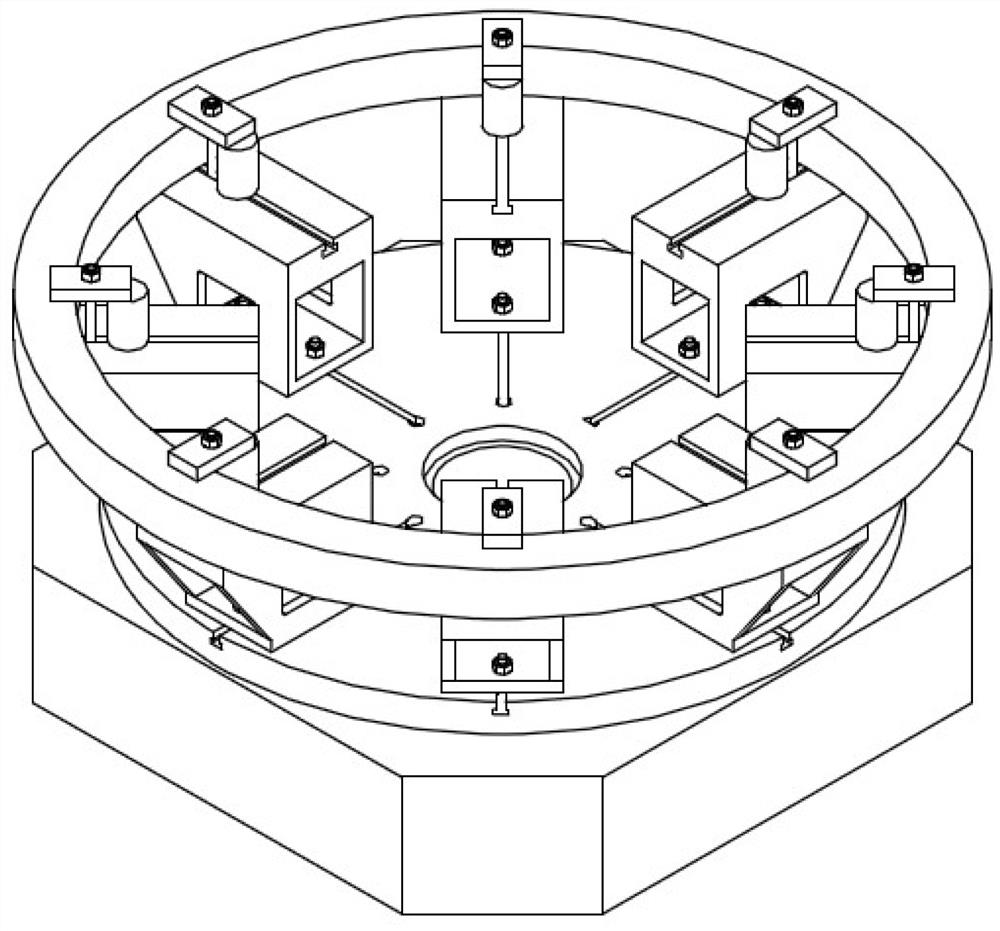

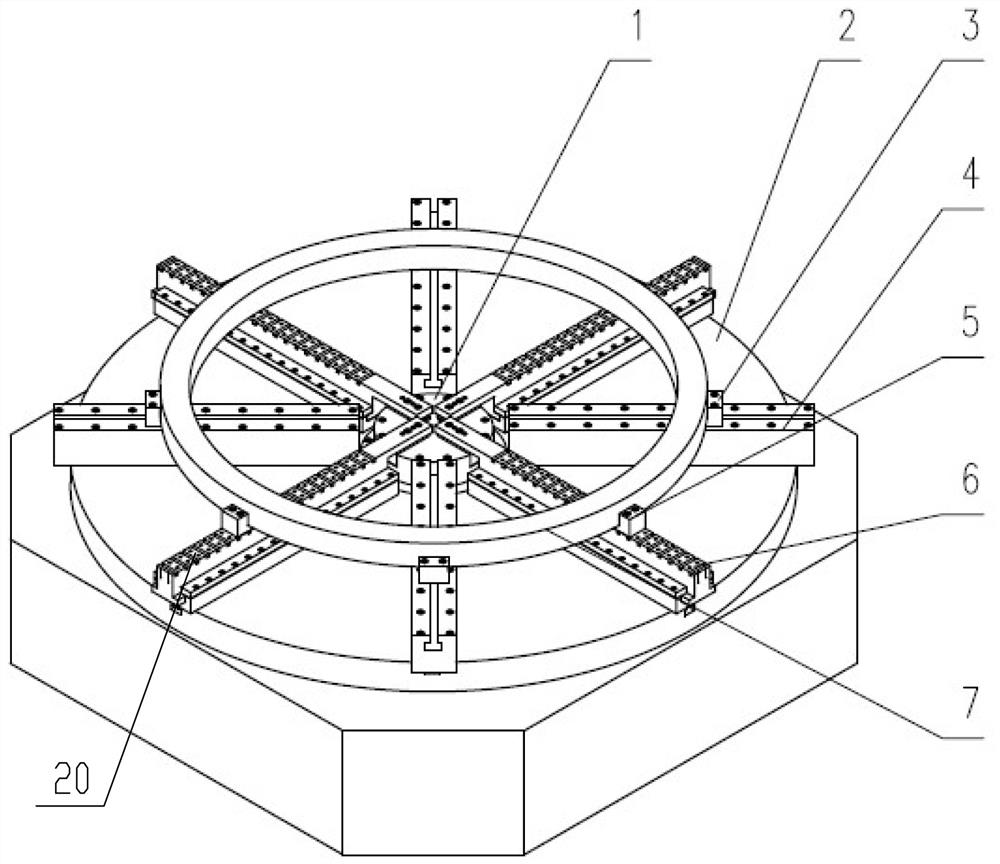

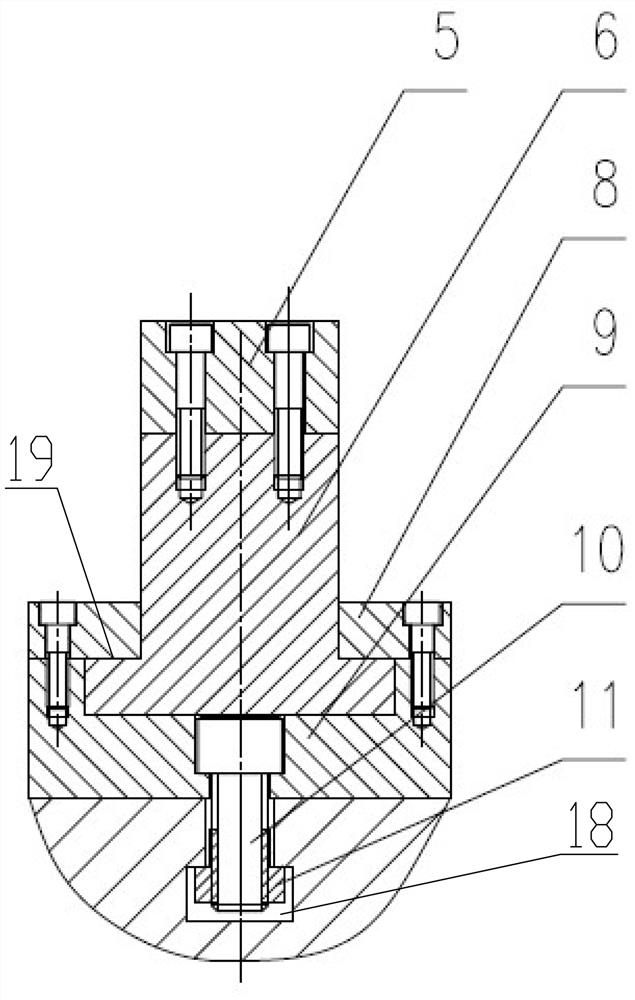

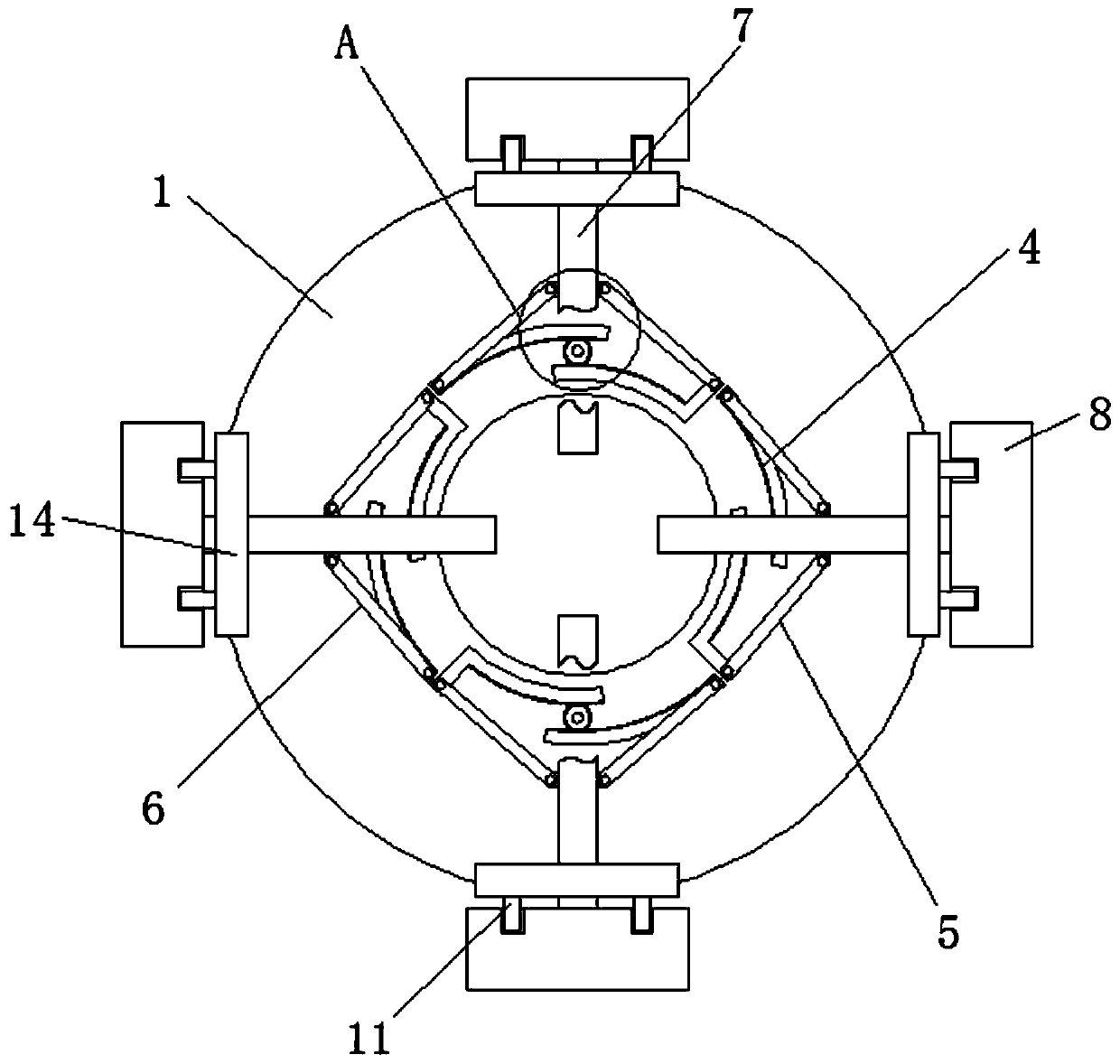

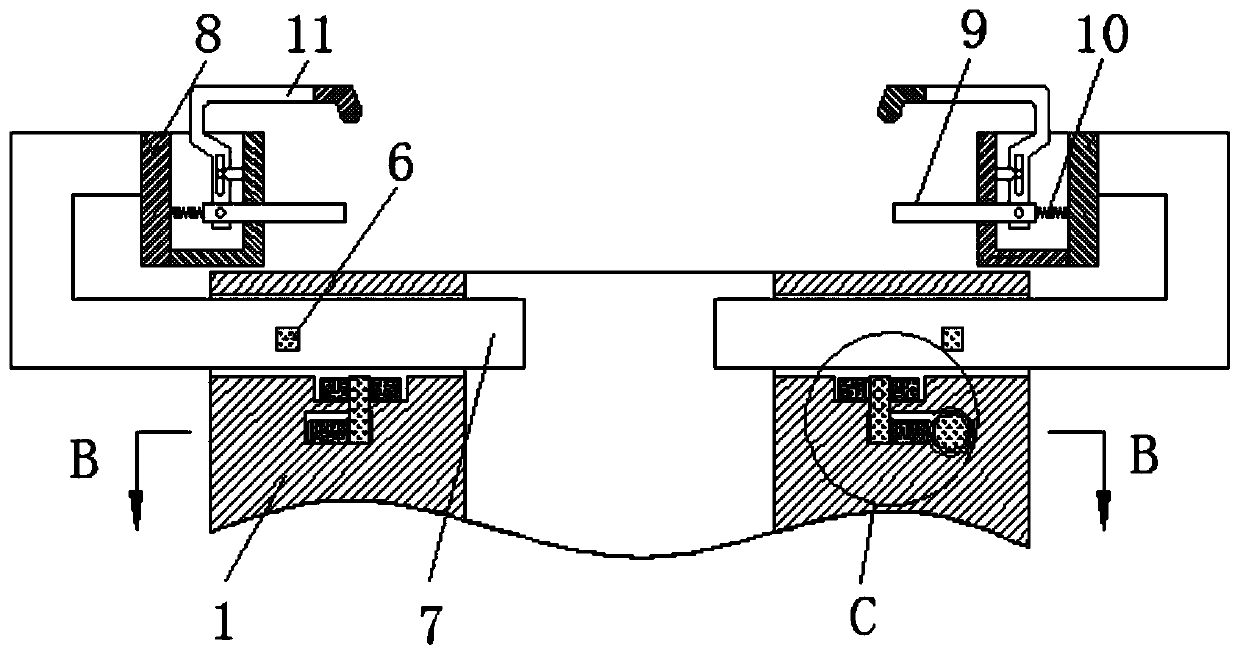

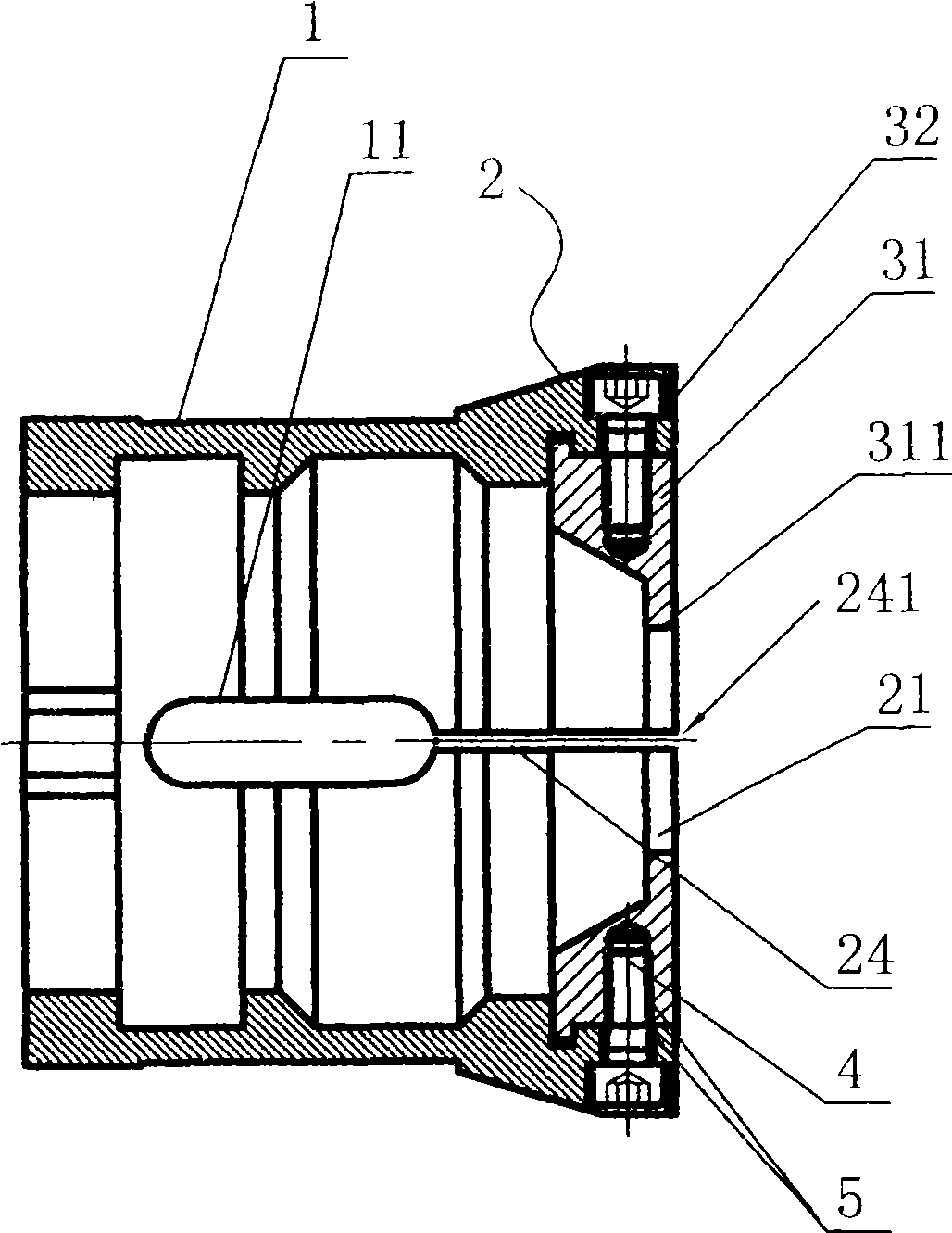

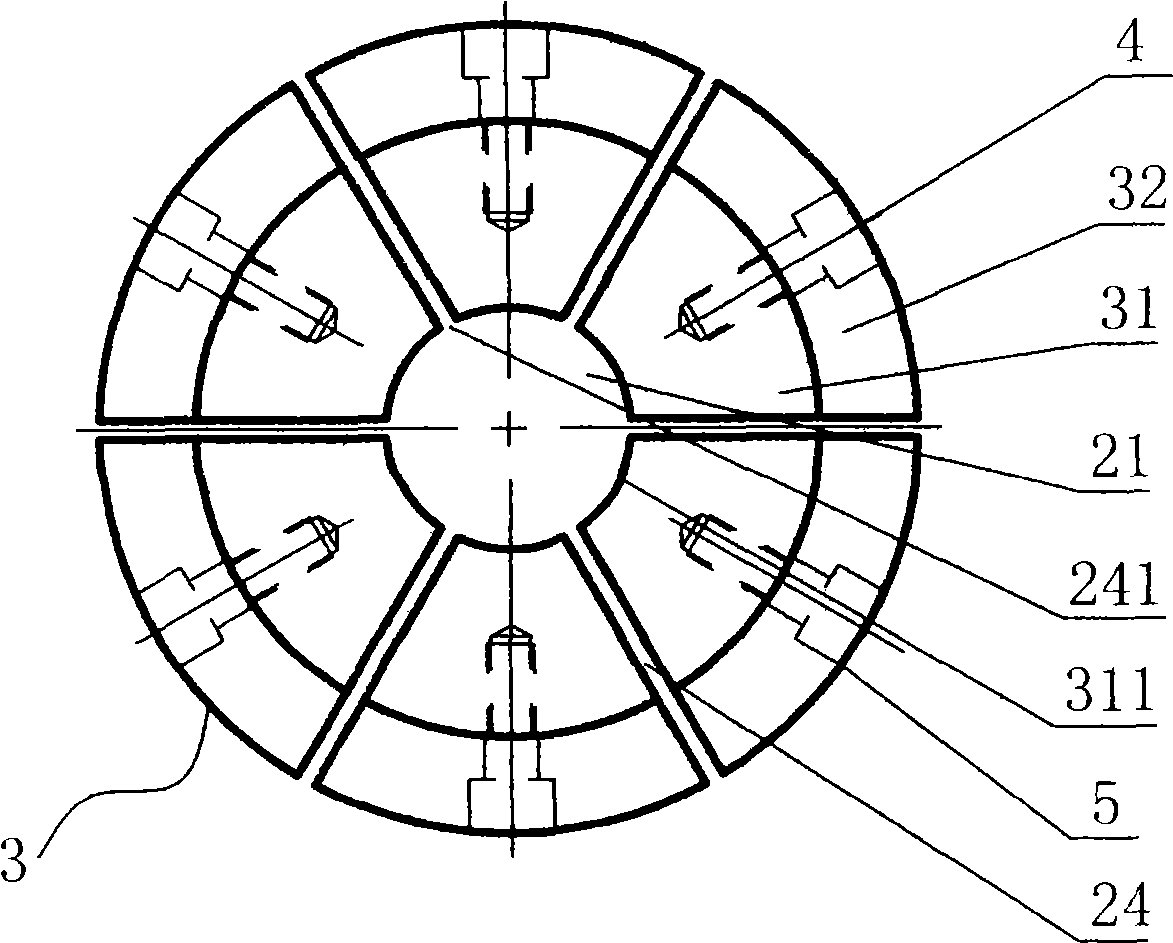

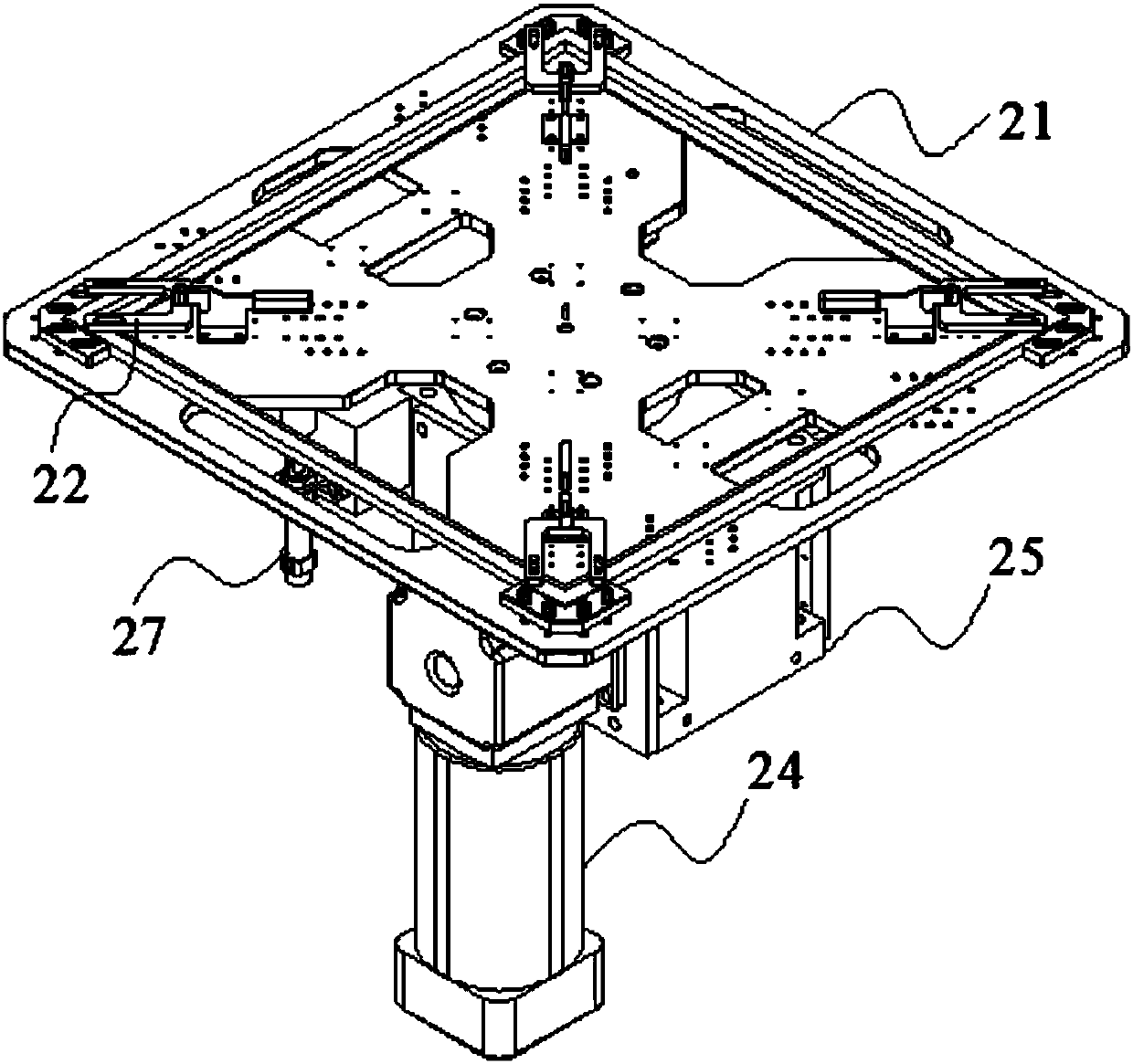

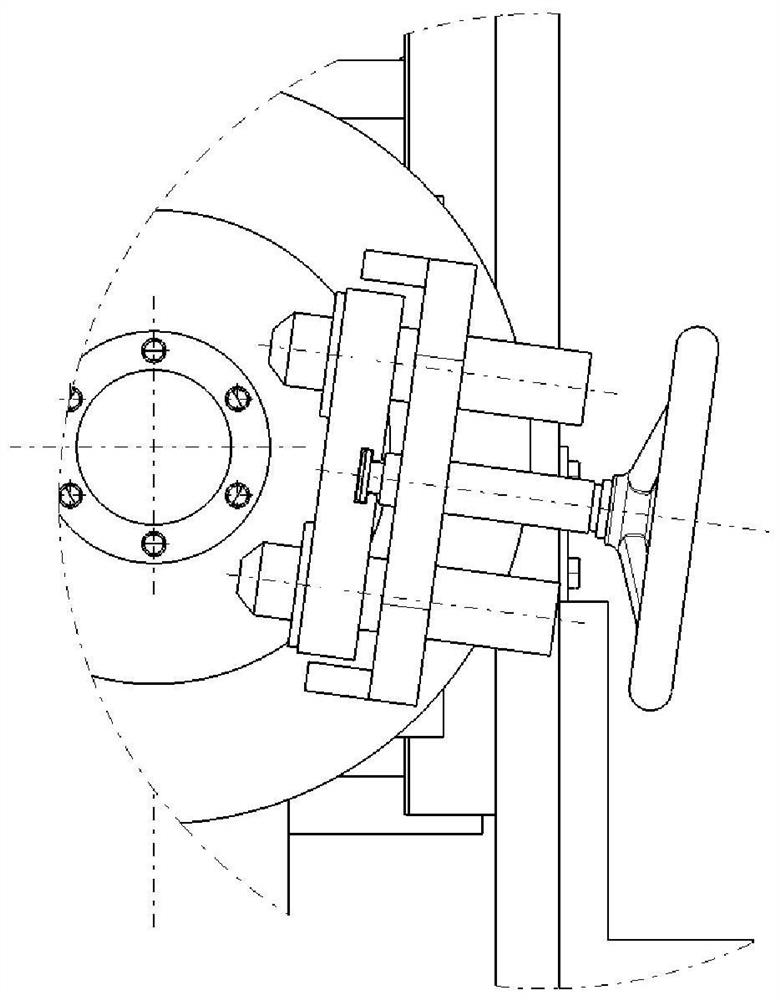

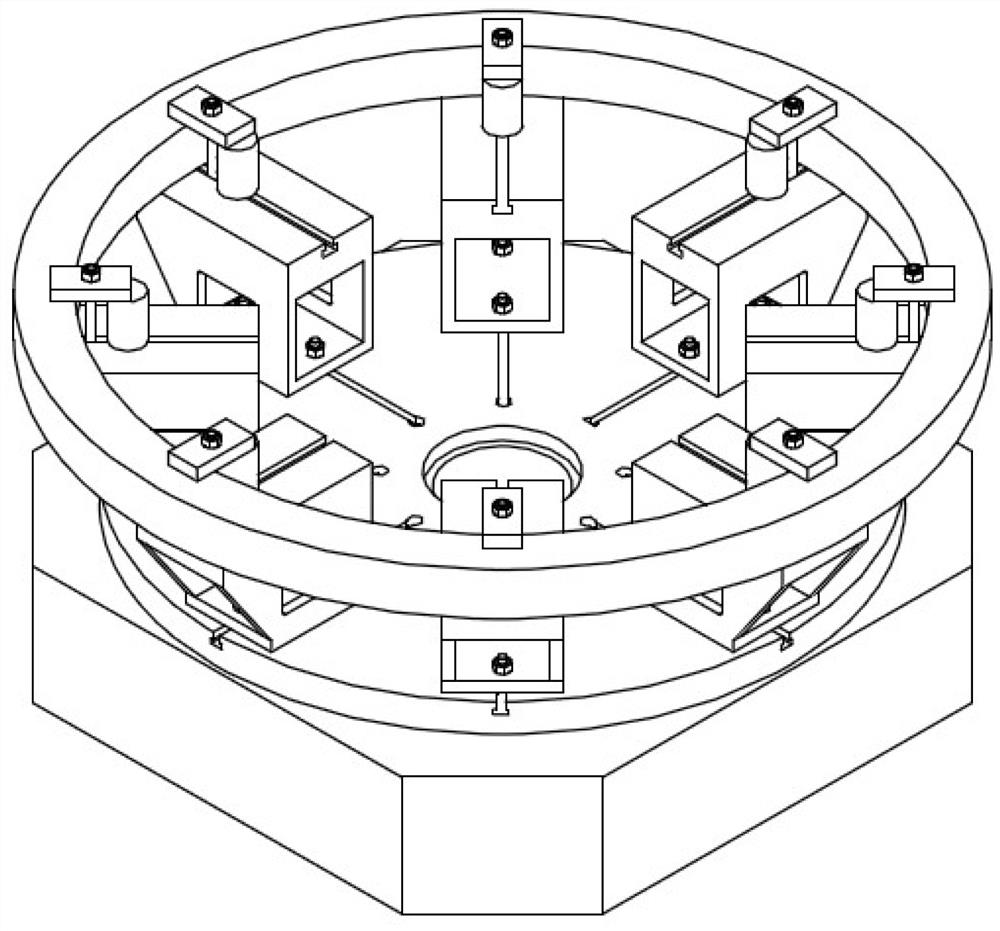

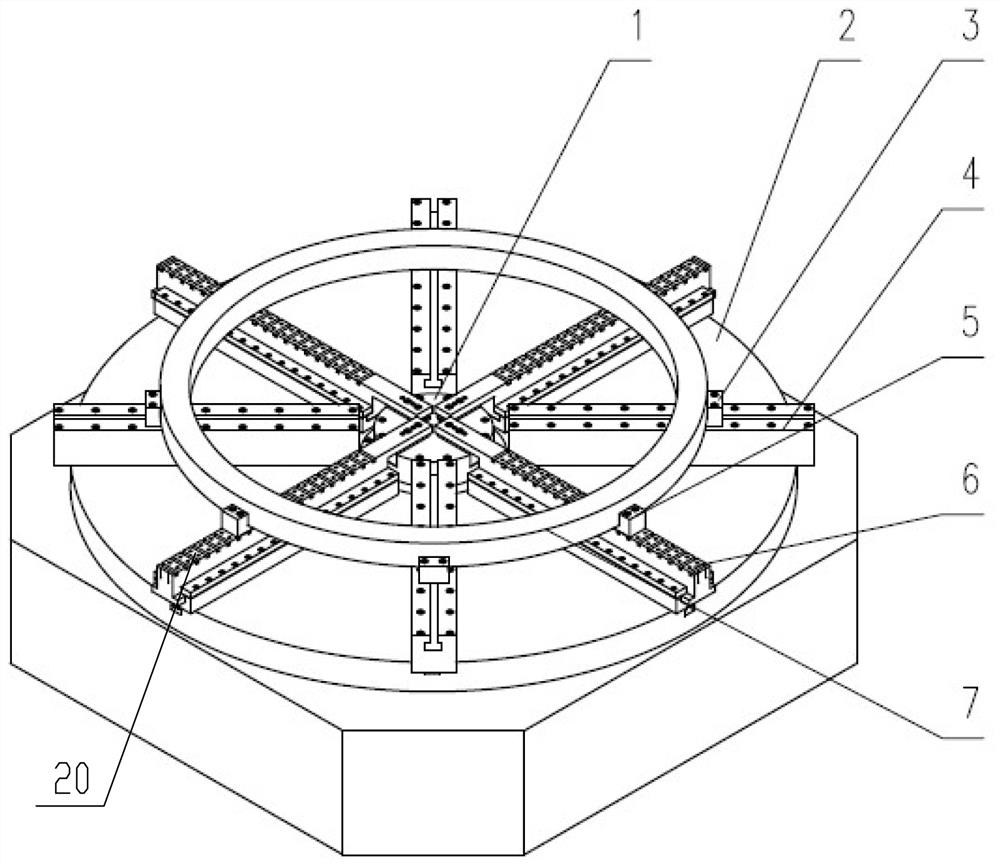

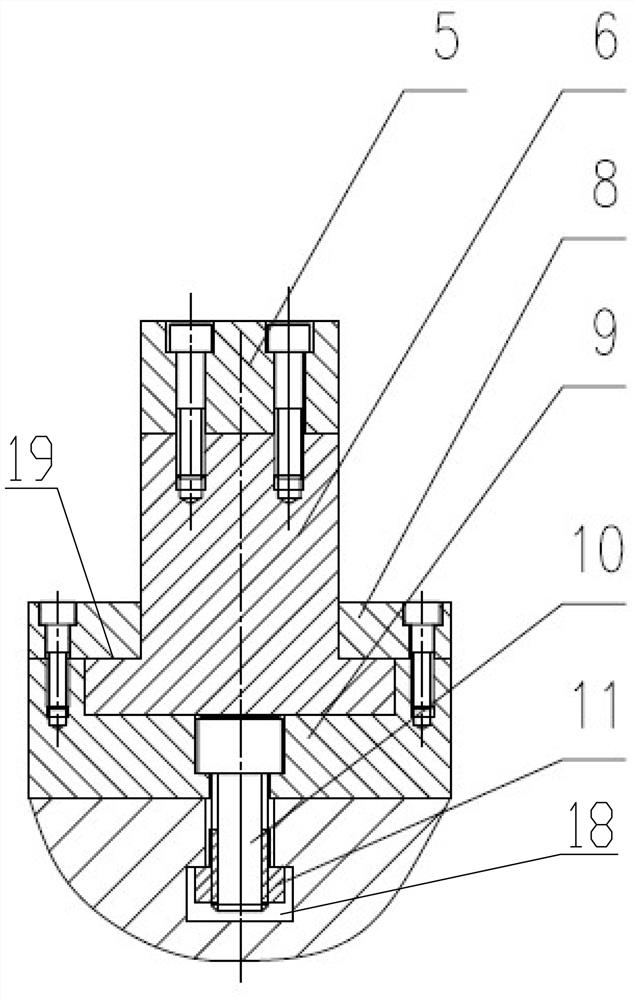

Automatic aligning and clamping device and method for circular parts

ActiveCN112917202ARealize the clamping functionRealize automatic alignmentPositioning apparatusMetal-working holdersStructural engineeringControl theory

Owner:宜昌长机科技有限责任公司

Non-contact scroll saw guide wheel slot type detector

ActiveCN101660901AHeavy loadMeet the clampingOptically investigating flaws/contaminationUsing optical meansImaging lensSoftware

The invention discloses a non-contact scroll saw guide wheel slot type detector, comprising a seat body for supporting a workpiece to be measured, an imaging lens and a computer processing element, wherein a CCD imaging lens is arranged above the workpiece to be measured corresponding to the side face of the seat body; a high-brightness white light LED adjustable light source and an X-axis and Y-axis measuring liner scale are arranged below the workpiece to be measured corresponding to the side face of the seat body; the imaging lens is fixed on the liner rail arranged on the seat body; and the trend of the rail is parallel to the axle center of the workpiece to be measured. When in measurement, the detector leads the central direction of the imaging camera to be tangent to the surface ofthe workpiece to be measured, projection imaging is carried out on the surface groove profile of the workpiece to be measured, the image can be amplified by processing of computer program after imaging to be displayed on software operator interface, therefore, the imaging on the workpiece is amplified for scores even hundreds of times after the above processes; in addition, a user can label multiterms of data such as groove spacing, angle, groove profile depth and the like of the workpiece to be measured according to image analysis software, and flaws on the surface of the workpiece to be measured can also be amplified and displayed on software interface, thereby being convenient for a client to detect and trace the quality of products.

Owner:ECO POWER WUXI

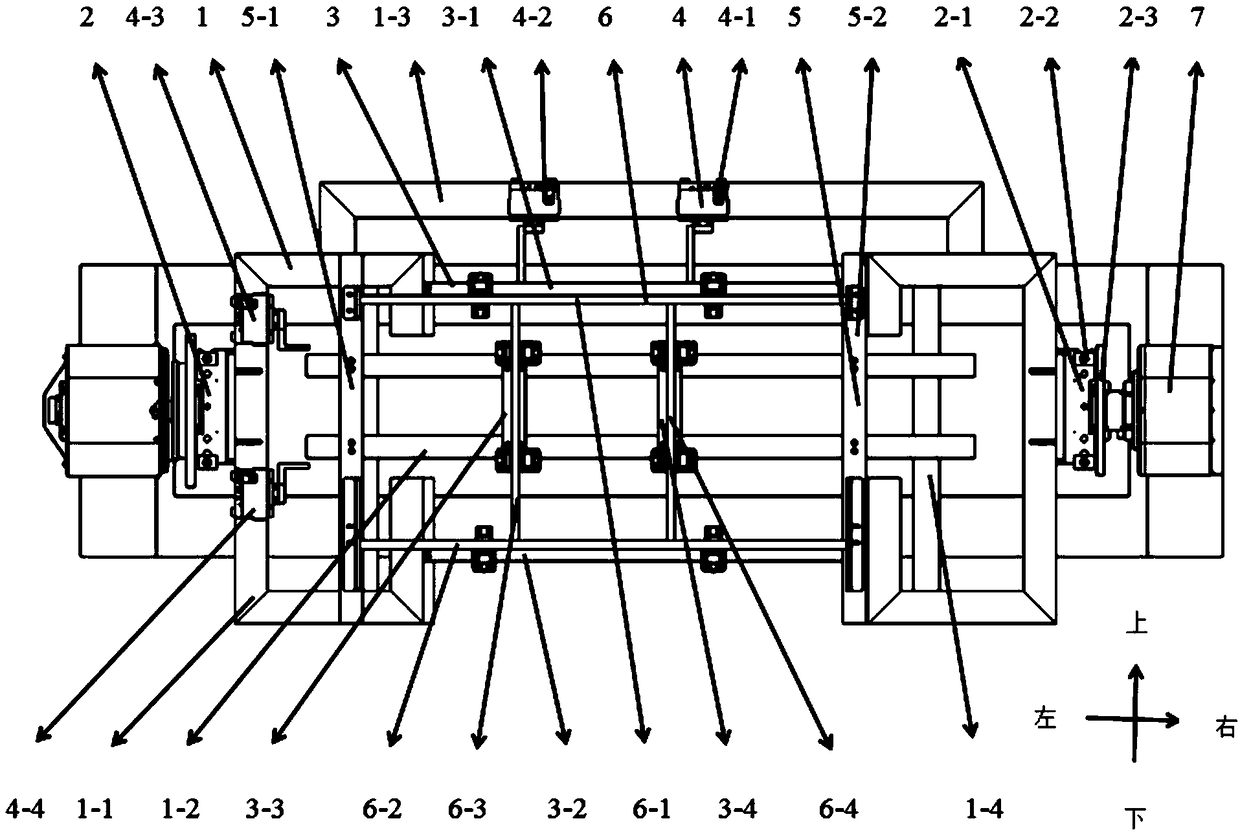

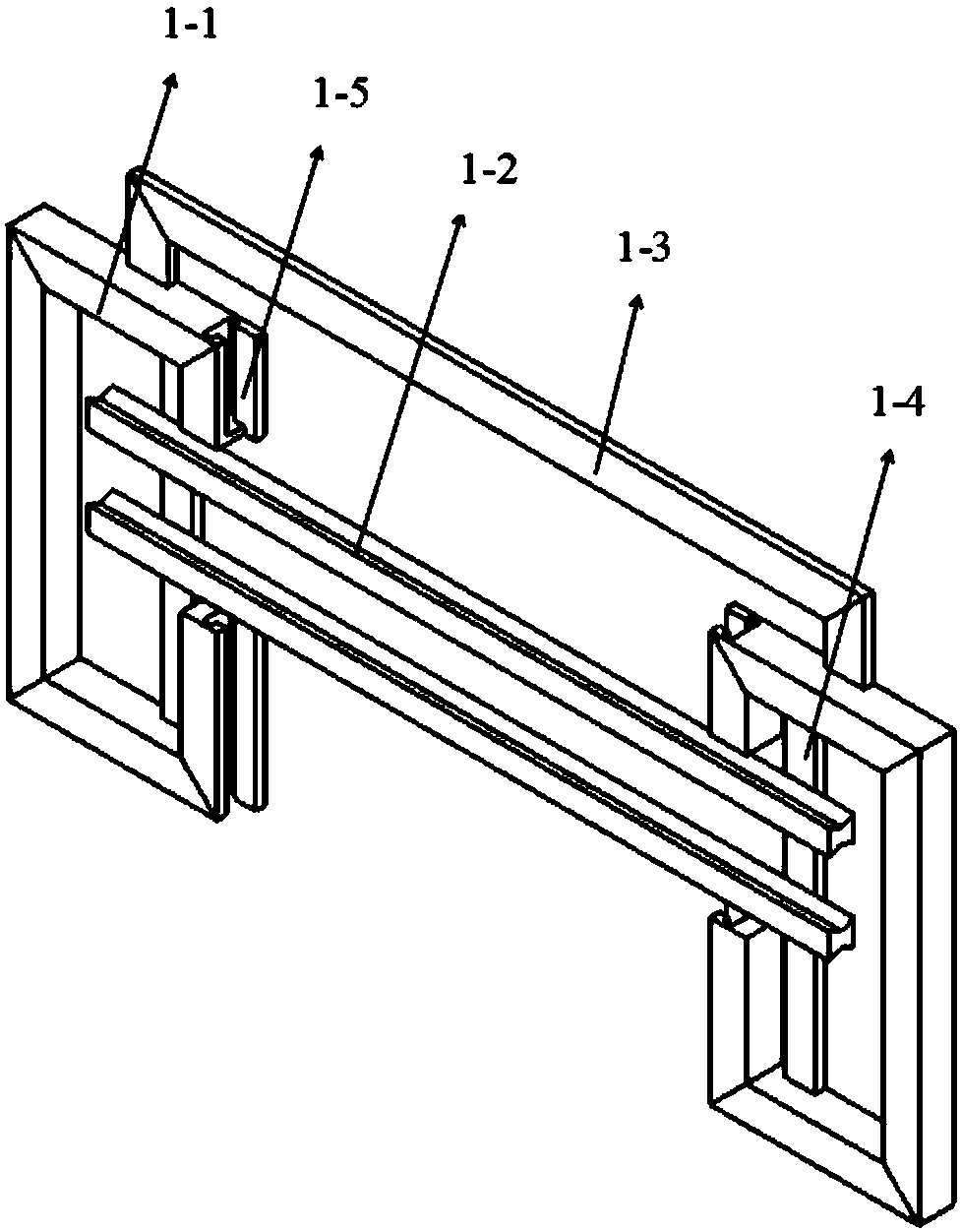

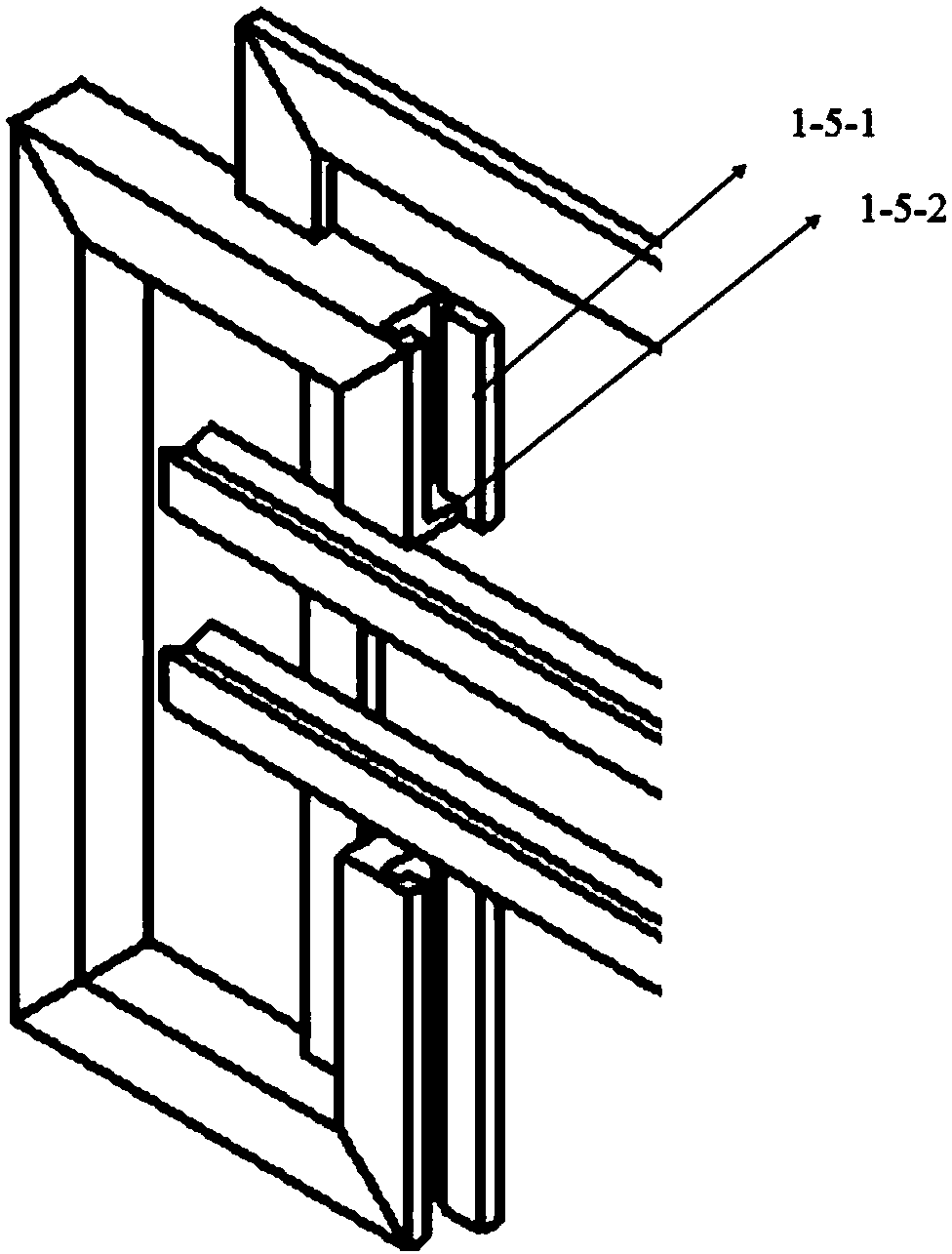

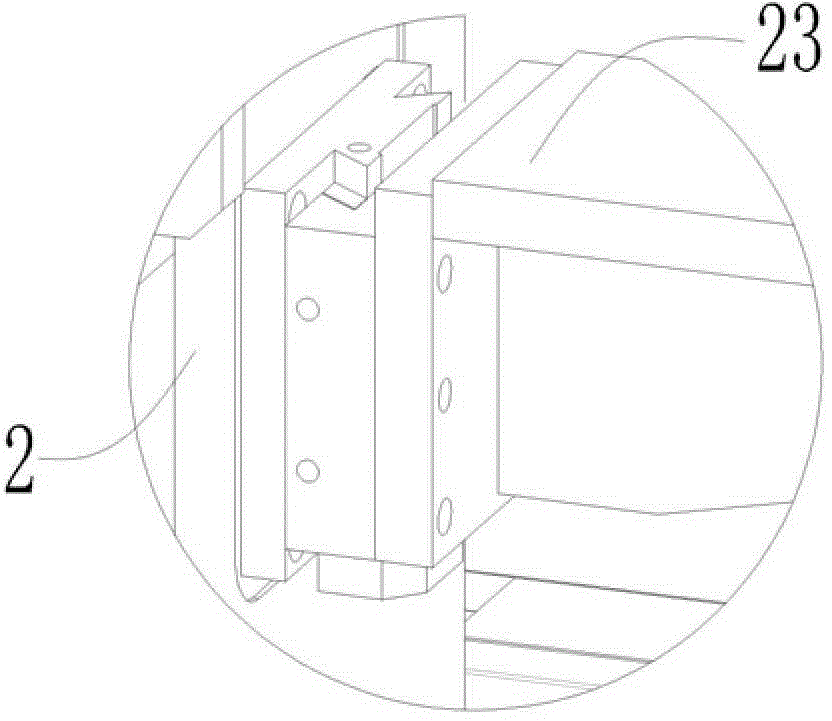

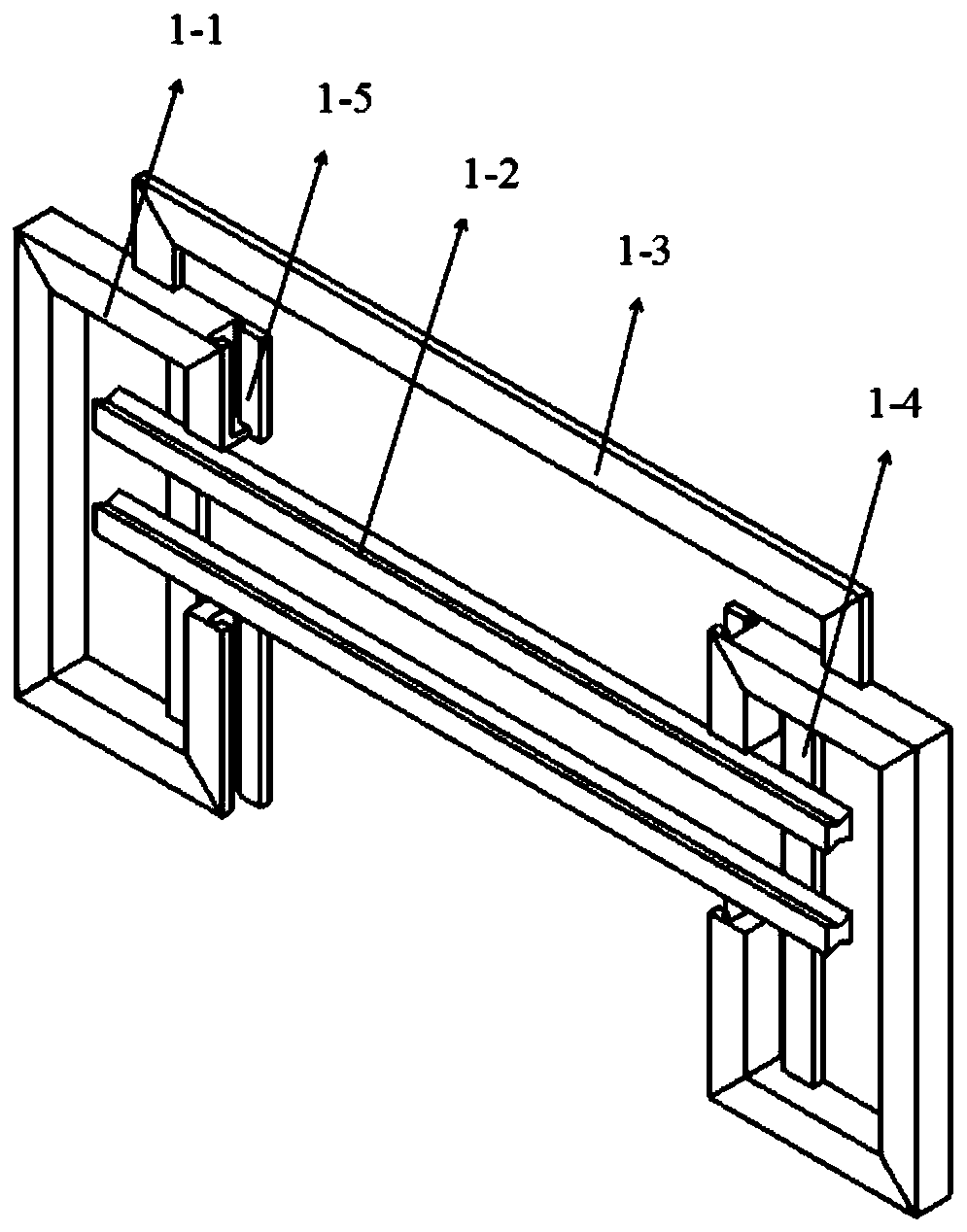

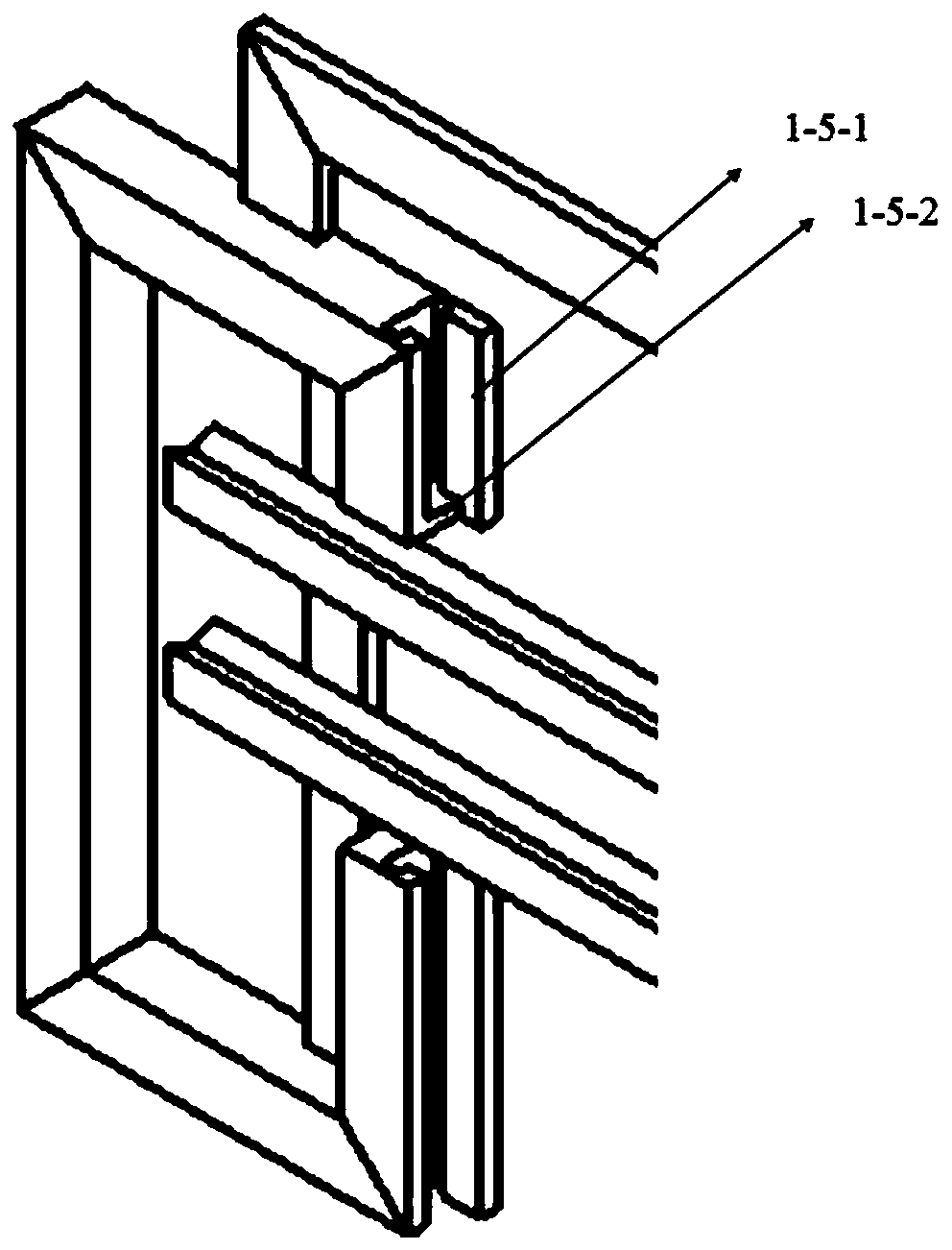

Large-scale adjustable frame structure welding fixture

ActiveCN108422145AMeet the clampingEasy clampingWelding/cutting auxillary devicesAuxillary welding devicesCarrying capacityEngineering

The invention discloses a large-scale adjustable frame structure welding fixture, comprising a fixture base, a quick-replacing structure, a fixing unit, a pressing device, a positioning device and a workpiece, wherein the base is composed of a square frame and a guiding rail, the quick-replacing structure is composed of a quick-replacing connector, a connecting plate and a reinforcing rib, the fixing unit is composed of a cross beam fixing unit and a longitudinal beam fixing unit, the pressing device comprises an air cylinder and a replaceable press block, the positioning device is composed ofa positioning plate and a sliding base, and the workpiece comprises a cross beam and a longitudinal beam. The large-scale adjustable frame structure welding fixture is combined with the currently used welding fixture of a welding work station, so that structural innovative design is realized, and the carrying capacity of 1500kg is realized by using an overturning positioner. By adopting the quick-replacing mechanism, different fixtures can be removed from and mounted on the overturning positioner, so that the mounting and replacing of the fixture are more convenient.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

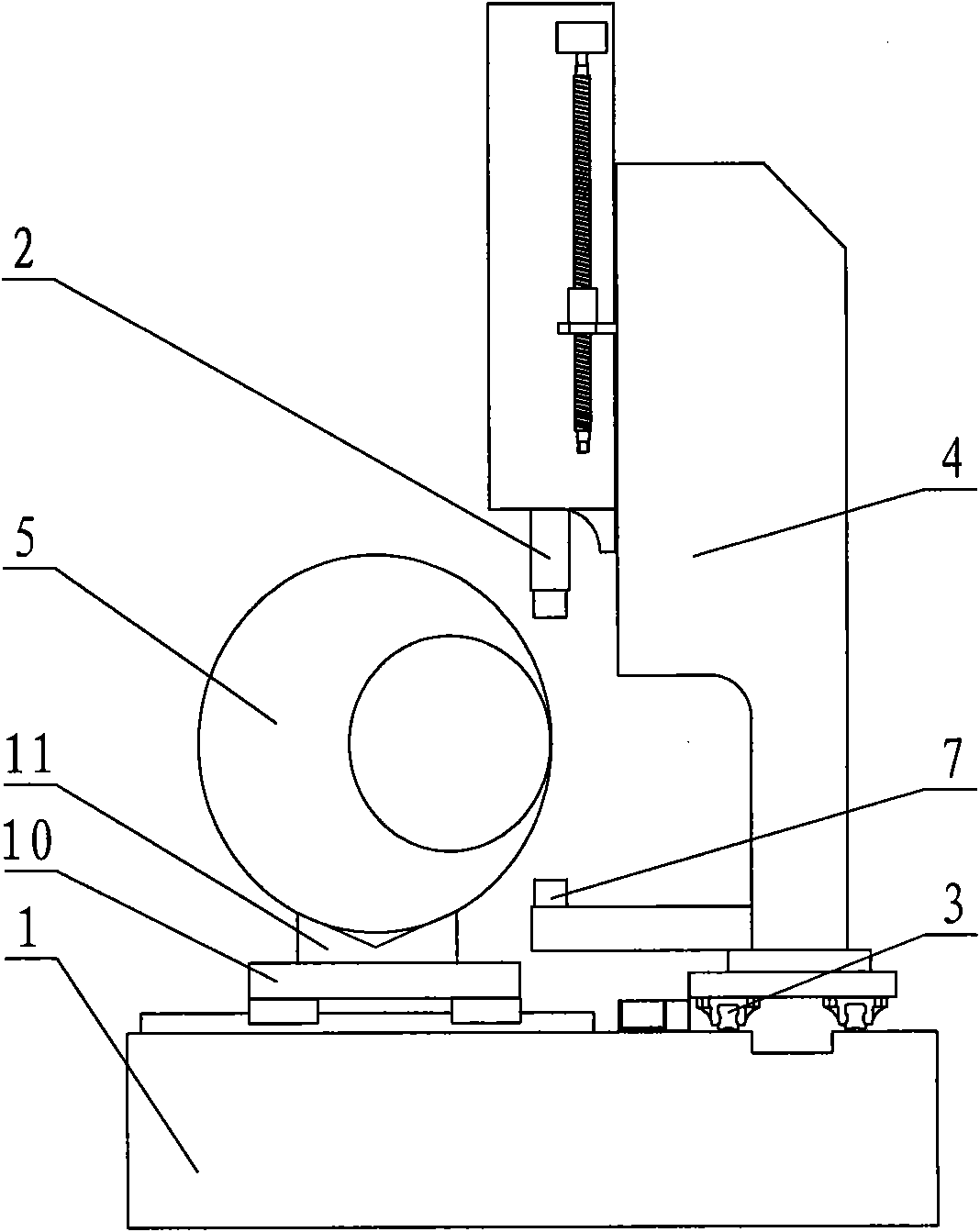

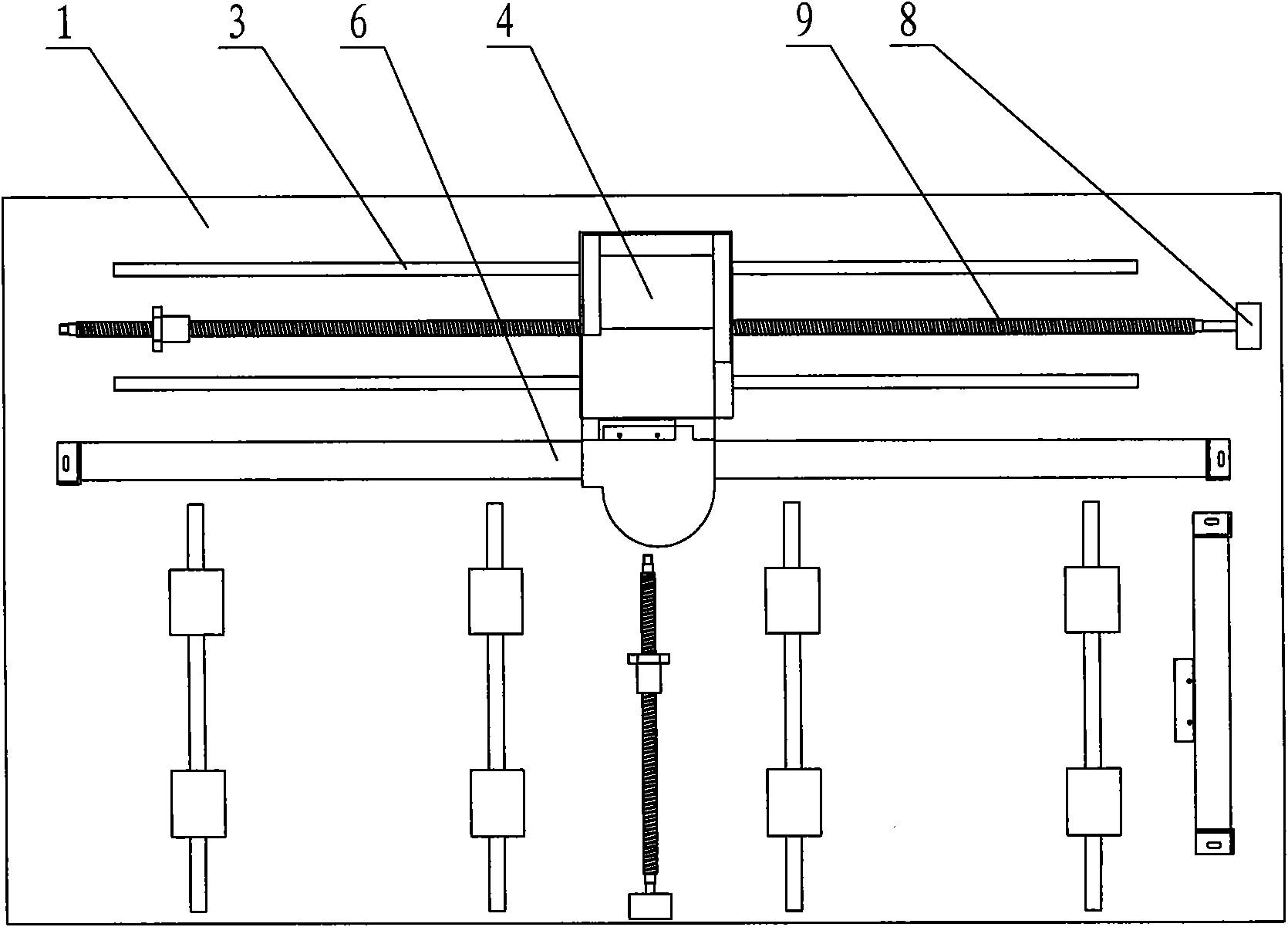

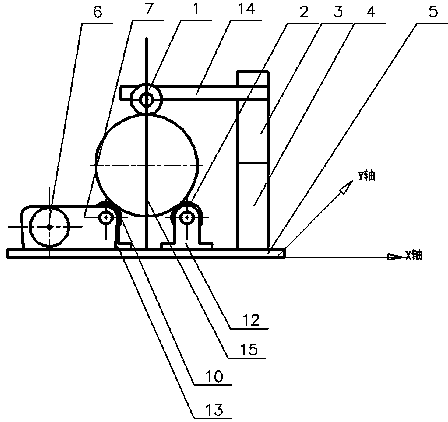

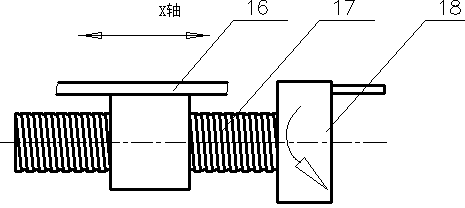

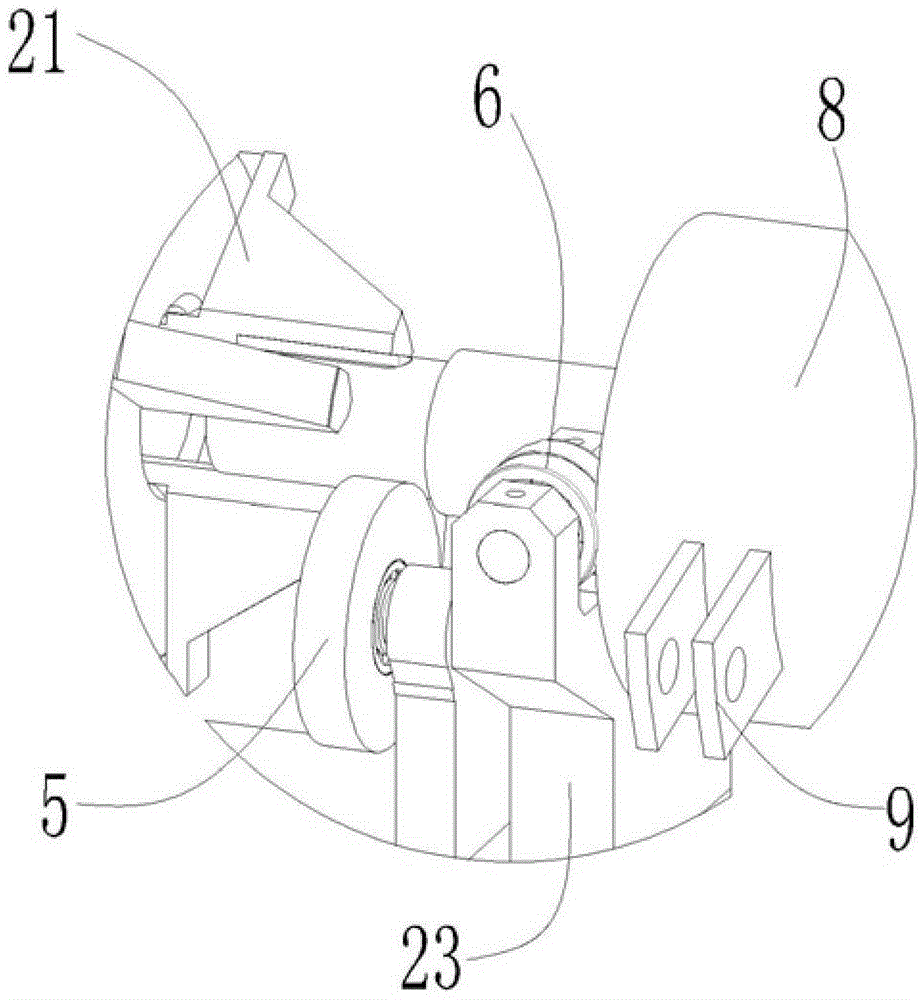

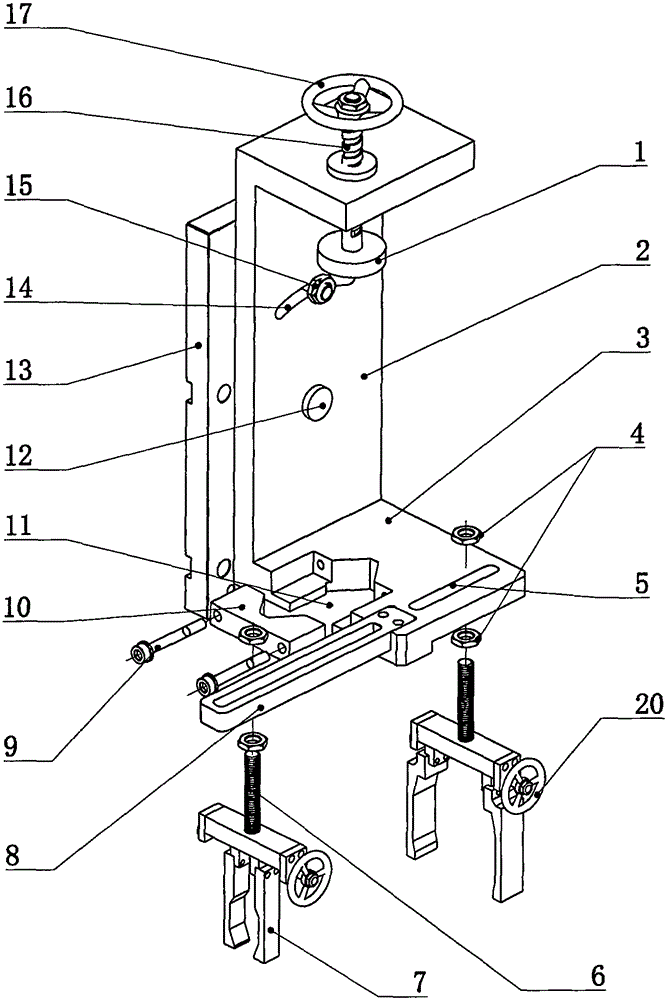

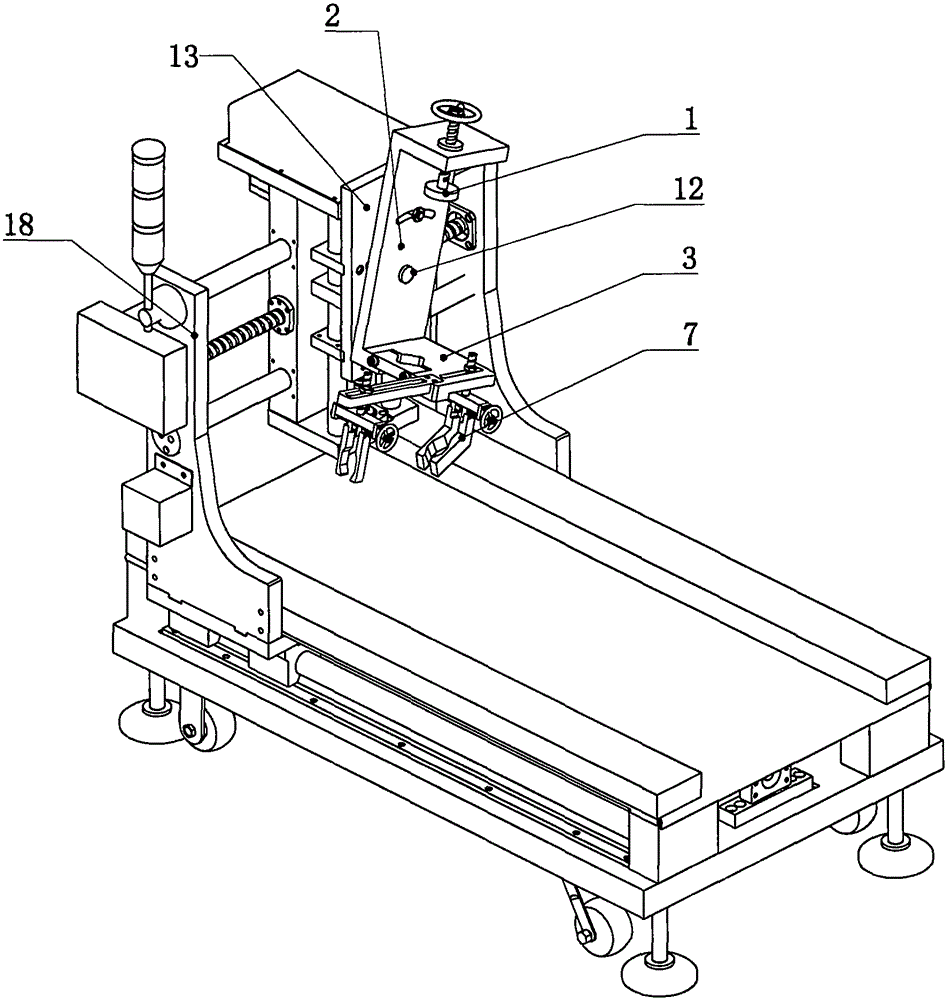

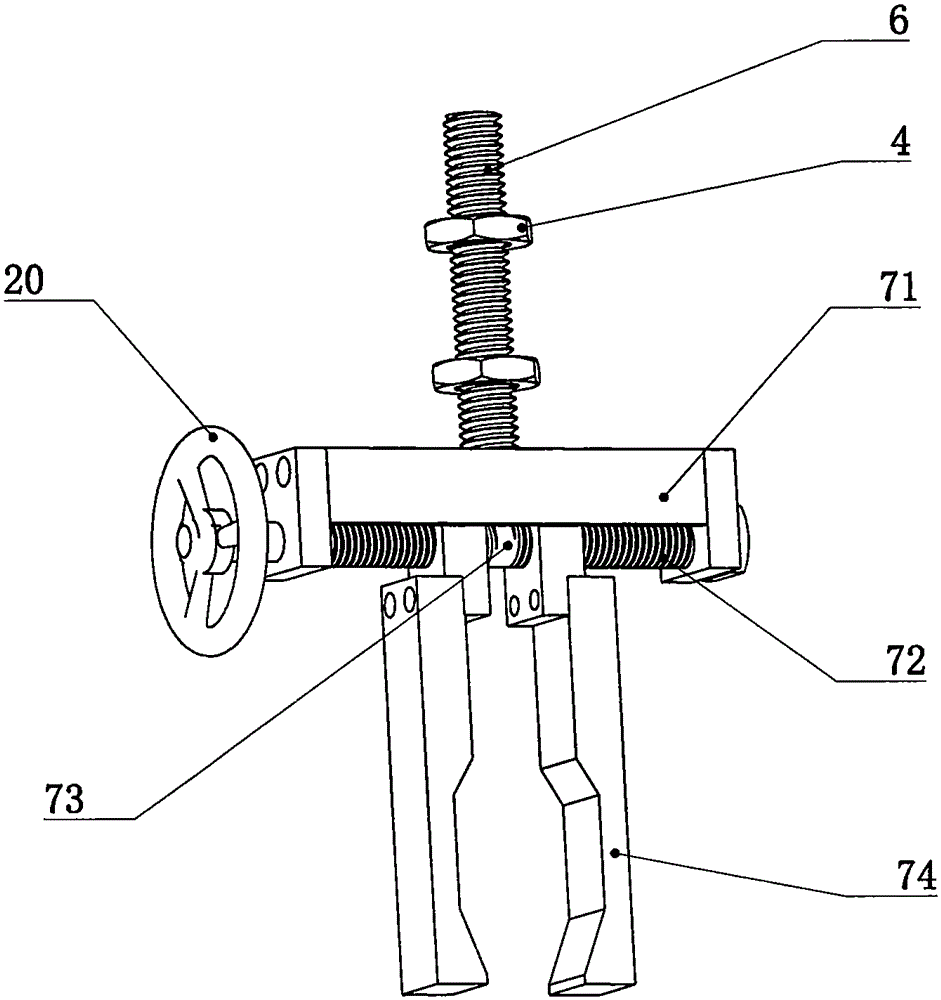

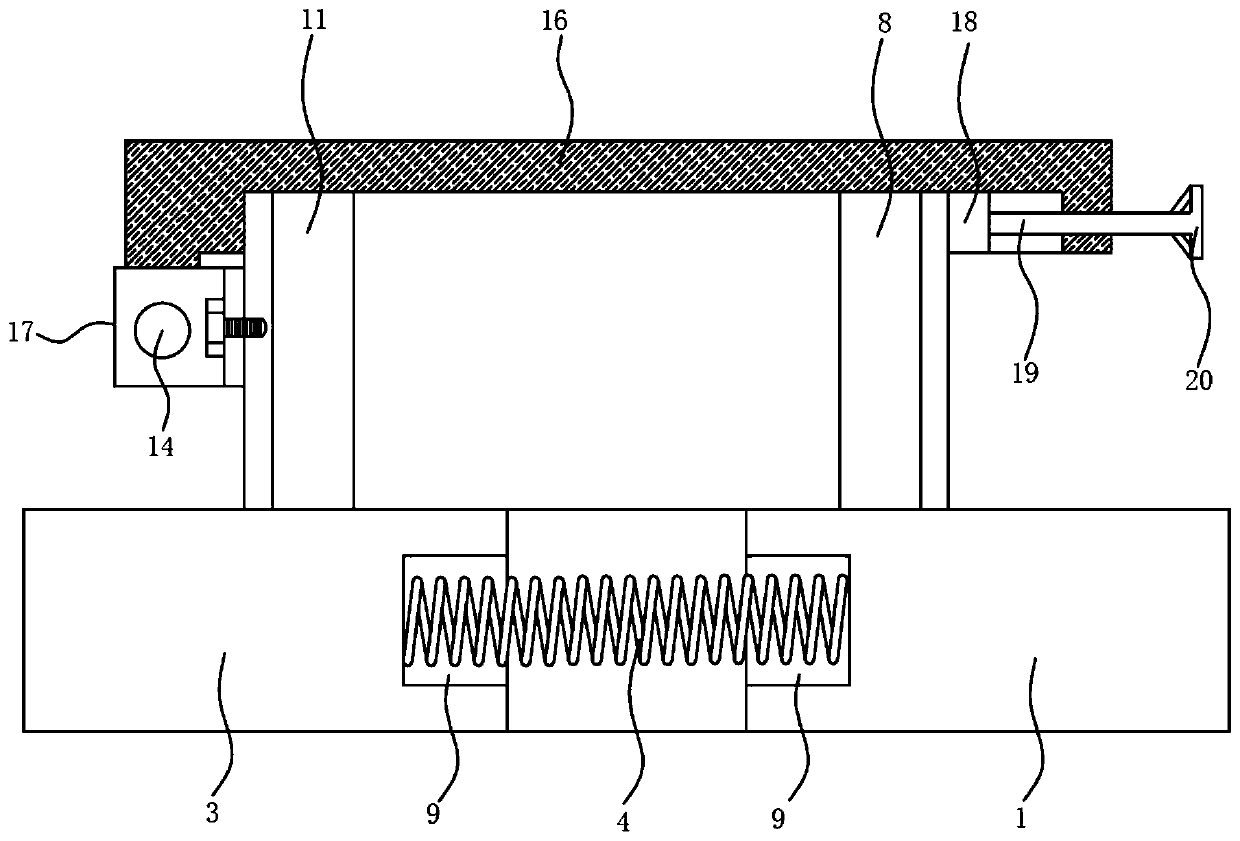

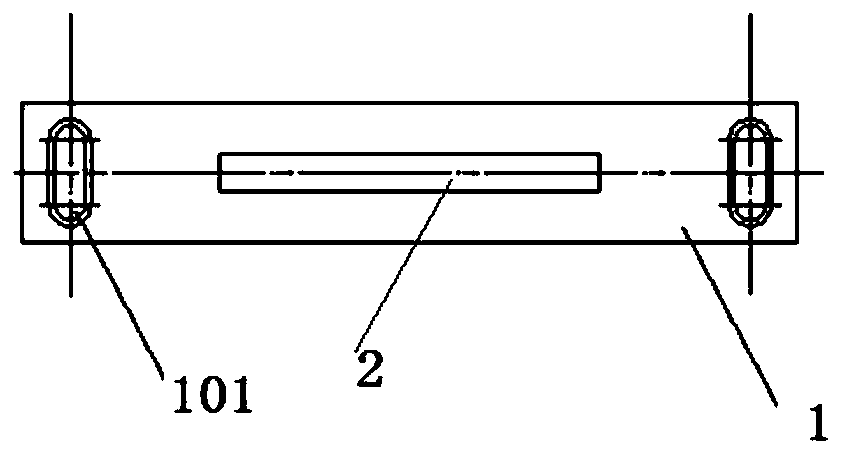

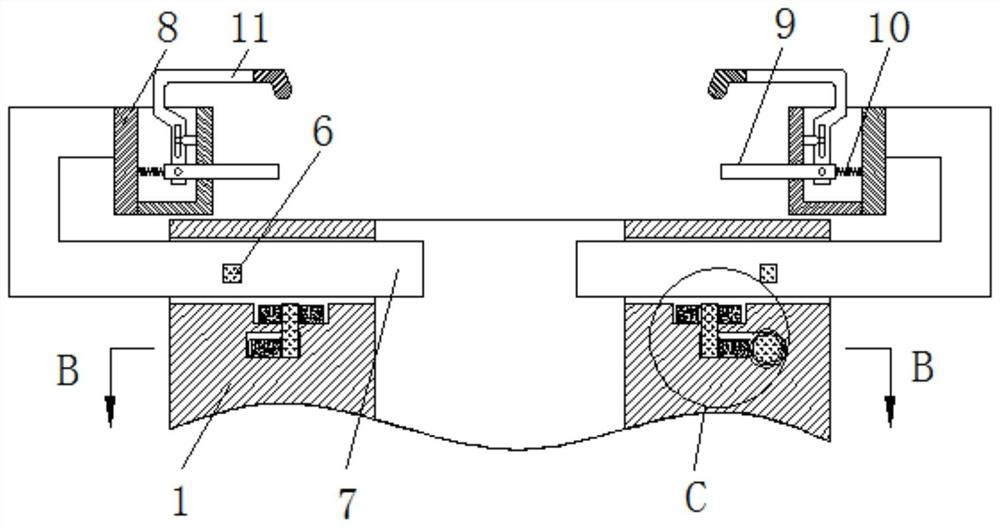

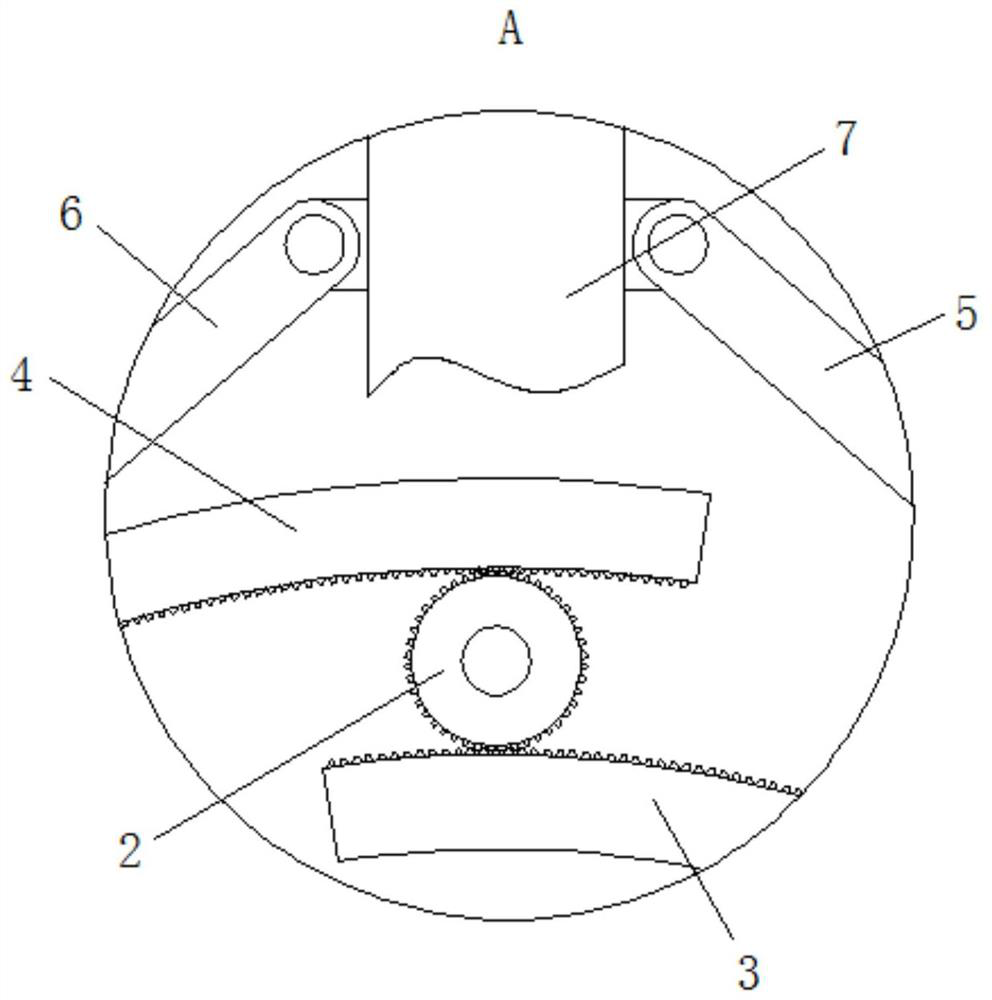

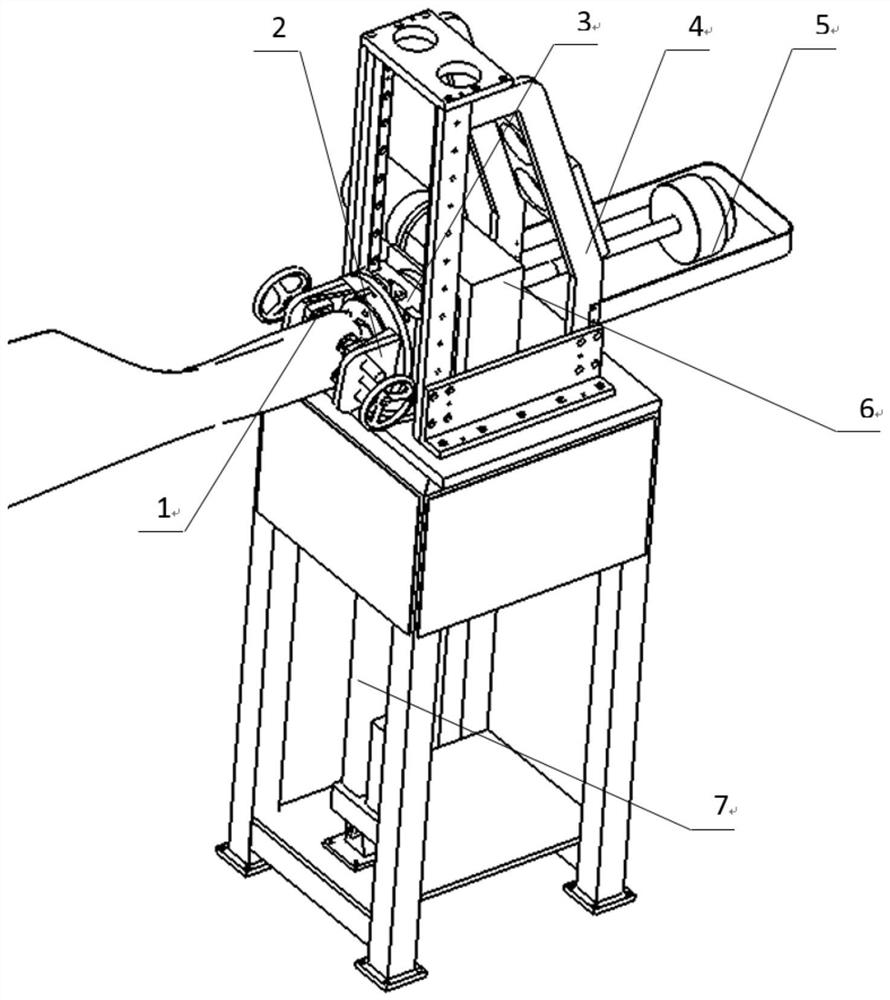

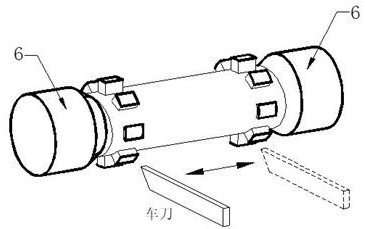

Main shaft online indexing module of numerical control wire-cut machine tool and use method of main shaft online indexing module

ActiveCN103506724AMeet the clampingAdjustable spacingPrecision positioning equipmentElectrical-based auxillary apparatusNumerical controlControl signal

The invention relates to a main shaft online indexing module of a numerical control wire-cut machine tool and a use method of the main shaft online indexing module. A fixed guide rail bracket is installed on a base, a drive motor, a servo speed reducer, a lower driven idler wheel support and a driving idler wheel support are installed on one side of the fixed guide rail bracket, a slide block is installed on the upper portion of the fixed guide rail bracket, and a cross rod is arranged on the upper portion of the slide block. An upper driven idler wheel, a lower driven idler wheel and a driving idler wheel form a three-point clamping device to fix a workpiece in the X direction and the Y direction, the drive motor drives the driving idler wheel to rotate through the servo speed reducer and a transmission shaft, and the driving idler wheel drives the workpiece to rotate through friction between the driving idler wheel and the workpiece. The main shaft online indexing module has the advantages that clamping is achieved in the mode of the three idler wheels, assembly and disassembly are convenient, and the distances between the idler wheels are adjustable so that clamping of workpieces with different diameters can be met; control signals of the machine tool are directly used without adding other control signals and changing a programming mode, the cost is low, and the workpiece is convenient to assemble and disassemble.

Owner:青岛德明石油机械有限公司 +1

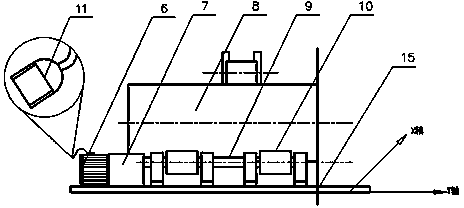

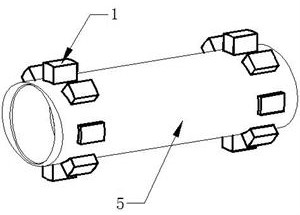

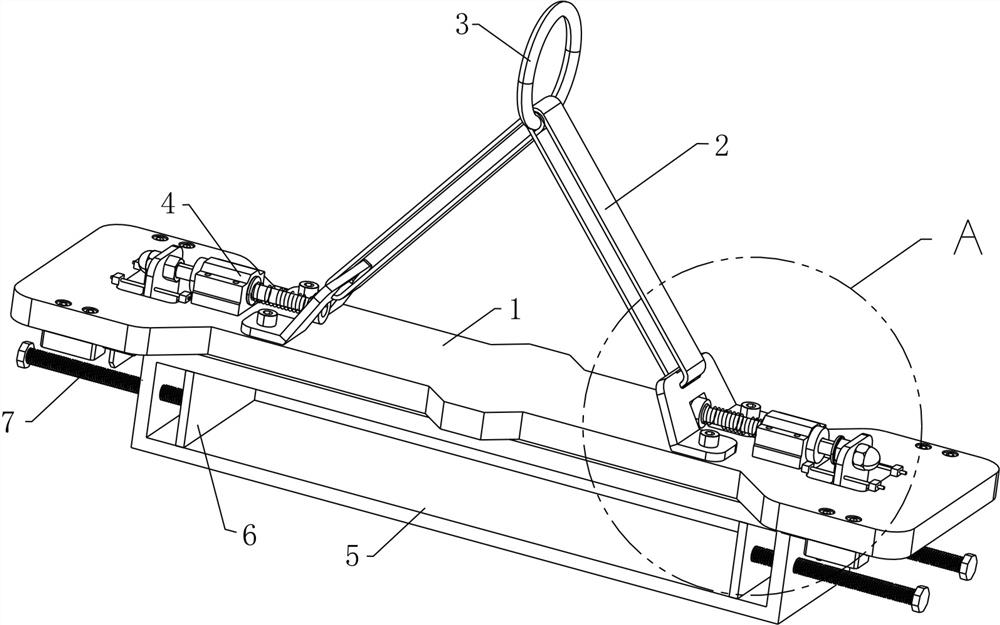

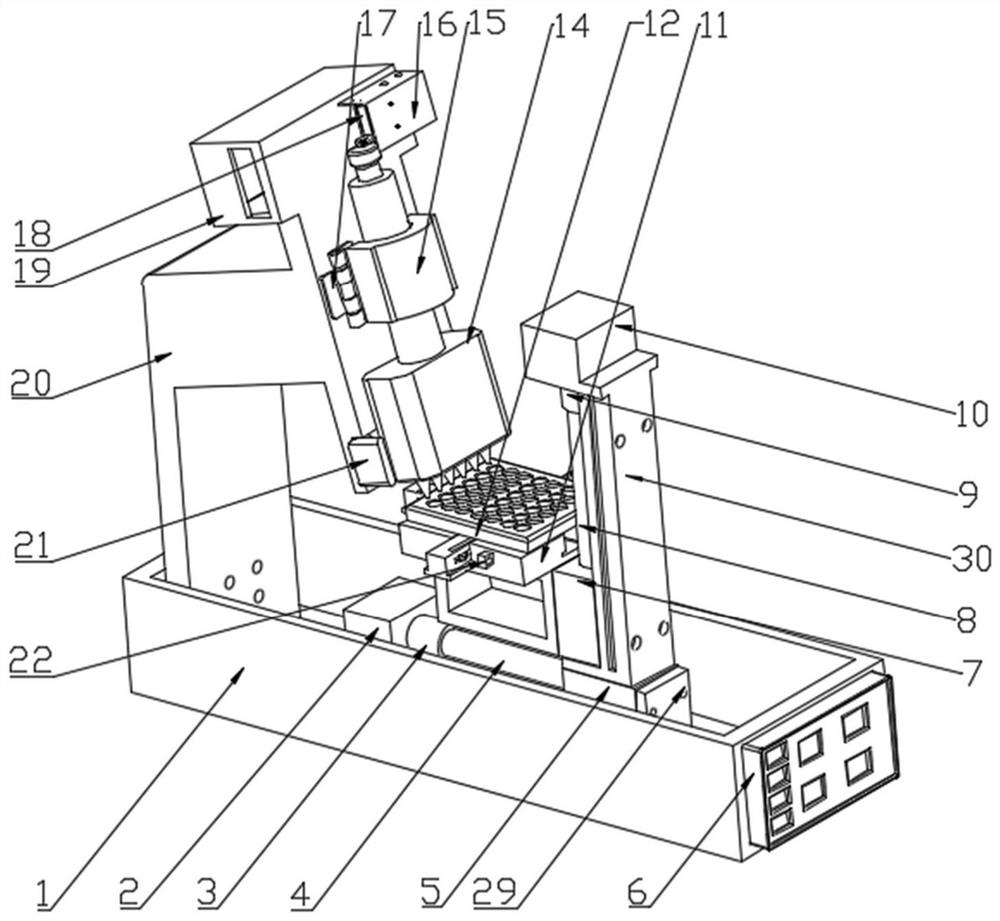

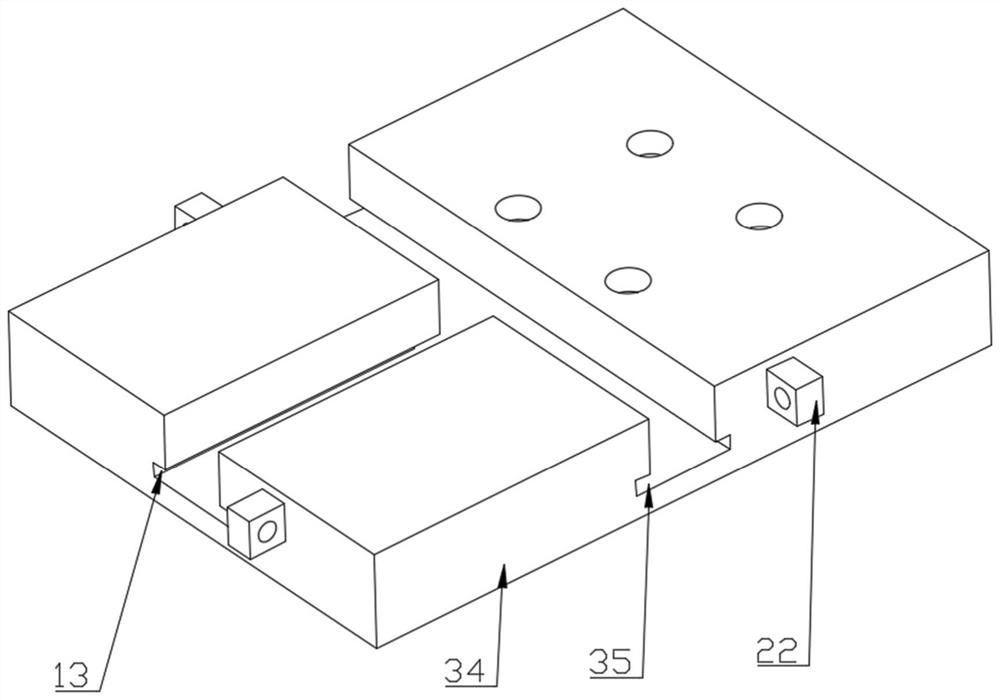

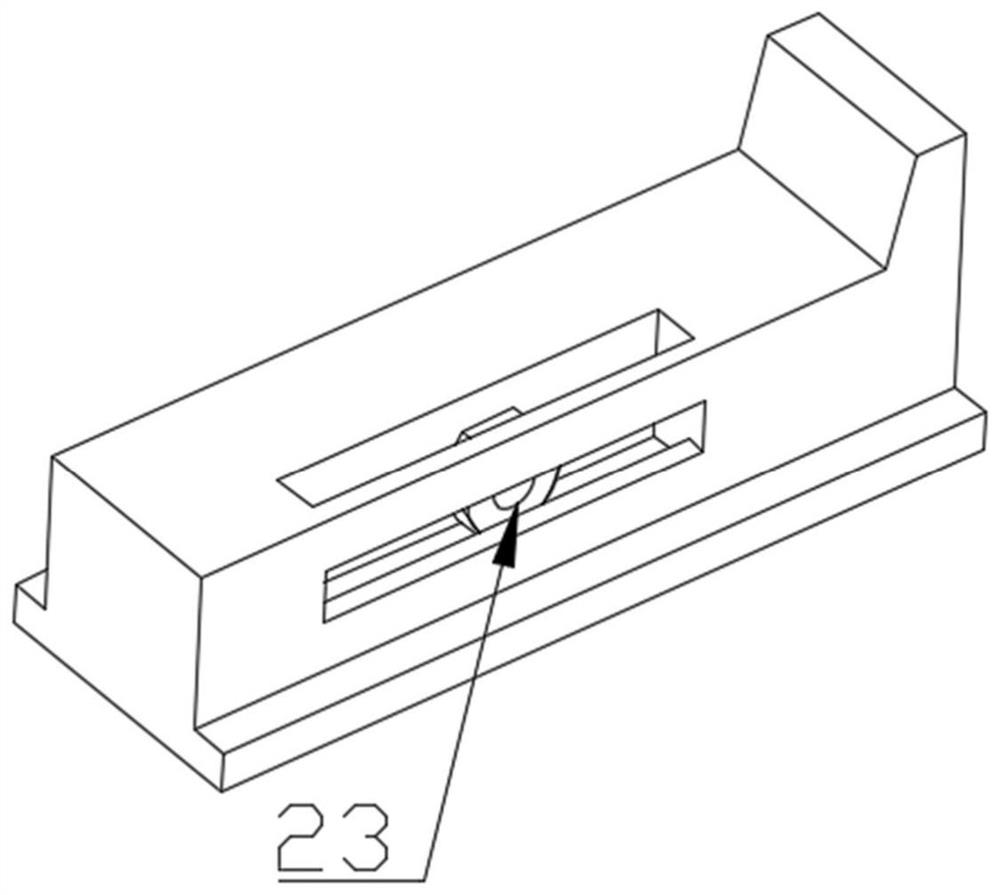

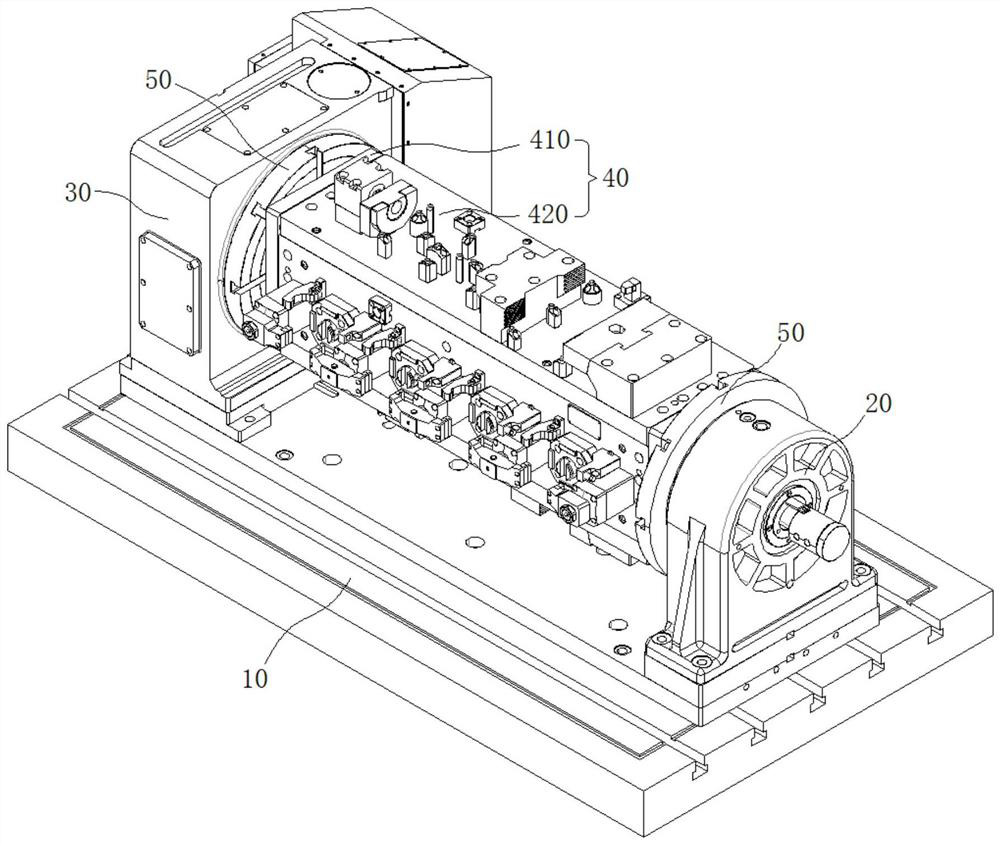

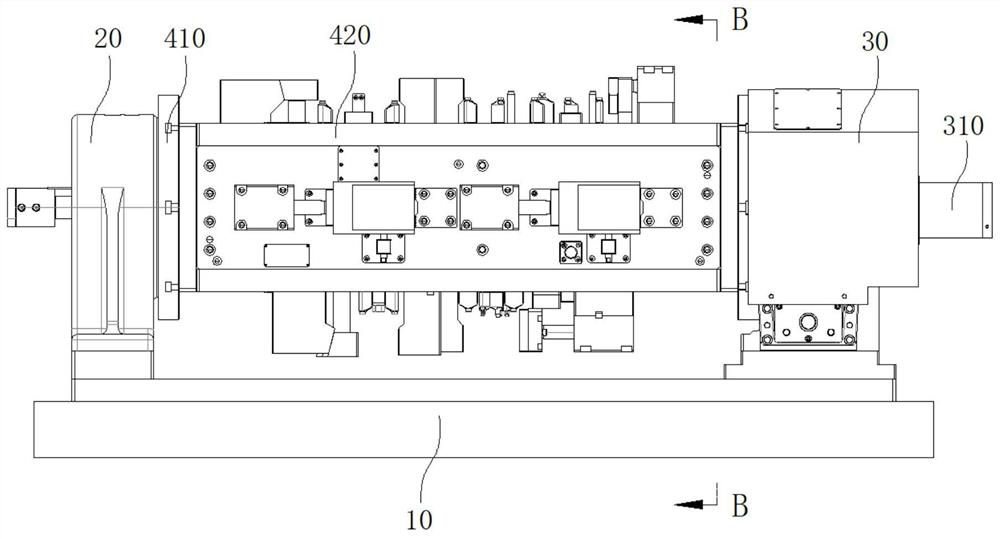

Multifunctional robot flexible tool positioning system for shafts

InactiveCN104985385AMeet the clampingSimple structureWelding/cutting auxillary devicesAuxillary welding devicesAlloyDrive motor

The invention discloses a multifunctional robot flexible tool positioning system for shafts. The system comprises a machine base. The machine base is provided with a first sliding rail and a second sliding rail. A rotary clamping vertical base is installed at one end of the first sliding rail. The rotary clamping vertical base is provided with a chuck and a rotation driving motor driving the chuck to rotate. A tip cone vertical base is installed at the other end of the first sliding rail in a sliding mode. A tip cone is installed on the tip cone vertical base. A taking sliding base for conveying an alloy tool apron is installed on the second sliding rail in a sliding mode and provided with a feeding platform for bearing the alloy tool apron. An air clamp for clamping the alloy tool apron is installed above the feeding platform. The taking sliding base is further provided with a taking driving device which is connected with the air clamp and drives the air clamp to reciprocate up and down. The multifunctional robot flexible tool positioning system for shafts is simple in structure, convenient to operate and flexible to adjust, has the high universality, meets the requirement for clamping different sizes of workpieces, is high in overall equipment utilization rate, saves a large amount of labor and time, and improves smashing shaft and alloy tool apron positioning production efficiency.

Owner:GUANGZHOU ROHE MACHINERY EQUIP TECH

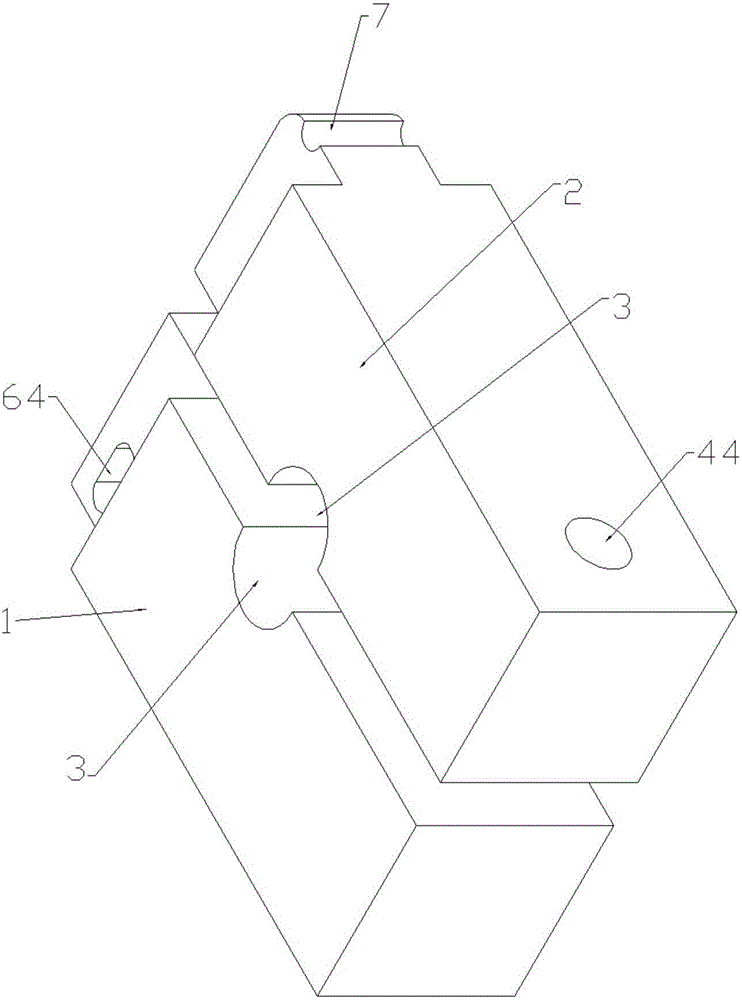

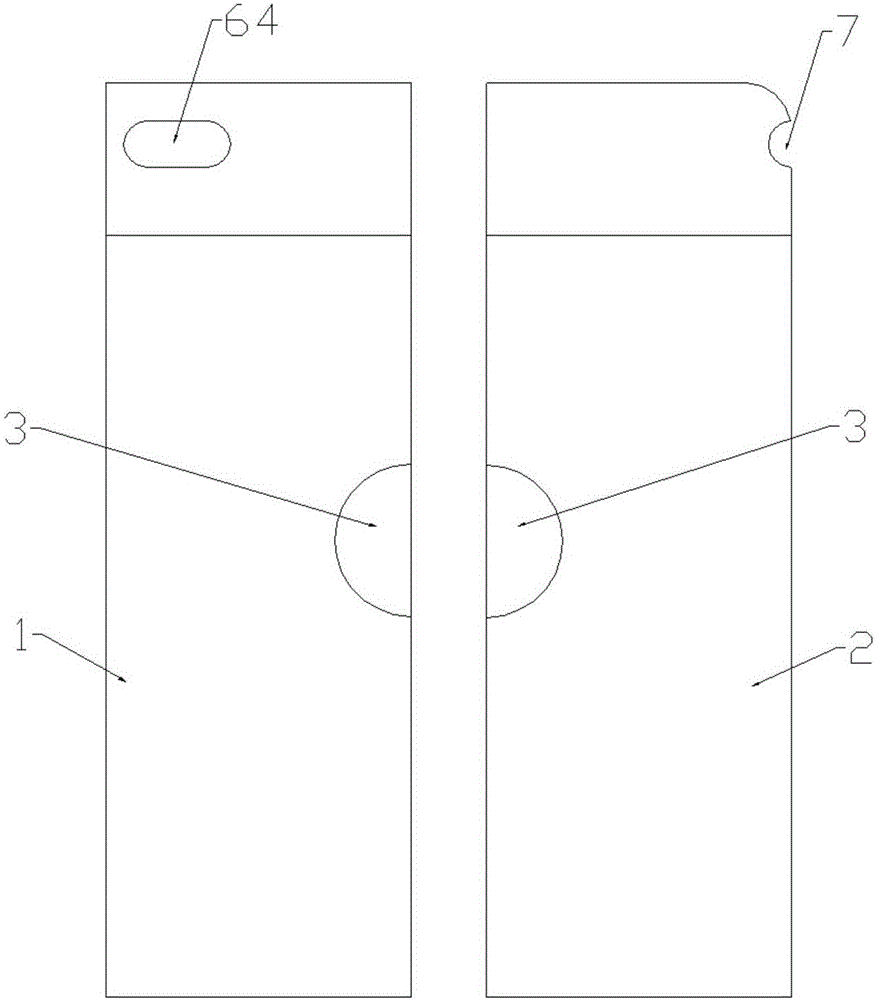

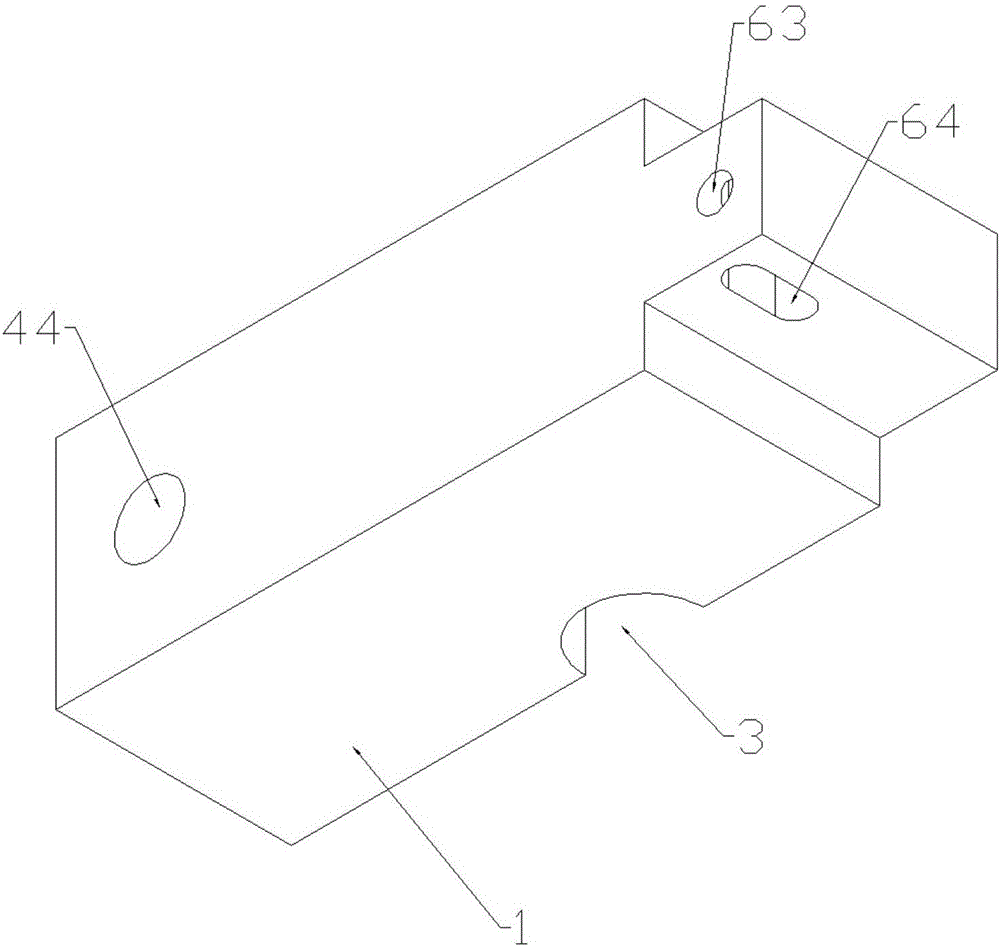

General clamping device for working condition test of electric tool

PendingCN106425919AGood versatilityChange shapeWork holdersPortable power-driven toolsPower toolEngineering

The invention provides a general clamping device for a working condition test of an electric tool, belongs to the technical field of clamping in electric tool tests, and solves the problem that no general tools are provided for clamping in conventional electric tool tests. The general clamping device comprises a longitudinal mounting plate, a mounting seat and an angle adjusting mechanism used for changing the position relation between the mounting seat and the mounting plate. A longitudinal clamping component and a butt clamp component are arranged on the mounting seat. The longitudinal clamping component comprises a pressure block, a pressure bock expansion driving mechanism and a datum plate. A locking groove is formed in the datum plate. A longitudinal clamping and pressing space is formed between the pressure block and the datum plate. The butt clamp component is arranged below the datum plate, and comprises two clamping jaws arranged side by side and a clamping jaw distance adjusting mechanism. The opening-closing surfaces of the clamping jaws are corresponding in the opposite directions. The general clamping device can realize clamping of electric tools of different shapes, and is high in generality, and the mounting angle of the mounting seat can be adjusted so as to meet the working condition tests of the electric tools with angle of inclination requirements during operation.

Owner:金华尤创自动化科技有限公司

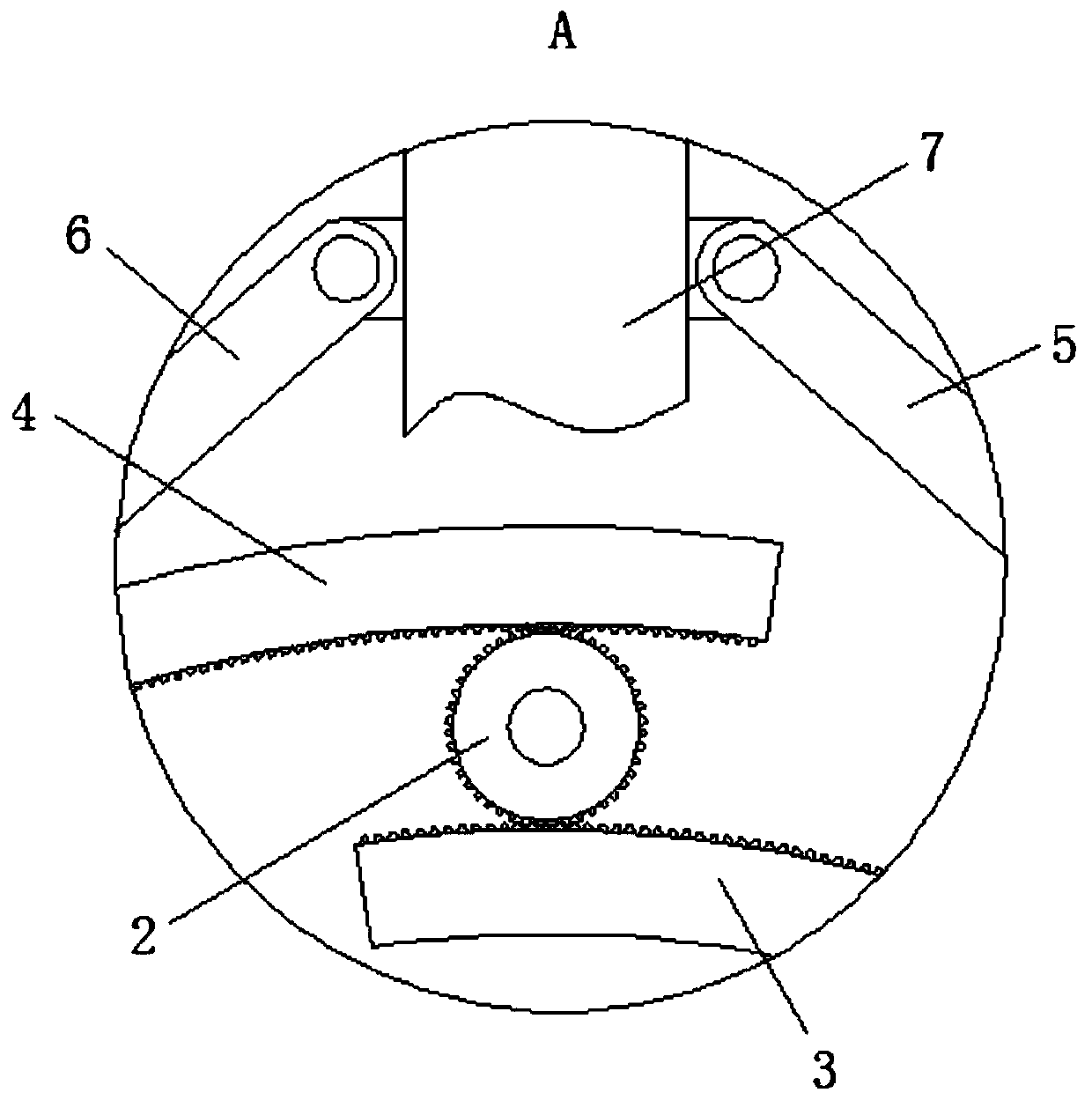

Flange fixing device utilizing lever transmission principle for dual fixing

ActiveCN111266892AGuaranteed accuracyReduce in quantityWork holdersPositioning apparatusGear wheelClassical mechanics

The invention relates to the technical field of flanges, and discloses a flange fixing device utilizing a lever transmission principle for dual fixing. The flange fixing device comprises a supportingseat, the supporting seat is internally and movably connected with gear columns, the gear columns are externally connected with inner arc-shaped toothed rods and outer arc-shaped toothed rods in a meshed mode, the inner arc-shaped toothed rods are externally connected with first pull rods in a hinged mode, the outer arc-shaped toothed rods are externally connected with second pull rods in a hingedmode, and the first pull rods and the second pull rods are externally connected with sliding rods in a hinged mode. Through cooperative use of the gear columns, the inner arc-shaped toothed rods, theouter arc-shaped toothed rods, the first pull rods, the second pull rods and the sliding rods, the effects of adjusting the sliding rods and enabling the sliding rods to drive fastening blocks to clamp flanges are achieved, clamping of flanges with different diameters can be achieved, so that the number of clamps is reduced, then the flange production cost is reduced, the clamp storage space is reduced, meanwhile, the axes of the flanges can be determined, the axes of the flanges and the axis of the supporting seat are collinear, and then the flange machining precision is guaranteed.

Owner:山东顺发重工有限公司

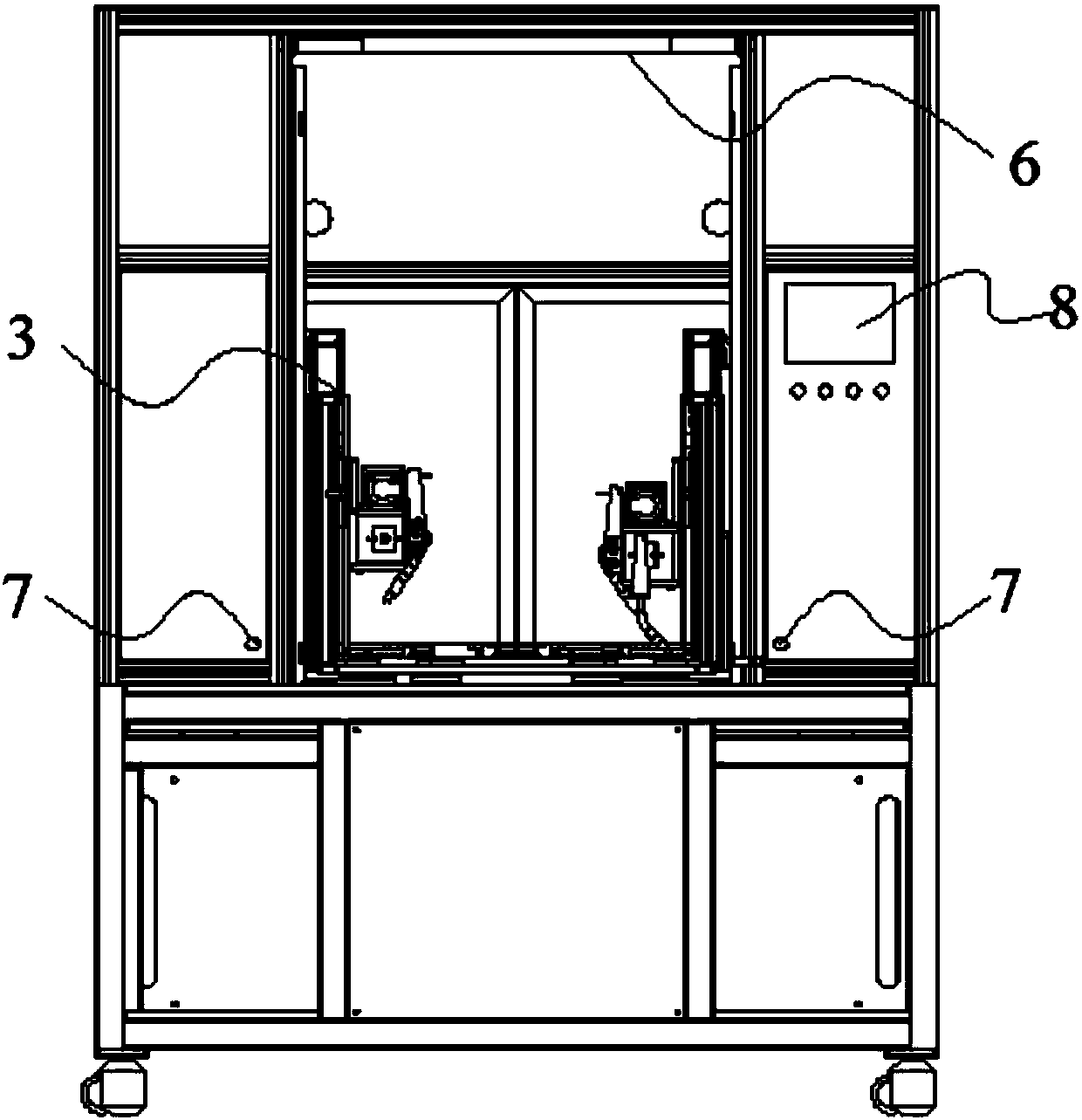

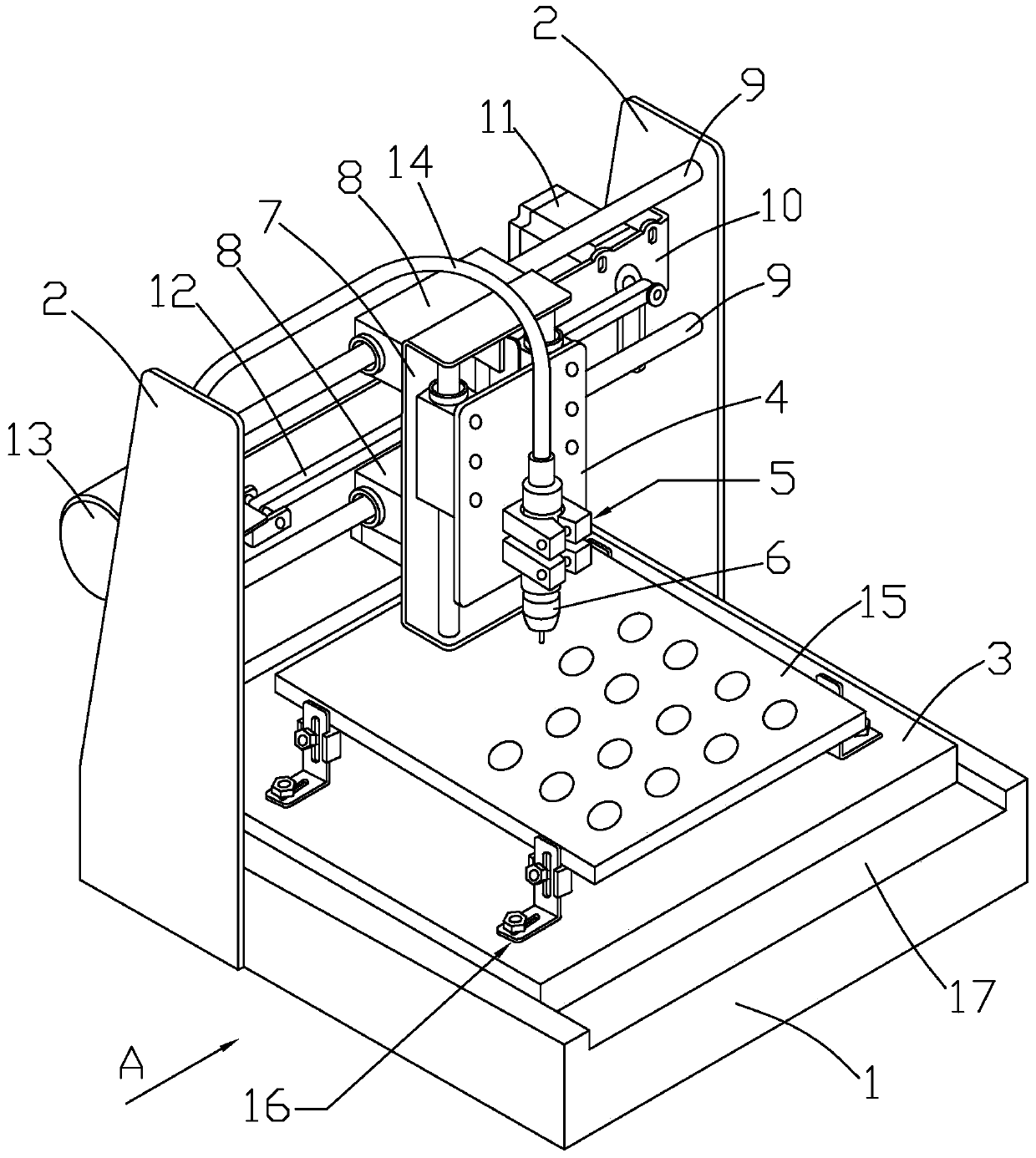

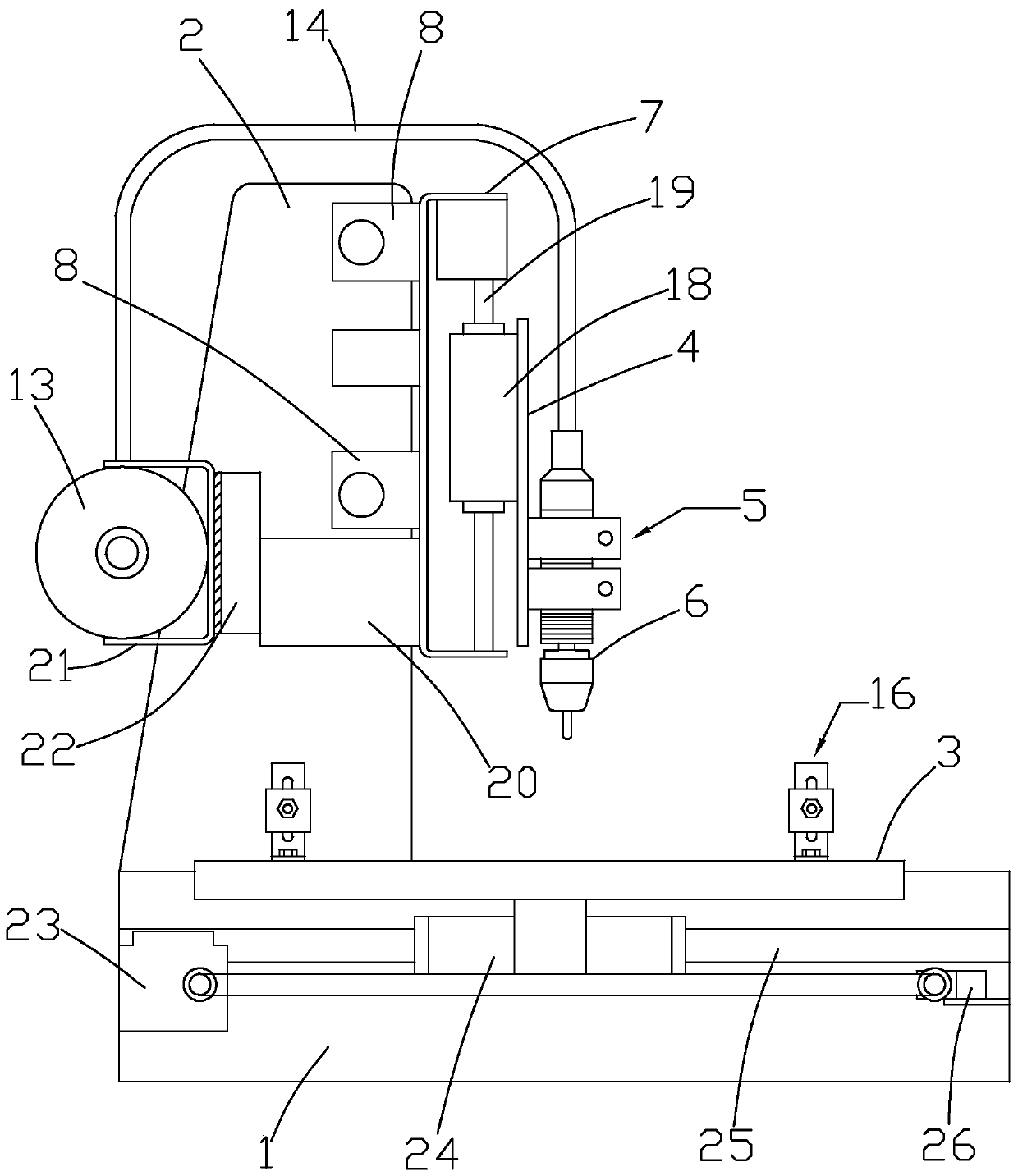

Keying and scribing durability test equipment

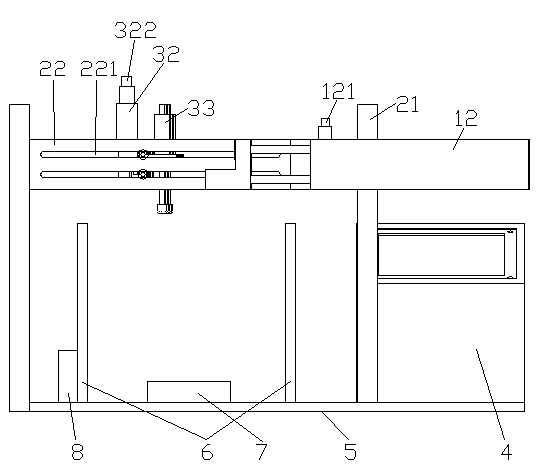

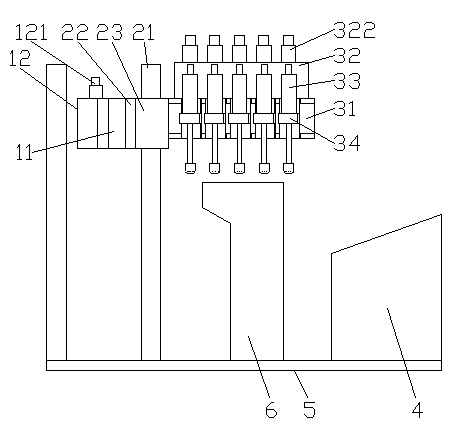

ActiveCN103176085AMeet the clampingMeet the testStructural/machines measurementCircuit interrupters testingElectricityKey pressing

The invention relates to the technical field of test equipment, in particular to keying and scribing durability test equipment which solves the technical problem that keying durability and scribing durability of a touch screen cannot be used on a same rack. The keying and scribing durability test equipment comprises a frame, a pressure regulator, an air source treater, a scribing module, an action switching module, a key module and a control module, wherein the pressure regulator, the air source treater, the scribing module, the action switching module, the key module and the control module are arranged on the frame, the control module is electrically connected with the air source treater, the scribing module and the key module are arranged on the action switching module, and the air source treater comprises two air outlets which are respectively connected with the scribing module and the key module through air guide tubes. The action switching module can simply switch, switching of test functions can be realized by simple replacement, so adjustment of test is simplified, cost is reduced, operation efficiency is improved, and clamping and testing of different samples can be met through simple adjustment.

Owner:GUANGZHOU GRG METROLOGY & TEST CO LTD

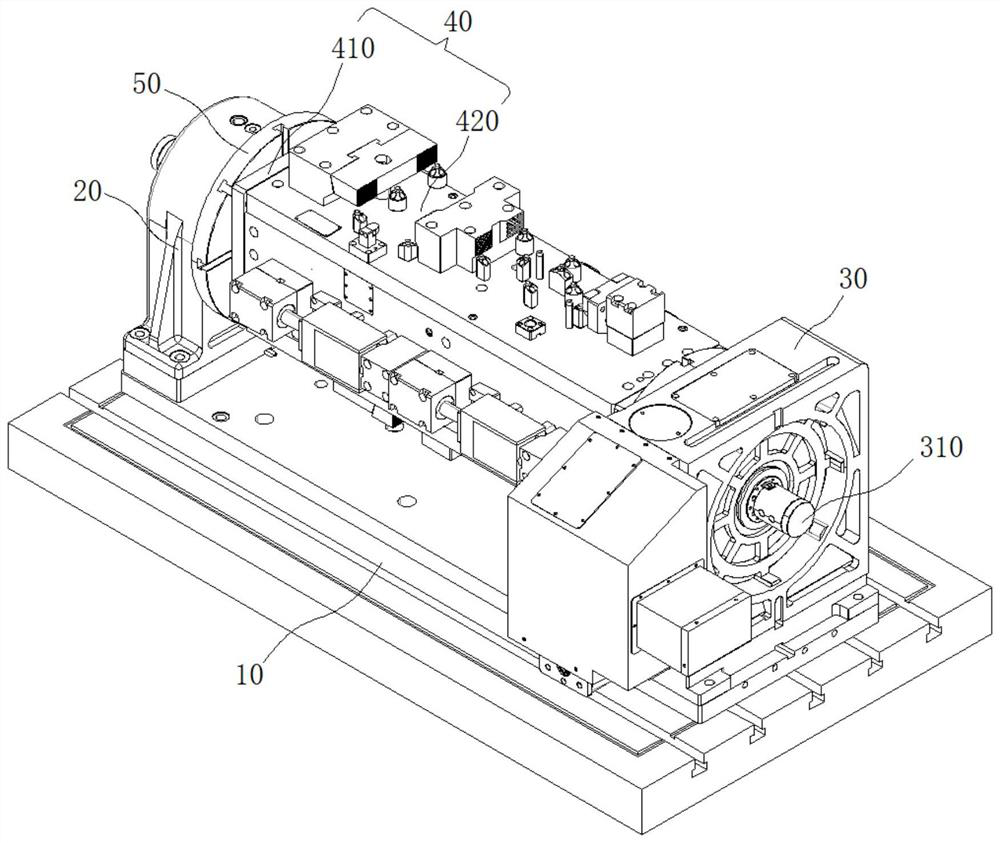

Testing machine for testing variable load reducer for washing machines

InactiveCN104792518AHighlight substantiveLong test periodMachine gearing/transmission testingReduction drivePneumatic valve

The invention relates to a testing machine for testing a variable load reducer for washing machines. The testing machine comprises a servo motor. The servo motor is connected with a reducer under test, through a shaft sleeve. The reducer under test is clamped with an adjustable clamp which is positioned via a guide rail; a pneumatic cylinder is connected with the shaft sleeve through a connecting line and loads the reducer under test; the connecting line is supported by a pulley; an air pipe is mounted on the pneumatic cylinder; the guide rail and the pulley are directly mounted on a base; the servo motor and the pneumatic cylinder are fixed on the base through a rib plate. The pneumatic cylinder loads the reducer, low heat is generated, and loading performance is stable; different loads can be acquired by adjusting a pneumatic valve through an industrial personal computer according to the load of the reducer for washing machines.

Owner:SHANGHAI UNIV

Clamp for cylindrical metallographic sample

Owner:HENAN UNIV OF SCI & TECH

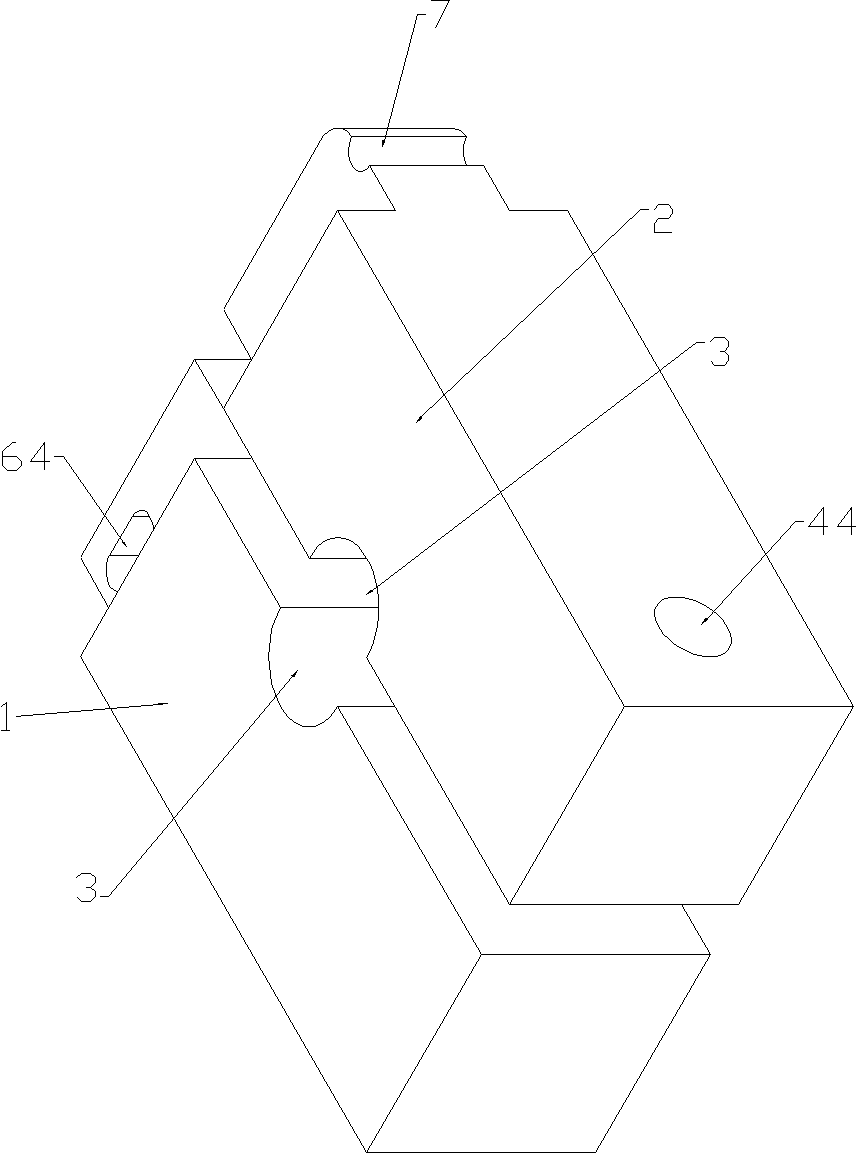

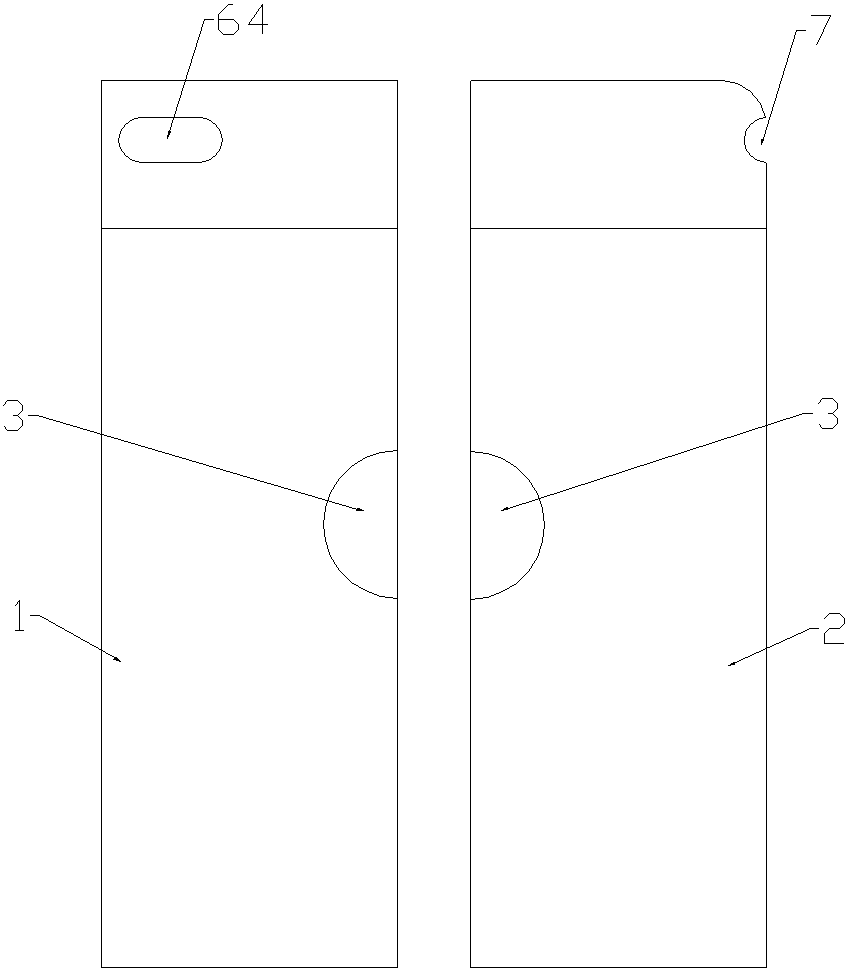

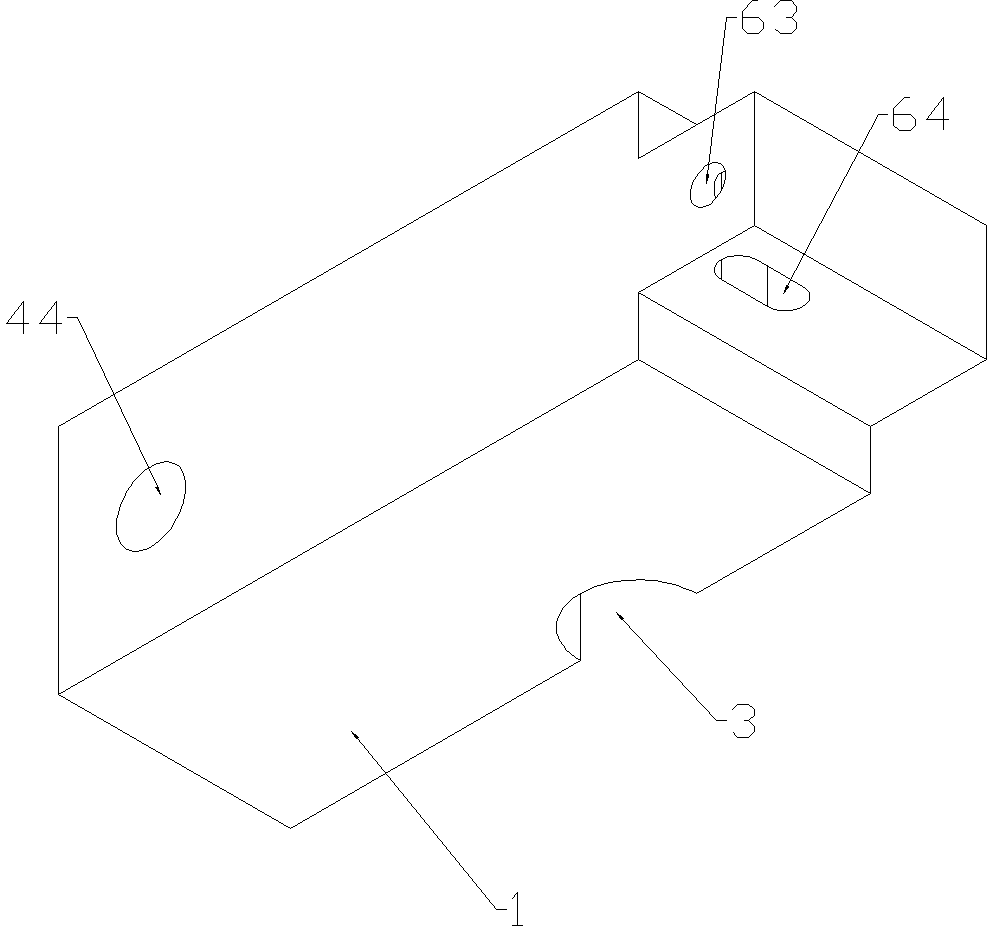

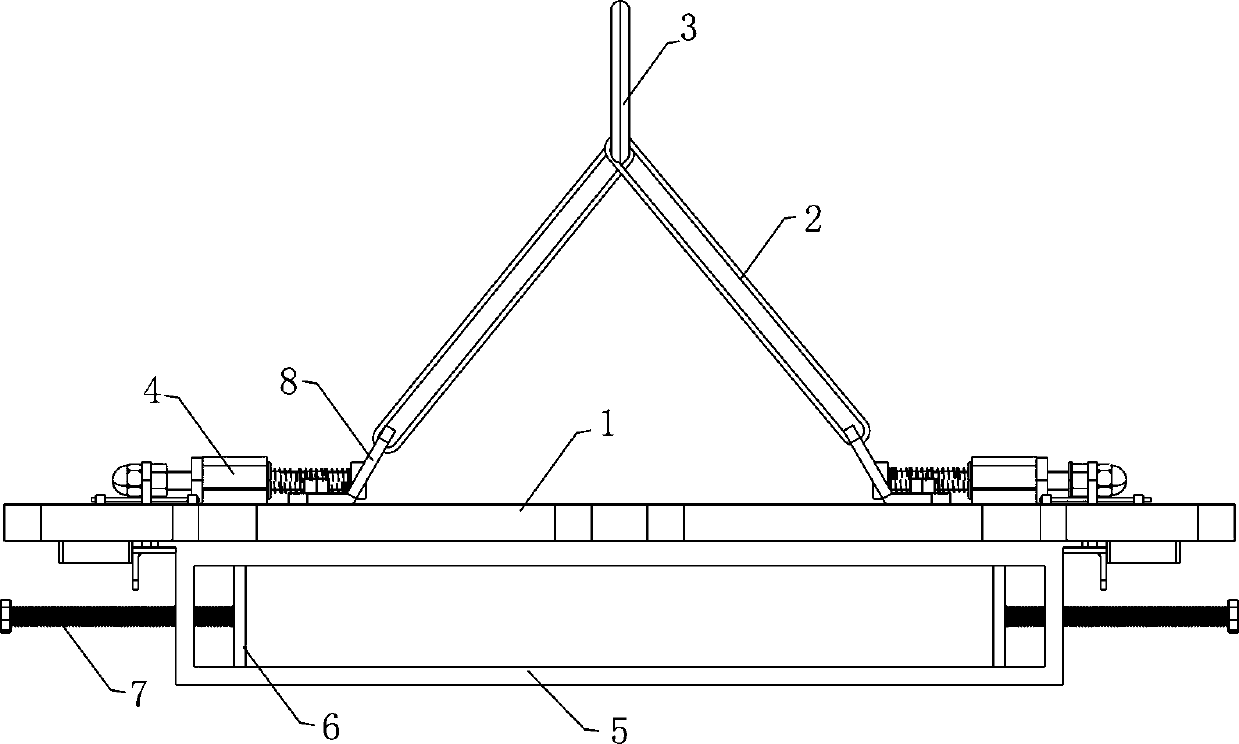

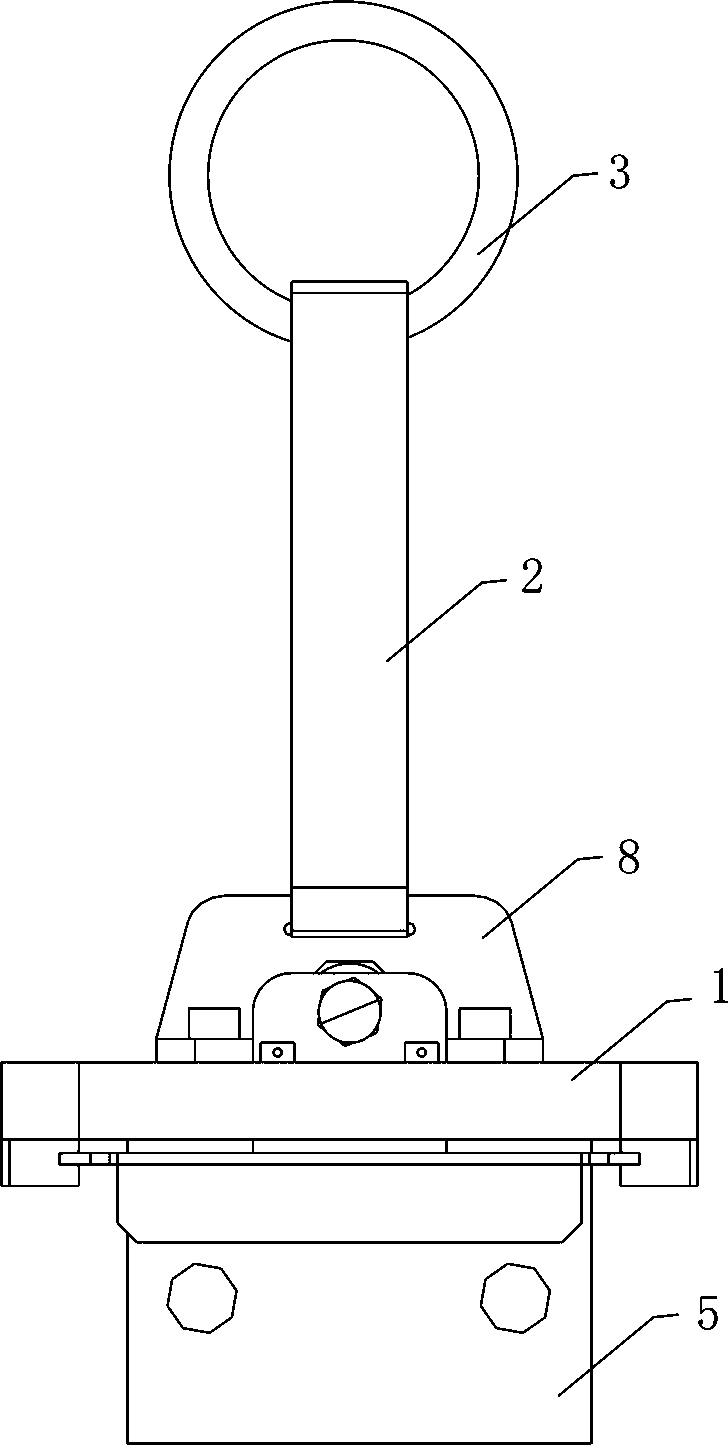

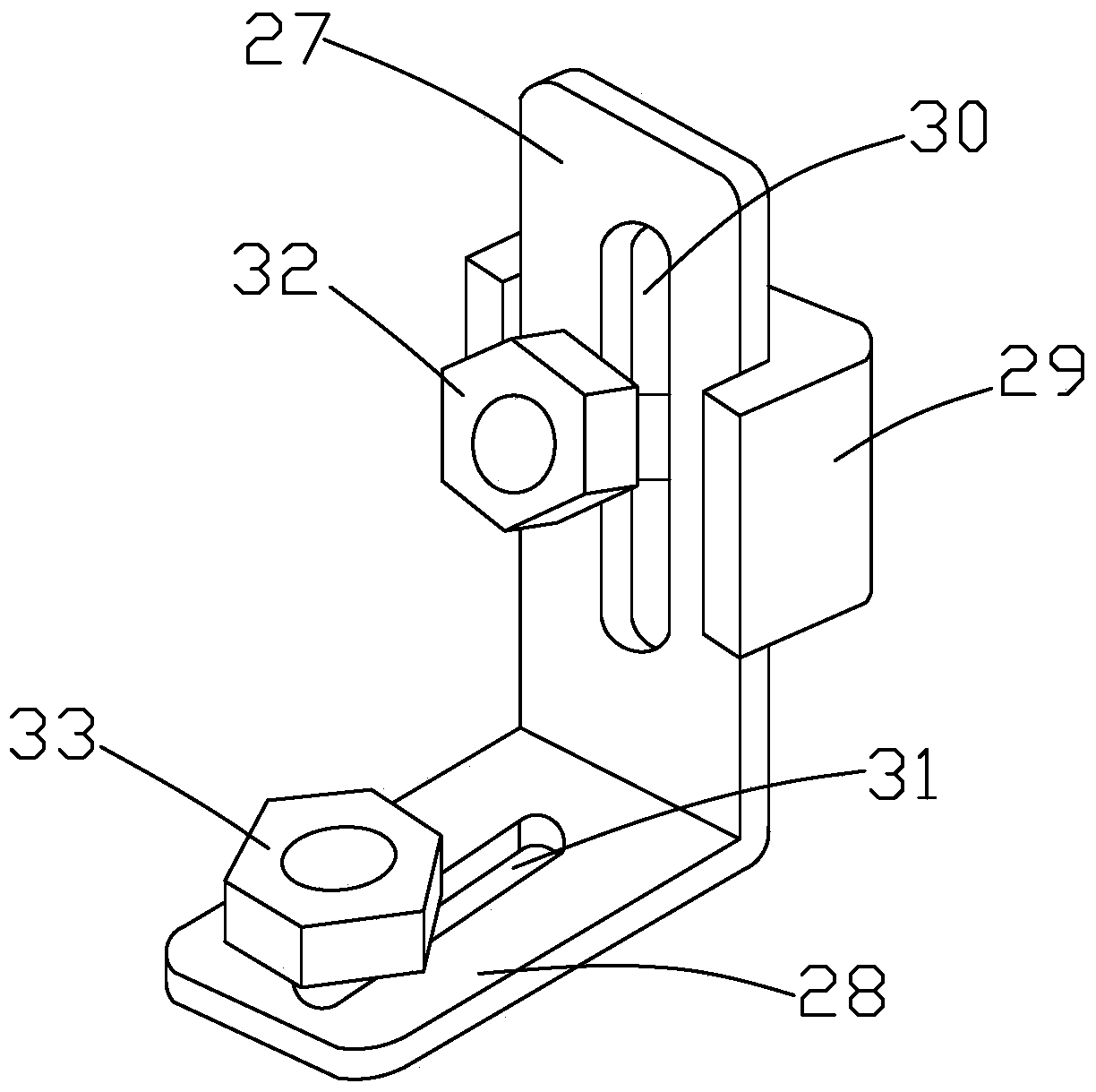

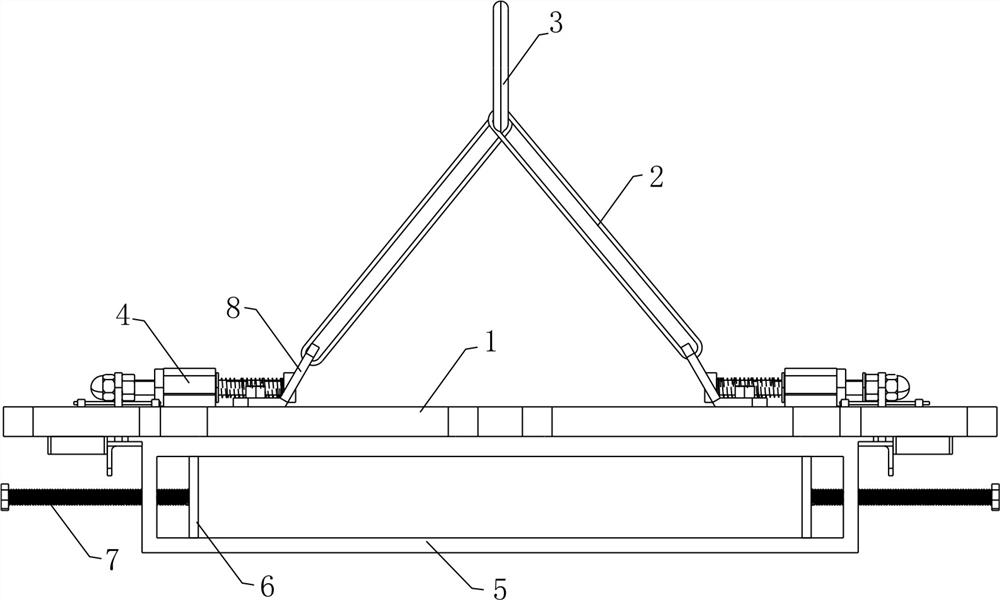

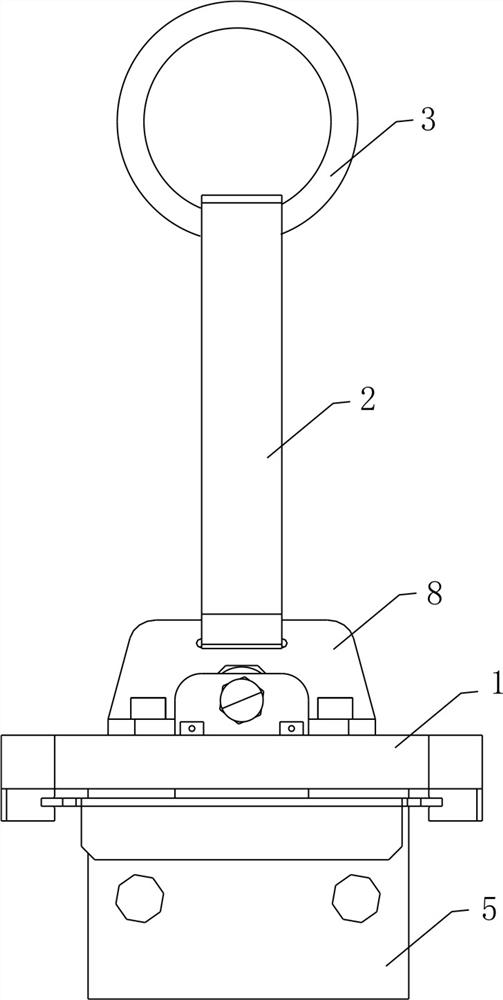

Hoisting tool applied to bridge accessories and using method thereof

ActiveCN109914247AReasonable designSimple structureBridge erection/assemblyLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a hoisting tool applied to bridge accessories and a using method thereof. The hoisting tool comprises a base plate, wherein a hoisting device for hoisting the base plate is mounted on the upper end surface of the base plate; adjusting plates are respectively arranged on two sides of the base plate; two adjusting plates penetrate through the base plate; clamping grooves forclamping the bridge accessories are formed by the two adjusting plates at the lower end of the base plate; the adjusting plates are mounted on the base plate through cross beams; the cross beams are mounted at the upper end of the base plate through mounting plates; adjusting devices for adjusting widths of the clamping grooves are formed in the inner sides of the adjusting plates; guide blocks for guiding or supporting the adjusting plates are arranged on the lower end surface of the base plate. The hoisting tool is reasonable in design and simple in structure, is used as the hoisting tool applied to bridge accessories and is used for assisting a hoisting machine to hoist and move the bridge accessories; the adjusting plates are reasonably designed; the two adjusting plates are mutually matched with the base plate to form the length-adjustable assembling grooves, so that the bridge accessories can be extremely rapidly and conveniently mounted and dismounted.

Owner:CITIC GUOAN CONSTR GRP CO LTD

Crystal inner carving clamp

ActiveCN110369888AMeet the clampingImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineeringCarving

The invention discloses a crystal inner carving clamp. The crystal inner carving clamp comprises a fixed seat and a movable seat, wherein the movable seat is slidably connected to two sets of slide rails at the front part and the rear part of the right end of the fixed seat, a crystal body is clamped between a left vertical clamping plate and a right vertical clamping plate, the left side of the left vertical clamping plate is movably connected with an end cover through a connecting mechanism, the end cover is clamped at the upper ends of the left vertical clamping plate and the right verticalclamping plate, the right end of the end cover is connected with a screw rod, the left end of the screw rod is connected with a moving block used for clamping the right vertical clamping plate, and the right end of the screw rod is connected with a hand wheel. According to the crystal inner carving clamp, the movable seat moves along two sets of slide rails, so that the distance between the movable seat and the fixed seat can be adjusted, the left vertical clamping plate and the right vertical clamping plate can meet the clamping of the crystal body with different left and right widths, and the firmness of the left vertical clamping plate and the right vertical clamping plate on the clamping of the crystal body can be further enhanced.

Owner:江苏富爱科技发展有限公司

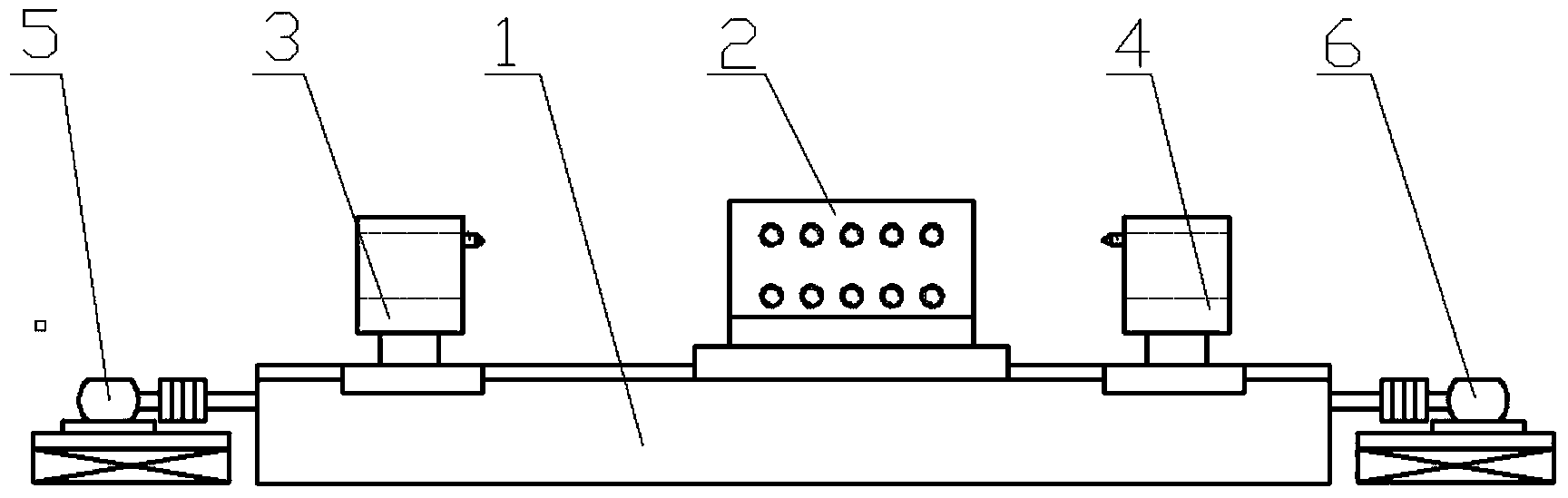

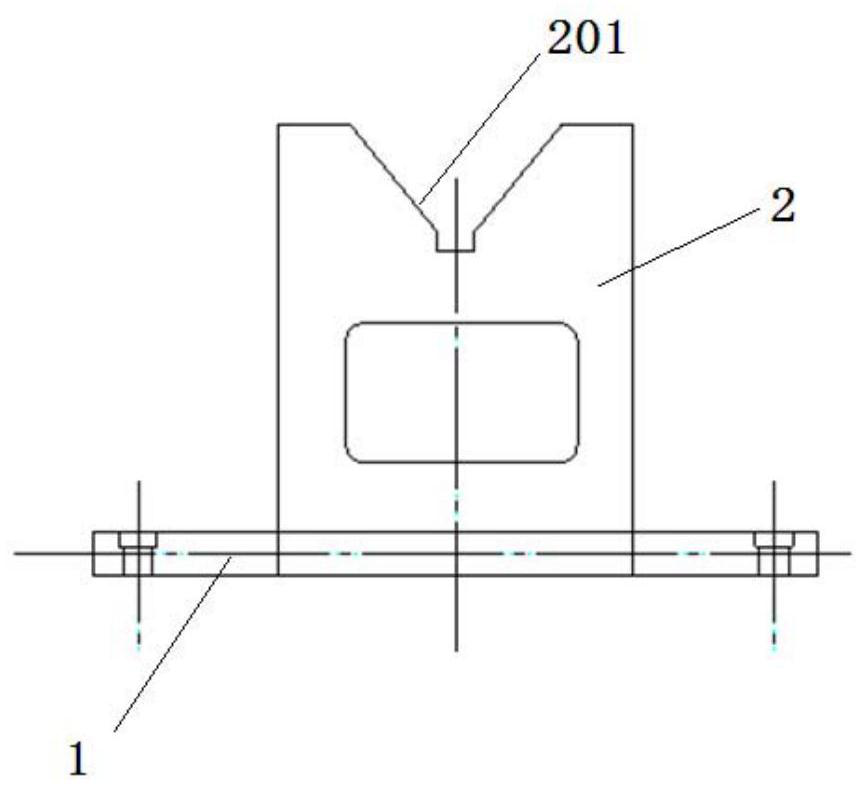

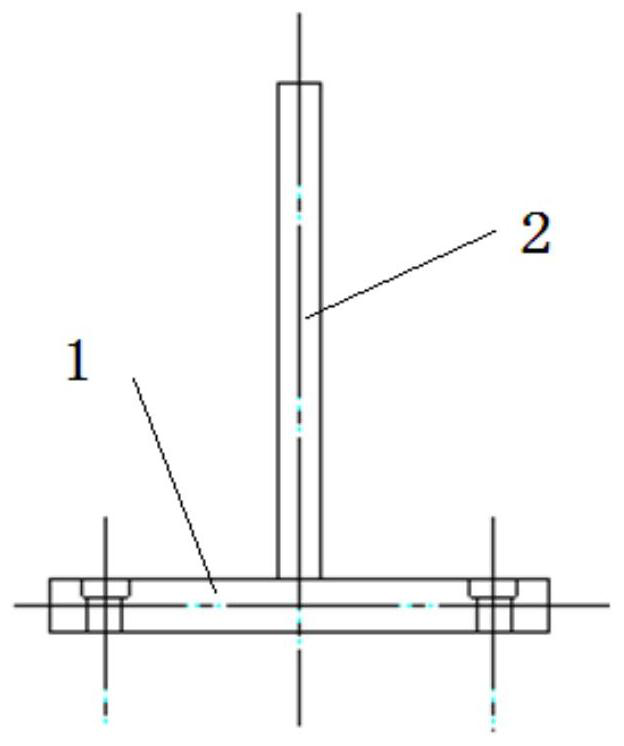

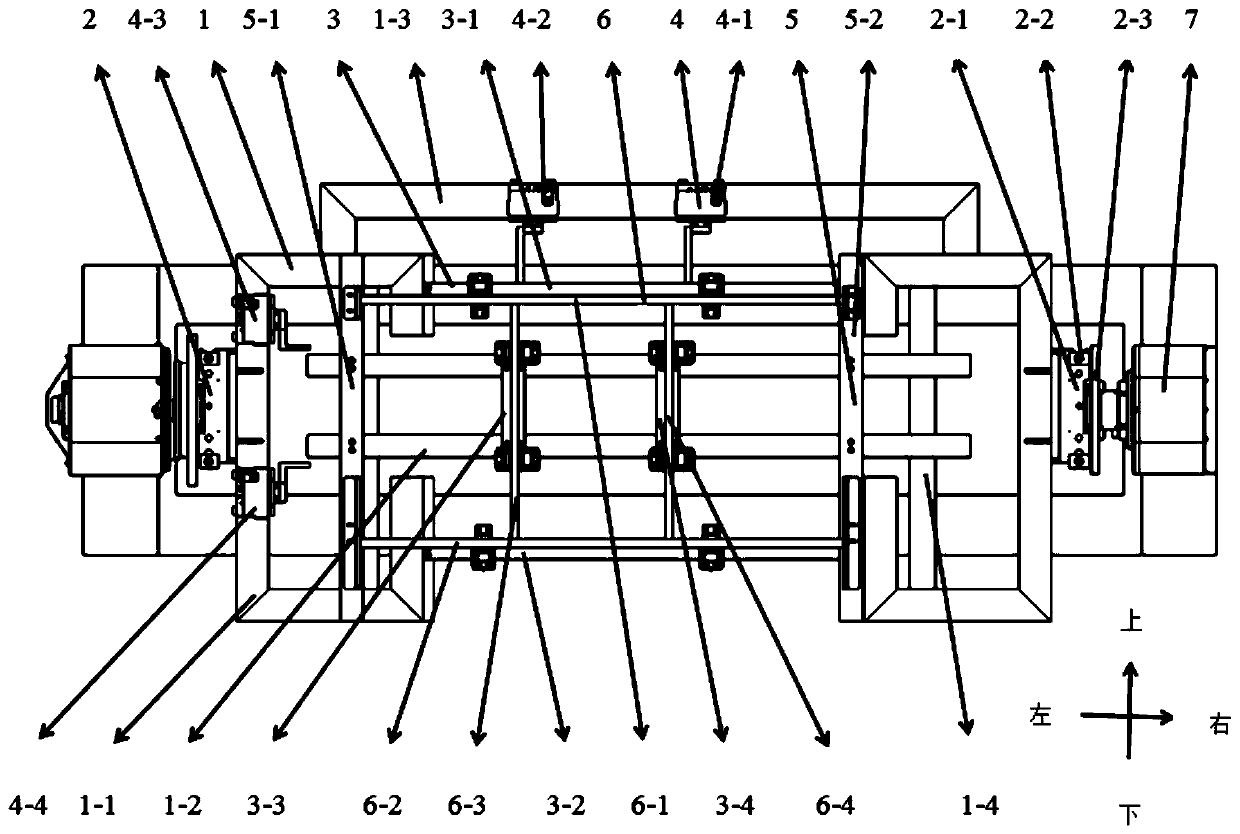

Large-scale water turbine guide vane two-end journal synchronous-processing device and method

InactiveCN104384583AReduce processing stepsAvoid repeated hangingWorkpiecesMilling equipment detailsWater turbineEngineering

The invention discloses a large-scale water turbine guide vane two-end journal synchronous-processing device and method. The device comprises a bed body, a guide vane positioning tool, a left milling head, a right milling head, a left driving tool and a right driving tool. Through one-step alignment, the device realizes synchronous-milling of two-end journals of a guide vane. The device and the method have the characteristics of strong versatility, operation simpleness, good repeatability and low production cost and satisfy processing requirements on various types of guide vane two-end journals.

Owner:HARBIN ELECTRIC MASCH CO LTD

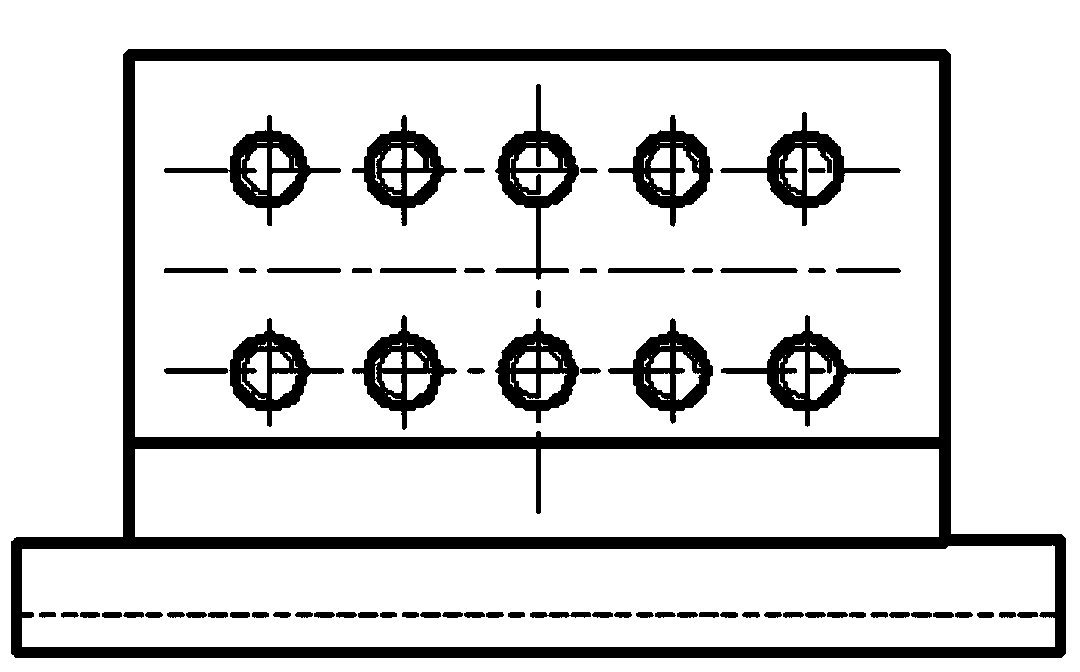

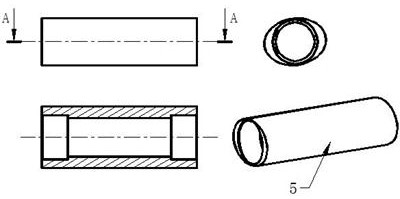

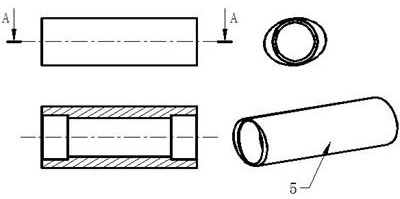

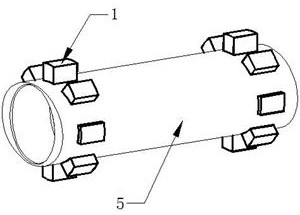

Bearing ring digital control lathe clamper

The invention discloses a bearing ring numerically-controlled lathe clamp which belongs to the technical field of machine tool elements. The clamp comprises a base arranged at one end of a lathe spindle, six waisted through holes are evenly distributed at the lateral side of the base, and a collet which is in a circular platform shape and provided with an inner hole is fixedly connected to the end surface of the base; the collet comprises six sector blocks, wherein a clearance between every two sector blocks forms a long and narrow groove; in addition, the long and narrow grooves are communicated with the waisted through holes; and each sector block is formed by splicing an internal sector block and an external sector block, an inner circular arc of each internal sector block forms an inner hole provided with a notch, and the internal sector blocks and the external sector blocks are fixedly connected by bolts. When the inner hole of the clamp is worn or workpieces of different specifications are required to be installed, the internal sector blocks just need to be replaced, the invention greatly saves the maintenance cost and the replacement cost, is convenient for the processing, and saves the time and the labor during the processes of dismounting and installing, thereby improving the whole production efficiency.

Owner:浙江东盛精密机械有限公司

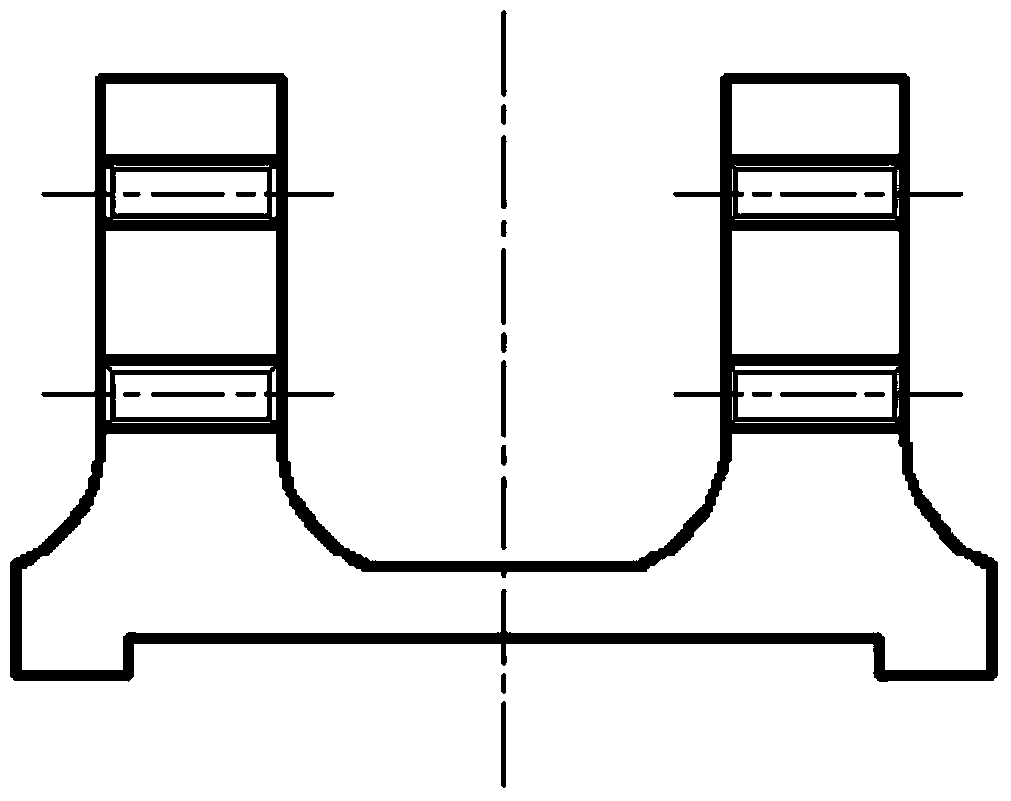

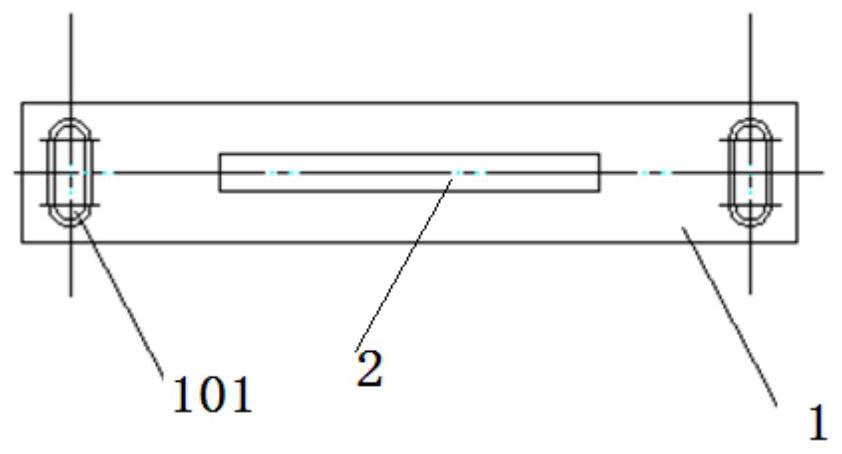

Measurement device of long-shaft part and application method

ActiveCN110243325AAccurate measurementEfficient measurementMechanical measuring arrangementsMeasurement deviceLong axis

The invention provides a measurement device of a long-shaft part. The measurement device comprises a fixture body and a measurement body, wherein the fixture body is used for fixedly locating the long-shaft part to the measurement body; the measurement body is a three-coordinate measuring machine and is used for measuring the dimensions of the long-shaft part; the fixture body comprises a first fixture part and a second fixture part, wherein one end of the long-shaft part is installed on the first fixture part, and the other end of the long-shaft part is installed on the second fixture part; and the first fixture part and the second fixture part are provided with a first V-shaped slot and a second V-shaped slot respectively. Through the measurement device, measurement of the long-shaft part can be completed accurately and efficiently.

Owner:AECC AVIATION POWER CO LTD

Machining method of high-precision inner circular hole of thin-wall special-shaped pipe

ActiveCN111673149AMeet the clampingImprove coaxialityWork clamping meansMilling cuttersMachiningThin walled

The invention relates to the technical field of machining, and discloses a machining method of a high-precision inner circular hole of a thin-wall special-shaped pipe. The machining method is suitablefor machining the high-precision inner hole of the thin-wall special-shaped pipe part in a non-circular shape on a lathe and solves the problem that a traditional chuck cannot directly clamp the thin-wall special-shaped pipe for machining. When machining, the coaxiality precision of inner holes in the two ends of the part is high, and the cylindrical precision is high.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

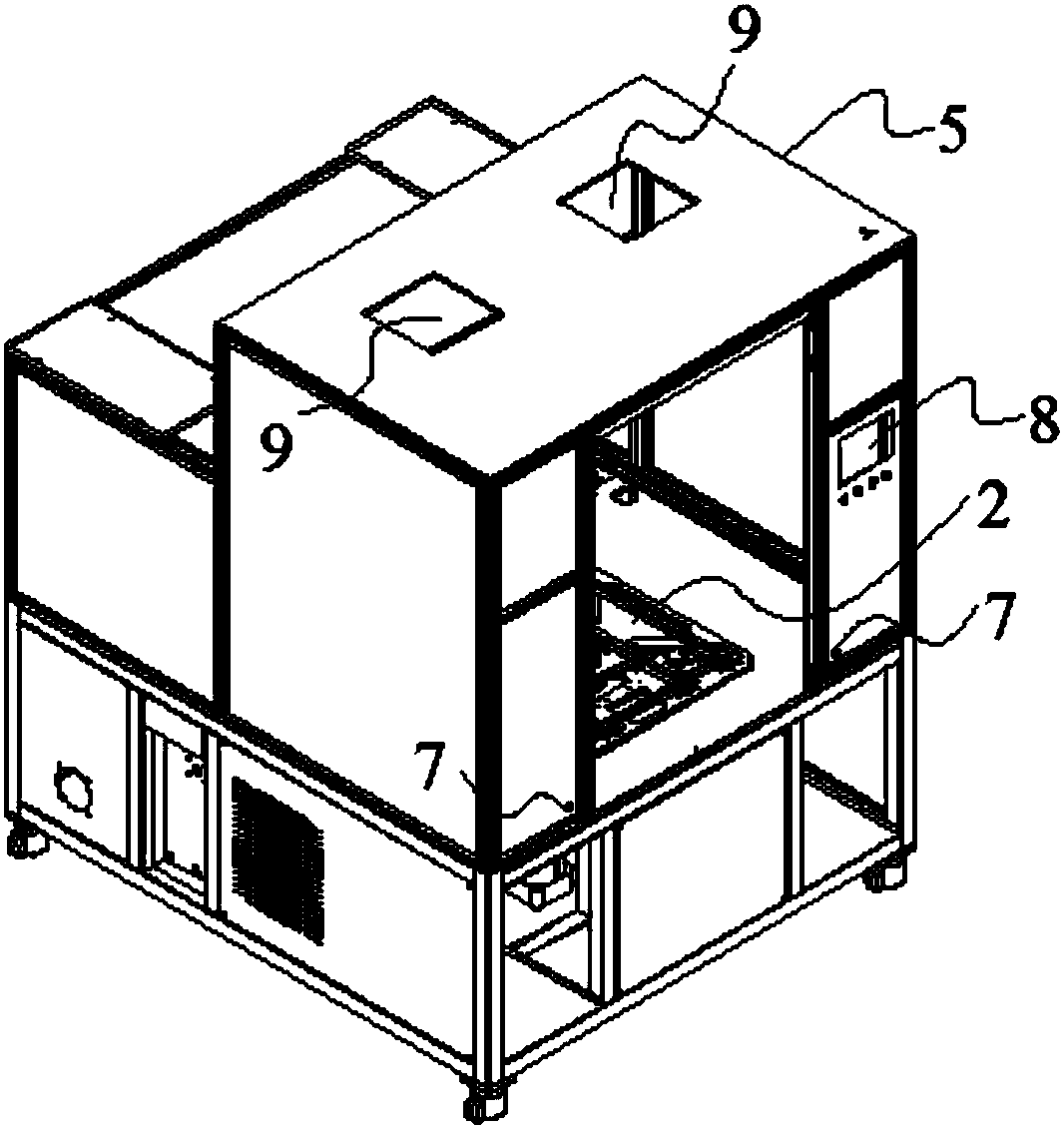

Multi-axis multi-station automatic welding equipment

ActiveCN106624510BSimple structureSmall footprintWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

The invention discloses multi-shaft multi-station full-automatic welding equipment. The welding equipment comprises a welding machine, a wire feeder, welding guns, a control system and at least one fixing and rotating platform used for fixing workpieces and can rotate horizontally. According to the multi-shaft multi-station full-automatic welding equipment, switching welding can be conducted on different welding spots on the workpieces through rotating of the fixing and rotating platforms; compared with the prior art, the welding equipment has the advantages of being capable of saving space and reducing cost, efficient and stable in welding spot switching and the like; in addition, the structural design of conductive support plates on the fixing and rotating platforms can meet the requirements for clamping of the workpieces with different shapes and sizes, and the universality and the application range of the full-automatic welding equipment are improved; the full-automatic welding equipment is elaborate in design, high in efficiency, low in cost, convenient to operate and suitable for being operated by ordinary persons; and furthermore, one person can operate multiple machines, the product batch production efficiency can be improved, and the product batch production cost can be reduced.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

A double-fixed flange fixing device using the principle of lever transmission

ActiveCN111266892BGuaranteed accuracyReduce in quantityWork holdersPositioning apparatusGear wheelClassical mechanics

Owner:山东顺发重工有限公司

Measuring device and using method of long-axis parts

ActiveCN110243325BAccurate measurementEfficient measurementMechanical measuring arrangementsMeasurement deviceEngineering

A measuring device for long-axis parts provided by the present invention includes a fixture body and a measuring body, wherein the fixture body is used to fix and position long-axis parts on the measuring body; the measuring body is a three-coordinate measuring machine for measuring The size of the long axis parts; the fixture body includes the first clamp body and the second clamp body, one end of the long axis parts is installed on the first clamp body, and the other end is installed on the second clamp body; the first clamp body and the second clamp body The two clamp bodies are respectively provided with a first V-shaped groove and a second V-shaped groove; the measuring device provided by the present invention can accurately and efficiently complete the measurement of long-axis parts.

Owner:AECC AVIATION POWER CO LTD

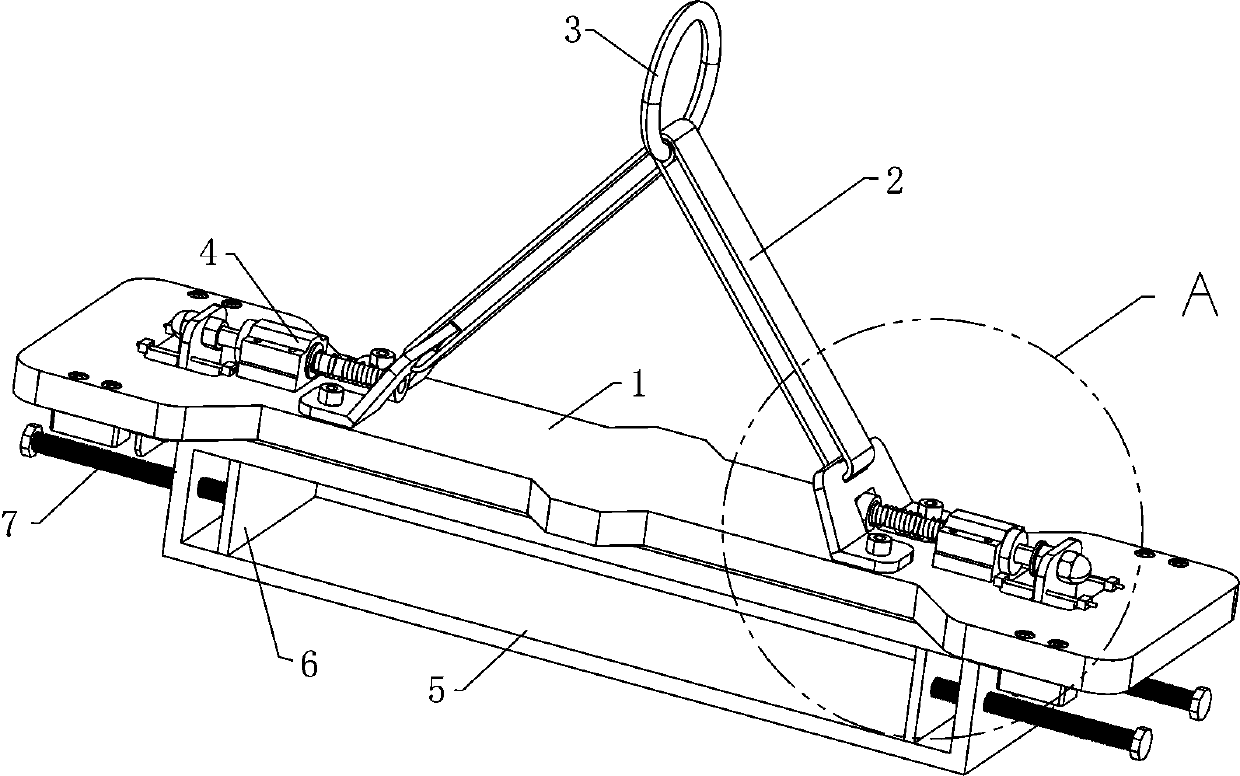

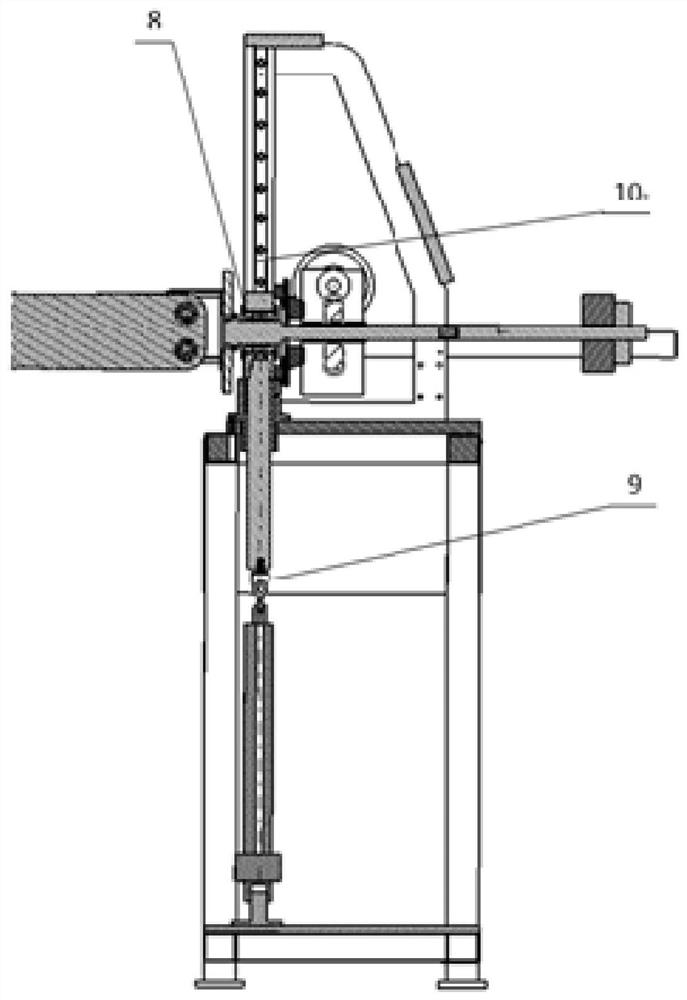

Lifting and rotating device and method for adjusting balance

ActiveCN112525423AEasy clampingImprove installation efficiencyStatic/dynamic balance measurementWind energy generationEngineeringReducer

The invention provides a lifting and rotating device and method for adjusting balance. The device comprises a sliding clamping head (1), a rotary supporting rod (2), a guide supporting rod (3), a lifting guide support (4), an adjustable counterweight (5), a worm and gear speed reducer (6), an actuating cylinder (7), a bearing (8) and a rail (10); the actuating cylinder (7) is connected with the guide supporting rod (3) and used for driving the guide supporting rod (3) to ascend and descend; a through hole is formed in the guide supporting rod (3), a bearing (8) is arranged in the through hole,and the rotary supporting rod (2) penetrates through the bearing (8) and is perpendicular to the guide supporting rod (3); and the first end of the rotary supporting rod (2) is connected with the sliding clamping head (1), the sliding clamping head (1) is used for clamping a paddle, and the second end of the rotary supporting rod (2) is connected with the adjustable counterweight (5). The bladesare convenient to clamp and rapid to position, the mounting and detecting efficiency of the blades can be effectively improved, the labor intensity is reduced, and the clamping, detecting and positioning requirements of batch production are met.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

A device and method for automatically aligning and clamping ring-shaped parts

ActiveCN112917202BRealize the clamping functionRealize automatic alignmentPositioning apparatusMetal-working holdersEngineeringClip device

Owner:宜昌长机科技有限责任公司

A Large Adjustable Frame Structure Welding Fixture

ActiveCN108422145BMeet the clampingEasy clampingWelding/cutting auxillary devicesAuxillary welding devicesStringerWelding

The invention discloses a large-scale adjustable frame structure welding fixture, comprising a fixture base, a quick-replacing structure, a fixing unit, a pressing device, a positioning device and a workpiece, wherein the base is composed of a square frame and a guiding rail, the quick-replacing structure is composed of a quick-replacing connector, a connecting plate and a reinforcing rib, the fixing unit is composed of a cross beam fixing unit and a longitudinal beam fixing unit, the pressing device comprises an air cylinder and a replaceable press block, the positioning device is composed ofa positioning plate and a sliding base, and the workpiece comprises a cross beam and a longitudinal beam. The large-scale adjustable frame structure welding fixture is combined with the currently used welding fixture of a welding work station, so that structural innovative design is realized, and the carrying capacity of 1500kg is realized by using an overturning positioner. By adopting the quick-replacing mechanism, different fixtures can be removed from and mounted on the overturning positioner, so that the mounting and replacing of the fixture are more convenient.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

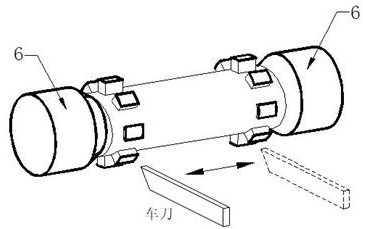

Engraving and milling machine for graphite rod production

ActiveCN105397923BGood for fallingImprove processing efficiencyWorking accessoriesStone-like material working toolsElectric machineryRelative motion

The invention discloses an engraving and milling machine for graphite rod production. The engraving and milling machine comprises a machine base, a horizontal movement table, supporting plates, a movable device and an engraving and milling mechanism. The horizontal movement table is connected with the machine base through a drive mechanism. Locating supporting mechanisms are arranged on the top face of the horizontal movement table. The movable device comprises a locating frame and a movable mechanism. A first motor is arranged on one side of the locating frame, and a limiting block is arranged on the other side of the locating frame. The limiting block is connected with a second U-shaped supporting plate through a connecting block. A gas conveying pump is arranged in the second U-shaped supporting plate and connected with the engraving and milling mechanism through a gas conveying guide pipe. The engraving and milling machine is simple in structure in structure and high in practicality, the stability of a graphite plate on the horizontal movement table is improved, and the flexibility and practicality of the engraving and milling mechanism are improved; the engraving and milling mechanism and the horizontal movable table do relative movement together so that the engraving and milling machine can achieve machining of graphite rods of different sizes; and graphite dust generated during machining can be effectively recycled.

Owner:SHENGZHOU SIGMA TECH

Annular steel pipe clamping arm

The invention provides an annular steel pipe clamping arm. The side, away from a fixing plate, of a clamping plate is an outer arc face, an arc groove is dug in the outer arc face of the clamping plate, a fixing groove and a limiting hole are dug in the middle of the side, away from the fixing plate, of the clamping plate, the fixing groove is formed in the side, away from the fixing plate, of thelimiting hole, a propelling rod penetrates the fixing plate, a rotation segment and a connecting segment are connected to the two ends of a thread segment, the connecting segment penetrates the limiting hole, and the end, away from the thread segment, of the connecting segment is connected with a limiting pin. According to the annular steel pipe clamping arm, the contact face of a clamp and a workpiece is designed to the corresponding arc face, and meanwhile, the contact face of the clamp and the workpiece is designed to a groove adapting to the tubular workpiece.

Owner:TIANJIN ZHI YUAN IND & TRADE

Hanging tooling for bridge fittings and using method thereof

ActiveCN109914247BReasonable designSimple structureLoad-engaging elementsClassical mechanicsStructural engineering

The invention discloses a hanging tool for bridge fittings and a method for using the same. The adjustment plate runs through the base plate, and the two adjustment plates form a clamping groove for clamping the bridge fittings at the lower end of the base plate. There is an adjustment device for adjusting the width of the clamping groove; a guide block for guiding or supporting the adjustment plate is arranged on the lower end surface of the base plate; the invention has reasonable design and simple structure, and is a hanging tool for bridge accessories, which is used to assist the hoisting machine Hanging and moving bridge accessories, through reasonable design of the adjustment plate, the two adjustment plates cooperate with the base plate to form a length-adjustable clamping groove, so that the installation and removal of the bridge accessories can be very fast and convenient.

Owner:CITIC GUOAN CONSTR GRP CO LTD

A processing method for high-precision inner circular holes of thin-wall special-shaped pipes

ActiveCN111673149BMeet the clampingImprove coaxialityWork clamping meansMilling cuttersEngineeringMachining

This application relates to the technical field of mechanical processing, and discloses a processing method for high-precision inner holes of thin-walled special-shaped pipes, which is suitable for processing high-precision inner holes of thin-walled special-shaped pipe parts with non-circular shapes on a lathe. This application solves the problem of It solves the problem that the traditional chuck cannot directly clamp the thin-walled special-shaped tube for processing, and during processing, the coaxiality and cylindricity of the inner holes at both ends of the part have high precision.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

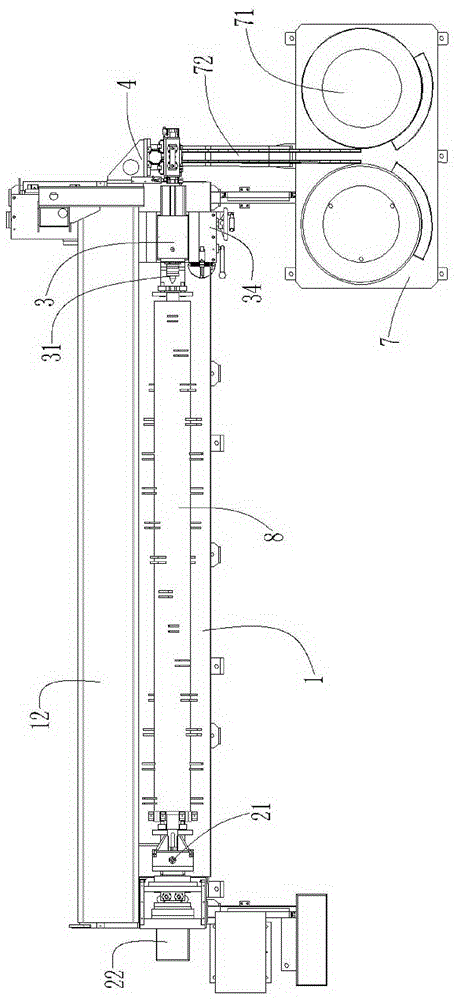

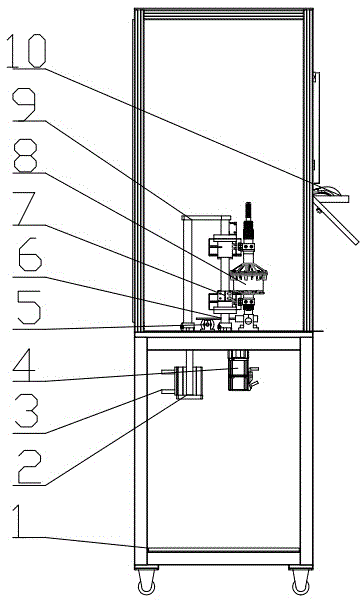

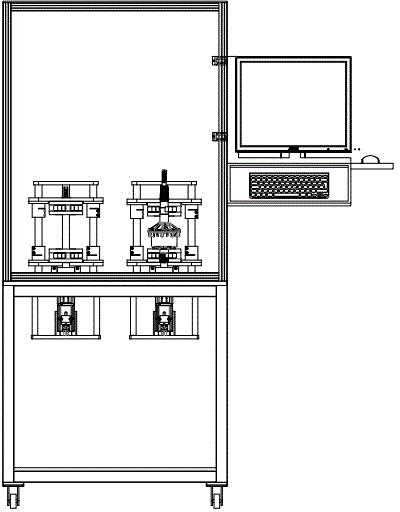

Pipette auxiliary operation device for step-by-step dilution

PendingCN112892631AMeet the clampingLarge travel rangePreparing sample for investigationBurettes/pipettesAutomatic controlPipette

The invention relates to a pipette auxiliary operation device for step-by-step dilution. The pipette auxiliary operation device comprises a base, a movement conveying device, a solution disc fixing device, a pipette clamping device and a pressing device; the movement conveying device is a two-axial conveying device and comprises a Y-axis linear motion assembly in the horizontal direction and a Z-axis linear motion assembly in the vertical direction; the solution disc fixing device is horizontally and fixedly connected to the front end face of the Z-axis sliding block through a connecting support and used for supporting and fixing a solution disc; the pipette clamping device is fixedly connected to the base, is positioned in front of the movement conveying device and is used for clamping the pipette above the solution disc; and the pressing device is fixedly connected to the upper part of a clamping back plate and is used for controllably pressing a button of the pipette. The device is simple in structure, can effectively realize automatic control on the pipette and the solution disc, and can automatically dilute sample liquid step by step, so that the purpose of replacing manual operation is achieved.

Owner:CHINA AGRI UNIV

Cylindrical metallographic specimen holder

Owner:HENAN UNIV OF SCI & TECH

Machining device for control valve body

PendingCN113334118AMeet the clampingImprove processing efficiencyPositioning apparatusMetal-working holdersControl valvesMachining

The invention provides a machining device for a control valve body. The machining device comprises a workbench, and further comprises a support and a positioning base which are fixedly arranged on a surface of the workbench and are arranged opposite to each other, wherein a tool is rotatably connected between the support and the positioning base, The tool comprises two end parts and a plurality of clamping parts, wherein the two end parts are rotationally connected with the support and the positioning base respectively, and the clamping parts are arranged between the two end parts, are evenly distributed in the circumferential direction of the two end parts and are used for fixing workpieces. The end of the tool is supported through the support and the positioning base, the multiple clamping parts can meet clamping of various products, that is, the products of the same kind are arranged on the same clamping part, so that the products of the multiple kinds are machined, in addition, different stations are arranged on the same clamping part, and a complete machining procedure of one product is integrated on one clamping part, so that the machining efficiency is improved, and the production requirements of small-batch enterprises needing to change products frequently can be met.

Owner:ANQING LIANDONG ENG TRUCKS ATTACHMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com