General clamping device for working condition test of electric tool

A technology for electric tools and clamping devices, which is applied in workpiece clamping devices, portable mobile devices, manufacturing tools, etc., can solve the problem that electric tools cannot be universally clamped, and achieves the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

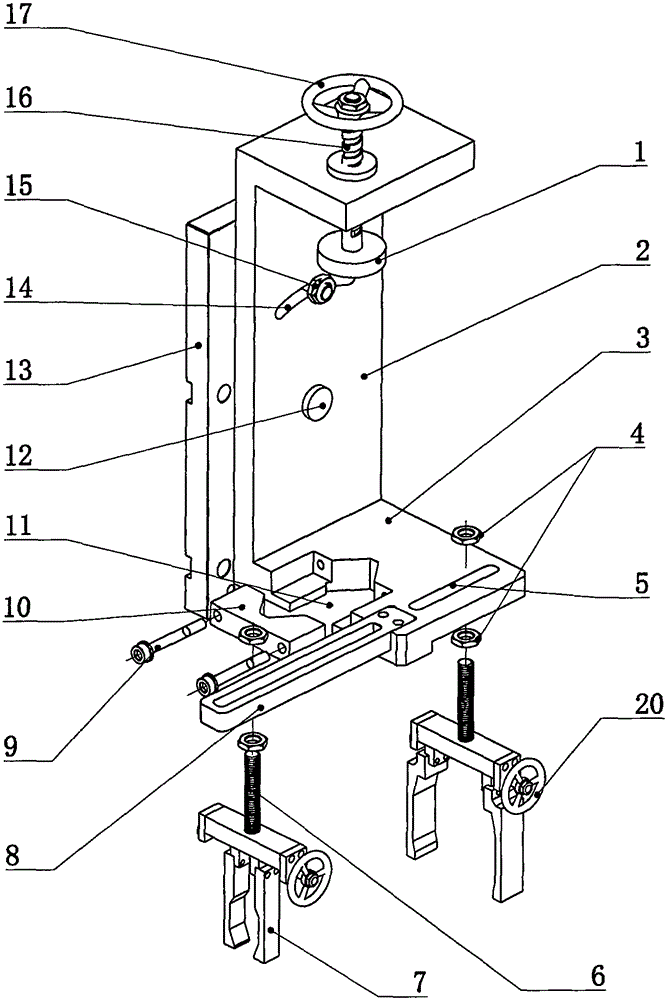

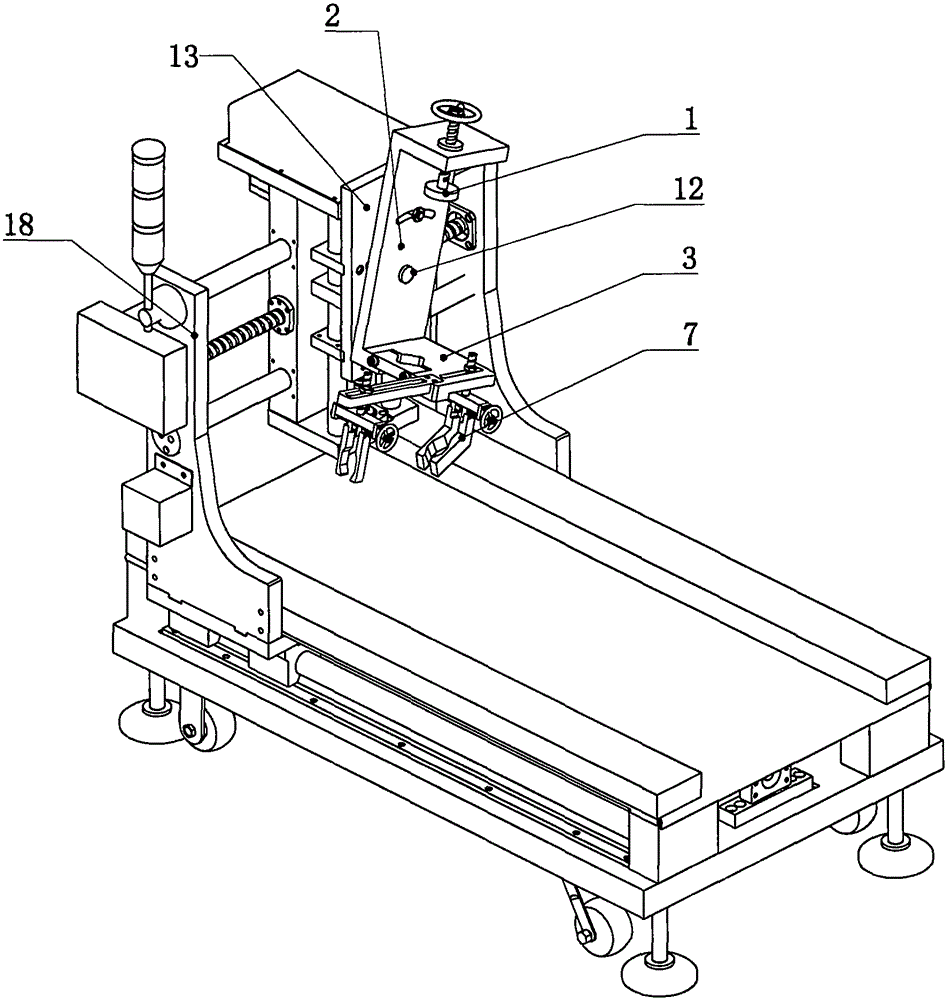

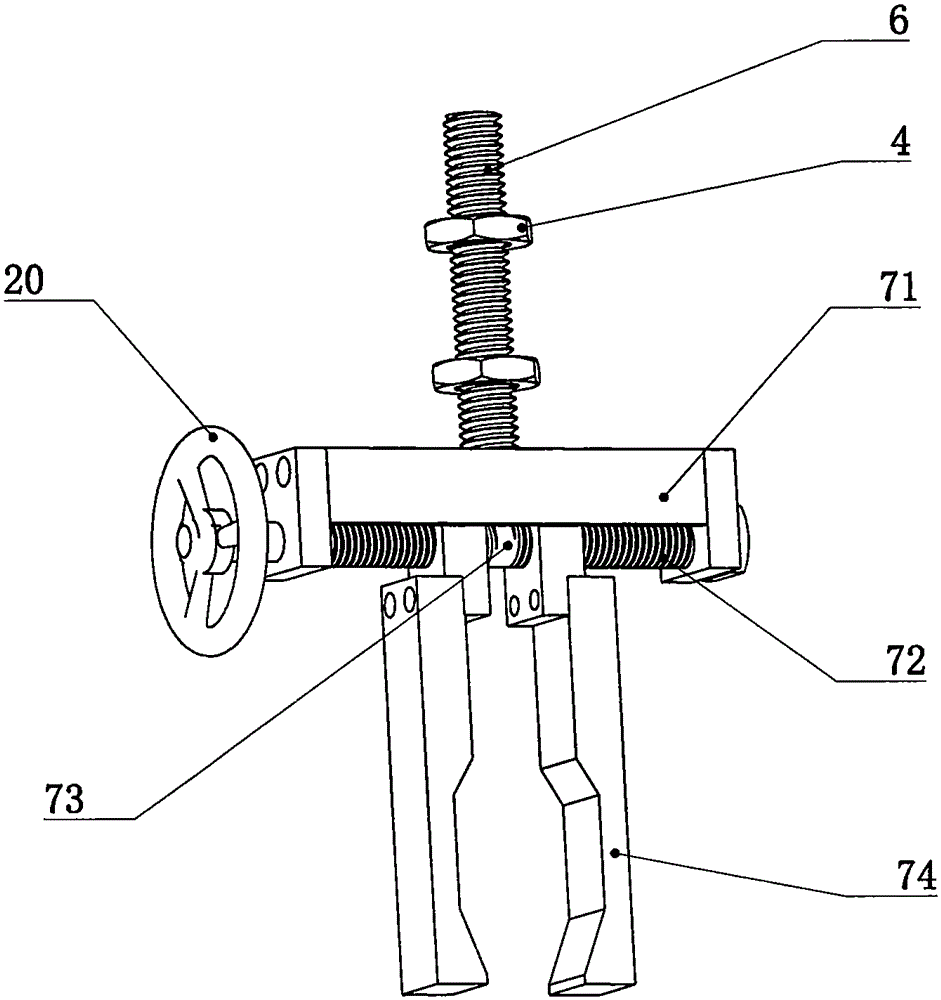

[0021] like Figures 1 to 2 As shown, the universal clamping device includes a longitudinal mounting plate 13 and a mounting base 2, and the mounting plate 13 is vertically connected to the gantry 18 and fixed. The mounting base 2 is connected to the mounting plate 13 through a horizontal rotating shaft 12 , and the mounting base 2 can rotate around the rotating shaft 12 in a vertical plane. The mounting seat 2 is provided with an arc-shaped chute 14 that is concentric with the rotating shaft 12 , and the mounting plate 13 is provided with a positioning screw 15 , the positioning screw 15 passes through the above-mentioned arc-shaped chute 14 and ends at the positioning screw 15 . A nut is screwed on the outer end thread, and the rotation angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com