Method for super-rapidly preparing metal-organic framework films through using external electric field method

A metal-organic framework and applied electric field technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as limiting the application of metal-organic framework materials, and achieve large-scale industrial production and simplify the operation process , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] With Zn(NO 3 ) 2 ·6H 2 O is a ZIF-8 film prepared by metal salt on anodized alumina, using Zn(NO 3 ) 2 ·6H 2 O provides zinc salts, and ZIF-8 films are fabricated ultra-fast on anodized aluminum by an applied electric field method, which specifically includes the following steps:

[0032] (1) The commercial anodized aluminum substrate was rinsed with ethanol for 2 minutes to remove surface stains;

[0033] (2) Prepare the solution required for ZIF-8 film growth: weigh out zinc nitrate hexahydrate (Zn(NO) 3 ) 2 ·6H 2 O) Dissolve 0.29 g of particles in 100 mL of methanol, then add 0.164 g of 2-methylimidazole (C 4 H 6 N 2 ) particles, sonicated at room temperature for 2 minutes to obtain a colorless transparent clear solution;

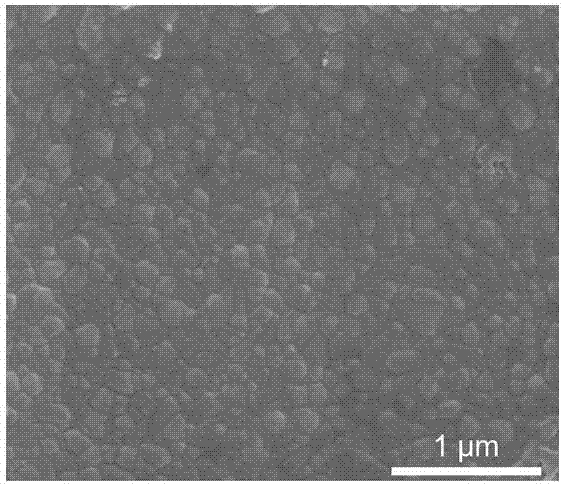

[0034] (3) Immerse the anodic alumina substrate cleaned in step (1) into the clear solution obtained in step (2); apply a voltage of 20V and react at 20° C. for 60 minutes to obtain a dense ZIF-8 film.

[0035] The obtained ZIF-8 film ...

Embodiment 2

[0037] With Zn(NO 3 ) 2 ·6H 2 O is a ZIF-8 film prepared by metal salt on anodized alumina, using Zn(NO 3 ) 2 ·6H 2 O provides zinc salts, and ZIF-8 films are fabricated ultra-fast on anodized aluminum by an applied electric field method, which specifically includes the following steps:

[0038] (1) The commercial anodized aluminum substrate was rinsed with ethanol for 2 minutes to remove surface stains;

[0039] (2) Prepare the solution required for ZIF-8 film growth: weigh out zinc nitrate hexahydrate (Zn(NO) 3 ) 2 ·6H 2 O) Dissolve 14.9 g of particles in 100 mL of methanol, then add 4.105 g of 2-methylimidazole (C 4 H 6 N 2 ) particles, sonicated at room temperature for 5 minutes to obtain a colorless transparent clear solution;

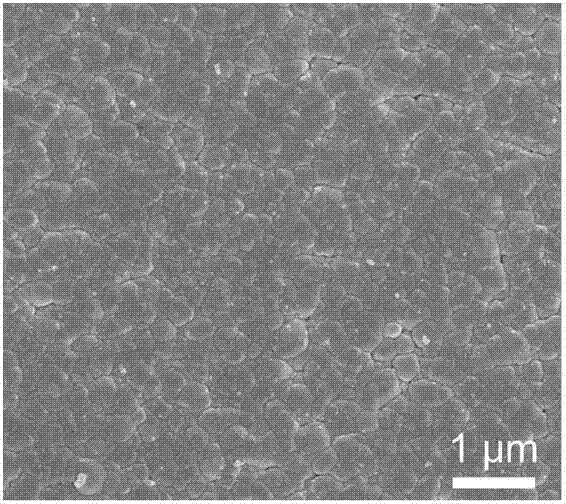

[0040] (3) Immerse the anodic alumina substrate cleaned in step (1) into the clear solution obtained in step (2); pass 1A current and react at 100° C. for 10 minutes to obtain a dense ZIF-8 film.

[0041] The obtained ZIF-8 film was ch...

Embodiment 3

[0043] With Zn(NO 3 ) 2 ·6H 2 O is a ZIF-8 film prepared by metal salt on anodized alumina, using Zn(NO 3 ) 2 ·6H 2 O provides zinc salts, and ZIF-8 films are fabricated ultra-fast on anodized aluminum by an applied electric field method, which specifically includes the following steps:

[0044] (1) The commercial anodized aluminum substrate was rinsed with ethanol for 2 minutes to remove surface stains;

[0045] (2) Prepare the solution required for ZIF-8 film growth: weigh out zinc nitrate hexahydrate (Zn(NO) 3 ) 2 ·6H 2 O) Dissolve 3.725g of particles in 100mL of methanol, then add 2.05g of 2-methylimidazole (C 4 H 6 N 2 ) particles, sonicated at room temperature for 10 minutes to obtain a colorless transparent clear solution;

[0046] (3) Immerse the anodic alumina substrate cleaned in step (1) into the clear solution obtained in step (2); pass 0.01A current and react at 70°C for 40 minutes to obtain a dense ZIF-8 film.

[0047] The obtained ZIF-8 film was char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com