Blocking extrusion forming die

A technology of forming molds and occlusive extrusion, applied in the field of metal pressure processing, to achieve the effects of good versatility, good economic benefits, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

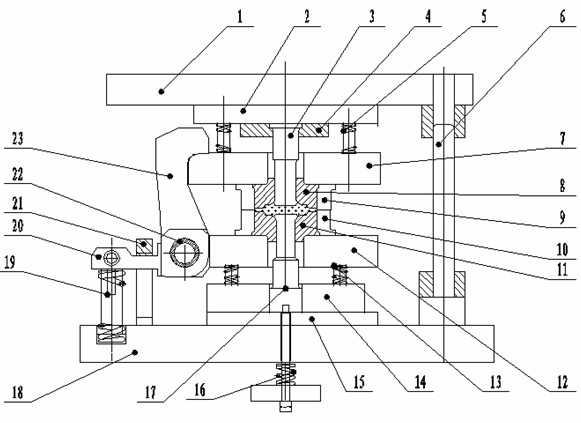

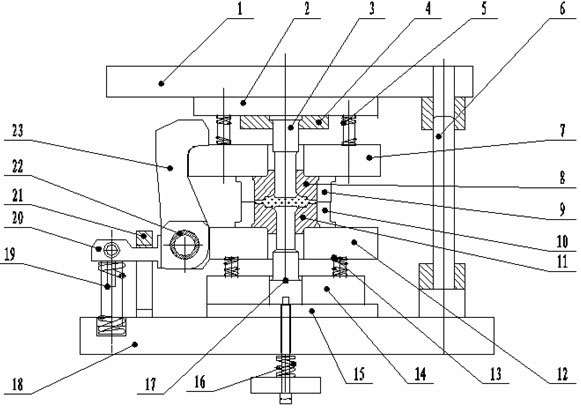

[0013] Attached below figure 1 The present invention is further described.

[0014] Upper punch 3 and lower punch 17 are fixed on upper die base 1 and lower die base 18 with screws and pins by upper fixing plate 4, lower punch guide limit plate 14 and backing plate 15. The upper floating mold base 7 and the lower floating mold base 12 are respectively supported by the upper floating formwork elastic element 5 and the lower floating formwork elastic element 13, and are guided by the inner guide column. Upper die core 8, lower die core 11 are installed on upper floating die base 7, lower floating die base 12 by upper die core cover 9, lower die core cover 10, fixed by pressing plate. The swing bar lock hook 23 is symmetrically installed on the lower floating mold base 12 through a living hinge, and realizes swinging and mold locking by the action of the lock hook support spring 19 during the up and down movement of the floating mold base. In the mold-locked state, a closed mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com