Pipette auxiliary operation device for step-by-step dilution

A step-by-step dilution and auxiliary operation technology, applied in the field of automation, to achieve the effect of light weight, splash prevention and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

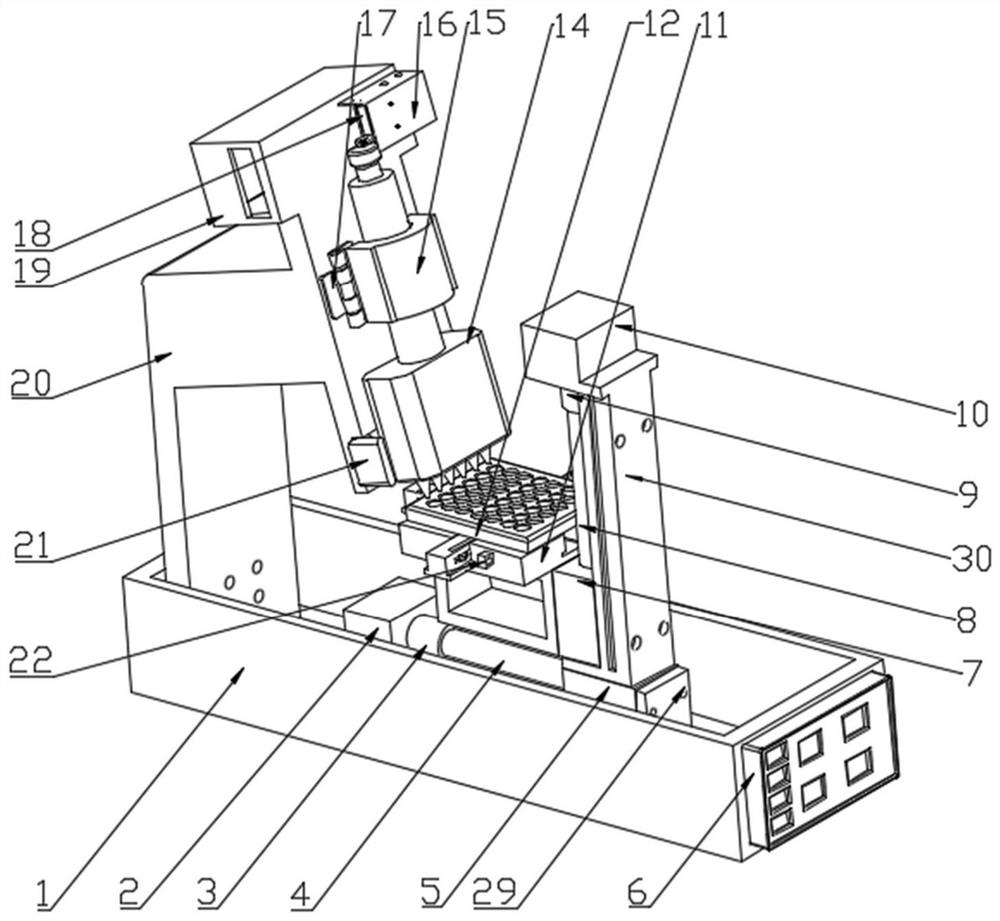

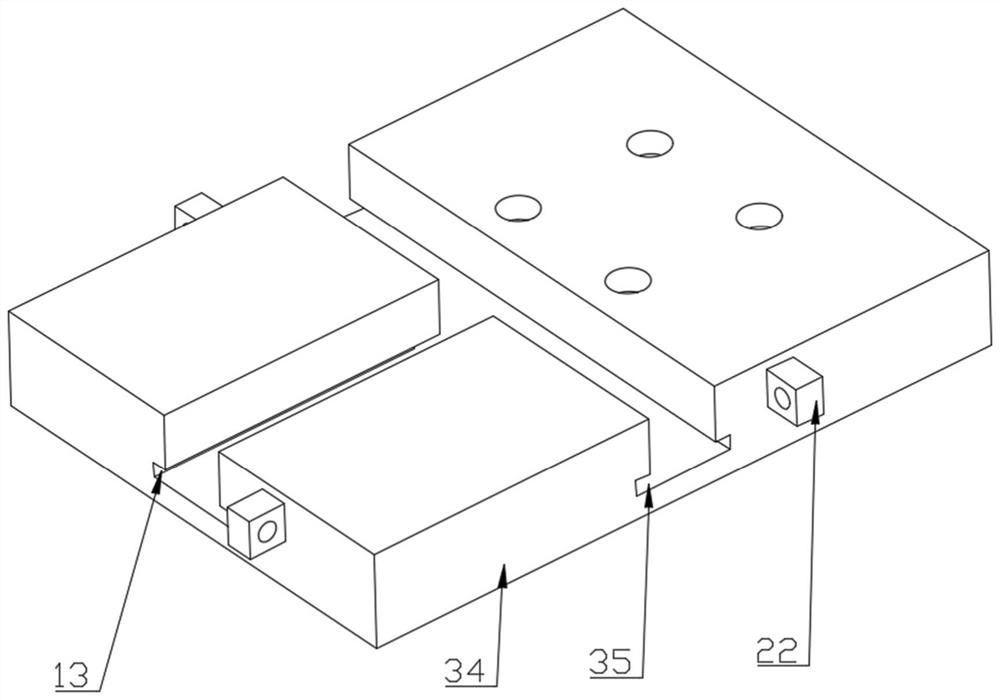

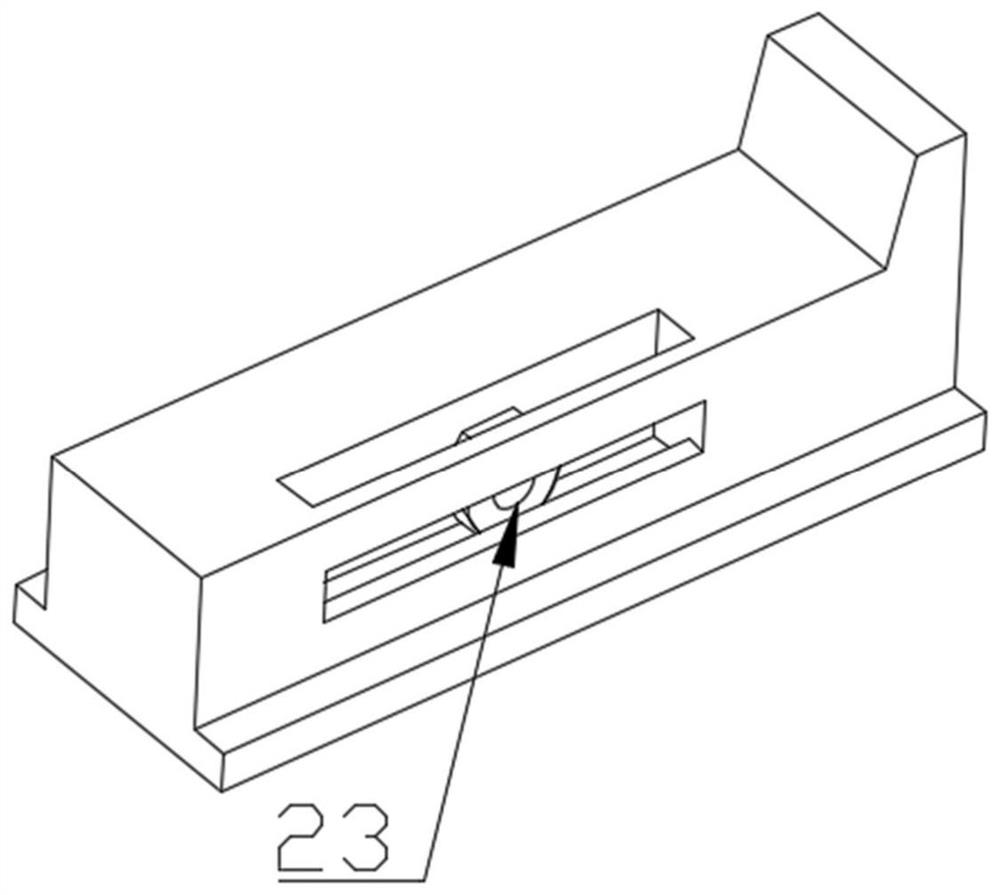

[0059] refer to Figure 1 to Figure 3 As shown, a pipette auxiliary operation device for stepwise dilution of the present invention includes a base 1, a motion transmission device, a solution tray fixing device 11, a pipette holding device, a pressing device 18 and a controller 6 .

[0060] The motion transmission device is a two-axis transmission device, including a Y-axis linear motion assembly in the horizontal direction and a Z-axis linear motion assembly in the vertical direction.

[0061] Such as figure 1 As shown, the Y-axis linear motion assembly includes a Y-axis linear motion base 29, a Y-axis stepper motor 2, a Y-axis coupling 3, a Y-axis ball screw 4 and a Y-axis slider 5; the Z-axis linear motion The motion assembly includes a Z-axis linear motion base 30 , a Z-axis slider 7 , a Z-axis ball screw 8 , a Z-axis coupling 9 and a Z-axis step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com