Machining device for control valve body

A processing device and valve body control technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of processing a single type of product, the processing device is difficult to meet production requirements, and the production efficiency is low, and achieves high clamping efficiency. , The effect of high positioning accuracy and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

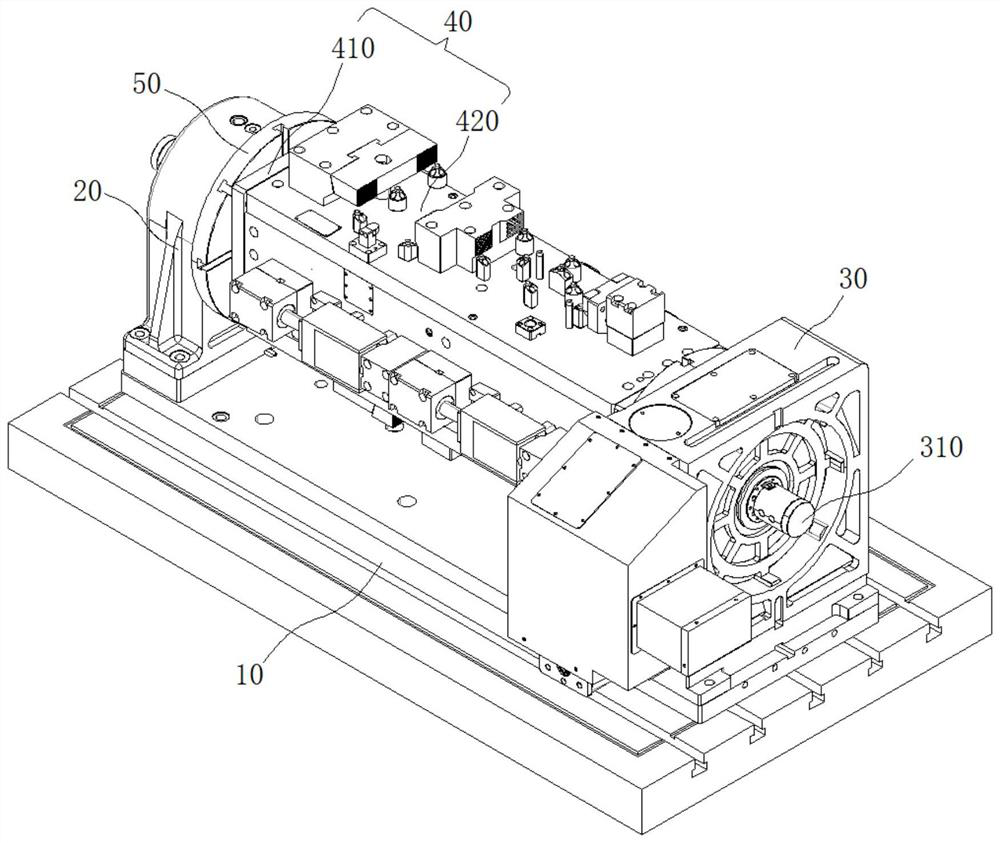

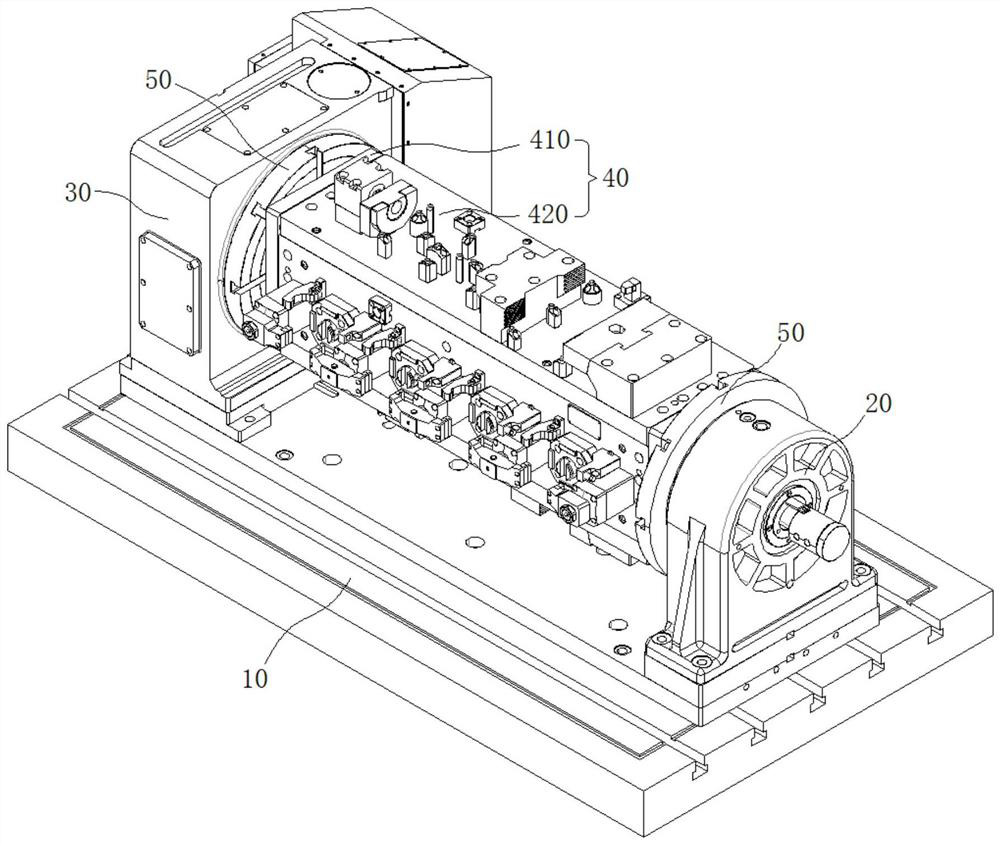

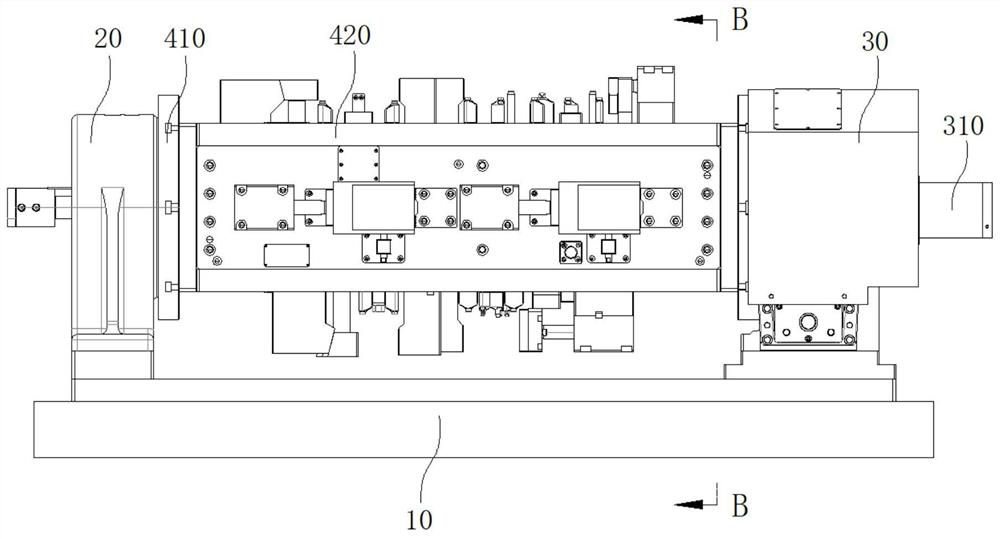

[0027] refer to figure 1 , figure 2 , a processing device for controlling a valve body, including a workbench 10, and also includes a support 20 and a positioning seat 30 fixed on the worktable and arranged opposite to each other, a tooling 40 is rotatably connected between the support and the positioning seat, Wherein, the tooling includes two end parts 410 which are respectively connected to the support and the positioning seat in rotation, and a plurality of clamping parts 420 arranged between the two ends and uniformly distributed along the circumferential direction of the two ends for fixing the workpiece. The tooling includes four clamping parts as an example. When in use, use the support and positioning seat to support the end of the tooling. The workpiece is clamped in the clamping part, that is, the same type of product is set on the same clamping part. It can realize the processing of multiple varieties of products, and can adapt to the production needs of enterpri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com