Patents

Literature

6114results about "Work clamping means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

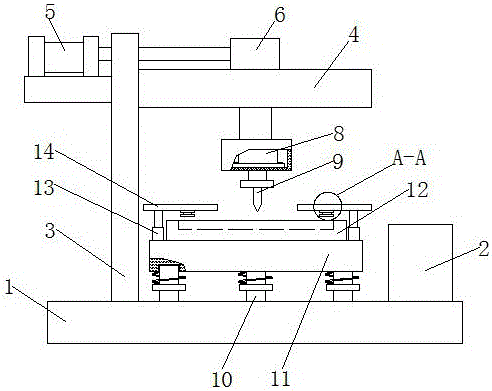

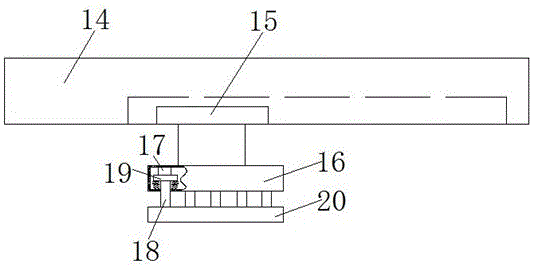

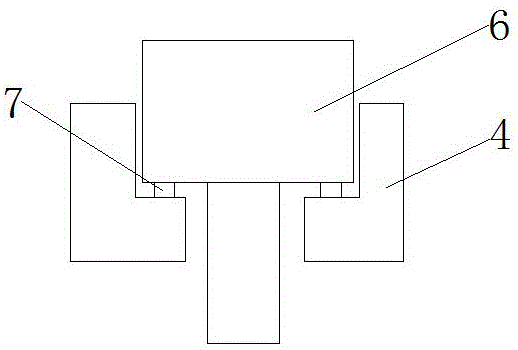

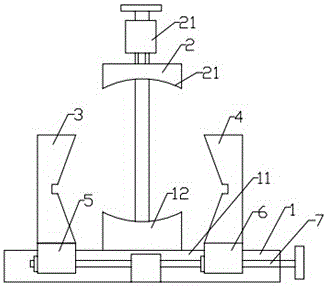

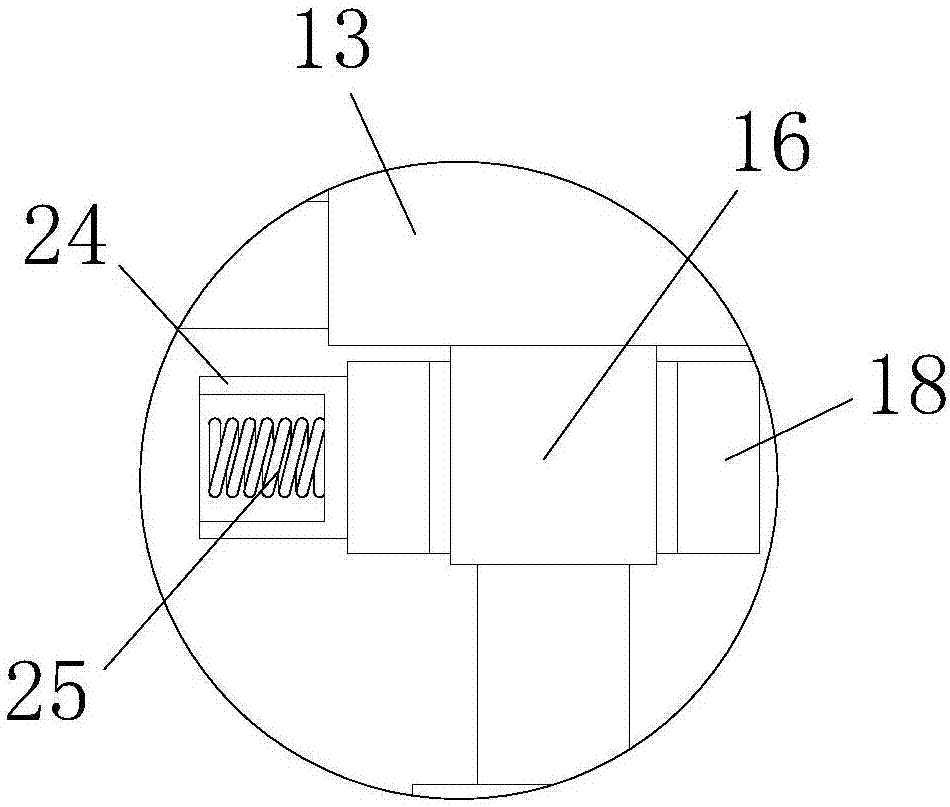

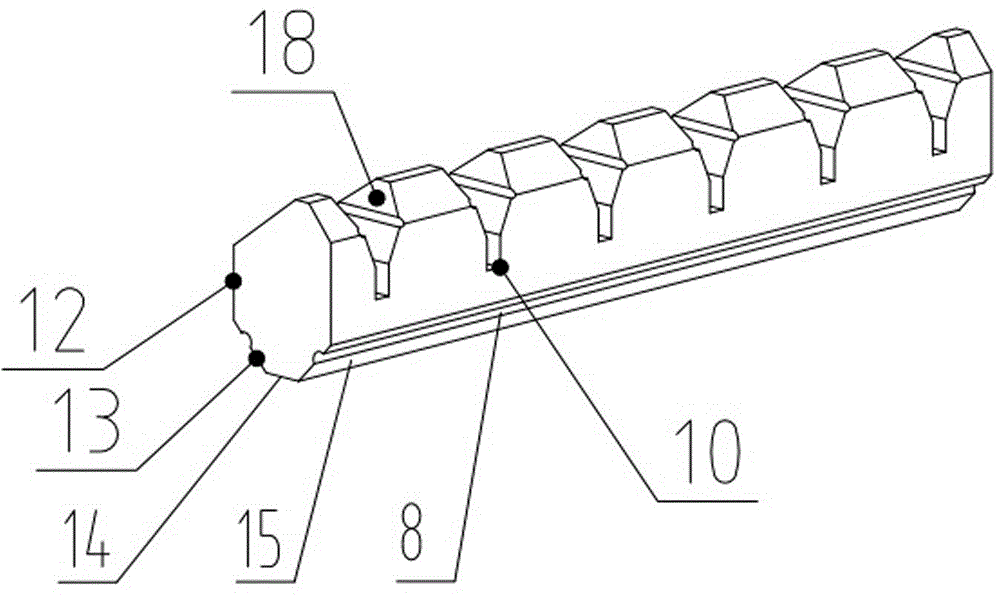

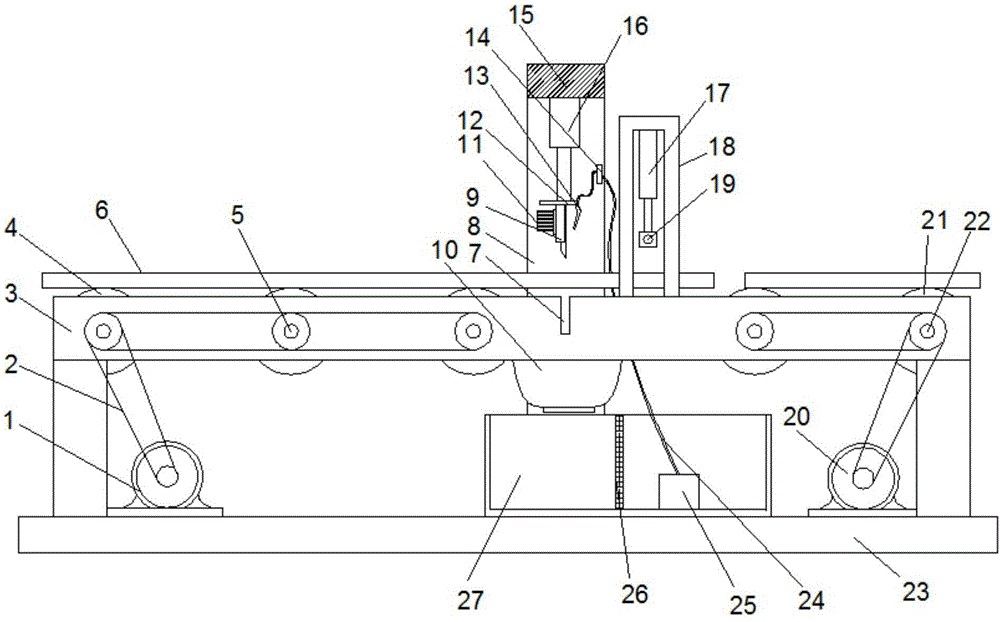

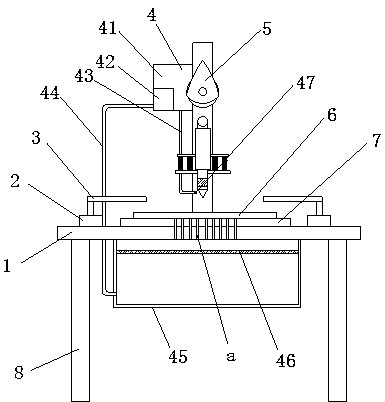

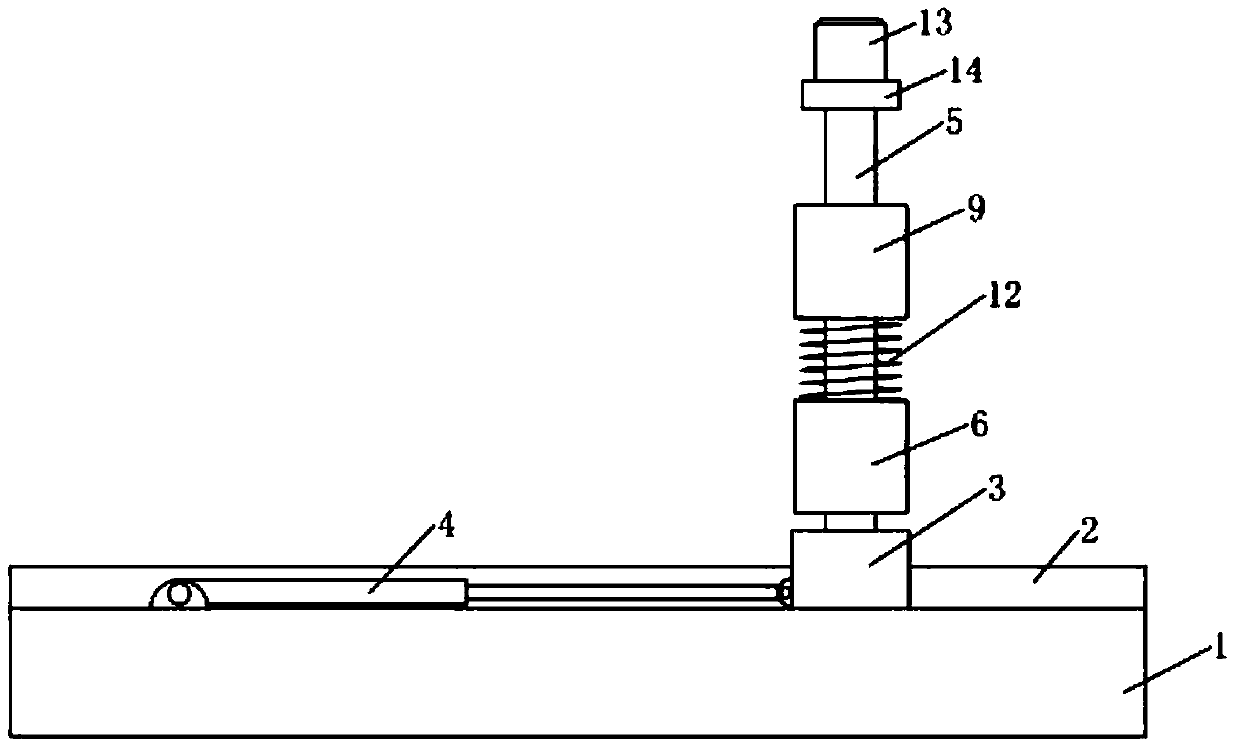

Drilling device for machining hardware

InactiveCN105817670AAchieve a fixed effectSolve the phenomenon of uneven holesWork clamping meansFeeding apparatusComputer hardwareEngineering

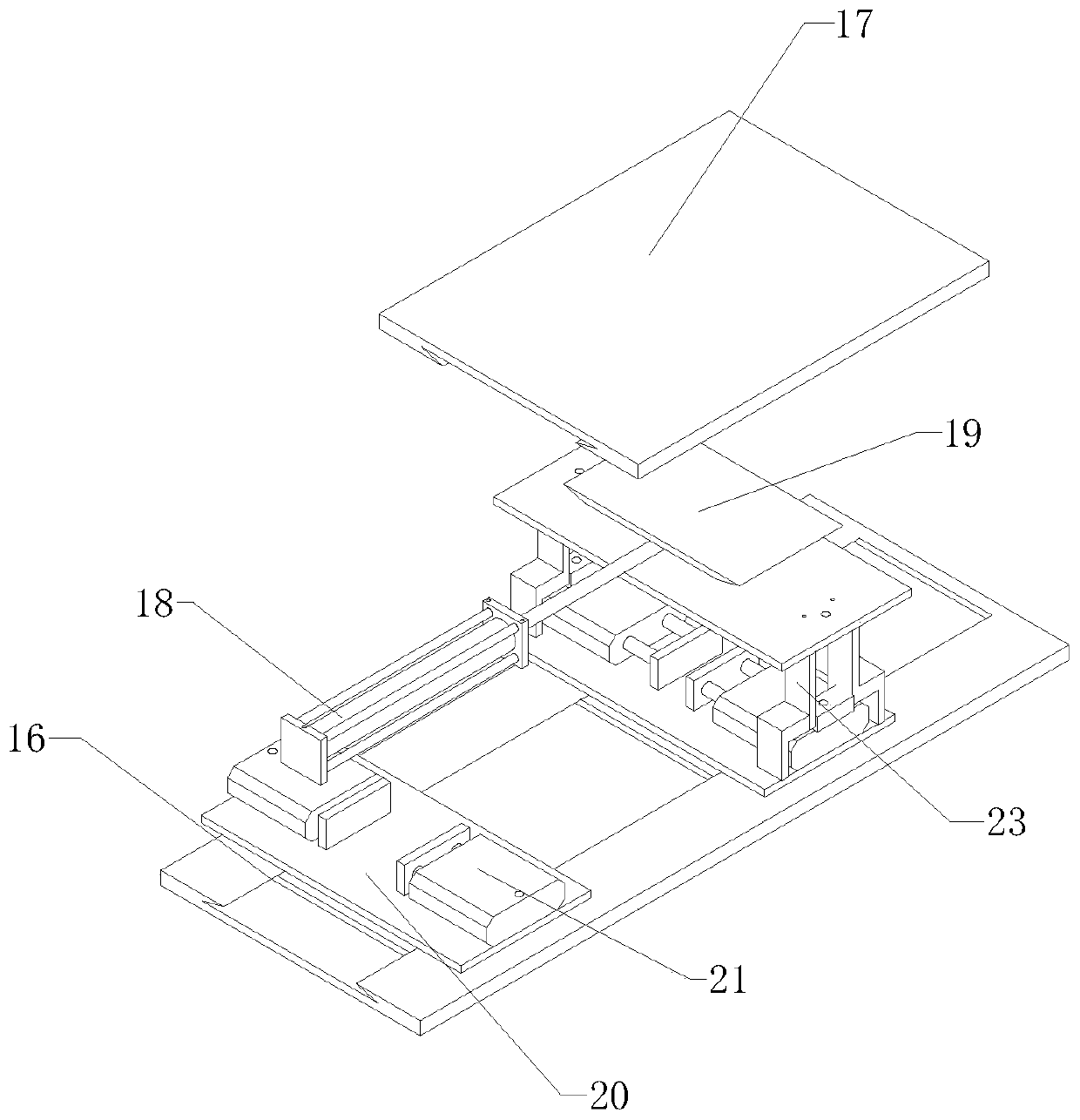

The invention discloses a drilling device for machining hardware. The drilling device comprises a base. A controller is arranged on one side of the top of the base. A supporting plate is arranged on the other side of the top of the base. A supporting plate is arranged on one side of the top of the supporting plate, and a first air cylinder is fixedly installed on the supporting plate. A long plate is arranged on the other side of the top of the supporting plate. A convex through groove is formed in the long plate. A second air cylinder is arranged in the convex through groove. By means of the drilling device for machining the hardware, due to the improvement on transverse rods and under the cooperation of a T-shaped rod, a pressing plate, a buffering block, a connecting rod and a fixing block, the effect of fixing the hardware is achieved, the phenomenon of non-aligned drilling caused by movement of the hardware during drilling is avoided, and the quality of the product is improved; and due to the improvement on supporting pillars at the bottom of a support and under the cooperation of buffering springs, a damping effect is achieved, the phenomenon of non-aligned holes of the hardware during drilling is avoided, the working efficiency is improved, and the service life of a worktable is prolonged.

Owner:CHANGZHOU JINHAILONG MACHINE MFG

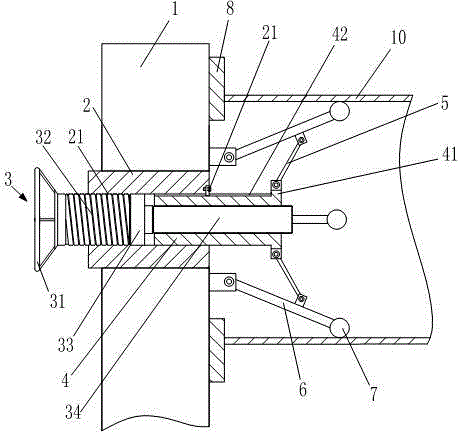

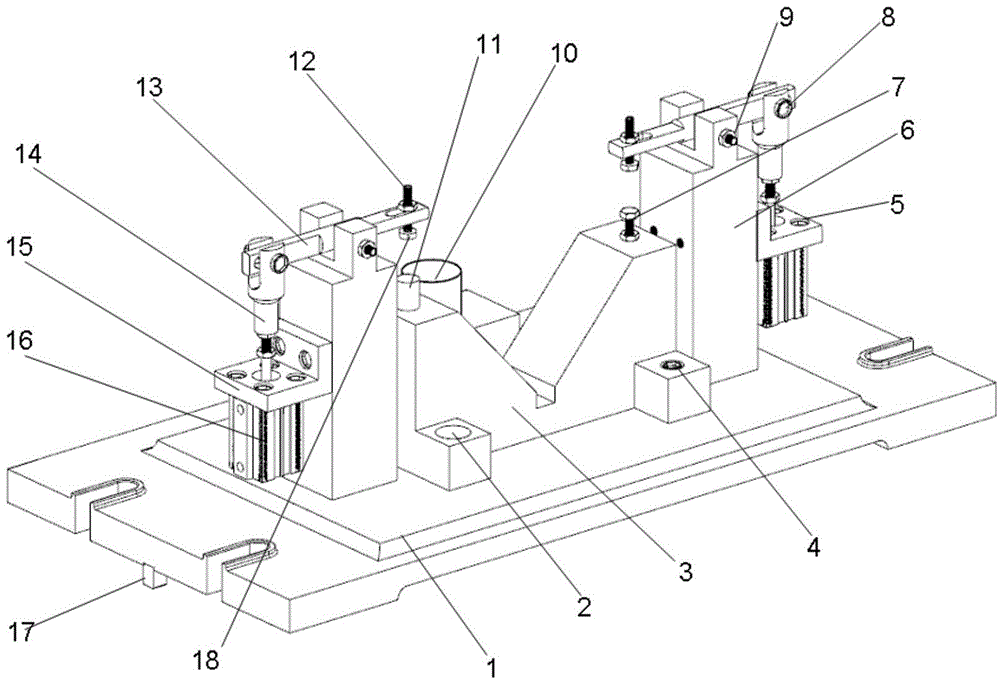

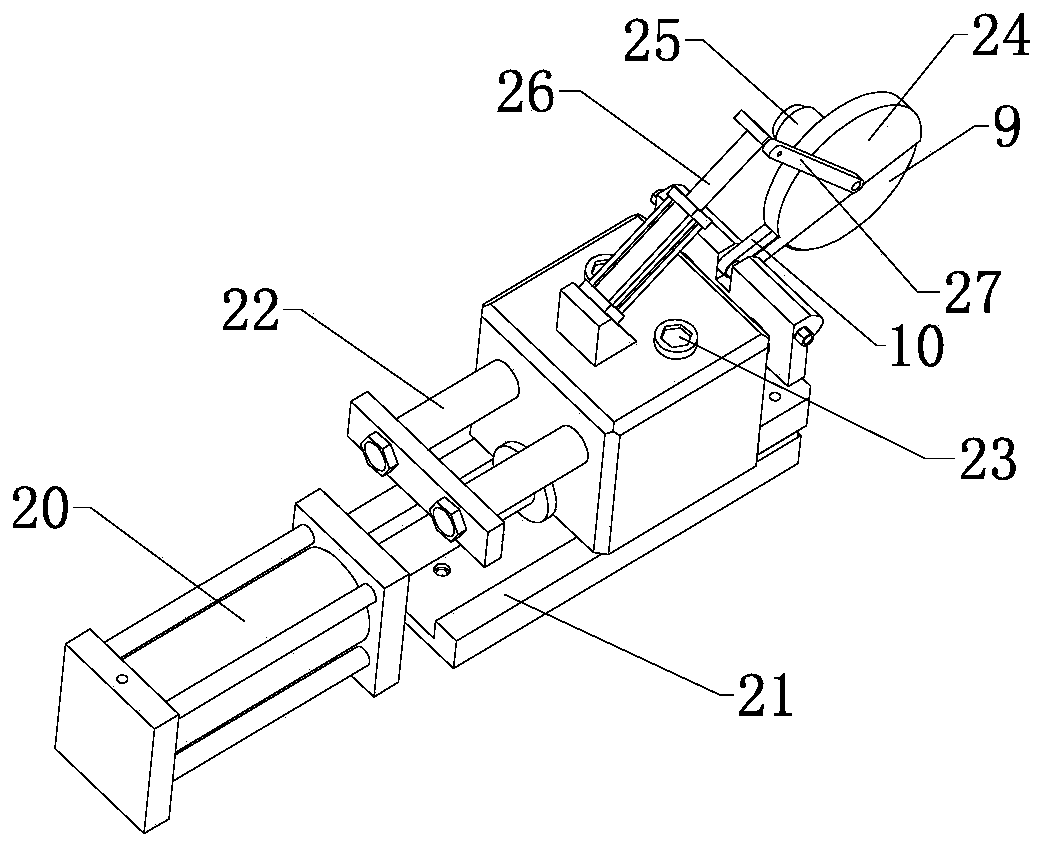

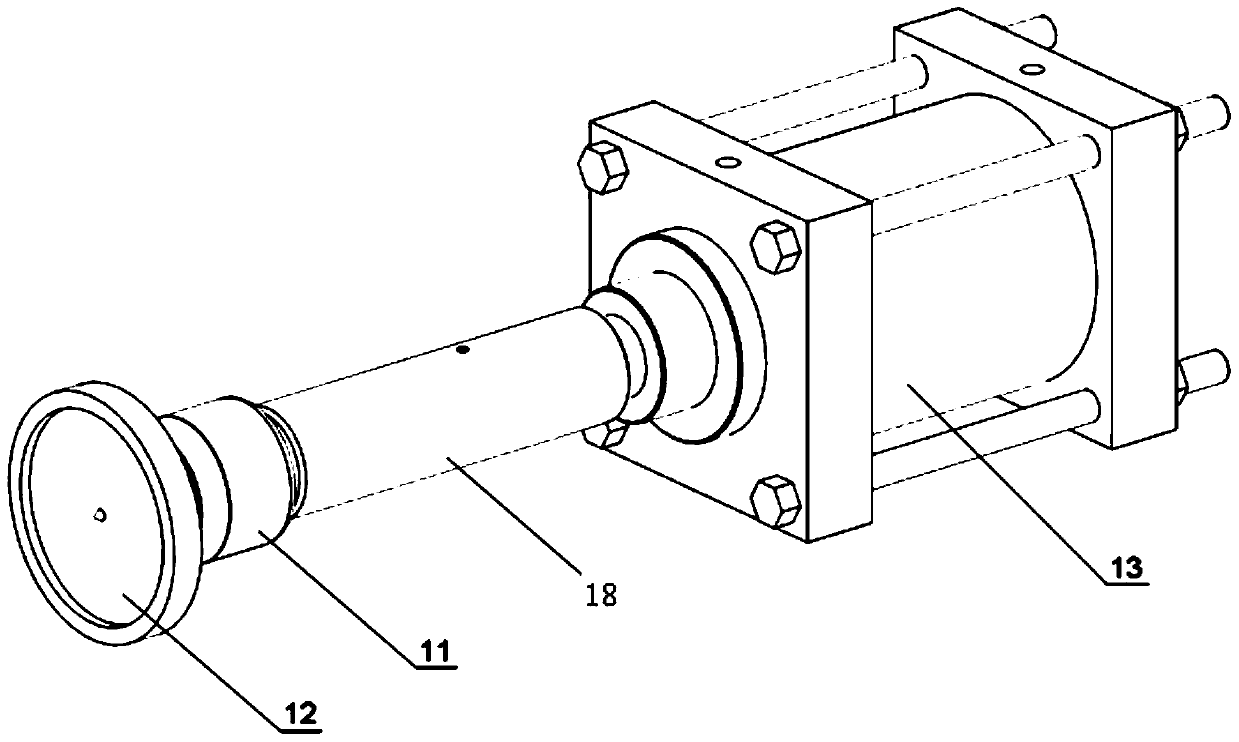

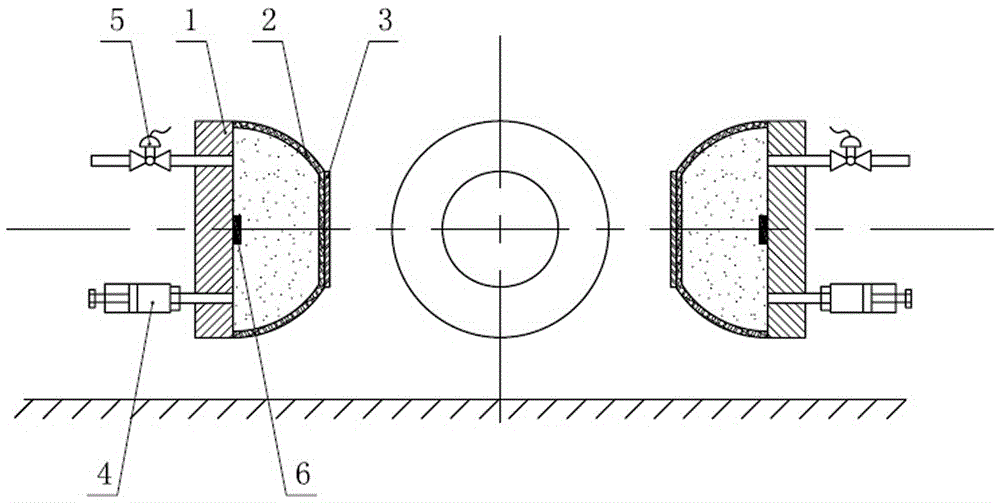

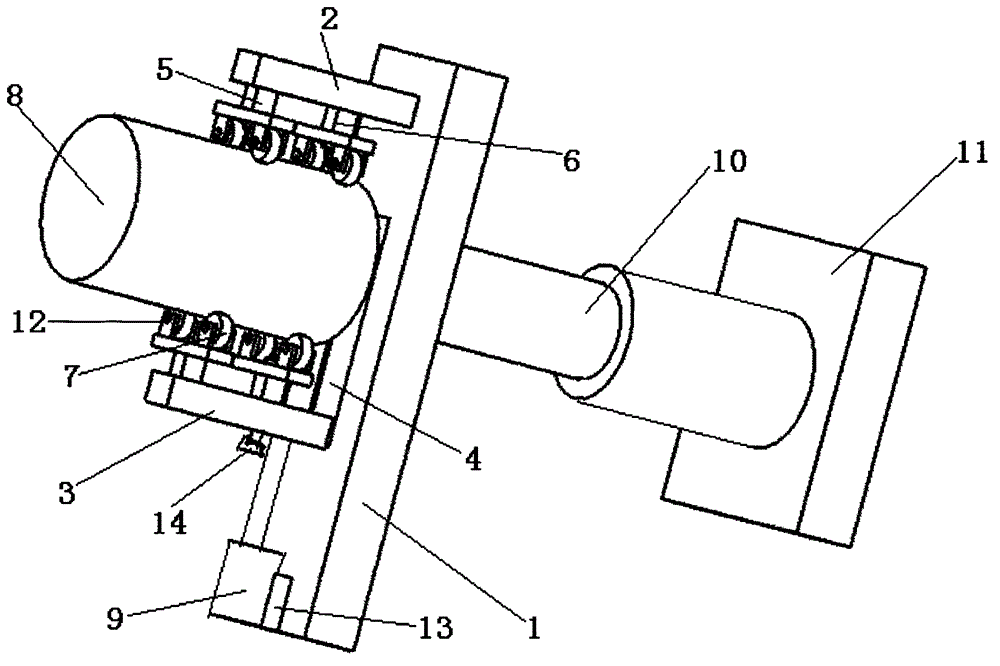

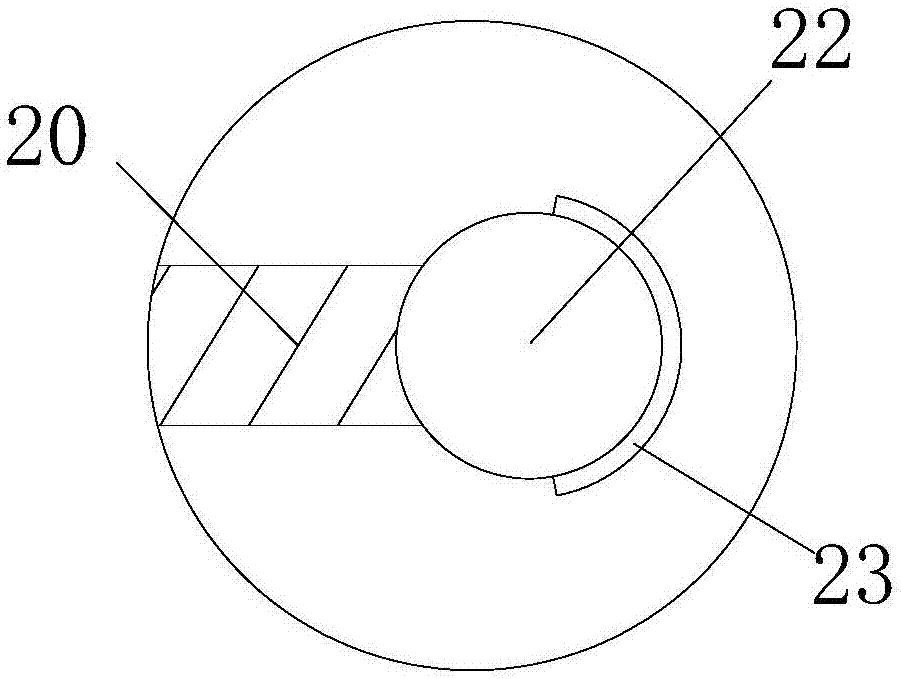

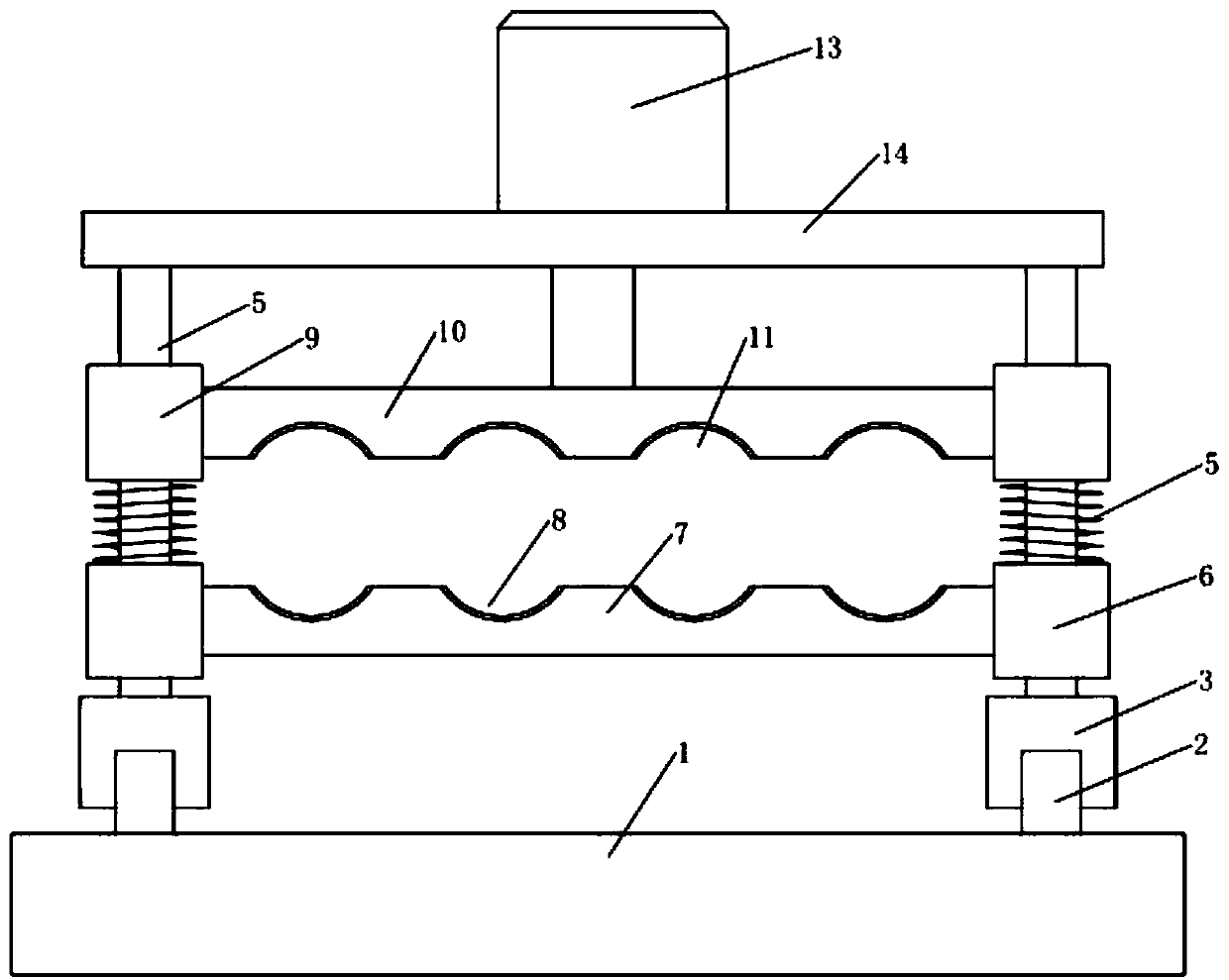

Locating clamp for pipeline machining

InactiveCN104625549AEasy to fixReduce labor intensityWork clamping meansWelding/cutting auxillary devicesBlock matchScrew thread

The invention relates to a locating clamp for pipeline machining. The locating clamp comprises a machine frame. A guide sleeve is fixedly installed on the machine frame, and one end of the guide sleeve is provided with internal threads. A threaded rod is connected to the guide sleeve. A fixed rotating wheel, external threads matched with the internal threads, a sliding portion matched with the guide sleeve in a sliding mode and a lead screw axially extending from the center of the sliding portion are sequentially arranged on the threaded rod. The lead screw is connected with a sliding sleeve matched with the guide sleeve in a sliding mode through threads. The end, extending out of the guide sleeve, of the sliding sleeve forms a hinged portion. The sliding sleeve is provided with a sliding groove. One side of the guide sleeve is fixedly connected with a guide block matched with a guide groove. At least three connecting rods are hinged to the hinged portion. The connecting rods are movably hinged to the supporting rods. The threaded rod and the lead screw are driven by the rotating wheel to rotate, so that the sliding sleeve is driven to horizontally move under the action of the guide sleeve and the guide block, and then the connecting rods drive the supporting rods to tightly support or release the pipeline; in this way, the pipeline is conveniently fixed and is convenient disassemble, the labor intensity of workers is relieved, and production efficiency is improved.

Owner:WUXI XINQITE PLATE WORK MACHINE

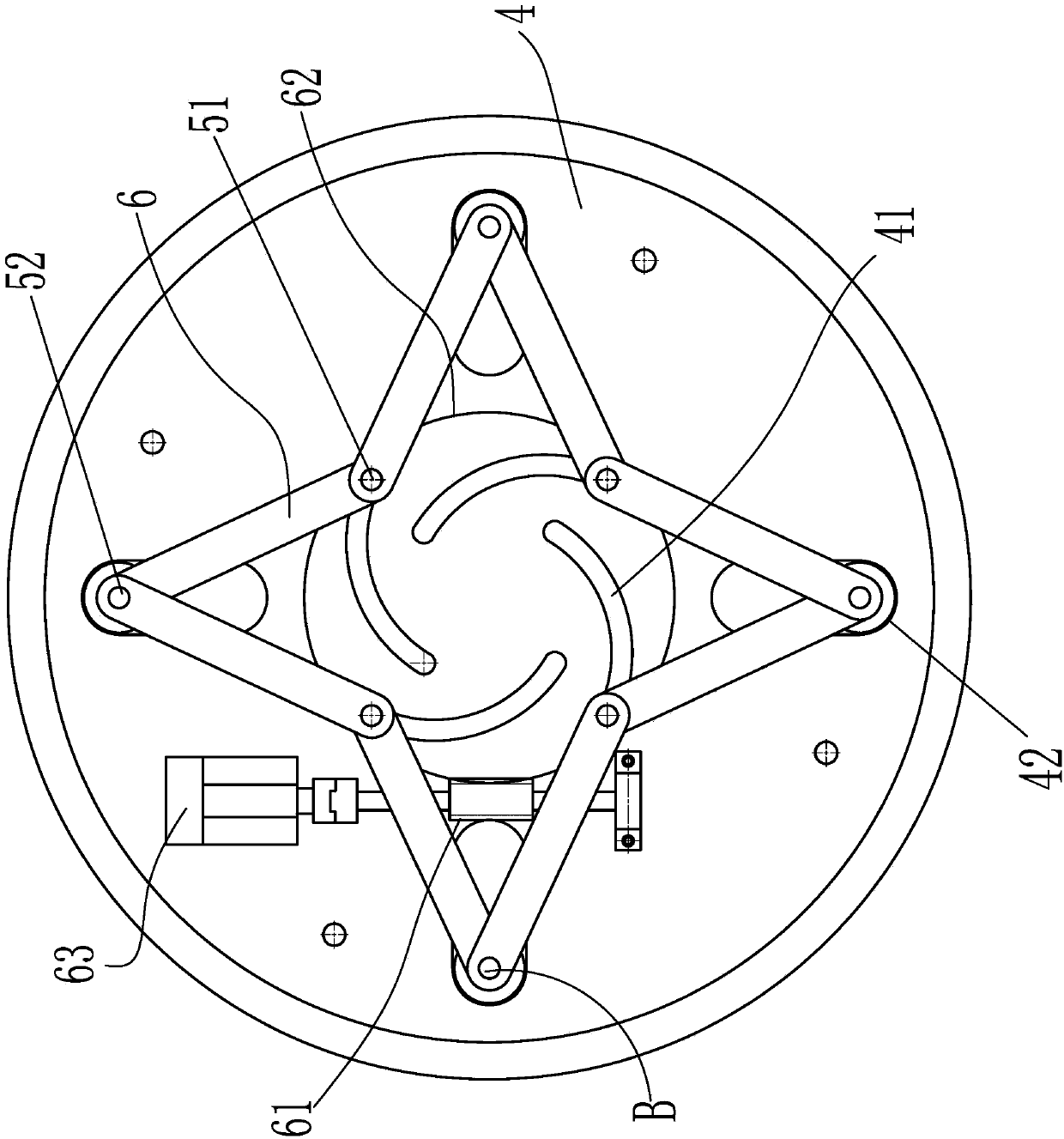

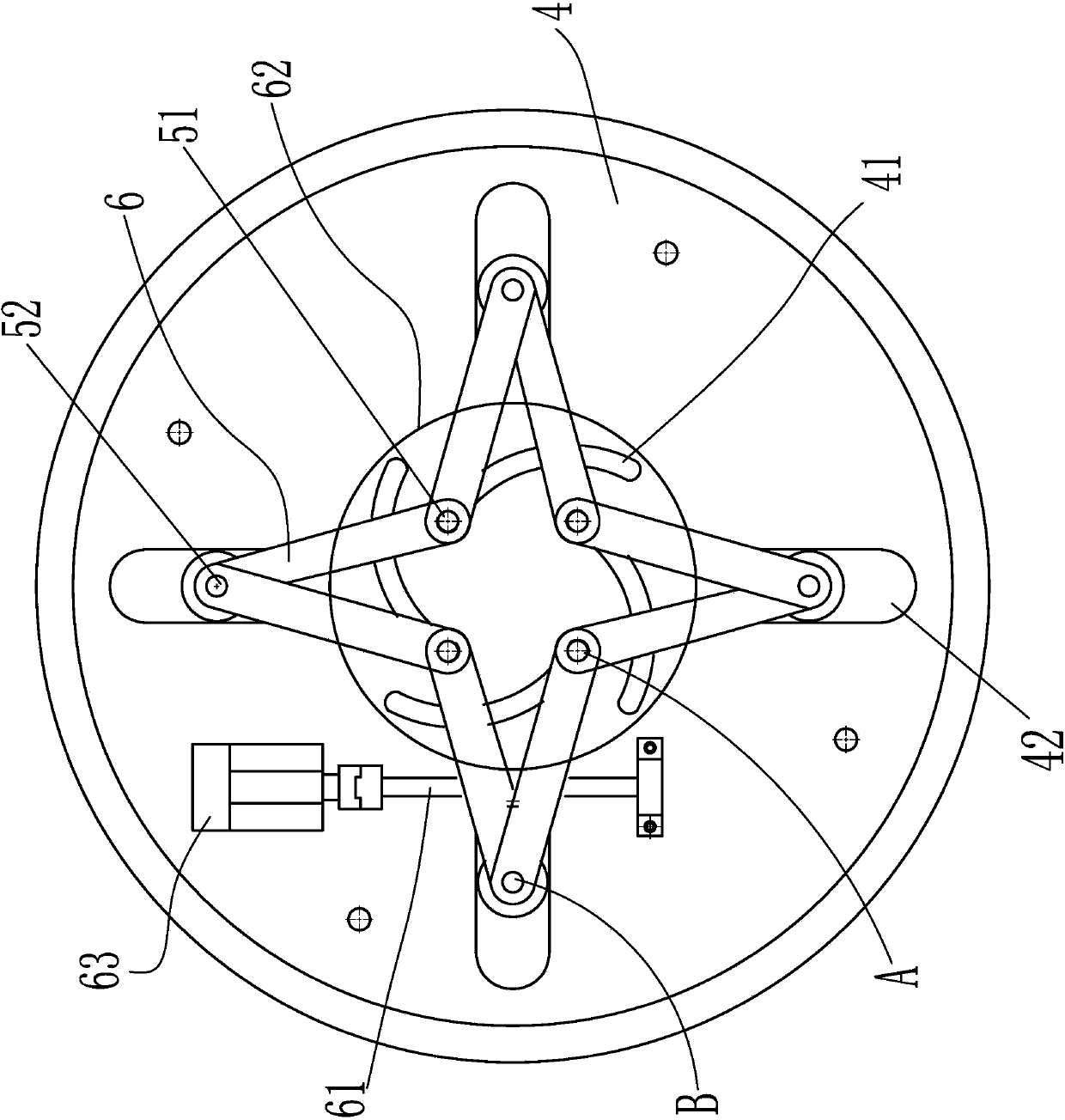

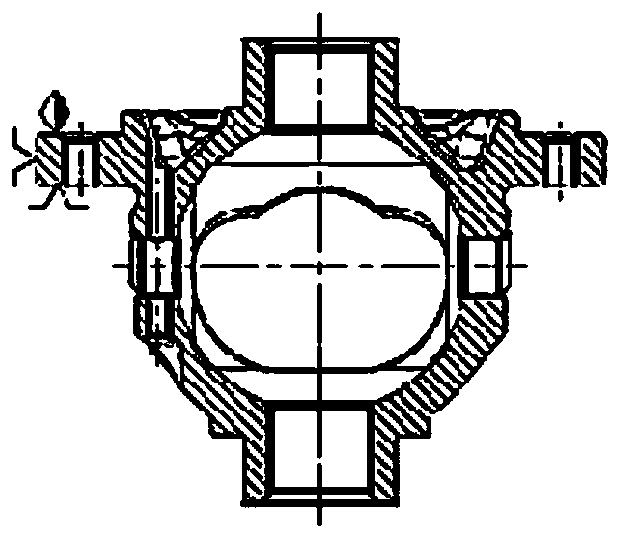

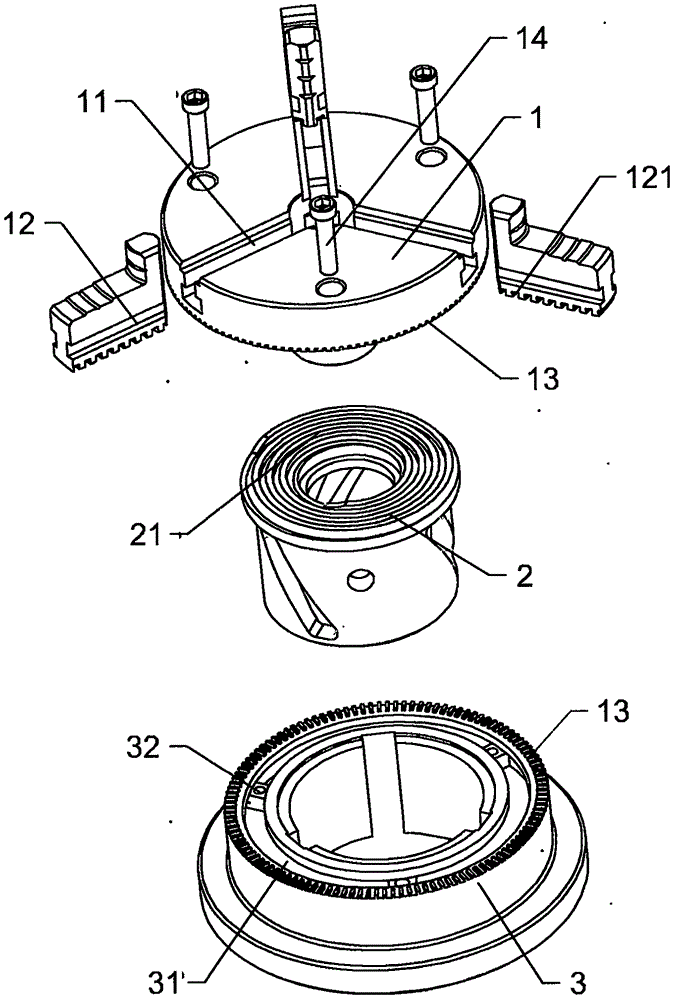

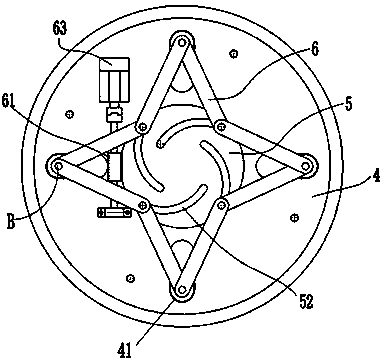

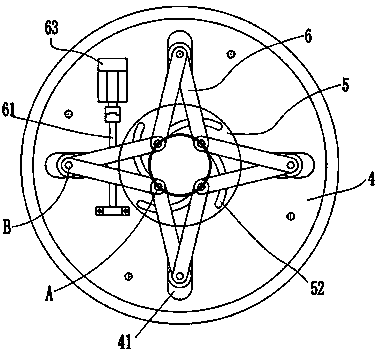

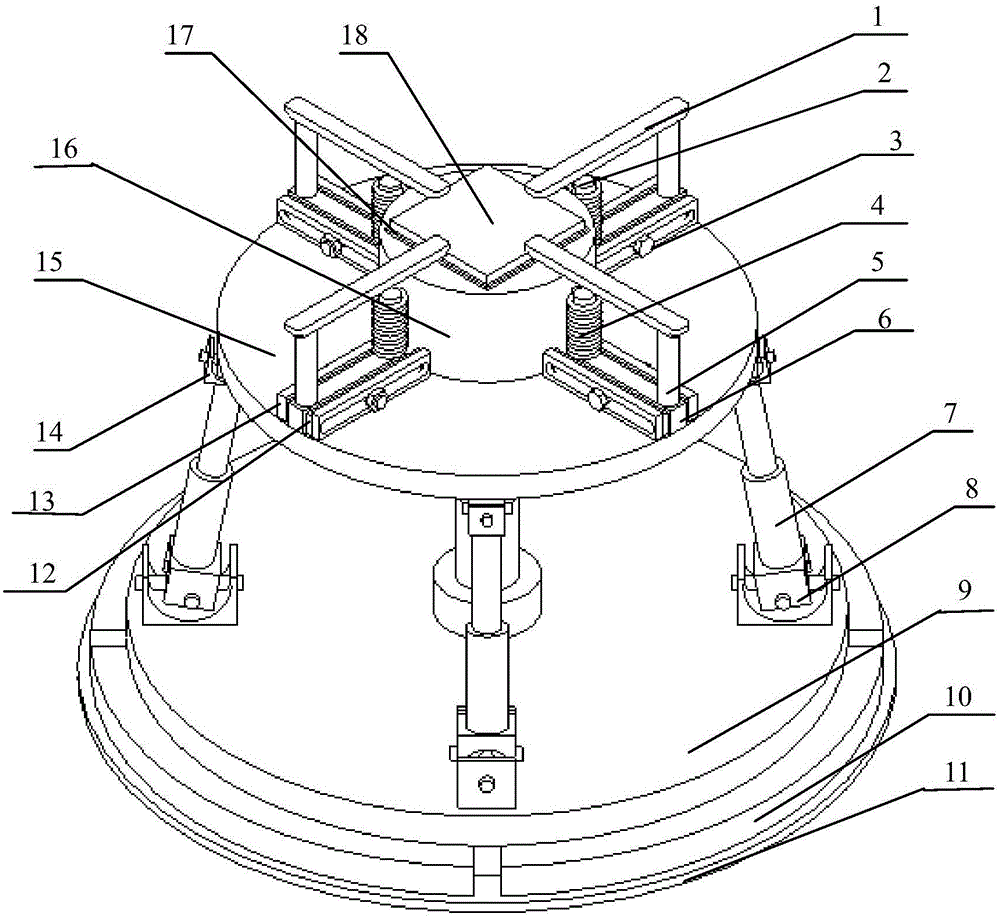

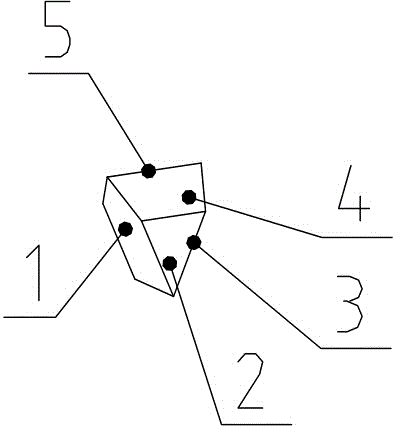

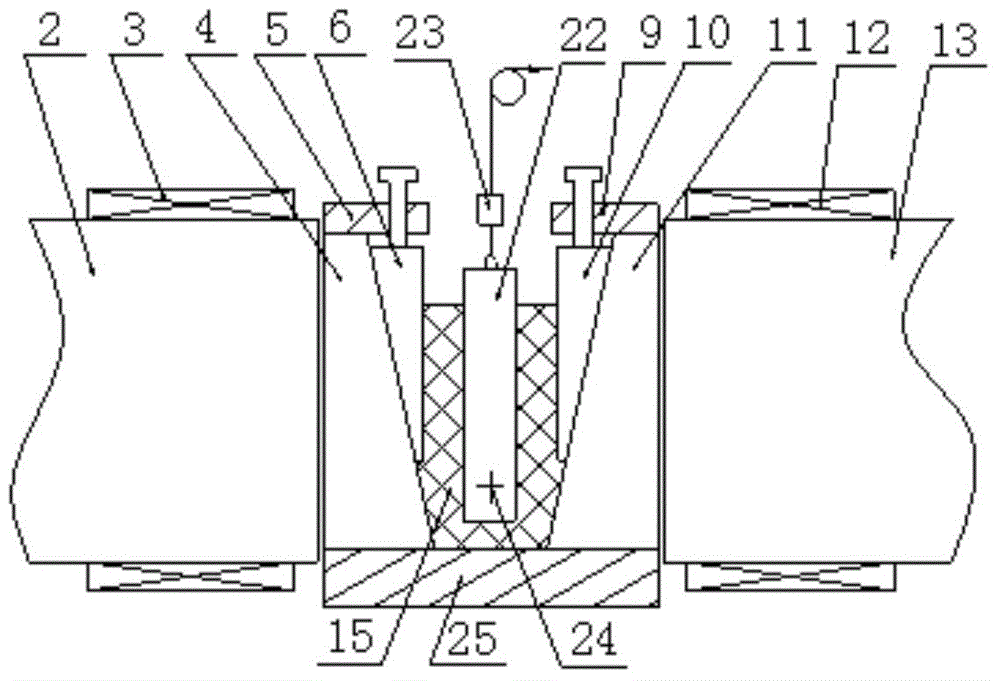

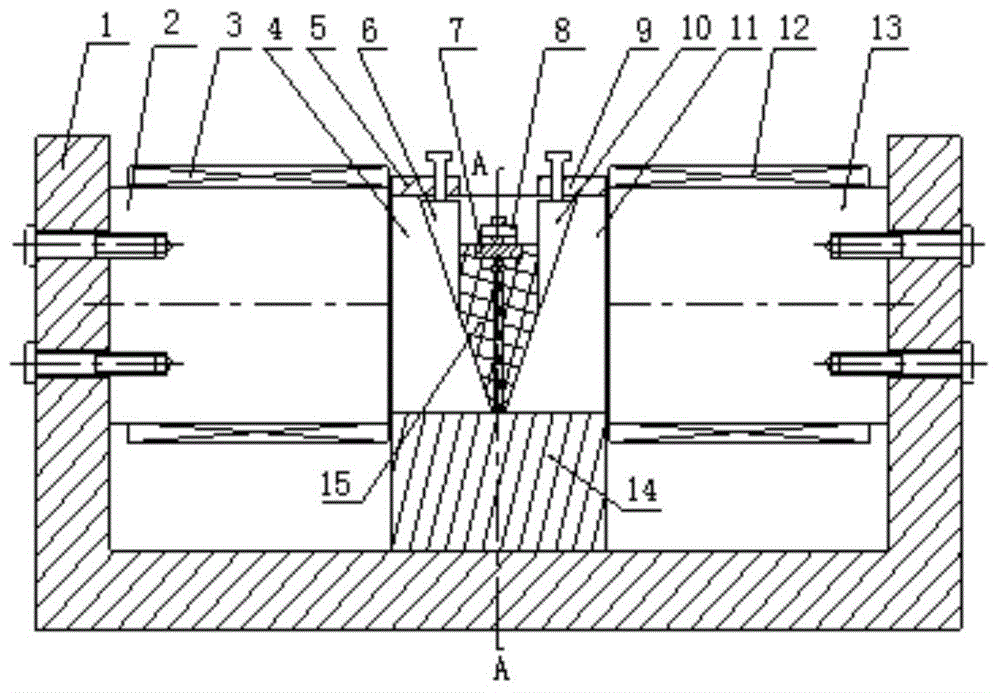

Self-centering clamping device of drill press workpiece

ActiveCN103801959AImprove processing efficiencyEasy to operateWork clamping meansFeeding apparatusLathe faceplateEngineering

The invention provides a self-centering clamping device of a drill press workpiece. The device can realize the self-centering function for a workpiece. The device comprises a connecting base, a workbench rotary disc, a main shaft, a parabola self-centering flower disc, a plurality of connecting rods and a plurality of positioning pawls, wherein the workbench rotary disc can be arranged above the connecting base in a rotary way, the main shaft is fixedly arranged below the middle part of the workbench rotary disc, the parabola self-centering flower disc can be arranged below the workbench rotary disc on the main shaft by a transmission mechanism in a rotary way, arc-shaped gradually slotting grooves are uniformly formed in the parabola self-centering flower disc in the radial direction, the head of one connecting rod is hinged to the end of the other connecting rod, both ends of each of the connecting rods are respectively a first hinging end and a second hinging end, the first hinging ends are respectively hinged to the arc-shaped gradually slotting grooves on the parabola self-centering flower disc, long hinging grooves corresponding to the positions of the peripheral sides of the arc-shaped gradually slotting grooves are respectively formed in the parabola self-centering flower disc, the second hinging ends are respectively hinged to the long hinging grooves in a hinge way, and the positioning pawls are respectively arranged above the second hinging ends of the connecting rods.

Owner:HUHANG TECH GRP CO LTD

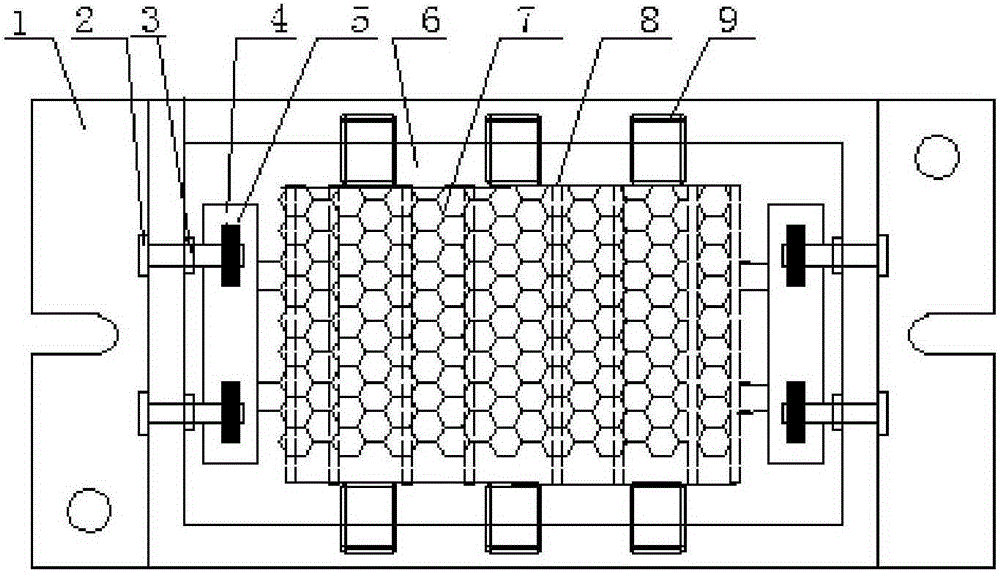

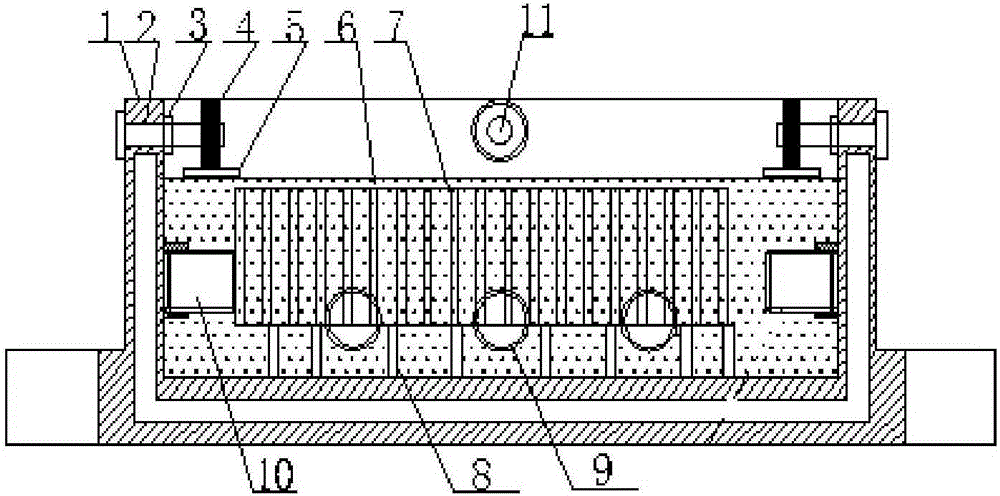

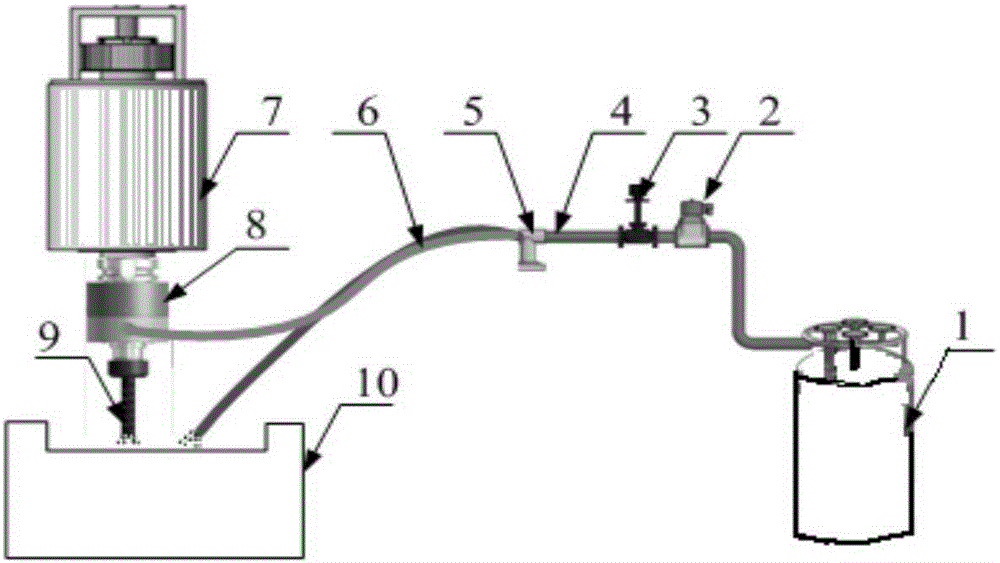

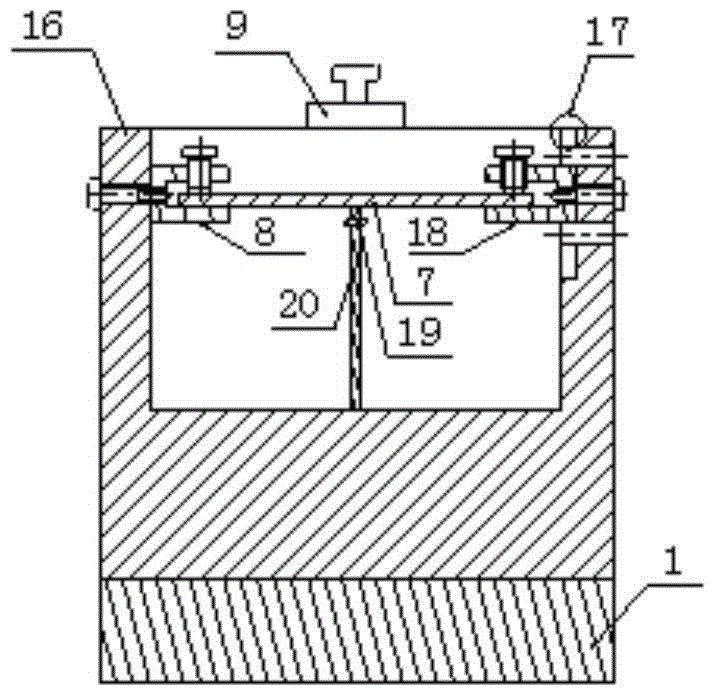

Ice immobilization machining method for metal honeycomb workpiece

ActiveCN105171460ASolve clamping problemsSuppression of processing defectsWork clamping meansMilling equipment detailsHoneycombLiquid nitrogen

The invention provides an ice immobilization machining method for a metal honeycomb workpiece, belongs to the field of machining technological methods and relates to a machine tool fixture device and a machining method for immobilizing a metal honeycomb material through an ice immobilization manner to achieve ultralow-temperature cutting. The method comprises the steps that after metal honeycomb holes arranged in a metal honeycomb ice immobilizing fixture are filled with low-temperature pure water or cutting liquid, the metal honeycomb ice immobilizing fixture is arranged in an adjustable refrigerating testing cabinet, and the freezing temperature and the refrigerating time are set; and then the metal honeycomb ice immobilizing fixture is clamped to a machine tool worktable, metal honeycombs are machined through a liquid nitrogen internal spraying cutter, and the freezing state is maintained through liquid nitrogen external spraying. The method achieves the purpose of clamping of the metal honeycomb workpiece difficult to machine, the freezing temperature of the pure water or the cutting liquid and the temperature maintaining degree are effectively controlled, the machining immobilizing effect can be better, and the cutting precision is improved; and the operation of the method is convenient, the immobilizing effect is stable, the machining efficiency is high, and the machining effect is good.

Owner:DALIAN UNIV OF TECH

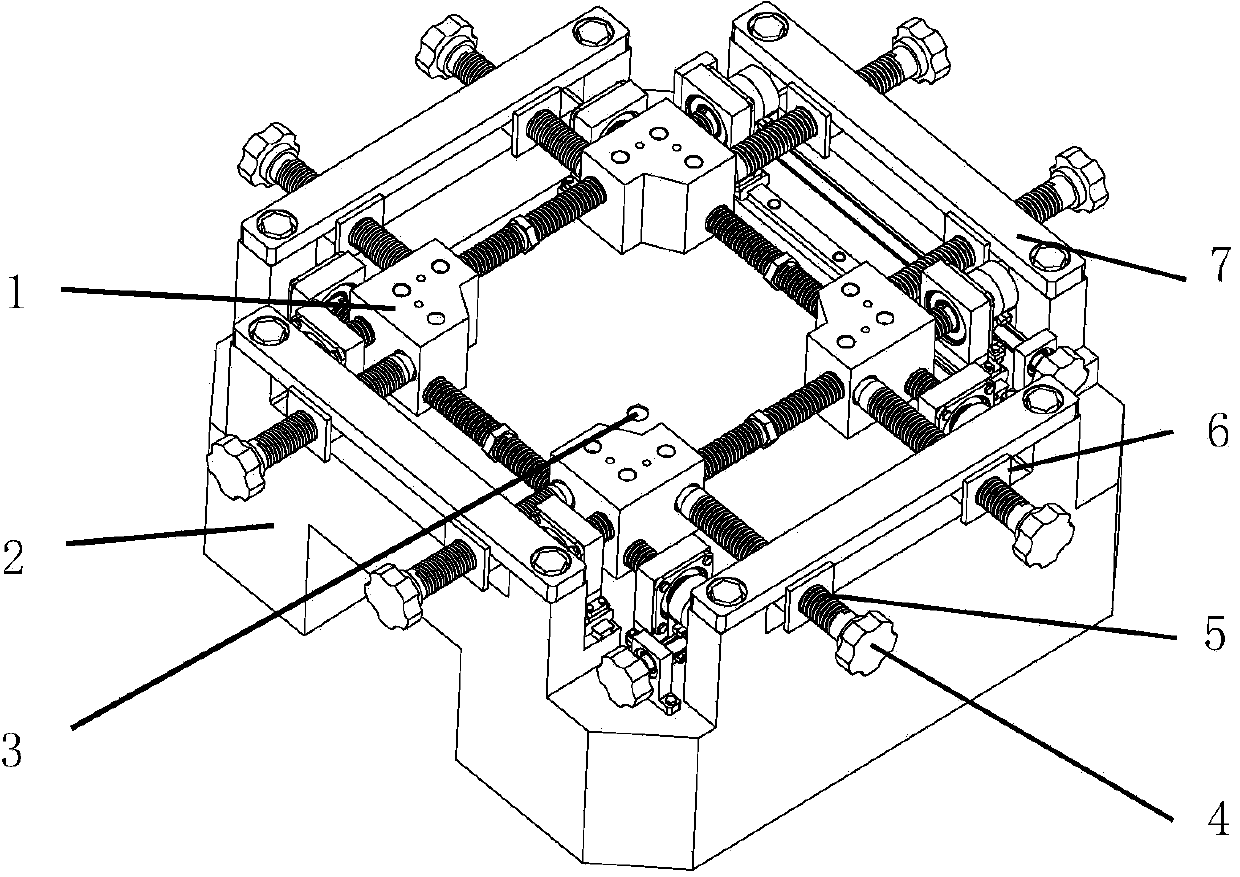

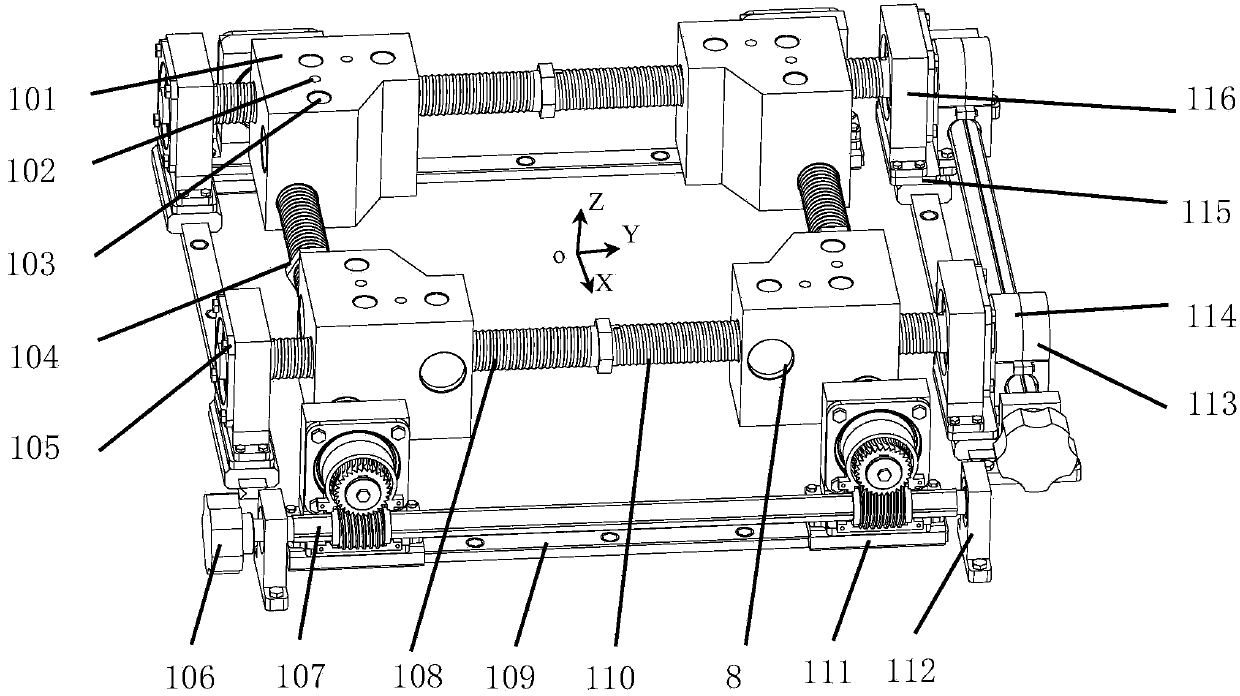

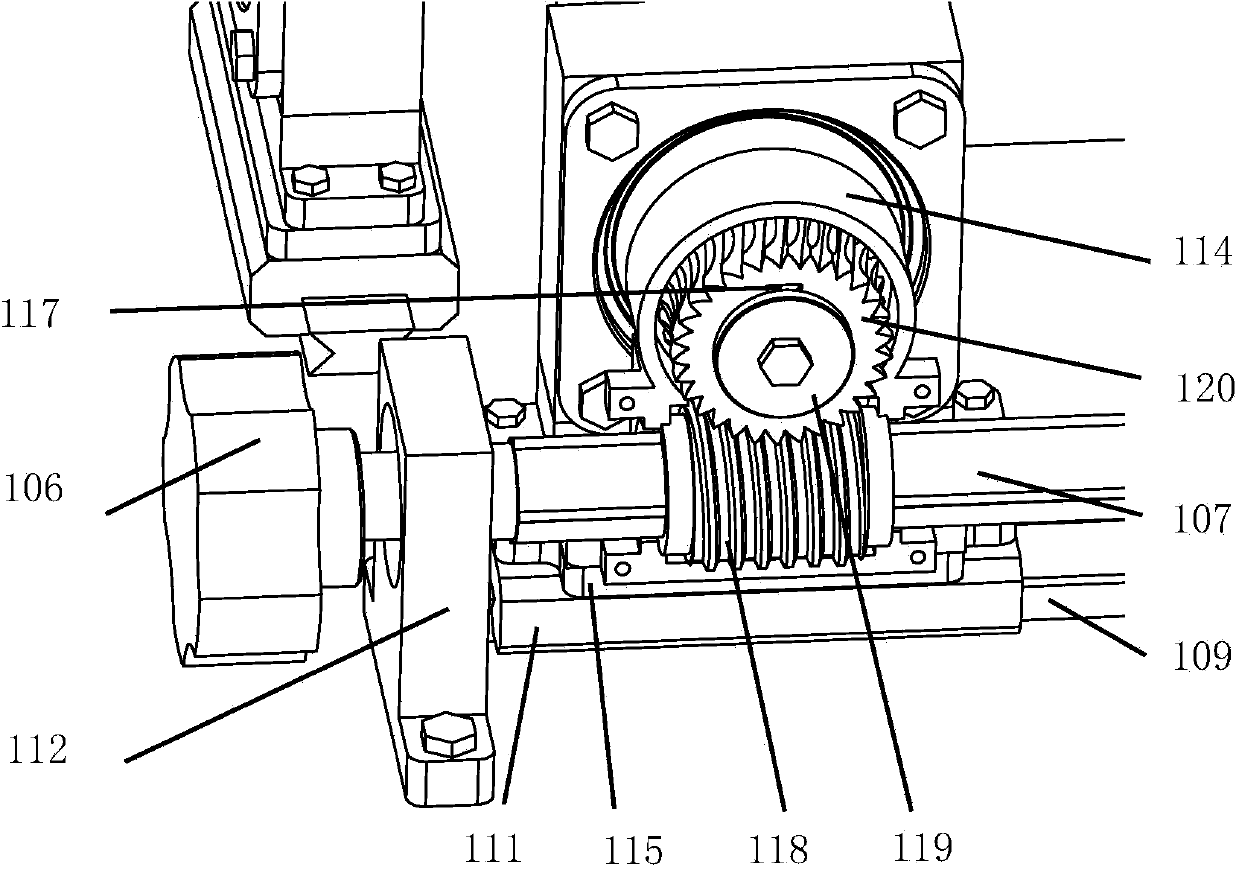

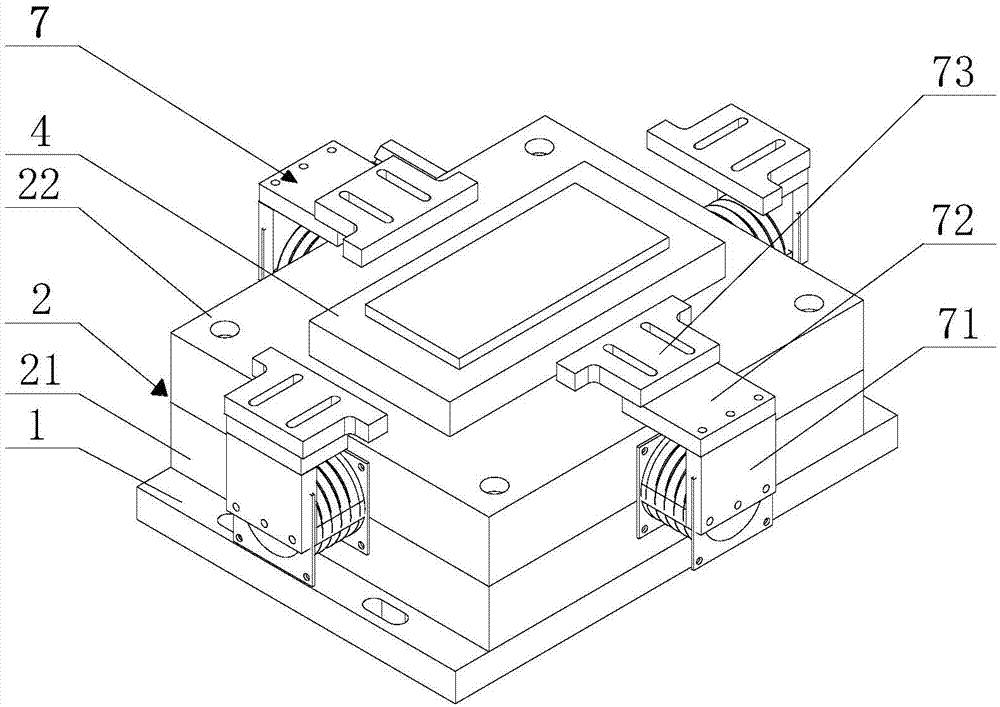

Bidirectional self-centering fixture for workpieces

ActiveCN104191268AHigh precisionStrong precisionWork clamping meansPositioning apparatusEngineeringScrew thread

The invention relates to a bidirectional self-centering fixture for workpieces, and belongs to the field of machinery manufacturing. A bidirectional self-centering clamping mechanism is fixedly connected with a base. A nut pressing plate is fixedly connected with the base. The nut pressing plate is connected with a locking nut in a pressed mode. A locking screw is connected with the locking nut in a threaded mode. The front end of the locking screw is in a semi-sphere shape and is connected with the bidirectional self-centering clamping mechanism in an abutted mode. A locking handle is fixedly connected with the rear end of the locking screw. A tip assembly is located below a conical face hole in the base. The bidirectional self-centering fixture is high in universality, especially suitable for the workpieces with the sections being quadrilateral or polygonal, high in bidirectional self-centering accuracy and easy to operate.

Owner:JILIN UNIV

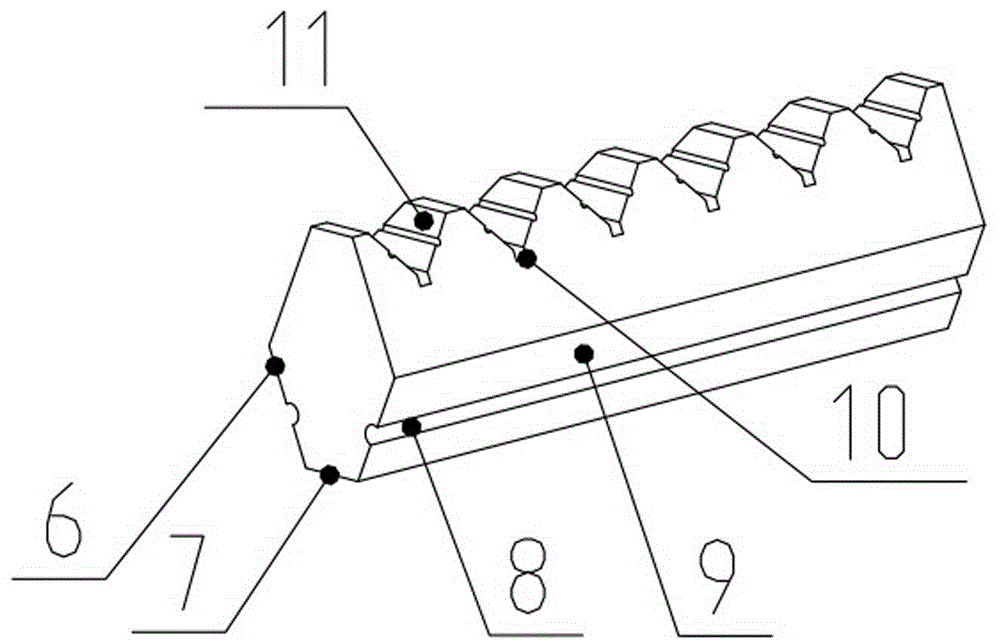

V-block-positioning pneumatic clamping machining center fixture

InactiveCN104128829ANovel structureEasy to operateWork clamping meansPositioning apparatusClassical mechanicsEngineering

The invention discloses a V-block-positioning pneumatic clamping machining center fixture comprising a fixture body, a positioning mechanism and a clamping mechanism. The positioning mechanism comprises a V-block fixed on the fixture body, a fixed support and an auxiliary support are fixed on the upper end faces of two ends of the V-block respectively, and a cylindrical stop pin is arranged on one side corresponding to the center of a V-opening of the V-block. The clamping mechanism comprises two cylinders respectively located on two sides of the V-block, a column is arranged between each cylinder and the V-block, the bottoms of the two columns are fixed on the fixture body, push rods of the cylinders are arranged vertically, a lever is mounted on the top of each push rod transversely and rotationally, the middle of each lever is rotationally mounted at the top of the corresponding column, the other end of each lever is fixed with a pressing block, and each pressing block is located on the lower end face of the corresponding lever and located over the fixing support or the auxiliary support. The V-block-positioning pneumatic clamping machining center fixture is quick and accurate in positioning, quick, controllable and reliable in clamping, and capable of guaranteeing machining stability.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

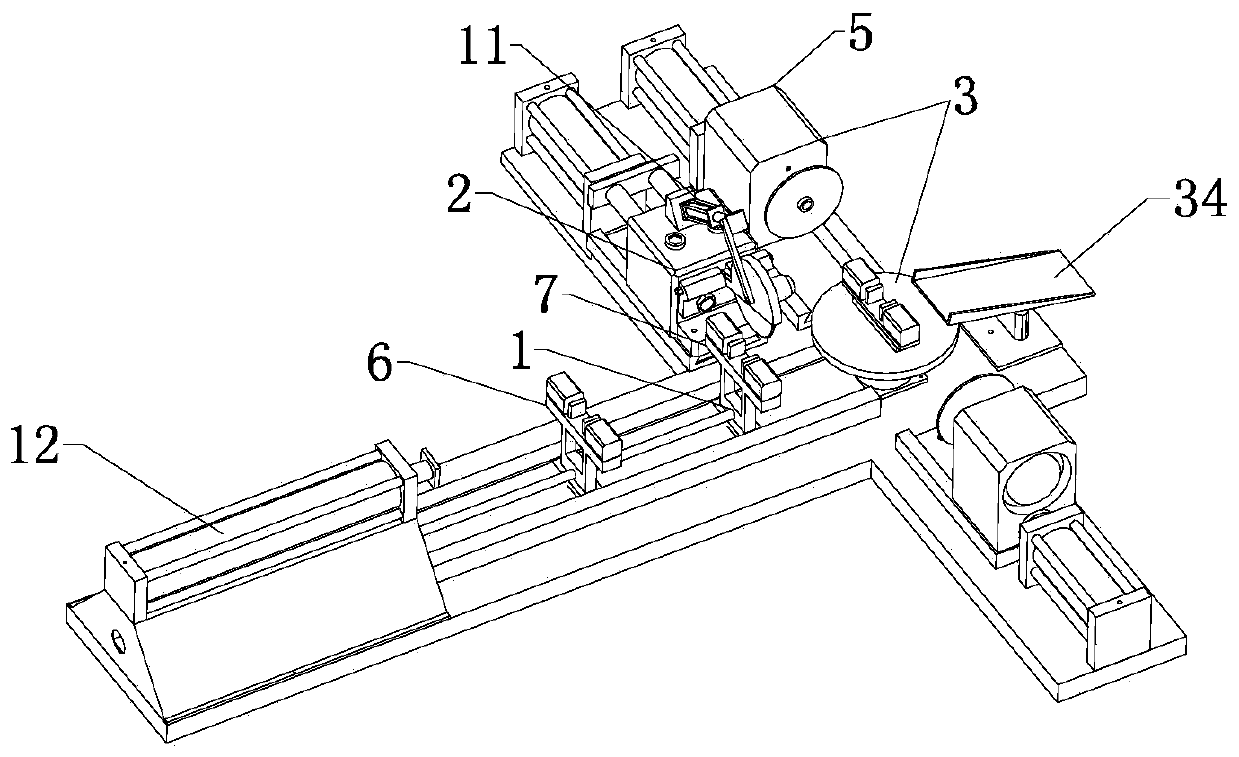

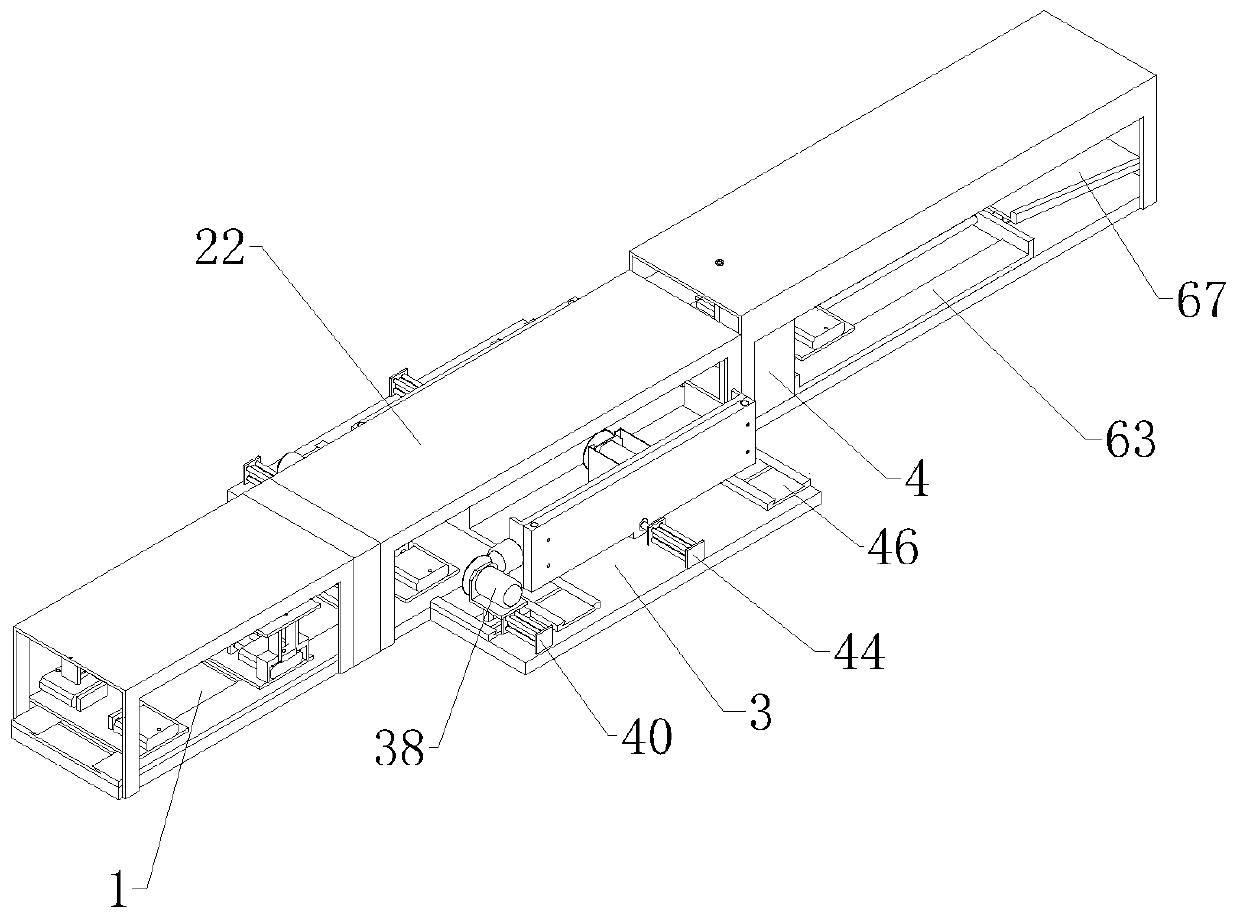

Square tube cutting and end surface grinding integrated equipment

InactiveCN110421356ADisadvantages of realizing that it cannot be completed at one timeWork clamping meansOther manufacturing equipments/toolsCircular sawEngineering

The invention relates to the field of cutting and grinding machines, in particular to square tube cutting and end surface grinding integrated equipment. The equipment comprises a feeding component, acutting component and an end grinding component, wherein the end grinding component comprises a rotary table and two grinding mechanisms symmetrically arranged on the two sides of the rotary table, the feeding component comprises a first fixed clamp and a movable clamp, the cutting component comprises a movable base and a circular saw blade, an angle adjusting mechanism connected with a free end of a supporting arm is arranged at the top of the movable base, a horizontal pushing air cylinder is arranged at the top of the starting end of the feeding component in a horizontal state, the horizontal pushing air cylinder, the first fixed clamp, the movable clamp and the rotary table are linearly arranged in sequence, and a second fixed clamp is arranged on the top of the rotary table. Accordingto the square tube cutting and end surface grinding integrated equipment, the cutting component carries out cutting on a square tube, and the end grinding component carries out grinding on the squaretube, so that the cutting and end surface grinding integrated equipment is realized, and a large amount of manpower and financial resources are reduced.

Owner:吴丽平

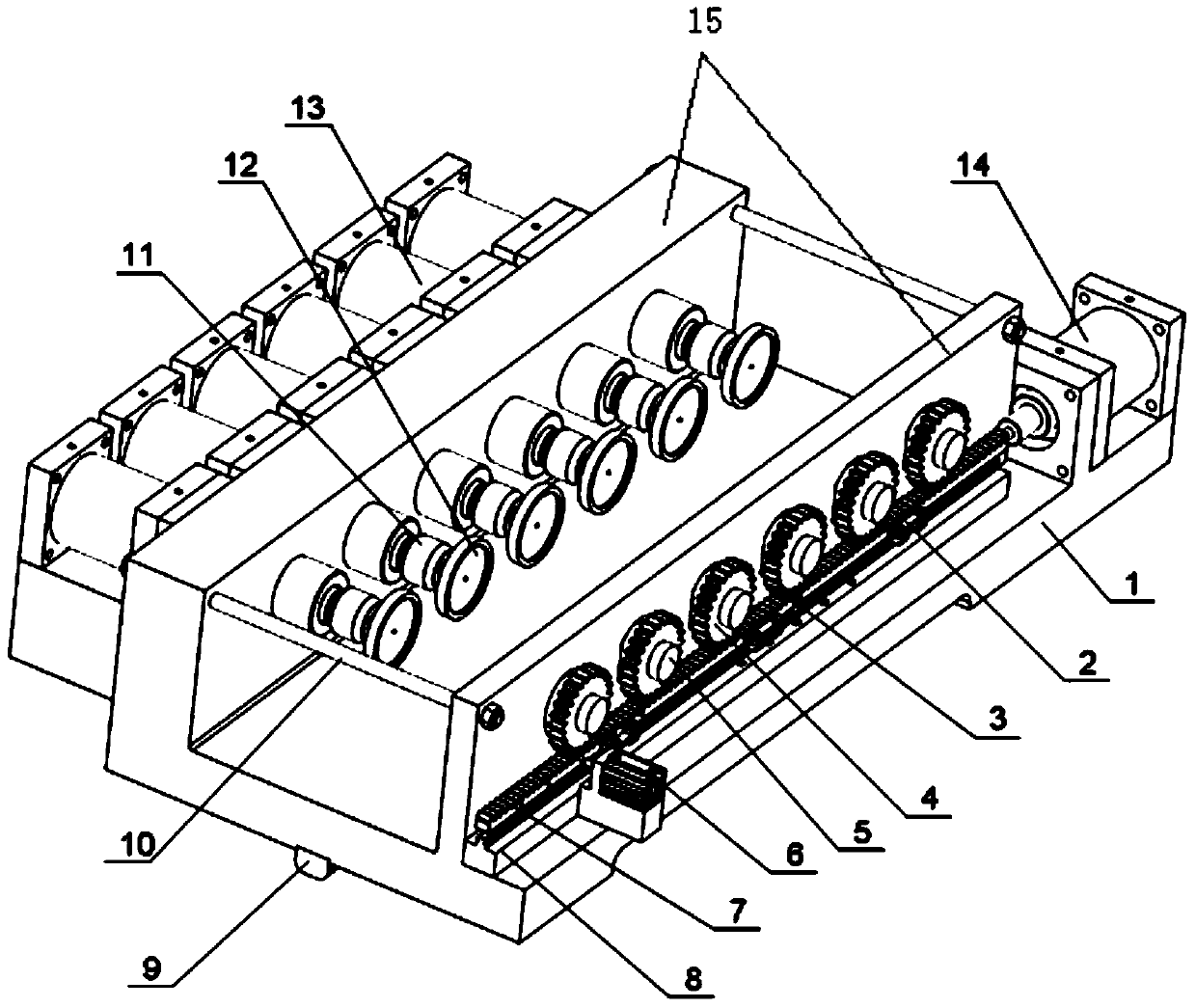

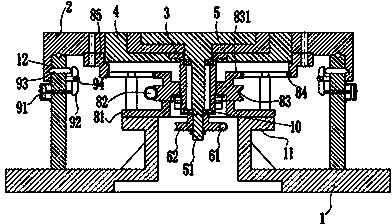

Rotational multi-workpiece clamping and multi-station pneumatic clamp

InactiveCN103990993AImprove processing productivityGive full play to the functions of the machine toolAutomatic control devicesWork clamping meansEngineeringMachine tool

The invention discloses a rotational multi-workpiece clamping and multi-station pneumatic clamp. The clamp comprises a clamp body, a locating rotating mechanism and a clamping mechanism, wherein the clamp body comprises two vertical boards parallel to each other, and the two vertical boards are provided with the locating rotating mechanism and the clamping mechanism respectively and are connected with each other through a plurality of pull rods; the locating rotating mechanism comprises a driving air cylinder, an output shaft of the driving air cylinder is connected with a toothed bar located on one side of one vertical board, the vertical boards are evenly provided with a plurality of rotary shafts, each rotary shaft is connected with a cylindrical gear through a key, and each cylindrical gear is meshed with the toothed bar; the clamping mechanism comprises a plurality of clamping air cylinders which are respectively in transmission connection with a rolling jacking rod, each rolling jacking rod penetrates through the other vertical board, and a pressing block is fixed to the other end of each rolling jacking rod. The rotational multi-workpiece clamping and multi-station pneumatic clamp can effectively achieve the function of a numerically-controlled machine tool, improve machining efficiency of workpieces, and guarantee machining quality.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

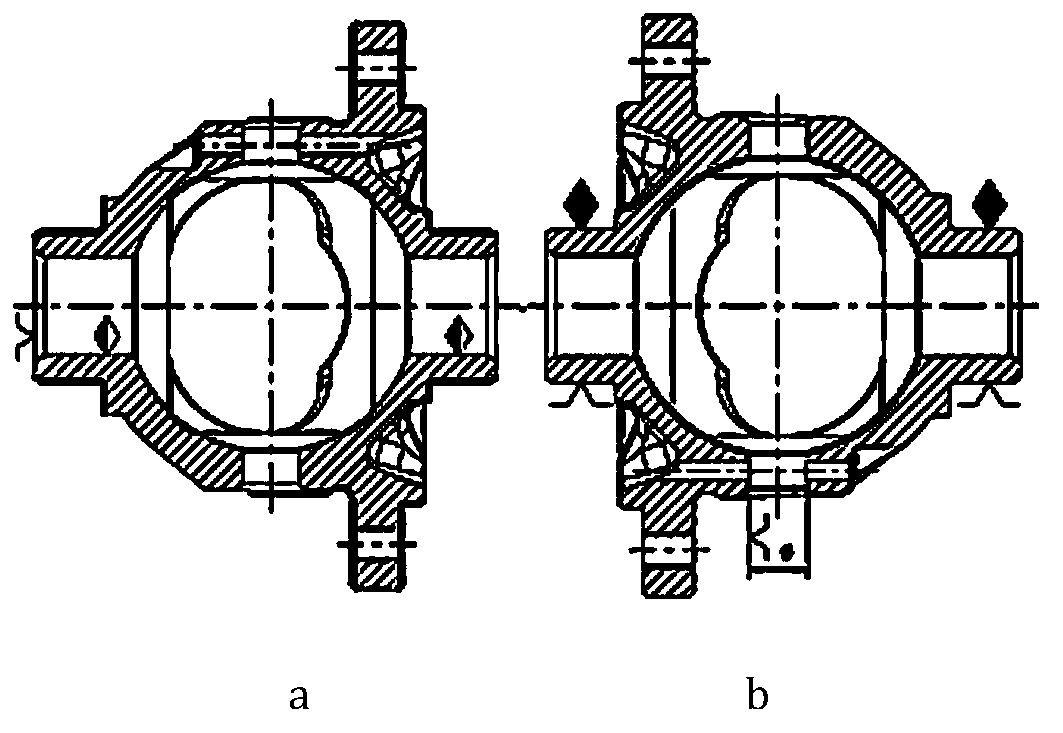

Device and process for machining differential housing

ActiveCN103753322ARealize batch production processingRealize inputWork clamping meansExpansion mandrelsNumerical controlCar manufacturing

The invention belongs to the technical field of automobile manufacturing and discloses a device and process for machining a differential housing. The device is composed of a rotary jig, an internally-expanding lathing jig and a spherical surface lathing jig, wherein the rotary jig is arranged on a machining center and comprises an operation part with the two ends arranged on the machining center through rotating assemblies, and the internally-expanding lathing jig and the spherical surface lathing jig are arranged on a common numerically-controlled lathe. Synchronous machining of two parts can be achieved through the high-precision rotary jig when the machining center is used for machining various axial inner holes, and therefore efficiency is higher; a high-precision numerically-controlled indexing table is applied to the jigs, rotating accuracy is as high as 20'' or higher, and precision of the critical size of a product is better guaranteed; the parts can be automatically clamped and dismounted by the jigs through numerical control programs, and therefore labor can be saved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

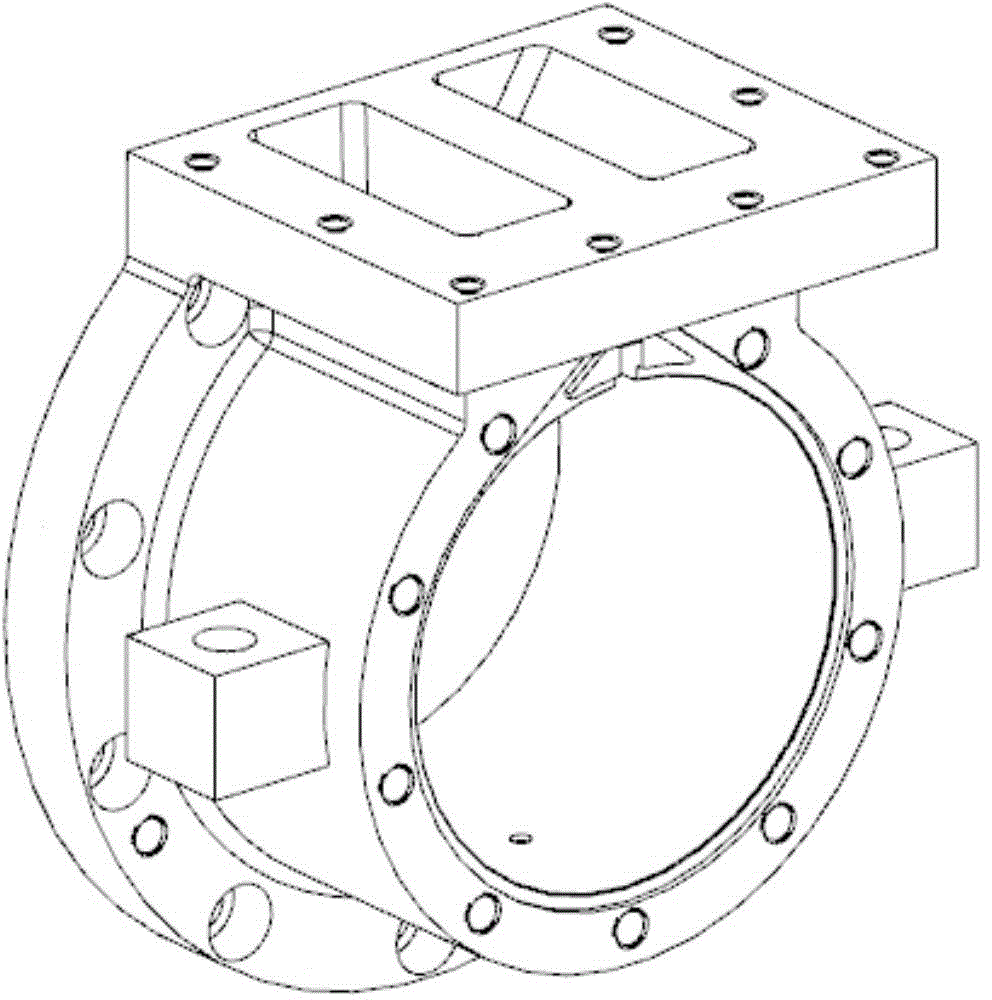

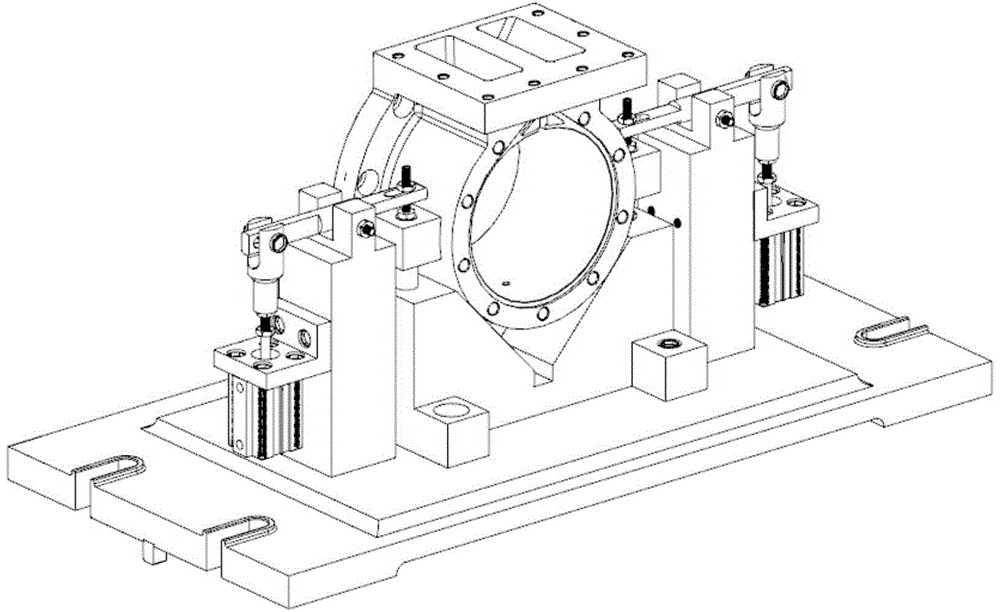

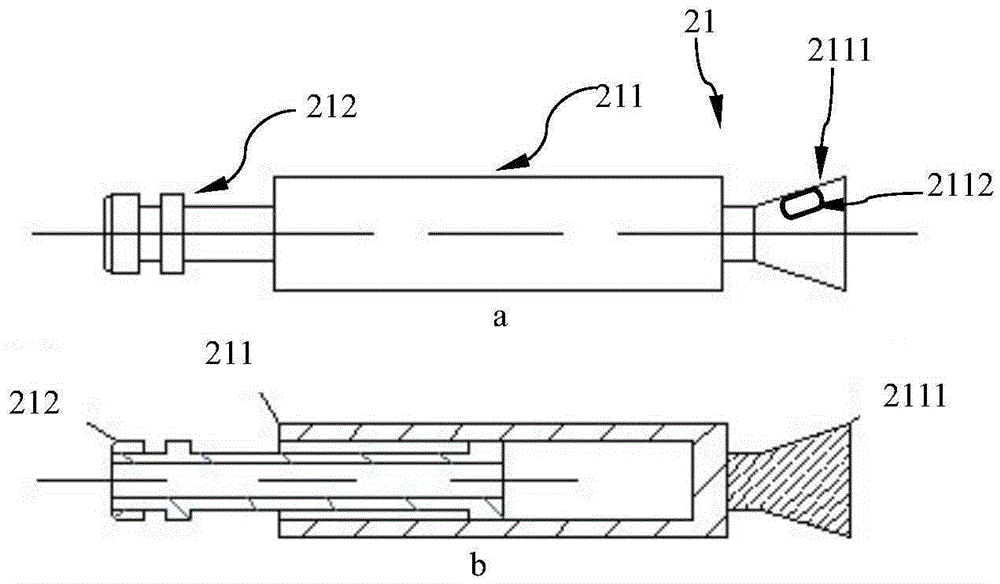

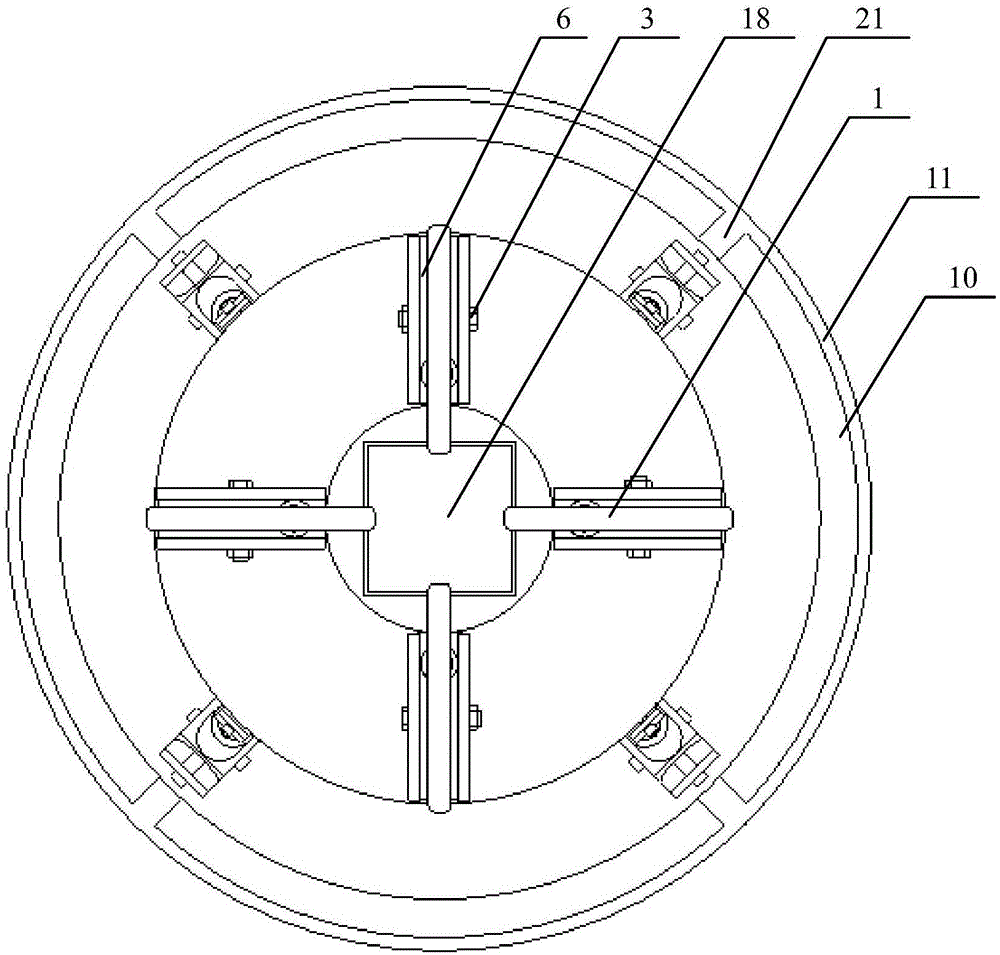

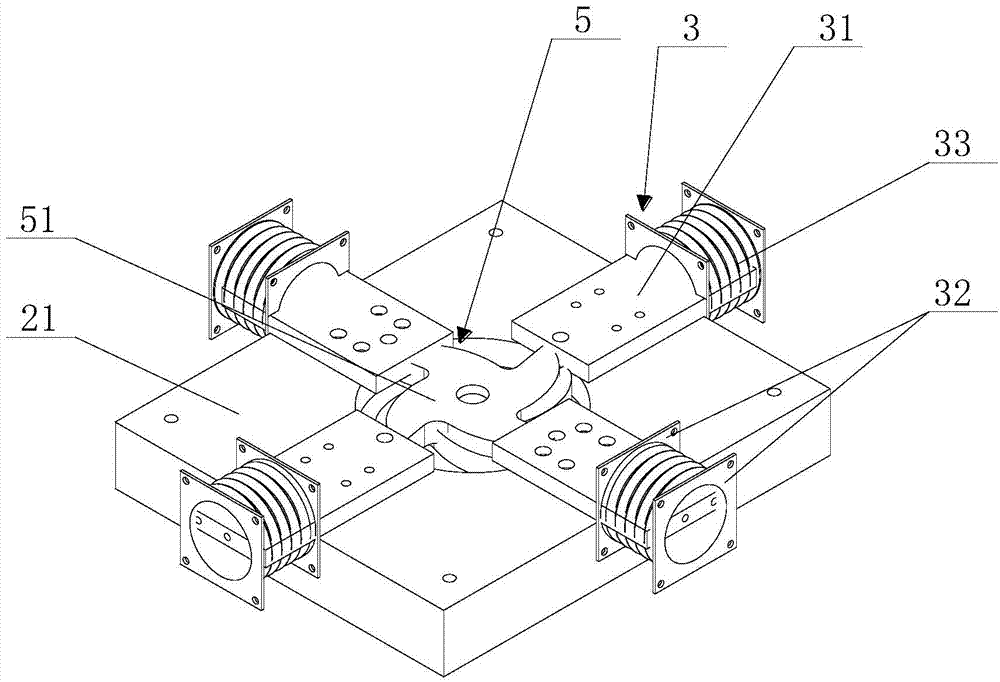

Air pressure flexible clamping device of frame-shaped parts with thin walls, and clamping method of air pressure flexible clamping device

InactiveCN105382741AStrong size applicabilityGuaranteed stabilityWork clamping meansWork holdersMachine partsAtmospheric pressure

An air pressure flexible clamping device of frame-shaped parts with thin walls is used for clamping and fixing of to-be-machined frame-shaped parts with thin walls and cylinder body parts when being machined, and comprises a support unit which comprises a base and a closed-ring support which is arranged on the base and is used for surrounding the to-be-machined parts; a clamping unit which is arranged on the wall of the closed-ring support, and comprises at least three air pressure clamping parts which are mutually cooperated for clamping and fixing the to-be-machined parts; a pneumatic unit which is communicated with the air pressure clamping parts for respectively controlling air pressure of multiple air pressure clamping parts, wherein the air pressure clamping parts are detachably connected on the closed-ring support, a head end is provided with a suction nozzle, the suction nozzle is in contact, clamped and fixed with the outer surface of each of the to-be-machined parts through negative pressure. The invention also provides a clamping method. The device and the method have the advantages of being flexible in operation, high in applicability to shapes and sizes of thin-walled workpieces, and capable of effectively ensuring the stability, accuracy and reliability of the clamping of the frame-shaped parts with thin walls during a machining process.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

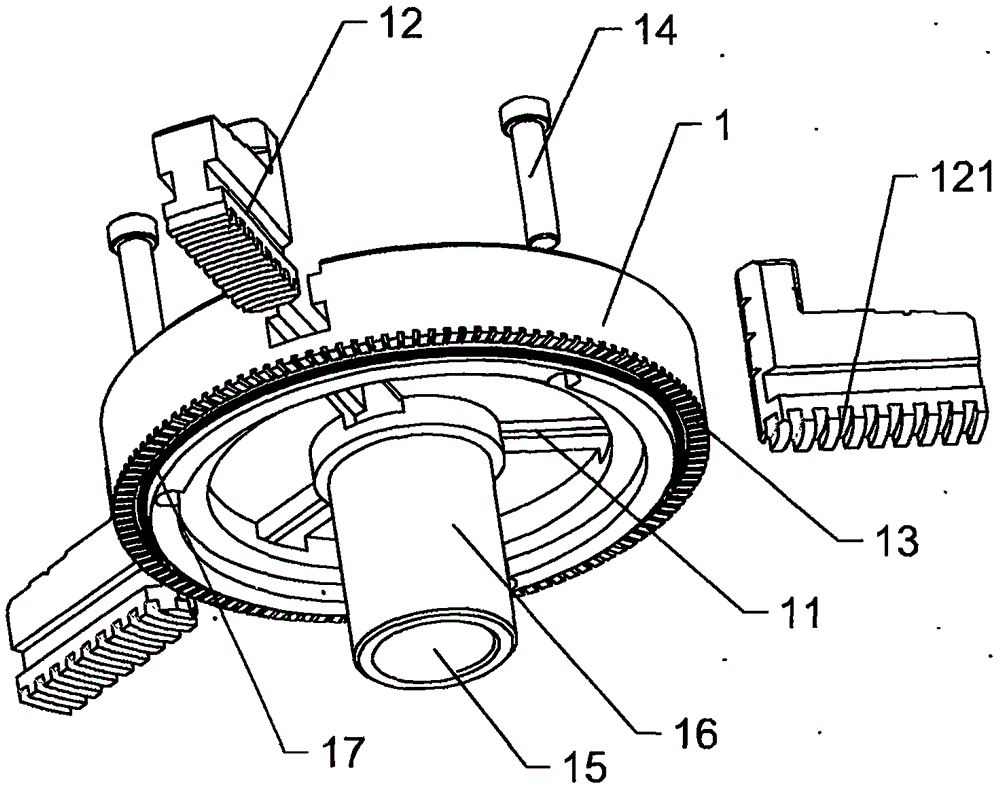

Clamp

ActiveCN105834770ATo achieve the purpose of adjusting the clamping distanceEasy to operateWork clamping meansPositioning apparatusModular compositionBiomedical engineering

The invention provides a clamp. The clamp comprises a shell and a spiral disc; the shell comprises a clamping jaw movable cover, and further comprises a positioning sleeve detachably connected with the clamping jaw movable cover, and the positioning sleeve is provided with a plurality of sliding blocks capable of sliding in the circumferential direction; the clamping jaw movable cover is provided with screws capable of being in matched connection with the sliding blocks, and the clamping jaw movable cover and the positioning sleeve are in axial fixation through the screws; and the end face, in contact with the clamping jaw movable cover, of the positioning sleeve is provided with a positioning assembly playing a role in circumferential fixation of the clamping jaw movable cover and the positioning sleeve, and the screws can enable spiral teeth and spiral grooves to keep in linkage fit when the clamping jaw movable cover circumferentially rotates on the positioning sleeve. By means of the clamp, clamp modularization combination is achieved, assembling and disassembling are convenient, the clamping jaw clip distance is conveniently adjusted, the clamping jaw movable cover can be replaced, and the clamp integrating a clamp air cylinder can be achieved.

Owner:曹正虎

Central symmetry type circular pipe positioning device

InactiveCN105729346APrecise positioningUniform clamping forceWork clamping meansWork holdersEngineeringCentral symmetry

The invention discloses a central symmetry type circular pipe positioning device. The central symmetry type circular pipe positioning device comprises a bottom positioning die, an upper pressing die, a left V-shaped block, a right V-shaped block, a levorotation nut slide block, a dextrorotation nut slide block and a two-way lead screw. The upper pressing die is arranged over the bottom positioning die. The left V-shaped block and the right V-shaped block are arranged on the left side and the right side of the bottom positioning die in a symmetrical manner. The levorotation nut slide block is arranged below the left V-shaped block. The dextrorotation nut slide block is arranged below the right V-shaped block. The two-way lead screw penetrates in one end of the levorotation nut slide block and then penetrates out of the other end of the dextrorotation nut slide block. By means of the manner, a circular pipe is positioned and clamped in four directions through the central symmetry type circular pipe positioning device, and the central symmetry type circular pipe positioning device has the beneficial effects of being accurate and reliable in positioning, uniform in clamping force, simple in structure and convenient to manufacture and is suitable for positioning and clamping circular pipes of various diameters.

Owner:SUZHOU DODRON MACHINERY MFG

Flexible clamp

InactiveCN105690155AAvoid damageIncrease the clamping degreeWork clamping meansMeasurement/indication equipmentsMechanical engineeringPhysics

The invention discloses a flexible clamp which comprises a plurality of platy baffles. Each baffle is covered with a flexible air bag. Each baffle is provided with an air inlet hole and an air outlet hole which communicate with the corresponding flexible air bag. Each air inlet hole is connected with an inflation pump. Each air outlet hole is connected with an air outlet adjusting valve. The working face, in contact with a workpiece, of each flexible air bag is provided with a pressure induction piece. The pressure induction pieces, the inflation pumps and the air outlet adjusting valves are in wireless signal connection with a controller. The controller judges whether the clamped workpiece is tightly clamped or not according to signals transmitted by the pressure induction pieces, and the clamping degree is controlled by adjusting the inflation pumps and the air outlet adjusting valves. By means of the flexible clamp, the probability that workpieces high in brittleness are damaged can be effectively lowered, in addition, the flexible air bags can be effectively attached to the outer surfaces of workpieces irregular in shape, and the clamping degree is improved.

Owner:SUZHOU HEYER PRECISION CO LTD

Workpiece automatic clamping device

ActiveCN103817553AAchieve self-centering functionImprove processing efficiencyWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention provides a workpiece automatic clamping device, which is convenient to operate, and the workpiece automatic centering function is realized. The workpiece automatic clamping device comprises a connecting base, a worktable turntable, a main shaft sleeve, an automatic centering disc chuck, a parabolic disc chuck, a plurality of connecting rods and a plurality of positioning claws, wherein the worktable turntable is rotationally arranged above the connecting base; the main shaft sleeve is fixedly arranged below the worktable turntable; the parabolic disc chuck is rotationally arranged on the worktable turntable; the automatic centering disc chuck is fixedly arranged on the worktable turntable; the parabolic disc chuck is provided with arc-shaped involute grooves from the inside to the outside in the radial direction; the connecting rods are hinged to each other end to end; two ends of each connecting rod are respectively a first hinge end and a second hinge end; the first hinge ends are respectively hinged to the involute grooves on the parabolic disc chuck; the automatic centering disc chuck is uniformly provided with long hinge grooves corresponding to the arc-shaped involute grooves in quantity; the second hinge ends are respectively hinged to the long hinge grooves; the positioning claws are respectively arranged above the connected first hinge ends.

Owner:南通棉锦纺织品有限公司

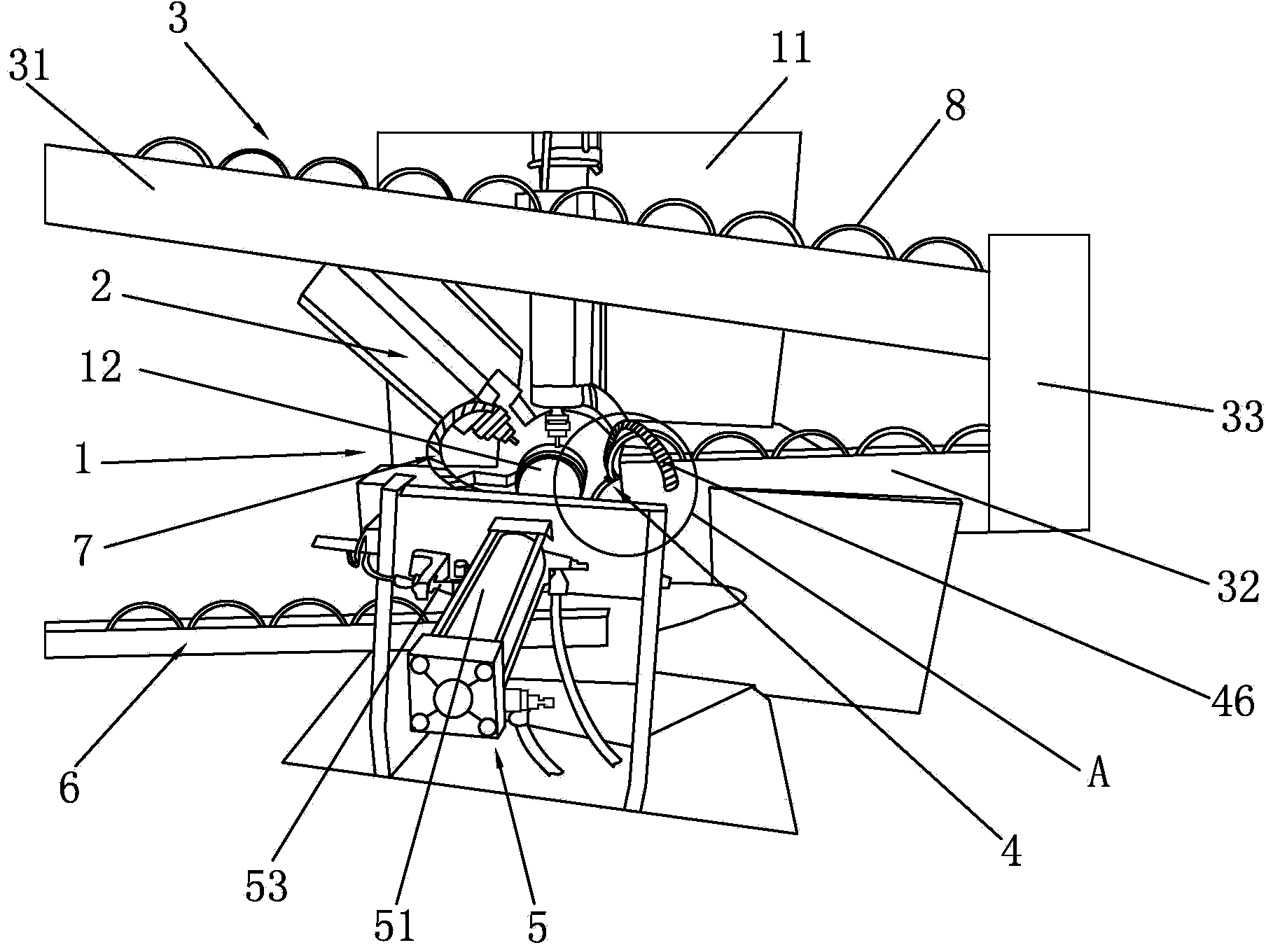

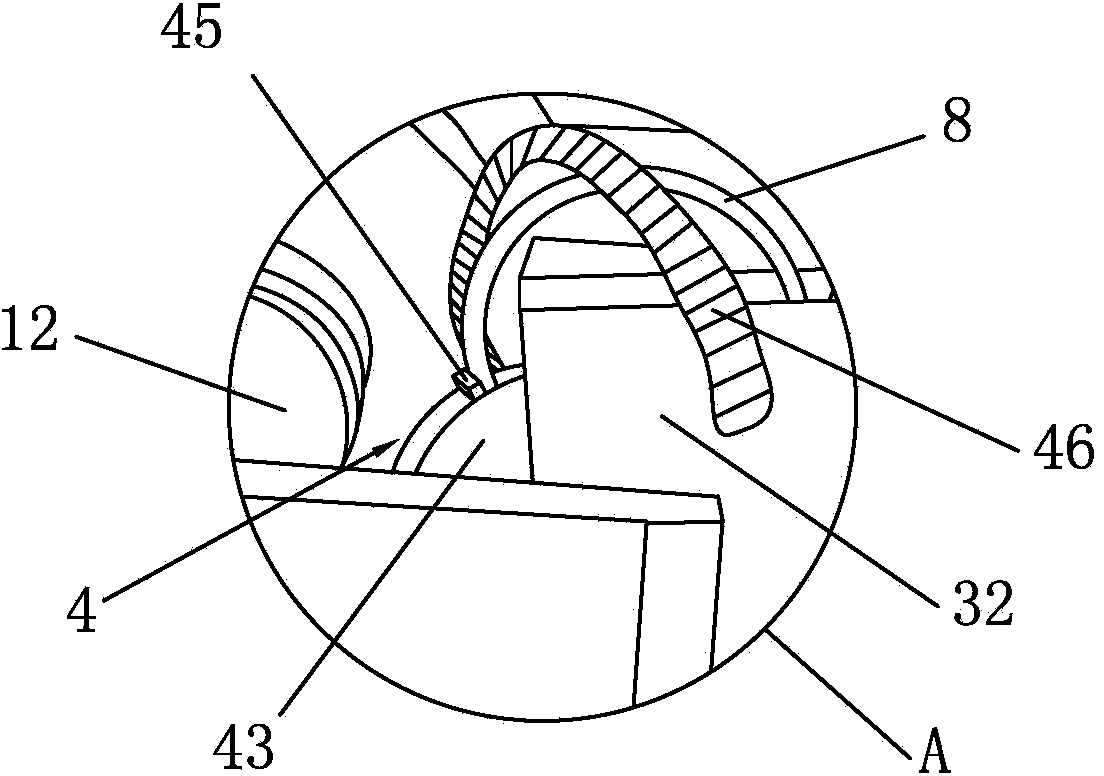

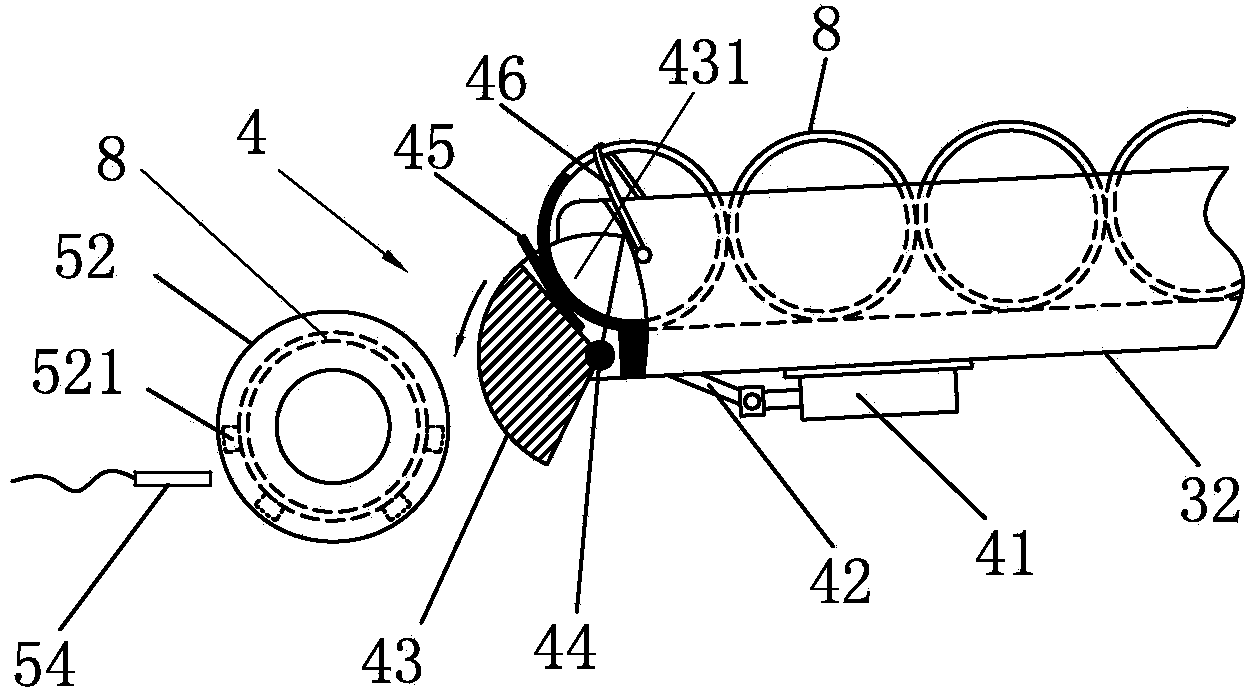

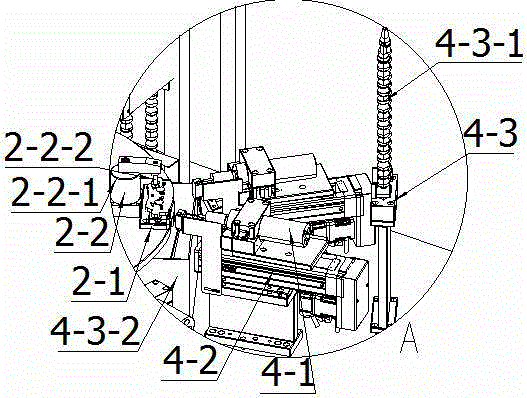

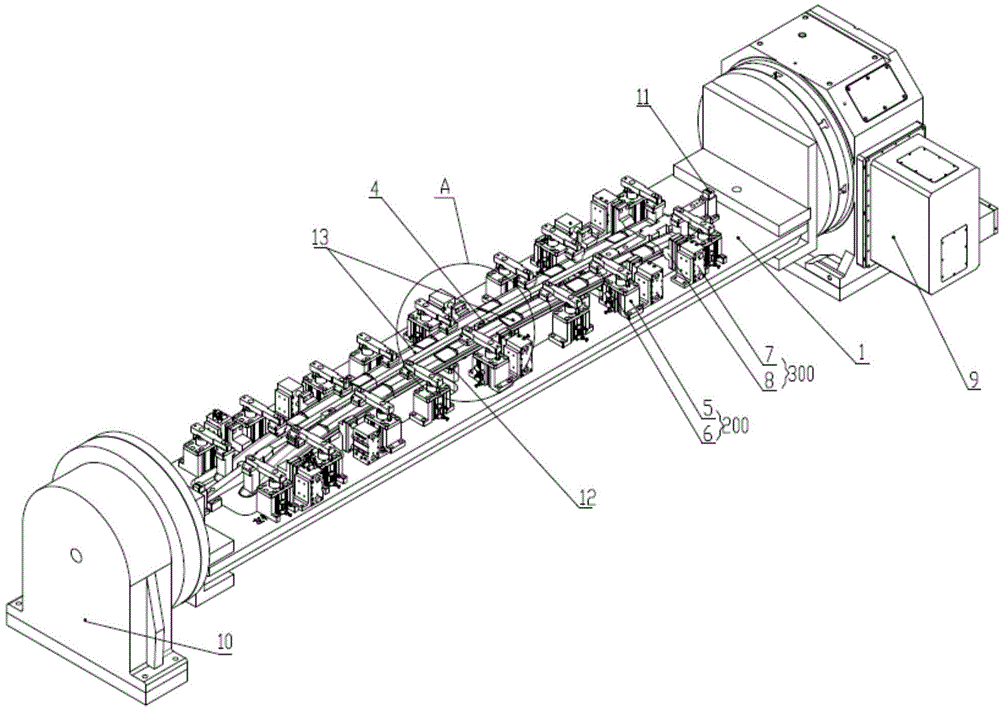

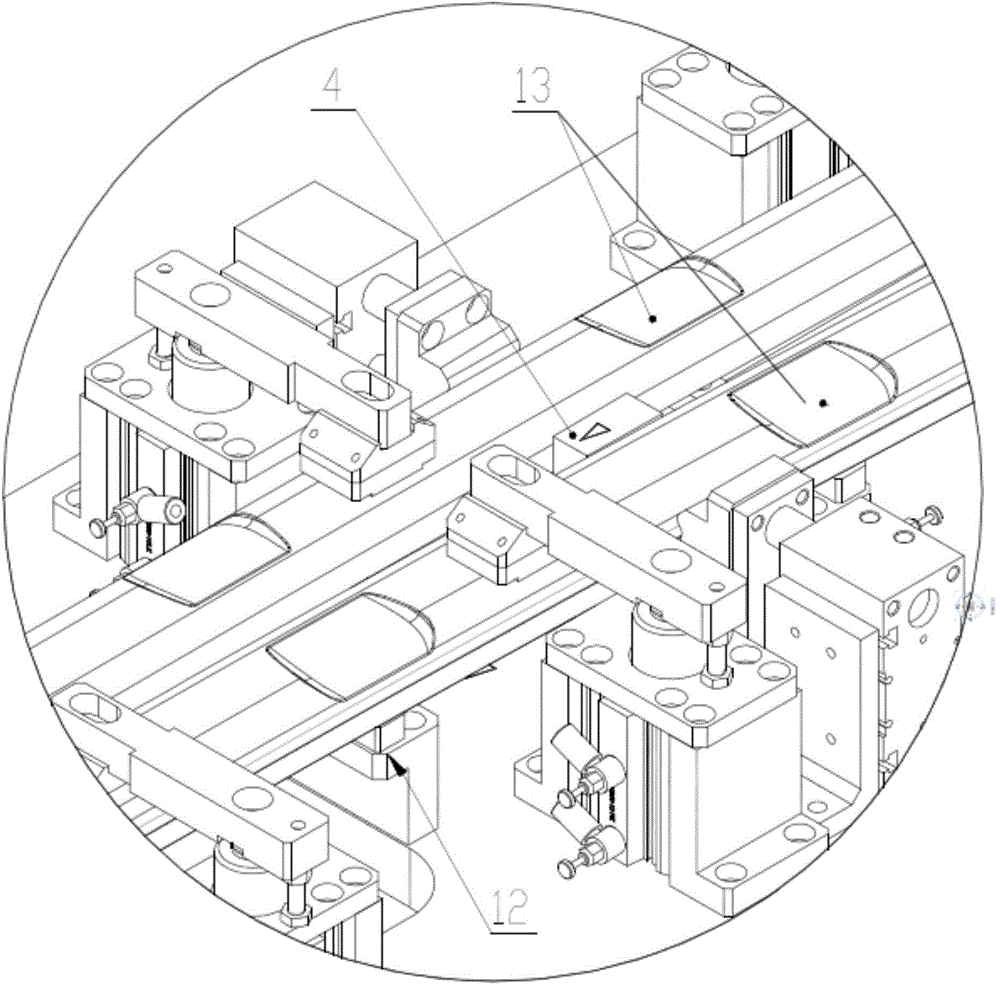

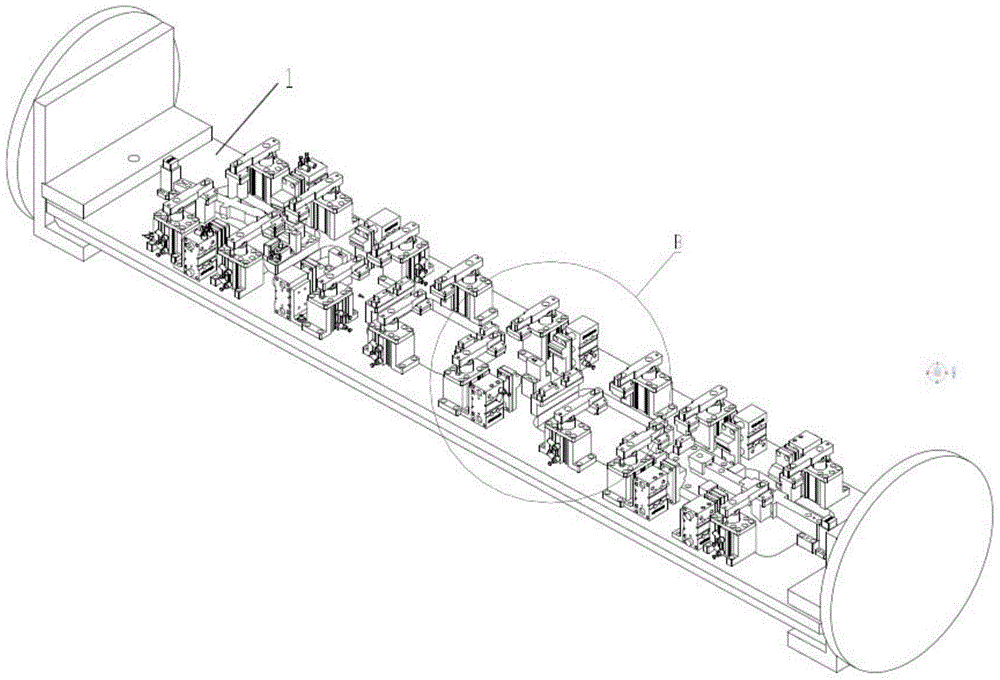

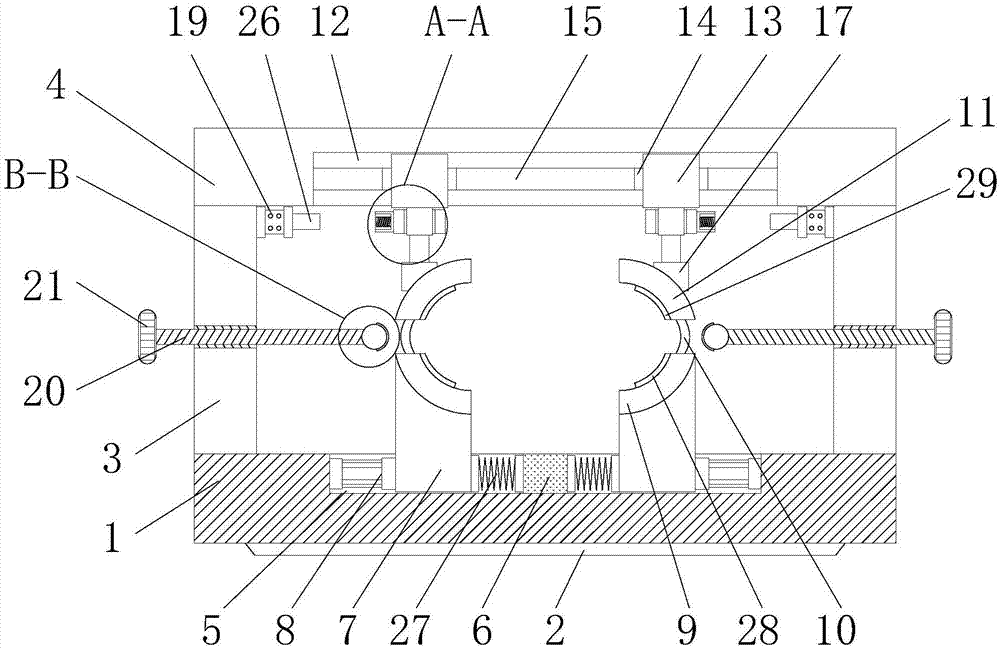

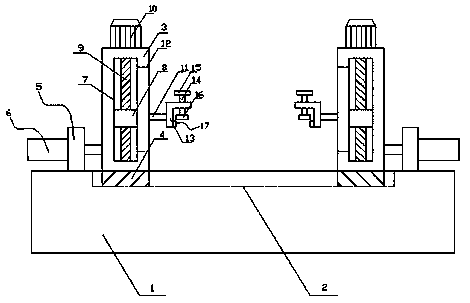

Automatic multihole processing machine for outer bearing rings

InactiveCN104275509AHigh degree of automationReduce labor intensityWork clamping meansBearing componentsMachining processPositioning system

The invention provides an automatic multihole processing machine for outer bearing rings. The processing machine comprises a frame, at least one drilling machine, a feeding device, a releasing device, a positioning and clamping device and a discharging device, a fixing mounting plate is arranged on the frame vertically, the drilling machines are mounted on the fixing mounting plate, and a positioning seat is arranged at the bottom of the fixing mounting plate. The feeding device is arranged on the frame, the releasing device is arranged at the discharge end of the feeding device and provided with a swingable stop block, and the outer bearing rings are controlled by the stop block to be released one by one and roll into the positioning and clamping device; the positioning and clamping device which is horizontally coaxial with the positioning seat is provided projections capable of receiving the outer bearing rings, and the discharging device is arranged below the positioning seat. The automatic multihole processing machine is high in automation degree, the processing process is unaffected by operation level of workers, processing efficiency is improved effectively, drilling processing quality is guaranteed, labor intensity of workers can be lowered effectively, and personal safety of workers is guaranteed.

Owner:FK BEARING GRP

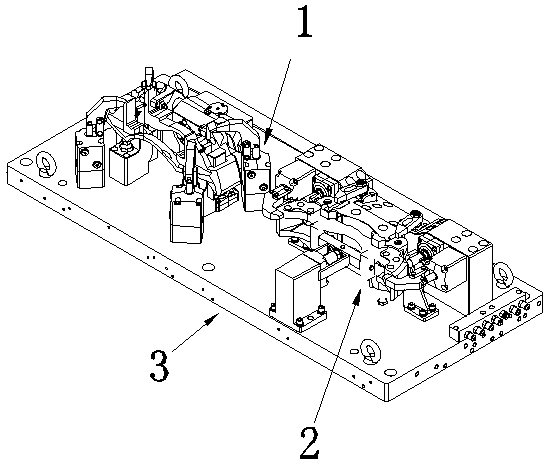

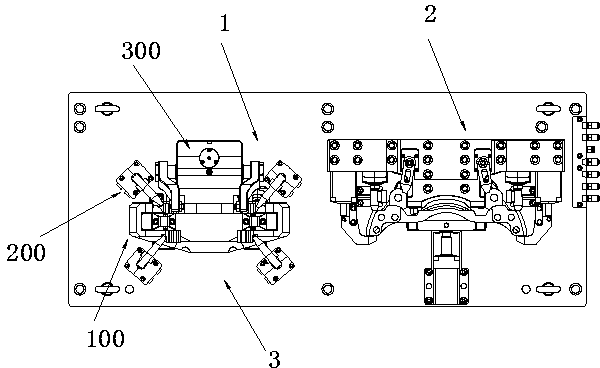

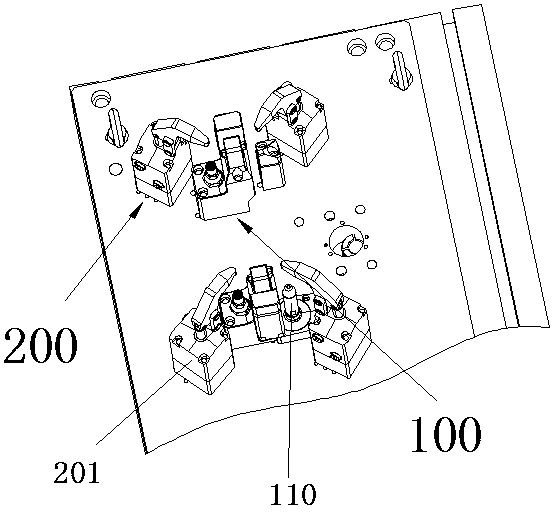

Fixture used for milling and boring support

ActiveCN103862309AHigh precisionUniform force distributionWork clamping meansPositioning apparatusWork supportDouble row

The invention discloses a fixture used for milling and boring a support. The fixture comprises a station I fixture body, a station II fixture body and a bottom plate, wherein the station I fixture body comprises a first positioning mechanism, a first clamping mechanism and a center positioning mechanism for strutting a workpiece outwards; the center positioning mechanism comprises a supporting seat, two pressing plates I, an angle pole, a guide screw and a driving device, wherein the two pressing plates I are symmetrically arranged at both ends of the supporting seat; the driving device comprises a gear mechanism and a driving oil cylinder; the gear mechanism comprises a double-row rack, gears II and a single-row rack, wherein the gears II are respectively meshed with the double-row rack, and the single-row rack is meshed with the gear II; one end of the angle pole is connected with the pressing plates I; the other end of the angle pole is connected with the single-row rack. According to the fixture disclosed by the invention, clamping can be performed rapidly, and is steady; the work support is not easy to deform, and therefore, the machining precision is improved; moreover, when the support of a symmetrical structure is milled, the center of the support can be rapidly and accurately positioned; moreover, the fixture can be suitable for volume production.

Owner:杭州钰友精密机械有限公司

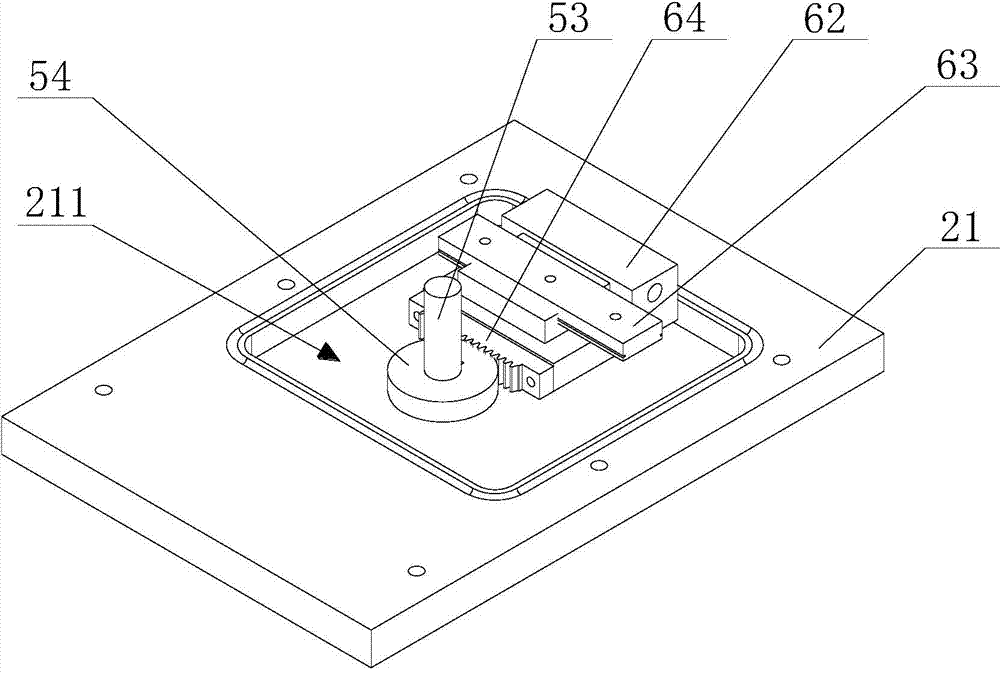

Precise clamp used for micro-miniature complex thin-walled part machining and control method of precise clamp

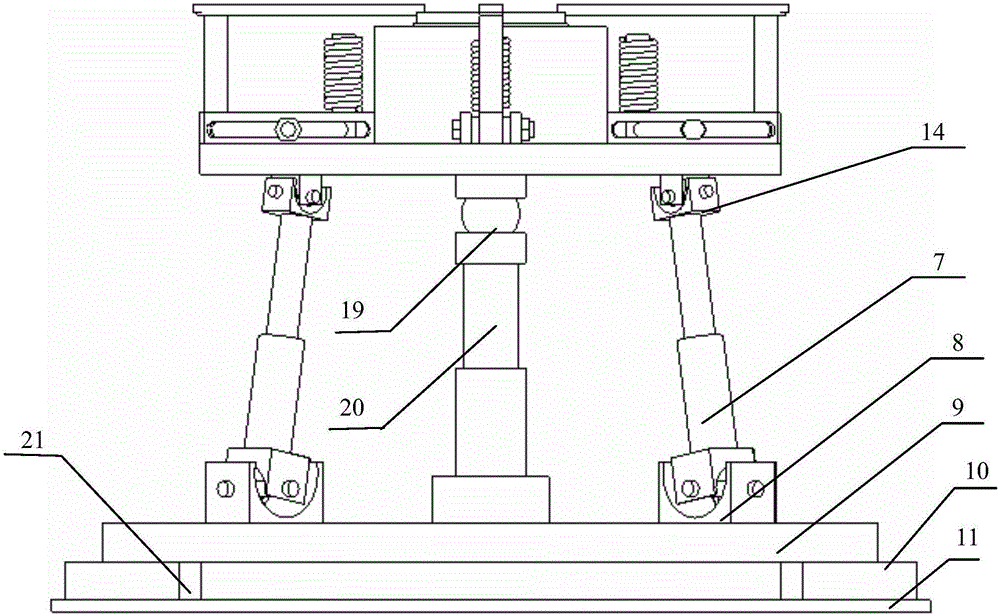

ActiveCN105127807ASimple structureCompact layoutWork clamping meansMeasurement/indication equipmentsFree formUniversal joint

The invention discloses a precise clamp used for micro-miniature complex thin-walled part machining and a control method of the precise clamp. According to the core part of the mechanical structure of the precise clamp, five gas-liquid damping cylinders connected through universal joints are adopted for the upper end and five gas-liquid damping cylinders connected through universal joints are adopted for the lower end, and therefore a platform which can rise, fall and deflect can rise and fall by 0-80 mm and deflect by 0-270 degrees according to the machining and processing requirements of thin-walled parts and can be suspended in any space and keep the required posture according to requirements, and a whole workpiece can be machined on a composite machine tool through one-time clamping; in addition, by arranging a visual system, visual and accurate machining information is provided when the micro-miniature complex thin-walled parts are machined by operators; industrial personal computer centralized control is adopted for the control method of the precise clamp, the control scheme is simple and reasonable, and the precise clamp and the control method have the advantages that the automation degree is high, control is convenient and efficient under the man-machine synergistic effect, and the precise clamp and the control method are suitable for machining micro-miniature thin-walled structural pieces with various three-dimensional complex morphologies or free-form surfaces.

Owner:SHANDONG UNIV OF SCI & TECH

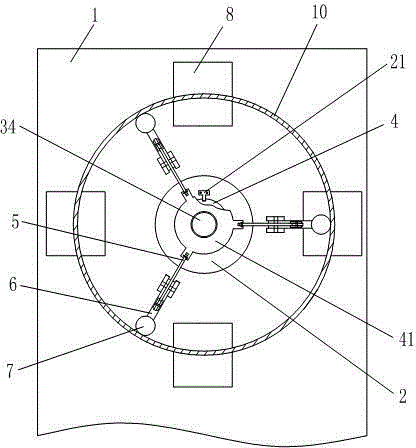

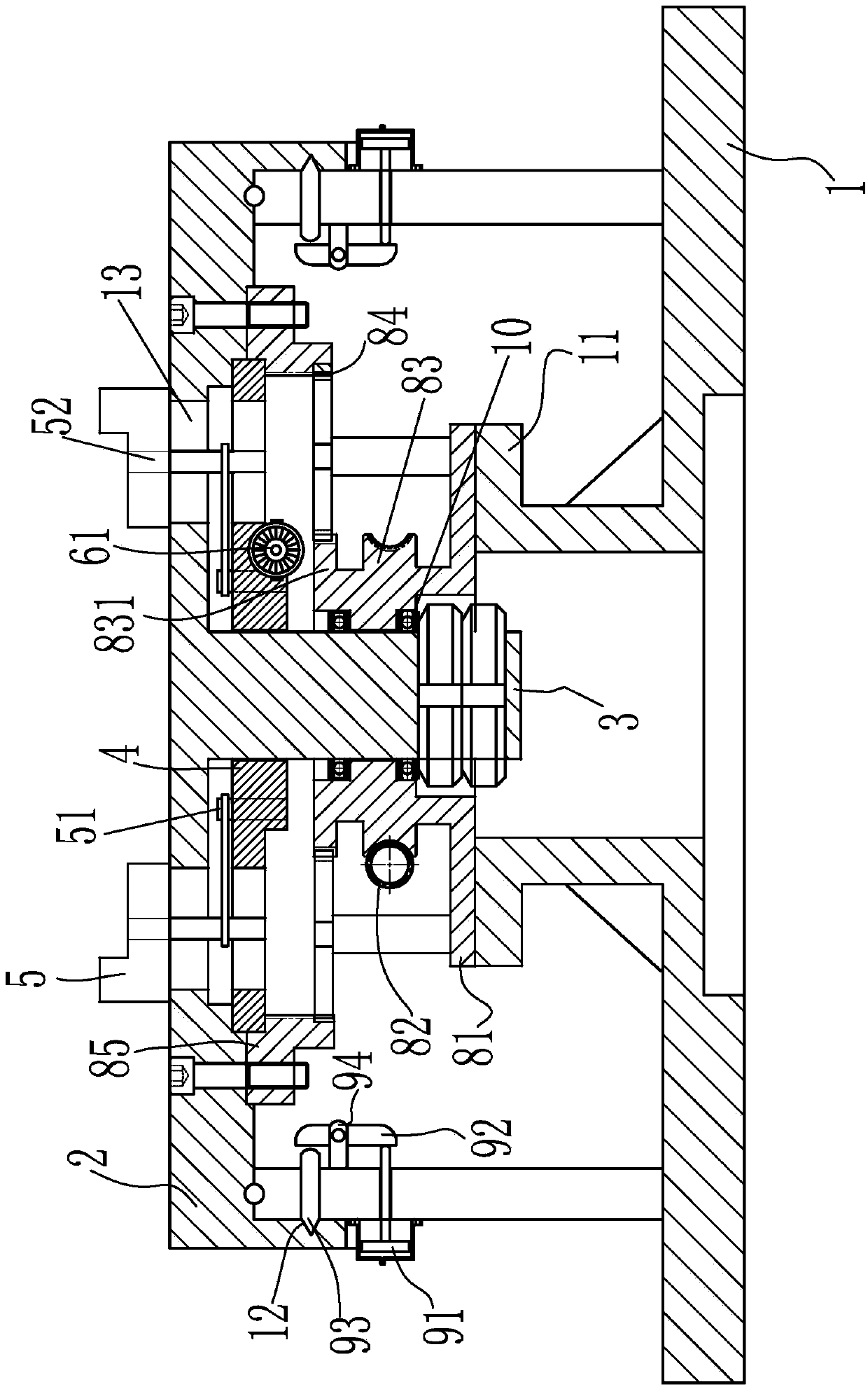

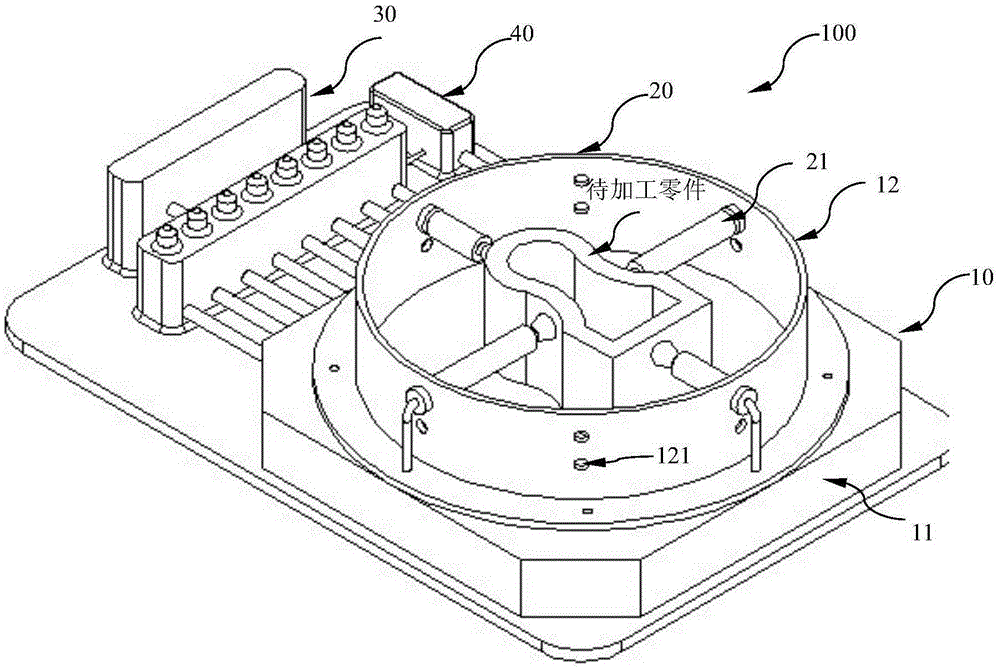

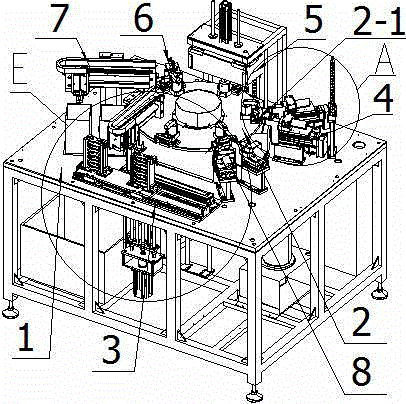

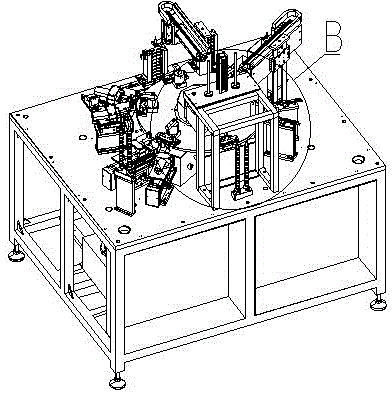

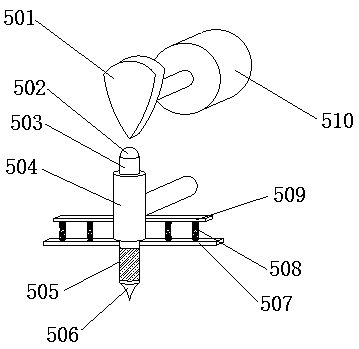

Automatic drilling machine

ActiveCN105081390AImprove efficiencyImprove yield rateWork clamping meansMeasurement/indication equipmentsManipulatorDrilling machines

The invention discloses an automatic drilling machine. The automatic drilling machine comprises a workbench, a rotary disc, a feeding system, a supply system, a chip removal system, a detection system and a discharging system, wherein the feeding system, the supply system, the chip removal system, the detection system and the discharging system are installed on the portion, around the rotary disc, of the workbench in sequence; the rotary disc is provided with at least one tool correspondingly; the supply system is provided with at least one drilling power head, the positions of the drilling power heads correspond to the drilling positions of workpieces on the supply station, and the drilling power heads are installed on a supply mechanism; the detection system is provided with drilling quality detectors, and the positions of the drilling quality detectors correspond to the drilling positions of workpieces on the detection station; and the discharging system comprises a discharging mechanical arm and at least two recycling boxes. The automatic drilling machine can feed, drill, detect, select and discharge workpieces automatically, thereby improving production efficiency, yield and productivity greatly.

Owner:烟台弘海自动化科技有限公司

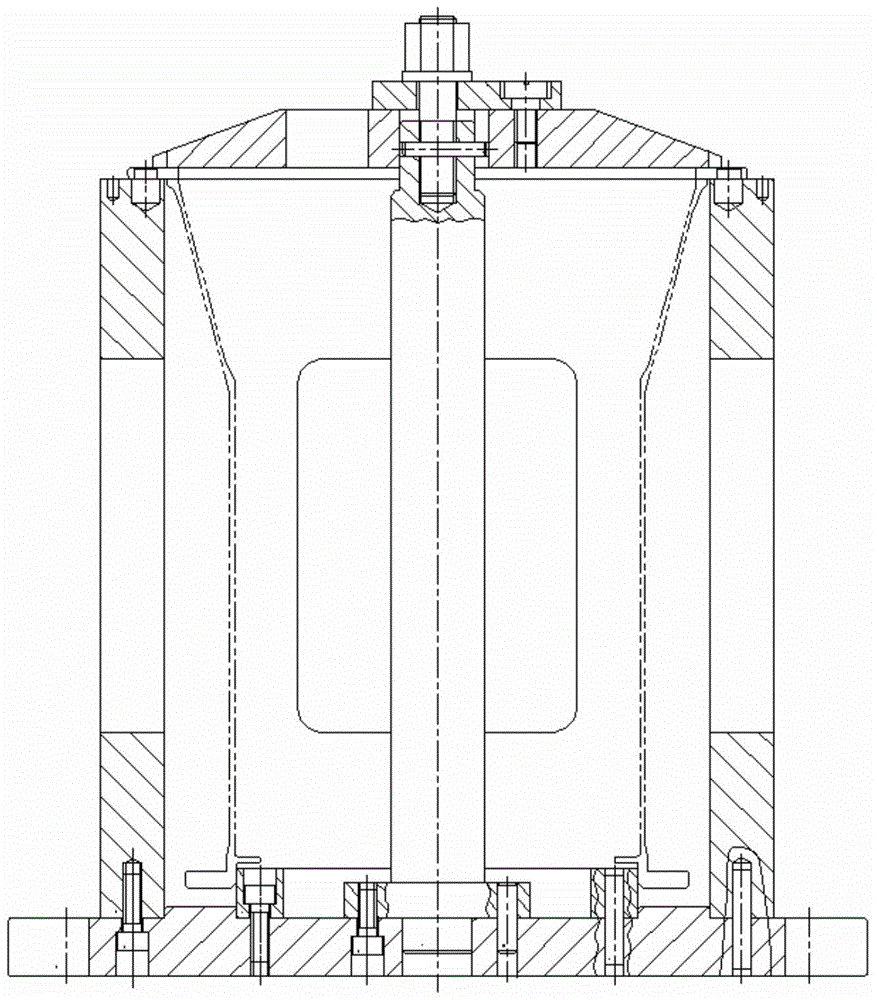

Machining method for deformation control of high-precision thin-wall cylinder shaft

InactiveCN106425286AHigh precision requirementsHigh hardnessWork clamping meansPositioning apparatusDeformation controlSuperalloy

The invention discloses a machining method for deformation control of a high-precision thin-wall cylinder shaft. A process scheme is determined: because a workpiece belongs to a thin-wall piece, the deformation control needs to be considered at the beginning of formulating a process route, the influence on deformation of the workpiece by machining stress in finish turning is controlled; an anti-deformation fixture structure is determined: a workpiece clamping mode is researched; a fixture clamping scheme is improved; a special anti-deformation fixture is used for finely turning inner and outer molded surfaces and machining a large end surface hole groove and a small end surface hole groove to solve the deformation problem caused in workpiece machining; the large end surface is axial reference of the whole workpiece to reach high precision requirement; and the small end surface is higher in technical condition requirement on the large end surface. The machining method has the following advantages: the technical difficulty of deformation of a high-temperature alloy thin-wall cylinder shaft is solved, a qualified workpiece is finally machined, the technical bottleneck of deformation of the high-temperature alloy thin-wall cylinder shaft is broken through, the workpiece design requirements are guaranteed, and the machining method can be popularized and applied in the same kind of workpieces to provide precious experiences for similar workpiece machining.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

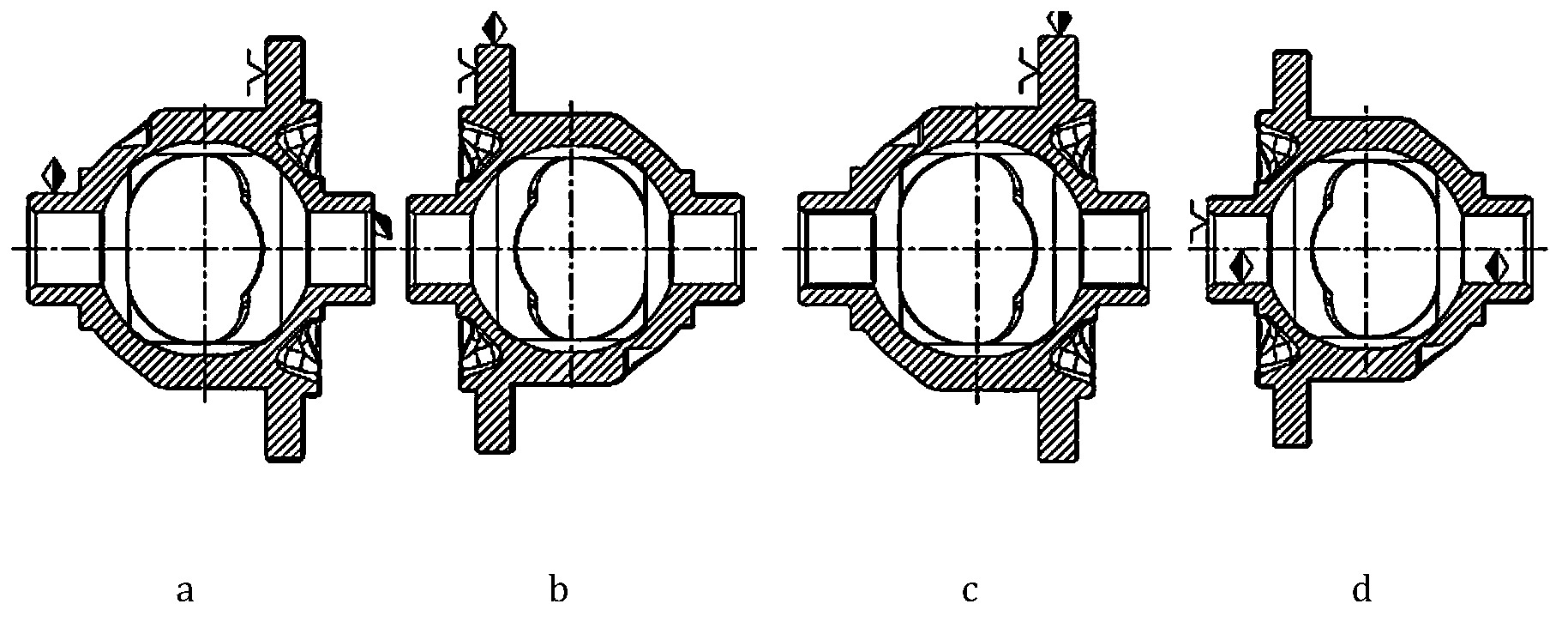

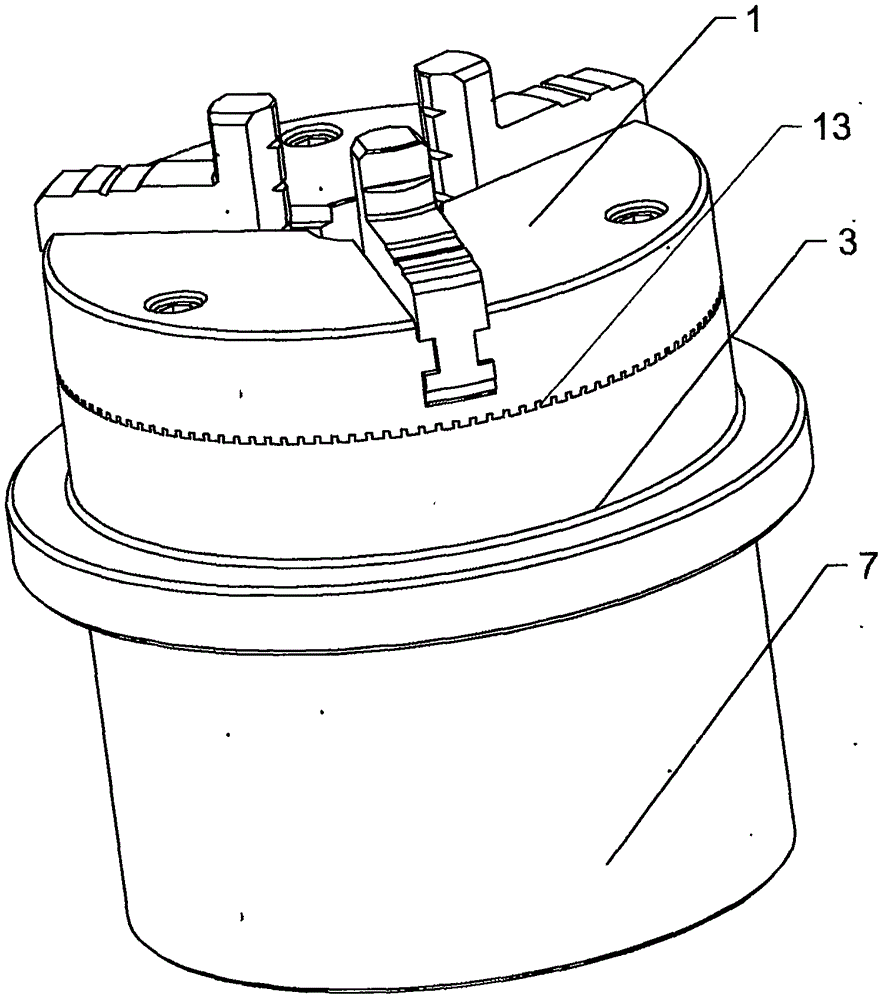

Self-centering clamp

The invention provides a self-centering clamp. The self-centering clamp is used for positioning and clamping workpieces to be machined and comprises a base, a main body, at least three executing components and a driving component, wherein the main body is arranged on the base; the executing components are horizontally arranged in the main body at equal angles and can move in a reciprocating manner in the direction of a connecting line between the center of the main body and the edge of the main body; the driving component is used for driving the executing components to move in a reciprocating manner; each executing component is provided with a clamping component; the clamping components can be used for clamping the workpieces when the executing components move towards the center of the main body; each executing component comprises at least three sliders; the driving component comprises a cam and a rotating shaft; the cam is provided with an outward pushing portion and an inward returning portion; the rotating shaft is connected with the cam; the cam can be driven to rotate by the rotating shaft; and the cam guides the sliders to move in a reciprocating manner, so that a workpiece clamping state and a workpiece unloading state of the clamping portions can be changed over. The existing complex working procedures of manually centering the workpieces and adjusting clamps during clamping are omitted.

Owner:深圳市速优精密机械有限公司

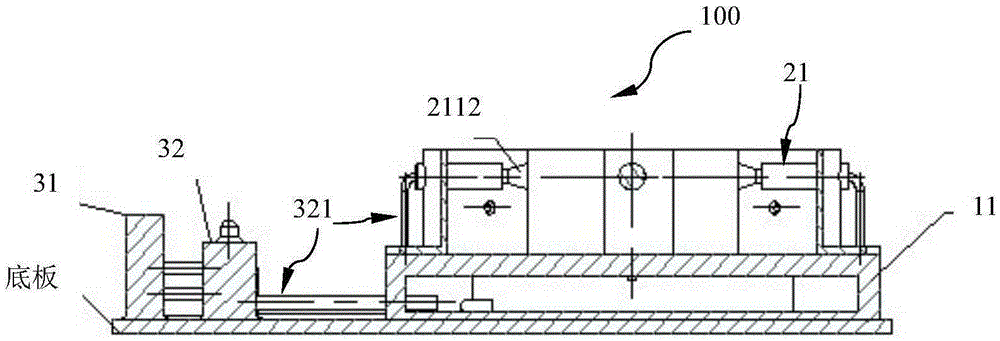

Machining tool for cylindrical workpieces

ActiveCN104985465AQuick clampingSmooth rotationWork clamping meansWelding/cutting auxillary devicesEngineeringMachine tool

The invention provides a machining tool for cylindrical workpieces. The machining tool comprises a bottom plate, a fixed support, a movable support, a first sliding groove, a fixed roller carrier, a sliding roller carrier, rollers, a first air cylinder, a second air cylinder and a locking bolt. By the adoption of the rollers, rapid workpiece clamping and accurate centering can be achieved, and workpieces can rotate conveniently in grinding or turning or welding or the like. By the adoption of the action of the air cylinders, automatic workpiece clamping can be achieved. By the arrangement of the first sliding groove and a second sliding groove, the distance between the fixed support and the movable support and the distance between the sliding roller carrier and the fixed roller carrier can be adjusted according to needs so that workpieces of different diameters can be clamped or different portions of workpieces can be clamped, and accordingly the universality and reliability of the tool are improved. The machining tool for the cylindrical workpieces is high in automation degree and clamping efficiency, greatly shortens the workpiece machining period, improves productivity and lowers the production cost.

Owner:ANHUI SCI & TECH UNIV

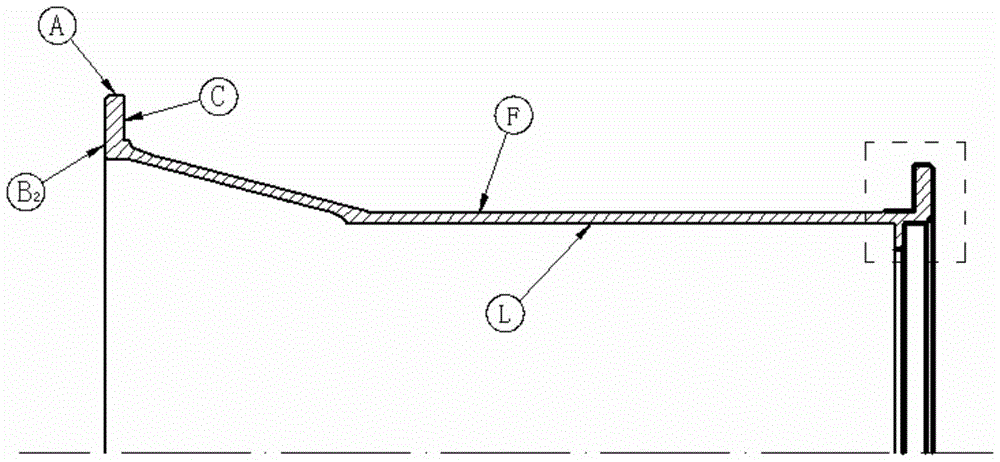

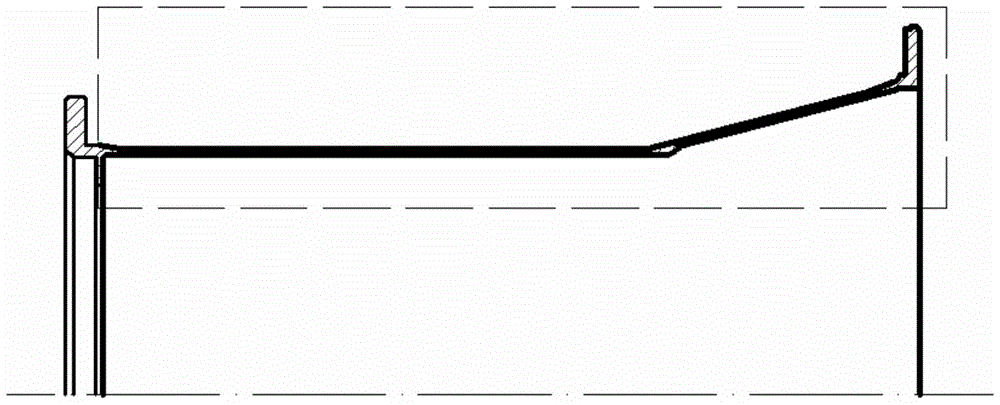

Sharing clamp for left and right workpieces of automobile luggage rack

InactiveCN104440193AReduce processing timeReduce labor intensityWork clamping meansPositioning apparatusGas cylinderSymmetric structure

The invention relates to a sharing clamp for left and right workpieces of an automobile luggage rack. The sharing clamp comprises a main bridge plate, a horizontal clamp and a vertical clamp, wherein a positioning block adopts a symmetrical structure, processing positions for supporting the left and right workpieces are respectively arranged on the left side and the right side of the positioning block; the horizontal clamp comprises a rotary gas cylinder as well as an upper pressing block and a lower pressing block, wherein the rotary output shaft of the rotary gas cylinder is vertically arranged; the upper and lower pressing blocks are arranged on the rotary output shaft. While the sharing clamp is not used for clamping, the upper and the lower pressing blocks are not positioned on the processing positions; when the common clamp is used for clamping, the rotary output shaft of the rotary gas cylinder drives the upper and lower pressing blocks to rotate to the processing positions for pressing the left and right workpieces in an up-and-down manner; the vertical clamp comprises a side pressing gas cylinder as well as a left pressing block and a right pressing block, wherein a side pressing output shaft of the side pressing gas cylinder is horizontally arranged, and the left and right pressing blocks are arranged on the side pressing output shaft; when the common clamp is used for clamping, the side pressing output shaft of the side pressing gas cylinder drives the left and right pressing blocks to clamp the left and right workpieces in a left-and-right manner, so that the processing efficiency is improved and the processing cost is lowered.

Owner:FOSHAN PRATIC CNC SCI & TECH

Pipe fitting clamping device for automatic machine

ActiveCN107971795ASolve the problem of poor clamping effectAccurately achieve the processing purposeWork clamping meansPositioning apparatusPipe fittingEngineering

The invention discloses a pipe fitting clamping device for an automatic machine. The pipe fitting clamping device comprises a bottom plate, a sliding rail is arranged at the bottom of the bottom plate, and supporting plates are fixedly connected to the two sides of the top of the bottom plate; and the tops of the two supporting plates are fixedly connected through a top plate, a first sliding groove is formed in the top of the bottom plate, and a fixing block is fixedly connected to the middle point of the bottom of the inner wall of the first sliding groove. According to the pipe fitting clamping device for the automatic machine, a second sliding groove, second sliding blocks, pneumatic telescopic rods, abutting blocks, annular sleeves and second air cylinders are arranged, and the problem that the clamping effect of a common pipe fitting clamping device is not good is solved, so that the stress at each part of the pipe fitting can be reasonably distributed; and when the pipe fittingis machined, shaking of the pipe fitting caused by unstable fixing due to the fact that the tensioning force in one part of the fitting is too large or too small does not occur, so that the expected machining purpose is achieved accurately, the clamping radius is conveniently adjusted according to the diameter of a pipe, and great convenience is brought to a user.

Owner:安徽新立滤清器有限公司

Tool clamp for machining prism and application method of tool clamp

ActiveCN104668988AImprove machining accuracyImprove work efficiencyOptical surface grinding machinesWork clamping meansPrismMechanical engineering

The invention discloses a tool clamp for machining a prism. The tool clamp comprises a support body I and a support body II which are fixed with the sucker of a milling and grinding machine in a suction manner. A first support face is disposed at the bottom of the support body I, a first plane and a second plane are disposed on two sides of the support body I, the upper portion of the support body I is provided with a plurality of ridge face V-shaped grooves, the first plane is parallel with one reflecting face of the to-be-machined prism adhered to the ridge face V-shaped grooves, and the second plane is parallel with another reflecting face. A second support face is disposed at the bottom of the support body II, a third plane, a fourth plane and a fifth plane are disposed on two sides of the support body II, a plurality of reflecting face V-shaped grooves are formed in the upper portion of the support body II, the fourth plane is parallel with one ridge face of the to-be-machined prism adhered to the reflecting face V-shaped grooves, and the fifthly plane is parallel with another ridge face. Compared with the prior art, the tool clamp has the advantages that the support bodies are provided with multiple turning planes, machining of the multiple planes of the prism is completed at one step by the benchmark after the prism is adhered to the support bodies, machining precision is increased, and machining efficiency is increased.

Owner:大宁洋名光电有限公司

Stainless steel pipe cutting machine

InactiveCN106424899ARealize feedingExtended service lifeWork clamping meansTube shearing machinesEngineeringMechanical engineering

The invention discloses a stainless steel pipe cutting machine which comprises a base and two racks. The racks are arranged at the upper end of the base front and back in parallel. Three sets of upper pipe rolls are arranged between the left ends of the racks at intervals, and the upper pipe rolls are connected with the racks through upper pipe rotary shafts. Belt wheels are arranged at the front ends of the upper pipe rotary shafts, the adjacent belt wheels are in transmission connection through belts, an upper pipe motor is arranged below the left ends of the racks, and the upper pipe motor is in transmission connection with the belt wheel of the upper pipe rotary shaft on the left side through the corresponding belt. The stainless steel pipe cutting machine is reasonable in structural design and convenient to use, and the pipe feeding, pressing, cutting and pipe discharging procedures of stainless steel pipes can be achieved. During cutting, effective cooling can be carried out, heating can be reduced, and the service life of a cutting tool can be prolonged. Sprayed cooling liquid can be recycled and filtered, circulating use is achieved, and cost is reduced.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Flexible supporting device

ActiveCN104625822AChange the curing strengthStable processingWork clamping meansPositioning apparatusThin walledMagnet

The invention discloses a flexible supporting device which is used for solving the technical problem that as an existing supporting device is low in positioning accuracy, the part machining accuracy is low. According to the technical scheme, the flexible supporting device comprises a left iron core, a left magnet exciting coil, a left wedge-shaped guide container wall, a left supporting plate, a left wedge-shaped block, a right supporting plate, a right wedge-shaped block, a right wedge-shaped guide container wall, a right magnet exciting coil, a right iron core and magnetorheological fluid, and further comprises a machine frame, a left primary positioning device, a right primary positioning device, a displacement sensor, a supporting rod and a direct current voltage stabilizing power source; blades are fixed to the left primary positioning device and the right primary positioning device through a bolt, and the left primary positioning device and the right primary positioning device are fixed to the container walls parallel to the direction of a magnetic field through bolts. The blades are immersed in the magnetorheological fluid, receding deformation, caused by insufficient rigidity of the blades, of the blades in the cutting process is avoided, the positioning accuracy of a complex thin wall part is improved, the rigidity of the complex thin wall part is accordingly improved, and the high-speed and efficient machining accuracy and the machining quality of the complex thin wall part are guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Puncher for steel plate

InactiveCN107838728AReduce wasteReduce mistakesWork clamping meansPositioning apparatusSheet steelFuel tank

The invention relates to a puncher for a steel plate. The puncher comprises cylinders, locating plates, a workbench, a cam, a connecting ball, a connecting rod, a telescopic pipe, a drill, a driving motor, an oil tank, an oil pump, an oil supply pipe, an oil return pipe, an oil collecting tank, a filter screen and an oil nozzle, wherein output shafts of the cylinders are fixedly connected with thelocating plates; the workbench is arranged in the middle position of the upper end face of a base; the cam is fixedly connected with the output end of the driving motor; the connecting ball is fixedly arranged on the upper end face of the connecting rod; and the lower end of the connecting rod is connected with the drill through the telescopic pipe. According to the puncher, the steel plate is punched through electric energy, the position of the drill does not need to adjusted, errors are decreased, cost is reduced, efficiency is improved, the oil nozzle is connected with the oil tank throughthe oil supply pipe, the filter screen is arranged on the upper side in the oil collecting tank, the oil pump is connected with the bottom end in the oil collecting tank through the oil return pipe,lubricating oil can be automatically sprayed onto the drill, labor force is reduced, redundant lubricating oil can be recycled, and waste of lubricating oil is reduced.

Owner:胡振锋

Clamping tooling with high stability

The invention discloses a clamping tooling with the high stability. Slide grooves are formed in the inner and outer sides of the upper end surface of a base correspondingly. Mounting bases are arranged on the left and right sides of the upper end surface of the base in a sliding mode correspondingly. Piston rods of air cylinders penetrate through fixing blocks and are fixedly connected with the mounting bases on the same sides correspondingly. Longitudinal rectangular grooves are formed in the mounting bases correspondingly. Lead screws are rotationally mounted in the rectangular grooves correspondingly through bearings, penetrate through slide blocks and are in threaded connection with threaded holes of the slide blocks correspondingly. Output shafts of motors are fixedly connected with the upper ends of the lead screws correspondingly. The end surfaces, facing the center side of the base, of the slide blocks are horizontally and fixedly connected with connecting rods correspondingly.Strip-shaped holes allowing the connecting rods to penetrate through are formed in the end surfaces, facing the center side of the base, of the mounting bases correspondingly. The other ends of the connecting rods are fixedly connected with L-shaped plates correspondingly. The upper portion of a horizontal portion of each L-shaped plate is in threaded connection with a screw vertically. The upperend of each screw is fixedly connected with a handle. The lower end of each screw is fixedly connected with a pressing block. A clamping plate is fixedly connected to the end surface, facing the center side of the base, of a vertical portion of each L-shaped plate. The clamping tooling has the advantages of being novel in structure and stable in clamping.

Owner:安徽龙锐模塑有限公司

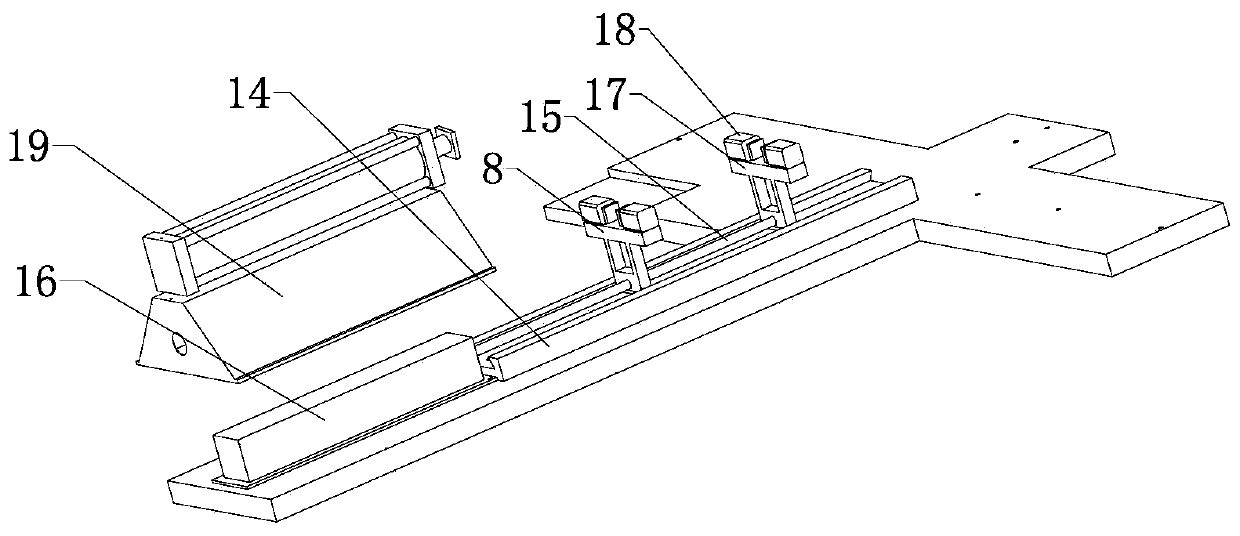

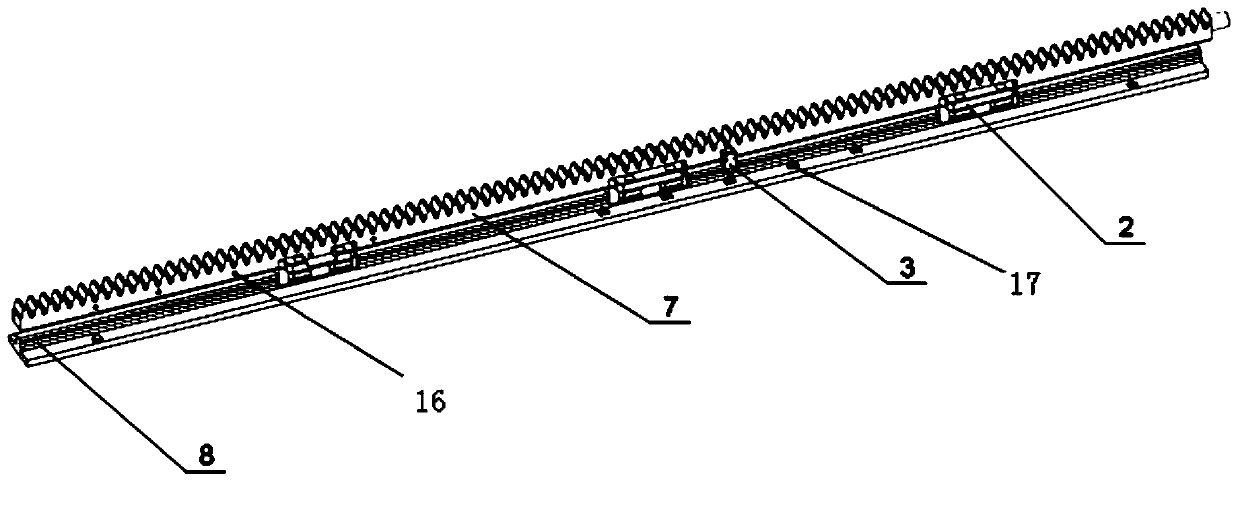

Tube batch feeding device

InactiveCN107717573AEasy feedingConsistent feed lengthWork clamping meansPositioning apparatusArchitectural engineeringSteel tube

The invention discloses a batch feeding device for pipe fittings, which relates to the technical field of steel pipe processing equipment, and comprises a workbench and two slide rails arranged along the length direction of the workbench; the two slide rails are provided with sliding sliders, And the first telescopic cylinder that drives the slide block to slide is hingedly arranged on the workbench; vertical screw rods are installed on the two slide blocks, and a lower fixing block is fixedly connected between the two screw rods, and a lower fixing block is set on the lower fixing block. There are a plurality of lower compression grooves; the upper ends of the two screws are provided with movable sleeves, and an upper fixed block is connected between the two movable sleeves, and the lower surface of the upper fixed block is provided with a plurality of lower compression grooves Corresponding multiple upper pressing grooves; the two screw rods are respectively sleeved with compression springs, the upper ends of the compression springs are pressed against the movable sleeve, and the lower ends of the telescopic springs are pressed against the sliding block. The invention not only facilitates the feeding of multiple steel pipes, but also makes the feeding lengths of the multiple steel pipes consistent, so that the cutting lengths of the multiple steel pipes are consistent during cutting.

Owner:四川精通机械科技有限公司

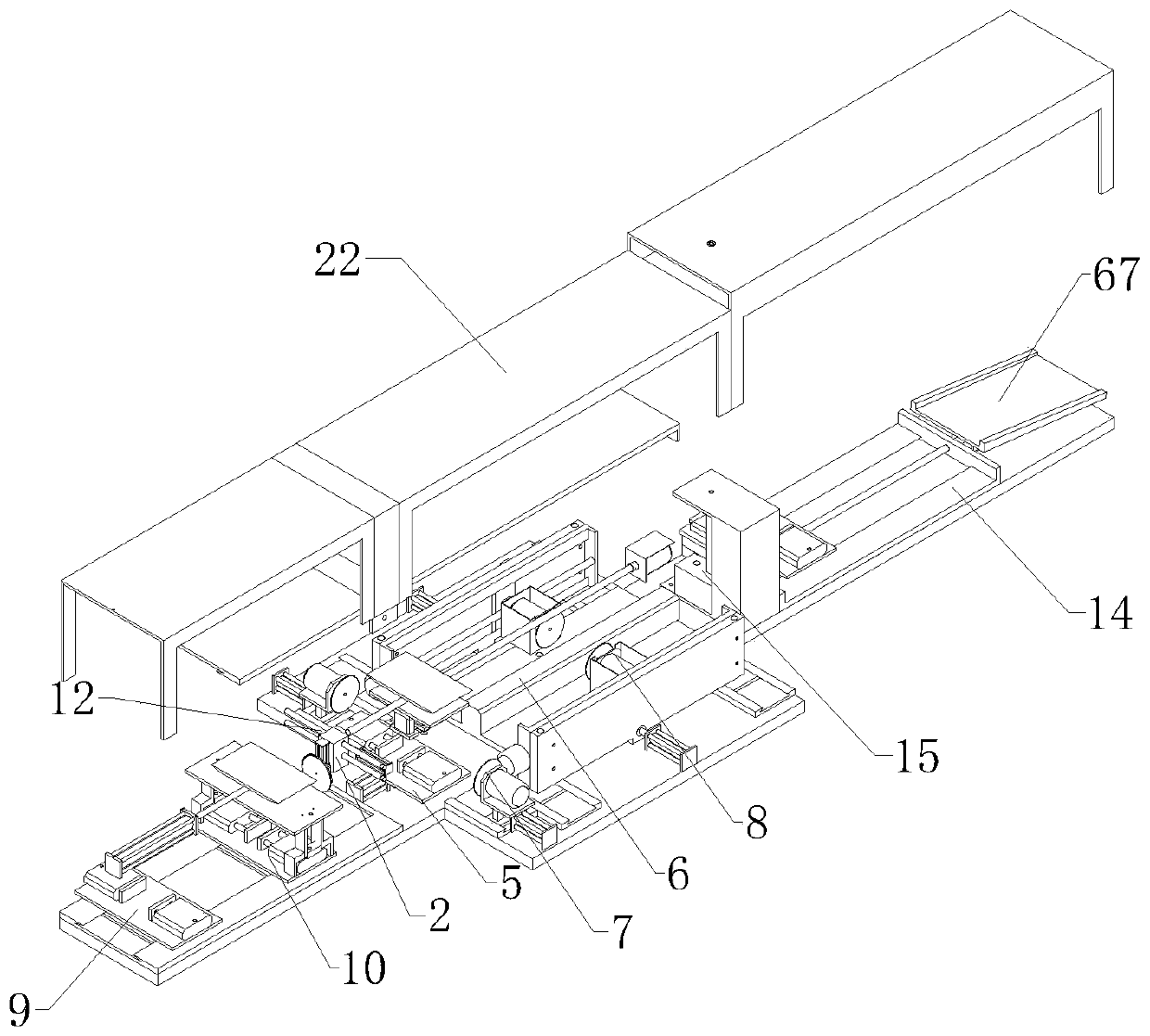

Integrated equipment for cutting, drilling and polishing aluminum substrate

ActiveCN110640477ASolve cutting and grindingSolve the problem that drilling cannot be completed at one timeWork clamping meansOther manufacturing equipments/toolsCircular discPolishing

The invention relates to the technical field of aluminum substrate production and machining, in particular to integrated equipment for cutting, drilling and polishing an aluminum substrate. The integrated equipment comprises a feeding assembly, a cutting assembly, a polishing assembly and a drilling assembly, wherein the polishing assembly comprises a turntable, a rectangular table, two end polishing mechanisms and two edge polishing mechanisms; the feeding assembly comprises a first fixed clamp and a first movable clamp; the arrangement directions among the turntable and the two end polishingmechanisms and among the rectangular table and the two edge polishing mechanisms are perpendicular to the arrangement direction among the first fixed clamp and the first movable clamp; the cutting assembly comprises a circular saw blade and a moving mechanism; the circular saw blade is fixedly connected with the moving mechanism through a telescopic cylinder; the drilling assembly comprises a discharging mechanism and a drilling mechanism; and the first fixed clamp, the first movable clamp, the turntable and the rectangular table are sequentially arranged in a straight line. According to theintegrated equipment, the problem that cutting, grinding and drilling cannot be completed at a time when the aluminum substrate is machined, the time is saved, and the manpower and the cost are reduced.

Owner:赣州逸豪新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com