Self-centering clamp

A self-centering fixture and self-centering technology, used in clamping, manufacturing tools, positioning devices, etc., can solve the problem of time-consuming, cumbersome operation, and reduce the speed of workpiece clamping and unloading, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

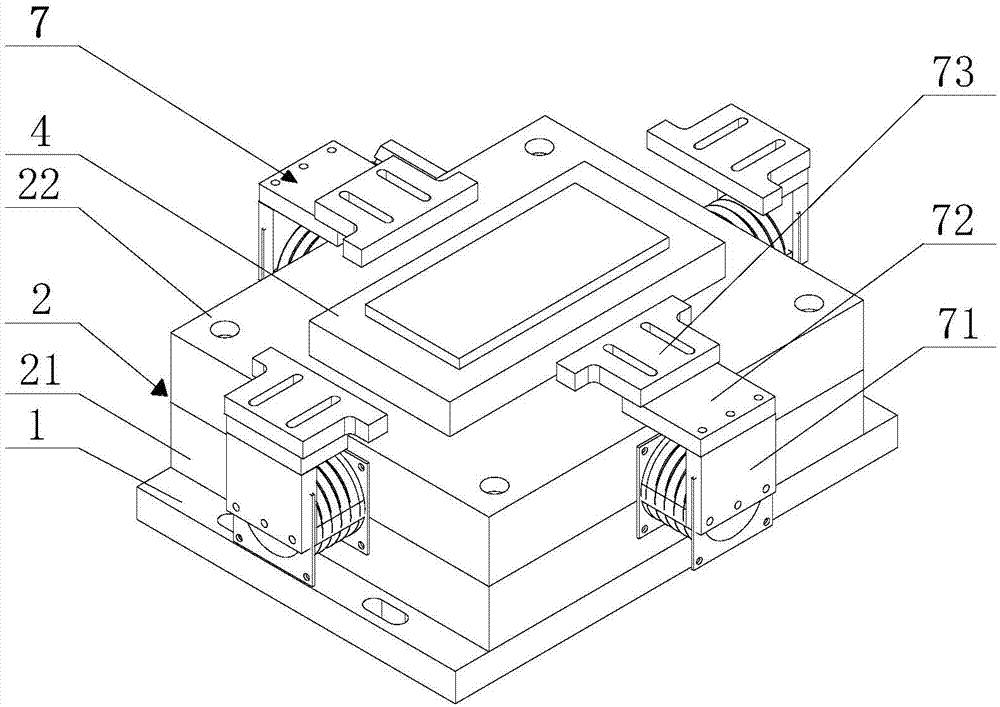

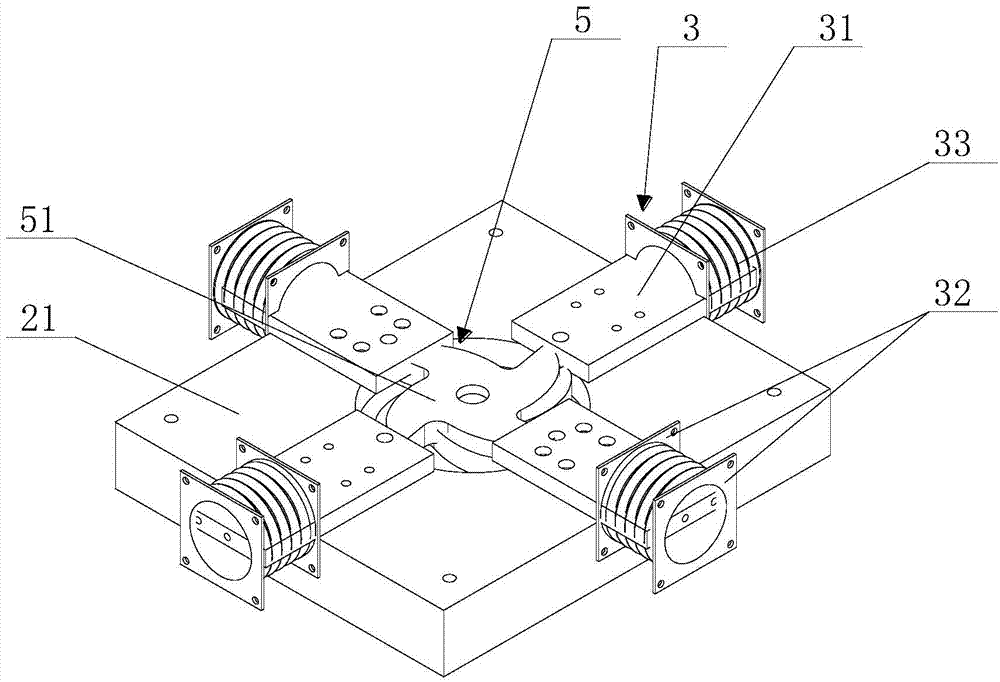

[0040] A self-centering fixture provided by the present invention such as figure 1 ,Please refer to Figure 1 to Figure 5 , Figure 7 , Figure 8 , as shown in the figure, includes a base 1 , a main body 2 , at least three actuator components 3 , a driving component 5 , and a clamping component 7 . The base 1 is fixed on the processing table of the machine tool through a fixed structure, the main body 2 is arranged on the base 1, and a storage cavity is formed inside it, and a plurality of execution components 3 and driving components 5 are arranged in the storage cavity, clamping The component 7 is connected to the execution component 3 . Driven by the execution part 5, a plurality of execution parts 3 uniformly distributed in the main body 2 at equal angles can reciprocate synchronously along the direction connecting the center and the edge of the main body 2. Through the reciprocating motion of the execution part 3, the The clamping part 7 automatically centers and clam...

Embodiment 2

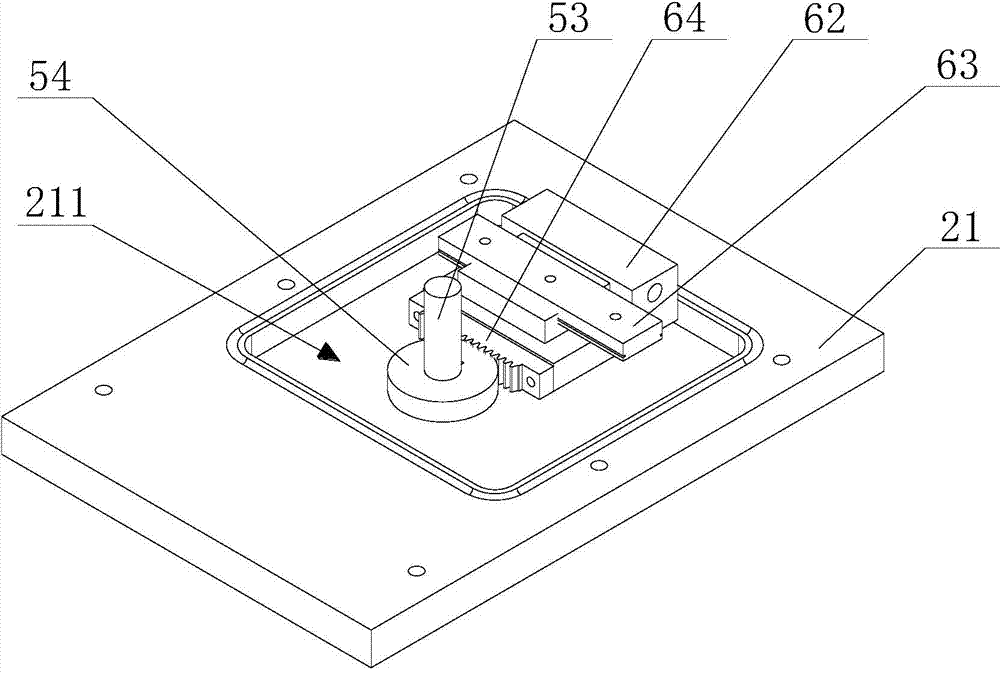

[0054] Another self-centering fixture provided by Embodiment 2 of the present invention is as Image 6 , Figure 9 , Figure 10 As shown, its overall structure is the same as that of the first embodiment, except that the cam in the second embodiment uses a guide groove cam 52 .

[0055] Please refer to Figure 9 , Figure 10 , the main body of the guide groove cam 52 is a circular structure, on the main body of the guide groove cam 52 corresponding to each slide block 31 is provided with a guide groove 52c, the guide groove 52c is spirally arranged along the center of the guide groove cam 52 and the direction connecting the edges, One end of the guide groove 52c close to the edge of the guide groove cam 52 forms an outer pushing portion 52a, and the other end thereof forms an inner return portion 52b. The center of the guide cam 52 is also provided with a connecting hole 52d connected with the rotating shaft 53 , and the rotating shaft 53 drives the guide cam 52 to rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com