Air pressure flexible clamping device of frame-shaped parts with thin walls, and clamping method of air pressure flexible clamping device

A technology of clamping device and air pressure, which is applied in the direction of workpiece clamping device, clamping device, positioning device, etc., can solve the problems of deformation, high cost and machining accuracy error of thin-walled frame parts, and achieve high flexibility, Strong dimensional applicability and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

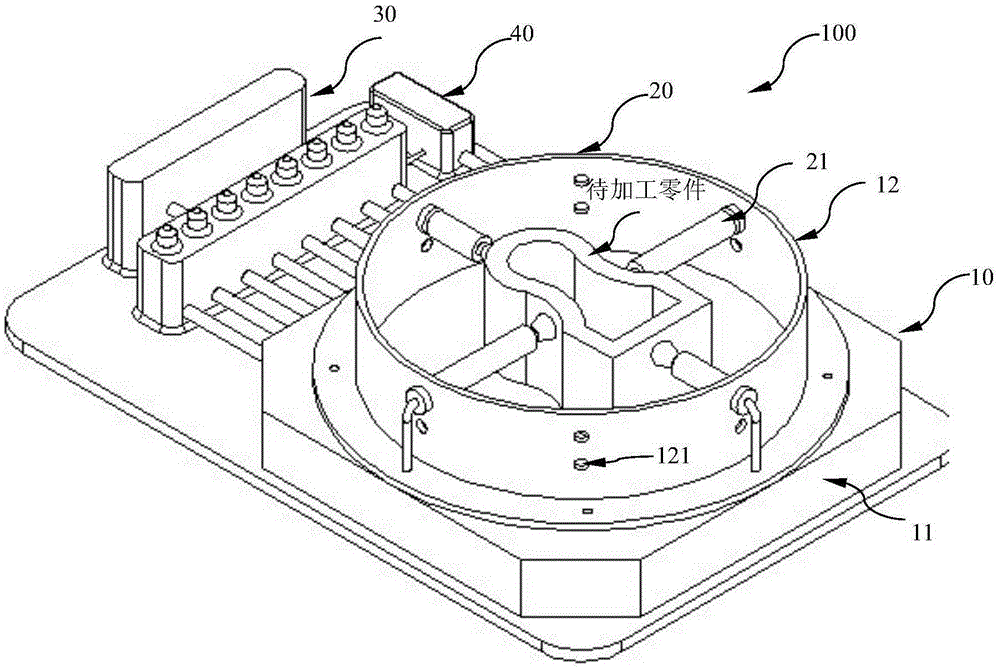

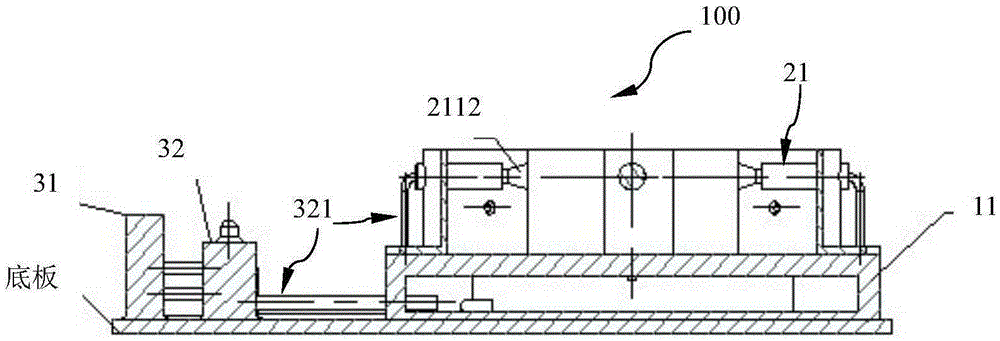

[0036] figure 1 It is a three-dimensional schematic diagram of the structure of the air pressure flexible clamping device for thin-walled frame parts in this embodiment

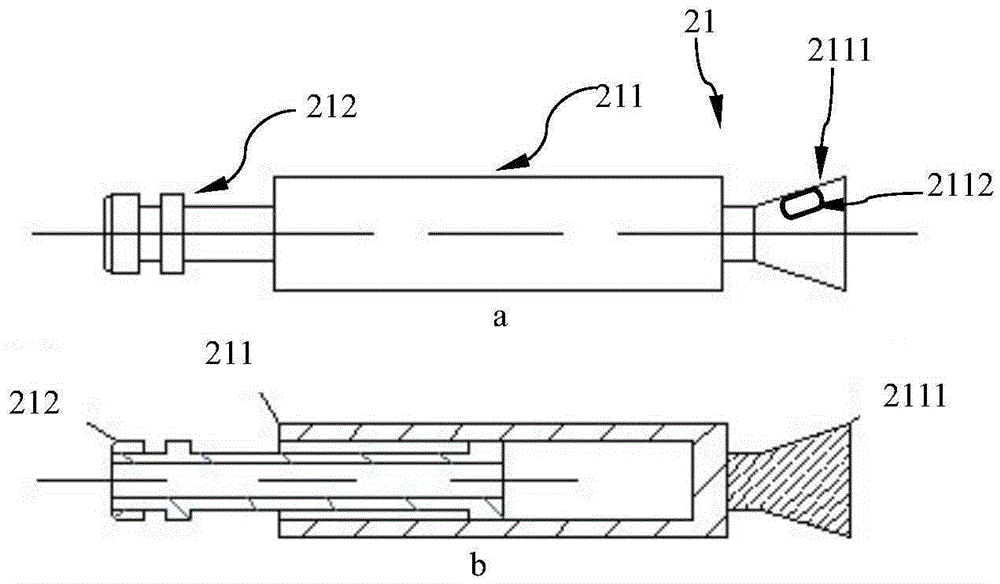

[0037] figure 2 It is a structural schematic diagram of the air pressure clamping part of the air pressure flexible clamping device for thin-walled frame parts in this embodiment

[0038] Such as figure 1 , shown in 2, the air pressure flexible clamping device 100 of thin-walled frame parts includes: a support unit 10, a clamping unit 20 arranged on the support unit 10, a pneumatic unit 30 communicated with the clamping unit 20 (including the same clamp The connecting pipeline 31 communicating with the holding unit 20) and the control unit 40 controlling the pneumatic unit 30. in,

[0039] The support unit 10 includes a base 11 and a closed-loop support 12 for enclosing the part to be processed,

[0040] The closed-loop bracket 12 is a rigid ring, which is fixed on the base 11 by welding, etc., and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com