Patents

Literature

385results about How to "High degree of flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

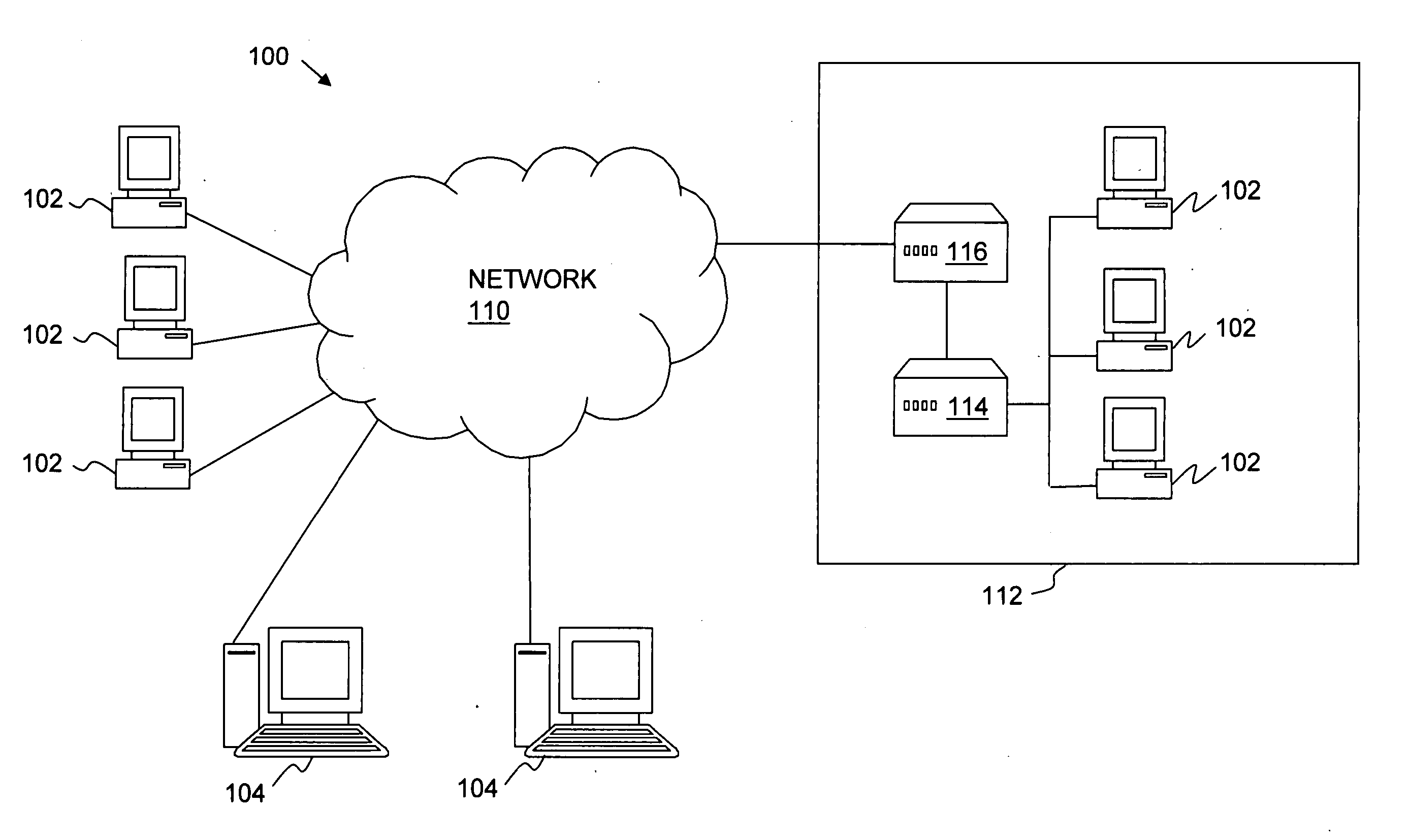

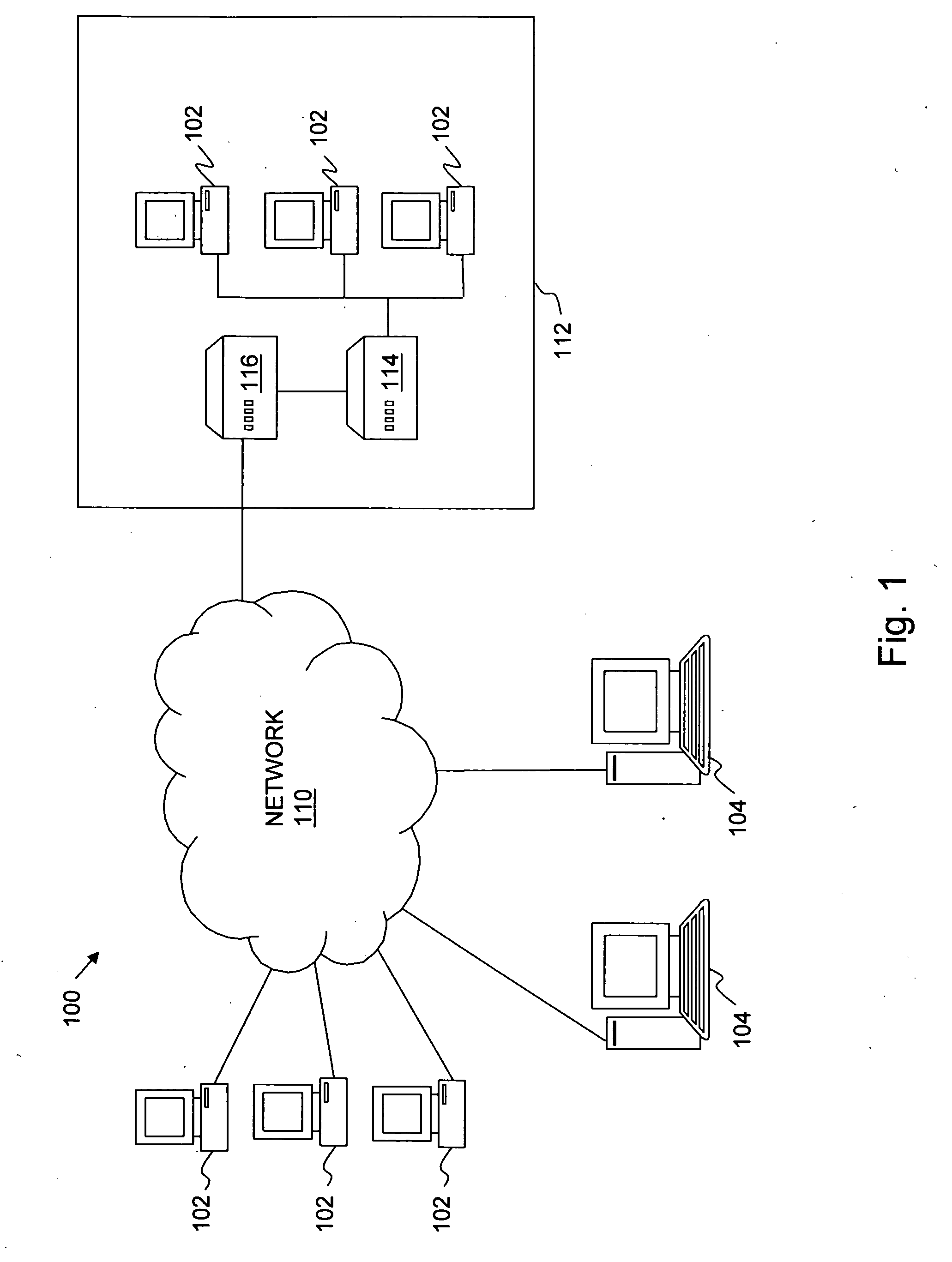

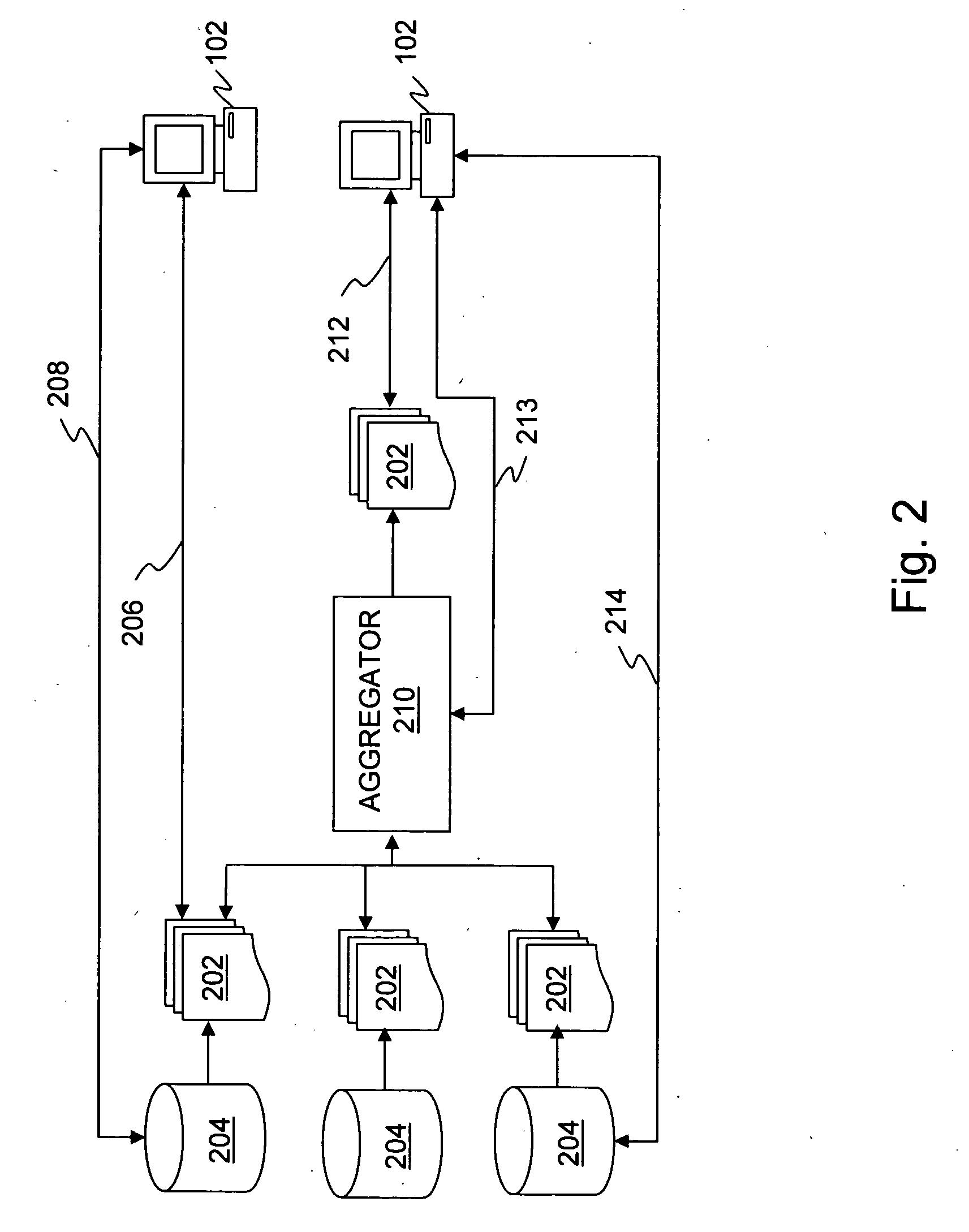

Security systems and methods for use with structured and unstructured data

InactiveUS20070061266A1High degree of flexibilityIncrease flexibilityData processing applicationsDigital data processing detailsContent managementSafe system

Disclosed herein are systems and methods including hardware, software and electronic service components and systems to provide large-scale, reliable, and secure foundations for distributed databases and content management systems combining unstructured and structured data, and allowing post-input reorganization to achieve a high degree of flexibility.

Owner:NEWSILIKE MEDIA GROUP

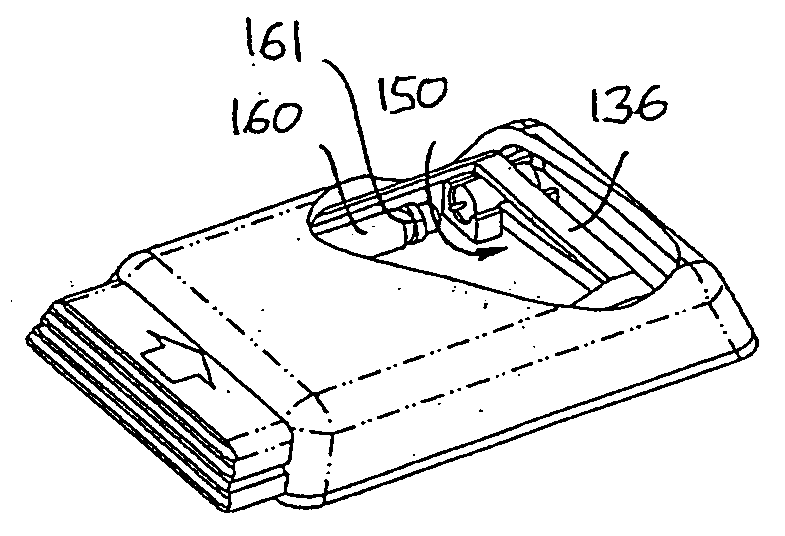

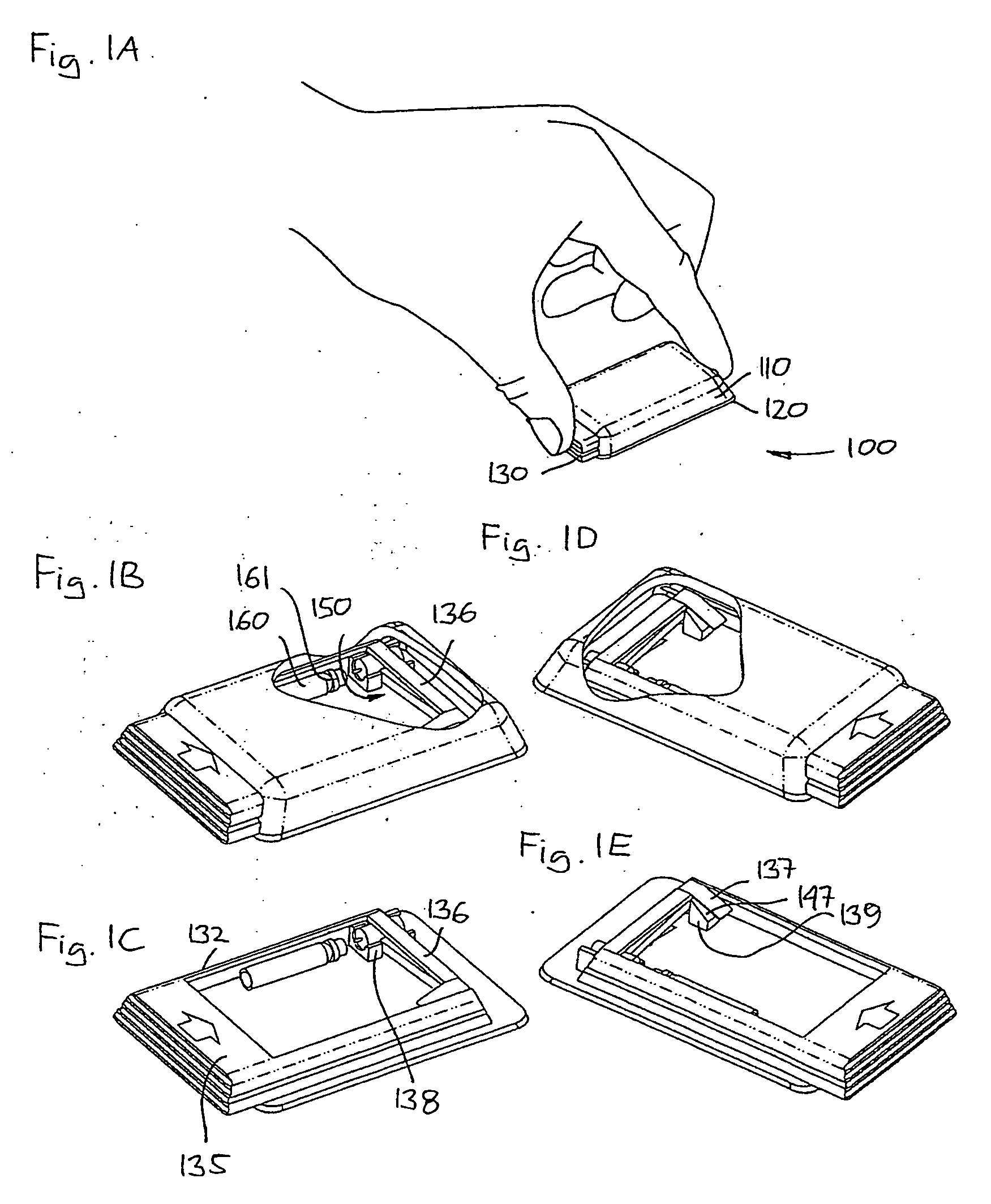

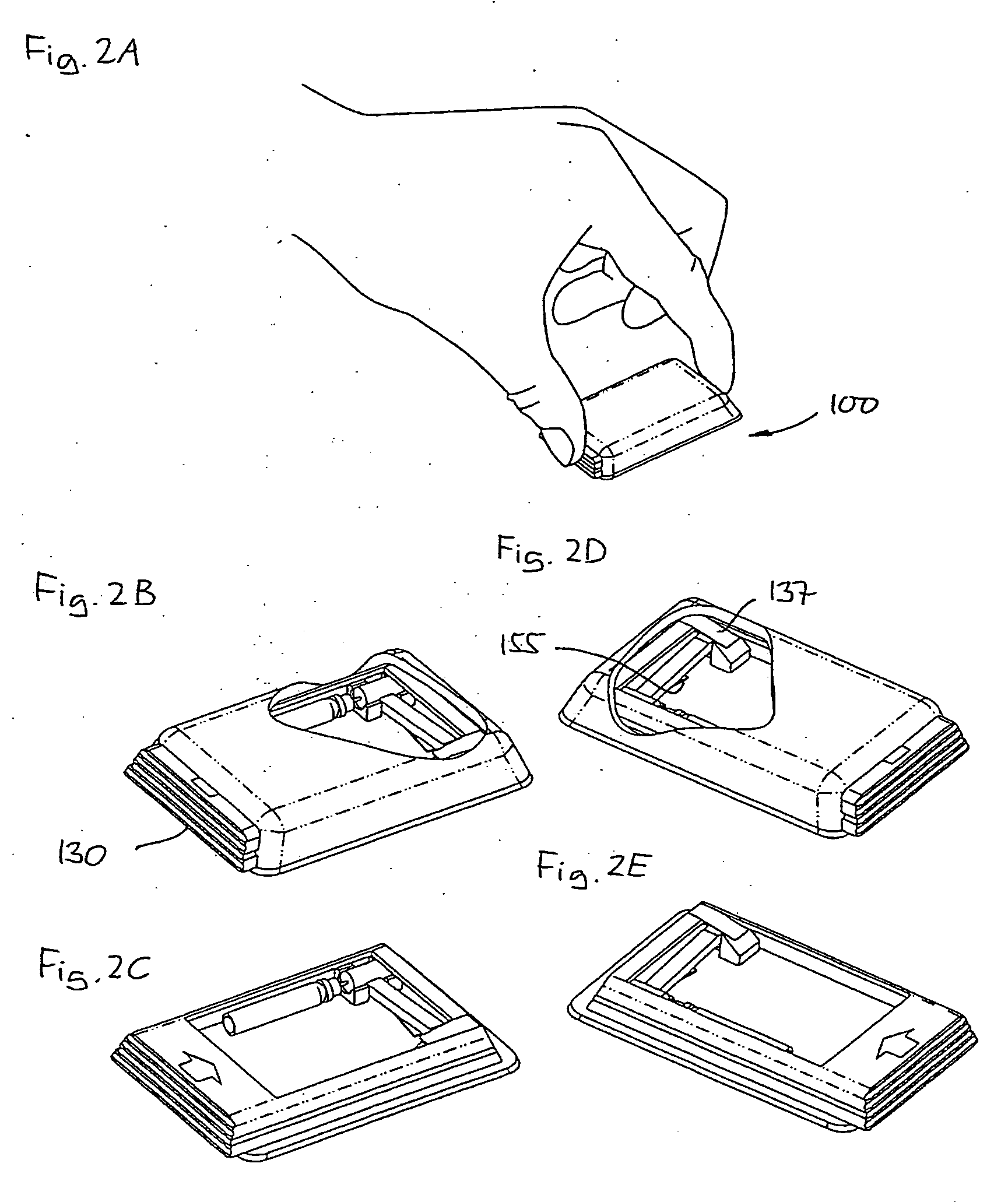

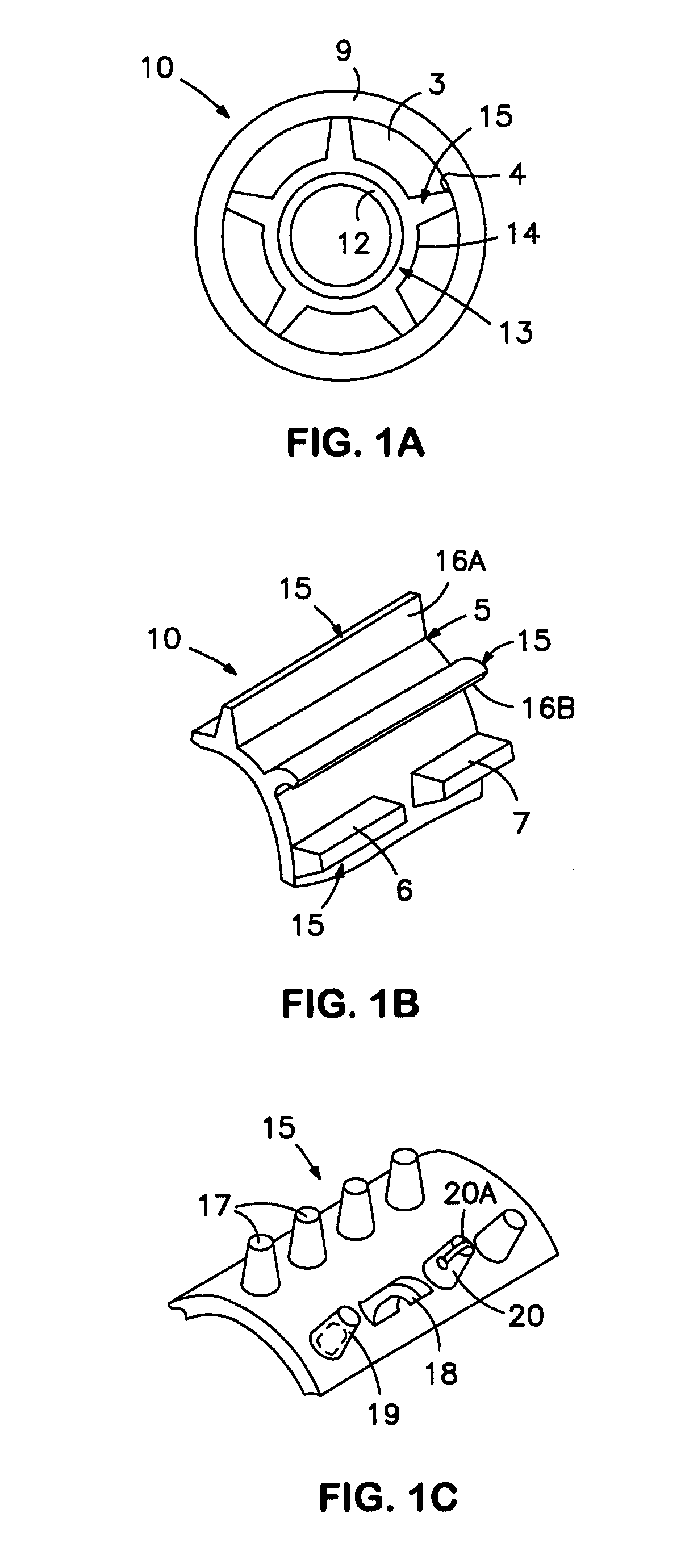

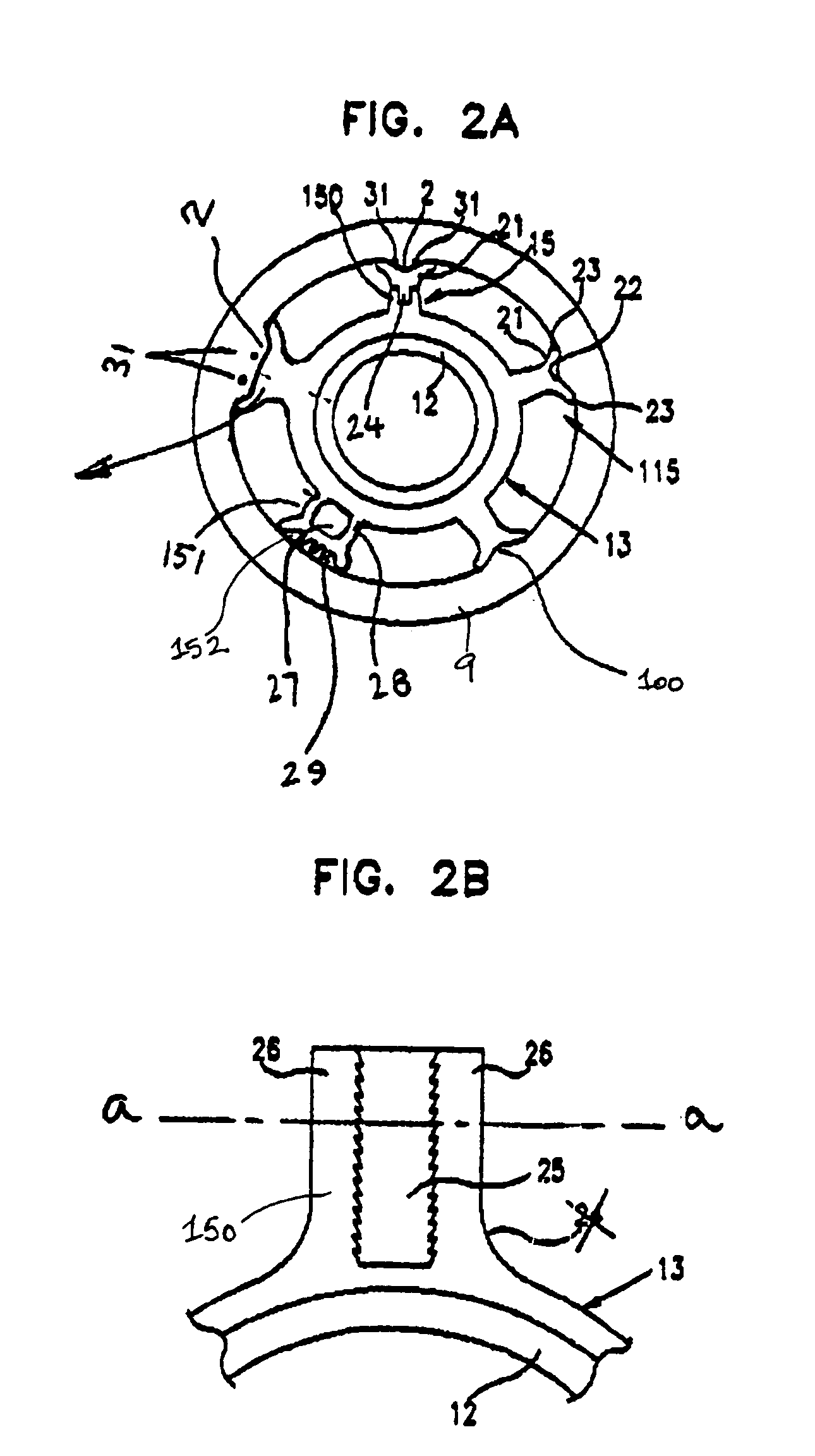

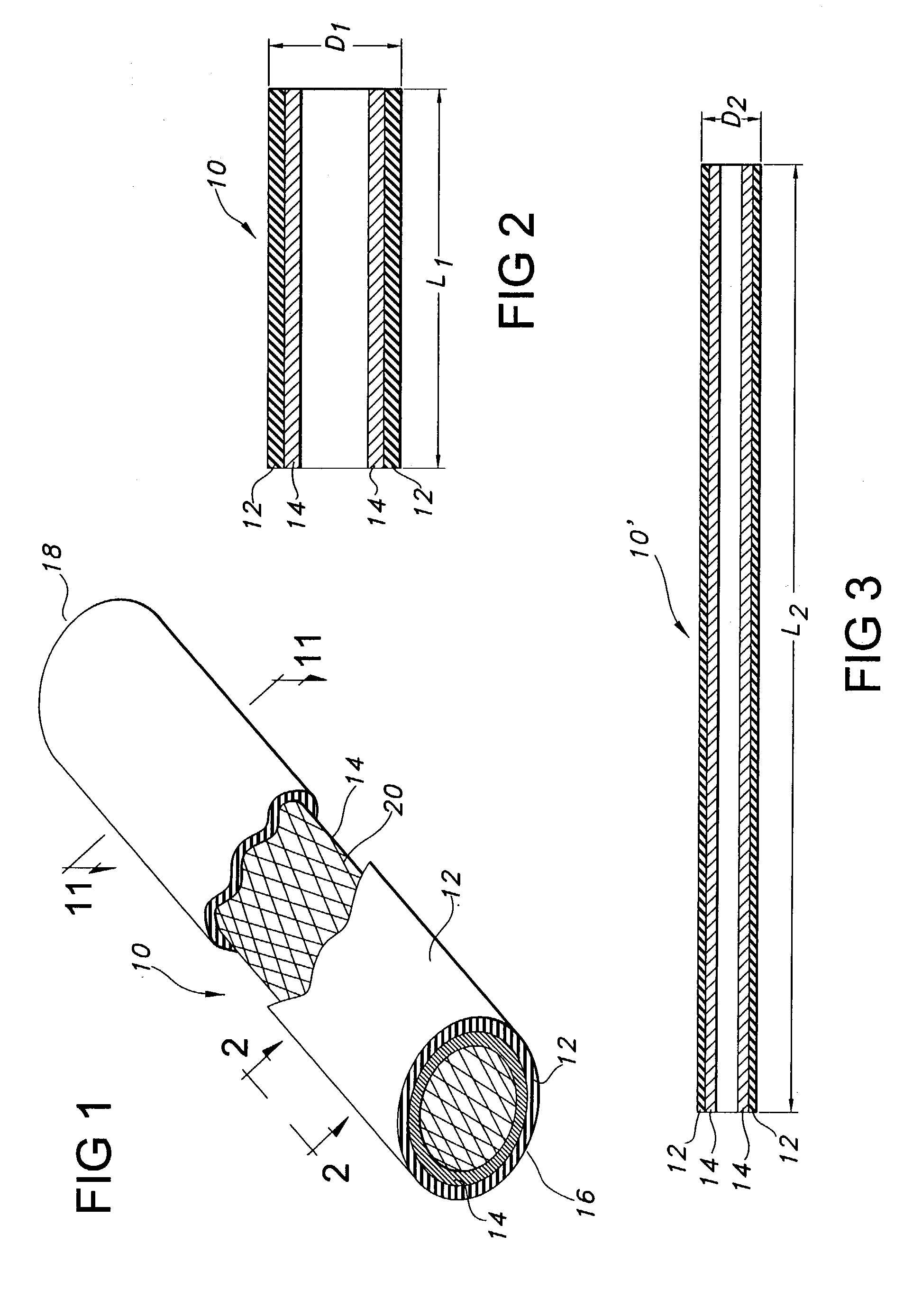

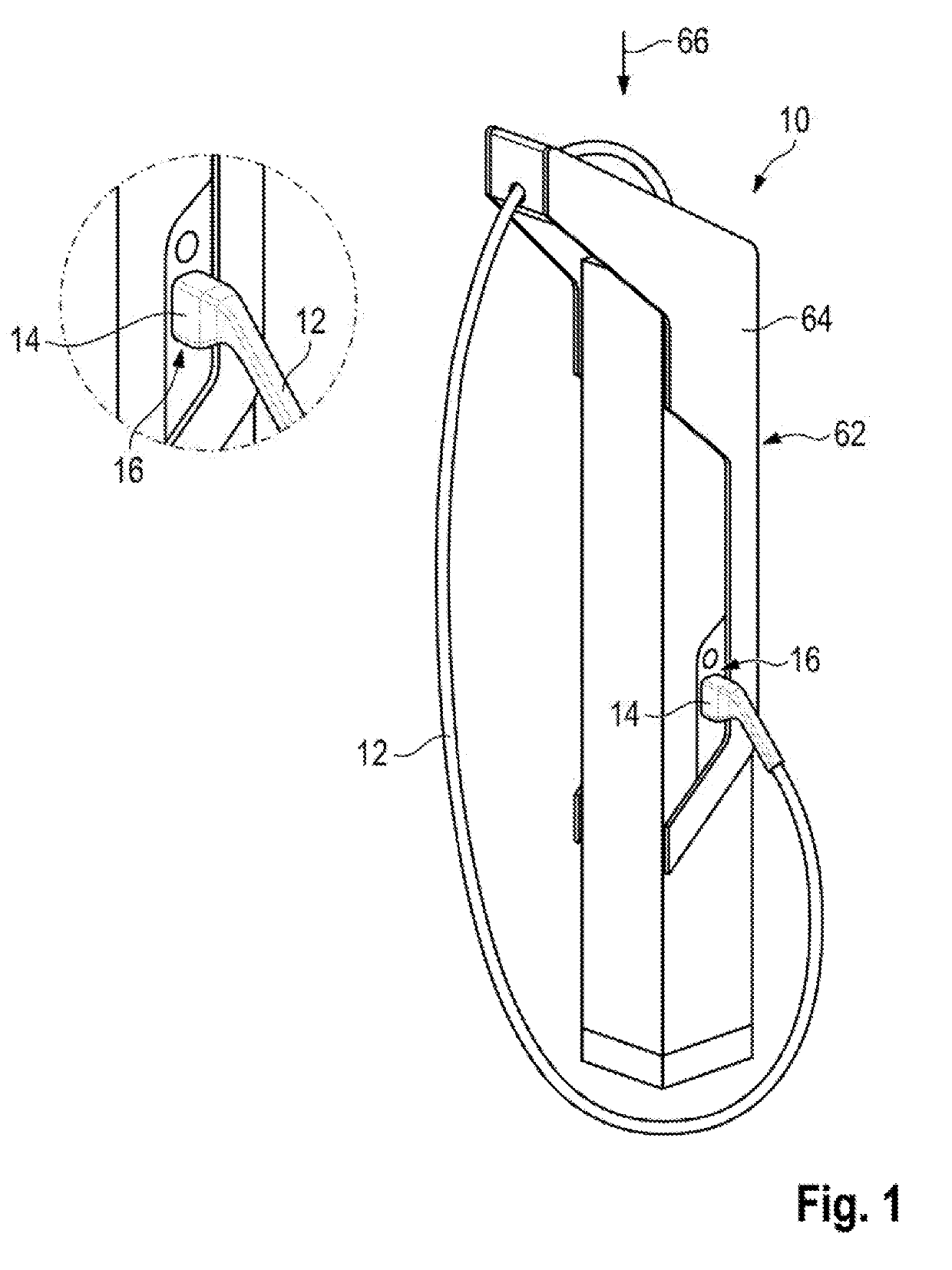

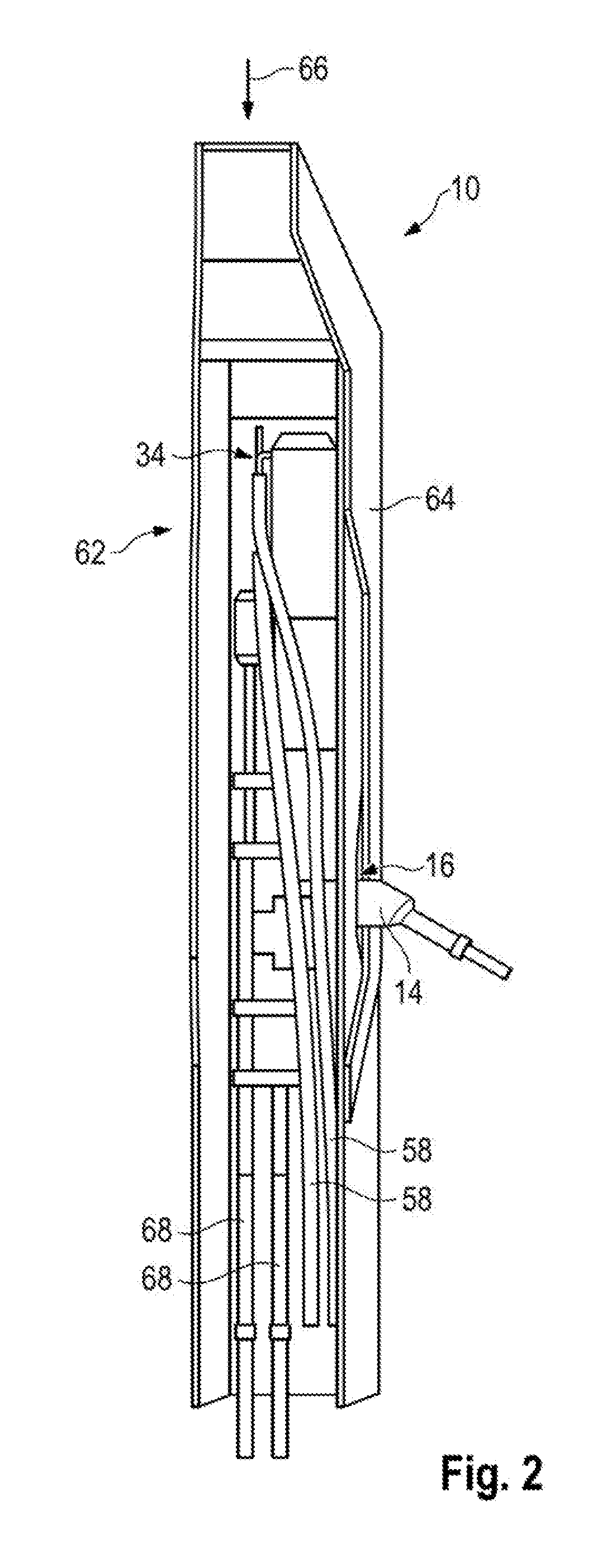

Pivotable needle unit

InactiveUS20060135913A1High degree of flexibilityImprove reliabilityMedical devicesPressure infusionDistal portionBiomedical engineering

The present invention generally relates to the insertion of needles or needle-like members. Thus, a device comprises a housing having a mounting surface adapted for application to the skin of a subject, and a needle unit connected to the housing by a hinge allowing the needle unit to pivot corresponding to a pivoting axis defined by the hinge, the pivoting axis being arranged substantially in parallel with the mounting surface. The needle unit comprises a needle having a distal pointed portion adapted to penetrate the skin of the subject, the distal portion extending generally perpendicular to the mounting surface, and a proximal portion arranged substantially corresponding to the pivoting axis, whereby the needle unit is arranged to pivot between a first position in which the distal portion of the needle is retracted within the housing, and a second position in which the distal portion projects relative to the mounting surface. The needle may e.g. be in the form of a hollow needle or a needle sensor.

Owner:NOVO NORDISK AS

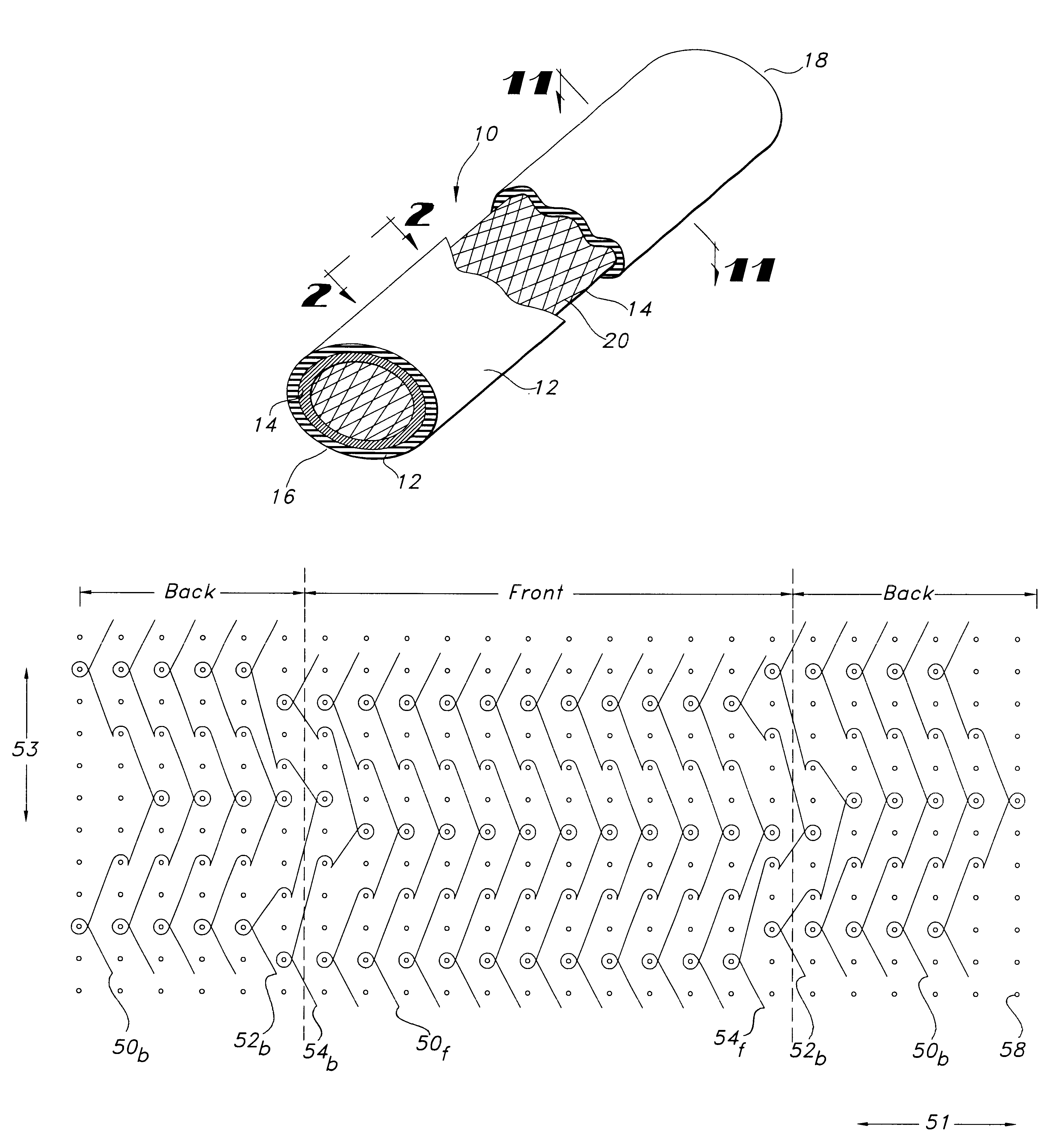

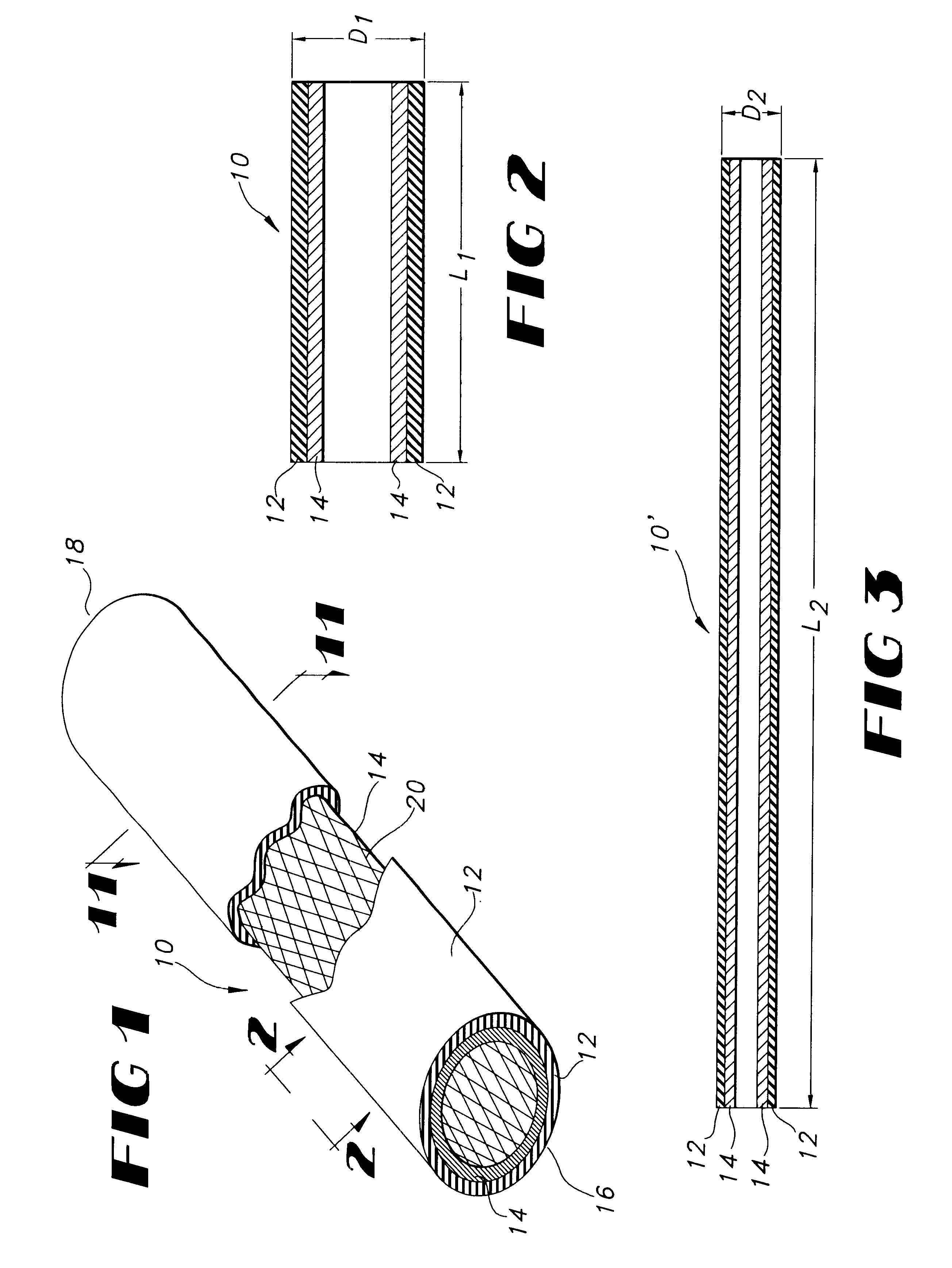

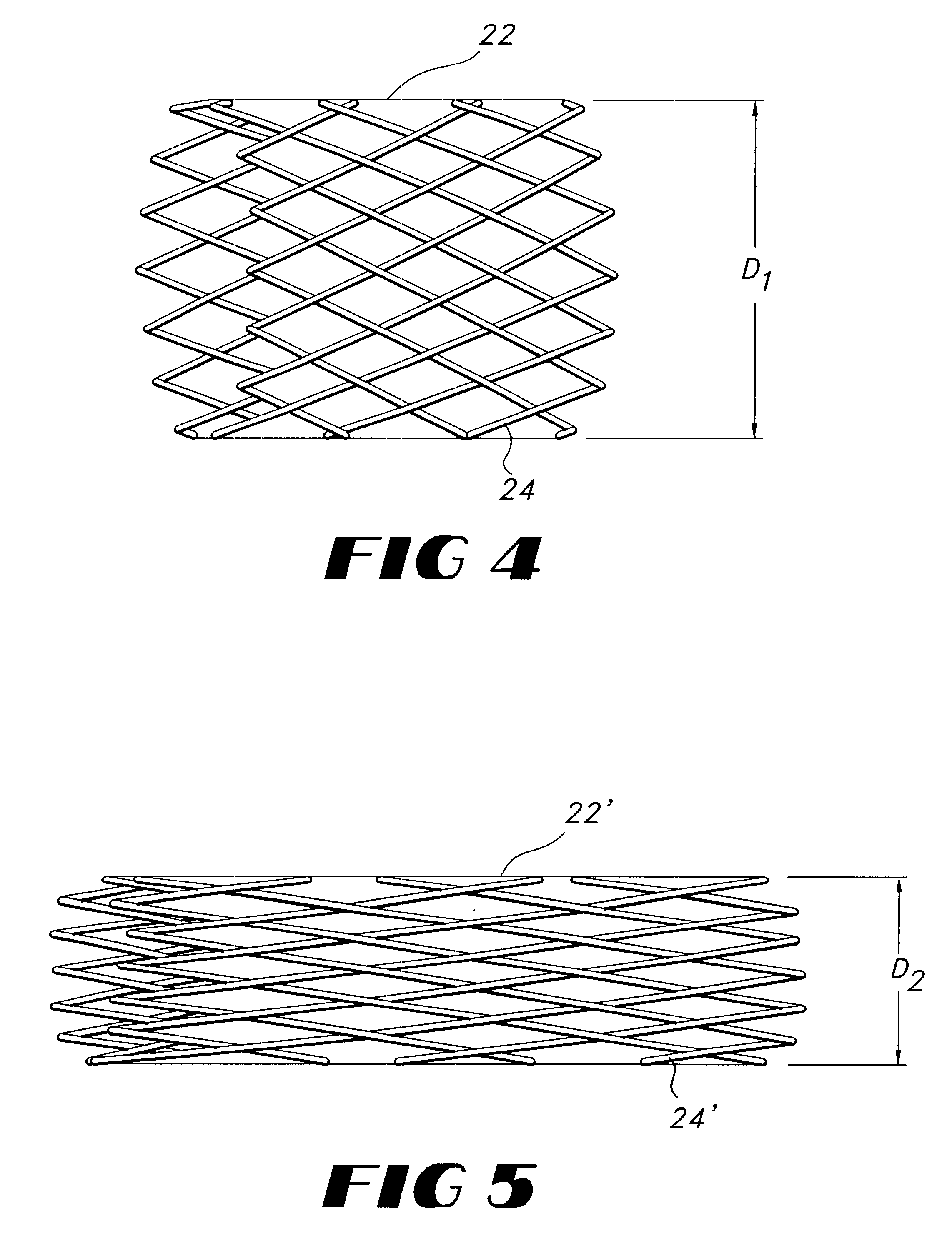

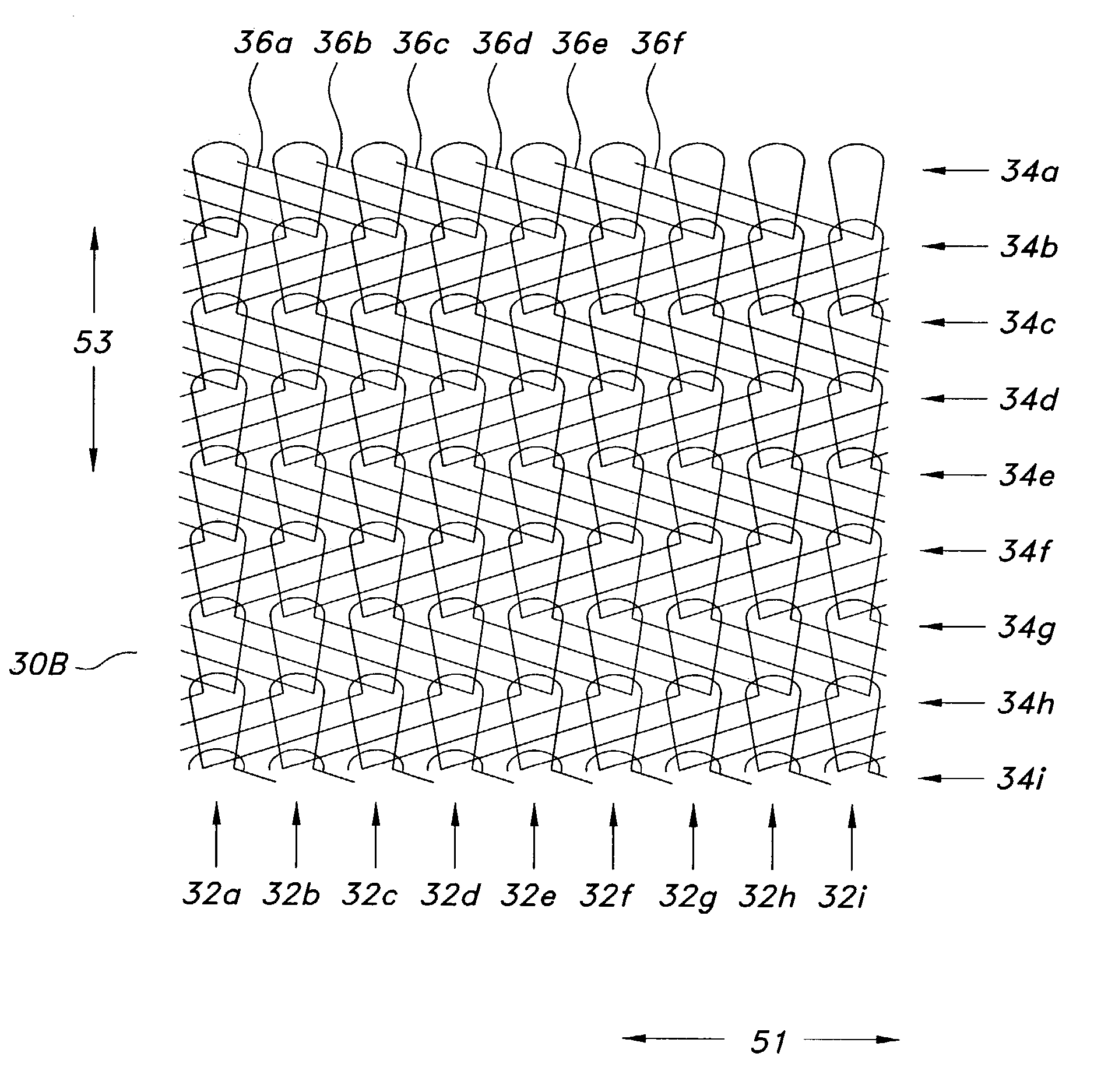

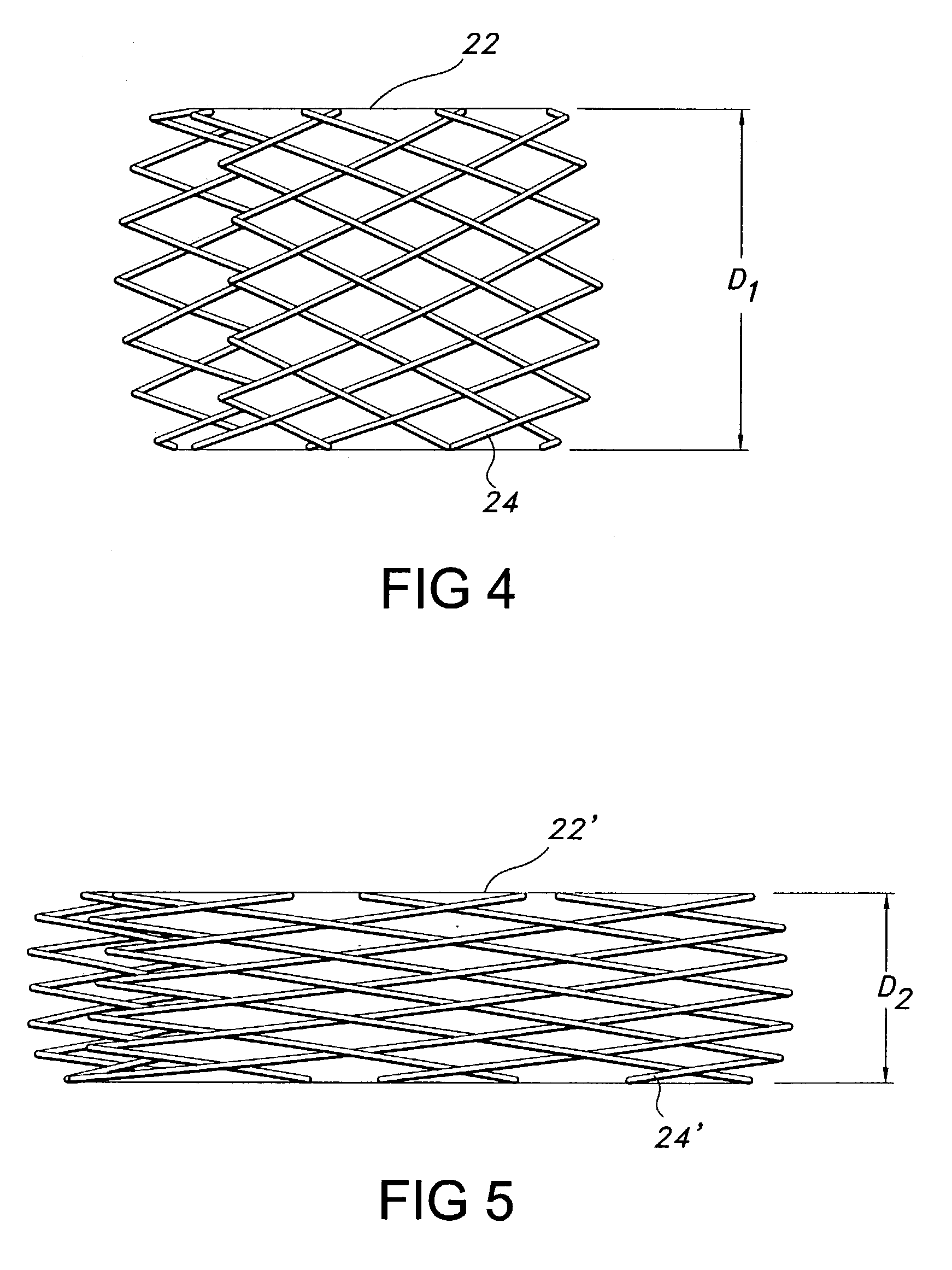

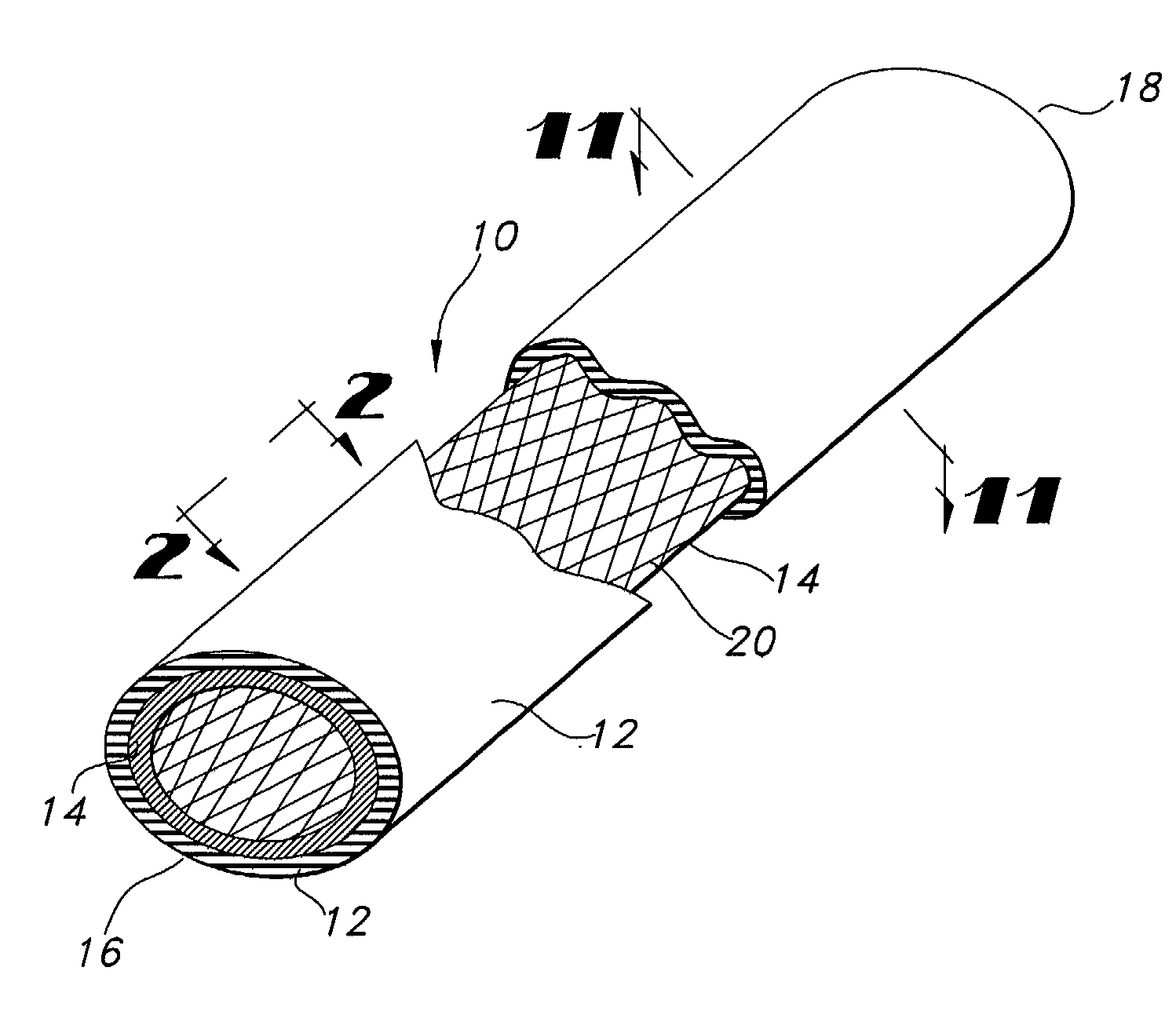

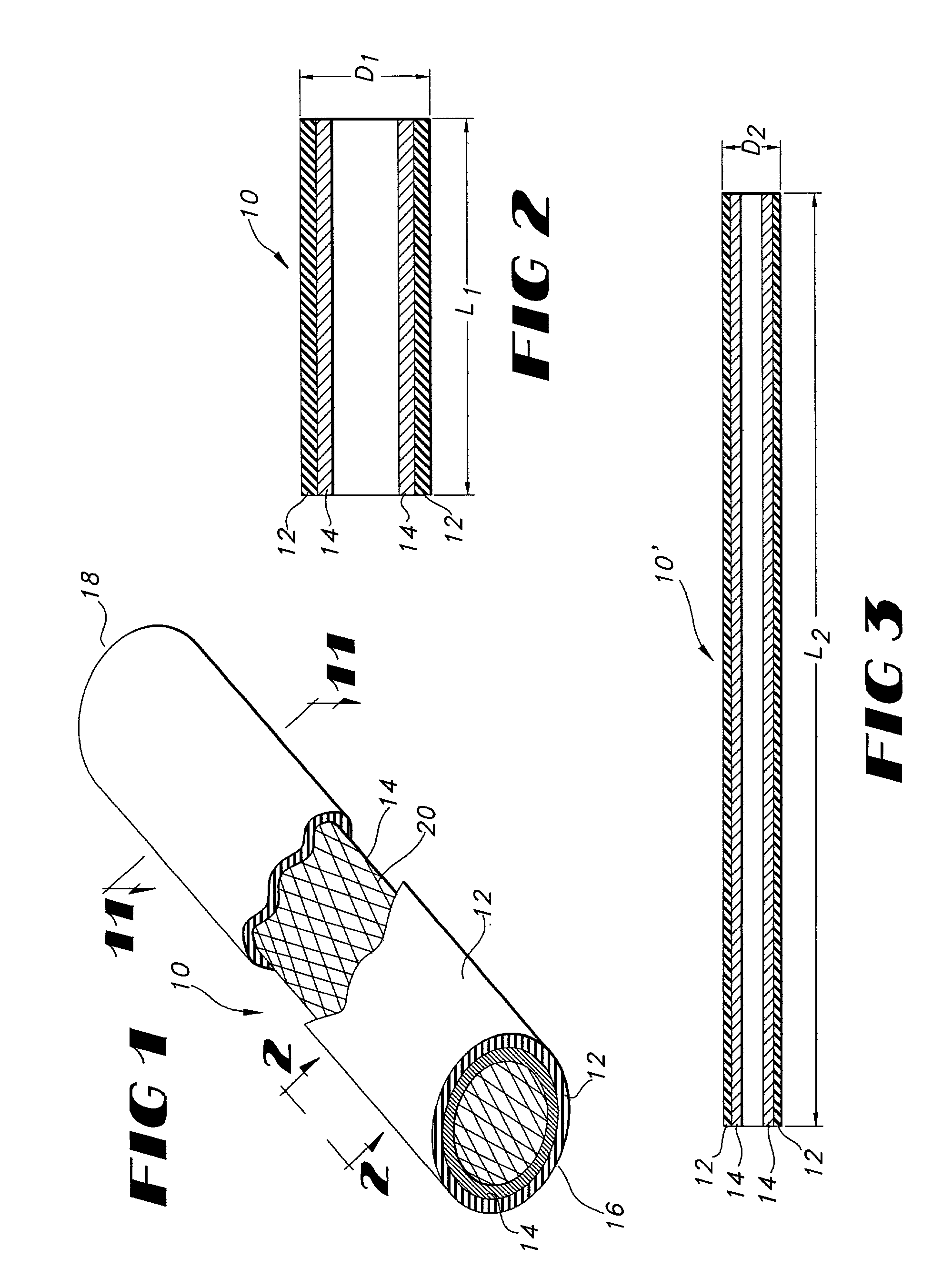

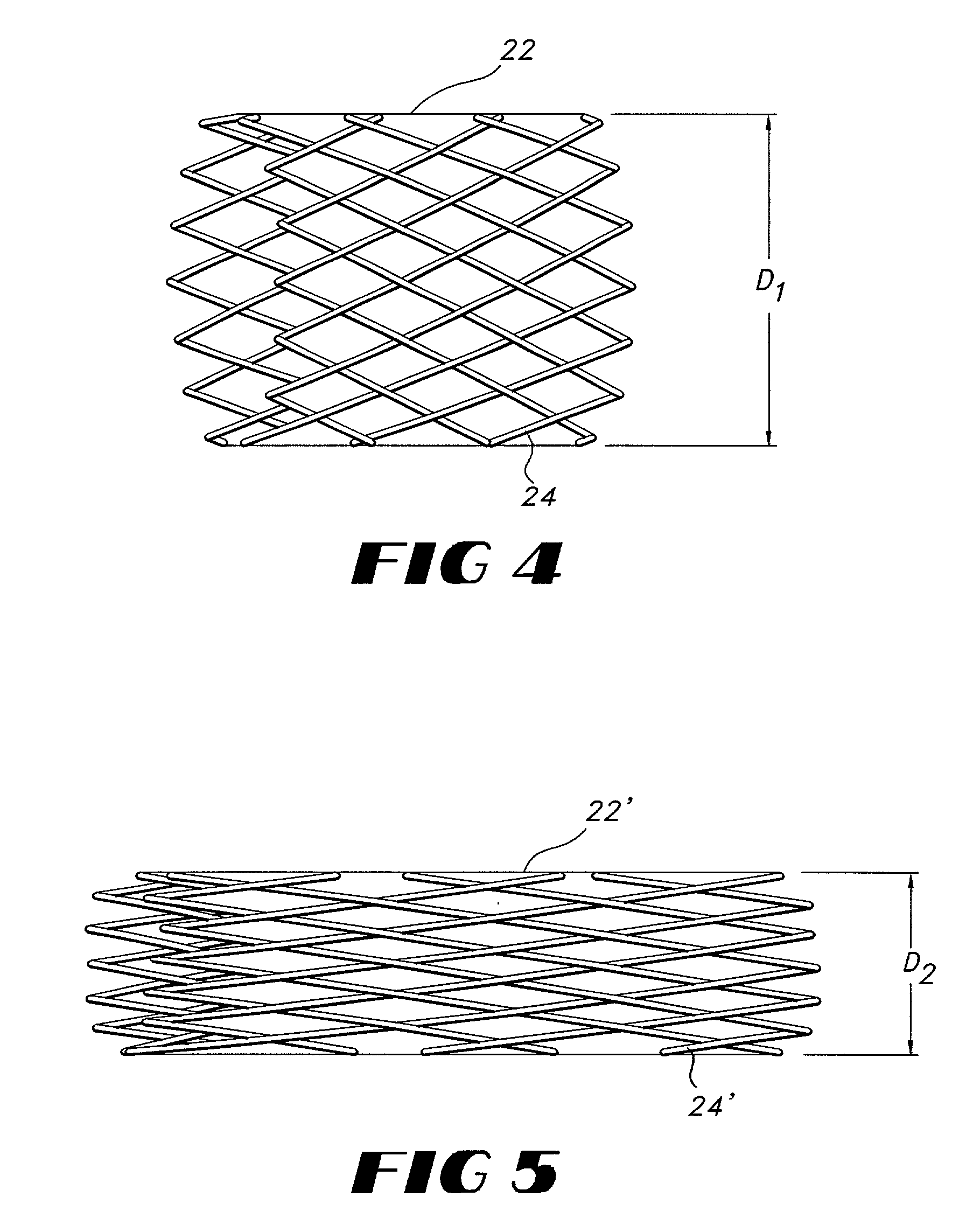

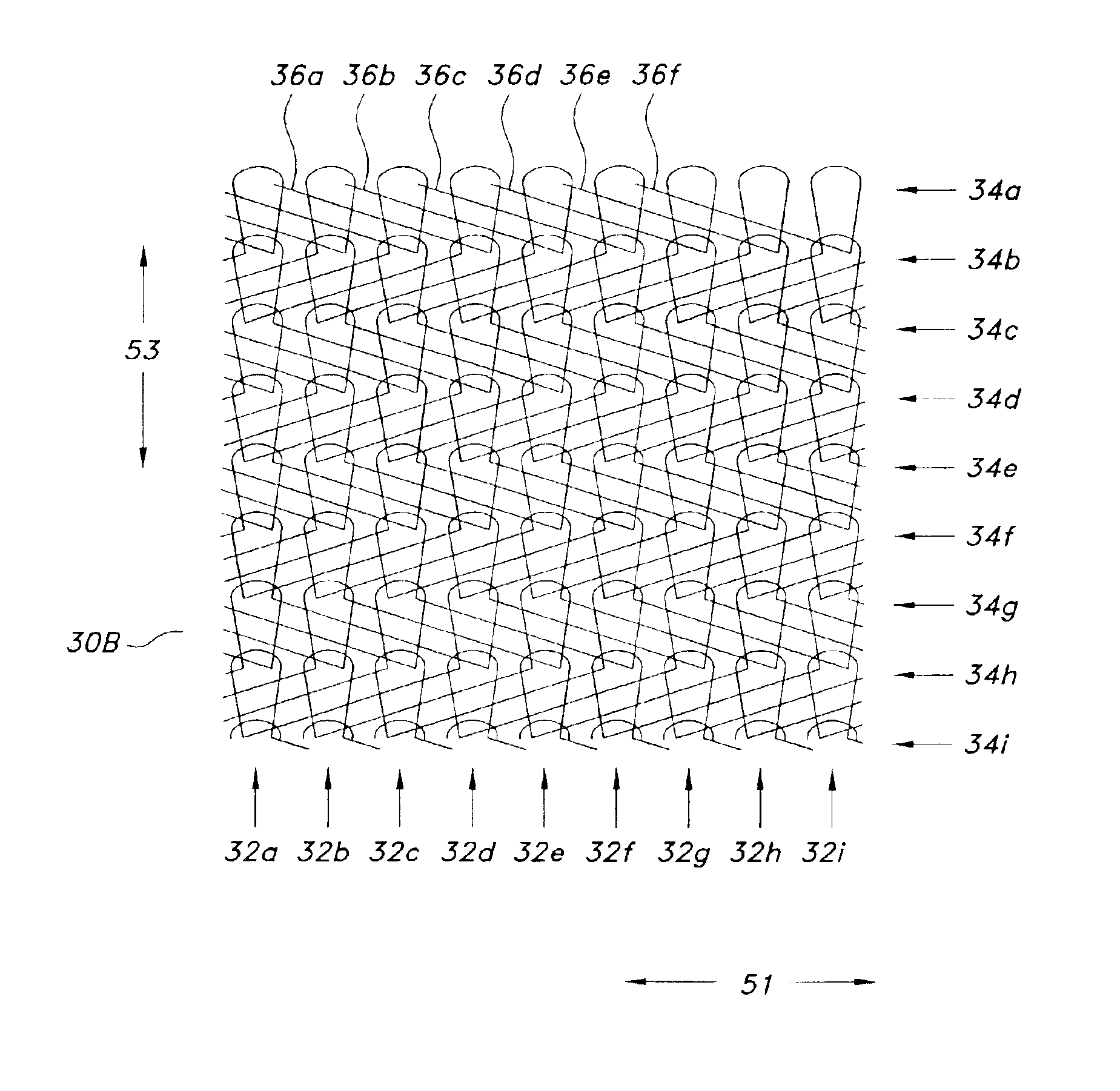

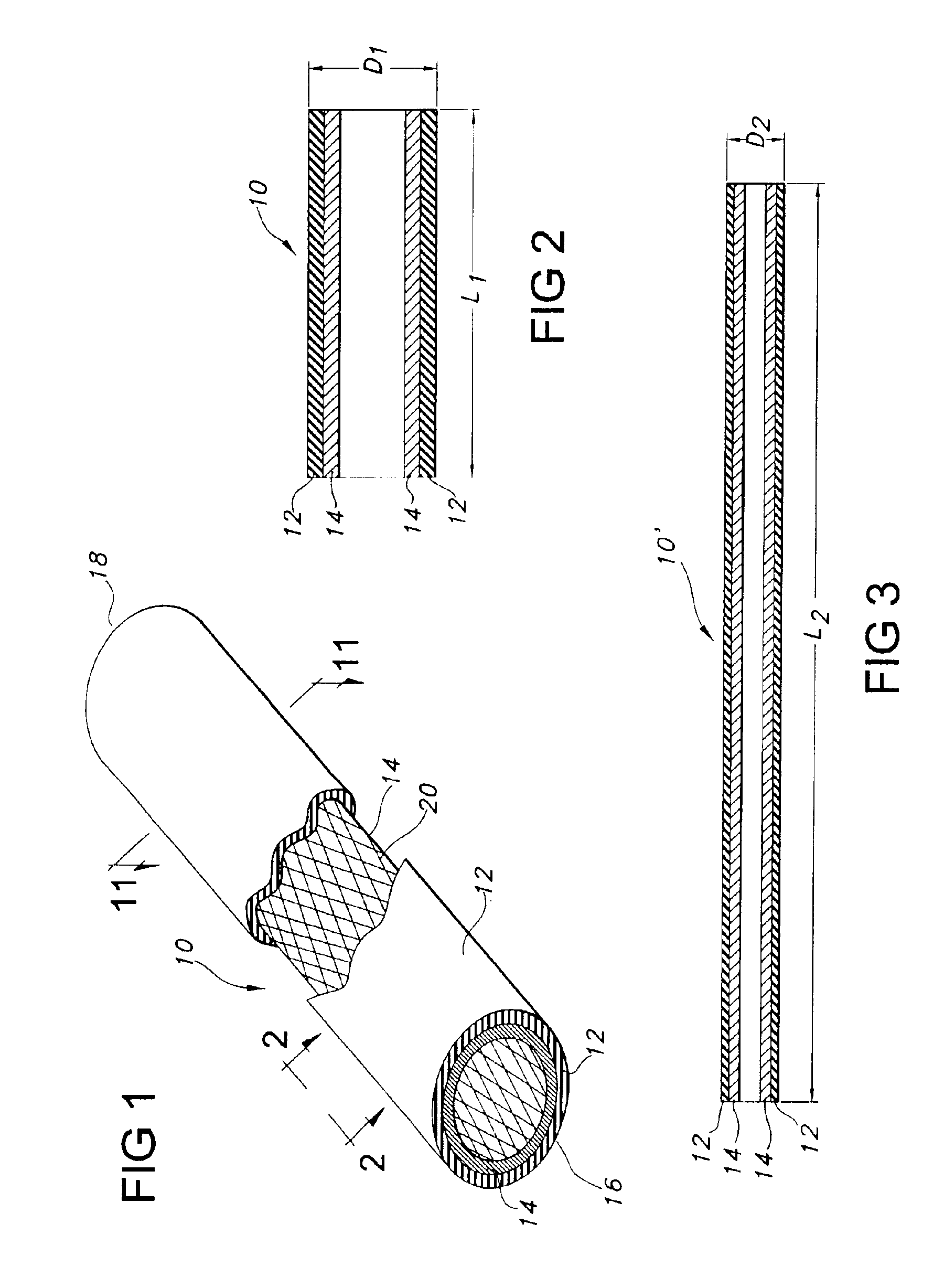

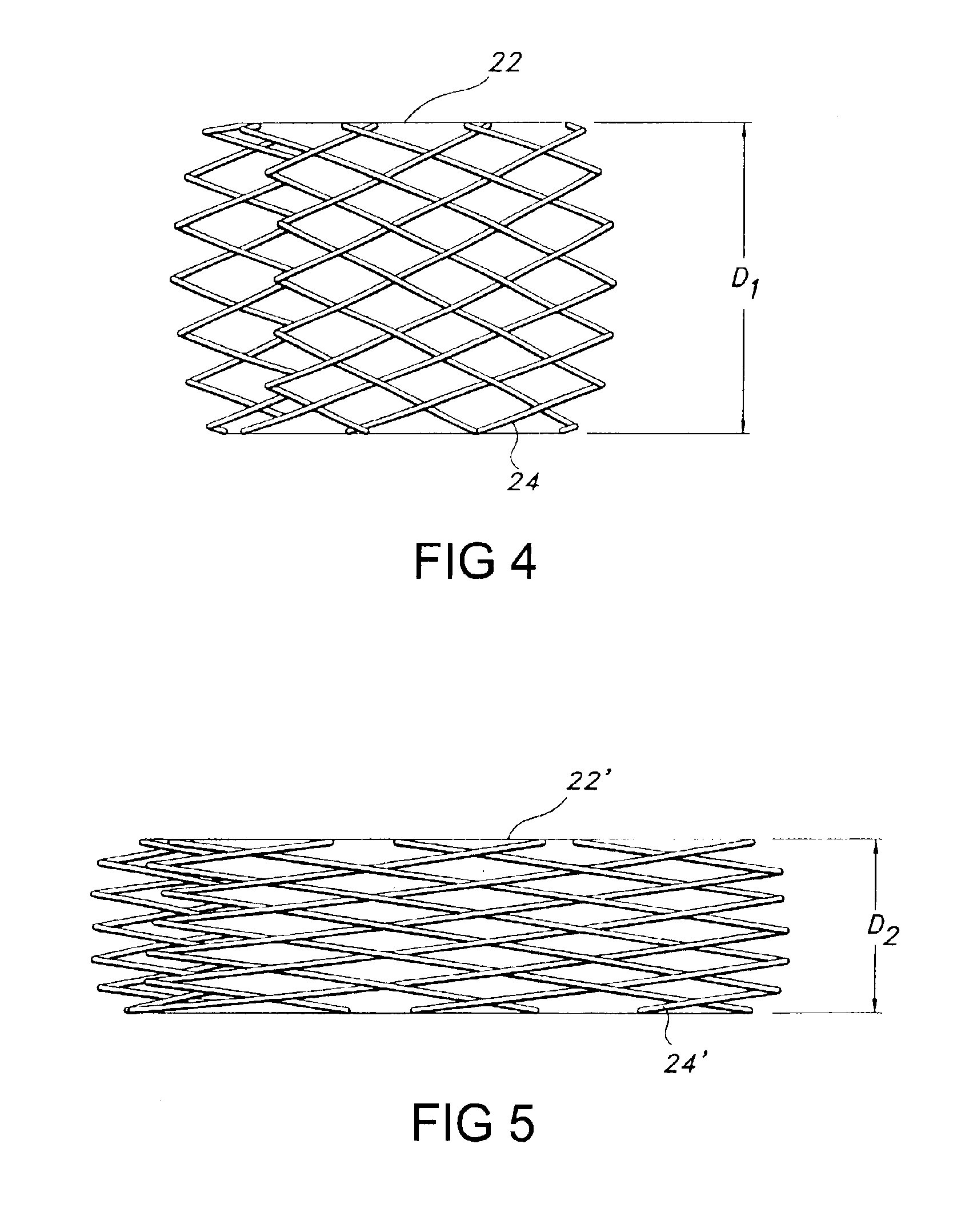

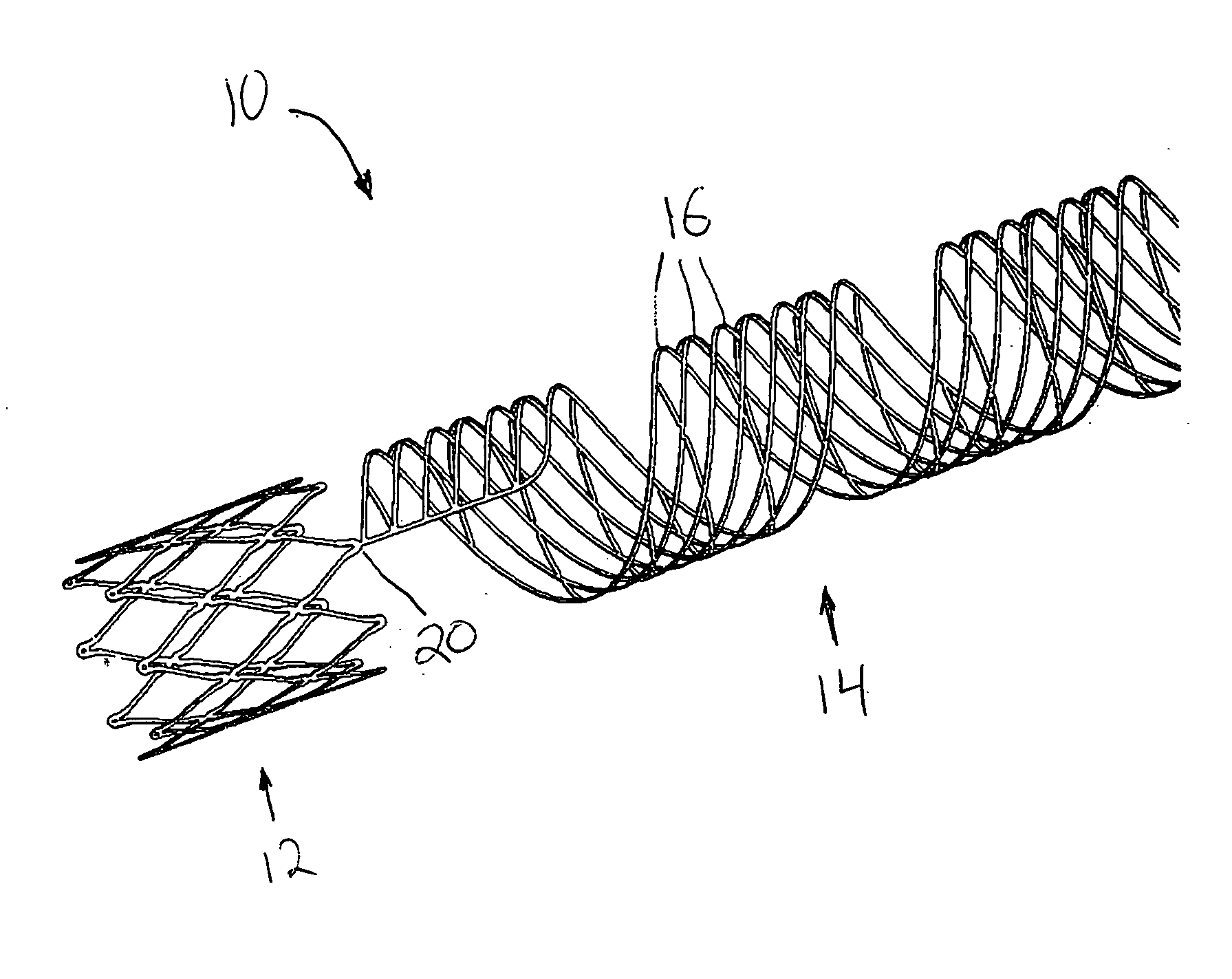

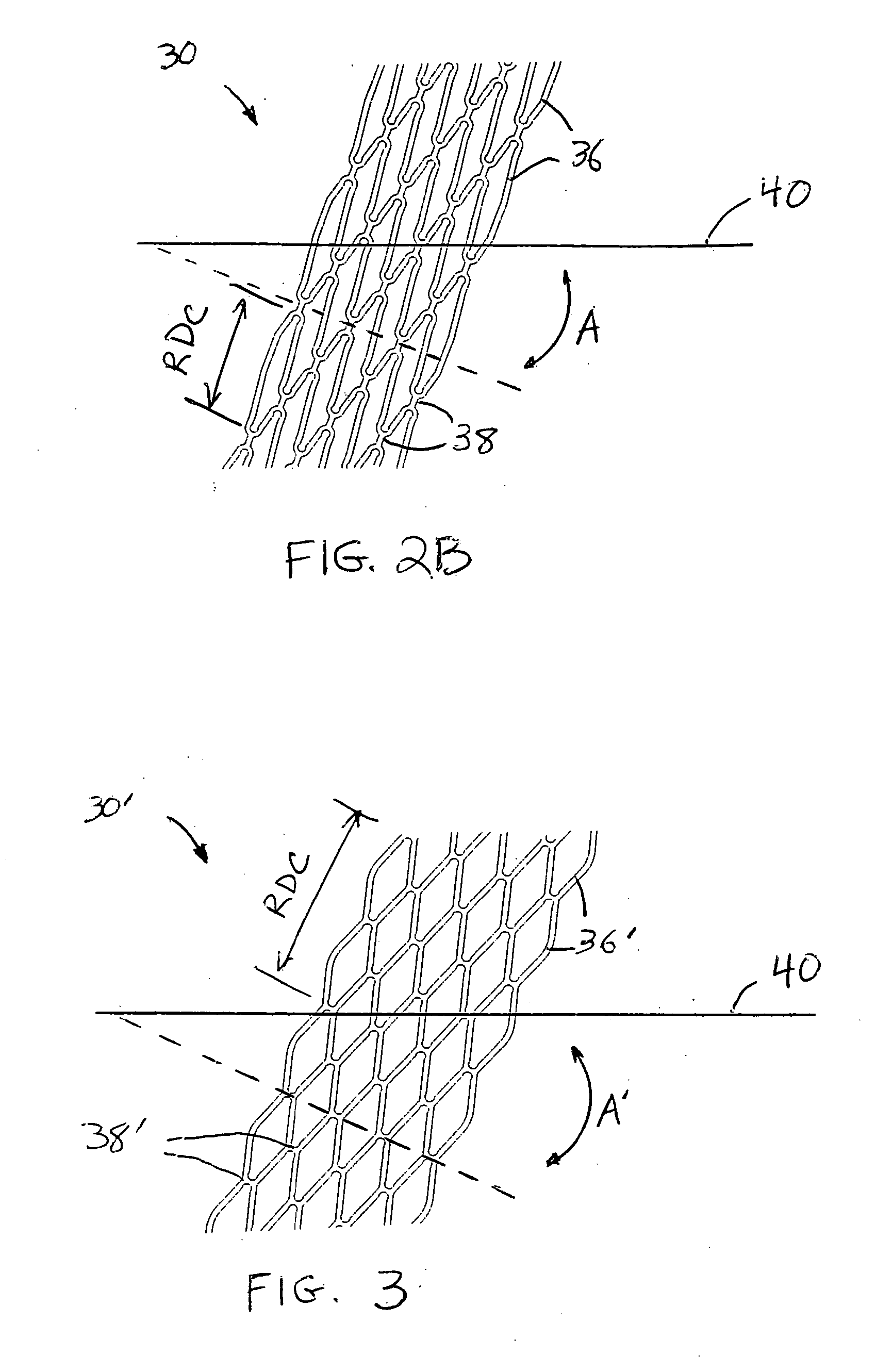

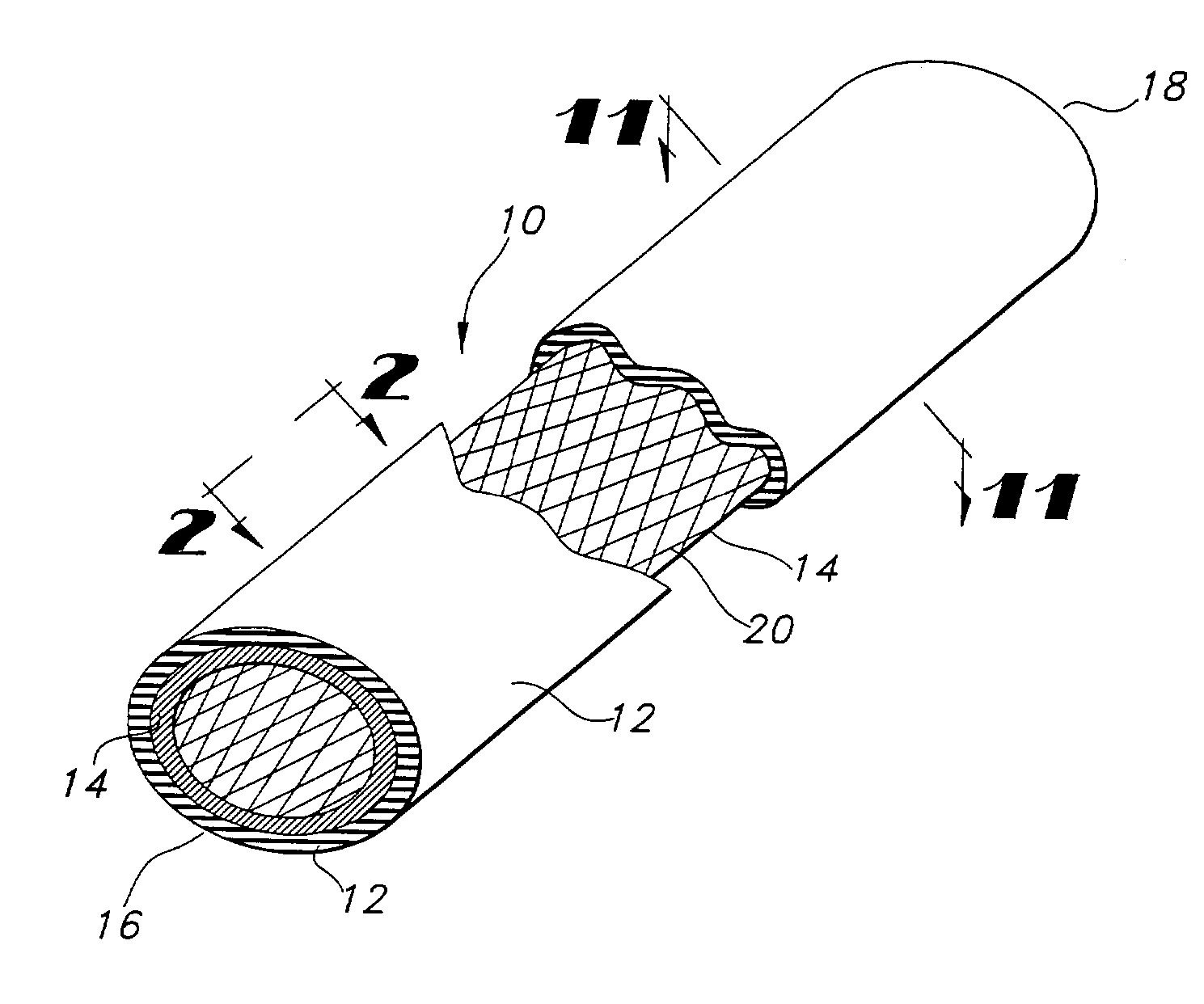

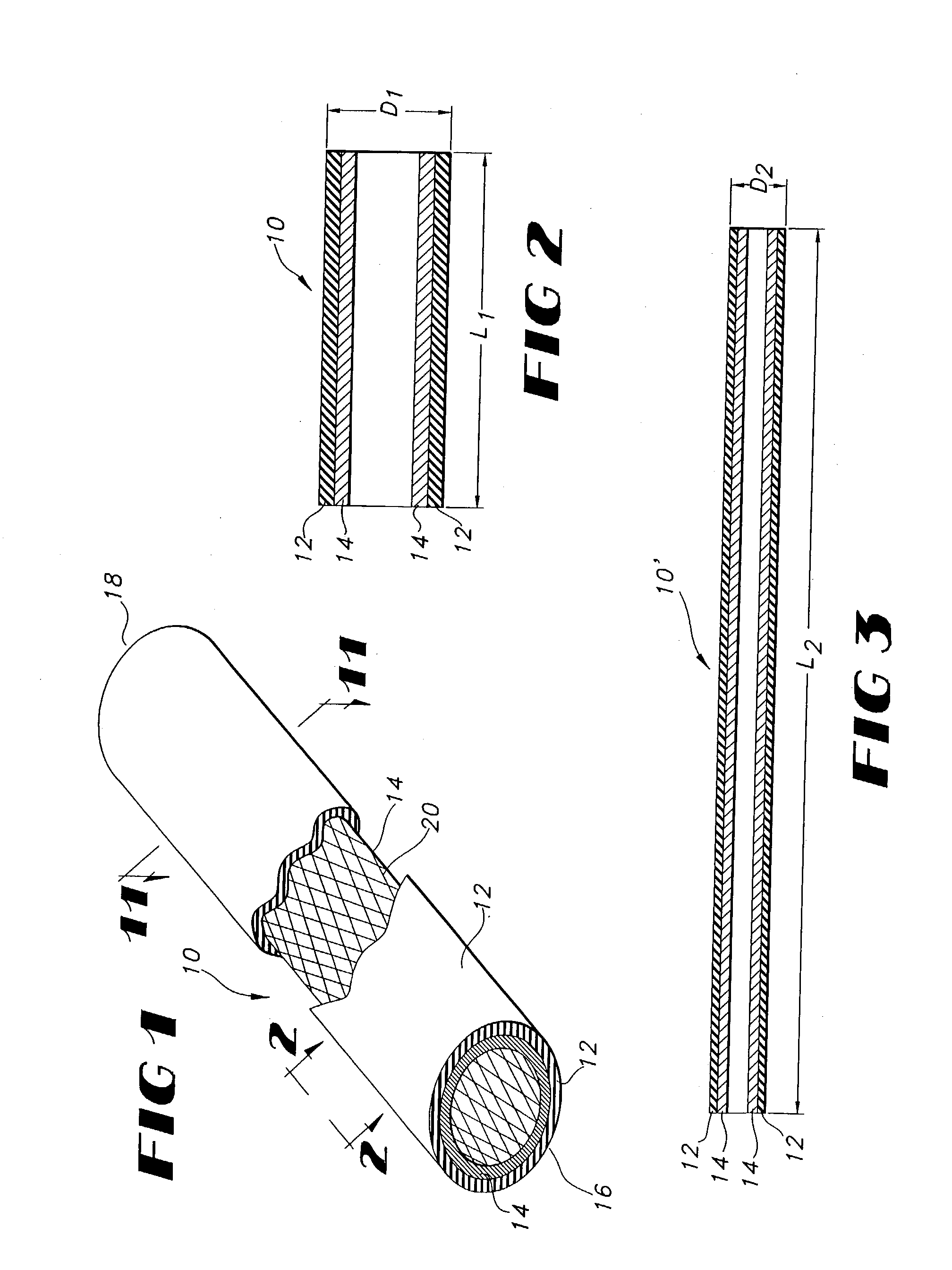

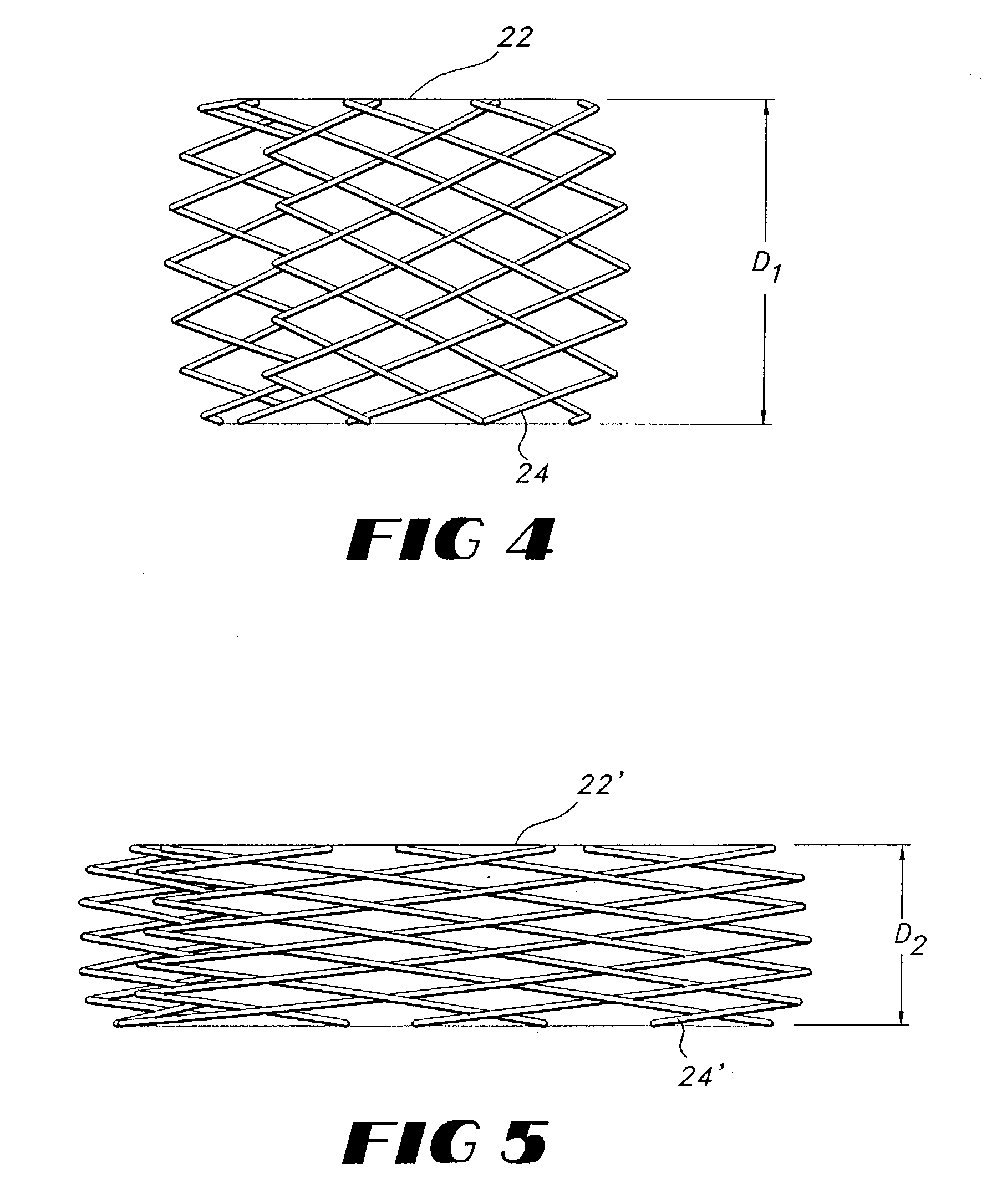

Low profile, high stretch knit prosthetic device

InactiveUS6540773B2High degree of flexibilityHigh degree of stretchabilityStentsWeft knittingYarnInsertion stent

A radially expandable stent-graft endoprosthesis is provided. The graft included in the stent-graft is a knitted tubular structure circumferentially disposed and securably attached to the stent. The knitted tubular structure has a knit pattern of interlacing yarns in an Atlas or a modified-Atlas pattern to provide greater than 150 percent longitudinal stretchability. A knitted tubular graft and a knitted medical fabric with greater than 150 percent longitudinal stretchability are also provided.

Owner:LIFESHIELD SCI

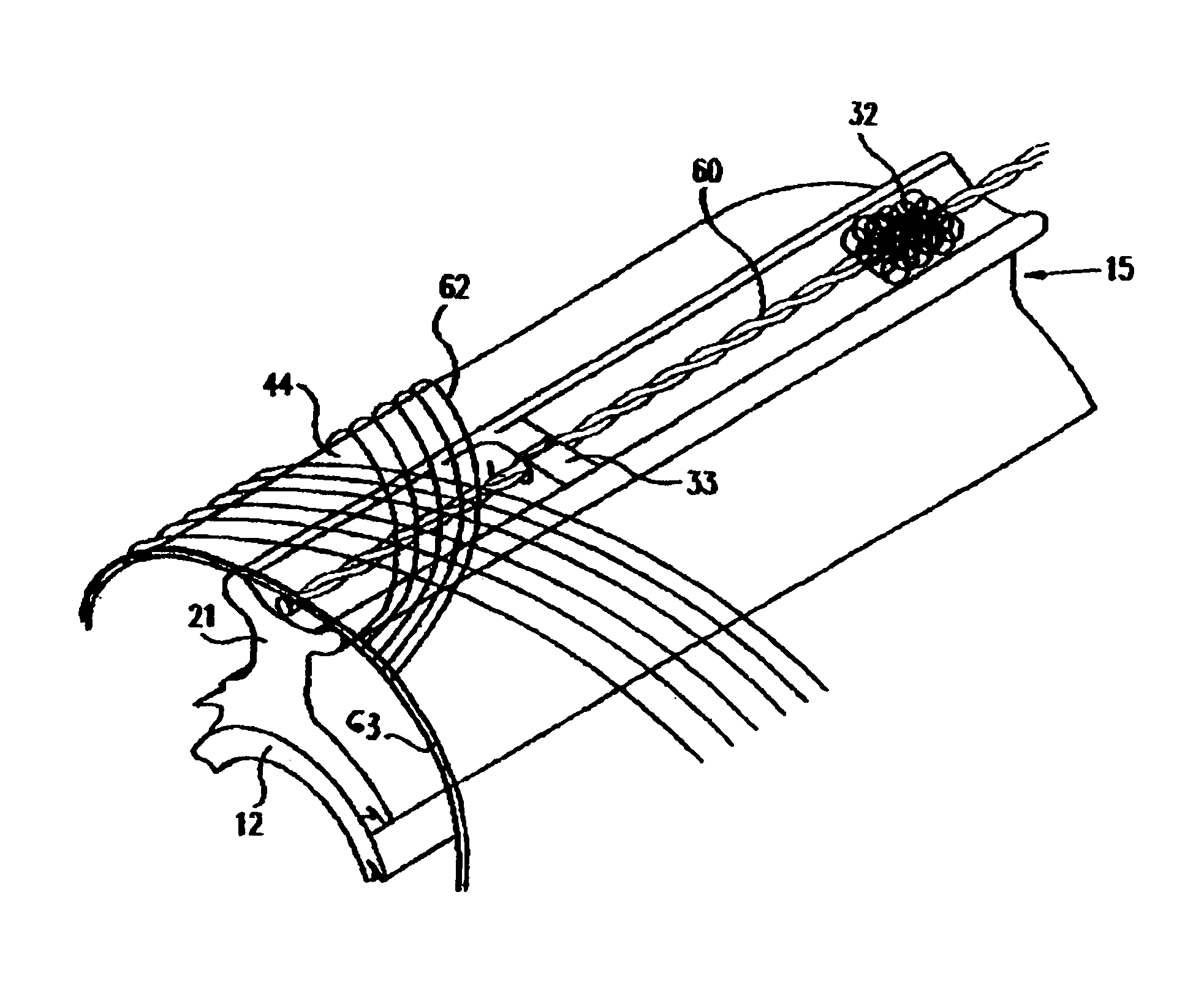

Bone growth promoting implant

InactiveUS7255712B1High of controlHigh degree of flexibilityInternal osteosythesisJoint implantsNatural boneStructural geometry

A stem-like bone implant includes longitudinal structural members and tension cables that provide curvature control and support, and rigidity against bending and buckling. The longitudinal structural members and tension cables may become an integral part of a composite regenerated bone having a substantially increased strength over natural bone. The flexibility of the implant is controlled by specifically varying the structural geometry of certain portions of the implant, and by adjusting the tension in the tension cables before, during and after the implantation operation to thereby adjust the stiffness of the implant. The tension cables may be adjusted to produce asymmetric or non-uniform levels of tension in the longitudinal structural members.

Owner:ACTIVE IMPLANTS LLC +1

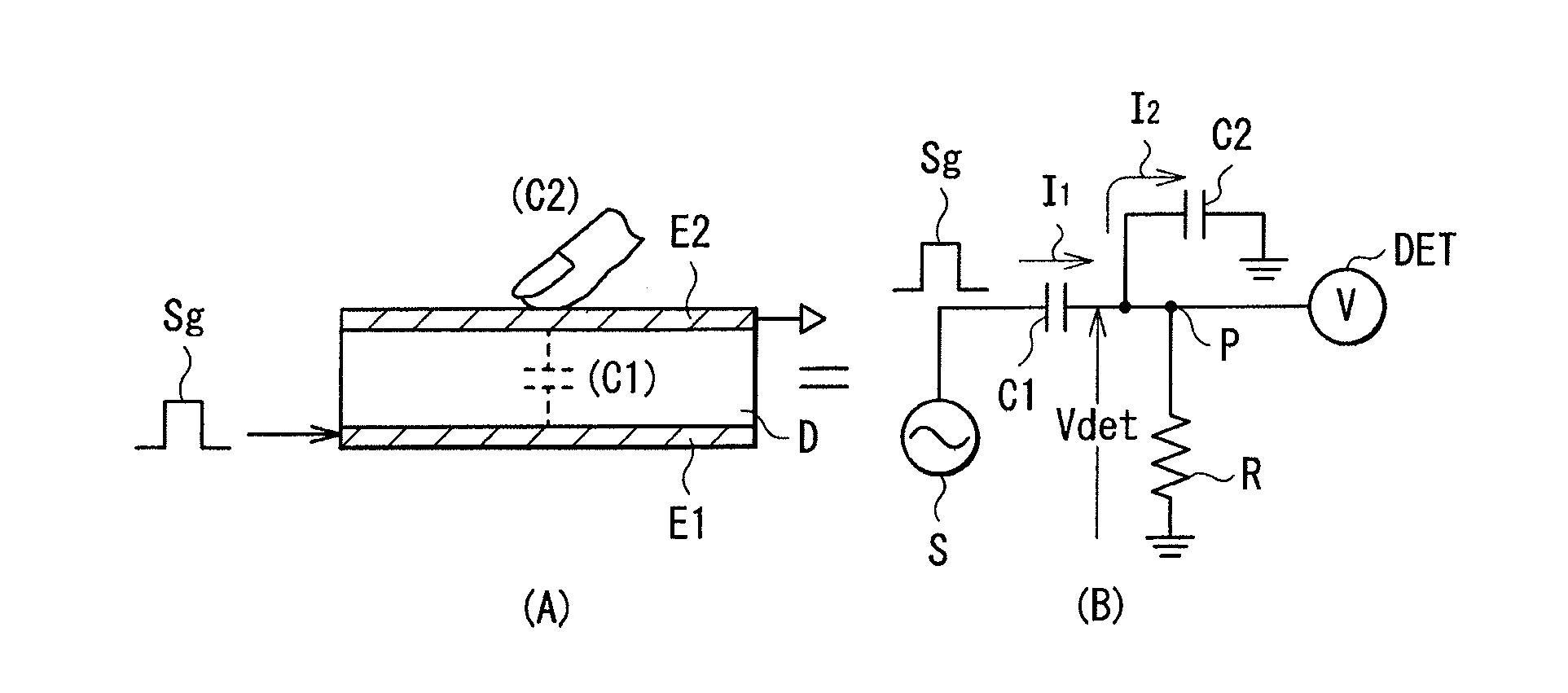

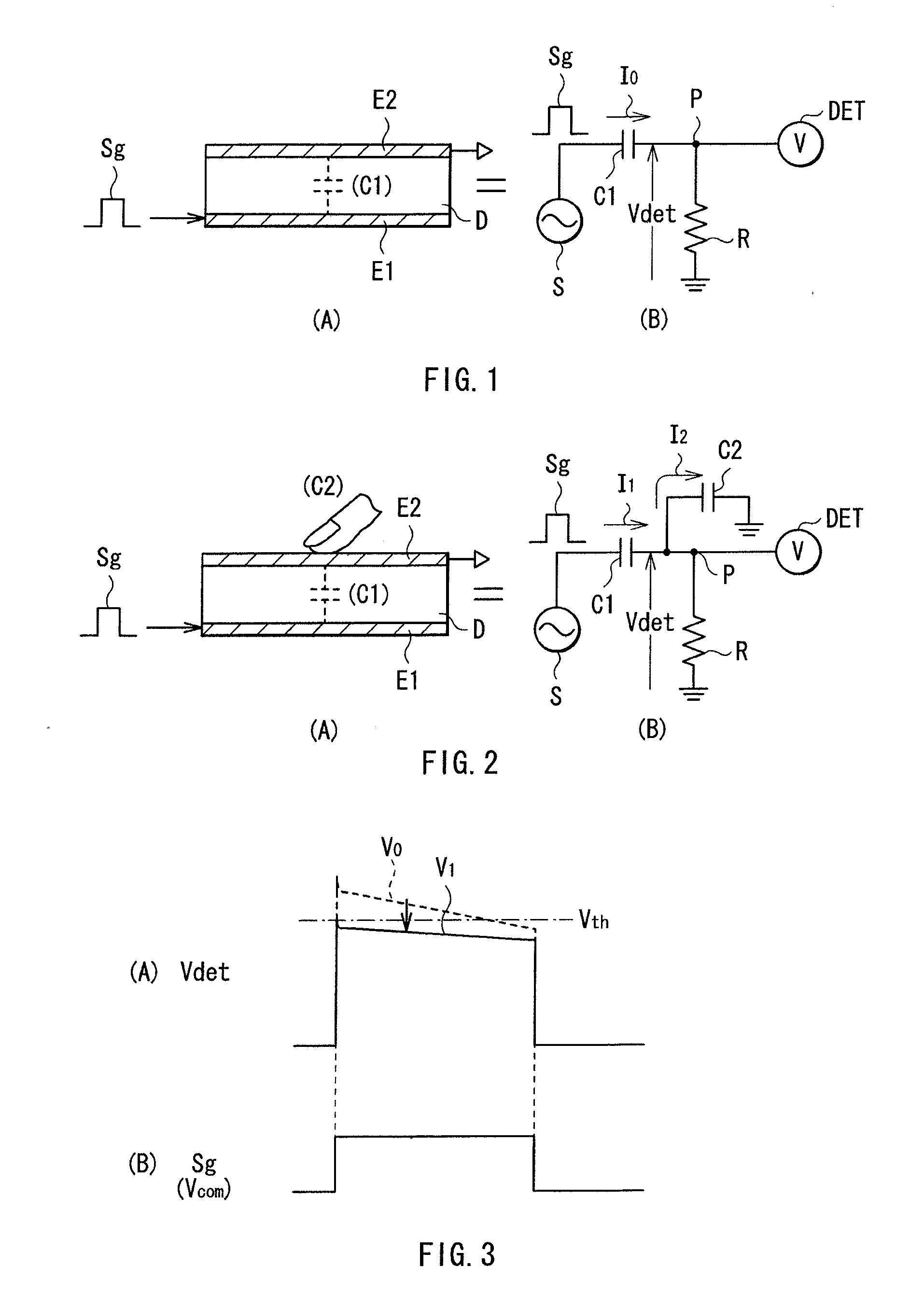

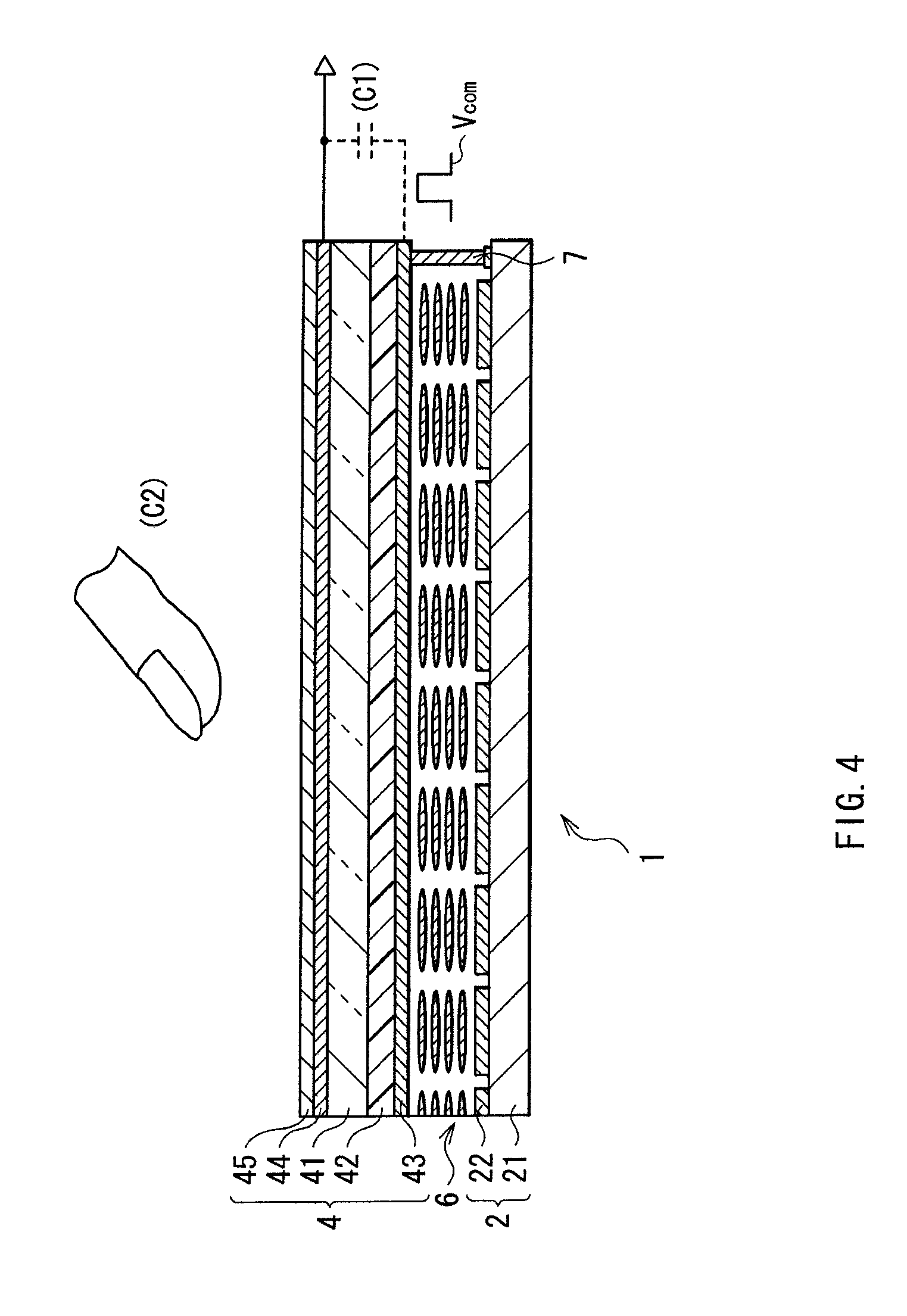

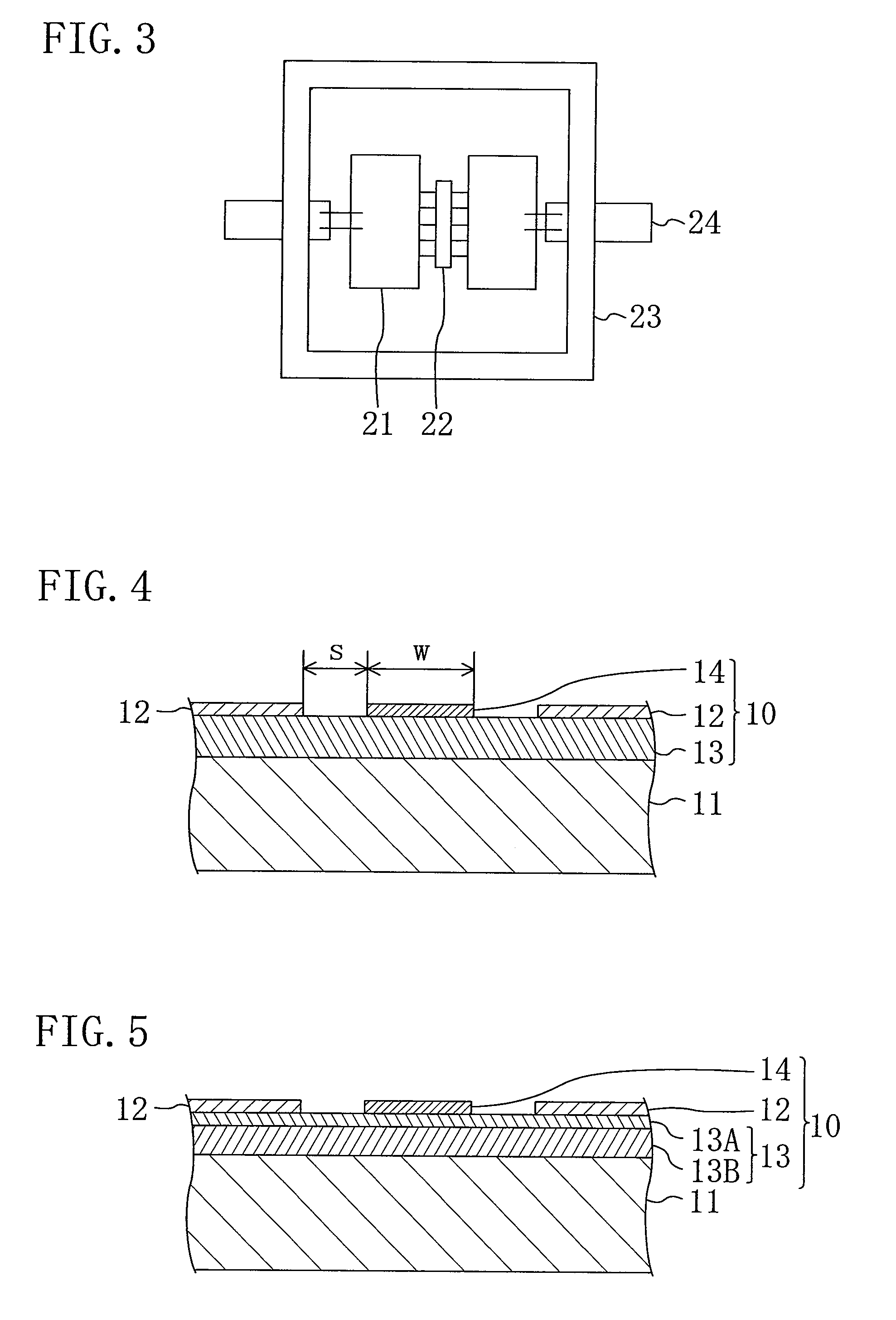

Touch sensor, display and electronic unit

ActiveUS20100328256A1High degree of flexibilityIntegration of circuit be easyNon-linear opticsInput/output processes for data processingVoltageFundamental frequency

A display includes: display pixel electrodes; common electrodes; a display layer; a display control circuit; touch detection electrodes; and a touch detection circuit detecting an external proximity object based on a detection signal obtained from the touch detection electrodes with use of a common drive voltage for display applied to the common electrode as a touch sensor drive signal. The touch detection circuit includes: a first filter allowing a fundamental detection signal, contained in the detection signal and having a frequency same as a fundamental frequency of the touch sensor drive signal, to pass therethrough, a plurality of second filters separately allowing two or more harmonic detection signals, contained in the detection signal and having frequencies same as respective harmonic frequencies of the touch sensor drive signal, to pass therethrough, and a detection section performing a detection operation based on the fundamental detection signal and the harmonic detection signals.

Owner:JAPAN DISPLAY WEST

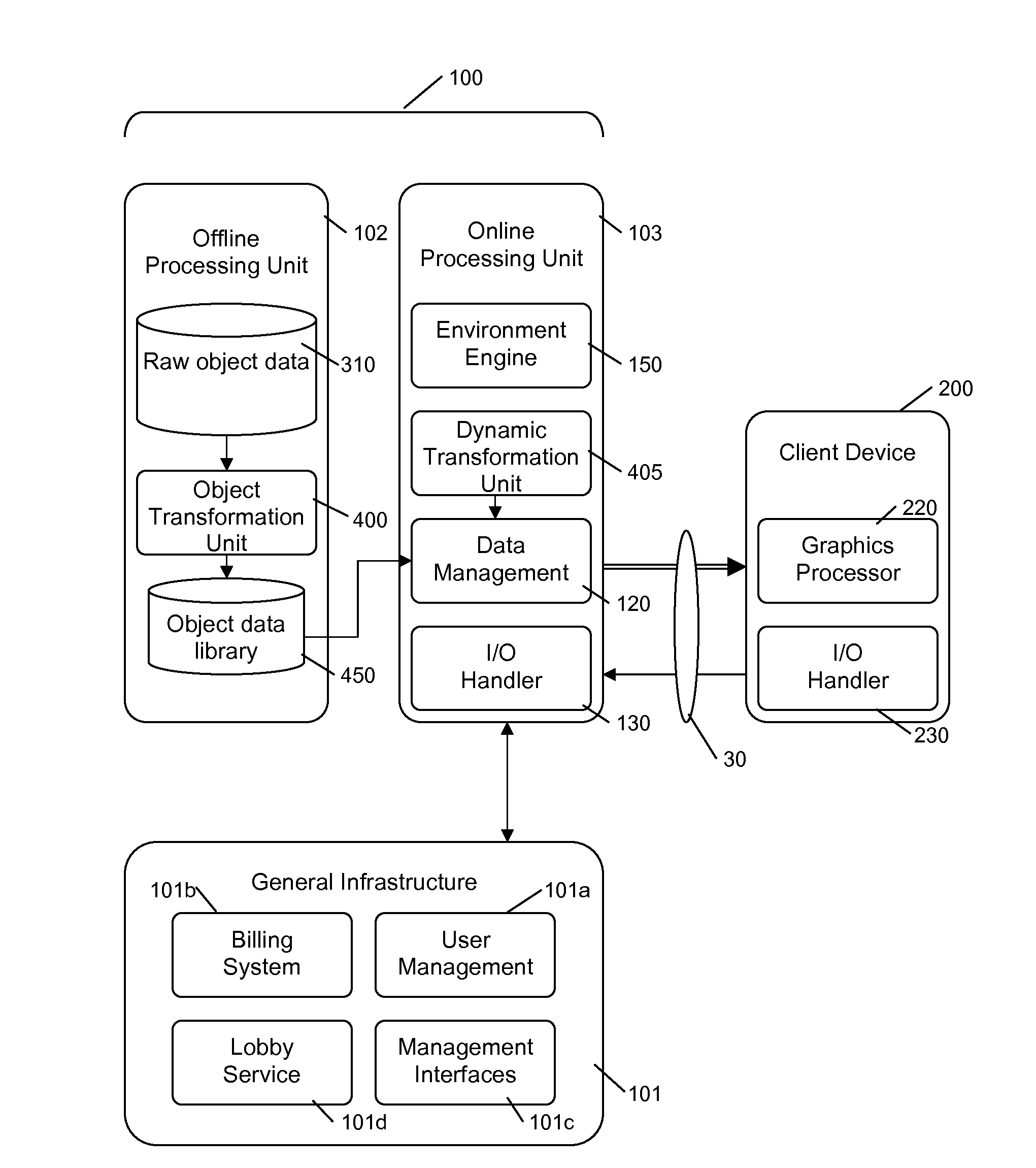

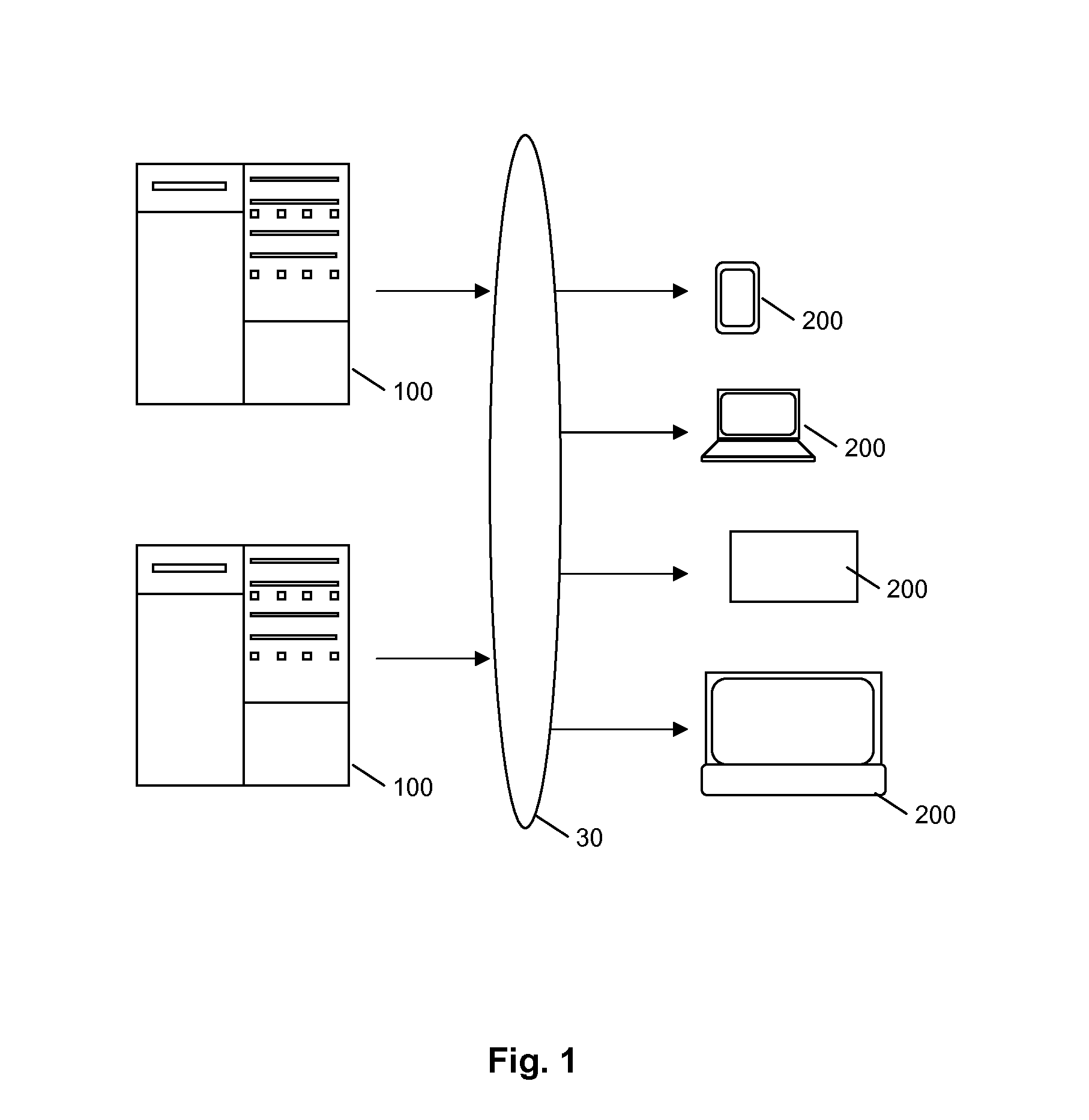

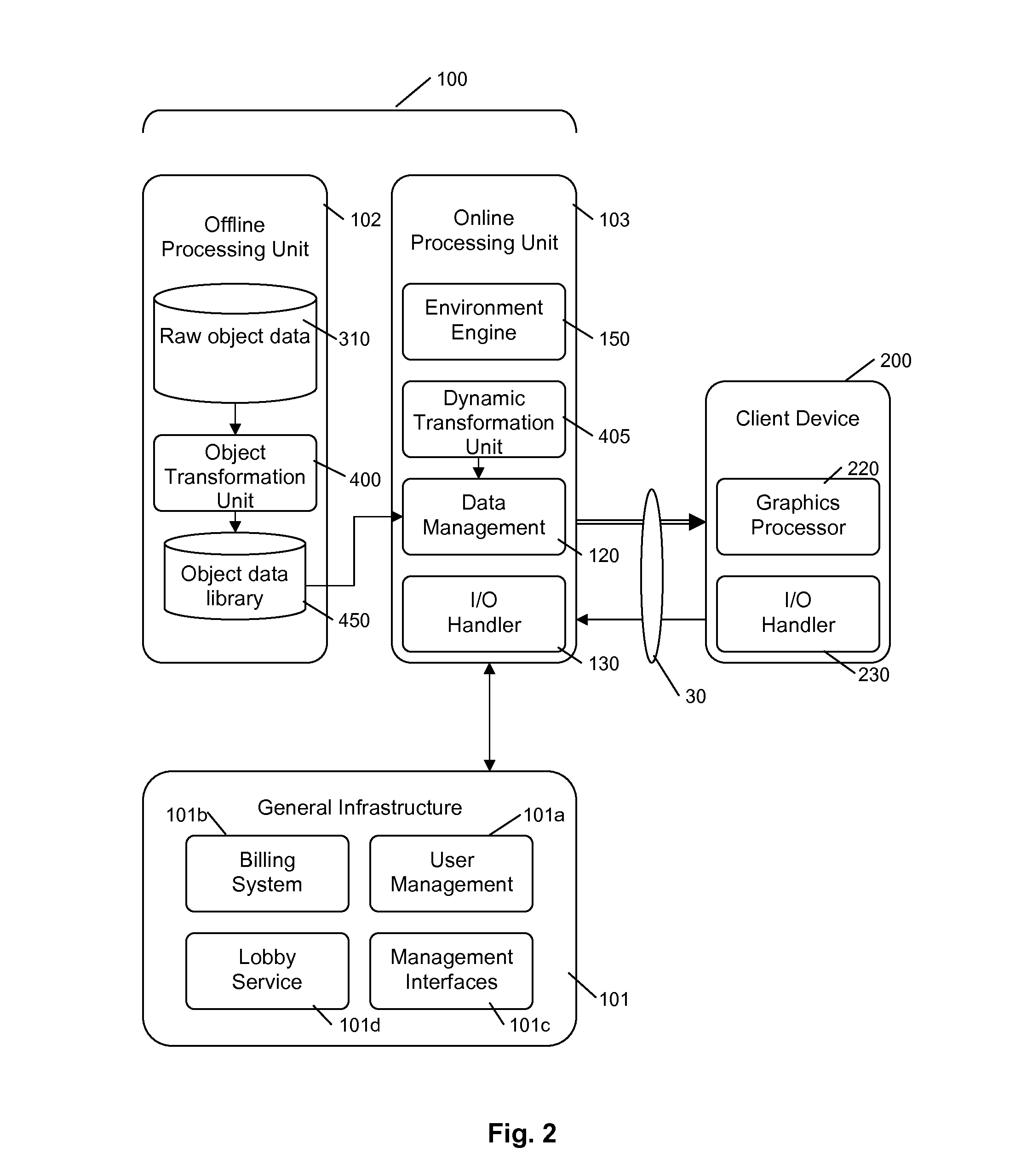

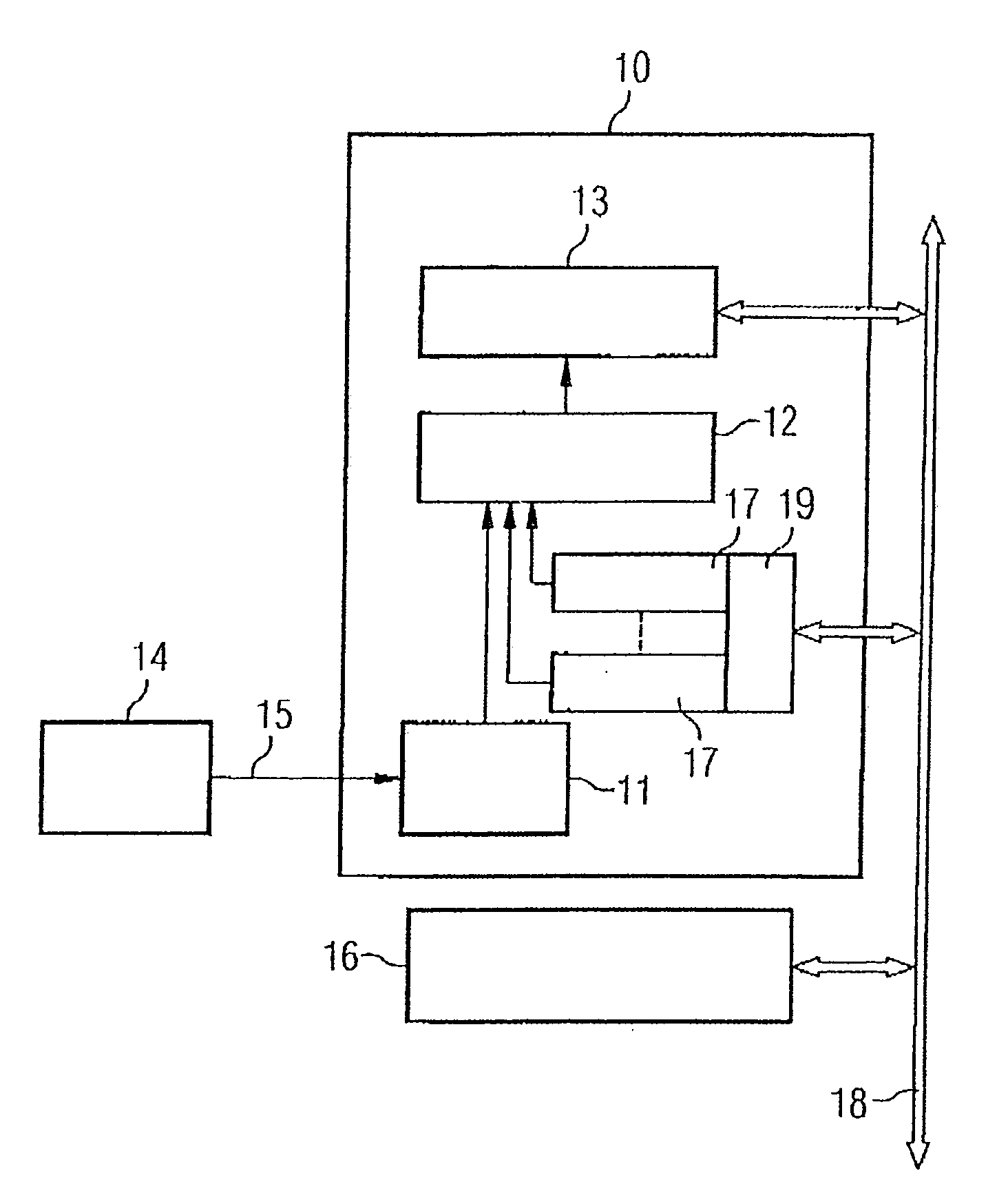

Multimedia content delivery system

ActiveUS20130024545A1High degree of controlHigh degree of flexibilityDetails involving 3D image dataImage codingGraphicsManagement unit

A multimedia content delivery system includes a server apparatus (100) for delivering graphical information across a network (30) to a client device (200). An environment engine (150) controls a virtual environment responsive to user commands. An object transformation unit (400, 405) transforms original object data (310) relating to a plurality of objects into compressed object data (350). A data management unit (120) transmits the compressed object data to the client device (200). The compressed object data (350) is decompressed and rendered by the client device (200) to output images to represent the virtual environment on a visual display device. Server-side and client side I / O handler units (130, 230) provide the user commands from the client device (200). The compressed object data (360) may comprise coefficients of a solution to a partial differential equation. Methods and apparatus are described relating to polygon-based object geometry (510) and pixel-based image files (600) which are transformed and regenerated using coefficients (540, 606) of a solution to a partial differential equation.

Owner:ANTI MATTER GAMES LTD

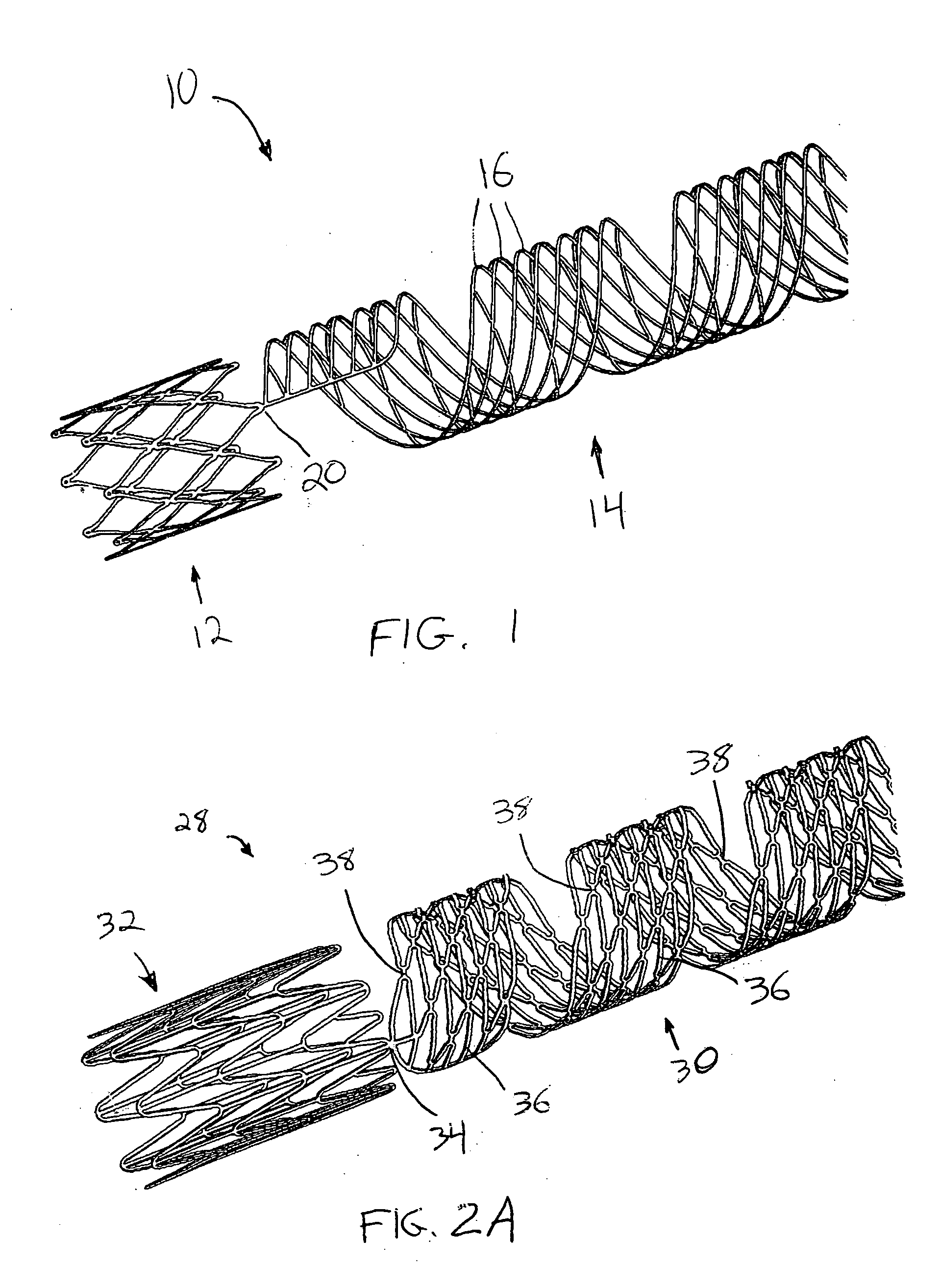

Low profile, high stretch, low dilation knit prosthetic device

InactiveUS20030204241A1High degree of flexibilityHigh degree of stretchabilityStentsWarp knittingYarnStent grafting

A radially expandable stent-graft endoprosthesis includes a knitted tubular structure circumferentially disposed and securably attached to the stent. The knitted tubular structure has a warp knit pattern of interlacing yarns with at least a two-needle underlap to provide greater than 50 percent longitudinal stretchability while substantially inhibiting dilation. A knitted tubular graft is combined with an ePTFE liner to form a composite with greater than 50 percent longitudinal stretchability is also provided. The knitted tubular graft also has a warp knit pattern of interlacing yarns with at least a two-needle underlap to provide the longitudinal stretchability while also substantially inhibiting dilation.

Owner:LIFESHIELD SCI

Low profile, high stretch knit prosthetic device

InactiveUS20030028239A1High degree of flexibilityHigh degree of stretchabilityStentsWarp knittingInsertion stentStent grafting

A radially expandable stent-graft endoprosthesis is provided. The graft included in the stent-graft is a knitted tubular structure circumferentially disposed and securably attached to the stent. The knitted tubular structure has a knit pattern of interlacing yarns in an Atlas or a modified-Atlas pattern to provide greater than 150 percent longitudinal stretchability. A knitted tubular graft and a knitted medical fabric with greater than 150 percent longitudinal stretchability are also provided.

Owner:LIFESHIELD SCI

Low profile, high stretch, low dilation knit prosthetic device

InactiveUS6939372B2High degree of flexibilityHigh degree of stretchabilityStentsWeft knittingYarnStent grafting

A radially expandable stent-graft endoprosthesis includes a knitted tubular structure circumferentially disposed and securably attached to the stent. The knitted tubular structure has a warp knit pattern of interlacing yarns with at least a two-needle underlap to provide greater than 50 percent longitudinal stretchability while substantially inhibiting dilation. A knitted tubular graft is combined with an ePTFE liner to form a composite with greater than 50 percent longitudinal stretchability is also provided. The knitted tubular graft also has a warp knit pattern of interlacing yarns with at least a two-needle underlap to provide the longitudinal stretchability while also substantially inhibiting dilation.

Owner:LIFESHIELD SCI

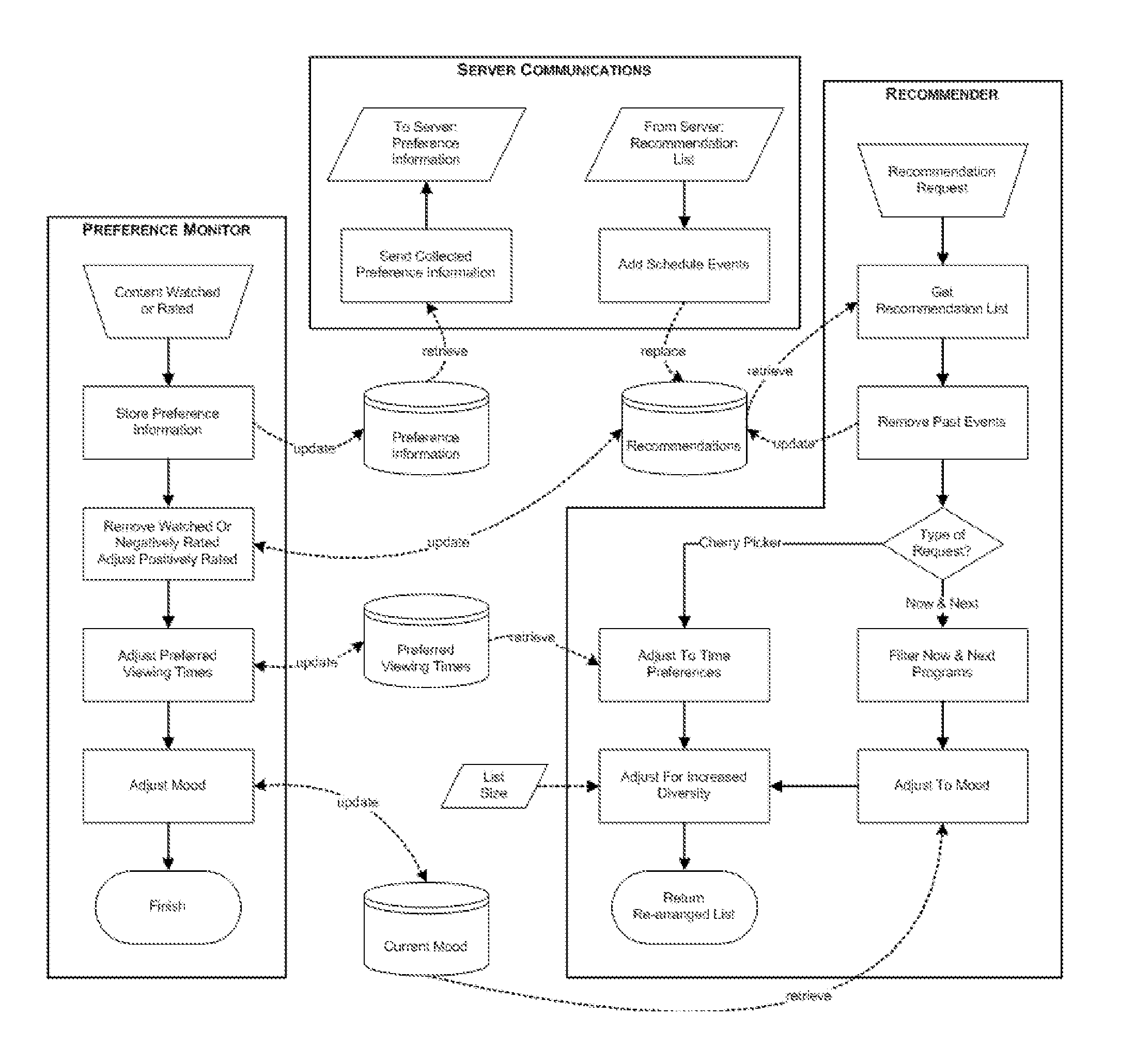

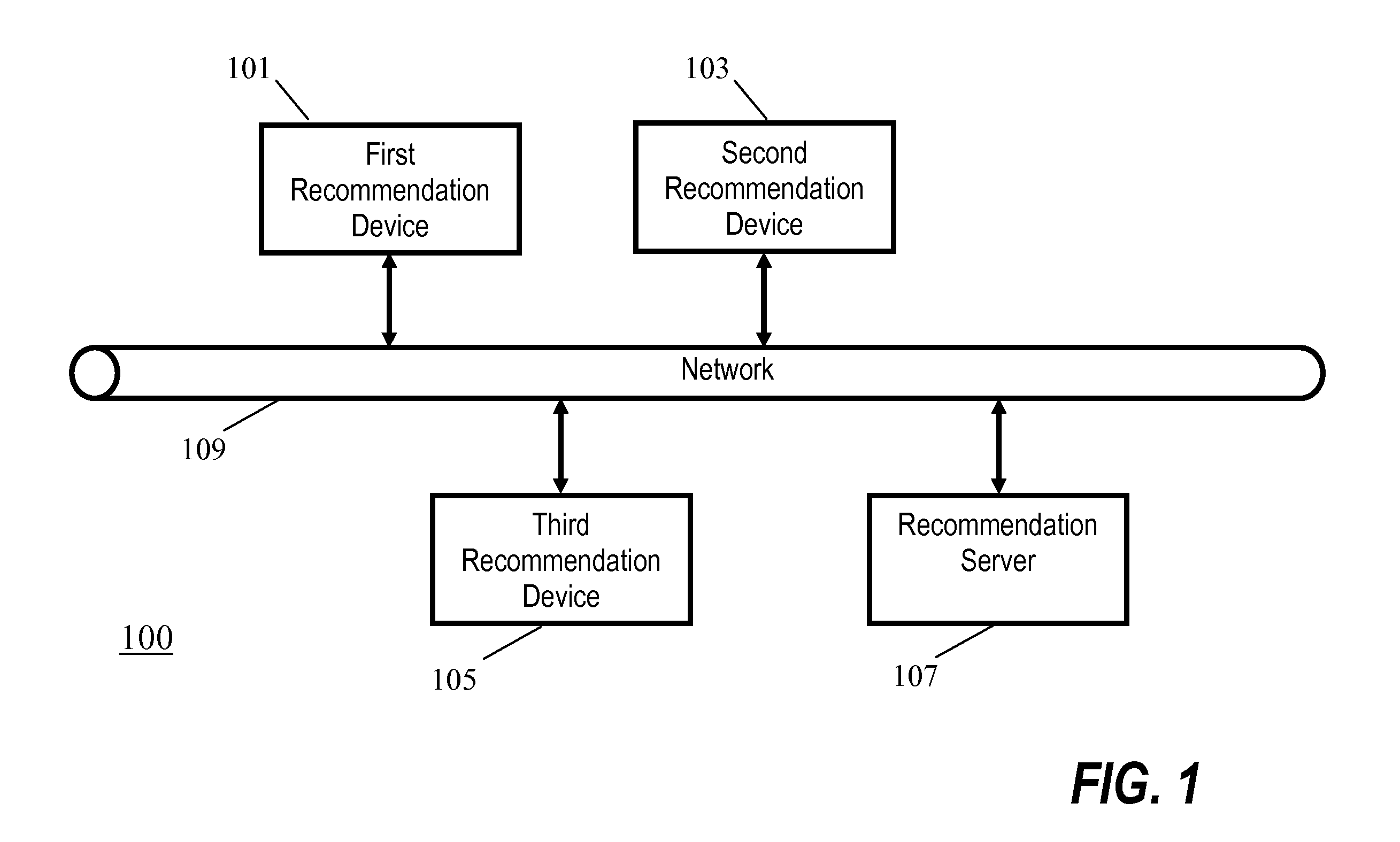

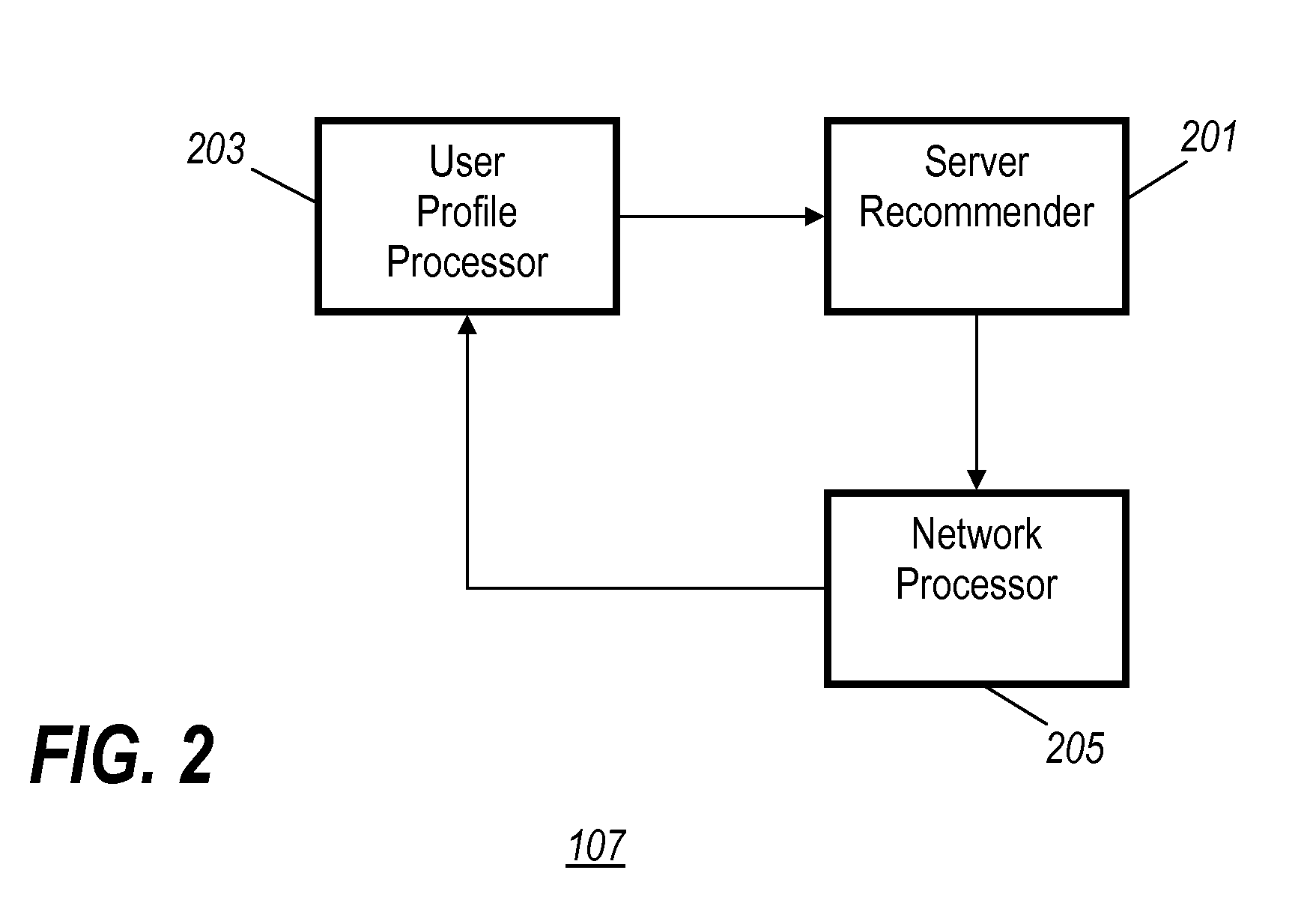

Method and system for generating recommendations of content items

InactiveUS20110184899A1Reduce computing resource usageReducing communication resourceTwo-way working systemsKnowledge representationRecommendation serviceUser profile

A recommendation system comprises a recommendation server (107) which generates a first recommendation set of recommended content items in response to a user profile associated with a first user and stored on the recommendation server (107). Content item identification data identifying the content items of the first recommendation set are transmitted to a first recommendation device (101). The first recommendation device (101) comprises a network interface (301) which receives the content item identification data from the recommendation server (107). A content list processor (303) determines the first recommendation set in response to the content item identification data. The first recommendation device (101) furthermore comprises application processors (309-313) which can execute different recommendation applications. A device recommender (307) generates a second set of recommended content items from the first recommendation set in response to a characteristic of the recommendation application being executed. The application then provides recommendations in response to the second set.

Owner:GOOGLE TECH HLDG LLC

Vascular prothesis having flexible configuration

InactiveUS20050033410A1High degree of flexibilityReduce delivery profileStentsBlood vesselsBiomedical engineeringHinge point

An implantable vascular prosthesis having improved flexibility is provided comprising a helical body portion having a reduced delivery configuration and an expanded deployed configuration, the helical body portion comprising a plurality of cells interconnected by hinge points that enhances flexibility of the vascular prosthesis in the reduced delivery configuration.

Owner:NOVOSTENT CORP

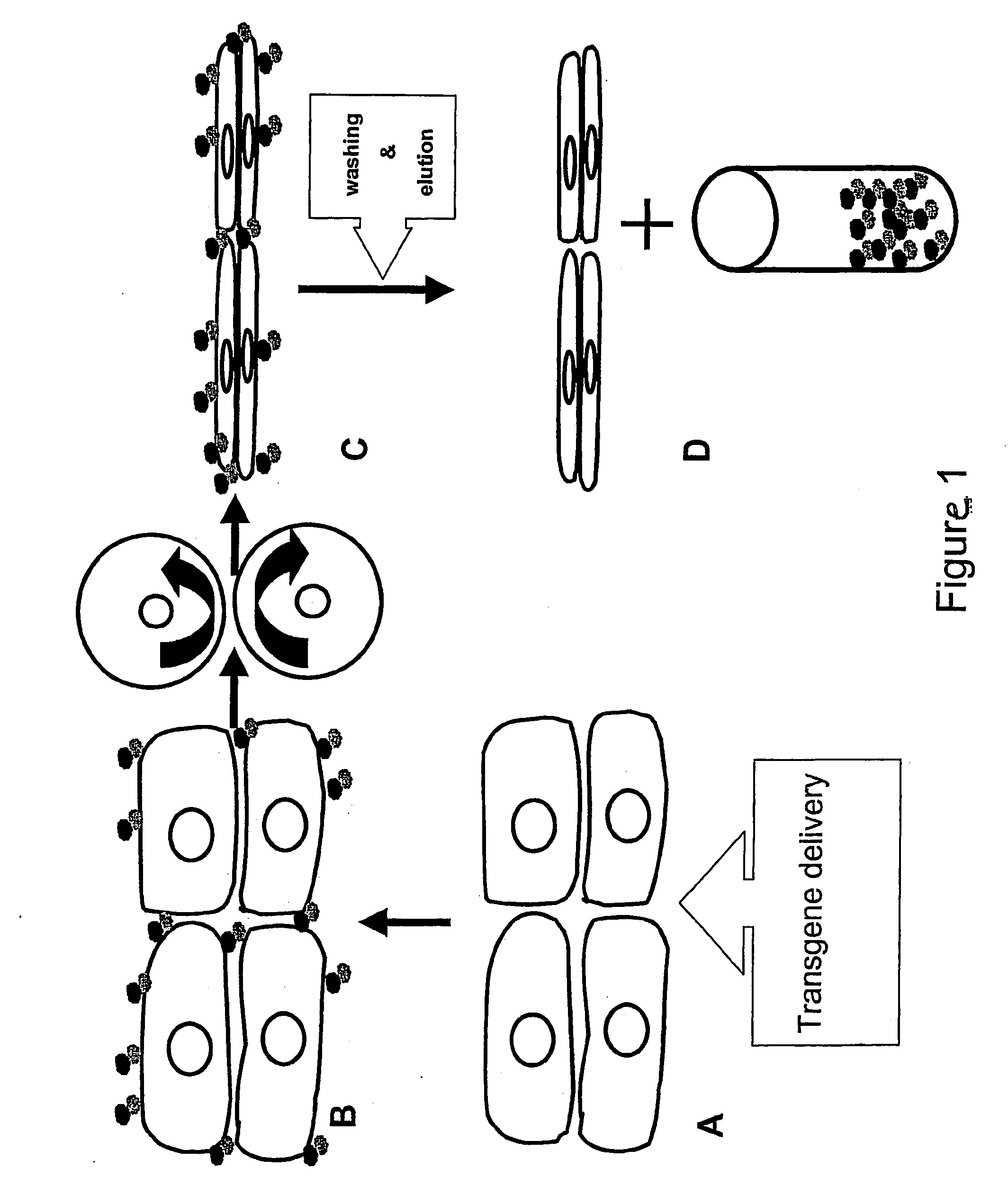

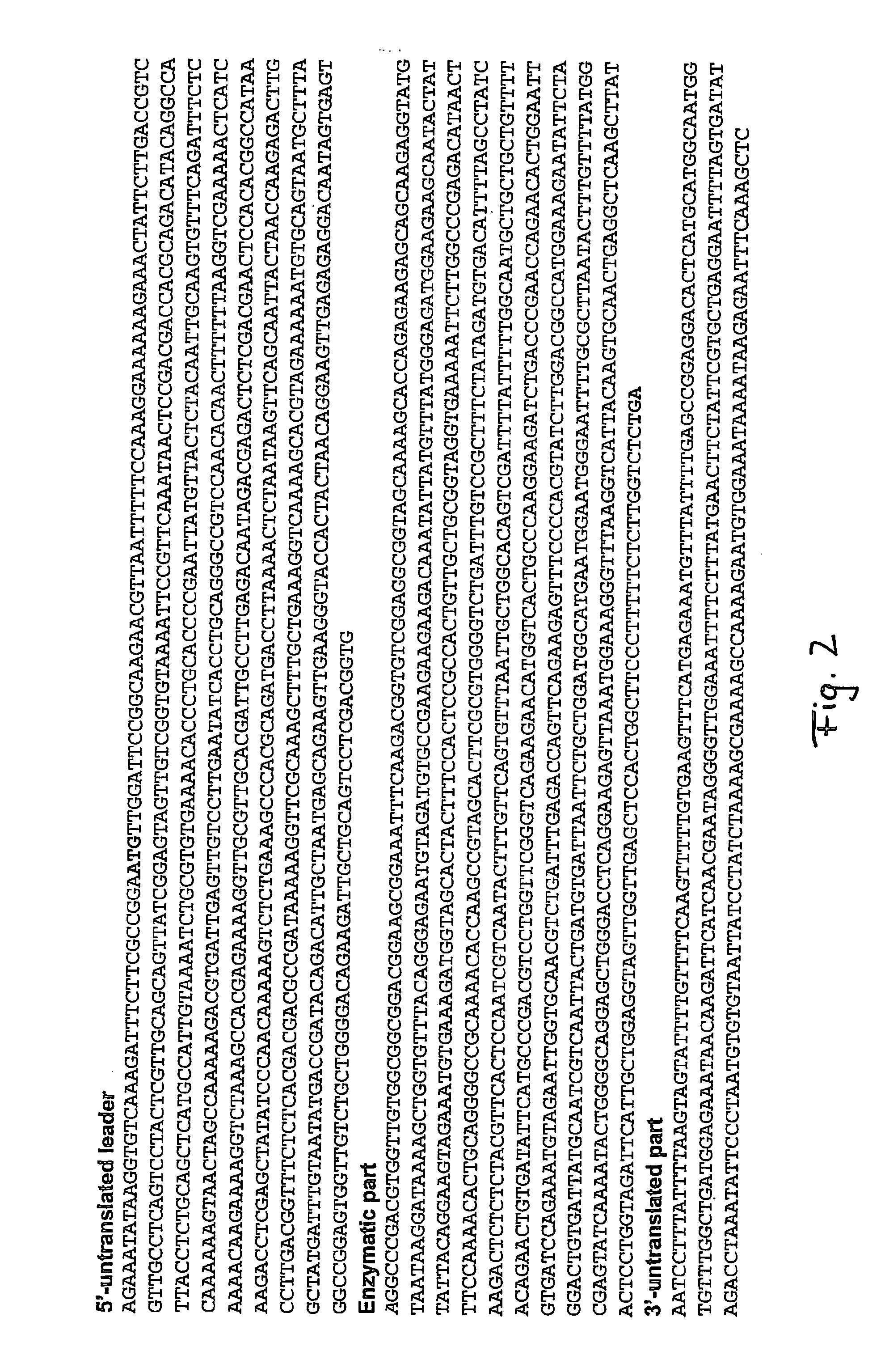

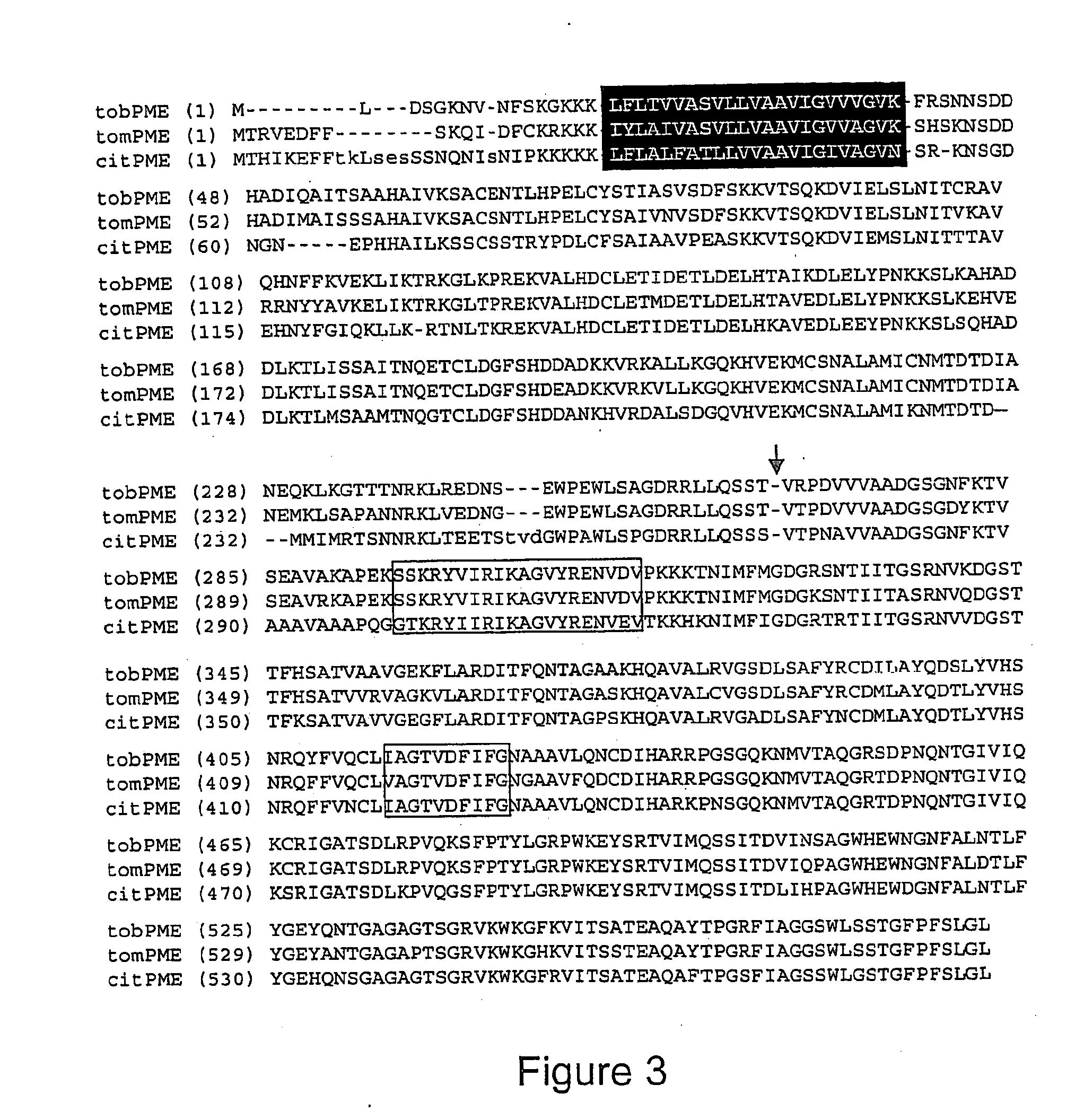

Method of protein production in plants

InactiveUS20050015830A1Increase flexibilityHigh expressionDepsipeptidesPeptide preparation methodsBiotechnologyNucleotide

A process of producing a protein or polypeptide of interest in a plant or in plant is provided, comprising: (i) transforming or transfecting a plant of plant cells with a nucleotide sequence having a coding region encoding a fusion protein comprising the protein or polypeptide of interest, a signal peptide functional for targeting said fusion protein to the apoplast, and a polypeptide capable of binding the fusion protein to a cell wall component, (ii) enriching cell wall components having expressed and bound fusion protein, and separating the protein or polypeptide of interest or a protein comprising the protein or polypeptide interest.

Owner:ICON GENETICS

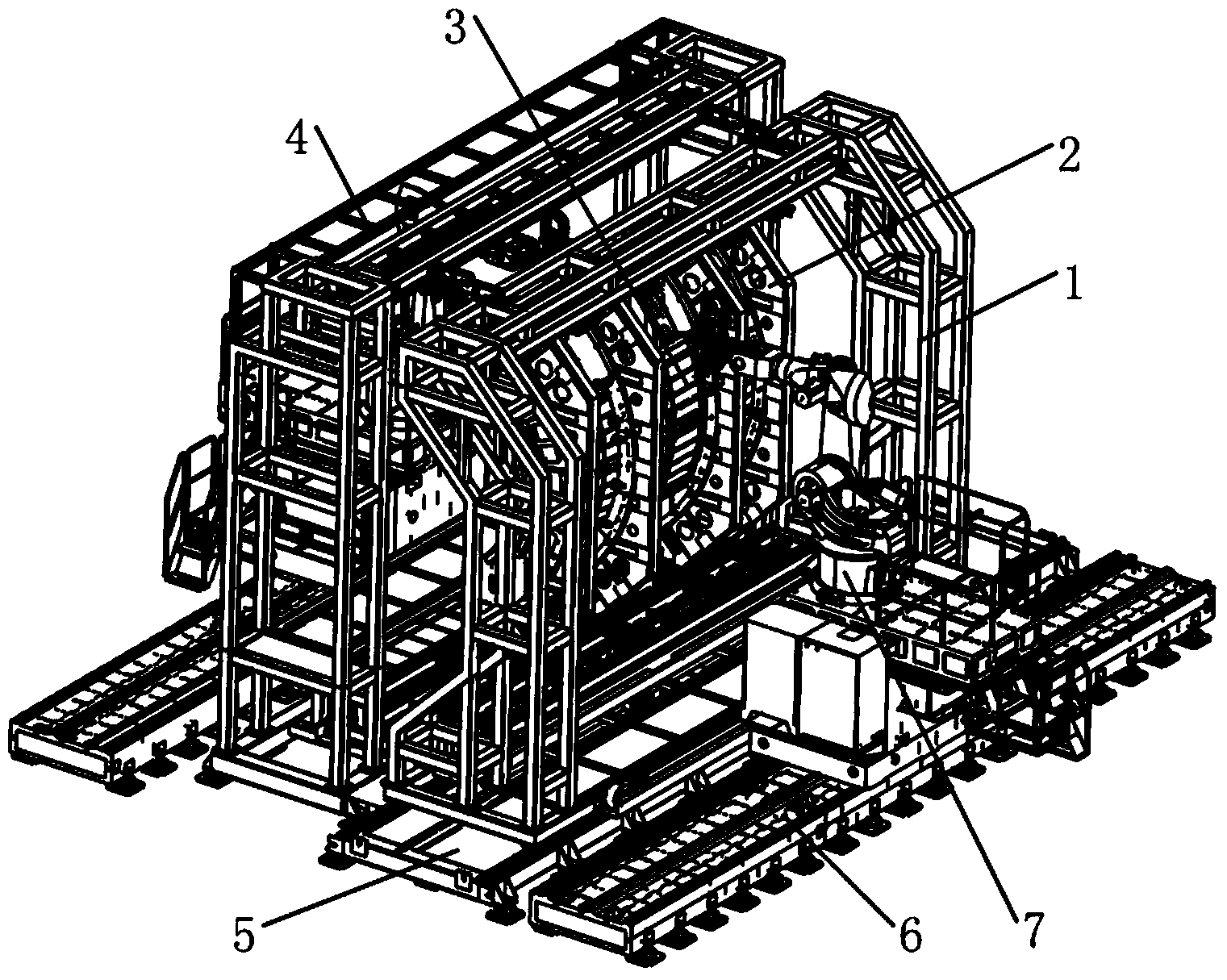

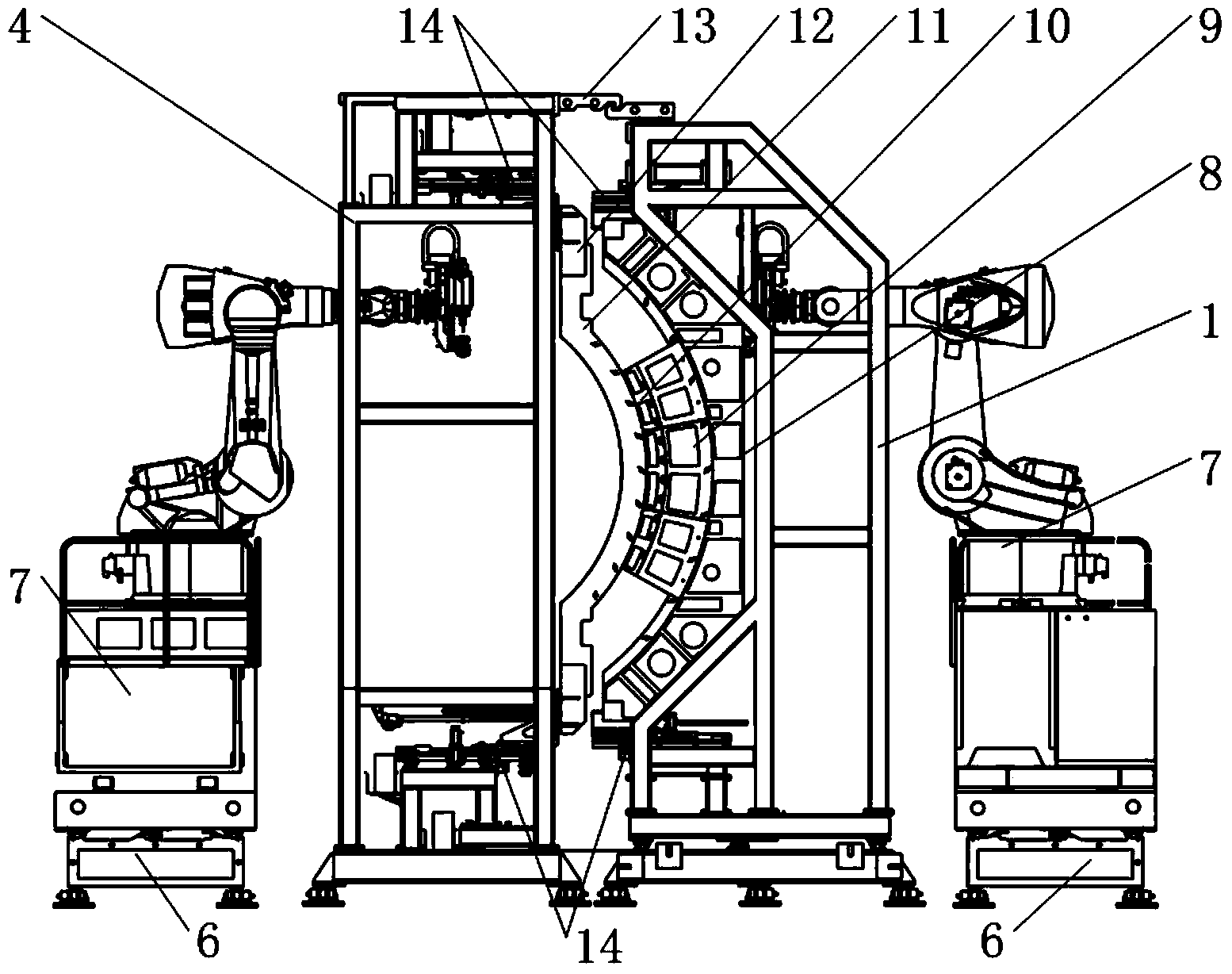

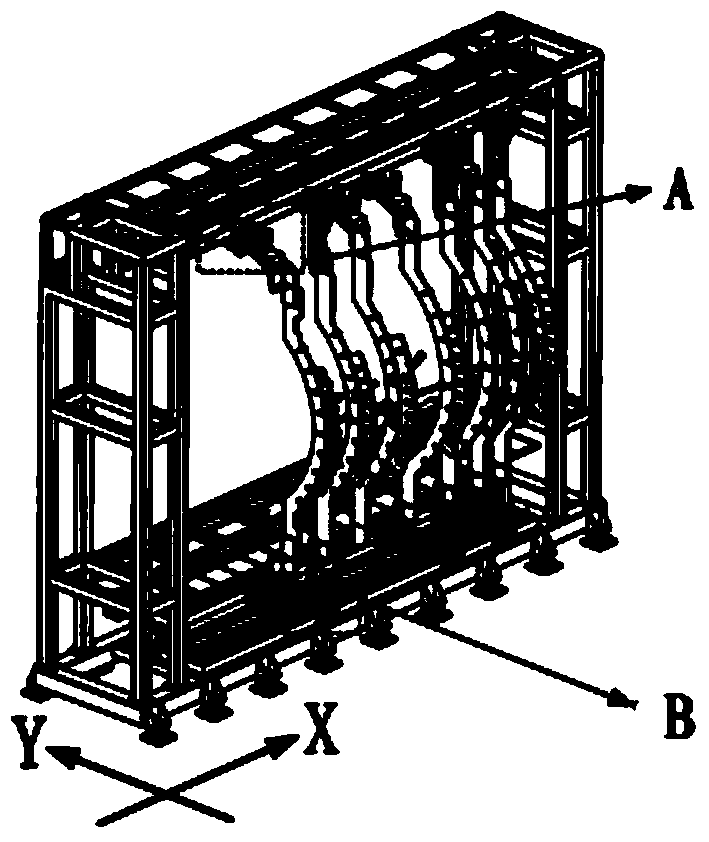

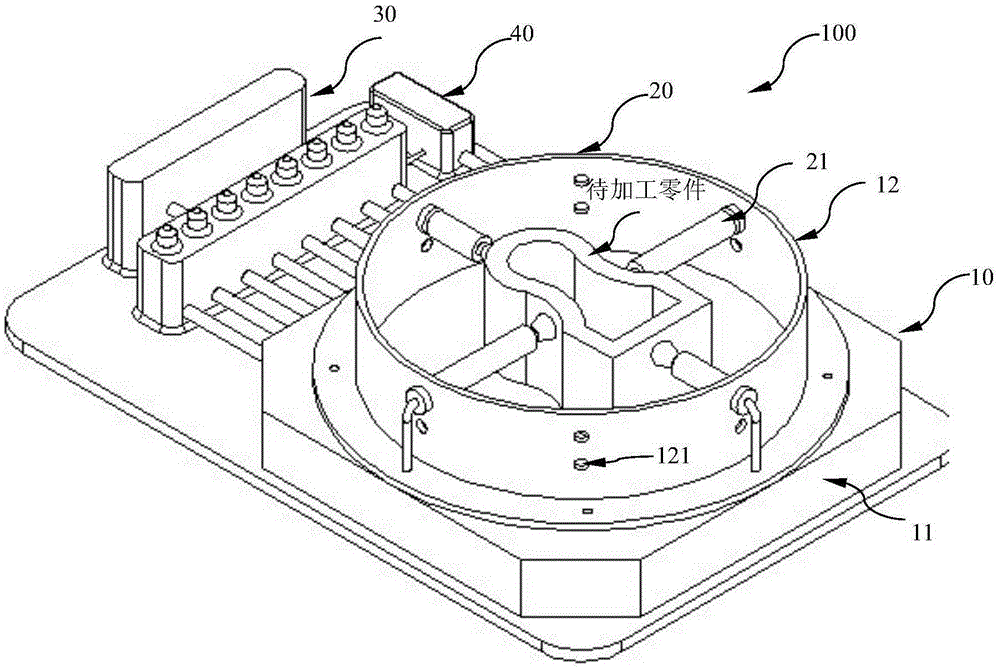

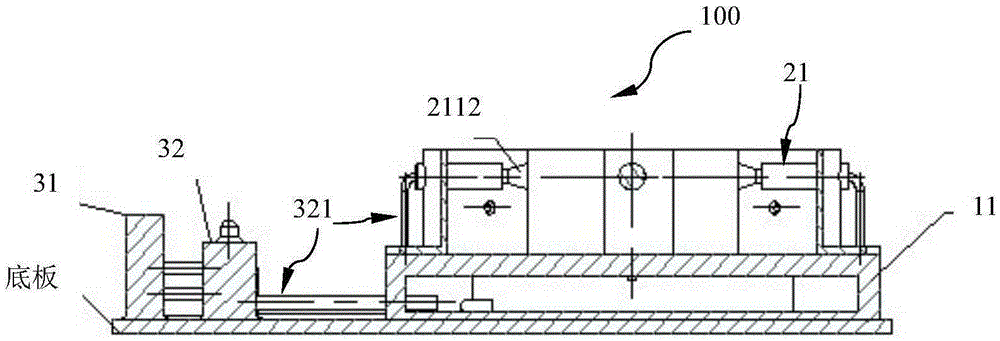

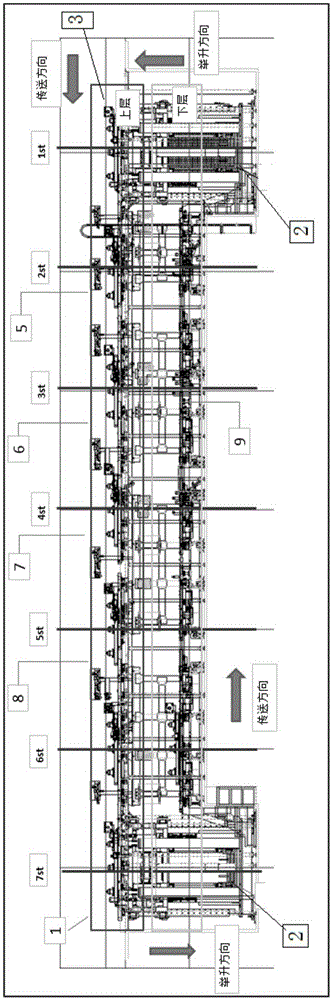

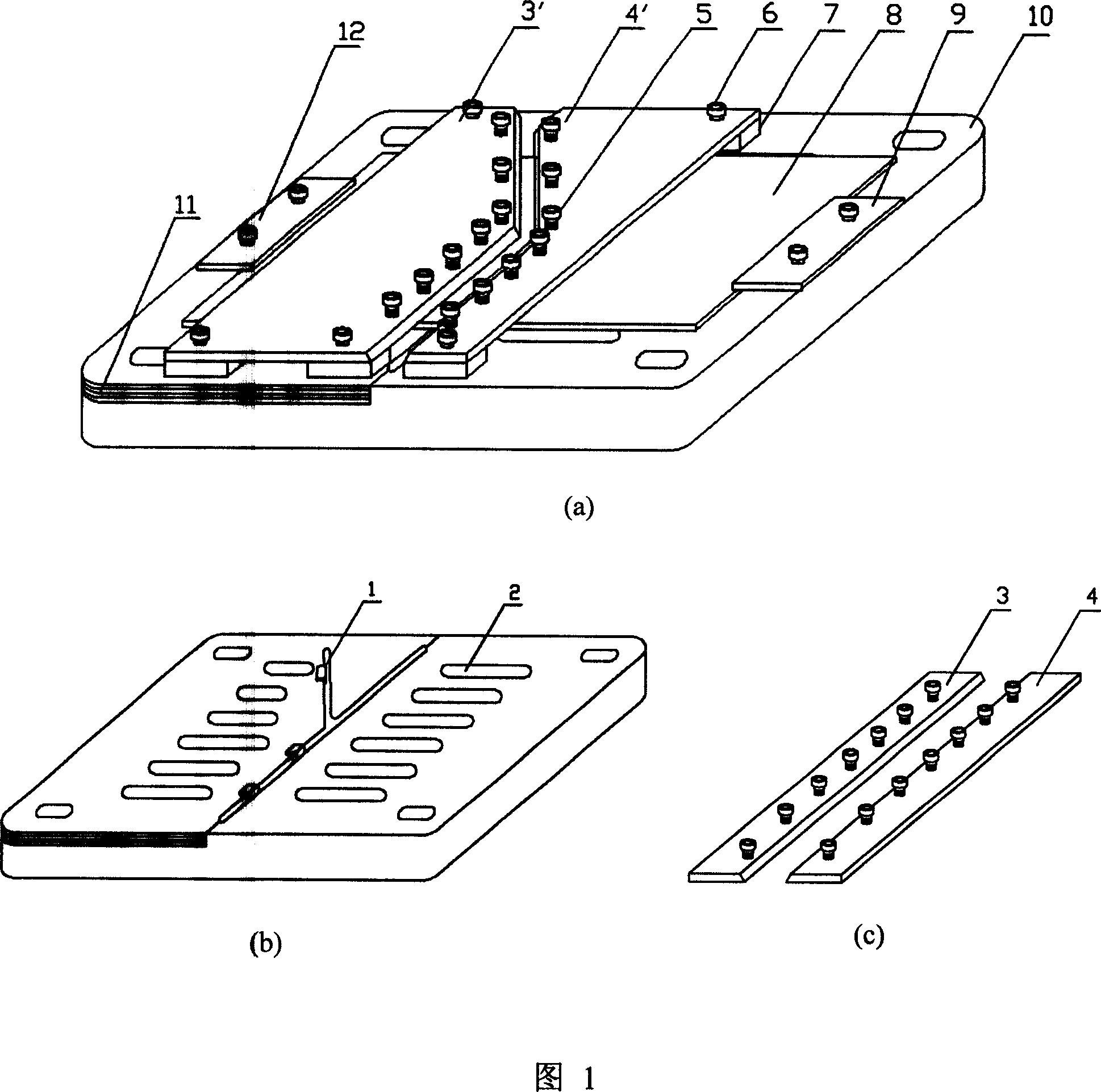

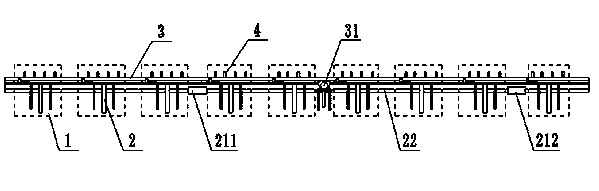

Flexible assembly system for aircraft panel

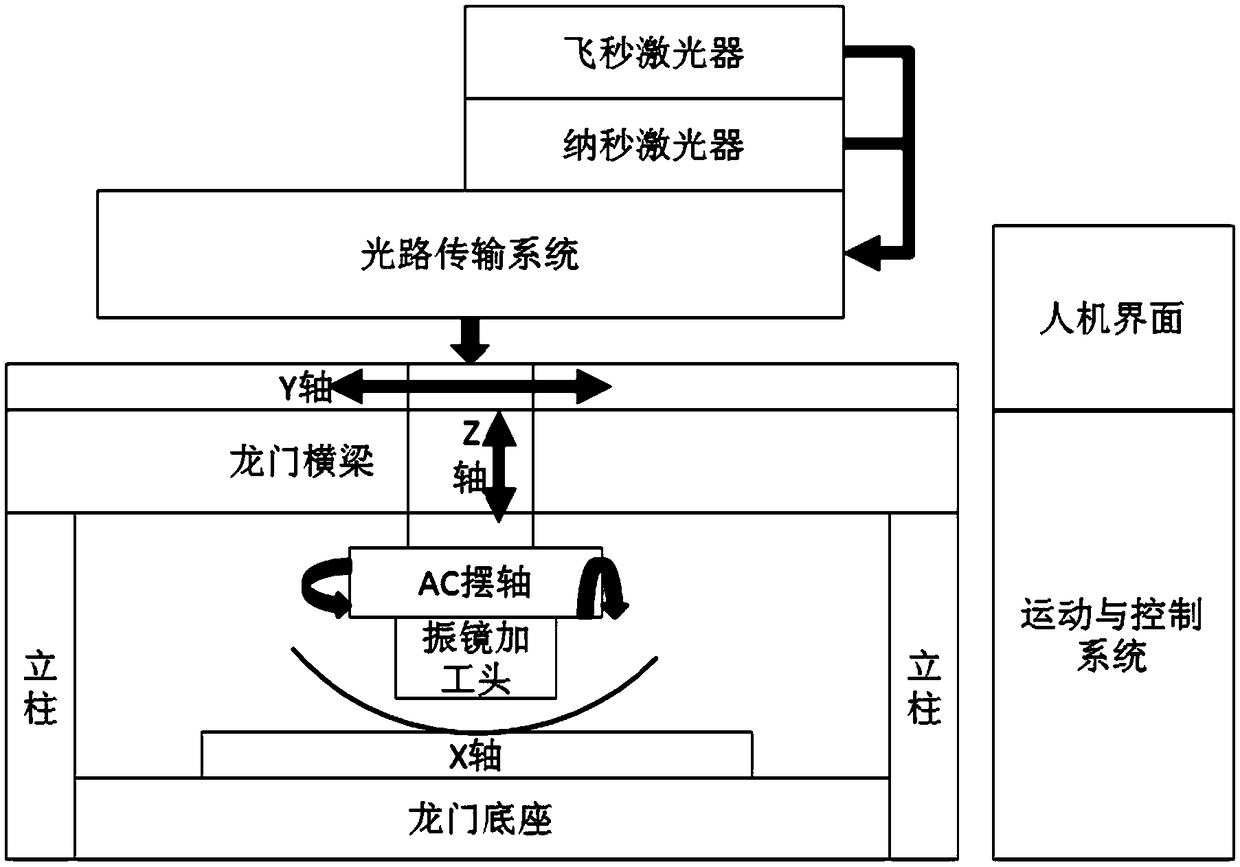

ActiveCN103921116AAchieve flexibilityHigh degree of flexibilityAssembly machinesWork holdersAerospace engineeringAssembly systems

The invention discloses a flexible assembly system for an aircraft panel. The flexible assembly system comprises a fixed base frame, a movable base frame which is capable of moving in the X-axis direction and is matched with the fixed base frame, a plurality of flexible clamping board assemblies arranged on the fixed base frame and the movable base frame and used for clamping the aircraft panel, a plurality of transmission positioning units arranged on the fixed base frame and the movable base frame and used for adjusting the positions of the flexible clamping board assemblies and robot perforating systems. The positioning assembly requirements of different aircraft panels can be satisfied by adjusting the positions of an inside fixing clamping board and an outside fixing clamping board and replacing a replaceable internal clamping board and a replaceable skin clamping board, and therefore the flexibility of the assembly system is achieved. The two robot perforating systems arranged on the two sides of a panel assembly tool are used for simultaneously satisfying the automatic perforating connecting requirements of the two sides of the aircraft panel. The flexible assembly system is high in flexibility, high-efficiency and high-quality assembly of the aircraft panel can be achieved, the assembly period is greatly shortened, and cost is reduced.

Owner:ZHEJIANG UNIV +1

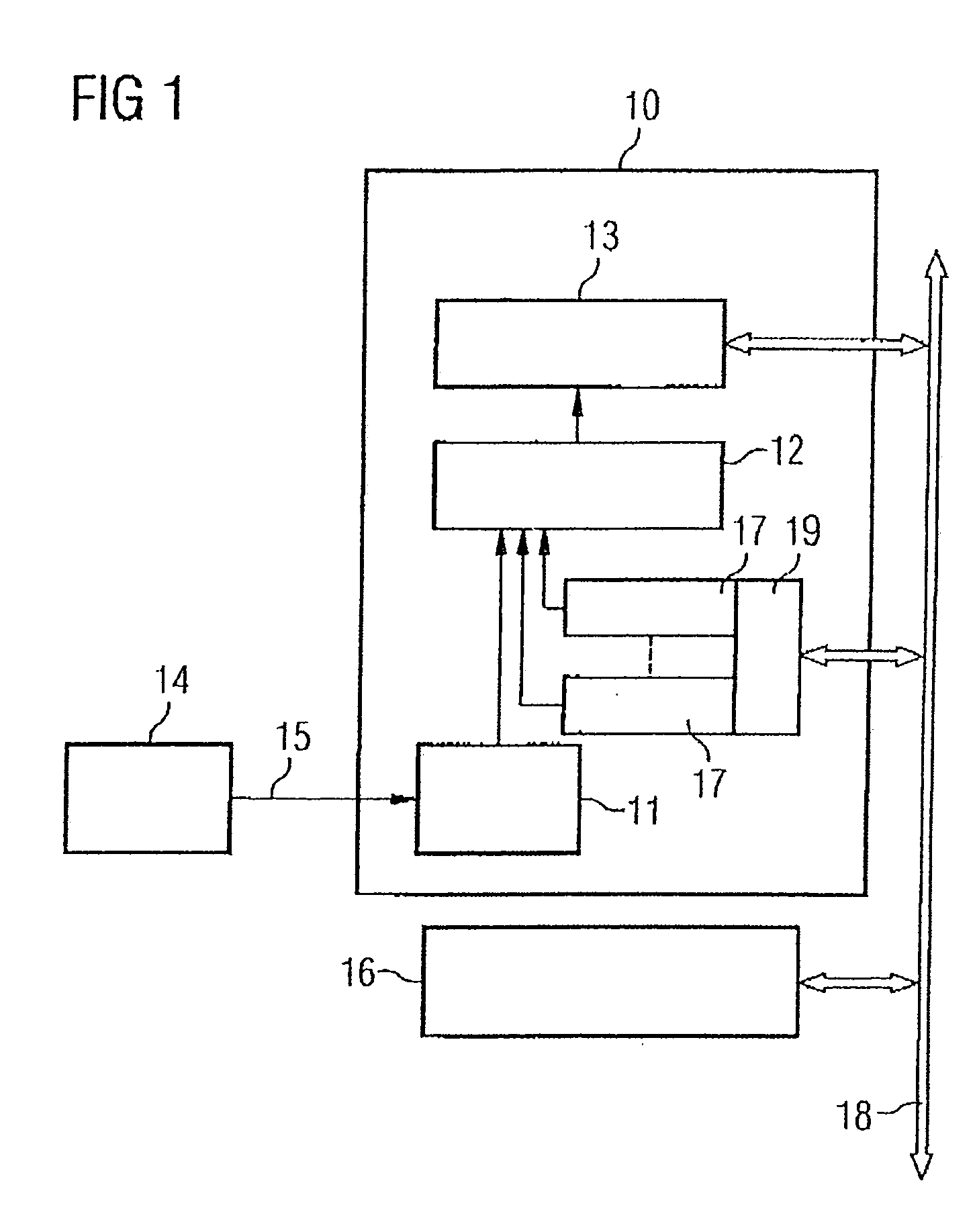

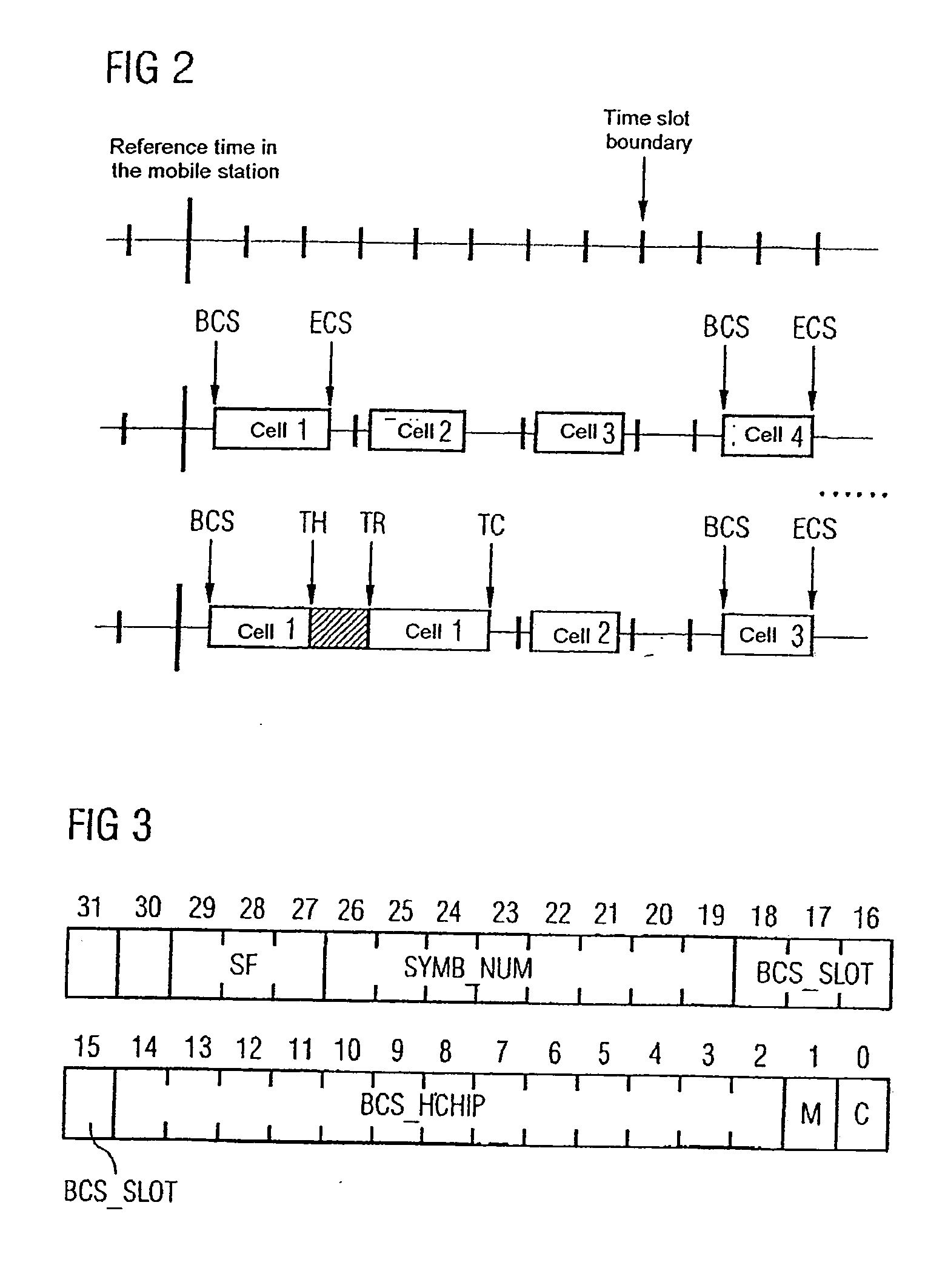

Apparatus and method for time control of the processing of a radio signal in a mobile station

InactiveUS20050008040A1High degree of flexibilitySimplify communicationTime-division multiplexSubstation equipmentTime frameTime control

Owner:INTEL CORP

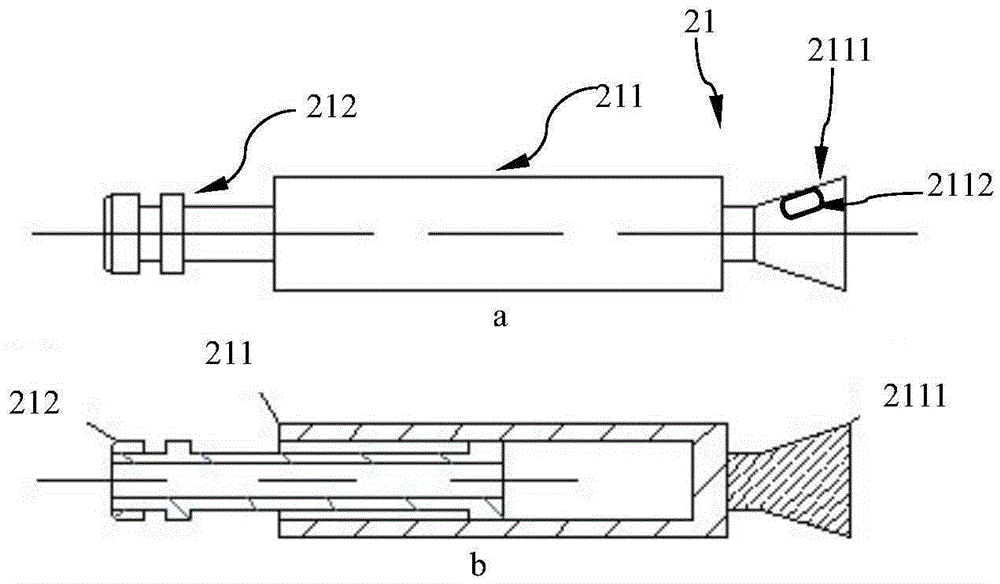

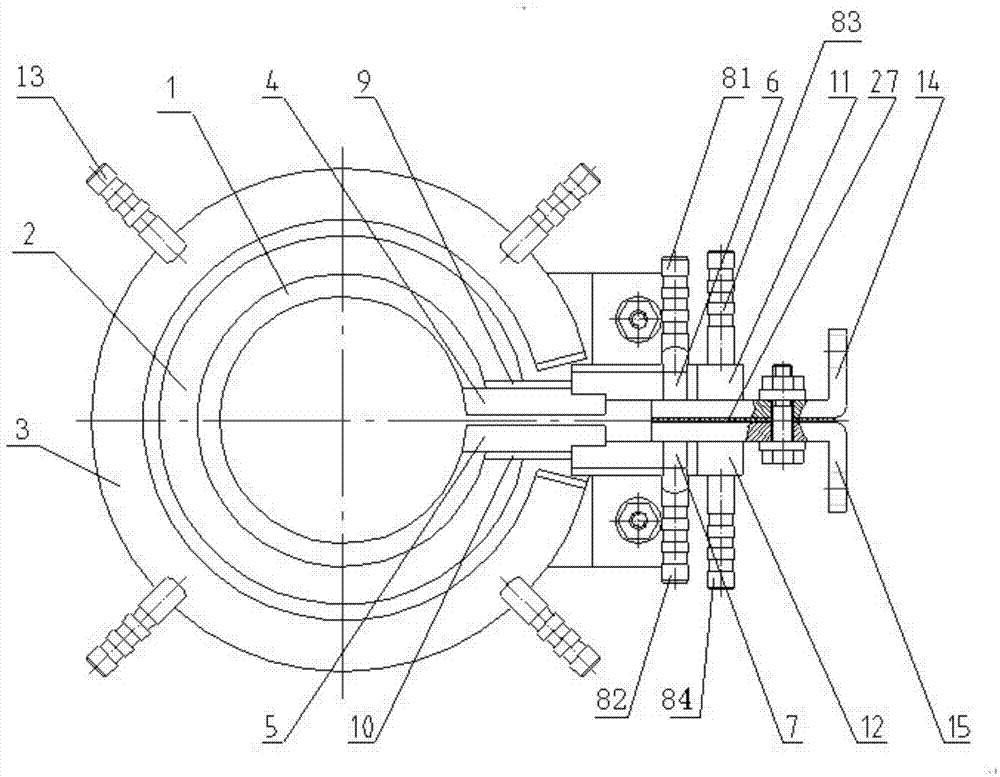

Air pressure flexible clamping device of frame-shaped parts with thin walls, and clamping method of air pressure flexible clamping device

InactiveCN105382741AStrong size applicabilityGuaranteed stabilityWork clamping meansWork holdersMachine partsAtmospheric pressure

An air pressure flexible clamping device of frame-shaped parts with thin walls is used for clamping and fixing of to-be-machined frame-shaped parts with thin walls and cylinder body parts when being machined, and comprises a support unit which comprises a base and a closed-ring support which is arranged on the base and is used for surrounding the to-be-machined parts; a clamping unit which is arranged on the wall of the closed-ring support, and comprises at least three air pressure clamping parts which are mutually cooperated for clamping and fixing the to-be-machined parts; a pneumatic unit which is communicated with the air pressure clamping parts for respectively controlling air pressure of multiple air pressure clamping parts, wherein the air pressure clamping parts are detachably connected on the closed-ring support, a head end is provided with a suction nozzle, the suction nozzle is in contact, clamped and fixed with the outer surface of each of the to-be-machined parts through negative pressure. The invention also provides a clamping method. The device and the method have the advantages of being flexible in operation, high in applicability to shapes and sizes of thin-walled workpieces, and capable of effectively ensuring the stability, accuracy and reliability of the clamping of the frame-shaped parts with thin walls during a machining process.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

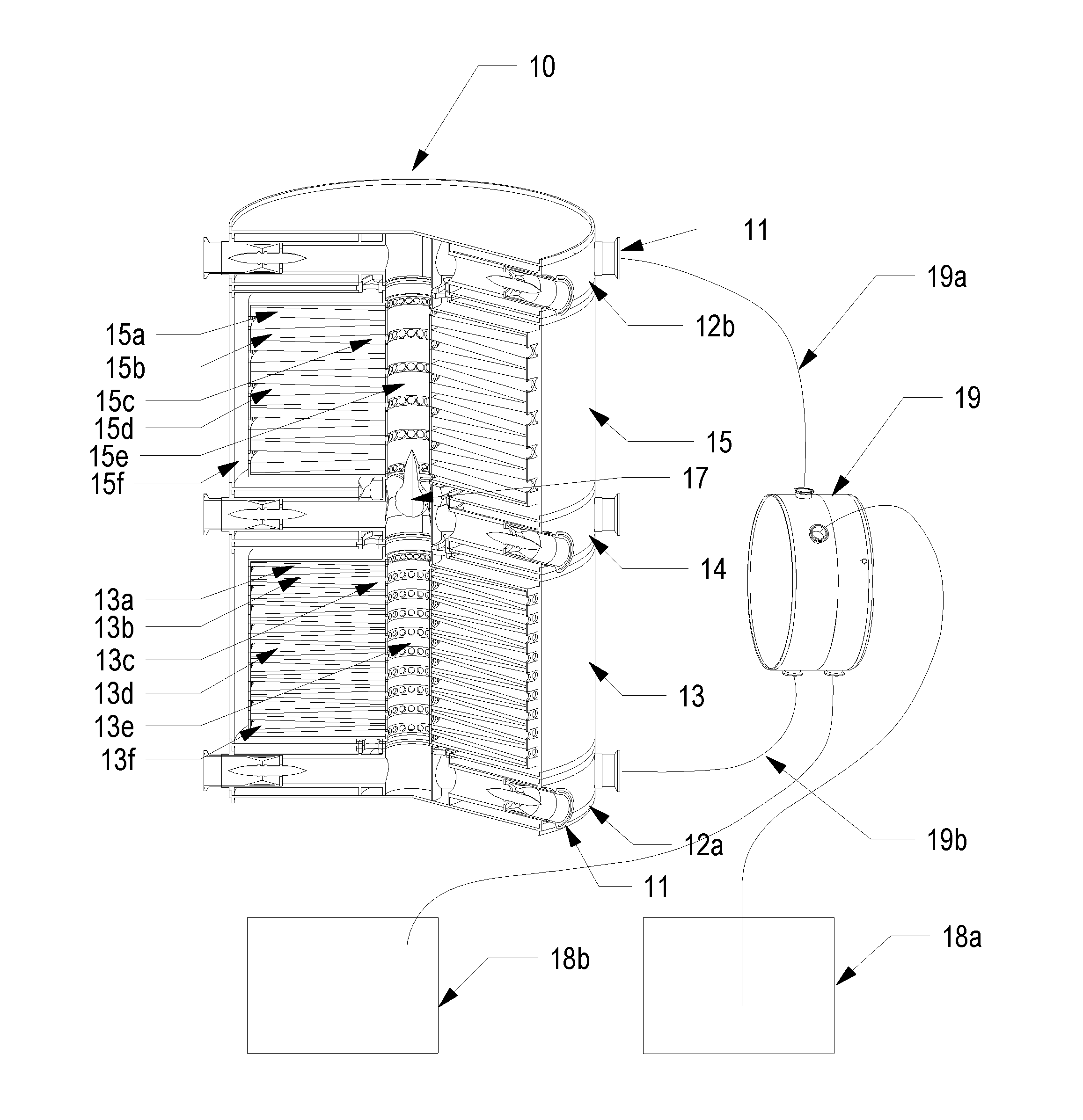

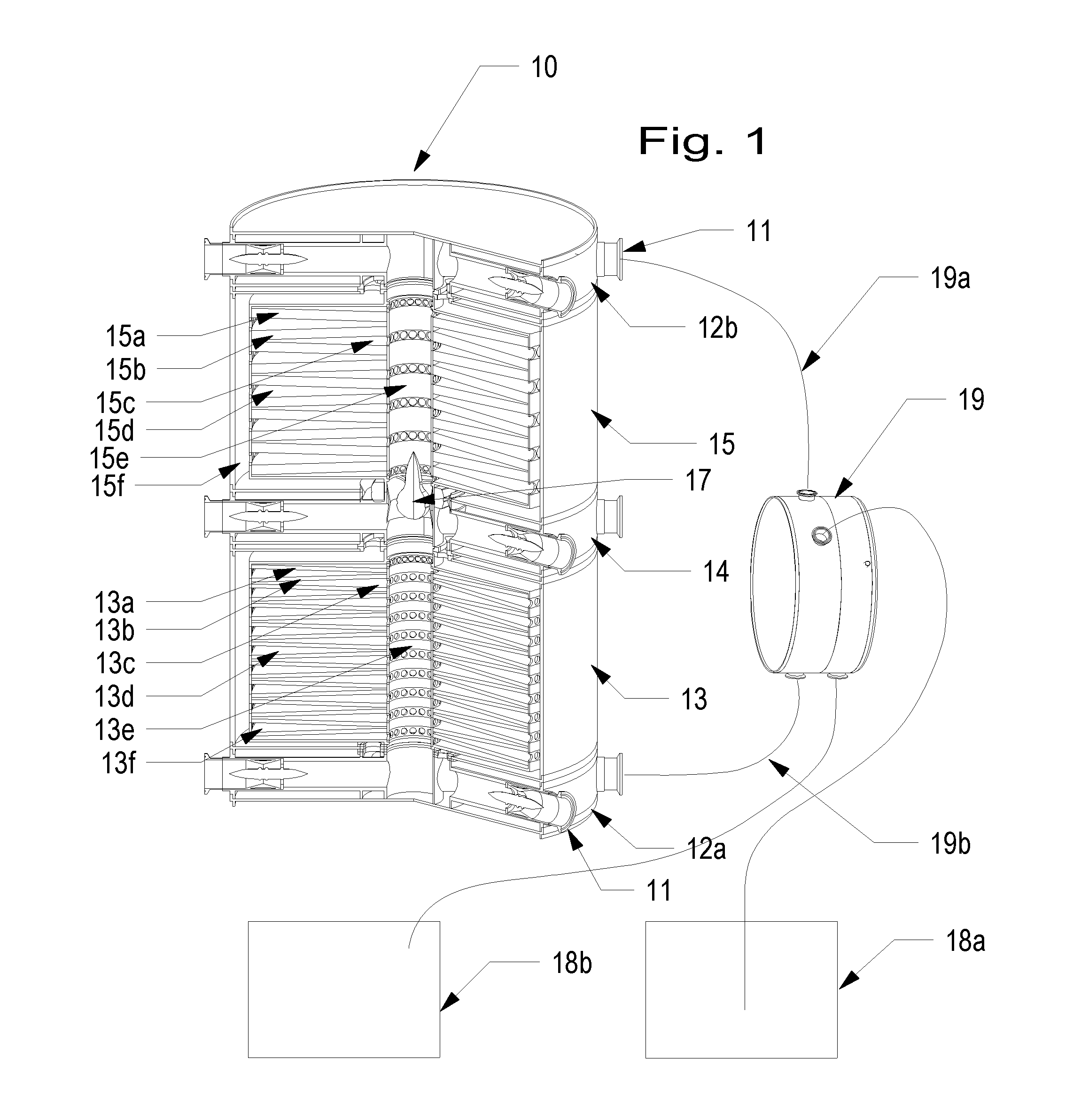

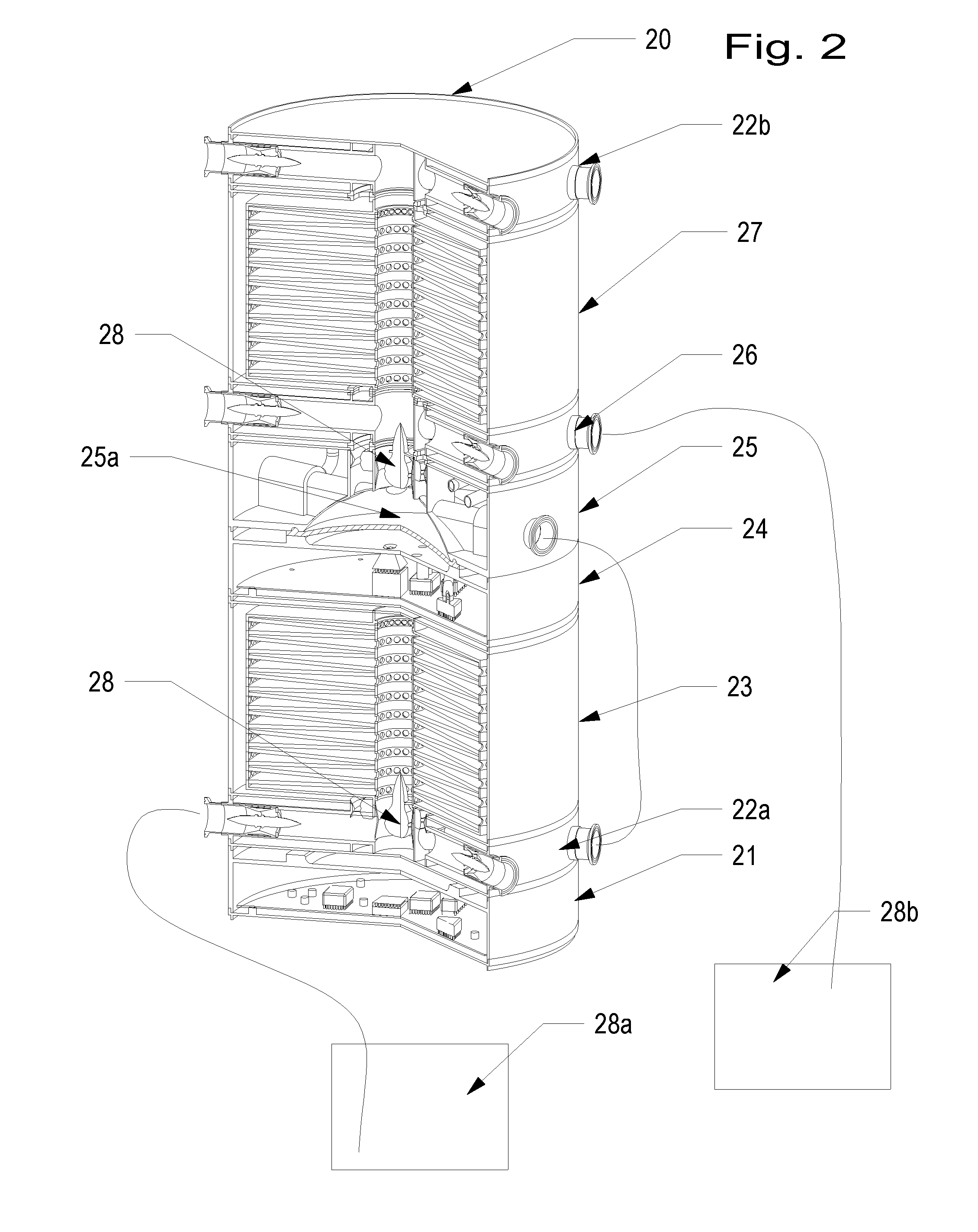

Biopharmaceutical process apparatuses assembled into a column

InactiveUS20130196375A1Elimination of preparation stepIncrease flexibilityIon-exchanger regenerationApparatus sterilizationDownstream processingProcess equipment

A bio factory apparatus capable of Up-Stream production of biologic material products or biologics products in a liquid volume and processing of biologic or biologic material products Down-Stream, comprising at least one first Up-Stream producing capsule and at least one second Down-Stream processing capsule, said capsules capable of being stacked in any order and any number within a column.

Owner:STOBBE TECH

Low profile, high stretch, low dilation knit prosthetic device

InactiveUS20030125796A1High degree of flexibilityHigh degree of stretchabilityStentsSurgeryYarnStent grafting

A radially expandable stent-graft endoprosthesis is provided. The graft included in the stent-graft is a knitted tubular structure circumferentially disposed and securably attached to the stent. The knitted tubular structure has a warp knit pattern of interlacing yarns with at least a two-needle underlap to provide greater than 150 percent longitudinal stretchability while substantially inhibiting dilation. A knitted tubular graft and a knitted medical fabric with greater than 150 percent longitudinal stretchability are also provided.

Owner:LIFESHIELD SCI

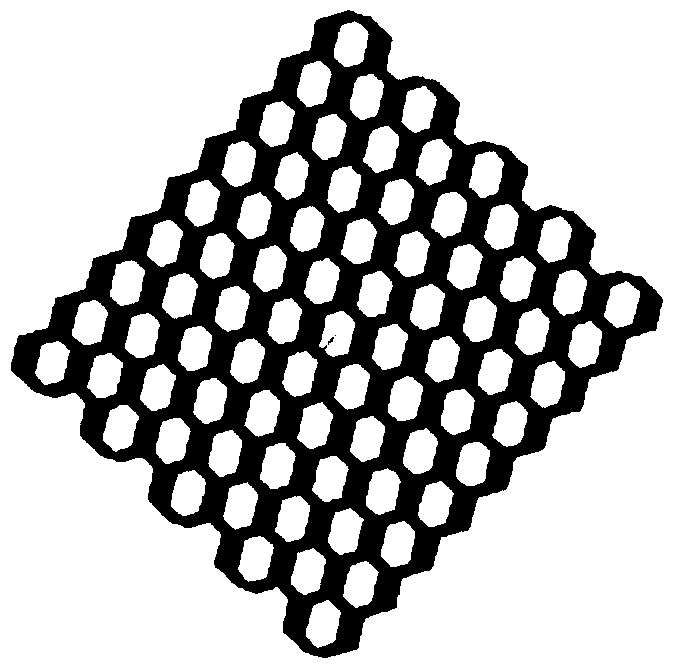

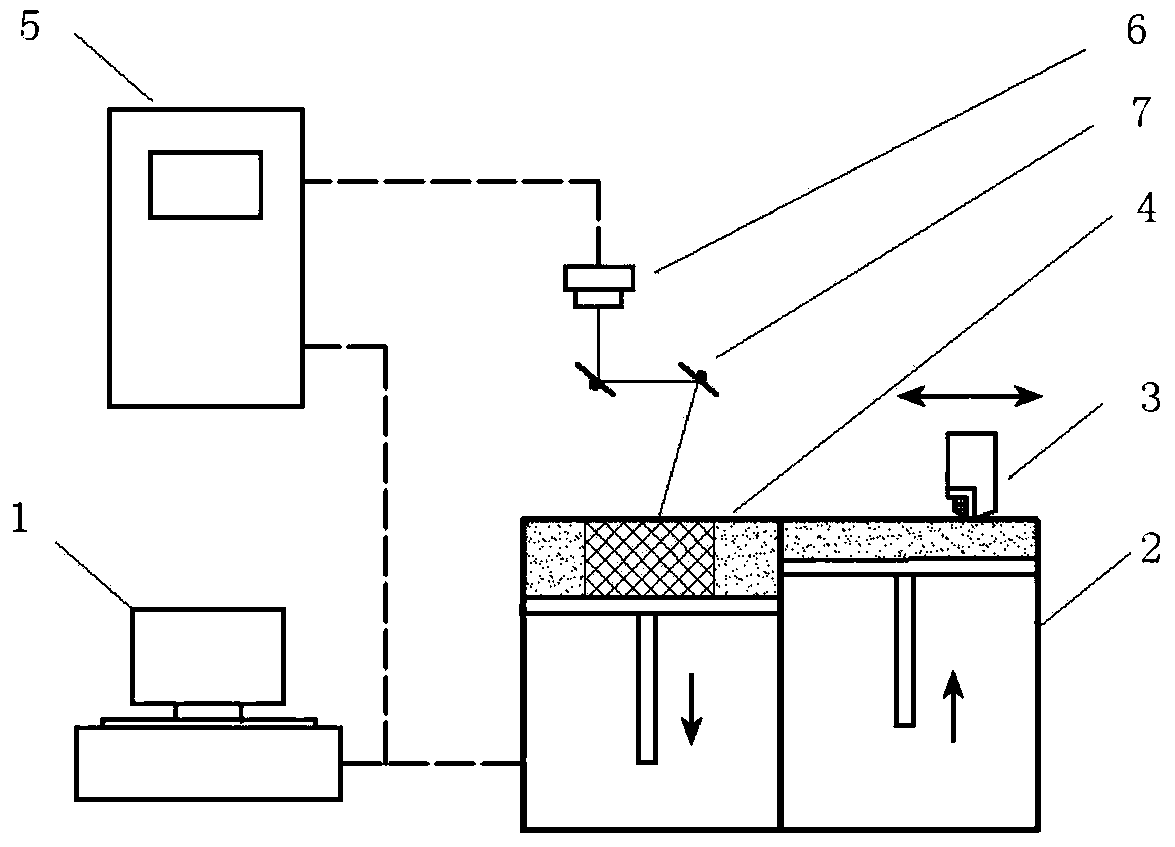

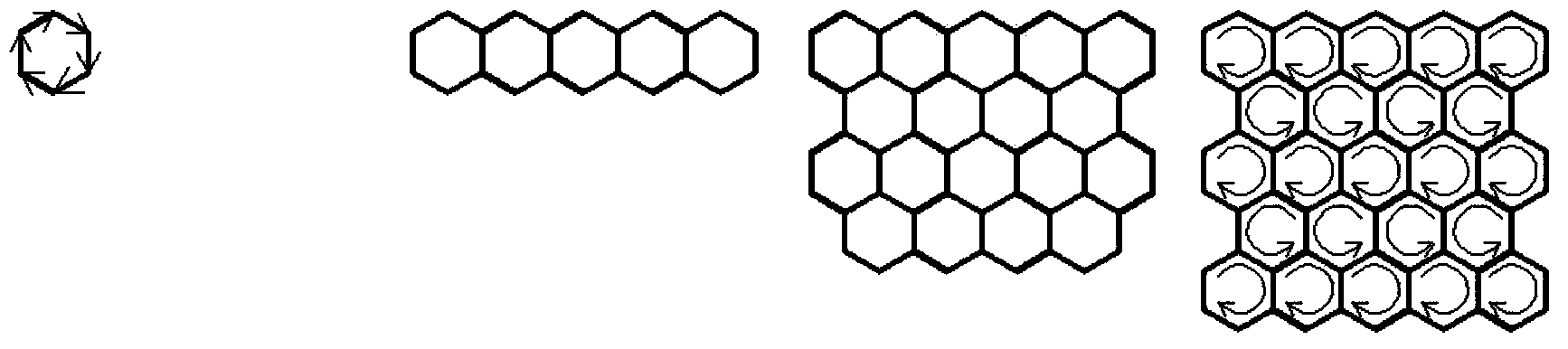

Preparation method of titanium alloy thin-wall honeycomb structure

The invention provides a preparation method of a titanium alloy thin-wall honeycomb structure. The preparation method comprises the steps that (a) a titanium alloy thin-wall honeycomb structure model is sliced and layered according to 20-30 mu m layer thickness; (2) titanium alloy powder is uniformly paved on a titanium alloy substrate, a laser beam which is emitted by a laser is used for selectively melting a titanium alloy powder layer according to the determined scan locus of the laser beam to complete the processing of one layer of titanium alloy thin-wall honeycomb structure; (c) the titanium alloy powder is paved on the layer of formed titanium alloy thin-wall honeycomb structure again, the laser beam which is emitted by the laser is used for selectively melting the titanium alloy powder layer according to the determined scan locus of the laser beam; (d) the titanium alloy thin-wall honeycomb structure is processed layer by layer, and the titanium alloy thin-wall honeycomb structure is finally formed. According to the method, the stress accumulation and the deformation of a forming piece in the forming process are reduced, the flexibility degree is high, and a thin-wall honeycomb component with variable honeycomb distance and a three-dimensional dot matrix structure can be prepared.

Owner:CAPITAL AEROSPACE MACHINERY +1

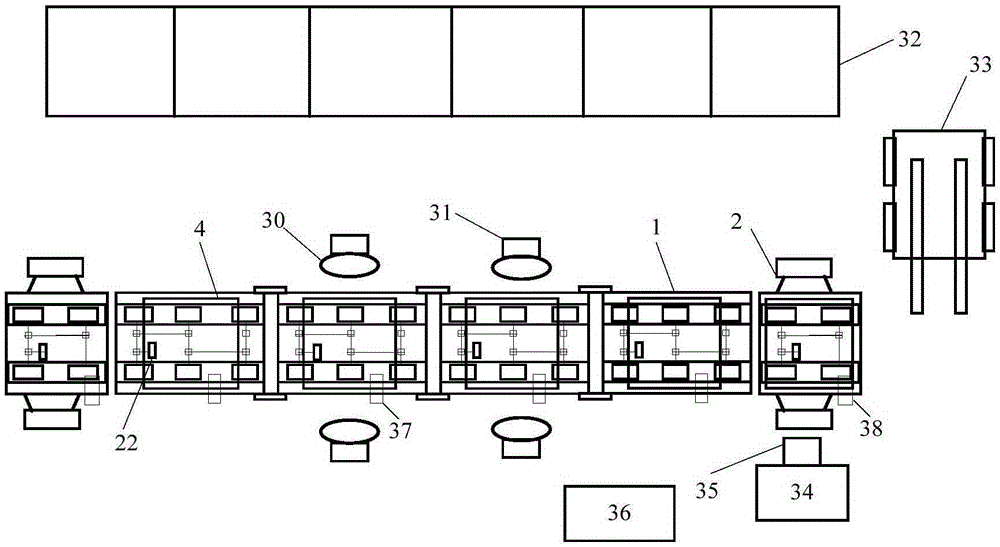

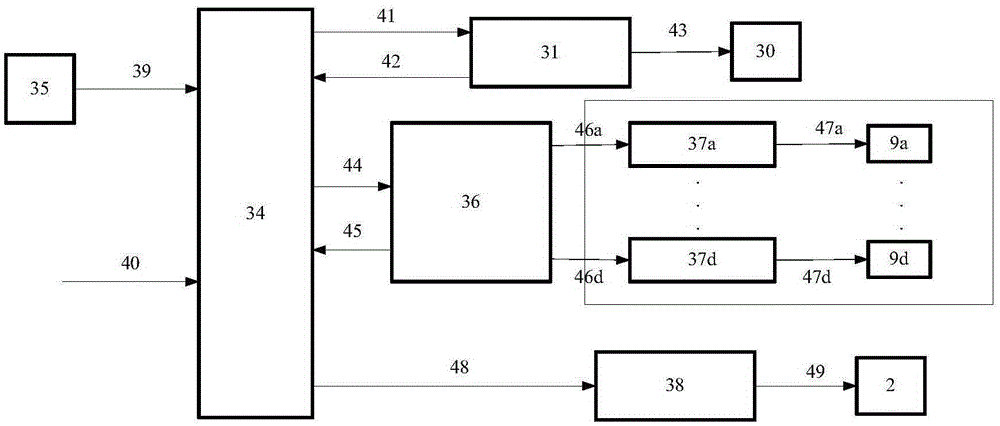

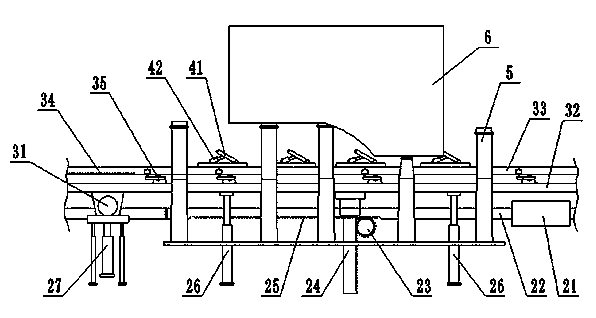

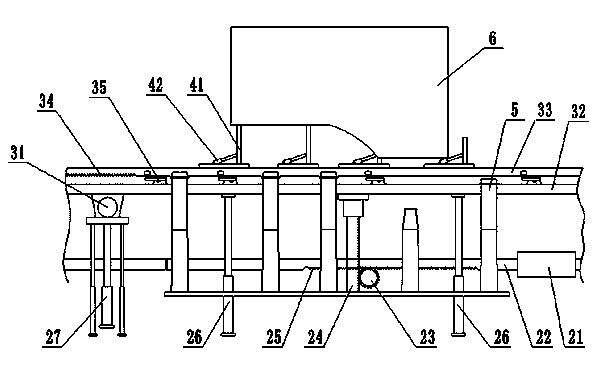

Reconfigurable automatic flexible welding production platform and operation method thereof

ActiveCN105252180ATo achieve high flexibility requirementsProduction task production capacity coordinationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineRe design

The invention discloses a reconfigurable automatic flexible welding production platform and an operation method thereof. The reconfigurable automatic flexible welding production platform comprises a production line main body, an accompanying platform, an accompanying fixture, a lifting mechanism, welding robots, a welding robot control center, a fixture transfer trolley, a fixture base and a production platform control center, wherein the accompanying platform can move on a line body; the accompanying clamp is positioned on the accompanying platform; the lifting mechanism is positioned on two sections of the line body; the welding robots are positioned at the two sides of a line body welding station; the welding robot control center controls movement of the welding robots and welding action of a fixed welding gun; the transfer trolley is responsible for replacing a fixture; the fixture base stores fixtures for producing different kinds of assemblies; the production platform control center controls movement of the whole production platform, wherein the movement comprises operation of a welding production line main body and operation of the lifting mechanism, so that high-flexibility requirements of automatic welding production for various small assembly components are reached, and production capacity is re-designed for realizing coordination of production tasks and production capacity.

Owner:YANGZHOU XINLIAN AUTO PARTS +1

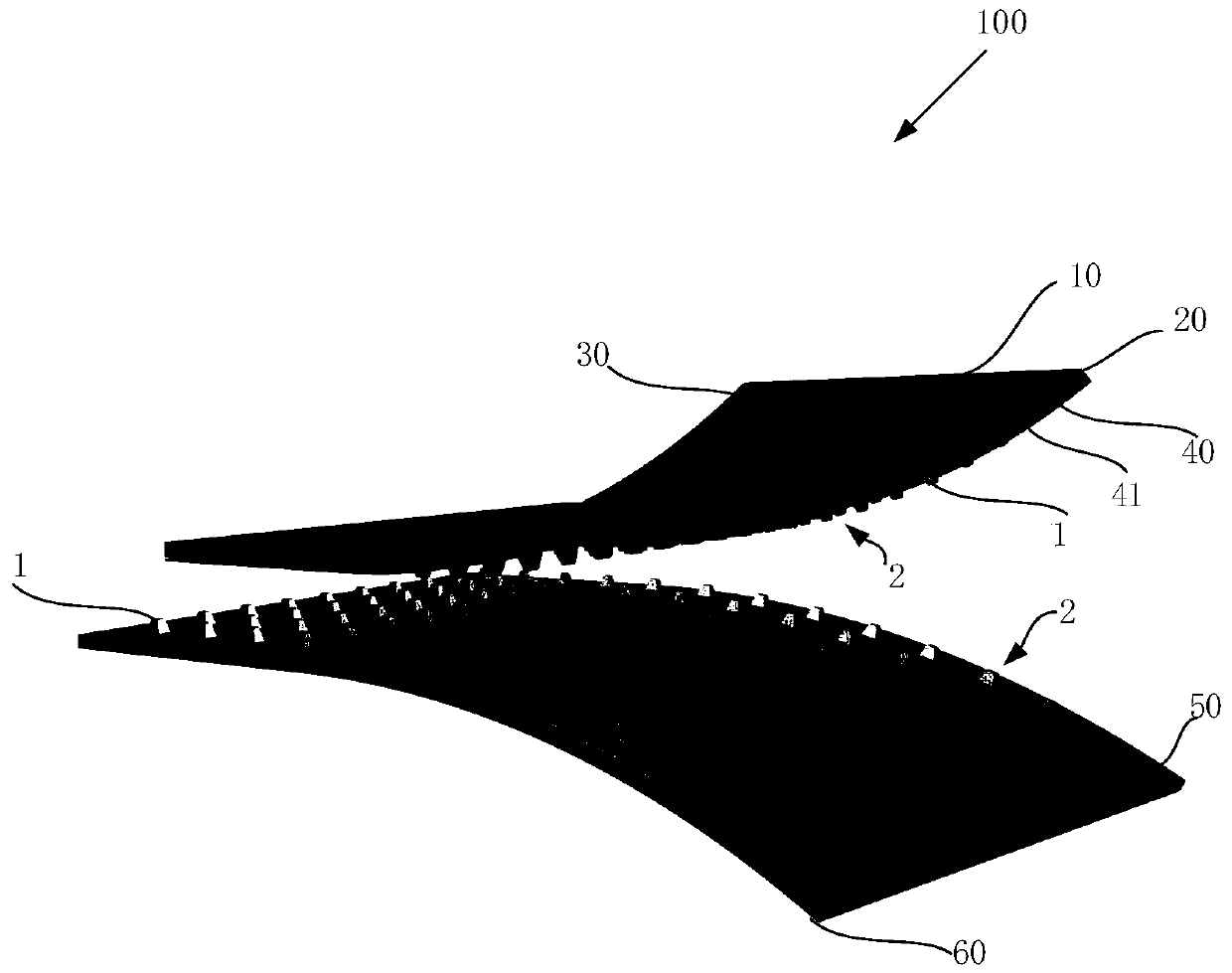

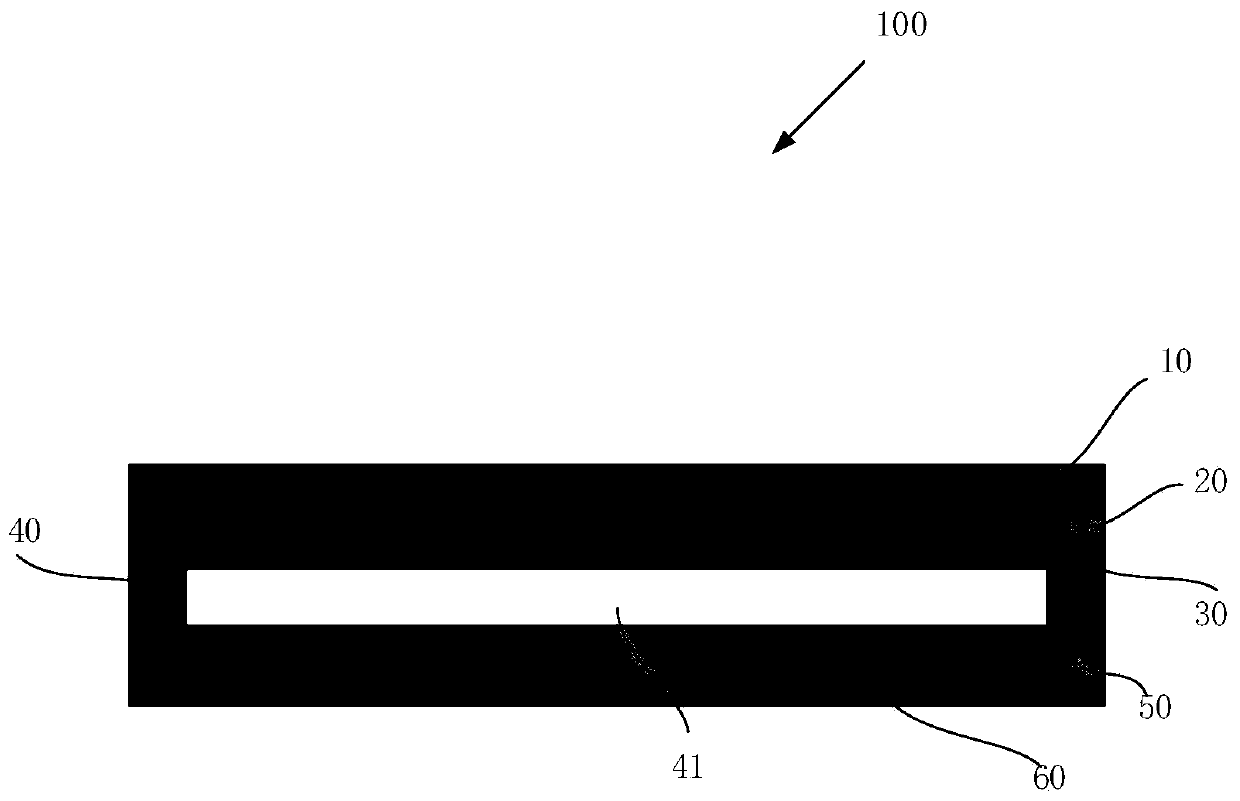

Flexible wearable sensor and corresponding wearable device and preparation method thereof

InactiveCN109738095AImprove output performanceHigh acquisition sensitivityFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesEngineeringMechanical engineering

The invention provides a flexible wearable sensor and a corresponding wearable device and preparation method thereof, wherein the flexible wearable sensor is small in size and high in flexible degreeand output capacity. The flexible wearable sensor comprises a first electrode layer, a piezoelectric layer, a second electrode layer, an interval layer, a friction layer and a third electrode layer which are arranged in sequence; a flexible mixed material at least constituted by a piezoelectric material and silicone rubber is contained in the piezoelectric layer, and the piezoelectric layer can generate a piezoelectric signal after being subjected to polarization treatment; a flexible mixed material at least constituted by silicone rubber is contained in the friction layer, a plurality of protrusion parts formed by a plurality of protrusion structures which are configured in an arrayed mode are formed on the opposite areas in the inner surface of the piezoelectric layer and the inner surface of the friction layer correspondingly, and the two inner surfaces are oppositely arranged; the outer surface and the inner surface of the piezoelectric layer are covered with the first electrode layer and the second electrode layer correspondingly; and the interval layer is provided with hollow parts opposite to the protrusion parts on the inner surface of the piezoelectric layer, and the outersurface of the friction layer is covered with the third electrode layer.

Owner:ZHONGBEI UNIV

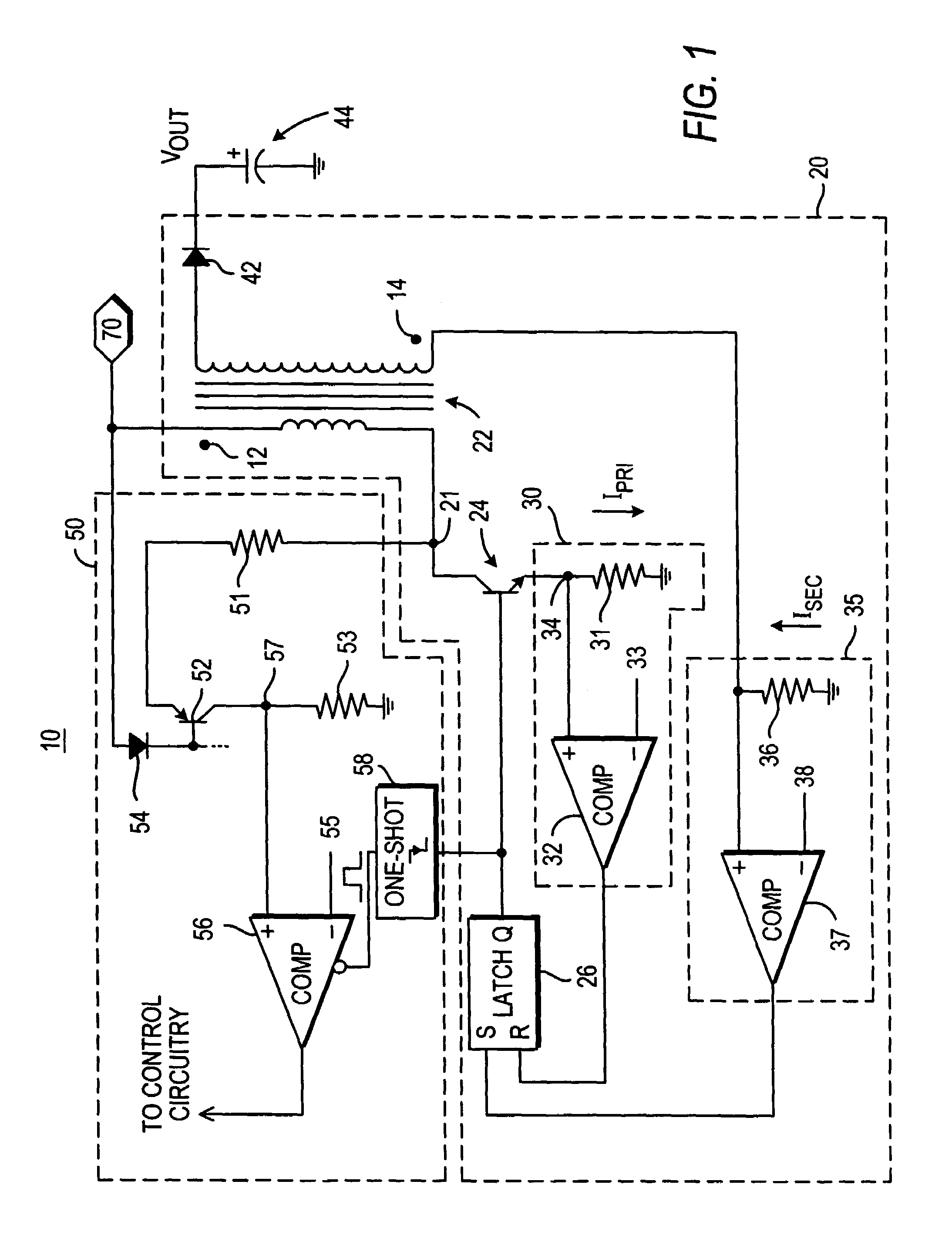

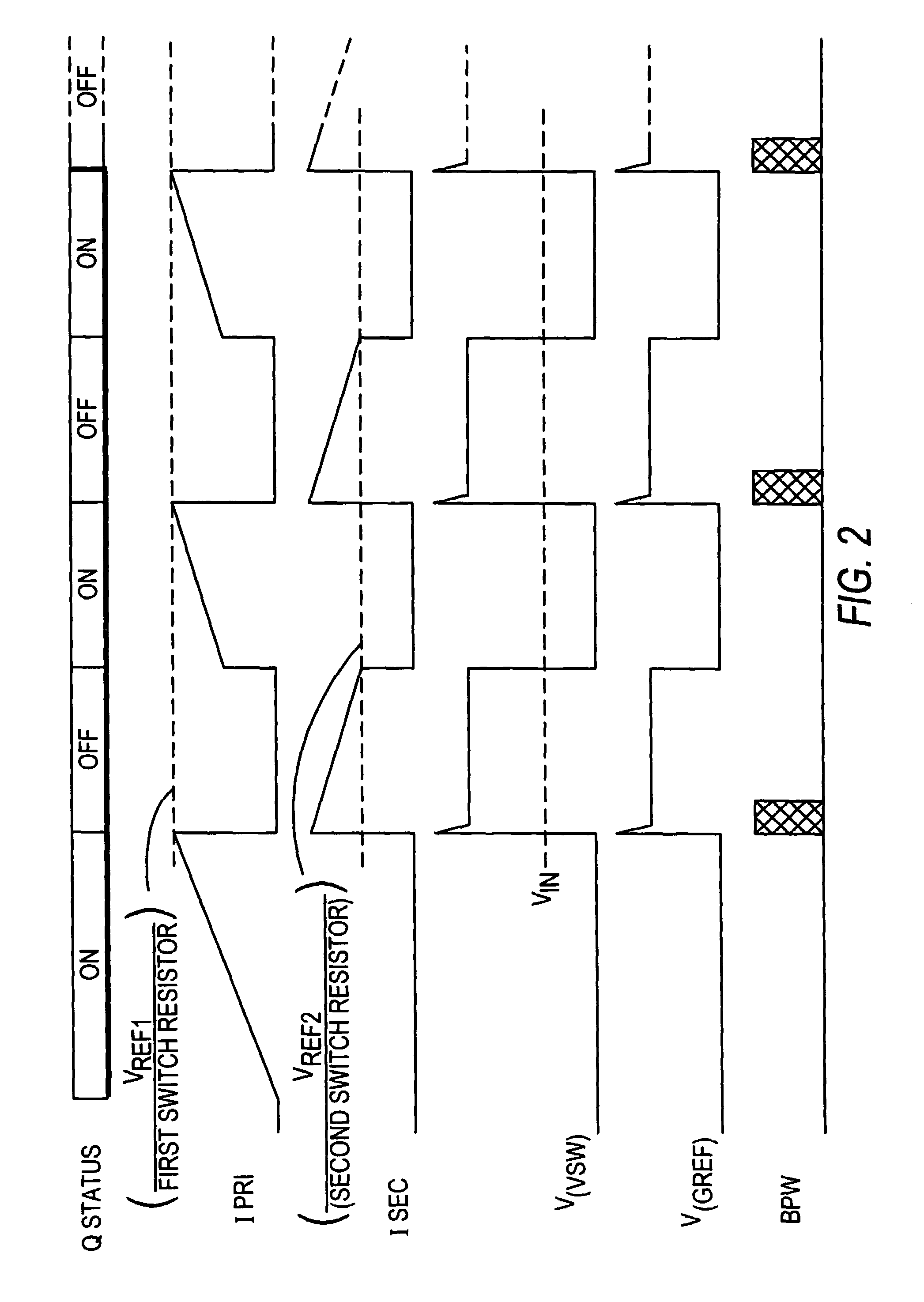

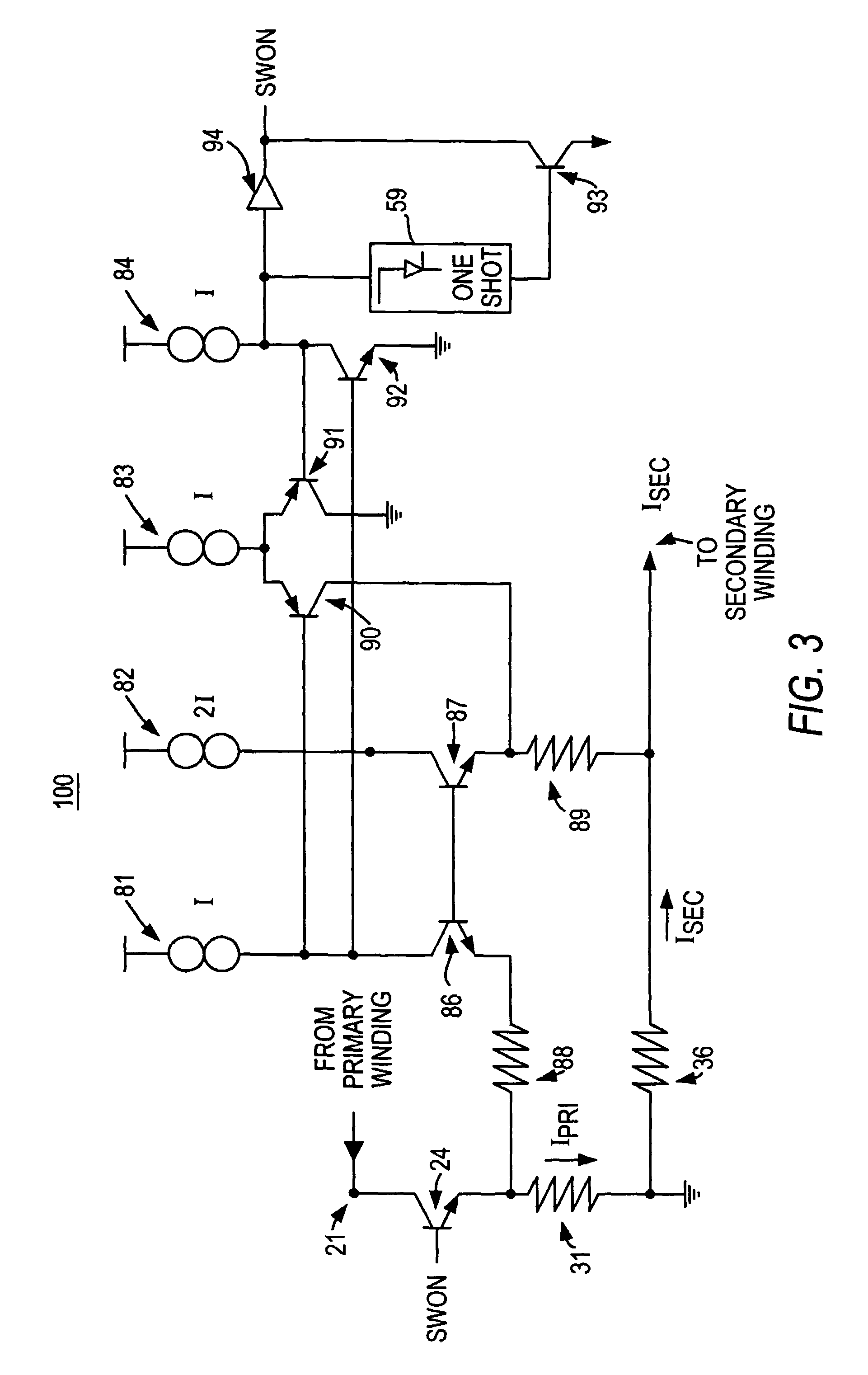

Capacitor charging circuitry and methodology implementing controlled on and off time switching

InactiveUS7292005B2Fast and efficient transferIncrease flexibilityDc network circuit arrangementsBatteries circuit arrangementsCapacitanceTransformer

The present invention provides a capacitor charging circuit that efficiently charges capacitive loads. In particular, circuits and techniques are preferably provided for using current from both the primary and secondary windings of a transformer to control ON-time and OFF-time of a switch. This arrangement preferably yields an adaptable ON-time and adaptable OFF-time switch that is capable of rapidly charging capacitor loads ranging from as low as zero volts to several hundred volts. The output voltage is preferably measured indirectly to prevent unnecessary power consumption. In addition, control circuitry can be provided to conserve power by ceasing the delivery of power to the capacitor load once the desired output voltage is reached. Control circuitry preferably operates an interrogation timer that periodically activates the power delivery cycle to maintain the capacitor output load in a constant state of readiness.

Owner:ANALOG DEVICES INT UNLTD

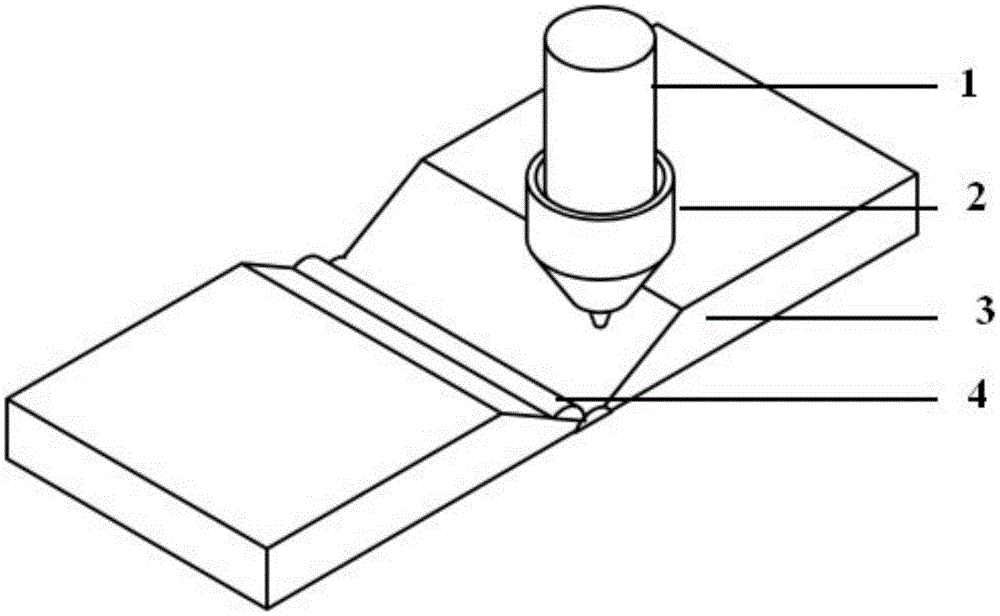

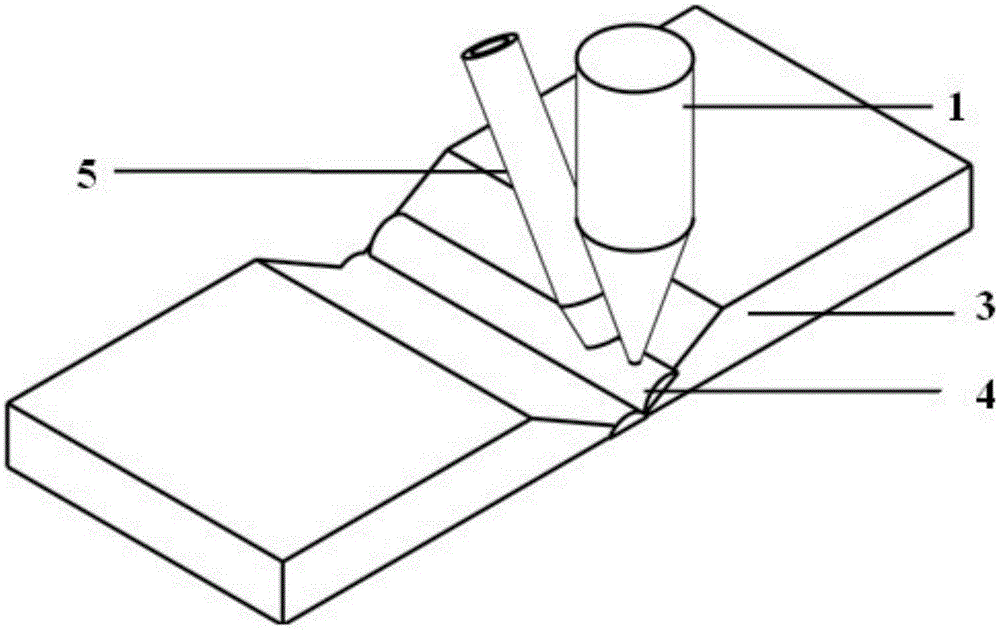

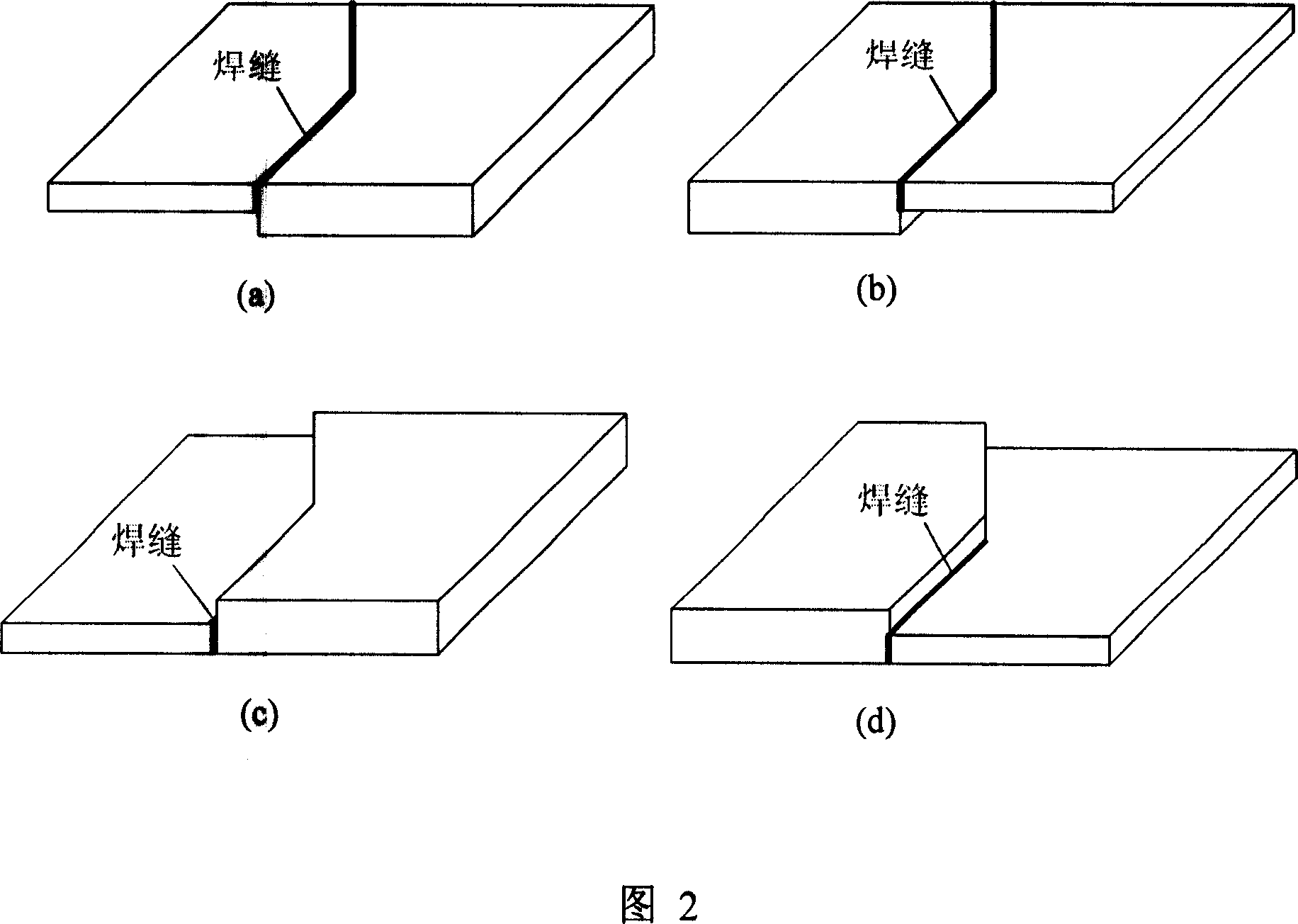

Laser connection method based on laser material additive manufacturing technology

InactiveCN105414762AImprove performanceControl deficienciesLaser beam welding apparatusManufacturing technologyWeld seam

A laser connection method based on the laser material additive manufacturing technology relates to a welded connection method of a special material. According to the laser material additive manufacturing principle, and by utilizing the laser depositing method and the layer-by-layer piling method, a new material shaped like the welding seam between two base materials is formed between the welding seam of two connecting materials and the formed new material is further utilized to connect the two base materials. According to the laser connection method based on the laser material additive manufacturing technology, provided by the invention, the metallurgical composition of the welding seam and the joint performance are improved, near-net forming connection is realized, materials are greatly saved, the cost is reduced, weld defects are controlled, the degree of automation is high, and the operation is easy; besides, a fiber laser, a YAG solid laser, a semiconductor laser or CO2 laser are taken as the core, and a powder feed device, a protective gas system and a cooling system are taken as auxiliary appliances, therefore the overall system is high in automation level, can realize whole-process computer control, and is simple in operation processes and further easy to implement.

Owner:HARBIN INST OF TECH

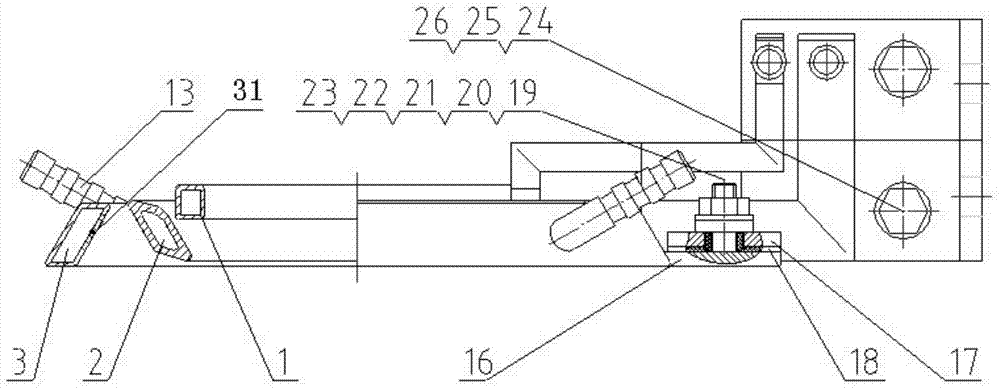

Deformable welding fixture for plate splicing welding with linear and curved weld seams

InactiveCN101020281AEasy clampingAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesSheet steelEngineering

The present invention is a double-purpose deformable welding fixture for welding linear and curved weld seams, and the fixture has linear welding slot and curved welding slot integrated onto one pedestal to reach the double-purpose aim. The double-purpose deformable welding fixture consists of one pedestal height difference structure comprising one thickness difference step and one height regulating tab for fitting different welding thickness, and one clamping screw mechanism comprising right and left pressing boards with screw holes and corresponding cap screws. It can regulate clamping force and control welding deformation by means of novel flexible location mode, and is suitable for linear and curved welding of common steel plate, high strength steel plate, aluminum plate, etc of different sizes.

Owner:JIANGSU UNIV

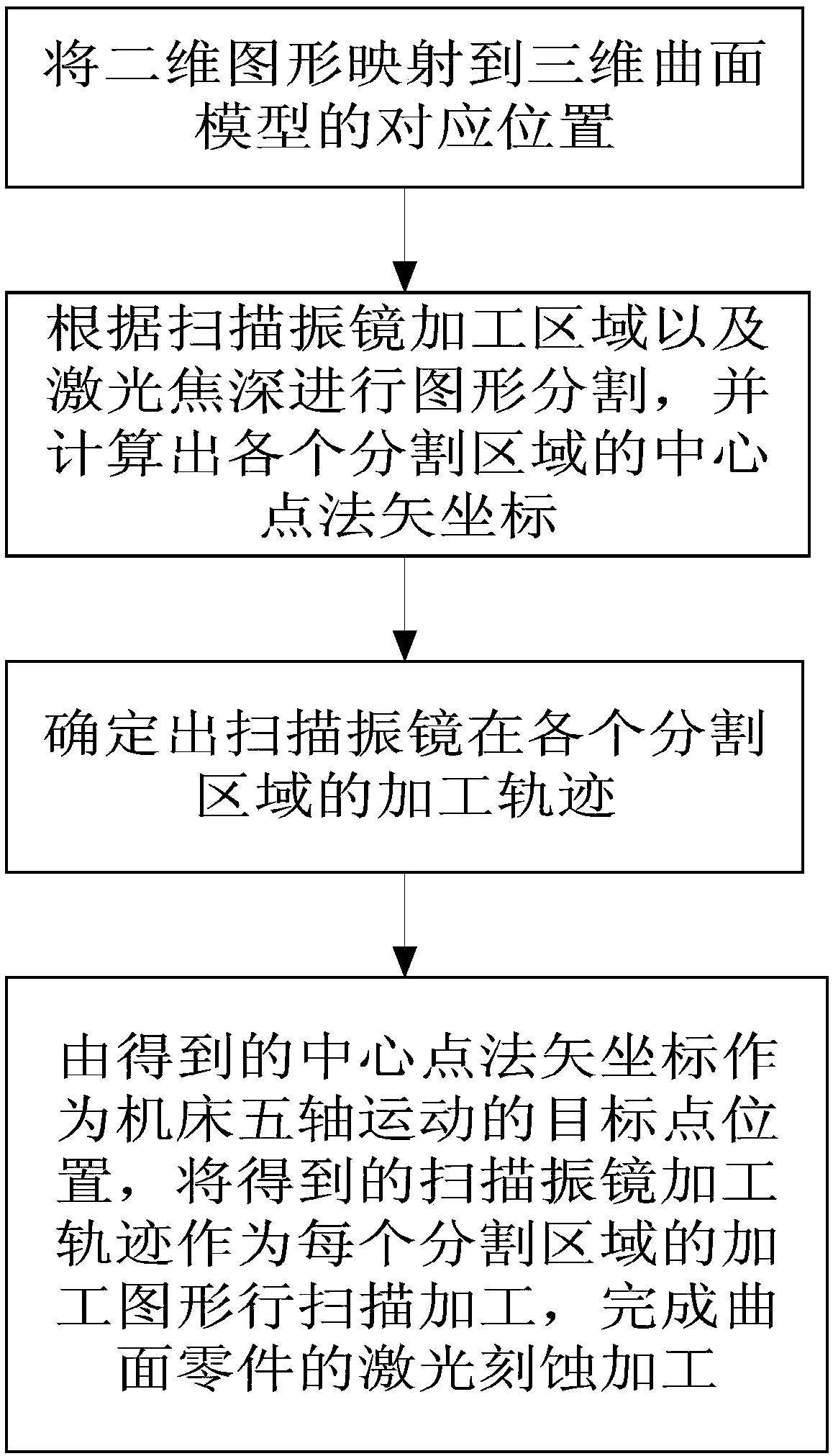

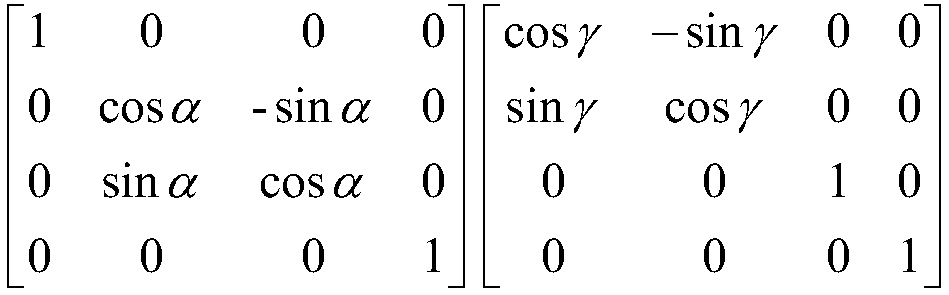

Laser etching method of three-dimensional curved surface

ActiveCN108838551ACorrect angle deviationImprove accuracyLaser beam welding apparatusLaser etchingTwo-dimensional graph

The invention relates to a laser etching method of a three-dimensional curved surface, is applied to the fields of aerospace, electronic and optical devices, and solves the problem that ideal texturegraphs cannot be acquired as a conventional three-dimensional curved surface laser processing method can only be utilized to process parts with to-be-processed surface texture characteristics and processed graphs have angle change. The laser etching method comprises the following steps that: (1) a two-dimensional graph is mapped to a corresponding position of a three-dimensional curved surface model; (2) the graph is cut according to a processing region of a scanning galvanometer and laser focus depth, and central point normal vector coordinates of cut regions are calculated; (3) processing tracks of the scanning galvanometer in the cut regions are confirmed; and (4) the central point normal vector coordinates acquired in the step (2) are adopted as target point positions of five-shaft motion of a machine tool, the processing tracks of the scanning galvanometer acquired in the step (3) are adopted as processing graphs of the cut regions, scanning processing is carried out, and laser etching processing of curved surface parts is achieved.

Owner:XIAN MICROMACH TECH CO LTD

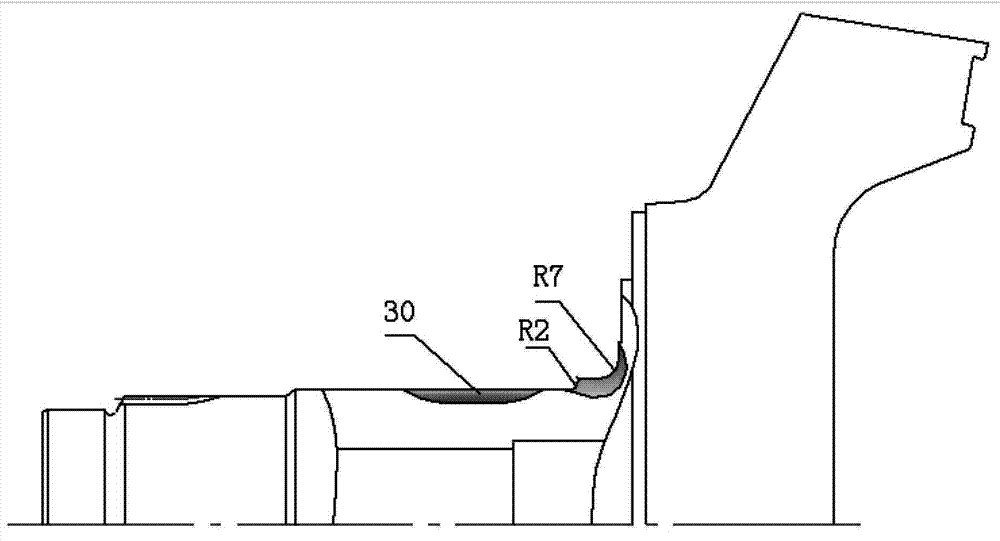

Quenching inductor for double steps of steering joint and quenching method for steering joint

ActiveCN103589846AAvoid safety accidentsContinuous distributionFurnace typesIncreasing energy efficiencyAcute angleInductor

The invention relates to a quenching inductor for double steps of a steering joint and a quenching method for the steering joint. The section of the lower part of an inner circumferential part of a second annular effective heating ring of the quenching inductor is of an acute angle shape; a first annular effective heating ring is positioned above the acute angle shape; two ends of the first annular effective heating ring and two ends of the second annular effective heating ring are assembled and welded with water pipe connectors through cooling water pipes to respectively form a first conductive loop and a second conductive loop; a circular water spraying ring is positioned on one side of the periphery of the second annular effective heating ring; a water spraying hole is formed in the inner circumferential surface of the circular water spraying ring. The quenching inductor can heat the double steps of the steering joint section by section through the two effective heating rings and cool the double steps of the steering joint through the circular water spraying ring and is high in heating efficiency and high in cooling capacity, and an effective hardening layer is distributed uniformly and continuously.

Owner:CHINA FIRST AUTOMOBILE

Car body welding lifting reciprocating transmission system

ActiveCN103754572ATransmission distance is easy to controlHigh precisionConveyorsProduction lineTransmission system

The invention discloses a car body welding lifting reciprocating transmission system which comprises a reciprocating transmission mechanism, a lifting mechanism and a car body supporting mechanism. The reciprocating transmission mechanism comprises a motor, a supporting beam, a walking beam, a gear rack and a rolling wheel component, the lifting mechanism is arranged at the bottom of the motor and the bottom of each work position supporting beam, and the supporting position and the height of the car body supporting mechanism can be adjusted. The car body welding lifting reciprocating transmission system has the advantages that the transmission distance is easy to control, precision is high, the operation is stable, efficiency is high, noise is low, the control is convenient and fast, the structure is compact, manufacturing cost is low, maintenance is convenient, and high safety performance is achieved, mixed routing manufacturing transmission of different car types can be achieved without shutdown, the application range of a production line is expanded, shutdown maintenance is avoided, production cost is saved, and good popularization and utilization value is achieved.

Owner:YIQI HONGTA YUNNAN AUTOMOBILE MFG

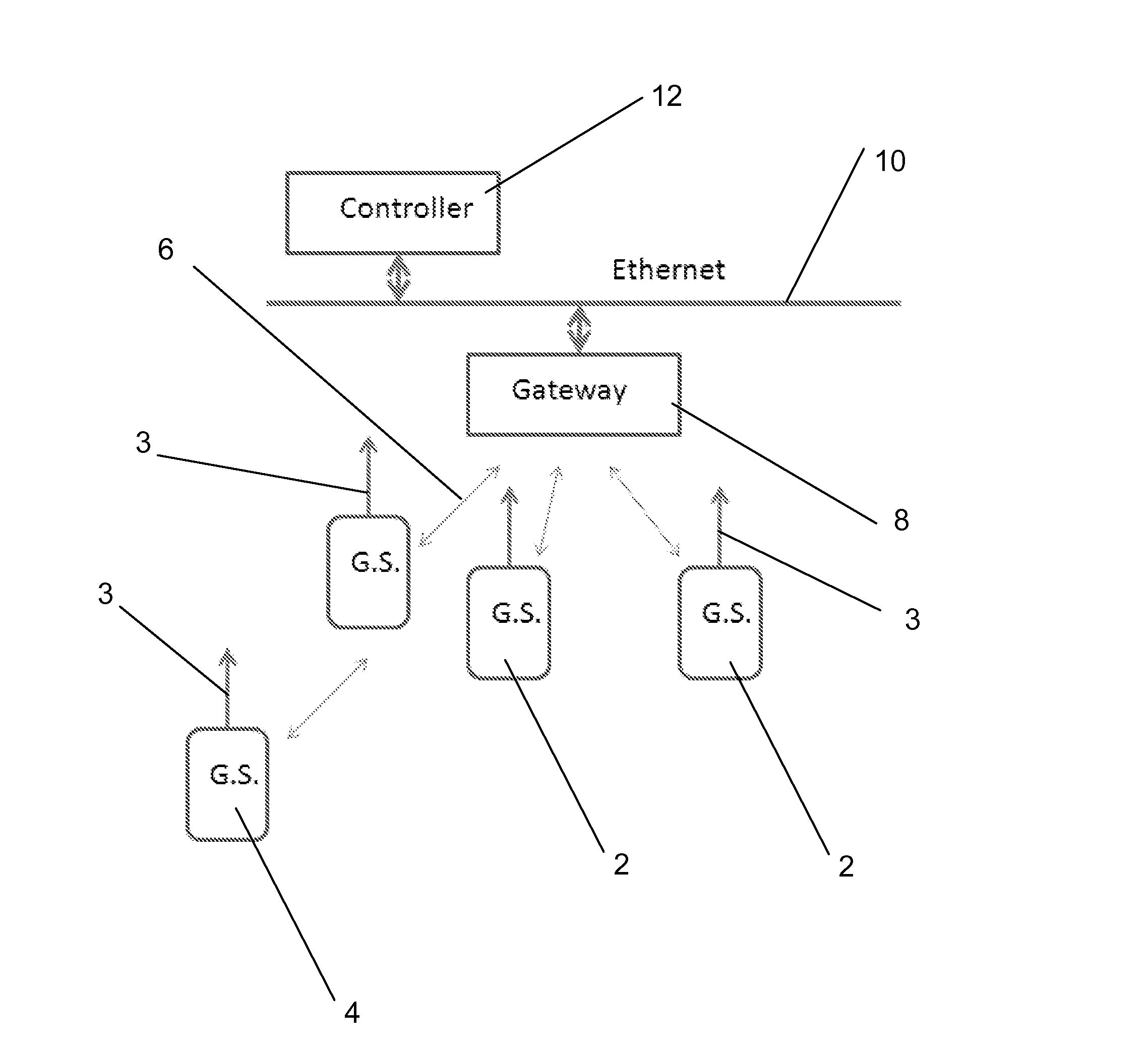

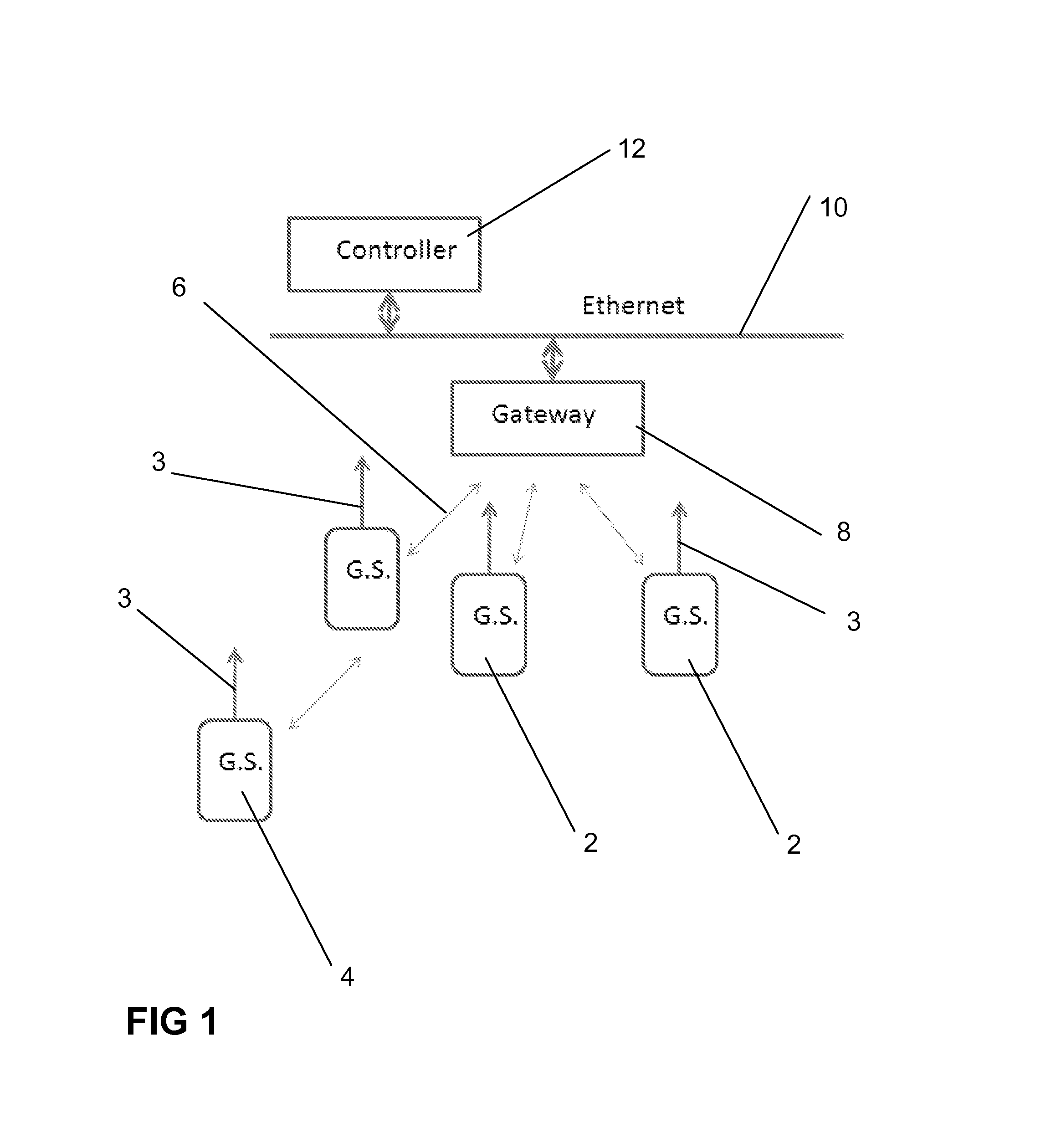

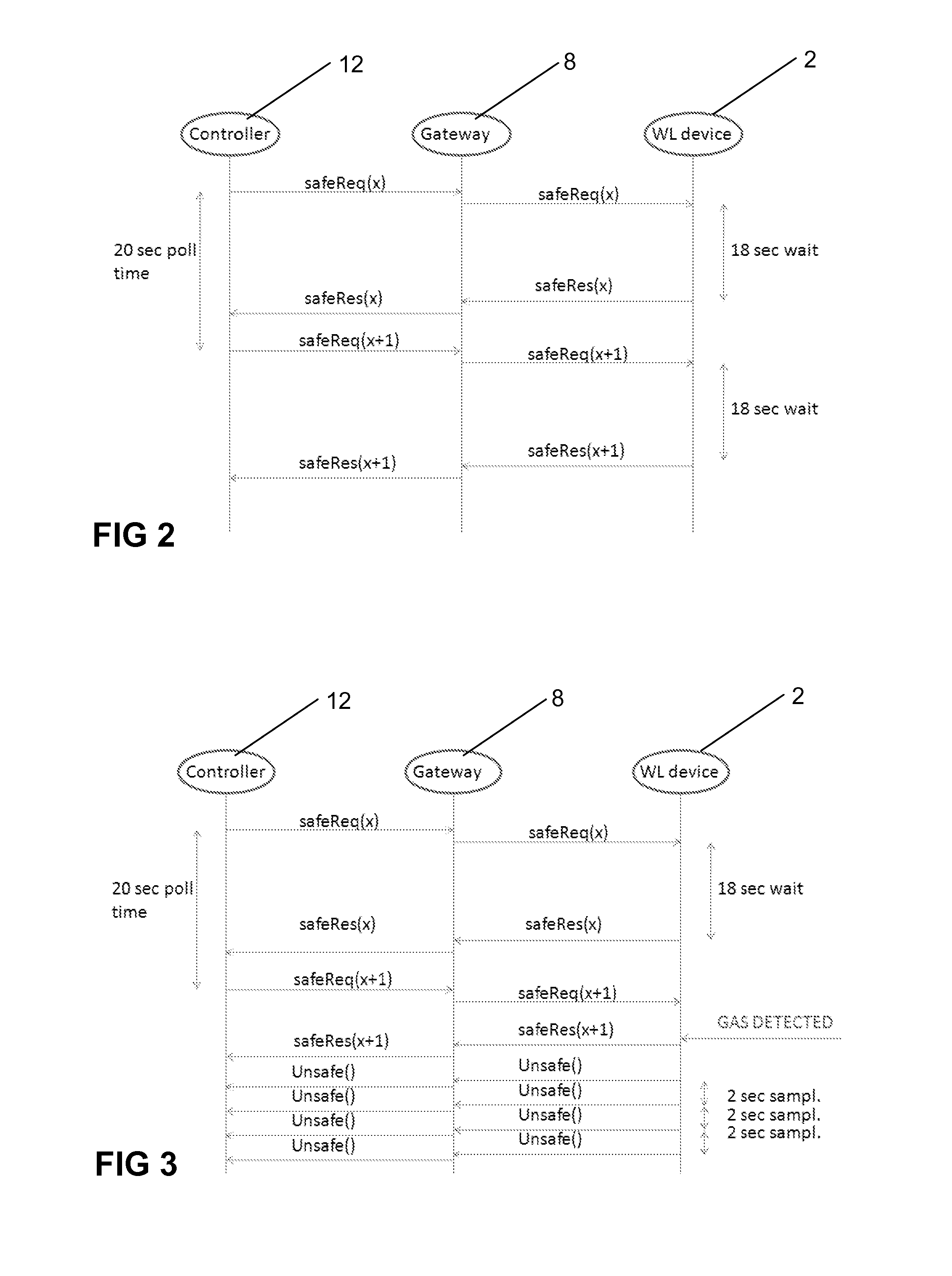

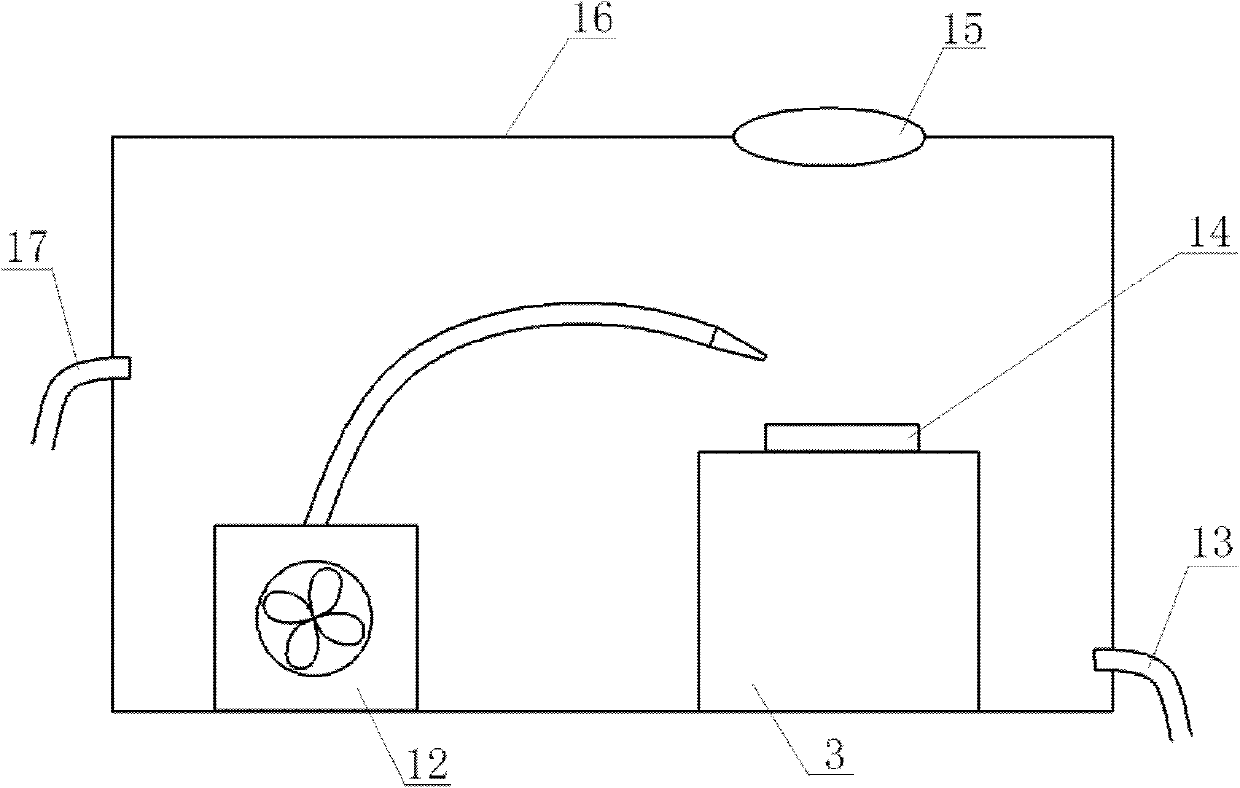

Wireless sensor networks

ActiveUS20140232555A1High degree of flexibilityExtend lifePower managementParticular environment based servicesEngineeringWireless sensor networking

A wireless sensor network comprises at least one sensor unit which comprises a sensor for sensing a parameter and at least one interrogating node. The interrogating node is arranged to transmit an interrogation message periodically to said sensor unit and to receive a reply message from said sensor unit. The sensor unit is arranged to transmit said reply message after a predetermined deliberate delay unless the sensor unit determines that an alarm condition has been met, in which case the sensor unit is arranged to transmit said reply message before the end of the deliberate delay.

Owner:DRAGER SAFETY

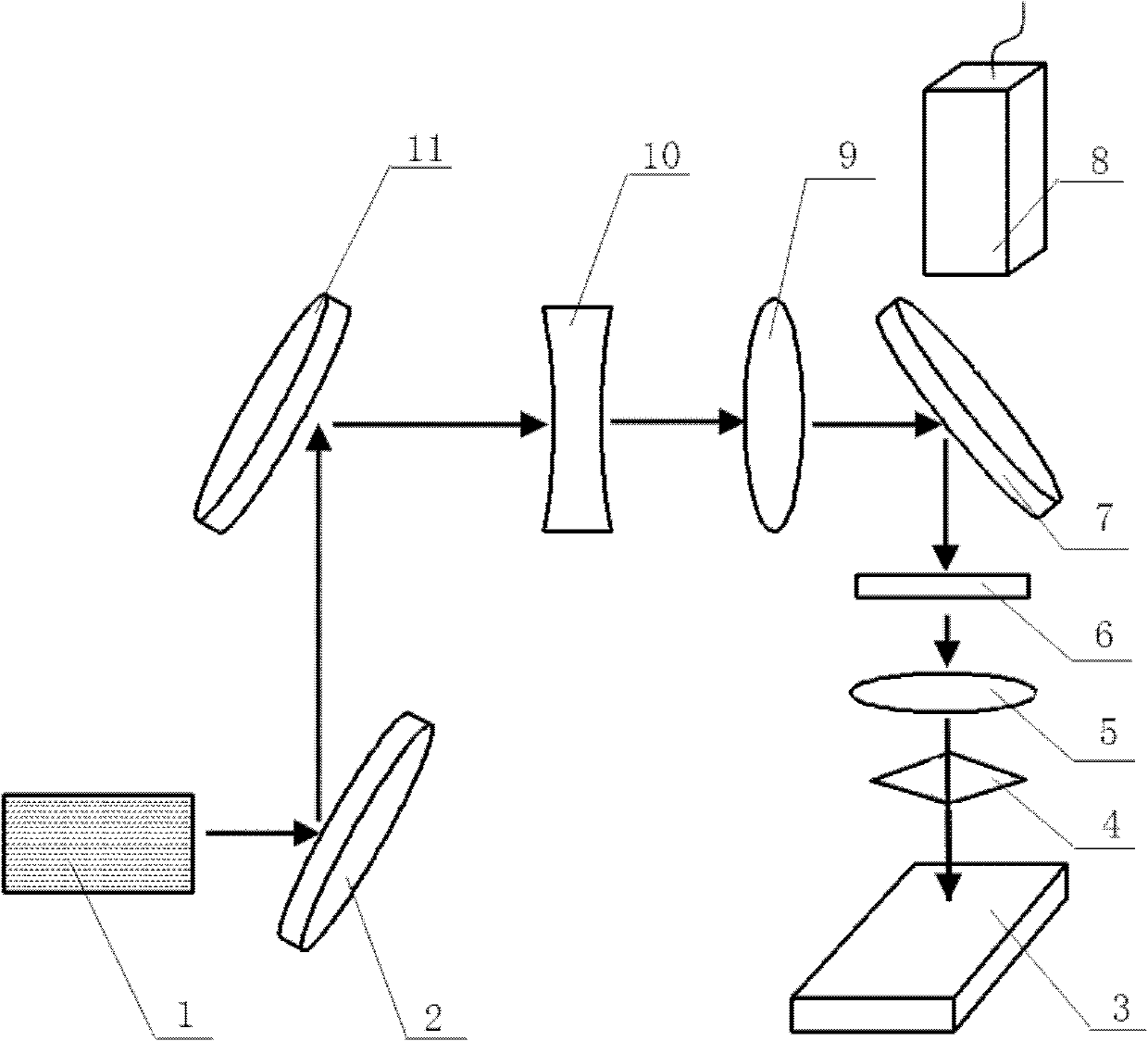

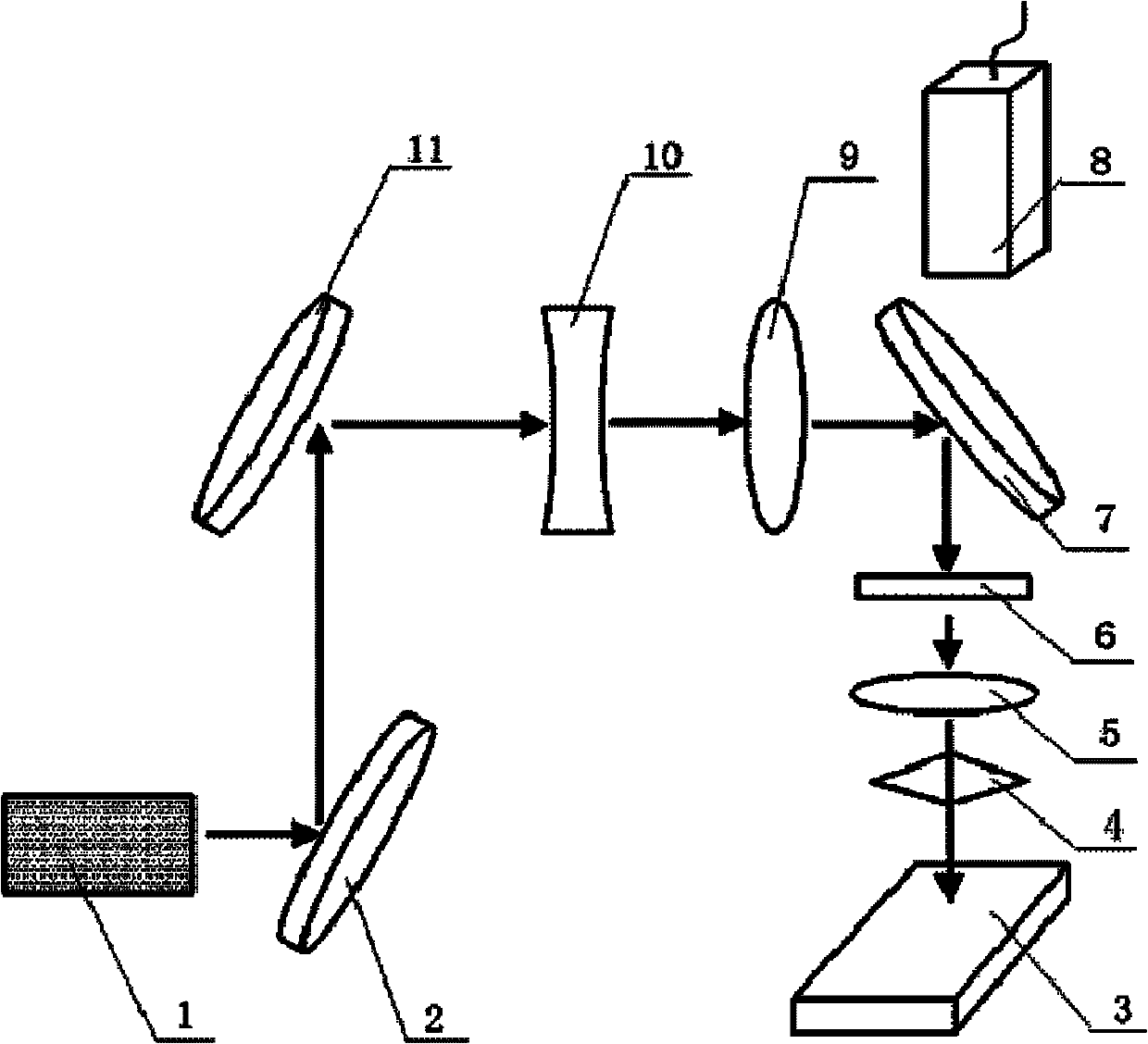

Microstructure-type excimer laser delaminated processing method and device of ceramic material sealing ring

InactiveCN101905381ASolve processing problemsAvoid embedding into the surface to be processedLaser beam welding apparatusNumerical controlCylindrical lens

The invention belongs to the technical field of ultrafine processing of hard and brittle ceramic materials, in particular to special microstructure-type excimer laser delaminated processing method and device of a ceramic material sealing ring. The method is characterized by comprising the following steps of: delaminating the special microstructure-type three-dimensional profile of a processed ceramic material; converting into NC (Numerical Control) codes and realizing the computer control of the position of a lens, the size and the shape of an aperture, the replacement of a round lens and a cylindrical lens, the aperture size and the shape of a light chopper and the movement of a worktable in an optical system by combining the generated NC codes so as to realize the automation and the flexibility of a processing process. The invention has the advantages that the ultrafine processing problem of the special microstructure-type hard and brittle ceramic material sealing ring is solved by applying an excimer delaminated processing technology. A non-contact, clean and high-efficiency processing mode is provided to effectively solve the problems of attached contact stress, embedded abrasive grains and low processing efficiency in a traditional processing method, and the processing flexibility is realized.

Owner:DALIAN UNIV OF TECH

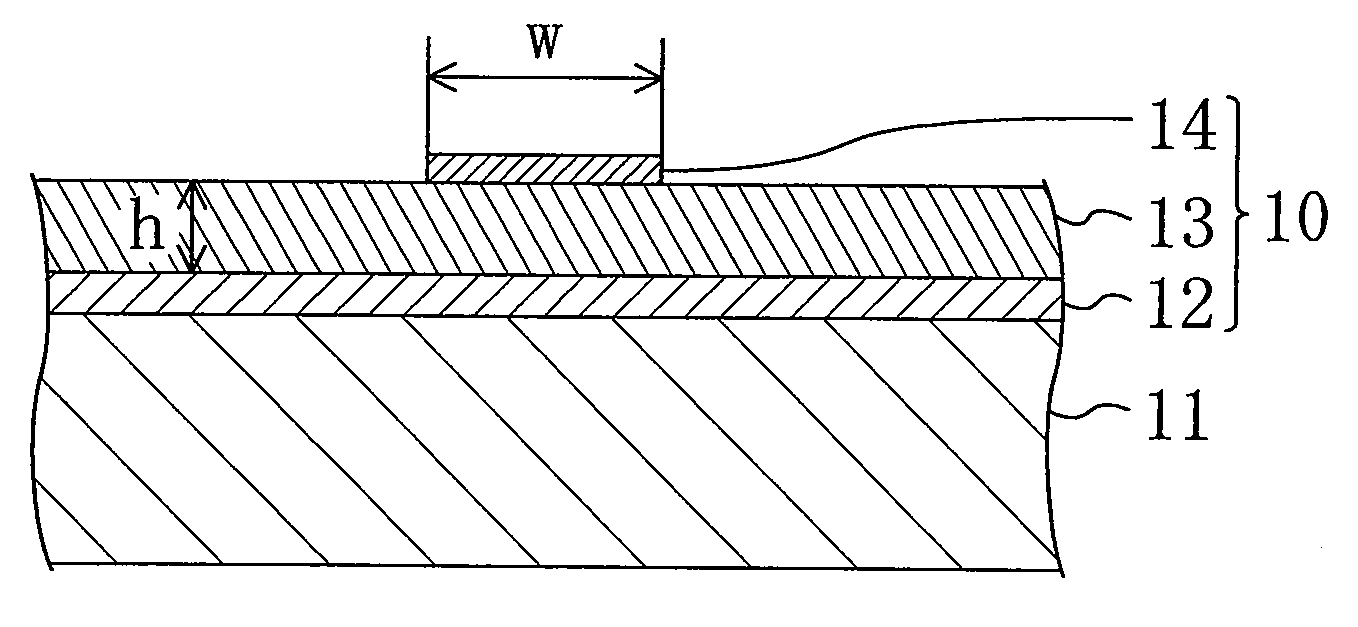

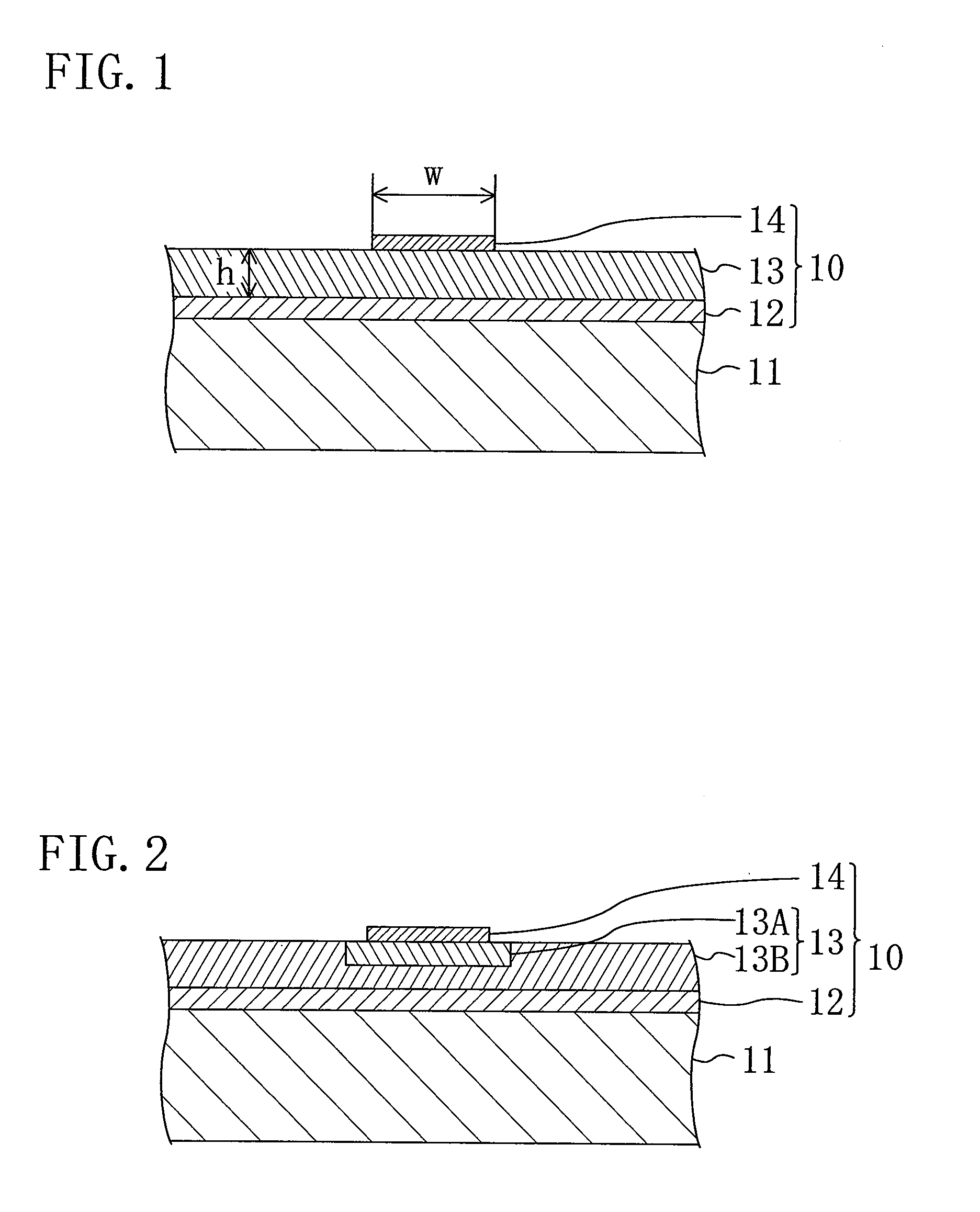

Circuit device

InactiveUS20100237967A1High degree of flexibilitySemiconductor/solid-state device detailsSolid-state devicesTransmission lineEngineering

A circuit device includes a substrate 11, and a transmission line 10. The transmission line 10 includes a dielectric film13 formed on the substrate 11, and a signal line formed on the dielectric film 13. The dielectric film 13 includes a nano-composite film in which particles of a first material are dispersed in a second material.

Owner:PANASONIC CORP

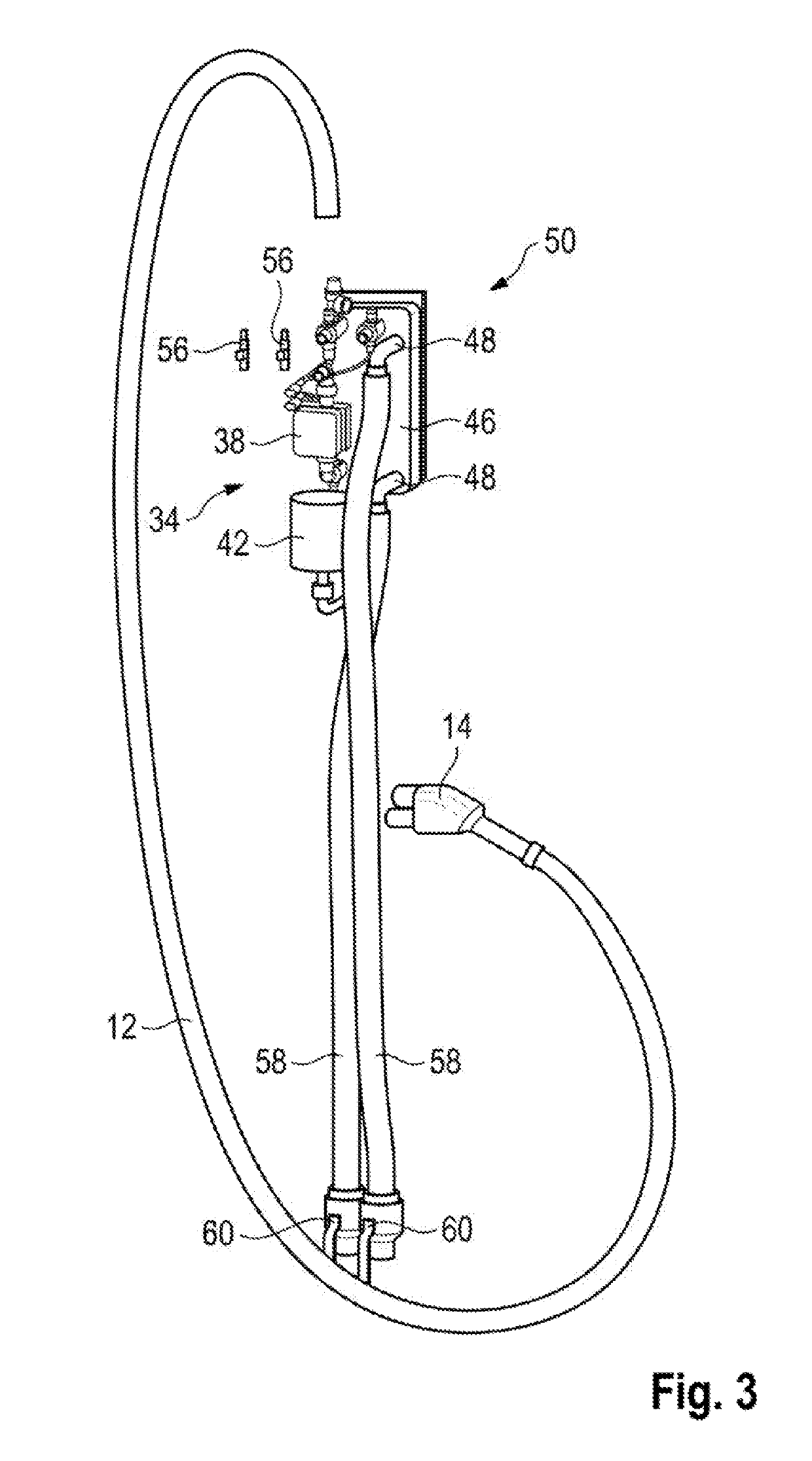

Fast charging station with charging cable and temperature control device for the charging cable

ActiveUS20190217728A1Reduce resistanceHigh degree of flexibilityCharging stationsGas pressure propulsion mountingElectric driveElectrical battery

A charging cable device for a fast charging station for fast charging a battery of a vehicle with an electric drive, having a temperature control device, and a charging cable connected thereto. The charging cable has a multiplicity of fluid lines which extend from an end of the charging cable facing the temperature control device to an end facing away from the temperature control device, and are connected to one another at the end facing away from the temperature control device. The temperature control device is connected to the fluid lines of the charging cable to form a fluid circuit. The temperature control device is designed to heat a fluid in the fluid circuit. Also disclosed is a fast charging station for fast charging a battery of a vehicle with an electric drive. The fast charging station has a charging cable device at the top.

Owner:DR ING H C F PORSCHE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com